Sand preventing oil well pump

An oil pump and sand control technology, which is applied to pumps, pump components, variable displacement pump components, etc., can solve problems such as sand sticking and sand burial, prevent sand sticking and sand burial, overcome heavy oil resistance, and reduce opening and closing. lag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

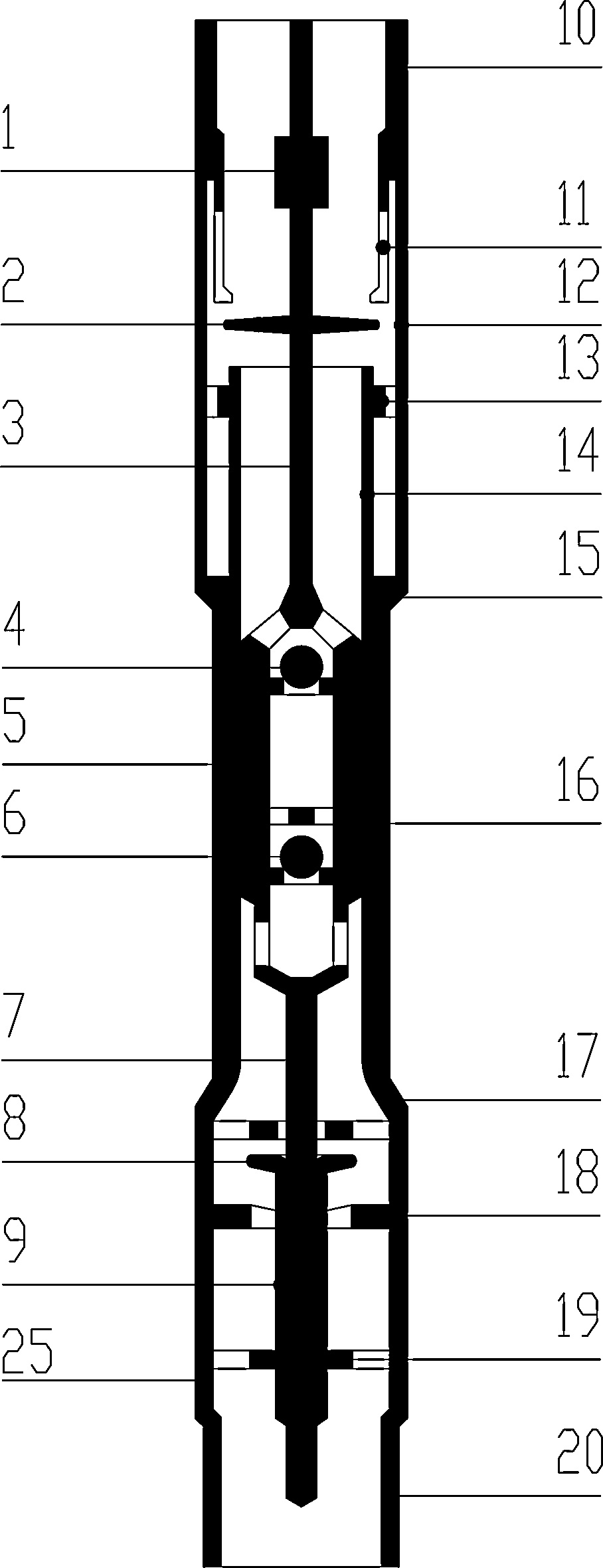

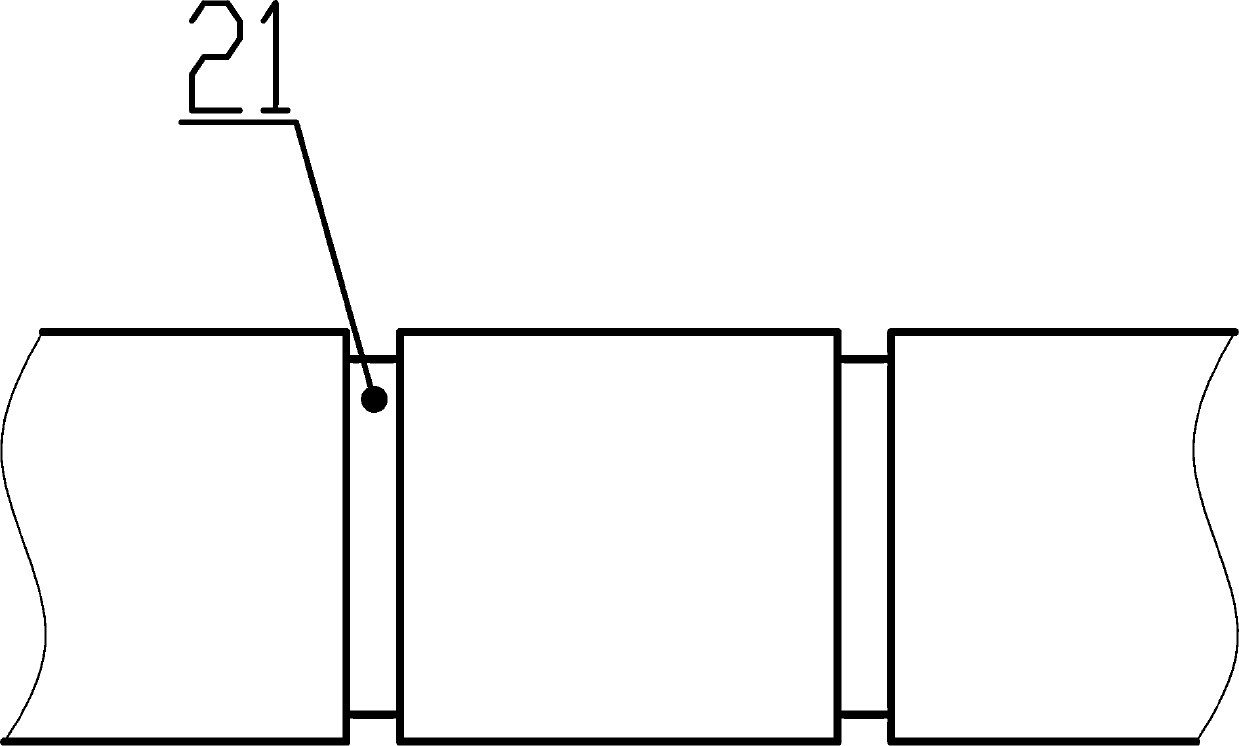

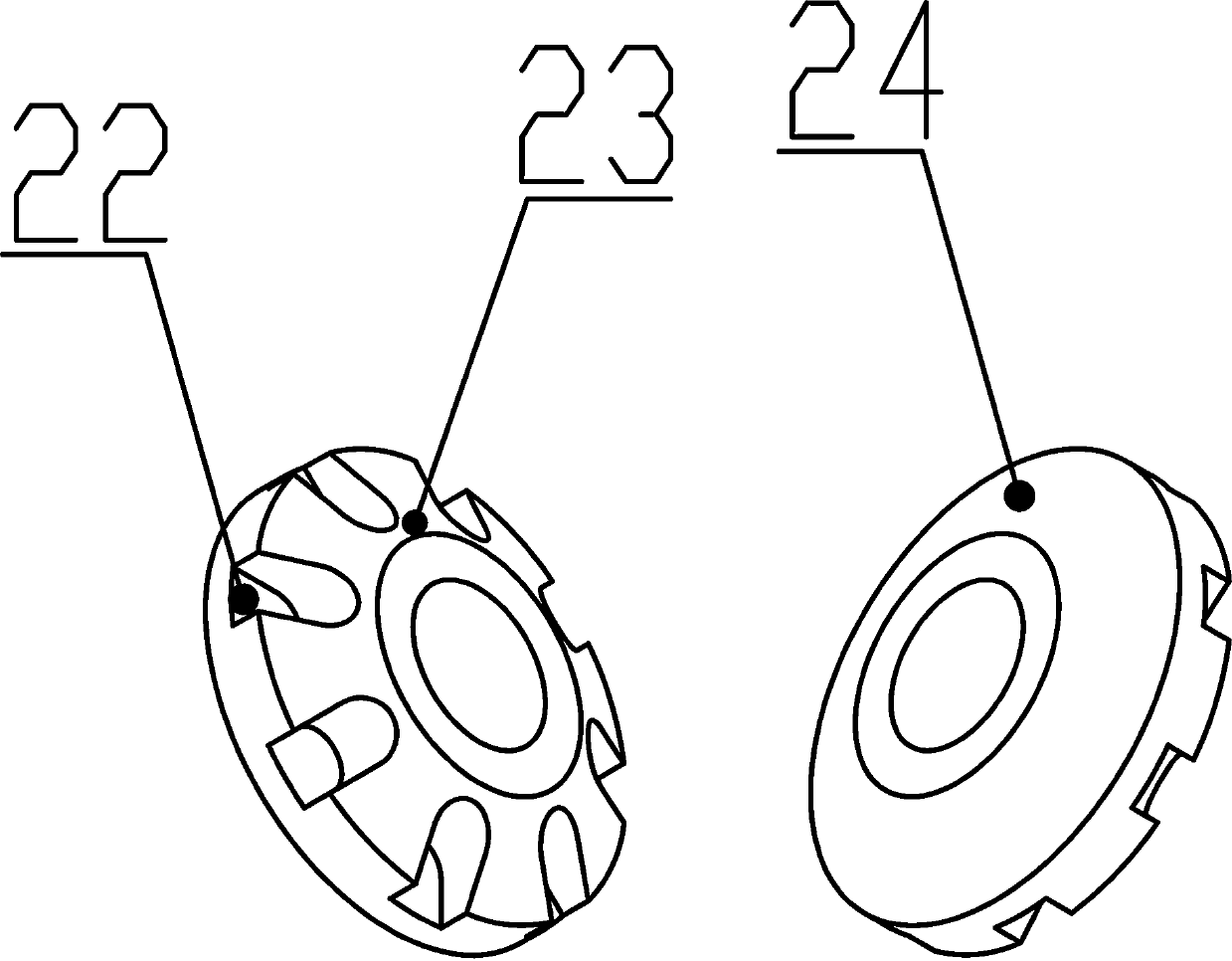

[0029] like Figure 1~3 As shown, a sand control oil well pump is composed of a plunger assembly and a pump cylinder assembly. There is an elastic limit claw 11 inside the cylinder 12, and the grit chamber 12 is set on the outer wall of the short pump cylinder 14 to form a grit settling ring. The outer oil pipe 25 communicates, the plunger assembly is arranged inside the pump barrel, the middle part of the plunger assembly is provided with a short plunger 5, the short plunger 5 is arranged inside the long pump barrel 16, and the outer surface of the short plunger 5 is provided with An annular groove 21 for storing sand, an upper oil outlet valve 4 and a lower oil outlet valve 6 are arranged at both ends of the short plunger 5, and the top of the upper oil outlet valve 4 is connected with the pull rod 3, and the pull rod 3 is provided with a sand retaining ring 2, and the sand retaining ring 2 Set between the short pump barrel 14 and the grit chamber 12, the bottom of the lowe...

Embodiment 2

[0039] Further illustrate in conjunction with embodiment 1, as Figure 1~3As shown in the figure, when going into the well, the upper end of the pump barrel assembly is connected to the tubing, the lower end is connected to the liner pipe, and the tubing string is lowered into the oil well to the designed position, and then the upper end of the plunger assembly is connected to the sucker rod, and then connected to the pumping rod. The oil rod strings are lowered into the oil pipe together.

[0040] During the pumping operation, the plunger assembly, driven by the sucker rod, reciprocates up and down in the pump barrel assembly.

[0041] During the upward stroke, the plunger assembly moves upward, the upper and lower oil outlet valves are closed, the volume of the annular pump chamber of the upper pump increases, the pressure drops, and the oil inlet valve opens under the action of the submerged pressure and the friction between the plunger and the pump barrel , Crude oil ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com