Patents

Literature

713results about How to "Avoid dents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

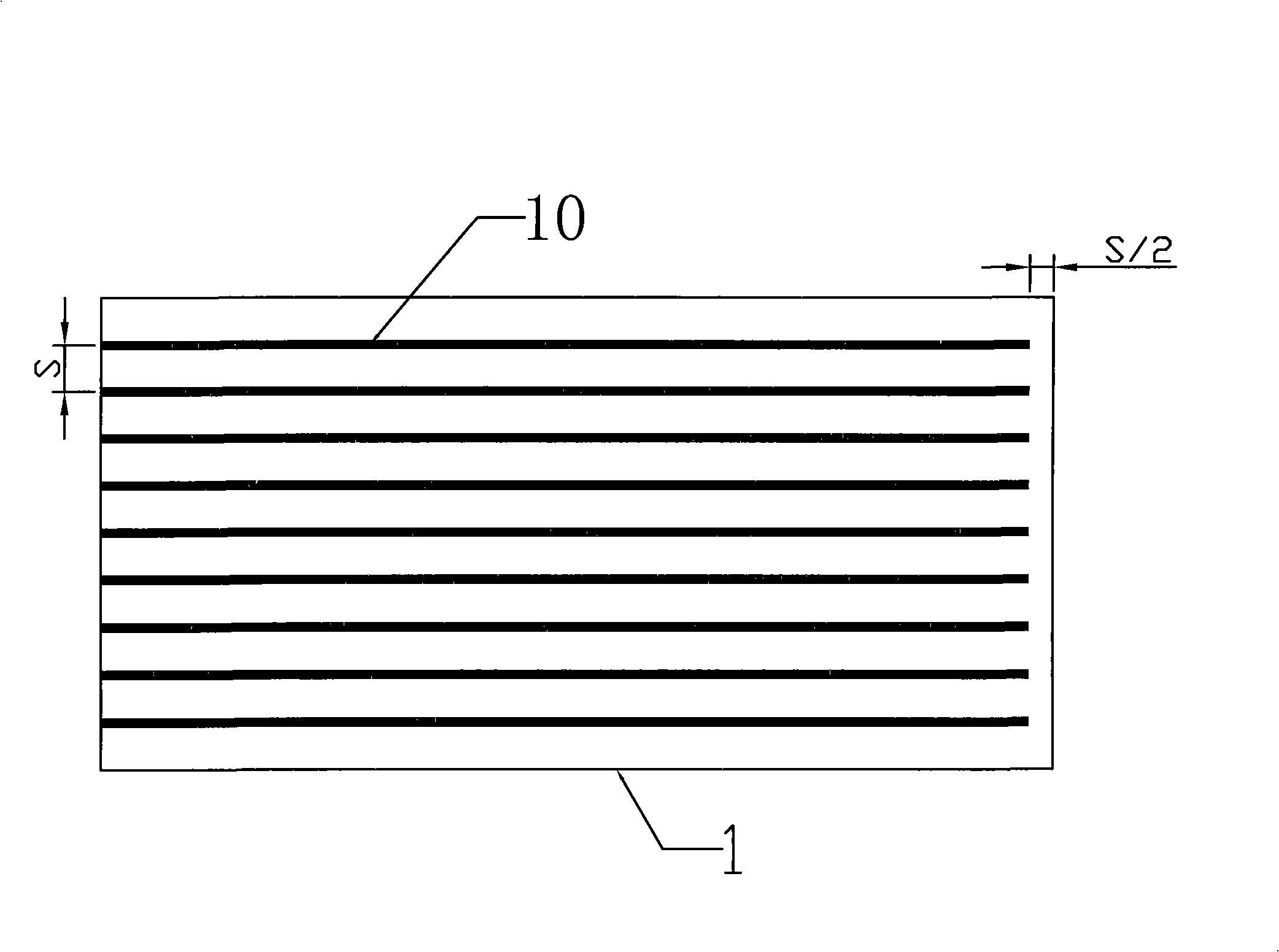

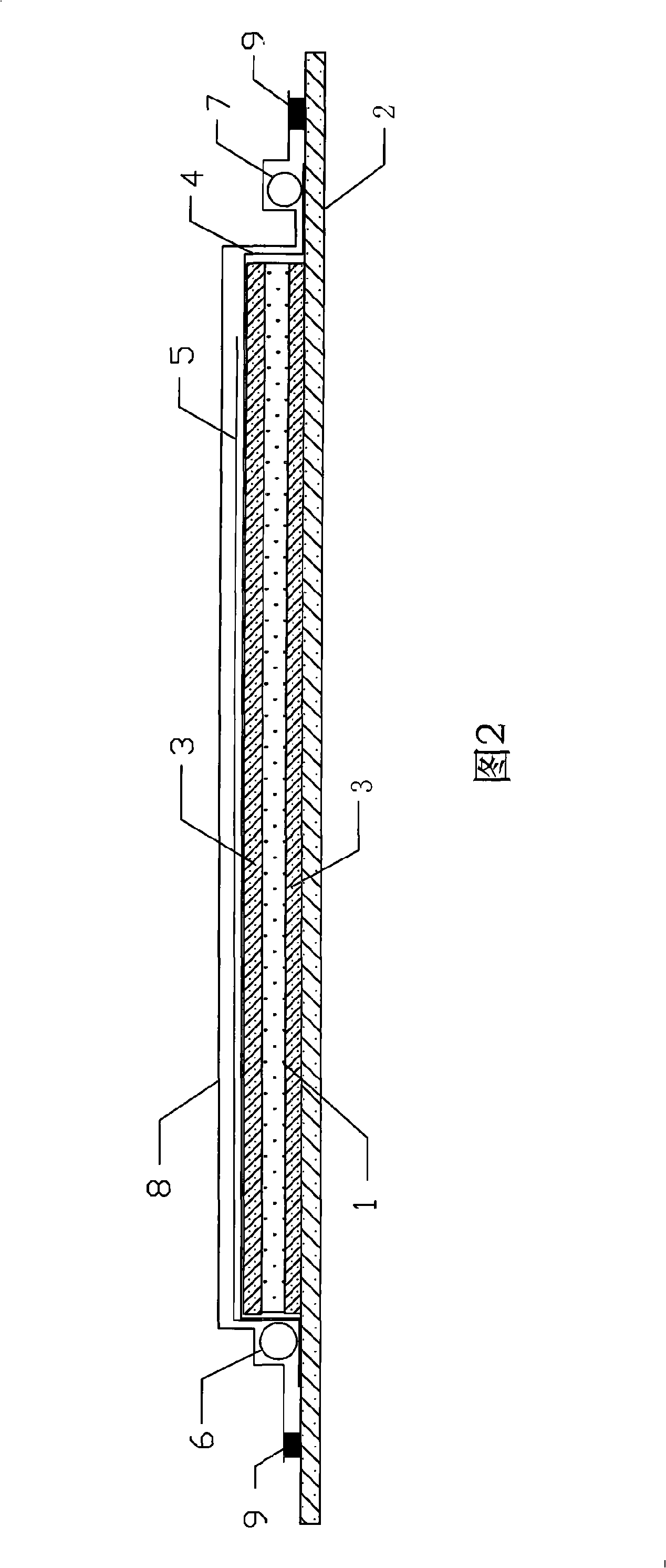

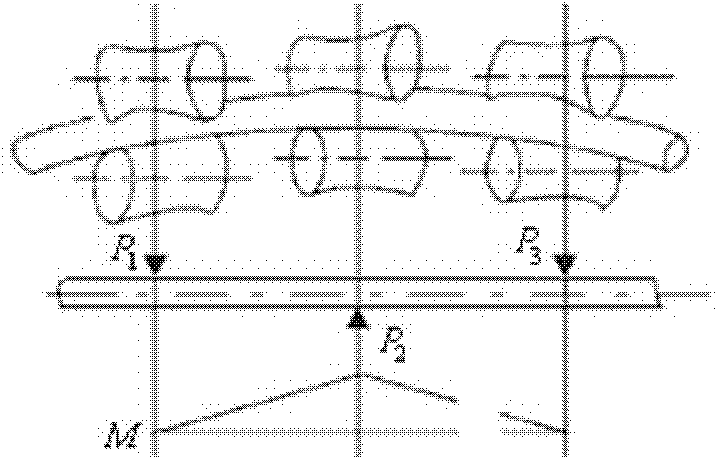

Vacuum auxiliary molding technique produced by large-sized sandwich composite material

The invention provides a vacuum assistant resin infused method for molding a large part of sandwich composite materials as follows: a set of grooves parallel to each other are arranged at the bottom of the foam core material; fiber fabrics are paved on a processed die according to the specified thickness, and then the grooved foam core material is arranged on the already-paved fiber fabrics, wherein, the machined surface of the grooves of foam core material contacts to the already-paved fiber fabrics, and then the fiber fabrics with a specified thickness are paved on the foam core material; a conduction pipe is arranged at one foam core material end with grooves and a vacuum pipe is arranged at the other end; sealed vacuum bag film and sealed adhesive tape are adopted to seal the fiber fabrics; when the vacuum pressure in the sealed bag film is equal to or less than negative 0.095Mpa, resin solution is inducted to the resin conduction system consisting of the conduction pipe and the conduction cloth after being poured with glue; after the resin immerses the fiber fabrics completely, glue pouring and evacuation are stopped; after the poured-in resin is heat-released and solidified, sandwich composite materials are obtained after 24 hours solidification under indoor temperature condition.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

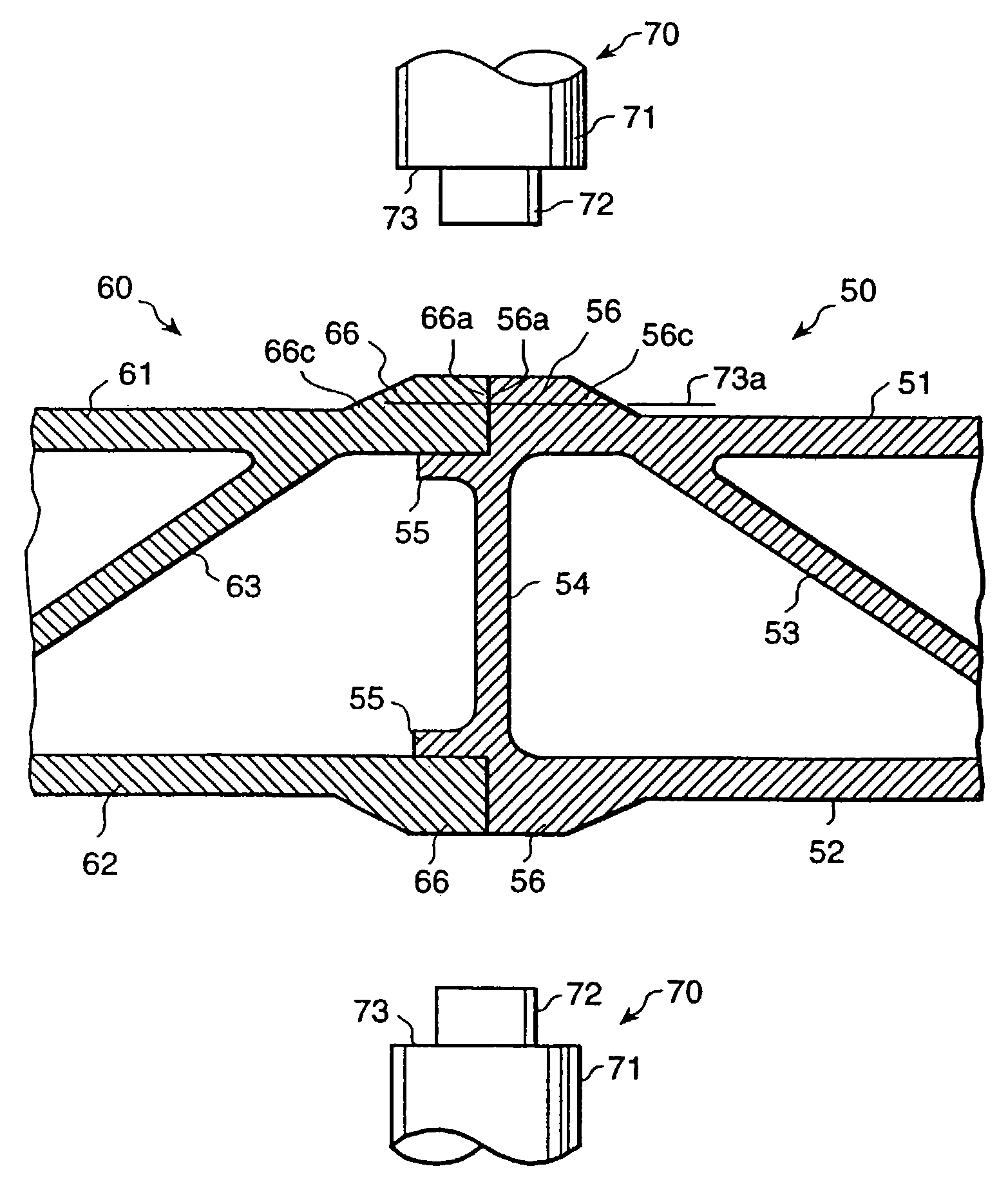

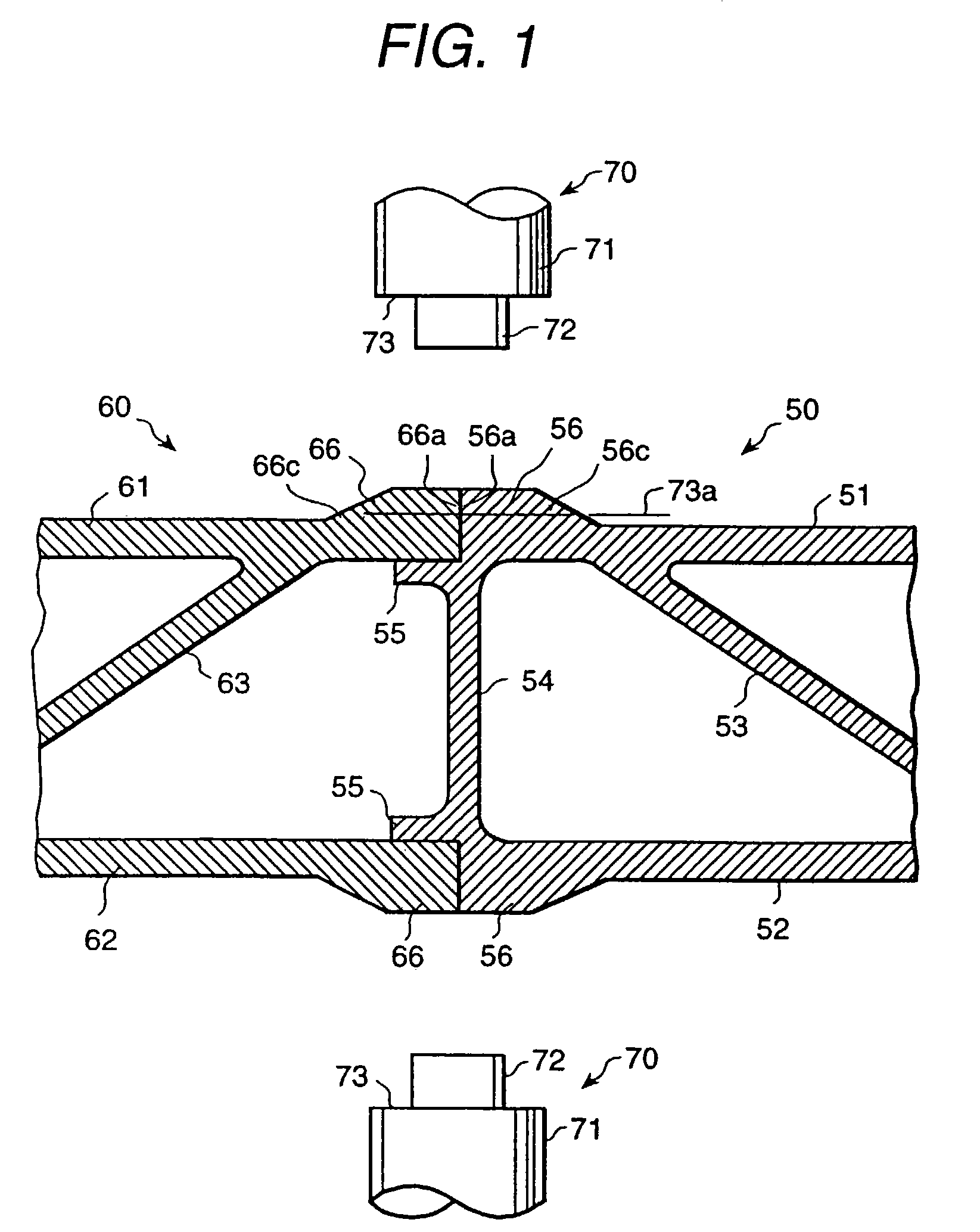

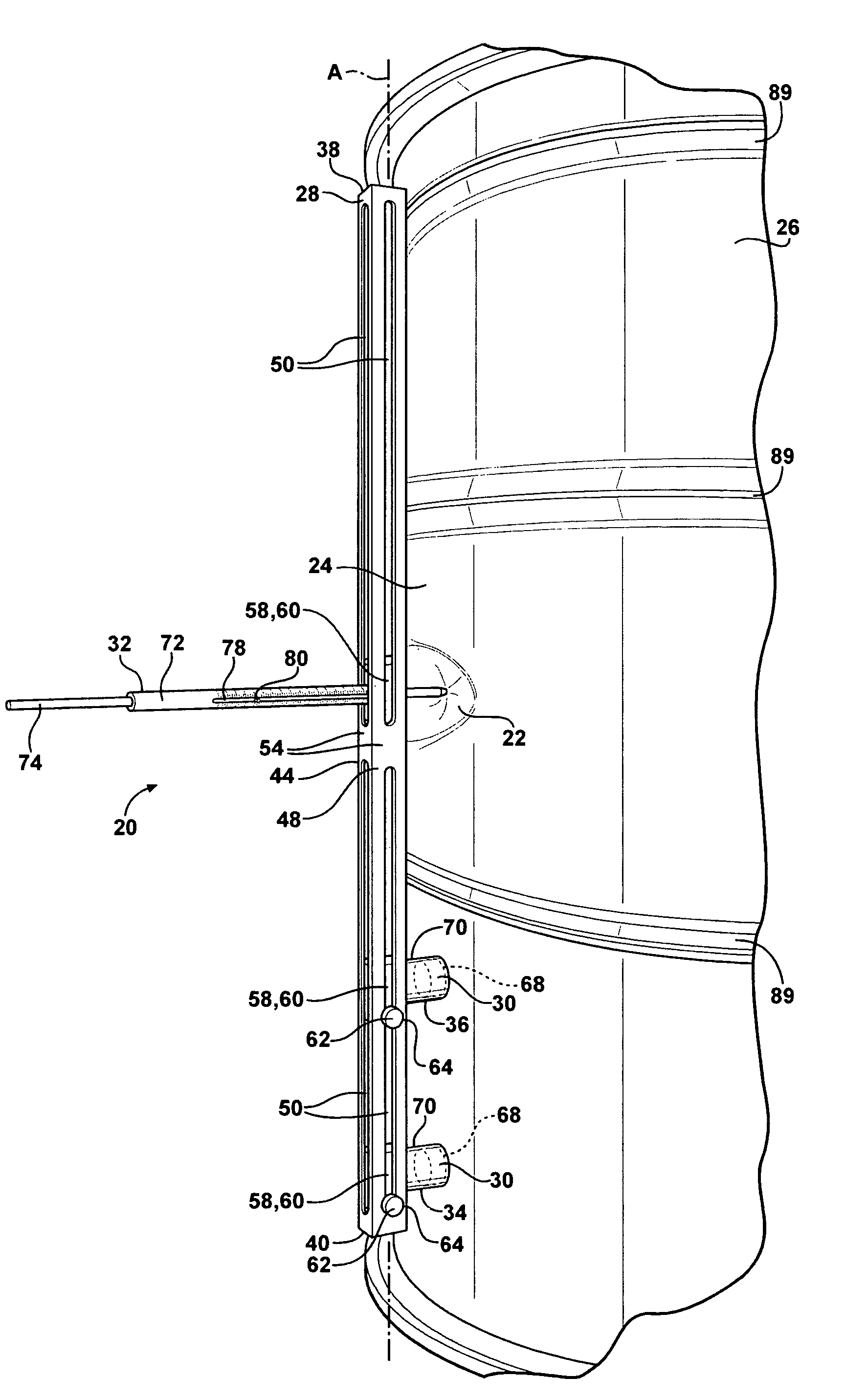

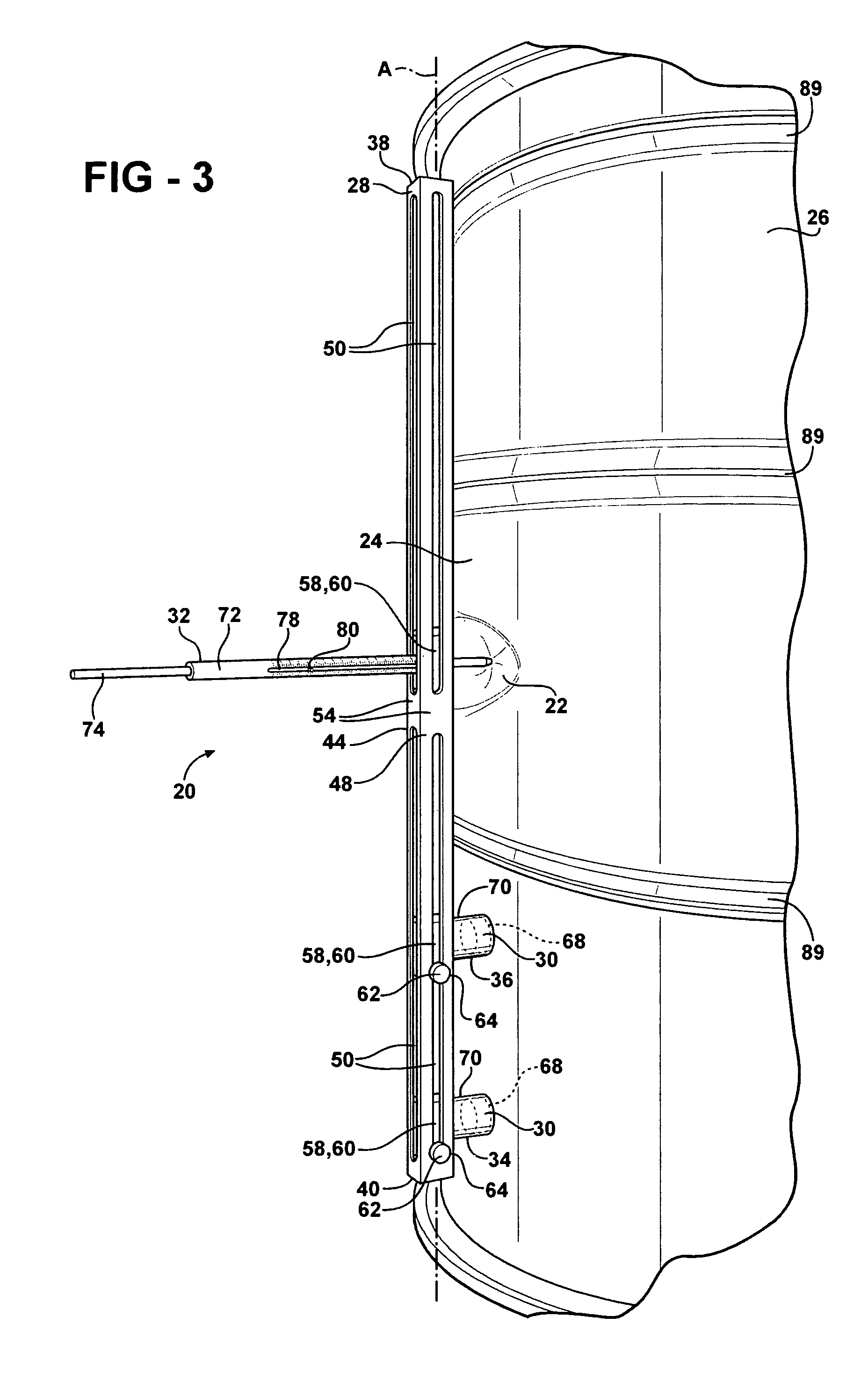

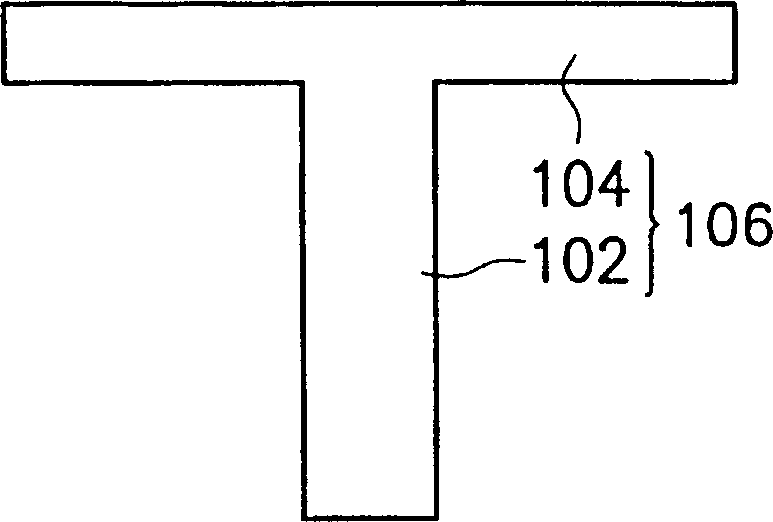

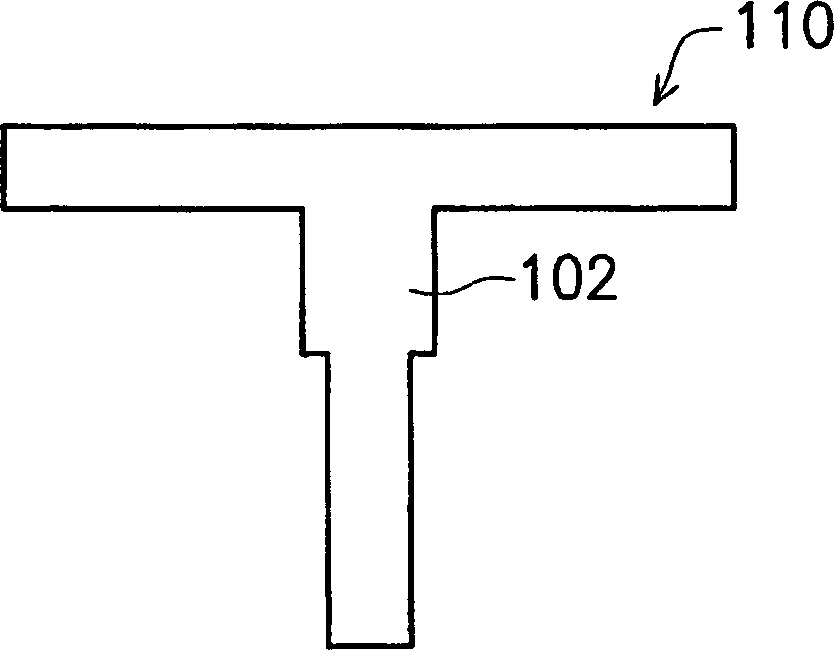

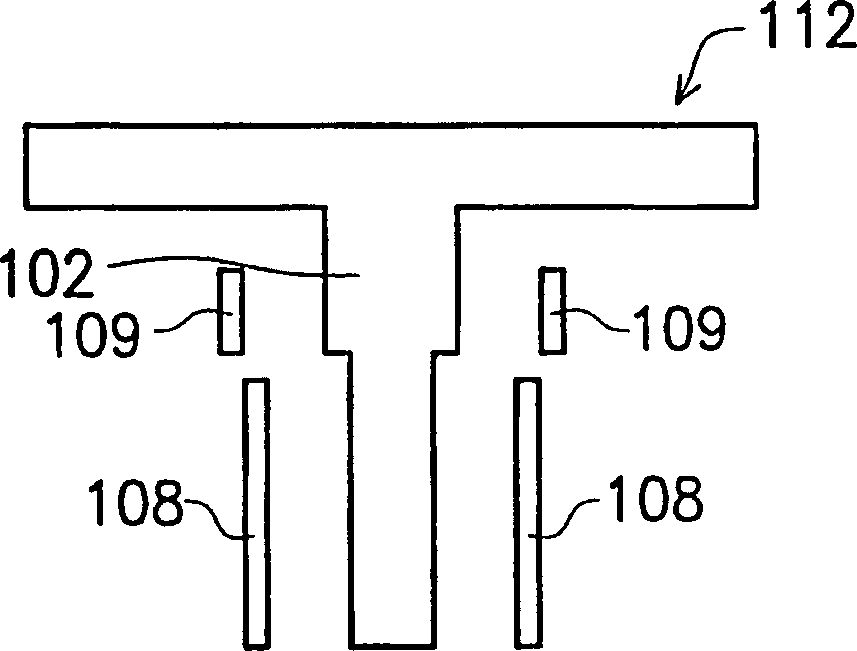

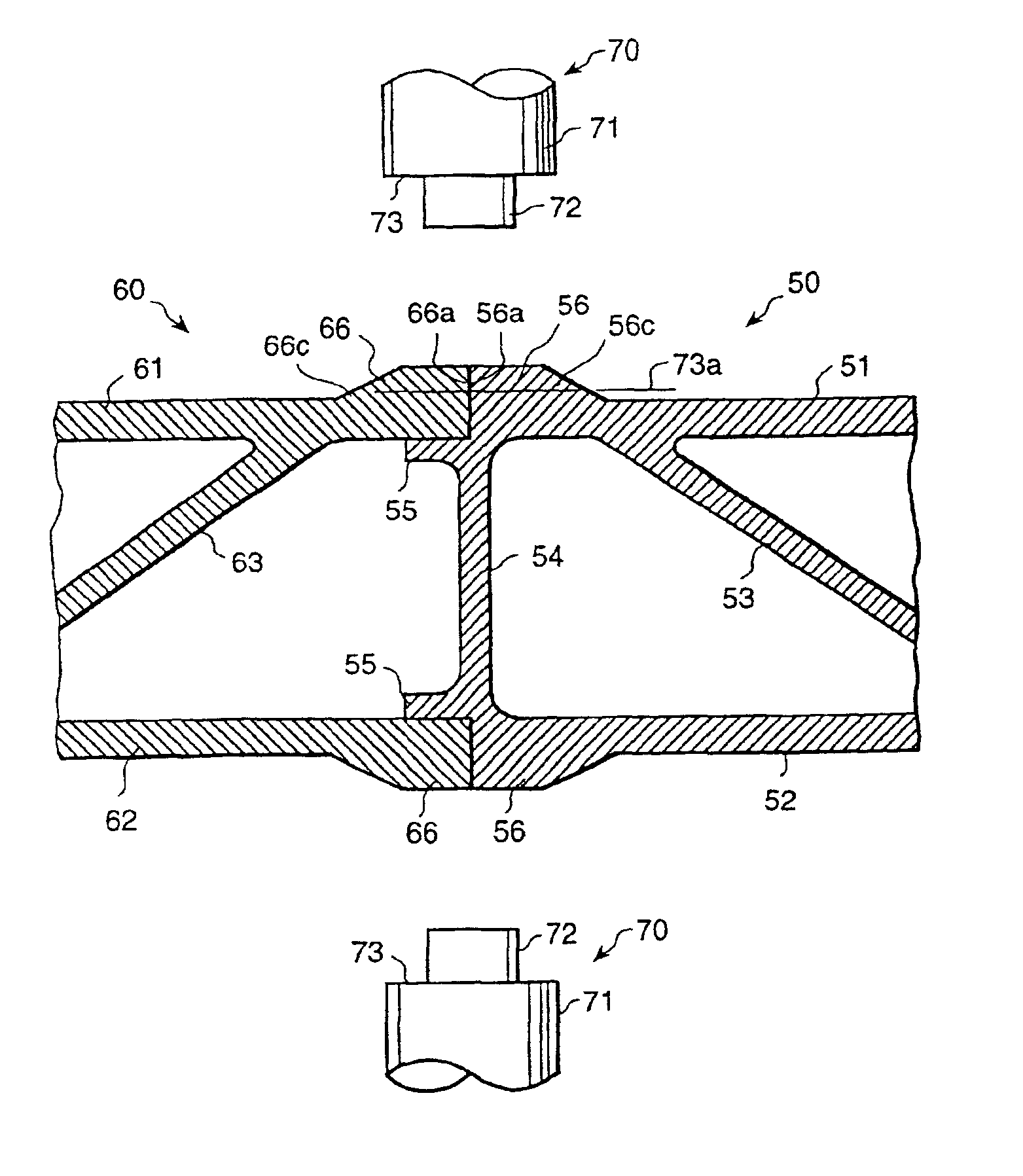

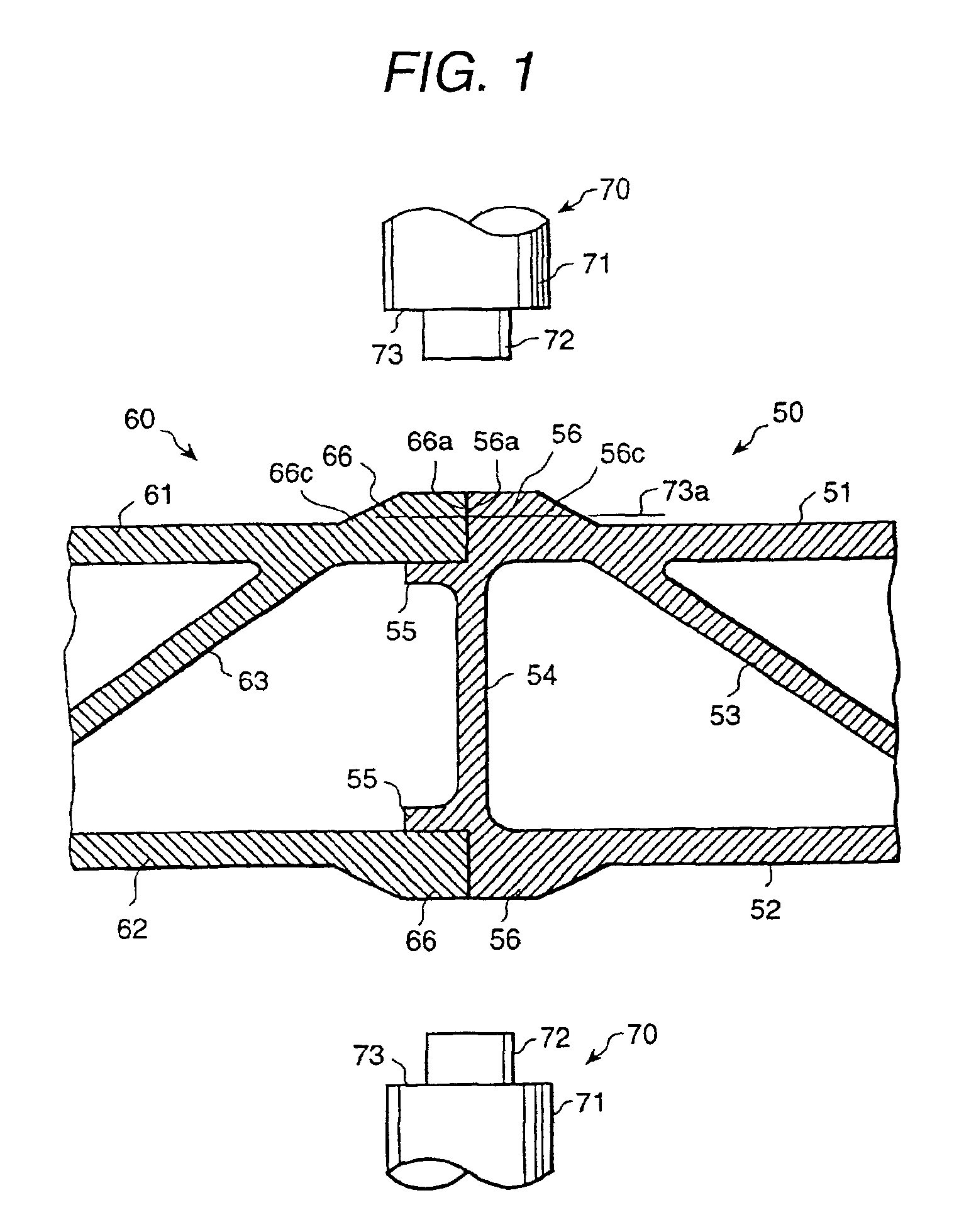

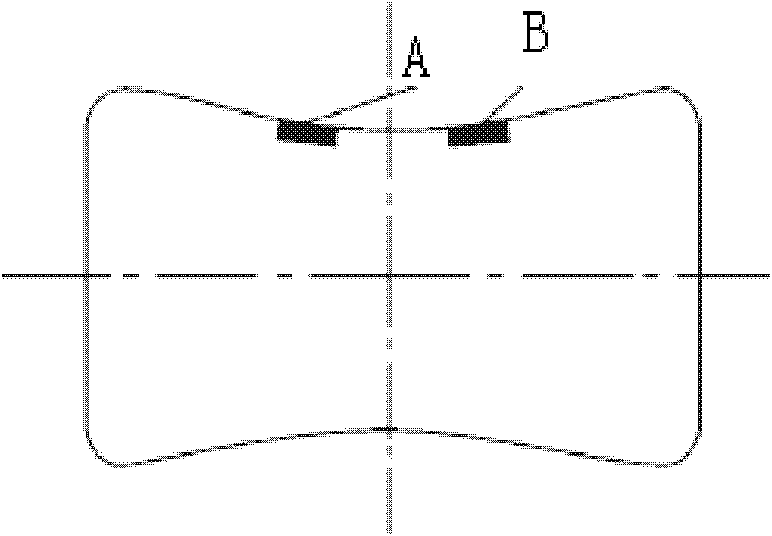

Friction stir welding method, frame members used therein, and product formed thereby

InactiveUS7036707B2High resultEasy to deleteWelding/cutting auxillary devicesStructural elementsEngineeringFriction stir welding

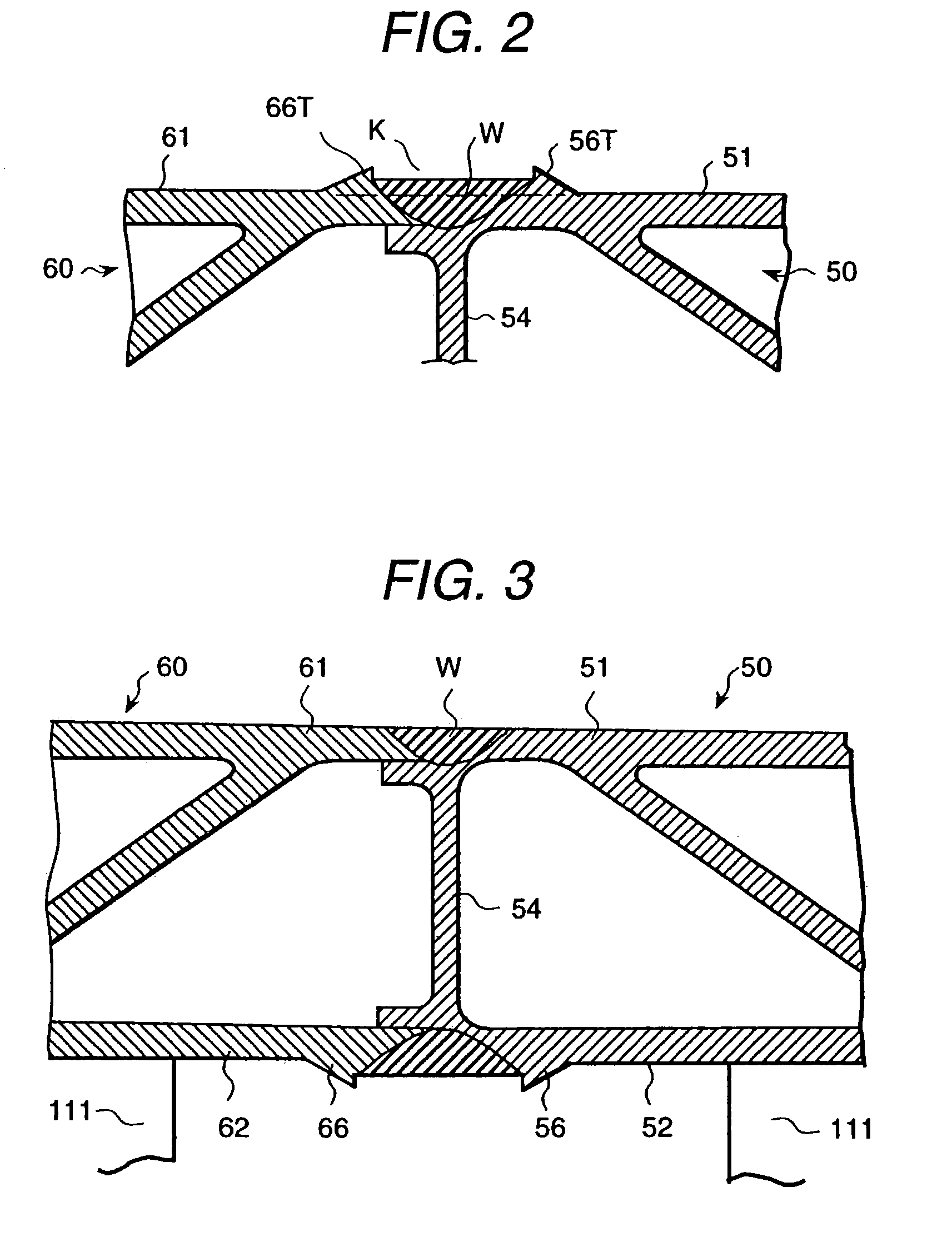

Disclosed is a friction stir welding technique which avoids occurrence of a dent, in a joining region, extending to a level beneath the joined surfaces. At end portions of the frame members to be joined, at the joining region, thickened parts which project toward the rotary body joining tool are provided. Two adjoining thickened parts, of adjacent members to be joined, can form a trapezoid shape. The rotary body joining tool has a small-diameter tip portion and a larger diameter portion. The rotary body joining tool is inserted in the thickened parts. In a state where the rotary body joining tool has been inserted small-diameter tip end first, to a level where the larger diameter portion of the rotary body joining tool overlaps the thickened part but does not extend below the upper surface of the non-thickened surfaces of the members joined, the rotary body is rotated and moved along the joining region. Even when a gap exists between two thickened parts, a desirable joining can be carried out. After the joining, the remaining parts of the thickened parts can be machined so as to form a smooth surface.

Owner:HITACHI LTD

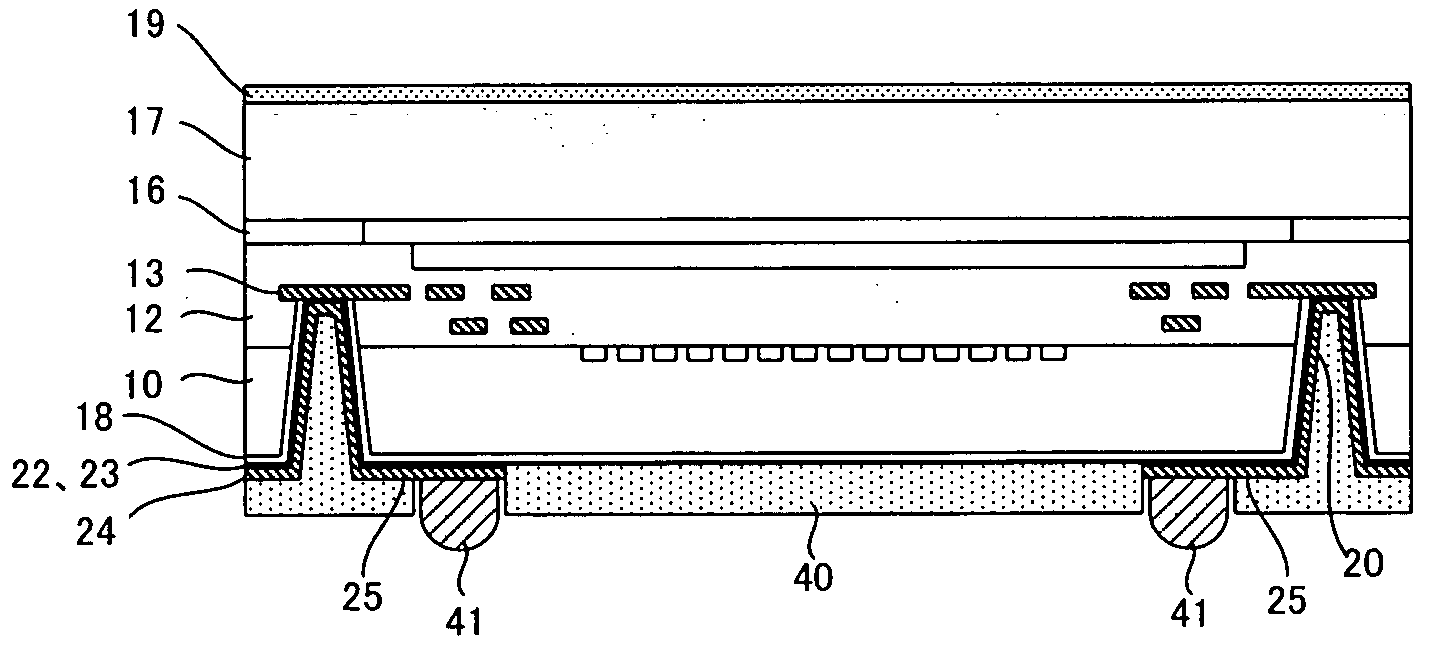

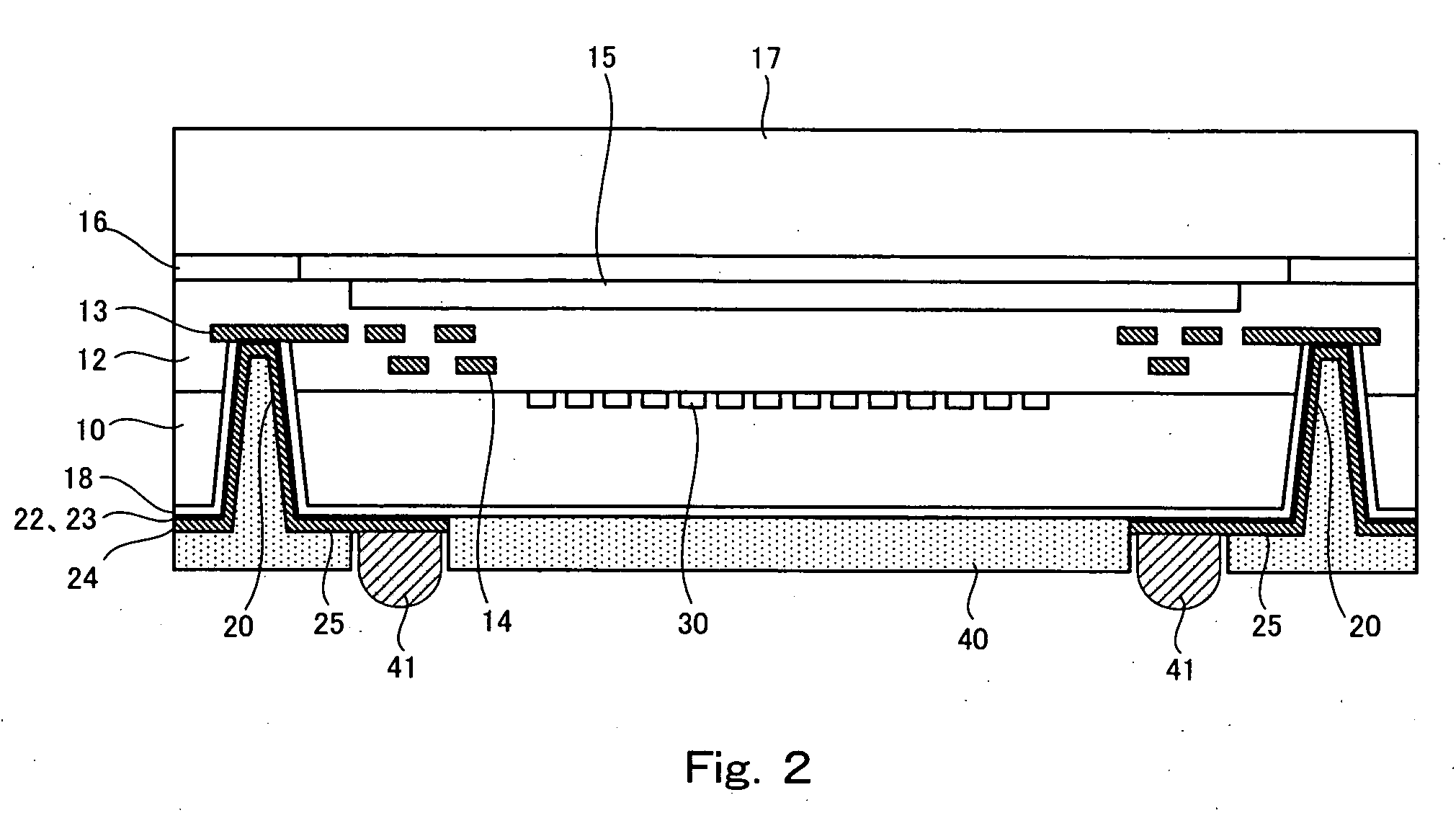

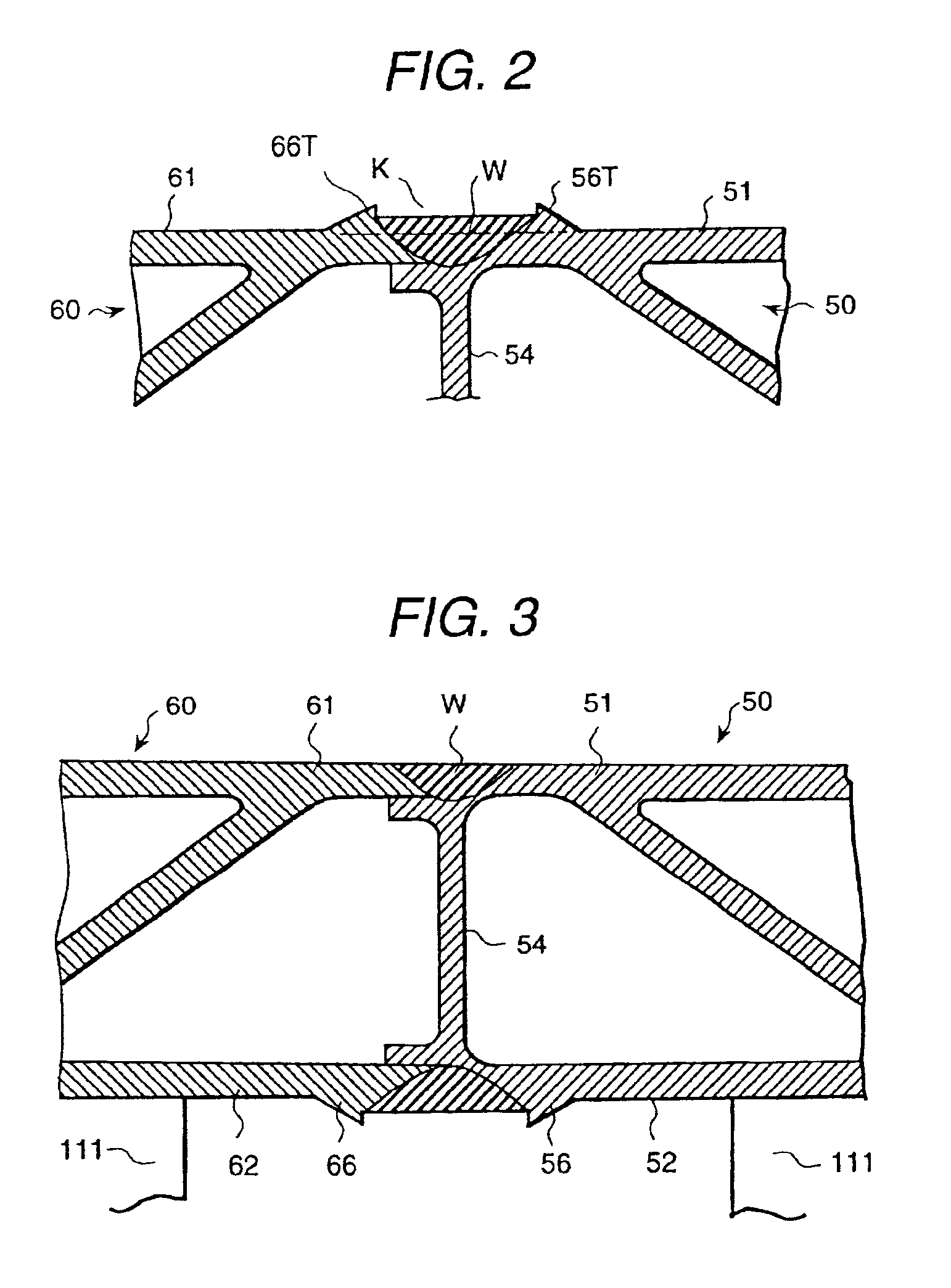

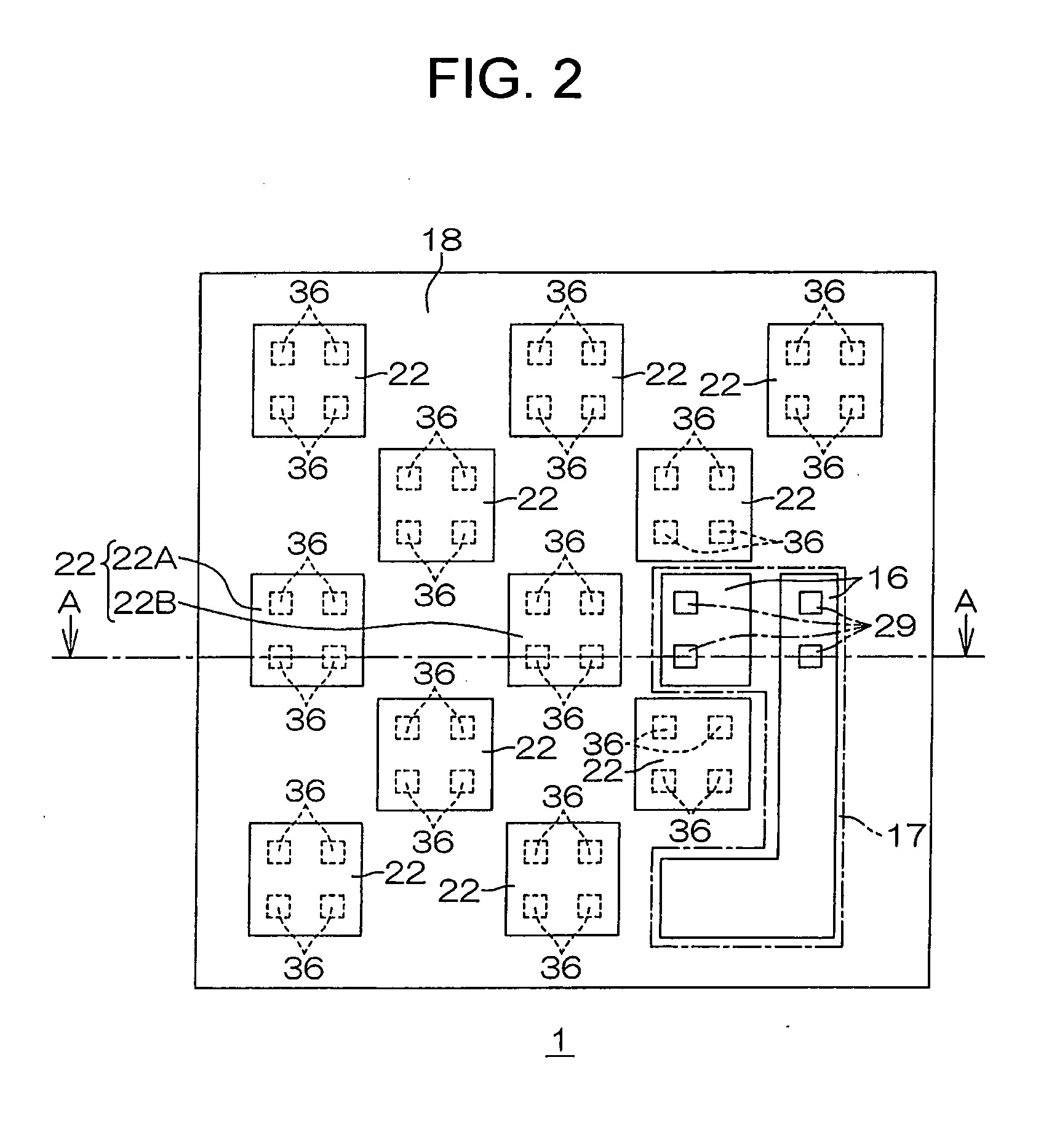

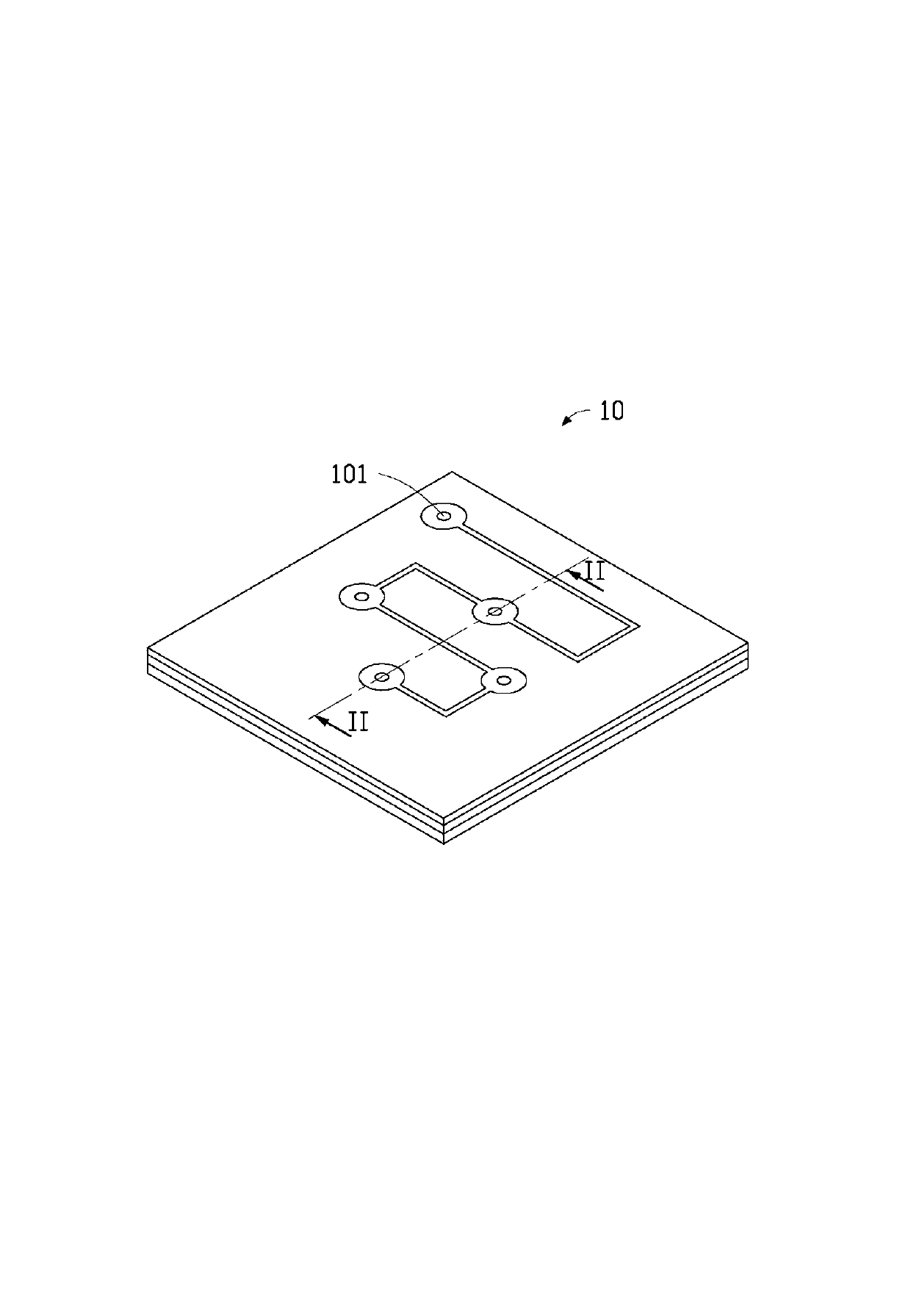

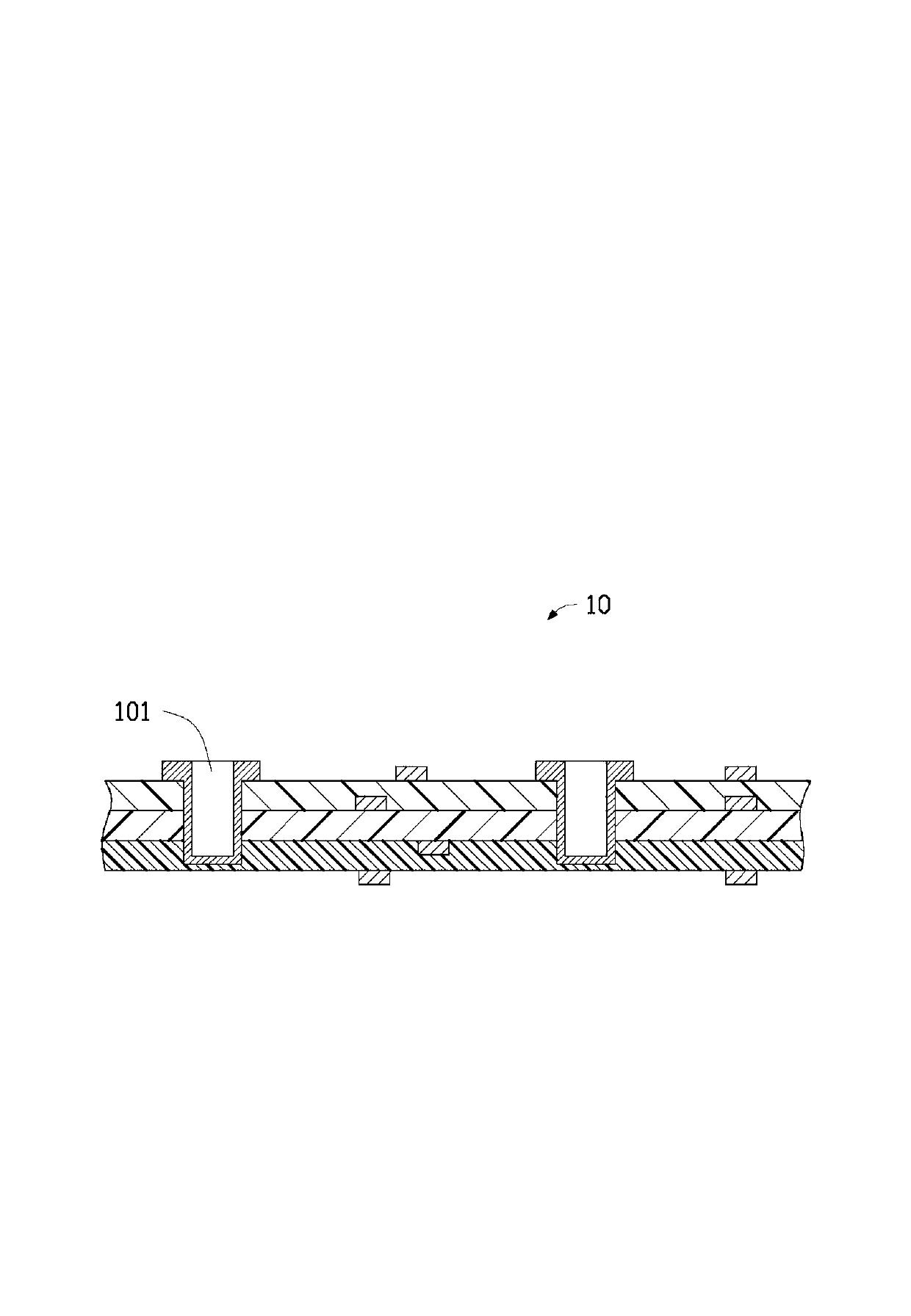

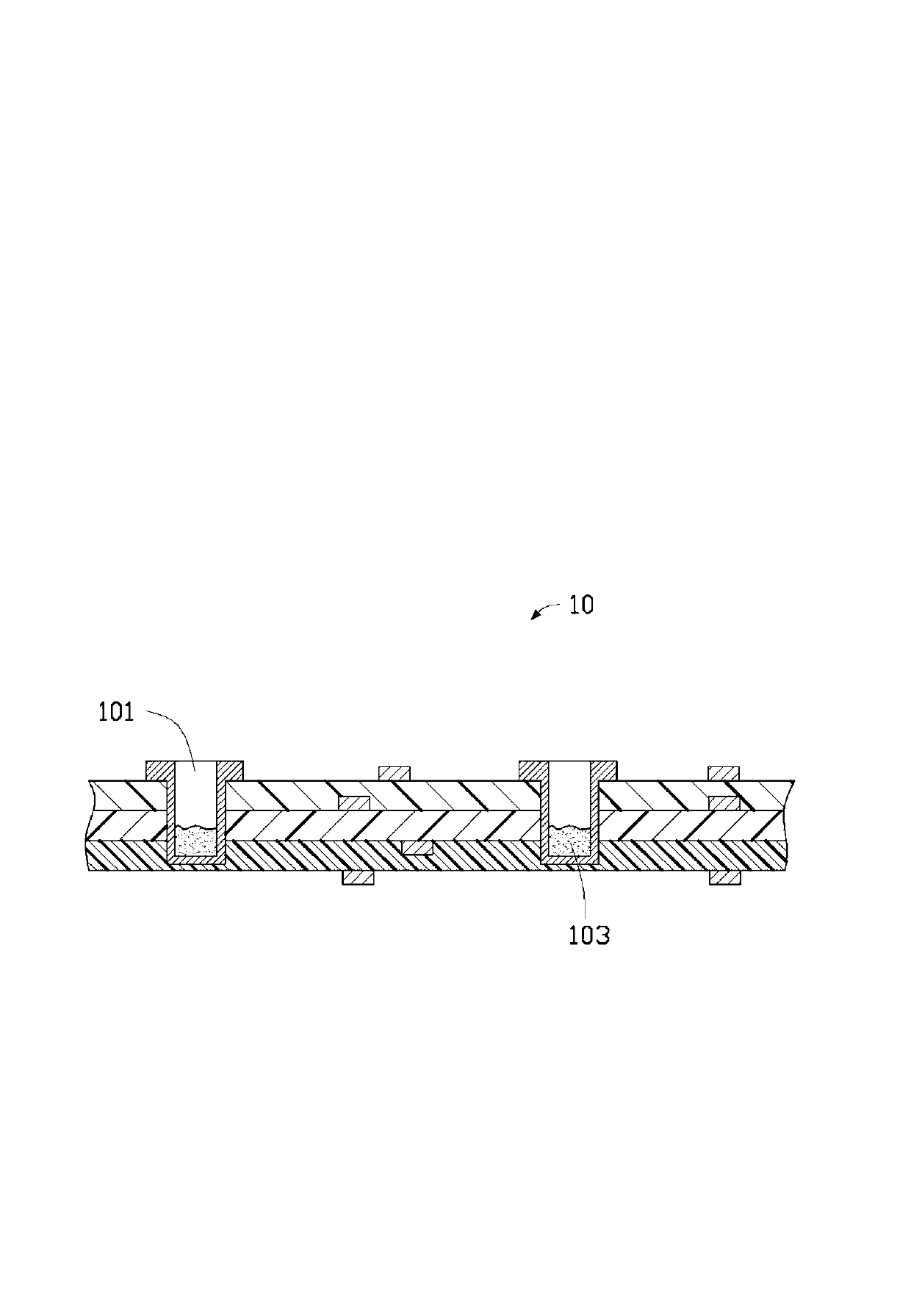

Semiconductor device, method for manufacturing semiconductor device, method for manufacturing semiconductor package

ActiveUS20100007030A1Prevent dishQuality improvementSemiconductor/solid-state device detailsSolid-state devicesEngineeringThrough-silicon via

There is provided a semiconductor device comprising a semiconductor substrate having an active area in which a plurality of active elements are formed, and a non-active area excepting the active area; at least one electrode pad electrically connected to any of the active elements. At least one Through Silicon VIA electrode is formed, being electrically connected to the electrode pad by way of the non-active area. The non-active area has an insulating region obtained by forming an insulating film on the semiconductor substrate, and a dummy section obtained by leaving a base material of the semiconductor substrate in the insulating region. The dummy section is provided in a position where an outer edge of the Through Silicon VIA electrode does not intersect with the boundary between the insulating region and the dummy section.

Owner:TAIWAN SEMICON MFG CO LTD

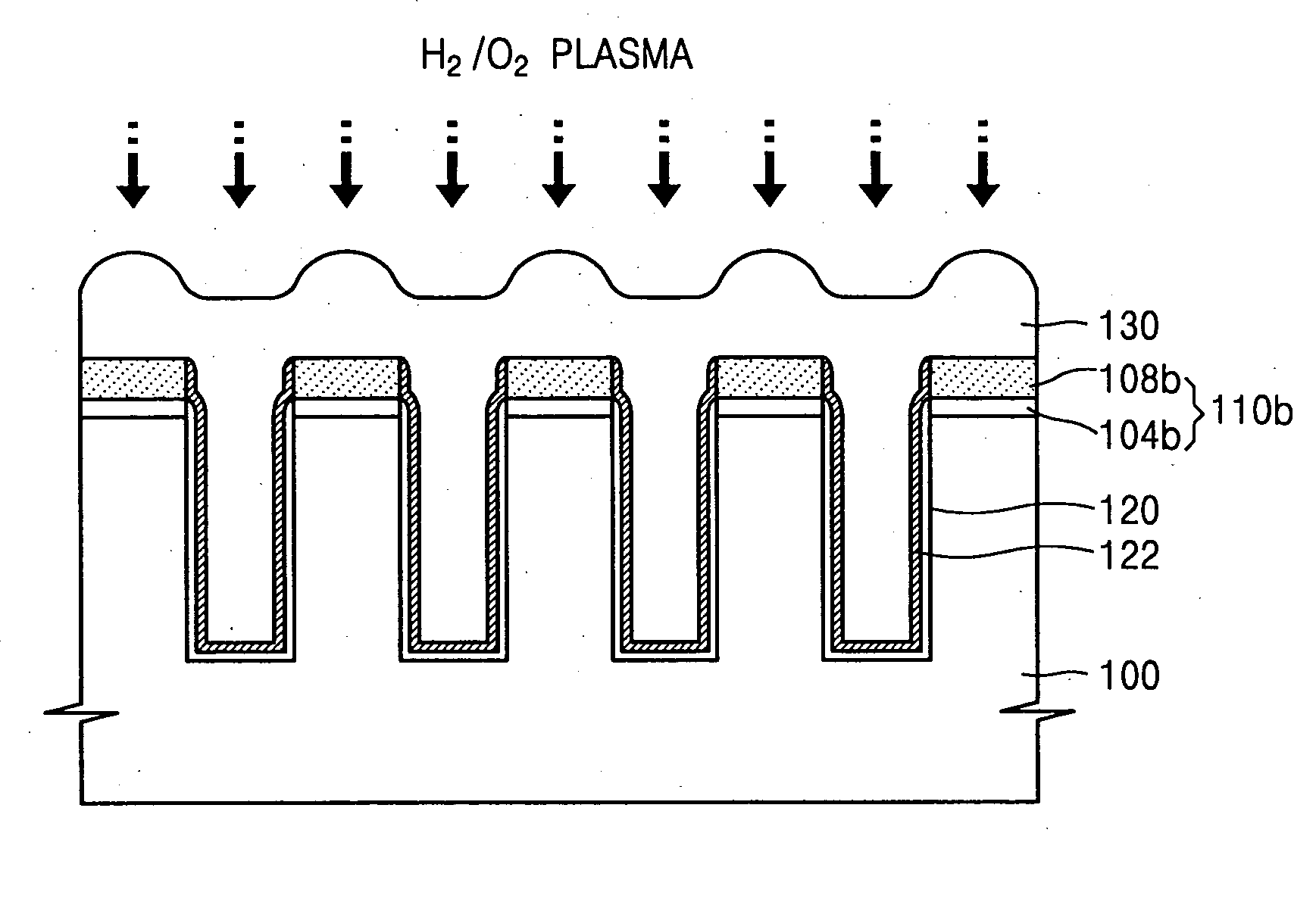

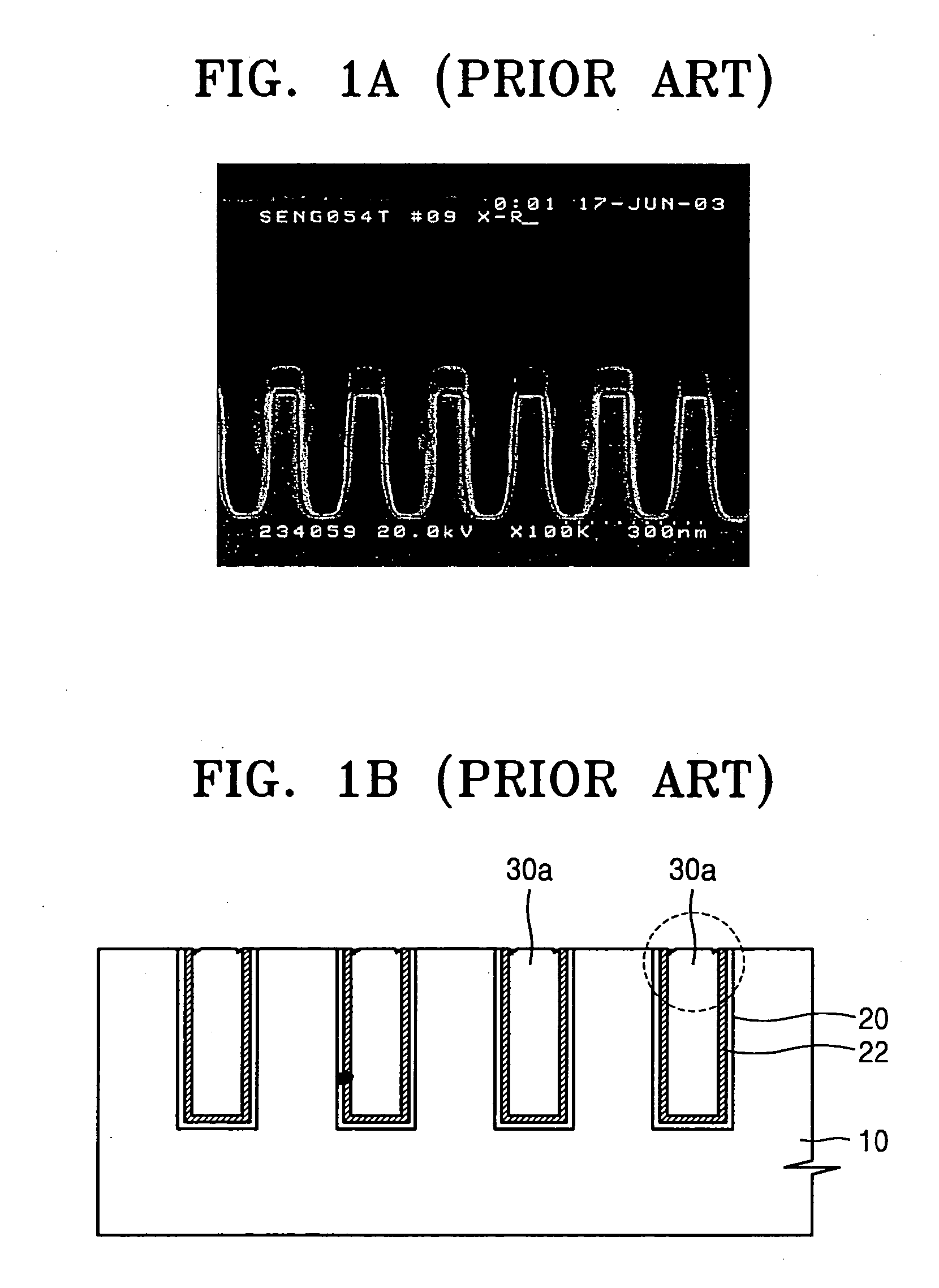

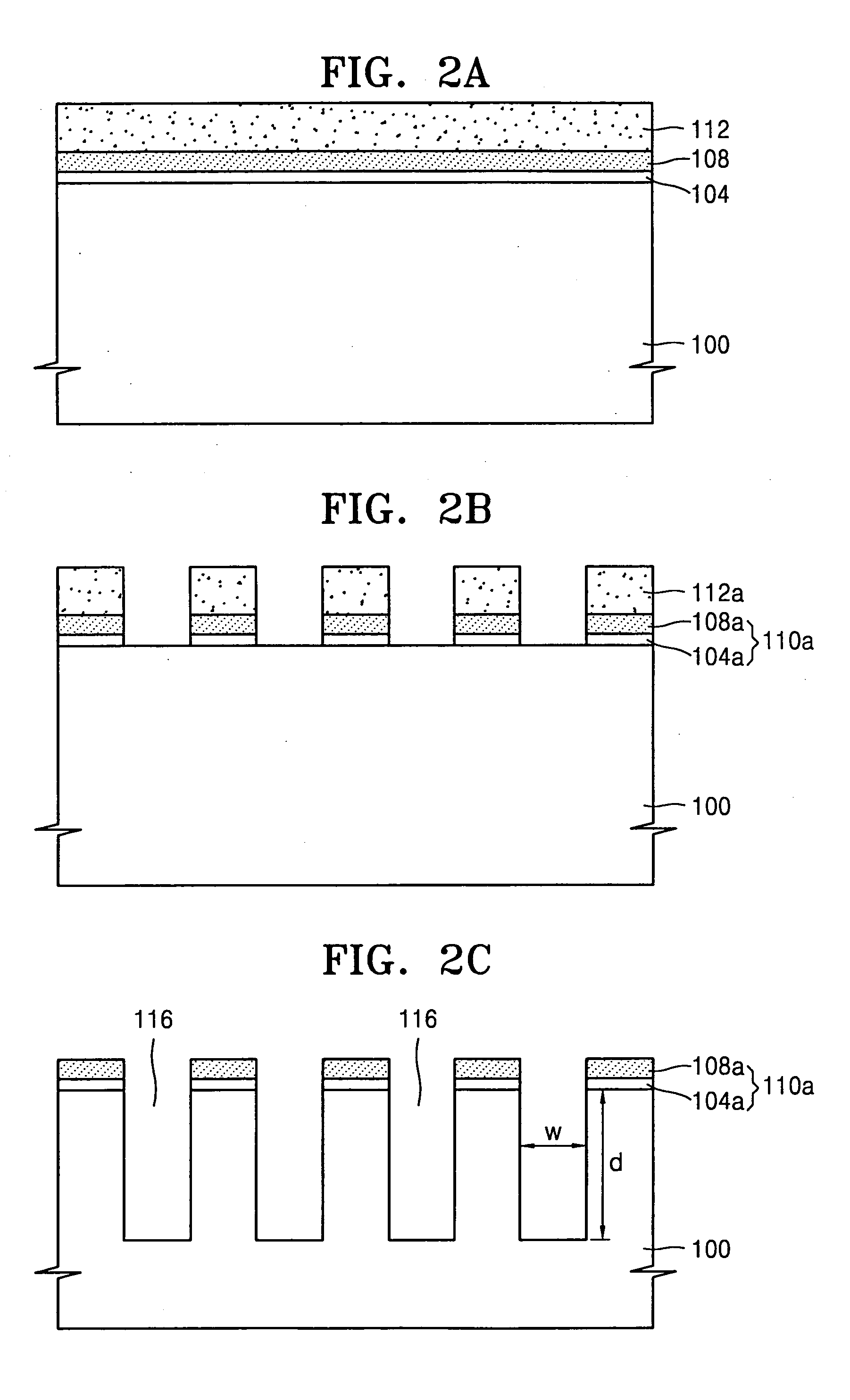

Gap-fill method using high density plasma chemical vapor deposition process and method of manufacturing integrated circuit device

InactiveUS20050136686A1Improve featuresPrevents a lung defect from occurringSemiconductor/solid-state device manufacturingHydrogenHigh density

A method of filling gaps in an integrated circuit device is provided, that is less likely to fill voids and does not cause a lung defect. In one embodiment, a method of manufacturing an integrated circuit device including the gap filling method includes: etching a predetermined area of an integrated circuit device to form a trench, filling the trench with a high density plasma oxide by performing an HDP-CVD process using a first process gas including comprising a gas containing an element from the fluorine group, silane gas, and oxygen to form a high density plasma oxide layer, and plasma treating the integrated circuit substrate with a second process gas including a hydrogen gas or hydrogen and oxygen gases.

Owner:SAMSUNG ELECTRONICS CO LTD

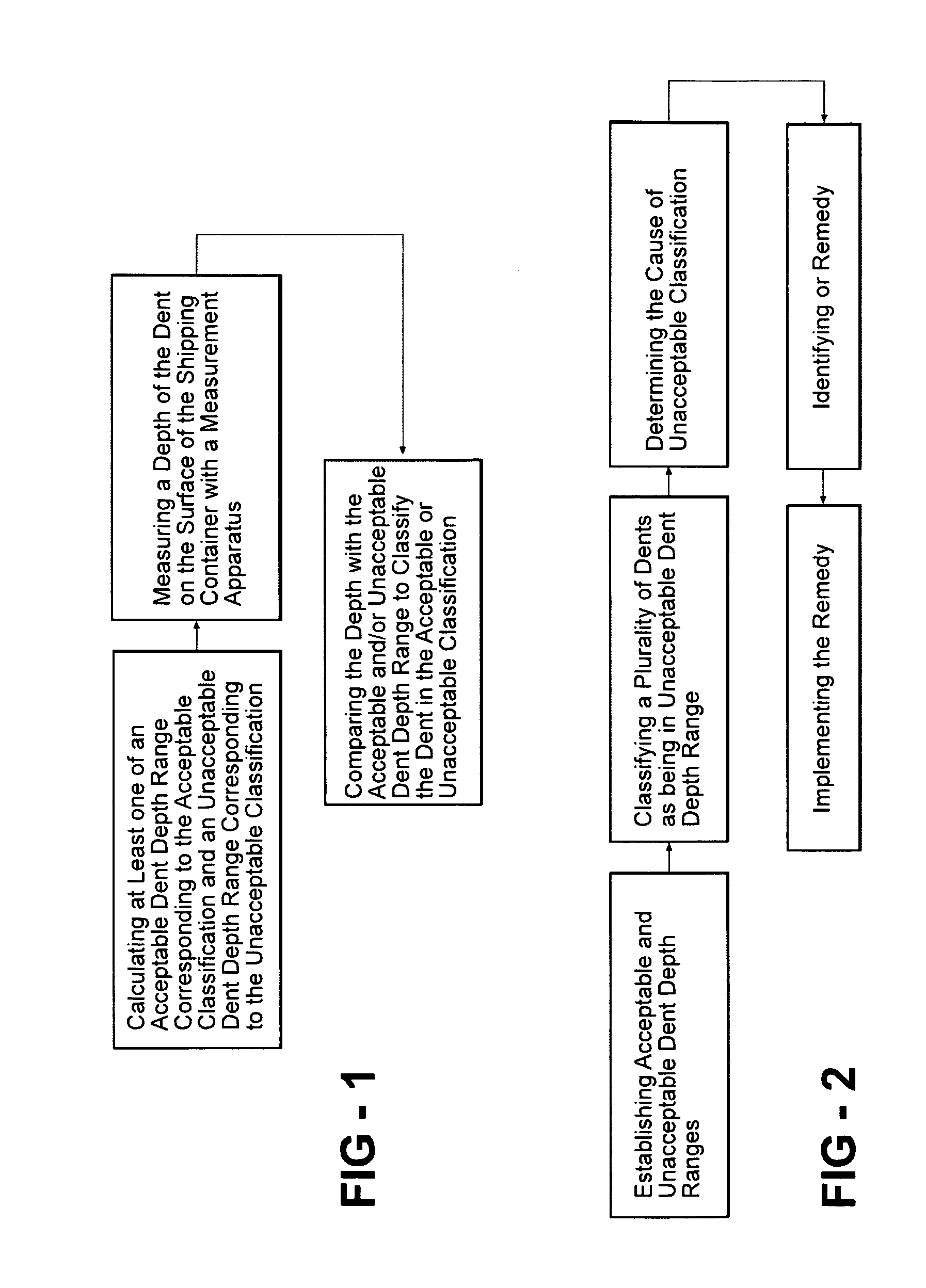

Method of measuring dents and method of classifying dents

InactiveUS8322044B2Improve efficiencyAccurate and repeatableWalking sticksDepth gaugesClassification methodsComputer science

Owner:DOW SILICONES CORP

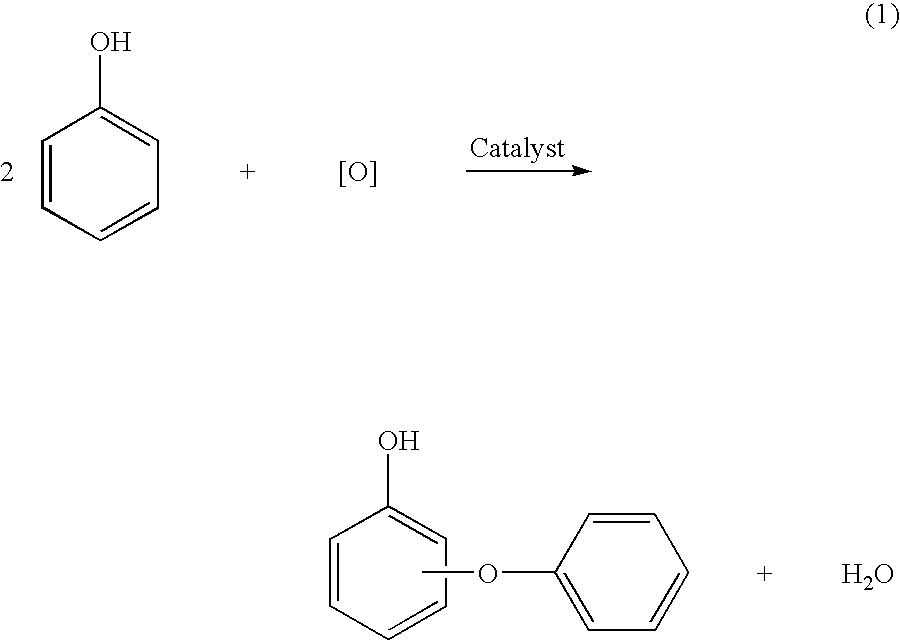

Metal polishing slurry and chemical mechanical polishing method

InactiveUS20090203215A1Avoid dentsIncrease polishing speedOther chemical processesSemiconductor/solid-state device manufacturingArylOrganic acid

A metal polishing slurry which is capable of simultaneously realizing a high polishing speed and reduced dishing in the polishing of a subject to be polished is provided. The metal polishing slurry includes a compound represented by the following general formula (1):wherein X represents a heterocyclic group containing at least one nitrogen atom, Y represents hydrogen atom, an aliphatic hydrocarbon group, an aryl group, or a —C(═O)Z′ wherein Z′ is as defined for Z, and Z represents hydrogen atom, an optionally substituted aliphatic hydrocarbon group, an optionally substituted aryl group, an optionally substituted heterocyclic group, —NZ1Z2, or —OZ3 wherein Z1, Z2, and Z3 independently represent hydrogen atom, an optionally substituted aliphatic hydrocarbon group, an optionally substituted aryl group, or an optionally substituted heterocyclic group, with the proviso that Y and Z may together form a ring; an oxidizing agent; and an organic acid.

Owner:FUJIFILM CORP

Composition for polishing metal, polishing metod for metal layer, and production method for wafer

InactiveUS20060042502A1Preventing dishingImprove planaritySemiconductor/solid-state device manufacturingPolishing compositions with abrasivesScratchingCopper

A metal polishing composition is used for polishing a metal layer and comprises a film forming compound which polymerizes on a surface of the metal layer, forming a polymer film on the surface of the metal layer. A polishing method for the metal layer comprises a step of polishing and planarizing the metal layer using the metal polishing composition. A production method for a wafer comprises a step of polishing and planarizing a metal layer which is formed on top of a wafer that contains recesses so as to fill and cover the recesses, by the polishing method for a metal layer. According to the composition and polishing method, dishing is prevented to improve the planarity, and the polishing rate for polishing metal layers, and particularly copper layers, is improved, enabling high speed polishing at low pressure. Furthermore, because scratching of the metal layer is also prevented, the yield improves.

Owner:SHOWA DENKO KK

Mask-pattern correction method

InactiveCN1405634AReduce file sizeWrite lessSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentEngineeringCorrection method

A correction method for mask patterns is first of all to provide a third pattern composed of a first strip pattern and a second pattern in which the first strip pattern is connected between the head and end of the second one, then two sides of the first strip pattern are added by an auxiliary pattern to form a first correction apttern. After that part of the first strip pattern is reduced to form a second correction pattern, the dimension of the reduced first strip pattern is the key on of a main pattern then the second correction pattern is modified by an optical adjacent correction method to form a third modified pattern.

Owner:UNITED MICROELECTRONICS CORP

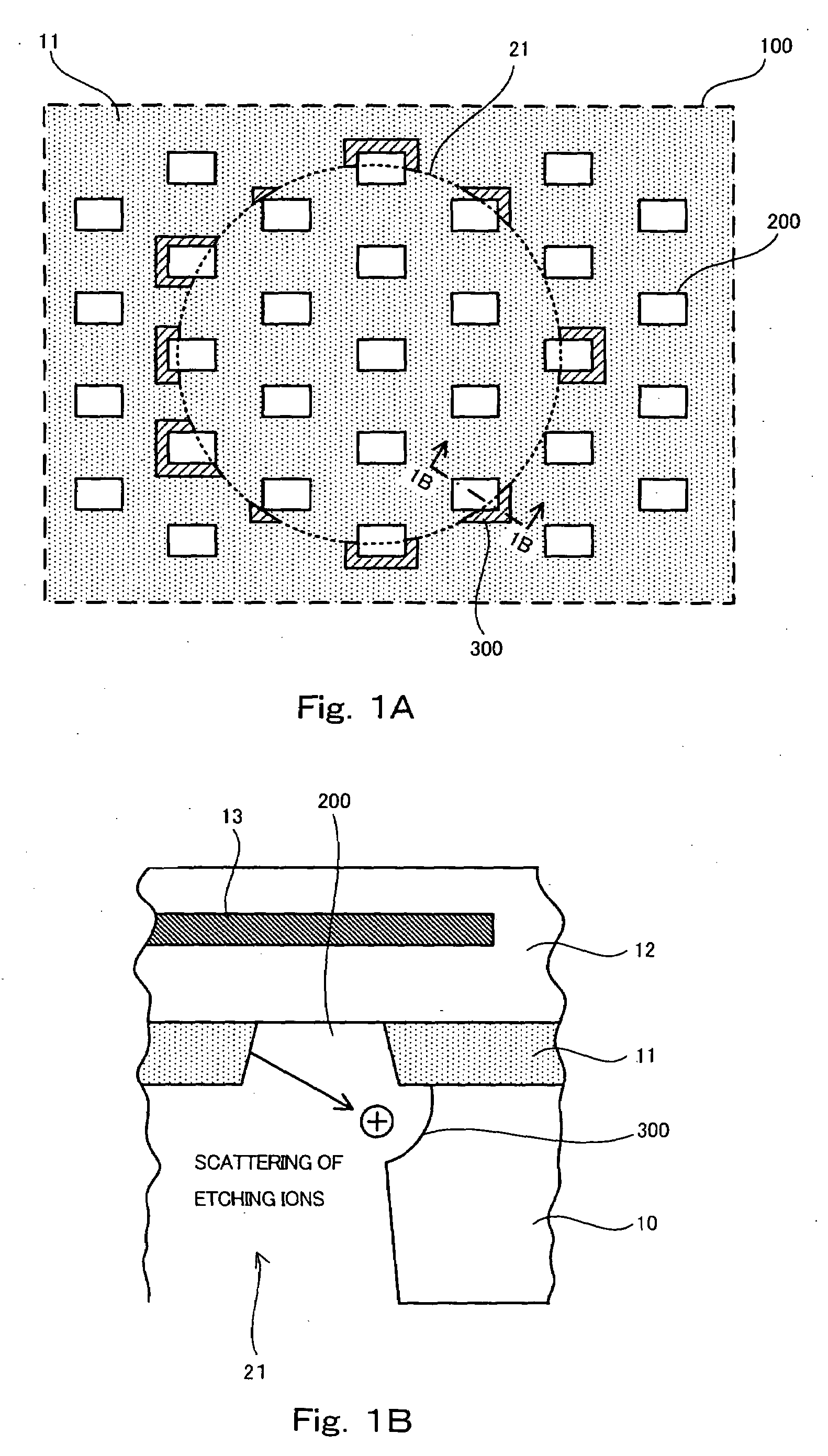

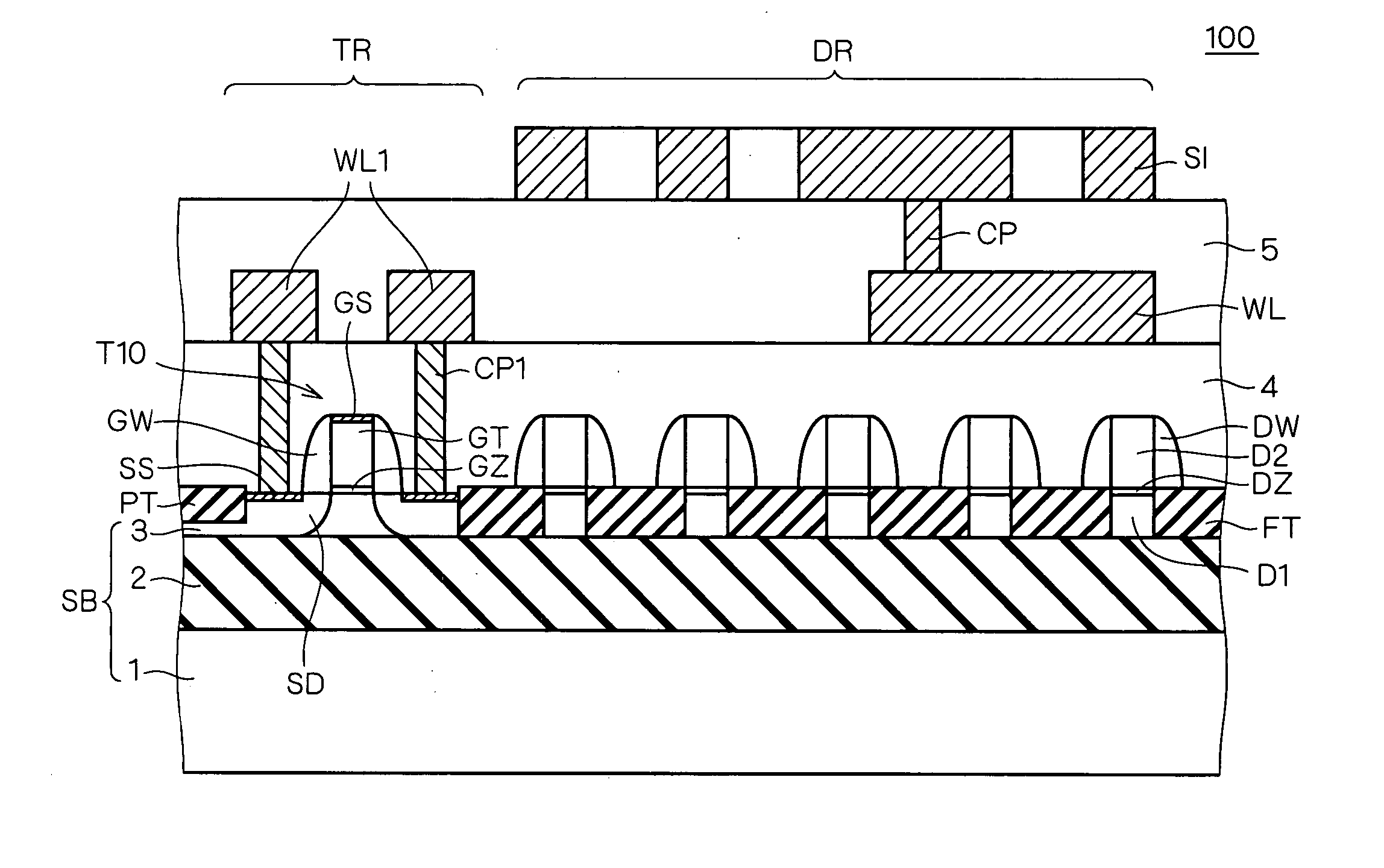

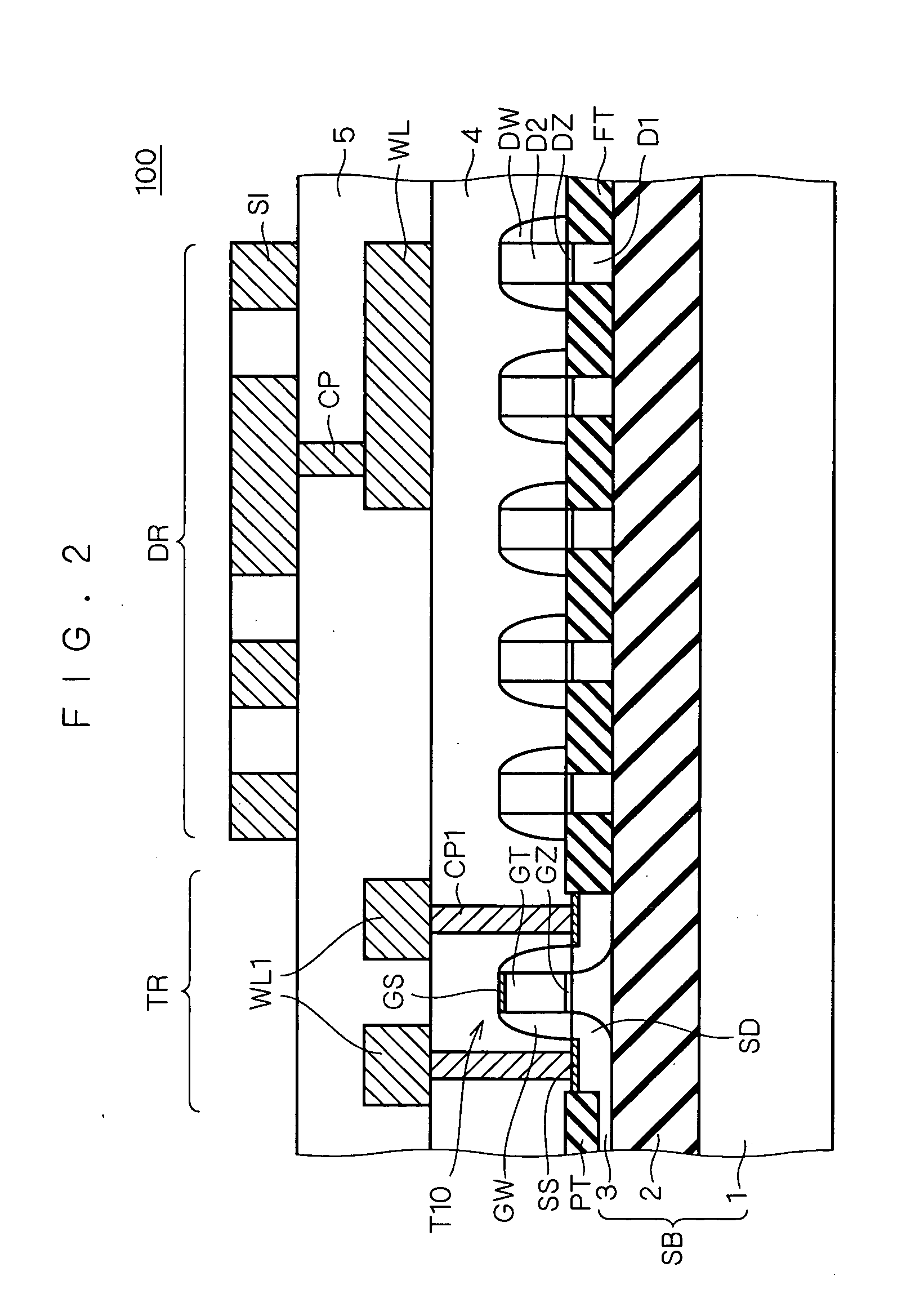

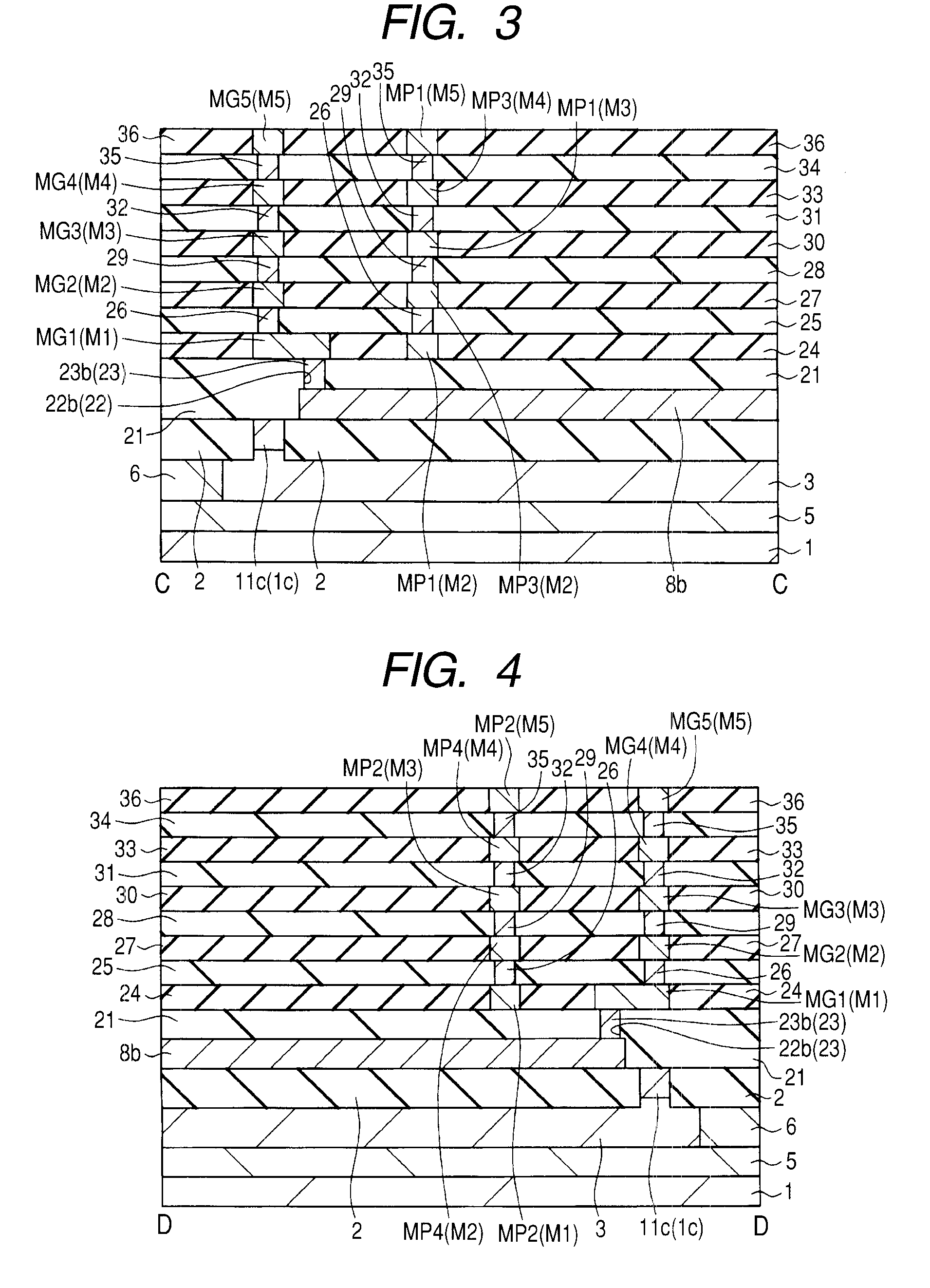

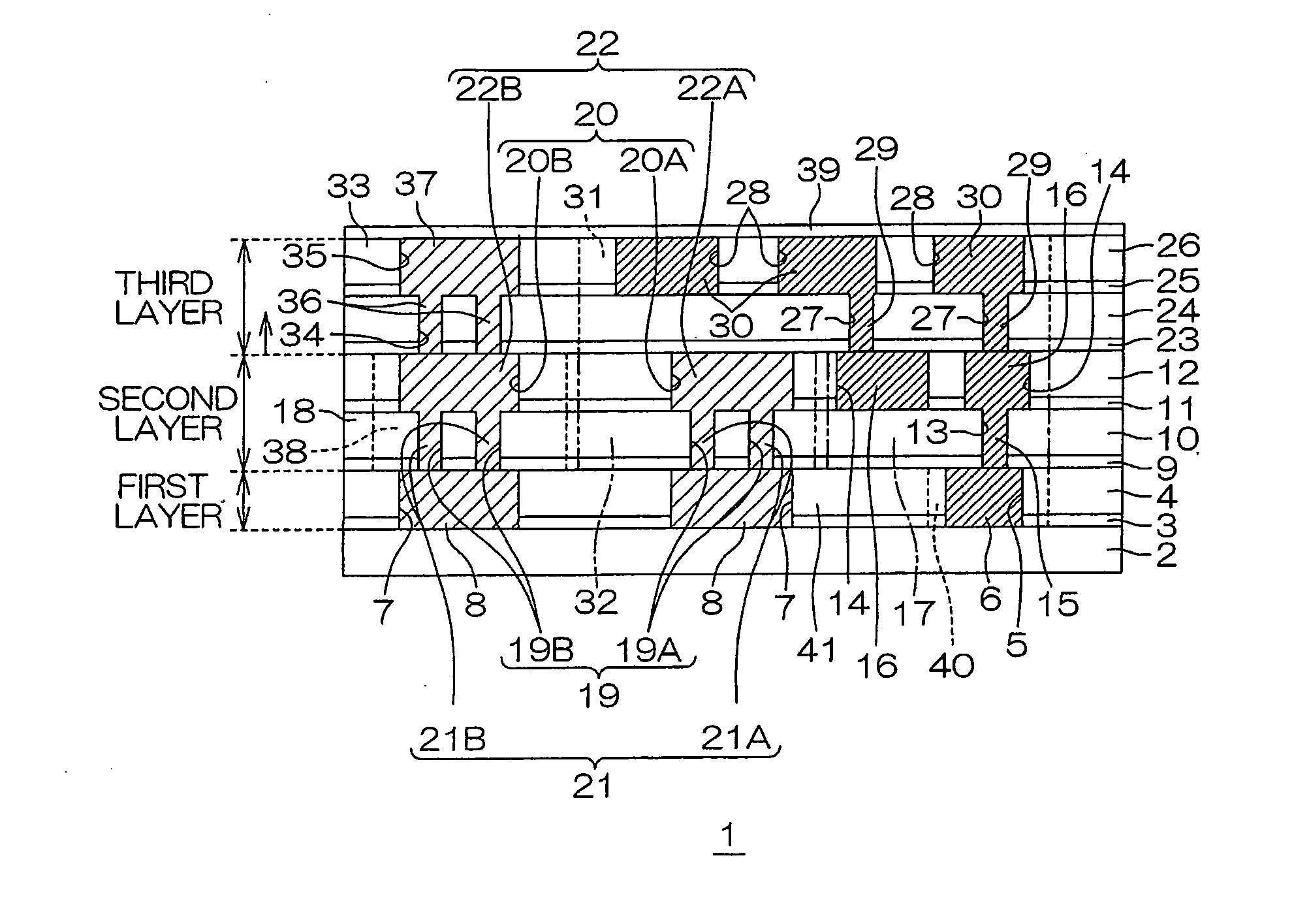

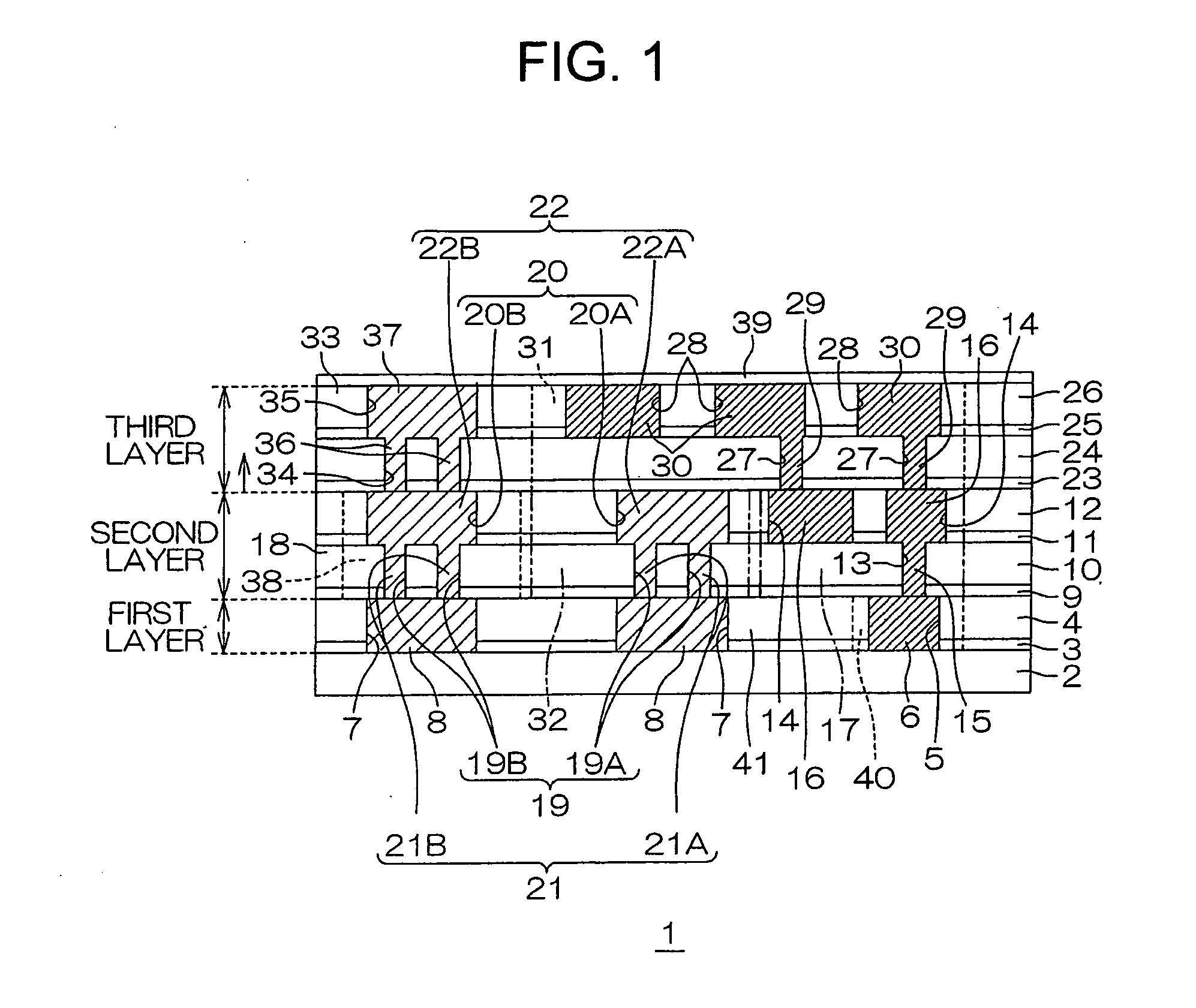

Semiconductor device

InactiveUS20050012153A1Avoid it happening againAvoid dentsTransistorSemiconductor/solid-state device detailsDevice materialSpiral inductor

A transistor region is a region where a plurality of MOS transistors, including an MOS transistor, are formed, and a dummy region is a region lying under a spiral inductor. In the dummy region, a plurality of dummy active layers are disposed in the main surface of an SOI substrate and a plurality of dummy gate electrodes are disposed covering the respective dummy active layers. The arrangement pattern of the dummy active layers and the arrangement pattern of the dummy gate electrodes nearly match, so that the dummy gate electrodes are aligned accurately on the dummy active layers.

Owner:RENESAS ELECTRONICS CORP

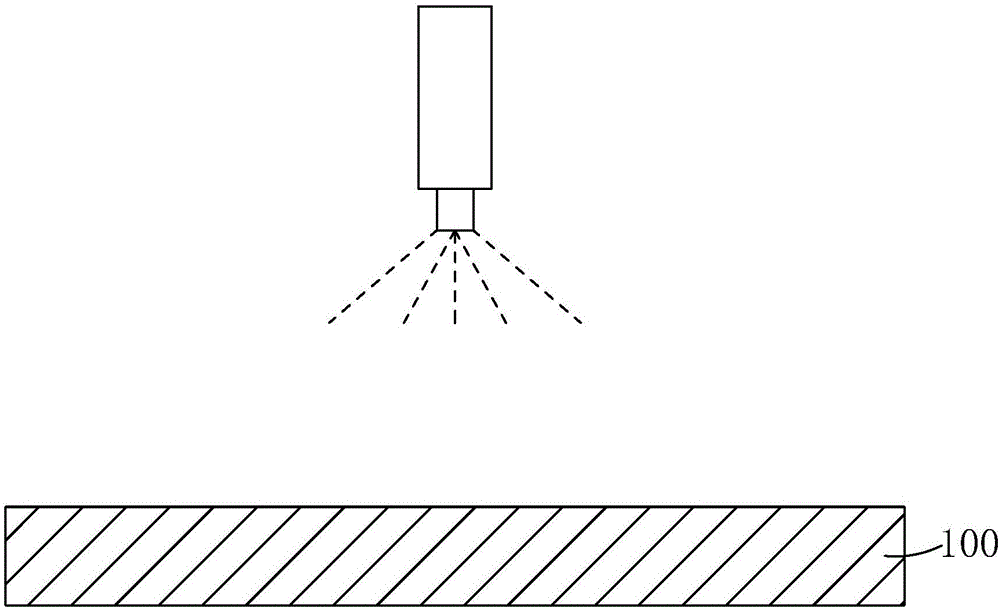

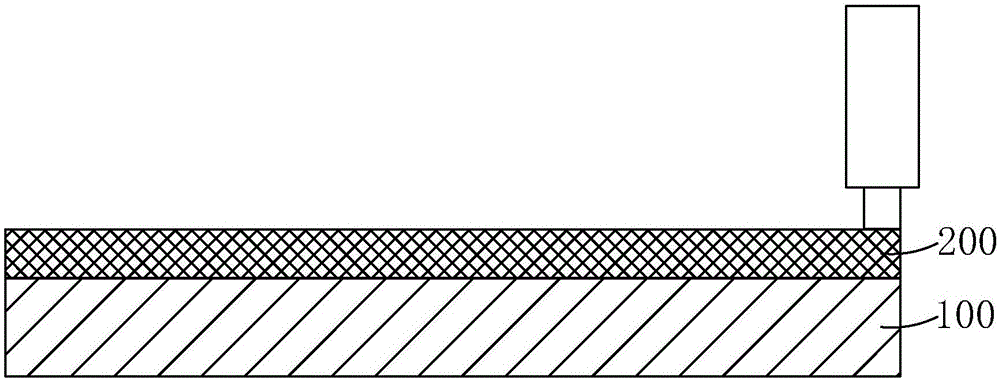

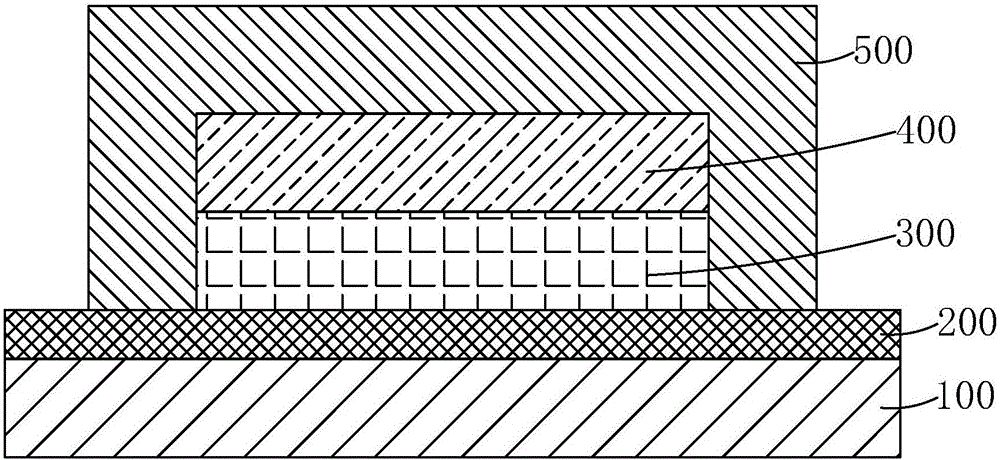

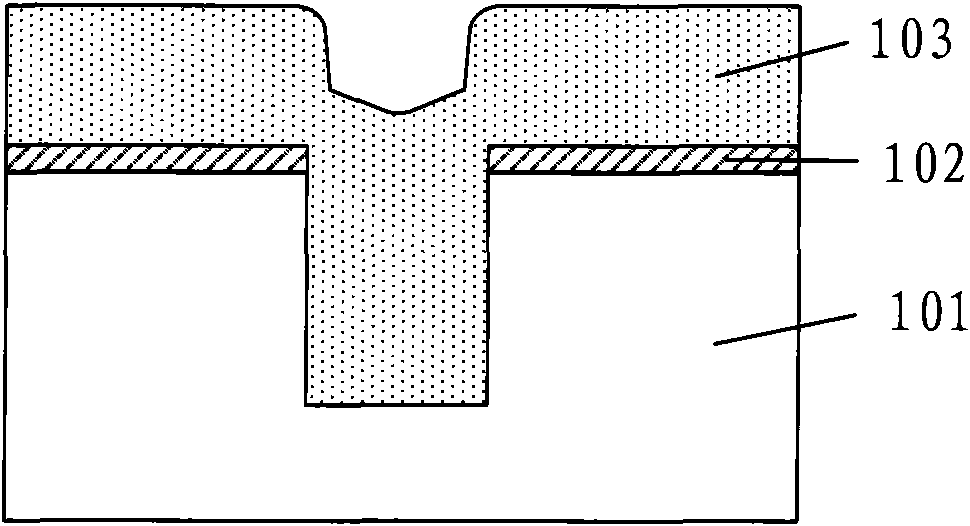

Flexible AMOLED display device preparation method

ActiveCN106449711AGuaranteed Optical PerformanceAvoid dentsSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsWater resistance

The invention provides a flexible AMOLED display device preparation method, before preparing a flexible substrate on a rigid substrate, firstly forming an inorganic substance film layer with flat surface, then coating a polymer material on the inorganic substance film layer, and forming the flexible substrate, the method not only can avoid the issue of bad pits and bulges on the flexible substrate caused by residual impurities from poor rinsing of the rigid substrate surface, but also can make the flexible substrate and the rigid substrate to easily be separated in the peeling process of the flexible substrate and the rigid substrate, protects the flexible substrate from being damaged, thereby enabling the prepared flexible substrate of the flexible AMOLED display device to have relatively high degree of evenness, the method increases the water resistance and oxygen resistance performance of the flexible substrate, and guarantees the optical performance of the flexible AMOLED display device.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

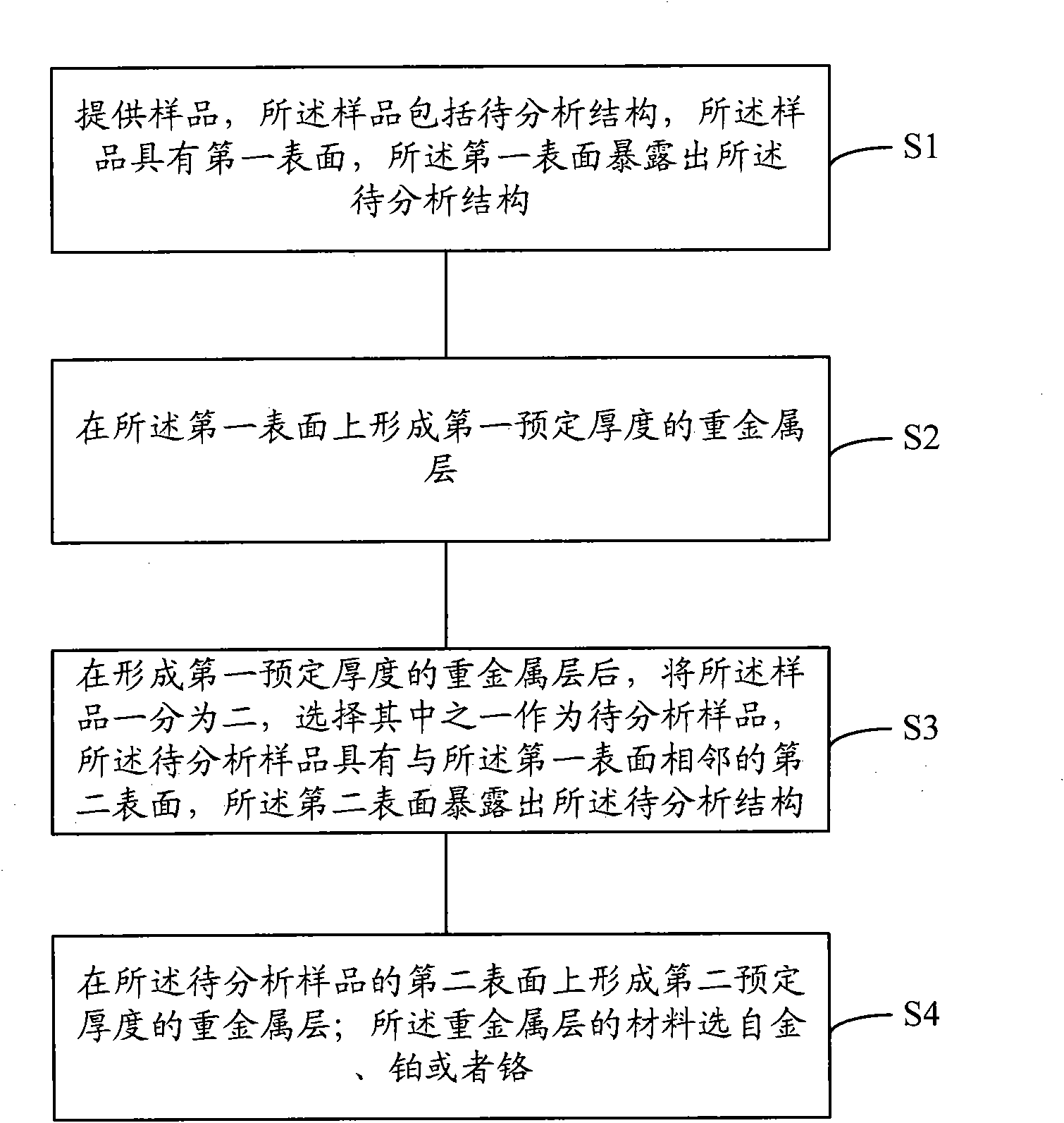

Method for preparing failure analysis sample

ActiveCN102384867AReduce interactionEliminate surface chargePreparing sample for investigationPlatinumAnalysis data

The invention discloses a method for preparing a failure analysis sample, which comprises a providing a sample, wherein the sample comprises a structure to be analyzed, and is provided with a first surface, the first surface is exposed out of the structure to be analyzed; forming a heavy metal layer with a first preset thickness on the first surface; after the heavy metal layer with the first preset thickness is formed, dividing the sample into two parts, selecting one part to be used as a sample to be analyzed, wherein the sample to be analyzed is provided with a second surface adjacent to the first surface, the second surface is exposed out of the structure to be analyzed; and forming a heavy metal layer with a second preset thickness on the second surface of the sample to be analyzed. The heavy metal layers are made of gold, platinum or chrome. When the sample prepared by using the method is subjected to the failure analysis, factors causing the deformation of a low-dielectric constant material and an ultra-low-dielectric constant material can be basically eliminated, original shapes of the sample can be kept and effective analysis data can be provided.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

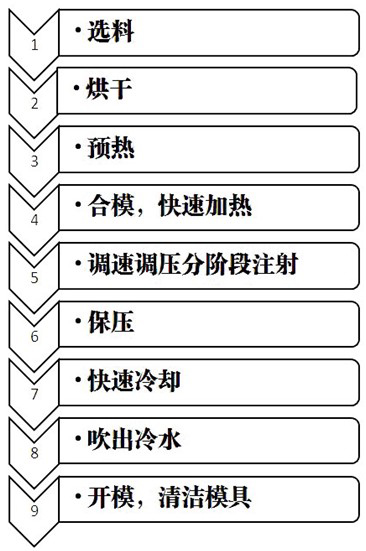

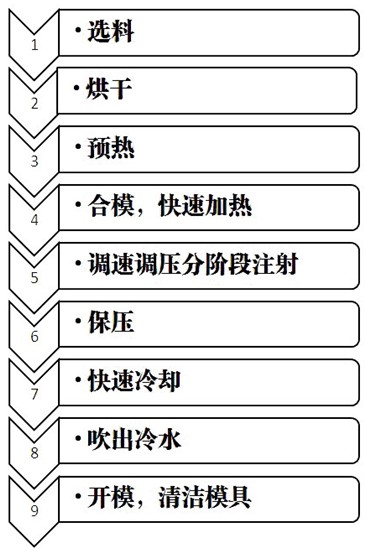

Steam type highlight and traceless injection-molding and forming process for complex precise product

The invention discloses a steam type highlight and traceless injection-molding and forming process for a complex precise product. The process sequentially comprises the following steps of: selecting raw materials, baking, pre-heating, combining a die, then quickly heating, adjusting speed and pressure, injecting in sections, maintaining the pressure, cooling quickly, blowing out cold air, opening the die and cleaning the die. An advanced pressure-regulation and speed-regulation staging injection process and an automatic blowing and impurity-removing technology are adopted in the invention. A special heating and cooling technology is that the shapes, the widths and the arrangement density of water passages are designed according to nonuniform heat and cold of the complex precise product in the injection-molding and forming course and the overall shape variation of the product. The steam type highlight and traceless injection-molding and forming process for the complex precise product has the advantages that the residual stress of the product is effectively decreased, various defects generated in the course of producing the plastic product are greatly reduced, the surface quality and the precision of the product are remarkably improved, and the life of the product is remarkably prolonged at the same time because the special process ensures heating and cooling rates of each part of the complex product in the injection-molding and forming course tend to be consistent.

Owner:海门市创豪工业设计有限公司

Extruded frame member for use in friction stir welding

InactiveUS6936332B2Avoid it happening againAvoid dentsWallsWelding/cutting auxillary devicesFriction weldingEngineering

The friction stir welding technique disclosed avoids occurrence of a dent in adjoining region extending to a level beneath the joined surfaces. At end portions of the frame members to be joined, thickened parts, which project toward the rotary body joining tool, are provided. The Two adjoining thickened parts form a trapezoid shape. The rotary body joining tool has a small-diameter tip portion and a larger diameter portion, and is inserted in the thickened parts. When the rotary body joining tool has been inserted small-diameter tip end first to a level where the larger diameter portion of the rotary body joining tool overlaps the thickened part, the rotary body is rotated and moved along the joining region. Even when a gap exists between two thickened parts, a desirable joining can be carried out. After the joining, the remaining parts of the thickened parts can be machined to form a smooth surface.

Owner:HITACHI LTD

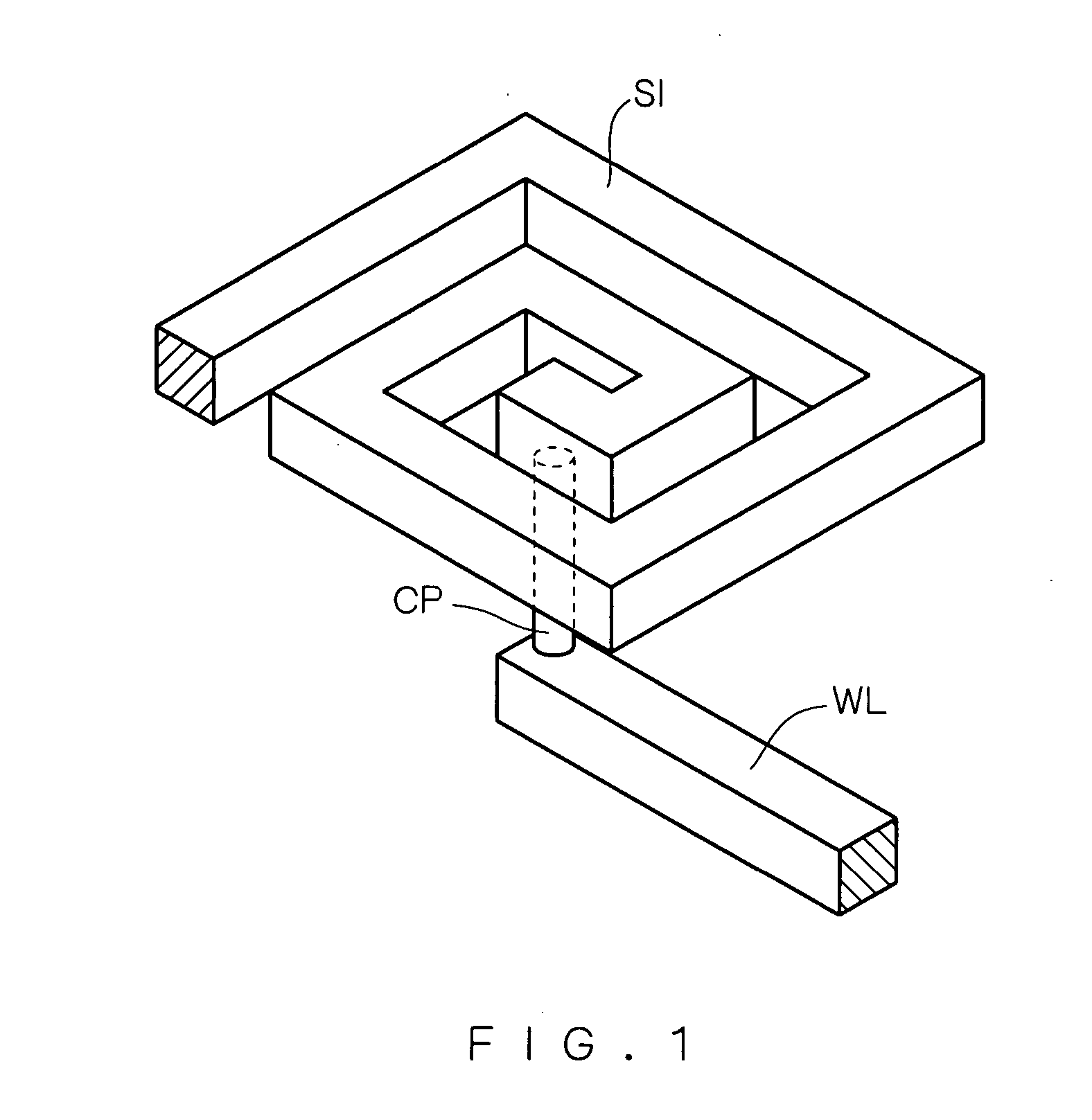

Semiconductor device

InactiveUS20090236648A1Improve semiconductor device performanceLarge capacitanceTransistorSemiconductor/solid-state device detailsCapacitanceElectrical conductor

To improve a performance of a semiconductor device having a capacitance element. An MIM type capacitance element, an electrode of which is formed with comb-shaped metal patterns composed of the wirings, is formed over a semiconductor substrate. A conductor pattern, which is a dummy gate pattern for preventing dishing in a CMP process, and an active region, which is a dummy active region, are disposed below the capacitance element, and these are coupled to shielding metal patterns composed of the wirings and then connected to a fixed potential. Then, the conductor pattern and the active region are disposed so as not to overlap the comb-shaped metal patterns in the wirings in a planar manner.

Owner:RENESAS ELECTRONICS CORP

Asphalt strip and preparation and construction methods thereof

ActiveCN104109399AEasy to carryImprove ductilityPaving detailsBuilding insulationsAntioxidantDust control

The invention discloses an asphalt strip and preparation and construction methods thereof, belonging to the technical field of asphalt pavement construction. The asphalt strip is characterized by comprising the following components in parts by weight: 70-90 parts of asphalt, 2-10 parts of a styrene-butadiene copolymer, 8-15 parts of solvent naphtha, 1-5 parts of a filler, 1-5 parts of a stabilizer and 0.1-0.3 part of an antioxidant, wherein the solvent naphtha is one of aromatic hydrocarbon oil, coal tar, diesel oil or kerosene; and the asphalt is petroleum asphalt or coal tar pitch. The construction method of the asphalt strip comprises the following steps: flushing, dedusting, caulking and welting. The asphalt strip has high viscidity and extensibility, filling of a pavement crack can be finished without heating, the construction method of the asphalt strip is short in used time, and can be finished without an assist of crack sealing equipment, and the construction effect is firm and lasting.

Owner:淄博恒信路面材料有限公司

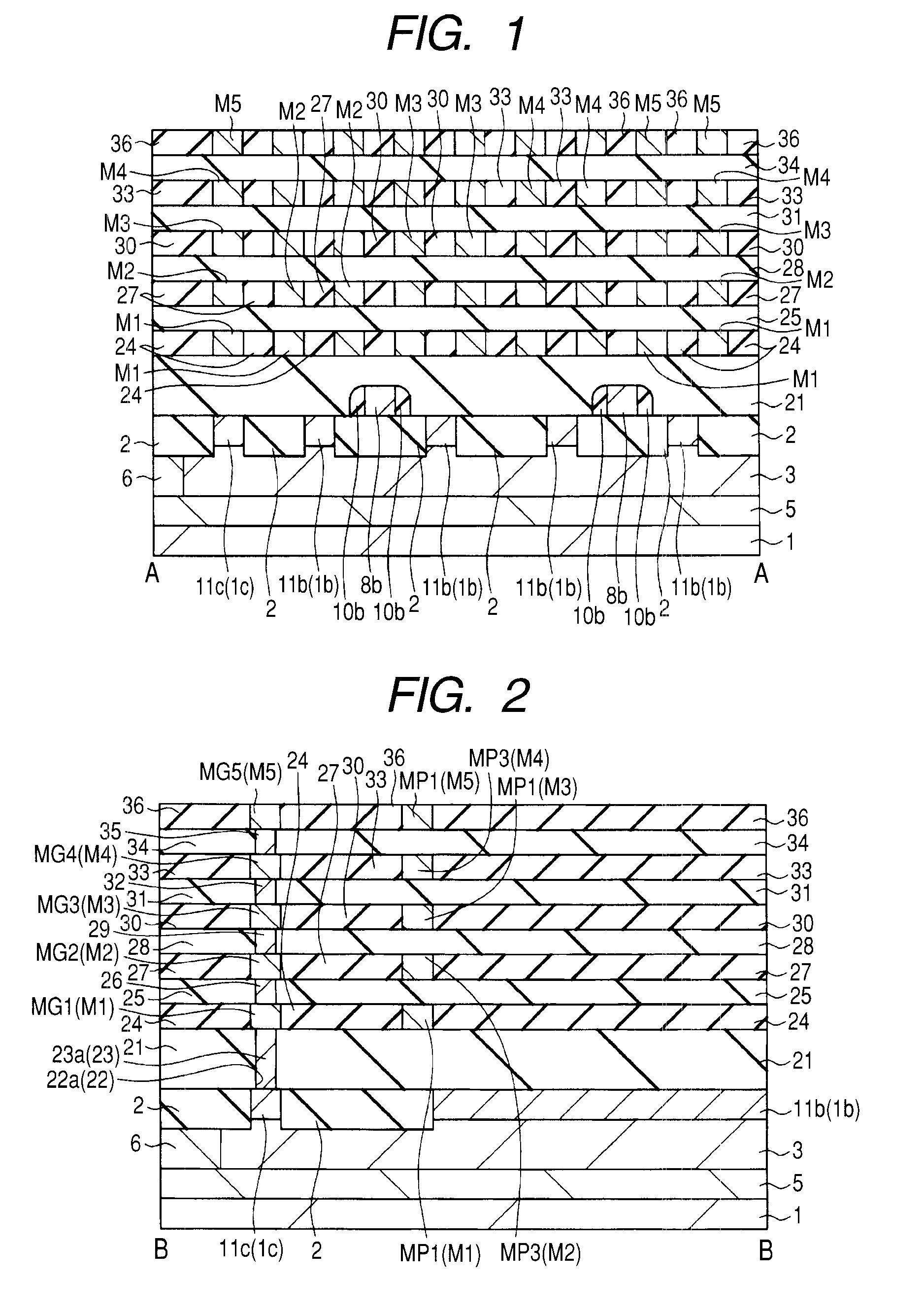

Semiconductor device

ActiveUS20100270686A1Avoid dentsMetal sawing devicesSemiconductor/solid-state device detailsSemiconductorMetal

The semiconductor device according to the present invention includes a semiconductor substrate, a first insulating layer laminated on the semiconductor substrate, a first metal wiring pattern embedded in a wire-forming region of the first insulating layer, a second insulating layer laminated on the first insulating layer, a second metal wiring pattern embedded in a wire-forming region of the second insulating layer and first dummy metal patterns embedded each in a wire-opposed region opposing to the wire-forming region of the second insulating layer and in a non-wire-opposed region opposing to a non-wire-forming region other than the wire-forming region of the second insulating layer, the wire-opposed region and the non-wire-opposed region each in a non-wire-forming region other than the wire-forming region of the first insulating layer.

Owner:ROHM CO LTD

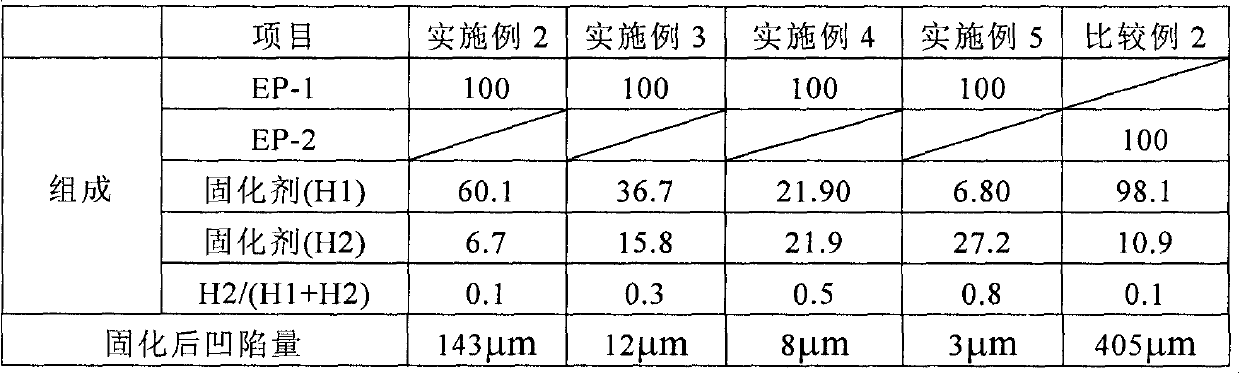

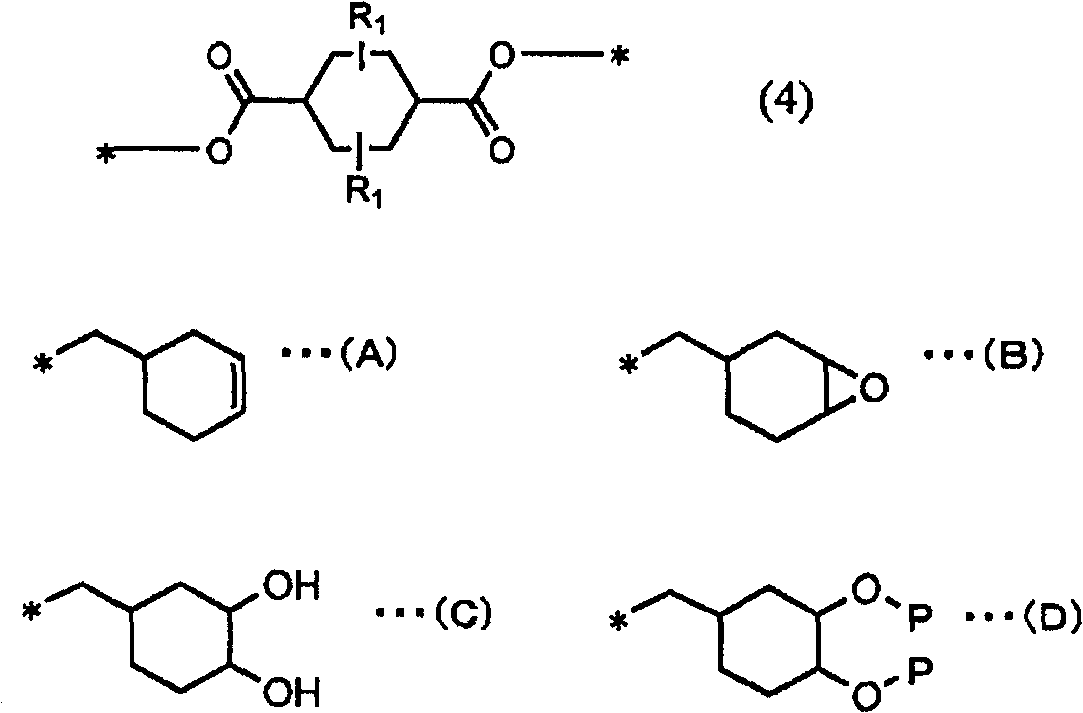

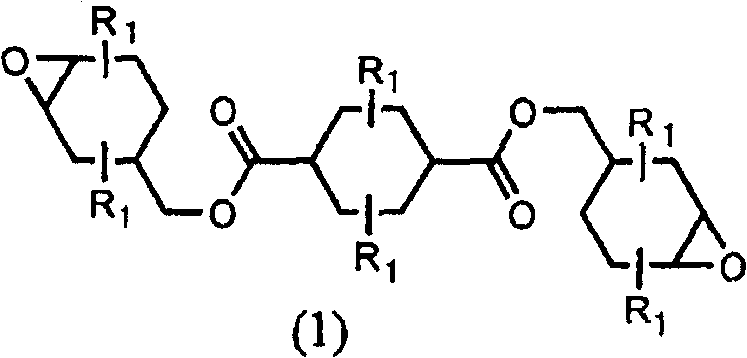

Curable resin composition for encapsulating optical semiconductor and cured product thereof

InactiveCN101942073AAvoid dentsExcellent resistance to corrosive gasesSolid-state devicesEpoxy resin adhesivesEpoxyHydrogen atom

The invention aims to provide a curable resin composition for encapsulating an optical semiconductor and a cured product thereof, which can prevent sinking after curing and have excellent property of etchant gas resistance and excellent dyeing resisting property. The curable resin composition contains epoxy resin, solidifying agent and / or solidifying booster expressed by formula (1) (in the formula, a plurality of R1 can be same or different and can independently present hydrogen atom or methyl). The curable resin composition of the invention, used as the optimized solidifying agent cyclohexane-1, 3, 4-triformic-3, 4-anhydride and methyl hexahydrophthalic anhydride, has particular effect in preventing sinking after curing.

Owner:NIPPON KAYAKU CO LTD

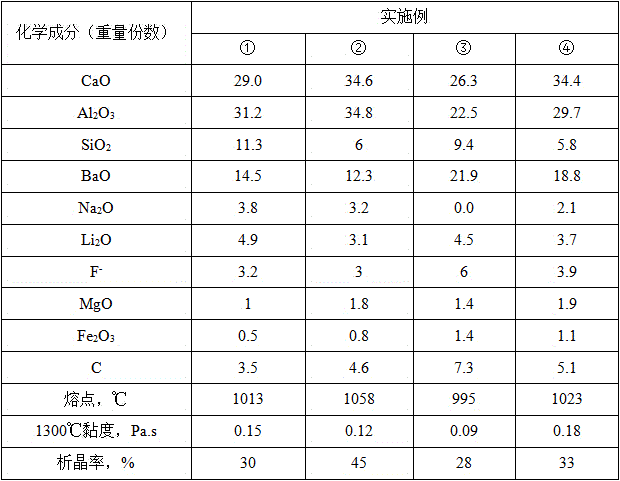

Crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of crystallizer covering slag

The invention provides a crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of the crystallizer covering slag. The covering slag is prepared from the following components in parts by weight: 20-38 parts of CaO, 20-35 parts of Al2O3, 5-18 parts of SiO2, 10-22 parts of BaO, 2-7 parts of Li2O, 5-12 parts of F<->, 1-4 parts of MgO, 2-8 parts of C and Fe2O3 which is less than or equal to 2 parts. According to the preparation method disclosed by the invention, wollastonite, limestone, quartz sand, fluorite, bauxite, barium carbonate, magnesia, soda, lithium carbonate and carbonaceous materials are used as raw materials, and the covering slag is prepared through the following steps of: calculating of consumption, melting, smashing, fine grinding, drying and granulation. The covering slag disclosed by the invention has the characteristics of being low in reactivity and good in property stability, the lubrication and the thermal transmission of casting blanks can be effectively coordinated and controlled, the smooth performing of the continuous casting process of the high-manganese high-aluminum steel can be guaranteed, high-manganese high-aluminum steel continuous casting blanks with excellent surface quality are cast, and multi-heat continuous casting can be realized.

Owner:CHONGQING UNIV

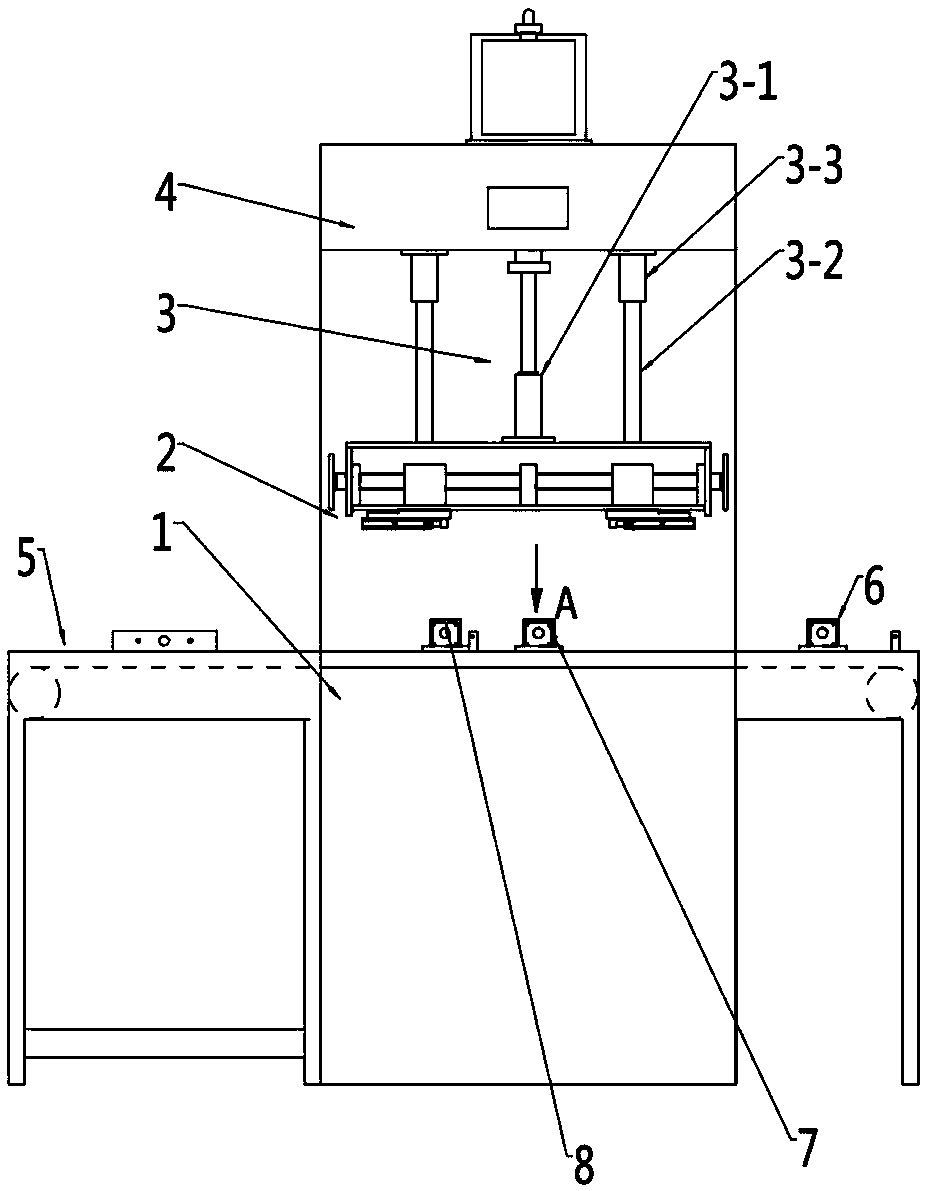

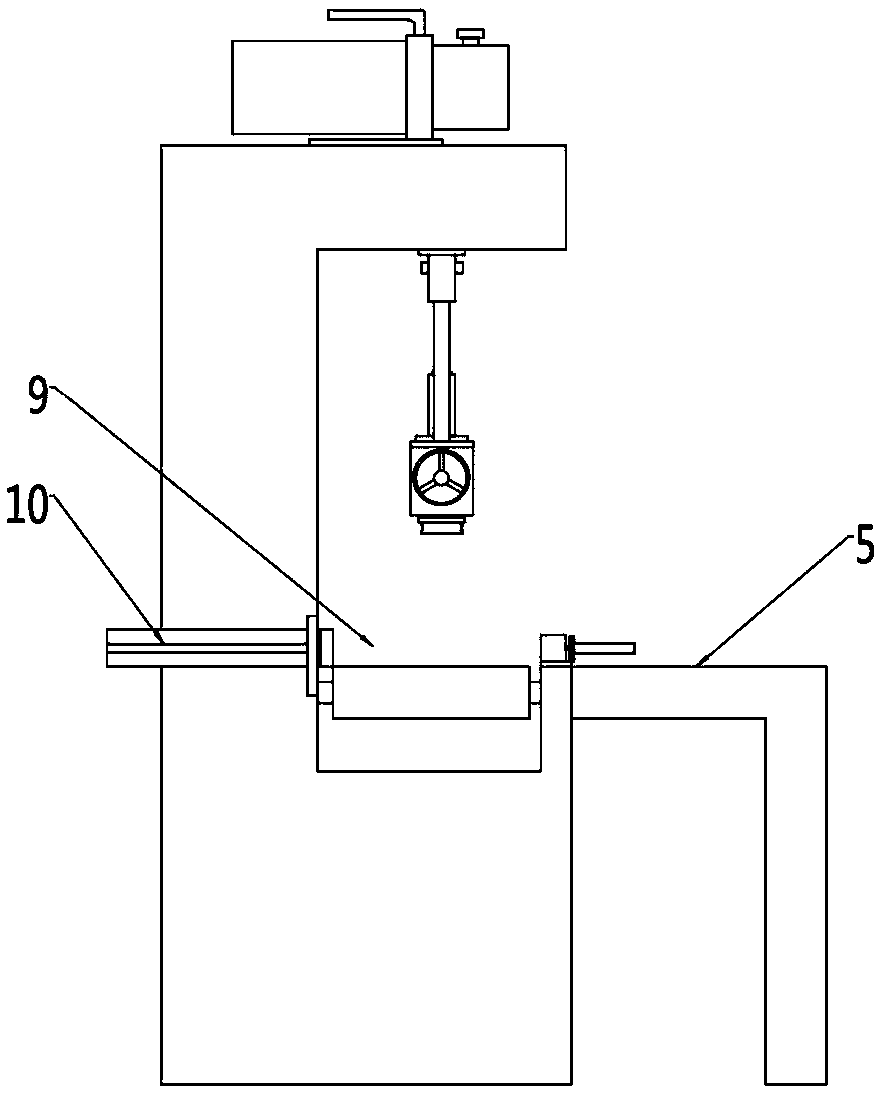

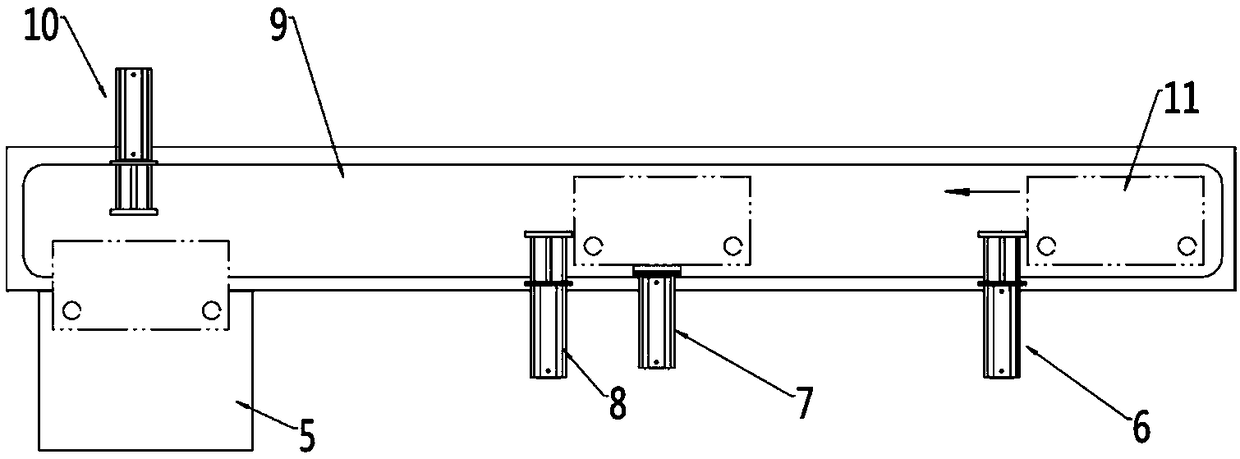

Storage battery airtightness detection and inflation method and equipment

PendingCN109141775AImprove detection efficiencyImprove inflation efficiencyMeasurement of fluid loss/gain rateAssembling battery machinesPositive pressureEngineering

The invention provides a storage battery airtightness detection and inflation method comprising the following steps: a, sealing the detected storage battery vent hole and vacuumizing the storage battery by a vacuum pump; b, maintaining the negative pressure state in the storage battery; c, judging whether the storage battery airtightness is qualified according to the time when the vacuum degree ofthe storage battery reaches the negative pressure requirement and the negative pressure change value in the storage battery after the end of pressure maintaining; and d, removing the defective storage batteries detected in the step c and piping the protective gas into the qualified storage batteries. The conventional method of using positive pressure inflation to detect the airtightness is changed into using negative pressure pumping to detect the airtightness so that convex deformation of the side wall of the storage battery tank caused by inflation can be effectively avoided; the protectivegas is piped into the qualified storage batteries at the detection position after detecting the airtightness by the negative pressure so that the deflation link can be reduced and the work efficiencycan be enhanced and the piping quality of the protective gas can be enhanced. The labor cost can be saved, the production efficiency can be enhanced and the inflation quality consistency can be guaranteed.

Owner:FENGFAN

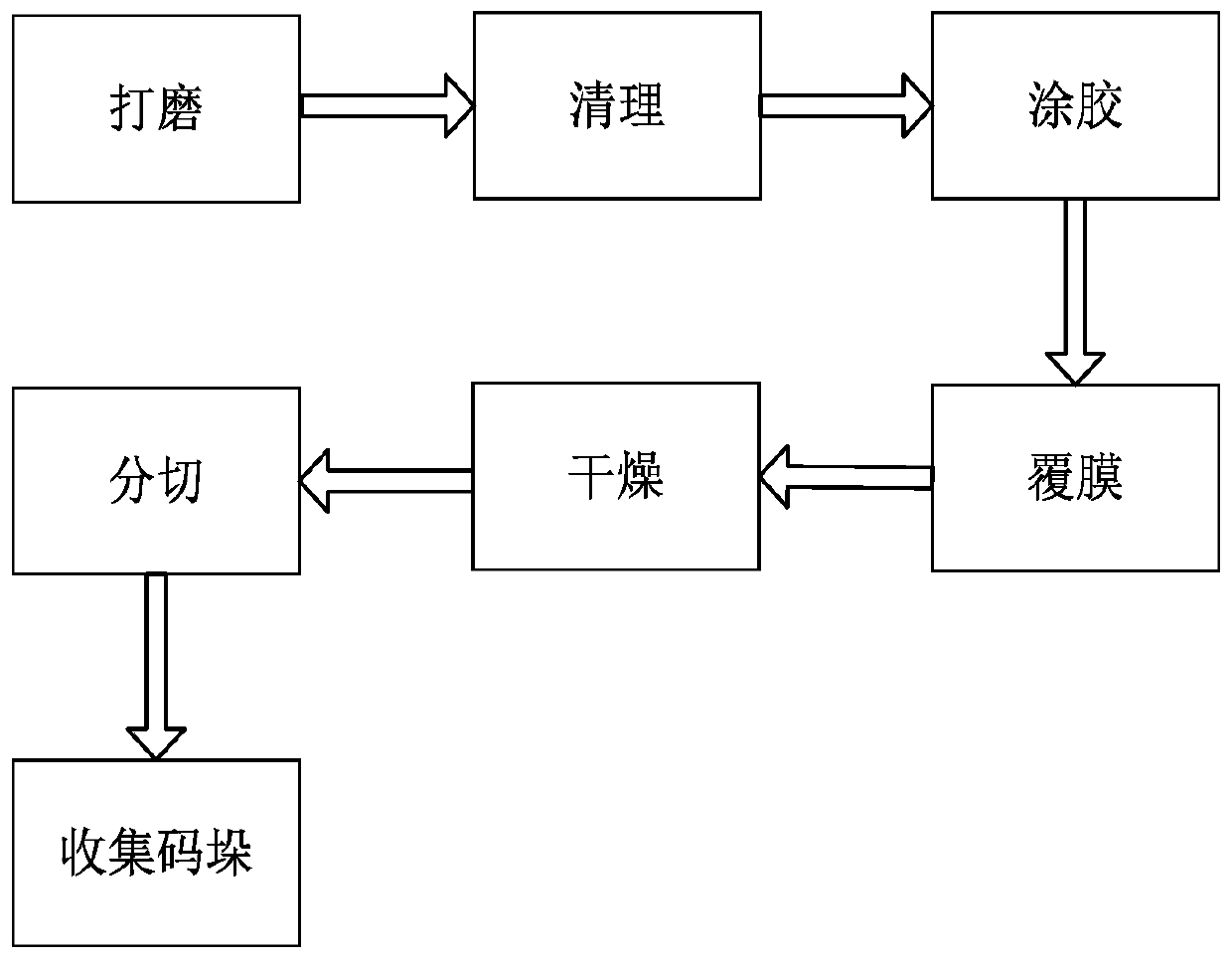

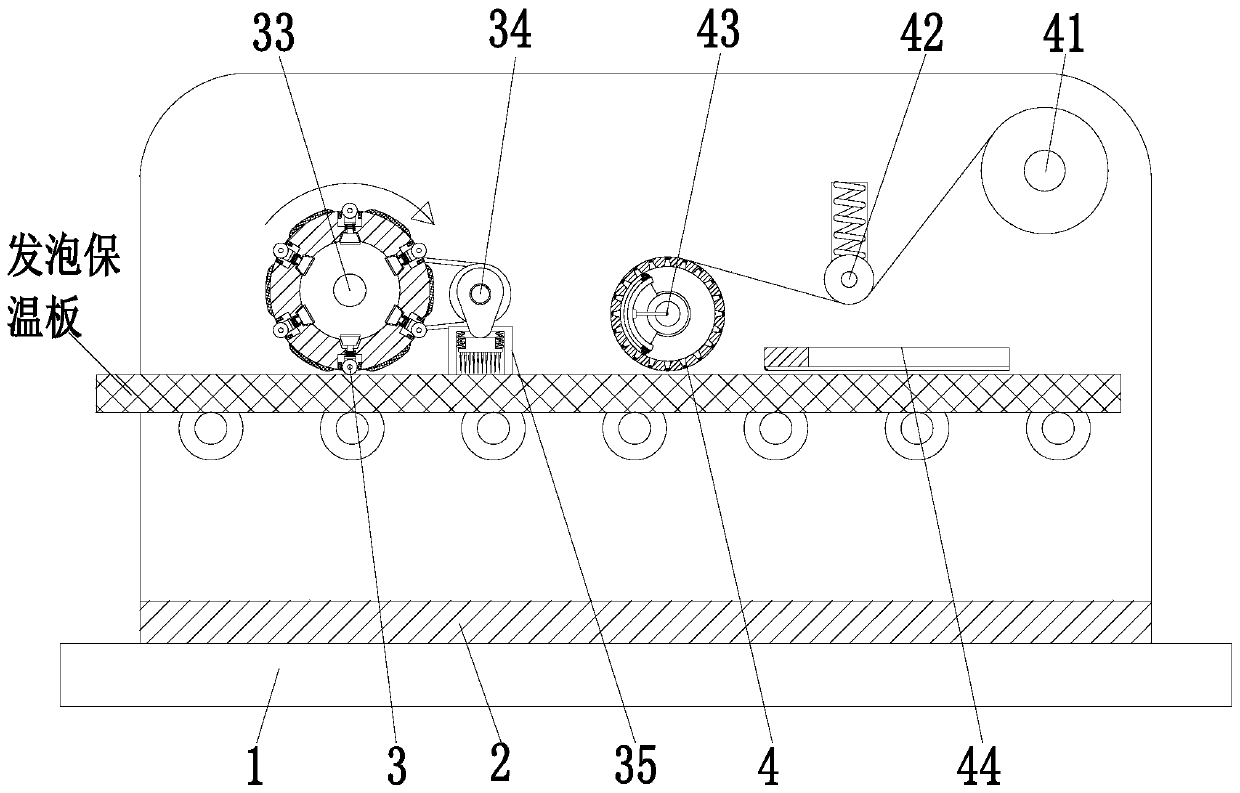

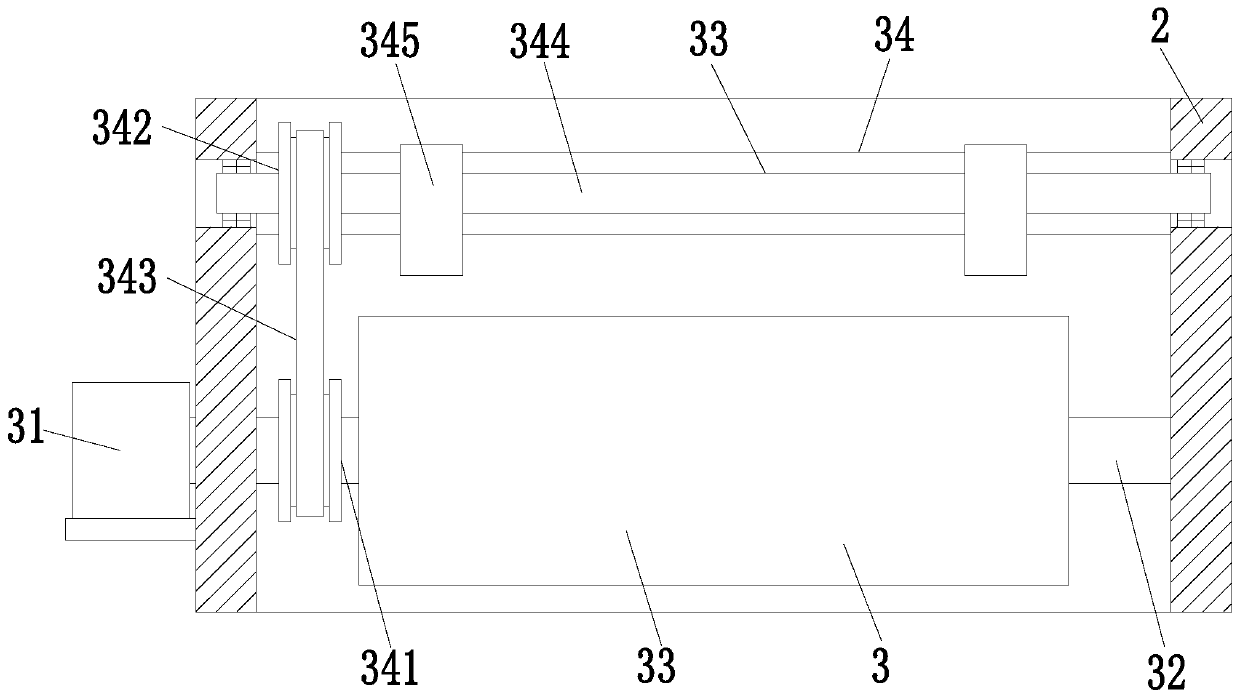

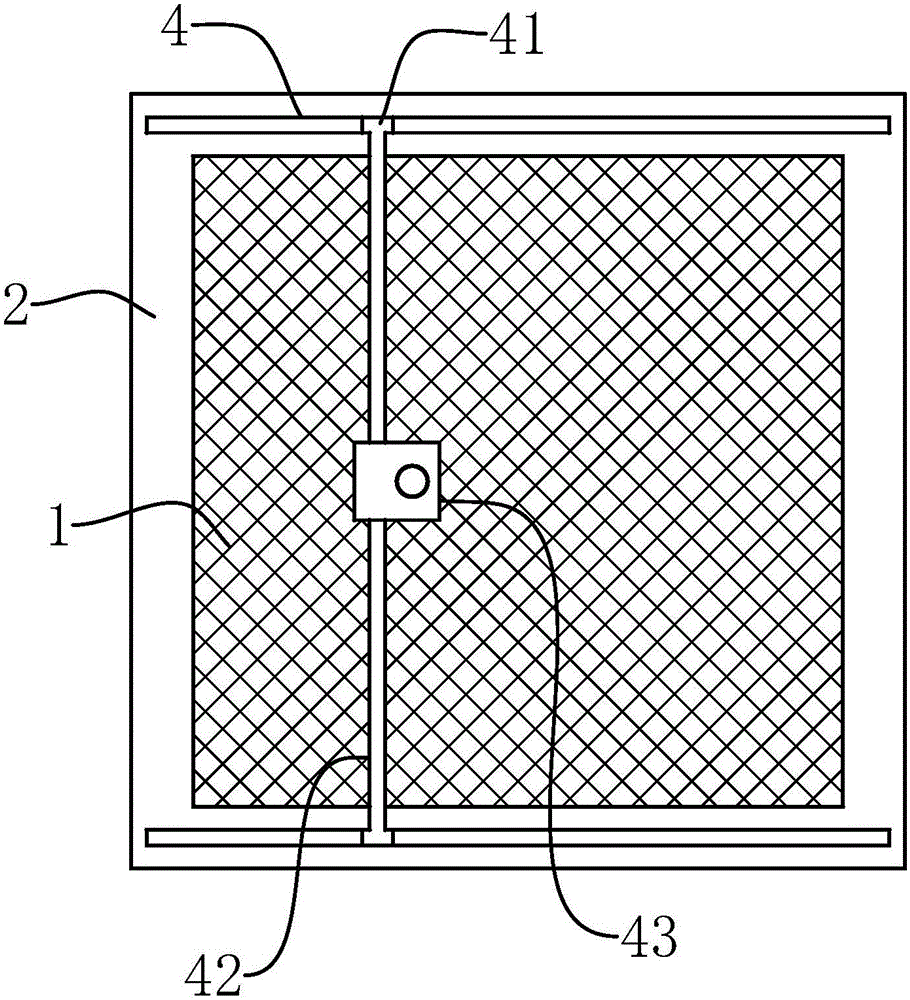

Surface treatment process for formed cement foaming insulation board

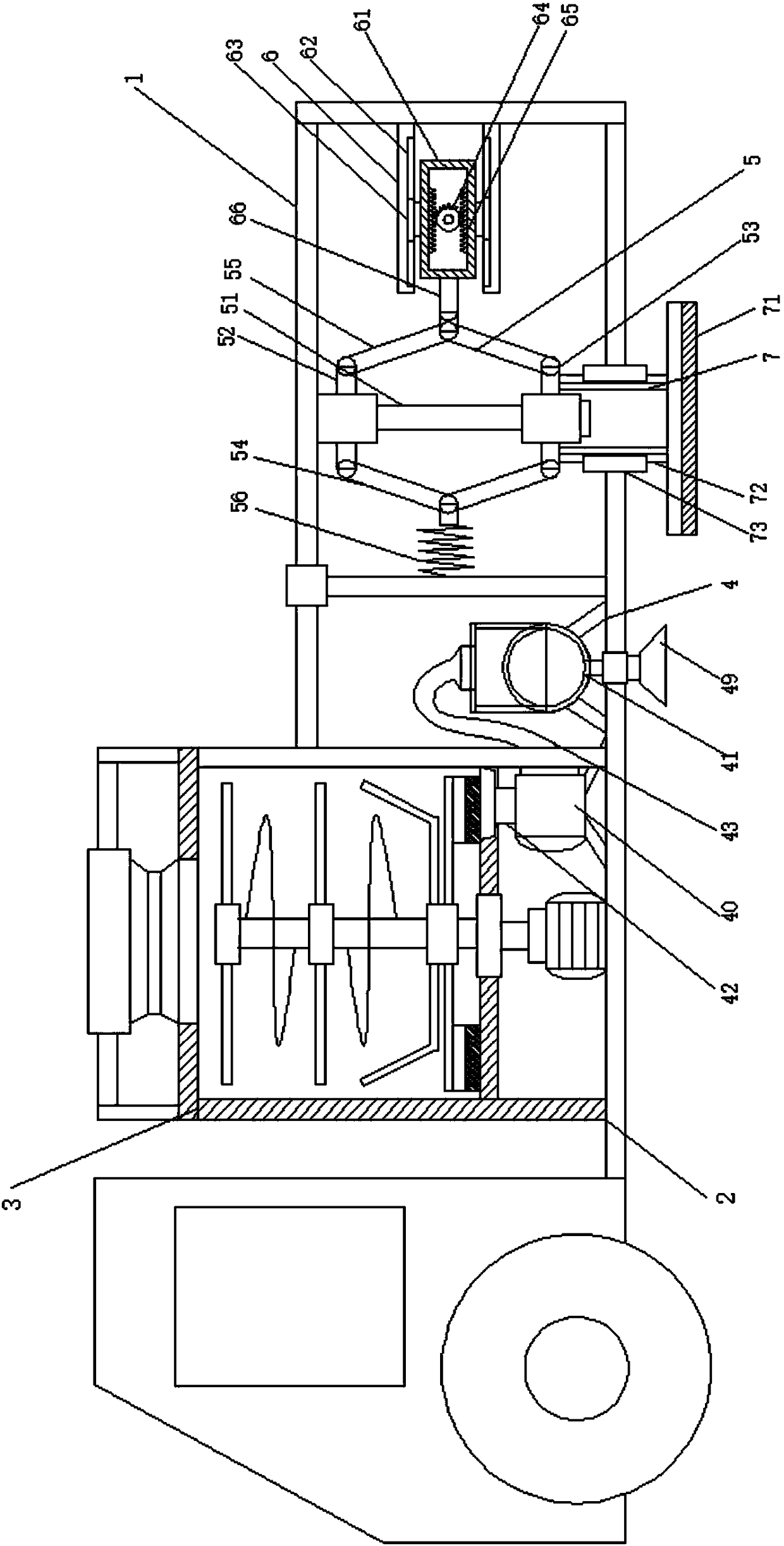

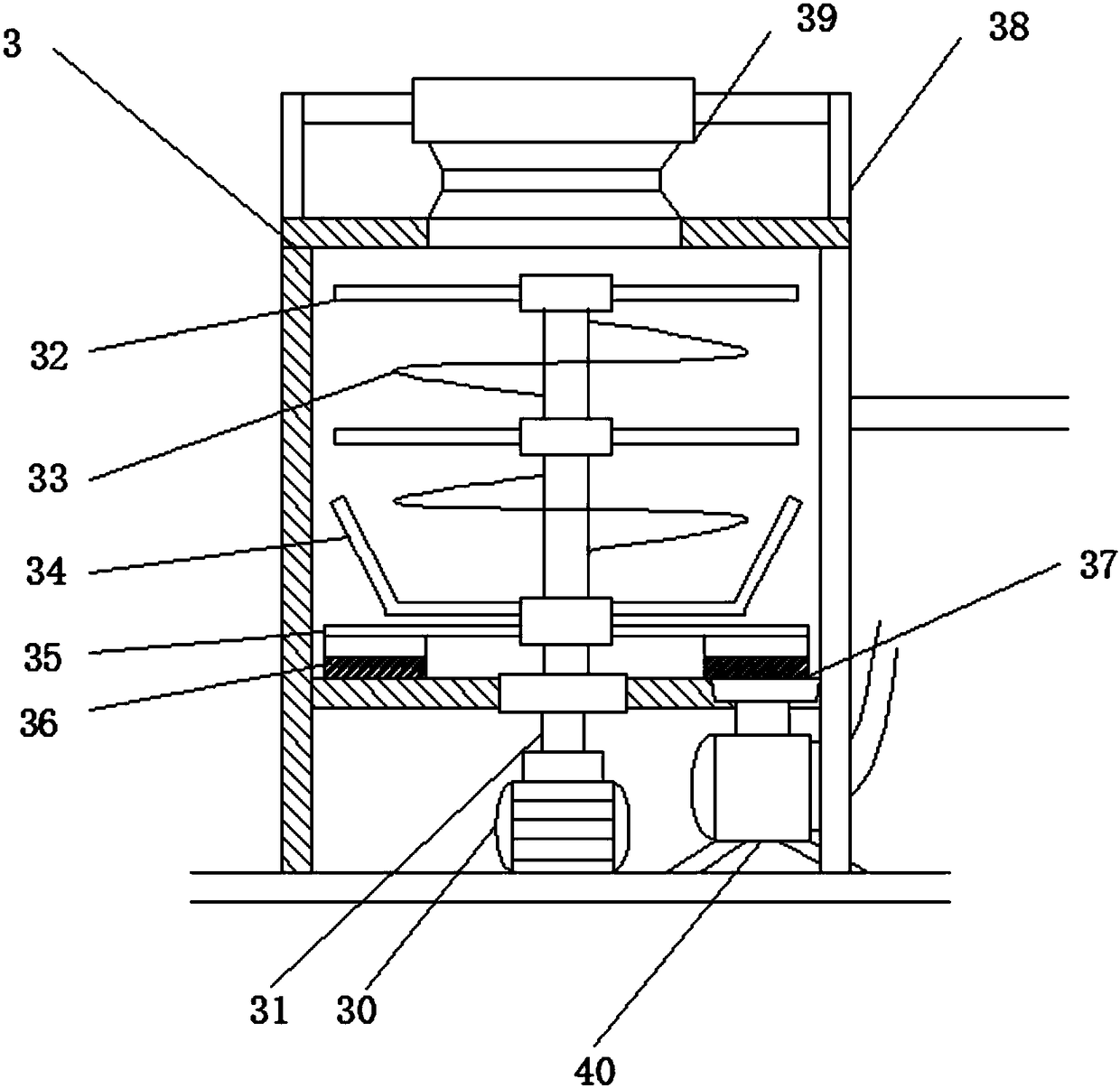

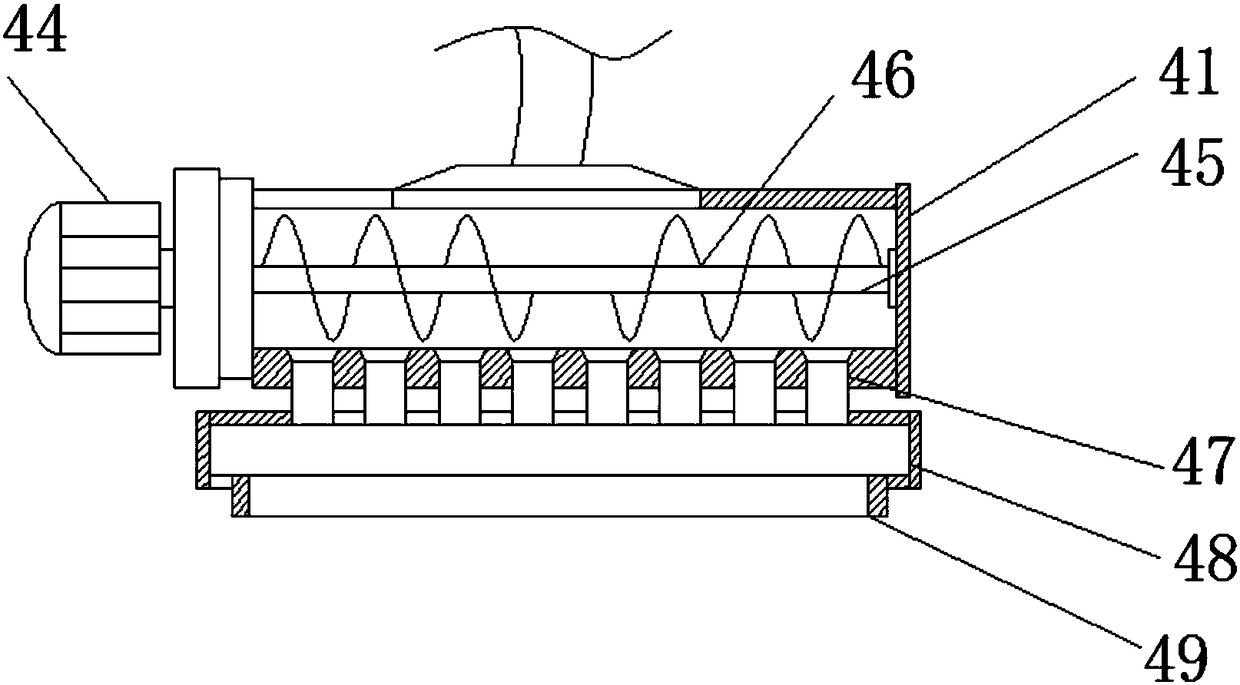

ActiveCN111391469AConducive to subsequent lamination processingEfficient coatingLamination ancillary operationsLaminationThin membraneFilm-coated tablet

The invention relates to a surface treatment process for a formed cement foaming insulation board, which comprises a bottom plate, a supporting frame, a gluing device and a laminating device, the supporting frame is installed at the upper end of the bottom plate, conveying rollers are evenly installed in the supporting frame through pin shafts, the gluing device is installed on the left side of the interior of the supporting frame, and the laminating device is installed on the right side of the interior of the supporting frame. According to the invention, the problems that the existing equipment is inconvenient to operate; the gluing effect is poor and the coating is not uniform; the foaming insulation board is of a porous structure; a glue solution cannot quickly permeate into the foaminginsulation board; a depression on the surface of the foam insulation board is generated after filming, which affects the surface quality; and meanwhile, when existing equipment is used for carrying out film coating processing on the foaming heat preservation plate, deviation usually occurs between a thin film and a plate, the phenomena of wrinkles and bubbles are likely to occur on the outer surface of the attached thin film, and the using effect is affected are solved.

Owner:深圳东诚装饰建筑集团有限公司

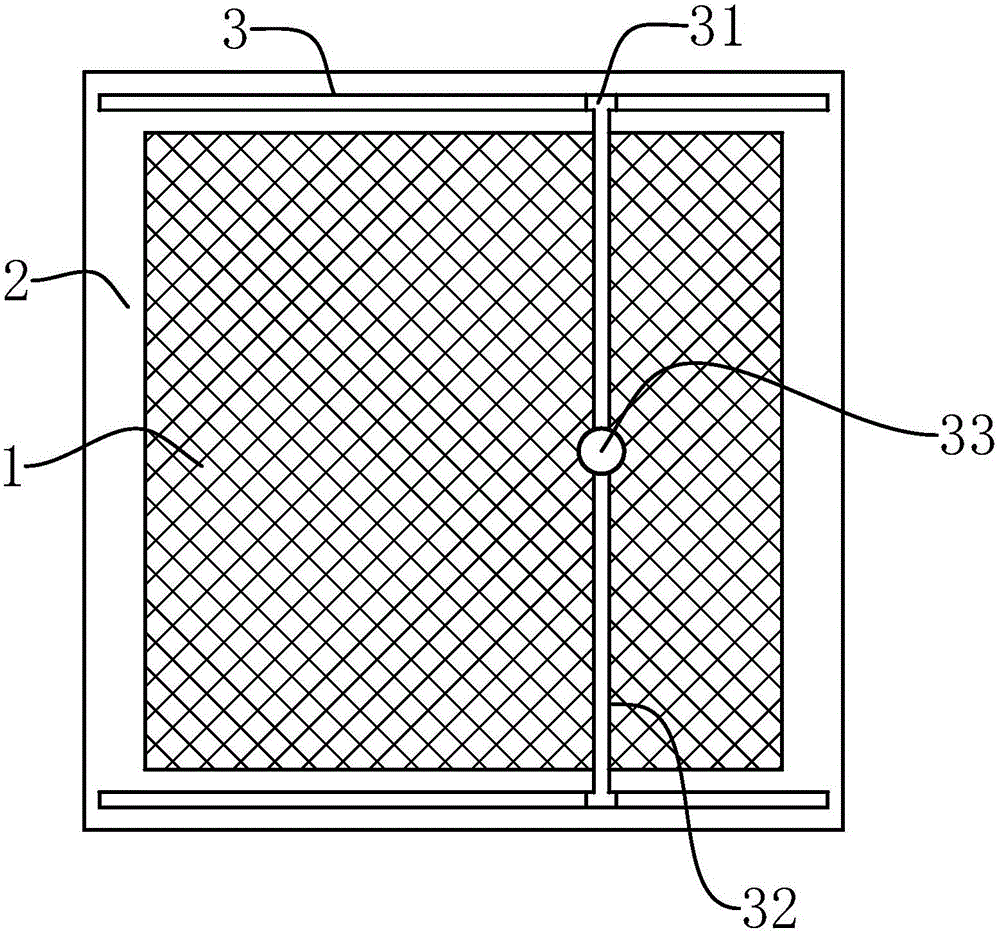

High-strength shock-resistance water purifier filtration screen rack

ActiveCN105833583AAvoid dentsJob impactStationary filtering element filtersFiltrationShock resistance

The invention provides a high-strength shock-resistance water purifier filtration screen rack and belongs to the field of water purifiers. The high-strength shock-resistance water purifier filtration screen rack is capable of solving the problem of high impact deformation of an existing filtration screen. The high-strength shock-resistance water purifier filtration screen rack comprises a rectangular frame and a rectangular filtration screen; the frame is bend and wraps the outer edges of two sides of the filtration screen; the parts, which are correspondingly positioned on the inner and outer sides of the filtration screen, of the filtration screen are respectively provided with two inner sliding chutes and two outer sliding chutes; the inner sliding chutes are parallel to the outer sliding chutes; the inner sliding chutes and the outer sliding chutes are respectively and slidably connected with inner sliding blocks and outer sliding blocks; a support rod capable of propping against the filtration screen is connected between the two sliding blocks; a fixing rod separated from the filter screen is connected between the two outer sliding blocks; the fixing rod is provided with a fixing base used for fixing an impact head, the outer sliding blocks can slide along the outer sliding chutes and absorb the inner sliding blocks by virtue of magnetism, so that the inner sliding blocks slide along the inner sliding chutes. The filtration screen rack is high in impact strength.

Owner:安徽优盾信息科技有限公司

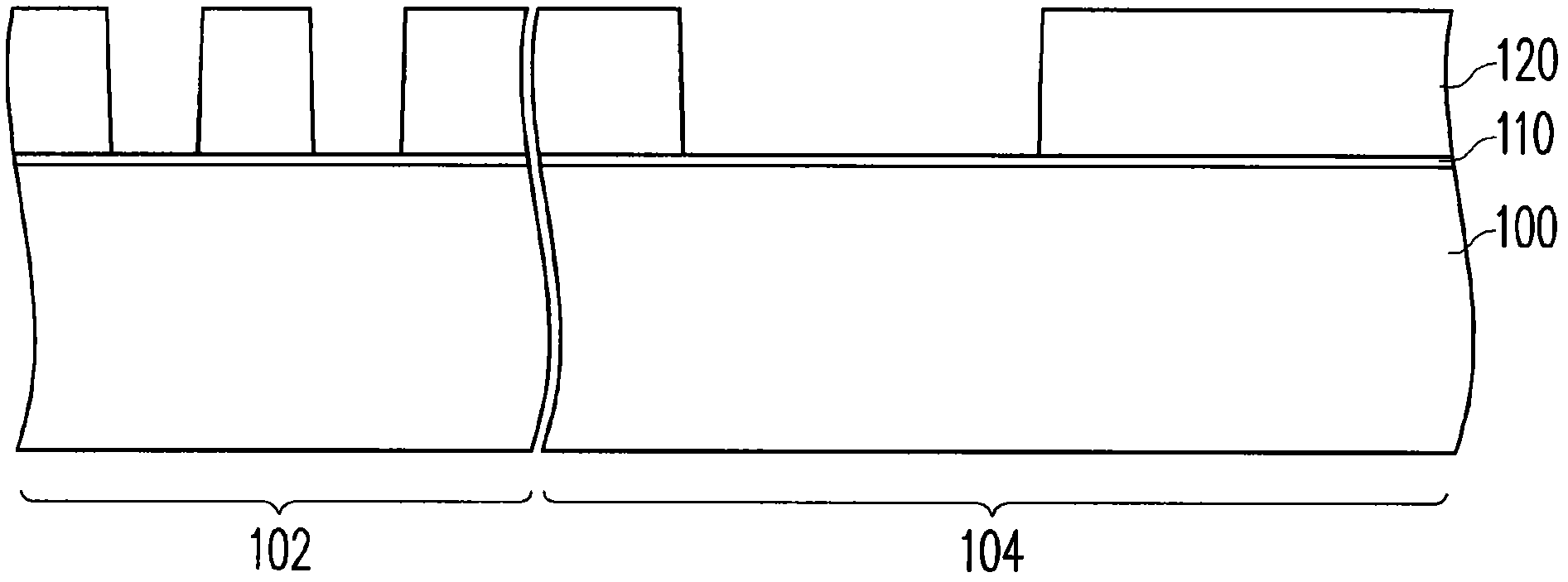

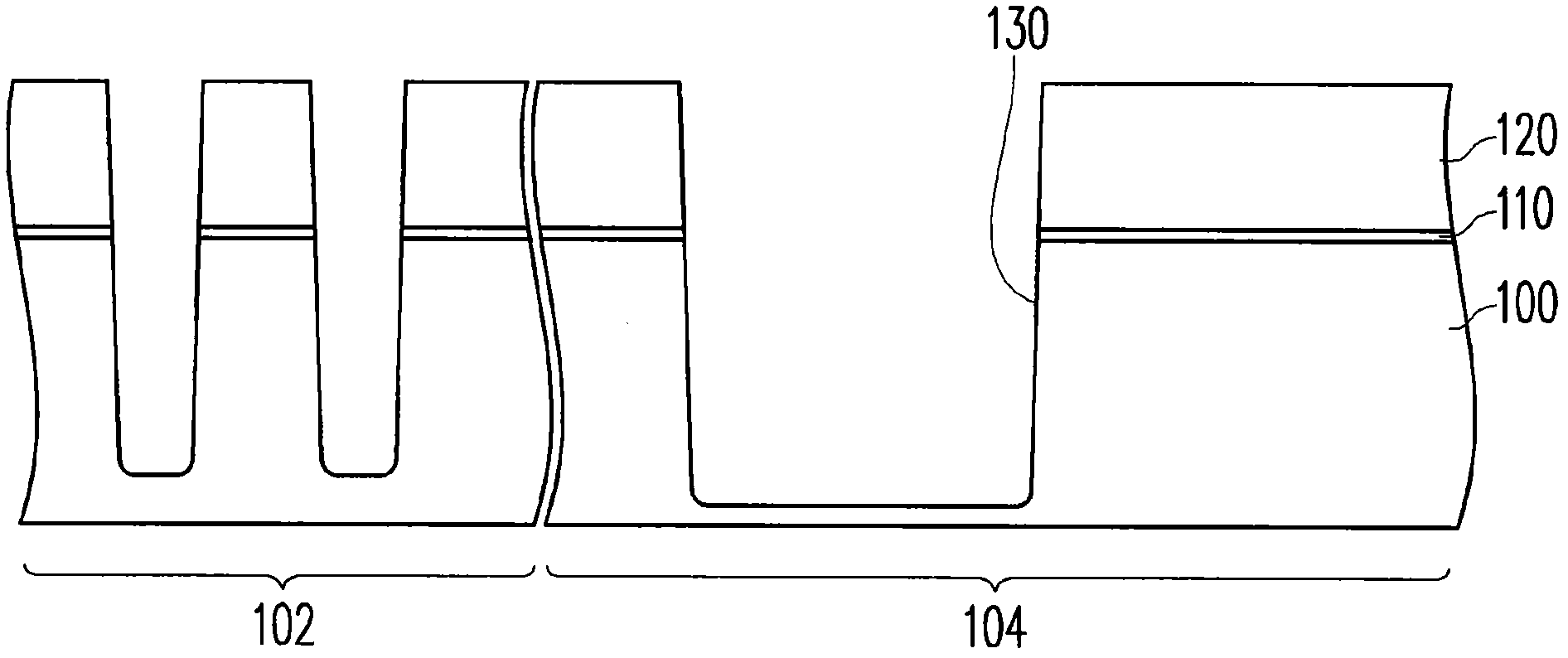

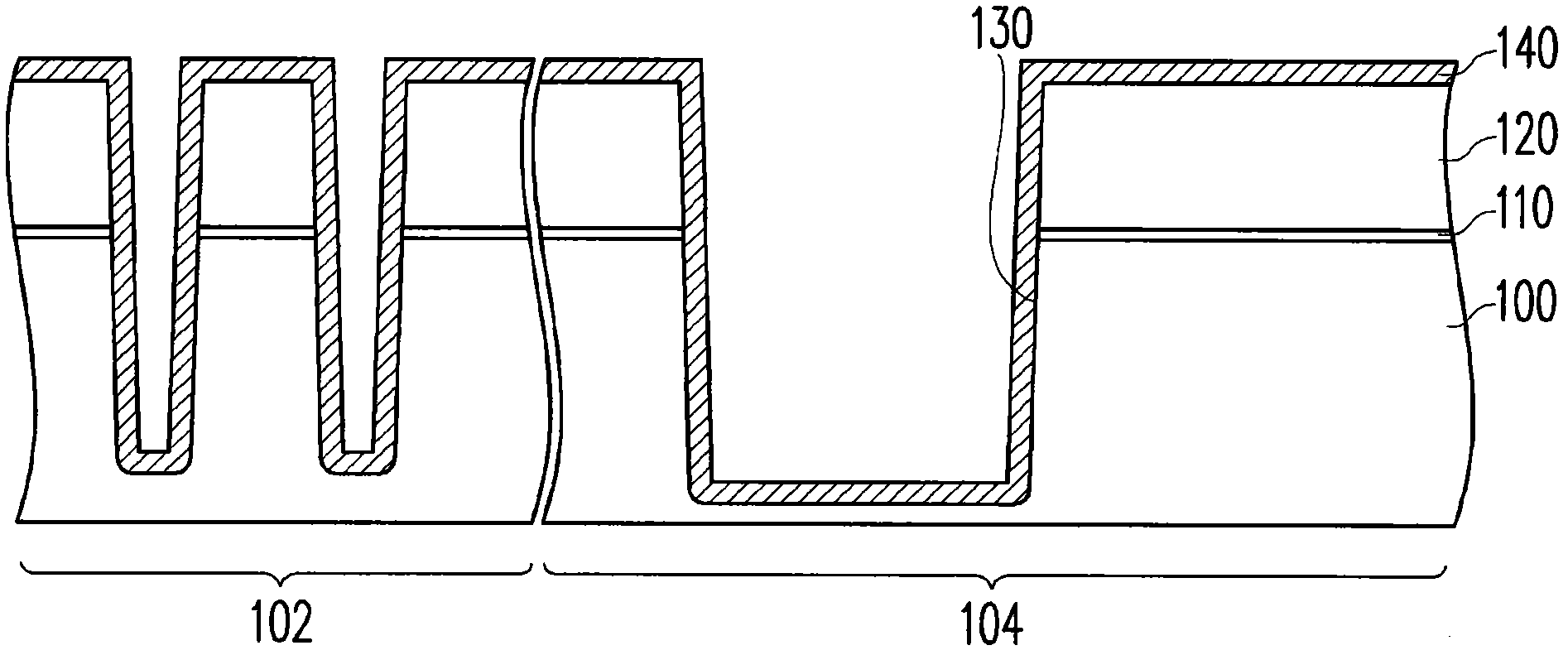

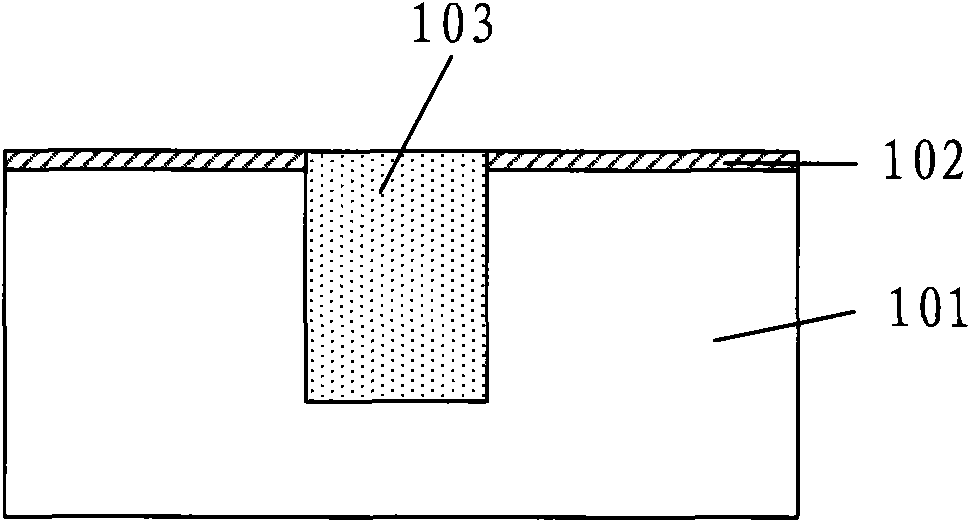

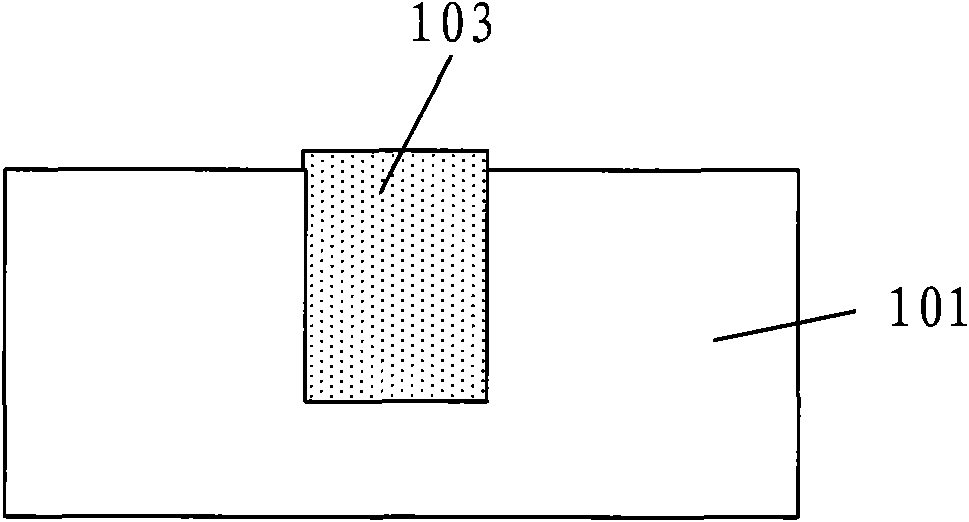

Manufacturing method of trench isolation structure

ActiveCN102651333AAppropriate indentationGood component characteristicsSemiconductor/solid-state device manufacturingBiomedical engineeringMask layer

The invention discloses a manufacturing method of a trench isolation structure. The manufacturing method of the trench isolation structure comprises the following steps of: sequentially forming a patterned cushion layer and a patterned mask layer on a substrate, wherein the substrate comprises a storage unit region and a peripheral region; taking the patterned mask layer as a mask to remove a part of the substrate so as to form a plurality of trenches; forming a first liner on the substrate so as to cover the patterned mask layer, the patterned cushion layer and the surfaces of the trenches; removing the first liner for covering the patterned mask layer, the patterned cushion layer and the surfaces of the trenches in the peripheral region; after removing the first liner in the peripheral region, contracting inwardthe patterned mask layer, so that the contracting amount of the patterned mask layer in the peripheral region is greater than that of the patterned mask layer in the storage unit region; and forming insulating layers in the trenches to form a plurality of shallow trench isolation structures. Through the manufacturing method, a storage device element has better element characteristics and reliability.

Owner:WINBOND ELECTRONICS CORP

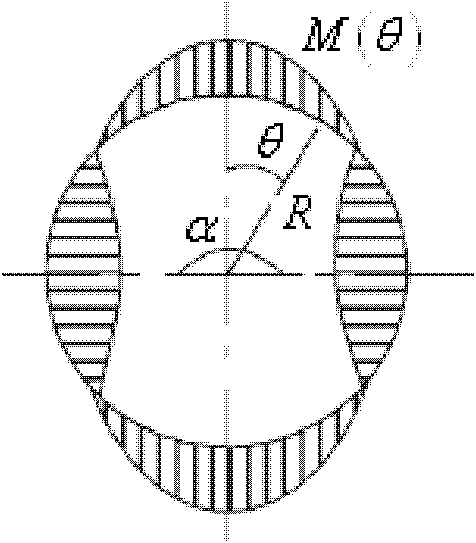

Method for realizing precision straightening of thin-wall seamless steel tubes by adopting six-roller straightener

InactiveCN101927278AReduce the number of squashesIncrease the number of squashesMechanical engineeringSteel tube

The invention discloses a method for realizing the precision straightening of thin-wall seamless steel tubes by adopting a six-roller straightener, aiming at providing a method for obtaining optimum technological parameters and producing thin-wall seamless steel tubes with high surface quality by calculating straightening press-down quantity and correcting press-down quantity, comparing the resultant force of straightening applied force and correcting applied force with and hertz contact force, and checking straightness accuracy and the diameter difference of long shafts and short shafts of an ellipse. The method comprises the following steps: confirming the press-down bending and straightening frequency and press-flat bending and correcting frequency; confirming the straightening press-down quantity, the straightening applied force, the correcting press-down quantity and the correcting applied force; working out the hertz contact force resulting in the sag deformation of the seamless steel tubes according to a hertz contact theory; comparing the hertz contact force with the resultant force of the straightening applied force and the correcting applied force; calculating straightness error according to the actual straightening press-down quantity from 1 to the last straightening; and calculating the corrected diameter difference of the long shafts of the ellipse and the diameter difference of the short shafts of the ellipse from 1 to the last correcting and comparing with a standard value.

Owner:TIANJIN UNIV OF COMMERCE

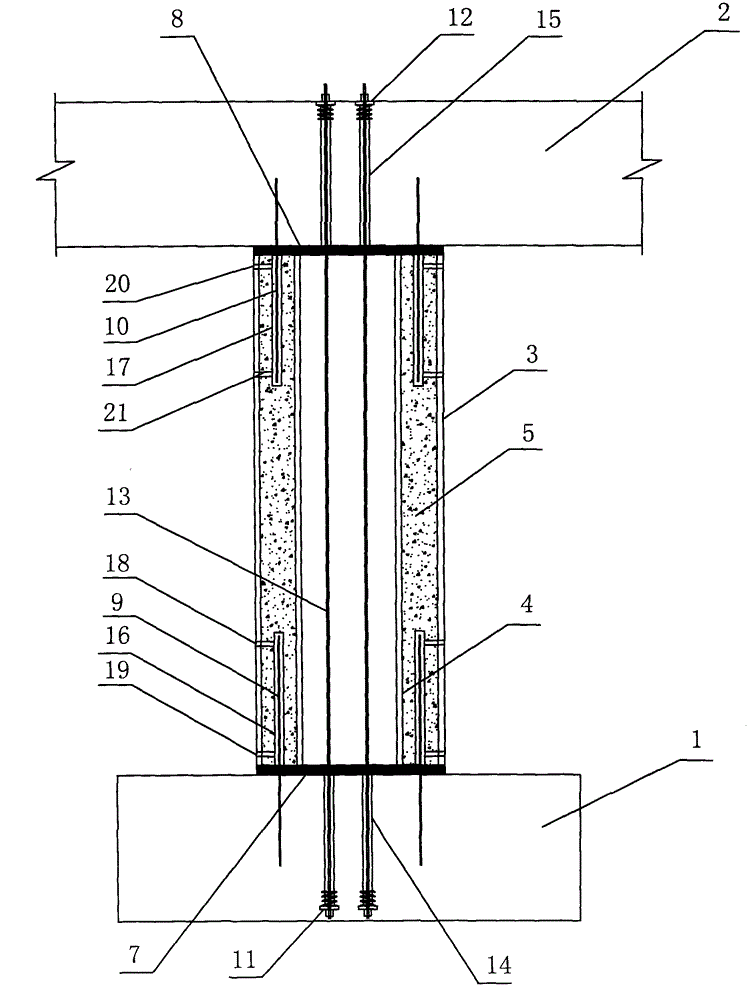

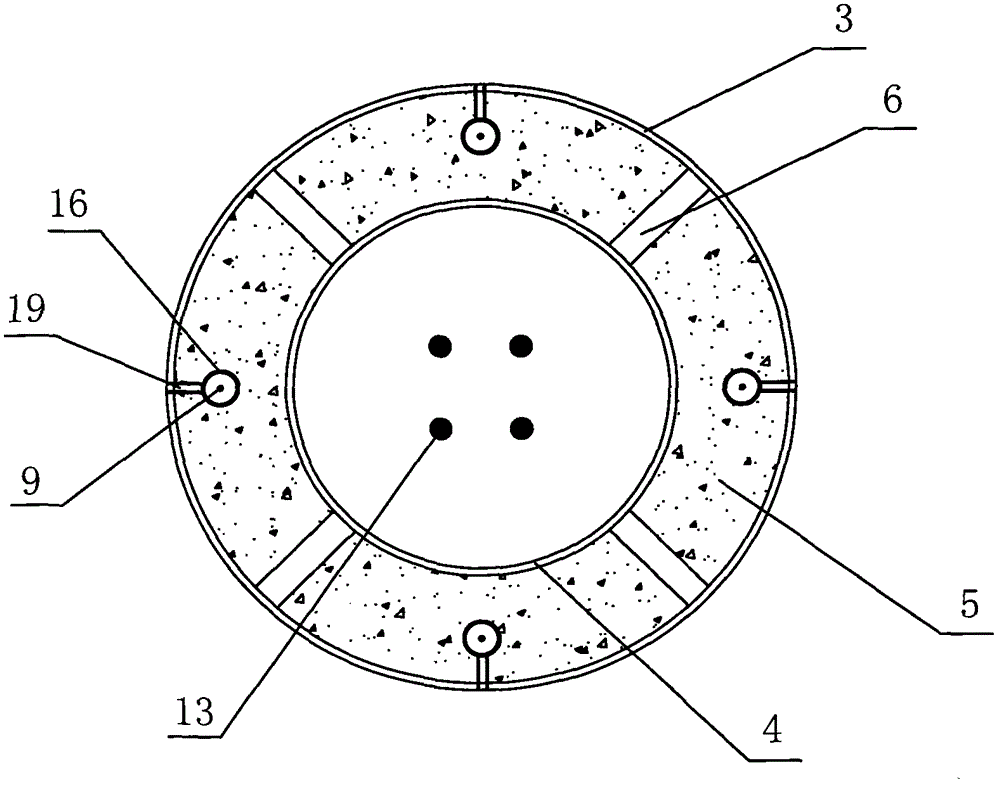

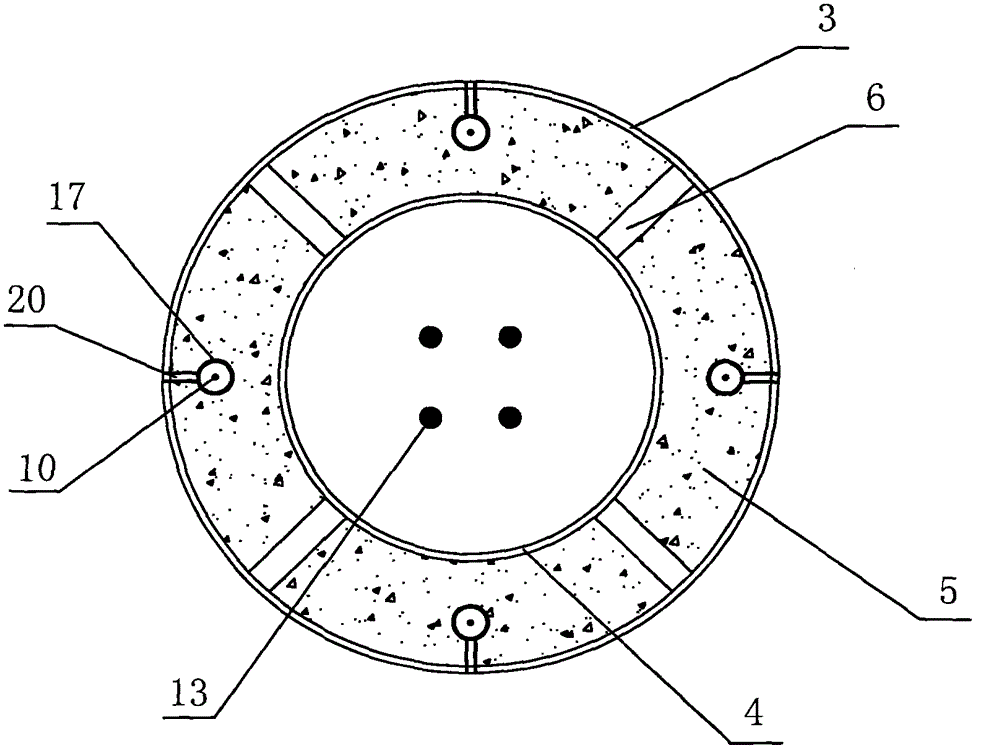

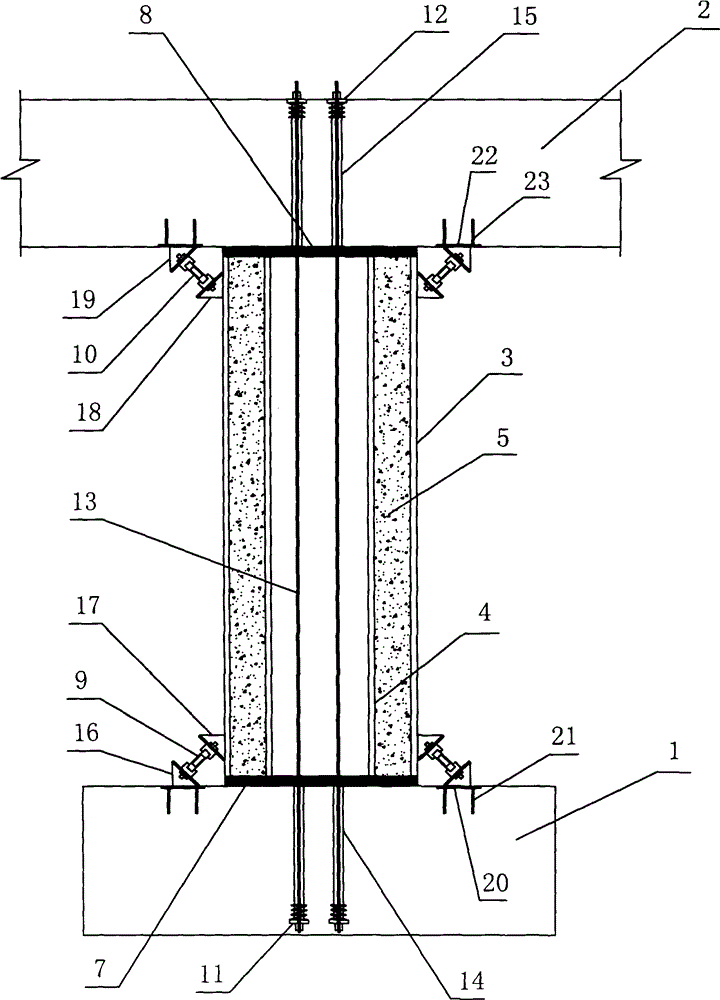

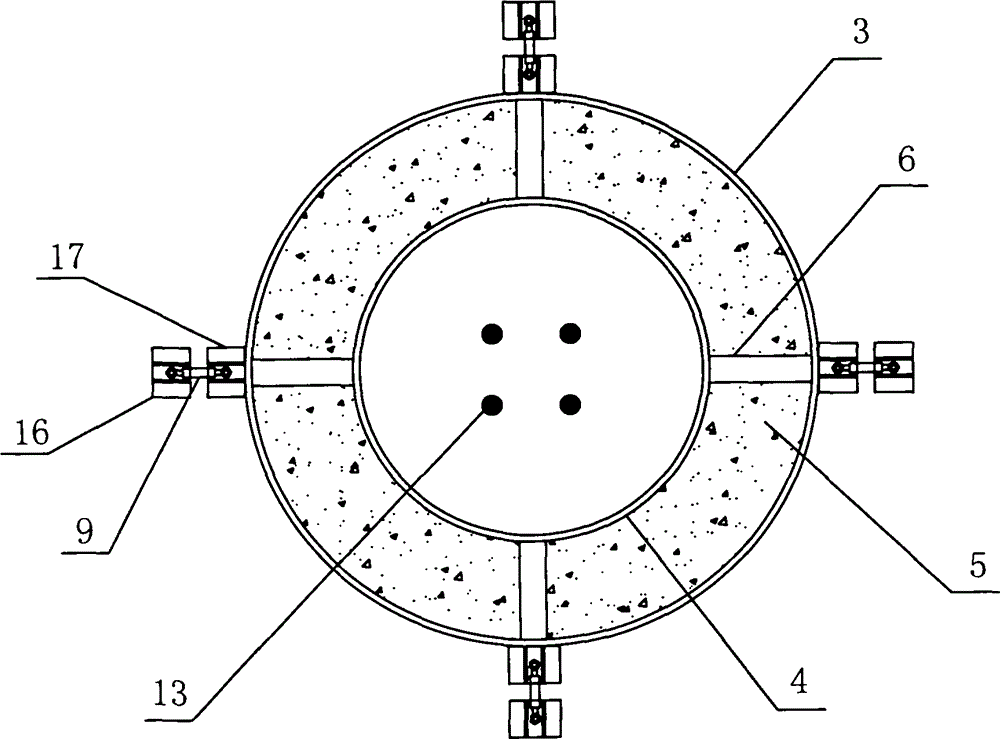

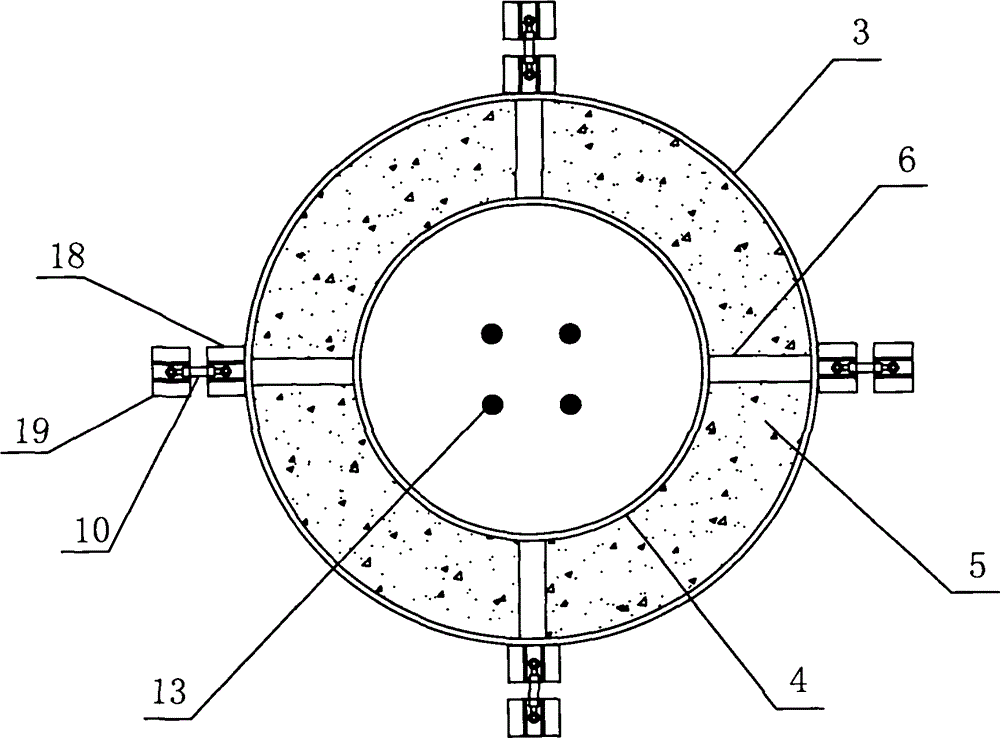

Energy-consuming rebar-attached unbonded post-tensioning prestressed concrete filled double-wall steel tube prefabricated assembly bridge pier

InactiveCN104532740AReduced displacement requirementsControl and reduce displacement requirementsBridge structural detailsBridge materialsFiberPre stress

The invention discloses an energy-consuming rebar-attached unbonded post-tensioning prestressed concrete filled double-wall steel tube prefabricated assembly bridge pier comprising a bearing platform, a prefabricated assembly bridge pier and a cover beam. The energy-consuming rebar-attached unbonded post-tensioning prestressed concrete filled double-wall steel tube prefabricated assembly bridge pier is characterized in that the prefabricated assembly bridge pier is a concrete filled double-wall steel tube prefabricated assembly bridge pier; the prefabricated assembly bridge pier comprises an outer steel tube, an inner steel tube and filled concrete; the end faces of the top and the bottom of the outer steel tube and the inner steel tube are respectively connected by four steel sheets; fiber-reinforced mortar layers are arranged between the top face of the bearing platform and the end face of the prefabricated assembly bridge pier and between the bottom face of the cover beam and the end face of the prefabricated assembly bridge pier; the bearing platform, the prefabricated assembly bridge pier and the cover beam are assembled integrally by a prestressed tension device; and four common ribbed energy-consuming rebars are respectively between the top face of the bearing platform and the end face of the prefabricated assembly bridge pier and between the bottom face of the cover beam and the end face of the prefabricated assembly bridge pier. The energy-consuming rebar-attached unbonded post-tensioning prestressed concrete fill double-wall steel tube prefabricated assembly bridge pier has the advantages that the construction quality is improved, the construction speed is increased, operational quantity of the scene is reduced, and impact on environment is alleviated. The energy-consuming rebars provide attached energy-consuming capacity for the bridge pier, and the displacement demand of the bridge pier under the action of horizontal load, such as earthquake can be controlled and reduced.

Owner:NINGBO UNIV

Unbonded post-tensioning prestress concrete-filled double-wall steel pipe prefabricated assembly piers with additional dampers

InactiveCN104612036AReduced displacement requirementsControl and reduce displacement requirementsBridge structural detailsBridge materialsPre stressDouble wall

The invention discloses unbonded post-tensioning prestress concrete-filled double-wall steel pipe prefabricated assembly piers with additional dampers. The piers comprise a bearing table, prefabricated assembly pier bodies and a cover beam. The piers are characterized in that prefabricated assembly pier bodies are concrete-filled double-wall steel pipe prefabricated assembly pier bodies, each prefabricated assembly pier body comprises an outer steel pipe, an inner steel pipe and filled concrete, the end faces of the tops and the end faces of the bottoms of the outer steel pipes and the end faces of the tops and the end faces of the bottoms of the inner steel pipes are connected through four steel sheets respectively, fiber reinforcement mortar layers are arranged between the top face of the bearing table and the end faces of the prefabricated assembly pier bodies as well as between the bottom face of the cover beam and the end faces of the prefabricated assembly pier bodies, the bearing table, the prefabricated assembly pier bodies and the cover beam are assembled through prestress tension device to form a whole, and the four viscous dampers are arranged between the top face of the bearing table and the side faces of the prefabricated assembly pier bodies as well as between the bottom face of the cover beam and the side faces of the prefabricated assembly pier bodies. The piers have the advantages that the construction quality is improved, the construction speed is increased, the site operation amount is reduced, and the impact on the environment is reduced; the viscous dampers provide additional energy-consuming abilities for the piers, and therefore the displacement requirement of the piers under horizontal load effects of earthquakes and the like can be controlled and reduced.

Owner:NINGBO UNIV

Method for retaining freshness of chilled fresh fish heads

ActiveCN102217668AReduce the initial bacterial countProduction process is environmentally friendlyMeat/fish preservation by coatingMeat/fish preservation using chemicalsChlorine dioxideElectrolysis

The invention provides a method for retaining freshness of chilled fresh fish heads, wherein freshwater fish heads are used as raw materials, and the freshness retaining of the fish heads is realized by virtue of sterilizing, coating, modified atmosphere packaging and other methods. The method comprises the main steps of: pre-treating: performing scaling, gill removing and cold-water cleaning on the fresh fish heads; sterilizing by electrolytic ozone water; draining; filling simulated gills; coating a compound fresh preserver; blowing to dry body surface water and sterilizing by using ultraviolet light; packaging under a modified atmosphere; and obtaining products. The main advantages of the method provided by the invention are as follows: (1) ginger is used for preparing the simulated gills and placed in gill covers, so that the function of assisting bacterial inhibition and fishy smell removal is achieved, the eye rims of the fish heads can be effectively prevented from sinking and the influence on the fish head appearances due to gill removal is eliminated; (2) the fish heads are sterilized by using the electrolytic ozone water and the ultraviolet light, so that the initial bacterial count of the raw materials is effectively decreased, and chlorine dioxide and preservative are not used so that the production technology is green and environment-friendly; and (3) the fish heads subjected to cold sterilization is coated with a green compound coating fresh preserver, so that the quality guarantee period of fish head products is effectively prolonged.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Hole tamping method of circuit board

InactiveCN103313531AImprove yieldAvoid dentsPrinted element electric connection formationScreen printingDetonation

The invention provides a hole tamping method of a circuit board. The method comprises the steps that the circuit board is provided, wherein the circuit board is provided with a number of conductive holes and the depth of each conductive hole is more than 3mm; through at least two hole tamping processes, a number of conductive holes are filled with hole tamping ink until each conductive hole is filled with the hole tamping ink, wherein each hole tamping process comprises the steps of filling the hole tamping ink in a number of conductive holes through screen printing and using ultrasonic to oscillate the circuit board with the conductive holes filled with the hole tamping ink for 30 seconds to 120 seconds to enable bubbles in the hole tamping ink to escape, wherein the filling depth of the hole tamping ink in each conductive hole is 1mm to 2mm; and ultrasonic is used to oscillate the circuit board with the conductive holes filled with the hole tamping ink for 30 seconds to 90 seconds, so as to acquire the circuit board with tamped holes. According to the hole tamping method provided by the technical scheme, more than two hole tamping processes and an additional oscillation process to eliminate the bubbles in the hole tamping ink, and the phenomenon of board detonation can be effectively prevented.

Owner:HONG HENG SHENG ELECTRICAL TECH HUAIAN +1

Cement flattening compacting device for road construction

PendingCN108385481AImprove stirring effectAvoid cloggingRoads maintainenceEngineeringMechanical engineering

The invention discloses a cement flattening compacting device for road construction. The cement flattening compacting device comprises a rack and a base. The rack is mounted on the base, and the rackis provided with a material box, a conveying mechanism, a transmission device and a transmission frame. The transmission device comprises a sliding bar, the sliding bar is vertically mounted on the rack, a top plate and a bottom plate are mounted on the sliding bar, the top plate and the bottom plate are mounted on the sliding bar through sliding sleeves, the top ends of the top plate and the bottom plate are provided with a first transmission link for connecting the two, the front ends of the top plate and the bottom plate are provided with a second transmission link for connecting the two, the transmission frame is mounted at the rear end of the rack, a sliding frame is mounted inside an inner cavity in the transmission frame, sliding blocks are mounted at the upper and lower ends of thesliding frame, the upper and lower sides of the inner wall of the transmission frame are provided with sliding rails, and the sliding blocks are limited in the sliding rails. The cement flattening compacting device has high stability and high operation consistency, can perform fully automated operation, and can save a lot of human resources.

Owner:HENAN GAOSHENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

Shallow trench isolation structure and forming method thereof

ActiveCN101577242AImprove formation qualityImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingEtchingEngineering

The invention discloses a forming method of a shallow trench isolation structure, comprising the steps: providing an substrate; forming a stop layer on the substrate; defining a shallow trench graph on the substrate; forming a trench in the substrate on which the stop layer is formed; depositing protective dielectric layers on the stop layer and the trench; corroding the protective dielectric layers until the protective dielectric layer on the stop layer is removed; depositing filler on the stop layer and in the trench; performing planarization process on the substrate where the filler is deposited; eliminating the stop layer on the substrate; and processing the filler by a method of wet etching. The invention also discloses the corresponding shallow trench isolation structure. The shallow trench isolation structure and the forming method thereof can prevent pits occurring at the edges of the shallow trench isolation structure, thereby the forming quality of the shallow trench isolation structure and the yield of devices are improved.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

Steel drum paint special for baking type alcohol acid amido and method of preparing the same

InactiveCN101270258AStrong adhesionImprove corrosion resistanceLinings/internal coatingsEpoxy resin coatingsEpoxySander

The invention discloses roasting type alkyd amino special steel drum paint and a preparation method thereof, and relates to the paint industry; alkyd resin, preformed gel and amino thinner are added into a container to be stirred at high speed; titanium dioxide is added in; the obtained paint paste is ground and dispersed by the pouring tray of the sander with dispersing and grinding grain size of below 15mm, and then poured into the large basin of the container; and then butanol, xylene, epoxy resin, n-butanol etherified melamine resin, adhesion promoting resin, interface activator and agent are added into to be stirred evenly, so as to obtain the qualified product of the invention finally.

Owner:天津大田包装容器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com