Patents

Literature

447 results about "Process capability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A process is a unique combination of tools, materials, methods, and people engaged in producing a measurable output; for example a manufacturing line for machine parts. All processes have inherent statistical variability which can be evaluated by statistical methods.

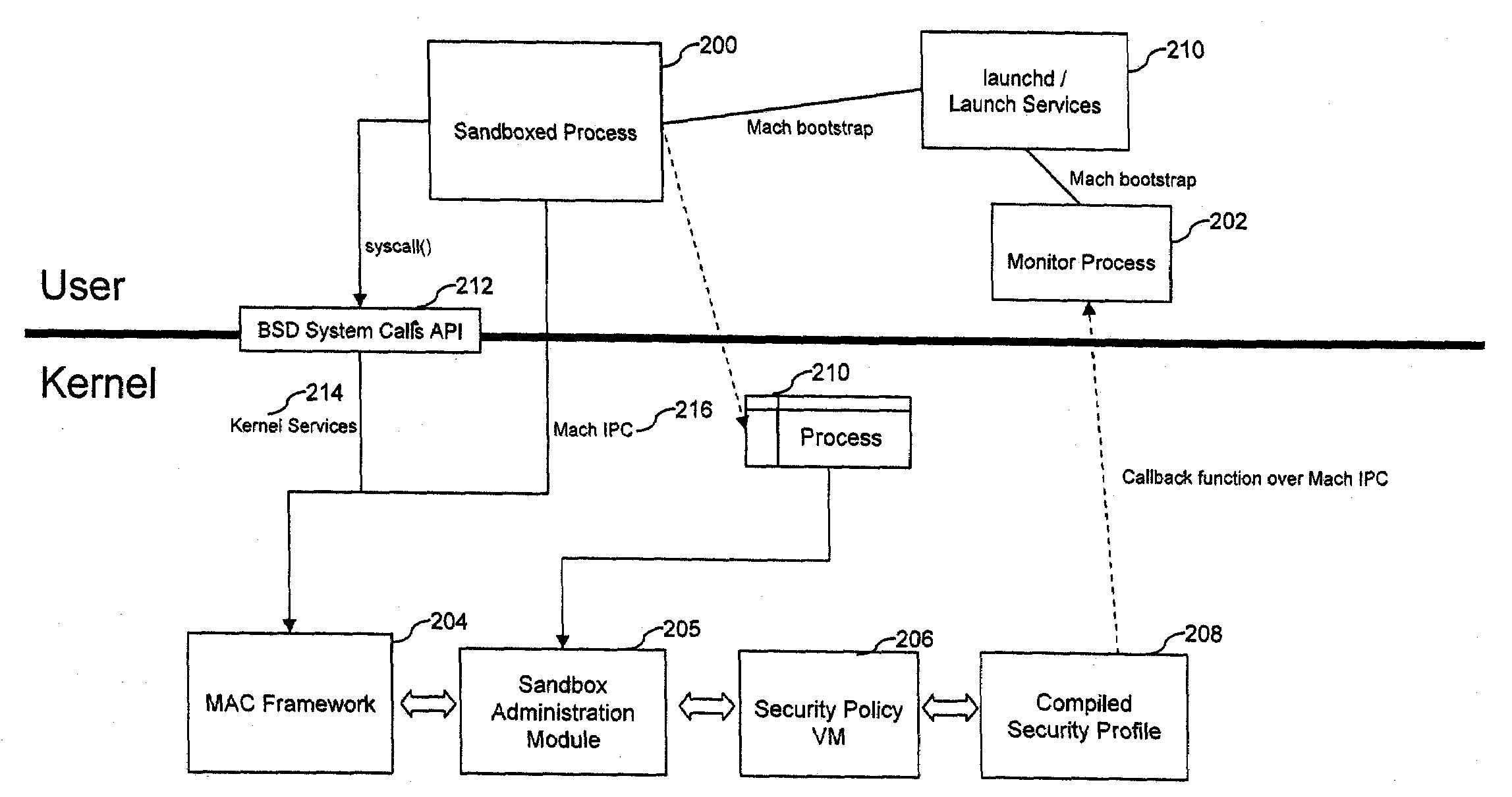

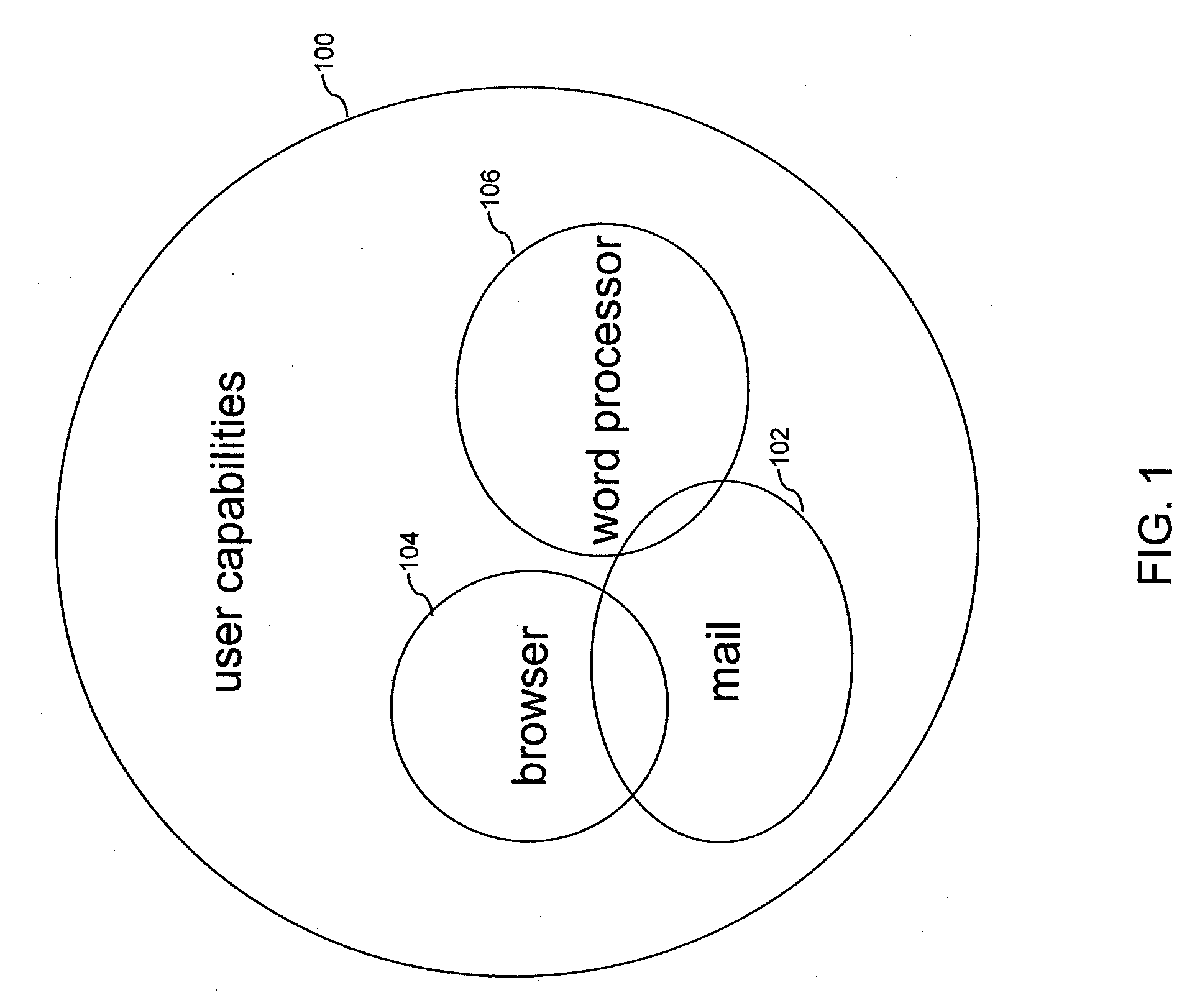

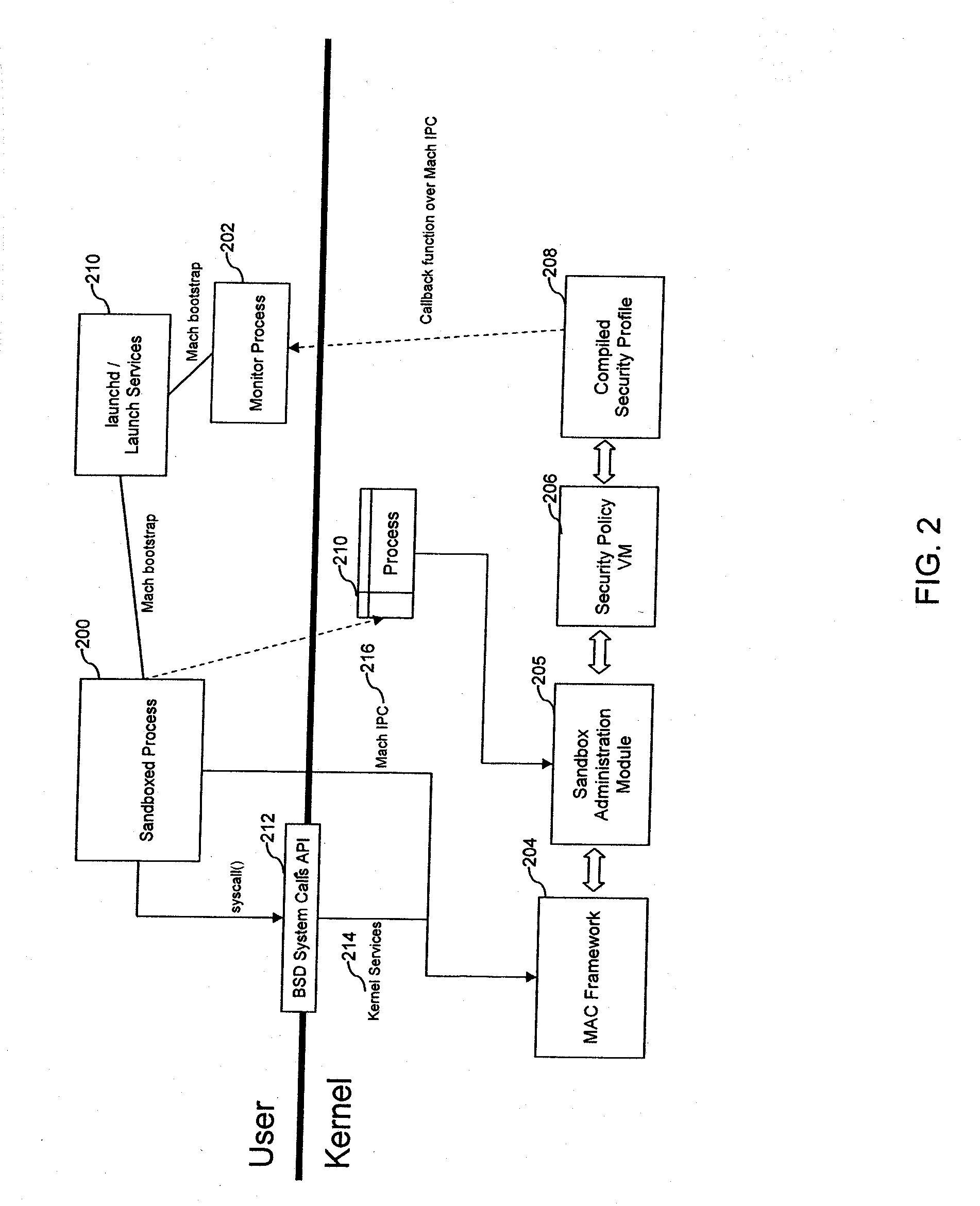

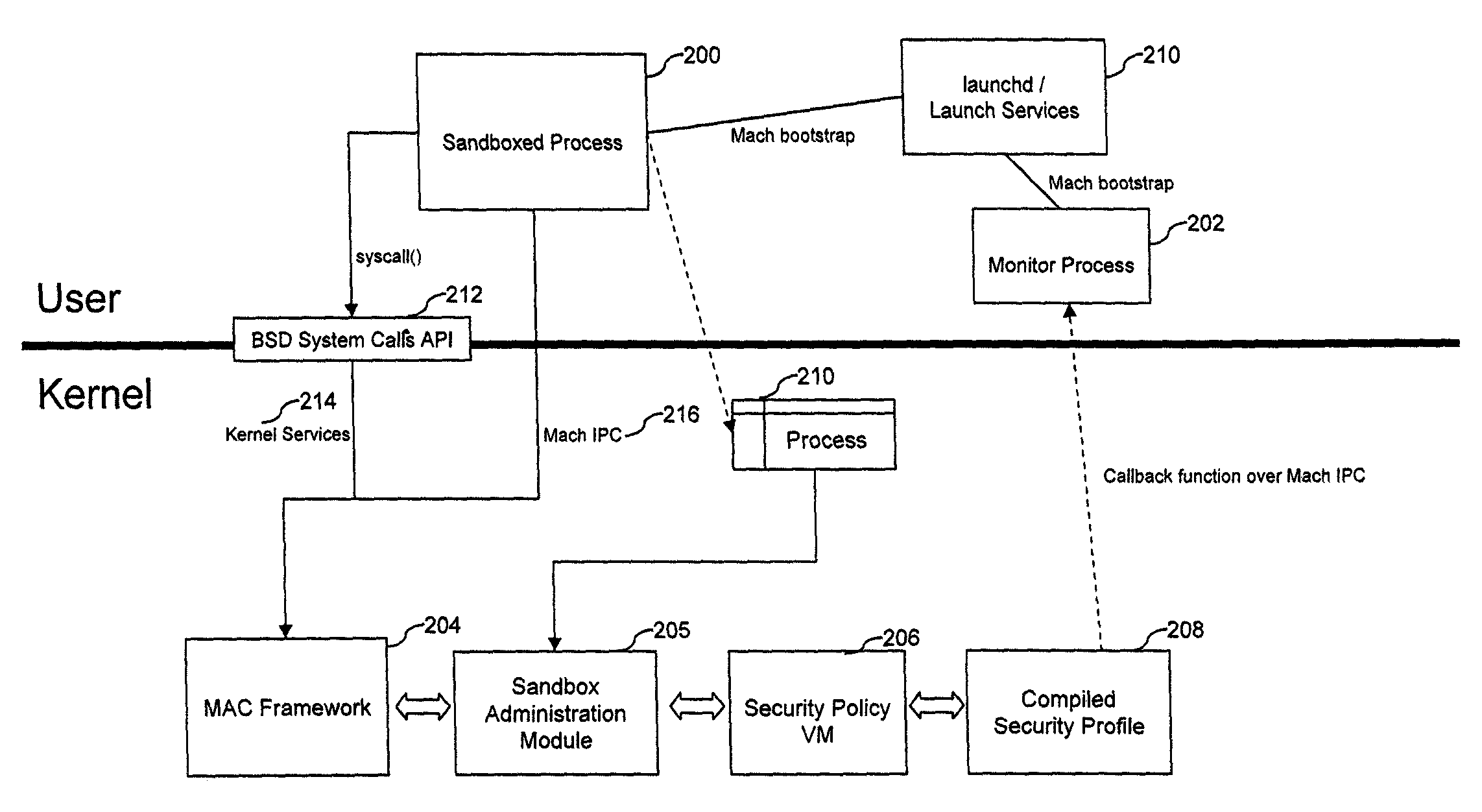

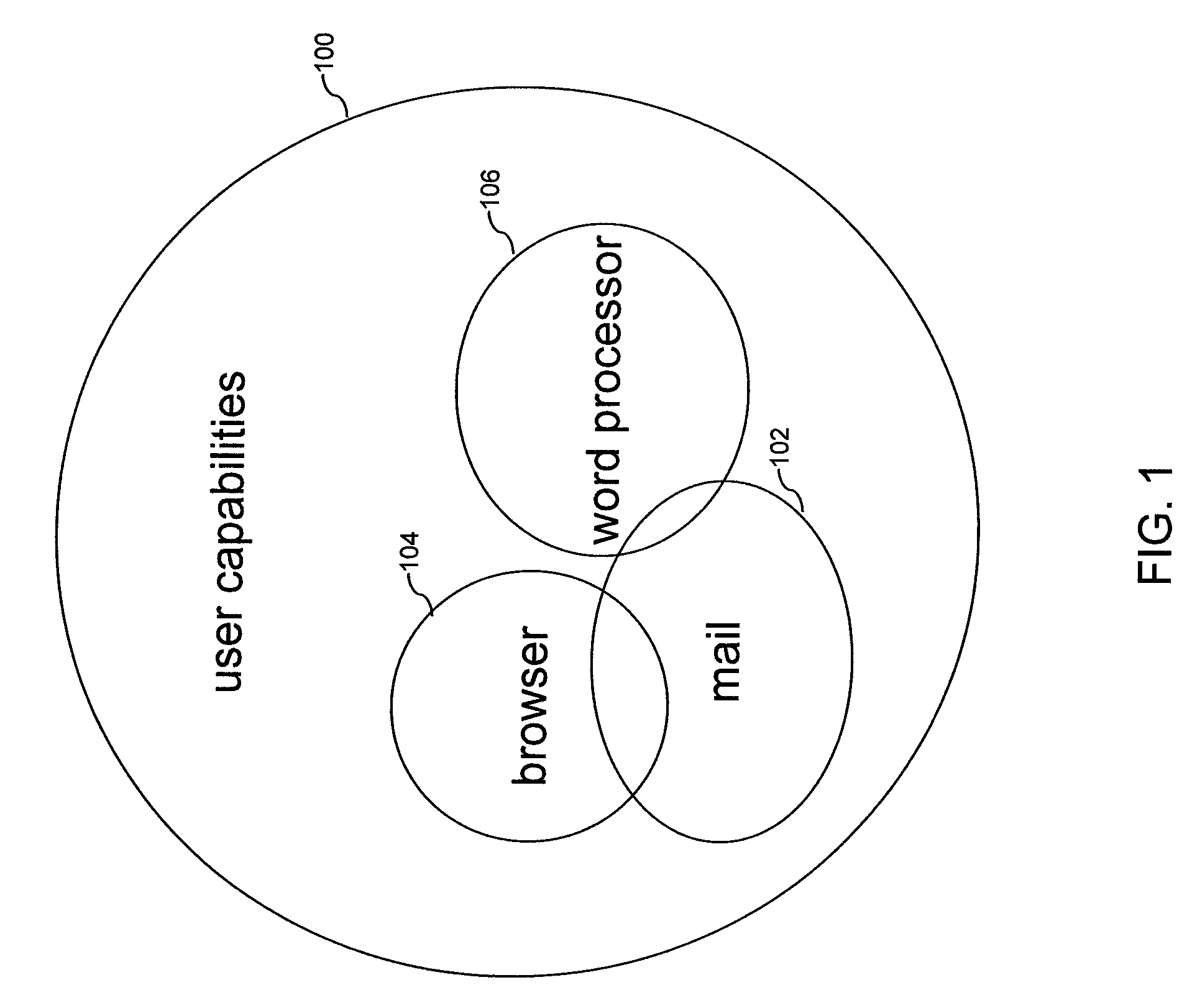

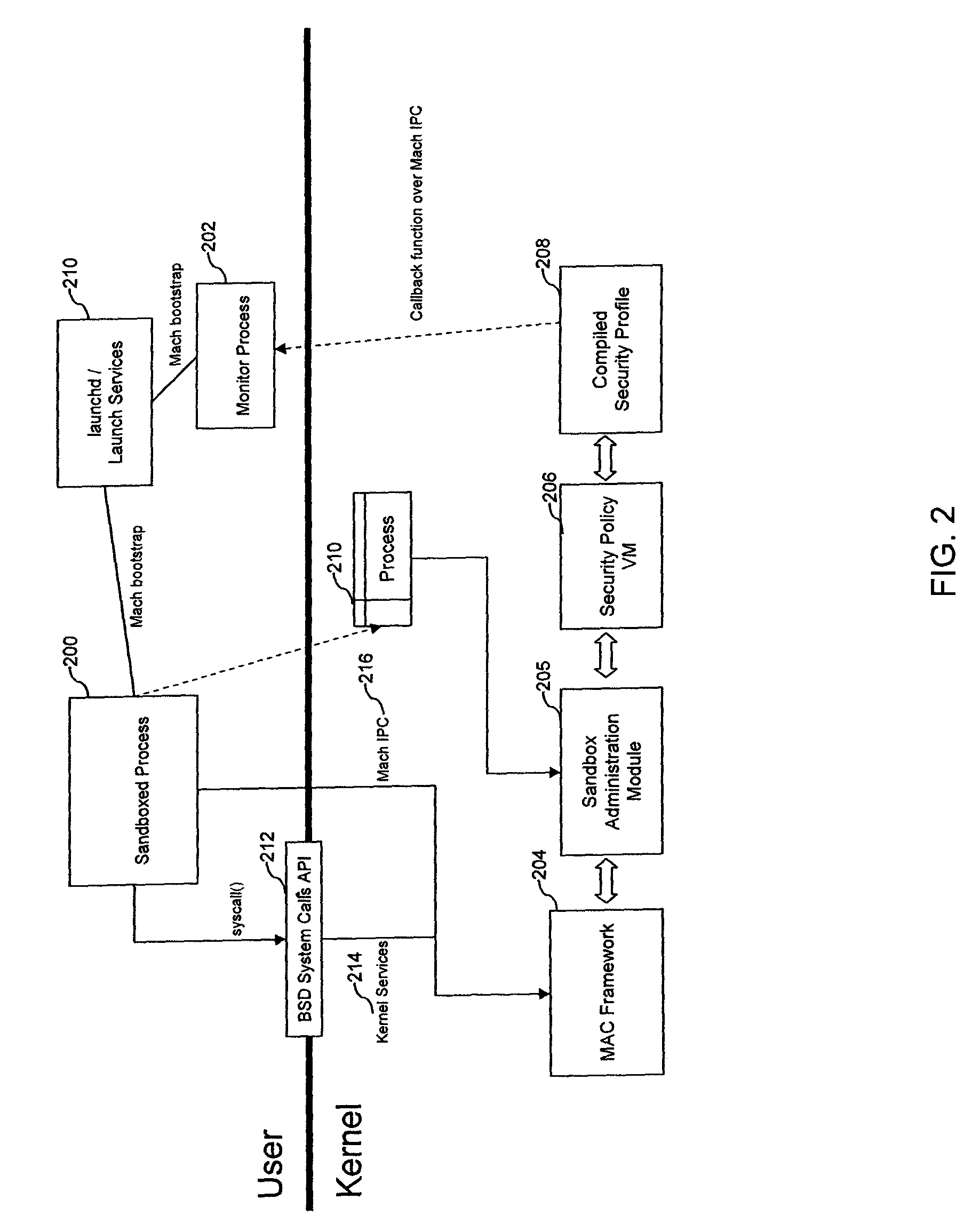

Restriction of program process capabilities

ActiveUS20080127292A1Digital data processing detailsUser identity/authority verificationOperational systemDecision taking

This document describes systems and methods for restricting program process capabilities. In some implementations, the capabilities are restricted by limiting the rights or privileges granted to an application. A plurality of rules may be established for a program, or for a group of programs, denying that program the right to take actions which are outside of the actions needed to implement its intended functionality. A security policy is implemented to test actions initiated in response to an application against the rules to enable decisions restricting the possible actions of the program. Embodiments are disclosed which process the majority of decisions regarding actions against a security profile through use of a virtual machine. In some embodiments, the majority of decisions are resolved within the kernel space of an operating system.

Owner:APPLE INC

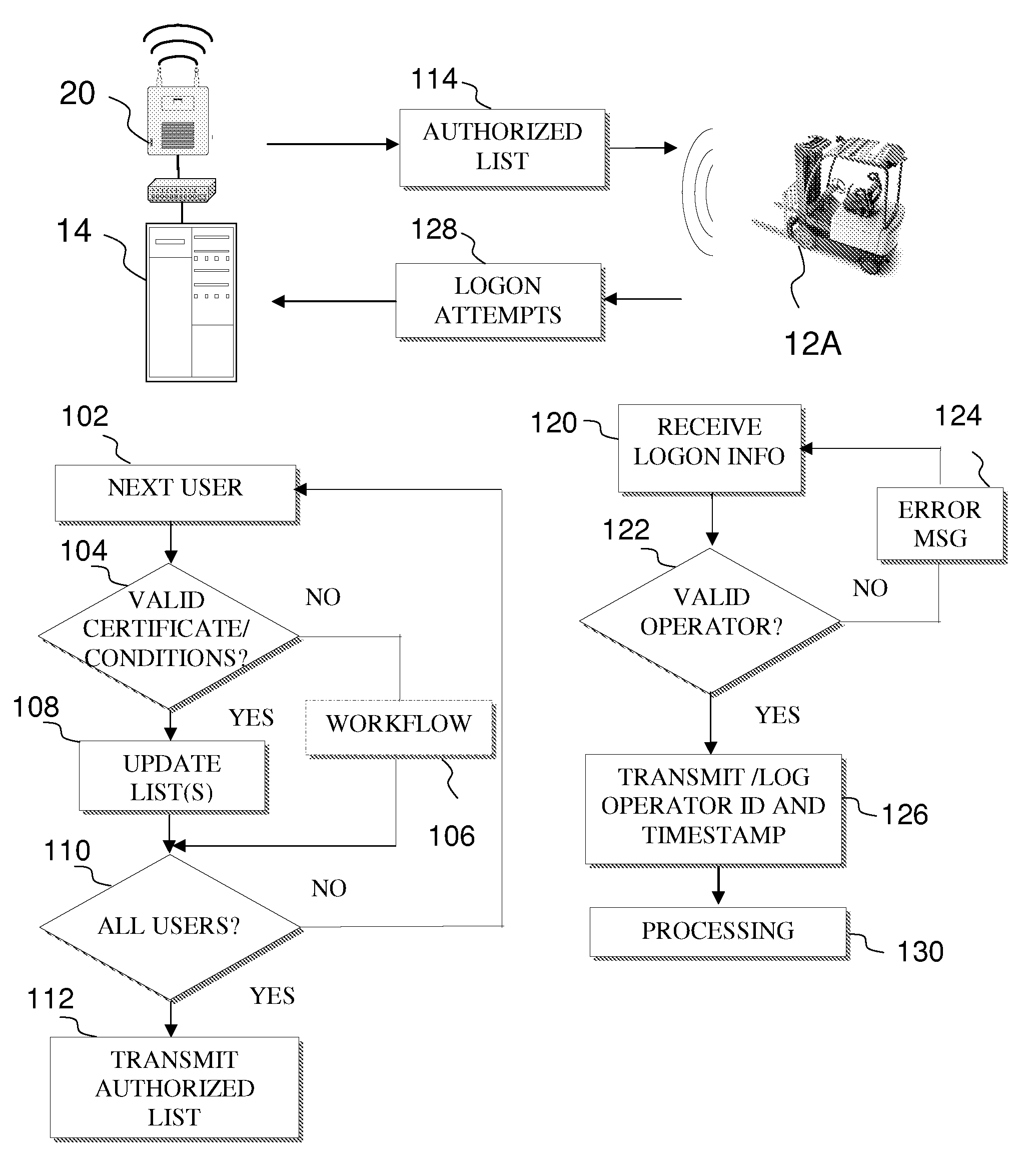

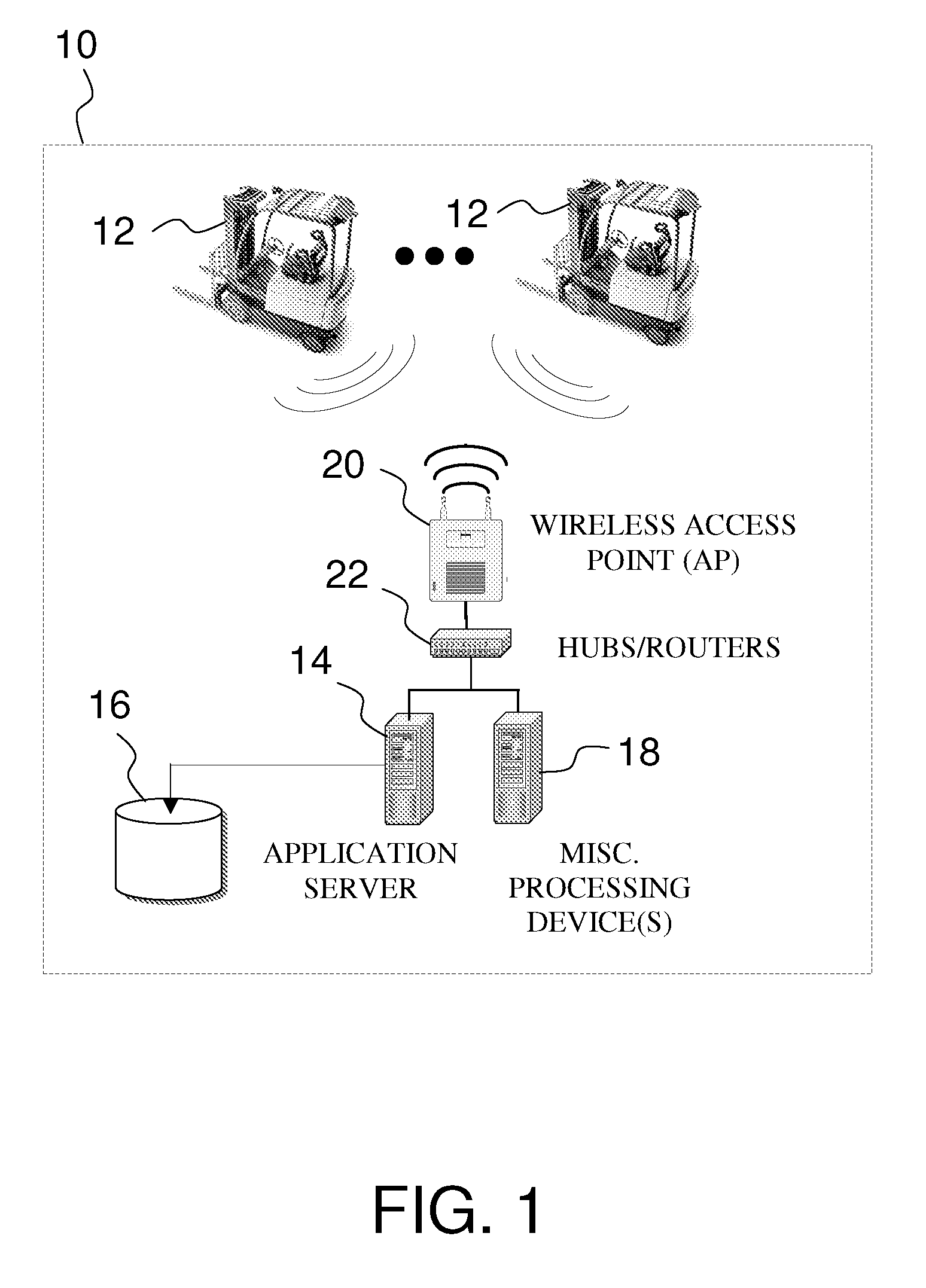

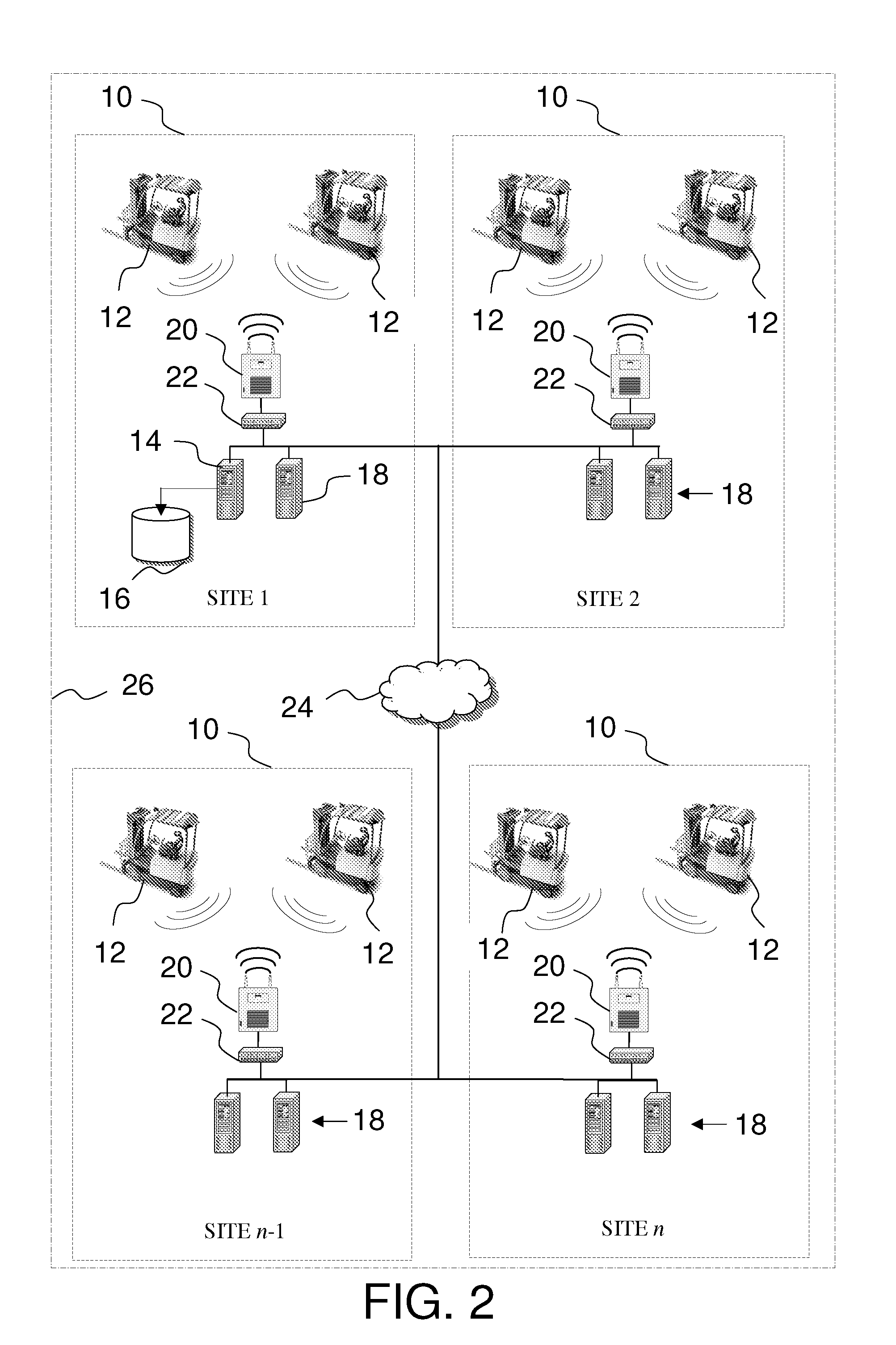

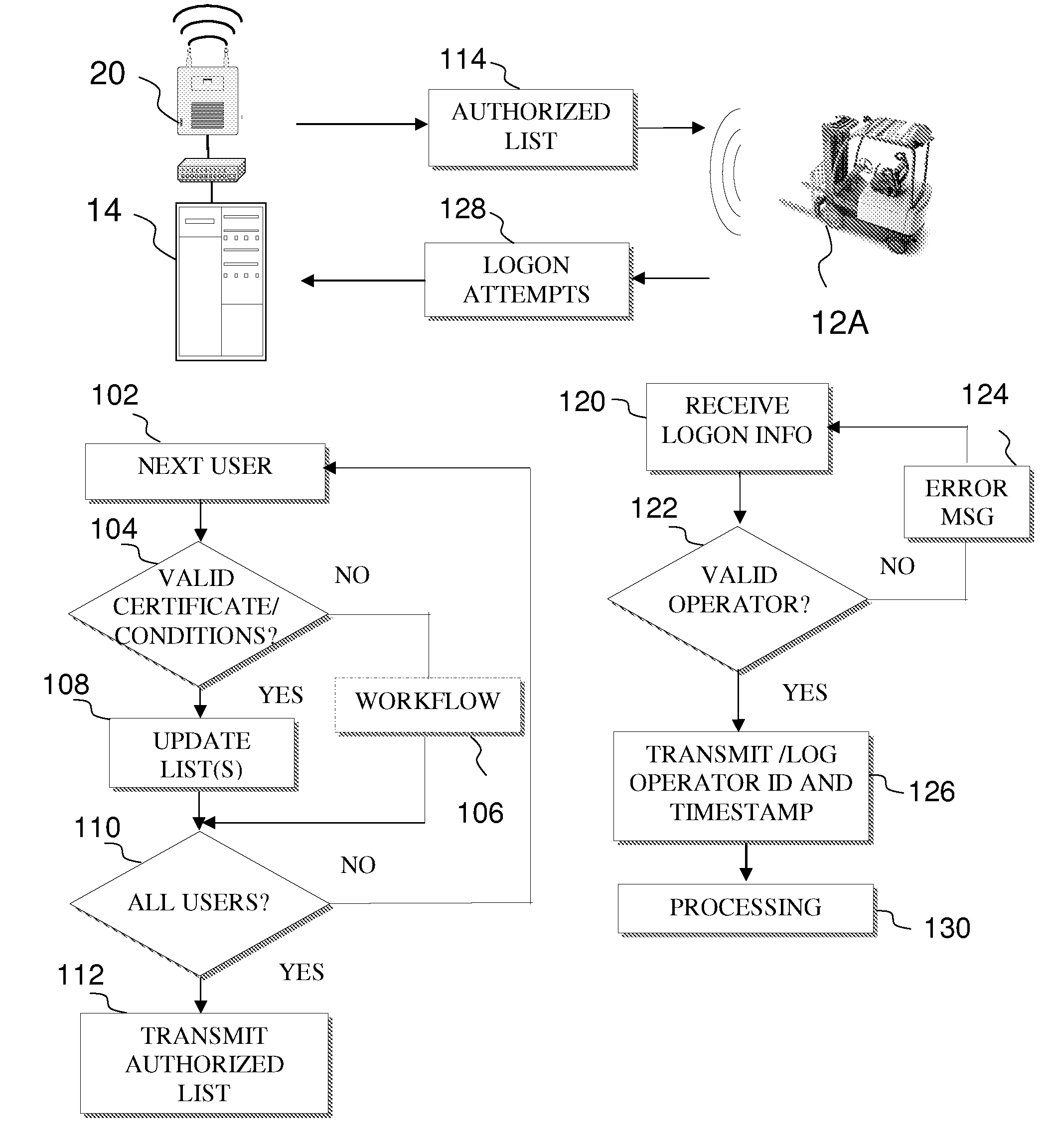

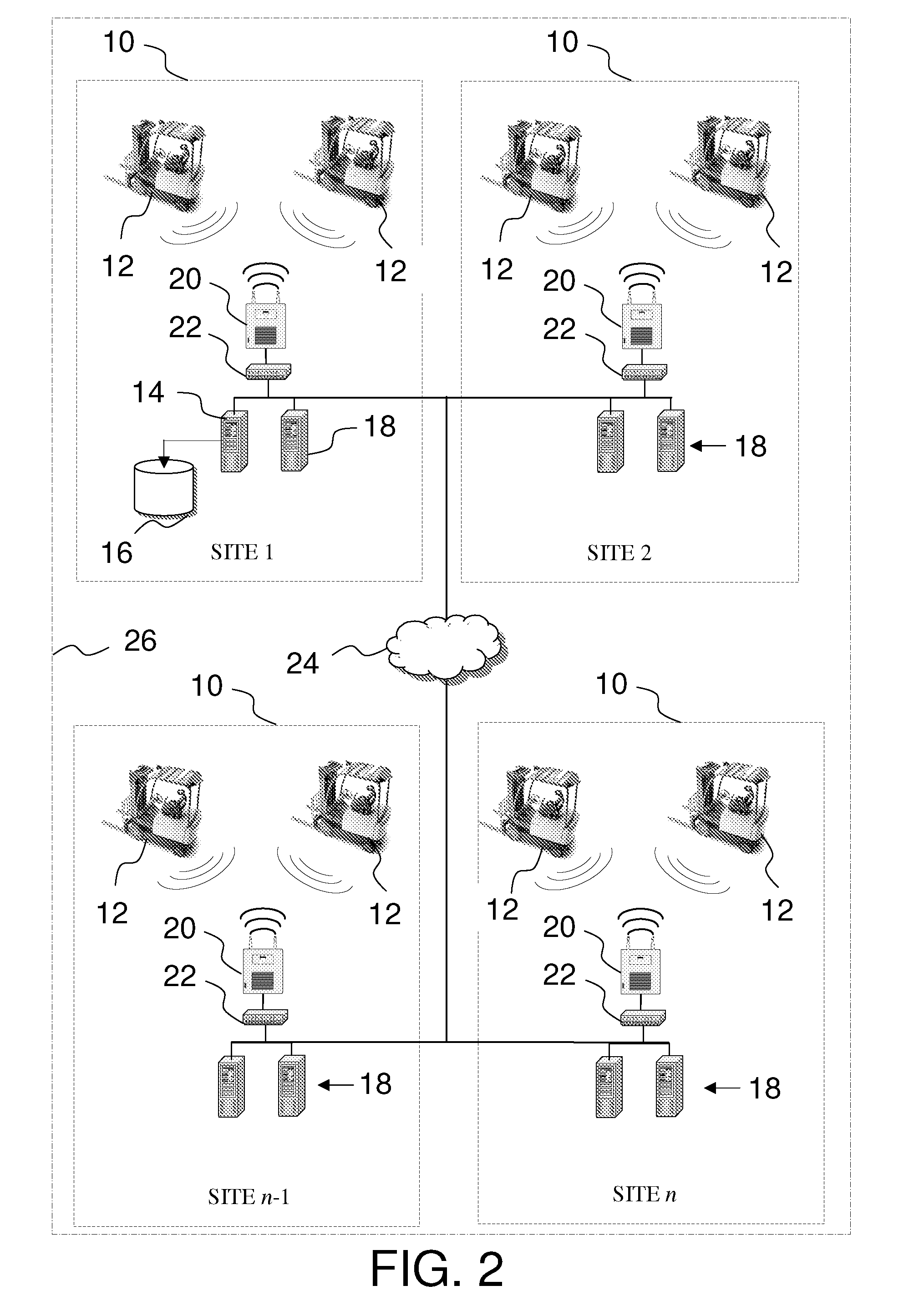

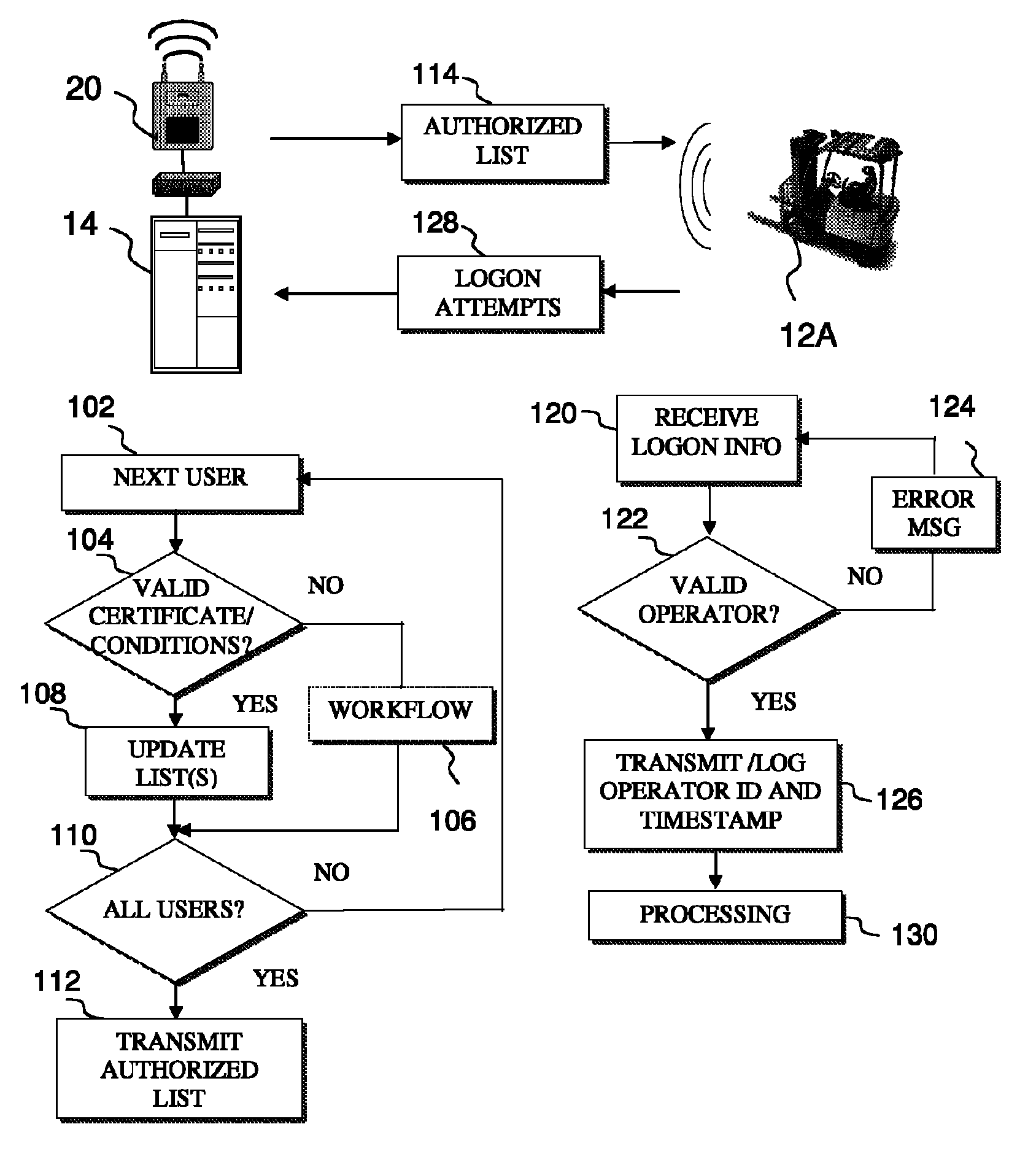

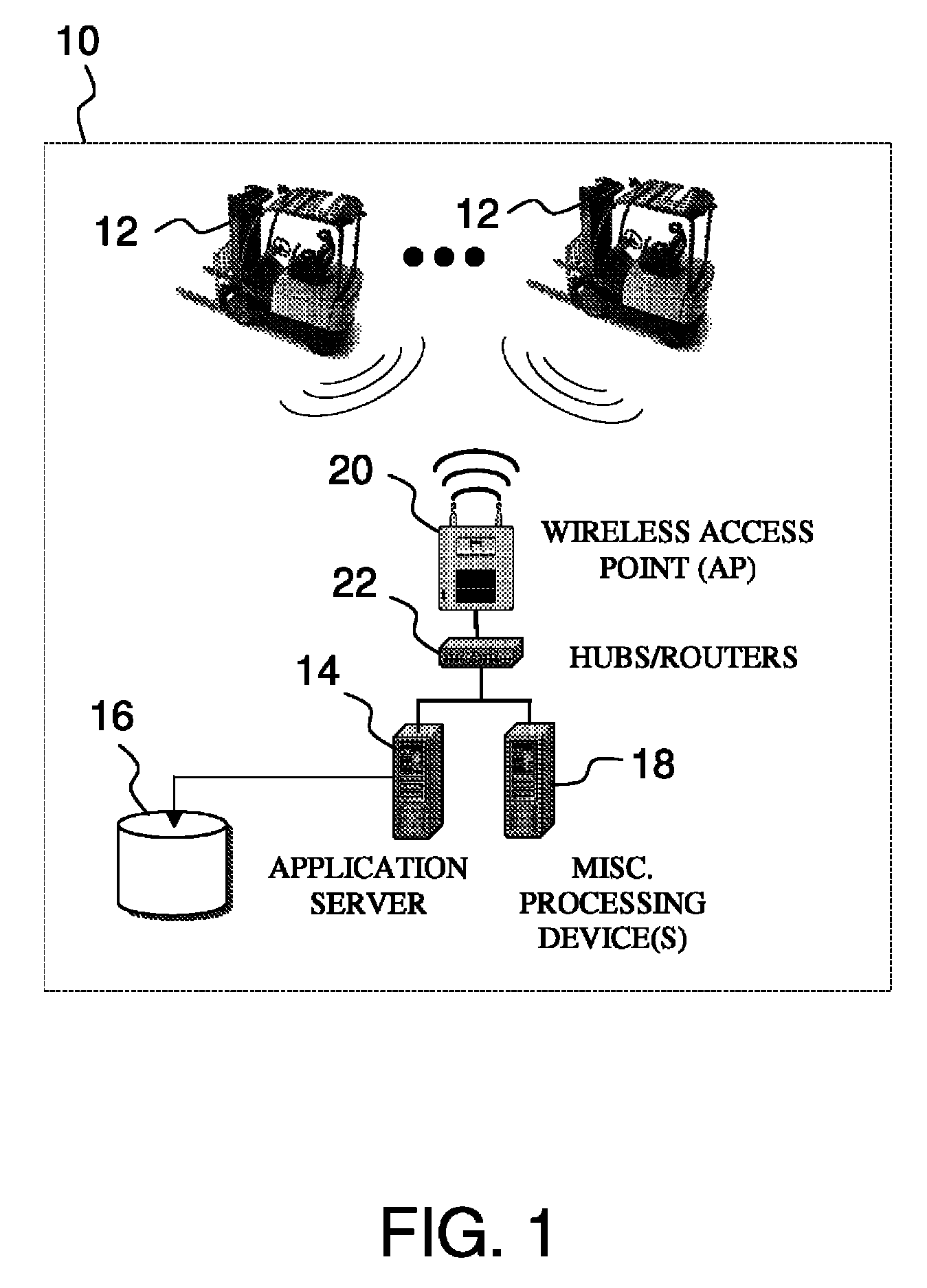

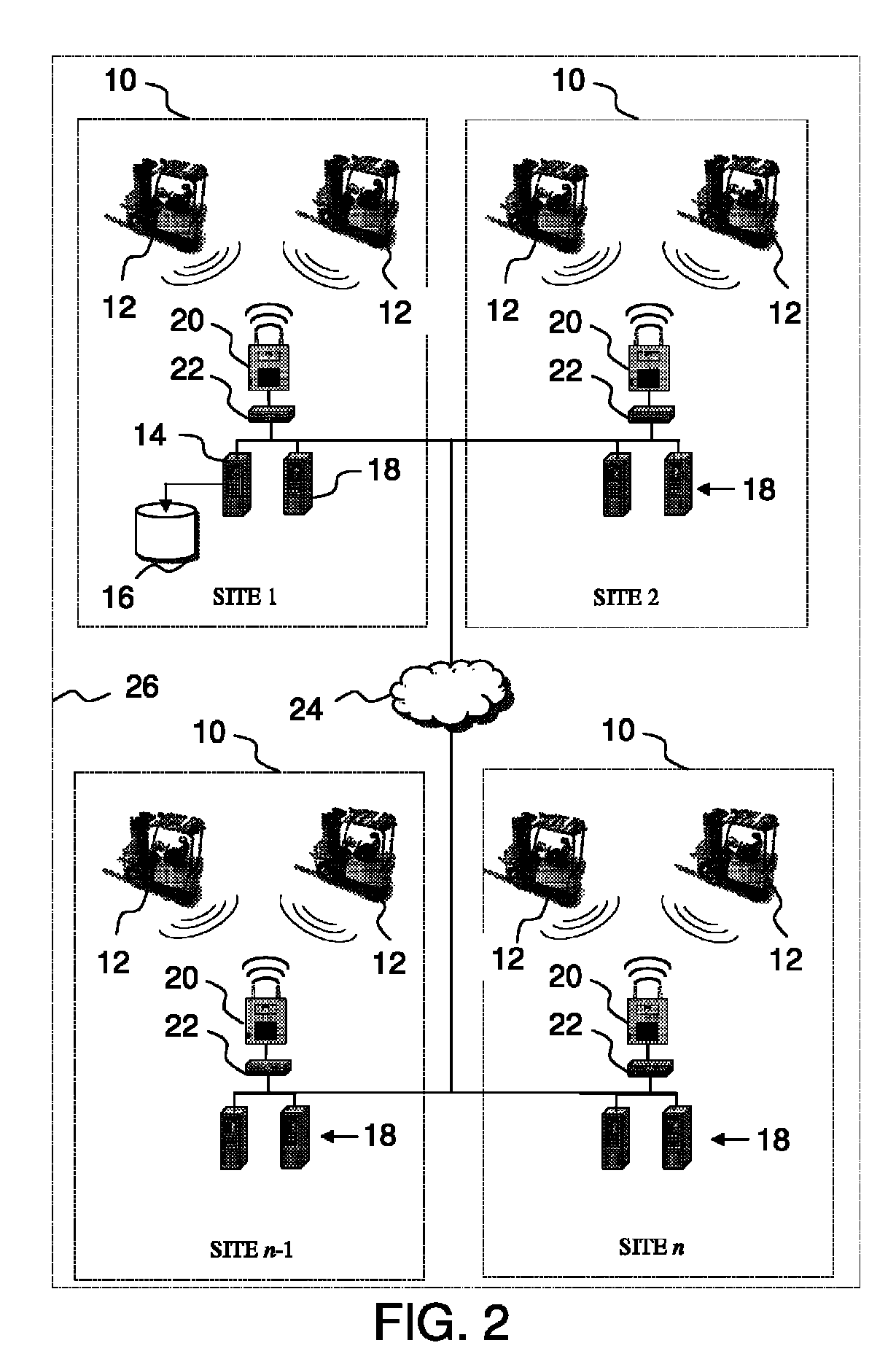

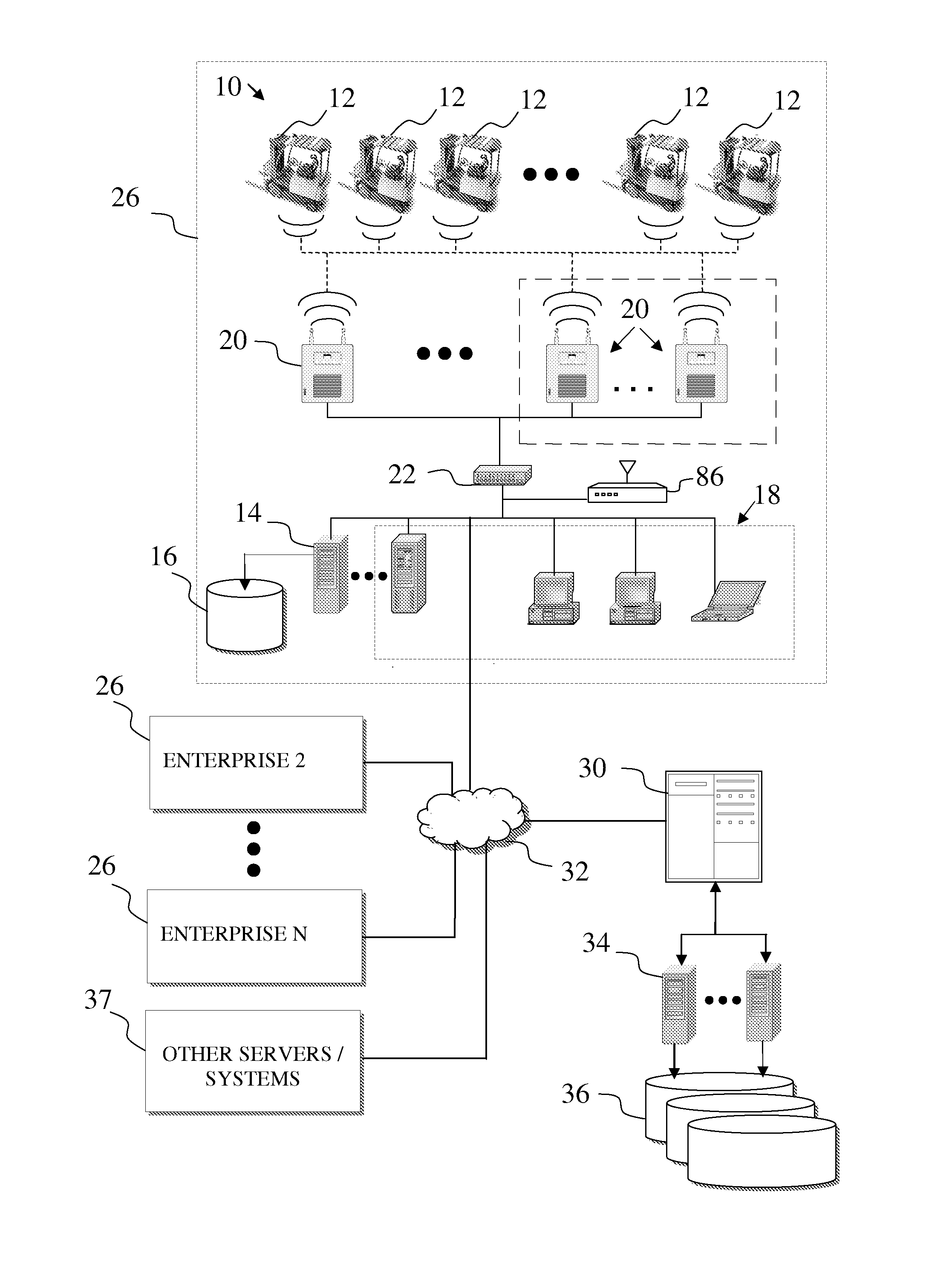

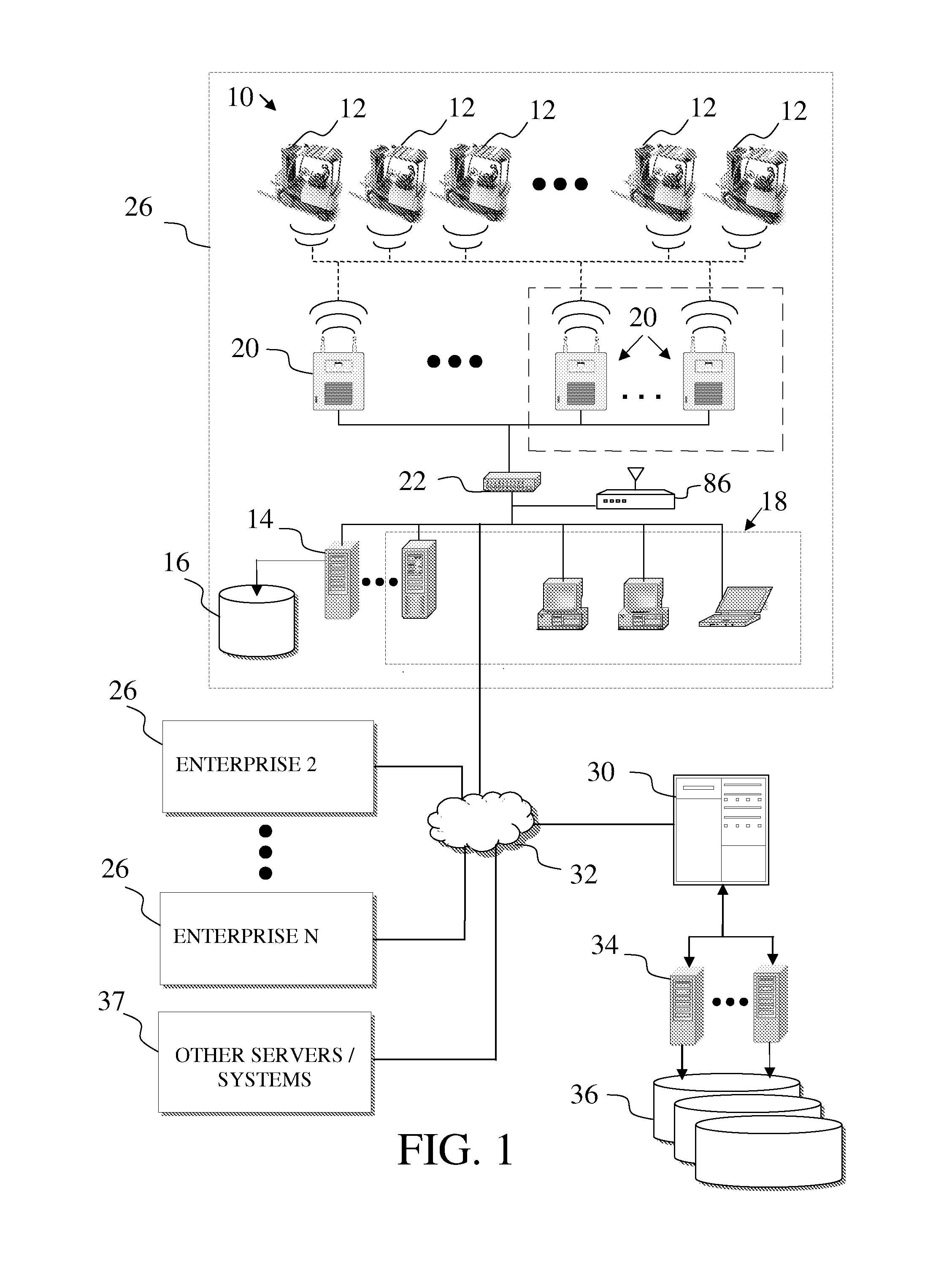

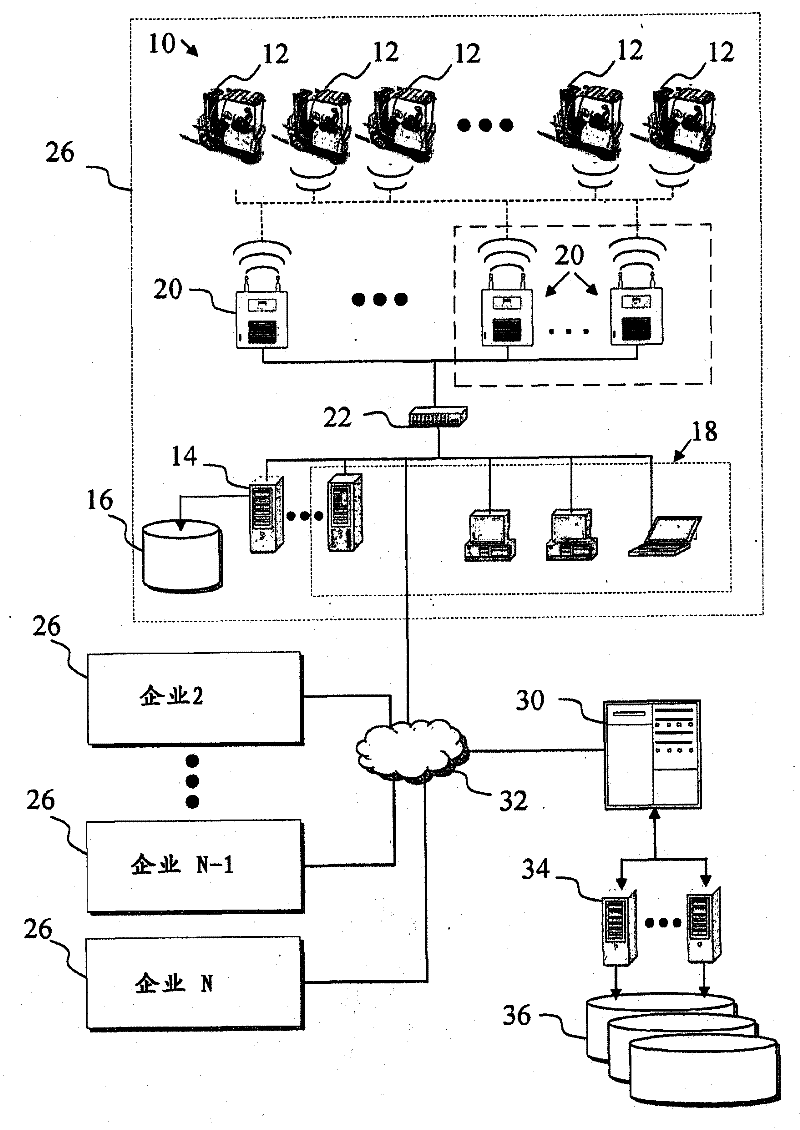

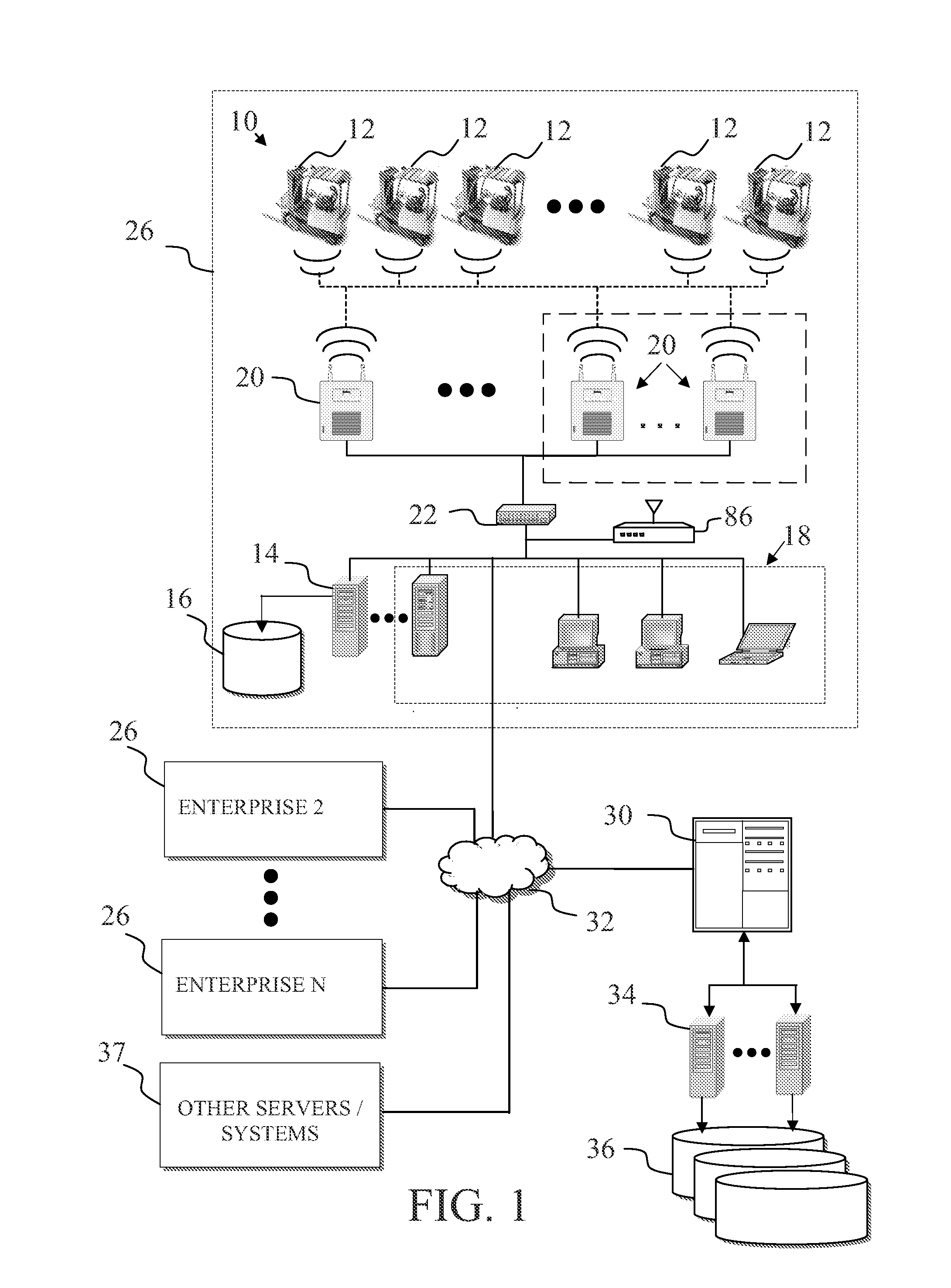

Fleet management system

ActiveUS20080154712A1Ticket-issuing apparatusRegistering/indicating working of vehiclesFleet managementSoftware system

Systems of hardware and software are provided for enabling mobile assets to communicate across a wireless network environment. Systems, computer-implemented methods and computer program products are also provided for leveraging wireless communication and / or processing capabilities of mobile assets against a robust software solution to implement enterprise wide asset management functions, to integrate mobile asset data into existing enterprise workflows and / or to enable trusted third party integration into the enterprise for enhanced asset and / or workflow management.

Owner:CROWN EQUIP CORP

Fleet management system

ActiveUS20080154691A1Registering/indicating working of vehiclesElectric testing/monitoringFleet managementSoftware system

Systems of hardware and software are provided for enabling mobile assets to communicate across a wireless network environment. Systems, computer-implemented methods and computer program products are also provided for leveraging wireless communication and / or processing capabilities of mobile assets against a robust software solution to implement enterprise wide asset management functions, to integrate mobile asset data into existing enterprise workflows and / or to enable trusted third party integration into the enterprise for enhanced asset and / or workflow management.

Owner:CROWN EQUIP CORP

Fleet management system

ActiveUS8060400B2Ticket-issuing apparatusRegistering/indicating working of vehiclesFleet managementSoftware system

Owner:CROWN EQUIP CORP

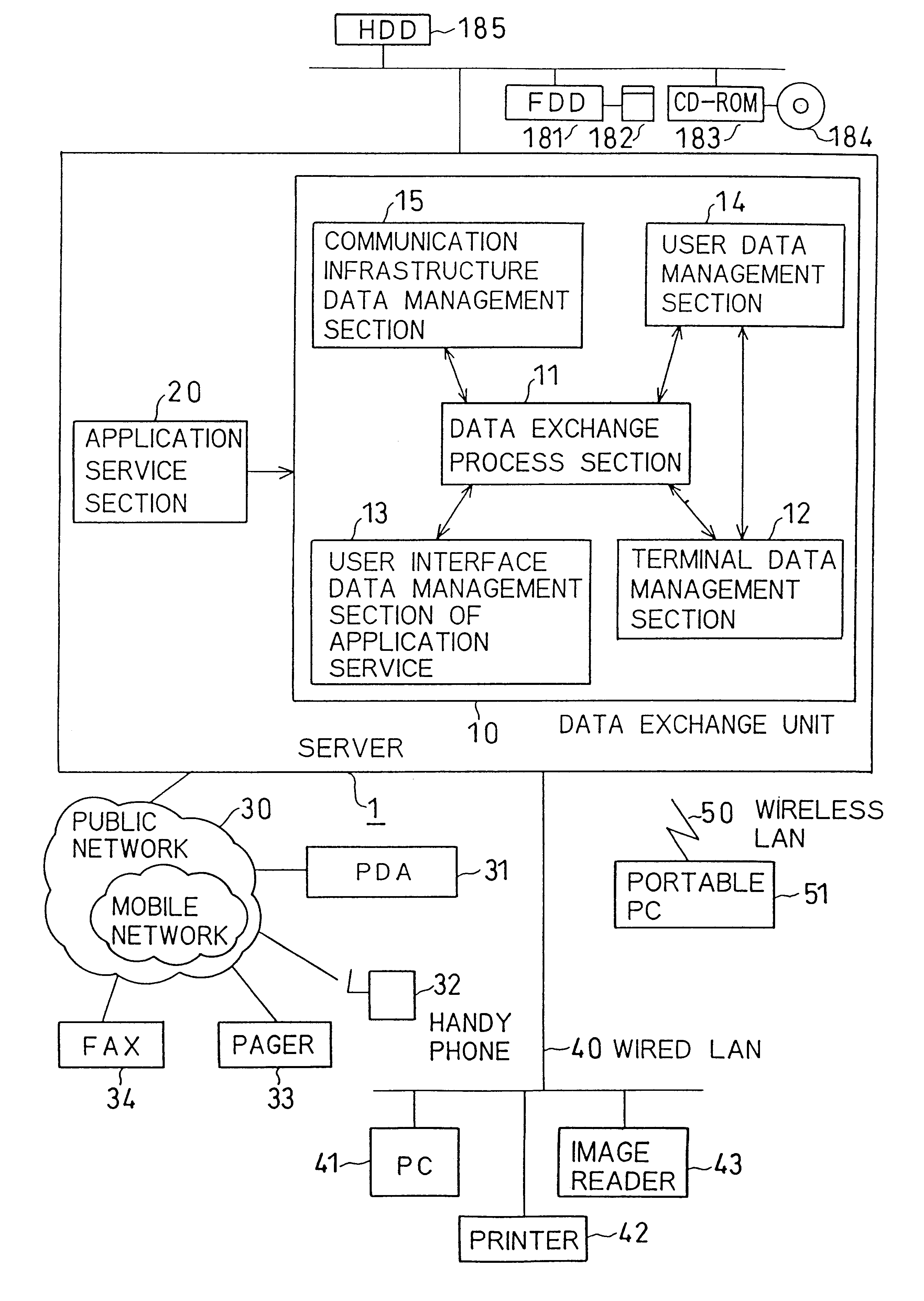

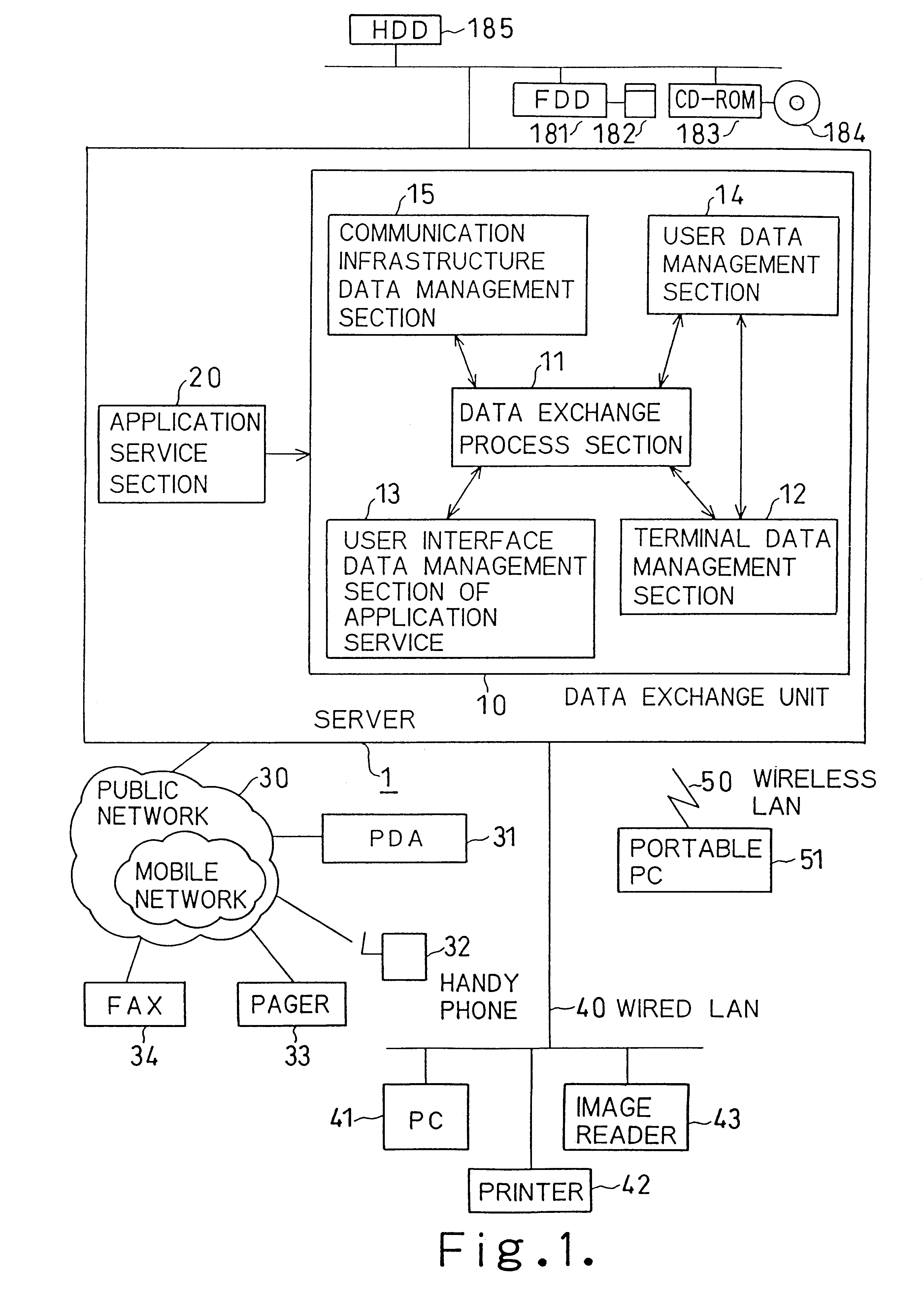

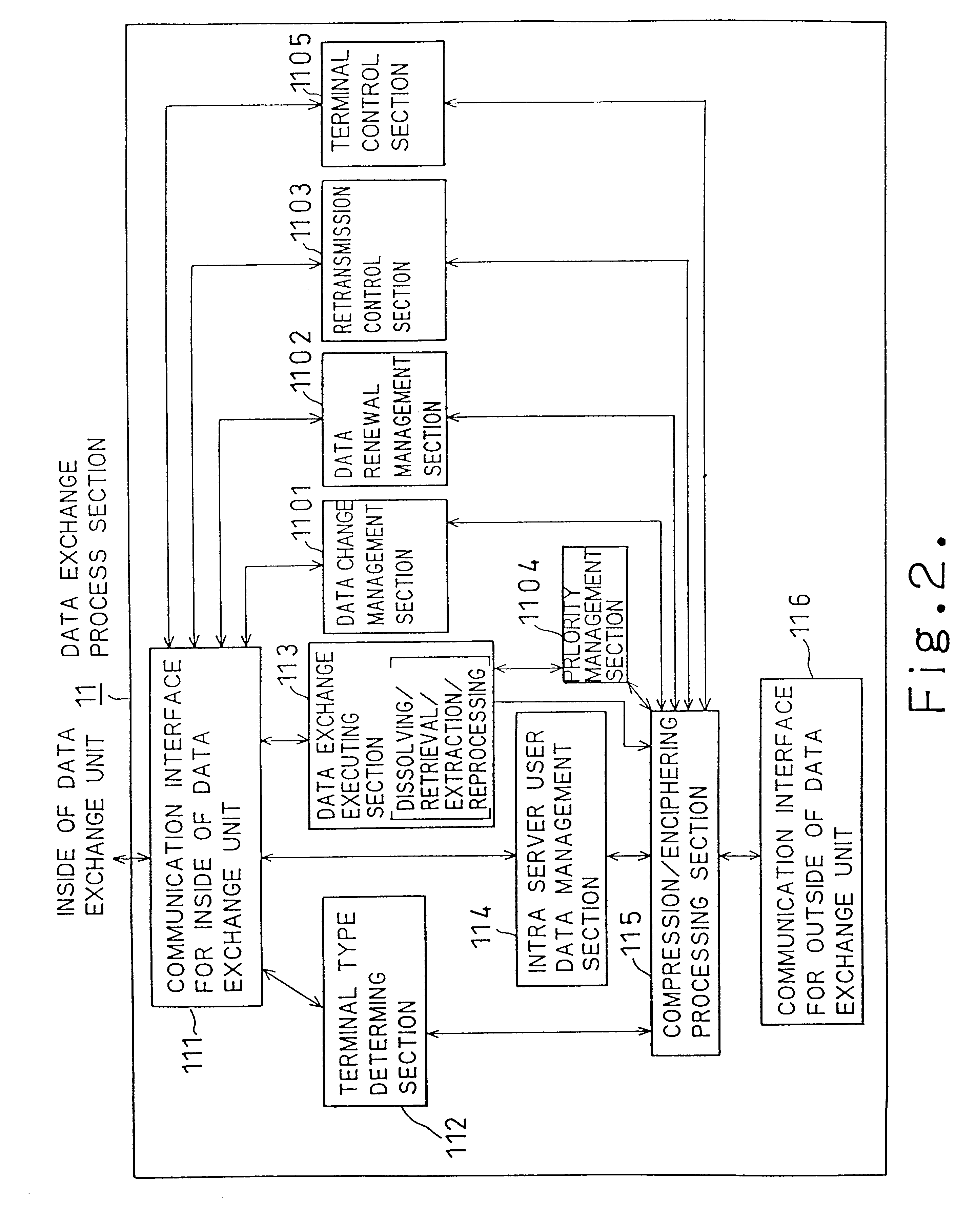

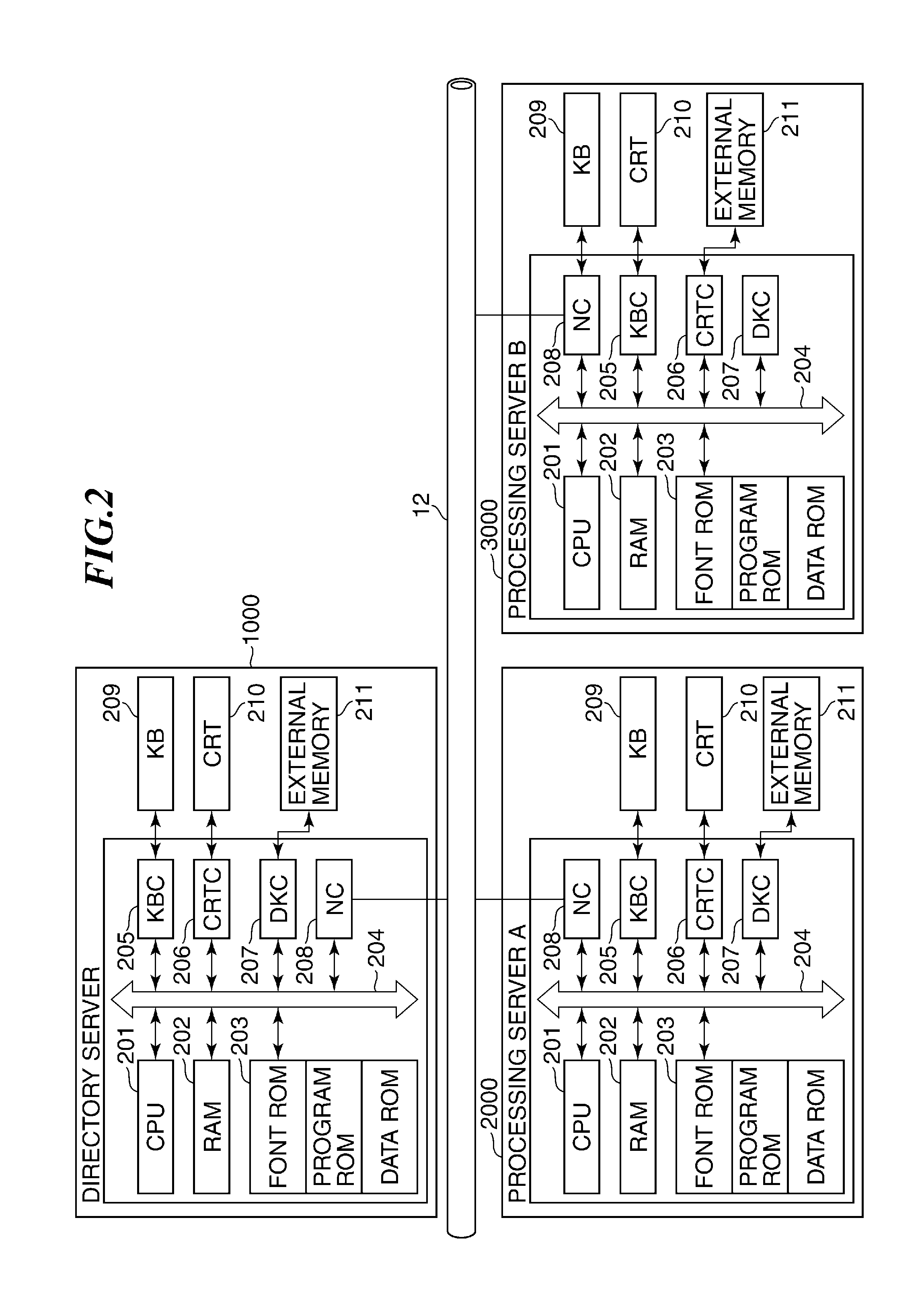

Distributed network computing system for data exchange/conversion between terminals

InactiveUS6195677B1Improve security featuresReduce data processingCharacter and pattern recognitionDigital data protectionService provisionTerminal equipment

A data exchange unit is arranged in a server. Service data provided as an application service is converted into a predetermined format on the basis of the attribute data of a terminal as a communication partner and is transmitted. With this processing, the application service can be provided while adjusting the relative difference in processing capability terminals. When the service data is converted into a predetermined format on the basis of the attribute of a communication network connected to the terminal and transmitted, the application service can be provided while adjusting the relative difference in communication capability among communication networks. Also, terminal equipment 51 is able to communicate with server computer while keeping the security function.

Owner:KK TOSHIBA

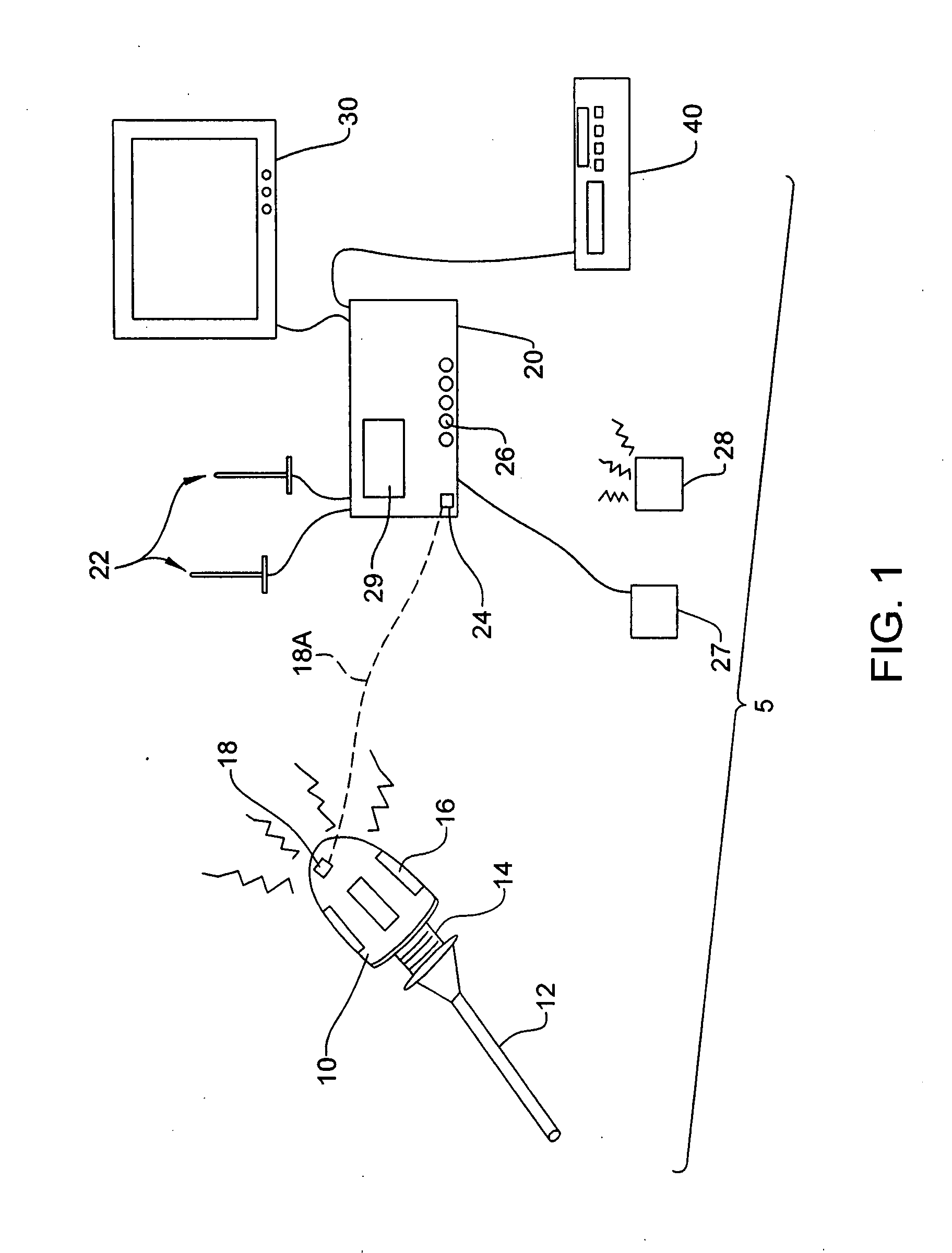

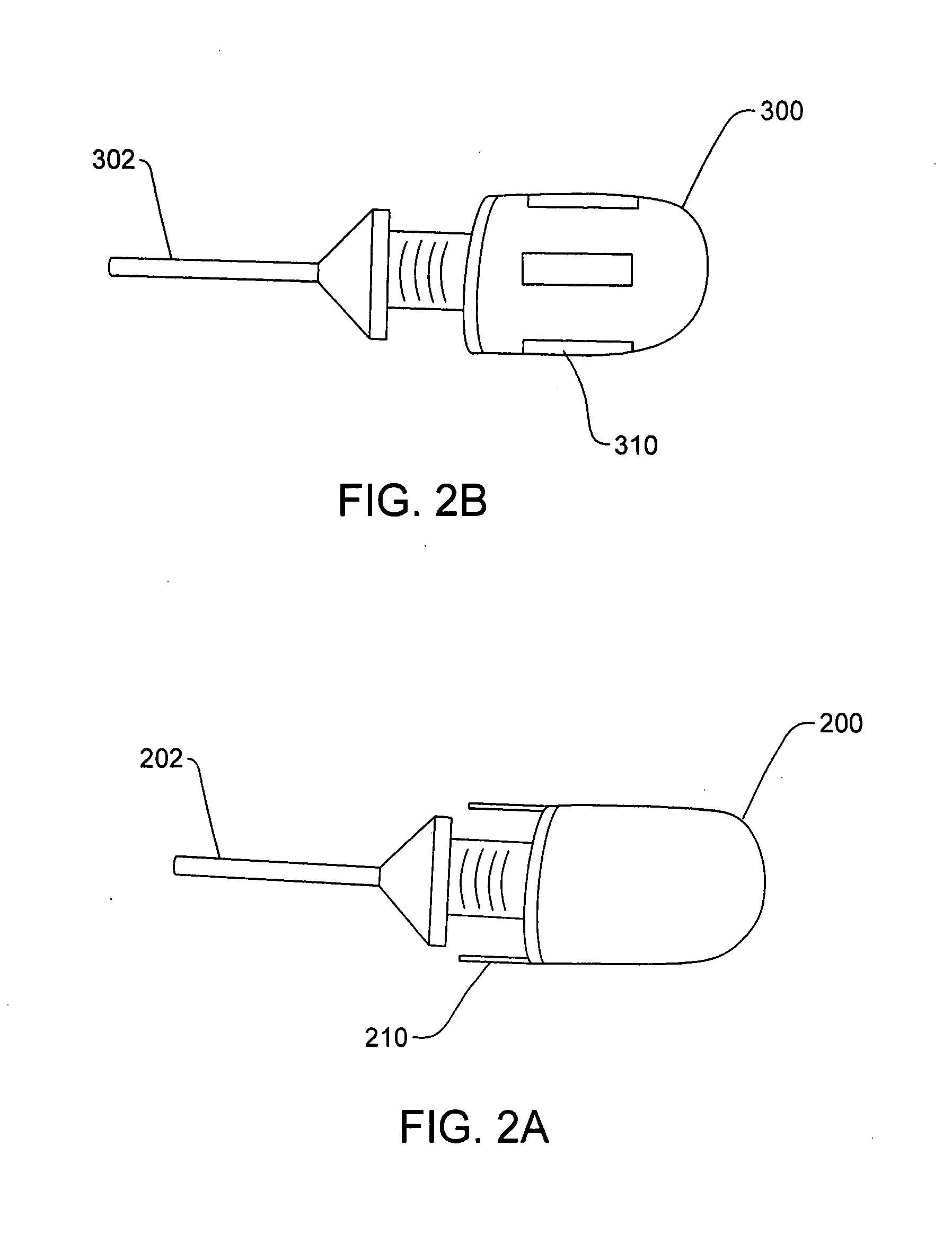

Wireless endoscopic camera

ActiveUS20080139881A1Reliable but high-performance wireless transmissionImprove fidelityEnergy efficient ICTTelevision system detailsData streamEndoscopic camera

A system and method for wirelessly transmitting a video image signal from an endoscopic camera to a receiver or control unit for storage and / or display on a video monitor. Use of a frame-specific, variable compression algorithm capable of progressively encoding a data stream provides for a better performing and higher quality wireless endoscopic camera system capable of generating images at varying resolutions. Use of a short-range, high-performance wireless technology, such as Ultrawideband (UWB), improves the performance capabilities of the system, while minimizing power consumption and extending battery life. Implementations of error correcting codes, as well as the use of multiple transmitting and receiving antennas, further improve the fidelity of the wireless communication.

Owner:STRYKER CORP

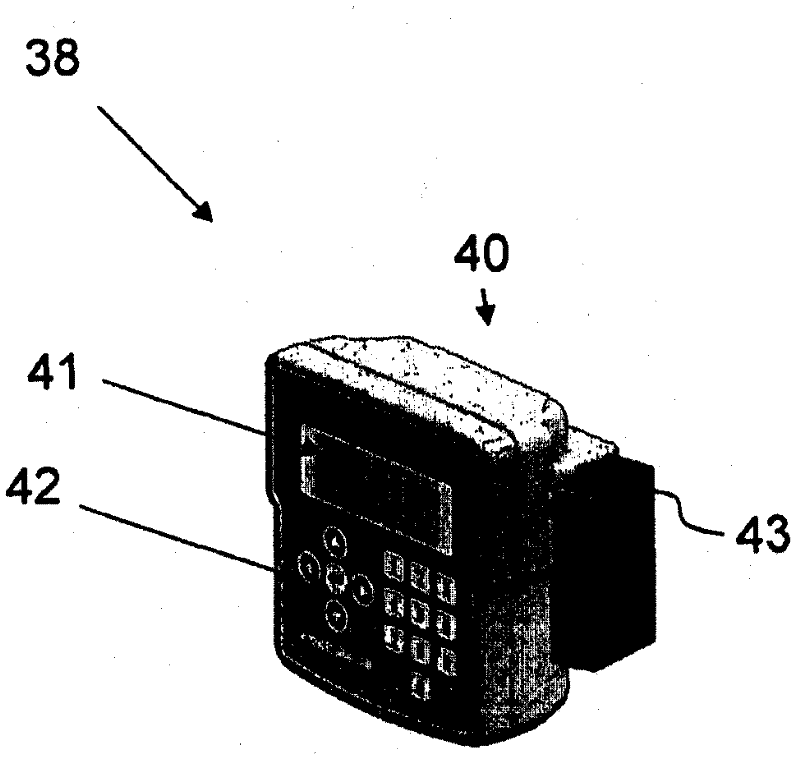

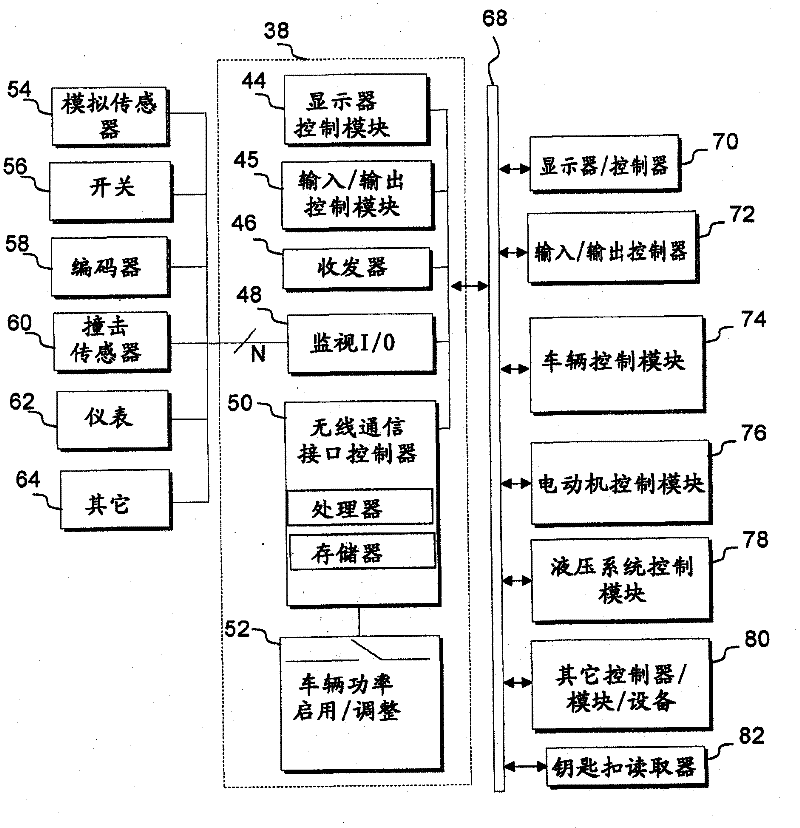

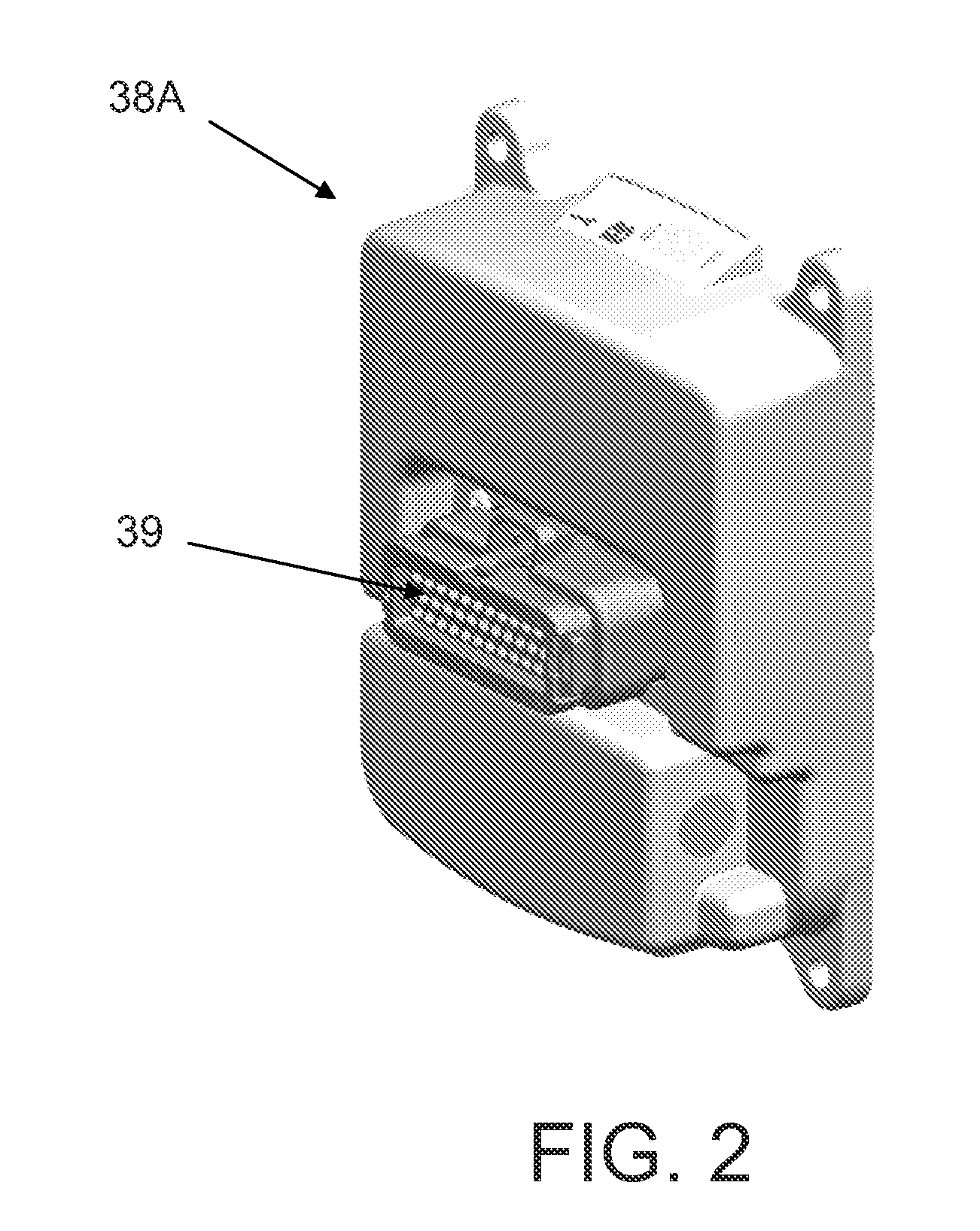

Information system for industrial vehicles

ActiveUS20110040440A1Vehicle testingRegistering/indicating working of vehiclesEngineeringTrusted third party

Industrial vehicles communicate across a wireless environment and the wireless communication, data collection and / or processing capabilities of industrial vehicles are utilized to implement dashboard functions that thread status information from detail level views, up through intermediate views and to summary level views to facilitate efficient fleet maintenance, management and control. Further, industrial vehicle data may be communicated to a trusted third party server. As such, wirelessly collected industrial vehicle information is utilized within robust software solutions that aggregate and analyze data across multiple enterprises.

Owner:CROWN EQUIP CORP

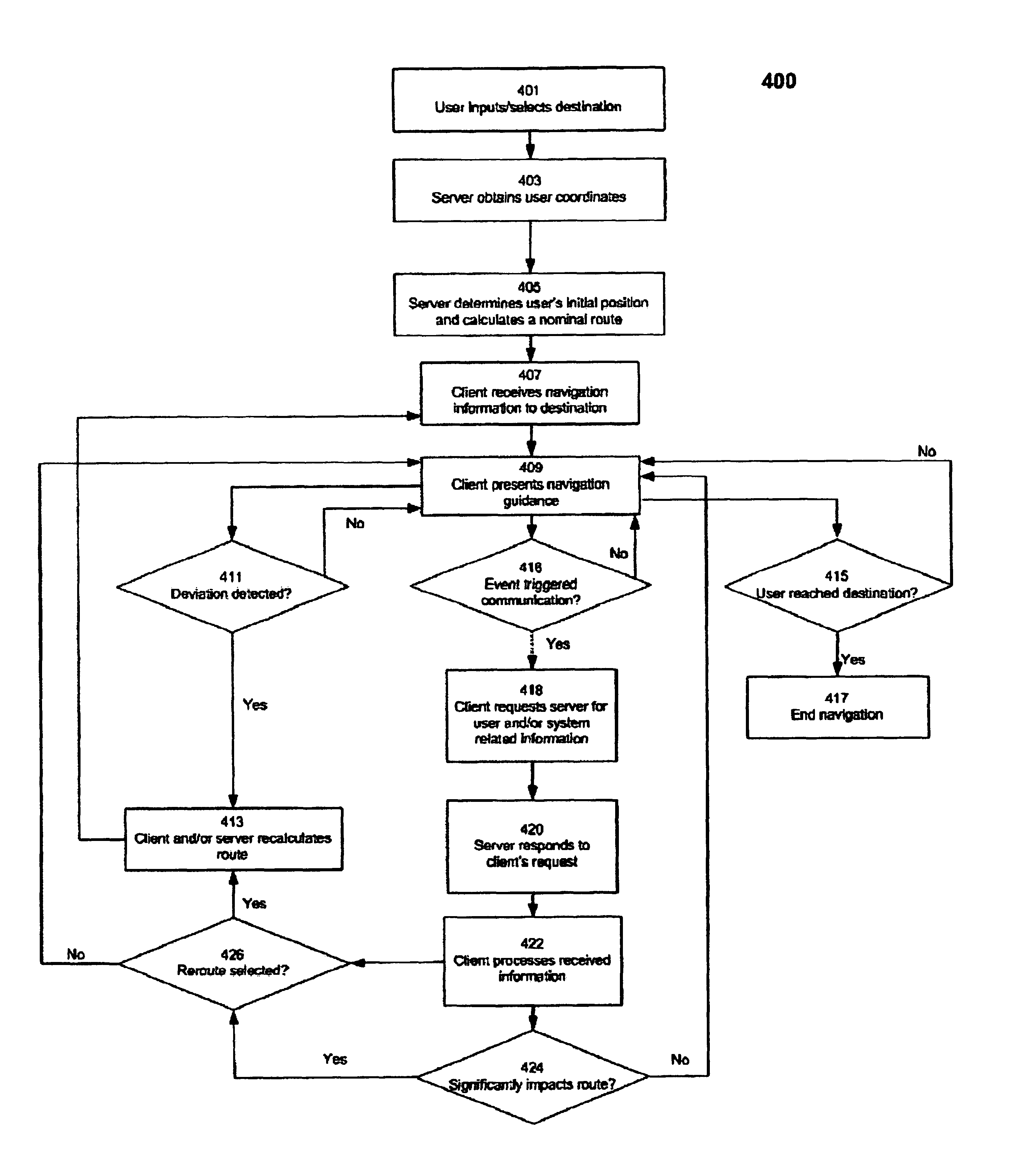

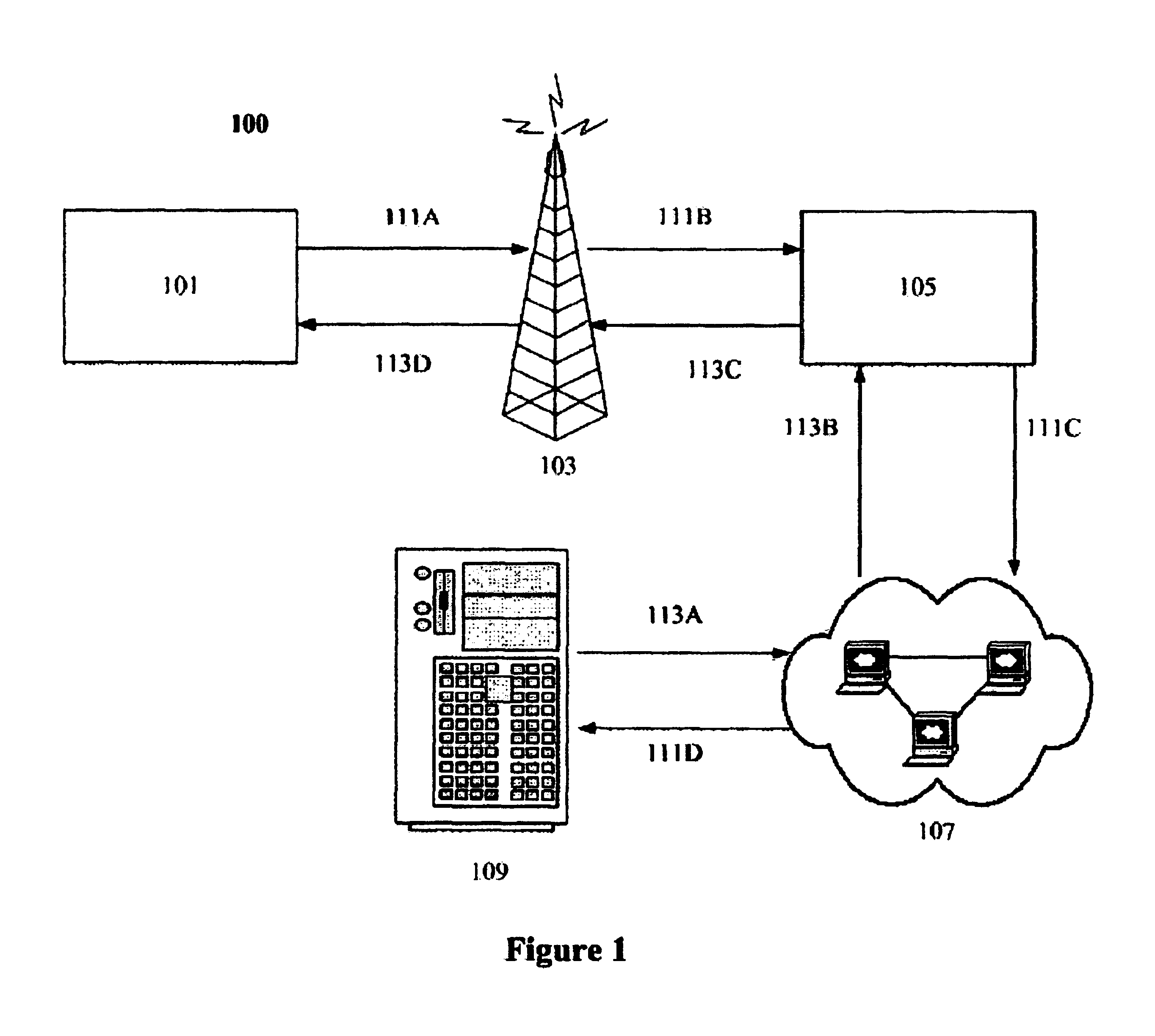

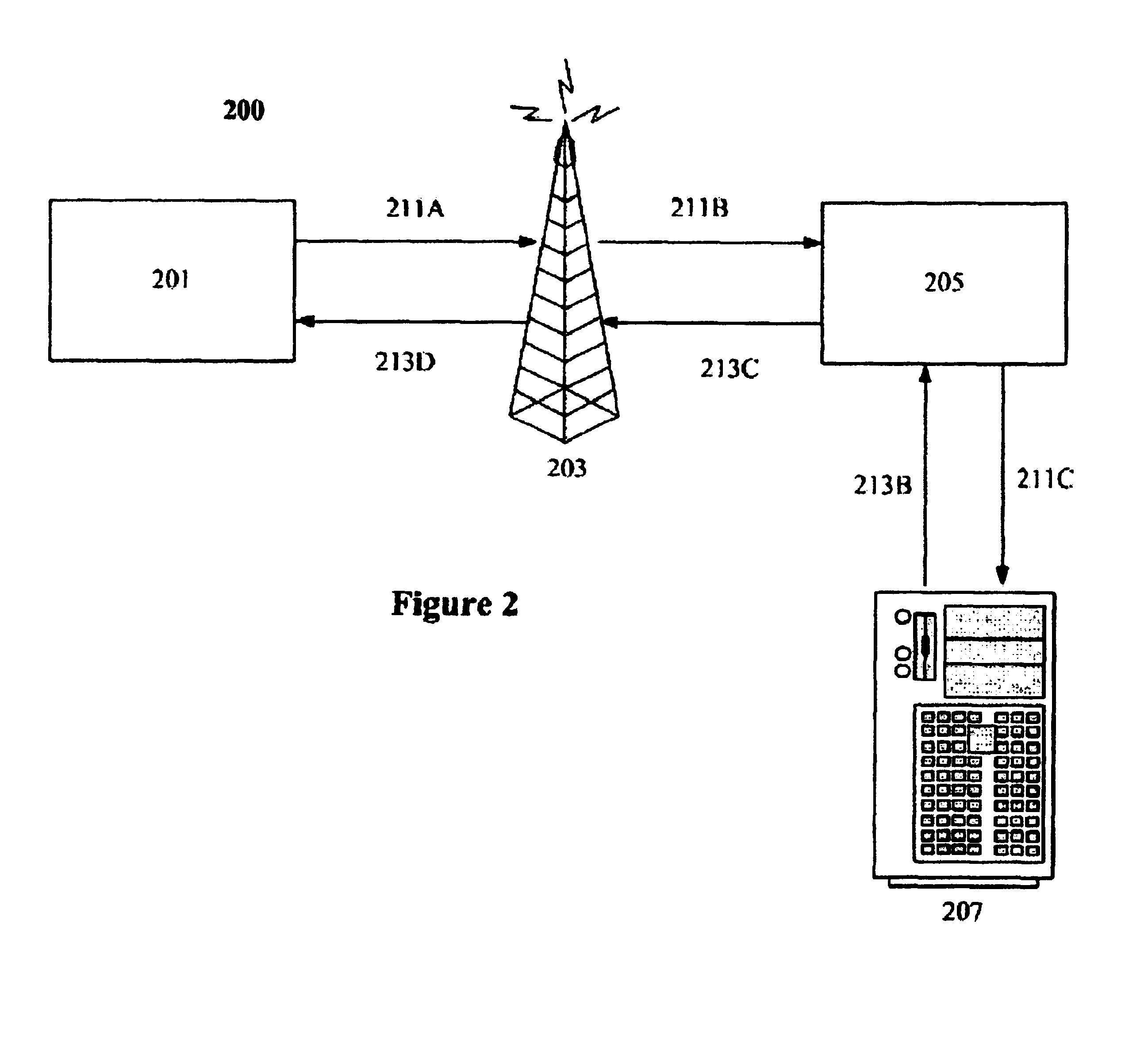

Method and system for distributed navigation

InactiveUS6845322B1Reduces excessive reroute communicationDiminishes possible reroute errorInstruments for road network navigationRoad vehicles traffic controlThe InternetNavigation system

Method and system for a distributed navigation system. The system comprises a client integrated with a mobile communication device (e.g. PDA, cellular telephone, etc.) and a server communicating via wireless carriers and the Internet. In one embodiment, the server obtains a user's initial position, a user-designated destination, and calculates a nominal route from the user's initial position to the destination. If a deviation from the nominal route is detected, the reroute tasks are divided between the server and the client according to a corridor area surrounding the nominal route. Mapping information related to the corridor area is stored in the client, and the amount of the stored mapping information depends on the storage and / or processing capabilities of the client.

Owner:TELENAV

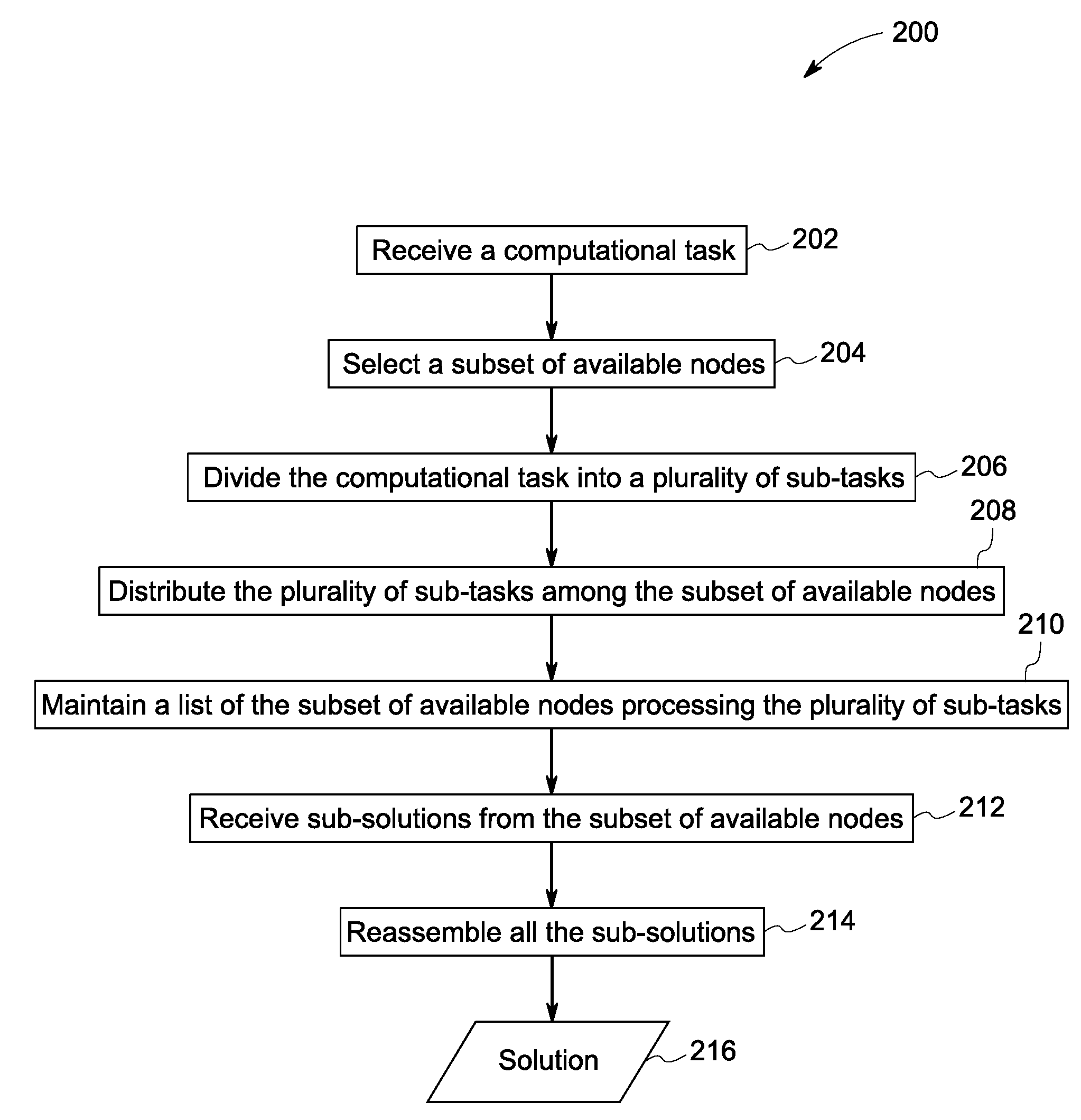

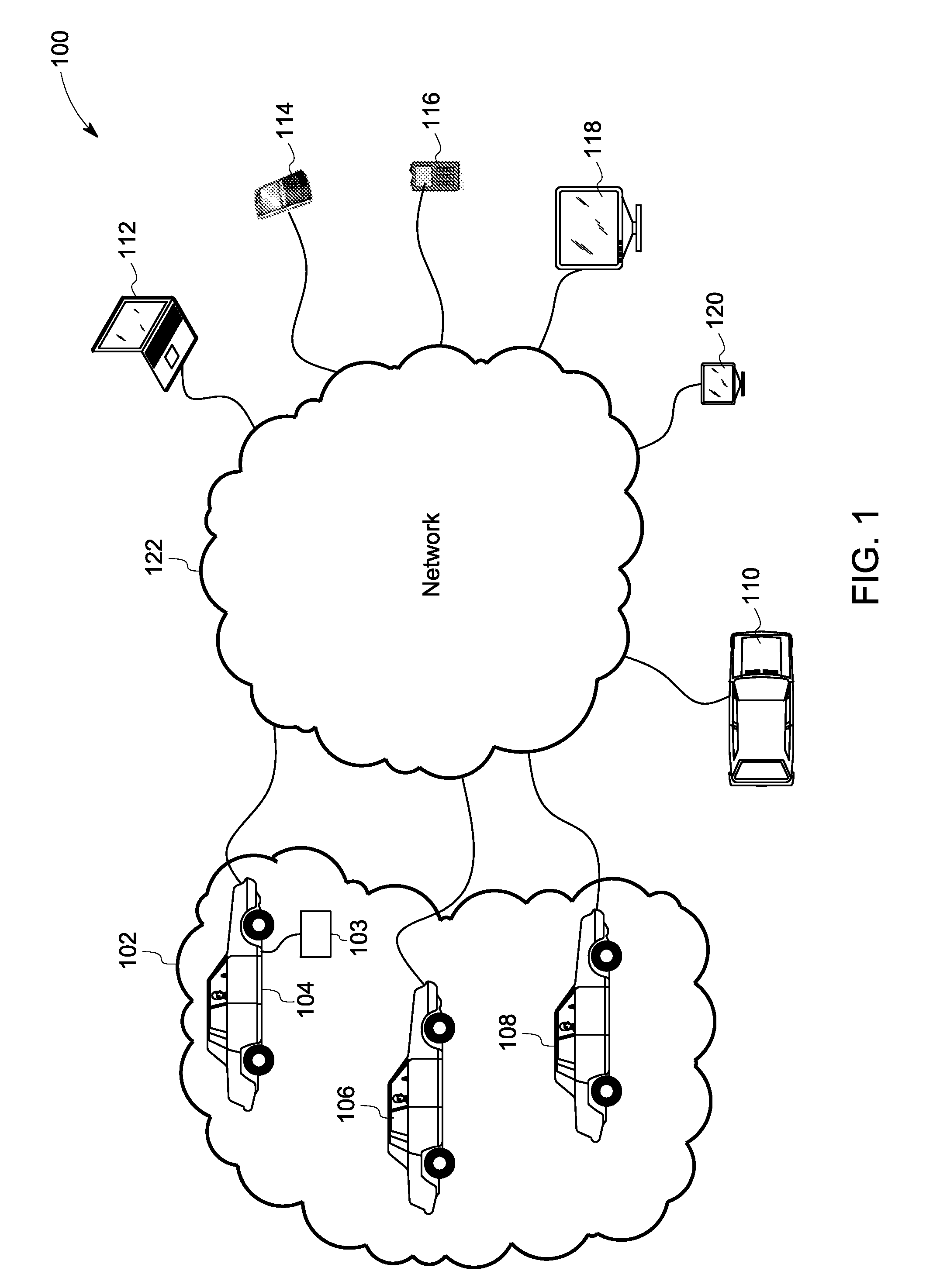

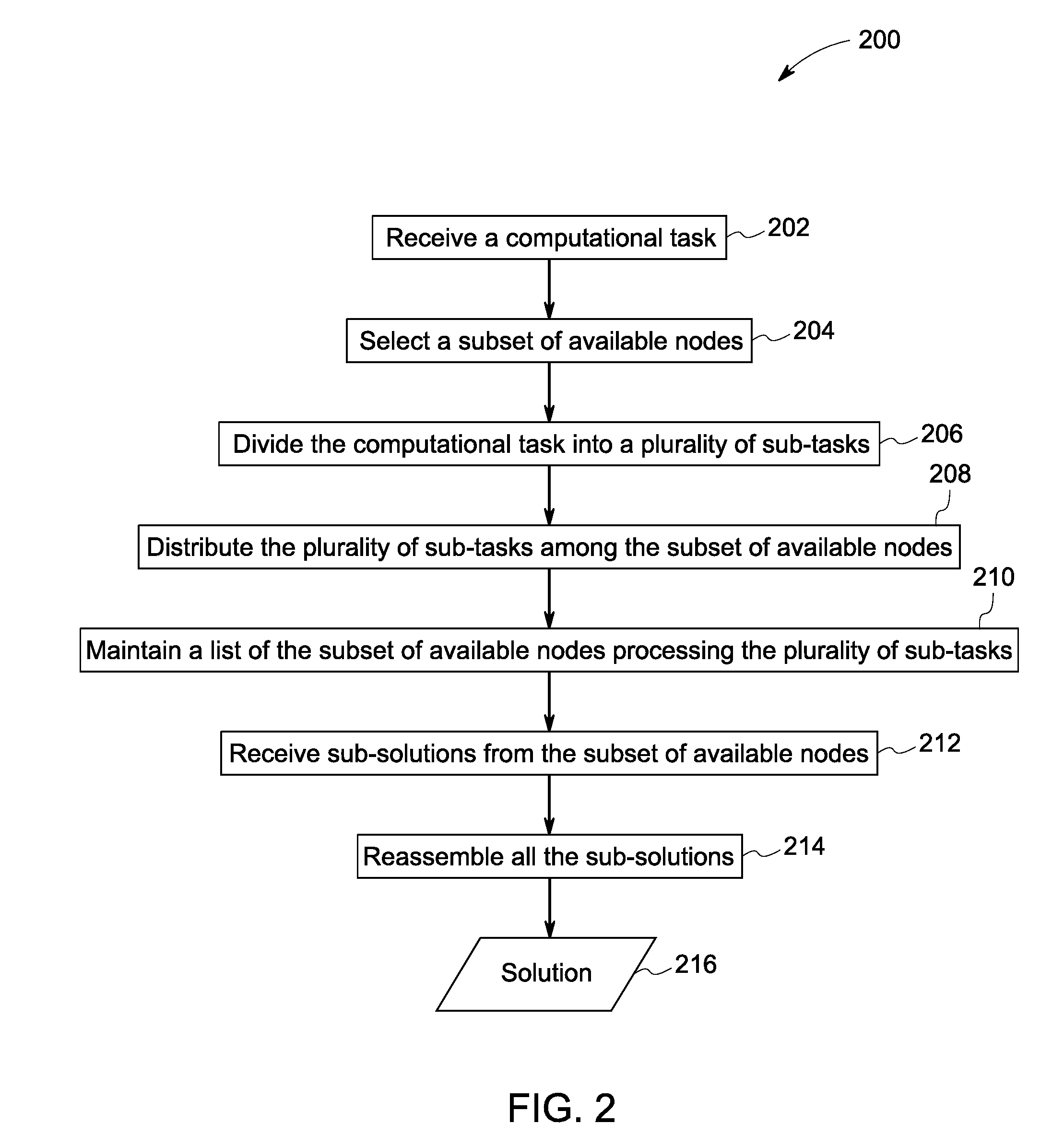

Method and system for distributed computation

A system for processing a computational task is presented. The system includes a plurality of nodes operationally coupled to one another via one or more networks. The plurality of nodes includes a base node including a processing subsystem configured to receive the computational task, select a subset of available nodes from the plurality of nodes based upon a present status, processing capability, distance, network throughput, range, resources, features, or combinations thereof of the plurality of nodes, divide the computational task into a plurality of sub-tasks, distribute the plurality of sub-tasks among the subset of available nodes based upon a number of nodes in the subset of available nodes, completion time period allowed for the plurality of sub-tasks, a distribution criteria, level of security required for the completion of the plurality of sub-tasks, resources available with the subset of available nodes, processing capability of the subset of available nodes, range of the subset of available nodes, features in the subset of available nodes, reliability of the subset of available nodes, trust in the subset of available nodes, the current load on the subset of available nodes, domain of the plurality of sub-tasks, or combinations thereof, receive sub-solutions corresponding to the plurality of sub-tasks from the subset of available nodes in a desired time period, and reassemble the sub-solutions to determine a solution corresponding to the computational task.

Owner:GENERAL ELECTRIC CO

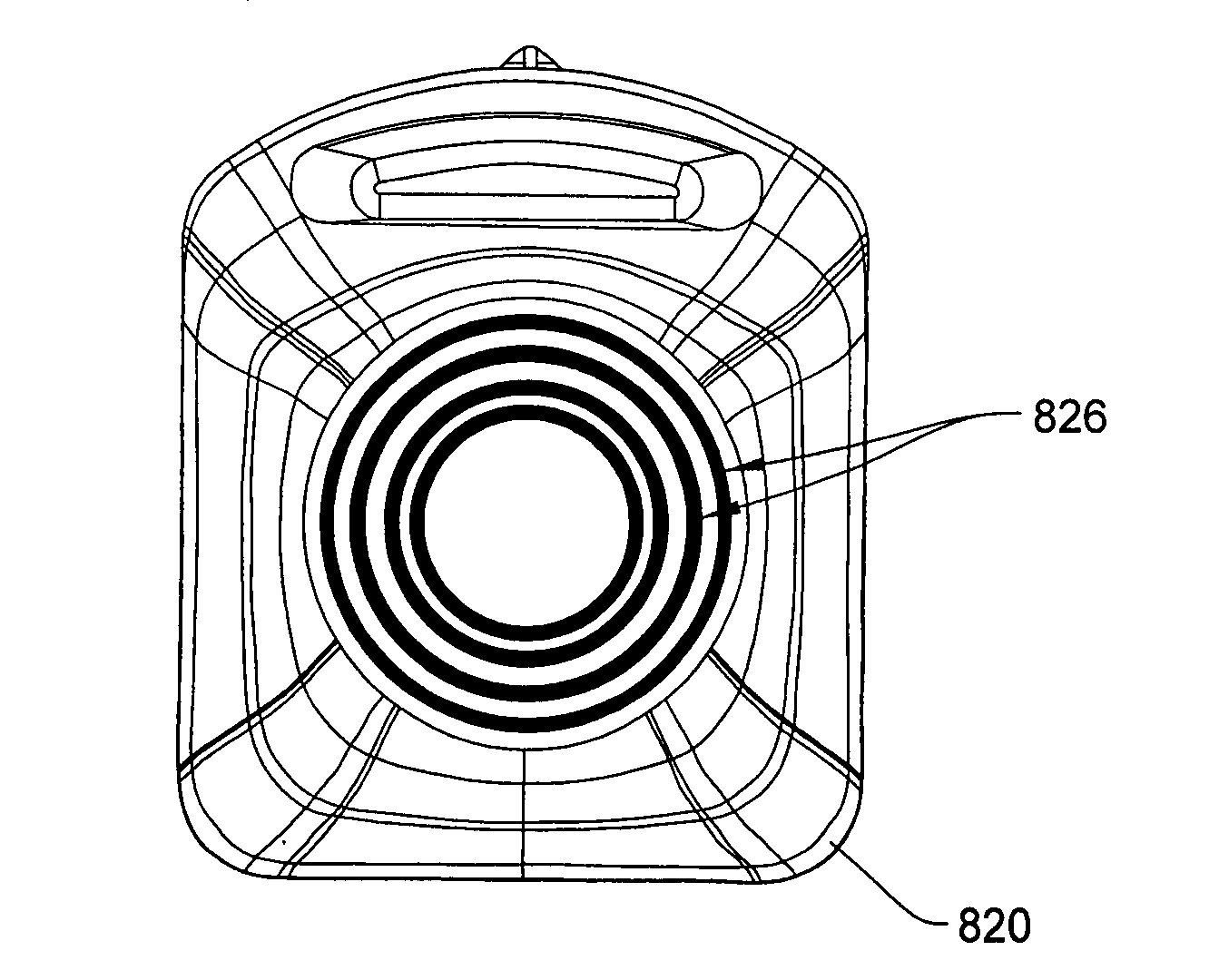

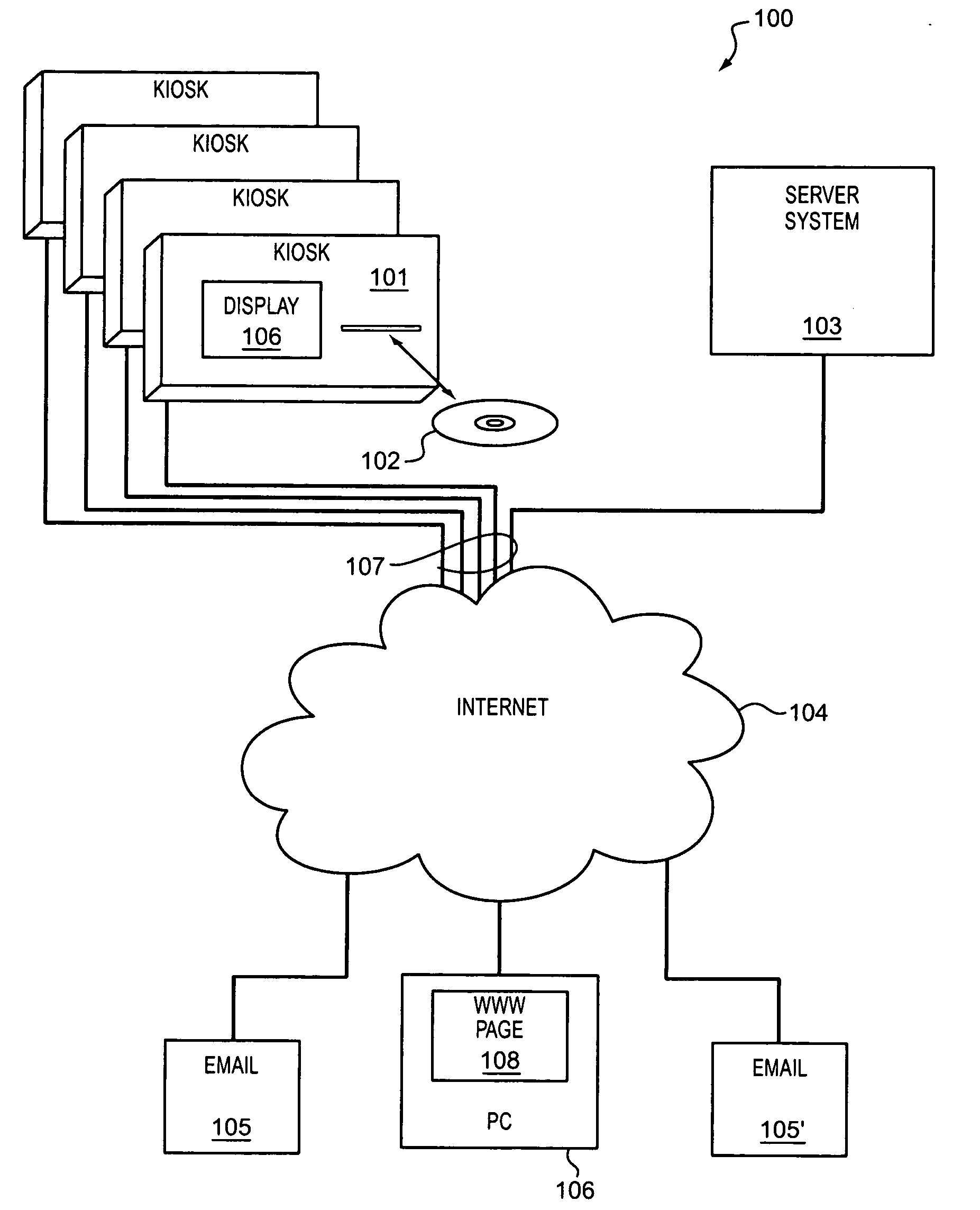

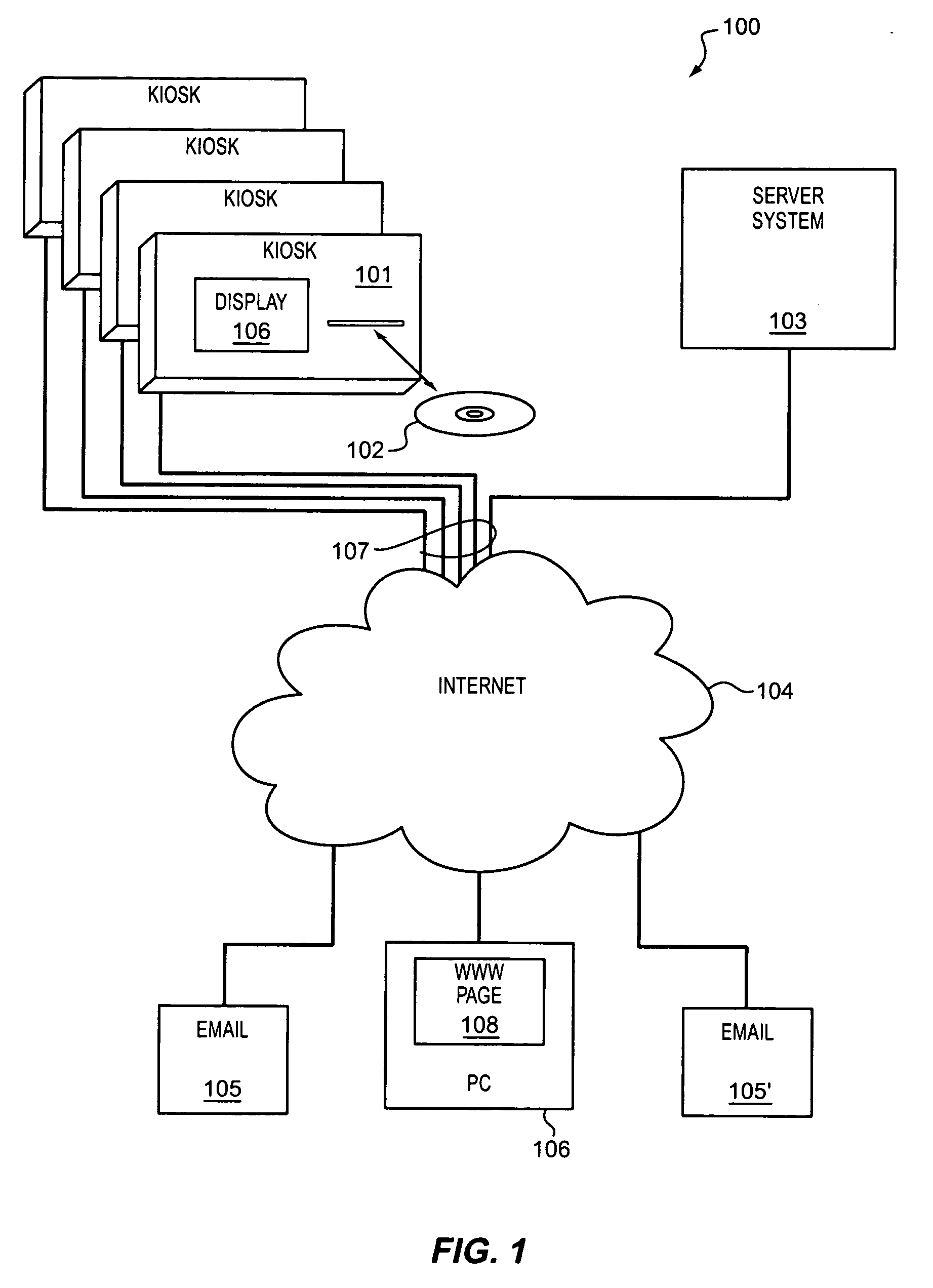

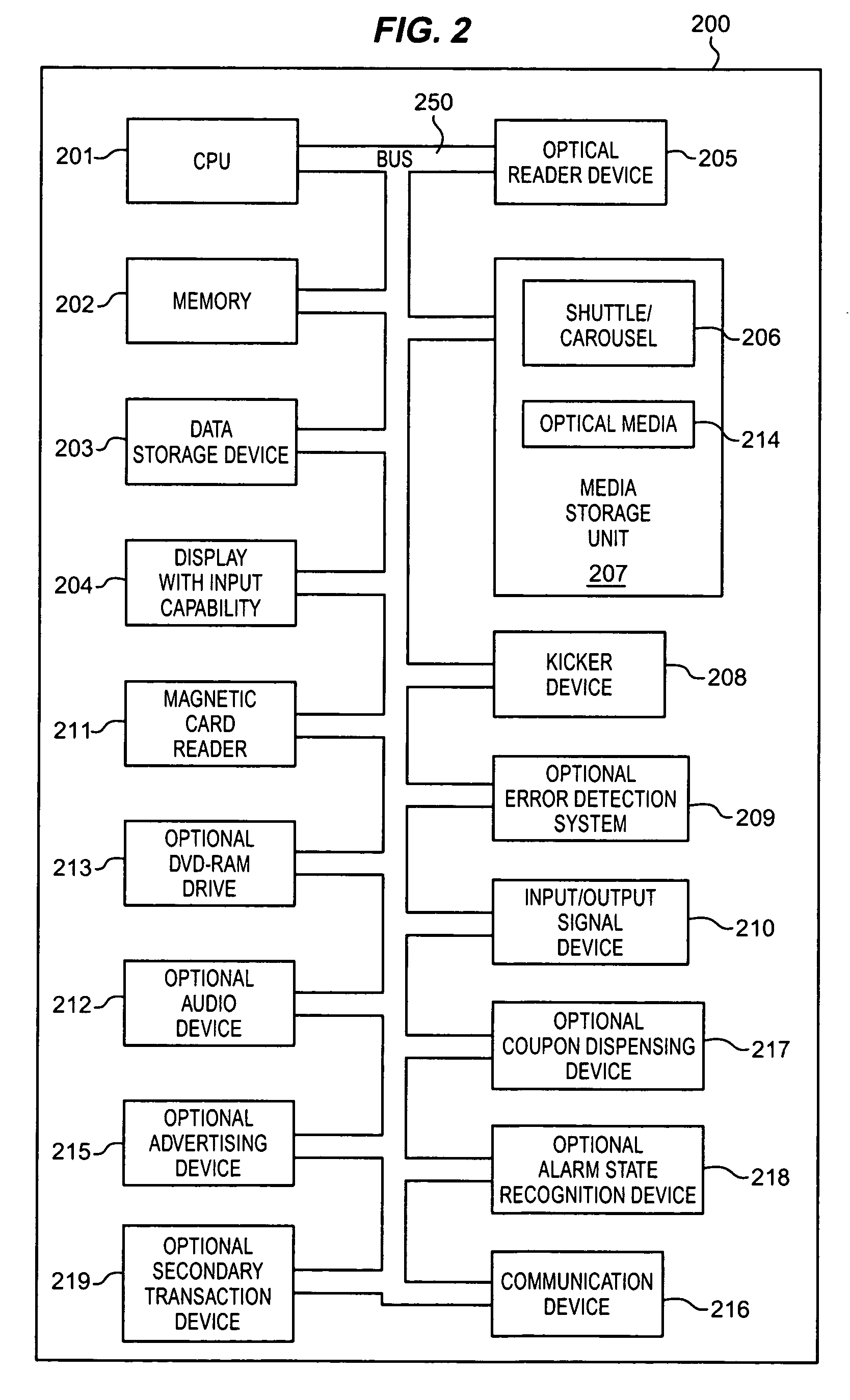

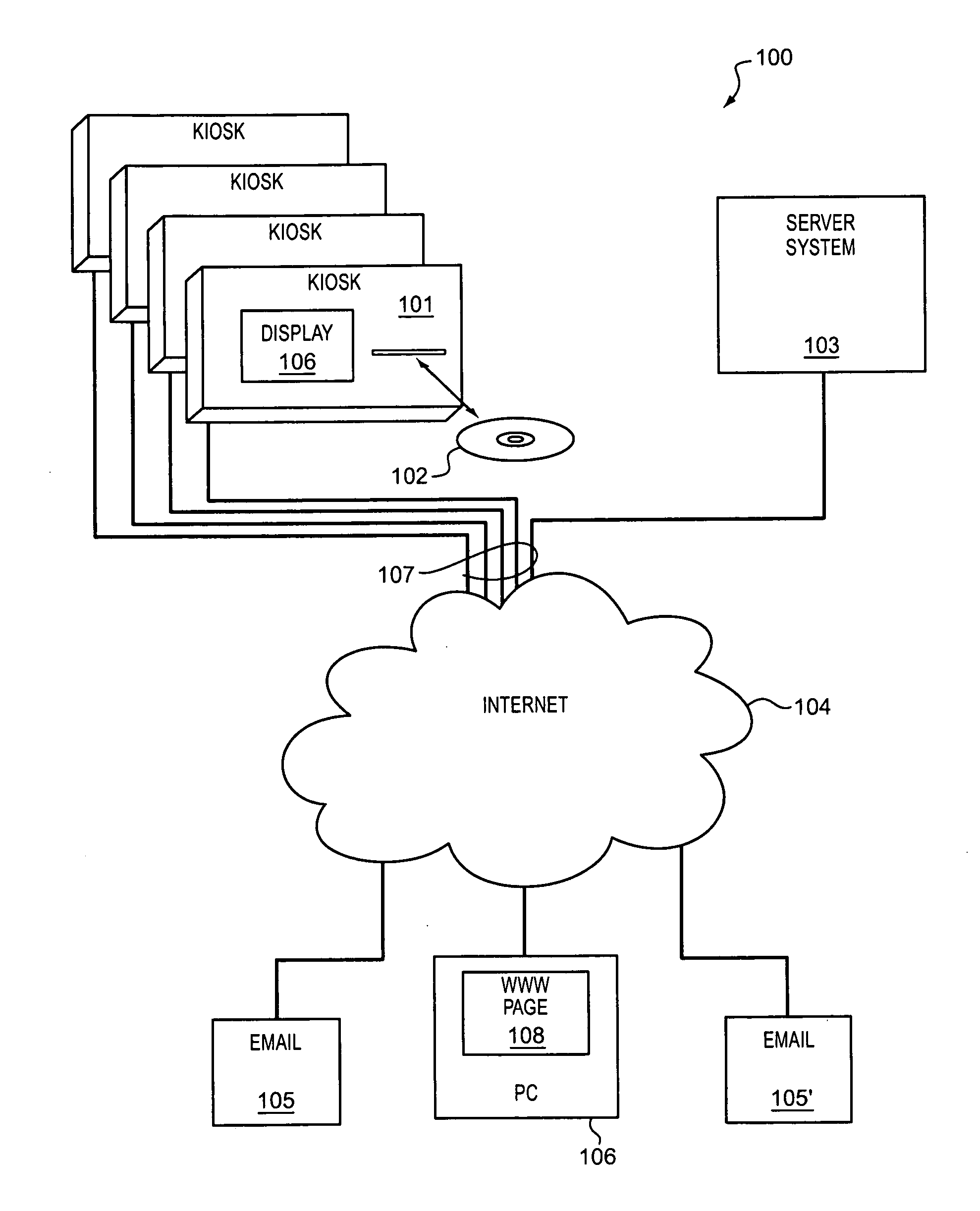

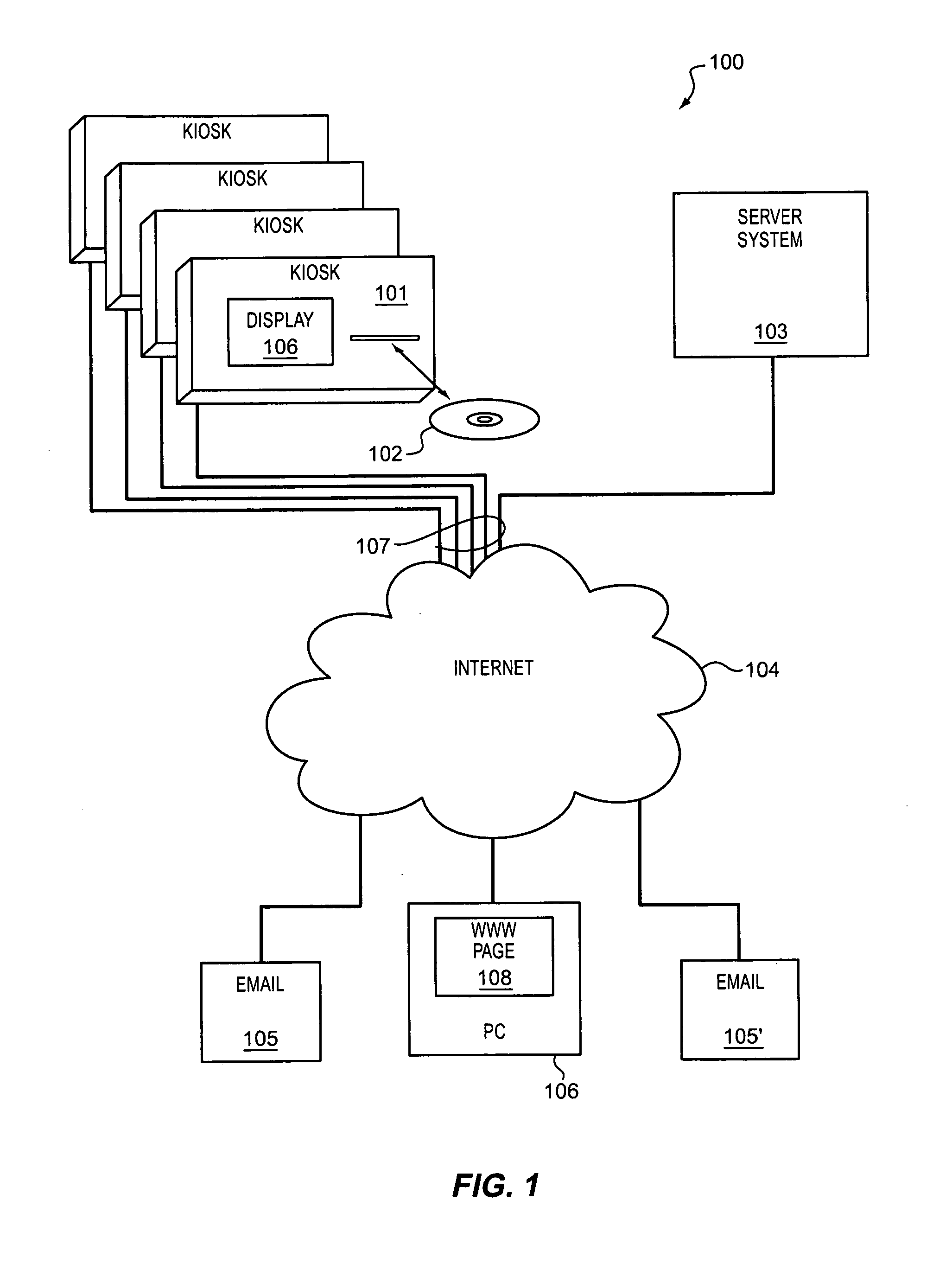

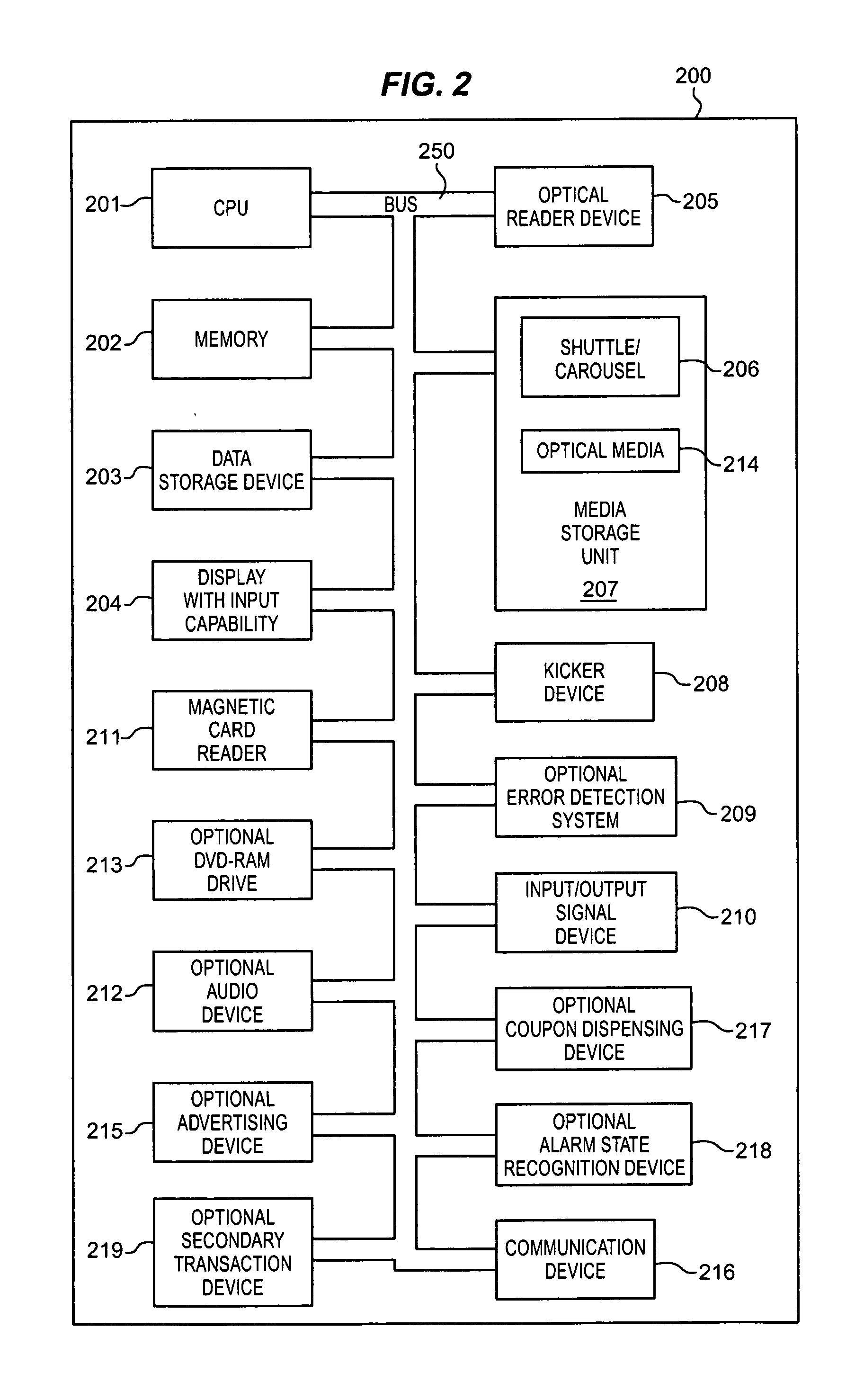

System and kiosk for commerce of optical media through multiple locations

InactiveUS20070050266A1Simple return processEasy maintenanceAcutation objectsFinanceCredit cardEmail address

A kiosk dispenses and receives recorded optical media using an interconnected central server, through an Internet Service Provider. The central server has databases and processing capabilities and is connected to a credit verification system. The databases collect inventory administration information and customer data (e.g., credit card information and email addresses) from the kiosks. The central server initiates credit verification, sends receipts to customers via email and maintains databases for remote inventory control and administration of the kiosk network. A kiosk may identify a recorded disk for automated restocking and perform quality assessment of a recorded disk. The kiosk may provide publishing-on-demand or act as a portal for remotely served advertisements. The kiosk preferably includes a rotatable carousel with a selection of DVDs. A digital camera captures a digital image of a disk barcode and internal software rotates the image to “read” the barcode, to control inventory and access issues.

Owner:REDBOX AUTOMATED RETAIL

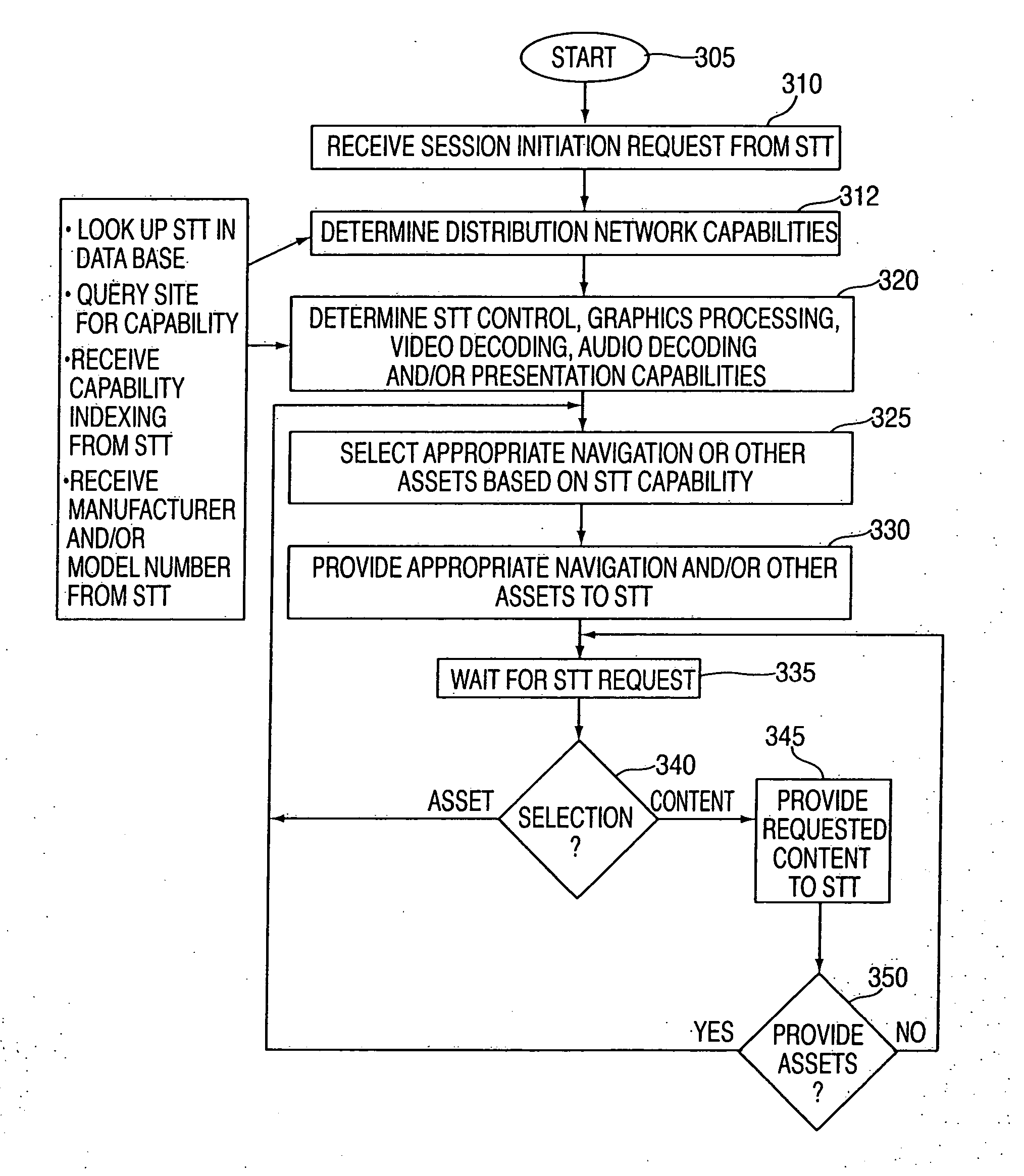

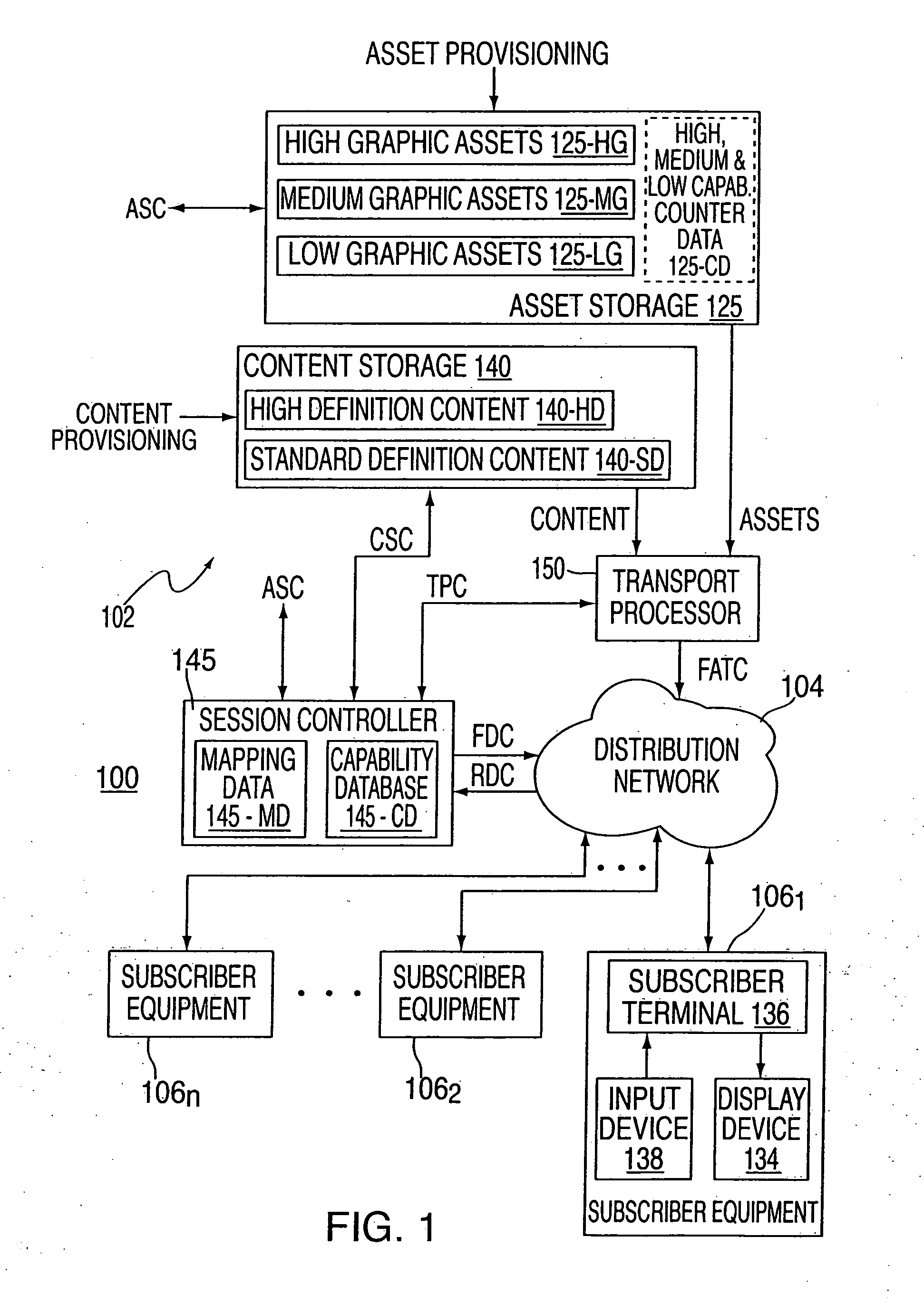

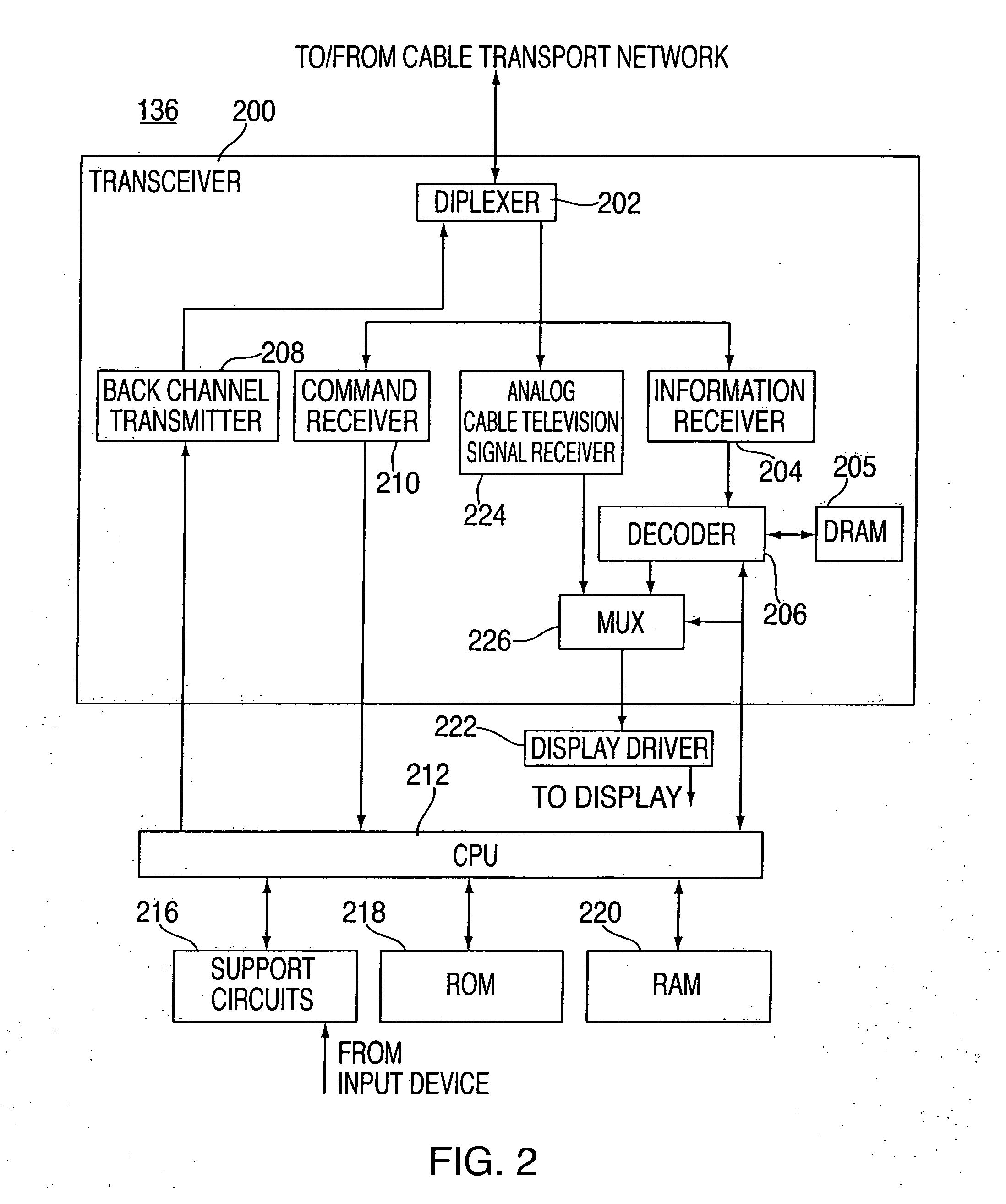

Method and apparatus providing process independence within a heterogeneous information distribution system

A method and apparatus for adapting the delivery of assets and / or content to set top terminals within a heterogeneous information distribution system based on graphics and / or processing capability of set top terminals receiving the assets and / or content.

Owner:COX COMMUNICATIONS

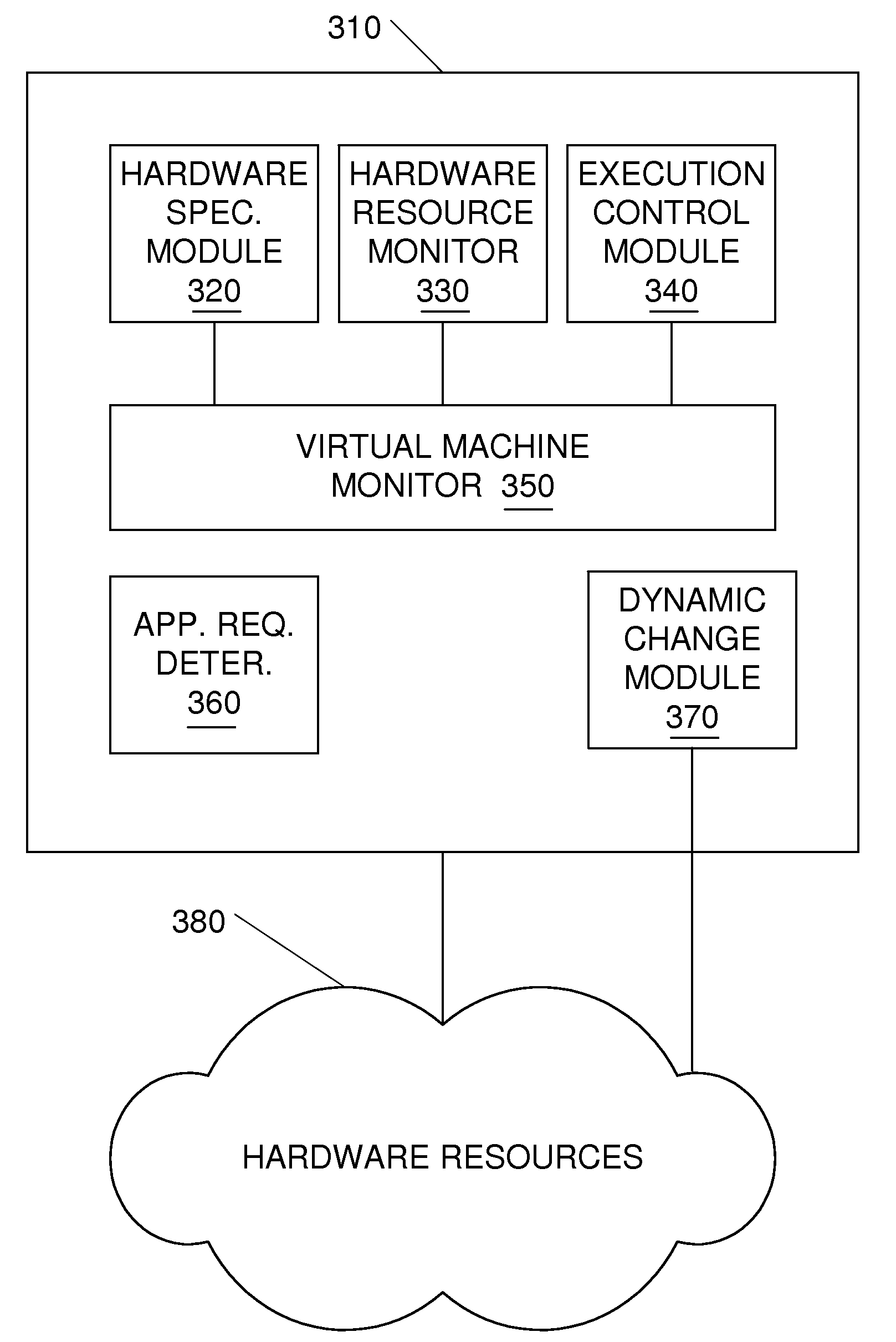

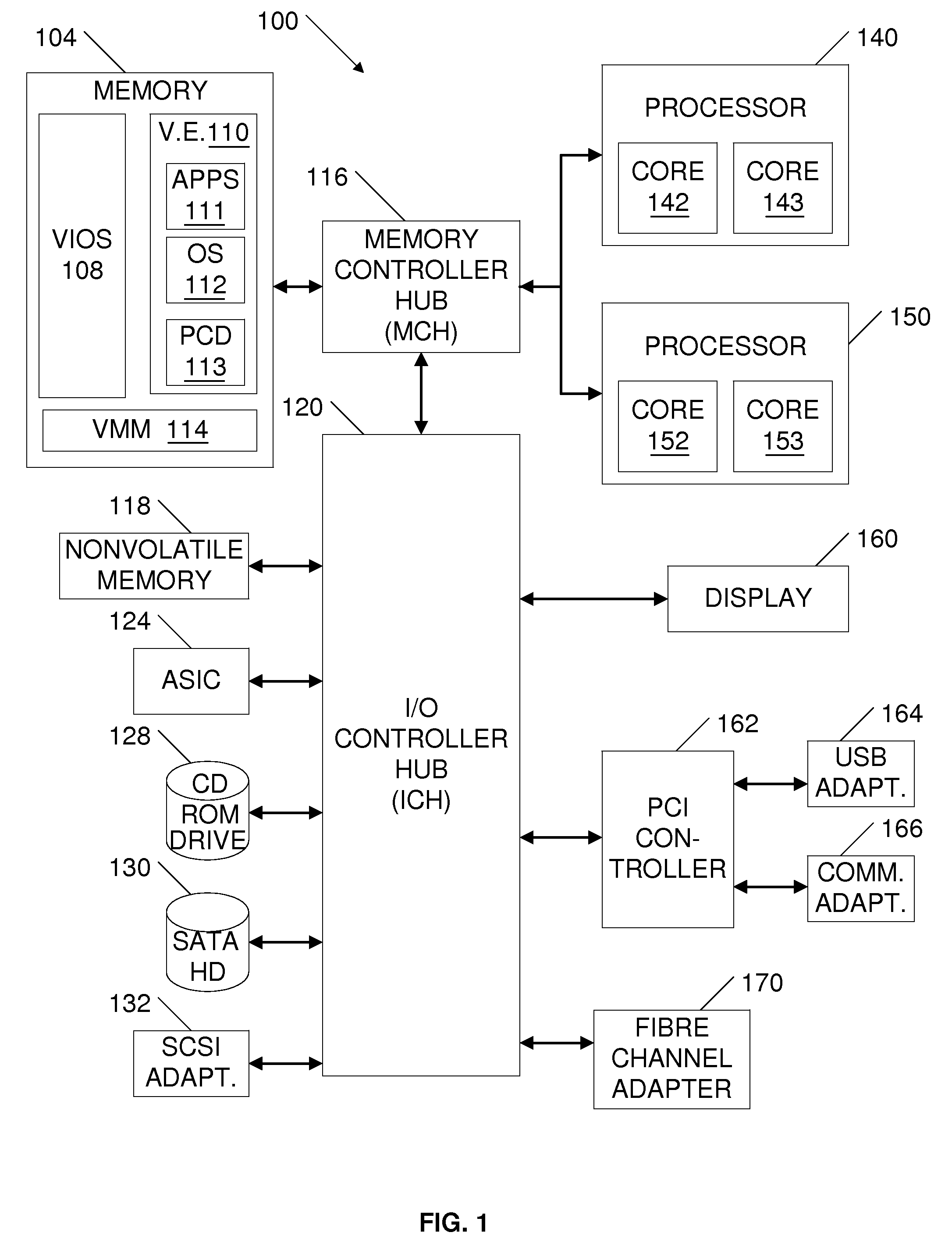

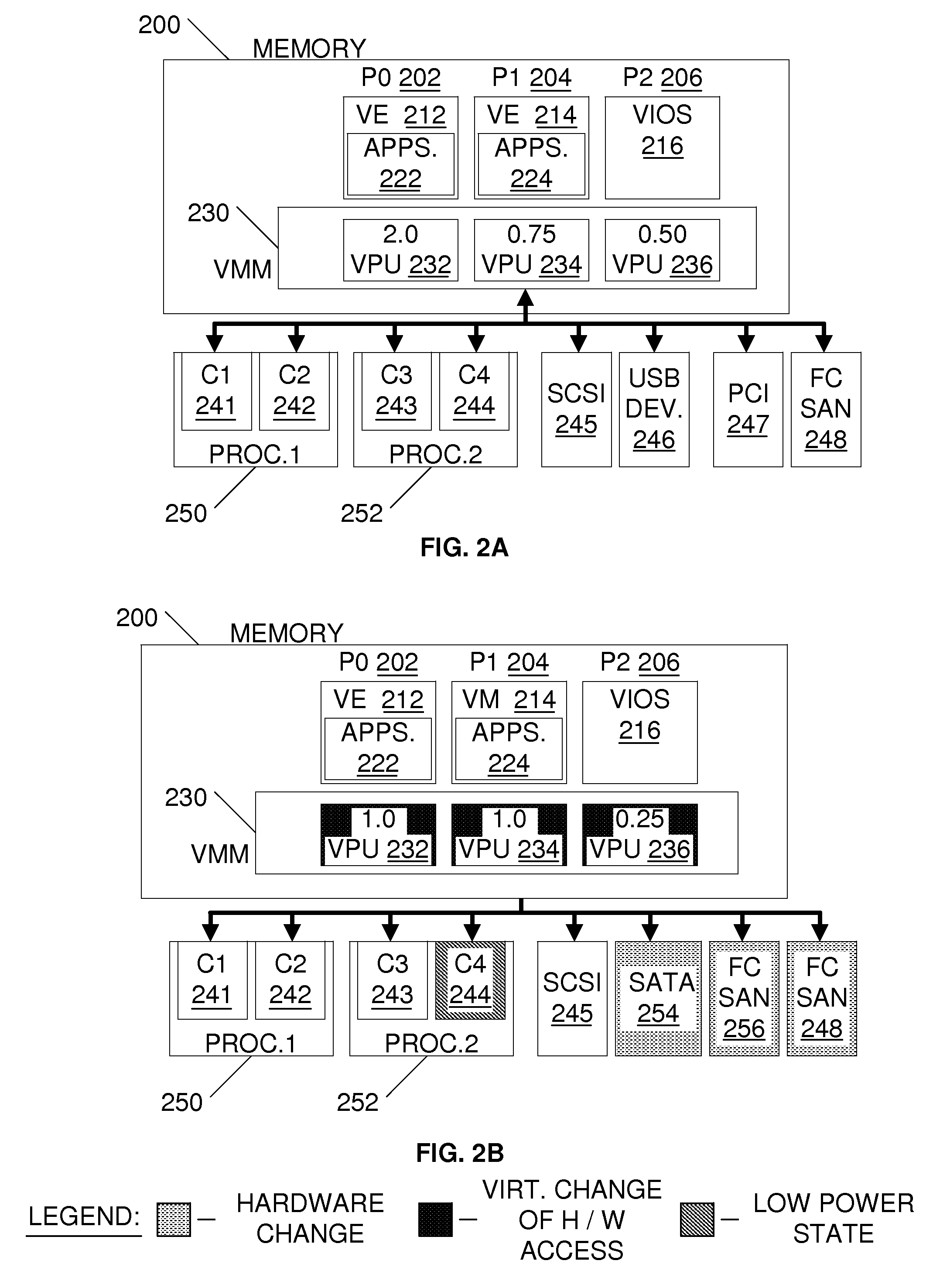

Dynamic Checking of Hardware Resources for Virtual Environments

ActiveUS20100186010A1Preventing executionResource allocationSoftware simulation/interpretation/emulationComputer hardwareApplication software

Embodiments that dynamically check availability of hardware resources for applications of virtual environments are contemplated. Various embodiments comprise one or more computing devices having various hardware resources available to applications of a virtual environment. Hardware resources may comprise, for example, amounts of memory, amounts or units of processing capability of one or more processors, and various types of peripheral devices. The embodiments may store hardware data pertaining to a specified amount of hardware recommended or required for an application to execute within the virtual environment. The embodiments may generally monitor for changes to the hardware configuration, which may affect amount of hardware available to the virtual environment and / or application. If the changes to the hardware reduce the amount of available hardware to a point beyond the specified amount of hardware, the embodiments may prevent the application from being executed or prevent the changes to the hardware configuration.

Owner:IBM CORP

System and kiosk for commerce of optical media through multiple locations

InactiveUS20070051802A1Effective maintenanceGuaranteed uptimeBilling/invoicingBuying/selling/leasing transactionsCredit cardEmail address

A kiosk dispenses and receives recorded optical media using an interconnected central server, through an Internet Service Provider. The central server has databases and processing capabilities and is connected to a credit verification system. The databases collect inventory administration information and customer data (e.g., credit card information and email addresses) from the kiosks. The central server initiates credit verification, sends receipts to customers via email and maintains databases for remote inventory-control and administration of the kiosk network. A kiosk may identify a recorded disk for automated restocking and perform quality assessment of a recorded disk. The kiosk may provide publishing-on-demand or act as a portal for remotely served advertisements. The kiosk preferably includes a rotatable carousel with a selection of DVDs. A digital camera captures a digital image of a disk barcode and internal software rotates the image to “read” the barcode, to control inventory and access issues.

Owner:REDBOX AUTOMATED RETAIL

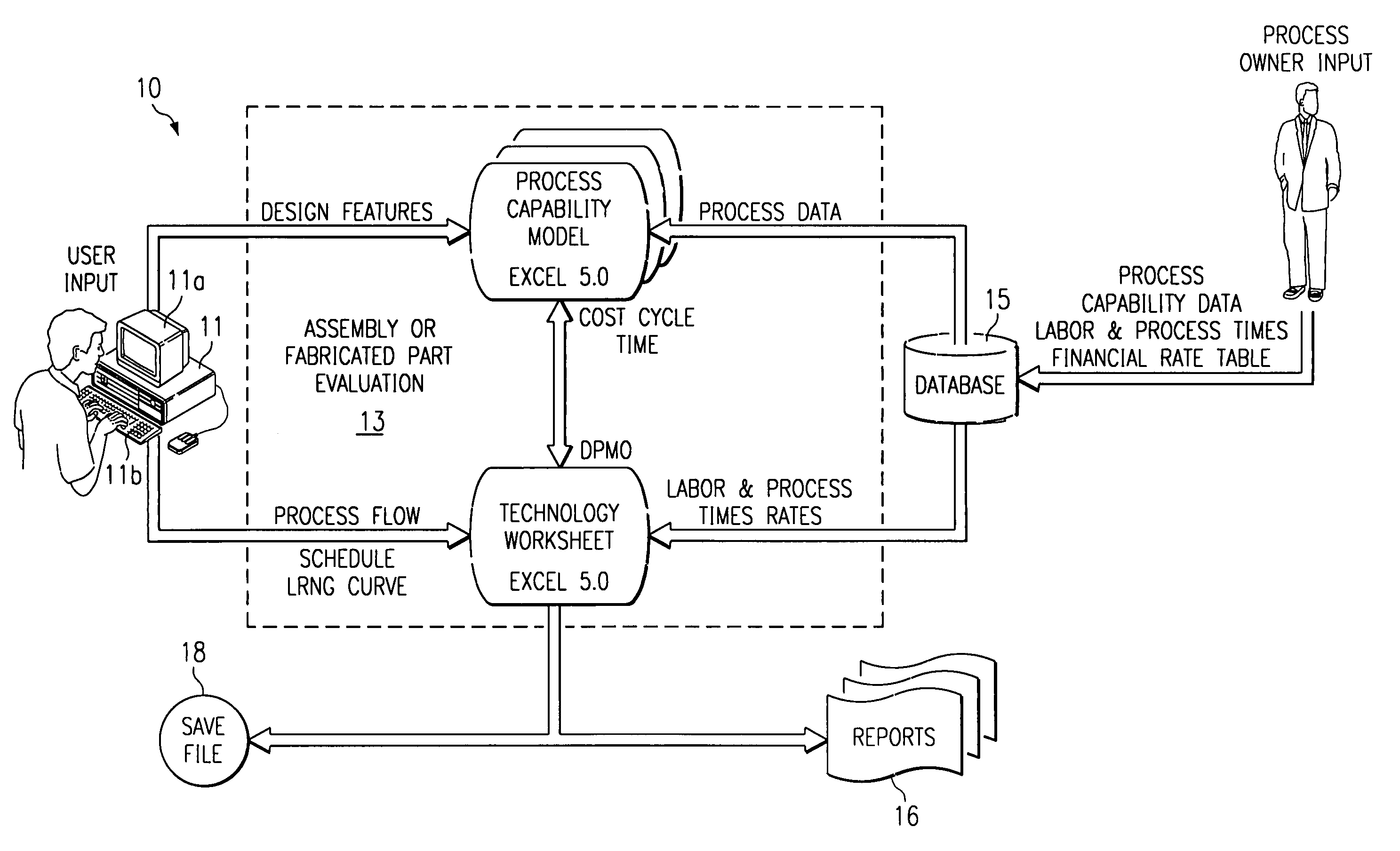

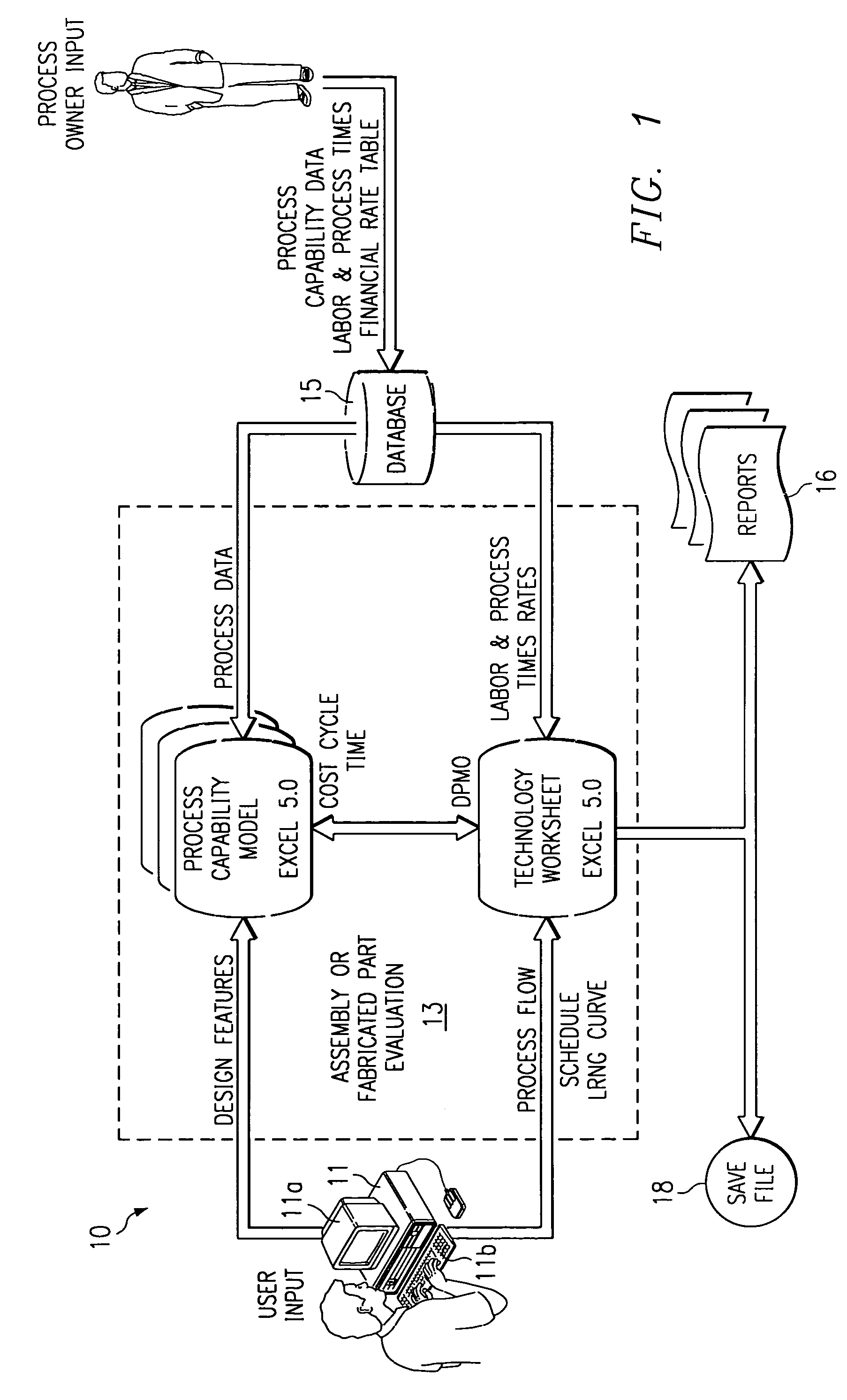

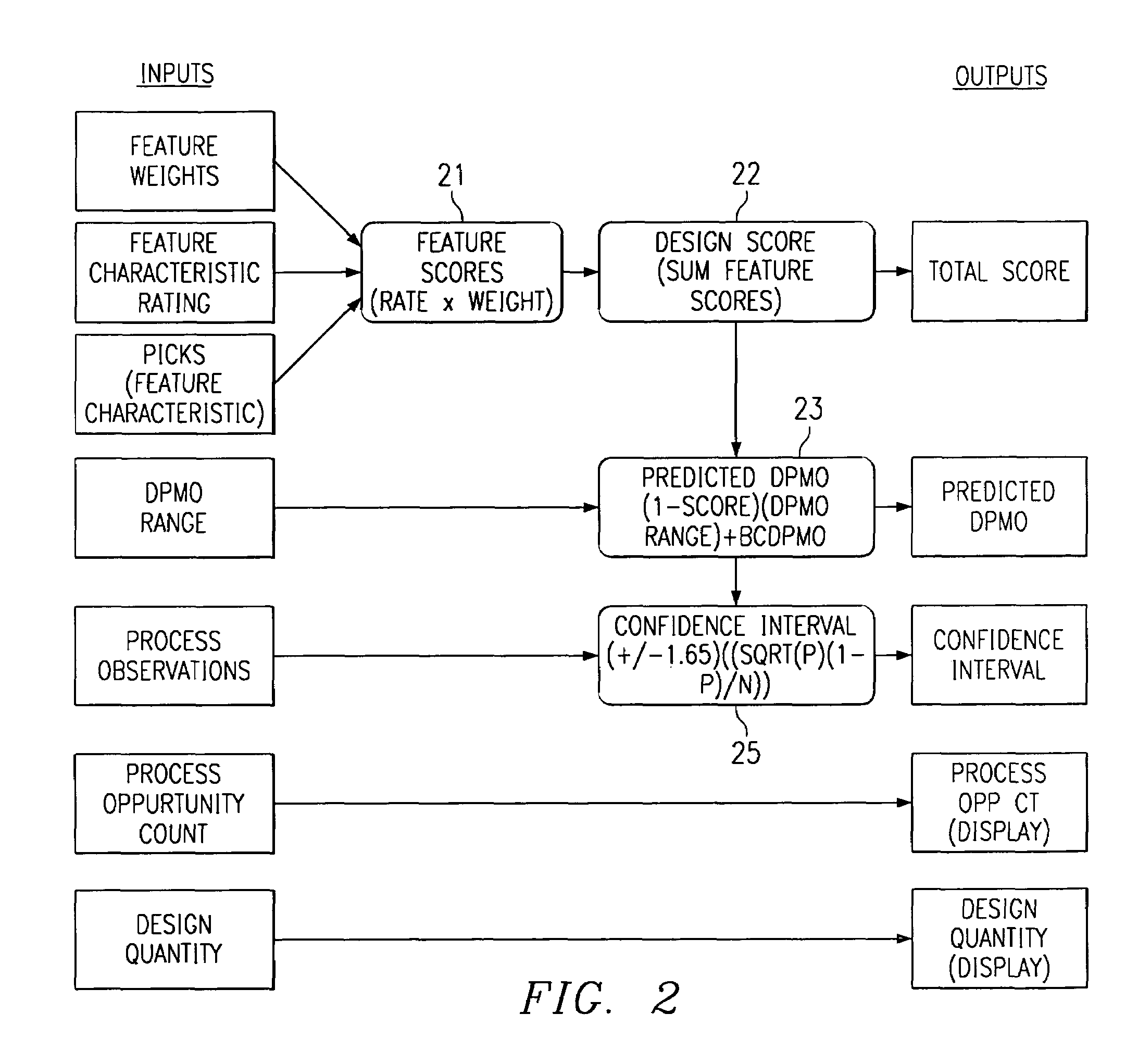

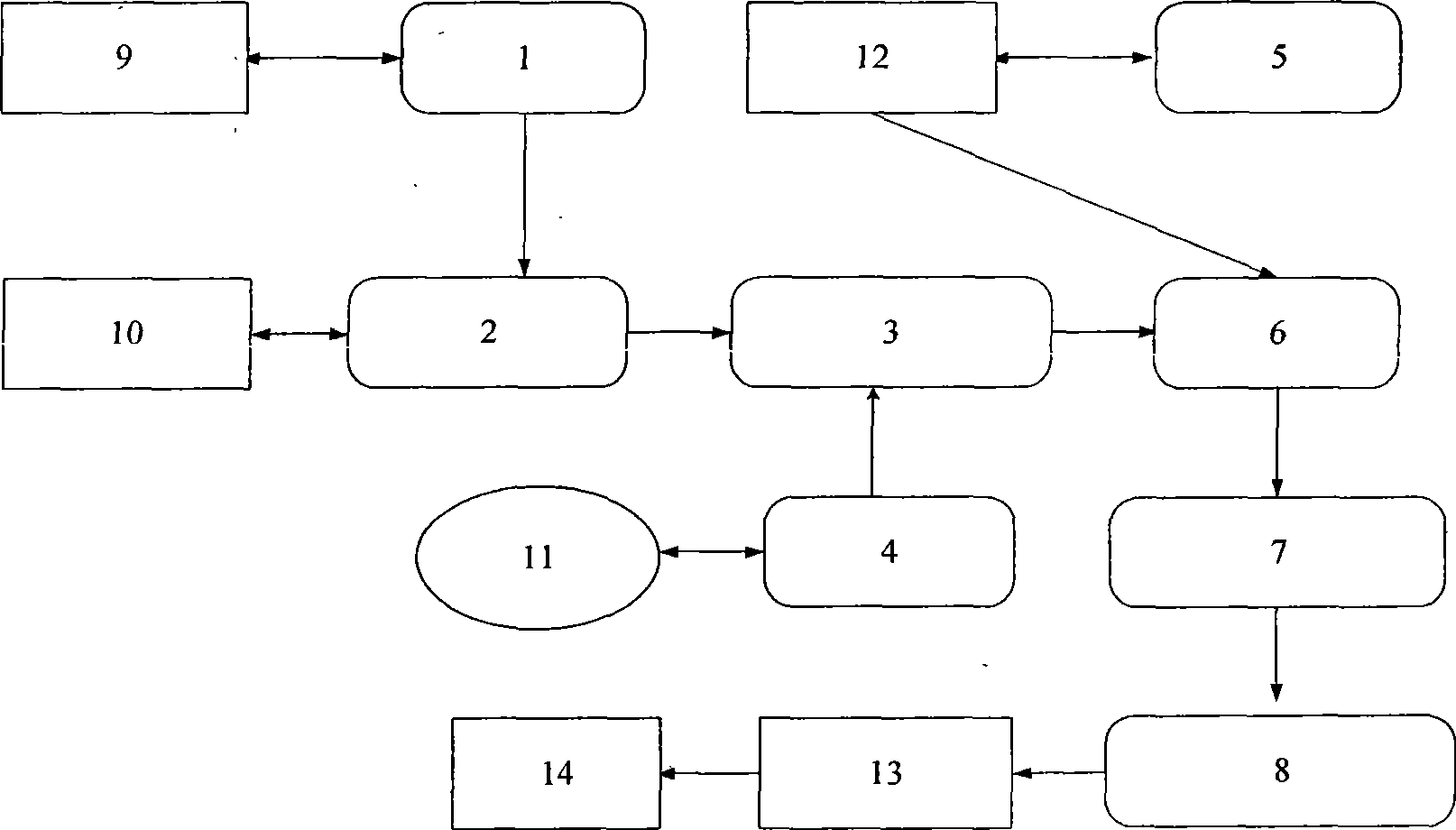

Capability predictor

A capability predictor that comprises a database 15 of capability of multiple designs is disclosed. The process capability data includes costs, quality, cycle time, and performance models. The process owner (expert) provides the data. The developer inputs equations necessary to calculate the predictions based in the selected design characteristics and the user selects the design. A processor 11 calculates the prediction based on the selected design and a display, such as monitor 11a or printer 16, displays the results of the predictions.

Owner:TEXAS INSTR INC

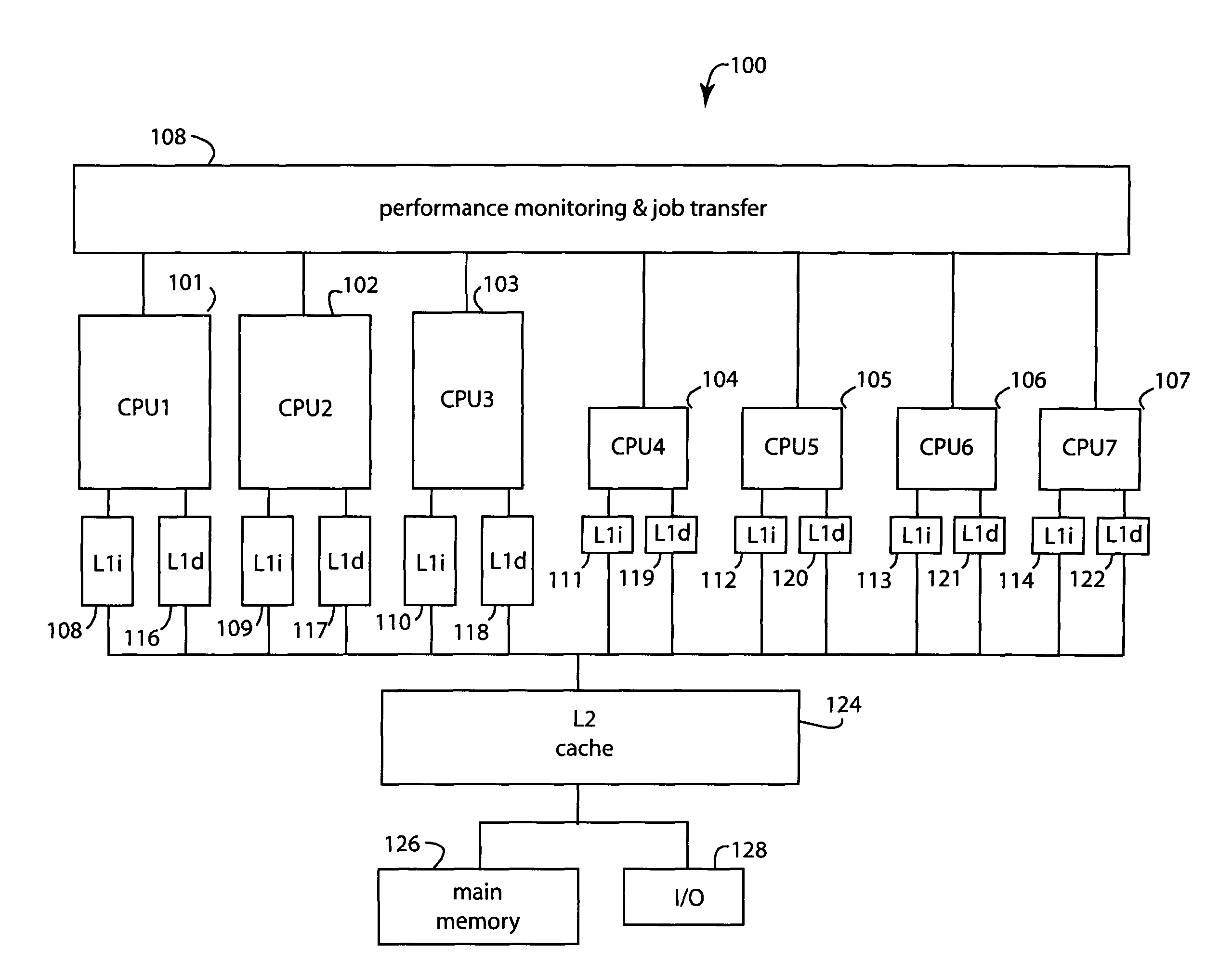

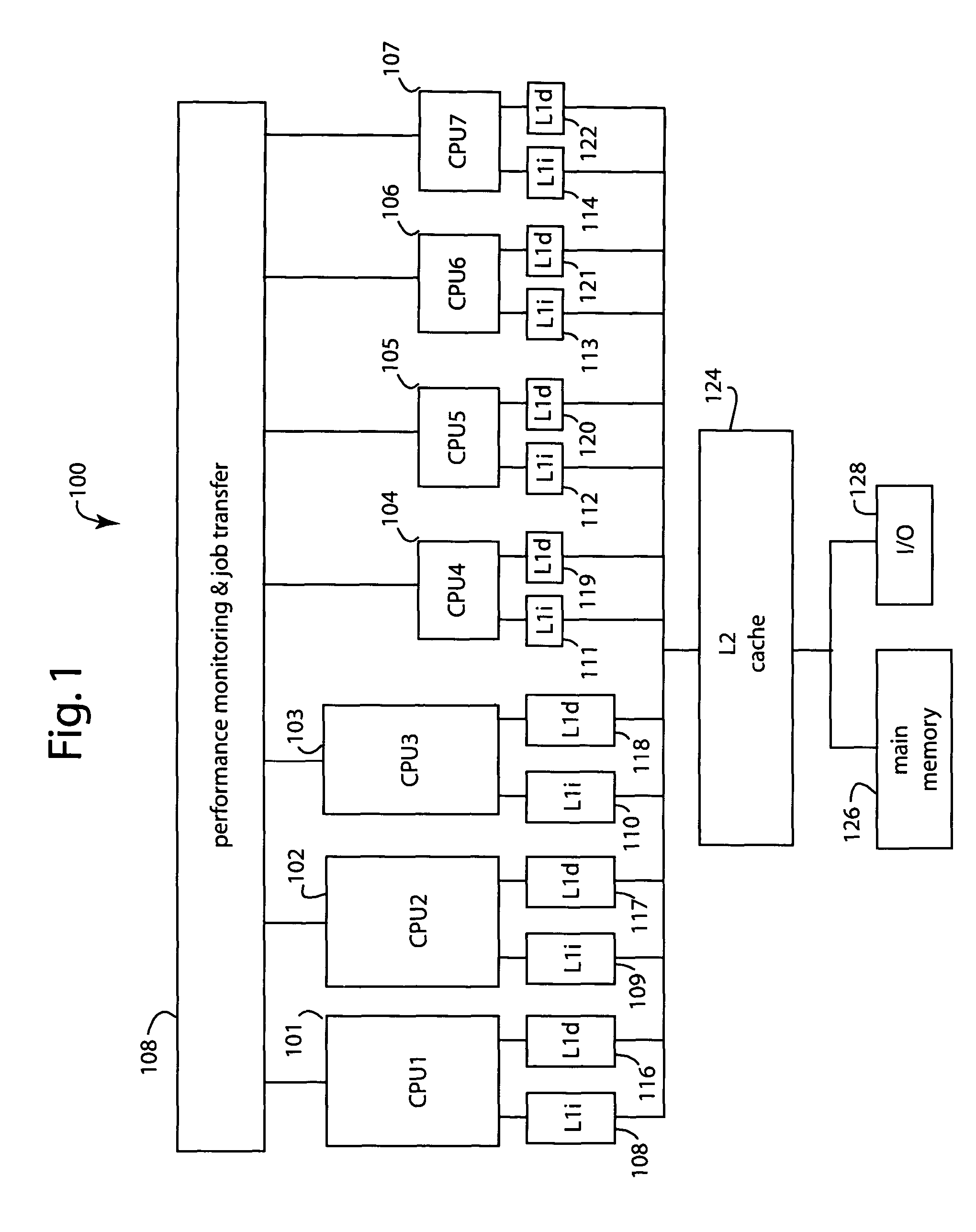

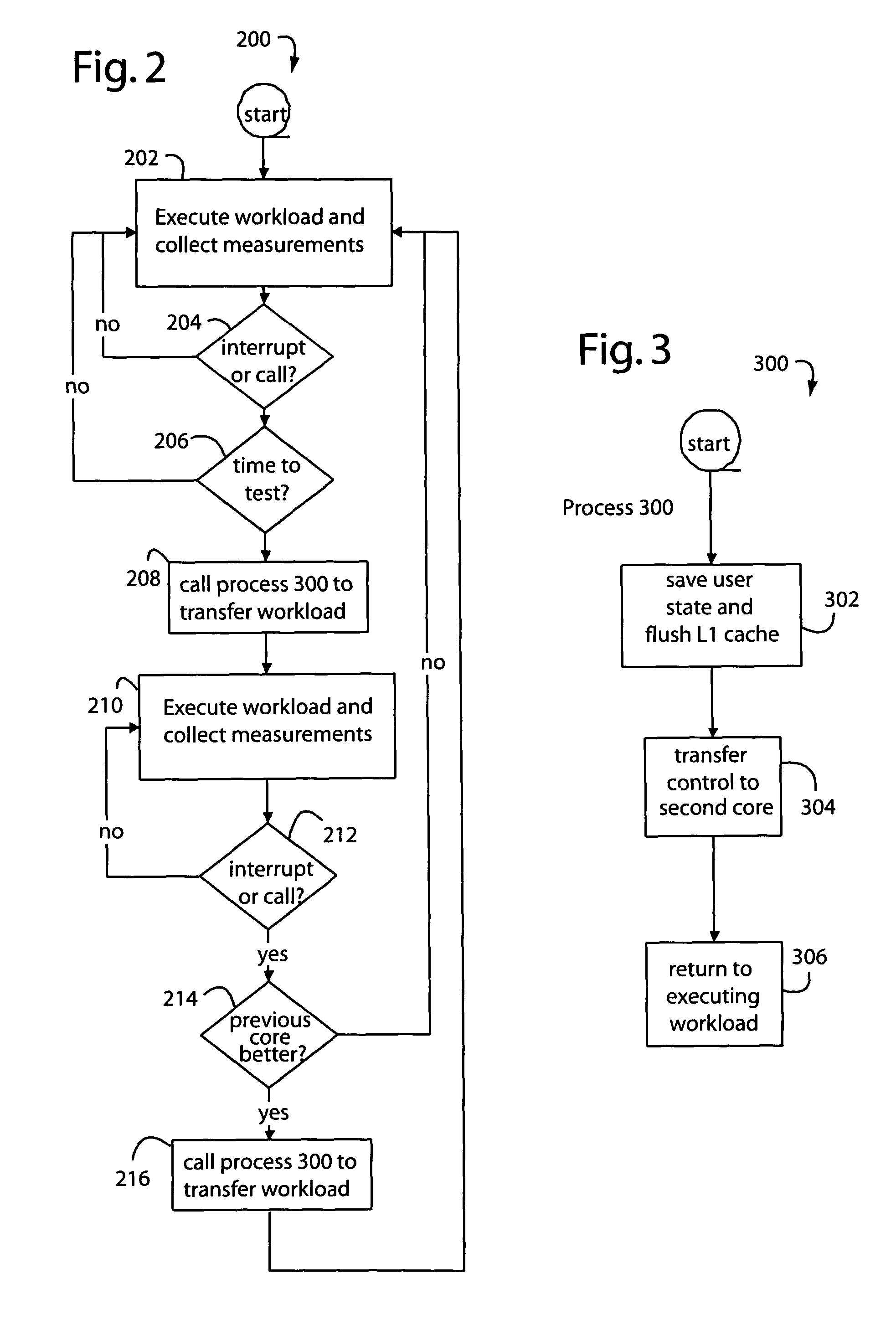

Heterogeneous processor core systems for improved throughput

InactiveUS7996839B2Improve performanceMaximize resource utilizationResource allocationNuclear monitoringComputerized systemParallel computing

Owner:HEWLETT PACKARD DEV CO LP

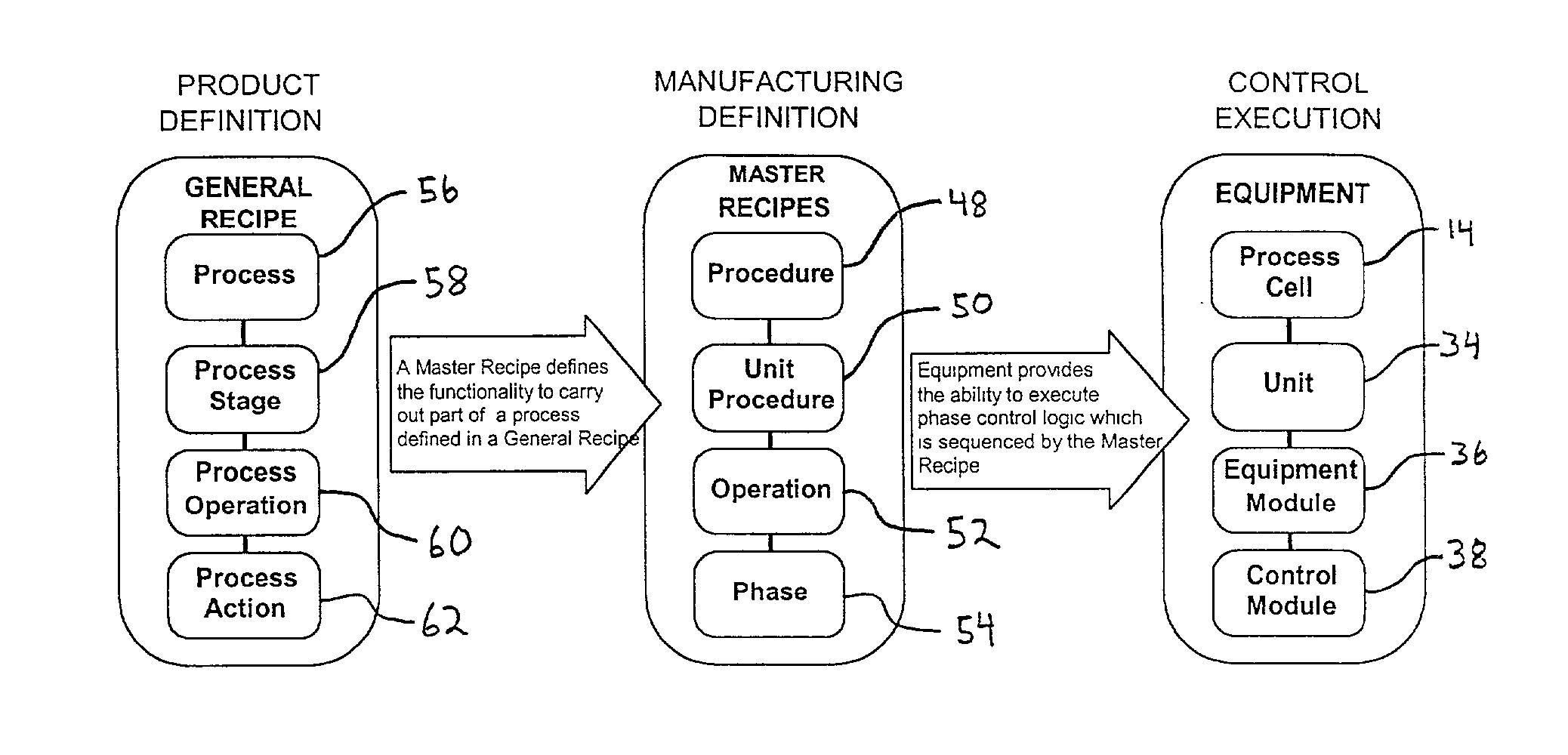

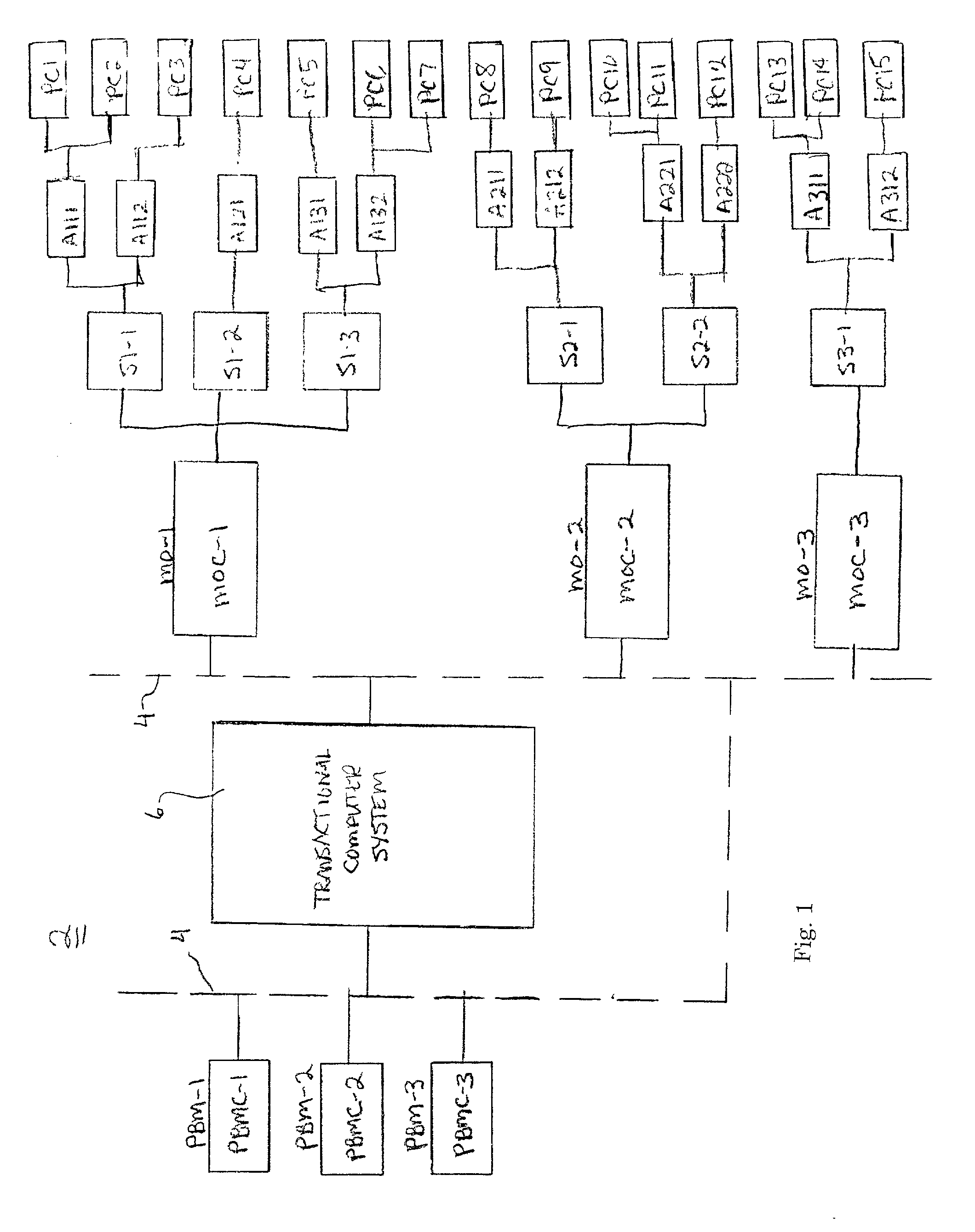

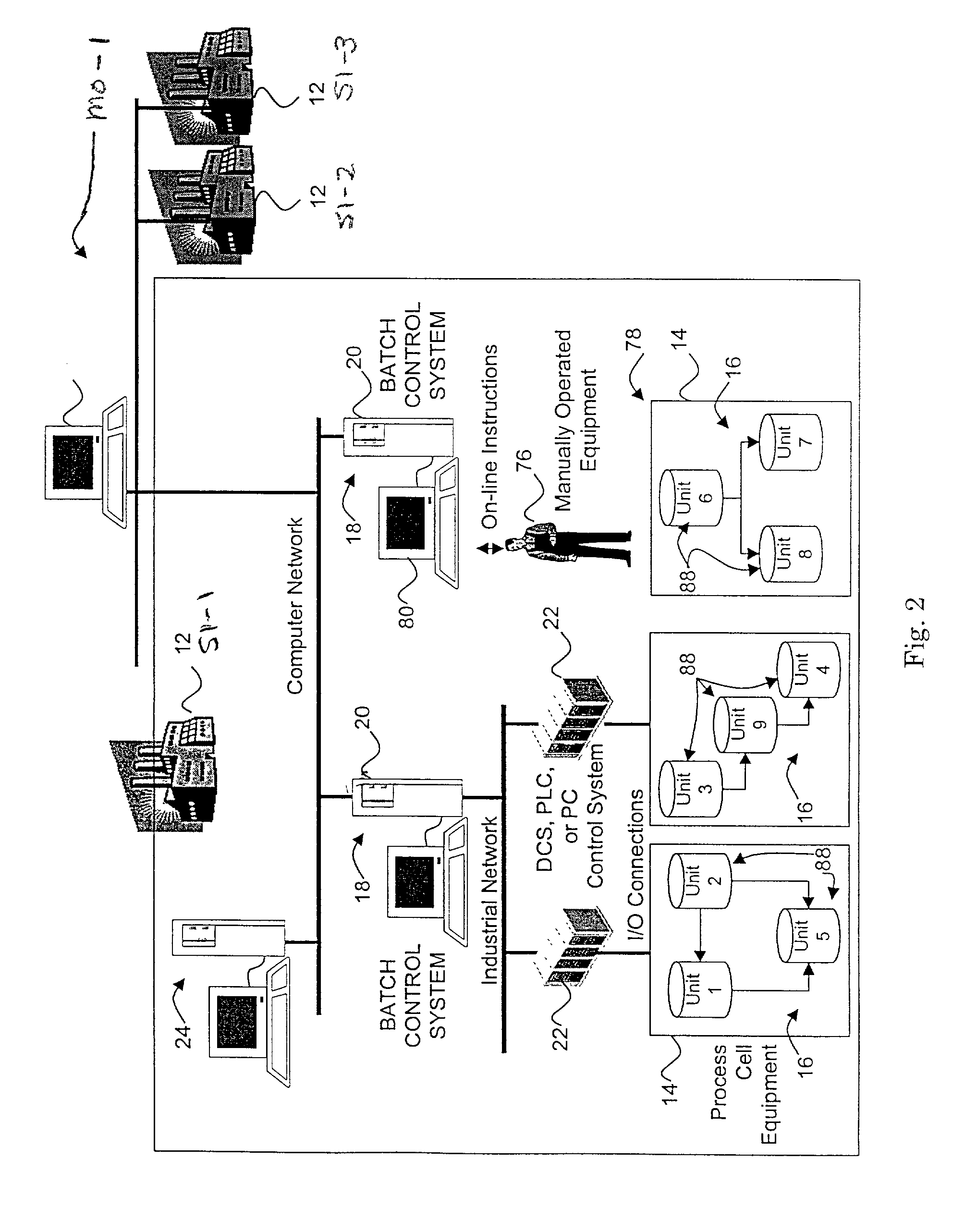

System and method for facilitating transactions between product brand managers and manufacturing organizations

InactiveUS20030139936A1Convenient transactionProduce quicklyOffice automationResourcesProcess capabilityCorrelation method

A method is provided for facilitating transactions between a product brand manager and manufacturing organizations using a transactional computer system. The product brand manager has a product brand and product brand information that includes information for manufacturing the product brand, and there is manufacturing organization information for each of the manufacturing organizations that includes the manufacturing process capabilities of the respective manufacturing organization. The method includes communicating the product brand information from the product brand manager to the transactional computer system, and communicating the manufacturing organization information for the manufacturing organizations from the manufacturing organizations to the transactional computer system. The method also includes using the transactional computer system to process the product brand information and the manufacturing organization information to select at least one candidate manufacturing organization from the manufacturing organizations and to generate selection information regarding the at least one candidate manufacturing organization. The selection processing uses the transactional computer system to compare the product brand information to the manufacturing organization information. The method further includes using the transactional computer system to communicate the selection information to the product brand manager. A related method is provided for the selection of product brand managers for the benefit of a manufacturing organization. Related systems also are disclosed.

Owner:OSI SOFTWARE

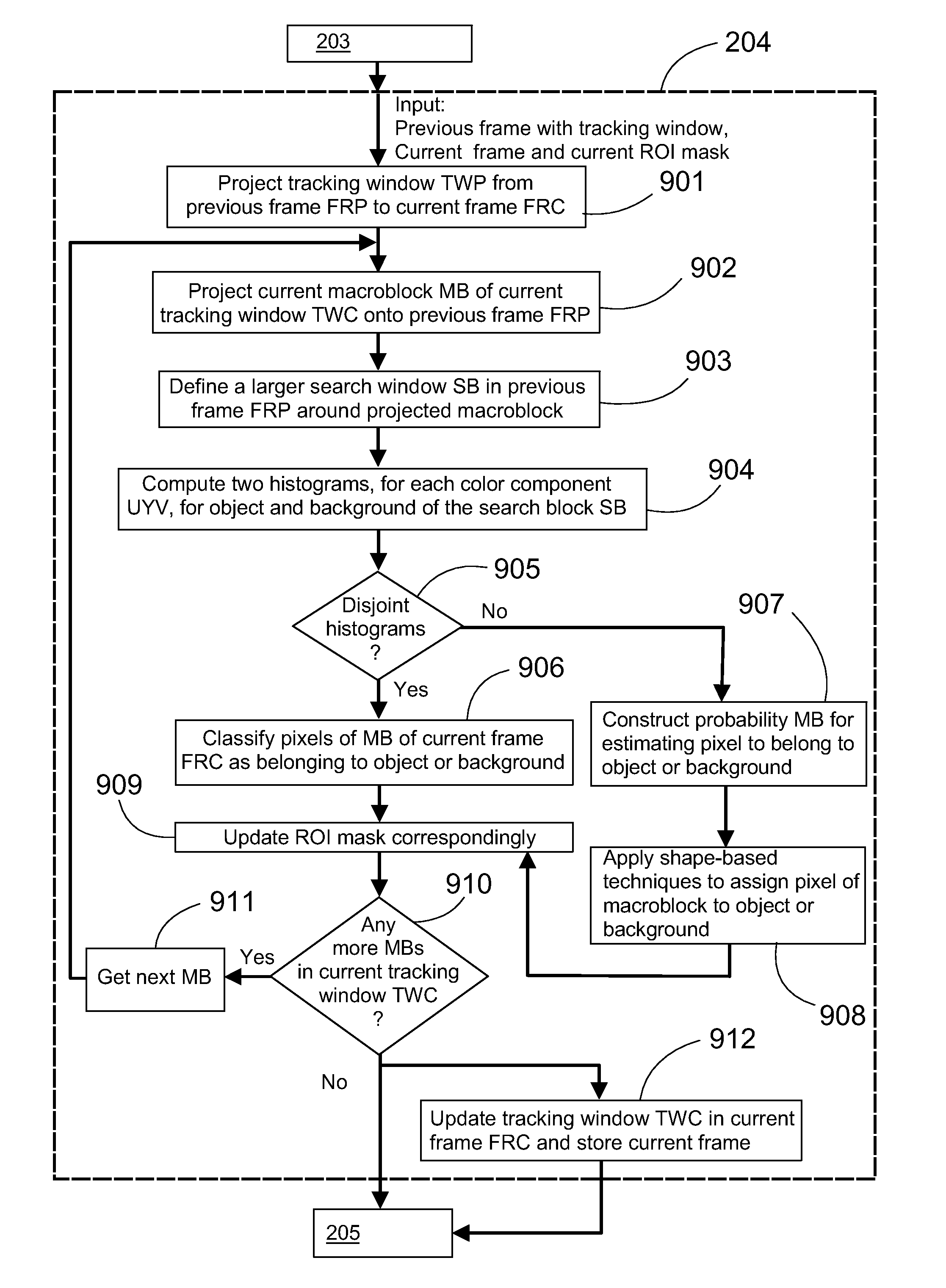

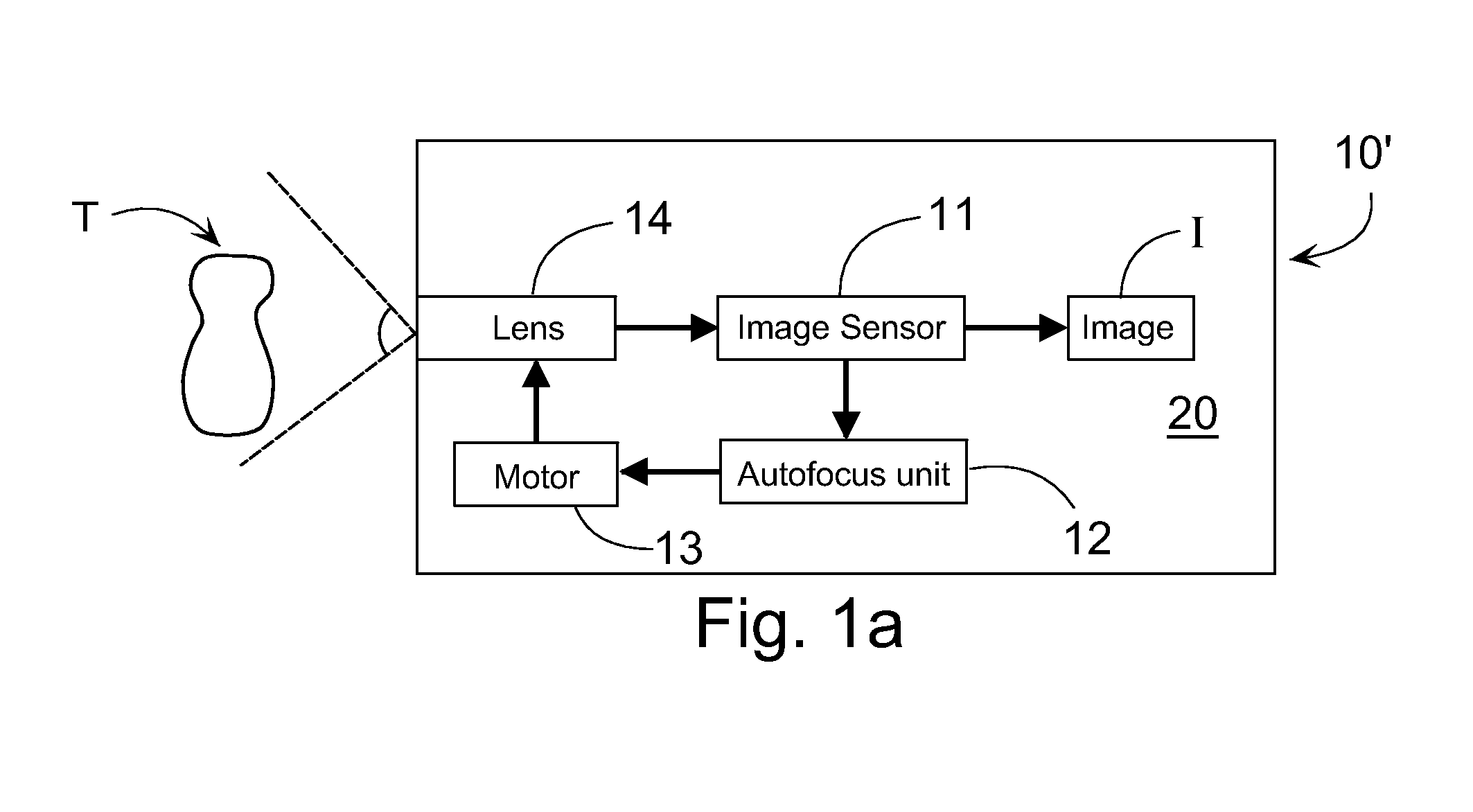

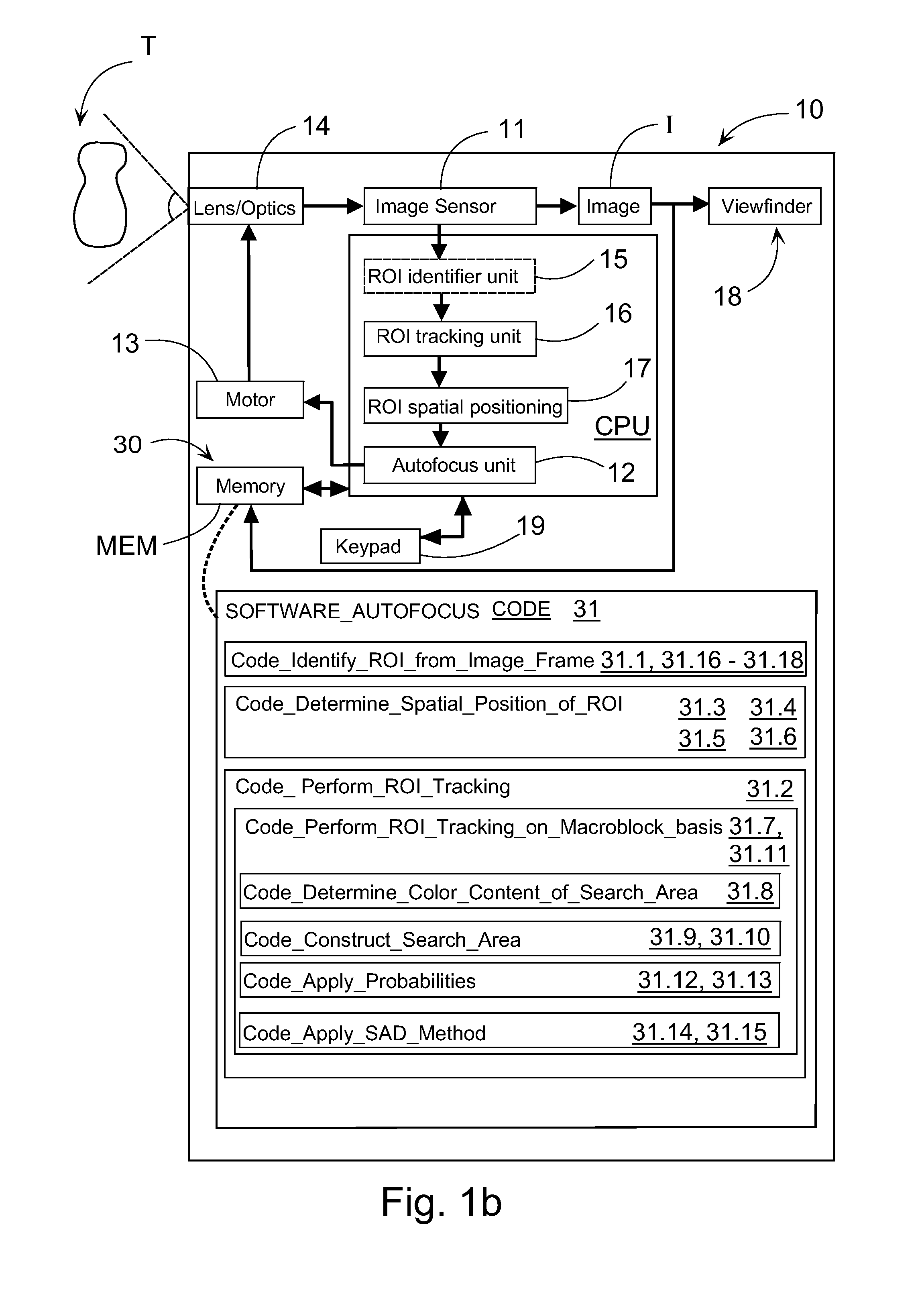

Method and device for controlling auto focusing of a video camera by tracking a region-of-interest

ActiveUS8089515B2Simple shape matching procedureReduce computational complexityTelevision system detailsImage analysisProcess capabilityRegion of interest

The invention concerns an electronic device equipped with a video imaging process capability, which device includes a camera unit arranged to produce image frames from an imaging view which includes a region-of-interest ROI, an adjustable optics arranged in connection with the camera unit in order to focus the ROI on the camera unit, an identifier unit in order to identify a ROI from the image frame, a tracking unit in order to track the ROI from the image frames during the video imaging process and an auto-focus unit arranged to analyze the ROI on the basis of the tracking results provided by the tracking unit in order to adjust the optics. The device is arranged to determine the spatial position of the ROI in the produced image frame without any estimation measures.

Owner:WSOU INVESTMENTS LLC

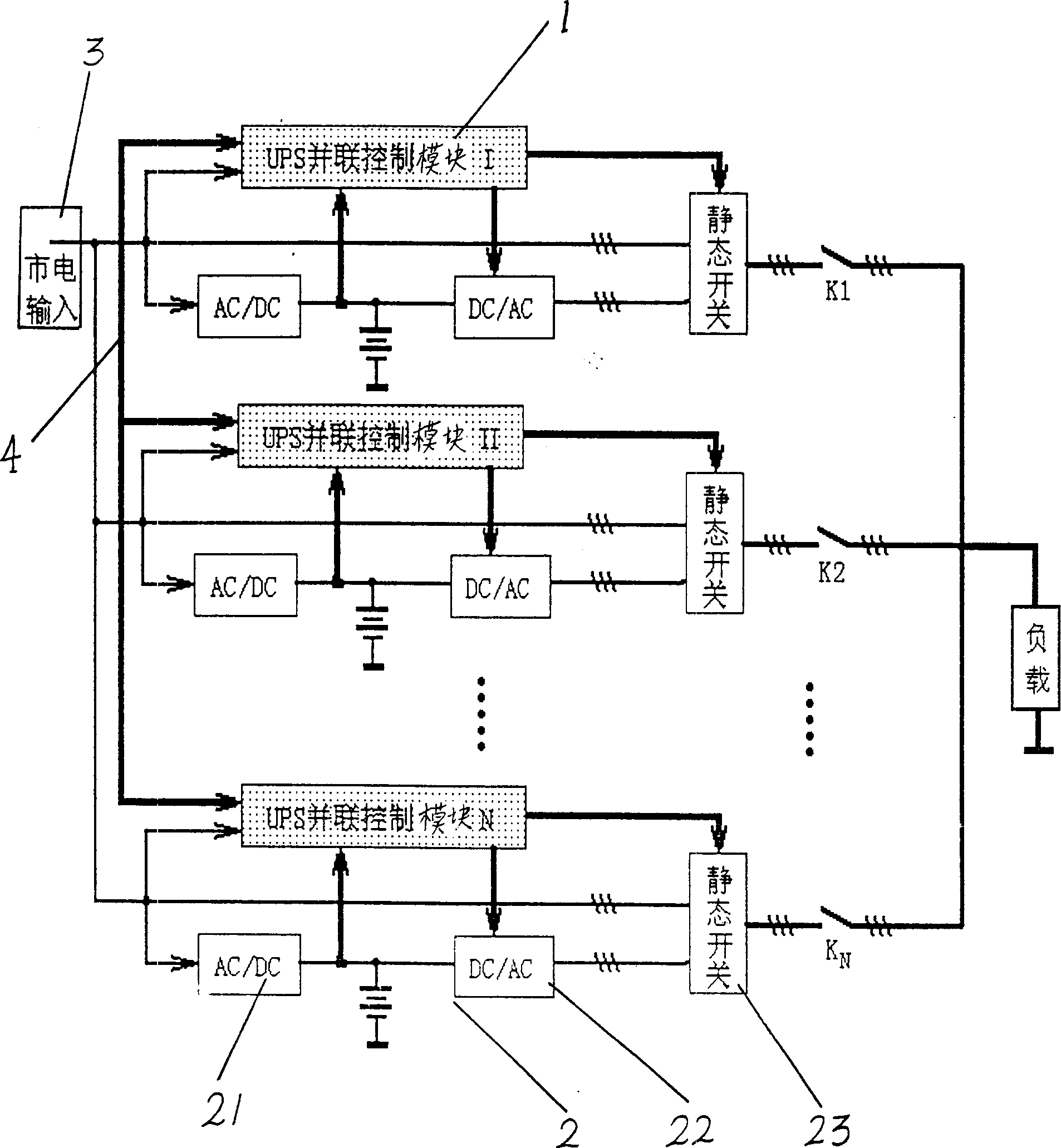

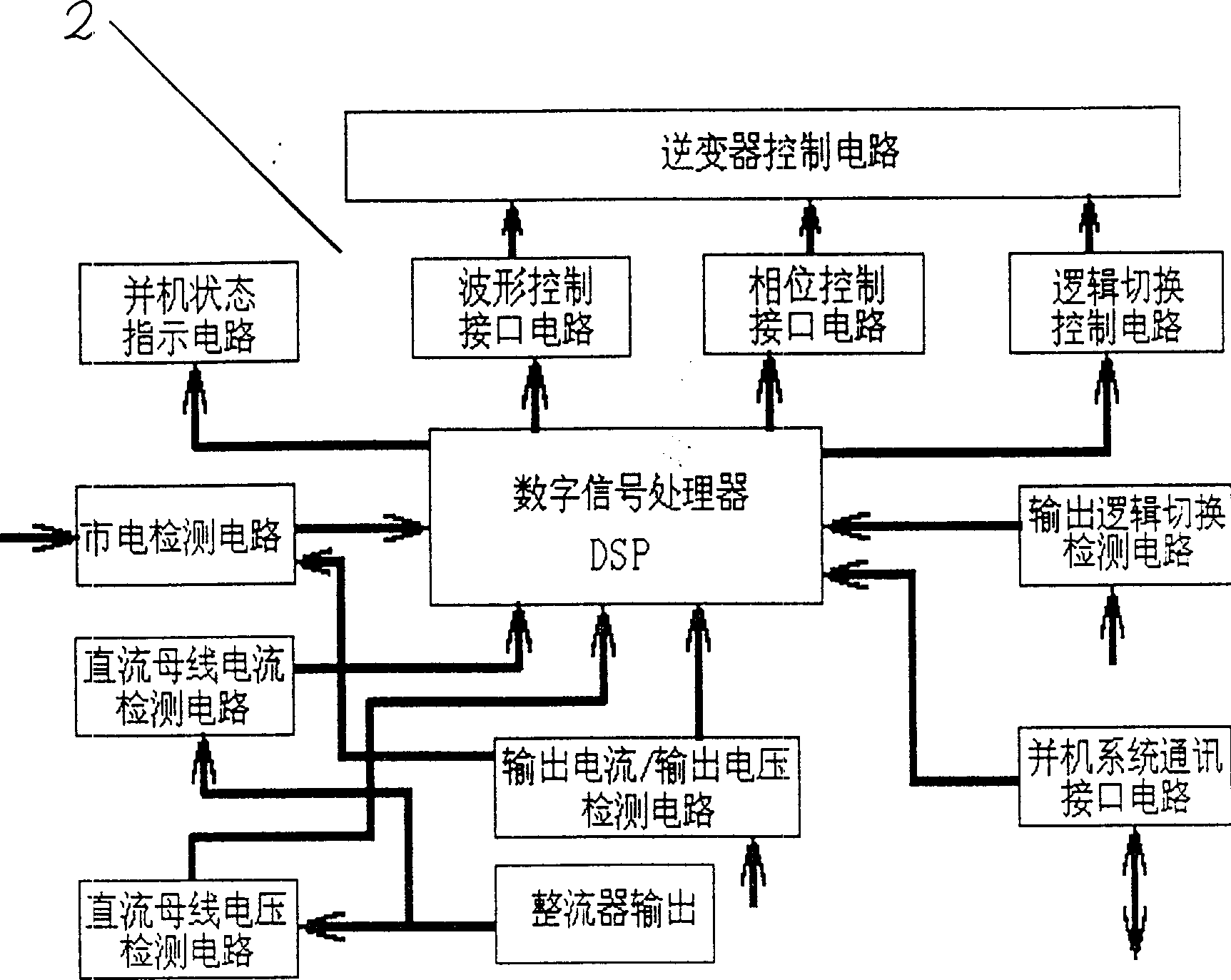

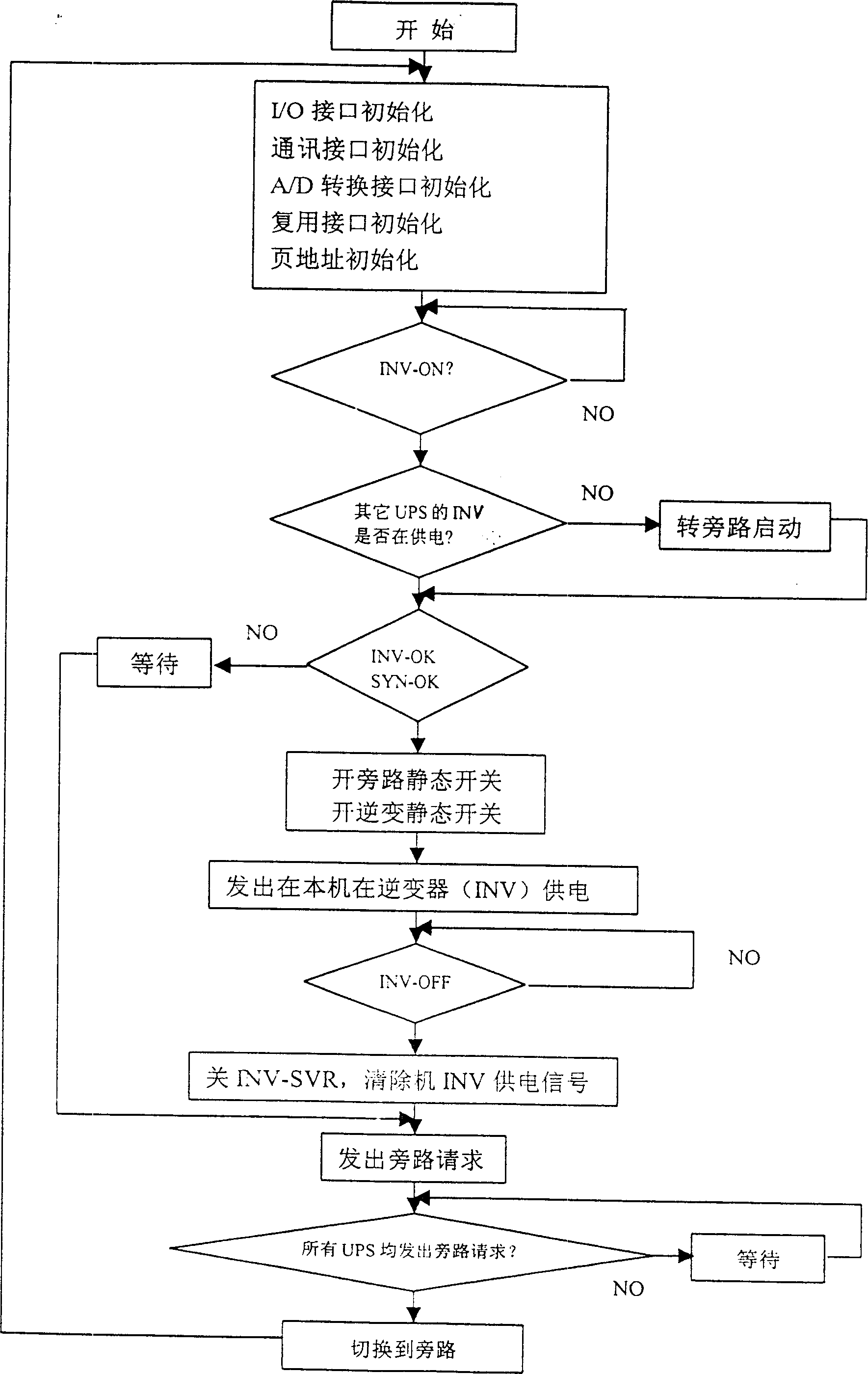

Bus-controlled parallel uninterrupted power source (UPS) system

InactiveCN1423389AAchieving even load sharingEnable redundant parallel operationBatteries circuit arrangementsElectric powerElectricityReal-time data

Parallel UPS system controlled by bus relates to power source equipment technology with the following scheme: UPS parallel control system is put in and connected with UPS, realizing N+1 redundant parallel operation and every UPS will supply electricity to load and shares the load to meet the requirement of parallel operation having very high real time data process capability to ensure the real time control and reliability of UPS parallel control system increased greatly.

Owner:GUANGDONG ZHICHENG CHAMPION GROUP

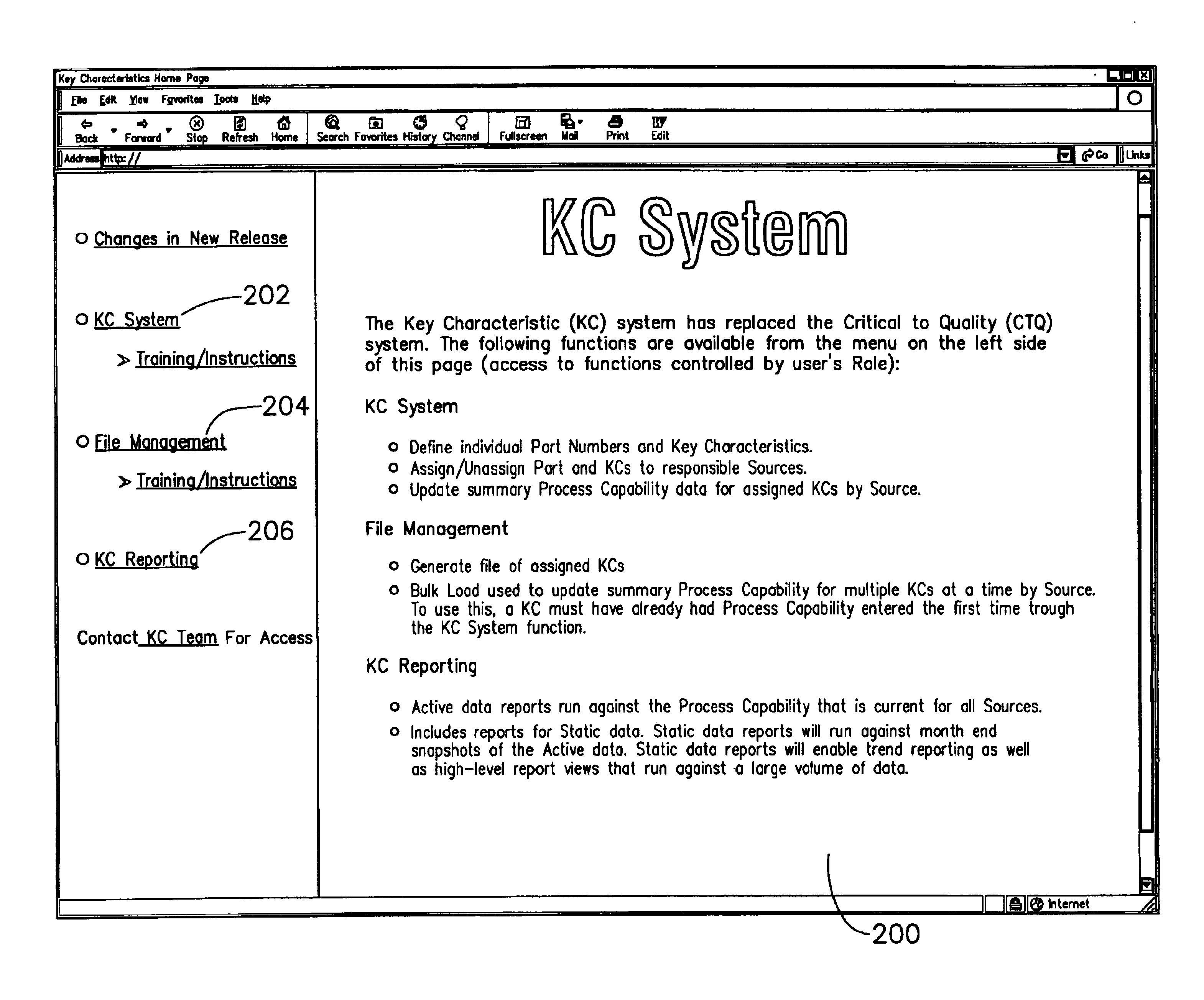

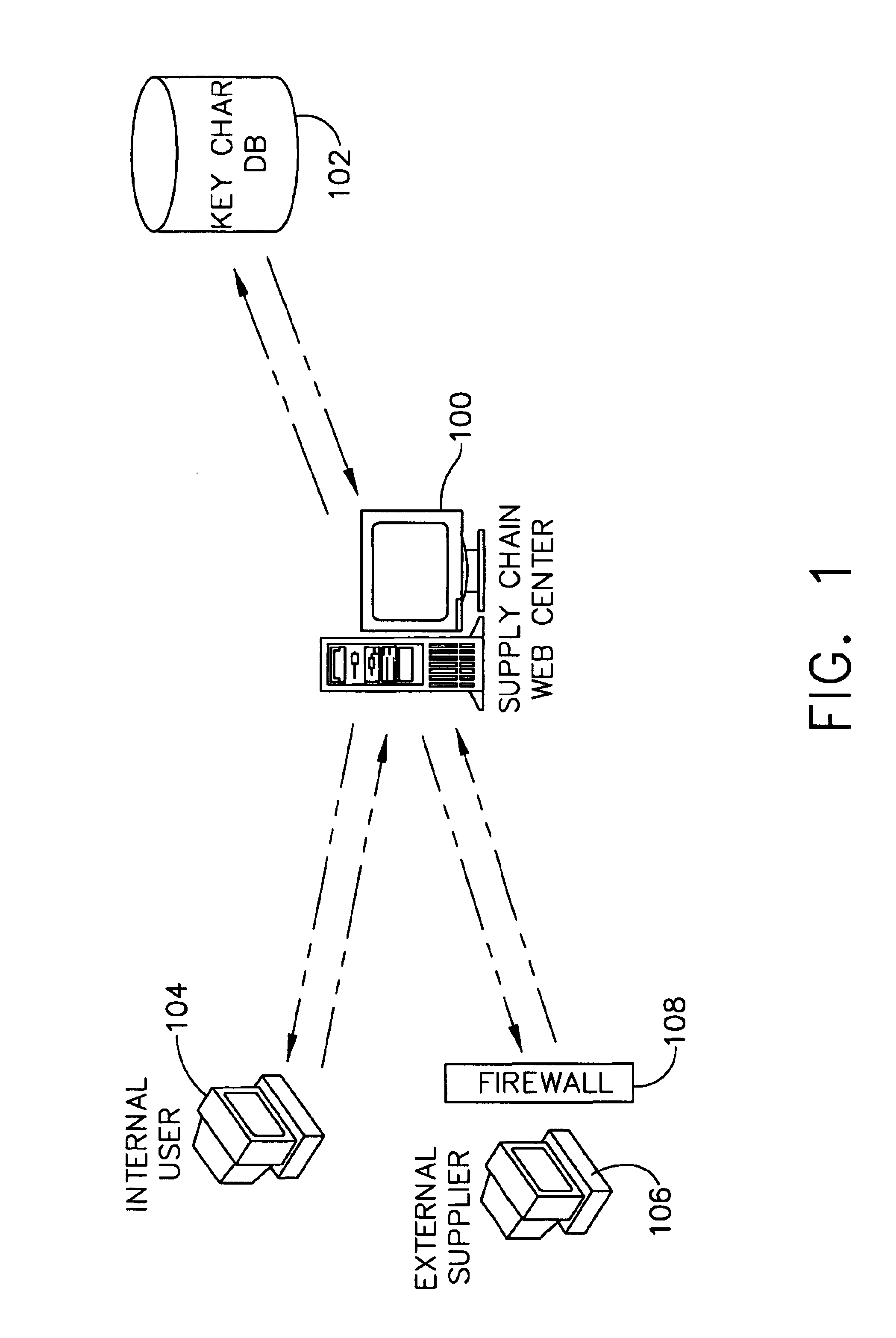

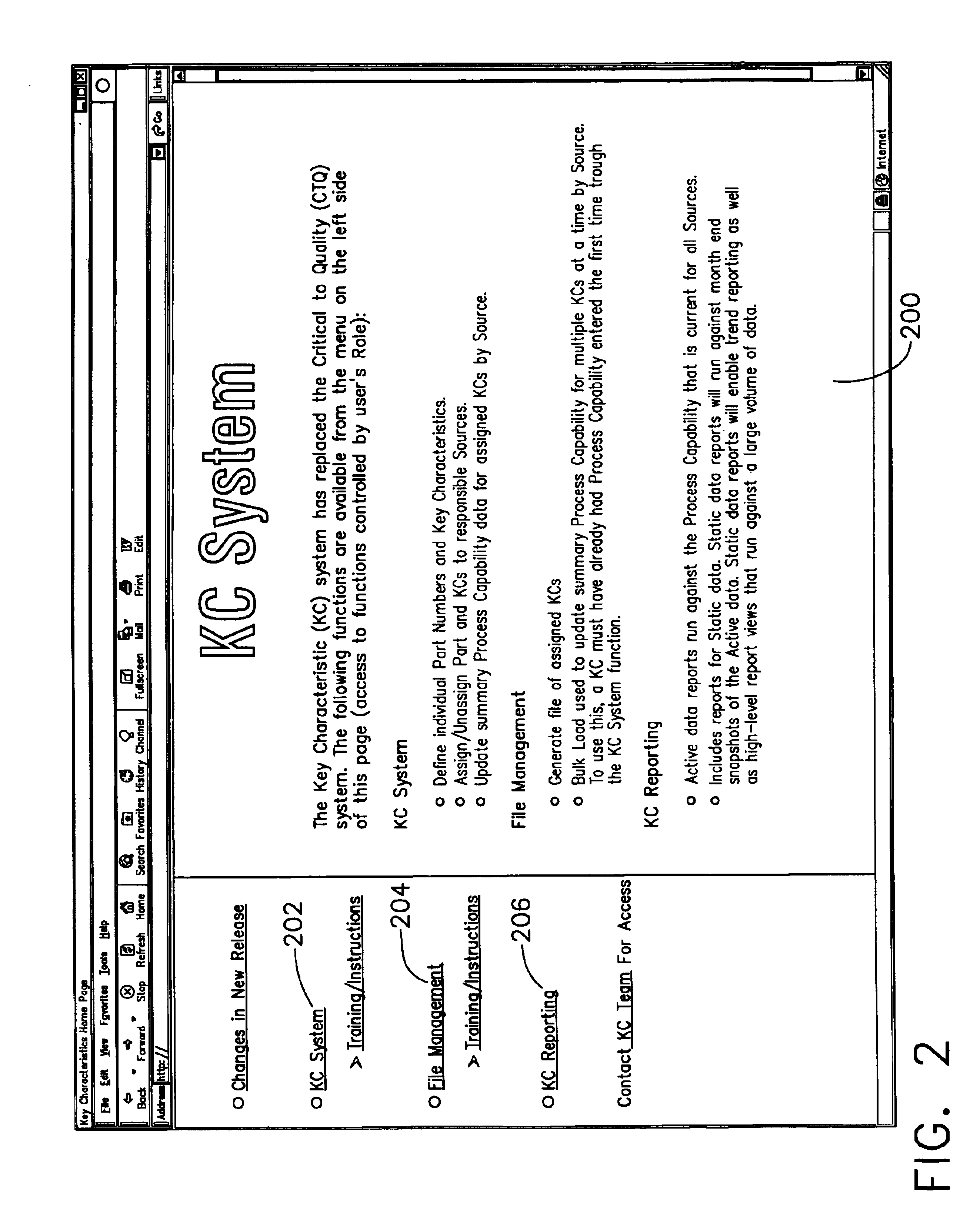

Web based process capability data collection and reporting system

InactiveUS6961732B2Fast uploadFast downloadDigital data processing detailsResourcesProcess capabilityDatabase

A system is provided that is accessible through a computer network and is used for collecting and tracking process capability data for manufacturers of parts. The recipient of the parts can input information on the characteristics of the parts that require process capability data into the system. The manufacturer of the parts can then access the system and enter process capability data relative to a specific part and characteristic. The system can then be used by both recipients and manufacturers to generate reports on the process capability status for all parts, processes, characteristics and manufacturers.

Owner:GENERAL ELECTRIC CO

Restriction of program process capabilities

ActiveUS8272048B2Digital data processing detailsUnauthorized memory use protectionDecision takingDocument preparation

This document describes systems and methods for restricting program process capabilities. In some implementations, the capabilities are restricted by limiting the rights or privileges granted to an application. A plurality of rules may be established for a program, or for a group of programs, denying that program the right to take actions which are outside of the actions needed to implement its intended functionality. A security policy is implemented to test actions initiated in response to an application against the rules to enable decisions restricting the possible actions of the program. Embodiments are disclosed which process the majority of decisions regarding actions against a security profile through use of a virtual machine. In some embodiments, the majority of decisions are resolved within the kernel space of an operating system.

Owner:APPLE INC

Information system for industrial vehicles

Industrial vehicles communicate across a wireless environment and the wireless communication, data collection and / or processing capabilities of industrial vehicles are leveraged against robust software solutions to implement enterprise wide asset management functions, to integrate industrial vehicle data into existing enterprise workflows and / or to enable trusted third party integration into the enterprise for enhanced asset and / or workflow management. Still further, wireless communication, data collection and / or processing capabilities of industrial vehicles are leveraged with robust software solutions that aggregate and analyze data across multiple enterprises and / or promote the exchange of information between independent entities.

Owner:CROWN EQUIP CORP

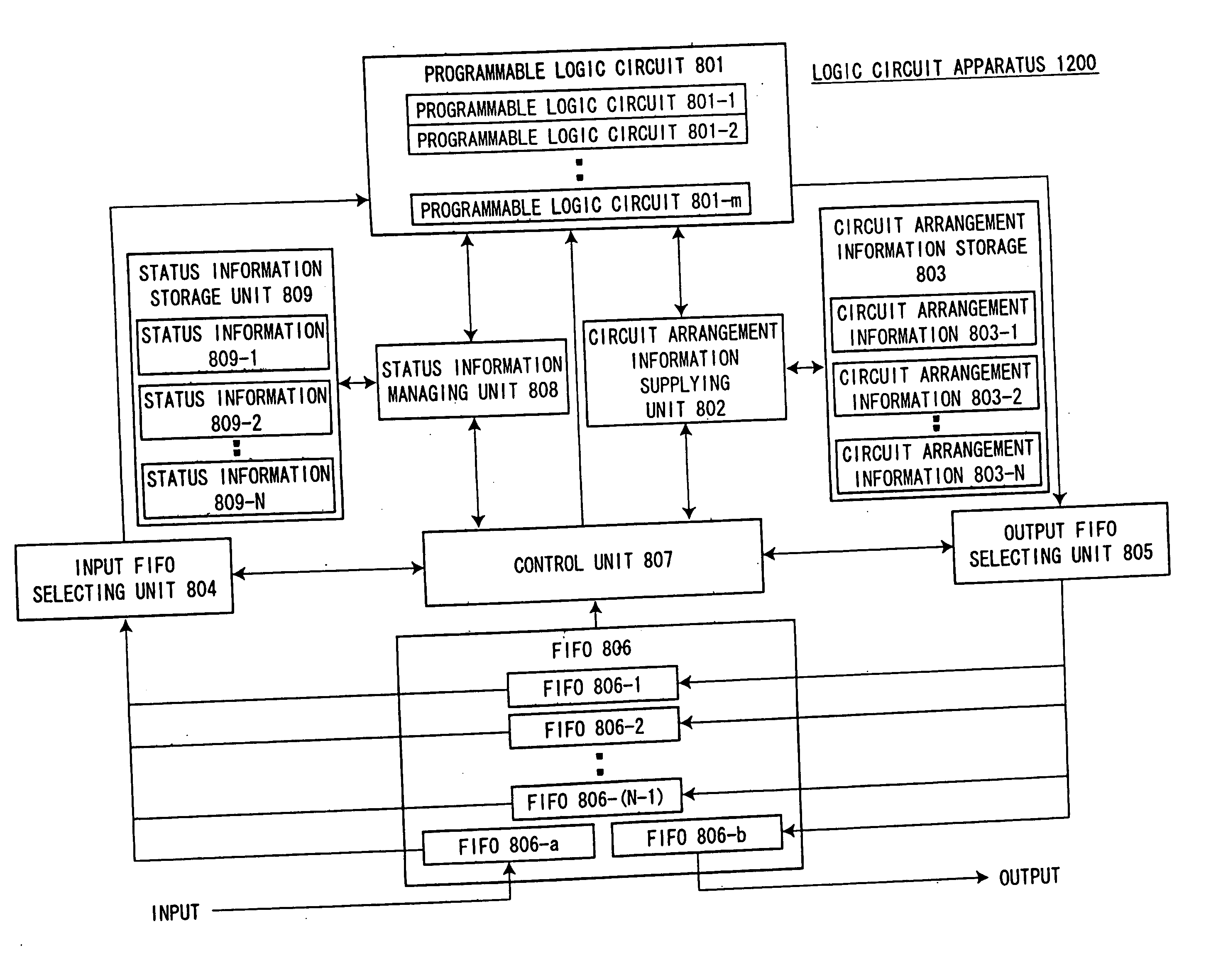

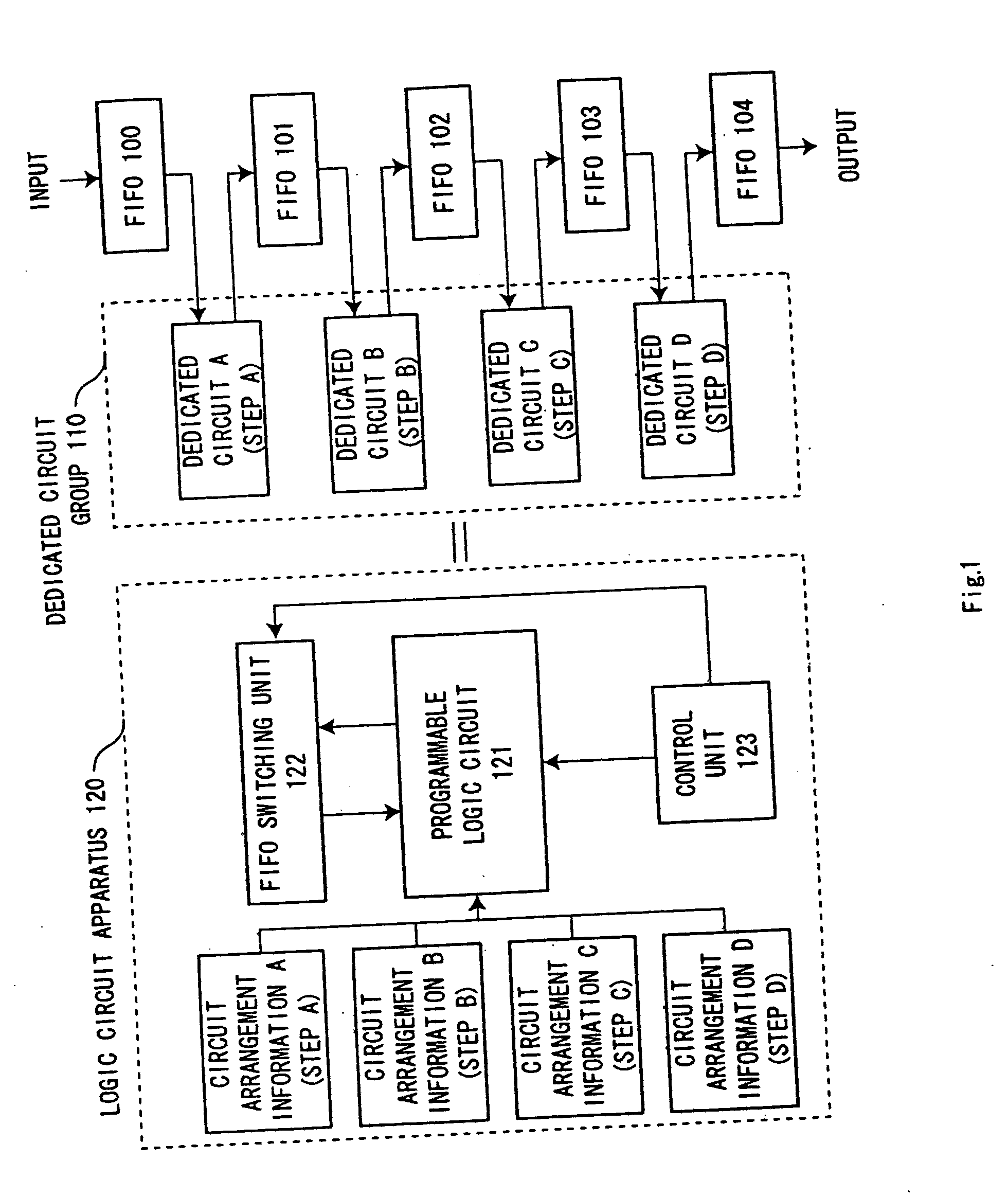

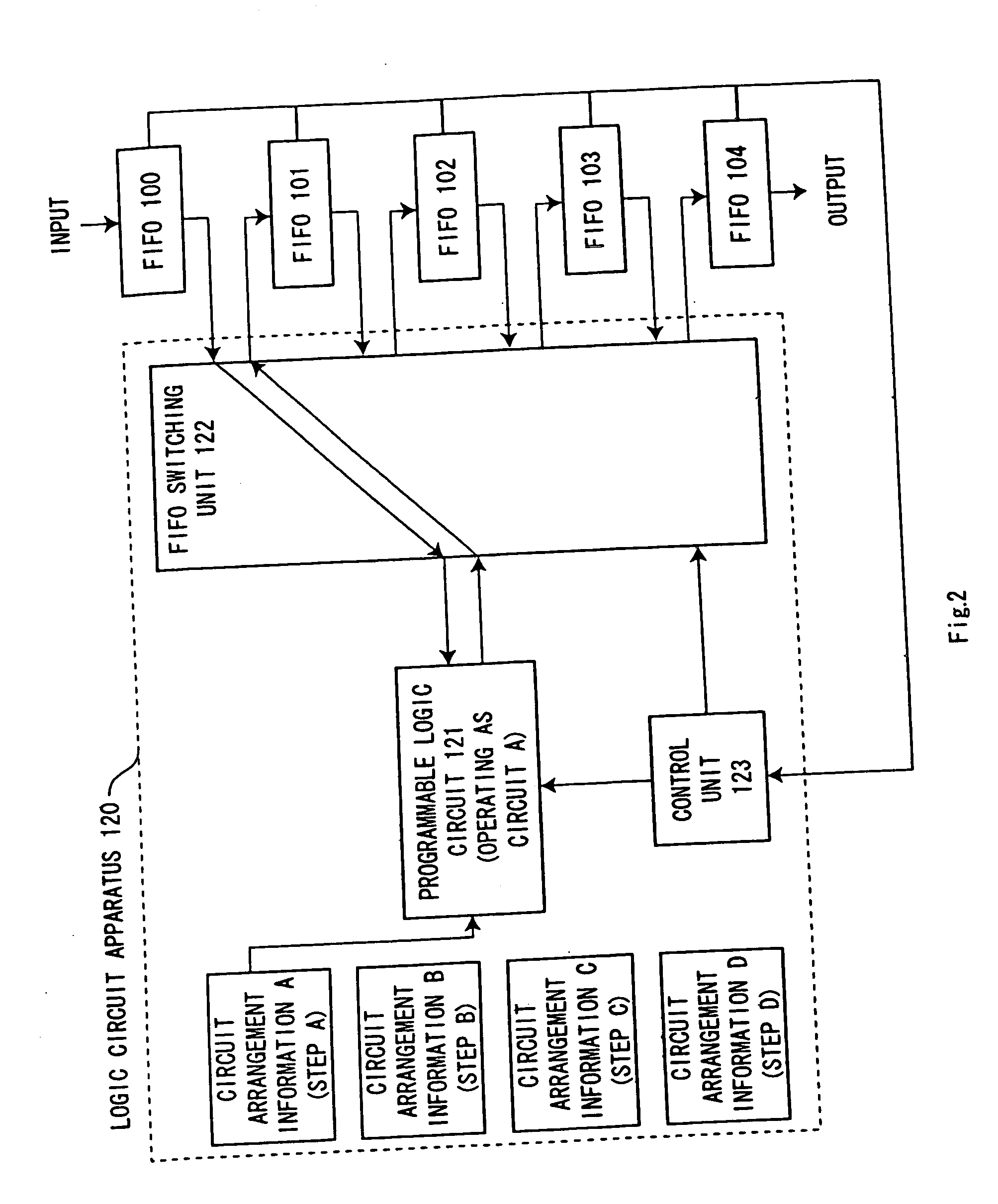

Logic circuit apparatus and timeshare operating method of a programmable logic circuit

InactiveUS20050110518A1Program control using stored programsError detection/correctionData memoryComputer science

A logic circuit apparatus that allocates process capability to unit circuits operated in a time divisional manner, including a circuit arrangement information memory which stores circuit arrangement information corresponding to each of plurality of unit circuits, and a programmable logic circuit with a circuit arrangement which can be reconfigured by employing the circuit arrangement information while the programmable logic circuit is being operated, a process data memory which stores both input data and output data related to a process operation of each of the circuits, and a controller which monitors a storage amount of the input data and / or a storage amount of the output data corresponding to each unit circuit, and which controls reconfiguration of the circuit arrangement of the programmable logic circuit when the storage amount satisfies a certain condition.

Owner:KK TOSHIBA

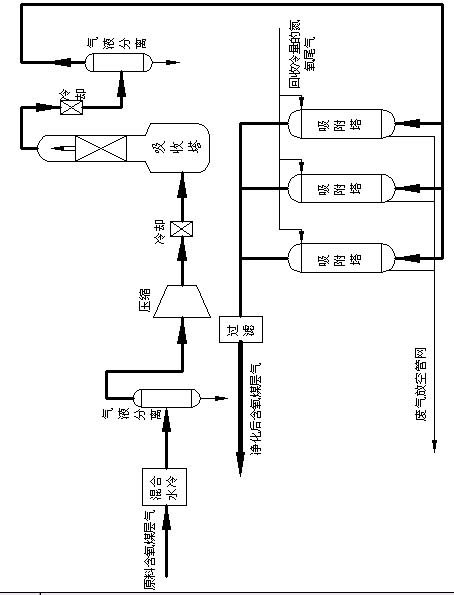

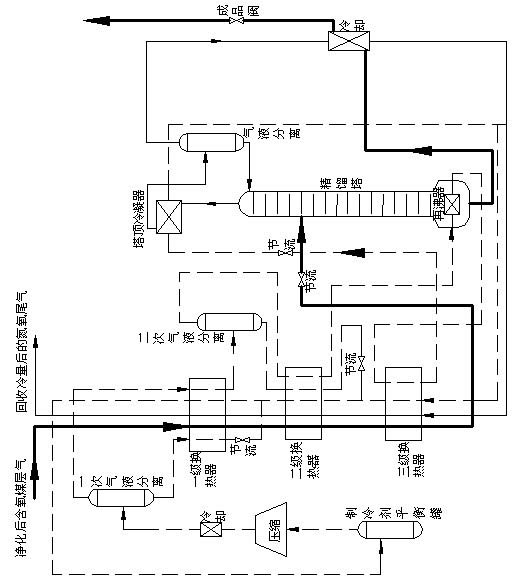

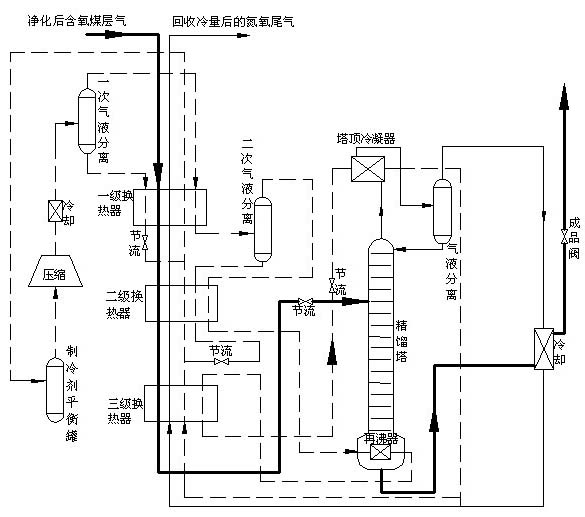

Method for utilizing coalbed methane containing oxygen to prepare liquefied natural gas

ActiveCN101922850AImprove cooling efficiencyEasy to handleSolidificationLiquefactionEnergy recoveryProcess engineering

The invention discloses a method for utilizing coalbed methane containing oxygen to prepare liquefied natural gas, which comprises compress purification working procedure and liquefying separation working procedure, wherein the liquefying separation working procedure comprises a main process technology and a refrigeration technology; and in the refrigeration technology, a special mixing refrigerating fluid is combined with throttle refrigeration and a special refrigerating fluid process. In the refrigeration process of the invention, the mixing refrigeration is combined with the throttle refrigeration, which changes the existing refrigeration technology, fully and reasonably utilizes the cold energy recovery process in the technology process, and improves the freezing capacity so as to relatively improve the process capability of the device; as for the coalbed methane with not-high individual-well producing rate, the production cost can be saved; and only one set of gas booster compressor is utilized, so that the power energy is saved.

Owner:CHONGQING INST OF COAL SCI RES INST +1

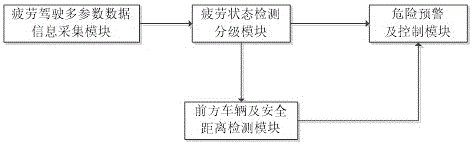

Vehicle anticollision pre-warning system considering driver fatigue state and response capability

InactiveCN106408878ASolve the problem of fatigue misjudgmentAvoid reactionAlarmsTraffic crashDistance detection

The invention discloses a vehicle anticollision pre-warning system considering the driver fatigue state and response capability. The system includes a fatigue driving multi-parameter information acquisition module, a fatigue state detection and grading module, a vehicle and safe distance detection module and a fatigue driving pre-warning and control module, and different fatigue driving control response mechanisms are adopted according to fatigue degree grades. The vehicle anticollision pre-warning system provided by the invention proposes individual difference of parameters during driving of a driver, through a self-learning method of individual difference, a driving fatigue state detection and fatigue degree grading model considering individual difference is established, and the problem of fatigue misjudgment caused by individual difference of driver fatigue characteristics is solved; and at the same time, the driver fatigue state and response capability are used as one of modeling considering factors of a safe distance detection model, the problem that response action is not in time due to fatigue is effectively solved, and the occurrence of road traffic accidents is effectively avoided.

Owner:SUZHOU TSINGTECH MICROVISION ELECTRONICS TECH

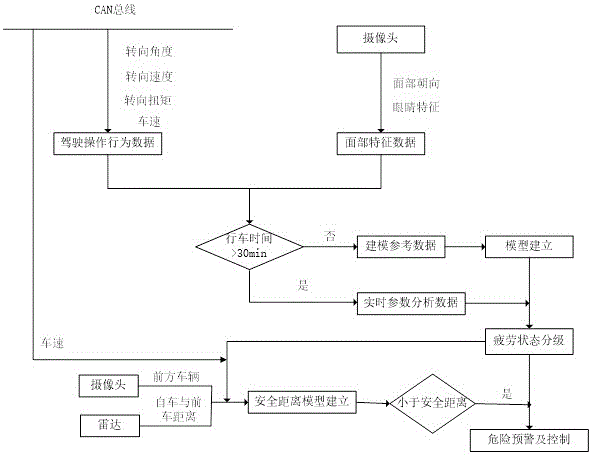

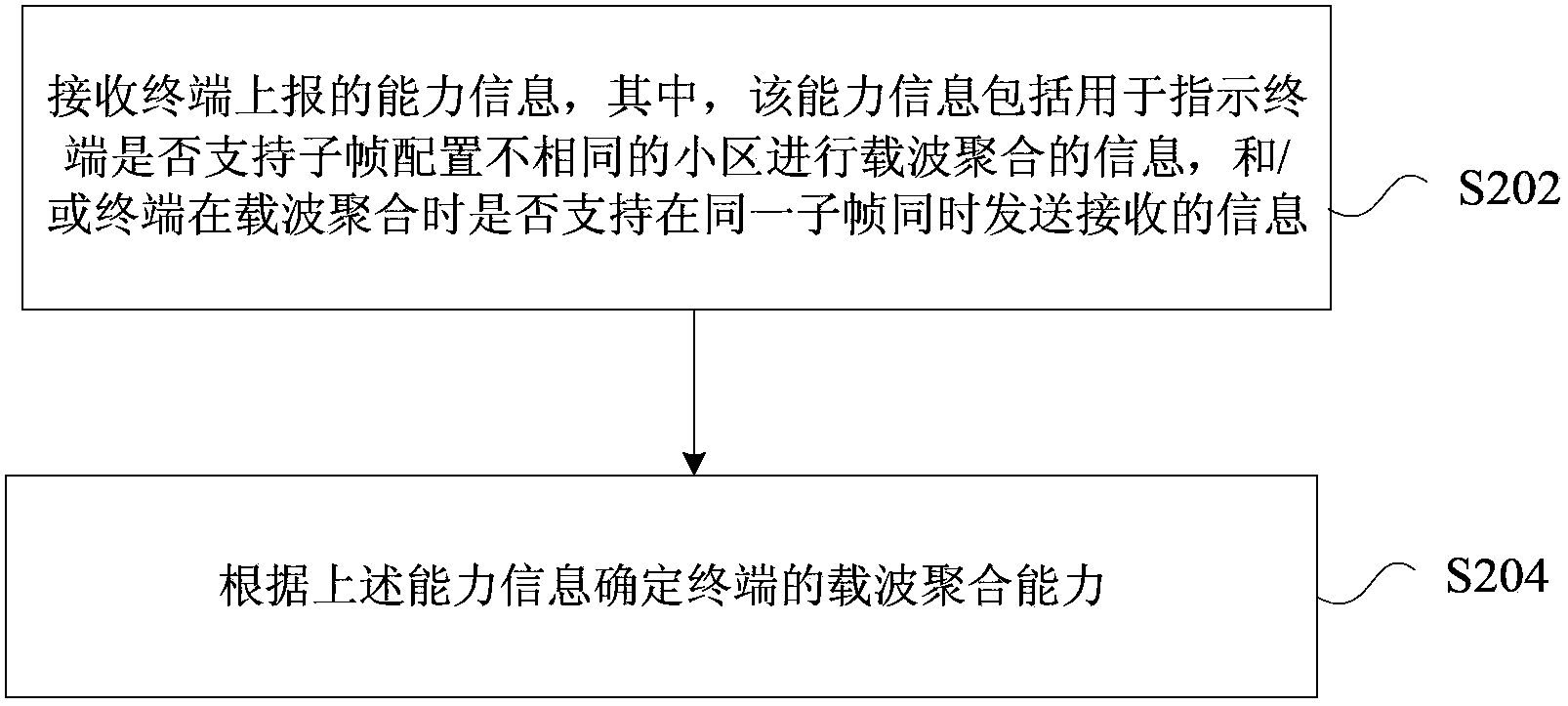

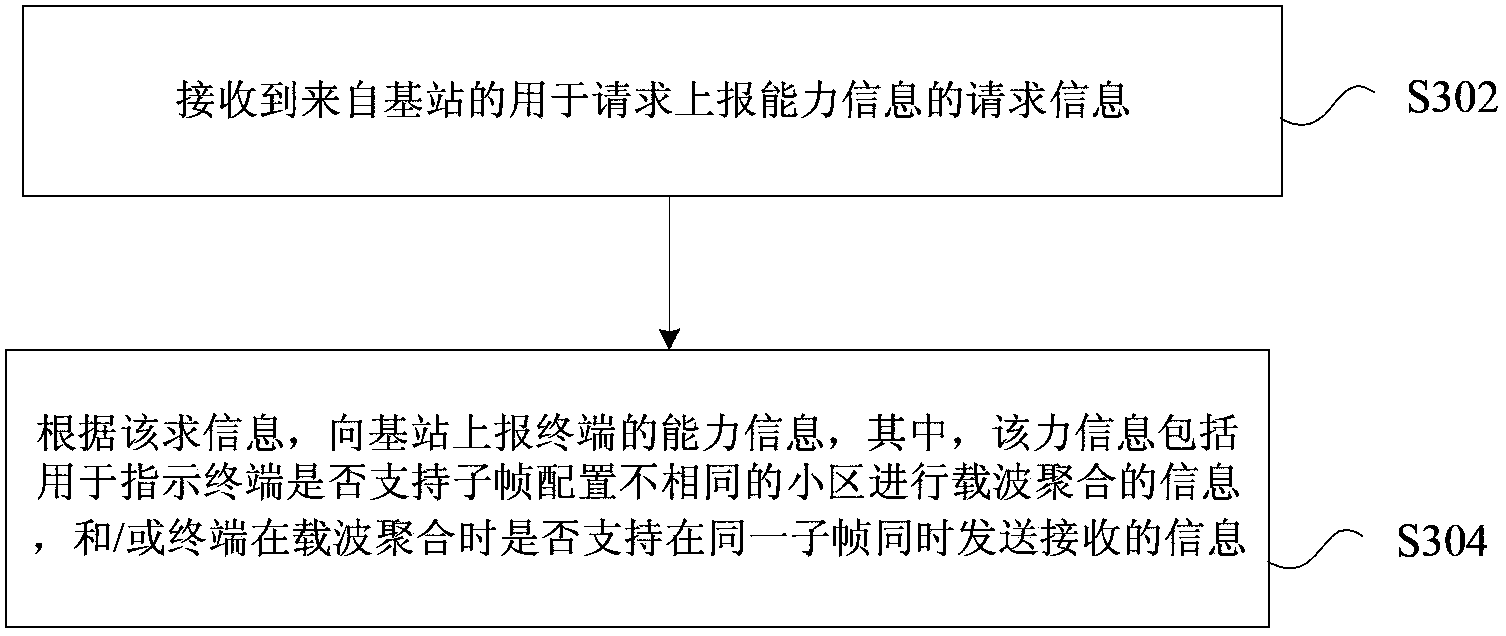

Method, device and base station for processing capability information

InactiveCN103580781AReasonable configurationCarrier aggregation is reasonable for cells with different configurationsError preventionTransmission path divisionCarrier signalProcess capability

The present invention provides a method, device and base station for processing capability information. the method comprises: receiving capability information reported by terminal, capability information comprises information for indicating the terminal whether supporting carrier aggregation with sub-frame configuration not to be the same cell or not, and / or information for the terminal whether supporting transmitting and receiving synchronously in the same sub-frame when the terminal is carrier aggregation or not; determining carrier aggregation capability of the terminal according to capability information. The problems existing in the relevant art to be solved in the present invention, are how to acquire the terminal whether supporting carrier aggregation with sub-frame configuration not to be the same cell or not, and how to support said way. The present invention achieves the effect that the base station obtains carrier aggregation capability of the terminal supporting different sub-frames configuration, and further provides more reasonable carrier aggregation for the terminal.

Owner:ZTE CORP

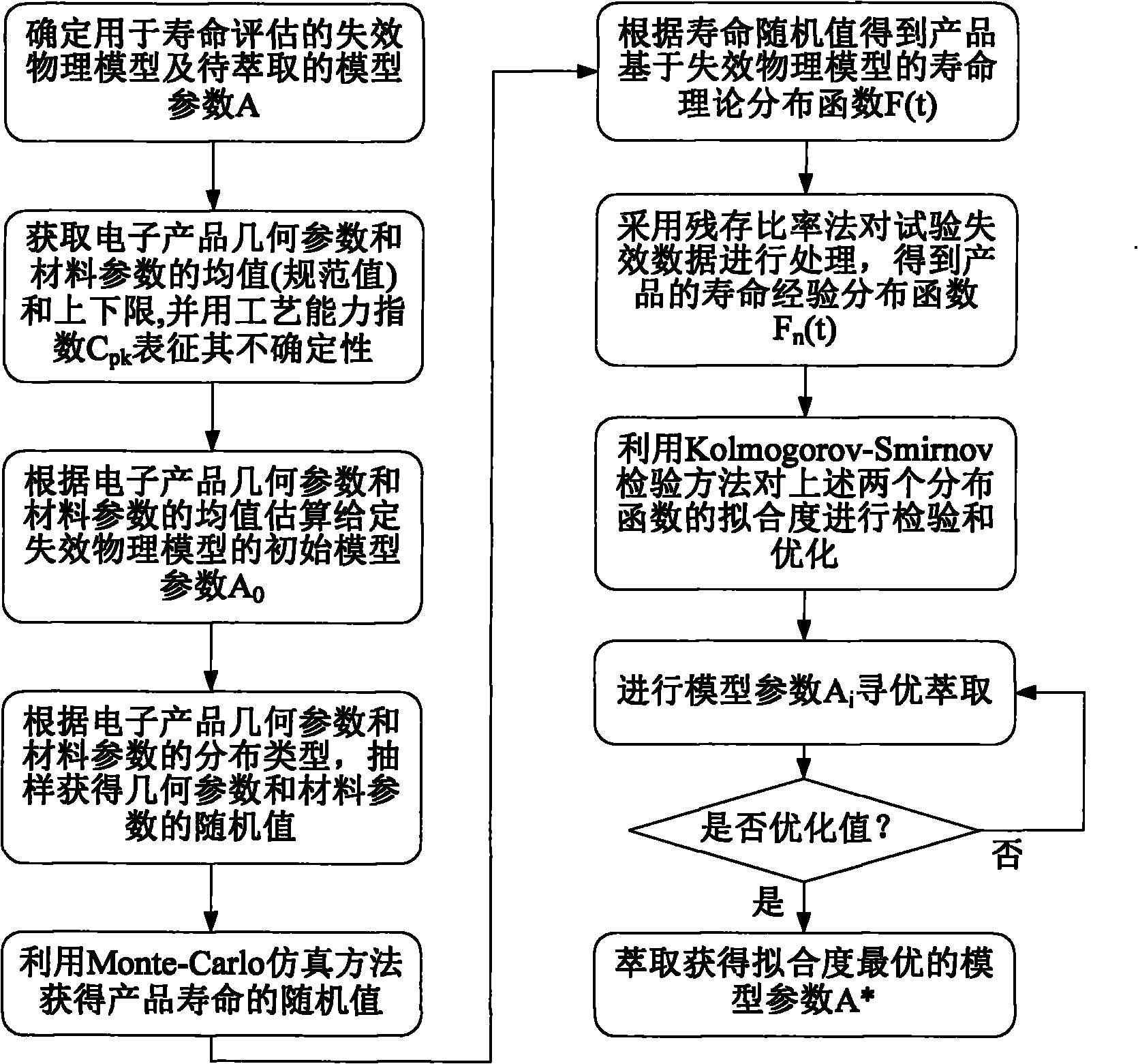

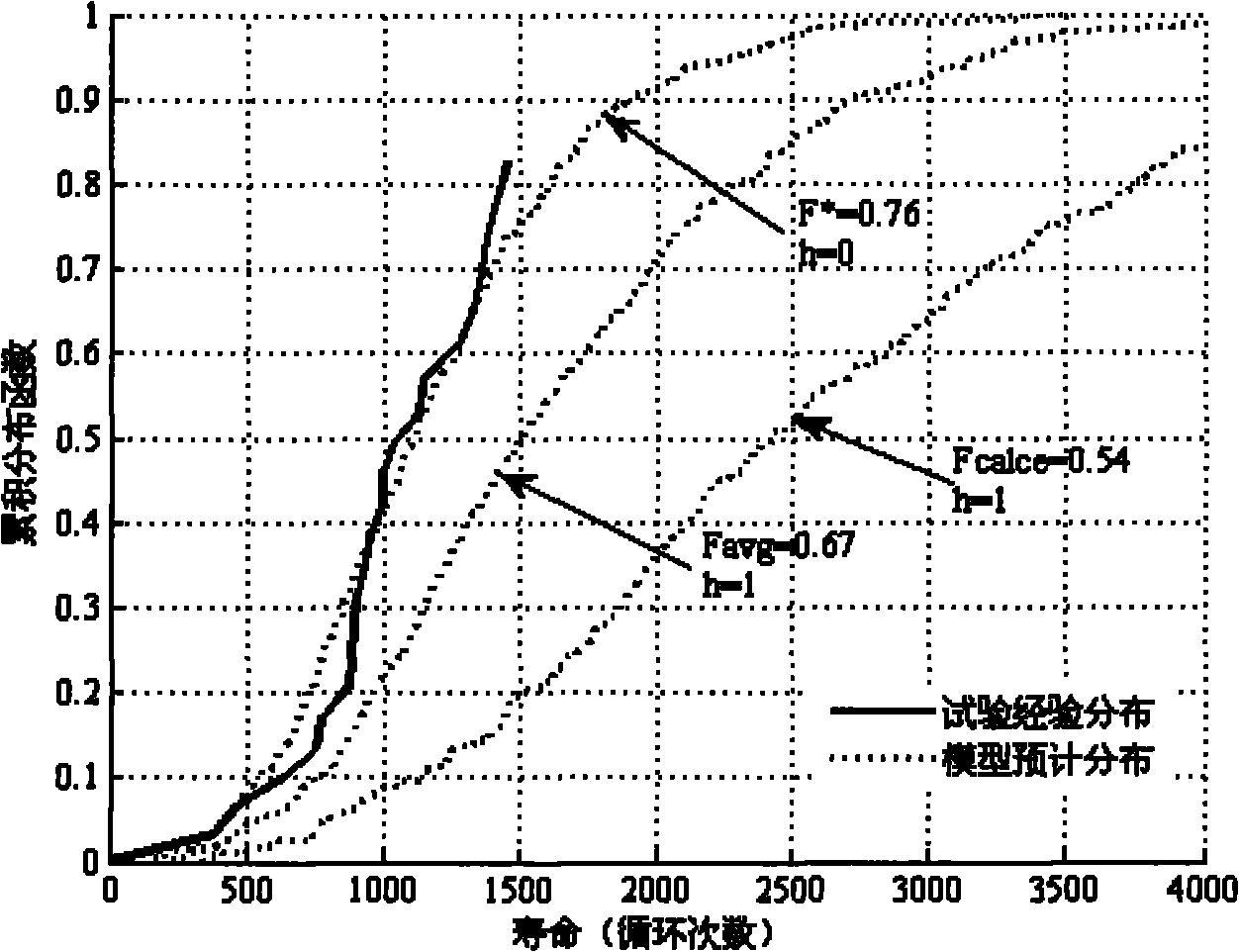

Practical electronic product service life evaluation model parameter high-accuracy extraction method

ActiveCN102103658AGuaranteed accuracyAddress usability bottlenecksSpecial data processing applicationsPhysical modelData mining

The invention discloses a practical electronic product service life evaluation model parameter high-accuracy extraction method, which comprises the following steps of: (1) determining a failure physical model and model parameters to be extracted; (2) acquiring mean values, upper limits and lower limits of geometric and material parameters of a product, and representing the uncertainty of the parameters by adopting process capability indexes; (3) evaluating initial model parameters of the failure physical model according to the mean values of the geometric and material parameters of the product; (4) performing sampling according to distribution types of the geometric and material parameters to obtain random values of the geometric and material parameters; (5) obtaining the random value of the service life of the product by combining a Monte-Carlo simulation method; (6) obtaining a theoretical distribution function of the service life of the product according to the random value of the service life; (7) processing experimental failure data by adopting a remaining ratio method to obtain an empirical distribution function of the service life of the product; (8) checking a degree of fitting of the two service life distribution function by utilizing a K-S checking method; and (9) performing optimal extraction on the model parameters until the model parameters with an optimal degree of fitting are obtained.

Owner:北京可维创业科技有限公司

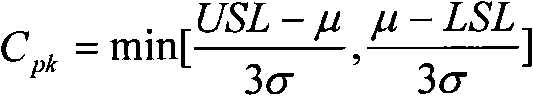

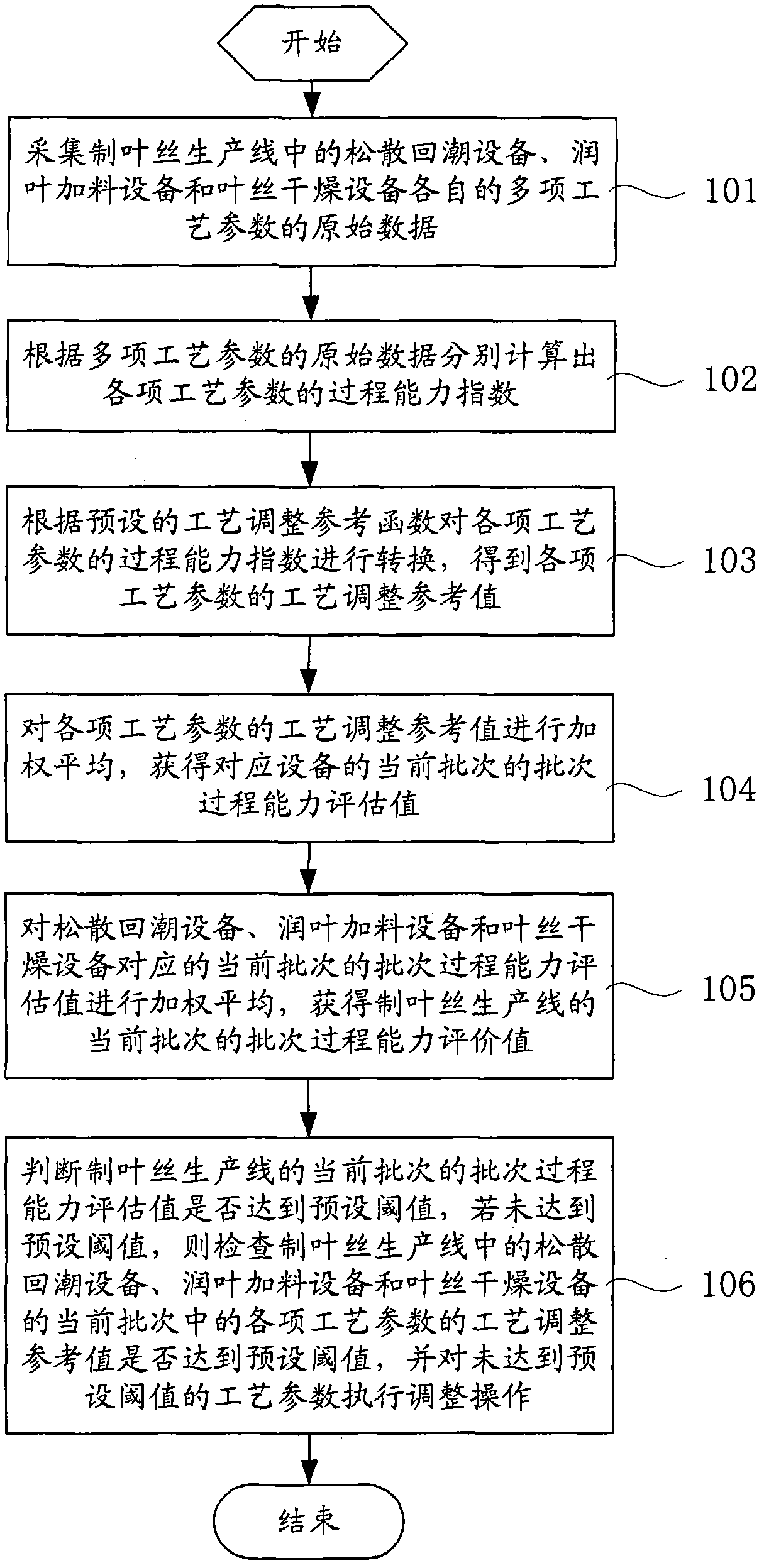

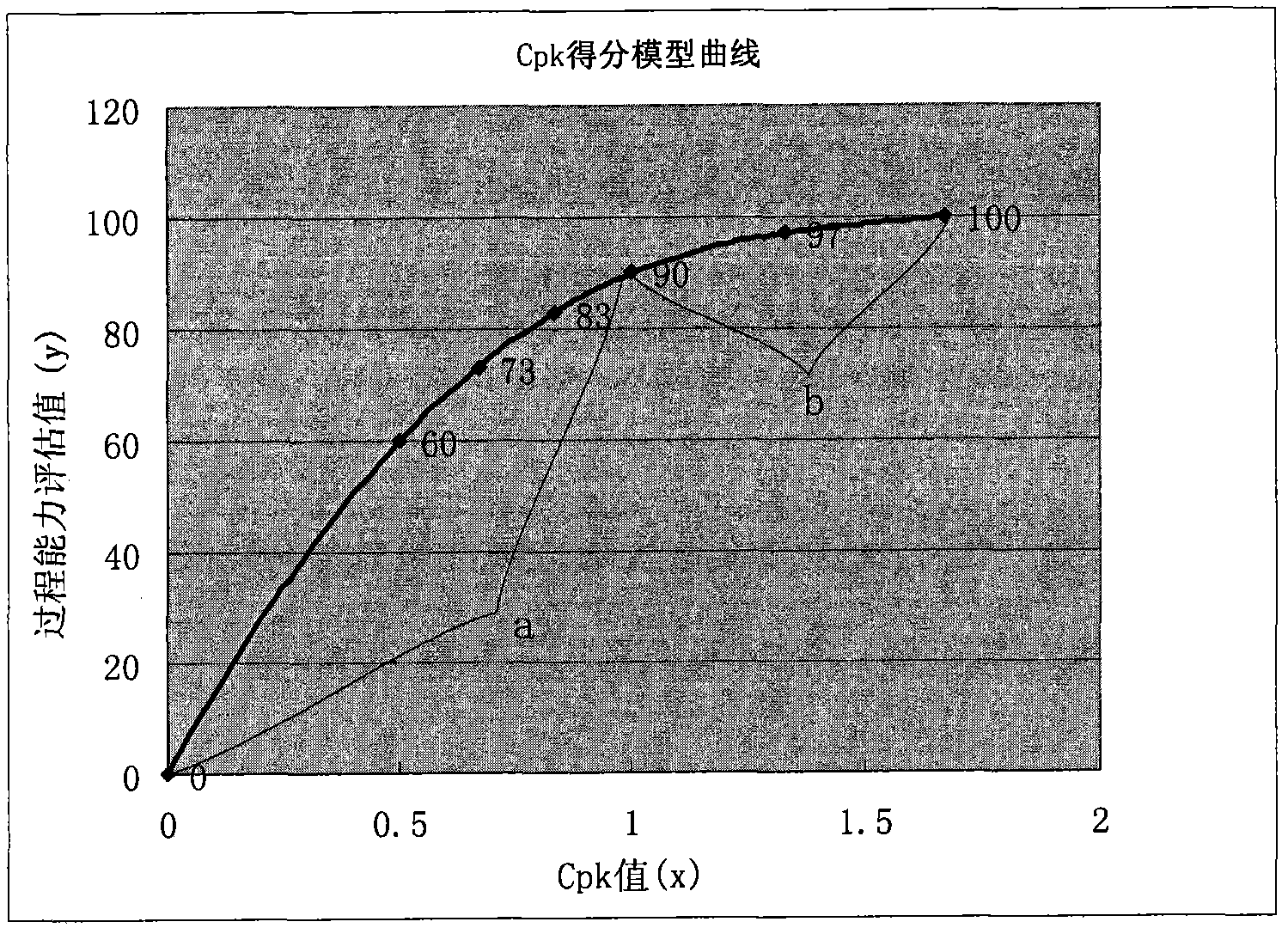

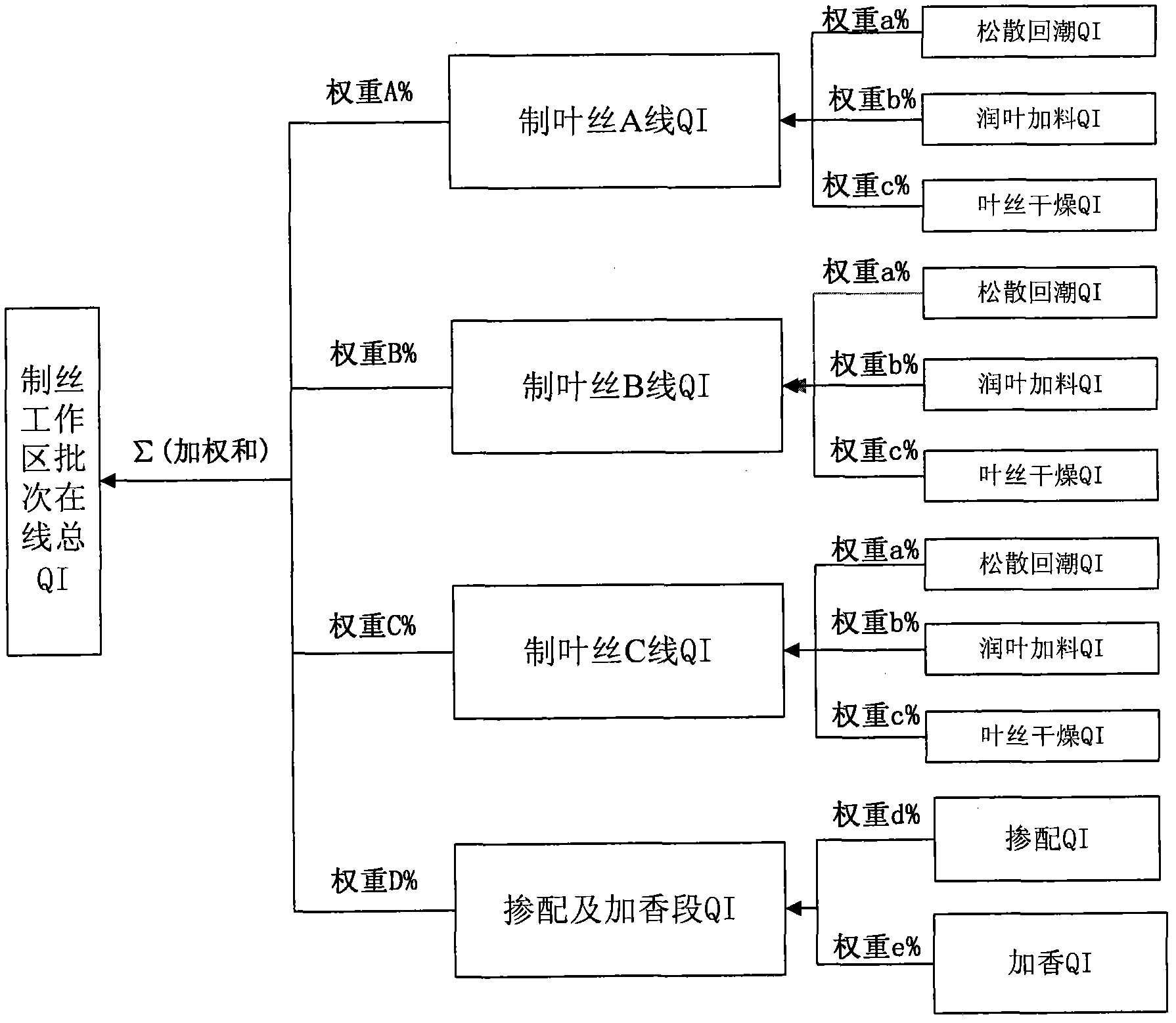

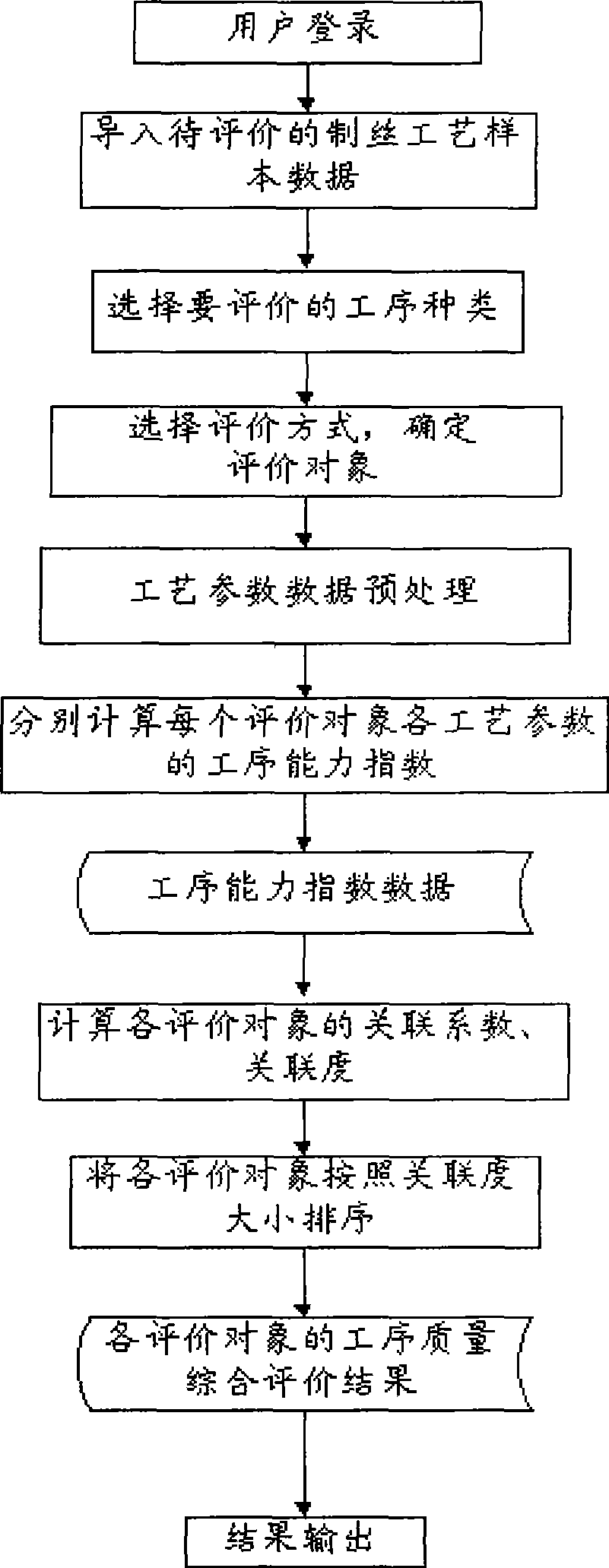

Method for improving batch procedure capability of tobacco shred making process

The invention relates to a method for improving the batch procedure capability of a tobacco shred making process, comprising the following steps of: acquiring original data of multiple process parameters of each device in a tobacco shred production line; respectively calculating procedure capability index of each process parameter; converting the procedure capability index of each process parameter to obtain a process regulation reference value of the each process parameter; carrying out the weighted mean on the process regulation reference value of the each process parameter to obtain an evaluation value of the batch procedure capability of the current batch of a corresponding device; obtaining an assessed value of the batch procedure capability of the current batch of the tobacco shred production line by the weighted mean; and judging whether the assessed value of the batch procedure capability of the current batch of the tobacco shred production line is up to a preset threshold; ifthe assessed value is not up to the preset threshold, detecting whether the process regulation reference value of the each process parameter in the current batch of the each device in the tobacco shred production line is up to the preset threshold, and regulating the process parameters which are not up to the preset threshold.

Owner:LONGYAN CIGARETTE FACTORY

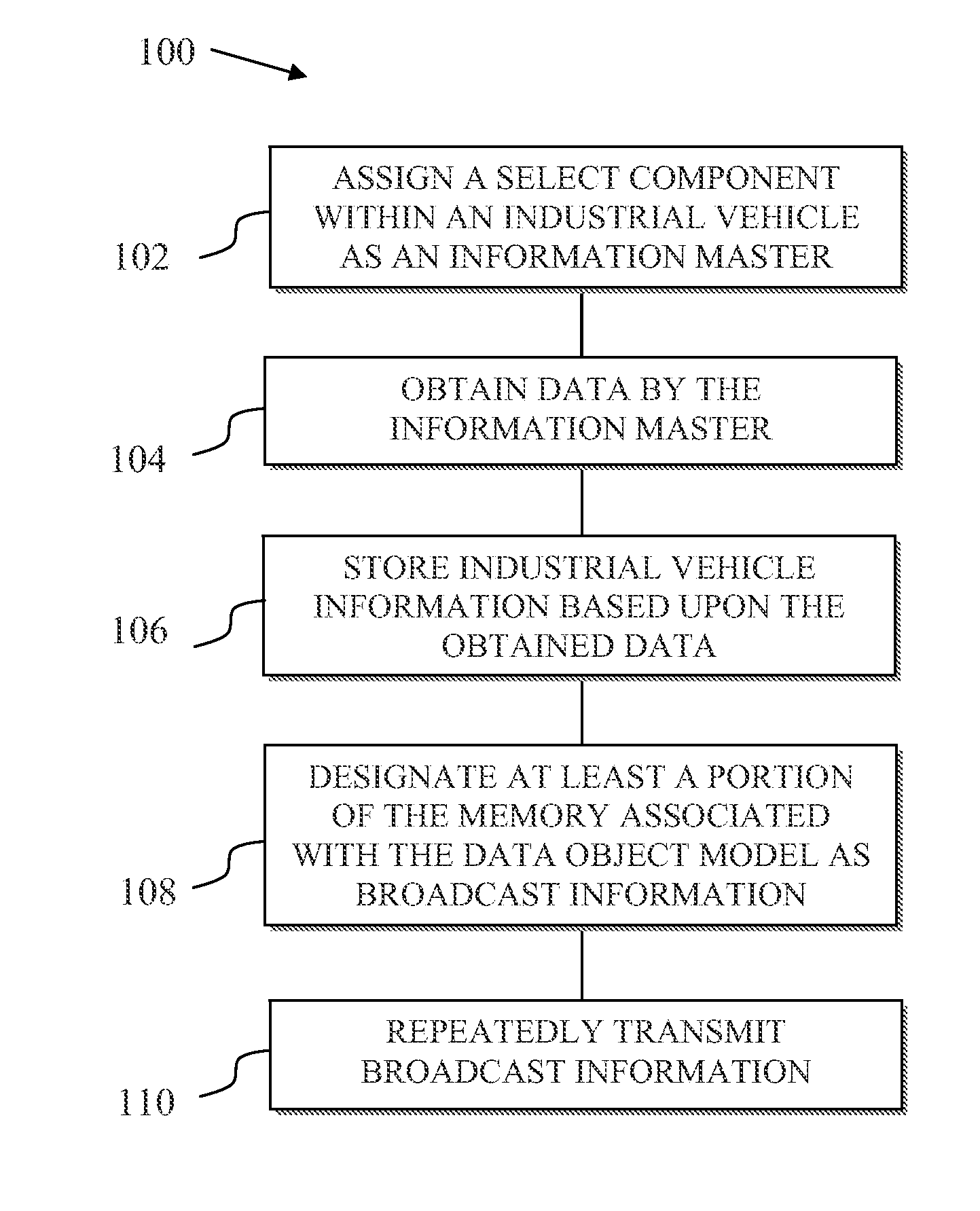

Information system for industrial vehicles including cyclical recurring vehicle information message

ActiveUS20110022442A1ResourcesVehicle position/course/altitude controlProcess capabilityTrust third party

Industrial vehicles communicate across a wireless environment and the wireless communication, data collection and / or processing capabilities of industrial vehicles are leveraged against robust software solutions to implement enterprise wide vehicle management functions, to integrate industrial vehicle data into existing enterprise workflows and / or to enable trusted third party integration into the enterprise for enhanced asset and / or workflow management. Still further, wireless communication, data collection and / or processing capabilities of industrial vehicles are leveraged with robust software solutions that aggregate and analyze data across multiple enterprises and / or promote the exchange of information between independent entities.

Owner:CROWN EQUIP CORP

Cigarette working procedure quality overall evaluation system and method based on gray correlation analysis

ActiveCN101414183ASolve the ambiguous situation of process capability evaluationFunctional job improvementTotal factory controlProgramme total factory controlGrey correlation analysisProcess quality

The invention discloses a comprehensive cigarette process quality evaluation system based on grey correlation analysis and a method thereof, aims at overcoming the disadvantage that the existing single process evaluation method can not comprehensively evaluate the overall process quality of the cigarette process, and changing the situation of fuzzy process capability evaluation of a whole line at present. The evaluation system and the method thereof help comprehensively evaluates the quality of a plurality of processes, and can effectively grasp comprehensive situation of the process quality so as to provide basis for the continuous improvement in the process quality, and provide assurance for quality improvement of cigarette products. The system and the method combine the single-process quality evaluation method and the grey correlation analysis method. The method comprises the following steps: firstly, computing process capability indexes of various process parameters; then, comprehensively evaluating a Cpk value by the grey correlation method; finally, obtaining a comprehensive evaluation result which is taken as a process quality rank of various evaluated objects. Production practice can be effectively directed by analyzing the Cpk and the process quality ranking result.

Owner:CHINA TOBACCO SHANDONG IND +1

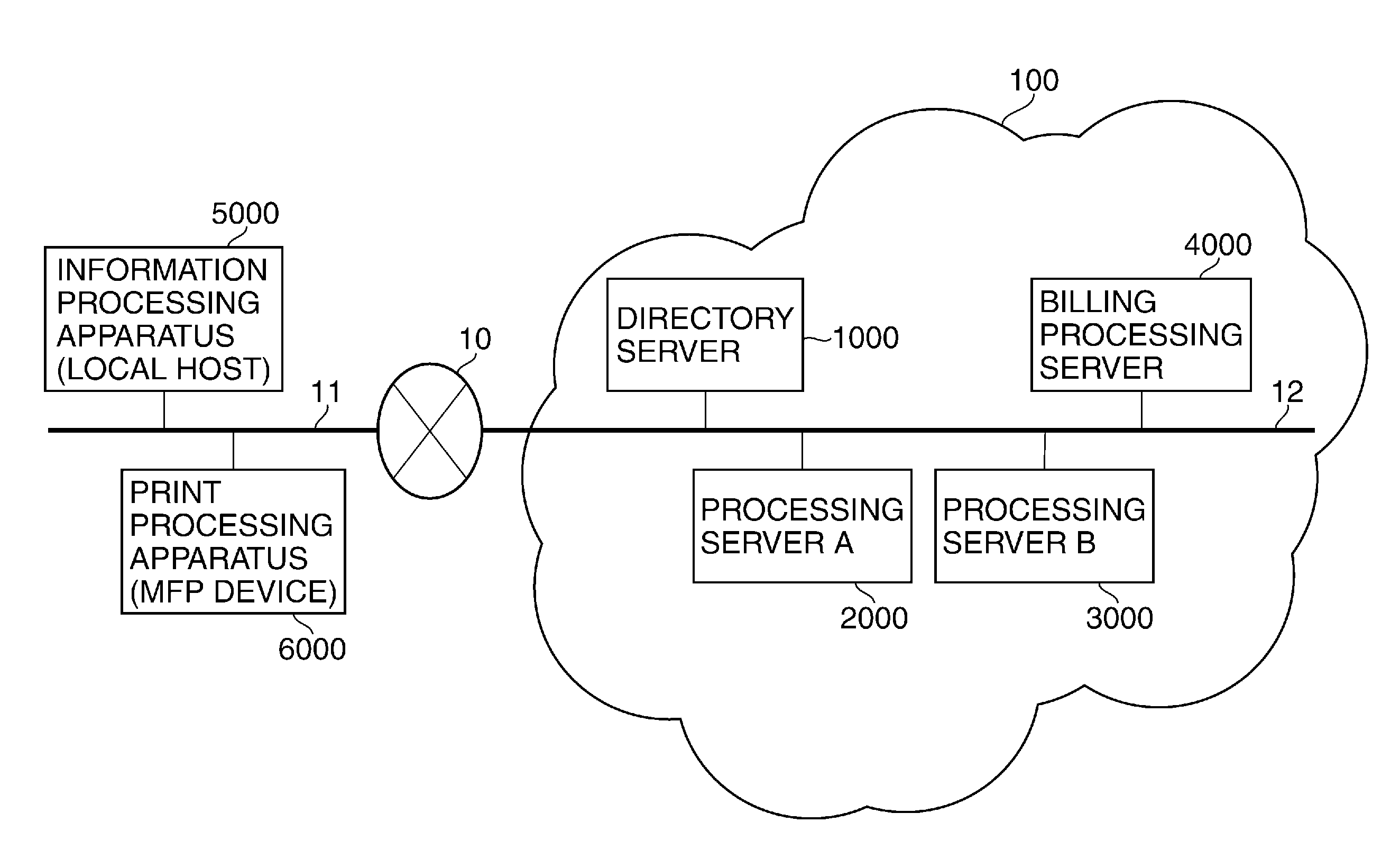

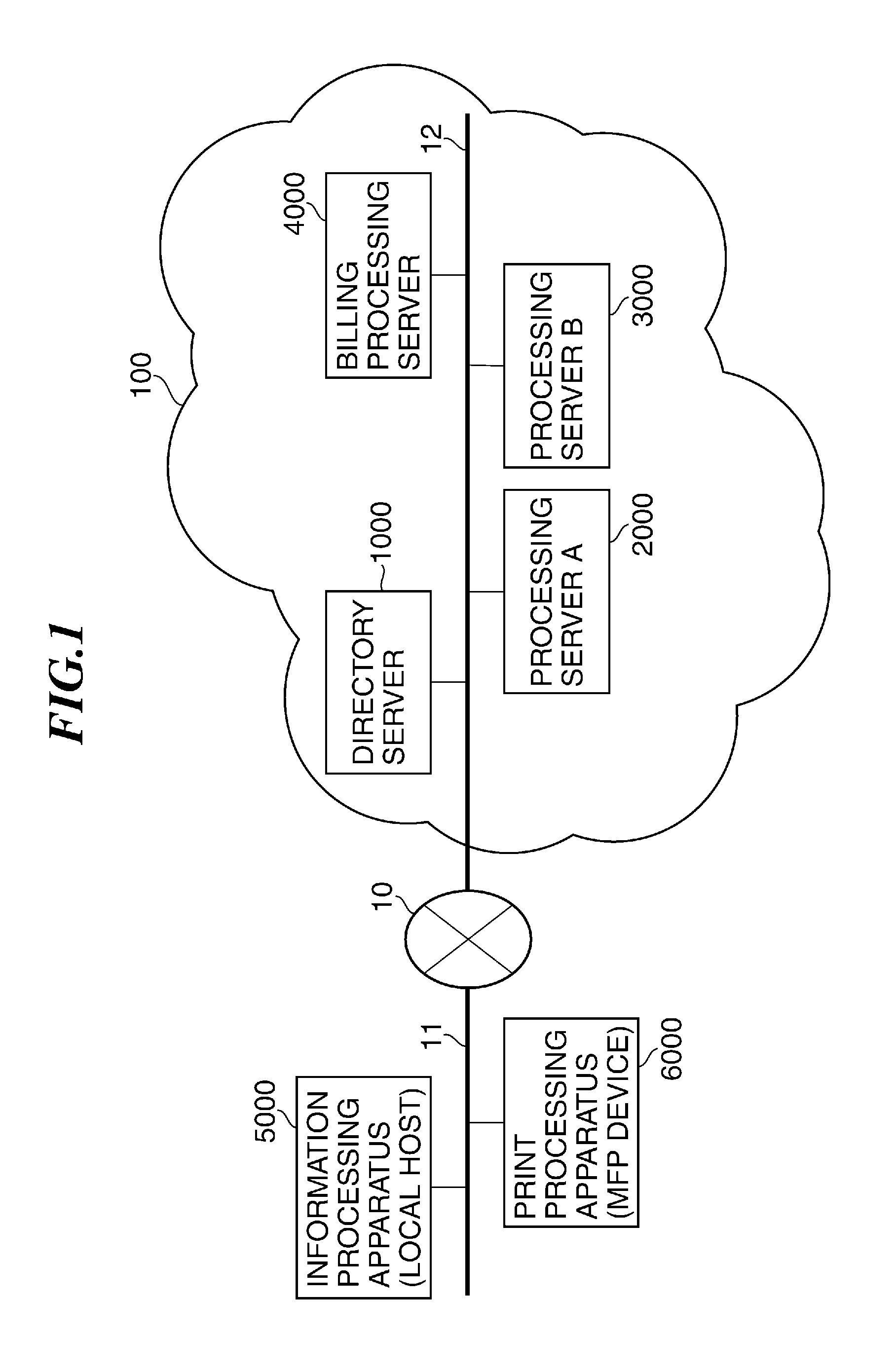

Information processing apparatus, image forming apparatus, control methods thereof and storage media

InactiveUS20120033257A1Visual presentation using printersTransmissionInformation processingWeb browser

An information processing apparatus that enables generation of an extended setting User Interface (UI) adapted to various classes devices including a device having low display capability and a device having a WEB browser. The information processing apparatus is connected to an image forming apparatus via a network. A function included in the image forming apparatus is discriminated based on processing capability information. Screen information used for setting an extended function is generated depending on the discriminated function. Extended setting information inputted through a screen displayed on the image forming apparatus based on the generated screen information is received. Image processing based on contents of the received extended setting information is applied to print data received from the image forming apparatus. The image processed print data is transmitted to the image forming apparatus.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com