Vapor deposition process for producing a stent-graft and a stent-graft produced therefrom

a technology of stent-graft and vapor deposition process, which is applied in the direction of prosthesis, blood vessels, catheters, etc., can solve the problems of poor blood flow pattern, prone to kinking of expanded polytetrafluoroethylene grafts, and prone to stent-graft endoprosthesis leakage therethrough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

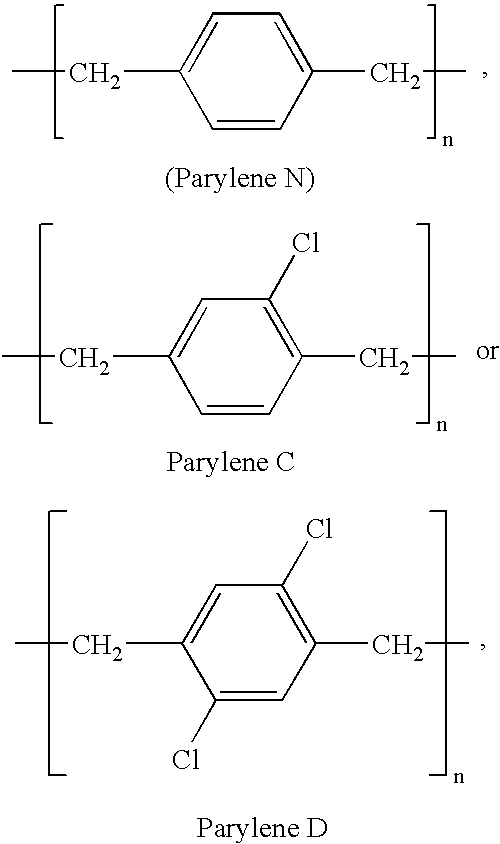

[0059] A tubular graft with a wall thick of about one half to one thousandth of an inch, or about 10 to 25 microns, was formed by vacuum vapor of parylene C. A dimer of di-chloro-di-p-xylylene, which is commercially available from Specialty Coating Systems, Inc., IN, was placed into a vaporization chamber within a vacuum deposition system. The pressure of the system was reduced to about 0.1 torr by means of a mechanical vacuum pump.

[0060] The dimer vaporized at about xylylene, 150.degree. C. and at about 1.0 torr. The vaporized dimer entered a pyrolysis chamber. The pyrolysis chamber was at about 680.degree. C. and about 0.5 torr. The vaporized dimer was pyrolyzed into diradicals. The diradicals entered a rotating deposition chamber having a mandrel. The deposition chamber was operated at about 25.degree. C. and about 0.1 torr. The diradicals were directed towards the outer cylindrical surfaces of the mandrel. The outer cylindrical surface of the mandrel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com