Patents

Literature

530 results about "Single effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single Event Effects. Single Event Effects (SEEs) are caused by a single, energetic particle, and can take on many forms. Single Event Upsets (SEUs) are soft errors, and non-destructive. They normally appear as transient pulses in logic or support circuitry, or as bitflips in memory cells or registers.

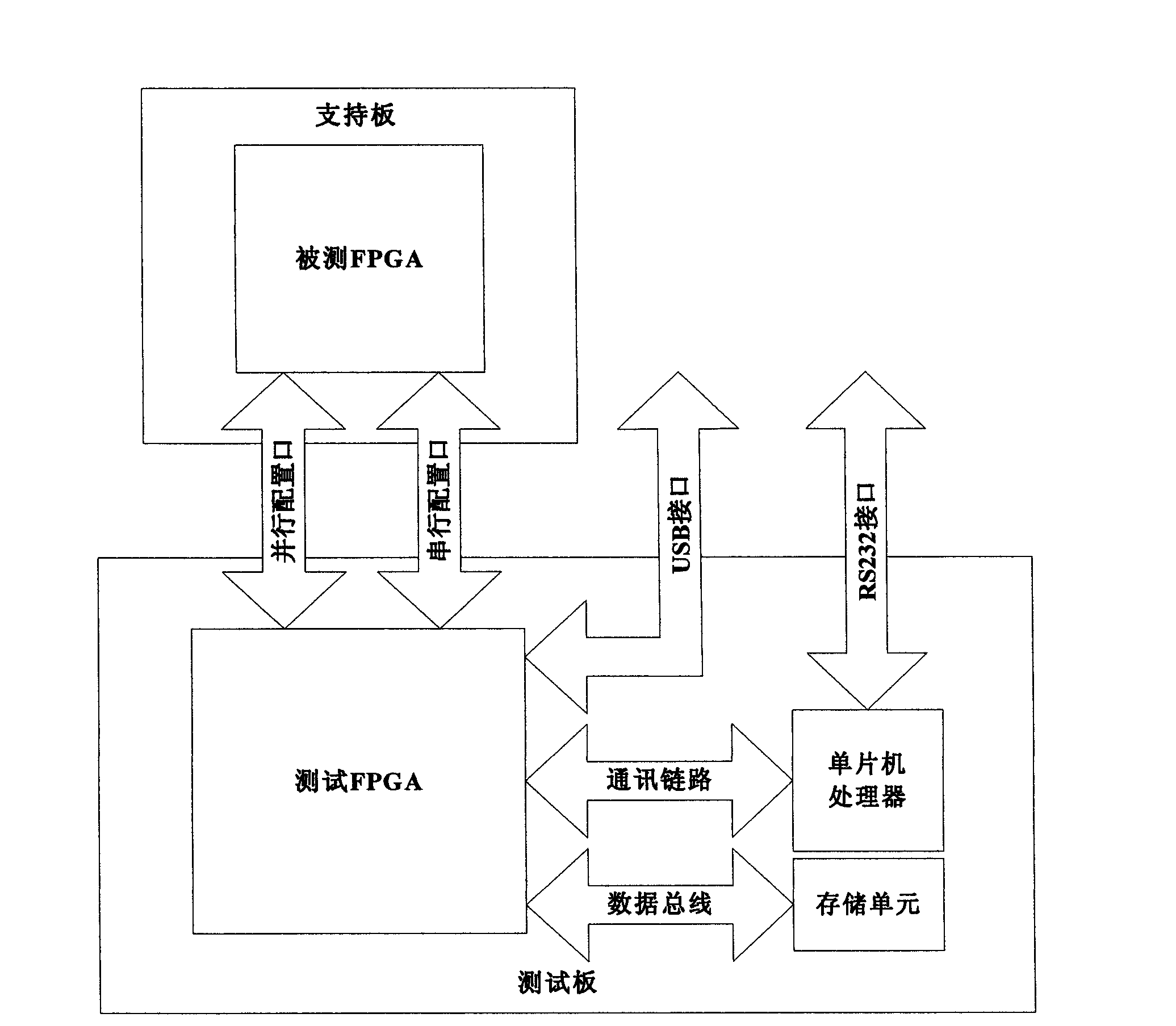

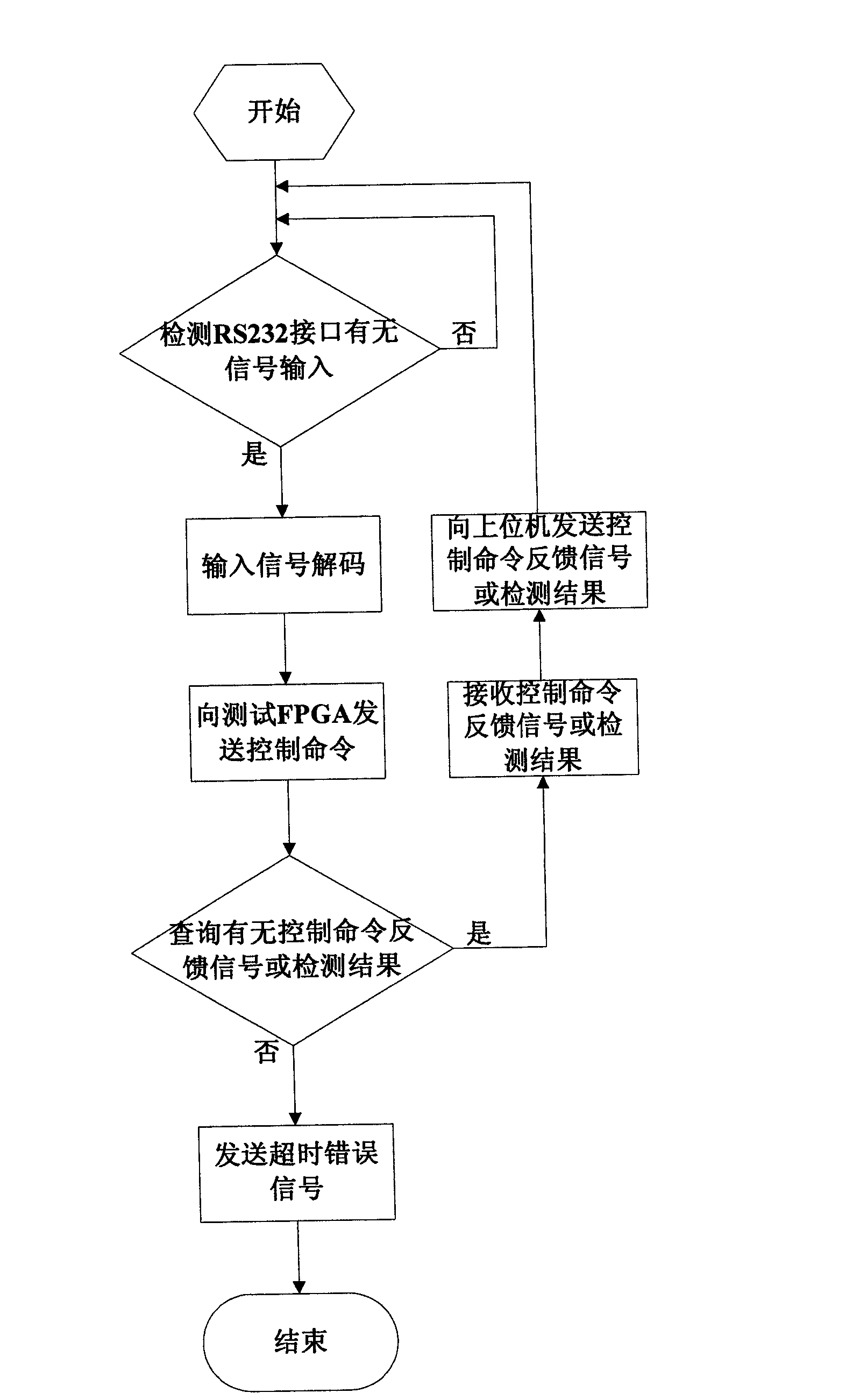

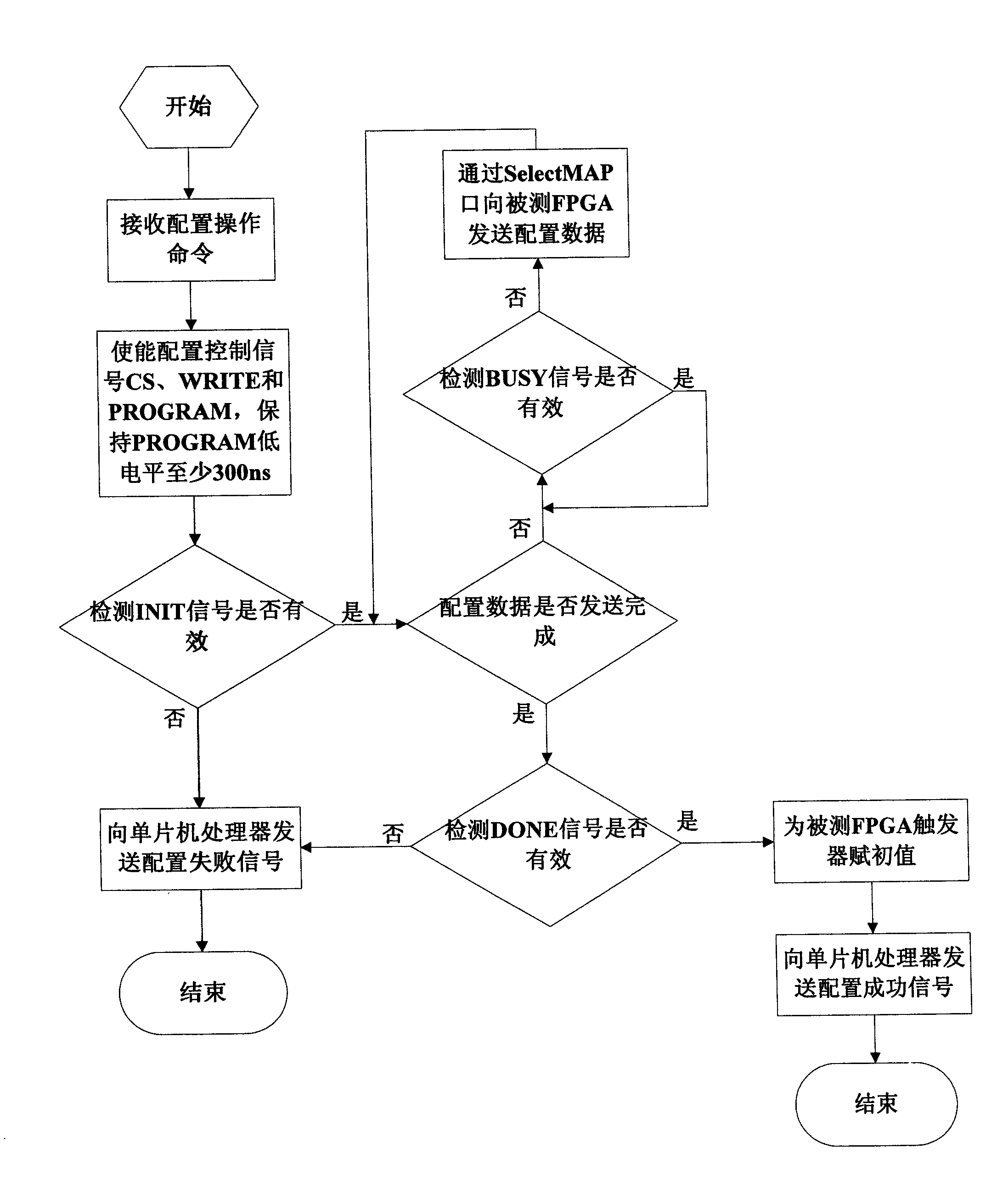

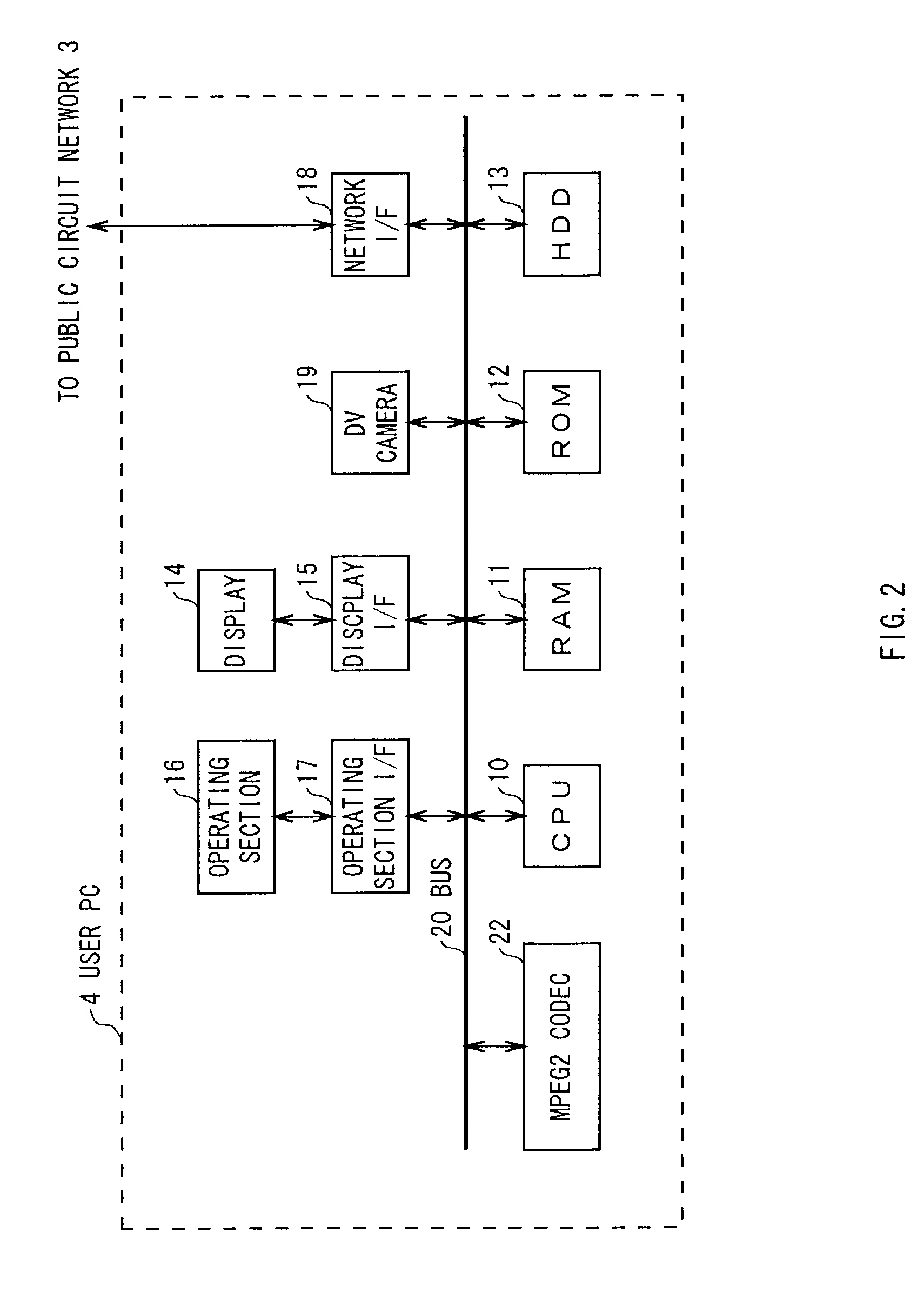

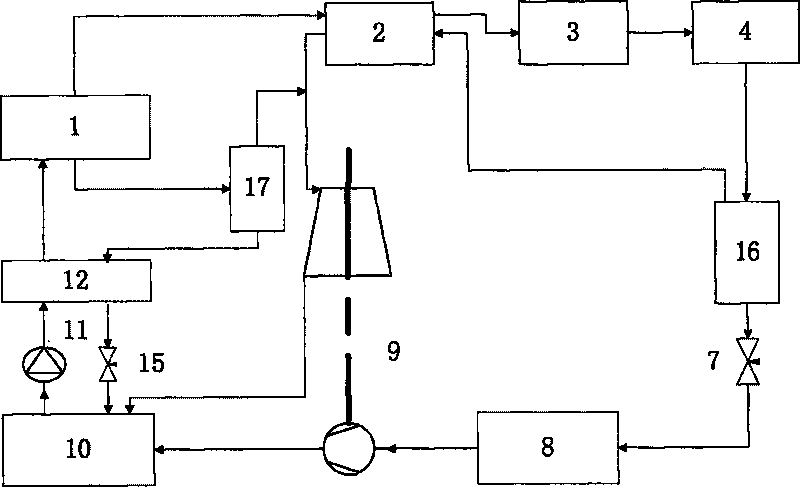

Test system and method for single event effect of SRAM (System Random Access Memory) type FPGA (Field Programmable Gate Array)

ActiveCN102332307AEasy to operateImplement rollover detectionStatic storagePilot systemRandom access memory

The invention provides a test system and method for a single event effect of an SRAM (System Random Access Memory) type FPGA (Field Programmable Gate Array). The test system comprises a single chip microcomputer processor, an RS232 interface circuit, a USB (Universal Serial Bus) interface circuit, a test FPGA and a storage unit. The test system and method can be used for fault injection tests of a configuration memory and a BRAM (Battery Random Access Memory) of the SRAM type FPGA, and single event function interrupting detection, single event locking detection and single event turning detection including single event turning detection for a configuration storage region, the BRAM and a trigger of the SRAM type FPGA are realized. The invention has the advantages of simplicity in operation, entirety in detection, high accuracy, good real-time property and strong universality.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

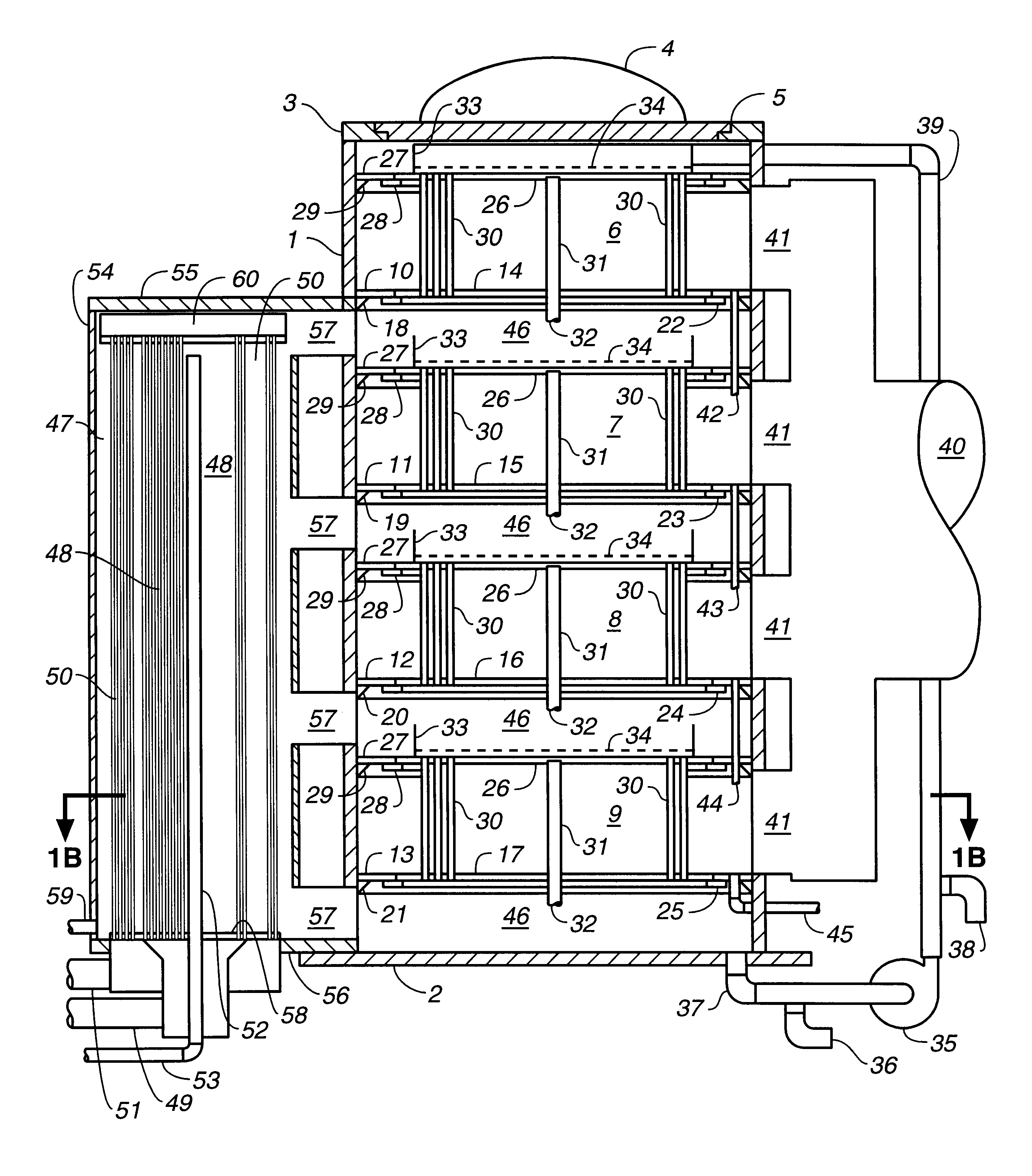

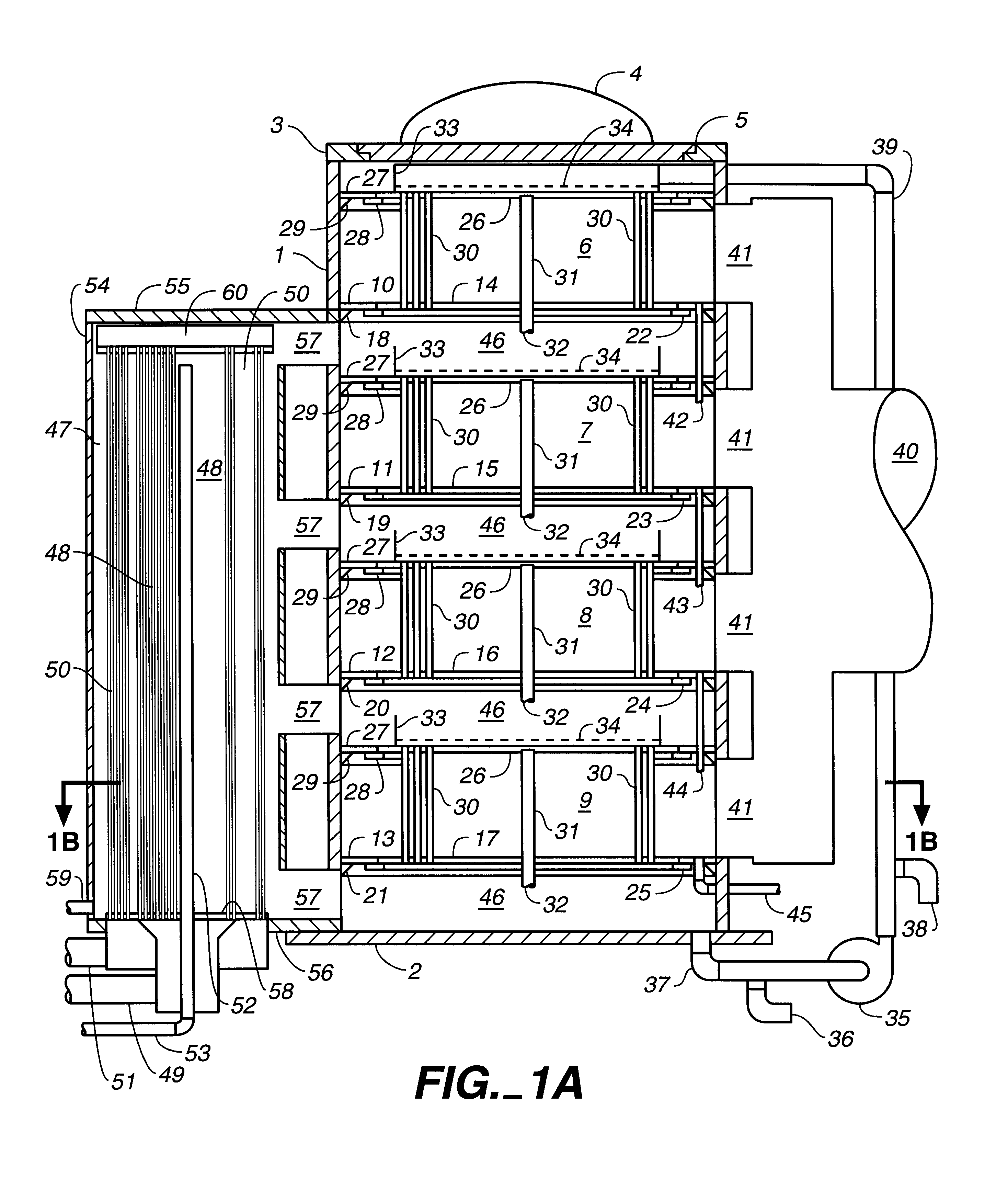

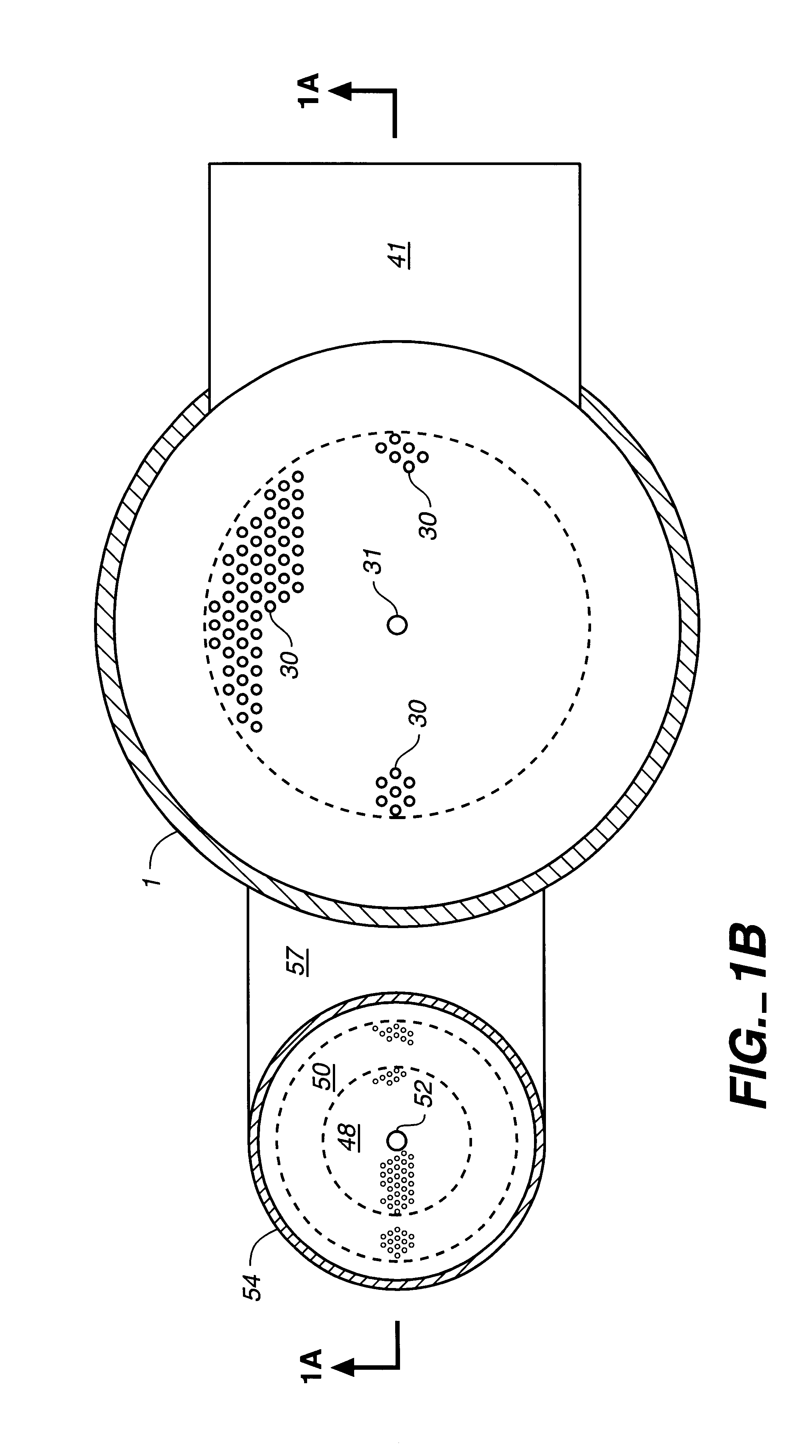

Desalination of seawater by evaporation in a multi-stack array of vertical tube bundles, with waste heat

InactiveUS6309513B1Large capacityEnsure adequate heatingGeneral water supply conservationDistillation in boilers/stillsSingle effectCogeneration

A large and economical type of multi-stack vertical tube evaporator (MS-VTE) is disclosed having units of multiple stacks of vertical tube bundles or stages mounted in a single vessel, and having its liquid feed pumped to the uppermost VTE bundle stack or stage and having the feed then cascading downward through the lower bundle stacks in series flow, and wherein all the tube bundles are heated with the same waste steam of no or low $-value, e.g. with turbine reject steam in parallel flow under vacuum into the steam-sides of all tube bundles in the unit through a common steam conduit; and wherein the feed liquid is progressively evaporated from stage to stage or stack to stack and the vapors produced in the tubes of each bundle during the partial evaporation of the feed are separated between the stacks and condensed by parallel flow into one or more condensers. Applied to seawater desalination in a co-generation procedure with a coastal power plant, this evaporator produces about one pound of distilled water per pound of turbine reject steam used under vacuum and applied to single-effect mode in one evaporator unit or several units mounted in a single vessel with a condenser, to substantially reduce the cost of such useful distilled water. When applied in a similar cogeneration procedure but in a multi-effect series mode of several such units, or multiple units, the rate of distilled water production can be increased several-fold based on the amount of turbine reject steam applied.

Owner:SEPHTON HUGO H

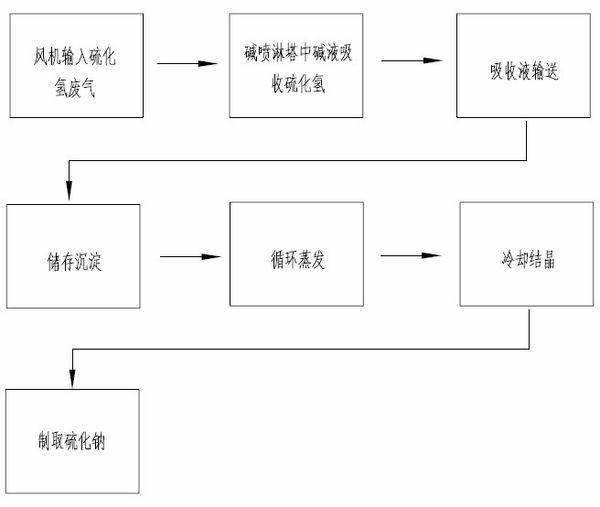

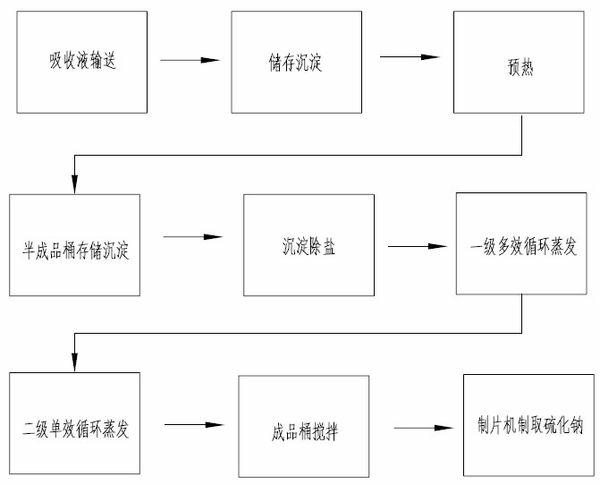

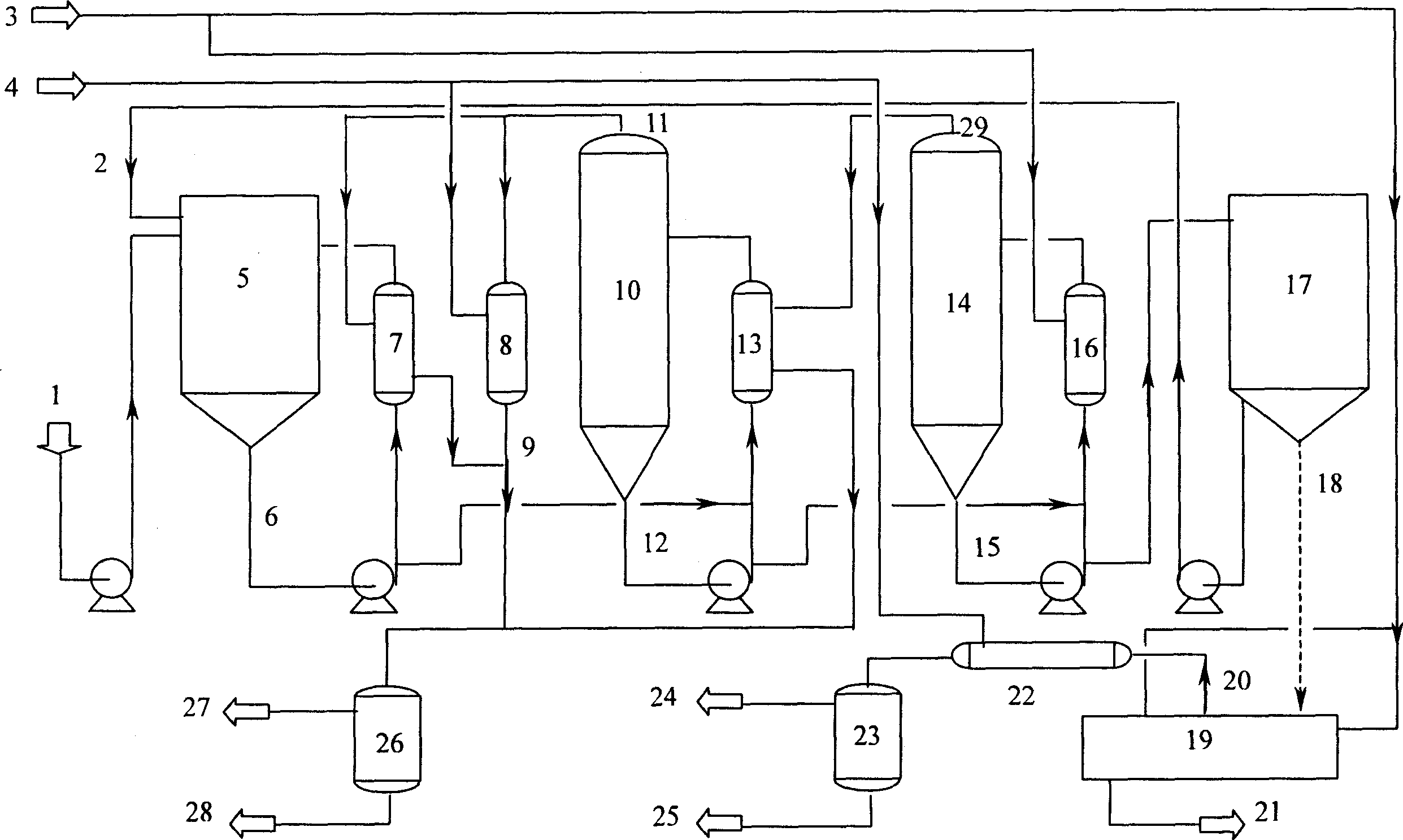

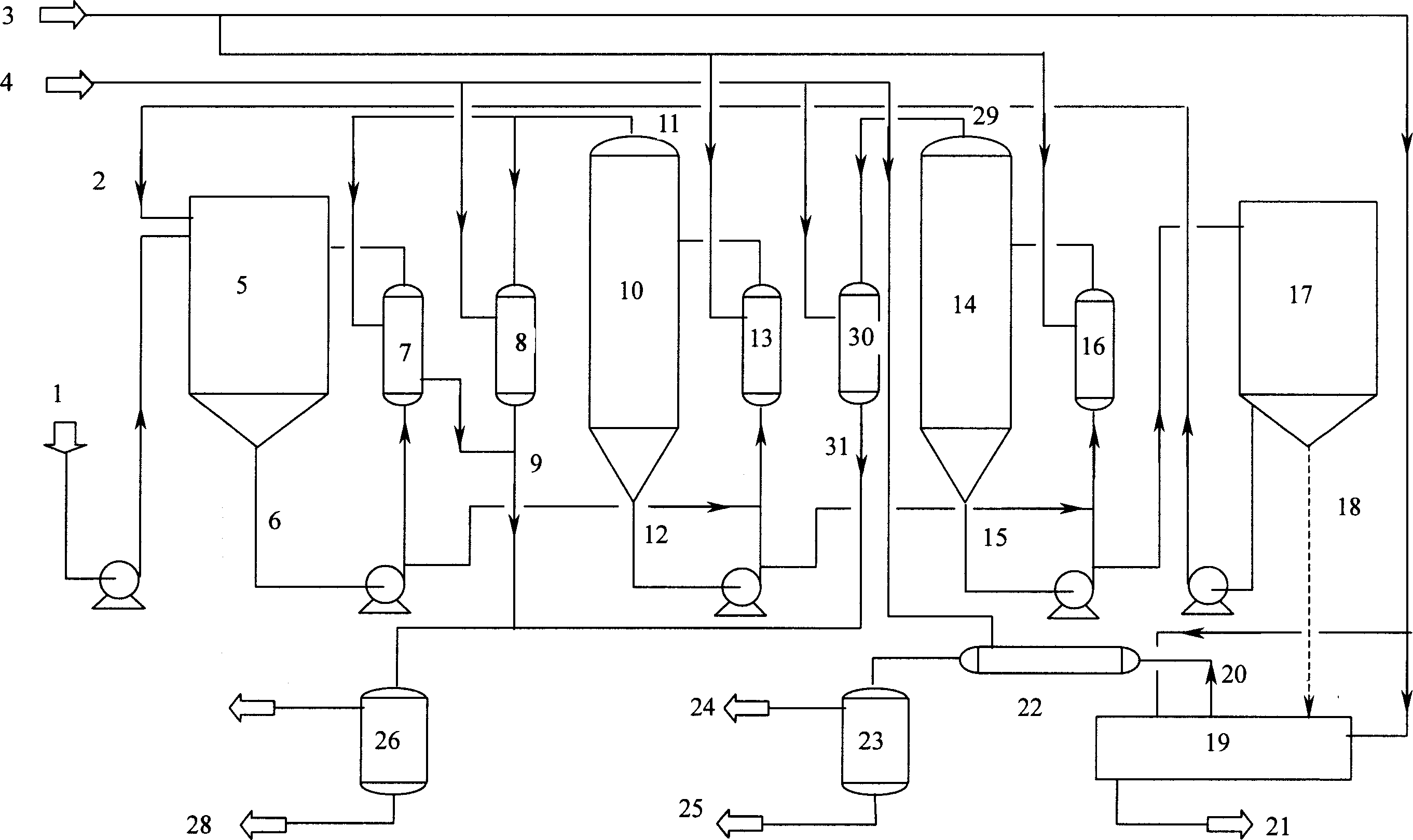

Method for preparing sodium sulfide from hydrogen sulfide waste gas produced in production of viscose fibre

InactiveCN102515112AAchieve optimized generationIncrease production costAlkali metal sulfides/polysulfidesImpurityWaste gas

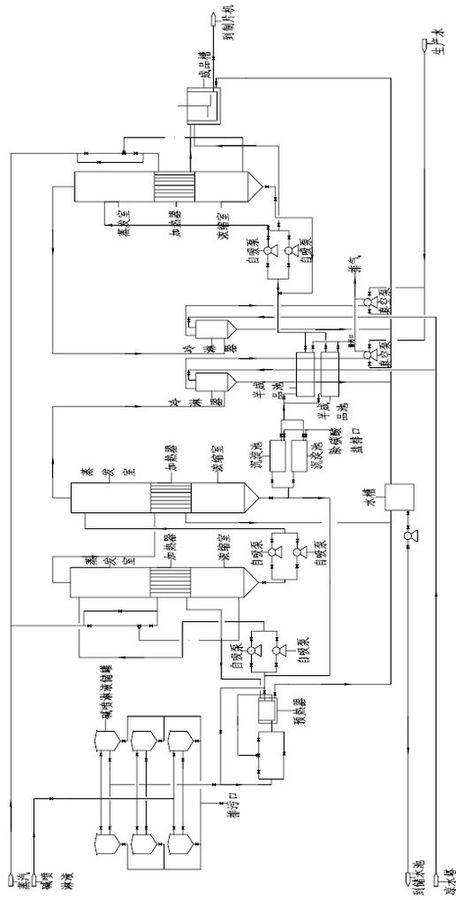

The invention relates to the field of production of viscose fibre in the textile industry, in particular to a method for preparing sodium sulfide from hydrogen sulfide waste gas produced in the production of the viscose fibre. The method comprises the steps as follows: A, the waste gas is fed into an alkali spray tower; B, hydrogen sulfide is absorbed in an alkali liquor in the alkali spray tower; C, impurities are removed; D, a preheated absorption liquid is delivered into a primary multi-effect evaporator; E, a solution is subject to settlement and desalination; F, the desalinated solution is filled into a semi-finished product barrel, and caustic soda is added into the desalinated solution; G, the solution in the semi-finished product barrel is delivered into a secondary single-effect evaporator; H, after undergoing the secondary evaporation, the solution is filled into a finished product barrel, and then is stirred for crystallization; and I, crystal sodium sulfide is made into tablets. The method has the advantage of realizing the optimal generation of sodium sulfide through the setting of processing parameters such as the size of main equipment, the pore diameter of a delivery pipeline, wind volume, wind velocity, the concentration of the alkali liquor, absorption time, circulating evaporation time, evaporation temperature, evaporation vacuum degree, precipitation time, stirring velocity, the rotational speed of a tablet making machine, and the like.

Owner:YIBIN HIEST FIBER +2

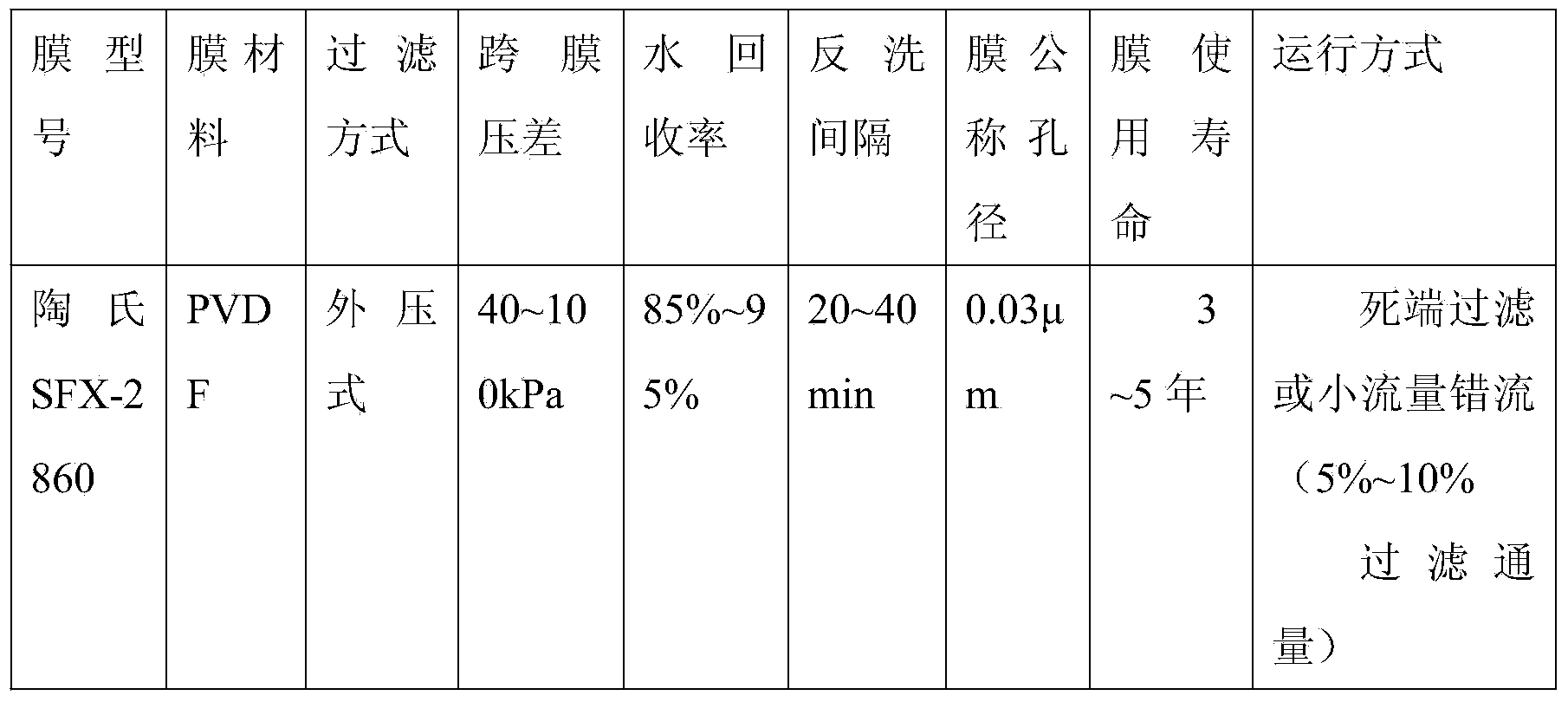

High salinity wastewater treatment method

InactiveCN106145223AEfficient recyclingReduce processing timeEnergy based wastewater treatmentWater/sewage treatment by heatingSingle effectChemistry

The invention relates to a treatment method for high-salt wastewater, which recovers sodium sulfate and sodium chloride through five treatment steps of first-effect heating, first-time evaporation and crystallization, cooling and crystallization, second-effect heating and second-time evaporation and crystallization. The advantages of the present invention are: the treatment method of the present invention, through the first-effect heating and the second-effect heating, enables the solution to quickly meet the temperature of evaporation and concentration, thereby shortening the treatment time; at the same time, through the treatment method, the high-efficiency effect on the coal chemical industry The sodium chloride and sodium sulfate in the brine wastewater are effectively recovered, which greatly reduces the pressure on environmental protection and the process conditions are simple and stable, which is convenient for industrialization.

Owner:JIANGSU SUNRISE CHEM ENG TECH

Mining method employing solid filling and fully-mechanized coal mining hybrid working face

ActiveCN104405437AAvoid pollutionSolve the tunnelingUnderground miningSurface miningSolid massFilling materials

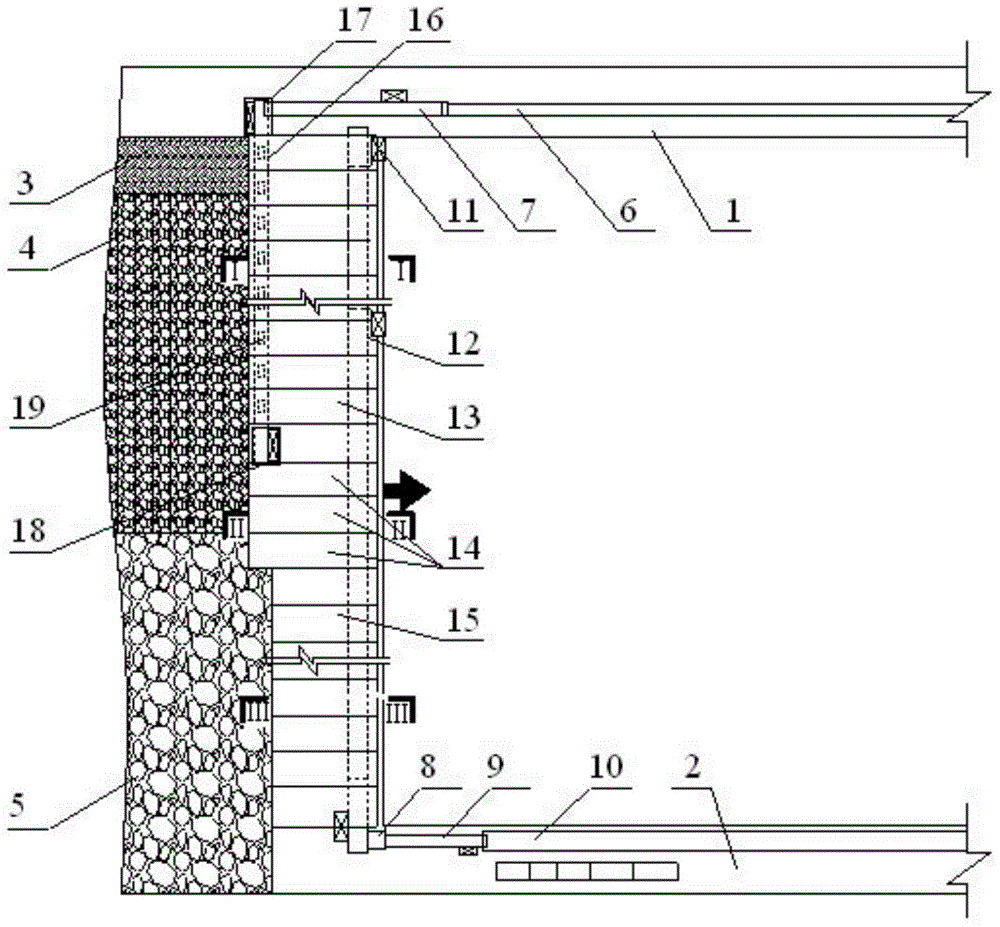

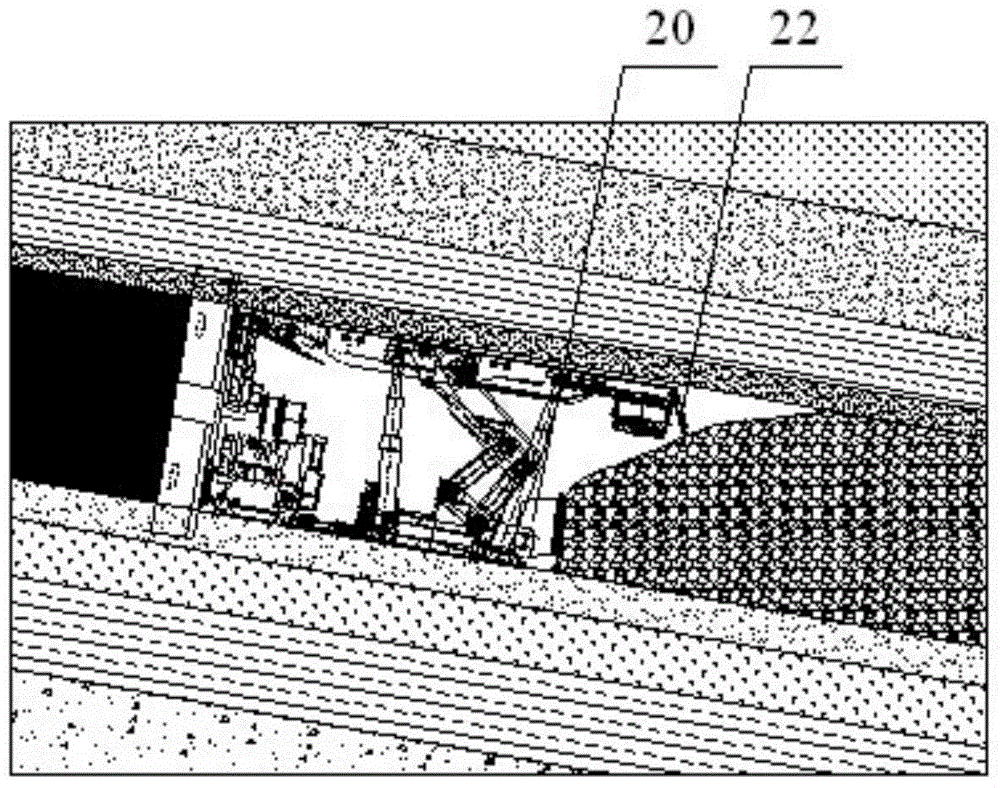

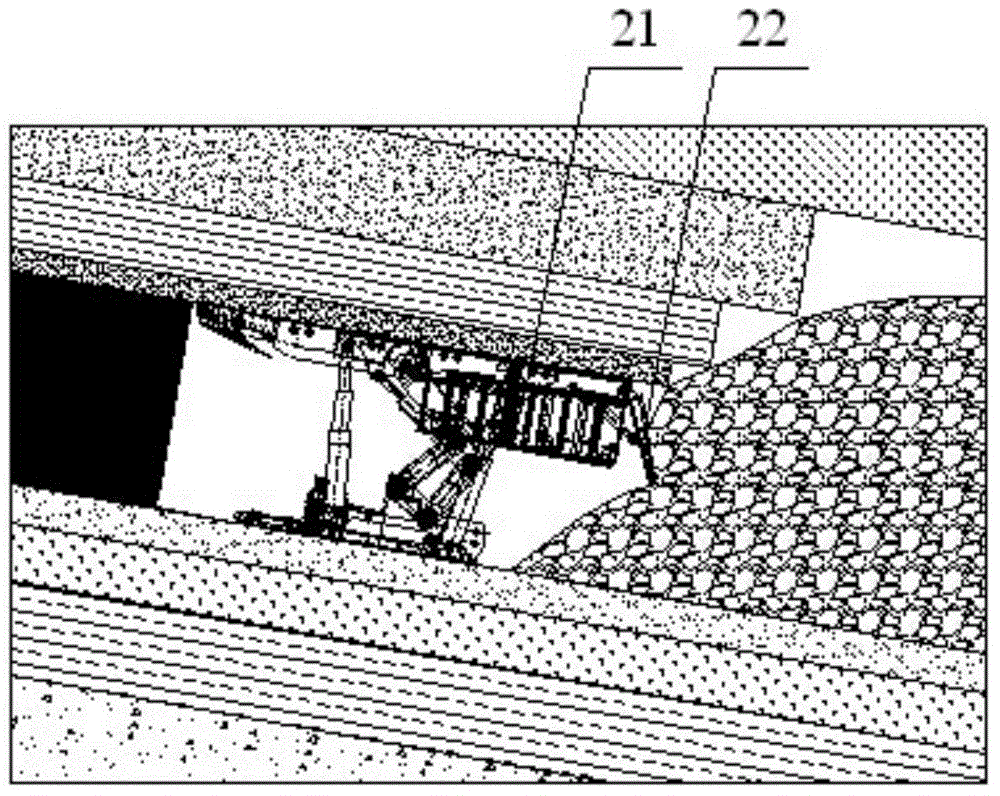

The invention discloses a mining method employing a solid filling and fully-mechanized coal mining hybrid working face, namely a method for carrying out coordinated and combined mining by combining solid filling with fully-mechanized coal mining on the same coal face. Coal mining is carried out by adopting a strike retreating-longwall mode; coal cutting, coal charging and coal handling procedures are the same as those of a fully-mechanized coal mining process; a solid filling section of the hybrid working face is used for supporting a roof by virtue of a filling and mining hydraulic support; solid filling materials are backfilled to a goaf management roof by virtue of a porous hopper conveyor which is suspended behind and below of the filling and mining hydraulic support; a fully-mechanized coal mining section is used for supporting the roof by virtue of a fully-mechanized coal mining hydraulic support; the goaf is managed by adopting a caving method. The mining method is beneficial for giving play to dual advantages of solid filling and fully-mechanized coal mining; the problem of environmental pollution caused by accumulation of solid wastes such as gangue, coal ashes and construction wastes on the ground is reduced by solid filling; the working face is lengthened by combining with fully-mechanized coal mining; tunneling of a mining roadway is reduced; the single yield and single effect of the working face are improved; the requirements of a modern mine on production capacity are met.

Owner:CHINA UNIV OF MINING & TECH +1

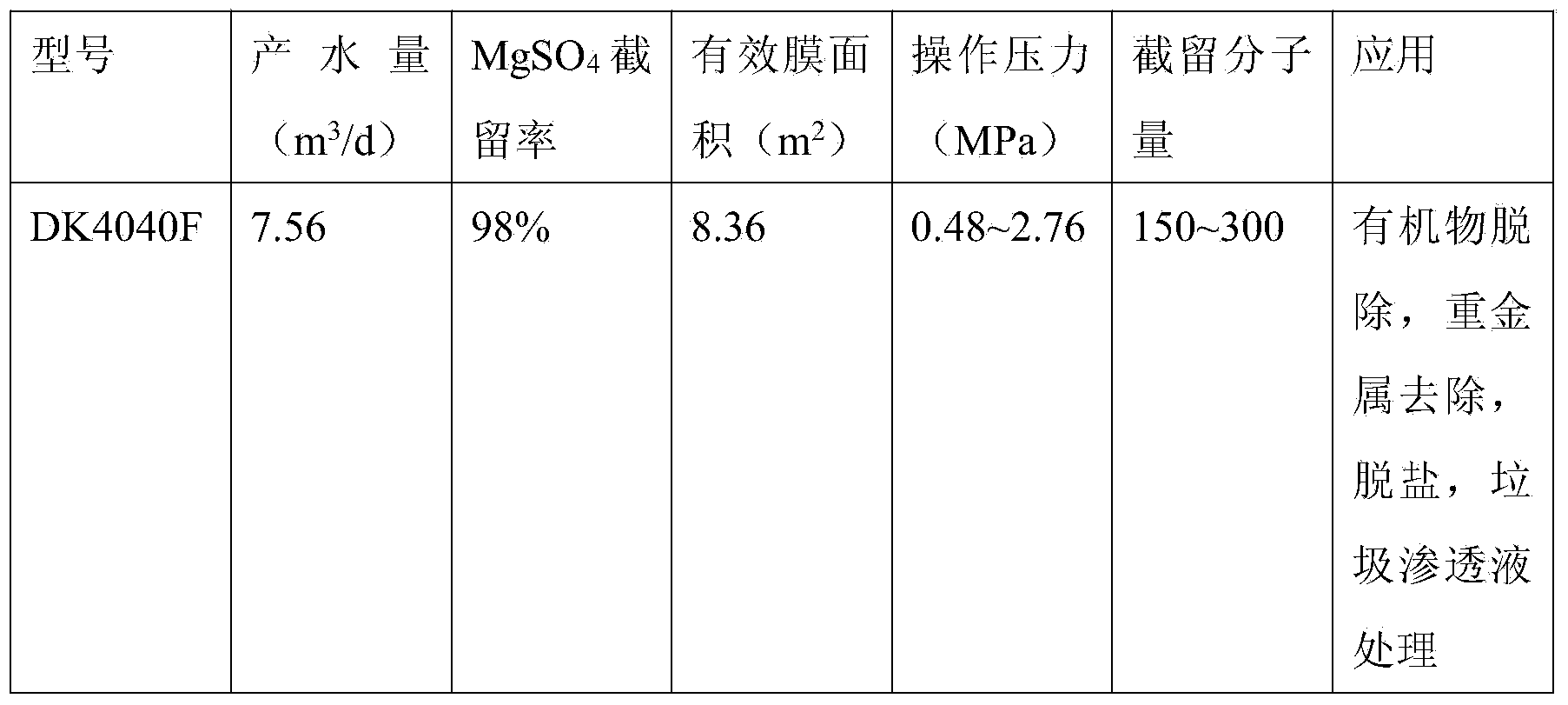

Method for preparing industrial salt through separation, evaporation and crystallization of coal chemical strong brine

ActiveCN104071808AWill not cause accumulationTake advantage ofAlkali metal chloridesAlkali metal halide purificationFiltrationUltrafiltration

The invention relates to a method for preparing industrial salt with coal chemical strong brine, particularly to a method for preparing the industrial salt through separation, evaporation and crystallization of the coal chemical strong brine, and aims to solve the problems that secondary pollution exists and resources are not recycled in existing coal chemical strong brine treatment processes. The method comprises the steps as follows: 1, adding lime milk, a coagulant and a magnesium agent into the coal chemical strong brine, and feeding the coal chemical strong brine into a clarifying tank or a coagulative precipitation tank for chemical precipitation treatment; 2, adjusting the pH; 3, performing ultra-filtration treatment; 4, performing nano-filtration treatment; 5, performing single-effect evaporating crystallization or quadruple-effect evaporating crystallization to obtain the industrial salt. The method is used for treating the coal chemical strong brine and preparing the industrial salt from the coal chemical strong brine.

Owner:中煤西安设计工程有限责任公司

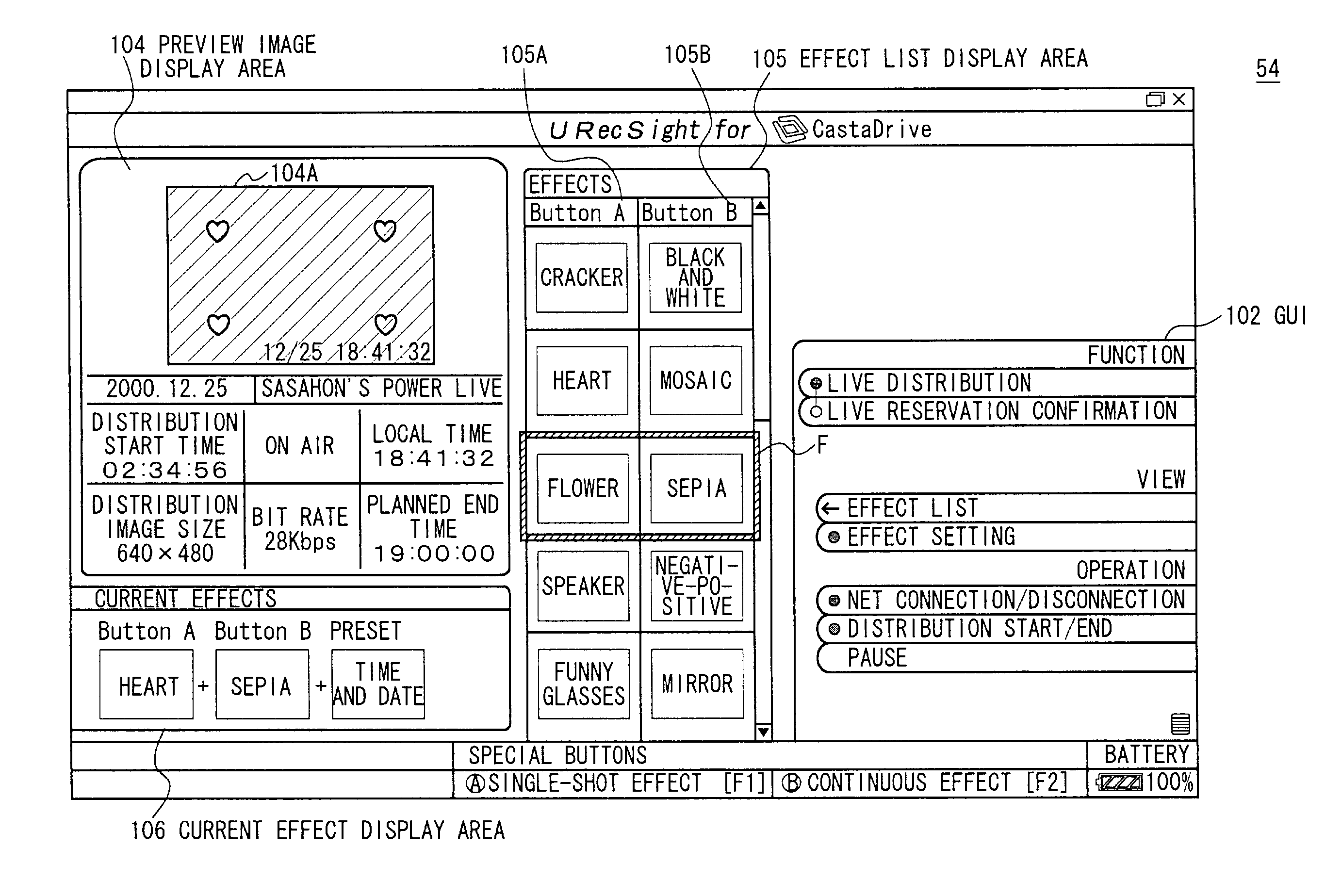

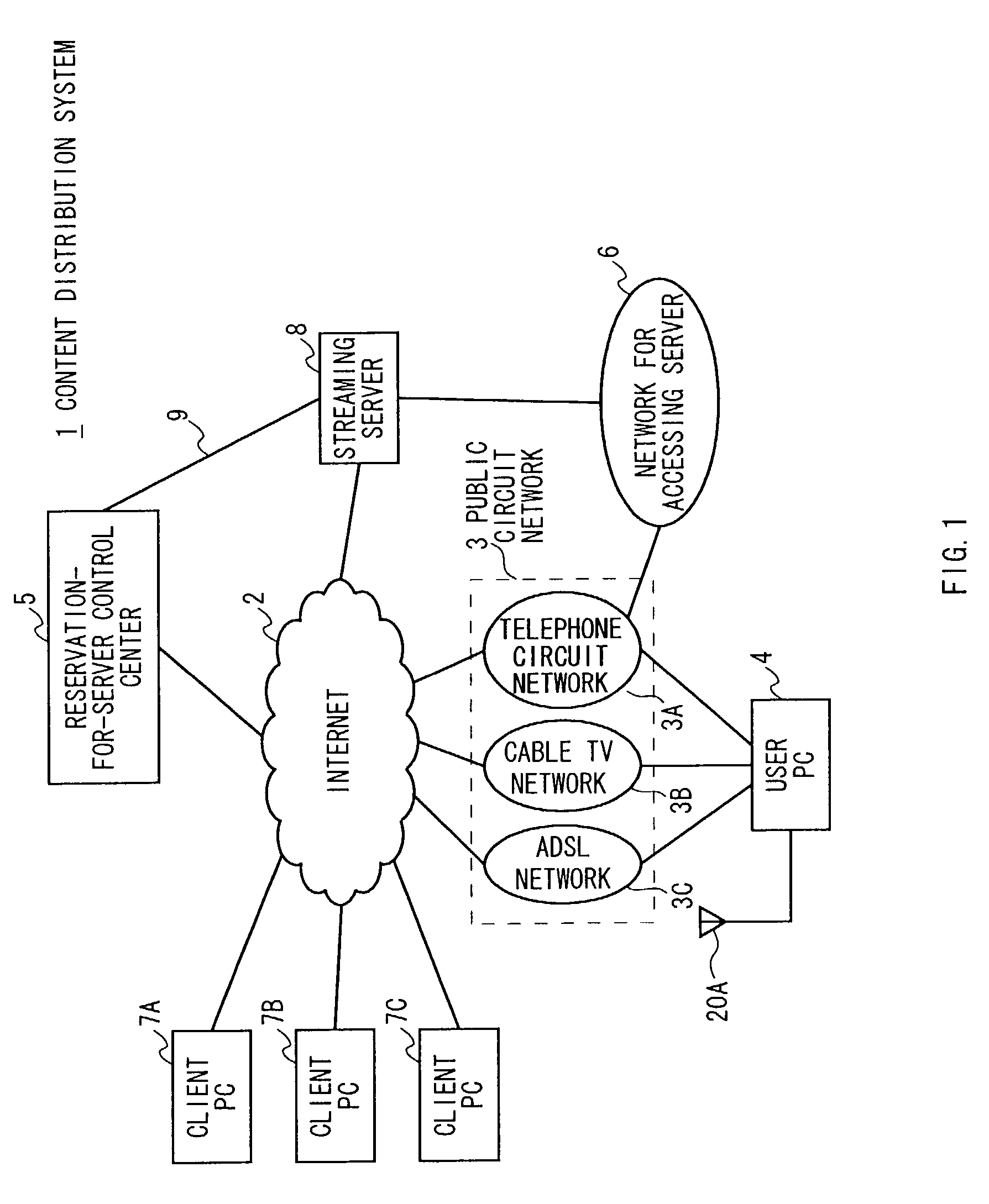

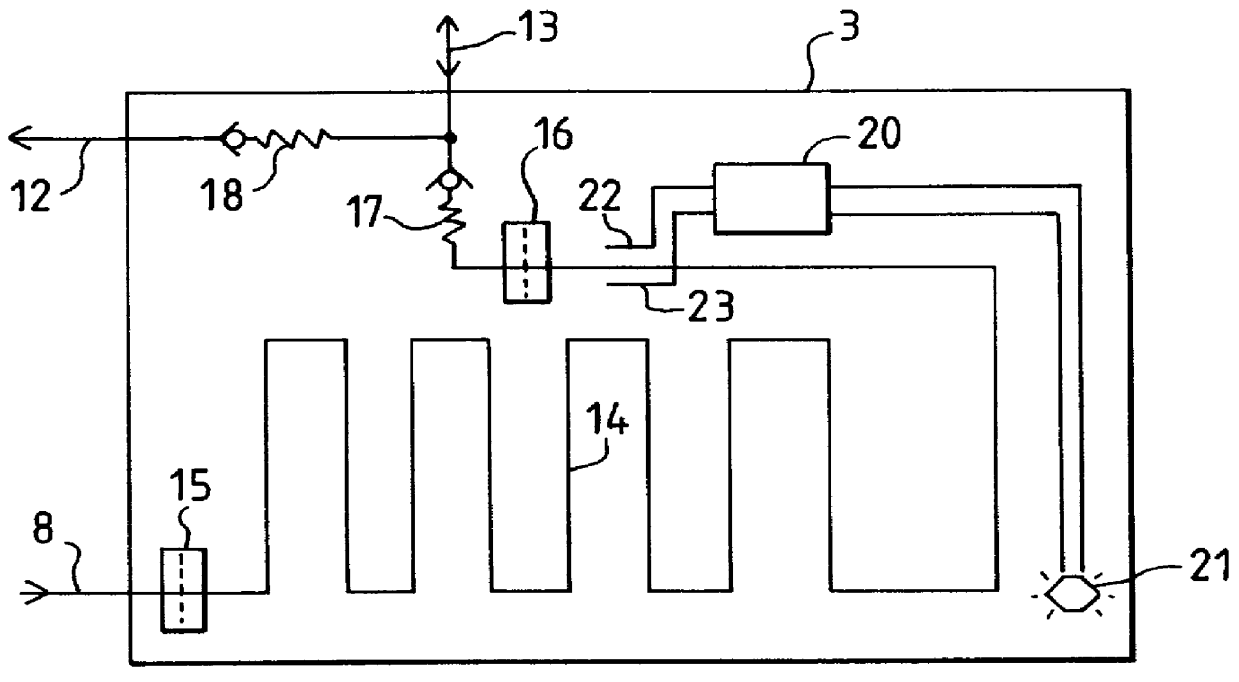

Effect adding device, effect adding method, effect adding program, storage medium where effect adding program is stored

InactiveUS7103840B2Simply and quickly selecting and applyingSimply and quickly selectTelevision system detailsElectronic editing analogue information signalsComputer graphics (images)Single effect

The present invention is capable of easily and quickly selecting and applying desired effects. In the present invention, single-shot effects and continuous effects for specifying special effects for images are arranged and displayed in the order of use in a single-effect display area 105A and a continuous effect display area 105B of an effect list display area 105, so that the user can easily and quickly select a single-shot effect and a continuous effect to apply desired special effects, in order to easily and quickly apply the desired special effects to input image at desired timing.

Owner:SONY CORP

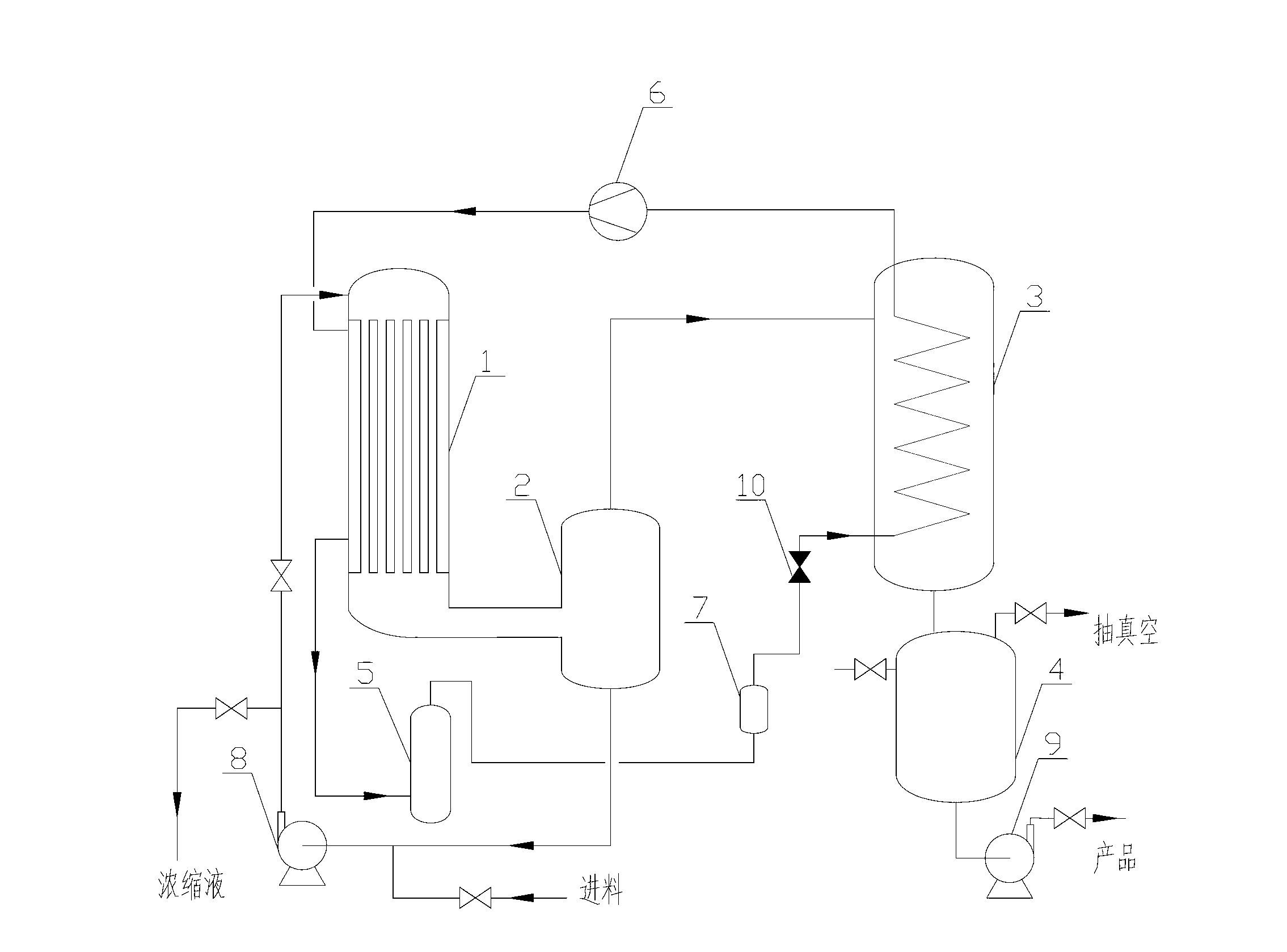

Heat pump type low-temperature evaporating device and method

InactiveCN102698451AEvaporator accessoriesMultiple-effect evaporationSteam condensationChemical separation

The invention relates to a heat pump type low-temperature evaporating device and method, belonging to the technical fields of chemical separation, energy conservation and emission reduction. The method is characterized in that a solvent is evaporated and condensed in the heating circulation process of a heat-carrying medium, so that the aim that a thermosensitive material liquid is evaporated and concentrated or an organic solvent is recovered at the low temperature can be achieved; the heat pump type low-temperature evaporating device mainly comprises a material liquid evaporator, a gas-liquid separator, a secondary steam condenser, a condensate tank, a heat medium storage tank, a heat medium steam compressor, a filter, a material liquid pump, a condensate pump, a throttling device and a pipeline valve, wherein a single-effect or multi-effect falling-film evaporator is used as the material liquid evaporator. The material liquid evaporating temperature is controlled to be within the range of 25-60 DEG C by adjusting the system vacuum degree; and the system heating capacity is controlled to be matched with the evaporation capacity by adjusting the input power of the compressor at the variable frequency. The heat pump type low-temperature evaporating device and method have the beneficial effects and advantages that the gas emission is reduced, so that the environment is protected, and the energy is saved; and furthermore, the active ingredients of the material liquid can be maintained by low-temperature evaporation, equipment is seldom corroded, and a pipeline is not easily blocked, so that the equipment cost is lowered.

Owner:DALIAN UNIV OF TECH

Oil-containing sludge disposal method

ActiveCN1765781AGuaranteed pumpabilityGuaranteed pumpability of sludge before and after dewateringSludge treatment by de-watering/drying/thickeningPositive pressureSludge

The invention discloses a treatment method for oil-containing sludge, which comprises: in extract dewater process, using multiple-effect or single-effect multiplestage extract evaporation system, wherein, in the latter, holding normal pressure in first stage and positive pressure in other stages; in the former, using normal pressure in all stages. Compared with prior art, this invention can decrease heat-exchange area and power consumption, and overcomes the problem from decompression operation in common multiple-effect multiplestage system.

Owner:CHINA PETROLEUM & CHEM CORP +1

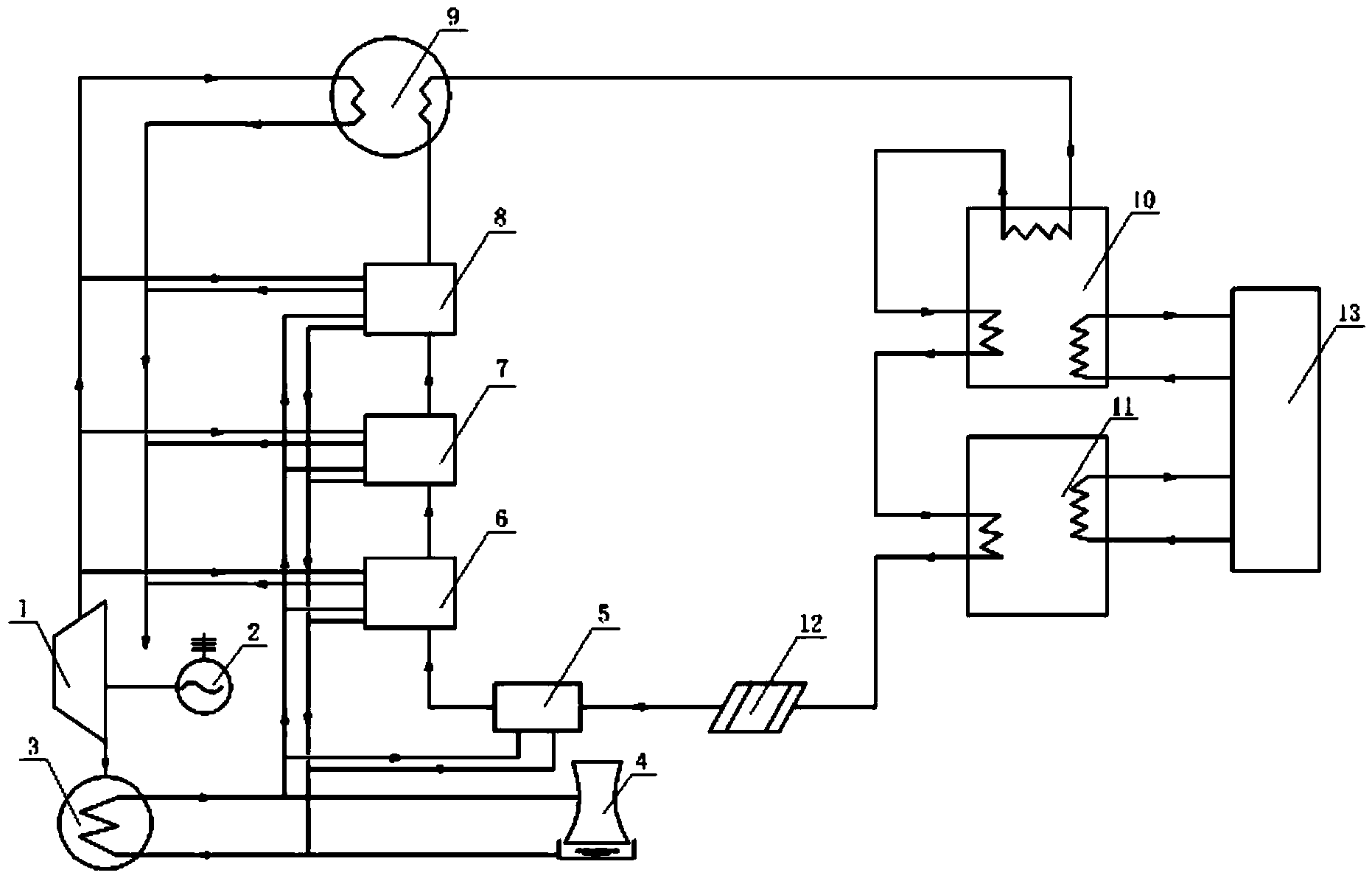

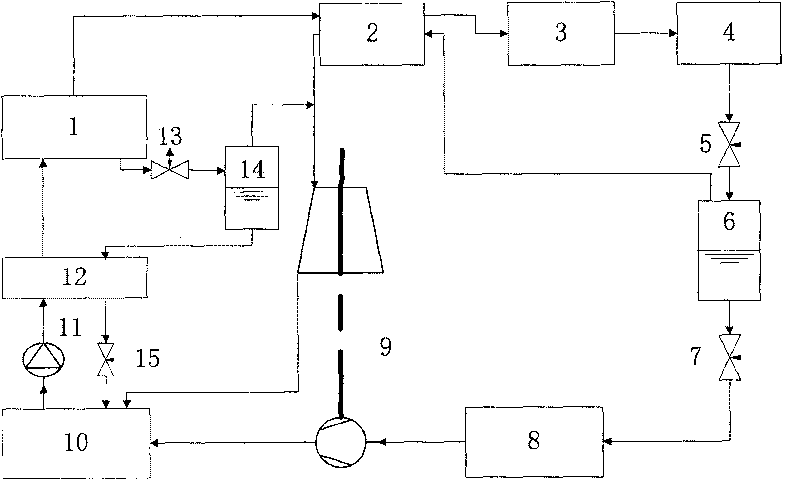

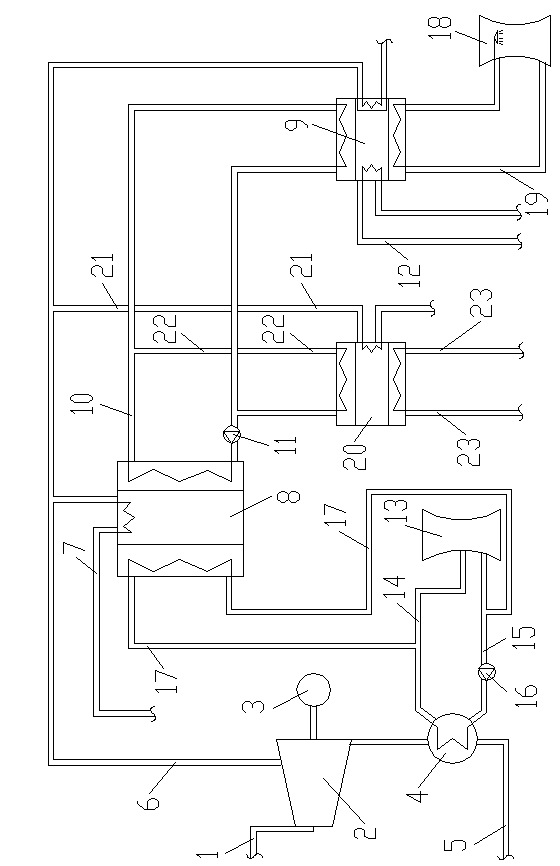

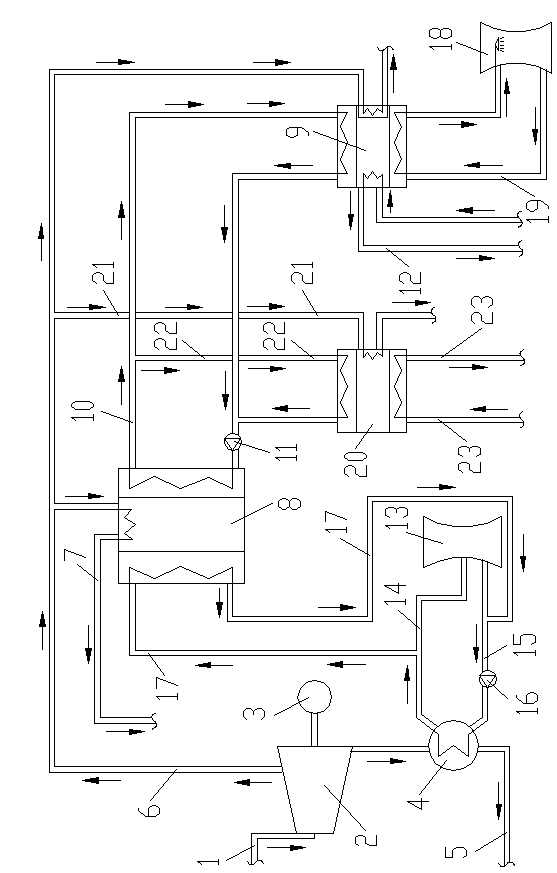

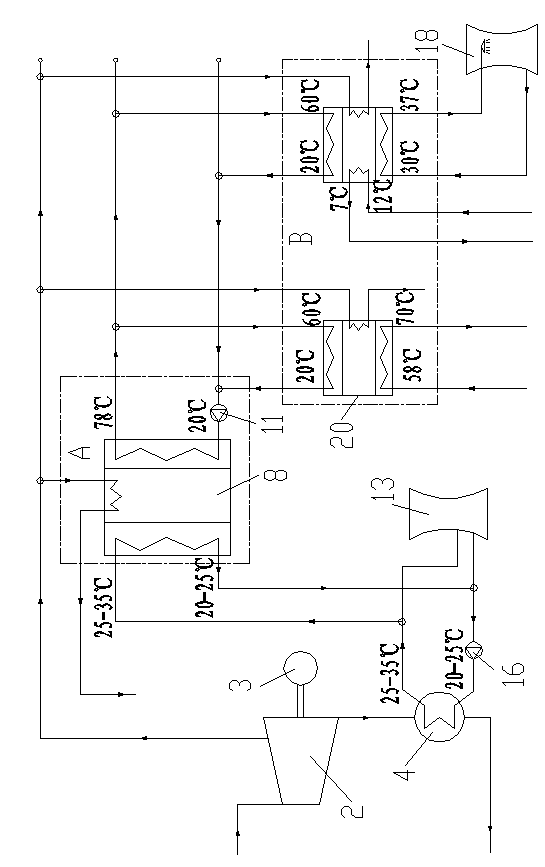

Heat and power cogeneration centralized heat supply system based on heat pump

ActiveCN103629857AImprove utilization efficiencyIncrease heatHeat pumpsClimate change adaptationElectricityCogeneration

The invention discloses a heat and power cogeneration centralized heat supply system based on a heat pump. An absorption type heat exchanger unit and a multi-stage electrically-driven heat pump are introduced, and a heat source is used as a power source and is used for heat exchange repeatedly, so that the utilization efficiency of a steam heat source is improved, and heat can be better supplied to a user; a solar heat collector is introduced, and primary grid backwater is heated by using clean energy namely solar energy, so that the energy is saved, and the environment is protected; in addition, a heat exchanger is additionally arranged in a thermal power plant, the temperature of the primary grid backwater is raised by using a low-grade heat source in a condensing engine, and a double-effect steam absorption type heat pump, a single-effect steam absorption type heat pump, a large-temperature-difference steam absorption type heat pump and a steam water heat exchanger are simultaneously introduced to recover low-grade heat step by step, so that exhaust steam in a turbine is effectively utilized, and the energy utilization efficiency is improved. According to the system, the power generation efficiency of a power plant is improved by over 30 percent.

Owner:DALIAN UNIV

Health-protection Chinese chestnuts and making method thereof

InactiveCN103999996ASolve the problem of single health care effectNutritional diversityConfectionerySweetmeatsDiseaseFood Component

The invention belongs to the technical field of food processing, and in particular relates to health-protection Chinese chestnuts and a making method thereof. The health-protection Chinese chestnuts are prepared from Chinese chestnuts, chufa, myrtles, mulberries, brown sugar and honey. Various health-protection natural fruits and medicinal and edible food components are added into Chinese chestnut kernels, so that the made Chinese chestnut products have refreshing taste, no sweetness, low heat and complete nutrition, and have multiple health-protection effects of enhancing immunity, maintaining beauty and keeping young, tonifying spleen, nourishing stomach, tonifying kidney, benefiting qi, preventing diseases and the like; the problems that a conventional single Chinese chestnut kernel product has a single effect, tastes sweet and the like are solved; demands of different markets and people can be met.

Owner:陈国勇

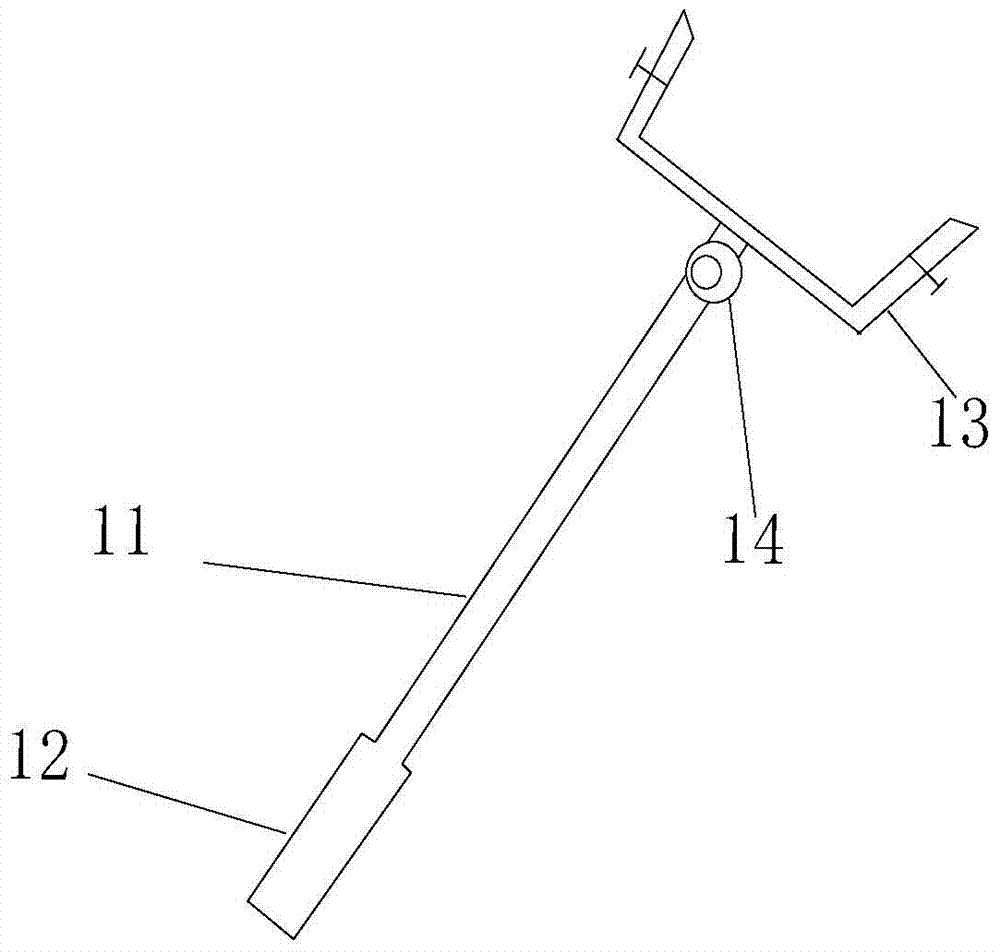

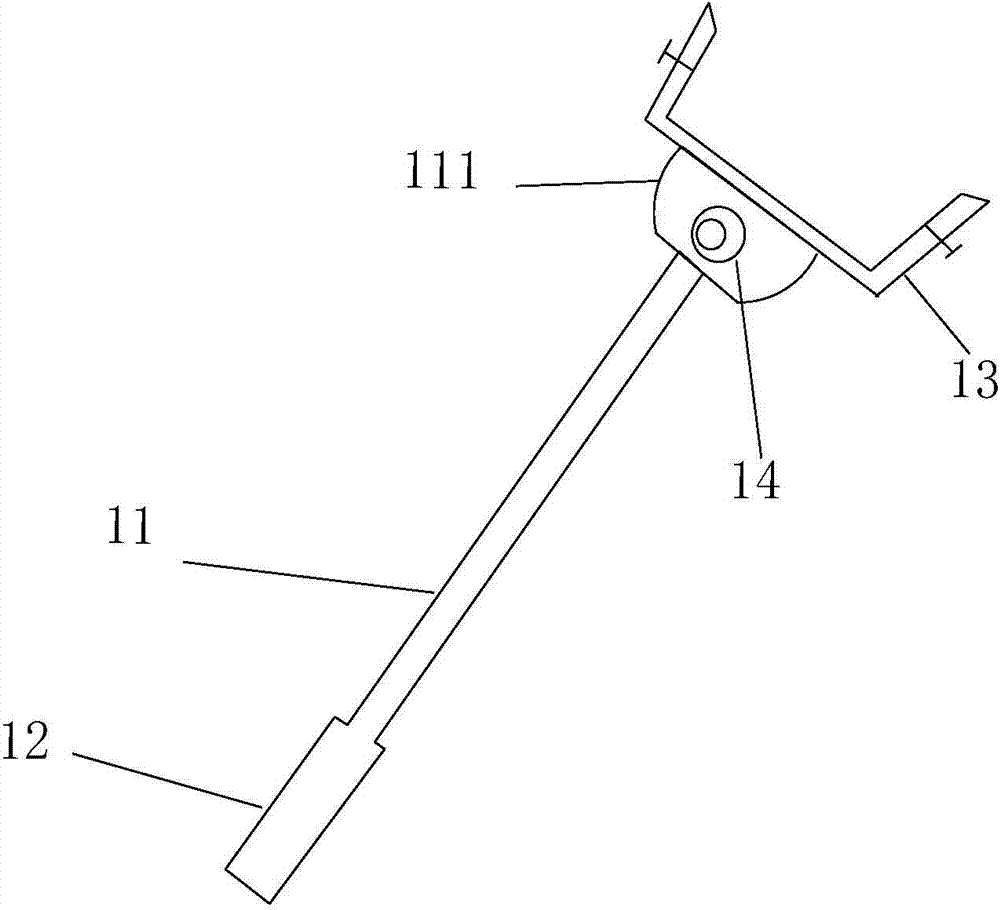

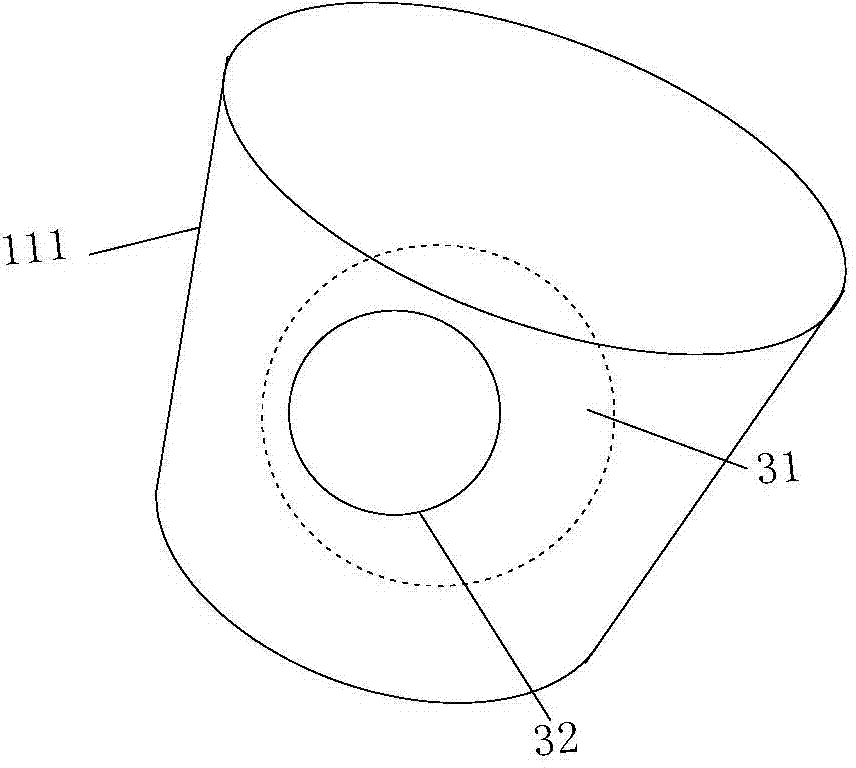

Selfie rod

ActiveCN104747887AImprove clarityPixel heightTelevision system detailsColor television detailsSingle effectMobile device

The invention discloses a selfie rod, relates to the field of camera shooting and aims at solving the problems of single effect and poor definition of images shot by use of the selfie rod in the prior art. The following major technical scheme is adopted: the selfie rod comprises a rod body, a handle connected with one end of the rod body, and a bracket connected with the other end of the rod body, wherein the bracket is used for fixing a mobile device; the selfie rod further comprises a camera arranged on the rod body; the camera is used for shooting images and in communication connection with the mobile device; the shot image data are transmitted to the mobile device in real time via the communication connection and the image data are displayed in real time on the screen of the mobile device. The selfie rod is mainly applied to outdoor activities.

Owner:BEIJING QIHOO TECH CO LTD +1

Combined solar refrigerating equipment

The composite solar refrigerating equipment mainly includes generator, condenser, throttle valve, evaporator, absorber, solution heat exchanger, compressor, solar heat collector, water pump, valve and solution pump. The solar heat collector, generator and water pump are formed into circulation of solar heat-collecting system, the solution heat exchanger is connected with generator and absorber and formed into the circulation of concentration solution, and the compressor is connected with generator, condenser, throttle valve, evaporator and absorb and formed into the circulation system of compression refrigeration. Said equipment can be operated all weather. Its working efficiency is high.

Owner:SHANGHAI JIAO TONG UNIV

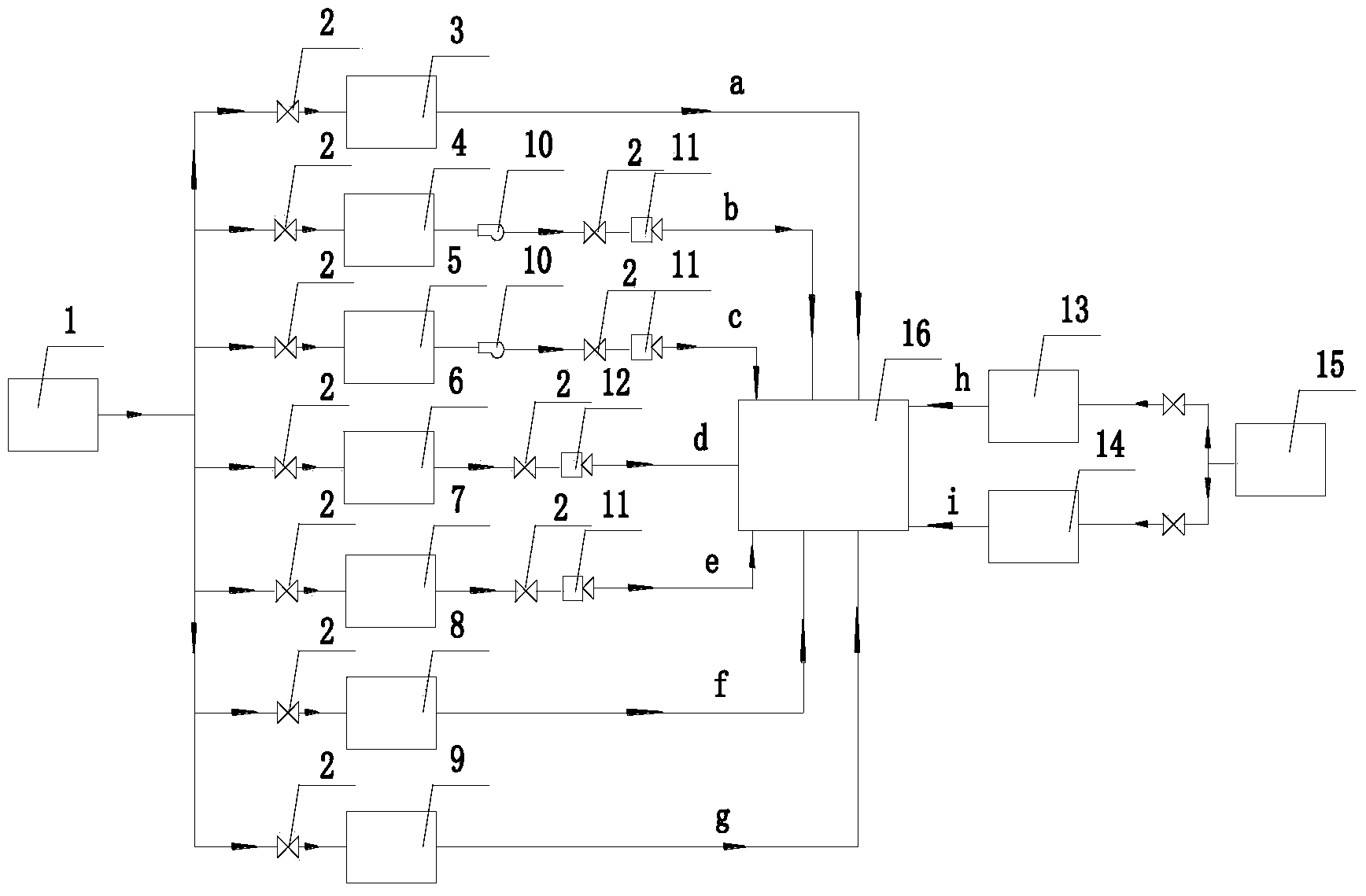

Sodium sulfate wastewater treatment process

ActiveCN106517626AImprove heat transfer efficiencyAchieve reuseWater/sewage treatment by centrifugal separationChemical industrySingle effectChemistry

The invention relates to a sodium sulfate wastewater treatment process. The treatment process sequentially comprises the following steps: (1) introducing new sodium sulfate wastewater into a preheating unit, and preheating to raise the temperature; (2) introducing the preheated sodium sulfate wastewater into a single-effect falling film evaporator, and performing heating evaporation concentration to obtain a single-effect concentrate; (3) introducing the single-effect concentrate into a double-effect falling film evaporator, and performing further heating evaporation concentration to obtain a double-effect concentrate; (4) feeding the double-effect concentrate into a forced circulation evaporation crystallizer through a material transfer pump, performing heating evaporation crystallization, and discharging crystal slurry containing sodium sulfate crystals from a salt leg at the bottom of an evaporation chamber of the forced circulation evaporation crystallizer; (5) separating the crystal slurry containing sodium sulfate crystals discharged from the salt leg by a centrifuge; (6) feeding the sodium sulfate crystals separated out by the centrifuge into a fluidized bed drying system through a material conveyor belt, and drying; and (7) introducing the dried sodium sulfate crystals into an automatic packaging system, and packaging to obtain an industrial sodium sulfate finished product. The process is low in energy consumption, and can realize full recovery of sodium sulfate.

Owner:JIANGSU MYANDE ENERGY SAVING EVAPORATION EQUIP CO LTD

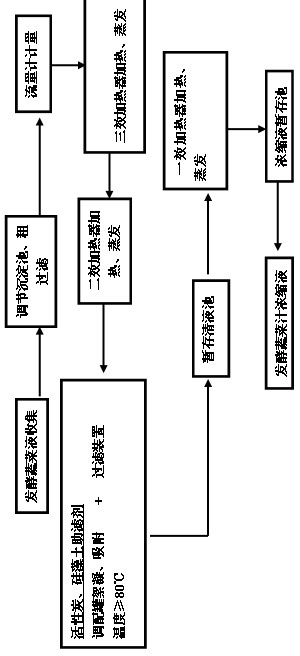

Yeast extract, preparation method and application thereof

InactiveCN101513246AFlavor coordinationTaste balanceFood preparationCaramel FlavorVegetable Proteins

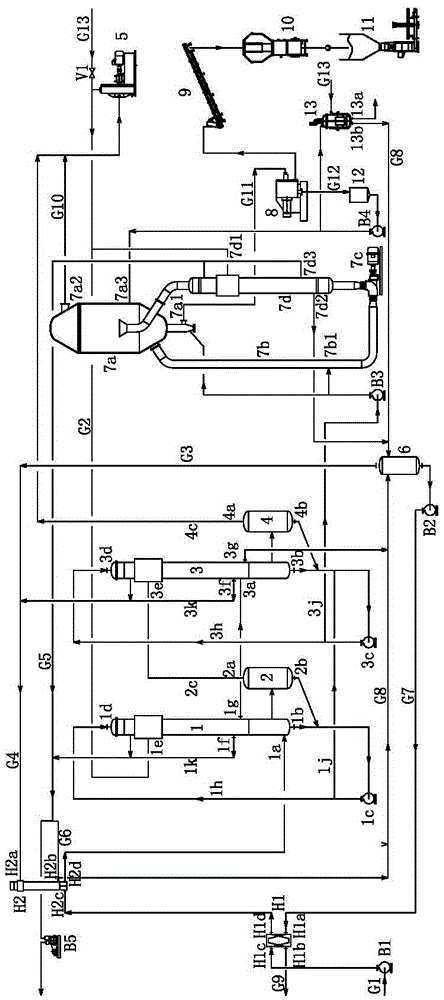

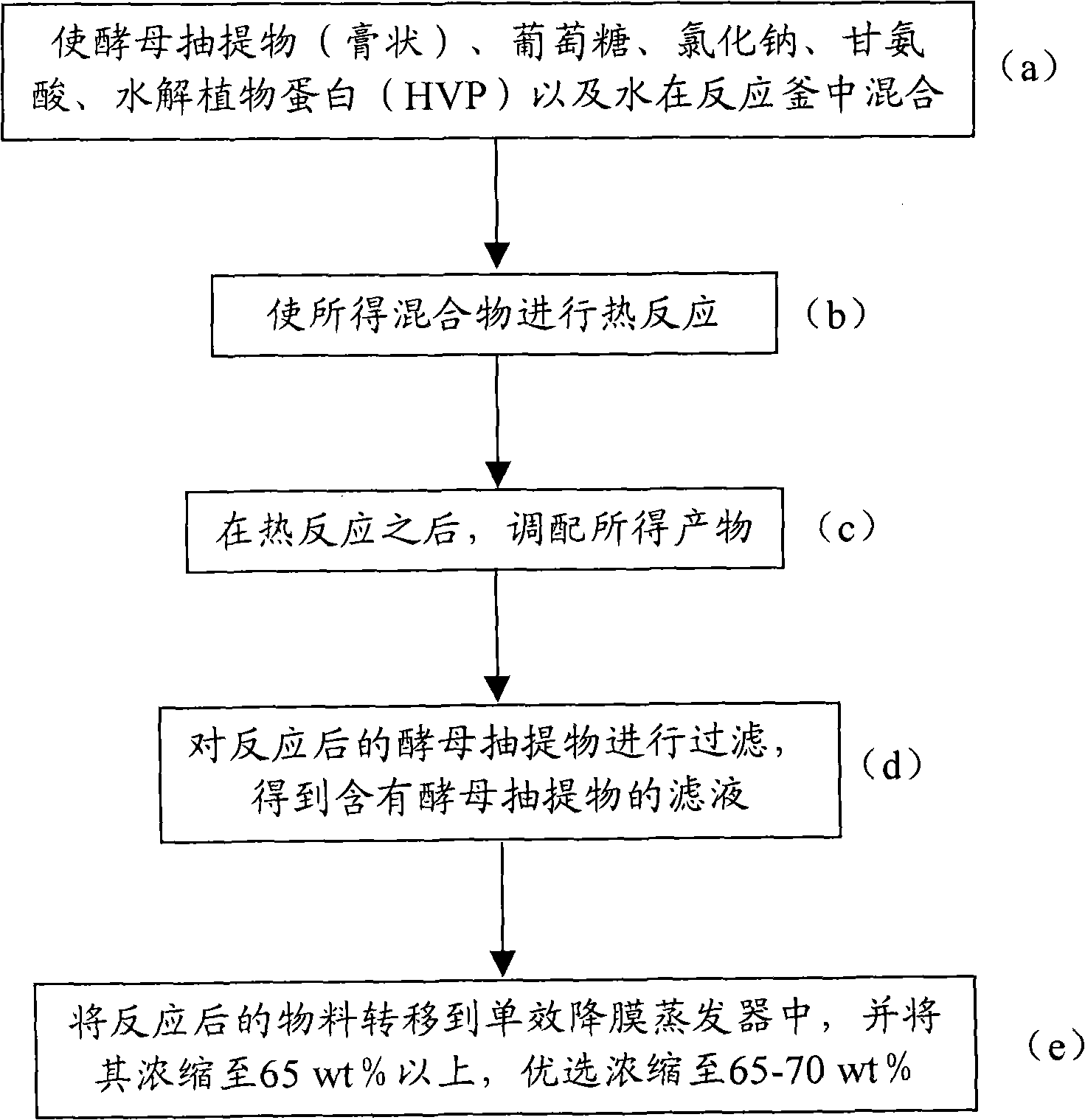

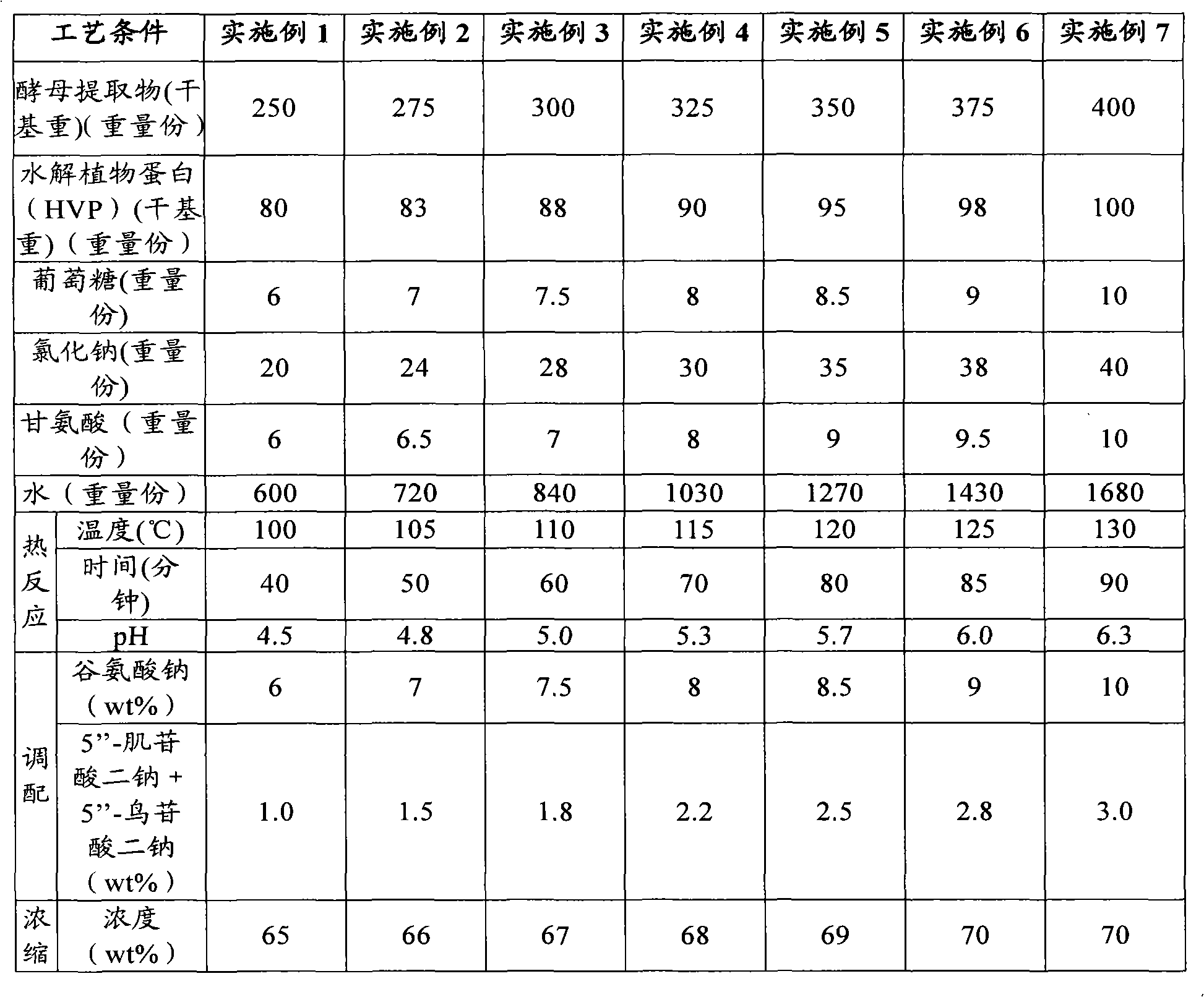

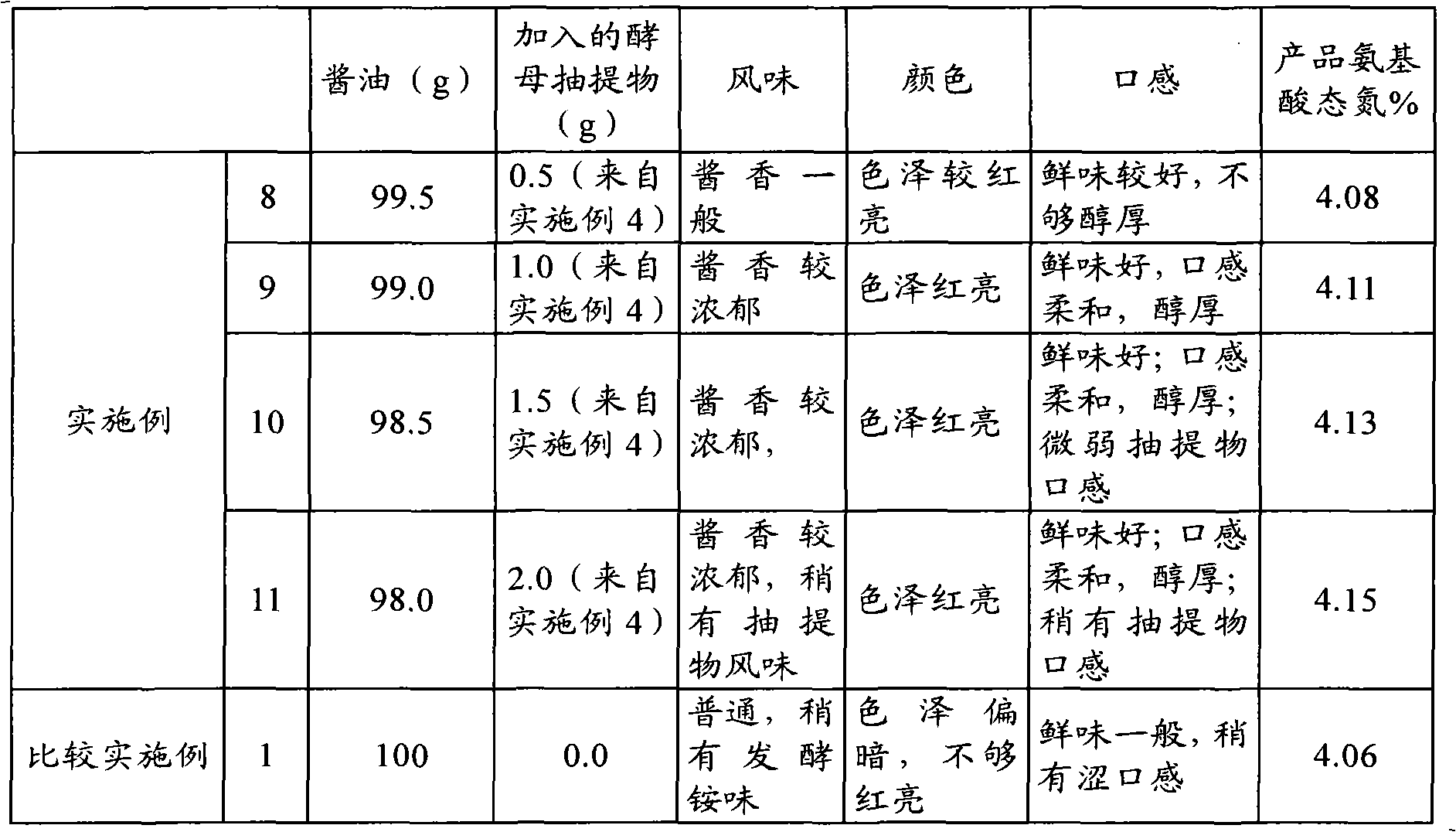

The invention provides a yeast extract, a preparation method and application thereof. The preparation method of the yeast extract comprises the following steps: (a) mixing the yeast extract, glucose, sodium chloride, glycin, hydrolyzed vegetable protein and water in a reaction kettle; (b) performing heat reaction on the mixture in step (a) for 40 to 90 minutes at a temperature of between 100 and 130 DEG C and pH of between 4.5 and 6.3; (c) after the heat reaction, adding 6 to 10 weight percent of sodium glutamate and 1.0 to 3.0 weight percent of disodium inosinate and disodium guanylate into an obtained product for preparation; (d) filtering the yeast extract after the reaction to obtain filtrate containing the yeast extract; and optional (e) transferring materials after the reaction to a single effect falling film evaporator, and concentrating the materials to more than 65 weight percent and preferably concentrating the materials to between 65 and 70 weight percent. The yeast extract prepared by the method has sauce fragrance and caramel like deep bright red color, and a water solution of the yeast extract has transparent bright red color and fresh and salty mouthfeel.

Owner:ANGELYEAST CO LTD

Exothermic insulating riser sleeve and preparation method thereof

InactiveCN103551512ALong holding timeFast feverFoundry mouldsFoundry coresSesquioxideThermal insulation

The invention discloses an exothermic insulating riser sleeve and a preparation method thereof and aims to solve the problems of bad heat insulation, insufficient heating and single effect in a conventional exothermic insulating riser sleeve. According to the formula, the exothermic insulating riser sleeve is prepared from quartz sand, vermiculite, potassium nitrate, calcium chloride, iron sesquioxide powder, graphite powder, aluminum powder, magnesium powder and modified sodium silicate. The method comprises the following steps: (1) weighing raw materials; (2) preparing a mixed wet material; and (3) filling the mixed wet material into a mold, pre-tightening while filling the wet material, performing compression molding, and demolding, thus finishing the operations. According to the formula of the exothermic insulating riser sleeve, the content of an exothermic agent is increased, the exothermic agent has the advantages of rapid heating, and a heating effect is improved. Moreover, the vermiculite serves as a thermal insulation material, is long in thermal insulation time and has a good thermal insulation effect, so that the molten iron feeding ratio in a riser is improved under the combined action of rapid heating and long thermal insulation.

Owner:HARBIN UNIV OF SCI & TECH

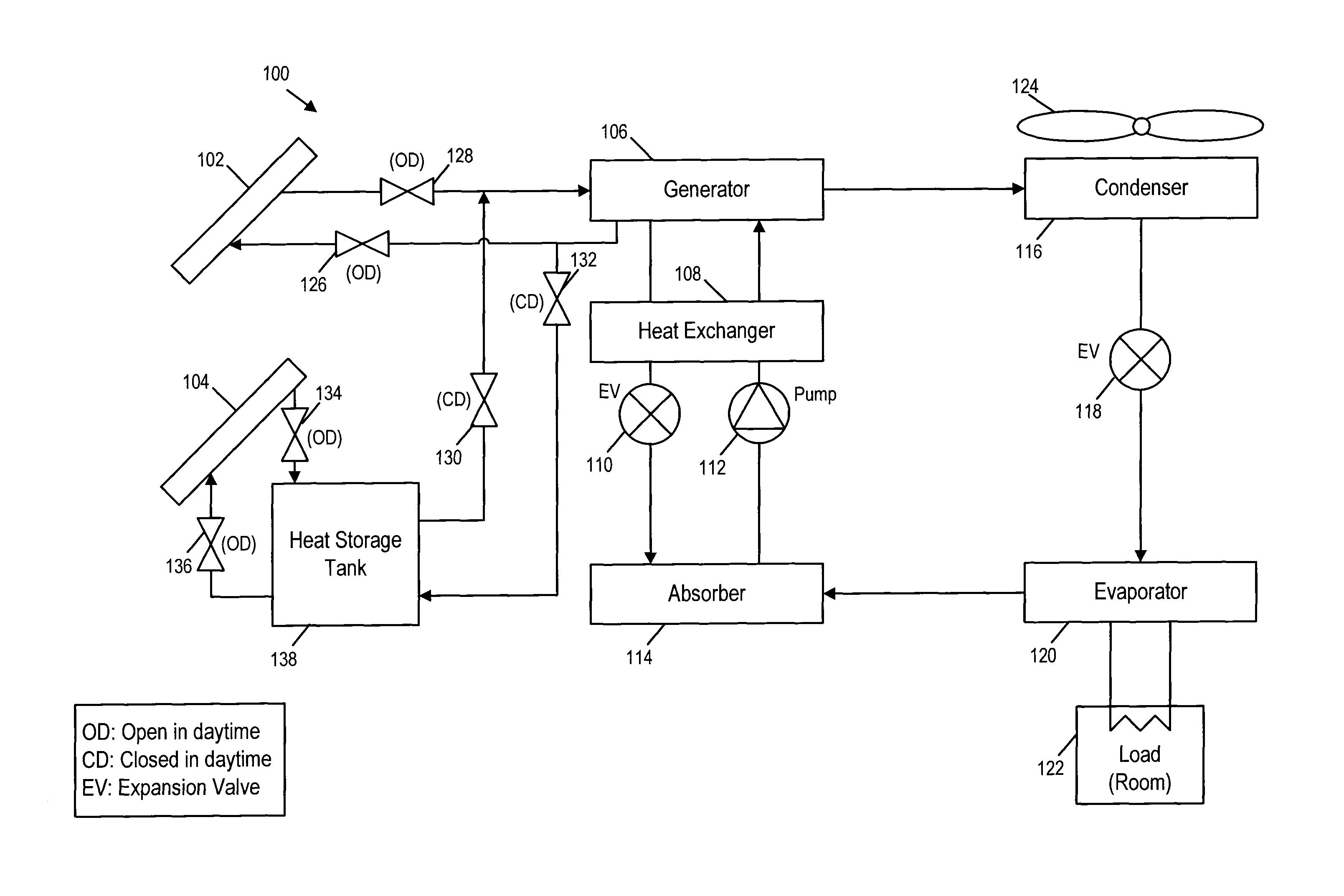

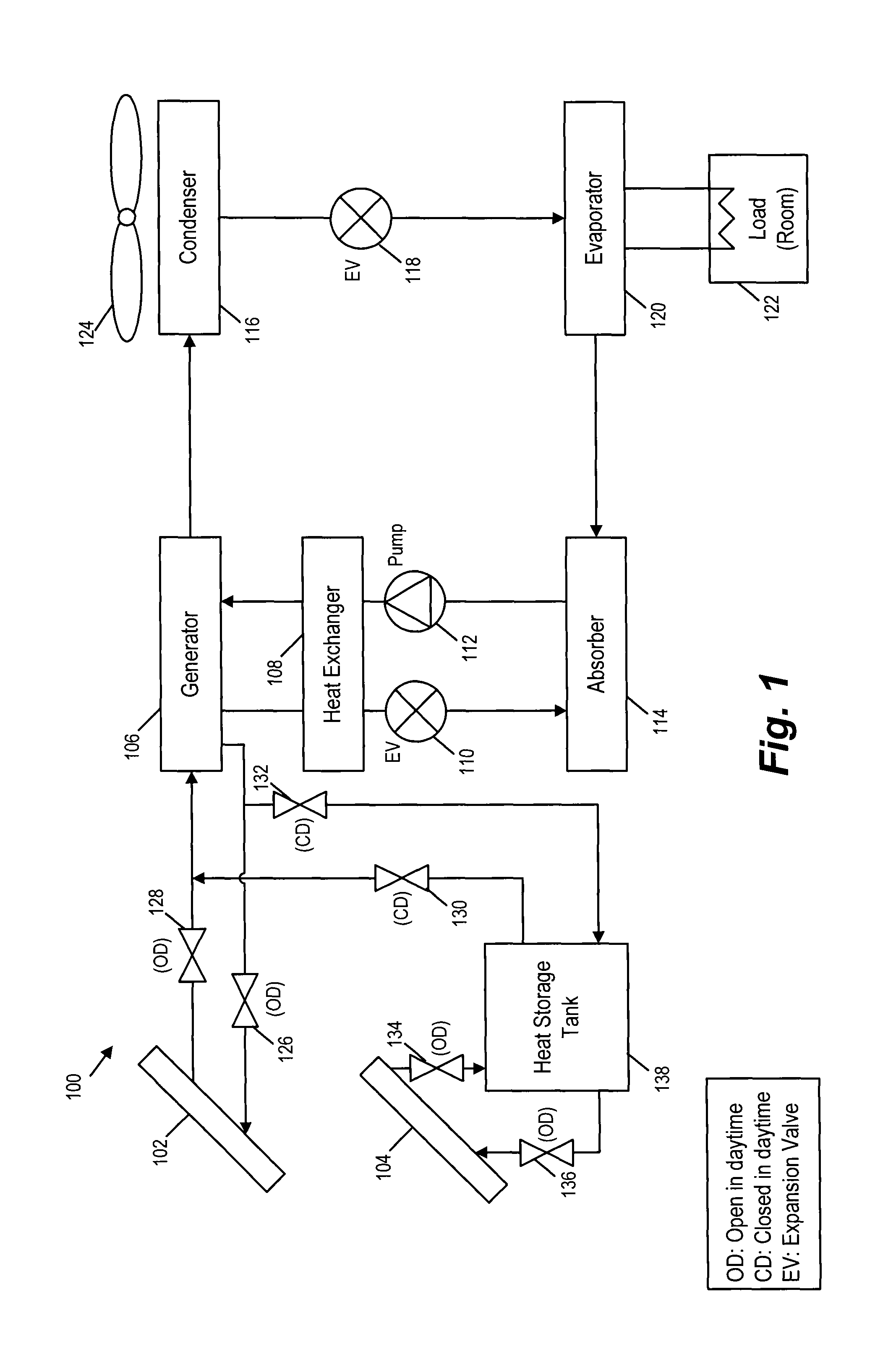

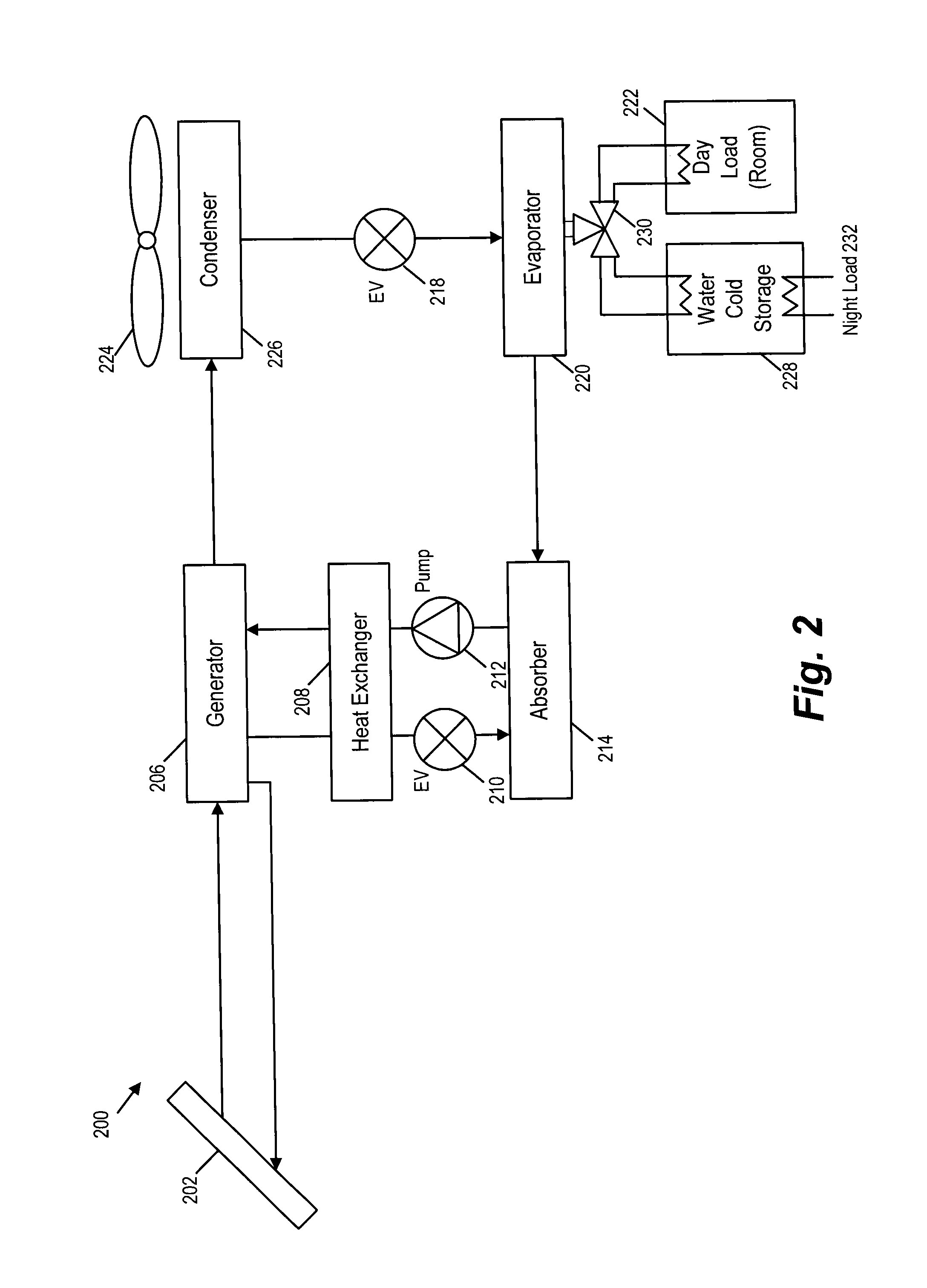

System and method for continuously operating a solar-powered air conditioner

InactiveUS9488394B1Facilitated releaseSolar heating energySolar heat devicesStored energyEngineering

An air-cooled, single-effect, air conditioning system includes a first set of solar collectors configured to obtain energy to facilitate release of refrigerant from an absorbent-refrigerant solution in a generator. A tank is configured to store the energy for nighttime operations of the air conditioning system. One or more valves are configured to regulate consumption of the stored energy to maintain continuous cooling of at least one load.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Method for synergistically degrading oil producing wastewater by using petroleum degrading bacteria

InactiveCN103803714APlay a synergistic roleEfficient degradation rateWaste water treatment from quariesBiological water/sewage treatmentBacterial strainBeef extract

The invention provides a method for synergistically degrading oil producing wastewater by using petroleum degrading bacteria. The method comprises the following steps: (1) inoculating purified single pseudomonas aeruginosa, bacillus subtilis, pseudomonas mendocina and acinetobacter baumannii strains into a beef extract-peptone medium, and culturing for 18 hours so as to obtain seed bacterium liquid; (2) preparing an acclimation culture solution of the seed bacterium liquid; (3) adding the prepared acclimation culture solution to a fermentation medium according to a single strain bacterium liquid isopyknic ratio, and culturing; (4) putting fermented bacterium liquid in an aeration tank so as to treat the oil producing wastewater. The composite high-efficiency oil removal bacterial strain can be used for degrading more than 94% of hydrocarbon compounds in the oil producing wastewater; the selected strains are respectively high in crude oil degradation rate and have synergistic effect; the combined degradation efficiency of several bacteria for crude oil is considerably higher than the simple superimposed effect of the single effect of the bacteria.

Owner:CHANGZHOU UNIV

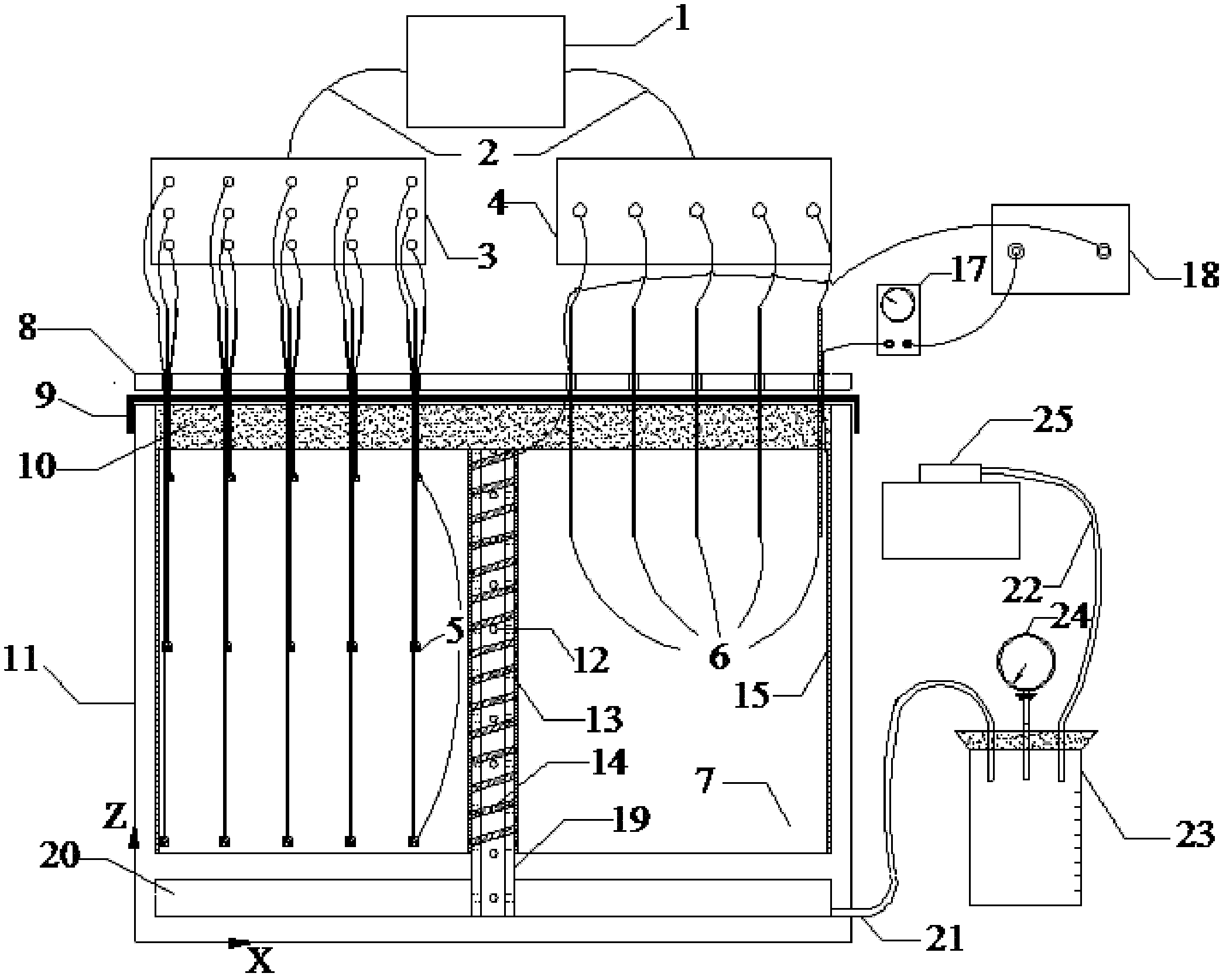

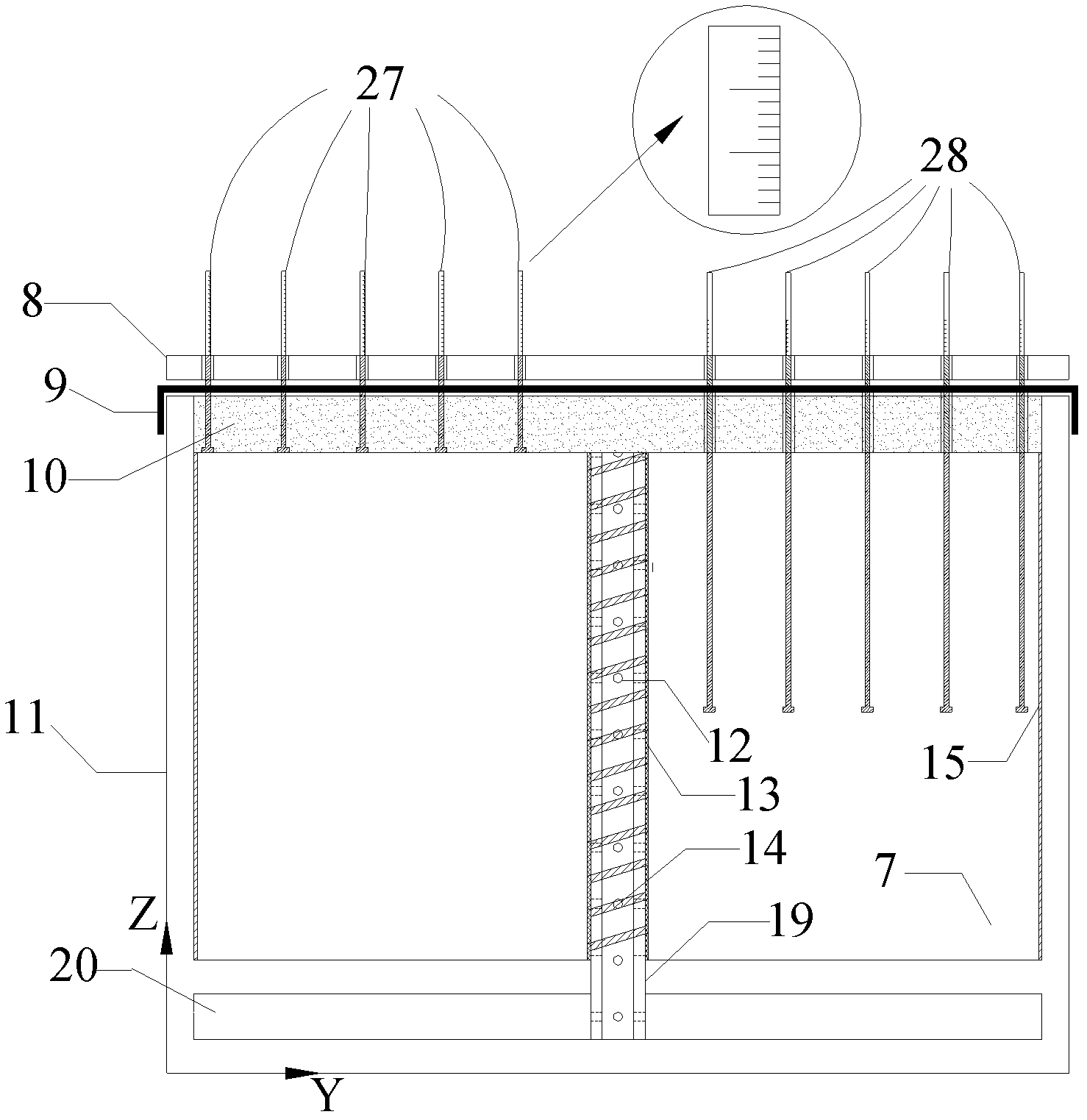

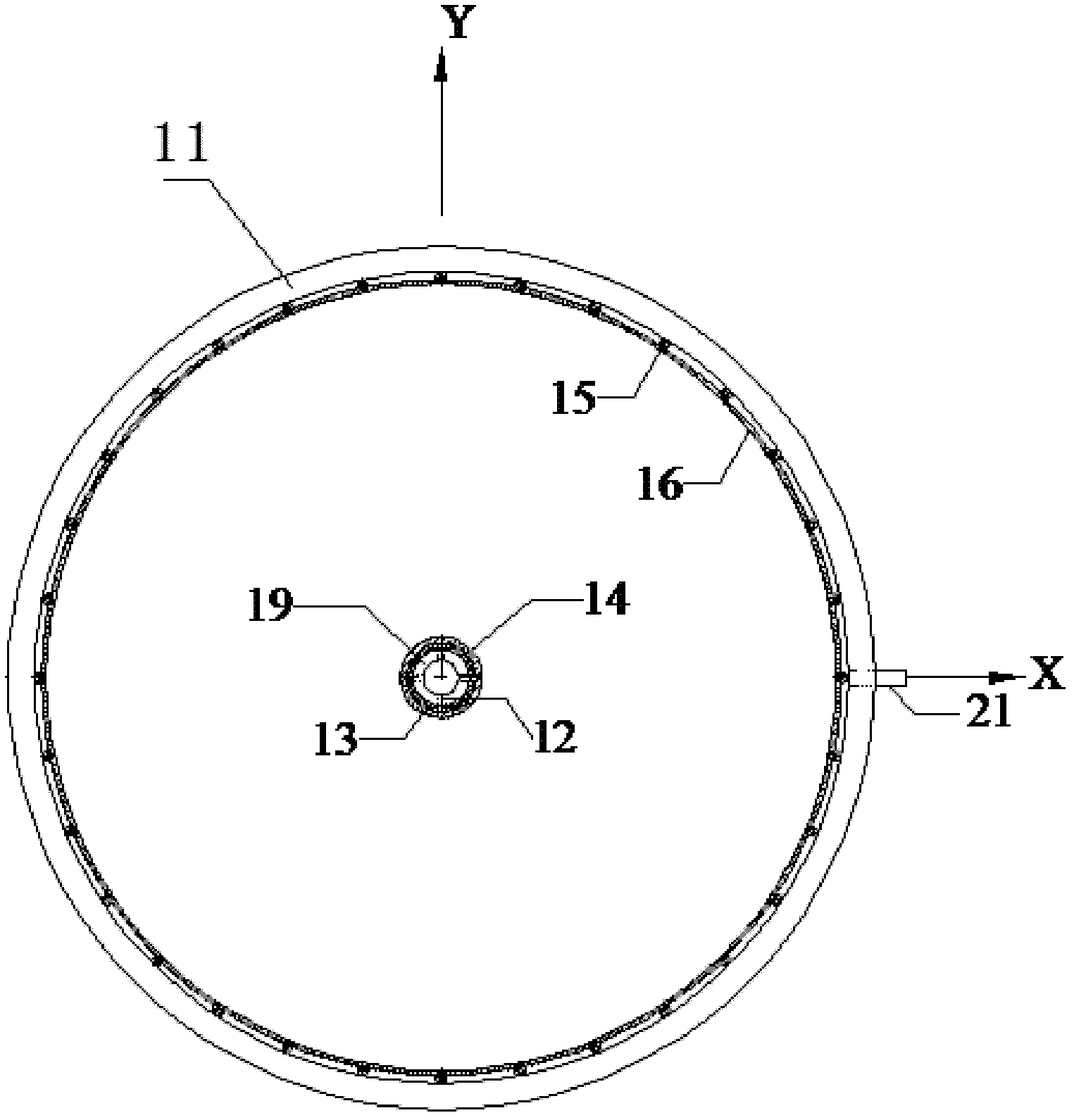

Indoor vacuum electro-osmosis combined solidification tester

ActiveCN102565139AHigh degree of automationReliable dataMaterial analysis by electric/magnetic meansEarth material testingVacuum pumpMaterials science

The invention relates to an indoor vacuum electro-osmosis combined solidification tester. An anode iron wire is arranged around a main cylinder and is connected with electrode collars. The soil sample layer and the water storage layer of the main cylinder are communicated through a vertical drain pipe. The vertical drain pipe is covered by a layer of geotextile. A cathode iron wire is wound outside the geotextile. The cathode iron wire, the anode iron wire, an ampere meter and a power supply are serially connected to form a loop. Four rows of guide holes are centrosymmetrically arranged on a top plate at the upper part of the main cylinder. Hole pressure sensors, level sensors, surface settlement marks and layered settlement marks respectively penetrate through the four rows of guide holes. The sensors are connected with a computer through acquisition instruments. A water storage layer at the lower layer of the main cylinder is communicated with a gas-water separation device. The upper part of the gas-water separation device is communicated with a vacuum meter and a vacuum pump. The indoor vacuum electro-osmosis combined solidification tester can be used for conducting indoor exploration tests to different soil body samples through a vacuum electro-osmosis combined effect or a single effect, can monitor the real-time change situation of various parameters in soil samples in the process and can quantitatively analyze the solidification result.

Owner:TSINGHUA UNIV

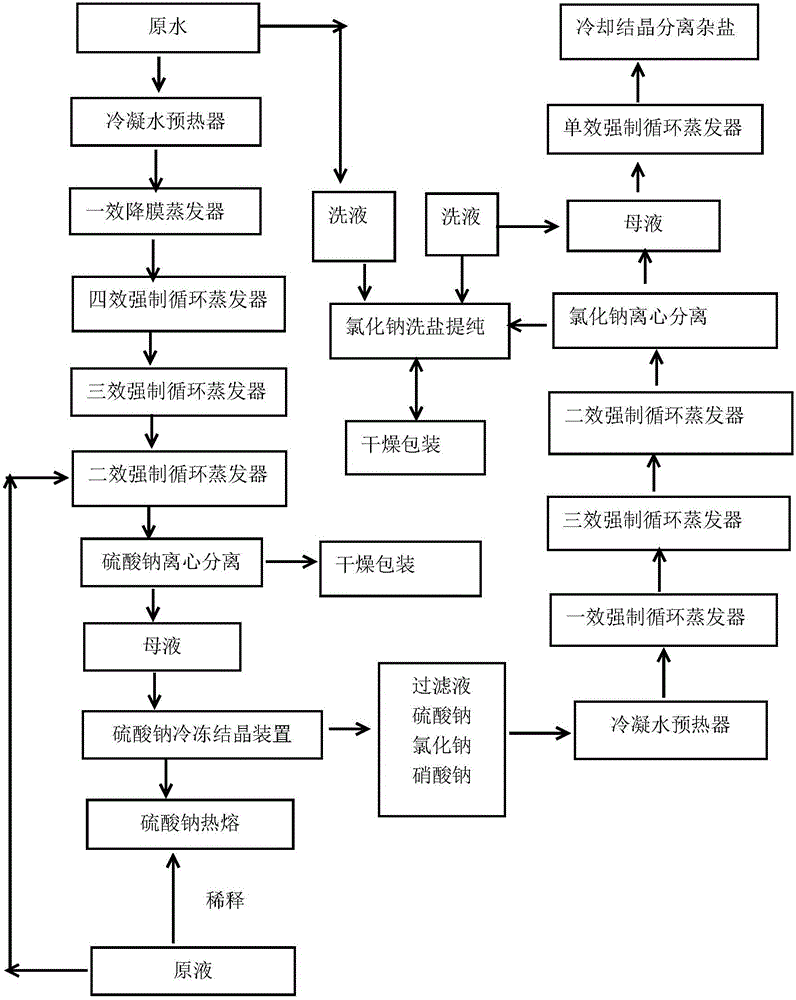

Desulfurization wastewater concentration, evaporation, crystallization and salt separation process

ActiveCN106007133AEfficient separationDissolution inhibitionWater/sewage treatment by centrifugal separationWater contaminantsWastewaterSingle effect

The invention discloses a desulfurization wastewater concentration, evaporation, crystallization, and salt separation process. The process comprises the steps as follows: introducing raw water into a quadruple-effect counter-flow forced circulation evaporator, treating sodium sulfate through evaporating, concentrating and crystalizing, separating sodium sulfate first, and freezing separated mother liquor, wherein most of sodium sulfate in the mother liquor is successfully separated; introducing the frozen mother liquor into a triple-effect evaporator after preheating, evaporating, concentrating and crystalizing sodium chloride, wherein the obtained crystal salt is used as an industrial raw material; introducing the mother liquor produced by a sodium chloride evaporator into a single-effect evaporator to obtain an abraum salt crystal. The process successfully separates the sodium sulfate in the desulfurization wastewater, and the sodium chloride is treated through evaporating, concentrating and crystalizing, the obtained sodium chloride crystal salt is used as the industrial raw material, the mother liquor produced by the sodium chloride evaporator enters the single-effect evaporator to obtain the abraum salt crystal, so that the sodium sulfate and the sodium chloride are effectively separated.

Owner:SUZHOU JOYFA ENVIRONMENTAL TECH CORP LTD

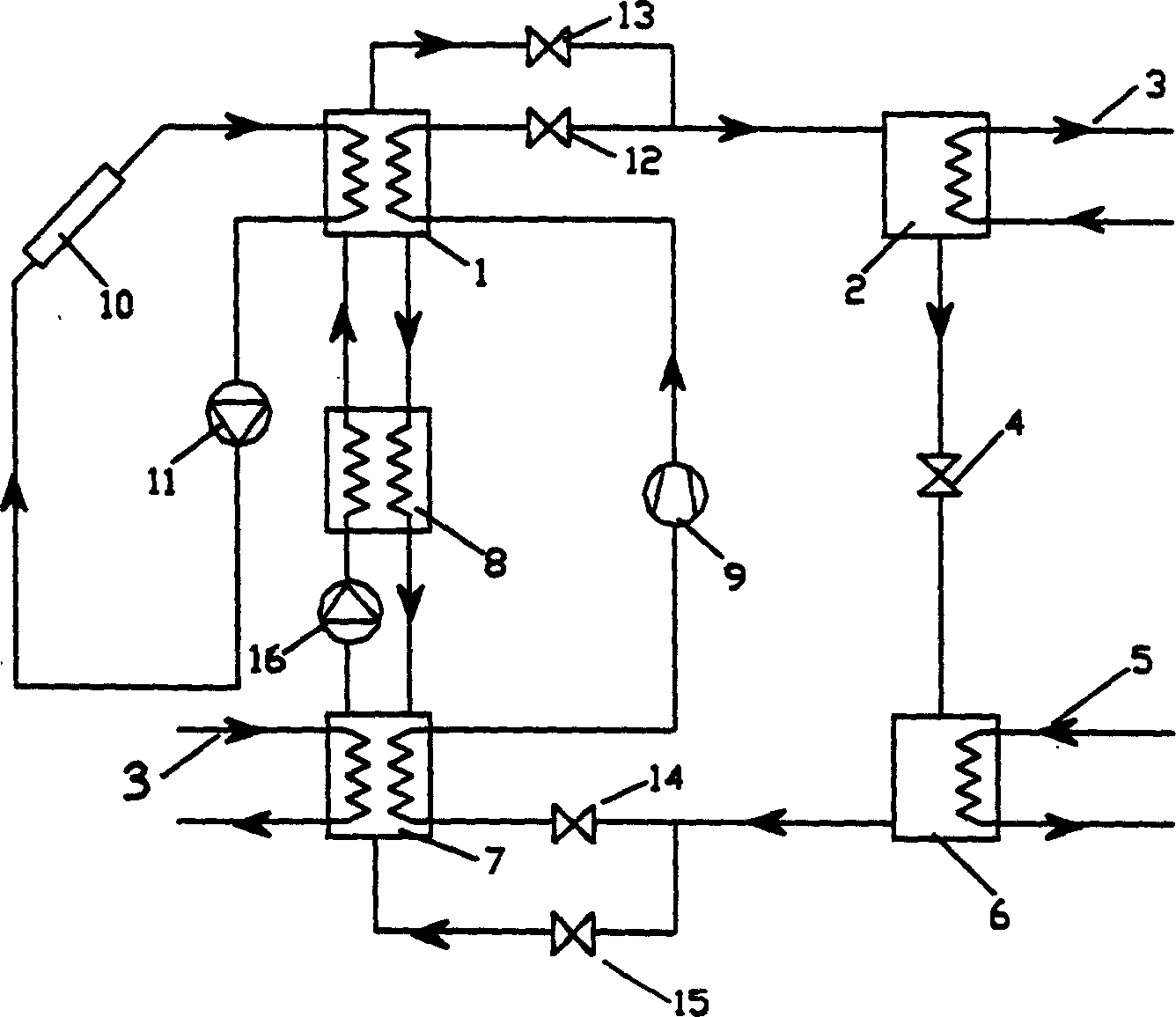

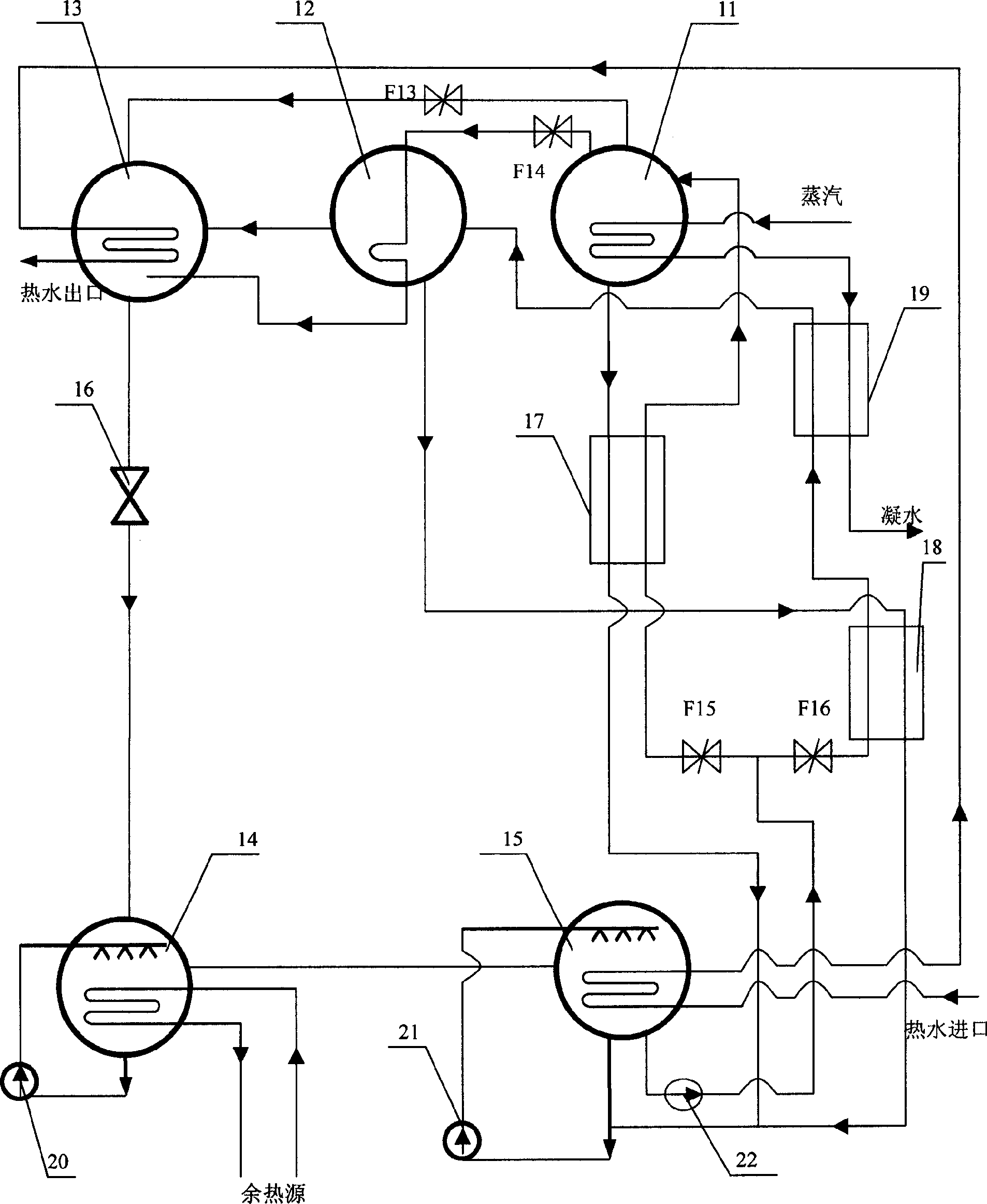

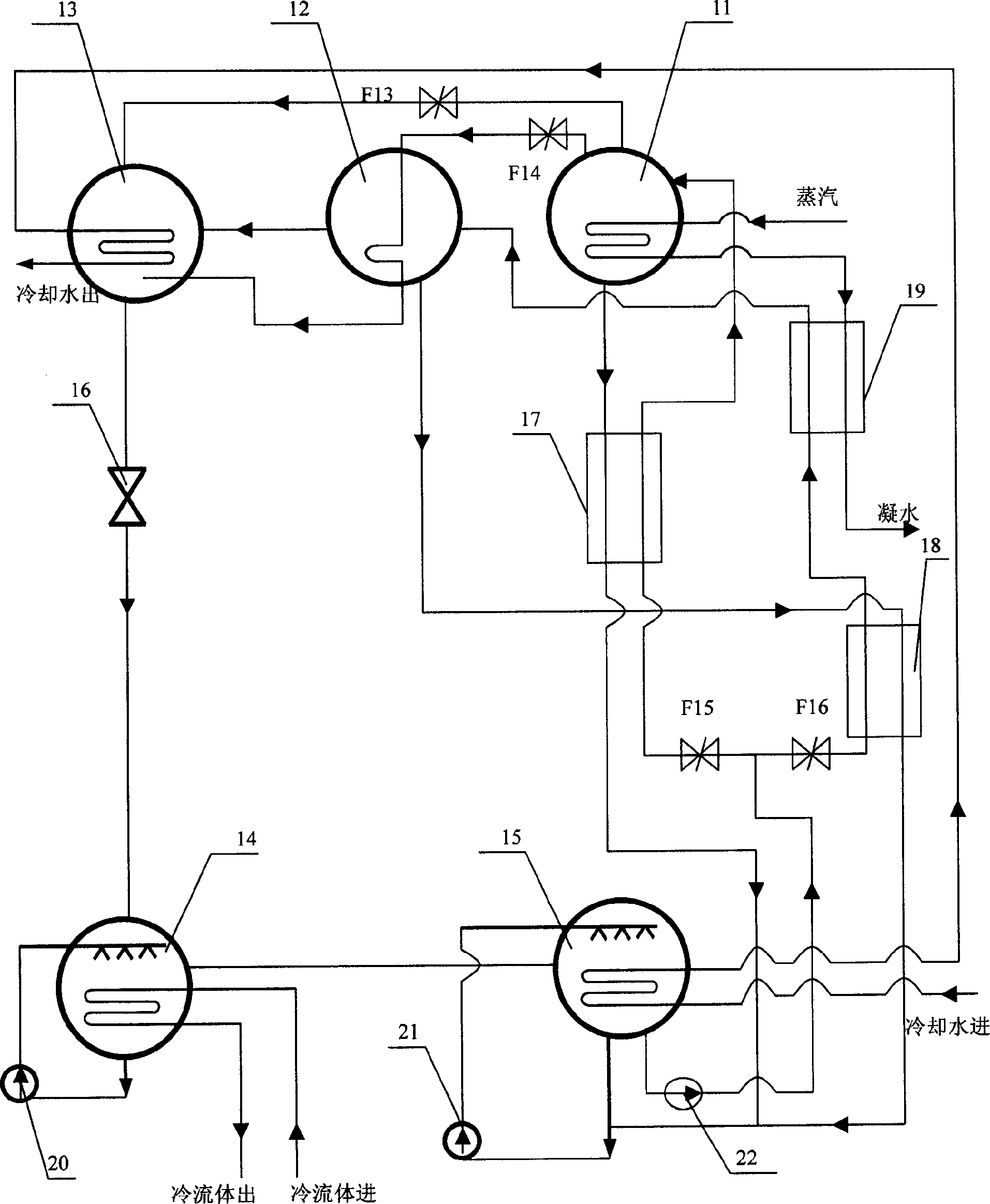

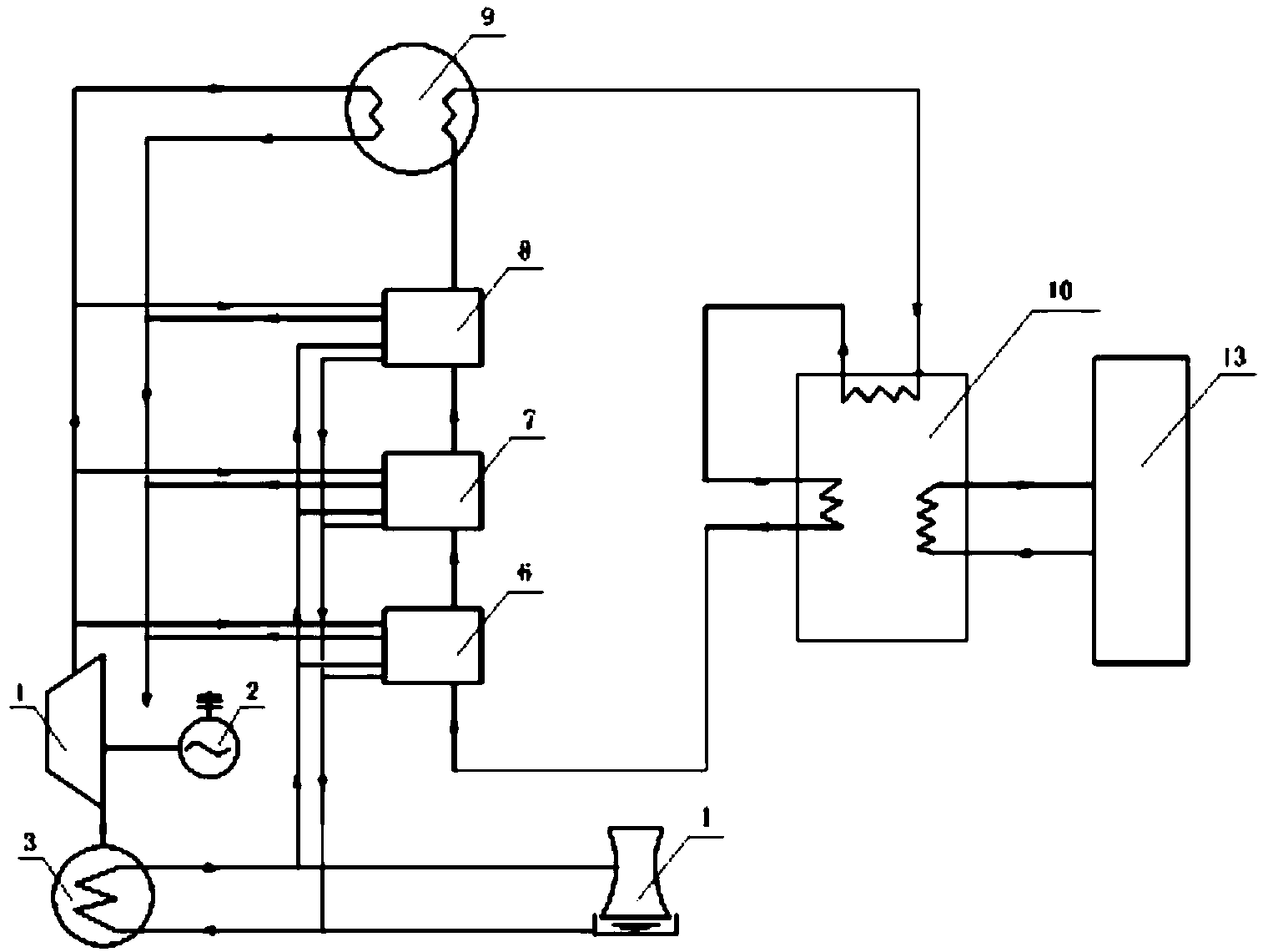

Single-effect heat pump/double-effect cooling absorption set and combined heat, electricity and cold supply system

InactiveCN1811303AGood energy savingOvercome the shortcoming that it cannot be used as a high-efficiency energy-saving heating deviceClimate change adaptationEnergy efficient heating/coolingCooling towerEngineering

The present invention provides a single-effect heat pump / double-effect cooling absorption set and a combined heat, electricity and cold supply system, and belongs to the field of afterheat utilizing and refrigerating technology. The integrated single-effect heat pump / double-effect cooling absorption set is mounted in a thermal power plant, and the exhaust of the steam turbine is connected to the high pressure generator of the integrated set and used as the driving energy for heating and refrigerating. The integrated single-effect heat pump / double-effect cooling absorption set operates either in single-effect heat pump mode for heating in winter or in double-effect cooling mode for refrigerating in summer. The present invention has the comprehensive advantages of saving in energy, low power consumption, being environment friendly, etc.

Owner:李华玉

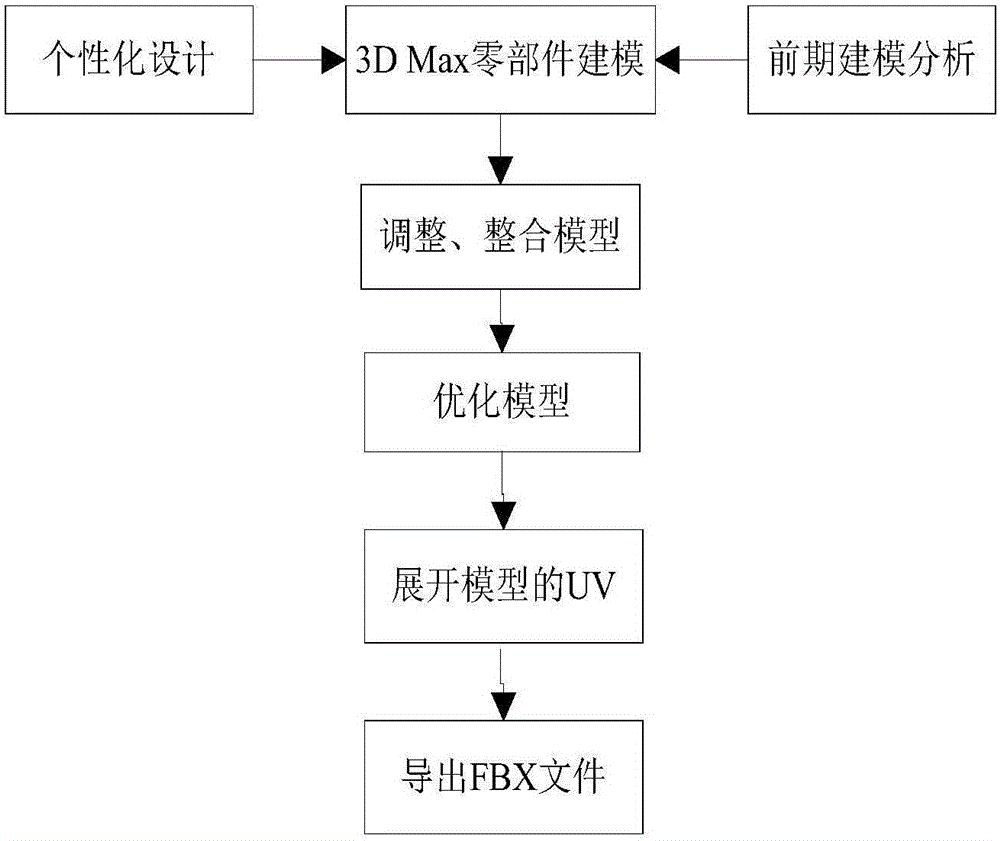

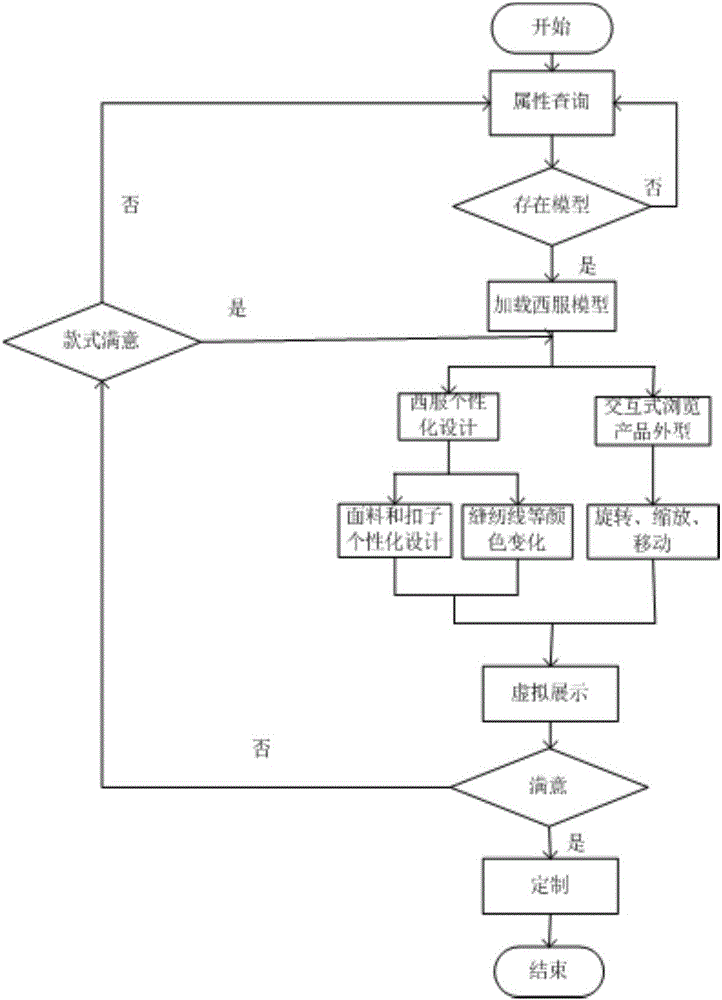

Suit personalized customization and three-dimensional virtual display method based on Unity3D

InactiveCN106023304AMeet the autonomyMeet customizationInput/output processes for data processing3D modellingPersonalizationSimulation

The invention discloses a suit personalized customization and three-dimensional virtual display method based on Unity3D. First of all, customized modeling is performed on a suit; afterwards, an obtained suit model is loaded to a Unity3D scene for user interaction; and finally, personalized design and three-dimensional virtual display are performed on suit fabrics and accessories. According to the invention, each part of the suit is modeled by use of 3Ds MAX, through combination of the Unity 3D, such functions as suit style selection, fabric selection, selection of buckles and other accessories, rotation, zoom and the like can be realized, a user can customize a suit style, fabrics and other part information in an interactive manner, can watch in real time a virtual display effect of a designed suit and can experience real textures and quality of fabrics, the demands of the user for automatic participation in customization and diversified display of a clothes effect are satisfied, and the problems of a single effect and lack of sense of reality by use of a conventional clothes display method are solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

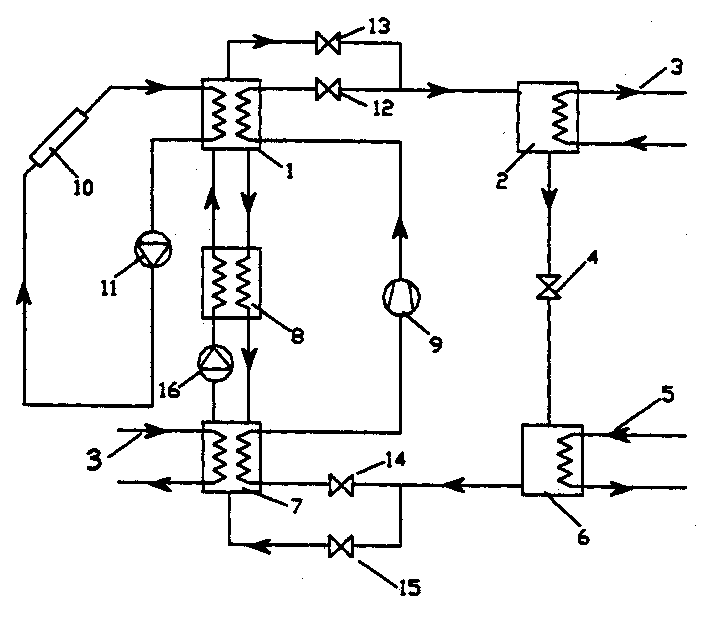

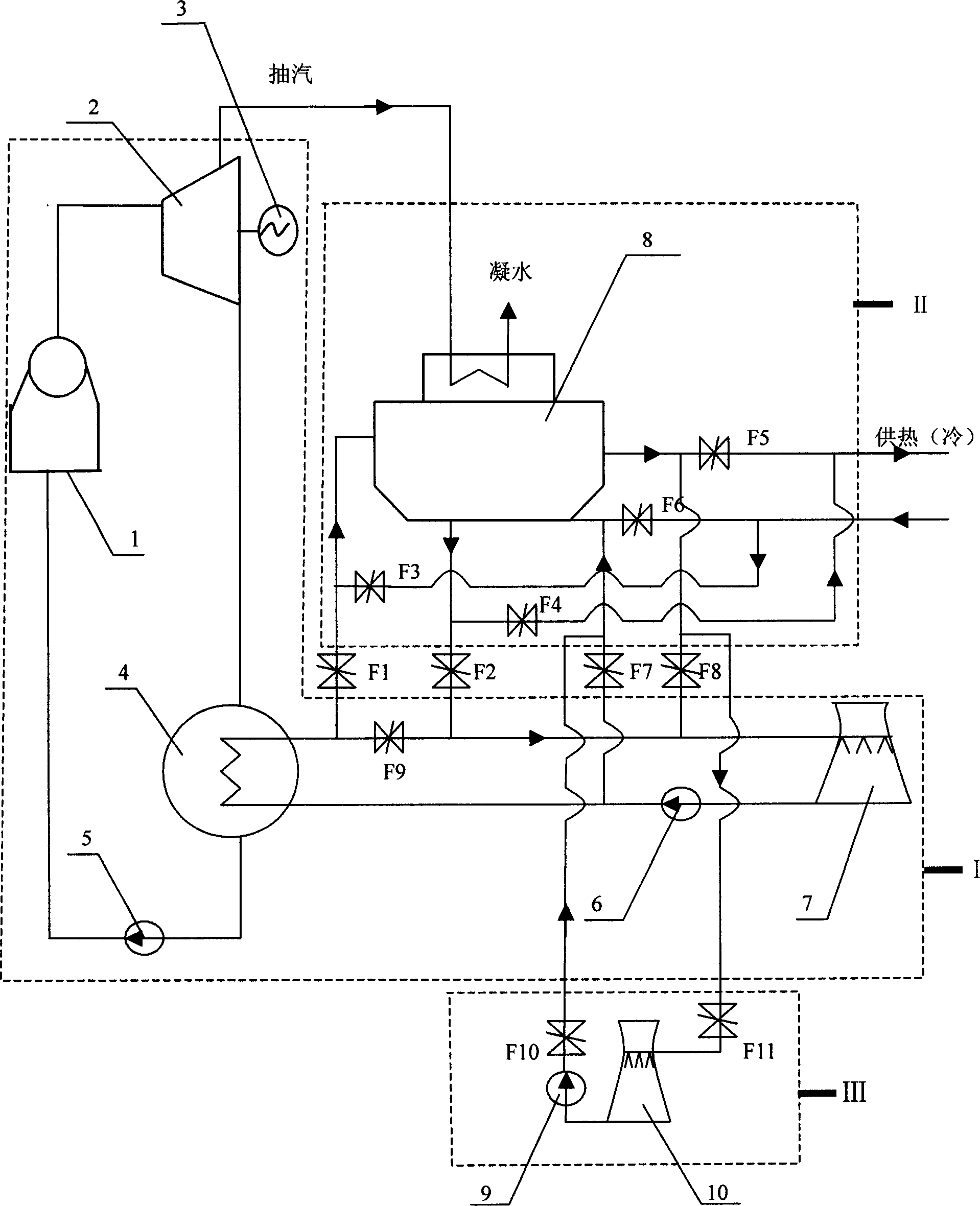

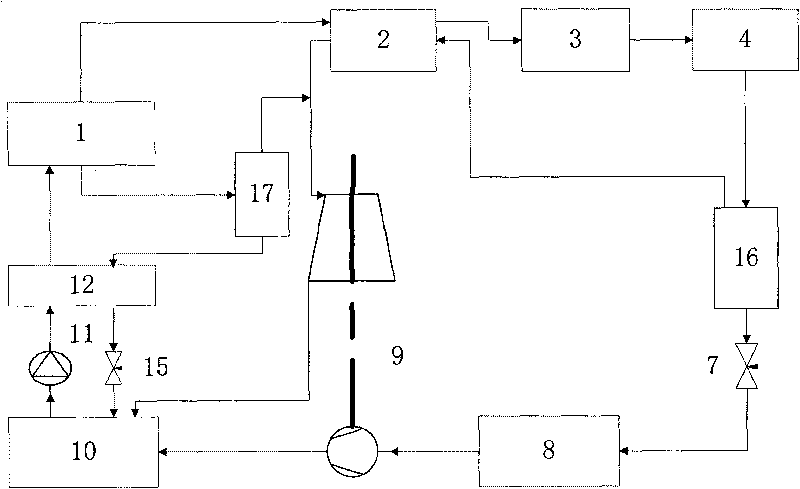

Heat and power cogeneration central heating system based on heat pump

InactiveCN103670548AImprove utilization efficiencyIncrease heatEnergy efficient heating/coolingClimate change adaptationLower gradeCogeneration

Provided is a heat and power cogeneration central heating system based on a heat pump. An absorption heat exchanging unit is introduced, a heat source is subjected to power source and heat exchanging using for multiple times, steam heat source using efficiency is improved, and heat is better provided for a user. A steam double-effect absorption heat pump, a steam single-effect absorption heat pump, a steam large-temperature-difference absorption heat pump and a steam-water heat exchanger are introduced for recycling low-grade heat step-by-step, dead steam in a steam turbine is effectively used, and energy using efficiency is improved. The system improves power plant generating efficiency by more than 30%.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

Load and environment synchronous coupling simulation testing system and method

InactiveCN103776683AFacilitate damage and deterioration mechanismFacilitate the research of prevention technologyWeather/light/corrosion resistanceStrength propertiesTest chamberEngineering

The invention discloses a load and environment synchronous coupling simulation testing system and method, and belongs to an environment test chamber and loading device integrated system and method. The load and environment synchronous coupling simulation testing system consists of two parts including a loading device and an environment simulation device, wherein the loading device consists of three parts including a counter-force frame, a hydraulic jack or actuator and a dowel bar; the environment simulation device consists of two parts including a control table and a chamber body; the chamber body internally comprises a temperature system, a salt mist system, a spraying system, an illumination system, a gas injection system, a humidity monitoring system and the like. The load and environment synchronous coupling simulation testing system can achieve the simulation environments of multiple tests including salt mist, salt rain, getting wet in the rain, high-low temperatures, humidity, ultraviolet lamp illumination, acid gases and the like, can develop the structure damage degradation performance test in multiple factors of dry and wet alternation, cycle of freezing and thawing, corrosive gas pickling, corrosive liquid erosion, namely acid erosion, alkaline erosion and salt erosion solutions under a single effect or synchronous coupling effects, realizes synchronous coupling of environment simulation and load simulation, and can truly reflect the actual operation situation of a structure.

Owner:CHINA UNIV OF MINING & TECH

Single-efficiency absorption type refrigerating device with expander-compressor

InactiveCN101737997AIncrease the range of preparation temperatureReduce system performanceRefrigeration machinesWorking pressureGas phase

The invention discloses a single-efficiency absorption type refrigerating device with an expander-compressor, comprising a generator, a preheater, a rectifier, a condenser, a second throttle valve, an evaporator, an expander-compressor, an absorber, a solution pump, a solution heat exchanger, a fourth throttle valve and two middle heat exchange parts, wherein the generator, the preheater, the rectifier, the condenser, a first middle heat exchange part, the second throttle valve, the evaporator, the expander-compressor, the absorber, the solution pump and the solution heat exchanger are sequentially connected; the generator, the second middle heat exchange part, the solution heat exchanger, the fourth throttle valve and the absorber are sequentially connected; a gas-phase outlet of the first middle heat exchange part, the preheater, the expander-compressor and the absorber are sequentially connected; and a gas-phase outlet of the second middle heat exchange part, the expander-compressor and the absorber are sequentially connected. In the invention, work produced by the device is utilized to compress steam at the outlet of the evaporator to improve the working pressure of the absorber so as to ensure that the device can prepare cold quantity having a higher grade than that prepared by a traditional single effect absorption type refrigerating device.

Owner:ZHEJIANG UNIV

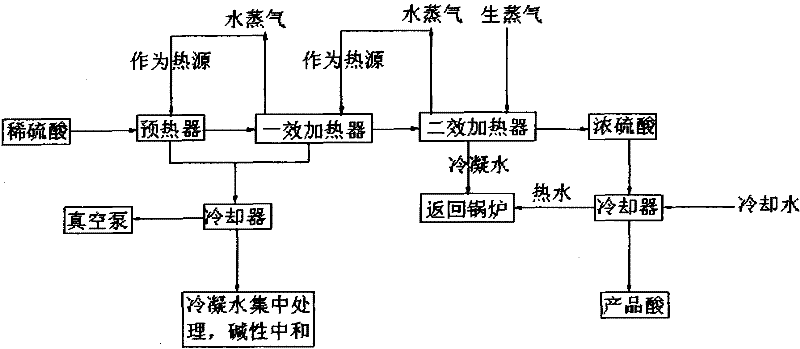

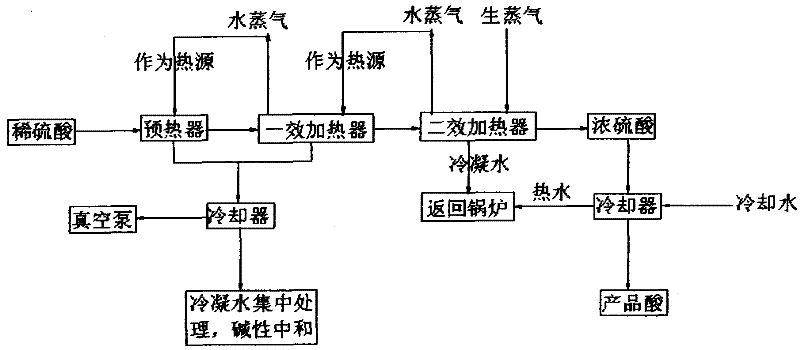

Technology for concentrating dilute sulfuric acid with multi-effect evaporation

The invention discloses a technology for concentrating dilute sulfuric acid with multi-effect evaporation. The method comprises the following steps: 1, heating with a first-effect heater after preheating dilute sulfuric acid with a preheater, and heating with a second-effect heater to prepare concentrated sulfuric acid; and 2, cooling by allowing generated concentrated sulfuric acid to go through a cooler to prepare products concentrated sulfuric acid. Sulfuric acid is concentrated with graphite equipment. Energy consumed by multi-effect evaporation adopted in the invention accounts for 40% of energy consumed by single-effect evaporation. The degree of the sulfuric acid concentration of the technology reaches 70%.

Owner:钱尉兵

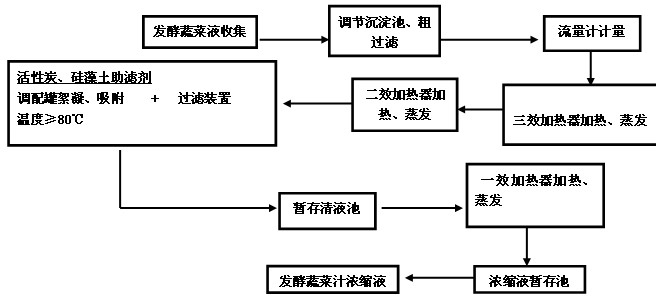

Preparation method of salted vegetable concentrated liquid

The invention discloses a preparation method of salted vegetable concentrated liquid, comprising the following steps of: collecting fermented and ripened salted vegetable fermentation liquid into a regulating settling tank, carrying out coarse filtration by a bottom filter screen of the regulating settling tank, and carrying out primary clarification on the salted vegetable fermentation liquid; feeding the coarsely filtered fermentation liquid into a triple-effect evaporation device, and heating and evaporating at the conditions that the vacuum degree is 0.08MPa and the boiling point is 50-55 DEG C; feeding the treated salted vegetable fermentation liquid into a double-effect evaporation device, and heating and evaporating at the conditions that the vacuum degree is 0.06MPa and the boiling point is 80-85 DEG C; feeding the treated salted vegetable fermentation liquid into an activated carbon and kieselguhr filtering device, and carrying out decoloration and foreign taste removal treatment on the salted vegetable fermentation liquid; and feeding the decolored clear liquid the foreign taste of which is removed into a single-effect evaporation device, and heating and evaporating at the conditions that the vacuum degree is 0.04MPa and the boiling point is 90-95 DEG C to prepare the required salted vegetable concentrated liquid. The invention has low production cost and realizes the recycle of the salted vegetable concentrated liquid.

Owner:吉香居食品股份有限公司

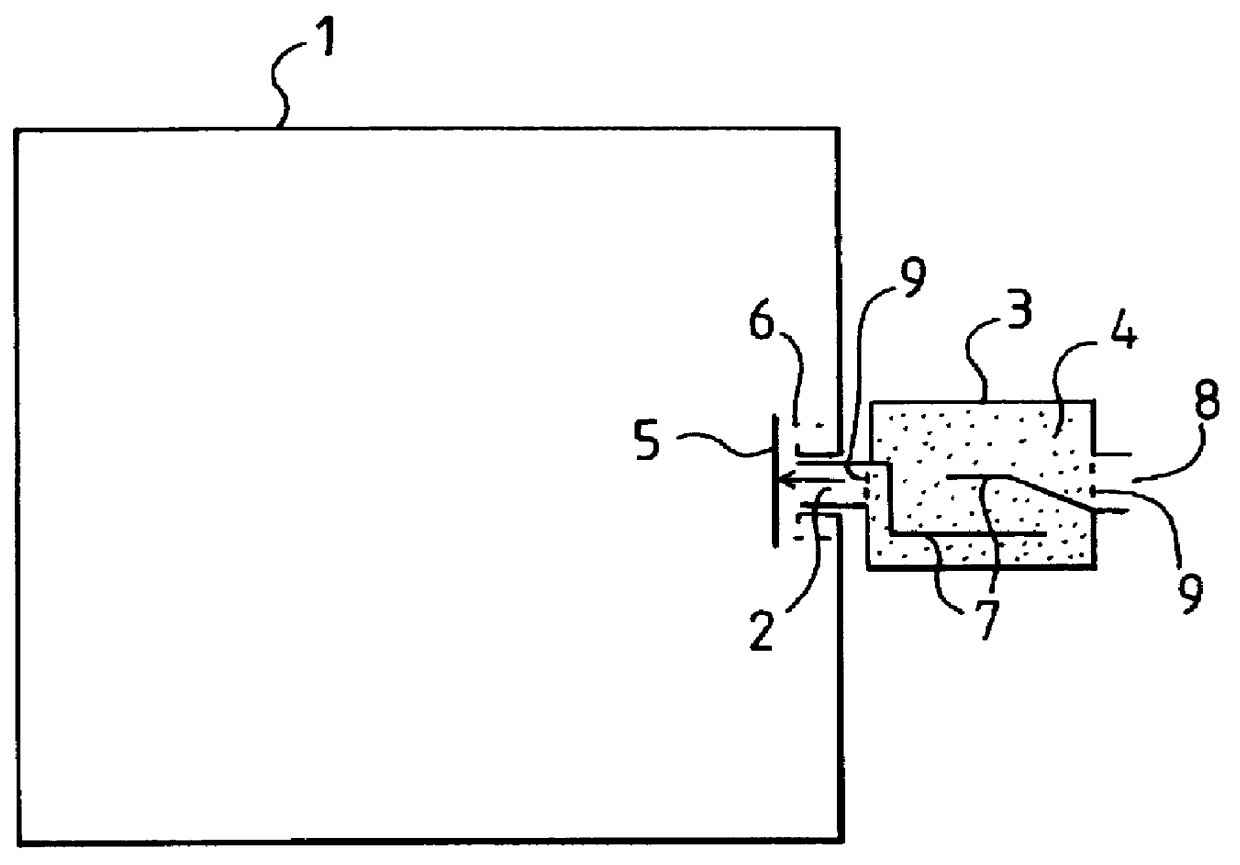

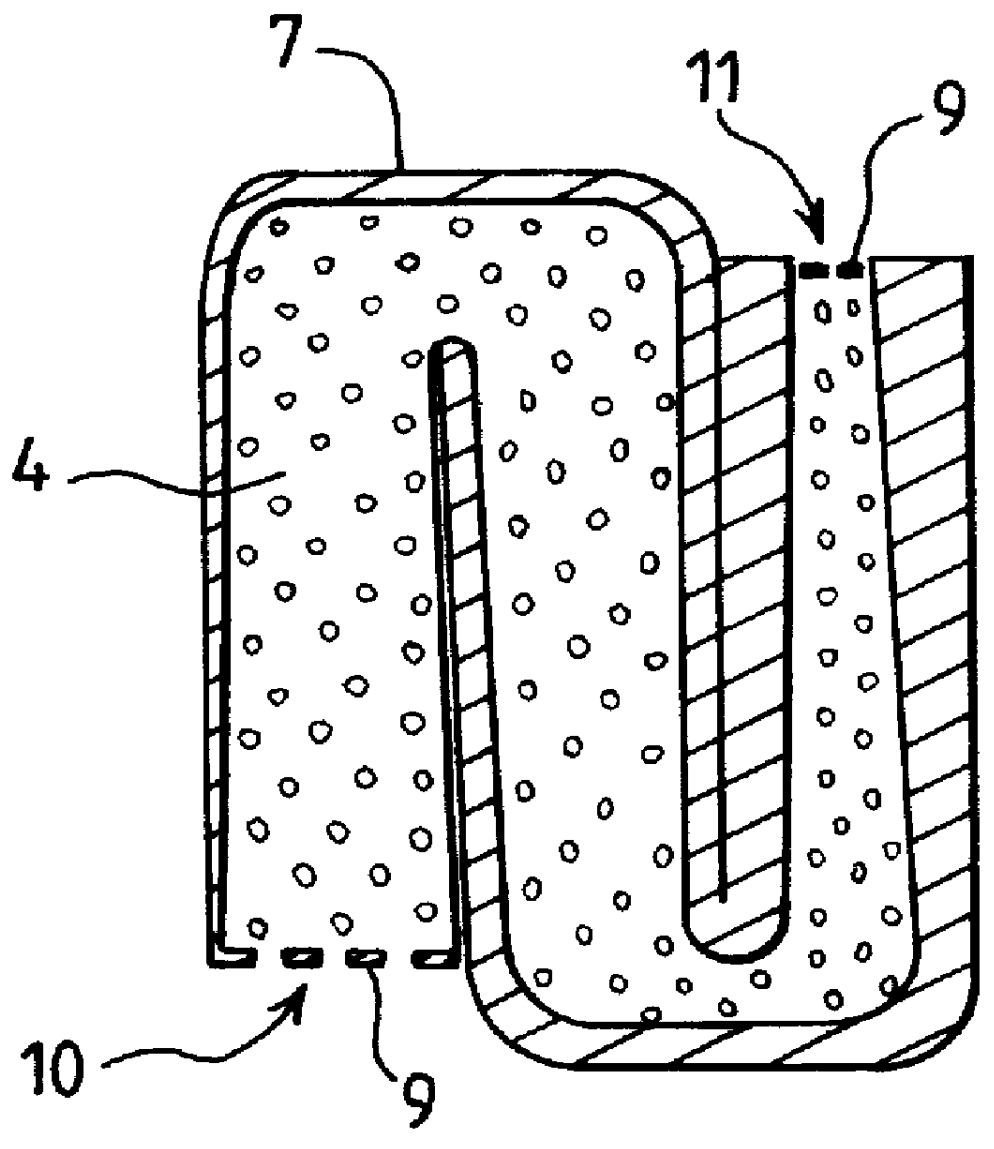

Chamber with drier

InactiveUS6110261AAvoid spreadingSingle instruction multiple data multiprocessorsDrying solid materials without heatAntechamberDesiccant

A chamber with drier comprises a clean chamber communicating with the outside environment through an orifice equipped with a detachable antechamber filled with desiccant granulates. The chamber comprises, between the orifice of the clean chamber and the detachable antechamber filled with desiccant granulates, a valve that is closed at rest and opened by the positioning, on the orifice of the clean chamber, of the antechamber filled with desiccant granulates and the antechamber filled with desiccant granulates contains a baffle that prevents the air from following a direct route and forces it to encounter the majority of the desiccant granulates. Advantageously, the baffle is convergent and there electronic monitoring of the moisture saturation of the desiccant granulates. Furthermore, there may be a single-effect back flow valve bypassing the baffle for a fast decompression of the clean chamber.

Owner:THES INVESTMENTS LLC

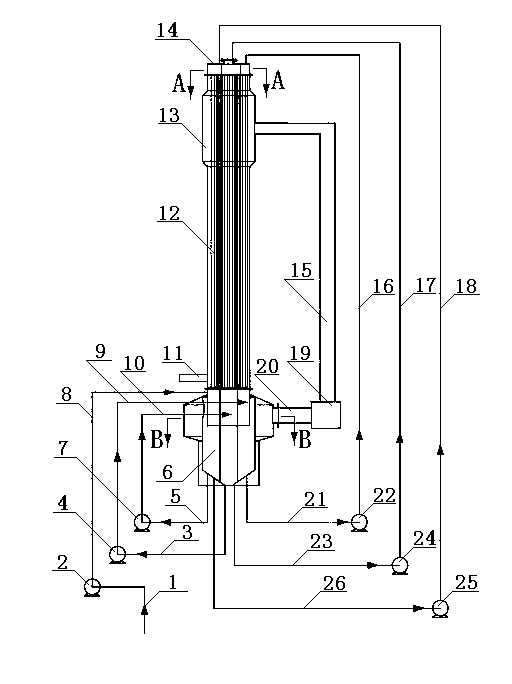

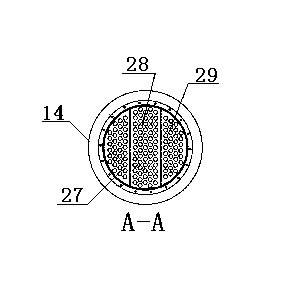

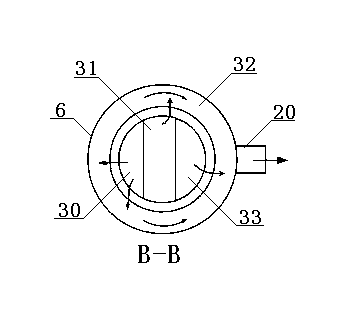

Compound type monomer multi-effect steam mechanical recompression evaporator

ActiveCN102989181ASave energyImprove efficiencyMultiple-effect evaporationEvaporators with vertical tubesCompression PumpEvaporation

The invention discloses a compound type monomer multi-effect steam mechanical recompression evaporator. The compound type monomer multi-effect steam mechanical recompression evaporator comprises a material distributing device, a heater, a steam-water separation chamber and a steam mechanical compression pump, and is characterized in that the material distributing device, the heater and the steam-water separation chamber are sequentially communicated from top to bottom and fixedly connected into a whole; the steam mechanical compression pump can communicate and connect the steam-water separation chamber with the heater through a pipeline; and a material input end of the steam-water separation chamber is connected with a feed pump through the pipeline, and a material output end is communicated and connected with the material distributing device through the pipeline and a circulating pump. The evaporator has the advantages of simple structure and small occupied space, and can achieve the effects of single-effect efficiency, multi-effect evaporation and energy conservation. Secondary steam produced by evaporation of material is recompressed by the steam mechanical pump and then used for heating the material, so that the circulating use is realized and the energy is saved. After the evaporator is opened and runs normally, the fresh steam does not need to be supplemented. The evaporator is suitable for evaporation and concentration of various liquid-containing materials.

Owner:贵港市飞创节能设备有限公司

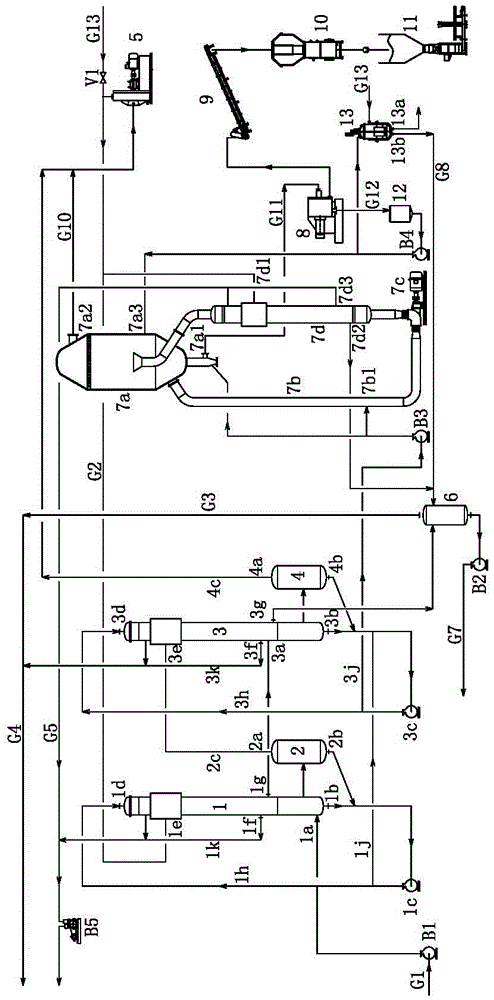

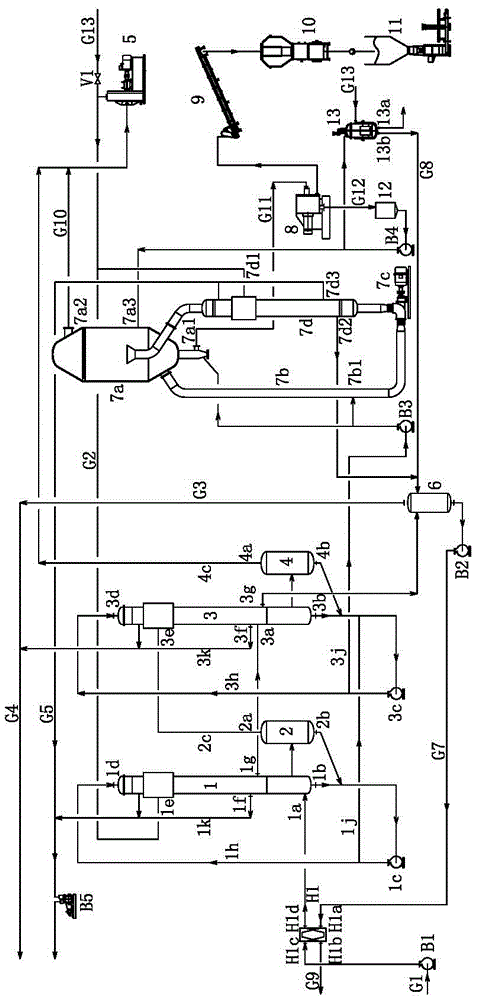

Novel low-temperature combined cooling, heating and power (CCHP) system based on heat pump

ActiveCN103075841AIncrease profitSimple structureClimate change adaptationHeating and refrigeration combinationsThermal energyCooling tower

The invention relates to a novel low-temperature combined cooling, heating and power (CCHP) system based on a heat pump. Currently, no novel low-temperature CCHP system based on the heat pump with a simple structure and a reasonable design exists. The novel low-temperature CCHP system based on the heat pump comprises a high-pressure steam pipe, a steam turbine, a power generator, a condenser and a boiler connecting pipe, and is characterized by also consisting of a heating low-pressure steam pipe, a heating condensate pipe, a power plant after-heat single-effect heat pump unit, a refrigeration single-effect absorbing heat pump unit, a heat pump unit loop pipe, a loop circulating pump, a user refrigeration pipe, a cooling tower, a cooling tower water inlet pipe, a cooling tower water outlet pipe, a cooling water circulating pump, a power plant circulating cooling water pipe, a heat pump cooling tower, a cooling tower circulating pipe, a heating single-effect absorbing heat pump unit, a heating heating pipe, a heat pump circulating pipe and a user heating pipe; the heating low-pressure steam pipe is connected with the refrigeration single-effect absorbing heat pump unit; and the heating condensate pipe is connected with the power plant after-heat single-effect heat pump unit. The novel low-temperature CCHP system based on the heat pump has the advantages of reasonable structural design, energy saving, environmental friendliness and high heat utilization rate.

Owner:杭州全能星科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com