Patents

Literature

952results about How to "Improve flushing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

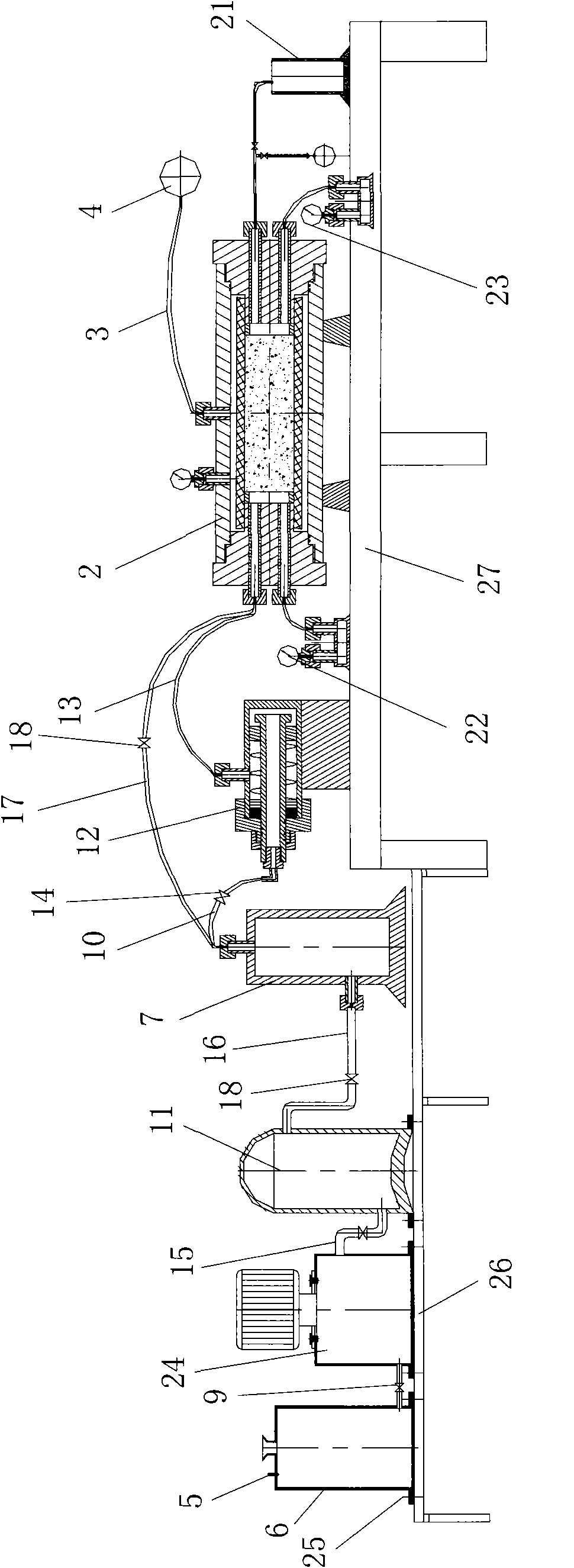

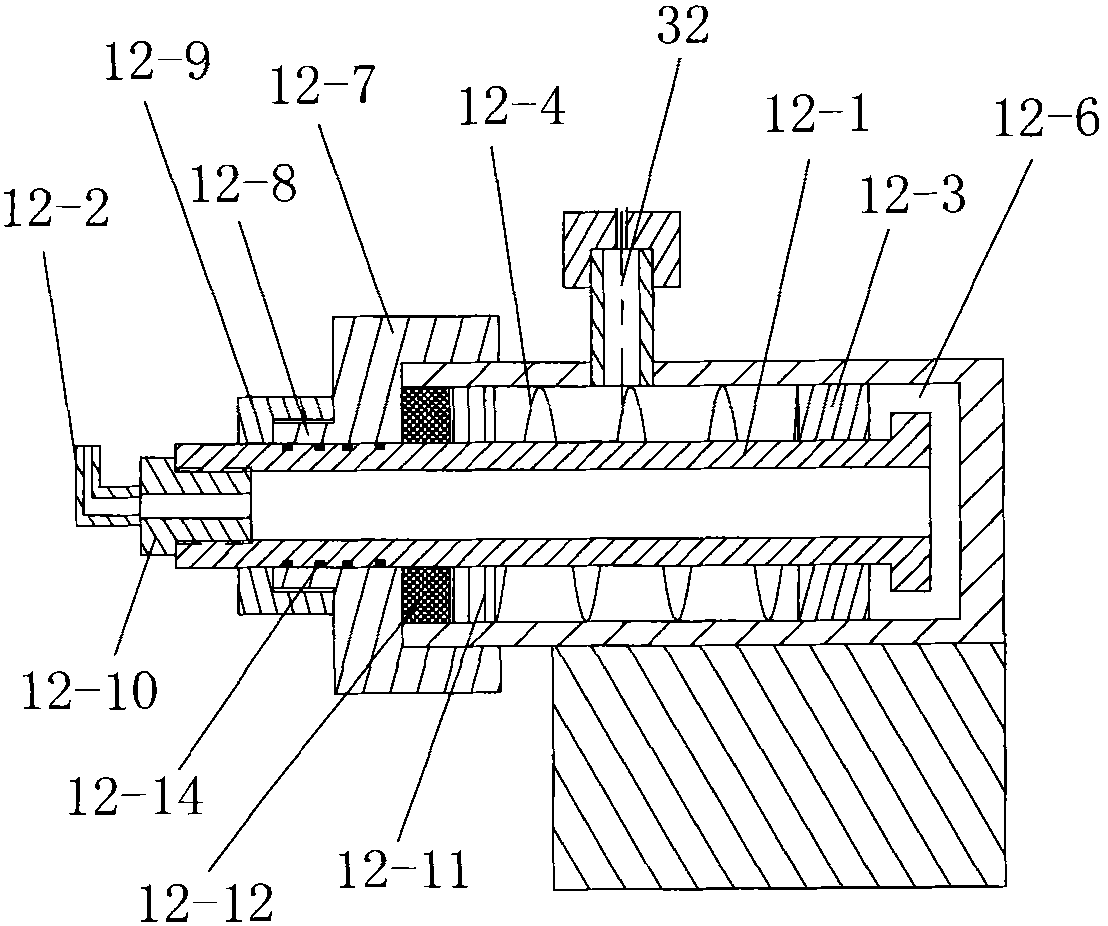

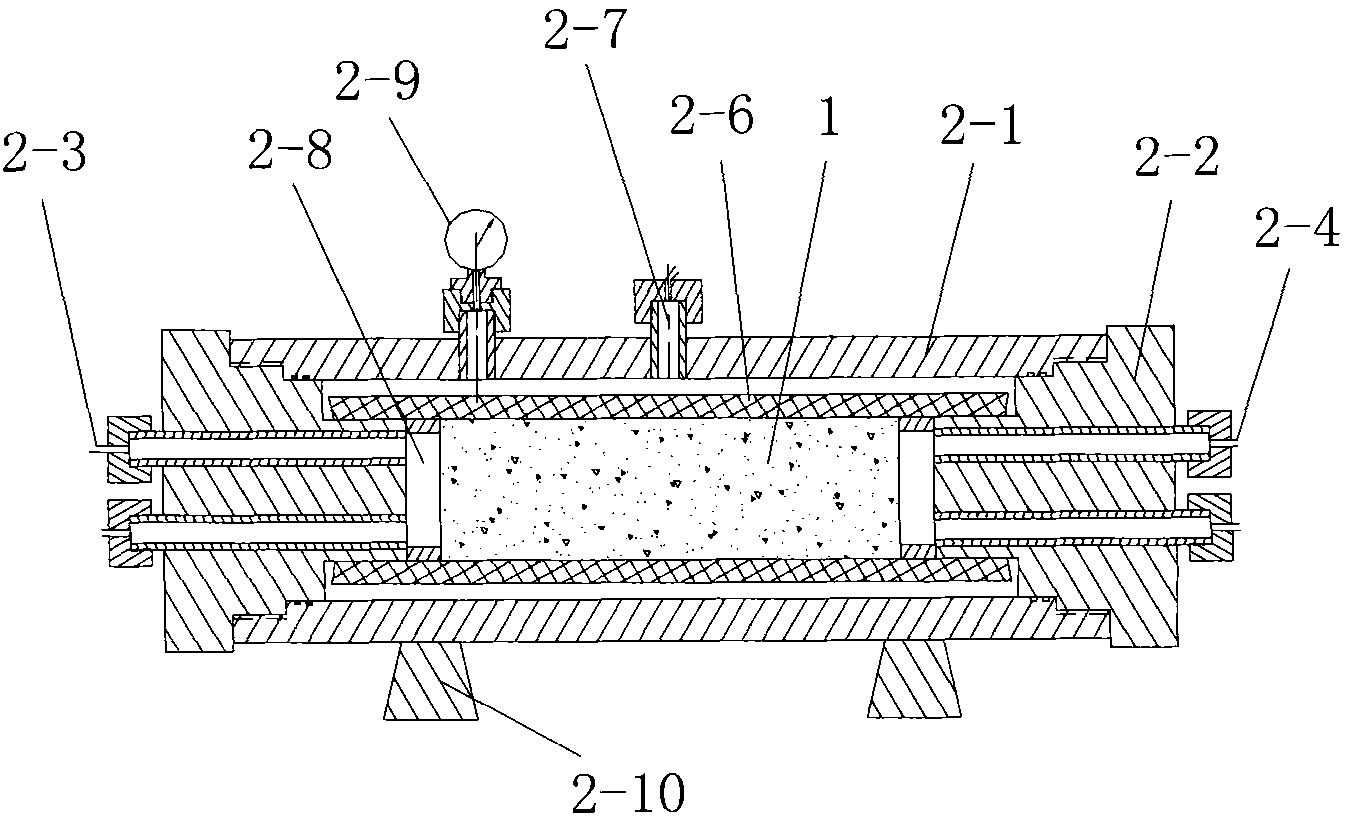

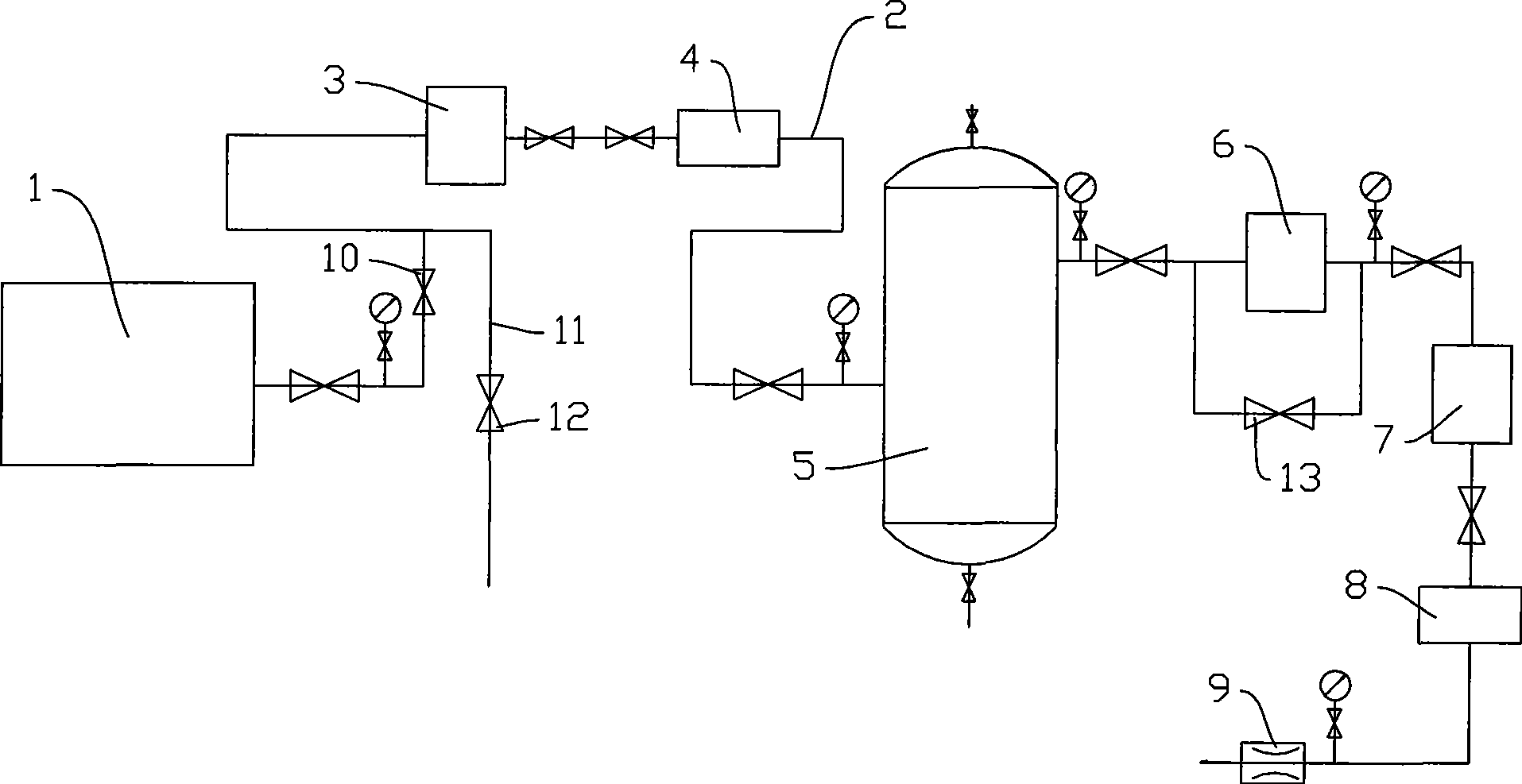

Hydraulic power pulse oil displacement experimental facility and experimental method thereof

ActiveCN101975053AImprove work efficiencyEnhanced overall recoveryFluid removalVibration devicesExperimental methodsWater storage tank

The invention discloses a hydraulic power pulse oil displacement experimental facility and an experimental method thereof. The experimental facility comprises a core clamping device, an annular pressure supply device, a hydraulic power pulse wave generating device, a water storage tank and an oil storage tank which are connected with the liquid inlet of the core clamping device by virtue of a water pipeline and an oil pipeline as well as a liquid container which is connected with the liquid outlet of the core clamping device; wherein the water pipeline and the oil pipeline are all provided with an intermediate container, a pumping device used for generating high pressure liquid flow and an energy storage tank. The experimental method includes the following steps: firstly, oil displacementexperiment is carried out under the condition that no hydraulic power pulse is added; secondly, oil displacement experiment is carried out while frequency and amplitude hydraulic power pulse wave of core are replaced, and meanwhile hydraulic power pulse auxiliary chemical oil displacement experiment is completed; thirdly, data processing is carried out. The invention has reasonable design, mounting convenience, simple operation and good simulation effect, can improve efficiency of oil displacement by water and crude oil recovery ratio, and experiment of hydraulic pulse wave oil displacement and hydraulic pulse wave auxiliary reservoir core oil displacement by water can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

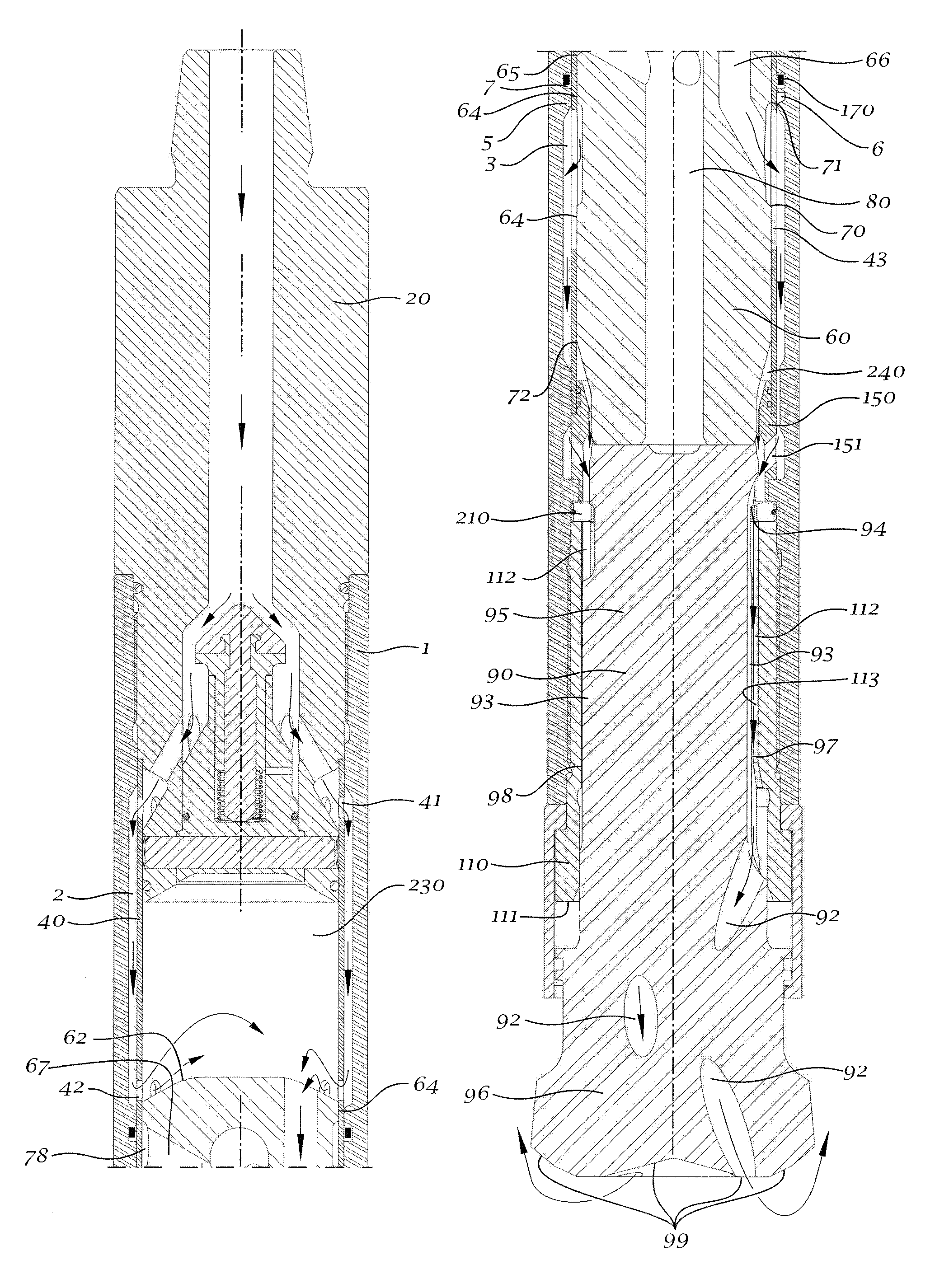

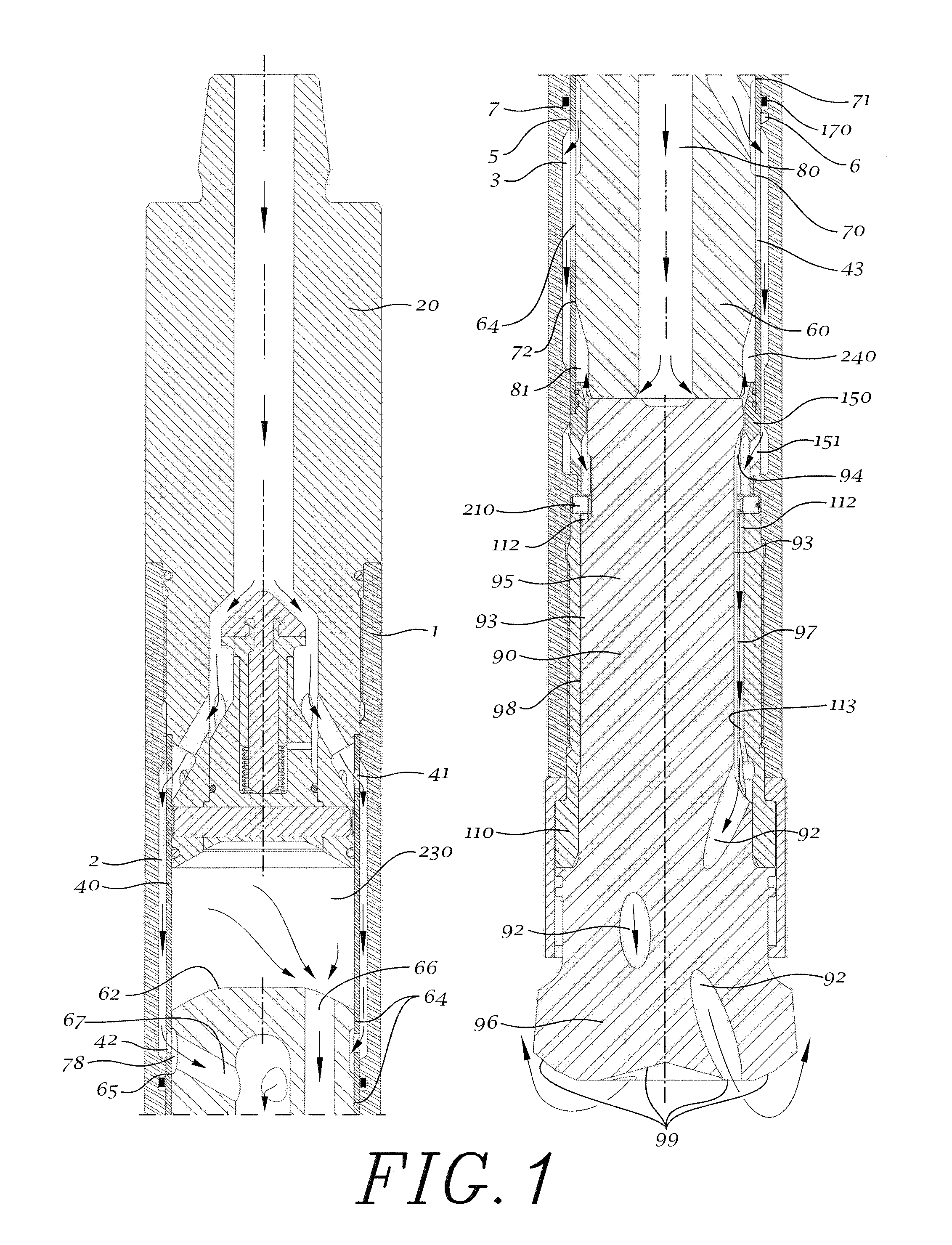

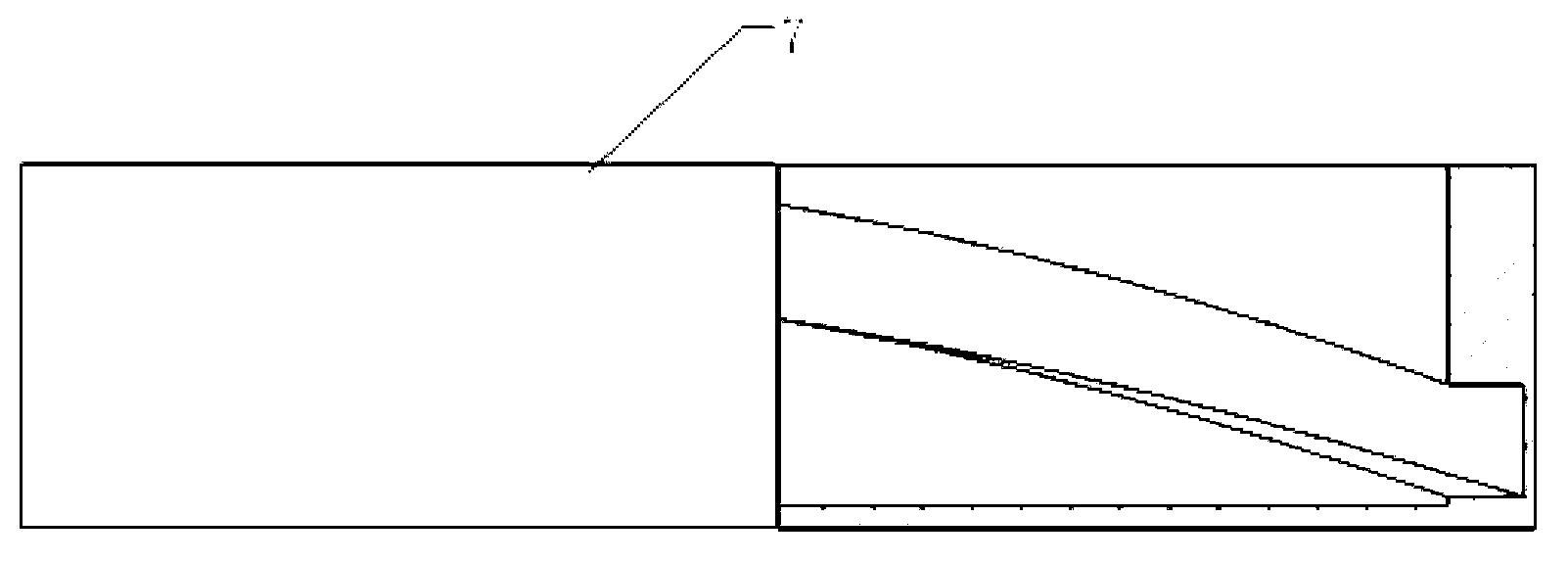

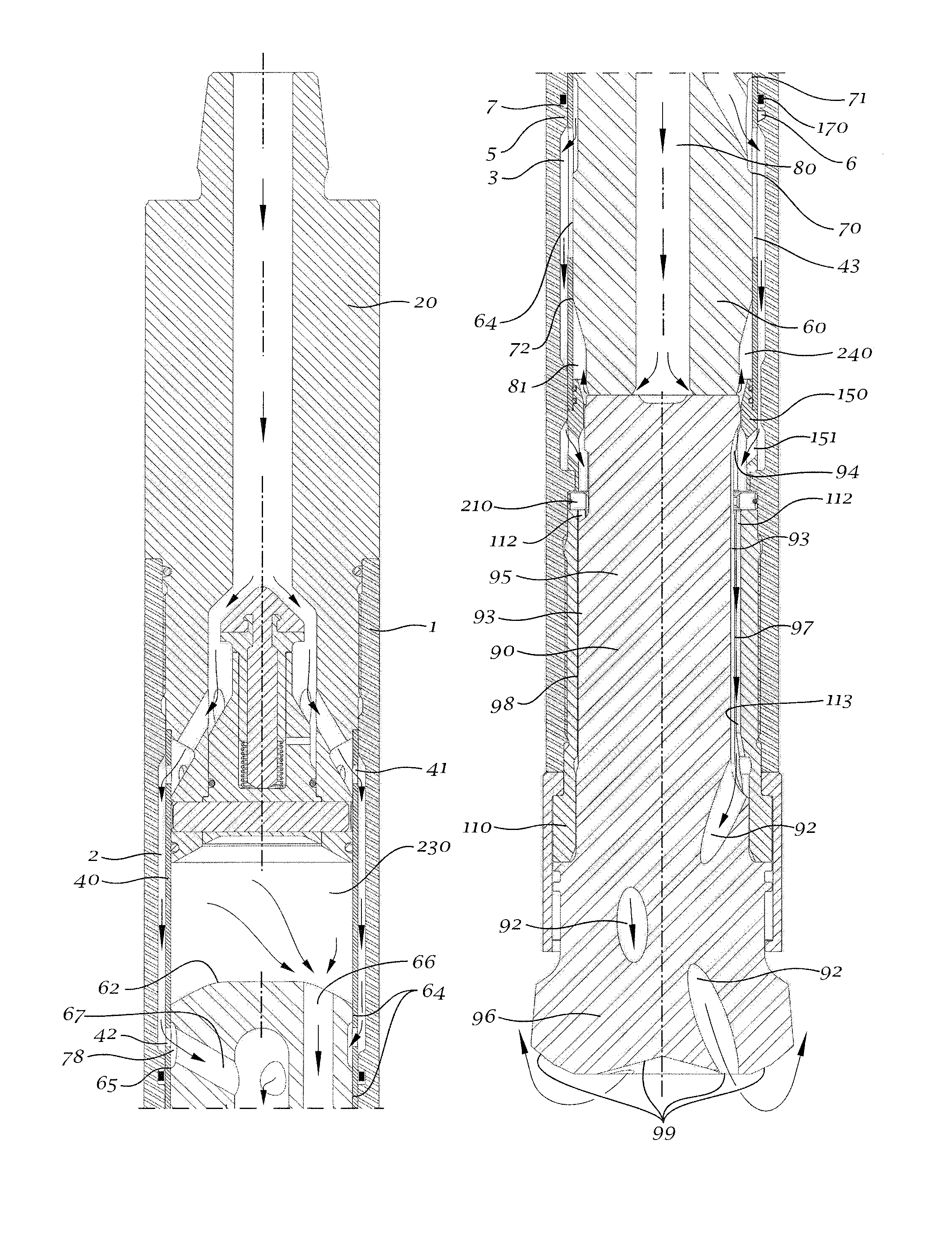

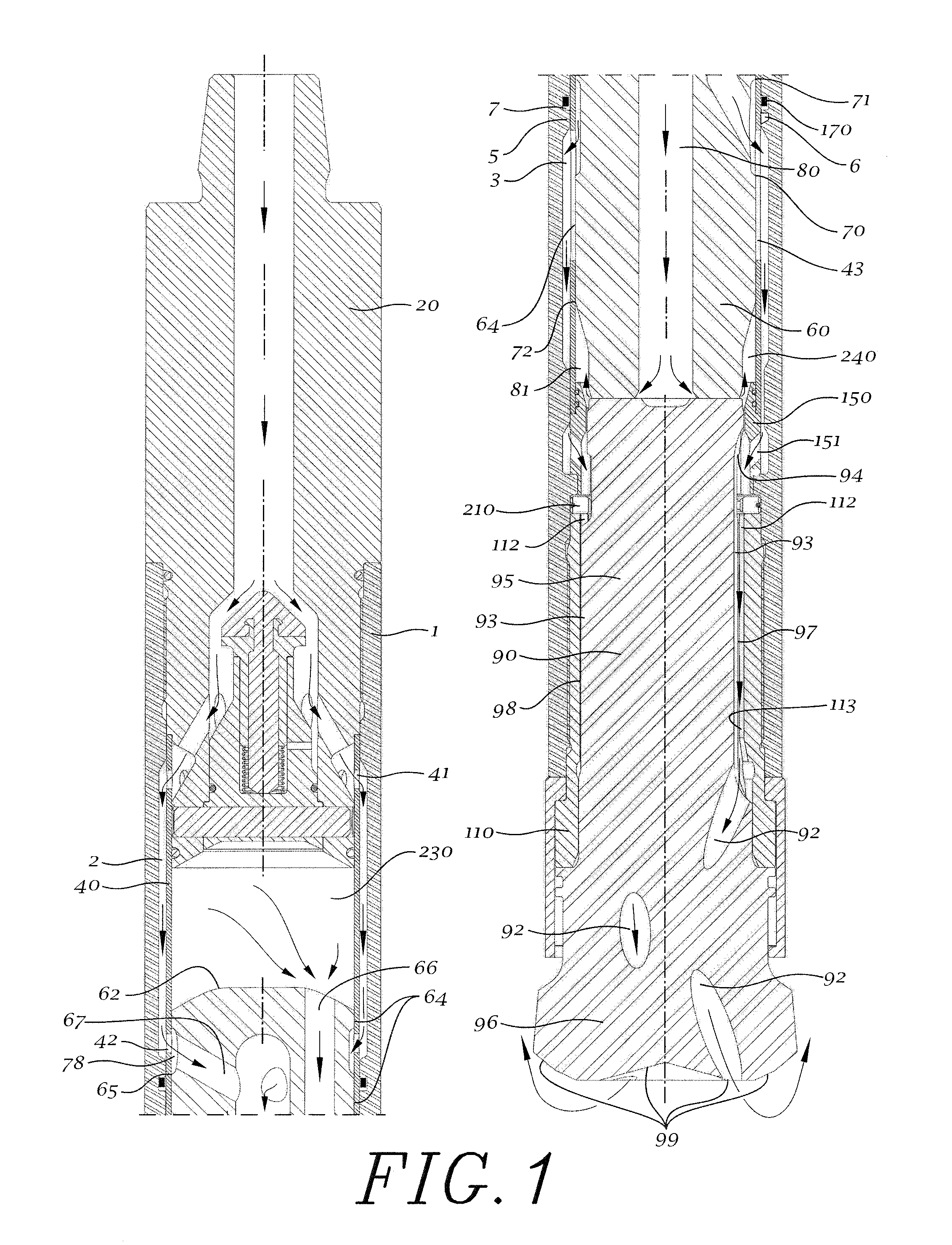

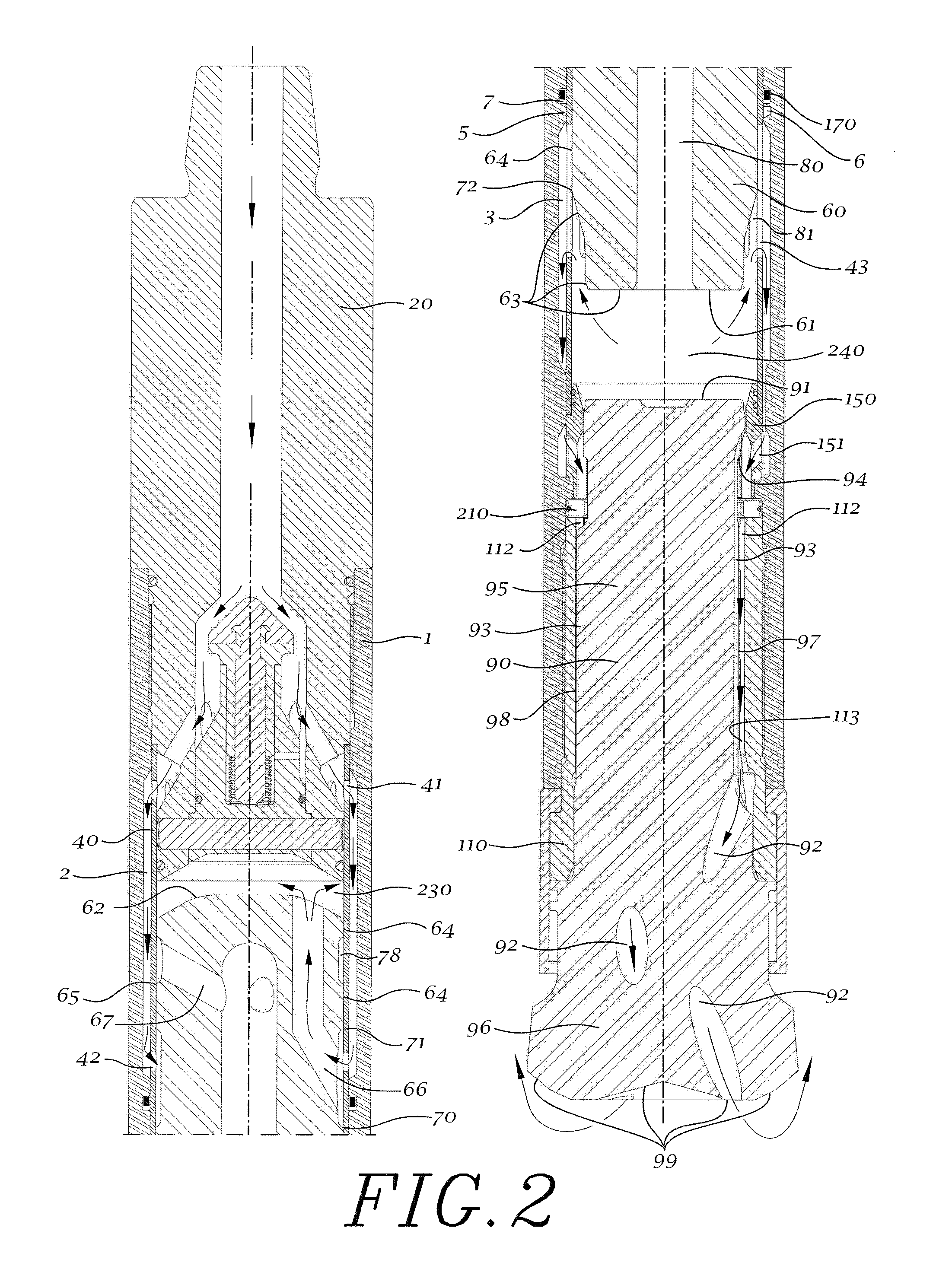

Pressurized fluid flow system for a normal circulation hammer and hammer thereof

ActiveUS20110209919A1Improve reliabilityHigh sturdinessDrill bitsBorehole drivesDrill bit shankReciprocating motion

A pressurized fluid flow system for a normal circulation down-the-hole hammer comprises a cylinder coaxially disposed in between an outer casing and a piston that reciprocates due to changes in pressure of the pressurized fluid contained inside of a front chamber and a rear chamber located at opposites sides of the piston, wherein the flow into and out of these chambers is controlled solely by the overlap or relative position of the piston and the cylinder as a supply chamber and a discharge chamber defined by recesses on the inner surface of the outer casing and separated by a dividing wall control the flow of pressurized fluid in and out of the front and rear chambers the. A down-the-hole normal circulation hammer with this system comprises a drill bit with one or more flushing passages that extend from channels cooperatively formed between splines on the inner surface of the driver sub and splines on the outer surface of the drill bit shank, to the front face of the drill bit for discharging the pressurized fluid out of the hammer.

Owner:DRILLCO TOOLS

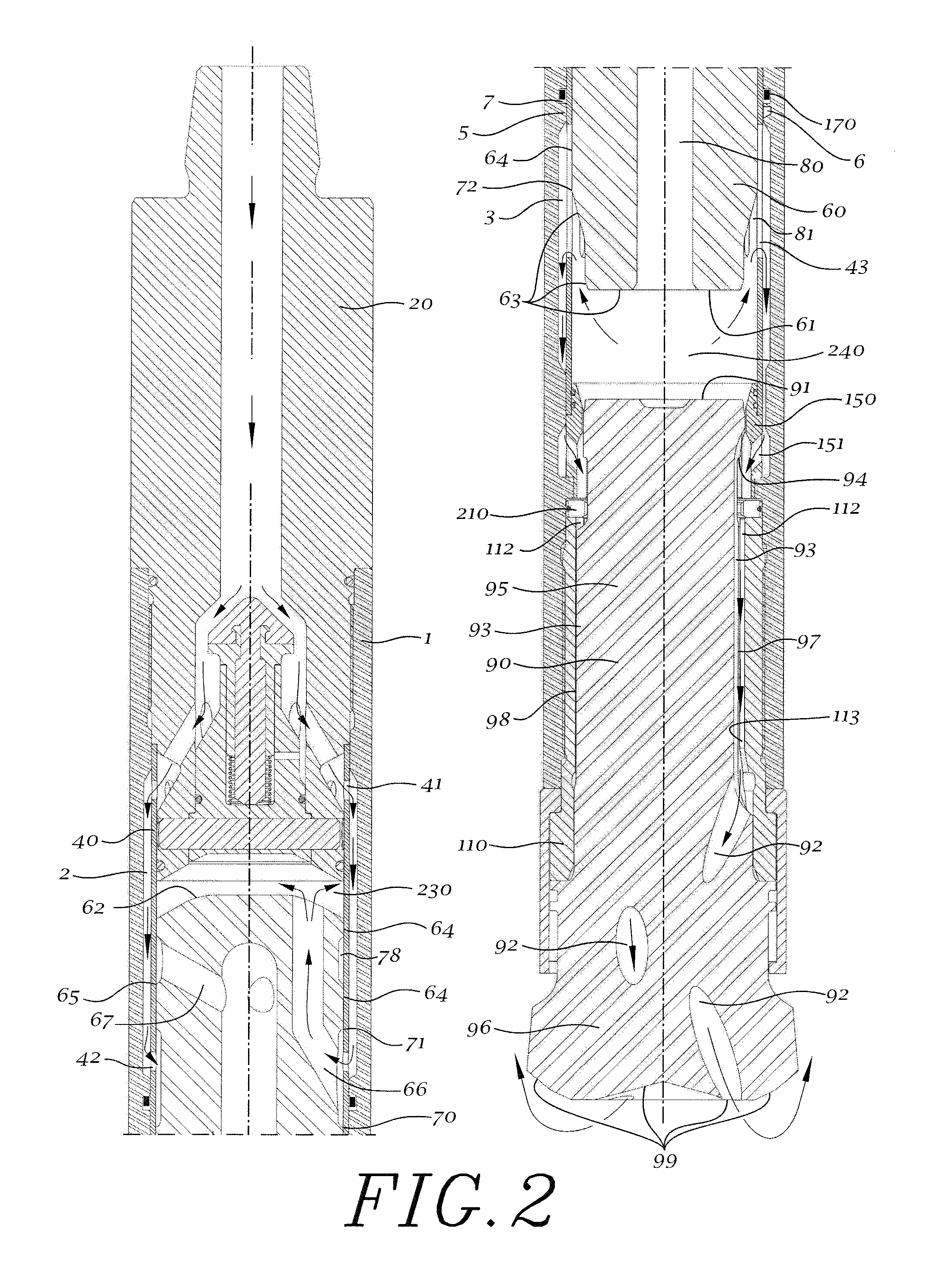

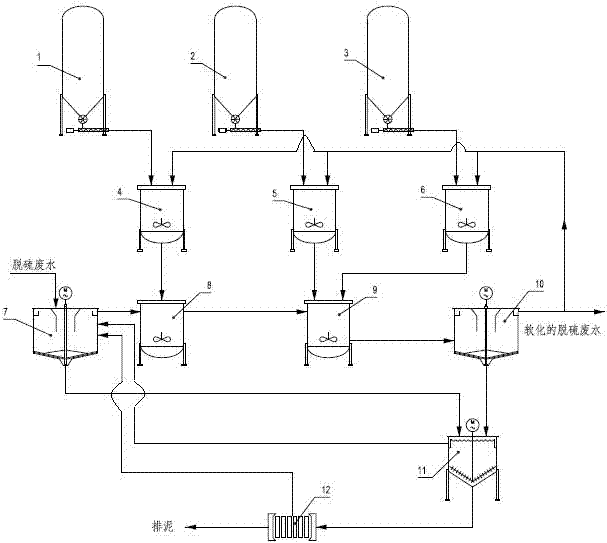

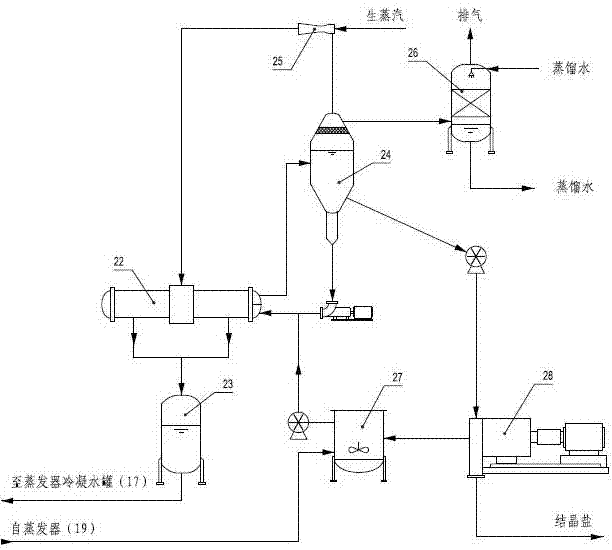

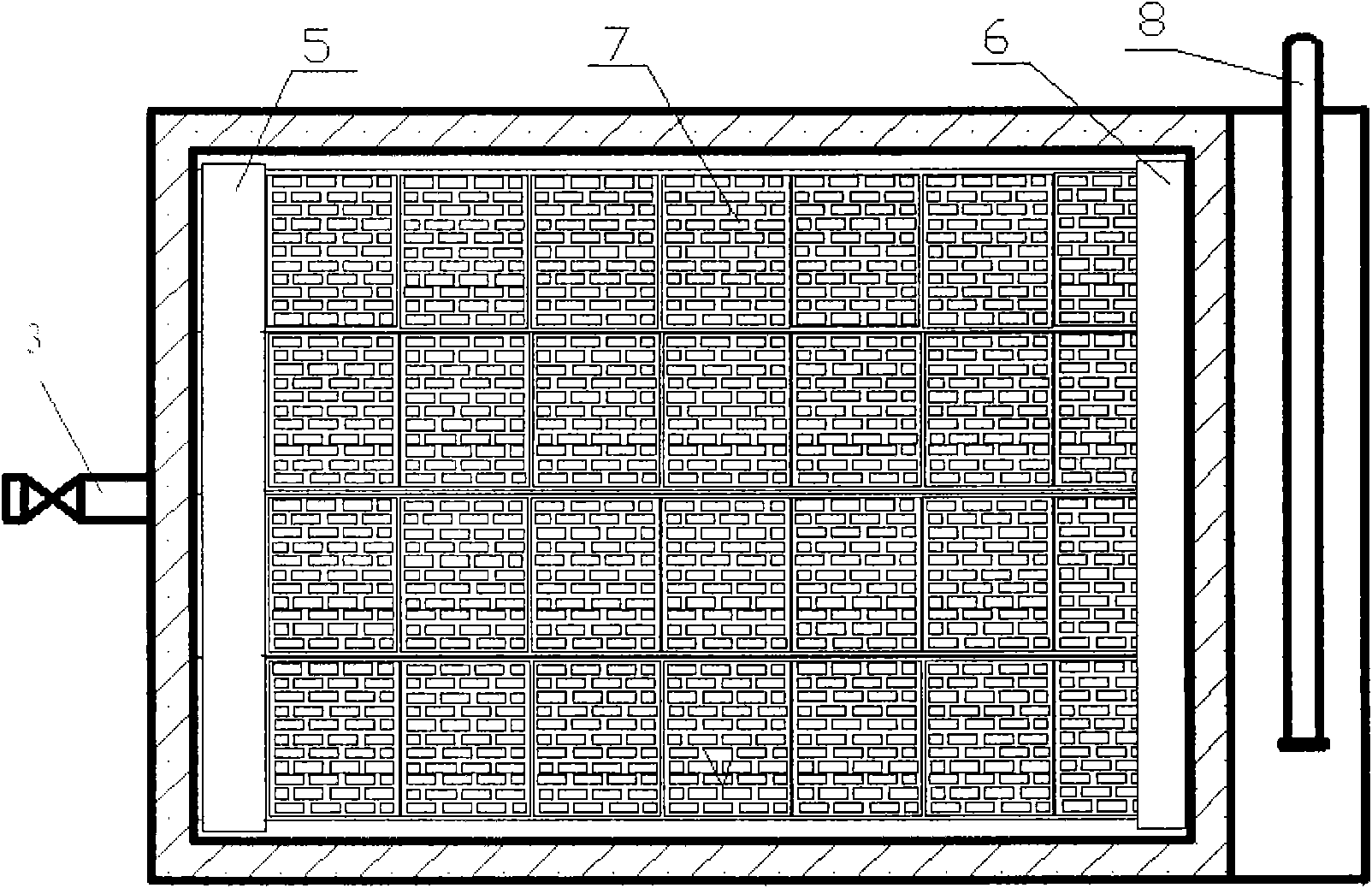

Power plant wastewater zero-discharge treatment technique

ActiveCN104276708AImprove flushing effectRemove supersaturationMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationProcess equipmentDegasser

The invention discloses a power plant wastewater zero-discharge treatment technique which comprises a pretreatment process, an evaporative concentration process and an evaporative crystallization process, wherein the pretreatment process equipment comprises a precipitation and concentration tank, a sludge dewatering machine, and a raw water precipitation tank, a primary softening reactor, a secondary softening reactor and a softening precipitation tank which are sequentially connected; the evaporative concentration process equipment comprises an automatic back flush filter, a plate-type preheater, a degasser and a falling film evaporator which are sequentially communicated; and the evaporative crystallization process equipment comprises a concentrated solution tank, a crystallizing heater and a crystallizer which are sequentially communicated. The desulfurization water treatment technique is reasonable in step design and performs the pretreatment, evaporative concentration and evaporative crystallization on the desulfurization wastewater, and the end products are only distilled water and crystalline salt, thereby reducing the discharge of the harmful substances, lowering the energy consumption and implementing the goal of zero discharge of desulfurization wastewater.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

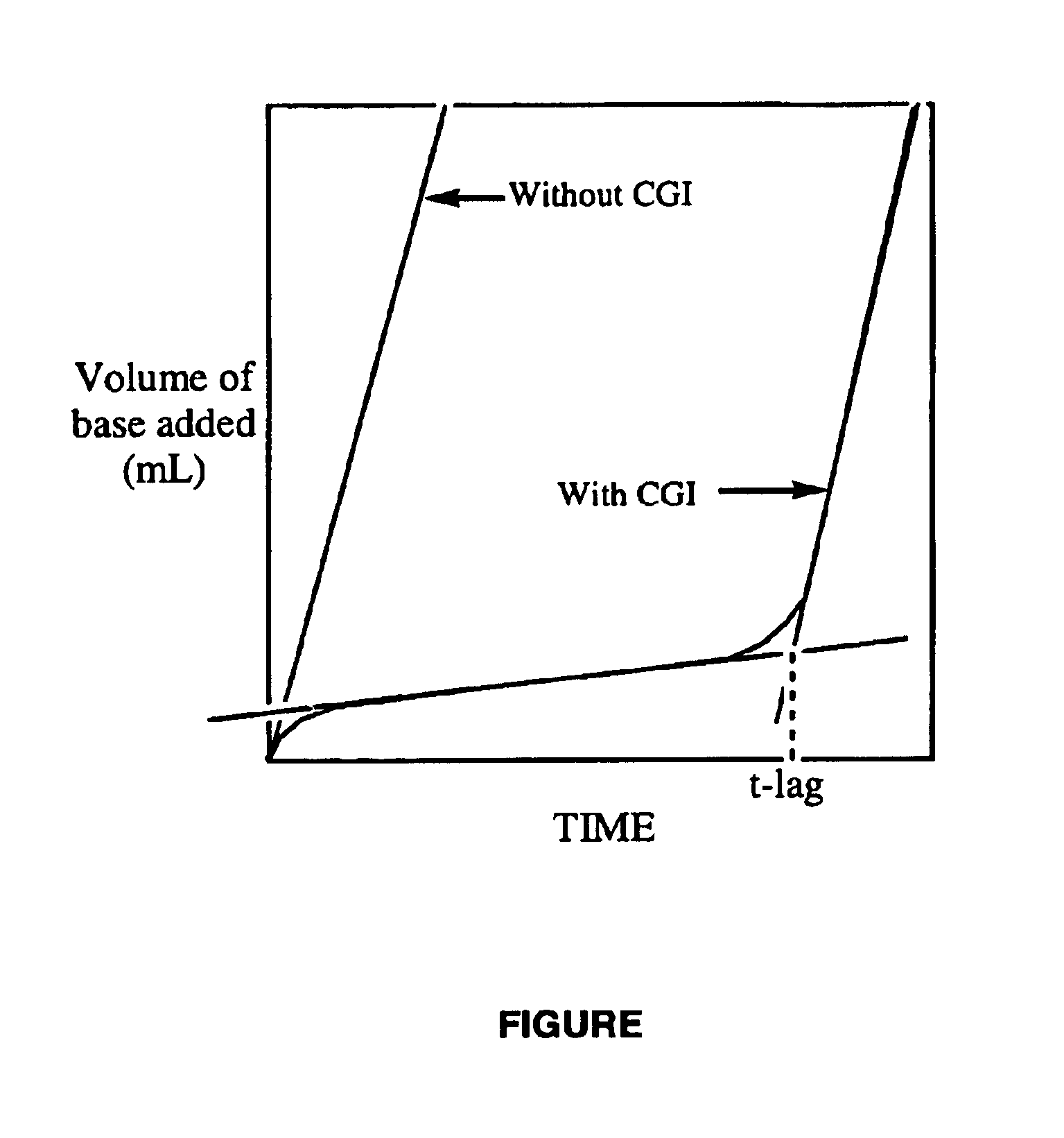

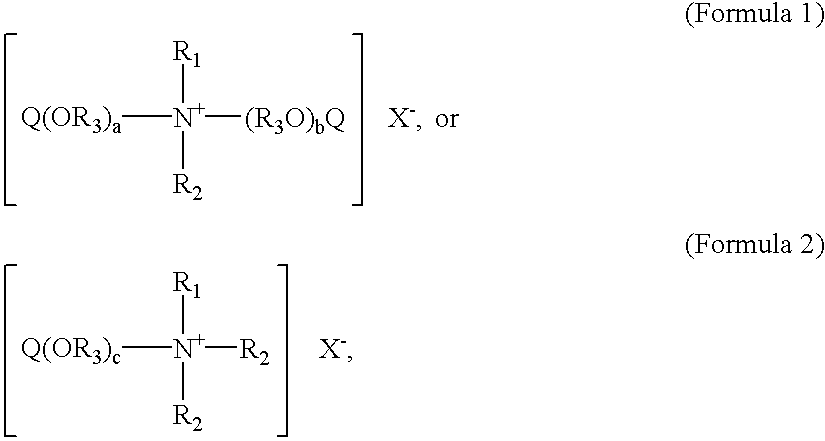

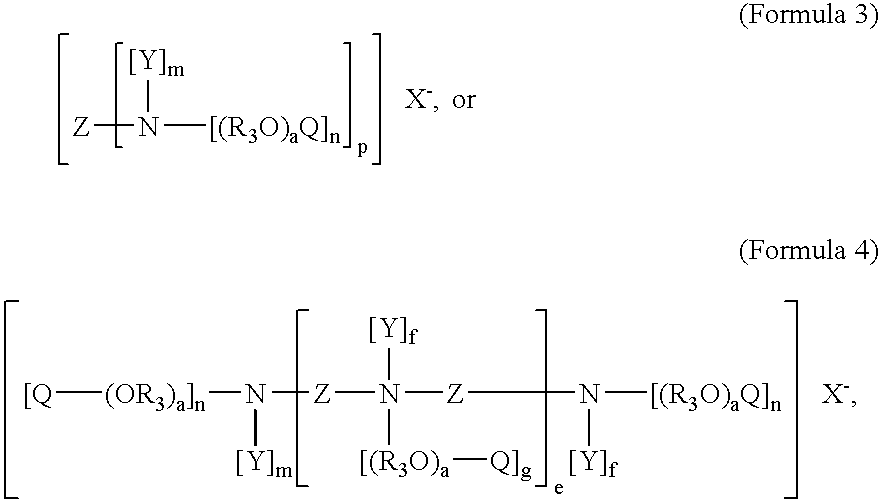

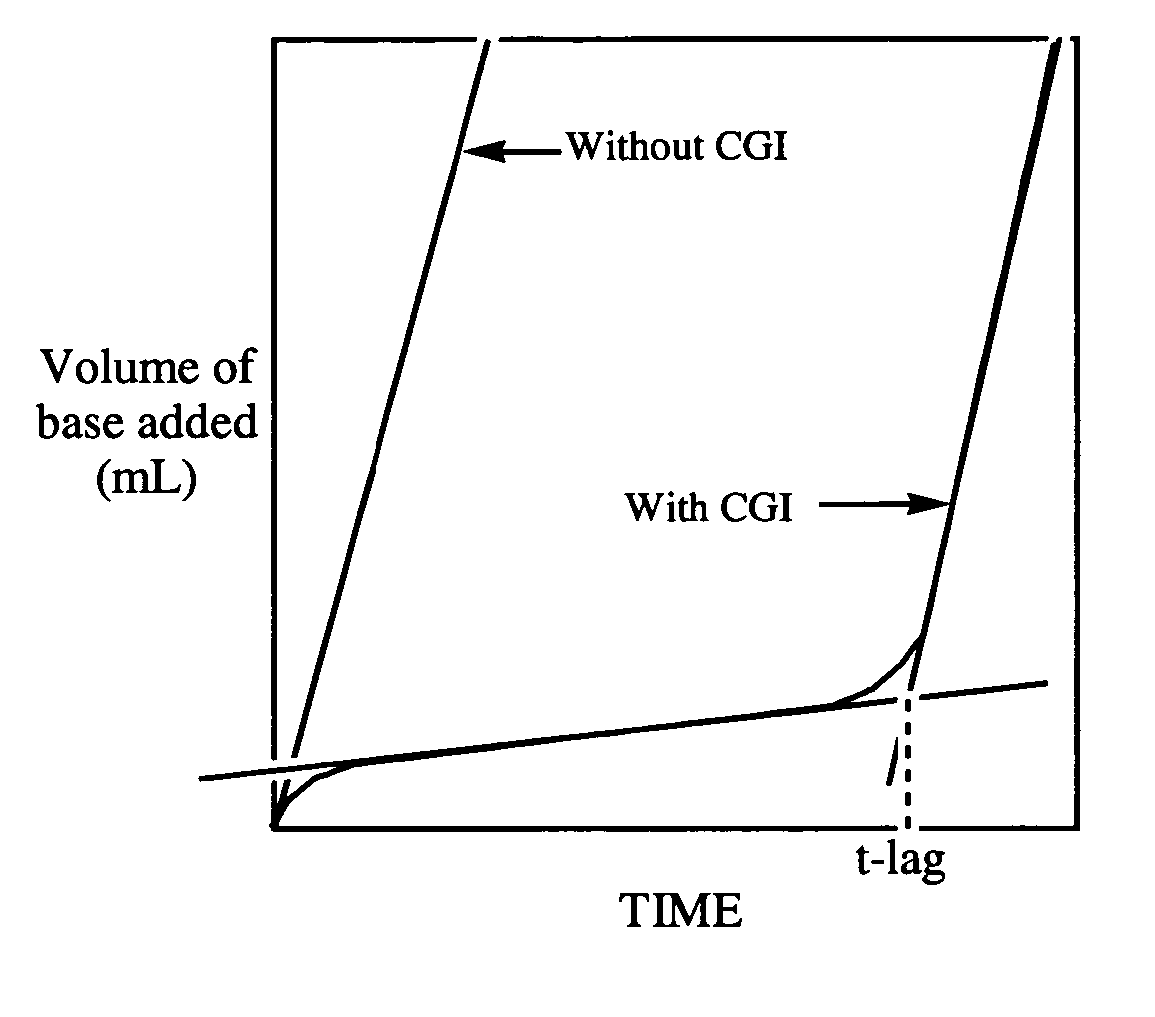

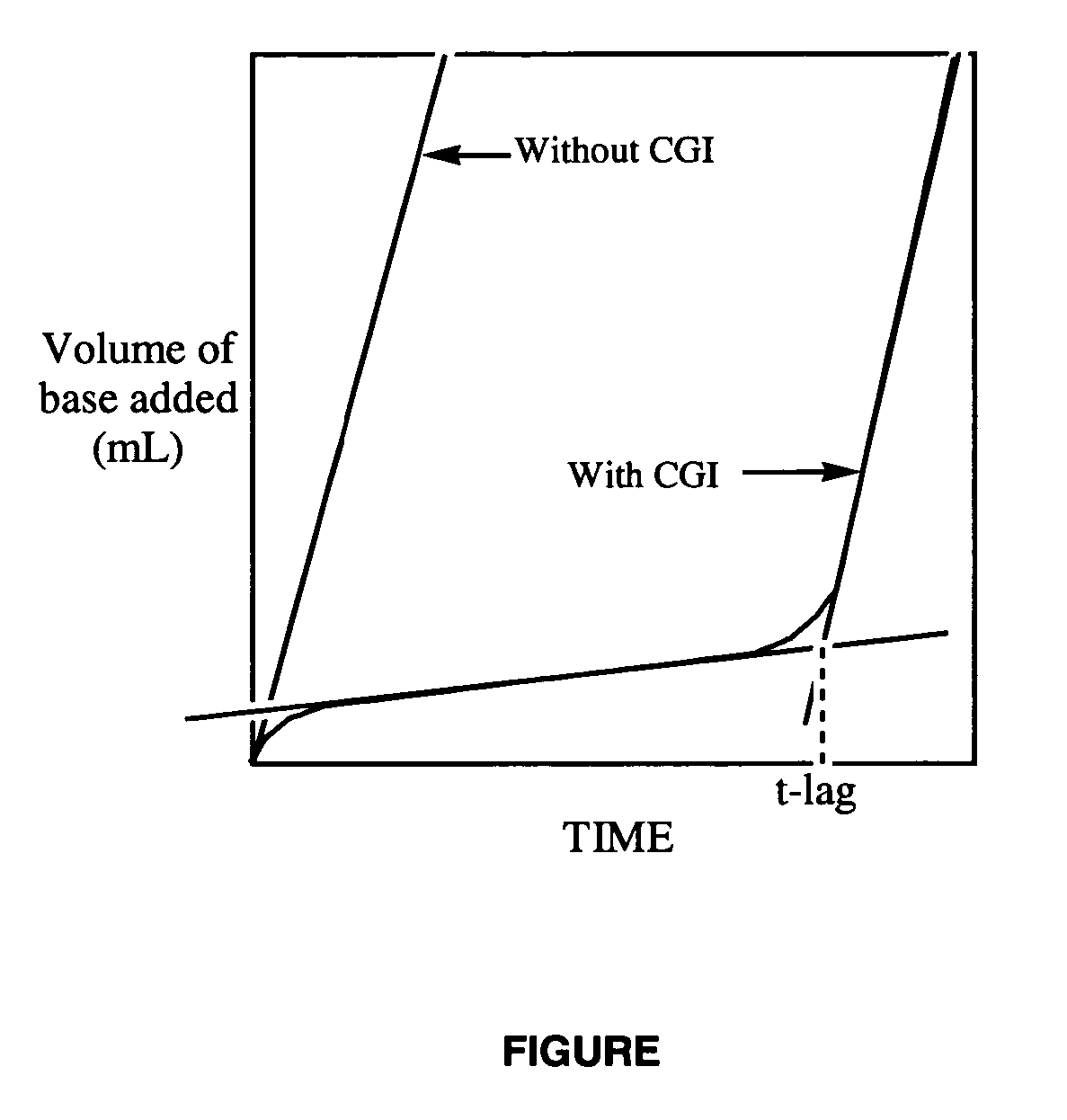

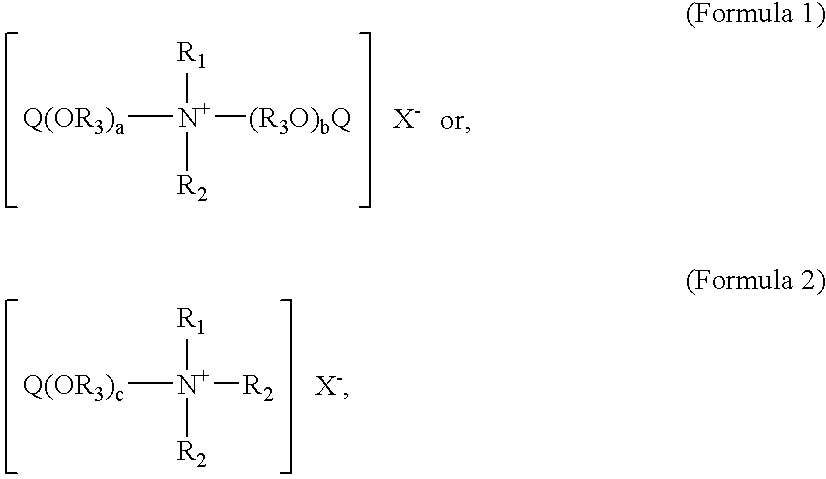

Rinse-added fabric treatment composition, kit containing such, and method of use therefor

InactiveUS7026278B2Increase volumeIncreasing amount of removedInorganic/elemental detergent compounding agentsCationic surface-active compoundsWater useSurface-active agents

A rinse-added fabric treatment composition having a rinse aid increases the rinse capacity of an aqueous rinse bath solution for removing laundry residue from laundered fabrics. When properly diluted in water, the rinse-added fabric treatment composition provides a rinse bath solution having a rinsing capacity of greater than 1. In addition, a rinse-added fabric treatment composition reduces the surfactant residue on a fabric, and includes from about 0.05% to about 10% of a residue reduction agent, a suds suppresser, and the balance adjunct ingredients. The residue reduction agent is selected from a cationic residue reduction agent, a zwitterionic residue reduction agent, and a combination thereof. Moreover, methods for reducing surfactant residue on fabric and a method for reducing the amount of water used in a rinsing step of a laundry process are included. A kit for improving the rinsing capacity of water includes a rinse-added fabric treatment composition and an instruction set.

Owner:THE PROCTER & GAMBLE COMPANY

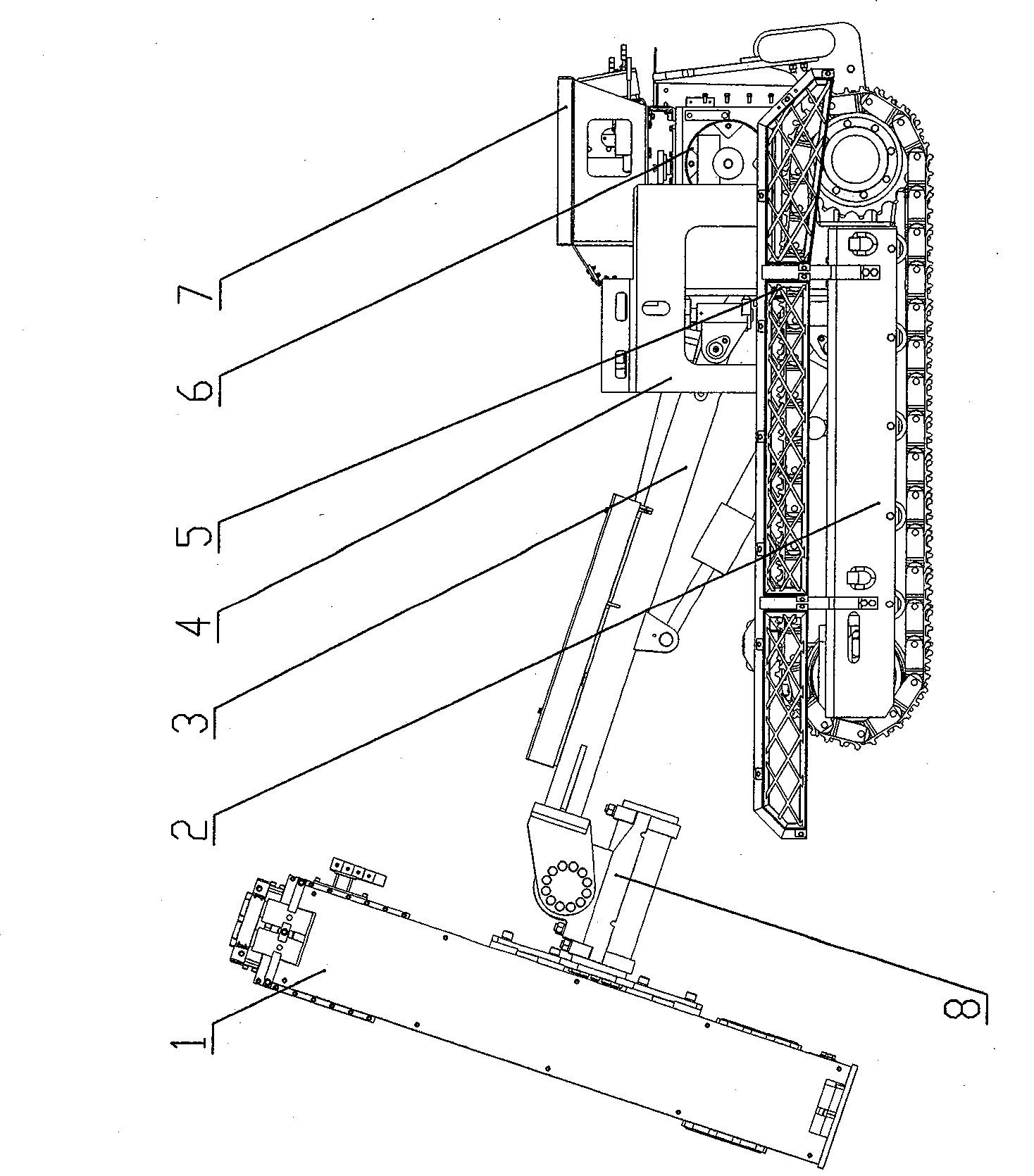

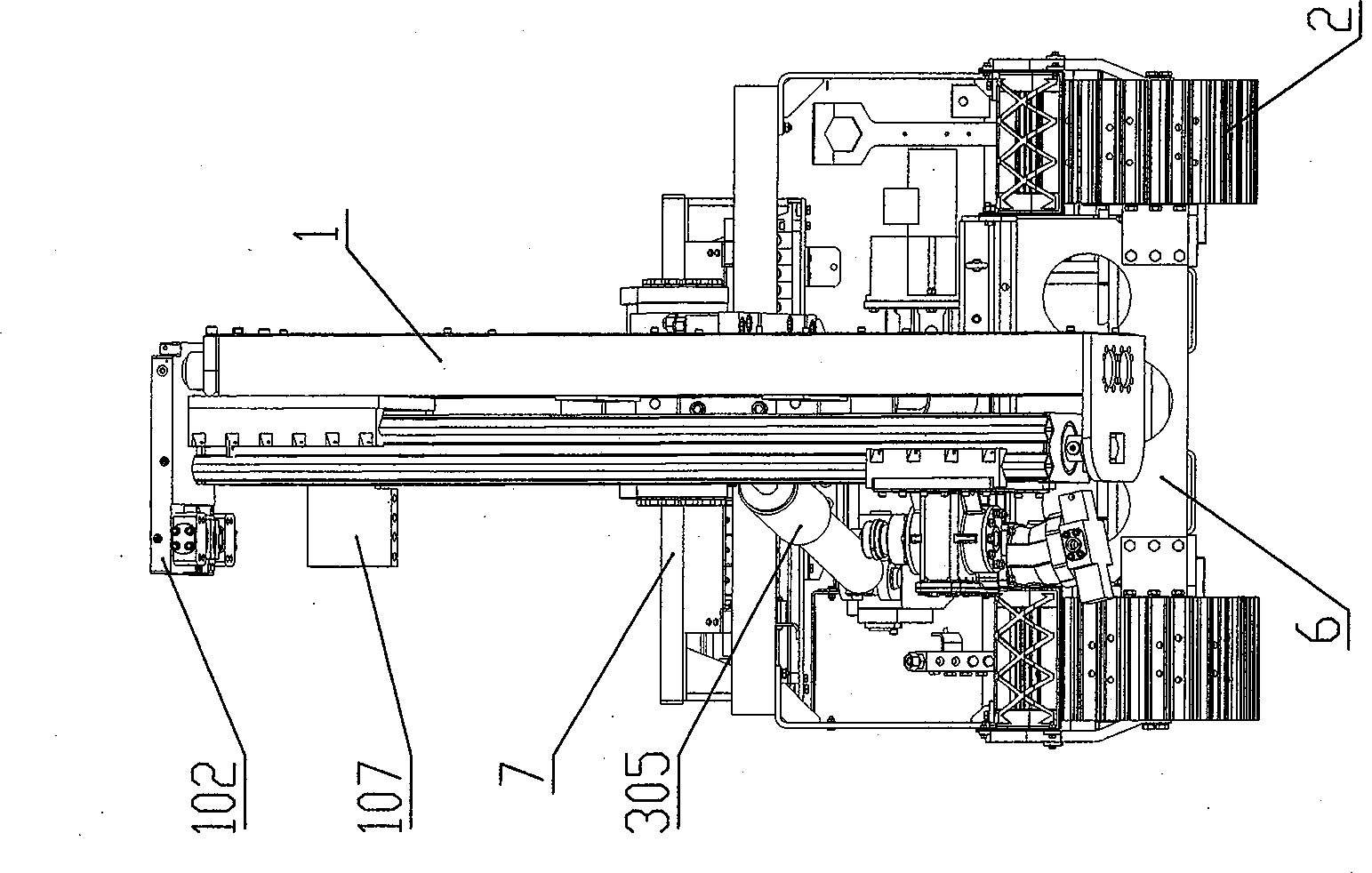

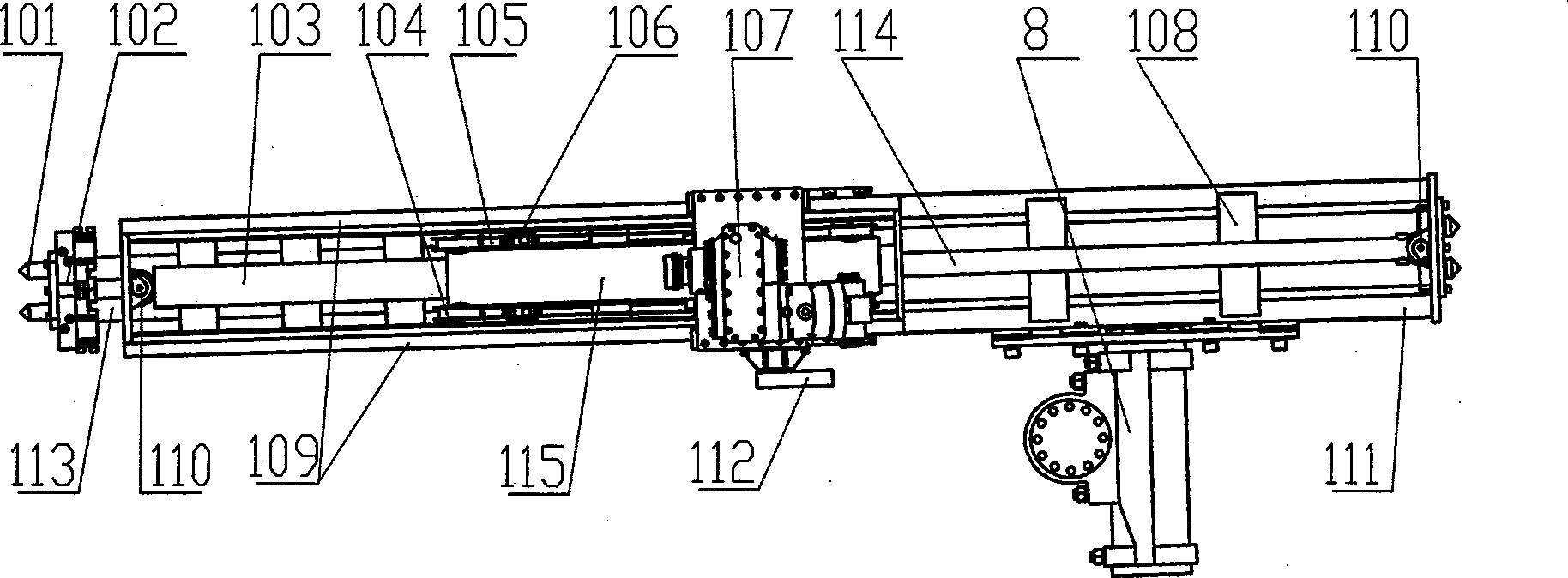

Pneumatic crawler hydraulic jumbo

InactiveCN101509350AAvoid it happening againTimely processingConstructionsDrilling drivesClosed loop designElectric devices

The invention discloses a pneumatic crawler-type hydraulic drill carriage which comprises a carriage body, a travelling gear, a working device for drilling connected with the carriage body, a hydraulic system for driving the devices, and an operating device; a pneumatic motor is used as power of the hydraulic system and operation of the drill carriage; an operating device, which adopts closed loop design, is used for driving the pneumatic motor, the pneumatic system, the hydraulic system and the various acting components to act; the travelling device is crawler-typed; a swinging device, which consists of a swinging arm and a cylinder, is arranged at the front of the carriage body; the front end of the swinging device is connected with the working device for drilling by a universal rotating device; the working device consists of a feeding device which comprises a supporting device, a secondary cylinder, and a chain pushing mechanism; and the pneumatic crawler-type hydraulic drill carriage uses a method combining water and gas to clean the boreholes. The pneumatic crawler-type hydraulic drill applies especially to mass drilling work sites of which change continuously; the whole carriage is free of electric devices and the pneumatic crawler-type hydraulic drill applies particularly to high gassy mine and can carry out universal hole drilling.

Owner:JIKAI EQUIP MFG CO LTD

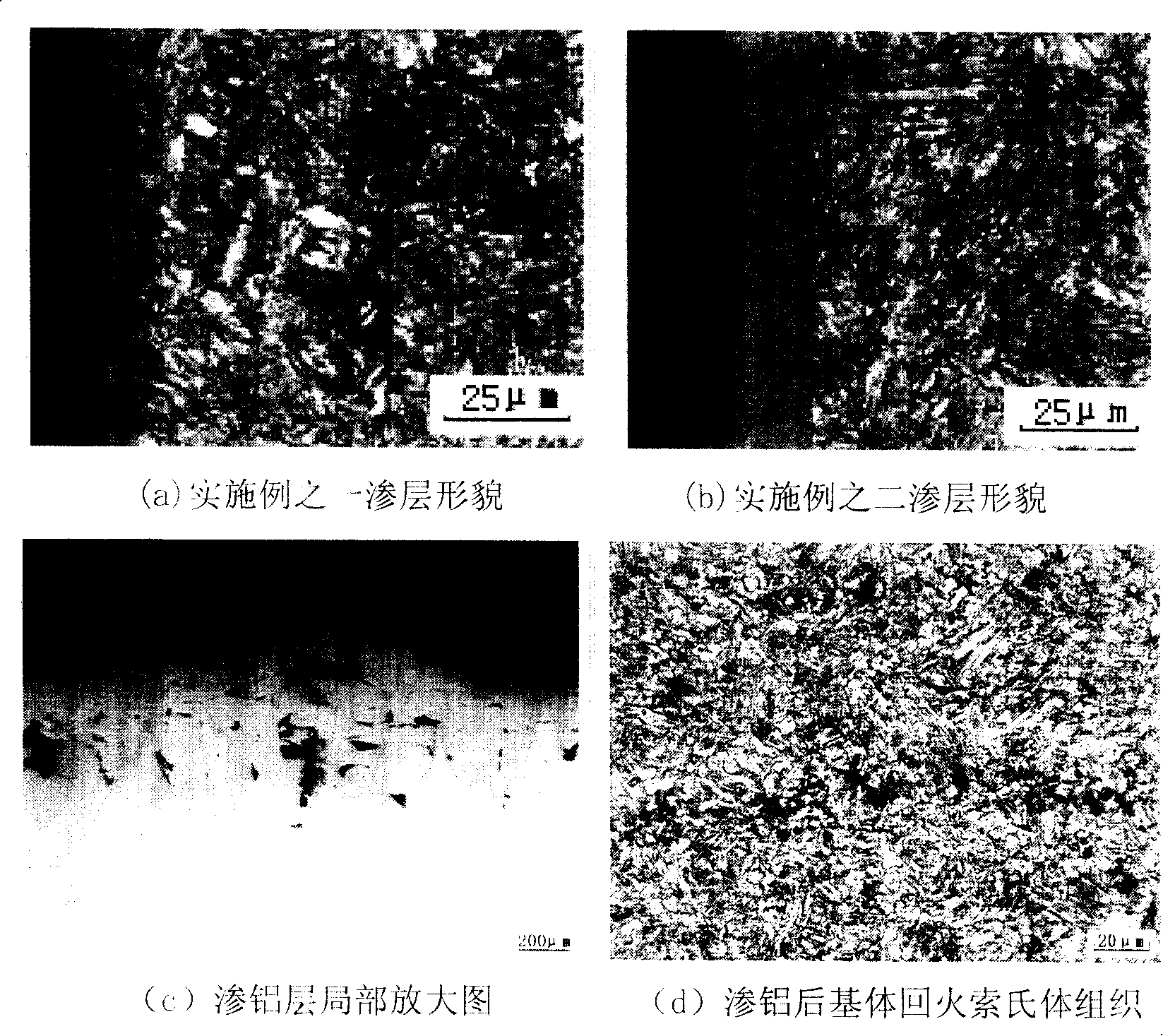

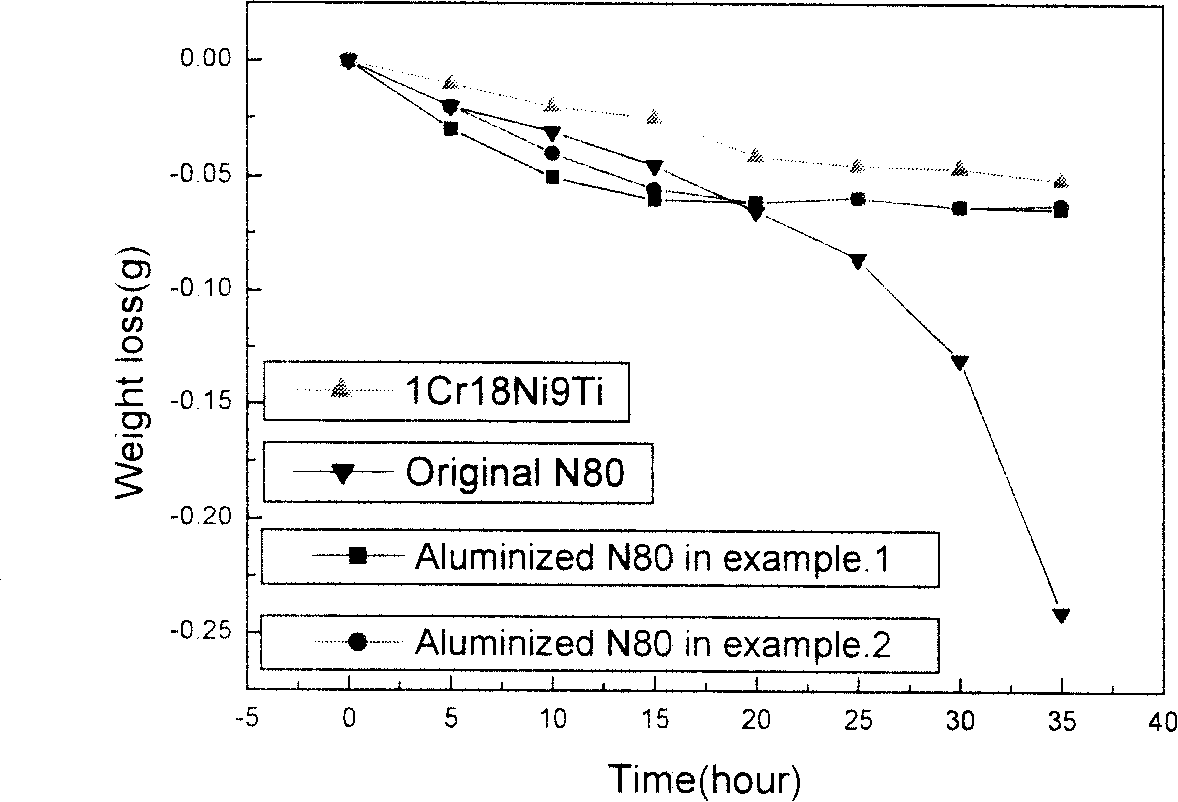

Oil and bushing low-temperature powder embedding aluminizing agent for petroleum

ActiveCN101165204AHigh bonding strengthDiffusion fastSolid state diffusion coatingAl powderSodium fluoride

The low temperature quick aluminizing agent specially for petroleum pipe and casing consists of metal source, activator, catalyst and stuffing. The metal source consists of 150-mesh Al powder in 10-20 wt% of the aluminizing agent, 120-mesh Zn powder in 10-25 wt%, 150-mesh Zn-Fe alloy powder in 10-20 wt% and / or 150-mesh Fe-Al alloy powder in 10-15 wt%. The activator consists of ammonium chloride, aluminum chloride, sodium fluoride and / or potassium bifluoride. The catalyst consists of 100-mesh Mo powder in 0-3 wt% and La and Os 0-3 wt%, with La and Os in the weight ratio of 1 to 1. The stuffing is 100-mesh alumina powder. The aluminizing agent is applied at 380-500 deg.c to obtain aluminized layer.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Rinse-added fabric treatment composition, kit containing such, and method of use therefor

InactiveUS20060075576A1Increase volumeIncreasing amount of removedCationic surface-active compoundsOrganic detergent compounding agentsWater useLaundry

Owner:PRICE KENNETH NATHAN +6

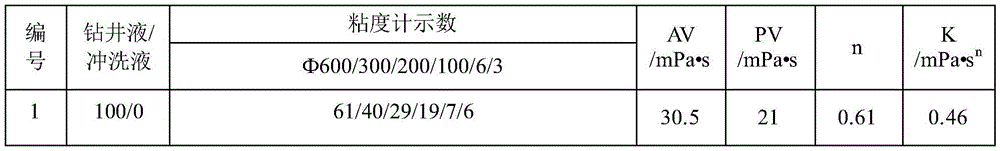

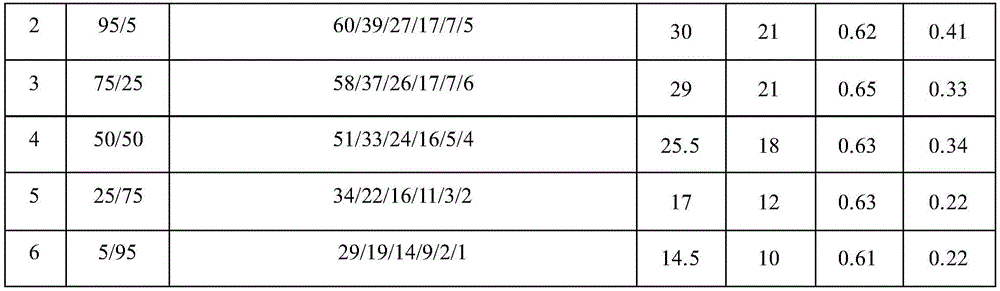

Well cementation flushing liquid system suitable for oil-based drilling fluid and preparation method thereof

InactiveCN105419758AReduce interfacial tensionImprove flushing effectDrilling compositionEngineeringVolumetric Mass Density

A well cementation flushing liquid system suitable for an oil-based drilling fluid and a preparation method thereof. The invention mainly solves the defects of low flushing efficiency, poor wetting conversion capability and poor interface cementing quality in the flushing liquids in the prior art. The flushing liquid system comprises the following components, by weight: 100 parts of clear water, 0.8-1.2 parts of an anionic surfactant, 0.6-0.8 parts of a nonionic surfactant, 0.7-1.0 part of a cosurfactant, 6.0-10.0 parts of an oil phase, 8.0-12.0 parts of a salt water phase, 0.15-5.0 parts of a polymer, 0.0-150 parts of a weighting agent and 1.0-2.5 parts of salt. The flushing liquid system is adjustable in density within 1.01-1.90 g / cm<3> and is 20-130 DEG C in available temperature range. The flushing liquid system can quickly remove residual oil-based drilling fluid, is strong in wetting conversion capability, ensures cementation between cement rings and an annular space, and is wide in application prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

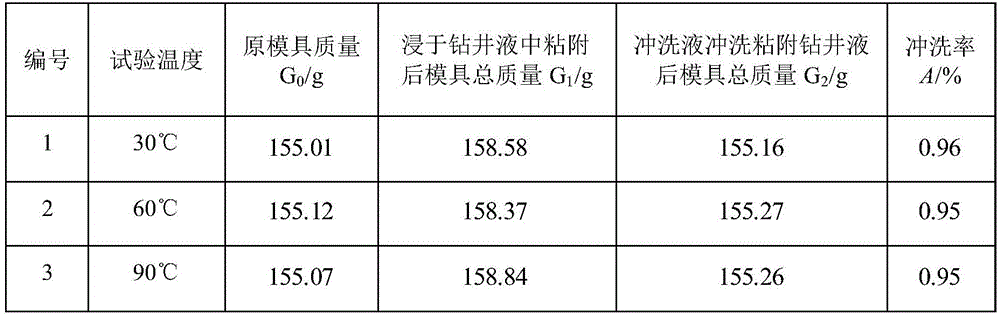

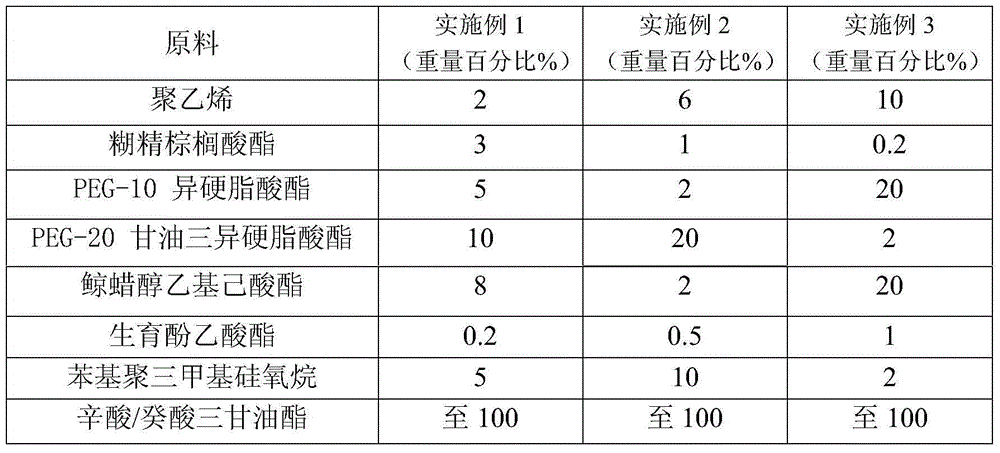

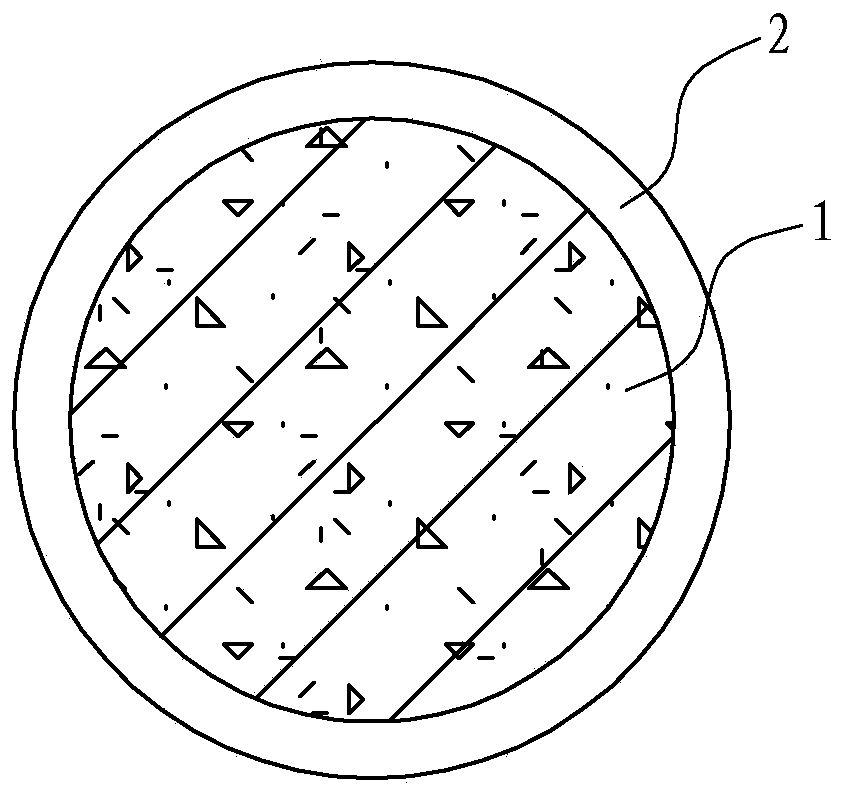

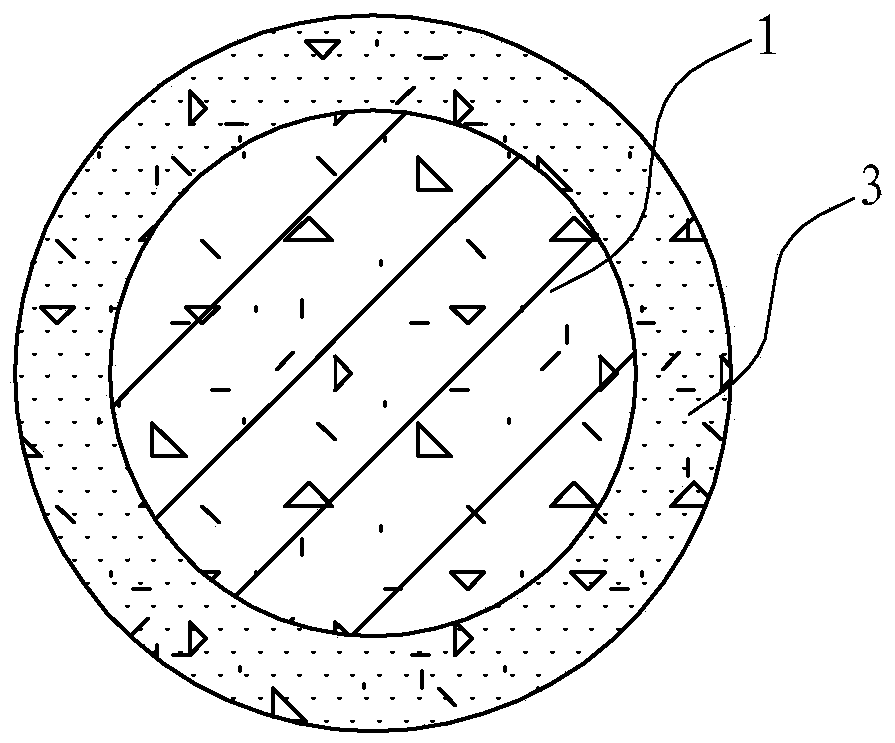

Mild and highly effective wash-free makeup removal cream and preparation method thereof

ActiveCN104800100AThe product is mild in natureGood flushing abilityCosmetic preparationsMake-upTocopheryl acetateCetyl alcohol

The invention relates to a mild and highly effective wash-free makeup removal cream. The mild and highly effective wash-free makeup removal cream is characterized in that the mild and highly effective wash-free makeup removal cream consists of the following components in percentage by weight: 2 to 10 percent of polyethylene, 2 to 20 percent of cetyl alcohol ethylhexoate, 2 to 20 percent of PEG-10 isostearate, 2 to 20 percent of PEG-20 glyceryl triisostearate, 0.2 to 1 percent of tocopheryl acetate, 2 to 10 percent of phenyl trimethicone, 0.2 to 3.0 percent of dextrin palmitate and the balance of caprylic / capric triglyceride. The makeup removal cream disclosed by the invention has the advantages of high makeup removal capability, mild properties, high safety and convenience and easiness in carrying.

Owner:FOSHAN WIN COSMETIC

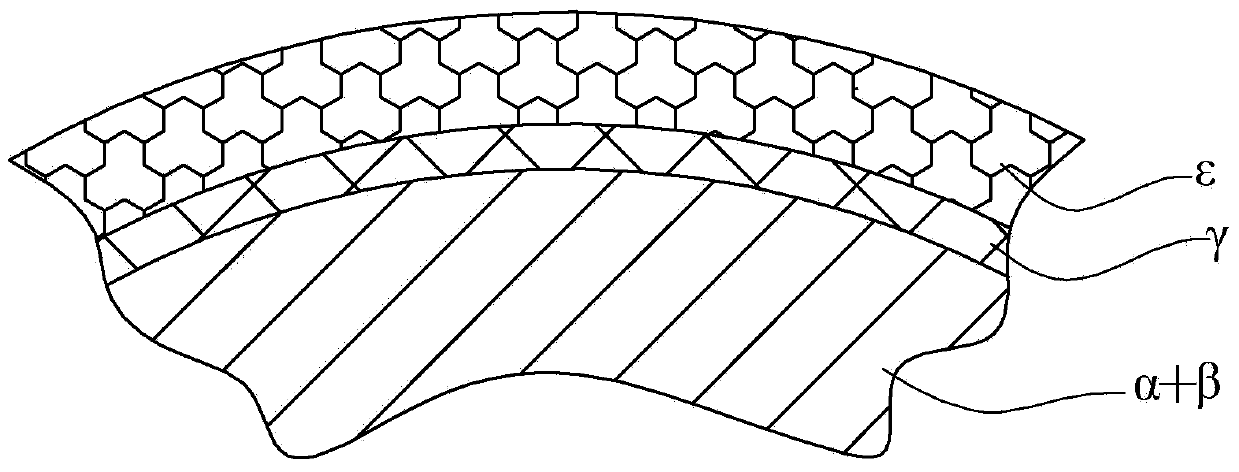

High-accuracy zinc base alloy electrode wire and preparing method thereof

ActiveCN104191056AGood for taking awayCutting discharge mitigationElectrical-based machining electrodesSurface finishImpurity

The invention relates to a high-accuracy zinc base alloy electrode wire. Components in a shell layer comprise, by weight, 70.5%-95% of Zn, 2.5%-27% of Cu, 0.02%-4.0% of X, 0.002%-0.4% of Y and inevitable impurities brought in by raw materials. X is any two kinds of metal from Ni, Ag, Cr, Si and Zr, the content ranges of the two kinds of metal are both 0.01%-2.0%, Y is any two kinds of elements of Ti, Al, Co, B and P, and the content range of the two elements are both 0.001%-0.2%. The epsilon phase content in the shell layer structure is over 80% by weight, the balance is a gamma phase or an eta phase, and epsilon phases are evenly distributed on the surface of core materials. Meanwhile, the invention relates to a preparing method of the electrode wire. Compared with the prior art, a metal workpiece subjected to cutting processing by the electrode wire is high in surface smoothness and good in surface quality, accordingly, cutting accuracy is high, meanwhile, the electrode wire preparing technology is simple, operability is high, the number of manufacturing steps is small, and large-scale and automatic production can be achieved easily.

Owner:NINGBO BODE HIGHTECH CO LTD

Nitrogen purging device of hydraulic line and method for cleaning hydraulic line

InactiveCN101480653AReduce adhesionEasy to useHollow article cleaningProcess engineeringNitrogen source

The invention provides a device and a method for cleaning hydraulic pipelines, in particular to a nitrogen purging device (cleaning device) for hydraulic pipelines, which has good cleaning effect, high efficiency and not pollution. The nitrogen purging device for hydraulic pipelines adopts the structure that a gas drier used for the drying treatment of nitrogen, a gas filter used for the filtering treatment of nitrogen and a flow control valve used for regulating the output flow of nitrogen are connected in series on an output pipeline which is connected with a nitrogen source. In addition, the cleaning method for hydraulic pipelines adopts nitrogen after being dried and filtered to purge the hydraulic pipelines.

Owner:CHINA 19TH METALLURGICAL CORP

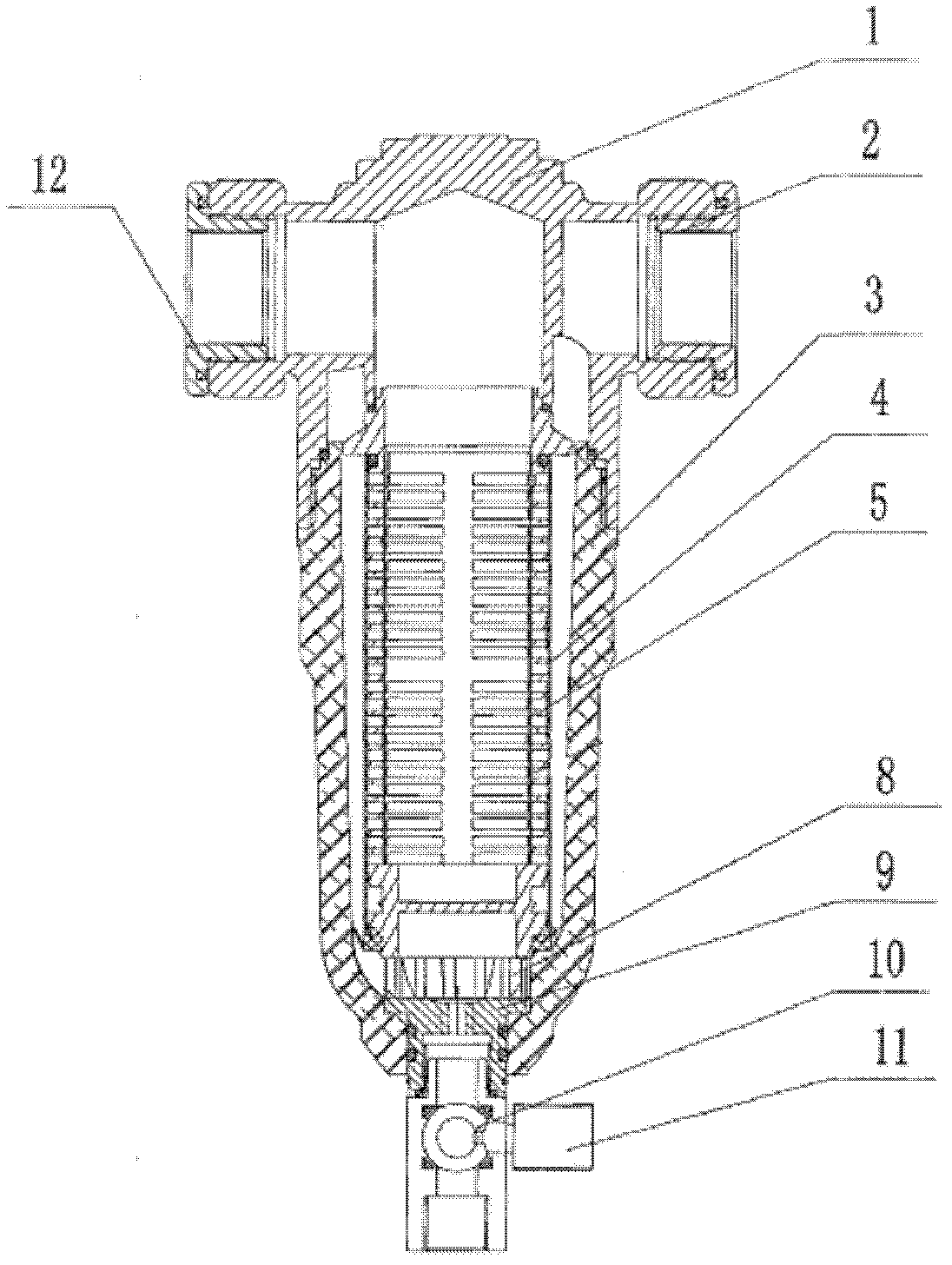

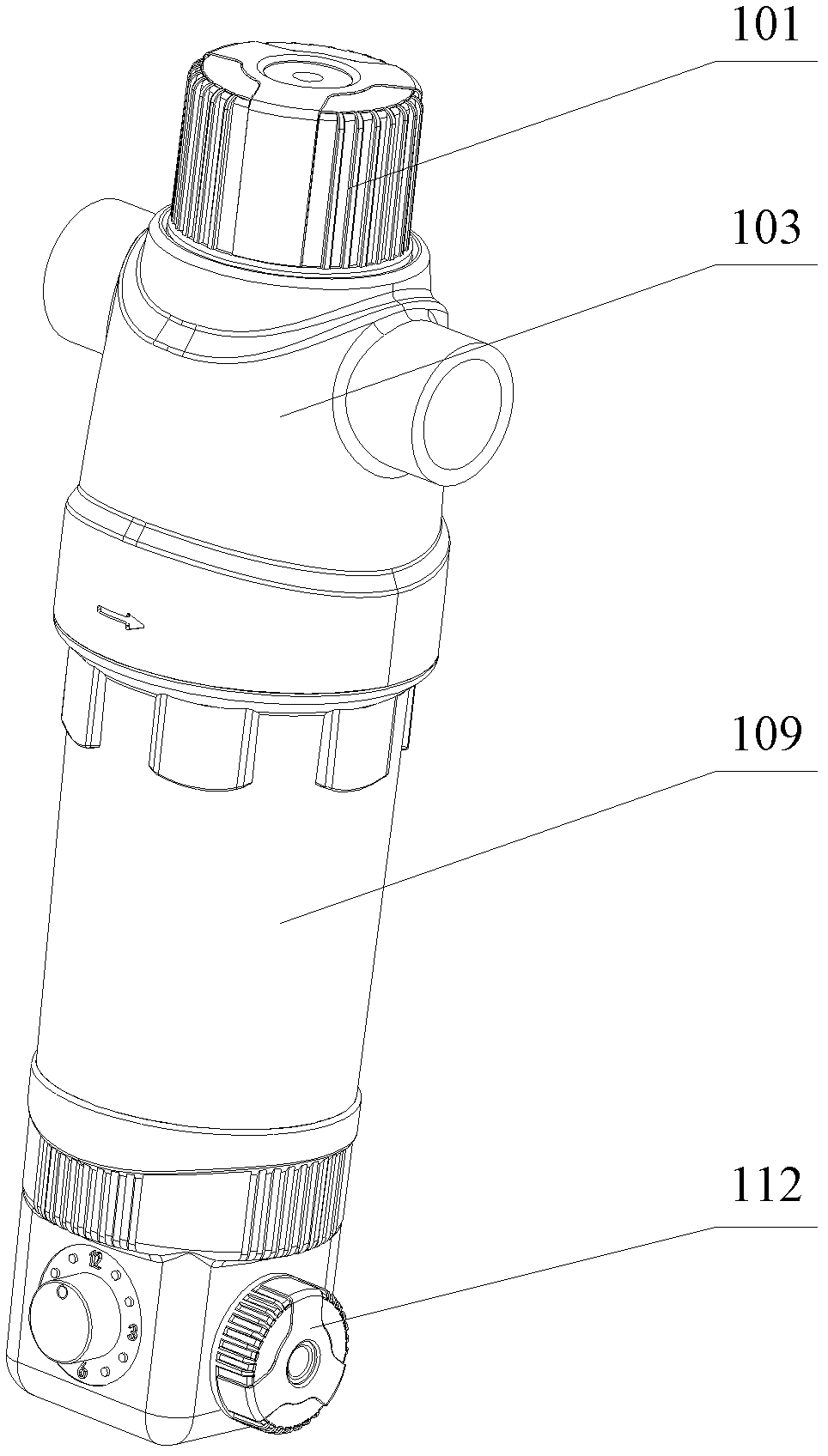

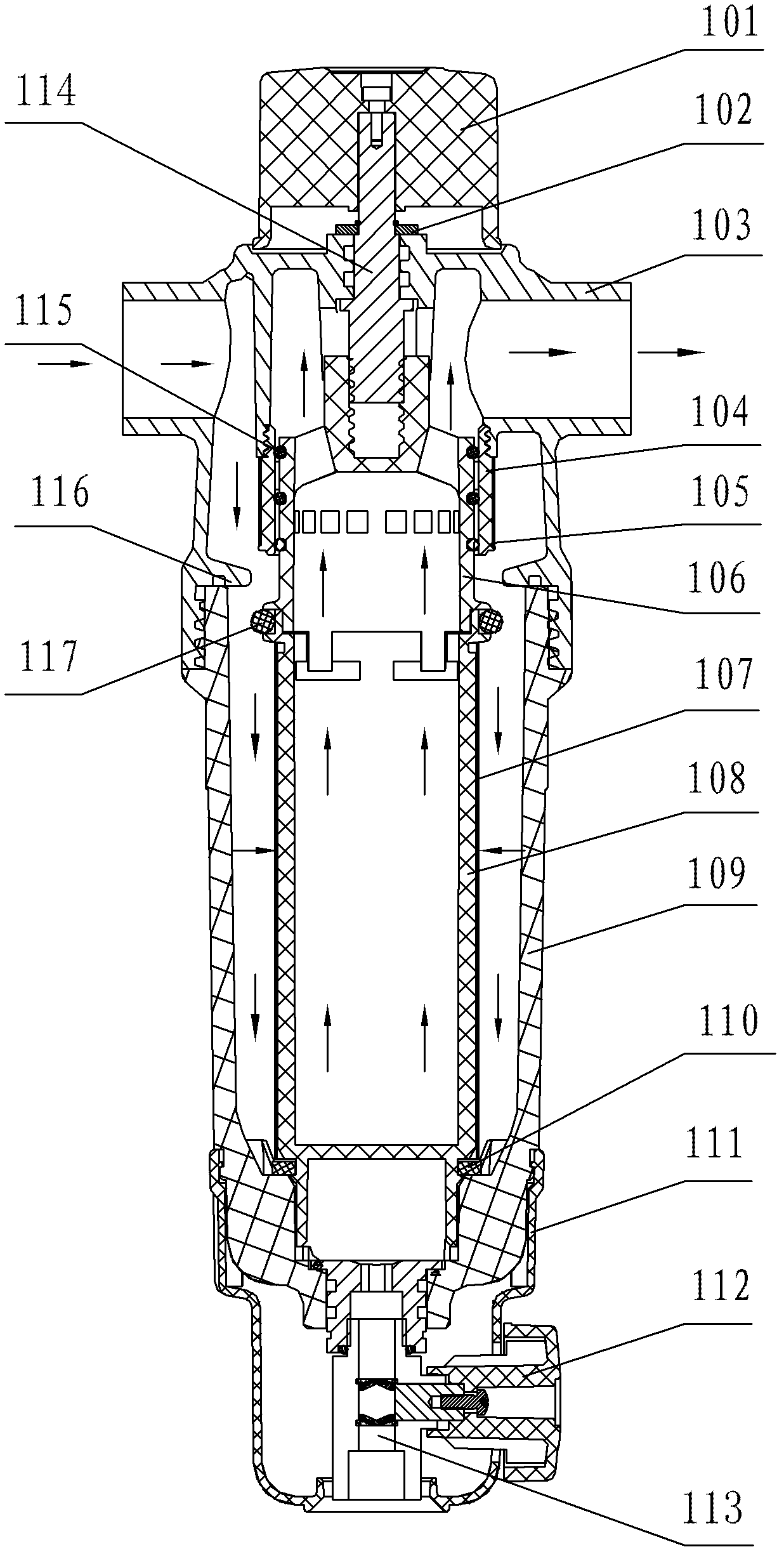

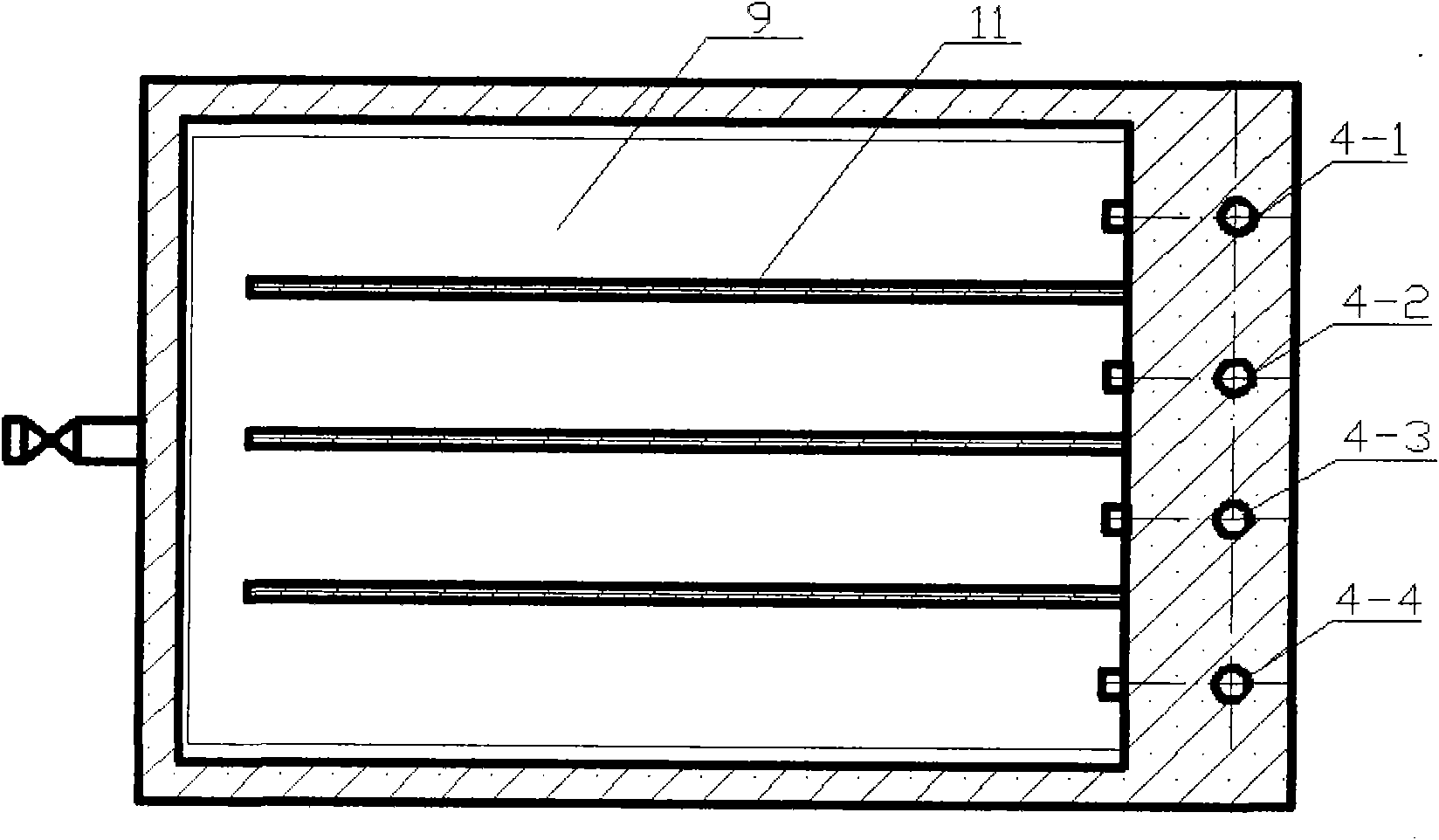

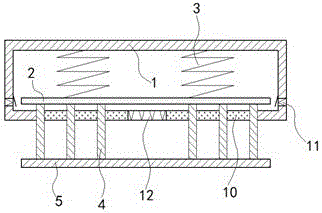

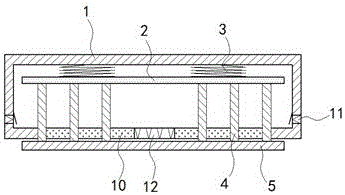

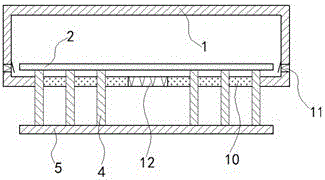

Prefilter

ActiveCN102824773AAvoid secondary pollutionImprove flushing effectStationary filtering element filtersArchitectural engineeringSewage

The invention discloses a prefilter which comprises a copper cover, a cylinder, a water drain valve assembly, a filtering screen framework and a first filtering screen and further comprises a water distributor, a lifting device and a bush. The copper cover is provided with a medium inlet and a medium outlet; the cylinder is provided with a sewage outlet; the water drain valve assembly is arranged at the sewage outlet; the filtering screen framework is arranged in the cylinder; the first filtering screen is arranged on the filtering screen framework; the water distributor is arranged in the copper cover, connected with the filtering screen framework and provided with a branched cavity sealing ring and a backwash switching hole; the copper cover is provided with a branched cavity raised ring which can in sealing fit with the branched cavity sealing ring; one end of the lifting device extends out of the copper cover, and the other end is connected with the water distributor; the bush is arranged in the copper cover, is in sealing fit with the water distributor and is provided with a backwash through hole; and when branched cavity sealing ring moves to contact the branched cavity raised ring, the stoke movement of the sealing ring is equal to the stoke movement of the backwash switching hole when the backwash switching hole moves to coincide with the backwash through hole. When the prefilter is switched to the wash state, the prefilter back washes to the outside from the inner wall of the first filtering screen, so that the prefilter has a good backwash effect.

Owner:HAINING SHUIXIANG WATER PURIFICATION EQUIP

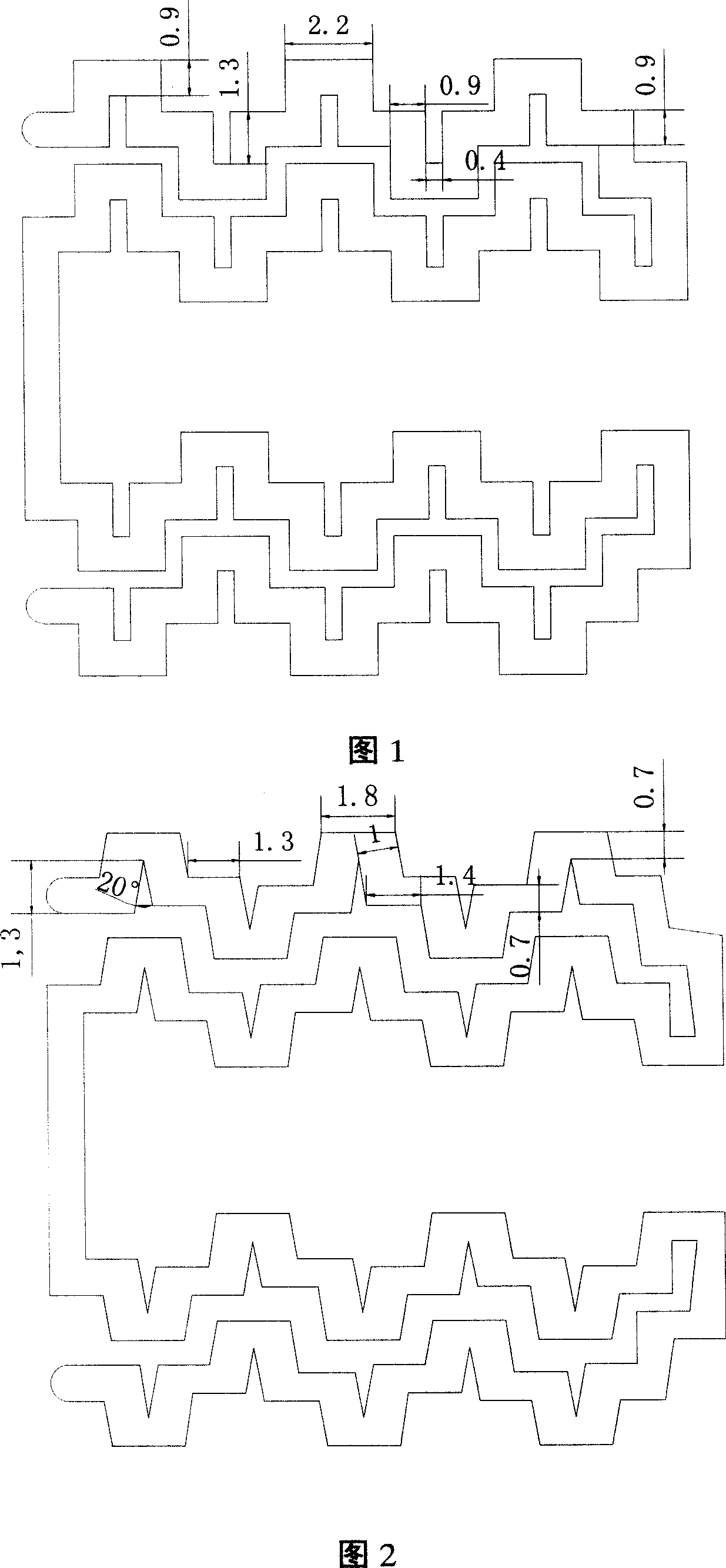

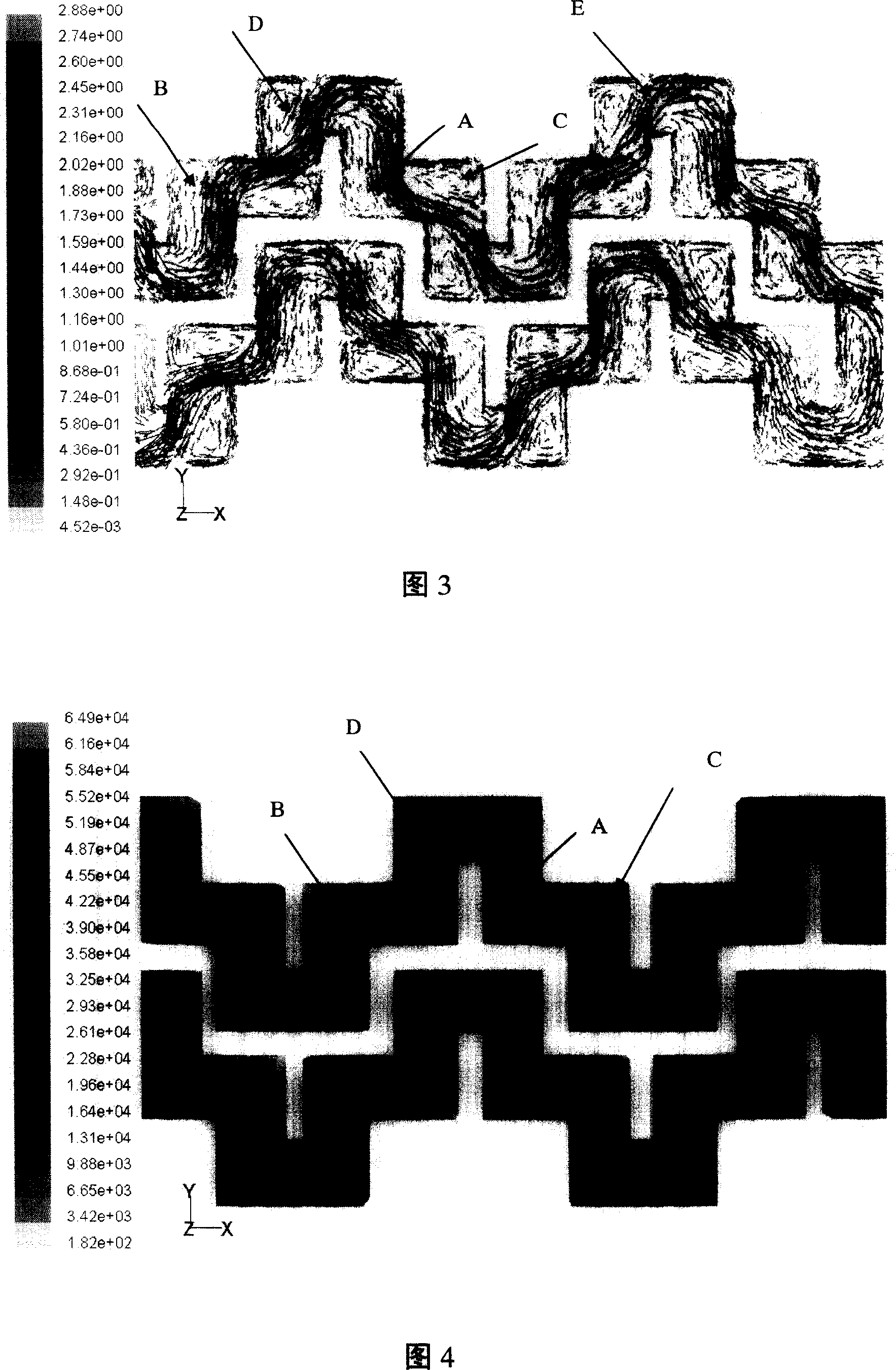

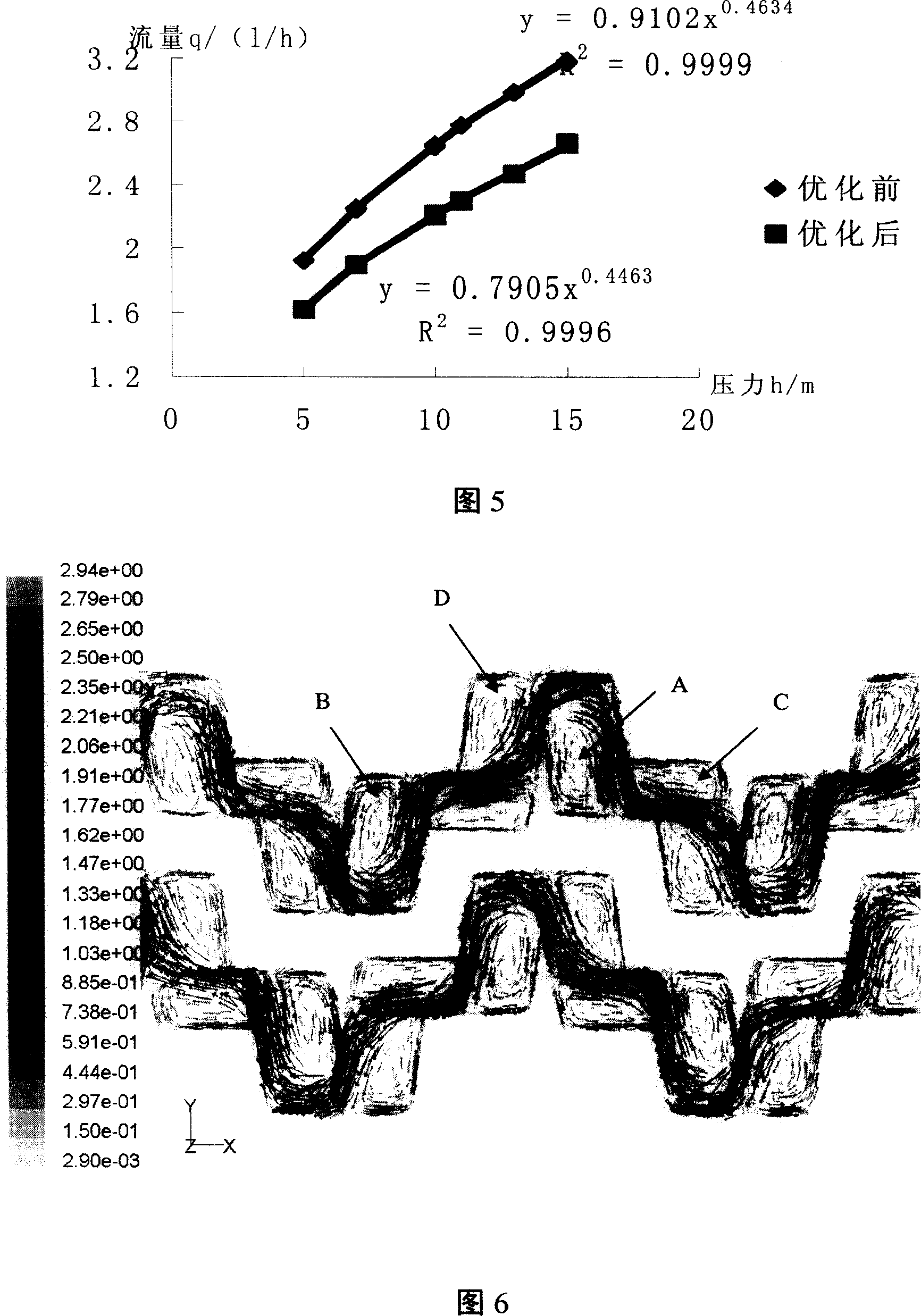

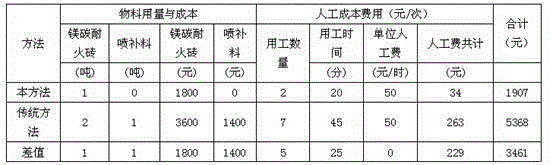

Antiplugging drip irrigation irrigator design method

InactiveCN101021881AReduce fluidity indexEnhanced flushingClimate change adaptationWatering devicesJet flowDrip irrigation

This invention provides a designing method for anti-jam drop-fill douches including: 1, setting up a structure model of the runner of a douche to divide it into lattices and design the border condition of the computed regions, 2, applying CFD evaluator to compute the runner of the drop head, 3, getting the velocity of flow field and eddy distribution parameter and determining the position of low flow rate regions in the head runner and the decision factor for pressure energy dissipation, 4, finishing borders of the runner structure and changing the tooth structure to reduce brush of the tooth tine place and the back surface to the runner borders to strengthen the eddy structure of the flow field, 5, computing repeatedly and balancing flow field parameters in the front and back runners to decide the anti-jam ability of the douche and testing the flow-pressure relation of the douche to guarantee its water power performance.

Owner:内蒙古兆通管道系统有限公司

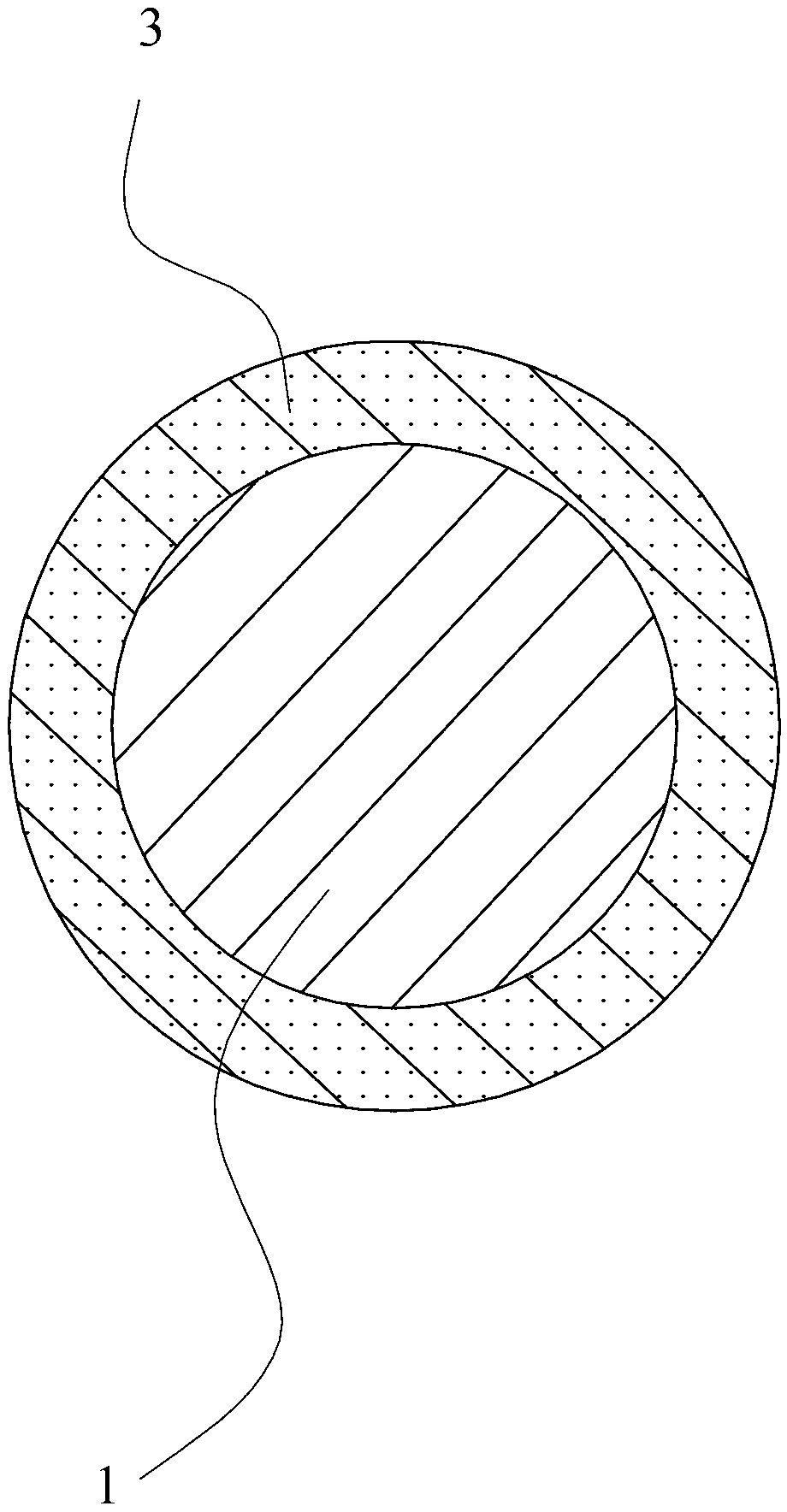

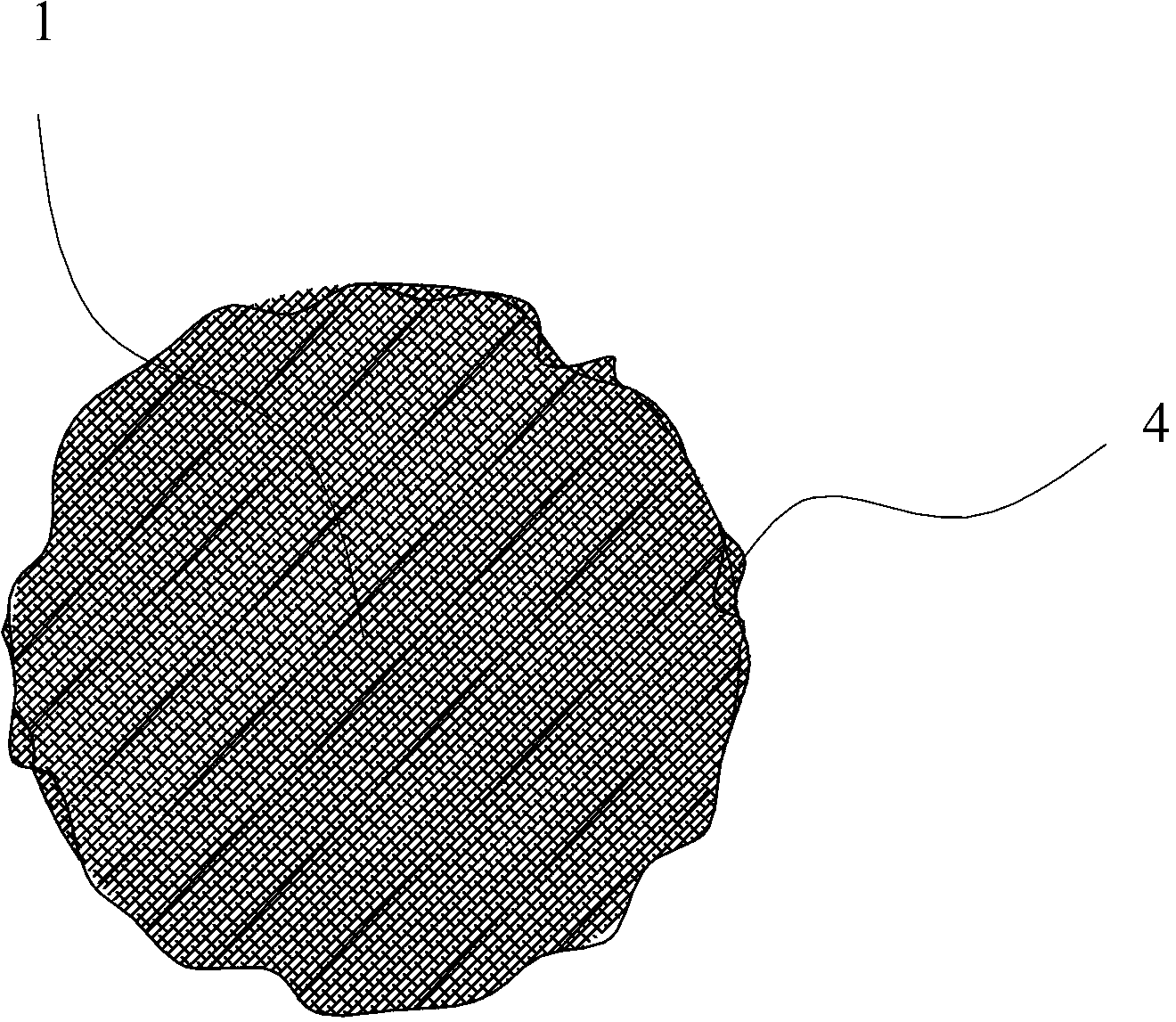

Method for rapidly maintaining converter lining

InactiveCN104673966AEasy to obtainEasy to burn throughManufacturing convertersProcess efficiency improvementBrickSlag

The invention discloses a method for rapidly maintaining a converter lining. The method comprises the following steps of: remaining slag after tapping of converter, pouring magnesia-carbon refractory brick blocks in the converter, shaking the converter till the magnesia-carbon refractory brick blocks and remained slag in the converter are flatly spread at a repaired part of the converter lining, and standing so that the mixture of the magnesia-carbon refractory brick blocks and the remained slag are stuck to the repaired part of the converter lining. According to the method disclosed by the invention, the converter repairing time is effectively shortened; the disadvantage that the time for pouring materials to repair the converter and sintering is long is changed; the operability of the converter is increased; high-temperature converter slag is easy to burn thoroughly; furthermore, a part of clearances can be filled by the molten part of converter repairing bricks; the erosion resistance and the scouring resistance are increased; the material collapse phenomenon due to non-thorough burning and half-baking of a part of positions in the event of traditionally repairing can be effectively avoided; the labour safety coefficient of workers is increased; a part of converter repairing materials and the labour cost are saved; the converter repairing cost is effectively reduced; compared with the original depletion speed, the depletion speed of the converter lining after the method is implemented is reduced; and therefore, the method has the characteristics of being rapid in maintenance speed, high in efficiency and safety and low in cost.

Owner:HEBEI IRON AND STEEL

Efficient electrode wire for precision mould cutting and preparing method of efficient electrode wire

ActiveCN103273150AImprove cutting efficiencyLarge discharge energyElectrical-based machining electrodesOperabilityZinc

The invention relates to an efficient electrode wire for precision mould cutting. The efficient electrode wire comprises a core material and a shell layer wrapping the surface of the core material, the core material is made of yellow copper from the processes of smelting, casting, stretching and annealing, the shell layer is a discontinuous shell layer formed by heating, continuously drawing and continuously annealing a zinc metal plating layer plated on the yellow copper core material, and the discontinuous shell layer comprises shell particles which radially cover 40-90% of the surface of the core material and are distributed at intervals along an axial direction of the surface of the core material. The invention further relates to a preparation method of the electrode wire. The preparation method is simple in production technology, strong in operability, less in preparation steps, simple in production equipment and easy to prepare satisfactory products and realize large-scale and automated production. The efficient electrode wire is strong in universality and is particularly suitable for precision mould cutting.

Owner:NINGBO BODE HIGHTECH CO LTD

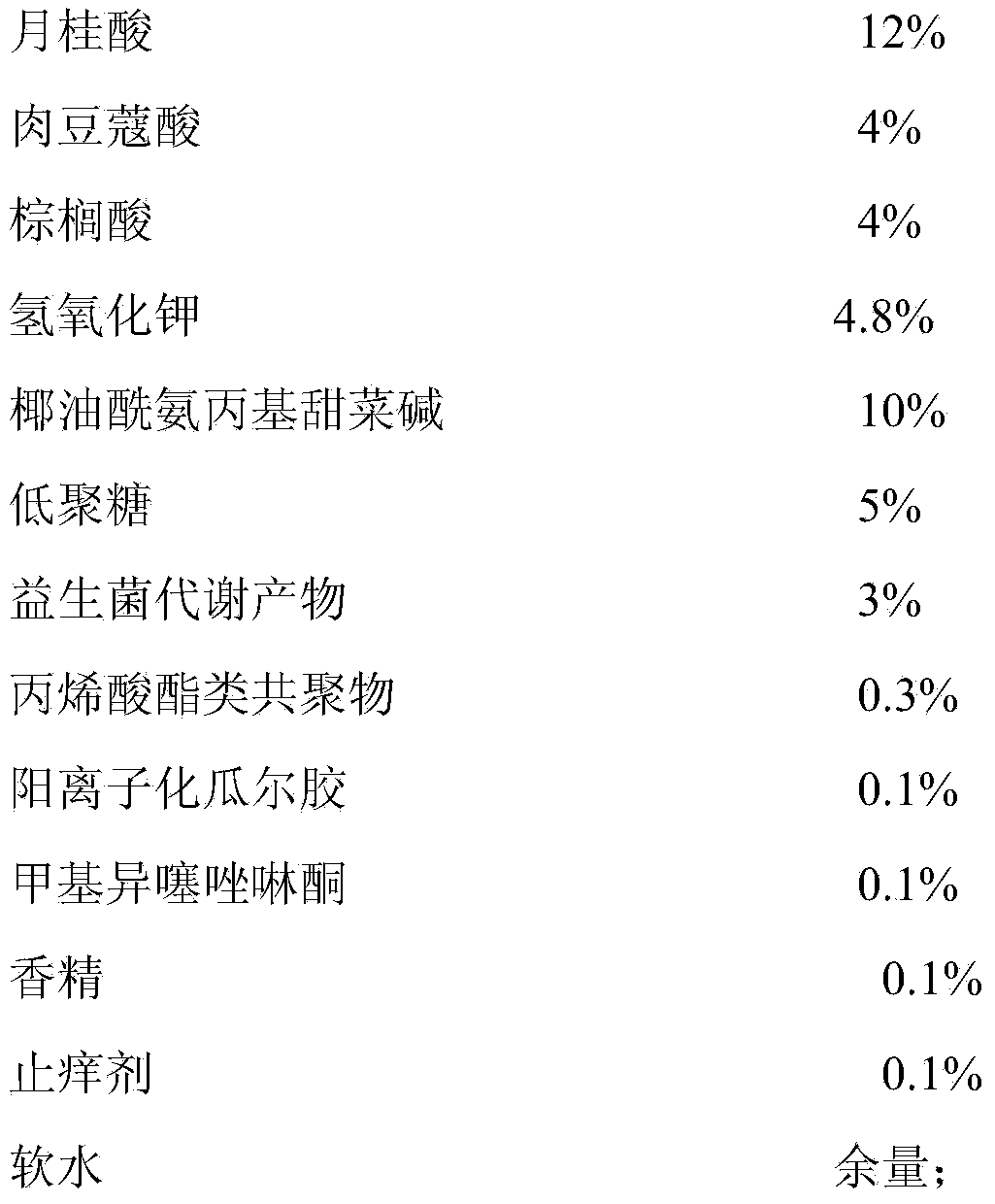

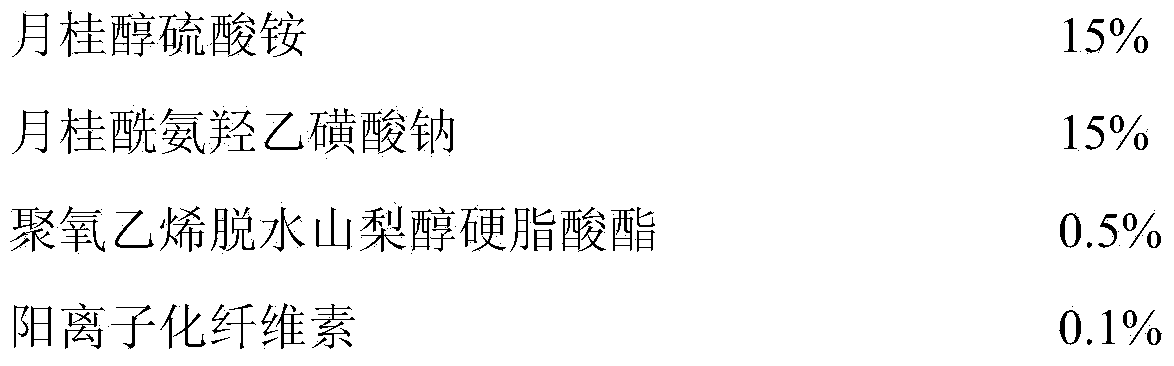

Skin cleaner composition capable of regulating microecological balance of skin and preparation method thereof

ActiveCN103622901APromote Microecological BalanceEasy to cleanCosmetic preparationsToilet preparationsCleansers skinMetabolite

The invention discloses a skin cleaner composition capable of regulating a microecological balance of skin. The raw material formula of the composition especially has the function of regulating the microecological balance of the skin by adding a composition of oligosaccharide and probiotic bacteria metabolites. By adopting the composition, not only can dirt on the skin be washed off, but also the skin can be moisturized and moistened, and the composition has the functions of proliferating beneficial bacteria on the skin surface, inhibiting harmful bacteria on the skin surface and maintaining normal ecological balance of the skin.

Owner:广州晟美个人护理用品有限公司

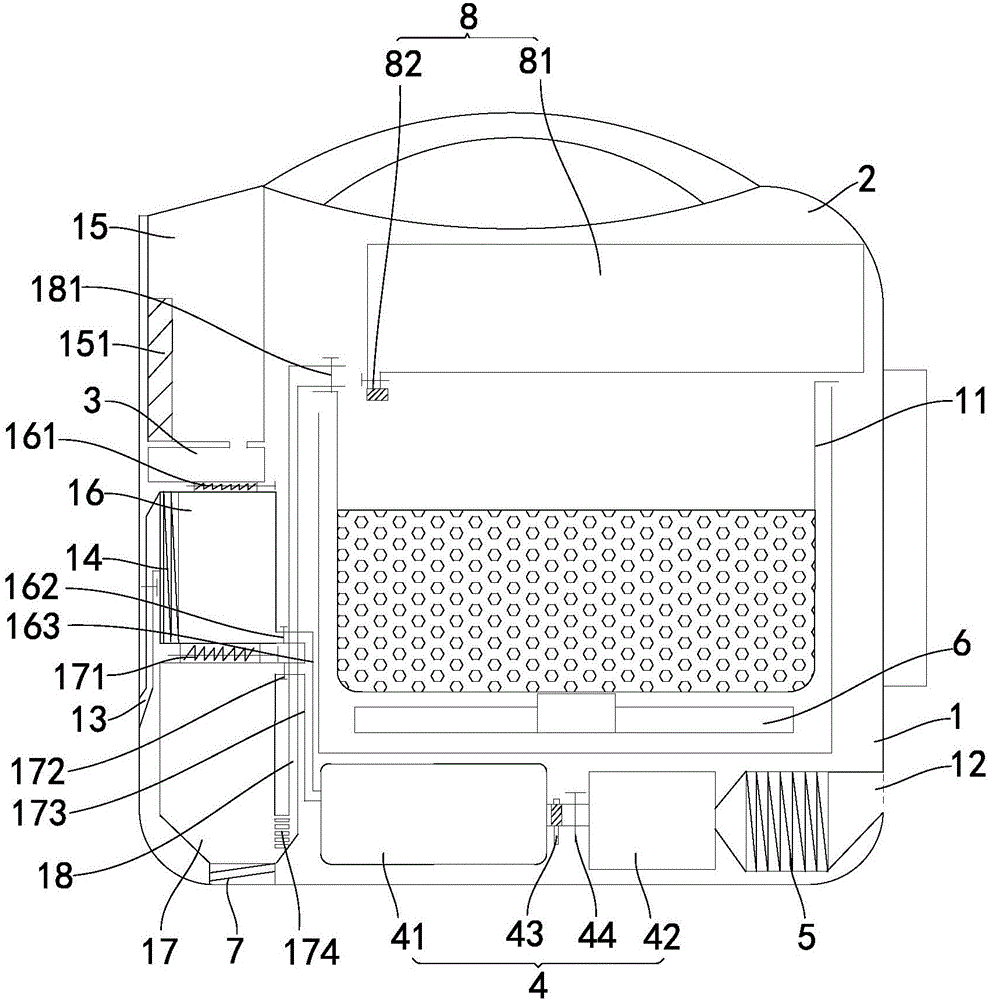

Intelligent electric cooker

The invention discloses an intelligent electric cooker, and belongs to the field of kitchen cooking electric appliance.The problems that rice is washed in an existing electric cooker, cost is high, and rice grain nutrition is lost are solved.The intelligent electric cooker comprises a pot body, a pot cover and an inner pot, the pot cover is connected to the pot body, and the inner pot is placed in the pot body.The intelligent electric cooker further comprises a storage bin, a washing bin and an air supplying device, the storage bin is used for supplying a material to the washing bin, and the air supplying device is used for supplying air to the washing bin to blow and wash the material in the washing bin.The intelligent electric cooker in the embodiment is used for cooking rice, congee and other coarse cereals.

Owner:HONGYANG HOME APPLIANCES

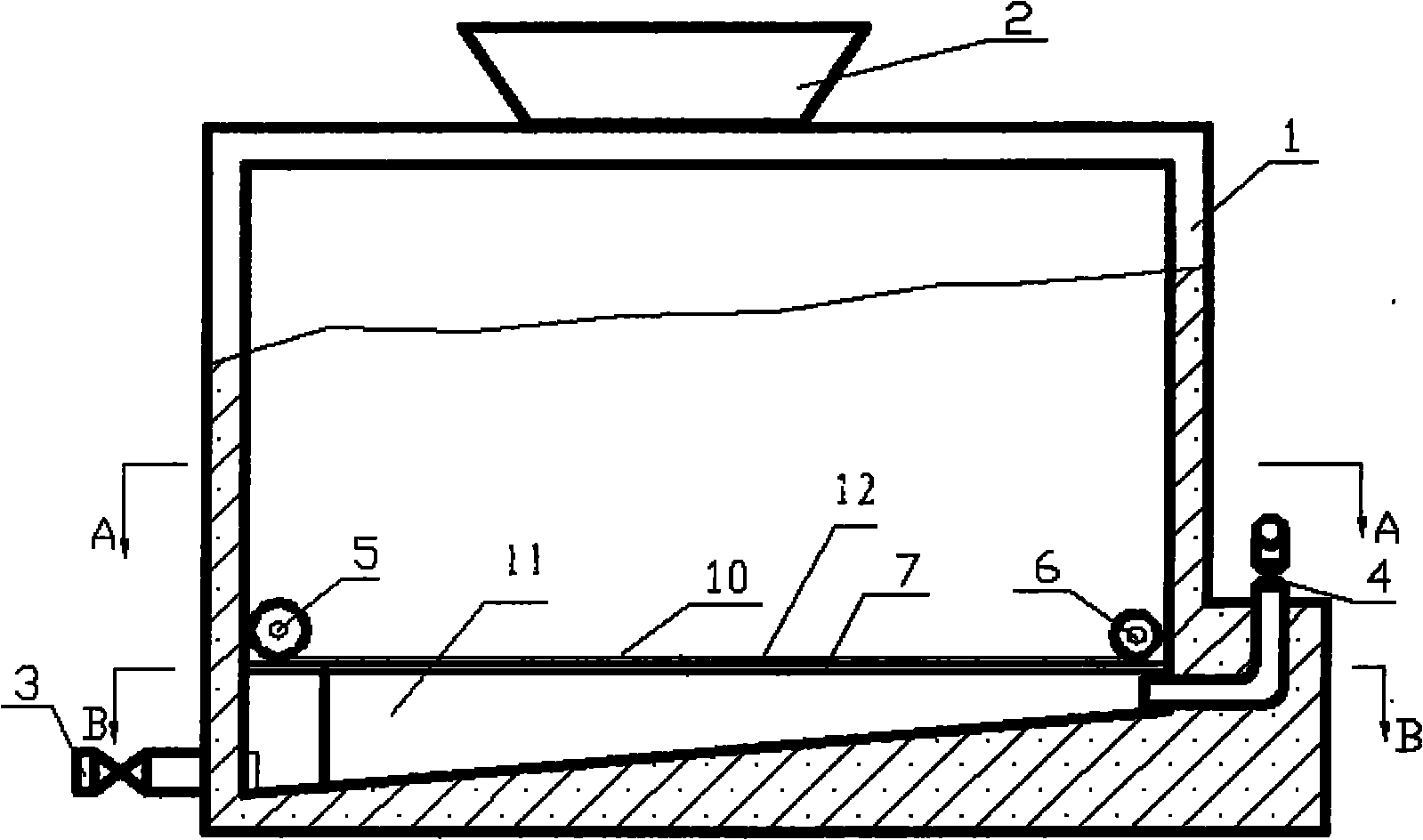

Automatic washing and precipitating pool

InactiveCN101829442AFree from pollutionImplement partition flushingSedimentation settling tanksGratingMarine engineering

The invention discloses an automatic washing and precipitating pool which comprises a pool body, wherein one end of the bottom of the pool body is connected and communicated with a dirt flushing pipeline, while the other end of the pool bottom is connected and communicated with a blow-down pipeline; the pool bottom is a slant pool bottom and provided with a grating plate; and shutter type watertight membrane cloth is horizontally arranged on the grating plate. In the invention, the bottom of the precipitating pool is built to be uniformly inclined towards the blow-down port for a certain gradient, and meanwhile, the bottom of the pool body is provided with the grating plate, and the shutter type watertight membrane cloth is horizontally arranged on the grating plate. During precipitating, the shutter type watertight membrane cloth is rolled up, so that dirt precipitates at the pool bottom; during flushing, the shutter type watertight membrane cloth is unfolded and used for dividing the precipitating pool into an upper area and a lower area, wherein the area above the grating plate is a clean water area, and the area below the grating plate is a sewage area, so that sewages below the grating plate cannot be mixed with clean water above the grating plate during flushing, thereby guaranteeing that water on the upper part of the precipitating pool cannot be polluted during flushing.

Owner:JIANGHAN UNIVERSITY

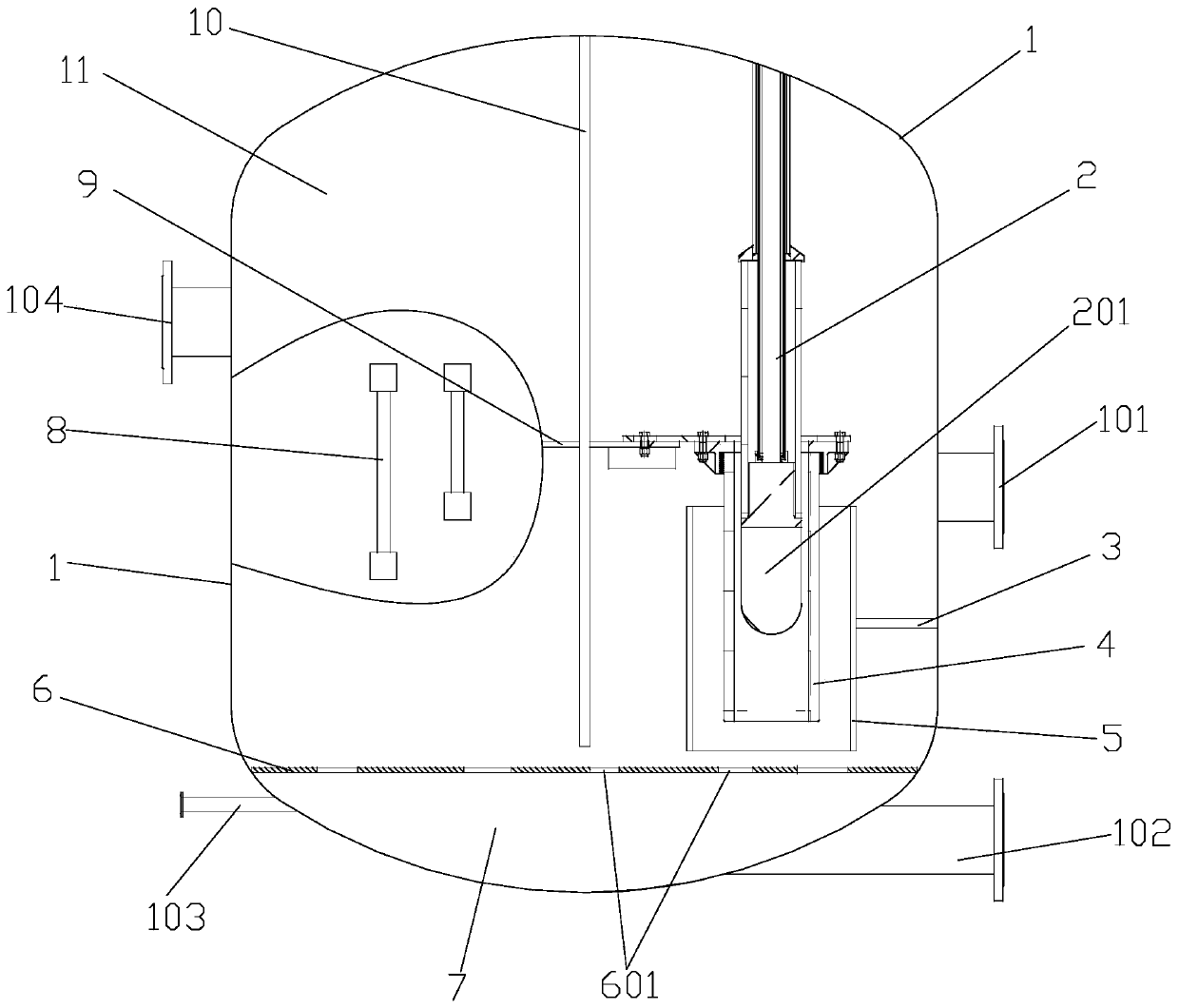

Fully submerged electrode steam boiler with circulating device

PendingCN110375286AMonitor water levelControl temperature differenceElectrode boilersSteam boilers componentsEngineeringLower half

The application discloses a fully submerged electrode steam boiler with a circulating device. The steam boiler comprises a boiler shell, a partition plate and a heating device; the partition plate isarranged in the boiler shell and divides the boiler shell into a lower half cavity and an upper half cavity which are independent and communicates with each other; the heating device is arranged in the upper half cavity; the lower half cavity is provided with a water replenishing port, and the upper half cavity is provided with a first outlet. The steam boiler also comprises a circulating water inlet, a circulating water outlet and a circulating power device; the circulating water inlet is arranged on the lower half cavity; the circulating water outlet is arranged on the upper half cavity; thecirculating power device is respectively connected with the circulating water inlet and the circulating water outlet; and the circulating power device is used for conveying the water in the upper half cavity to the lower half cavity.

Owner:ZHEJIANG SHANGNENG BOILER

Vehicle cleaning system and method for construction site

InactiveCN110395218APrevent slippingSudden drop in speedTreatment involving filtrationMultistage water/sewage treatmentWater filterWater storage tank

The invention discloses a vehicle cleaning system and method for a construction site. The vehicle cleaning system comprises a water storage tank, a controller, a water delivery pump, a water suction pump, a lateral flushing frame, water distribution pipes, a filtering pool, a sedimentation tank and a water filtering pool, wherein the water suction pump is used for connecting the water storage tankand the water filtering pool, the water delivery pump is connected with one ends of the water distribution pipes, the water distribution pipes are arranged on the filtering pool, the lateral flushingframe is arranged between the water distribution pipes, nozzles are uniformly distributed on the lateral flushing frame, a bearing plate and a U-shaped water spraying pipe are correspondingly arranged between the water distribution pipes, and the U-shaped water spraying pipe is movably connected with a bending nozzle. The cleaning method comprises the following steps of (a) parking cleaning, (b)moving cleaning and c) waste water circulating. The cleaning system is novel in structure, wide in flushing range, high in cleaning efficiency, and good, comprehensive and thorough in cleaning effect,water resources are recycled, the cost is reduced, the cleaning method is orderly conducted by steps, the labor is saved, convenience and rapidity are realized, control is easy, and the cleaning effect and the cleaning quality are ensured.

Owner:浙江永安工程咨询集团有限公司

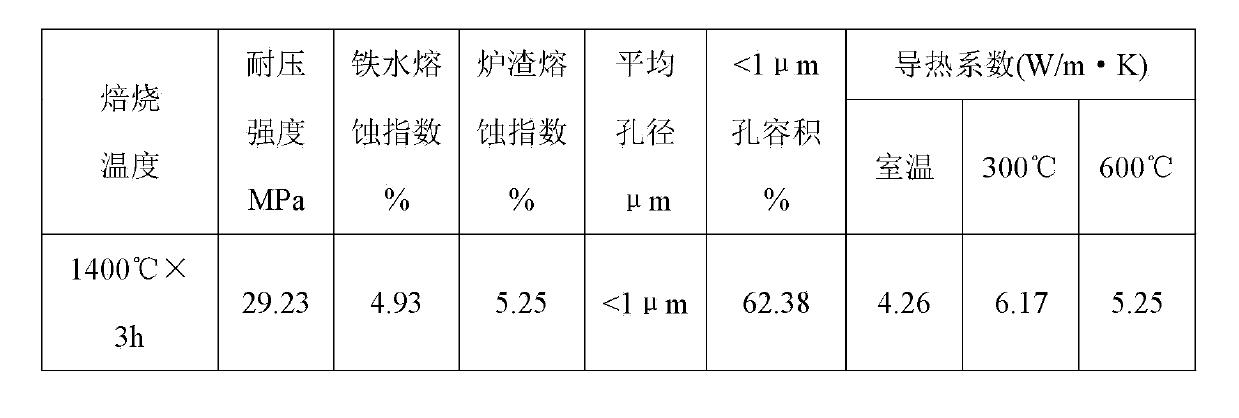

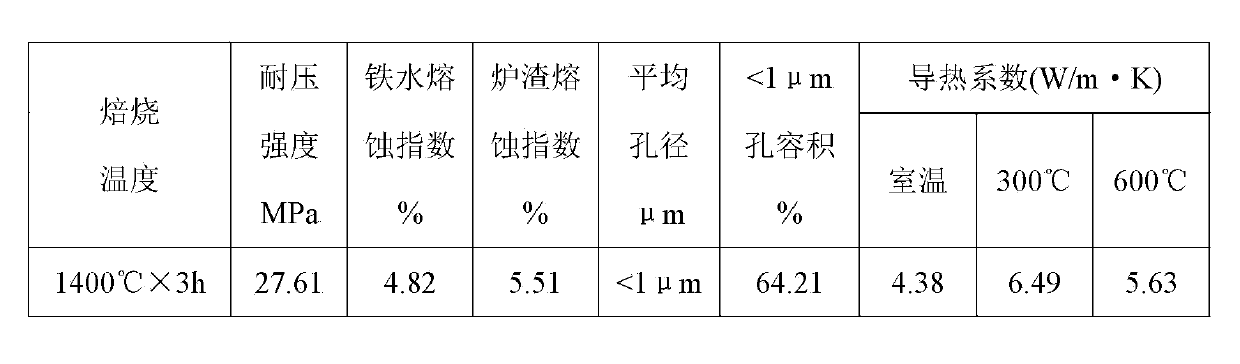

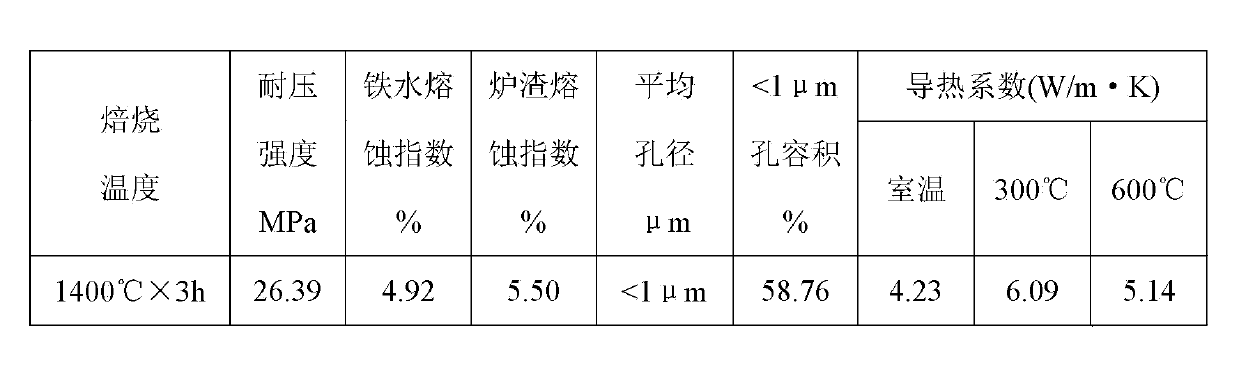

Tap hole stemming for large-scale blast furnace and preparation method

The invention discloses a tap hole stemming for a large-scale blast furnace and a preparation method. The stemming is composed of a binder and the following ingredients: by weight, 40-50 parts of brown aluminum oxide, 8-15 parts of silicon carbide, 6-12 parts of ferro-silicon nitride, 10-15 parts of clay, 6-9 parts of silicon powder, 2-5 parts of alpha-Al2O3, 6-10 parts of coke powder, 1-3 parts of graphite, and 4-6 parts of high-temperature pitch. The binder is tar. The preparation method comprises steps: according to the above ingredients and weight parts, raw materials are prepared, and mixed uniformly, then tar is added into the raw materials, the mixture is subjected to roller compaction and mixing to form a stemming material. The addition amount of the tar is controlled to make the Marshall value of the stemming material be 1100-1400 KPa, the stemming material is then subjected to pressing and molding to obtain final products. The prepared stemming is advantaged by good integrated performances, high intensity, small average hole size, good heat conductivity coefficient and good performances of resistance to slag and iron, corrosion and washing.

Owner:武钢集团有限公司

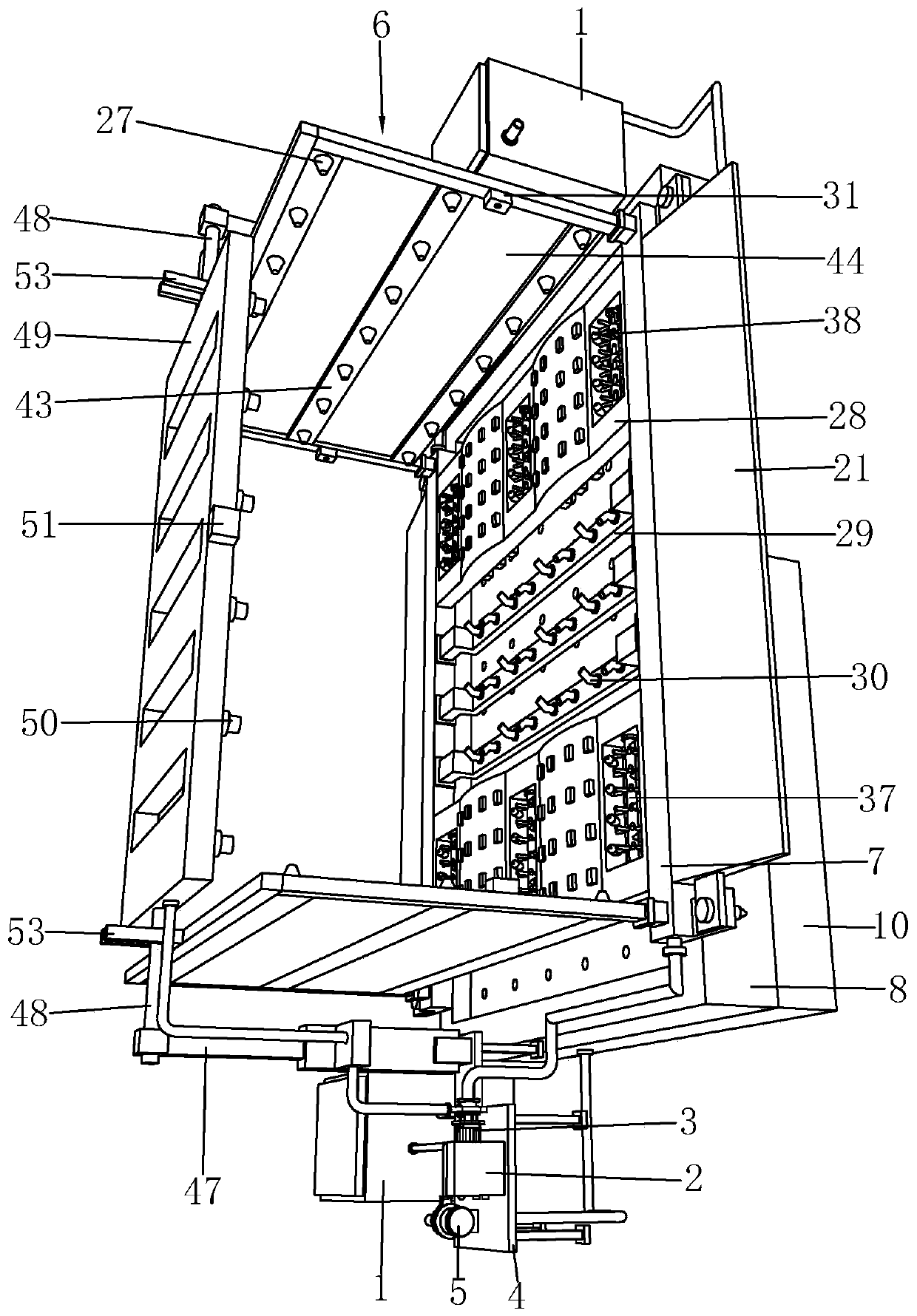

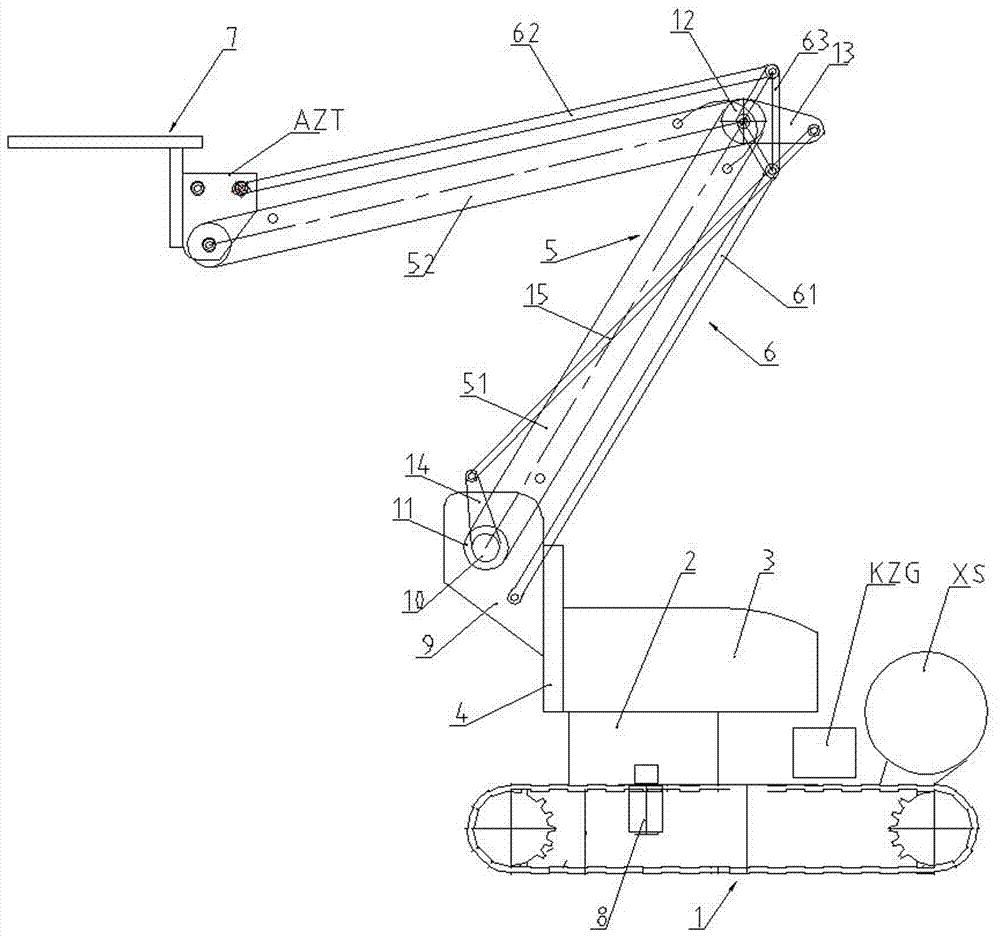

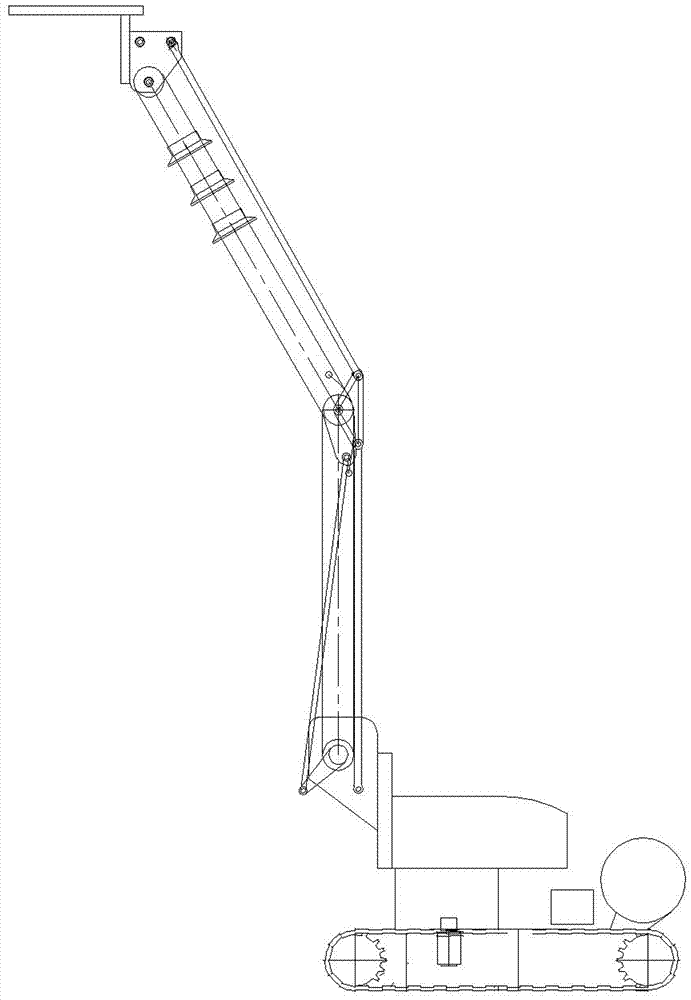

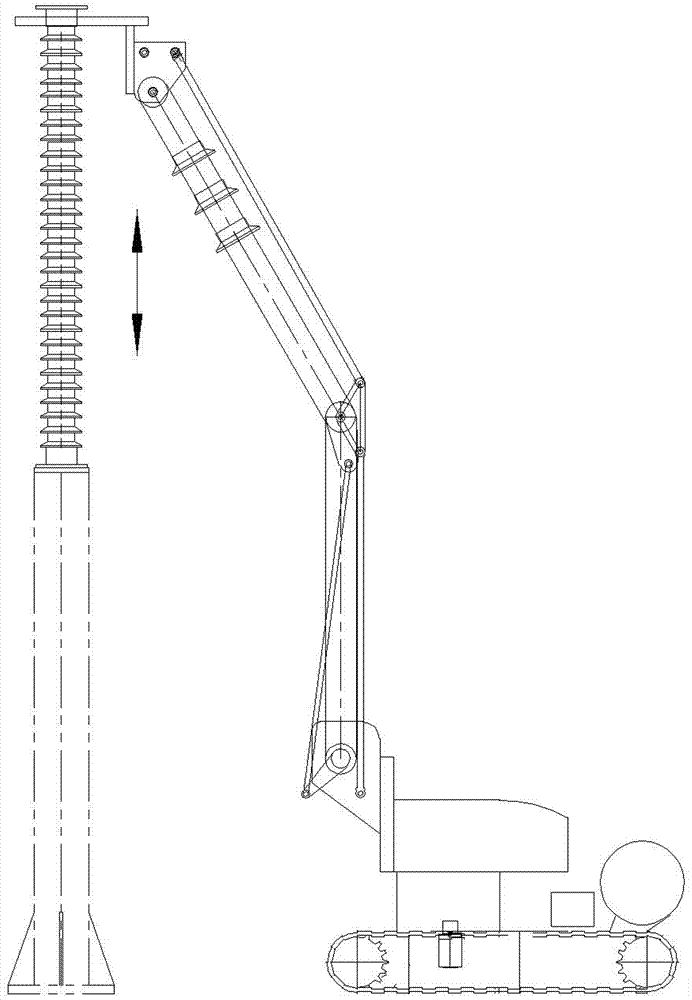

Equipment having live line water washing and deicing operation functions for power transmission system and application method of equipment

ActiveCN106926256AImprove cleaning efficiencyEasy to cleanCleaning using toolsCleaning using liquidsElectric power transmissionElectric machinery

The invention discloses equipment having live line water washing and deicing operation functions for a power transmission system and an application method of the equipment. The equipment comprises a crawler chassis, a rotary support, a horizontal rotary table, an insulation operation arm and a washing device; the horizontal rotary table is fixed to the crawler chassis through the rotary support; the insulation operation arm comprises an insulation large arm and an insulation small arm that are hinged mutually; one side of the horizontal rotary table is connected with a rotary disc arranged in the vertical direction; the outer side of the rotary disc is connected with a mounting seat; a large arm driving gear motor and a small arm driving gear motor are arranged on the mounting seat; the lower end of the insulation large arm is hinged to an output shaft of the large arm driving gear motor; the insulation small arm is hinged to an output shaft of the small arm driving motor through a drag link mechanism; a rotary disc driving device is arranged on the horizontal rotary table; and the washing device is connected with the upper end of the insulation operation arm and carries out close range washing on insulators. The horizontal rotary table, the rotary disc and the two driving gear motors are matched for use, so that the equipment has the advantages of position adjustment accuracy, high cleaning efficiency, a good cleaning effect and low water consumption.

Owner:LIVE WORKING CENT OF STATE GRID HUNAN ELECTRIC POWER +2

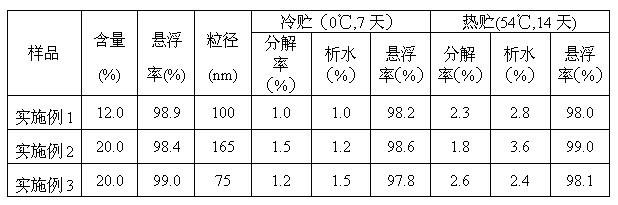

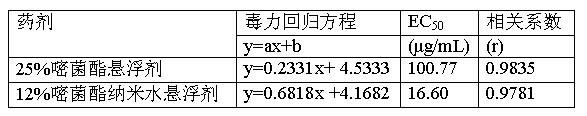

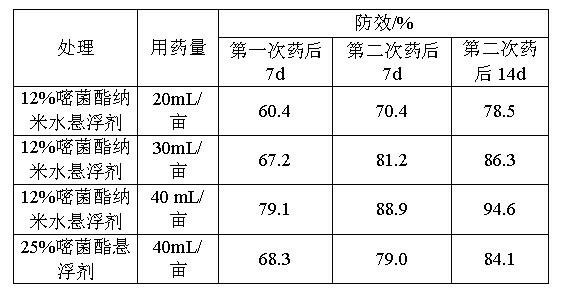

Azoxystrobin nano-water suspending agent and its preparation method

InactiveCN102626084AGranularity controllableSmall granularityBiocideFungicidesDuration periodPesticide residue

The invention relates to an azoxystrobin nano-water suspending agent, which comprise, by mass: 10-20% of azoxystrobin, 10-30% of hydrophobic dispersible nano-silica, 2-10% of a wetting dispersant, 0.2-3% of a thickening agent, 1-5% of an antifreezing agent, 0.01-0.2% of a preservative, and the balance water. The azoxystrobin nano-water suspending agent of the invention has the advantages of: small particle size, high fluidity, and enhanced penetration and conductivity within leaves. Due to enhanced surface energy, the nano-water suspending agent provided in the invention is easier to be adsorbed by plants. As wind blow and rain wash resistance are strengthened, pesticide residues flowing into water and soil can be reduced. With certain slow release effect, the azoxystrobin nano-water suspending agent in the invention can reach the purposes of improving drug effects and prolonging the duration period.

Owner:HENAN AGRICULTURAL UNIVERSITY +1

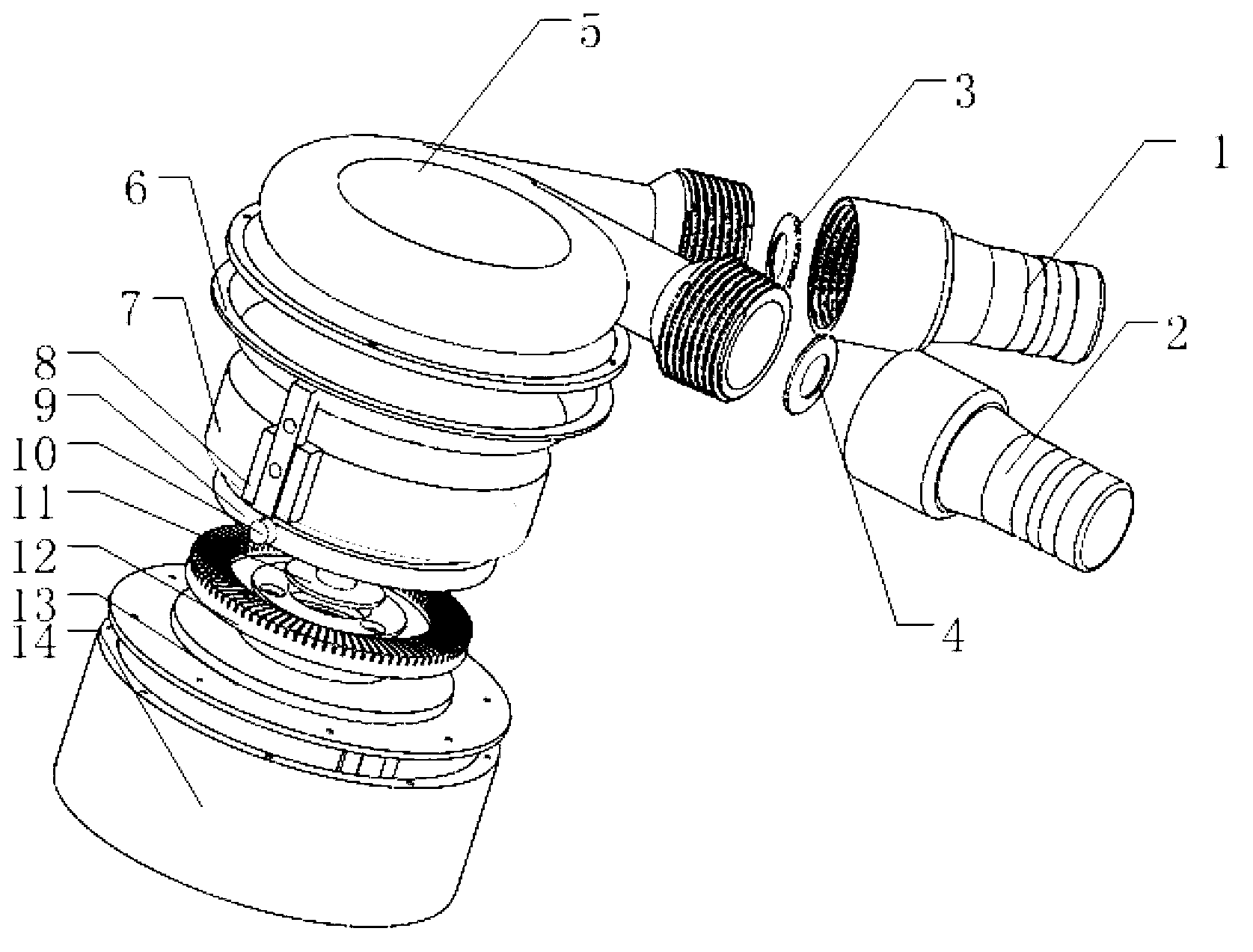

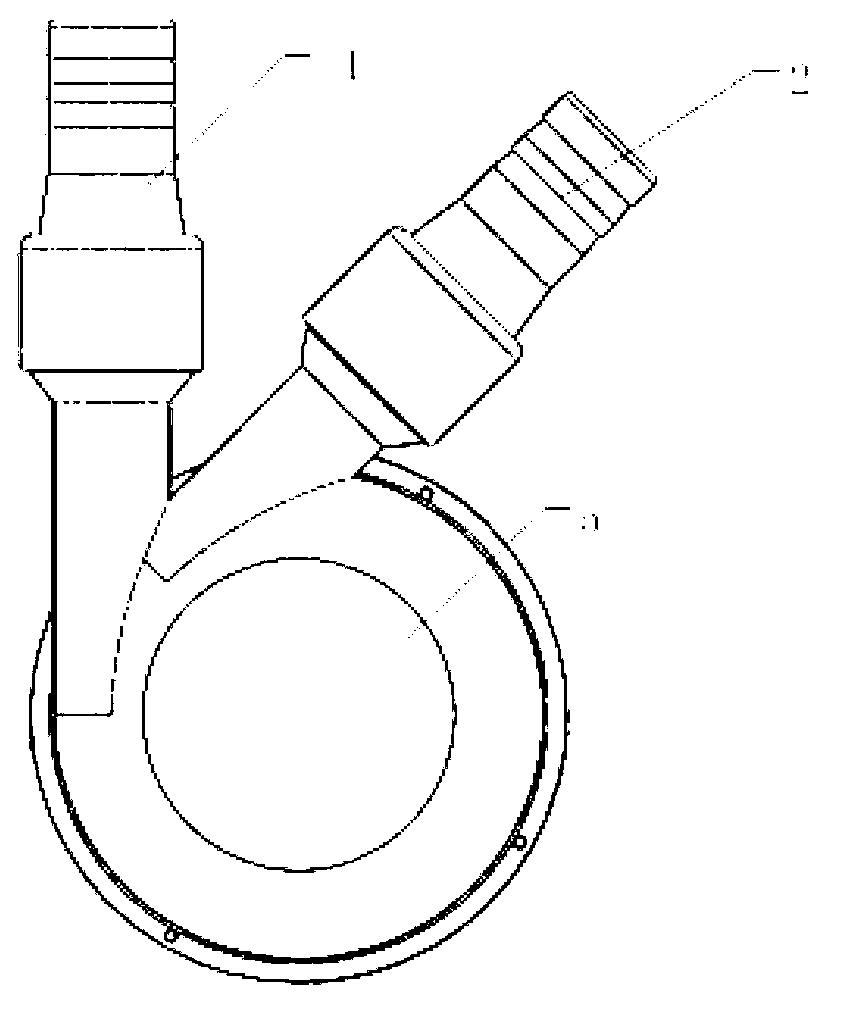

Vortex type implantable pulse ventricle assisting blood pump

The invention discloses a vortex type implantable pulse ventricle assisting blood pump. The vortex type implantable pulse ventricle assisting blood pump comprises an inlet joint, an outlet joint, an inlet valve, an outlet valve, an upper cap, an elastic membrane, an inner cylindrical cam, a linear guide rail, an ultrasonic motor rotor, two rolling bearings, a pretension shaft, an ultrasonic motor stator, a base and a shell. By adopting a mechanical motion converting mechanism of the reverser inner cylindrical cam in the vortex type implantable pulse ventricle assisting blood pump, the top of the cylindrical cam and a push plate embedded at the bottom of the elastic membrane are combined into one, the number of motion transmission parts is decreased, and pump volume is reduced and easy to implant. Meanwhile, according to the relative position of the left ventricle and the ascending aorta, a blood inlet and a blood outlet are respectively arranged at adjacent positions on one side of a blood cavity with a hemispherical recess, so that a vortex flow is formed in the blood cavity, flushing effect on the wall surface of the blood cavity is improved and thrombus formation is reduced.

Owner:SHANGHAI JIAO TONG UNIV

Splash-proof floor tile

The invention relates to a splash-proof floor tile which comprises a hollow rectangular floating tile. Flow guide holes are equidistantly formed in the side peripheral wall of the floating tile and cling to a bottom plate of the floating tile; a piston plate is movably mounted inside the floating tile, and the size of the piston plate is matched with that of the inner bottom surface of the floating tile; compression springs are fixedly mounted between the piston plate and a top plate of the floating tile; support columns are further fixed to the lower surface of the piston plate, vertically extend out of the bottom plate of the floating tile and are fixed onto a support plate. The splash-proof floor tile has the advantages that flow of accumulated water on the ground can be effectively guided by the floor tile, and the accumulated water can be effectively prevented from splashing.

Owner:YANCHENG RONGLI NEW BUILDING MATERIAL

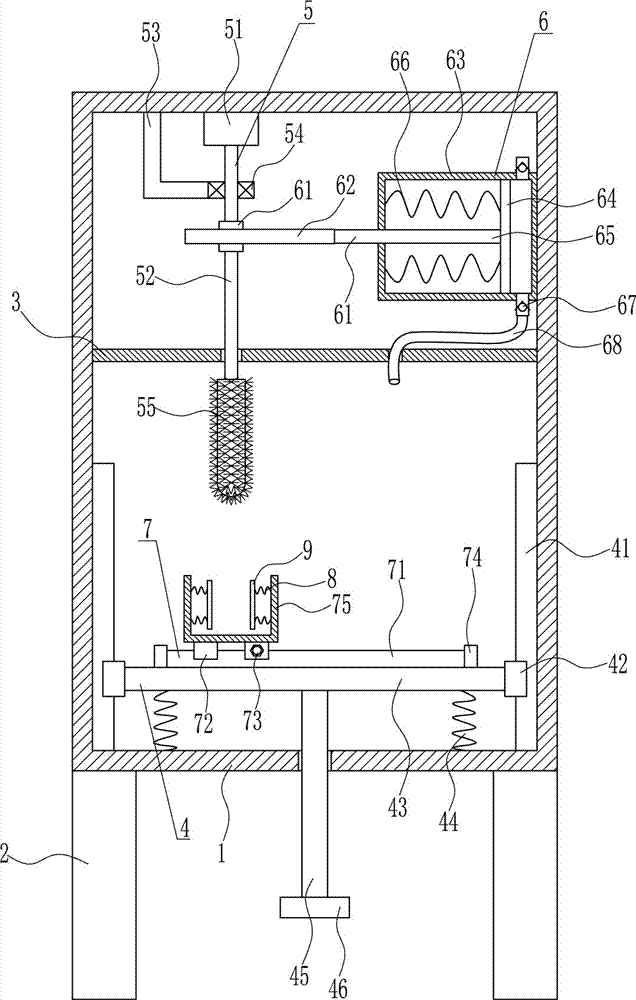

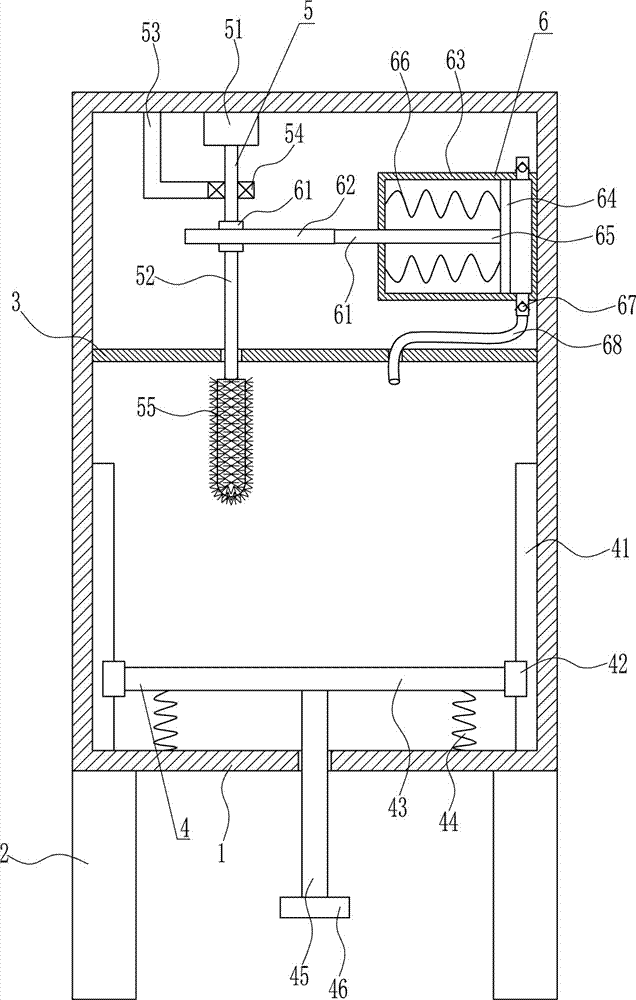

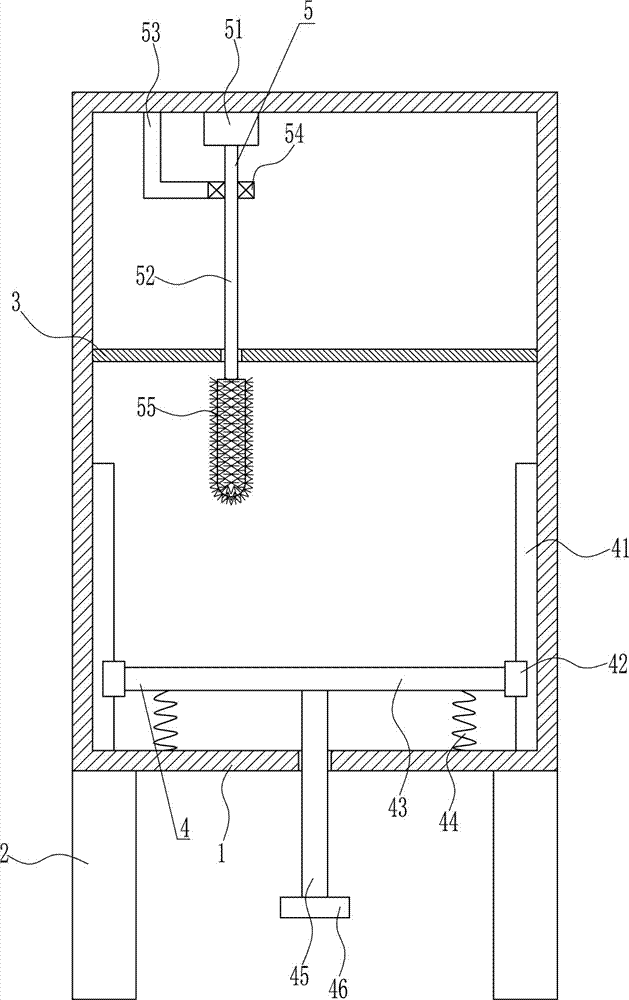

Hospital efficient washing device for feeding bottles

InactiveCN107374540AEfficient scrubbingImprove cleaning efficiencyTableware washing/rinsing machine detailsCleaning equipmentEngineeringBrush device

The invention relates to a washing device, in particular to a hospital efficient washing device for feeding bottles. The technical problem to be solved herein is to provide a hospital efficient washing device for feeding bottles which is high in washing efficiency, good in effect and low in time and labor consumption. In order to solve the technical problem, the hospital efficient washing device for feeding bottles also comprises a moving device that includes a second slide rail and the like; the second slide rail is connected to the top of a transverse plate by bolt connection, a second slider is slidably mounted on the second slide rail, a fastening screw is screwed to the middle of the front of the second slider and is matched with the second slide rail, a retainer is connected to each of the left and right ends of the second slide rail by bolt connection, and a holding trough connected to the top of the second slider. The inside of a feeding bottle is brushed and flushed through a brushing device and a flushing device; a lifting device drives the feeding bottle to move up and down, so that washing efficiency is improved; therefore, the hospital efficient washing device for feeding bottles is high in washing efficiency, good in effect, and low in time and labor consumption.

Owner:刘养青

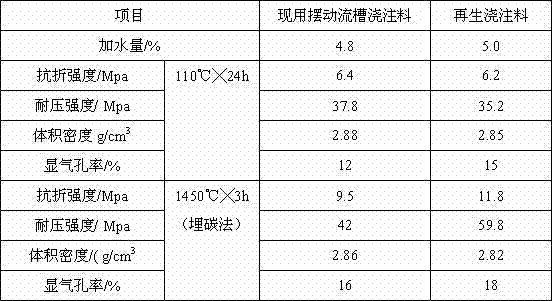

Regenerated pouring material used for swinging runner and prepared from waste slide plates and preparation method of regenerated pouring material

The invention discloses a regenerated pouring material used for swinging runner and prepared from waste slide plates. The pouring material comprises the following materials in parts by weight: 25-40 parts of waste slide plate particles, 15-25 parts of high-aluminum alumina, 10-20 parts of white corundum, 10-25 parts of silicon carbide, 5-10 parts of alpha-Al2O3 micro powder, 2-5 parts of zircon sand, 1-3 parts of silicon micro powder, 2-4 parts of calcium aluminate cement, 1-3 parts of metal silicon, 0.08-0.12 part of anti-explosion fibers and 0.05-0.15 part of an additive FS200. The preparation method disclosed by the invention is simple, easy to realize, capable of lowering cost of the casting material for the swinging runner by over 20%, saving excellent refractory raw material resources and effectively prolonging service life of the regenerated pouring material, and has remarkable economic and social benefits for improving environment and realizing resource recycling.

Owner:东海县茂福石英有限公司

Pressurized fluid flow system for a normal circulation hammer and hammer thereof

ActiveUS8640794B2Increase powerImprove efficiencyDrill bitsBorehole drivesDrill bit shankReciprocating motion

A pressurized fluid flow system for a normal circulation down-the-hole hammer comprises a cylinder coaxially disposed in between an outer casing and a piston which reciprocates due to changes in pressure of pressurized fluid contained inside a front chamber and rear chamber located at opposites sides of the piston, supply / discharge of fluid to / from these chambers being conducted through a supply chamber and a discharge chamber defined by recesses on the inner surface of the casing and separated by a dividing wall, the front / rear chambers' in / out fluid flow being controlled solely by the overlap of the piston and the cylinder. A hammer having this system comprises a drill bit with one or more flushing passages which extend from channels cooperatively formed between splines on the inner surface of the driver sub and on the outer surface of the drill bit shank up to the front face of the drill bit.

Owner:DRILLCO TOOLS

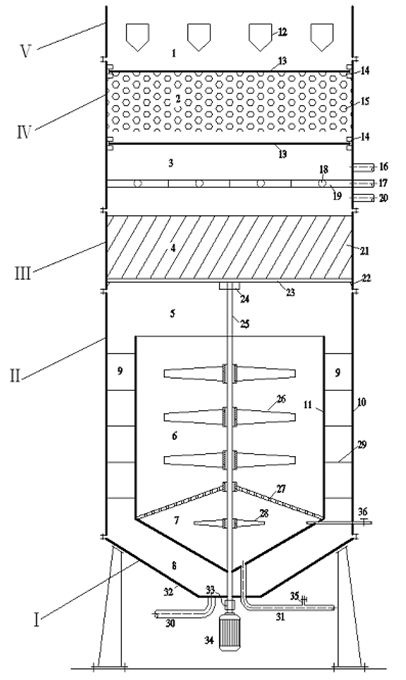

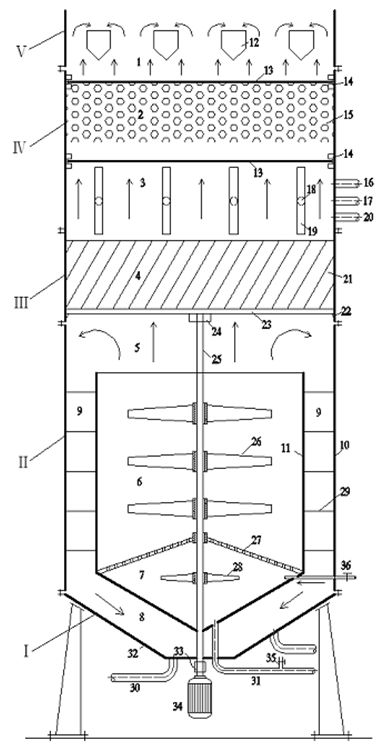

Intensive integrated water purification equipment

InactiveCN102120655ASmall footprintImprove land utilizationMultistage water/sewage treatmentFlocculationSludge

The invention discloses intensive integrated water purification equipment. The equipment is separated into five sections according to difference of water purification units, and the five sections are connected through flanges; and the equipment is provided with a mud collecting area, a primary flocculation area, an inner-cylinder clustering flocculation area / and an outer-cylinder sludge concentration area, a sludge separation area, an inclined tube sedimentation area, a backwashing gas distribution area, a filtration area, and a clear water area from bottom to top. The equipment is provided with devices such as an agitator blade used for particles to form agglomerated floc, a rotary gas distribution plate used for gas-water backwashing of a filter material, small-space spiral sloping panels used for concentrating sludge and the like; and the whole equipment is simple in structure, water purification functional units are compactly connected, the flat plane utilization rate is high, and the equipment is convenient to operate, can maximize the water purification function, and has important practical significance for medium and small water supply systems.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

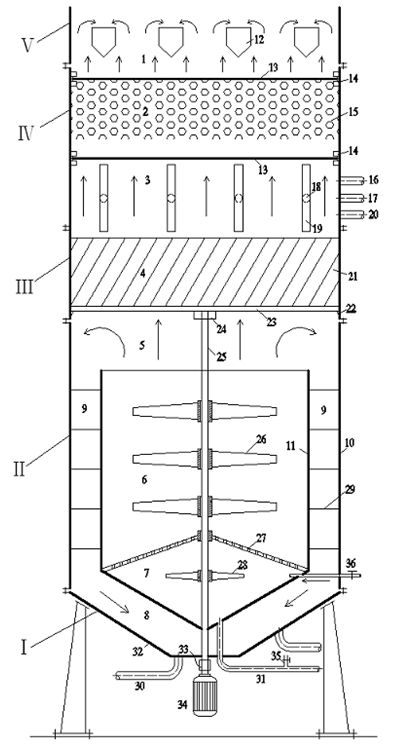

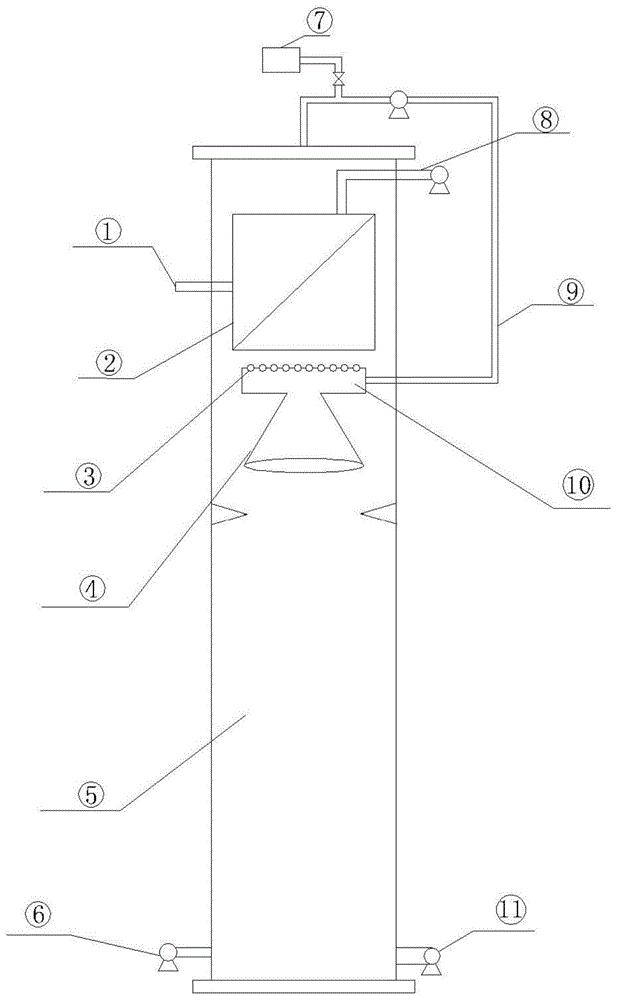

Immersed type anaerobic membrane bioreactor capable of effectively controlling membrane pollution and treatment method

InactiveCN105110466AReduce pollutionExtended service lifeTreatment with anaerobic digestion processesReaction zoneThree-phase

The invention relates to a membrane bioreactor, in particular to an immersed type anaerobic membrane bioreactor capable of effectively controlling membrane pollution and a treatment method. A methane collection device is arranged at the top end of the bioreactor; a sludge discharge pipe is arranged at the bottom of the bioreactor; the bioreactor internally comprises a membrane component, a three-phase separator and a main reaction zone from top to bottom sequentially; a water inlet pipe is arranged at the bottom of the bioreactor; a gas distribution device is arranged at the upper part of the three-phase separator; a water outlet pipe and a washing pipe are all connected with the membrane component. By adopting the membrane bioreactor provided by the invention, membrane pollution can be reduced effectively, the service life of a membrane is prolonged, the treatment capacity of the anaerobic membrane bioreactor to pollutants is enhanced and in-situ flushing of the membrane component is realized.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com