Method for producing paraxylene comprising an adsorption step and two isomerization steps

一种对二甲苯、异构化的技术,应用在异构化制烃、吸附纯化/分离、化学仪器和方法等方向,能够解决二甲苯纯度二甲苯收率限制等问题,达到成本低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0116] Example 2 has the same loop, but with a capacity increase of 30% according to the invention.

Embodiment 1

[0117] Embodiment 1 (comparison)

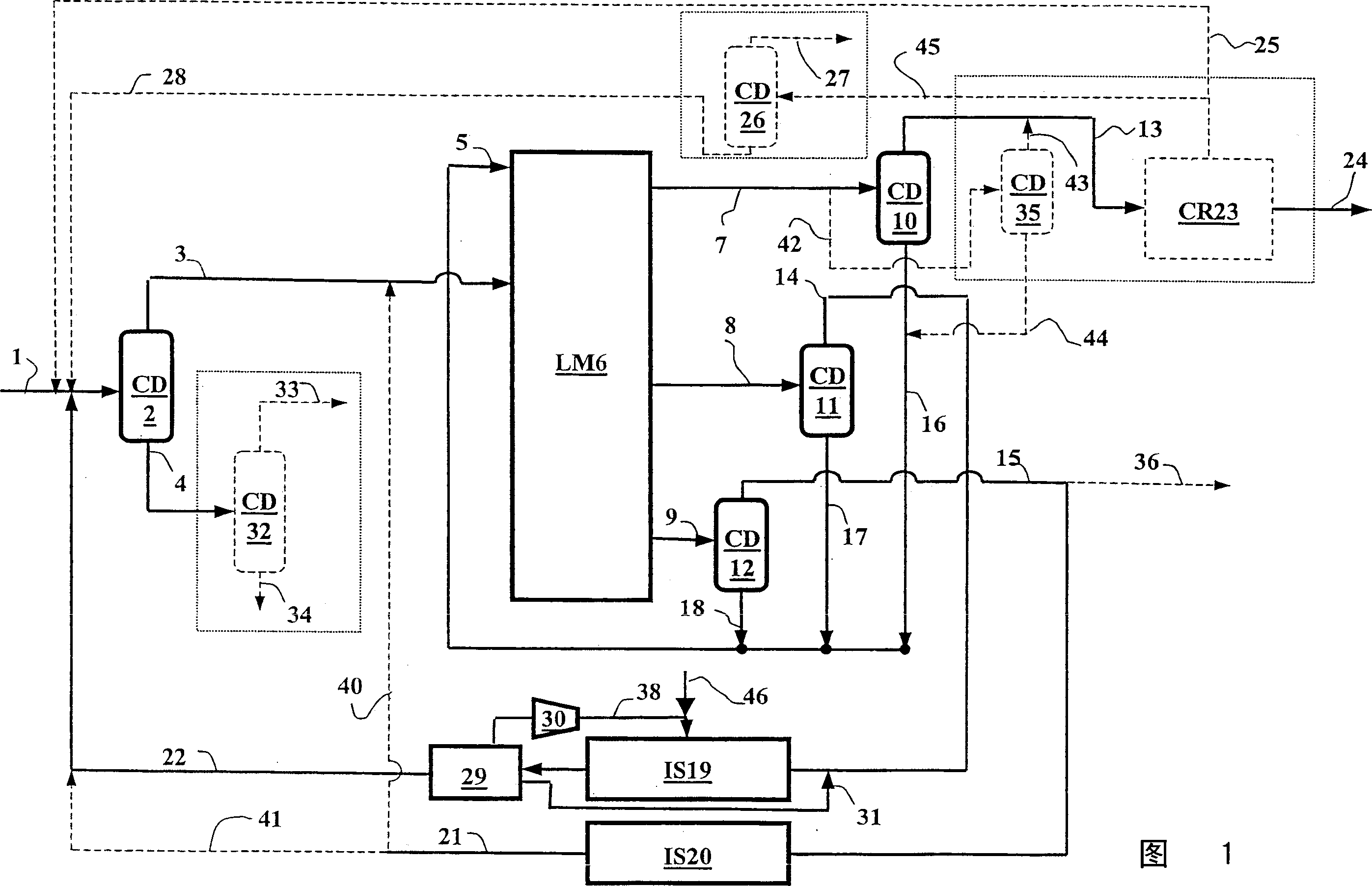

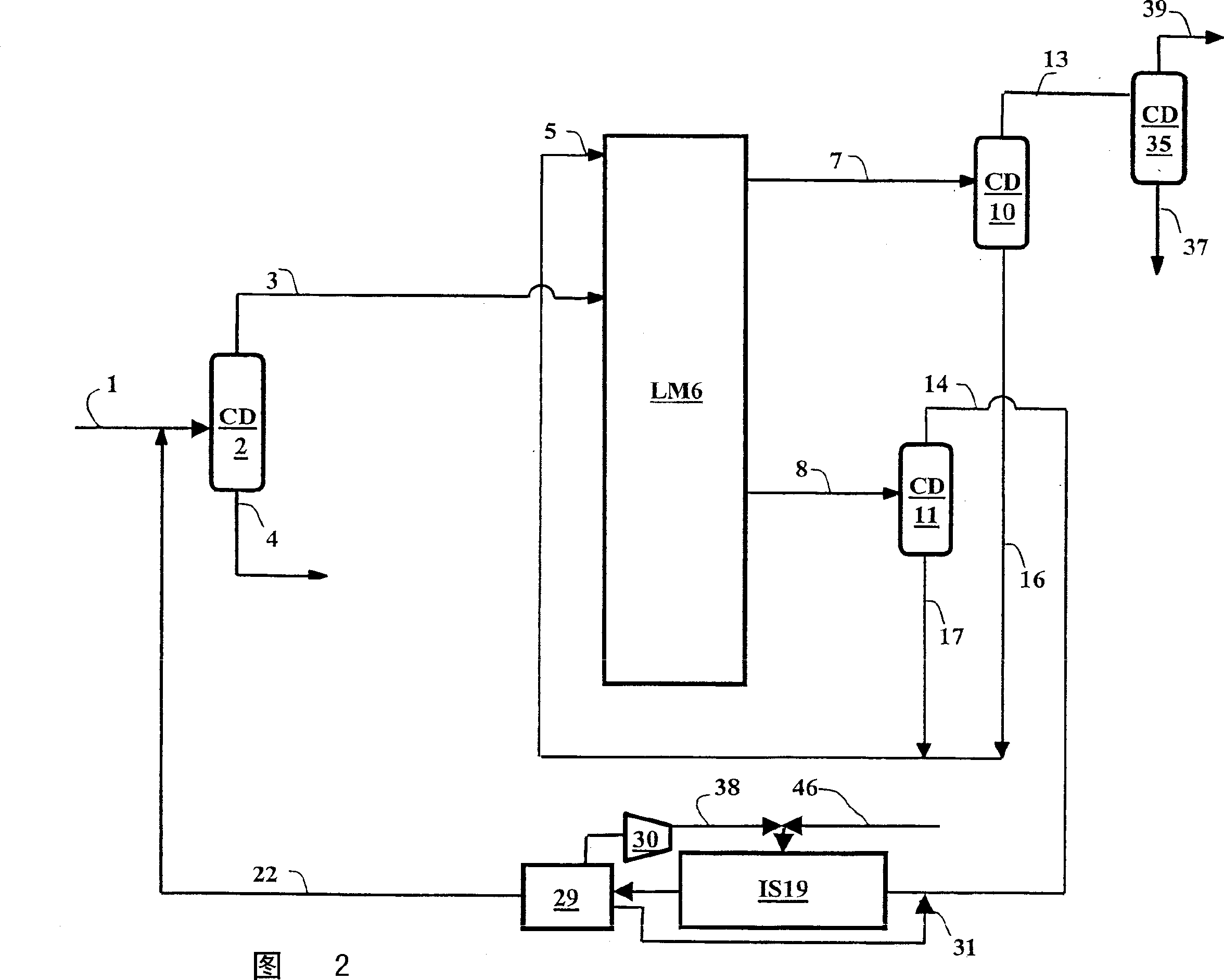

[0118] This example illustrates the prior art and describes the aromatic compound loop shown in Figure 2, which consists of:

[0119] xylene column (CD2) for extracting C9 and C10 aromatics (stream 4) and feeding the stream (3) consisting essentially of C8 aromatics to the adsorption unit (LM6);

[0120] Simulated moving bed adsorption unit (LM6) with 4 zones, from which extract (7) and single raffinate (8) are discharged;

[0121] an isomerization unit (IS19), in which a part (14) of the raffinate (8) after removal of the desorbent by the distillation column (CD11) is fed;

[0122] • A p-xylene purification column (CD35) located downstream of the distillation column (CD10). Para-xylene (stream 37) with a purity of more than 99.7% is withdrawn from the bottom of the column (CD35).

[0123] The units used for flow rate are kilotons per year (kt / yr).

[0124] Feed (1) to the aromatics loop was obtained from reforming with a flow rate of 460...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| rate of recovery | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com