Method for utilizing coalbed methane containing oxygen to prepare liquefied natural gas

A technology for liquefied natural gas and coalbed methane, applied in refrigeration and liquefaction, liquefaction, chemical industry, etc., can solve problems such as low refrigeration efficiency, reduced processing capacity of separation and liquefaction devices, complex structure, etc., to improve processing capacity and improve refrigeration efficiency , the effect of saving power energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

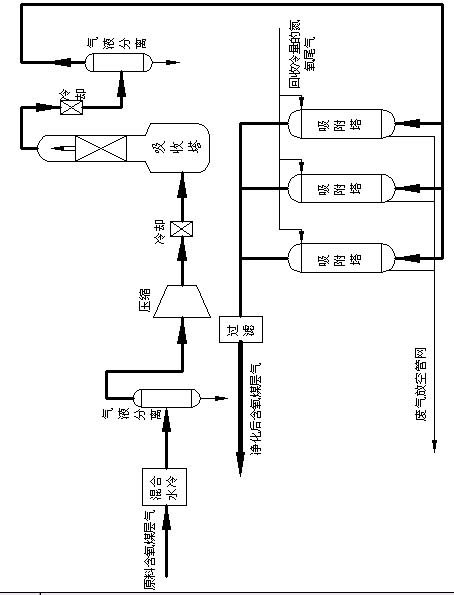

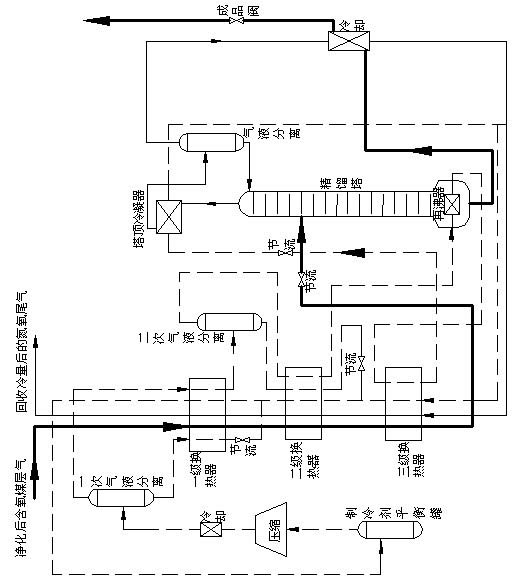

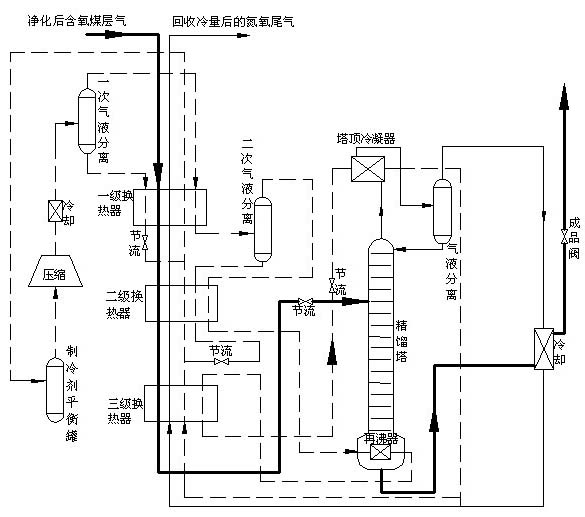

[0031] figure 1 It is a block diagram of the technical process of the compression and purification process of the present invention, figure 2 It is a process flow diagram of the liquefaction separation process of the present invention, as shown in the figure: the method for producing liquefied natural gas by utilizing oxygen-containing coalbed methane in this embodiment includes:

[0032] A. Compression and purification process: the low-concentration oxygen-containing coal seam raw material gas from coal mines is mixed with water cooling, compressed and purified to remove impurities to obtain purified oxygen-containing coal seam gas;

[0033] B. Liquefaction separation process:

[0034] The liquefaction separation process includes:

[0035] B1. Main process process: the purified oxygen-containing coalbed methane is cooled to about -180°C through the first heat exchanger, the second heat exchanger and the third heat exchanger in turn, and then enters the rectification towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com