Gangue filling three-dimensional grouting construction method of short-wall roadway mining horizontal working face

A short-wall roadway mining and construction method technology, which is applied to filling materials, mining equipment, earth square drilling, etc., can solve problems such as high cost, large demand for fly ash, and large interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0023] The present invention designs a three-dimensional grouting construction method for gangue filling in the horizontal working face of short-wall roadway mining, which is realized through the following steps:

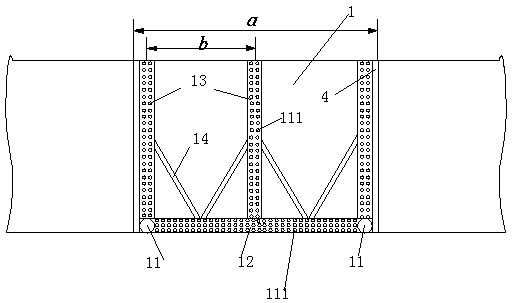

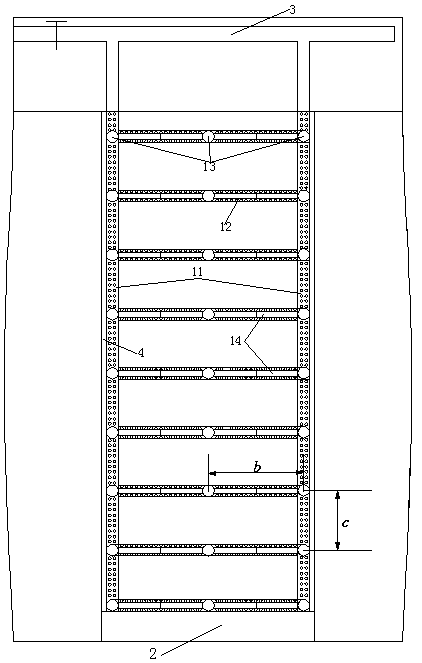

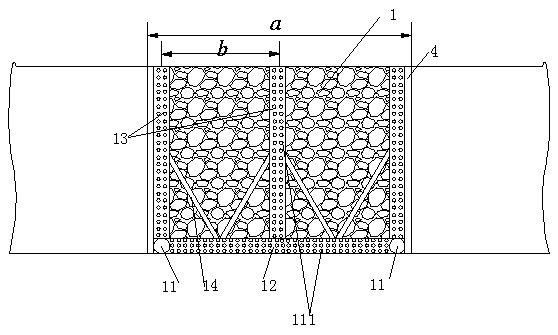

[0024] 1) Headway excavation: Excavate a number of sideways 1 in the horizontal working face, and set up gangue and slurry walls 2 at one end of each levelway 1, such as figure 1 , 2 As shown, the width of the lane is a , a Satisfy the following formula: , where, m is the thickness of the immediate roof; is the direct top tensile strength; is the bulk density of the direct top.

[0025] 2) Arrangement of grouting pipes: two side grouting pipes 11 are arranged at the bottom of both sides of each entryway 1, and the two side grouting pipes 11 are connected with the main road grouting pipe 3, and the main road grouting pipe 3 It is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com