Azoxystrobin nano-water suspending agent and its preparation method

A technology of azoxystrobin and nano-water, which is applied in the field of azoxystrobin nano-aqueous suspension agent and its preparation, can solve the problems of high difficulty, low drug loading and adsorption rate, and high energy consumption, and achieves the effect of avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

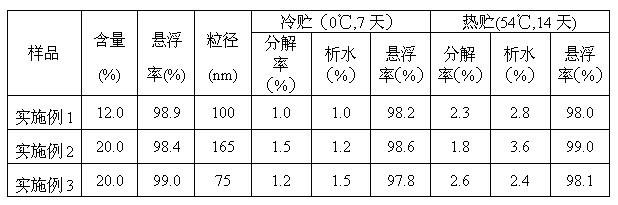

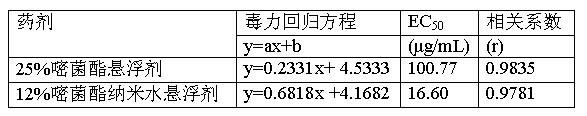

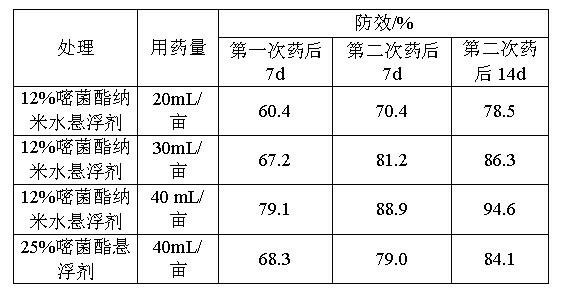

Embodiment 1

[0018] Weigh 12 g of azoxystrobin original drug, add 600 mL of methanol and stir to dissolve, then add 12 g of hydrophobic and dispersible nano-silica to obtain an oil phase; add 2 g of calcium lignosulfonate and 4 g of fatty alcohol polyoxyethylene ether into 60 g of water , 5 g of ethylene glycol, and 0.05 g of sodium o-phenylphenate were stirred and dissolved to obtain a water phase, and the water phase was slowly added dropwise to the oil phase, stirring rapidly while adding the water phase; Distill under reduced pressure in a water bath to completely distill methanol out; finally add 0.2g of xanthan gum, 1g of magnesium aluminum silicate, and make up to 100g of water to shear and emulsify evenly to obtain 12% azoxystrobin nano-water suspension. The average particle size of the product was detected to be 100 nm.

Embodiment 2

[0020] Weigh 20 g of azoxystrobin original drug, add 300 mL of acetone and stir to dissolve, then add 10 g of dispersible nano-silica to obtain an oil phase; add 2 g of calcium lignosulfonate, alkylphenol formaldehyde condensate sulfonic acid to 50 g of water 0.8g of salt, 4.8g of nonylphenol polyoxyethylene ether phosphate, 5g of ethylene glycol, and 0.05g of benzoic acid were stirred and dissolved to obtain a water phase, and the water phase was slowly added dropwise to the oil phase, and stirred rapidly while adding; After the water phase is added dropwise, distill under reduced pressure in a 30°C water bath with stirring to completely distill the acetone; finally add 0.2g of xanthan gum, 1g of magnesium aluminum silicate, and make up to 100g of water to shear and emulsify evenly to obtain 20% pyrimidine Strostrobin nano-water suspension. The average particle size of the product was detected to be 165 nm.

Embodiment 3

[0022] Weigh 20 g of azoxystrobin original drug, add 300 mL of acetone and stir to dissolve, then add 30 g of dispersible nano-silicon dioxide to obtain an oil phase, add 2 g of calcium dodecylbenzenesulfonate, styrene ethyl phenol to 35 g of water 3g of oxyethylene polyoxypropylene ether, 1g of methylene bis-naphthalene sulfonate, 5g of ethylene glycol, and 0.05g of benzoic acid were stirred and dissolved to obtain a water phase, and the water phase was slowly added dropwise to the oil phase, stirring rapidly while adding After the addition of the water phase is completed, distill under reduced pressure in a water bath at 30°C under stirring to completely distill the acetone; finally add 0.2 g of xanthan gum and 1 g of magnesium aluminum silicate, make up to 100 g of water and emulsify evenly to obtain 20 % azoxystrobin nano water suspension. The average particle size of the product was detected to be 75 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com