Tap hole stemming for large-scale blast furnace and preparation method

A tap hole and blast furnace technology, which is applied in the field of tap hole taphole mud for large blast furnaces and its preparation, can solve the problem that the use requirements of large blast furnaces cannot be better met, the taphole mud has weak resistance to molten iron scouring and erosion, and has no slag resistance. Iron erosion performance indicators and other issues, to achieve the effect of improving the resistance to slag iron corrosion and scouring, improving microporation indicators, and improving opening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

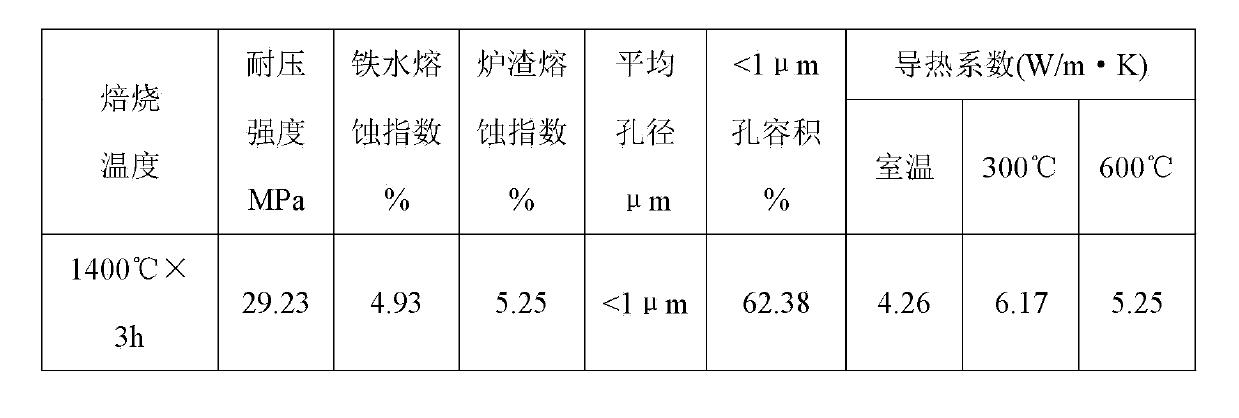

Embodiment 1

[0035] Embodiment 1: carry out batching according to the following requirements, and its component is by mass percentage:

[0036] Brown corundum with a particle size of 1mm<≤3mm: 20 parts by weight;

[0037] 320 mesh < particle size ≤ 1mm brown corundum: 10 parts by weight;

[0038] Particle size ≤ 320 mesh brown corundum: 11 parts by weight;

[0039] Silicon carbide with 0mm<particle size≤1mm: 9 parts by weight;

[0040] Particle size ≤ 180 mesh ferrosilicon nitride: 12 parts by weight

[0041] Particle size ≤ 200 mesh clay: 15 parts by weight, the clay is a mixture of Guangxi white clay and ring clay, wherein Guangxi white clay is 8 parts by weight, ring clay is 7 parts by weight, and the ring clay is purchased from Wuhan Mining Company The product;

[0042] Silicon powder with a particle size of ≤320 mesh: 7 parts by weight;

[0043] α-alumina with a particle size of ≤5 μm: 3 parts by weight;

[0044] Coke powder with 0mm<particle size≤2mm: 6 parts by weight;

[004...

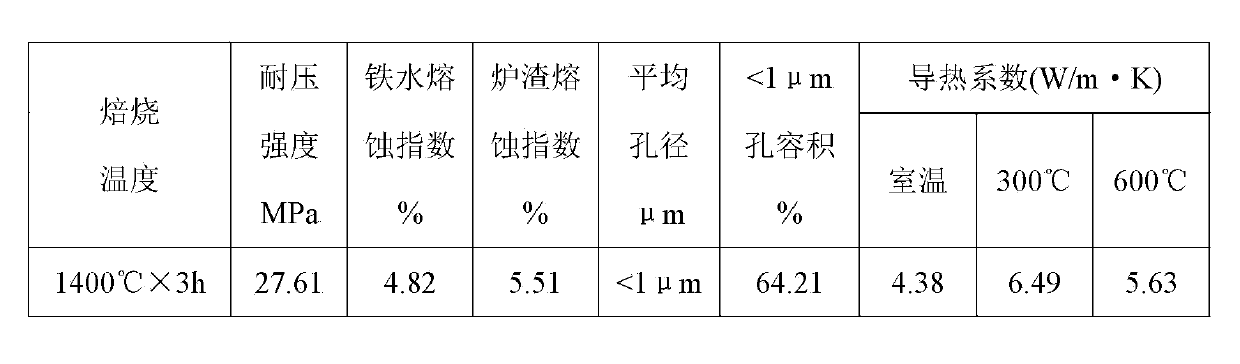

Embodiment 2

[0051] Embodiment 2: carry out batching according to the following requirements, and its component is by mass percentage:

[0052] Brown corundum with a particle size of 1mm<≤3mm: 20 parts by weight;

[0053] 320 mesh < particle size ≤ 1mm brown corundum: 10 parts by weight;

[0054] Particle size ≤ 320 mesh brown corundum: 10 parts by weight;

[0055] Silicon carbide with 0mm<particle size≤1mm: 15 parts by weight;

[0056]Particle size ≤ 180 mesh ferrosilicon nitride: 7 parts by weight

[0057] Clay with a particle size of ≤200 mesh: 11 parts by weight, the clay is Guangxi white clay;

[0058] Silicon powder with a particle size of ≤320 mesh: 9 parts by weight;

[0059] α-alumina with a particle size of ≤5 μm: 2 parts by weight;

[0060] Coke powder with 0mm<particle size≤2mm: 7 parts by weight;

[0061] Graphite with a particle size of ≤100 mesh: 3 parts by weight;

[0062] High-temperature asphalt with 0mm<particle size≤2mm: 6 parts by weight.

[0063] Weigh the abo...

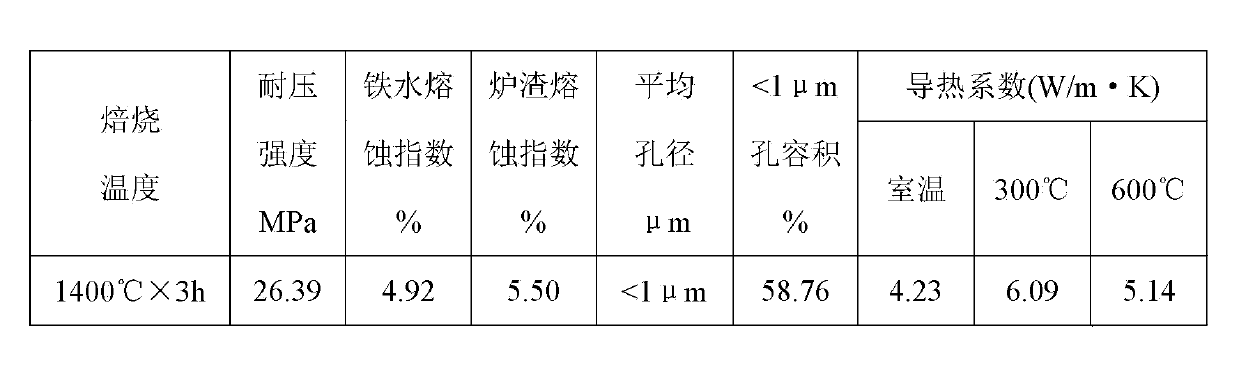

Embodiment 3

[0067] Embodiment 3: carry out batching according to the following requirements, and its component is by mass percentage:

[0068] Brown corundum with a particle size of 1mm<≤3mm: 20 parts by weight;

[0069] 320 mesh < particle size ≤ 1mm brown corundum: 12 parts by weight;

[0070] Brown corundum with a particle size of ≤320 mesh: 18 parts by weight;

[0071] Silicon carbide with 0mm<particle size≤1mm: 8 parts by weight;

[0072] Ferrosilicon nitride with a particle size of ≤180 mesh: 6 parts by weight;

[0073] Particle size ≤ 200 mesh clay: 10 parts by weight, the clay is cycloclay, and the cycloclay is a product purchased from Wuhan Mining Company;

[0074] Silicon powder with a particle size of ≤320 mesh: 6 parts by weight;

[0075] α-alumina with a particle size of ≤5 μm: 5 parts by weight;

[0076] Coke powder with 0mm<particle size≤2mm: 10 parts by weight;

[0077] Graphite with a particle size of ≤100 mesh: 1 part by weight;

[0078] 0mm

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com