Patents

Literature

1424 results about "Solid mass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

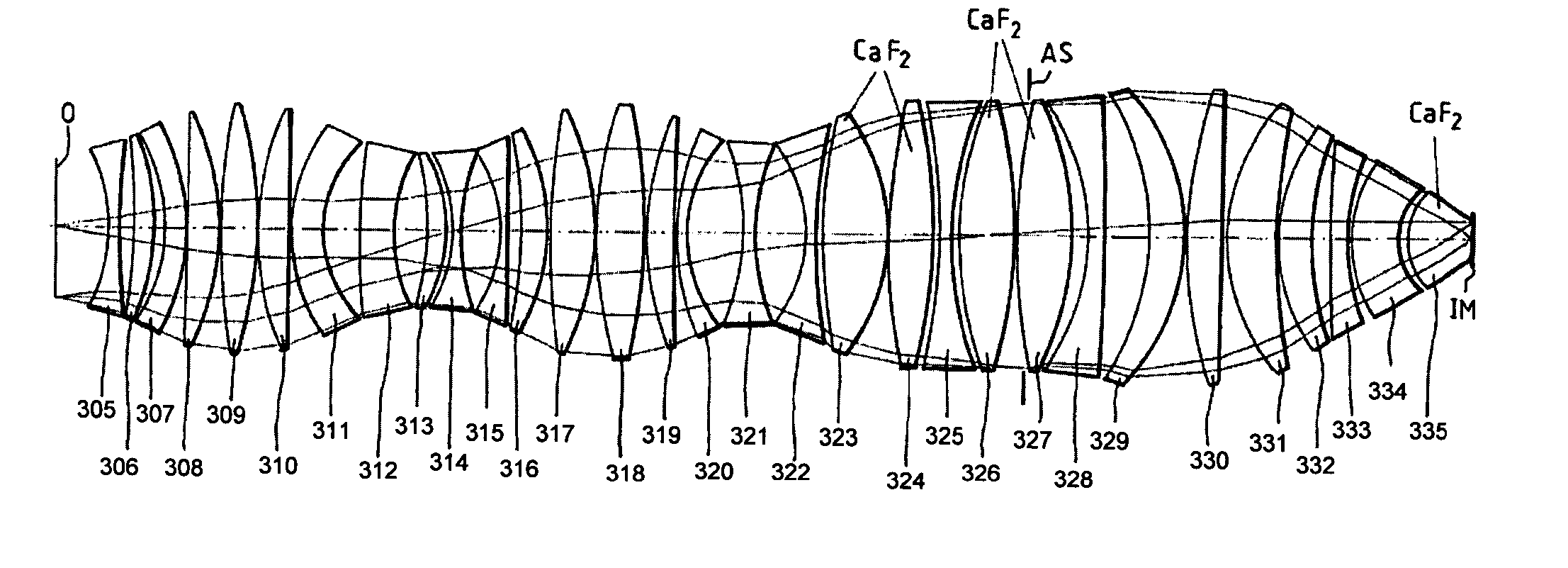

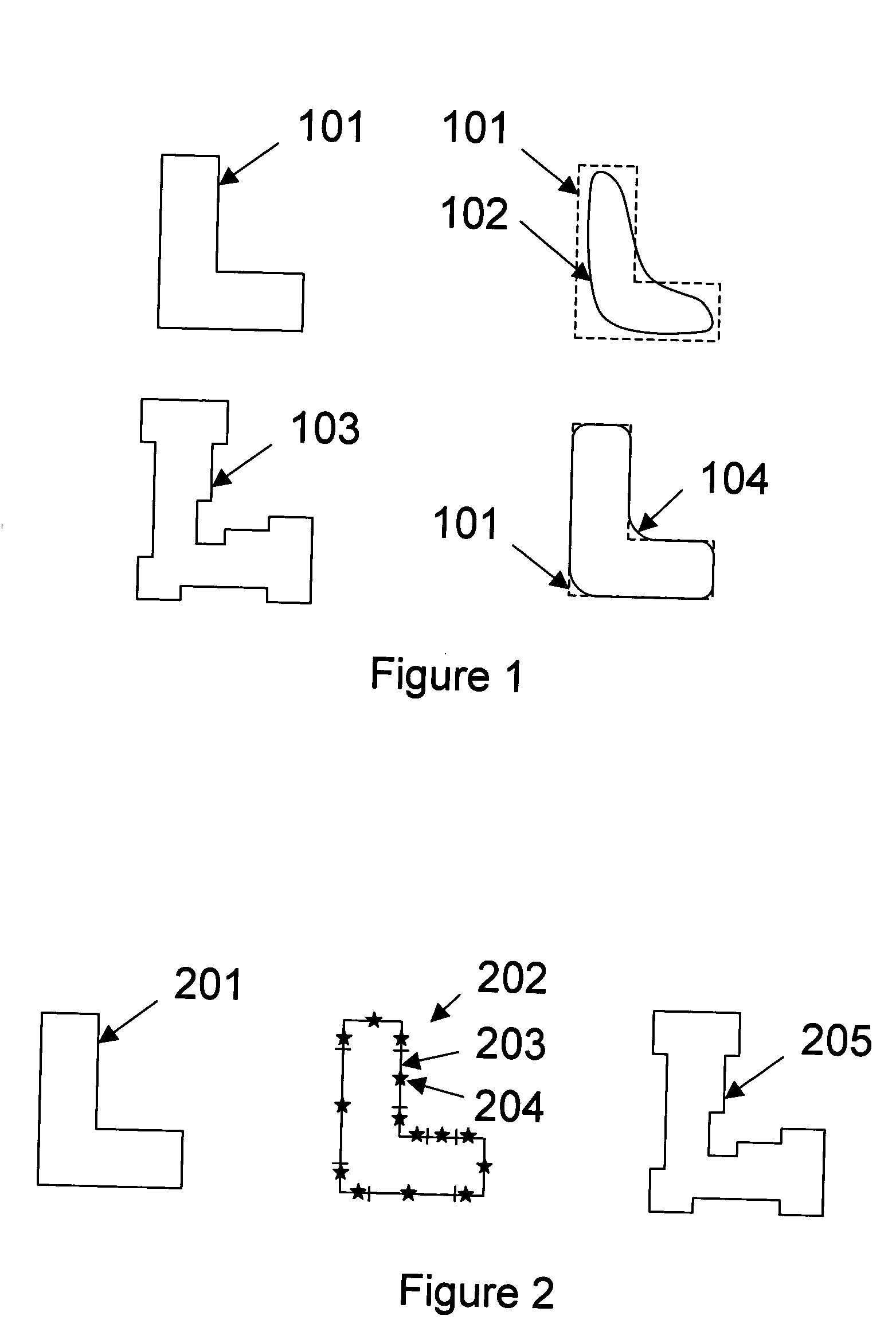

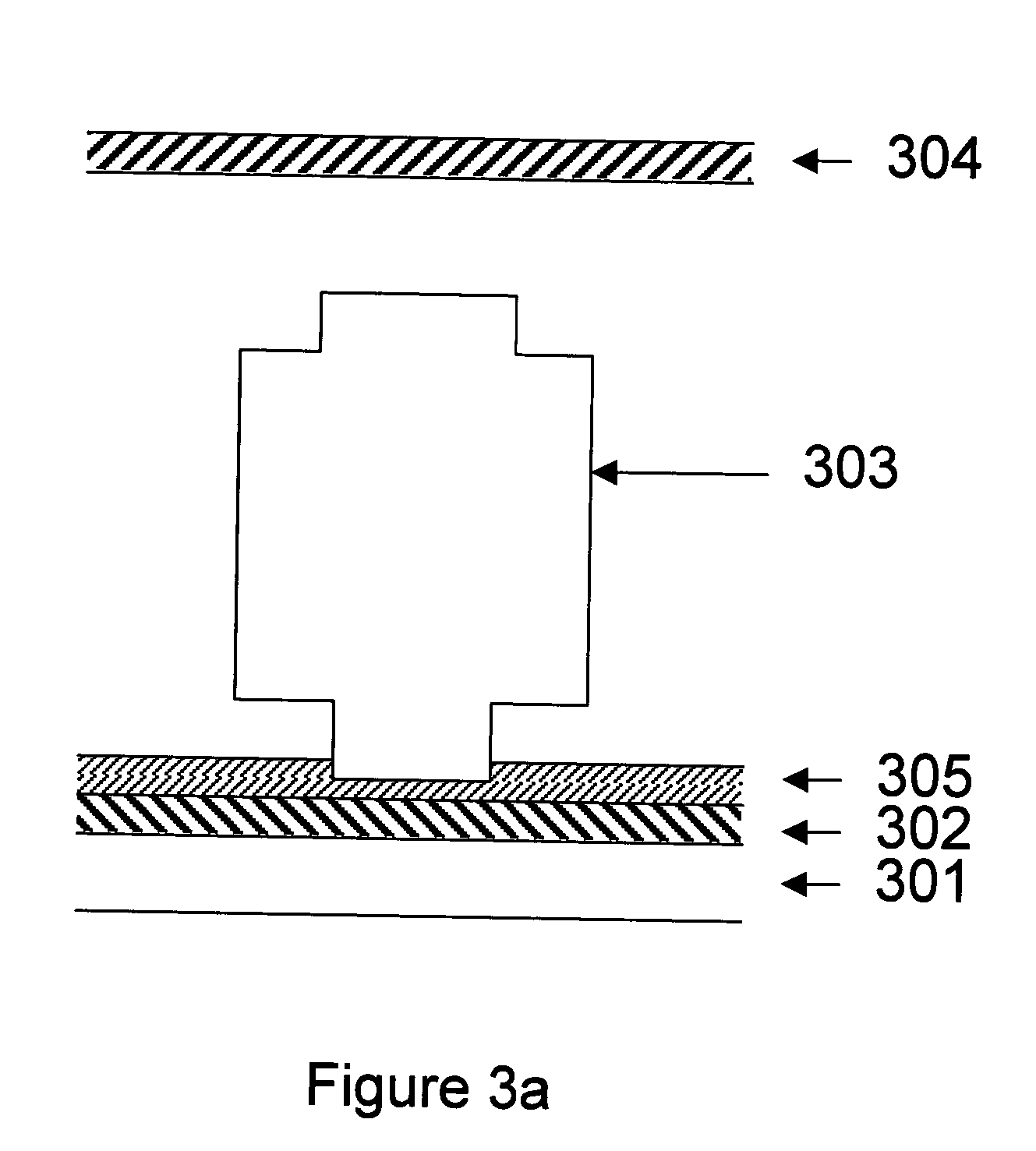

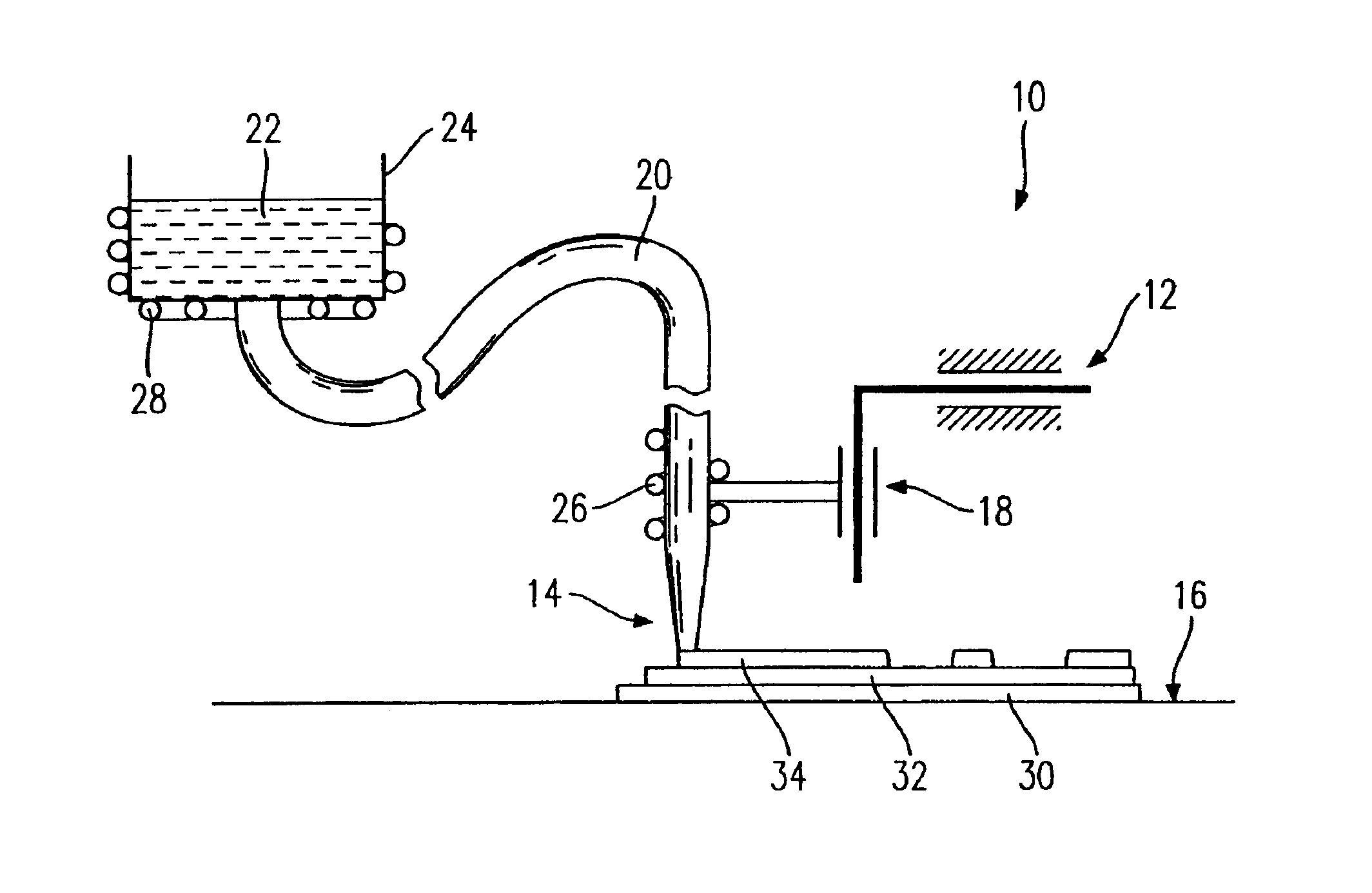

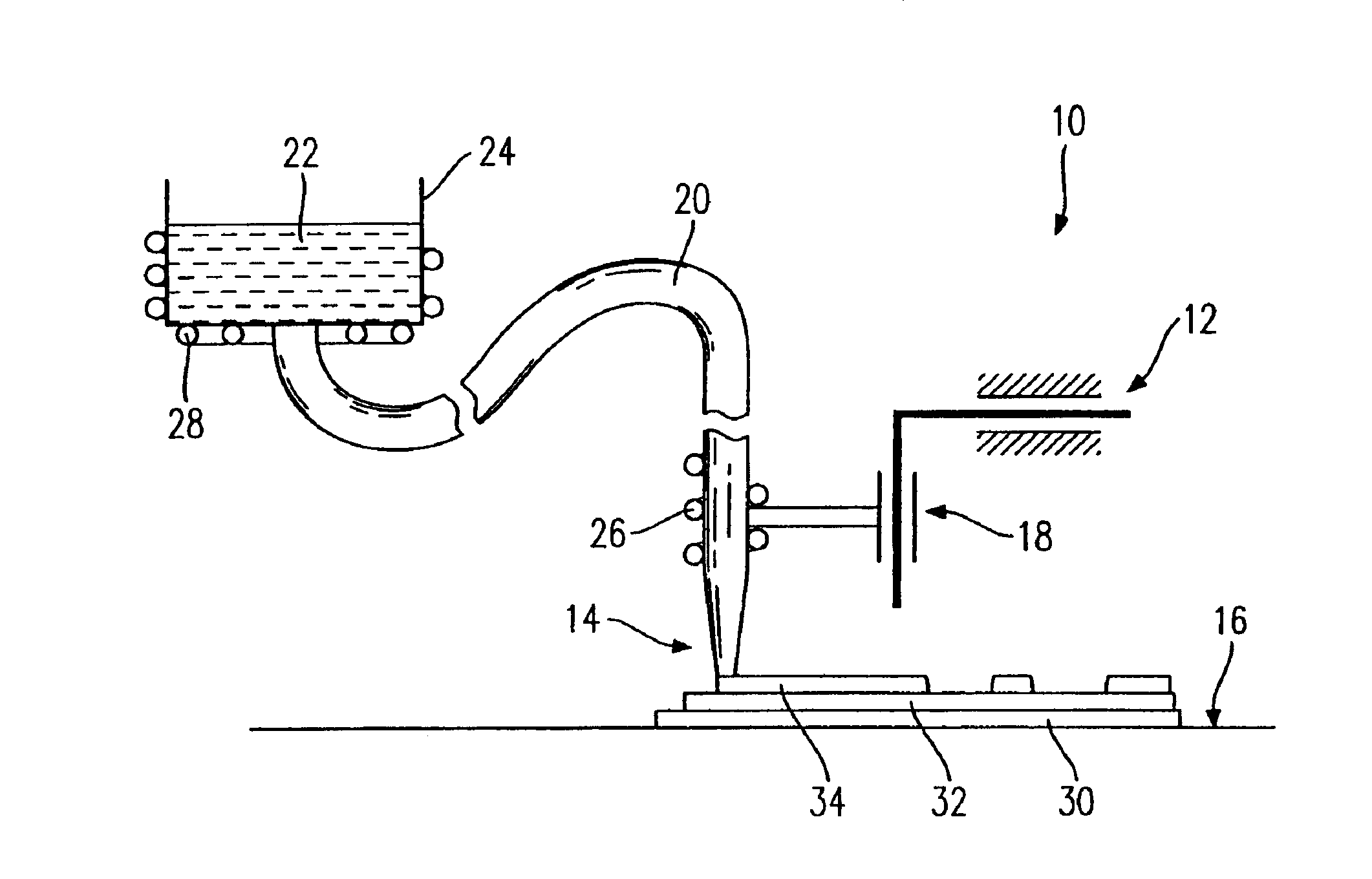

Contact printing using a magnified mask image

InactiveUS20050068639A1Avoid stickingPhotomechanical exposure apparatusMicrolithography exposure apparatusRefractive indexOff-axis illumination

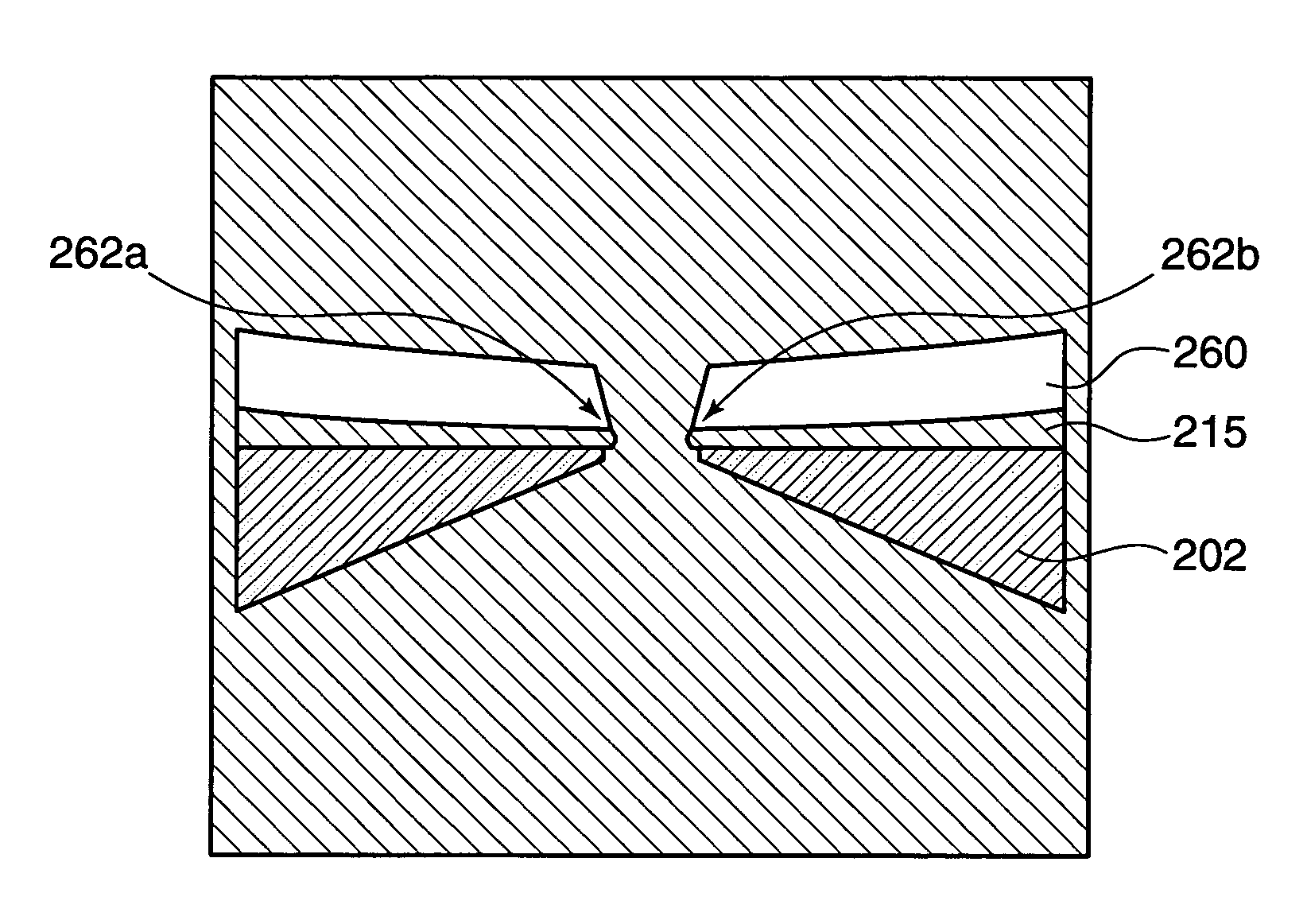

Improvements in the fabrication of integrated circuits are driven by the decrease of the size of the features printed on the wafers. Current lithography techniques limits have been extended through the use of phase-shifting masks, off-axis illumination, and proximity effect correction. More recently, liquid immersion lithography has been proposed as a way to extend even further the limits of optical lithography. This invention described a methodology based on contact printing using a projection lens to define the image of the mask onto the wafer. As the imaging is performed in a solid material, larger refractive indices can be obtained and the resolution of the imaging system can be increased.

Owner:APPLIED MATERIALS INC

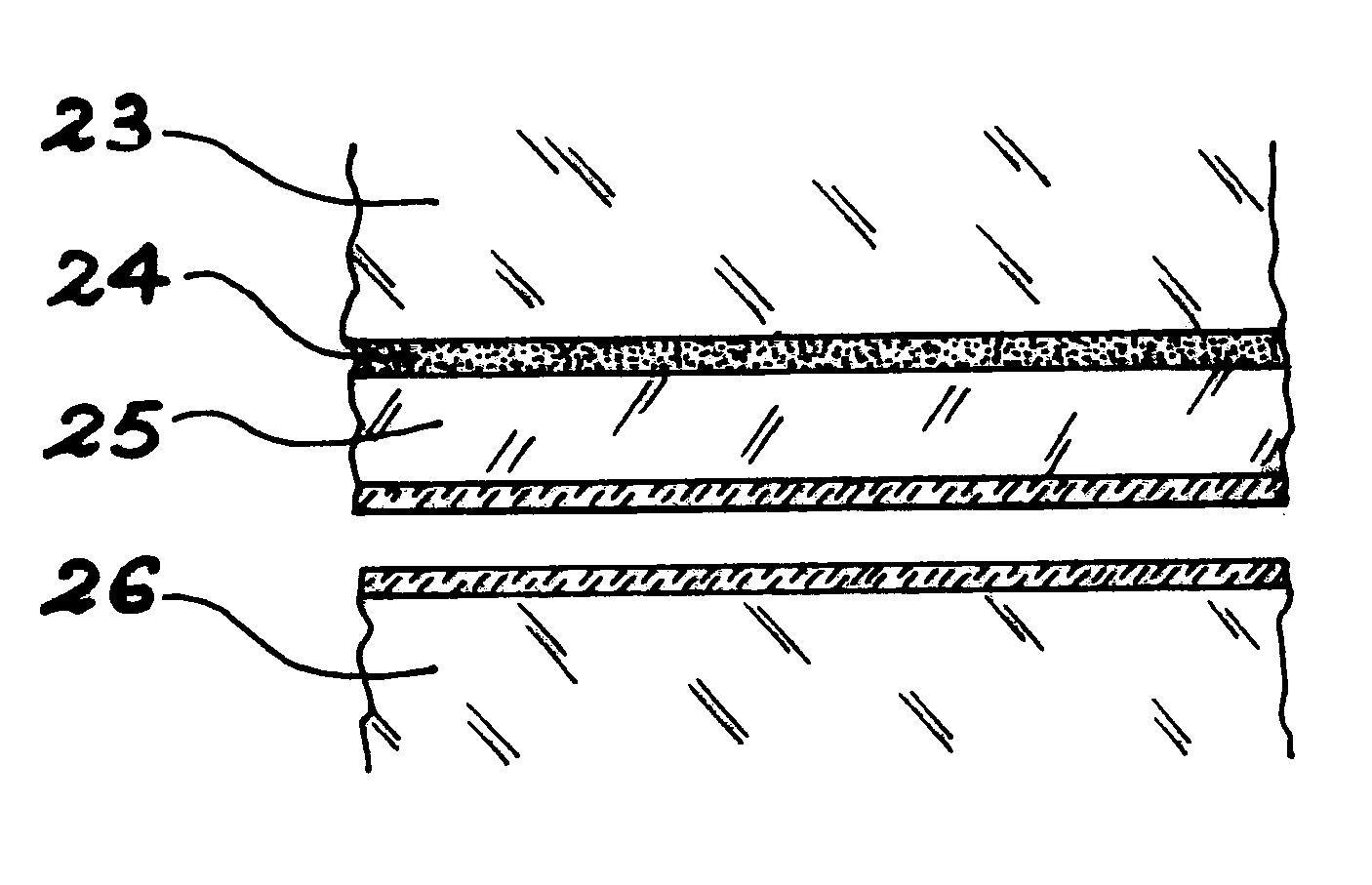

Method for transferring a thin film comprising a step of generating inclusions

InactiveUS6756286B1Reduce surface roughnessBudget is reducedSolid-state devicesSemiconductor/solid-state device manufacturingSolid massFracture plane

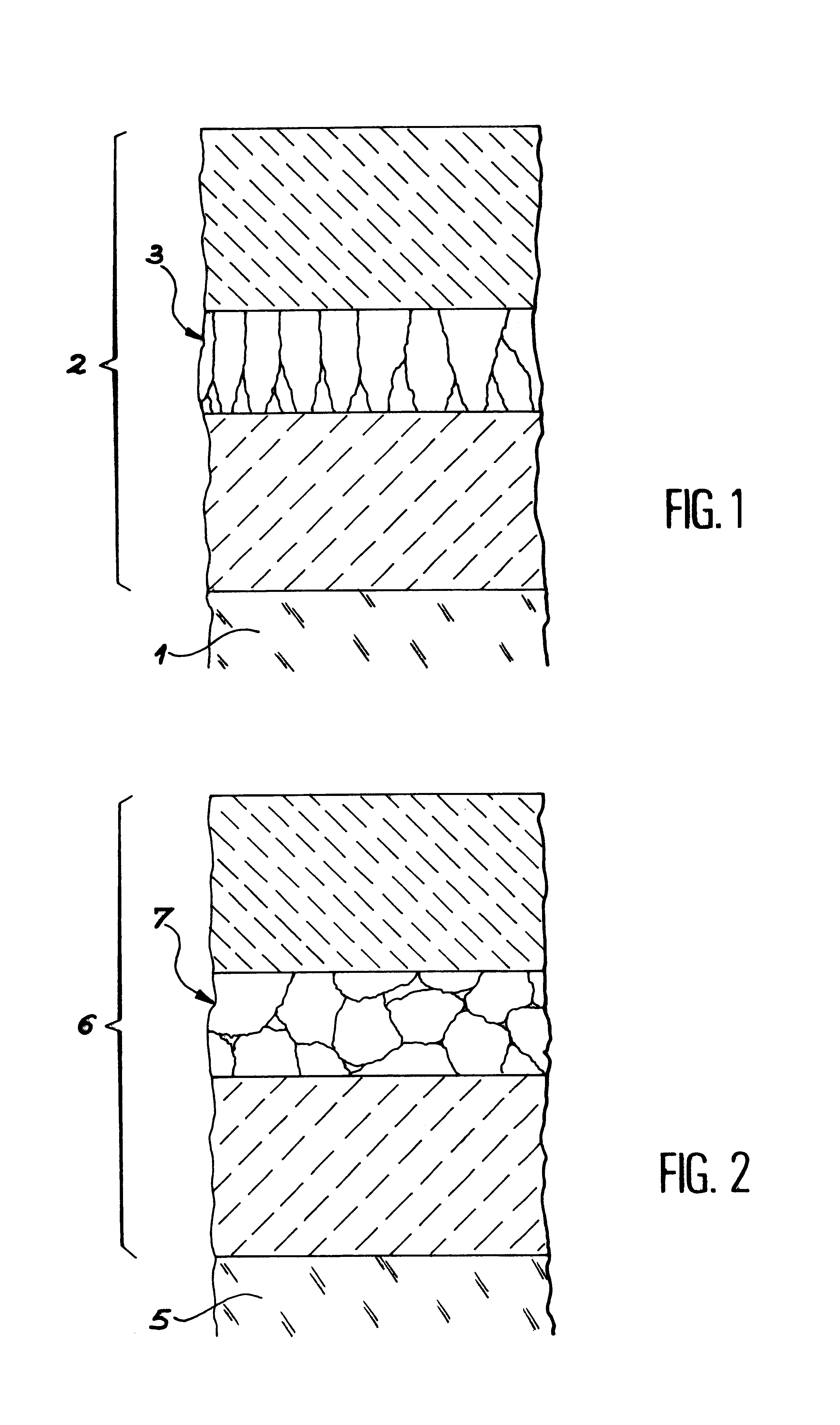

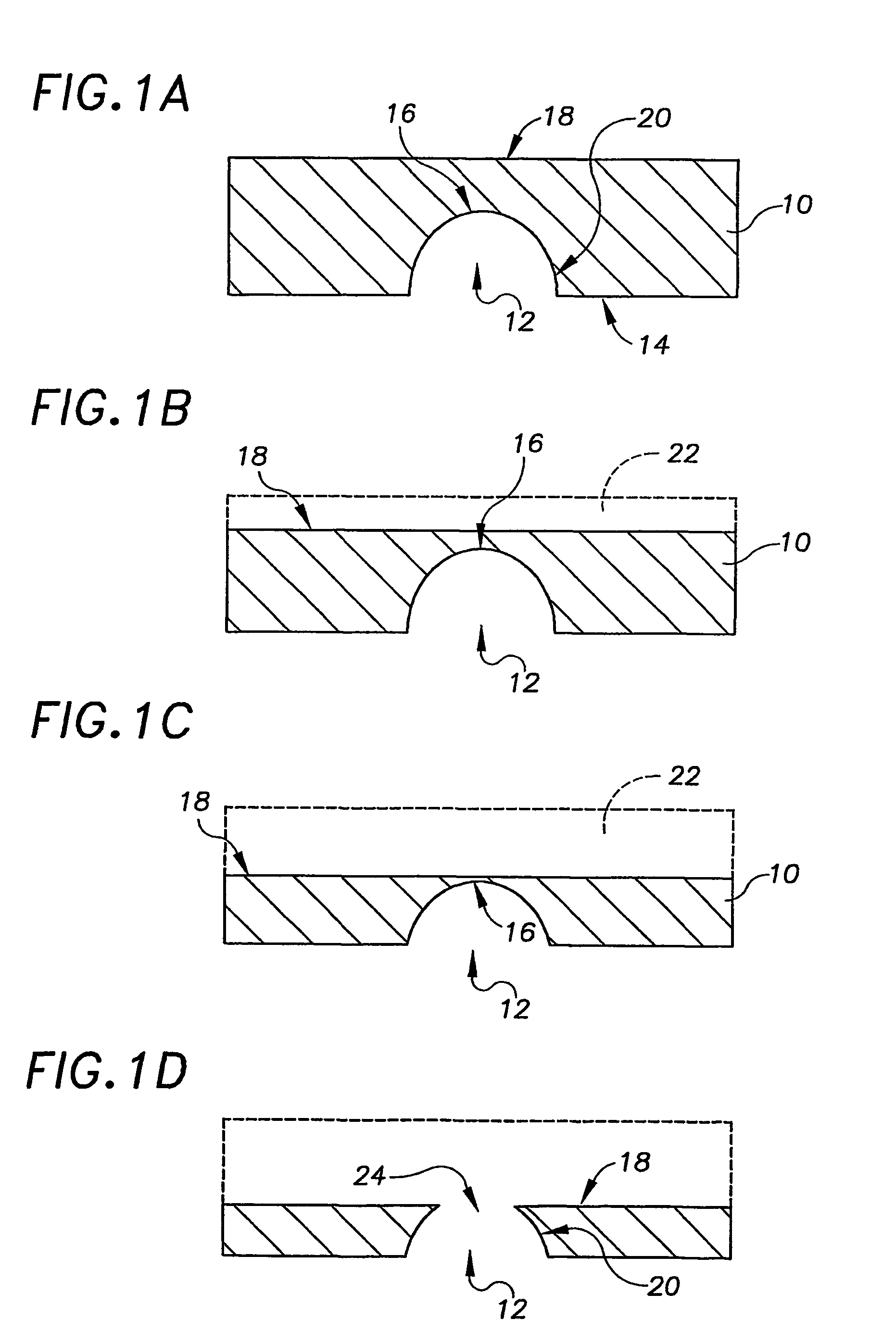

A process for transfer of at least one thin film of solid material delimited in an initial substrate. The process includes a step in which a layer of inclusions is formed in the initial substrate at a depth corresponding to the required thickness of the thin film. These inclusions are designed to form traps for gaseous compounds which subsequently are implanted. In a subsequent step gaseous compounds are implanted in a manner to convey the gaseous compounds into the layer of inclusions. The dose of implanted gaseous compounds is made sufficient to cause the formation of micro-cavities to form a fracture plane along which the thin film can be separated from the remainder of the substrate.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Methods for using polishing pads

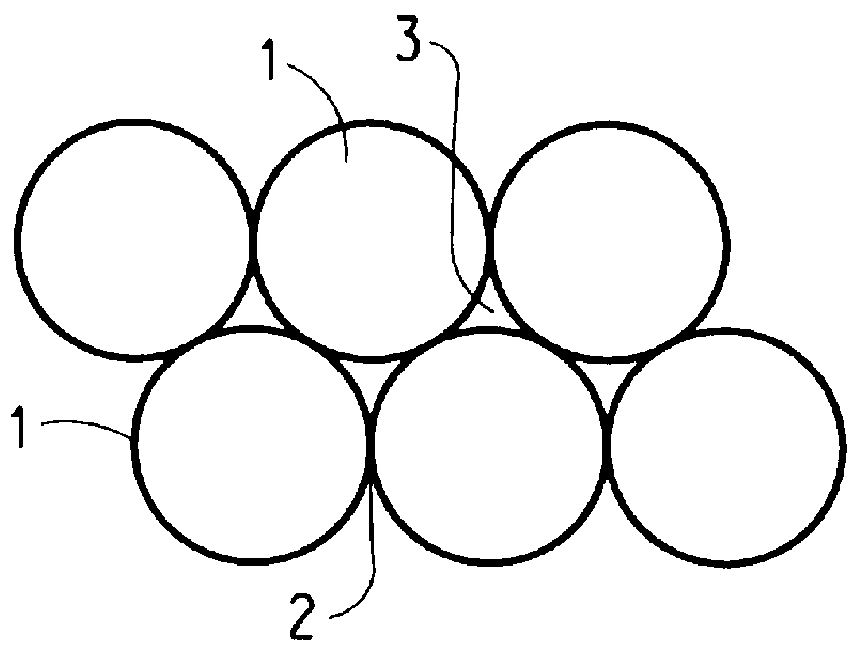

Polymer-based pads useful for polishing objects, particularly integrated circuits, having interconnected porosity which is uniform in all directions, and where the solid portion of said pad consists of a uniform continuously interconnected polymer material of greater than 50% of the gross volume of the article, are produced directly to final shape and dimension by pressure sintering powder compacts of thermoplastic polymer at a temperature above the glass transition temperature but not exceeding the melting point of the polymer and at a pressure in excess of 100 psi in a mold having the desired final pad dimensions. In a preferred version, a mixture of two polymer powders is used, where one polymer has a lower melting point than the other. When pressure sintered at a temperature not to exceed the melting point of the lower melting powder, the increased stiffness afforded by incorporation of the higher melting polymer component gives improved mechanical strength to the sintered product. Conditions for producing the pads of this invention are such that the polymer powder particles from which the pads are produced essentially retain their original shape and are point bonded to form the pad.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Solid state molecular probe device

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

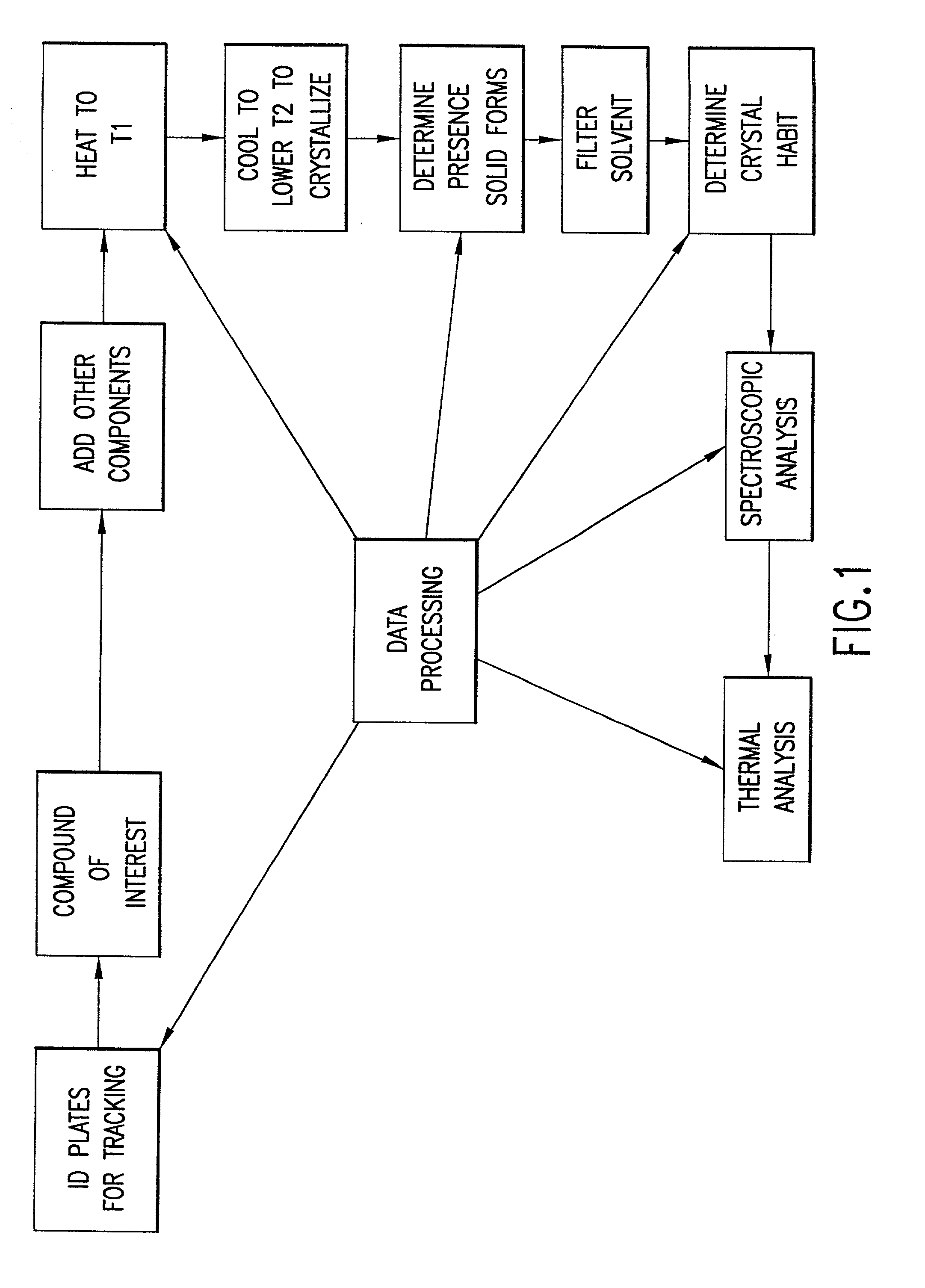

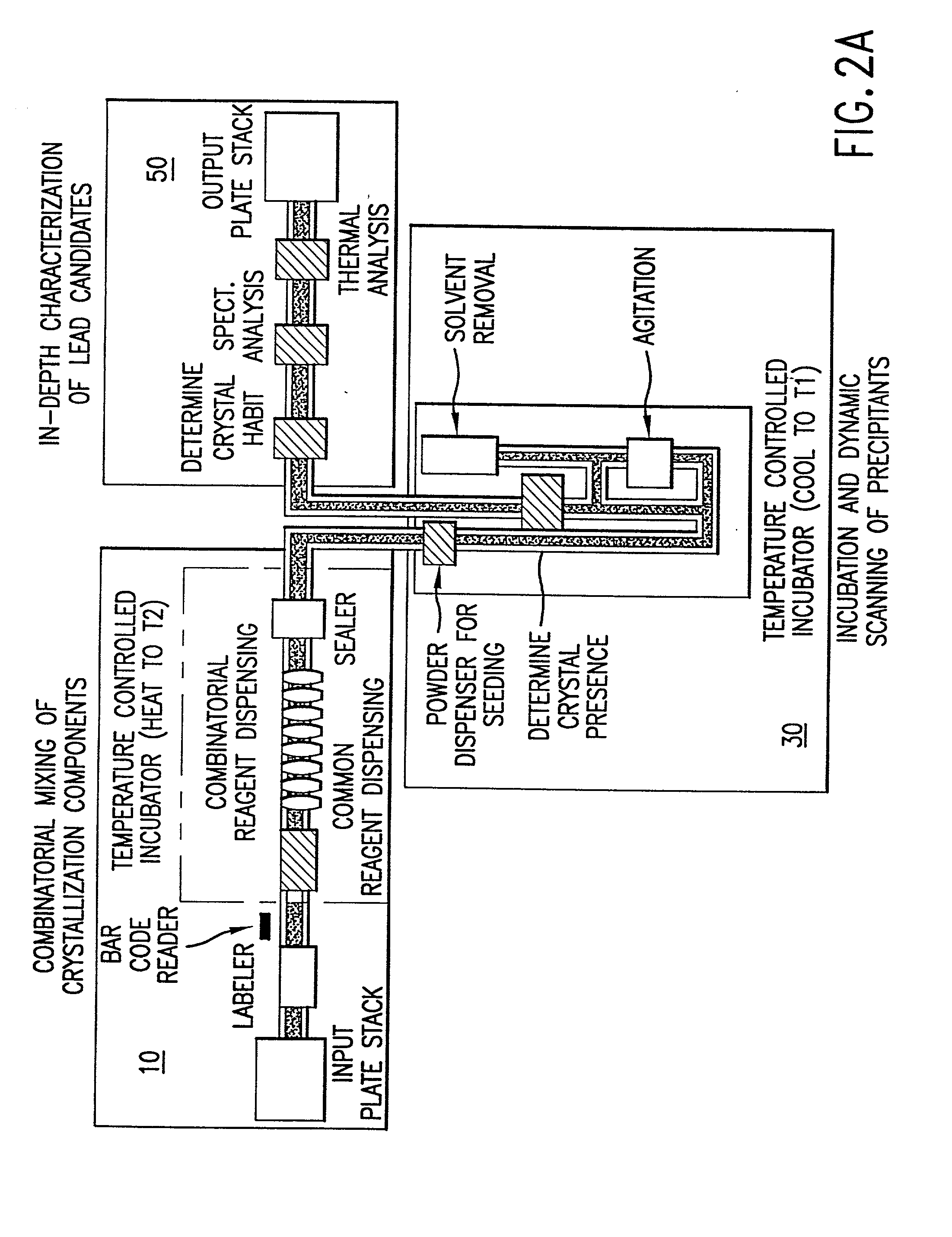

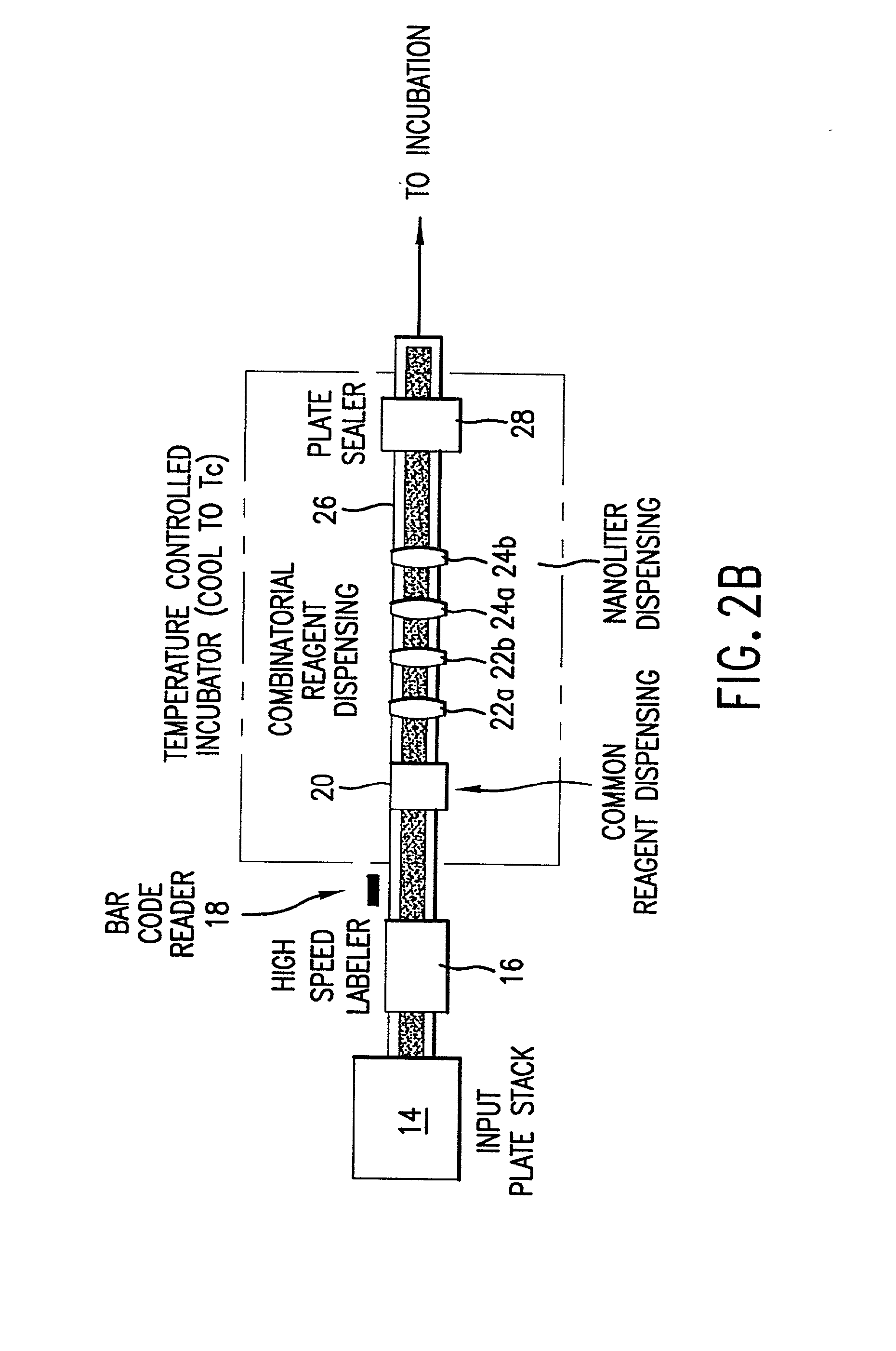

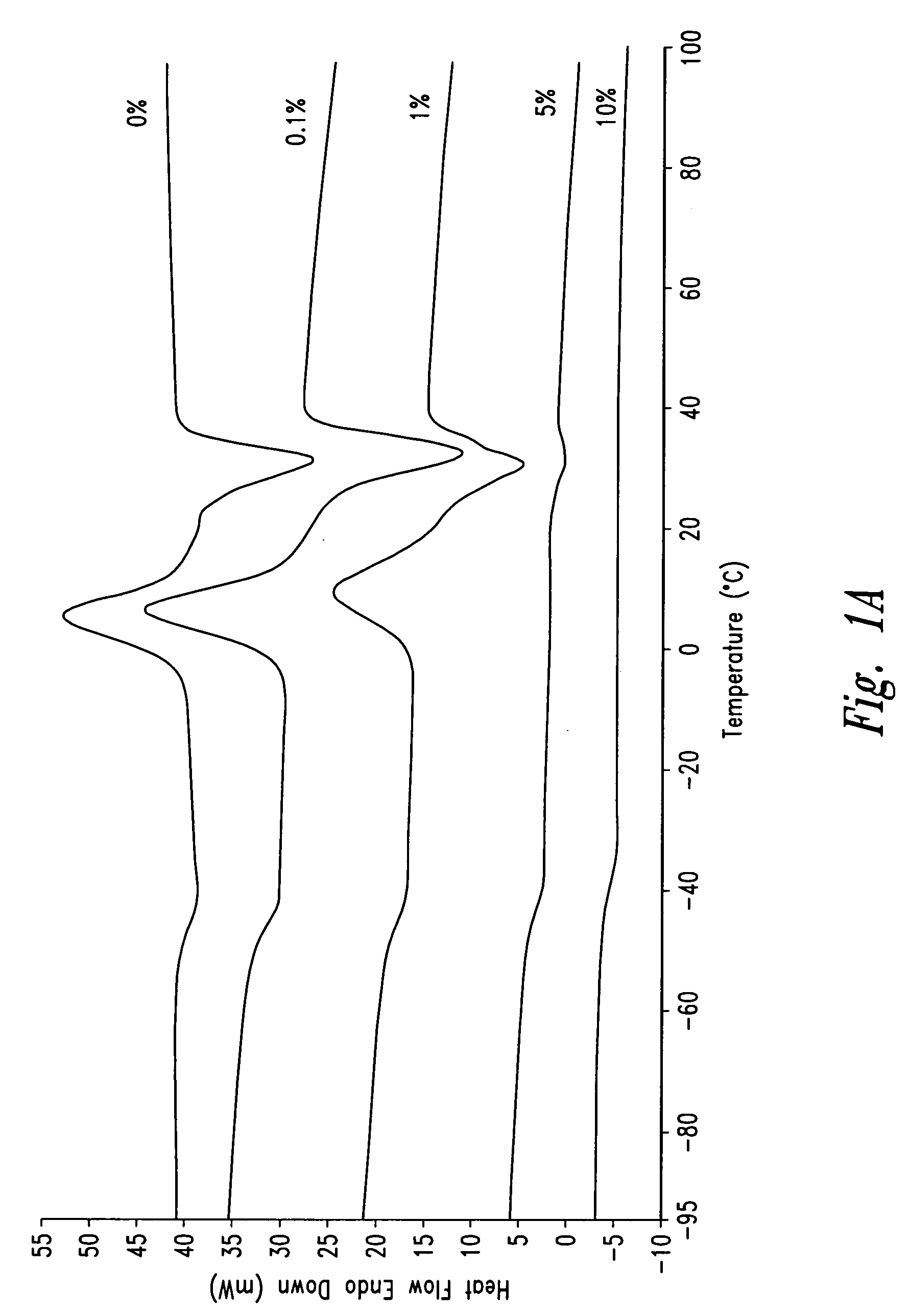

High-throughput formation, identification, and analysis of diverse solid-forms

InactiveUS20020048610A1Cost-effectiveImprove bioavailabilitySequential/parallel process reactionsFrom normal temperature solutionsSolubilitySolid mass

The invention concerns arrays of solid-forms of substances, such as compounds and rapid-screening methods therefor to identify solid-forms, particularly of pharmaceuticals, with enhanced properties. Such properties include improved bioavailability, solubility, stability, delivery, and processing and manufacturing characteristics. The invention relates to a practical and cost-effective method to rapidly screen hundreds to thousands of samples in parallel. The invention further provides methods for determining the conditions and / or ranges of conditions required to produce crystals with desired compositions, particle sizes, habits, or polymorphic forms. In a further aspect, the invention provides high-throughput methods to identify sets of conditions and / or combinations of components compatible with particular solid-forms, for example, conditions and / or components that are compatible with advantageous polymorphs of a particular pharmaceutical.

Owner:MILLENNIUM PHARMA INC +1

Bandgap grading in thin-film devices via solid group IIIA particles

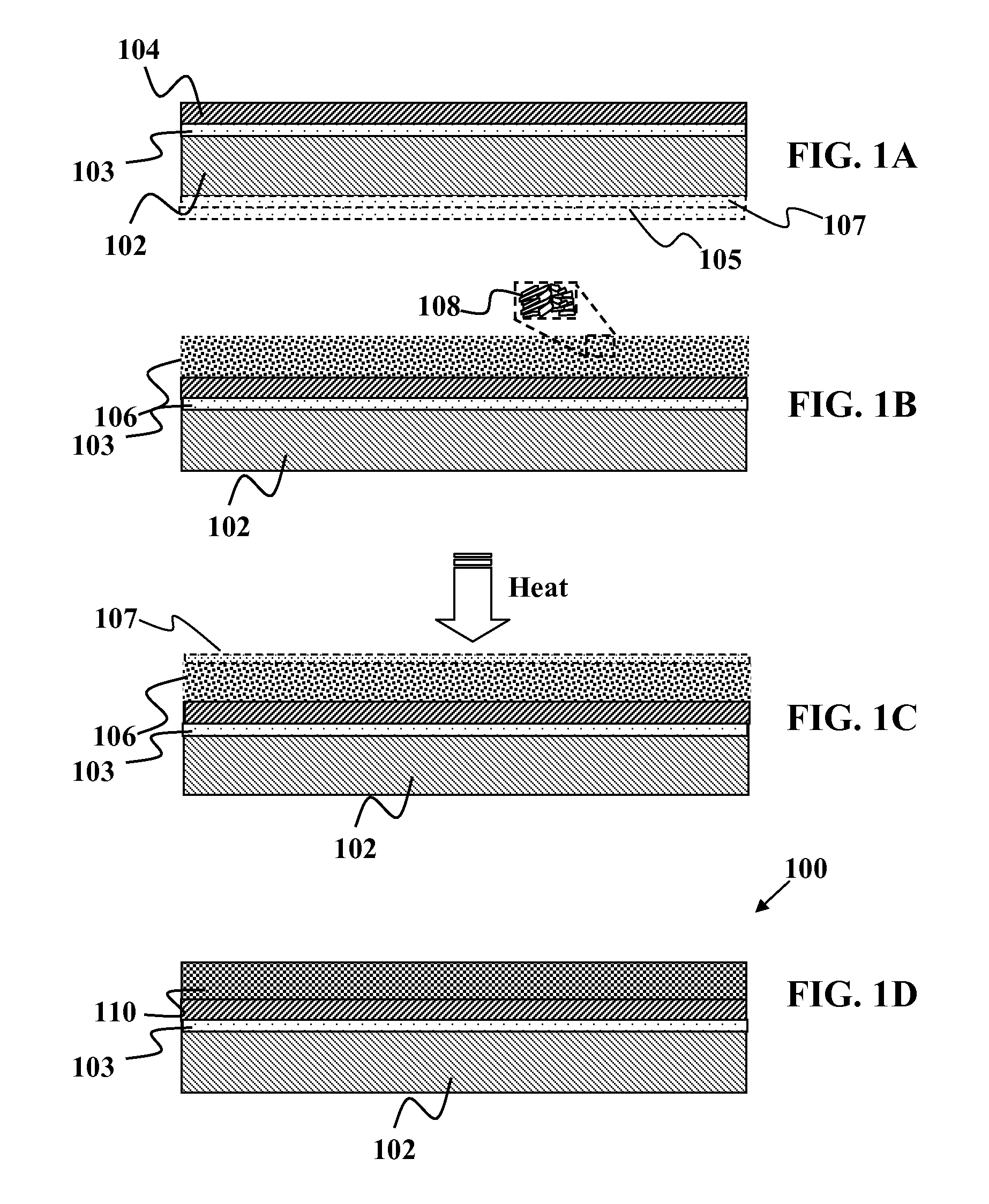

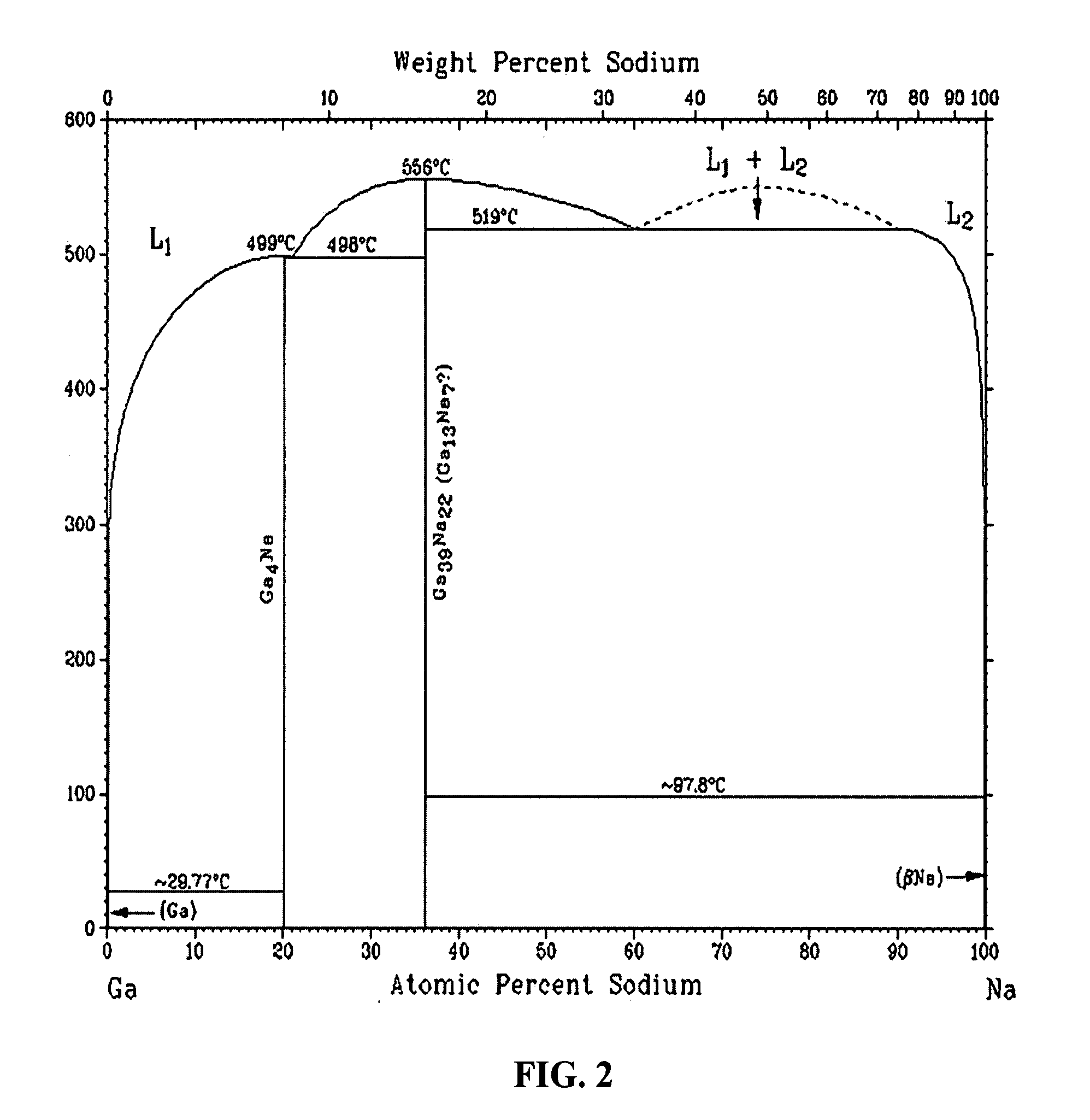

InactiveUS20080057616A1Efficient and simplified creationPrevent leaching and phase separationSemiconductor/solid-state device manufacturingPhotovoltaic energy generationHigh concentrationBandgap grading

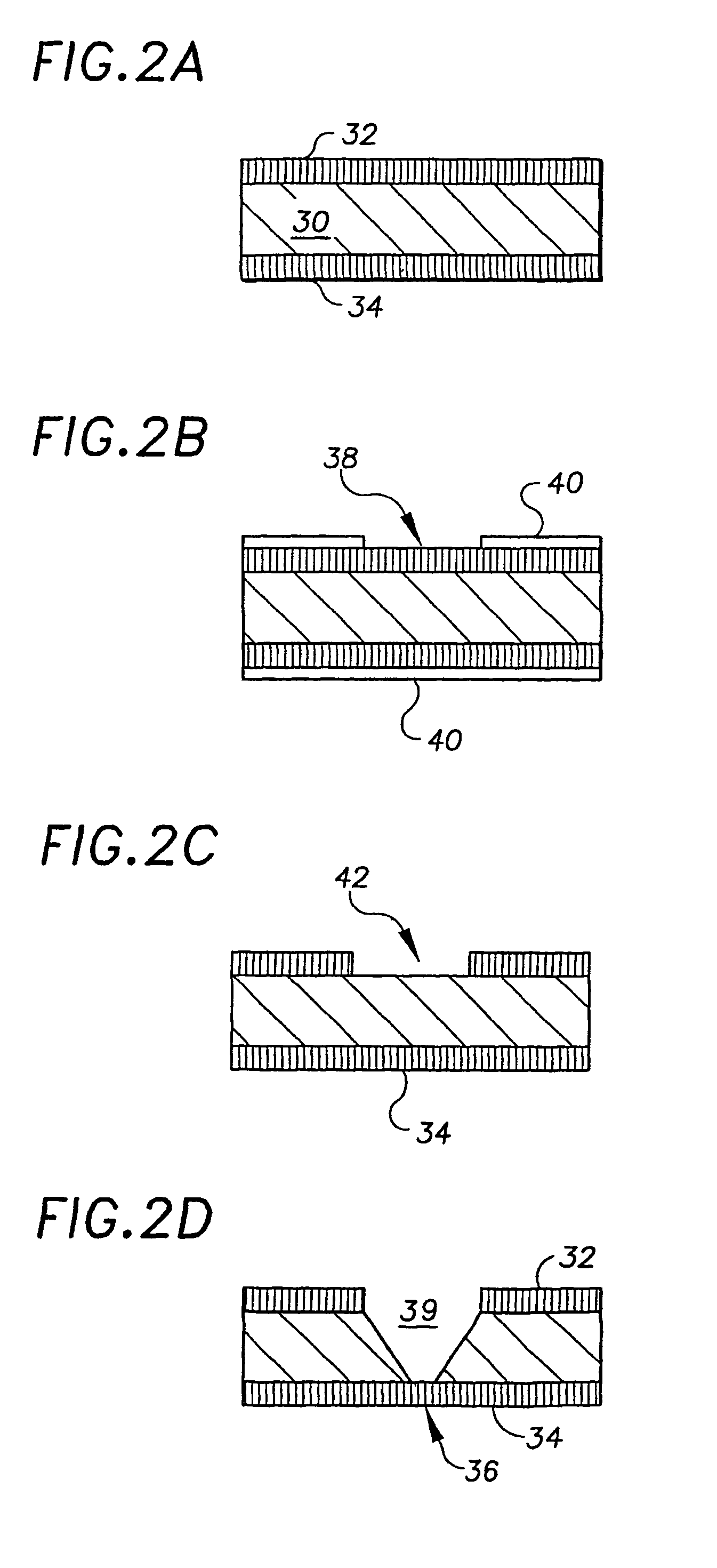

Methods and devices are provided for forming thin-films from solid group IIIA-based particles. In one embodiment, a method is provided for bandgap grading in a thin-film device using such particles. The method may be comprised of providing a bandgap grading material comprising of an alloy having: a) a IIIA material and b) a group IA-based material, wherein the alloy has a higher melting temperature than a melting temperature of the IIIA material in elemental form. A precursor material may be deposited on a substrate to form a precursor layer. The precursor material comprising group IB, IIIA, and / or VIA based particles. The bandgap grading material of the alloy may be deposited after depositing the precursor material. The alloy in the grading material may react after the precursor layer has begun to sinter and thus maintains a higher concentration of IIIA material in a portion of the compound film that forms above a portion that sinters first.

Owner:AERIS CAPITAL SUSTAINABLE IP

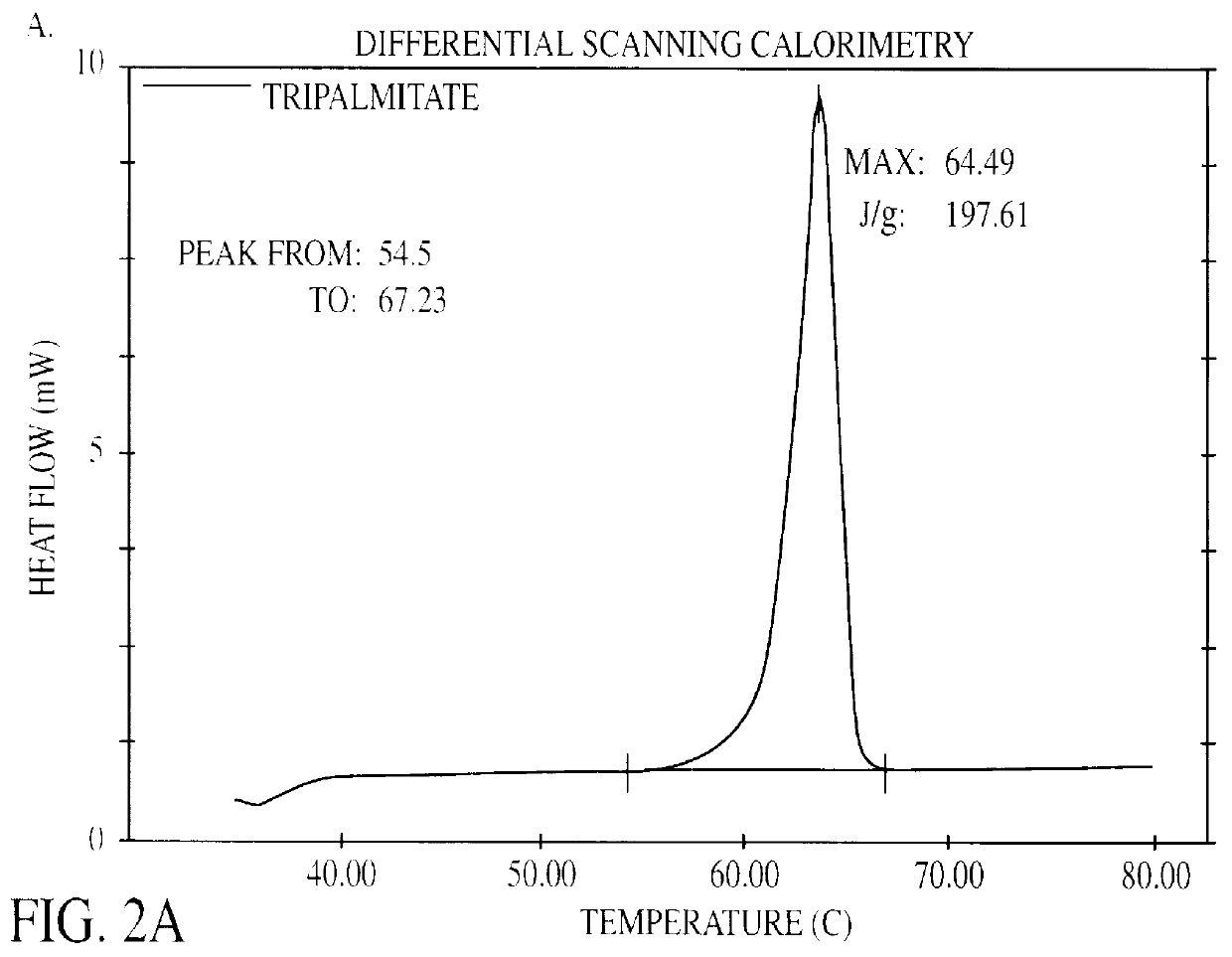

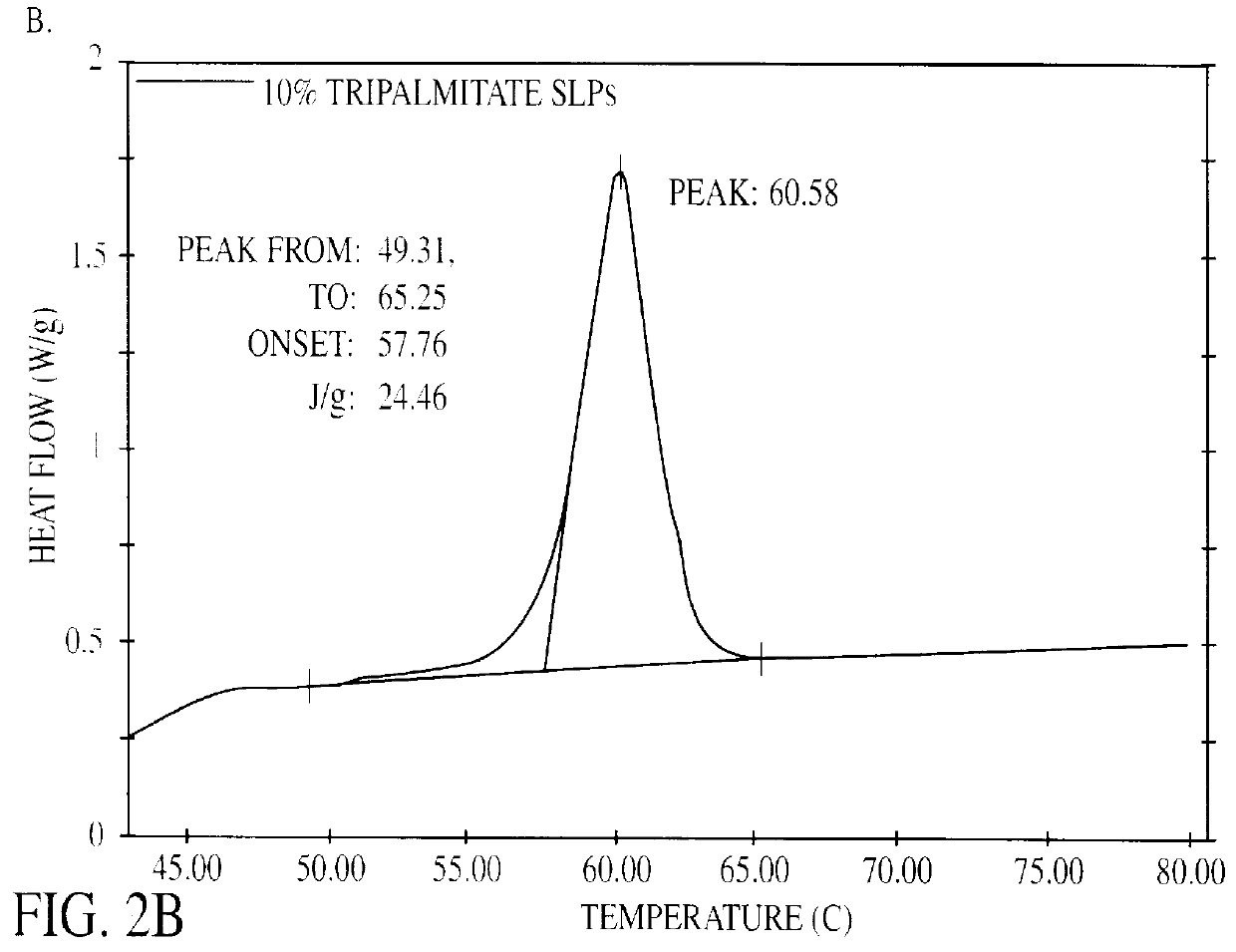

Solid lipid particles, particles of bioactive agents and methods for the manufacture and use thereof

InactiveUS6207178B1Suppresses decrease in specific surface areaImprove bioavailabilityBiocideCosmetic preparationsLipid formationLipid particle

The present invention is in the area of administration forms and delivery systems for drugs, vaccines and other biologically active agents. More specifically the invention is related to the preparation of suspensions of colloidal solid lipid particles (SLPs) of predominantly anisometrical shape with the lipid matrix being in a stable polymorphic modification and of suspensions of micron and submicron particles of bioactive agents (PBAs); as well as to the use of such suspensions or the lyophilizates thereof as delivery systems primarily for the parenteral administration of preferably poorly water-soluble bioactive substances, particularly drugs, and to their use in cosmetic, food and agricultural products. SLPs and PBAs are prepared by the following emulsification process: (1) A solid lipid or bioactive agent or a mixture of solid lipids or bioactive agents is melted. (2) Stabilizers are added either to the lipid or bioactive agent and to the aqueous phase or to the aqueous phase only depending on their physicochemical characteristics. Stabilizers may also be added or exchanged after homogenization. (3) Drugs or other bioactive substances to be incorporated into the SLPs may be melted together with the lipids if the physicochemical characteristics of the substance permit or may be dissolved, solubilized or dispersed in the lipid melt before homogenization. (4) The aqueous phase is heated to the temperature of the melt before mixing and may contain for example stabilizers, isotonicity agents, buffering substances, cryoprotectants and / or preservatives. (5) The molten lipid compounds and the bioactive agents are emulsified in an aqueous phase preferably by high-pressure homogenization.

Owner:PHARMACIA AB

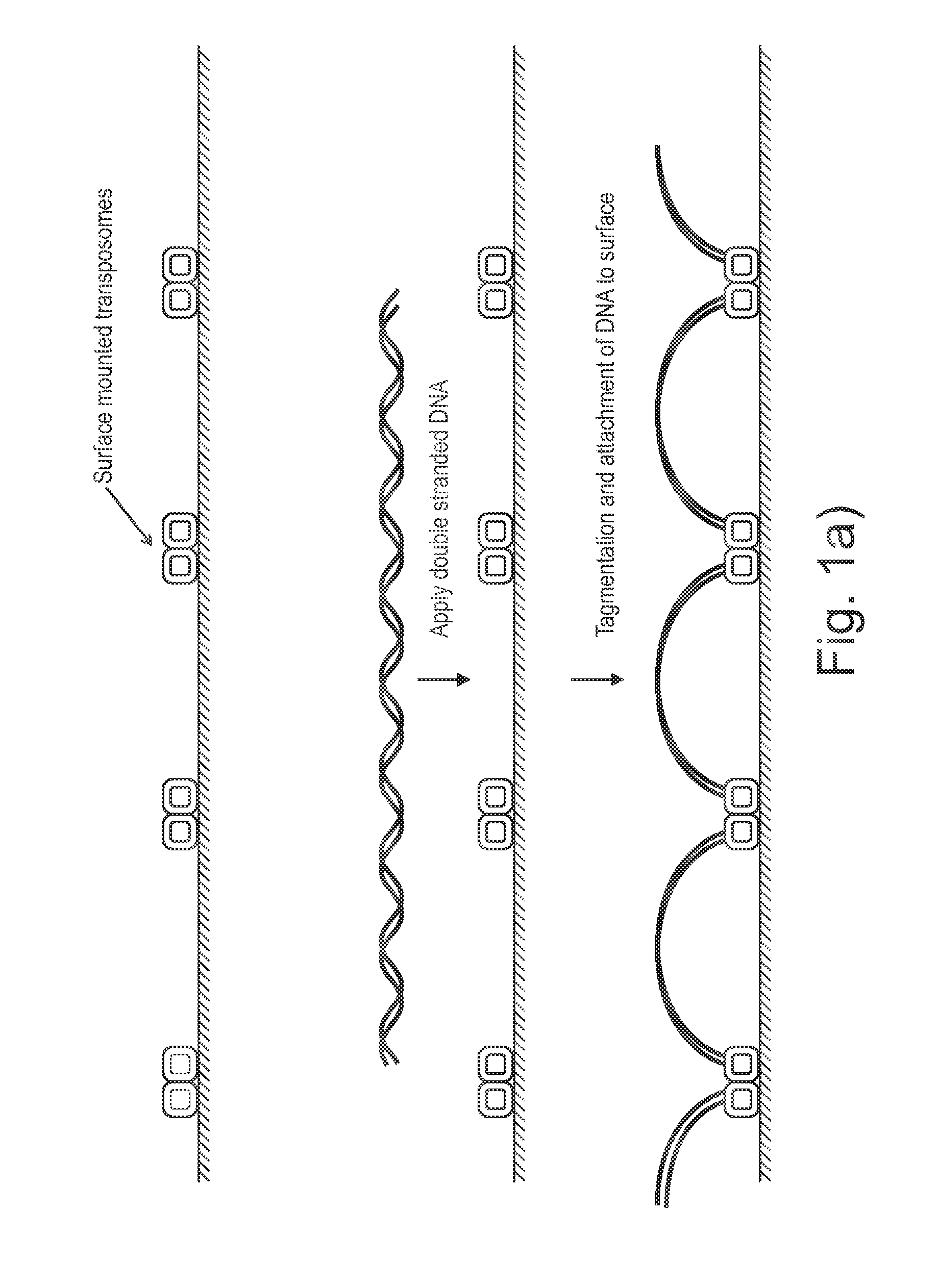

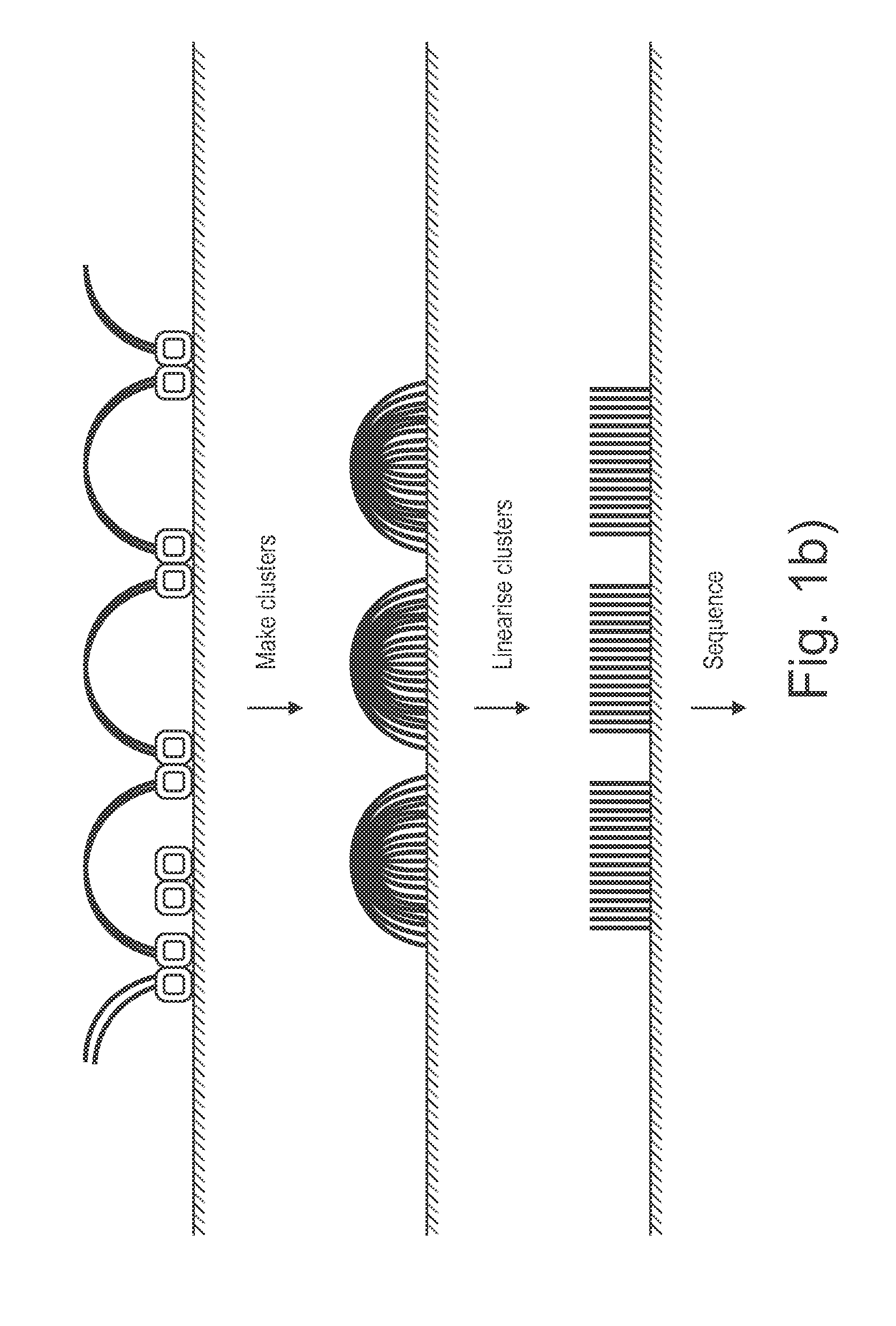

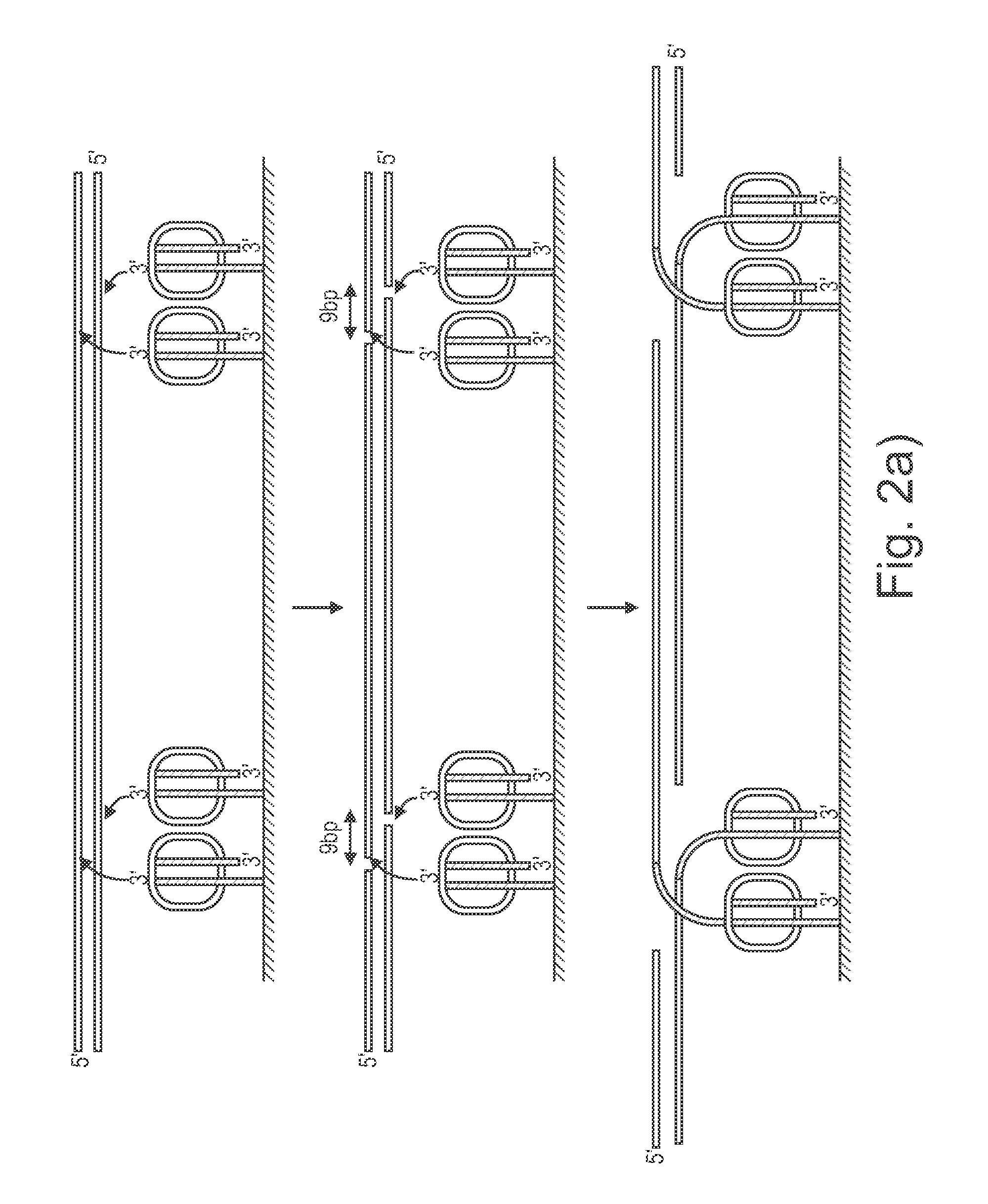

Sample preparation on a solid support

ActiveUS20140194324A1Sequential/parallel process reactionsMicrobiological testing/measurementSolid massDNA fragmentation

Presented are methods and compositions for using immobilized transposase and a transposon end for generating an immobilized library of 5′-tagged double-stranded target DNA on a surface. The methods are useful for generating 5′- and 3′-tagged DNA fragments for use in a variety of processes, including massively parallel DNA sequencing.

Owner:ILLUMINA CAMBRIDGE LTD

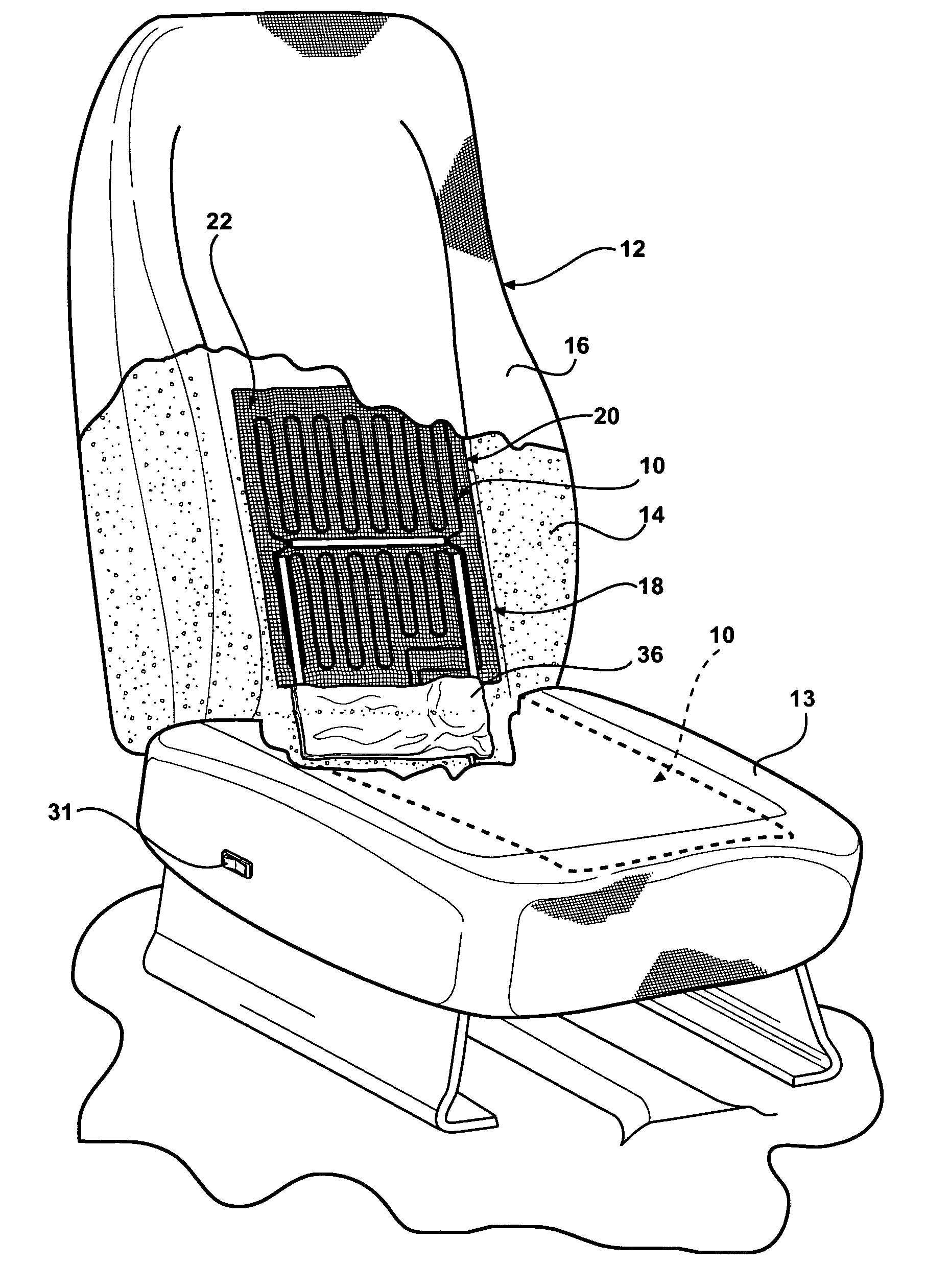

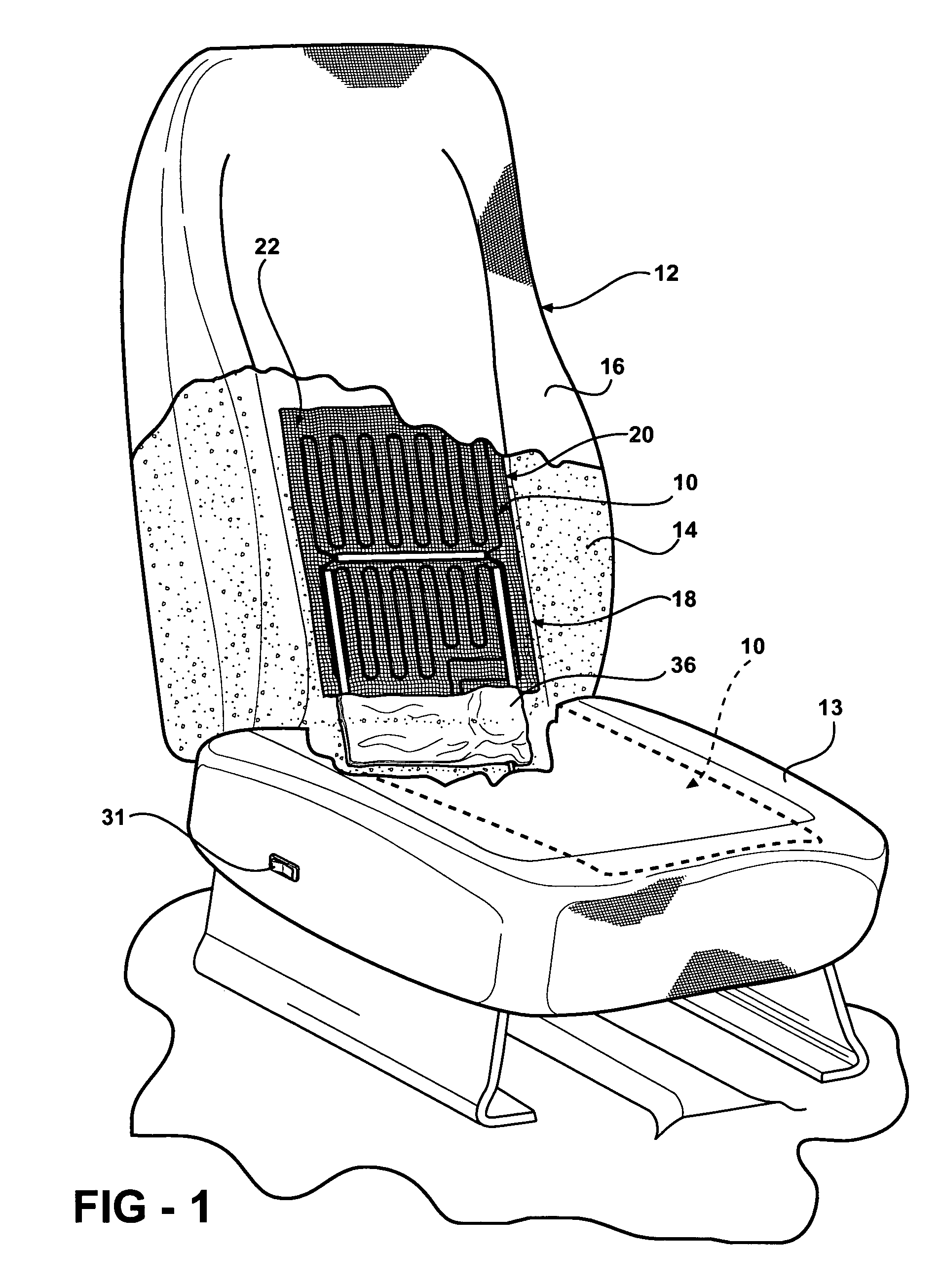

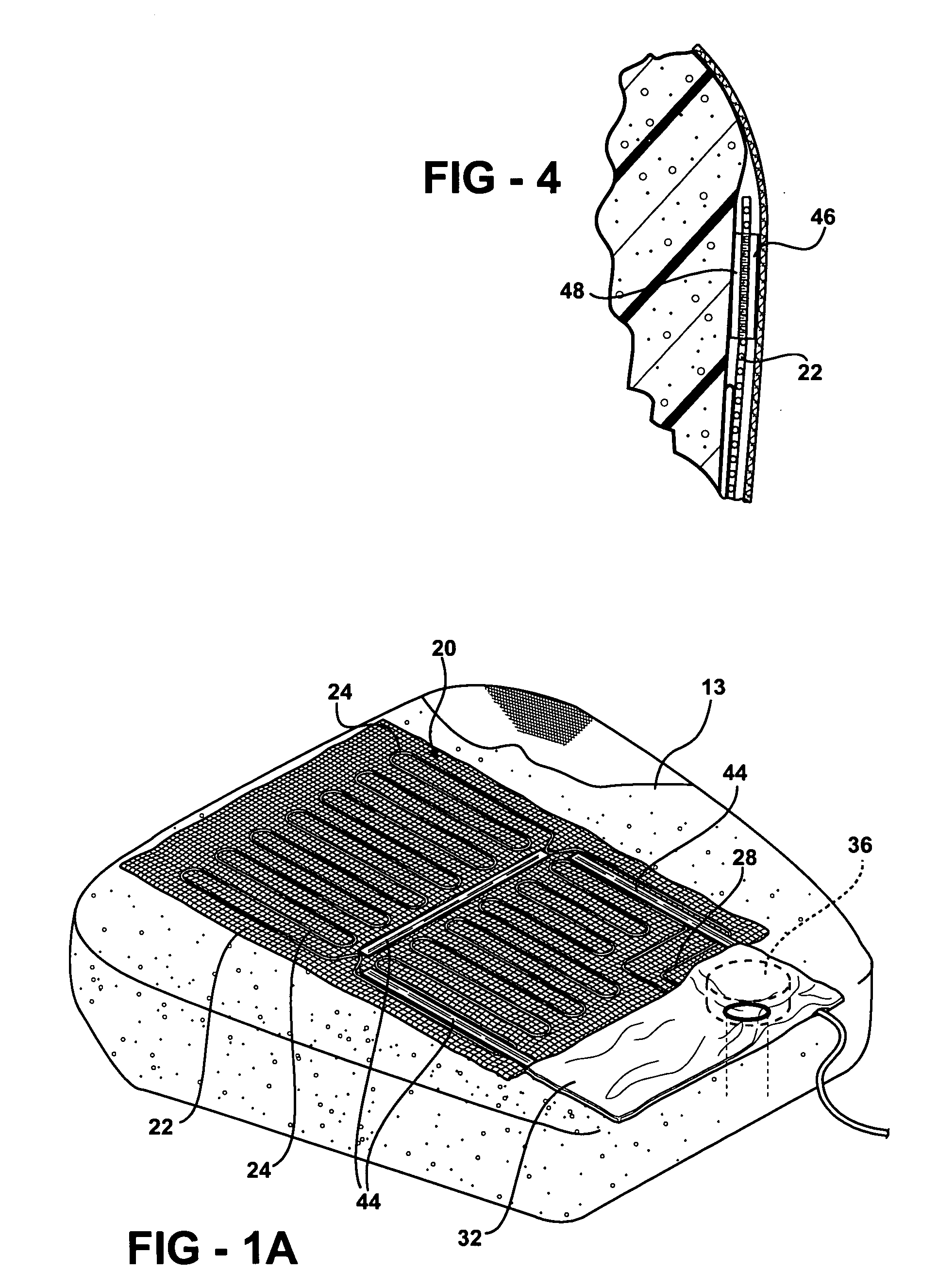

Arrangement and method for providing an air flow within an upholstered seat

InactiveUS6988770B2Large runnerHeating fastSeat heating/ventillating devicesStoolsSolid massEngineering

An arrangement and method for producing an air flow within an upholstered seat back or bottom in which a seat insert has a blower mounted in a pouch at the crotch region between the seat back and bottom and has an outlet which directs air flow up through a spacer layer so as to distribute air flow out through a porous seat back cover or beneath a nonporous cover. A solid plastic backing sheet underlies the spacer layer to direct all air flow out from the spacer layer, the plastic sheet also forming the blower pouch. A mesh layer is bonded to the plastic sheet and used to attach the insert to the seat cushion as well as to carry a heating element pattern extending thereover to also enable electrical heating of the seat back or bottom.

Owner:WITCHIE RONALD G

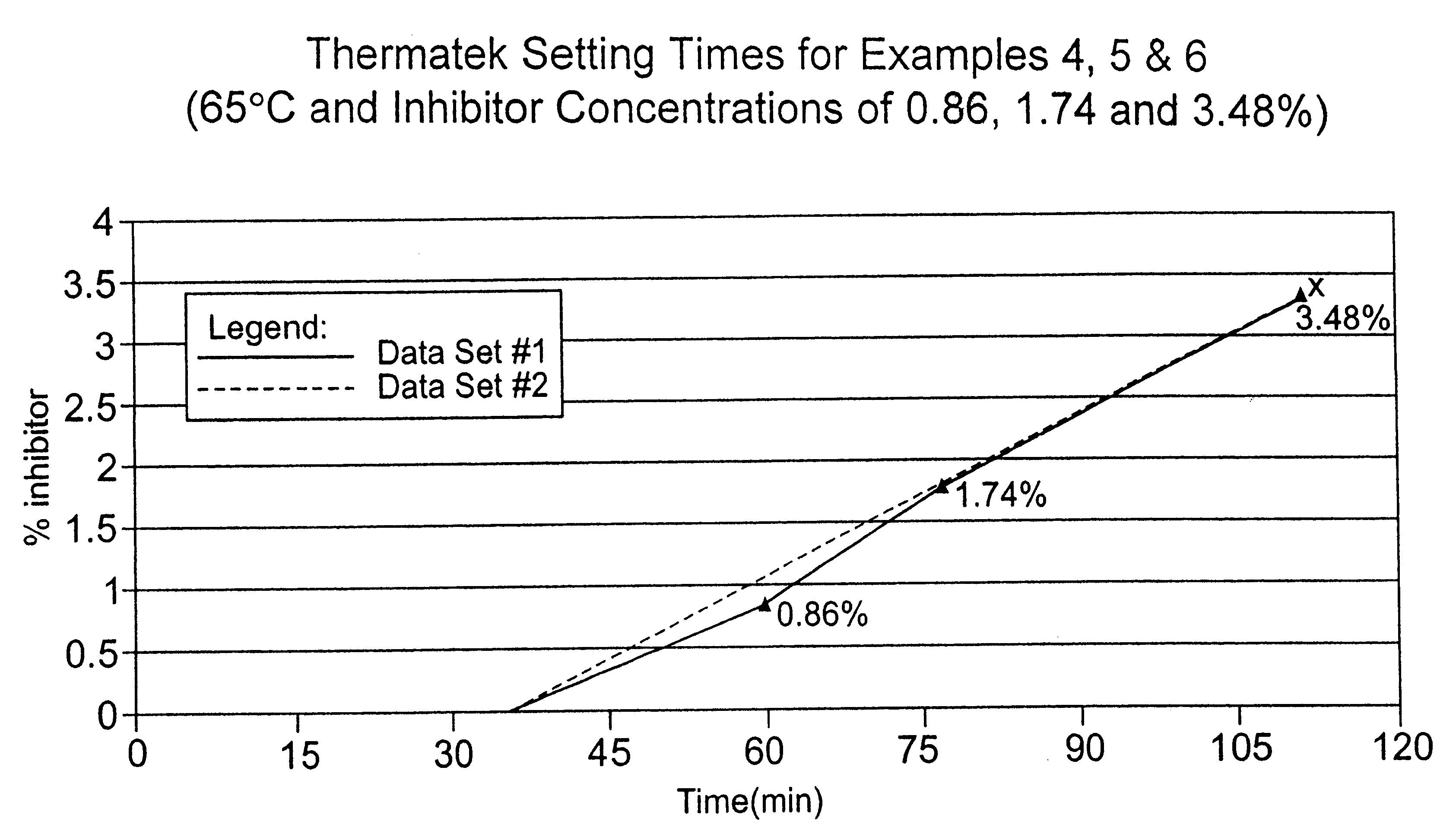

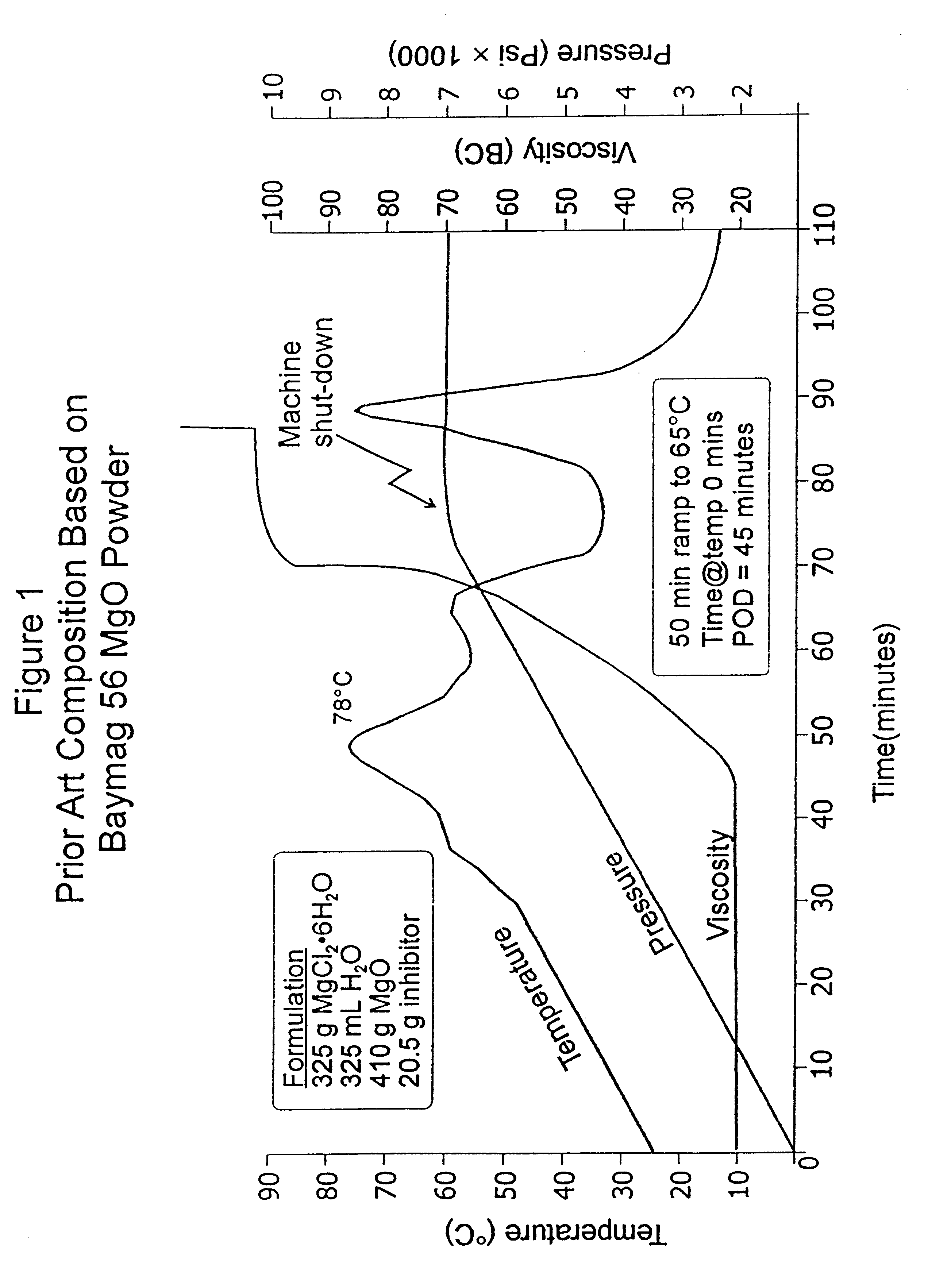

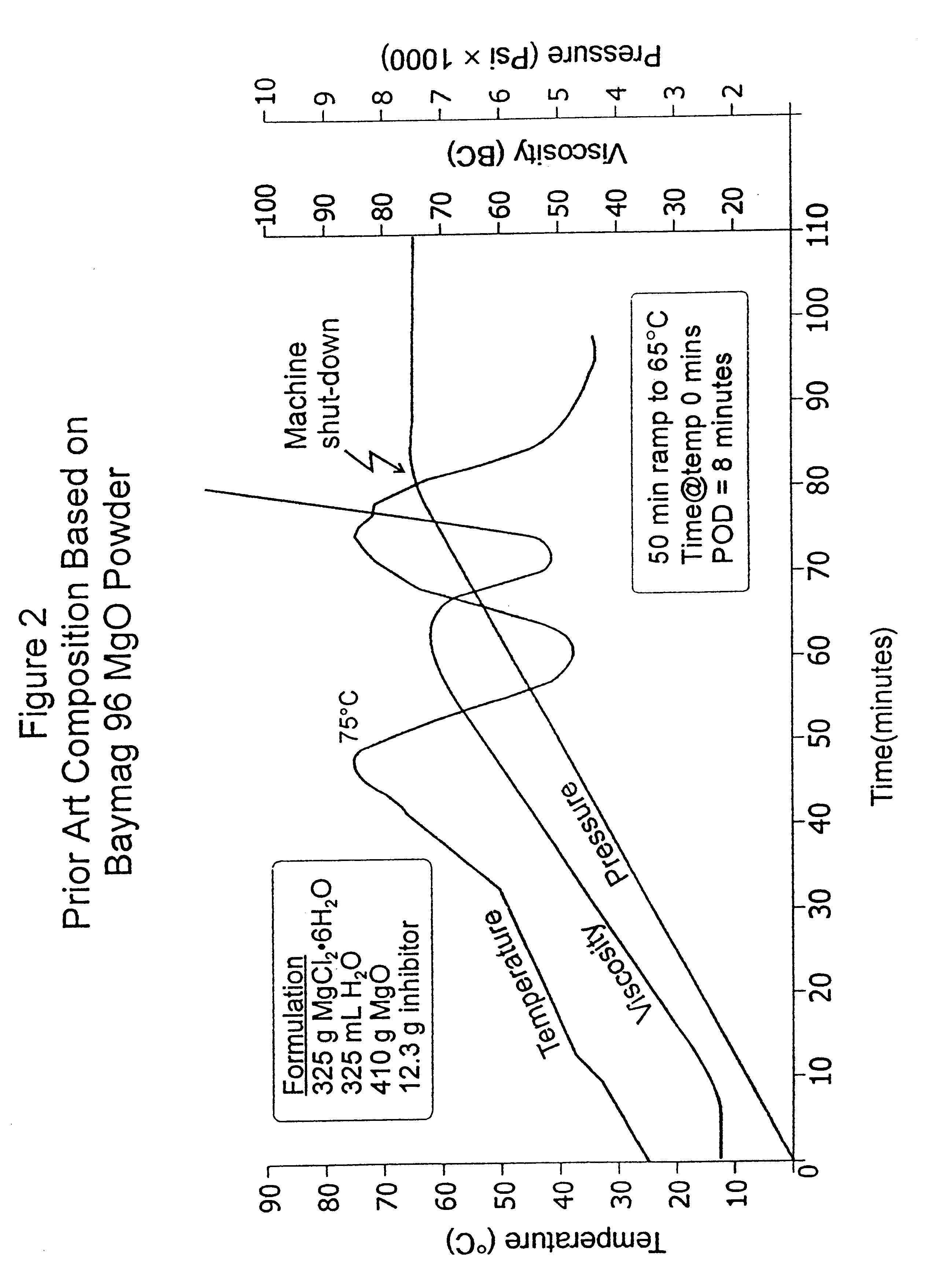

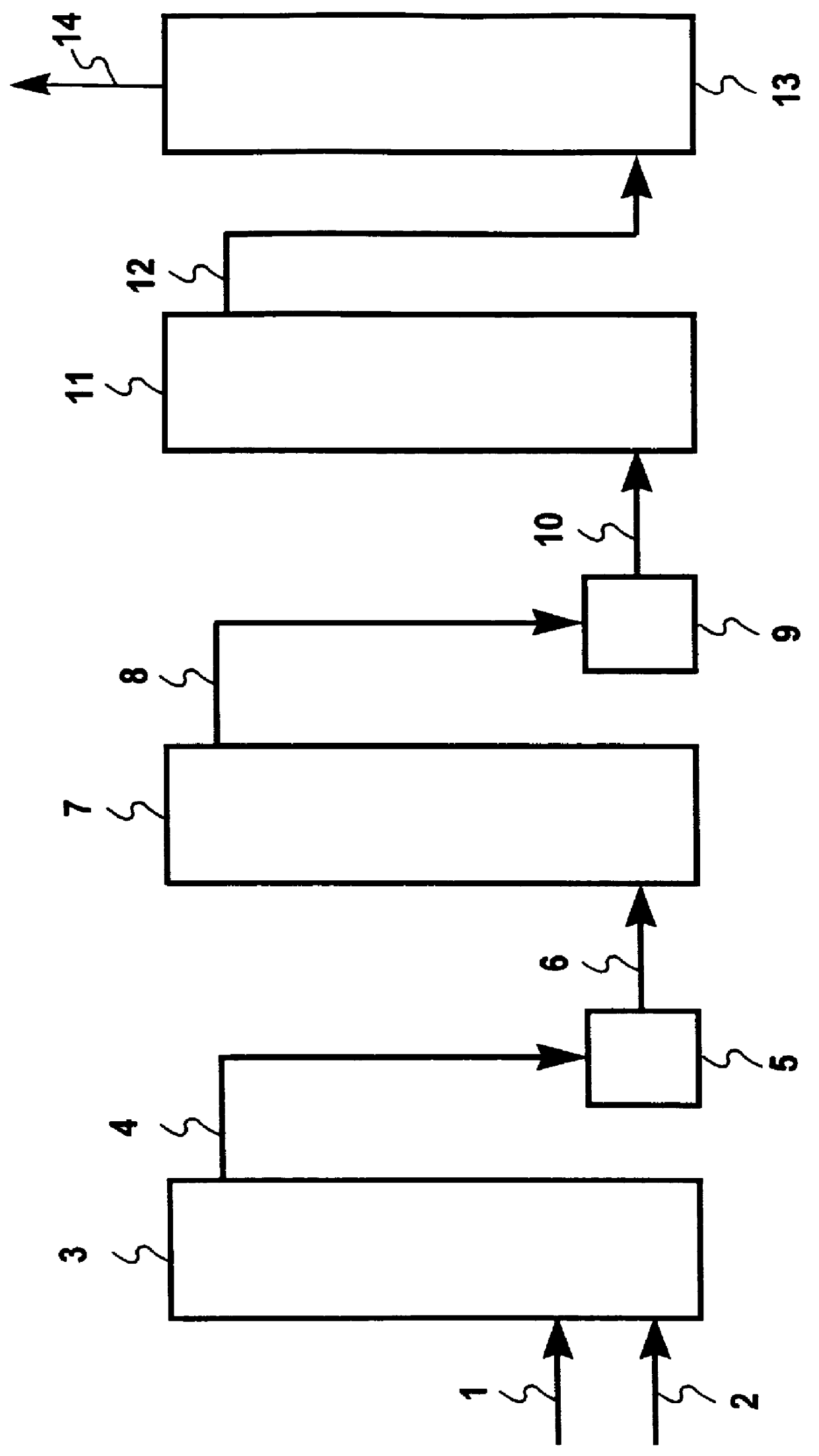

Composition for controlling wellbore fluid and gas invasion and method for using same

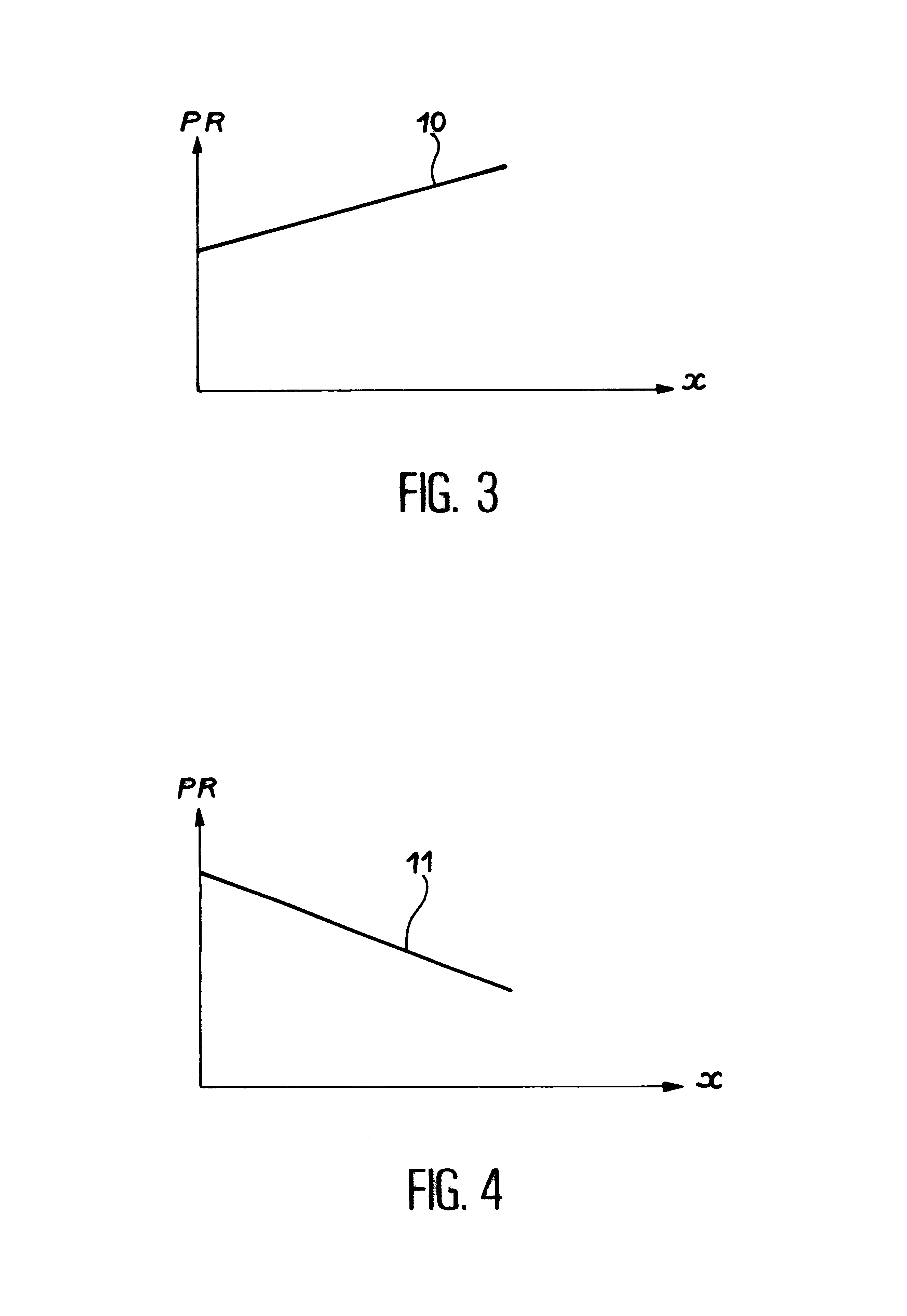

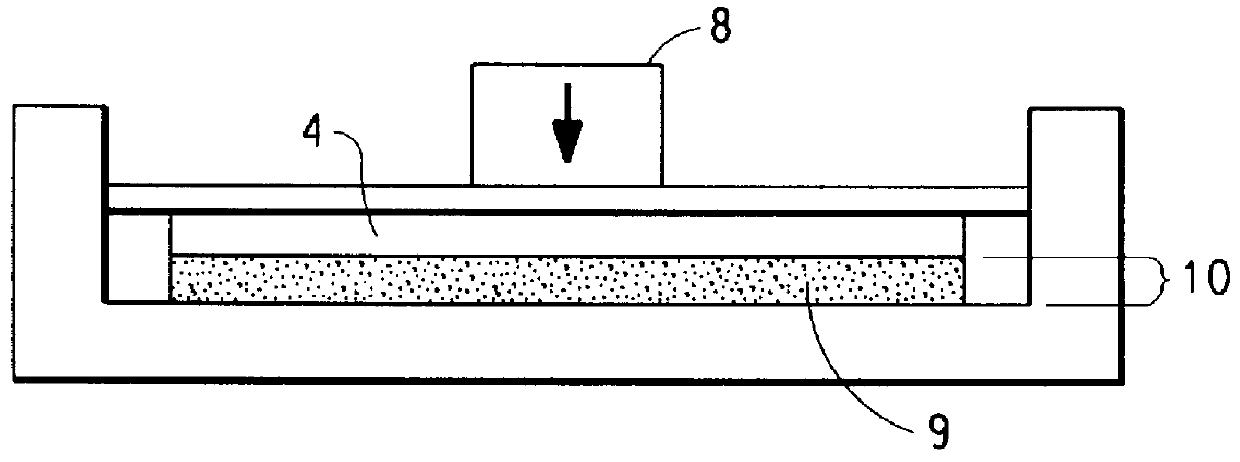

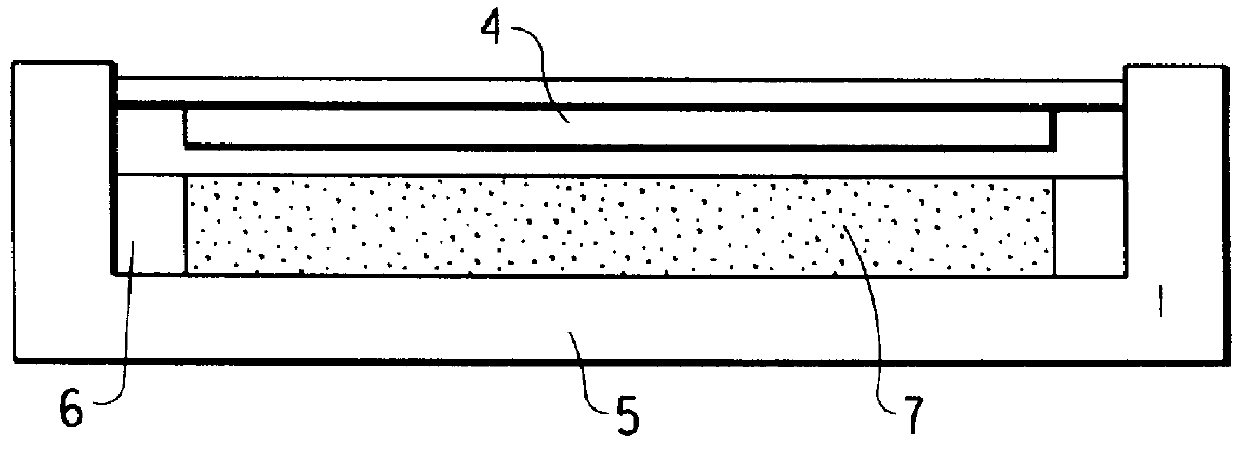

InactiveUS6664215B1Reduce hydrostatic pressureReadily cut through by a drill bitOther chemical processesFlushingLinear relationshipSlurry

The disclosure is directed to a composition for controlling wellbore fluid and gas invasion including methods for using said composition. The composition of the invention is a flowable slurry preferably comprising about 70 to 30% by weight of magnesium oxychloride and about 70 to 30% by weight of water. The composition is a flowable slurry at composition temperatures below about 60° C. and sets to form a substantially solid mass upon reaching a composition temperature of about 60-68° C. The phase transition is rapid, thereby limiting or avoiding formation of gel states which contribute to incomplete wellbore seals. The rapid set of the slurry further avoids invasive contamination of earthen formations surrounding the wellbore. The composition has a near-linear relationship between the time required for the phase transition to occur and the composition temperature at which the phase transition occurs. This advantageous property permits the composition set time to be accurately determined and modified as required through the addition of accelerators and inhibitors. The phase transition occurs predictably at high pressures typical of those encountered in wellbore operations. Additives may be included to modify the properties of the composition. The method includes use of the composition to control the loss of fluids and gases from the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

Method to control mercury emissions from exhaust gases

InactiveUS6136281AElimination of mercury in flue gas emissionsEasy to collectCombination devicesExhaust apparatusSolid massGas phase

The present invention relates to a method to catalyze the oxidation of Hg(0) in a flue gas stream prior to standard emissions control equipment. The oxidized mercury has been found to be more condensable than Hg(0) and consequently more easily removed from the gas phase. Accordingly, mercury in its oxidized form can be trapped from a flue gas stream or the like by absorption onto a solid mass or can be more efficiently removed from flue gas streams by wet processes such as a two-stage wet FGD. The gist underlying the inventive concept of the instant invention relates to the use of a porous bed of gold-coated material that is saturated with Hg(0) to the point that the gold in the presence of HCl in the exhaust stream catalyses the oxidation of Hg(0).

Owner:TENNESEE VALLEY AUTHORITY

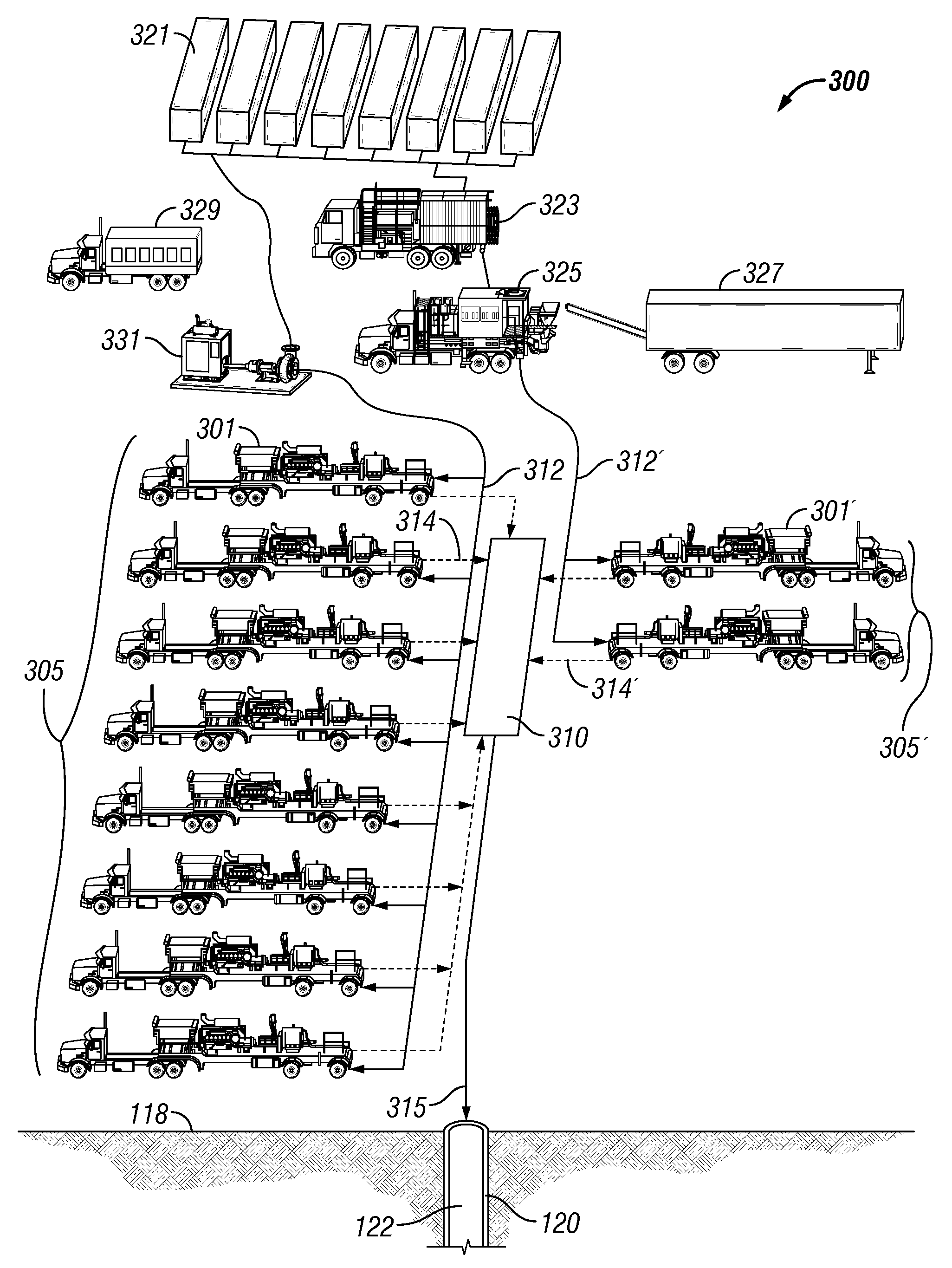

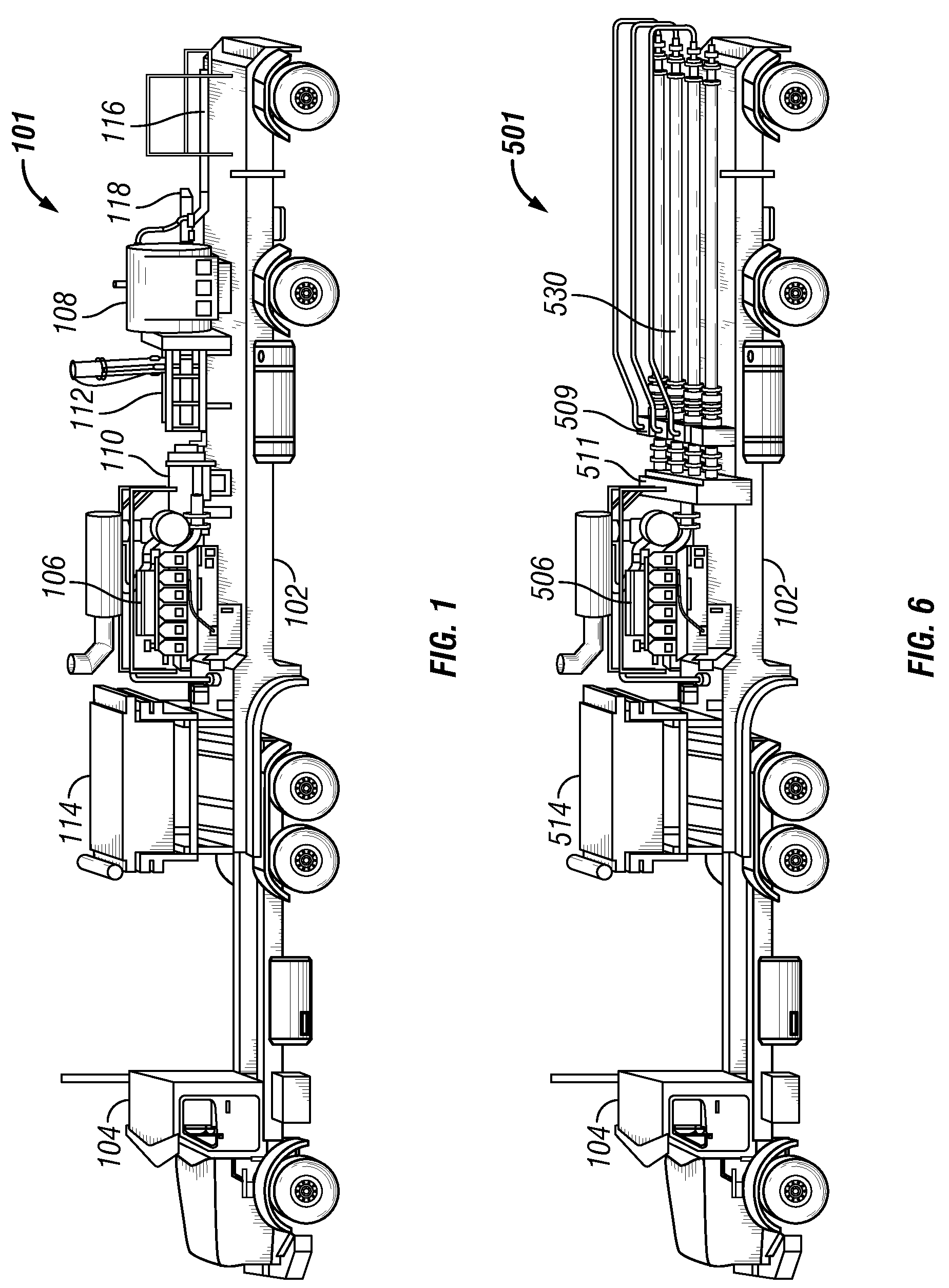

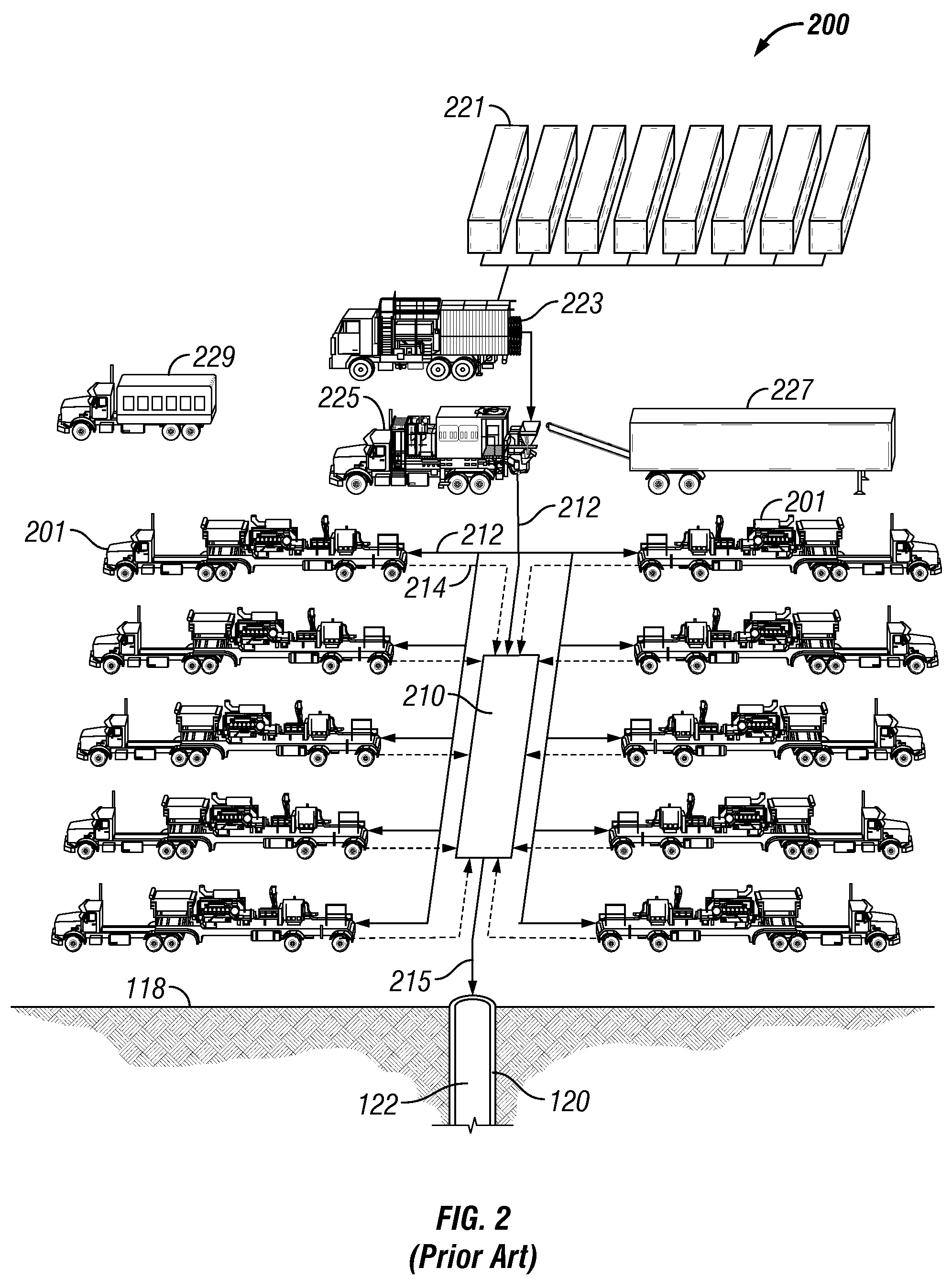

Split stream oilfield pumping systems

Owner:SCHLUMBERGER TECH CORP

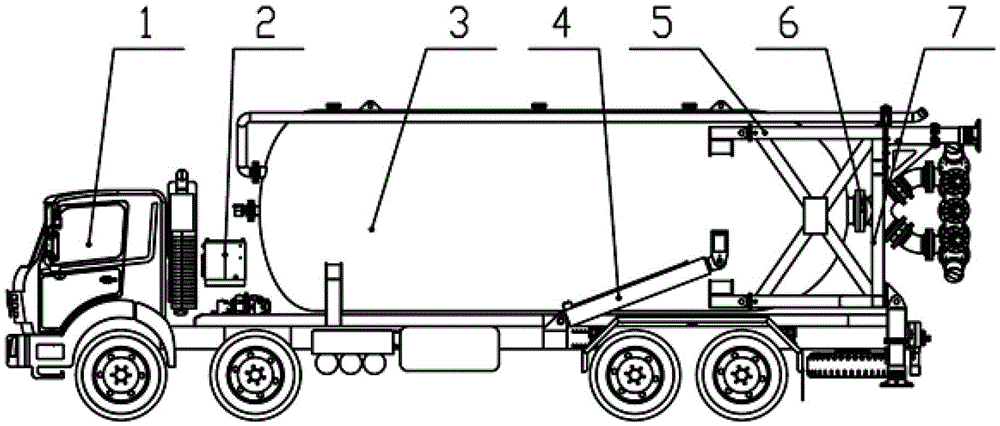

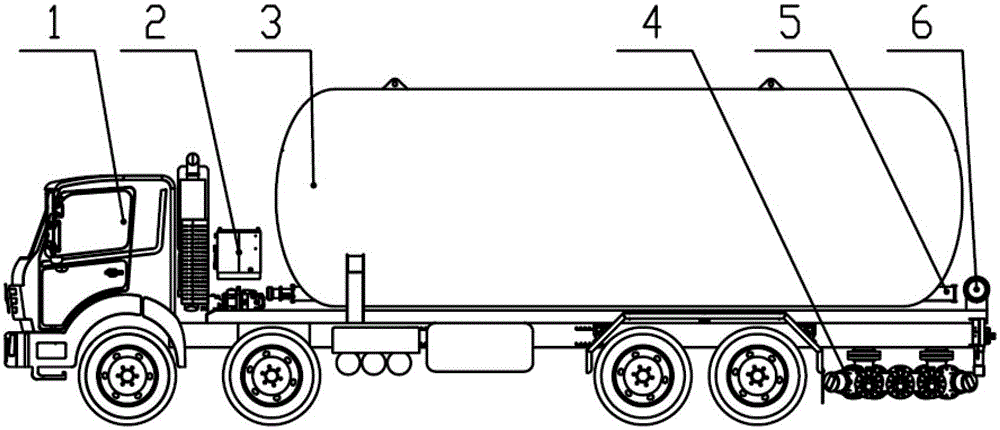

A fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid-liquid mixing device, and the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

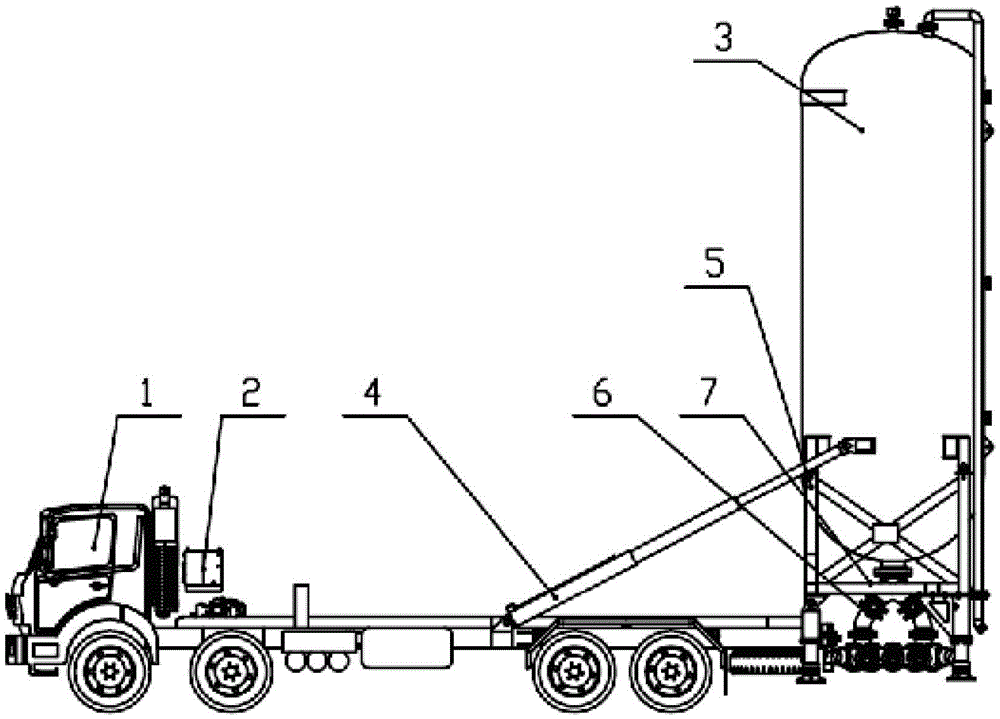

A fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid conveying device and a solid-liquid mixing device communicated with the solid conveying device, wherein the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid output by the solid conveying device, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

Desktop process for producing dental products by means of 3-dimensional plotting

InactiveUS6939489B2Low investment costHigh viscosityImpression capsAdditive manufacturing apparatusSolid massOligomer

Owner:IVOCLAR VIVADENT AG

Encapsulation of sensitive liquid components into a matrix to obtain discrete shelf-stable particles

InactiveUS7201923B1Improve hydrophobicityPrevent and delays penetration of waterPowder deliveryBiocideSolid particleHeat sensitive

A liquid encapsulant component which contains an active, sensitive encapsulant, such as a live microorganism or an enzyme dissolved or dispersed in a liquid plasticizer is admixed with a plasticizable matrix material. The matrix material is plasticizable by the liquid plasticizer and the encapsulation of the active encapsulant is accomplished at a low temperature and under low shear conditions. The active component is encapsulated and / or embedded in the plasticizable matrix component or material in a continuous process to produce discrete, solid particles. The liquid content of the liquid encapsulant component provides substantially all or completely all of the liquid plasticizer needed to plasticize the matrix component to obtain a formable, extrudable, cuttable, mixture or dough. Removal of liquid plasticizer prior to extrusion is not needed to adjust the viscosity of the mixture for formability. Release of an active component from the matrix may be delayed or controlled over time so that the active component is delivered when and where it is needed to perform its intended function. Controlled release, discrete, solid particles which contain an encapsulated and / or embedded component such as a heat sensitive or readily oxidizable pharmaceutically, biologically, or nutritionally active component are continuously produced without substantial destruction of the matrix material or encapsulant.

Owner:GENERAL MILLS INC

Polymeric systems for drug delivery and uses thereof

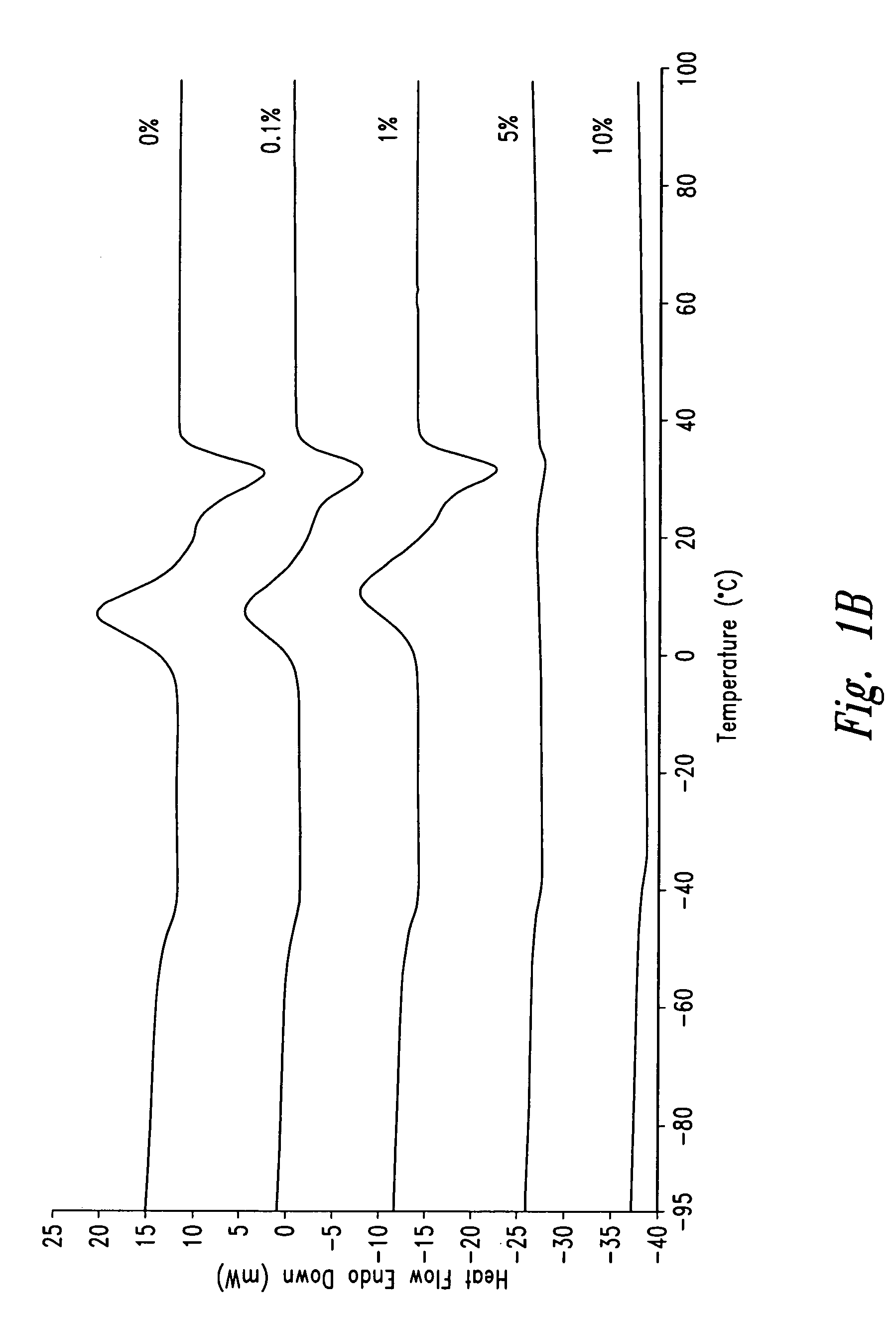

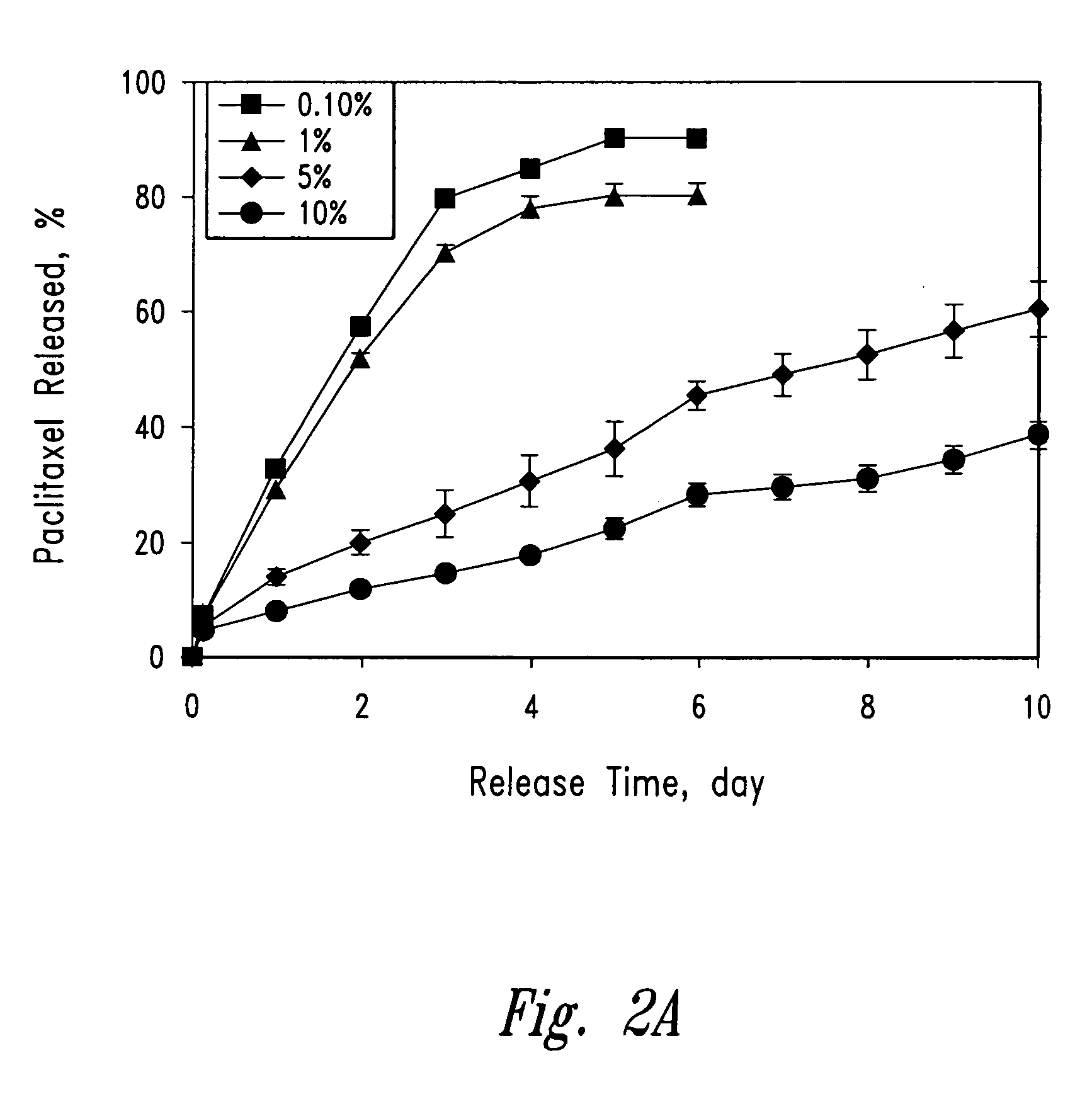

InactiveUS20050042293A1Precise moldingMore solid formPowder deliveryKetone active ingredientsWater insolubleIn vivo

Biodegradable polymeric implants can provide a safe and efficient means to deliver drugs in the treatment of various diseases. Although a polymeric drug delivery system can be implanted as a solid device within a subject, it is also possible to administer such a system as an injectable liquid which solidifies in vivo. An improved formulation of a polymeric drug delivery system comprises a water insoluble copolymer that is a solid or wax at 37° C., a water soluble polymer that is a liquid at 25° C., and a hydrophobic drug. These drug delivery systems can be administered by injection, and do not require the use of a toxic curing agent or inconvenient temperature manipulations.

Owner:ANGIOTECH INT AG (CH)

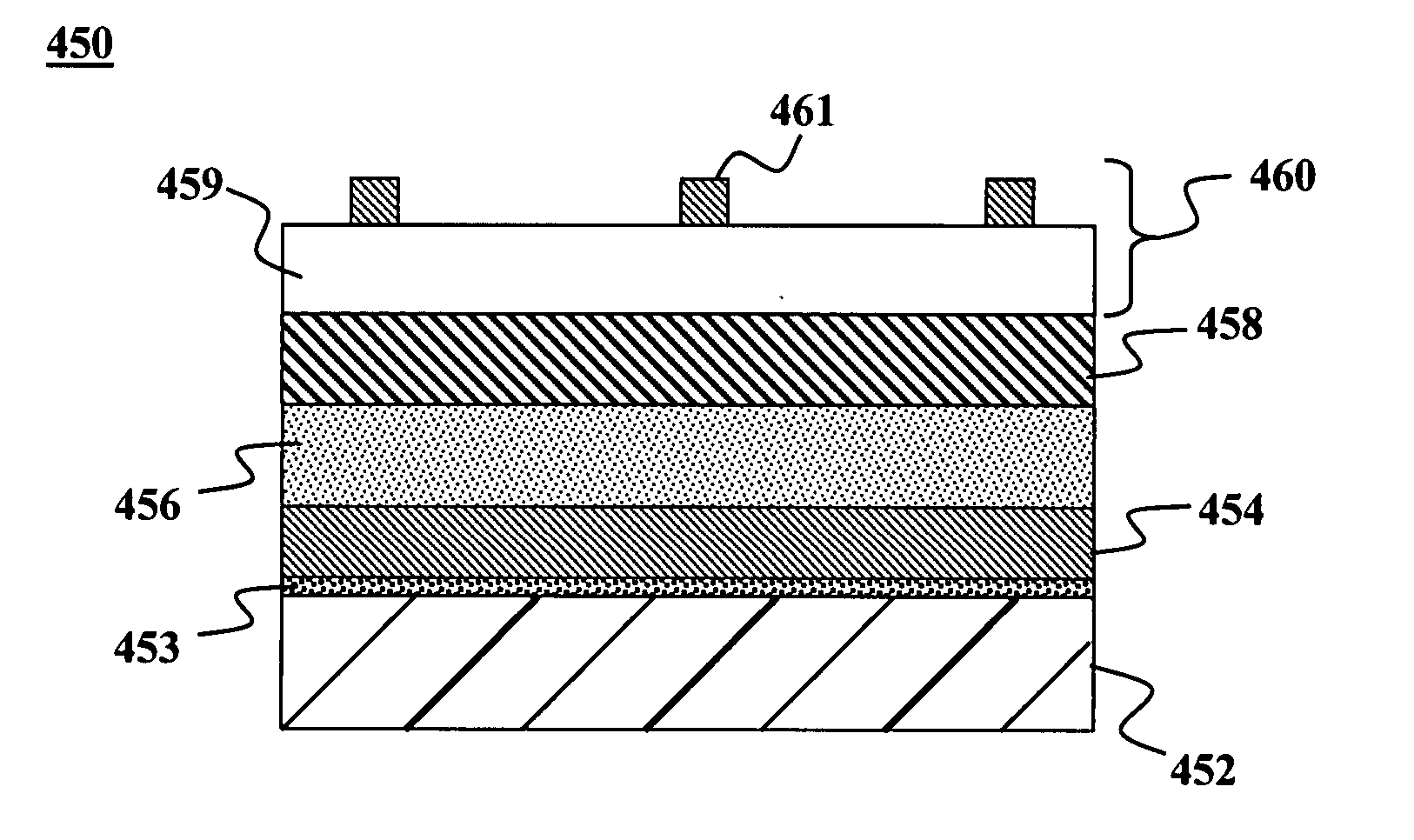

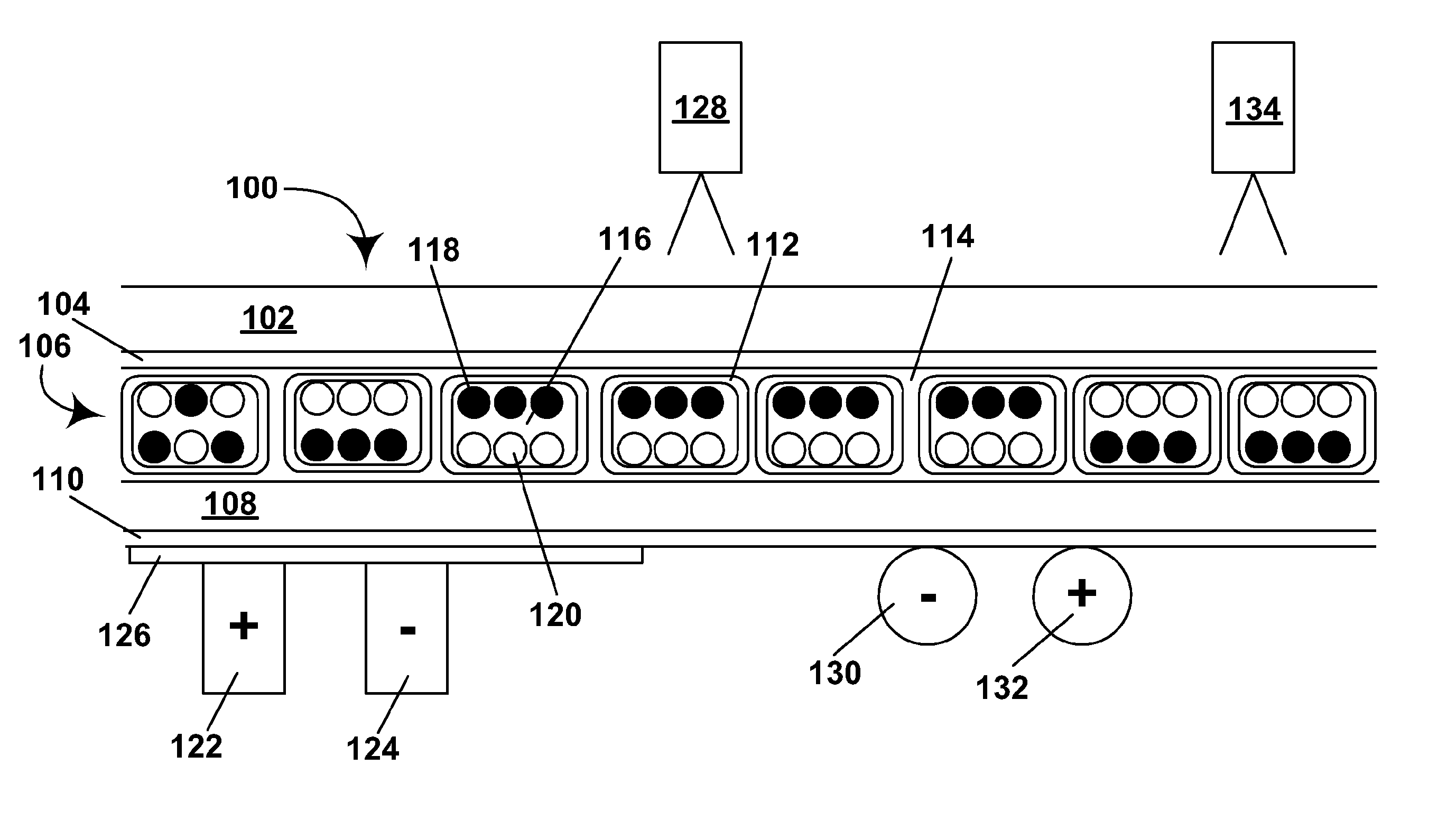

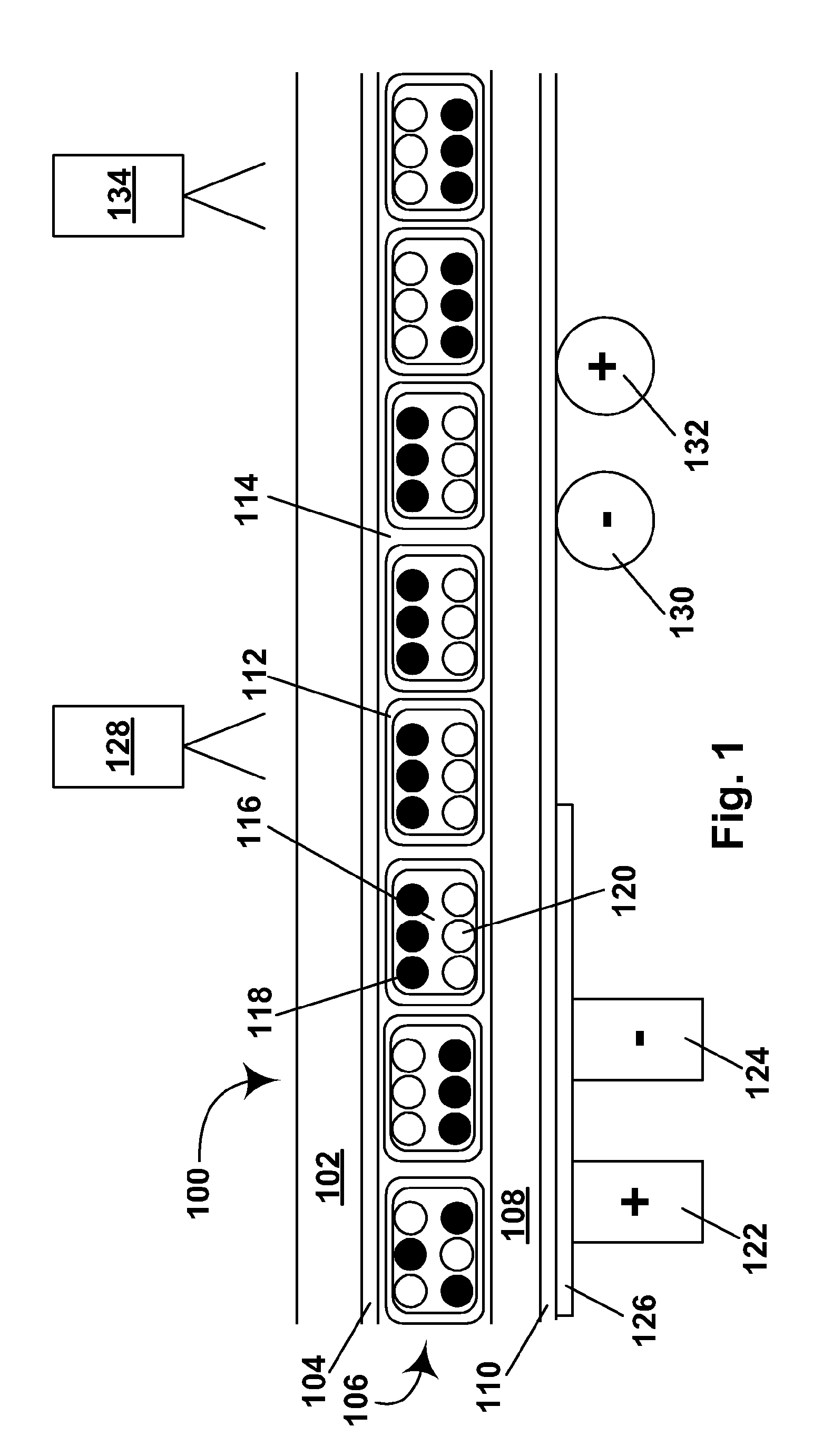

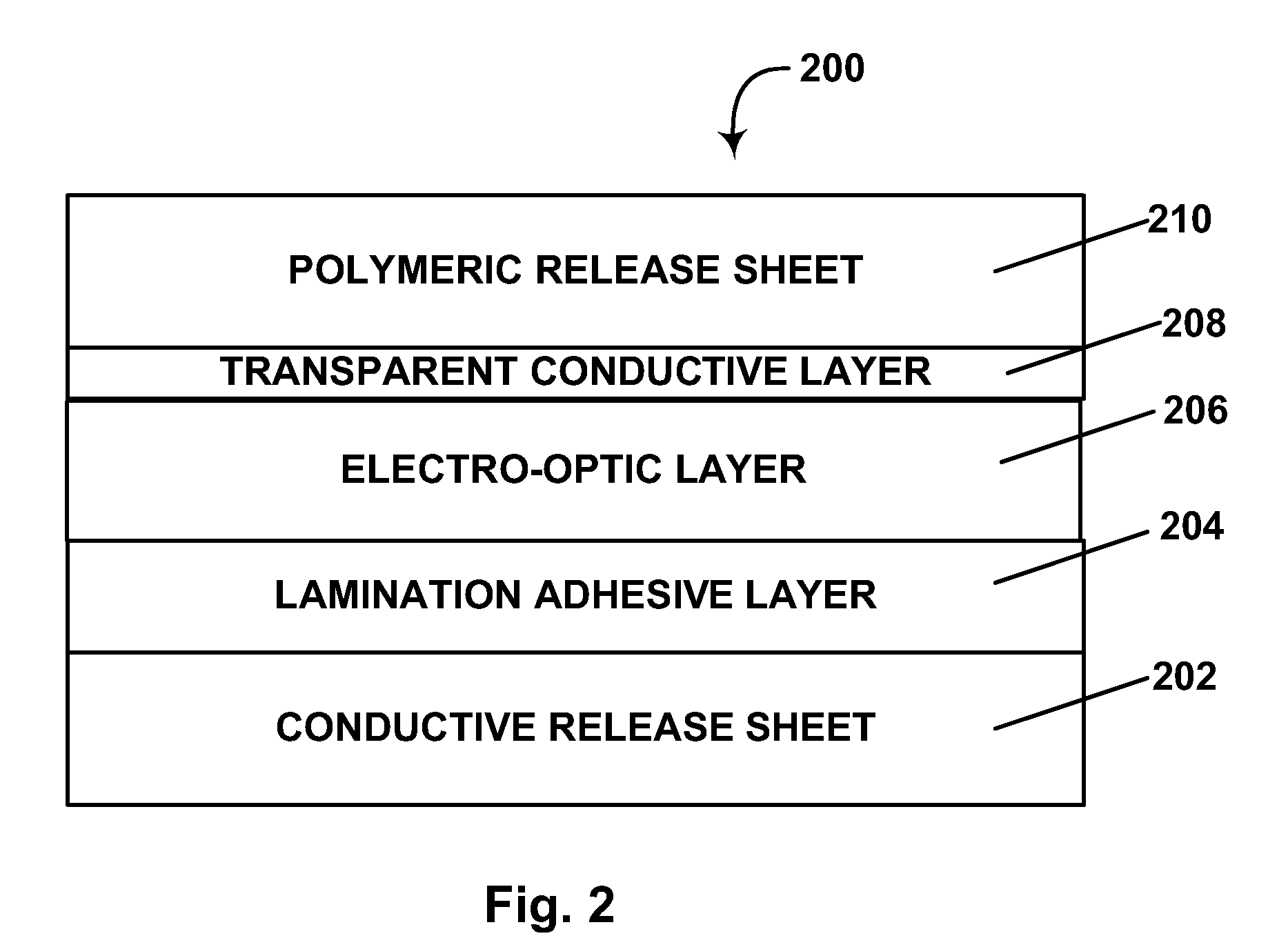

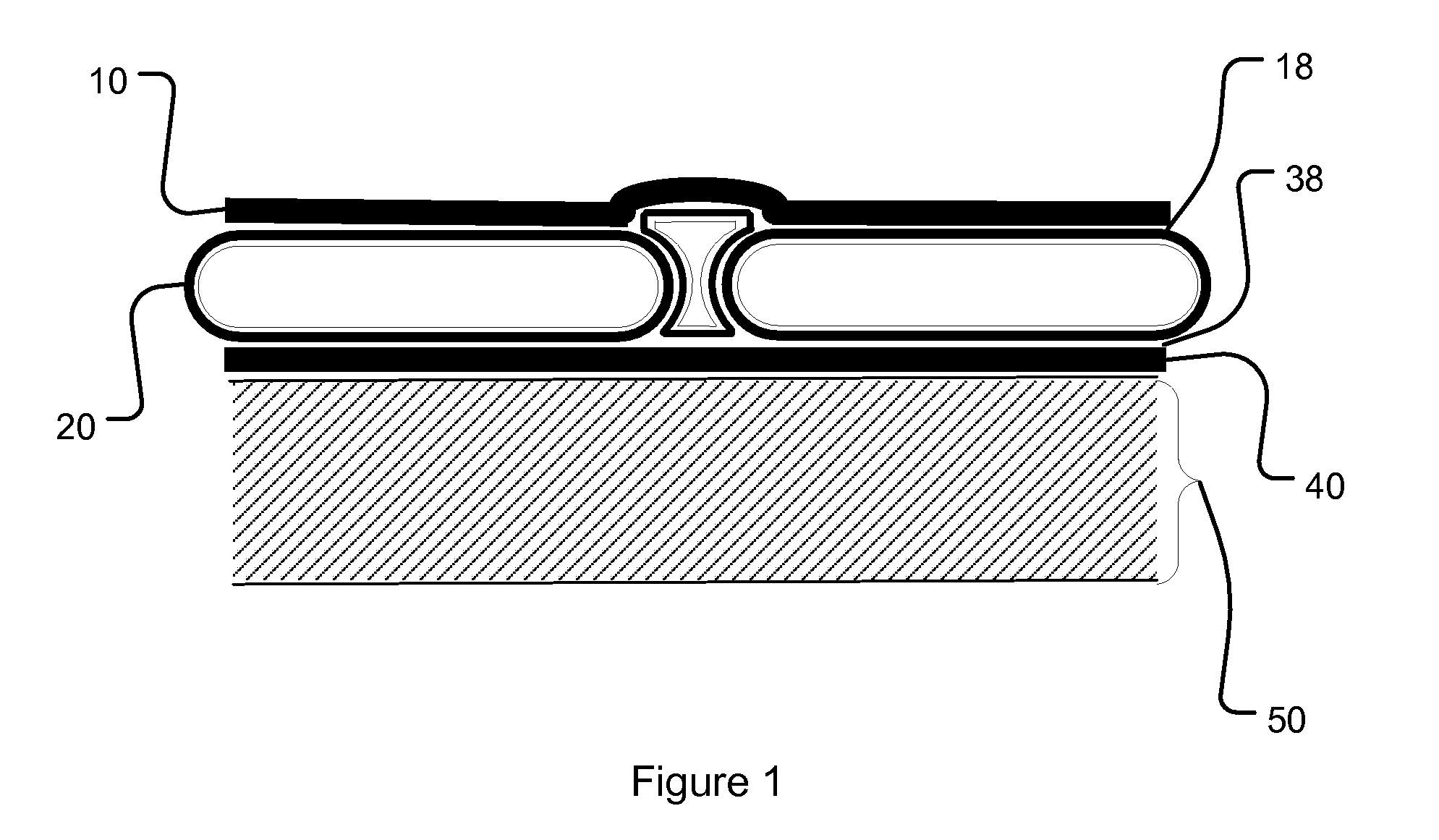

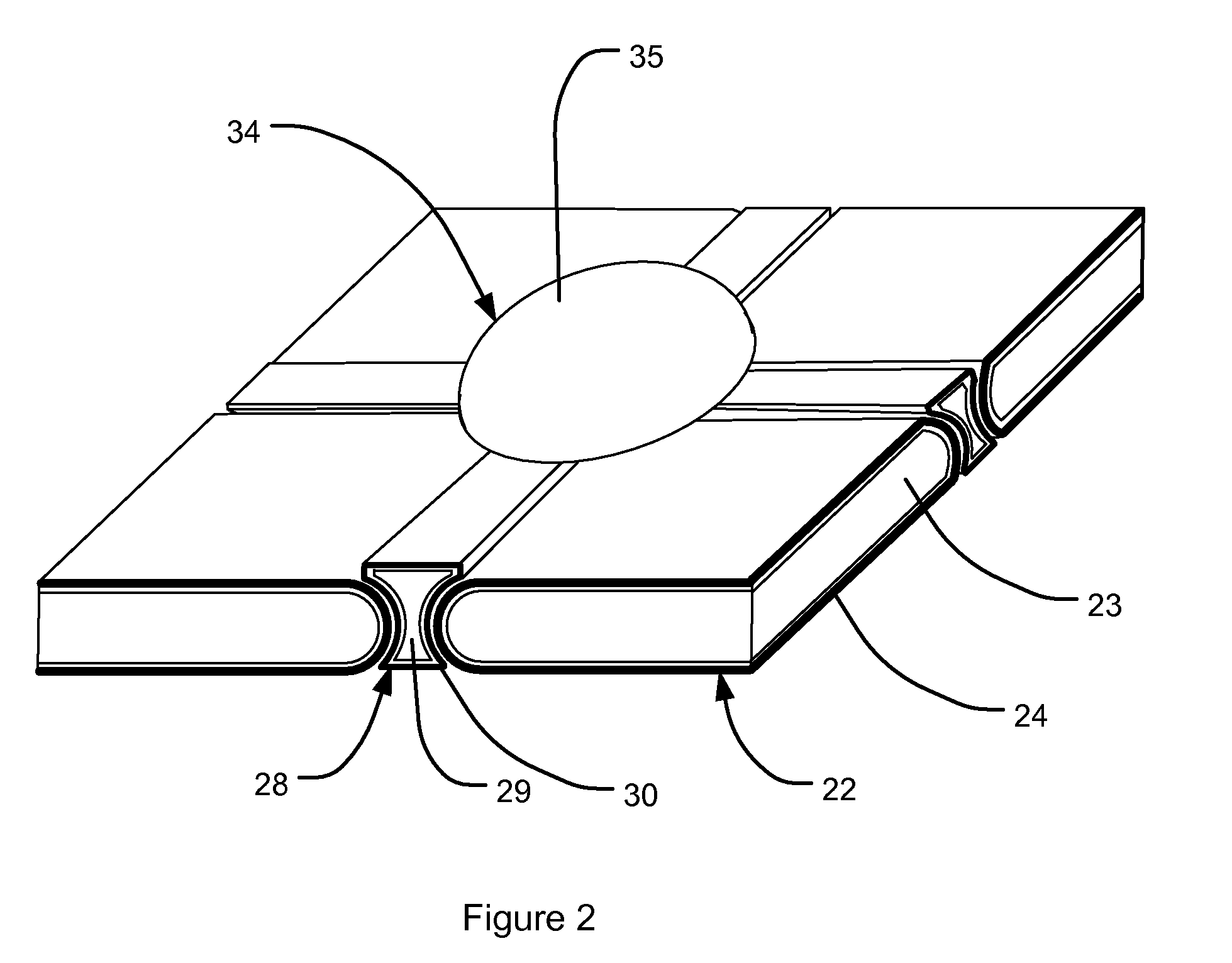

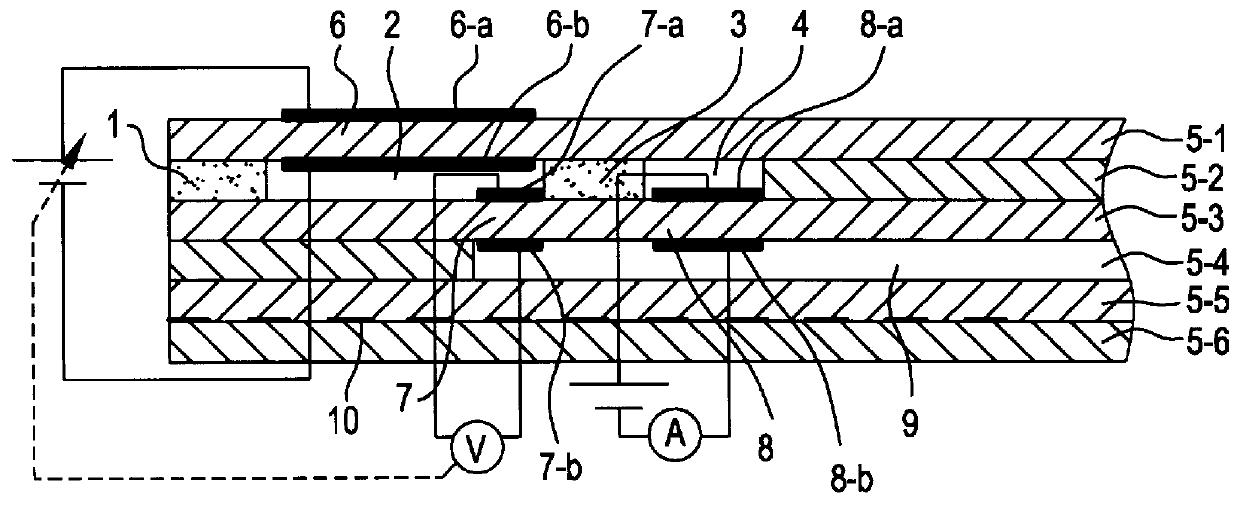

Components and testing methods for use in the production of electro-optic displays

A laminate comprising a solid electro-optic medium and an electrically conductive layer is tested by passing it over a pair of electrodes at different potentials, with the electrically conductive layer lying on the opposed side of the electro-optic medium from the electrodes. An article which can be tested by this method, and which is useful in the manufacture of electro-optic displays, comprises a layer of a solid electro-optic medium and a release sheet comprising an electrically conductive layer.

Owner:E INK CORPORATION

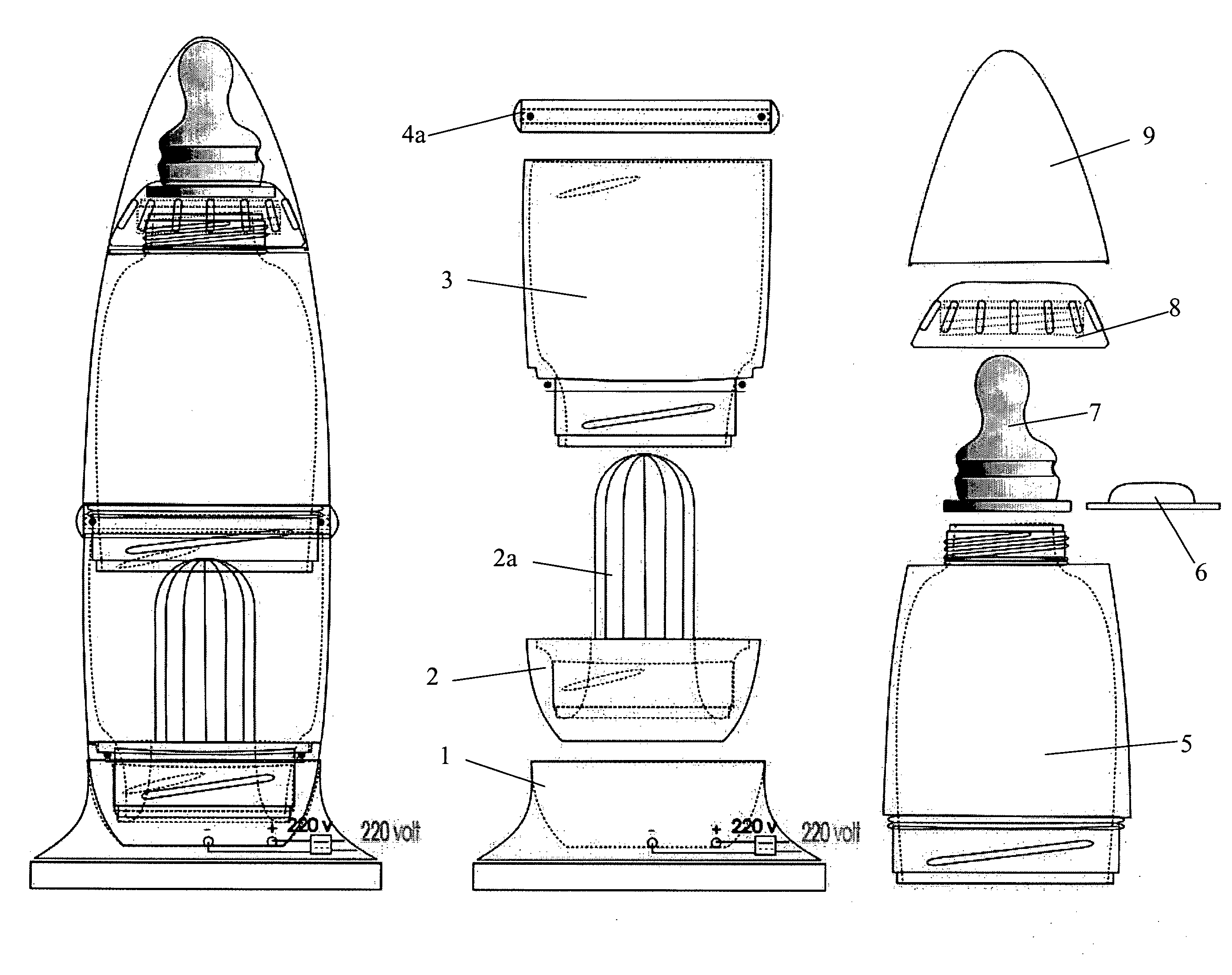

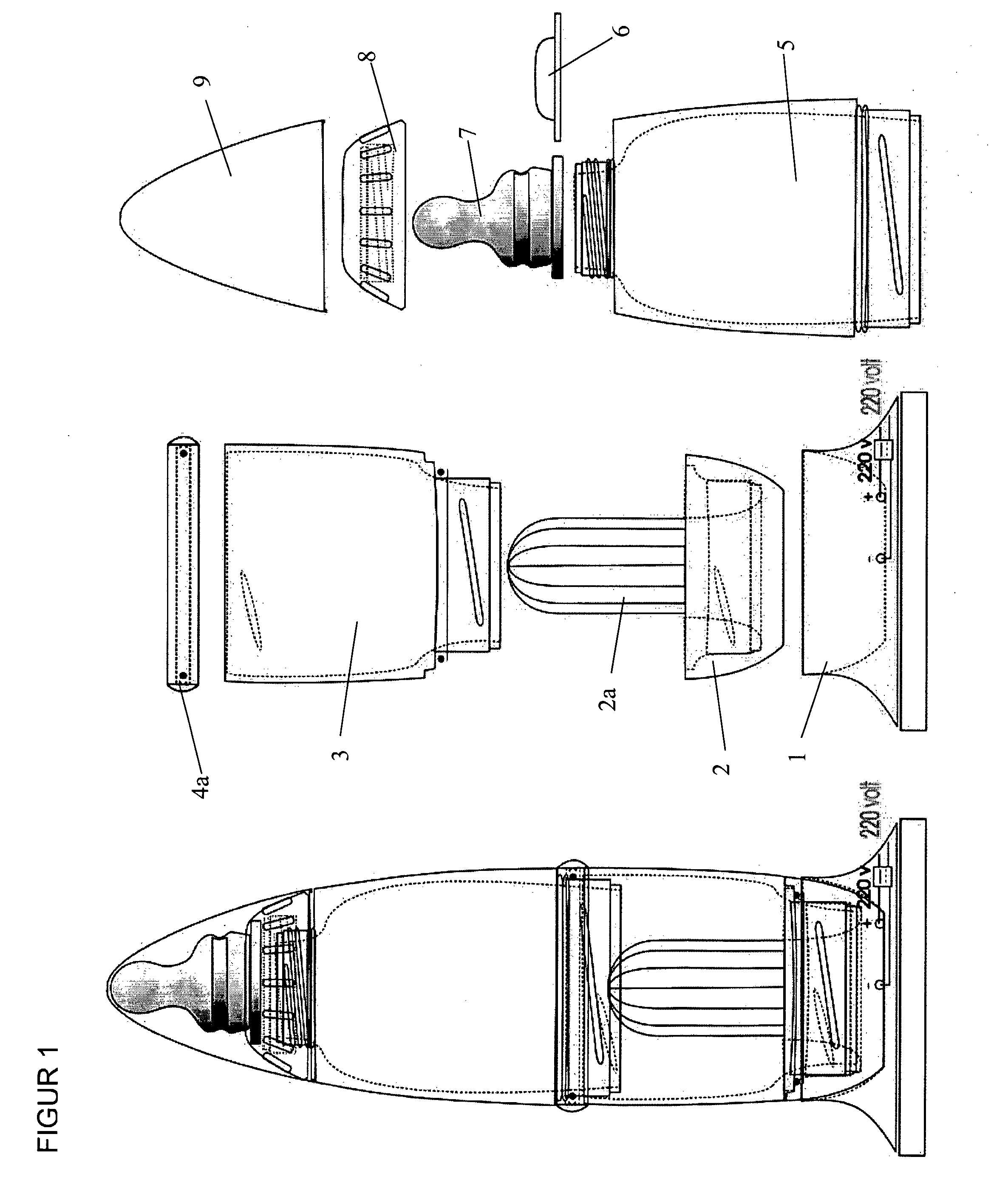

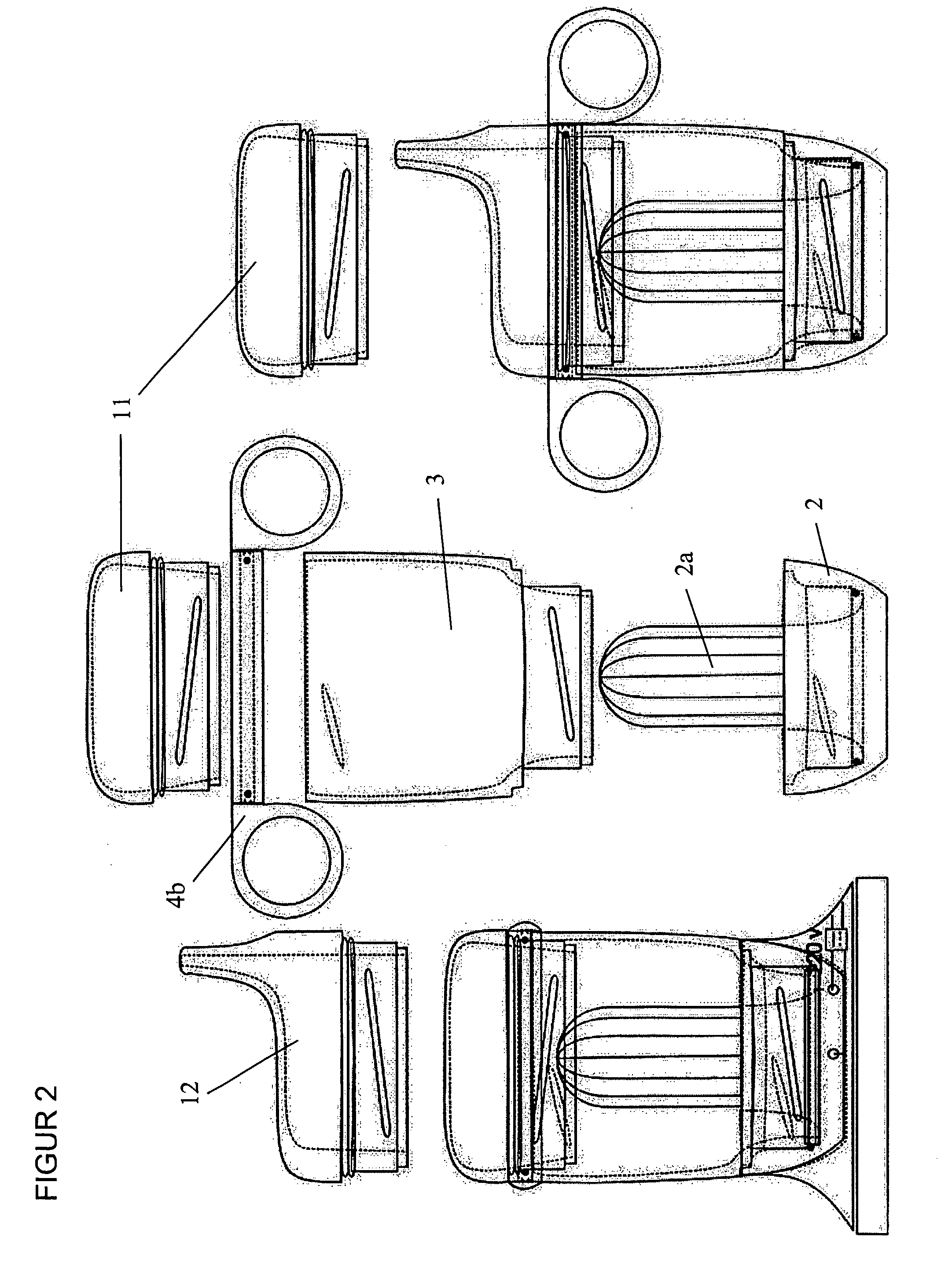

Modular Transportable Heating Device

During journeys, and at other times when no stationary heating devices such as microwave ovens or hotplates are available, providing hot foods, liquid or solid, can be problematic. By providing a container with an in-built heating arrangement, the present invention solves the problem. Furthermore, the container is of a modular design. Its parts are easily interchangeable and new configurations for different purposes can be readily put together.

Owner:TEGLBJARG CASPER

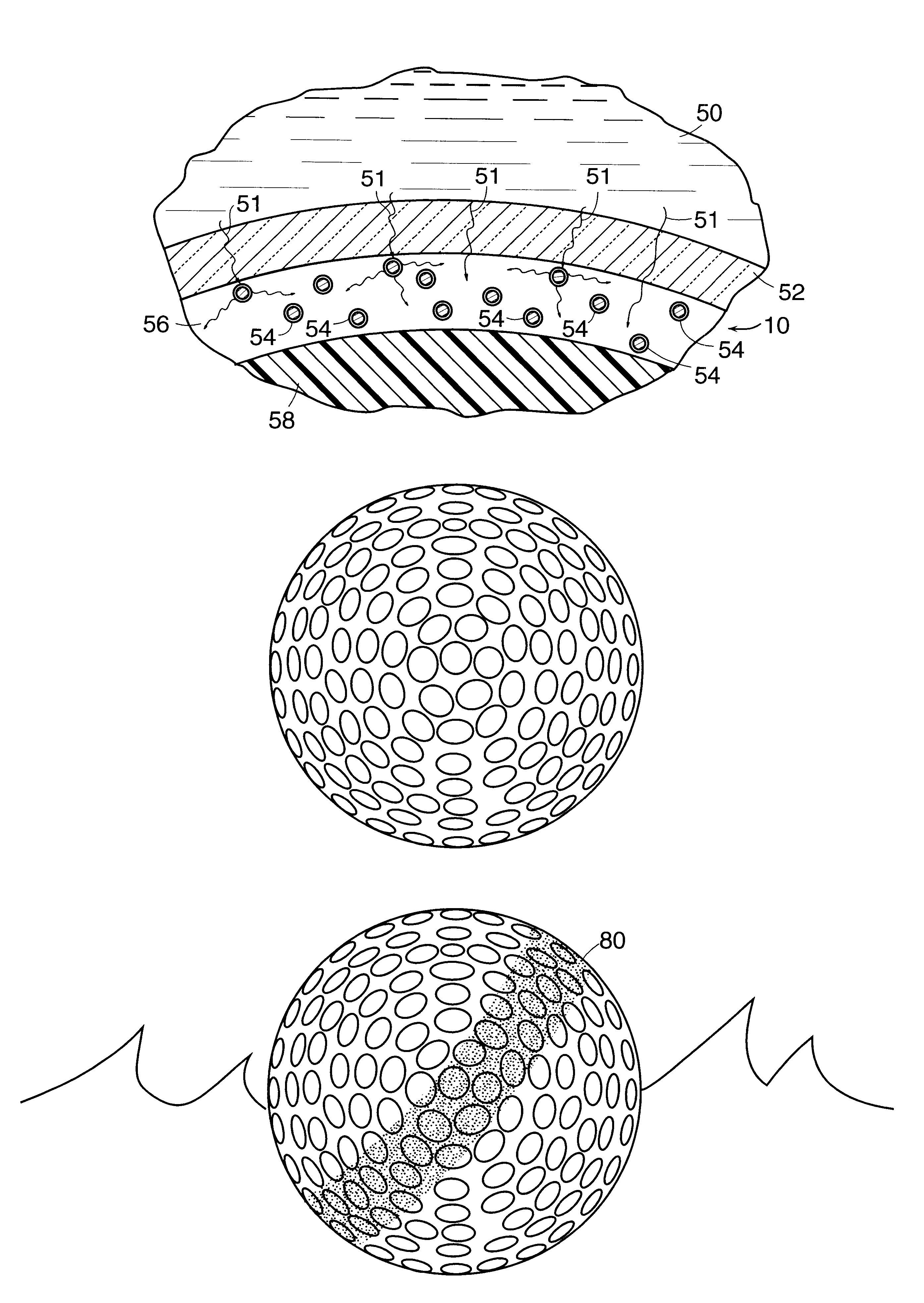

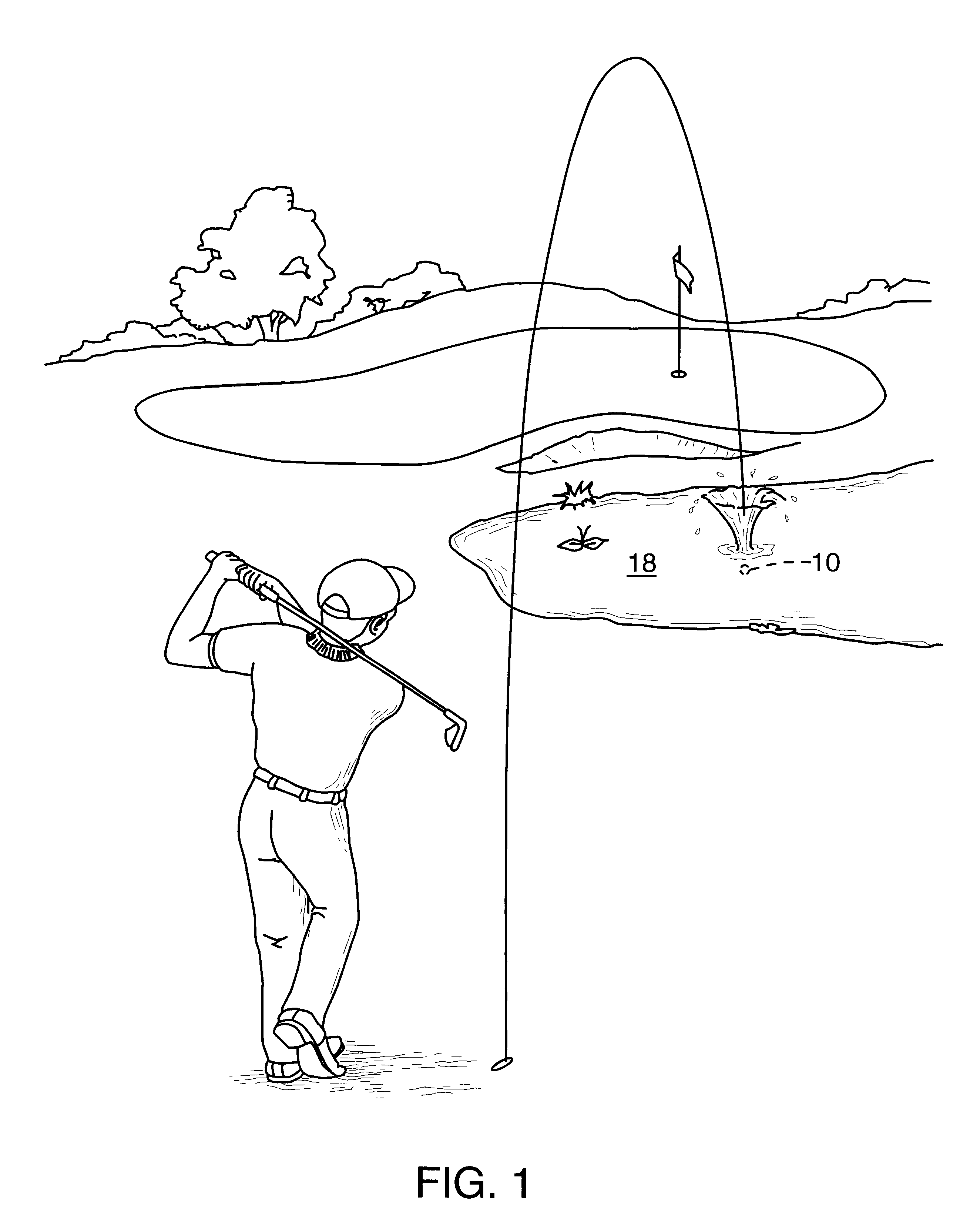

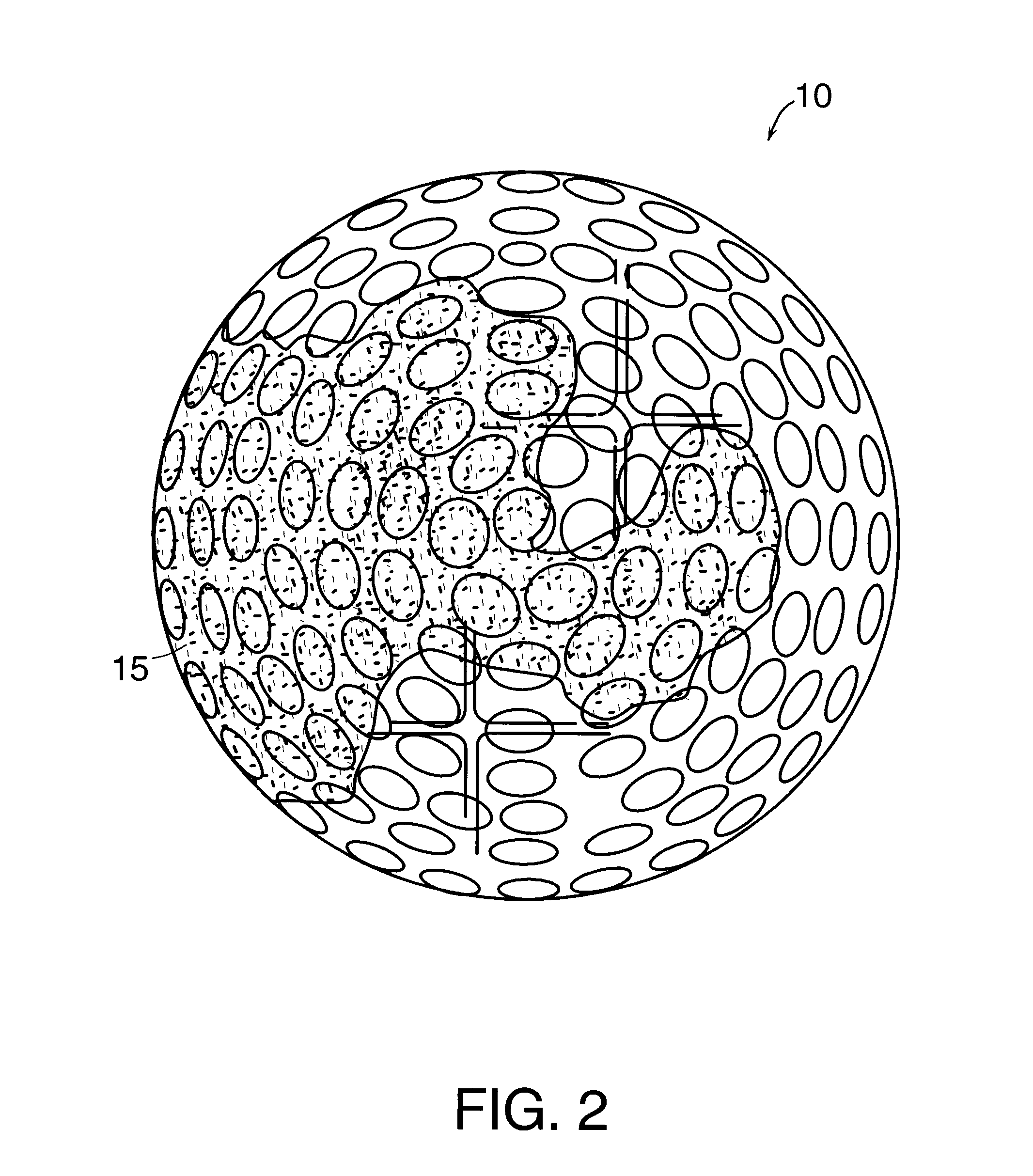

Golf ball with water immersion indicator

InactiveUS6358160B1High gloss finishAvoid stainsOther chemical processesGolf ballsSolid massChange color

A golf ball is provided which changes color or other indicia after significant immersion in water to indicate that the ball has been recovered from a water hazard and may not have predictable flight characteristics which may result in loss of carry and roll. In one embodiment, a microencapsulated dye layer is formed immediately below the final gloss coat, with controlled dye release causing a stained look to the ball after significant immersion in water. In another embodiment, the dye or ink is provided in pelletized form for ease of manufacture. In other embodiments, a dye, ink, or chemical is compounded with other materials and introduced into or applied onto the golf ball's composite materials in a solid, liquid, or gaseous form. In still other embodiments imprints on the ball are made with a water activated ink which either appears or disappears upon the immersion of the golf ball in water.

Owner:PERFORMANCE INDICATOR LLC

Mosaic extremity protection system with transportable solid elements

A flexible armor system adaptable to a garment suitable for extremity protection uses planar, polygon-shaped solid elements made of ceramic cores wrapped in high strength fabric and arranged with rotable edge and intersection protection as a flexible mosaic array which is bonded between an elastic strike side spall cover and a high tensile strength flexible backer layer, further supported by a substantial fiber pack. A progressive mode of localized system failure during a ballistic strike includes: a projectile penetrating the spall cover, fracturing the ceramic core of a wrapped SE while being partially deformed; the deformed projectile accelerating the fractured but still wrapped solid element before it so as to free the solid element from the array and drive it through the flexible backer as a combined mass at a reduced velocity into the fiber pack.

Owner:WARWICK MILLS INC

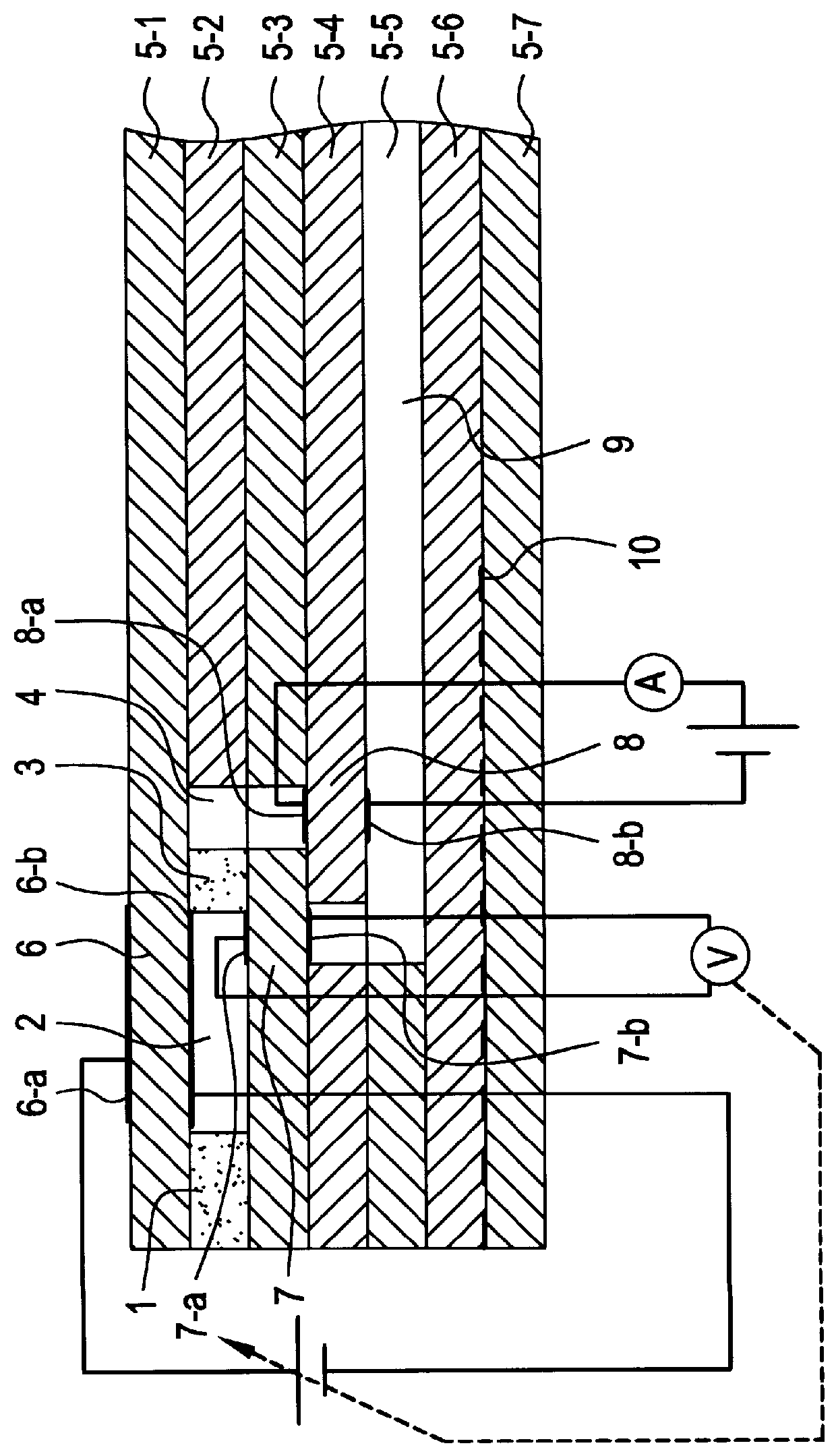

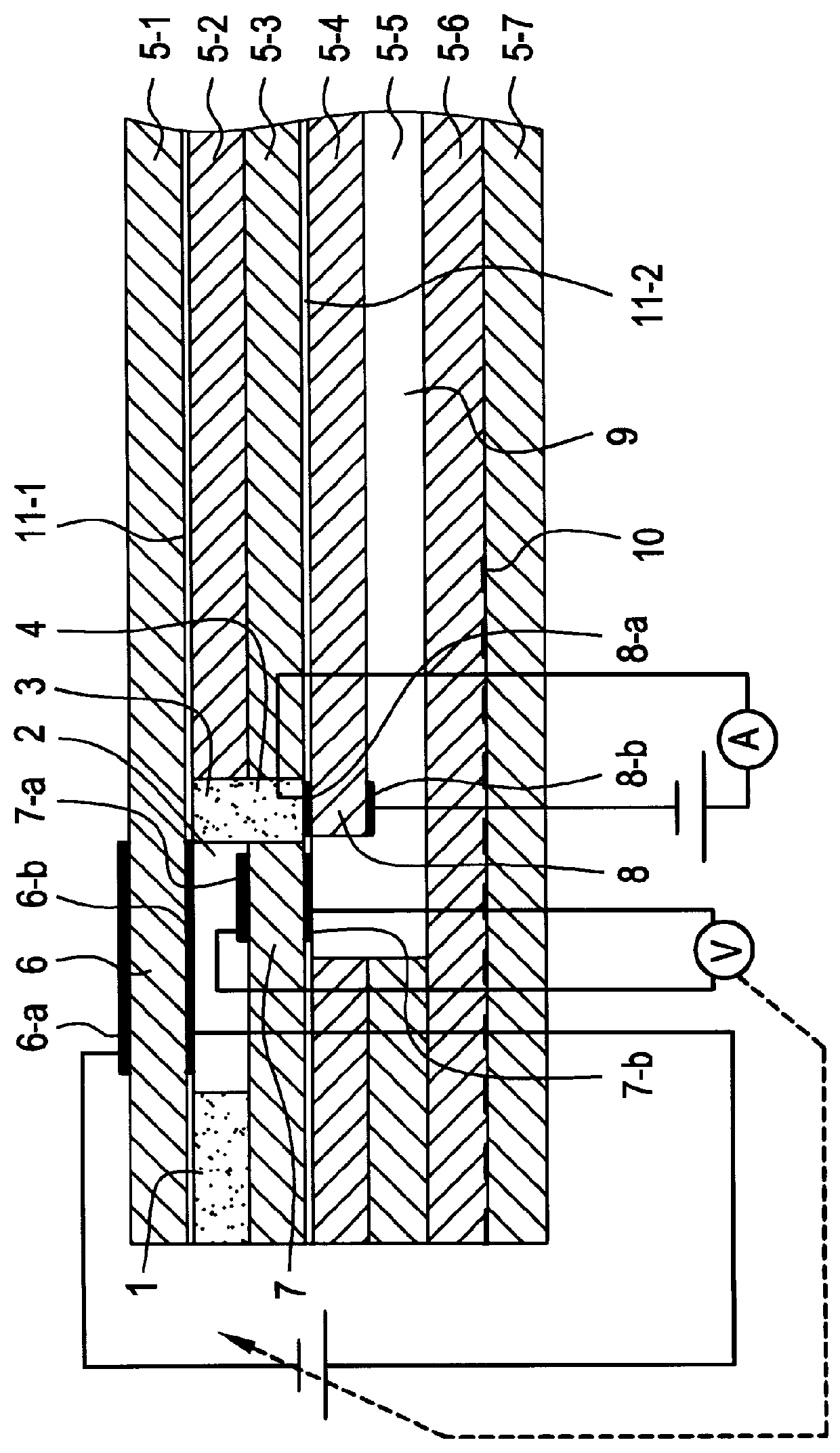

Nitrogen oxide concentration sensor

InactiveUS6071393AImproving oxygen concentration detection accuracyAccurate detectionWeather/light/corrosion resistanceVolume/mass flow measurementSolid massNitrogen oxide

A small-sized inexpensive nitrogen oxide concentration sensor capable of measuring the concentration of the nitrogen oxide in a measuring gas to a high accuracy. A first oxygen pumping cell, an oxygen concentration measuring cell and a second oxygen pumping cell are formed in different solid electrolyte layers of zirconia and electrodes of oxygen concentration measuring cell are isolated from electrodes of the oxygen pumping cells by insulating film.

Owner:NGK SPARK PLUG CO LTD

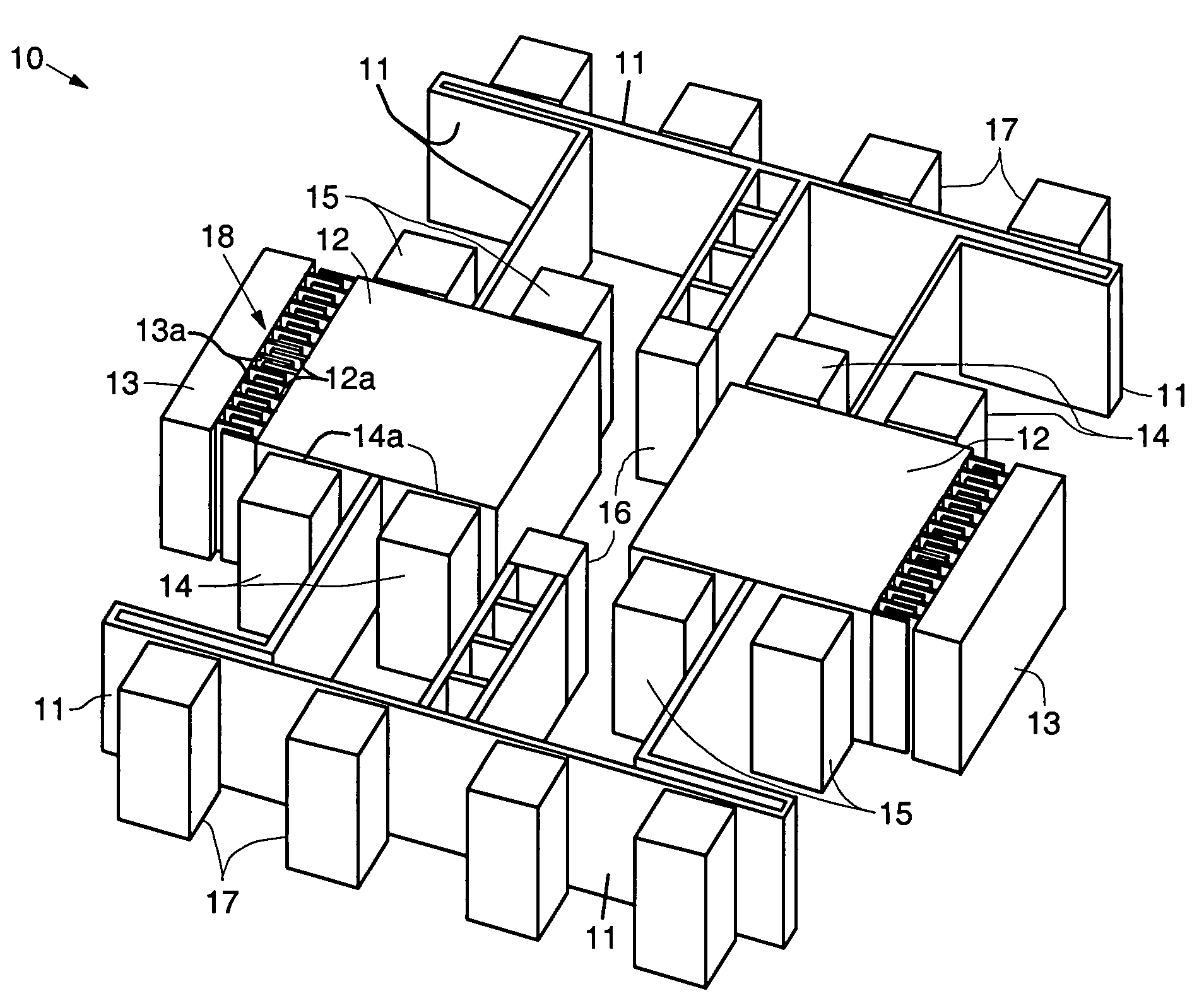

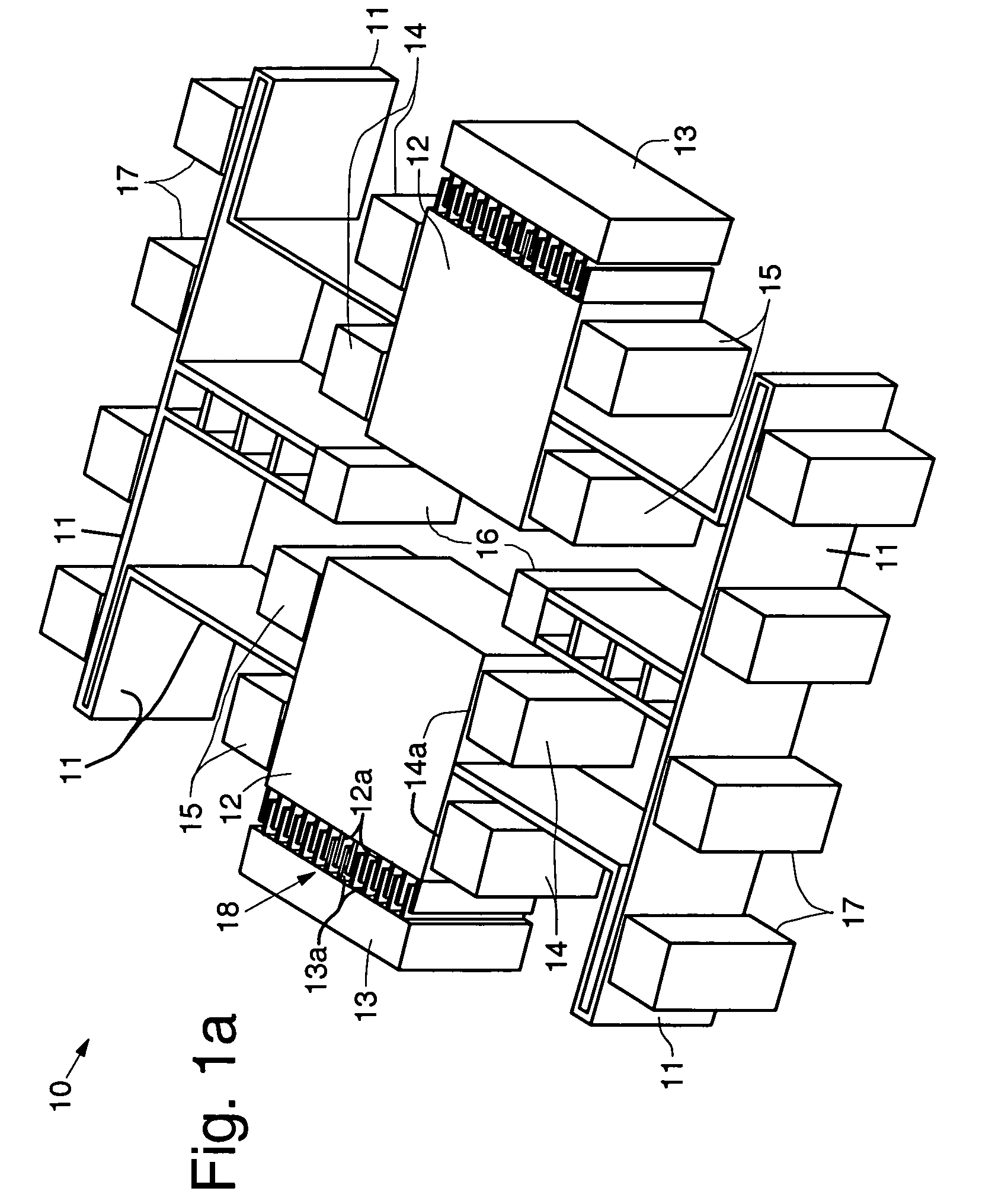

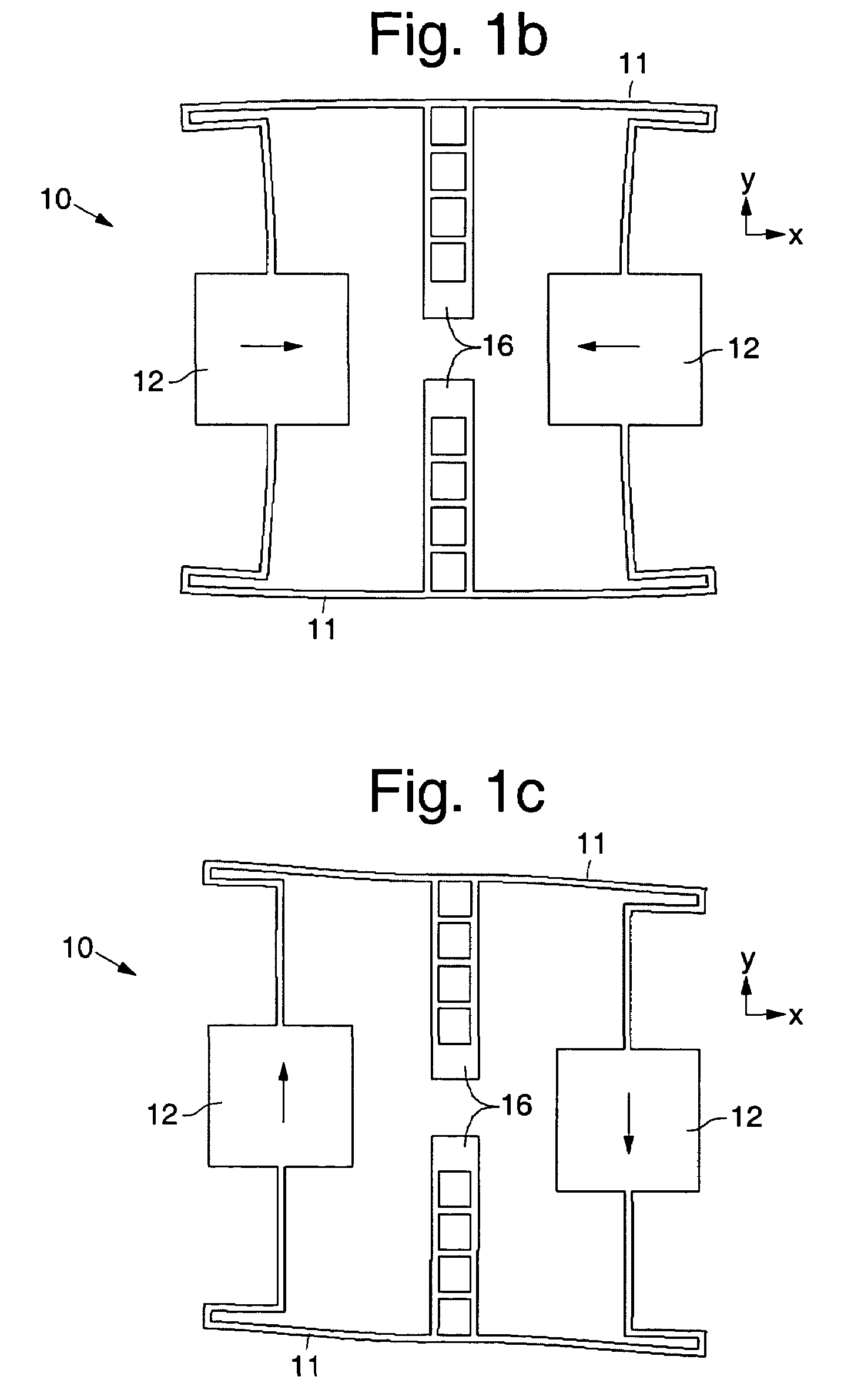

High-resolution in-plane tuning fork gyroscope and methods of fabrication

ActiveUS7043985B2Acceleration measurement using interia forcesWave amplification devicesTuning forkSolid mass

A microstructure comprising an in-plane solid-mass electrically conductive tuning fork gyroscope and fabrication methods. The gyroscope is formed using substrate material having lower and upper layers sandwiching a sacrificial insulating layer. An exemplary gyroscope comprises a low-resistivity single-crystal silicon substrate having a lower support layer and an upper flexible support layer. Two opposed proof masses that are separated from the lower support layer lie in and are supported by the upper flexible support layer. Two drive electrodes are disposed adjacent to the proof masses and are insulatably supported by the lower support layer and are separated from the upper flexible support layer. Sense, balance and tuning electrodes are disposed adjacent to the proof masses and are insulatably supported by the lower support layer and are separated from the upper flexible support layer. The operational mode shapes are in-plane with the substrate surface and only measures angular motion that are orthogonal to the plane of the substrate. The microstructure flexural design enables the sense and the drive resonant frequencies to occur in close proximity of one another. This enables matched-mode operation of the device thereby ensuring maximum sensitivity.

Owner:GEORGIA TECH RES CORP

Phononic crystal devices

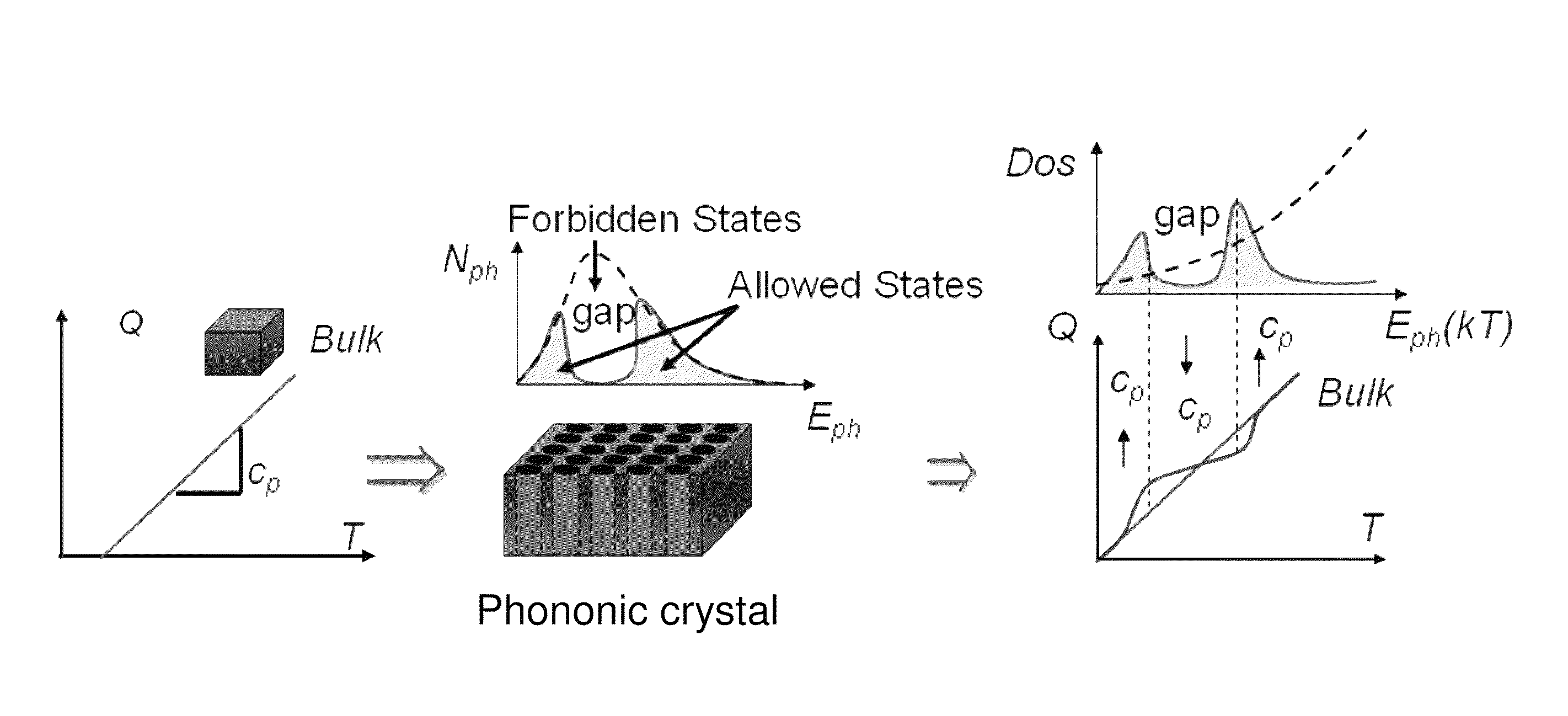

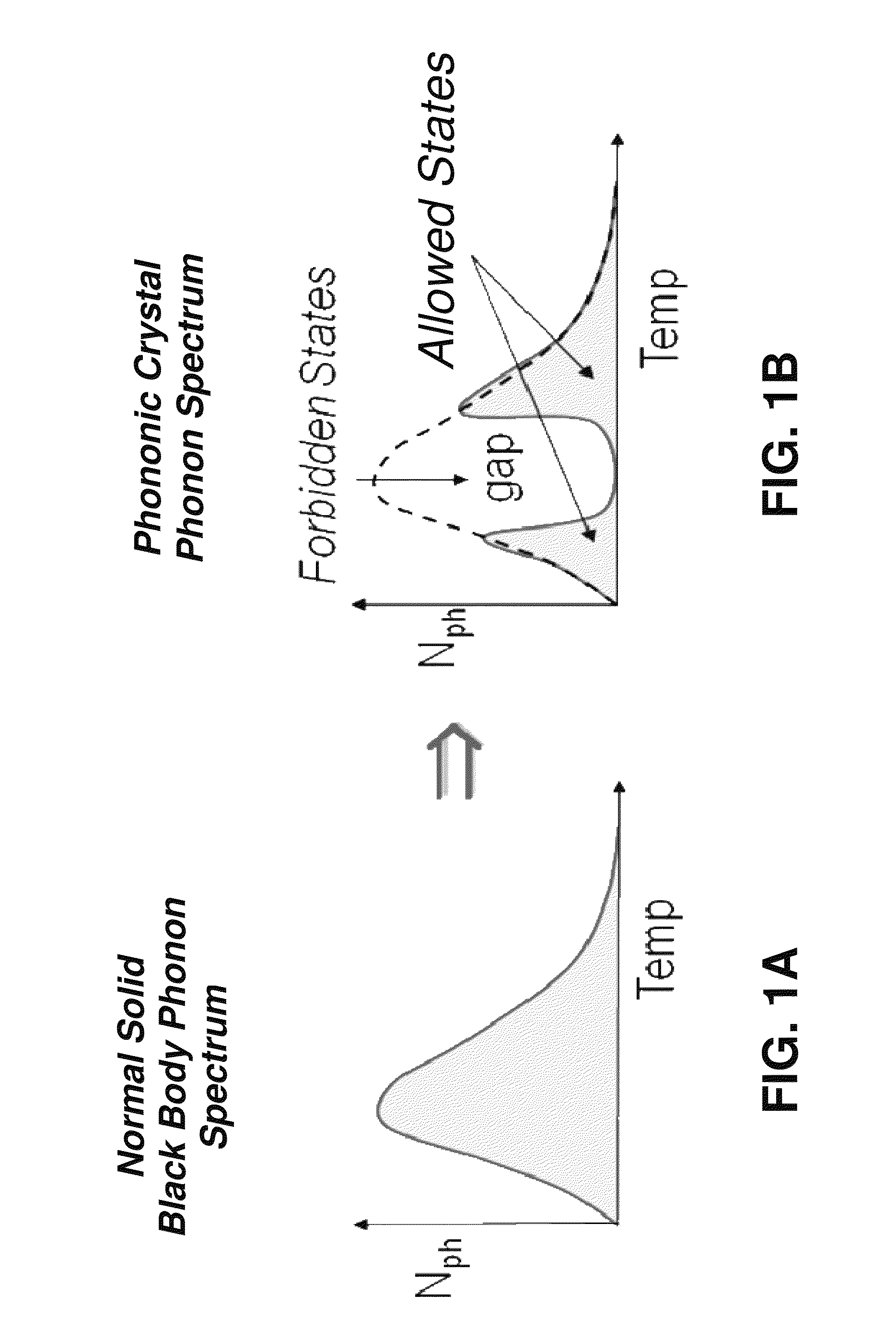

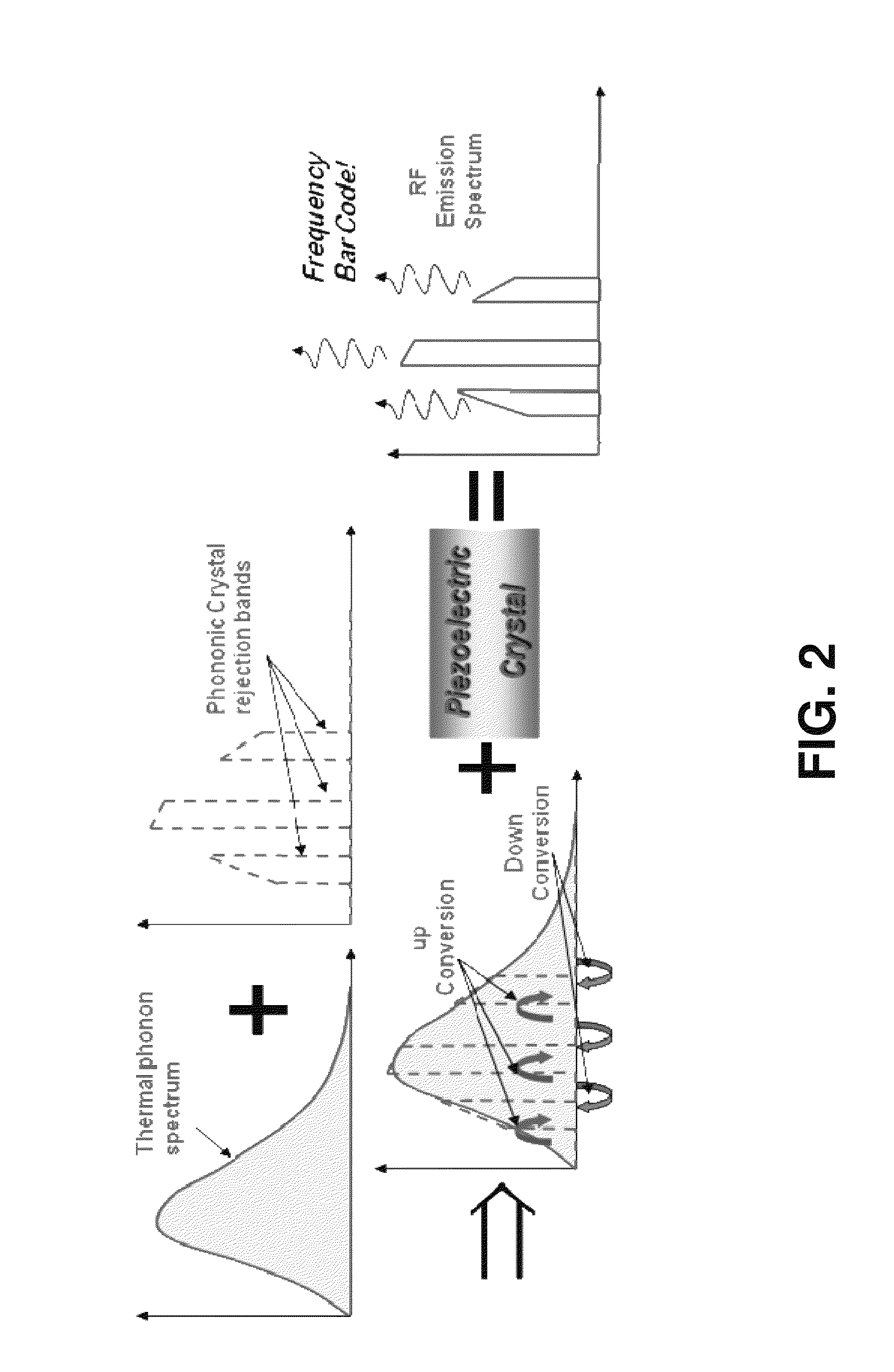

ActiveUS8094023B1Low thermal conductivityRaise the ratioFire alarmsElectric signalling detailsThermoelectric materialsDielectric

Phononic crystals that have the ability to modify and control the thermal black body phonon distribution and the phonon component of heat transport in a solid. In particular, the thermal conductivity and heat capacity can be modified by altering the phonon density of states in a phononic crystal. The present invention is directed to phononic crystal devices and materials such as radio frequency (RF) tags powered from ambient heat, dielectrics with extremely low thermal conductivity, thermoelectric materials with a higher ratio of electrical-to-thermal conductivity, materials with phononically engineered heat capacity, phononic crystal waveguides that enable accelerated cooling, and a variety of low temperature application devices.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

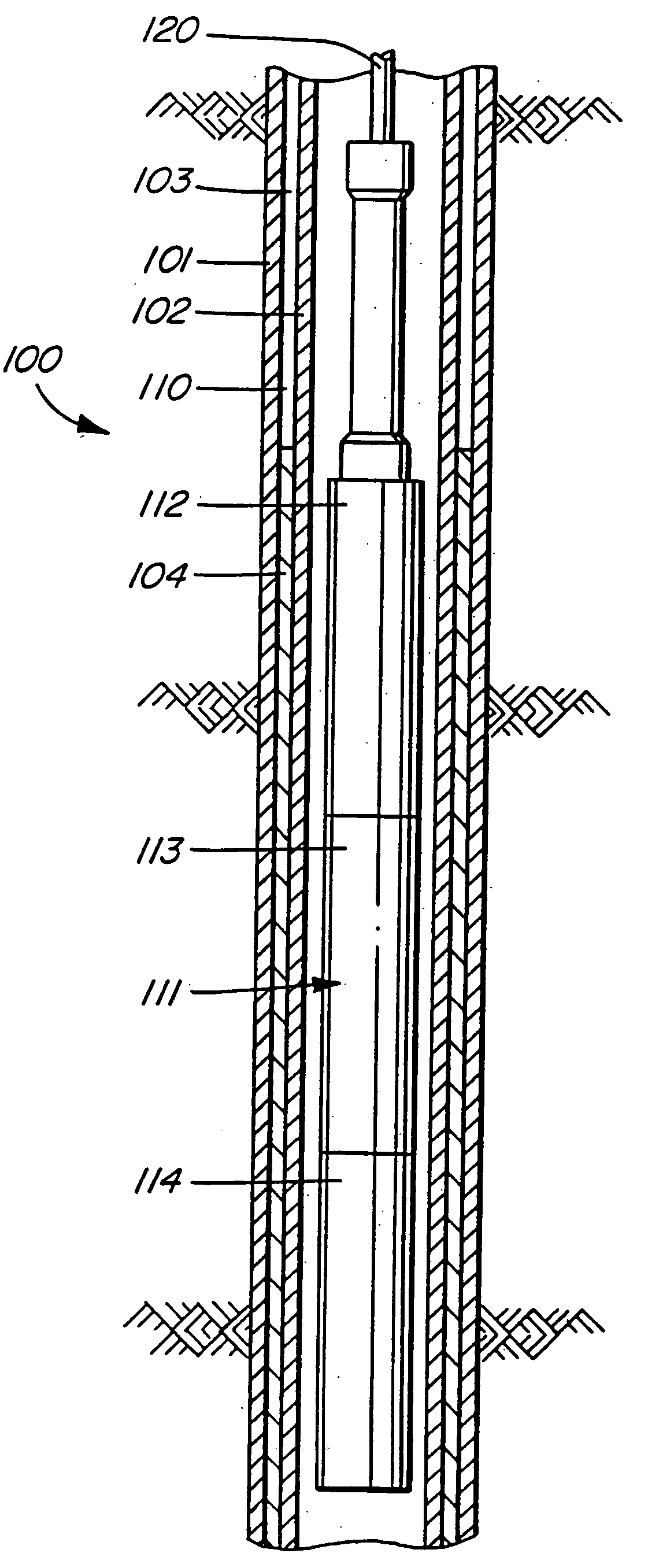

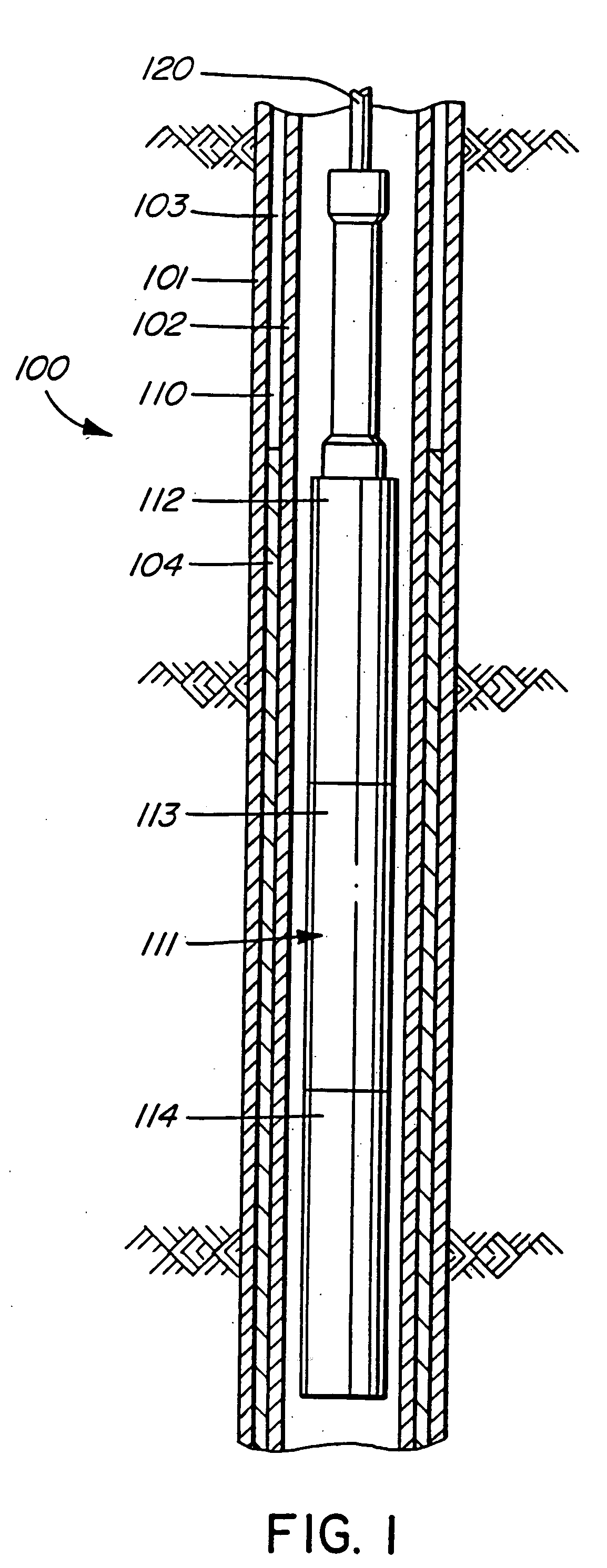

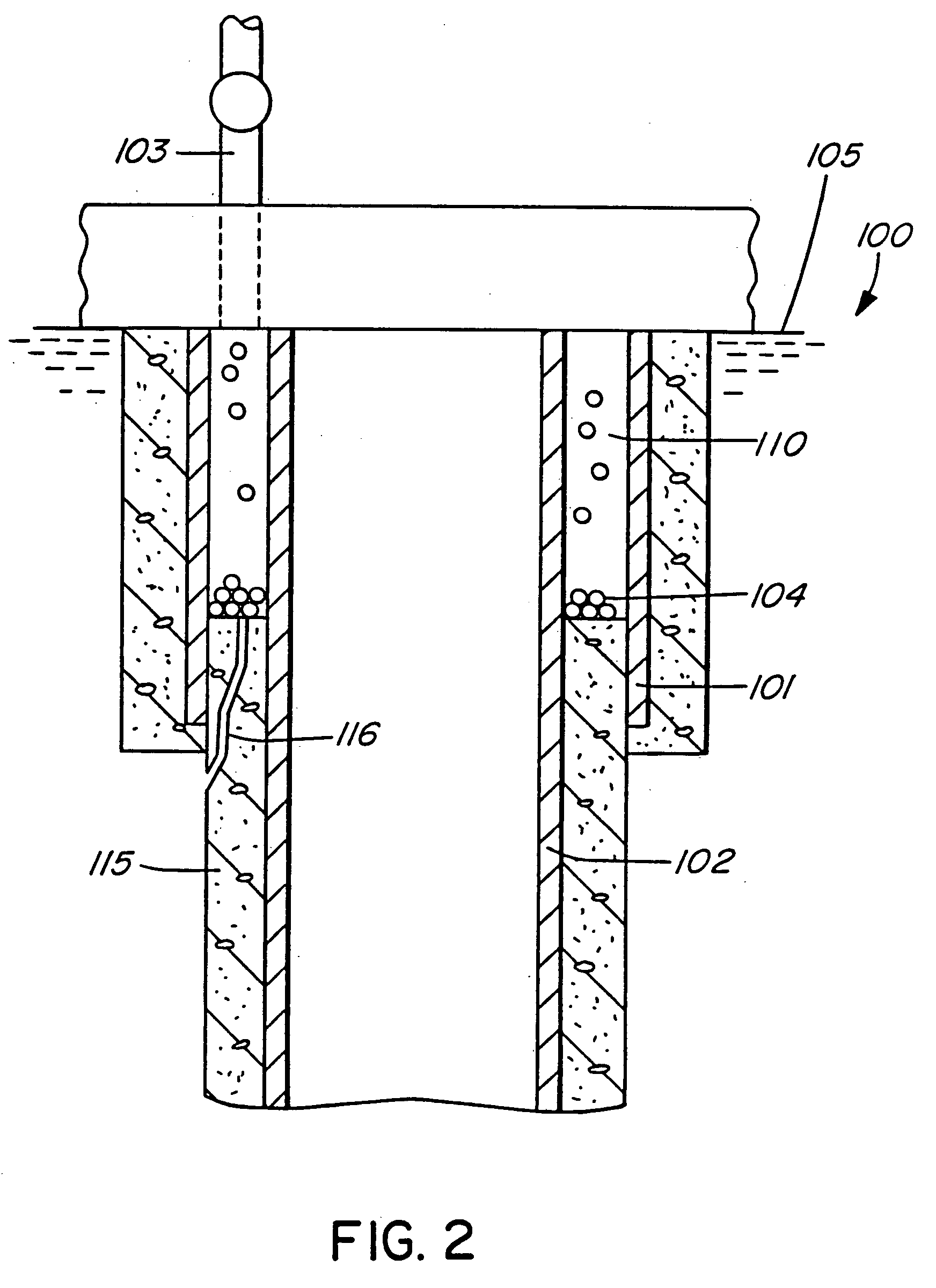

Oil and gas well alloy squeezing method and apparatus

Method and apparatus for melting a material and squeezing the melted material through casing perforations into a fault within the cement or formation of an oil or gas well. A heating tool carries solid material which is melted at depth within the well and adjacent to the casing perforations. The liquefied material is forced through the perforations and into the formation or the well cement. When the material cools and solidifies, the faults become sealed.

Owner:CANITRON SYST

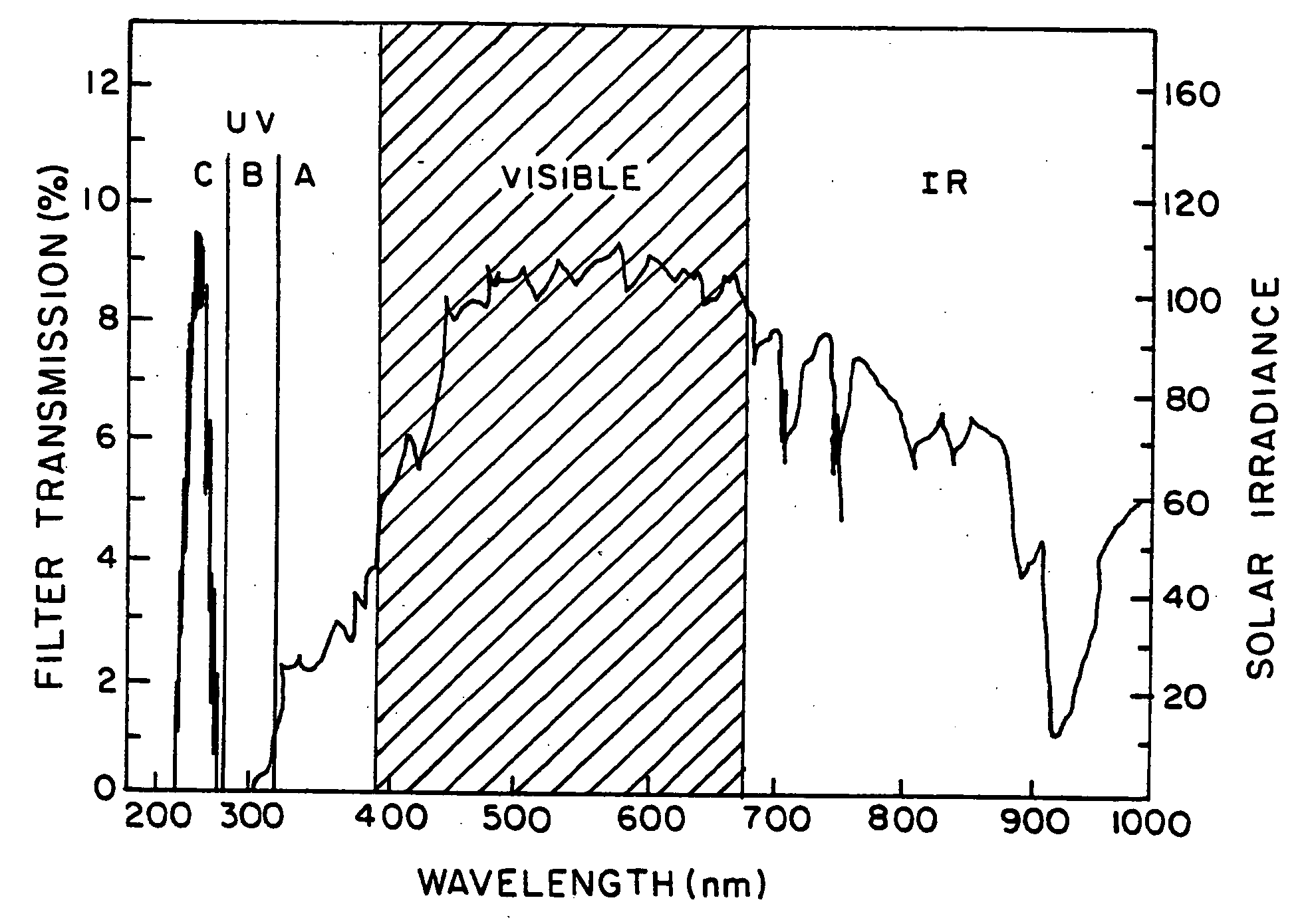

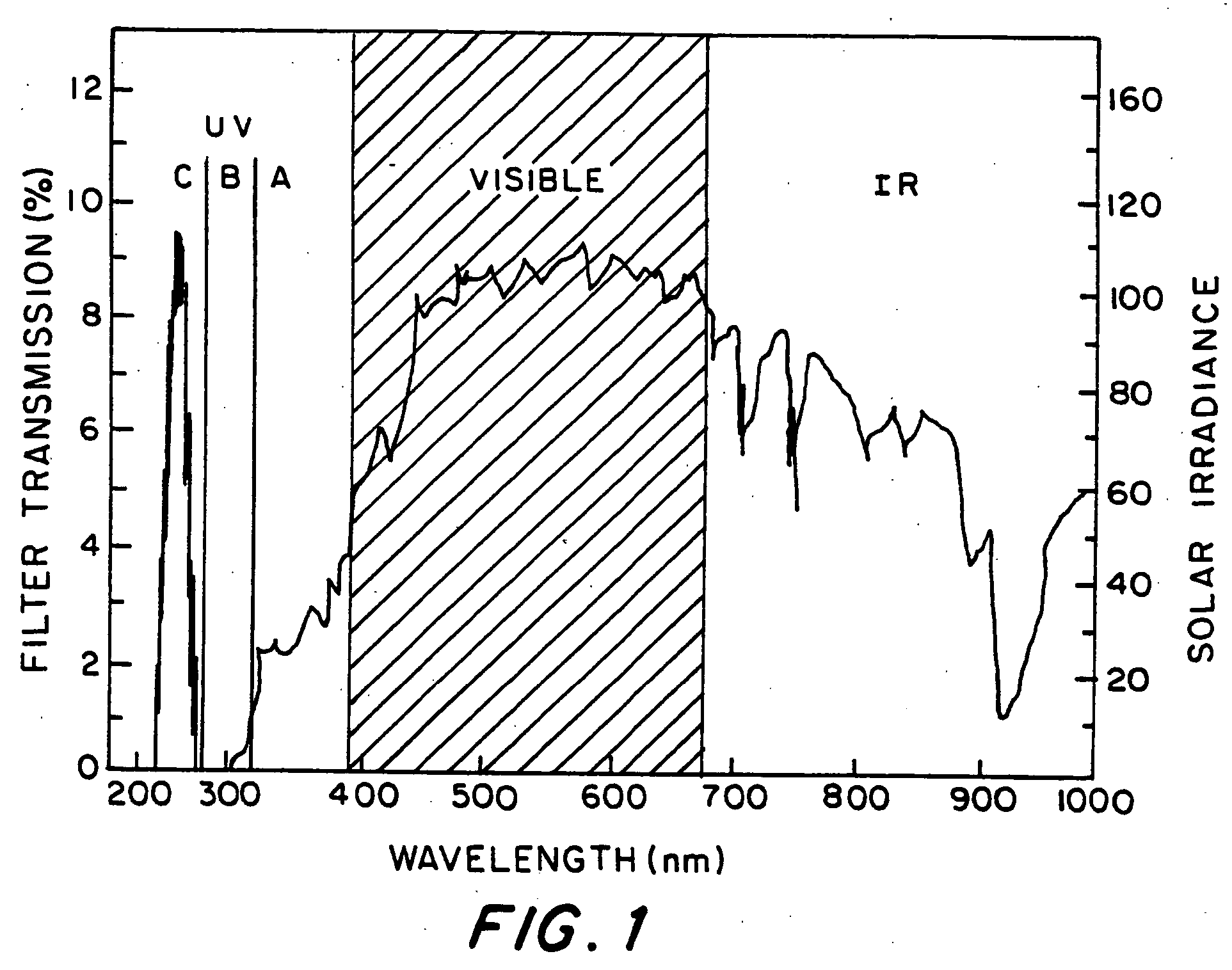

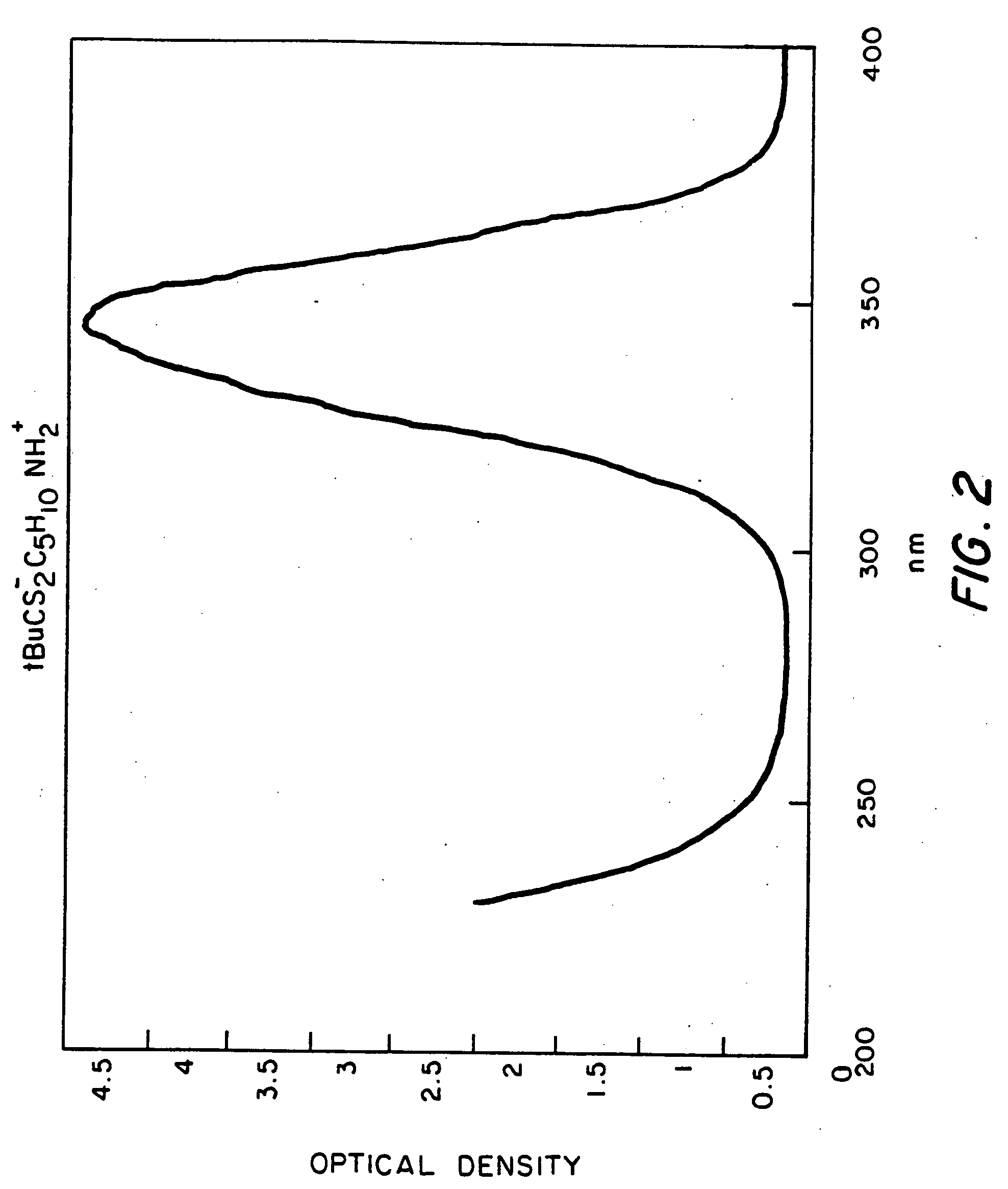

Optical filter comprising solar blind dyes and UV-transparent substrates

The invention provides an optical filter comprising: a. an organic, solar blind filter dye; and b. a UV-transparent, non-scattering and chemically stable substrate. The substrate may be a UV-transparent nanoporous silica glass solid having pores that are substantially filled with a UV-transparent solvent, which has been selected to dissolve said dye and also to match the refractive index of the nanoporous silica glass solid. Alternatively, the substrate may be a UV-transparent inorganic salt compressed to form a solid body. The invention also provides for methods of making these embodiments and an optical device comprising such an optical filter. The filter provides an efficient solar blind filter that is chemically and dimensionally stable.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

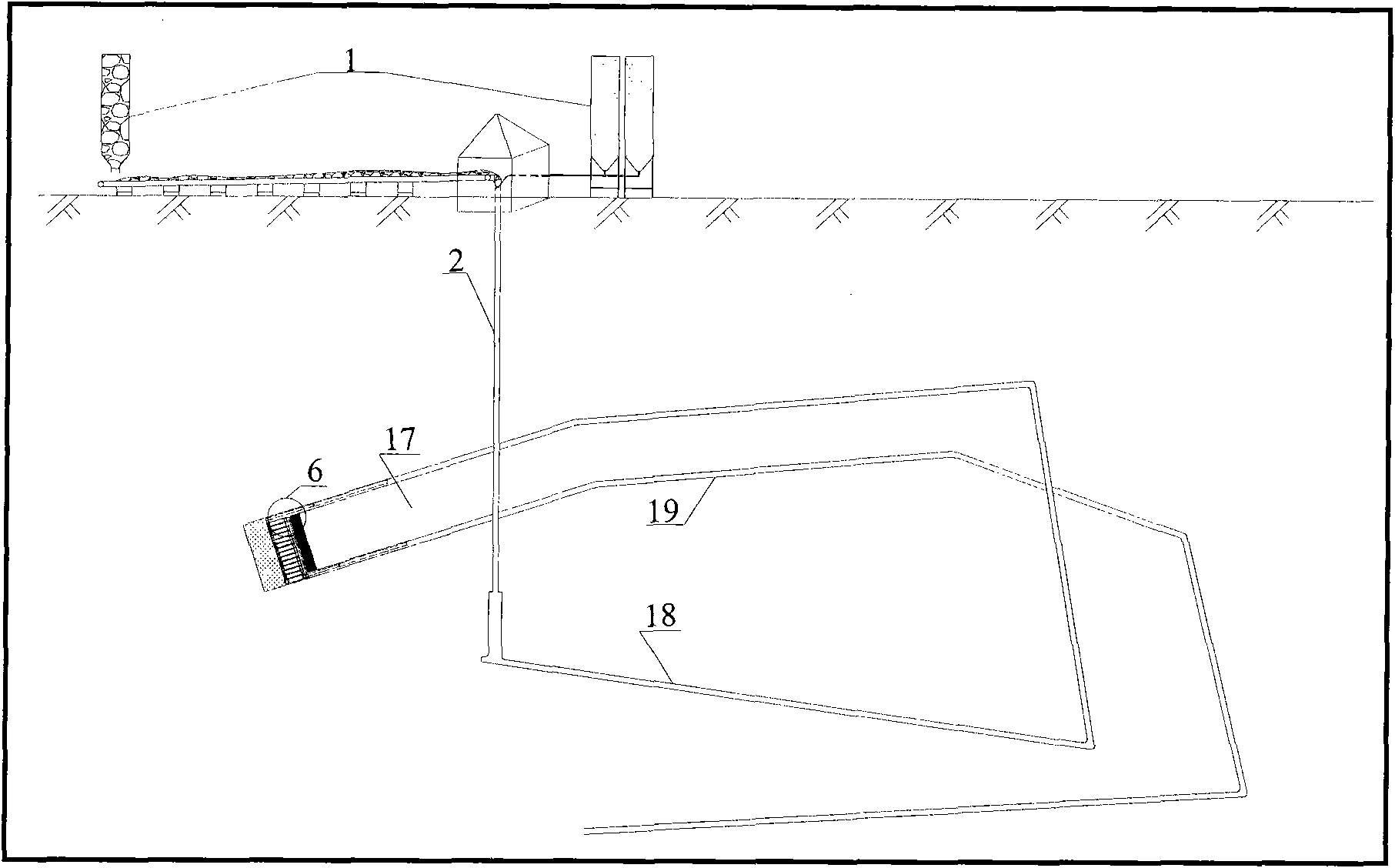

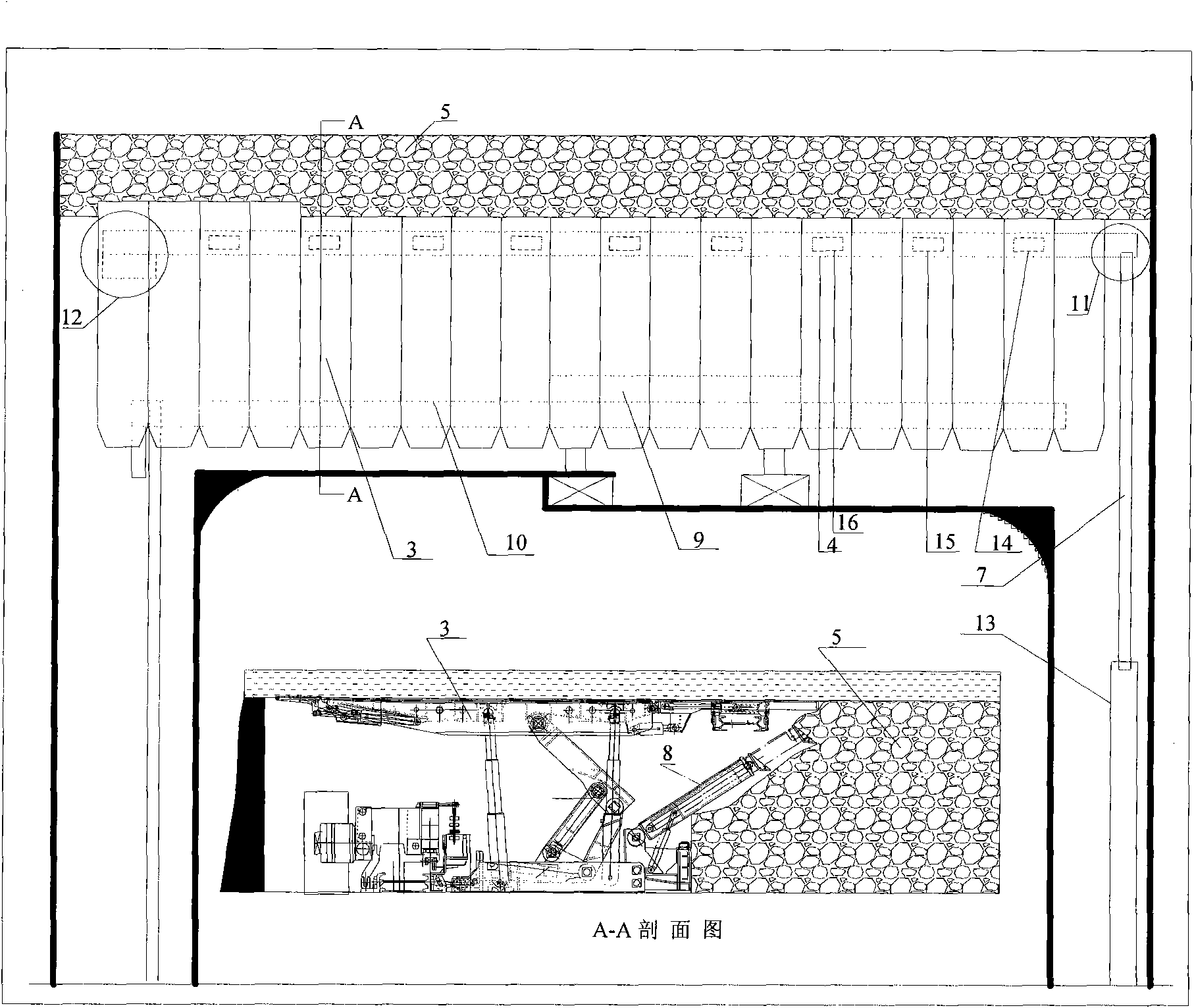

Coal mining solid filling method

InactiveCN101586460AHelps control sinkingEasy to useUnderground miningSurface miningSolid massFilling materials

A coal mining solid filling method comprises following steps: using the stacked solids on the ground as the filling materials for the working surface goaf, directly putting the solid filling materials from the ground to a belt conveyor in the underworkings by a perpendicular feeding well, transporting to the end of a coal face through the underground belt conveyor, reloading the solid filling materials to a solid filling mining conveyor hung under a back tail beam of a self-impacting type filling hydraulic support by a self-moving type filling material reloading machine. In the process of mining work, the coal is mined and the filling materials are filled on the bottom; and the solid filling materials are compacted by means of a compactor of the self-impacting type filling hydraulic support. The method solves the problem of coal compaction under the building and low coal recovery.

Owner:CHINA UNIV OF MINING & TECH +1

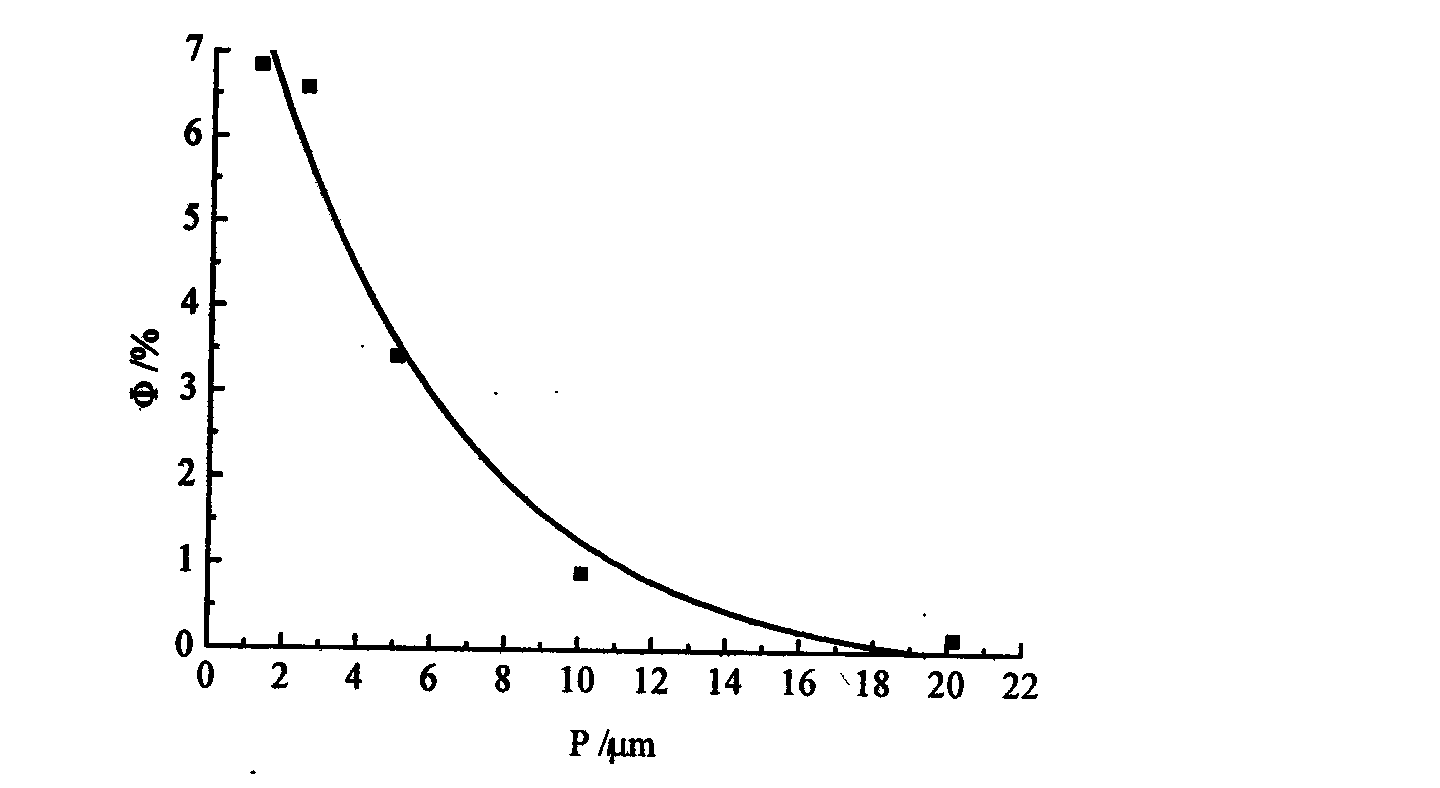

Method for analyzing pore structure of solid material based on microscopic image

InactiveCN101639434ACalculated pore sizeCalculate porosityPermeability/surface area analysis3D-image renderingPorosityMicroscopic image

The invention provides a method for analyzing the pore structure of solid material based on microscopic image, belonging to the technical field for analyzing the pore structure of the solid material.The method is characterized of: obtaining the CT single cross section image of the solid material by microscopic CT scanning; using computer language to digitally image process the CT single cross section image; taking the pixel side of the image as the size of hole diameter; computing the hole diameter of the solid material, porosity and change regularity of the hole diameter and the porosity based on the microscopic CT single image; selecting the CT single image after processing a plurality of digital image; generating a CT image sequence; three dimensionally rebuilding the CT single image with a volume rendering algorithm in a visual rebuilding algorithm; generating the three dimensional digital image of the solid material; and computing the hole diameter of the solid material, the porosity and the change regularity of the hole diameter and the porosity based on the microscopic CT single image. The method is widely used for analyzing and computing the hole size and the porosity of the solid material under the various hole sizes of the solid material.

Owner:TAIYUAN UNIV OF TECH

Semisolid system and combination semisolid, multiparticulate system for sealing tissues and/or controlling biological fluids

InactiveUS20060127437A1Alter viscosityAlter consistencyAbsorbent padsSynthetic polymeric active ingredientsSolid massMedical product

A semisolid system and combination semisolid, multiparticulate system for controlling biological fluids is provided which includes a body fluid control composition. The body fluid control composition is adapted for utilization both as an independent mixture for direct topical application to body tissue for human or veterinary application and for incorporation with a standard medical products in order to facilitate absorption, moisture balance, hemostasis, infection control, and wound healing.

Owner:SOUTHEASTERN MEDICAL TECH

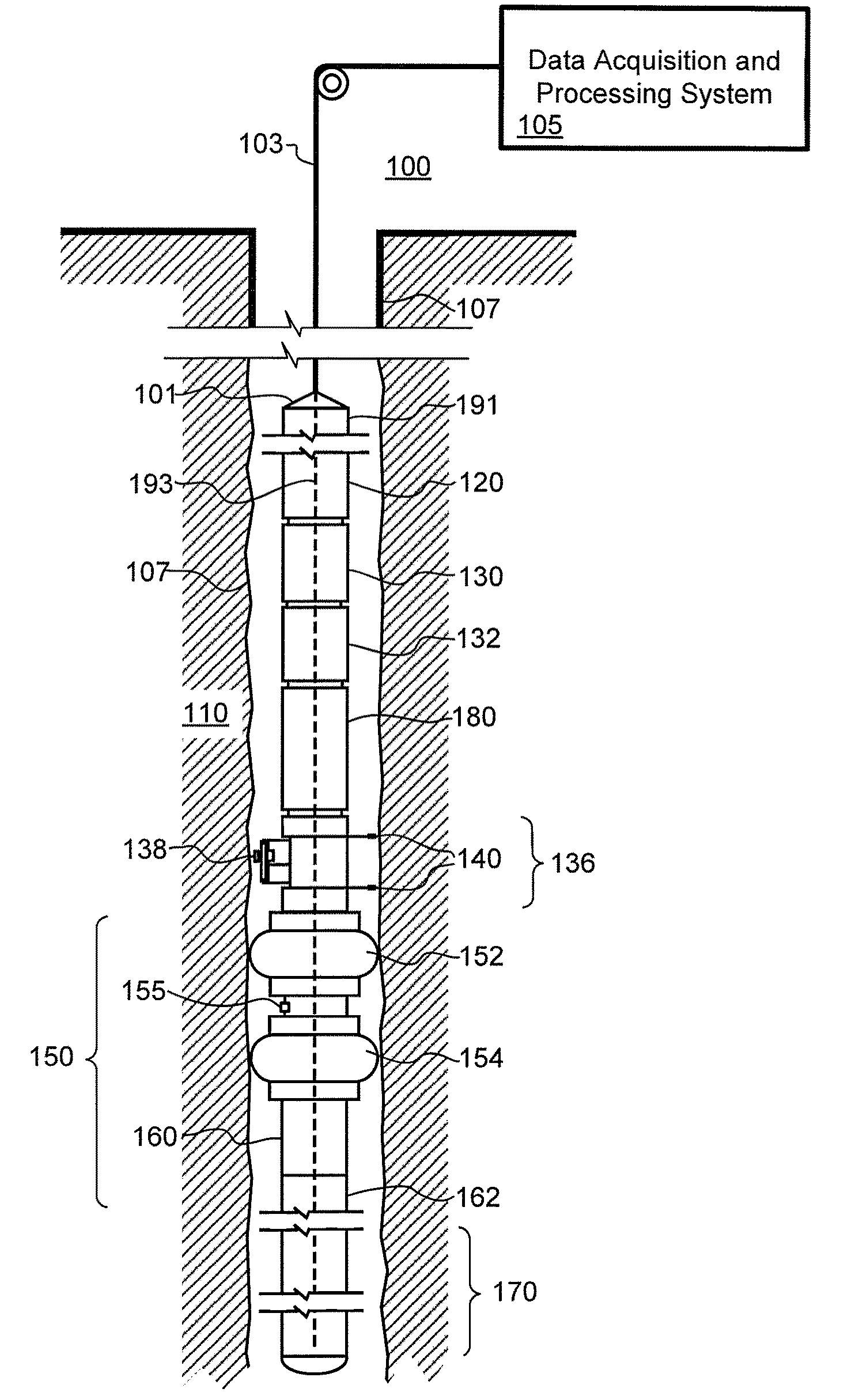

In-situ evaluation of reservoir sanding and fines migration and related completion, lift and surface facilities design

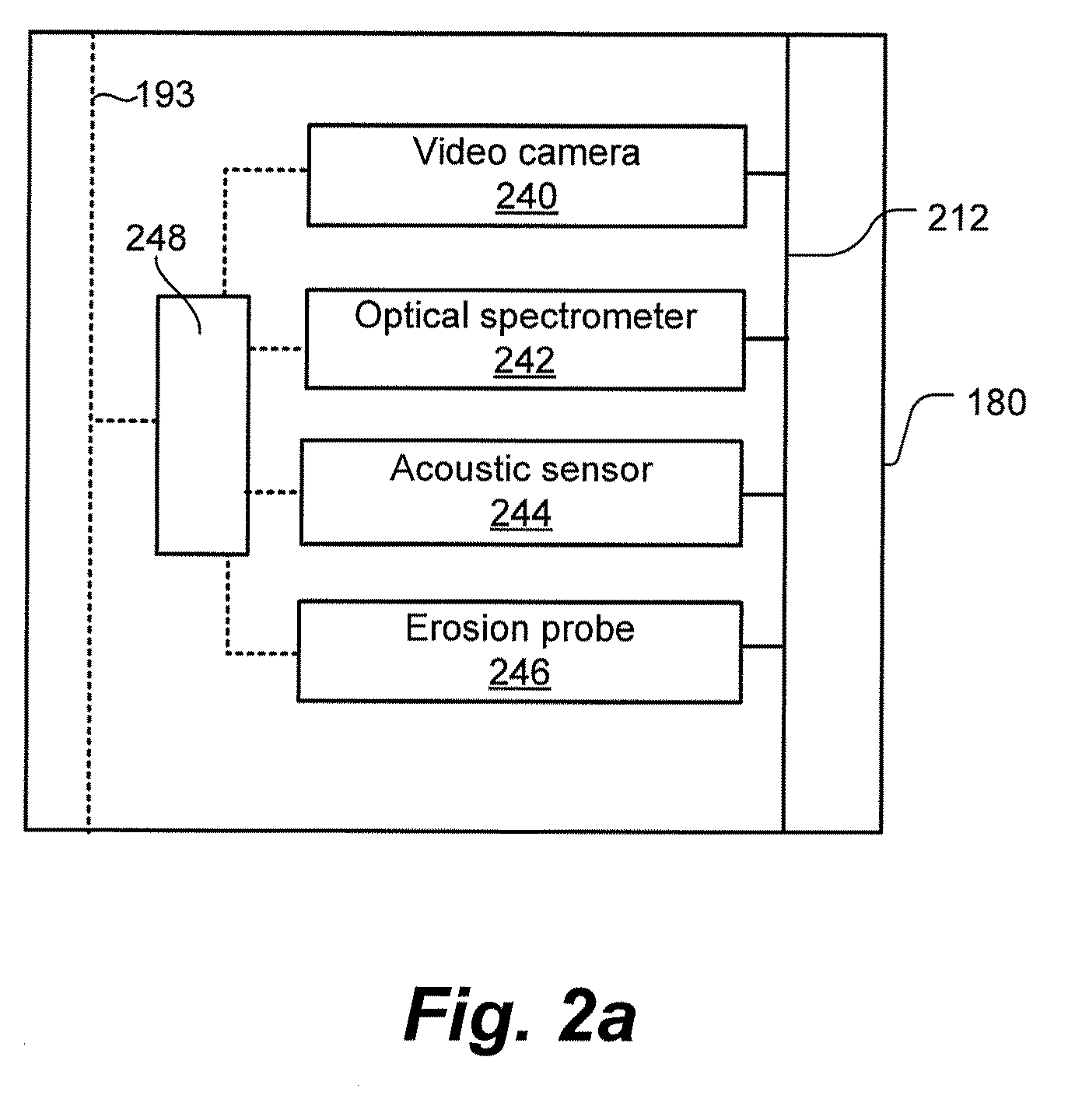

Methods and related systems are described relating to monitoring particulates downhole at in-situ conditions. Solid particles being carried in the fluid as the fluid is produced from the reservoir formation are monitored. The downhole solid particle monitoring can include measuring the quantity (e.g., volume fraction, weight fraction, or the like) of solid particles, measuring the distribution of sizes of the solid particles, and / or measuring the shape of the particles. The solid particles can be monitored using one or more of sensors such as optical spectrometers, acoustic sensors, video cameras, and erosion probes. A sanding prediction is generated based at least in part on the monitoring of the solid particles, and the sanding prediction is then used to design a completion, lift system, and surface facilities for the wellbore and / or select operating conditions so as to control sanding during production.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com