Method for preparing p-xylene through methanol/dimethyl ether conversion

A p-xylene and dimethyl ether technology, applied in the field of p-xylene preparation, can solve the problems of low market value and complicated products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

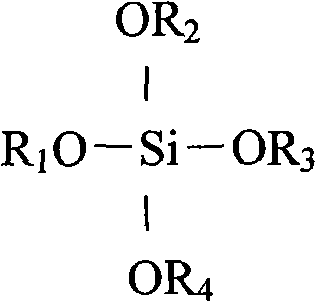

[0028] The present invention uses the preparation method of catalyst, wherein the siloxane compound is shown in the following formula:

[0029]

[0030] where R 1 , R 2 , R 3 and R 4 is an alkyl group of 1-10 carbon atoms.

[0031] The invention uses a catalyst preparation method, wherein the siloxane-based compound is ethyl silicate.

[0032] The reaction mode of the present invention is a contact reaction between the reaction material and the catalyst, the reaction temperature range is 350-550°C, the preferred temperature range is 400-500°C; the reaction pressure is 0-2MPa, preferably 0-1MPa; methanol / dimethyl Ether feed weight space velocity is 0.1-20h -1 , preferably 1-10h -1 . The selectivity of p-xylene in the reaction aromatic products is greater than 80wt%, and the selectivity of p-xylene among xylene isomers is greater than 99wt%.

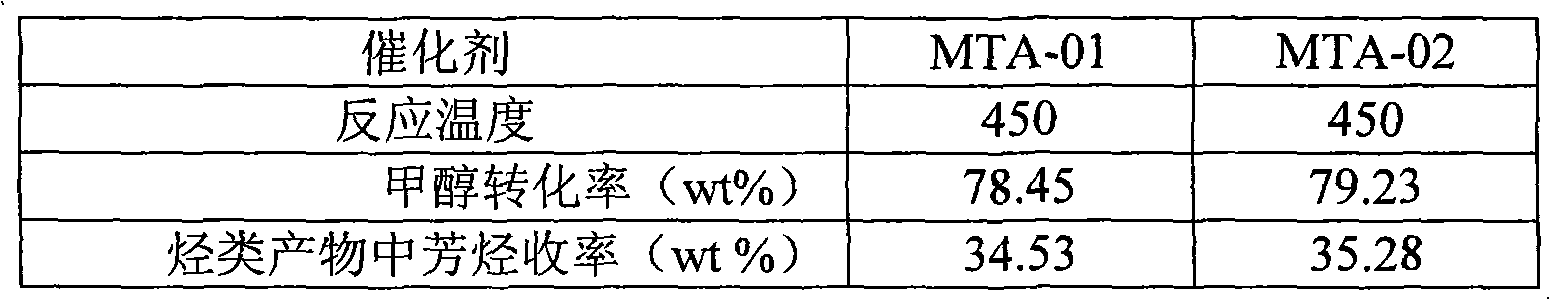

Embodiment 1

[0034] Embodiment 1 fixed-bed catalyst preparation

[0035] 1) 500g ZSM-5 zeolite molecular sieve former powder (Nankai University Catalyst Factory) (SiO 2 / Al 2 o 3 =50) Roast at 550°C to remove template agent, exchange 4 times with 0.5 molar equivalent ammonium nitrate solution in 80°C water bath, dry in air at 120°C after exchange, and roast at 550°C for 3 hours to obtain HZSM-5 Zeolite molecular sieve.

[0036] 2) Take 20 g of the HZSM-5 zeolite molecular sieve prepared in step 1) and form it into tablets, obtain a 40-60 mesh sample after crushing and screening, divide it into two parts, and use two kinds of nitric acid with different mass concentrations of 3% and 9% respectively Zinc [Zn(NO 3 ) 2 ] solution at room temperature for 4 hours, after drying at 120°C, roasting in air at 550°C for 6 hours; using orthoethyl silicate (TEOS) to impregnate zinc-modified HZSM-5 zeolite molecular sieve at room temperature for 24 hours, and pour out the upper liquid for 120 ℃ dry...

Embodiment 2

[0037] Embodiment 2 fixed-bed catalyst preparation

[0038] Get 20g of the HZSM-5 zeolite molecular sieve prepared in Example 1 for tablet molding, obtain a 40-60 mesh sample after crushing and screening, divide it into two parts, and use molybdenum nitrate [Mo (NO 3 ) 3 ] The solution was impregnated with HZSM-5 molecular sieve at room temperature for 4 hours, and after drying at 120°C, it was roasted in air at 550°C for 6 hours; the HZSM-5 zeolite molecular sieve after molybdenum modification was impregnated with orthoethyl silicate (TEOS) at room temperature for 24 hours, and poured out The upper layer liquid was dried at 120°C and calcined in air at 550°C for 6 hours to obtain the HZSM-5 catalyst jointly modified by metal and silanization, and the Mo content in the catalyst was about 1wt% and 3wt%, respectively. The two catalysts were named MTA-03 and MTA-04, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com