Patents

Literature

48results about How to "Large runner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

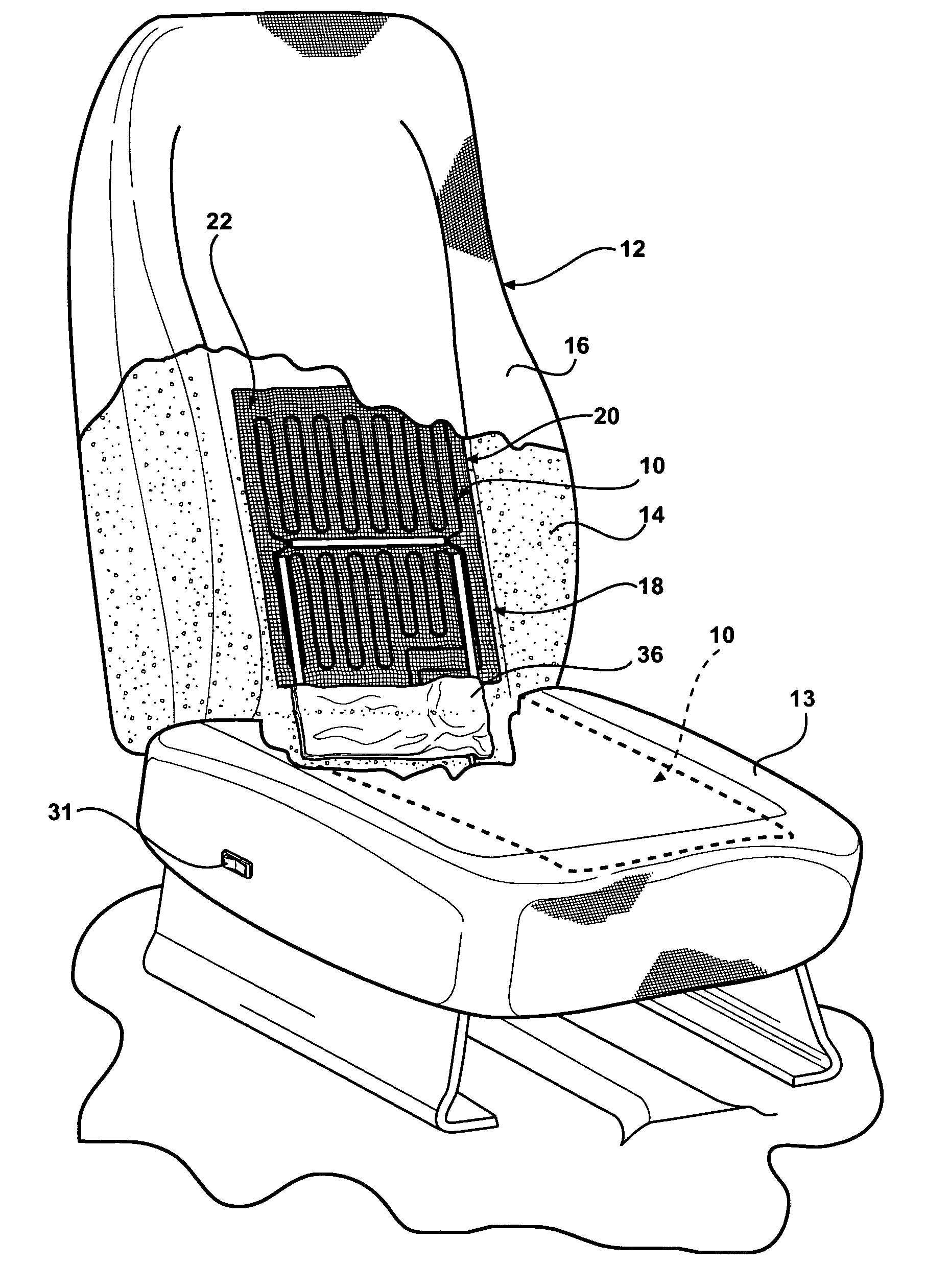

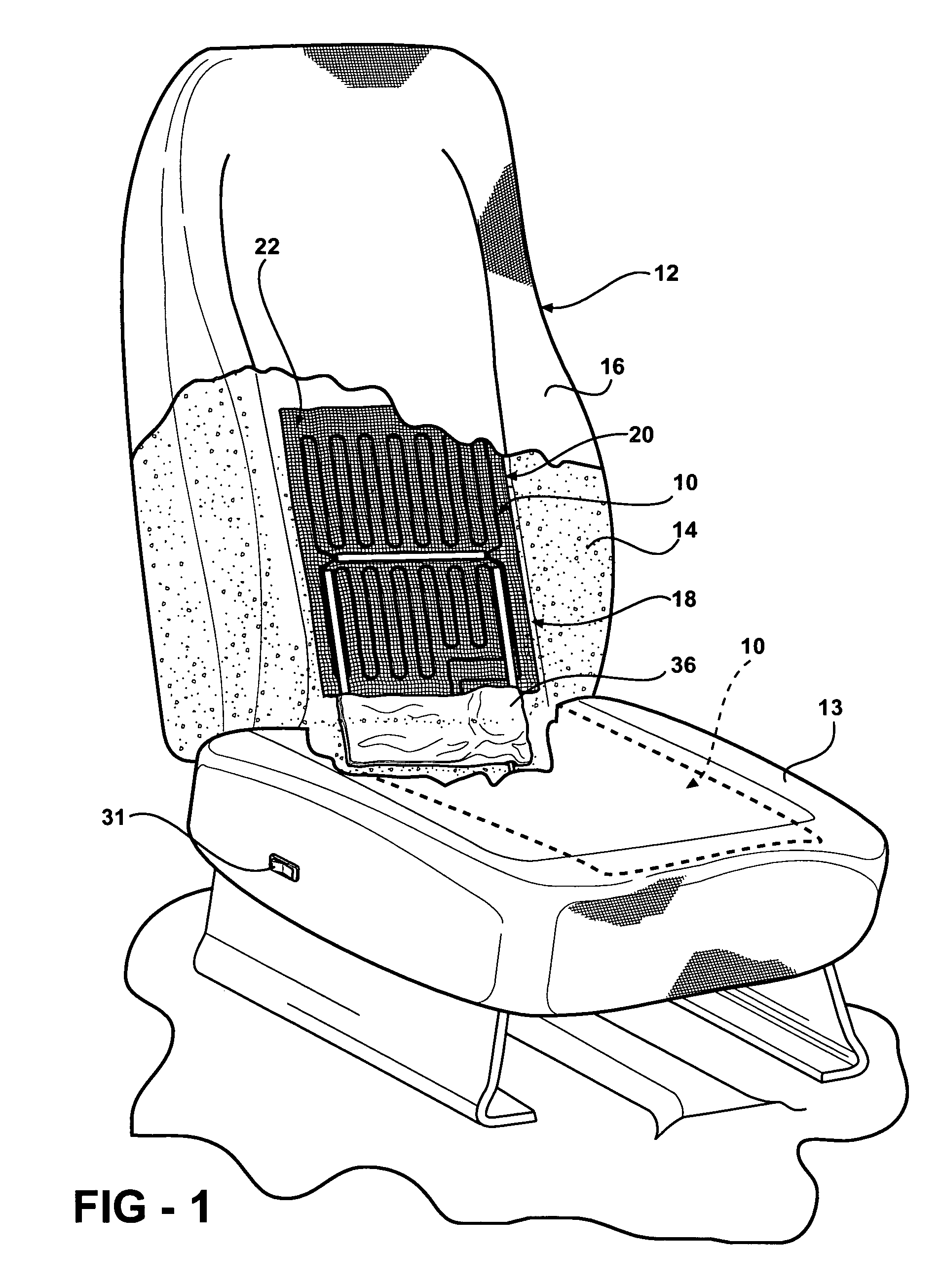

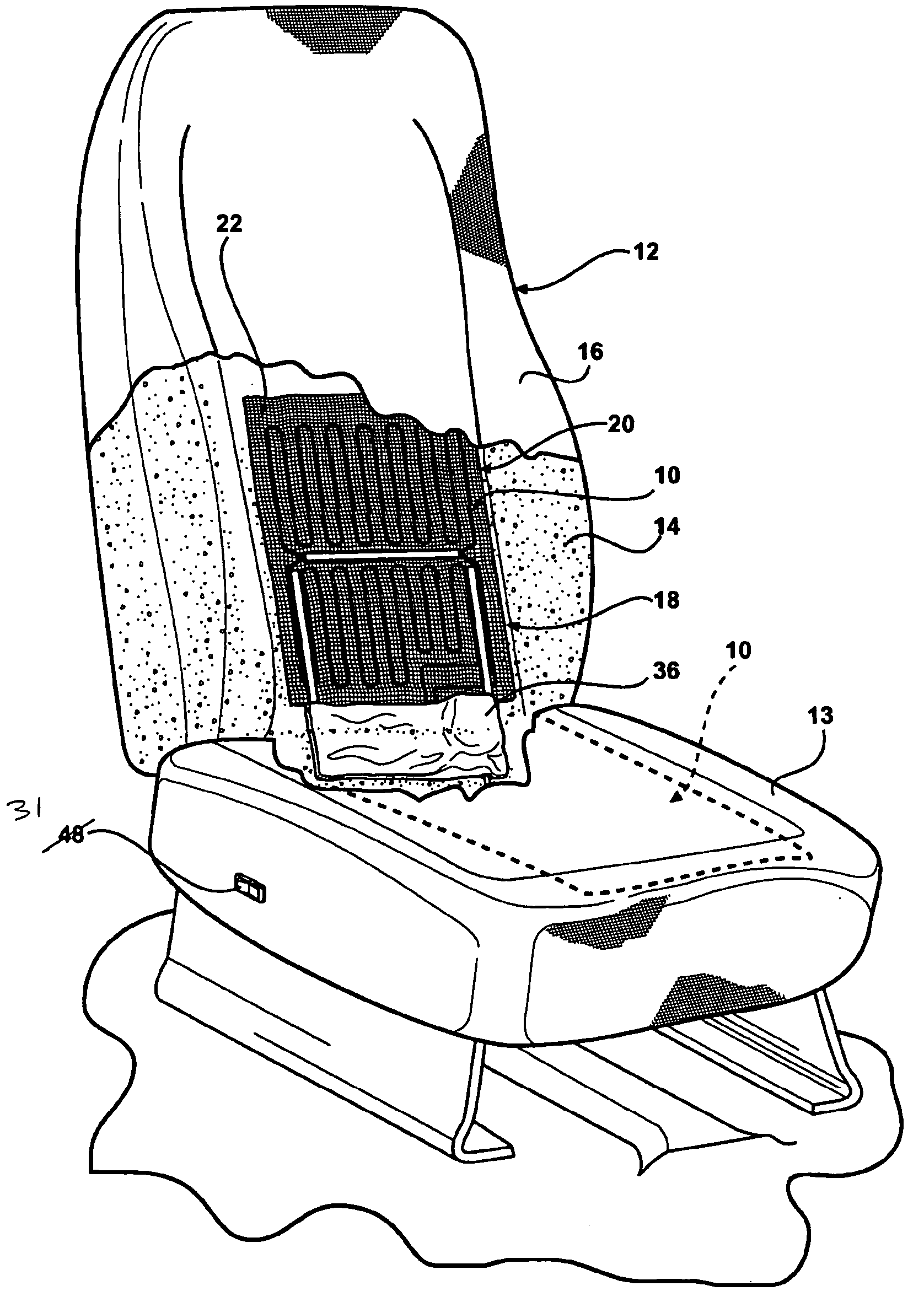

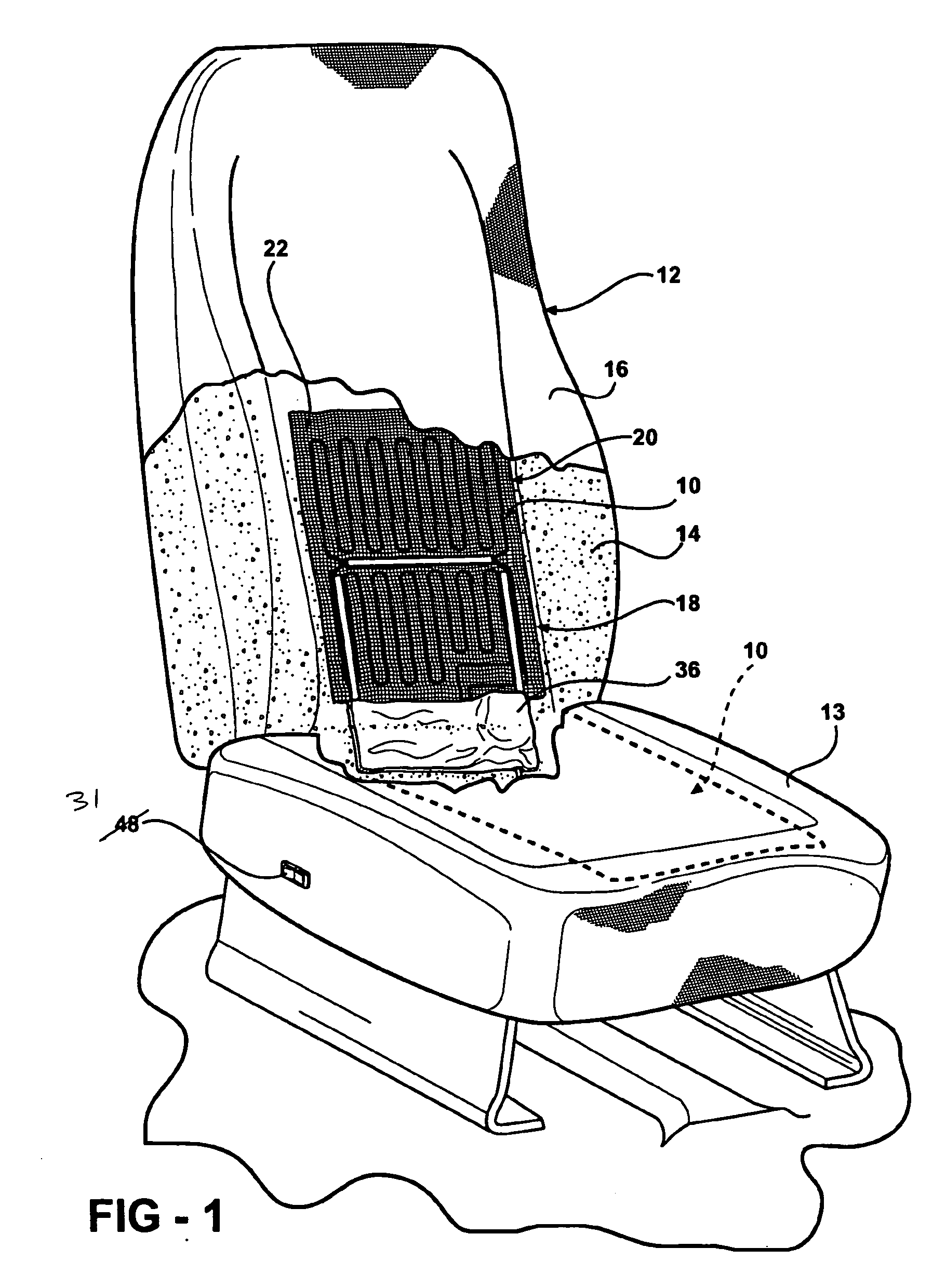

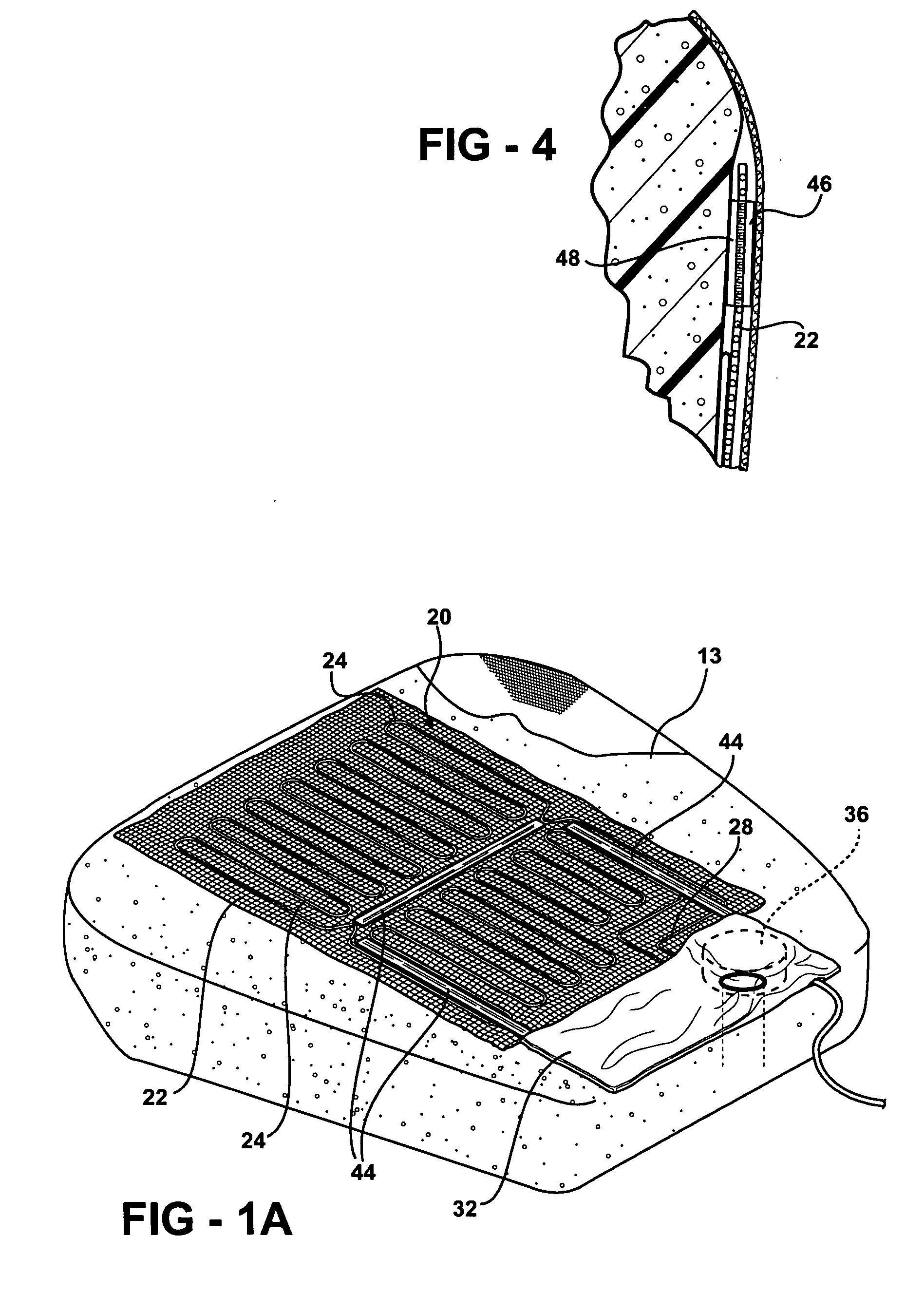

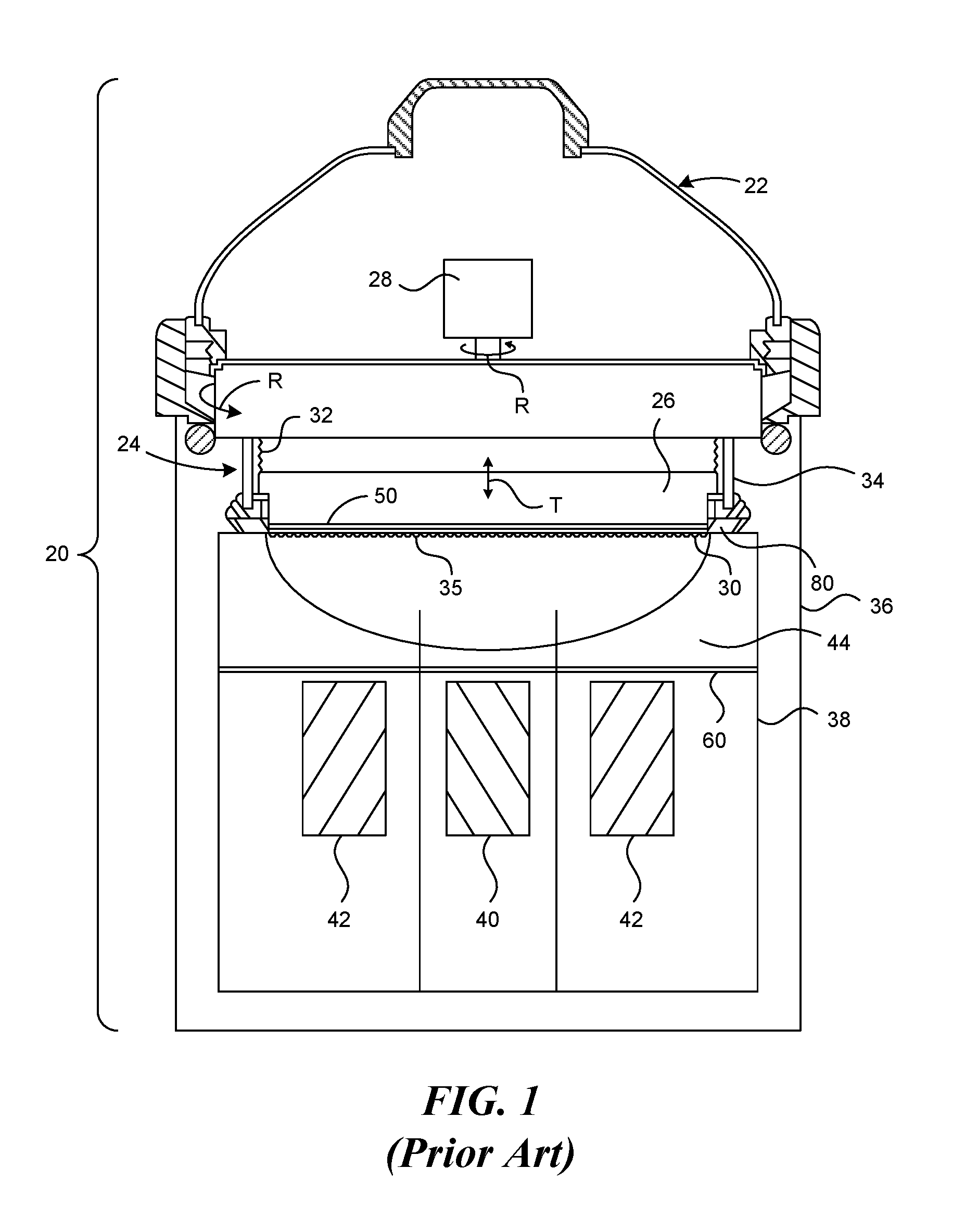

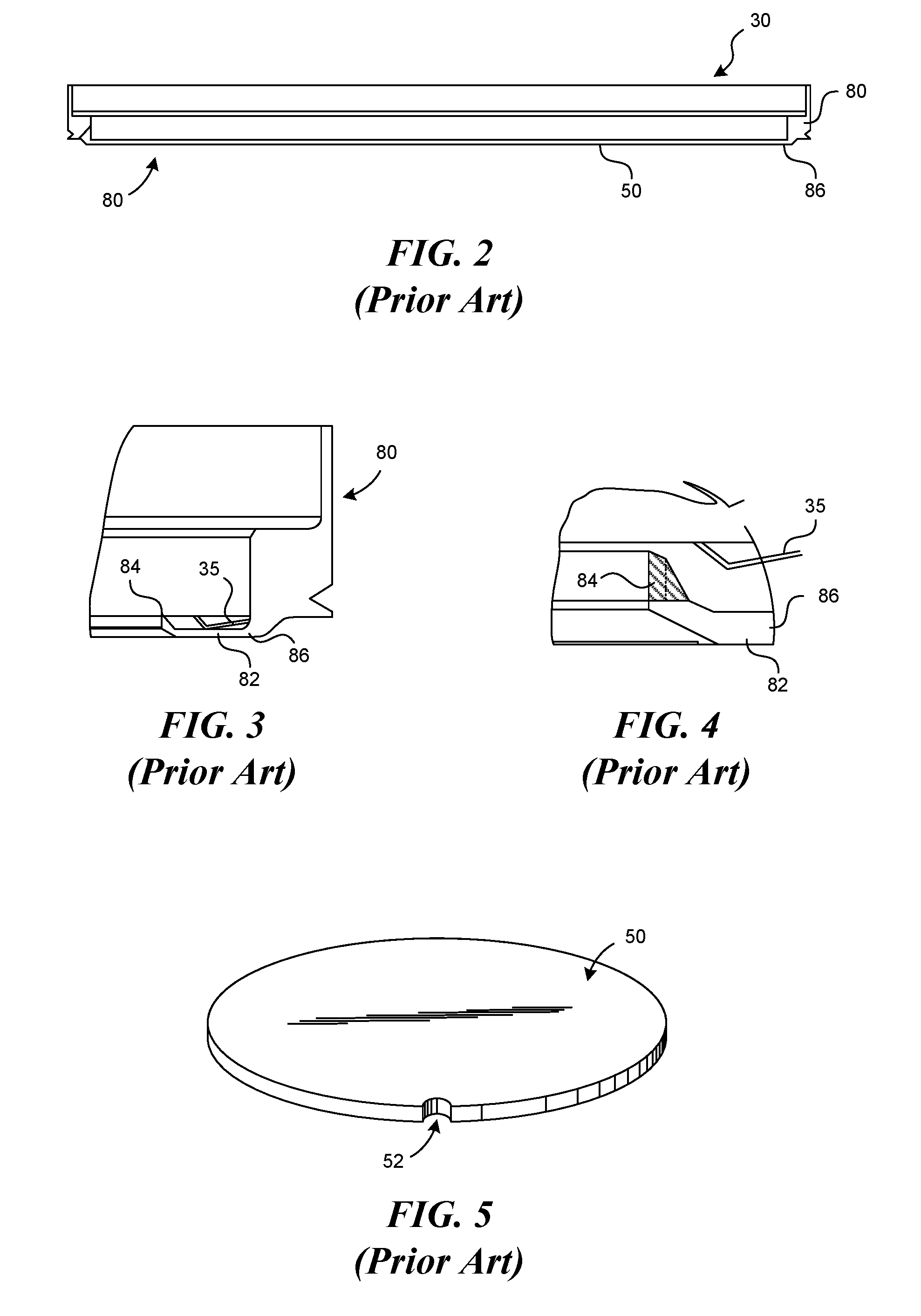

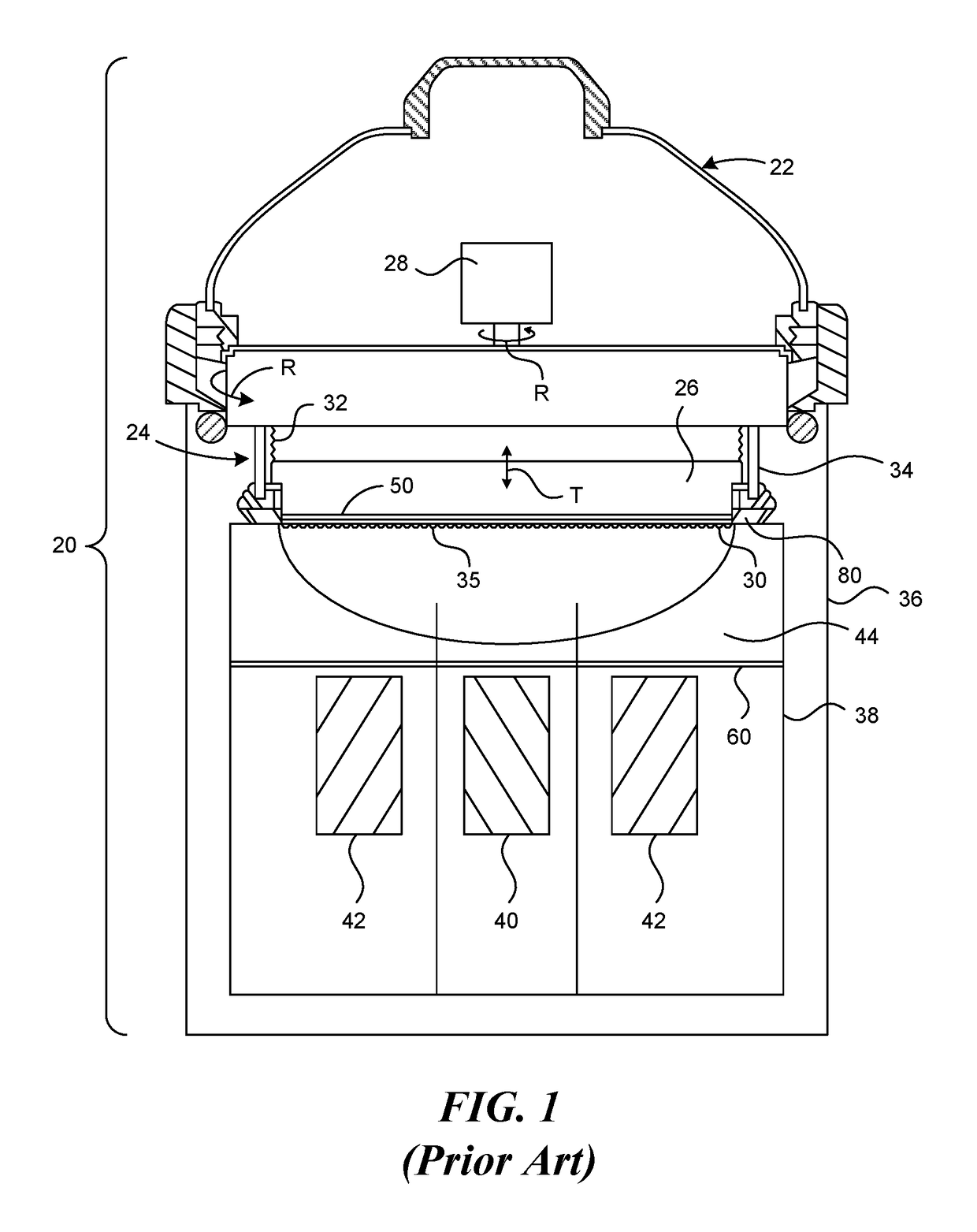

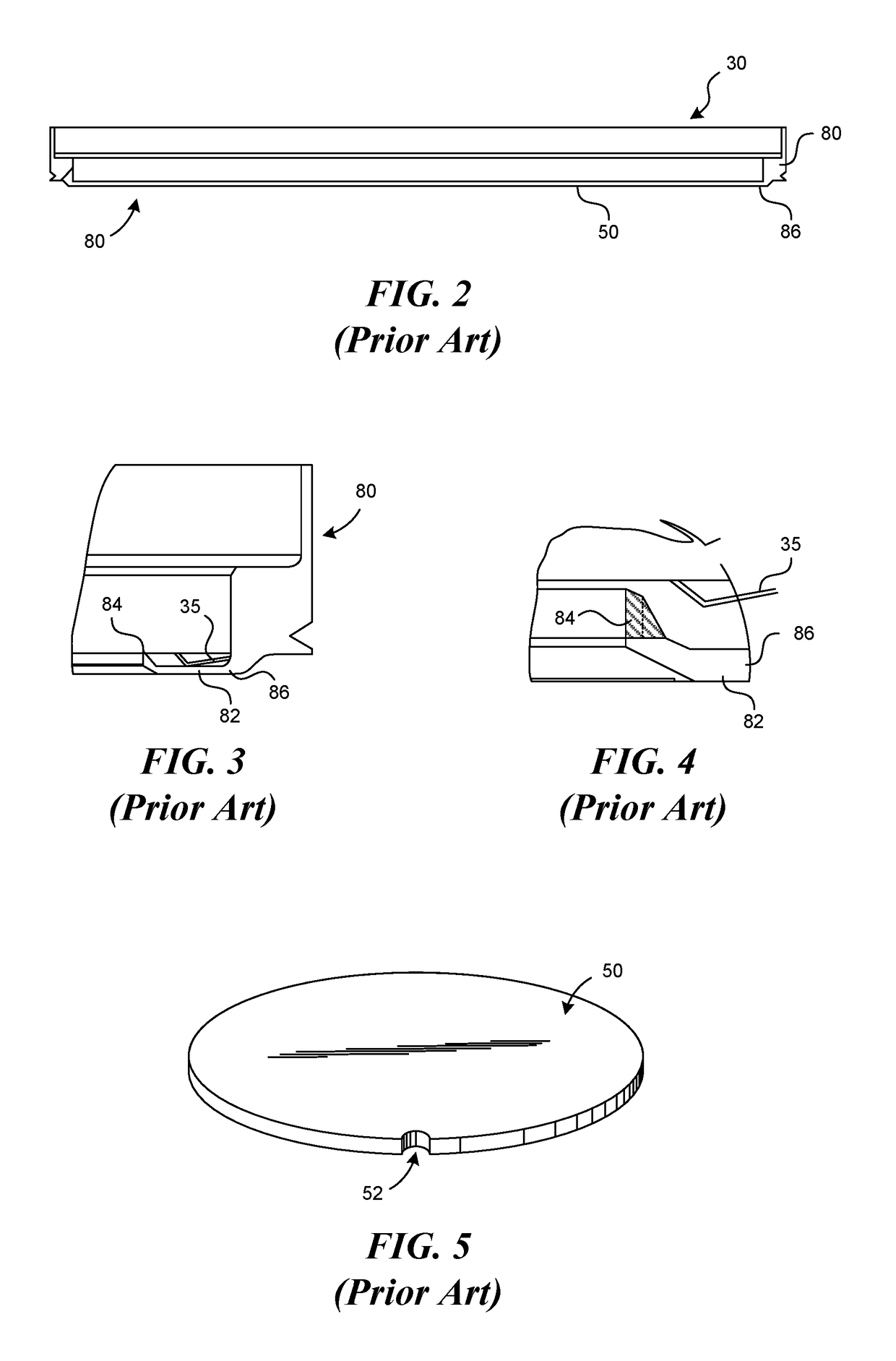

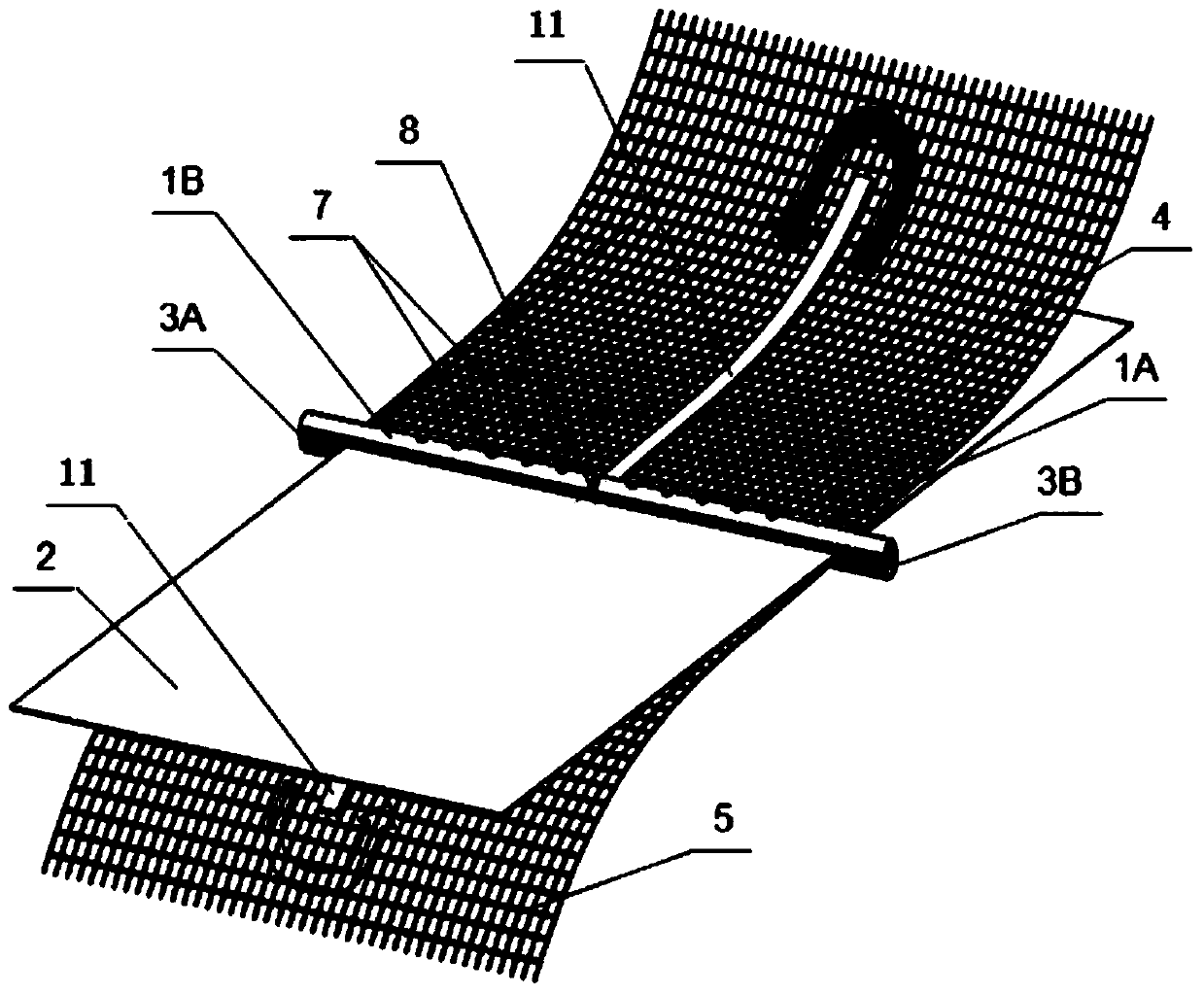

Arrangement and method for providing an air flow within an upholstered seat

InactiveUS6988770B2Large runnerHeating fastSeat heating/ventillating devicesStoolsSolid massEngineering

An arrangement and method for producing an air flow within an upholstered seat back or bottom in which a seat insert has a blower mounted in a pouch at the crotch region between the seat back and bottom and has an outlet which directs air flow up through a spacer layer so as to distribute air flow out through a porous seat back cover or beneath a nonporous cover. A solid plastic backing sheet underlies the spacer layer to direct all air flow out from the spacer layer, the plastic sheet also forming the blower pouch. A mesh layer is bonded to the plastic sheet and used to attach the insert to the seat cushion as well as to carry a heating element pattern extending thereover to also enable electrical heating of the seat back or bottom.

Owner:WITCHIE RONALD G

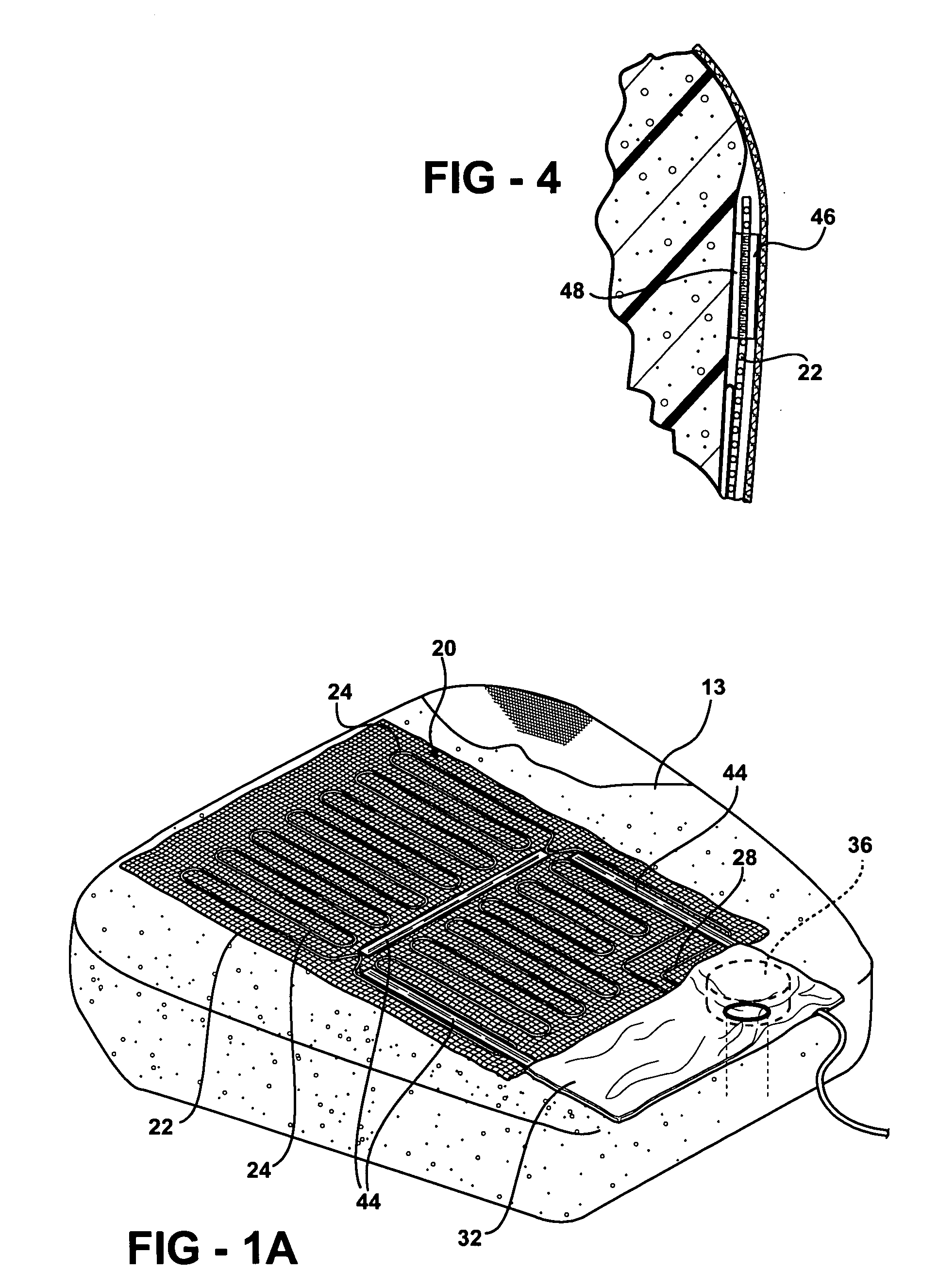

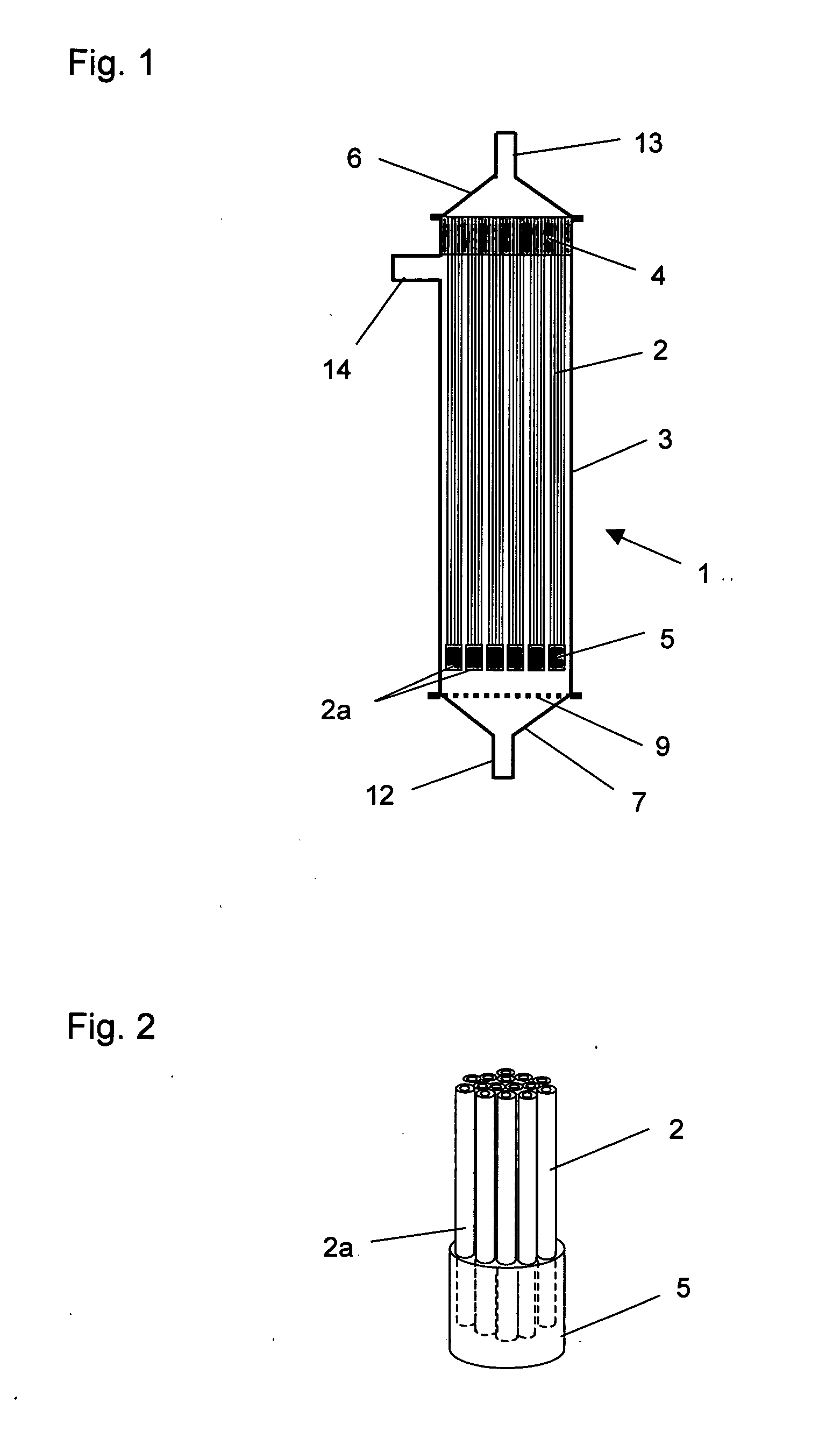

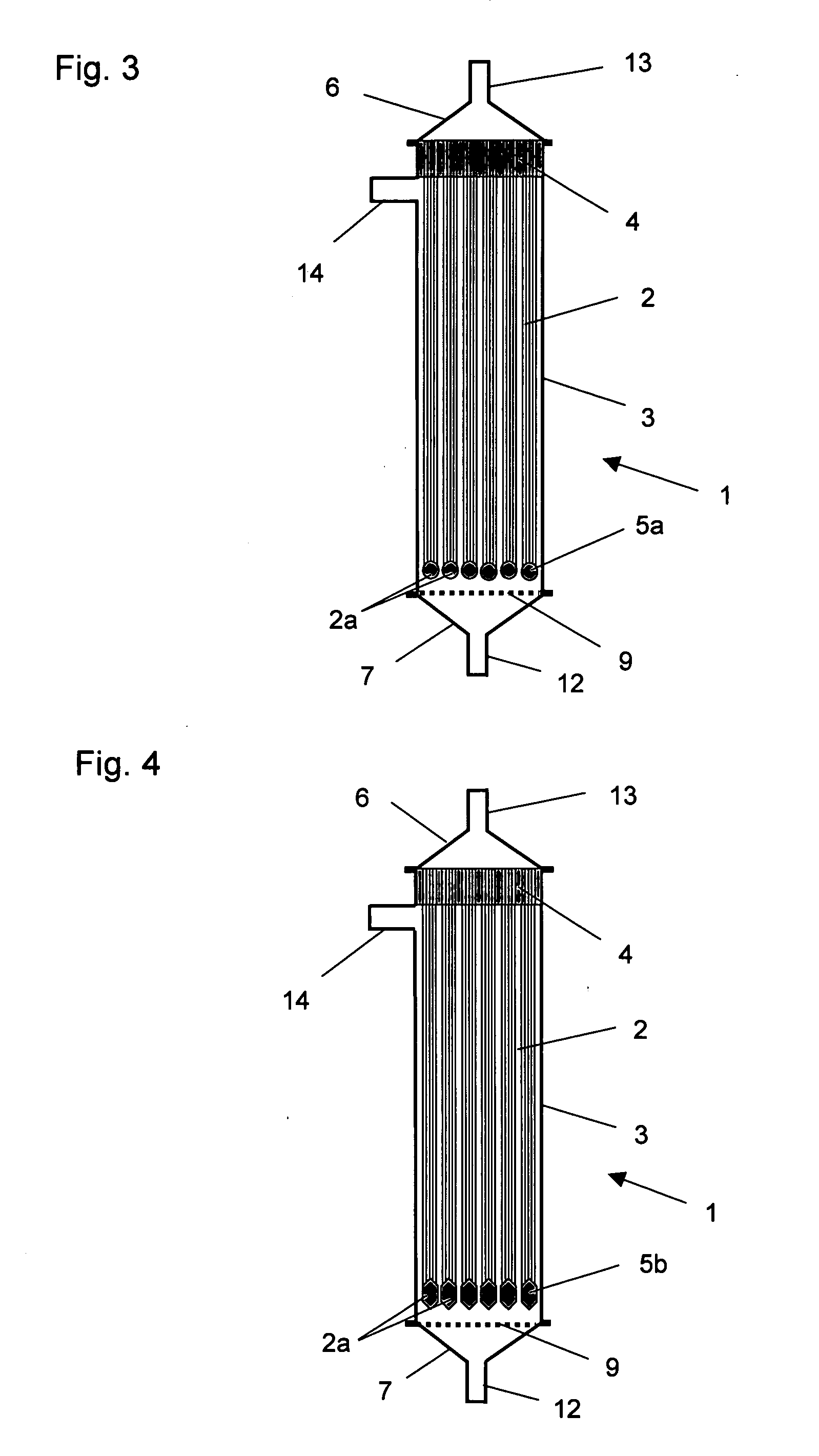

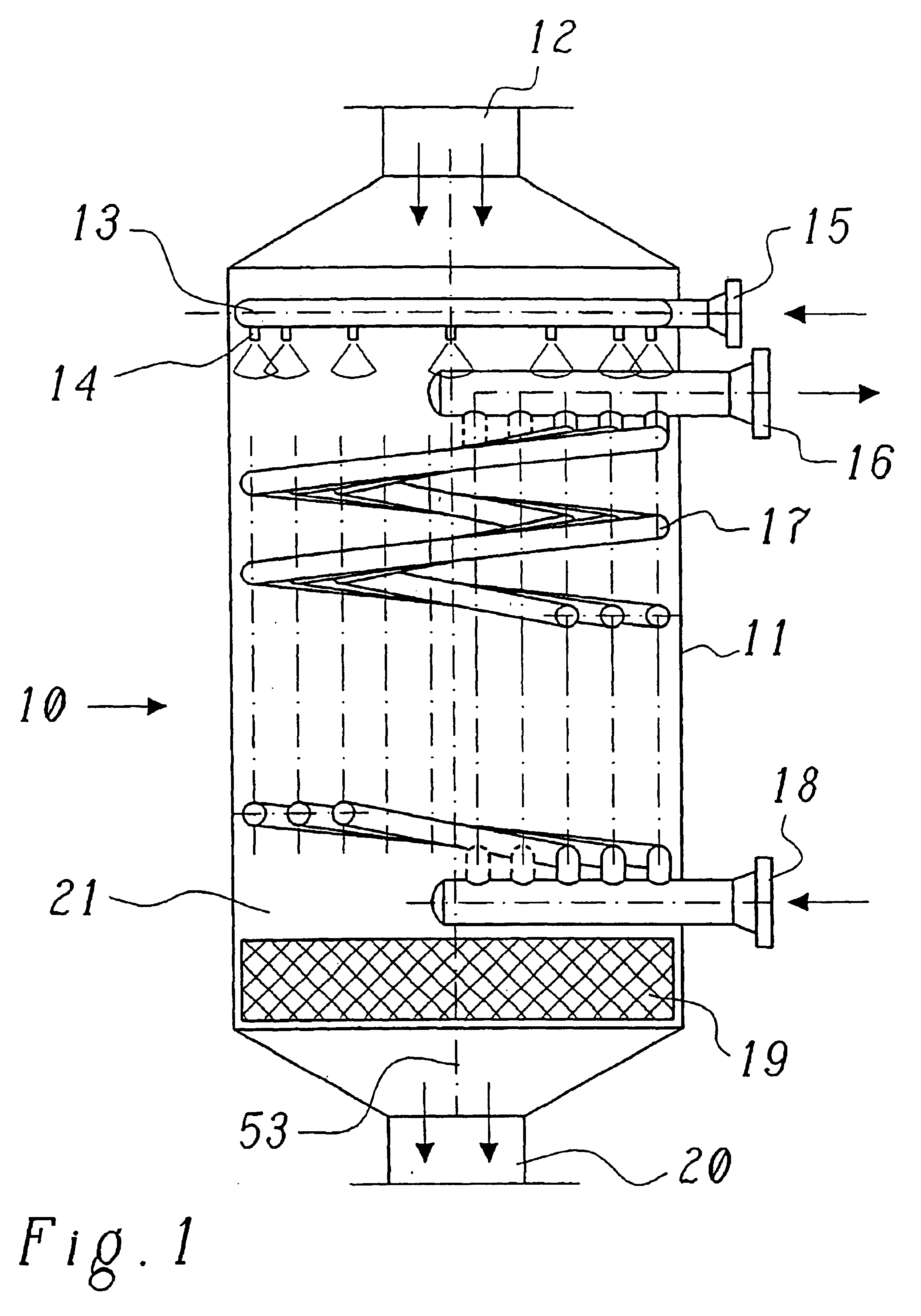

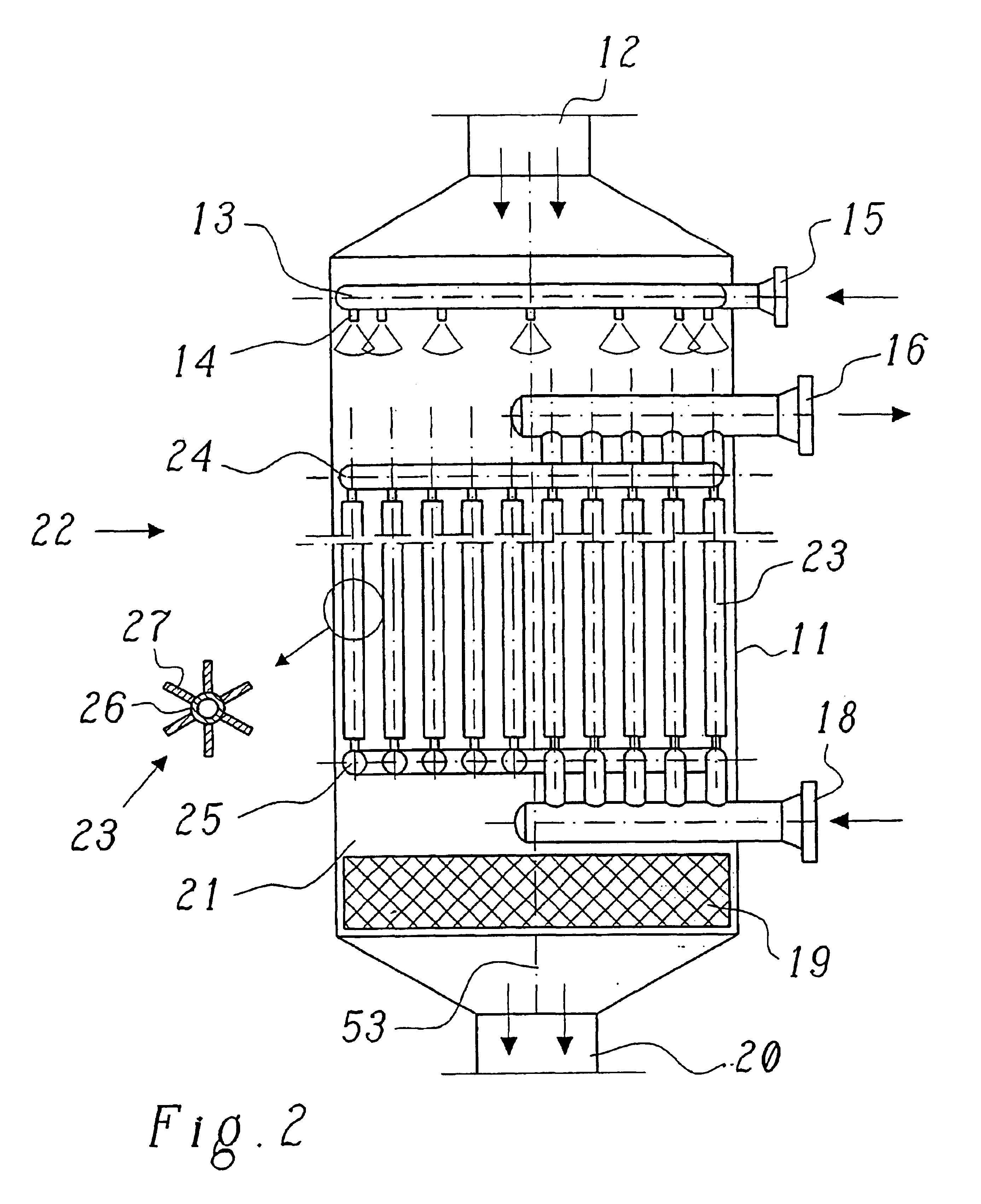

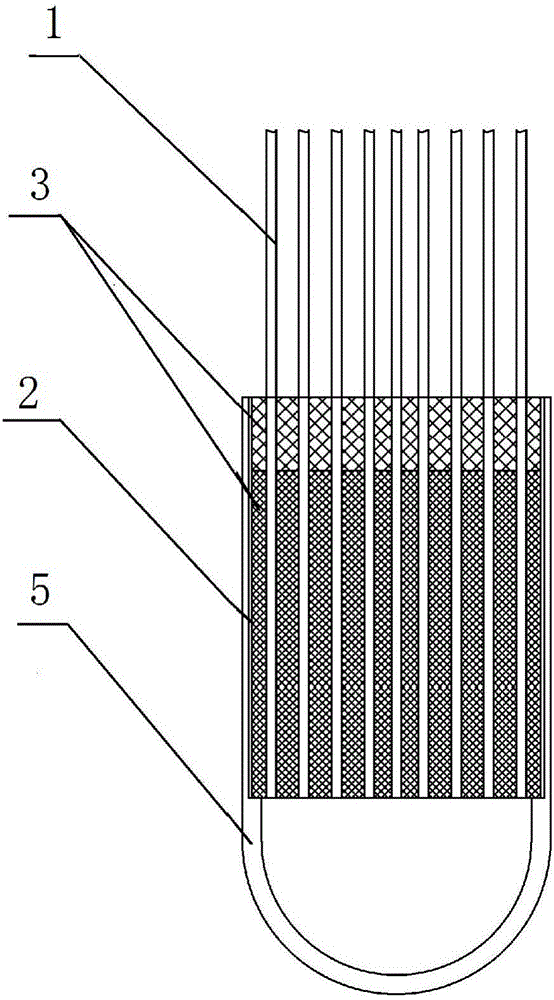

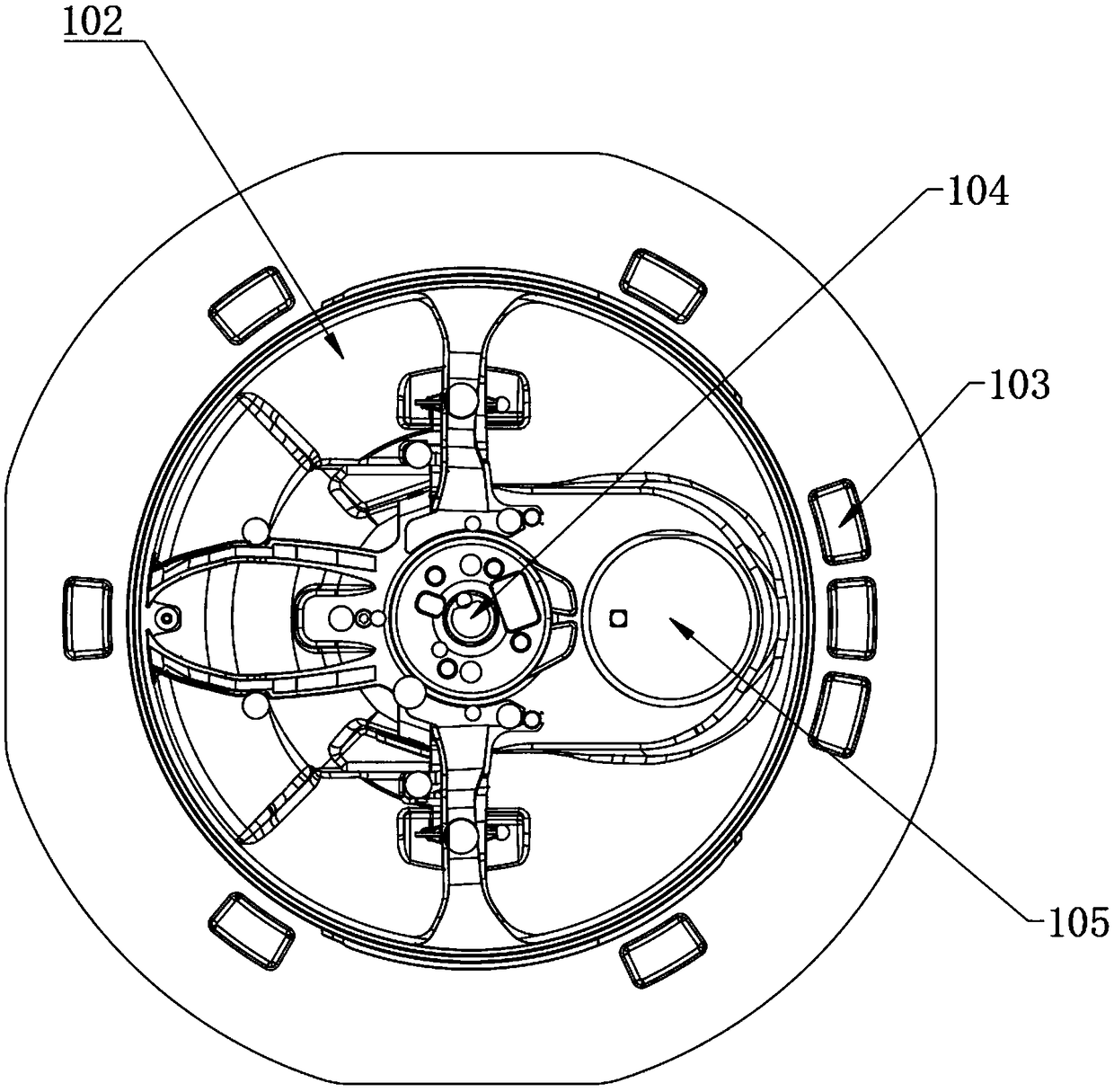

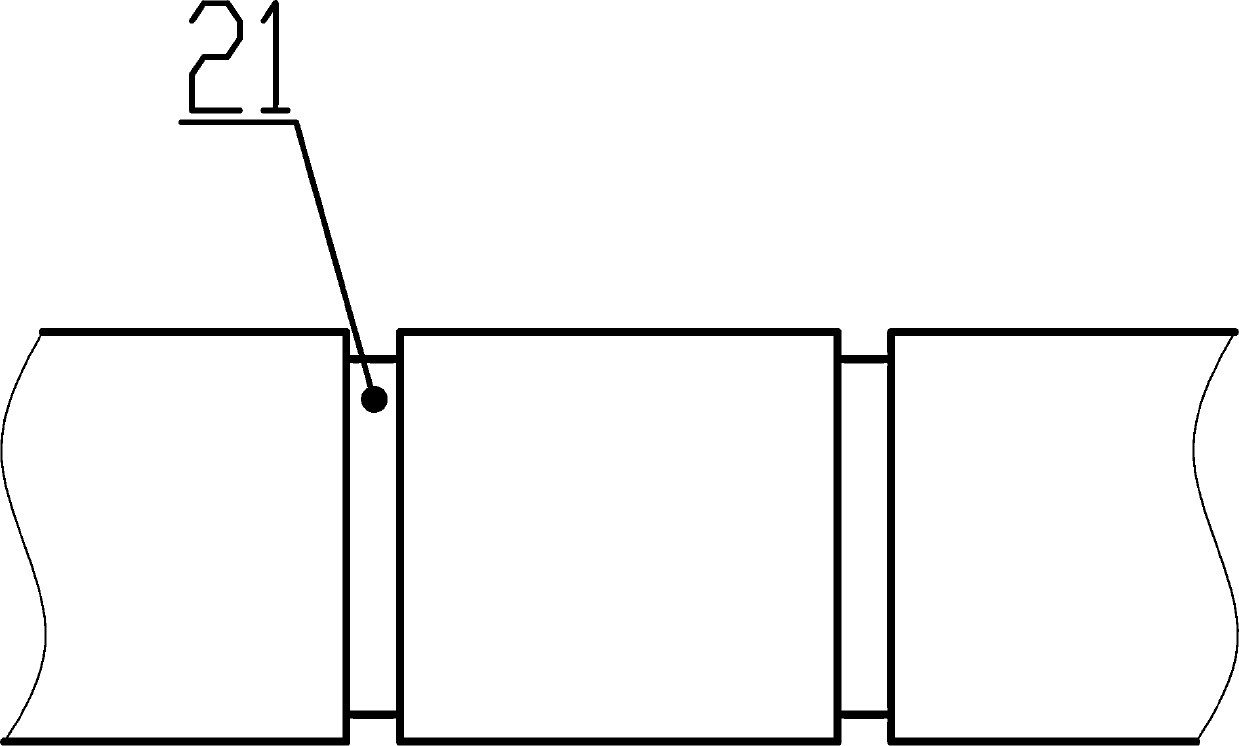

Hollow fiber membrane module

InactiveUS20070163942A1Efficiently removeFacilitate preventingMembranesSemi-permeable membranesMechanical engineeringHollow fiber membrane

A hollow fiber membrane module comprising a large number of hollow fiber membranes contained in a cylindrical case, wherein one end of each hollow fiber membrane, which is left open, is fixed to the cylindrical case, while the other ends of the hollow fiber membranes are divided into more than one small bundles, with the ends, contained in separate small bundles, being kept together and plugged.

Owner:TORAY IND INC

Drip emitter with an independent non-drain valve

An elastomer membrane based, regulated drip emitter unit, equipped with a non-drip valve, wherein the drip emitter is characterized by that it includes an opening that is exposable to an approximate atmospheric pressure that prevails on the water outlet from the drip emitter; and an additional elastomer membrane portion that is strained and biased against the water inlet opening of the drip emitter for creating a seal with its one side for a non-drain valve and on its other (second) side it is connected to that atmospheric pressure prevailing opening, and wherein the elastomer membrane portion is movable towards that opening in order to open the water inlet opening for enabling a water flow passage from a water supply conduit to the drip emitter, and this from the specific instant that the force exerted by the water pressure prevailing in the water supply conduit on one side of that elastomer portion, overcomes the strain at which that portion was strained and biased against the water inlet opening, as well as the approximate atmospheric pressure that prevails on the other side of that elastomer portion.

Owner:RIVULIS PLASTRO LTD

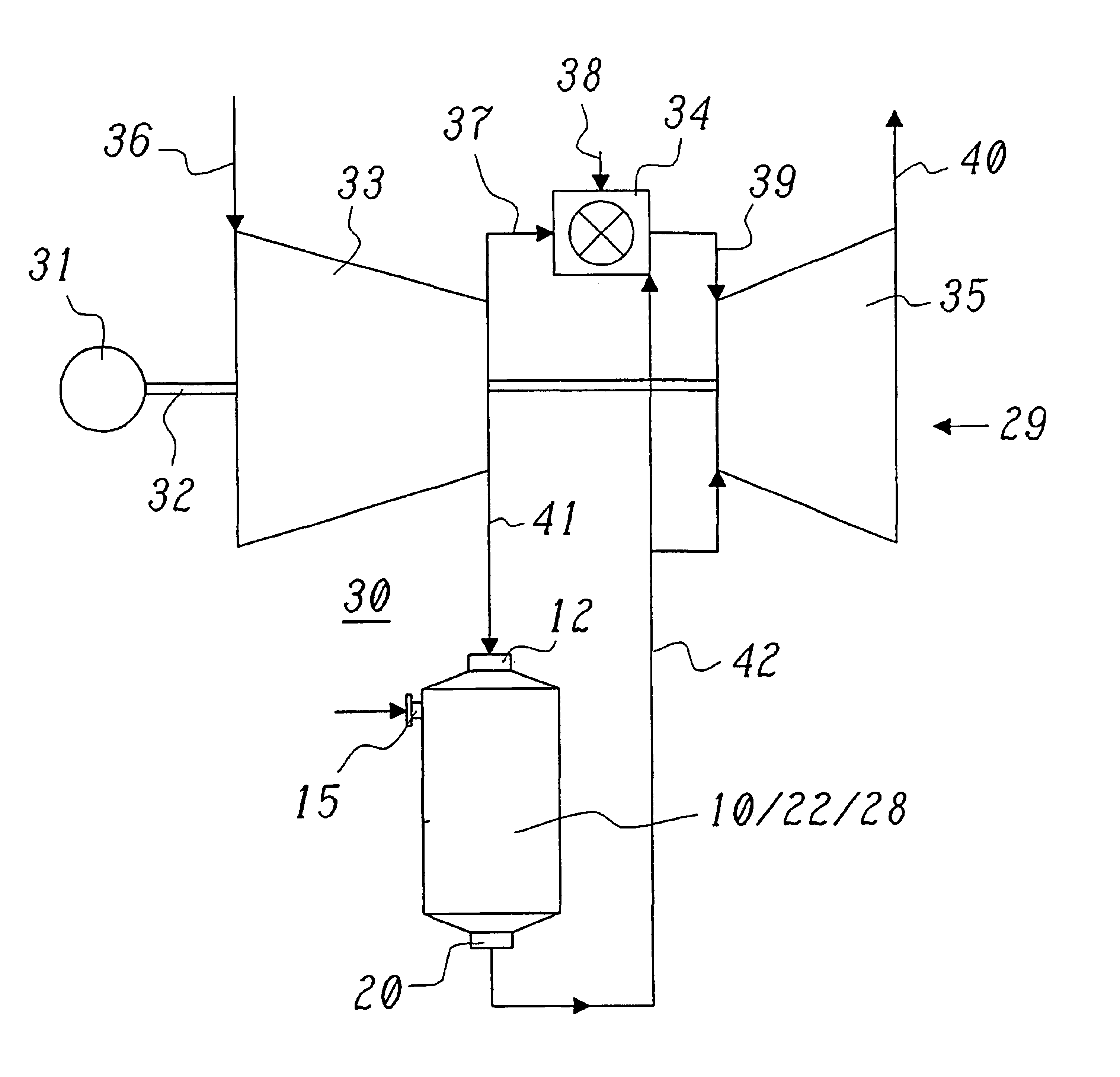

Cooling-air cooler for a gas-turbine plant and use of such a cooling-air cooler

InactiveUS6892523B2Demand is very smallImprove cooling effectTurbine/propulsion engine coolingGas turbine plantsPower stationGas turbines

In a cooling-air cooler for a gas-turbine plant of a power plant, in which cooling-air cooler first means for spraying water into the cooling-air flow and second means for generating steam are arranged in a pressure vessel, through which the cooling air flows, between a cooling-air inlet and a cooling-air outlet in the cooling-air flow, simplified operation is achieved in that a water separator is provided on the cooling-air side in the direction of flow downstream of the first means.

Owner:ALSTOM TECH LTD

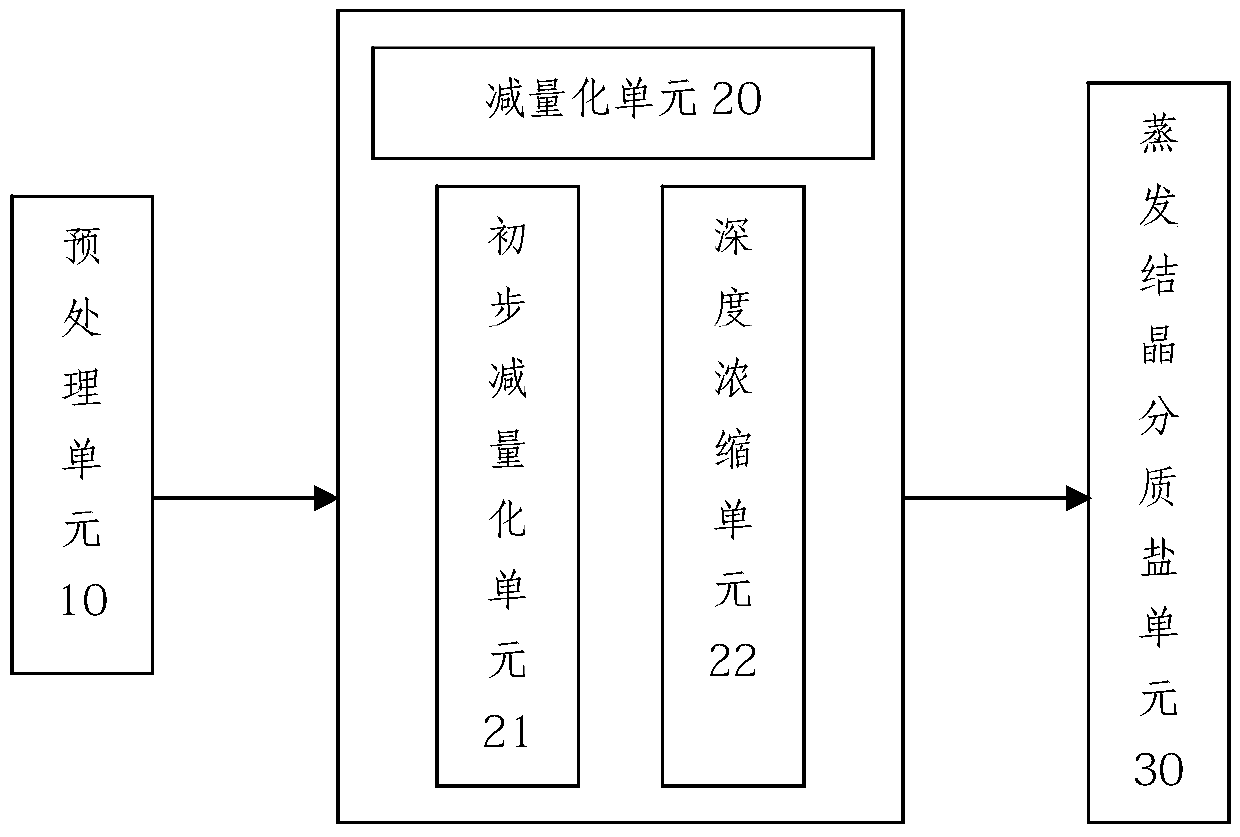

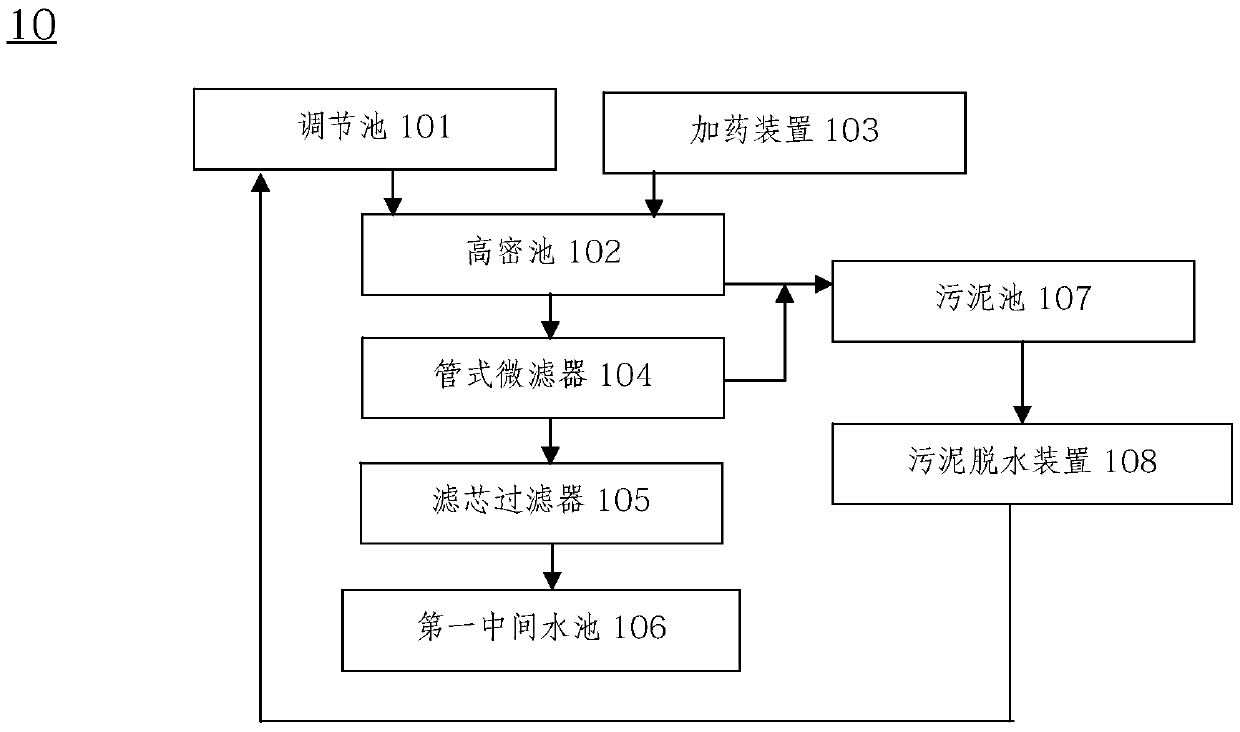

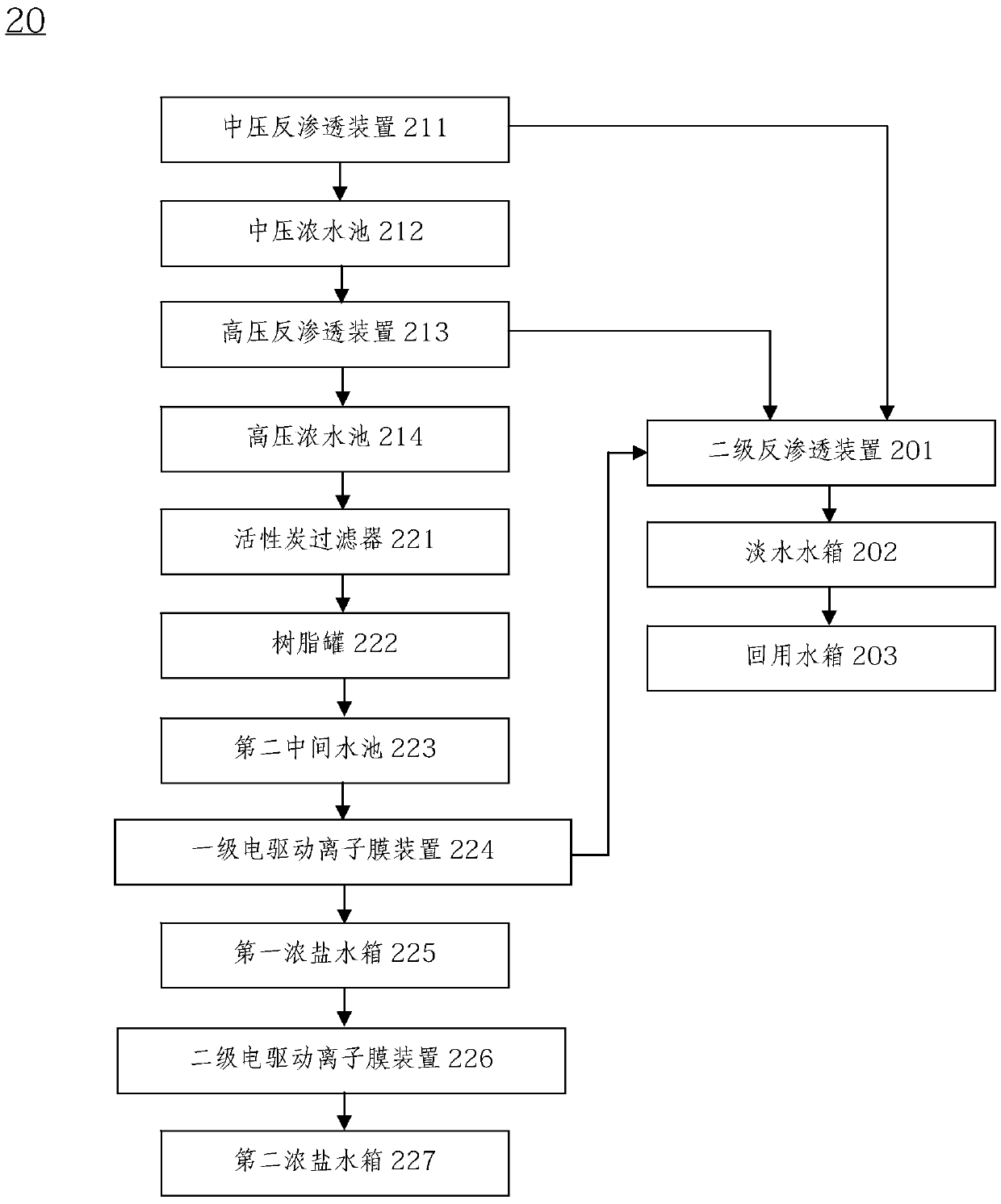

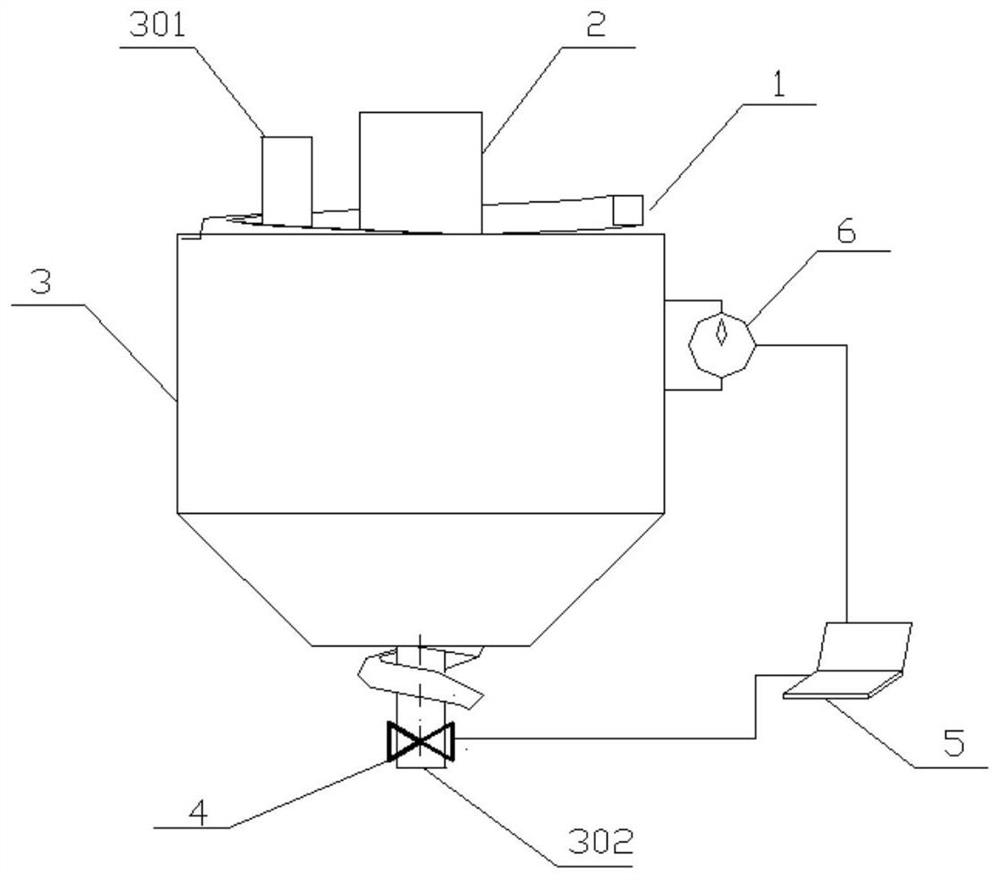

Zero emission treatment method of high-salinity wastewater

ActiveCN105502787AAdvantages of zero-discharge treatment methodsReduce processing costsTreatment involving filtrationMultistage water/sewage treatmentPositive pressureReverse osmosis

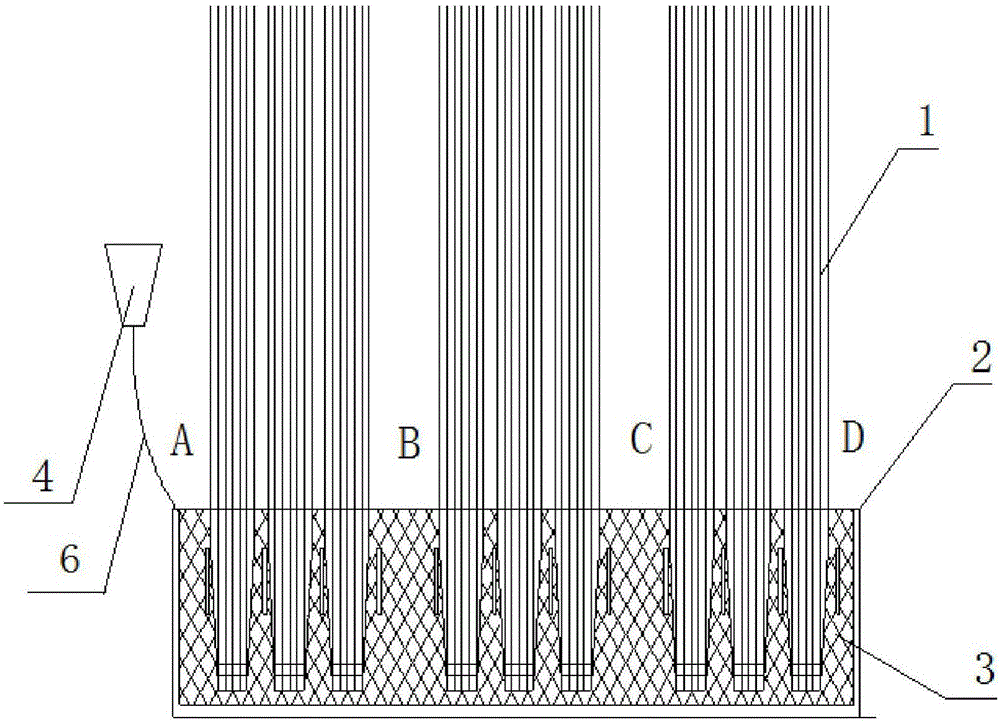

The invention relates to a zero emission treatment method of high-salinity wastewater. The method comprises a pre-treatment technology of wastewater, a reduction technology of the wastewater and an evaporative crystallization technology of the high-salinity wastewater, wherein the pre-treatment technology is implemented as follows: a flocculation and / or sedimentation chemical agent is added, heavy metal ions, hard ions and organic substances in the high-salinity wastewater are removed from a chemical reactor, and the pH of the wastewater is adjusted until the wastewater is alkaline; the reduction technology is implemented as follows: the pretreated wastewater is subjected to preliminary reduction treatment through a medium-pressure reverse osmosis device and a high-pressure reverse osmosis device to form high-pressure reverse osmosis concentrated water, the high-pressure reverse osmosis concentrated water is subjected to deep concentration treatment through a primary electric drive ionic membrane device and a secondary electric drive ionic membrane device, high-salinity concentrated water is obtained through concentration, and producing water in the reduction process is recovered to a recycling water tank; the evaporative crystallization technology is implemented as follows: salts in the high-salinity concentrated water are recovered under the negative pressure or micro-positive pressure condition through a nitrate evaporative crystallization device and a salt evaporative crystallization device, and sodium sulfate and sodium chloride are formed.

Owner:BGT GRP CO LTD

Adhesive sealing method and packaging device for hollow fiber curtain type membrane element

The invention relates to an adhesive sealing method for a hollow fiber curtain type membrane element. A hollow fiber membrane tow, a box, sealant and a membrane box are included. The method includes the steps that a plurality of hollow fiber membrane yarns are bundled to form the tow; the bottom of the hollow fiber membrane tow is tied up and cut flat, and the whole tow is hung on a tool; inner holes of the hollow fiber membrane yarns are plugged by hole plugging substances; the box is horizontally arranged on the tool, the hollow fiber membrane tow is inserted to the bottom of the box, and the hollow fiber membrane tow is well fixed; the sealant is injected into the box; the other end of the hollow fiber membrane tow is manufactured by repeating the steps; the membrane element obtained after the sealant is cured is cut, so that membrane yarn holes are smooth, then the membrane element is inserted into a cavity of the membrane box, the cavity is filled with sealant, and the membrane element is attached. The invention further relates to a packaging device formed through the method. The method and the device have the advantages that operation is easy, cost is low, production efficiency is high, product quality is high and the method and the device are suitable for large-scale production.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

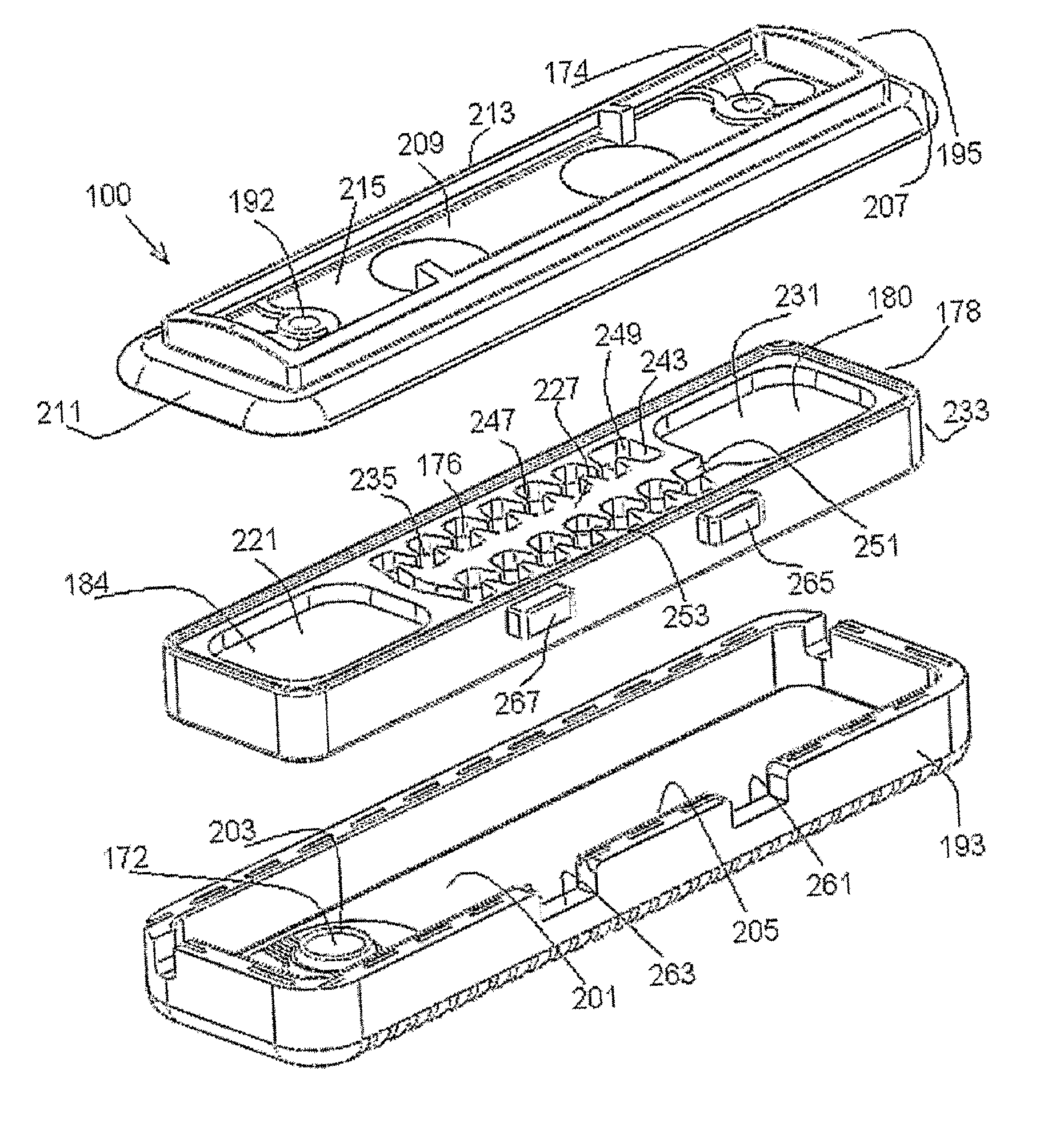

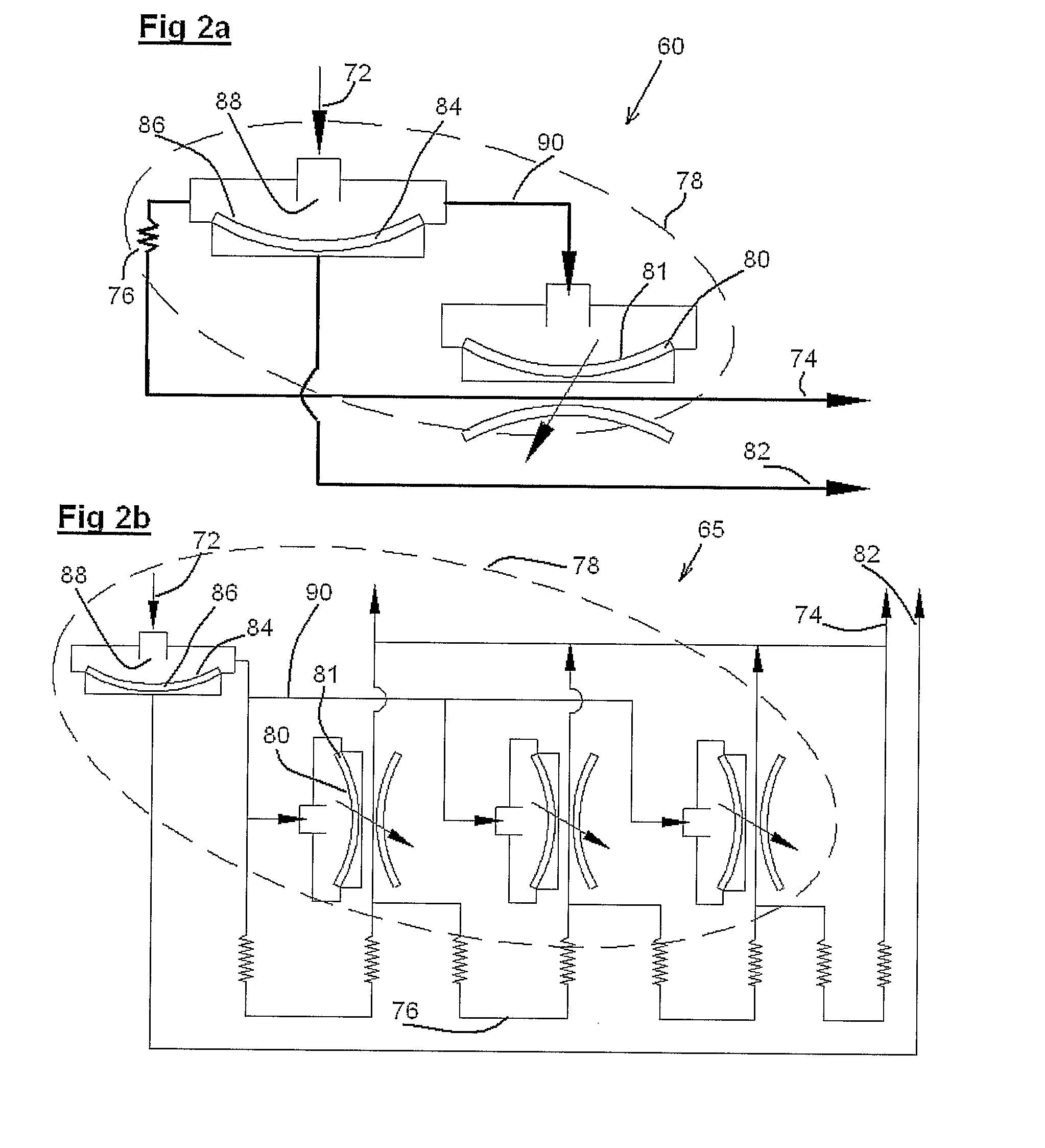

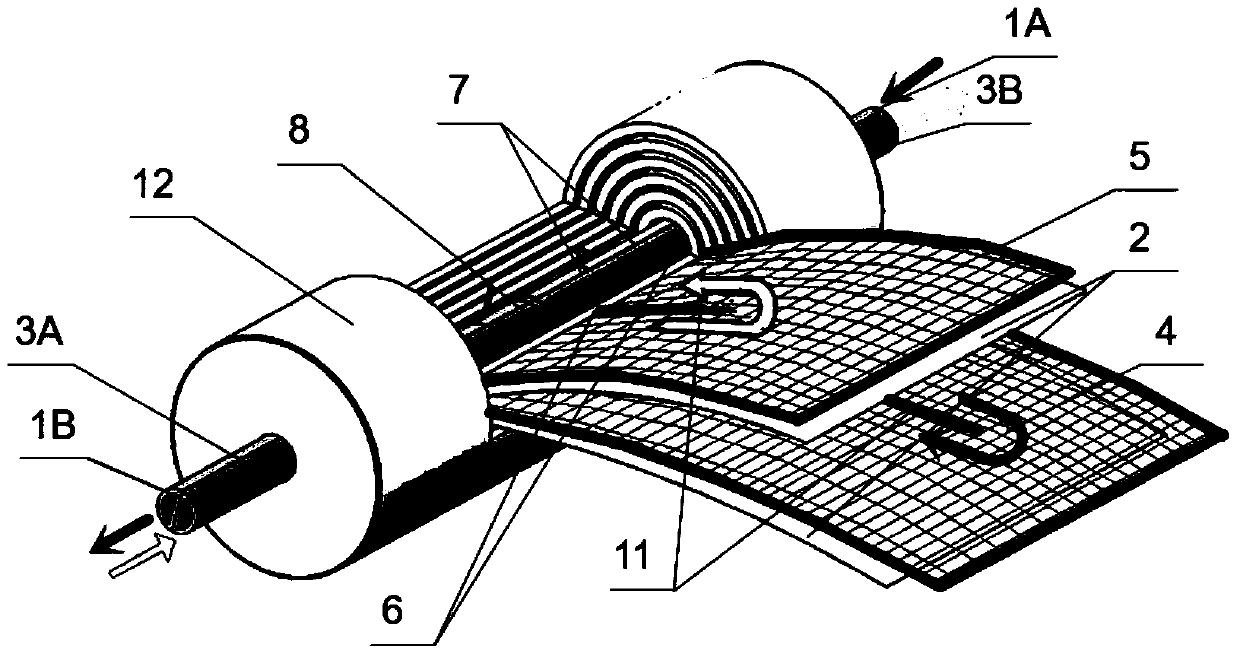

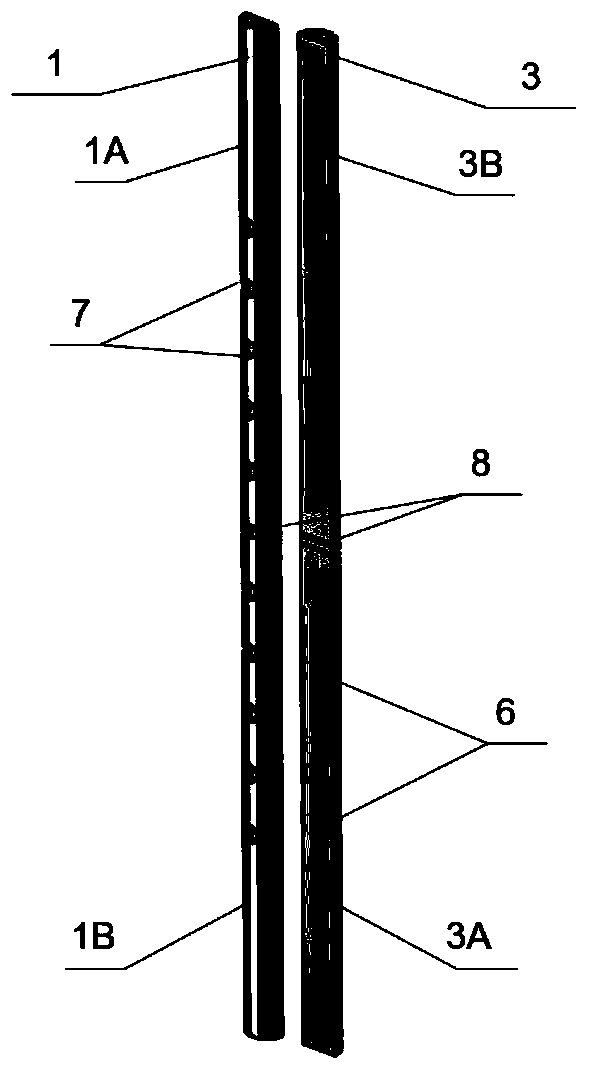

Arrangement and method for providing an air flow within an upholstered seat

InactiveUS20050093346A1Heating fastLarge runnerSeat heating/ventillating devicesStoolsIsolation layerEngineering

An arrangement and method for producing an air flow within an upholstered seat back or bottom in which a seat insert has a blower mounted in a pouch at the crotch region between the seat back and bottom and has an outlet which directs air flow up through a spacer layer so as to distribute air flow out through a porous seat back cover or beneath a nonporous cover. A solid plastic backing sheet underlies the spacer layer to direct all air flow out from the spacer layer, the plastic sheet also forming the blower pouch. A mesh layer is bonded to the plastic sheet and used to attach the insert to the seat cushion as well as to carry a heating element pattern extending thereover to also enable electrical heating of the seat back or bottom.

Owner:WITCHIE RONALD G

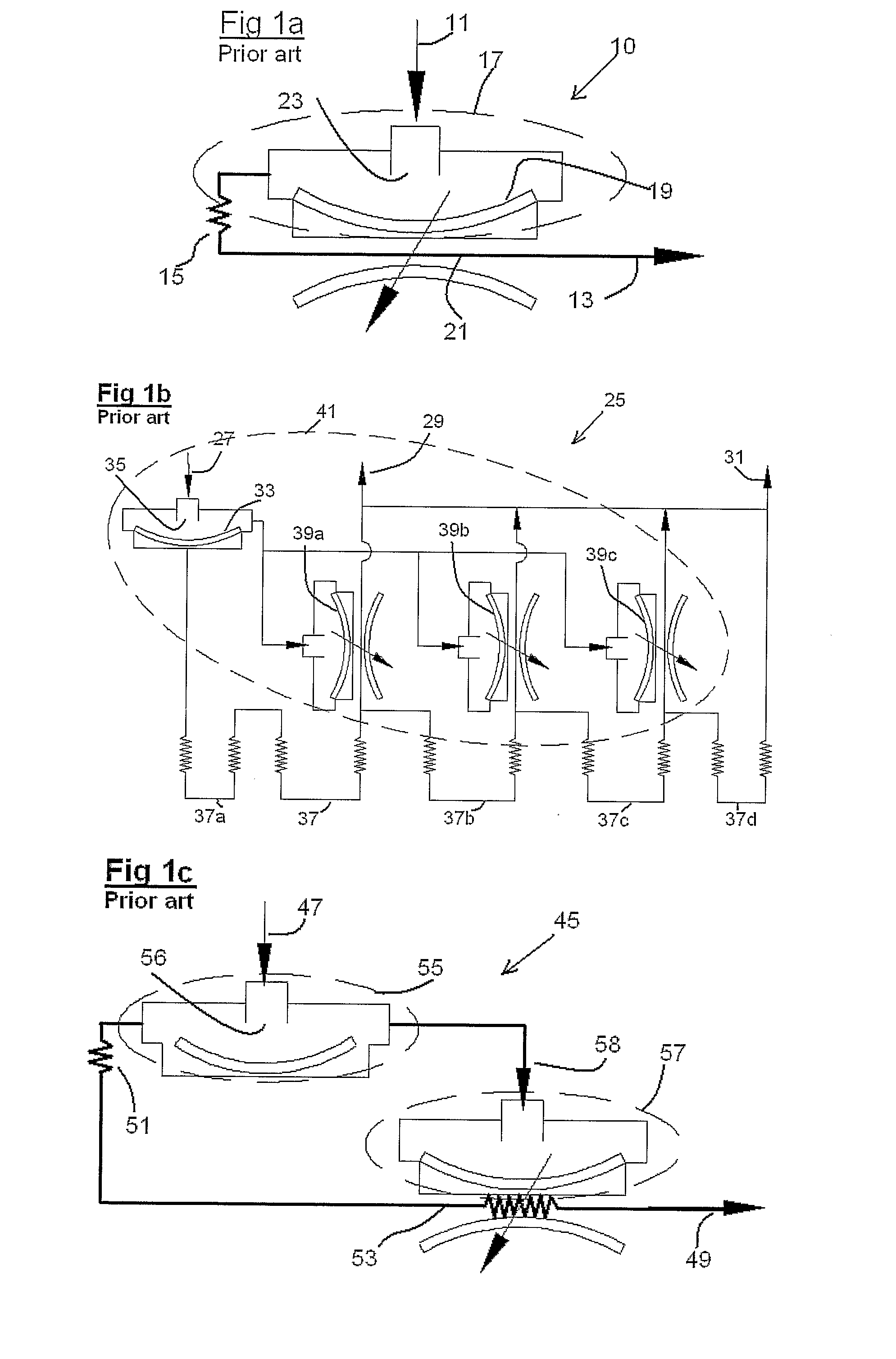

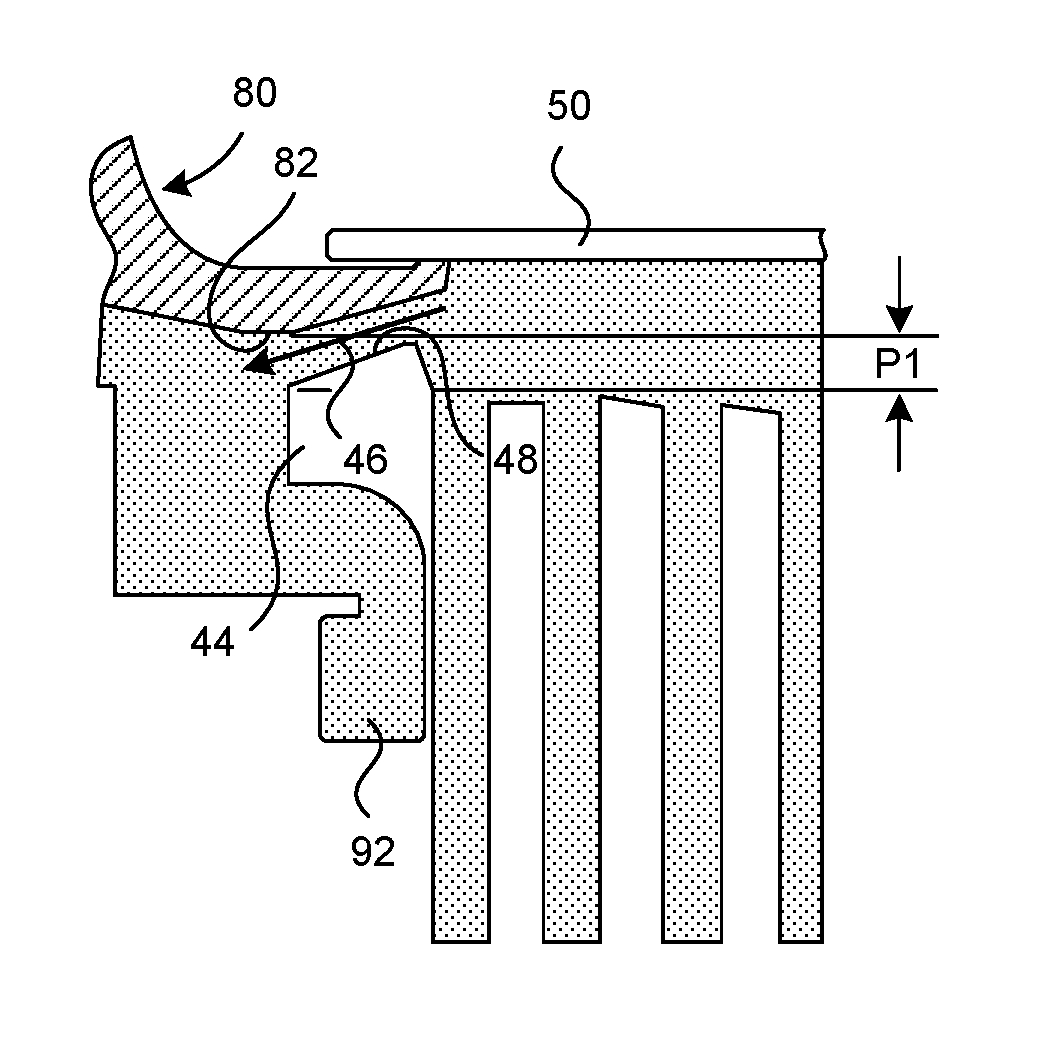

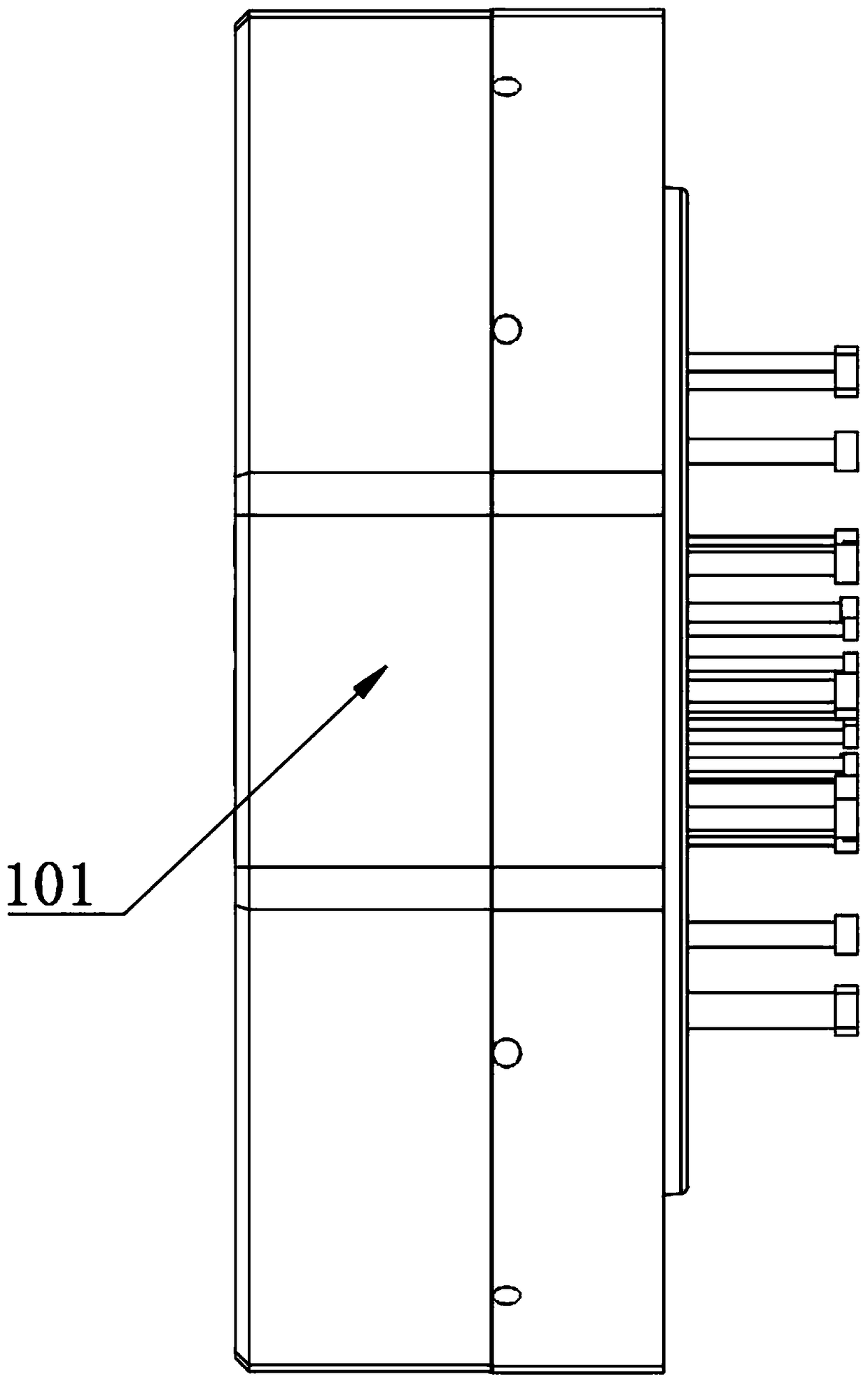

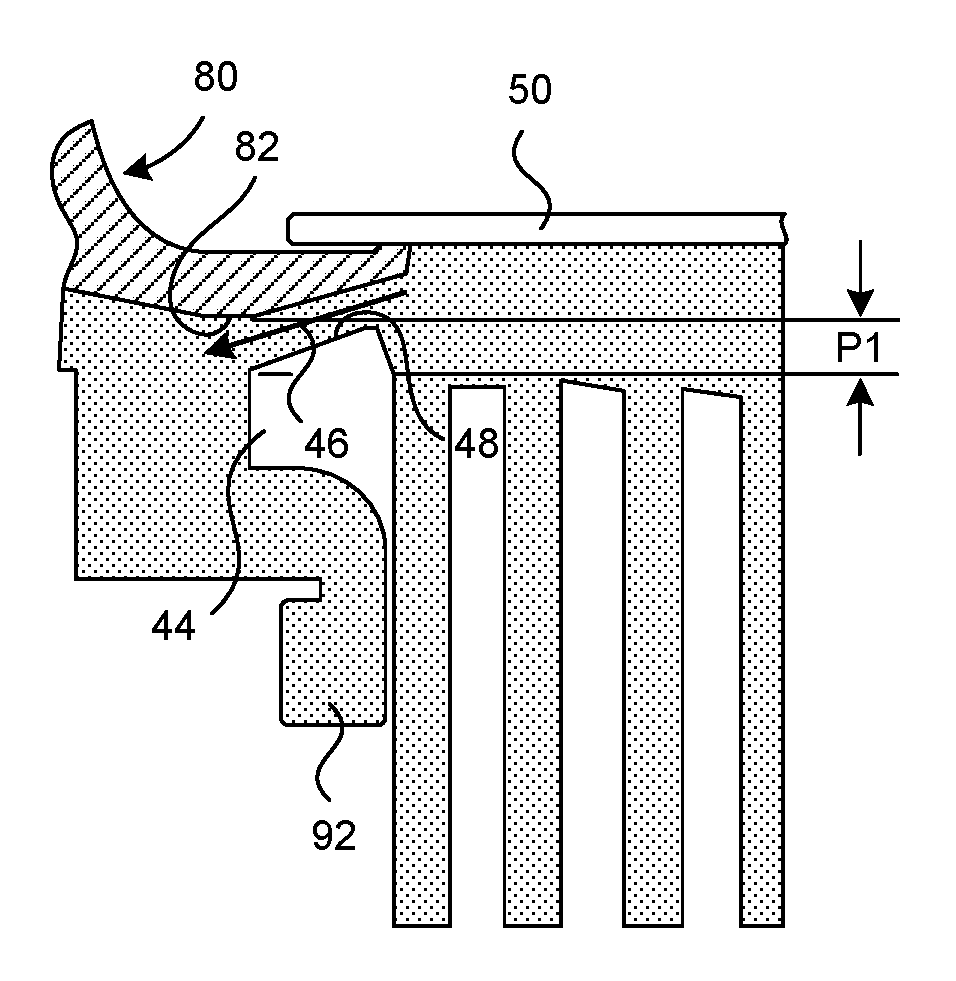

Electroplating apparatus with notch adapted contact ring seal and thief electrode

ActiveUS20160215409A1Large runnerIncrease exposureCellsContacting devicesElectrical resistance and conductanceShape change

An electro-processing apparatus has a contact ring including a seal which is able to compensate for electric field distortions created by a notch (or other irregularity) on the wafer or work piece. The shape of the contact ring at the notch is changed, to reduce current crowding at the notch. The change in shape changes the resistance of the current path between a thief electrode and the wafer edge to increase thief electrode current drawn from the region of the notch. As a result, the wafer is plated with a film having more uniform thickness.

Owner:APPLIED MATERIALS INC

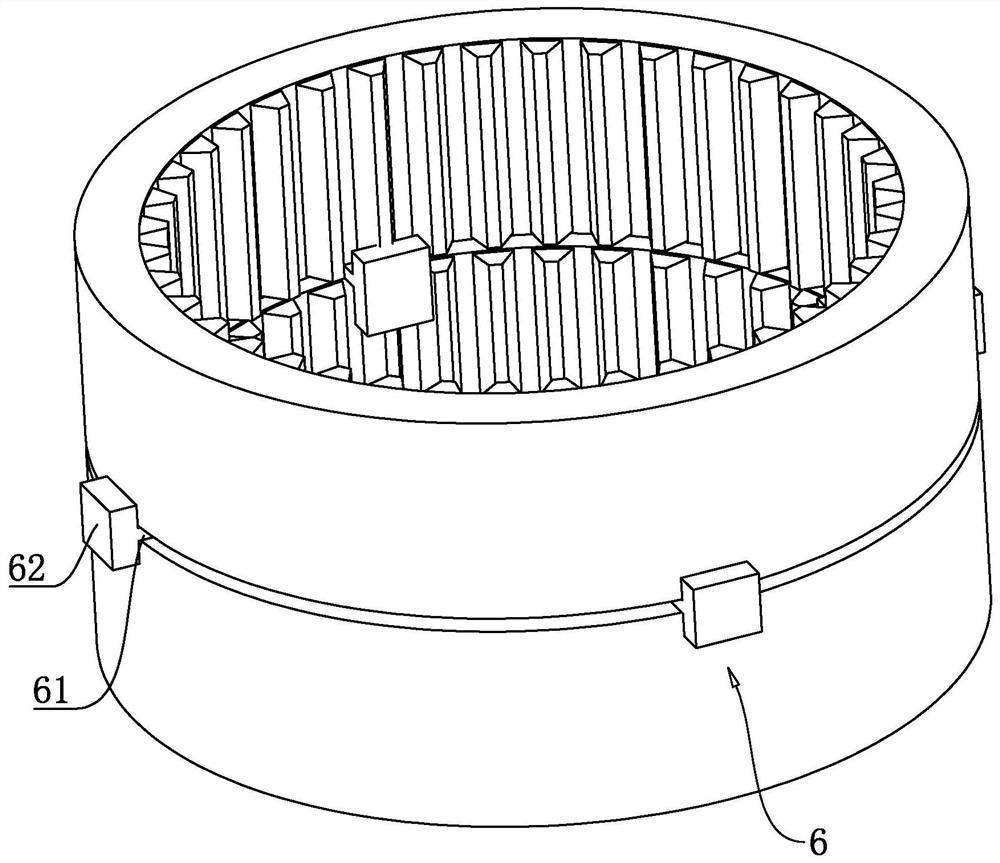

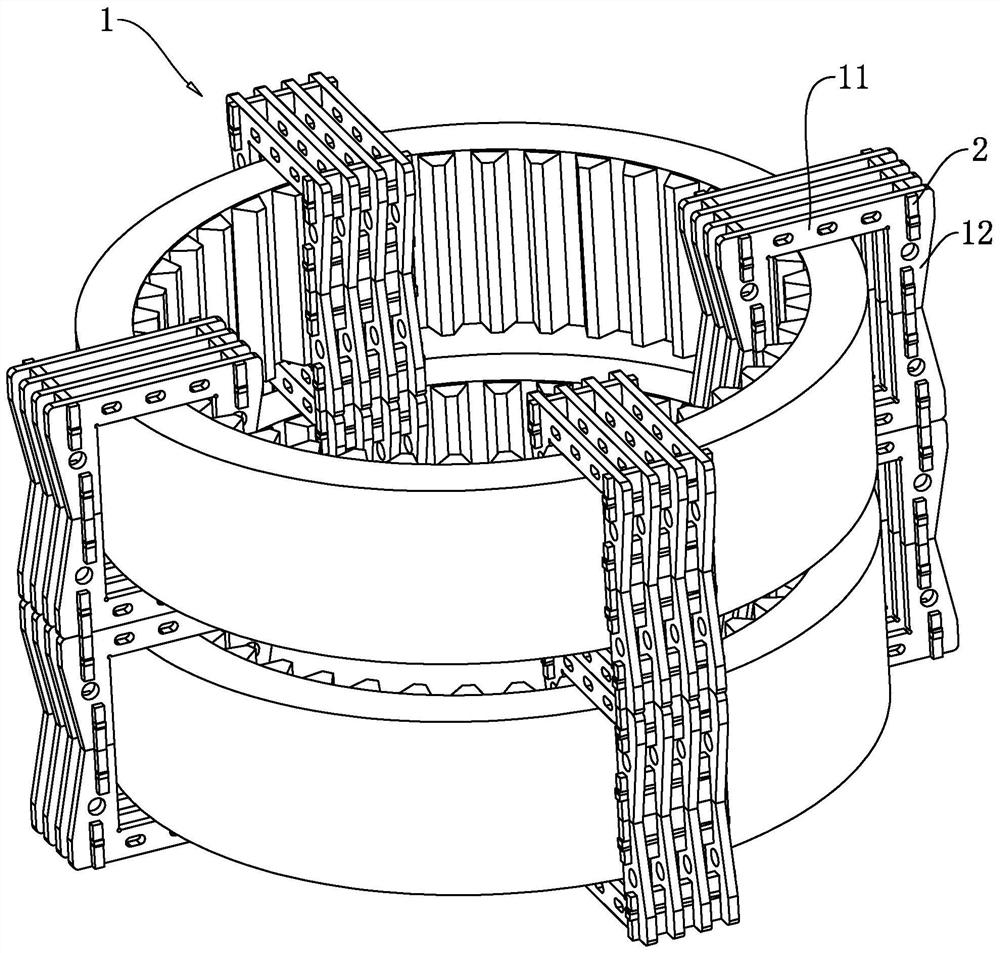

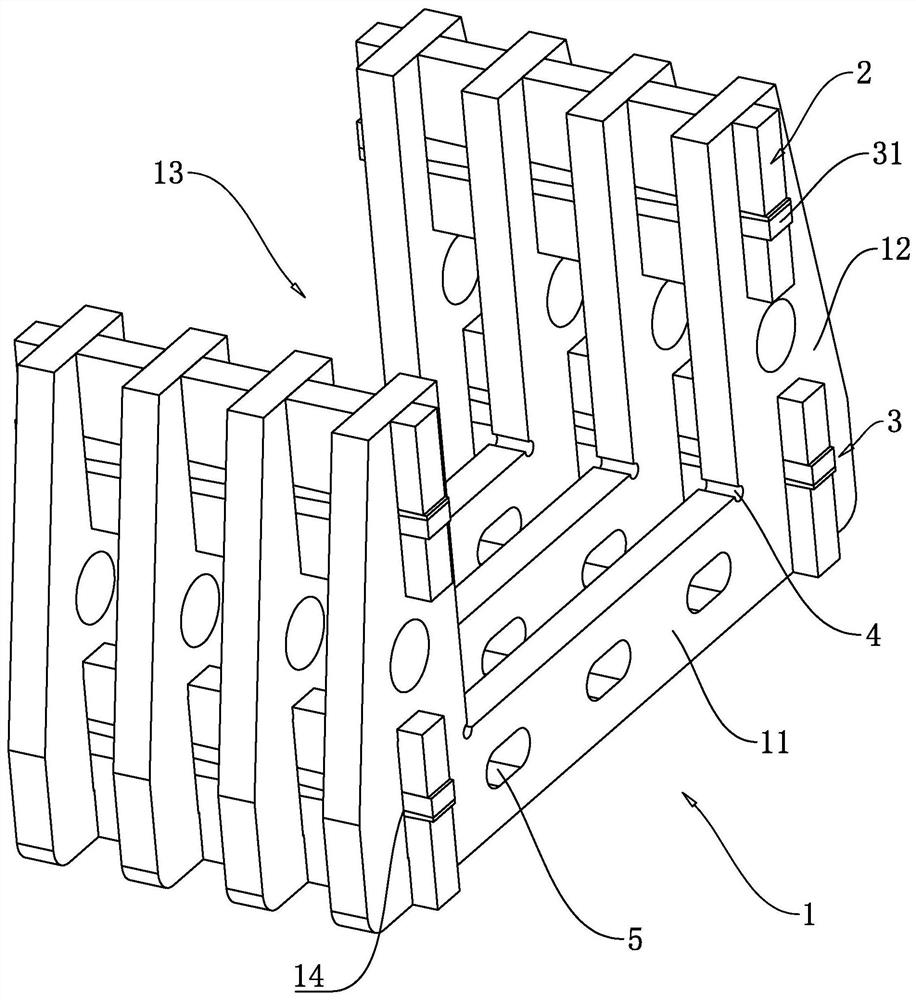

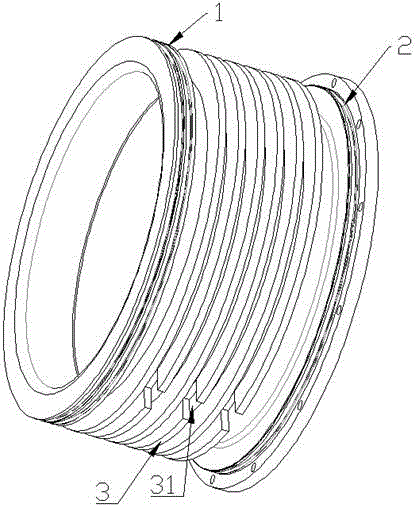

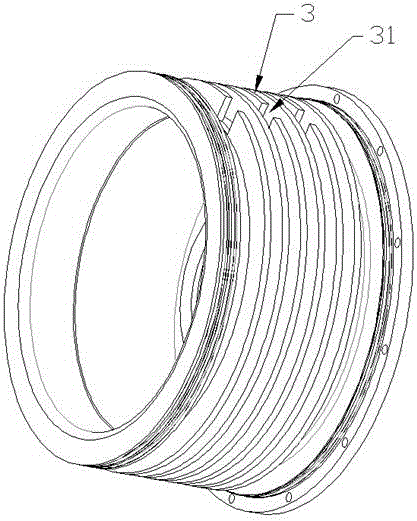

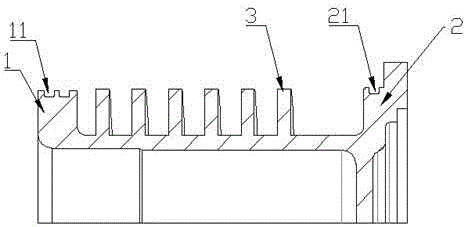

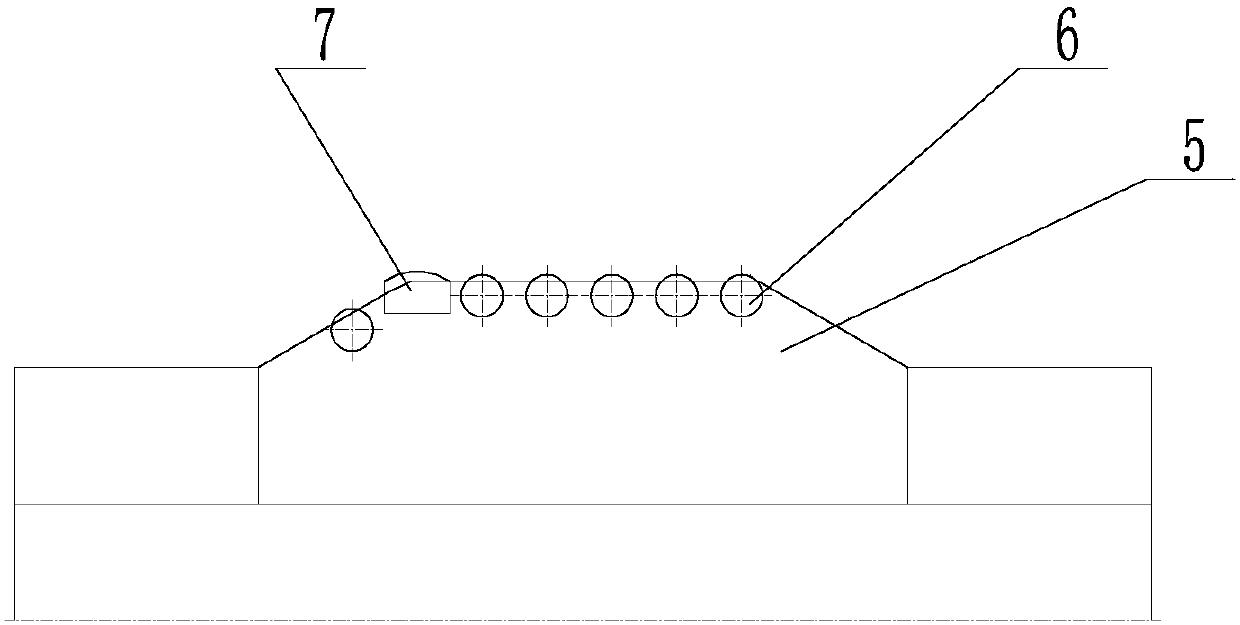

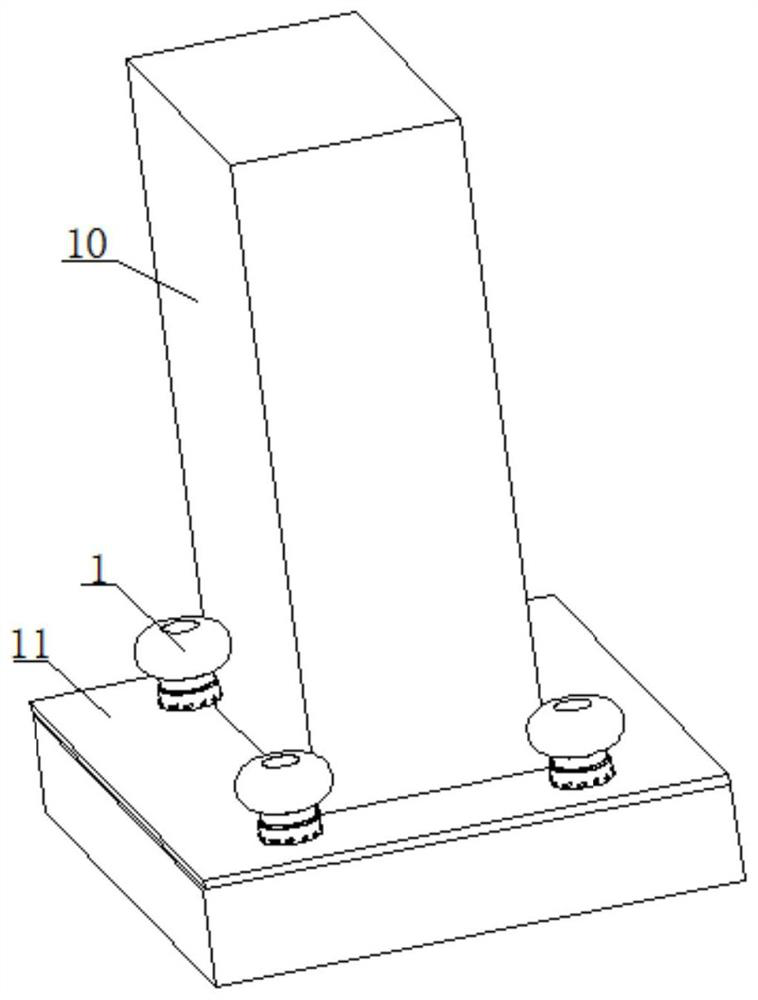

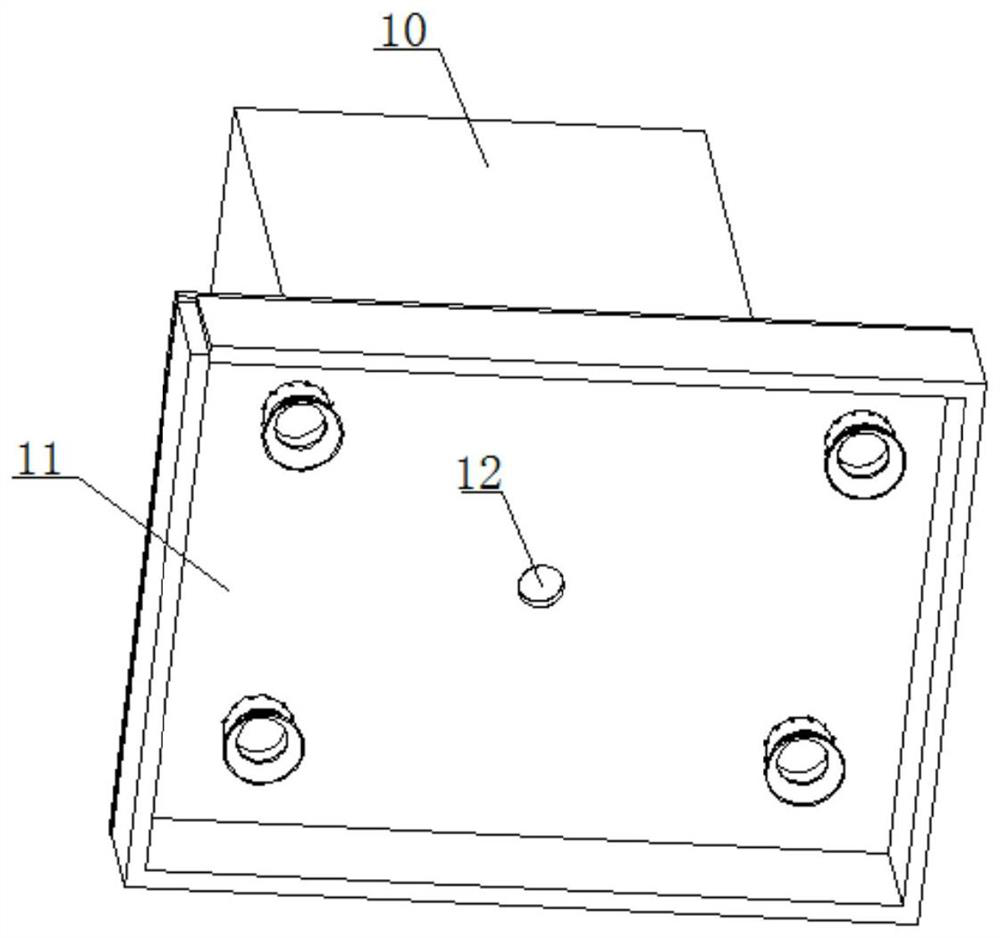

Assembly type cushion for heat treatment of ring workpieces

PendingCN112126769AExtended service lifeNot easy to loosenFurnace typesHeat treatment furnacesEngineeringHeat stress

The invention relates to an assembly type cushion for heat treatment of ring workpieces, and belongs to the technical field of heat treatment auxiliary tools. The assembly type cushion comprises a plurality of supporting plates arranged side by side, wherein each supporting plate comprises a supporting base and supporting stand columns fixed to the two ends of the supporting base; a containing space is formed between the supporting base and the supporting stand columns; assembly holes are formed in the supporting stand columns; and at least one rib plate used for connecting the plurality of supporting plates is inserted in the assembly holes. The supporting plates are arranged in an assembly type, heat stress is not likely to be generated at the joints of the supporting stand columns and the supporting bases, the tearing phenomenon at the joints of the supporting stand columns and the supporting bases is reduced, and therefore the service life of the supporting plates is prolonged.

Owner:溧阳市永恒热处理有限公司

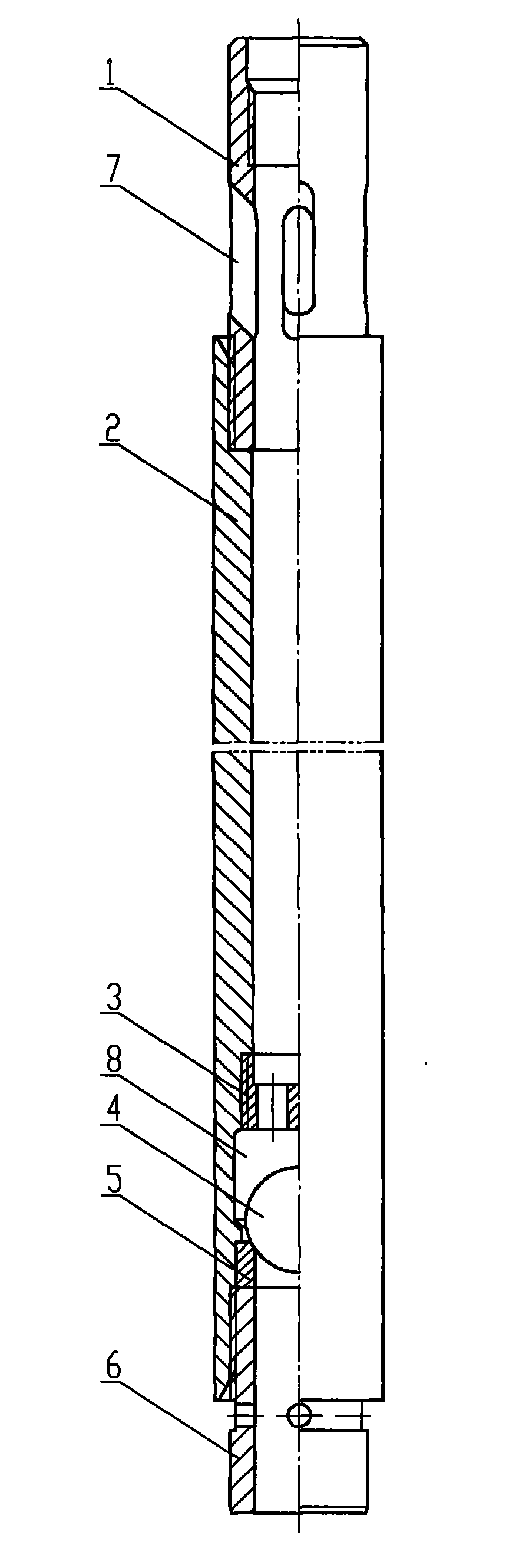

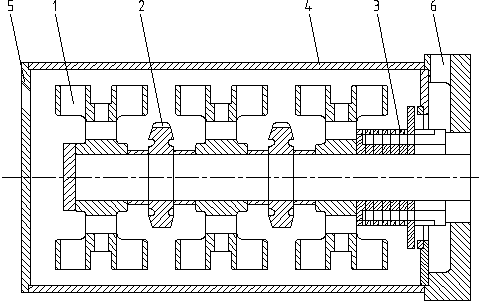

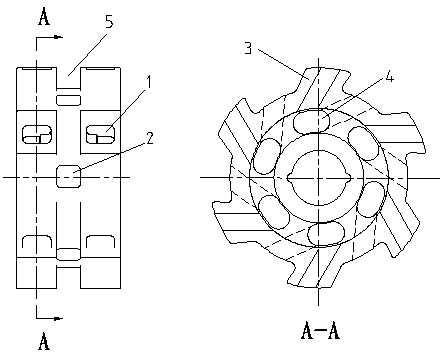

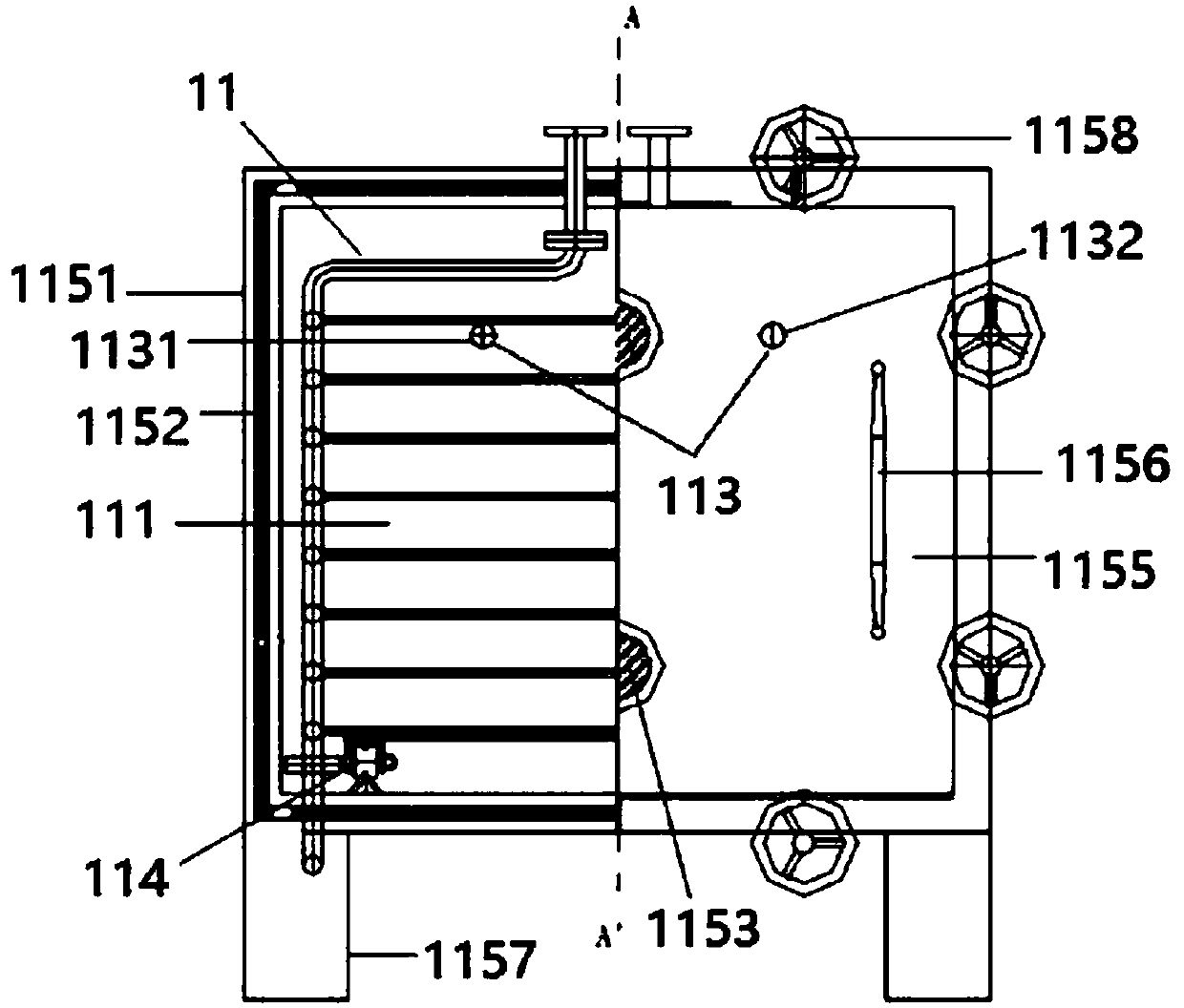

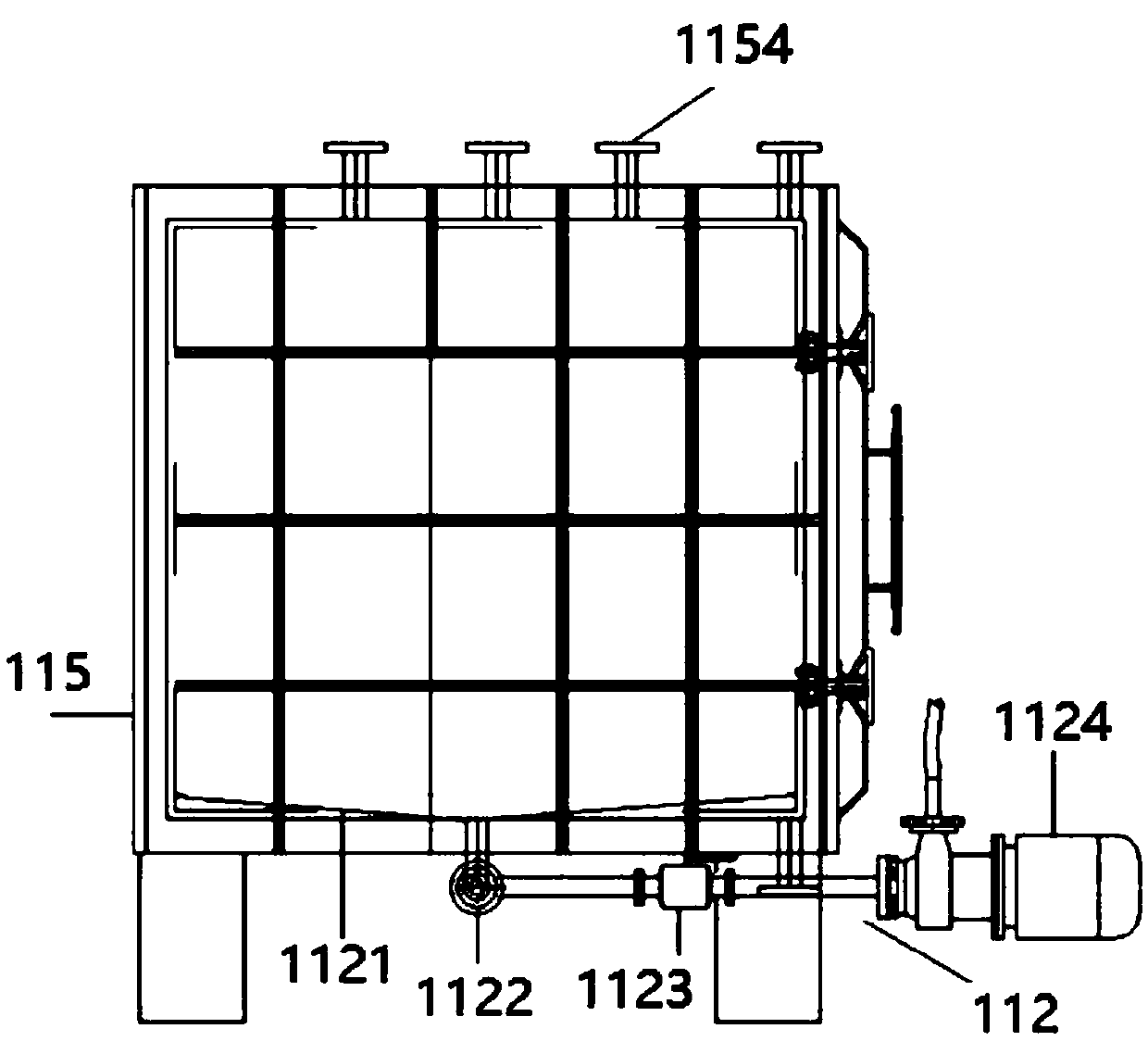

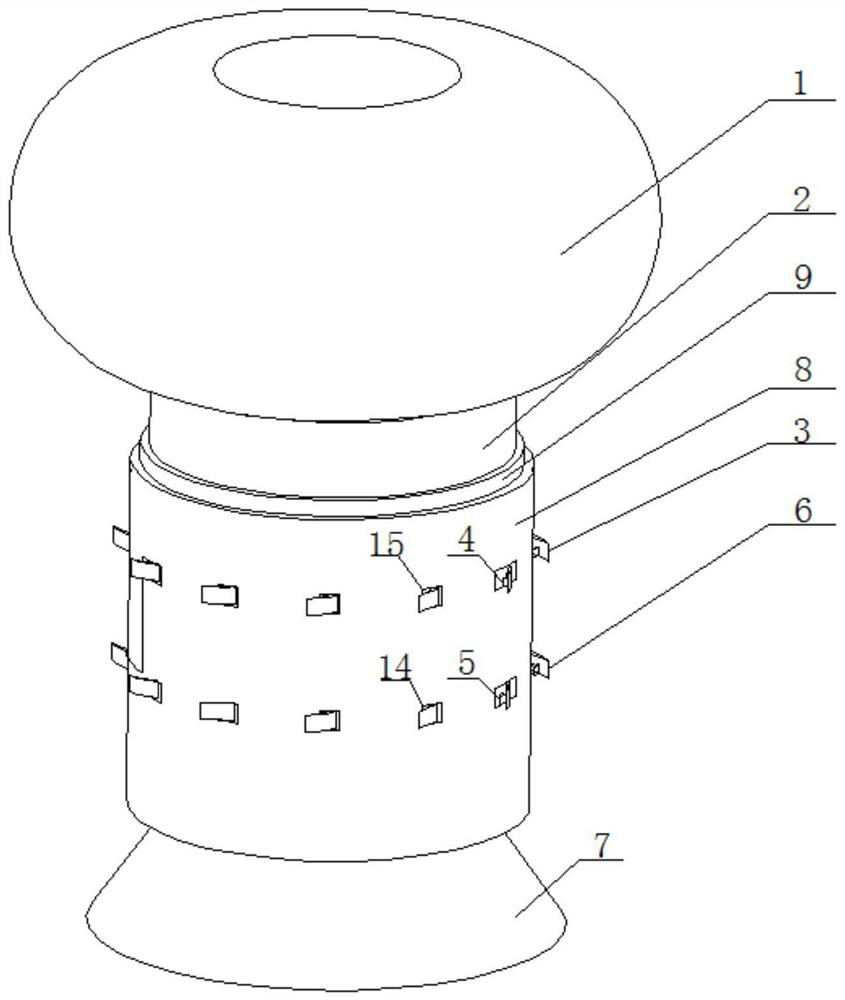

Cooler in driving gearbox, and cooling structure and method of driving gearbox

InactiveCN106402359ASimple structureImprove sealingGear lubrication/coolingCooling effectMechanical engineering

The invention discloses a cooler in a driving gearbox. The cooler in the driving gearbox is in the cylindrical structure with an opening in the top, and is characterized in that a first sealing plate which is annular is arranged on the top of the body of the cooler, a second sealing plate which is annular is arranged at the bottom of the body of the cooler, annular separation layers are further arranged on the body of the cooler and between the first sealing plate and the second sealing plate, the separation layers, the first sealing plate and the second sealing plate are arranged at intervals in the axial direction, a water pass notch is formed in each separation layer, and the water pass notches of every two adjacent separation layers are staggered by a certain angle in the circumferential direction of the separation layers. The cooler in the driving gearbox is simple in structure, small in occupied space, large in heat dissipating area, long in cooling flow path, good in cooling effect and reliable in sealing. The invention further provides a cooling structure and method of the driving gearbox.

Owner:株洲格尔科技有限责任公司

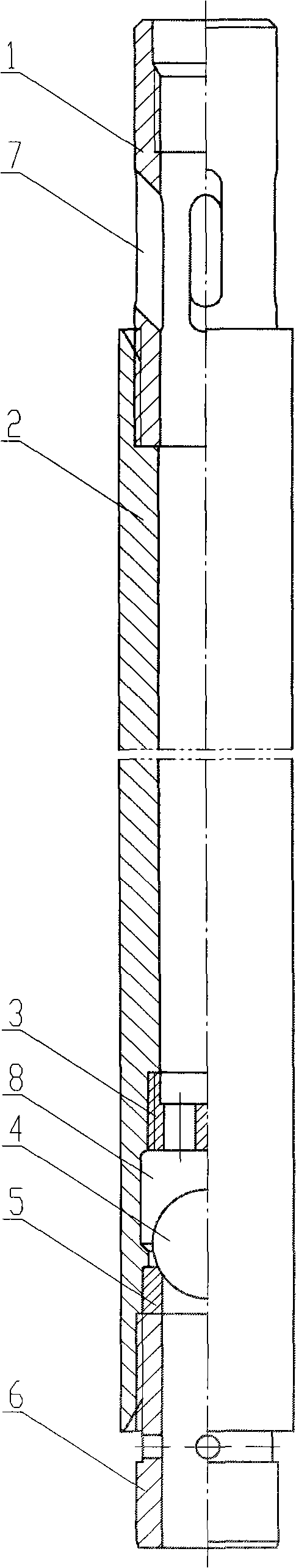

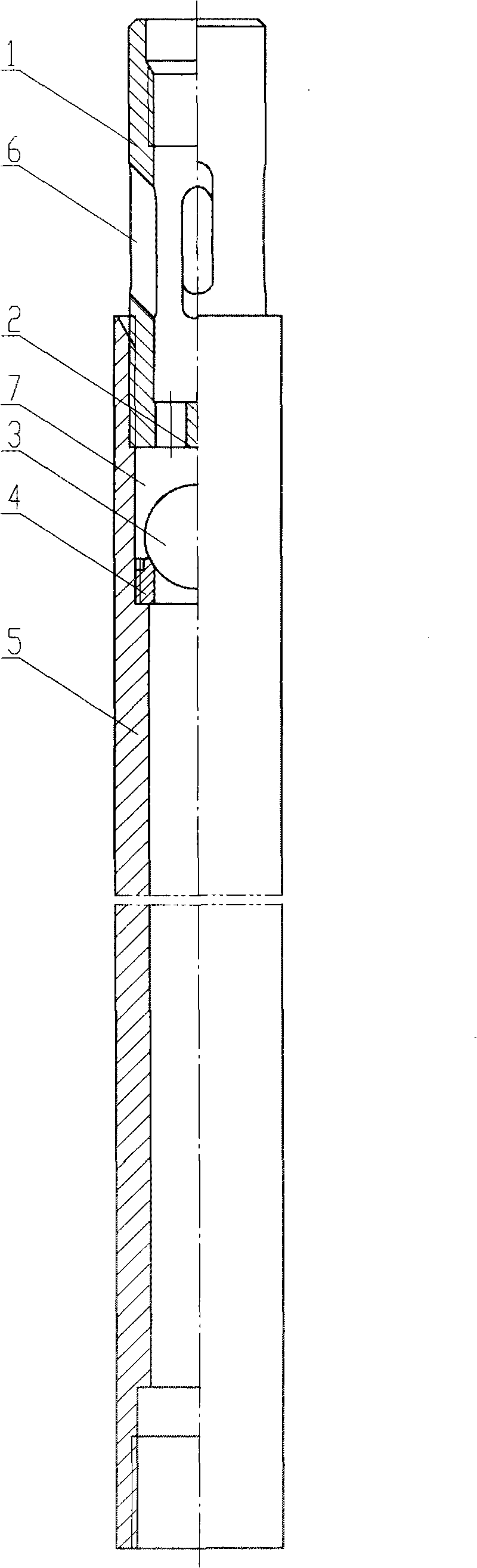

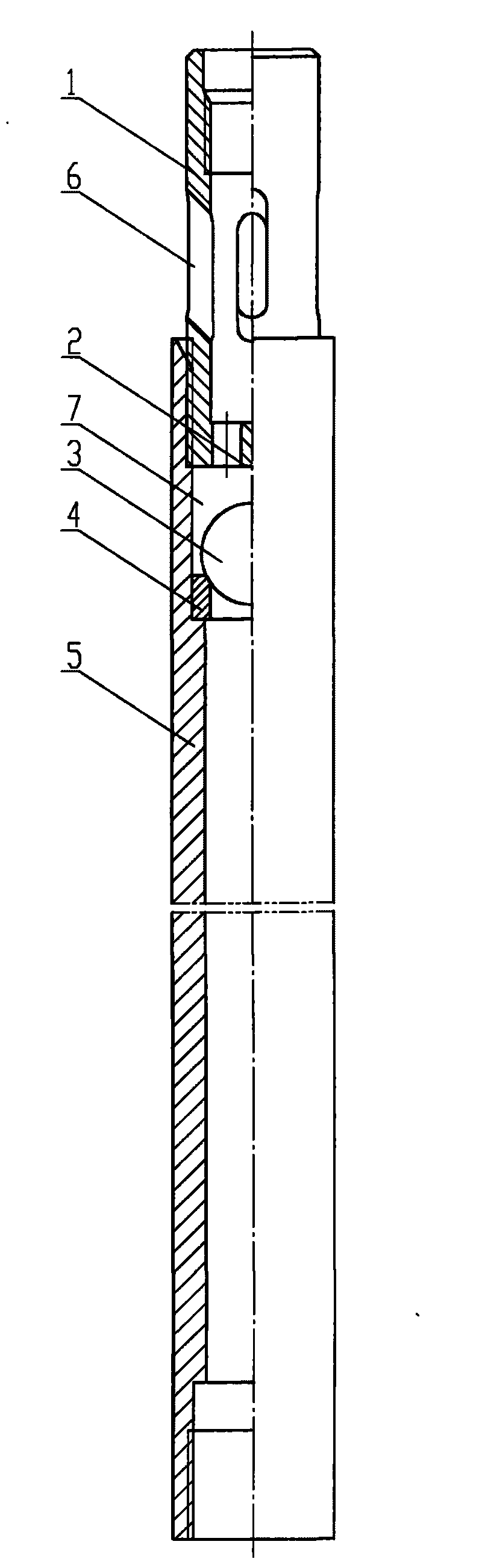

Equant oil pump plunger assembly

InactiveCN101769248AExtended service lifeSimple structurePositive displacement pump componentsLiquid fuel engine componentsEconomic benefitsEngineering

The invention relates to an equant oil pump plunger assembly, comprising an upper oil outlet joint, an equant plunger, a traveling valve ball, a traveling valve seat and a valve seat joint. The upper oil outlet joint is provided with an oil outlet groove; the upper oil outlet joint, the equant plunger and the valve seat joint are sequentially connected together; the traveling valve ball seat is arranged at the upper port of the traveling seat; a valve seat hole and a valve ball chamber are arranged above a screw under the equant plunger; the traveling valve seat is installed in the valve seat hole; the traveling valve ball is arranged in the valve ball chamber; and a shielding cover is installed above the valve ball chamber and fixed in the equant plunger. The valve ball chamber is arranged in the equant plunger, without installing a traveling valve bonnet. The equant plunger has simple structure, high reliability; the oil pump has long service life; and the valve ball chamber has a large flow channel and small flow resistance. When an oil pump with a small diameter is designed as the equant plunger, the flow channel area can not be reduced and is same as that of the common oil pump. Therefore, the equant oil pump plunger assembly has wide application range, good use performance and remarkable economic benefit.

Owner:南通通力油泵有限公司

Novel framework die-casting die for steering wheel

The invention provides a novel framework die-casting die for a steering wheel. The novel framework die-casting die for the steering wheel comprises a fixed die, a fixed die frame, a fixed die core, apositioning hole, a circular rod, a positioning block, a sprue sleeve, a through hole, a movable die core and a front core drawing structure, wherein the positioning hole is formed in the surface of the top part of the fixed die frame; the through hole is formed in the movable die frame; the circular rod is arranged on the fixed die frame and is in fitting connection with the through hole; the movable die core is mounted in the lower end surface of the movable die frame; and the fixed die core is mounted in the upper end surface of the fixed die frame. According to the novel framework die-casting die for the steering wheel, the front core drawing structure and a rear core drawing structure are mounted between the movable die frame and the fixed die frame; the front core drawing structure is mounted at the front end of the movable die frame, and the rear core drawing structure is mounted at the rear end of a lower die frame of the fixed die frame, so that the die can be conveniently smoothly released from the steering plate, and the die adhering problem of a die-casting part can be reduced, and the shift productivity can be effectively improved.

Owner:十堰卓环汽车零部件有限公司

Waste heat recovery system for thermal power plant

The invention discloses a waste heat recovery system for a thermal power plant. The waste heat recovery system comprises a fixing plate, and a water circulation device, a heat exchange device, a flue gas treatment device A and a flue gas treatment device B are installed at the top end of the fixing plate; a flue gas inlet pipe is fixedly installed on one side of the heat exchange device, and a water inlet pipe and a return pipe are installed on the side of the heat exchange device; and a circulating pump is fixedly installed on one side of the water circulation device, and the water inlet end of the circulating pump communicates with the interior of the circulating pump. According to the waste heat recovery system, the water circulation device is connected with the heat exchange device, heat conduction blocks and partition plates are additionally arranged in the heat exchange device, flowing of flue gas increased, recovery of heat in the flue gas is effectively improved, and the loss of heat in the flue gas is reduced; the flue gas after waste heat recovery is treated through the installed flue gas treatment device A and the flue gas treatment device B; and dust, sulfur-containing compounds and nitrate-containing compounds in the flue gas are effectively removed through filtration, electrostatic rod dust removal and chemical reaction, and harmful substances in the flue gas are reduced.

Owner:XIAN TPRI THERMAL CONTROL TECH

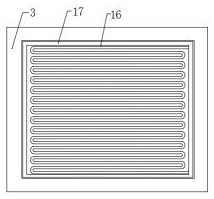

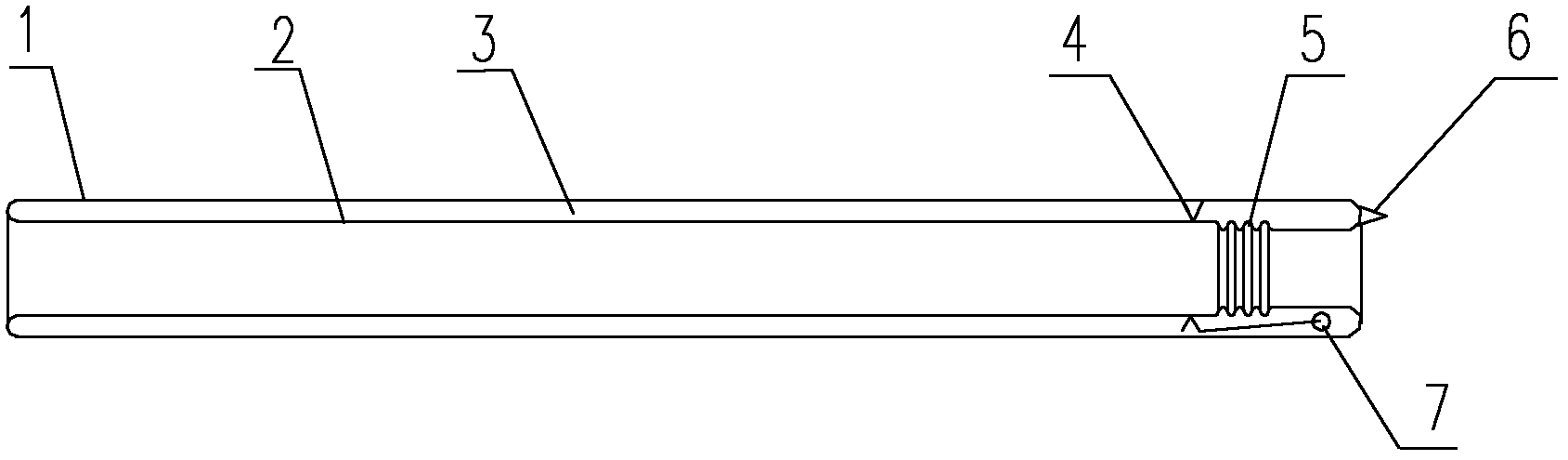

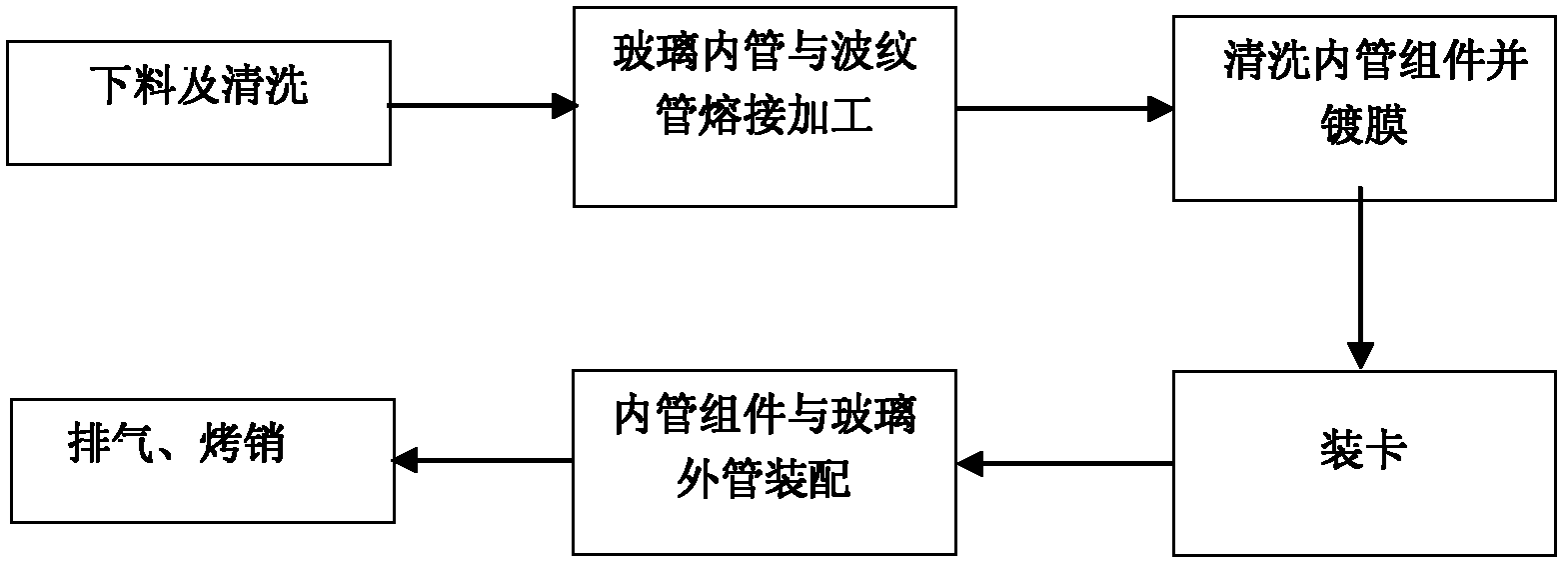

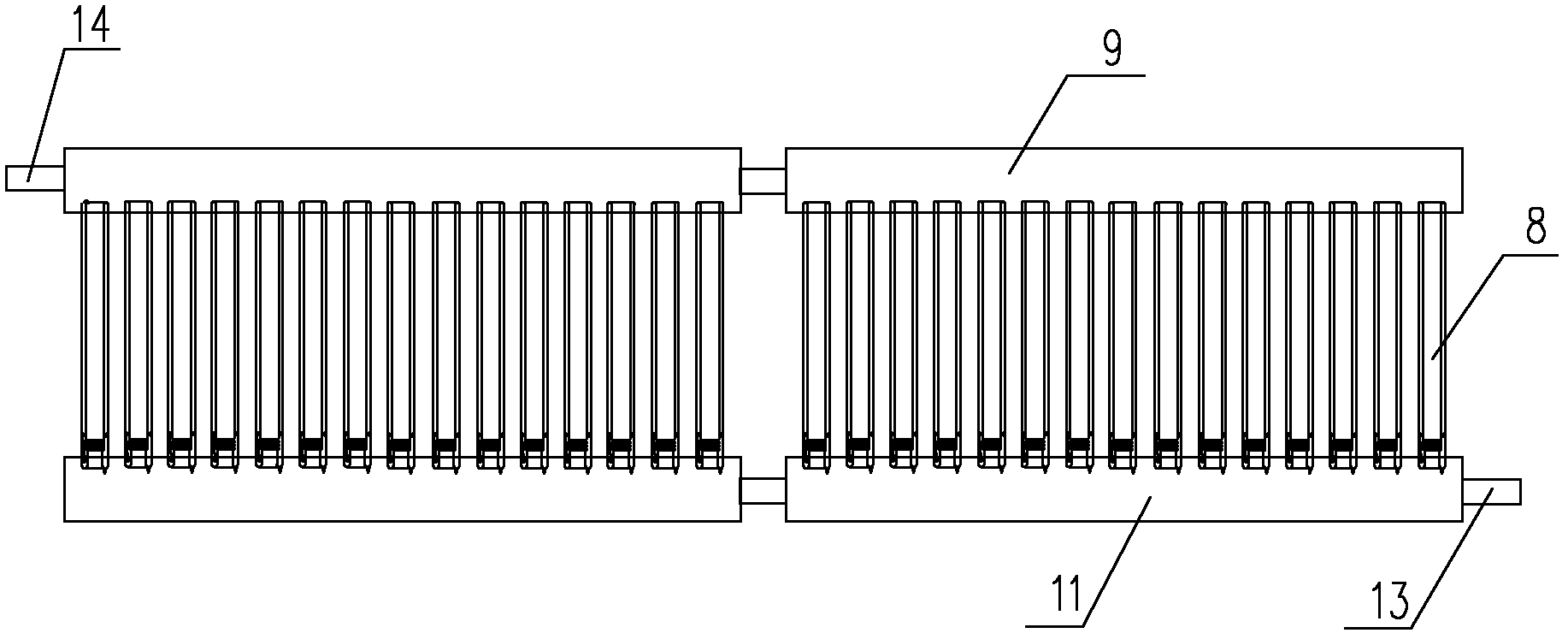

Direct through glass vacuum pipe, manufacture method and air heat collector

InactiveCN102635963AEfficient weldingAvoid damageSolar heat devicesSolar thermal energy generationCollector deviceEngineering

The invention discloses a direct through glass vacuum pipe which comprises a glass outer pipe, an inner pipe assembly formed through respectively welding two ends of a metal bellows with two sections of glass inner pipe, a stainless steel support clamp and a getter, wherein a selective coating is plated on the outer wall of the inner pipe assembly and is arranged at the inner part of the glass outer pipe, the inner pipe assembly is in vacuum sealing with the glass outer pipe, and the stainless steel support clamp and the getter are assembled between the inner pipe assembly and the glass outer pipe. The direct through glass vacuum pipe is manufactured by adopting the following steps of blanking and washing, welding the glass inner pipe with the bellows, coating a film, assembling the clamp, assembling, exhausting, baking a pin and the like. An air heat collector consisting of the direct through glass vacuum pipe comprises at least one group of heat collector units which are transversely or longitudinally arranged and communicated. According to the invention, the problems of air blockage of the vacuum pipe air heat collector and easy oxidization of a melting port of the metal bellows are solved, and the production quality is improved. Meanwhile, the heat utilization efficiency is increased, the processing difficulty and cost are reduced, and the industrialized production is facilitated.

Owner:北京天普太阳能工业有限公司

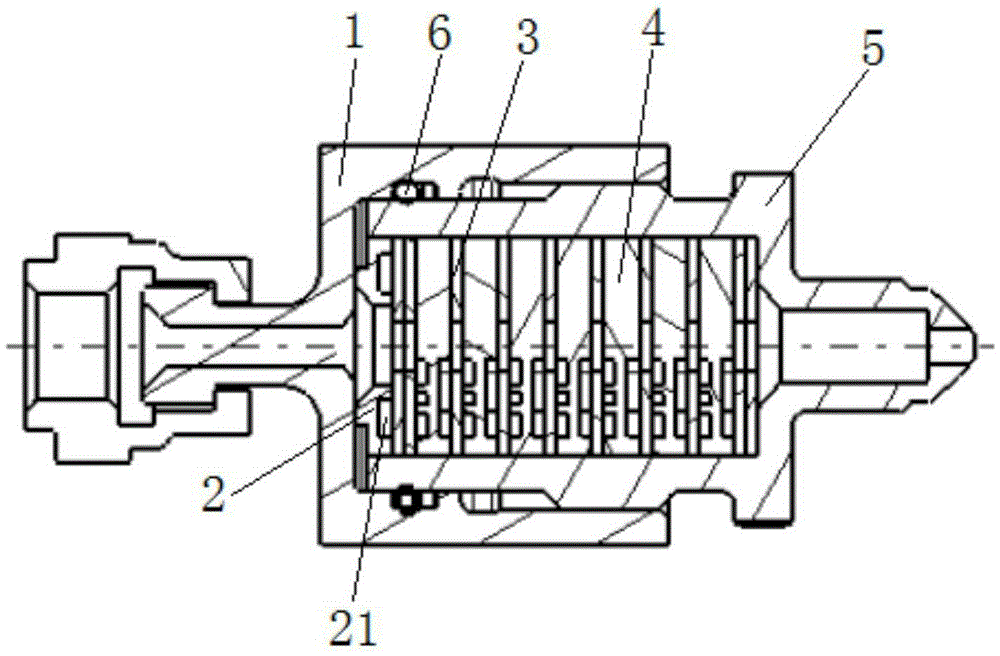

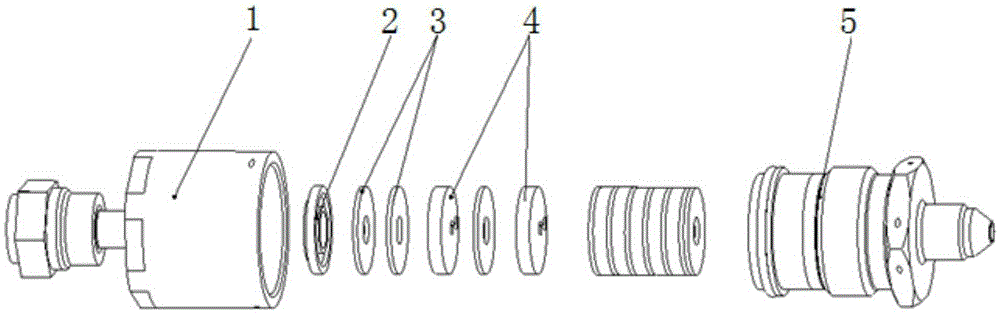

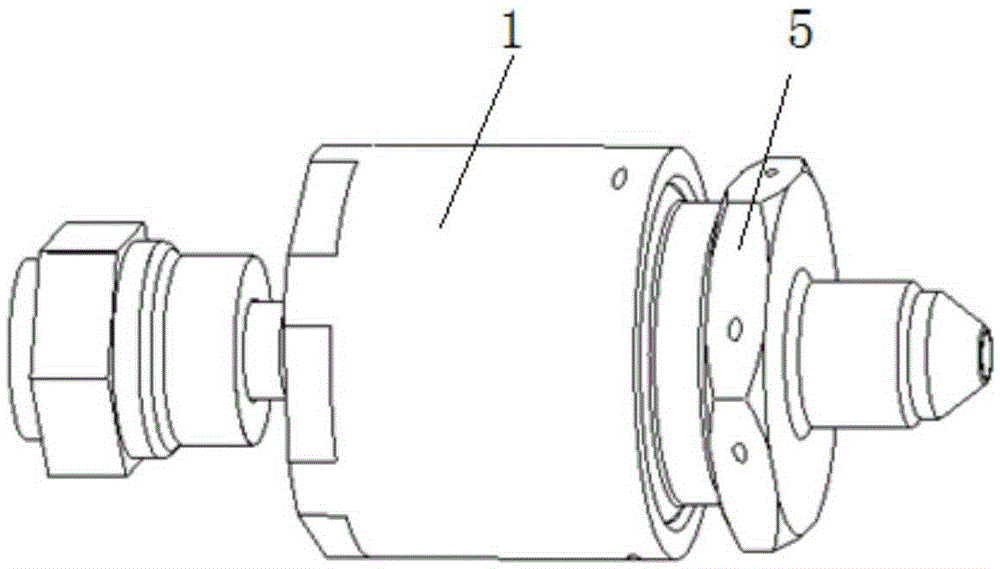

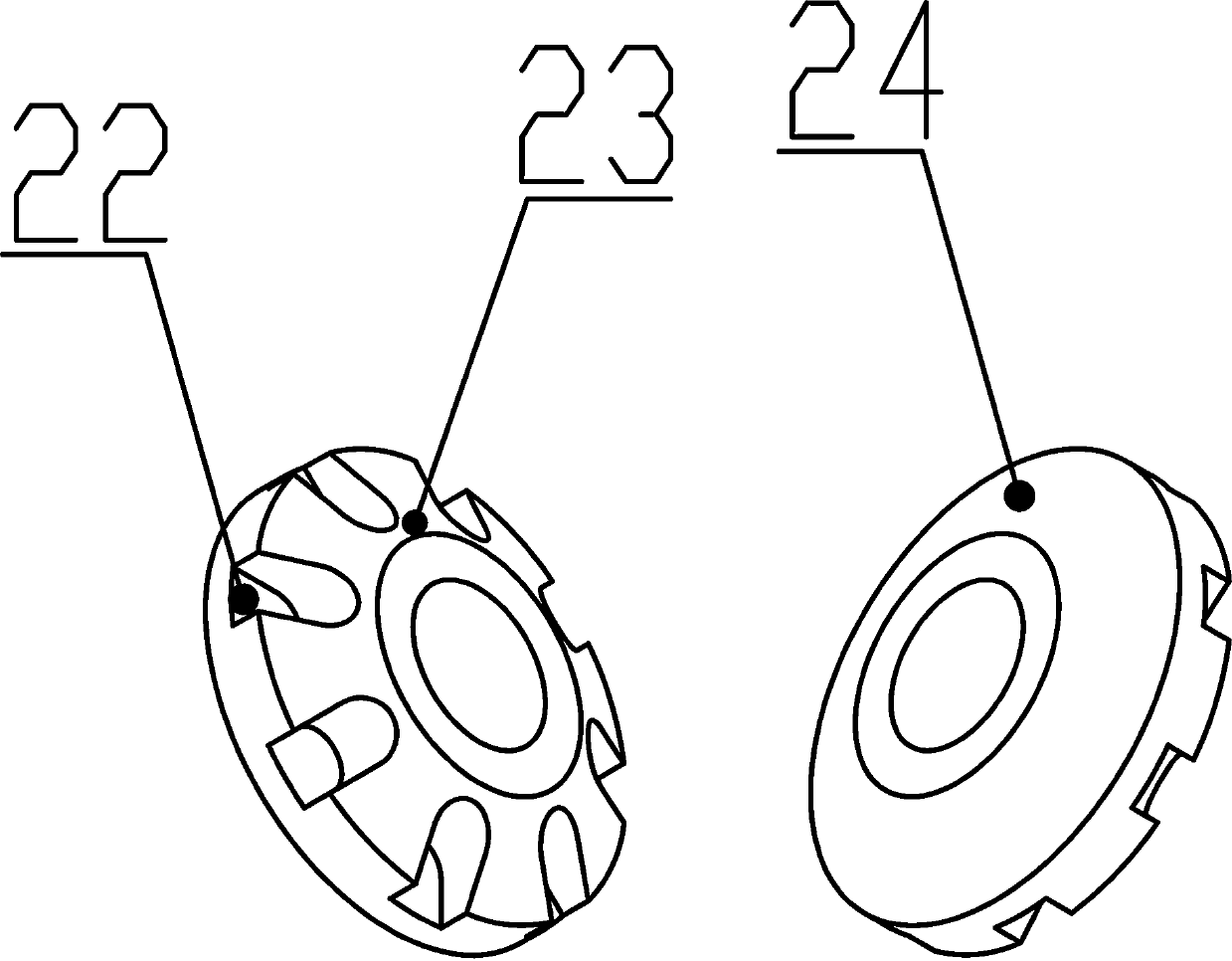

Flow limiting valve

InactiveCN105422534AReduce flow rateImprove reliabilityServomotor componentsFluid dynamicsEngineeringHydraulic pressure

The invention discloses a flow limiting valve and relates to the technical field of hydraulic pressure. The flow limiting valve comprises an end cover, a plurality of gaskets, flow limiting pieces and a shell. A first through hole is formed in each gasket. Vortex grooves are formed in the two sides of each flow limiting piece, and the vortex grooves in the two sides of each flow limiting piece are communicated. The gaskets are arranged on the two sides of the flow limiting piece, and the vortex grooves are communicated with the first through holes. The shell is provided with a containing cavity. The gaskets and the flow limiting pieces are placed in the containing cavity. The shell is sleeved with the end cover, and the end cover is fixedly connected with the shell and tightly presses the gaskets and the flow limiting pieces in the axial direction. The flow limiting valve has the advantages that the vortex grooves are formed in the flow limiting pieces, liquid passes through the vortex grooves to form vortexes, the flow speed of the liquid is decreased, multiple flow limiting pieces can be arranged according to the flow control requirements, and the effective control over the extremely small flow is achieved.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

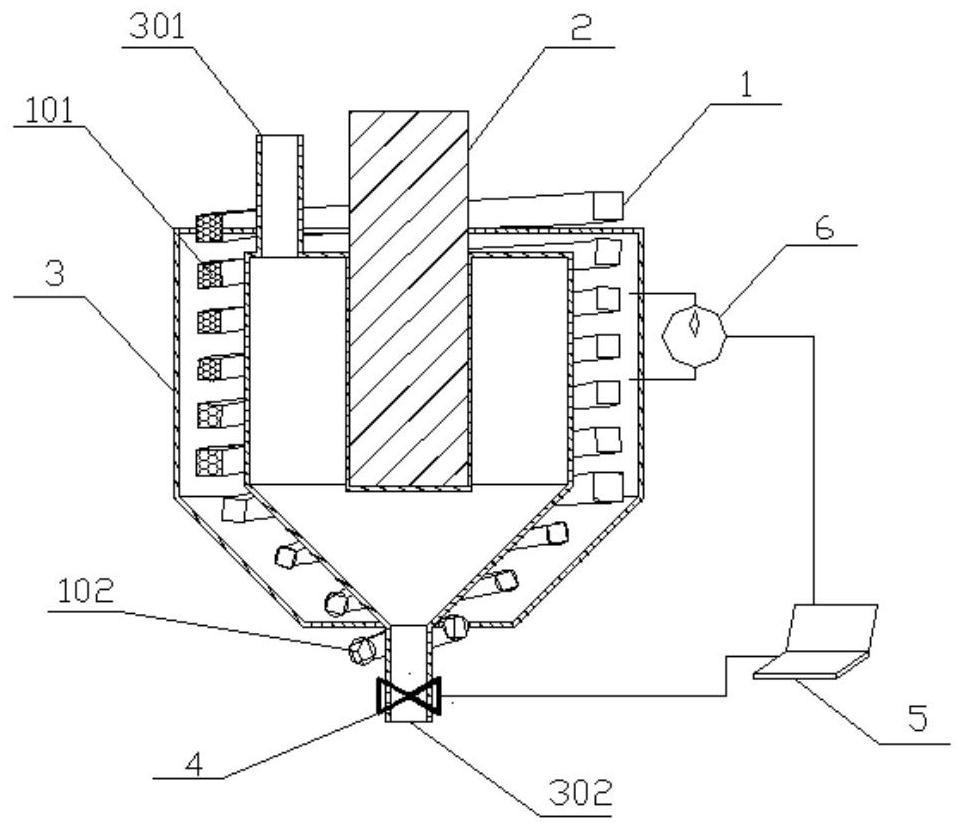

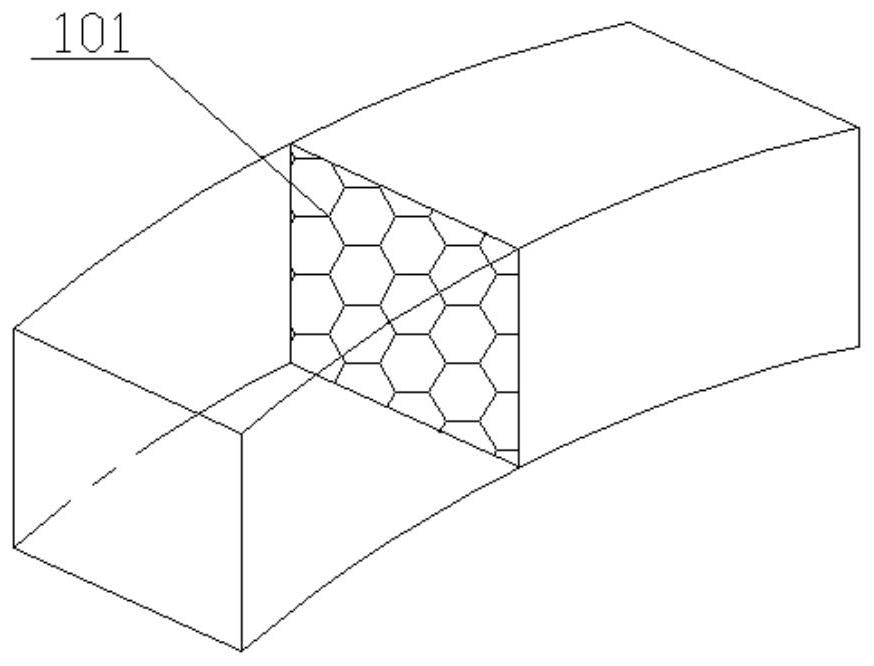

Collecting electric field-ultrasonic wave field-centrifugal field coupled anti-scaling temperature control electric coalescence dehydrator

ActiveCN111704926AIncreased chance of collision coalescenceCoalescence failureDewatering/demulsification with mechanical meansDewatering/demulsification with electric/magnetic meansTemperature controlEngineering

The invention discloses a collecting electric field-ultrasonic wave field-centrifugal field coupled anti-scaling temperature control electric coalescence dehydrator, which comprises a heat preservation system, an ultrasonic wave generating device and a demulsification device, wherein the demulsification device comprises a spiral demulsification chamber, the spiral demulsification chamber is spirally wound on the heat preservation system, and temperature conditions are provided for demulsification through the heat preservation system; the ultrasonic generation device is arranged in the heat preservation system and used for generating an ultrasonic field; an electrode is arranged on the spiral demulsification chamber, wherein a negative electrode is arranged on the inner side of the spiral demulsification chamber, and a positive electrode is arranged on the outer side of the spiral demulsification chamber, the electrode being used for generating an electric field in the spiral demulsification chamber. The electric dehydration technology, the ultrasonic demulsification dehydration technology, the hydrocyclone separation dehydration technology and the heat treatment dehydration technology are combined, and the demulsification efficiency of the device is improved through the synergistic effect.

Owner:申文初

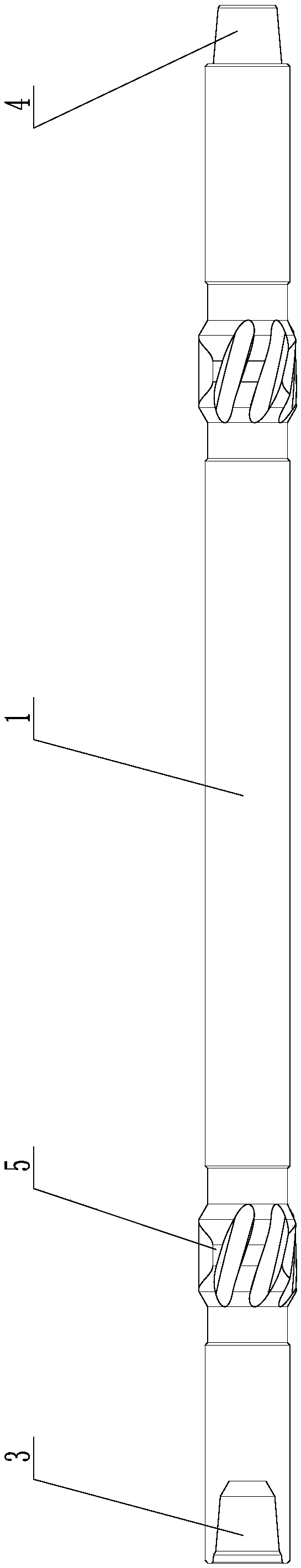

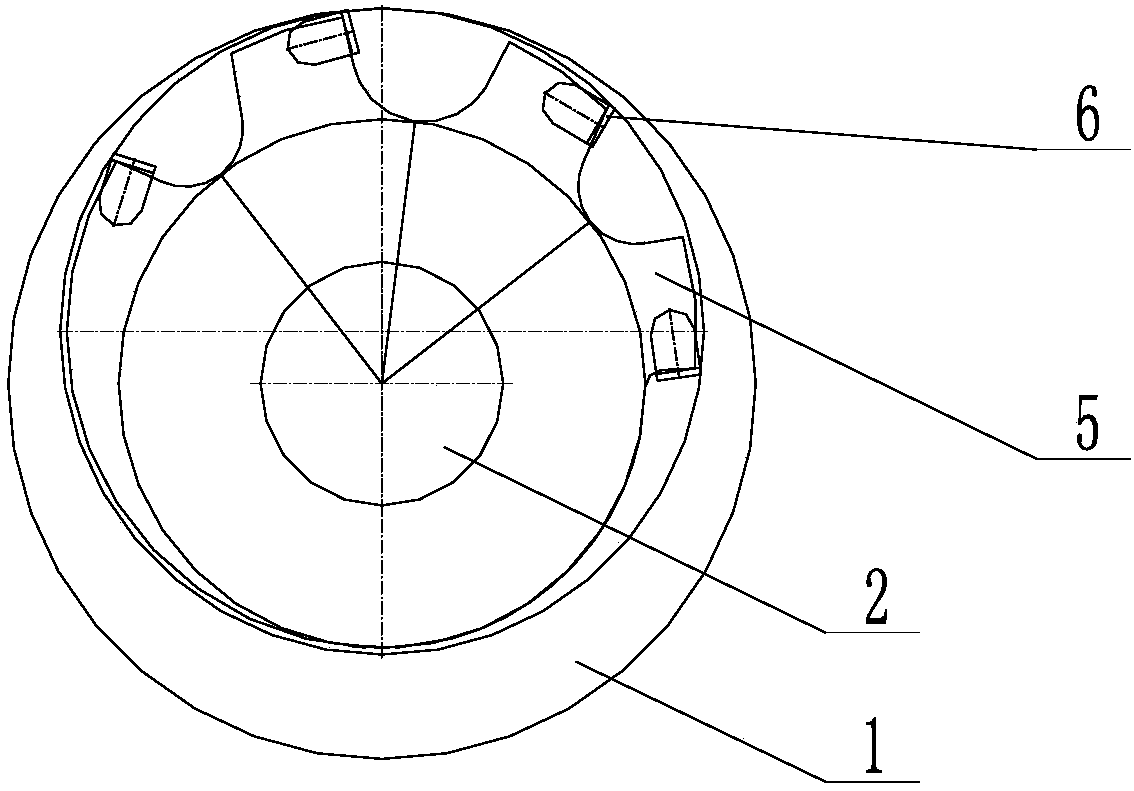

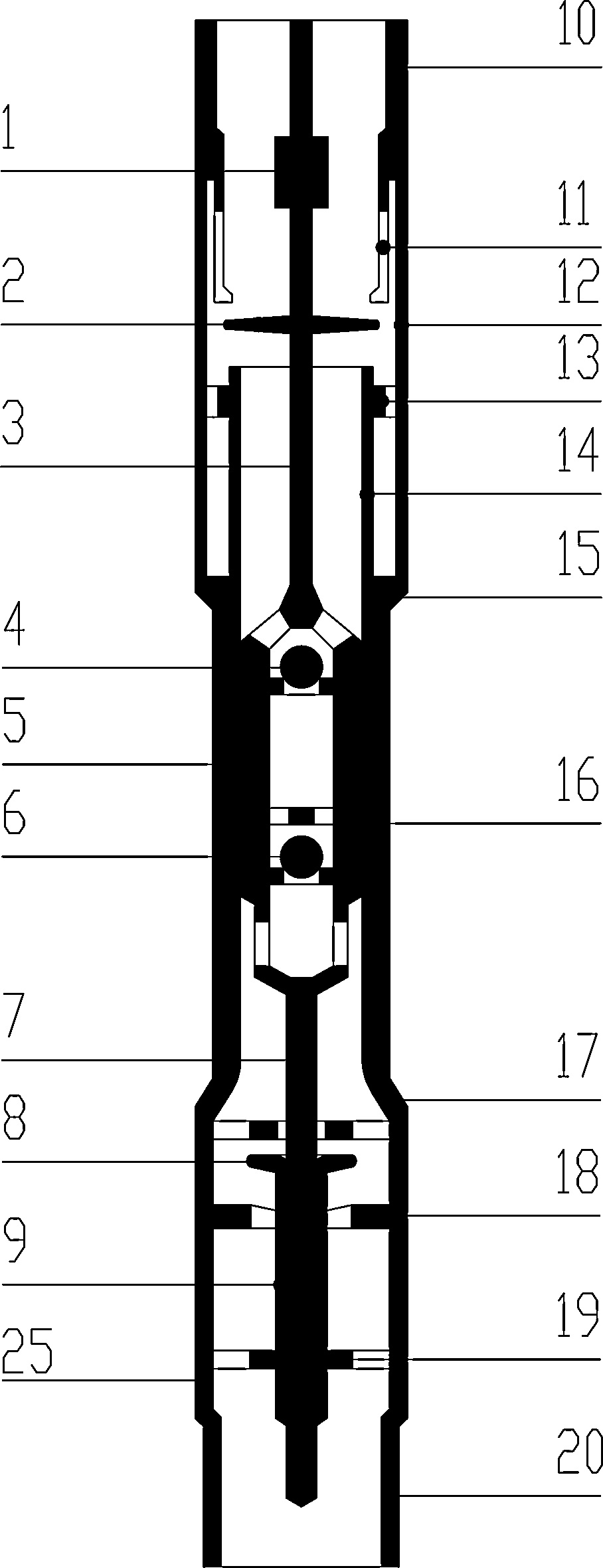

Underground while-drilling bidirectional eccentric nipple reaming drilling tool

InactiveCN109681121AEliminate damagePlay a protective effectDrilling machines and methodsReamerPetroleum

The invention relates to the technical field of petroleum natural gas drilling tools, in particular to an underground while-drilling bidirectional eccentric nipple reaming drilling tool. The underground while-drilling bidirectional eccentric nipple reaming drilling tool structurally comprises a body, wherein a water hole is arranged in the center of the body; one end of the body is provided with afemale buckle connected with an upper drill string, and the other end of the body is provided with a male buckle connected with a lower drill string; two groups of eccentric reamers are arranged outside the body; each group of reamers comprises four blades; and PDC cutting teeth are arranged on each blade in a brazing manner. By adopting the underground while-drilling bidirectional eccentric nipple reaming drilling tool, the problems of drill pipe sticking by cuttings bed, drill pipe sticking by borehole necking as well as difficulty in loading a casing pipe at soft formations or easy-to-collapse formations and the like can be solved.

Owner:天津北地天祥贸易有限公司

Electroplating apparatus with notch adapted contact ring seal and thief electrode

ActiveUS9758897B2Thicker plating in the region of the notch is reduced or eliminatedLarge runnerCellsContacting devicesElectrical resistance and conductanceShape change

An electro-processing apparatus has a contact ring including a seal which is able to compensate for electric field distortions created by a notch (or other irregularity) on the wafer or work piece. The shape of the contact ring at the notch is changed, to reduce current crowding at the notch. The change in shape changes the resistance of the current path between a thief electrode and the wafer edge to increase thief electrode current drawn from the region of the notch. As a result, the wafer is plated with a film having more uniform thickness.

Owner:APPLIED MATERIALS INC

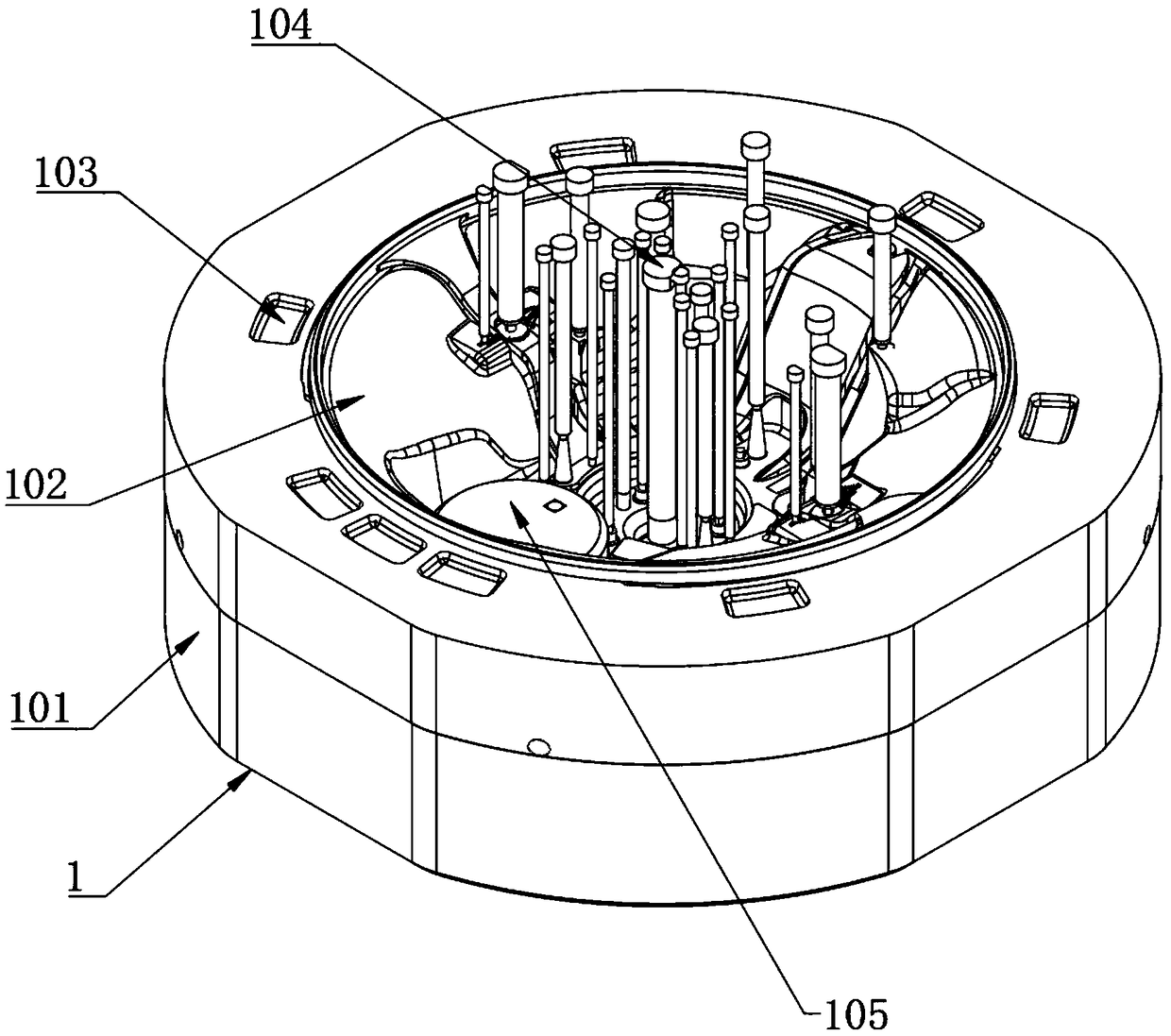

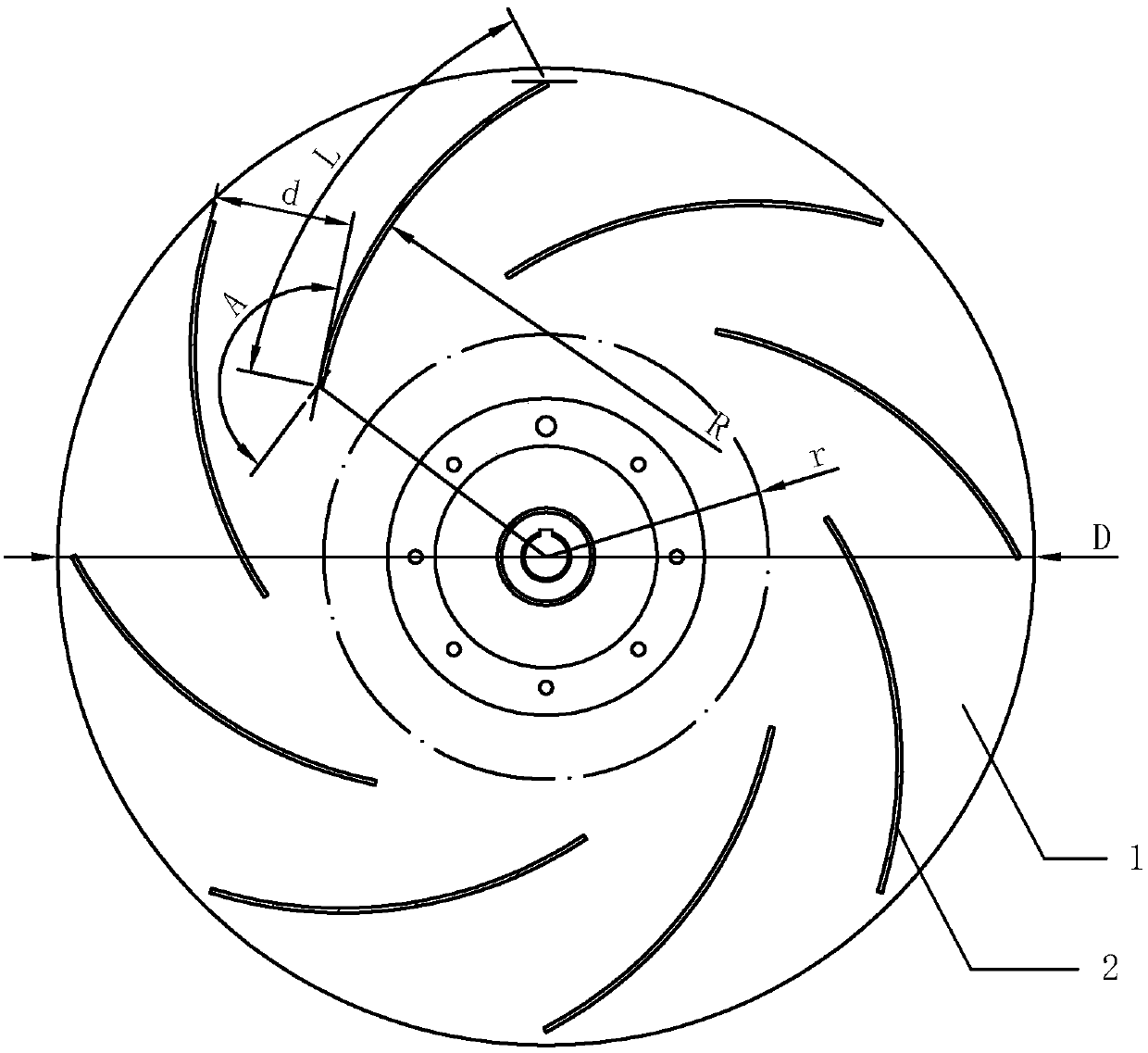

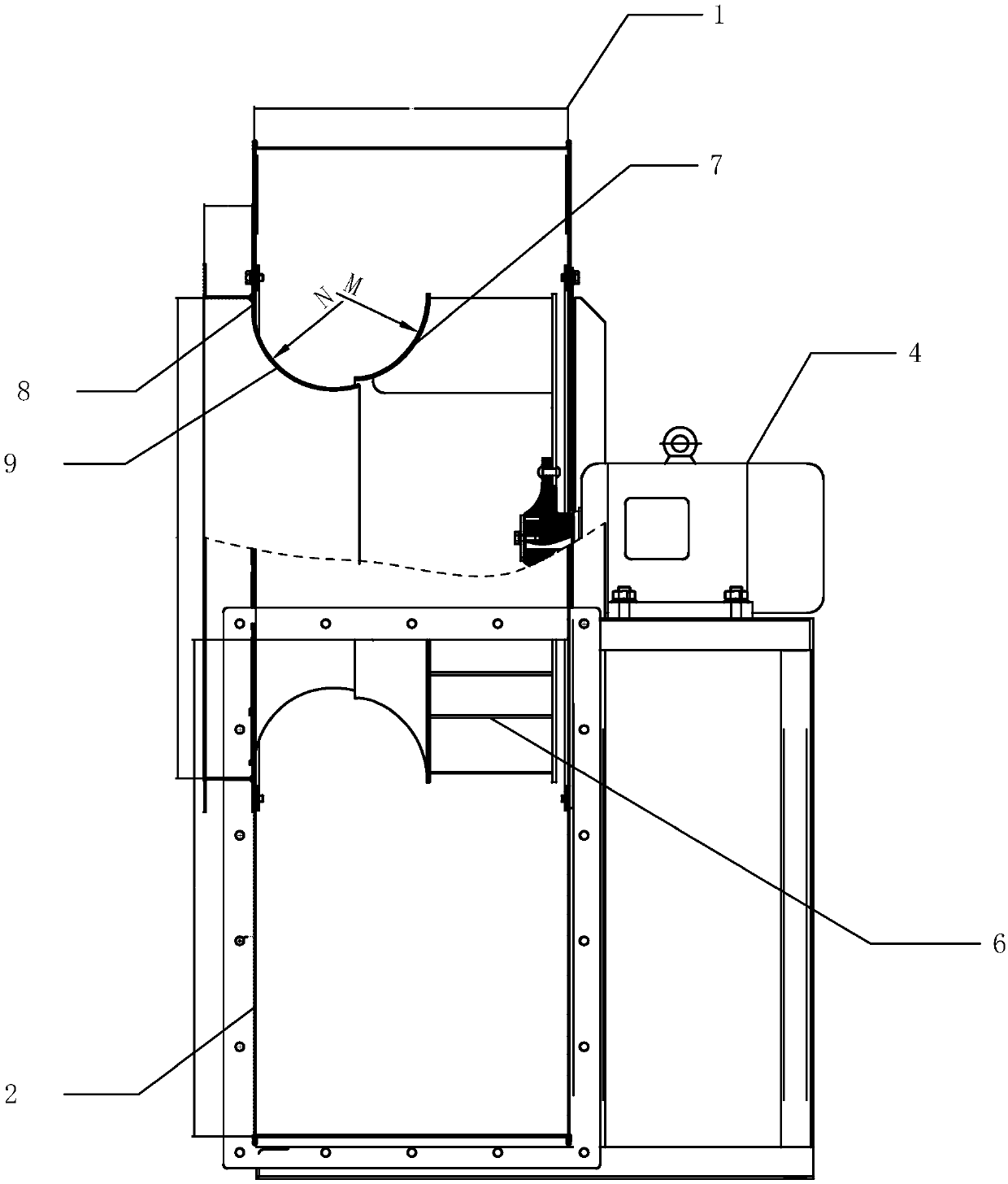

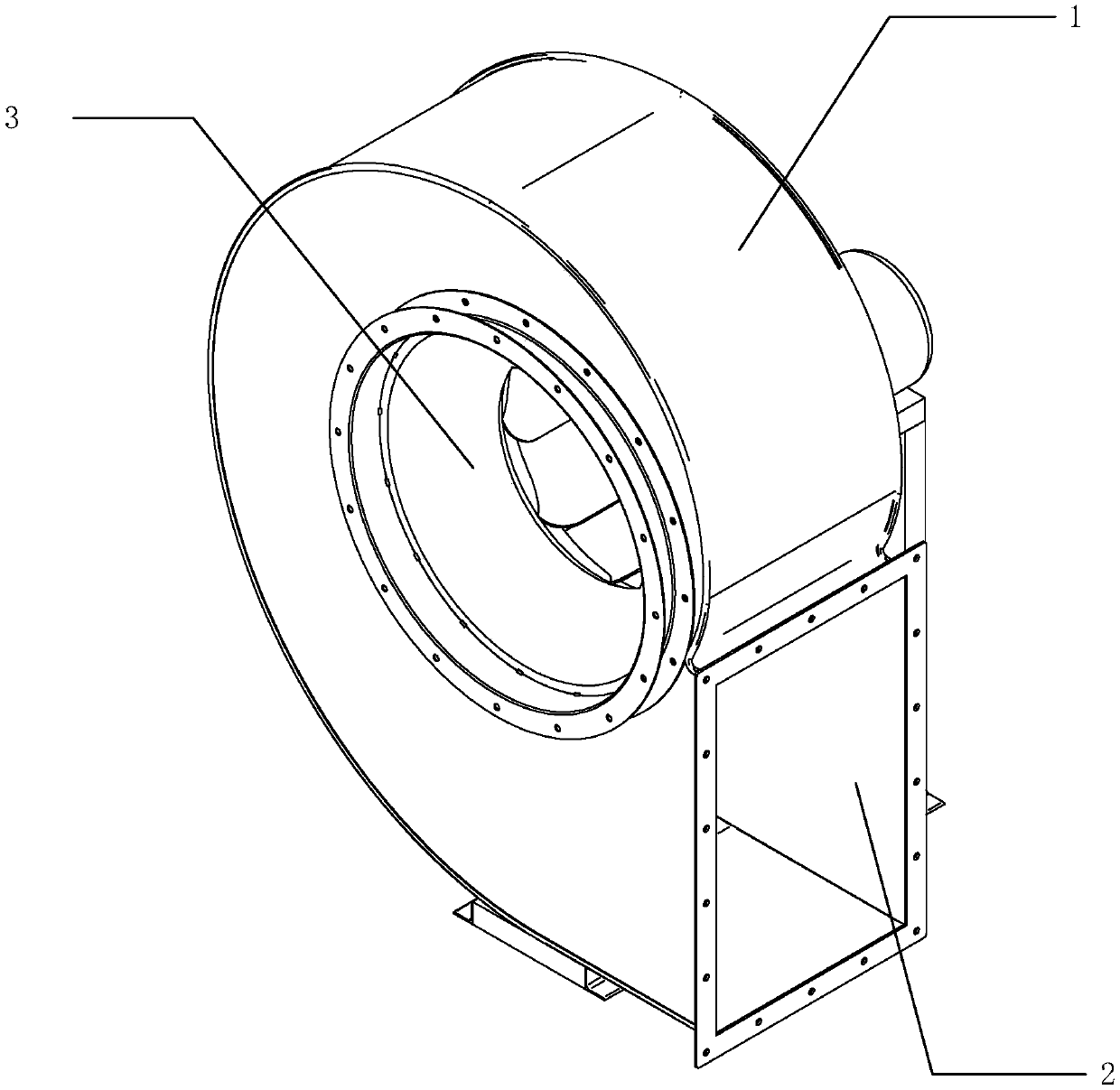

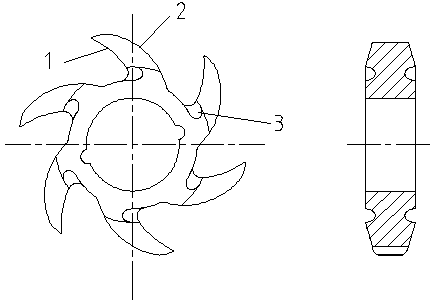

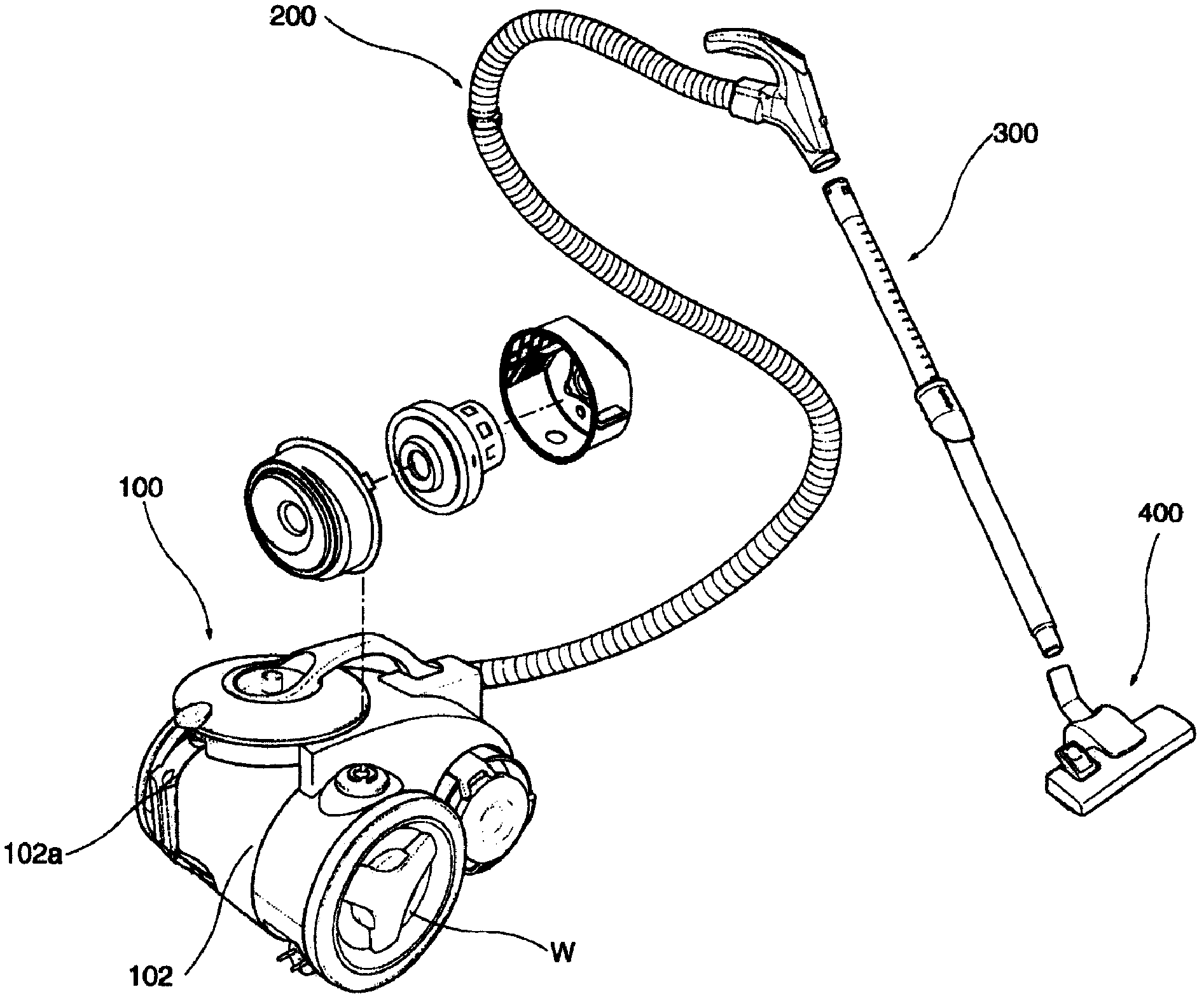

Fan

The invention discloses a fan comprising a casing. One end face of the casing is provided with a motor, and the other end face of the casing is provided with an air inlet which is internally providedwith an air inlet tube; the peripheral surface of the casing is provided with an air outlet, and the casing is internally provided with an impeller; the impeller comprises a baseplate, blades and a front disk, and an air outlet cavity is formed between the baseplate and the front disk; the air inlet communicates with the air outlet, and the blades are arc-shaped, and the arc centers of the bladesare in the baseplate; the proximal ends of the blades are inlet angles, and the distal ends of the blades are outlet angles; and a line connecting the outlet angles and the circle center of the baseplate is a distal radius. According to the fan, the optimal structural design of the blades on the fan is provided, and the air outlet efficiency of the fan is improved by adopting the air inlet tube and the front disk; and the overall power consumption is reduced, and the operation is more steady and smoother.

Owner:FOSHAN CITY NANHAI POPULA FAN

Ball-stirring mill for convex pin turbine

The invention provides a ball-stirring mill for a convex pin turbine. The ball-stirring mill comprises one or more convex pin turbines, zero or more jaw wheels, a material-ball separating assembly, a milling cavity cylinder body, a charging cylinder cover and a discharging room, wherein a plurality of convex pins are arranged on the turbine(s), and the middle parts of the convex pins are hollowed to form vortex grooves; each turbine is provided with a plurality of through holes along the radial direction, and the through holes are communicated with the plurality of middle vortex grooves; and when the turbines run, a sizing agent and a milling media (i.e. milling balls) are driven to circularly move along the peripheral direction and the radial direction, and a high shearing force is generated by the stirring function of the pins. When the jaw wheels rotate, a powerful centripetal driving force is generated. The materials thrown out of the turbine and the milling balls are driven to enter inner holes of the turbines, so that the circular flow can be enhanced. According to the ball-stirring mill, a circular driving force and a stirring force of liquid are enhanced, so that the milling efficiency can be greatly improved, and the granularity of products milled for once can be obviously reduced; and therefore, the ball-stirring mill can be wildly applicable to the field of extra-fine grinding and extra-fine dispersing of materials, and in particular, the ball-stirring mill has preferable effects on the extra-fine grinding and dispersing of prepared nanometer-level products or high-viscosity products.

Owner:深圳市叁星飞荣机械有限公司

Multistage rectification slideway vertical shaft rotational flow flood discharge tunnel

InactiveCN113605330AAvoid accumulationSolve the problem of accumulation that is difficult to cleanBarrages/weirsCleaning using liquidsWater flowHydrology

The invention relates to the technical field of rotational flow energy dissipation structures in the technical field of vertical shaft drop energy dissipation structures, and particularly relates to a multistage rectification slideway vertical shaft rotational flow flood discharge tunnel. The multistage rectification slideway vertical shaft rotational flow flood discharge tunnel comprises a straight inlet section, a straight outlet section and a vertical flow channel, wherein the upper end of the vertical flow channel is connected with the straight inlet section, and the lower end of the vertical flow channel is connected with the straight outlet section; a plurality of sets of spiral slideways enabling water flow in the vertical flow channel to flow downwards in a winding mode in the tangential direction of the inner wall of the flow channel are arranged in the vertical flow channel and are arranged at intervals in the vertical direction; and an overflow structure is arranged in the straight outlet section and suspended in the center of the flow channel of the straight outlet section to divide the flow channel of the straight outlet section into a fluid circulation flow channel above the overflow structure and a fluid sand washing flow channel below the overflow structure. The flood discharge tunnel is simple in structure, the flow speed of fluid can be greatly decreased through the arranged multistage spiral slideways, a good energy dissipation effect is achieved on the fluid, and the problems of sand and stone accumulation and overflow water recession can be effectively solved through the arranged overflow structure.

Owner:HUBEI PROVINCIAL WATER RESOURCES & HYDROPOWER PLANNING SURVEY & DESIGN INST

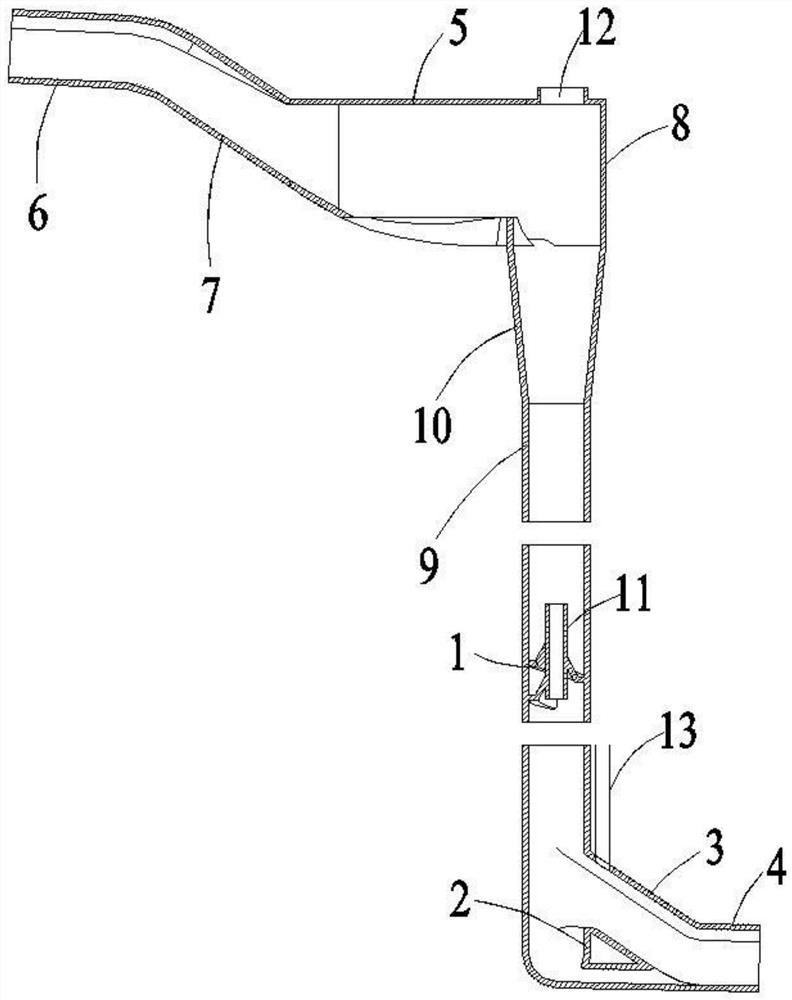

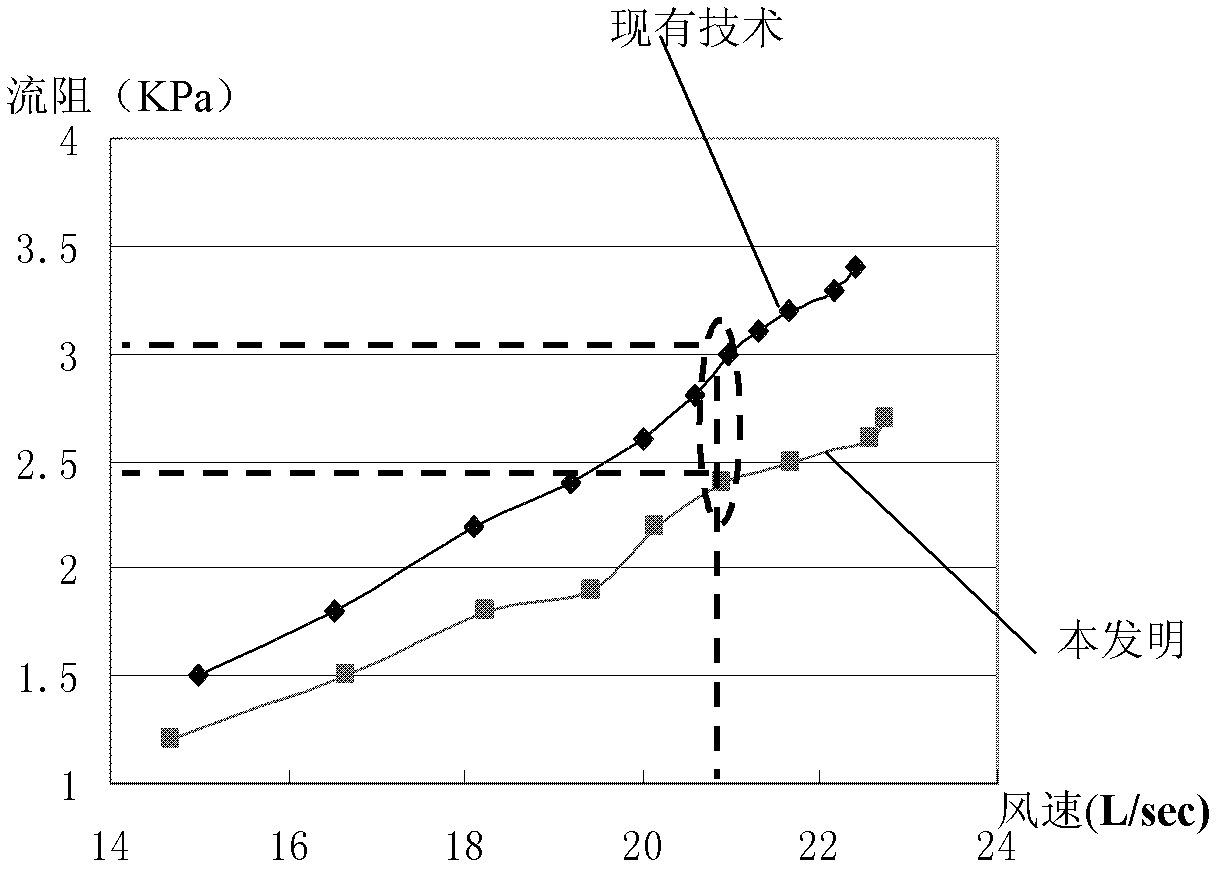

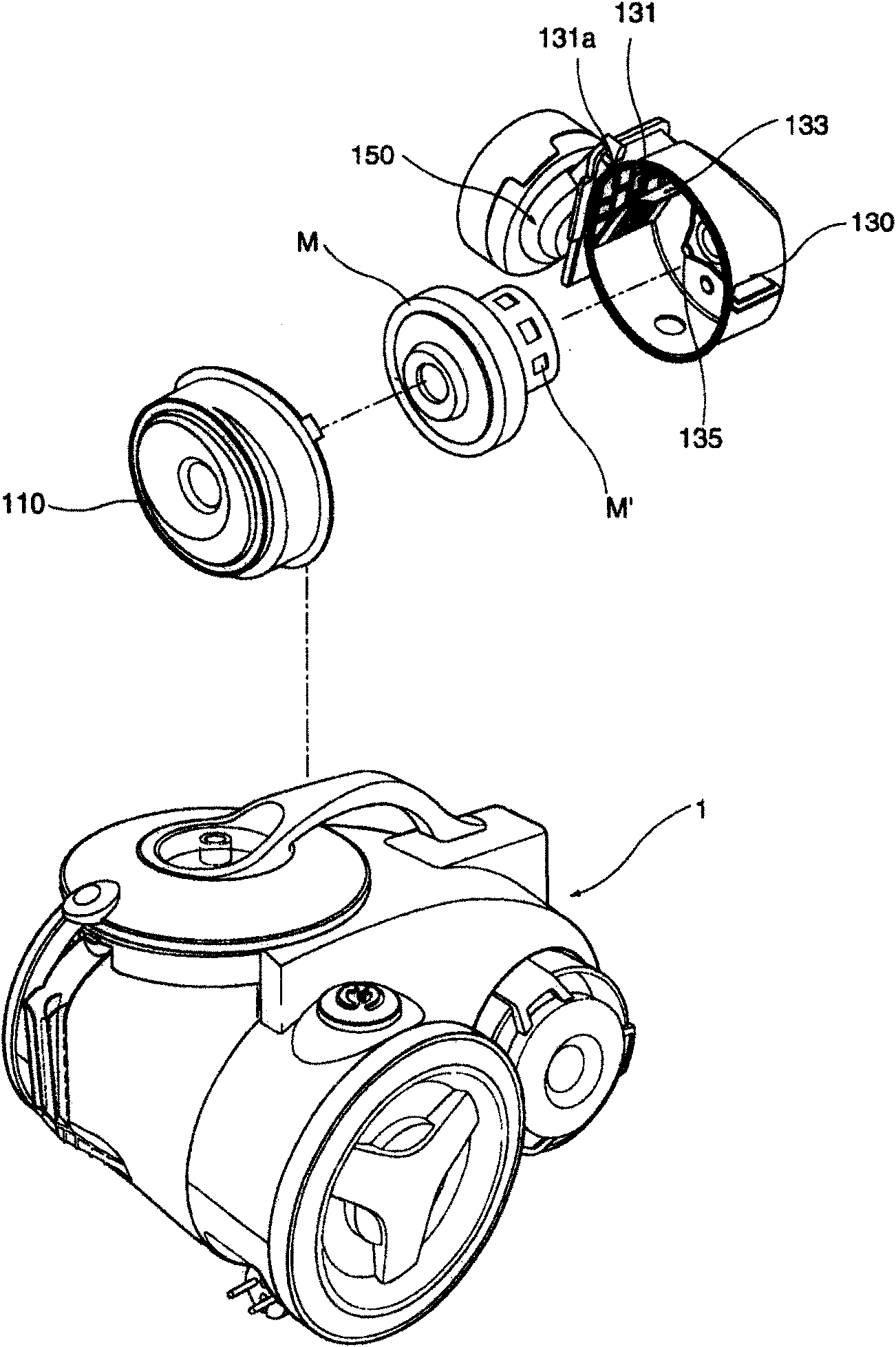

Motor casing with spiral airflow chamber

InactiveCN102599852AReduce noiseImproved low-frequency aerodynamic noiseSuction cleanersSupports/enclosures/casingsExpansion chamberSpiral flow

The invention discloses a motor casing with a spiral airflow chamber, which comprises a chamber body, an air inlet and an air outlet. The air inlet is located at the bottom of the chamber body, and the air outlet is located on the lateral surface of the chamber body. The chamber body is provided with a baffle plate which is formed by a panel and a curved plate connected alternately. An expansion chamber and a contraction chamber which are communicated and arranged alternately are arranged between the baffle plate and the outer wall of the chamber body. A grid-shaped air hole is arranged at a position opposite to the air outlet. A flow channel of spiral air-out passing through the air inlet, the alternated expansion chamber and contraction chamber and the air outlet sequentially. The motor casing is provided with a longer spiral flow channel. The flow resistance of the spiral flow channel is smaller, so that the motor casing provided is further beneficial for improving the overall efficiency of the dust collector and reducing the noise. And the alternate expansion chamber and contraction chamber are arranged in the spiral flow channel so as to increase the loss of sound energy.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Built-in oil well pump plunger for upward-traveling valves

InactiveCN101737318AExtended service lifeSimple structurePositive displacement pump componentsLiquid fuel engine componentsInterference fitEconomic benefits

The invention provides a built-in oil well pump plunger for upward-traveling valves. An upper oil-outlet joint is in threaded connection with the upper part of an equal-diameter plunger; a traveling valve ball seat is on an upper port of a traveling valve seat; a valve ball cavity and a valve seat hole are arranged under a thread of the upper part of the equal-diameter plunger; the traveling valve seat is fixedly arranged in the valve seat hole; a traveling valve ball is positioned in the valve ball cavity; and the lower part of the upper oil-outlet joint is provided with a block cover. The traveling valve seat and the valve seat hole in the equal-diameter plunger are in interference fit which plays a role in sealing and fixing, or the traveling valve seat and the equal-diameter plunger are connected and fixed through threads, and the lower end face of the traveling valve seat is a sealing surface. As the valve ball cavity is arranged in the equal-diameter plunger, no traveling valve cover needs to be installed; the plunger is simple in structure and high in reliability, and ensures long lifespan of oil well pumps, large flow channel of the valve ball cavity and low flow resistance; and when a small-diameter oil well pump is designed as an equal-diameter oil well pump, the area of the flow channel cannot be reduced while the flow channel of the equal-diameter oil well pump is the same with that of common oil well pump. Therefore, the plunger has the advantages of wide application range, good use performance and significant economic benefit.

Owner:南通市通州区生产力促进中心

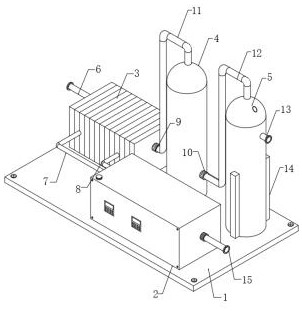

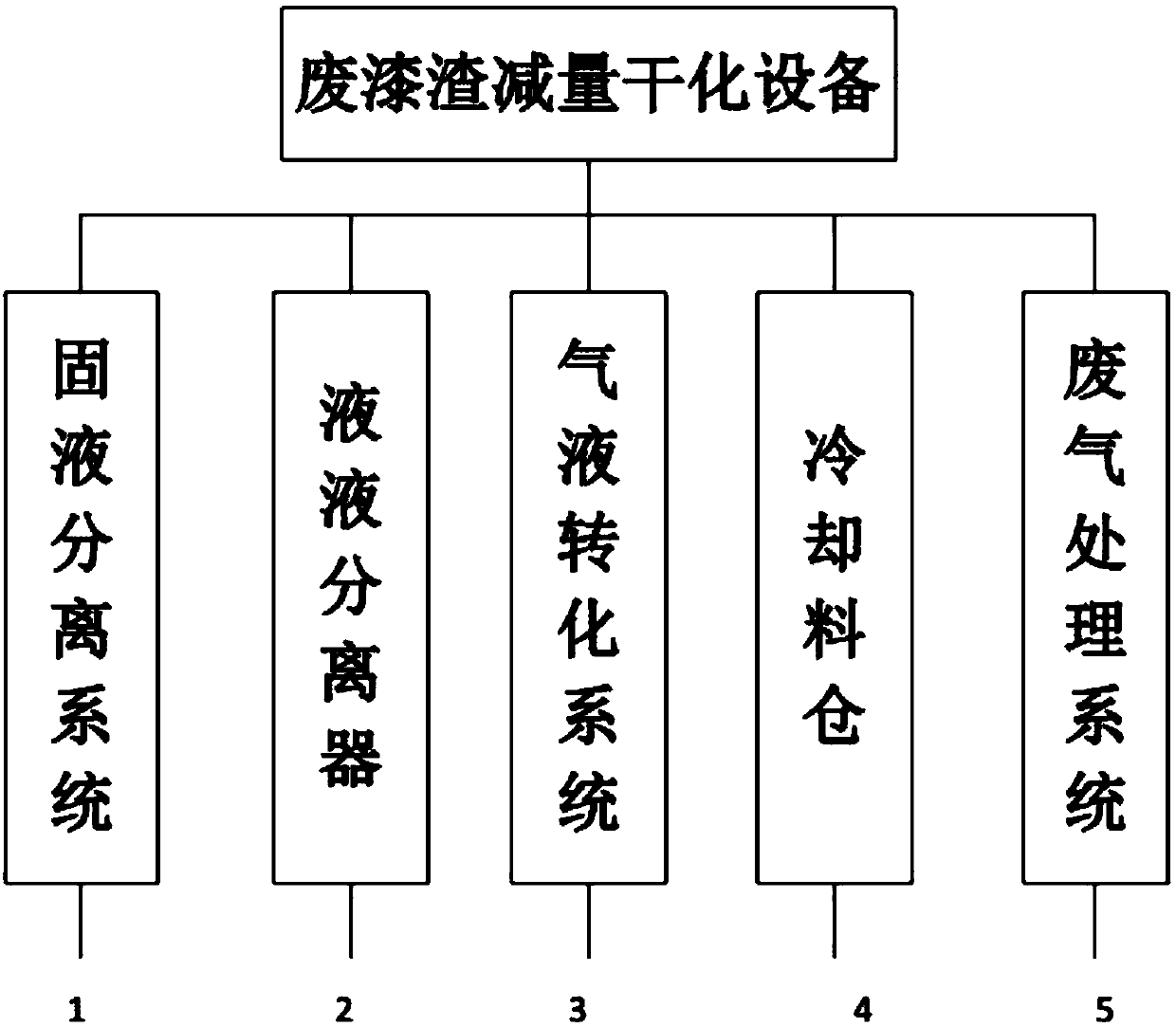

Gas-liquid conversion system and equipment with same

PendingCN107606897AAchieve reductionAvoid pollutionLiquid separation auxillary apparatusVapor condensationOrganic solventBuffer tank

The invention discloses a gas-liquid conversion system and equipment with the same. The gas-liquid conversion system comprises a condensing device; the condensing device is connected with a freezing unit used for providing required condensed water for the condensing device, and the other end of the condensing device is connected with a buffer device used for buffering liquid which is formed aftergas is condensed; the buffer device is connected with a first vacuum device; and the other end of the first vacuum device is connected with a water tank device, and the first vacuum device utilizes water in the water tank device to convert the gas which is not converted timely into liquid through water circulation. Organic solvents can be prevented from adhering and flow to a buffer tank through the gravity, a vacuum pump device pumps cooled air to a water tank through water circulation, parts of the residual organic solvents are intercepted in the water tank, and thus secondary pollution is prevented.

Owner:江苏瑞德斯环保科技有限公司

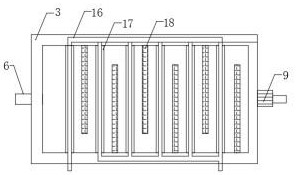

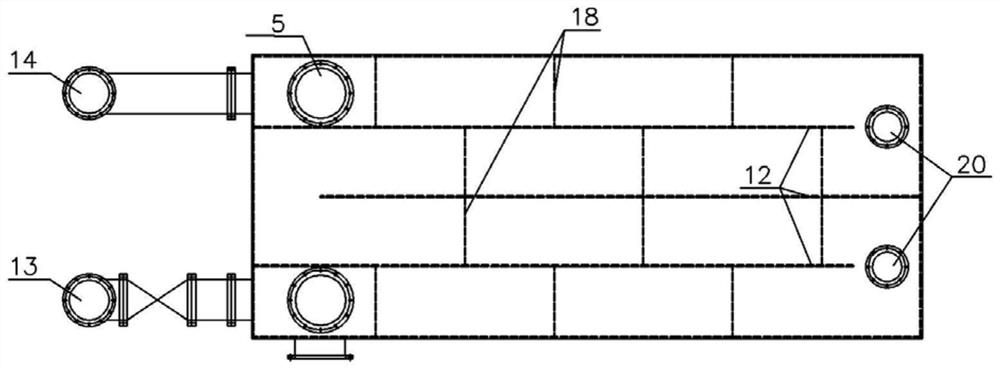

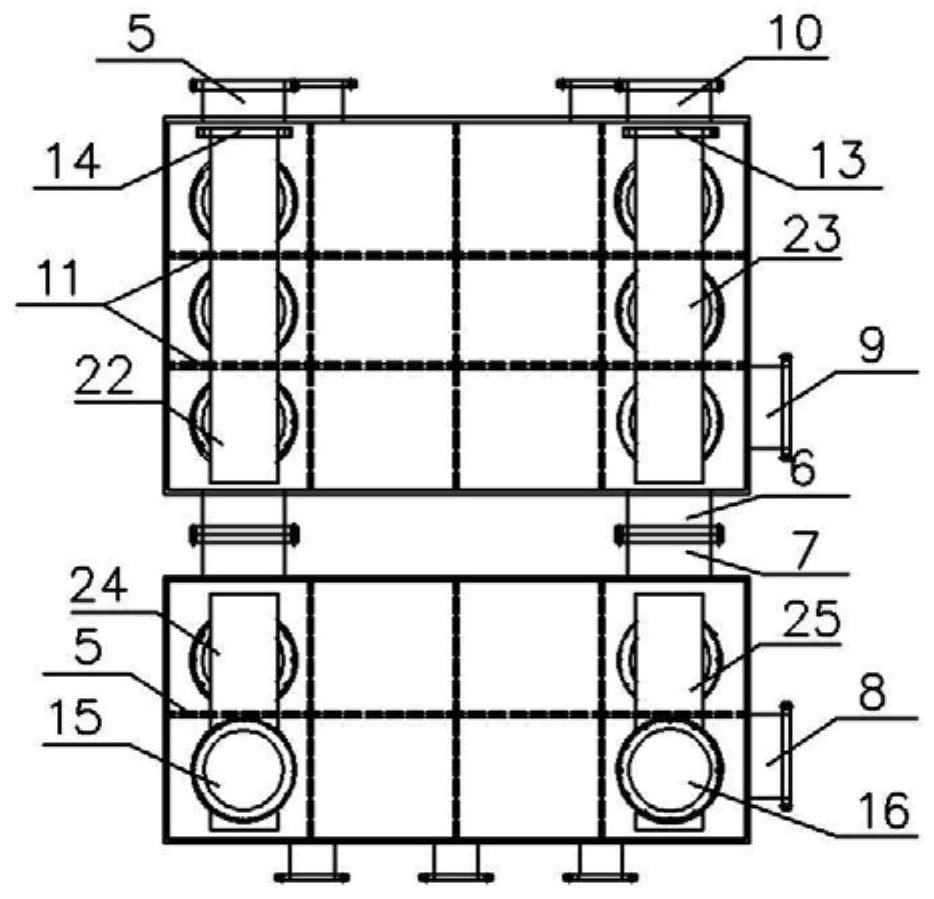

A double-pass spiral-wound diffusion dialysis membrane module and its preparation method

The present invention discloses a two-way spiral wound diffusion dialysis membrane assembly and a preparation method thereof. According to the two-way spiral wound diffusion dialysis membrane assembly, an ion exchange membrane and flow channel separation nets closely contact with each other and are wound by using a pair of spliced center pipes as the axis to form a cylinder; the spaces supported by the flow channel separation nets form fluid channels, and the fluid channels are always positioned on both sides of the ion exchange membrane so as to respectively form a diffusion liquid flow channel and a dialysis liquid flow channel; the axial middles of each center pipe are blocked by a blocking plate so as to form a left part and a right part, and the leaf part and the right part are not communicated to each other; the edge of the flow channel separation net is sealed; a baffle is arranged at the 1 / 2 width position of the flow channel separation et and extends from the center pipe to a position a certain distance away from the bottom edge; and a diffusion liquid and a dialysis liquid form two-way spiral countercurrent flow in the membrane assembly. According to the present invention, the membrane assembly has advantages of high packing density, high mass transfer efficiency, high unit membrane area liquid treatment capacity, and easy automated production.

Owner:HEFEI CHEMJOY POLYMER MATERIALS CO LTD

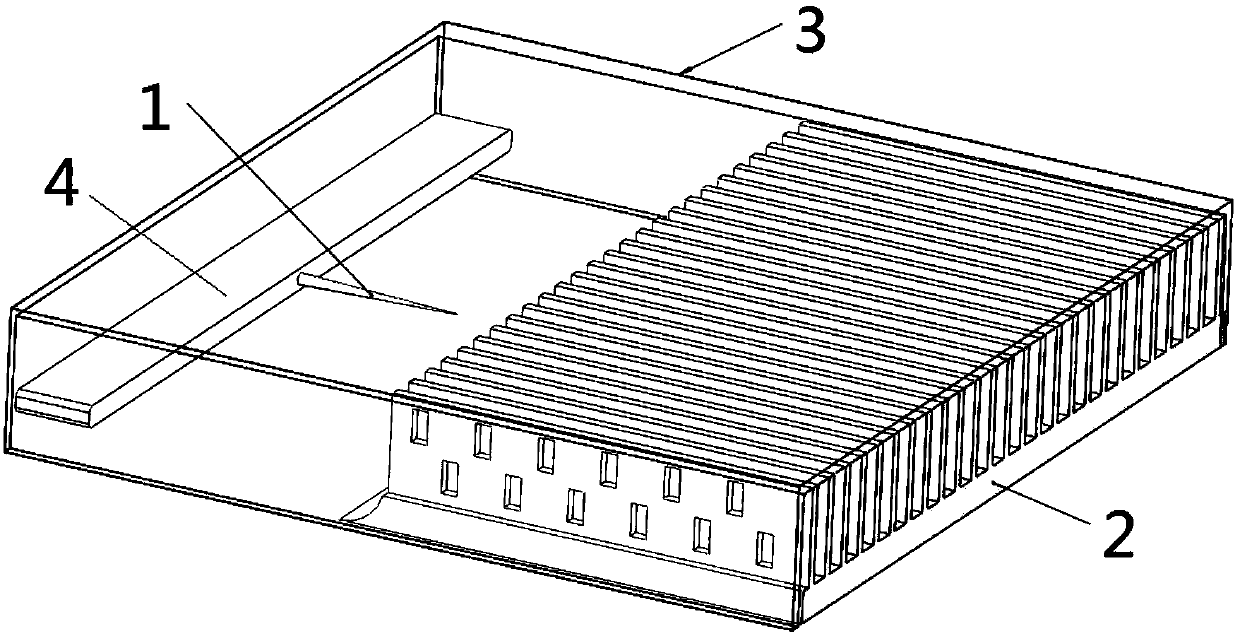

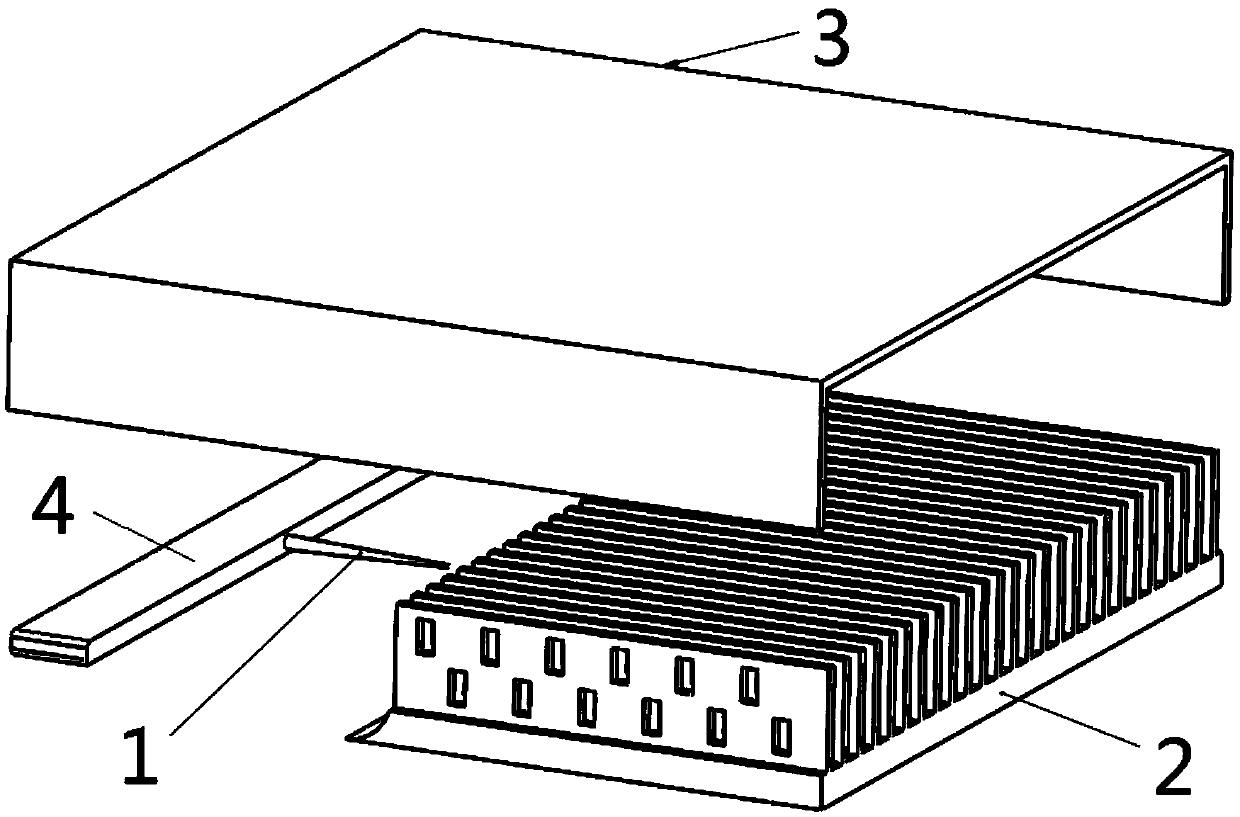

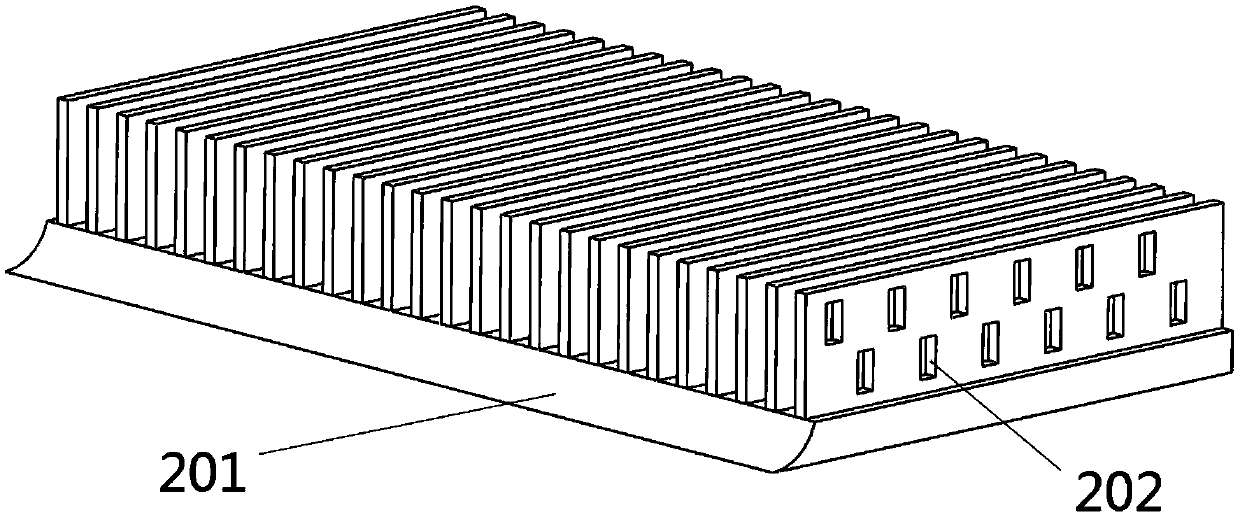

a cooling device

ActiveCN106612608BSimple structureReduce volumeCooling/ventilation/heating modificationsDc currentHigh-voltage direct current

The invention belongs to the field of electronic products, and particularly relates to a heat radiation device. The heat radiation device comprises an outer shell, a fin body and a primary emitting electrode. The fin body is arranged at one side of the interior of the outer shell; the discharging end of the primary emitting electrode which is dead against the fin body is arranged at the other side of the interior of the outer shell; the discharging end of the primary emitting electrode has a first preset distance to the fin body; and a high-voltage DC current is arranged between the primary emitting electrode and the fin body. The heat radiation device can generate ionic wind by directly converting electric energy into air kinetic energy and improves the heat radiation efficiency by combining the ionic wind cooling technology with a fin radiation technology cleverly. Meanwhile, the heat radiation device is simple in structure, small in volume and convenient to disassemble, maintain and clean.

Owner:GUANGDONG UNIV OF TECH

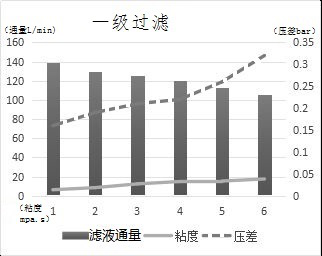

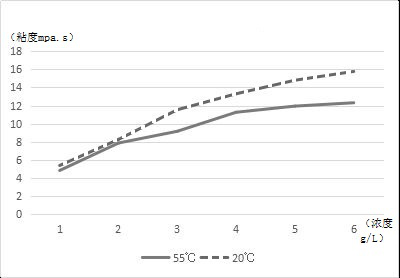

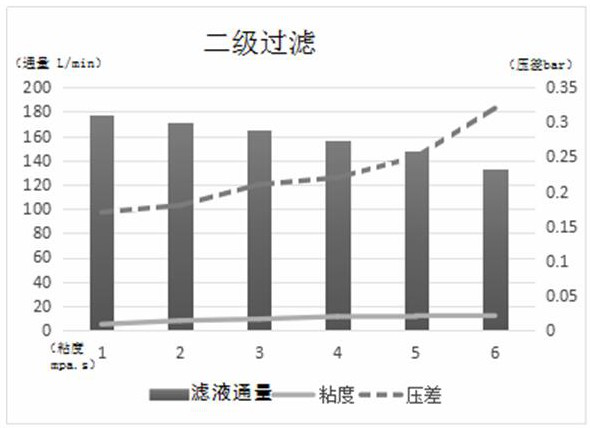

A kind of lye multistage recovery process

ActiveCN109554948BLow viscosityReduce differential pressureRegeneration of alkali lyeFiltrationPapermaking

An alkali liquid multi-stage recovery process is disclosed, belonging to the technical field of viscose fiber production, papermaking, and the like. The process includes first-stage dilution, first-stage filtration, second-stage dilution, first-stage temperature rising, second-stage filtration, second-stage temperature rising, third-stage filtration, third-stage dilution and fourth-stage filtration. Different devices are adopted by combination of process characteristics, namely different nanofiltration systems are adopted in different process stages so that the process adapts to alkali liquidrecovery better. Multi-stage dilution and temperature rising and other types of treatment are adopted to reduce the viscosity of fed liquid, increase the net liquid flux, and reduce differential pressure among films, thus ensuring controllable, stable and efficient alkali liquid recovery.

Owner:YIBIN GRACE +1

Sand preventing oil well pump

PendingCN109578256AGood reliabilityOvercome heavy oil resistancePositive displacement pump componentsFlexible member pumpsOil wellWaste management

The invention provides a sand preventing oil well pump which is composed of a plunger assembly and a pump cylinder assembly. A pull rod is connected with a short plunger. The short plunger is matchedwith a long pump cylinder in the pump cylinder assembly in a sliding and sealing manner. A sand storing ring-shaped groove is formed in the outer surface of the short plunger. A sand settling cylinderin the pump cylinder assembly is arranged on the outer wall of the short pump cylinder in a sleeving manner and forms a sand settling ring. An elastic limiting claw is arranged in the sand settling cylinder. The pump has the characteristics that the pumping efficiency is high, the sand preventing effect is good, the bearing ability is high, forward and reverse well washing and sand flushing of immovable pipe columns are achieved, and the oil well pump is applicable to exploitation of sand producing heavy oil wells.

Owner:CSIC ZHONGNAN EQUIP

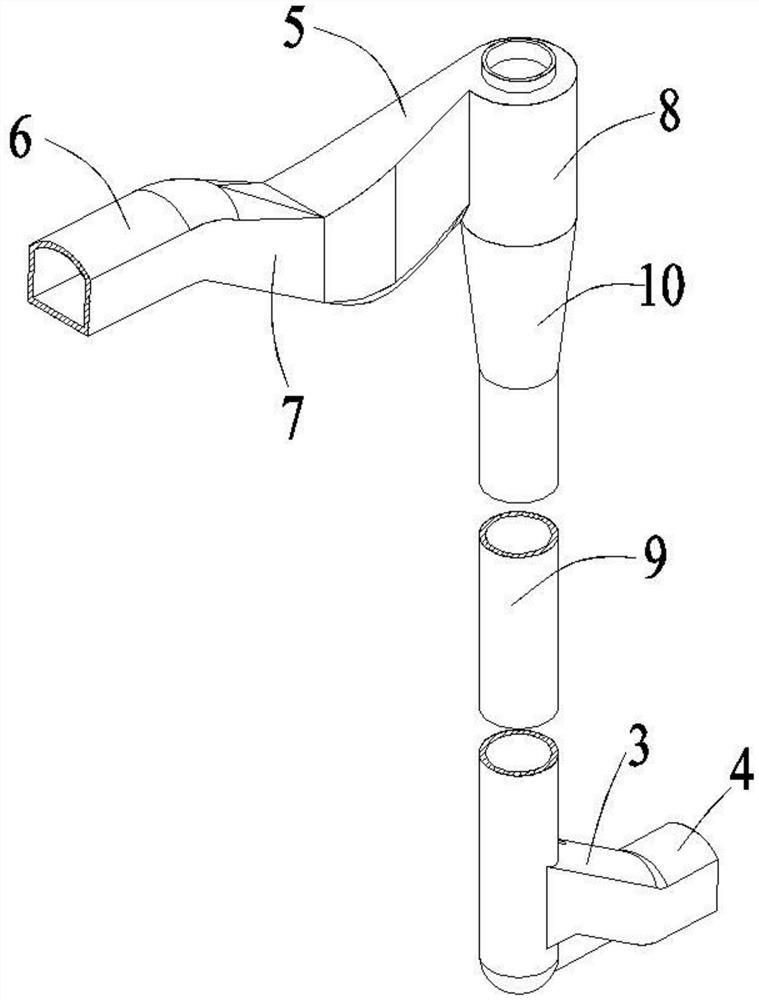

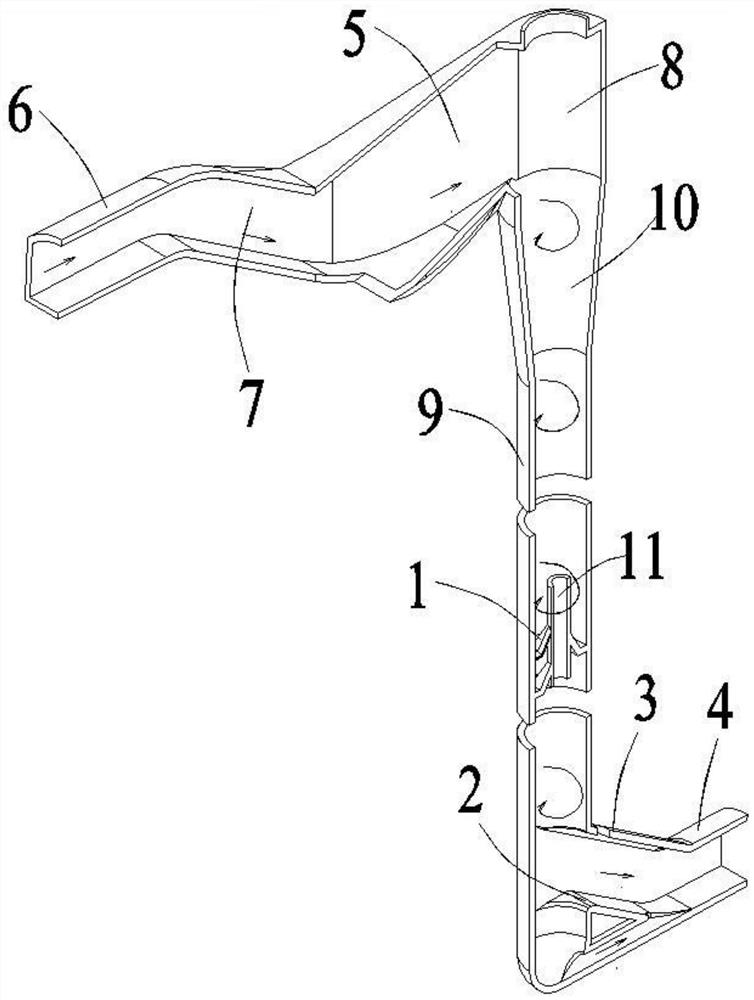

An anti-condensation non-assisted ventilation device for ring network cabinets

ActiveCN109494596BReduce the temperatureAvoid enteringSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsRing networkStructural engineering

The invention discloses an anti-condensation unassisted ventilation device for a ring main unit, and relates to the technical field of ring main unit ventilation devices. The device comprises a support seat disposed above a cable trench and a cabinet body disposed above the support seat, wherein the cabinet body is connected with the support seat, and the upper end face of the support seat is provided with a plurality of ventilation devices. Each ventilation device comprises a wind cap, a connecting pipe and a support cylinder. The upper end of each connecting pipe is connected with the wind cap, and each support cylinder sleeves the corresponding connecting pipe. Each support cylinder is connected with the corresponding connecting pipe, and cooperates with a through hole in the upper endface of the support seat. A limiting plate is disposed between the connecting pipes and the support cylinders, and an elastic part is disposed between the limiting plate and the connecting pipes. Thewall of each support cylinder is provided with an installation hole, and the installation holes cooperate with the limiting plates. According to the invention, the hot air in the cable trench can be prevented from entering the cabinet body to generate a condensation phenomenon, and the device prevents the rusting of a switch in the cabinet body from causing the wrong operations, thereby improvingthe power supply reliability. Moreover, there is no need of a large amount of manpower and material resources for removing the condensation of the ring main unit, and the potential safety hazards arereduced.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

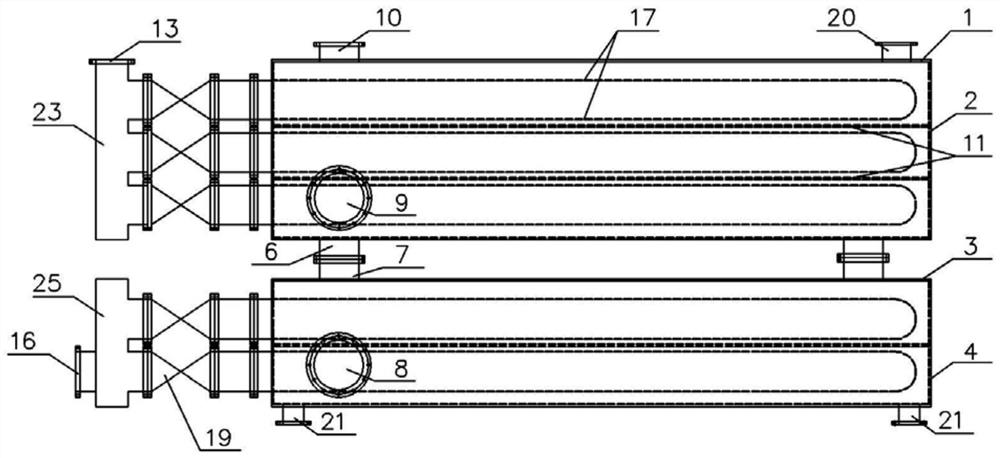

Split type blast furnace slag flushing water heat exchange device and method

PendingCN113218213AFlexible structureImprove reliabilityStationary tubular conduit assembliesSlagEngineering

The invention provides a split type blast furnace slag flushing water heat exchange device and method. The split type blast furnace slag flushing water heat exchange device comprises an upper box cover, an upper box body, a lower box cover, a lower box body, heat exchange pipe bundles and communicating pipes. The upper box cover is fixed to the top of the upper box body to form an upper heat exchange box, the lower box cover is fixed to the top of the lower box body to form a lower heat exchange box, the upper heat exchange box is connected to the upper portion of the lower heat exchange box, the heat exchange pipe bundles are arranged in the upper heat exchange box and the lower heat exchange box, two ports of each heat exchange pipe bundle communicate with a water outlet main pipe and a water inlet main pipe correspondingly, the water inlet main pipe and the water outlet main pipe of each single heat exchange box are not overlapped, the water outlet main pipes and the water inlet main pipes of the different heat exchange boxes are connected through the communicating pipes to achieve parallel connection or series connection switching of the upper heat exchange box and the lower heat exchange box, or independent heat exchange between the upper heat exchange box and the lower heat exchange box is achieved by disconnecting the communicating pipes. The split type blast furnace slag flushing water heat exchange device and method solve the problems that a sewage heat exchange device is prone to corrosion, blockage and scaling, and the heat exchange efficiency is high.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com