Patents

Literature

1505 results about "P-Xylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

P-Xylene (para-xylene) is an aromatic hydrocarbon. It is one of the three isomers of dimethylbenzene known collectively as xylenes. The p- stands for para-, indicating that the two methyl groups in p-xylene occupy the diametrically opposite substituent positions 1 and 4. It is in the positions of the two methyl groups, their arene substitution pattern, that it differs from the other isomers, o-xylene and m-xylene. All have the same chemical formula C₆H₄(CH₃)₂. All xylene isomers are colorless and highly flammable. The odor threshold of p-xylene is 0.62 parts per million (ppm).

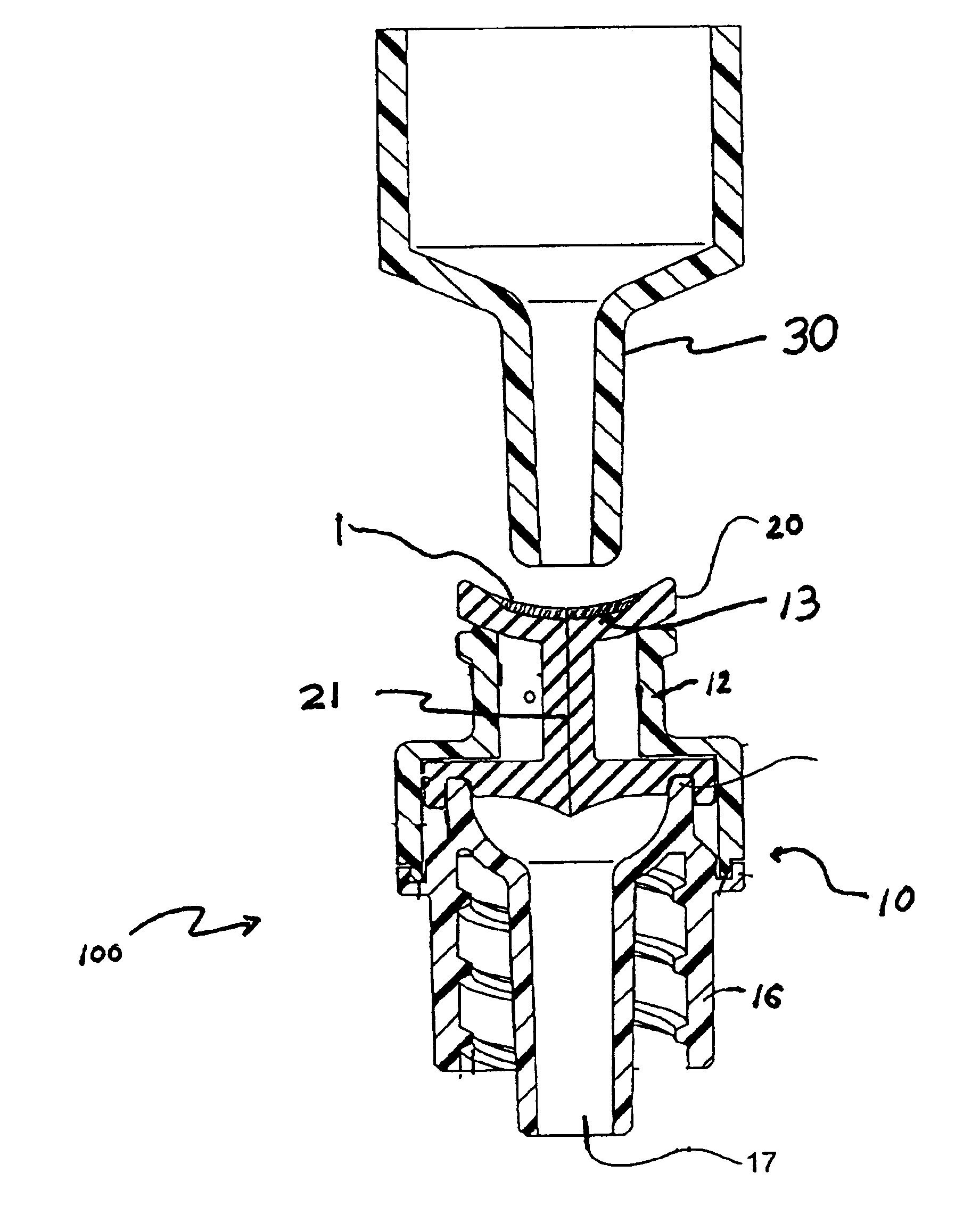

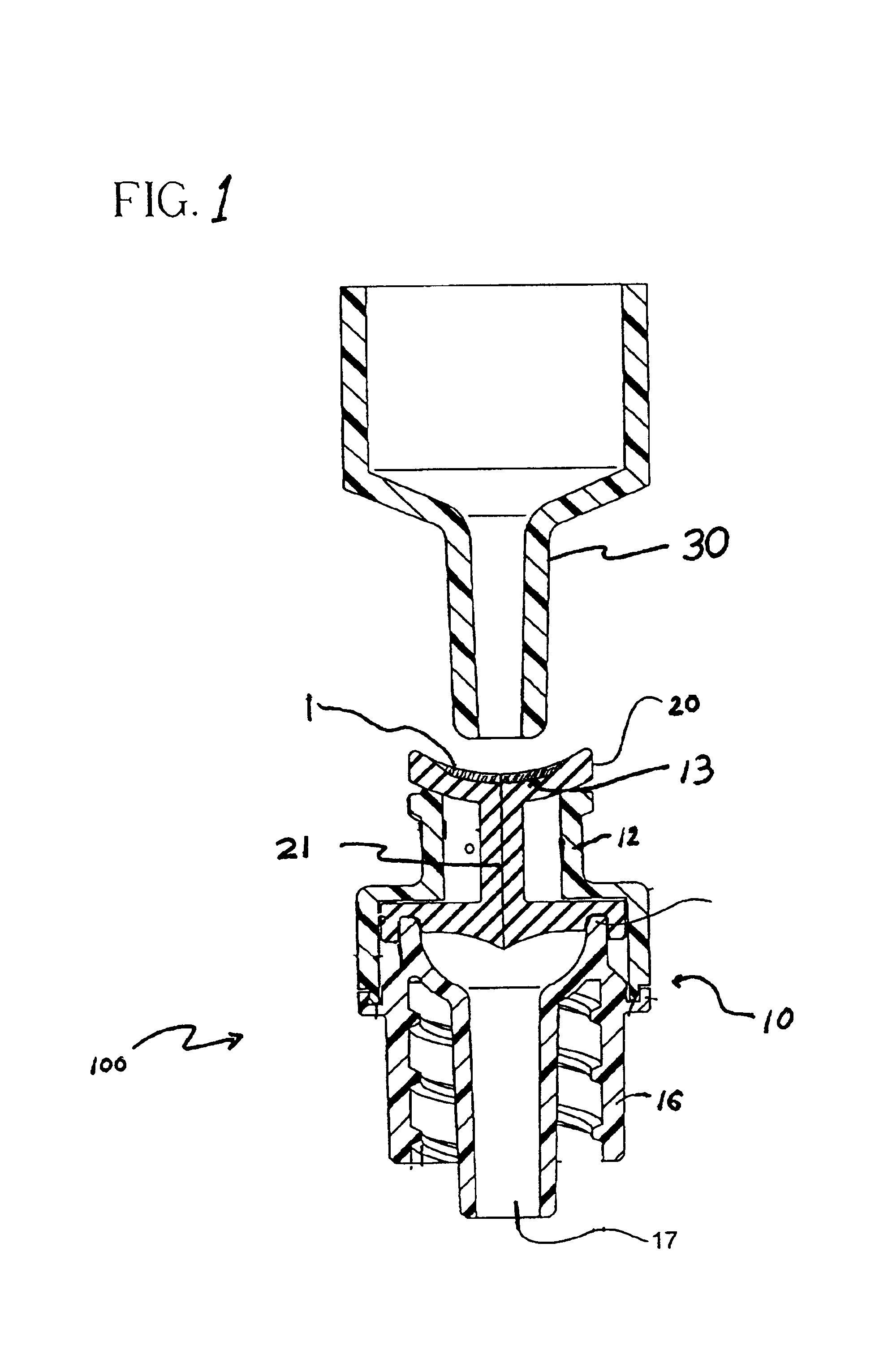

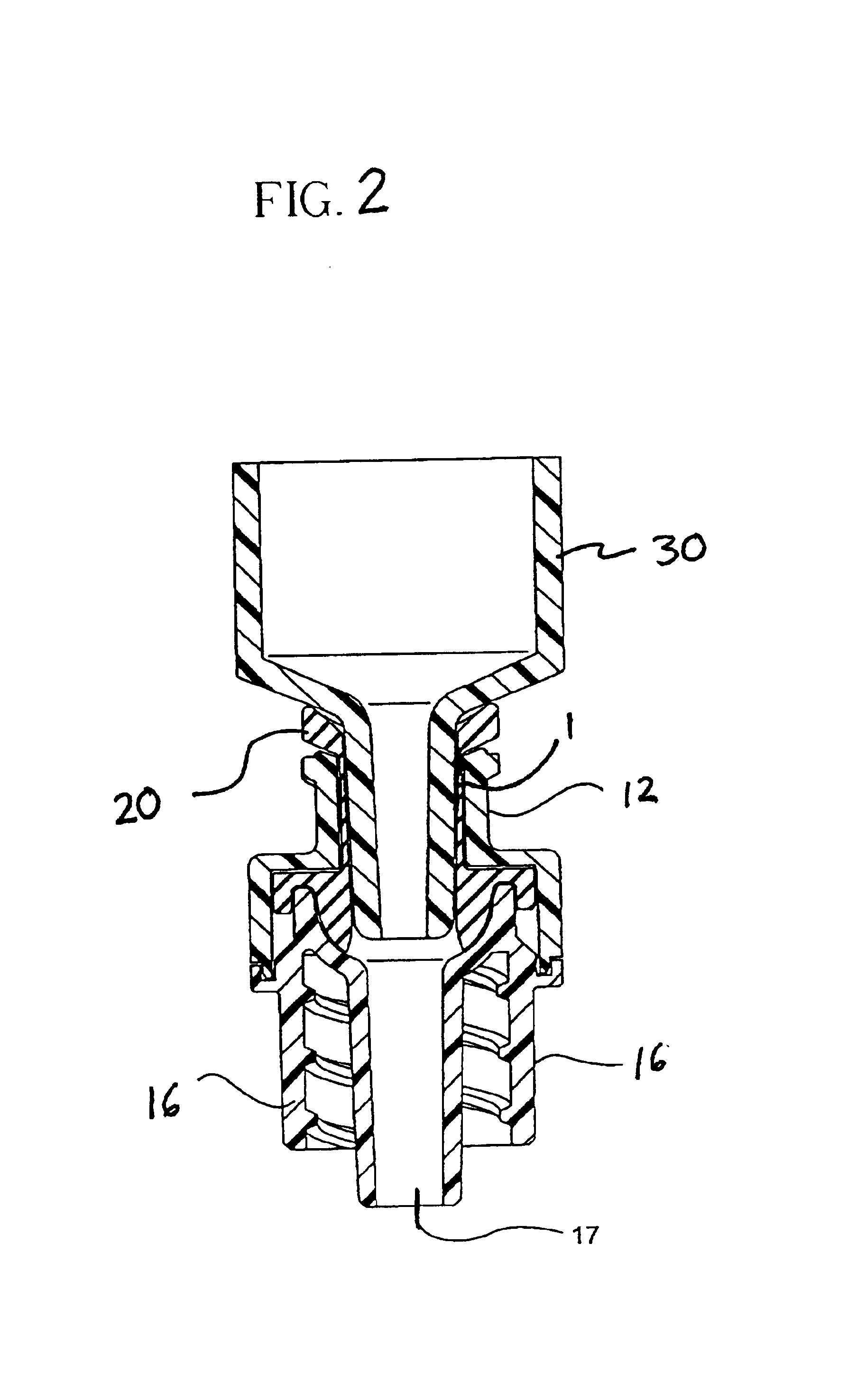

Lubricious coating for a medical device

InactiveUS6866656B2Reduce frictionNot degradedFilm/foil adhesivesSynthetic resin layered productsElastomerChemical Linkage

A lubrication system is disclosed which minimizes friction and that is useful for application on the surface of a flexible portion of a medical device. Such a lubrication system includes a lubricant that is able to move when the flexible portion of the medical device flexes and is biocompatible and is not degraded by the application of alcohol or other conventional medical sterilizing and cleaning agents. The lubricant is bonded to the surface of the flexible portion of the medical device. The lubrication system may be used on an elastomeric septum, such as a silicone rubber elastomer. The lubricant coating may be any type of coating that can be chemically bonded to the elastomer, such as di-paraxylene, poly-(p-xylene), polytetrafluoroethylene, or polyvinylpyrrolidone.

Owner:BECTON DICKINSON & CO

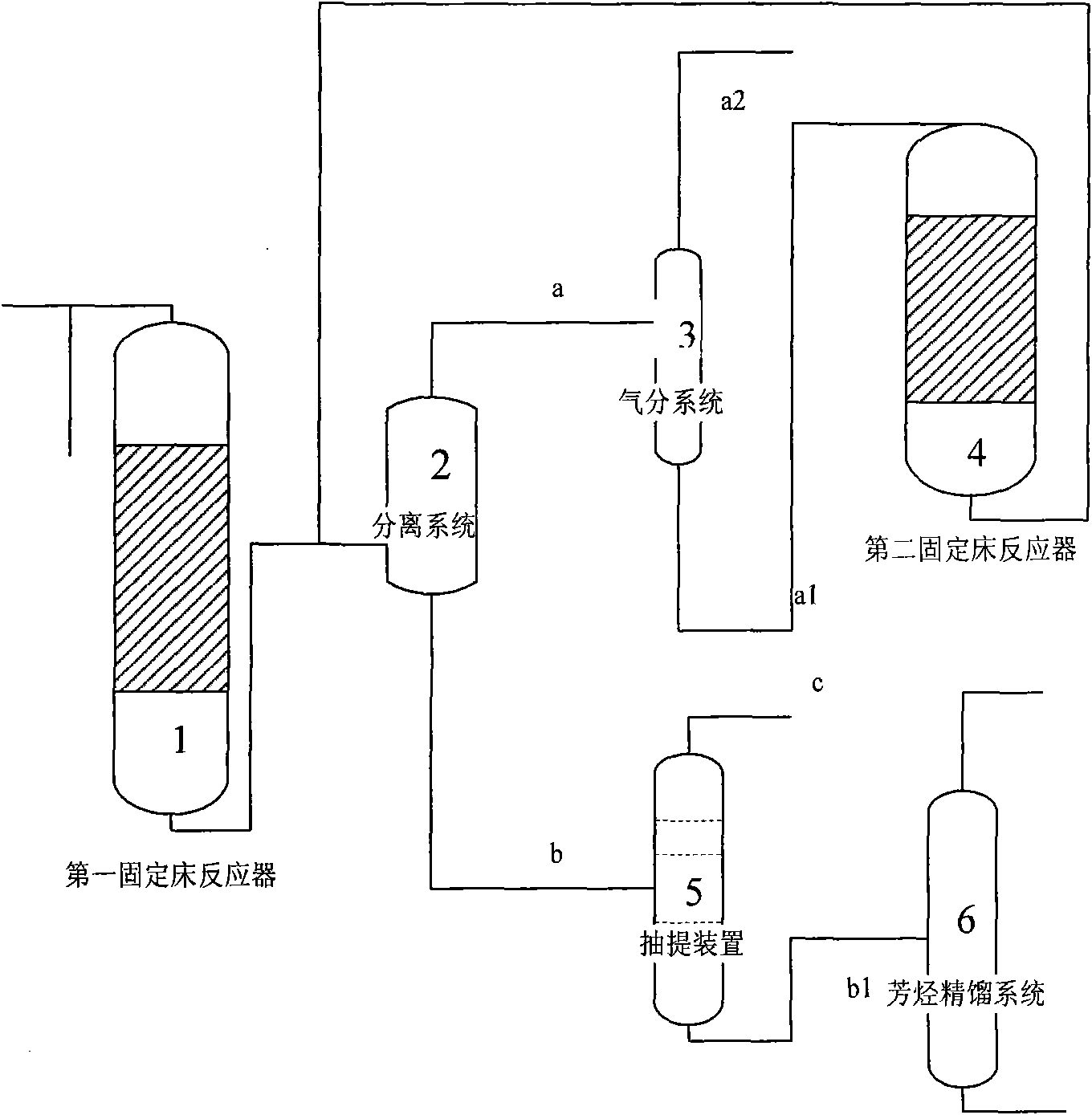

Method for preparing aromatic hydrocarbons and propylene simultaneously employing methanol/dimethyl ether

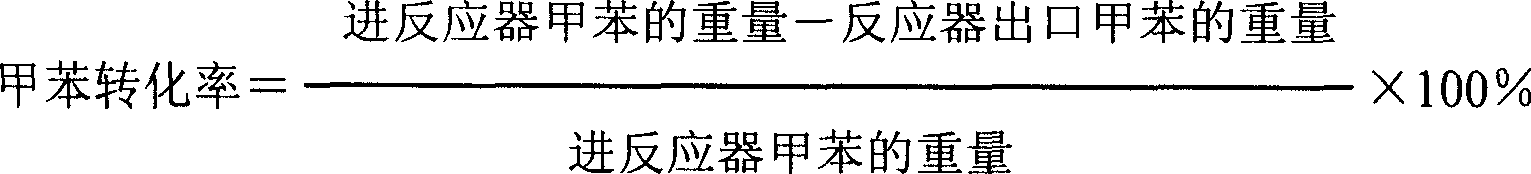

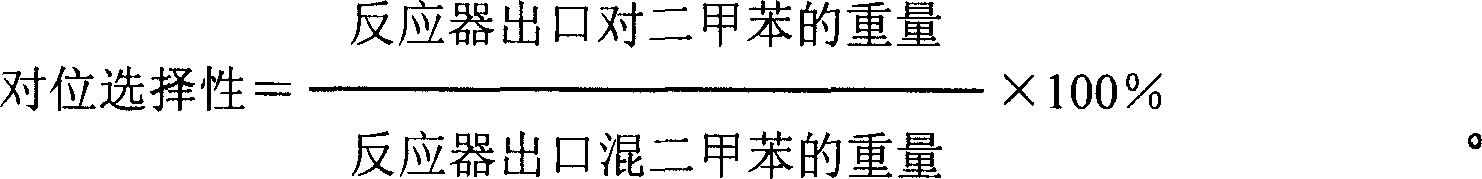

InactiveCN101607858AHigh selectivityIncrease added valueMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveFixed bed

The invention discloses a method for preparing aromatic hydrocarbons and propylene simultaneously employing methanol / dimethyl ether, comprising the following steps: 1) placing raw materials containing methanol or / and dimethyl ether, metals and molecular sieve based catalyst which is modified through silanizing in a first fixed bed reactor to perform catalytic reaction; 2) separating the products obtained in step 1) to obtain propylene, then placing propylene in a second fixed bed reactor with molecular sieve based catalyst which is modified by using metals to react, then performing aromatization on the obtained product in step 1) and obtaining aromatic hydrocarbons; then separating to obtain toluene and sending toluene back to the outlet of the first fixed bed reactor as a raw material. In the method, methanol is converted and prepared to aromatic hydrocarbons while propylene is produced at the same time and the content of paraxylene in aromatic hydrocarbons is high. In the products prepared by the method, the content of propylene can reach above 20%, the content of aromatic hydrocarbons can reach above 58wt% and the content of paraxylene in aromatic hydrocarbons is more than 35wt%.

Owner:CHINA NAT OFFSHORE OIL CORP +2

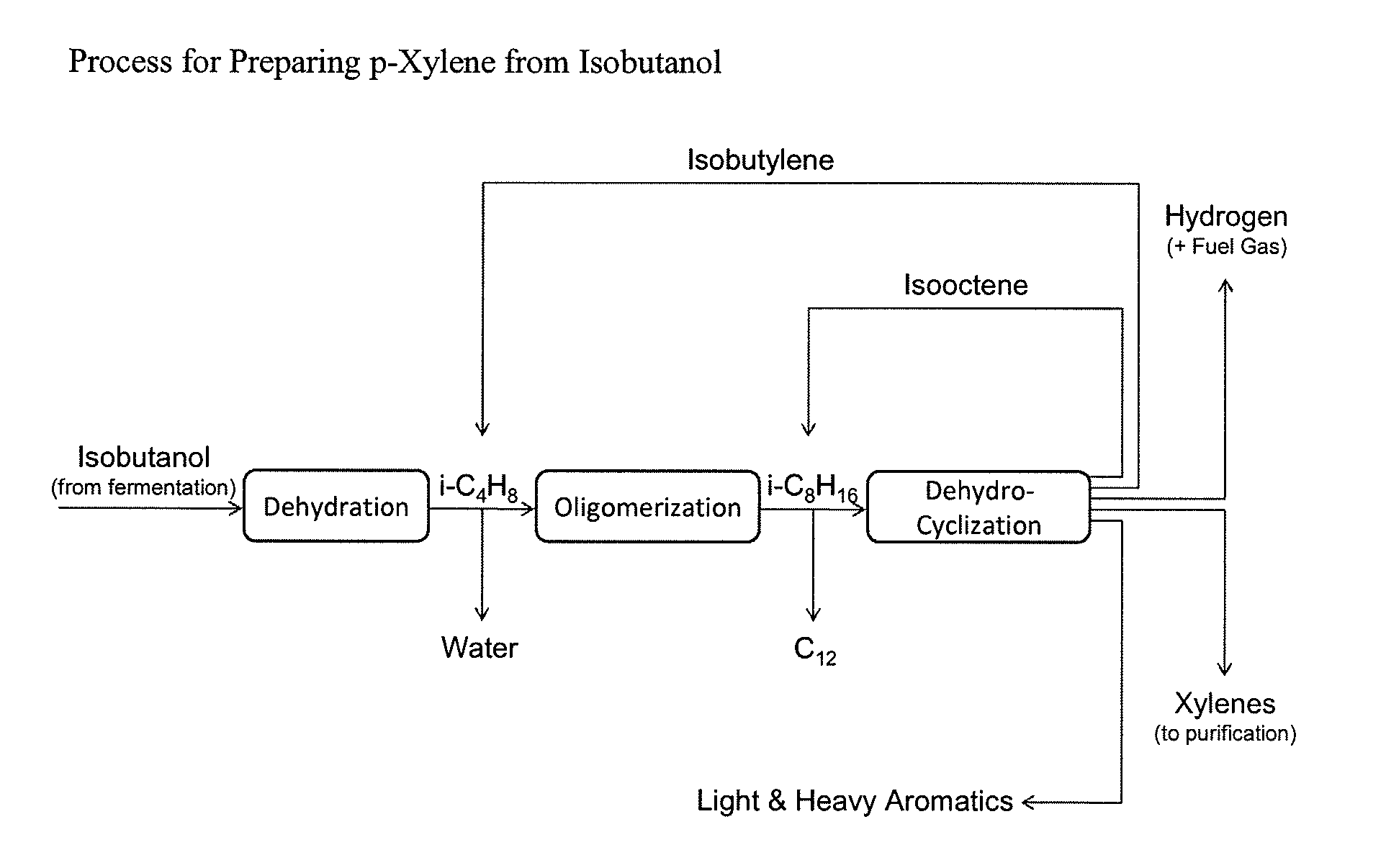

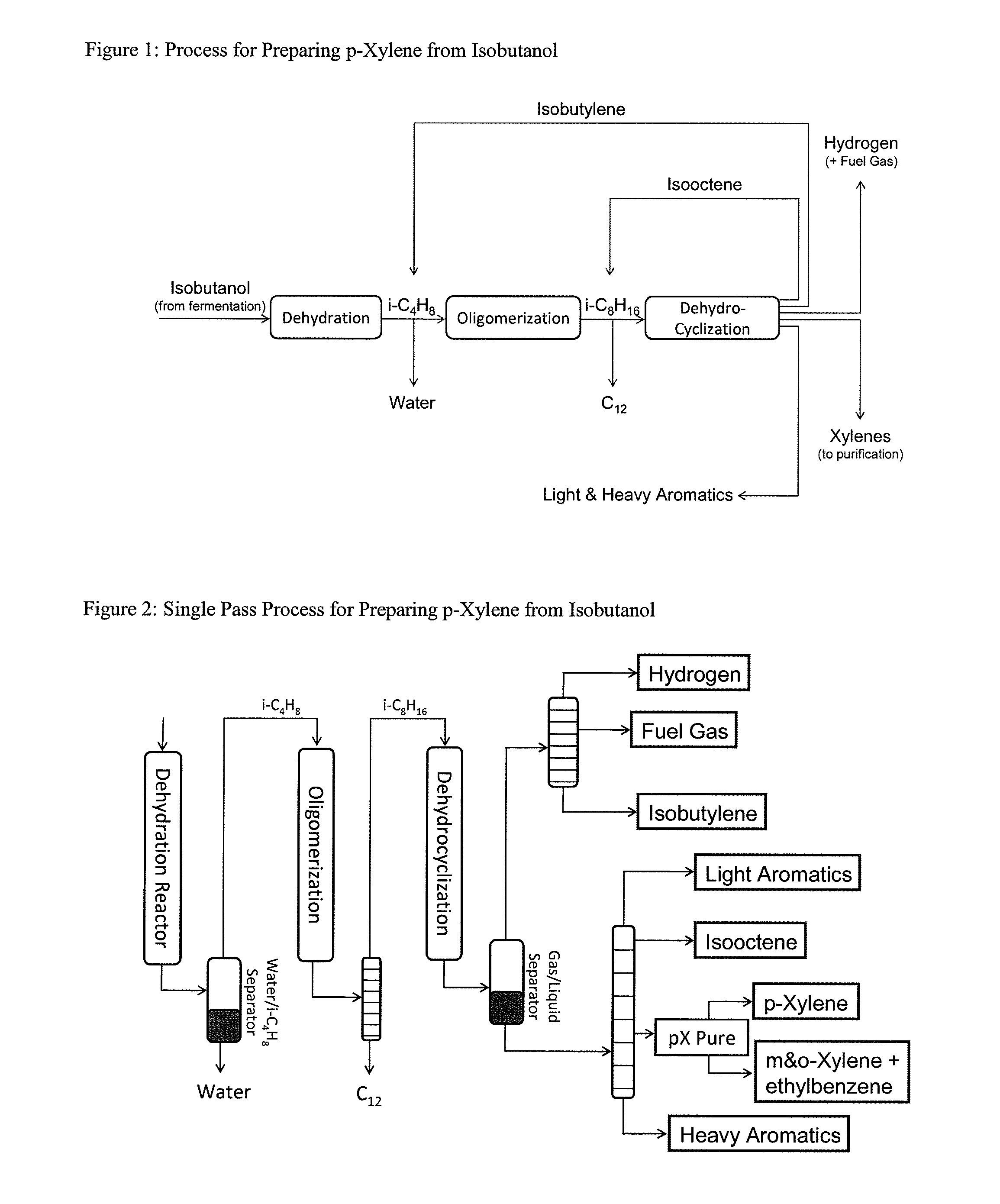

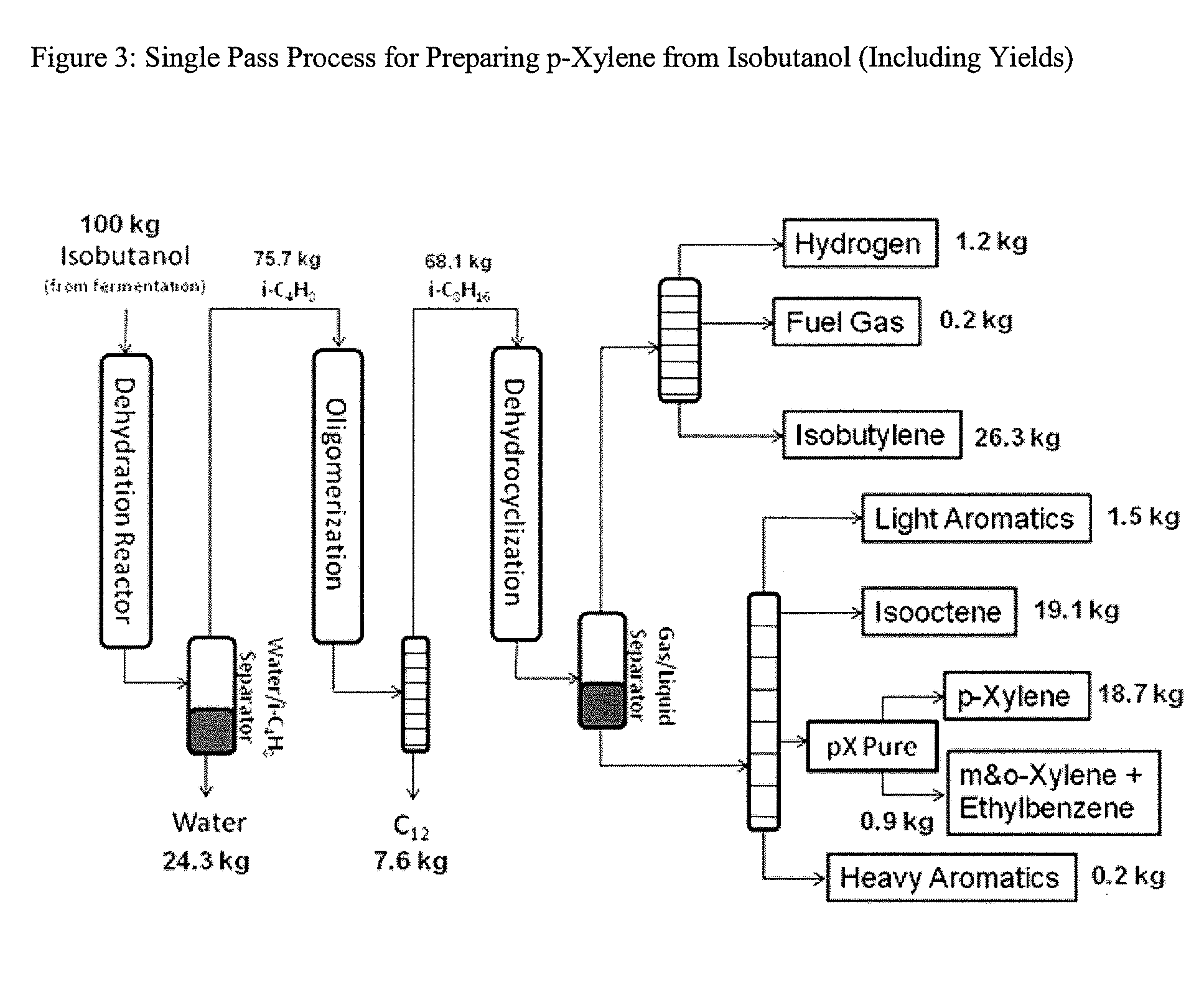

Integrated Process to Selectively Convert Renewable Isobutanol to P-Xylene

The present invention is directed to a method for preparing renewable and relatively high purity p-xylene from biomass. For example, biomass treated to provide a fermentation feedstock is fermented with a microorganism capable of producing a C4 alcohol such as isobutanol, then sequentially dehydrating the isobutanol in the presence of a dehydration catalyst to provide a C4 alkene such as isobutylene, dimerizing the C4 alkene to a form one or more C8 alkenes such as 2,4,4-trimethylpentenes or 2,5-dimethylhexene, then dehydrocyclizing the C8 alkenes in the presence of a dehydrocyclization catalyst to selectively form renewable p-xylene in high overall yield. The p-xylene can then be oxidized to form terephthalic acid or terephthalate esters.

Owner:GEVO INC

Liquid phase process for C8 alkylaromatic isomerization

InactiveUS6872866B1Saving considerable capitalImprove stabilityHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationAcid washing

A liquid or partially liquid phase process for isomerizing a non-equilibrium mixture of xylenes and ethylbenzene uses a zeolitic catalyst system preferably based on zeolite beta and on pentasil-type zeolite. The invention obtains an improved yield of para-xylene from the mixture relative to prior art processes in a more economical manner. A preferred beta zeolite is a surface-modified zeolite beta resulting from acid washing of a templated native zeolite at conditions insufficient to effect bulk dealumination. A preferred pentasil zeolite is a MTW-type with a silica-to-alumnina ratio between 20 and 45.

Owner:UOP LLC

Selective xylenes isomerization and ethylbenzene conversion

This invention is drawn to a process for isomerizing a non-equilibrium mixture of xylenes and ethylbenzene using an oil-dropped catalyst comprising a zeolite, a platinum-group metal and an aluminophosphate binder, resulting in a greater yield of para-xylene at favorable conditions compared to processes of the known art.

Owner:UOP LLC

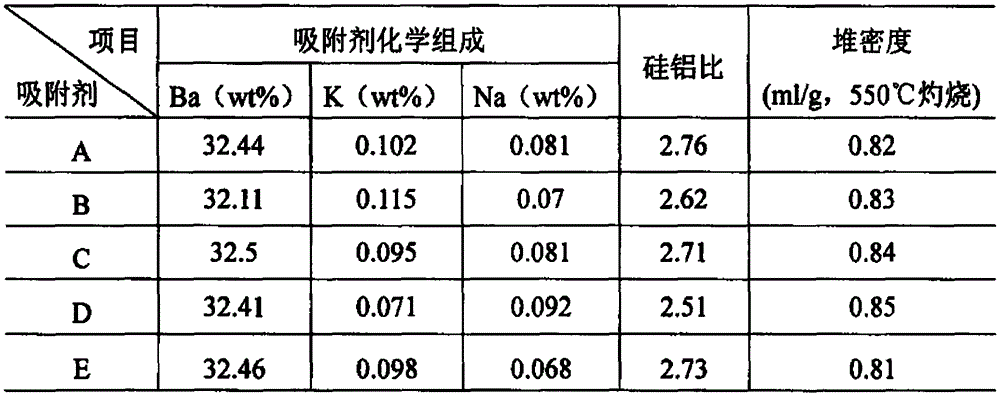

Agglomerated zeolite adsorbents, process for their preparation, and their use for adsorbing paraxylene from aromatic C8 fractions

InactiveUS6410815B1Improve efficiencyImproved kineticsMolecular sieve catalystsOther chemical processesSorbentPotassium

The present invention relates to agglomerated zeolite adsorbents based on faujasite with an Si / Al ratio such that 1<=Si / Al<=1.15, at least 70% exchanged with barium and optionally with potassium, and on a binder, preferably a zeolitizable binder.They are obtained by agglomerating zeolite powder with a binder, followed by exchange of the zeolite ions for barium ions and activation of the adsorbents thus exchanged.These adsorbents are particularly suitable for the adsorption of the para-xylene contained in aromatic C8 hydrocarbon fractions in the liquid phase, in processes of simulated fluid-bed type.

Owner:INST FR DU PETROLE +1

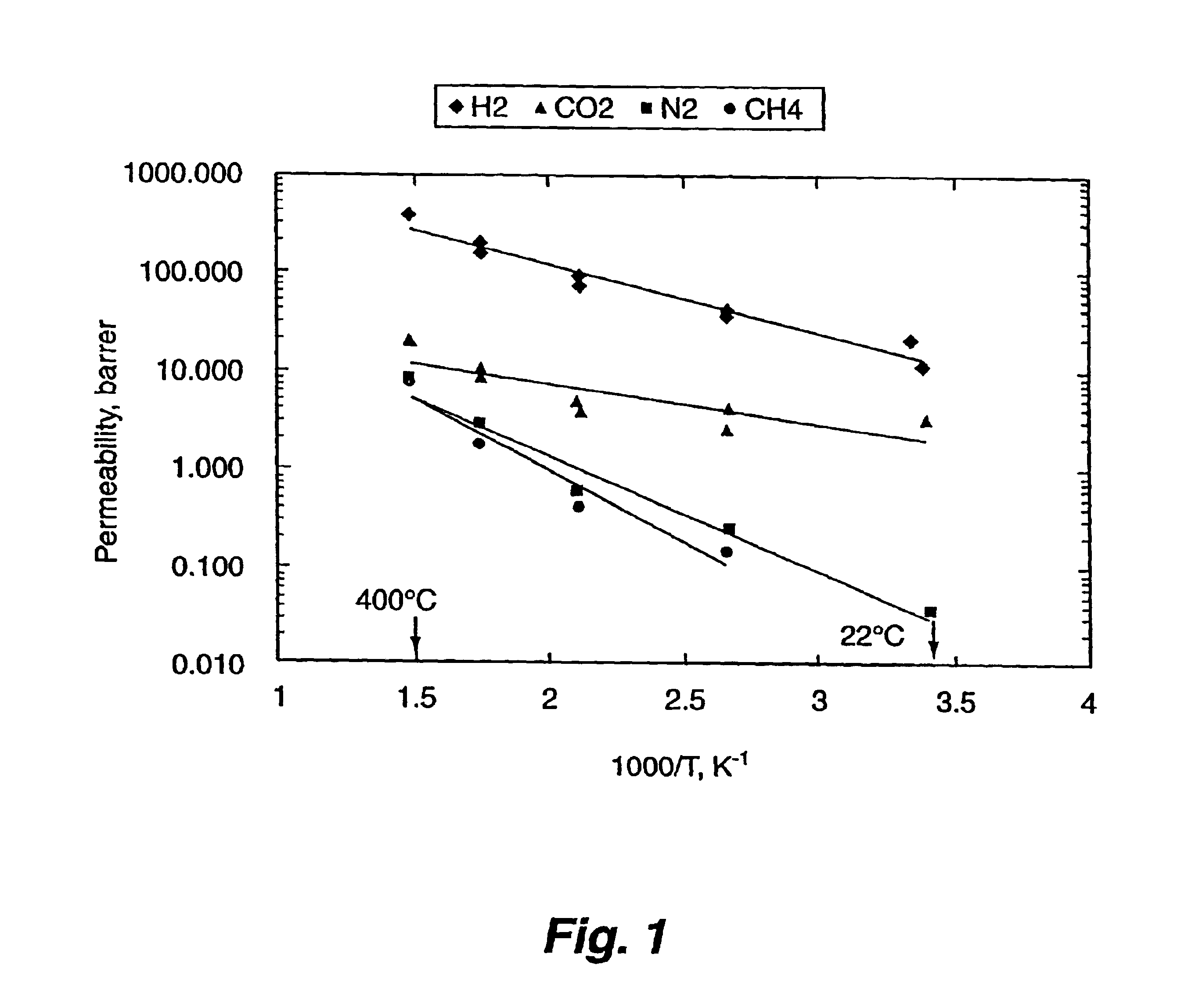

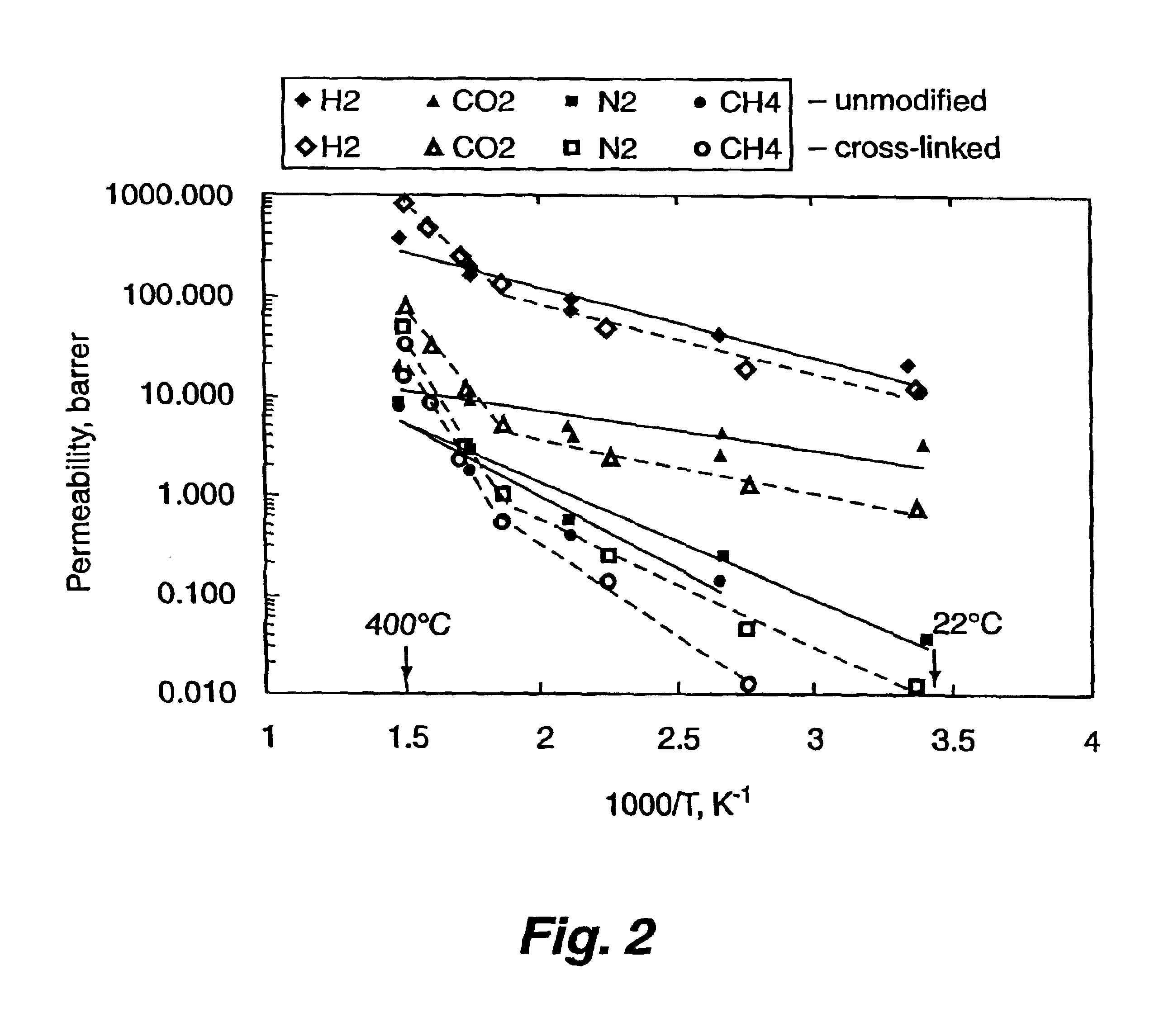

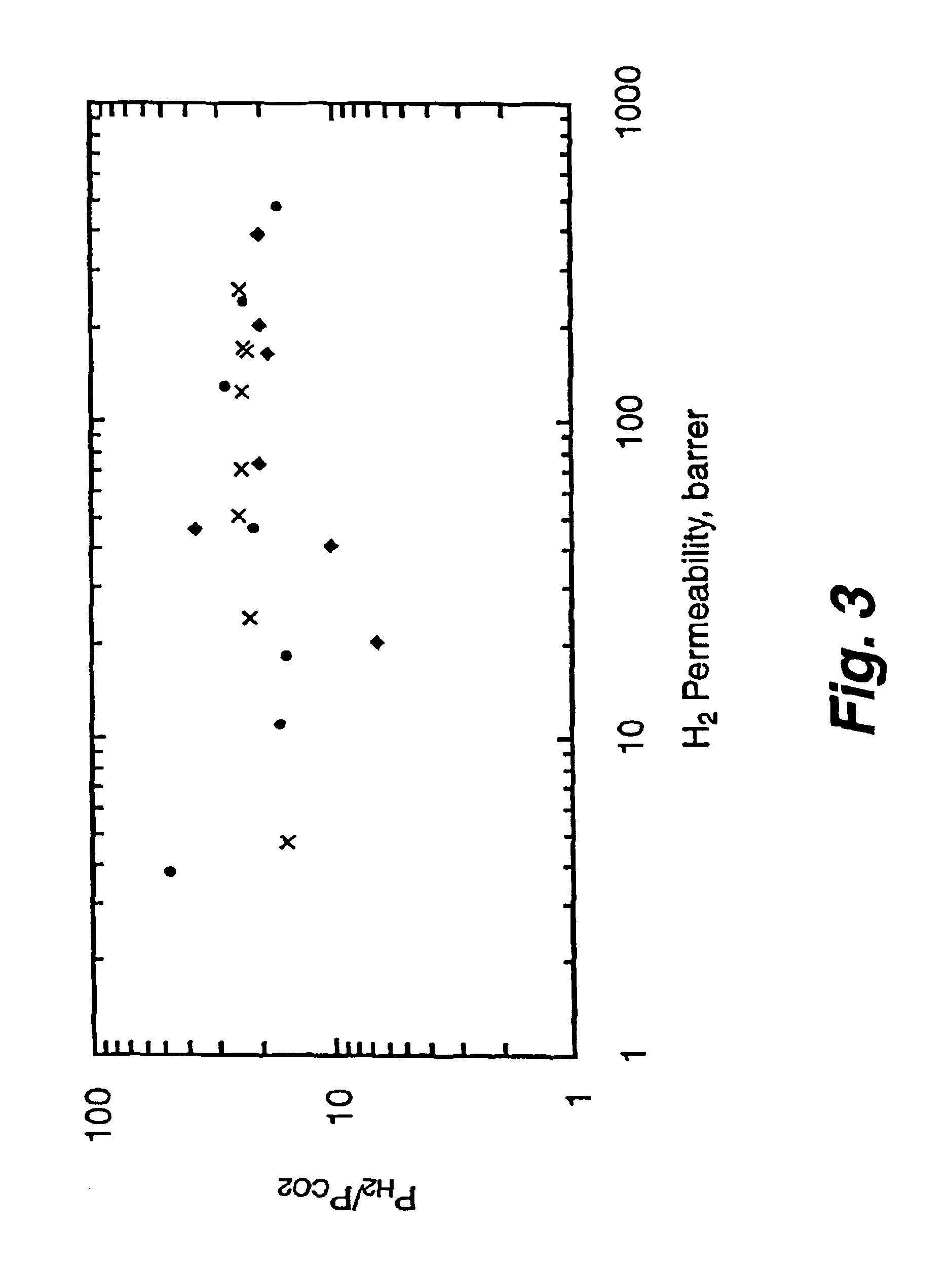

Cross-linked polybenzimidazole membrane for gas separation

A cross-linked, supported polybenzimidazole membrane for gas separation is prepared by layering a solution of polybenzimidazole (PBI) and α,α′dibromo-p-xylene onto a porous support and evaporating solvent. A supported membrane of cross-linked poly-2,2′-(m-phenylene)-5,5′-bibenzimidazole unexpectedly exhibits an enhanced gas permeability compared to the non-cross linked analog at temperatures over 265° C.

Owner:LOS ALAMOS NATIONAL SECURITY

Binderless adsorbents with improved mass transfer properties and their use in the adsorptive separation of para-xylene

ActiveUS7812208B2Improve performanceImprove mass transfer effectOther chemical processesMolecular-sieve and base-exchange compoundsProduction rateSorbent

Owner:UOP LLC

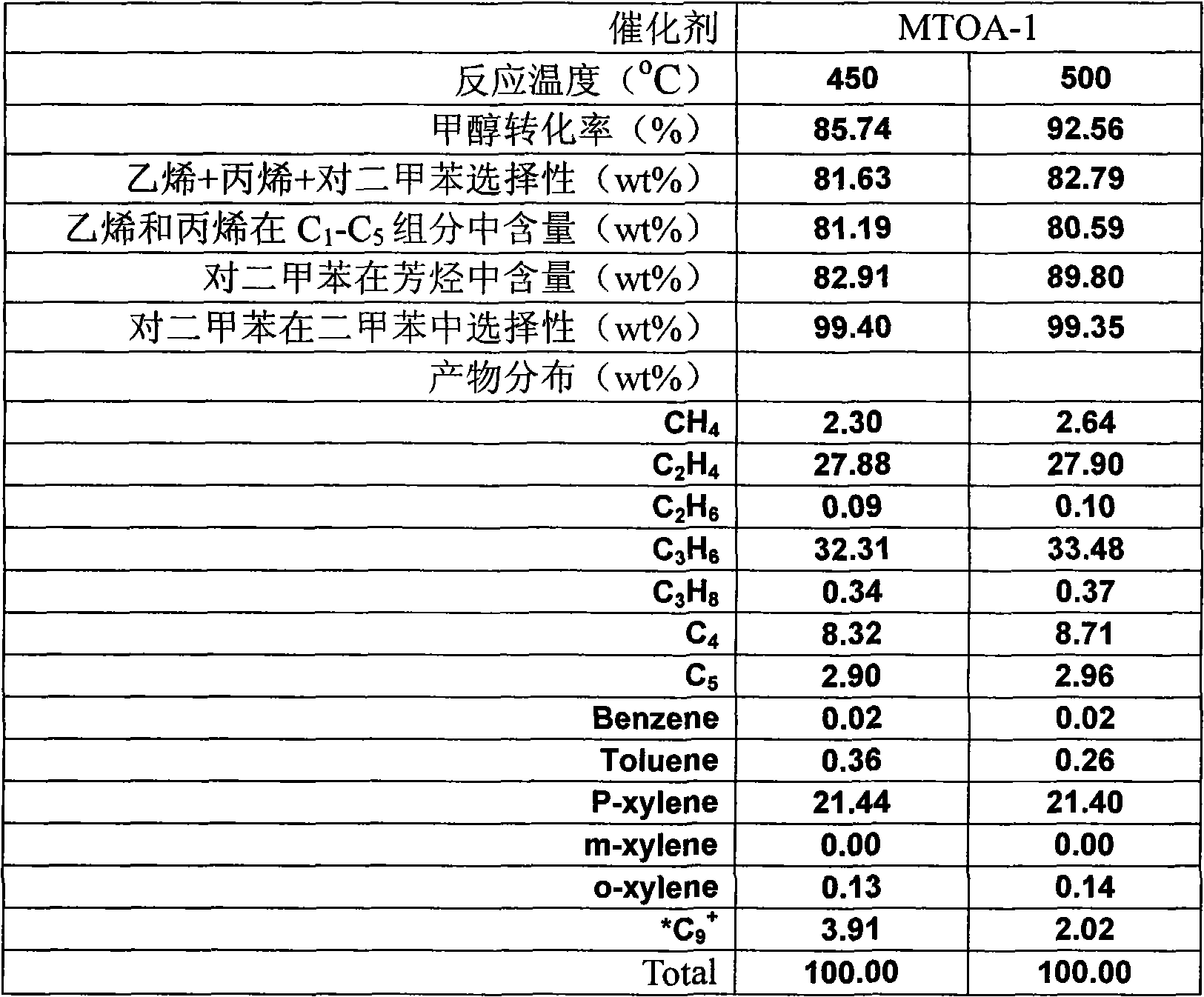

Method for preparing ethylene and propylene and co-producing p-xylene through methanol/dimethyl ether conversion

InactiveCN101602643AHigh yieldIncrease profitMolecular sieve catalystsHydrocarbon from oxygen organic compoundsXylylenePolymer science

The invention provides a method for preparing ethylene and propylene and co-producing p-xylene through methanol / dimethyl ether conversion. The method adopts a silanization-modified zeolite catalyst to co-produce p-xylene as a main component in aromatic hydrocarbon while preparing ethylene and propylene through methanol conversion. The overall selectivity of ethylene, propylene and p-xylene in hydrocarbon products is more than 80 percent by weight. The selectivity of p-xylene in xylene isomers is more than 99 percent by weight.

Owner:CHINA NAT OFFSHORE OIL CORP +2

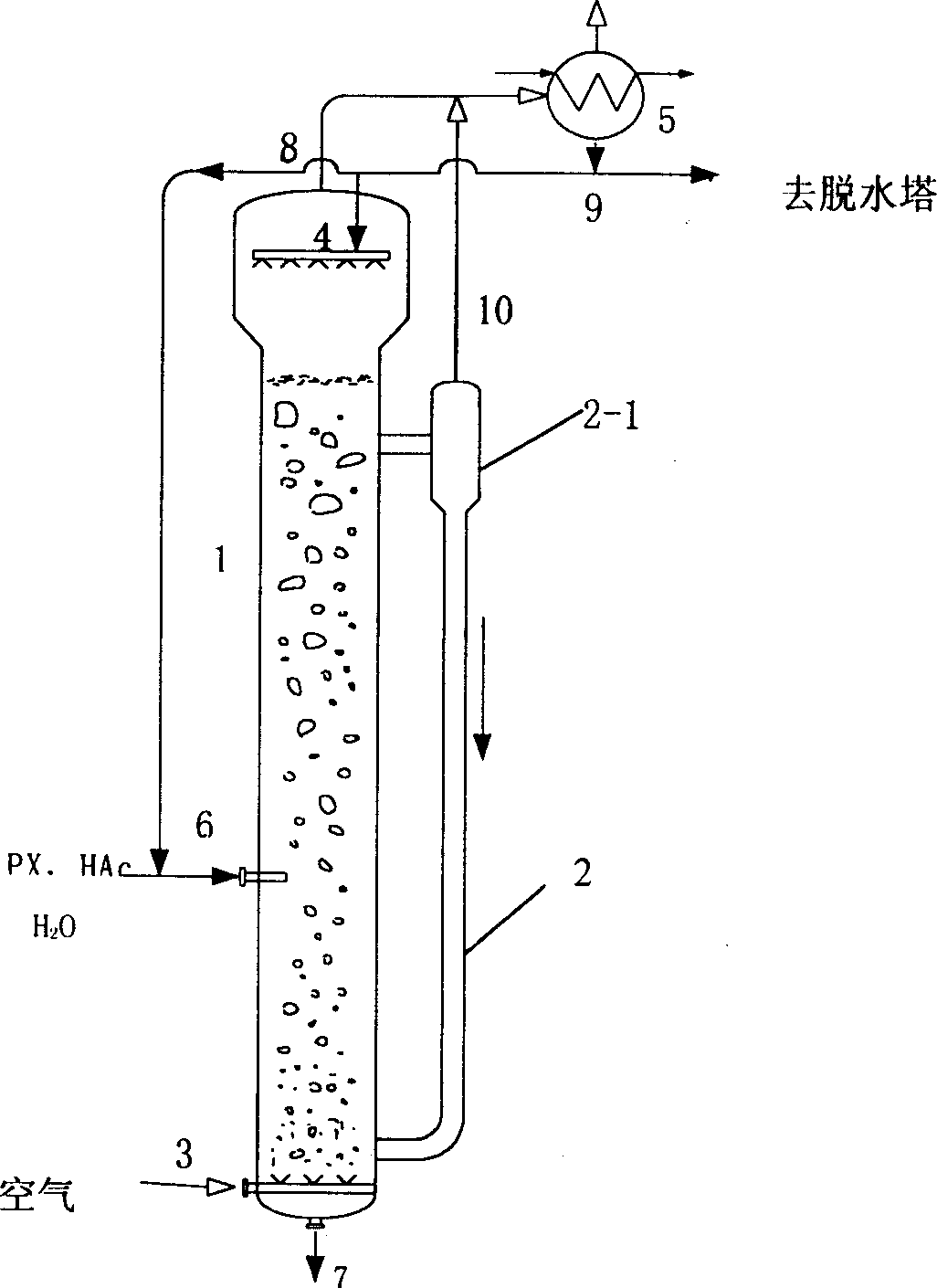

Air lift externally circulating bubble fower oxidation unit for producing terephthalic acid

InactiveCN1486968ASimple structureLow costOrganic compound preparationCarboxylic compound preparationCatalytic oxidationEngineering

The air lift externally circulation bubble tower oxidation apparatus includes cylinder bubble tower with top expanded section, outer circulating pipe, gas distributor, reflux liquid distributor and condensator. The outer circulating pipe has its upper end and lower end communicated with the upper part and the lower part of the bubble tower reaction section separately and is used to lead slurry from the upper part of the tower to the lower part via air lift effect so as to form the fluid circulation in the whole tower and complete the liquid phase catalytic oxidation of xylene. The bubble tower has relatively high height / diameter ratio and thus reinforced gas-liquid mass transfer and the air lift outer circulation pipe improves the temperature distribution and concentraion distribution inside the tower. The tower has no moving part, simple structure and low cost and is suitable for oxidizing xylene to prepare terephthalic acid via different technological processes.

Owner:CHINA TEXTILE IND ENG INST +2

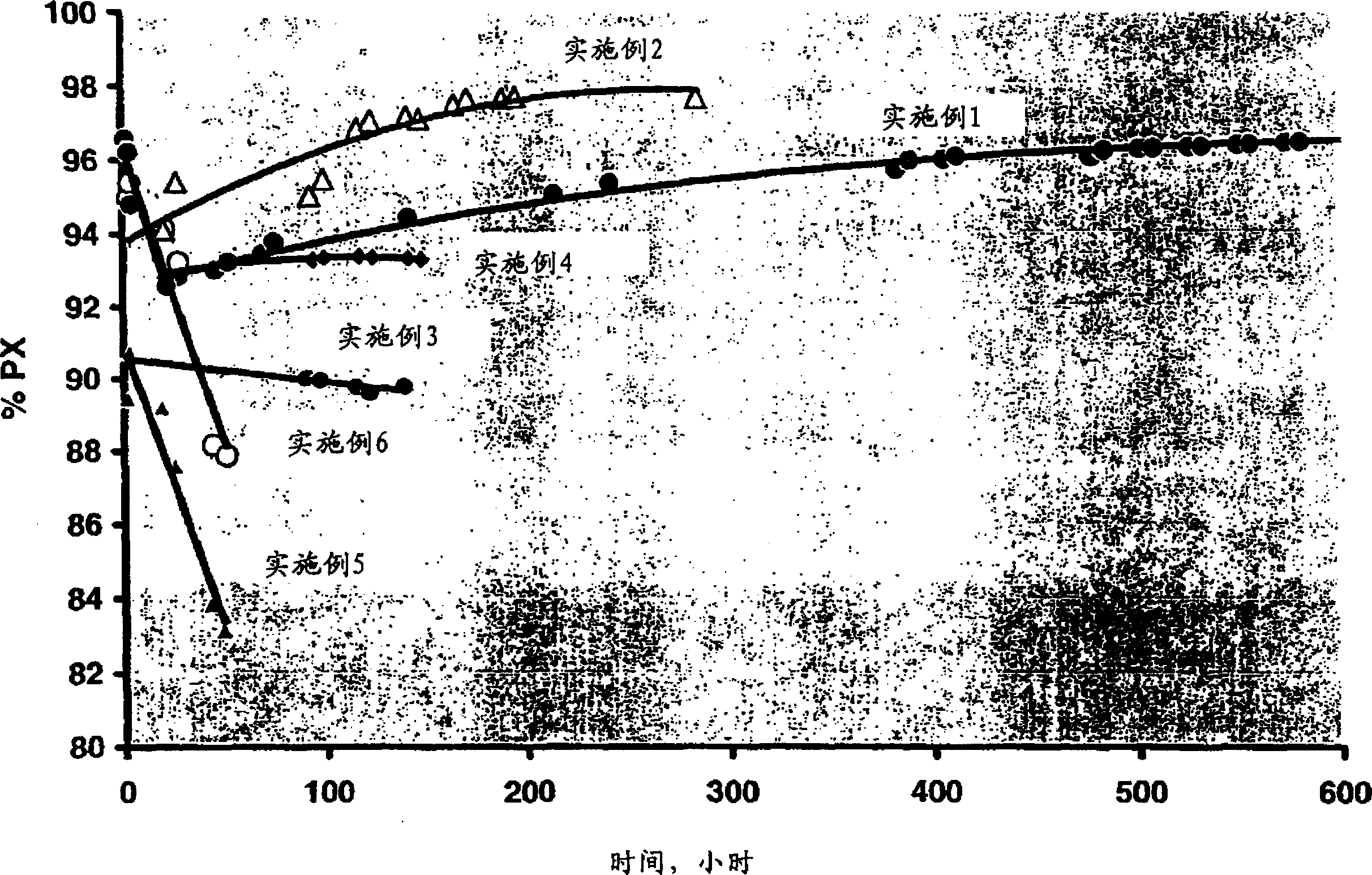

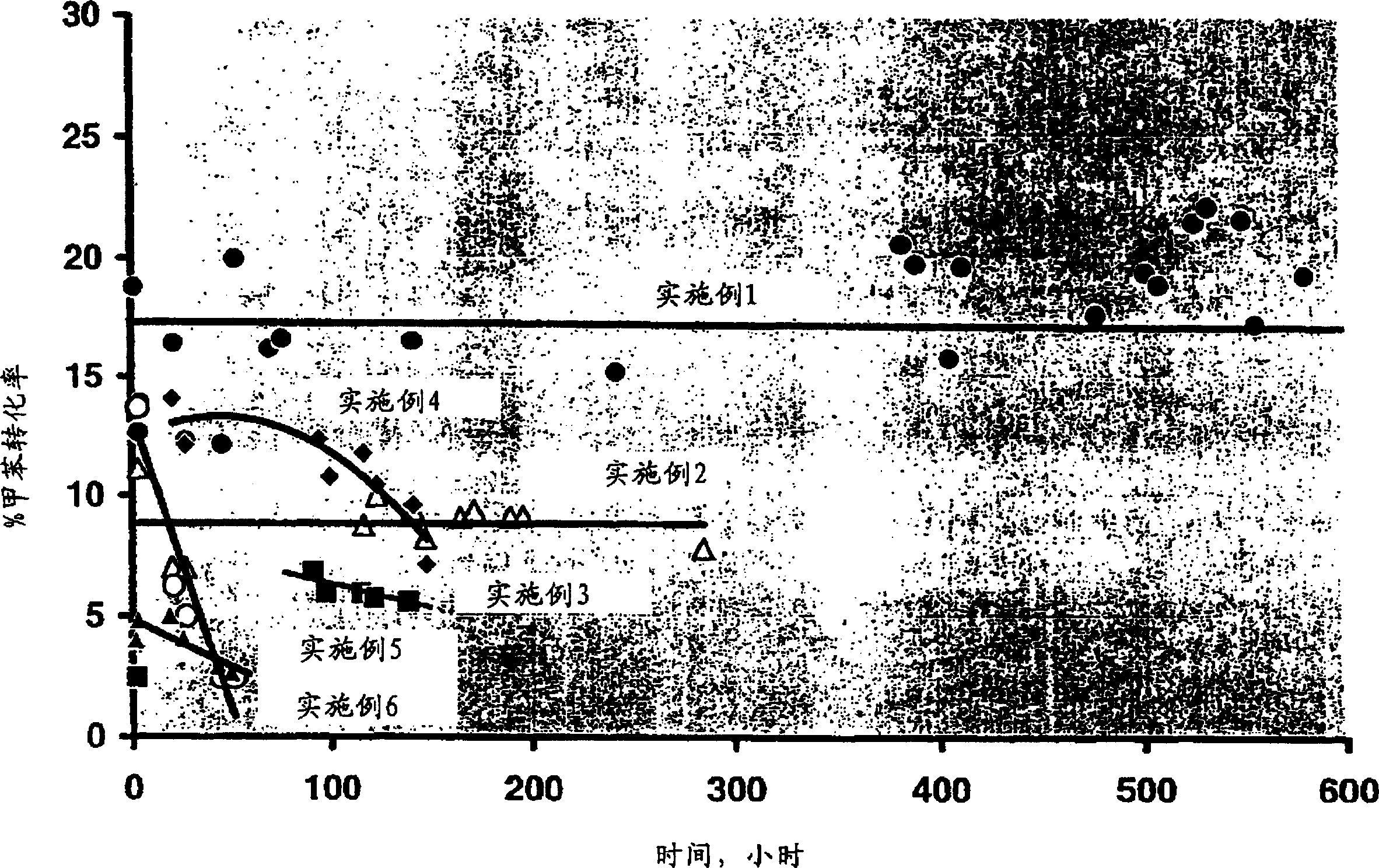

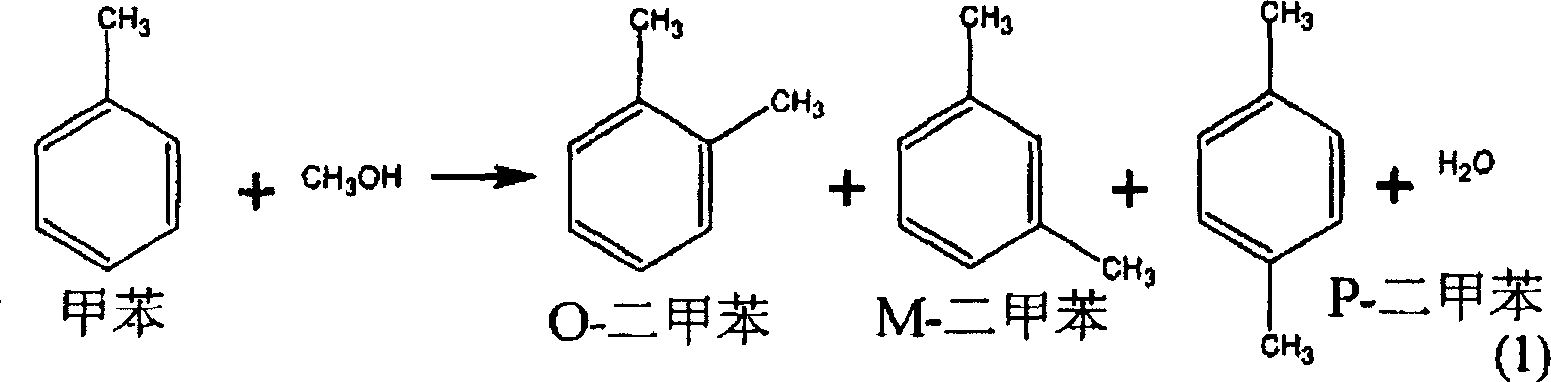

Catalyst for alkylation of toluene methanol

ActiveCN1915512AHigh activityImprove para-selectivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAlkyl transferHydrogen

Owner:CHINA PETROLEUM & CHEM CORP +1

Agglomerated zeolitic adsorbents, method for obtaining same uses thereof

InactiveUS6884918B1Amino compound purification/separationOrganic compound preparationSorbentSimulated moving bed

The present invention relates to agglomerated zeolitic adsorbents based on zeolite X with an Si / Al ratio such that 1.15<Si / Al≦1.5, at least 90% of the exchangeable cationic sites of the zeolite X of which are occupied either by barium ions alone or by barium ions and potassium ions whose Dubinin volume is greater than or equal to 0.240 cm3 / g.They are obtained by agglomerating zeolite powder with a binder, followed by the zeolitization of the binder, the exchange of the ions of the zeolite by barium ions (and potassium ions) and the activation of the adsorbents thus exchanged.These adsorbents are particularly suited to the adsorption of the para-xylene present in C8 aromatic hydrocarbon fractions in the liquid phase in processes of simulated moving bed type but also to the separation of sugars, polyhydric alcohols, cresols or substituted toluene isomers.

Owner:ARKEMA FRANCE SA

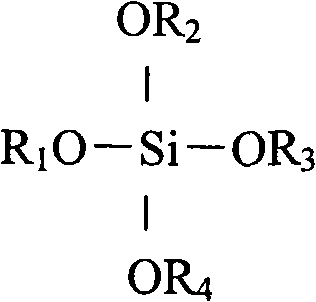

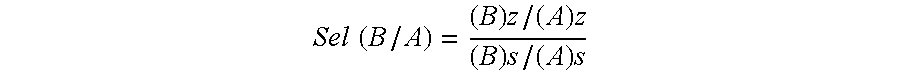

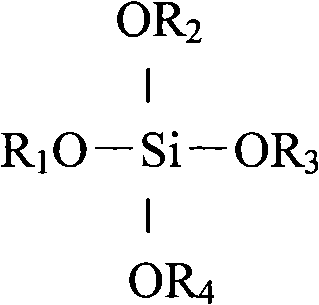

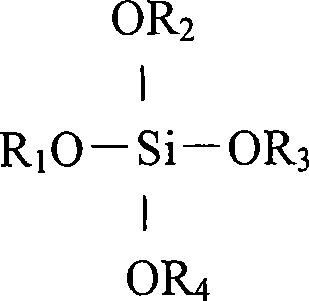

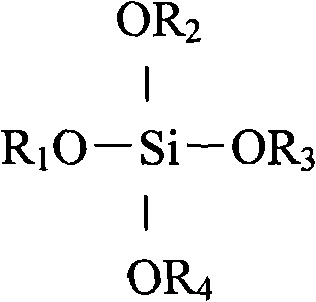

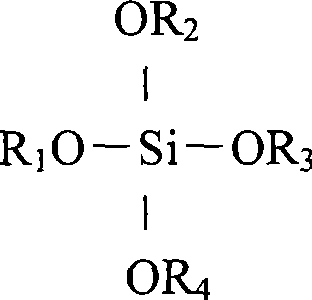

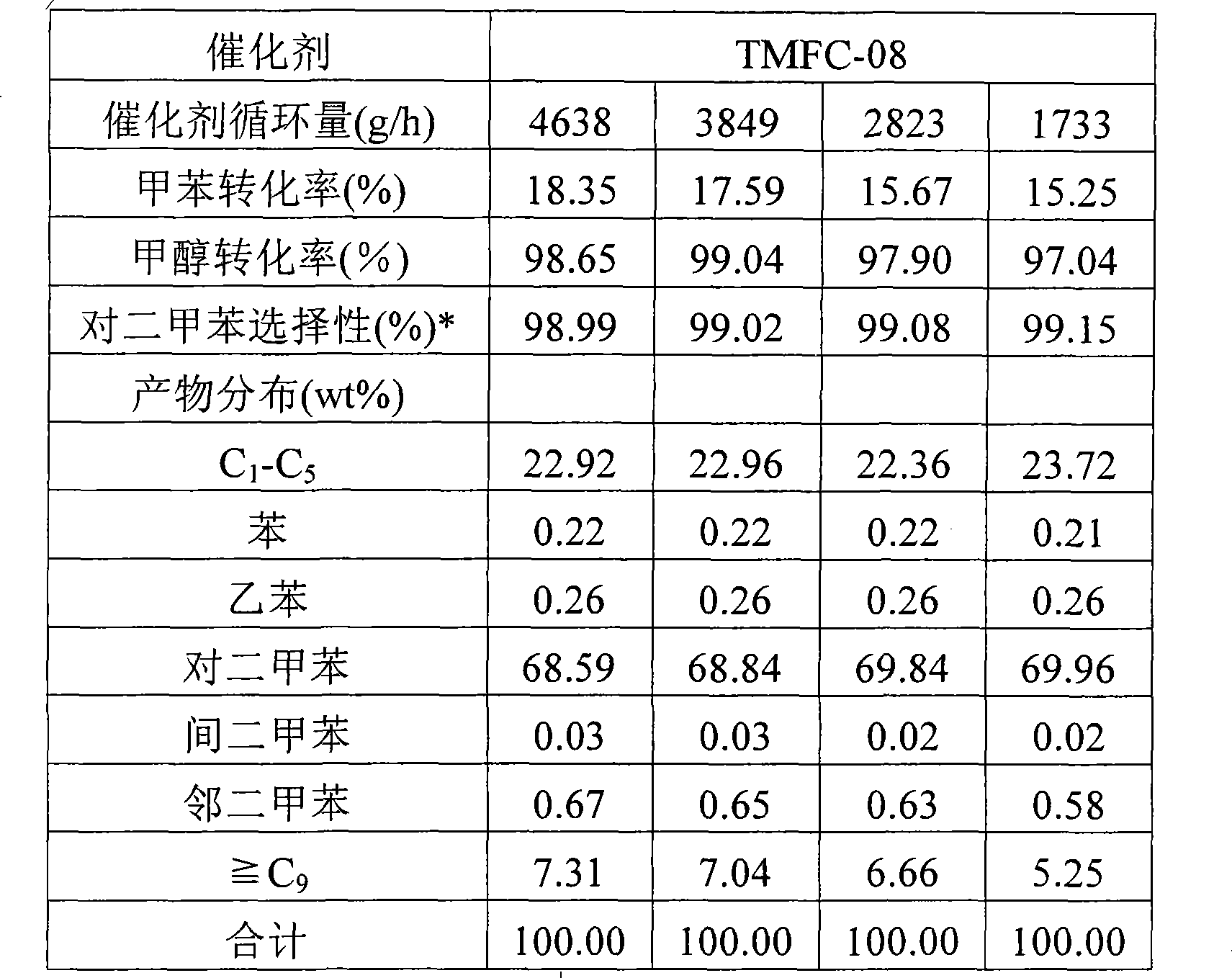

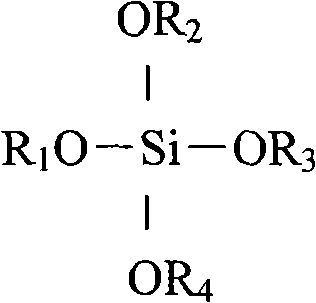

Catalyst for preparing paraxylene and low-carbon olefin by methyl alcohol conversion, preparation method and application thereof

ActiveCN101780417AMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveAlcohol

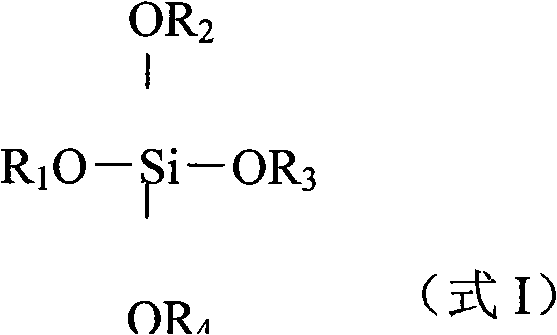

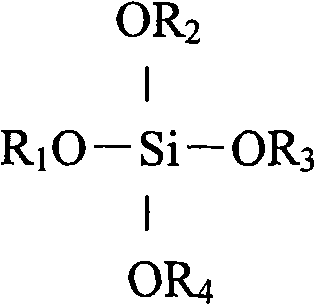

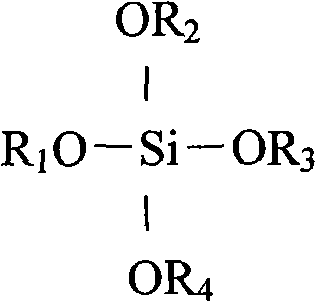

The invention discloses a catalyst for preparing paraxylene and low-carbon olefin by methyl alcohol conversion, a preparation method and application thereof. The catalyst provided by the invention is obtained by the method that a zeolite molecular sieve modified by transition metal and rare-earth metal is performed with the surface acidity and the pore structure modification by a siloxy group compound, wherein the transition metal is 0.1-10 wt% of the total weight of catalyst, the rare-earth metal is 0.1-5 wt% of total weight of the catalyst, and the modified siloxy group compound which is accounted by Si is 0.1-8 wt% of total weight of the catalyst; the catalyst can realize that methyl alcohol is used for directly preparing three basic chemicals in one reaction process, i.e. ethylene, propylene and paraxylene; the selectivity of the obtained hydrocarbon products in paraxylene is more than 80 wt%, and the selectivity of ethylene and propylene in C1-C5 is more than 80 wt%.

Owner:CHINA NAT OFFSHORE OIL CORP +2

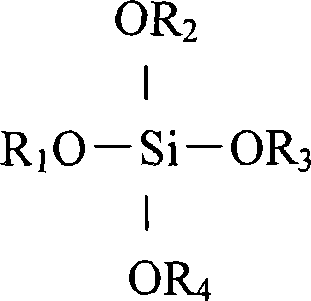

Movable bed catalyst for alkylation of toluene and methanol to produce paraxylene and low-carbon olefin

ActiveCN101417236AMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAlkaline earth metalRare earth

The invention provides a catalyst used for preparing para-xylene and low-carbon olefin fluidized bed by selective methylation of toluene with methanol, which is obtained by the modification of zeolite molecular sieve by metal, nonmetal or / and rare earth metal, mixing, spraying, drying and forming of amorphous adhesive containing silicon or aluminium and the zeolite molecular sieve, and decoration of surface acidity and porous structure by siloxane-based compounds, wherein, the content of the alkaline earth metal is 0.1-8wt percent of the total weight of the catalyst, the content of the nonmetal is 0.1-8wt percent of the total weight of the catalyst, the content of the rare earth metal is 0.1-5wt percent of the total weight of the catalyst, and the loading of the Si decorated by the siloxane-based compound is 0.1-10wt percent of the total weight of the catalyst; the catalyst is used for the reaction of preparing para-xylene and low-carbon olefin fluidized bed by selective methylation of toluene with methanol; in the products, the selectivity of the para-xylene in the xylene isomers is more than 99 percent and the selectivity of the ethane and propylene in the composition C1-C5 is more than 90 percent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Toluene methylation process

InactiveCN1775715AHigh selectivityMolecular sieve catalystsMolecular sieve catalystHydrogenMethylation

Owner:SAUDI BASIC IND CORP SA

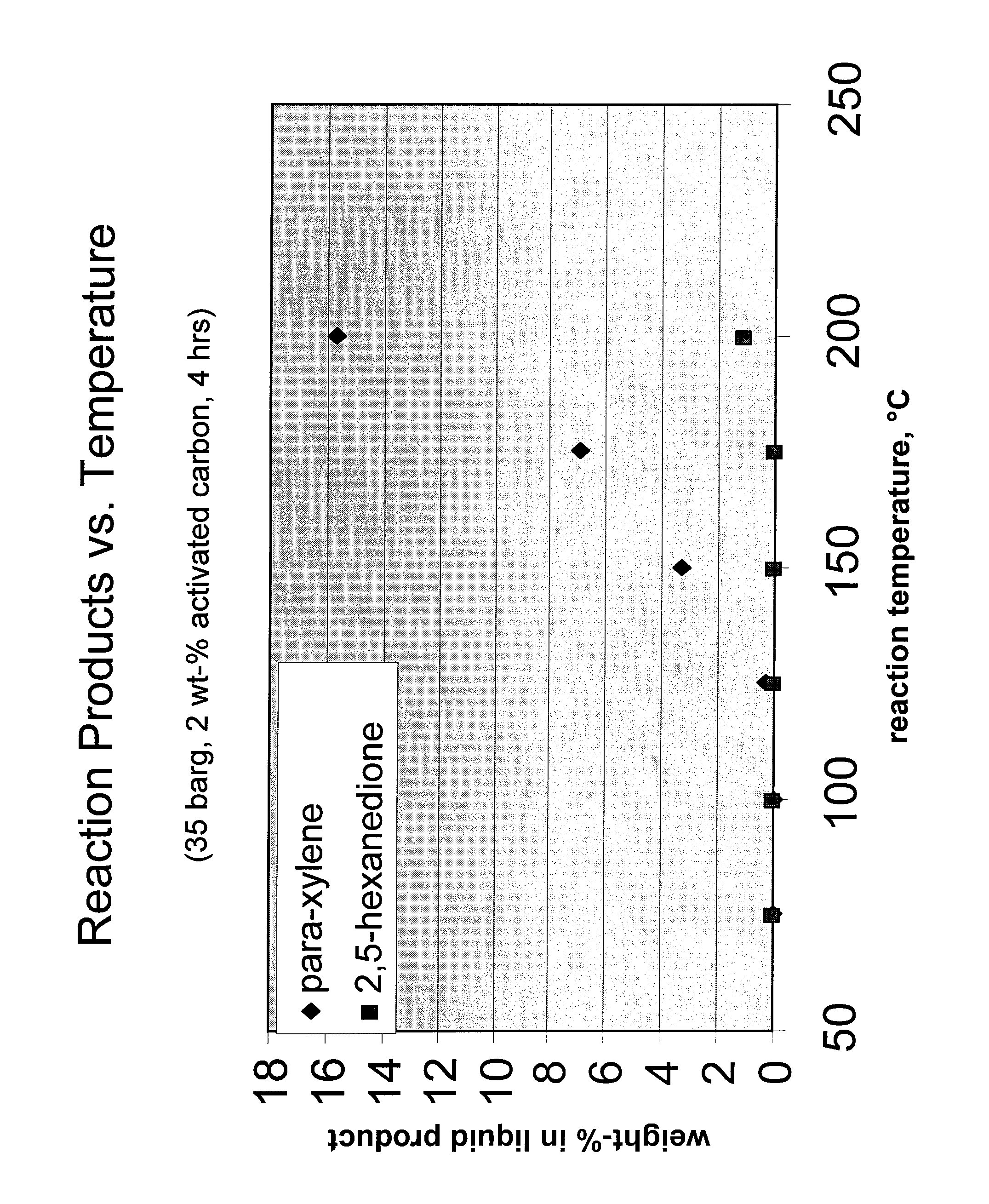

Carbohydrate route to para-xylene and terephthalic acid

Catalytic processes for the conversion of 2,5-dimethyl furan (DMF) to para-xylene are described. Para-xylene is a key product that is currently obtained commercially from petroleum sources. However, it has now been determined that the cycloaddition of ethylene to DMF provides an alternative route to para-xylene. Advantageously, the DMF starting material for the processes may be synthesized from carbohydrates (e.g., glucose or fructose), thereby providing a pathway that relies at least partly, if not completely, on renewable feedstocks.

Owner:UOP LLC

Method of purifying aromatic dicarboxylic acids

InactiveUS6265608B1MinimizationReduce usageOrganic compound preparationCarboxylic compound separation/purificationPalladium catalystCarboxylic acid

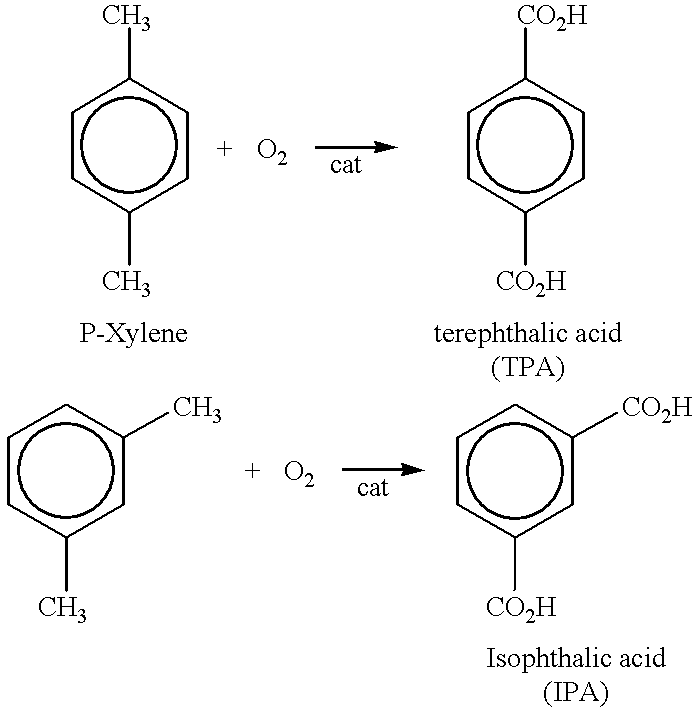

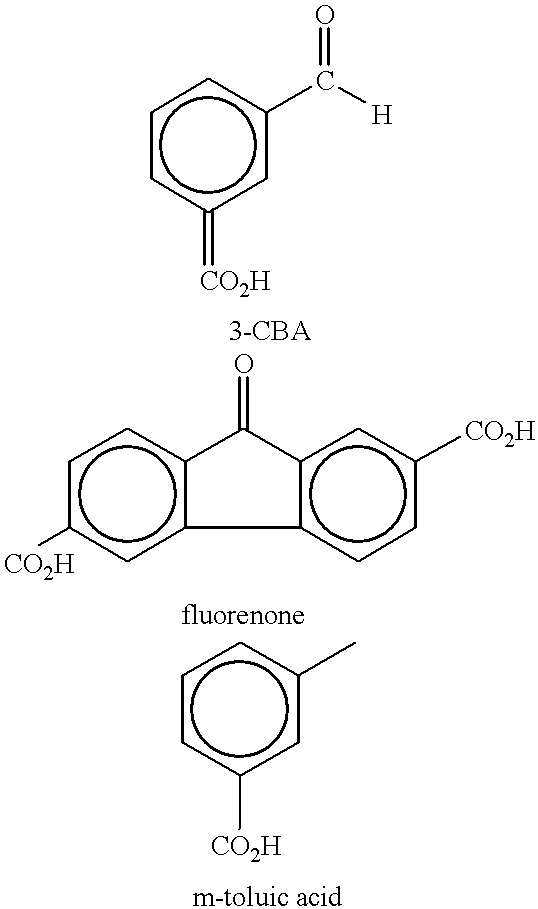

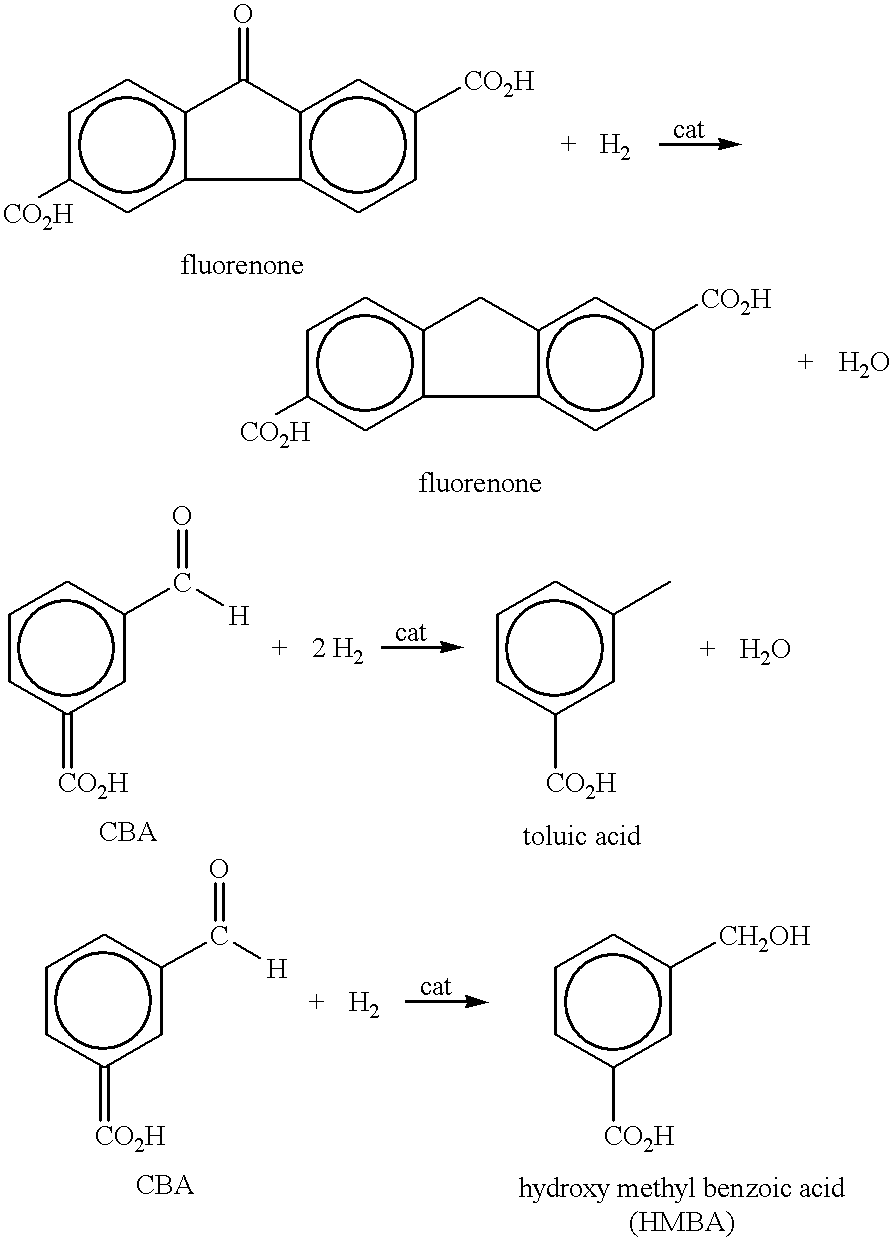

An aromatic dicarboxylic acid is purified by oxidizing m-xylene or p-xylene to produce crude isophthalic acid or crude terephthalic acid, respectively. The products of the oxidizing step are hydrogenated in the presence of a palladium catalyst. Carbon monoxide is introduced during the hydrogenation step. The palladium catalyst is provided on a carbon substrate. The products of the oxidizing step are dissolved in a solvent, which may be water, prior to the hydrogenation step. The products of the oxidizing step may be dissolved at an elevated temperature, above the normal boiling point of the solvent. The oxidation step produces isophthalic acid, 3-carboxybenzaldehyde and fluorenones in the case of oxidizing m-xylene and produces terephthalic acid, 4-carboxybenzaldehyde and fluorenones in the case of oxidizing p-xylene. It may be helpful to monitor the disappearance of 3-carboxybenzaldehyde in the case of oxidizing m-xylene and 4-carboxybenzaldehyde in the case of oxidizing pxylene, and reducing the amount of carbon monoxide when the rate of disappearance is below a predetermined minimum. After the hydrogenation step, the isophthalic acid or terephthalic acid may be crystallized. The carbon monoxide may be maintained at a concentration of 100 to 500 ppm based on added hydrogen and carbon monoxide. Other aromatic dicarboxylic acids may also purified by this procedure.

Owner:GRUPO PETROTEMEX DE C V

Binderless adsorbents and their use in the adsorptive separation of para-xylene

ActiveUS7820869B2Improve performanceIncrease mass transfer rateMaterial nanotechnologyMolecular sieve catalystsProduction rateSorbent

Adsorbents and methods for the adsorptive separation of para-xylene from a mixture containing at least one other C8 aromatic hydrocarbon (e.g., a mixture of ortho-xylene, meta-xylene, para-xylene, and ethylbenzene) are described. Suitable binderless adsorbents (e.g., formulated with the substantial absence of an amorphous material that normally reduces selective pore volume), particularly those with a water content from about 3% to about 5.5% by weight, improve capacity and / or mass transfer. These properties are especially advantageous for improving productivity in low temperature, low cycle time adsorptive separation operations in a simulated moving bed mode.

Owner:UOP LLC

Method for preparing p-xylene through methanol/dimethyl ether conversion

InactiveCN101602648AHigh market valueMolecular sieve catalystsHydrocarbon from oxygen organic compoundsSilanizationMetal

The invention provides a method for preparing p-xylene through methanol / dimethyl ether conversion. The method adopts a zeolite catalyst modified with metal and silanization to directly prepare high-selectivity p-xylene through methanol / dimethyl ether conversion. The selectivity of p-xylene in aromatic products of methanol / dimethyl ether conversion is more than 80 percent by weight. The selectivity of p-xylene in xylene isomers is more than 99 percent by weight.

Owner:CHINA NAT OFFSHORE OIL CORP +2

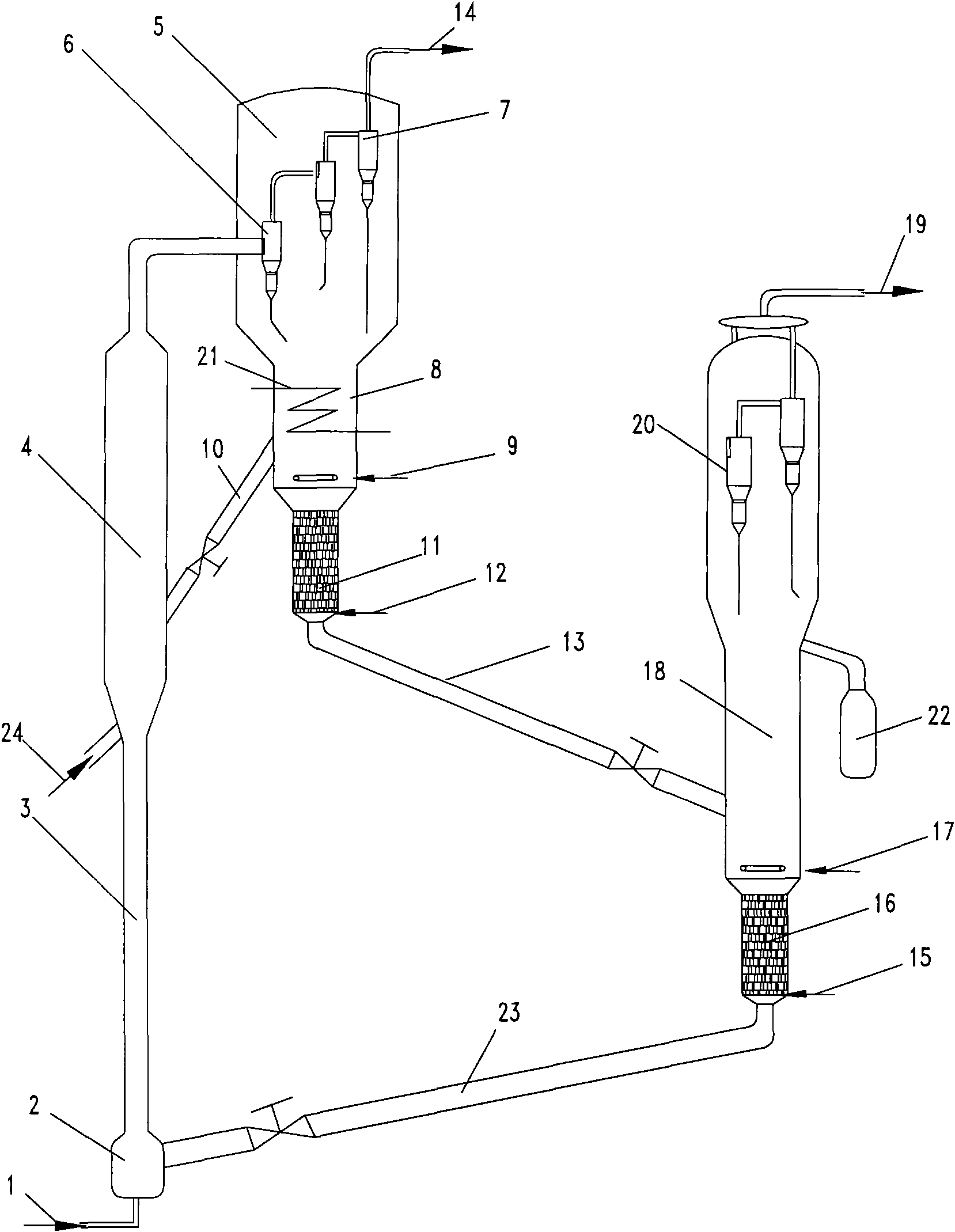

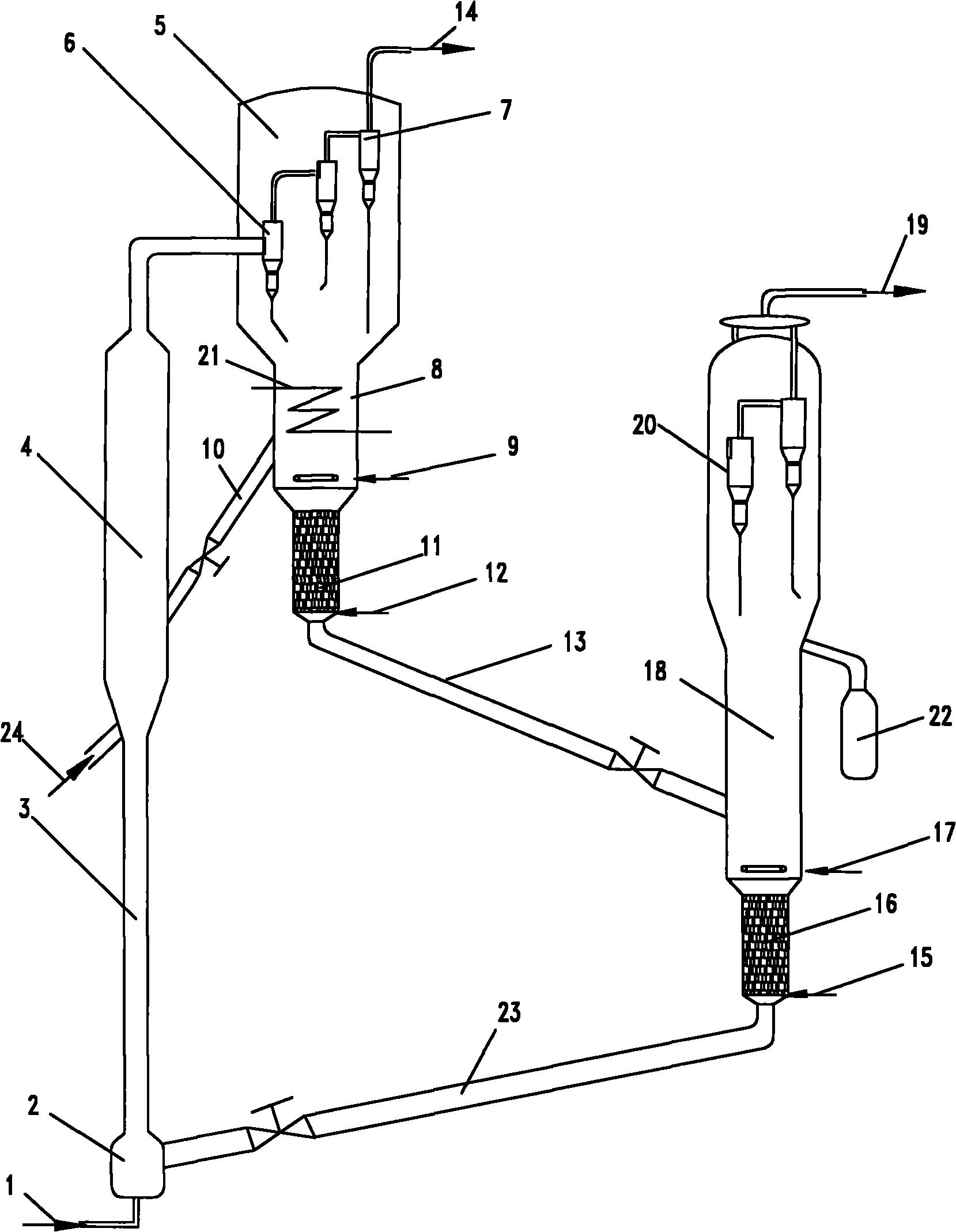

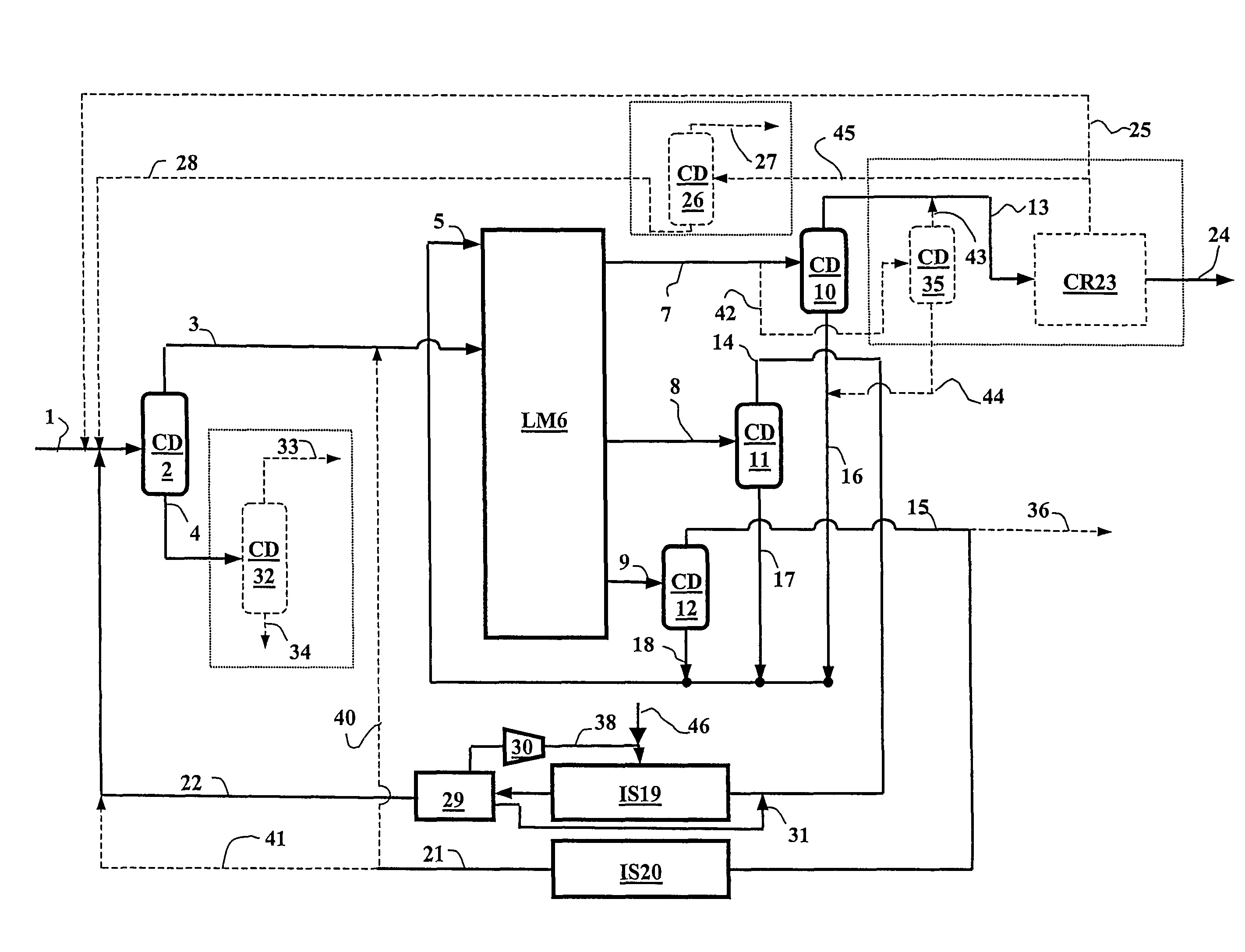

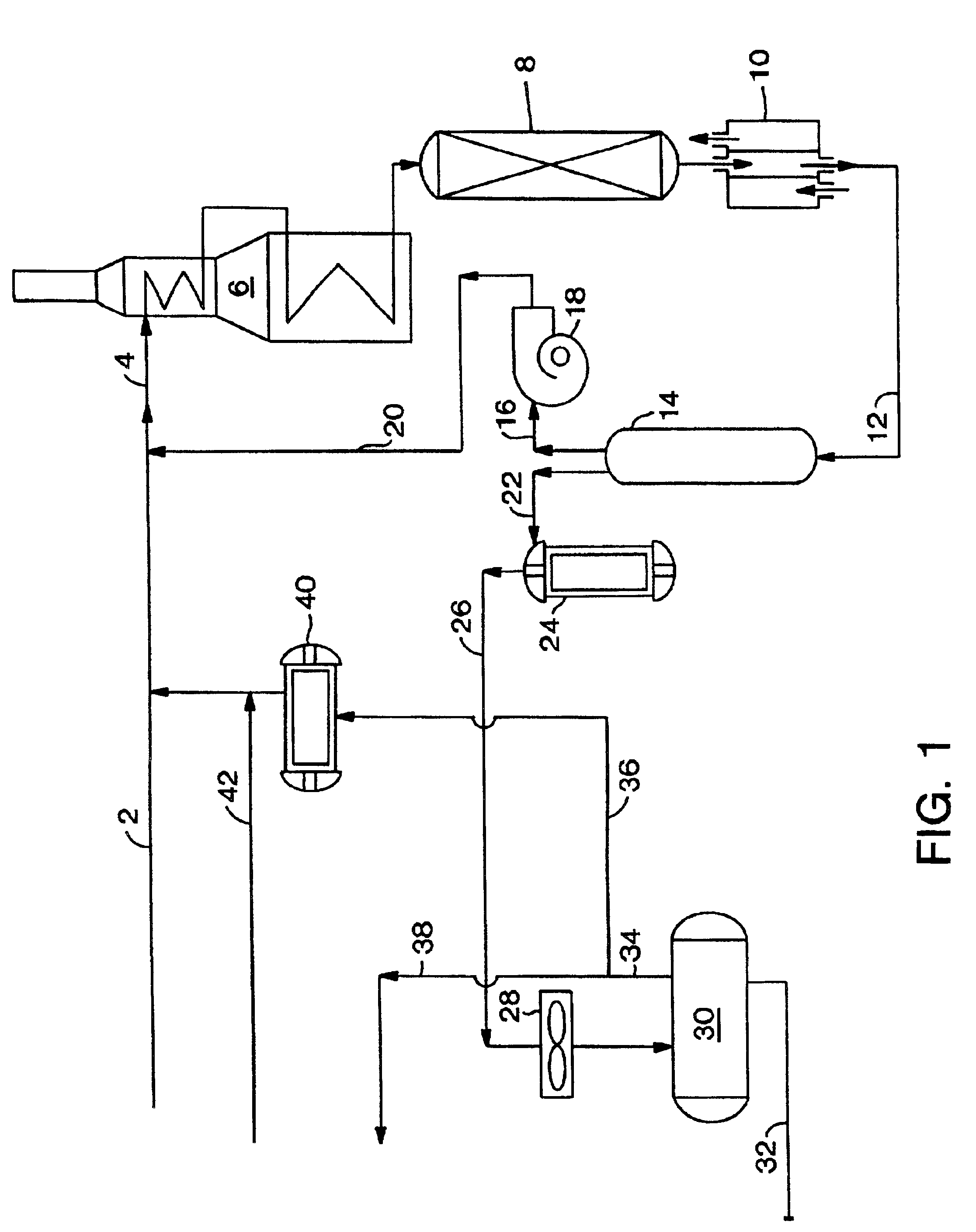

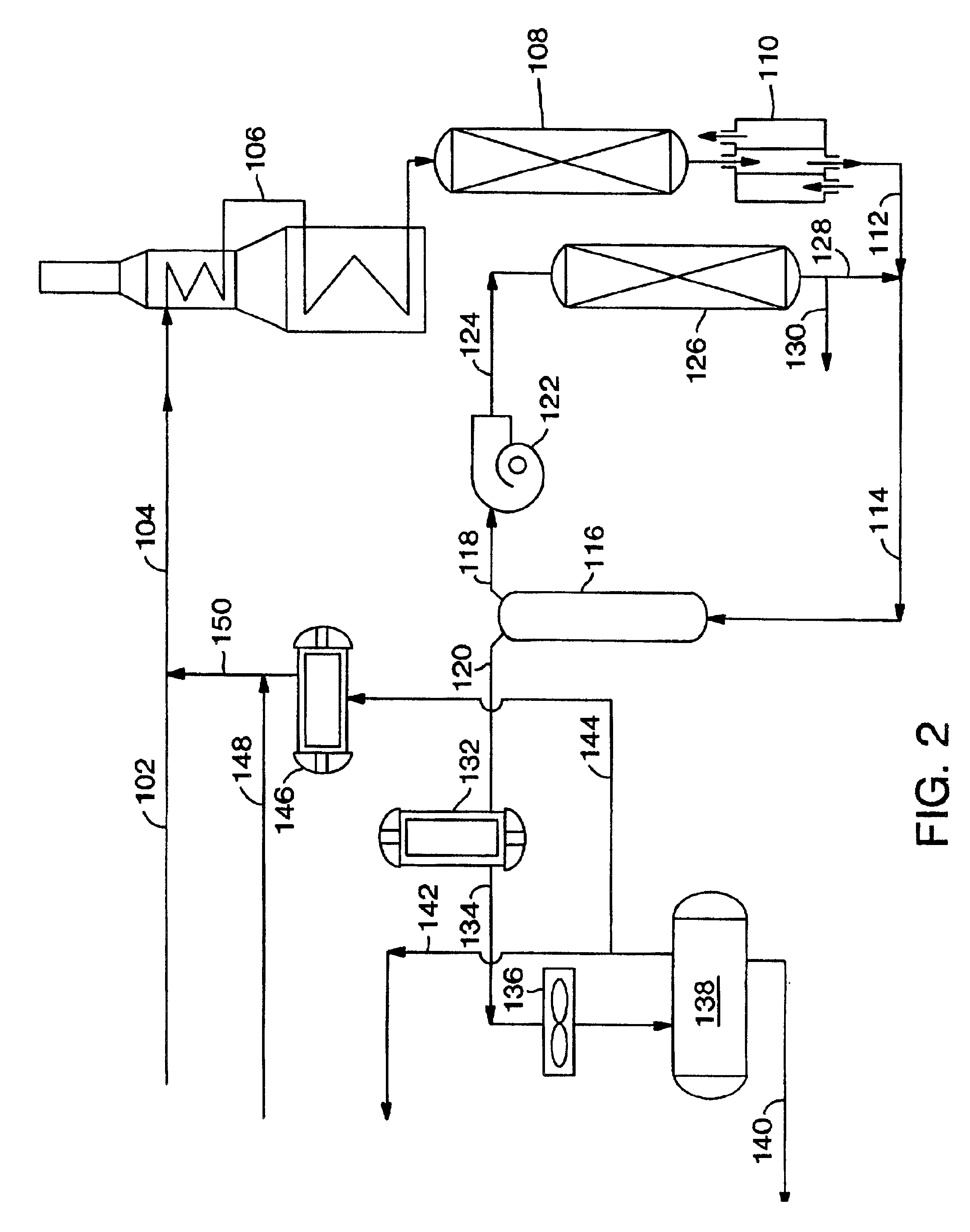

Reaction device for co-producing low-carbon olefin and p-xylene

The invention relates to a reaction device for co-producing low-carbon olefin and p-xylene, which is used for mainly solving the problem of lower yield of low-carbon olefin and p-xylene in the prior art. The problem is well solved by adopting the technical scheme as follows: the reaction device disclosed by the invention mainly comprises a first reaction zone 3, a second reaction zone 4, a third reaction zone 8, a gas-solid separation zone 5 and a regeneration zone 18 of a regenerator; the top of the first reaction zone 3 is connected with the second reaction zone 4; the outlet of the second reaction zone 4 is connected with the gas-solid separation zone 5; a product outlet 14 is arranged on the top of the gas-solid separation zone 5; the bottom of the gas-solid separation zone 5 is connected with the third reaction zone 8; the bottom of the third reaction zone 8 is connected with a stripping zone 11; the bottom of the stripping zone 11 is connected with the regeneration zone 18 of the regenerator through a spent catalyst inclined pipe 13; the bottom of the regeneration zone 18 of the regenerator is connected with a degassing zone 16; and the bottom of the degassing zone 16 is connected with the first reaction zone 3 through a regeneration catalyst inclined pipe 23. The reaction device for co-producing the low-carbon olefin and the p-xylene disclosed by the invention can be used in industrial production of the low-carbon olefin and the p-xylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

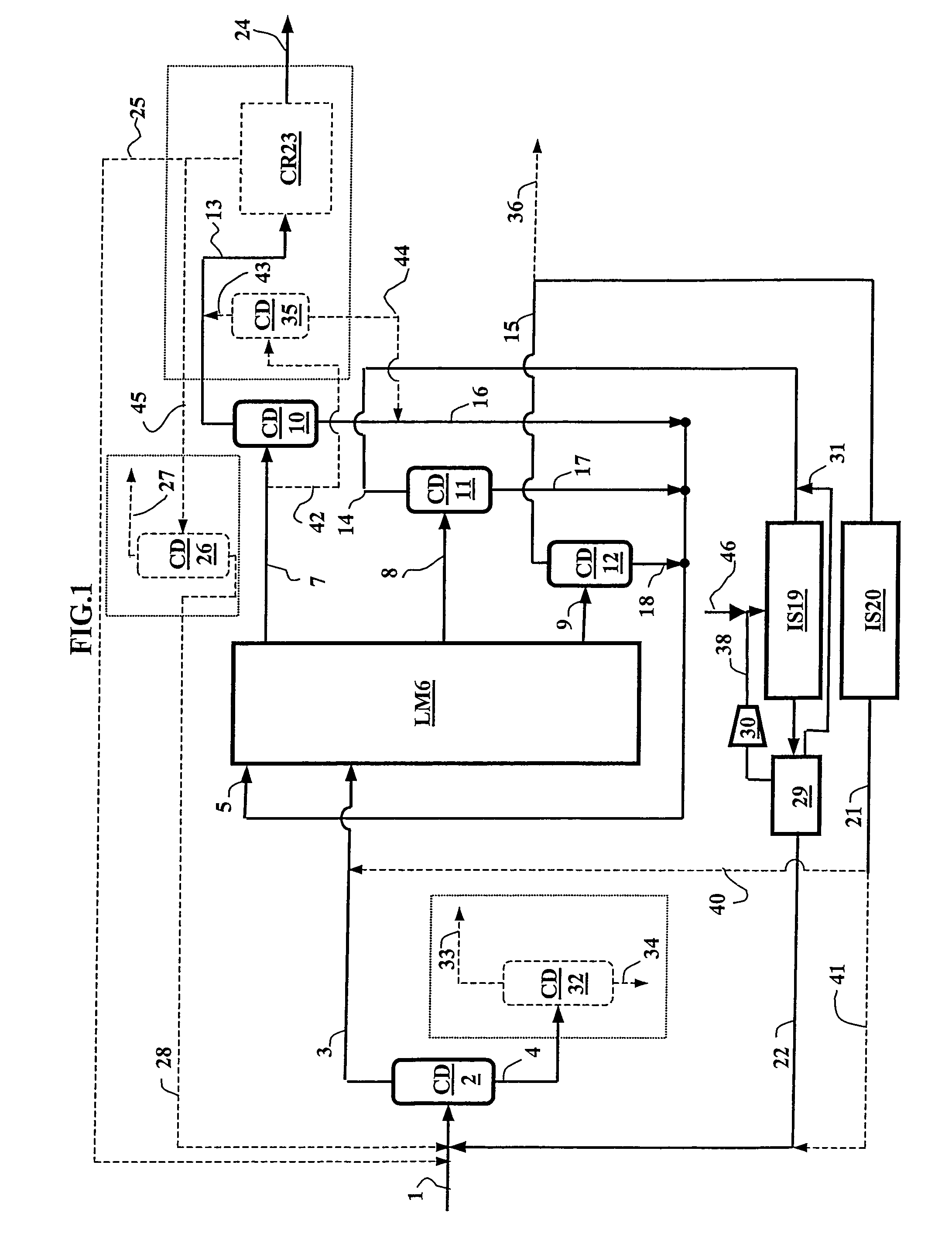

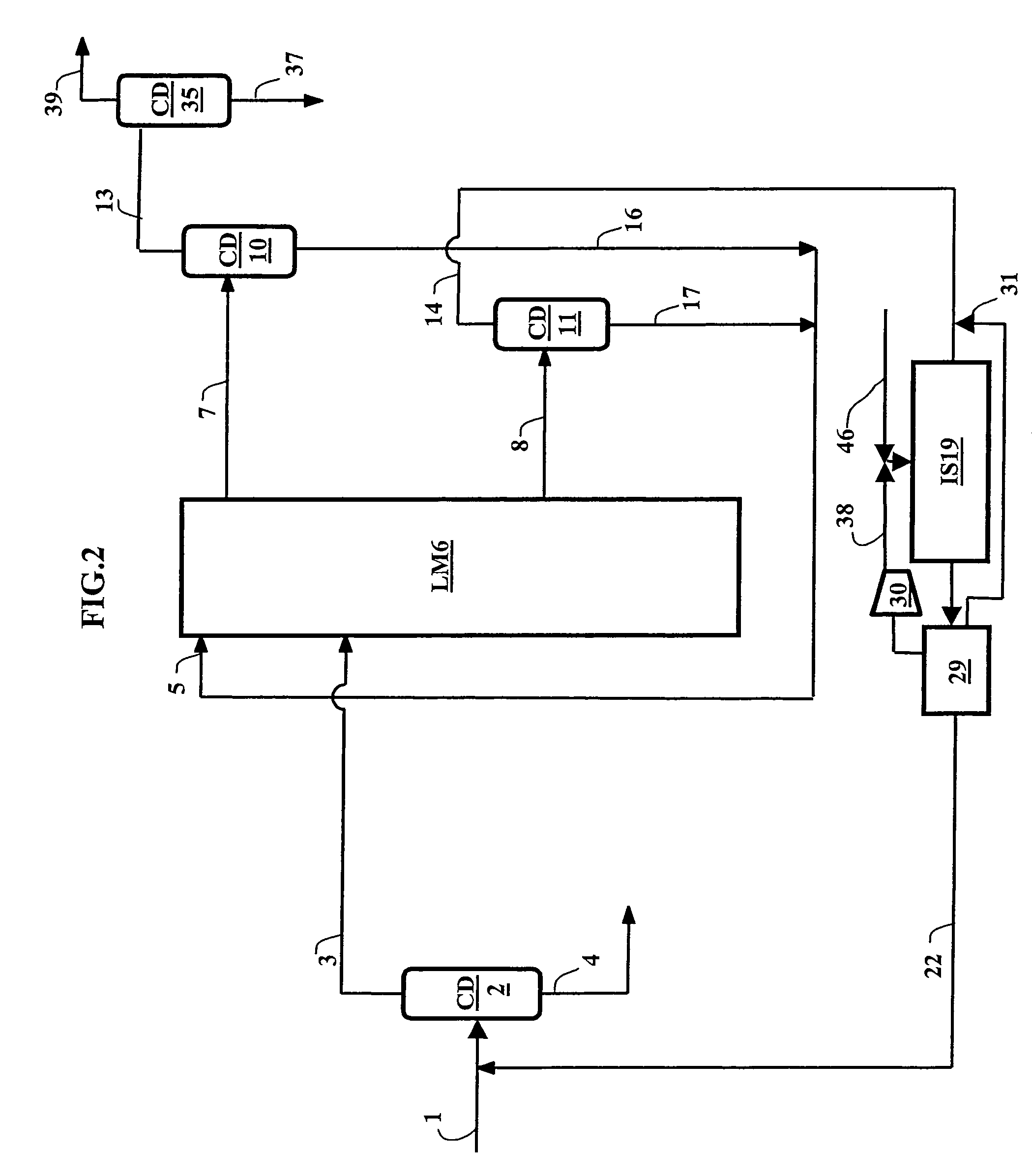

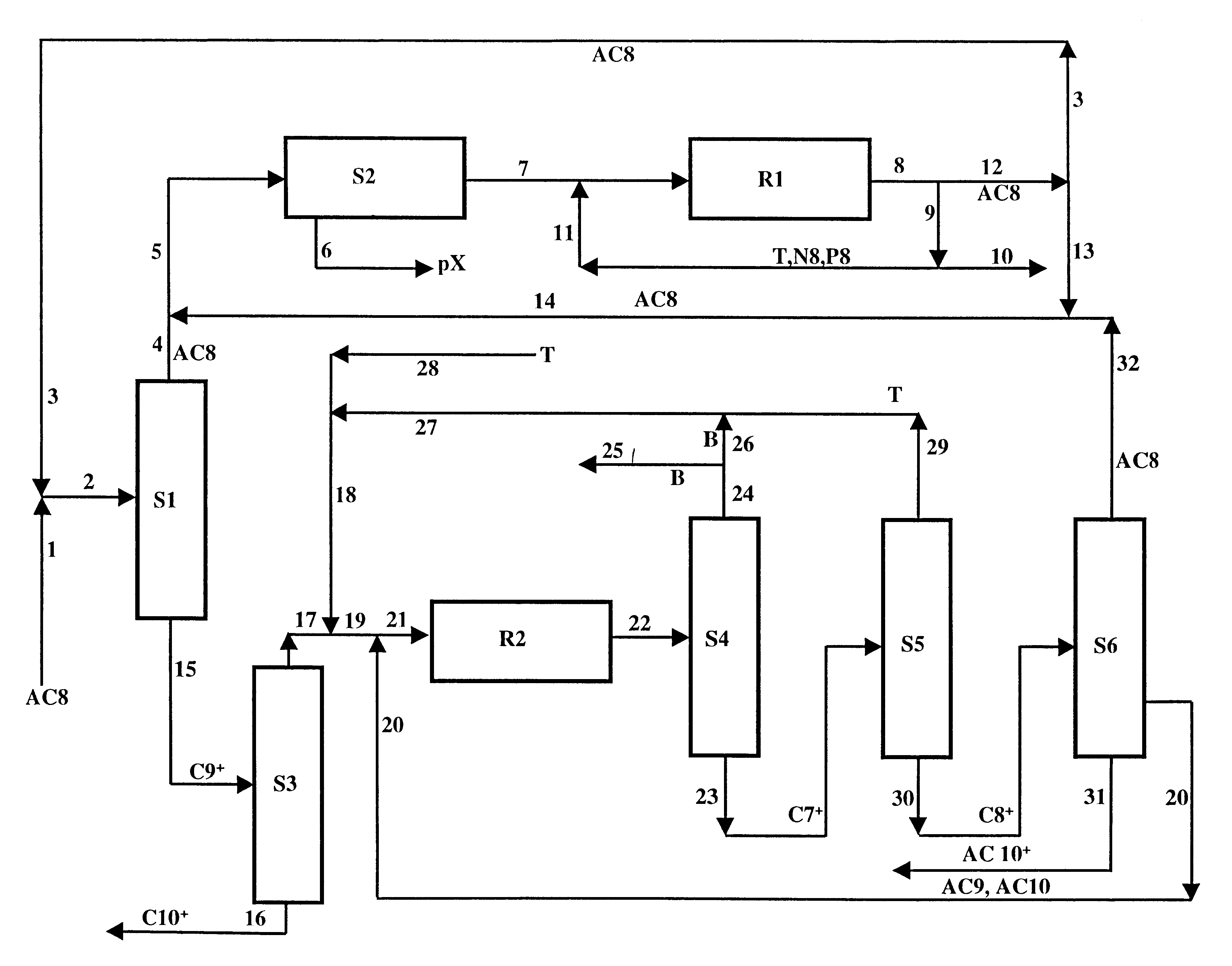

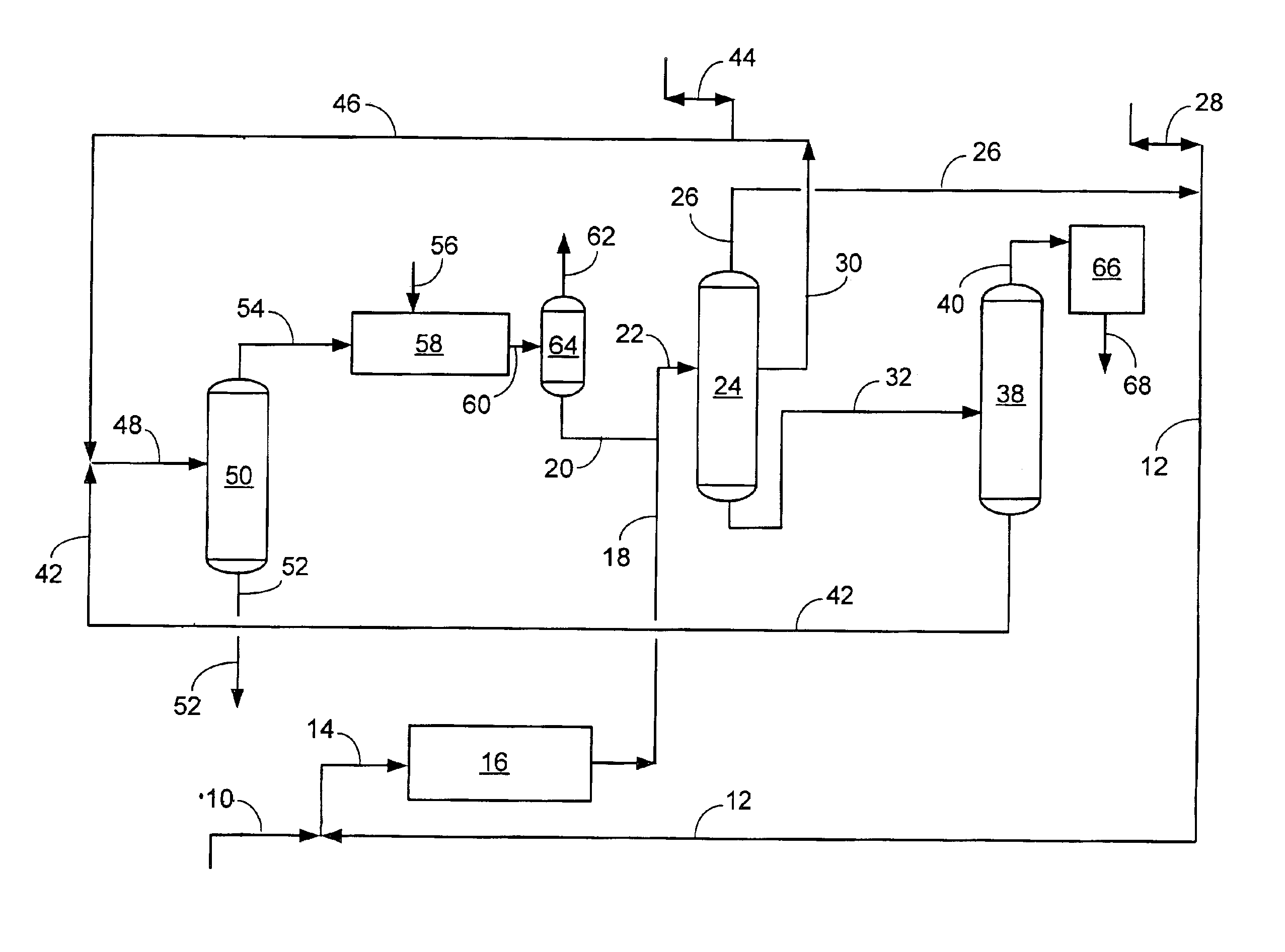

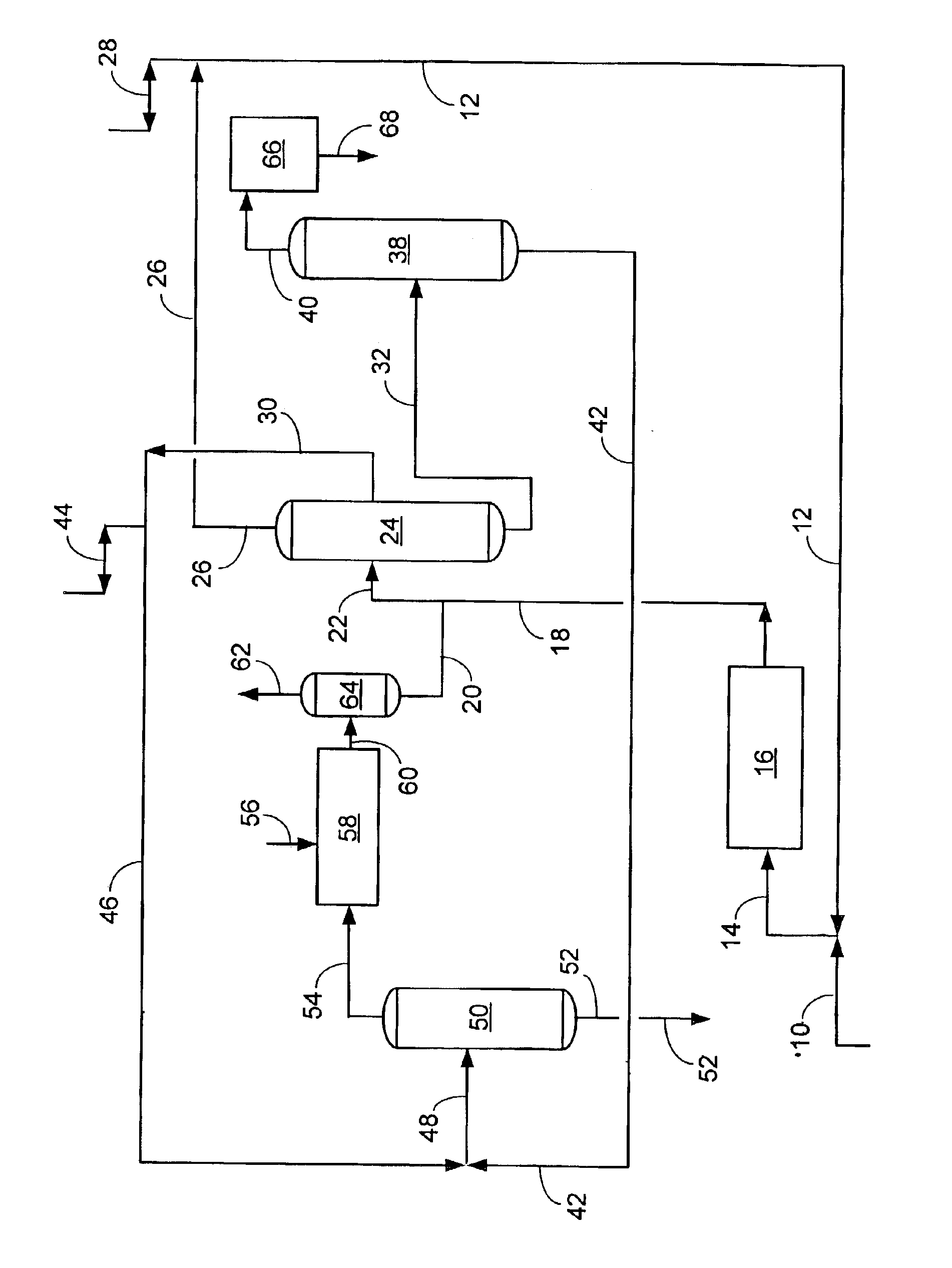

Method for producing paraxylene comprising an adsortion step and two isomerization steps

ActiveUS7915471B2Overcome disadvantagesHydrocarbon by isomerisationSolid sorbent liquid separationIsomerizationSimulated moving bed

A process for producing para-xylene from a hydrocarbon feed is described in which an adsorption column operating as a simulated moving bed with at least five zones delivers an extract, a 2-raffinate and an intermediate raffinate.The extract is distilled and the distillate is optionally re-crystallized to recover para-xylene with a purity of at least 99.7%. The 2-raffinate is distilled then isomerized in a reactor preferably operating in the liquid phase and at a low temperature. The intermediate raffinate with an enriched ethylbenzene content is distilled then isomerized in the vapour phase.

Owner:INST FR DU PETROLE

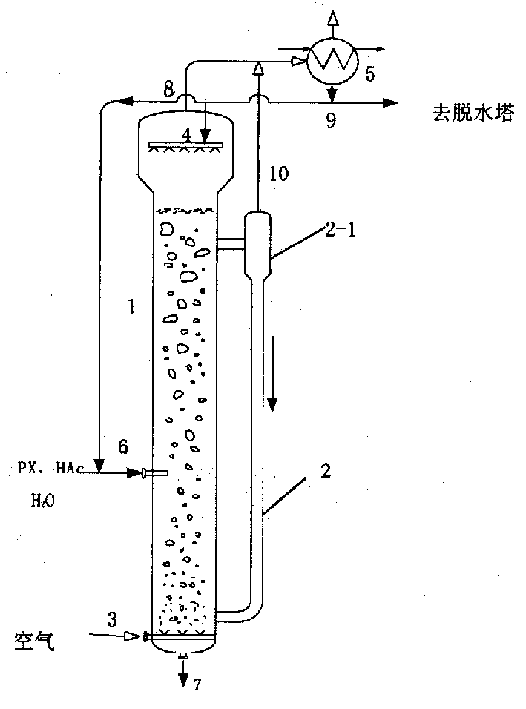

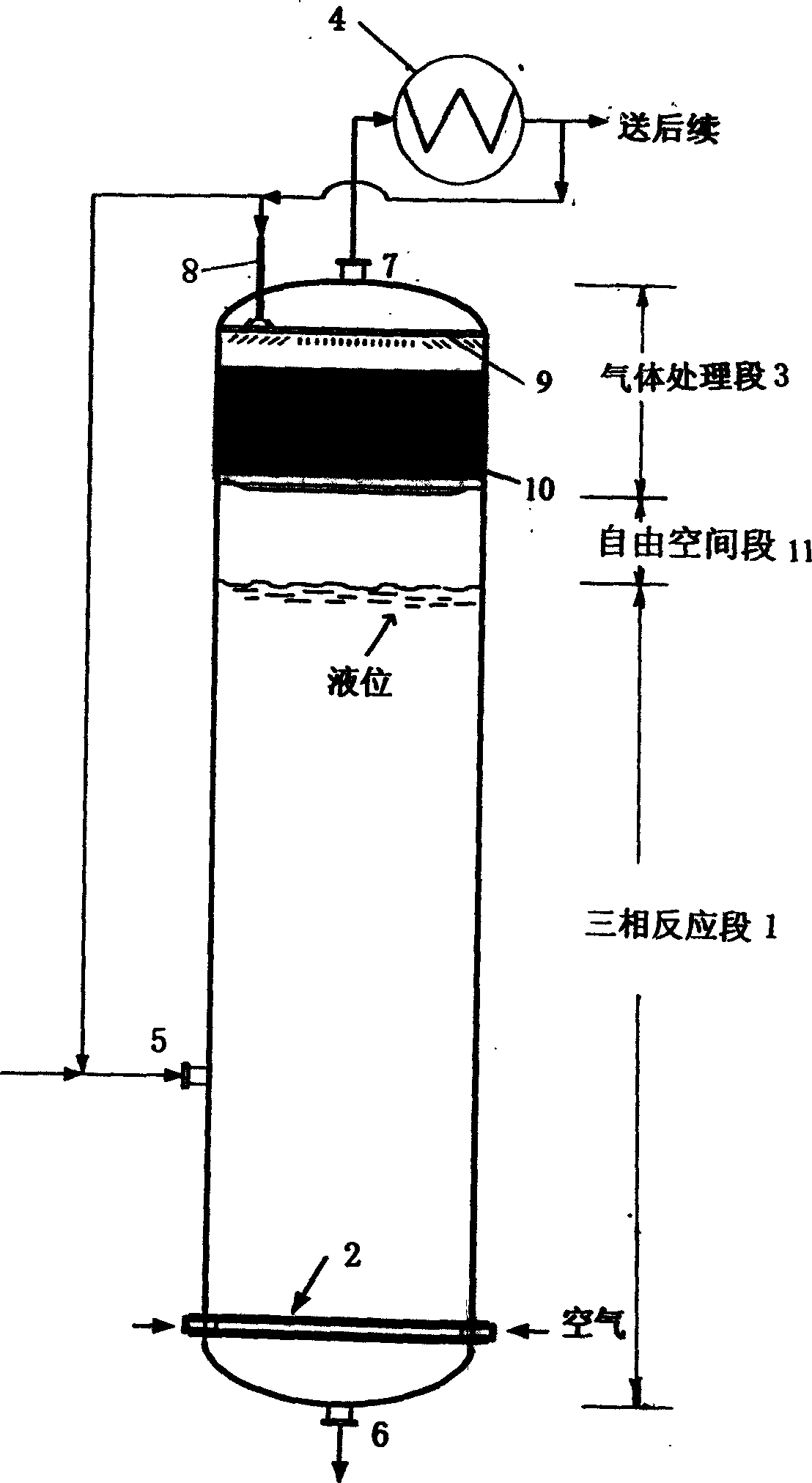

Bubble tower oxidation reaction unit for producing terephthalic acid

InactiveCN1528732ASimple structureLow costOrganic compound preparationCarboxylic compound preparationBubble columnTower

The invention discloses a bubbling column oxidizing reaction device to produce p-phthalic acid, including a uniform straight-cylindrical bubbling column, where there are gas processing segment, free space segment and three phase reaction segment in turn form top to bottom in the bubbling column, there are liquid distributor and filling or liquor-holding board installed in the gas processing segment, there is a gas distributor installed at the bottom of the three phase reaction segment, there is a raw material feeding pipe set at 1 / 4-1 / 2 of the height of reaction segment, there is a discharge pipe set at the bottom of the bubbling column, there is a tail-gas pipe and a liquor condensate reflux pipe on the top of the bubbling column, the inlet of the condenser is linked with the tail-gas pipe, the gas outlet is linked with the follow-up tail-gas processing unit, the liquid outlet of the condenser is linked with raw material feeding pipe, liquor condensate reflux pipe and follow-up dehydration tower. It is applied to the process of preparing p-phthalic acid by high temperature oxidization.

Owner:ZHEJIANG UNIV

Method for preparing p-xylene and co-producing light olefins by toluene and methylating reagent

ActiveCN101456786AHigh activitySimple processMolecular sieve catalystsHydrocarbonsBiological activationCarbon deposit

The invention relates to a fluidized bed reaction method for preparing para-xylene and coproducing low-carbon olefin with high selectivity by reacting toluene and a methylated reagent. The method adopts fluidized bed reaction technology and uses a catalyst to highly selectively produce the para-xylene and simultaneously highly selectively coproduce ethylene and propylene. The method is characterized in that the raw materials, namely the toluene and the methylated reagent enter a vaporizer for mixing and gasification, pass through a distribution plate, enter a fluidized bed reactor, and are taken as a fluidizing medium and subjected to catalysis with a fluidized catalyst; and gaseous mixture products after reaction are exhausted from the top of a tower and separated. The selectivity of the para-xylene in products in a xylene isomer is more than 99 weight percent, and the selectivity of the ethylene and the propylene in low-carbon hydrocarbon between C1 and C5 is more than 90 weight percent. The carbon deposit catalyst in the reactor continuously enters a regenerator for regeneration and activation and enters the reactor for recycling, can be continuously regenerated and has stable activity; and the method has simple technological flow and is easy to realize large-scale industrialization.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

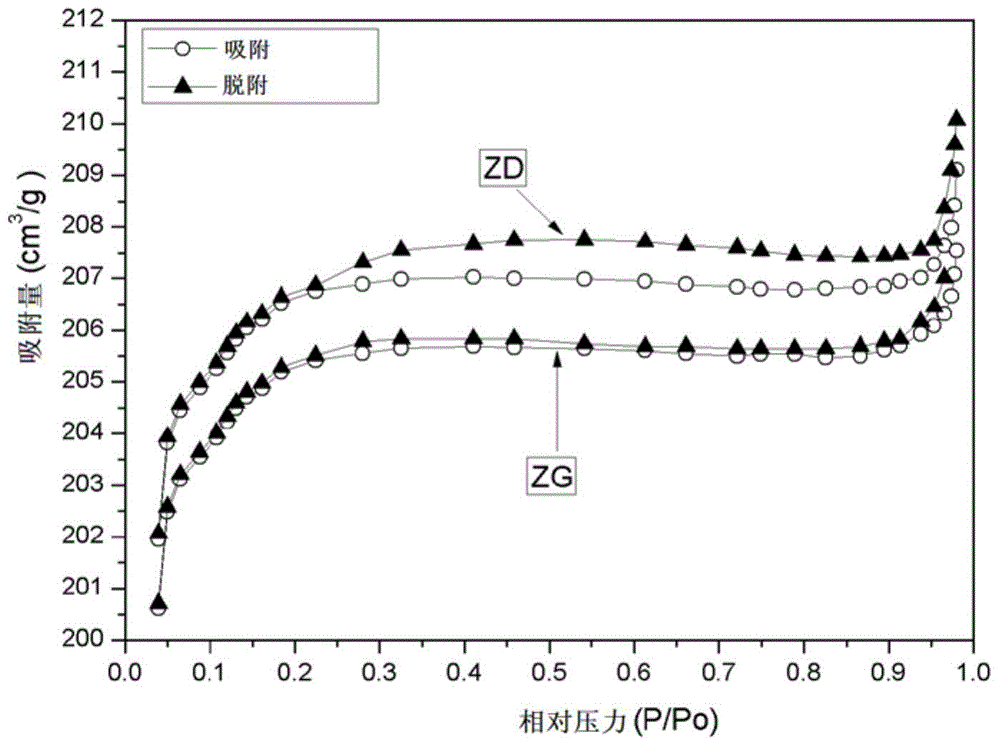

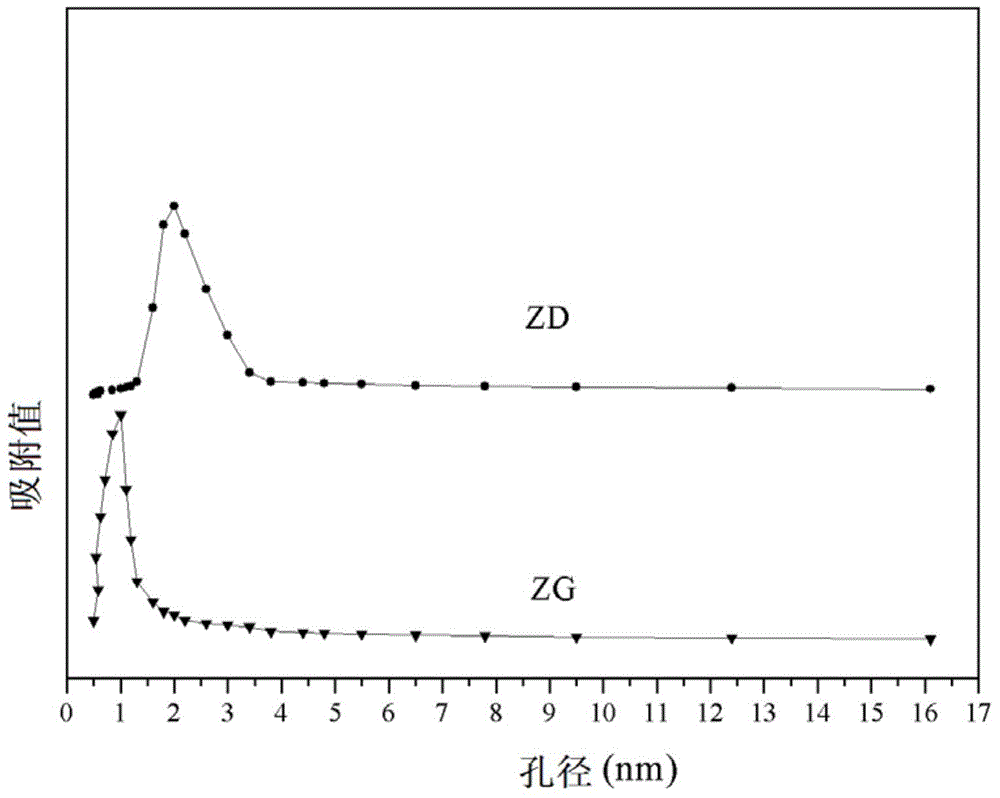

Mesoporous X-type molecular sieve, adsorbent based on molecular sieve, and preparation and application thereof

InactiveCN104477937AHigh adsorption selectivityImprove adsorption capacityOther chemical processesFaujasite aluminosilicate zeolitePore distributionSorbent

The invention relates to a preparation method of a mesoporous X-type molecular sieve and a method for preparing an adsorbent by using the molecular sieve as an active component. The prepared adsorbent based on the mesoporous X-type molecular sieve is used as a paraxylene adsorptive separation adsorbent. The method for preparing the mesoporous X-type molecular sieve comprises the following steps: by using water glass as a silicon source and aluminum hydroxide as an aluminum source, adding a template, and carrying out hydrothermal synthesis to obtain the mesoporous X-type molecular sieve. The mesoporous molecular sieve and kaolin are proportionally molded to obtain 0.3-0.8mm granules, and the granules are subjected to barium ion or (and) potassium ion exchange until the exchange degree is greater than 99%, thereby obtaining the adsorbent which has excellent adsorptive separation capacity for paraxylene in C8 aromatic hydrocarbons. Compared with the prior art, the active component mesoporous X-type molecular sieve of the adsorbent, which is prepared by using the template, has the crystal form structure of the X-type molecular sieve and the pore distribution of the mesoporous and microporous dual models; the mesoporous pore size distribution is 2nm or so; and thus, the problem of overlow mass transfer rate in the adsorbent can be solved.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

Carbohydrate route to para-xylene and terephthalic acid

ActiveUS8314267B2Organic compound preparationHydrocarbon by hydrocarbon and non-hydrocarbon condensationFuranCycloaddition

Catalytic processes for the conversion of 2,5-dimethyl furan (DMF) to para-xylene are described. Para-xylene is a key product that is currently obtained commercially from petroleum sources. However, it has now been determined that the cycloaddition of ethylene to DMF provides an alternative route to para-xylene. Advantageously, the DMF starting material for the processes may be synthesized from carbohydrates (e.g., glucose or fructose), thereby providing a pathway that relies at least partly, if not completely, on renewable feedstocks.

Owner:UOP LLC

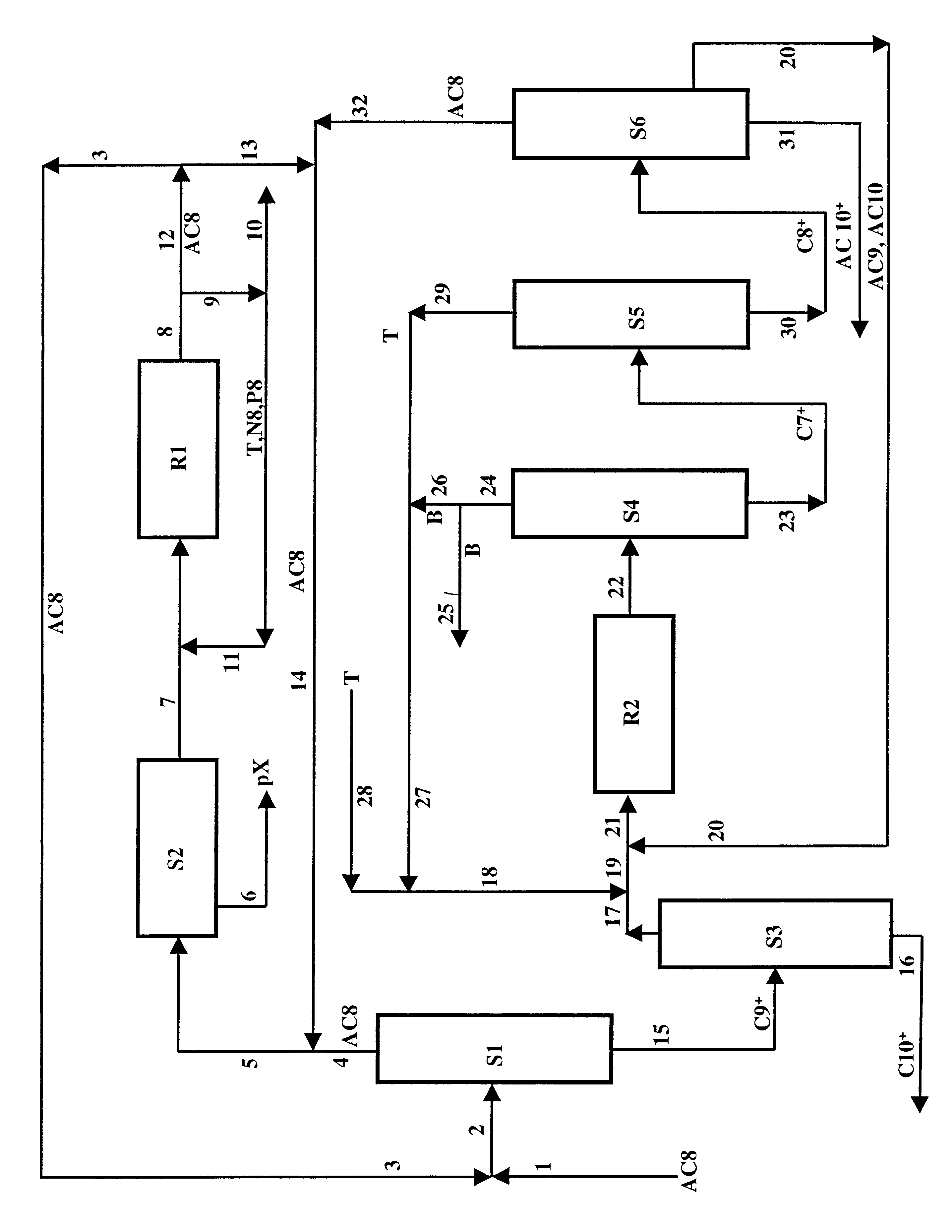

Production of a xylene isomer in three stages: separation, isomerization with a catalyst with an EUO zeolite base and transalkylation with recycling of C10-aromatic compounds

A process for the production of at least one xylene isomer, paraxylene, metaxylene or orthoxylene from an aromatic feedstock that has 7 to 10 carbon atoms per molecule. The process comprises a stage for transalkylation of C7- and C9-aromatic compounds, a stage for separation of xylenes and a stage for isomerization of xylenes. The isomerization catalyst used in the process comprises at least one EUO zeolite composition whose crystals are grouped in aggregates that have a grain size with a value of Dv,90 less than or equal to 500 microns and at least one element of group VIII.

Owner:INST FR DU PETROLE

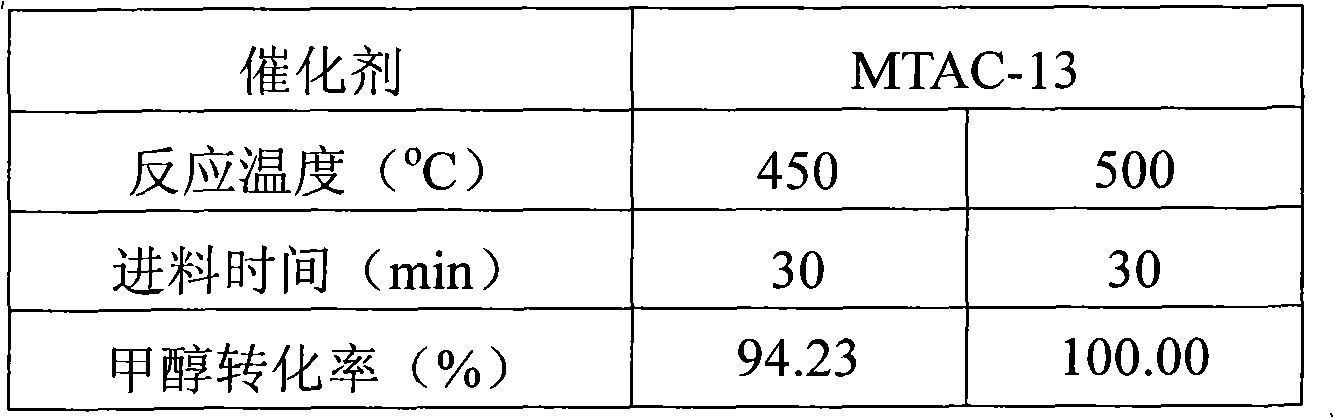

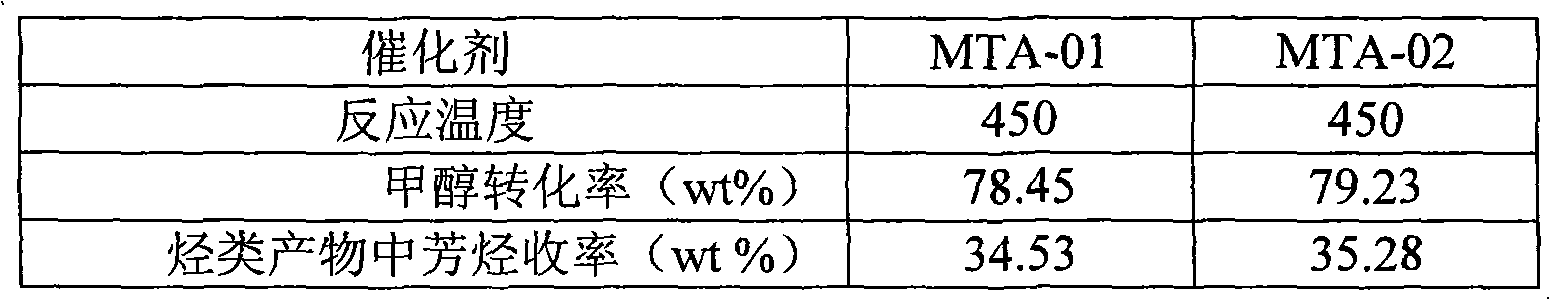

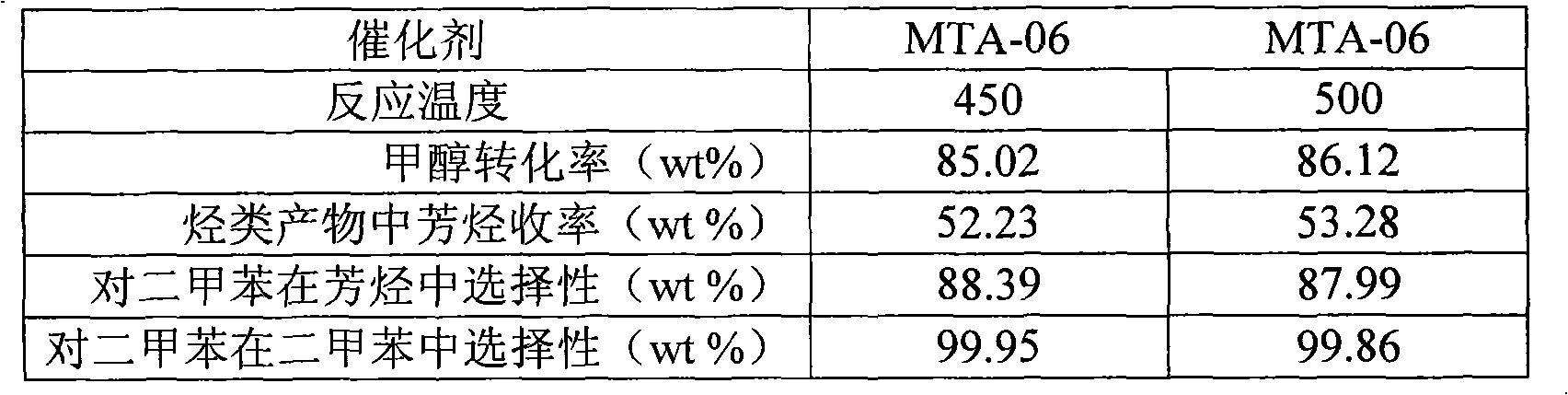

High yield preparation method of paraxylene by methanol/dimethyl ether conversion

InactiveCN101607864AMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveAromatic hydrocarbon

The invention relates to a high yield preparation method of paraxylene by methanol / dimethyl ether conversion and the method can increase the yield of paraxylene in the converted products of methanol / dimethyl ether by adopting molecular sieve based catalyst which is modified with metals or through silylanization and adding aromatic hydrocarbons in the raw materials. The aromatic hydrocarbons is the separated benzene and / or toluene which is generated through the methanol / dimethyl ether conversion reaction and part or whole of aromatic hydrocarbons is recycled in the reaction system; otherwise, additional benzene and / or toluene is added in the raw materials. By adopting the method, the content of aromatic hydrocarbons in the products of the methanol / dimethyl ether conversion reaction can be more than 50wt%; wherein, the content of paraxylene in aromatic hydrocarbons is more than 80wt% and the selectivity of paraxylene in xylene isomers is more than 99wt%.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Binderless adsprbents and their use in the adsorptive separation of para-xylene

ActiveUS20090326309A1High adsorbent capacity/mass transfer propertyIncreased para-xylene productivityMaterial nanotechnologyMolecular sieve catalystsSorbentSimulated moving bed

Adsorbents and methods for the adsorptive separation of para-xylene from a mixture containing at least one other C8 aromatic hydrocarbon (e.g., a mixture of ortho-xylene, meta-xylene, para-xylene, and ethylbenzene) are described. Suitable binderless adsorbents (e.g., formulated with the substantial absence of an amorphous material that normally reduces selective pore volume), particularly those with a water content from about 3% to about 5.5% by weight, improve capacity and / or mass transfer. These properties are especially advantageous for improving productivity in low temperature, low cycle time adsorptive separation operations in a simulated moving bed mode.

Owner:UOP LLC

Process for producing para-xylene

InactiveUS6878855B2High yieldExcellent isomerization performanceHydrocarbon by isomerisationMolecular sieve catalystIsomerizationP-Xylene

Owner:EXXONMOBIL CHEM PAT INC

Process and apparatus for ethylbenzene production and transalkylation to xylene

InactiveUS6855854B1High selectivityHigh yieldHydrocarbon by isomerisationMolecular sieve catalystCarbon numberGas phase

The use of two transalkylation catalysts to react aromatic compounds of carbon number nine (and heavier carbon numbers) with benzene to form carbon number eight aromatics is disclosed. The two catalyst system preserves ethyl-group species on the heavier aromatics that would otherwise de-ethylate over most gas-phase transalkylation catalysts to form undesired ethane gas with benzene or toluene. Thus, by using a transalkylation step to save ethylbenzene, a greater yield of para-xylene or other carbon number eight aromatics may be achieved within an integrated complex. An apparatus and process for the two transalkylation catalyst system is disclosed with a liquid-phase unit and a gas-phase unit.

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com