Patents

Literature

39results about How to "Low hardness value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

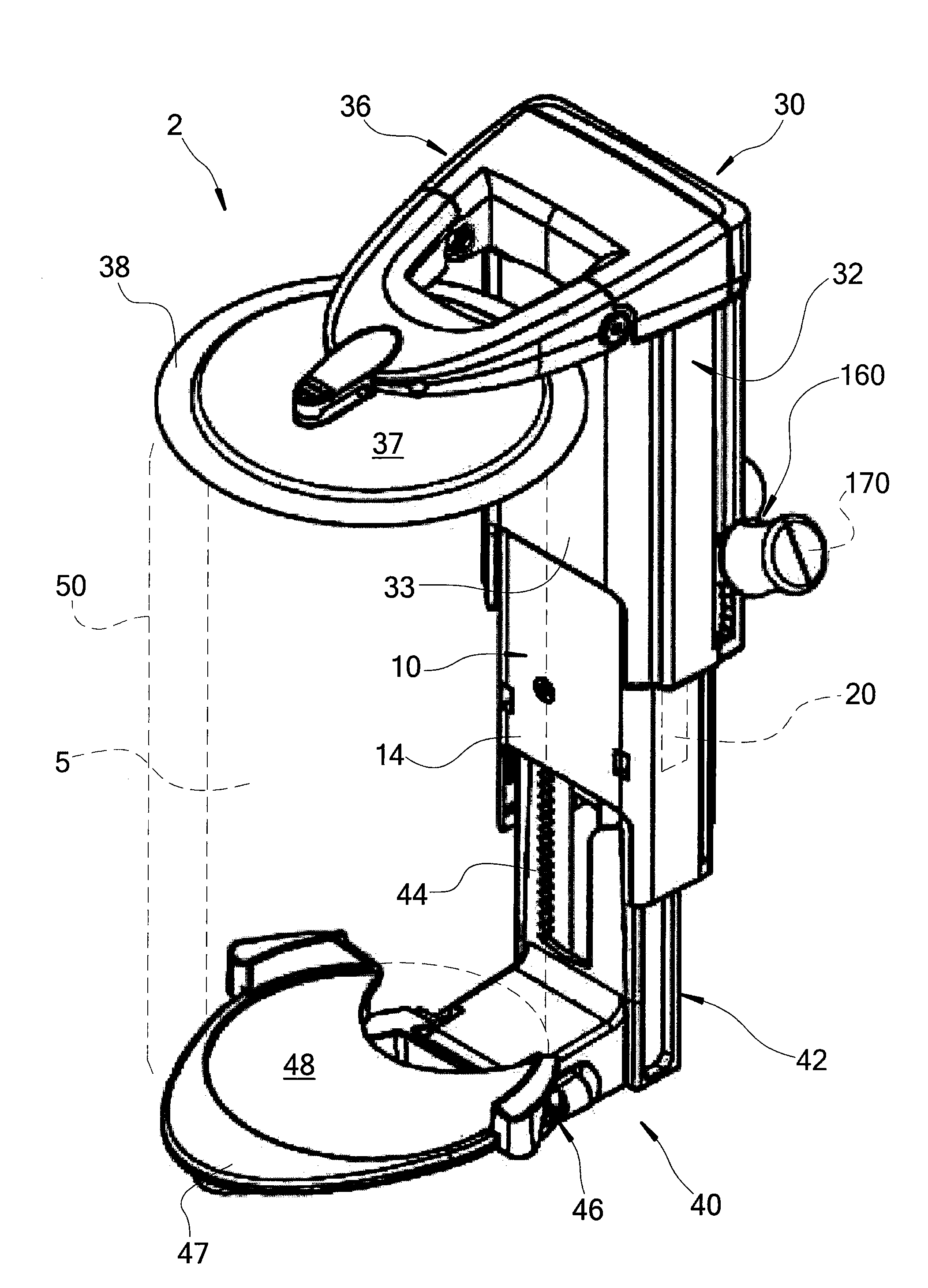

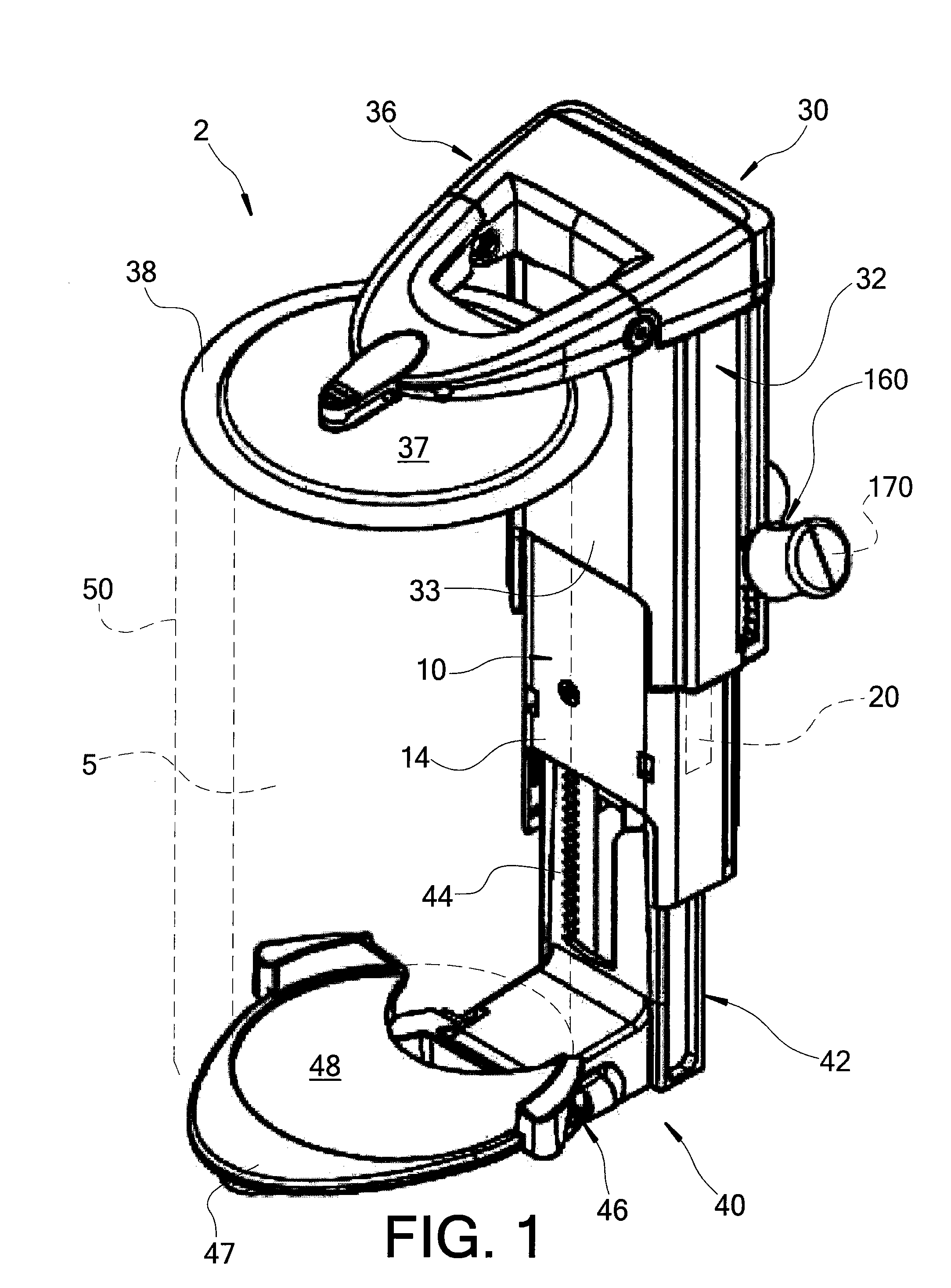

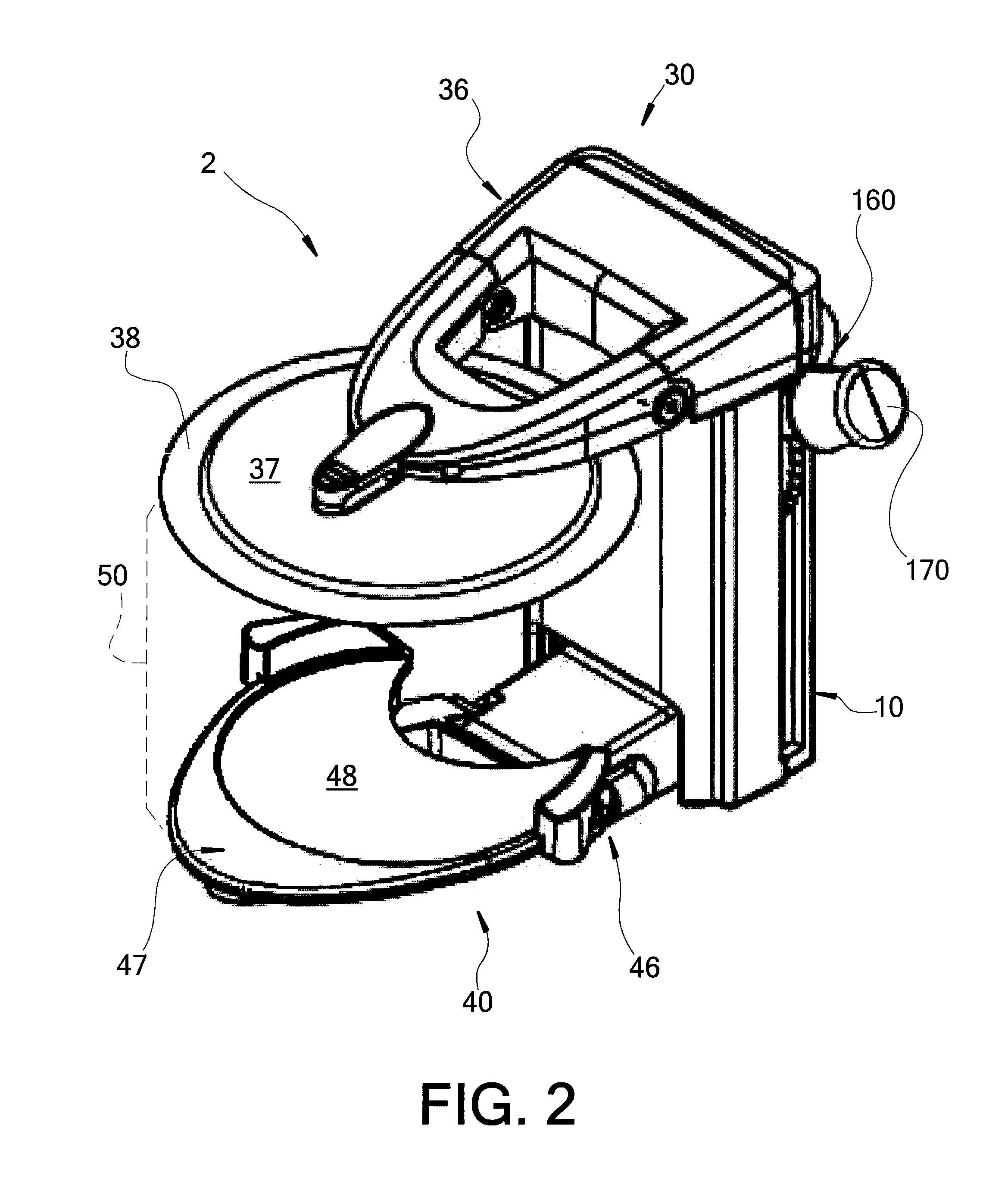

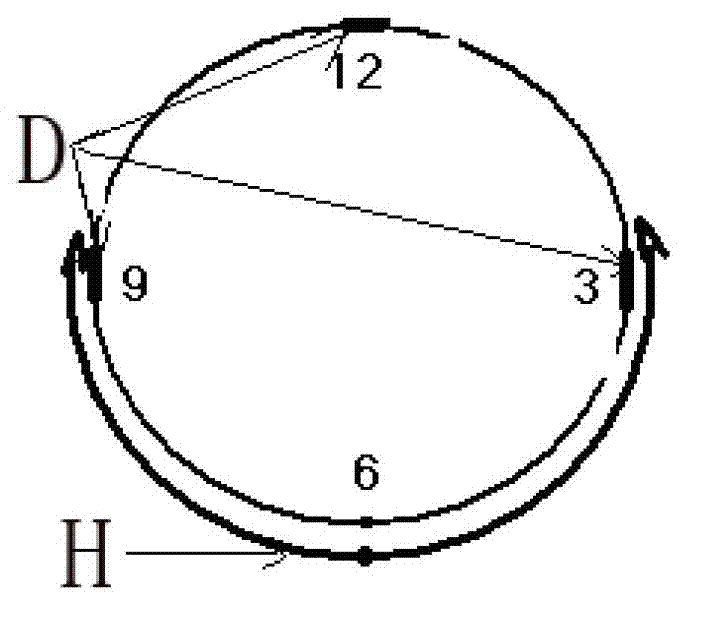

Holder for Beverage Containers

InactiveUS20100096396A1Easy to holdEasy loadingVehicle arrangementsRigid containersForeign matterUpper Arms

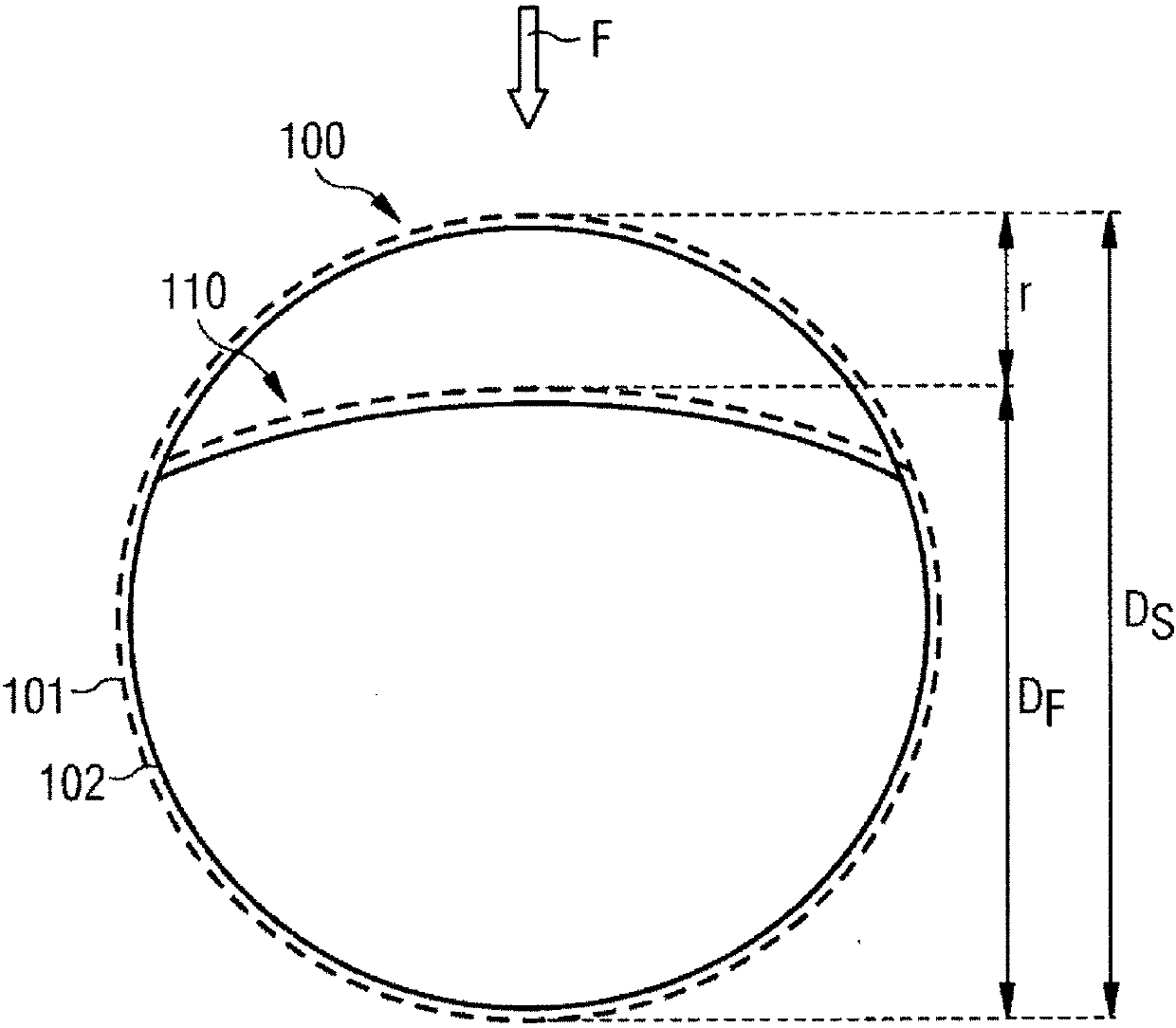

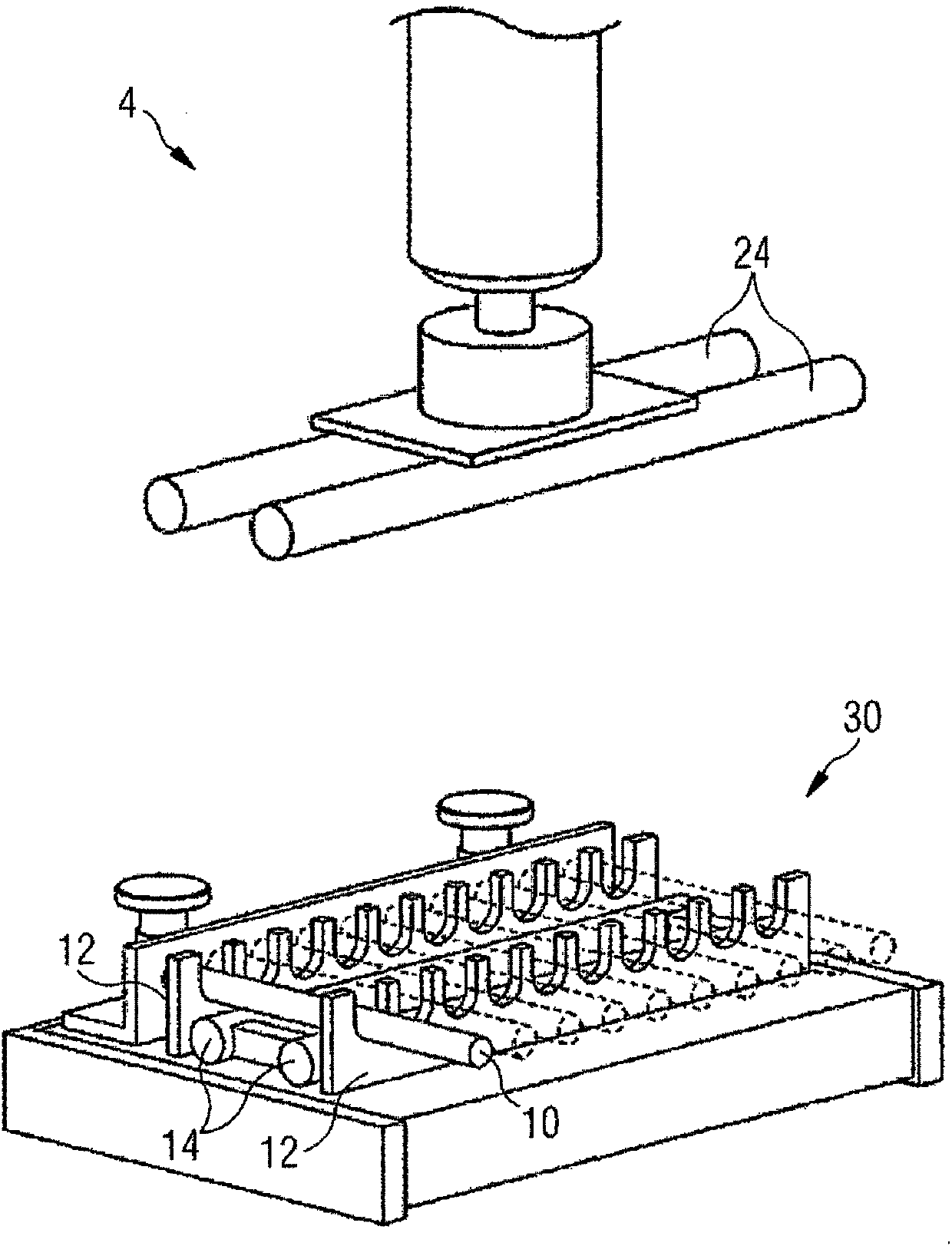

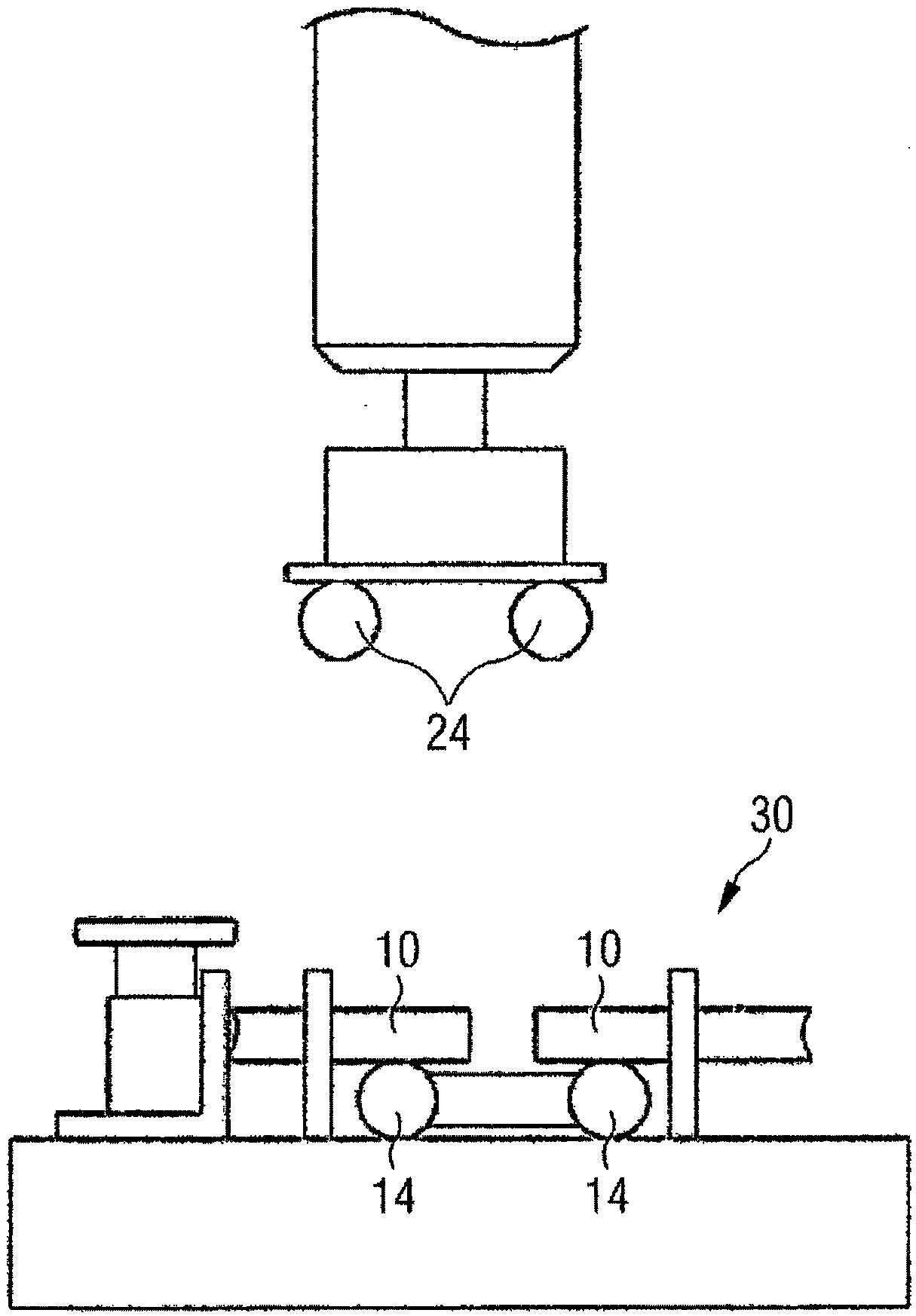

Holders for beverage containers are provided that can hold a beverage container in place and also seal or cover the beverage container, making it more difficult for foreign matter to enter the beverage container. The holder includes a base in which an actuator is mounted. Upper and lower rails are connected to and biased toward each other by the actuator. Upper and lower arms and upper and lower plates are, respectively, connected to the upper and lower rails. The upper and lower plates axially restrain the beverage container from above and below. A locking arm selectively engages at least one of the actuator and the upper and lower arms in a manner that supplements the biasing force provided by the actuator, clamping the upper and lower plates more tightly against the beverage container, and fixing the upper and lower plates in that condition, so that the beverage container is securely and tightly held between the upper and lower plates.

Owner:DOIG THOMAS STEVEN +3

42CrMoE thermal treatment technique

ActiveCN101368275AHigh surface hardnessImprove surface wear resistanceSolid state diffusion coatingFurnace typesMiddle frequencyCase hardening

The invention belongs to a heat processing technique of 42CrMoE material used for a reciprocating compressor. The technique is suitable for the heat processing technique for the 42CrMoE piston rods used for all the reciprocating compressors and can also be applied to the mechanical devices which require high rigidity, wear resistance and corrosion resistance. The invention can solve the problems of cracks, low surface hardening rigidity as well as poor wear resistance, poor acid resistance and poor corrosion resistance generated when the traditional surface heating processing technique is applied to the 42CrMoE piston rod, and the like. The invention includes the forging and shaping, hardening and tempering, stabilizing, nitriding, middle frequency or high frequency quenching as well as low temperature annealing of the 42CrMoE material; a surface compounded heat processing technology combined with nitriding and middle frequency or high frequency quenching is adopted: the 42CrMoE material is arranged in a nitriding furnace; ammonia gas is pumped in after the treatments of temperature rising and pro-oxidation to carry out nitriding treatment; then the middle frequency or high frequency quenching on the surface is carried out. The heat processing technique can be adopted to completely prevent the quenching cracks generated during the traditional high frequency quenching, improve the surface rigidity to be more than HRC60, improve the wear resistance by 34 percent and improve the acid and corrosion resistance by 40 percent.

Owner:SHENYANG BLOWER WORKS GROUP CORP

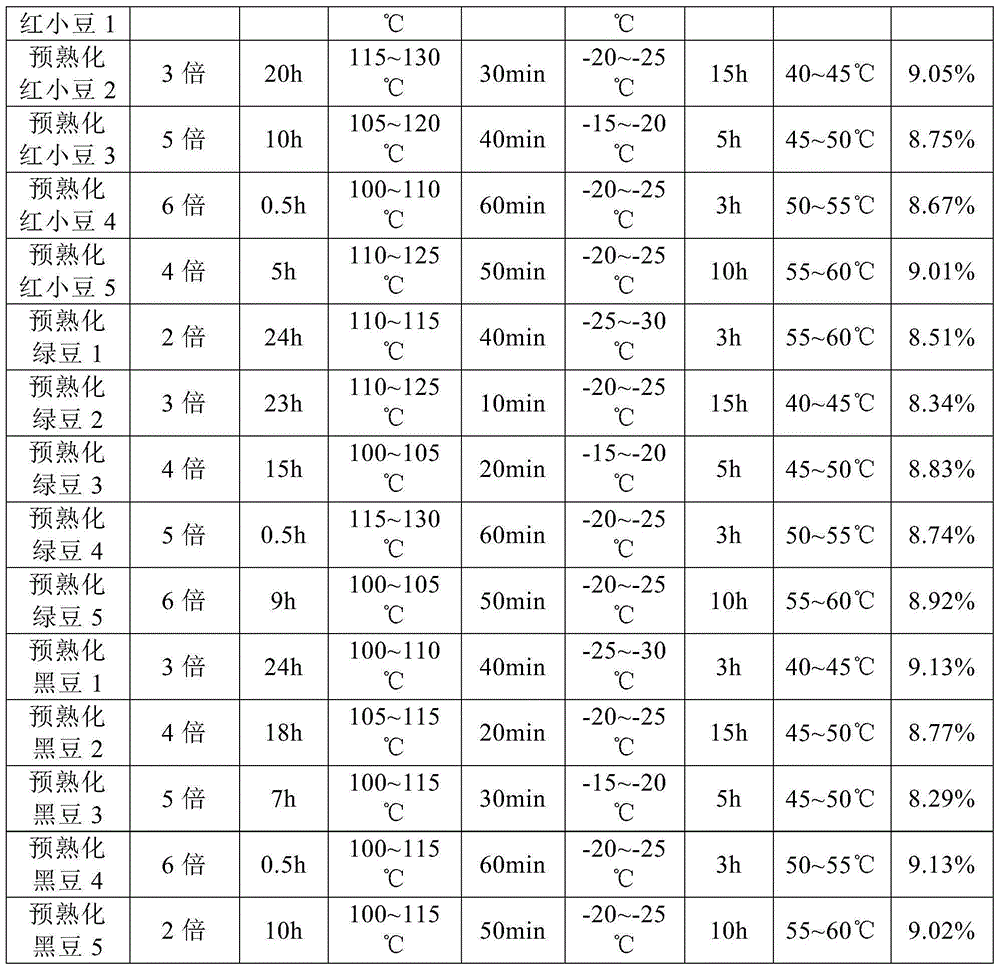

Coarse cereal food and preparation method thereof

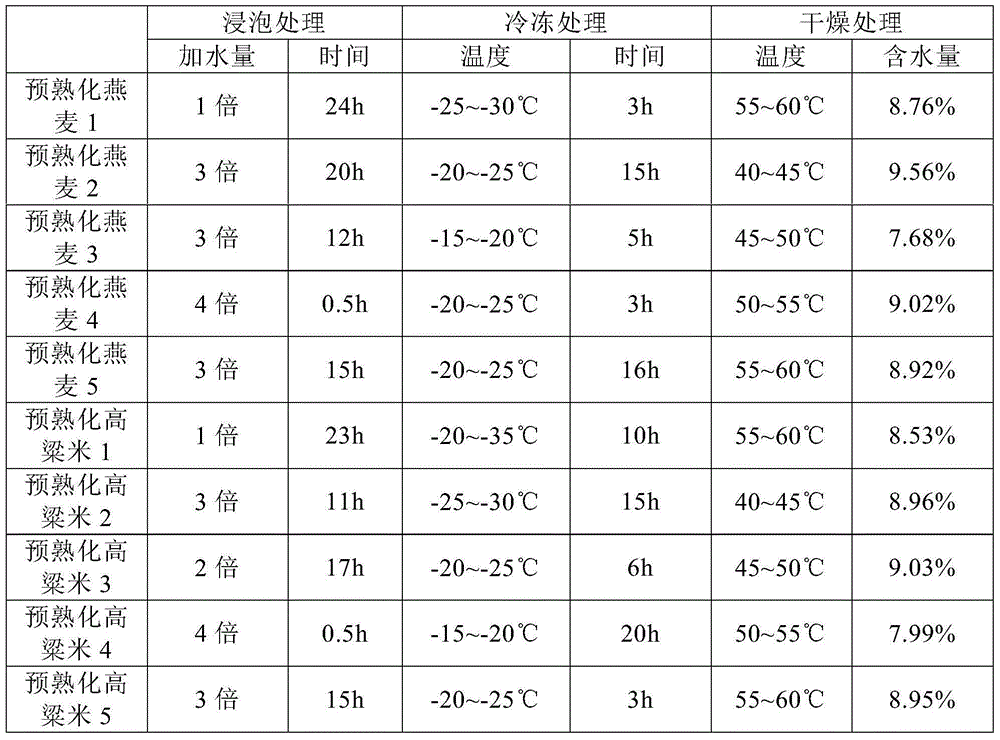

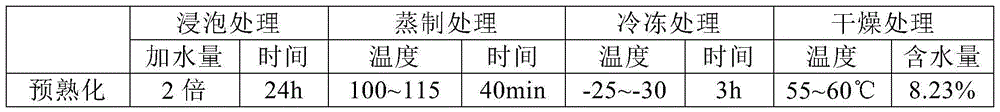

The present invention discloses a formula coarse cereal food. The formula coarse cereal food mainly comprises the following coarse cereals in parts by weight: 30 to 45 parts of oat, highland barley and / or barley, 20 to 40 parts of green bean and / or red bean, 1 to 10 parts of black beans, chickpea, garden pea, cowpea, rice bean and / or soybean; 15 to 20 parts of black rice; 5 to 15 parts of sorghum rice, red rice, brown rice and / or pearl barley; 10 to 20 parts of buckwheat, millet, and / or sticky millet. And the mixed beans cereal, the oat and the sorghum rice are subject to a pre-aging treatment, and then mixed with the rest of cereal in a proportion to obtain the formula coarse cereal food. According to the present invention, the formula coarse cereal food has more complete shape retention and has better market prospects as commodity for sale. The formula cereal food has a short aging time when cooking with rice; the cooked cereal porridge has characteristics of rich flavor, soft mouthfeel, good viscosity and uniform dispersion. The formula cereal food can provide a human body with necessary dietary fiber, vitamins and minerals.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

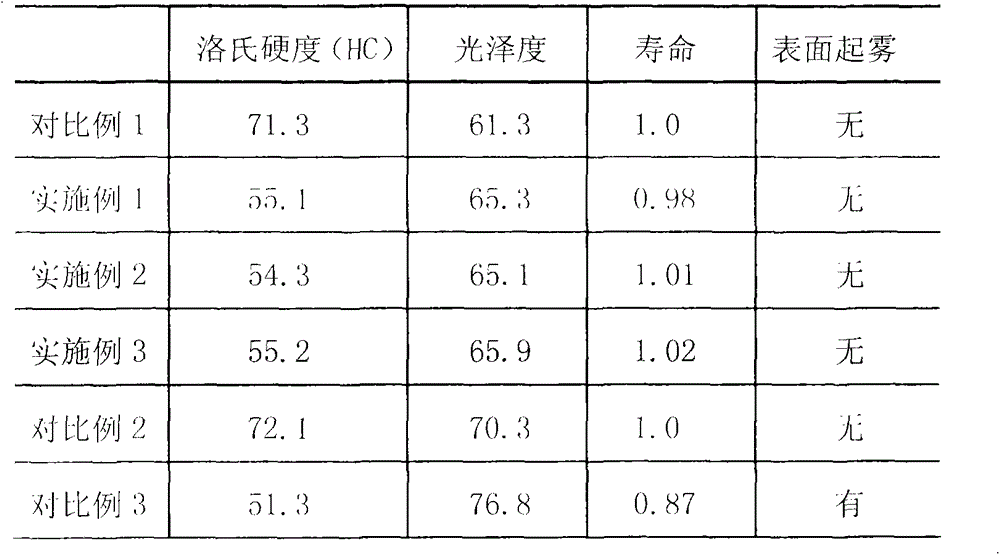

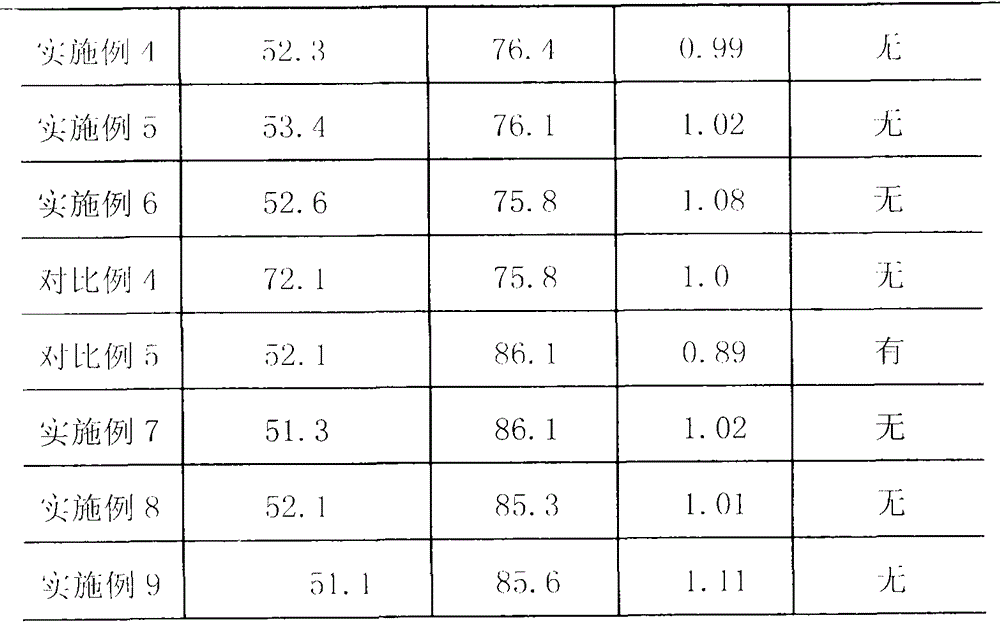

Preparation method for epoxy resin binding agent diamond grinding tool with high polishing performance

ActiveCN104057403ALow hardness valueReduce pollutionAbrasion apparatusGrinding devicesEpoxyRare earth

The invention discloses a preparation method for an epoxy resin binding agent diamond grinding tool with high polishing performance. A working layer is mainly prepared from a diamond grinding material, an auxiliary grinding material, epoxy resin, a curing agent, rare earth polishing powder, filler and a dilution agent. The preparation method comprises the steps of uniformly and mechanically mixing 5-20 parts of the diamond grinding material, 5-20 parts of the auxiliary grinding material, 5-25 parts of the rare earth polishing powder and 5-40 parts of the filler to obtain a first mixture, then uniformly mixing and stirring the first mixture with 20-40 parts of the epoxy resin, 7-15 parts of the curing agent and 0.5-10 parts of the dilution agent to obtain a final mixture, injecting the mixture with flowability into a plastic mold in a pouring manner, and curing the mixture to obtain the epoxy resin binding agent diamond grinding tool with high polishing performance. The materials are in percentage by mass. Compared with the conventional hot pressing molding method, the preparation method has the advantages that the technology is simple, the energy is saved, and the emission is reduced; the pollution, which is caused by solid dust, to the environment is reduced, and the production speed is high; compared with the conventional product in the foreign country, the epoxy resin binding agent diamond grinding tool has the advantages of good polishing effect, high polishing efficiency, few air hole defects of the grinding tool and the like.

Owner:惠安宇信金刚石工具有限公司

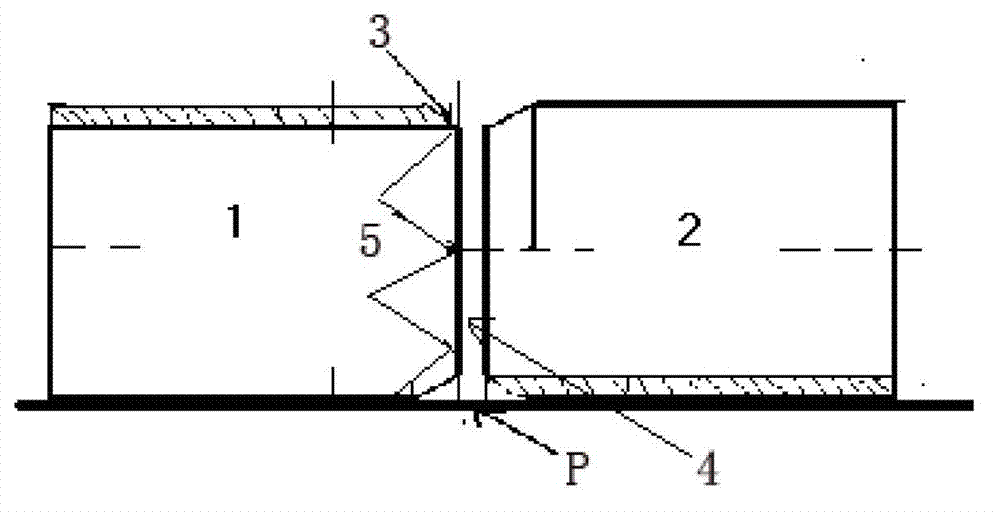

Welding process for red copper and stainless steel dissimilar materials

ActiveCN102962543AMeet the use requirementsImprove mechanical propertiesArc welding apparatusFurnace typesForeign matterDehydrogenation

The invention discloses a welding process for red copper and stainless steel dissimilar materials. The welding process comprises the following steps of: (A) machining grooves on the opposite sides of a red copper component and a stainless steel component, cleaning foreign matters on the edges of the grooves, placing the red copper component and the stainless steel component on the same plane for pairing, and reserving a gap; (B) performing before-welding preheating on one side of the red copper component at 600 to 680 DEG C; (C) tackingperforming point fixing in a plurality of positions between the red copper component and the stainless steel component according to a tacking sequence; (D) welding the red copper component and the stainless steel component by adopting shielded metal arc welding direct current electrode positive; (E) heating a welding joint to 130 to 180 DEG C after the red copper component and the stainless steel component are welded, cooling the welding joint to room temperature, and performing dehydrogenation treatment to reduce hydrogen content in a welding seam; and (F) after the dehydrogenation treatment and cooling, performing stabilization treatment on one side of the stainless steel component at 840 to 890 DEG C, and quickly cooling the stainless steel component to reduce the formation of chromium carbide and improve the plasticity and toughness of the welding seam.

Owner:PETROCHINA CO LTD

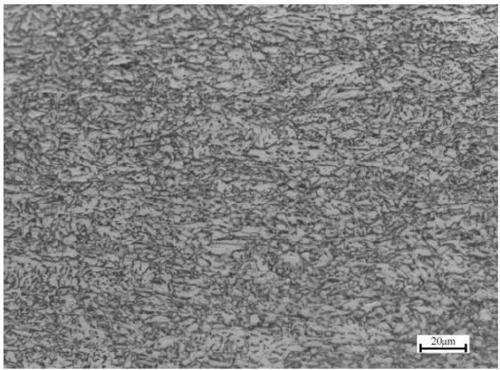

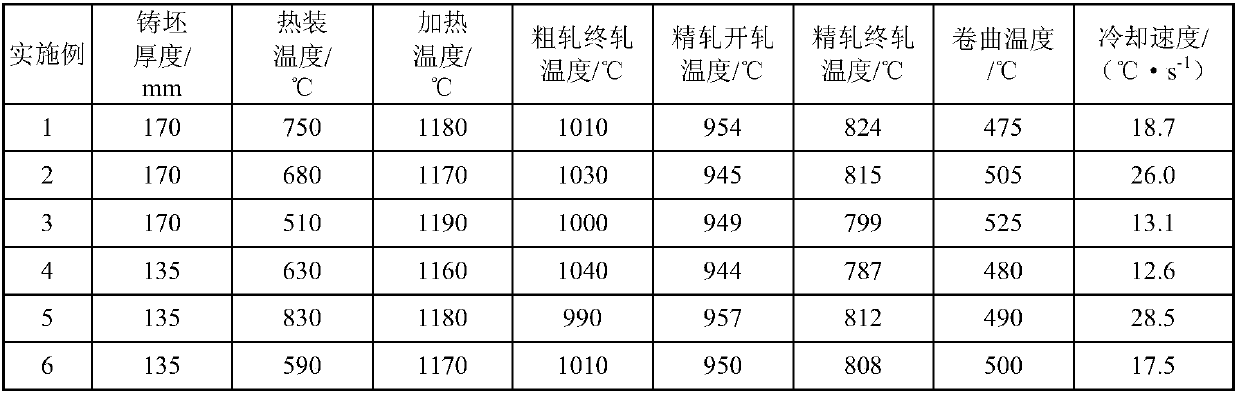

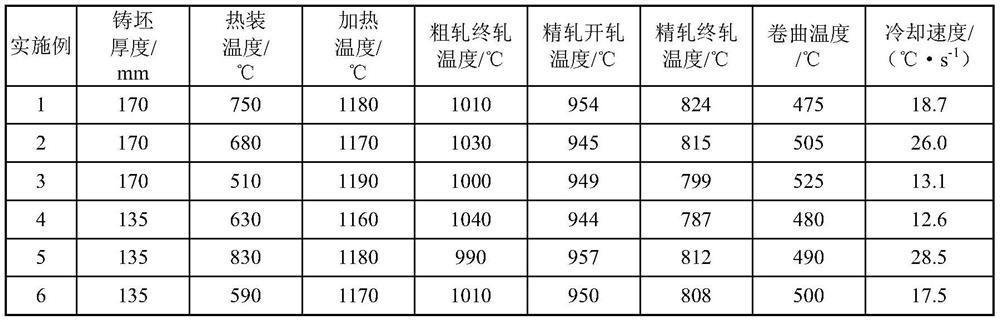

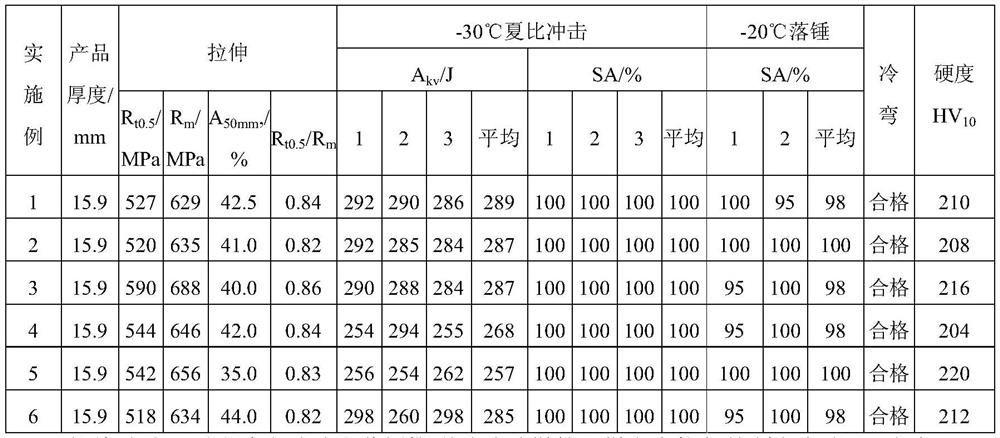

Low-hardness X70M pipeline steel hot-rolled plate coil and manufacturing method thereof

The invention discloses a low-hardness X70M pipeline steel hot-rolled plate coil and a manufacturing method thereof. Wherein the steel contains 0.061%-0.061% of C; 0.080%, si 0.15%- 0.35%, mn 1.41% toMn 1.41% 1.59%, nb0.060%- 0.080% of V, 0.010%-0.030% of V, 0.008%-0.020% of Ti, 0.13%-0.18% of Mo, 0.13%-0.19% of Cr, 0.020%-0.060% of Al, smaller than or equal to 0.018% of P, smaller than or equalto 0.004% of S and smaller than or equal to 0.007% of N; wherein Pcm is smaller than or equal to 0.19%, and the balance Fe and inevitable impurities. Casting blank thickness below 200 mm. And a casting blank is subjected to hot charging at 500-850 DEG C and heated to 1150-1200 DEG C, the finish rolling temperature of rough rolling is 980-1050 DEG C, the finish rolling starting temperature of finish rolling is 910-960 DEG C, the finish rolling temperature is 780-840 DEG C, the cooling speed is 12-30 DEG C / s, and the coiling temperature is 470-530 DEG C. And the hardness value of the producedX70M-grade hot-rolled plate coil is smaller than or equal to 230 HV10.

Owner:ANGANG STEEL CO LTD

Alloy material of copper, nickel, silicon and bronze and preparation method thereof

The invention discloses an alloy material of copper, nickel, silicon and bronze and a preparation method thereof. The alloy material comprises the following substances in percent by weight: 1.6% to 2.2% of nickel, 0.4% to 0.8% of silicon, 0.008% of rare earth alloy and 96.002% to 97.002% of copper. The alloy material of copper, nickel, silicon and bronze is prepared by the processes of proportioning, melting, casting, sawing, extruding, drawing, straightening, inspecting and packing into a warehouse, enhances the stress corrosion resistant capability, and has the main performance change of reducing a hardness value and the grain size.

Owner:甘肃大鑫铜业有限责任公司

High-carbon high-chrome ledeburite steel explosive welded wearing-resistant composite material

InactiveCN1836819AReduce Explosive Welding CostsReduce shock waves and noiseHeat treatment process controlNon-electric welding apparatusPre treatmentChromium

The production process of explosive welded wear resistant high carbon high chromium ledeburite steel composite material includes pre-treatment, explosive welding compounding, and annealing treatment. The composite material has structure including one base layer and high carbon high chromium ledeburite steel combined to cover one or two surfaces of the base layer. Compared with available technology, the explosive welding process has 30-40 % lowered explosive consumption, low cost, reduced blast wave and noise explosive welding produces. The annealed composite material has high interface combining strength and lowered hardness of covering high carbon high chromium ledeburite steel layer.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

Corrosion-resistant soft cold-rolling tin plate and production method thereof

InactiveCN101892418ALow hardness valueImprove corrosion resistanceBell type furnacesChemical compositionHydrogen

The invention discloses a corrosion-resistant soft cold-rolling tin plate and a production method thereof. The corrosion-resistant soft cold-rolling tin plate comprises the following chemical components by weight percent: 0.01%-0.04% of C, less than or equal to 0.02% of Si, 0.10%-0.40% of Mn, less than or equal to 0.01% of P, less than or equal to 0.012% of S, less than or equal to 0.011% of Sn, less than or equal to 0.01% of As, 0.005%-0.050% of solAl, less than or equal to 0.004% of N and the balancing of Fe and unavoidable impurities. The production method comprises the steps of hot-metal desulphurization, dephosphorization, converter melting, RH (Ruhrstahl-Heraes) vacuum treatment, continuous casting, continuous hot-rolling, pickling, cold-rolling, electrolytic degreasing, full-hydrogen furnace bell-type annealing (BA), leveling and electrotinning and the like. According to the practice, the uncoated tin plate base of the invention has the advantages of low hardness value and high corrosion resistance at the same time; since the production method thereof is based on the bell-type annealing manner, the production method of the invention has the advantages of low difficulty level of production control, low cost and easy implementation in large-scale production and helps users reduce the cost.

Owner:武钢集团有限公司

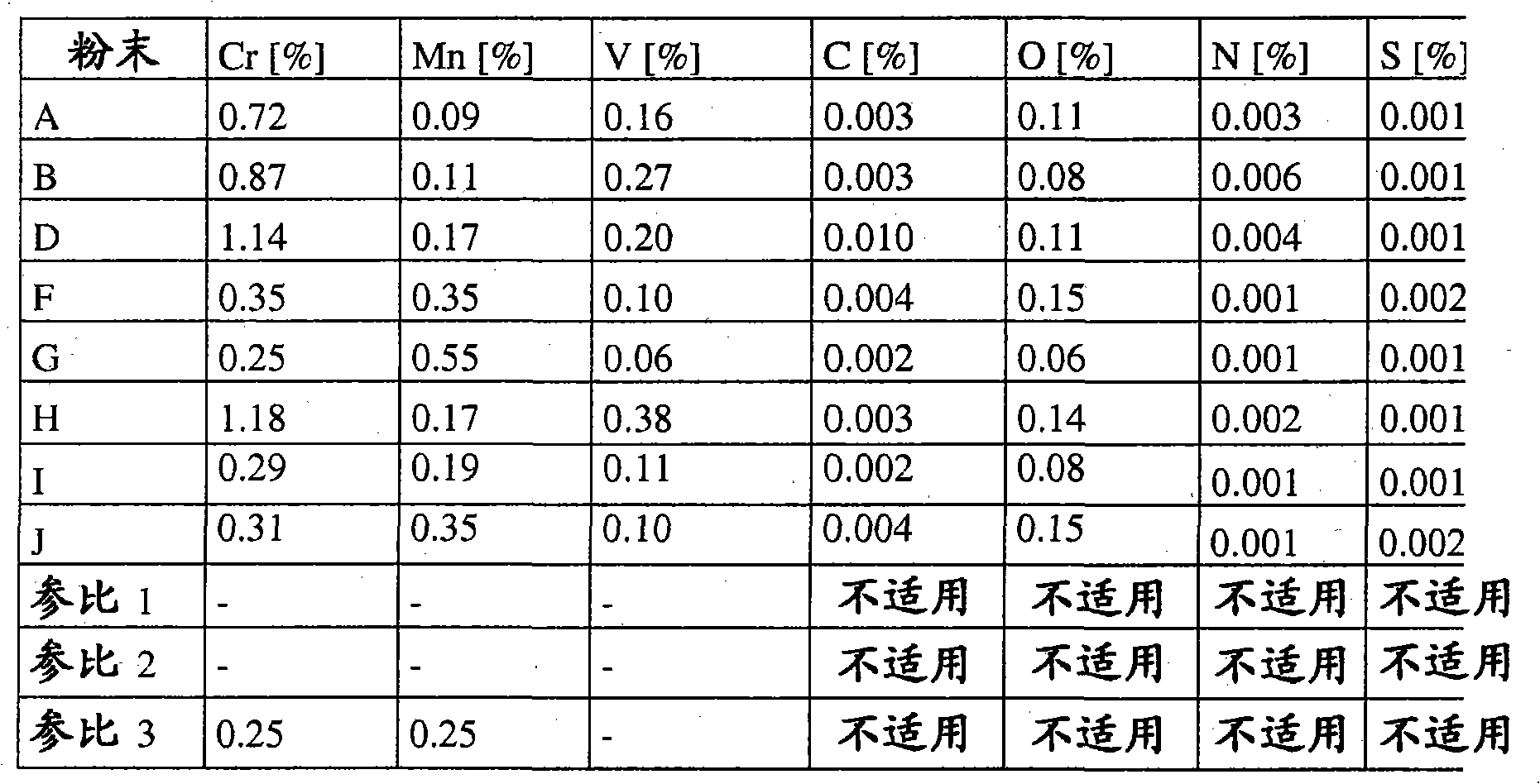

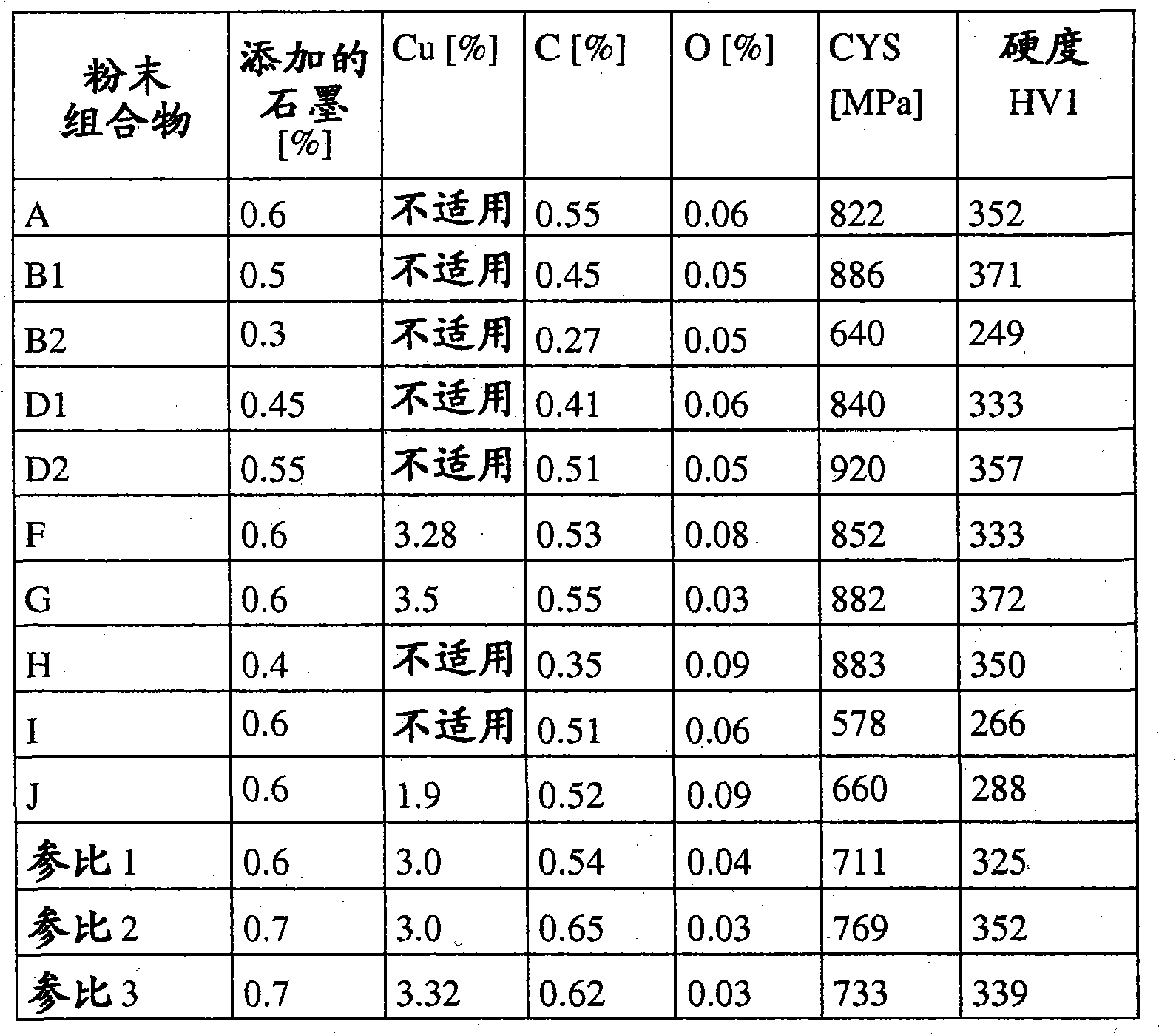

Low alloyed steel powder

InactiveCN101925684ALow hardness valueHigh compressive yield stressConnecting rodsTransportation and packagingMetallurgyImpurity

A water atomised prealloyed iron-based steel powder which comprises by weight-%: 0.2-1.5 Cr, 0.05-0.4 V, 0.09 -0.6 Mn, less than 0.1 Mo, less than 0.1 Ni, less than 0.2 Cu, less than 0.1 C, less than 0.25 O, less than 0.5 of unavoidable impurities, the balance being iron.

Owner:HOGANAS AB

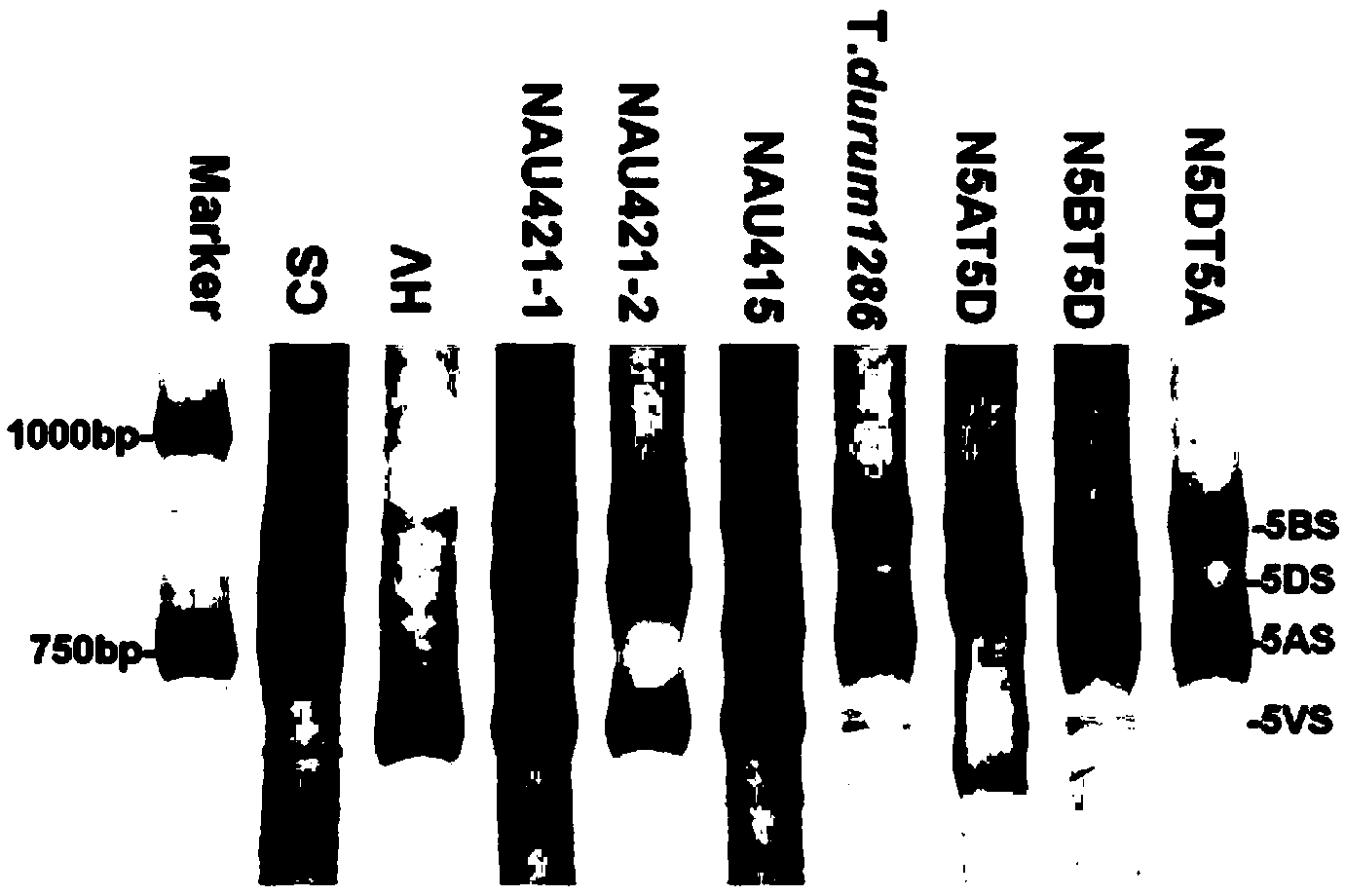

Breeding and identifying method of soft and powdery mildew resistant triticum aestivum-Dasypyrum villosum translocation line

ActiveCN104365471AValid identificationExcellent agronomic traitsMicrobiological testing/measurementPlant genotype modificationAgricultural scienceTriticeae

The invention discloses a breeding and identifying method of a soft and powdery mildew resistant triticum aestivum-Dasypyrum villosum translocation line. The method comprises the steps of hybridizing and backcrossing a triticum aestivum-Dasypyrum villosum 5V alien addition line DA5V and a Chinese spring ph1b1b mutant, identifying individual plants relevant to 5VS and ph1b1bph1b1b from BC1F1 by use of a molecular marker, identifying individual selfed seeds by use of GISH (genomic in situ hybridization) technology, and analyzing individual plants containing translocated chromosomes by use of C-zoning, GISH and molecular markers to prove that the translocated chromosome is T5VS.5AL. A PCR (polymerase chain reaction) primer is designed by use of an EST (Expressed Sequence Tag) located on the homologous chromosome group of the fifth part of triticum, a co-dominant marker capable of identifying the translocated chromosome specially can be screened, and homozygosis and heterozygosis translocations can be distinguished. The breeding utilization value of the translocation line can be disclosed through agronomic traits, kernel hardness analysis and powdery mildew resistance identification.

Owner:NANJING AGRICULTURAL UNIVERSITY

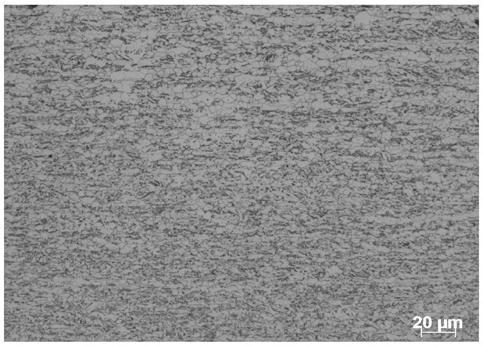

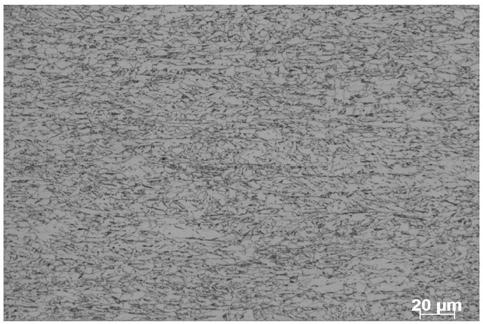

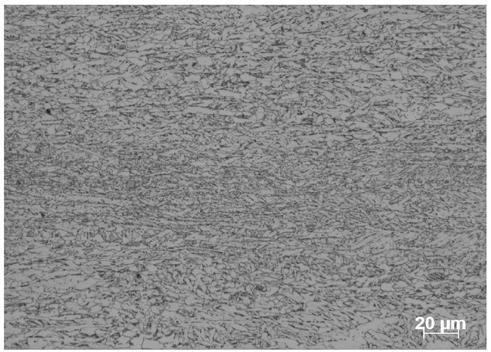

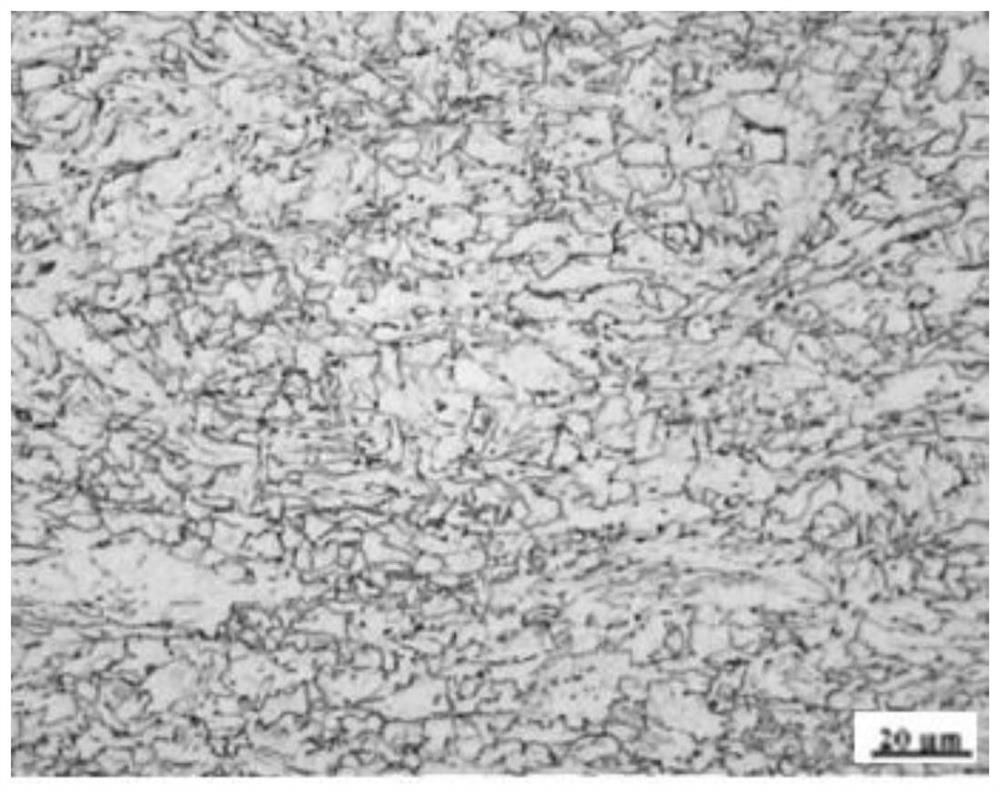

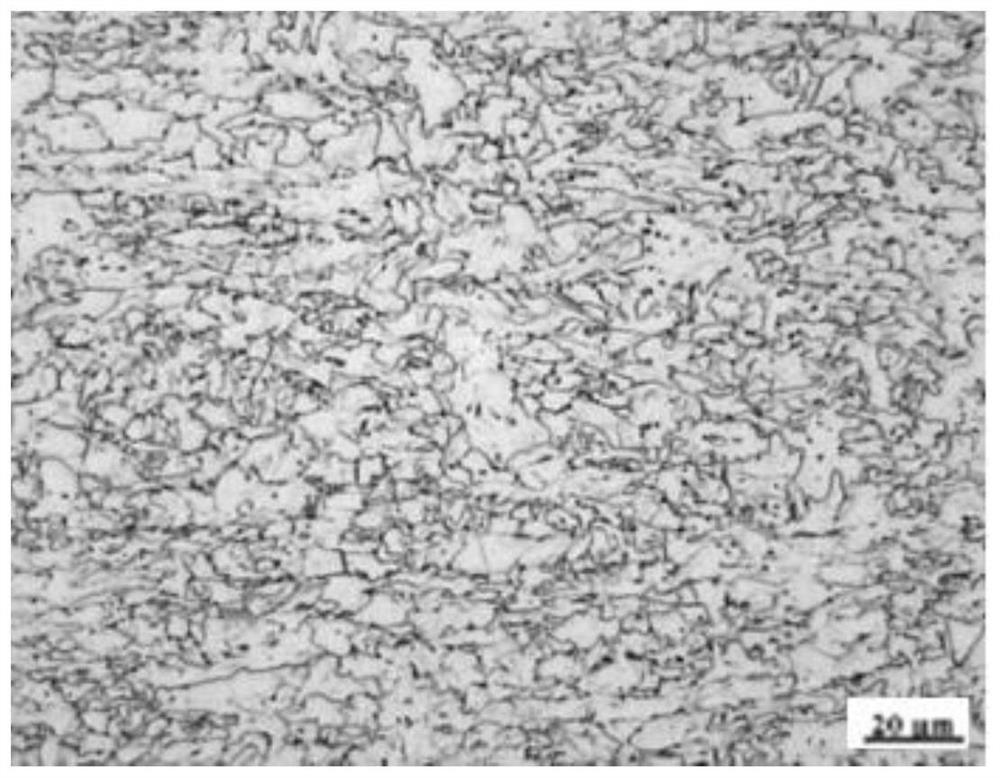

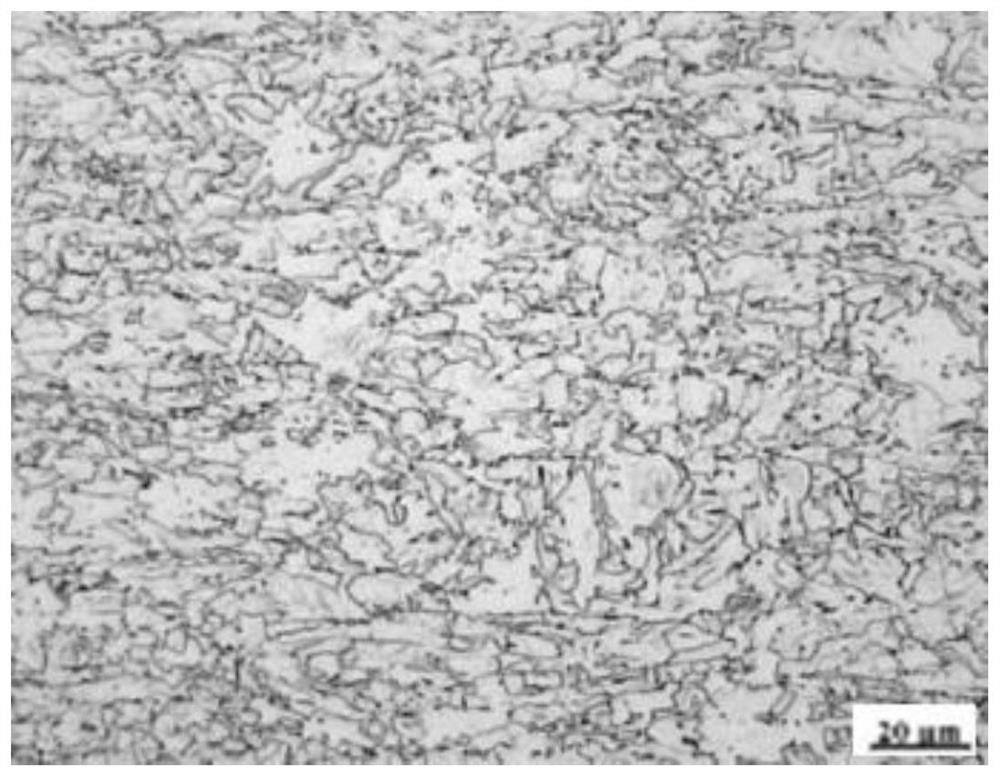

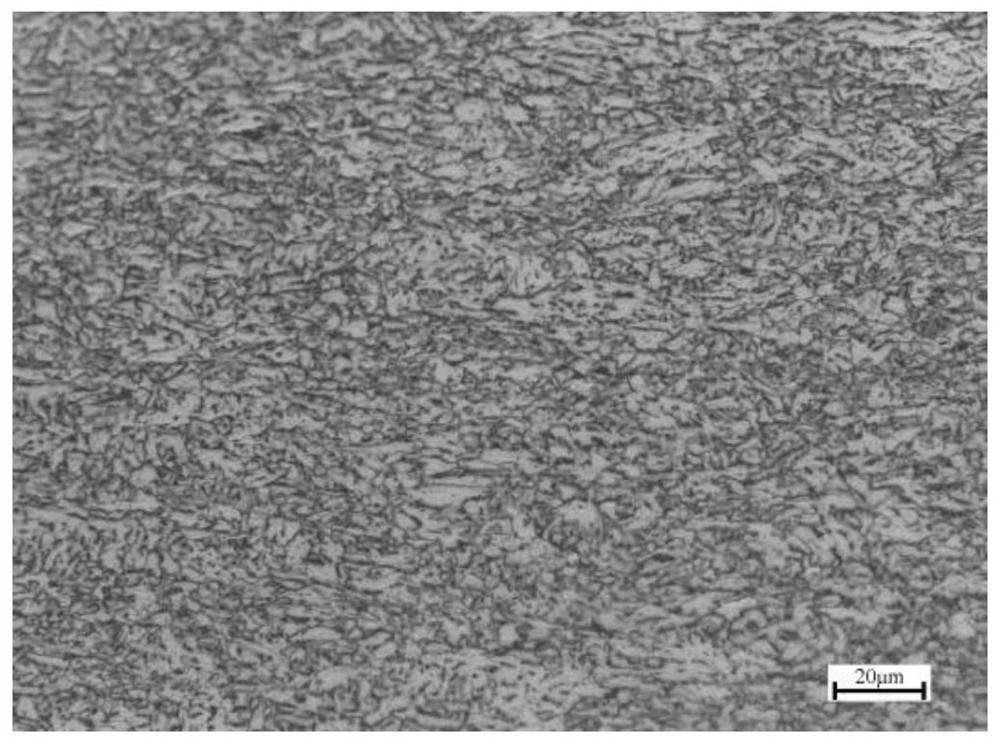

Production method for reducing hardness of X80M-grade pipeline steel

The invention discloses a production method for reducing the hardness of X80M-grade pipeline steel. Through a high-temperature rolling process, reasonable adjusting of phosphorus removal process and perfecting of rolling schedule, a laminar flow cooling process is optimized, a hybrid tissue structure is obtained, wherein the edge of the hybrid tissue structure is mainly made of quasi-polygonal ferrite, and the core of the hybrid tissue structure is mainly made of acicular ferrite, bainite and a small amount of martensite and austenite islands, it is ensured that the Wechsler hardness value ofthe surface and the section of a steel plate is stabilized within 220, the performance requirements for the steel plate are ensured, and economic benefits are remarkable.

Owner:NANJING IRON & STEEL CO LTD

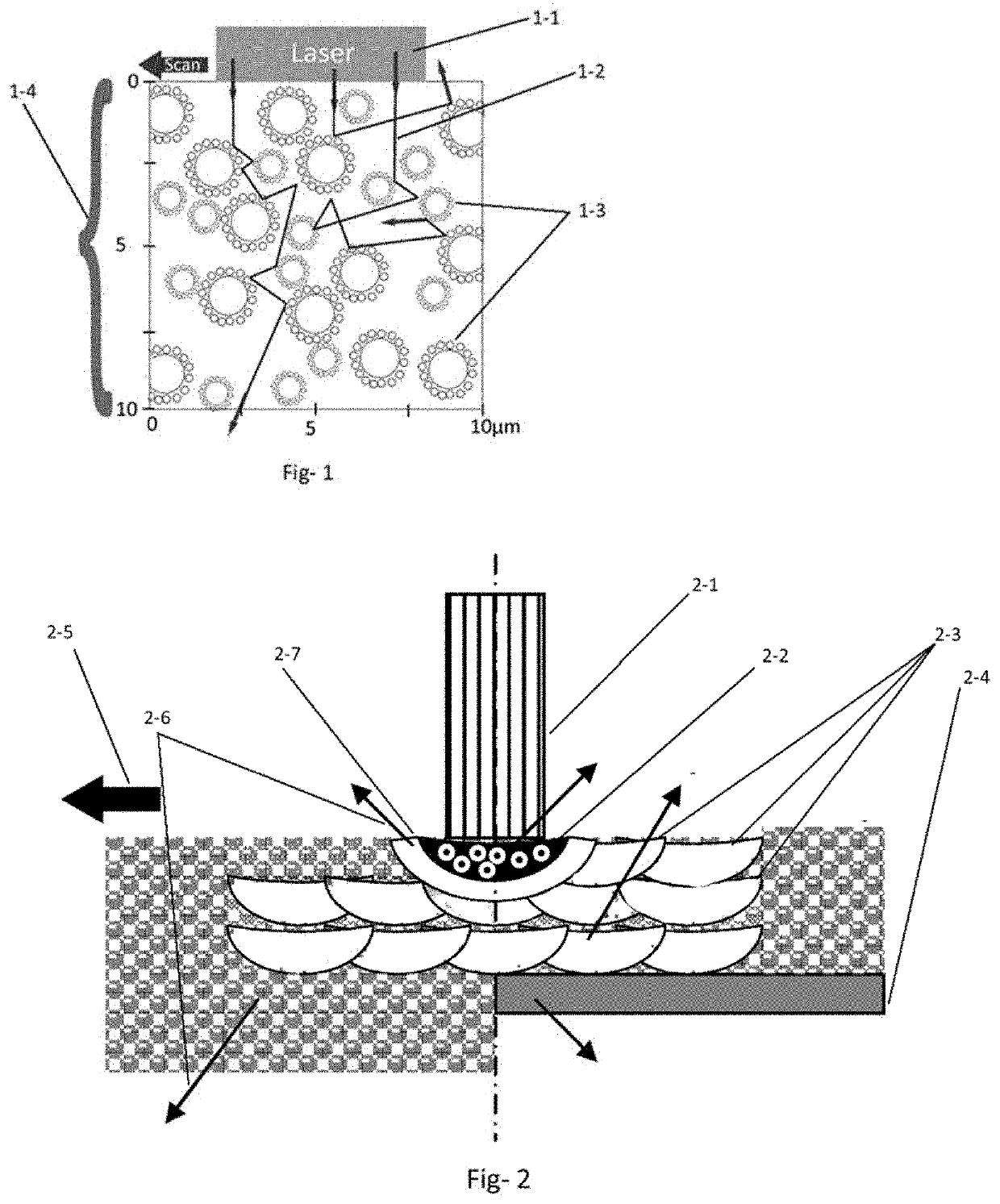

Process for manufacturing a titanium zirconium alloy and its embodiment by additive manufacturing

PendingUS20200055118A1Increased strength and corrosion resistanceLow hardness valueAdditive manufacturing apparatusCeramic shaping apparatusPowder mixtureTitanium zirconium

The invention relates to a method for producing a composite material consisting of a metal and ceramic alloy, comprising steps of: producing a mixture of metal powder and ceramic powder, the particle size of the metal powder being micrometric and the particle size of the ceramic powder being nanometric; and exposing said mixture to a focused energy source that selectively fuses part of a bed of said powder mixture.

Owner:DJEMAI ABDELMADJID

Production method of anti-aging tinning black plate

InactiveCN101643828BProduction control is less difficultLow costManufacturing convertersImpurityMaterials science

The invention relates to a production method of an anti-aging tinning black plate with hardness HR30Tm of 55+ / -4 and discloses a production method of an anti-aging tinning black plate. The method comprises the following steps: smelting: adopting KR desulfurization, smelting in a converter, RH vacuum treatment and continuous casting; hot rolling: carrying out the hot rolling of a continuous casting blank comprising the following chemical components in percentage by weight: C: 0.02-0.06, Si: smaller than or equal to 0.025, Mn: smaller than or equal to 0.50, P: smaller than or equal to 0.020, S:smaller than or equal to 0.030, Als: 0.005-0.040, Ti: 0.005-0.020, N: smaller than or equal to 0.005, the balance of Fe and inevitable impurities; and carrying out pickling, cold rolling, electrolytic degreasing, full-hydrogen bell furnace annealing and leveling of a tinning black plate with hardness HR30Tm of 51-59. The invention has the advantages of small production control difficulty and low cost and hardness value, is beneficial for users to use the anti-aging tinning black plate to manufacture deep drawing cans and can lids with complicated deformation, lessens the canning defects of cracks, crazing slip lines or corded bent surfaces, and the like and improves the canning yield rate and the canning qualified rate.

Owner:武钢集团有限公司

Softening heat treatment process of small-specification 22Si2MnCrNi2MoA rolled steel

The invention discloses a softening heat treatment process of small-specification 22Si2MnCrNi2MoA rolled steel, and belongs to the field of metal heat treatment. The softening heat treatment process comprises the following steps of a, rolling into products, steel ingots are conveyed to a rolling machine after being discharged, and at least six passes of reversible rolling are carried out continuously; b, full annealing, wherein the products in step a are placed in an annealing furnace and heated to 880+ / -10 DEG C, heat preservation is carried out for 3-5 h, then the products is cooled to be lower than or equal to 200 DEG C along with the furnace, and finally the products are subjected to air cooling to reach room temperature; and c, high-temperature tempering, wherein the products in stepb are placed in a tempering furnace and heated to 720+ / -10 DEG C, heat preservation is carried out for 20-25 h, then the products are cooled to be lower than or equal to 450 DEG C to be discharged, and the products are subjected to air cooling to reach the room temperature. According to the softening heat treatment process, by means of multi-pass reversible rolling, crystals of the structure are refined, then a softened structure with ferrite+pearlite+a little bainite as a matrix structure can be obtained through the full annealing procedure, and finally a tempered sorbate structure is obtained through the high-temperature tempering procedure; and the hardness value of the steel ranges from 235 HB to 250 HB after final high-temperature tempering, and machining requirements are completely met.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Special temperature-control cooling thermal treatment technology

The invention discloses a special temperature-control cooling thermal treatment technology which is characterized by comprising the following steps of: placing a blank workpiece to be processed after warm forging in a continuous mesh-belt temperature control furnace; and controlling the temperature in the furnace so as to transform the structure in a constant-temperature environment, wherein a heating area of the continuous mesh-belt temperature control furnace is divided into four areas, the temperature of the first and second areas is 630-660 DEG C, the temperature of the third area is 590-630 DEG C, and the temperature of the fourth area is not higher than 560 DEG C; the time of the workpiece passing through the whole mesh belt is 75-90 minutes; and the workpiece enters a slow-cooling area and is discharged when the temperature is lower than 500 DEG C. The technology is relatively simple, the requirements on equipment are low, the production efficiency is high, the production period is short, and the cost is low.

Owner:JIANGSU SUNWAY PRECISION FORGING

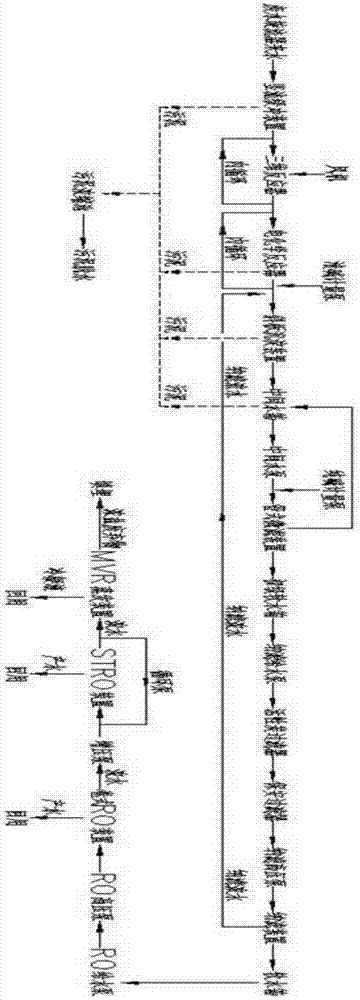

Desulfurization wastewater treatment process

ActiveCN107151072ALow costEasy to handleTreatment involving filtrationMultistage water/sewage treatmentSalting outWastewater

The invention discloses a desulfurization wastewater treatment process, which comprises a desulfurization wastewater pretreatment step, a desulfurization wastewater membrane concentration treatment step and a desulfurization wastewater salting-out pretreatment step, wherein the desulfurization wastewater pretreatment step comprises a two-stage electrochemical treatment step and a two-stage softening treatment step, the membrane concentration treatment section is designed into two-stage membrane treatment and comprises a rolled RO device and a mesh pipe type STRO device, and an MVR evaporator and a spray evaporator are combined in the salting-out the treatment section. According to the present invention, any organic agents are not added in the whole process.

Owner:江苏八达科技股份有限公司

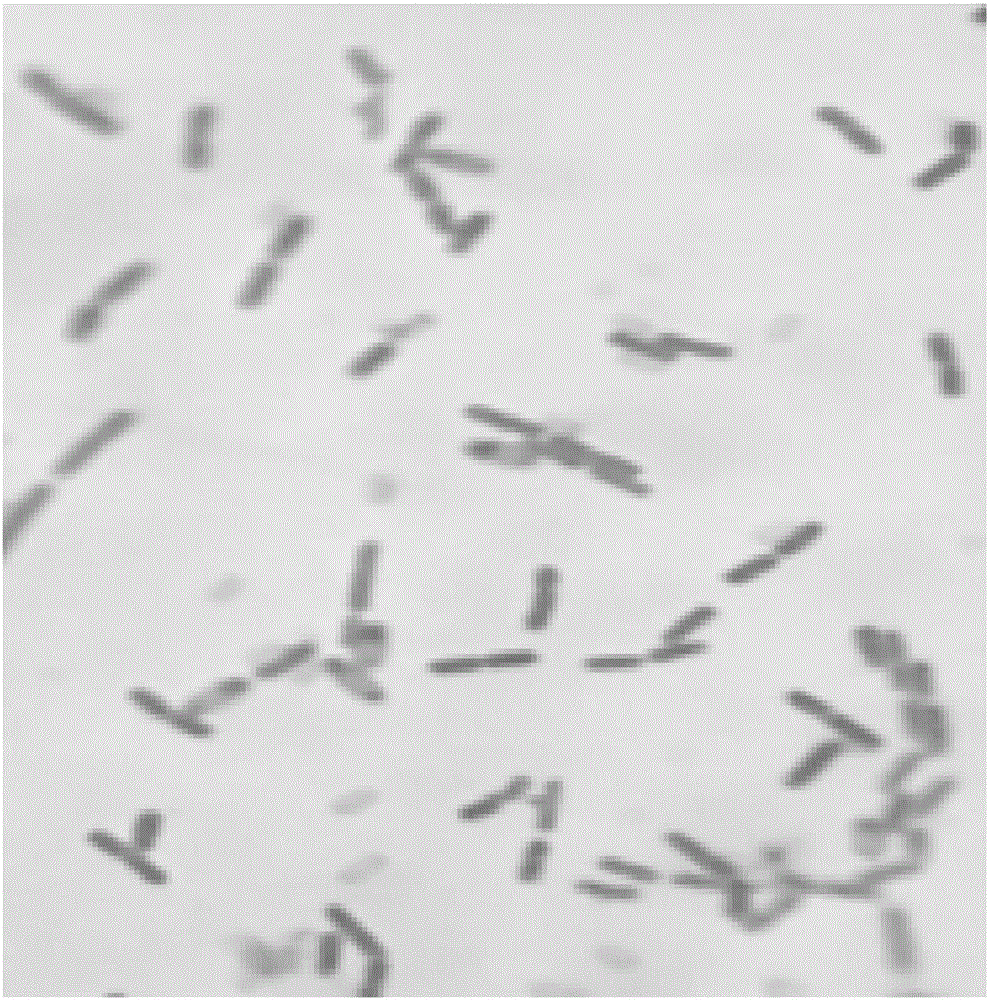

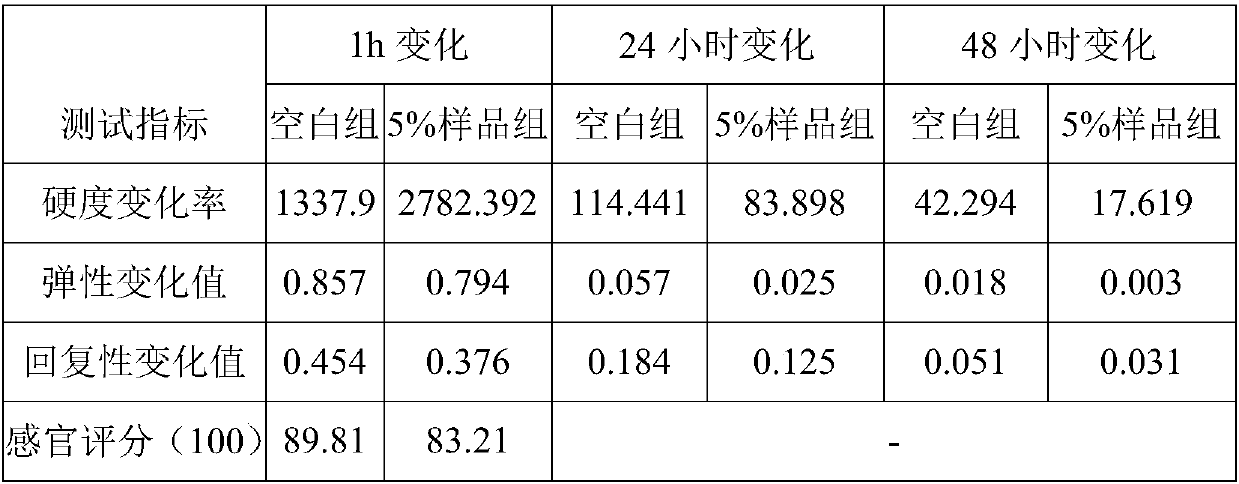

Bacillus amyloliquefaciens strain and microbial agent and preparation method of microbial agent

InactiveCN106701625AThe flowering effect is obviousImprove food safetyBacteriaMicroorganism based processesMicroorganismProteinase activity

The invention provides a bacillus amyloliquefaciens strain, a microbial agent and a preparation method of the microbial agent. The bacillus amyloliquefaciens strain is Bacillus amyloliquefaciens D7 and collected in the General Microbiological Center of China Microbiological Culture Collection Management Committee on November 10th, 2016, and the collection number is CGMCC No.13250. The strain is activated and subjected to fermentation culture to prepare the microbial agent of the bacillus amyloliquefaciens strain, and the preparation method of the microbial agent comprises the following steps: inoculating the bacillus amyloliquefaciens strain into a broth culture medium to be activated so as to obtain an activation solution; and inoculating the activation solution to a fermentation culture medium to be subjected to the fermentation culture so as to obtain the microbial agent of the bacillus amyloliquefaciens. The bacillus amyloliquefaciens strain disclosed by the invention can produce proteases, and is obvious in tenderizing effect on beef products.

Owner:HUNAN AGRICULTURAL UNIV

Corrosion-resistant soft cold-rolling tin plate and production method thereof

InactiveCN101892418BLow hardness valueImprove corrosion resistanceBell type furnacesChemical compositionHydrogen

Owner:武钢集团有限公司

Smoking article

InactiveCN108024569ALow hardness valueLow costCigar manufactureCigarette manufactureEngineeringFilter material

Owner:JT INT SA

Preparation method of composite trehalose product

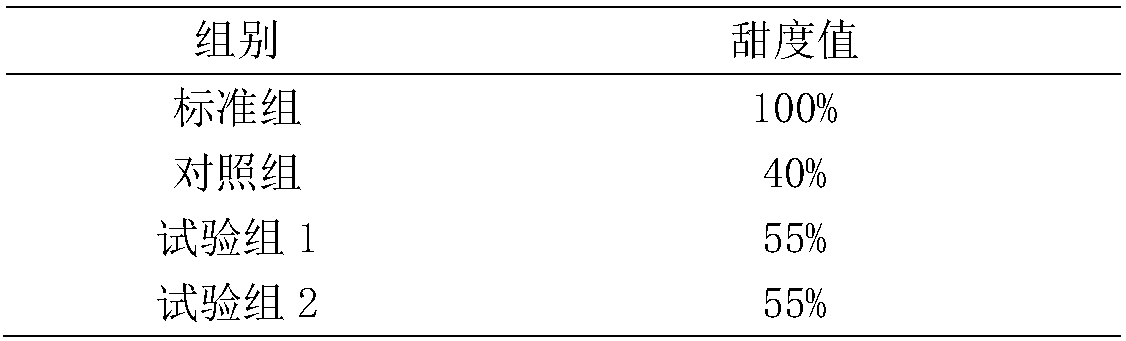

The invention discloses a preparation method of a composite trehalose product. The preparation method sequentially comprises the following steps: (1) preparing starch milk; (2) performing liquefying; (3) performing composite enzymolysis; (4) performing filtering to remove protein; (5) performing decoloring; (6) performing desalinating; and (7) performing concentrating. The preparation method has the advantages that the content of trehalose in the product is 20-80%, the content of maltose, trisaccharide, tetrasaccharide and polysaccharide is 20-80%, and the composite trehalose product has the advantages of the trechalose and the advantages of a common sweetening agent, and is broad in application scope. The product contains trehalose, and is good in water preserving capability. When the product is used for baking, the fluffy degree of the baked product can be increased, the hardness value of the product is reduced, the product quality is improved, and the storage time is prolonged. The generation of the Maillard reaction can be effectively reduced, and the color protection capacity is high. The product also contains polysaccharides of the maltose, the trisaccharide, the tetrasaccharide and the like. Compared with the common sweetening agent, the composite trehalose product and the trehalose can together reduce the sweetness of product, and can restrain the crystallizing of the granulated sugar and the glucose, the dissolving speed is high, and the composite trehalose product is convenient to store and use, and easy to absorb by human bodies.

Owner:TONGLIAO MEIHUA BIOLOGICAL SCI TECH CO LTD

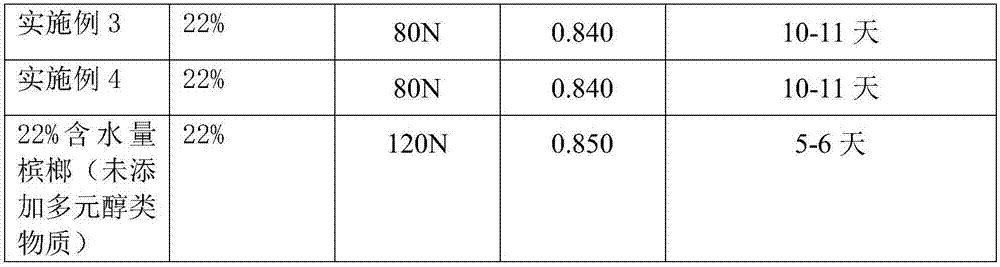

Method and composition for inhibiting mildew of betel nuts

InactiveCN107996690AImprove mildew resistanceLow hardness valueFruit and vegetables preservationBetel nutsAlcohol

The invention provides a method and composition for inhibiting mildew of betel nuts. The method is characterized in that a polyhydric alcohol type substance accounting for 2%-10% of a dry basis of betel nuts is added in a fermentation step in existing production of betel nuts. The invention also discloses the composition for inhibiting mildew of the betel nuts and the composition is prepared frommultiple polyhydric alcohol type substances by combination. The method and the composition can effectively inhibit mildew of the betel nuts and simultaneously can also maintain the original softness and the mouthfeel of the betel nuts.

Owner:HUNAN ONYEAR FOOD

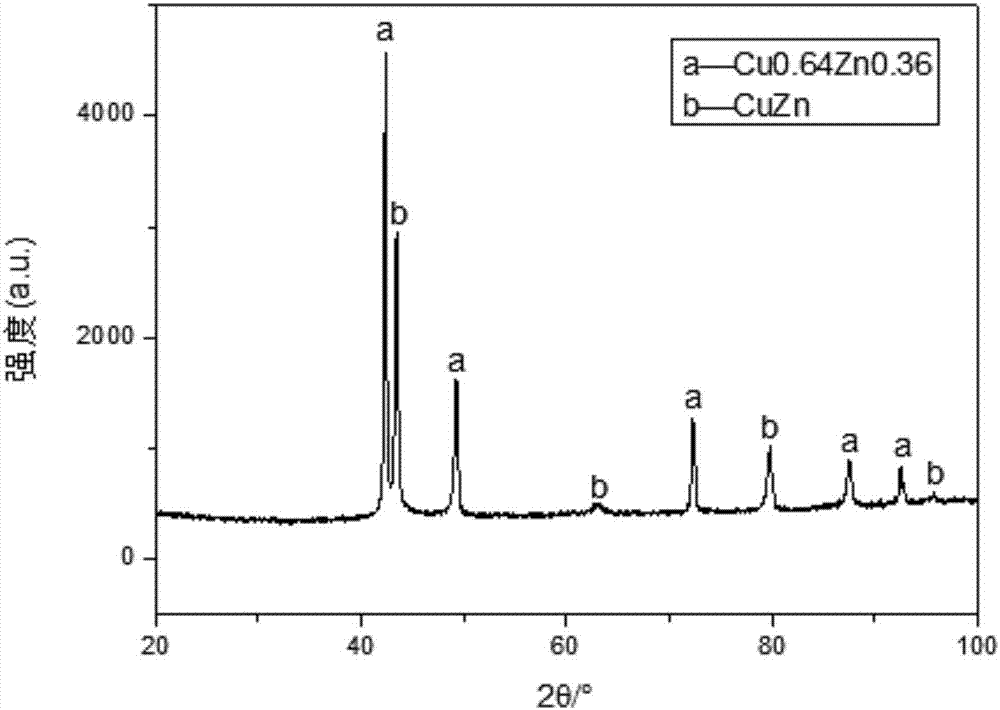

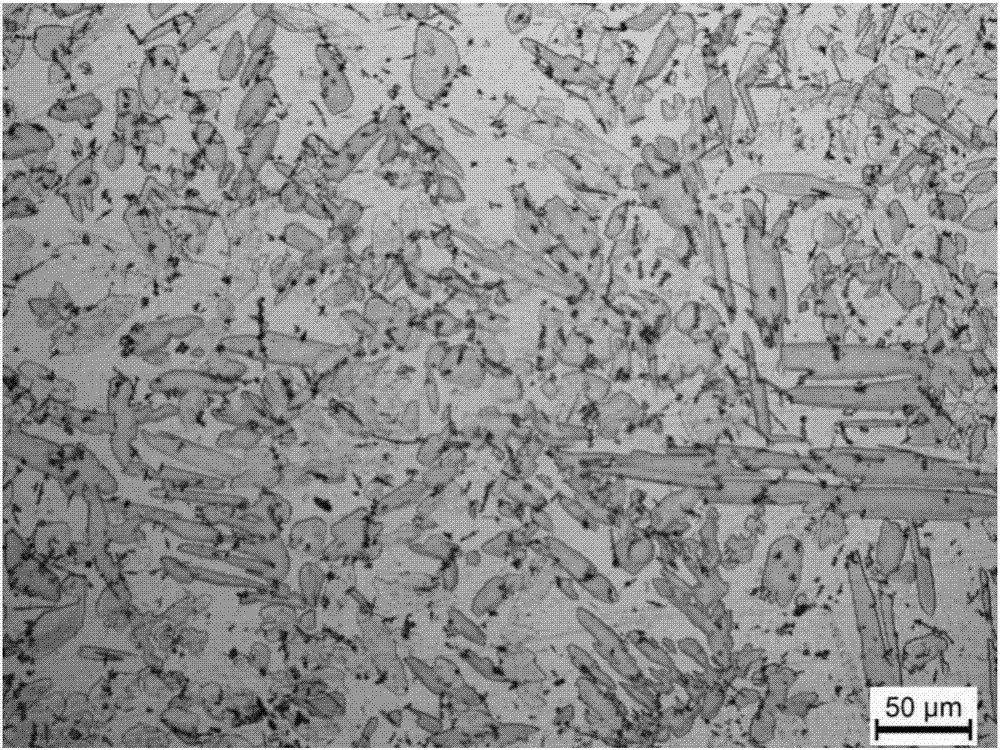

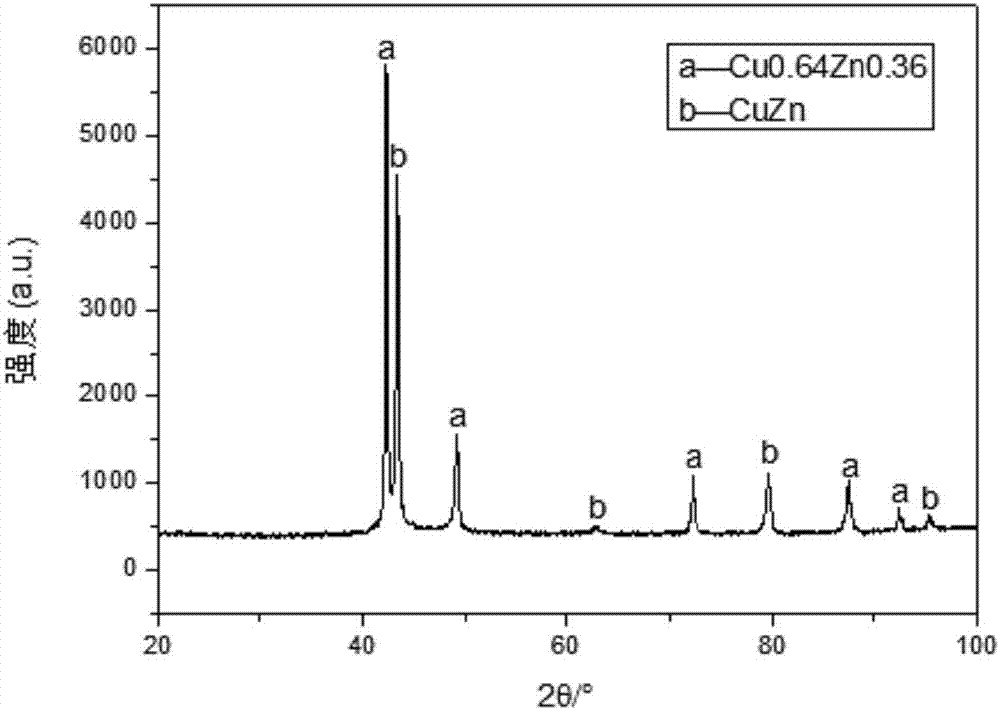

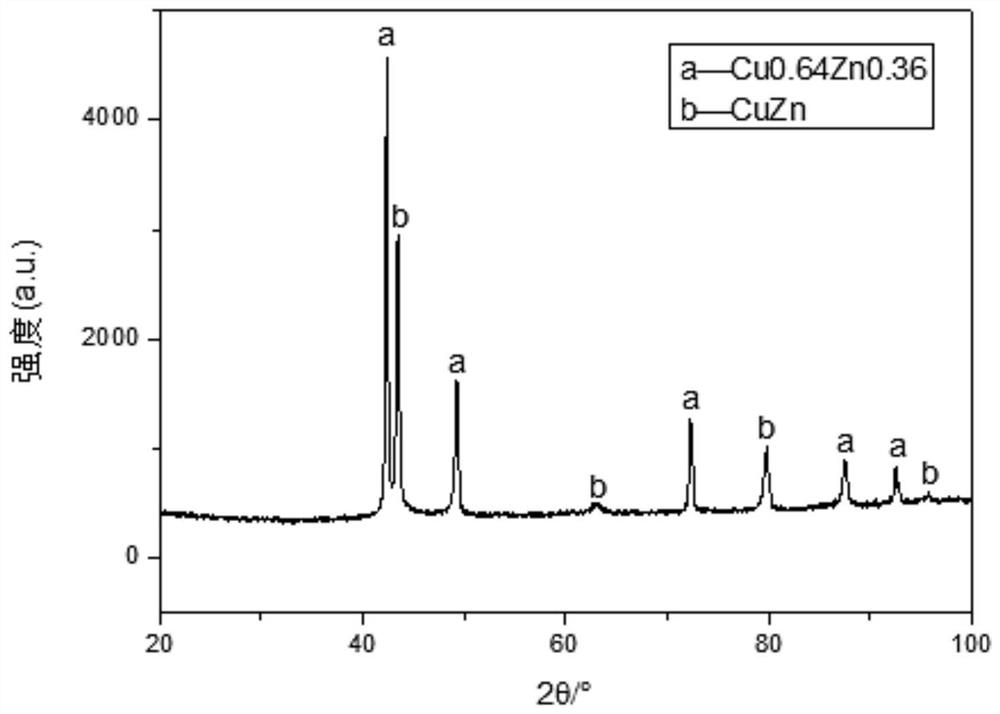

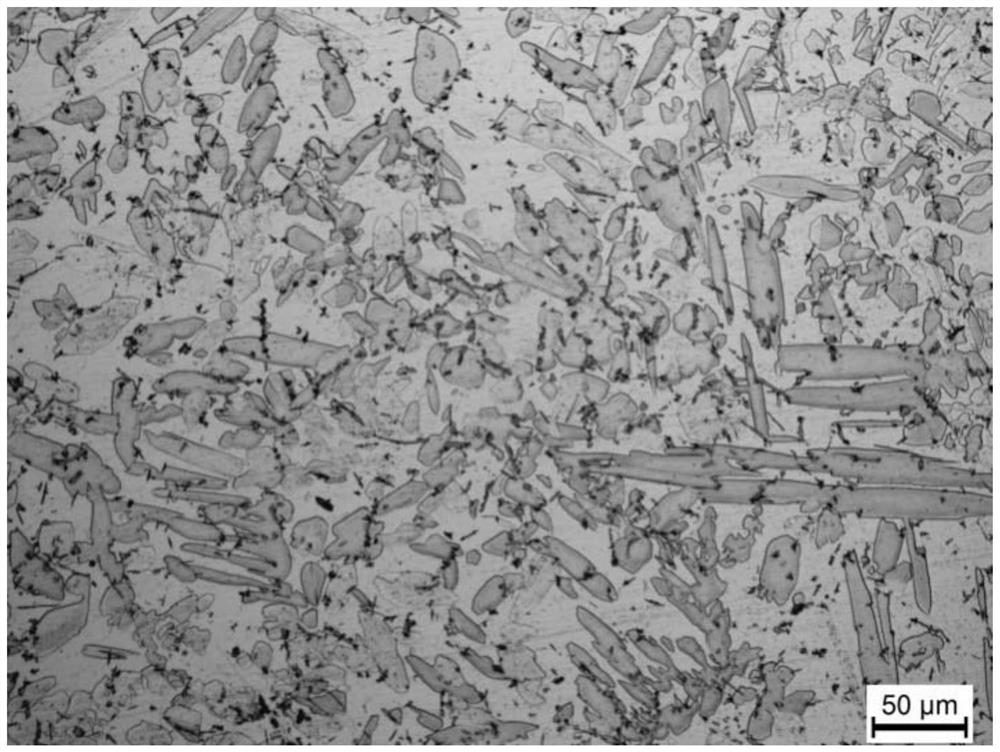

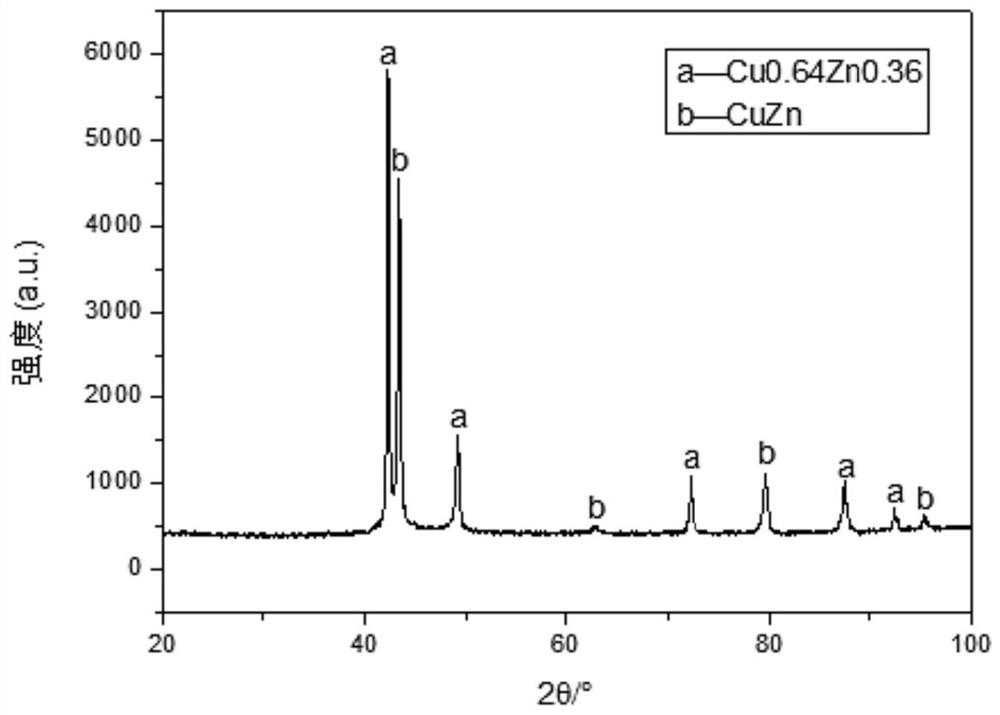

Lead-free free-cutting silicon magnesium phosphorus brass alloy and preparation method thereof

The invention discloses a lead-free free-cutting silicon magnesium phosphorus brass alloy and a preparation method thereof. The silicon magnesium phosphorus brass alloy comprises, by weight percentage, 60% of Cu, 0.5-0.9% of Si, 0.5-0.9% of Mg, 0.5-0.7% of P, 0.2-0.4% of Al, 0-0.6% of selectively-added elements, and the balance Zn and impurities, wherein the summation of the impurities is less than 1 wt%. According to the lead-free free-cutting silicon magnesium phosphorus brass alloy, the adding proportion of Mg, Si and P is required strictly, and the sum of the contents of the elements of Mg, Si and P is 1.8-2.4 wt%, wherein the sum of the contents of Mg and Si is 1.3-1.6 wt%. The preparation method comprises the following steps of melting components of raw materials, refining at the high temperature after homogenizing the components, pouring, cooling to indoor temperature for demoulding, and obtaining the lead-free free-cutting silicon magnesium phosphorus brass alloy. The lead-free free-cutting silicon magnesium phosphorus brass alloy is excellent in cutting property, corrosion resistance property and mechanical property, and low in cost, can replace lead brass, and has good application prospects.

Owner:SOUTH CHINA UNIV OF TECH

Chamfering-free pipe row welding technology of ultra-supercritical boiler high-temperature screen type overheater

InactiveCN105290578AReduce thicknessLess restraintArc welding apparatusWelding/cutting media/materialsCrack resistanceEngineering

The invention discloses a chamfering-free pipe row welding technology of an ultra-supercritical boiler high-temperature screen type overheater. Compared with the prior art, the chamfering-free pipe row welding technology is characterized in that firstly, the thickness of flat steel is reduced to 6 mm, and the restraint intensity of welding lines is reduced; secondly, an alkaline soldering flux is adopted, and plasticity and tenacity of a connector are improved; and thirdly, small-standardization parameters are adopted for strict welding. On one hand, the heat input amount is reduced, and the high temperature standing time of a welding pool is shortened; and on the other hand, the crack resistance of the connector is improved. The double-layer single-pass welding is adopted, firstly, the fracture surfaces of all the welding lines of the welding connector can be reduced, the cooling speed can be increased, the one-time crystallization condition is improved, the sequential thermal treatment action is achieved among all layers of welding lines, and accordingly a secondary structure is improved; and secondly, the position of welding line metal crystallization lines is changed. Improving of the strength of the connector is the final purpose. In addition, the thermal treatment parameters of corner welding lines are reasonably adjusted, the standard post-welding thermal treatment of 730-760 DEG C*1 h is carried out, and accordingly the hardness value of the corner welding lines is obviously reduced.

Owner:SHANGHAI BOILER WORKS

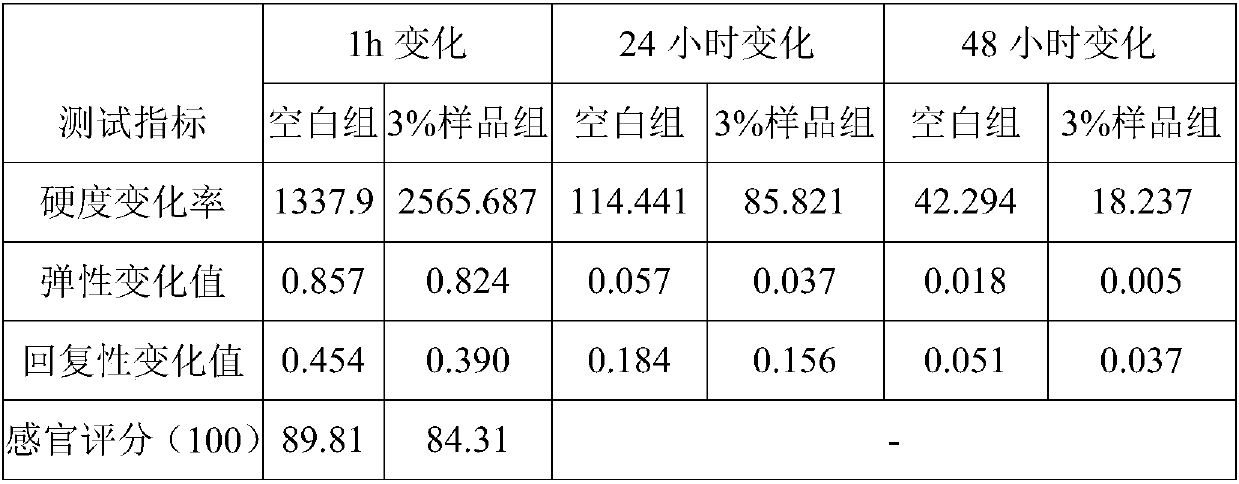

Making method of okra aging-resistant steamed buns and method for delaying aging of steamed buns

The invention provides a making method of okra aging-resistant steamed buns, and belongs to the technical field of aging resistance of steamed buns. The making method of the okra aging-resistant steamed buns comprises the following steps of preparing whole okra powder; activating yeast; adding the whole okra powder to flour, performing uniform mixing, and then adding distilled water, an activatedyeast aqueous solution and a pectinase solution, wherein the addition quantity of the whole okra powder is 1-9% (m / m) of the mass of the flour, and the addition quantity of pectinase is 30-180ppm(m / m); performing dough mixing, and making dough; enabling the dough to stand; pressing the dough, performing shaping, fermenting the steamed buns, and performing steaming. The okra aging-resistant steamedbuns made by the making method disclosed by the invention are rich in nutrient value, in the storage process of the okra aging-resistant steamed buns, the changes of the hardness and the relevant aging indexes of the okra aging-resistant steamed buns are small, the freshly-steamed buns can be stored for a longer time, the mouth feel and the flavor of the steamed buns can be maintained, the shelflife of the steamed buns can be prolonged, and besides, the effect of reducing blood lipid can also be achieved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

A kind of lead-free free-cutting silicon-magnesium-phosphorus brass alloy and preparation method thereof

The invention discloses a lead-free free-cutting silicon magnesium phosphorus brass alloy and a preparation method thereof. The silicon magnesium phosphorus brass alloy comprises, by weight percentage, 60% of Cu, 0.5-0.9% of Si, 0.5-0.9% of Mg, 0.5-0.7% of P, 0.2-0.4% of Al, 0-0.6% of selectively-added elements, and the balance Zn and impurities, wherein the summation of the impurities is less than 1 wt%. According to the lead-free free-cutting silicon magnesium phosphorus brass alloy, the adding proportion of Mg, Si and P is required strictly, and the sum of the contents of the elements of Mg, Si and P is 1.8-2.4 wt%, wherein the sum of the contents of Mg and Si is 1.3-1.6 wt%. The preparation method comprises the following steps of melting components of raw materials, refining at the high temperature after homogenizing the components, pouring, cooling to indoor temperature for demoulding, and obtaining the lead-free free-cutting silicon magnesium phosphorus brass alloy. The lead-free free-cutting silicon magnesium phosphorus brass alloy is excellent in cutting property, corrosion resistance property and mechanical property, and low in cost, can replace lead brass, and has good application prospects.

Owner:SOUTH CHINA UNIV OF TECH

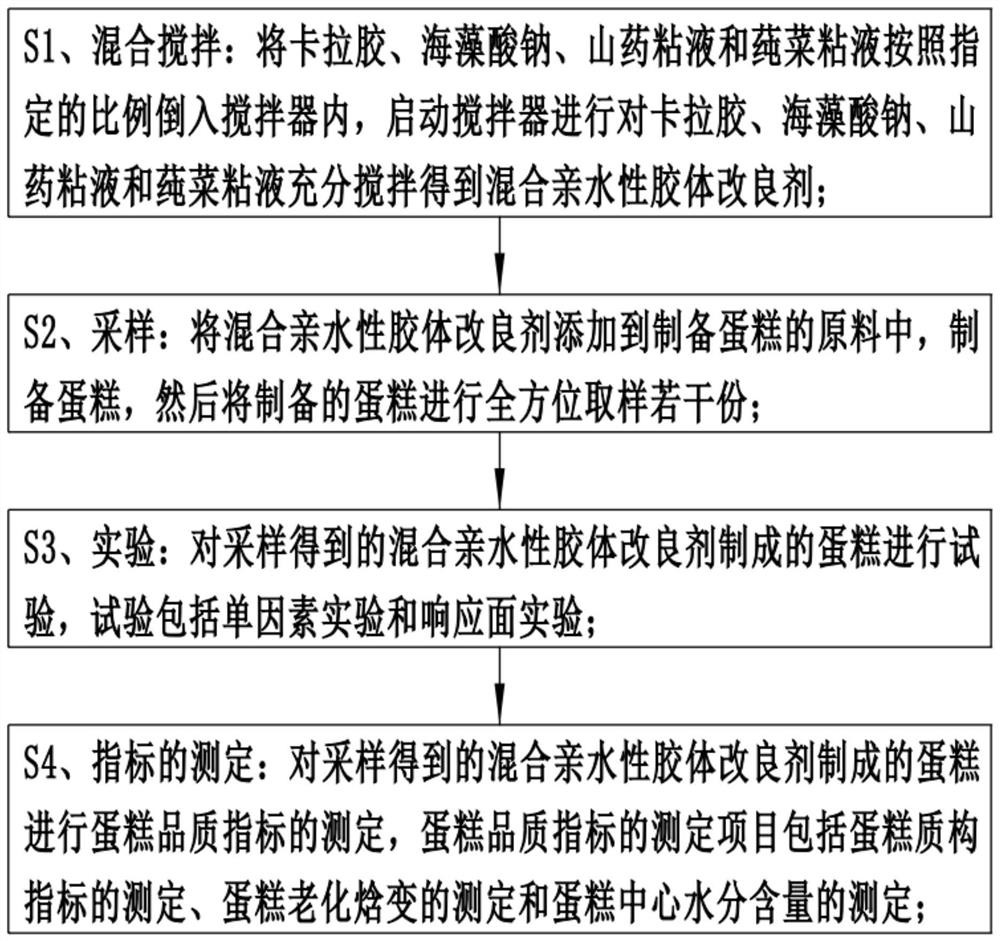

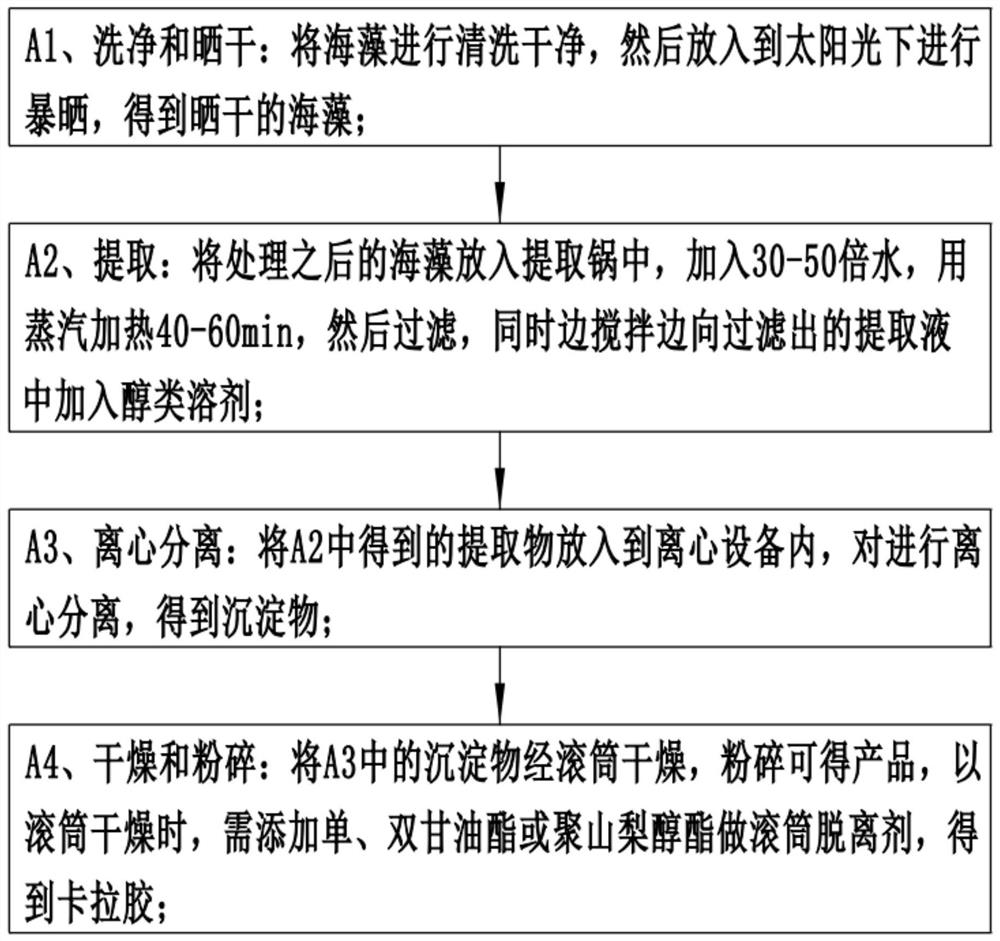

Cake compound hydrophilic colloid amendment and preparation method thereof

PendingCN113498797AGood water absorptionIncrease moisture contentDough treatmentPreparing sample for investigationCarrageenanHemicellulose

The invention relates to the technical field of improvers for cakes, in particular to a cake compound hydrophilic colloid amendment and a preparation method thereof. The cake compound hydrophilic colloid amendment comprises the following components: 0.1-0.3% of carrageenan; 0.1% - 0.3% of sodium alginate ; 3-15% of Chinese yam mucilage; and 4-20% of brasenia schreberi mucus. The cake compound hydrophilic colloid amendment has the beneficial effects that the cake compound hydrophilic colloid amendment has a good water absorption characteristic, the specific volume is reduced by combining a large amount of water, so that the water loss of the cake during baking is reduced, the effect of increasing the water content is achieved, the cake texture is improved, the sodium alginate is beneficial to the emulsifying effect of egg slurry, the foaming property is good during whipping, the relative density of batter is reduced, and the cake is softer in texture and improved in quality; mannan in the Chinese yam mucilage serves as hemicellulose dissolved in water and can absorb water to swell and enhance satiety, mucoprotein contains pectin, vegetable gum, viscose and the like, atherosclerosis can be prevented easily, and the compound colloid has a more obvious anti-aging effect.

Owner:CHUZHOU UNIV

Special temperature-control cooling thermal treatment technology

The invention discloses a special temperature-control cooling thermal treatment technology which is characterized by comprising the following steps of: placing a blank workpiece to be processed after warm forging in a continuous mesh-belt temperature control furnace; and controlling the temperature in the furnace so as to transform the structure in a constant-temperature environment, wherein a heating area of the continuous mesh-belt temperature control furnace is divided into four areas, the temperature of the first and second areas is 630-660 DEG C, the temperature of the third area is 590-630 DEG C, and the temperature of the fourth area is not higher than 560 DEG C; the time of the workpiece passing through the whole mesh belt is 75-90 minutes; and the workpiece enters a slow-cooling area and is discharged when the temperature is lower than 500 DEG C. The technology is relatively simple, the requirements on equipment are low, the production efficiency is high, the production period is short, and the cost is low.

Owner:JIANGSU SUNWAY PRECISION FORGING

Subsea pipeline steel L485MO with low yield ratio and low hardness and production method thereof

The invention relates to subsea pipeline steel L485MO with low yield ratio and low hardness. The subsea pipeline steel L485MO comprises the following chemical components in percentage by mass: 0.060-0.080% of C, 0.10-0.15% of Si, 1.50-1.70% of Mn, less than or equal to 0.008% of P, less than or equal to 0.001% of S, 0.015-0.035% of Als, 0.050-0.060% of Nb, 0.005-0.020% of Ti, 0.10-0.20% of Mo and the balance of Fe and inevitable impurities. The production method comprises a rolling process, rough rolling adopts 3+5 passes of rolling, the reduction rate of the last pass of R2 rough rolling is larger than or equal to 24%, and during finish rolling, 0-2 racks are determined to be thrown according to the thickness of produced strip steel, specifically, when the thickness of the strip steel is less than or equal to 8mm, the racks are not thrown; when the thickness of the strip steel is larger than 8mm and smaller than 13mm, one rack is thrown; and when the thickness of the strip steel is larger than or equal to 13mm, two racks are thrown. The hardness value of the produced pipeline steel is lower than the standard requirement upper limit value 30HV10, the yield ratio is smaller than or equal to 0.85, a finished product has high strength and toughness, high crack arrest resistance and seawater corrosion resistance, and the production cost is low.

Owner:HANDAN IRON & STEEL GROUP +1

A kind of low-hardness x70m pipeline steel hot-rolled coil and its manufacturing method

The invention discloses a low-hardness X70M pipeline steel hot-rolled plate coil and a manufacturing method thereof. Wherein the steel contains 0.061%-0.061% of C; 0.080%, si 0.15%- 0.35%, mn 1.41% toMn 1.41% 1.59%, nb0.060%- 0.080% of V, 0.010%-0.030% of V, 0.008%-0.020% of Ti, 0.13%-0.18% of Mo, 0.13%-0.19% of Cr, 0.020%-0.060% of Al, smaller than or equal to 0.018% of P, smaller than or equalto 0.004% of S and smaller than or equal to 0.007% of N; wherein Pcm is smaller than or equal to 0.19%, and the balance Fe and inevitable impurities. Casting blank thickness below 200 mm. And a casting blank is subjected to hot charging at 500-850 DEG C and heated to 1150-1200 DEG C, the finish rolling temperature of rough rolling is 980-1050 DEG C, the finish rolling starting temperature of finish rolling is 910-960 DEG C, the finish rolling temperature is 780-840 DEG C, the cooling speed is 12-30 DEG C / s, and the coiling temperature is 470-530 DEG C. And the hardness value of the producedX70M-grade hot-rolled plate coil is smaller than or equal to 230 HV10.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com