Patents

Literature

369results about How to "Granularity controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

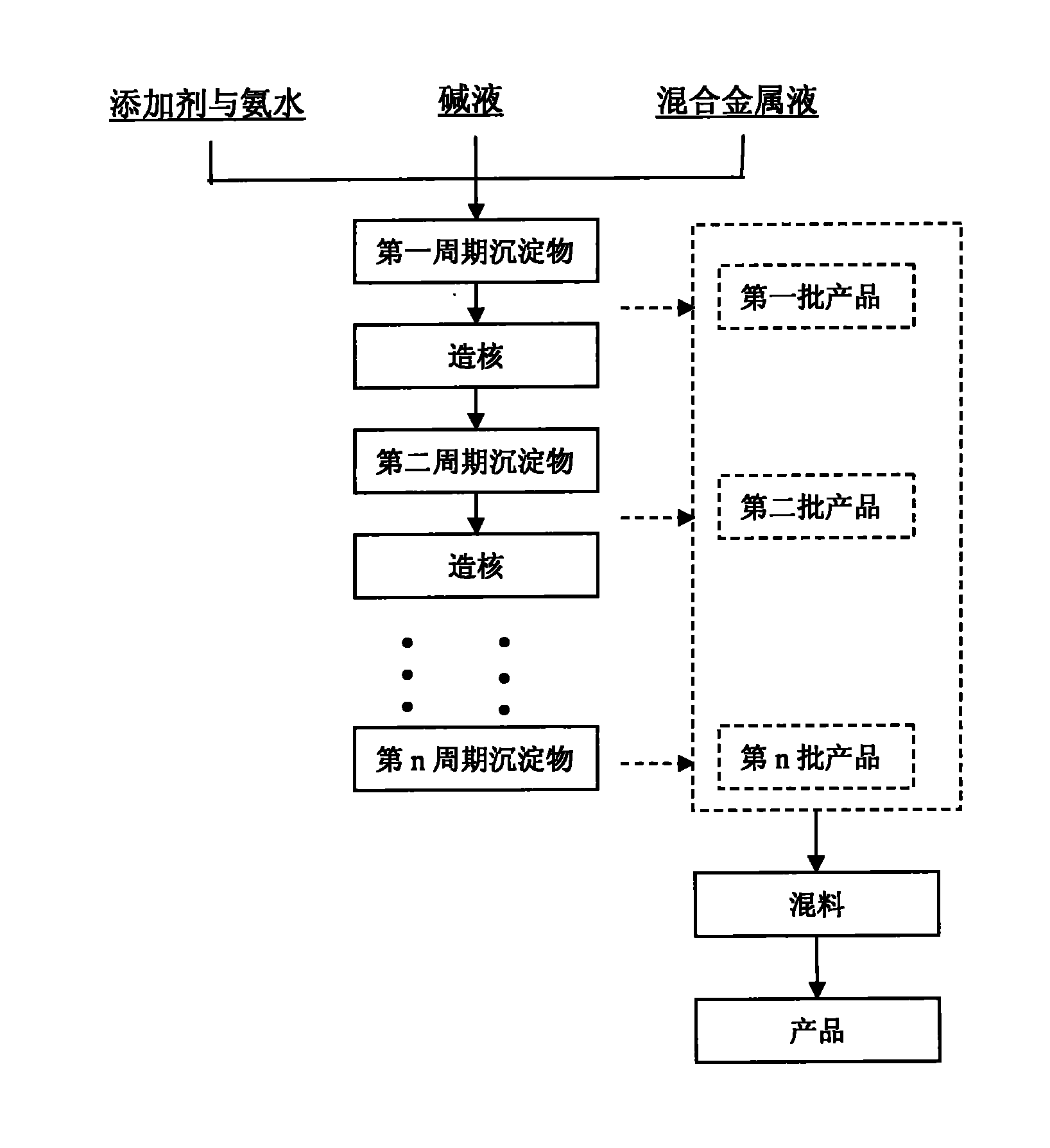

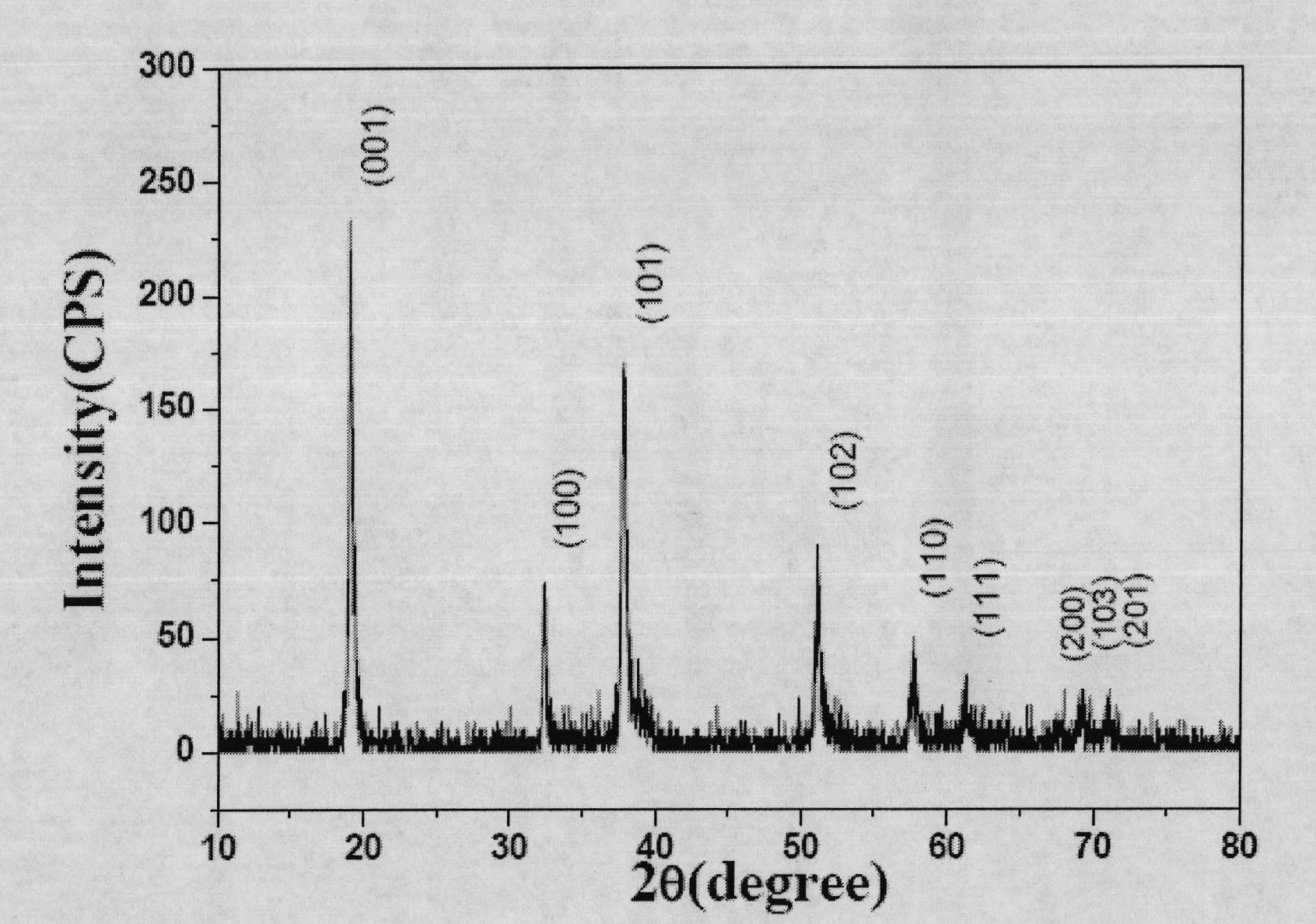

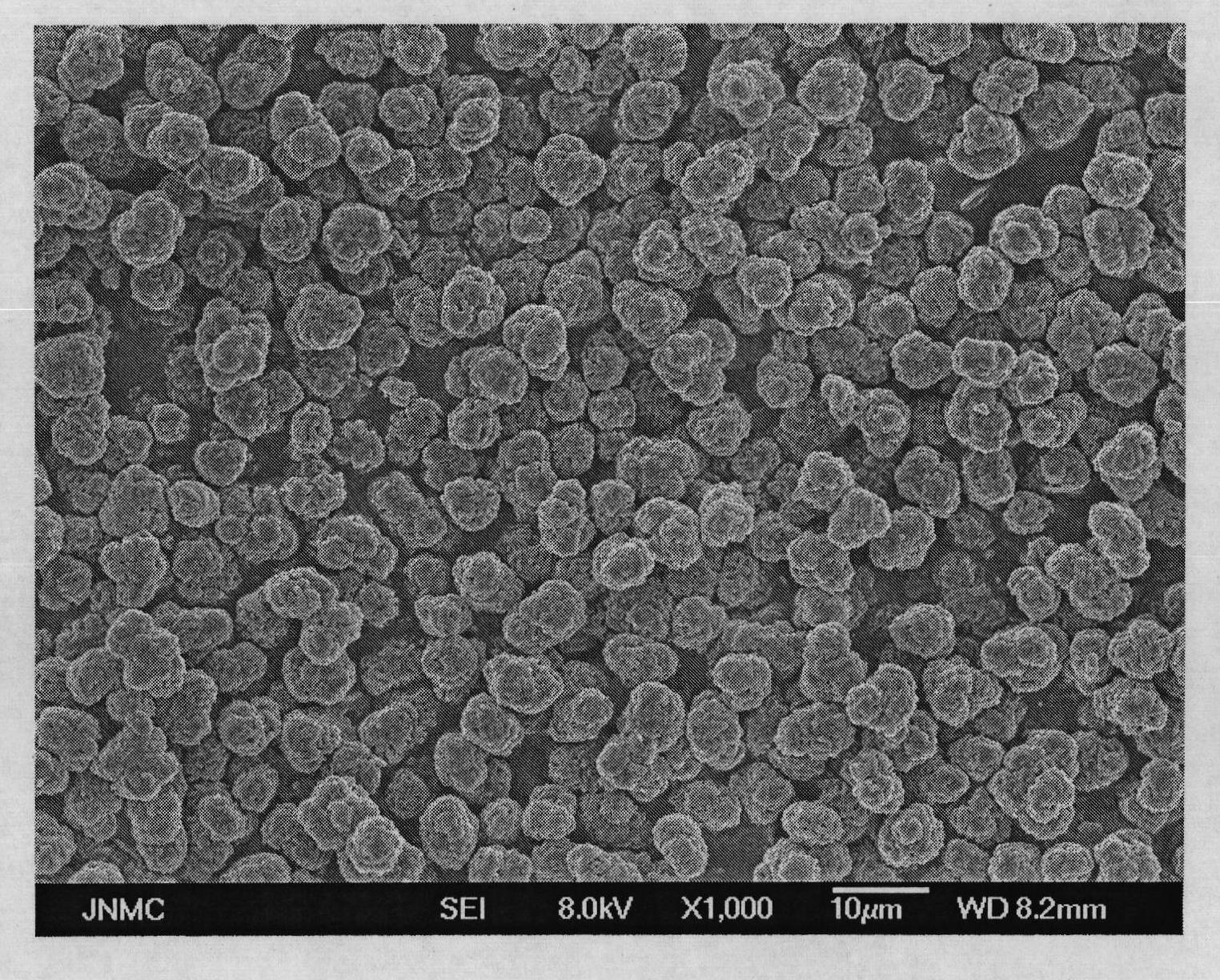

Method for continuously synthesizing precursor of lithium ion battery positive material

InactiveCN102092798AInhibition formationSolve the problem of easy oxidationCell electrodesManganese oxides/hydroxidesSynthesis methodsManganese

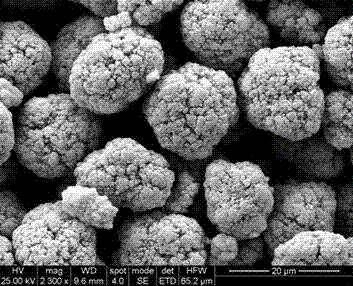

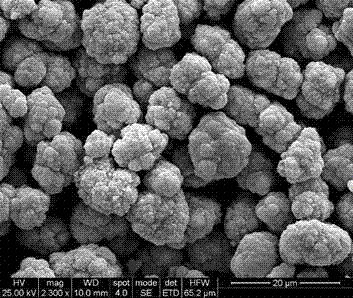

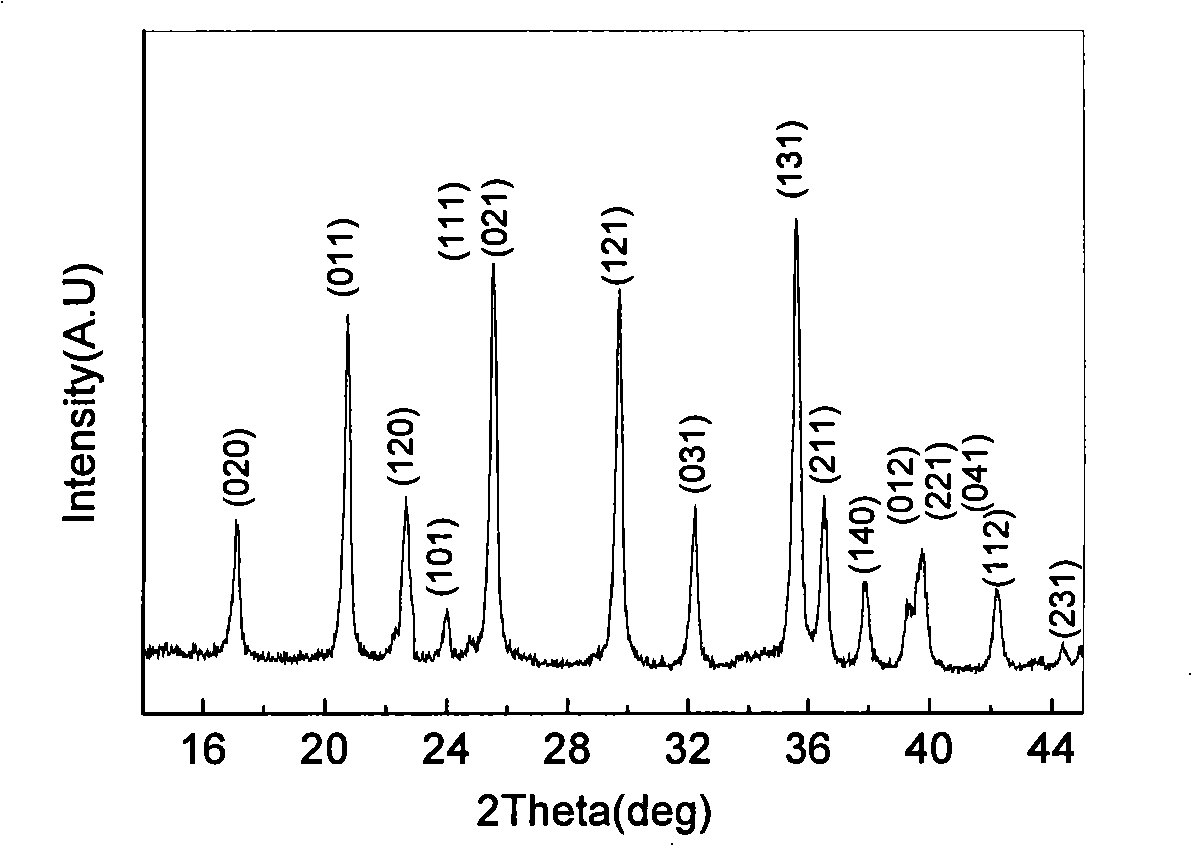

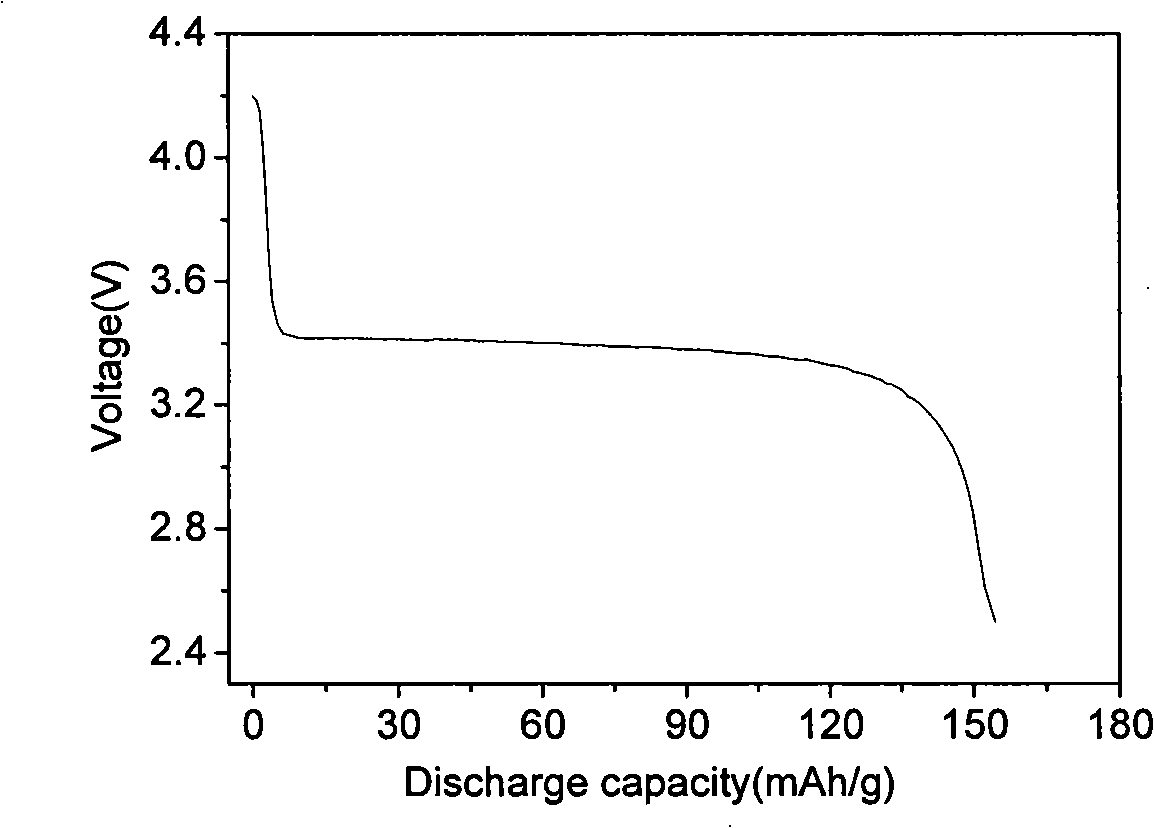

The invention provides a method for continuously synthesizing a precursor of a lithium ion battery positive material, relating to an improvement of a synthesis method of a nickle cobalt manganese termary positive material nickle cobalt lithium manganate of the lithium ion battery positive material. The method is characterized in that the synthesis process is as follows: merging a complexing agent ammonia, an aqueous solution of metal nickle cobalt manganese ions and a precipitator sodium hydroxide solution and then continuously adding the substances into a reaction kettle for a synthesis reaction under the strong stirring condition in the presence of protective gas; and aging, filtering and washing the effluent from the reaction kettle, and then drying to obtain the lithium ion battery positive material precursor spherical nickle cobalt manganese termary hydroxide. The method has the advantages that the preparation process is continuous, the particle size of the prepared nickle cobalt manganese compound hydroxide powder is controlled in a range of 5-20 microns, and the prepared nickle cobalt manganese compound hydroxide powder is even in distribution and excellent in electrochemistry property. The method has the advantages of high production efficiency, low production cost and significant economic and social benefits, and the energy is saved.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH +1

Preparation method of quantum point microspheric for bio-medical fluorescence probe

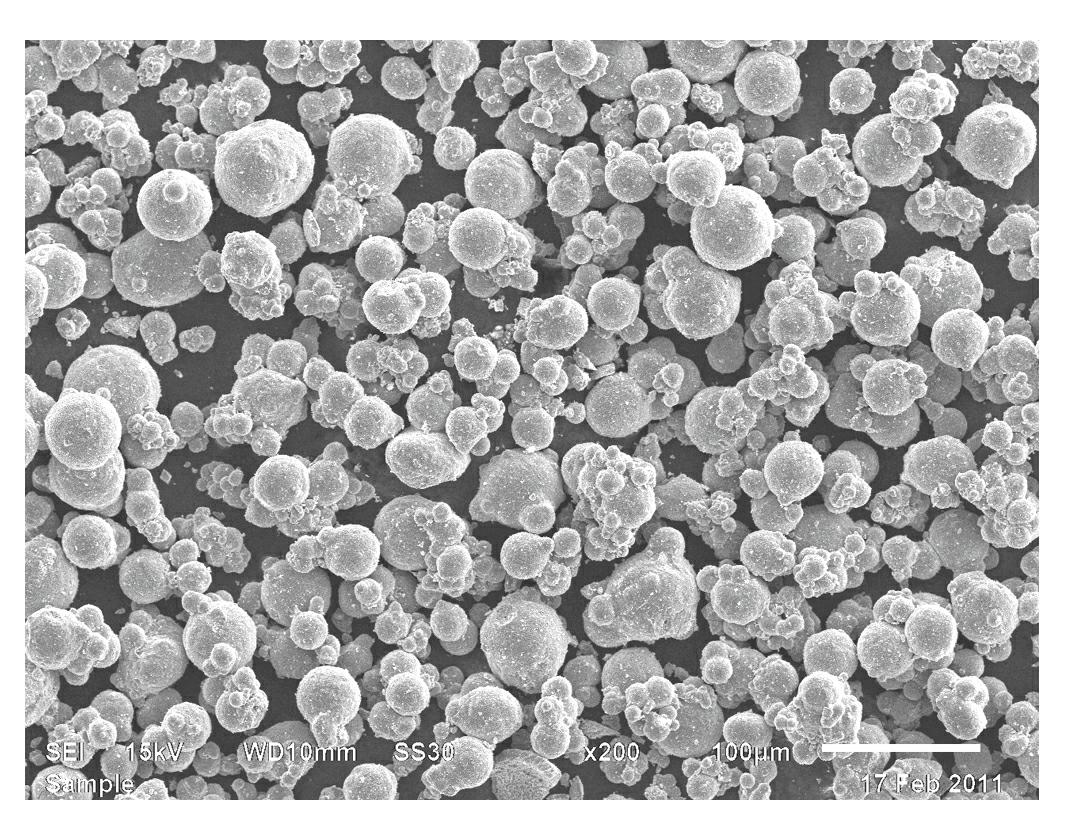

InactiveCN1560633AGranularity controllableImprove efficiencyBiological testingFluorescence/phosphorescenceMicrosphereFluorescence

The invention is a manufacturing method for quanta point microsphere used as biomedicine fluorescence probe. It belongs to chemical engineering, material and biomedicine field. The invention uses spray and drying method to embeds the quanta point into high molecular material, forms quanta microsphere with particle distribution less than 10 micrometers, the quanta point nanometer particle with different quantity and different fluorescence character is dispersed in the high molecular liquid, then carries on spray and drying, it changes the fluorescence character of the microsphere through changing type of quanta point material, quantity of the quanta point and the color and intensity of the quanta point, controls the particle size and figure of the quanta microsphere through adjusting the condition of spray and drying.

Owner:SHANGHAI JIAO TONG UNIV

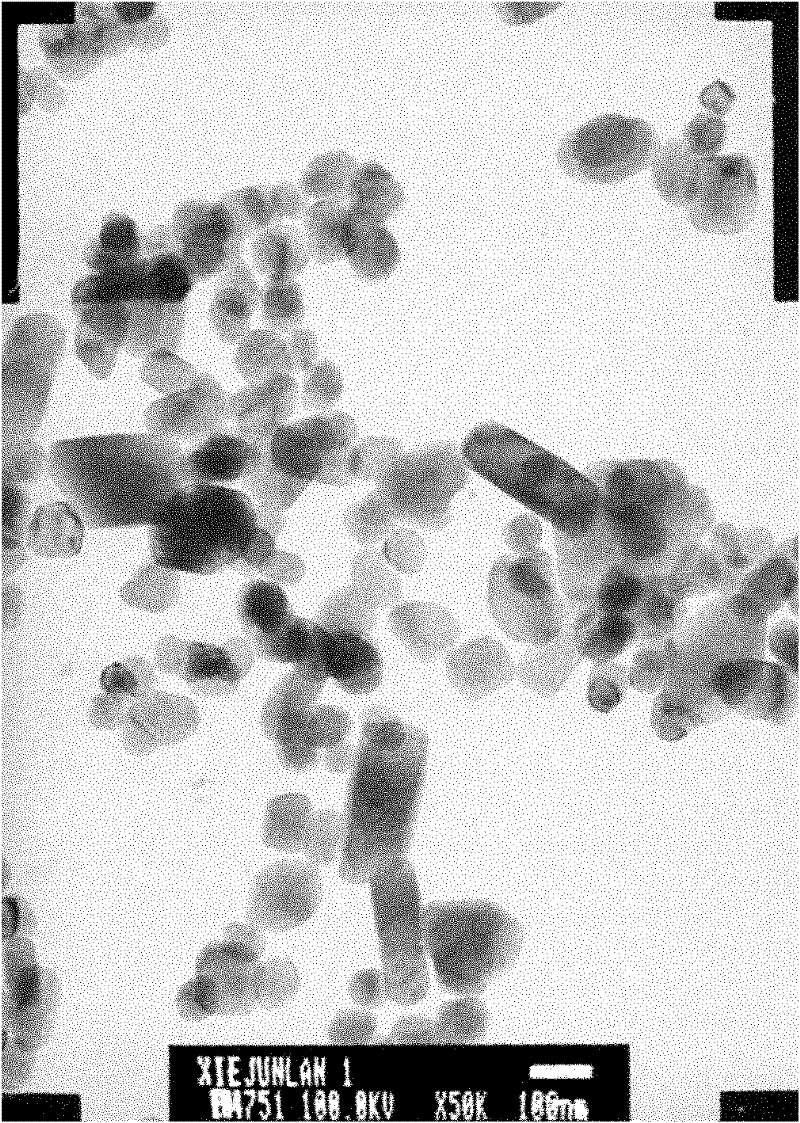

Nano copper powder for electronic paste and preparation process

InactiveCN102205422AUniform particle size distributionGranularity controllableHigh surfaceVacuum drying

The invention discloses nano copper powder for electronic paste and a preparation process. The process is characterized in that: nano copper powder is prepared through the reduction of a reducing agent under the condition of the temperature and the pressure which are produced by a hydrothemal method, and nano copper powder with different appearances and grain diameters can be prepared under the conditions of different temperatures, pressures, reducing agents and dispersing agents. The method comprises the following steps of: adding aqueous solution of a complexing agent into aqueous solution of water soluble copper salt to form the complex aqueous solution of copper; adding an appropriate amount of dispersing agent, stirring to uniformly disperse the mixture, adding an appropriate amount of reducing agent, and adding the finally-obtained mixed solution into a stainless steel high-temperature reaction kettle with a polytetrafluoroethylene lining; heating to a certain temperature; preserving heat for certain time; naturally reducing temperature to room temperature; filtering off precipitate; cleaning by using deionized water and ethanol for multiple times; and performing vacuum drying to finally obtain high-purity nano copper powder with high surface activity and controllable granularity.

Owner:SHENZHEN SENLONT ELECTRONICS

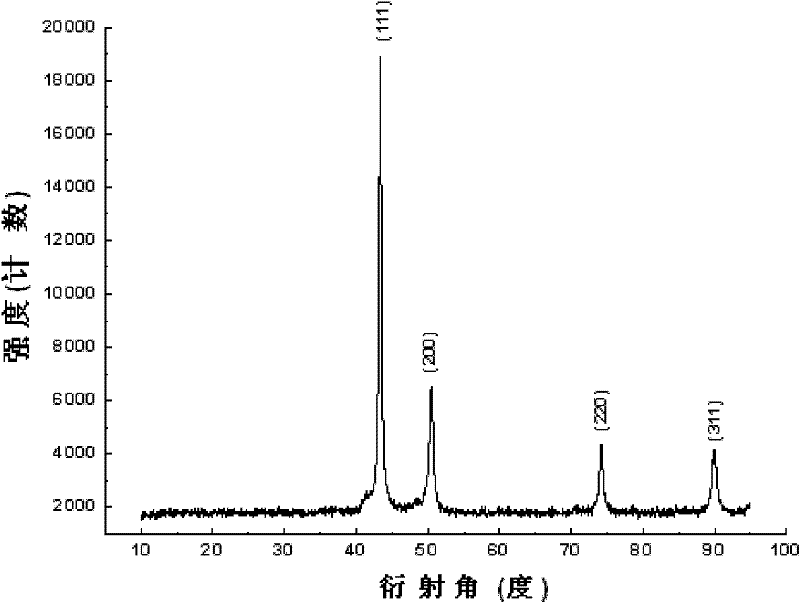

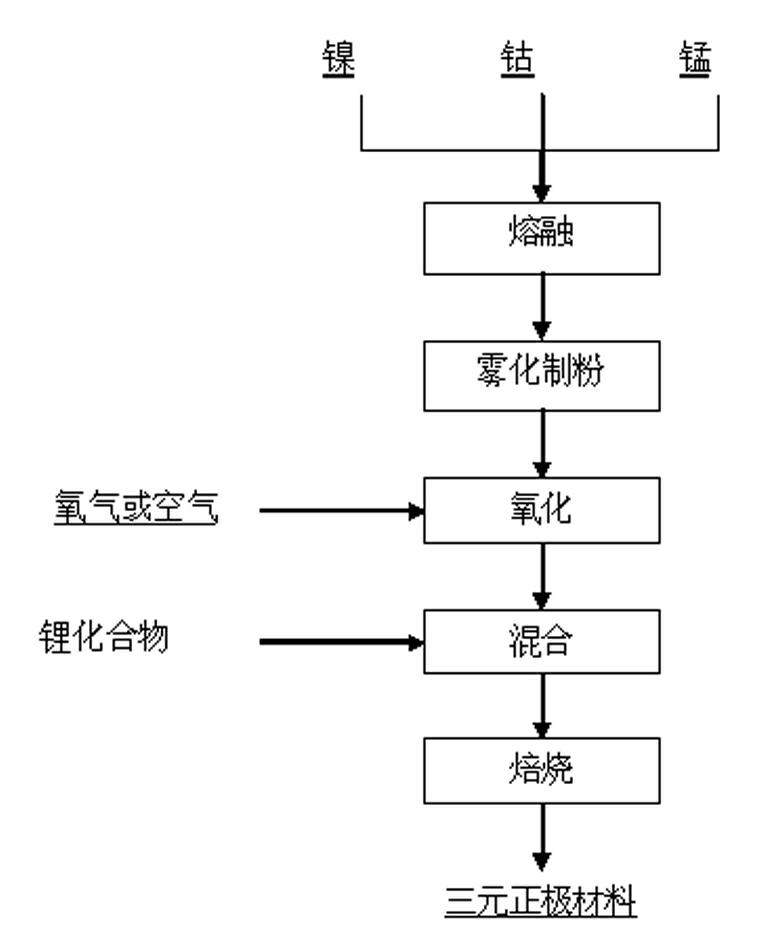

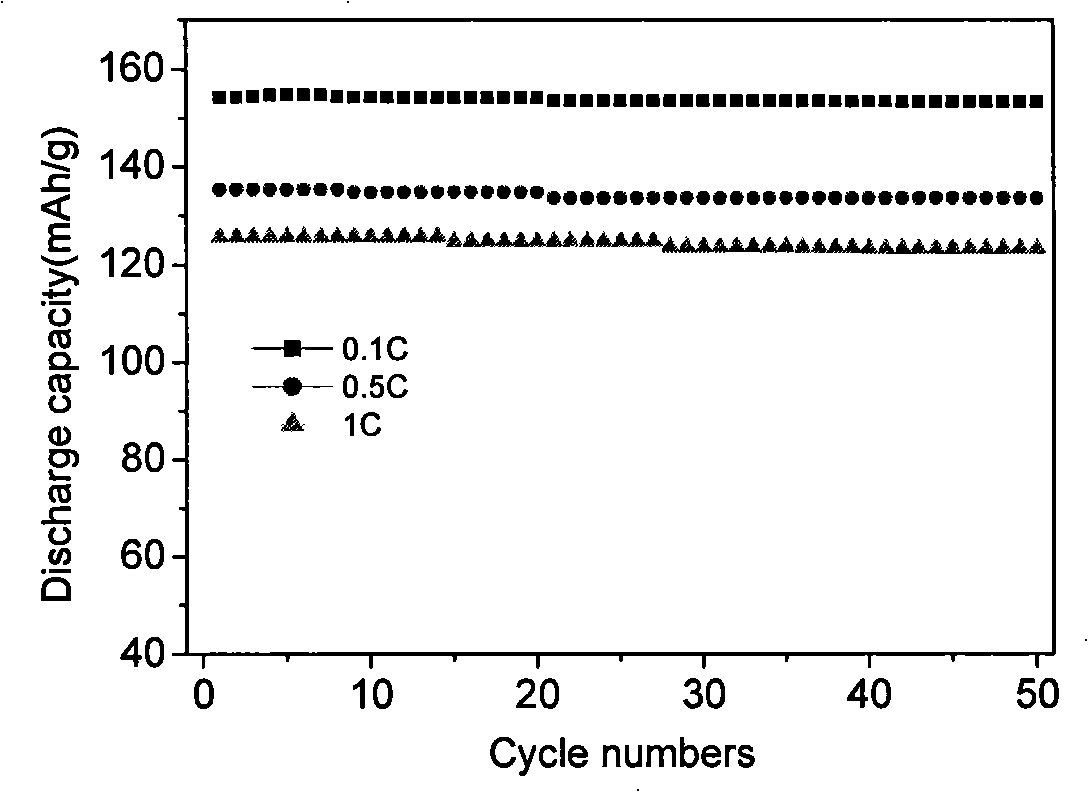

Ternary cathode material and production method thereof

The invention discloses a ternary cathode material and a production method thereof. The production method comprises the following steps of melting mixing materials of metallic nickel, cobalt and manganese at high temperature under the protection of inert gas or nitrogen; executing spray granulation after melting, and then oxidizing to obtain nickel, cobalt and manganese alloy oxide; and roasting the nickel, cobalt and manganese alloy oxide and a lithium compound at a temperature of 600-1050 DEG C after mixing according to the metallic element content mole ratio of (Ni+Co+Mn): Li=1:(1-1):1.15 to obtain the ternary cathode material, wherein the ternary cathode material is epigranular, regular spherical or similar to sphere, has large tap density, higher charge-discharge capacity and better electrochemical cycle performance. The ternary cathode material is prepared by adopting nickel, cobalt and manganese as raw materials and adopting full solid-phase reaction so as to completely avoid the environment pollution caused in the process of preparing a precursor by adopting a wet process. The invention has the advantages of simple process flow, convenience for operation and high production efficiency.

Owner:先进储能材料国家工程研究中心有限责任公司

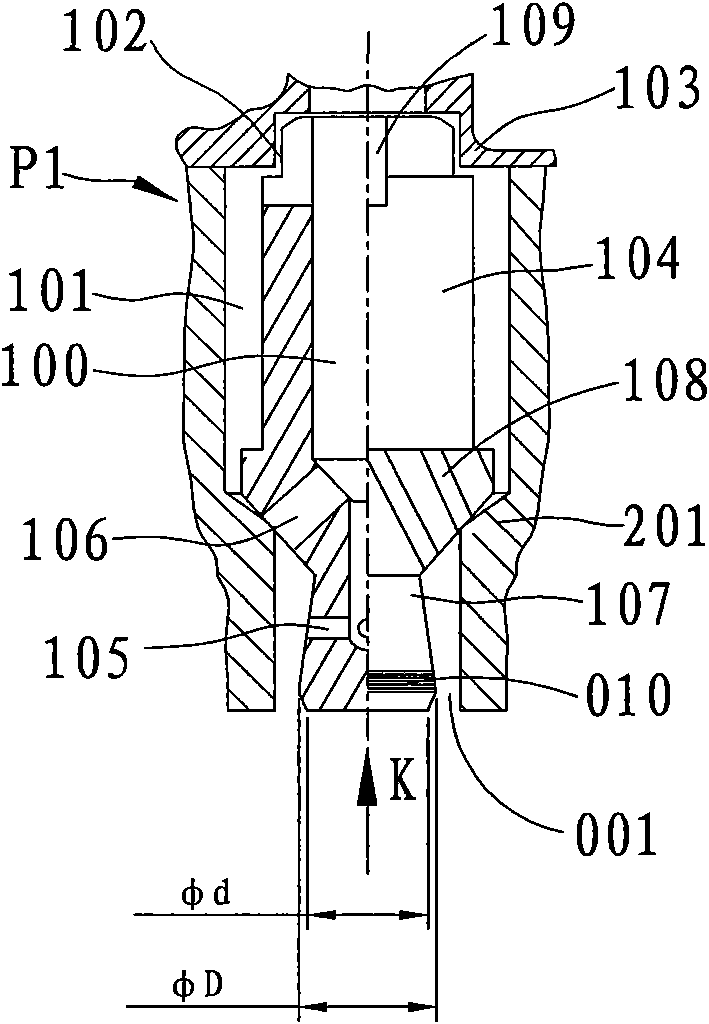

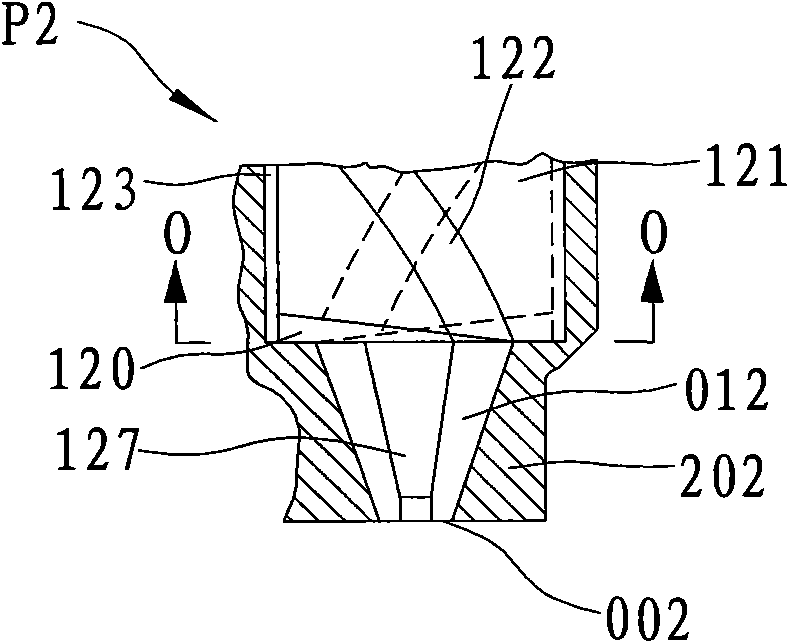

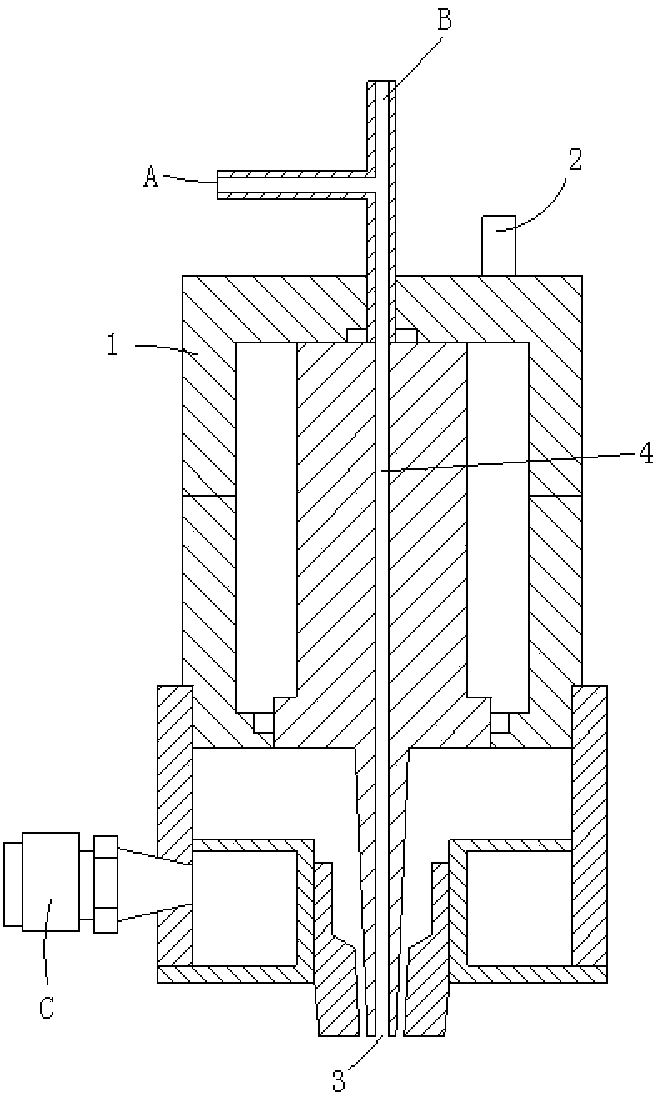

Rotary annular-seam spray nozzle and spraying device thereof

InactiveCN102039228AEasy ultra-fine atomizationUltra-fine atomization promotionSpray nozzlesLiquid spraying apparatusSpray nozzleFineness

The invention discloses a rotary annular-seam spray nozzle comprising a core seat, a rotary core and a rotary annular-seam spray hole, wherein a core cavity is arranged in the core seat, an inlet and an outlet which are communicated with the core cavity are arranged on the core seat, a core seat inlet is communicated with a pressure flow source, the rotary core can be sleeved into the core cavity in positioning and rotating modes and is concentric with the core cavity, a rotation-promoting flow path is arranged on the rotary core or / and the wall of the core cavity in order to mutually rotate the rotary core and the core cavity by using flow power, one end of the rotary core is penetrated into the core seat outlet, and the penetrating end forms the rotary annular-seam spray hole with the inner wall of the core seat outlet. The cross section of the spray hole of the rotary annular-seam spray nozzle is an annular seam, the annular seam and a diameter can be set to respectively and conveniently control the fineness and the flow of pressure spray and make liquid drop sizes more evenly and finely distributed. The rotary annular-seam spray nozzle has a self-cleaning function, is not easy to block and is in a self-closing dust-resisting type; the rotary annular-seam spray nozzle is arranged on a spray head body or the core seat of the rotary annular-seam spray nozzle is connected with the spray head body, the spray head body is communicated with the pressure flow source, and therefore, the spray device with the rotary annular-seam spray nozzle can be formed.

Owner:韩铁夫

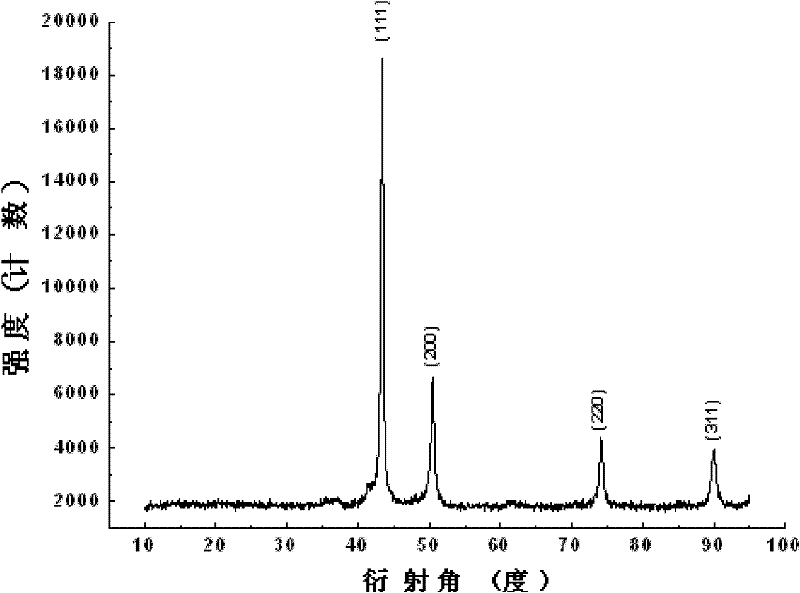

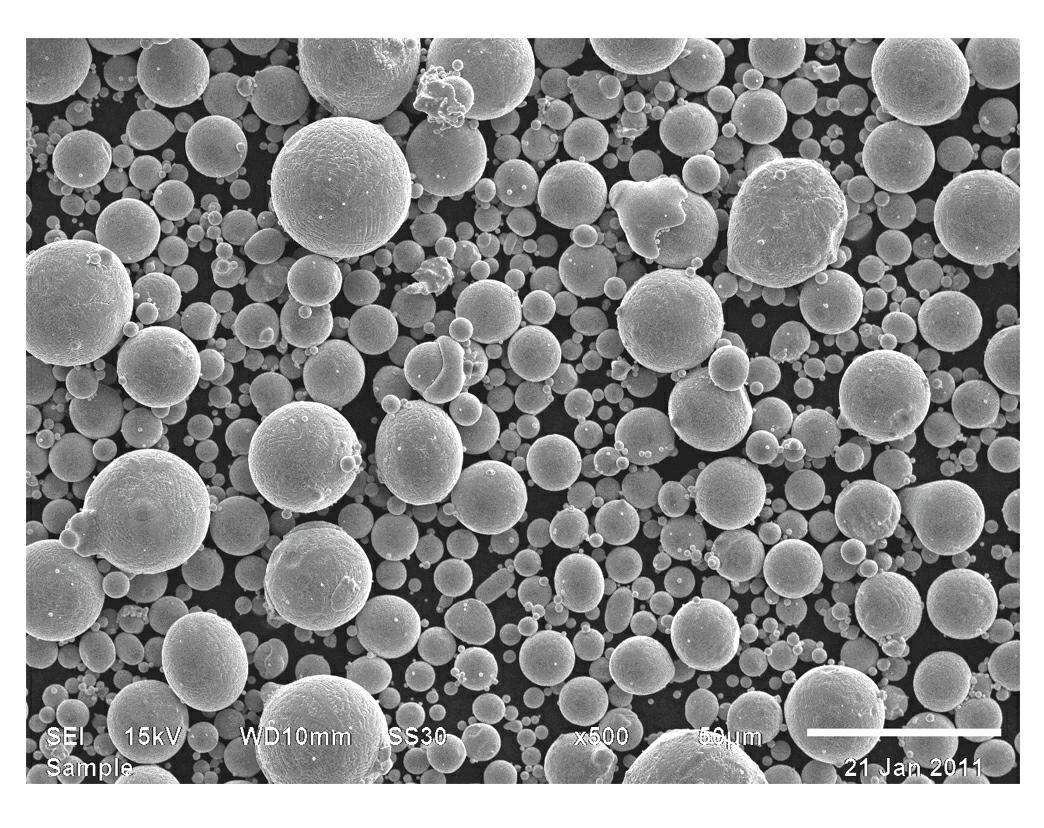

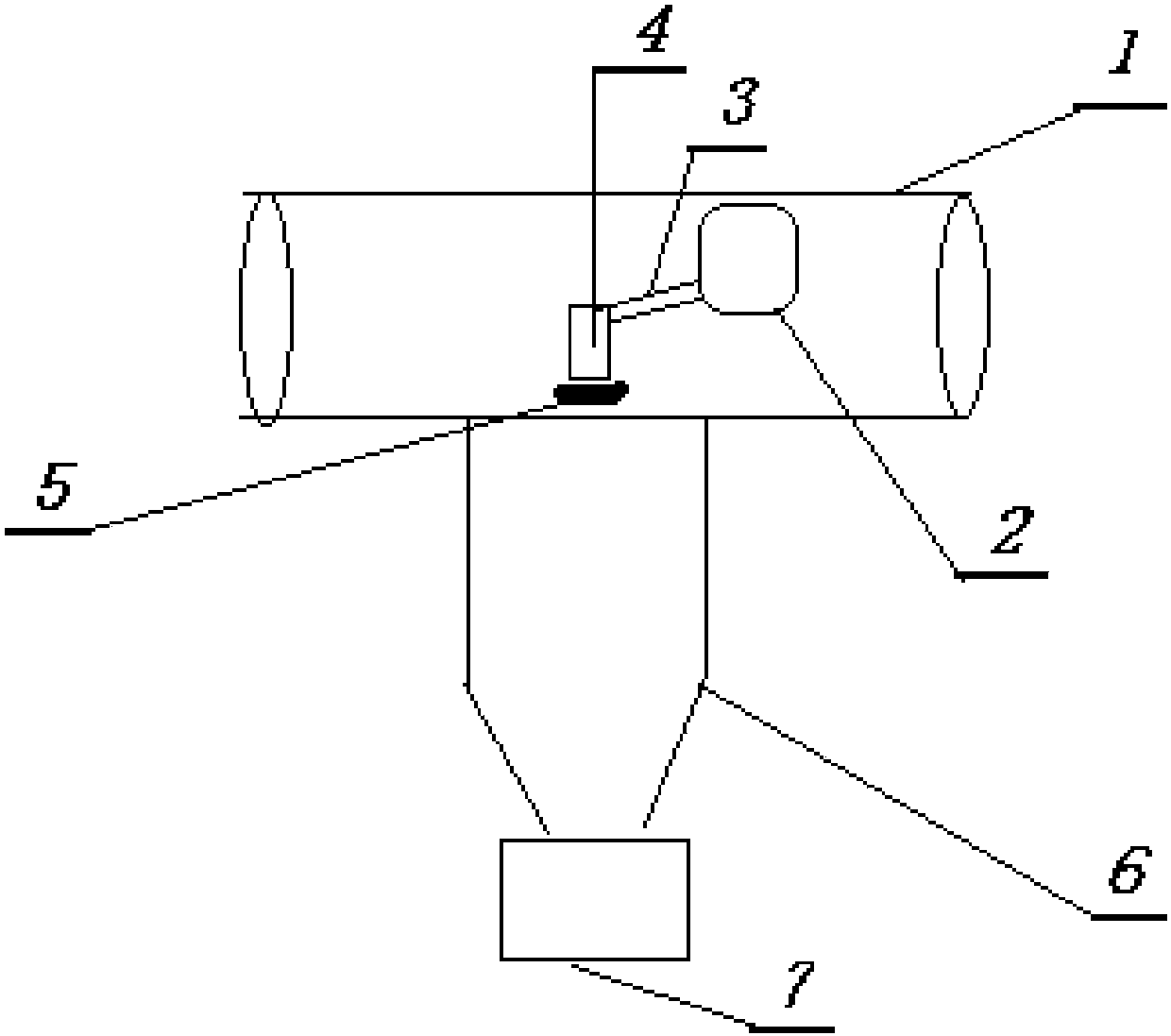

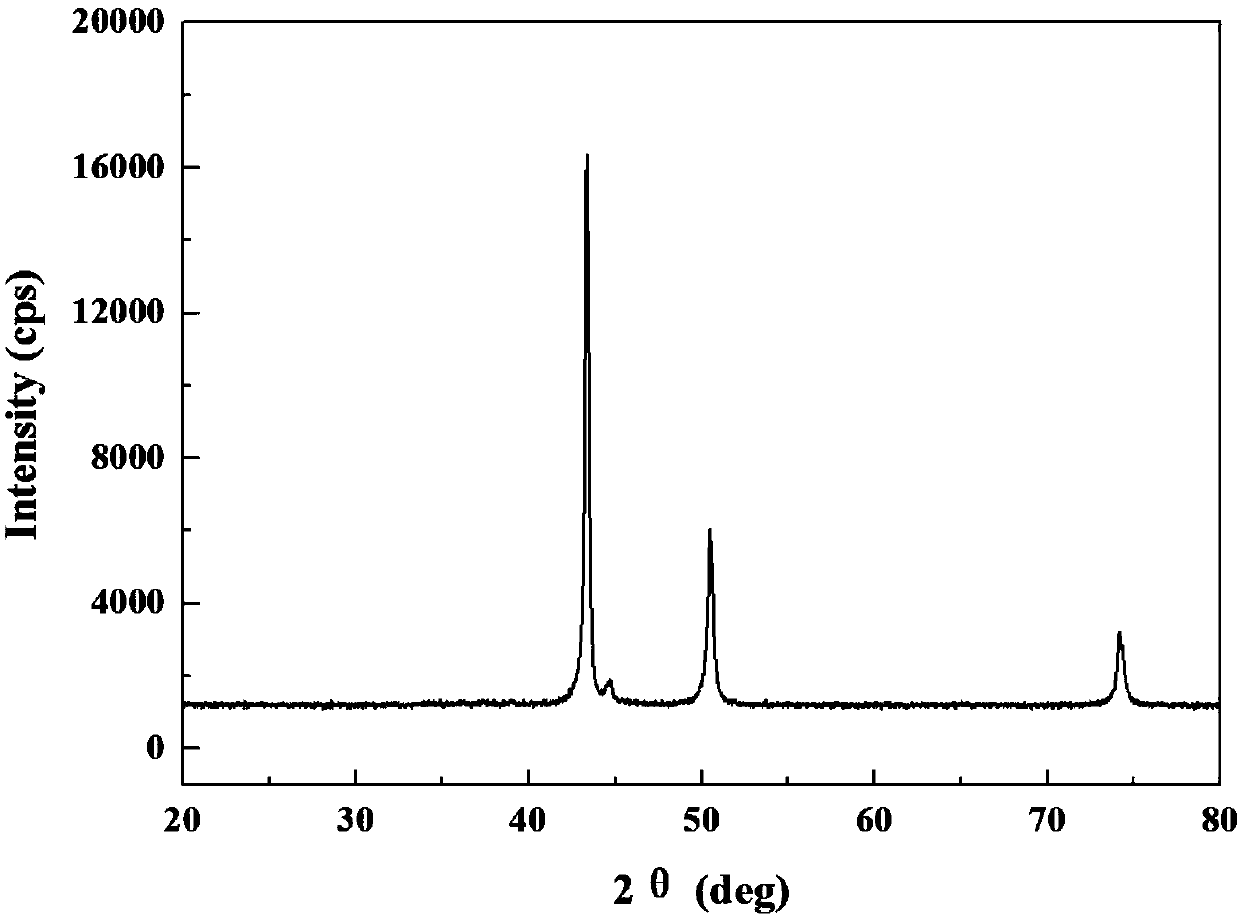

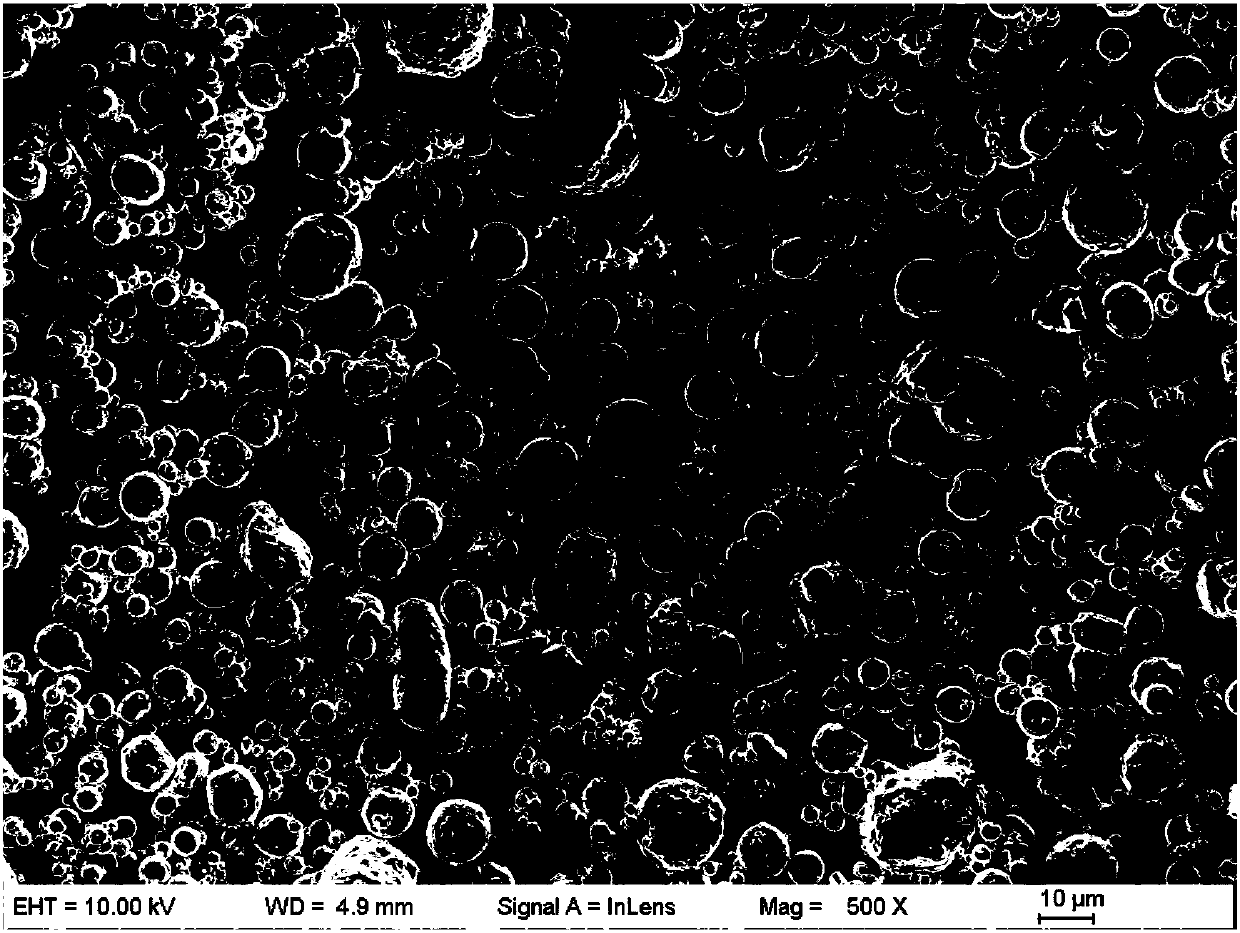

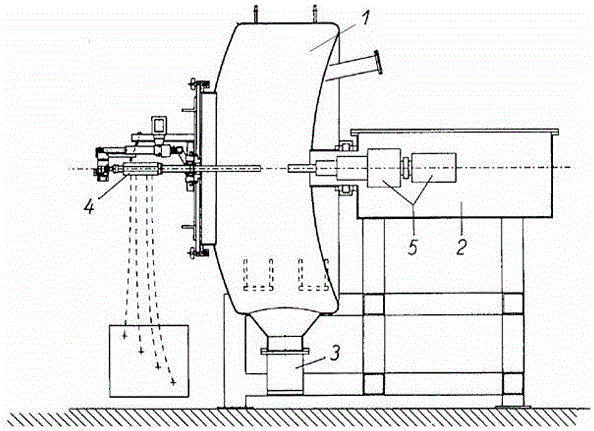

Iron-rich high-entropy alloy powder material for 3D printing and preparation method thereof

ActiveCN105950947AHigh sphericityGranularity controllableAdditive manufacturing apparatusTransportation and packagingHigh entropy alloysGuide tube

The invention discloses an iron-rich high-entropy alloy powder material for 3D printing and a preparation method thereof. The molar ratio of the iron-rich high-entropy alloy powder material FexAlCoCrNiB0.3 is as follows: the molar weight of Fe is 2 to 3, the molar weights of Al, Co, Cr and Ni are 1, the molar ratio of B is 0.3, and B is added in an Ni-B alloy form. The iron-rich high-entropy alloy powder material is prepared through a medium frequency induction melting gas atomization one-step method, namely, a metal liquid subjected to medium frequency induction melting and refining is directly fed into a gas atomization device through a guide tube and a tundish to be atomized for powder material preparation. According to the iron-rich high-entropy alloy powder FexAlCoCrNiB0.3material prepared through the method, a phase structure is composed of solid solutions of simple face-centered cubic and body-centered cubic structures, and a product is good in degree of sphericity, controllable in particle size, uniform in components, low in oxygen content and good in fluidity; and according to the preparation method provided by the invention, the technology is simple, the energy consumption is low, the control is easy, the product quality is stable, and the method is applicable to large-scale industrial production, pollution-free to the environment, and environment-friendly in utilization.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

Method of preparing ultrafine alloy powder by coprecipitation coreduction

A process for preparing the superfine alloy powder by codeposition-coreduction method includes such steps as liquid-phase codeposition to prepare the precursor powder of each component in alloy, calcining to obtain nano-class composite metallic oxide powder, and reducing by H2 or decomposed ammonia in tubular reducing furnace while alloying to obtain superfine alloy powder.

Owner:UNIV OF SCI & TECH BEIJING

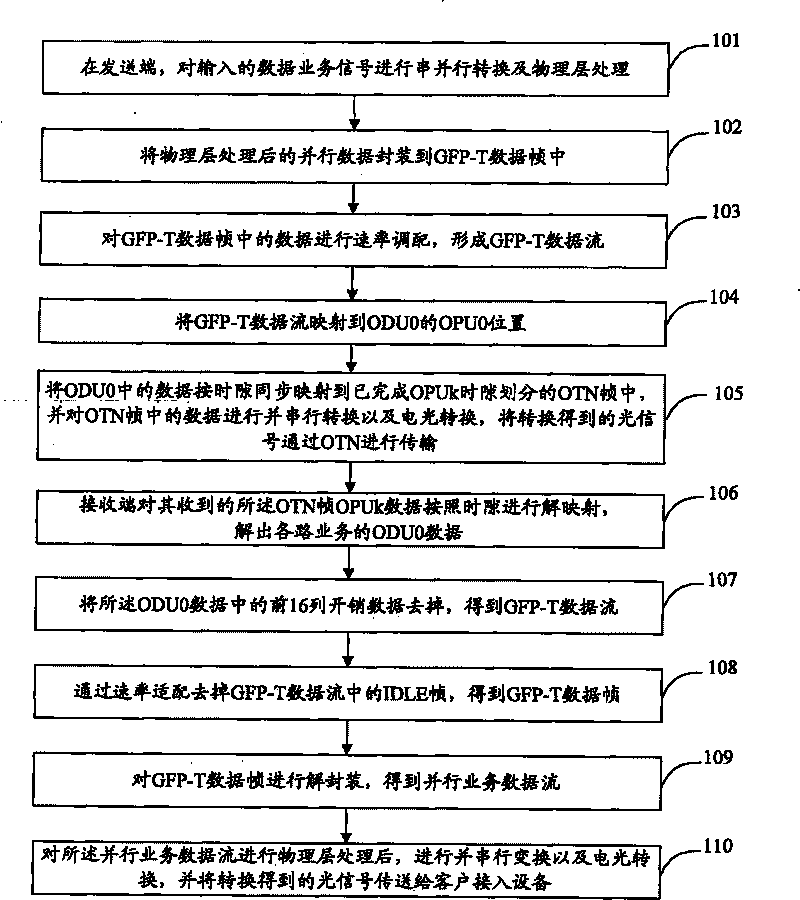

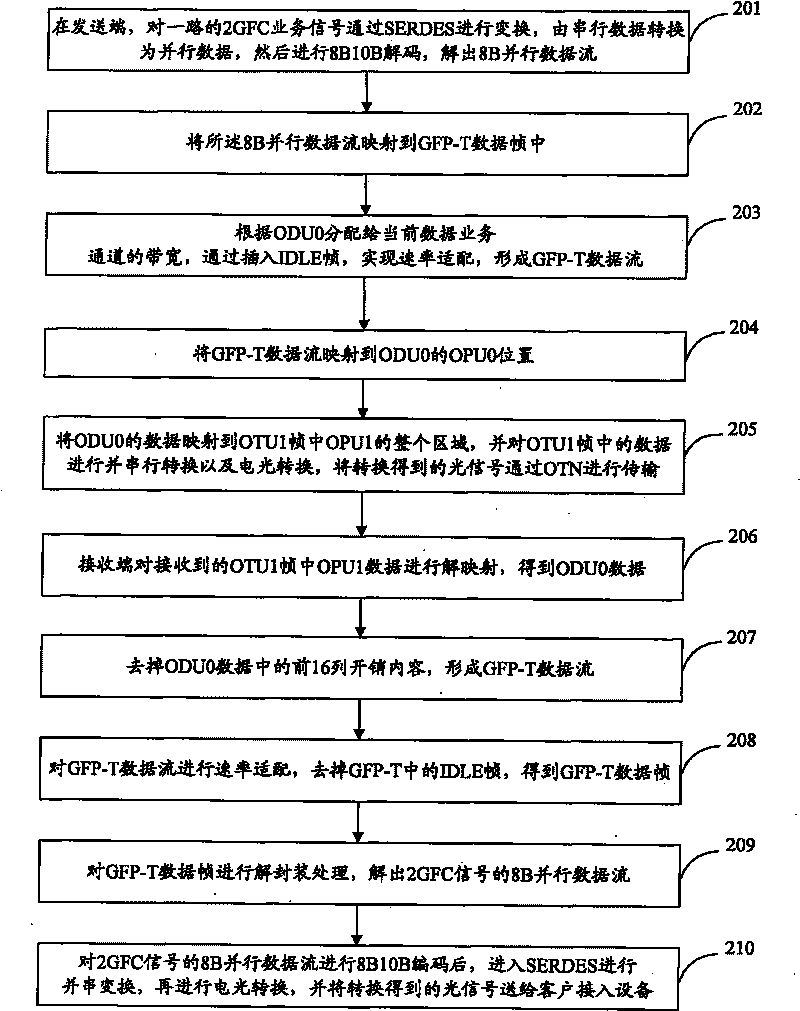

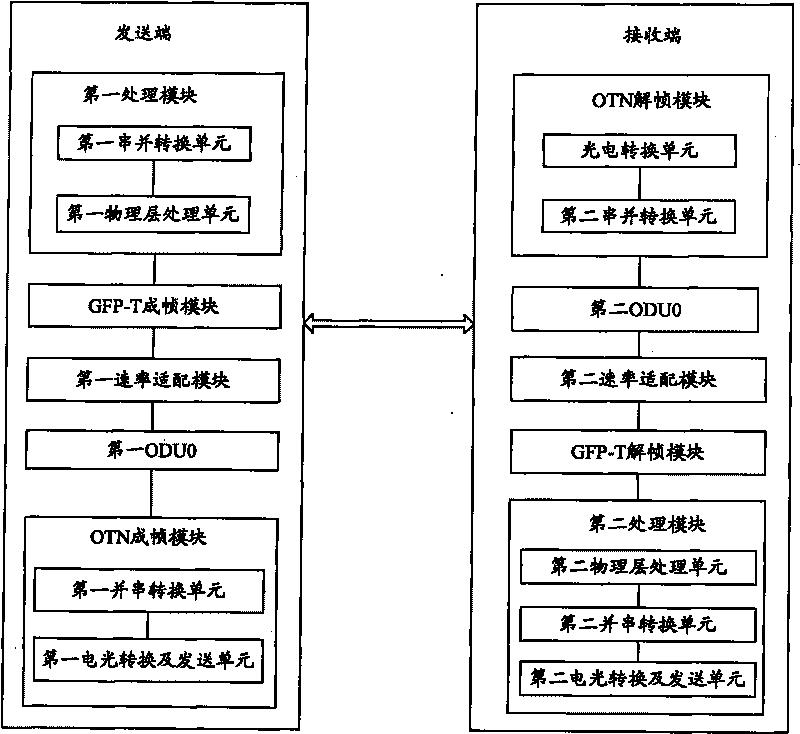

Method supporting multi-service access and output and system thereof

InactiveCN101695144ARealize transmissionEasy accessMultiplex system selection arrangementsTime-division multiplexMultiplexingComputer network

The invention discloses a method supporting multi-service access and output and a system thereof. At a transmission terminal, multiple channels of data service signals with different rates or a single channel of data service signals are mapped into a GFP frame, mapped into ODU0 to realize cross multiplexing after rate adaptation, synchronously mapped into an OTZ frame through slot time division, and then are converted to be transmitted by OTN. At a receiving terminal, multi-channel low-rate data service can be realized via an OTN deframing process after the OTN frame is received. Therefore, the method supporting multi-service access and output and the system thereof can realize multi-channel access and output of data service with various rates and increase utilization rate and transmission efficiency of wide bands.

Owner:ZTE CORP

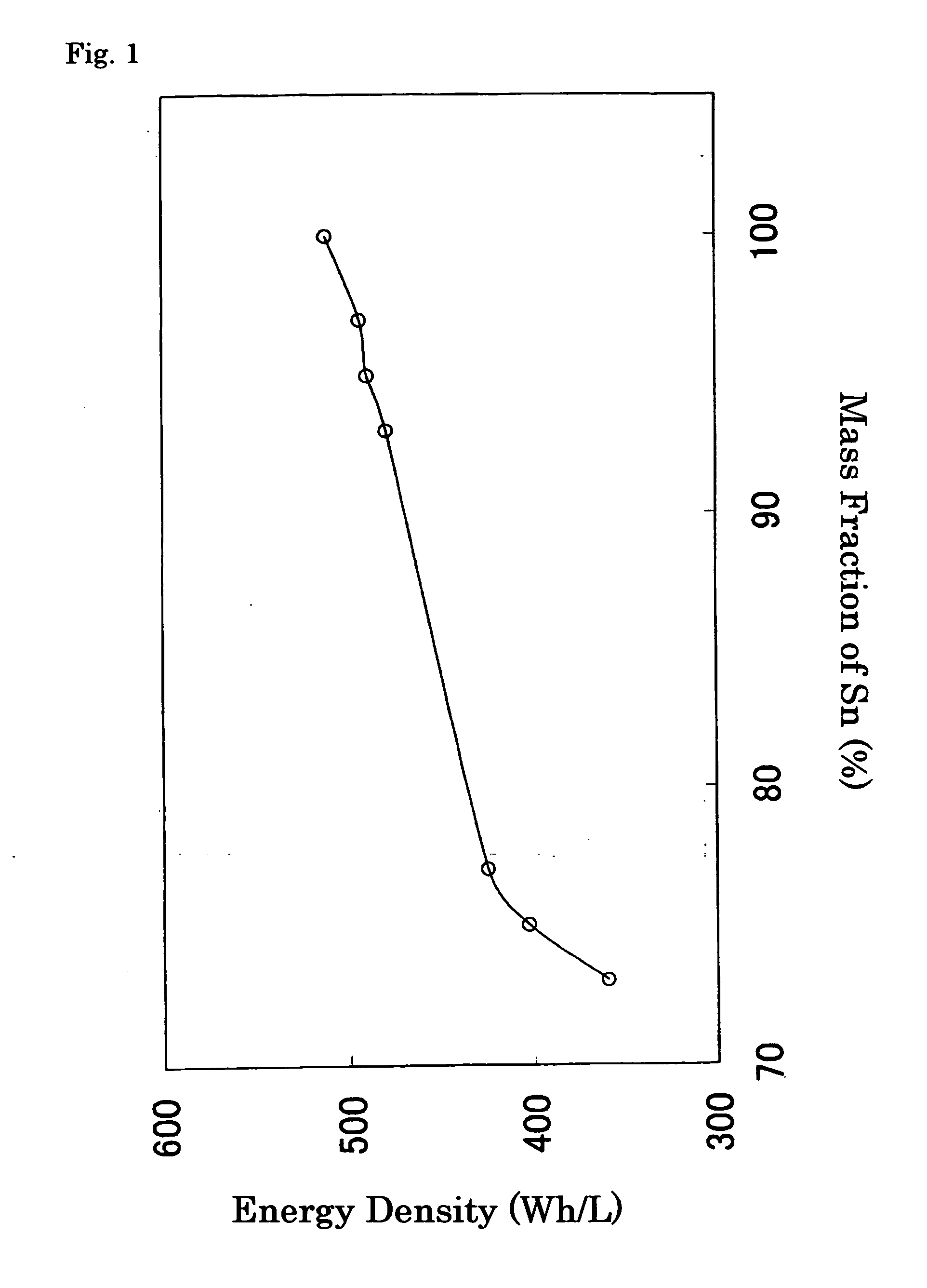

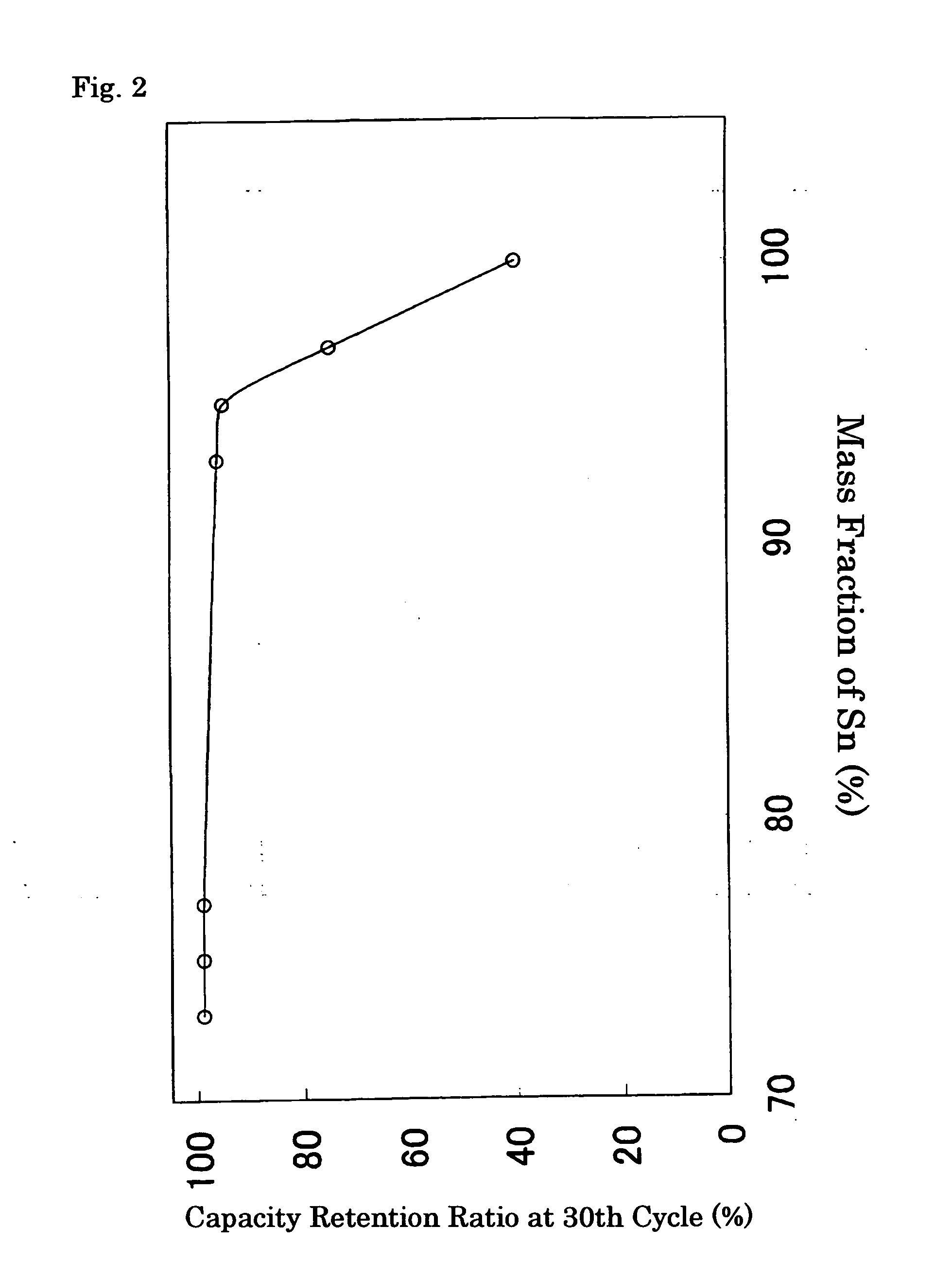

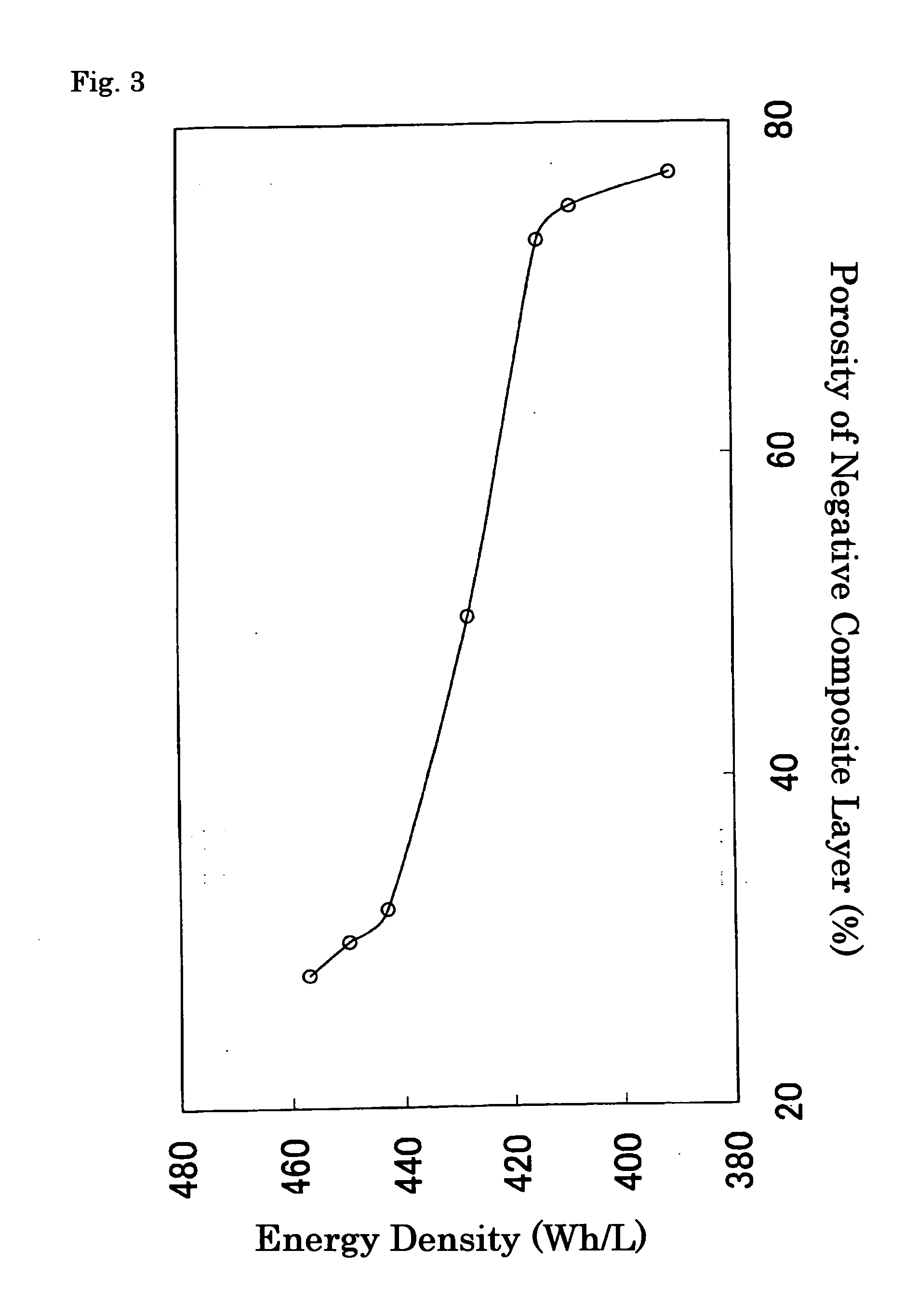

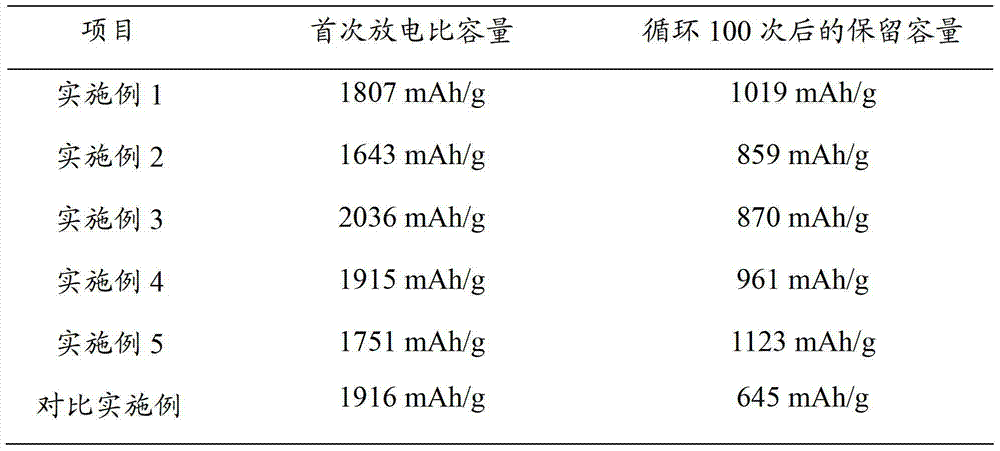

Nonaqueous electrolyte secondary cell

InactiveUS20060127766A1Increase energy densitySatisfactory performanceNegative electrodesSecondary cellsHigh energyAlloy

It is an object of the present invention to provide a non-aqueous electrolyte secondary battery having high energy density and satisfactory cycle performance by using an alloy comprising Ni and Sn as a negative active material; and the non-aqueous electrolyte secondary battery comprising a negative electrode with a composite layer containing a negative active material, a positive electrode and a non-aqueous electrolyte is characterized in that said negative active material consists of an alloy containing 5 to 25 mass % of nickel and 75 to 95 mass % of tin, and that such alloy contains Sn4Ni3 phase and Sn phase. It is preferable that the content ratio of Sn4Ni3 phase and Sn phase in the above described alloy be 0.2≦Z≦3, supposing that ml is the mass of Sn4Ni3 phase, m2 is the mass of said Sn phase, and Z=m1 / m2; and that the above described composite layer contain carbon material.

Owner:GS YUASA INT LTD

Preparation and use methods of nitrogen-vanadium co-doped modified titanium dioxide catalyst

InactiveCN101972662AHigh visible light activityImprove dust removal efficiencyPhysical/chemical process catalystsSulfur compoundsEngineering industryMixed crystal

The invention discloses preparation and use methods of a nitrogen -vanadium co-doped modified titanium dioxide catalyst, belonging to the technical field of preparation and use of catalysts. The preparation method comprises the following steps of: adding a nitrogen source and a vanadium source in a process of preparing titanium dioxide by using a sol-gel method; hydrolyzing the mixture to obtain gelatin and standing, aging and drying to form particles; then grinding and carbonizing and heating to 600 to 800 DEG C for roasting to obtain a mixed crystal type titanium dioxide catalyst with different doping amounts. The compounding of electron-hole pair is influenced by doping metal ions to improve utilization ratios of visible light.With simple operation and easy control, the prepared nitrogen -vanadium co-doped modified titanium dioxide catalyst can achieve greatly improved visible light activity and can be applied to sulphuric acid production in the chemical engineering industry, SO2 tail gas treatment in the smelting industry, sulfur dioxide control of coal-fired and fuel boilers, acid rain prevention and control, smoke gas adjustment of coal-fired power plants, improvement on the dust removal efficiency of an electric precipitator, and other fields.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for preparing superfine even Fe2O3

InactiveCN101049976AGood dispersion and uniformitySimple processNanostructure manufactureFerroso-ferric oxidesIonSal ammoniac

This invention discloses a method for preparing uniform nanoscale Fe3O4. The method comprises: adjusting the pH value of ferrous salt solution or waste acid solution containing ferrous ions to 8.7-10 with NaOH, adding H2O2 at room temperature to prepare amorphous delta-FeOOH precursor, adding ferrous salt solution at a delta-FeOOH / ferrous salt mol. ratio of (1.32-1.92):1, adjusting the pH value to 8-13 with NaOH, refluxing under boiling for 1.5-2.5 h, filtering the product, washing with water, washing with diluted ammonia solution, and drying to obtain spherical Fe3O4 nanopowder. The particle sizes of the Fe3O4 nanopowder are 30-70 nm, and can be artificially controlled. The Fe3O4 nanopowder has high crystallinity. The method has such advantages as simple process, short reaction time, mild reaction conditions, abundant raw material, and no pollution.

Owner:HEBEI NORMAL UNIV

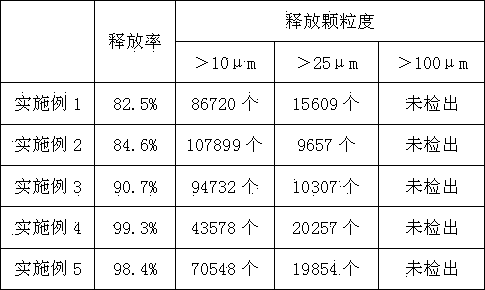

Method for preparing balloon dilatation catheter medicinal coating for treatment

The invention relates to a method for preparing a balloon dilatation catheter medicinal coating for treatment. The method comprises the following steps: adding a diluted solvent into a glass bottle filled with a medicine for treating vascular endothelial re-proliferation, oscillating to completely dissolve the medicine to prepare a medicine solution; mixing the medicine solution and an interference solvent which is incompatible with the medicine, and feeding into a dual-channel ultrasonic nozzle to coat a balloon dilatation catheter; drying, sterilizing and packaging the coated balloon dilatation catheter. According to the method, the medicine solution is mixed with another incompatible interference solvent before ultrasonic coating, so that the shape of the medicine in the solution is changed, and the mixture is fed into the ultrasonic nozzle to perform ultrasonic coating to achieve the aims of controlling the coating granularity, increasing the coating binding force and controlling the releasing rate of the medicine. The medicine coating formed by the method has the characteristics of uniformity, strong binding force with balloon, controllable crystal granularity, durable drug effect and the like.

Owner:ZHEJIANG BELONGS TO A MEDICAL INSTR

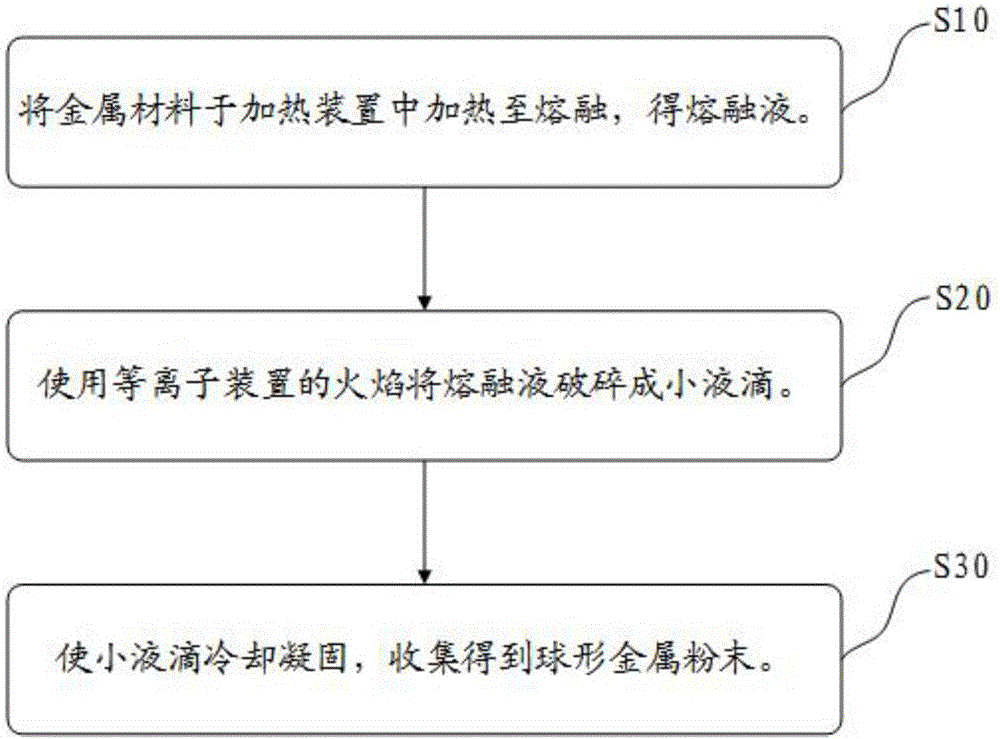

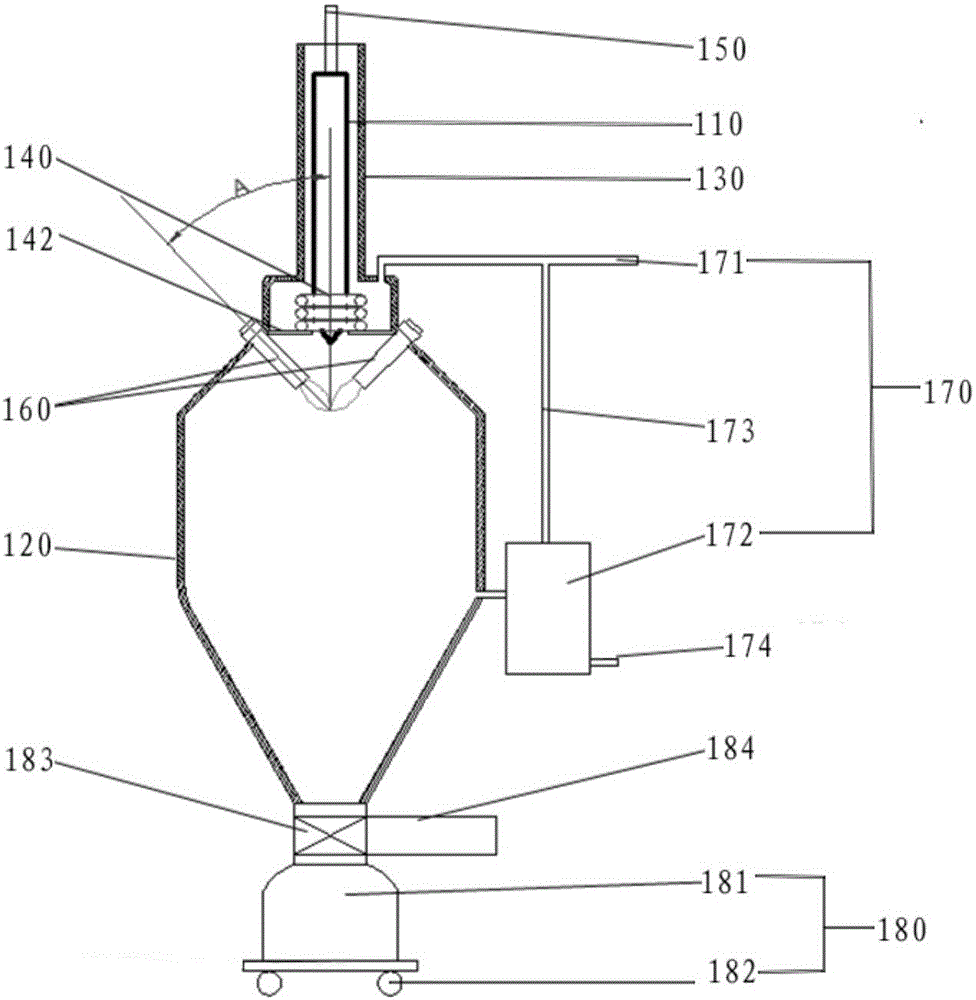

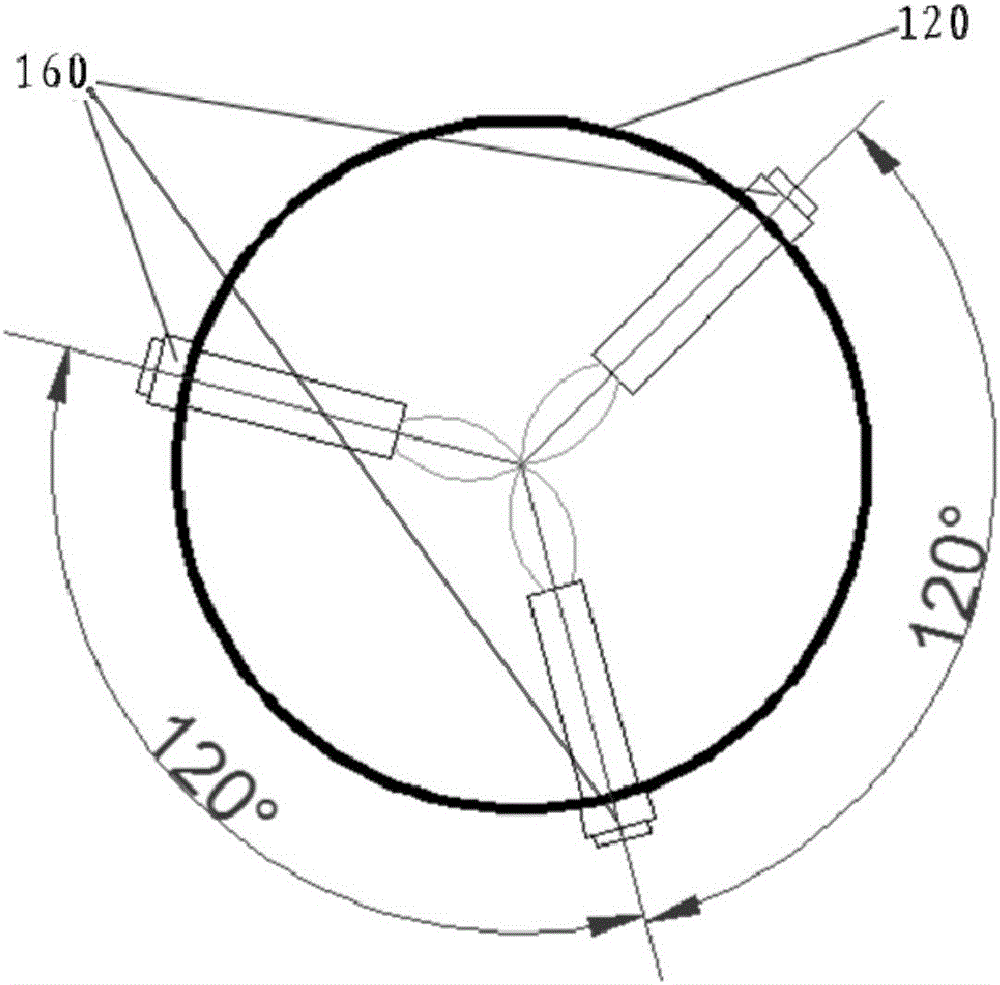

Spherical metal powder and preparation method thereof

ActiveCN105855560AReduce surface tensionReduce consumptionTransportation and packagingMetal-working apparatusSmall dropletPrill

The invention relates to a preparation method of spherical metal powder. The preparation method comprises the steps of heating a metal bar to melt in a heating device, so as to obtain melted liquid, and breaking the melted liquid into small droplets by using plasma as droplet breakage power, so that the small droplets are cooled and solidified and are collected so as to obtain the spherical metal powder. According to the spherical metal powder prepared by adopting the preparation method, almost no satellite particle exists, the oxygen content is less than 1200 ppm, and the occupancy of the powder below 53 mum reaches 90% according to weight percent; the spherical metal powder has the advantages of high degree of sphericity, narrow particle size distribution, low impurity content, good flowability, low oxygen content, no satellite particle, simple process, reliable technique, easiness in control over product particle size, high production efficiency and low inert gas consumption and is suitable for mass production, and the particle size distribution satisfies the 3D printing requirements.

Owner:GUANGZHOU NALIAN MATERIAL TECH CO LTD

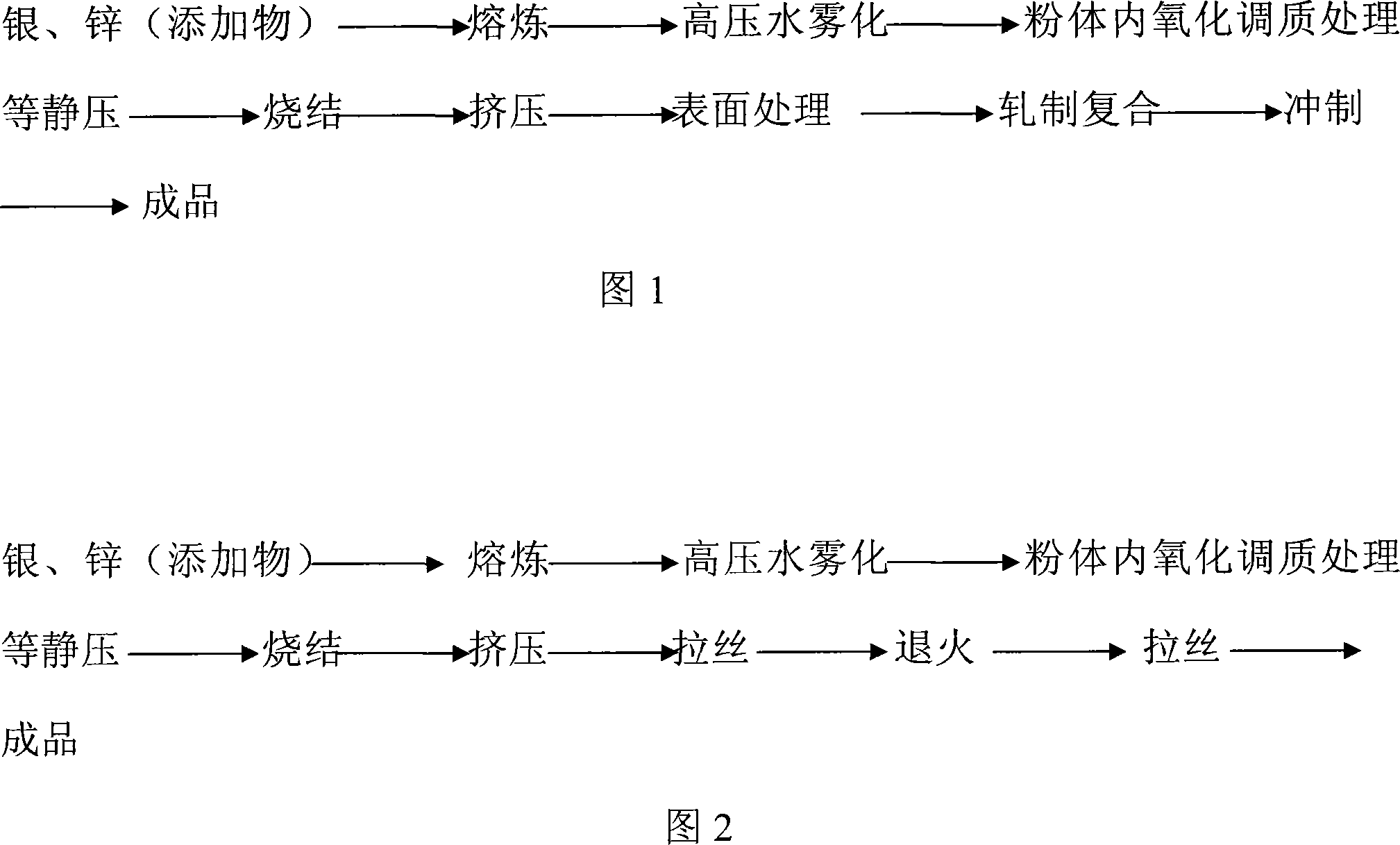

Technique for preparation of novel silver zinc oxide contact material

InactiveCN101202168AParticle surface activity is highEasy to processContactsHigh densityIntermediate frequency

The invention relates to a novel preparing process of a material used for a silver zinc oxide contact. The invention has a process that a material prepared by silver, zinc and additives according to a certain proportion is put into an intermediate frequency smelter for melting; a high pressure water atomizing device is adopted for high pressure alloy atomization; atomized alloy powder is dried and oxidated for modification; an equal static ingot is formed after equal static treatment; the ingot is agglomerated in a heating furnace; the agglomerated ingot is delivered into an extruding machine to extrude plates or wires; the extruded plate is rolled and punched for shaping after surface treatment and silver restoring; the extruded wire is pulled and annealed to get a finished wire which is used for making rivets or different shape materials. The silver zinc oxide contact material prepared by the process has uniform metallographic structure, high density and good machining performance.

Owner:FUDA ALLOY MATERIALS

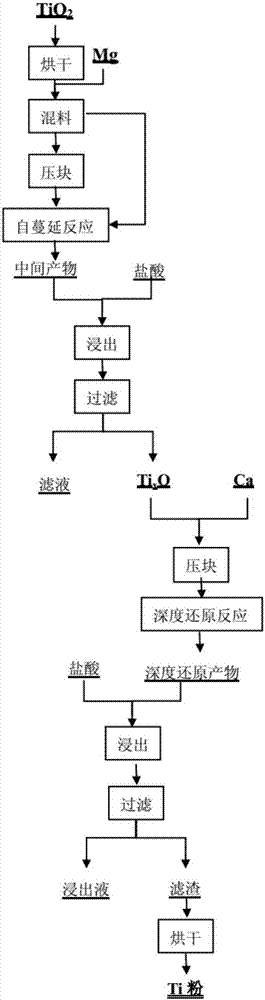

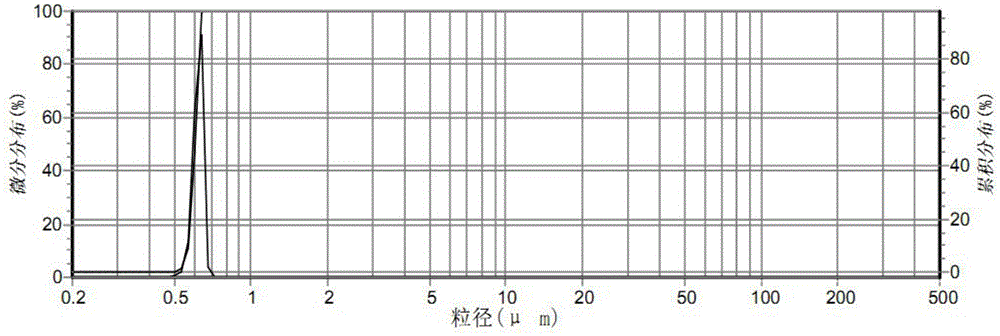

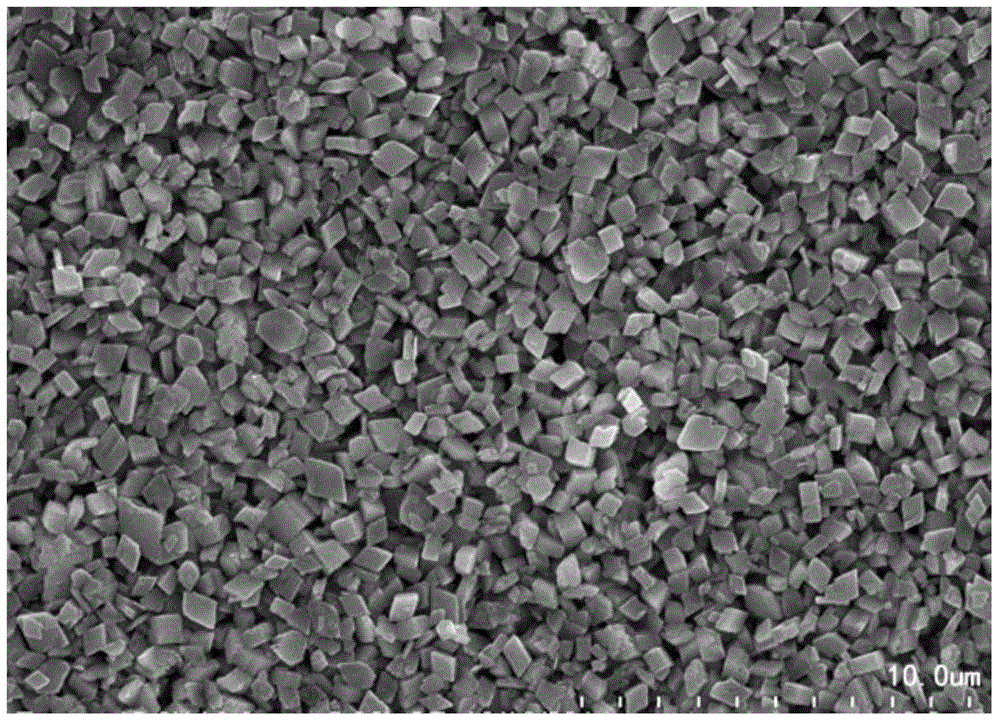

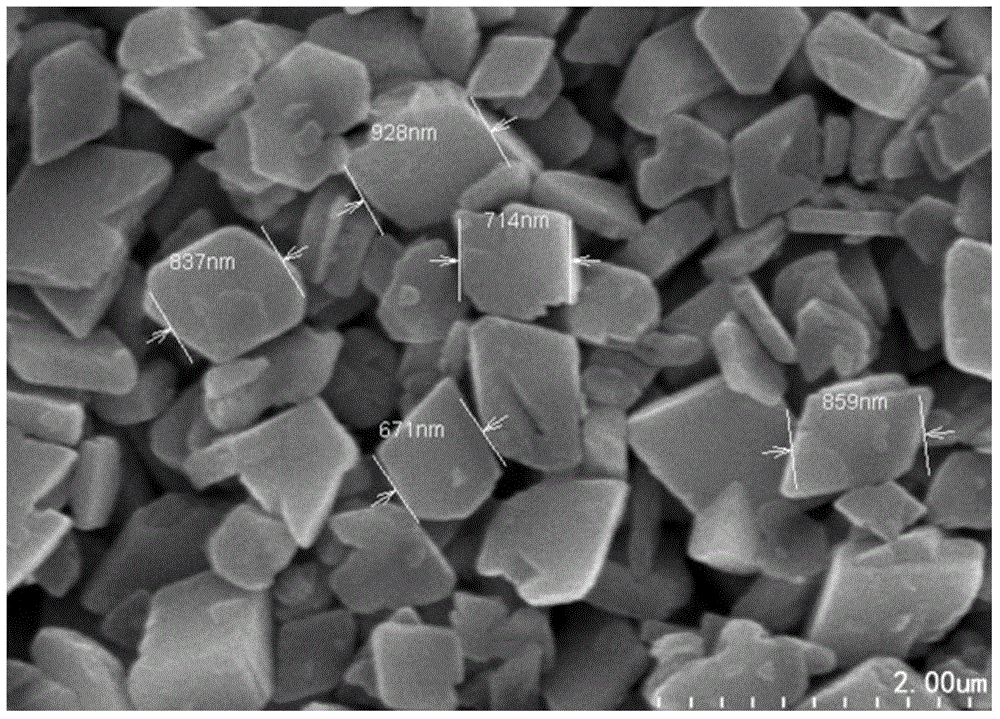

Method for preparing reduced titanium powder by multi-stage deep reduction

ActiveCN107236869AHigh activityRaise the temperature gradientProcess efficiency improvementProcess conditionsVacuum drying

The invention provides a method for preparing reduced titanium powder by multi-stage deep reduction and belongs to the technical field of powder preparation. The method comprises the steps as follows: mixing dried titanium dioxide powder and magnesium powder evenly, adding the mixture to a self-propagating reaction furnace and initiating a self-propagating reaction to obtain an intermediate product, dispersed in a MgO matrix, of low-valent titanic oxide TixO; leaching the intermediate product with hydrochloric acid as a leaching solution, and performing filtering, washing and vacuum drying to obtain a low-valent titanium oxide TixO precursor; mixing the low-valent titanium oxide TixO precursor with calcium powder, pressing the mixture, and placing the mixture in a vacuum reduction furnace for secondary deep reduction; leaching a deep reduction product with the hydrochloric acid as the leaching solution to obtain the reduced titanium powder. According to the method, the cost of raw materials is low, operation is simple, requirements for technological conditions and equipment are low, a basis is laid for industrial production, and the obtained reduced titanium powder has the advantages of high purity, fine particle size, controllable particle size distribution, high powder activity and the like.

Owner:NORTHEASTERN UNIV LIAONING

Granularity-controllable boehmite preparation method

InactiveCN104944454AGranularity controllableNarrow particle size distributionMaterial nanotechnologyAluminium oxides/hydroxidesDispersityMicrometer

The invention provides a granularity-controllable boehmite preparation method and relates to the field of new materials. The granularity-controllable boehmite preparation method comprises the following steps: mixing Al(OH)3 and water to form a suspension with the concentration of 20-60% (by weight percent); adjusting the pH of the suspension to be 2-9; treating the suspension for 24-40 h at the temperature of 170-240 DEG C and the pressure of 1.0-1.7 MPa; filtering, drying and dispersing the treated suspension to obtain monodispersed boehmite with the granularity of 0.1-10 micrometers. The granularity-controllable boehmite preparation method is a wet preparation method of boehmite, and the prepared high-purity boehmite is narrow in grain distribution, uniform in appearance, controllable in granularity and favorable in dispersity. The granularity of boehmite can be adjusted through adjusting the pH value and the time of reaction and the granularities of the raw materials.

Owner:ANHUI ESTONE MATERIAL TECH CO LTD

Preparation method of spherical 304 stainless steel powder

The invention discloses a preparation method of spherical 304 stainless steel powder. Materials are mixed according to components of 304 stainless steel, a 304 stainless steel alloy bar is prepared with forging and machining preparation methods and then is machined into a 304 stainless steel electrode bar, the electrode bar is loaded into a reaction chamber, the reaction chamber is subjected to vacuum pumping, pre-vacuum-pumping treatment is performed on atomizing equipment, the reaction chamber is filled with inert gas in a certain ratio, and the oxygen content of the atmosphere is smaller than 0.1wt%; the electrode bar is sent into an atomizing chamber through a feeding system, the end surface of the electrode bar is heated by a plasma torch, the end melts uniformly, metal droplets are prepared under the centrifugal effect of a rotating electrode and then are instantaneously solidified into spherical metal powder, and finally, the powder is packaged through multi-layer vacuum heat sealing. The 304 stainless steel powder prepared with the method is not oxidized easily at the high temperature and is high in sphericity degree, free of hollow powder and satellite powder and controllable in particle size distribution.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Active copper oxide powder preparation method

The invention relates to an active copper oxide powder preparation method which is characterized in that: a copper ammonia complex solution is prepared from a copper plate as a raw material by use of ammonia leaching method, by precision filtration and micro negative pressure evaporation basic copper carbonate is obtained, and an active copper oxide powder product is obtained by low temperature calcination. When in reaction, first a certain proportion of ammonia water, water and ammonium hydrogen carbonate are added into a reaction kettle to be used as a base solution, a certain mass of cyclone copper plate is added into the base solution, air is blown into the reaction kettle, stirring is started for reaction at room temperature, the reaction time is controlled in 6-12 hours to ensure the concentration of copper ions to achieve preparation requirements, and the active copper oxide powder product is obtained by precision filtration, evaporation, solid-liquid separation and calcinations of the prepared copper ammonia solution. The copper oxide prepared by the method has high product activity, high purity, controllable granularity, low energy consumption, easy continuous production and other advantages.

Owner:JINCHUAN GROUP LIMITED

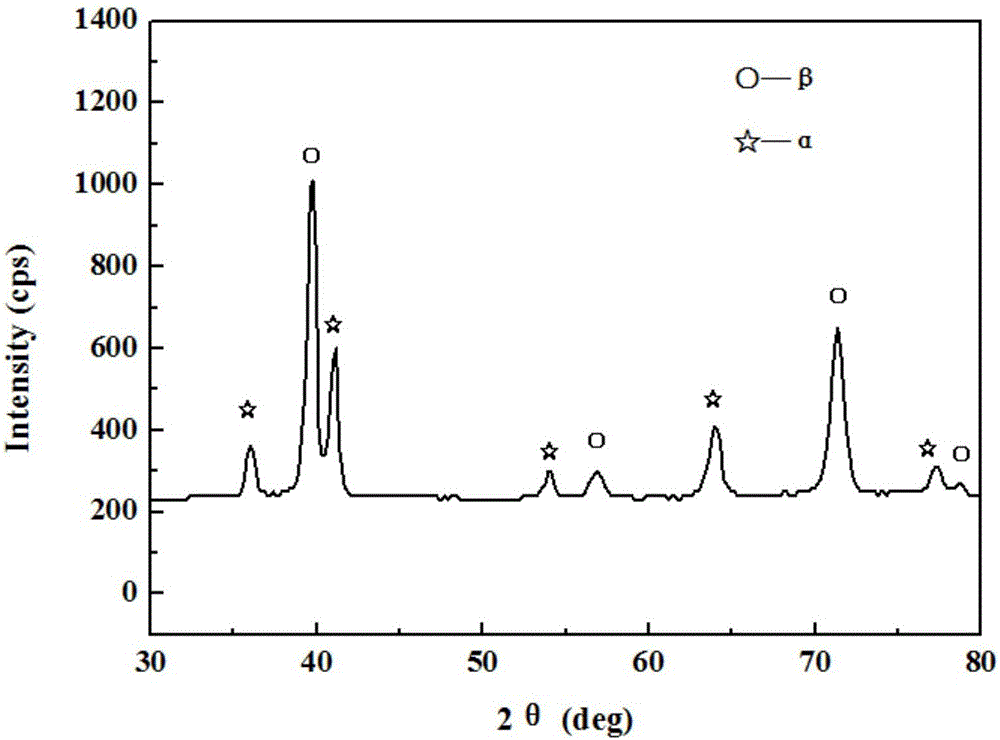

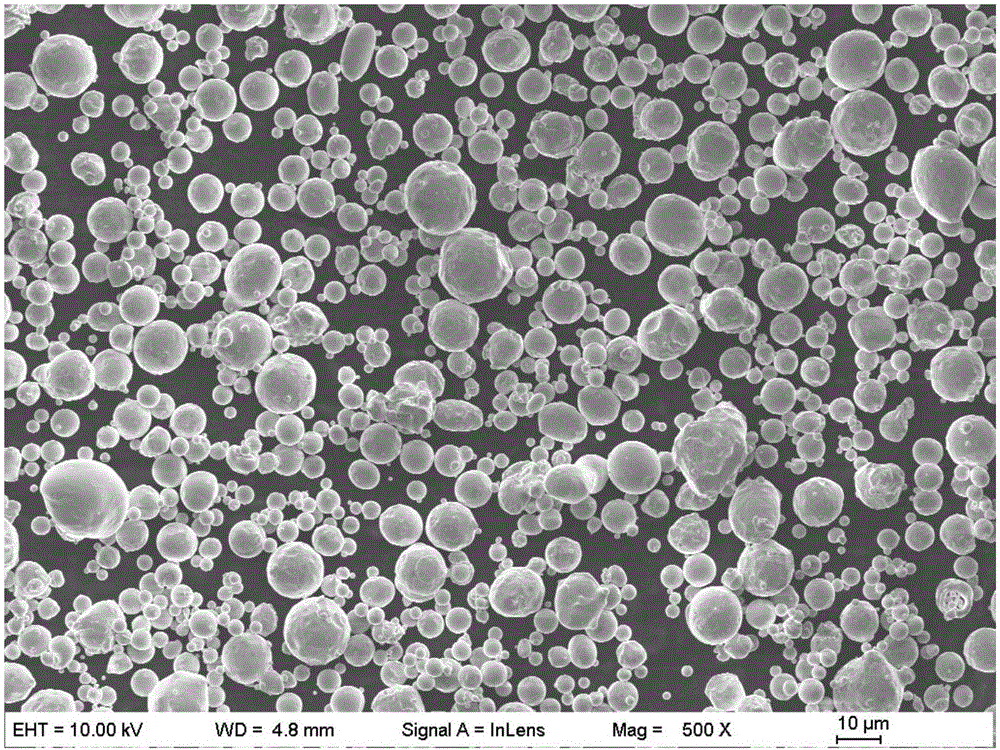

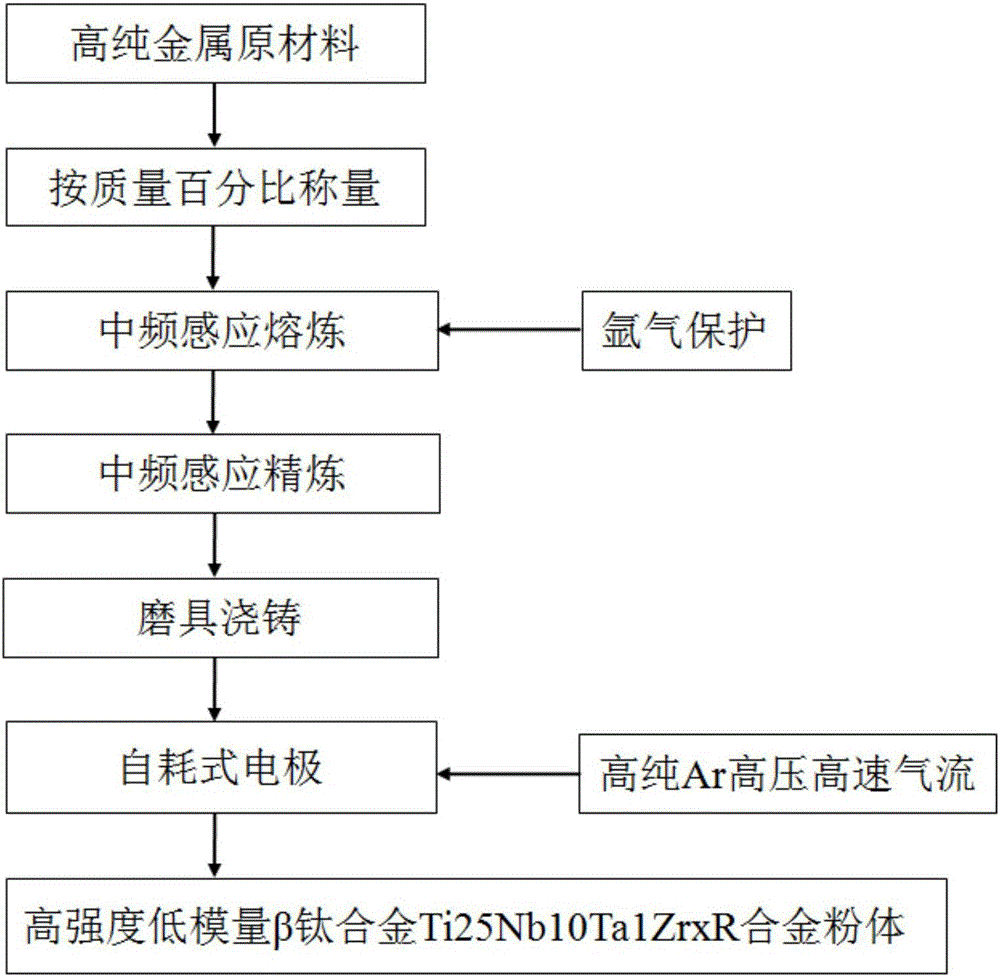

Medical beta-titanium alloy powder material used for 3D printing and preparation method thereof

ActiveCN106148760AGuaranteed purityImproved cold working propertiesAdditive manufacturing apparatusLow modulusElastic modulus

The invention discloses a medical beta-titanium alloy powder material used for 3D printing and a preparation method thereof. The beta-titanium alloy molecular formula is Ti25Nb10Ta1ZrxR, and the medical beta-titanium alloy powder material is composed of, by weight, 25% of Nb, 10% of Ta, 1% of Zr, and the balance Ti, wherein R represents rear earth, the value range of x is 0.05-0.1, R is at least one of Y, La, Ce and Er, and Ta represents Ti20Ta alloy. The titanium alloy powder material is prepared through electrode induction smelting gas atomization, that is, metal liquid subjected to medium-frequency induction smelting and refining is cast into a grinding tool to obtain a metal cast rod, and the metal cast rod serves as a consumable electrode of electrode induction gas atomization; and then the powder material is prepared through an electrode induction atomization method. The high-strength low-modulus powder material Ti25Nb10Ta1Zr0.1R prepared through the method is high in purity, high in sphericity degree and free of toxicity, printed titanium alloy is high in strength (with the yield strength being 800-850 Mpa and the tensile strength being 1100-1250 Mpa) and low in elastic modulus (35-40 Gpa). The preparation method provided by the invention is suitable for large-scale industrial production, does not pollute the environment and is environmentally friendly.

Owner:浙江亚通新材料股份有限公司

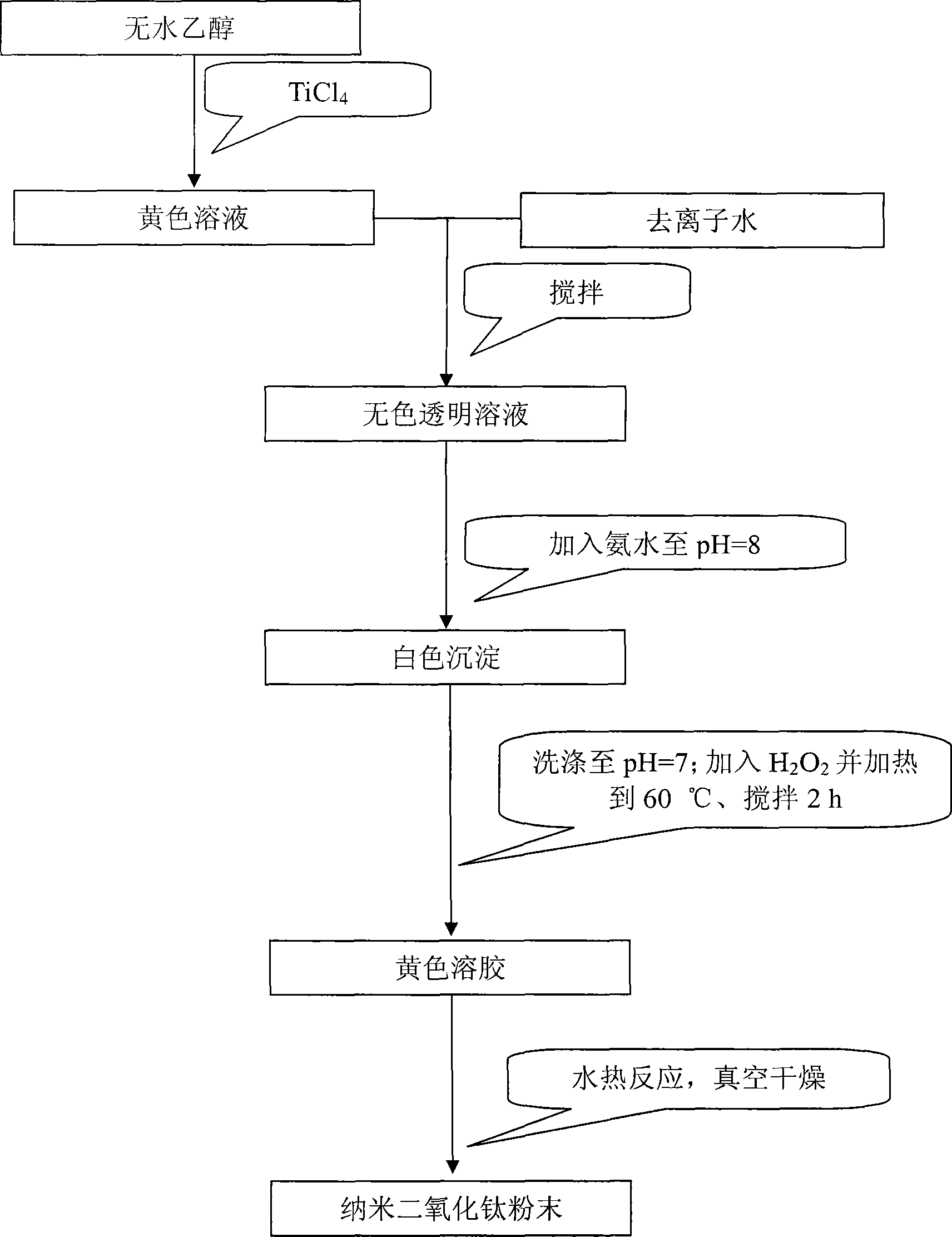

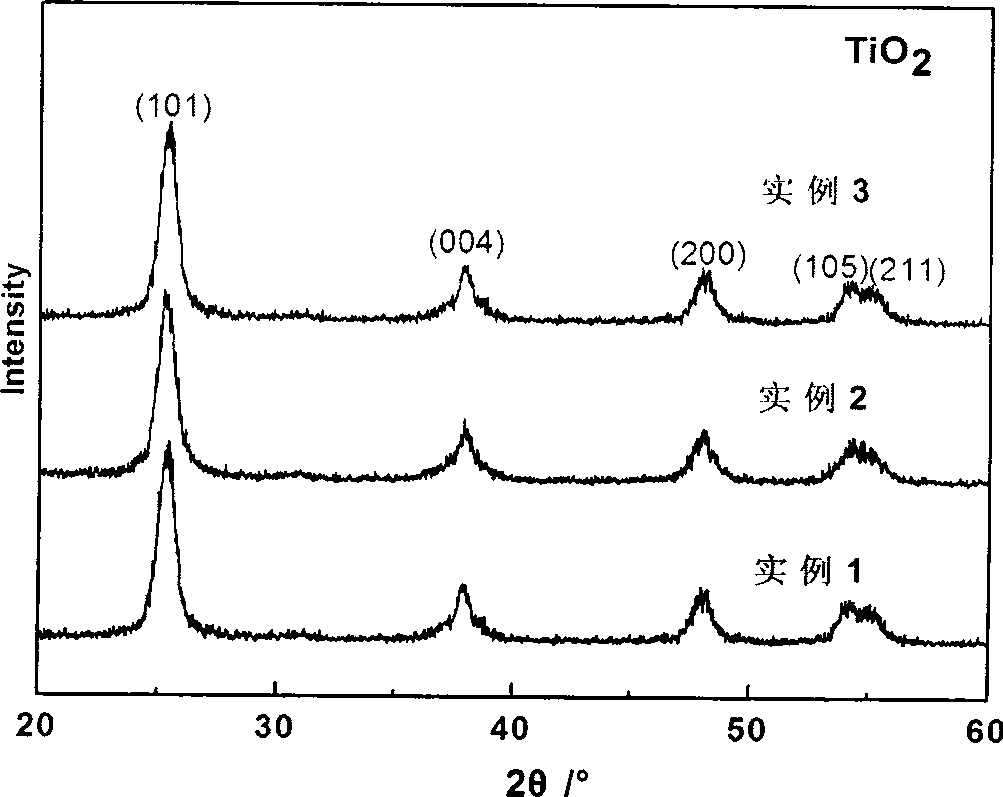

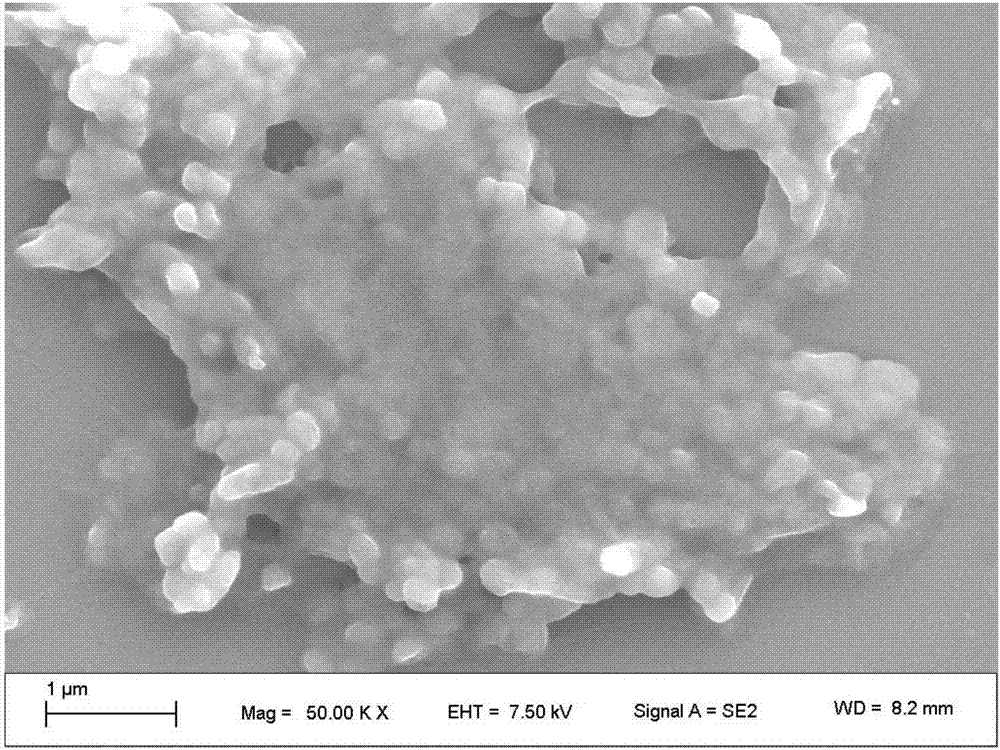

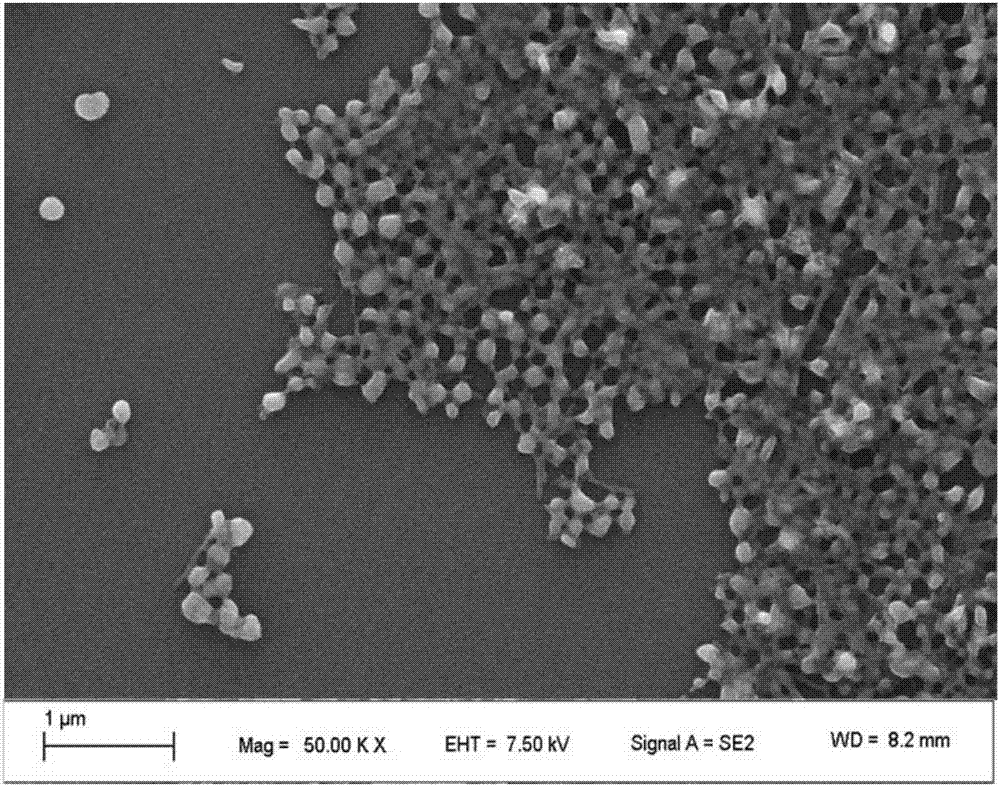

Process for preparing anatase type nano-titanium dioxide

The invention relates to a method for preparing anatase type nanometer titanium dioxide. The method is characterized by comprising the following steps: 1) TiCl4 hydrolyzation, in which, selecting the TiCl4, absolute ethyl alcohol and deionized water according to a ratio of 10 ml:50-200 ml:50-300 ml; placing the absolute ethyl alcohol into ice-water bath to be dripped with the TiCl4; and adding the deionized water into the solution to keep on violent stirring for 10 to 120 minutes so as to obtain an achromatic transparent solution; 2) precursor preparation; and 3) hydro-thermal treatment, in which, adding H2O2 with rho of 1.11*10kg / m into the precursor to be stirred for 2 hours at 60 DEG C so as to obtain yellow sol; then, transferring the yellow sol into a reaction kettle with a polyfluortetraethylene lining at a temperature of hydro-thermal treatment of between 140 and 180 DEG C for 2 to 8 hours; and directly drying the product subjected to the hydro-thermal treatment in vacuum at 60 DEG C to obtain anatase type nanometer titanium dioxide powder. The method has the characteristics of low cost, high purity, simple process, high activity and controllable granularity.

Owner:WUHAN UNIV OF TECH

High-gloss PTFE (polytetrafluoroethylene) anti-drop agent and preparation method thereof

The invention relates to a high-gloss PTFE (polytetrafluoroethylene) anti-drop agent and a preparation method thereof. The preparation method includes: 1), adding a small amount of an emulsified monomer A solution to a PTFE emulsion and performing irradiation treatment on the PTFE emulsion in high energy ray, and grafting a small number of monomers on the surface of PTFE particles; 2), in the absence of oxygen, initiating monomer B to perform polymerization reaction in the treated PTFE emulsion by the aid of an initiator and adding a cross-linking agent at a later stage to form nuclear-shell nano PTFE composite particles with PTFE particles as nuclears and a polymer as a shell; 3), filtering the modified PTFE emulsion and subjecting a filtrate to spray drying to obtain the high-gloss PTFE anti-drop agent. With the method, under the condition that no dispersants or compatibility agents are added, the anti-drop agent can be well-dispersed in thermoplastic resin with good compatibility, and light transmission, glossiness and the like of matrix resin are unaffected by the anti-drop agent dispersed in engineering plastics of PA, PC and the like.

Owner:安徽申嘉聚合物科技有限公司

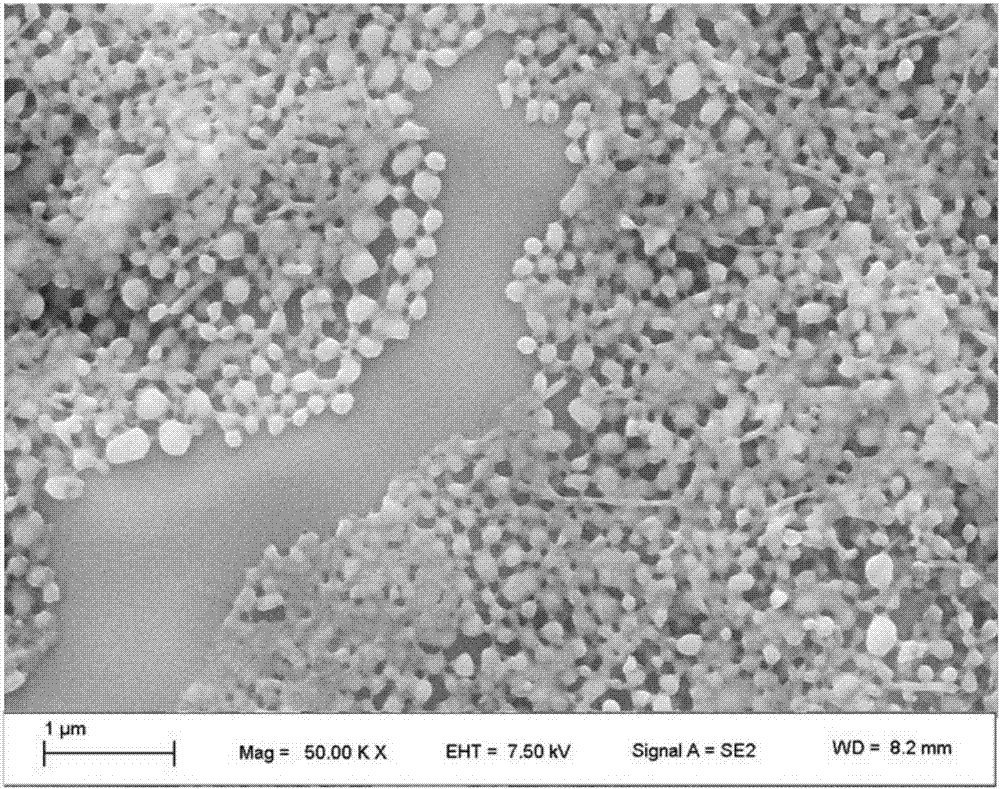

Nanometer silicon/graphene lithium ion battery cathode material and preparation method thereof

ActiveCN103400970AImprove cycle performanceGranularity controllableCell electrodesSolventLithium-ion battery

The invention relates to a nanometer silicon / graphene lithium ion battery cathode material and a preparation method thereof. The cathode material comprises nanometer silicon and graphene, wherein the granularity of nanometer silicon granules is 10-100nm, and the mass ratio of nanometer silicon to graphene is 1:(5-10). The preparation method of the nanometer silicon / graphene lithium ion battery cathode material comprises the following steps of: preparing an electron solution; reducing a silicon tetrachloride liquid phase into nanometer silicon; preparing a graphene oxide glue sample solution; loading the graphene oxide glue sample solution on nanometer silicon; and drying and sintering the semi-finished product of the composite electrode material. According to the preparation method, after the nanometer silicon granules the granularity of which can be controlled are obtained through a liquid phase reducing method; in a mode that a glue body is separated out through replacing a solvent graphene is reduced and a glue layer is formed at the same time, and moreover the glue layer is adsorbed on an existing nanometer silicon glue nucleus; the obtained nanometer silicon has a better size and a better structure, can combine graphene and nanometer silicon efficiently in the term of molecule size; the obtained silicon carbon material has stable circulation performance and excellent electric conducting performance.

Owner:湖北高地石墨烯科技有限公司

Method for preparing copper-oxide powder

InactiveCN102320644AHigh purityGood sphericityNanotechnologyCopper oxides/halidesReaction temperatureCopper oxide

The invention relates to a preparation method of metallic-oxide powder, in particular to a method for preparing copper-oxide powder. The method for preparing the copper-oxide powder is characterized in that the metallic-oxide powder is prepared through reaction by using copper sulfate as a raw material, ammonia water as a buffering agent and sodium hydroxide as a precipitator. The method for preparing the copper-oxide powder disclosed by the invention comprises the following steps of: by using the copper sulfate as the raw material, the ammonia water as the buffering agent and the sodium hydroxide as the precipitator, firstly adding a certain proportion of copper-sulfate aqueous solution, the ammonia water and water as a base solution into a reaction kettle during the reaction, then simultaneously adding the copper-sulfate aqueous solution, the ammonia water and a sodium-hydroxide aqueous solution into the base solution, controlling the pH value of the reaction to be 10.0 to 12.0, controlling the reaction temperature at 80 DEG C to 100 DEG C, and controlling the reaction time to be 8 to 12 hours. Copper oxide prepared by the method has the advantages of high product purity, good sphericity degree, granularity controllability, low energy consumption, easiness in continuous production and the like.

Owner:JINCHUAN GROUP LIMITED

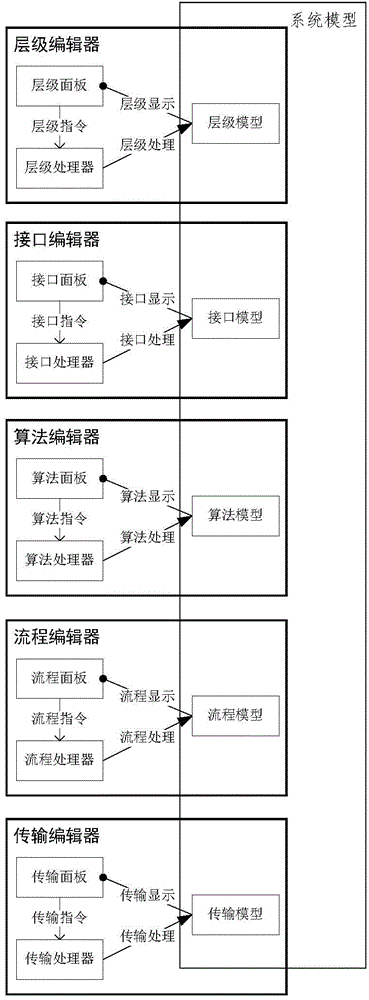

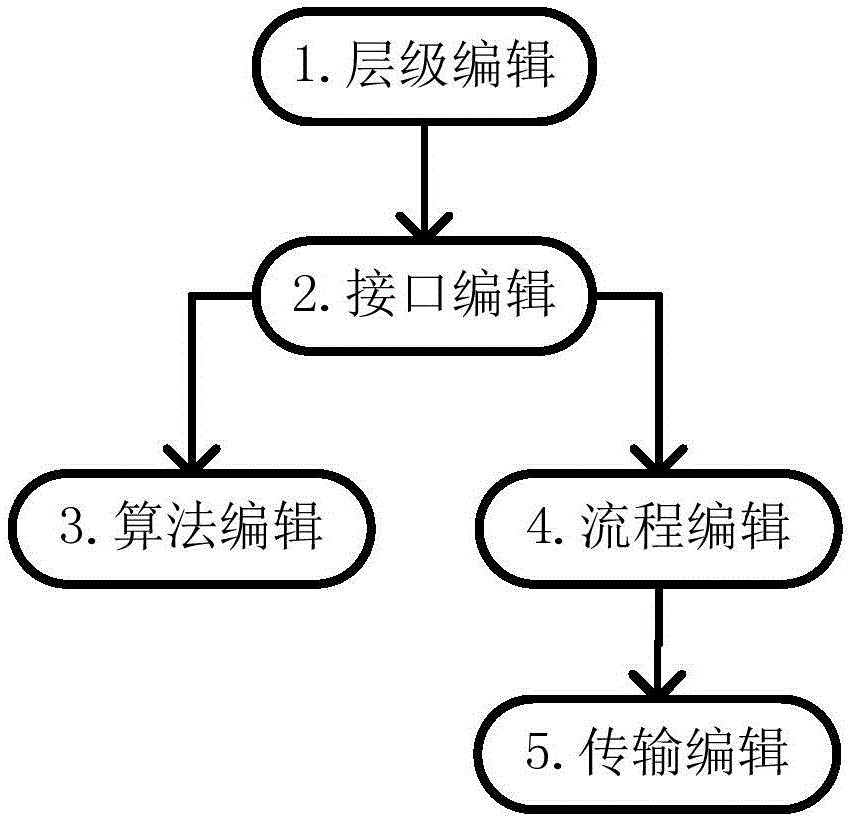

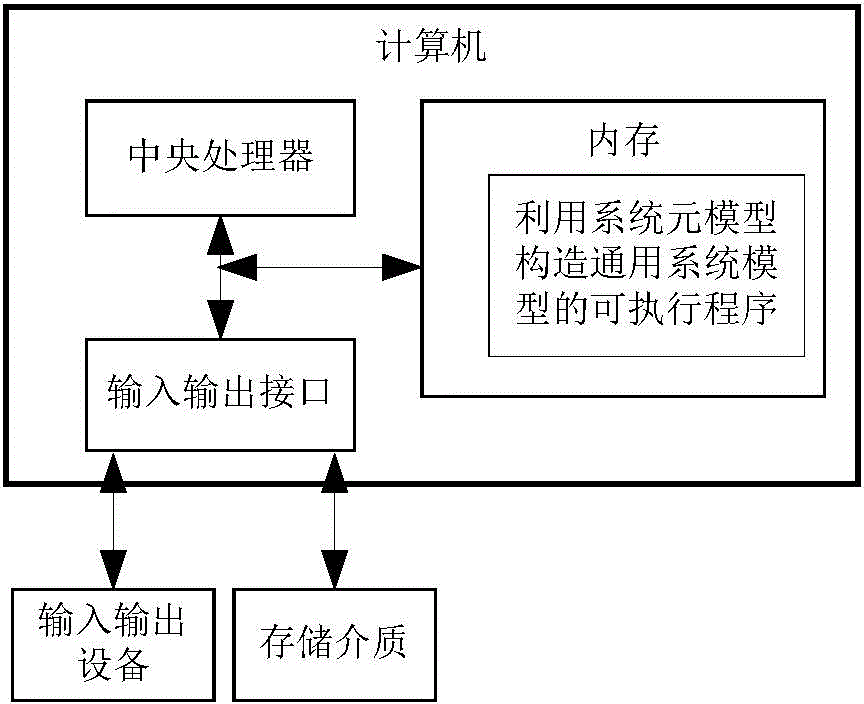

Visual modeling editor for constructing system model

ActiveCN105302532AOperationalVersatilitySpecific program execution arrangementsSoftware systemSimulation

The invention discloses a system meta-model based visual modeling editor for constructing a system model. The editing of the system model and a system view is finished by taking a hierarchical model, an interface model, an algorithm model, a process model, a transmission model and a corresponding view as editing objects through a hierarchical editor, an interface editor, an algorithm editor, a process editor and a transmission editor. A visual system modeling tool with the advantages of computability, universality and usability is provided for various fields. The system model and the system view constructed by the editor are explicit in structure, adjustable in hierarchy and controllable in modeling granularity, and have computable full consistency. Methods are unified, so that top-down analysis design and bottom-up integration are convenient, and the editor is suitable for modeling various systems including software systems and information systems in various application environments. The modeling method is simple and complete in visual modeling, so that even personnel in general fields can independently and easily edit the system model and the system view.

Owner:CHENGDU PUZHONG SOFTWARE CO LTD

Method for preparing copper oxide based on acidic etching liquid as raw material

ActiveCN102303892AHigh purityUniform particle sizeCopper oxides/halidesPhysical chemistryPotassium hydroxide

The invention relates to a method for preparing copper oxide based on an acidic etching liquid as a raw material. The method comprises the following steps: (1) regulating the pH of the acidic etching liquid to 10-13 with sodium hydroxide or potassium hydroxide; (2) transferring the etching liquid obtained in the step (1) into a stainless steel reaction kettle with a teflon lining, adding pure water to 70%-80% of total kettle volume, and carrying out hydrothermal synthesis for 2-10 hours at the temperature of 120-200 DEG C; and (3) after the reaction is finished, naturally cooling to room temperature, collecting materials at the kettle bottom, and successively washing with deionized water and alcohol, and then drying so as to obtain copper oxide. According to the invention, copper oxide isprepared from the acidic etching liquid by using the hydrothermal synthesis method, and obtained copper oxide has the advantages of high purity, high activity and uniform particle diameter. In addition, the method has no secondary pollution and low production cost.

Owner:昆山德阳新材料科技有限公司

Preparation method for titanium-aluminum-vanadium alloy powder

The invention relates to a preparation method for titanium-aluminum-vanadium alloy powder and belongs to the field of titanium alloys. A technical problem to be solved in the invention is to provide the preparation method for the titanium-aluminum-vanadium alloy powder. The preparation method for the titanium-aluminum-vanadium alloy powder comprises the following steps: a, preparing an electrode, namely uniformly mixing TiO2, Al2O3 and V2O5 powder, pressing for forming, and sintering at a high temperature to prepare a titanium-aluminum-vanadium electrode; and b, carrying out molten salt electrolysis reaction, namely with the prepared titanium-aluminum-vanadium electrode as a cathode, a graphite rod as an anode and NaCl-CaCl2 as molten salt electrolysis liquor, carrying out molten salt electrolysis reaction, wherein powder obtained in a cathode frame is titanium-aluminum-vanadium alloy powder. The product prepared by the method disclosed by the invention is alloy powder, so that materials are prepared into powder by one step, alloy ingots are not needed to be firstly prepared and then prepared into alloy powder; meanwhile, the preparation method has the advantages of being controllable in product grain size, capable of continuously producing and the like.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

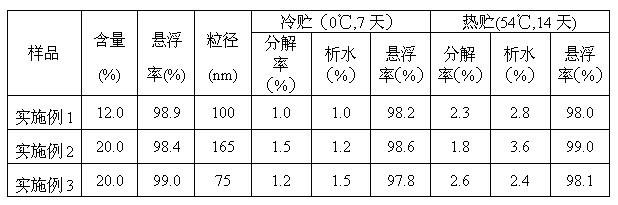

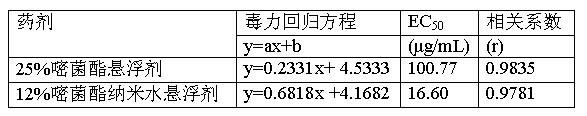

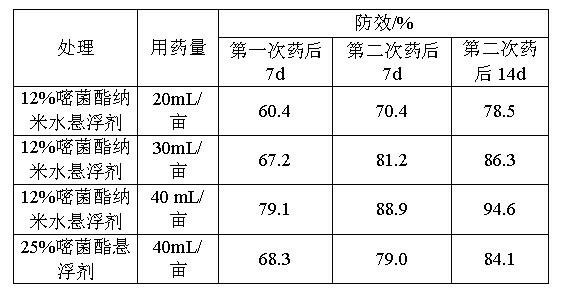

Azoxystrobin nano-water suspending agent and its preparation method

InactiveCN102626084AGranularity controllableSmall granularityBiocideFungicidesDuration periodPesticide residue

The invention relates to an azoxystrobin nano-water suspending agent, which comprise, by mass: 10-20% of azoxystrobin, 10-30% of hydrophobic dispersible nano-silica, 2-10% of a wetting dispersant, 0.2-3% of a thickening agent, 1-5% of an antifreezing agent, 0.01-0.2% of a preservative, and the balance water. The azoxystrobin nano-water suspending agent of the invention has the advantages of: small particle size, high fluidity, and enhanced penetration and conductivity within leaves. Due to enhanced surface energy, the nano-water suspending agent provided in the invention is easier to be adsorbed by plants. As wind blow and rain wash resistance are strengthened, pesticide residues flowing into water and soil can be reduced. With certain slow release effect, the azoxystrobin nano-water suspending agent in the invention can reach the purposes of improving drug effects and prolonging the duration period.

Owner:HENAN AGRICULTURAL UNIVERSITY +1

Spherical cobaltosic oxide and preparation method thereof

ActiveCN103359794ANo emissionsGranularity controllableCobalt oxides/hydroxidesFluid phaseCobalt(II,III) oxide

The invention discloses spherical cobaltosic oxide and a preparation method thereof. Salt, a precipitator and an oxidant are adopted in a liquid-phase synthesis process; the salt, the precipitator and the oxidant simultaneously flow inside a reaction kettle to react; and the spherical cobaltosic oxide is continuously prepared by adopting the methods of ageing, centrifuging, washing, secondary centrifuging and burning. The particle size is controllable; D50 is 2-20 microns; the spherical cobaltosic oxide is even in distribution of particle size, high in compactness, high in product consistency, and simple in preparation method; a complexing agent does not need to be added; and no harmful substance is discharged in the process, so that the preparation method is safe and friendly.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Preparation of positive electrode material of lithium ion cell namely lithium iron phosphate

InactiveCN101290988AEvenly distributedShape is easy to controlElectrode manufacturing processesPhosphorus compoundsPhosphorous acidPhosphoric acid

The invention discloses a method for making a LiFePO4 positive pole material of a lithium ion battery, which comprises preparing uniformly distributed FePO4 precursor powder with controllable shape and granularity by a chemical precipitation method using ferric compounds and phosphorous acid as raw materials; mixing the molten salt of lithium source, Carbon source and FePO4 precursor together by a molten salt method to obtain LiFePO4 by baking. The method making LiFePO4 by chemical precipitation and molten salt allows materials to be made into target materials with excellent crystal structure at a relatively lower temperature in a short period as the precursor is uniformly distributed and the molten salt can serve as a flux. The materials made by the method have excellent electrochemical properties.

Owner:CENT SOUTH UNIV

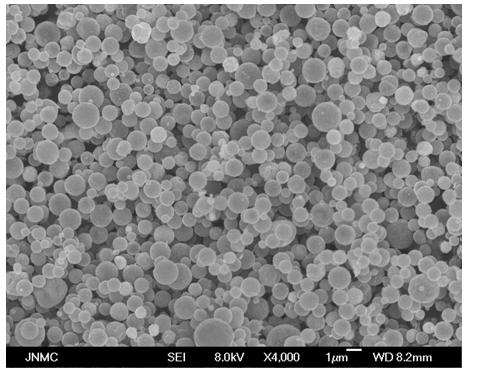

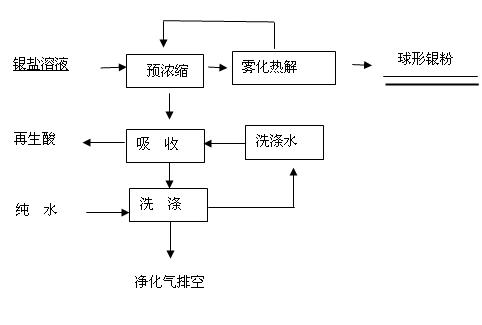

Method for preparing spherical silver powder

The invention discloses a method for preparing spherical silver powder, relating to a method for preparing conductive silver paste in electronic industry. The method for preparing spherical silver powder is characterized by comprising the following steps: atomizing the dissolvable silver salt solution, carrying out thermal decomposition under conditions of high temperature and controllable atmosphere and then preparing spherical silver powder. In the method, the dissolvable silver salt solution is used as raw materials and is atomized, and then thermal decomposition is conducted to the mixing solution at high temperature and under controllable atmosphere so as to generate the spherical silver powder. With the method, the preparation process from the solution to the spherical silver powder can be continuously realized by one step, the granularity of the prepared spherical silver powder is controllable within the range of 0.2-20 micrometers, the granularity of the powder is uniformly distributed and has even compositions and is excellent in performance. The preparation method is energy-saving and environment-friendly, and has low production cost and obvious economic and social benefits.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com