Coarse cereal food and preparation method thereof

A technology for miscellaneous grains and food, applied in the field of miscellaneous grain products and their preparation, can solve the problems of unfavorable pre-cooking of miscellaneous grains, use of pre-cooked miscellaneous grains, poor pre-cooking effect, damage to the shape of miscellaneous grains, etc. and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0151] Embodiment 1, pre-curing treatment

[0152] Select oats, sorghum rice, mung beans, red beans and black beans with full grains, no insects and no defects, and carry out pre-ripening treatment respectively. Among them,

[0153] 1) The pre-cooking method of oats and sorghum rice is as follows:

[0154] a. Add 1-4 times (mass) of water and soak for 0.5-24 hours to make it saturated with water;

[0155] b. Freeze at a temperature of -15°C to -30°C for 3 to 20 hours;

[0156] c. Dry with hot air at a temperature of 40°C to 60°C until the moisture content is below 10%.

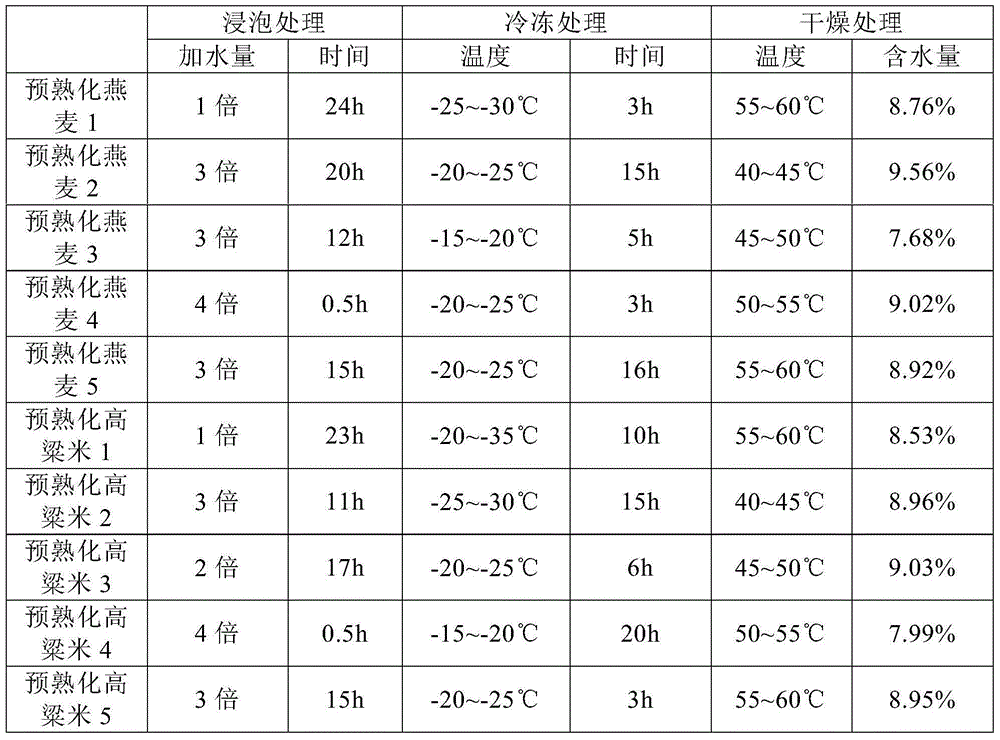

[0157] The specific parameters are shown in Table 1.

[0158] Table 1. Pre-cooking process of oats and sorghum rice

[0159]

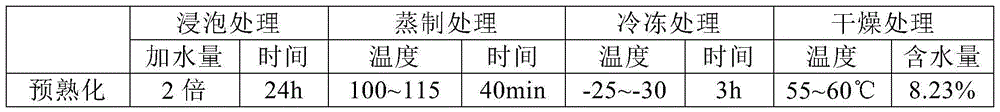

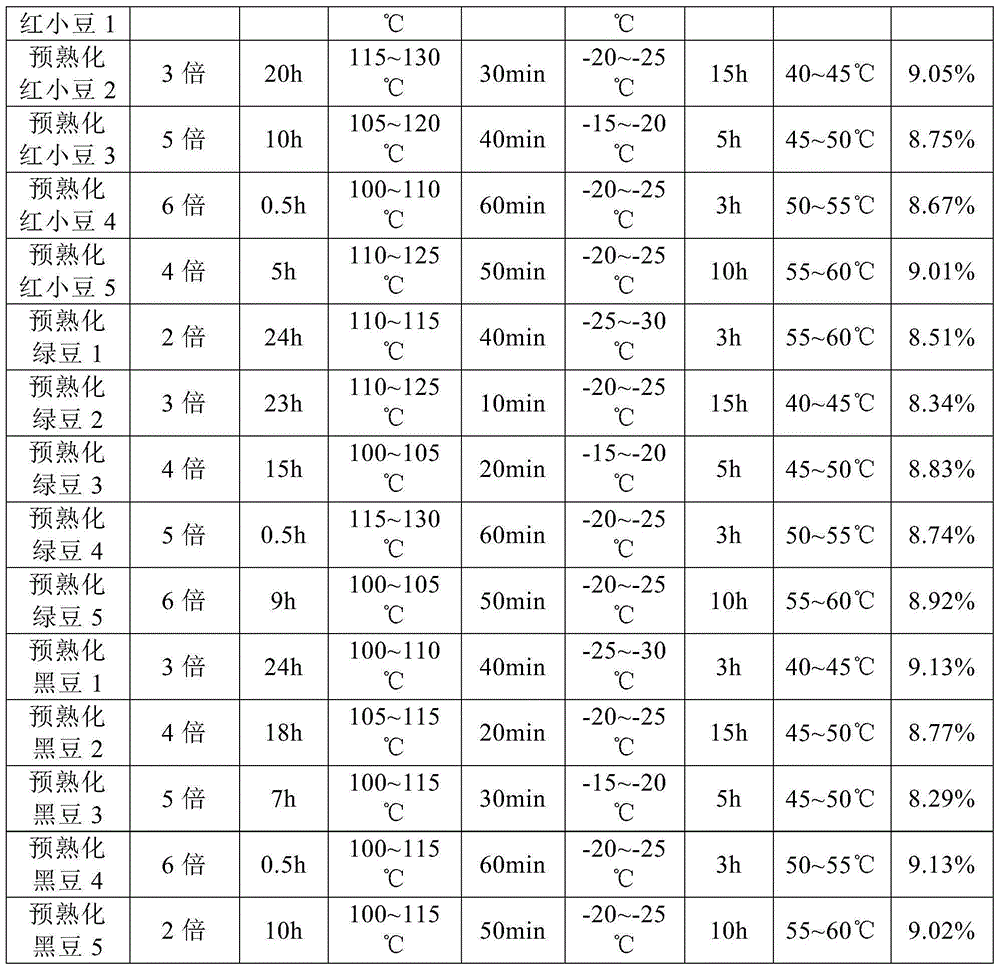

[0160] 2) The pre-cooking process of mung bean, red bean and black bean is as follows:

[0161] a. Add 2-6 times (mass) of water to soak for 0.5-24 hours to make it saturated with water;

[0162] b. Drain the water-saturated miscellaneous beans and miscellaneous grains and ste...

Embodiment 2-6

[0180] Mix precooked oats, sorghum rice, mung bean, adzuki bean and black bean, and uncooked black rice and buckwheat to prepare mixed miscellaneous grains 6-10, wherein,

[0181] Mixed cereals 6: 30 parts by weight of pre-cooked oat 1, 15 parts by weight of pre-cooked mung bean 1, 13 parts by weight of pre-cooked red bean 1, 2 parts by weight of pre-cooked black bean 1, 5 parts by weight of pre-cooked sorghum rice 1, 15 parts by weight of black Rice, 20 parts by weight buckwheat rice are mixed;

[0182] Mixed grains 7: 30 parts by weight of pre-ripened oats 2, 13 parts by weight of pre-ripened mung beans 2, 15 parts by weight of pre-ripened red beans 2, 2 parts by weight of pre-ripened black beans 2, 8 parts by weight of pre-ripened sorghum rice 2, 15 parts by weight of black Rice, 17 parts by weight of buckwheat rice are mixed;

[0183] Mixed grains 8: 33 parts by weight of pre-ripened oats 3, 16 parts by weight of pre-ripened mung beans 3, 10 parts by weight of pre-ripened...

Embodiment 7

[0187] Detect the rehydration rate of the pre-ripened oats, sorghum rice, mung beans, red adzuki beans and black beans obtained in Example 1 respectively, and carry out the oats, sorghum rice, mung beans, red bean, unripe and pre-cured according to the method of CN101961094B respectively Adzuki beans and black beans were used as controls, and the results are shown in Table 4. It can be seen from the precooked miscellaneous grains obtained in Example 1 that the precooked miscellaneous grains can keep the original shape of the miscellaneous grains very well, and has a good market prospect as a commodity sale.

[0188] Mix the precooked oats, sorghum rice, mung bean, adzuki bean and black bean obtained in Example 1 with rice at a weight ratio of 1:6, add drinking water 1.5 times the weight of the mixture, and cook for 0.5 h in a rice cooker. Sensory evaluation was carried out on the obtained miscellaneous grains, and the hardness of the miscellaneous grains after cooking was dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com