Manufacturing method of trench isolation structure

A technology of isolation structure and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of deteriorating the characteristics and reliability of memory components, and achieve the effect of optimal component characteristics and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

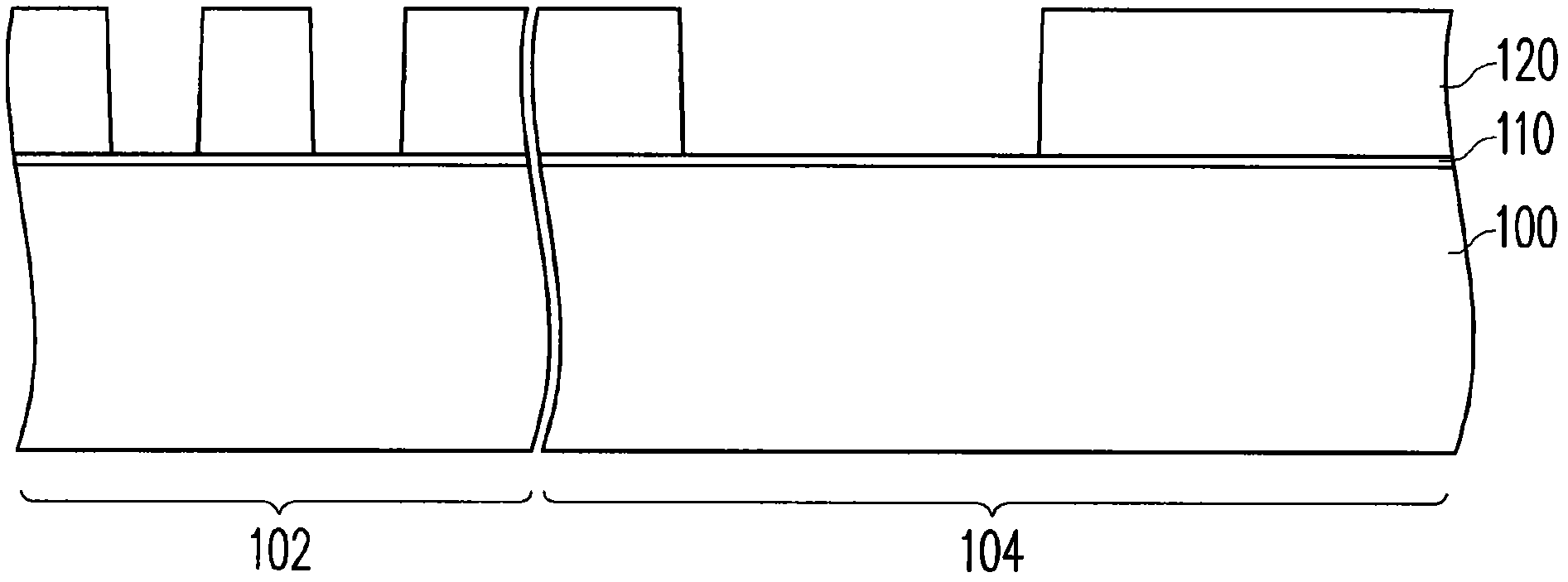

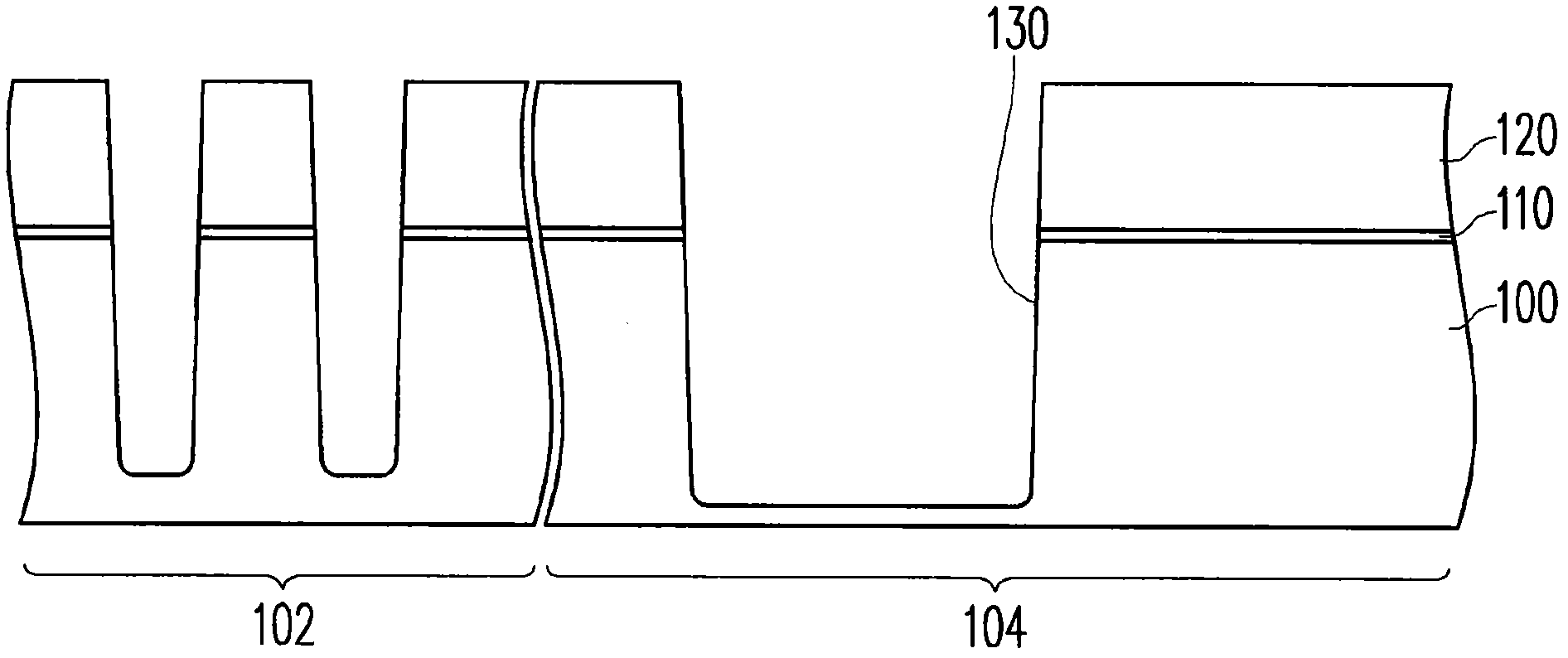

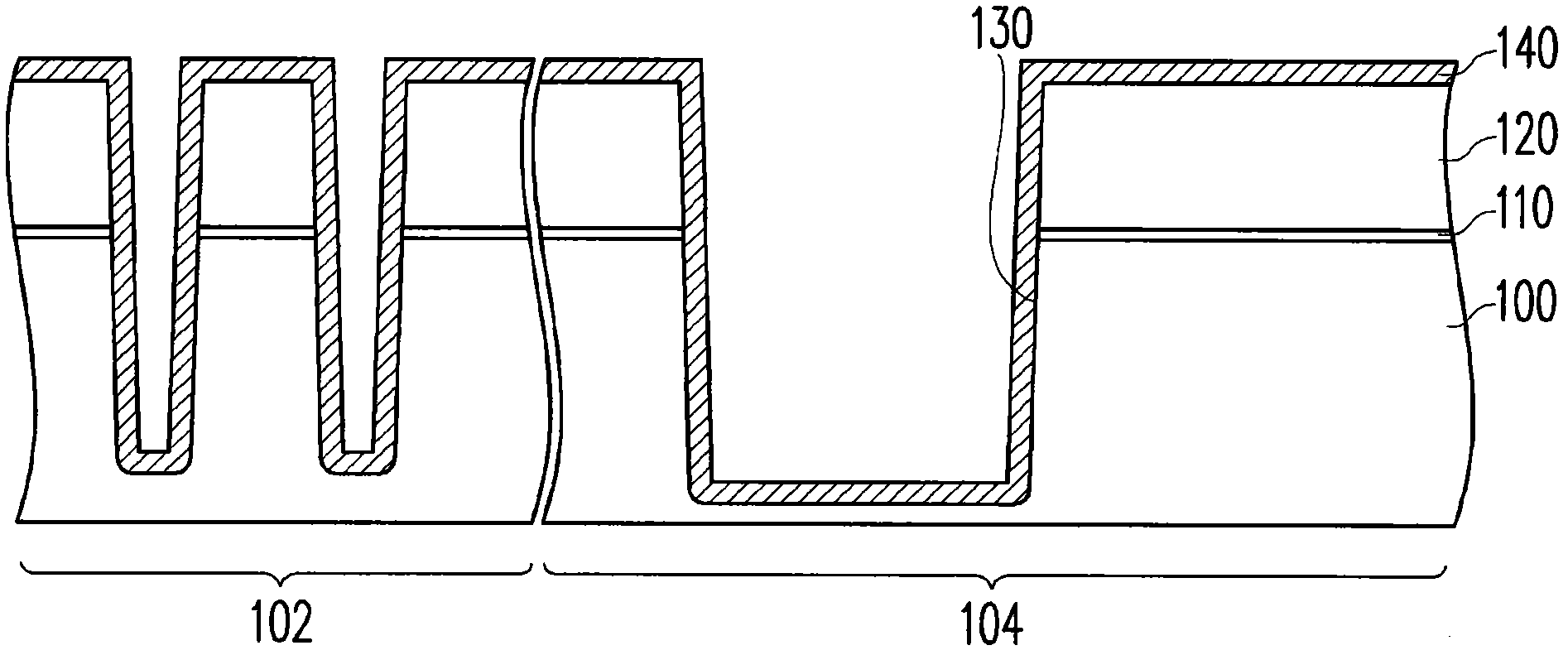

Embodiment Construction

[0040] Generally speaking, since the peripheral area is usually used to form high-voltage elements and low-voltage elements, before the formation of the gate oxide layer, the peripheral area usually bears more wet etching than the memory cell area, and the high-voltage gate oxide layer in the peripheral area usually bears more wet etching. Thickness reduction is difficult or limited, so the corner thinning problem of the high-voltage gate oxide layer is also more serious in the peripheral region, and the low-voltage gate oxide layer may even grow in the recess. As a result, the device characteristics and reliability of the memory device are degraded. Therefore, the present invention forms the shallow trench isolation structure according to the characteristics of the peripheral area of the memory element and the memory cell area, so as to avoid the angle thinning of the tunnel oxide layer and the gate oxide layer formed on the edge of the shallow trench isolation structure sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com