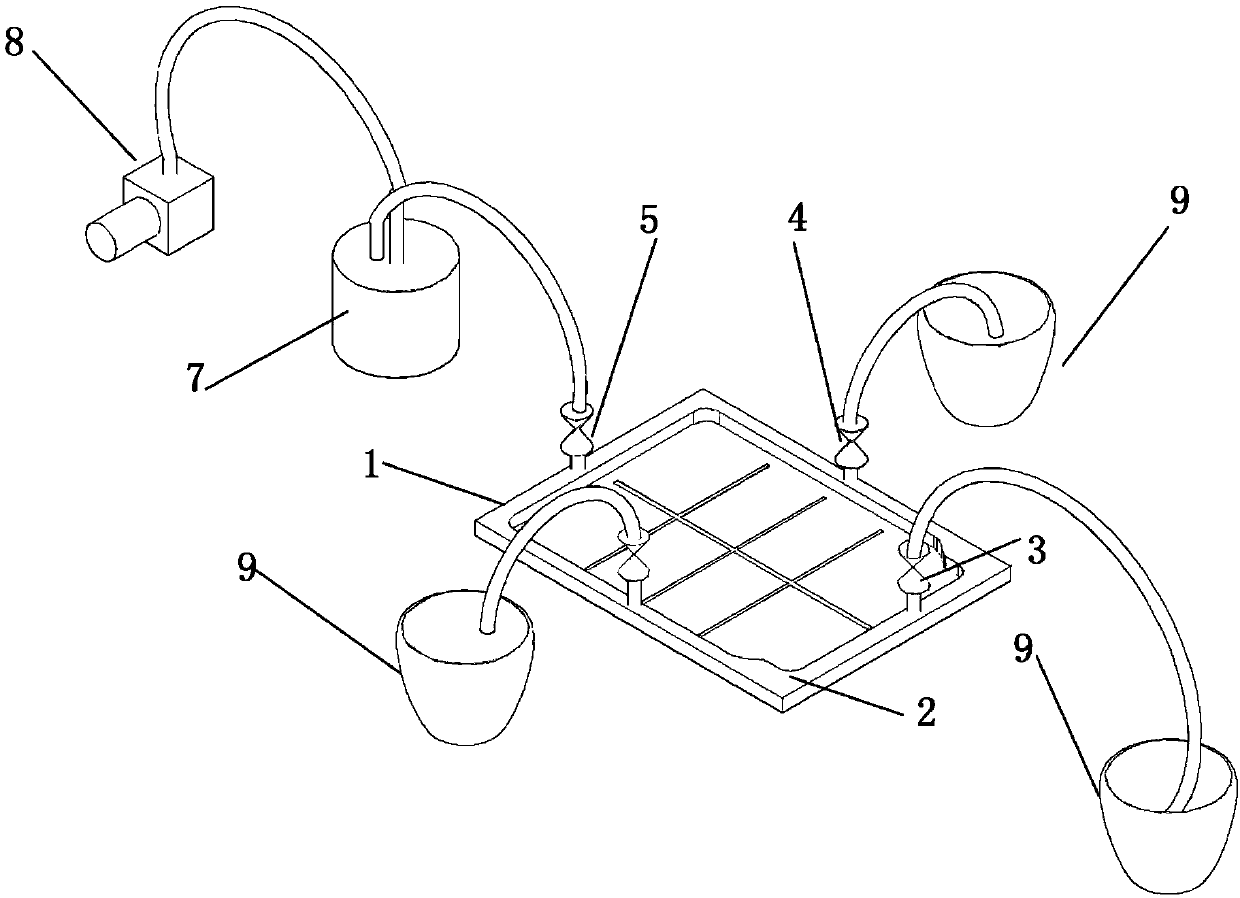

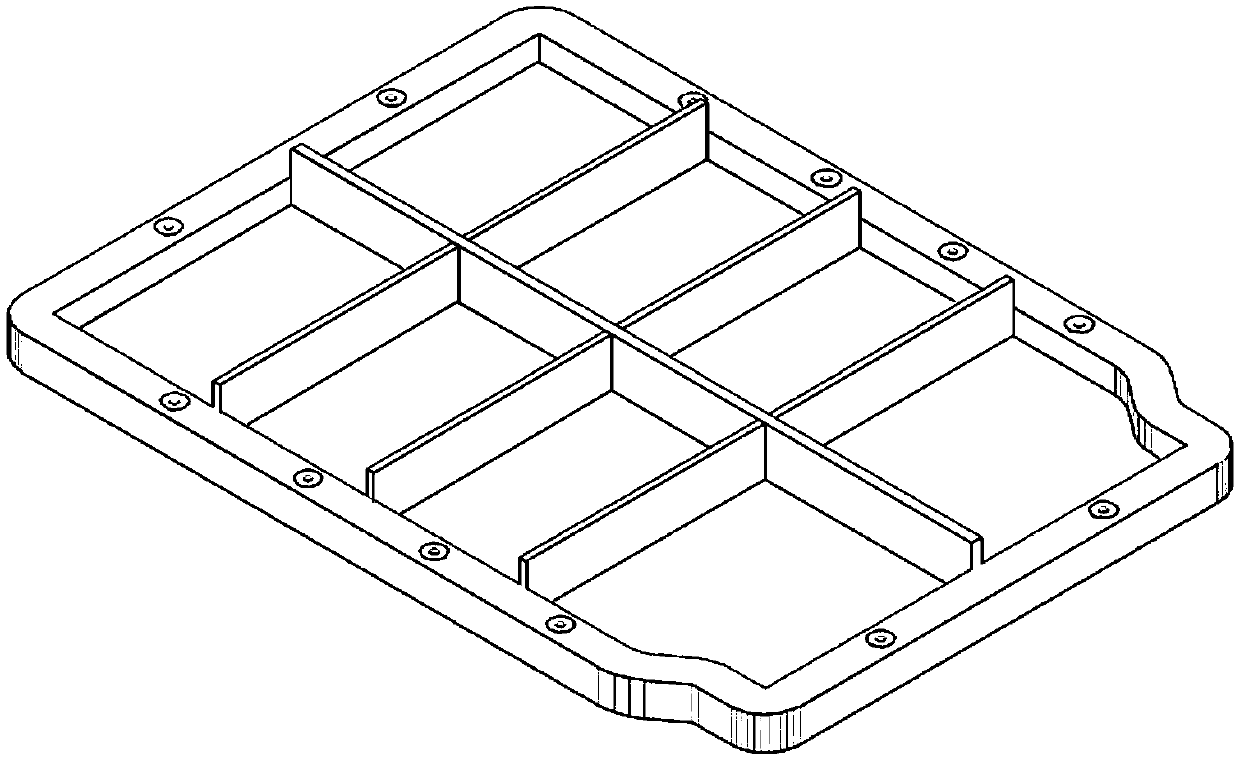

Preparation device for battery tray based on graphene toughened high-performance carbon fiber resin-based composite and preparation method thereof

A carbon fiber resin-based, battery tray technology, used in other household appliances, household appliances, household components, etc., can solve the problems of mechanical property failure of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

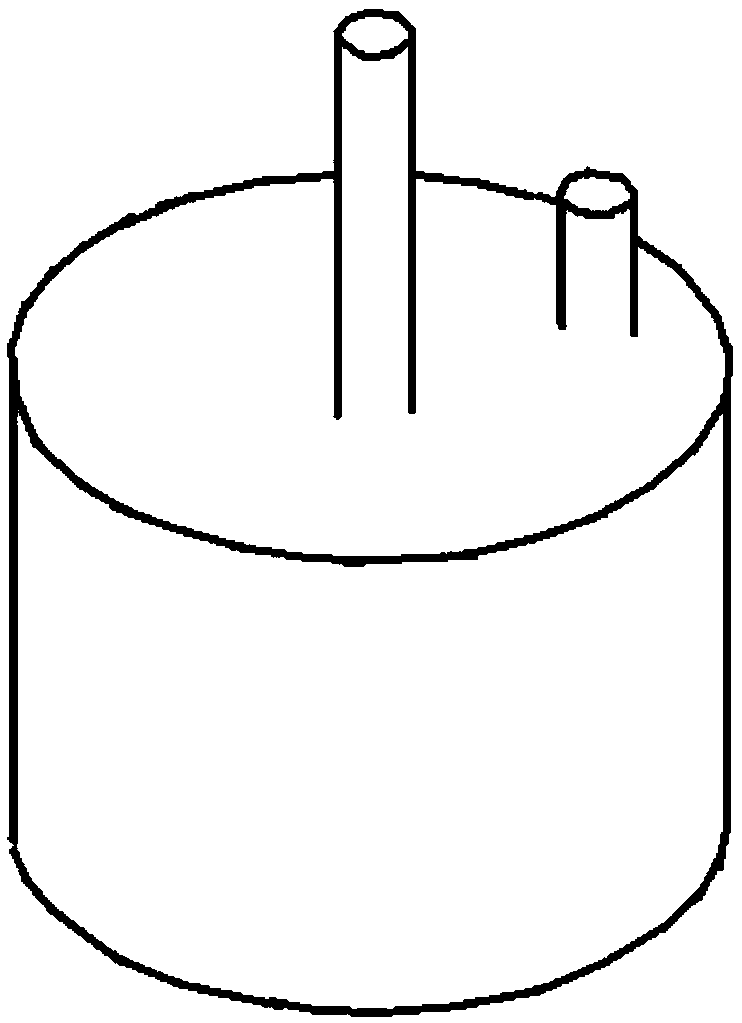

Method used

Image

Examples

Embodiment 1

[0049] The method for preparing battery tray of the present invention, its specific steps are as follows

[0050] 1) The preparation of pre-product: in nitrogen atmosphere, take tetramethylcyclotetrasiloxane and styrene as raw material, take the isopropanol solution of chloroplatinic acid as catalyst (wherein tetramethylcyclotetrasiloxane, benzene The molar ratio of ethylene and isopropanol solution of chloroplatinic acid is 80:20:4); the catalyst and styrene are mixed to prepare the styrene catalyst solution, and the styrene catalyst solution is slowly added dropwise into tetramethylcyclotetrasiloxane. Control the styrene catalytic liquid to be added dropwise within 30 minutes, and then continue to react for 20 hours under the condition of nitrogen protection at 45°C, and then use activated carbon adsorption at 45°C to adsorb too much catalyst, and filter the obtained after 45 minutes of adsorption The filtrate is distilled under reduced pressure, the vacuum degree is contro...

Embodiment 2

[0069] The method for preparing battery tray of the present invention, its specific steps are as follows

[0070] 1) The preparation of pre-product: in nitrogen atmosphere, take tetramethylcyclotetrasiloxane and styrene as raw material, take the isopropanol solution of chloroplatinic acid as catalyst (wherein tetramethylcyclotetrasiloxane, benzene The molar ratio of ethylene and isopropanol solution of chloroplatinic acid is 100:30:8); the catalyst and styrene are mixed to prepare the styrene catalyst solution, and the styrene catalyst solution is slowly added dropwise into tetramethylcyclotetrasiloxane. Control the styrene catalytic liquid to be added dropwise within 30 minutes, and then continue to react for 28 hours under the condition of nitrogen protection at 65°C, and then use activated carbon adsorption at 45°C to adsorb too much catalyst, and filter it after 45 minutes of adsorption The filtrate is distilled under reduced pressure, the vacuum degree is controlled at 5...

Embodiment 3

[0089] The method for preparing battery tray of the present invention, its specific steps are as follows

[0090] 1) The preparation of pre-product: in nitrogen atmosphere, take tetramethylcyclotetrasiloxane and styrene as raw material, take the isopropanol solution of chloroplatinic acid as catalyst (wherein tetramethylcyclotetrasiloxane, benzene The molar ratio of the isopropanol solution of ethylene and chloroplatinic acid is 90:2:6); the catalyst and styrene are mixed to prepare the styrene catalyst solution, and the styrene catalyst solution is slowly added dropwise. Slowly added dropwise to tetramethylcyclotetrasiloxane. Control the styrene catalytic solution to be added dropwise within 30 minutes, and then continue to react for 25 minutes under the condition of nitrogen protection at 5°C, and then use activated carbon adsorption at 45°C to adsorb too much catalyst, and filter it after 45 minutes of adsorption The filtrate is distilled under reduced pressure, the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com