Hydrofracturing-based method and equipment for diminishing dust and eliminating outburst of coal bed

A hydraulic fracturing and coal seam technology, applied in the field of dust reduction and outburst elimination based on hydraulic fracturing of coal seams, can solve problems such as inability to prevent rock burst, ineffective water injection pressure, and unsatisfactory drainage effects, etc., to achieve gas drainage Significant yield, good dust reduction effect, and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

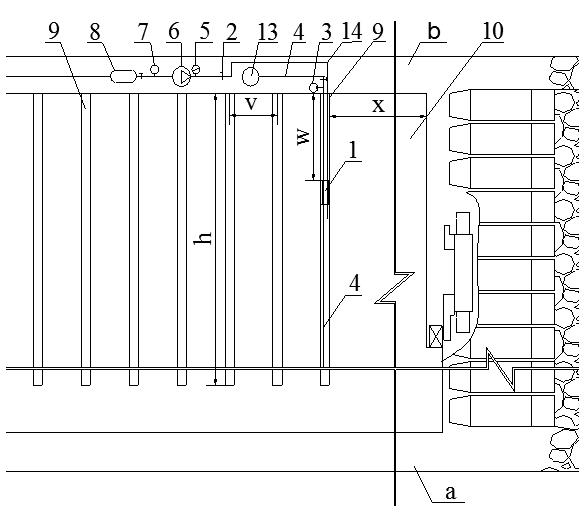

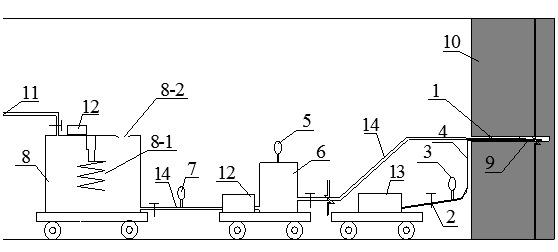

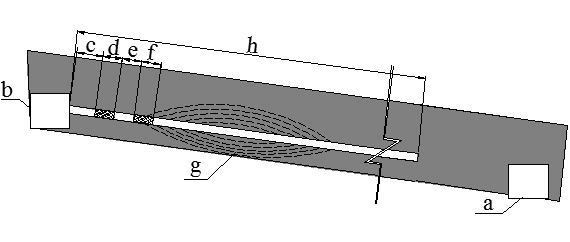

[0020] Such as figure 1 As shown, the average thickness of the coal seam in a certain mine is 15m, the hardness of the coal seam is 3, the inclination angle of the coal seam is 11°, the buried depth of the coal seam is 550m, and the working length is 168m. , the roof is sandstone, and the hardness of sandstone is 6. According to the time required for drilling and fracturing, gas extraction, coal moistening and softening and other processes and the actual advancing speed of the working face, the distance x of the advanced coal wall during fracturing drilling construction is determined to be 20m; b drill holes 9 with a length of 130m along the coal body 10 at a distance of 1.5m from the bottom plate, the depth of the drill holes 9 is not less than 1 / 2 of the length of the coal face, the diameter of the holes is 75mm, and the hole spacing v is 16m. Connect the high-pressure rubber hose 4 with the flow / pressure real-time display monitor 3 at the orifice for real-time flow / pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com