Bus-controlled parallel uninterrupted power source (UPS) system

A technology of bus control and control system, which is applied in the direction of emergency power supply arrangements, collectors, electric vehicles, etc., can solve problems such as poor power supply quality, poor power supply quality, and power supply interruption, and achieve high real-time data processing capabilities and good maintainability , Improve the effect of dynamic response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

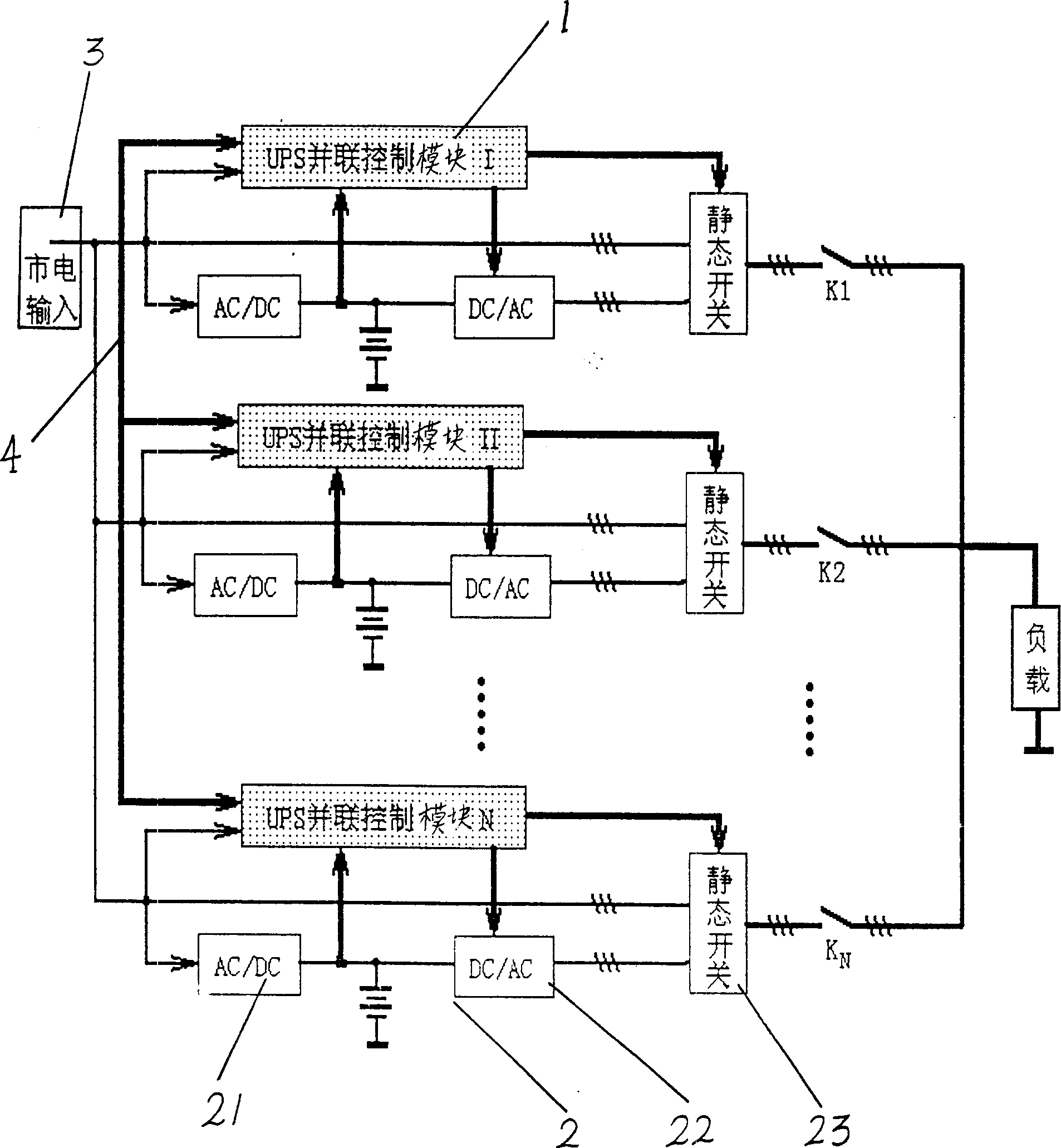

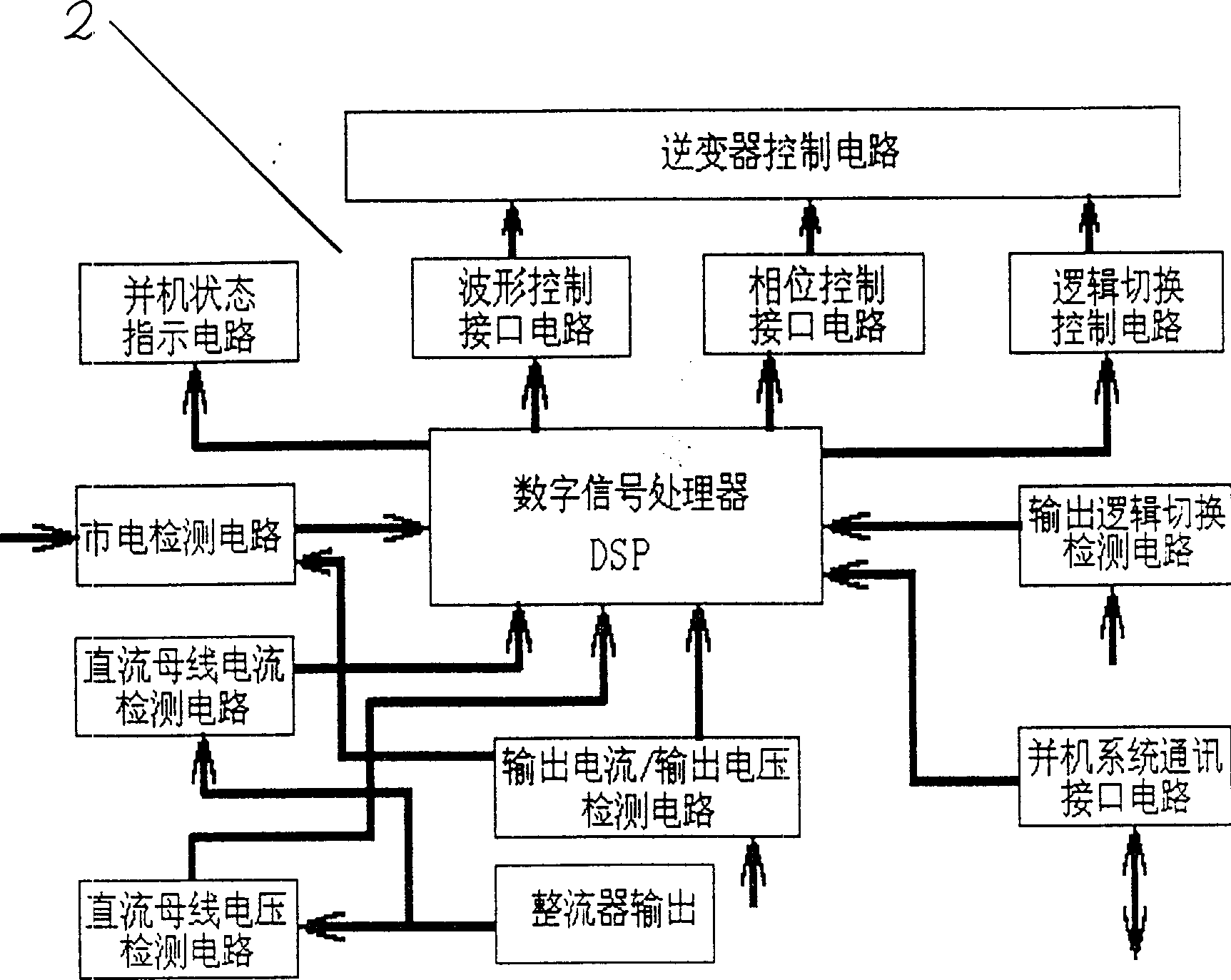

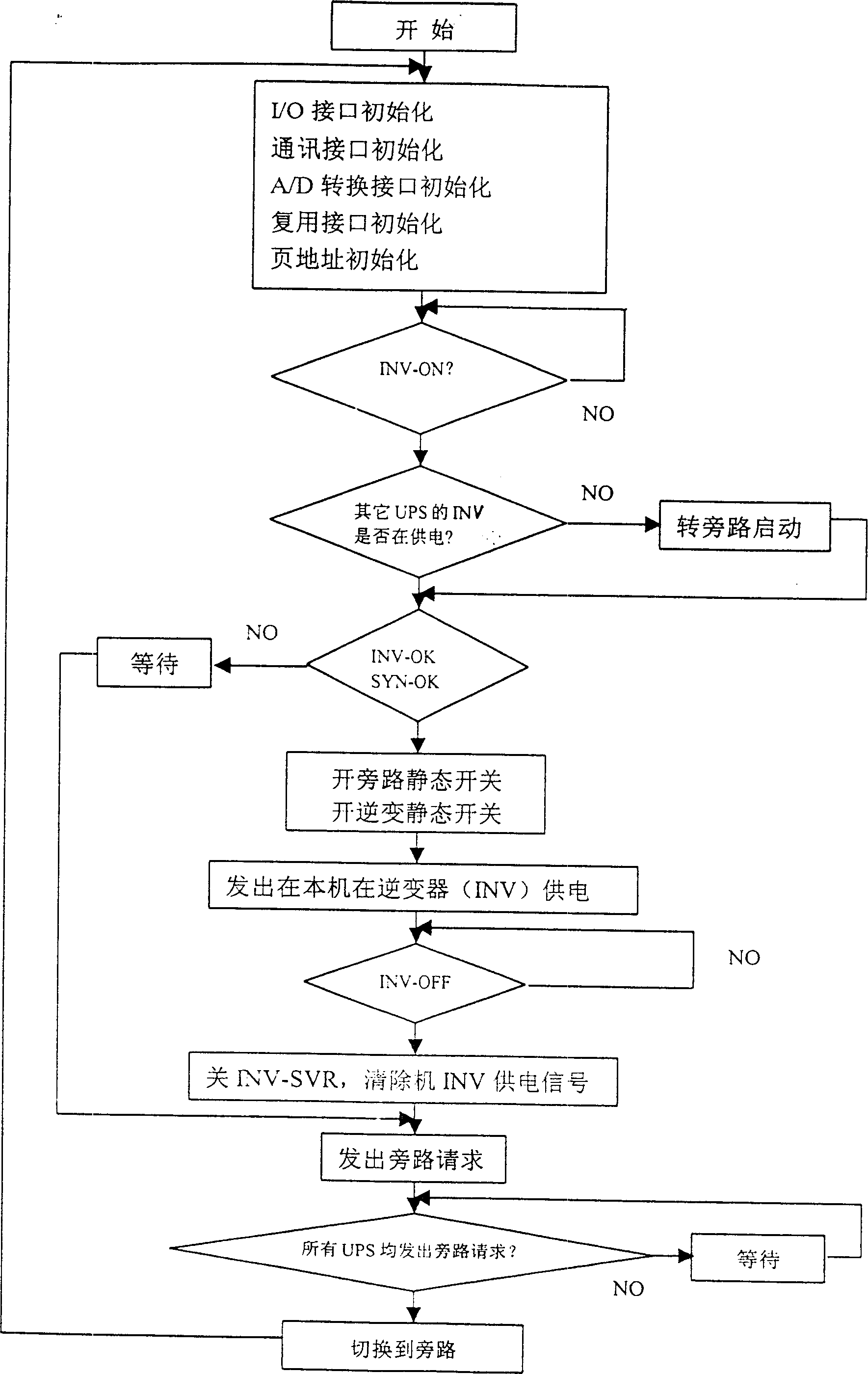

[0029] See attached Figure 1-4 , the UPS parallel control system 1 of the present invention is placed in the UPS2 and connected to the UPS2, and is connected to each other through the data bus 4; wherein, the UPS parallel control system 1 includes a digital signal processor DSP as a core and a waveform control interface of a peripheral functional unit circuit circuit, phase control interface circuit, logic switching control circuit, parallel machine state indication circuit, DC bus current detection circuit, DC bus voltage detection circuit, output current and output voltage detection circuit, mains power detection circuit, parallel system communication interface circuit, output logic switching detection circuit; and, the digital signal processor DSP of the UPS parallel control system 1 respectively passes through the mains power detection circuit, the DC bus current detection circuit, the DC bus voltage detection circuit, the output current and output voltage detection circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com