Patents

Literature

1153 results about "Hole size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

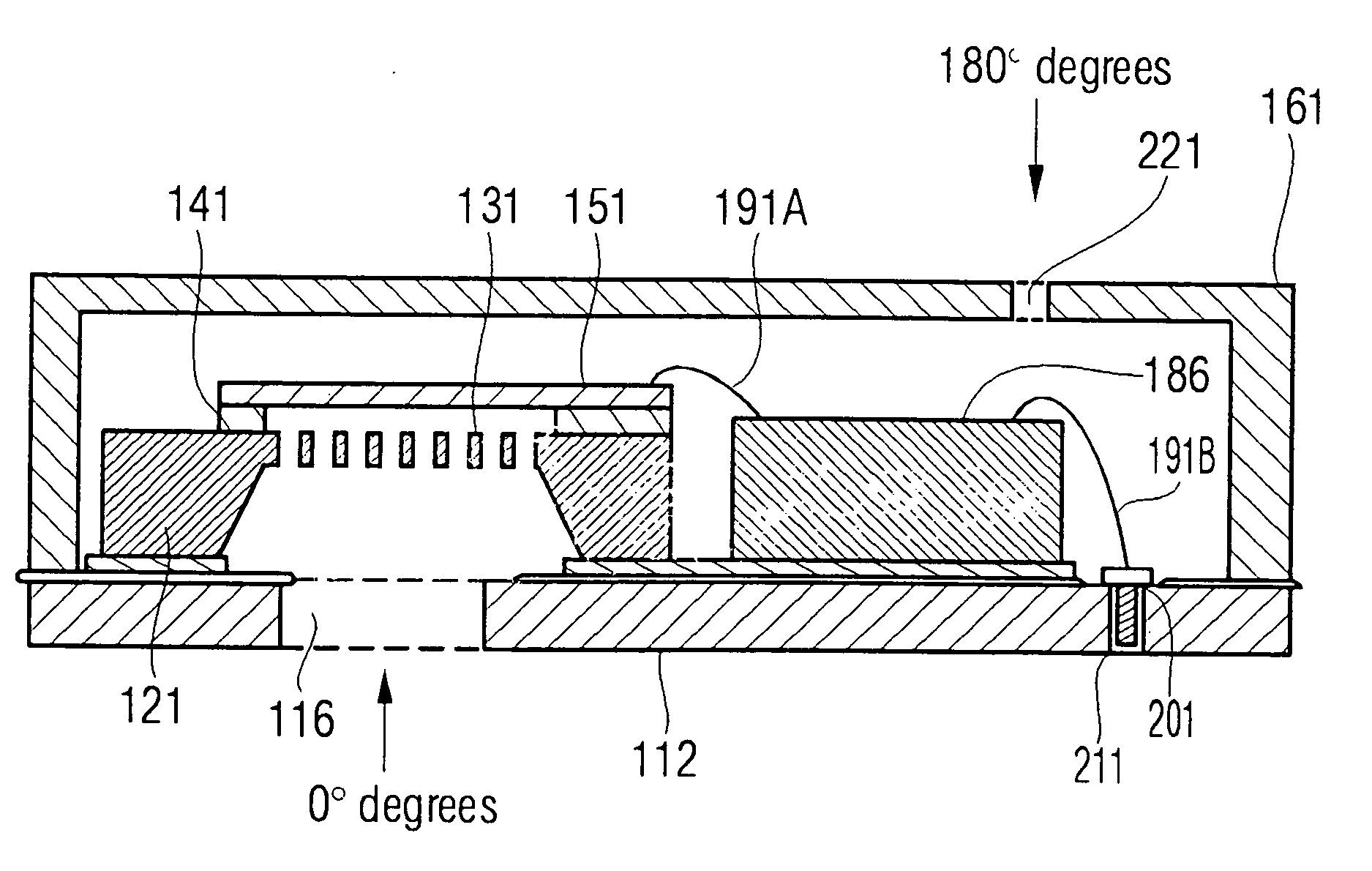

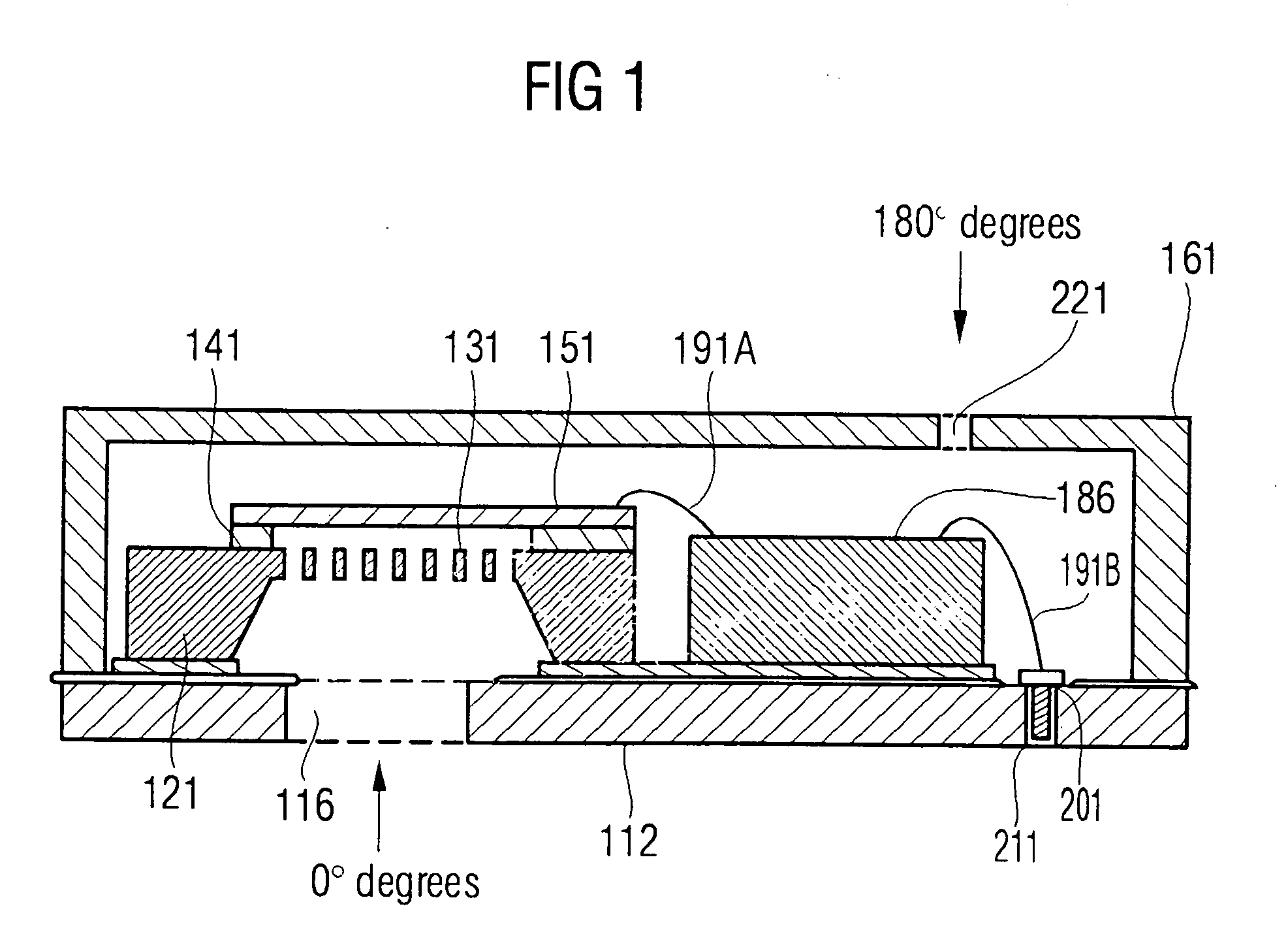

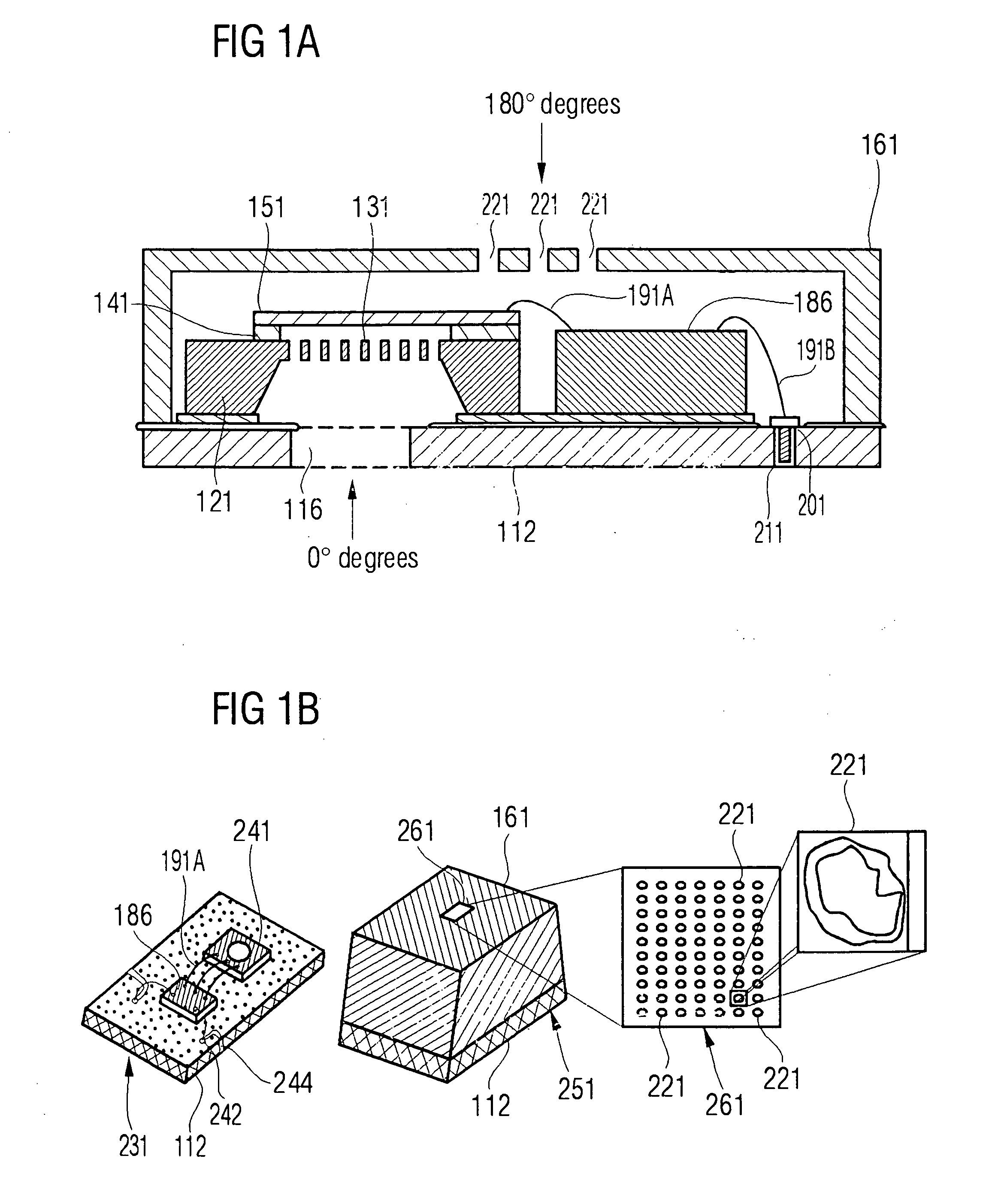

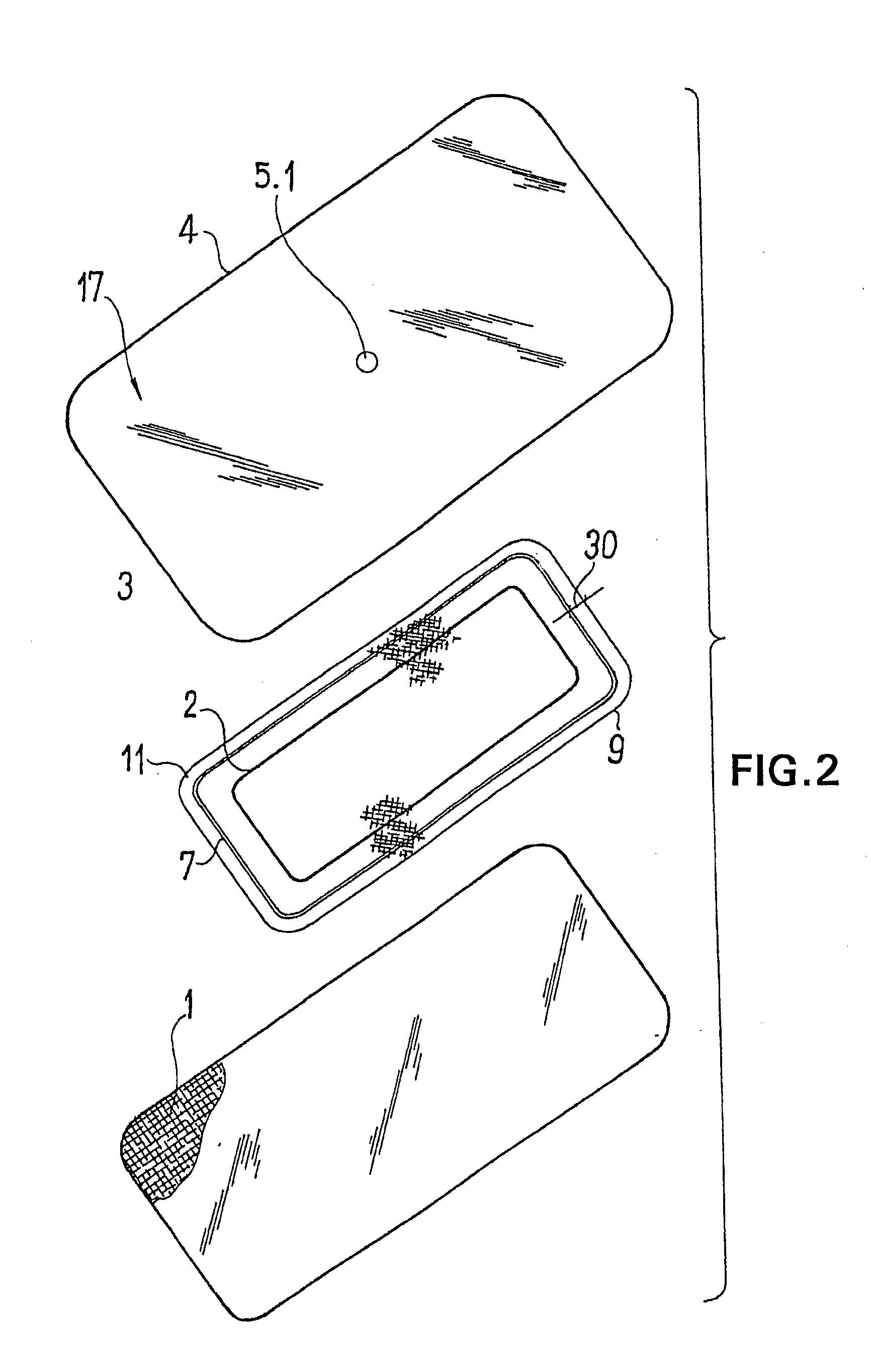

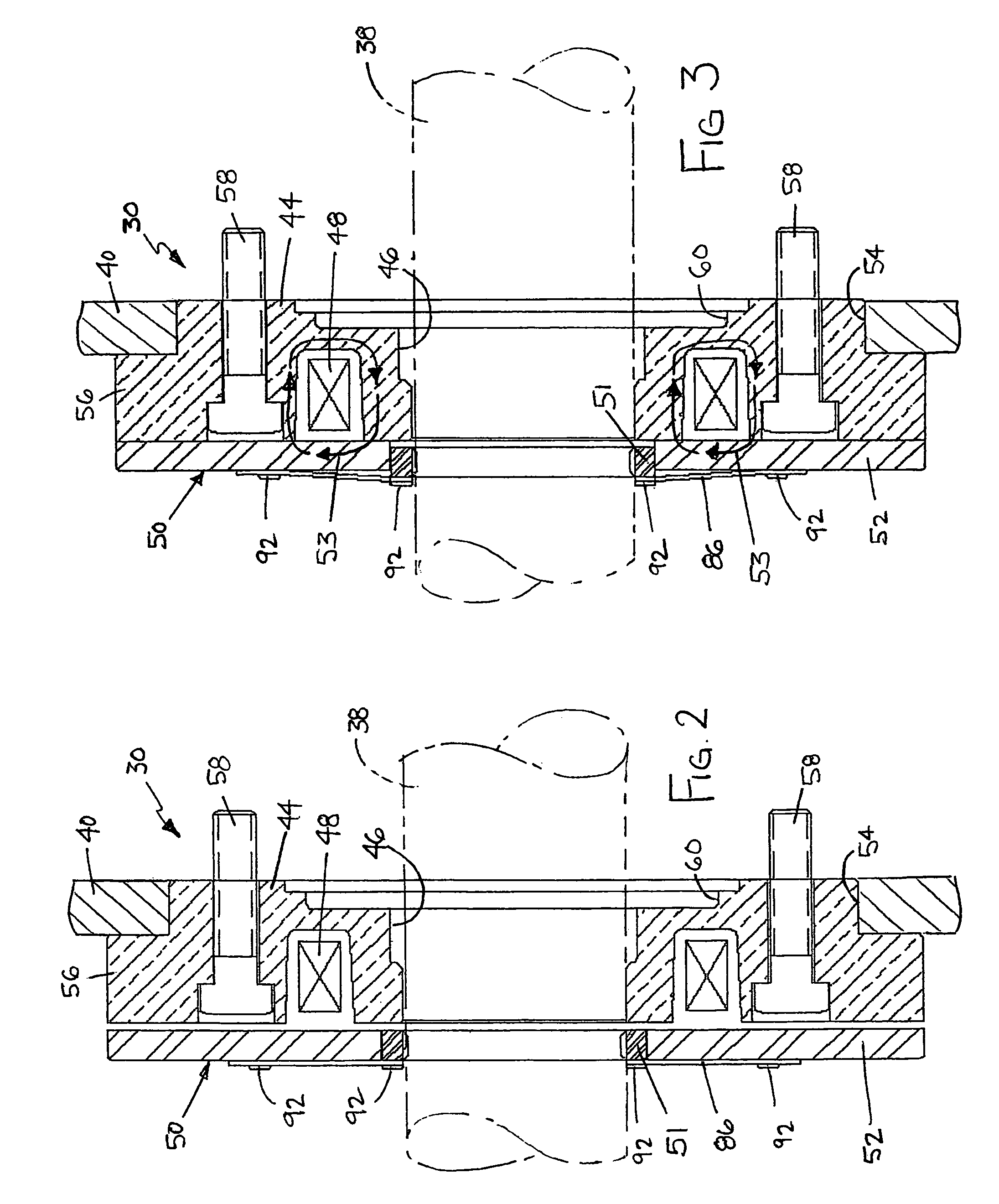

Microphone and method of producing a microphone

InactiveUS20050207605A1High degree of automationEasy to producePiezoelectric/electrostrictive microphonesElectrets selectrostatic transducerAcoustic impedanceMembrane configuration

A microphone has a substrate including an acoustically transparent substrate region, a lid with an acoustically transparent lid region, and a membrane which is held by a membrane carrier between the lid and the substrate. The acoustically transparent substrate region or the acoustically transparent lid region is provided with at least one impedance hole sized so that an acoustic impedance of the impedance hole is larger than an acoustic impedance of the acoustically transparent region of the respective other region of substrate region and lid region.

Owner:INFINEON TECH AG

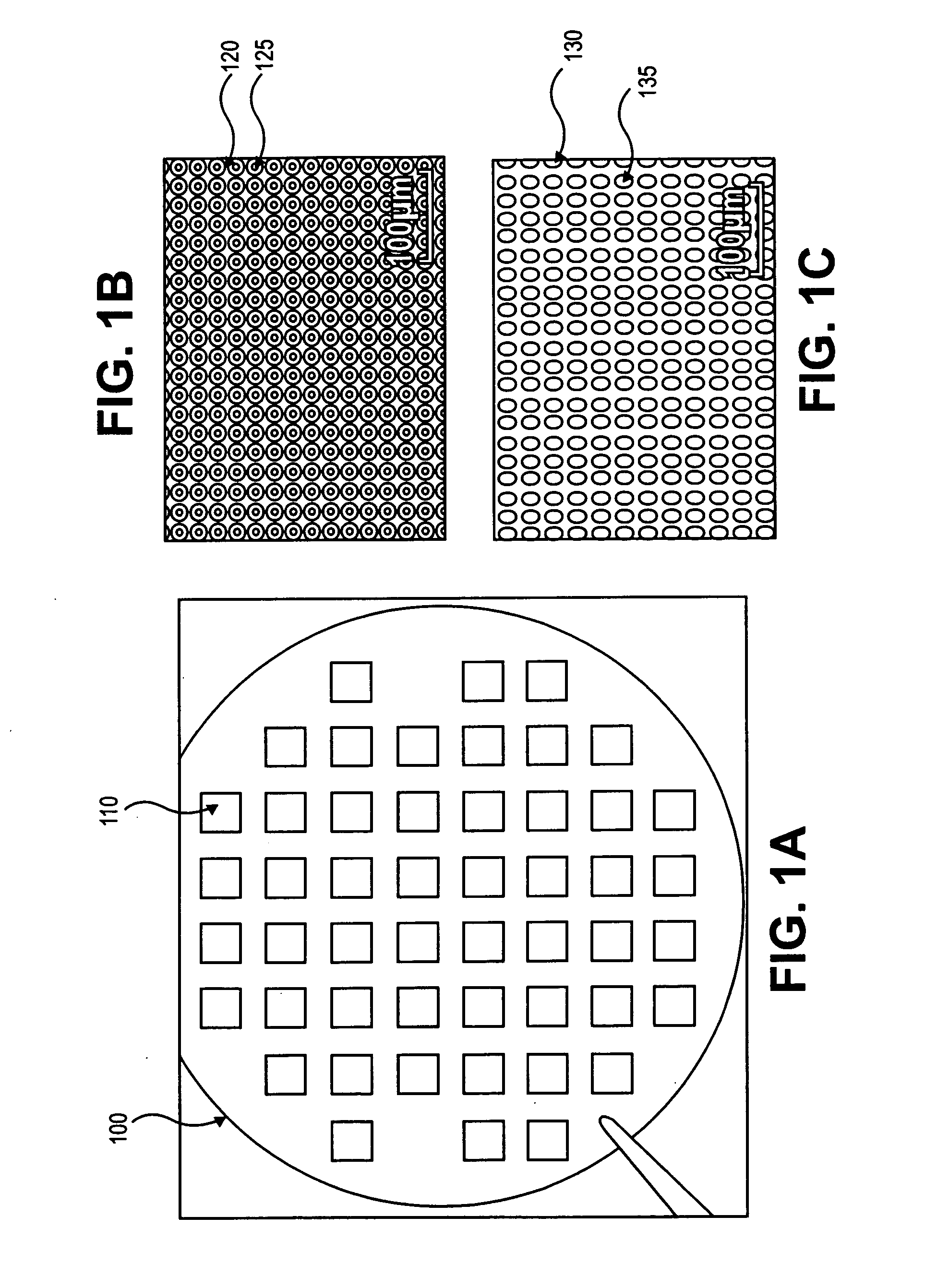

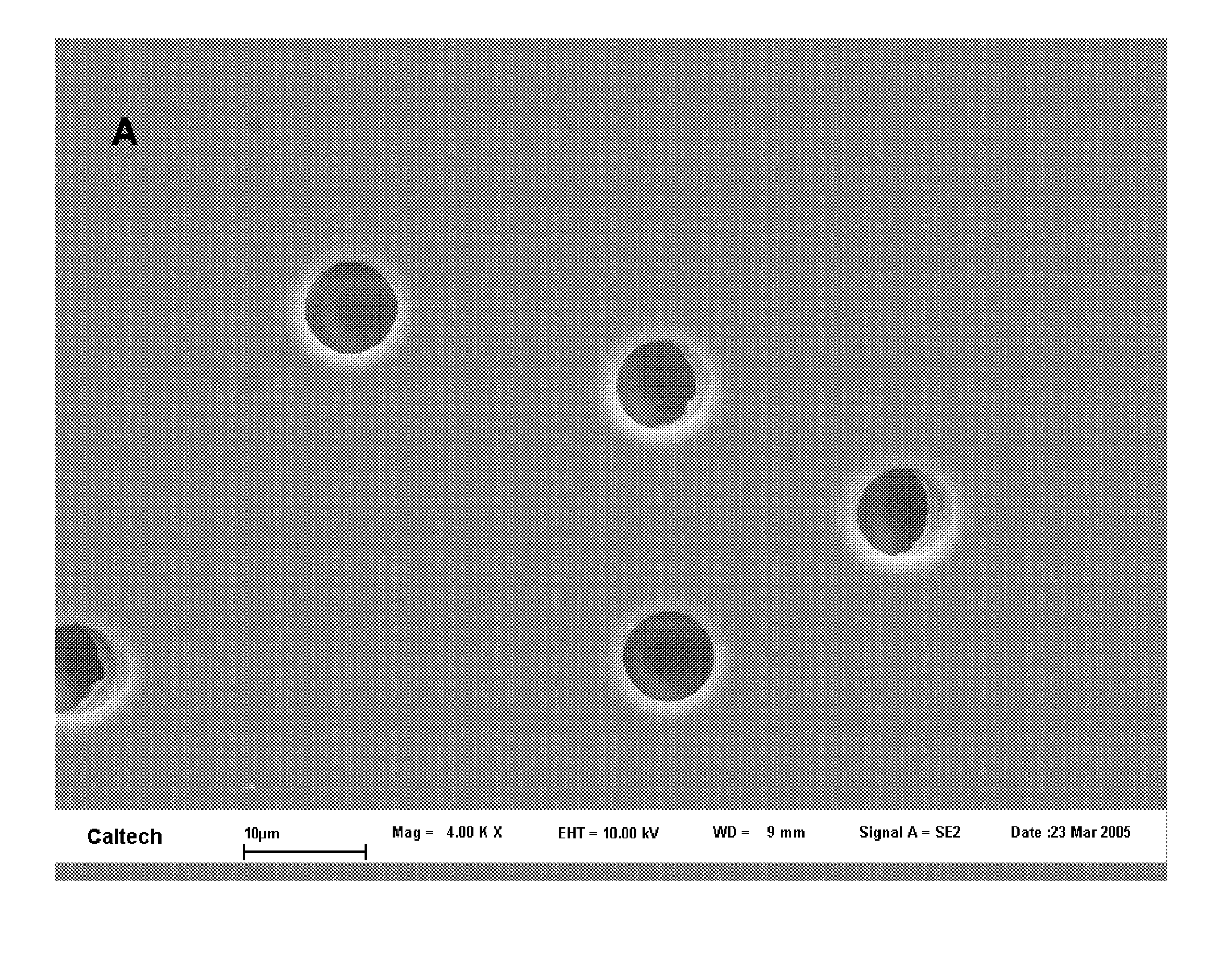

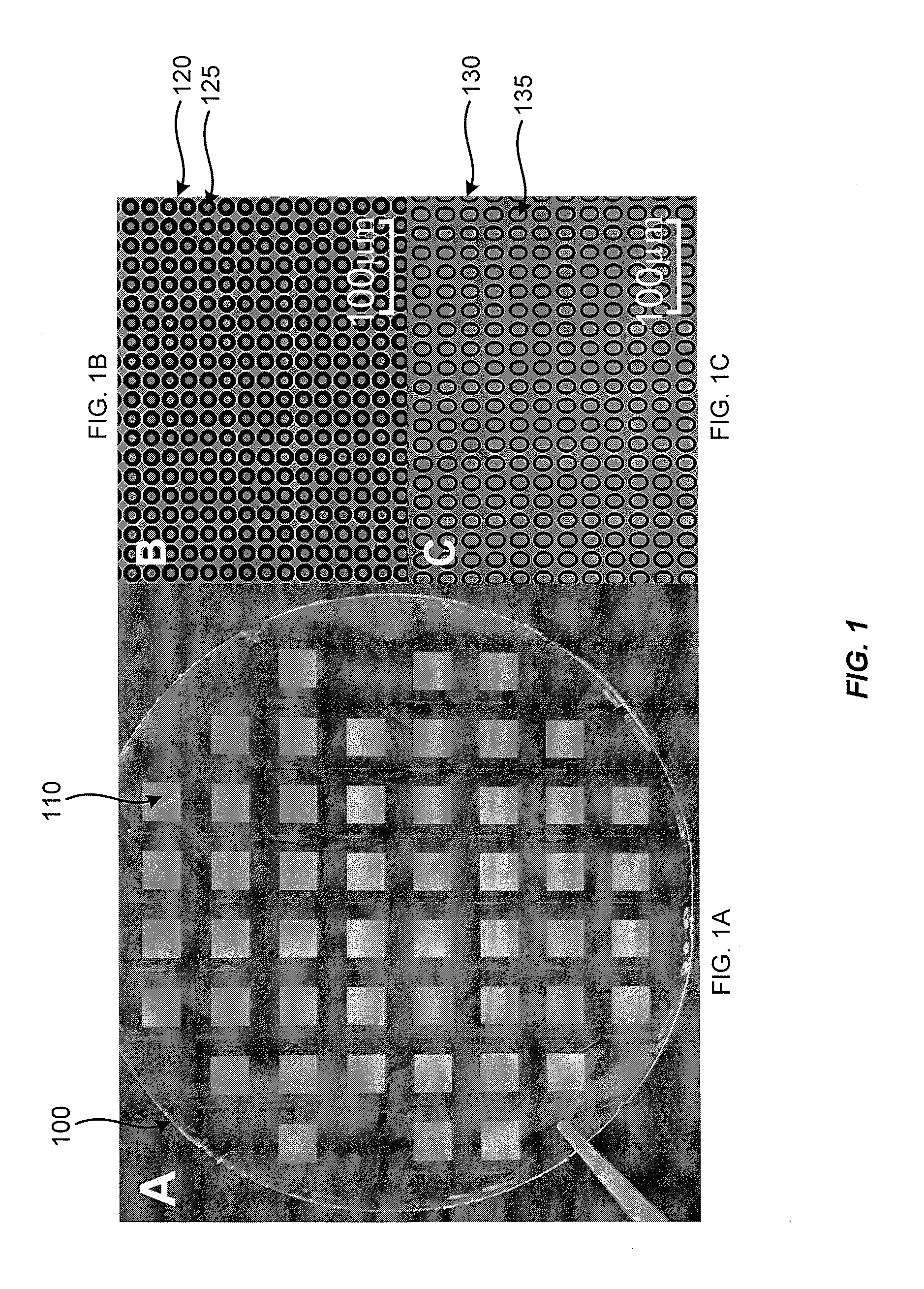

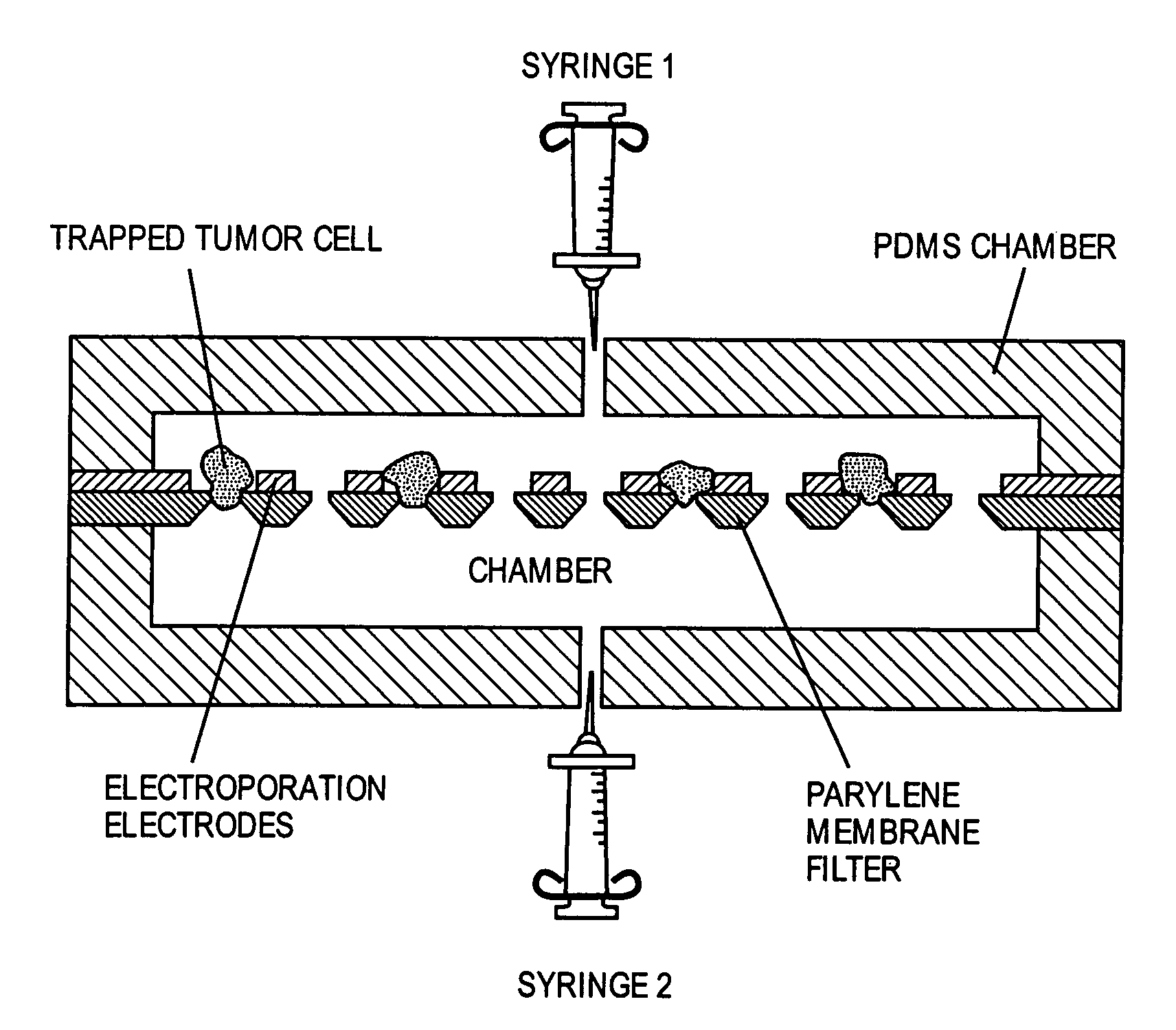

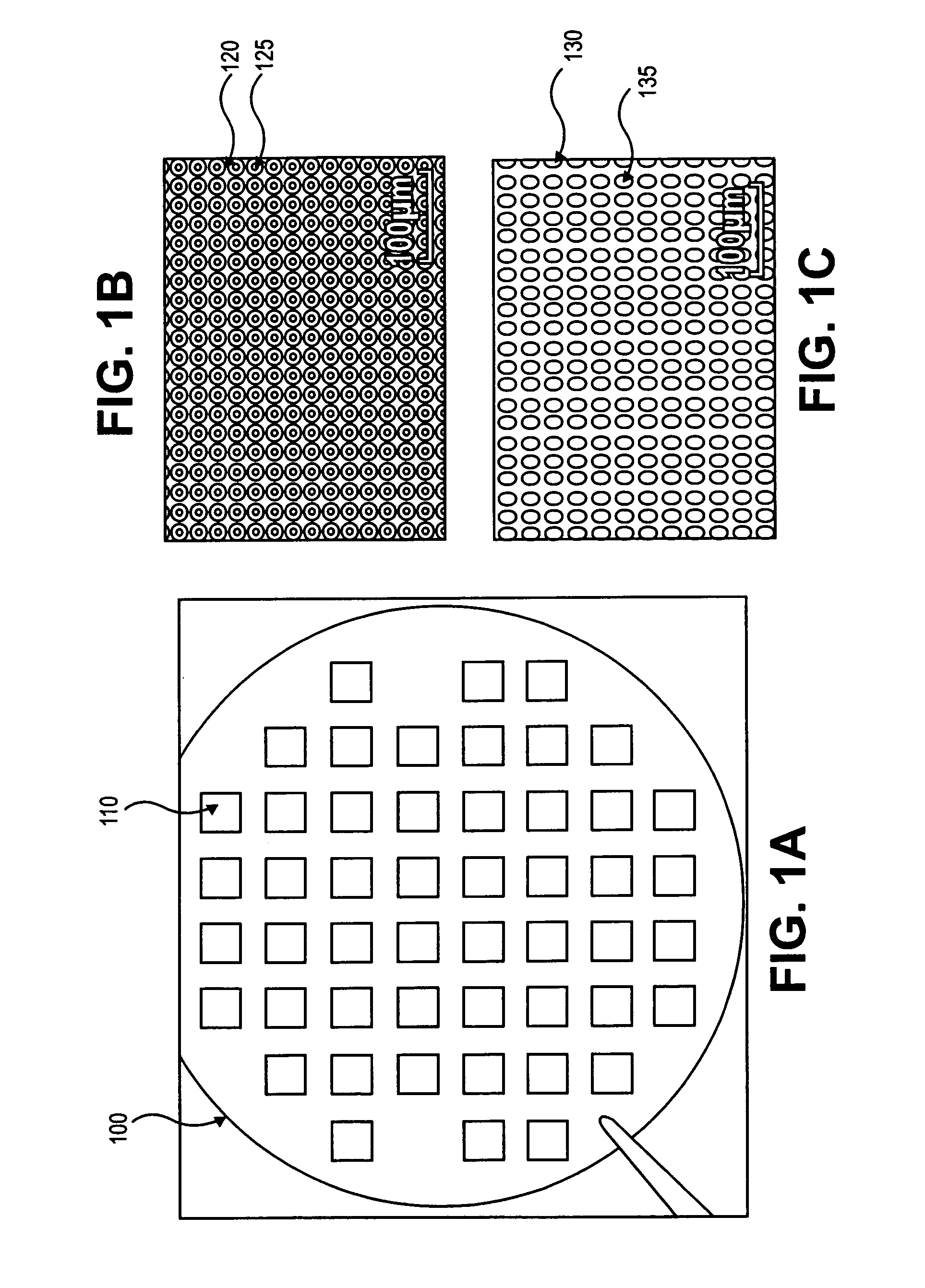

Uses of parylene membrane filters

ActiveUS20070025883A1Improve efficiencyEffective meanUltrafiltrationLaboratory glasswaresParyleneFigure of merit

The invention provides parylene membrane filters, filter devices and methods of making them and using them in the mechanical separation of cells and particles by size. The provision of parylene membrane filters with high figures of merit and finely controlled hole sizes allows the separation of cells and particles in a variety of biological and other fluids according to sizes.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

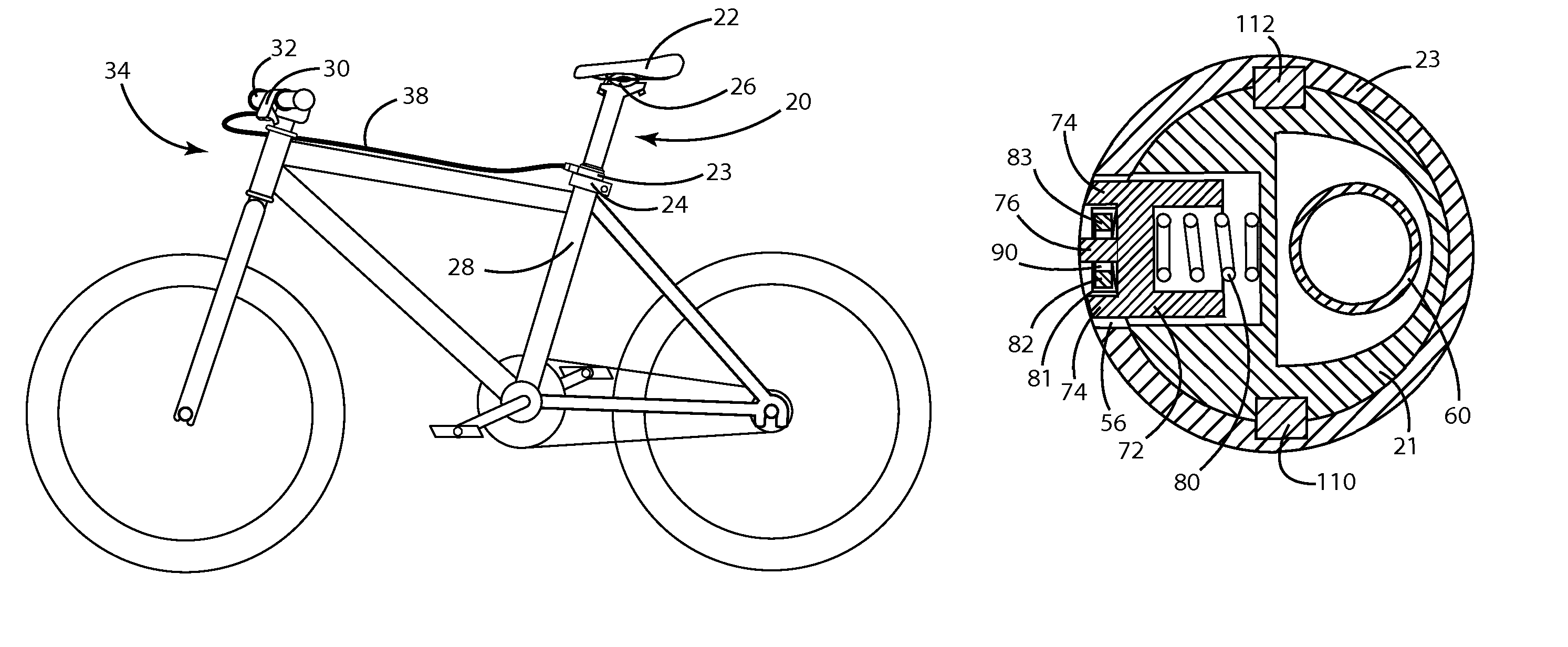

Bicycle seat height adjusting assembly

Owner:WALSH AUSTIN A

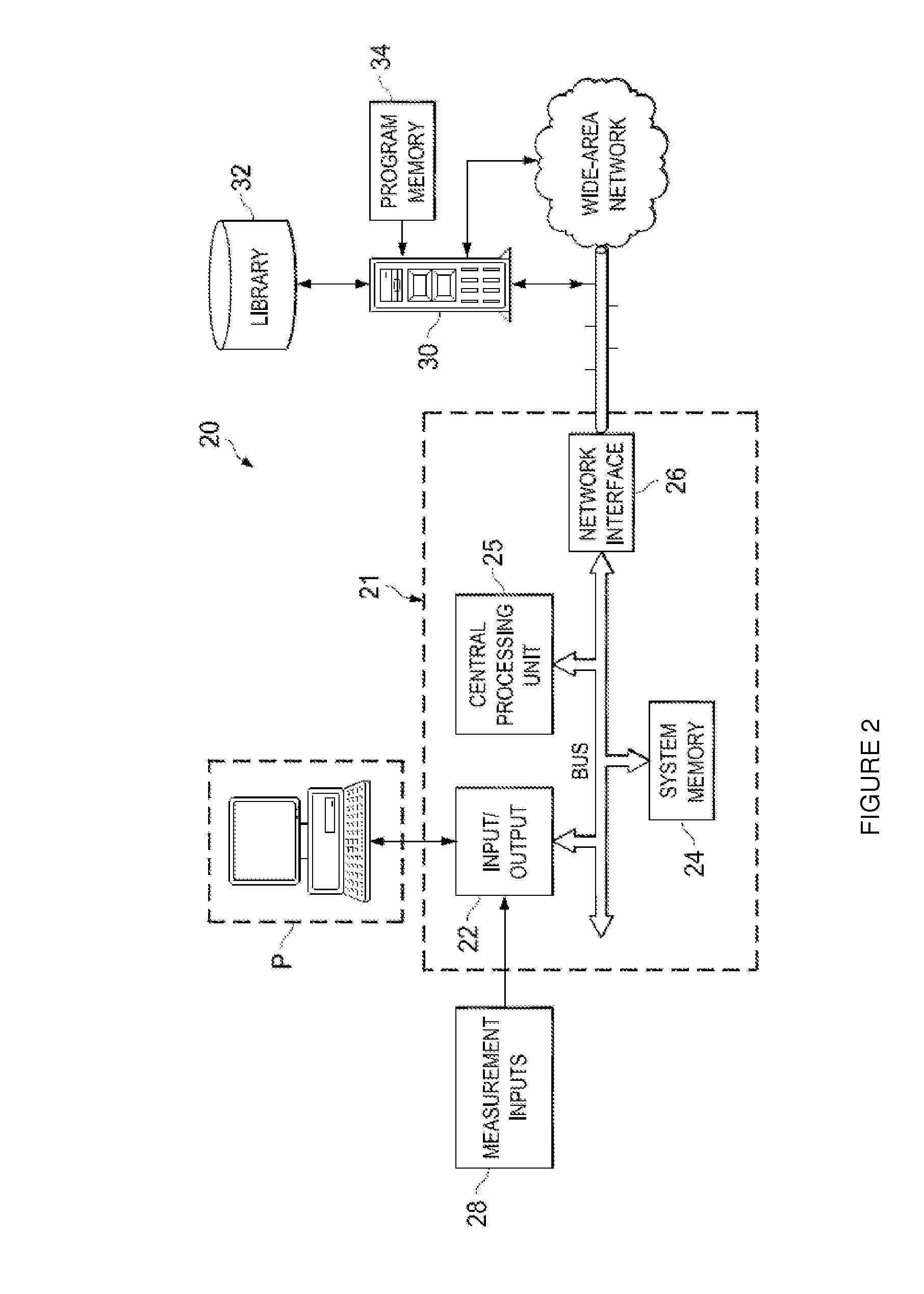

Method and apparatus for motion detection

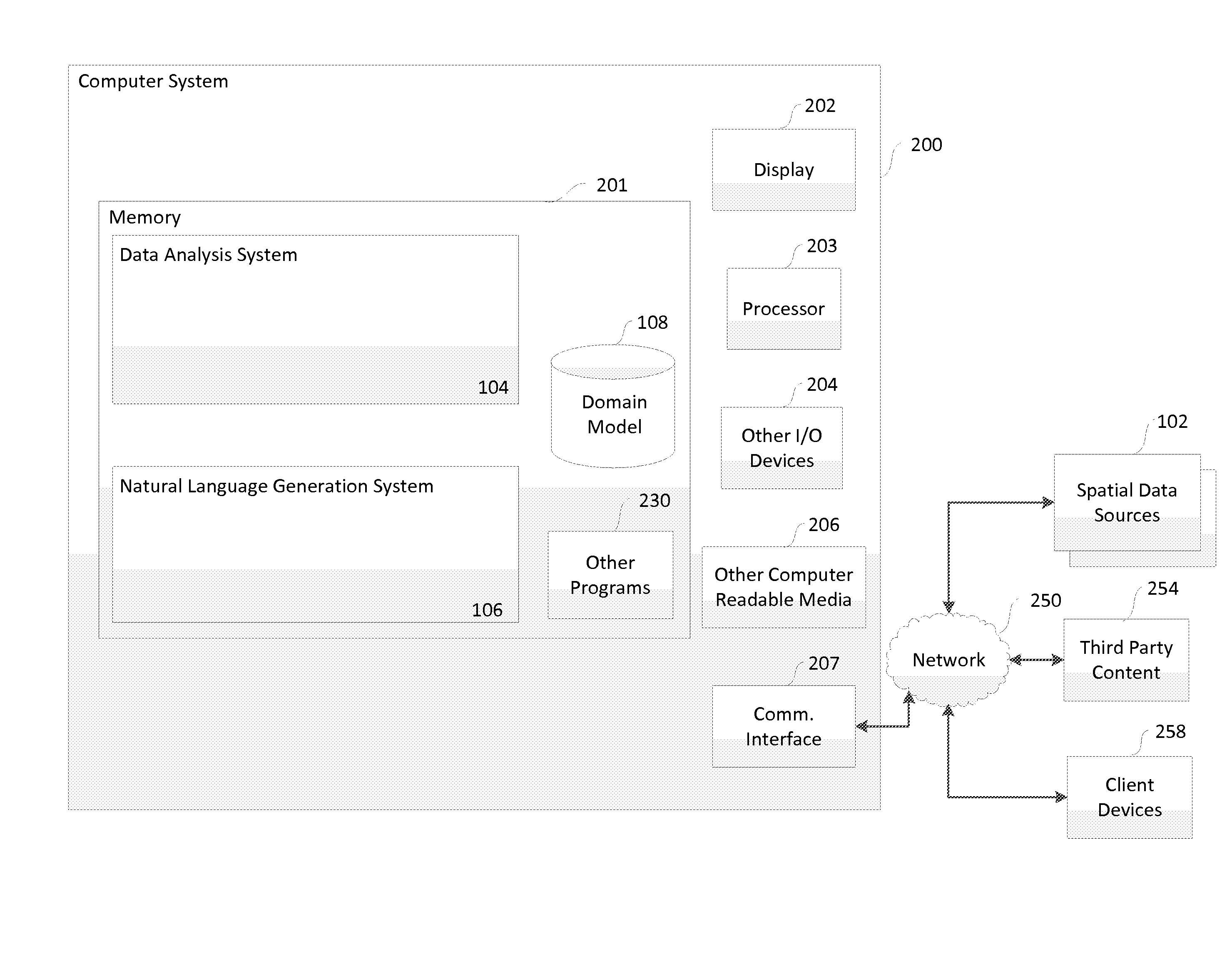

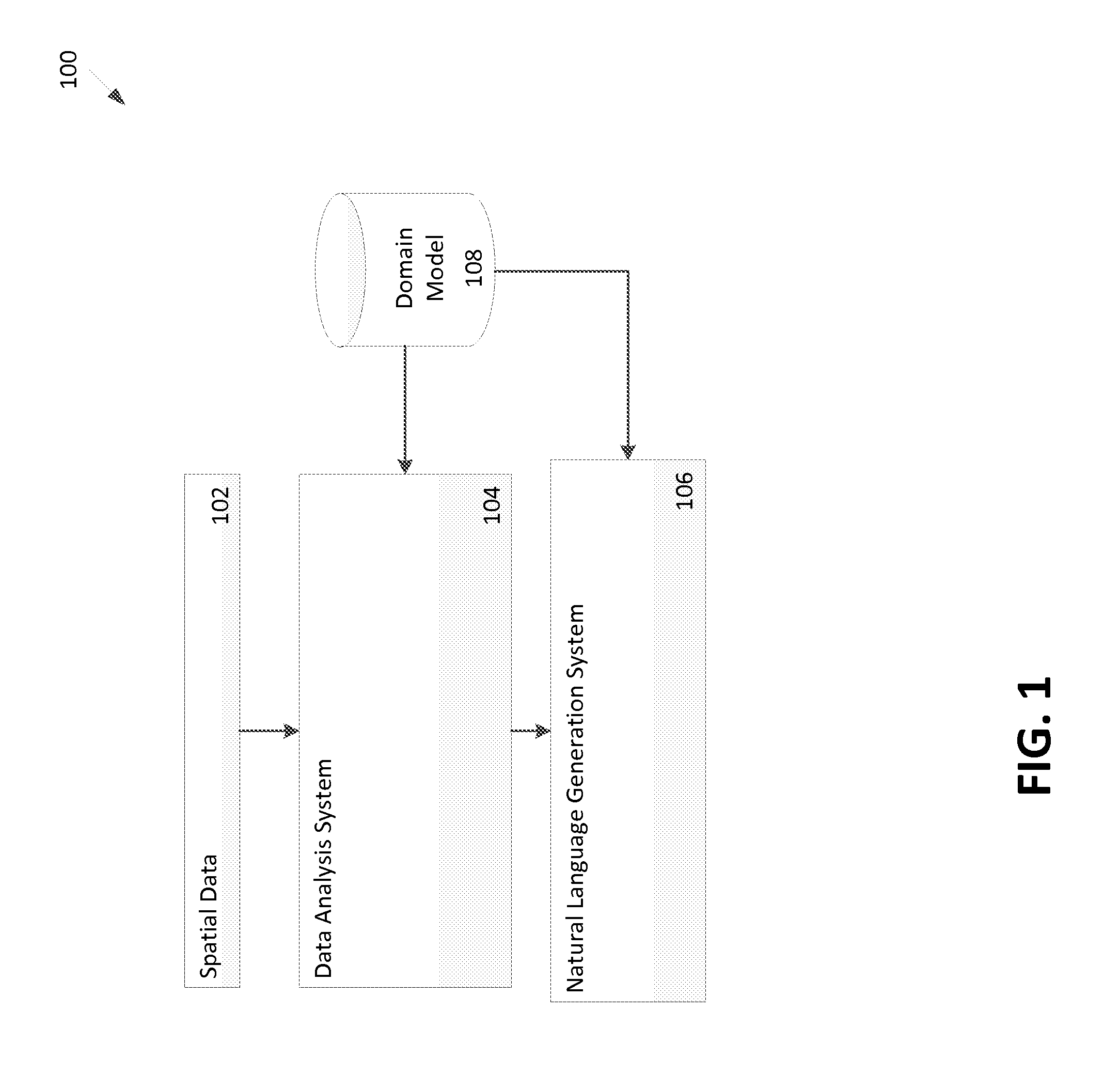

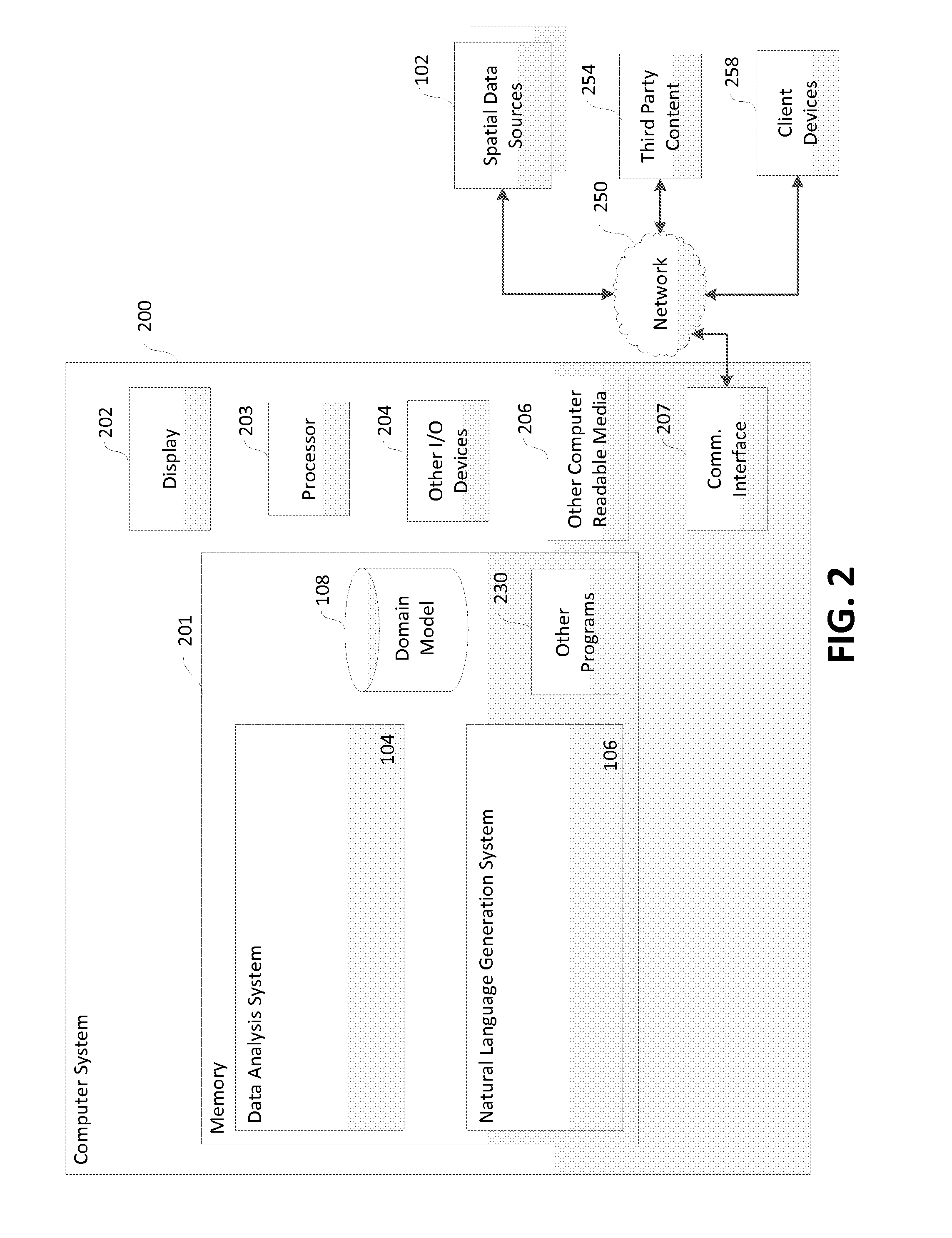

Image analysis techniques may be employed to identify moving and / or static object within a sequence of spatial data frames (102, 300). Attributes of interest may be identified within a sequence of spatial data frames (102, 300). The attributes of interest may be clustered and examined across frames of the spatial data to detect motion vectors. A system (200) may derive information about these attributes of interest and their motion over time and identify moving and / or static objects, and the moving and / or static objects may be used to generate natural language messages describing the motion of the attributes of interest. Example uses include description of moving and / or static objects in data such as weather data, oil spills, cellular growth (e.g., tumor progression), atmospheric conditions (e.g., the size of a hole in the ozone layer), or any other implementation where it may be desirable to detect motion vectors in a sequence of spatial data frames.

Owner:ARRIA DATA2TEXT +1

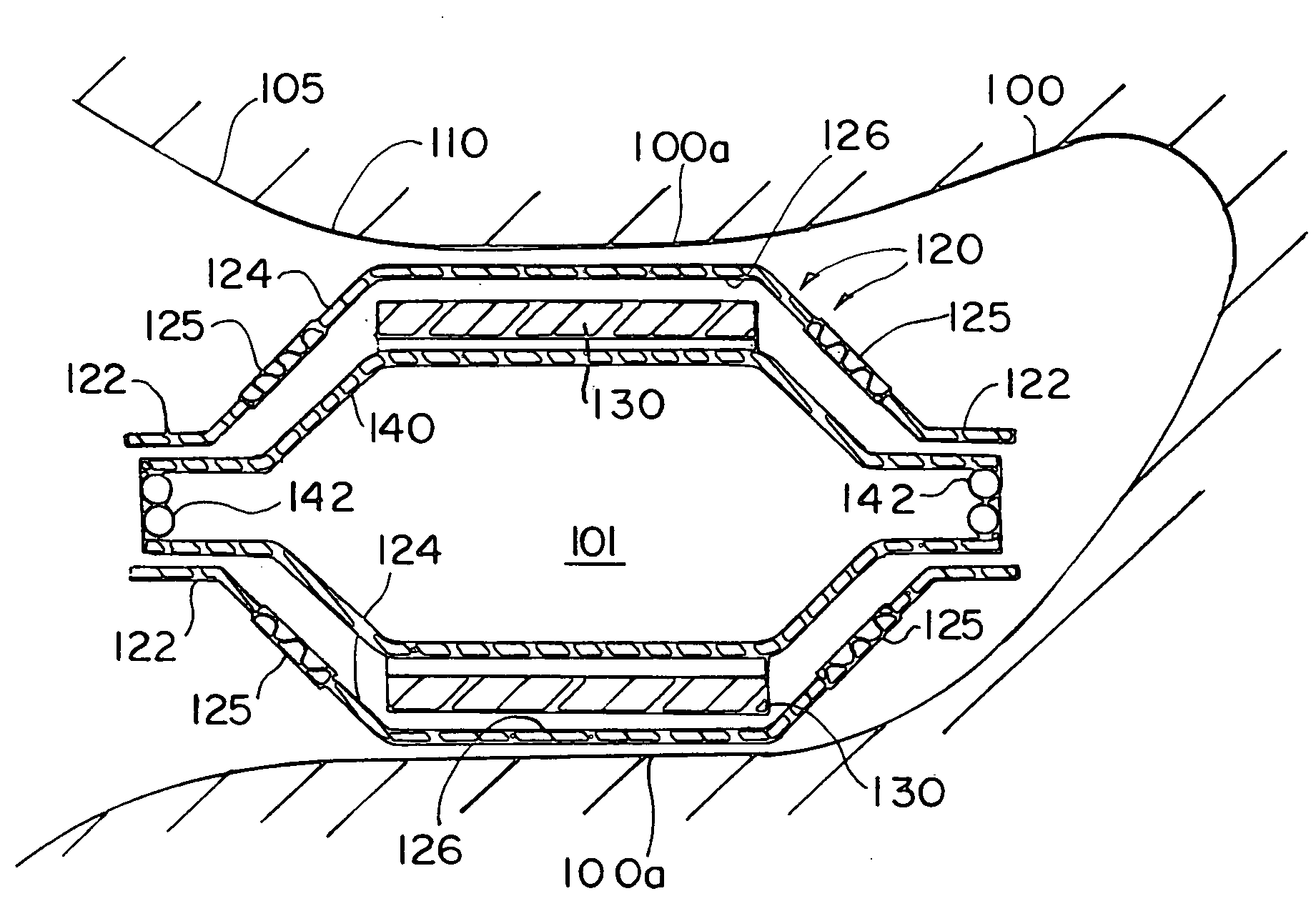

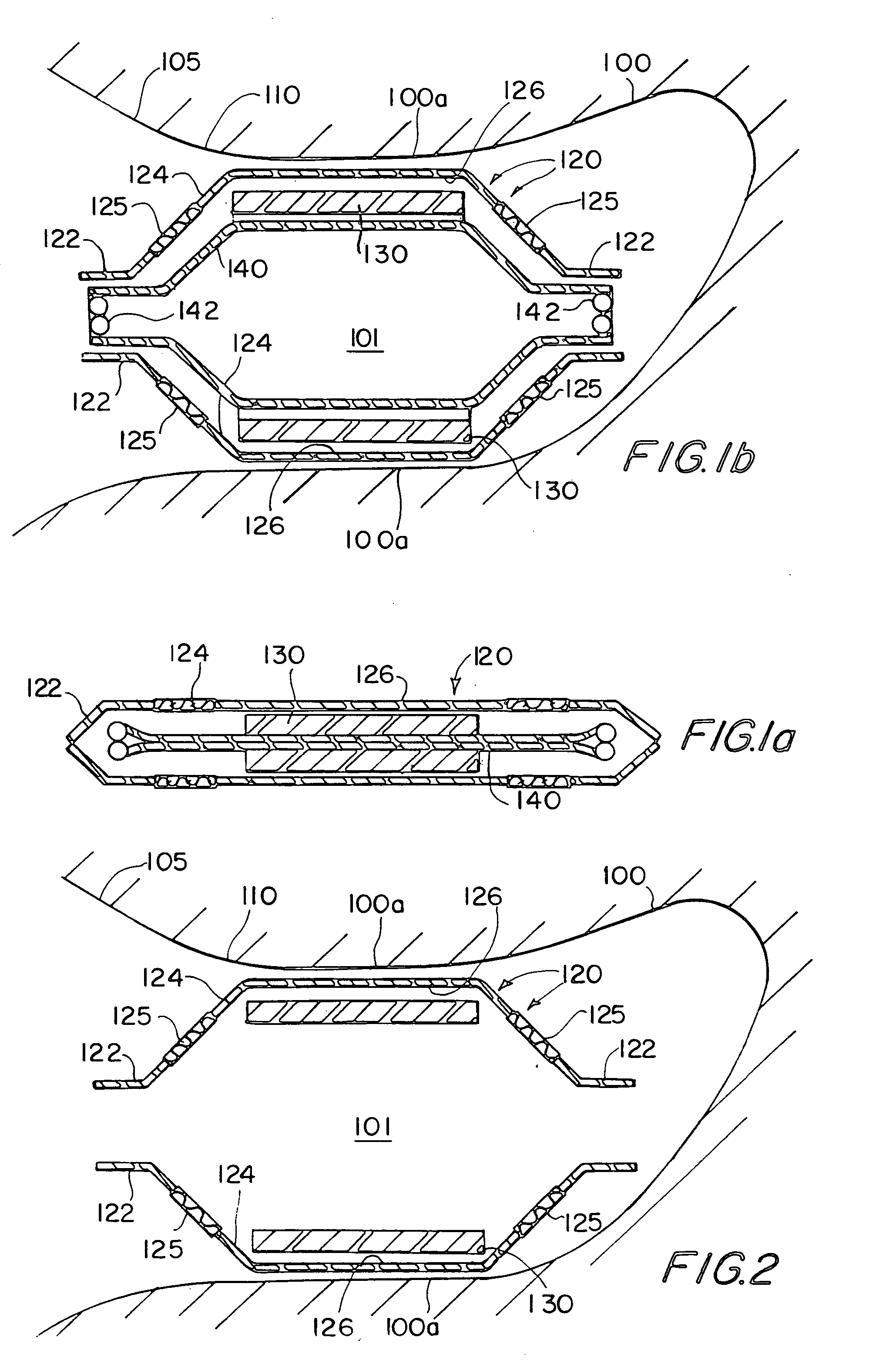

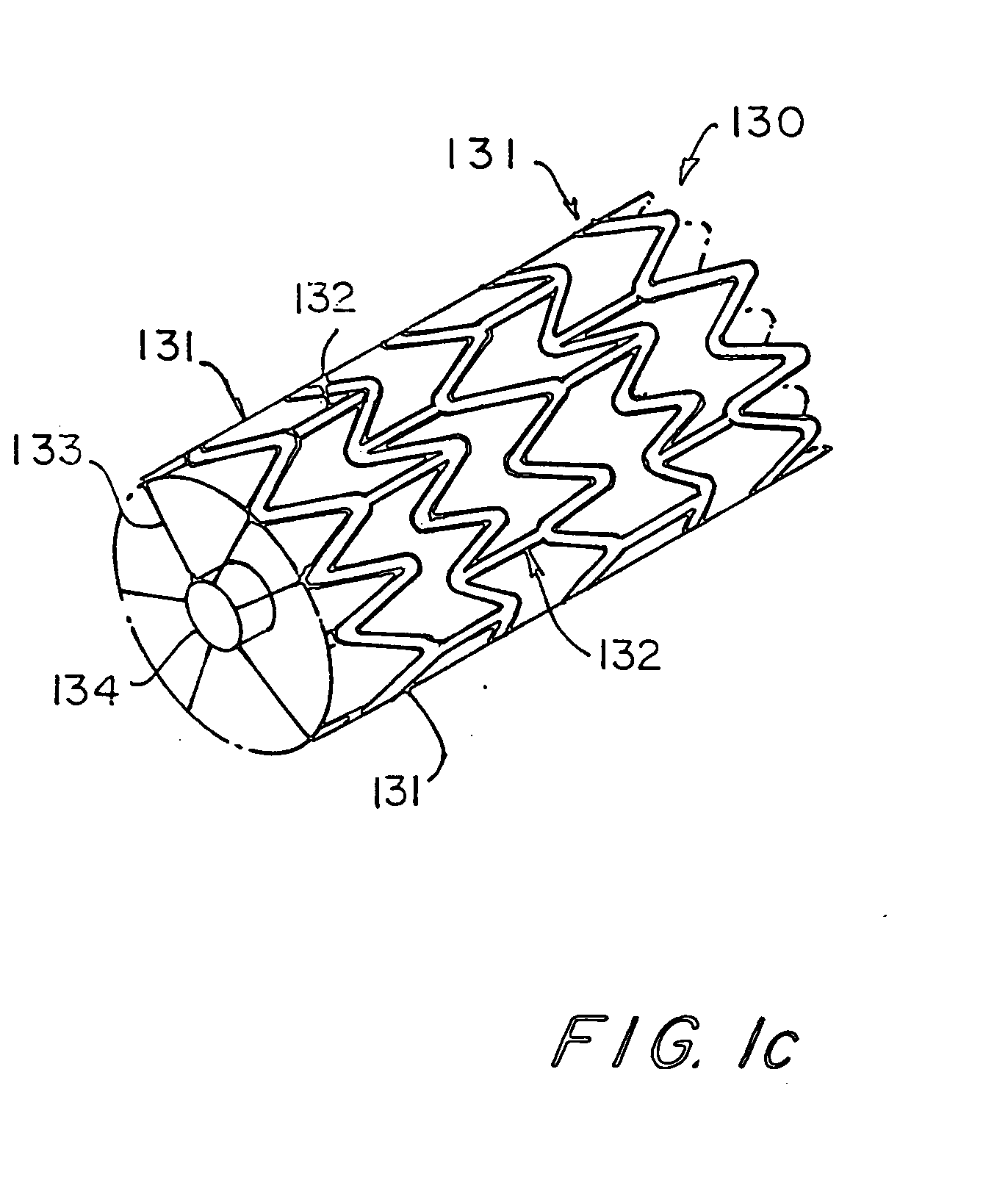

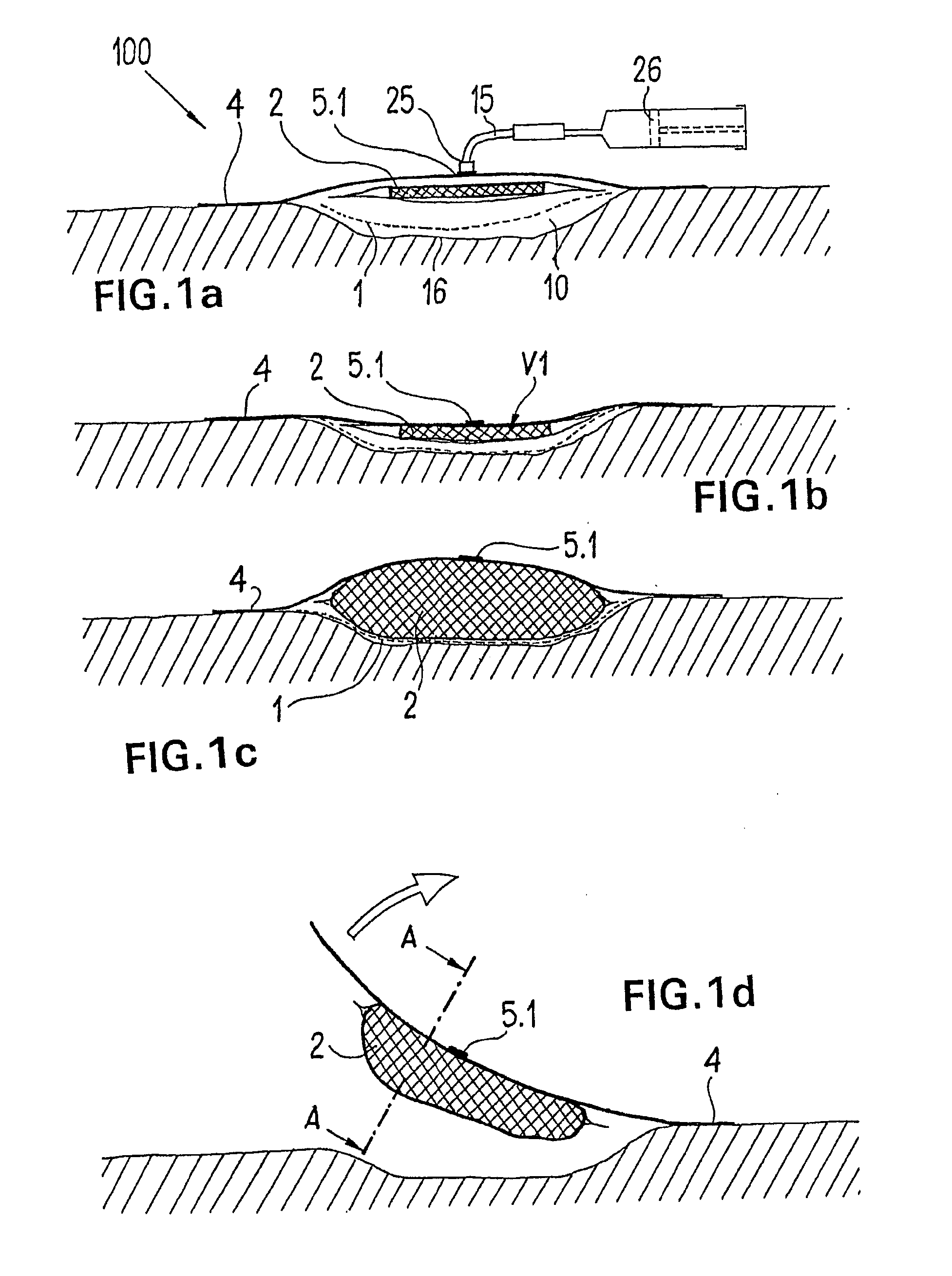

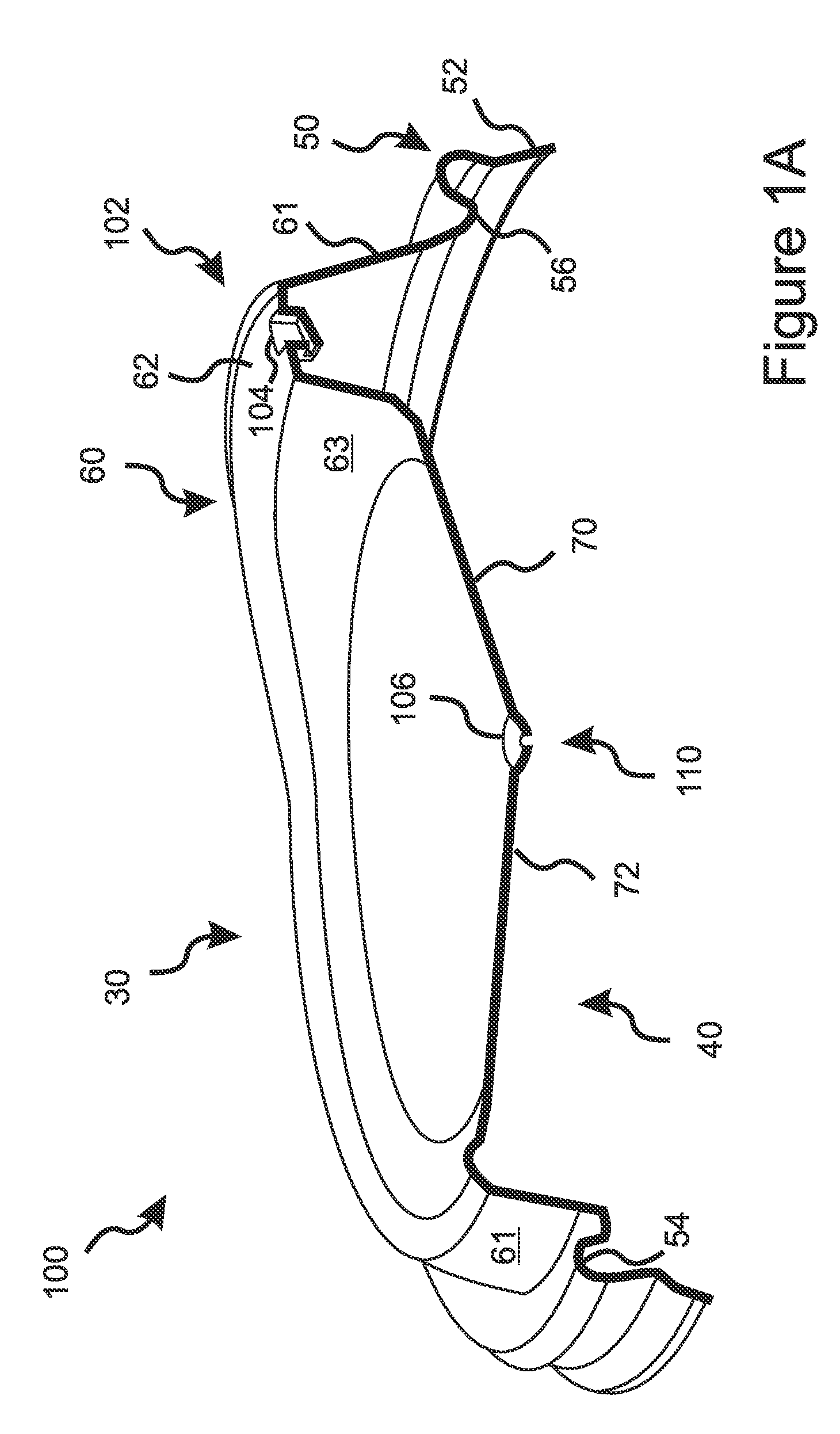

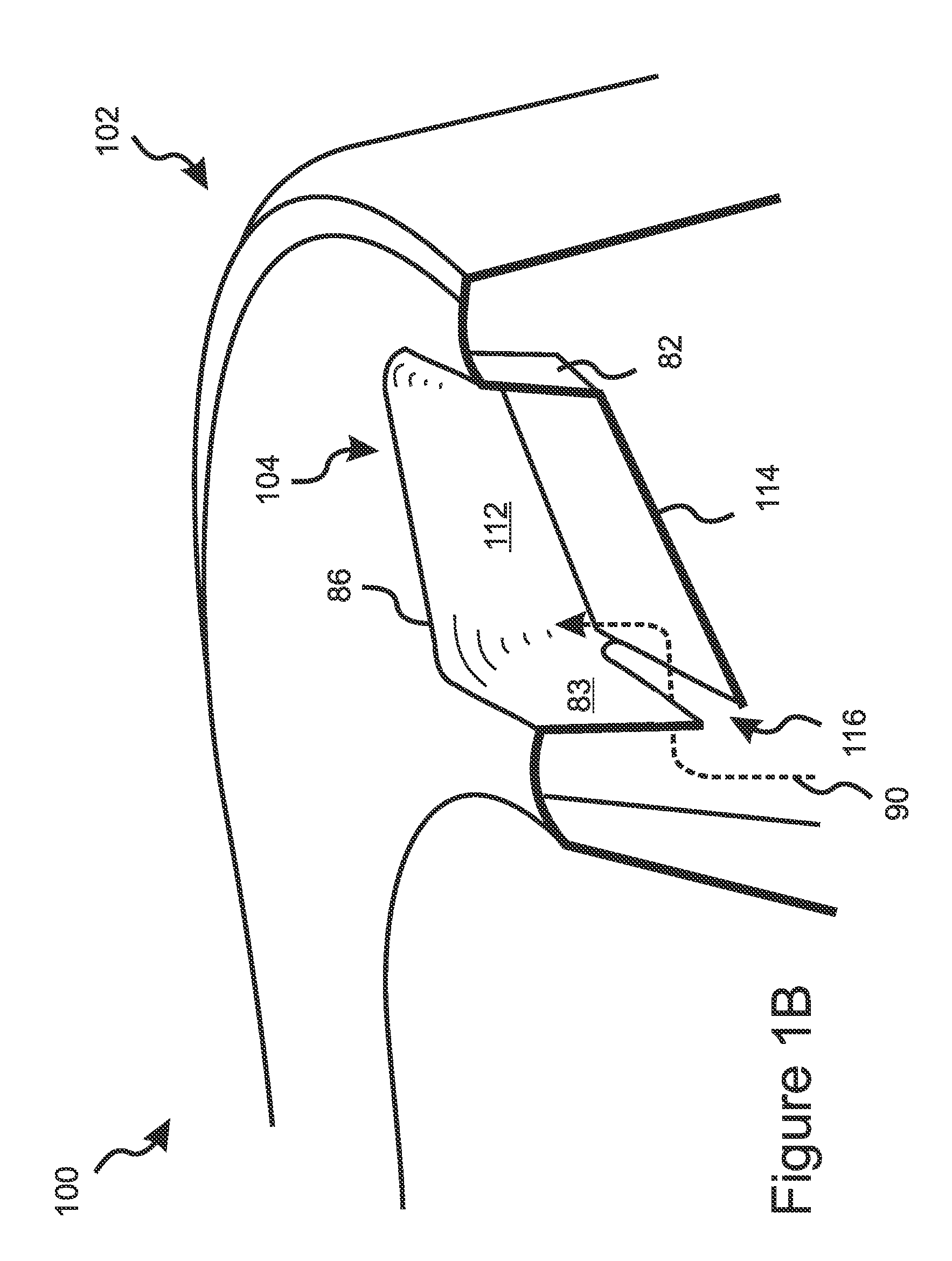

Expandable implant devices for filtering blood flow from atrial appendages

Implant devices for filtering blood flowing through the ostium of an atrial appendage have component structures one or more of which are expandable. Devices with component structures in their unexpanded state have a compact size suitable for intra-cutaneous delivery to an atrial appendage situs. The expandable component structures are expanded in situ to deploy the devices. A device may have sufficiently short axial length so that most or almost all of the device length may fit within the ostium region. An expandable component structure in the device may include a blood-permeable filter element. The device may be deployed so that this component structure covers the ostium so as to direct the blood flow to pass through the filter element. The filter elements used in the devices may have hole size distributions selected to filter out harmful-size emboli. The filter elements may be embedded in elastic material so that hole-size distributions remain substantially unaffected by expansion of the device structures. Anchors attached to a component structure engage tissue surrounding the device and maintain the devices in position. The anchors may include inflatable anchors which engage interior walls of the atrial appendage.

Owner:BOSTON SCI SCIMED INC

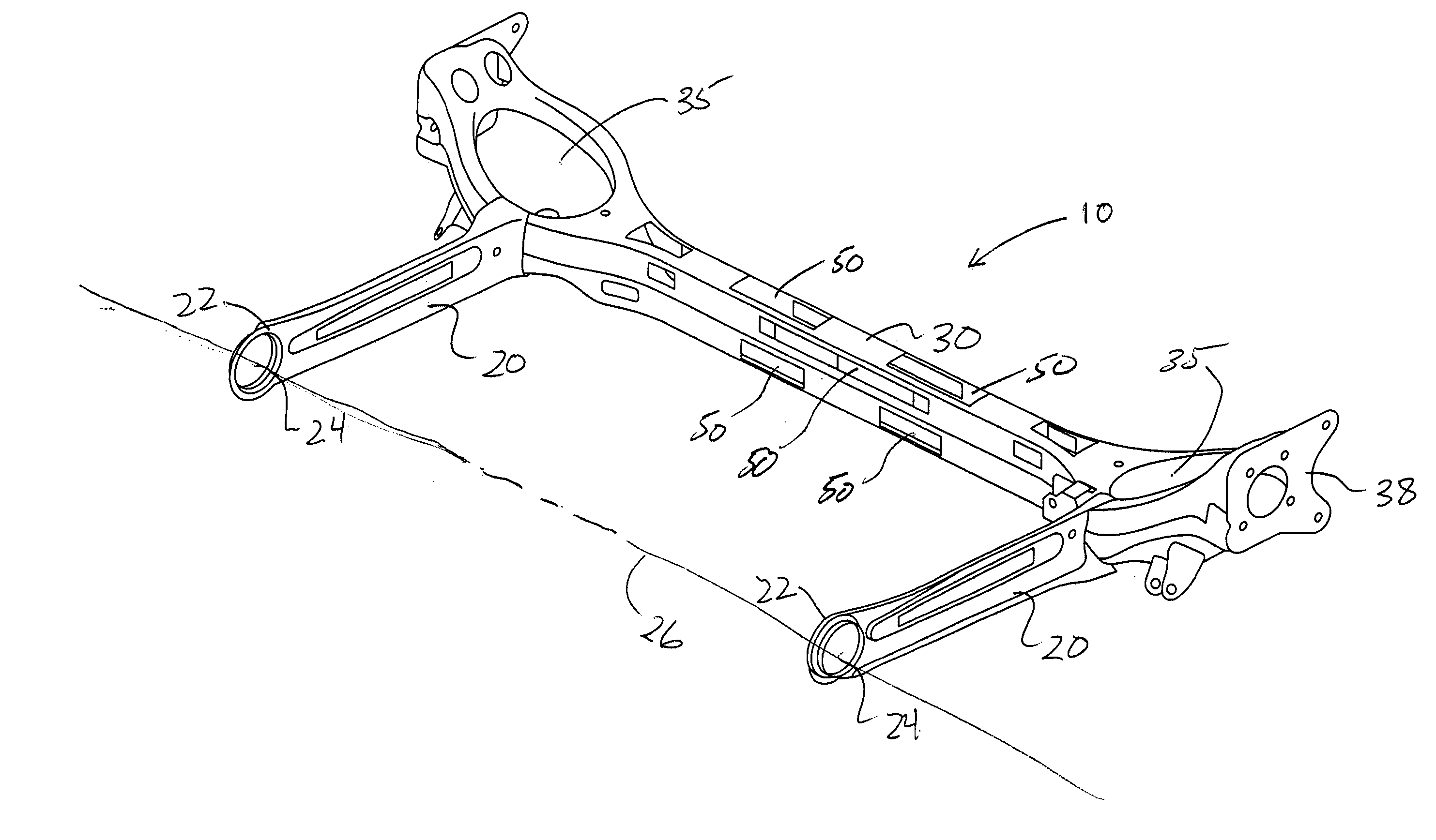

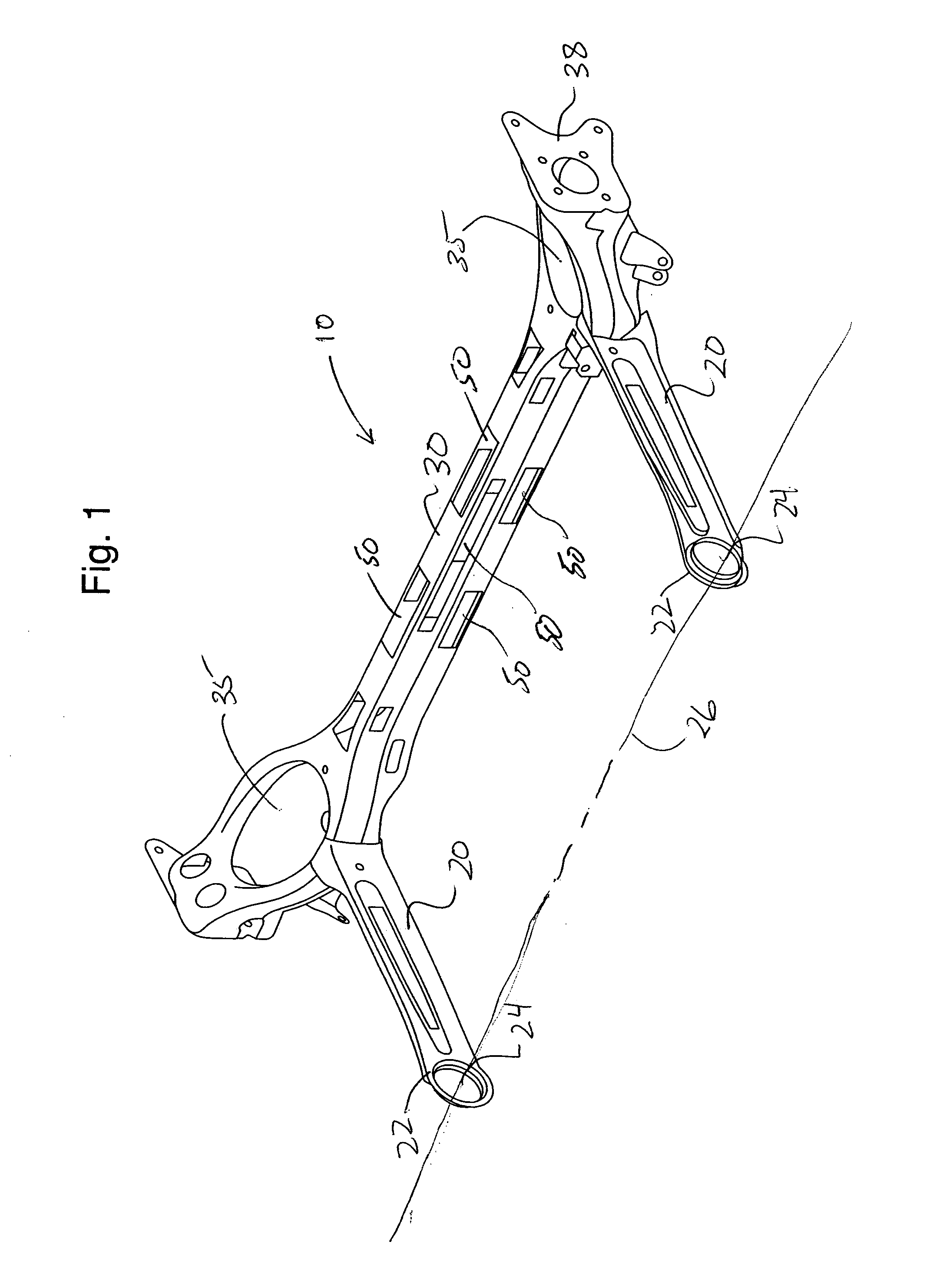

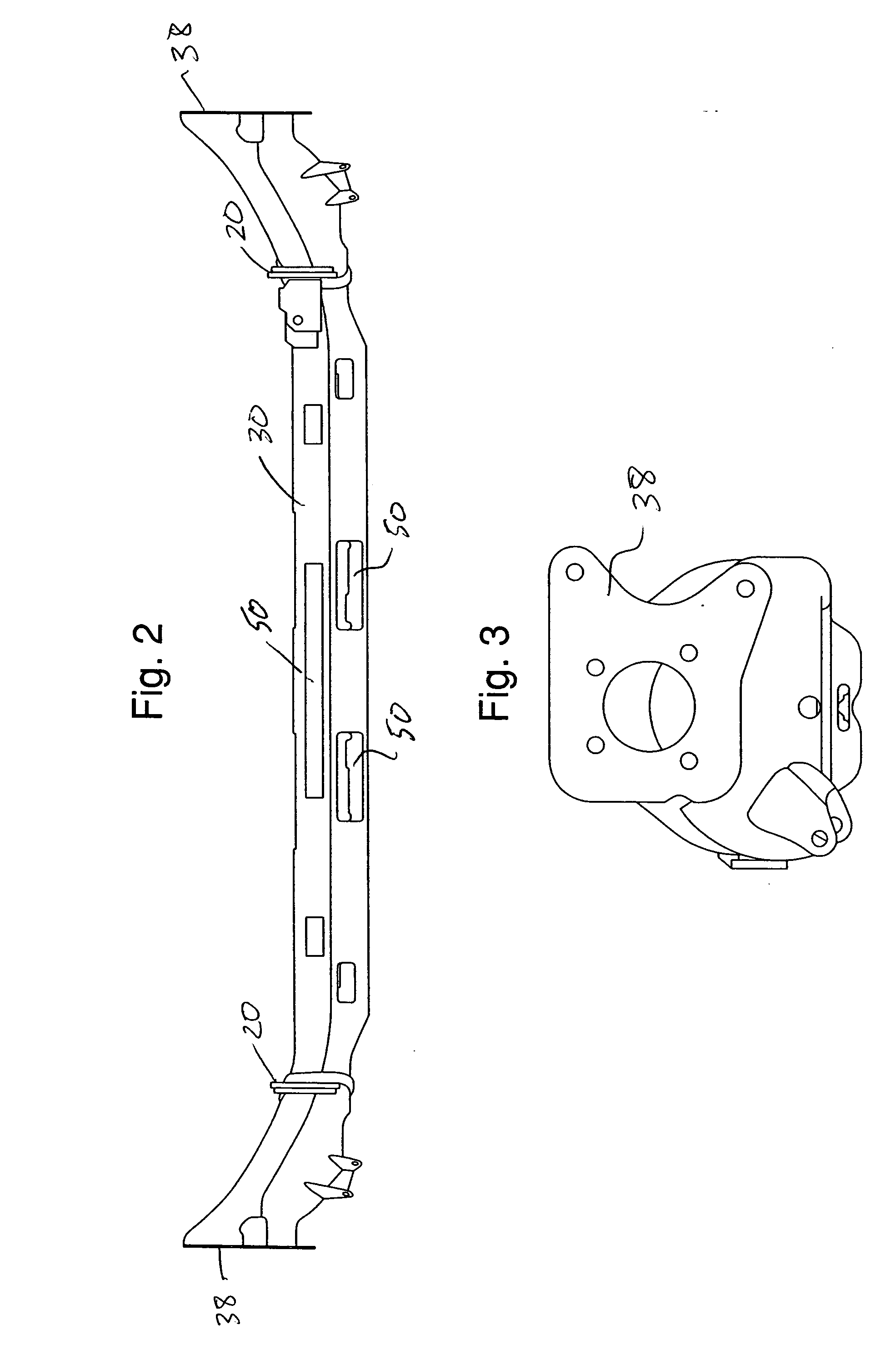

Torsion beam suspension member

A torsion beam suspension member using two u-shaped, stamped members that are superimposed and welded to form a torsion arm. No additional torsion tube or bar is needed. Tuning holes (rectangular, oblong, round or any other suitable shape) are used to change or tune the torsional resilience of the suspension. In the preferred embodiment, the tuning holes are oblong and located near the center of the cross member. The tuning holes are selected based on having target value for torsional compliance or resilience. The size, quantity and location of the tuning hole are chosen based on computer analysis. An optimization or iterative process is used to arrive at the final hole size, quantity and location.

Owner:DANA AUTOMOTIVE SYST GRP LLC

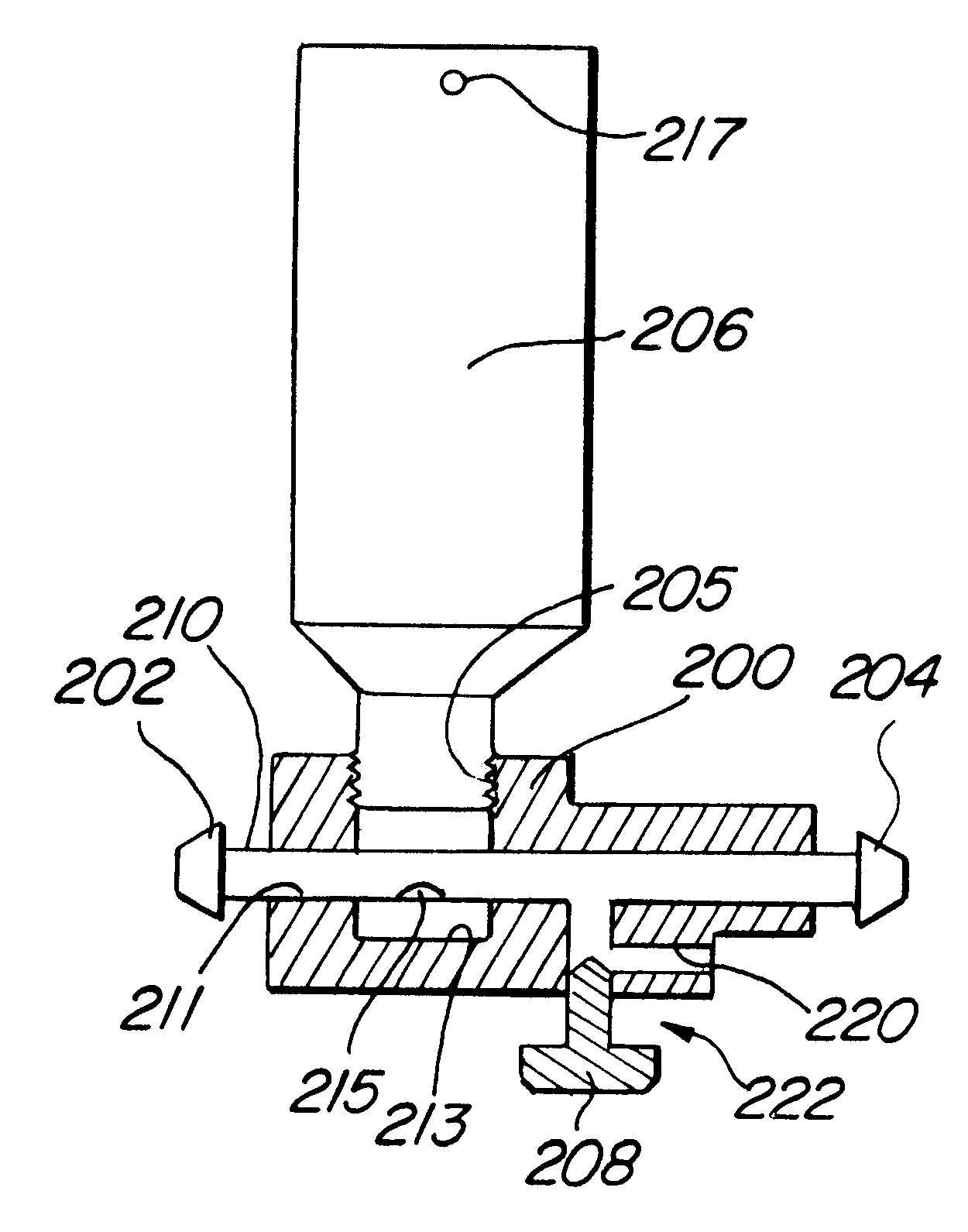

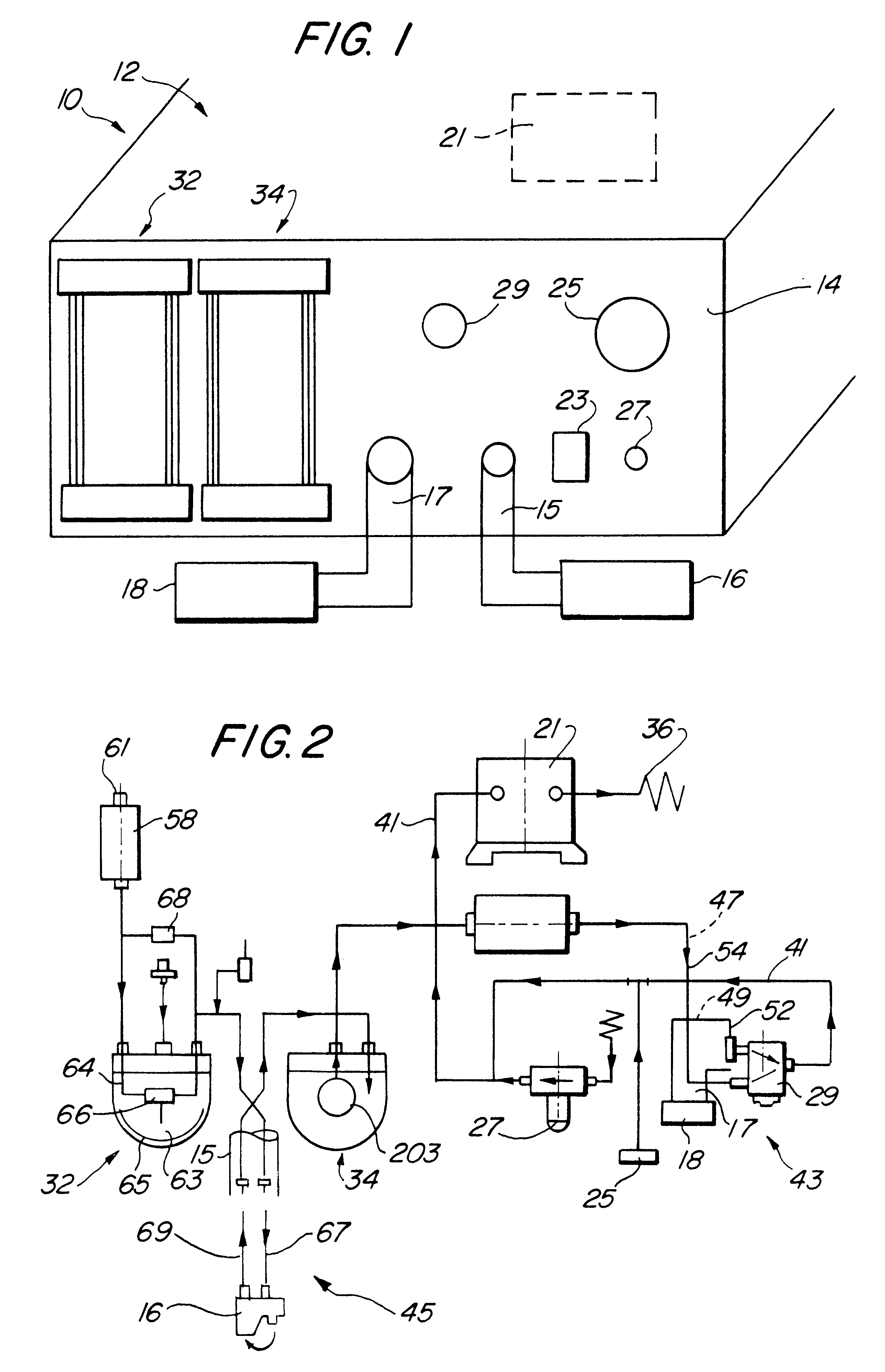

Microdermabrasion and suction massage apparatus and method

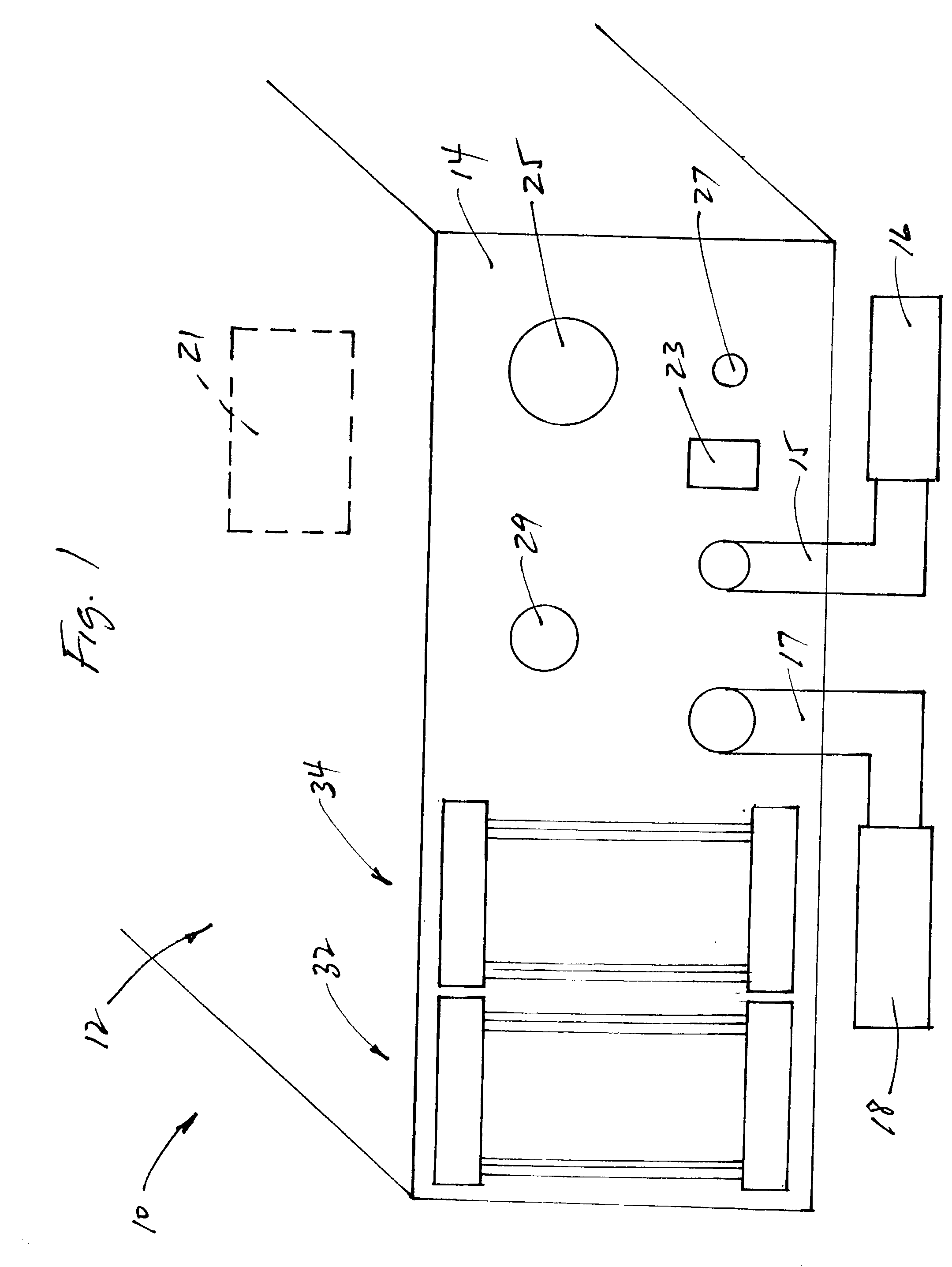

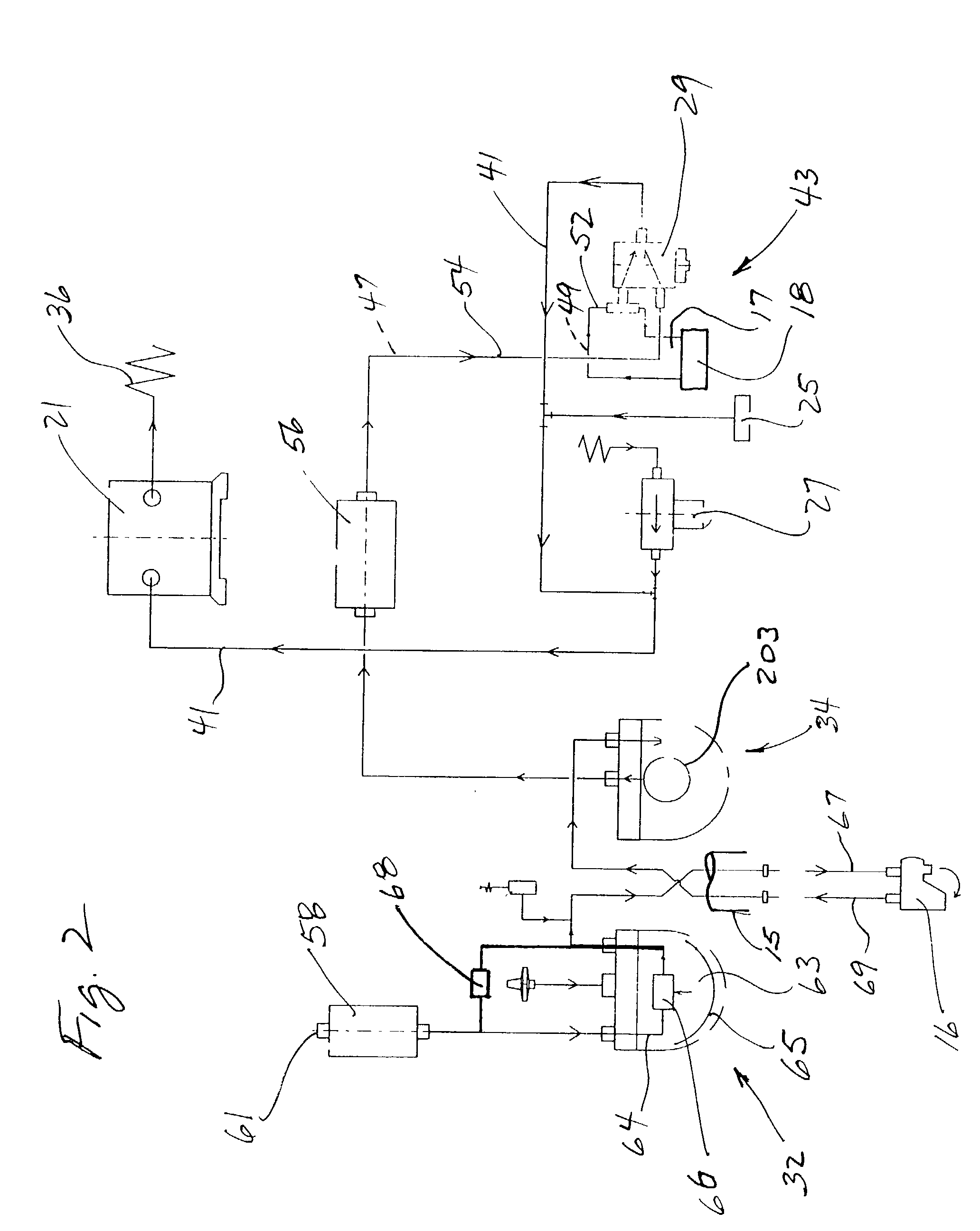

Microdermabrasion and suction massage apparatus are included in a single unit and alternatively connectable through a mode switch to a source of vacuum. The microdermabrasion section of the unit includes a crystal pick up station operating with a venturi effect to draw crystals through a hole into an air stream. The size of the hole is variable to control crystal density. A bleed valve is provided to control crystal velocity without controlling crystal density, while a bypass valve is provided to control crystal density without controlling crystal velocity. In an associated method, a microdermabrasion procedure is performed on the skin of a patient at an operative site. The mode switch is operated to activate the suction massage apparatus within the unit. This step is followed by performing a suction massage procedure at the operative site in order to promote healing of the abraded skin. The unit can be back-flushed by connecting various portions of the unit to a pressurized output of the source of vacuum.

Owner:EDGE SYST CORP

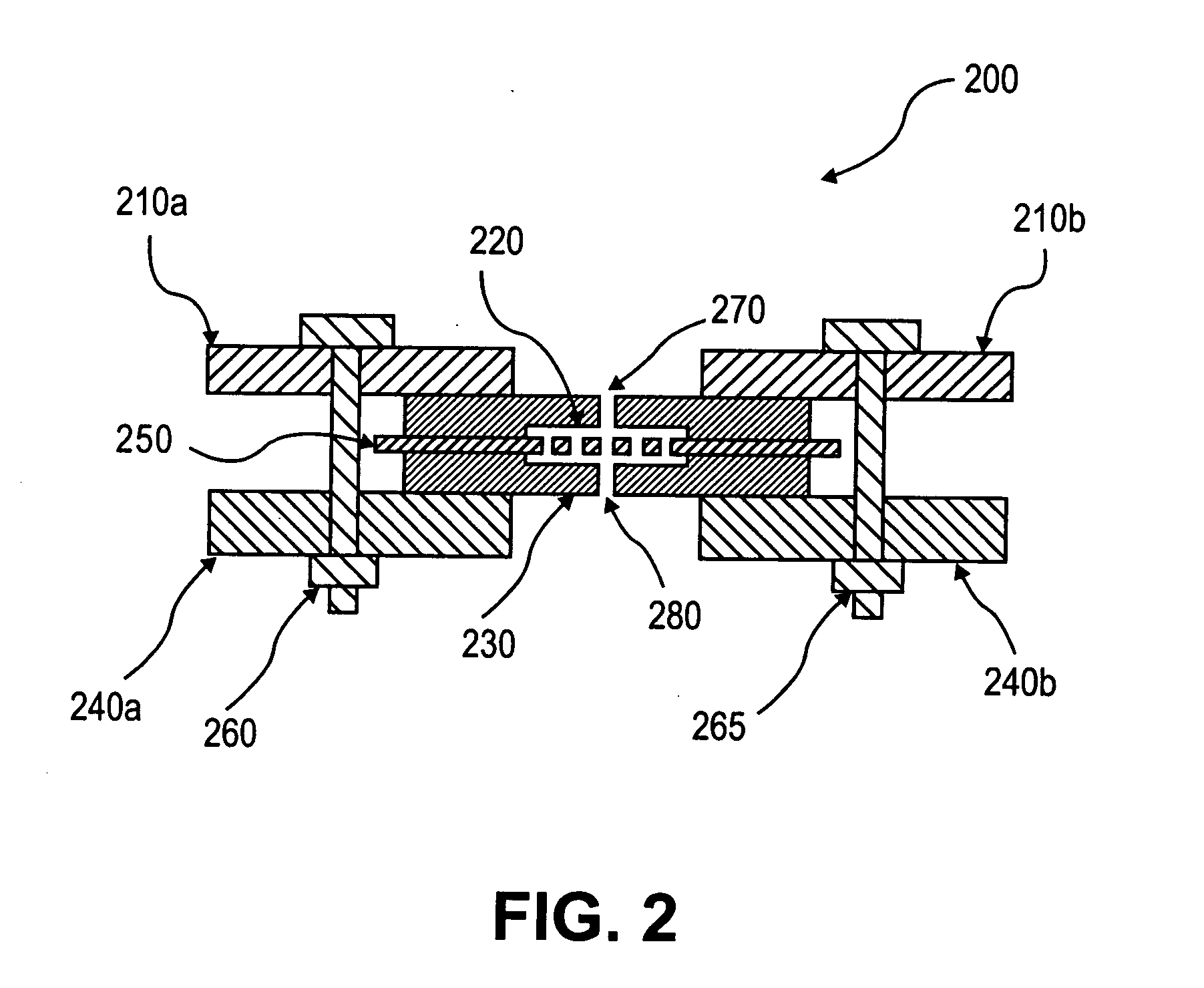

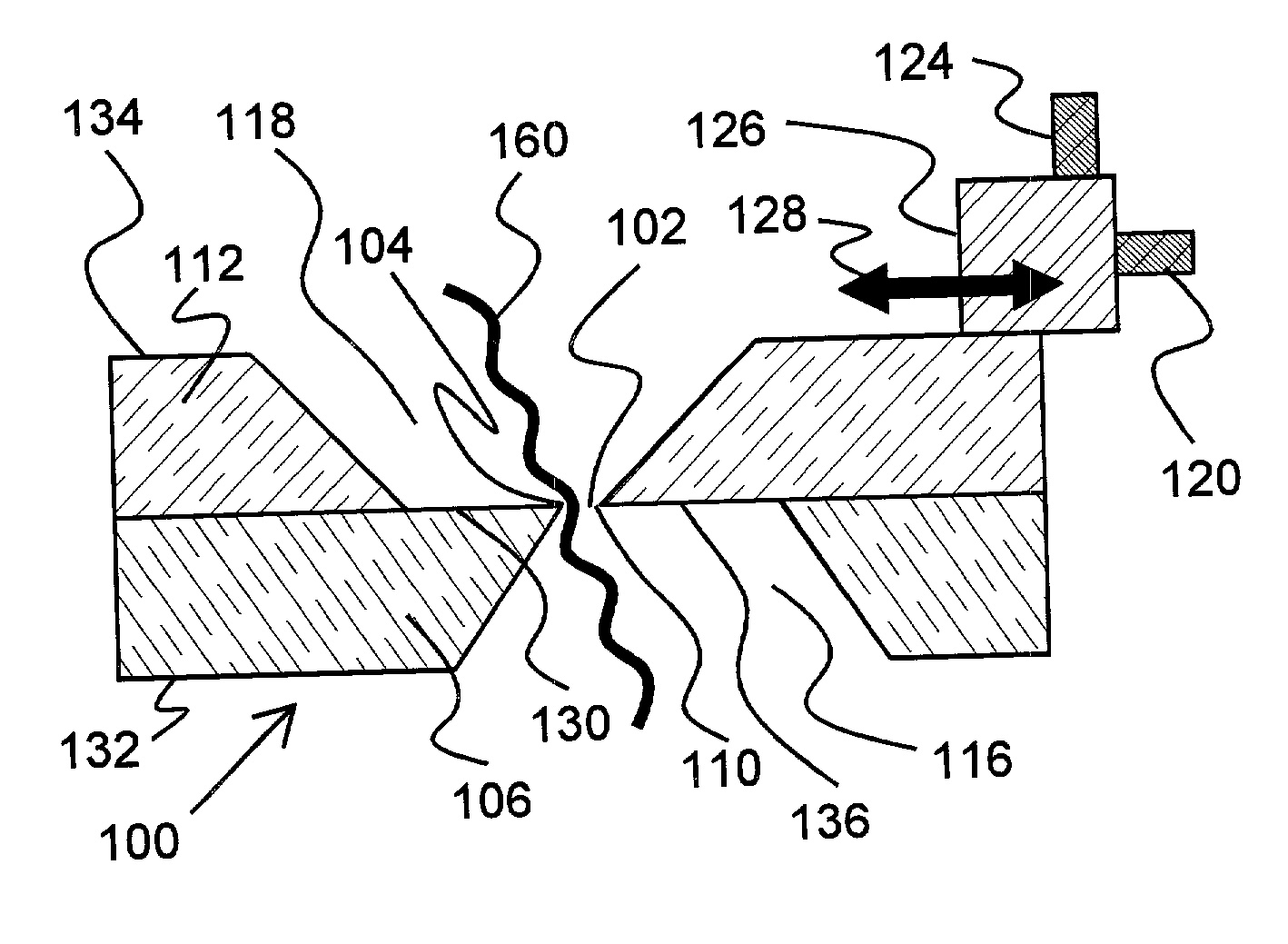

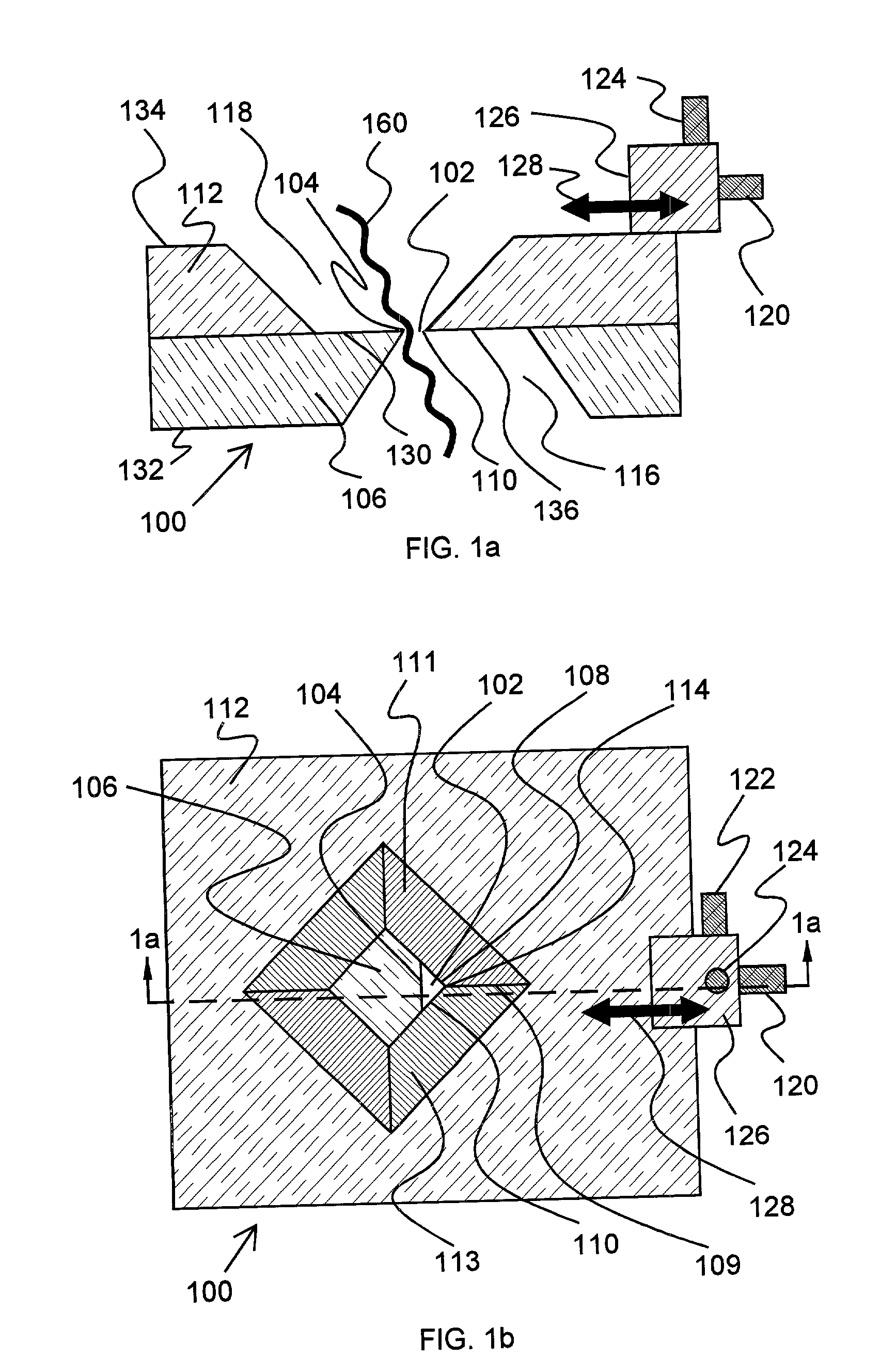

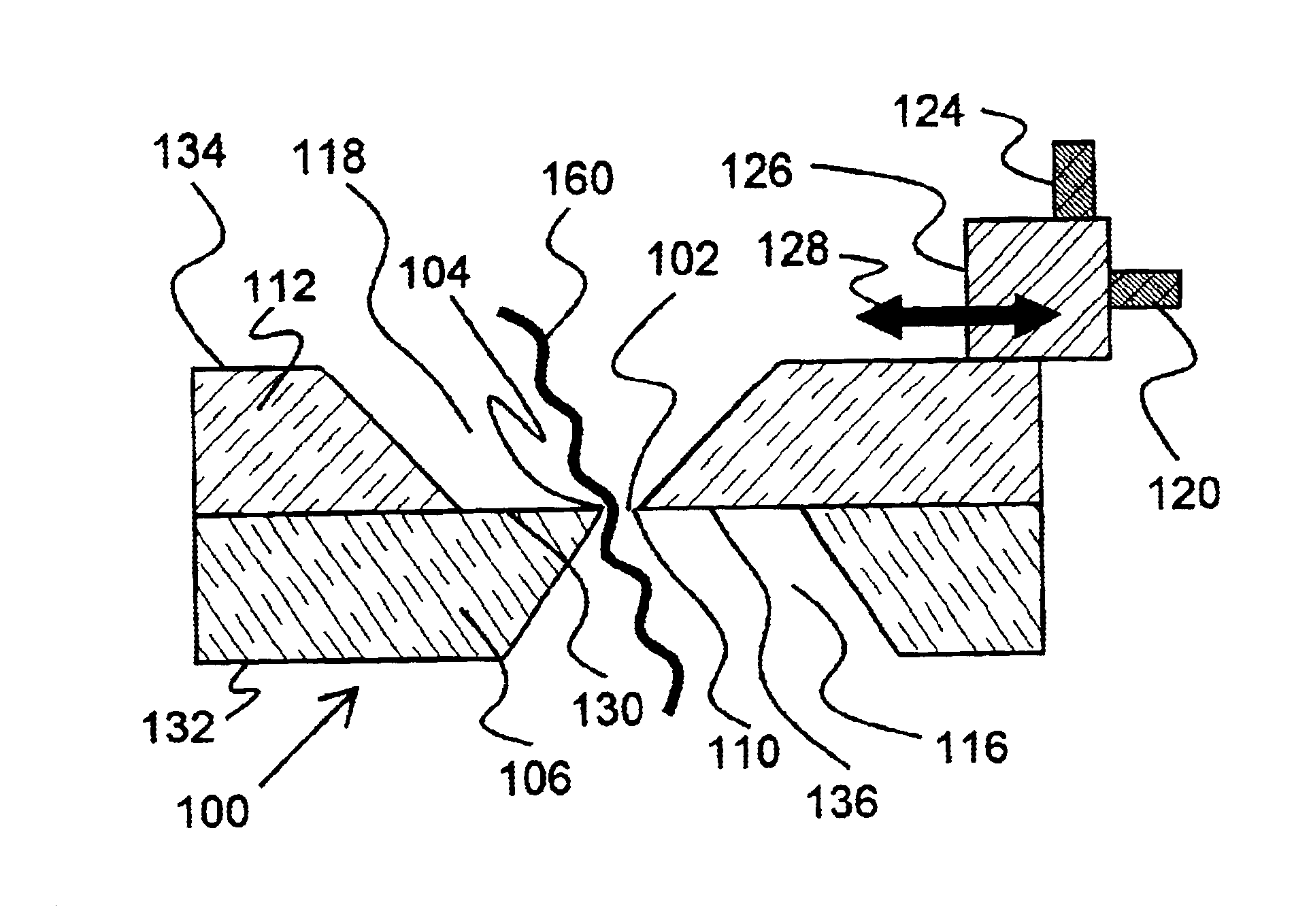

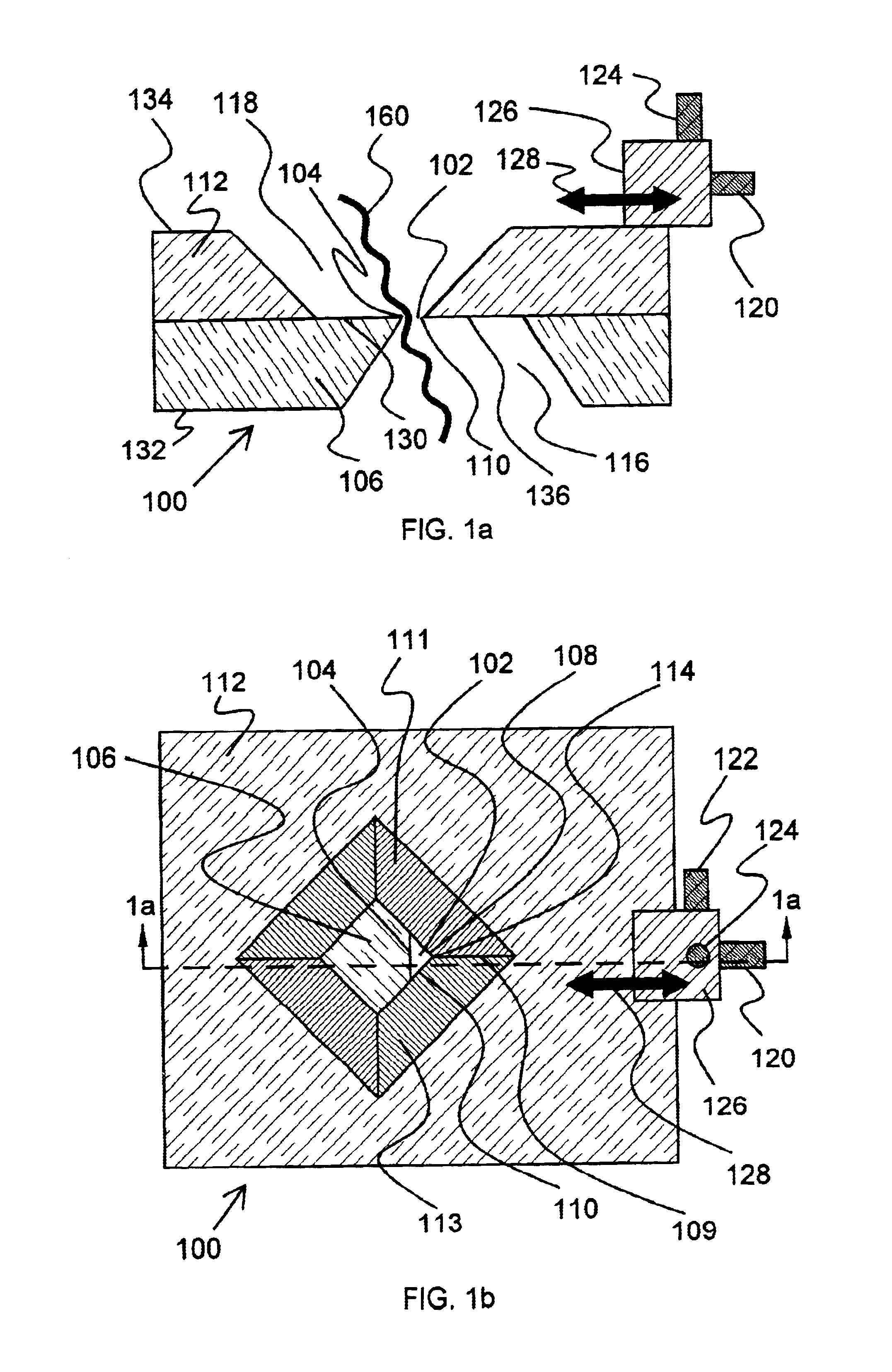

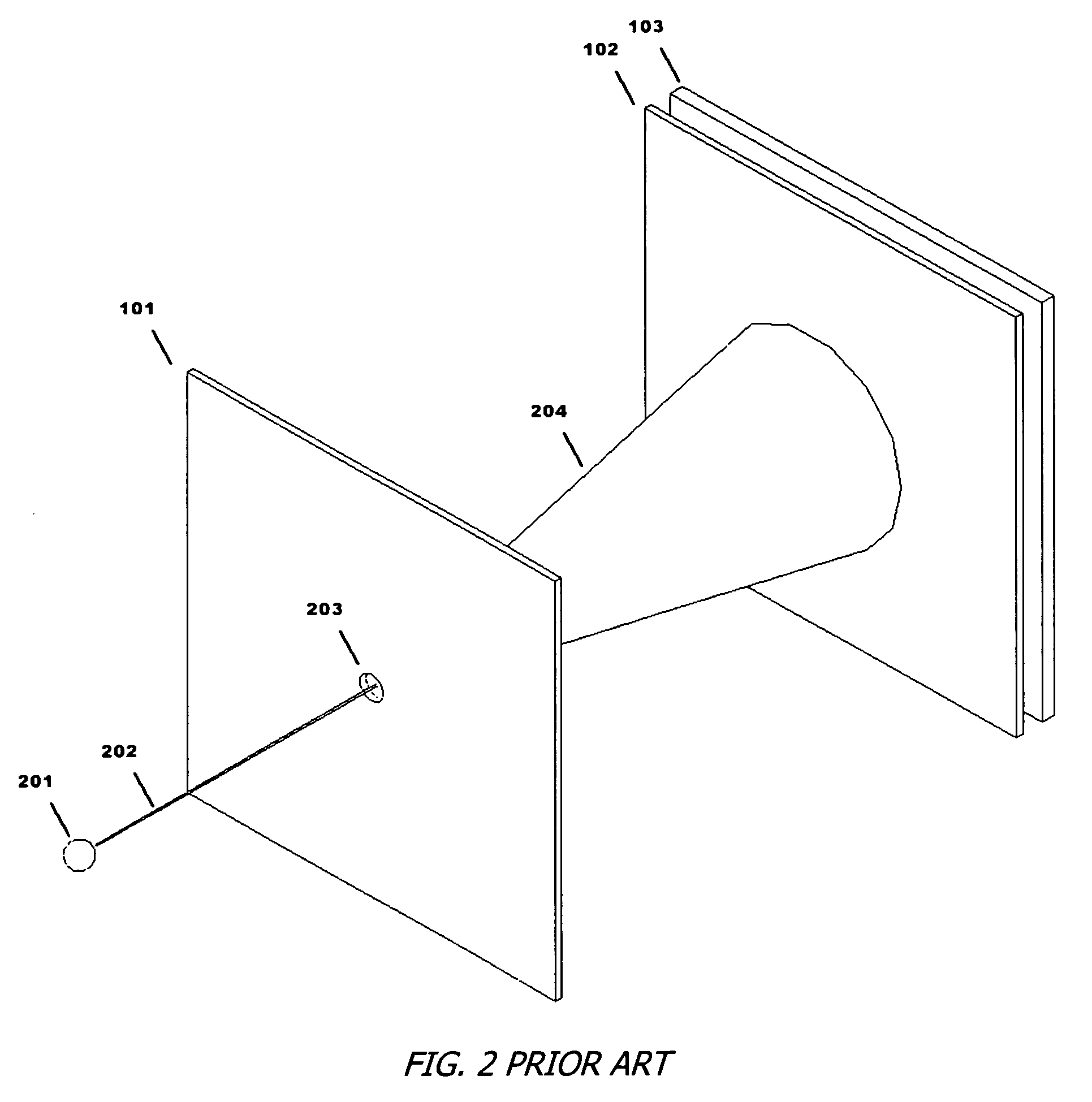

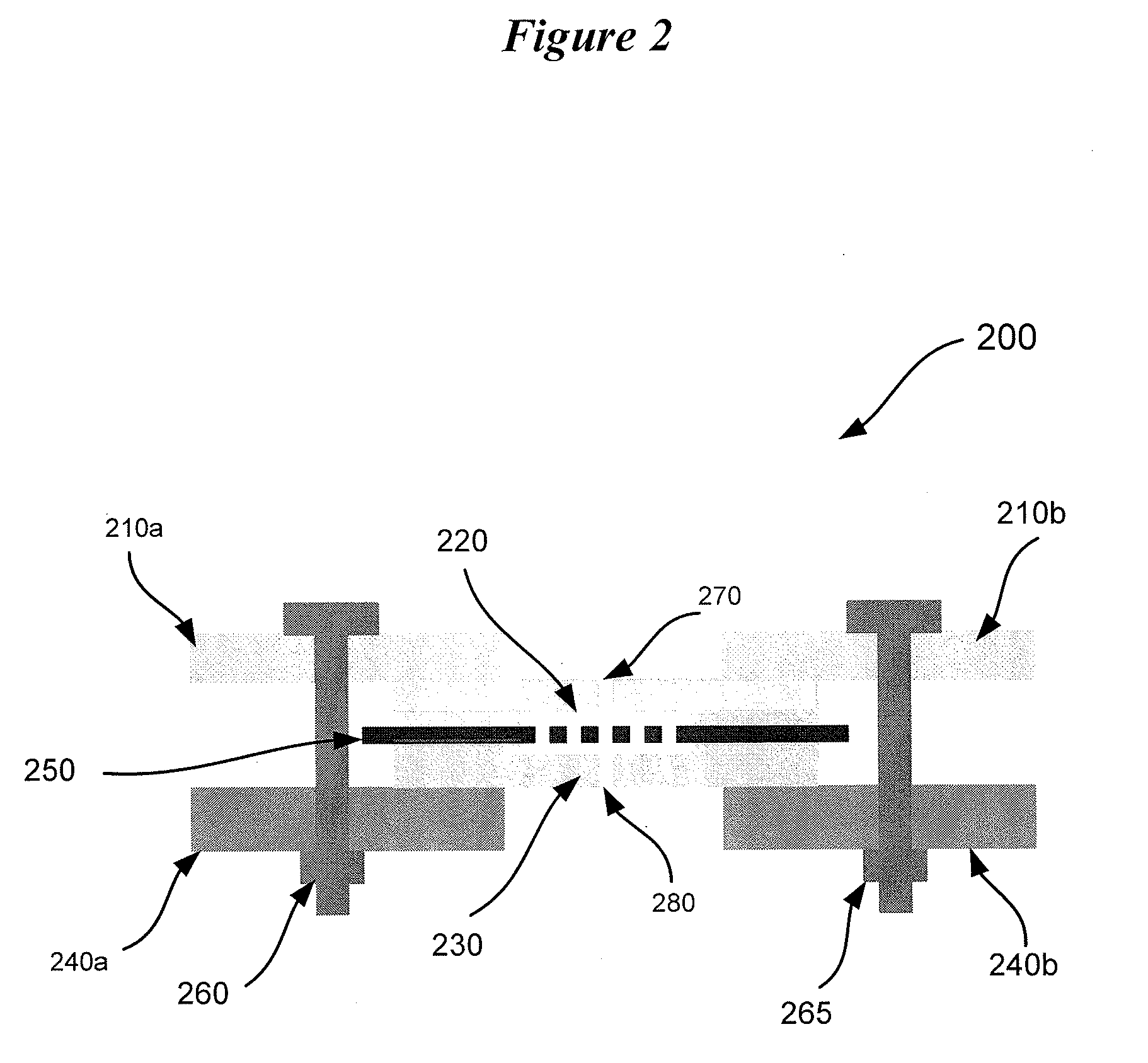

Adjustable nanopore, nanotome, and nanotweezer

InactiveUS20030080042A1Material nanotechnologyPaper/cardboard articlesRotational axisPlanar substrate

An adjustable nanopore is fabricated by placing the surfaces of two planar substrates in contact, wherein each substrate contains a hole having sharp corners and edges. A corner is brought into proximity with an edge to define a triangular aperture of variable area. Ionic current in a liquid solution and through the aperture is monitored as the area of the aperture is adjusted by moving one planar substrate with respect to the other along two directional axes and a rotational axis. Piezoelectric positioners can provide subnanometer repeatability in the adjustment process. The invention is useful for characterizing, cleaving, and capturing molecules, molecular complexes, and supramolecular complexes which pass through the nanopore, and provides an improvement over previous devices in which the hole size of nanopores fabricated by etching and / or redeposition is fixed after fabrication.

Owner:AGILENT TECH INC

Method for analyzing pore structure of solid material based on microscopic image

InactiveCN101639434ACalculated pore sizeCalculate porosityPermeability/surface area analysis3D-image renderingPorosityMicroscopic image

The invention provides a method for analyzing the pore structure of solid material based on microscopic image, belonging to the technical field for analyzing the pore structure of the solid material.The method is characterized of: obtaining the CT single cross section image of the solid material by microscopic CT scanning; using computer language to digitally image process the CT single cross section image; taking the pixel side of the image as the size of hole diameter; computing the hole diameter of the solid material, porosity and change regularity of the hole diameter and the porosity based on the microscopic CT single image; selecting the CT single image after processing a plurality of digital image; generating a CT image sequence; three dimensionally rebuilding the CT single image with a volume rendering algorithm in a visual rebuilding algorithm; generating the three dimensional digital image of the solid material; and computing the hole diameter of the solid material, the porosity and the change regularity of the hole diameter and the porosity based on the microscopic CT single image. The method is widely used for analyzing and computing the hole size and the porosity of the solid material under the various hole sizes of the solid material.

Owner:TAIYUAN UNIV OF TECH

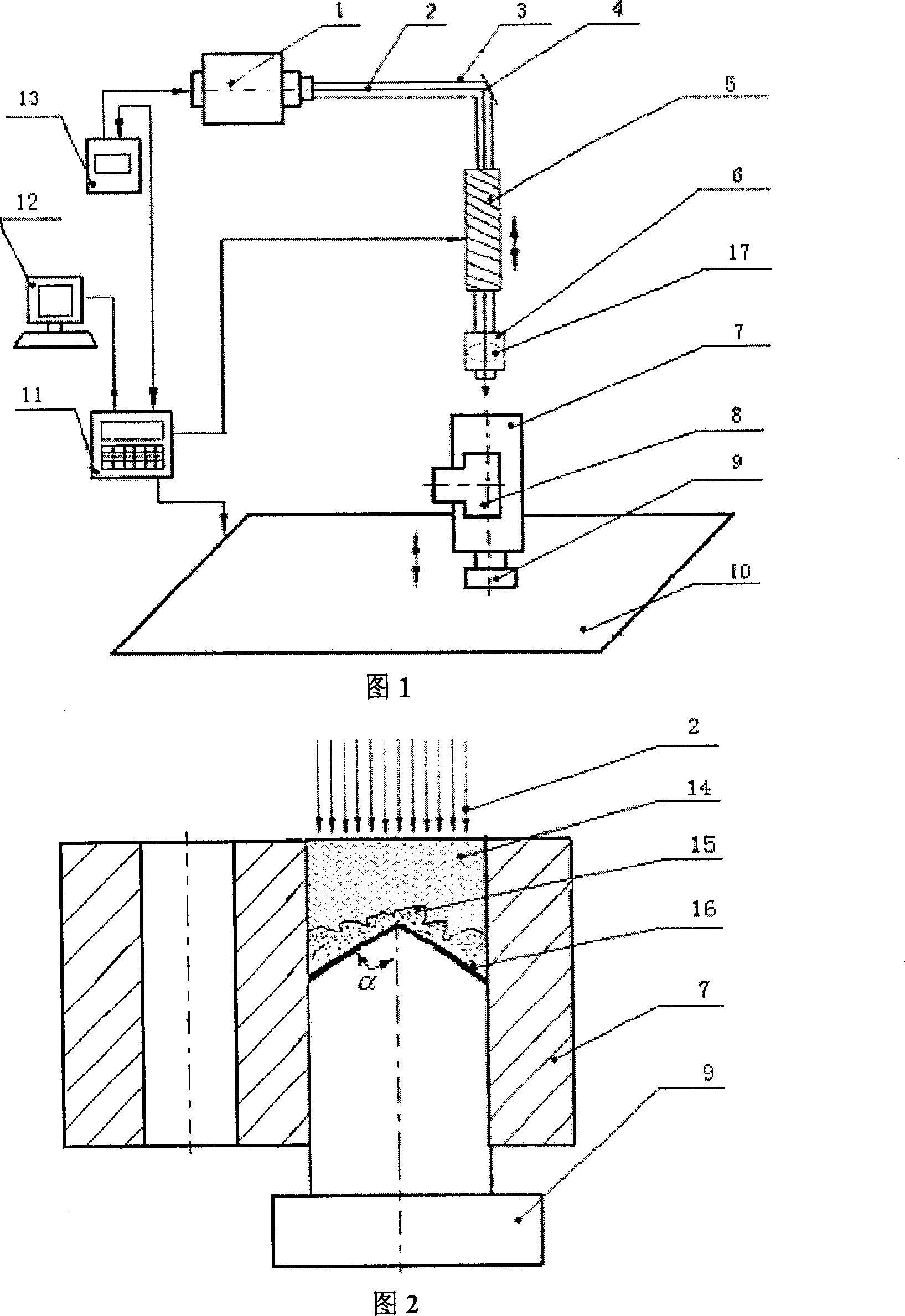

Technical hole wall intensifying method based on laser impaction wave and apparatus

The invention is a hole wall strengthening method and device based on laser shock wave technique, relating to the laser machining field. And the invention firstly determines the corresponding reflecting cone diameter according to the principle of cooperation of hole size and hole shaft of a to-be-machined workpiece, coating energy absorbing layer material on the concial surface of the reflecting cone and then inserting the reflecting cone in the workpiece, installing the workpiece on a clamp, injecting constraint layer in the to-be-machined hole; a laser generates a laser pulse which irradiates the energy absorbing layer through light guiding system and constraint layer, and the energy absorbing layer absorbs the laser energy to vaporize, ionize, form plasma explosion, generate high amplitude shock wave, and strengthen the hole wall. And the invention can strengthen the walls of holes with larger diameters and strengthen the walls of micropores. And the strength and hardness of the strengthened hole wall are remarkably improved, and the surface layer has helpful remaining compression stress and it can obtain higher size accuracy and lower surface roughness and directly act as the final procedure of hole machining.

Owner:JIANGSU UNIV

Device for the treatment of wounds using a vacuum

InactiveUS20110313373A1Simple designCost effectiveAdhesive dressingsIntravenous devicesSecretionBiomedical engineering

A device for treating wounds using a vacuum and having a gas-tight wound-covering element, which, when placed in contact with the body of the patient, forms a wound space between the respective wound and the wound-covering element. The device includes an absorption body, which is a layer, enclosed in an envelope, of a textile section, interspersed with super-absorbing particles. The liquid-permeable envelope has pores, the size of which does not exceed that of the super-absorbing particles. The absorption body, inserted in the wound space, has an initial volume, which enlarges in the course of the absorption process, and a final volume, so that, due to the size of the pores of the envelope, the absorbed wound secretions remain within the absorption body and, with that, below the wound-covering element, until the absorption body is removed from the wound space.

Owner:RIESINGER BIRGIT

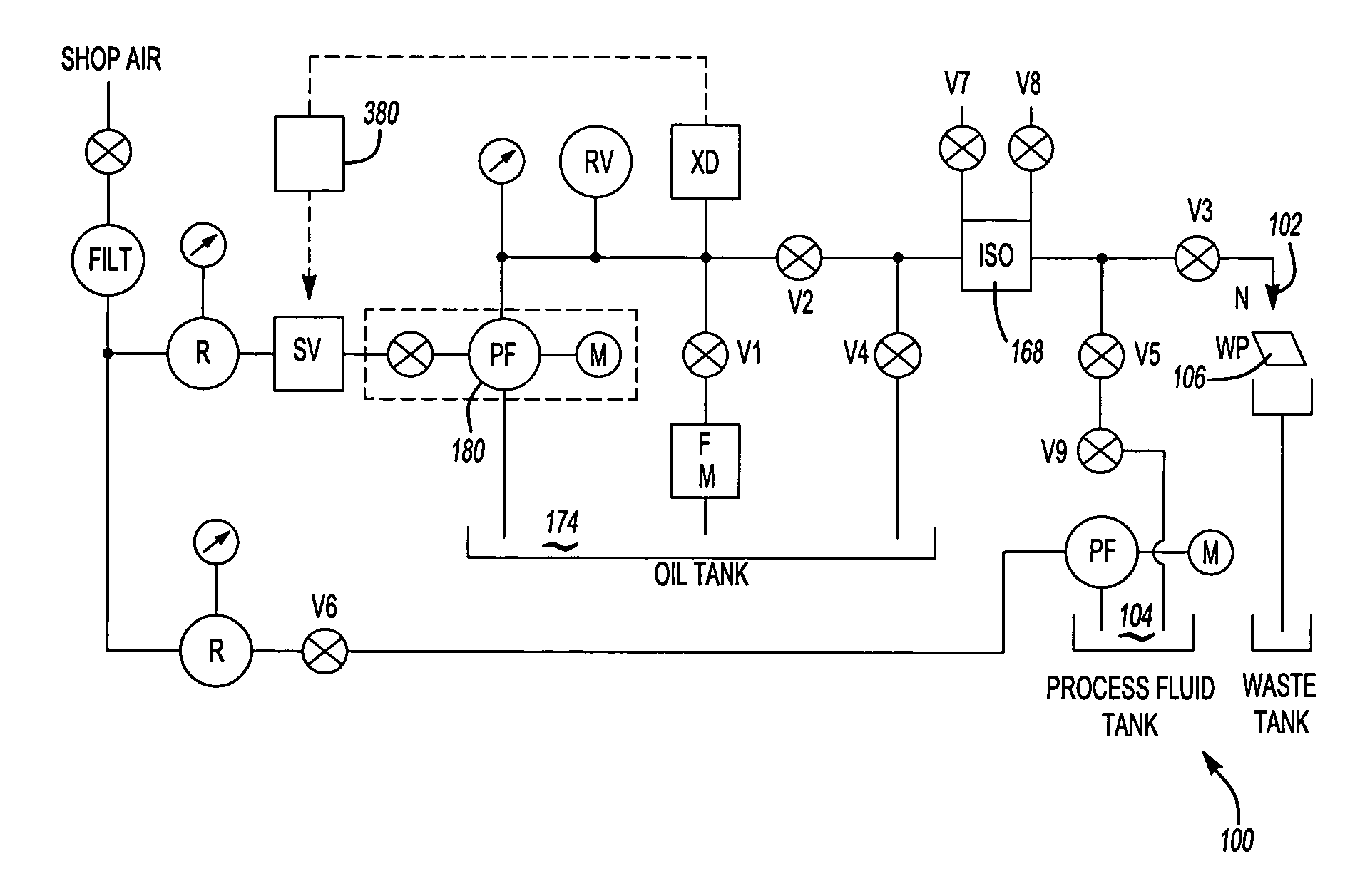

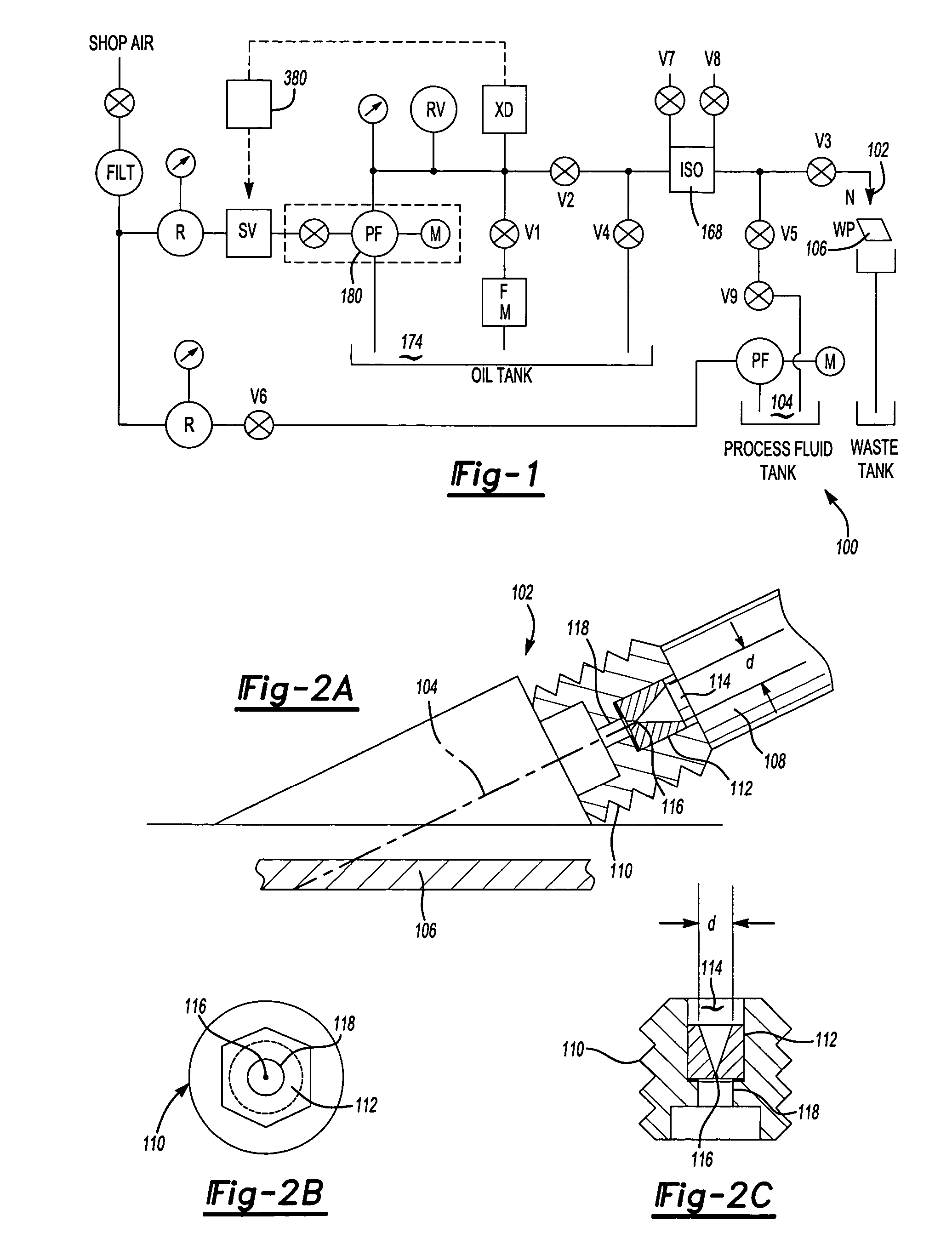

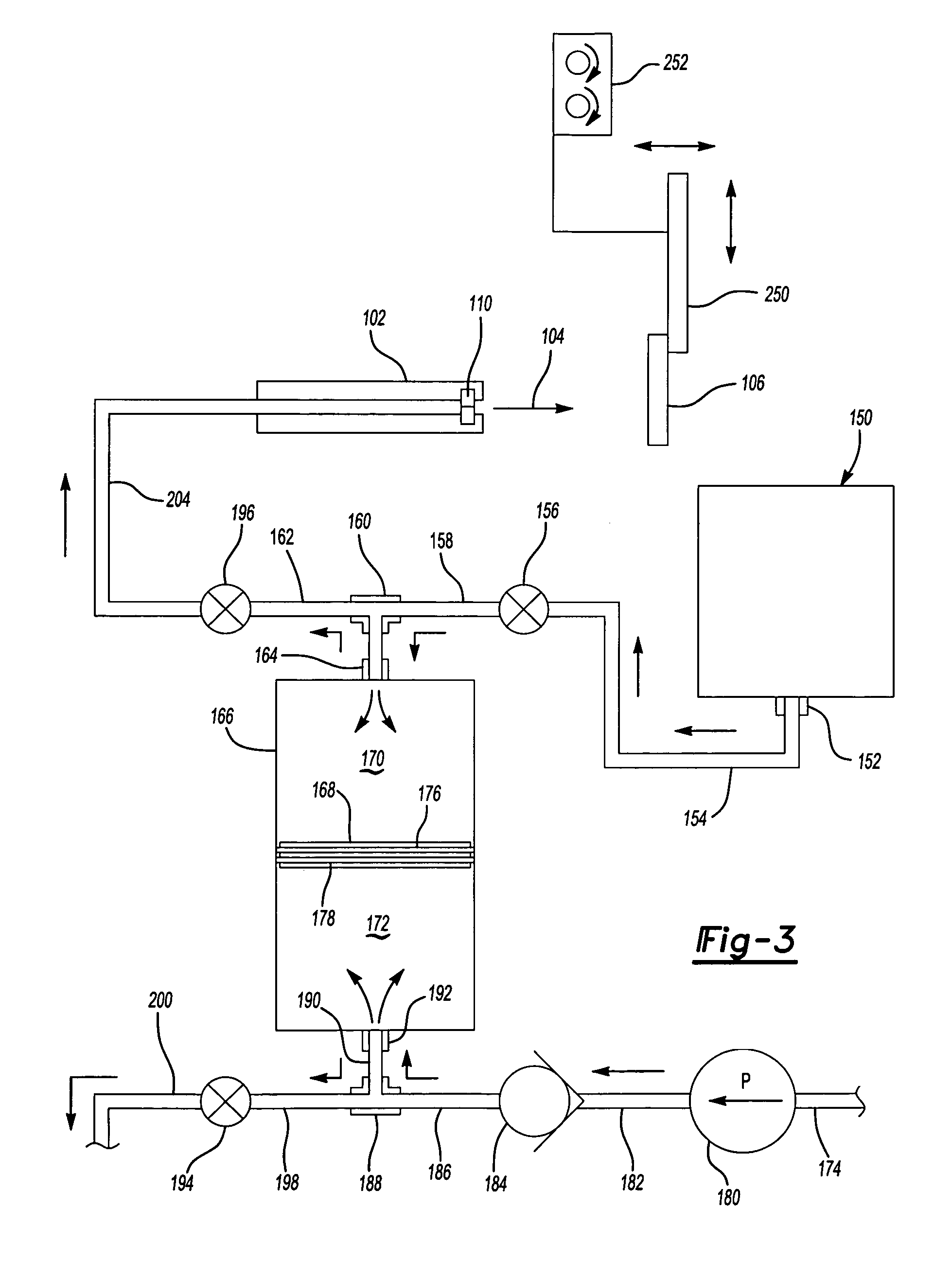

Suspended abrasive waterjet hole drilling system and method

ActiveUS7186167B2High viscosityVelocity increasesBlast gunsLiquid/gas jet drillingEngineeringDrilling system

A suspended abrasive waterjet narrow kerf cutting method is reconfigured to simultaneously drill multiple, closely-spaced holes in a target, including holes in confined non line-of-sight locations. Working fluid nozzles can be located on a flat or non-flat tool surface and arranged in uniform or non-uniform patterns, in an angled or perpendicular orientation, and in parallel or non-parallel arrangements. Individual nozzles or nozzle groups can be easily changed to provide increased or diminished working diameters, allowing control over the hole sizes and resultant airflow thru the drilled workpiece.

Owner:RTX CORP

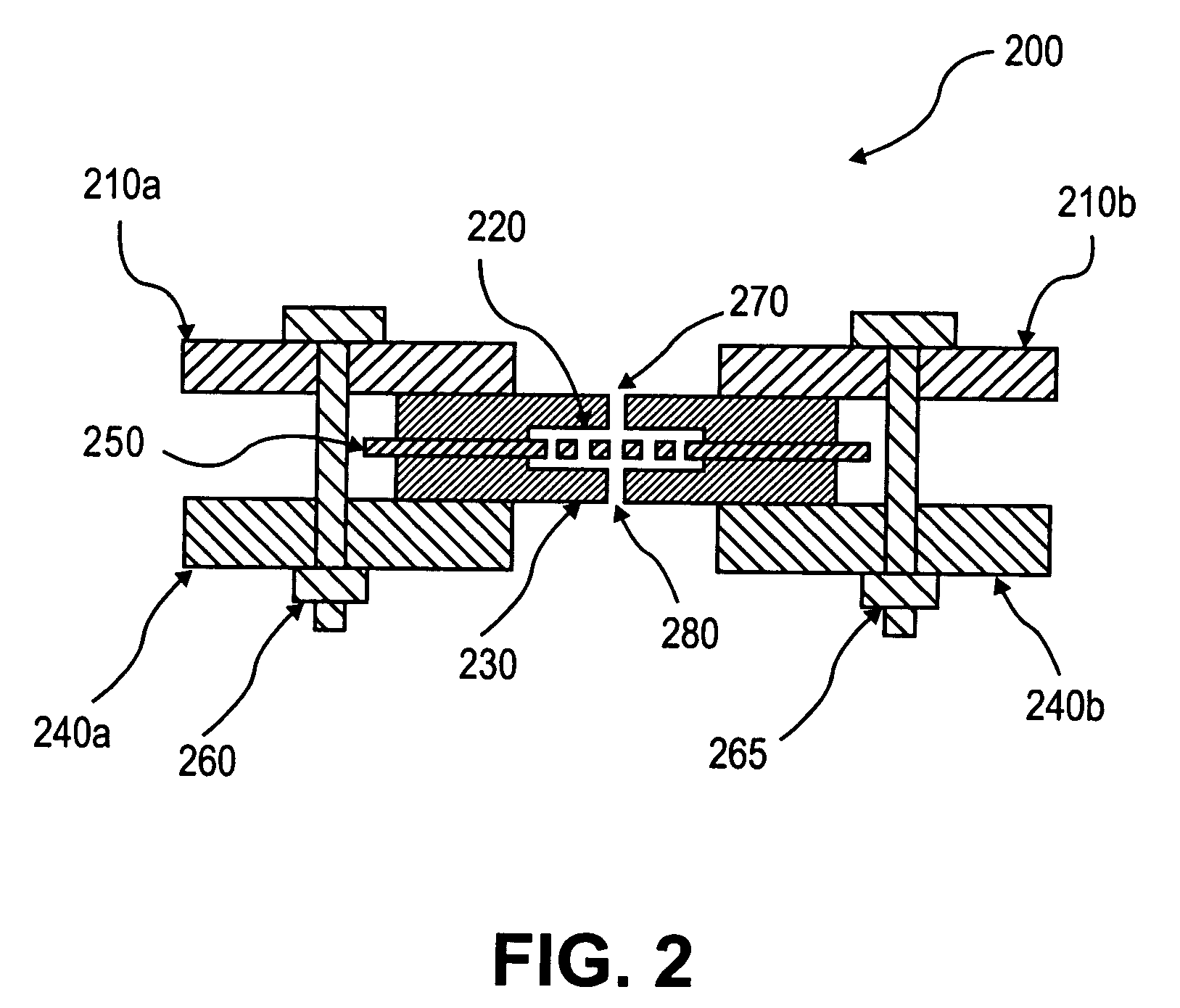

Adjustable nanopore, nanotome, and nanotweezer

An adjustable nanopore is fabricated by placing the surfaces of two planar substrates in contact, wherein each substrate contains a hole having sharp corners and edges. A corner is brought into proximity with an edge to define a triangular aperture of variable area. Ionic current in a liquid solution and through the aperture is monitored as the area of the aperture is adjusted by moving one planar substrate with respect to the other along two directional axes and a rotational axis. Piezoelectric positioners can provide subnanometer repeatability in the adjustment process. The invention is useful for characterizing, cleaving, and capturing molecules, molecular complexes, and supramolecular complexes which pass through the nanopore, and provides an improvement over previous devices in which the hole size of nanopores fabricated by etching and / or redeposition is fixed after fabrication.

Owner:AGILENT TECH INC

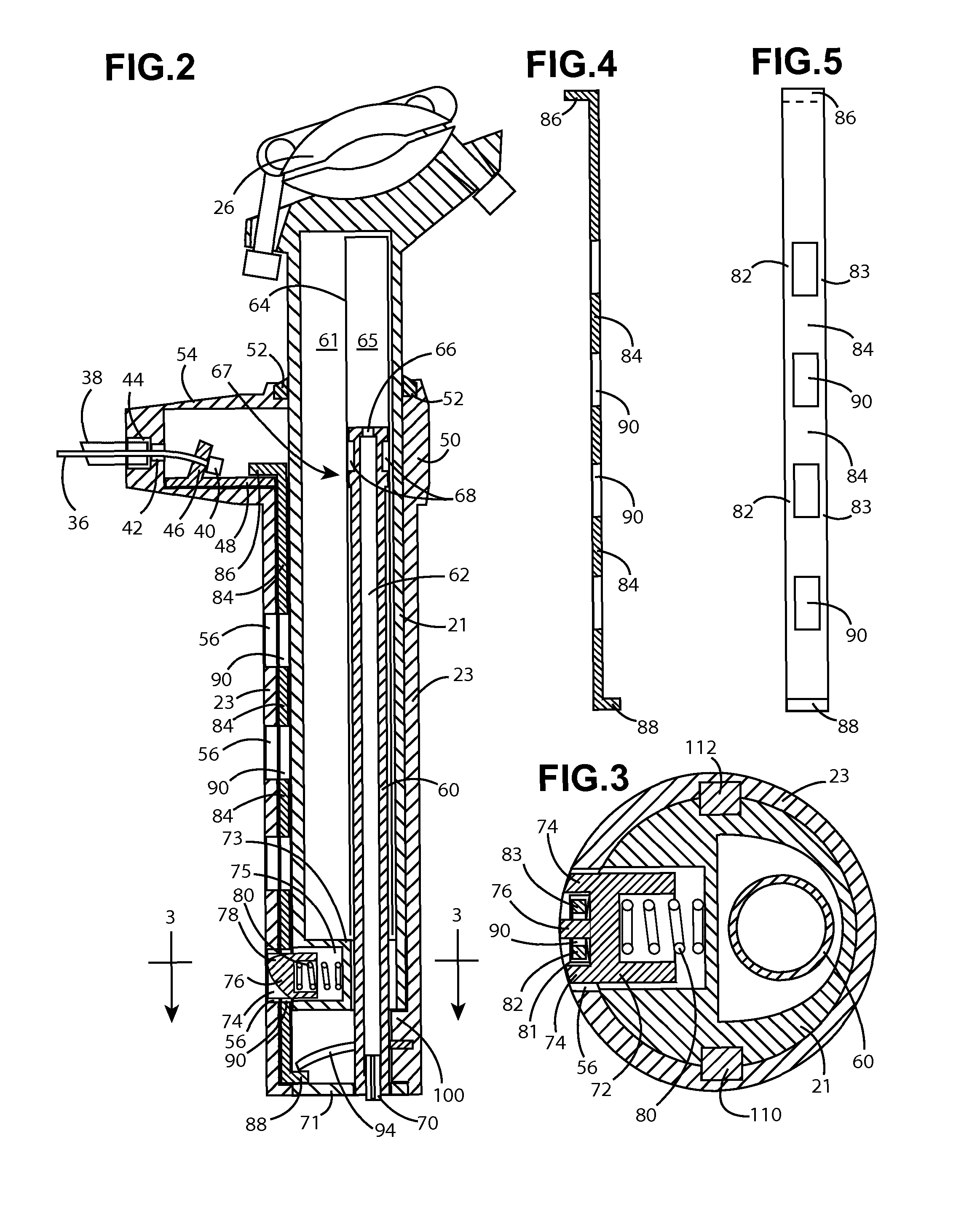

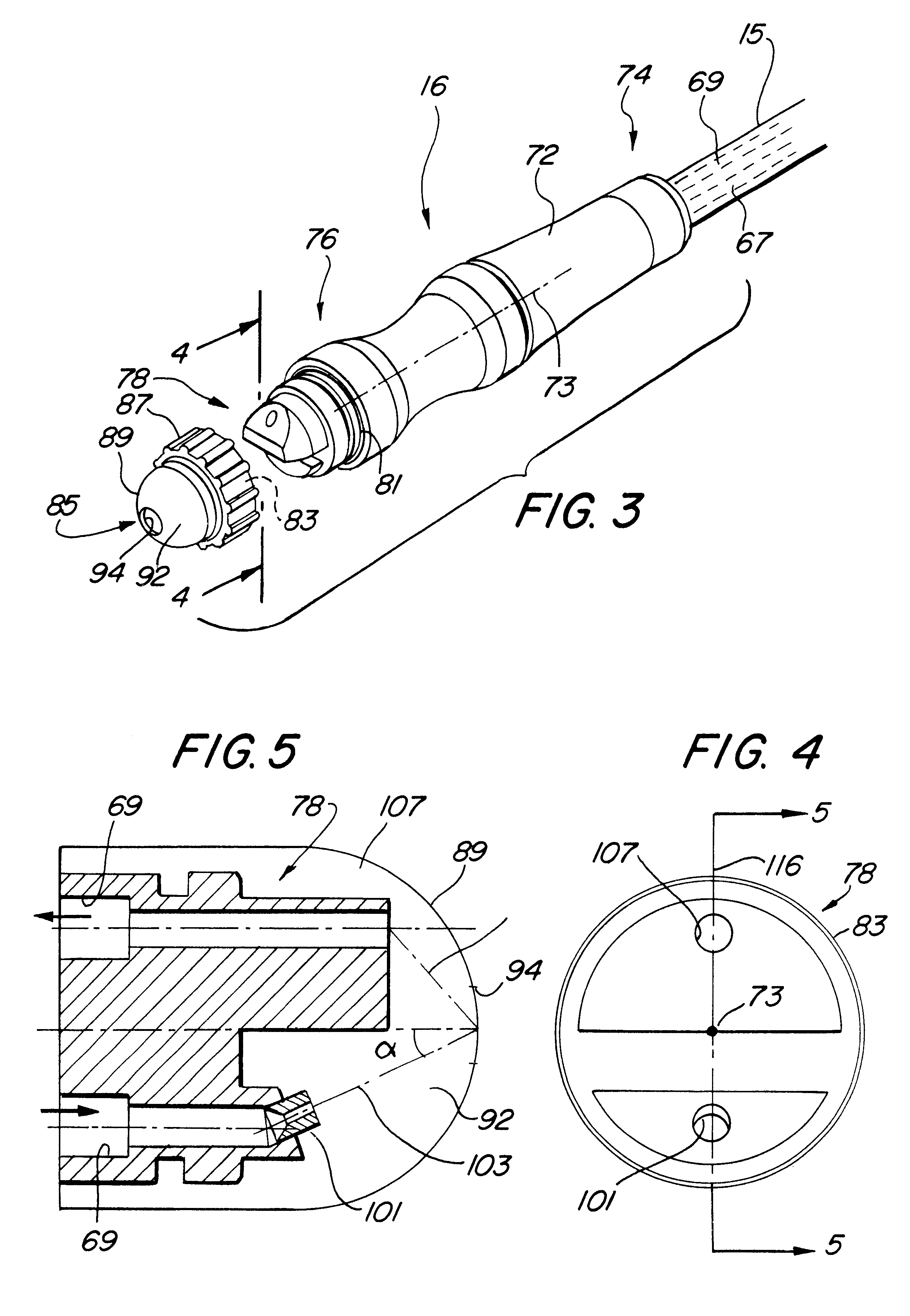

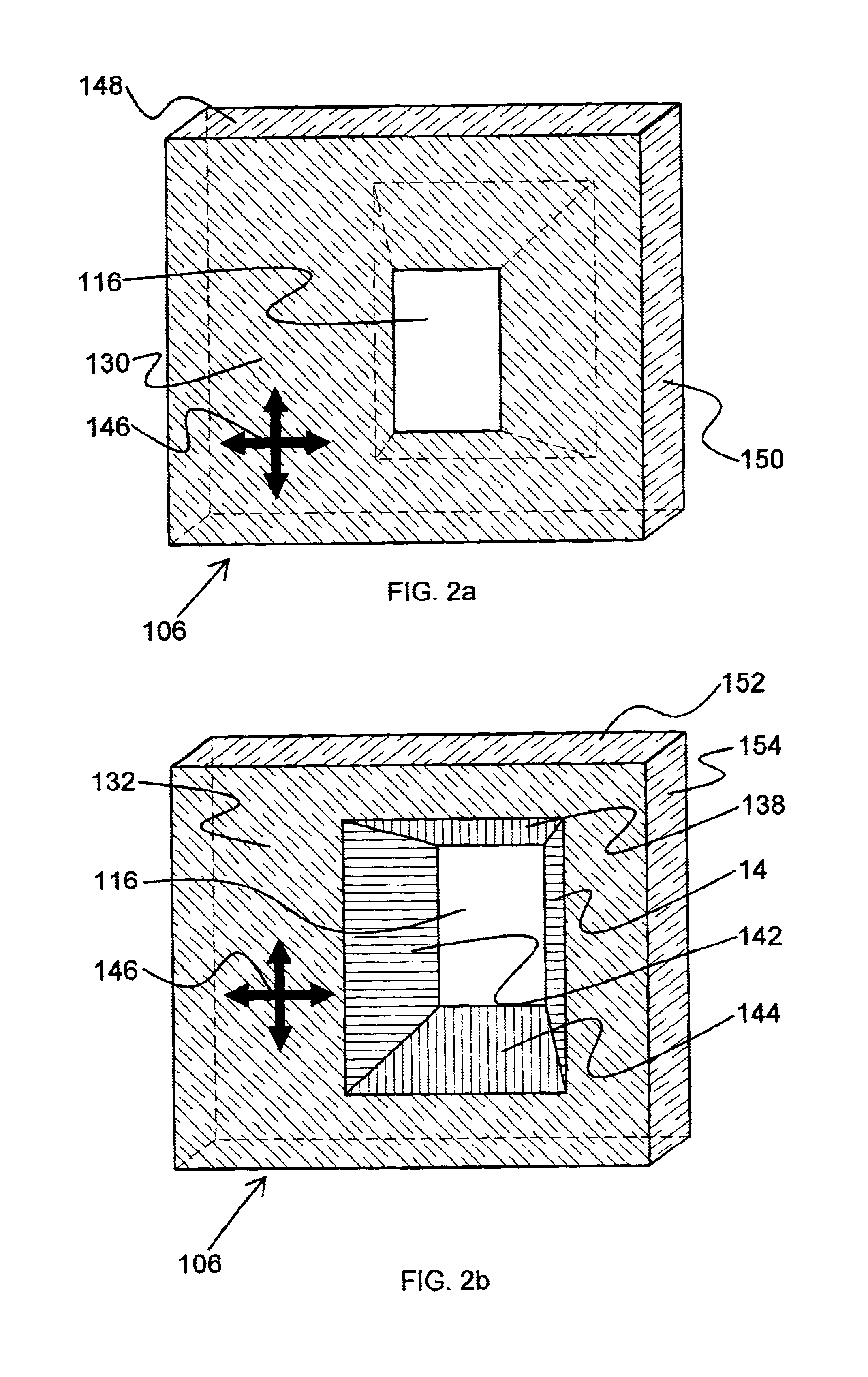

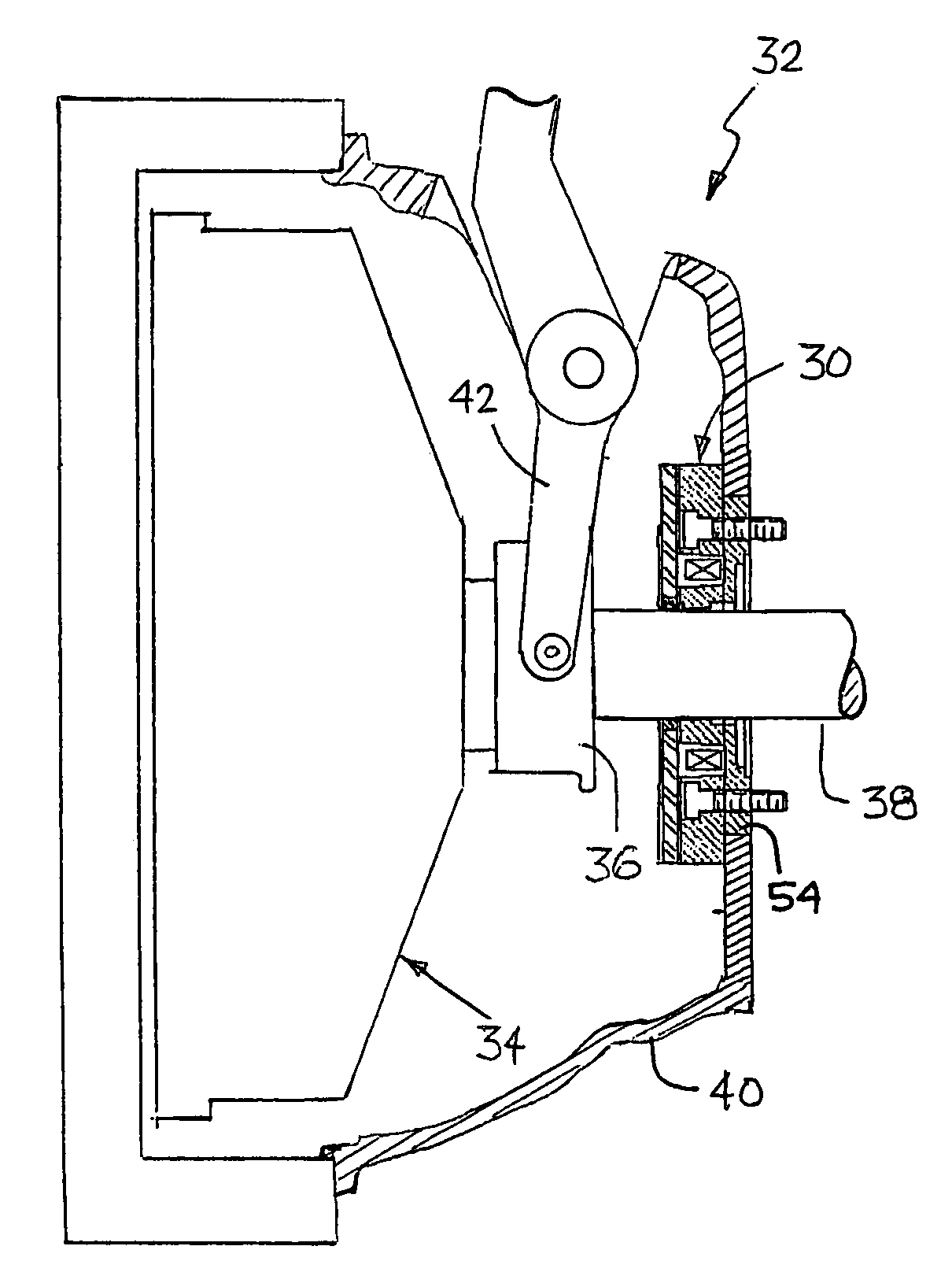

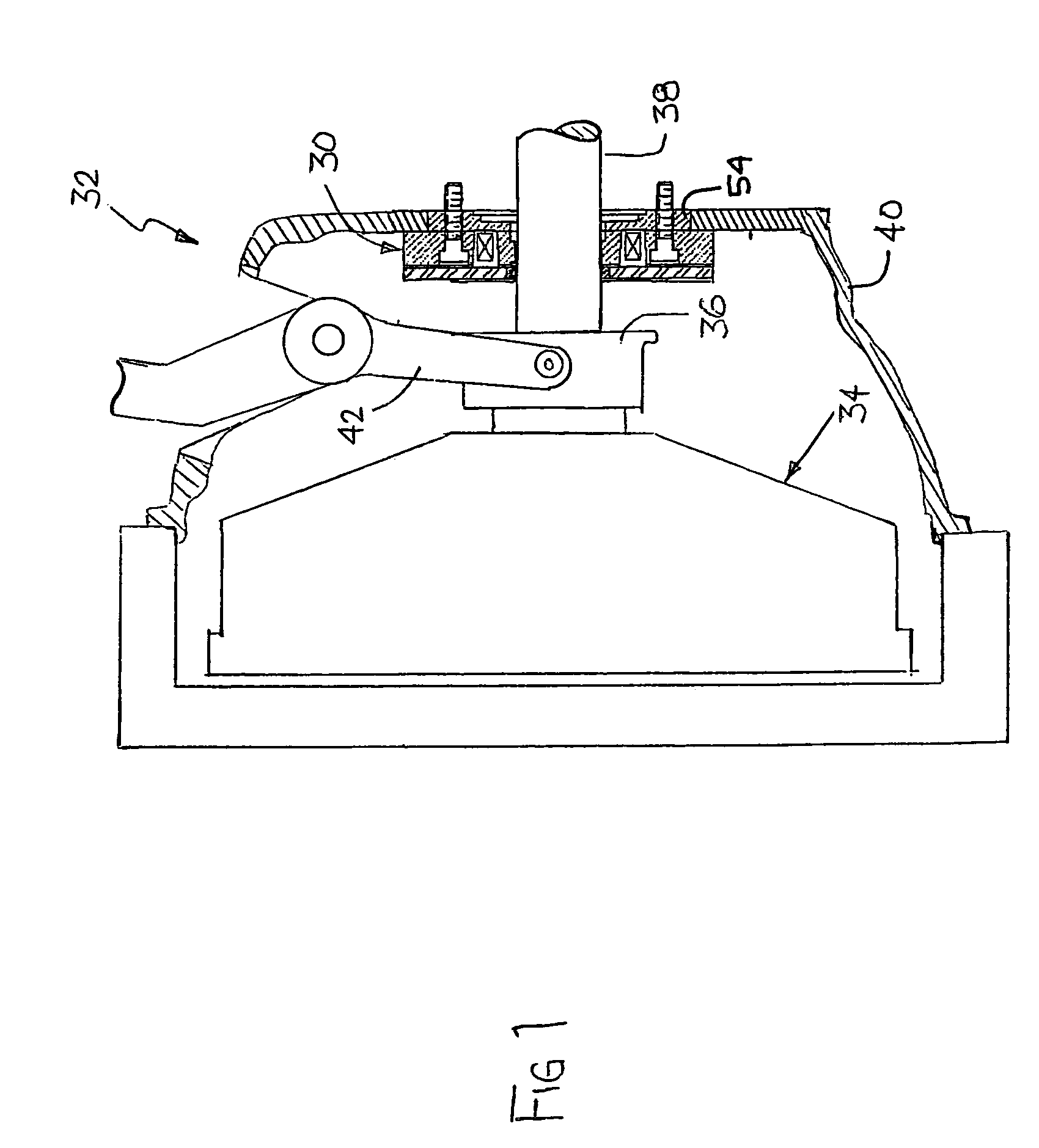

Microdermabrasion and suction massage apparatus and method

Microdermabrasion and suction massage apparatus are included in a single unit and alternatively connectable through a mode switch to a source of vacuum. The microdermabrasion section of the unit includes a crystal pick up station operating with a venturi effect to draw crystals through a hole into an air stream. The size of the hole is variable to control crystal density. A bleed valve is provided to control crystal velocity without controlling crystal density, while a bypass valve is provided to control crystal density without controlling crystal velocity. In an associated method, a microdermabrasion procedure is performed on the skin of a patient at an operative site. The mode switch is operated to activate the suction massage apparatus within the unit. This step is followed by performing a suction massage procedure at the operative site in order to promote healing of the abraded skin. The unit can be back flushed by connecting various portions of the unit to a pressurized output of the source of vacuum.

Owner:EDGE SYST CORP

Fiber optic impact detection system

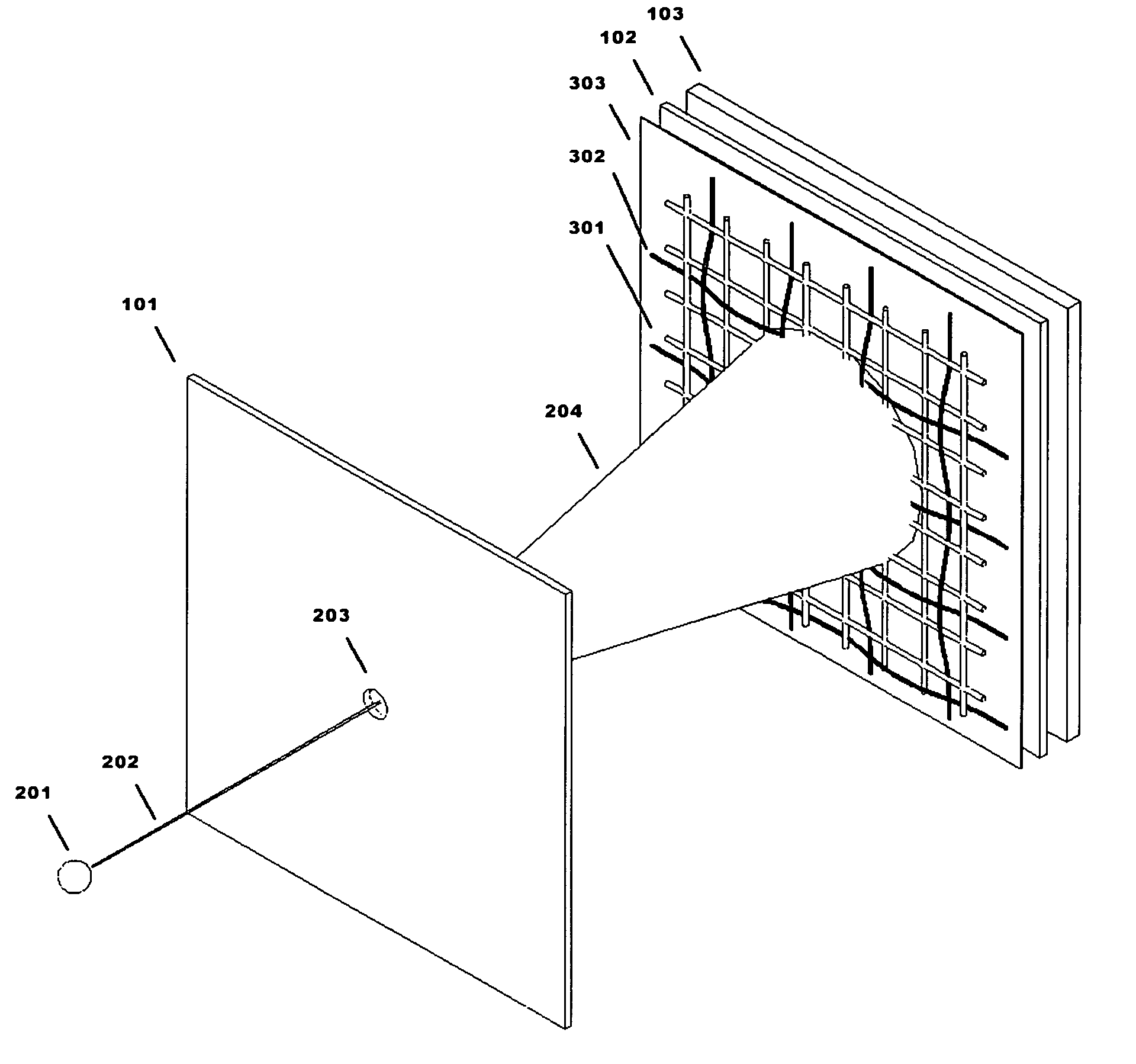

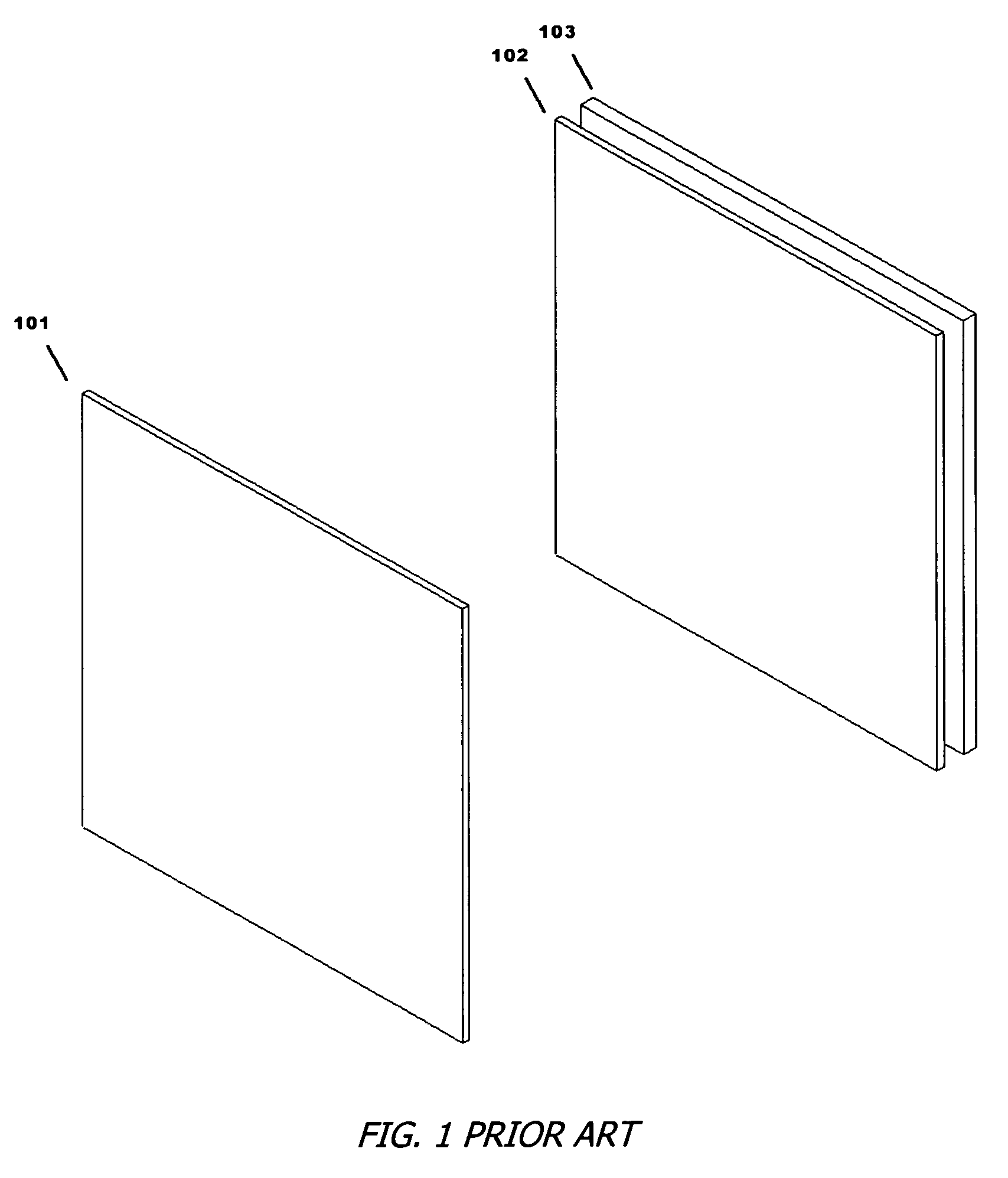

Closely spaced conventional optical fibers are arranged in a grid placed between a first surface and a second surface. A penetrating impact onto the first surface results in a hole of a size proportional to the diameter and velocity of the impacting object. The size and shape of the debris plume that travels between the first and second surfaces is also proportional to the diameter and velocity of the impacting object. If the debris plume is sufficiently energetic, a number of the fibers in the grid are broken. The size and shape of the area defined by the broken fibers can be determined simply by determining which fibers are no longer transmitting light. Analytical methods are then used to relate the extent of the damaged area to the location of an MOD impact, the direction from which the impact occurred, and the size of the impacting object.

Owner:FIBER OPTIC SYST TECH

Uses of Parylene Membrane Filters

ActiveUS20110111412A1Improve efficiencyEffective meanMembranesMicrobiological testing/measurementParyleneFigure of merit

The invention provides parylene membrane filters, filter devices and methods of making them and using them in the mechanical separation of cells and particles by size. The provision of parylene membrane filters with high figures of merit and finely controlled hole sizes allows the separation of cells and particles in a variety of biological and other fluids according to sizes.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

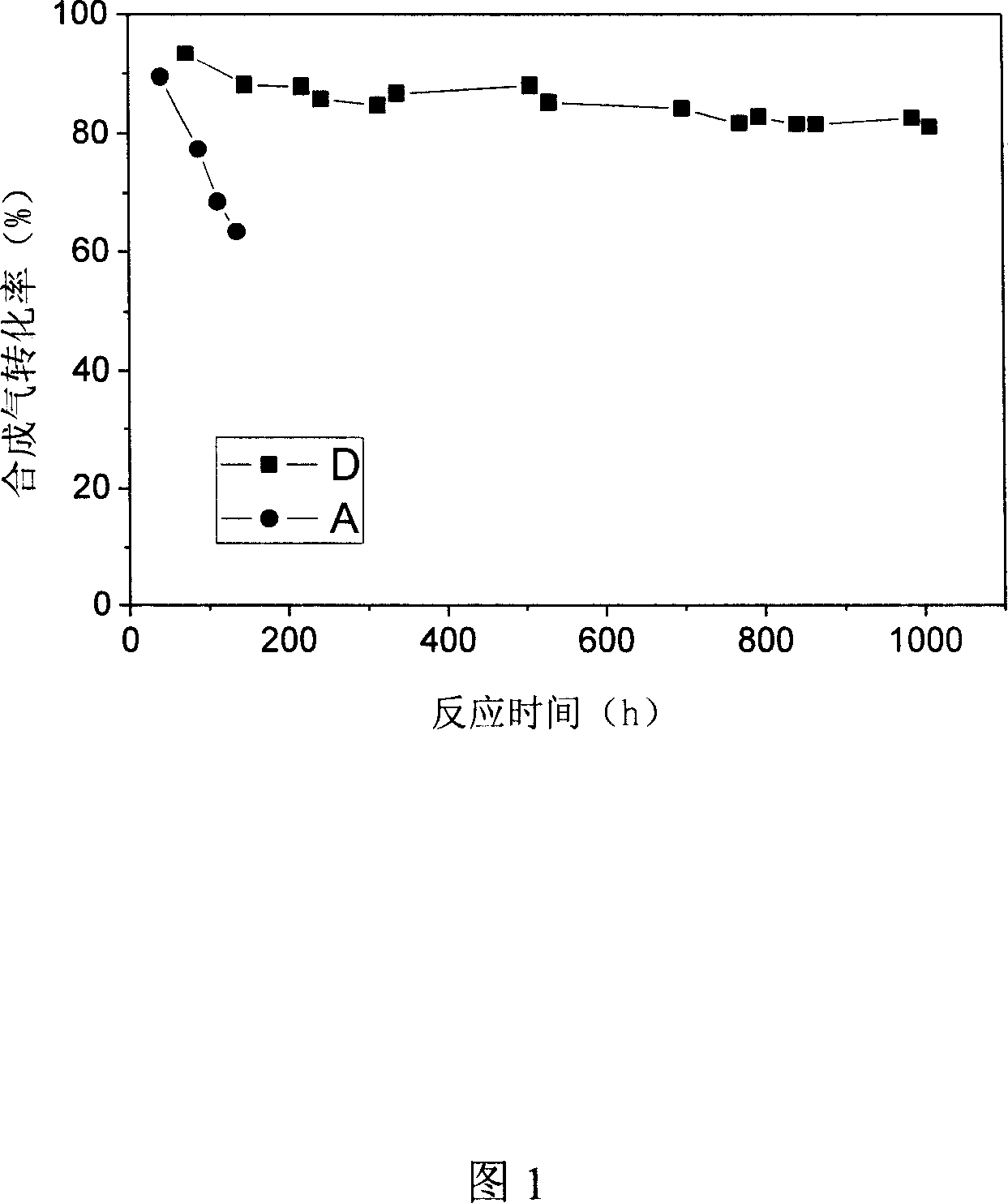

Catalyst for preparing heavy hydrocarbon with synthetic gas and its prepn process

ActiveCN101020137ALow costImprove stabilityHydrocarbon from carbon oxidesCatalyst activation/preparationHydrogenActive component

Owner:PETROCHINA CO LTD

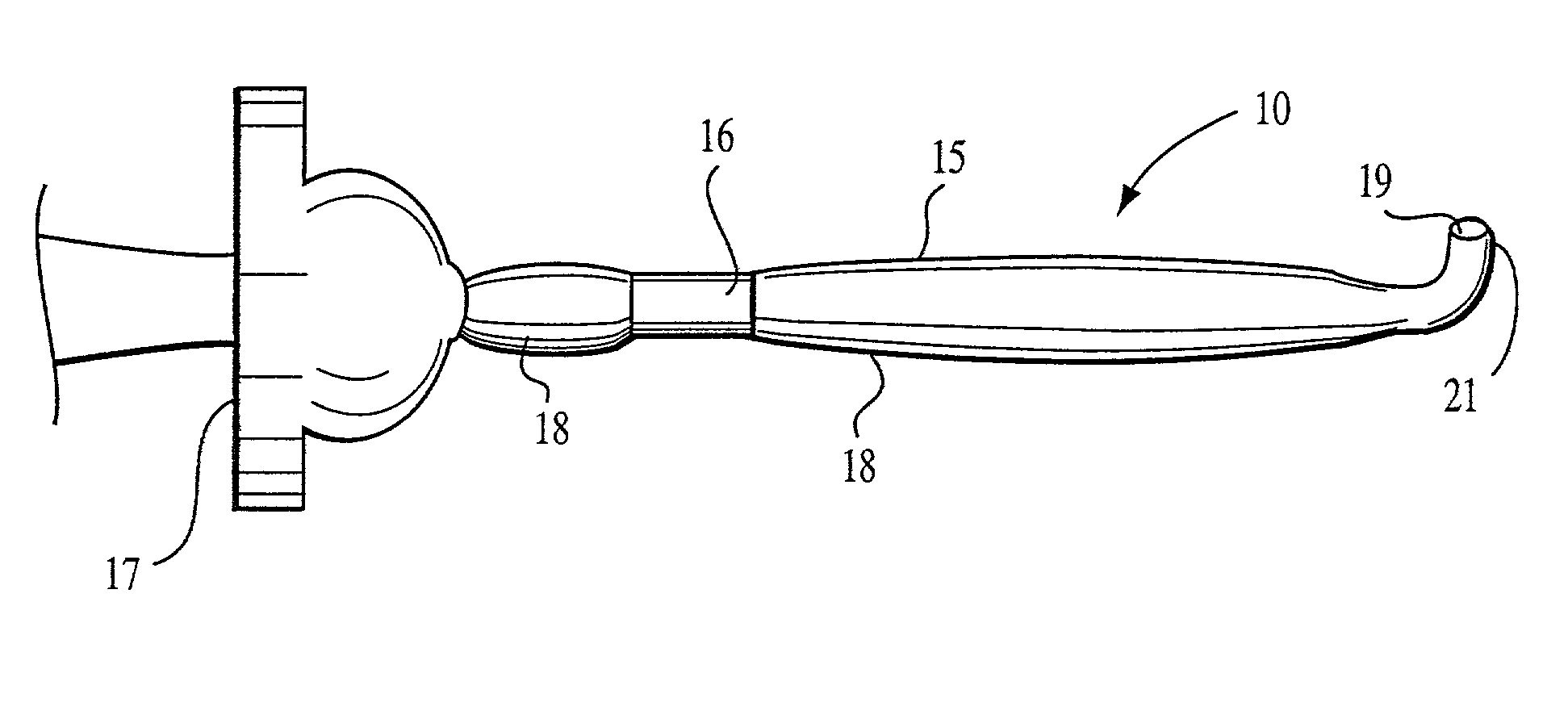

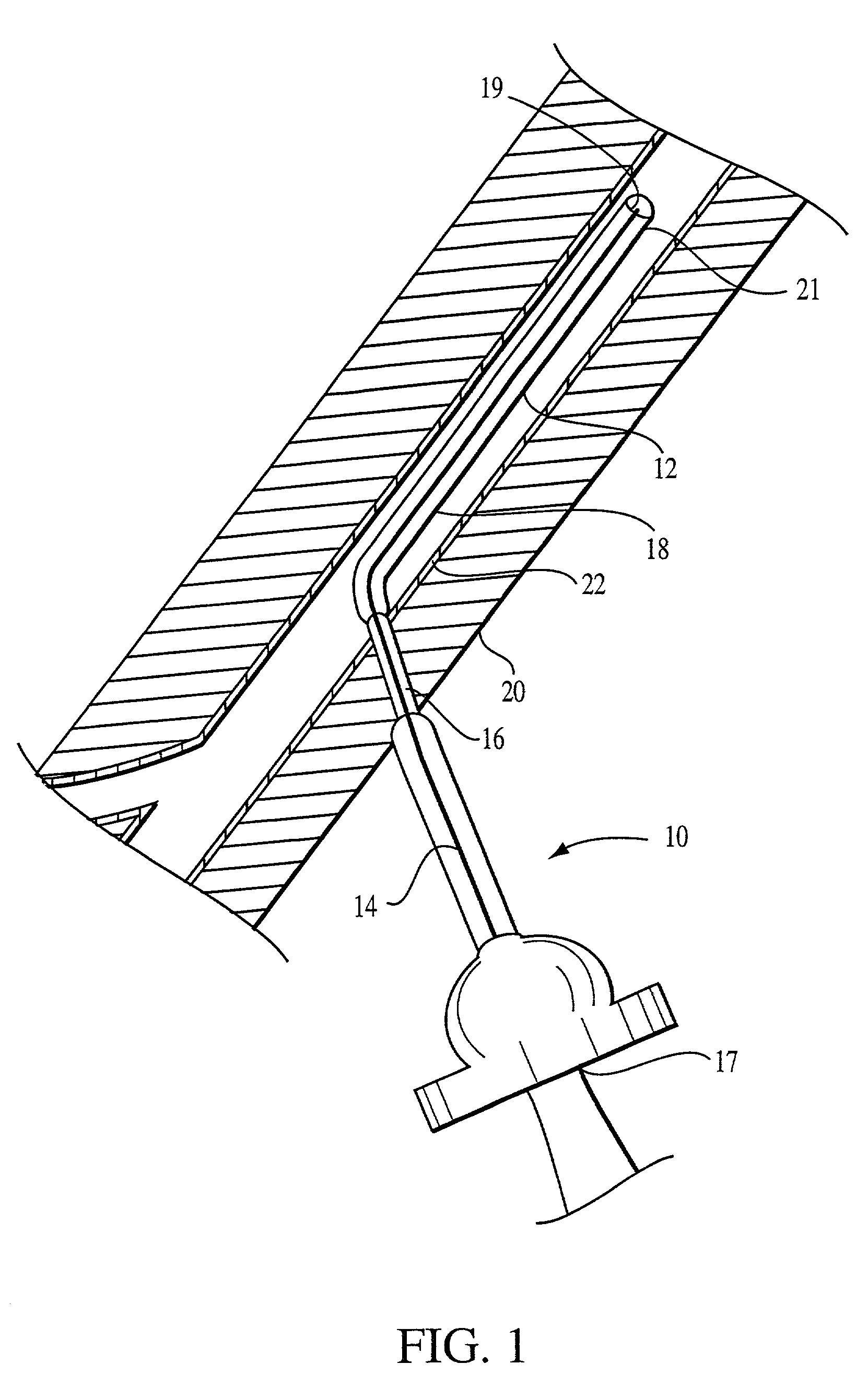

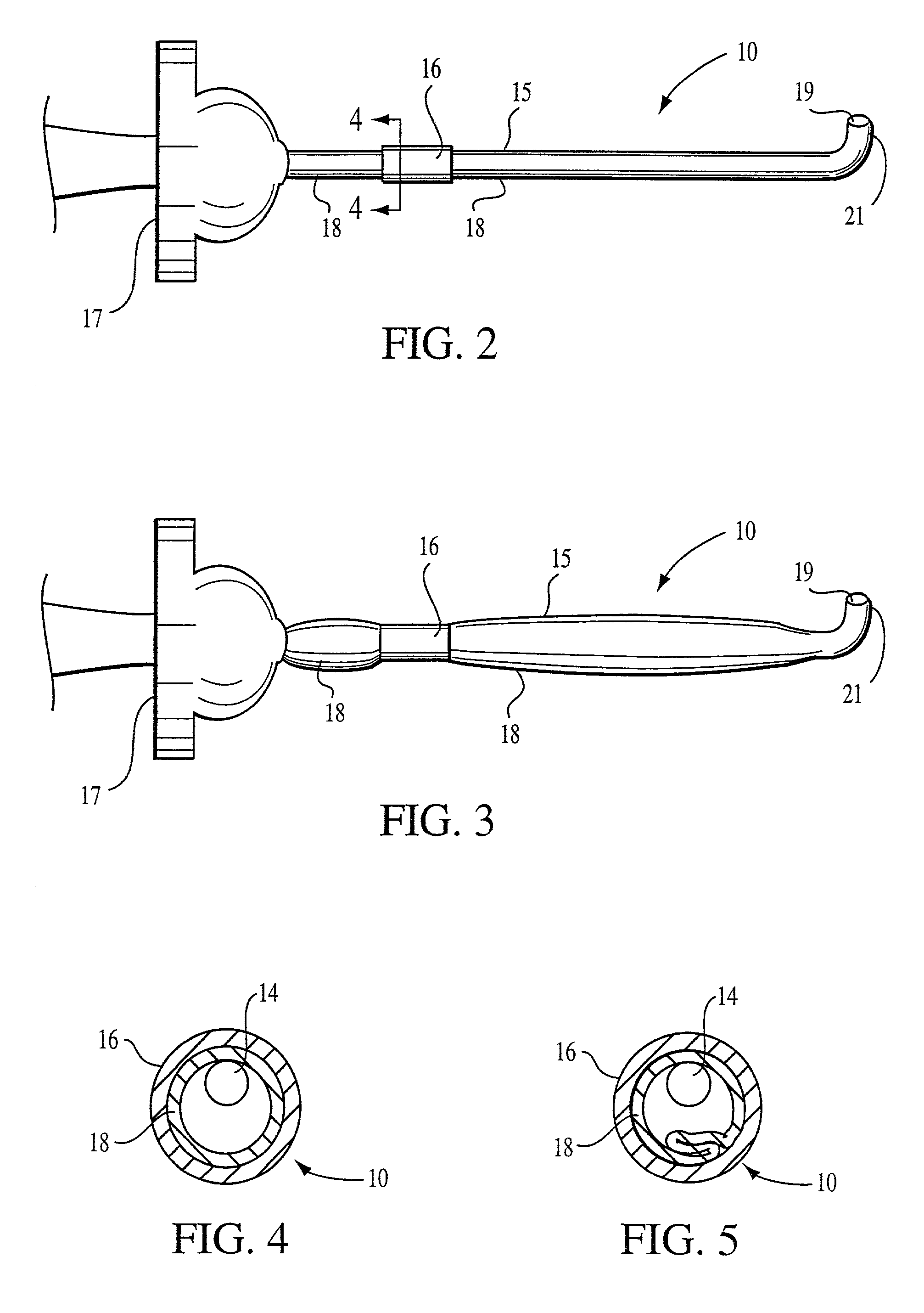

Dynamically compliant catheter

InactiveUS20020095117A1Minimizes wound sizeLow production costInfusion syringesCatheterGuide tubeBlood vessel

A catheter enabling a reduced puncture hole size into the skin and blood vessel is disclosed. In one embodiment, the catheter has an elongate body having an expandable sheath extending at least a portion of its length. A pressure constraining sheath is positioned to surround the expandable sheath, at a selected region to prevent expansion of the inner sheath at the region of the constraining sheath. In one preferred use, the constraining sheath is positioned at the puncture hole. During use, the catheter increases in cross-section by an expandable sheath expanding from a first diameter to a second diameter. However, the outer sheath does not expand, maintaining a small diameter at the puncture site.

Owner:WILSON ROBERT F +1

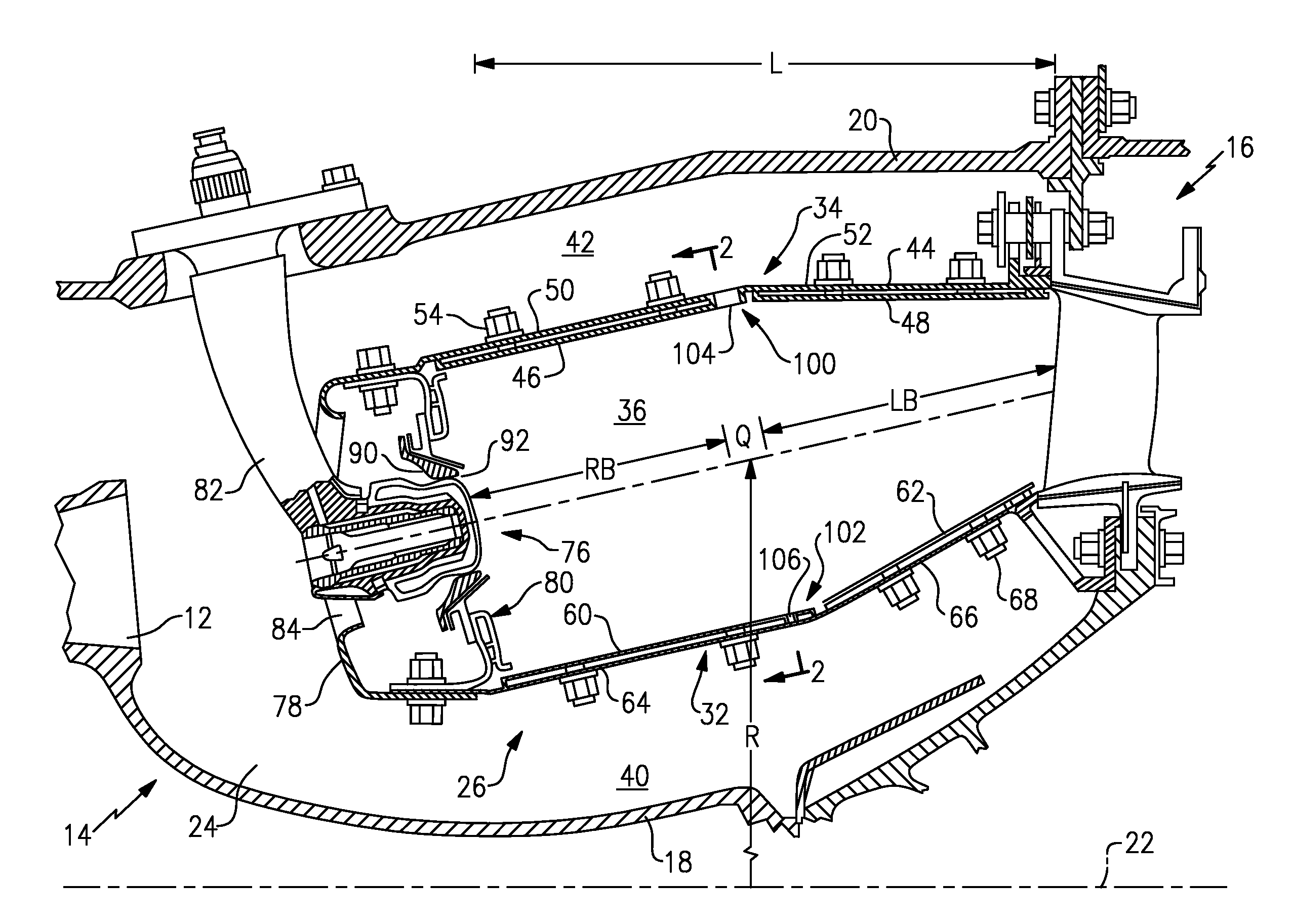

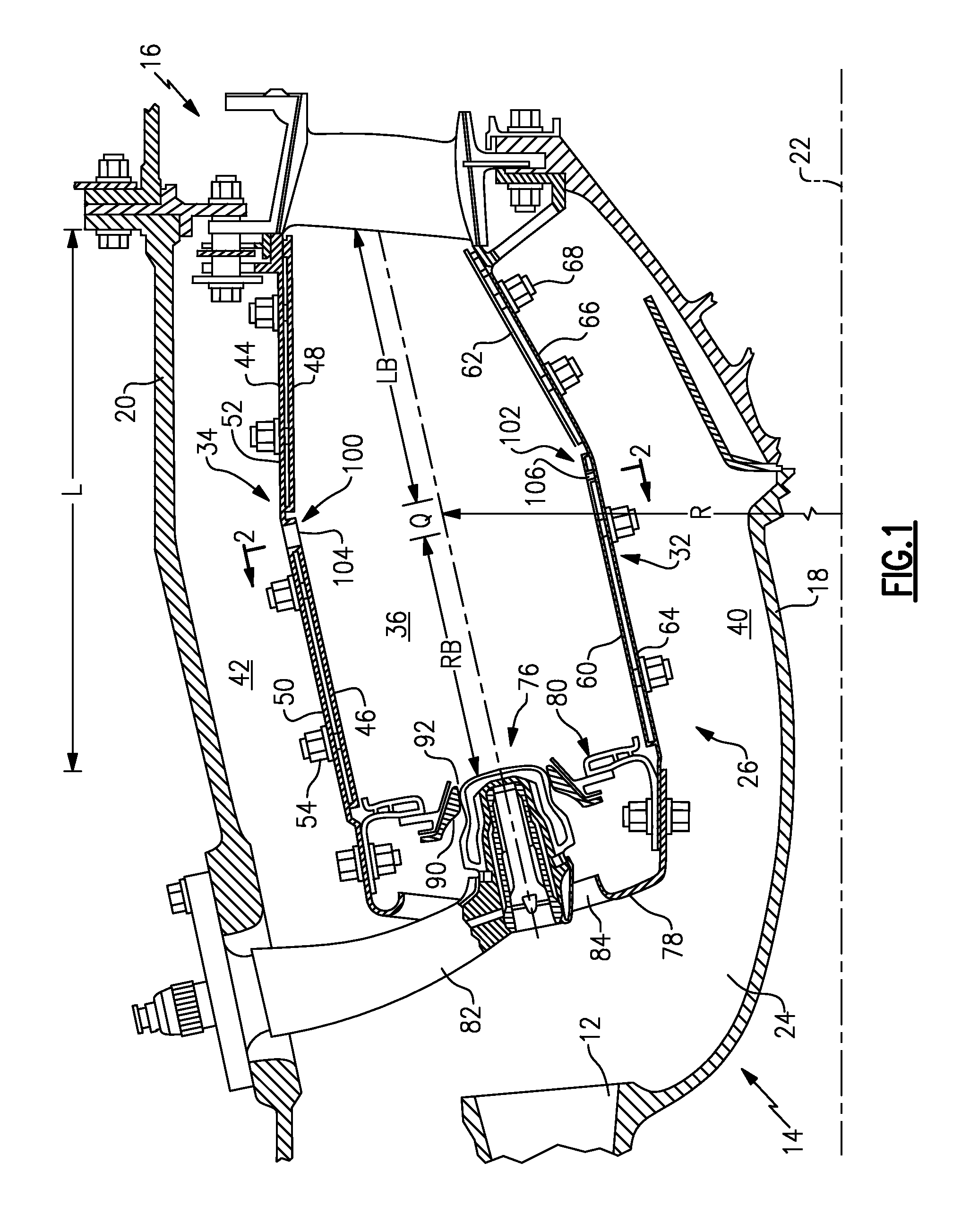

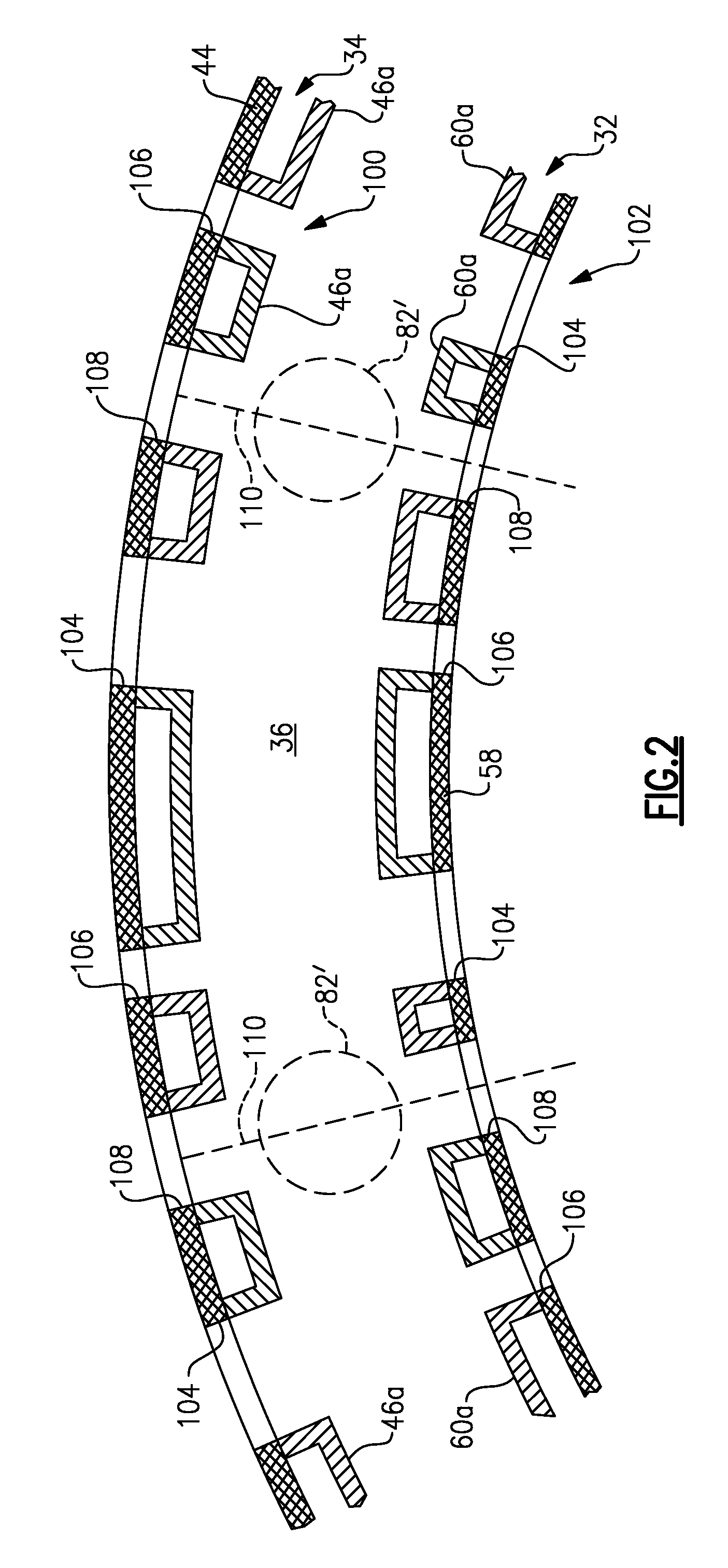

Hole pattern for gas turbine combustor

ActiveUS20090308077A1Continuous combustion chamberEfficient propulsion technologiesCombustorCombustion chamber

A combustor for a turbine engine includes an outer liner having a row of circumferentially distributed outer combustion air holes and an inner liner circumscribed by the outer liner and having a row of circumferentially distributed inner combustion air holes. The inner and outer liners each include at least a major air hole having a first hole size, an intermediate air hole having a second hole size, and a minor air hole having a third hole size. The first, second, and third hole sizes are all different from each other.

Owner:RTX CORP

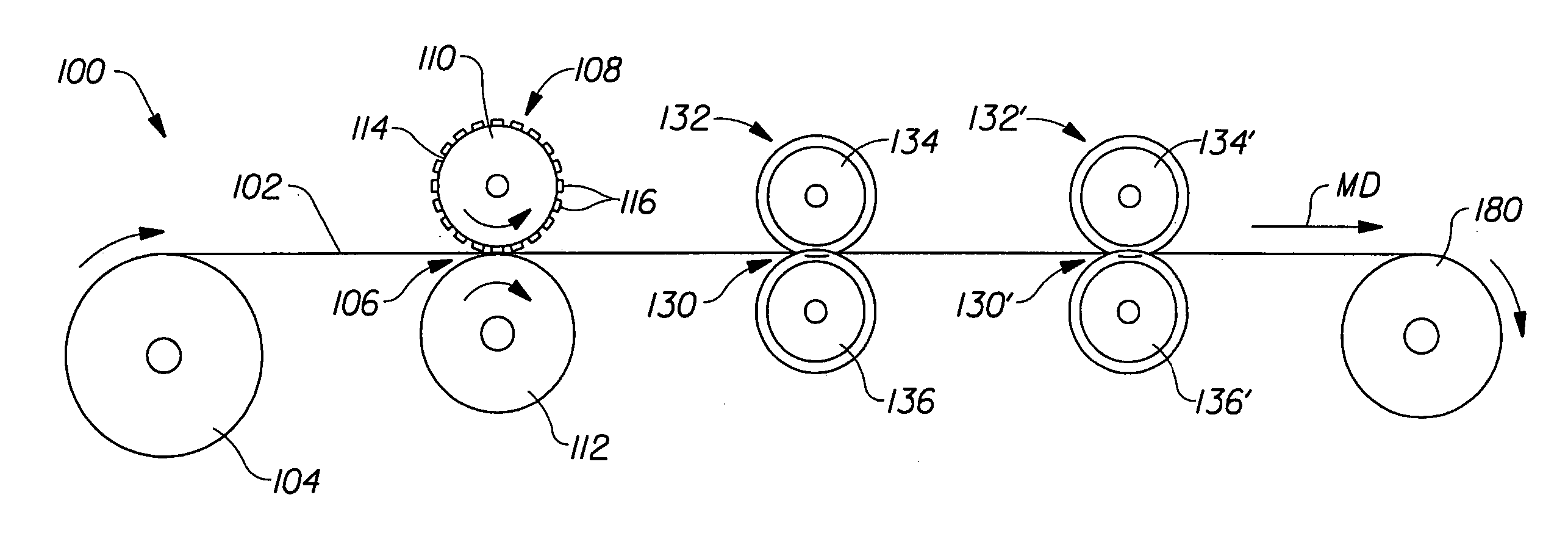

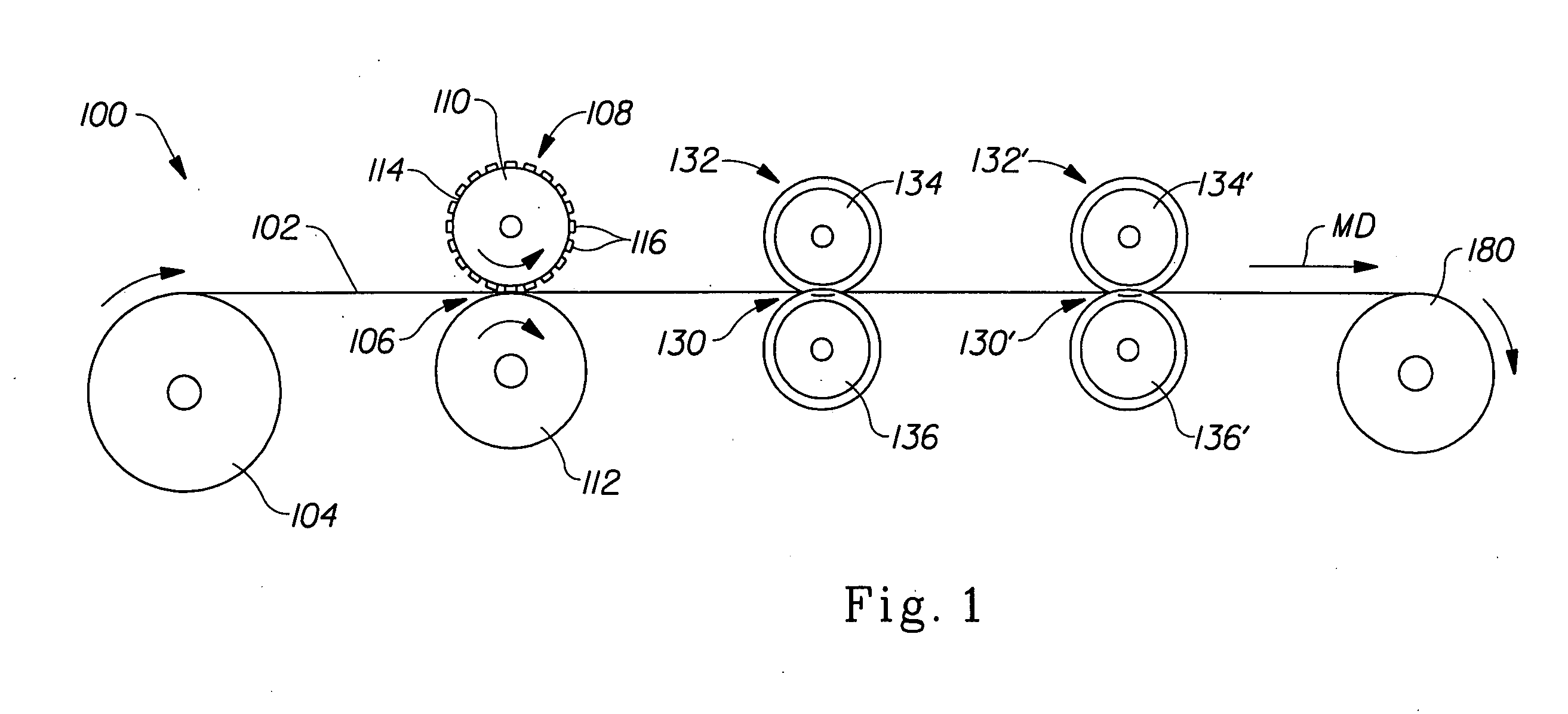

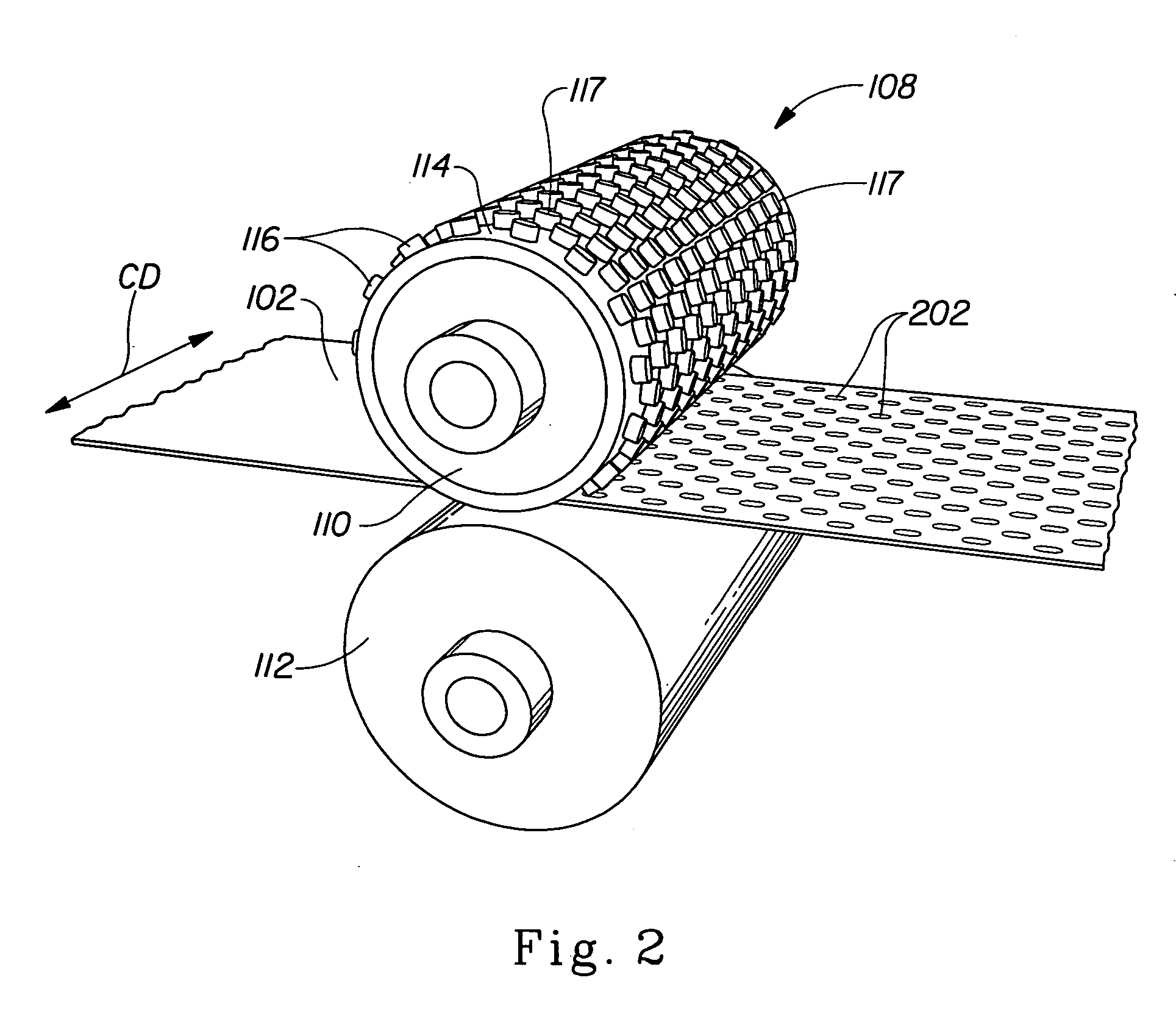

High-elongation apertured nonwoven web and method for making

An extensible apertured nonwoven web, and a method for making such an apertured nonwoven web. In one embodiment the method comprises the steps of providing an apertured nonwoven web, incrementally stretching it in a direction substantially parallel to the cross machine direction, and applying tension in the machine direction such that the web width after applying tension is less than the web width after incremental stretching. In another embodiment the method comprises the steps of providing a nonwoven web; weakening the nonwoven web at a plurality of locations to create a plurality of weakened, melt-stabilized locations; applying a first tensioning force to the nonwoven web to cause the nonwoven web to rupture at the plurality of weakened, melt-stabilized locations creating a plurality of apertures in the nonwoven web coincident with the weakened, melt-stabilized locations, incrementally stretching the nonwoven web in a direction substantially parallel to the cross machine direction, and applying tension in the machine direction such that the web width after applying machine direction tension is less than the web width after incremental stretching. An apparatus for producing a web of the present invention by this method is also disclosed. The extensible apertured nonwoven web produced has a plurality of apertures each having a hole size greater than 2 mm2, and a hole aspect ratio less than 6, the nonwoven web having an open area greater than 15% and being capable of at least 70% extension in the cross machine direction at a loading of 10 g / cm.

Owner:THE PROCTER & GAMBLE COMPANY

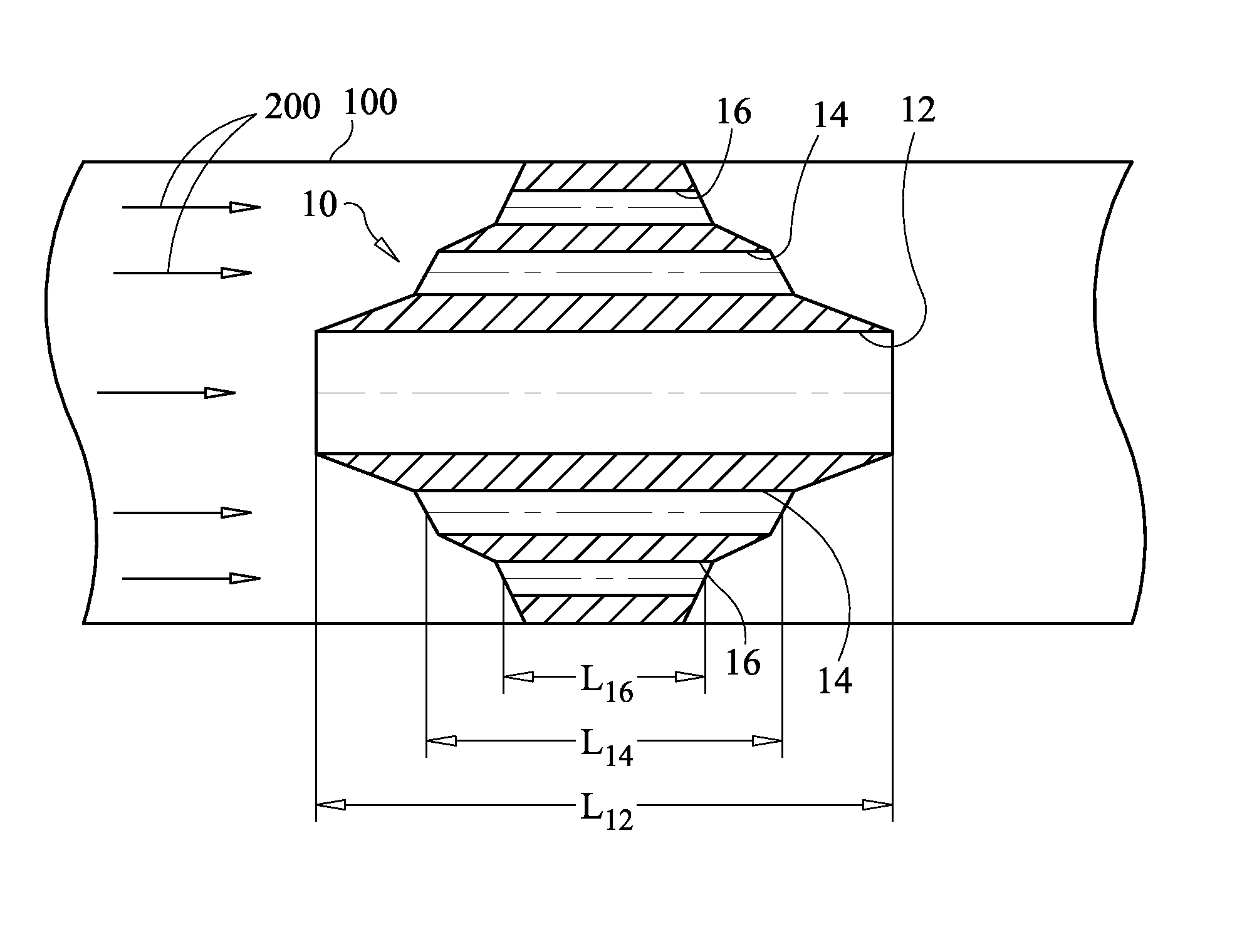

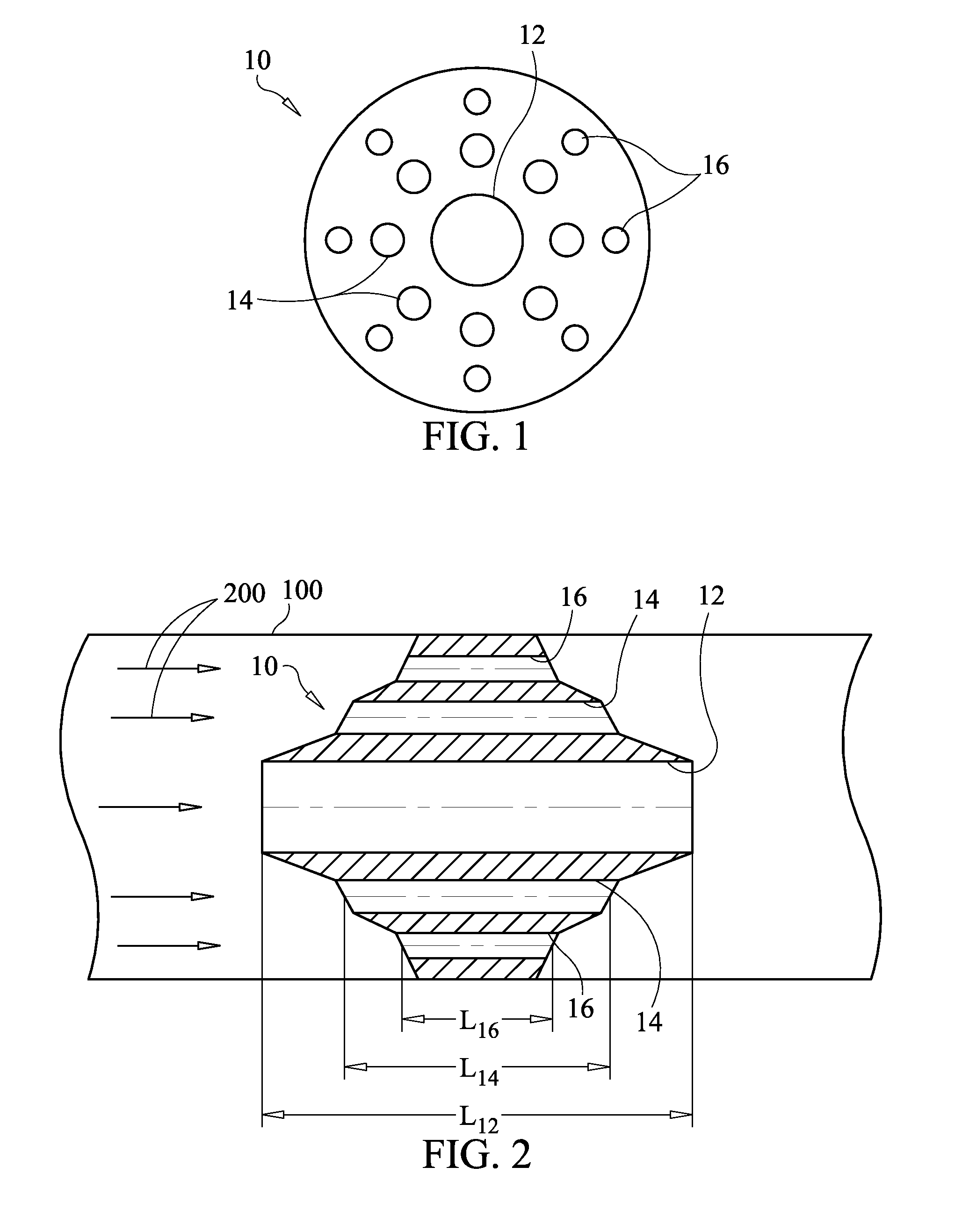

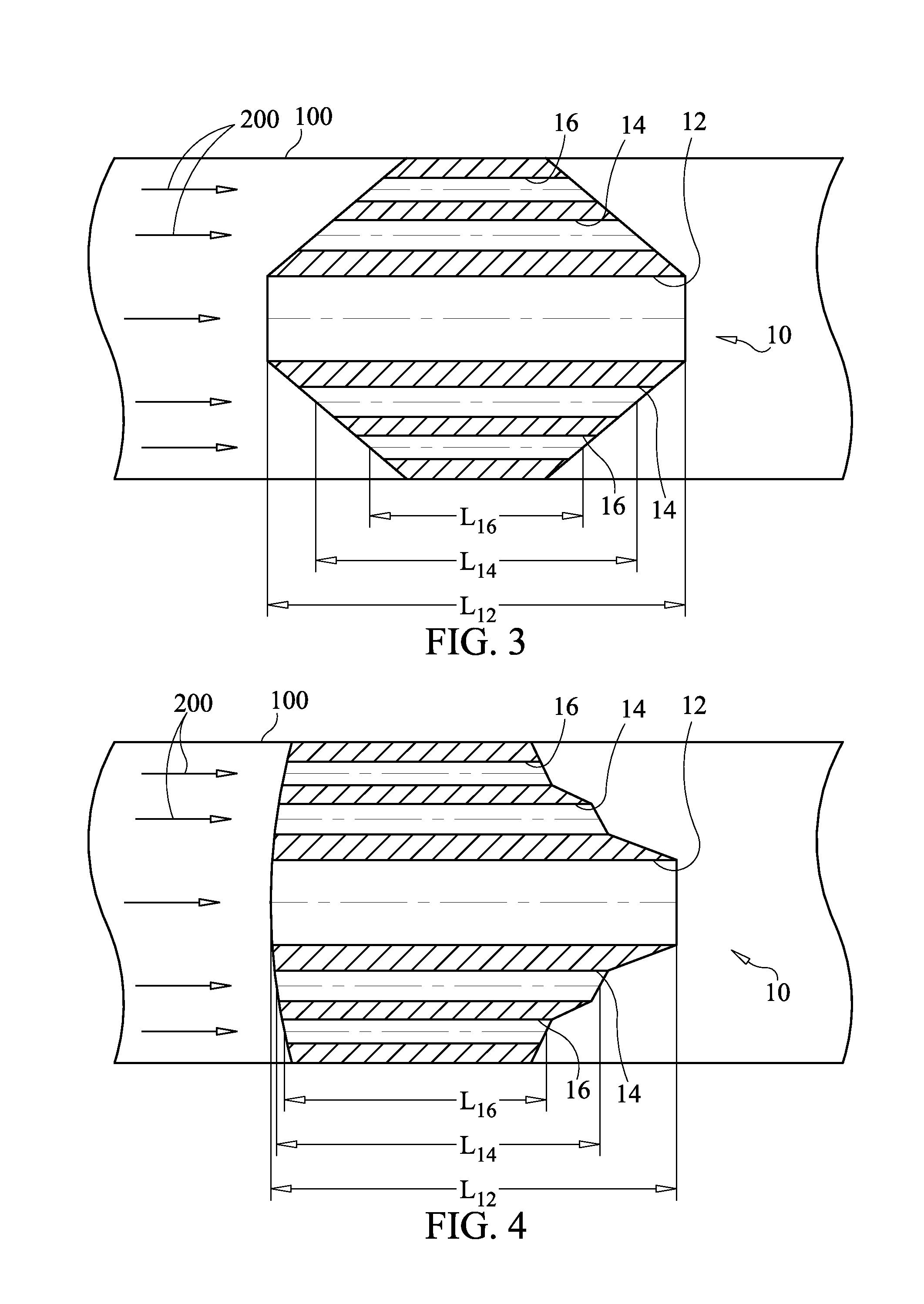

Flow plug with length-to-hole size uniformity for use in flow conditioning and flow metering

A flow plug of varying thickness has a plurality of holes formed therethrough. The plug fits in a conduit such that a fluid flow in the conduit passes through the plug's holes. Each hole is defined by a parameter indicative of size in terms of the cross-sectional area thereof. A ratio of hole length-to-parameter is approximately the same for all of the holes.

Owner:NASA

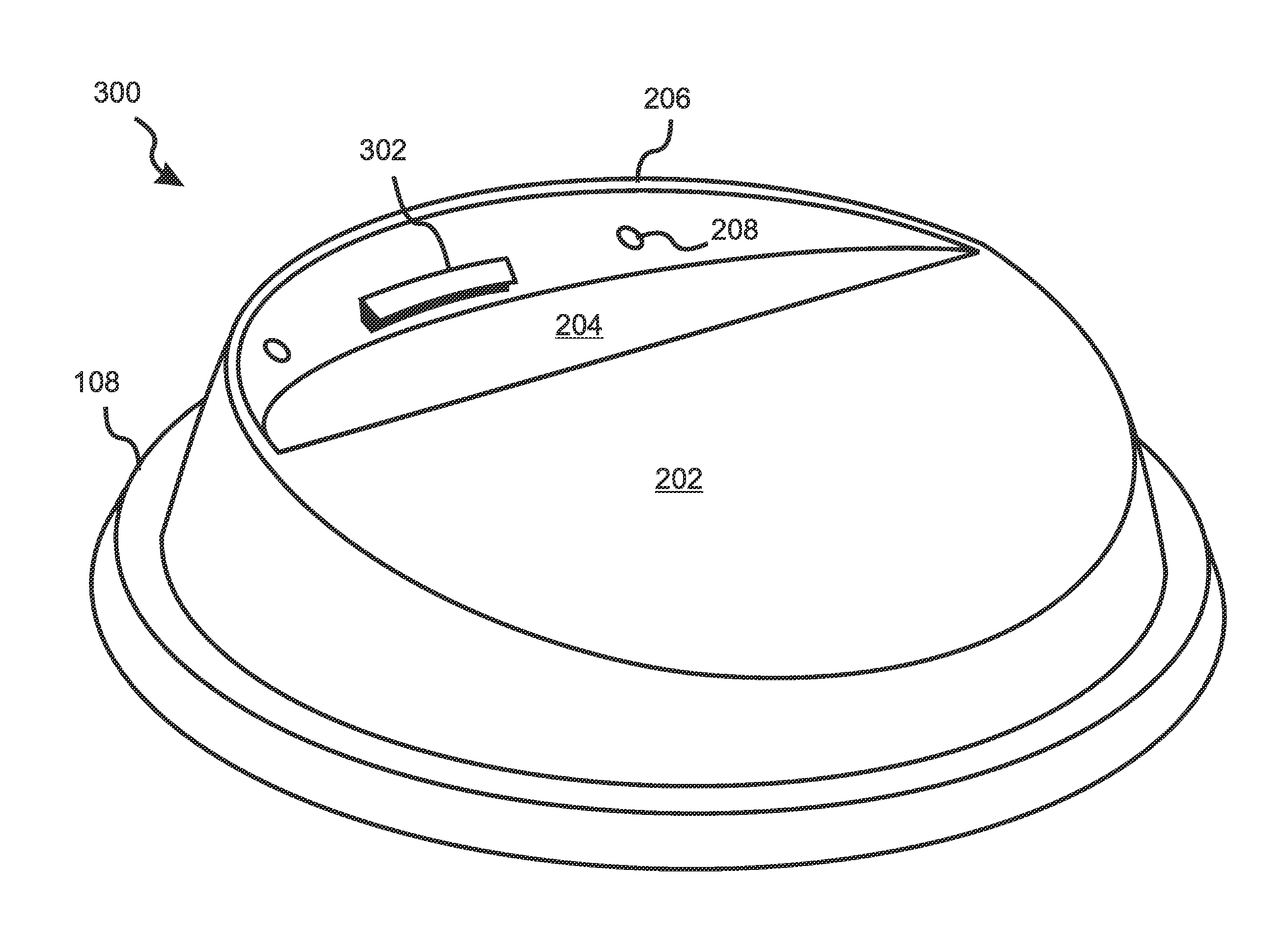

One-piece splash and spill resistant lid

A one-piece disposable cup lid enables drinking while inhibiting splashing and spilling by blocking straight-line paths through the lid and dispensing beverage through a well. A drinking spout can include a well having a sidewall, a bottom and a penetration into the cup, or a sloping lid section can intersect a raised rim to create a well therebetween, with a penetration in the sloping section or the rim configured to block straight-line paths, for example by upwardly hinging of a flap or depressing half of a split, convex bubble. Embodiments include baffles that force a beverage to flow through a convoluted path and / or through chambers before being consumed. Baffles can be formed in place, or by hinged movement of flaps after forming. Textures and / or protruding structures can intercept, direct, and / or influence surface tension as beverage flows across surfaces. Vent hole sizes and locations can further limit flow and spilling.

Owner:SCHEW +1

Uses of parylene membrane filters

ActiveUS7846743B2Improve efficiencyEffective meanUltrafiltrationLaboratory glasswaresParyleneFigure of merit

The invention provides parylene membrane filters, filter devices and methods of making them and using them in the mechanical separation of cells and particles by size. The provision of parylene membrane filters with high figures of merit and finely controlled hole sizes allows the separation of cells and particles in a variety of biological and other fluids according to sizes.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

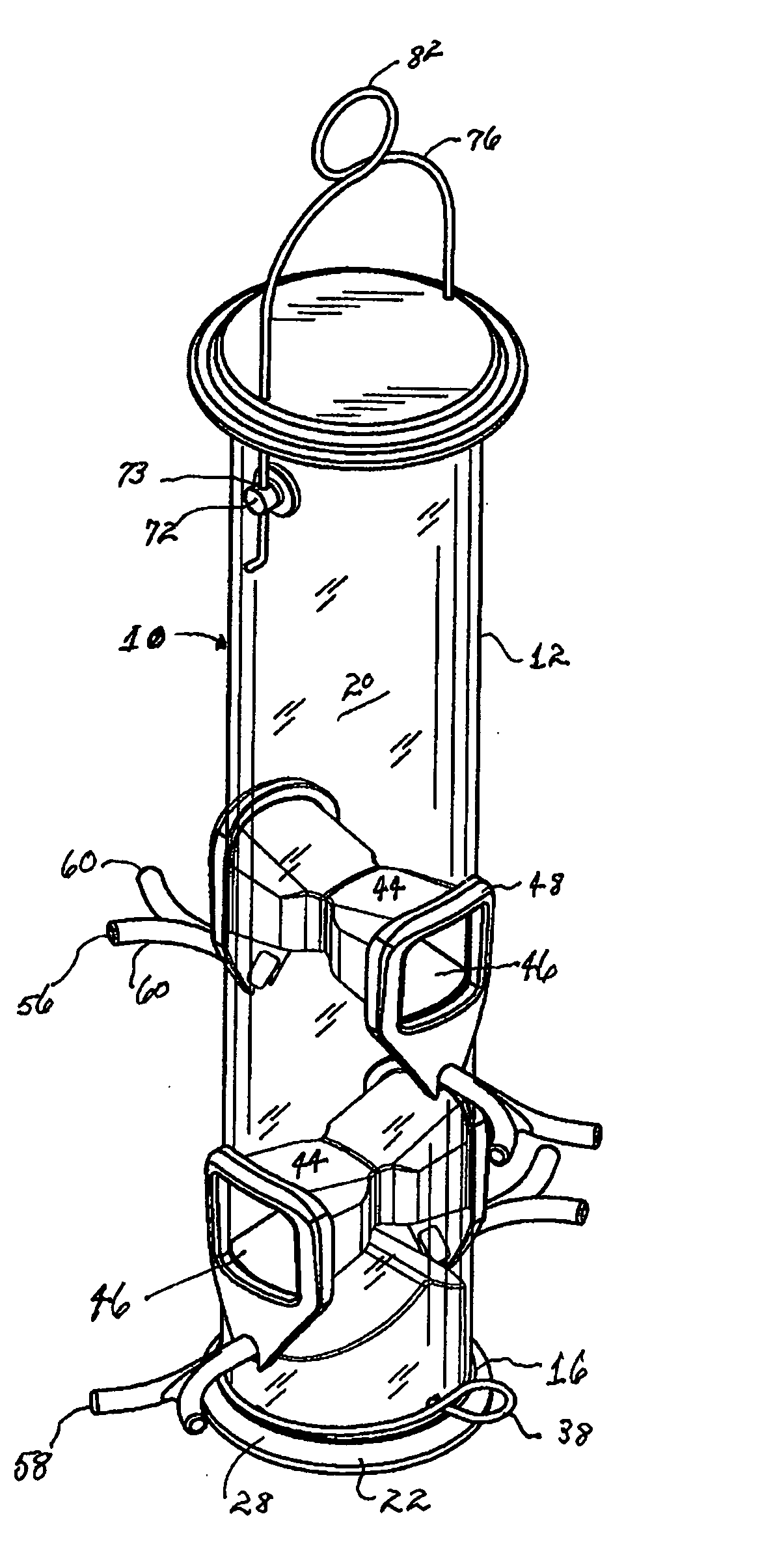

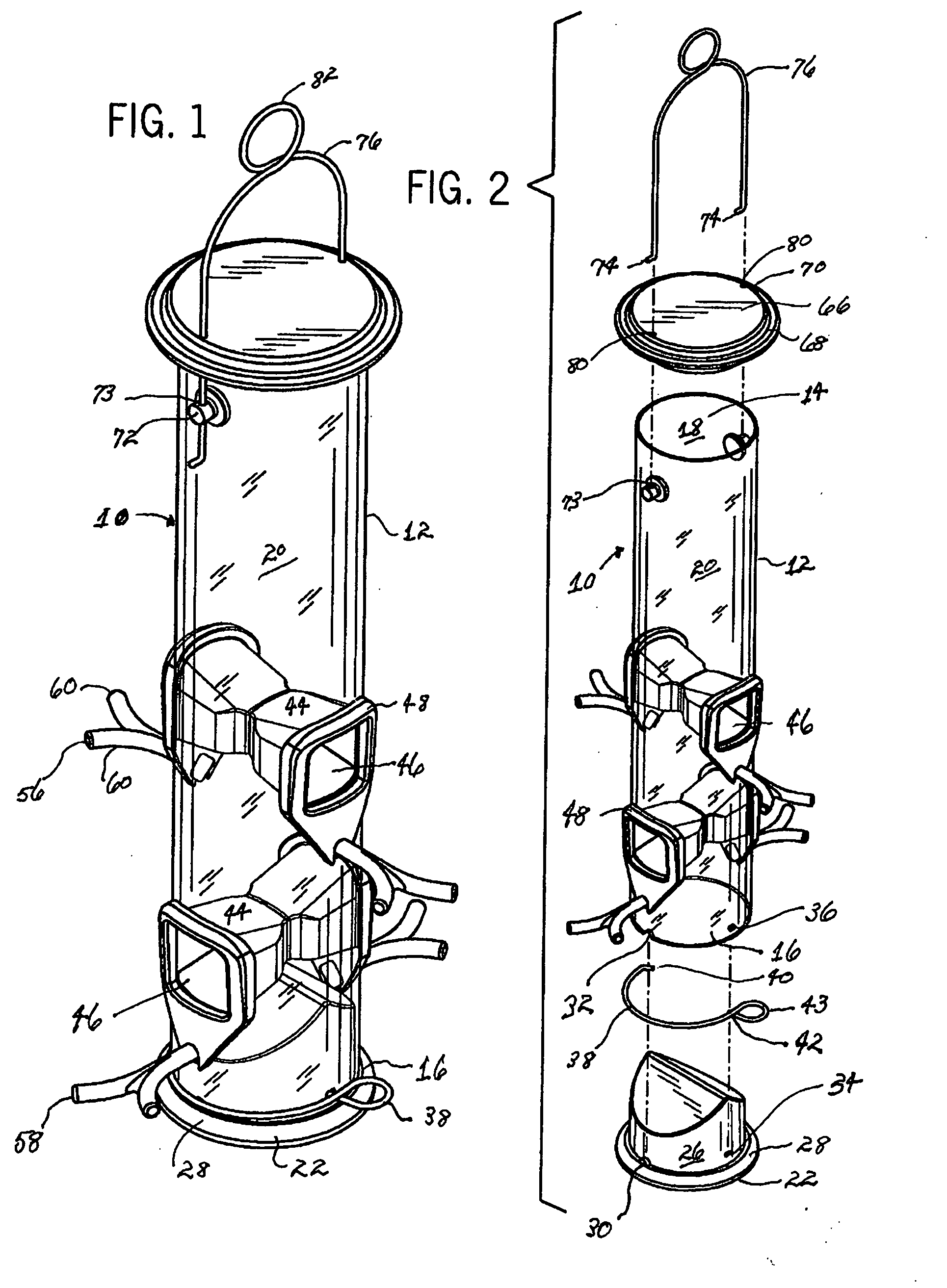

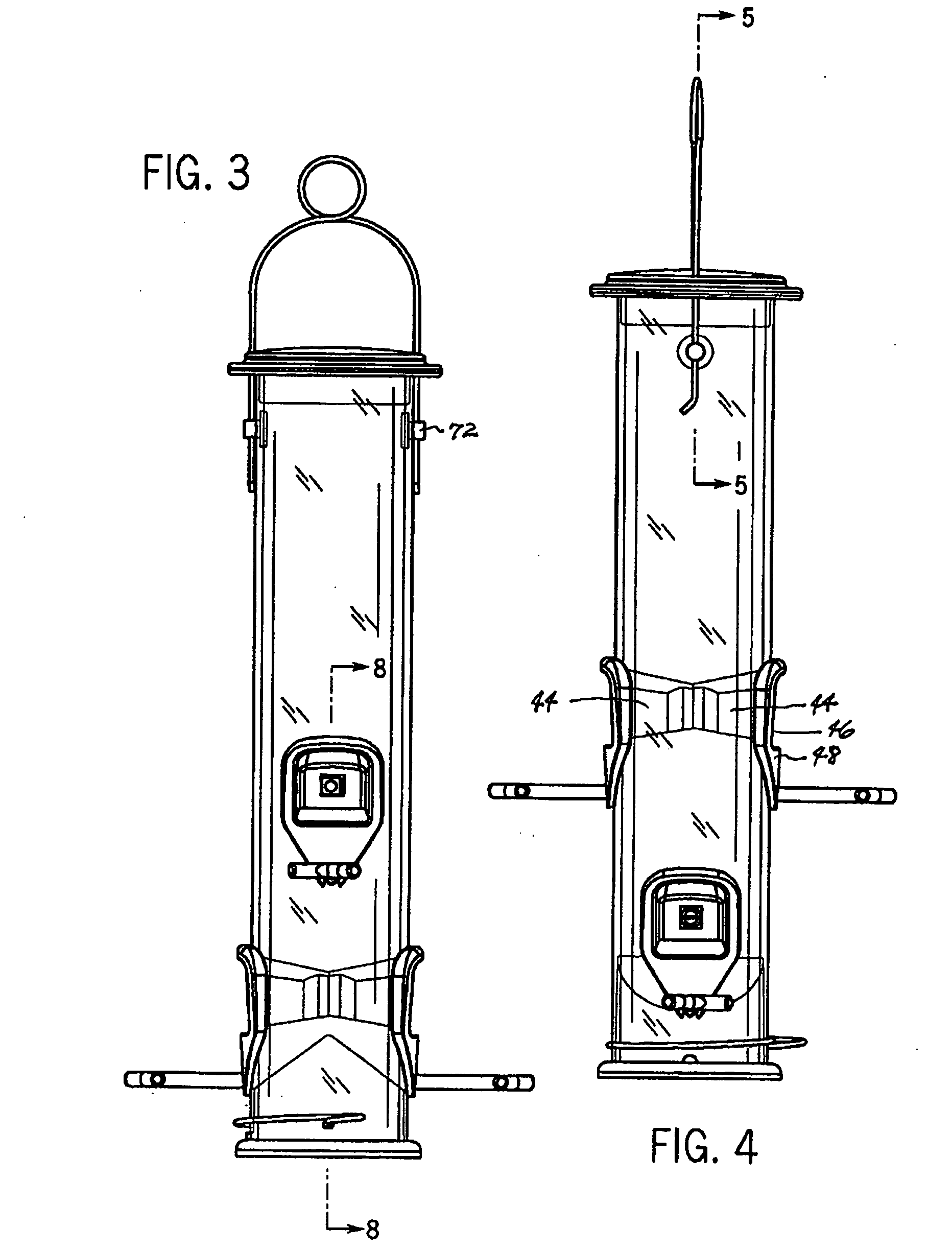

Bird feeder

InactiveUS20070163506A1Easy to cleanEfficient fillingPisciculture and aquariaAvicultureBird feederEngineering

A bird feeder is provided having a pivotal wire bail to allow the top cap to be lifted and rotated away from the top opening for easy filling of bird food without unnecessary spillage. Additionally, the invention provides for a detachable base cap having a spring clip retention feature that holds the base cap in place when in use but provides for its intentional removal when desired for cleaning purposes. The feeder has an optional detachable tray where birds can rest while feeding. The invention also provides multiple embodiments, having a body constructed of metal or plastic alternatives. The metal bodies, preferably tubular in shape, are each formed of perforated or expanded metal, having holes therethrough, the size of the holes being dependent upon the size of the seed or other feed selected. The plastic tube feeder provides feeder ports for seed access, as well as rotatable perches for the birds to rest on while feeding.

Owner:BACKYARD NATURE PRODS

Clutch brake

A clutch brake is provided that includes a brake housing adapted to be non-movably secured relative to a driveline master clutch. The brake housing includes a through-hole sized to allow passage of a shaft and at least one source of magnetic flux. The clutch brake also includes an armature secured for rotation with the shaft and positioned axially adjacent the brake housing in a disengaged state. At least a portion of the armature is adapted to move axially on the shaft in the presence of magnetic flux to contact the brake housing in an engaged state and inhibit rotation of the armature and the shaft.

Owner:EATON CORP

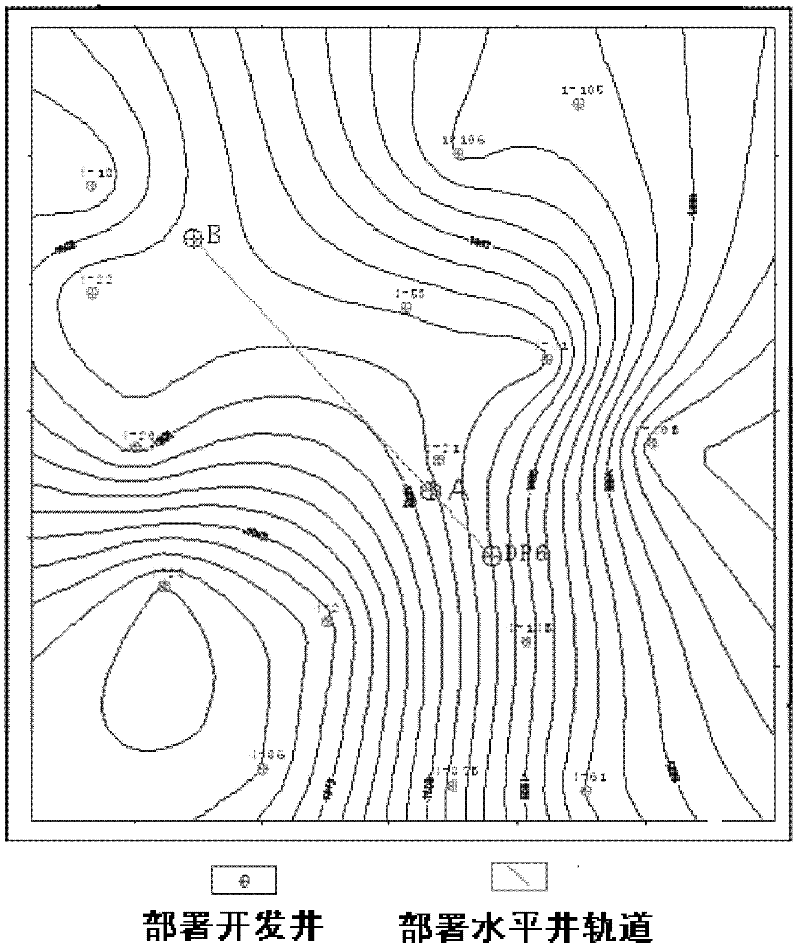

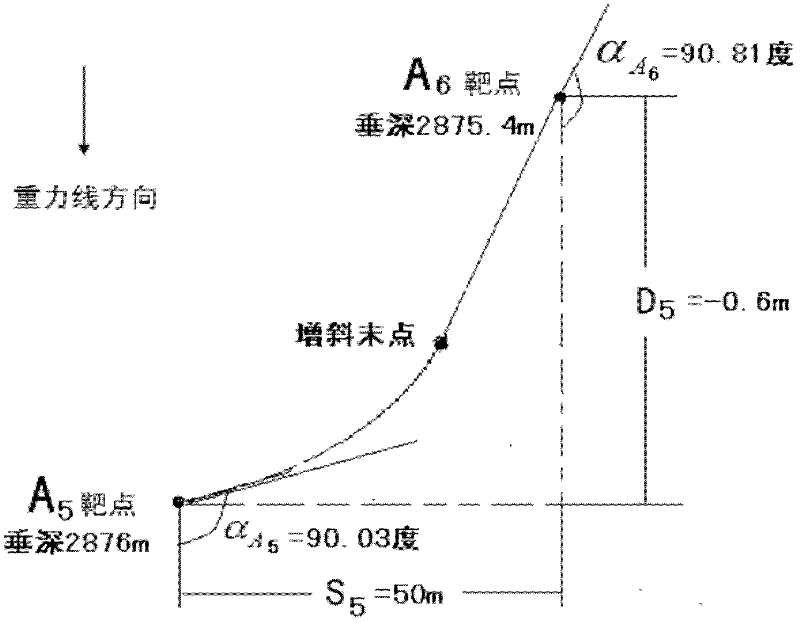

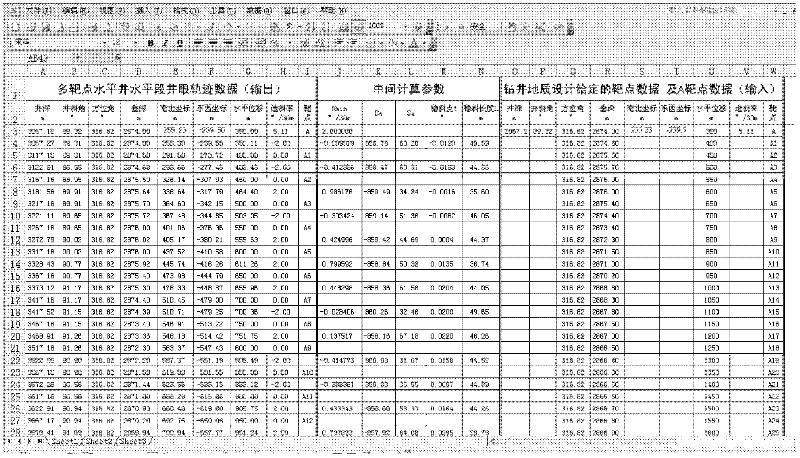

Method for determining hole trajectory of multi-target horizontal well

ActiveCN102392601ARealize the designThere is no azimuth driftDirectional drillingGeomorphologyStructure diagram

The invention relates to a method for determining a hole trajectory of a multi-target horizontal well. The method comprises the following steps of: drawing a reservoir planar structure diagram or a contour chart according to seismic data, geological log data and geophysical logging data, determining reservoir sand body distribution, determining pre-target displacement in combination with the hole size and the drill capacity, and determining a well coordinate, a target coordinate and a target vertical depth in combination with a field exploration result; determining the hole trajectory ranging from a hole to a first target; and determining the curvature of the hole at a horizontal section and the deviation angle of each control target according to the parameter of the first target, the coordinate and vertical depth of each control target and the deflecting capacity of a deflecting tool to determine the hole trajectory at the horizontal section. In the method, engineering is combined with geology, so that the hole trajectory of the multi-target horizontal well can be realized, the phenomenon of bearing shifting is avoided, and the method is particularly suitable for thin reservoirs with high anisotropism. The method is easy and convenient to implement, and can be implemented by both engineering design personnel and field technical personnel.

Owner:CHINA PETROLEUM & CHEM CORP +1

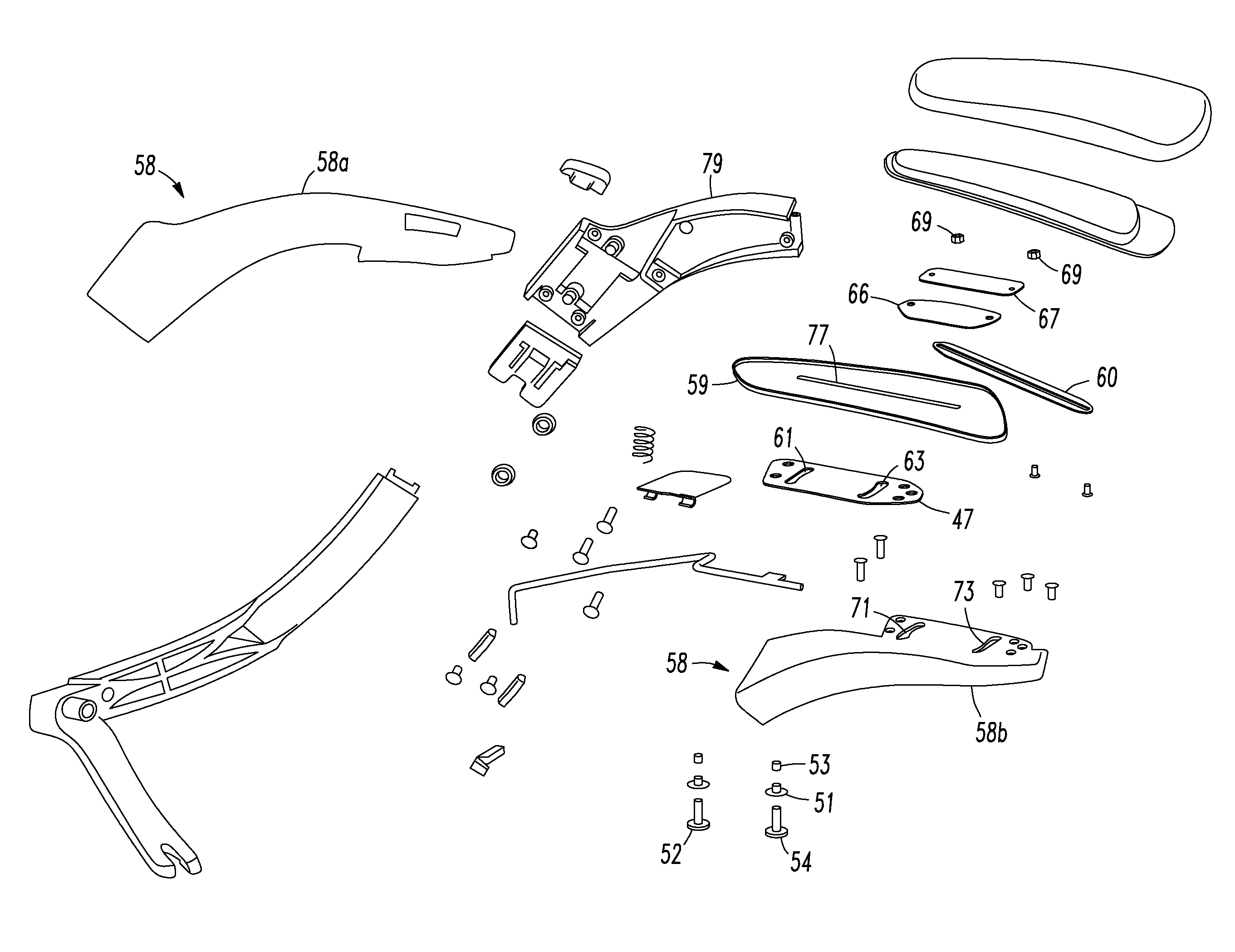

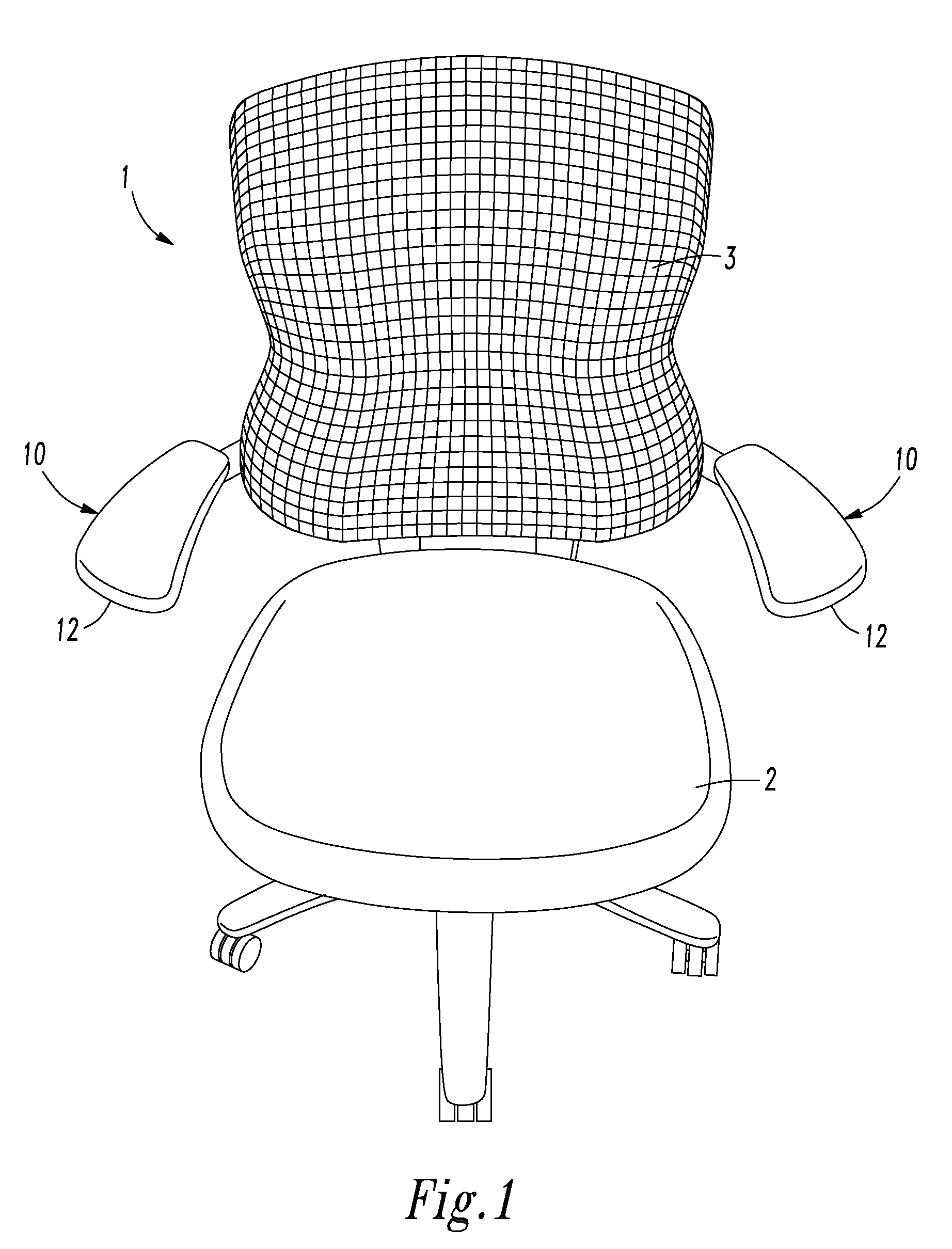

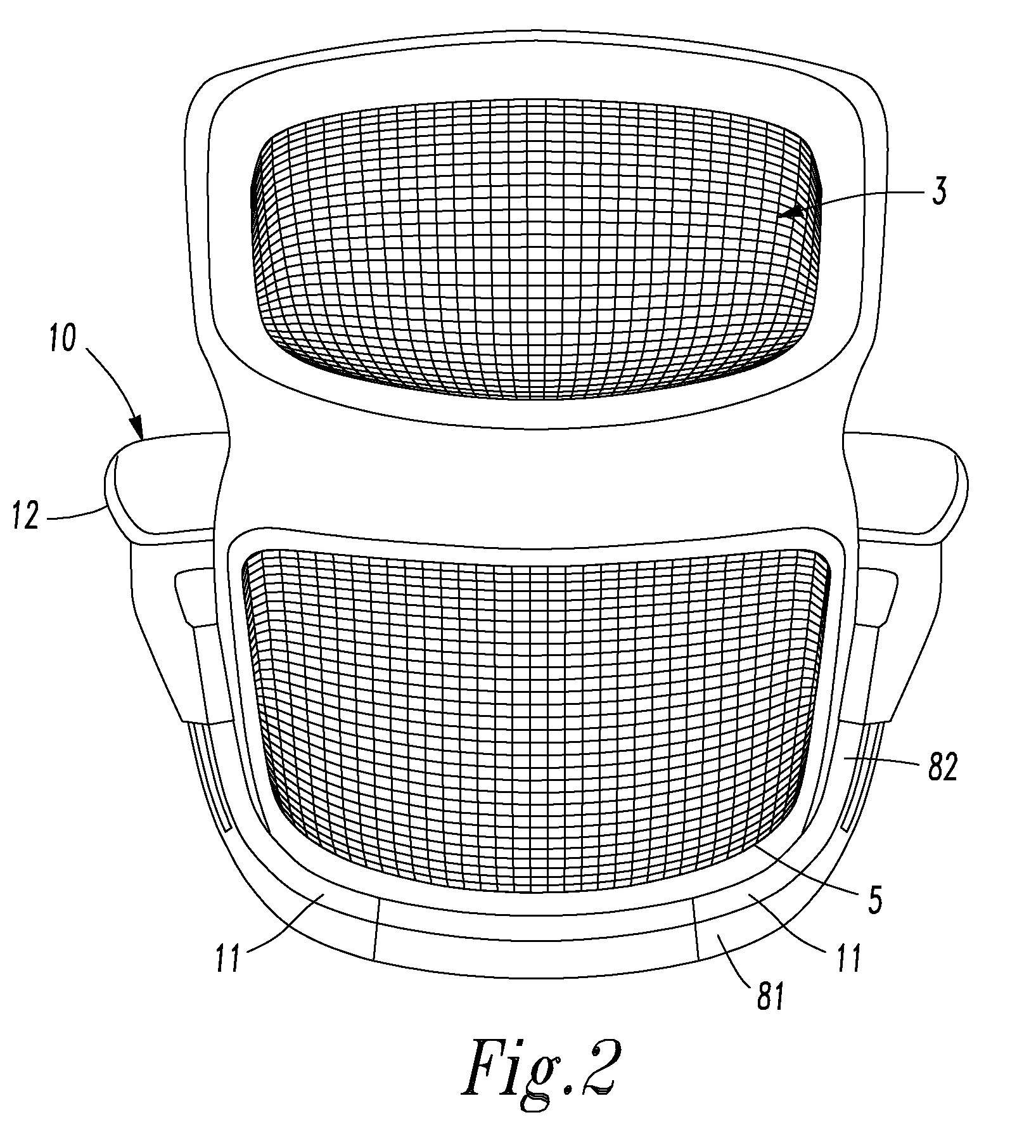

Armrest apparatus

Owner:KNOLL INC

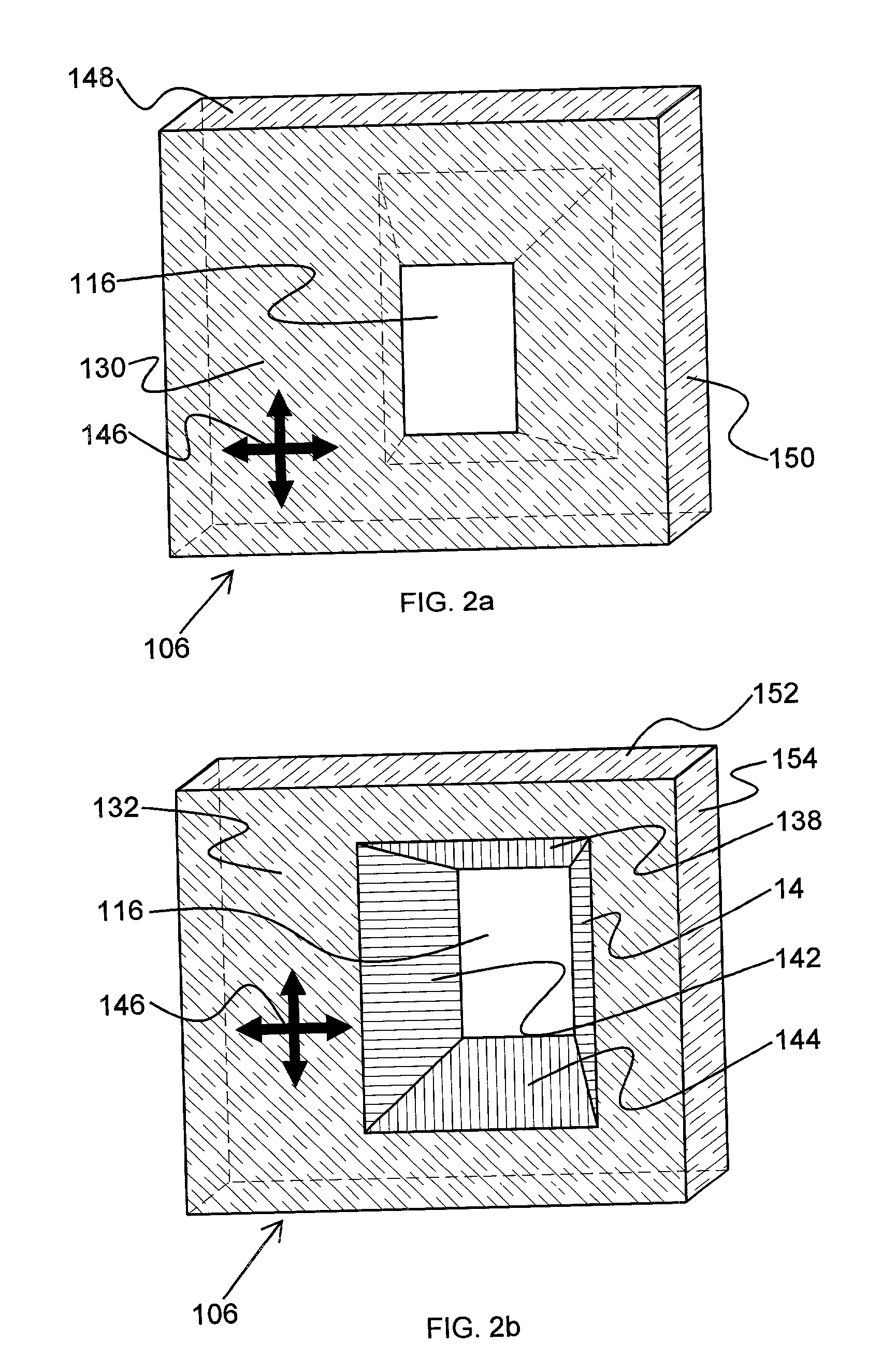

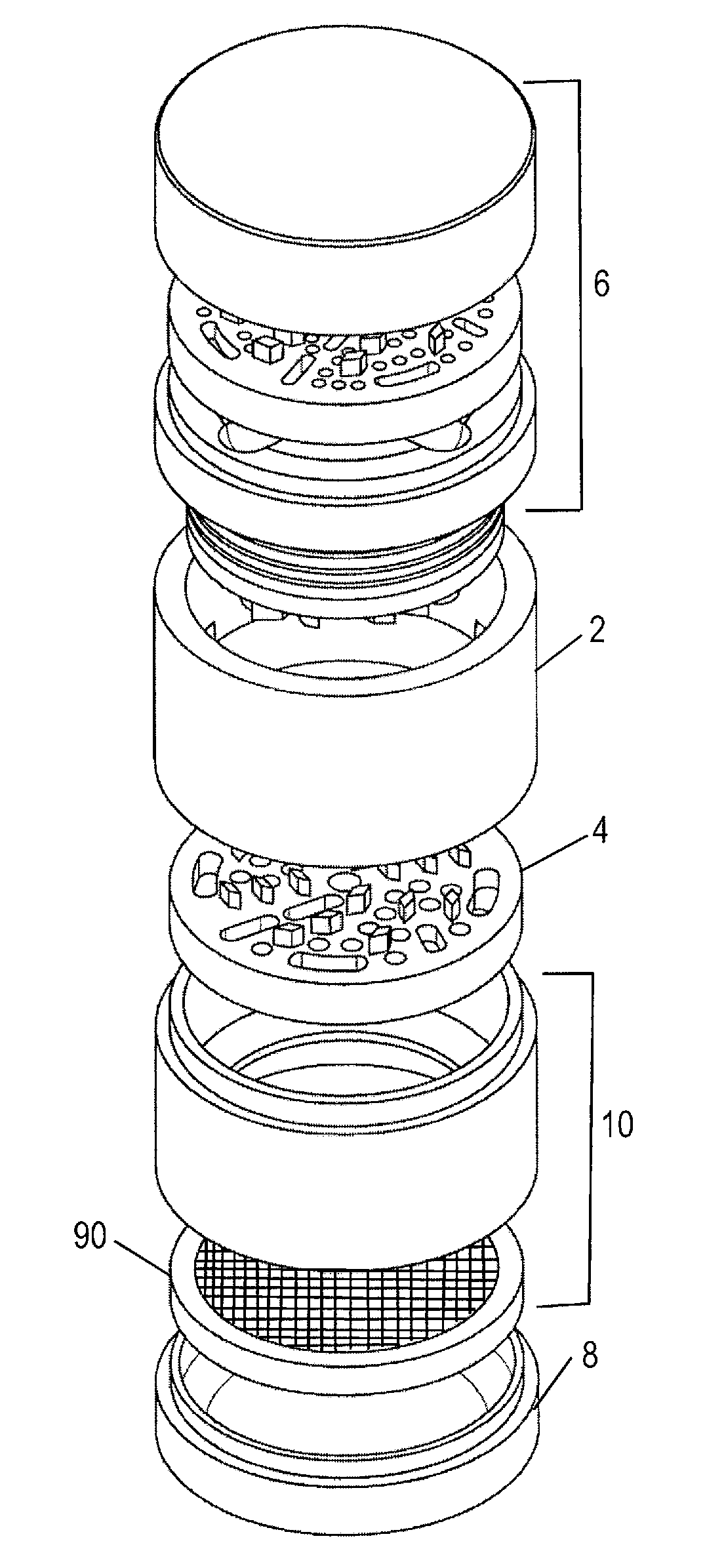

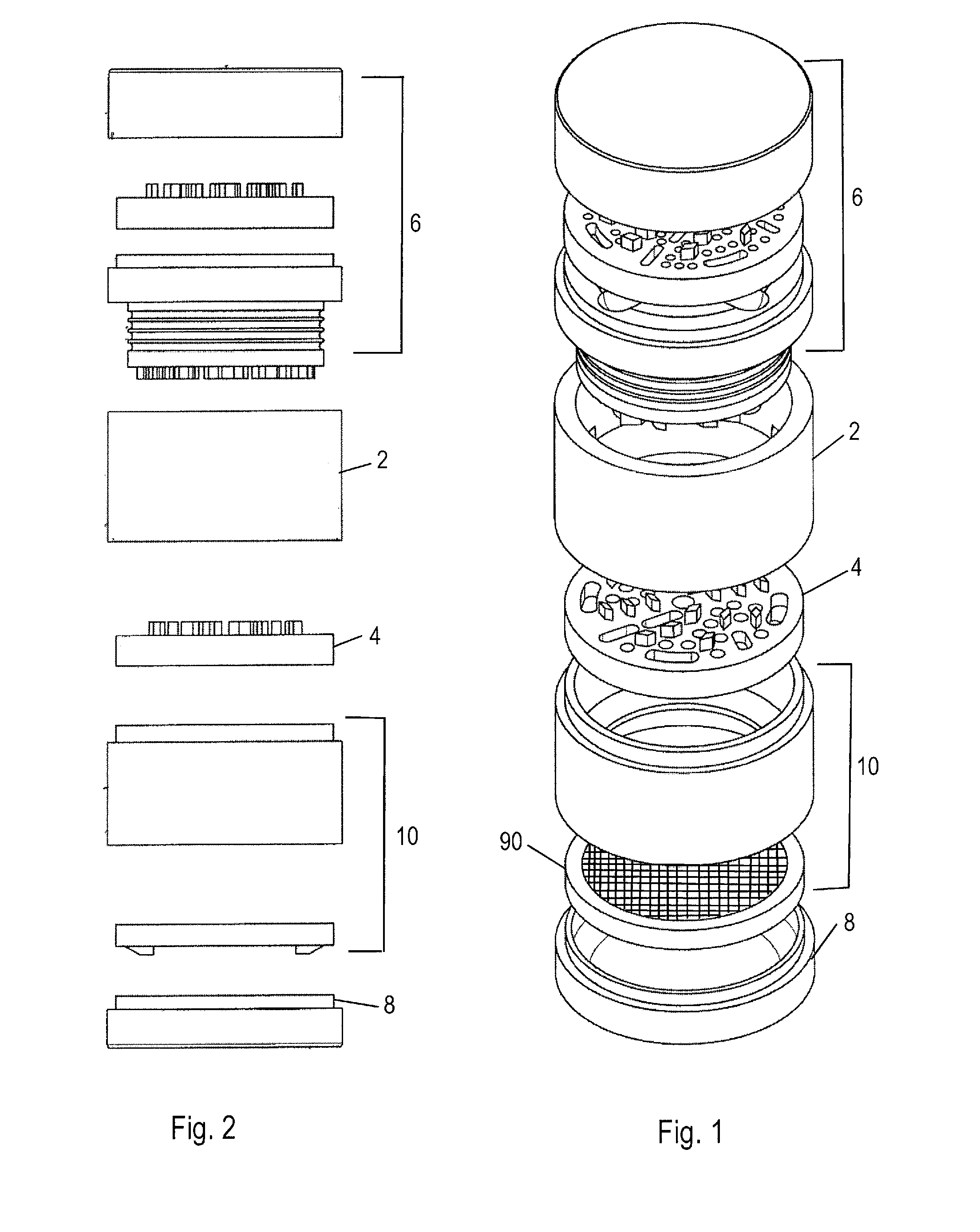

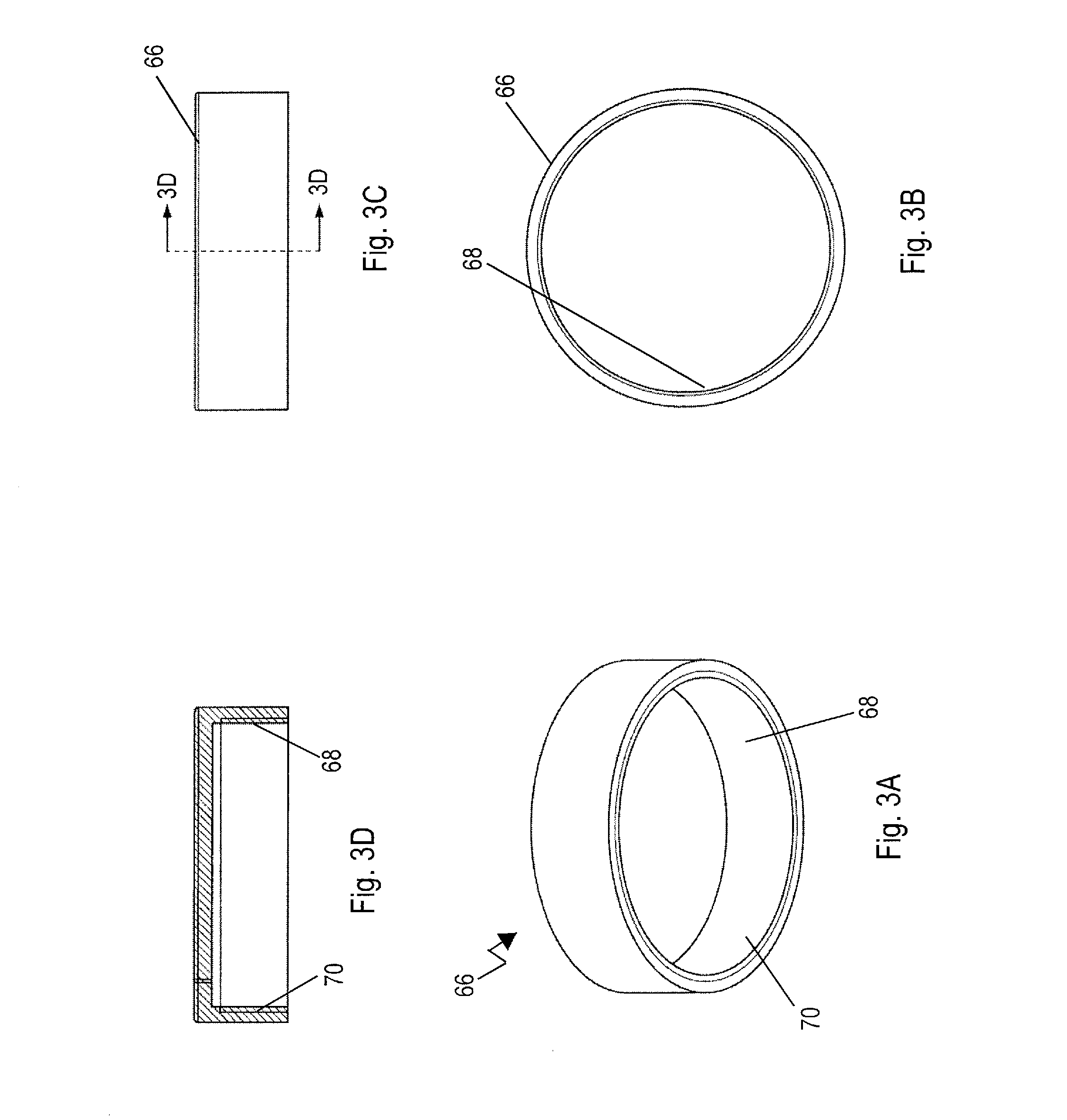

Herb grinder system

ActiveUS20160100715A1Easy and fast assemblySatisfies needCoffee millsSpice millsLeading edgeEngineering

The present invention involves a system and method for grinding herbs, tobacco, marijuana and the like. The herb grinder system herein includes interchangeable and replaceable lower grinder plates that are secured in place with threading, bayonet mounts or the like. The upper and lower grinding plates are provided with blades having a modified diamond shape which provides extremely sharp leading edges regardless of which direction the grip assembly of the grinder housing is rotated. The lower plates are also provided with variations in the size, shape and arrangement of hole sizes through which the ground material is allowed to pass through. This construction provides the user with the ability to control his / her grind size mixture, which may be consistent sized grinds or a mixture of different sized grinds.

Owner:VOLO TRADE

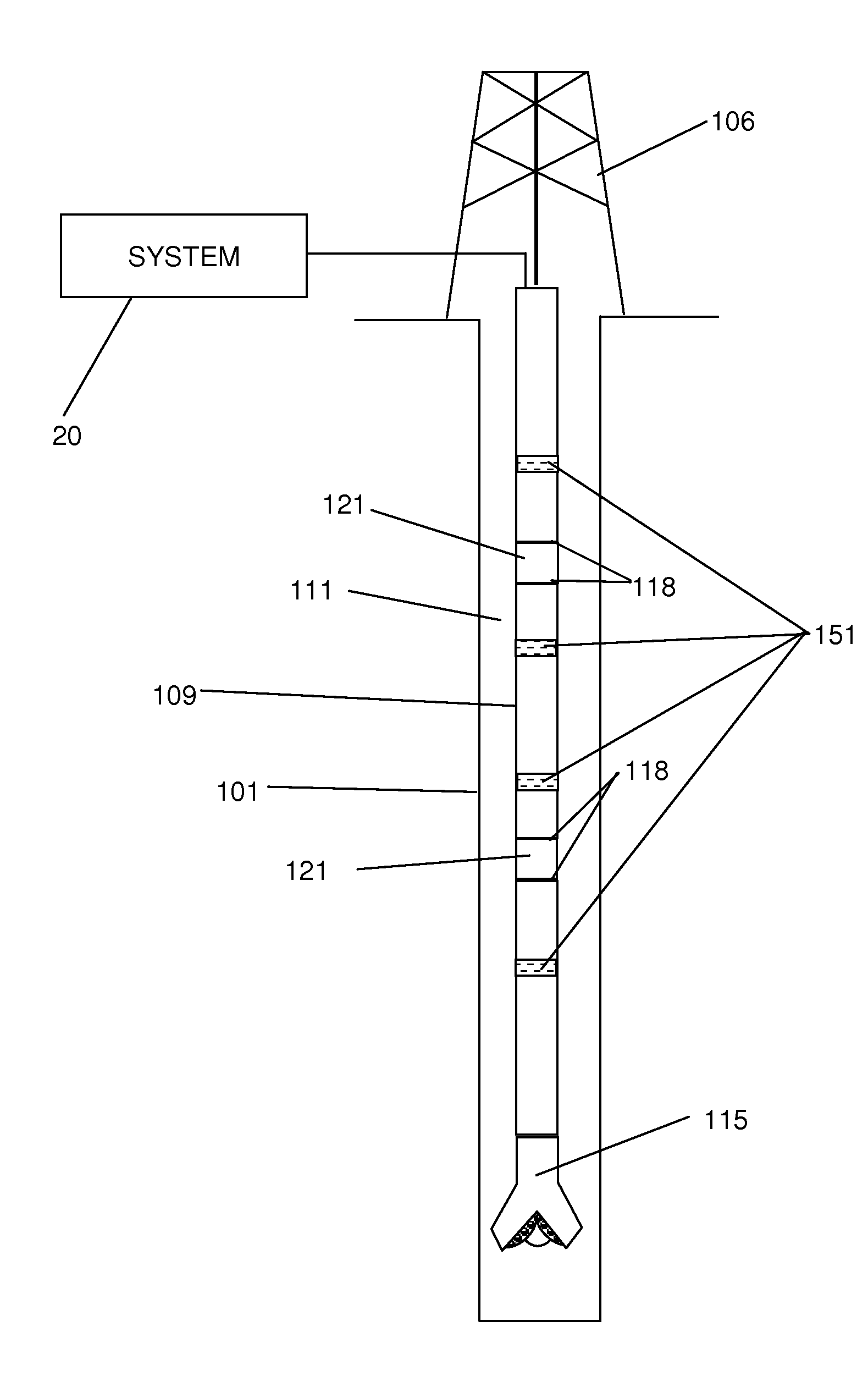

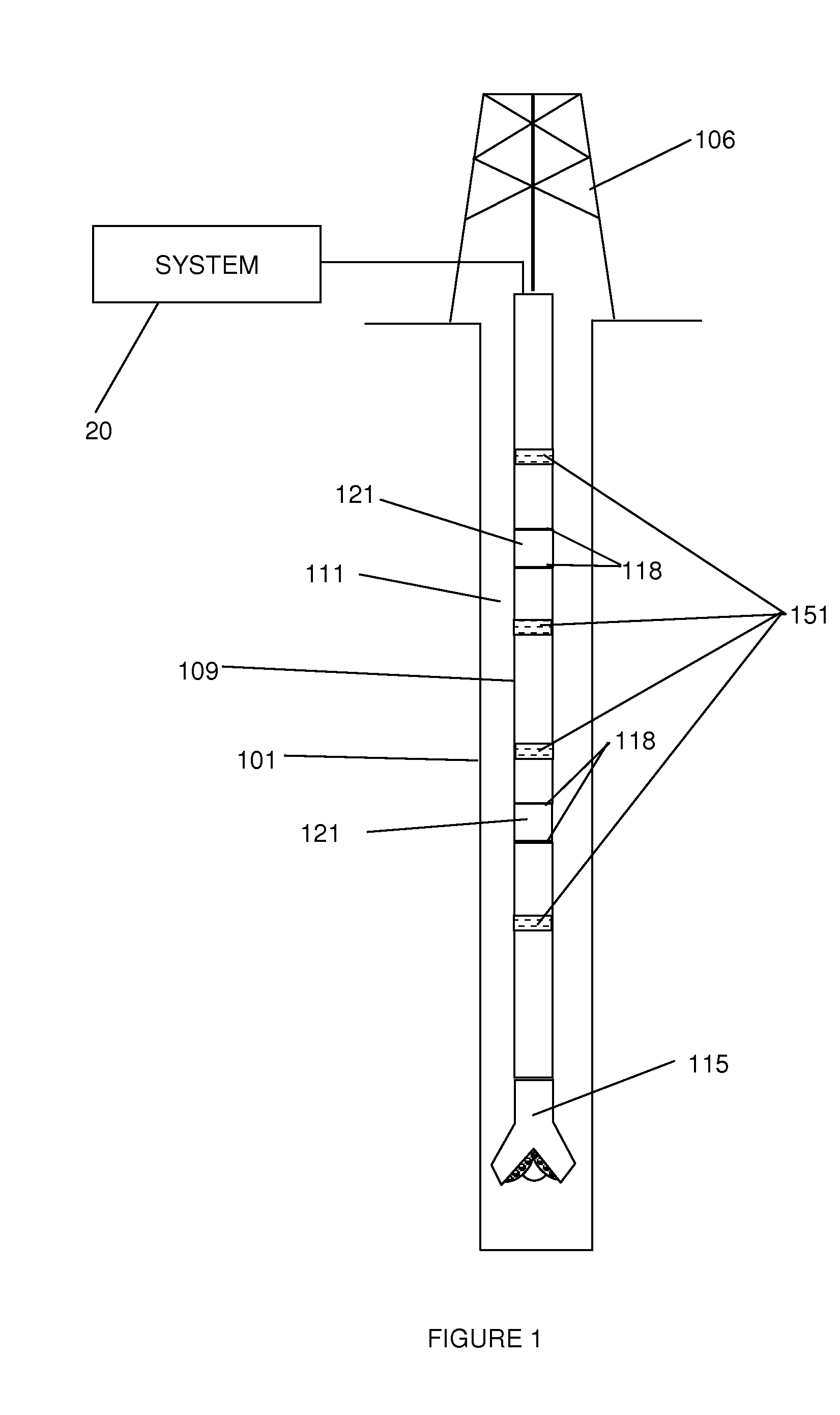

Method of determining borehole conditions from distributed measurement data

Methods of determining borehole conditions using distributed measurement data are disclosed herein. The disclosed methods utilize real time data measurements taken from sensors distributed along the length of a drill string to assess various conditions or properties of the borehole. The disclosed methods of processing or using distributed measurement data have not been described before. In particular, the distributed data may be used for example, to track the progress of a chemical pill or also track the location of different types of borehole fluids, and also to determine the hole size or volume of the borehole.

Owner:BP EXPLORATION OPERATING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com