Patents

Literature

457 results about "Parylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

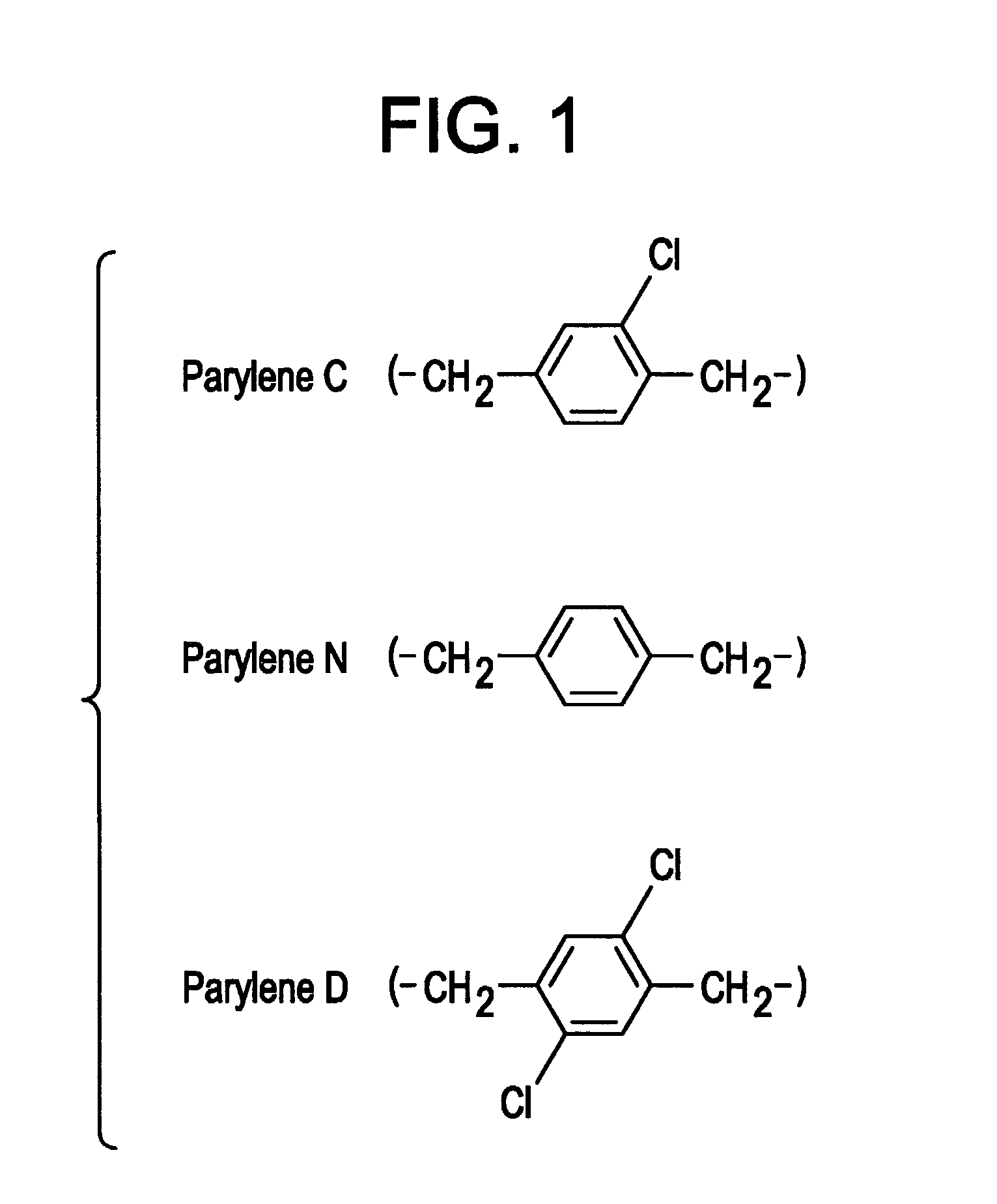

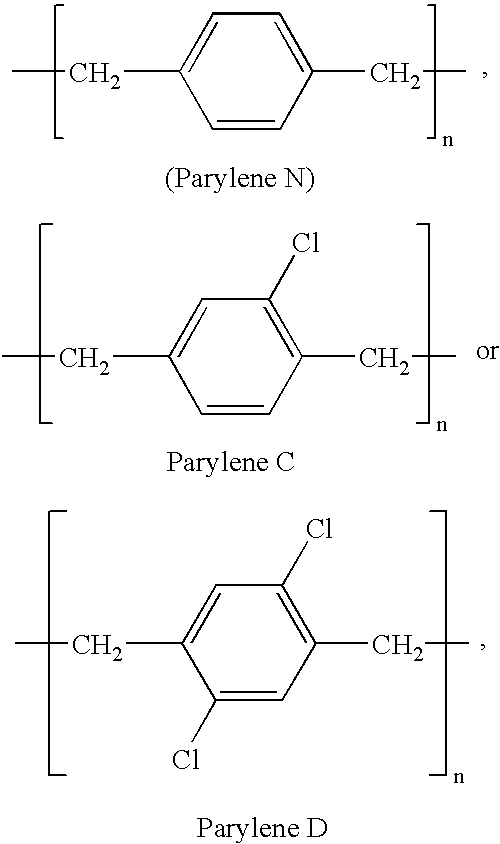

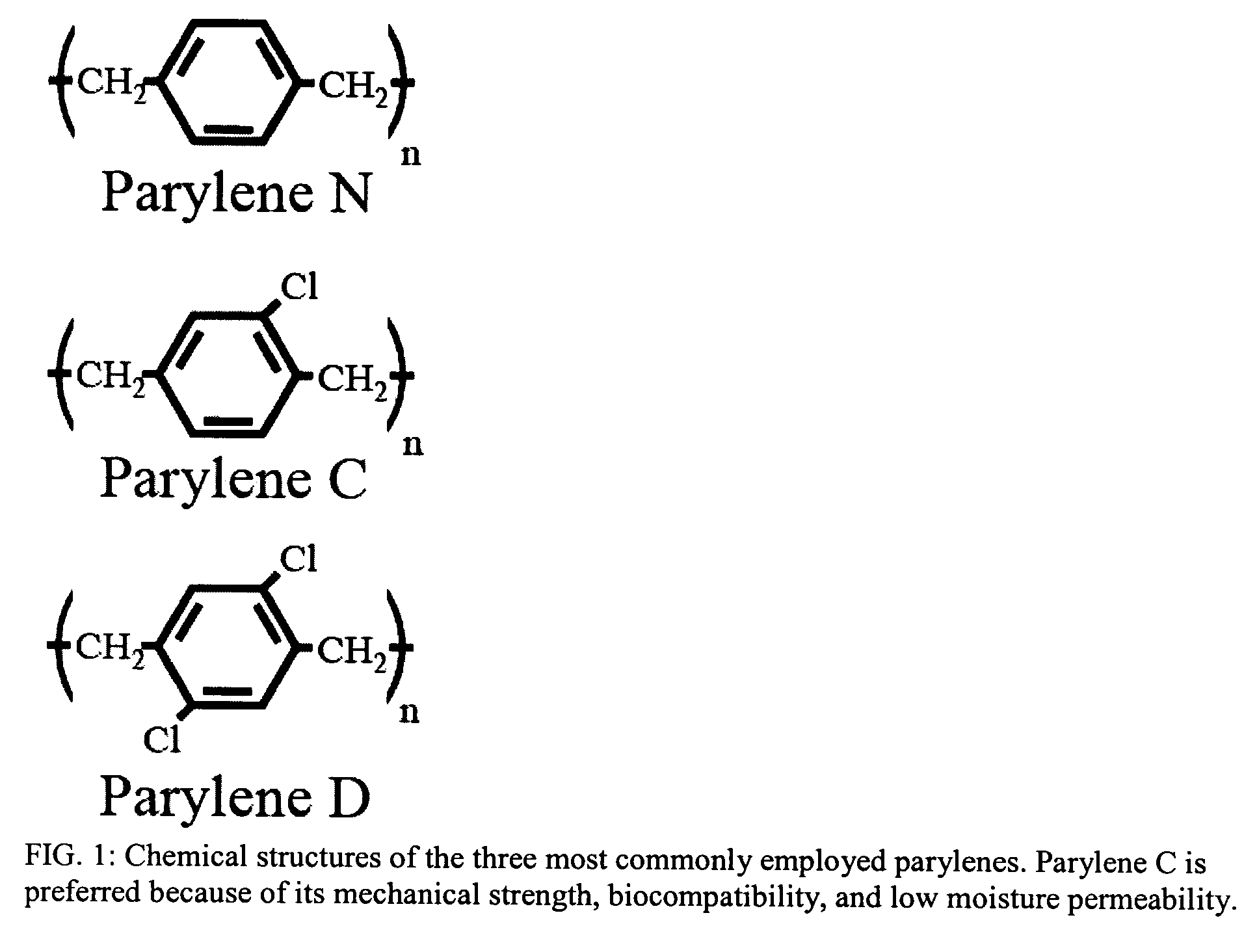

Parylene is the trade name for a variety of chemical vapor deposited poly(p-xylylene) polymers used as moisture and dielectric barriers. Among them, Parylene C is the most popular due to its combination of barrier properties, cost, and other processing advantages.

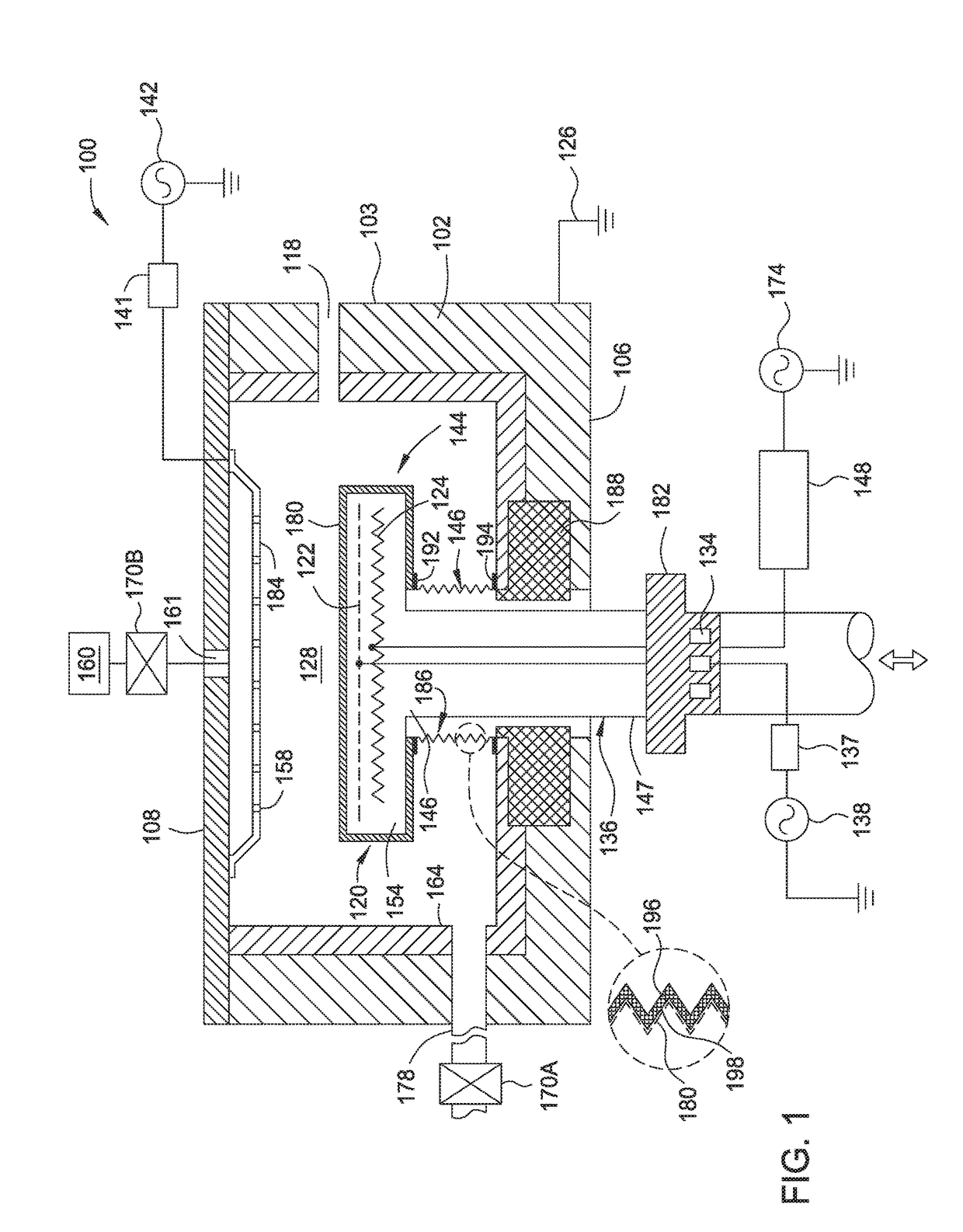

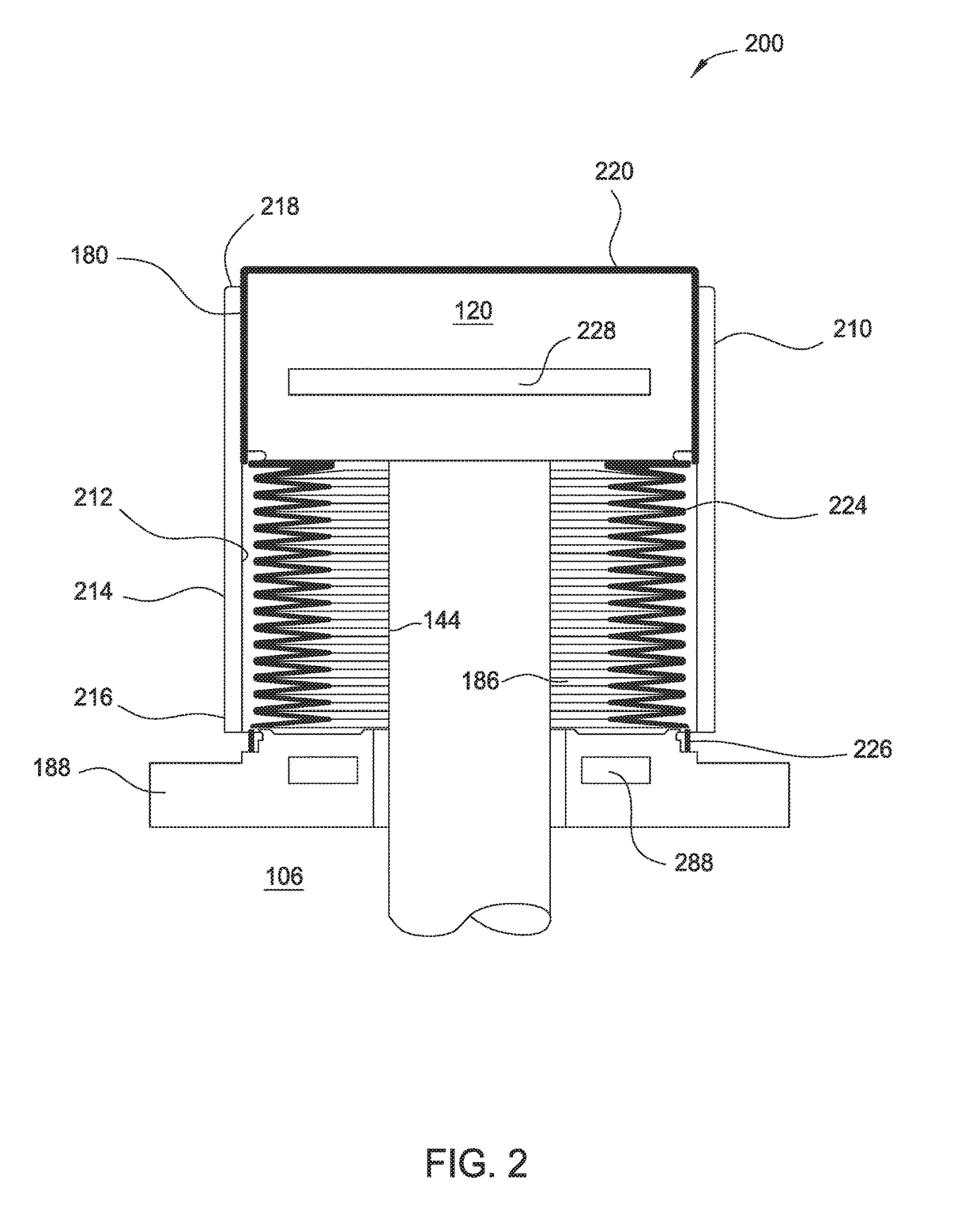

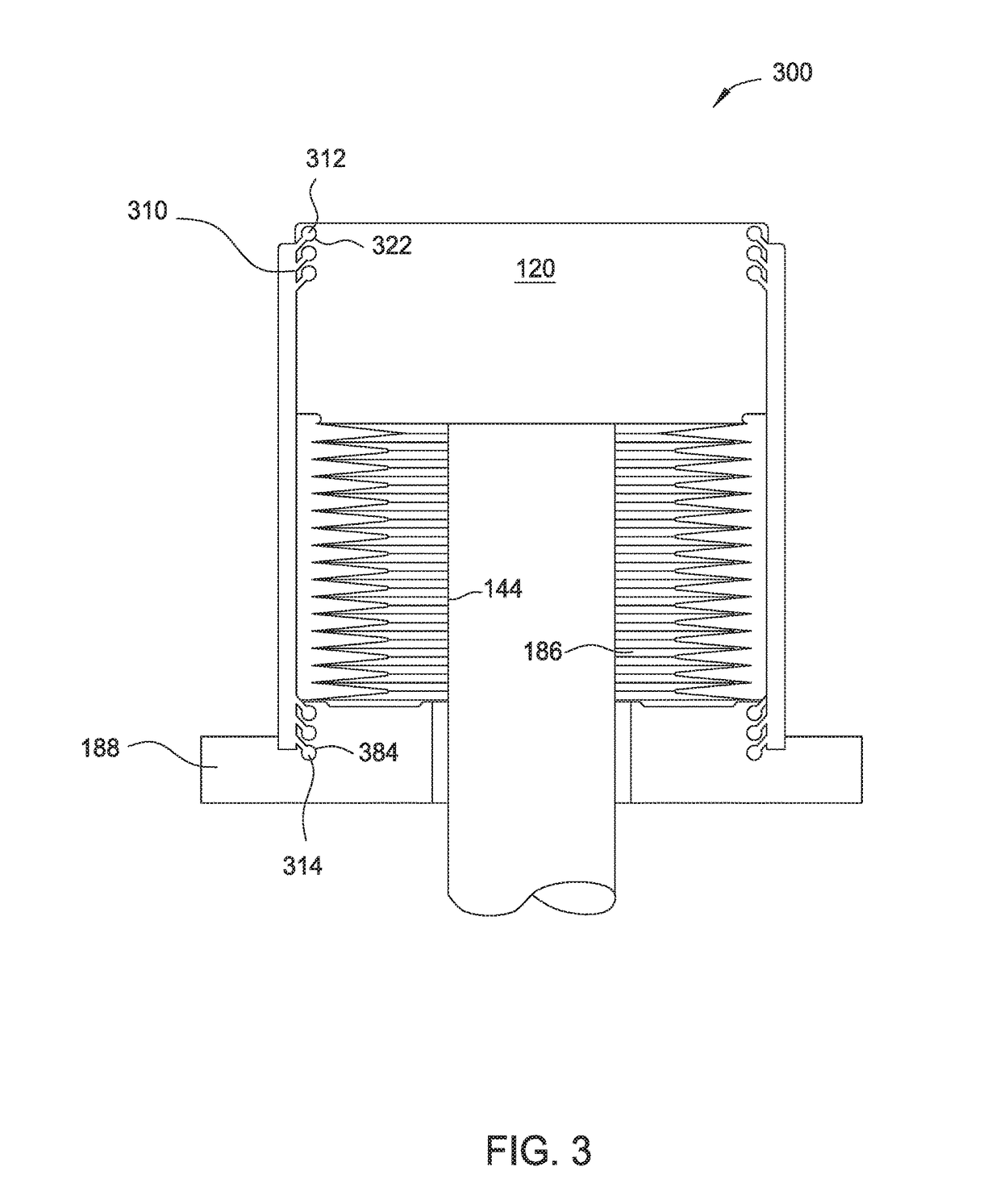

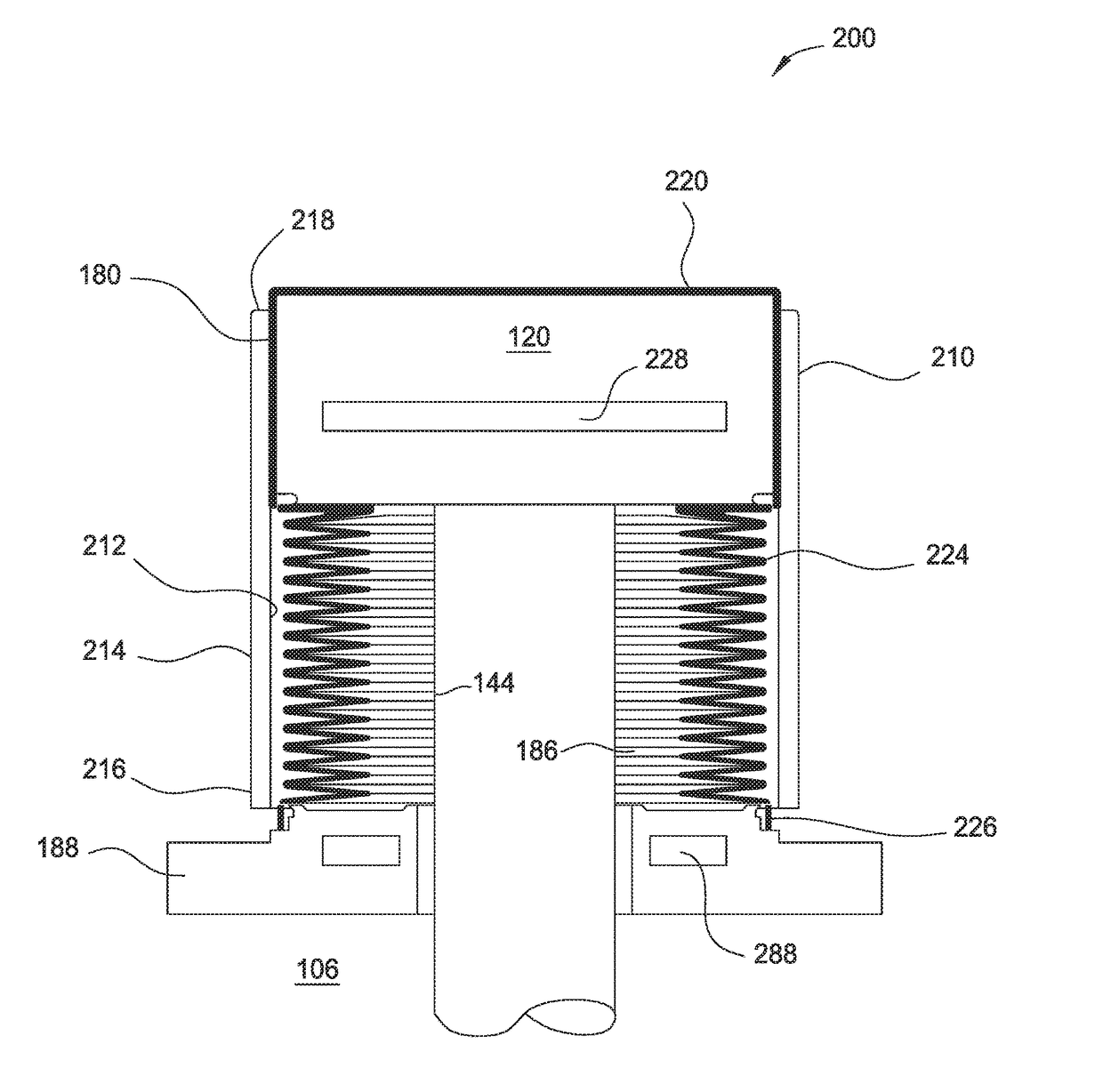

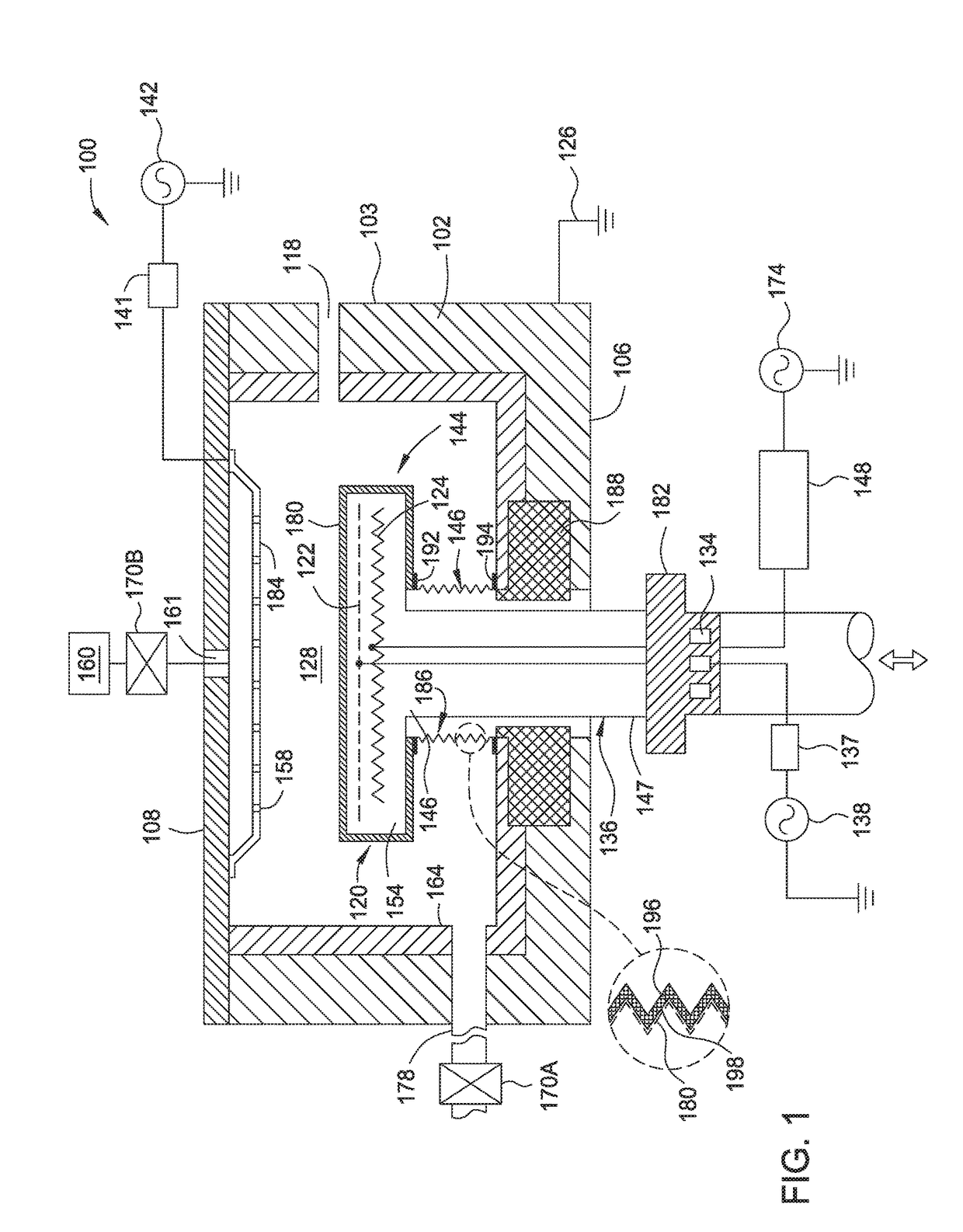

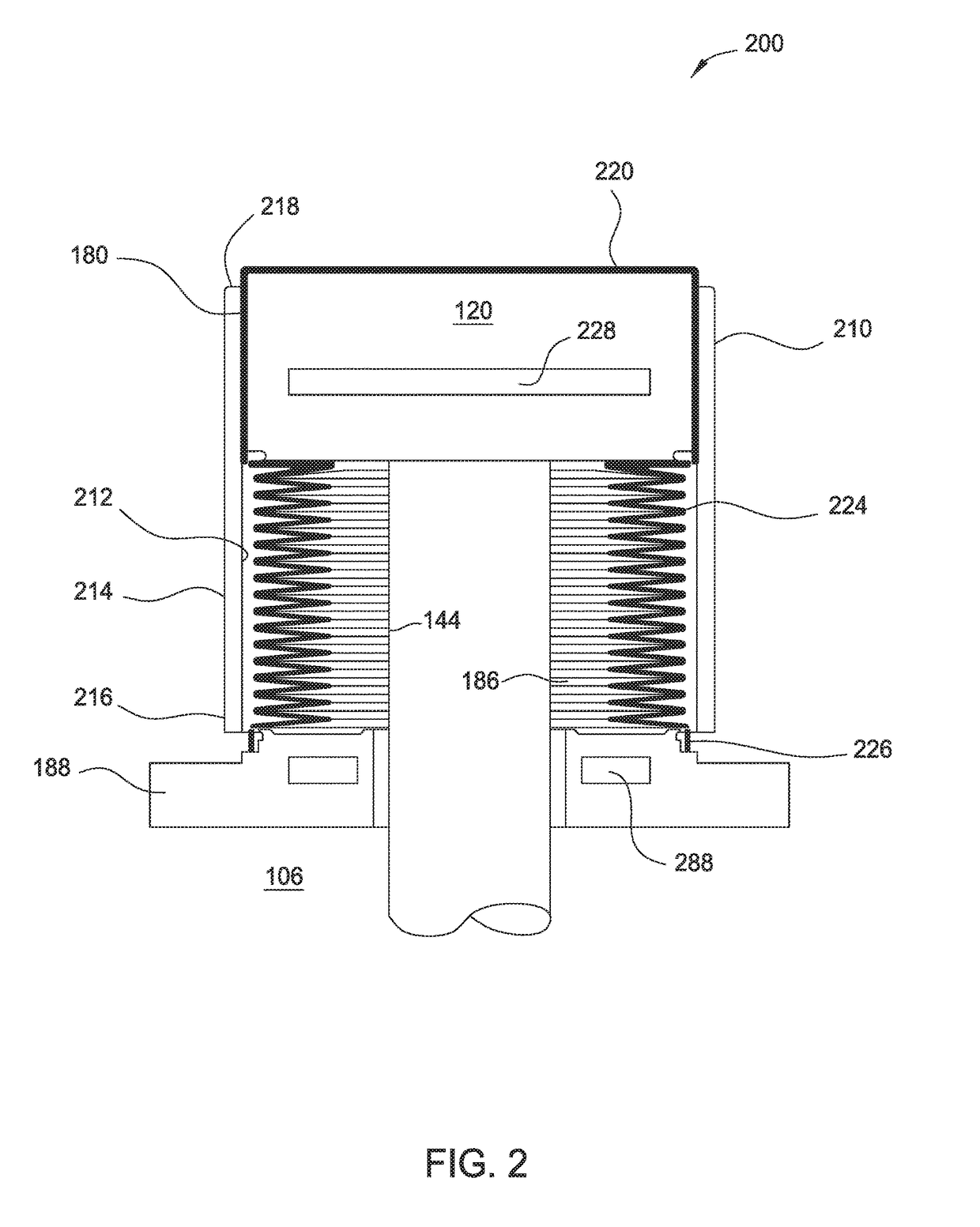

Corrosion control for chamber components

Owner:APPLIED MATERIALS INC

Corrosion control for chamber components

ActiveUS20170152968A1Protection cleanSpindle sealingsElectric discharge tubesParyleneDiamond-like carbon

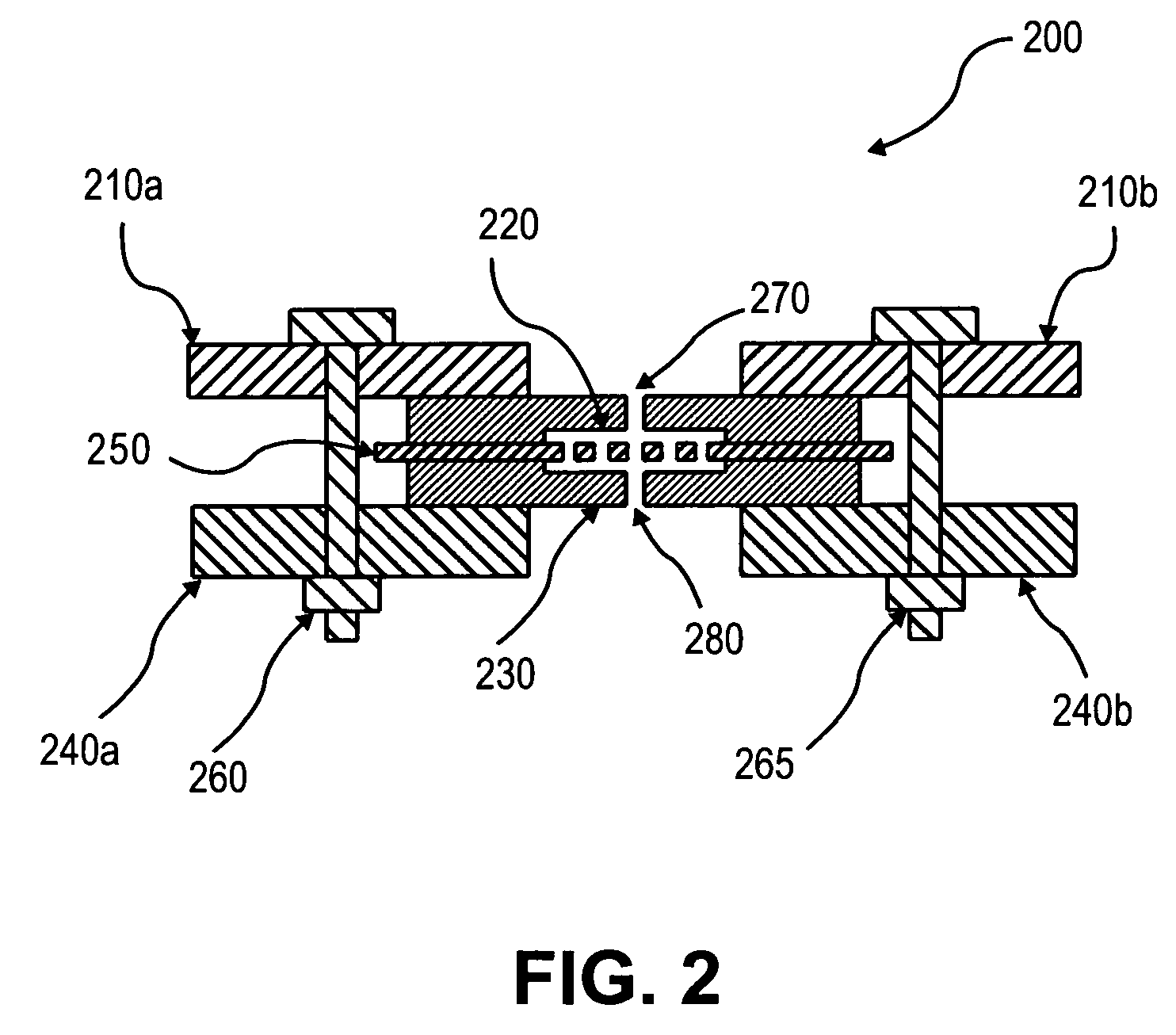

Implementations described herein protect a chamber components from corrosive cleaning gases used at high temperatures. In one embodiment, a chamber component includes at least a bellows that includes a top mounting flange coupled to a bottom mounting flange by a tubular accordion structure. A coating is disposed on an exterior surface of at least the tubular accordion structure. The coating includes of at least one of polytetrafluoroethylene, parylene C, parylene D, diamond-like carbon (DLC), yttria stabilized zirconia, nickel, alumina, or aluminum silicon magnesium yttrium oxygen compound. In one embodiment, the chamber component is a valve having an internal bellows.

Owner:APPLIED MATERIALS INC

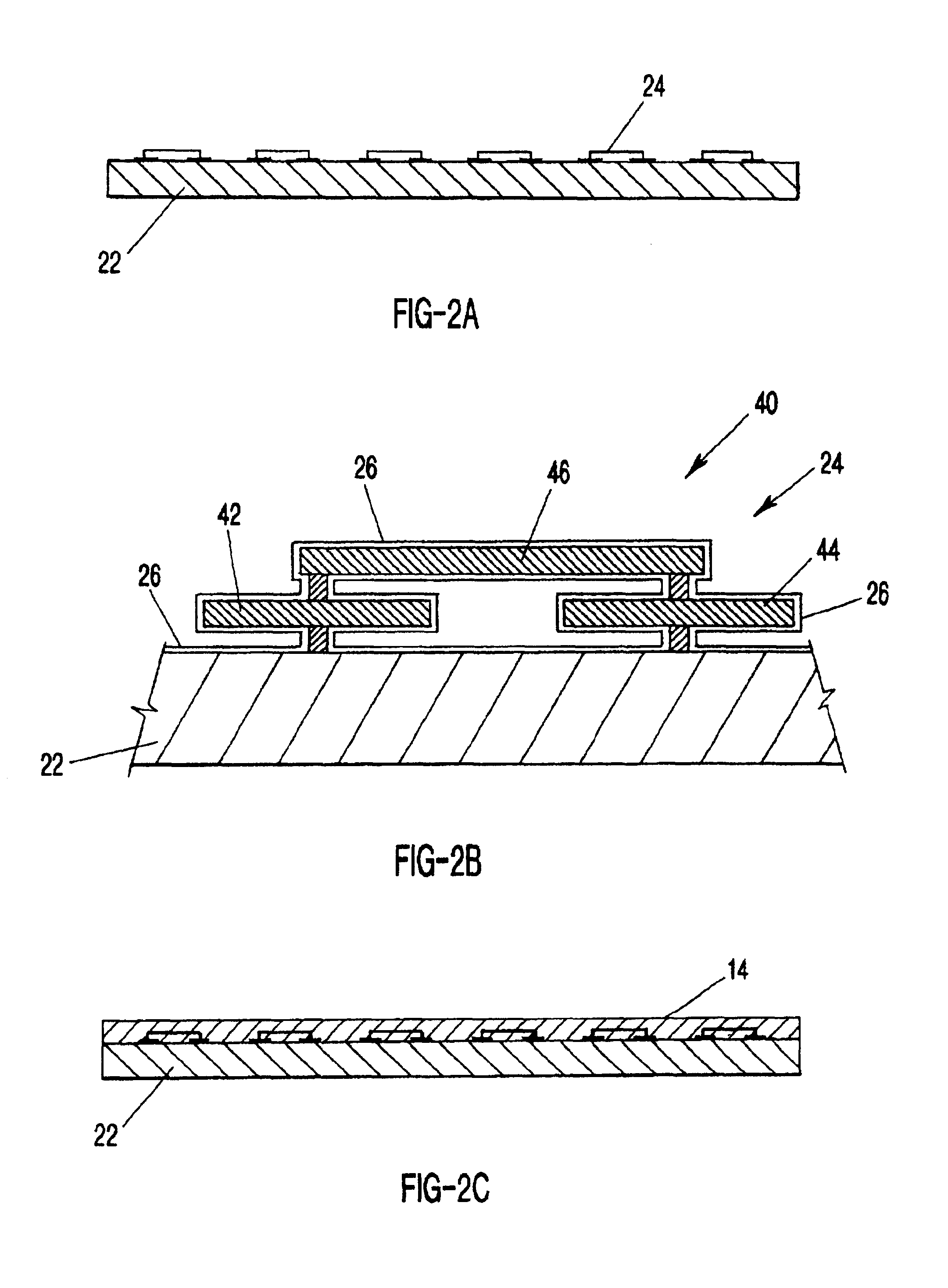

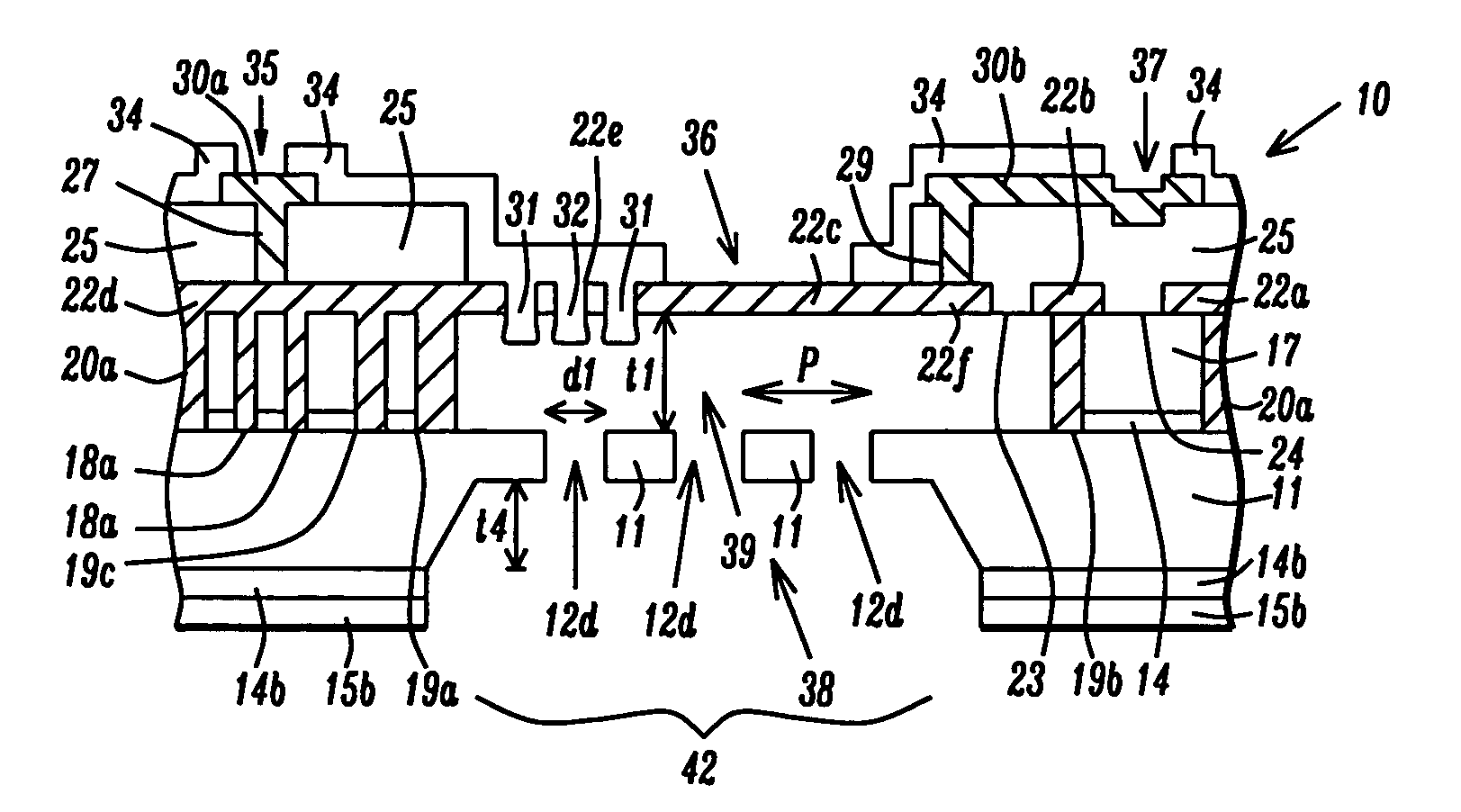

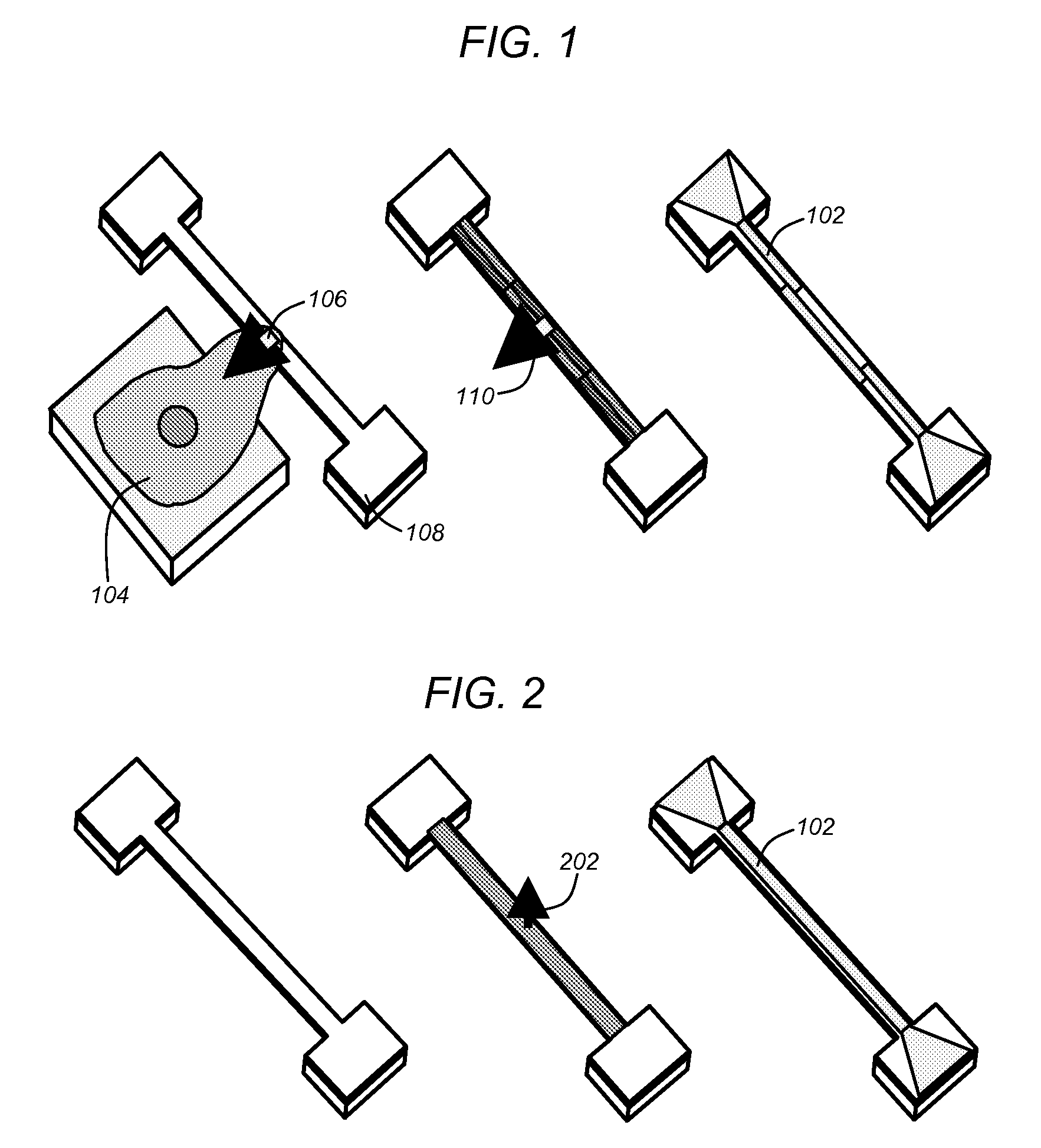

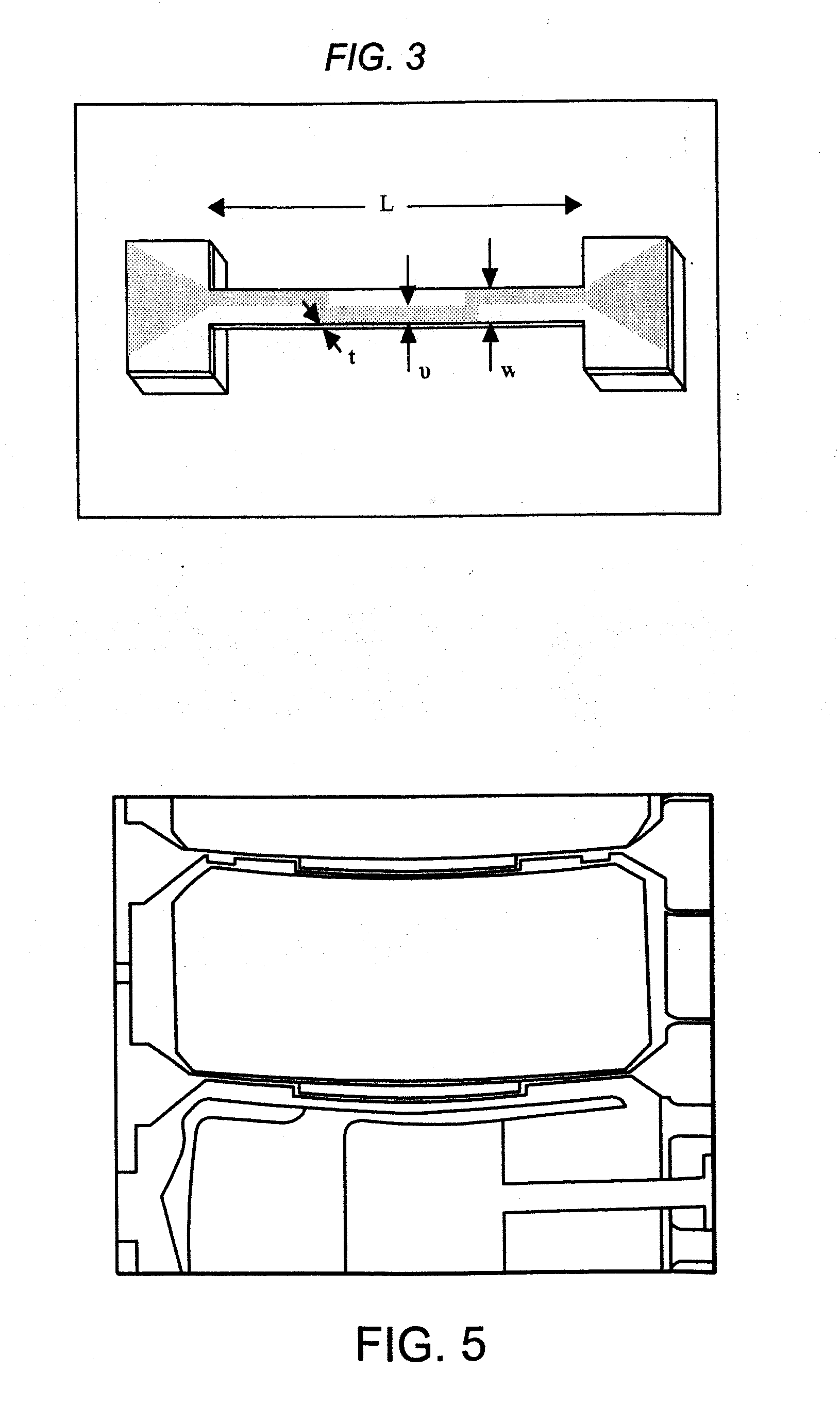

Methods for conformal coating and sealing microchip reservoir devices

InactiveUS6973718B2Reduce adverse reactionsPrinted circuit assemblingLiquid surface applicatorsParyleneGas phase

Methods are provided for conformally coating microchip devices and for sealing reservoirs containing molecules or devices in a microchip device. One method comprises (i) providing a substrate having a plurality of reservoirs having reservoir openings in need of sealing; (ii) loading reservoir contents comprising molecules, a secondary device, or both, into the reservoirs; and (iii) applying a conformal coating barrier layer, such as a vapor depositable polymeric material, e.g., parylene, onto the reservoir contents over at least the reservoir openings to seal the reservoir openings. Another method comprises vapor depositing a conformal coating material onto a microchip device having at least two reservoirs and reservoir caps positioned over molecules or devices stored in the reservoirs, and providing that the conformal coating does not coat or is removed from the reservoir caps.

Owner:MICROCHIPS INC

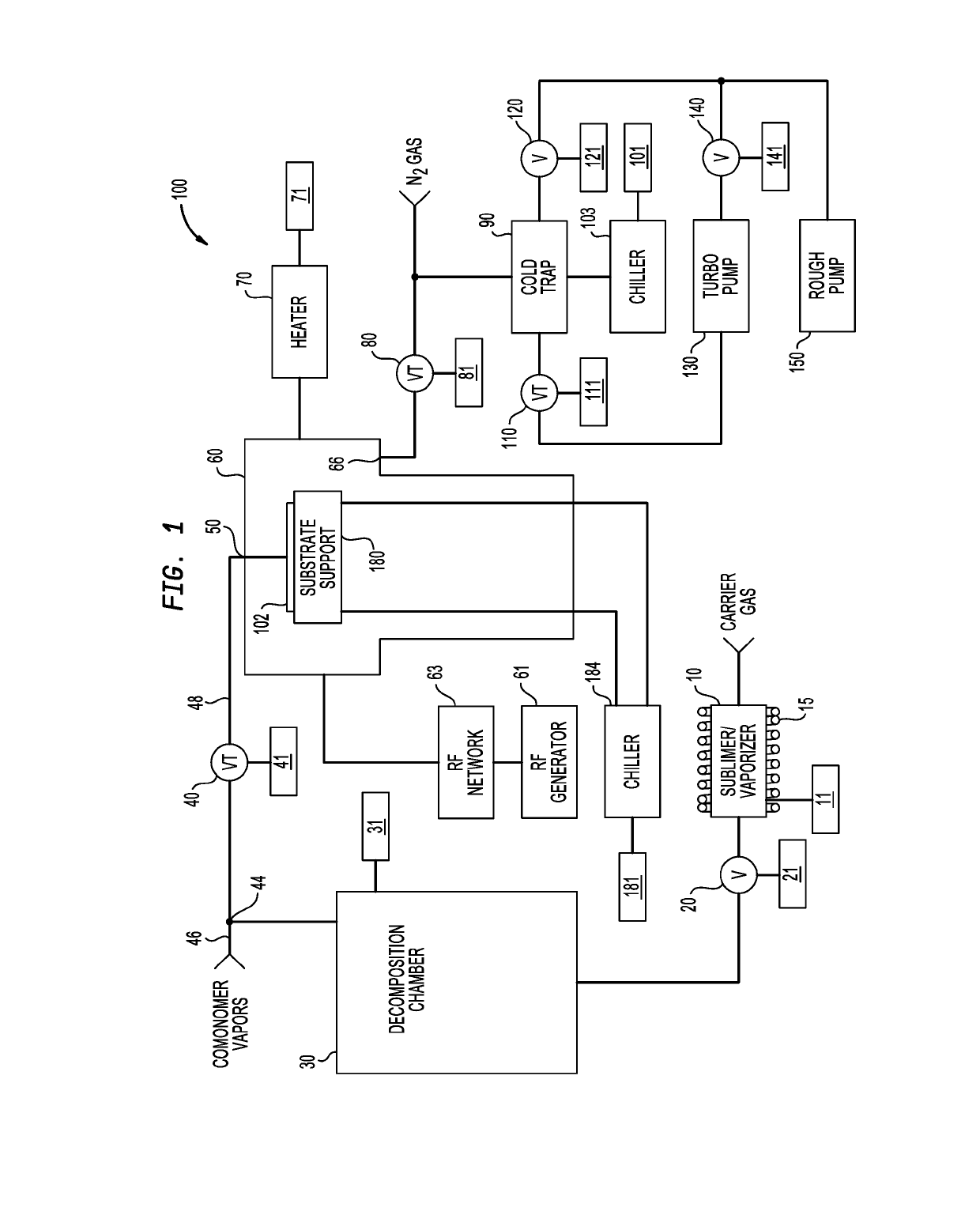

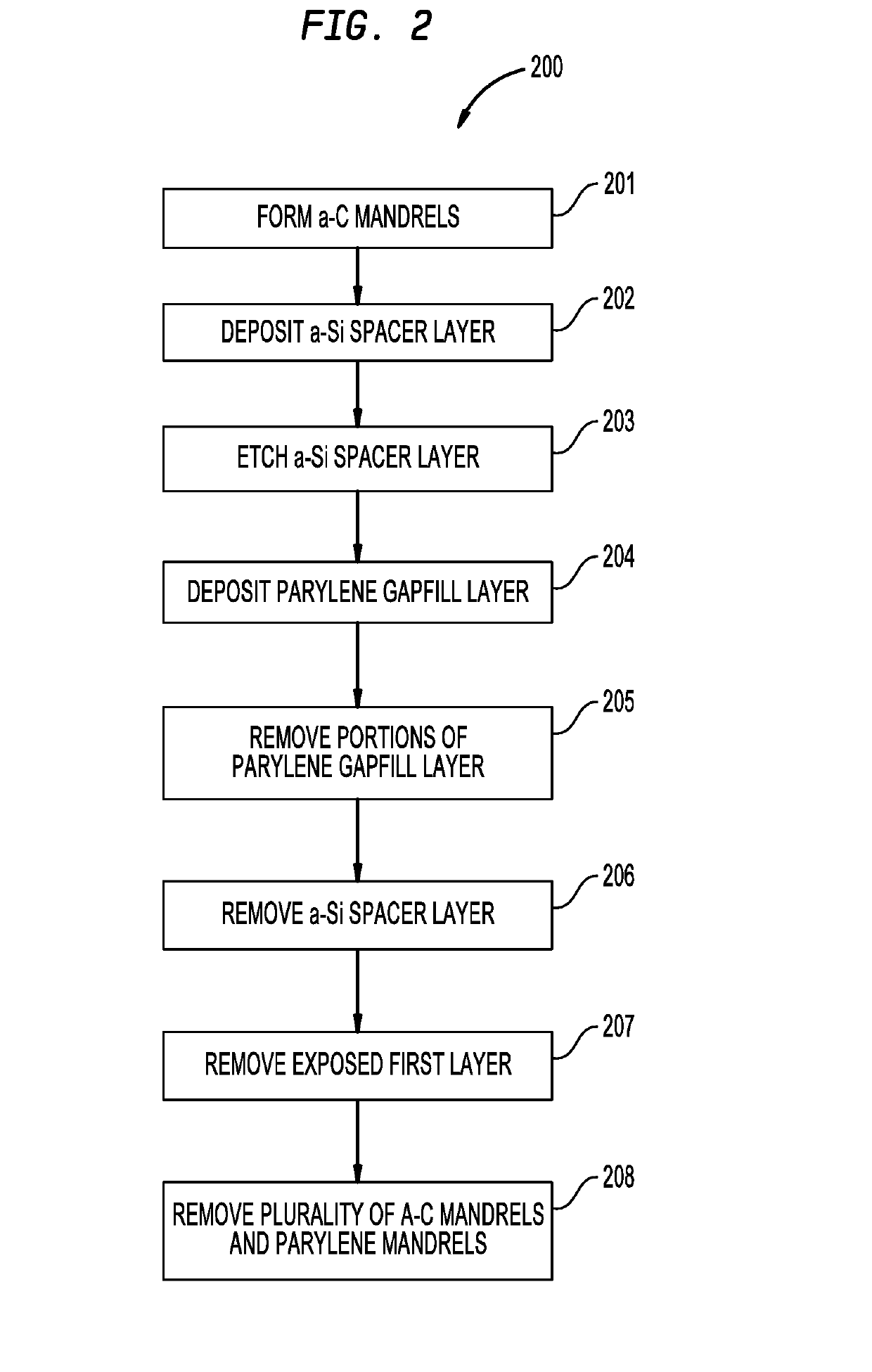

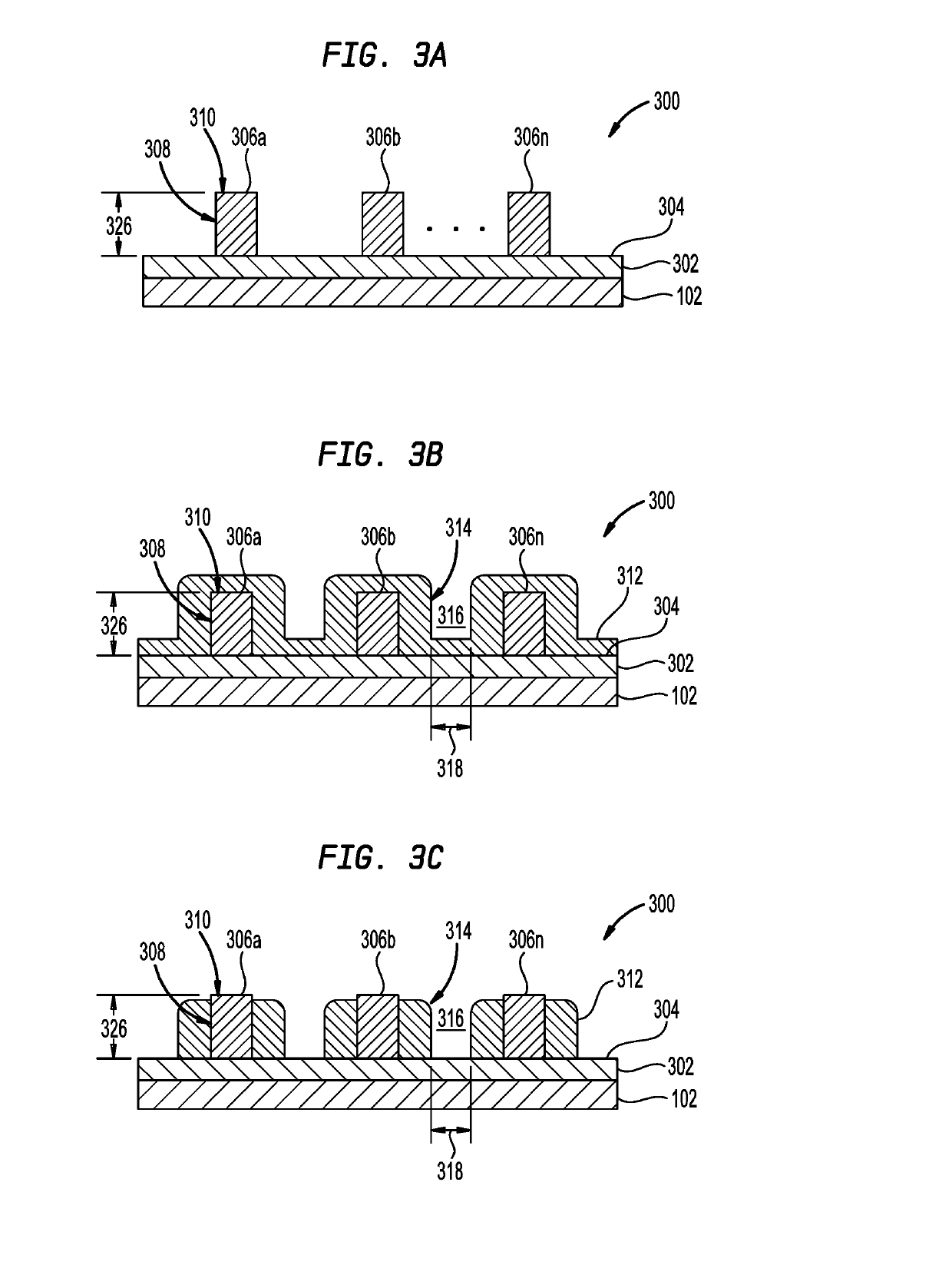

Carbon film gapfill for patterning application

Embodiments described herein relate to methods for forming patterns of semiconductor devices utilizing parylene gapfill layers deposited using a thermal chemical vapor deposition (CVD) process. In one embodiment the patterns of semiconductor devices are formed by forming amorphous carbon (a-C) mandrels on first layers, depositing amorphous silicon (a-Si) layers over the a-C mandrels and the first layers, etching the a-Si spacer layers to expose top surfaces of the a-C mandrels and to expose the first layers, depositing parylene gapfill layers using the CVD process, removing portions of the parylene gapfill layers until the top surfaces are exposed; and removing the a-Si spacer layers to expose the first layers and form patterns of semiconductor devices having a-C mandrels and parylene mandrels.

Owner:APPLIED MATERIALS INC

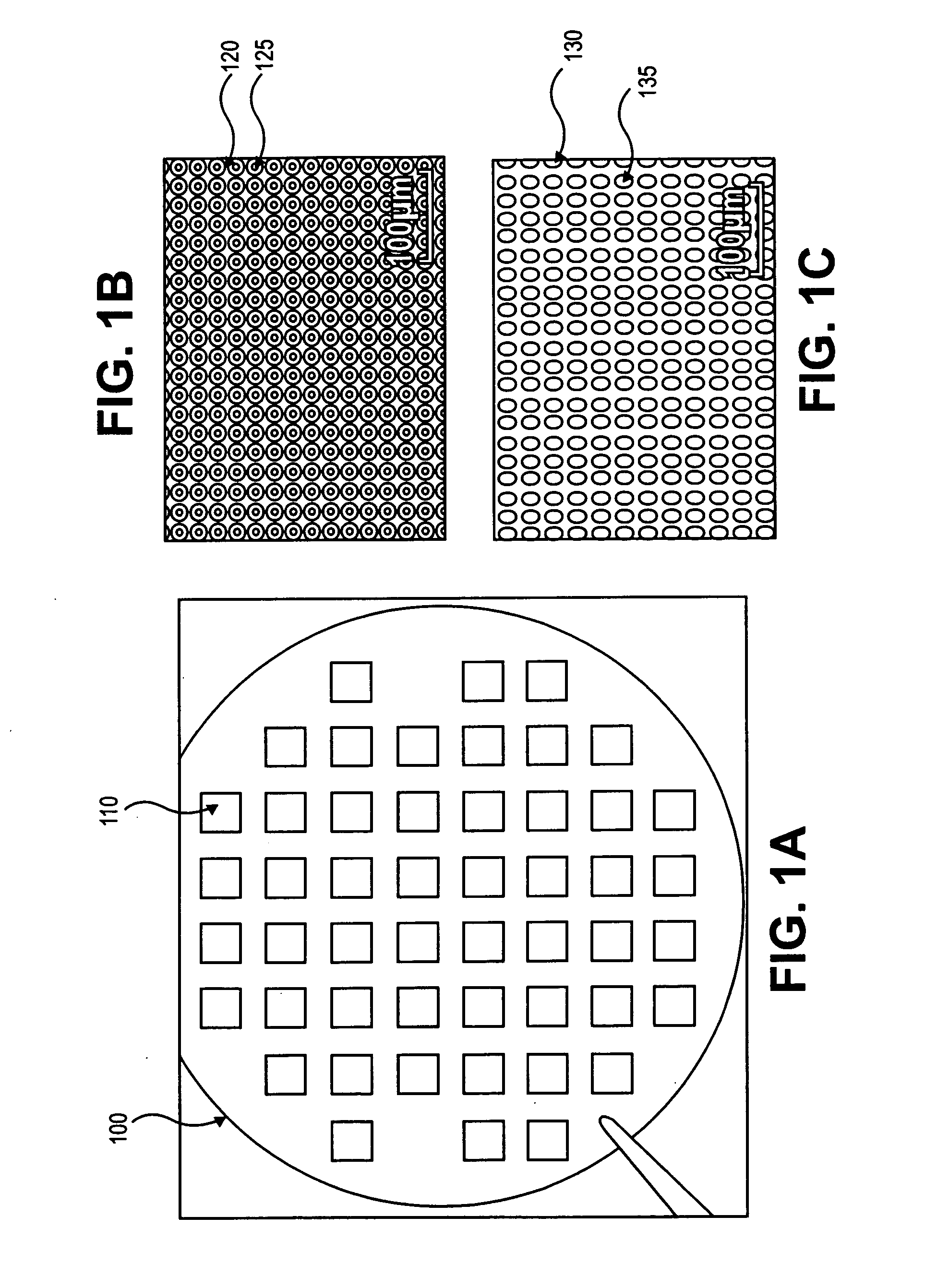

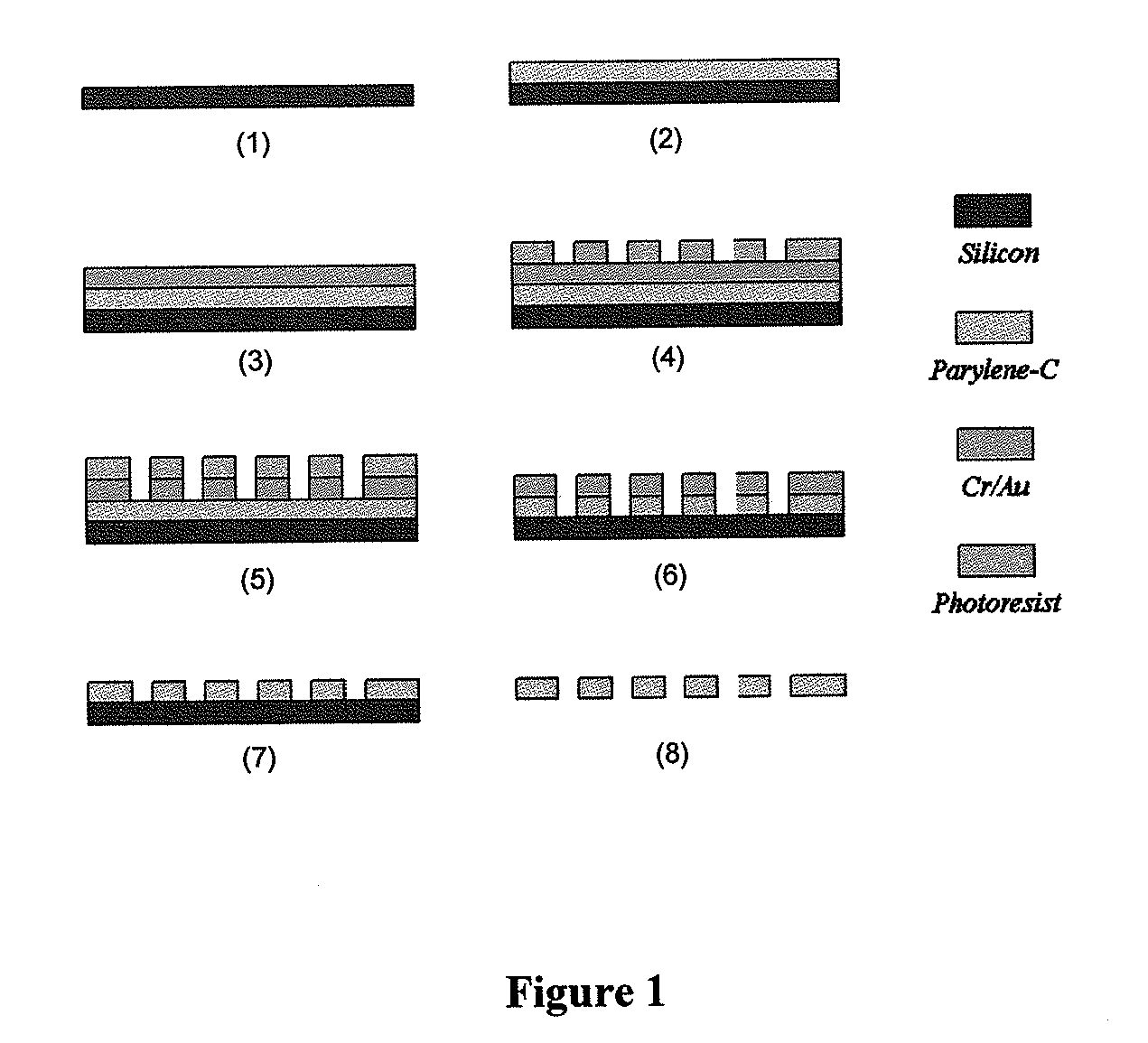

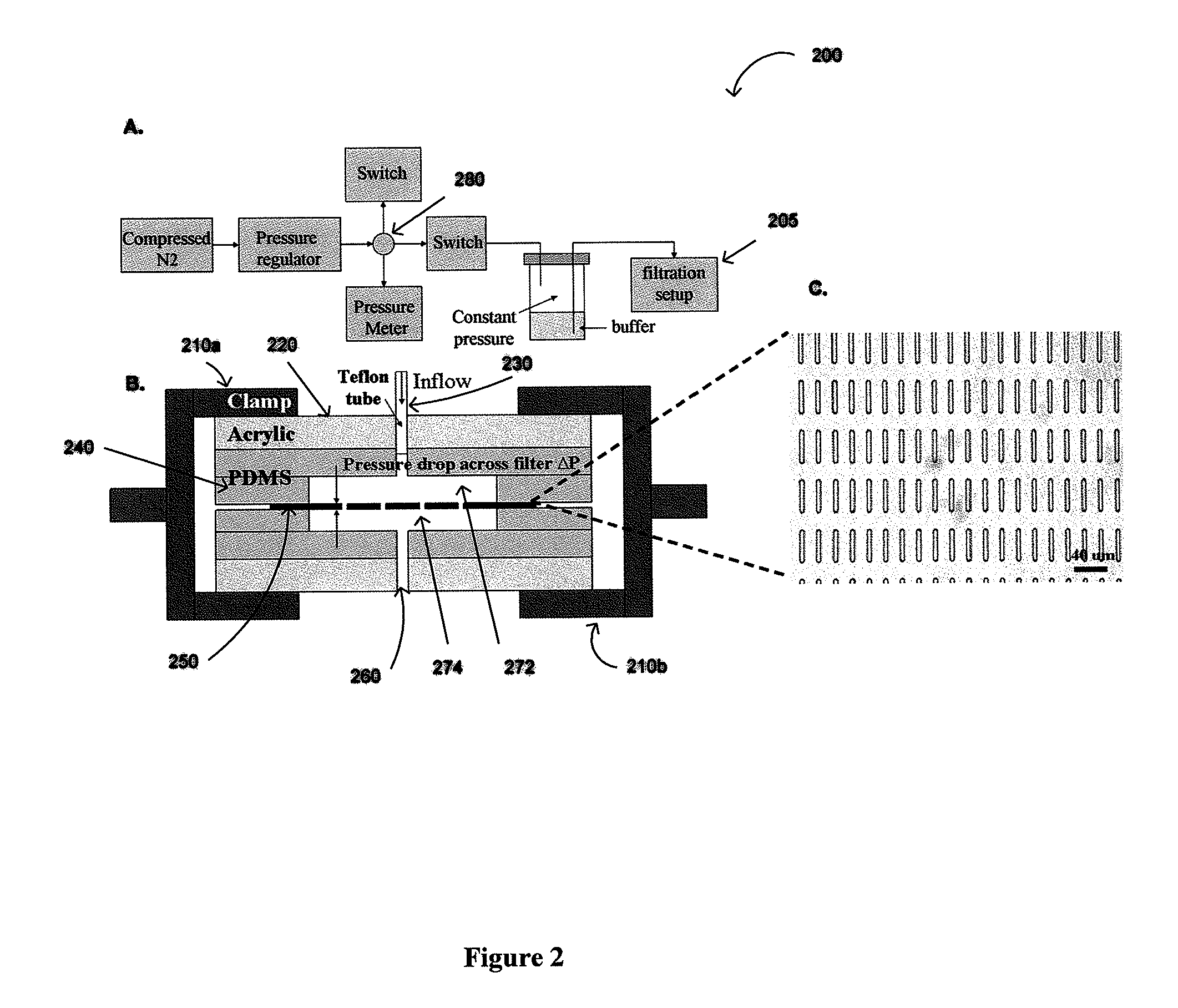

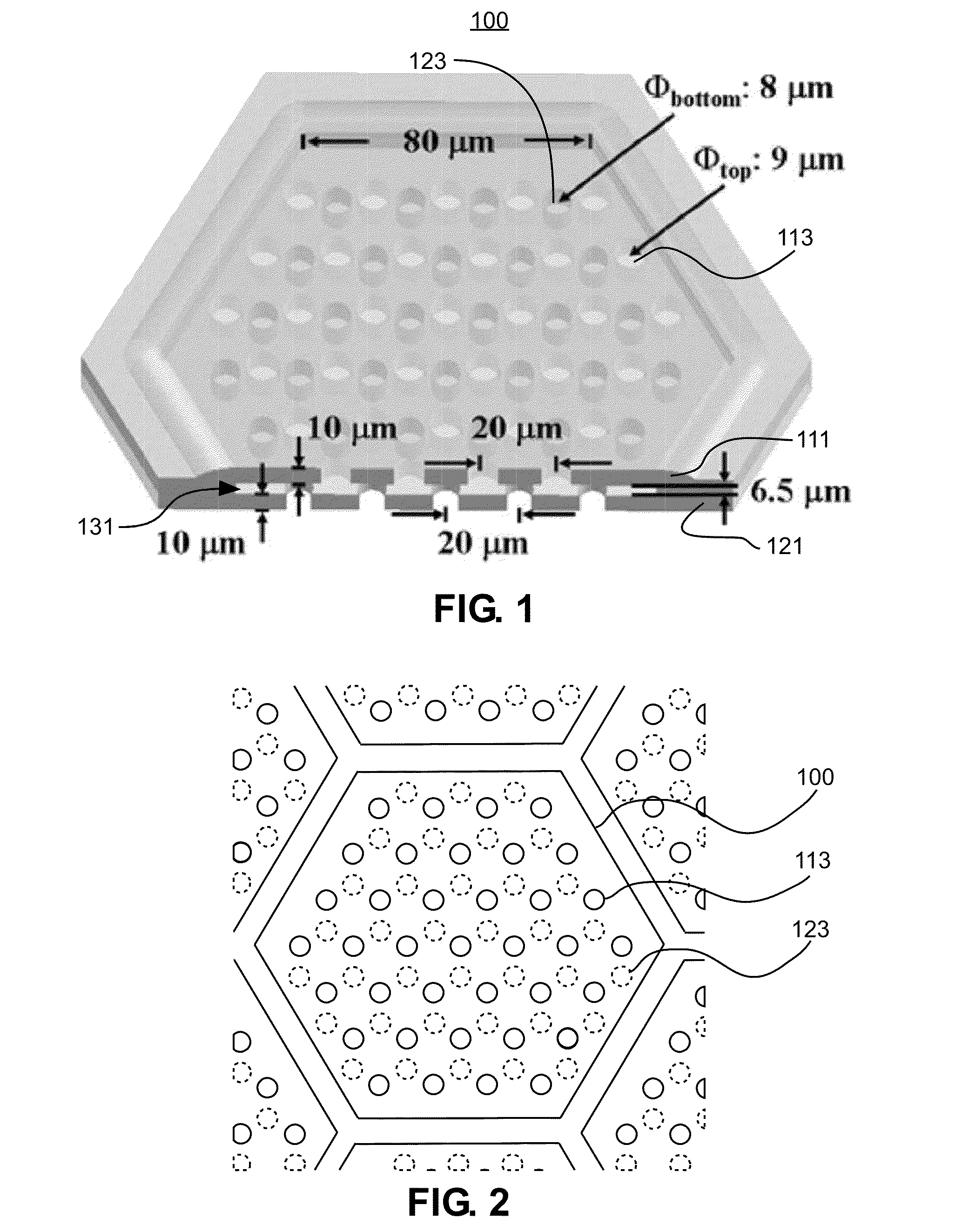

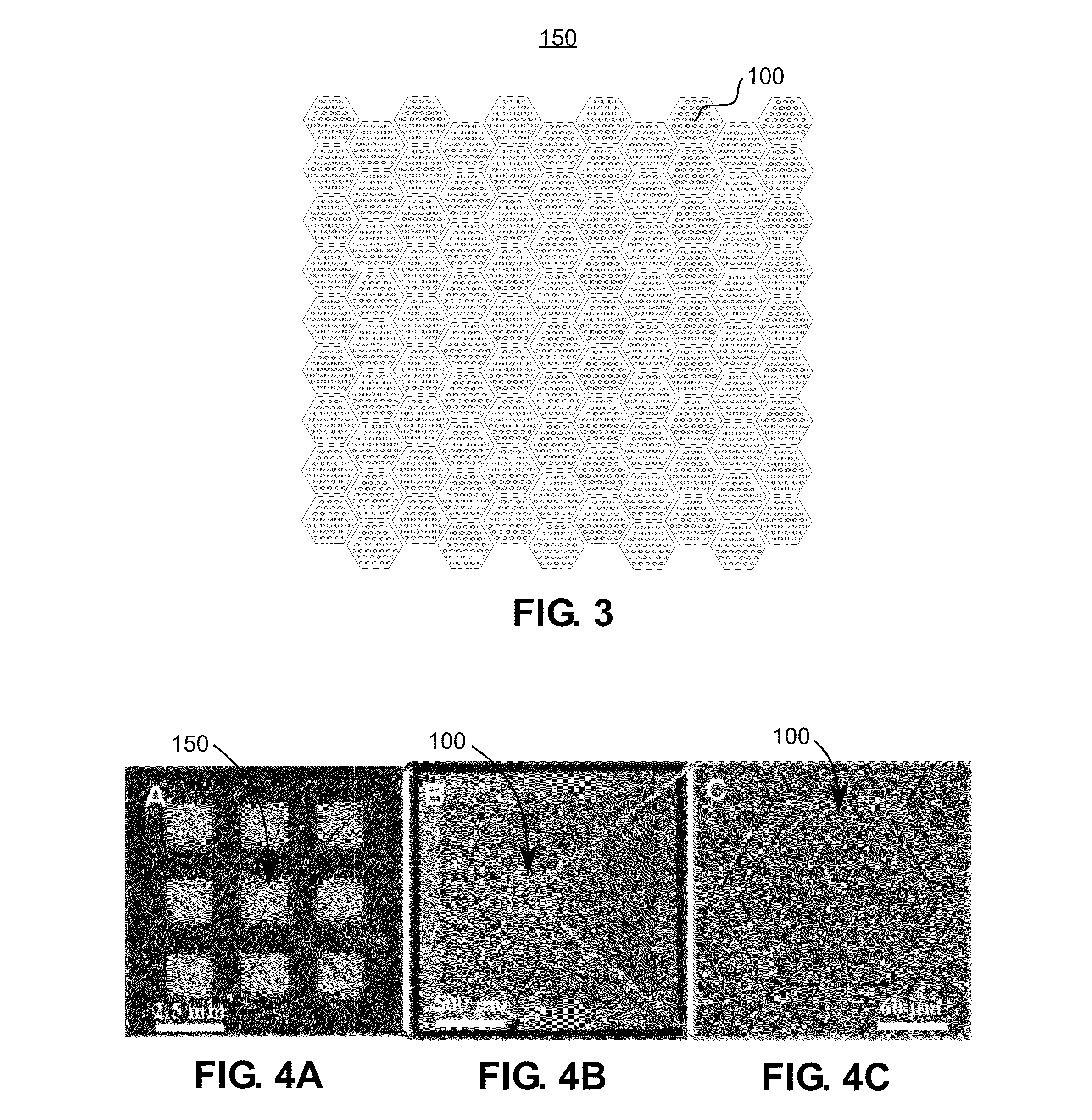

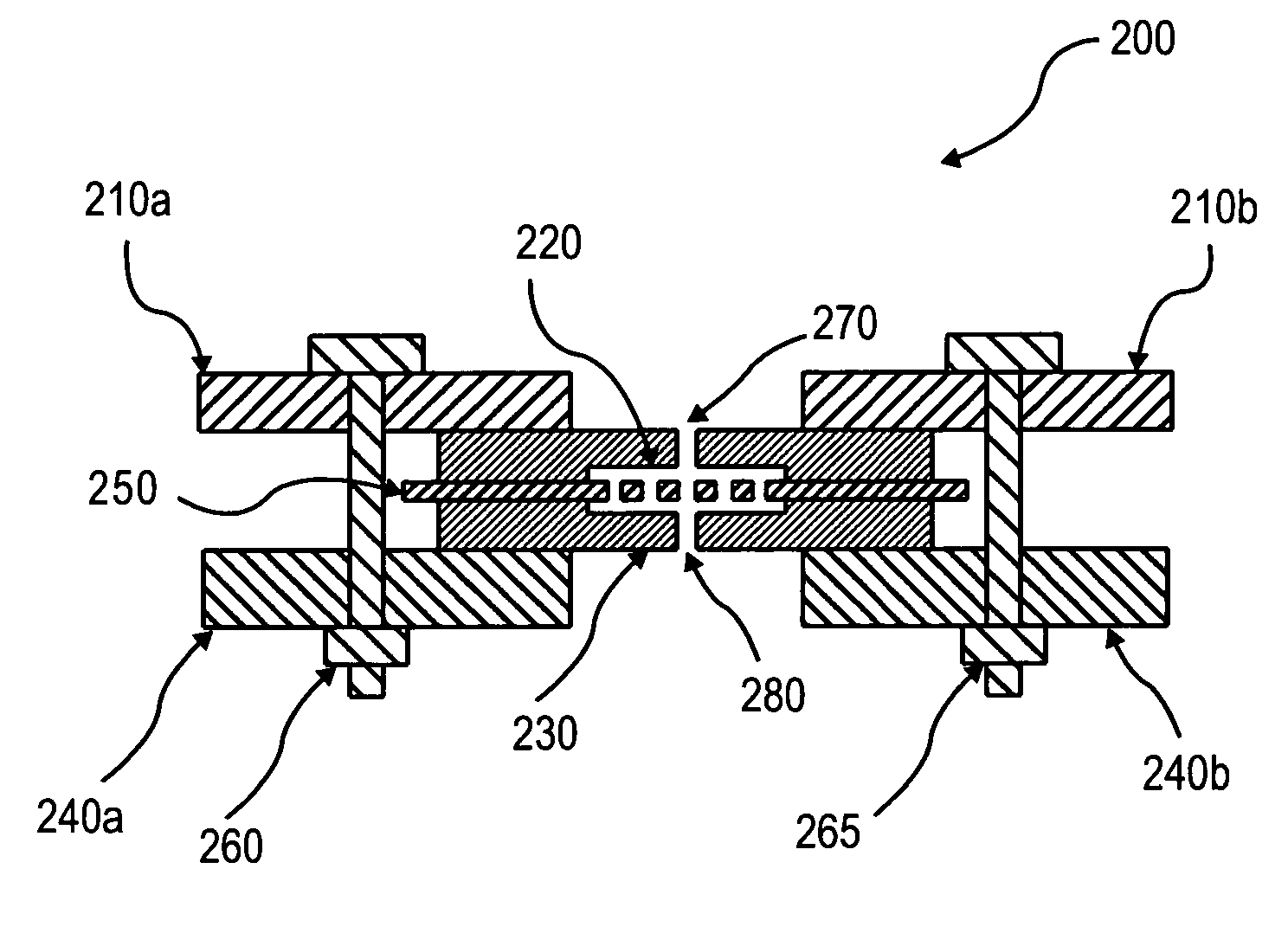

Uses of parylene membrane filters

ActiveUS20070025883A1Improve efficiencyEffective meanUltrafiltrationLaboratory glasswaresParyleneFigure of merit

The invention provides parylene membrane filters, filter devices and methods of making them and using them in the mechanical separation of cells and particles by size. The provision of parylene membrane filters with high figures of merit and finely controlled hole sizes allows the separation of cells and particles in a variety of biological and other fluids according to sizes.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

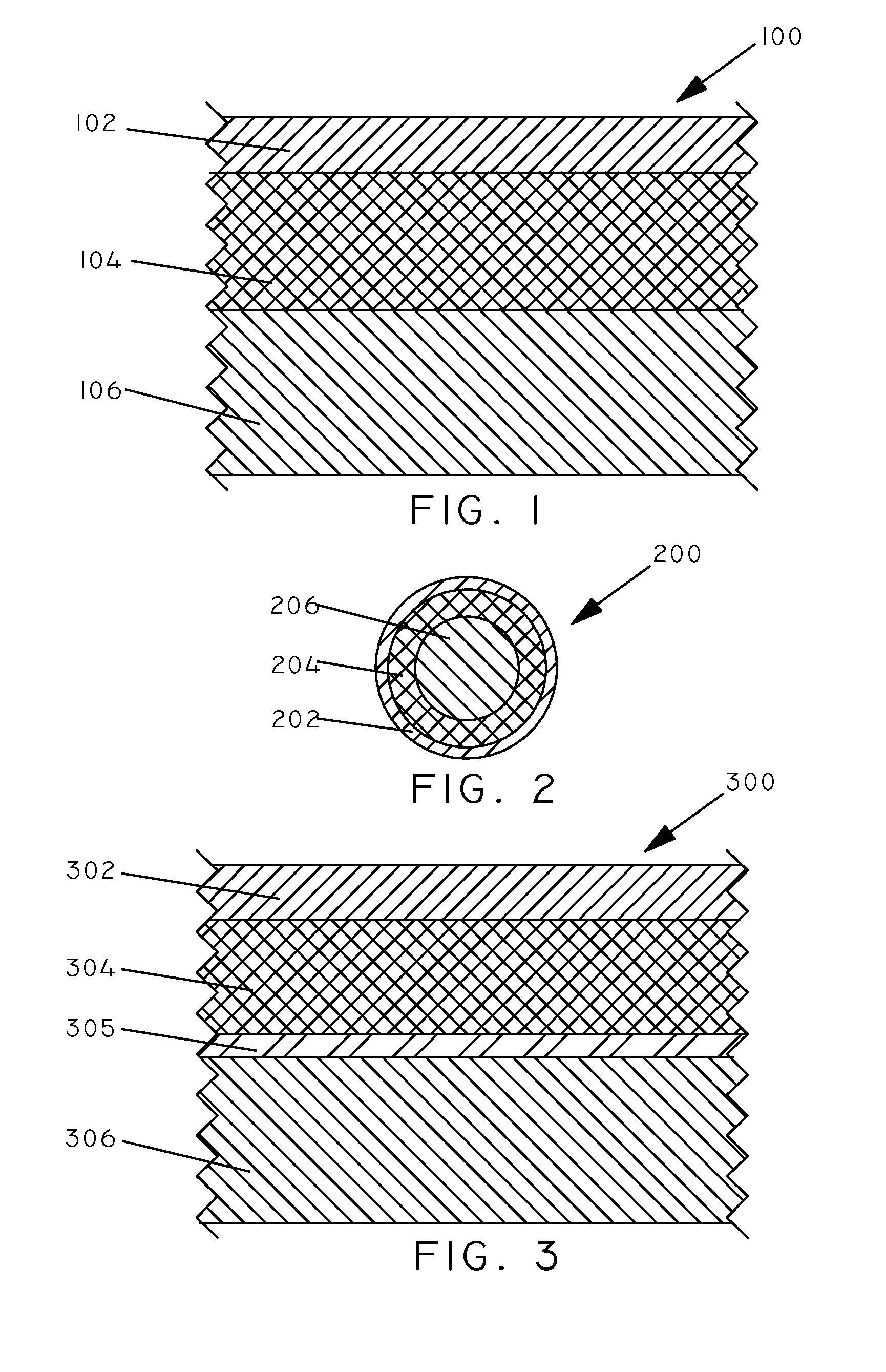

Multi-layered coatings and methods for controlling elution of active agents

Embodiments of the invention include multi-layered coatings for controlling the elution rates of active agents and methods. In an embodiment, the invention includes a method of applying an elution control coating to a substrate. The method can include depositing a coating solution onto the substrate to form a base layer. The method can also include selecting a desired concentration of the solvent based on a desired elution rate. The method can further include removing solvent from the base layer to reach a desired concentration of the solvent and depositing a layer of parylene on the base layer. In an embodiment, the invention can include a medical device including a substrate, a base layer, and a porous layer. The base layer can include a polymeric matrix and an active agent dispersed within the polymeric matrix. The porous layer can include parylene. Other embodiments are also included herein.

Owner:SURMODICS INC

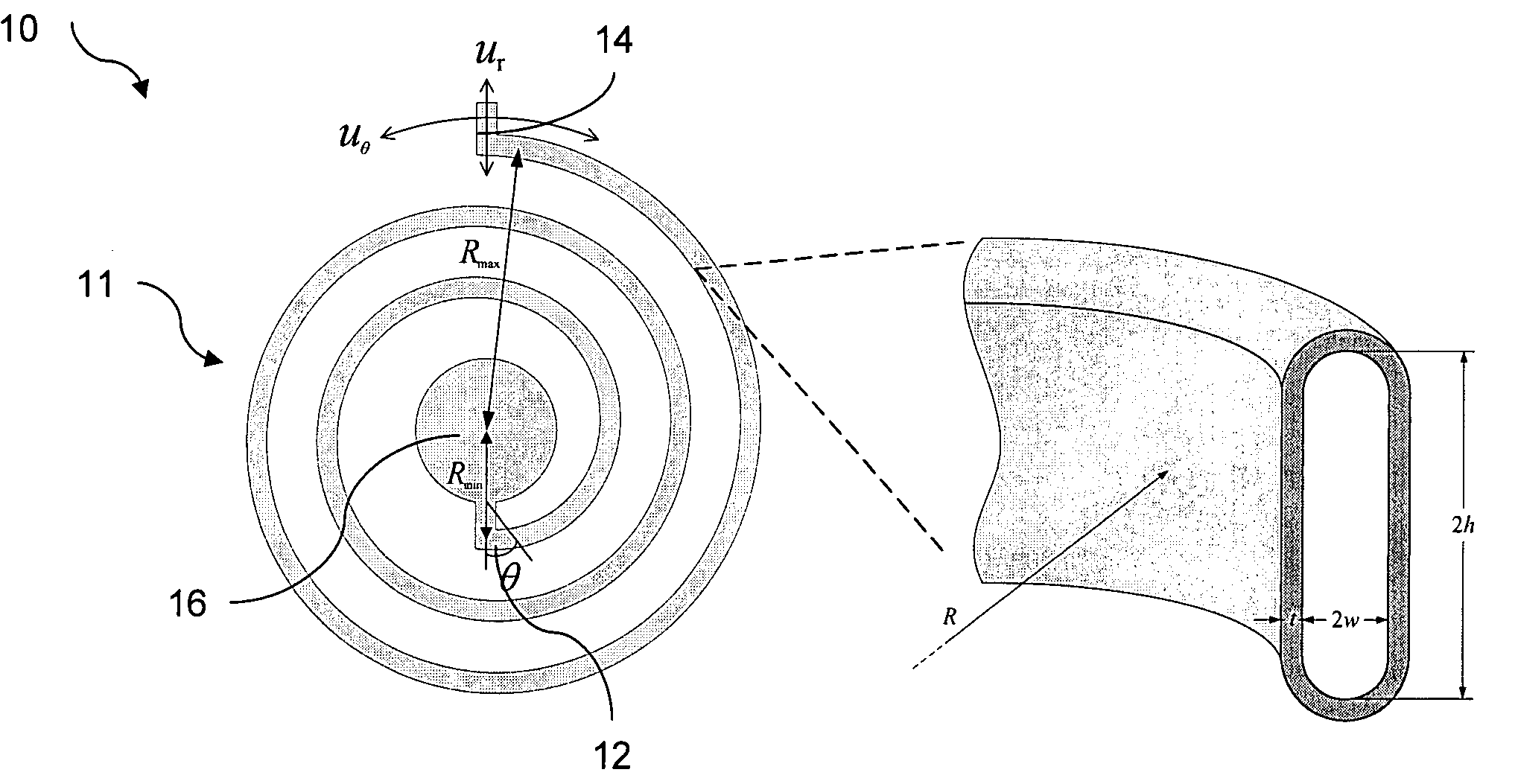

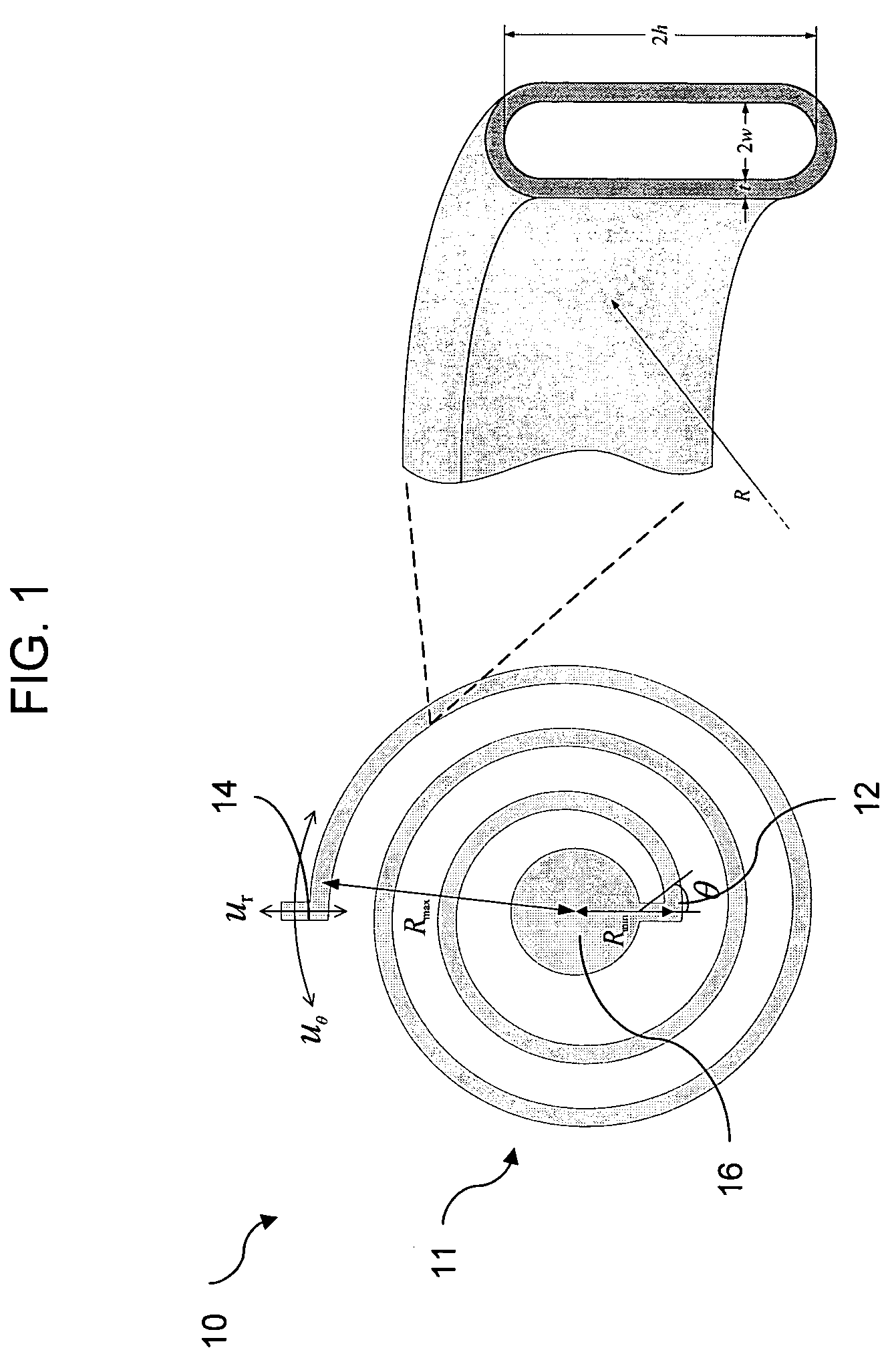

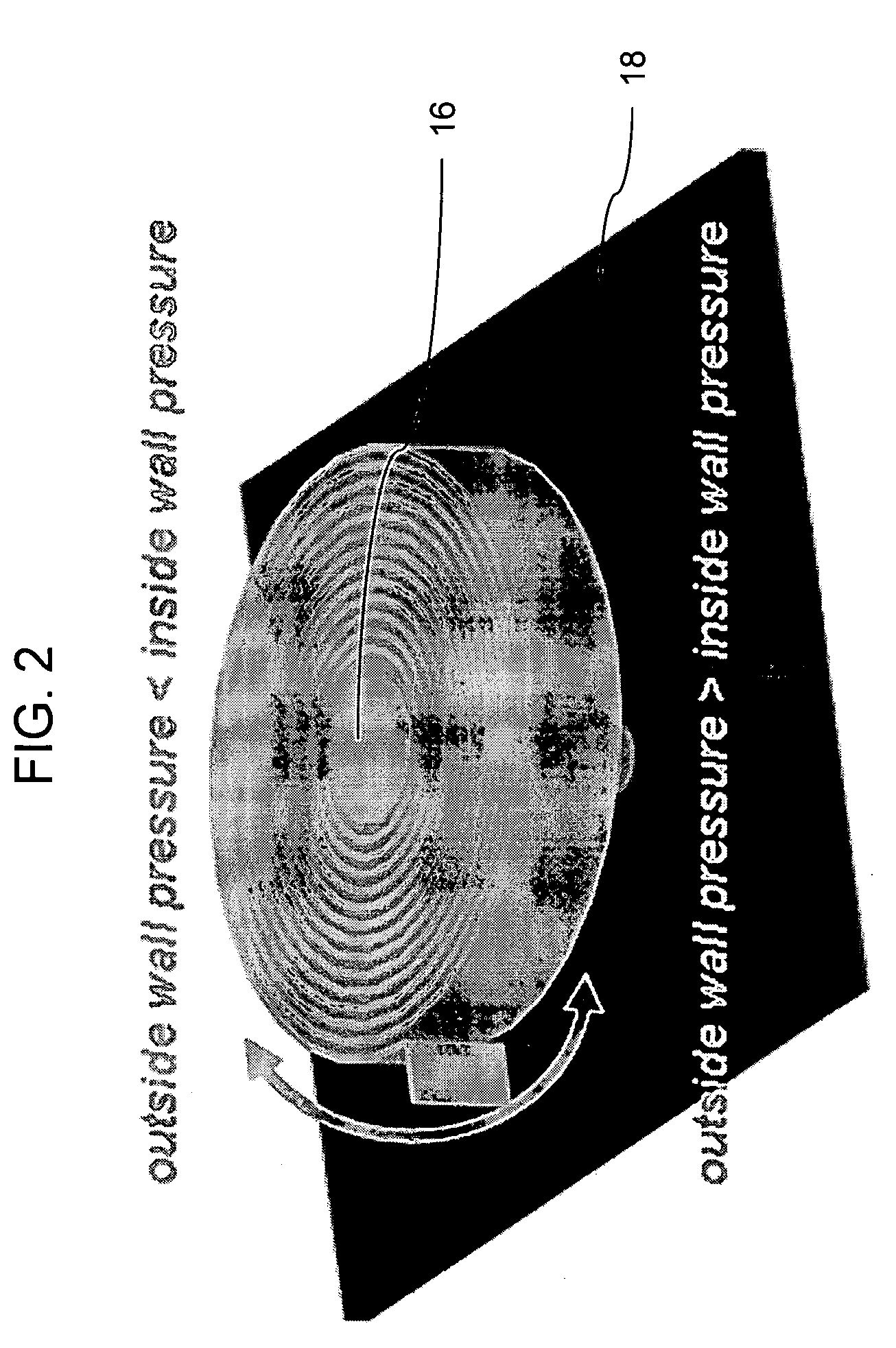

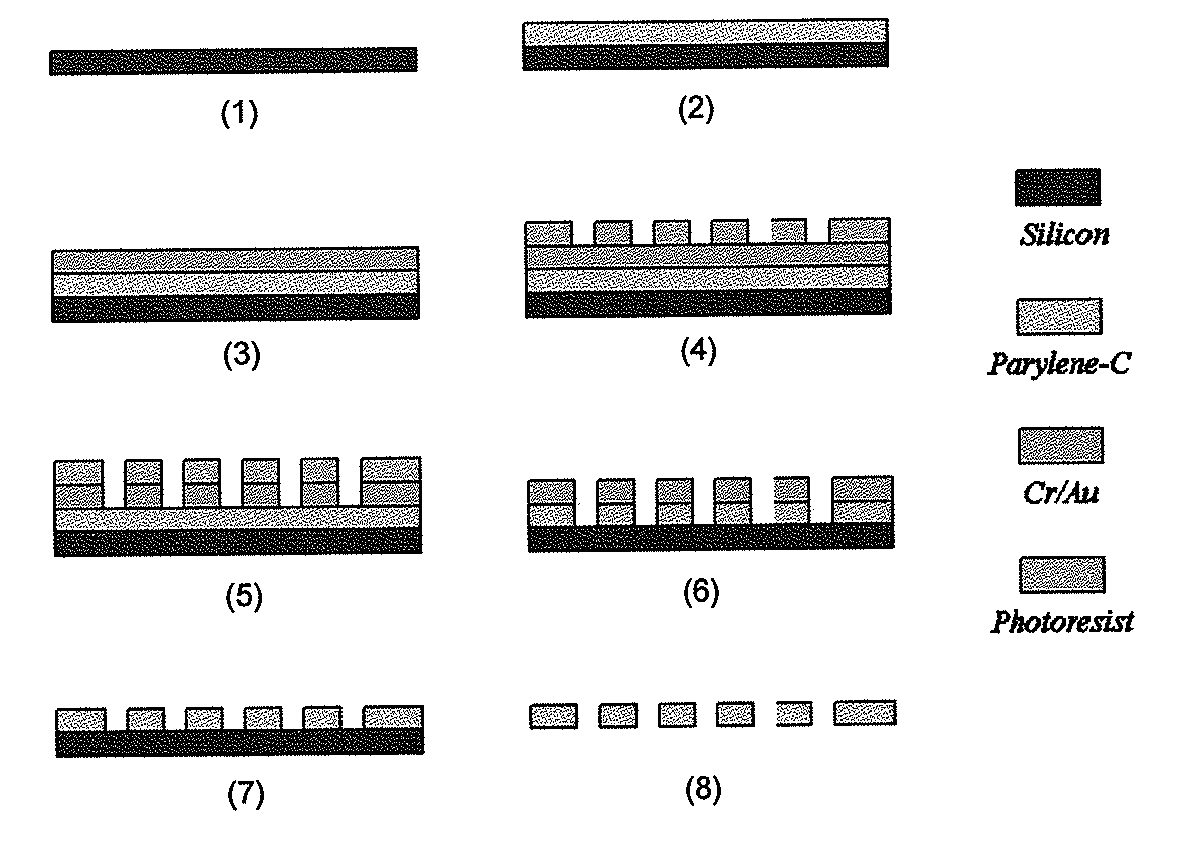

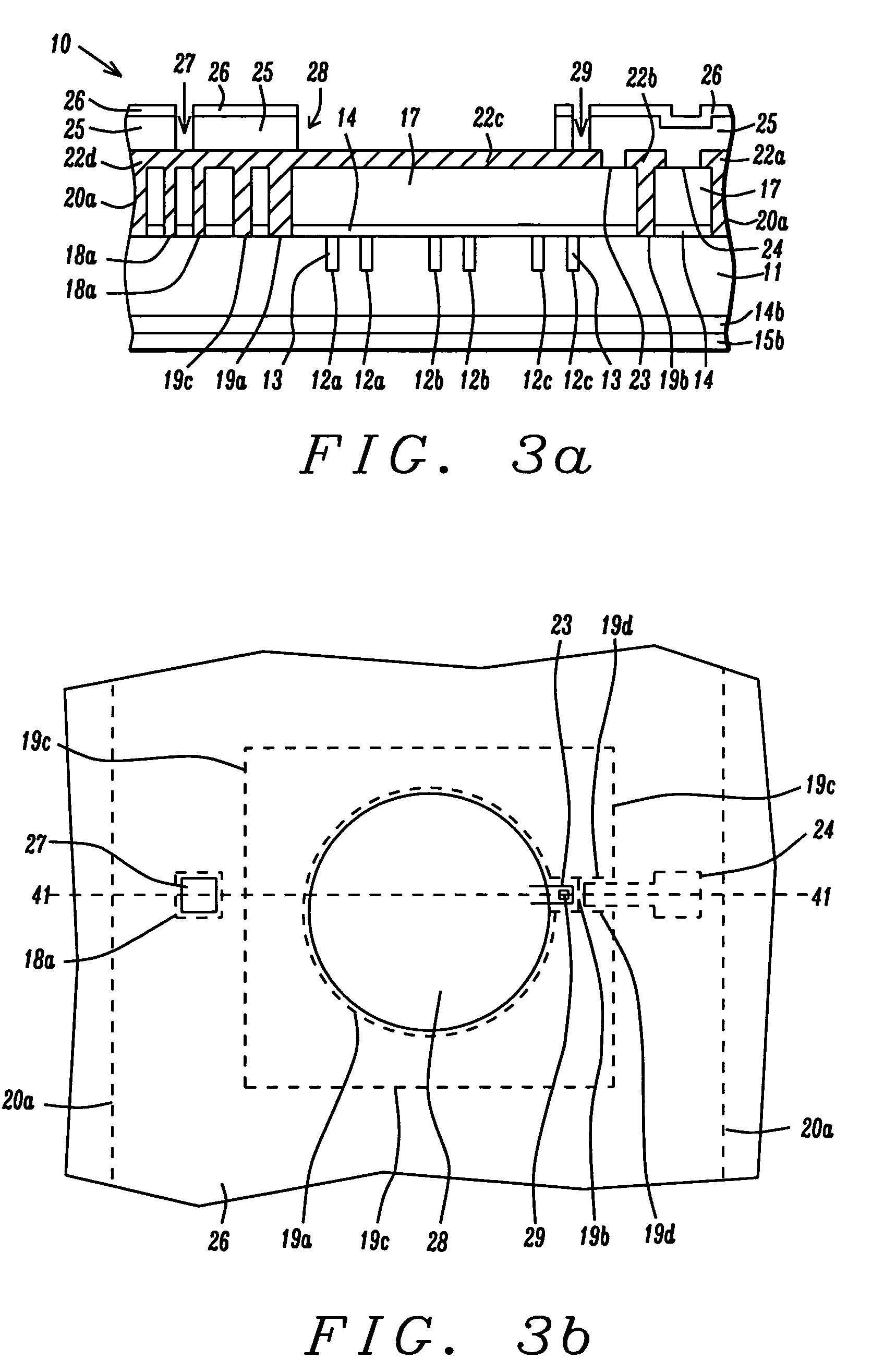

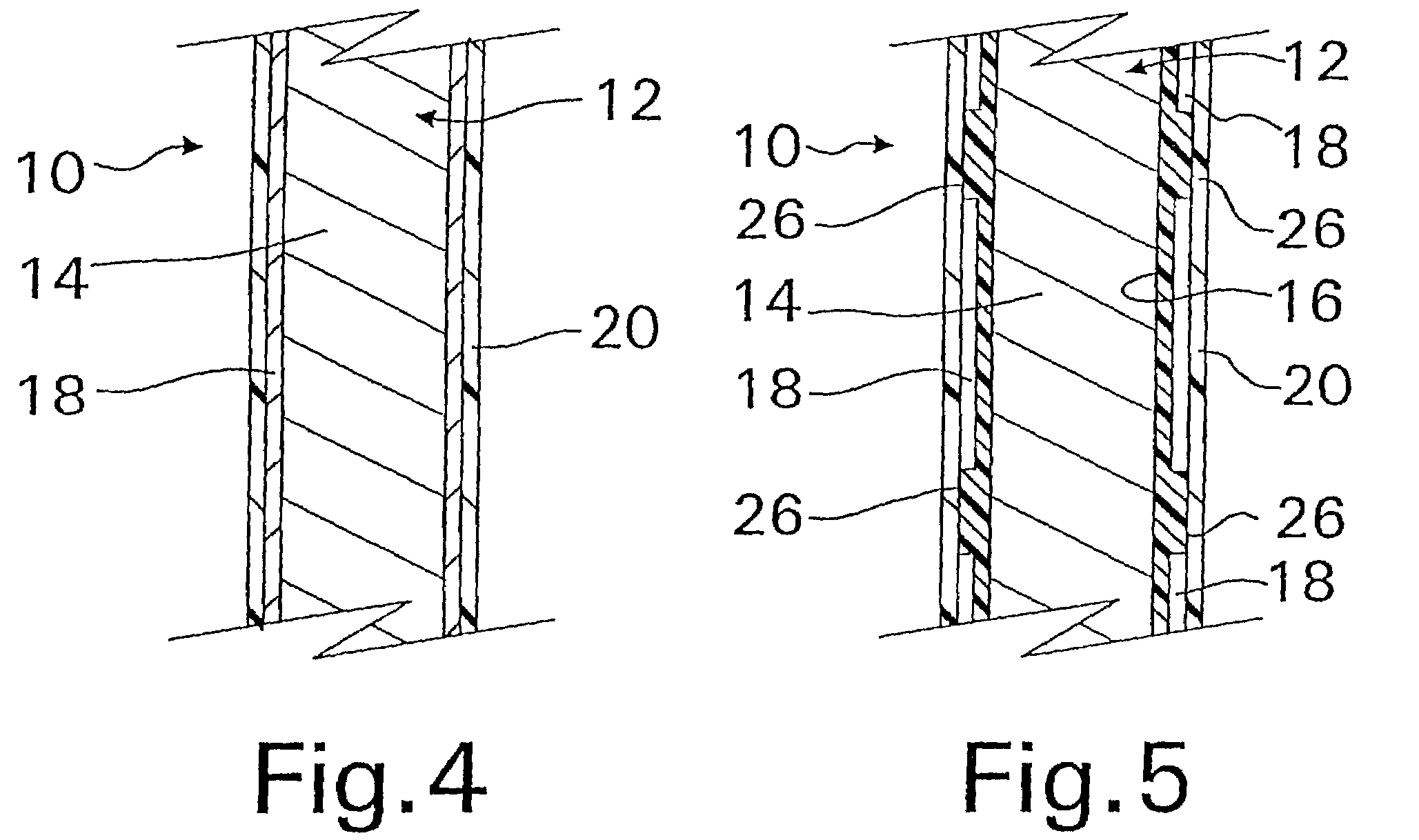

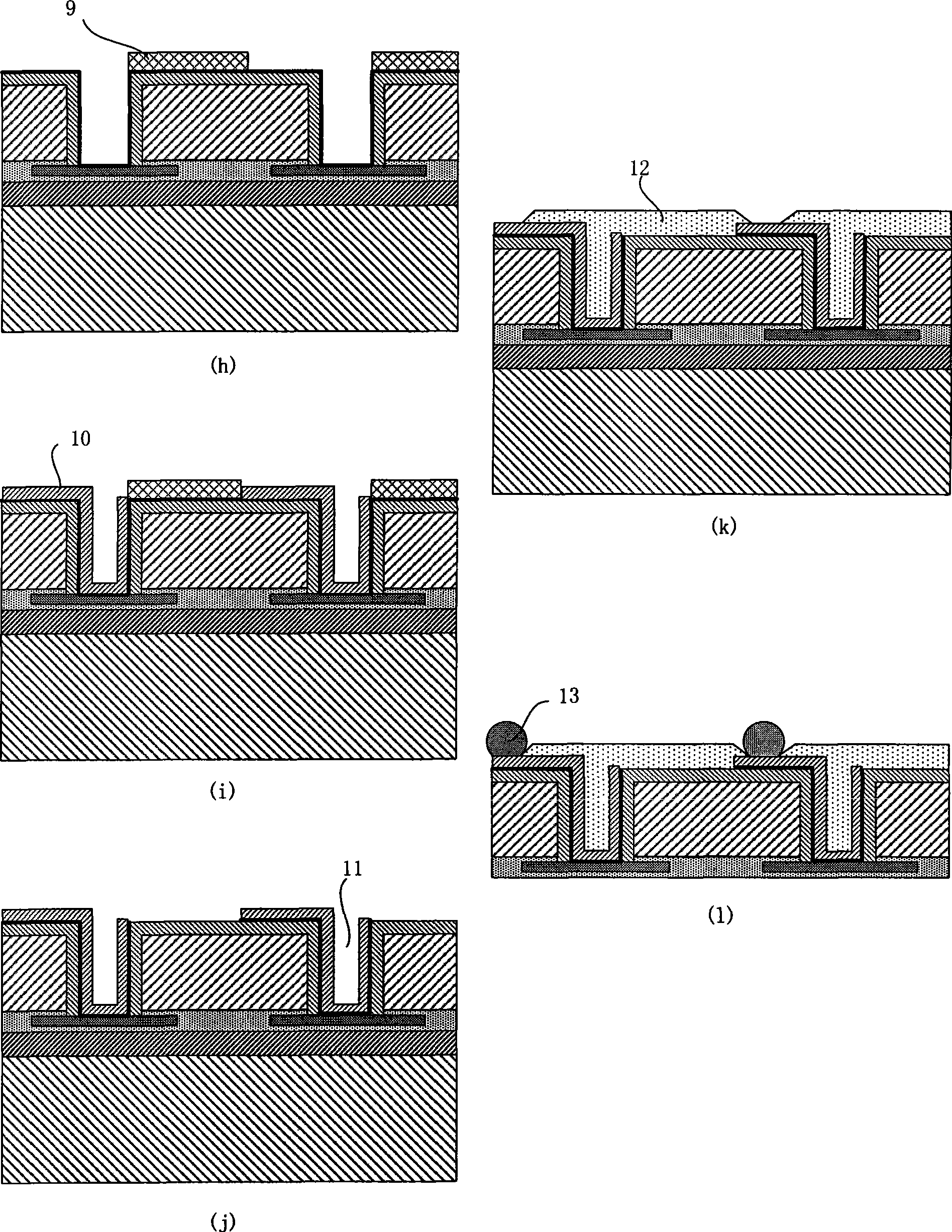

Implantable mechanical pressure sensor and method of manufacturing the same

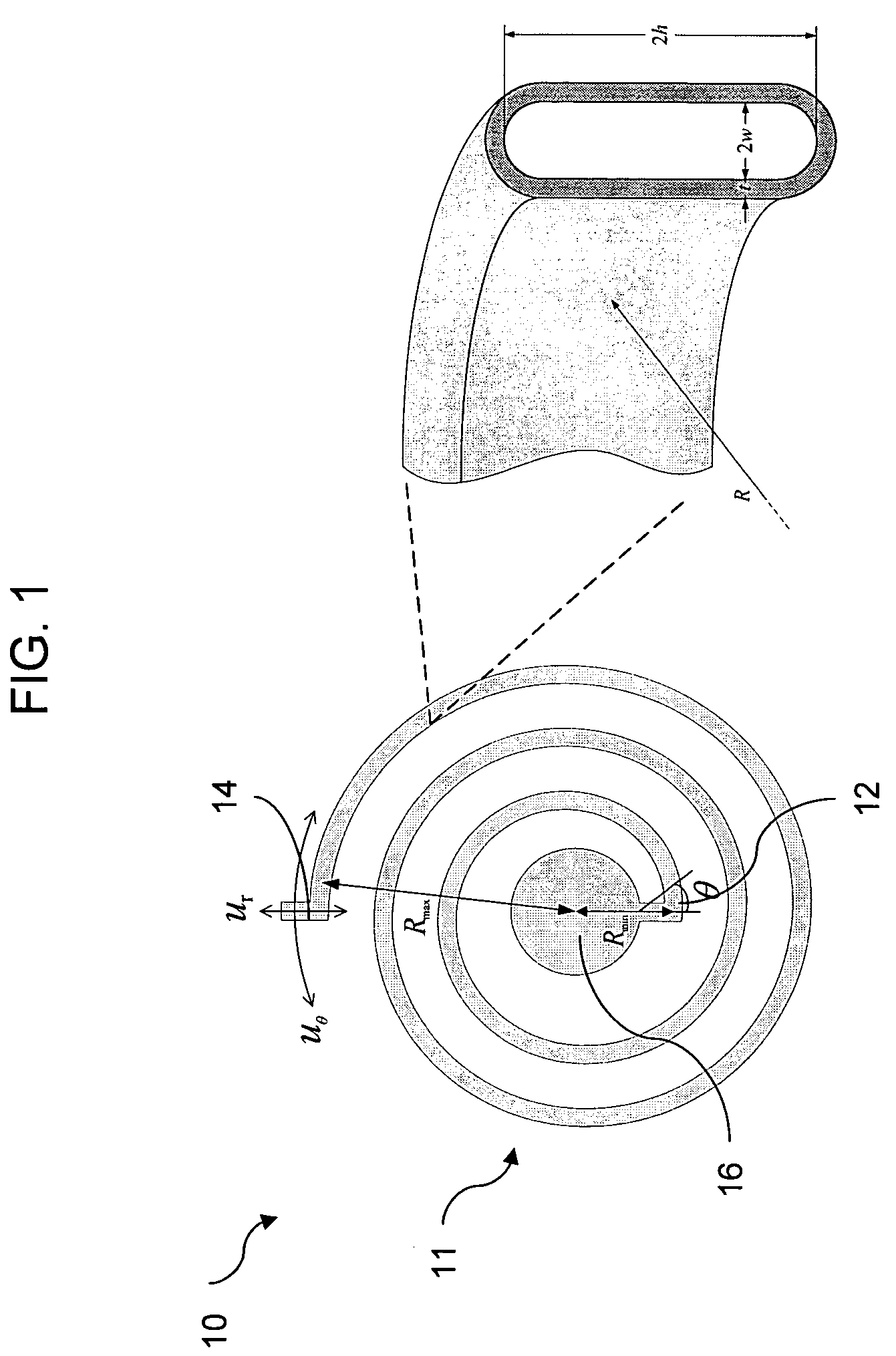

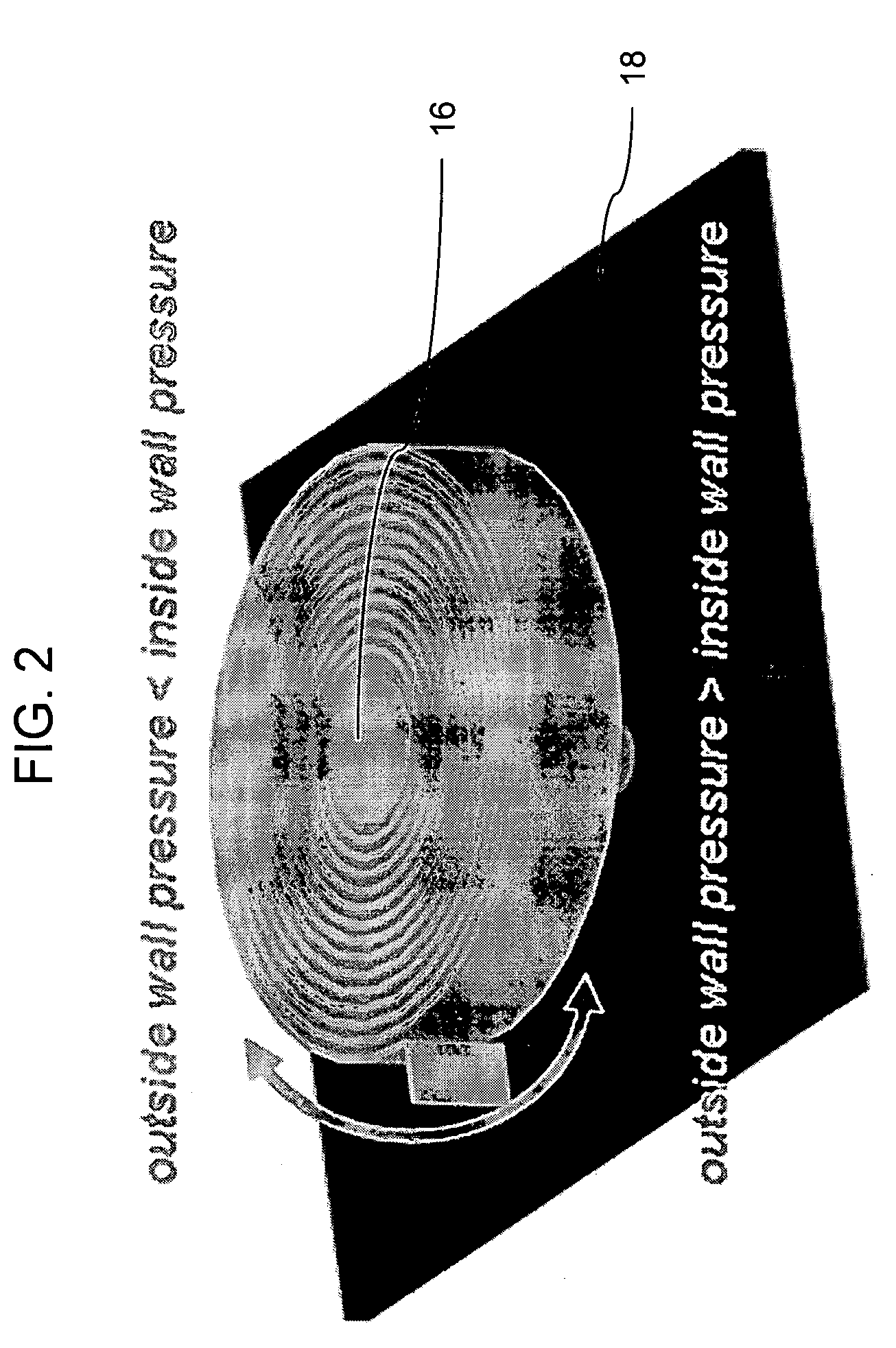

InactiveUS7252006B2Fluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsIn planeGlaucoma

A biocompatible, mechanical, micromachined pressure sensor and methods of manufacturing such a pressure sensor are provided. The pressure sensor of the current invention includes a high-aspect-ratio curved-tube structure fabricated through a one-layer parylene process. The pressure sensor of the current invention requires zero power consumption and indicates the pressure variation by changes of the in situ in-plane motion of the sensor, which can be gauged externally by a direct and convenient optical observation. In one embodiment, the pressure sensor of the current invention has been shown to work as an IOP sensor for eye implantation where the intraocular in-plane motion of the sensor can be recorded from outside of the eye, such that the intraocular pressure in glaucoma patients can be constantly monitored.

Owner:CALIFORNIA INST OF TECH

Silicon microphone with softly constrained diaphragm

ActiveUS20060093171A1Reduce stressSimple methodSemiconductor electrostatic transducersFluid pressure measurement by electric/magnetic elementsParyleneEngineering

A microphone sensing element and a method for making the same are disclosed. The sensing element has a diaphragm and an attached electrical lead-out arm preferably made of polysilicon that are separated by an air gap from an underlying backplate region created on a conductive silicon substrate. The backplate region has acoustic holes created by removing an oxide filling in a continuous trench that surrounds hole edges and by removing oxide to form the air gap. The diaphragm is softly constrained along its edge by an elastic element that connects to a surrounding rigid polysilicon layer. The elastic element is typically a polymer such as parylene having a Young's modulus substantially less than that of the diaphragm. First and second electrodes are connected to the diaphragm through the lead-out arm and to the substrate through polysilicon via fillings, respectively, and thereby establish a variable capacitor circuit for acoustic sensing.

Owner:SHANDONG GETTOP ACOUSTIC

Method of forming parylene-diaphragm piezoelectric acoustic transducers

InactiveUS6857501B1Improve structural qualityTransducer detailsDecorative surface effectsParyleneTransducer

Owner:UNIV OF HAWAII

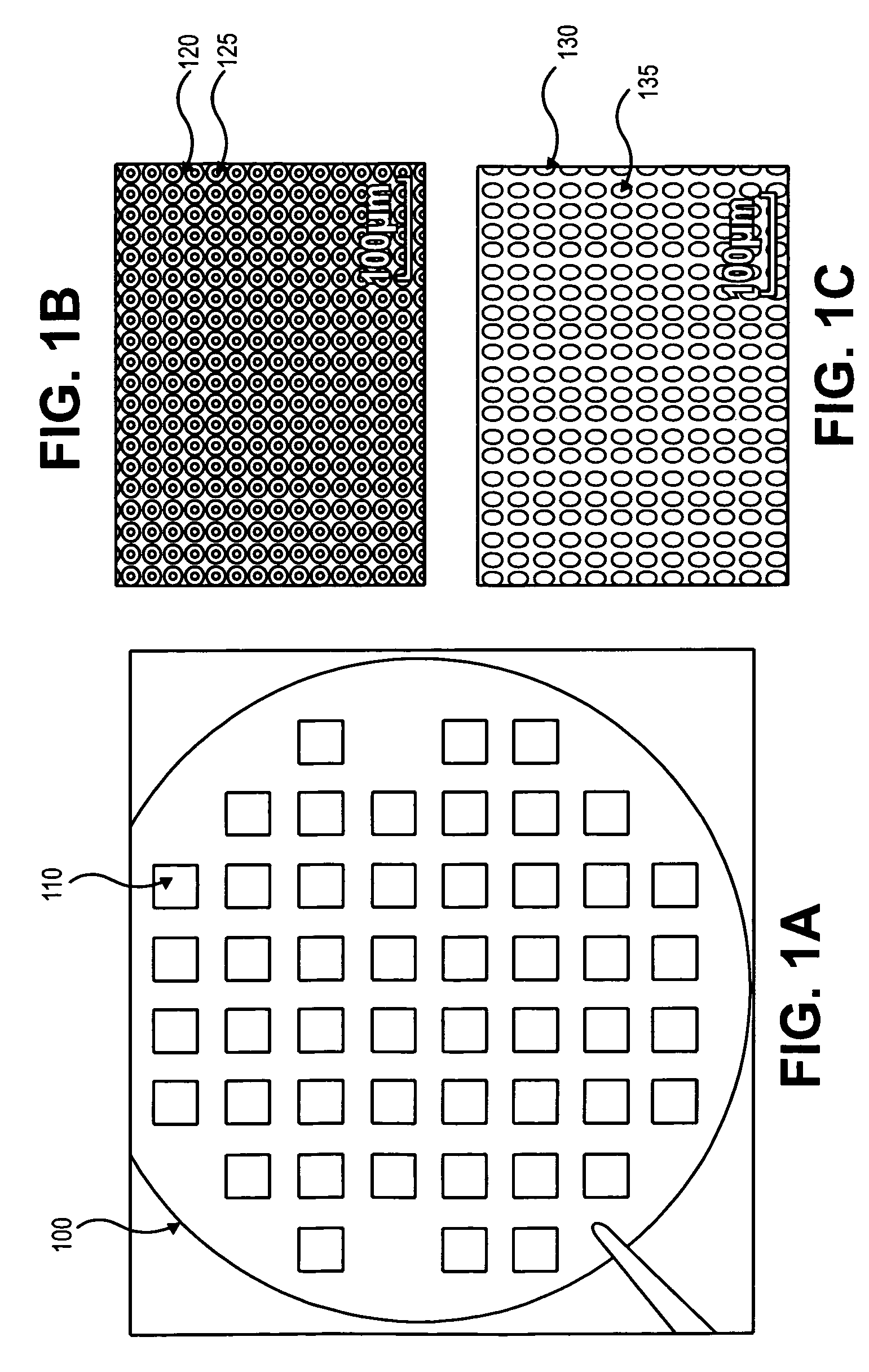

Method for cancer detection, diagnosis and prognosis

ActiveUS20110053152A1Rapidly and efficiently captureImprove capture efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsTelomeraseParylene

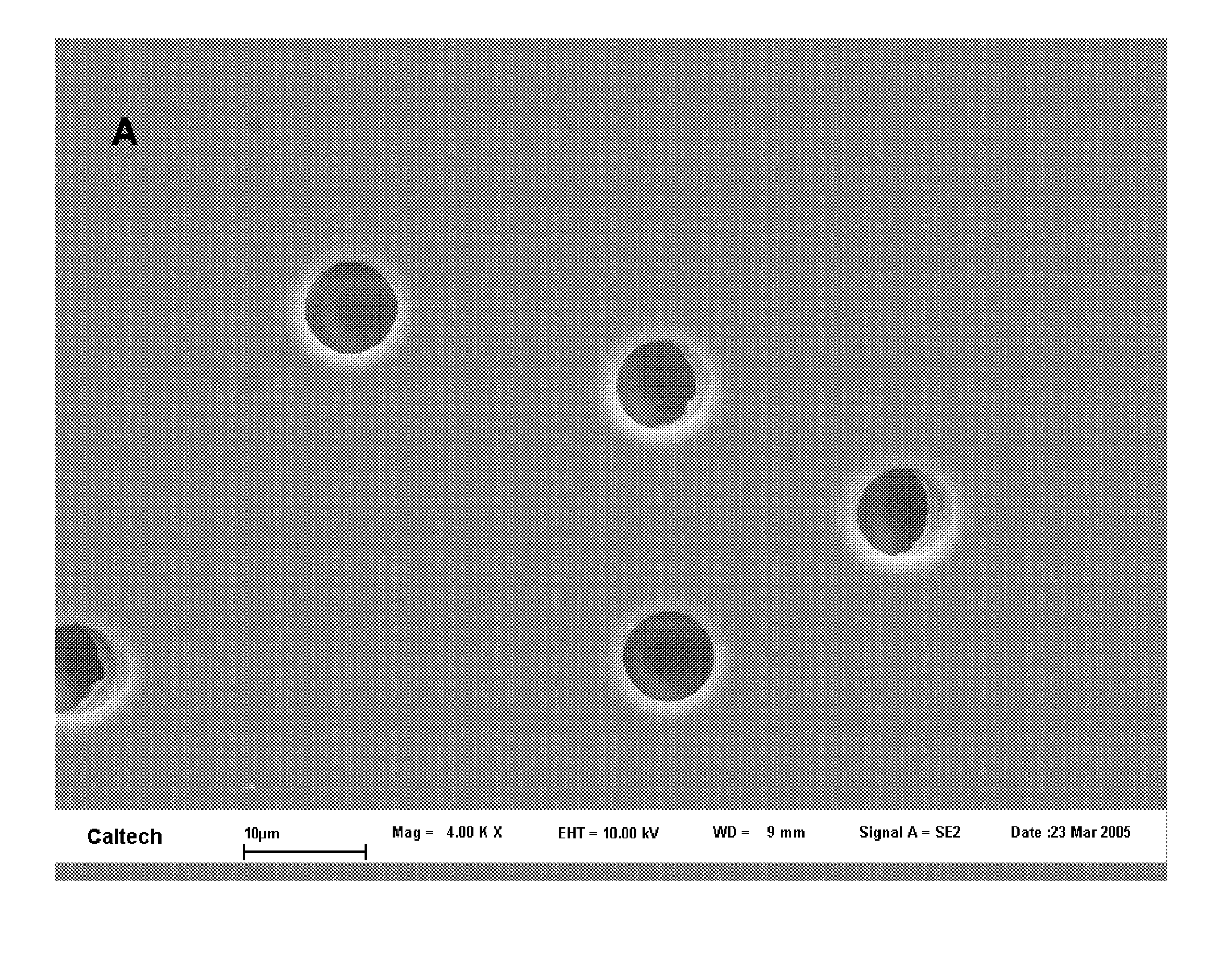

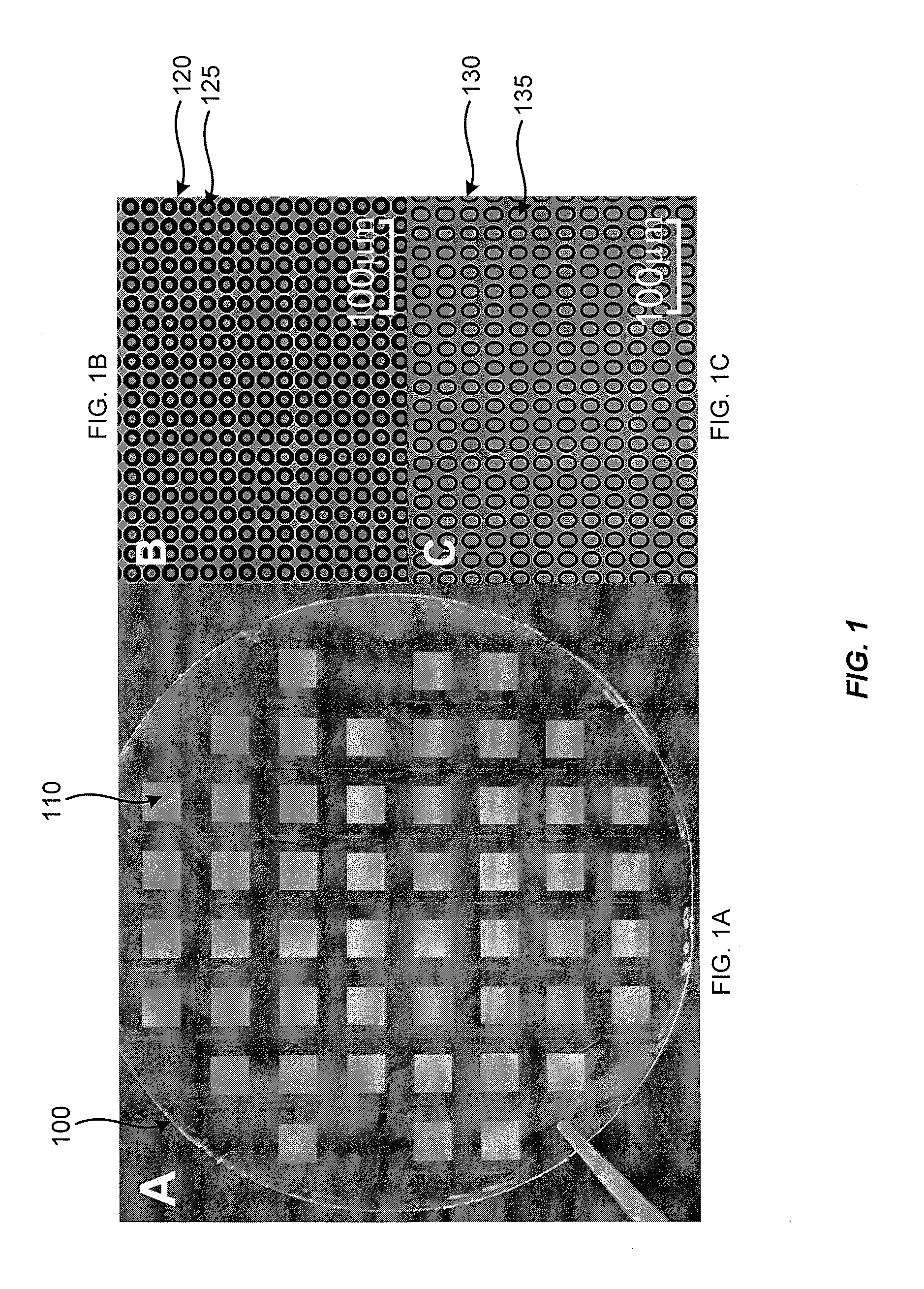

The present invention provides a method for diagnosing cancer, predicting a disease outcome or response to therapy in a patient sample. The method involves isolating a circulating tumor cell (CTC), for example, a viable CTC, from a sample using a parylene microfilter device comprising a membrane filter having or consisting of a parylene substrate, which has an array of holes with a predetermined shape and size; and detecting and quantifying telomerase activity in blood circulating tumor cells. The invention further provides methods of using cells live-captured in various applications.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

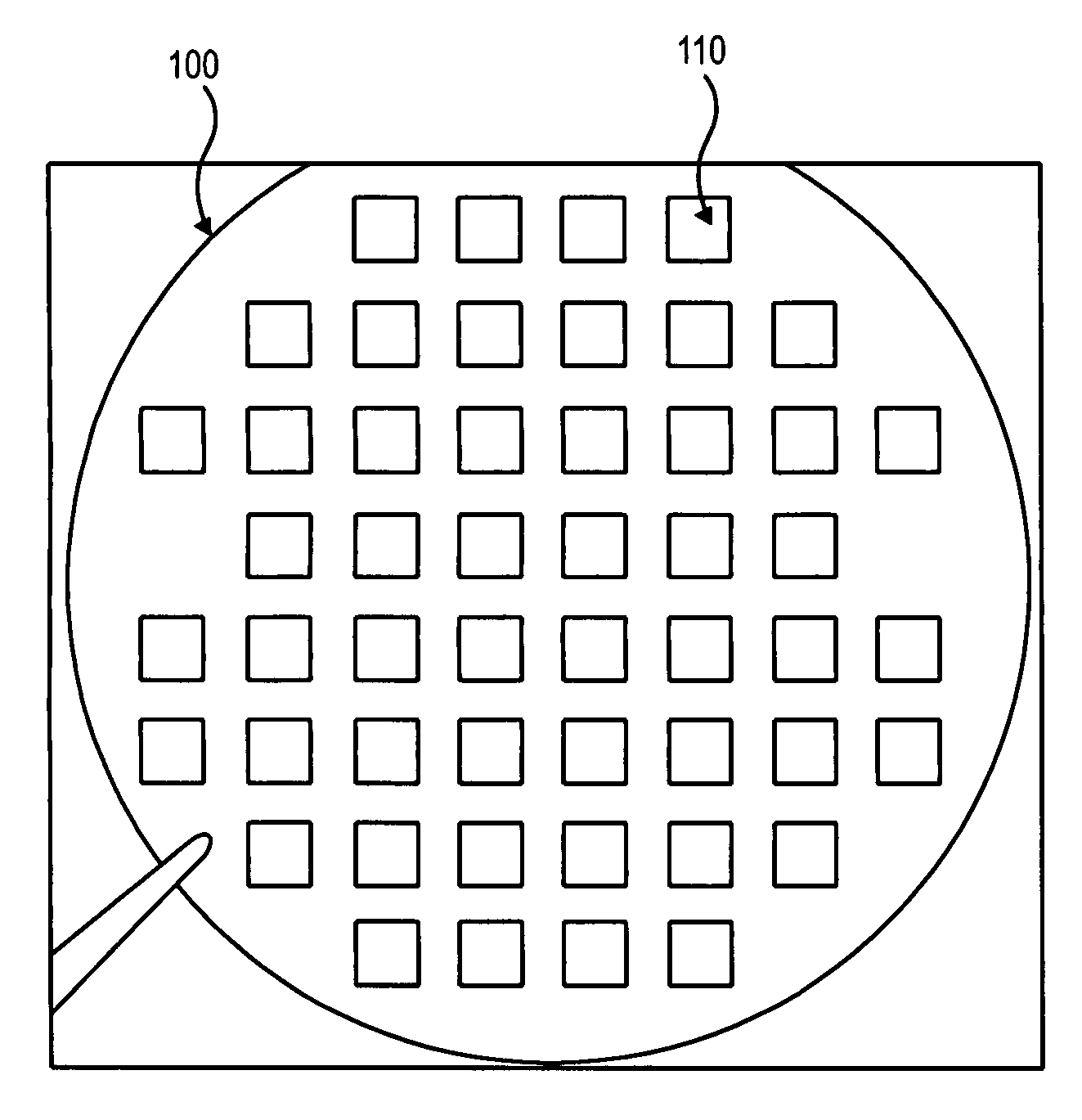

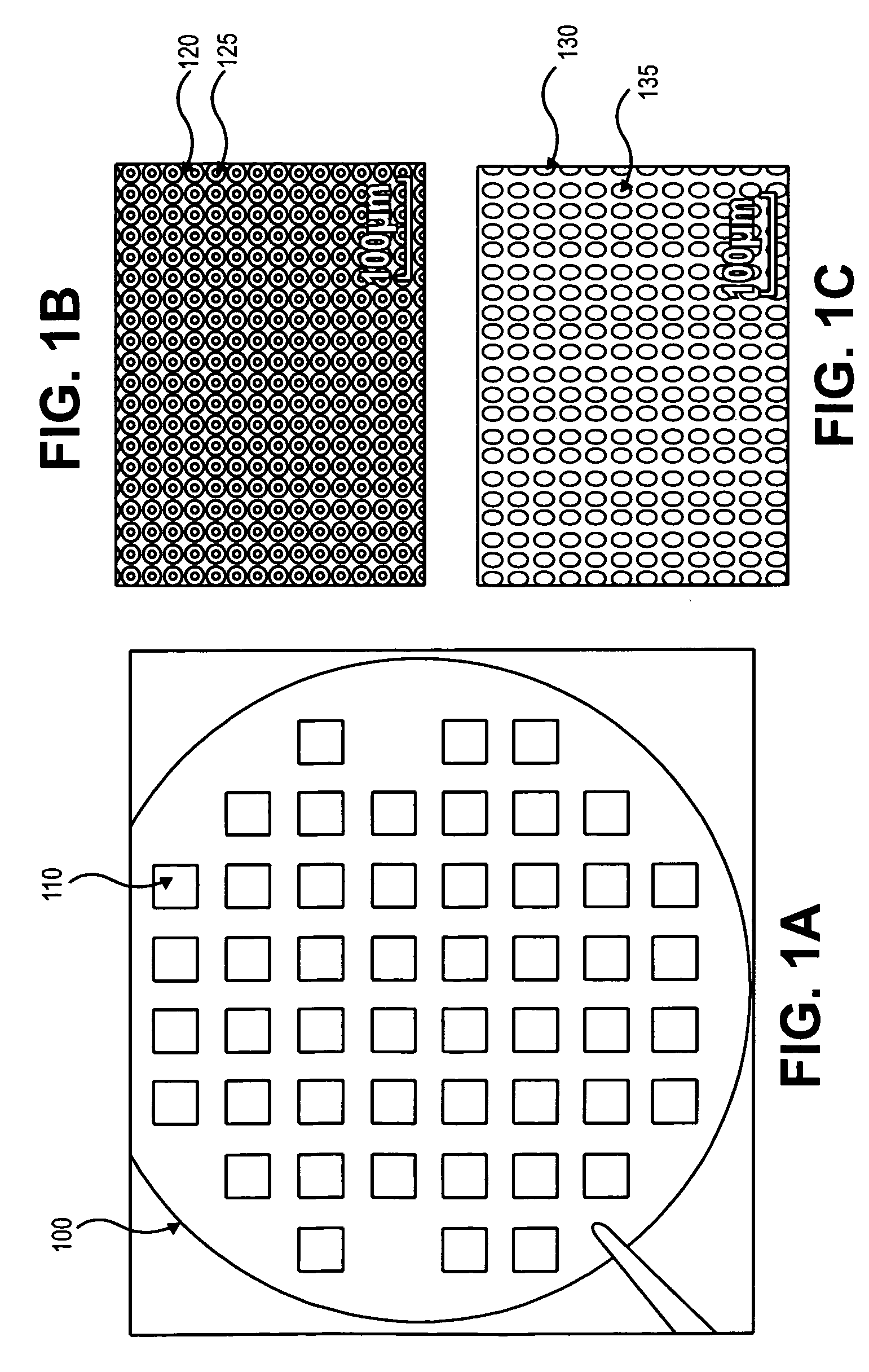

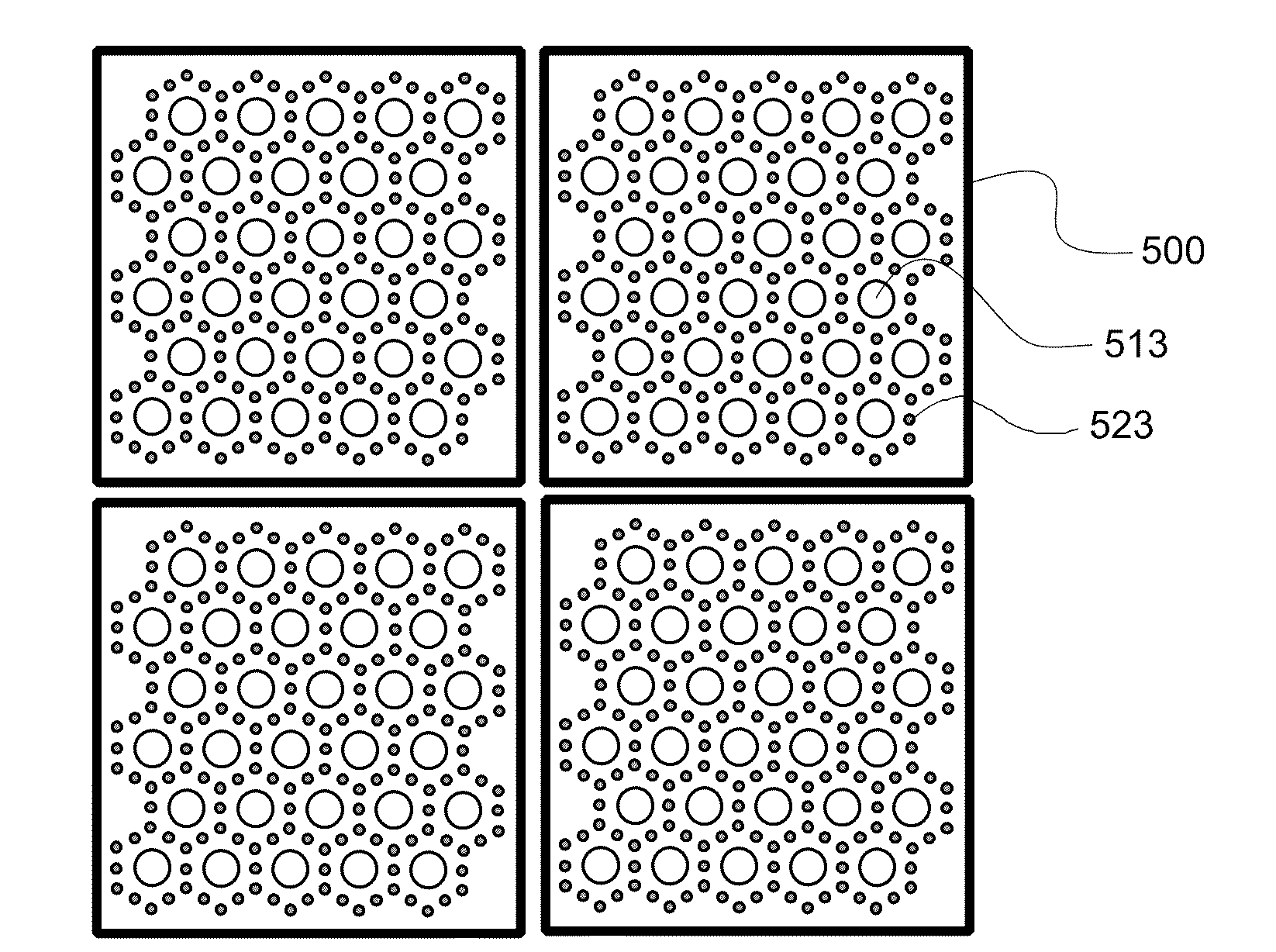

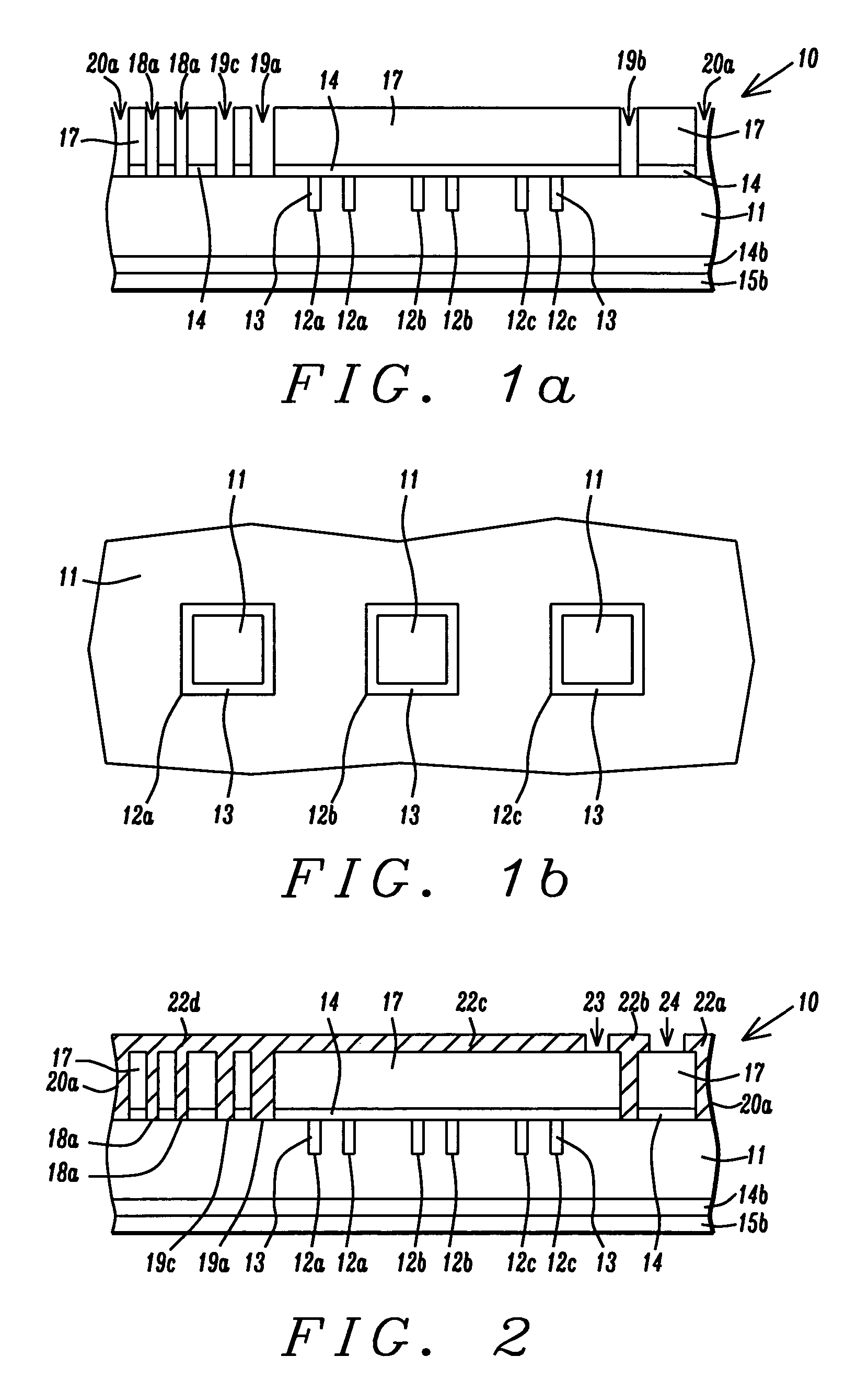

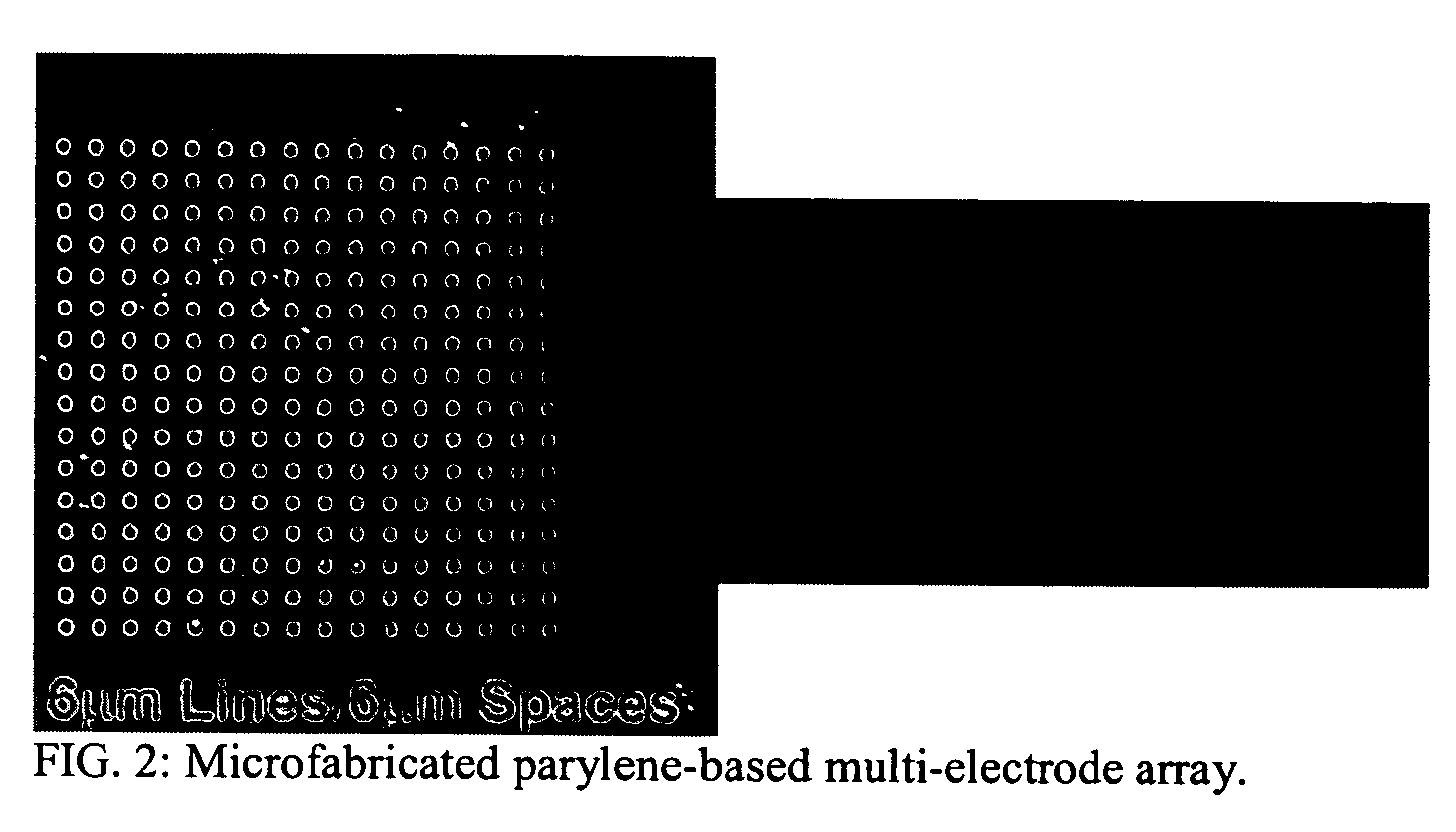

Membrane filter for capturing circulating tumor cells

ActiveUS20060254972A1Highly efficient in capturingEffective membraneBioreactor/fermenter combinationsBiological substance pretreatmentsParyleneGeometric design

The present invention provides a parylene-based membrane filter device for capturing of circulating tumor cells (CTC). The membrane filter has an array of holes having a predetermined geometric design with precisely controlled size, shape and density. In one aspect, the device has a stack of substantially parallel membrane filters with uniformly-spaced and / or monodispersed holes.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

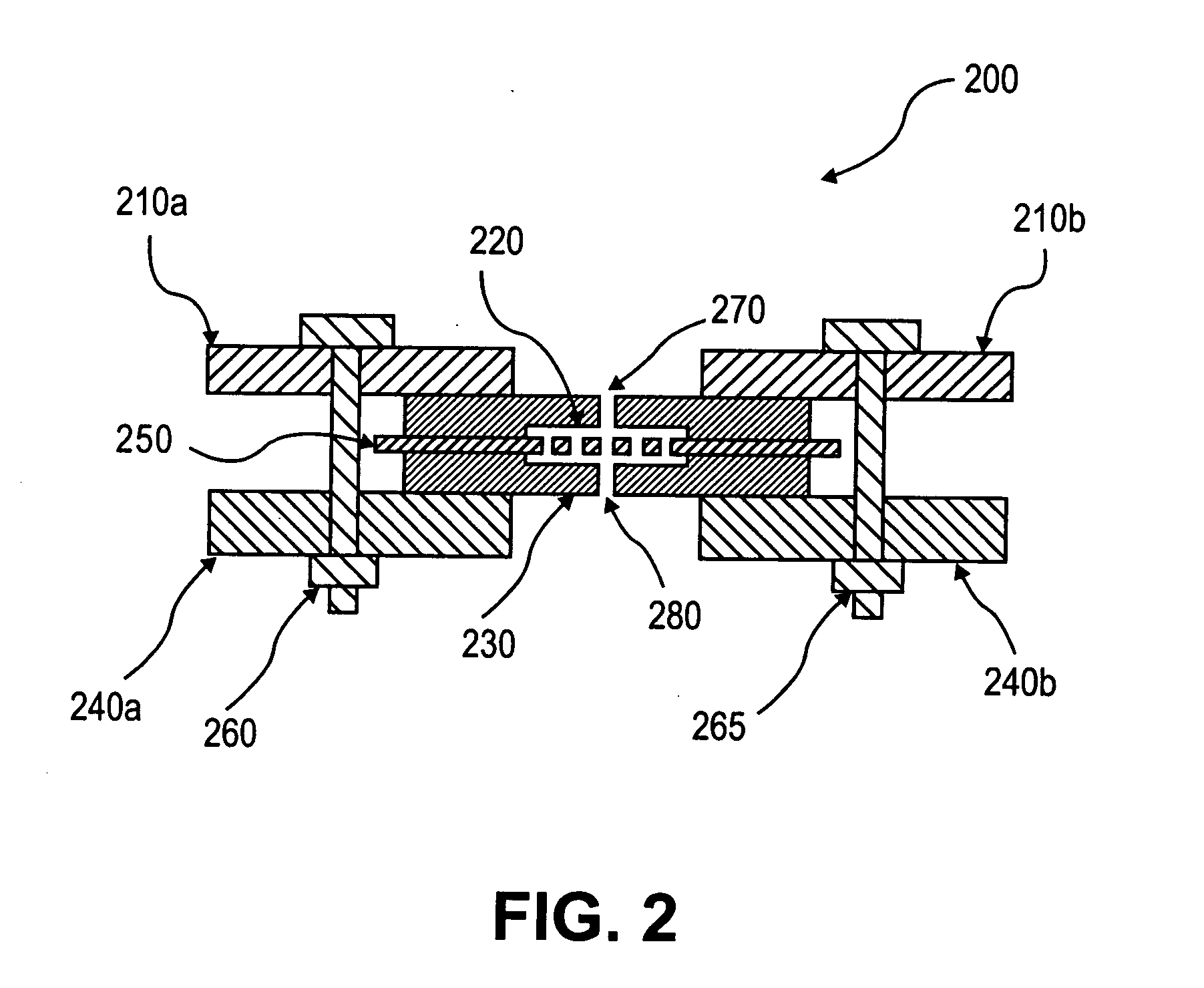

Method and apparatus for microfiltration to perform cell separation

ActiveUS20090188864A1Laborious and expensiveMembranesDecorative surface effectsParyleneMicrofabrication

A microfiltration apparatus and method for separating cells, such as circulating tumor cells, from a sample using a microfiltration device having a top porous membrane and a bottom porous membrane. The porous membranes are formed from parylene and assembled using microfabrication techniques. The porous membranes are arranged so that the pores in the top membrane are offset from the pores in the bottom membrane.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

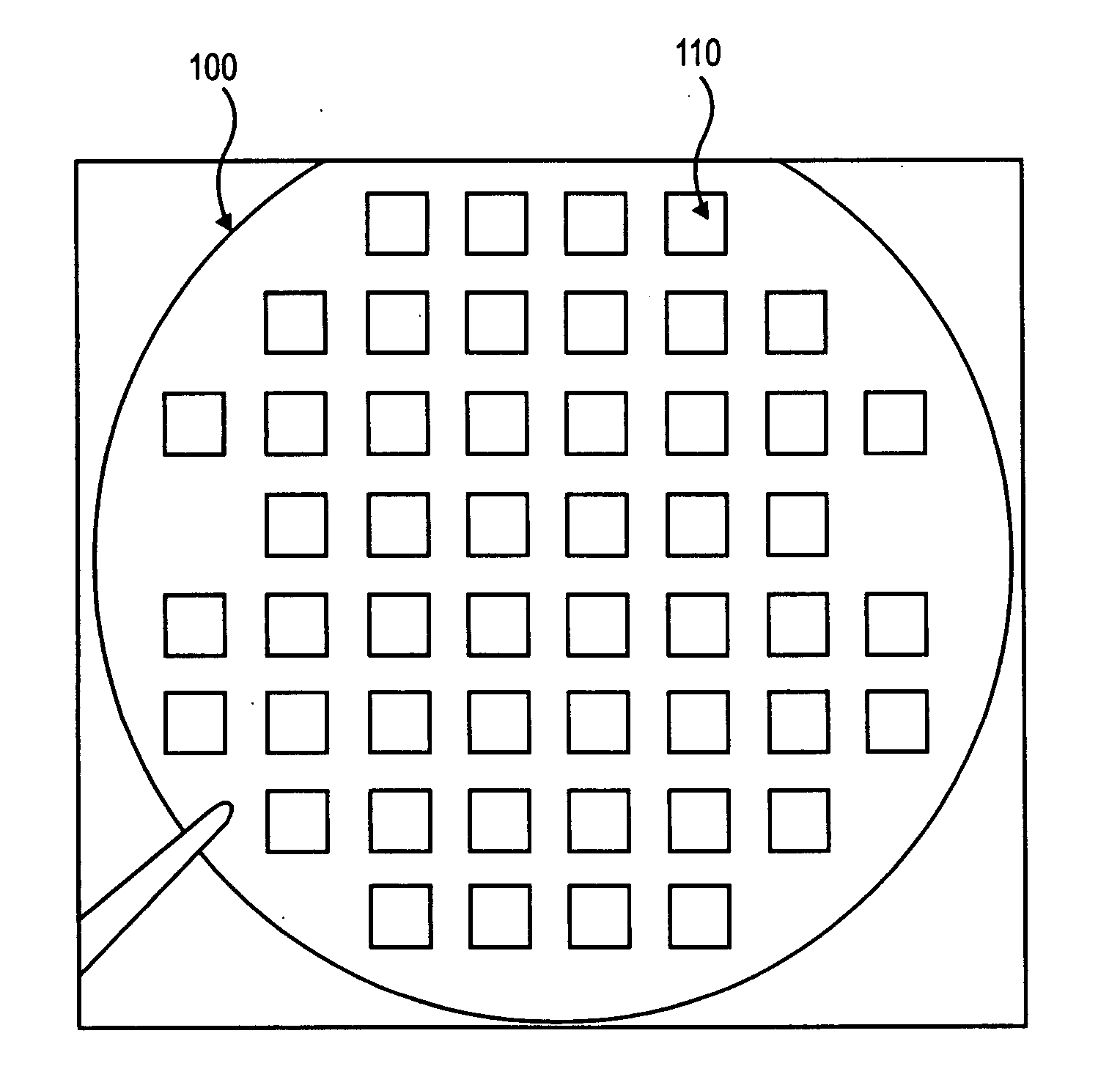

Temporary coatings for protection of microelectronic devices during packaging

InactiveUS6844623B1Decorative surface effectsSemiconductor/solid-state device detailsCarbon filmParylene

The present invention relates to a method of protecting a microelectronic device during device packaging, including the steps of applying a water-insoluble, temporary protective coating to a sensitive area on the device; performing at least one packaging step; and then substantially removing the protective coating, preferably by dry plasma etching. The sensitive area can include a released MEMS element. The microelectronic device can be disposed on a wafer. The protective coating can be a vacuum vapor-deposited parylene polymer, silicon nitride, metal (e.g. aluminum or tungsten), a vapor deposited organic material, cynoacrylate, a carbon film, a self-assembled monolayered material, perfluoropolyether, hexamethyldisilazane, or perfluorodecanoic carboxylic acid, silicon dioxide, silicate glass, or combinations thereof. The present invention also relates to a method of packaging a microelectronic device, including: providing a microelectronic device having a sensitive area; applying a water-insoluble, protective coating to the sensitive area; providing a package; attaching the device to the package; electrically interconnecting the device to the package; and substantially removing the protective coating from the sensitive area.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

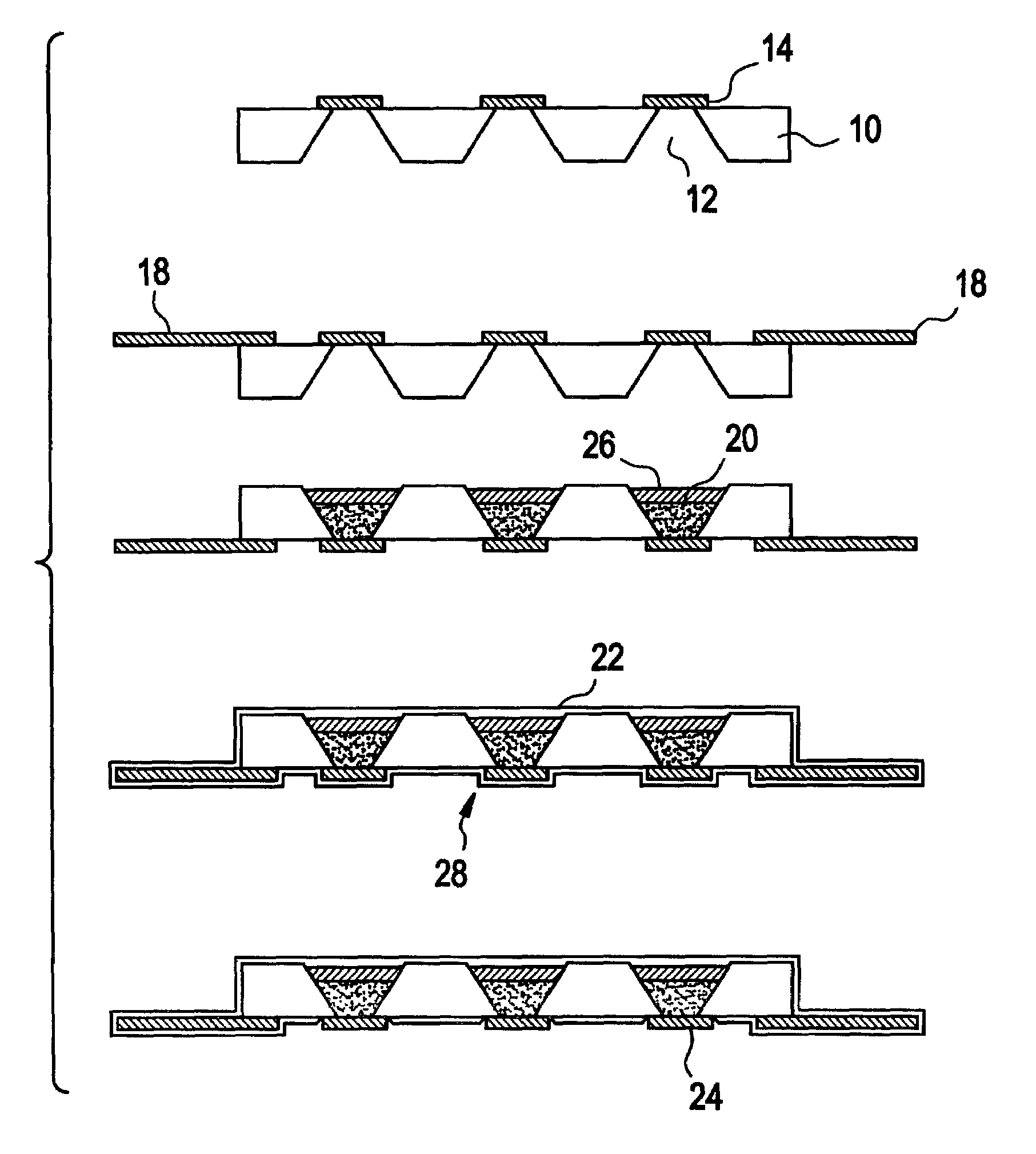

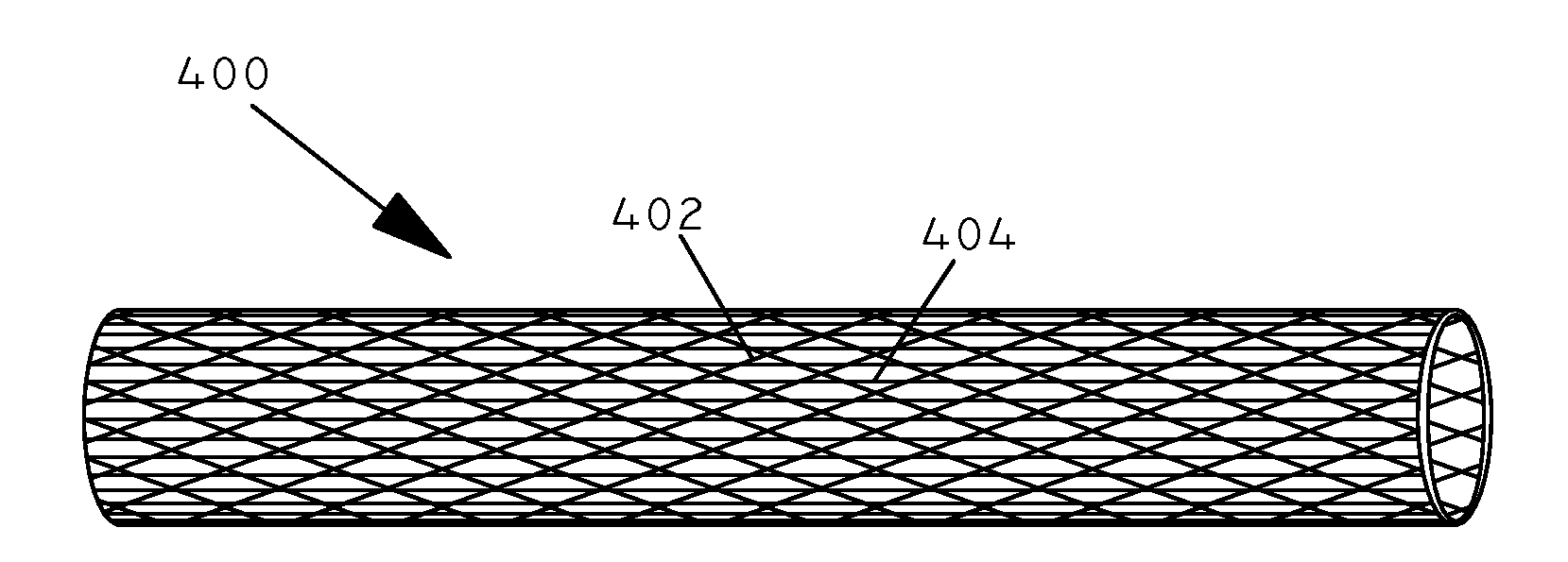

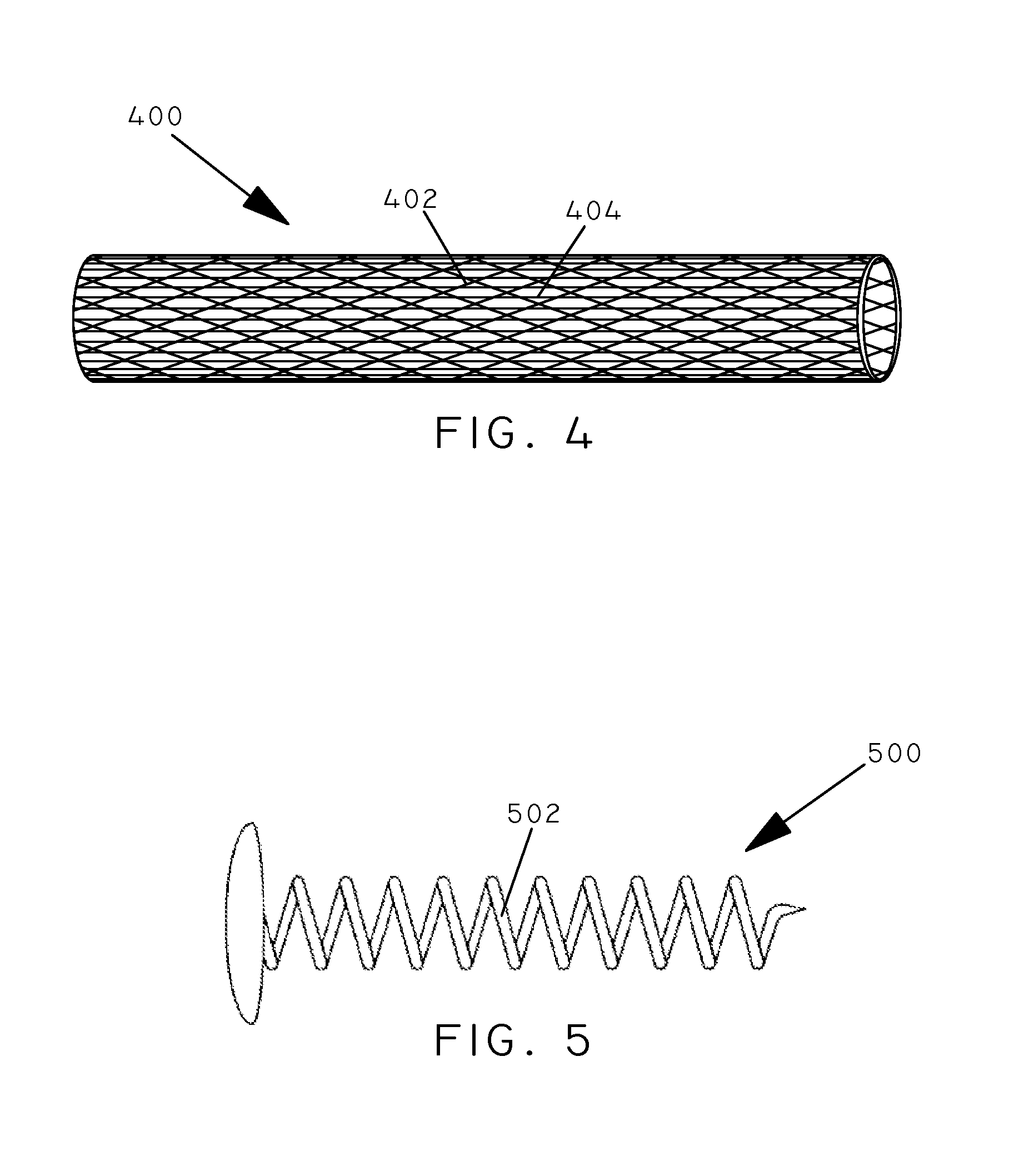

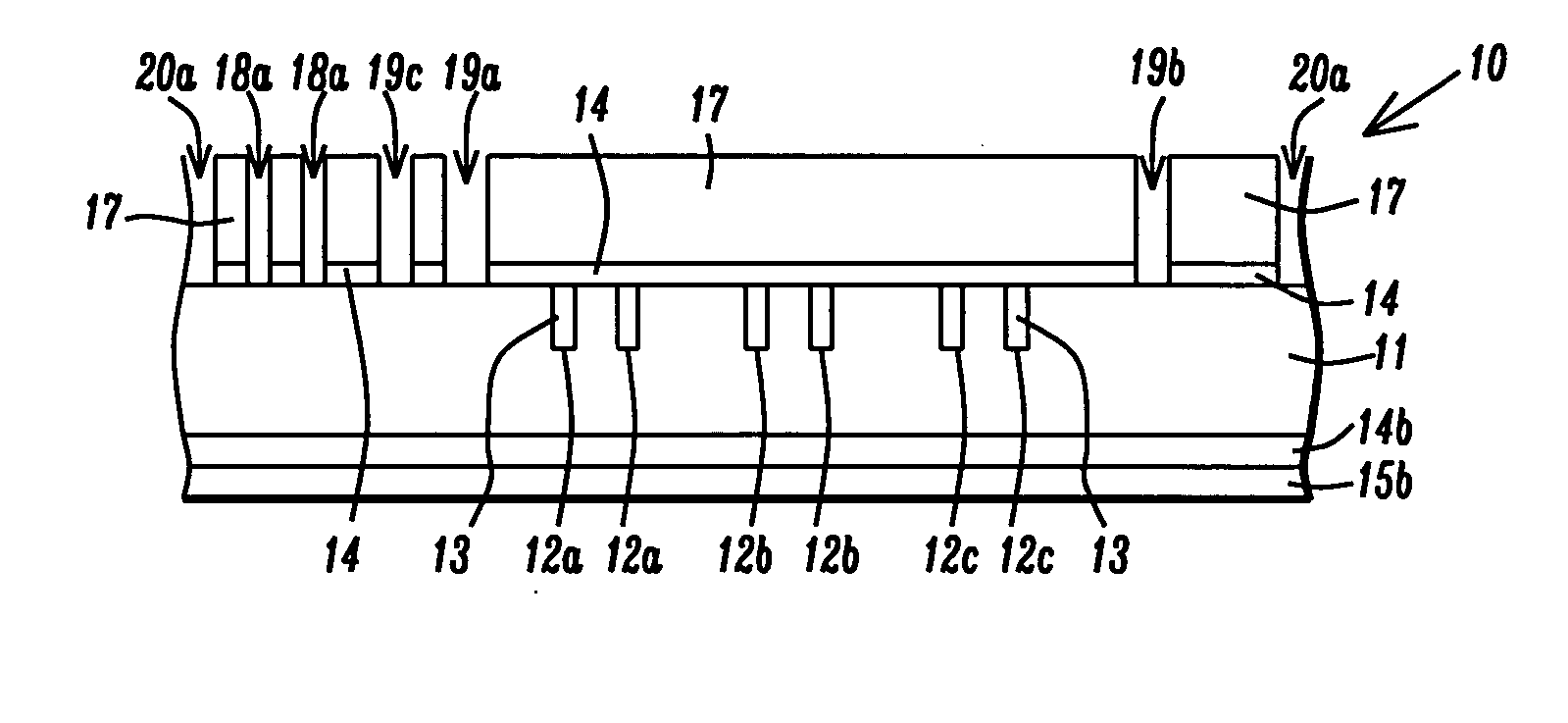

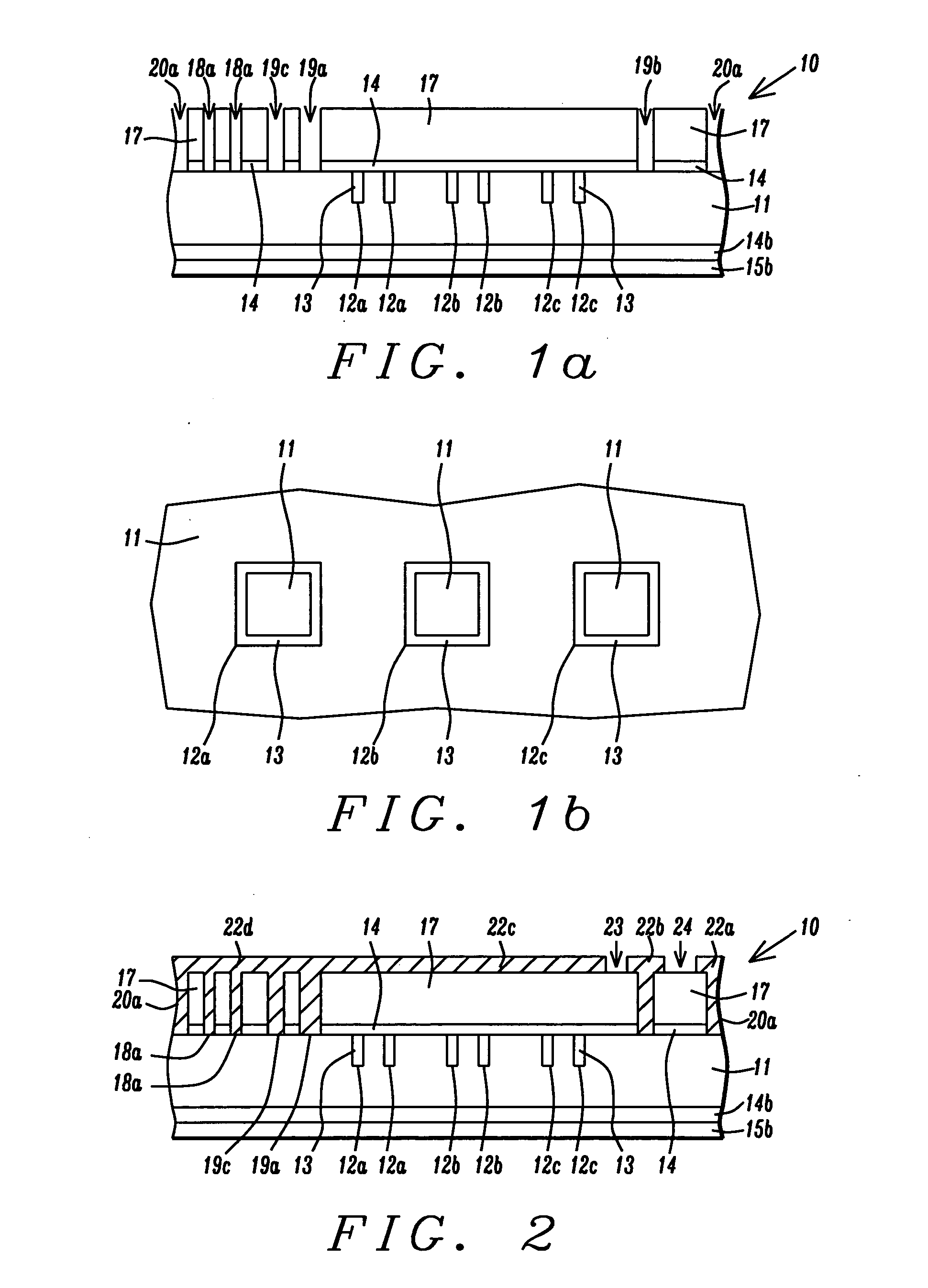

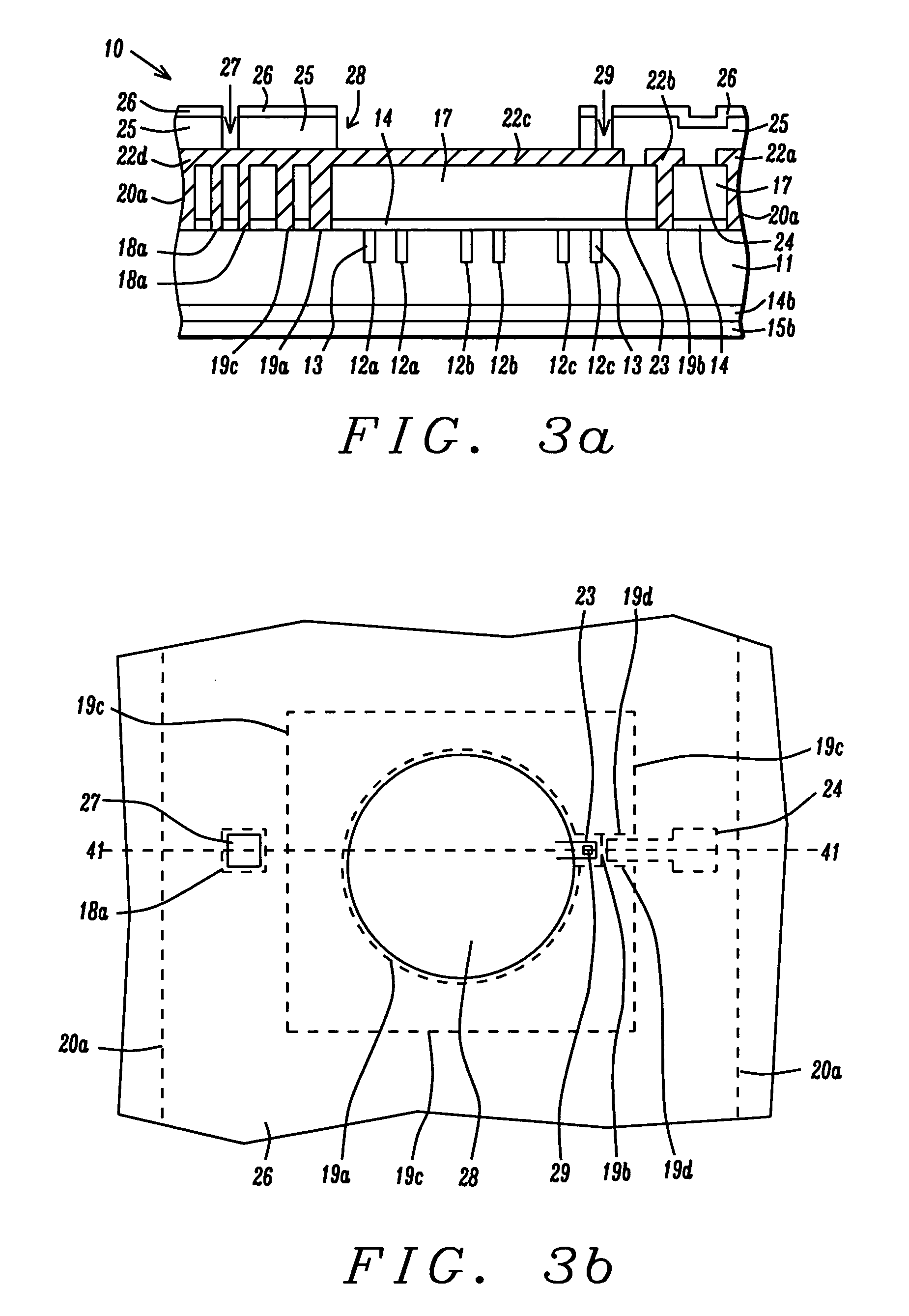

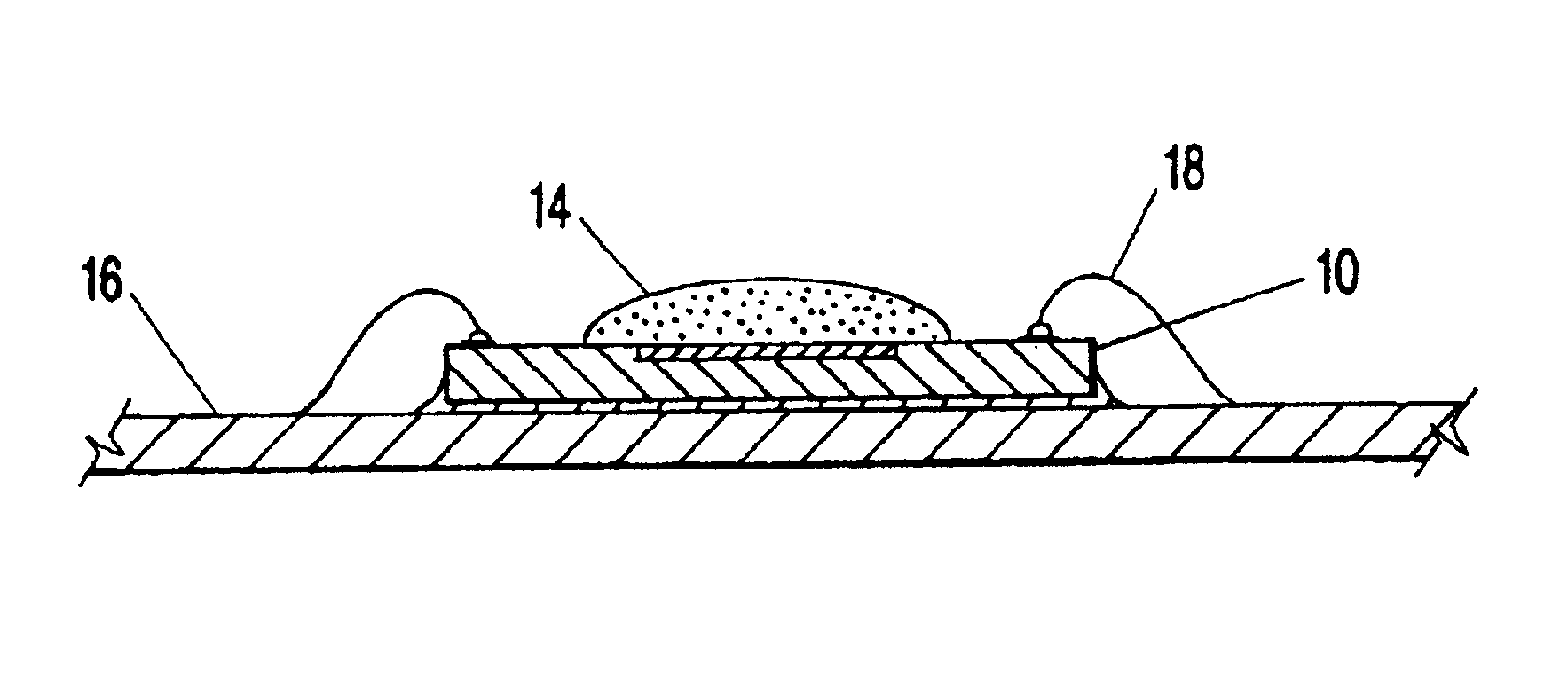

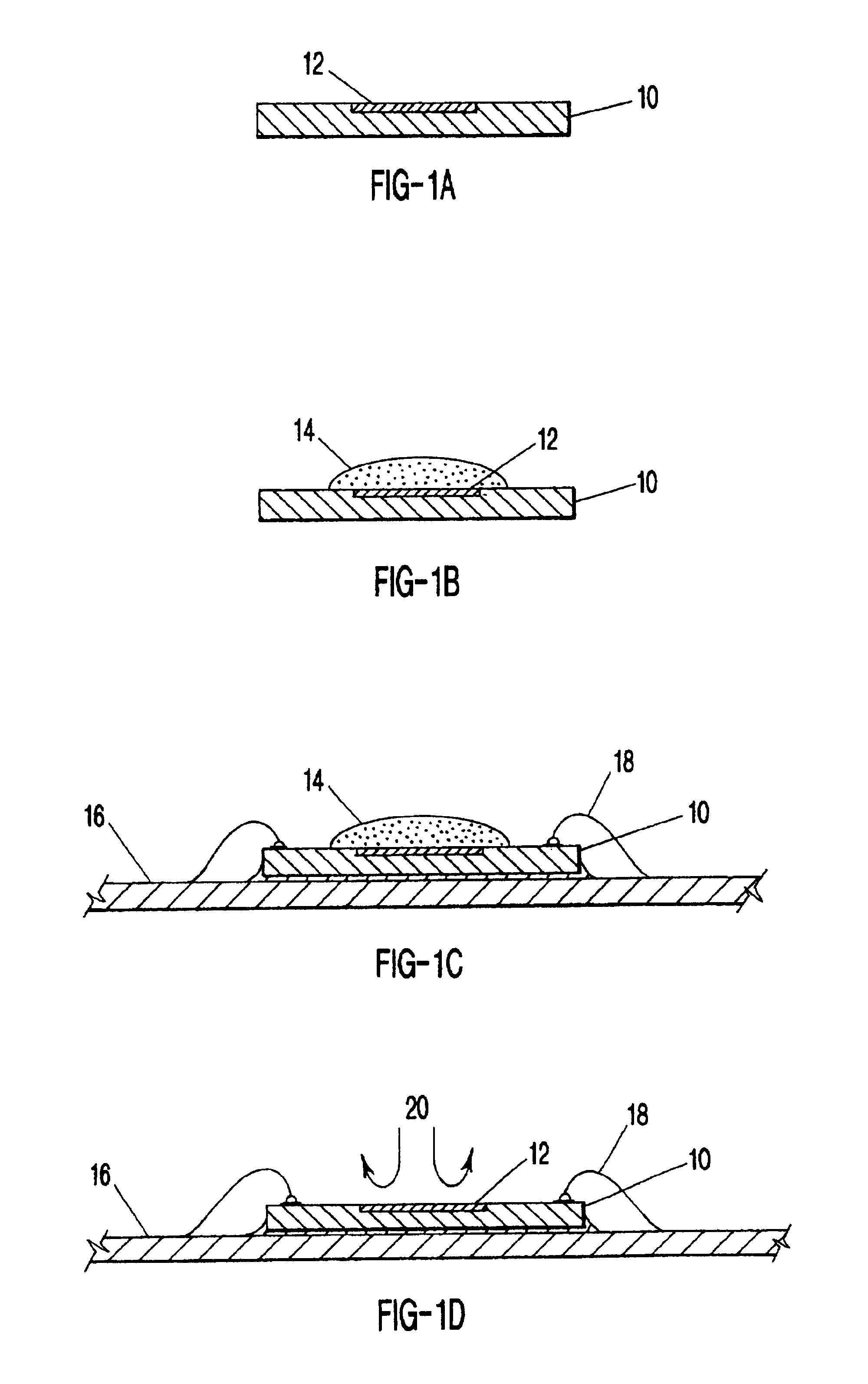

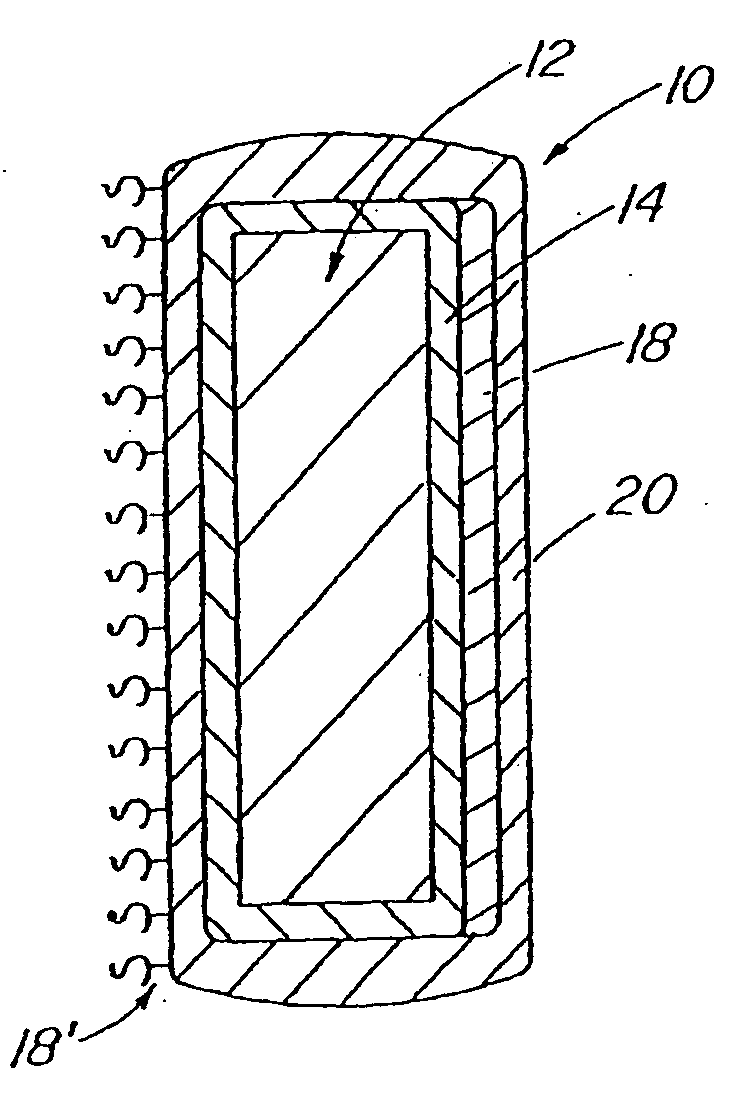

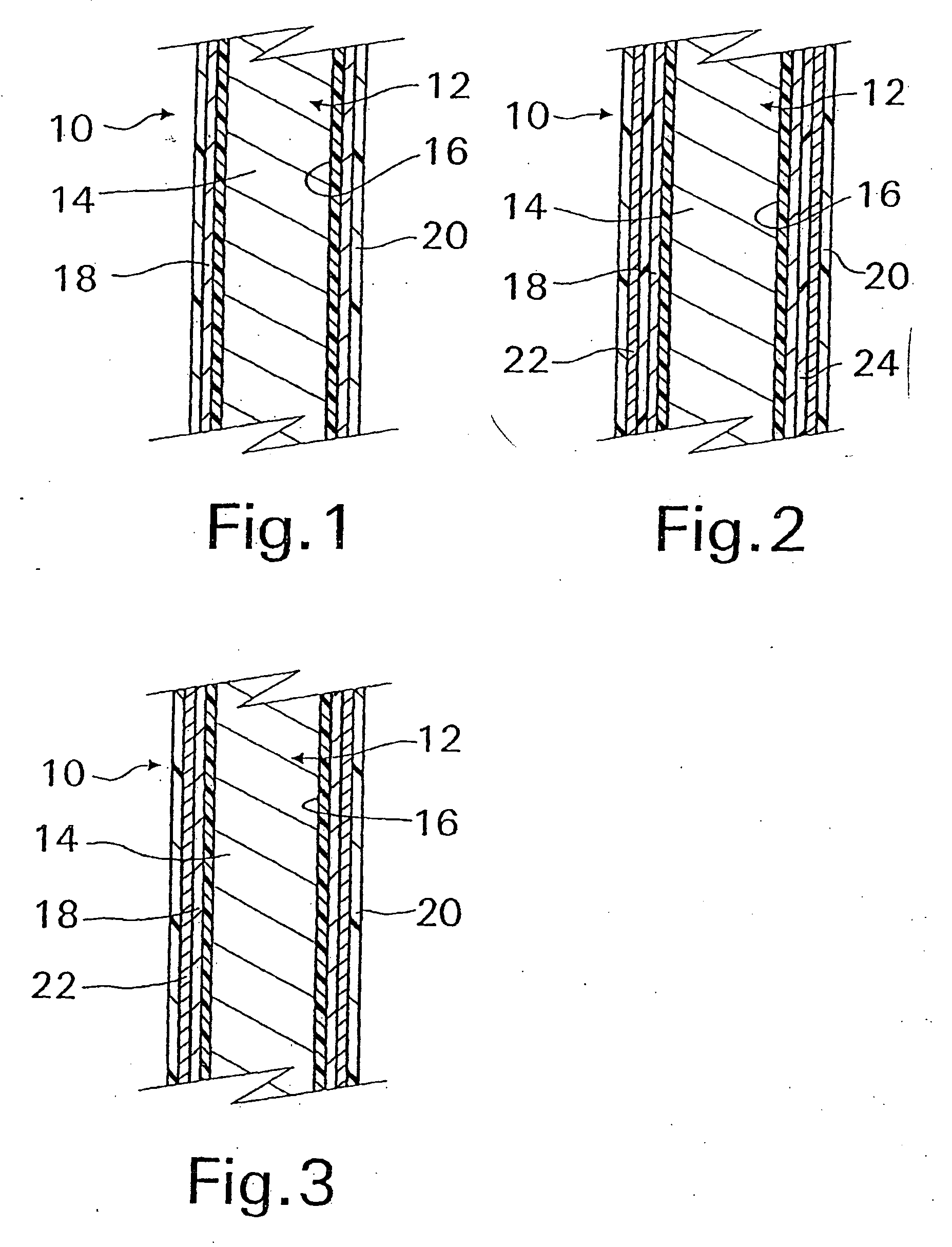

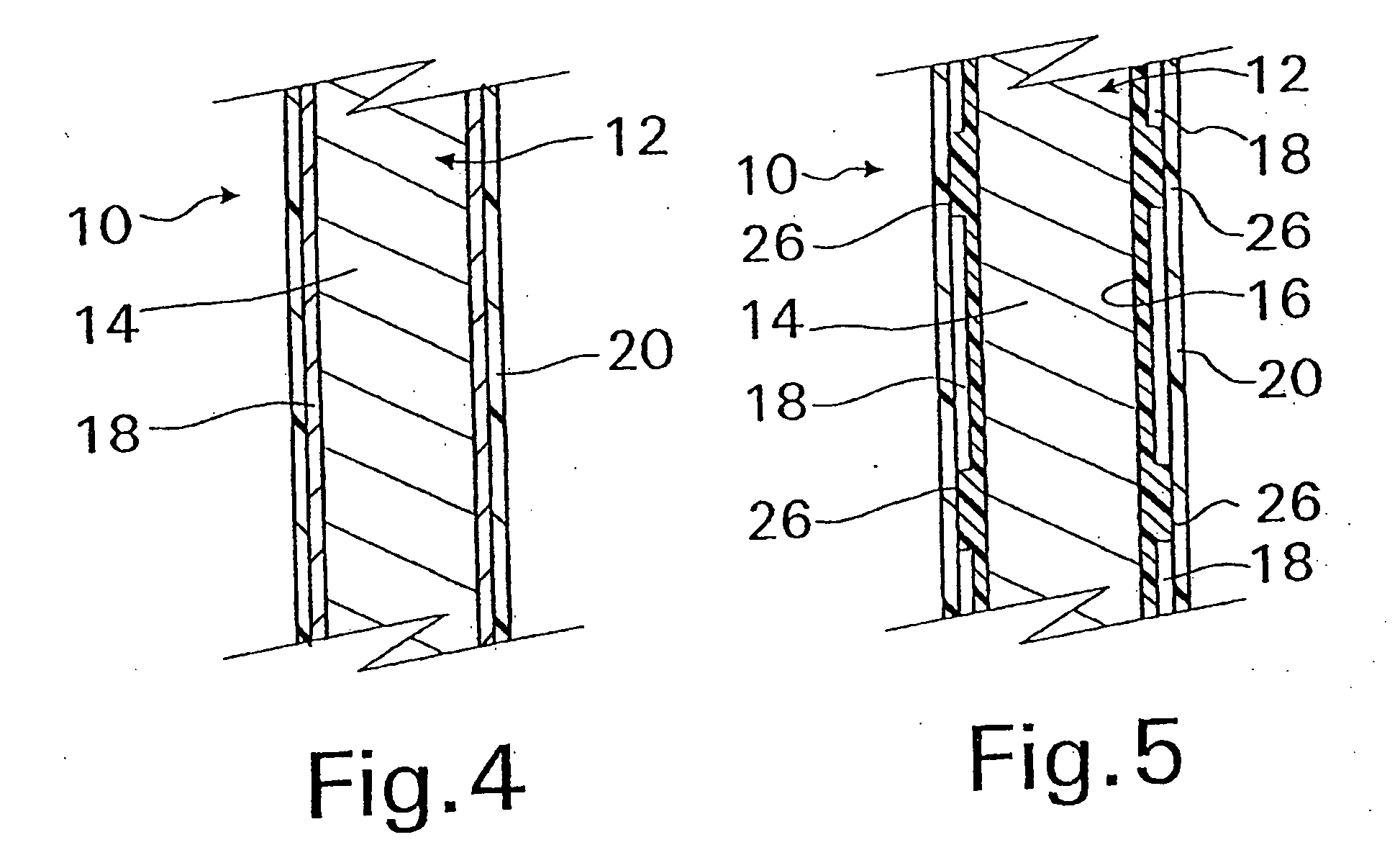

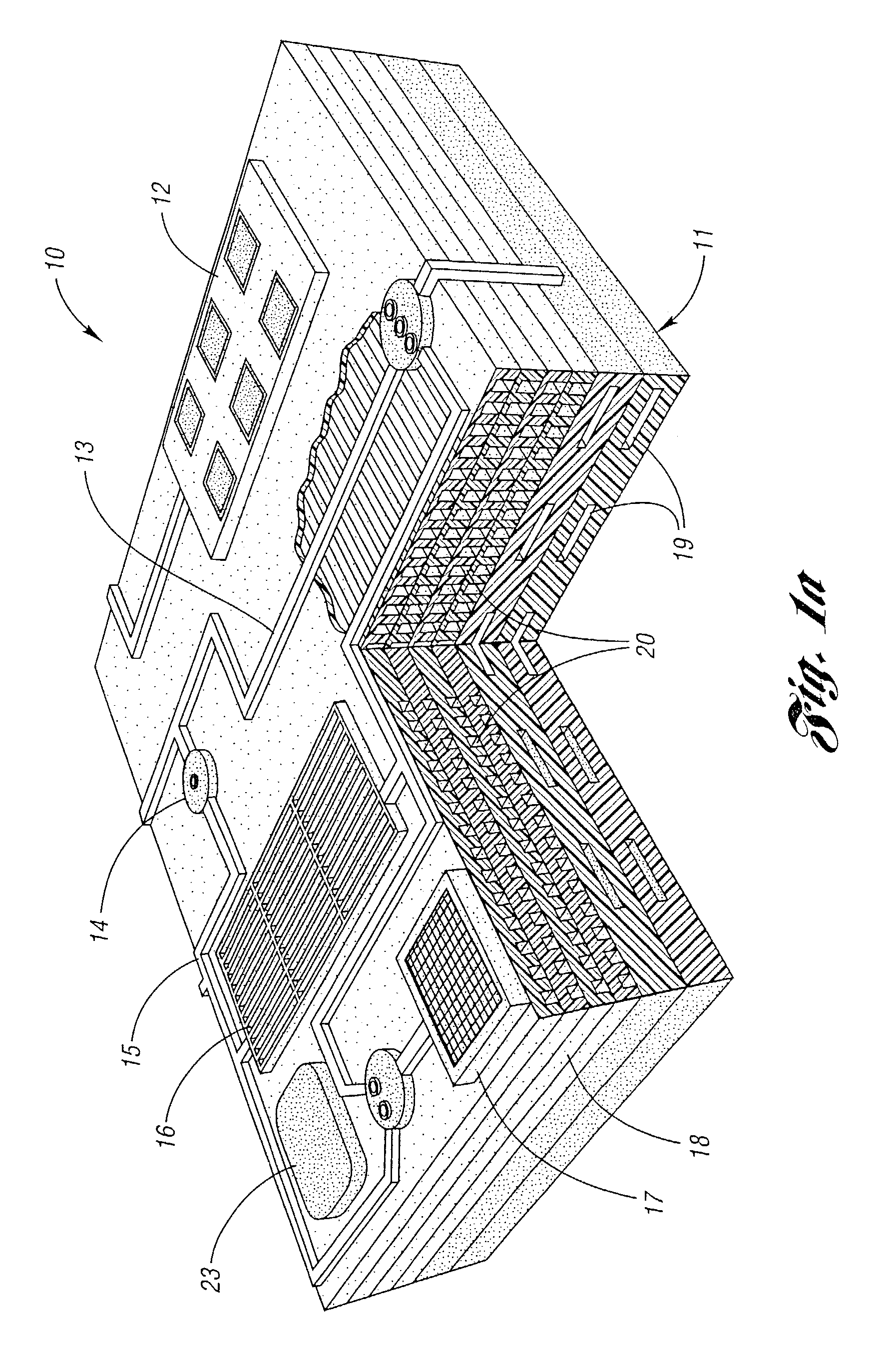

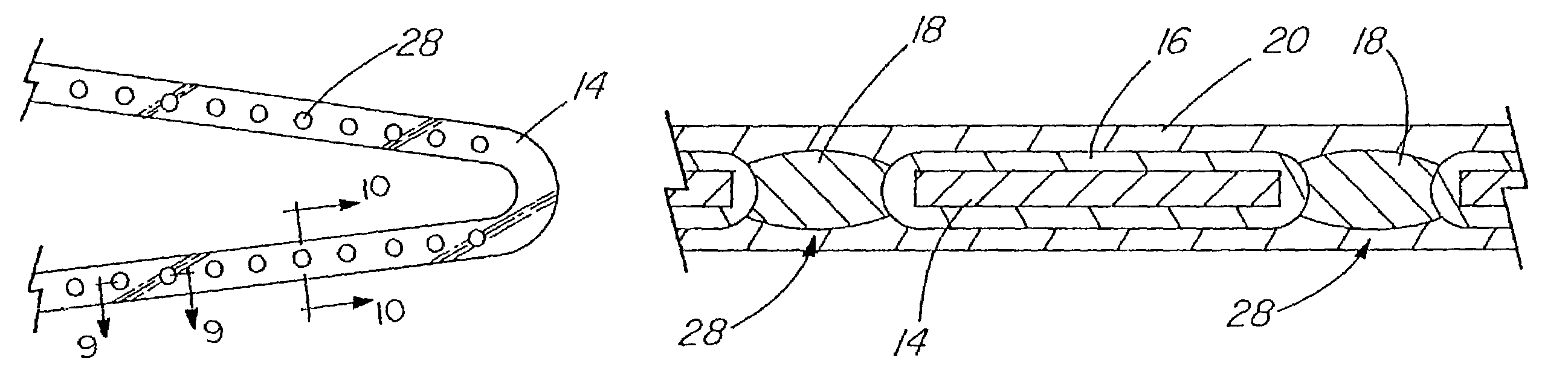

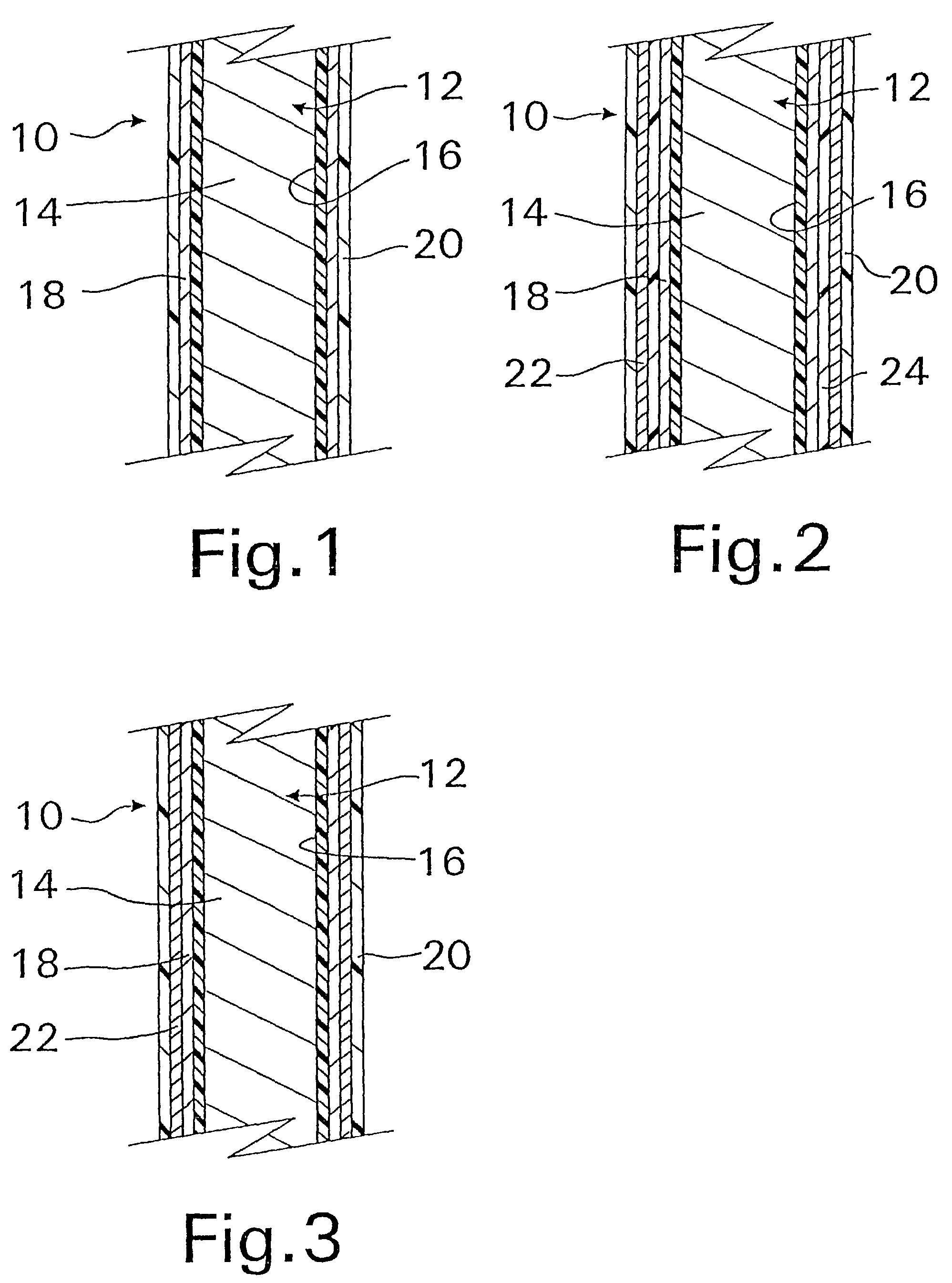

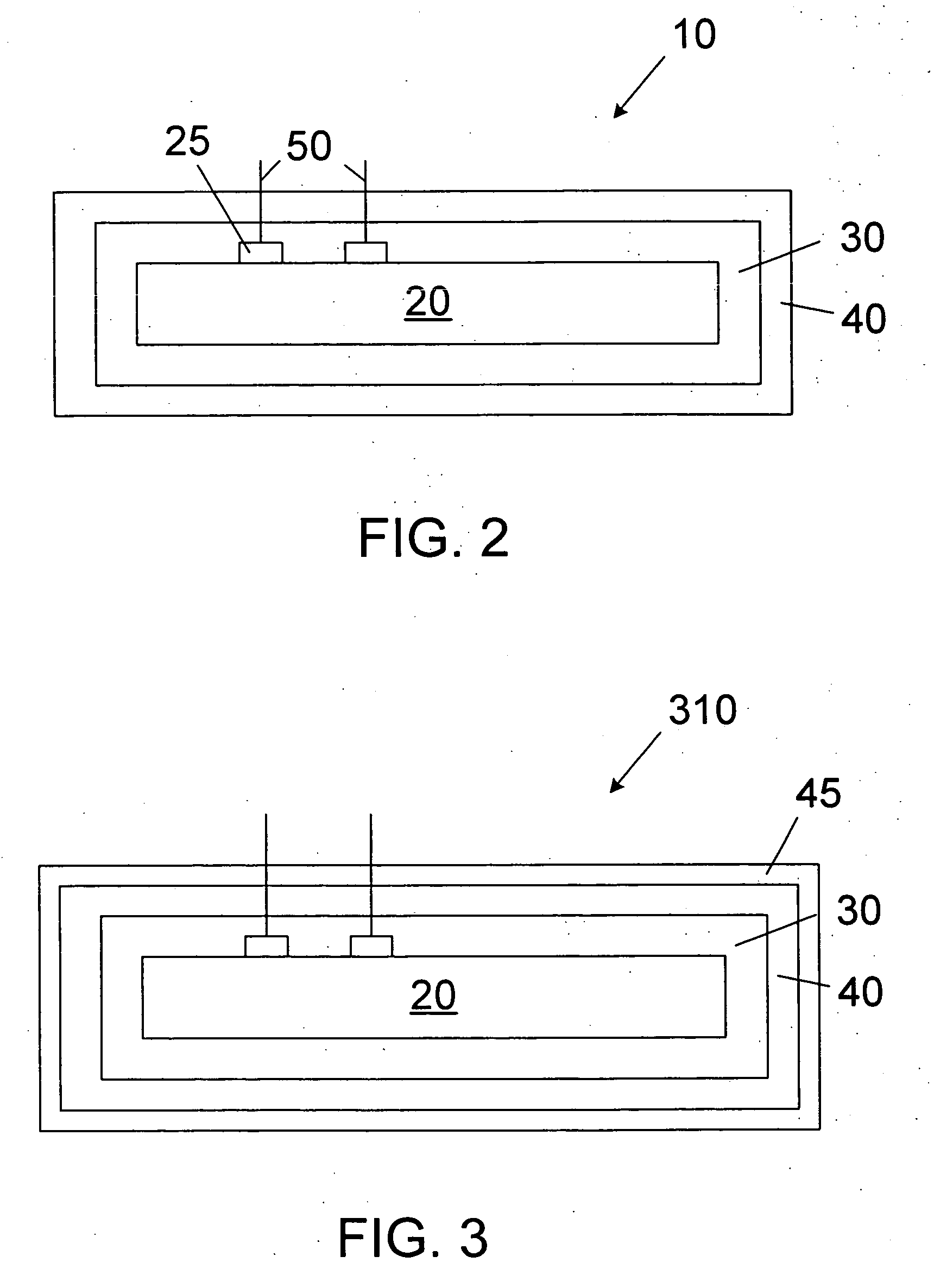

Coated implantable medical device

InactiveUS20070050010A1Prevent degradationIncrease release rateStentsIn-vivo radioactive preparationsParyleneGas phase

A coated implantable medical device 10 includes a structure 12 adapted for introduction into the vascular system, esophagus, trachea, colon, biliary tract, or urinary tract; at least one coating layer 16 posited on one surface of the structure; and at least one layer 18 of a bioactive material posited on at least a portion of the coating layer 16, wherein the coating layer 16 provides for the controlled release of the bioactive material from the coating layer. In addition, at least one porous layer 20 can be posited over the bioactive material layer 18, wherein the porous layer includes a polymer and provides for the controlled release of the bioactive material therethrough. Preferably, the structure 12 is a coronary stent. The porous layer 20 includes a polymer applied preferably by vapor or plasma deposition and provides for a controlled release of the bioactive material. It is particularly preferred that the polymer is a polyamide, parylene or a parylene derivative, which is deposited without solvents, heat or catalysts, and merely by condensation of a monomer vapor.

Owner:COOK MEDICAL TECH LLC

Silicon microphone with softly constrained diaphragm

ActiveUS7329933B2Reduce stressSimple methodSemiconductor electrostatic transducersFluid pressure measurement by electric/magnetic elementsParyleneYoung's modulus

A microphone sensing element and a method for making the same are disclosed. The sensing element has a diaphragm and an attached electrical lead-out arm preferably made of polysilicon that are separated by an air gap from an underlying backplate region created on a conductive silicon substrate. The backplate region has acoustic holes created by removing an oxide filling in a continuous trench that surrounds hole edges and by removing oxide to form the air gap. The diaphragm is softly constrained along its edge by an elastic element that connects to a surrounding rigid polysilicon layer. The elastic element is typically a polymer such as parylene having a Young's modulus substantially less than that of the diaphragm. First and second electrodes are connected to the diaphragm through the lead-out arm and to the substrate through polysilicon via fillings, respectively, and thereby establish a variable capacitor circuit for acoustic sensing.

Owner:SHANDONG GETTOP ACOUSTIC

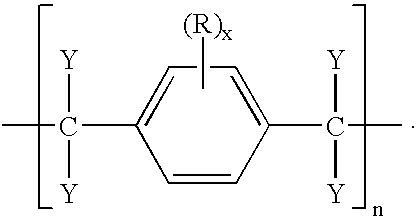

Porous Articles Formed From Polyparaxylylene and Processes For Forming The Same

PendingUS20160032069A1Large deformationSemi-permeable membranesSynthetic resin layered productsFiberParylene

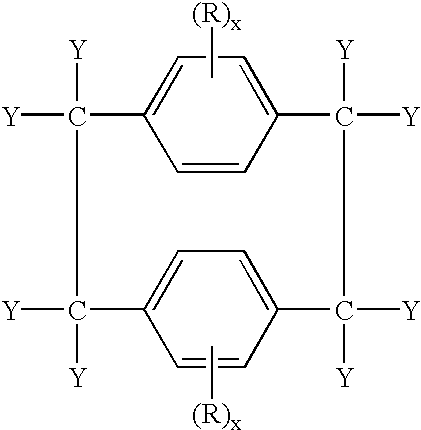

Polyparaxylylene (PPX) polymers that can be expanded into porous articles that have a node and fibril microstructure are provided. The fibrils contain PPX polymer chains oriented with the fibril axis. The PPX polymer may contain one or more comonomer. PPX polymer articles may be formed by applying PPX to a substrate by vapor deposition. The nominal thickness of the PPX polymer film is less than about 50 microns. The PPX polymer film may be removed from the substrate to form a free-standing PPX polymer film, which may then be stretched into a porous article. Alternatively, a PPX polymer article can be formed by lubricating PPX polymer powder, heating the lubricated powder, and calendering or ram extruding to produce a preform that can subsequently be stretched into a porous article. The heating and expansion temperatures are from about 80° C. to about 220° C. or from about 220° C. to about 290° C. or from about 290° C. to about 450° C.

Owner:WL GORE & ASSOC INC

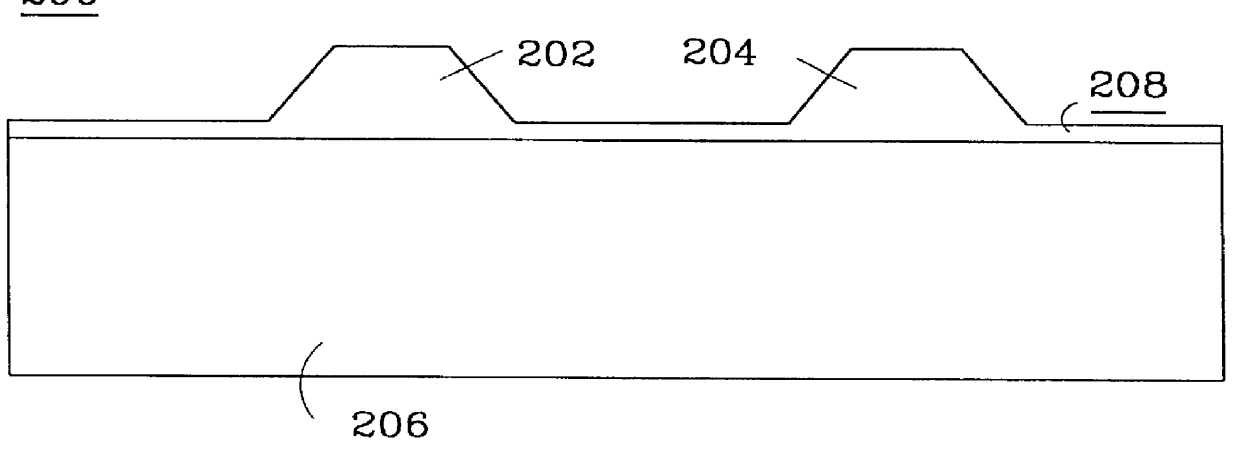

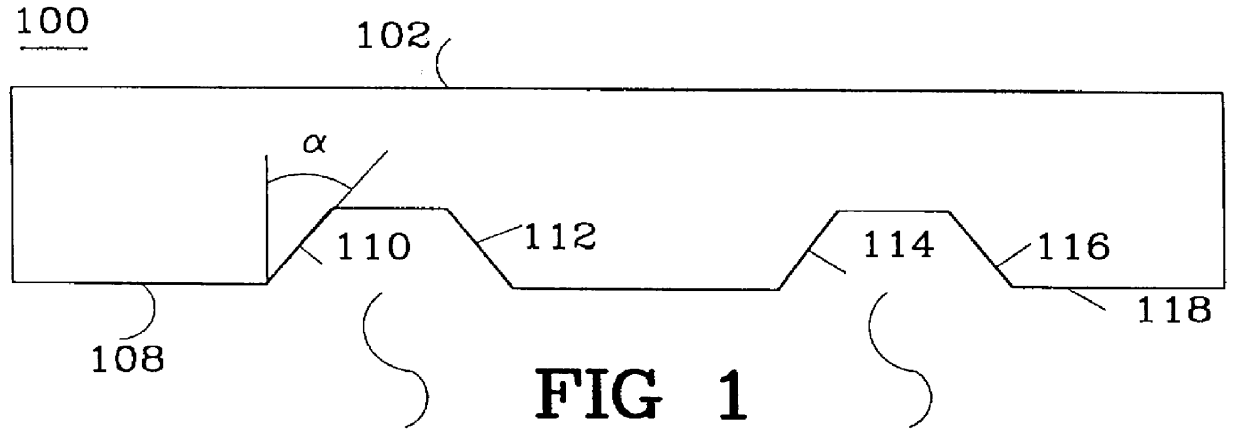

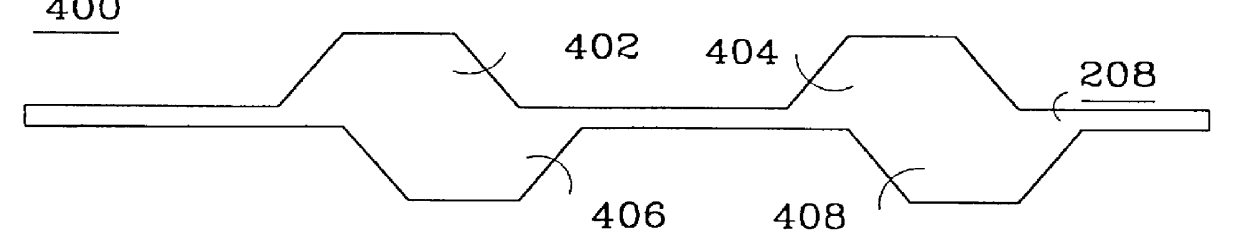

Method for making elastic bumps from a wafer mold having grooves

This invention relates to a manufacturing process for making elastic bumps in the micro-electronic field. It solves the problem to mould micrometer sized elastic features by means of a micro-machined mould. The method is a reproducible moulding technology to achieve elastic bumps being a perfect replication of the mould. The mould is made of one or several grooves etched in a silicon wafer. The method includes the steps of: cleaning the surface of the mould (100) from dust and other particles; depositing a release agent on the mould and the release agent, e.g. Parylene or silane, forming a conformal self-assembled layer (118) on the surface of the mould; putting on a curable elastomer, to form an elastomeric structure (208) on the mould; curing the mould and the structure; and separating the structure from the mould.

Owner:INFINEON TECH AG

Vapor deposition process for producing a stent-graft and a stent-graft produced therefrom

A stent-graft endoprosthesis is provided. The graft is a non-textile graft made from biocompatible polymers. The biocompatible compatible polymers include poly-para-xylylene polymeric material. The stent is also coated with a poly-para-xylylene polymeric material. The graft is formed by vacuum vapor deposition of diradicals forming the poly-para-xylylene material. The stent is also coated with the poly-para-xylylene material by vacuum vapor deposition.

Owner:BOSTON SCI SCIMED INC

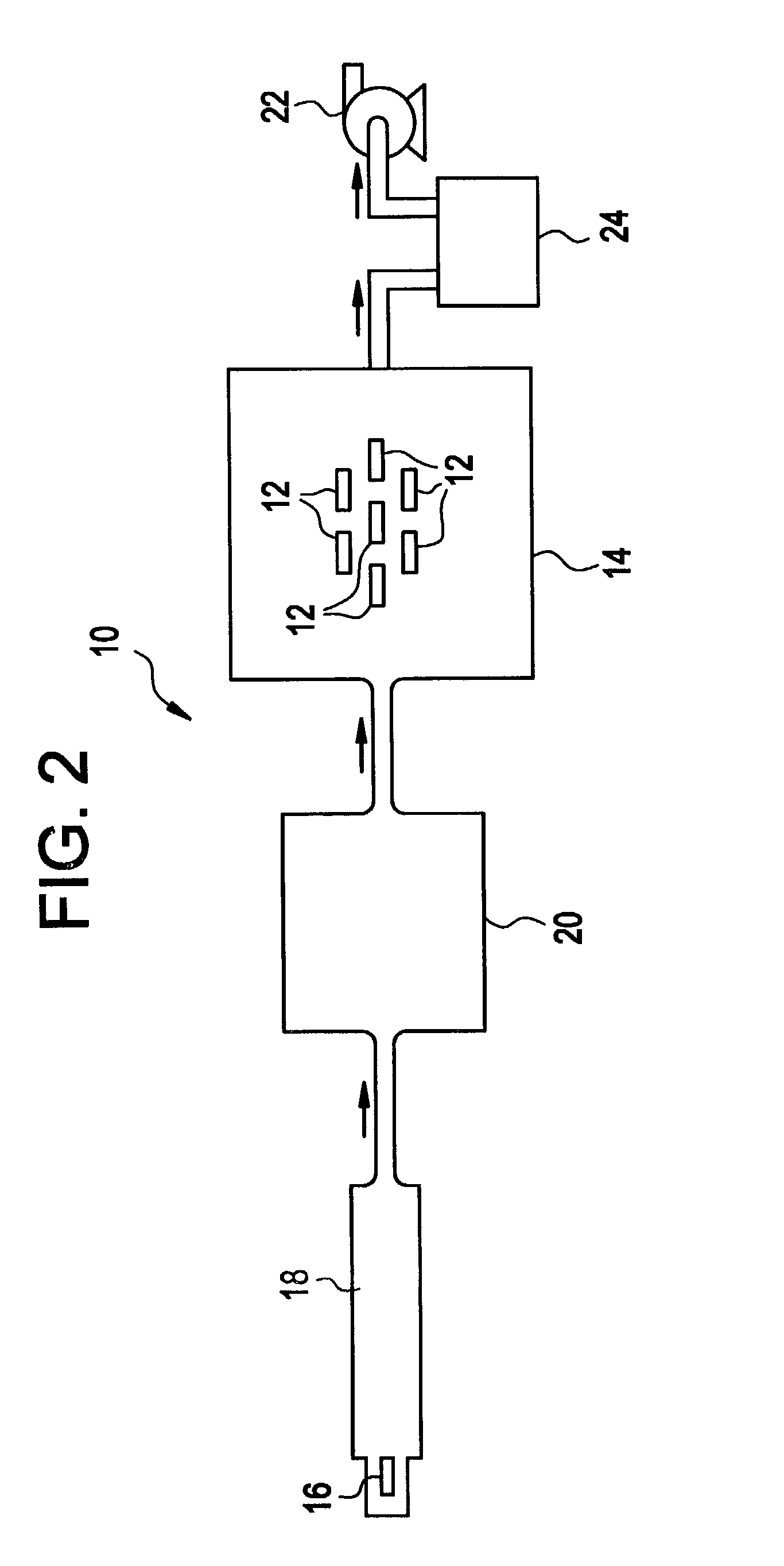

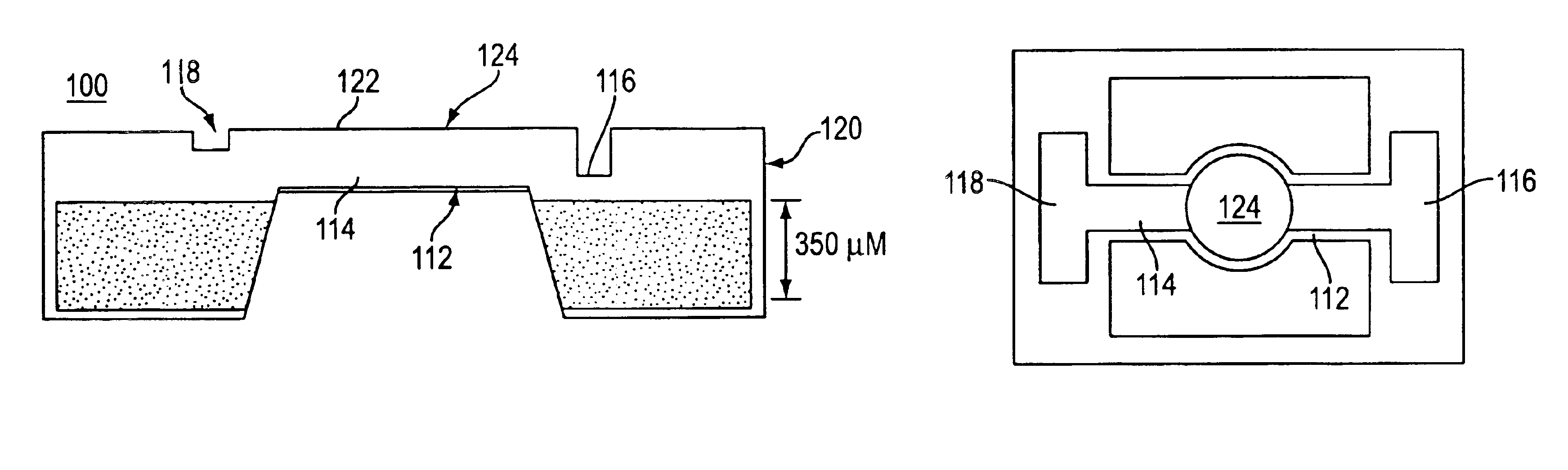

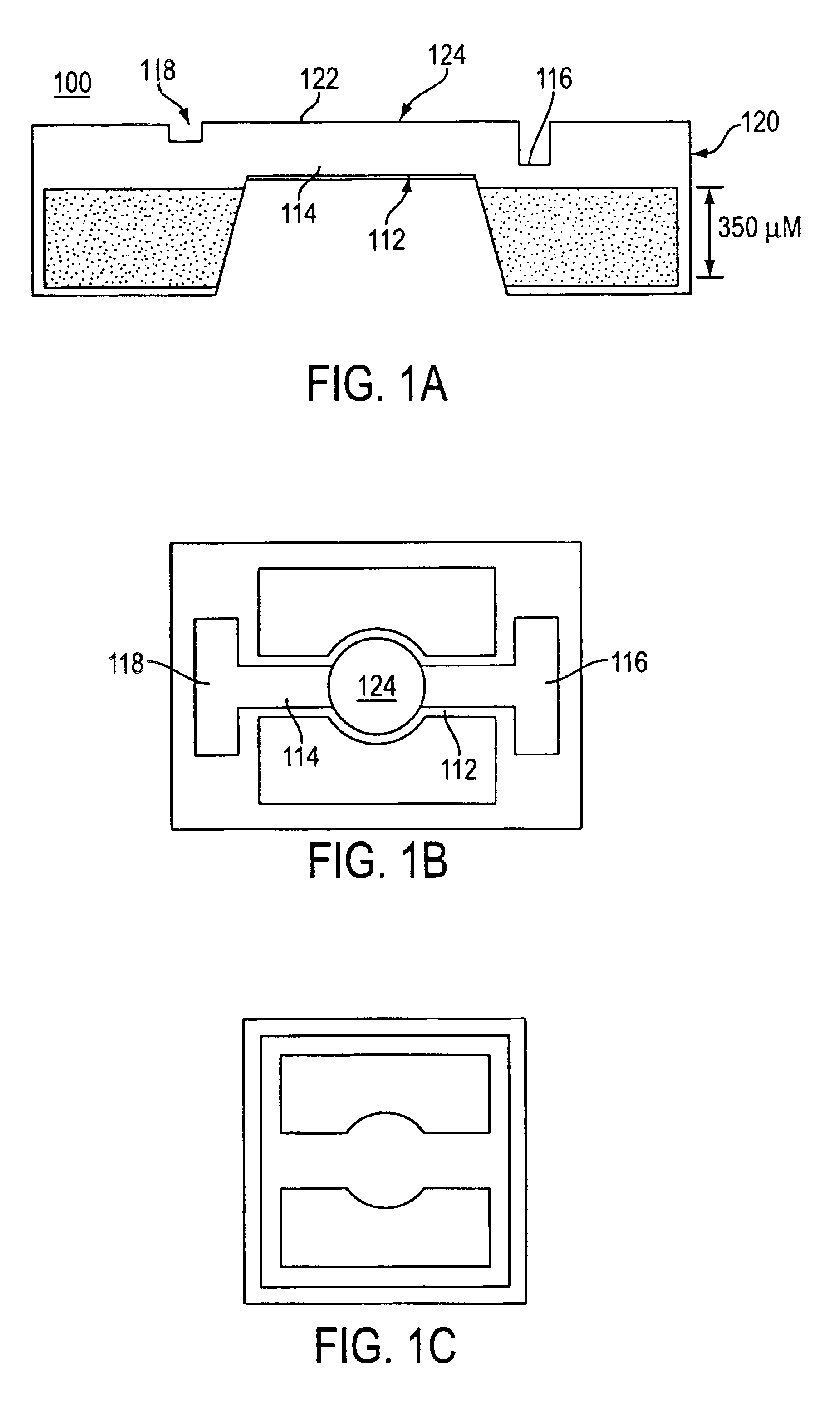

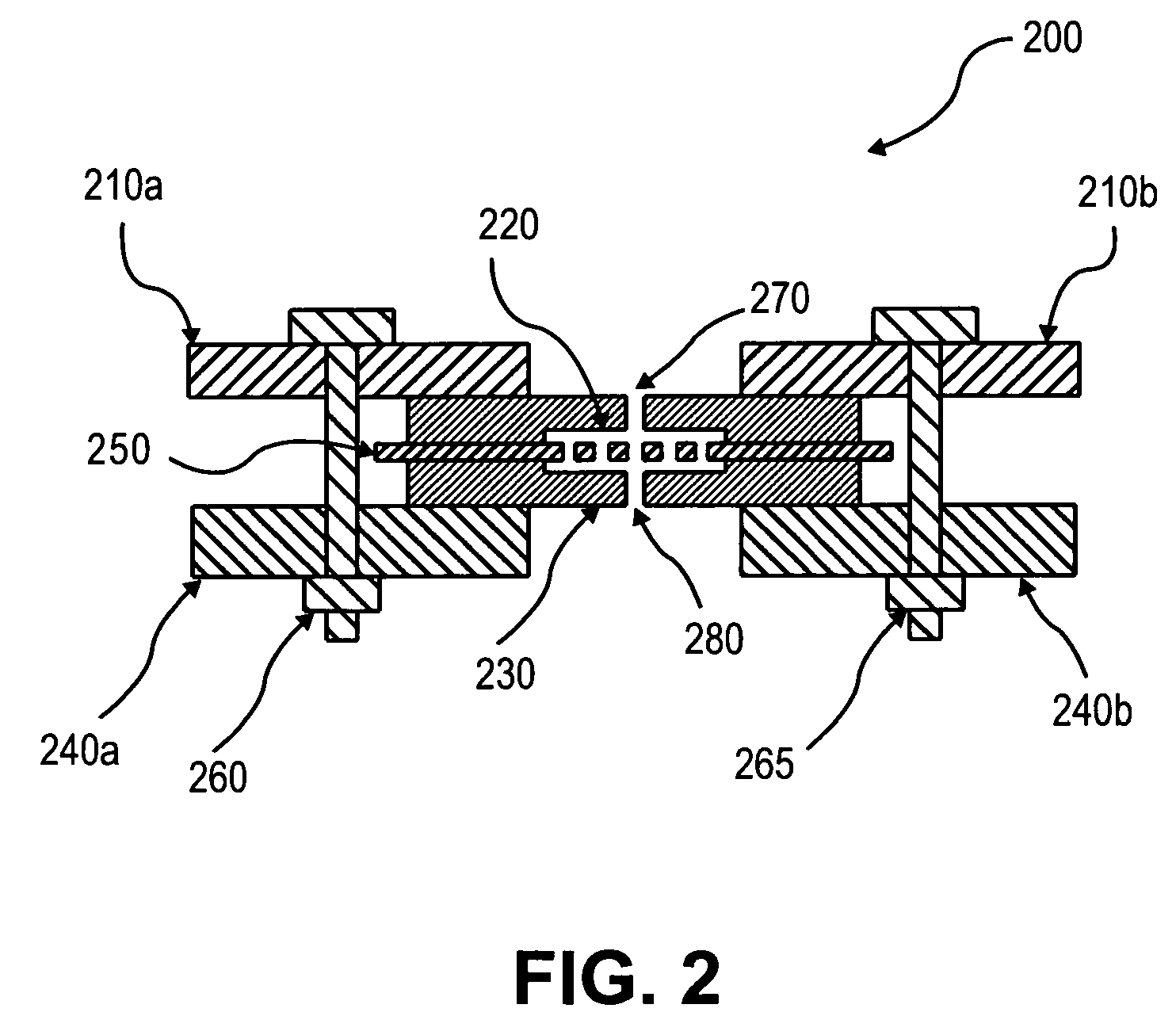

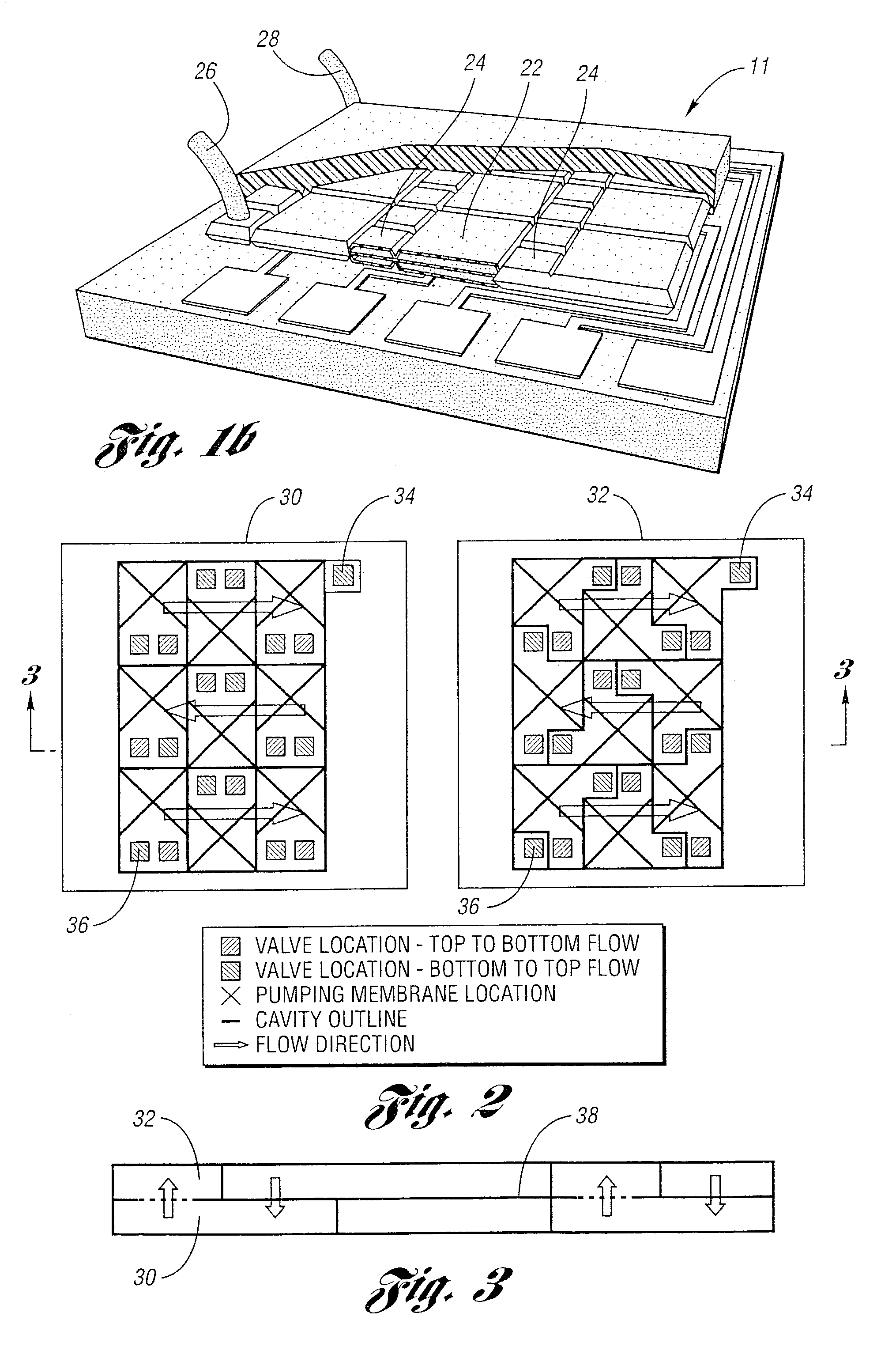

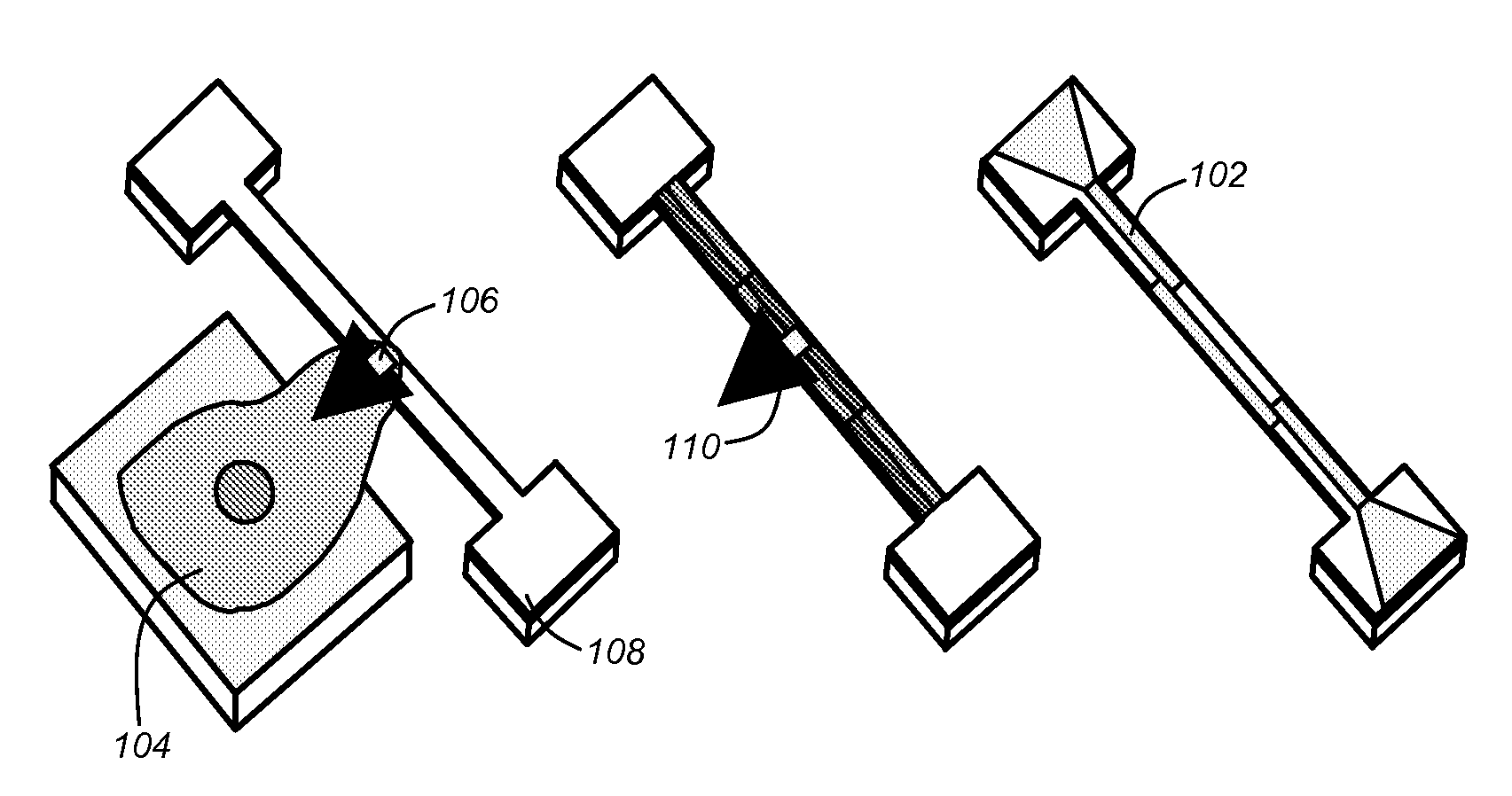

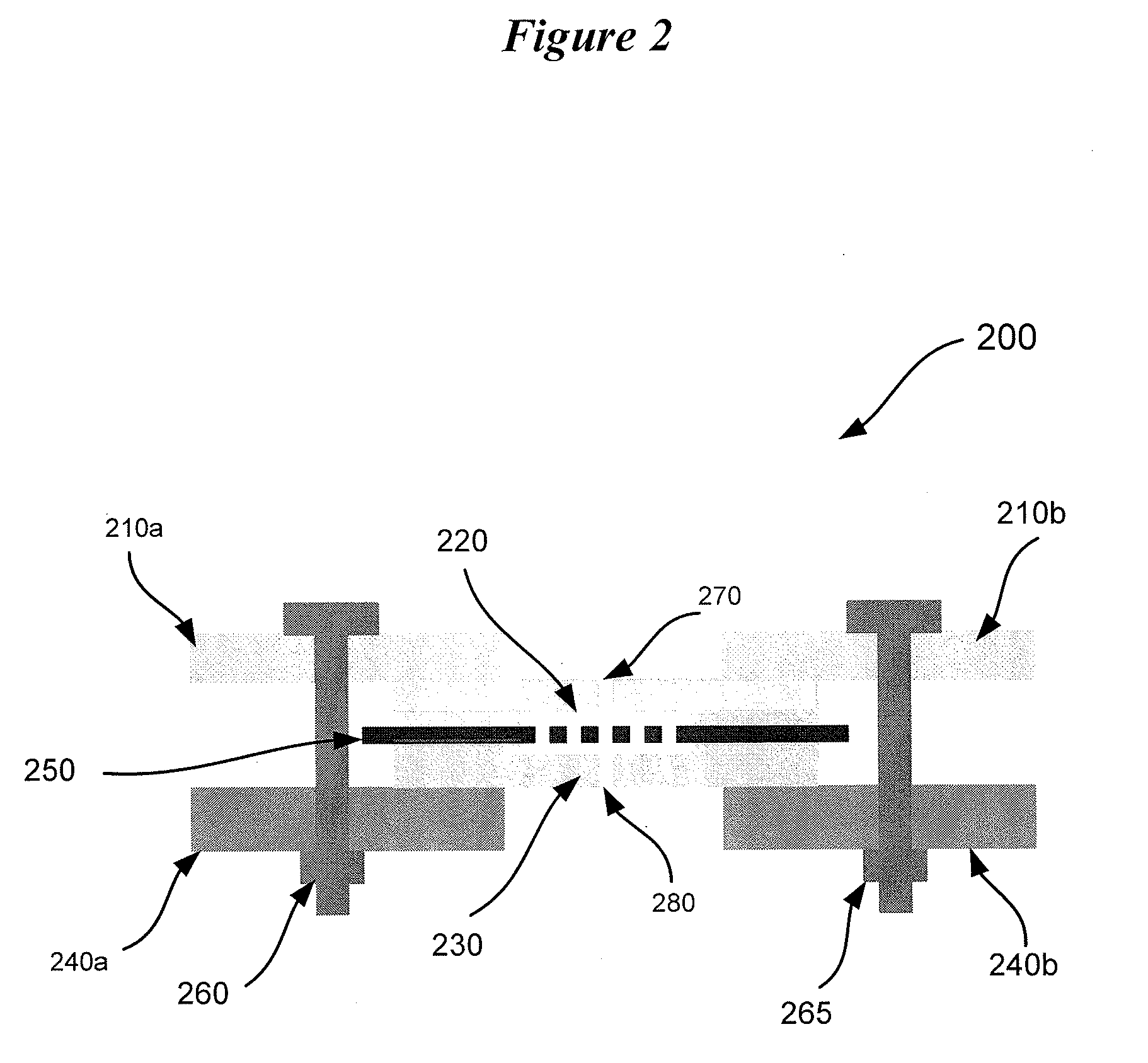

Micropump assembly for a microgas chromatograph and the like

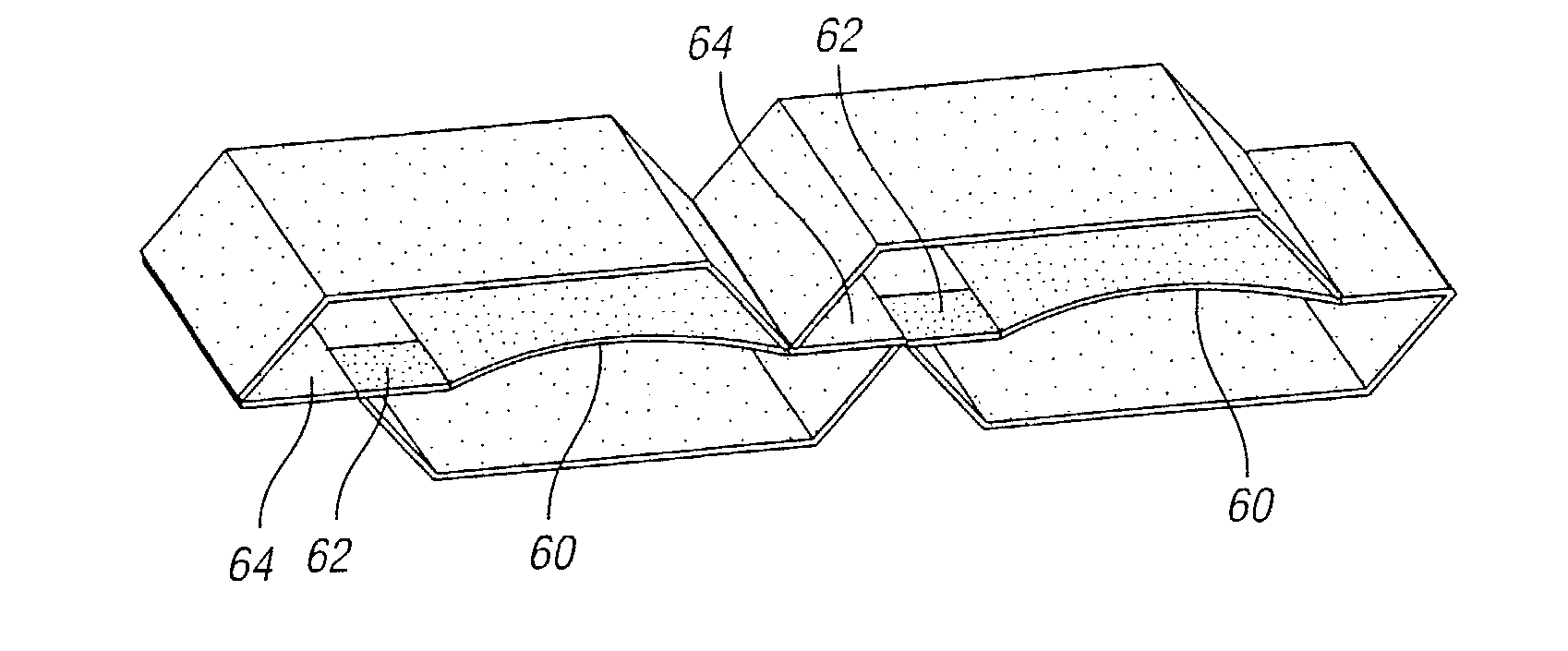

A MEMS-fabricated microvacuum pump assembly is provided. The pump assembly is designed to operate in air and can be easily integrated into MEMS-fabricated microfluidic systems. The pump assembly includes a series of pumping cavities with electrostatically-actuated membranes interconnected by electrostatically-actuated microvalves. A large deflection electrostatic actuator has a curved fixed drive electrode and a flat movable polymer electrode. The curved electrodes are fabricated by buckling the electrode out-of-plane using compressive stress, and the large deflection parallel-plane electrostatic actuators are formed by using the curved electrode. The curved electrode allows the movable electrode to travel over larger distances than is possible using a flat electrode, with lower voltage. The movable electrode is a flat parylene membrane that is placed on top of the curved electrode using a wafer-level transfer and parylene bonding process. Using this approach, large out-of-plane deflection of the parylene membrane is achieved using a voltage smaller than is achievable using flat parallel-plate electrodes.

Owner:RGT UNIV OF MICHIGAN

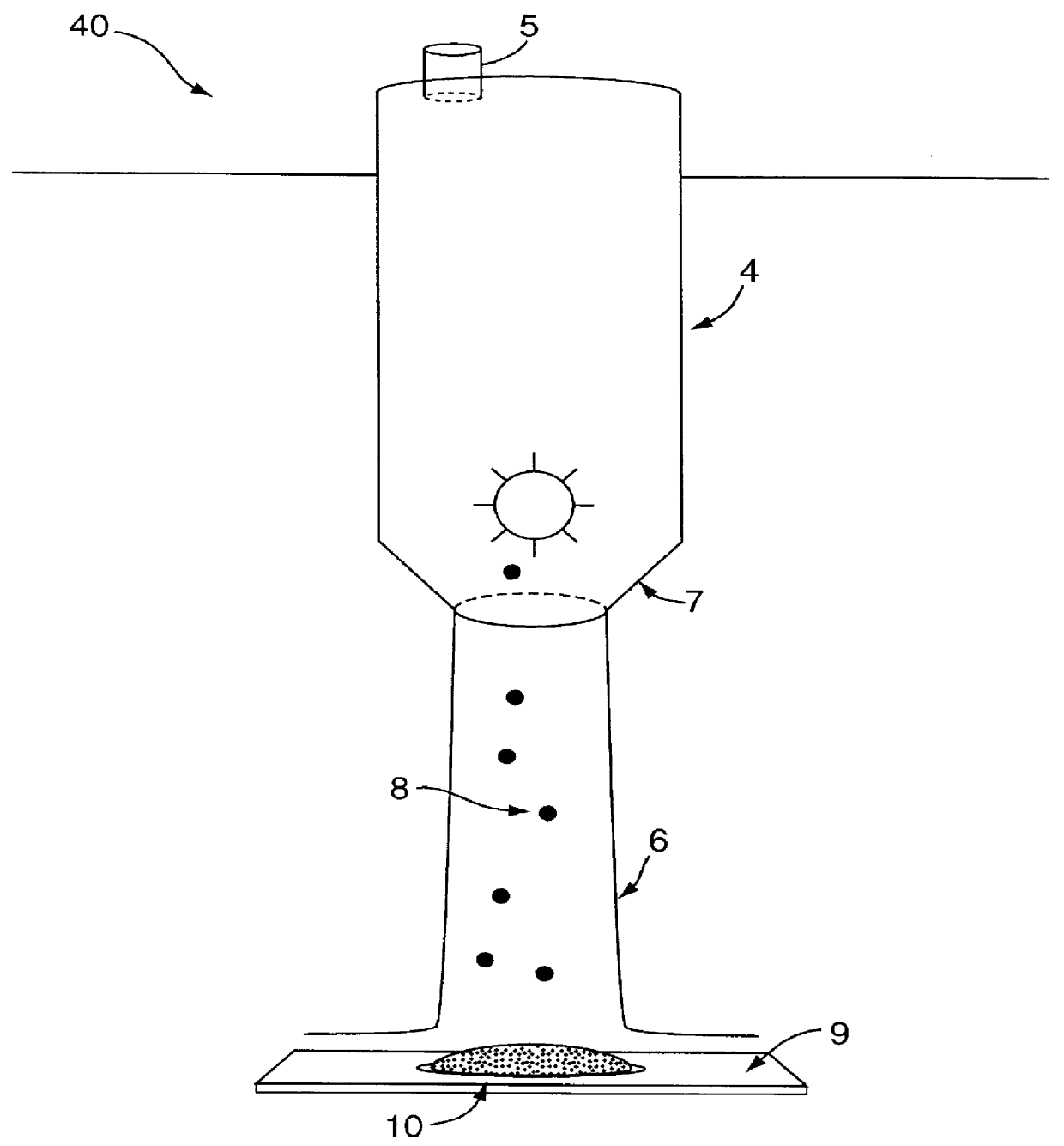

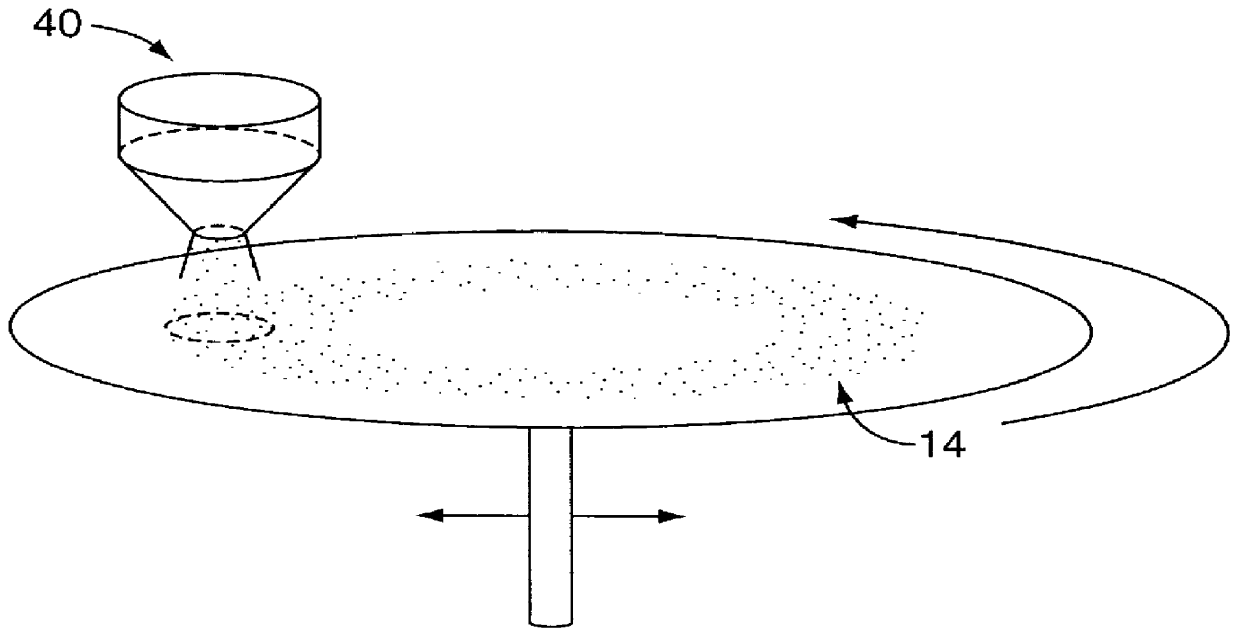

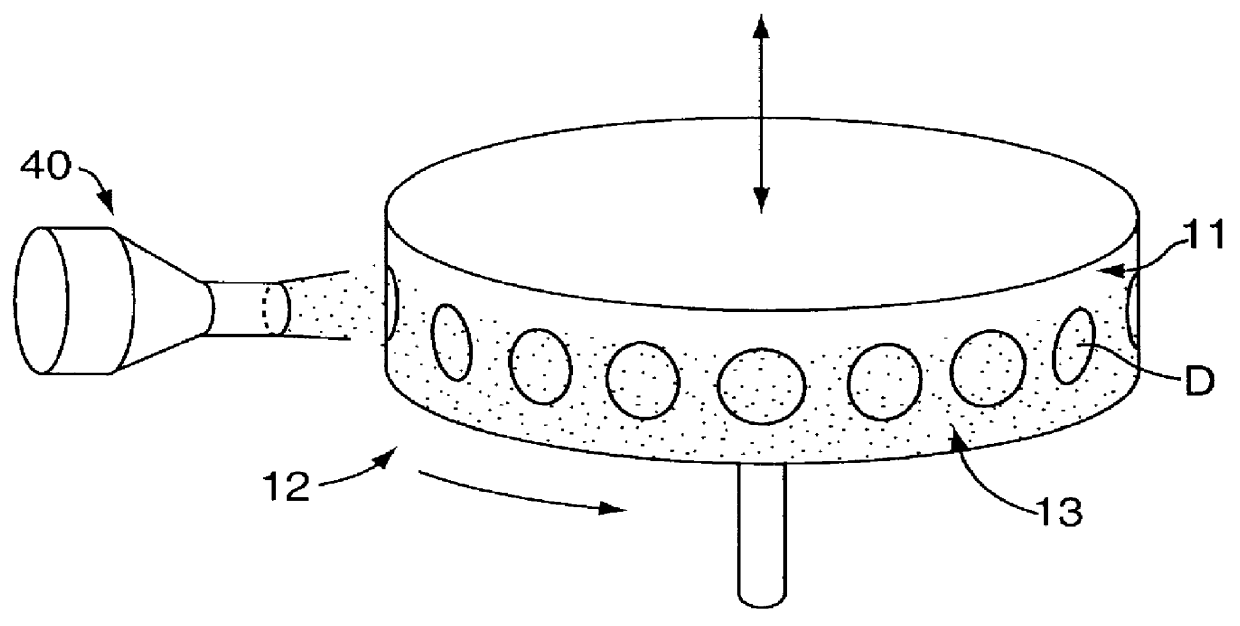

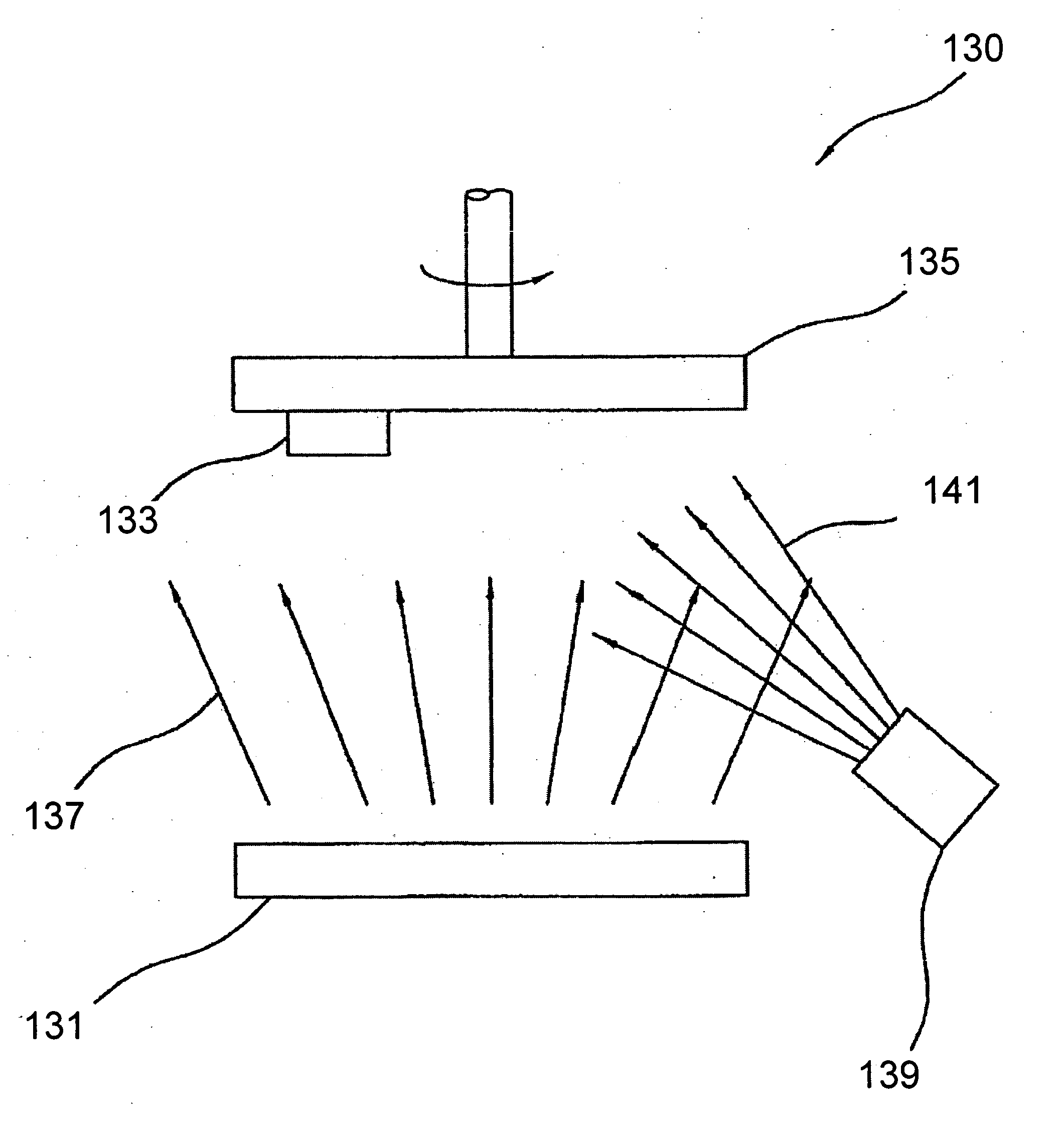

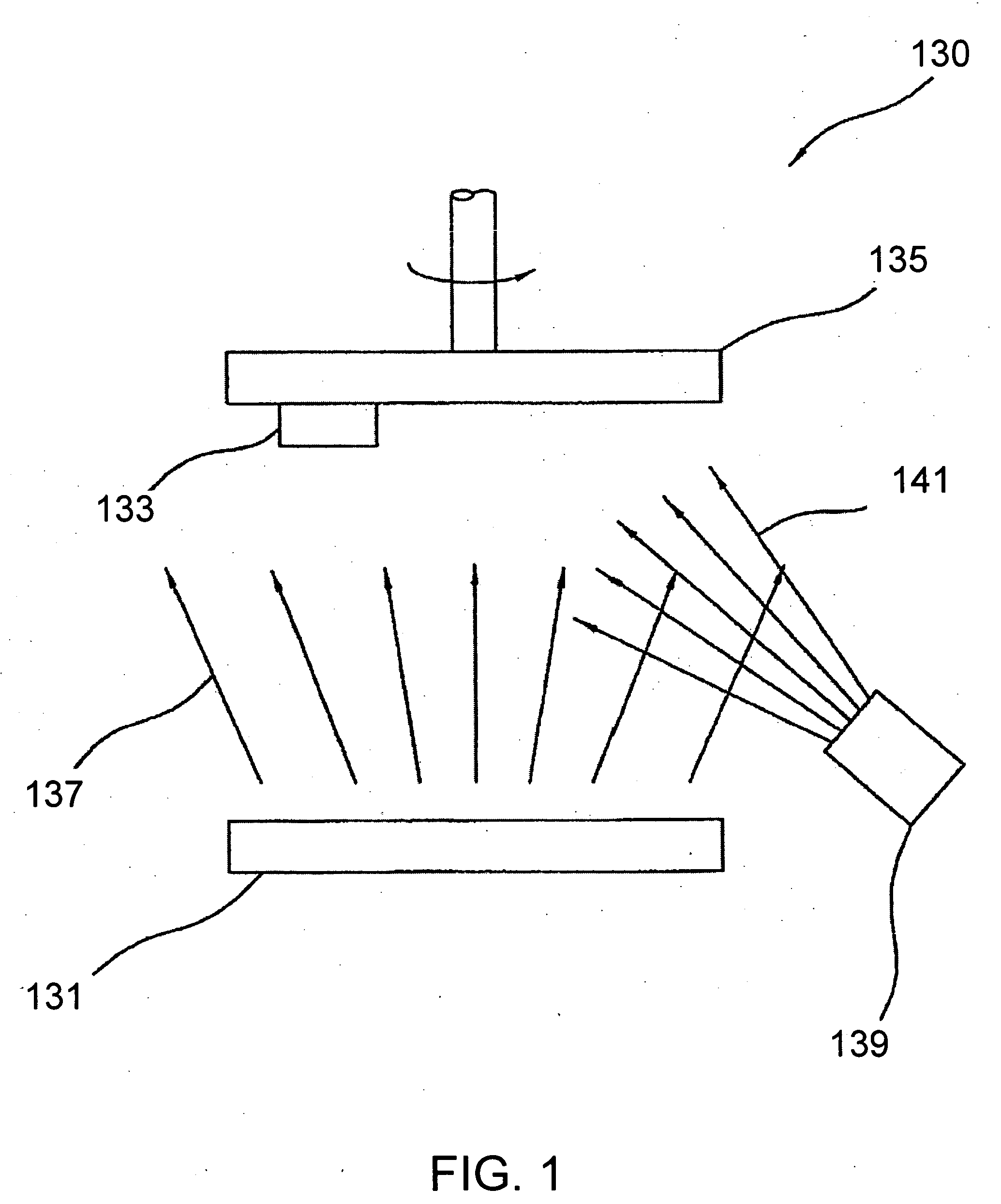

Method for hydrogen atom assisted jet vapor deposition for parylene N and other polymeric thin films

InactiveUS6165554AImprove adhesionIncrease deposition rateLiquid surface applicatorsMolten spray coatingHydrogen atomParylene

A method is presented for the vapor deposition of a material film upon a substrate. The method comprises the use of a Jet Vapor Deposition process with a vaporized polymer gas flowing at supersonic velocity. The vaporized polymer gas consists of a carrier gas and a vaporized polymer, such as Parylene. The vaporized polymer gas impinges upon the substrate through a port and forms the material film.

Owner:JET PROCESS

Coated implantable medical device

InactiveUS7550005B2Prevent degradationIncrease release rateStentsHeart valvesParylenePlasma deposition

A coated implantable medical device 10 includes a structure 12 adapted for introduction into the vascular system, esophagus, trachea, colon, biliary tract, or urinary tract; at least one coating layer 16 posited on one surface of the structure; and at least one layer 18 of a bioactive material posited on at least a portion of the coating layer 16, wherein the coating layer 16 provides for the controlled release of the bioactive material from the coating layer. In addition, at least one porous layer 20 can be posited over the bioactive material layer 18, wherein the porous layer includes a polymer and provides for the controlled release of the bioactive material therethrough. Preferably, the structure 12 is a coronary stent. The porous layer 20 includes a polymer applied preferably by vapor or plasma deposition and provides for a controlled release of the bioactive material. It is particularly preferred that the polymer is a polyamide, parylene or a parylene derivative, which is deposited without solvents, heat or catalysts, and merely by condensation of a monomer vapor.

Owner:COOK MEDICAL TECH LLC

Polymer nems for cell physiology and microfabricated cell positioning system for micro-biocalorimeter

ActiveUS20100024572A1Rapid and parallel implementationShorten the timeBioreactor/fermenter combinationsForce measurement by measuring frquency variationsParyleneThermopile

A microfluidic embedded nanoelectromechanical system (NEMs) force sensor provides an electrical readout. The force sensor contains a deformable member that is integrated with a strain sensor. The strain sensor converts a deformation of the deformable member into an electrical signal. A microfluidic channel encapsulates the force sensor, controls a fluidic environment around the force sensor, and improves the read out. In addition, a microfluidic embedded vacuum insulated biocalorimeter is provided. A calorimeter chamber contains a parylene membrane. Both sides of the chamber are under vacuum during measurement of a sample. A microfluidic cannel (built from parylene) is used to deliver a sample to the chamber. A thermopile, used as a thermometer is located between two layers of parylene.

Owner:CALIFORNIA INST OF TECH

Membrane filter for capturing circulating tumor cells

ActiveUS7846393B2Highly efficient in capturingEffective membraneBioreactor/fermenter combinationsBiological substance pretreatmentsParyleneGeometric design

The present invention provides a parylene-based membrane filter device for capturing of circulating tumor cells (CTC). The membrane filter has an array of holes having a predetermined geometric design with precisely controlled size, shape and density. In one aspect, the device has a stack of substantially parallel membrane filters with uniformly-spaced and / or monodispersed holes.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

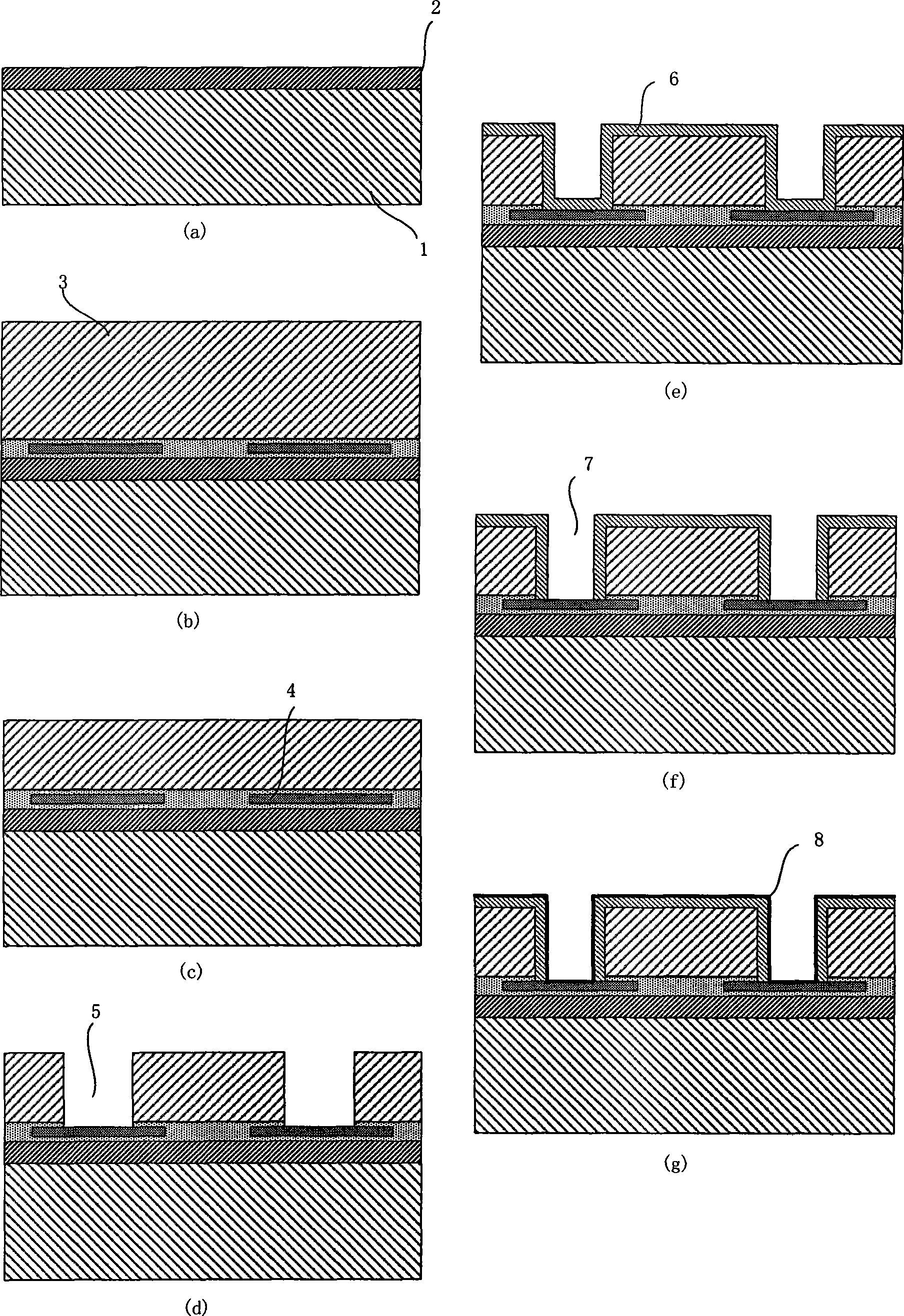

Production method for through wafer interconnection construction

ActiveCN101483149AMitigate Thermal MismatchThe process steps are simpleSemiconductor/solid-state device manufacturingParyleneParasitic capacitance

The invention discloses a through wafer interconnect structure preparation method comprising: 1. bonding a bonding silicon device wafer on a silicon wafer substrate; 2. thinning the silicon device wafer, etching the silicon device and forming a blind hole; 3. coating a layer of pattern dielectric material (such as poly-p-xylene) on the silicon device wafer; 4. etching the pattern dielectric substance layer, etching the dielectric material at the bottom of the blind hole, keeping a blind hole side wall; forming a dielectric substance hole on the substrate and enabling the dielectric substance hole and the blind hole coaxial; 5. depositing a layer of conductive material on the dielectric substance hole as a conductive layer and forming a conductive hole; 6. re-depositing a layer of pattern dielectric substance on the conductive layer; 7. forming a solder micro-convex point on the conductive layer. The invention simplifies the process steps, reduces the process time and the cost; depresses a parasitic capacitance, improves a interconnect electrical behavior, suits for the RF three-dimensional interconnection structure; releases the thermal mismatch between the conductive material and the silicon and greatly reduces the thermal mechanical stress.

Owner:HUAZHONG UNIV OF SCI & TECH

Implantable mechanical pressure sensor and method of manufacturing the same

InactiveUS20050268722A1Fluid pressure measurement using elastically-deformable gaugesCatheterIn planeParylene

A biocompatible, mechanical, micromachined pressure sensor and methods of manufacturing such a pressure sensor are provided. The pressure sensor of the current invention comprises a high-aspect-ratio curved-tube structure fabricated through a one-layer parylene process. The pressure sensor of the current invention requires zero power consumption and indicates the pressure variation by changes of the in situ in-plane motion of the sensor, which can be gauged externally by a direct and convenient optical observation. In one embodiment, the pressure sensor of the current invention has been shown to work as an IOP sensor for eye implantation where the intraocular in-plane motion of the sensor can be recorded from outside of the eye, such that the intraocular pressure in glaucoma patients can be constantly monitored.

Owner:CALIFORNIA INST OF TECH

Uses of Parylene Membrane Filters

ActiveUS20110111412A1Improve efficiencyEffective meanMembranesMicrobiological testing/measurementParyleneFigure of merit

The invention provides parylene membrane filters, filter devices and methods of making them and using them in the mechanical separation of cells and particles by size. The provision of parylene membrane filters with high figures of merit and finely controlled hole sizes allows the separation of cells and particles in a variety of biological and other fluids according to sizes.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

Micro-miniature implantable coated device

ActiveUS20060173497A1Internal electrodesVacuum evaporation coatingParyleneIon beam-assisted deposition

An implantable micro-miniature device is disclosed. The device comprises a thin hermetic insulating coating and at least one thin polymer or metal secondary coating over the hermetic insulating layer in order to protect the insulating layer from the erosive action of body fluids or the like. In one embodiment the insulating layer is ion beam assisted deposited (IBAD) alumina and the secondary coating is a parylene polymer. The device may be a small electronic device such as a silicon integrated circuit chip. The thickness of the insulating layer may be ten microns or less and the thickness of the secondary layer may be between about 0.1 and about 15 microns.

Owner:SECOND SIGHT MEDICAL PRODS +1

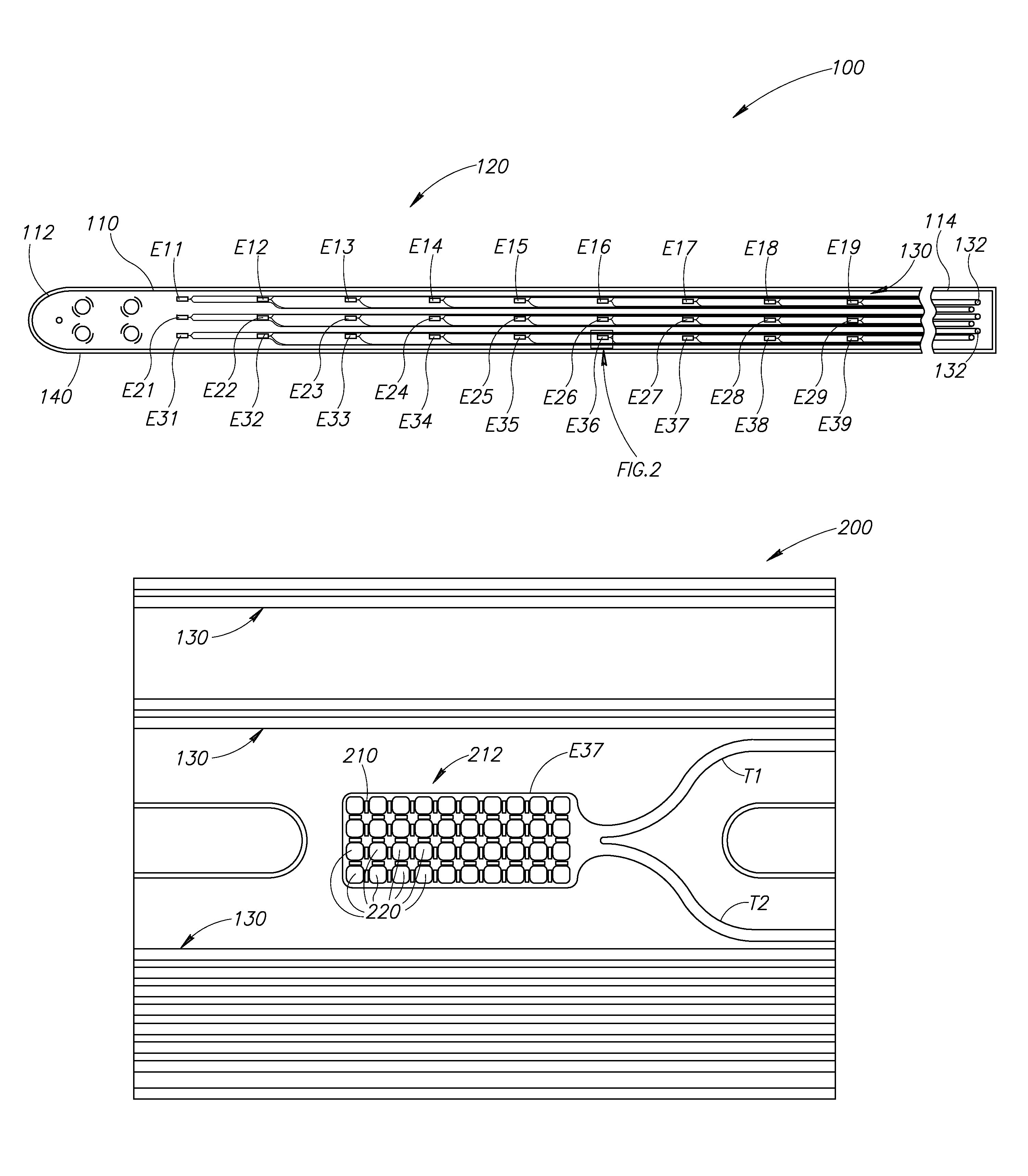

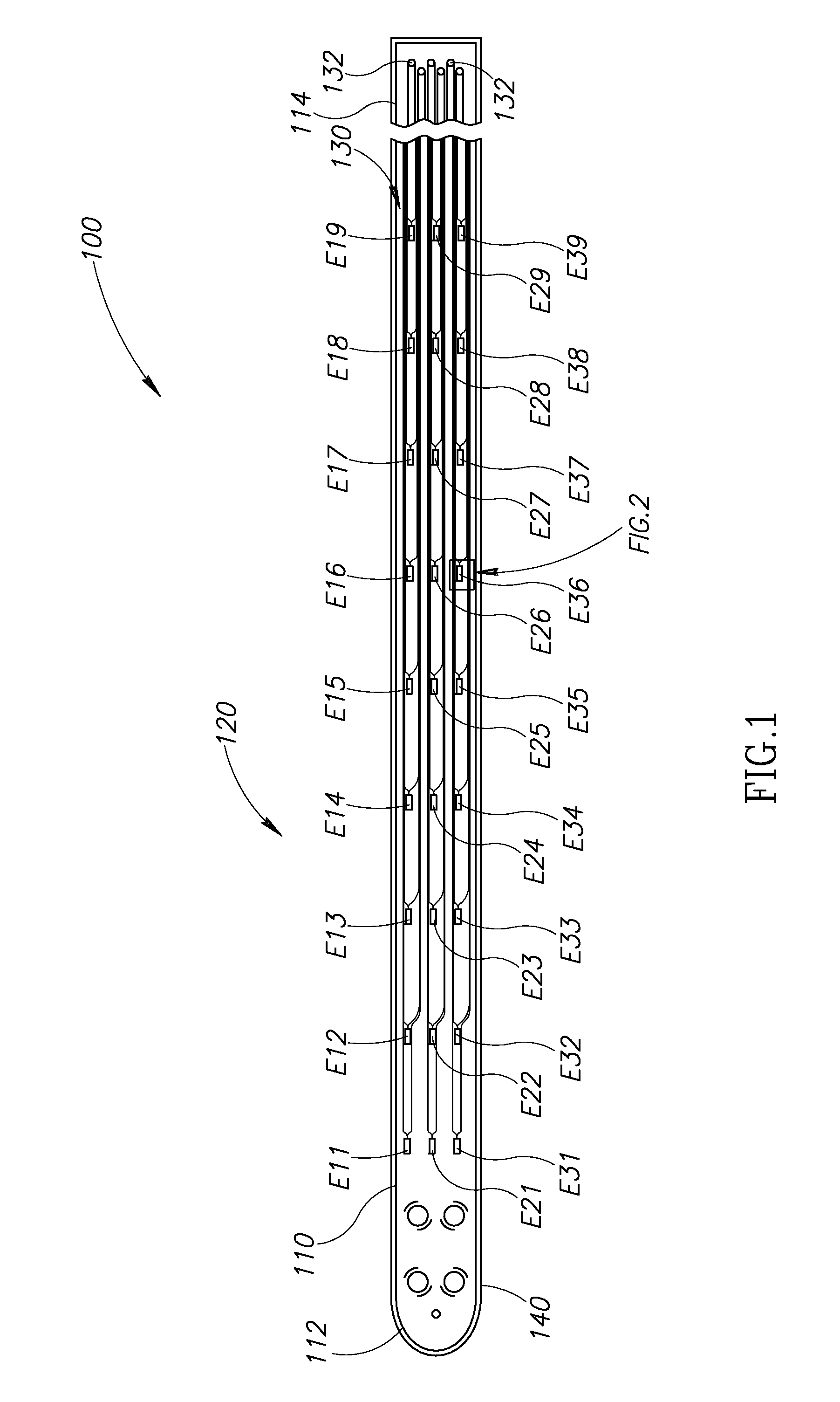

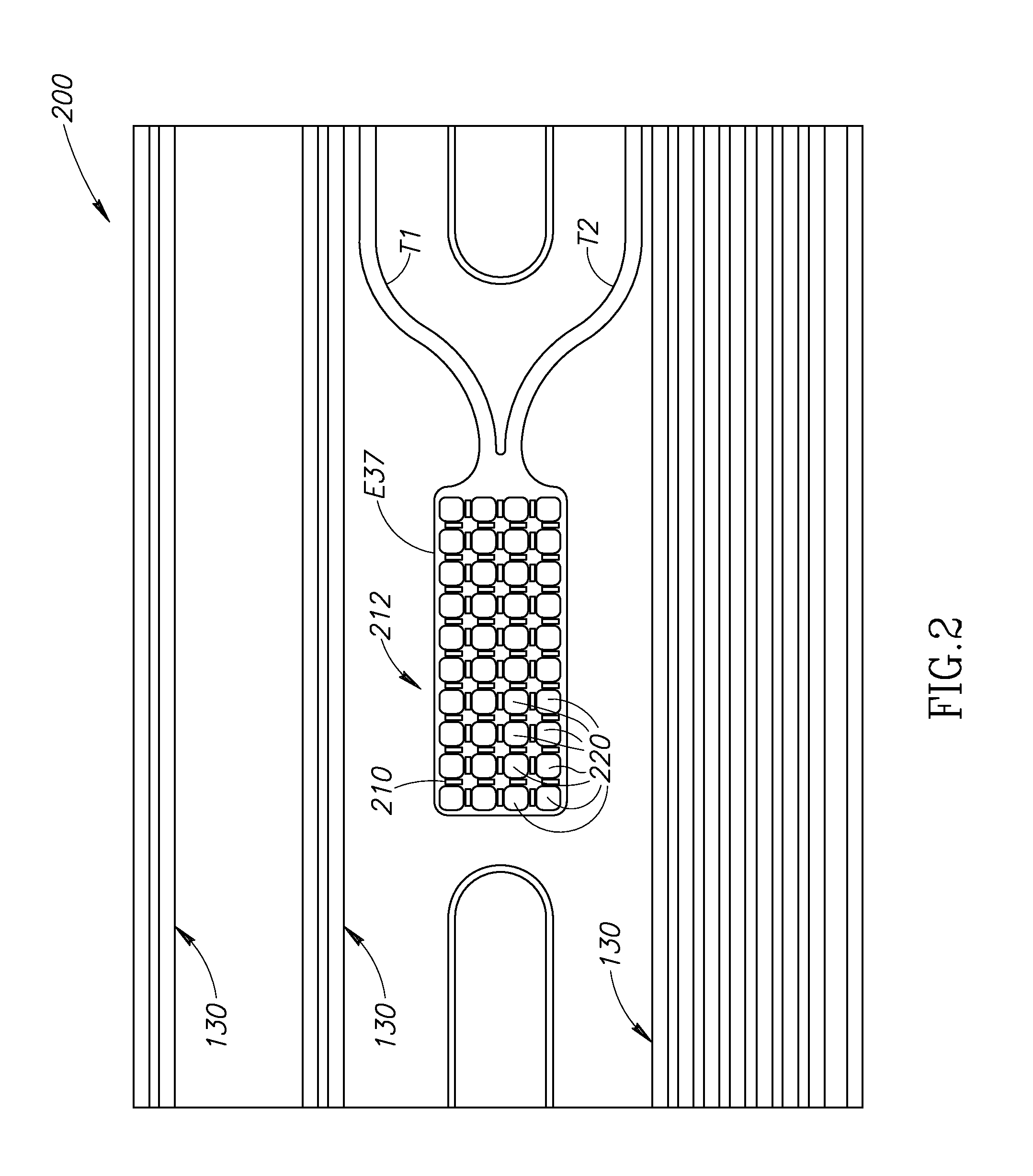

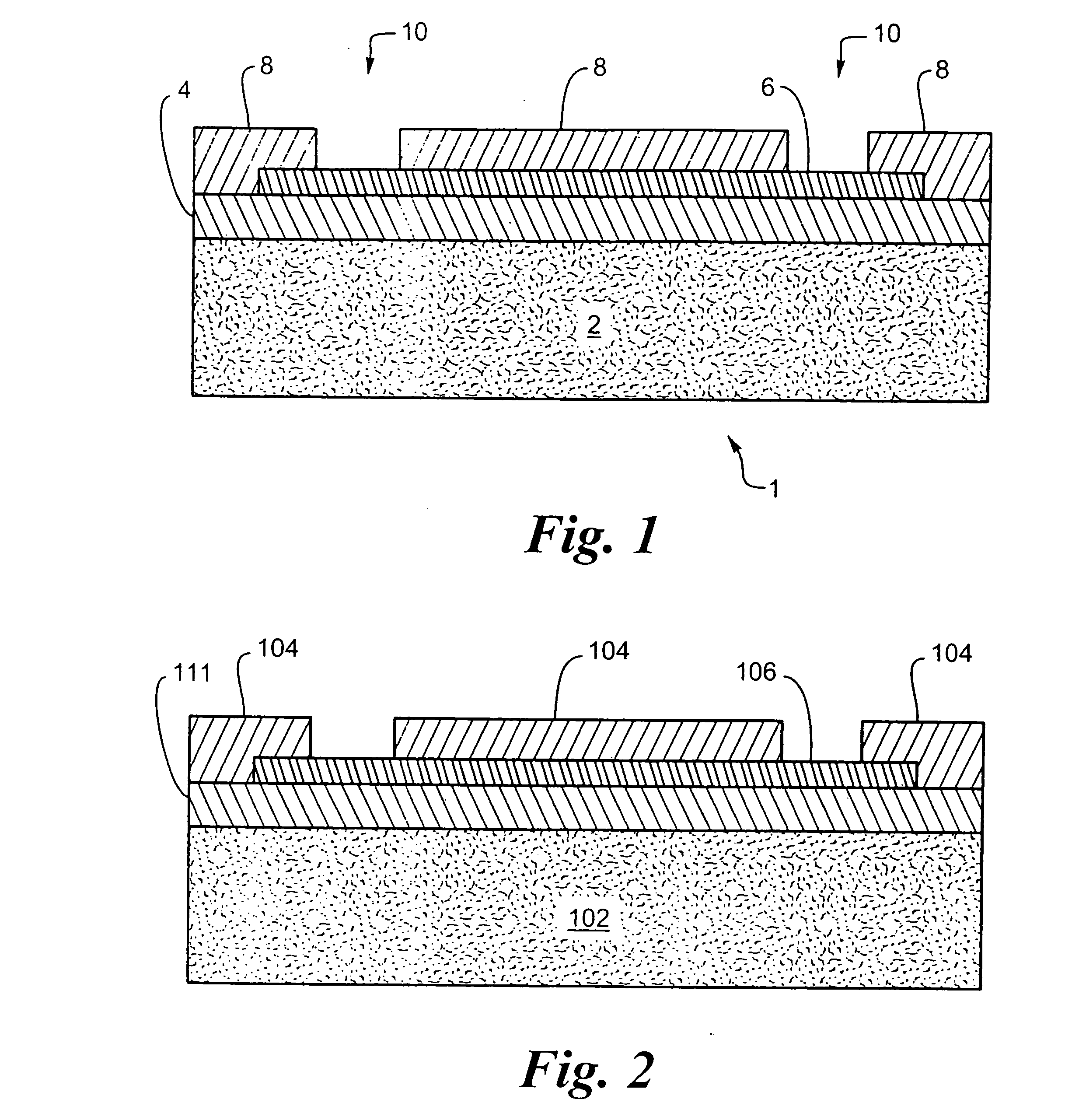

Parylene-based microelectrode array implant for spinal cord stimulation

ActiveUS8805542B2Spinal electrodesConductive layers on insulating-supportsImplantable ElectrodesParylene

An implantable electrode array assembly configured to apply electrical stimulation to the spinal cord. A substantially electrically nonconductive layer of the device has a first portion positionable alongside the spinal cord that includes a plurality of first openings and a second portion that includes a plurality of second openings. Electrodes and traces are positioned inside a peripheral portion of a body portion of the device and alongside the layer. At least one of the first openings is adjacent each of the electrodes to provide a pathway through which the electrode may provide electrical stimulation to the spinal cord. At least one of the second openings is adjacent each of the traces to provide a pathway through which the trace may receive electrical stimulation. At least one trace is connected to each electrode and configured to conduct electrical stimulation received by the trace(s) to the electrode.

Owner:RGT UNIV OF CALIFORNIA +2

Insulated implantable electrical circuit

The invention is directed to an implantable insulated electrical circuit that utilizes polyparaxylylene, preferably as Parylene, a known polymer that has excellent living tissue implant characteristics, to provide for chronic implantation of conductive electrical devices, such as stimulators and sensors. The device is thin, flexible, electrically insulated, and stable after long exposure to living tissue. Layers of Parylene may be combined with layers of a polymer, such as polyimide, to yield greater design flexibility in the circuit. Multiple electrical conduction layers may be stacked in the circuit to increase packing density.

Owner:SECOND SIGHT MEDICAL PRODS

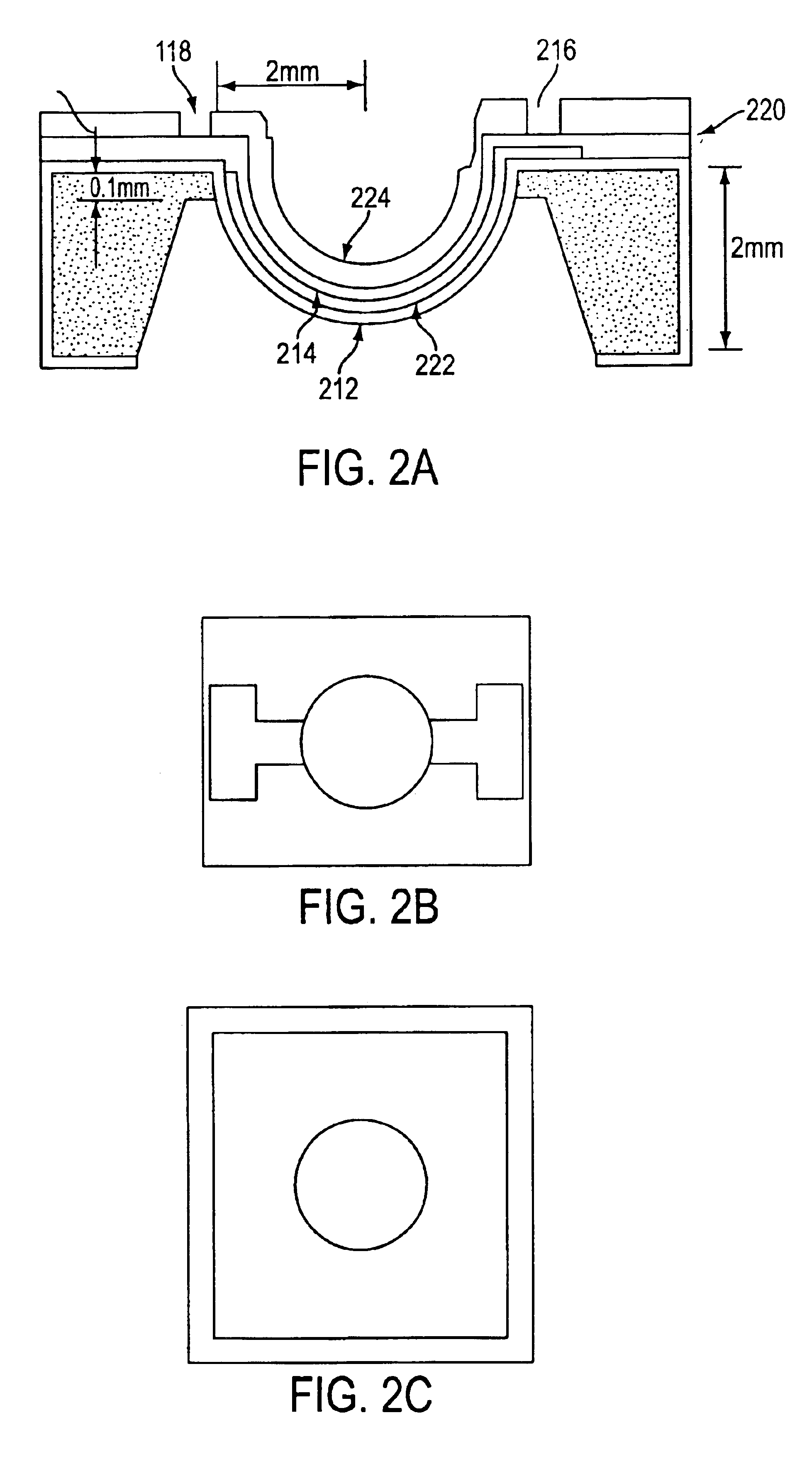

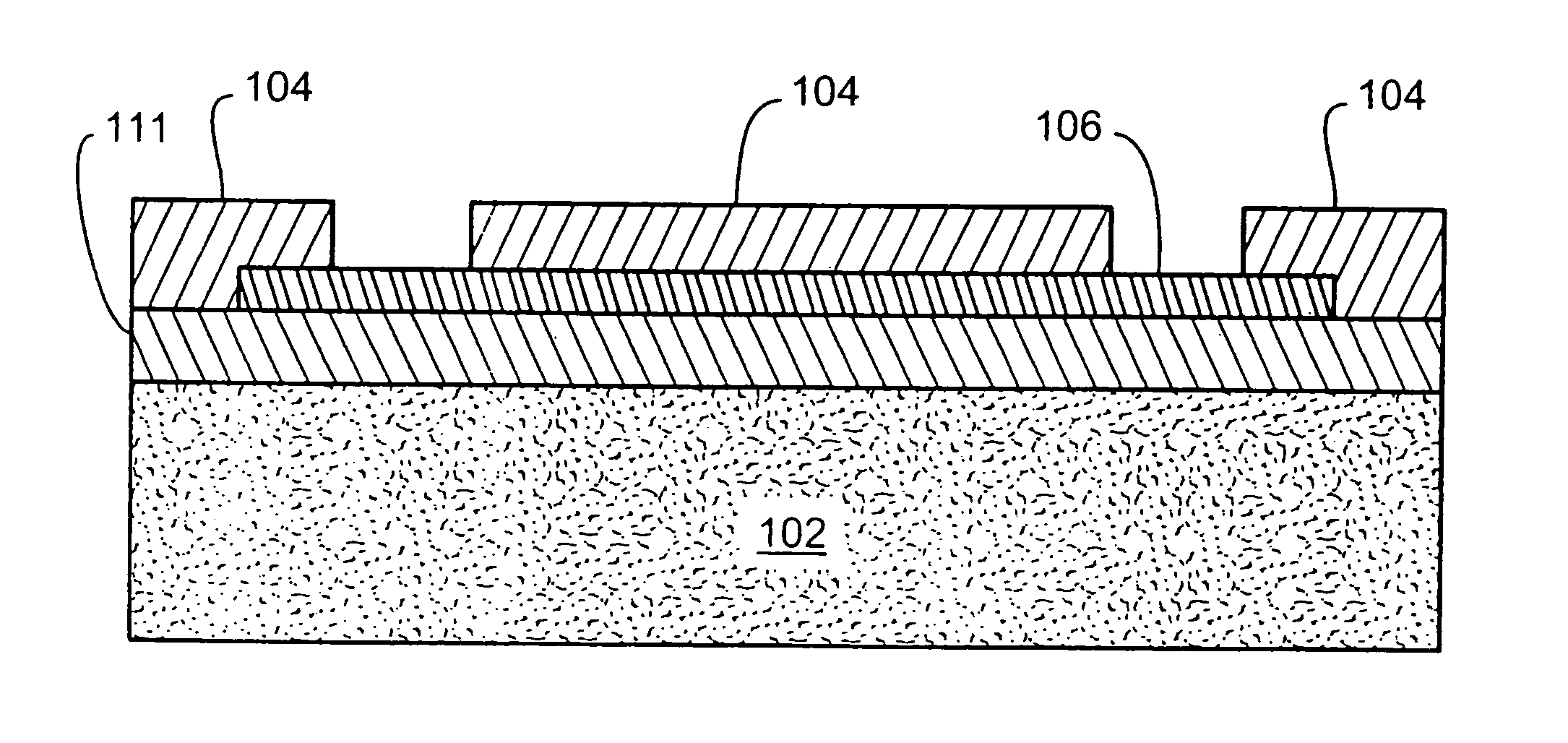

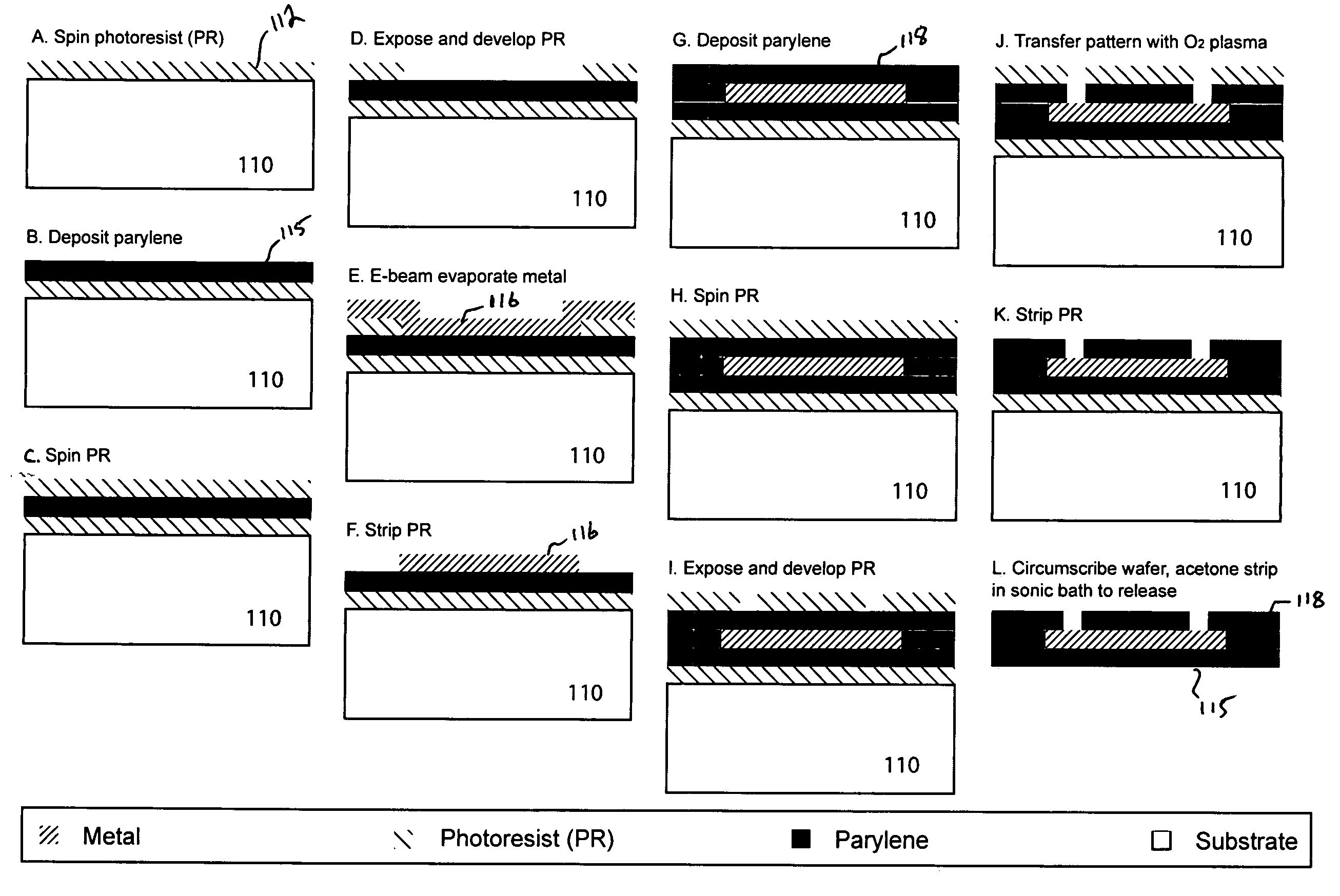

Parylene-based flexible multi-electrode arrays for neuronal stimulation and recording and methods for manufacturing the same

ActiveUS7326649B2Environment can be compatibleSemiconductor/solid-state device detailsSolid-state devicesNeuronal stimulationParylene

Method for manufacturing a parylene-based electrode array that includes an underlying parylene layer, one or more patterned electrode layers comprising a conductive material such as a metal, and one or more overlying parylene layers. The overlying parylene is etched away or otherwise processed to expose the electrodes where stimulation or recording is to occur. All other conductive material in the device is occluded from the environment by the two layers of parylene surrounding it.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com