Patents

Literature

109results about How to "Increase polishing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition for polishing semiconductor wafer, and method of producing the same

InactiveUS20080237535A1Improve polishing effectBig advantagePigmenting treatmentOther chemical processesSilica particleGas phase

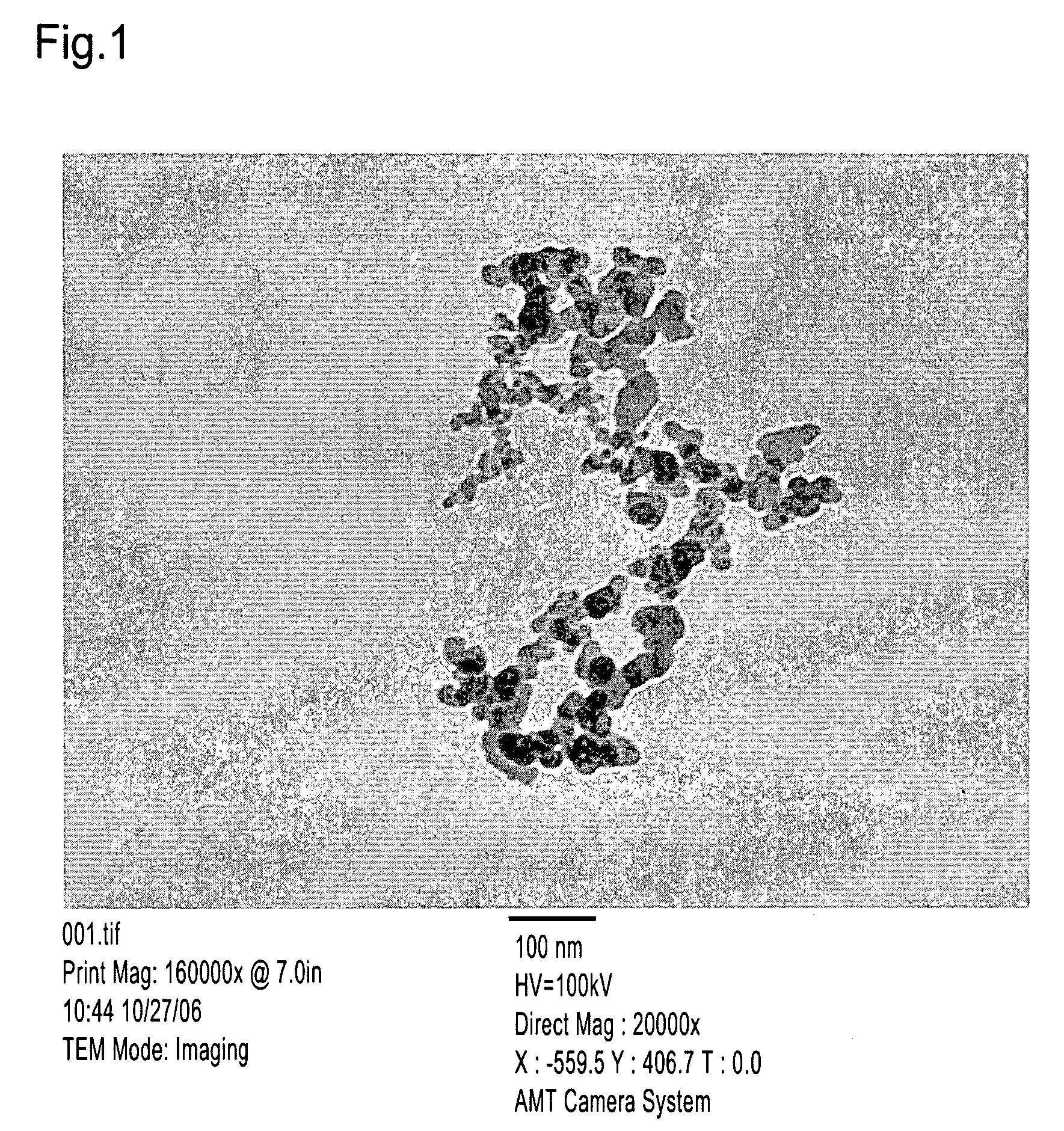

A composition for polishing a semiconductor wafer contains fumed silica particles that are produced by wet grinding using a grinding medium and that have characteristics (A) to (C):(A) a specific surface area in the range of 50 to 200 m2 / g measured by a BET method;(B) an average particle diameter in the range of 10 to 50 nm measured by a laser light-scattering method; and(C) an average ratio A / B of the major axis A to the minor axis B of the fumed silica particles in the range of 1.2 to 2.0 measured by TEM observation,wherein the concentration of silica particles containing the fumed silica particles is in the range of 0.5 to 50 weight percent relative to the total weight of an aqueous dispersion.

Owner:NIPPON CHECMICAL IND CO LTD +1

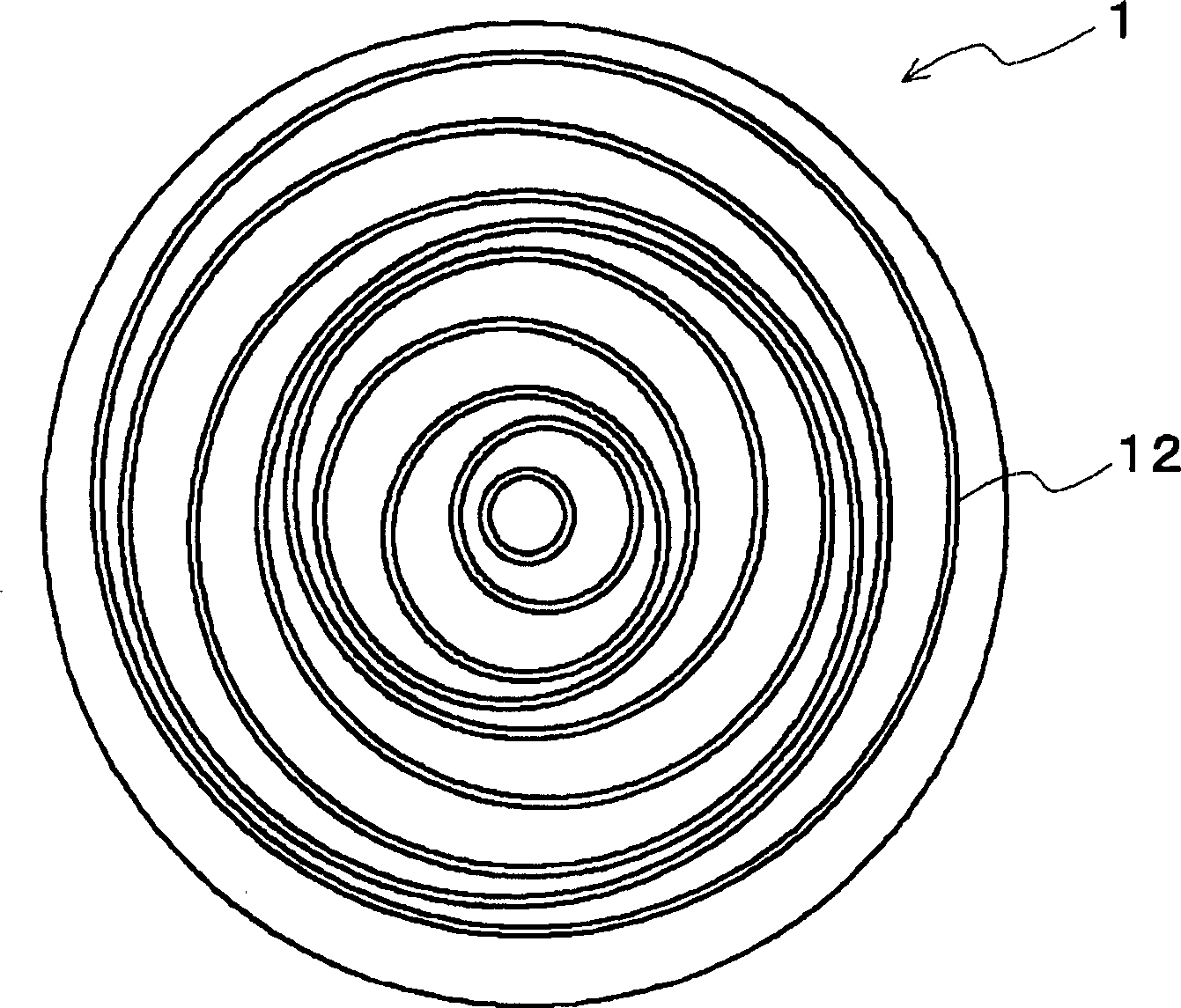

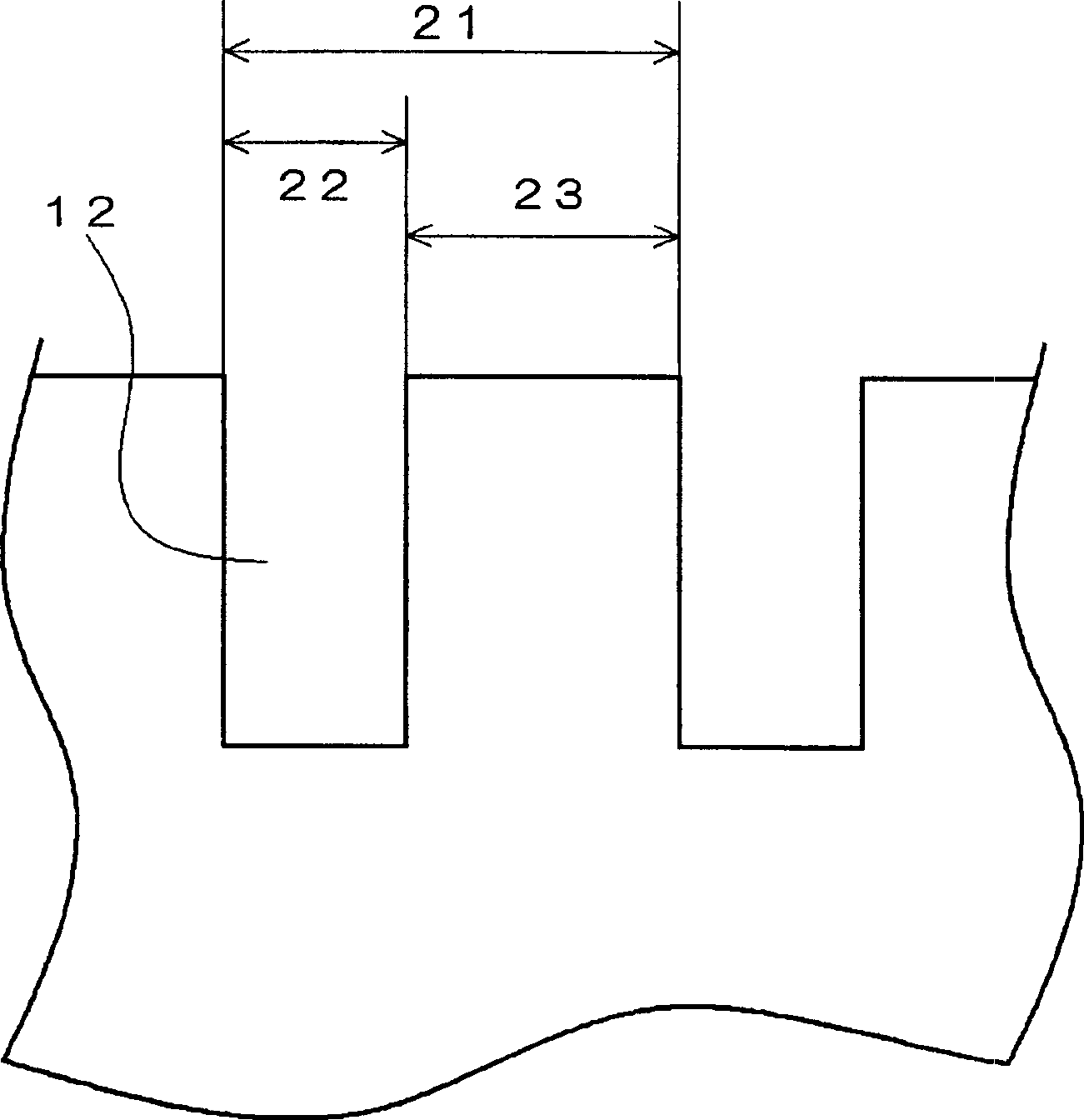

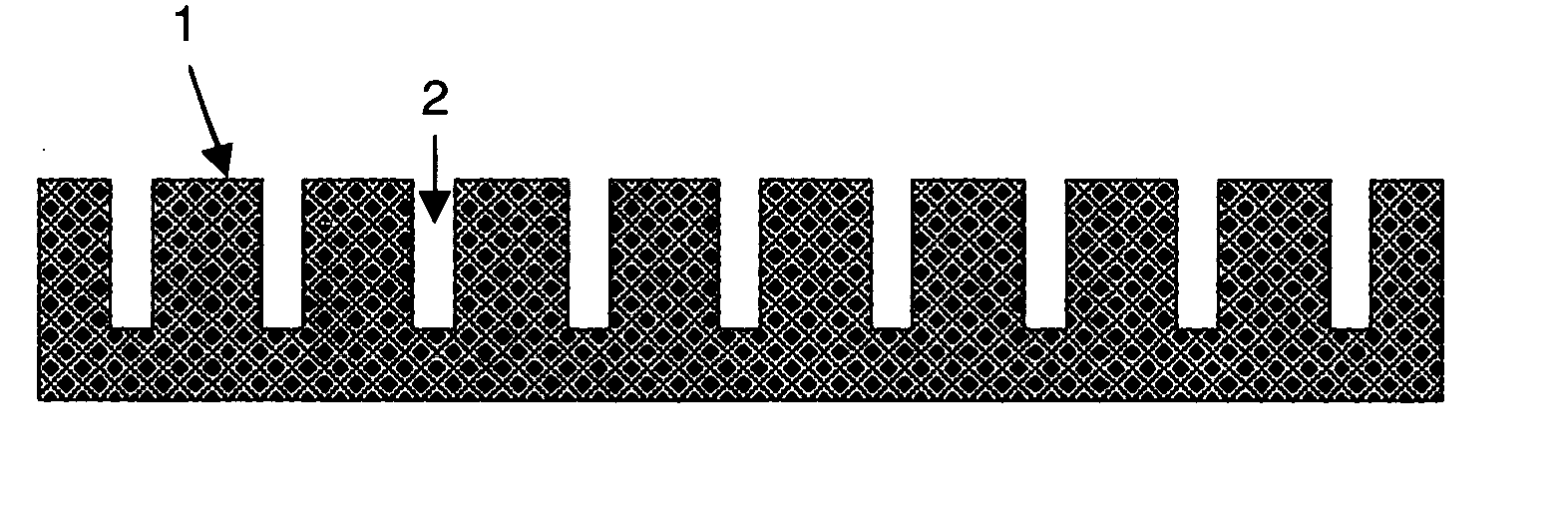

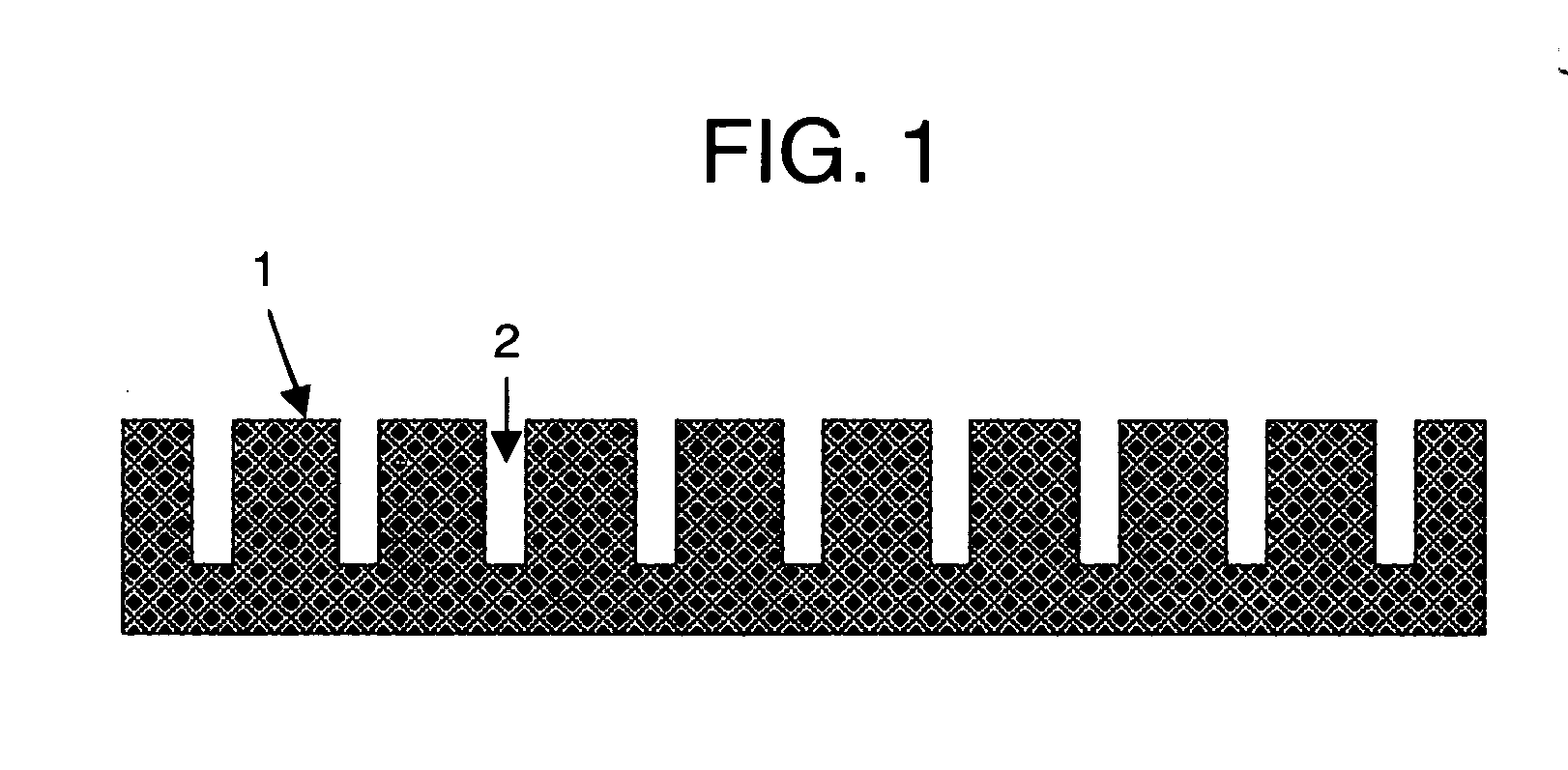

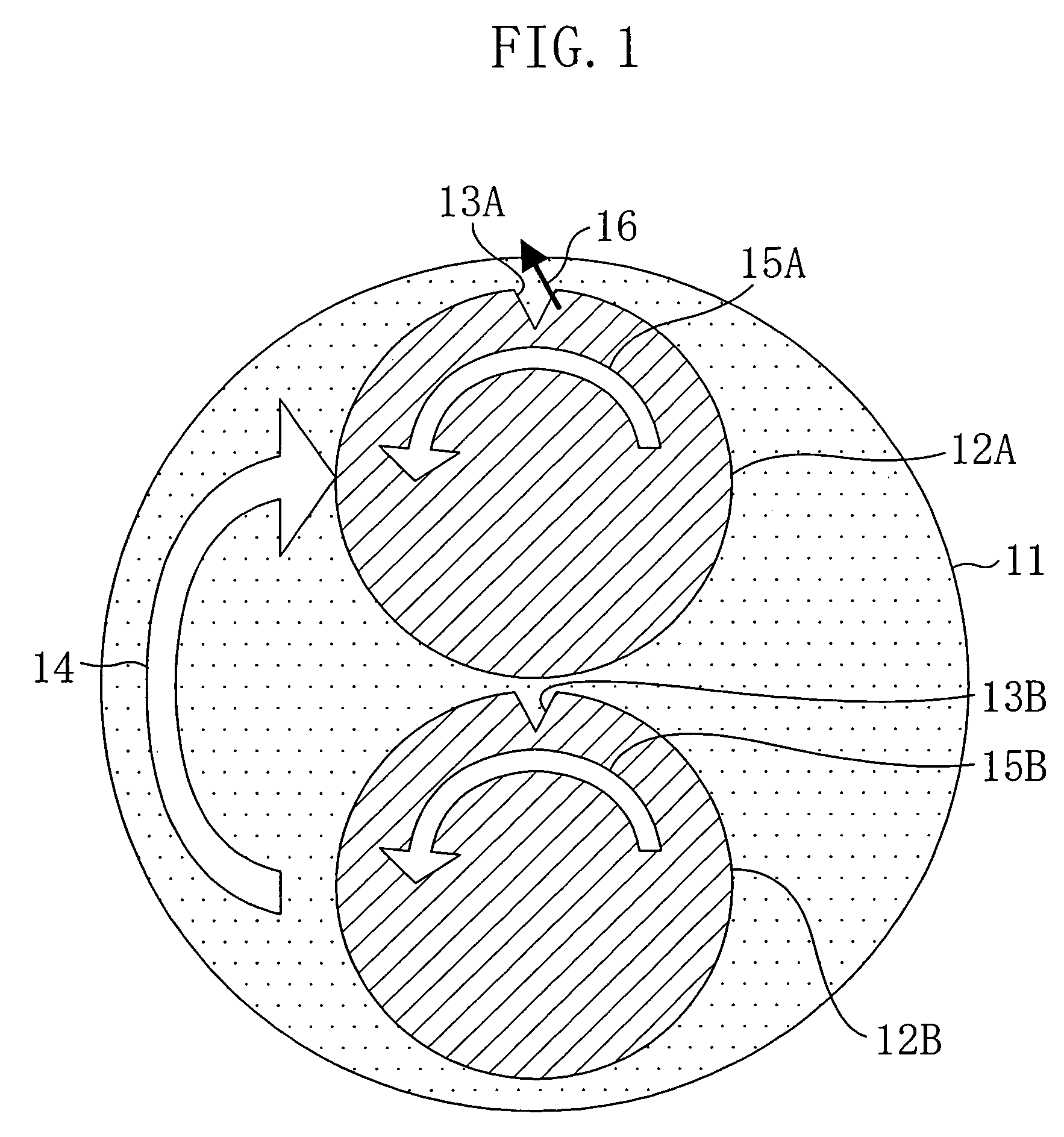

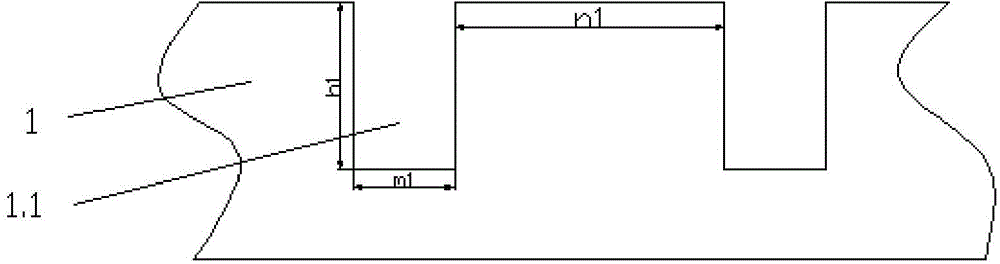

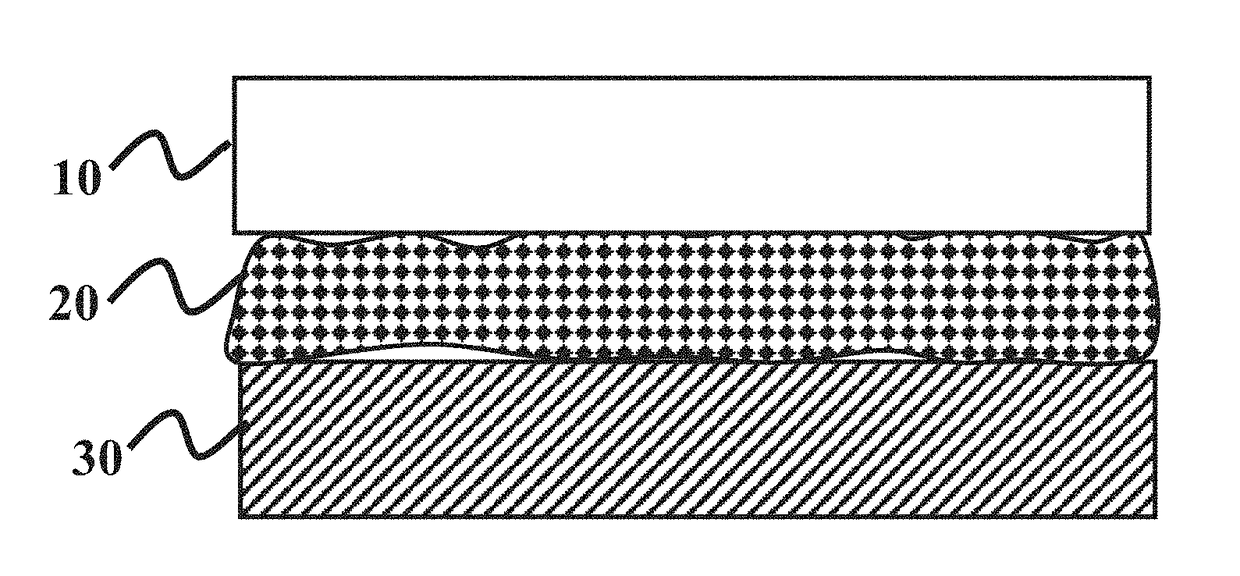

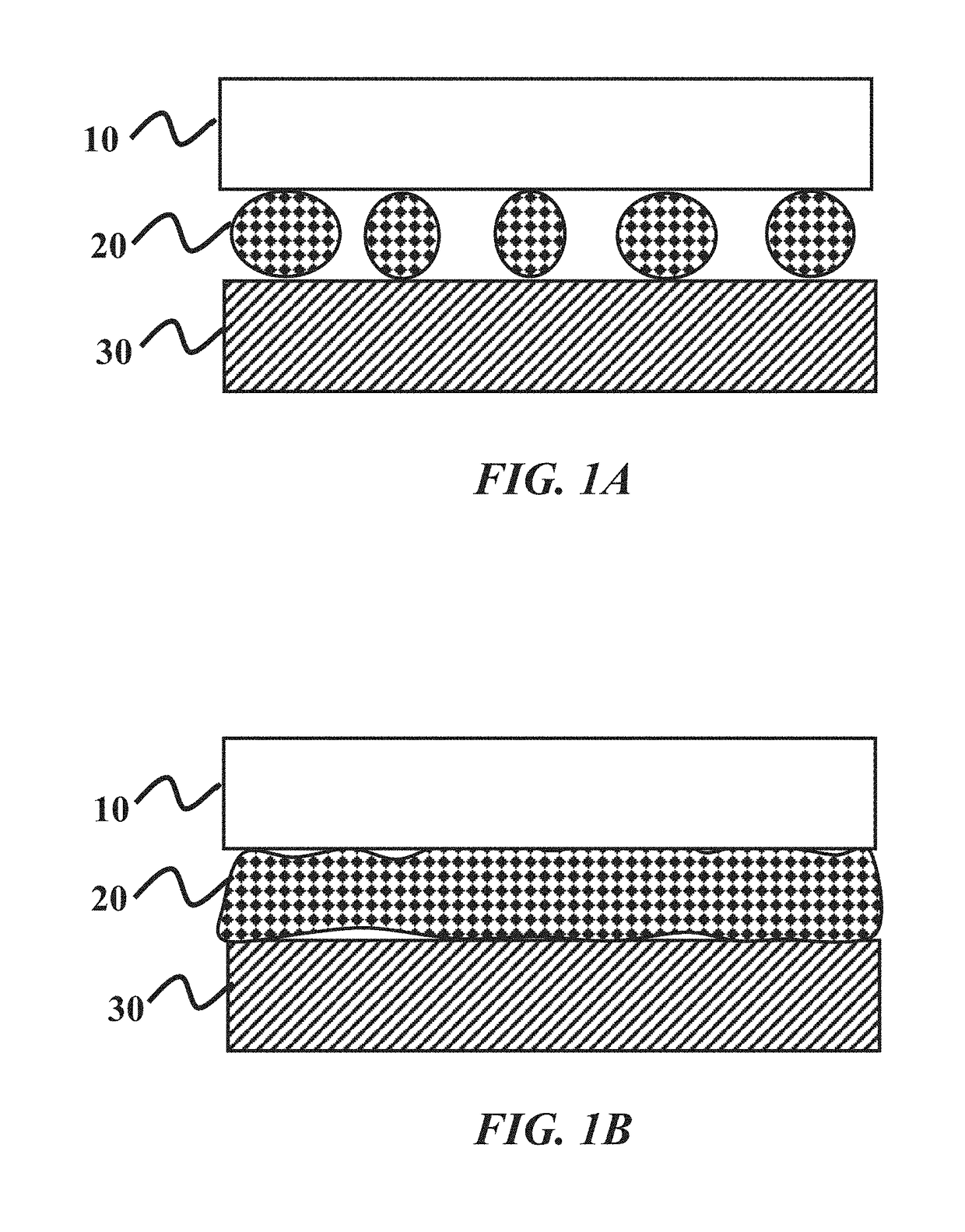

Polishing mattress and multilayer polishing mattress

InactiveCN1494983AInhibit chafingImprove flatnessSemiconductor/solid-state device manufacturingFlexible-parts wheelsSurface roughnessBiomedical engineering

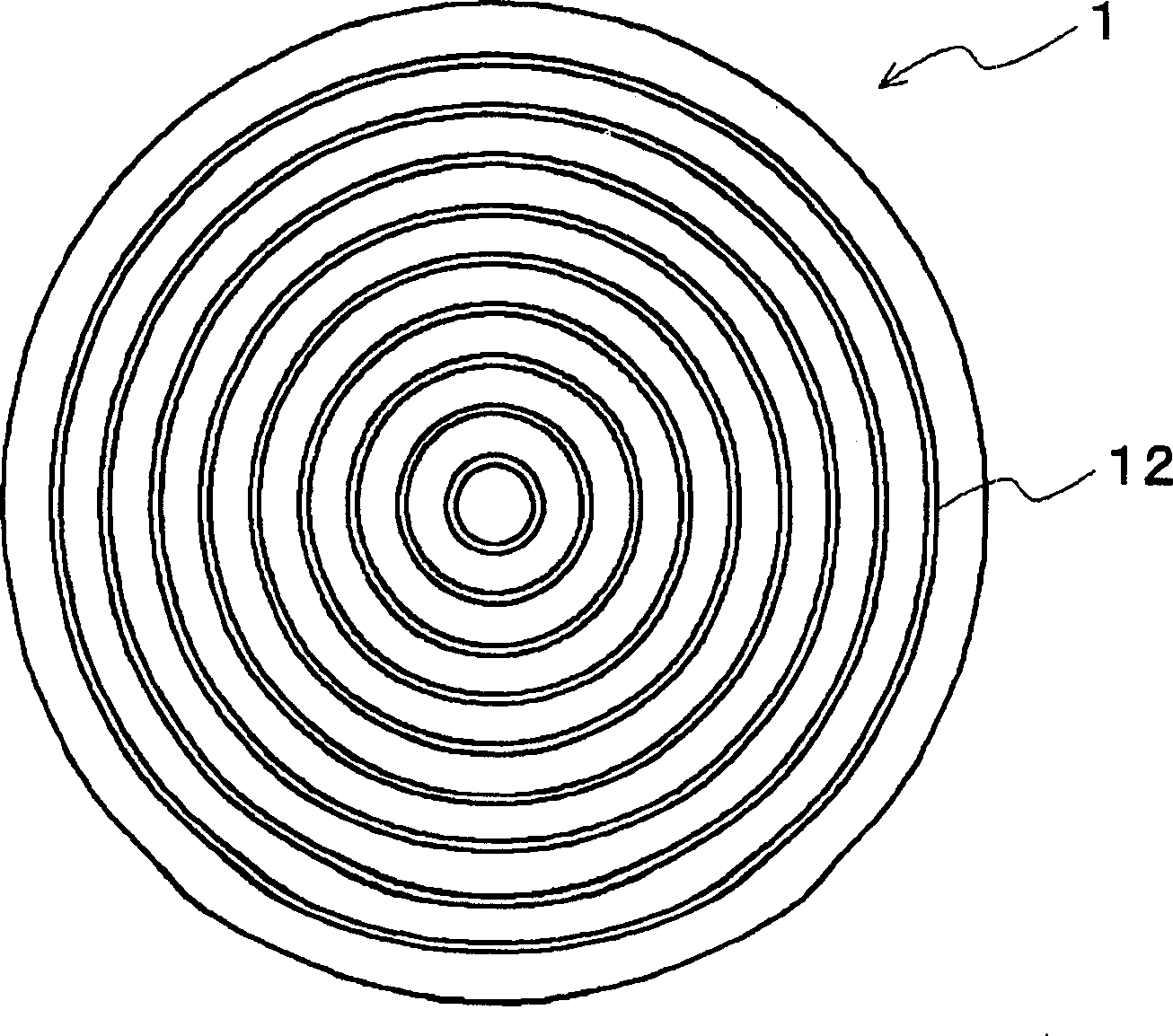

The present invention intends to provide a polishing pad and a multi-layer polishing pad (1) that can particularly effectively suppress scratch from occurring. The polishing pad (1) of the invention comprises at least one part selected from a groove (a) having at least one kind of shape selected from annular, lattice-like and spiral form on a polishing surface side, a concave portion (b) and a through hole (c). In the above, surface roughness of an inner surface of the part is 20 mu m or less and the polishing pad (1) is used for chemical mechanical polishing.

Owner:JSR CORPORATIOON

Polishing solution for cmp and polishing method using the polishing solution

ActiveUS20110275217A1Good water solubilitySatisfactory maintenance of dispersibilityOther chemical processesSemiconductor/solid-state device manufacturingMetallurgySilicon oxide

The polishing solution for CMP of the invention comprises abrasive grains, a first additive and water, wherein the first additive is at least 1,2-benzoisothiazole-3(2H)-one or 2-aminothiazole. The polishing method of the invention is a polishing method for a substrate having a silicon oxide film on the surface, and the polishing method comprises a step of polishing the silicon oxide film with a polishing pad while supplying the polishing solution for CMP between the silicon oxide film and the polishing pad.

Owner:RESONAC CORP

Metal polishing slurry and chemical mechanical polishing method

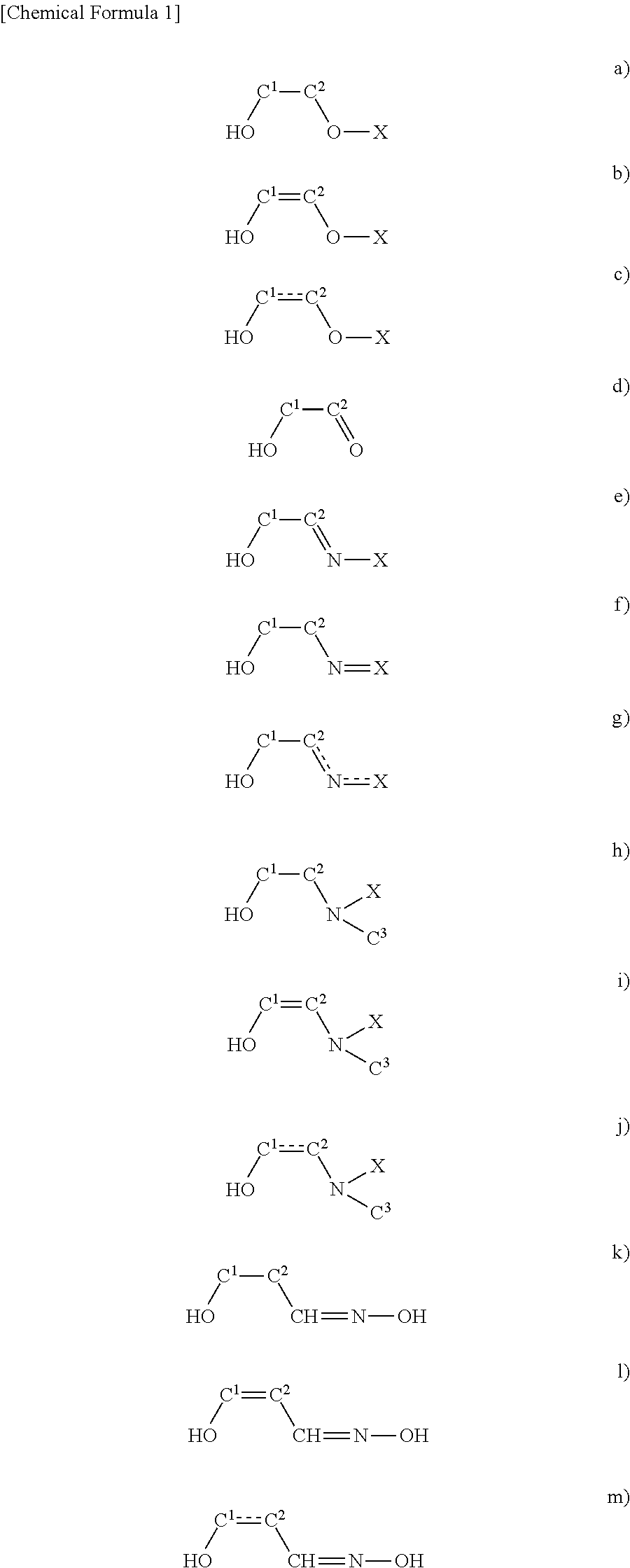

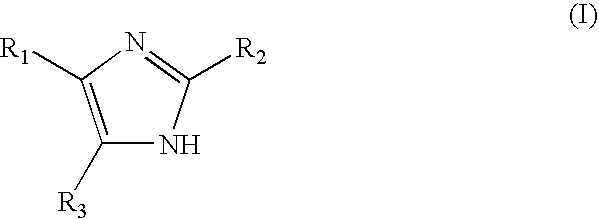

InactiveUS20090203215A1Avoid dentsIncrease polishing speedOther chemical processesSemiconductor/solid-state device manufacturingArylOrganic acid

A metal polishing slurry which is capable of simultaneously realizing a high polishing speed and reduced dishing in the polishing of a subject to be polished is provided. The metal polishing slurry includes a compound represented by the following general formula (1):wherein X represents a heterocyclic group containing at least one nitrogen atom, Y represents hydrogen atom, an aliphatic hydrocarbon group, an aryl group, or a —C(═O)Z′ wherein Z′ is as defined for Z, and Z represents hydrogen atom, an optionally substituted aliphatic hydrocarbon group, an optionally substituted aryl group, an optionally substituted heterocyclic group, —NZ1Z2, or —OZ3 wherein Z1, Z2, and Z3 independently represent hydrogen atom, an optionally substituted aliphatic hydrocarbon group, an optionally substituted aryl group, or an optionally substituted heterocyclic group, with the proviso that Y and Z may together form a ring; an oxidizing agent; and an organic acid.

Owner:FUJIFILM CORP

Solution for ruthenium chemical mechanical planarization

InactiveUS6797624B2Increase polishing speedLow pressureOther chemical processesSemiconductor/solid-state device manufacturingRutheniumOxidizing agent

A solution for ruthenium chemical mechanical planarization containing a nitric acid and an oxidizer is disclosed. A method of forming ruthenium pattern using a polished ruthenium layer is also disclosed. The disclosed solution improves the polishing speed of ruthenium under low polishing pressure, reduces the dishing of ruthenium and decreases scratches generated in the interlayer insulating film. As a result, the disclosed solution and methods improve the techniques for device isolation and reduction of step coverage.

Owner:SK HYNIX INC

Preparation method for epoxy resin binding agent diamond grinding tool with high polishing performance

ActiveCN104057403ALow hardness valueReduce pollutionAbrasion apparatusGrinding devicesEpoxyRare earth

The invention discloses a preparation method for an epoxy resin binding agent diamond grinding tool with high polishing performance. A working layer is mainly prepared from a diamond grinding material, an auxiliary grinding material, epoxy resin, a curing agent, rare earth polishing powder, filler and a dilution agent. The preparation method comprises the steps of uniformly and mechanically mixing 5-20 parts of the diamond grinding material, 5-20 parts of the auxiliary grinding material, 5-25 parts of the rare earth polishing powder and 5-40 parts of the filler to obtain a first mixture, then uniformly mixing and stirring the first mixture with 20-40 parts of the epoxy resin, 7-15 parts of the curing agent and 0.5-10 parts of the dilution agent to obtain a final mixture, injecting the mixture with flowability into a plastic mold in a pouring manner, and curing the mixture to obtain the epoxy resin binding agent diamond grinding tool with high polishing performance. The materials are in percentage by mass. Compared with the conventional hot pressing molding method, the preparation method has the advantages that the technology is simple, the energy is saved, and the emission is reduced; the pollution, which is caused by solid dust, to the environment is reduced, and the production speed is high; compared with the conventional product in the foreign country, the epoxy resin binding agent diamond grinding tool has the advantages of good polishing effect, high polishing efficiency, few air hole defects of the grinding tool and the like.

Owner:惠安宇信金刚石工具有限公司

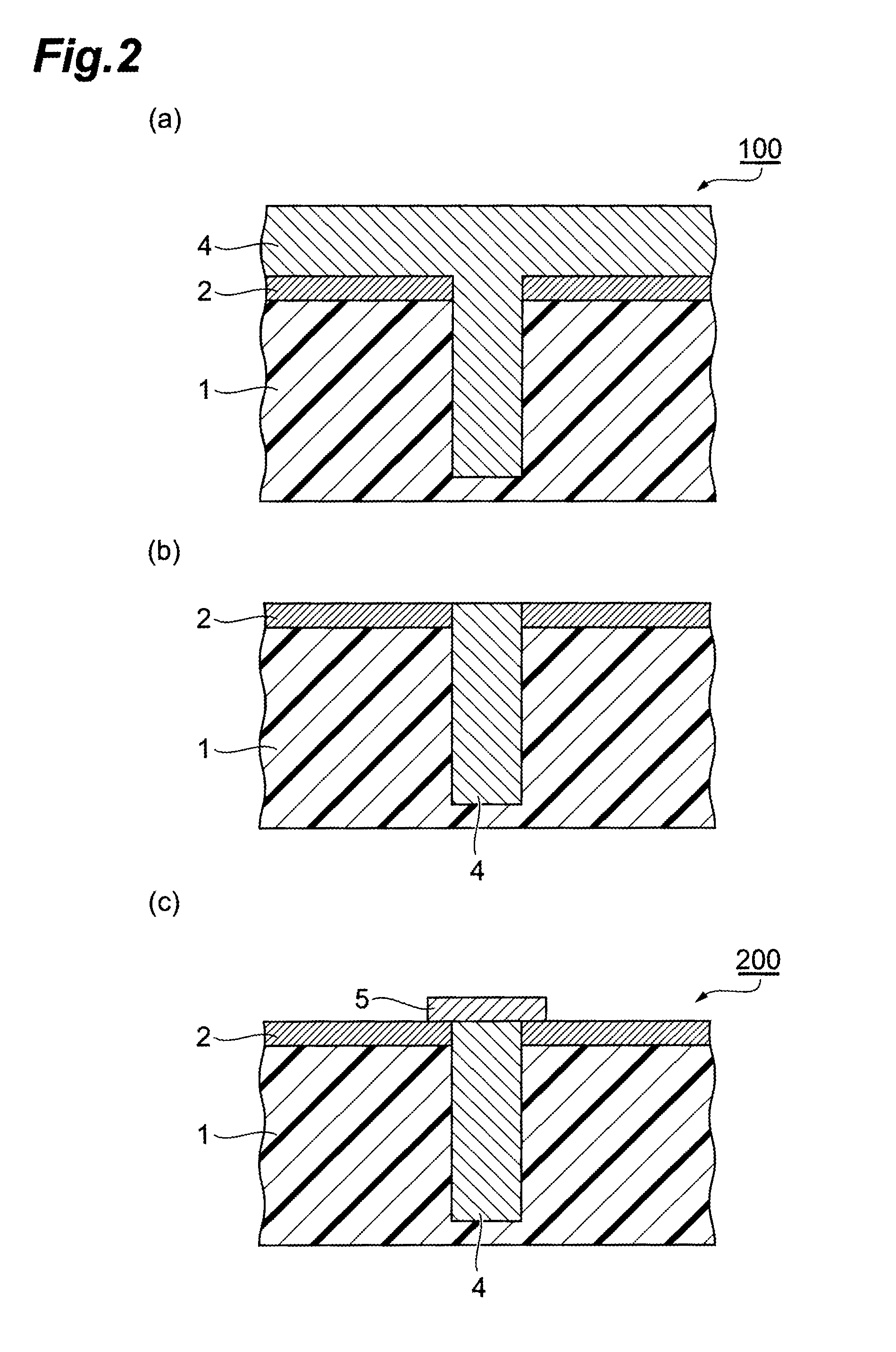

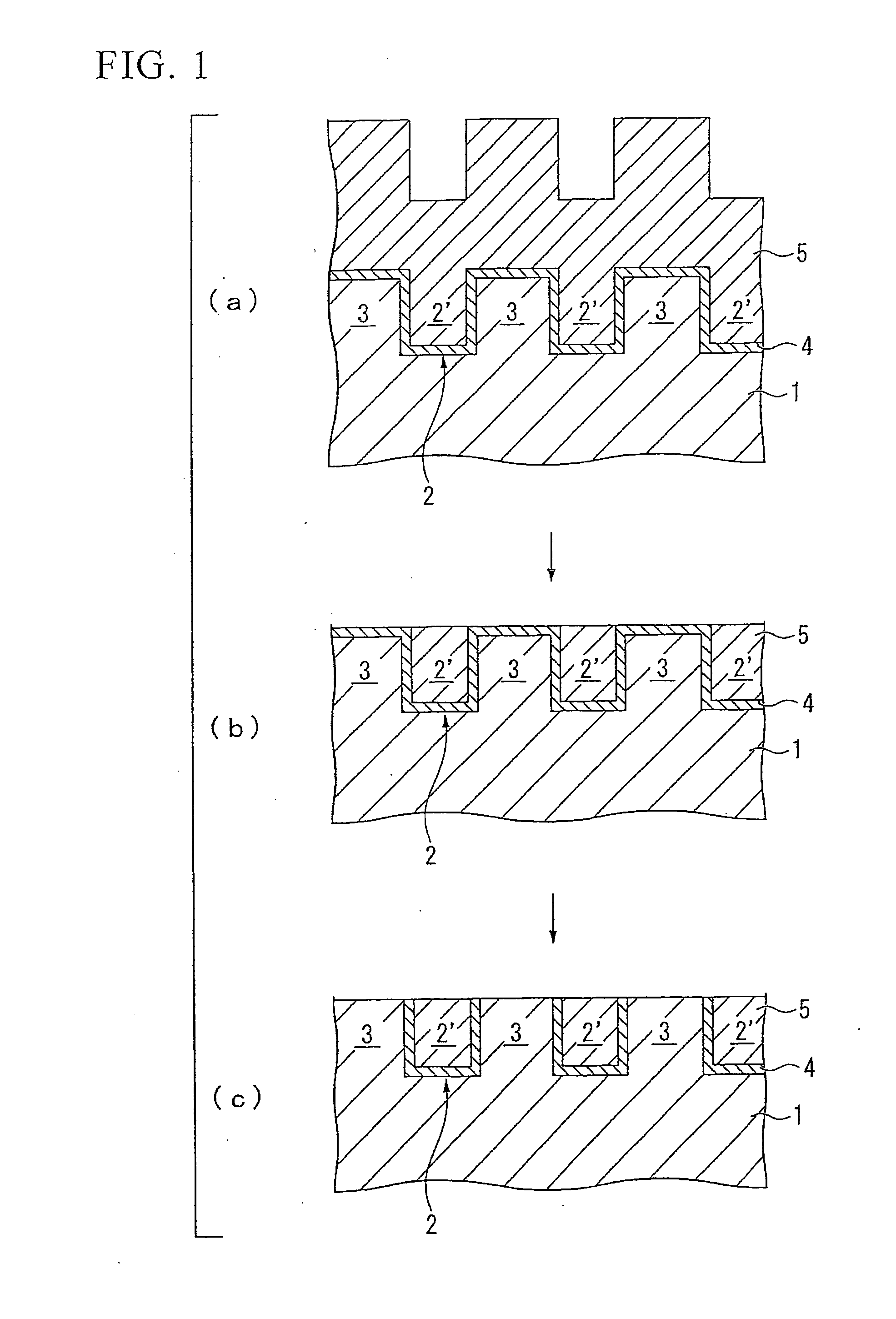

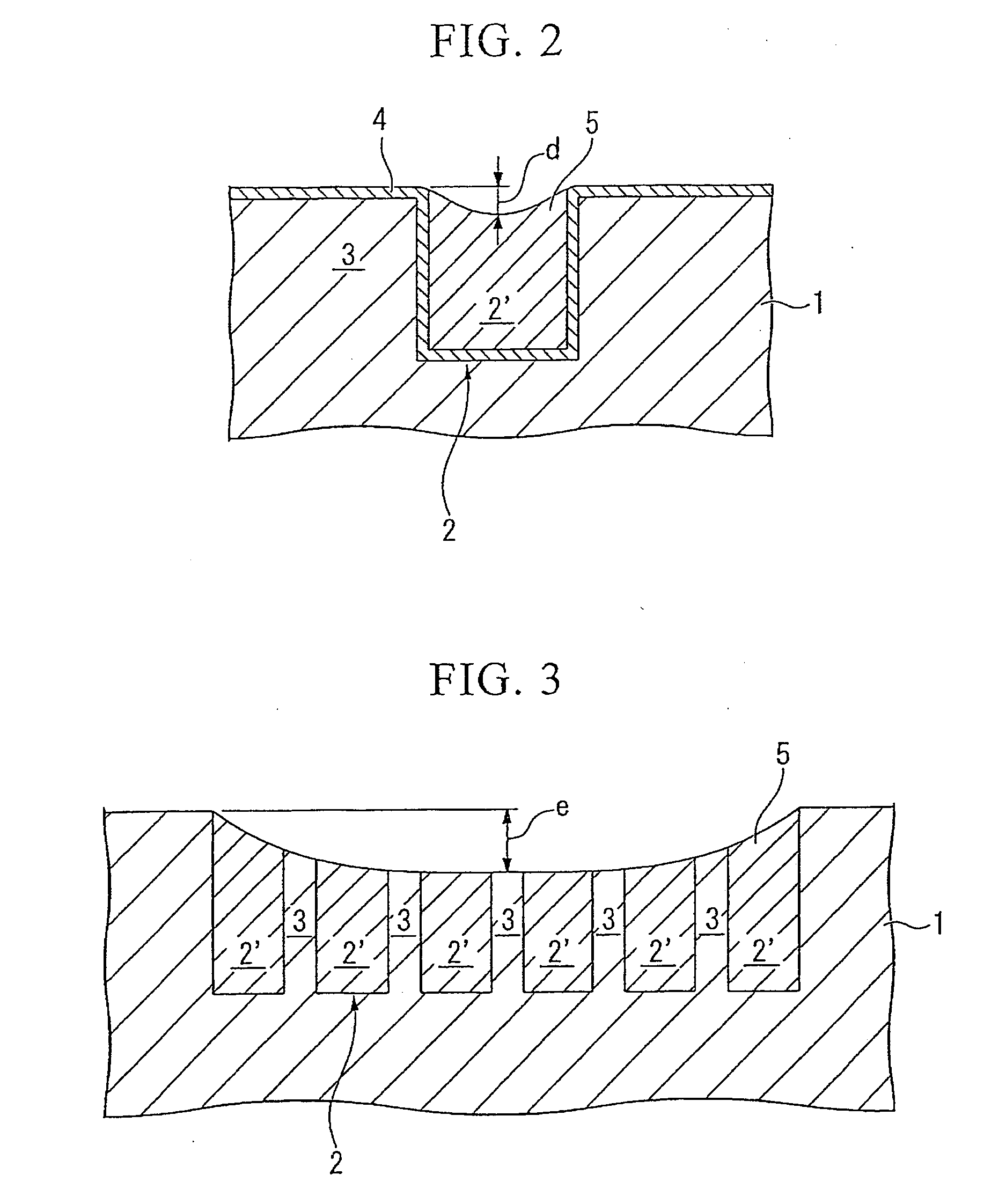

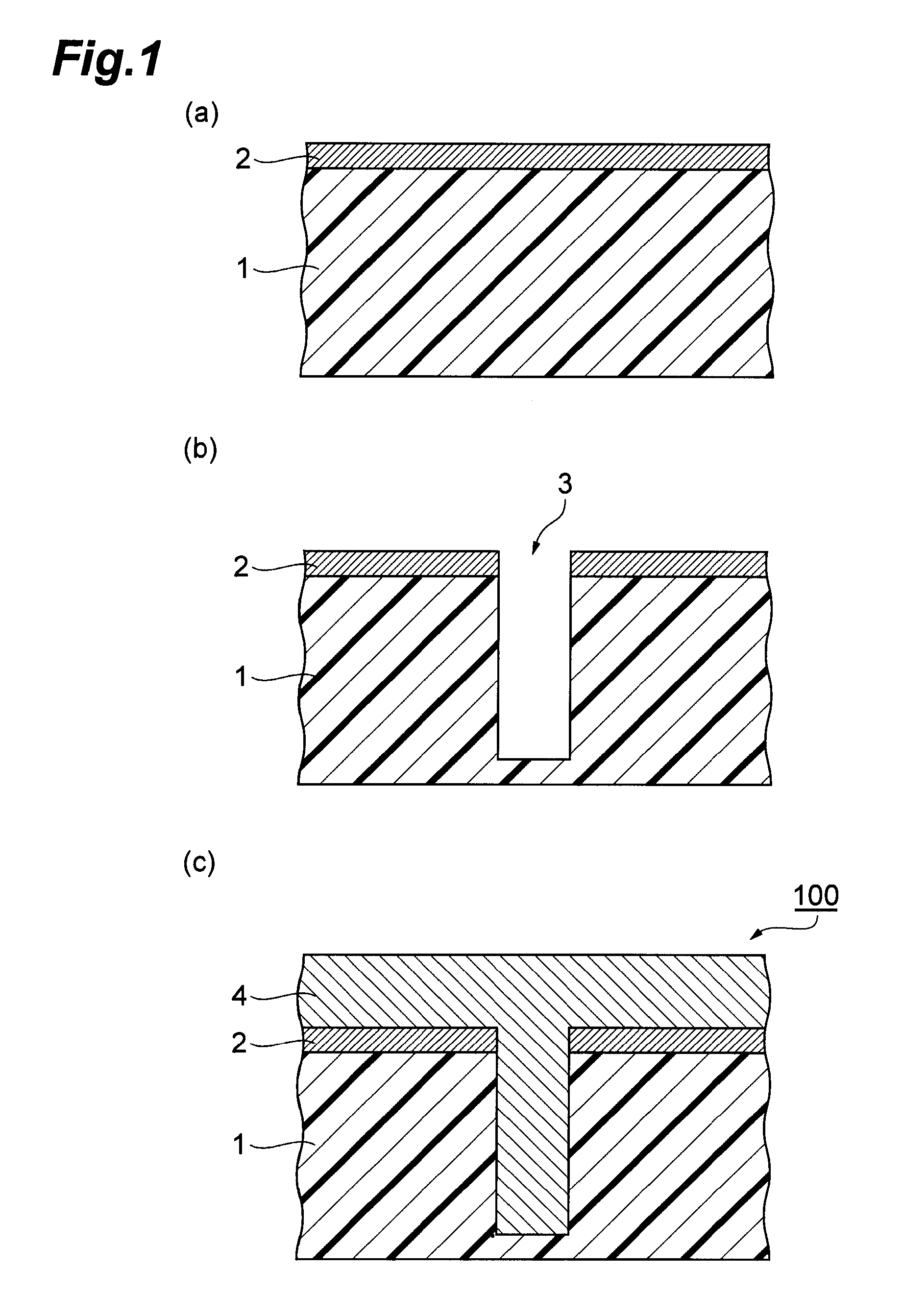

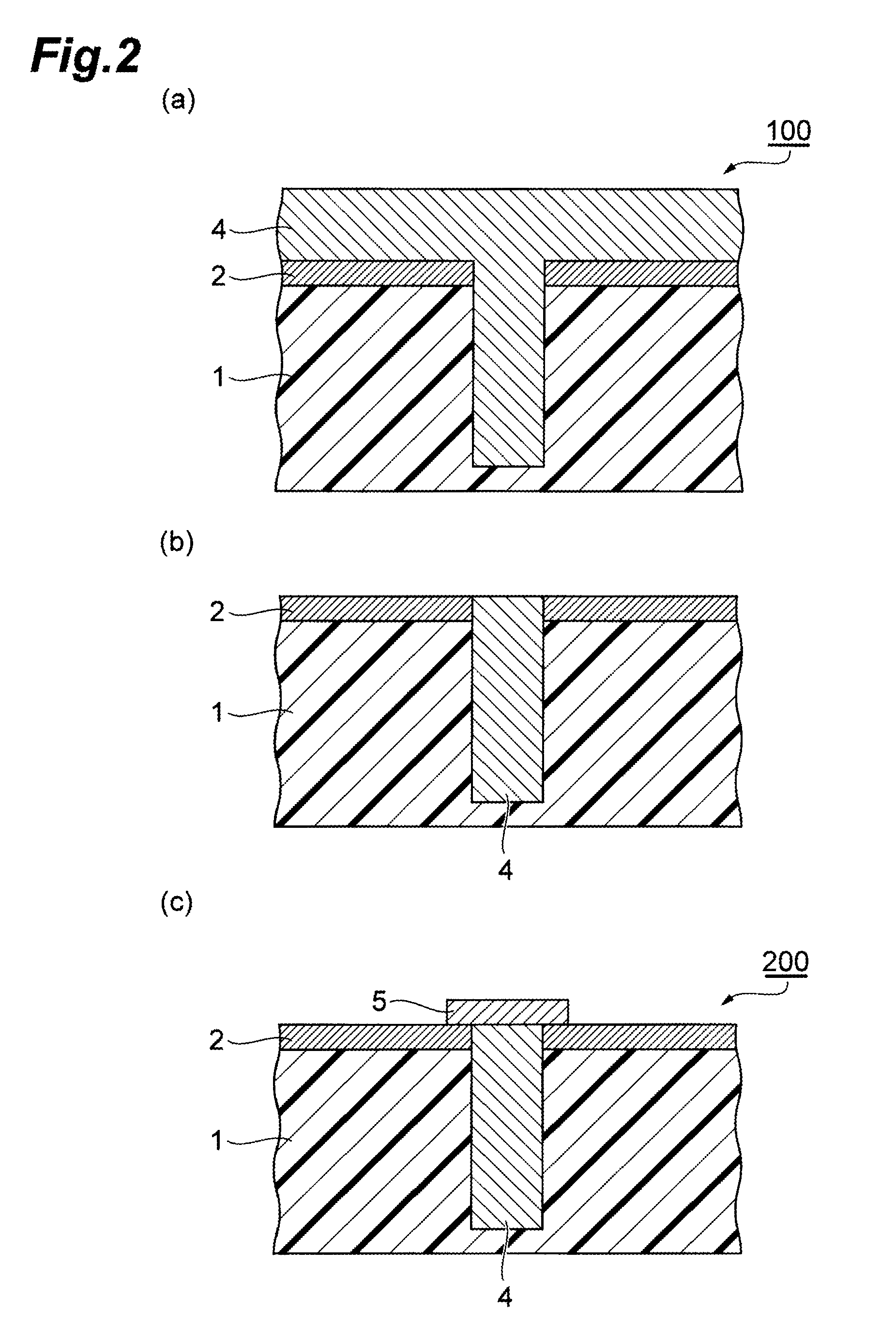

Polishing pad for cmp, method for polishing substrate using it and method for producing polishing pad for cmp

InactiveUS20040224623A1InhibitionHigh frequencySemiconductor/solid-state device manufacturingFlexible-parts wheelsFiberSilicon oxide

In CMP technology for planarizing an interlayer insulation film, a BPSG film, an insulation film for shallow trench isolation, or the like, in the production process of a semiconductor element, irregularities of a matter being polished, e.g. a silicon oxide film, are planarized efficiently at a high speed while suppressing the occurrence of polishing flaws on the substrate by employing a polishing pad having organic fibers exposed on the surface thereof abutting against the matter being polished.

Owner:HITACHI CHEM CO LTD +1

Slurry composition for secondary polishing of silicon wafer

ActiveUS20060242912A1Sufficient dispersion effectPoor dispersionPigmenting treatmentOther chemical processesColloidal silicaSlurry

Disclosed is a slurry composition for secondary polishing of silicon wafers comprising: 2˜10 weight % of colloidal silica having an average particle size of 30˜80 nm; 0.5˜1.5 % by weight of ammonia; 0.2˜1 weight % of a hydroxyalkycellulose-based polymer for modifying rheology of the composition; 0.03˜0.5 weight % of a polyoxyethylenealkylamine ether-based nonionic surfactant; 0.01˜1 weight % of a quaternary ammonium base and the balance of deionized water.

Owner:CHEIL IND INC

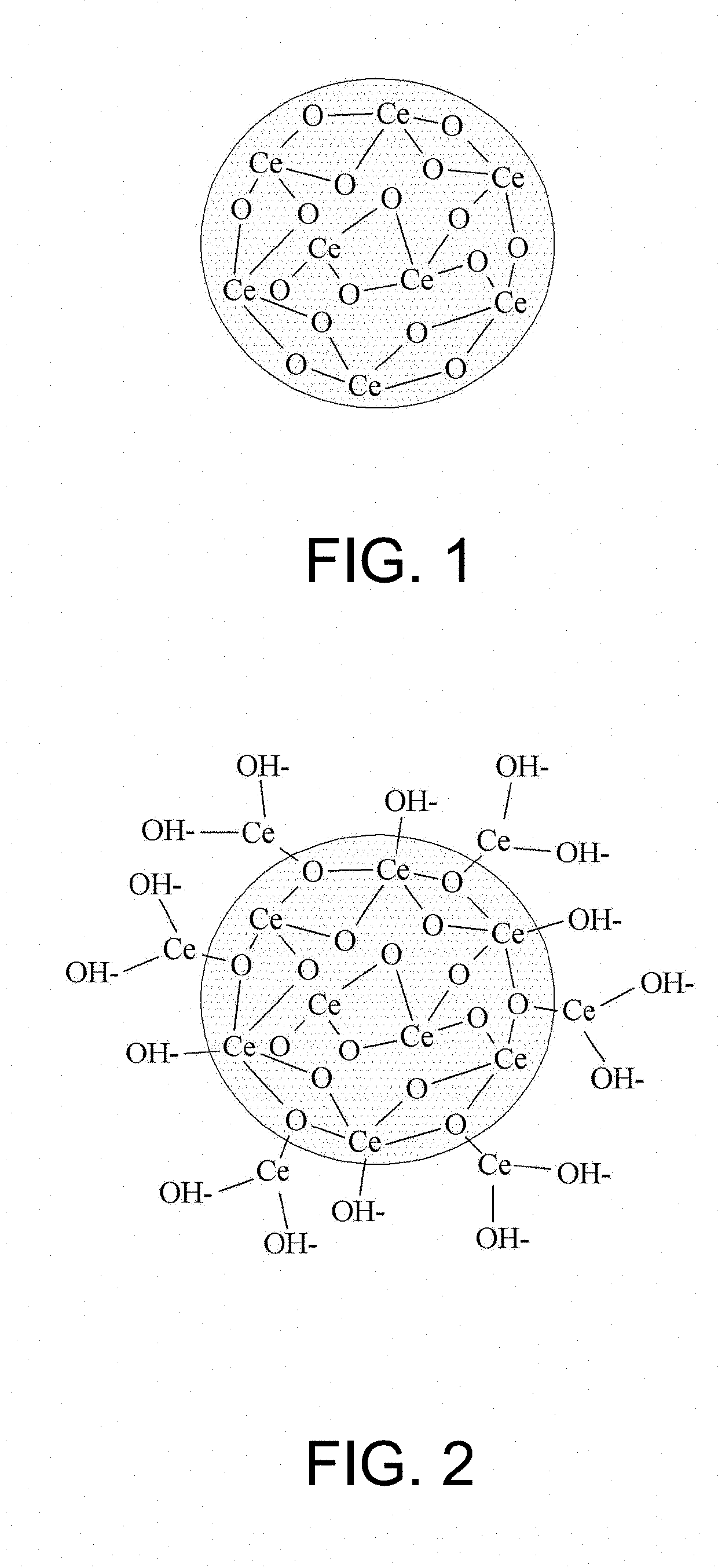

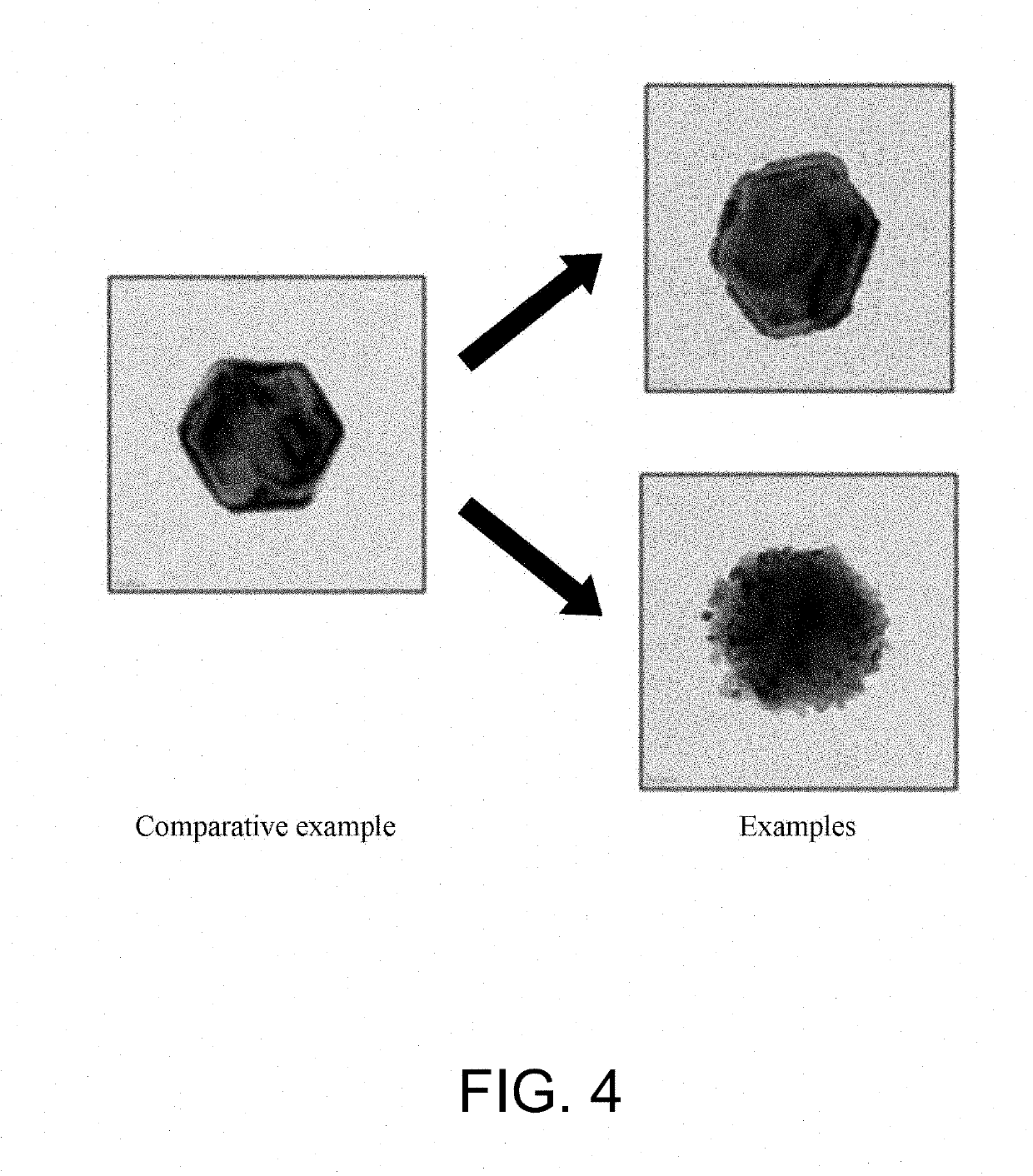

Surface-modified colloidal ceria abrasive particles, preparation method therefor, and polishing slurry composition containing same

InactiveUS20190211245A1High reactivityIncrease surface areaOther chemical processesCerium oxides/hydroxidesCeriumSlurry

The present invention relates to surface-modified colloidal ceria abrasive particles, a preparation method therefor, and a polishing slurry composition containing the same. According to one embodiment of the present invention, the surface-modified colloidal ceria abrasive particles comprise: colloidal ceria abrasive particles; and cerium atoms and hydroxyl groups (—OH) formed on the surface of the colloidal ceria abrasive particles.

Owner:K C TECH

High concentration silica slurry

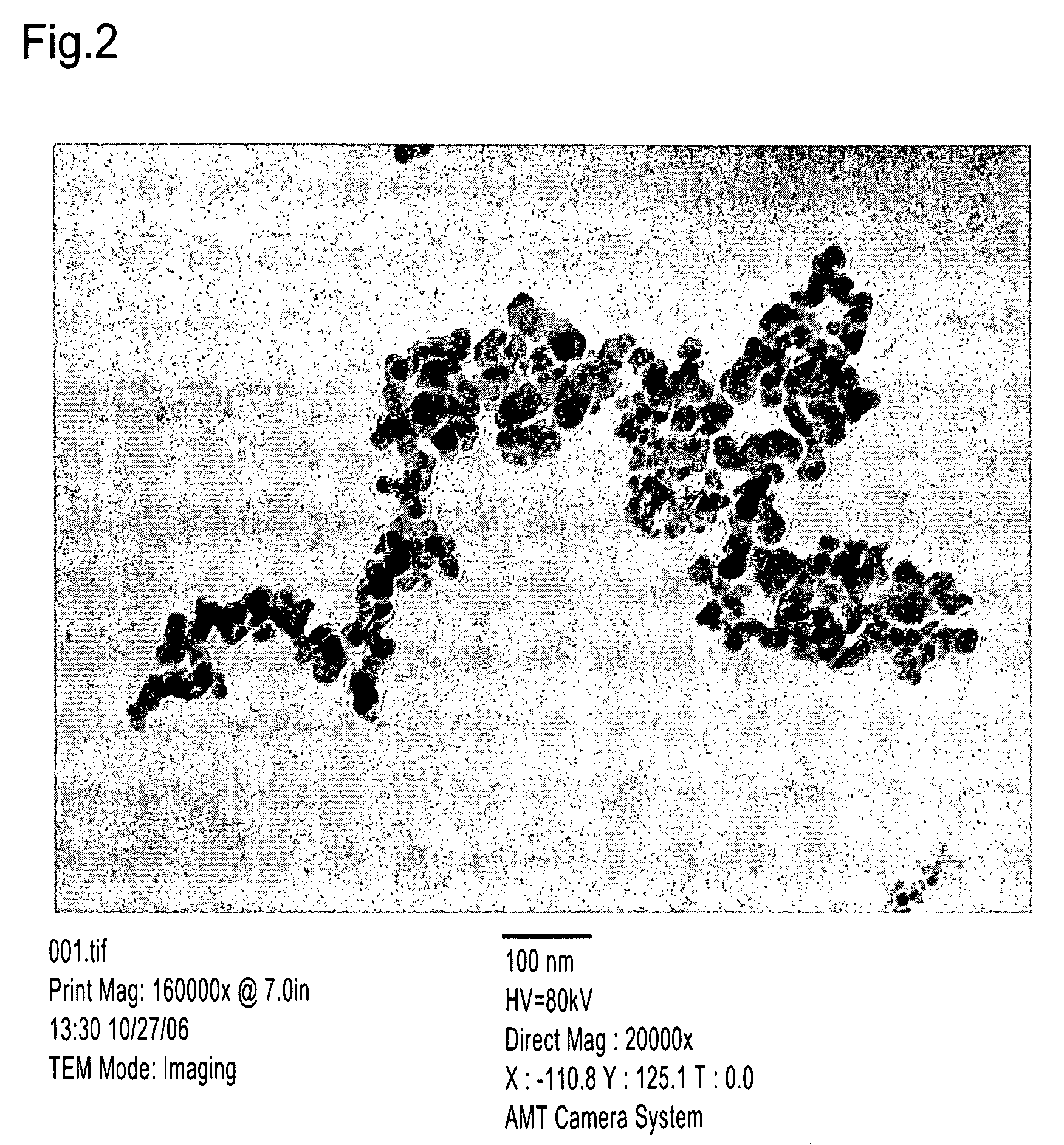

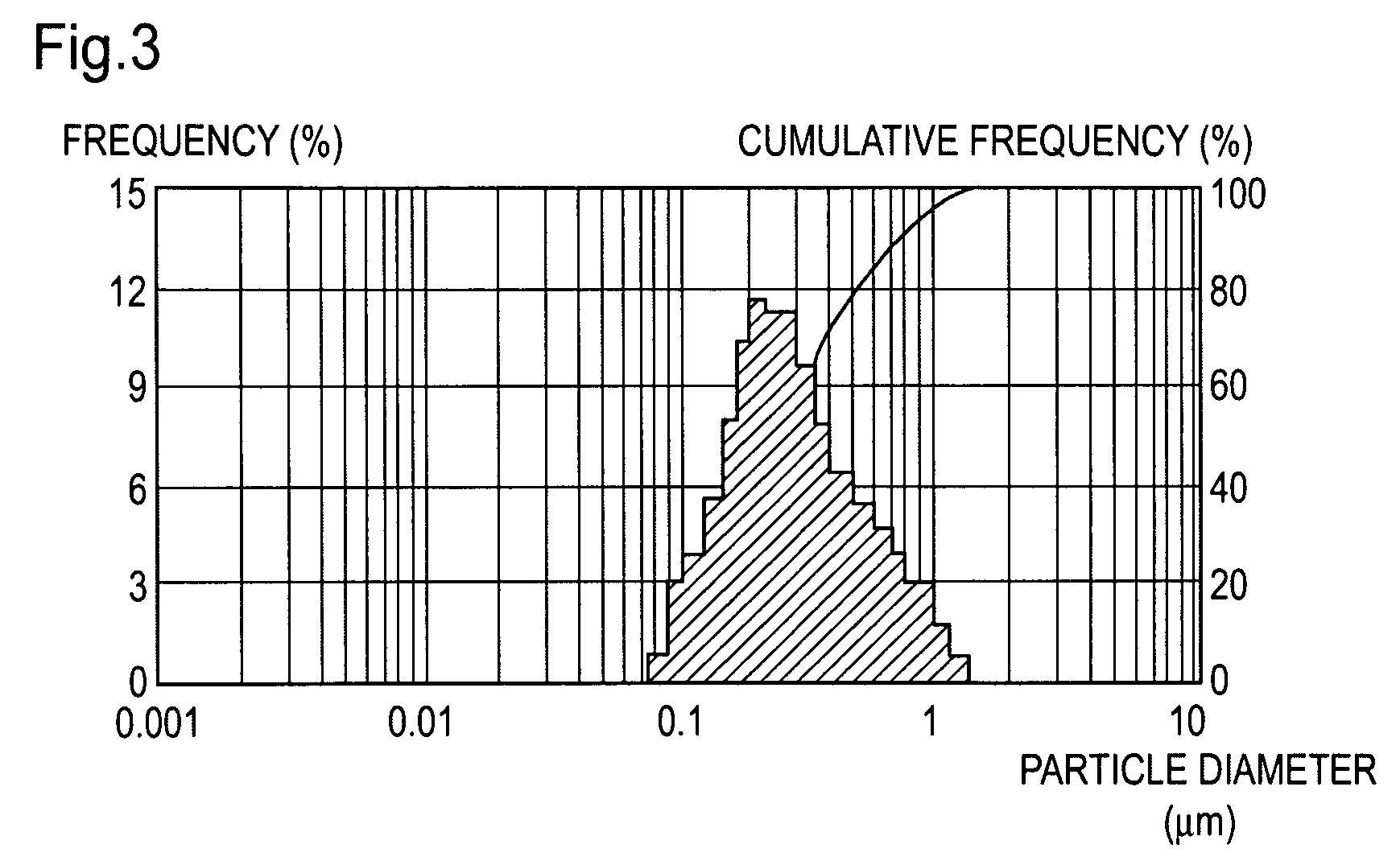

InactiveUS7192461B2High silica concentrationLow viscosityPigmenting treatmentSilicaSolventHigh concentration

A high concentration silica slurry can be used for polishing of substrates, such as semiconductor materials. The slurry contains a silica powder dispersed in an solvent. The silica slurry has a silica concentration of more than 50% by weight and a viscosity of less than 1000 mPa·s, wherein the silica powder has a ratio DL / DT of less than 1.3, wherein DL is an average particle size of the silica powder measured by a laser diffraction particle size distribution method and DT is an average primary particle size of the silica powder measured by a TEM photography observation, and wherein the silica powder has an average primary particle size of from 0.08 μm to 0.8 μm.

Owner:NIPPON AEROSIL

Polishing agent for copper polishing and polishing method using same

ActiveUS20120024818A1Increase polishing speedRapid of large amountOther chemical processesDecorative surface effectsOrganic acidFilm-forming agent

A polishing agent for copper polishing, comprising (A) an inorganic acid with divalent or greater valence, (B) an amino acid, (C) a protective film-forming agent, (D) an abrasive, (E) an oxidizing agent and (F) water, wherein the content of the component (A) is at least 0.08 mol / kg, the content of the component (B) is at least 0.20 mol / kg, the content of the component (C) is at least 0.02 mol / kg, and either or both of the following conditions (i) and (ii) are satisfied.(i): The proportion of the content of the component (A) with respect to the content of the component (C) is 2.00 or greater.(ii): It further comprises (G) at least one kind selected from among organic acids and their acid anhydrides.

Owner:RESONAC CORP

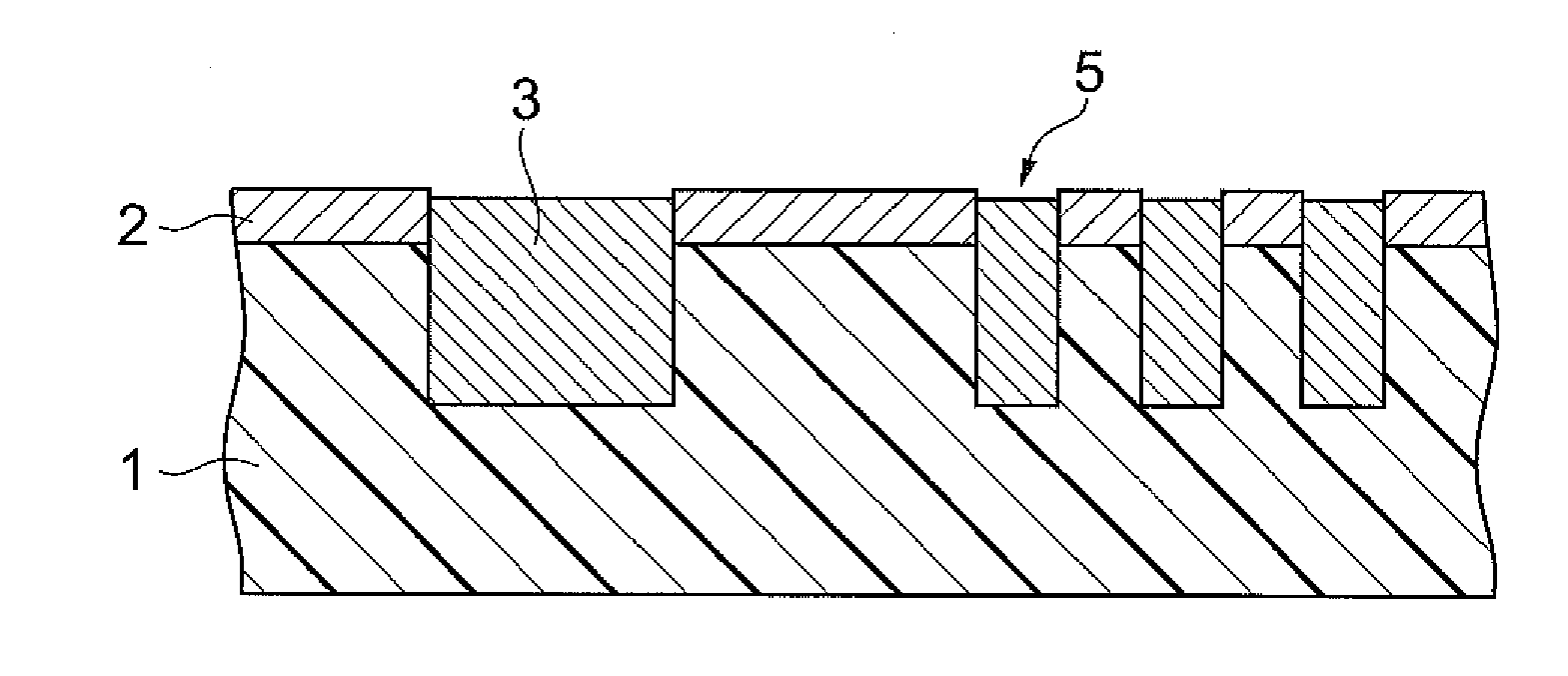

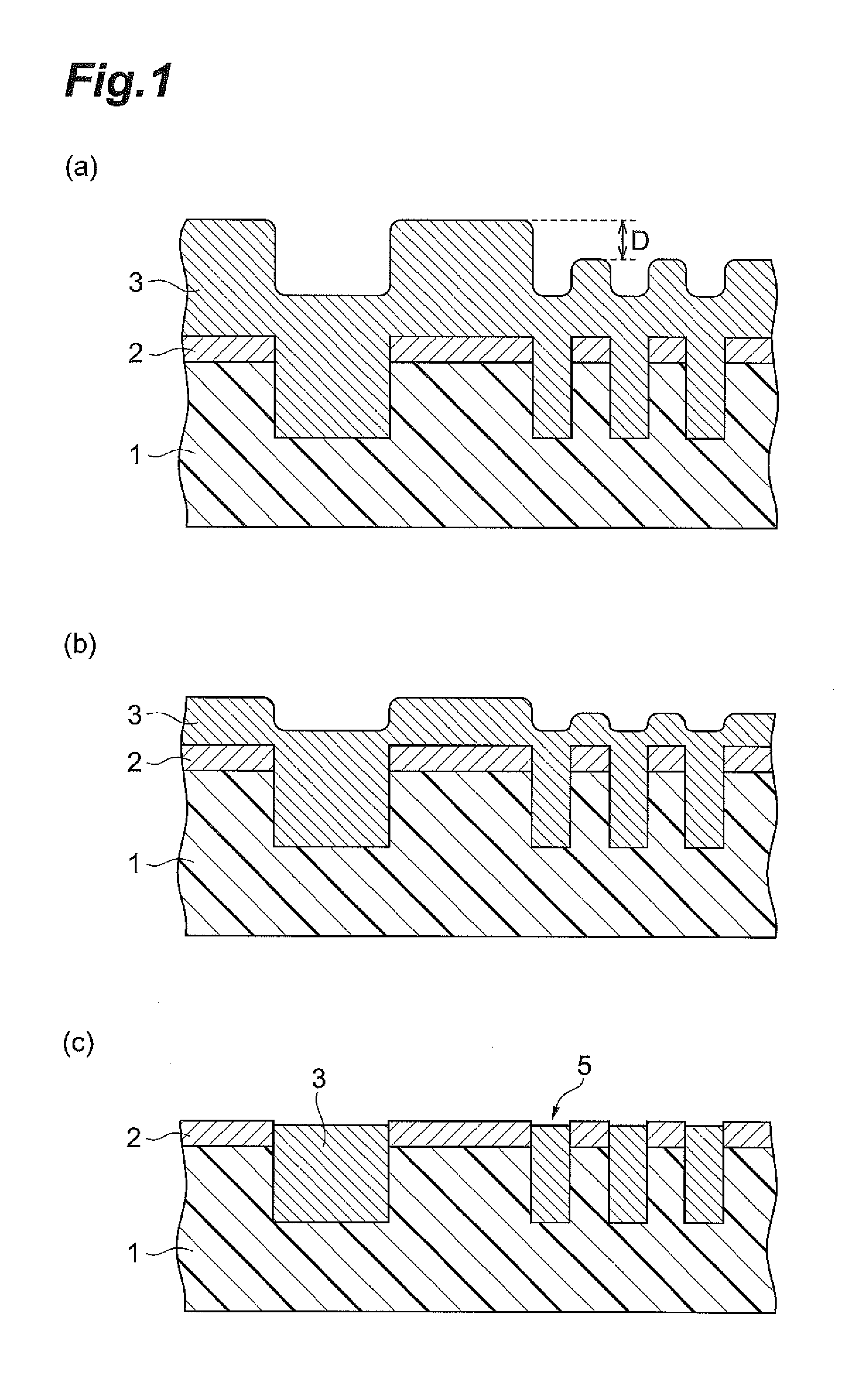

Polishing pad process for producing the same and method of polishing

InactiveUS20050107007A1Increase polishing speedImprove uniformitySemiconductor/solid-state device manufacturingFlexible-parts wheelsOligomerEngineering

According to the present invention, there is provided a polishing pad for polishing the surface of wafers for creating semiconductor integrated circuits, wherein said pad has a high polishing speed, said polishing is uniform, and said pad has a long life. Preferably, the polishing pad of the present invention comprises nonwoven fabric (base matrix) and a nonporous photo-setting resin that fills the space between the nonwoven fabric, and can be produced by impregnating the base matrix with a photo-sensitive resin composition containing at least one selected from the group consisting of a hydrophilic photopolymeric polymer or oligomer, and / or a hydrophilic photopolymeric monomer, and then photo-setting the same.

Owner:ASAHI KASEI ELECTRONICS CO LTD

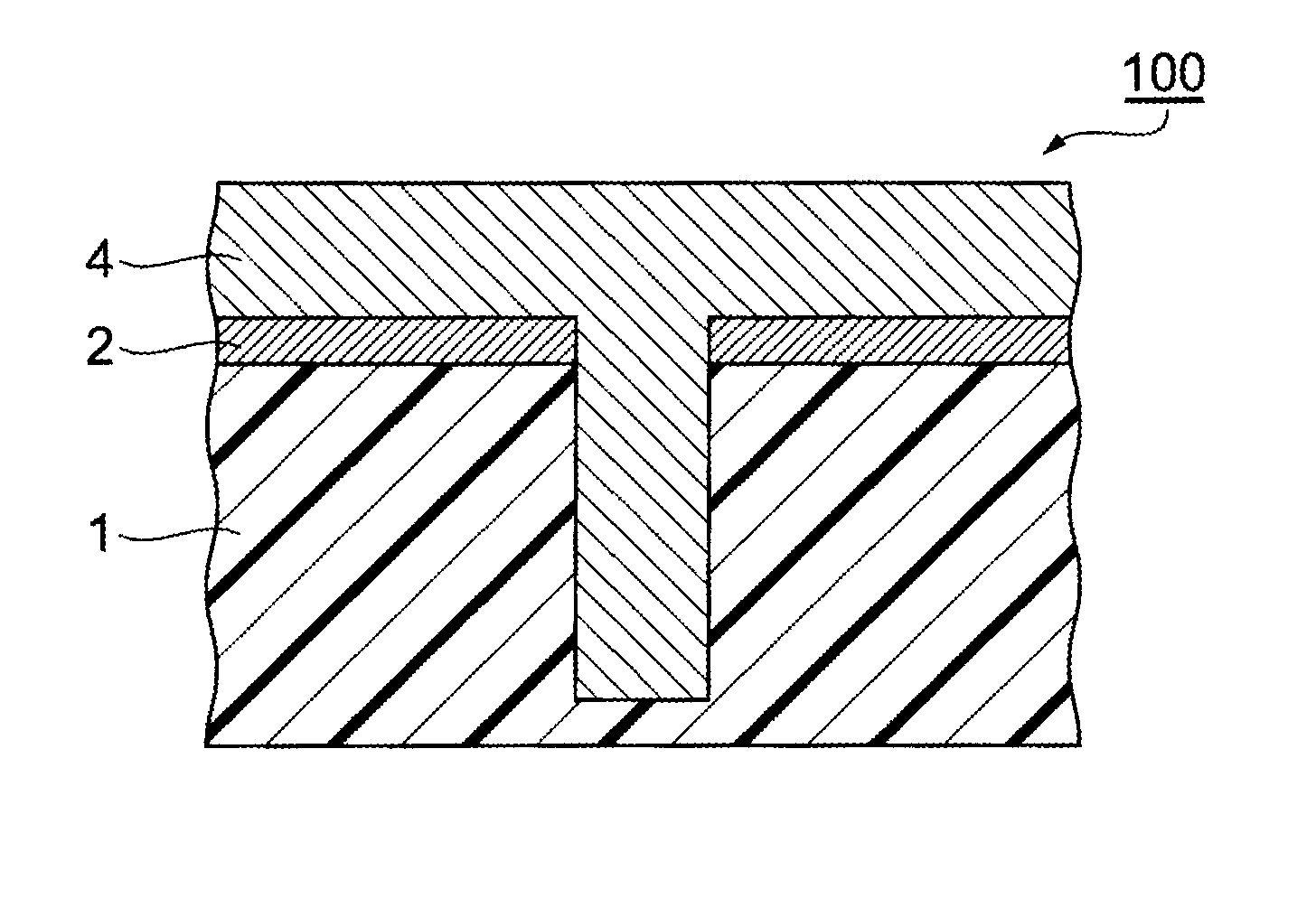

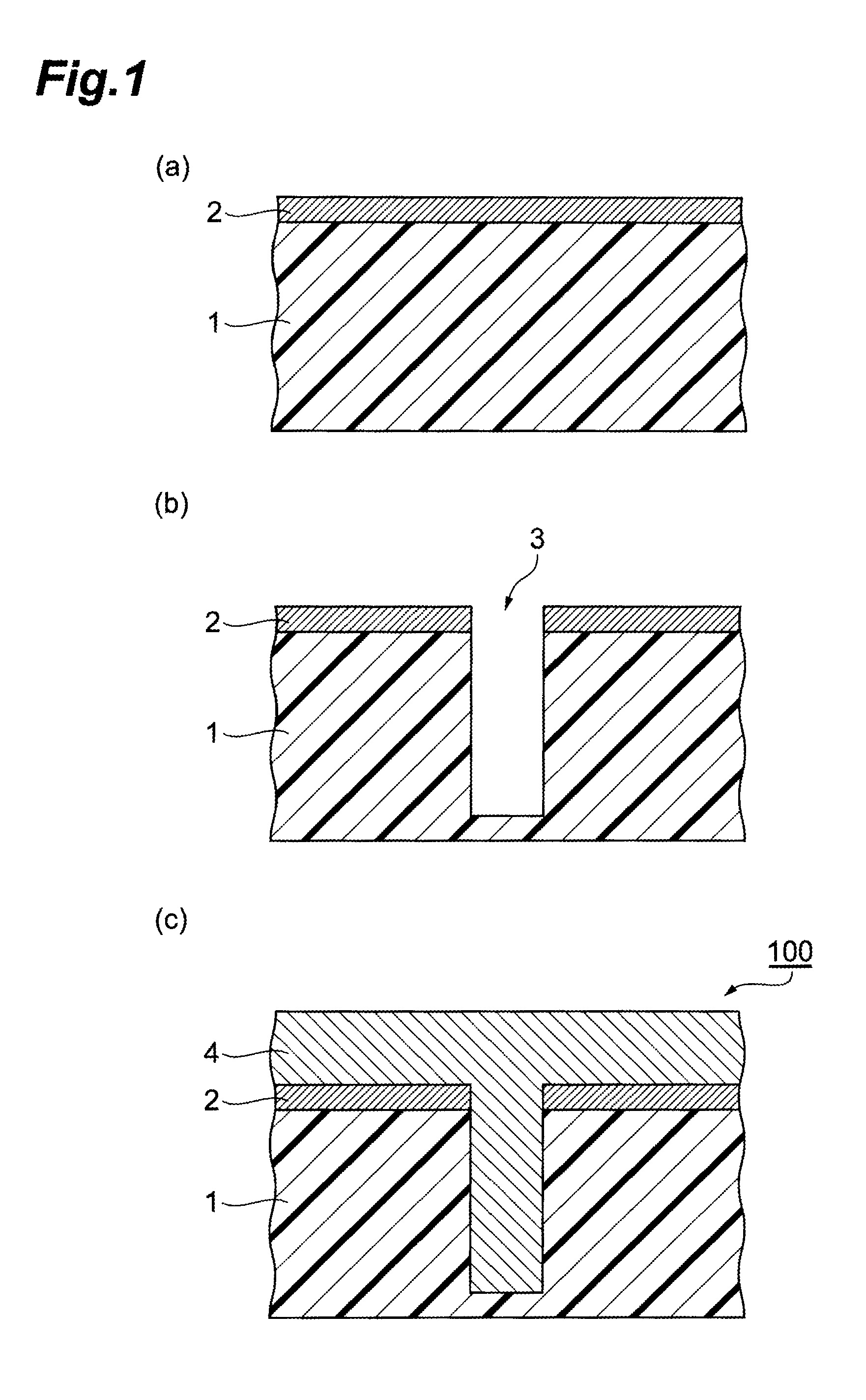

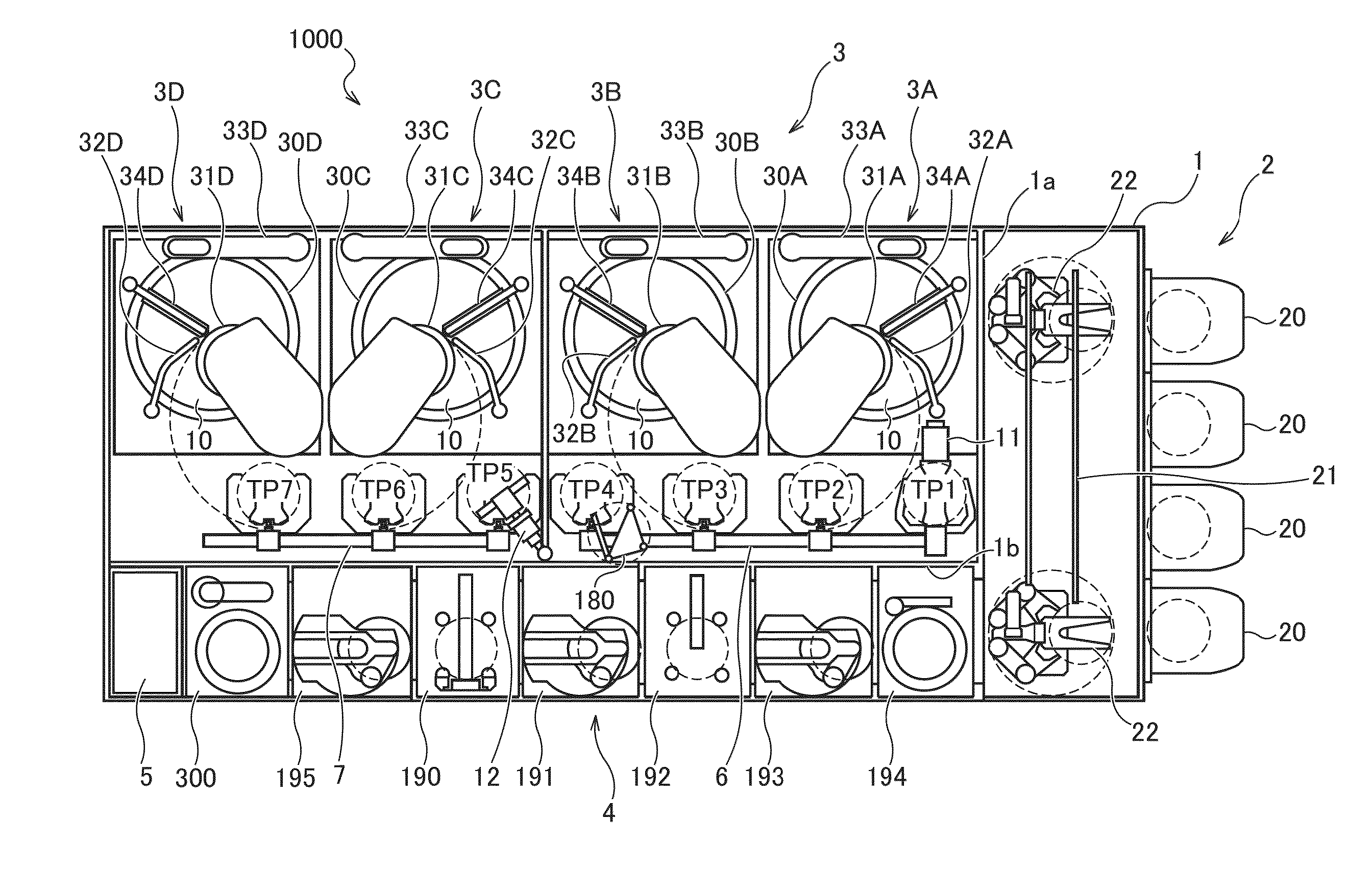

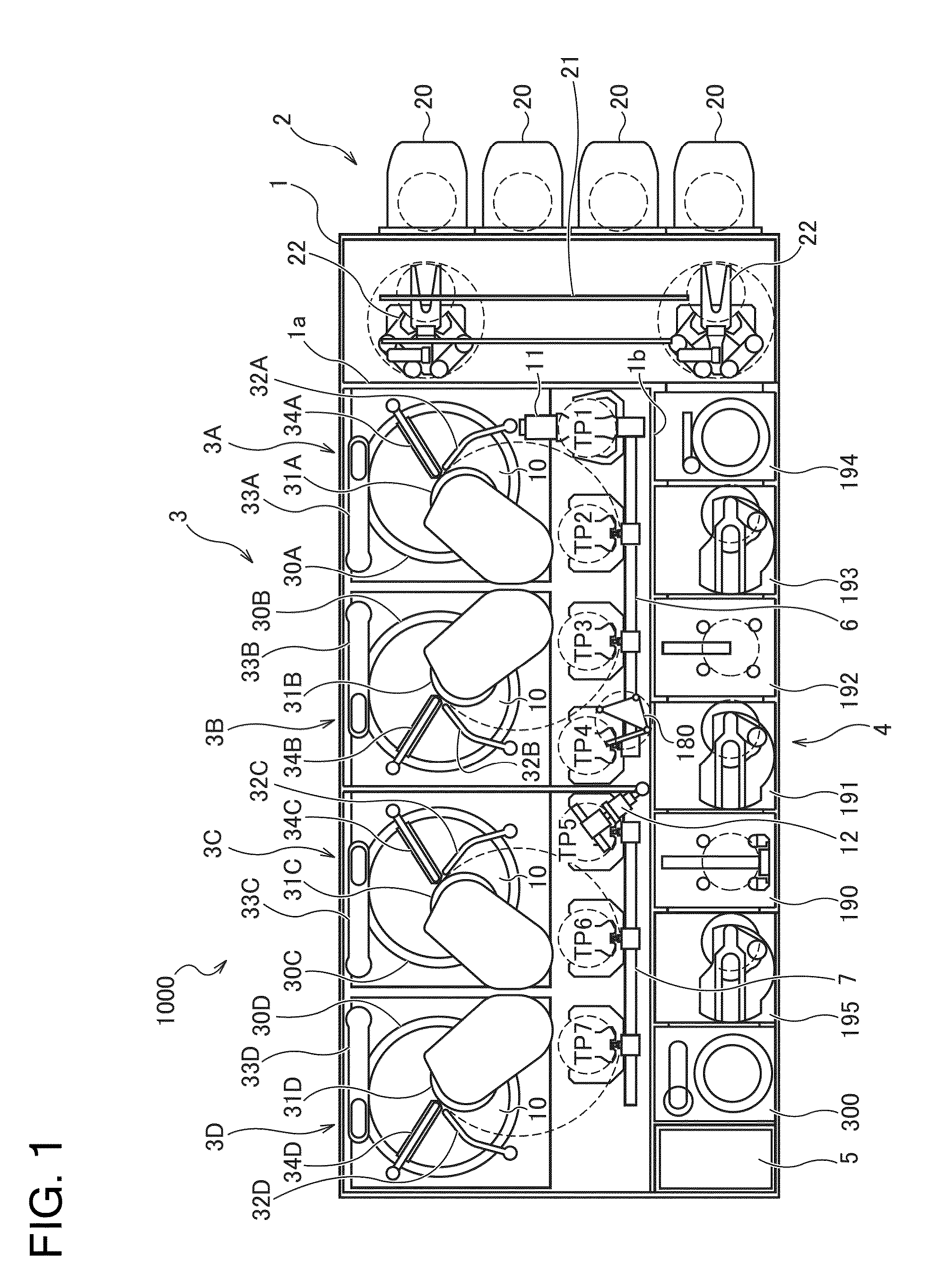

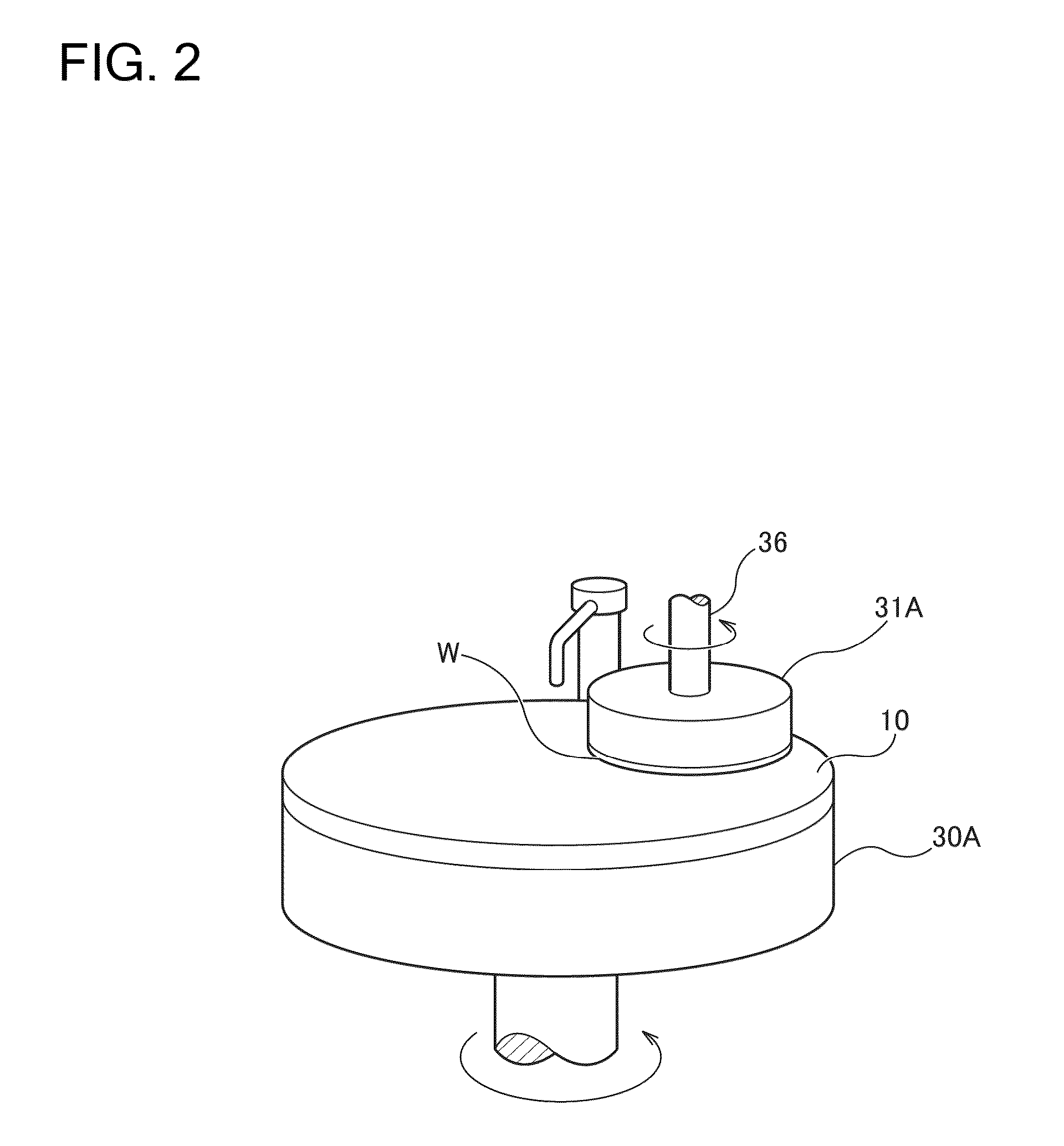

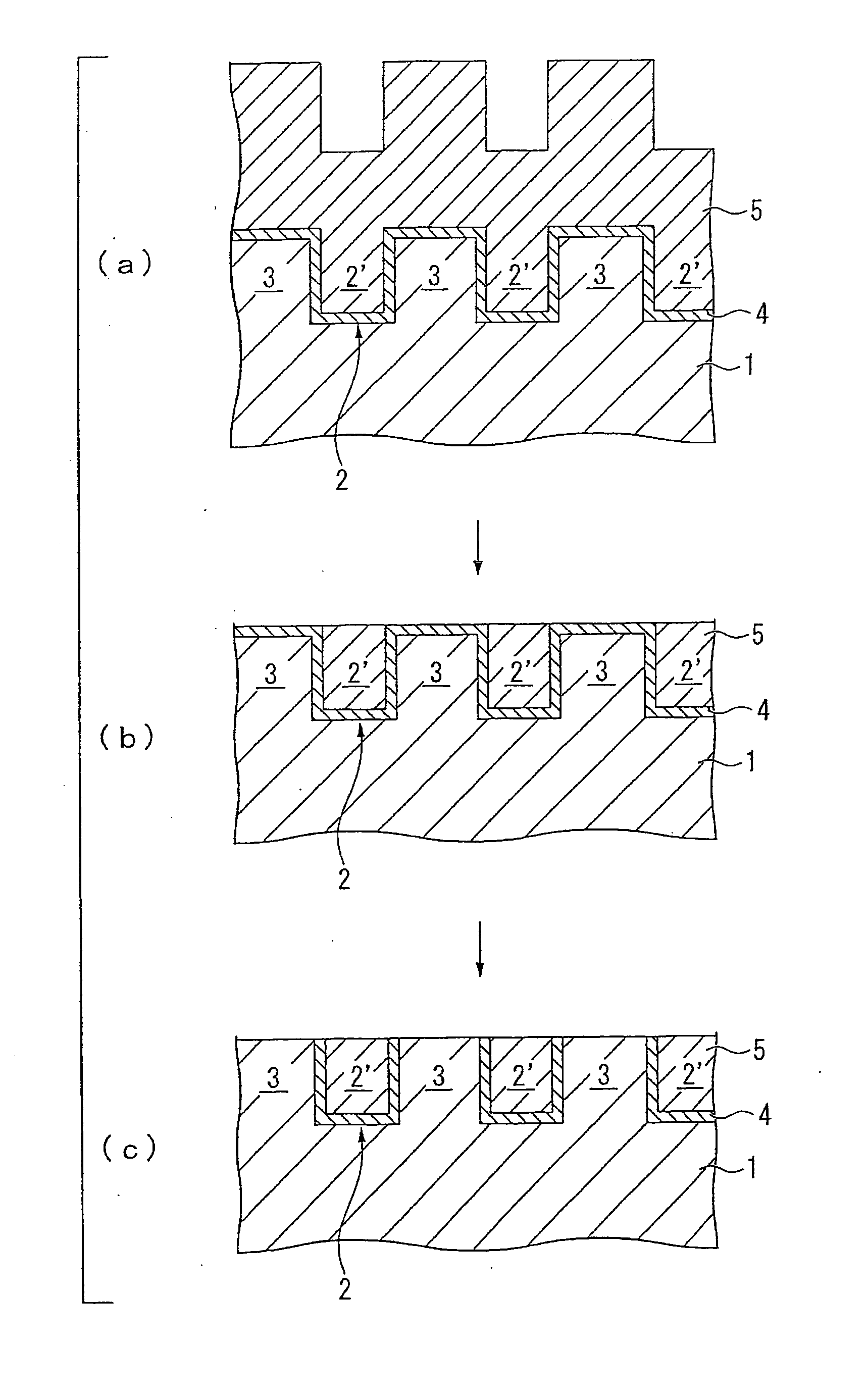

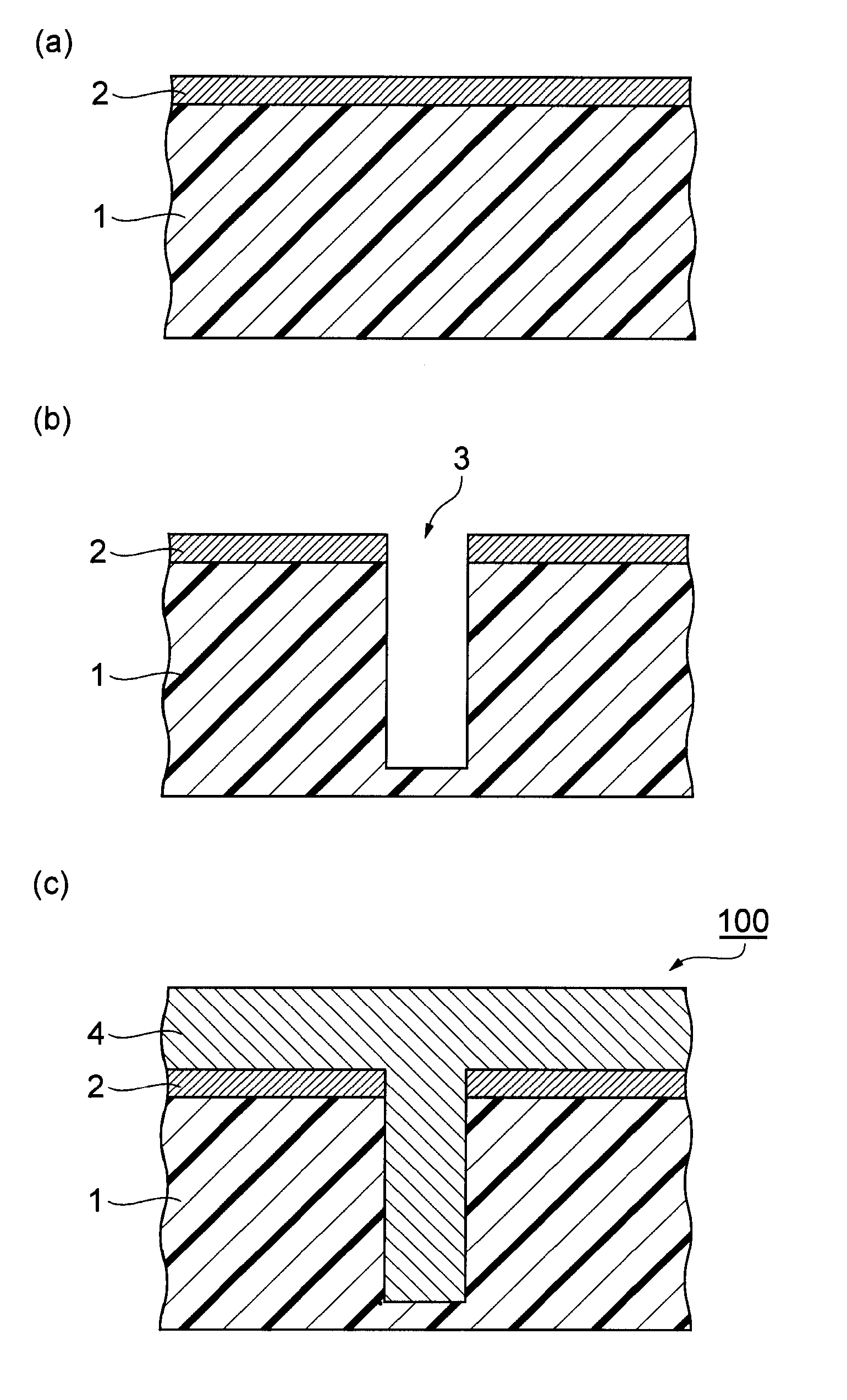

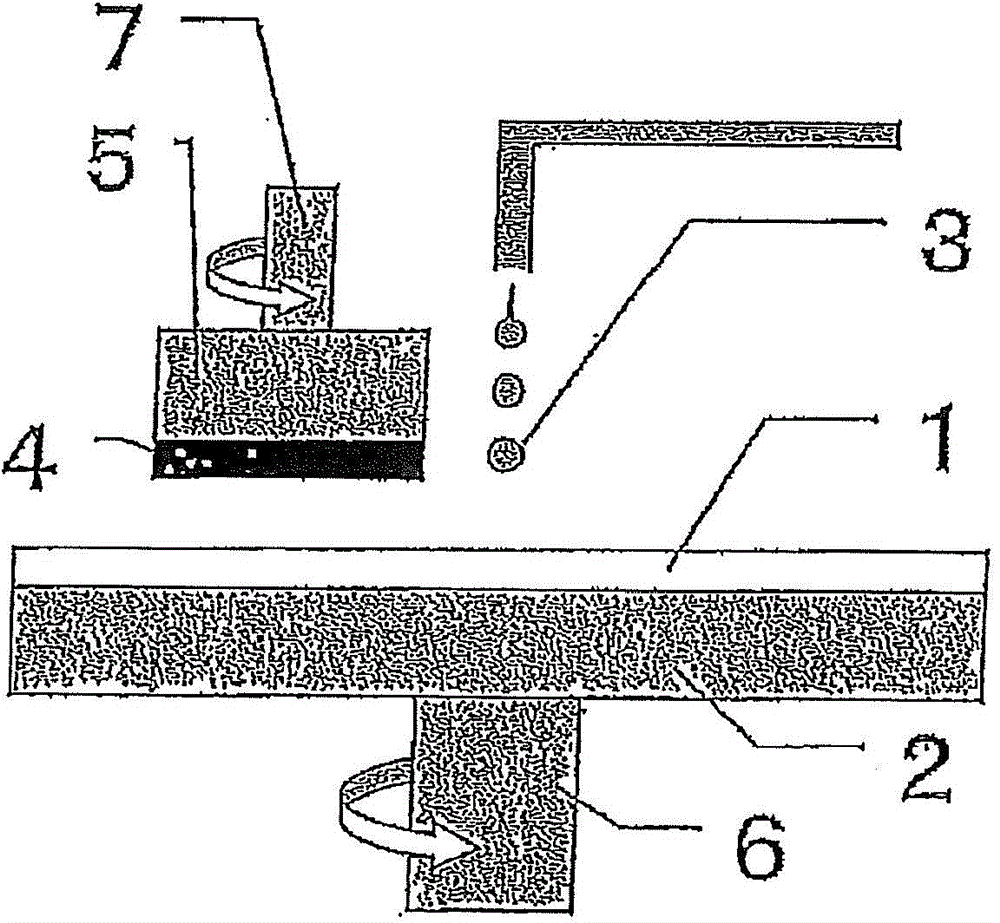

Substrate processing apparatus and processing method

InactiveUS20160099156A1Improve removal rate and in-plane uniformityFlatten local unevennessSemiconductor/solid-state device manufacturingLapping machinesEngineeringElectrical and Electronics engineering

A polishing apparatus is provided. The polishing apparatus includes: a polishing unit configured to polish a substrate by bringing a polishing tool into contact with the substrate and moving the substrate relatively to the polishing tool; a cleaning unit; and a first transfer robot configured to transfer the substrate before polishing to the polishing unit and / or configured to transfer the substrate after polishing from the polishing unit to the cleaning unit. The cleaning unit includes: at least one cleaning module, a buff processing module configured to perform a buff process to the substrate, and a second transfer robot configured to transfer the substrate between the cleaning module and the buff processing module, the second transfer robot being different from the first robot.

Owner:EBARA CORP

Polishing pad for CMP, method for polishing substrate using it and method for producing polishing pad for CMP

InactiveUS7374474B2Efficiently planarizedIncrease speedSemiconductor/solid-state device manufacturingFlexible-parts wheelsFiberSilicon oxide

In CMP technology for planarizing an interlayer insulation film, a BPSG film, an insulation film for shallow trench isolation, or the like, in the production process of a semiconductor element, irregularities of a matter being polished, e.g. a silicon oxide film, are planarized efficiently at a high speed while suppressing the occurrence of polishing flaws on the substrate by employing a polishing pad having organic fibers exposed on the surface thereof abutting against the matter being polished.

Owner:RESONAC CORPORATION +1

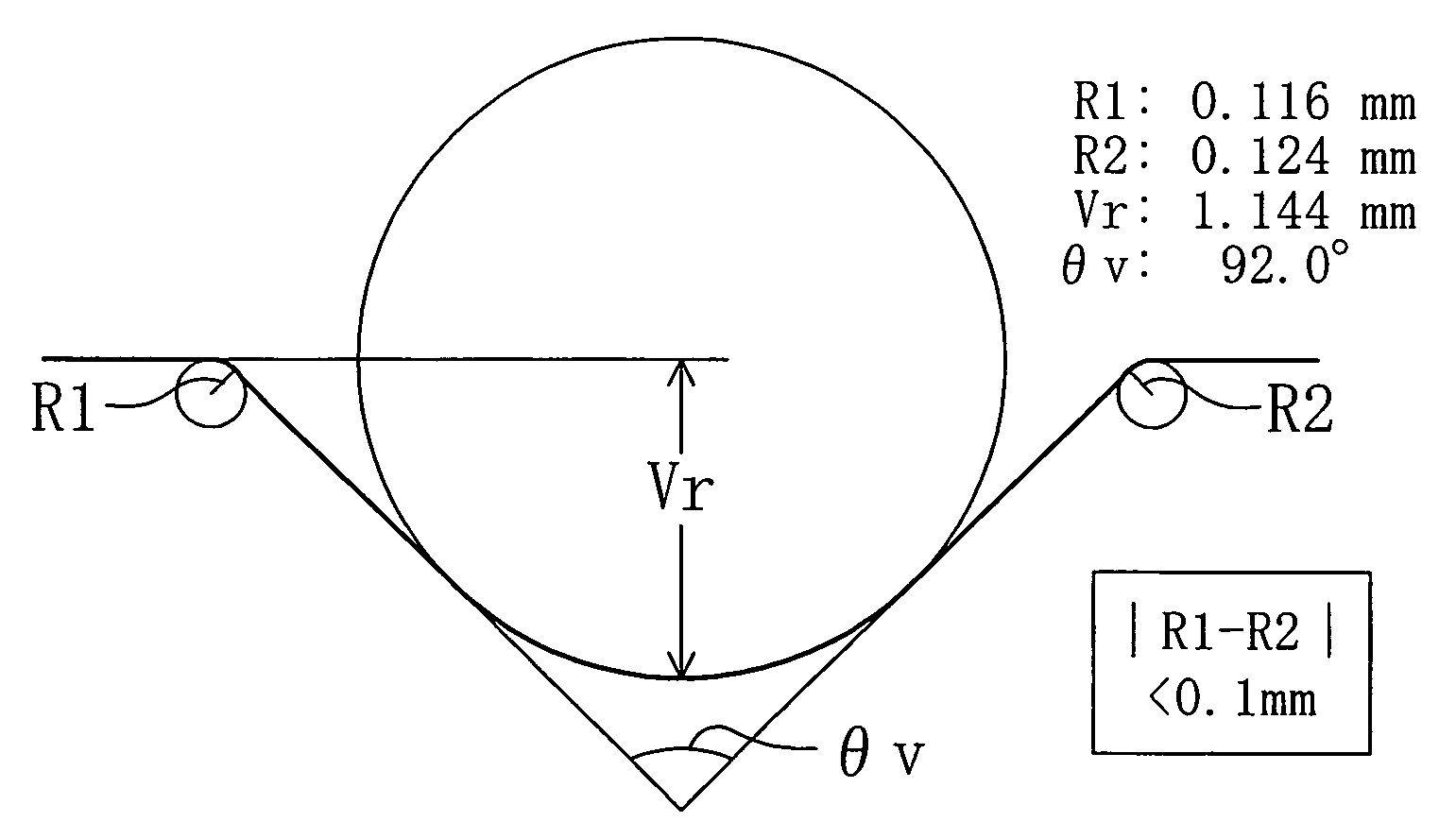

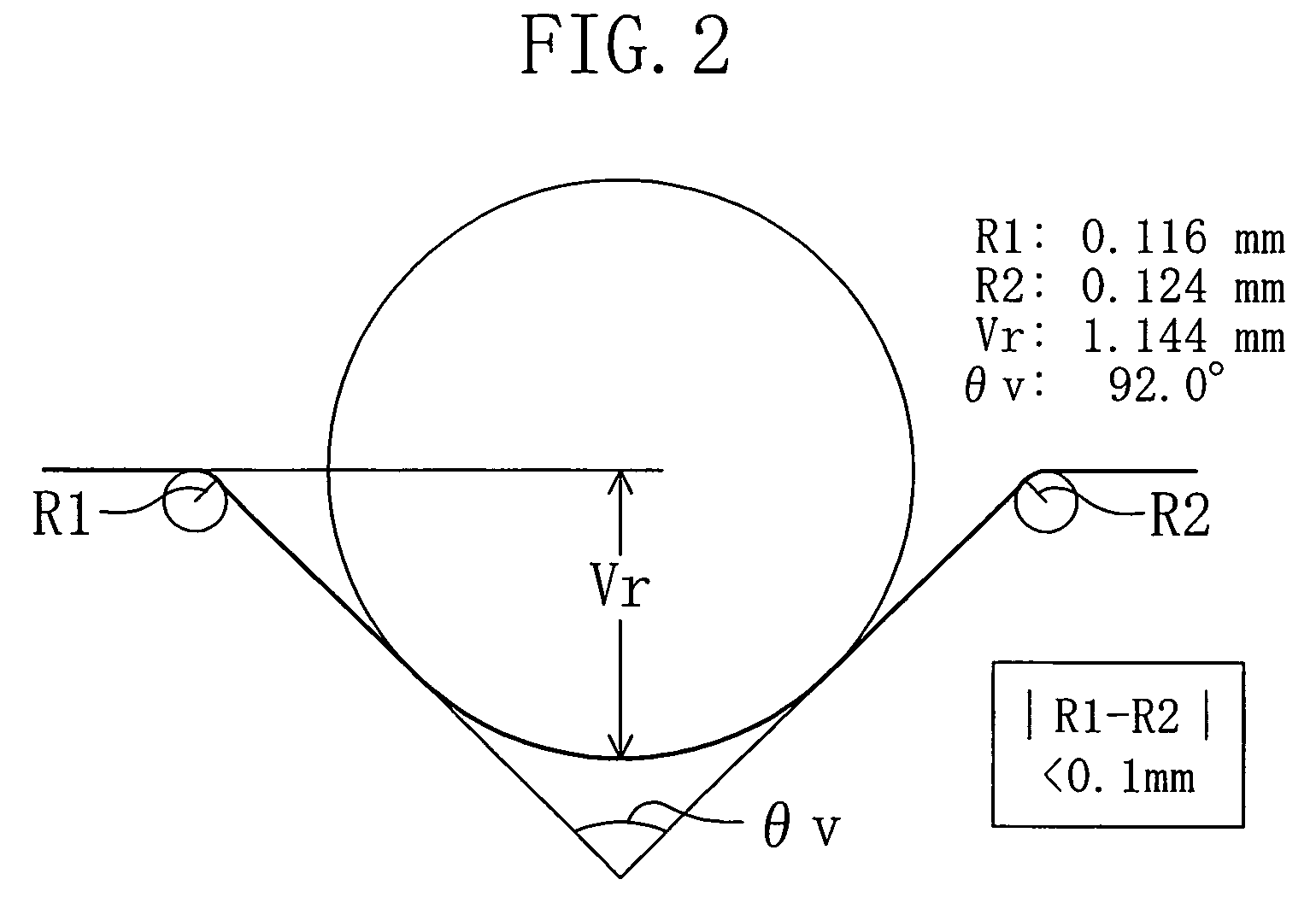

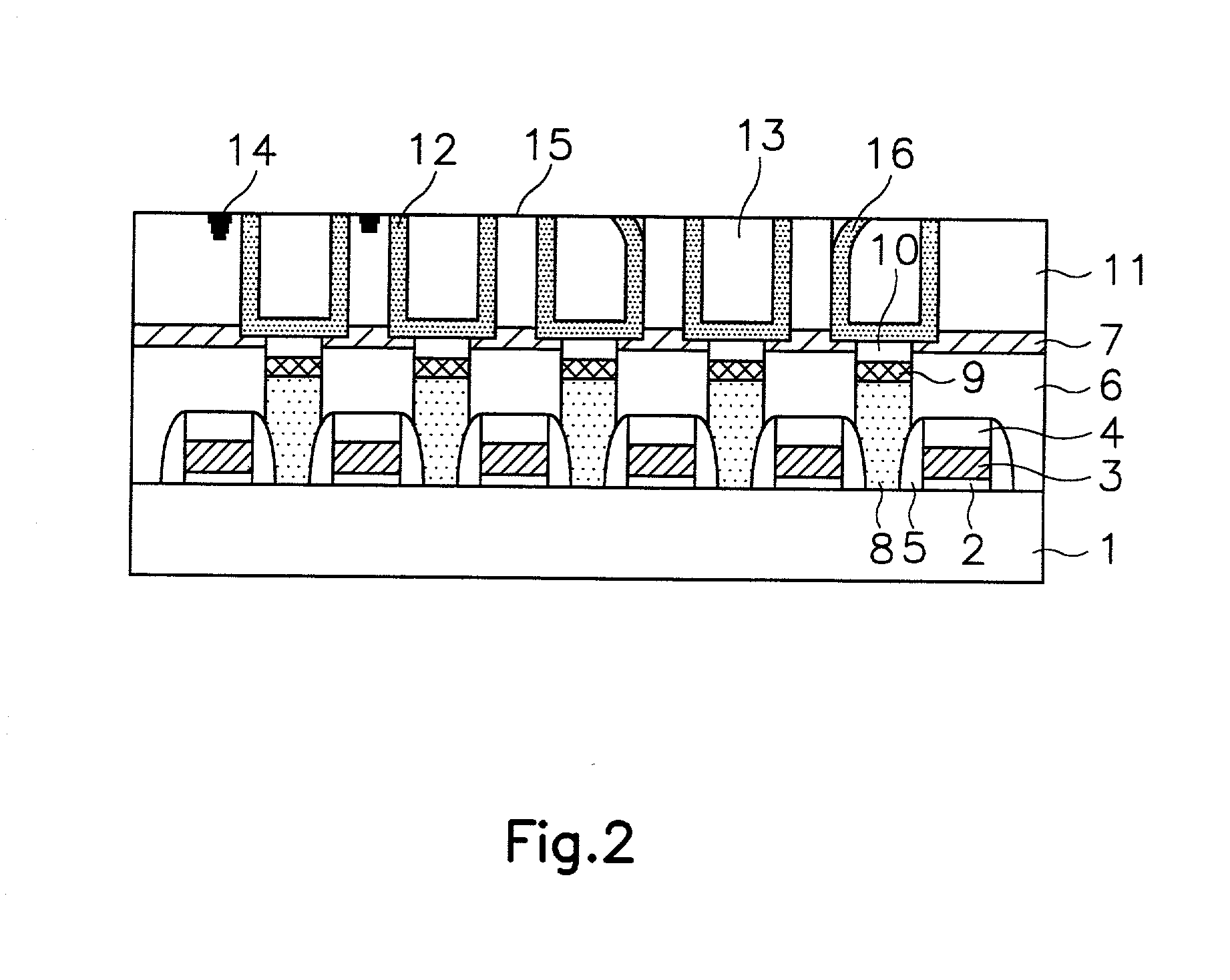

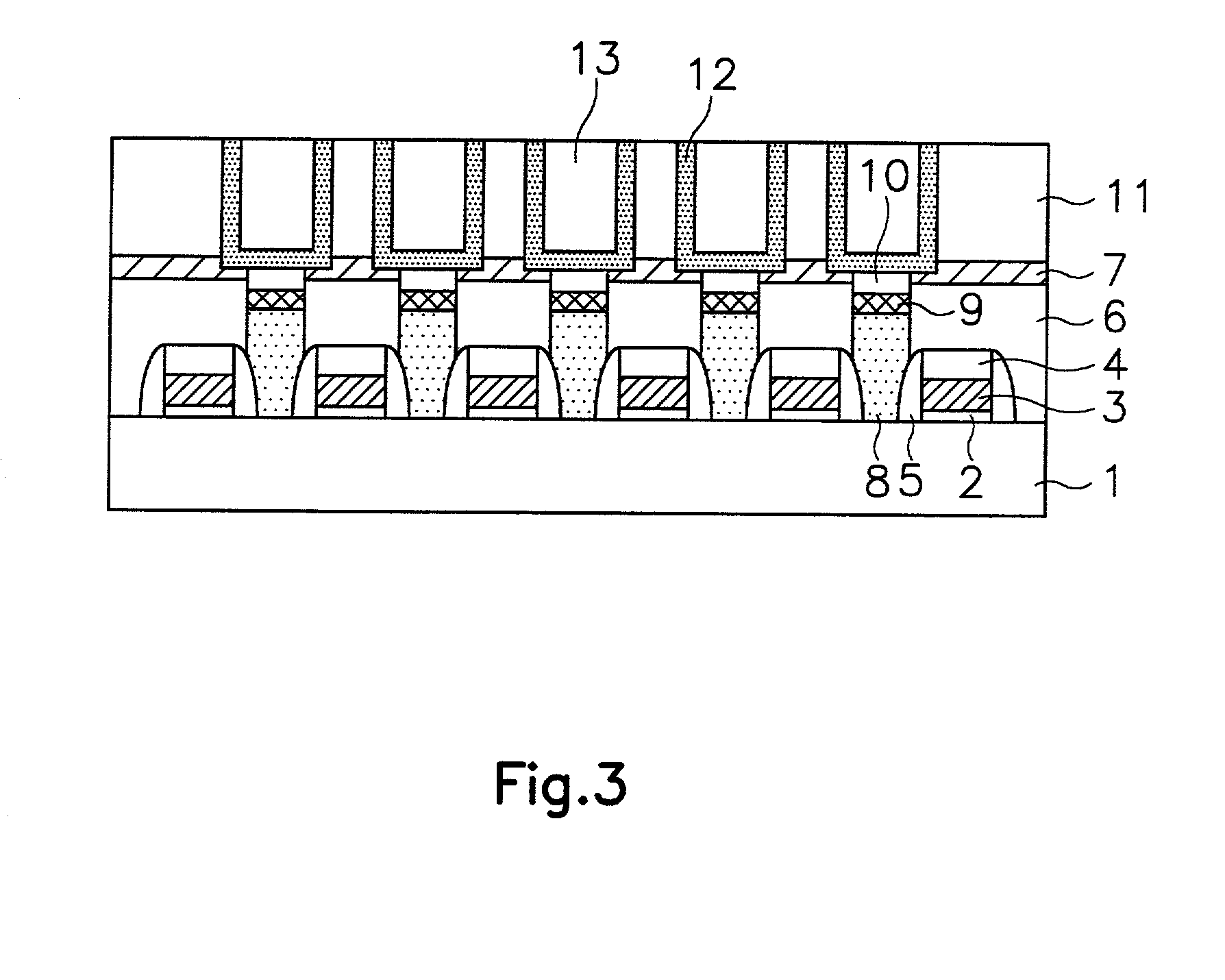

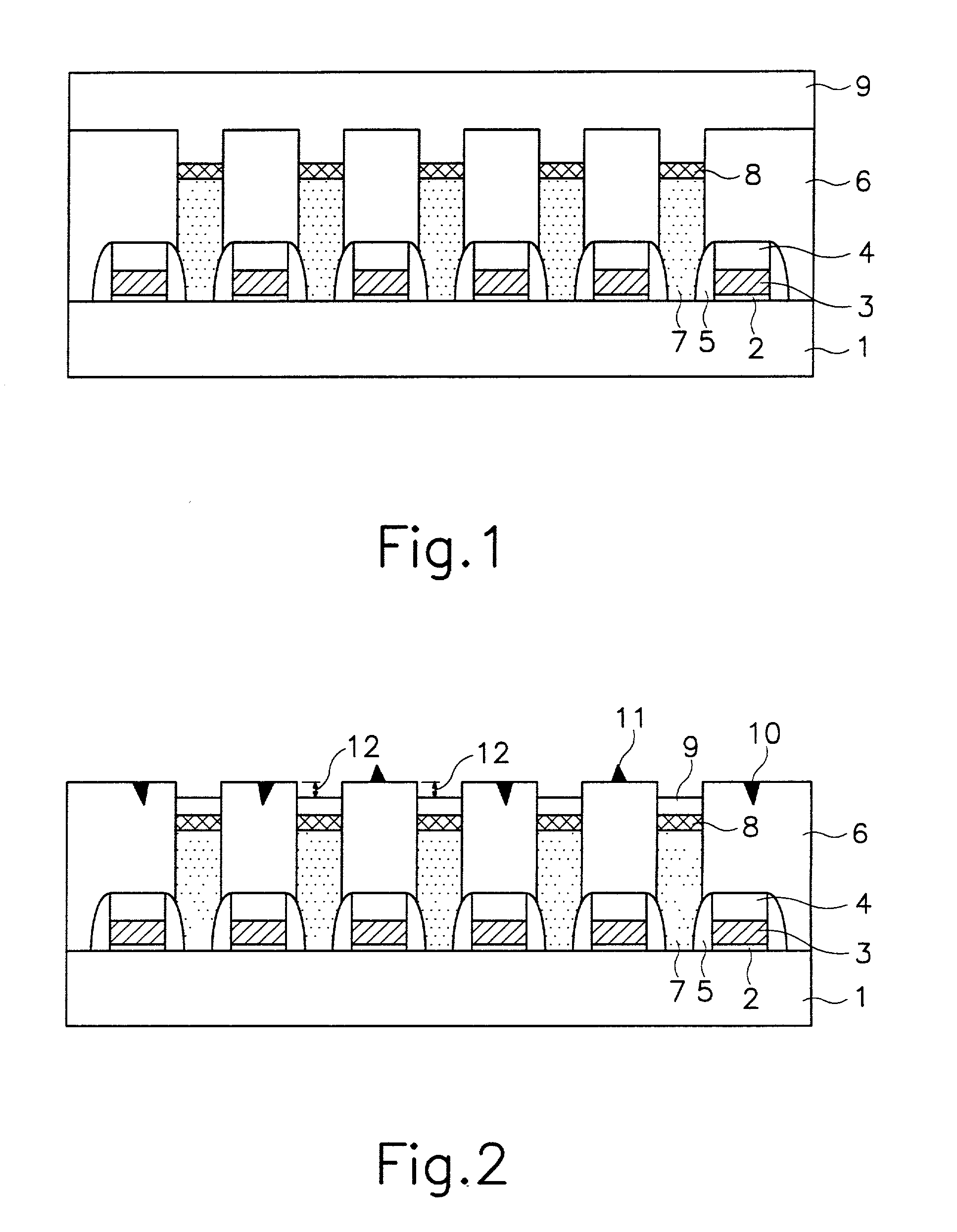

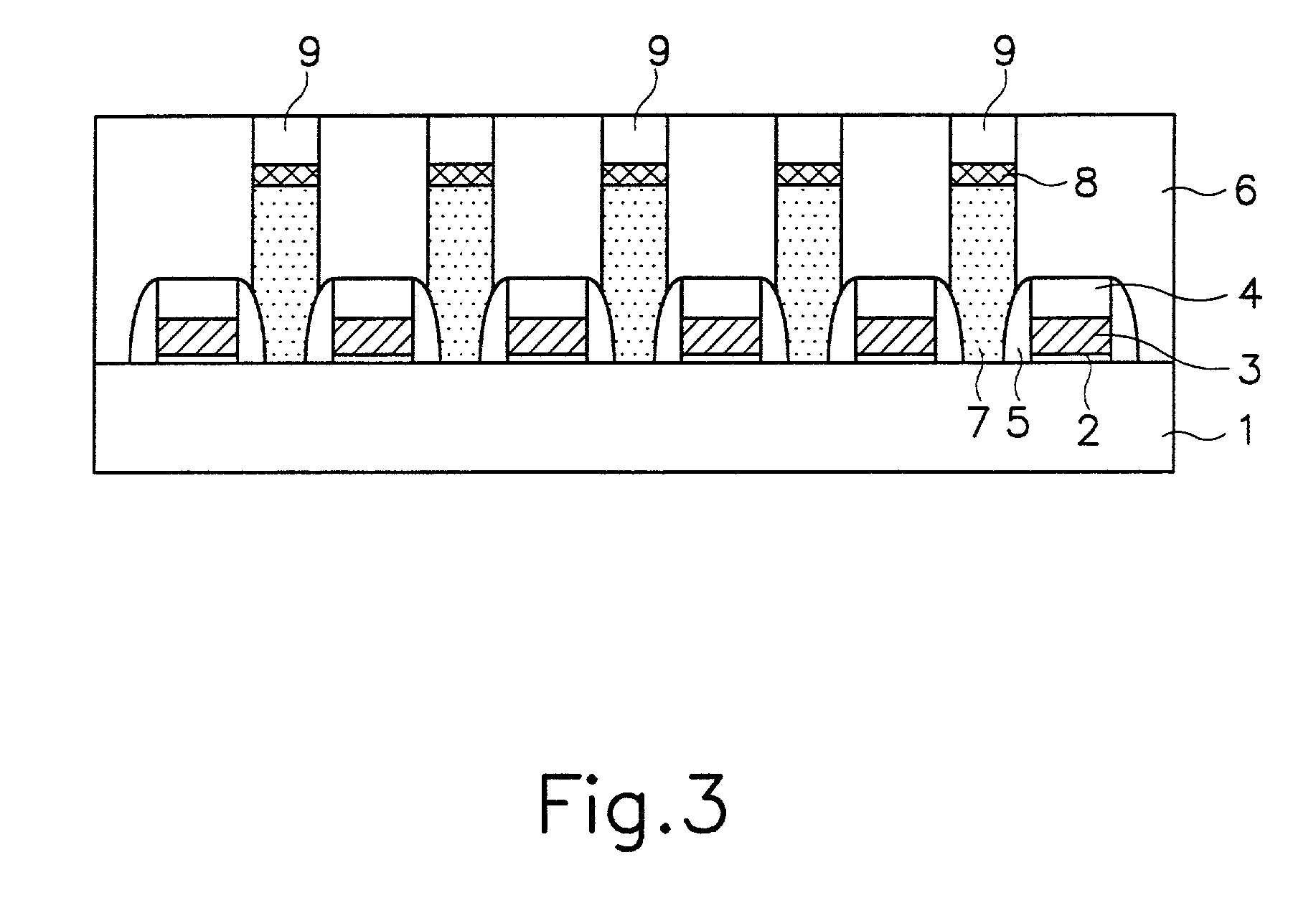

Semiconductor substrate, method for fabricating the same, and method for fabricating semiconductor device

InactiveUS7102206B2Stable polishing speedReduced polishing speedSemiconductor/solid-state device detailsSolid-state devicesMetallurgySemiconductor

In a semiconductor substrate having a notch in an edge portion thereof, each of the two shoulder portions of the notch is configured as an arc and the difference in curvature between the two shoulder portions of the notch is not less than 0 mm and not more than 0.1 mm.

Owner:PANASONIC CORP

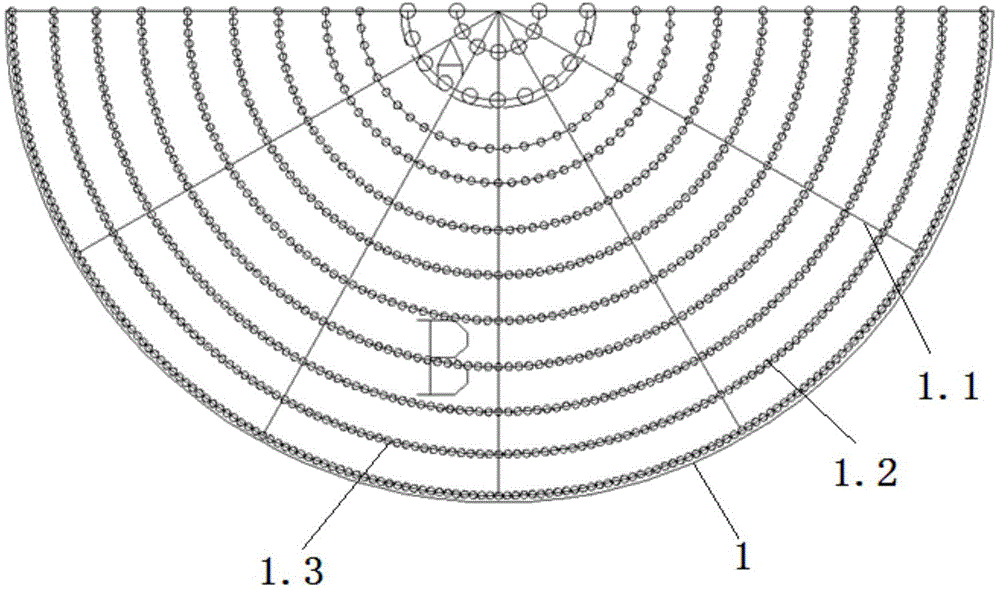

Chemical-mechanical polishing pad

The invention discloses a chemical-mechanical polishing pad and solves the problem that an existing polishing pad is scratched easily and low in polishing efficiency. According to the technical scheme, the chemical-mechanical polishing pad comprises a polishing layer, a plurality of holes are formed in the polishing surface of the polishing layer, the center of the polishing surface is a circle center, and the holes are arranged into multiple rows of concentric rings different in diameter. The center of the polishing surface is an end point, and a plurality of grooves extending to the edge of the polishing surface are evenly radiated from the end point. The surface roughness of the polishing surface is below 15 micrometers. The polishing pad is simple in structure, capable of increased polishing removing efficiency and inhibiting scratches, and long in service life.

Owner:HUBEI DINGLONG CO LTD

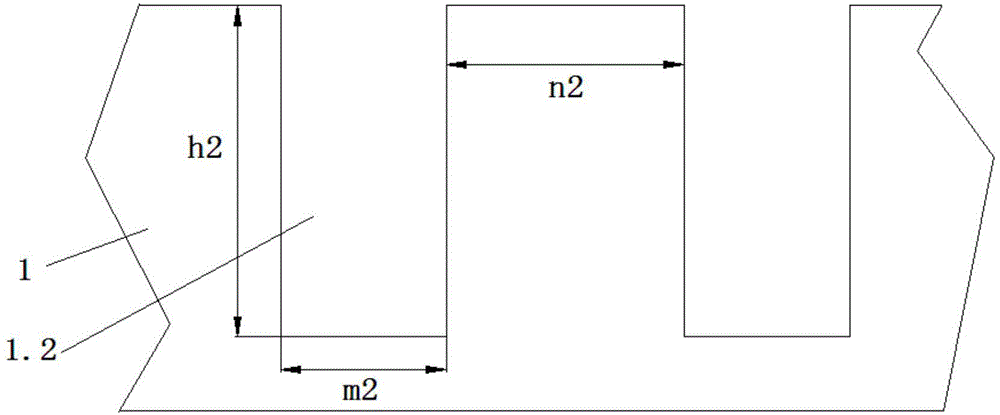

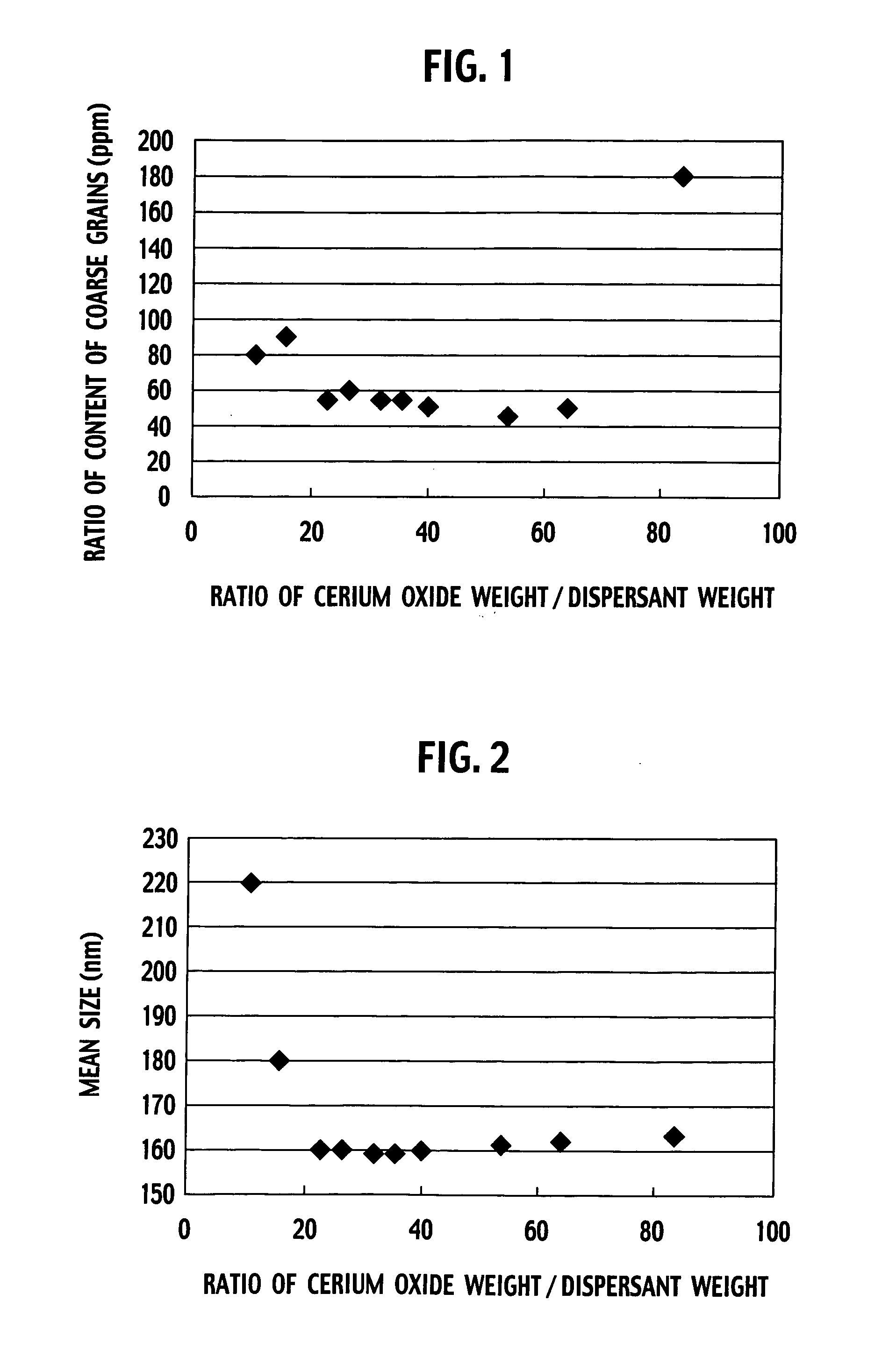

Cerium oxide slurry, cerium oxide polishing slurry and method for polishing substrate using the same

InactiveUS20070093183A1Reduce scratchesDecrease polishPigmenting treatmentOther chemical processesWater solubleSlurry

The present invention provides a cerium oxide slurry, a cerium oxide polishing slurry, and a method of polishing a substrate by using the same, wherein decrease of scratches and polish at high speed can be realized by reducing the content of coarse grains by improving in the disperse state of cerium oxide particles. The invention relates to a cerium oxide slurry containing cerium oxide particles, dispersant and water, in which the ratio of weight of cerium oxide / weight of dispersant is in a range of 20 to 80 and relates a cerium oxide polishing slurry comprising the cerium oxide slurry and additives such as a water-soluble polymer.

Owner:HITACHI CHEM CO LTD

Diamond resin binder abrasive disc and preparation method and application thereof

ActiveCN110842800AImprove stabilityThe polishing process is environmentally friendlyAbrasion apparatusGrinding devicesA diamondAbrasive

The invention provides a diamond resin binder abrasive disc and a preparation method and an application thereof and belongs to the technical field of polishing grinding apparatuses. The diamond resinbinder abrasive disc is prepared from the following raw materials in parts by mass: 20-40 parts of thermosetting resin, 4-30 parts of a curing agent, 15-30 parts of a diamond, 10-20 parts of an auxiliary grinding material, 10-30 parts of micro filler, 1-10 parts of nano filler and 1-5 parts of a coupling agent. The diamond resin binder abrasive disc is used for polishing a marble and has the advantages of being good in polishing effect, high in efficiency, environmental-friendly and safe and the like.

Owner:惠安宇信金刚石工具有限公司 +1

Concentrate of fine ceria particles for chemical mechanical polishing and preparing method thereof

InactiveUS20070212289A1Easy to produceImprove economyMaterial nanotechnologyPigmenting treatmentContinuous reactorCerium

Disclosed are a concentrate of fine ceria particles for chemical mechanical polishing, and a method of preparing the same. The method includes reacting a reactant mixture comprising i) water, ii) an aqueous solution of water-soluble cerium salt compound, and iii) ammonia or ammonium salt at a reaction temperature of 250-700 ? under a reaction pressure of 180-550 bar for 0.01 sec to 10 min in a continuous reactor to obtain a solution containing the fine ceria particles, the cerium salt compound being contained at an amount of 0.01 to 20 wt % in the reactant mixture; and concentrating the solution containing the fine ceria particles in a concentrator having a filter with a pore size of 0.01 to 10 ?. The concentrate is advantageous in that a CMP slurry and a dispersing solution are easily produced by diluting the concentrate and adding an additive to the concentrate.

Owner:HANWHA CHEMICAL CORPORATION

Polishing fluid for metal, and polishing method

InactiveUS20060143990A1Increase productivityImprove workabilityPigmenting treatmentOther chemical processesTriazole antifungalsCorrosion

A polishing slurry for metal comprises an oxidizer, a metal oxide dissolving agent, a metal inhibitor, and water, wherein the metal inhibitor is at least one of a compound having an amino-triazole skeleton and a compound having an imidazole skeleton. The use of the polishing slurry for metal makes it possible to raise the polishing speed sufficiently while keeping the etching speed low, restrain the generation of corrosion of the surface of a metal and dishing, and form a metal-film-buried pattern having a high reliability in the process of formation of wiring of semiconductor devices.

Owner:HITACHI CHEM CO LTD

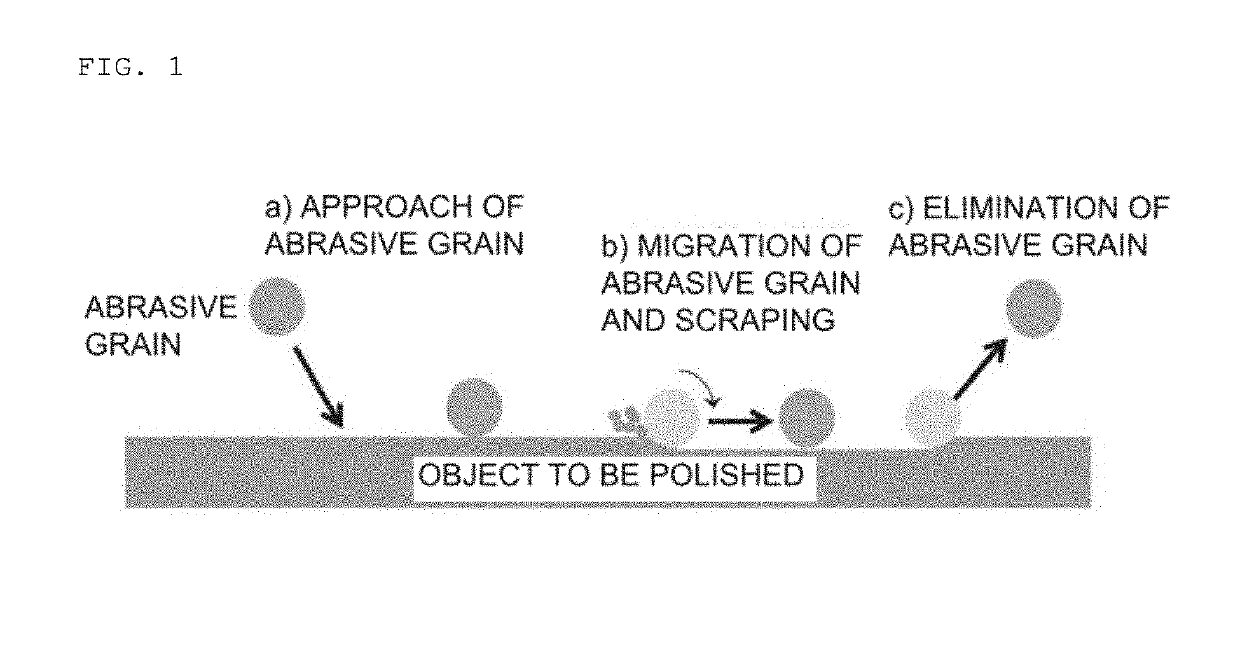

Chemical mechanical polishing slurry, cmp process and electronic device process

InactiveUS20070270085A1Increase polishing speedSufficient polishing selectivityPigmenting treatmentOther chemical processesNegative potentialProcess capability

To provide a slurry for Chemical Mechanical Polishing, a Chemical Mechanical Polishing method using said slurry, and a method of producing electronic devices using said method that makes it possible to achieve a low scratch process capability in processing surfaces such as SiO2 film surfaces and the like and also to enable speed polishing to attain a high processing efficiency.Slurry for Chemical Mechanical Polishing characterized in comprising abrasive grains and water, wherein said abrasive grains are composite particles coated with ceria particles consisting of organic host particles and ceria particles, zeta potential of said composite particles being a negative potential, the organic host particles constituting the composite particles coated with ceria particles are organic host particles to which carboxyl groups and sulfonyl groups are introduced; the slurry is added with panarization additive; and the planarization additive is poly(methyl)acrylic acid ammonium salt.

Owner:HITACHI CHEM CO LTD

Polishing composition

InactiveUS20100267315A1Sufficient polishing speedAvoid erosionOther chemical processesDecorative surface effectsCarboxylic acidFatty acid

The present invention provides a polishing composition for polishing copper or copper alloy, comprising: an oxidizing agent (A); at least one acids (B) selected from amino acids, carboxylic acids of 8 or less carbon atoms, or inorganic acids; a sulfonic acid (C) having an alkyl group of 8 or more carbon atoms; a fatty acid (D) having an alkyl group of 8 or more carbon atoms; and an N-substituted imidazole (E) represented by the following general formula (1).(In the formula (1), Ra, Rb, and Rc represent H or an alkyl group of 1 to 4 carbon atoms, and Rd represents a group selected from the group consisting of a benzyl group, a vinyl group, an alkyl group of 1 to 4 carbon atoms, and a group in which a portion of H of these groups has been substituted with OH or NH2.)

Owner:HITACHI CHEM CO LTD

Polishing composition, method for producing polishing composition, and polishing method

InactiveUS20190256742A1Increase polishing speedIncrease speedOther chemical processesSemiconductor/solid-state device manufacturingDispersed mediaSpectroscopy

The present invention provides a polishing composition that can polish an object to be polished at a high polishing speed with fewer scratches (defects). The present invention relates to a polishing composition including silica and a dispersing medium, the polishing composition having, when analyzed by pulse NMR spectroscopy, a specific relaxation rate (R2sp) of from 1.60 to 4.20 as determined by the following Formula (1):R2sp=(R(silica)) / (R(medium))−1 Formula (1):wherein R(silica) represents the reciprocal of the relaxation time of silica (unit: / millisecond), and R(medium) represents the reciprocal of the relaxation time of the dispersing medium (unit: / millisecond).

Owner:FUJIMI INCORPORATED

Abrading agent and abrading method

ActiveUS20110300778A1Reduce surface roughnessIncrease polishing speedOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidPotassium hydroxide

A polishing agent which comprises a composition containing an inorganic acid, an amino acid, a protective film-forming agent, an abrasive, an oxidizing agent, an organic acid and water, adjusted to a pH of 1.5-4, wherein the amount of potassium hydroxide required to raise the pH of the composition without the organic acid to 4 is at least 0.10 mol with respect to 1 kg of the composition without the organic acid, and the organic acid contains at least two carboxyl groups, wherein the logarithm of the inverse of the first acid dissociation constant (pKa1) is no greater than 3.

Owner:RESONAC CORP

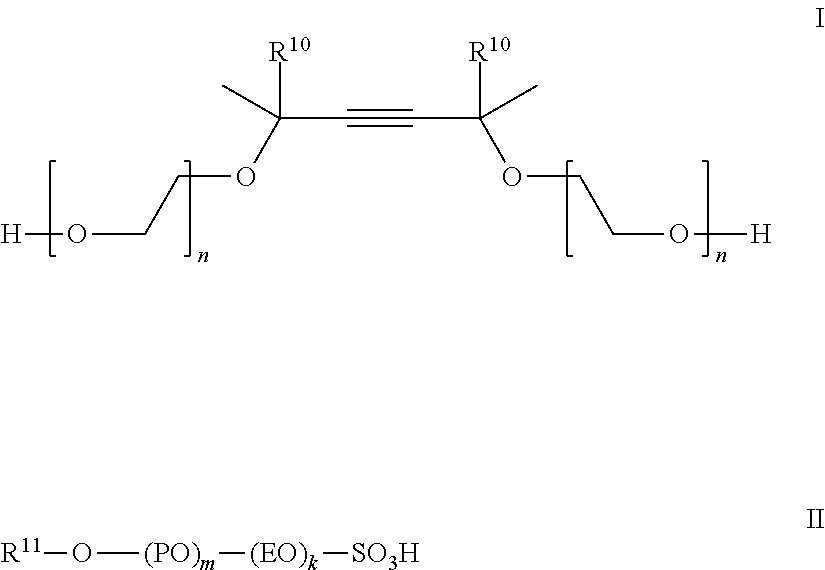

Increased wetting of colloidal silica as a polishing slurry

ActiveUS20180244532A1Surface be wetImprove speedOther chemical processesLapping machinesColloidal silicaSapphire

A method, kit, and composition for polishing a sapphire surface are described here. The invention involves a sapphire surface polishing composition comprising colloidal silica particles and an extended or gemini surfactant that can reduce the contact angles of the polishing composition on both polishing pads and sapphire surfaces.

Owner:ECOLAB USA INC

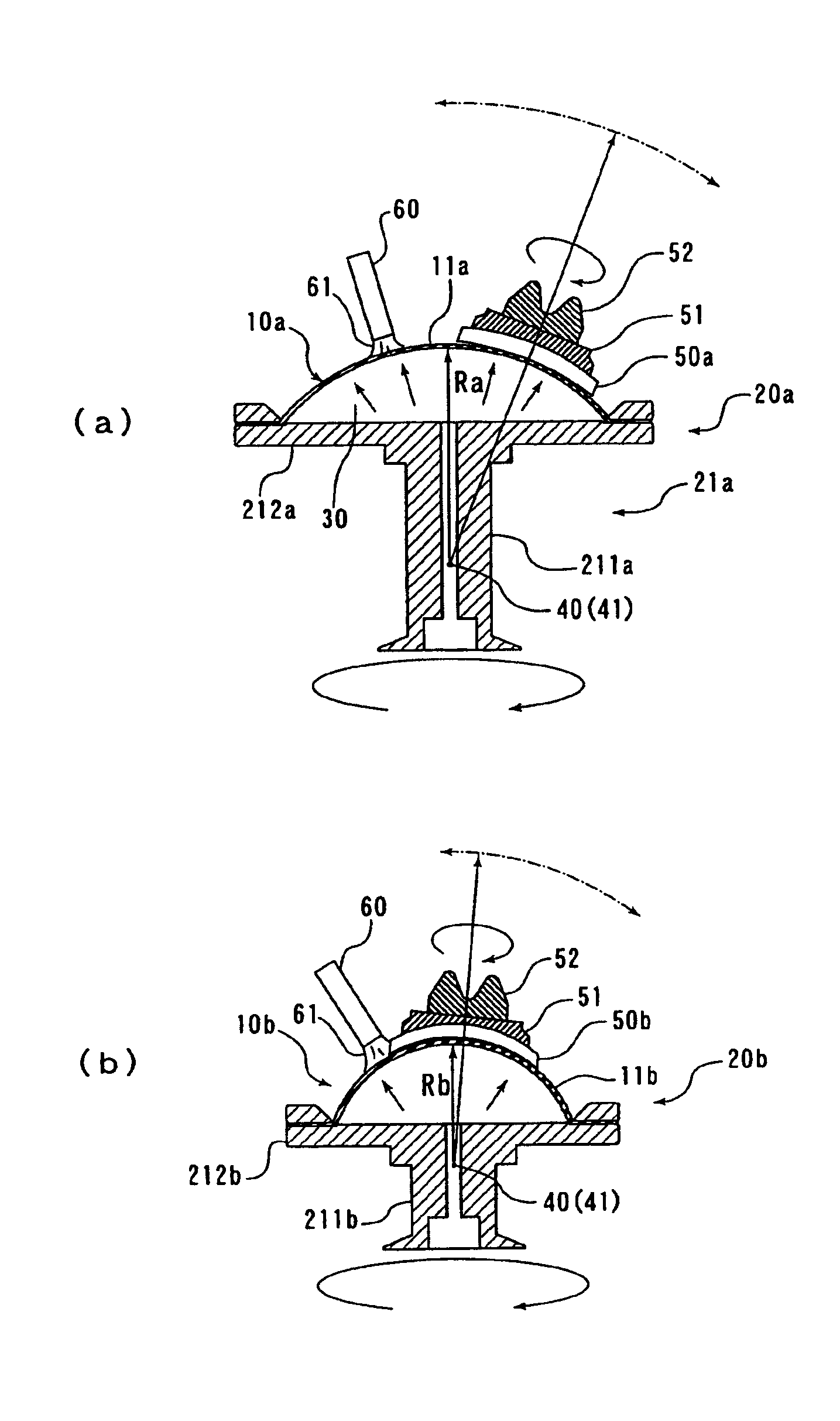

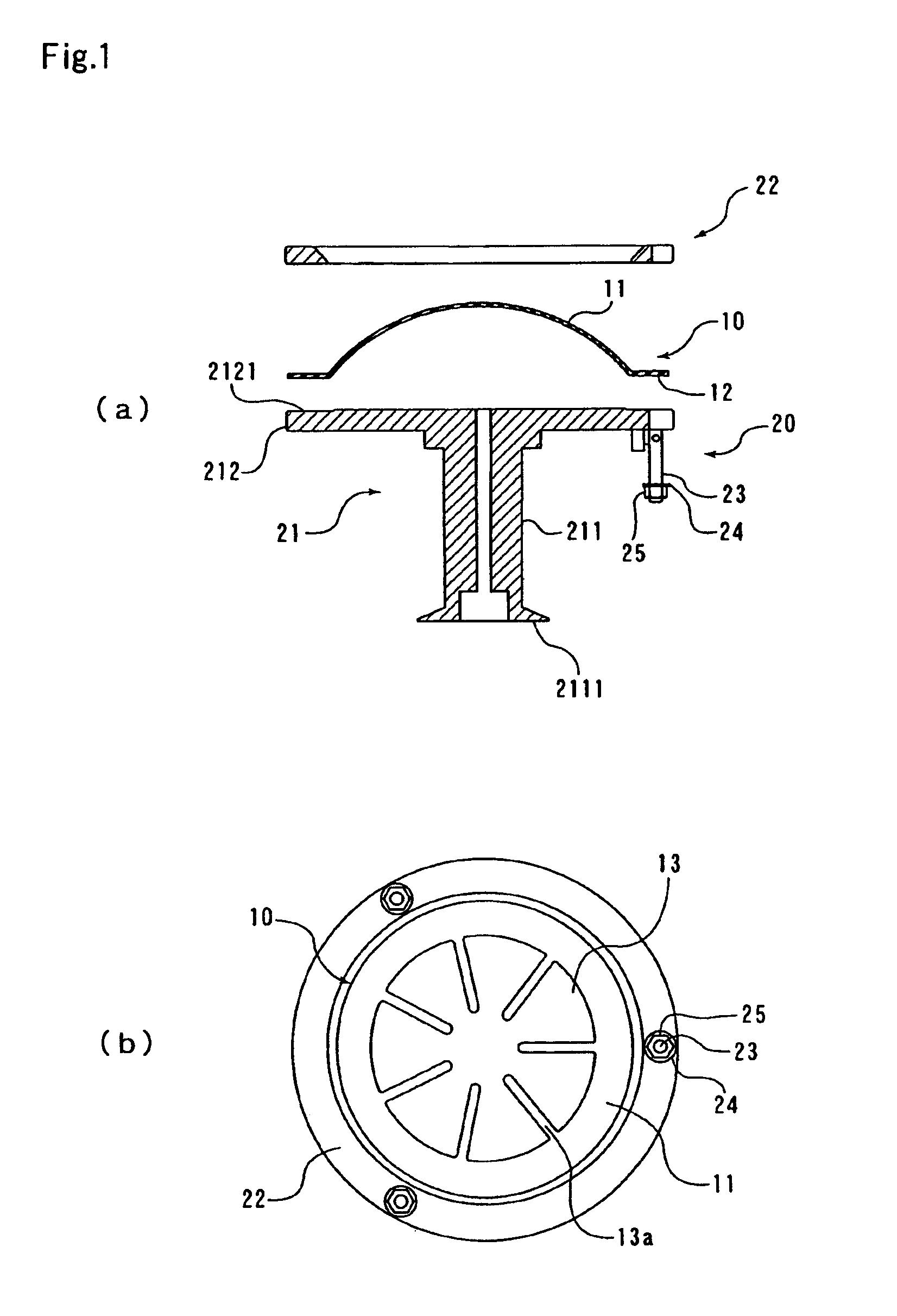

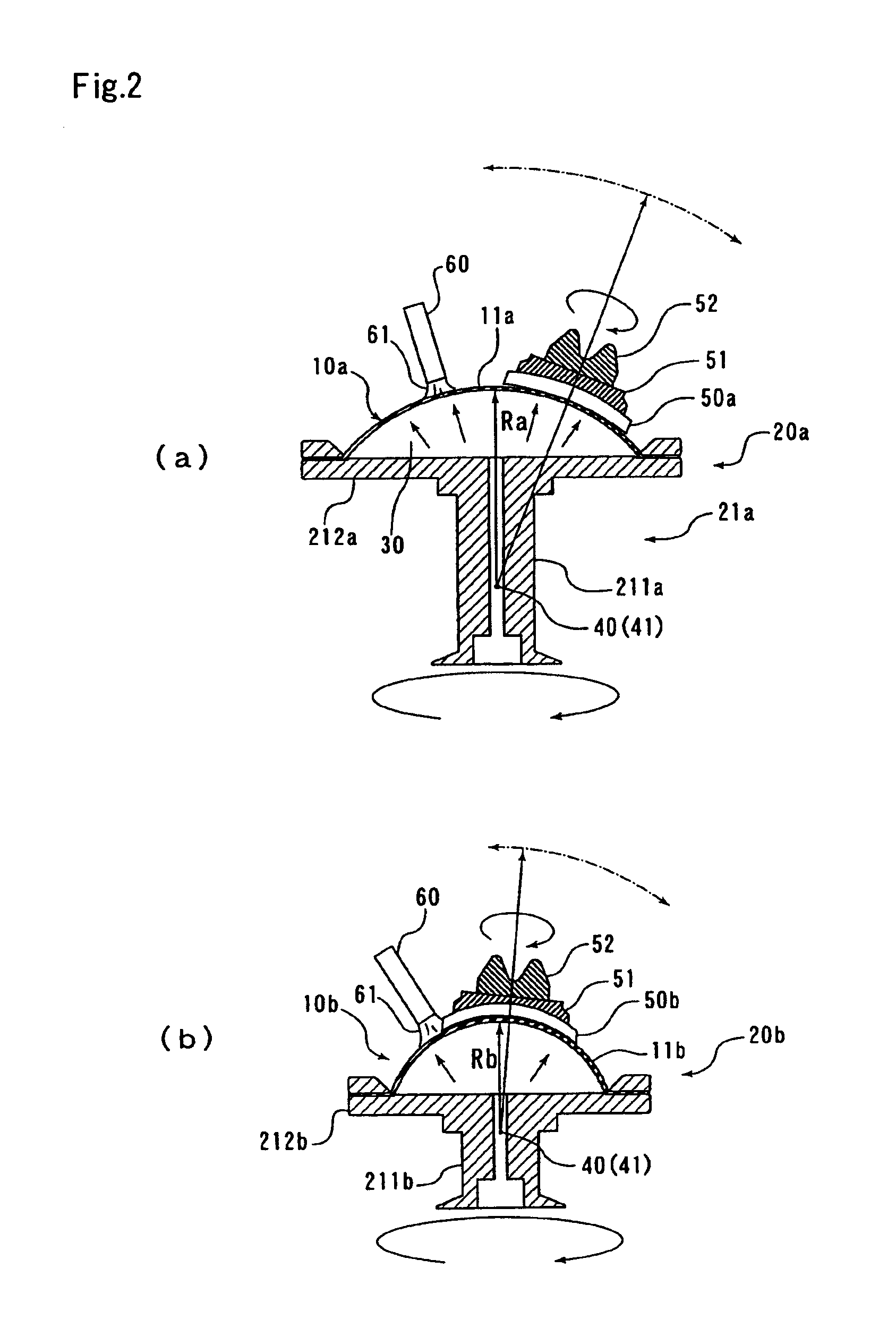

Polishing method and polishing device

InactiveUS6945849B2Polishing workEfficient polishingOptical surface grinding machinesSupport wheelsEngineeringMechanical engineering

A polishing method particularly suitable for mirror-polishing the concave surface of a lens and a polishing device, the method characterized by including the step of polishing work surfaces (50a, 50b) while allowing parts of the dome-shaped parts of elastic polishing objects (10a, 10b) matching the curved shapes of the concaved work surfaces of the works (50a, 50b) selected from among the plurality of the elastic polishing bodies having the dome-shaped parts (11a, 11b) different in curvature and larger in area than the concaved work surfaces of the works (50a, 50b) to come into contact with the generally entire surfaces of the work surfaces, wherein the curvature centers (40) of the dome-shaped parts are generally aligned with the swing centers (41) of the works, whereby the concaved work surfaces can be rapidly and uniformly polished.

Owner:HOYA LENS MFG PHILIPPINES

Polishing agent for copper polishing and polishing method using same

ActiveUS20120160804A1Increase polishing speedRapid of large amountMaterial nanotechnologyOther chemical processesOrganic acidFilm-forming agent

A polishing agent for copper polishing, comprising (A) an inorganic acid with divalent or greater valence, (B) an amino acid, (C) a protective film-forming agent, (D) an abrasive, (E) an oxidizing agent and (F) water, wherein the content of the component (A) is at least 0.08 mol / kg, the content of the component (B) is at least 0.20 mol / kg, the content of the component (C) is at least 0.02 mol / kg, and either or both of the following conditions (i) and (ii) are satisfied.(i): The proportion of the content of the component (A) with respect to the content of the component (C) is 2.00 or greater.(ii): It further comprises (G) at least one kind selected from among organic acids and their acid anhydrides.

Owner:RESONAC CORP

Chemical mechanical polishing slurry and process for ruthenium films

InactiveUS20020197855A1Increase polishing speedTransistorOther chemical processesRutheniumThin membrane

A CMP slurry for ruthenium and a polishing process using the same. In a process technology below 0.1 mum, when a capacitor using a (Ba1-xSrx)TiO3 film as a dielectric film is fabricated, the slurry is used to polish a ruthenium film deposited as a lower electrode according to a CMP process. The CMP process is performed by using the slurry, to improve a polishing speed of ruthenium under a low polishing pressure. In addition, the CMP process is performed according to an one-step process by using one kind of slurry. As a result, defects on an insulating film are reduced and a polishing property is improved, thereby simplifying the CMP process.

Owner:SK HYNIX INC

Chemical mechanical polishing slurry for ruthenium titanium nitride and polishing process using the same

InactiveUS20030003747A1Increase polishing speedLow pressureOther chemical processesSemiconductor/solid-state device detailsMetallurgyTitanium nitride

A CMP slurry for ruthenium titanium nitride and a polishing process using the same. In a process technology below 0.1 mum, when a capacitor using a (Ba1-xSrx)TiO3 film as a dielectric film is fabricated, the slurry is used to polish a ruthenium titanium nitride film deposited as a barrier film according to a CMP process. The CMP process is performed by using the slurry, to improve a polishing speed of ruthenium titanium nitride under a low polishing pressure. In addition, the CMP process is performed according to an one-step process by using one kind of slurry. As a result, defects on an insulating film are reduced and a polishing property is improved, thereby simplifying the CMP process.

Owner:SK HYNIX INC

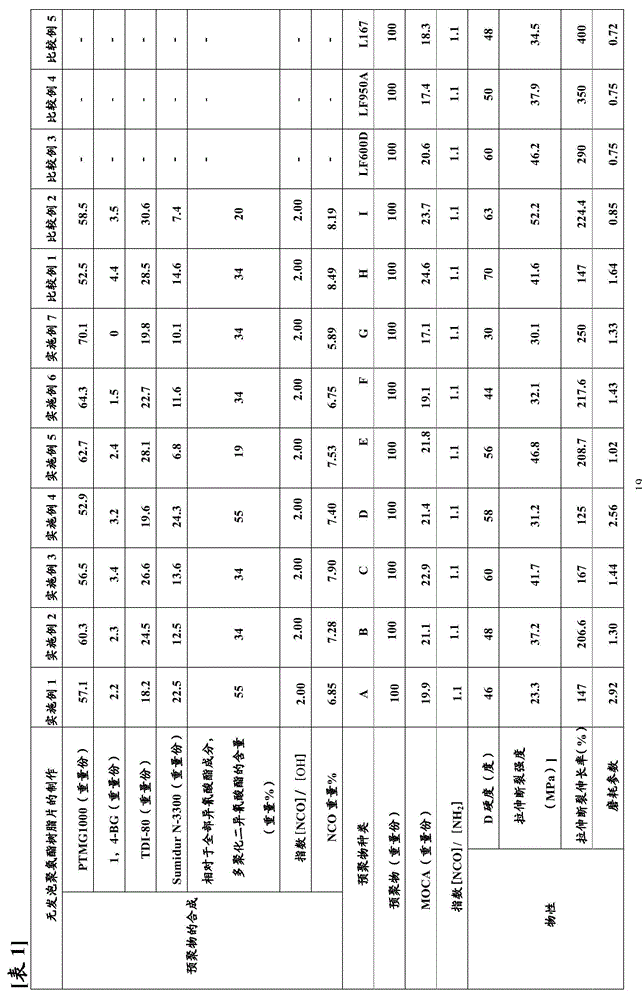

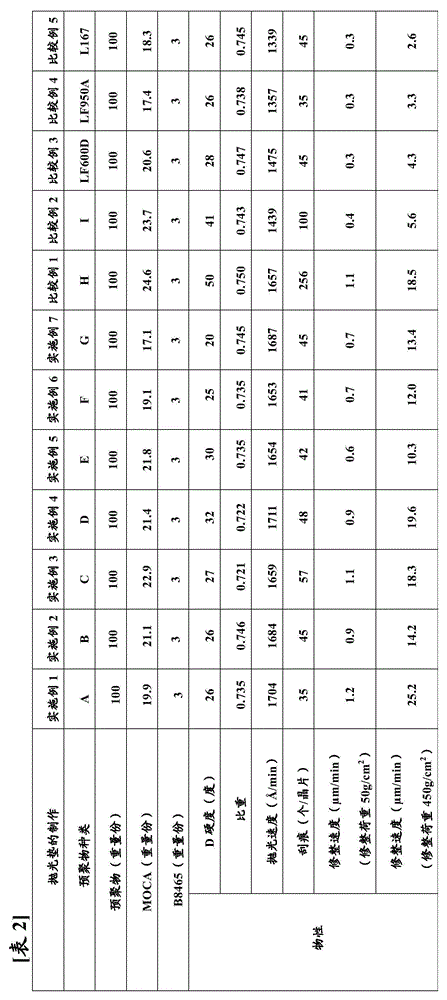

Polishing pad

InactiveCN103958125ALow hardness and softLarge wear parametersAbrasion apparatusSemiconductor/solid-state device manufacturingBreaking strengthHardness

An aim of the present invention is to provide a polishing pad which generates almost no scratches on the surface of an object to be polished, and has improved dressability. Another aim of the present invention is to provide a semiconductor device manufacturing method using the polishing pad. The polishing pad according to the present invention comprises a polishing layer formed of a microbubble-containing polyurethane resin foam. The polyurethane resin foam contains a polyurethane resin whose asker D hardness is between 20 degrees and 60 degrees, and whose wear parameter, which is expressed by the following formula, is between 1 and 3. Wear parameter = {1 / (tensile breaking strength [MPa] tensile breaking elongation [%] / 100)} 100

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com