Pressure sensor with porous graphene foam structure and preparation method thereof

A porous graphene, pressure sensor technology, applied in the field of sensors, can solve the problems of low sensitivity of flexible pressure sensors, expensive materials, small measurable range, etc., and achieve high market value and industrialization potential, low price, low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

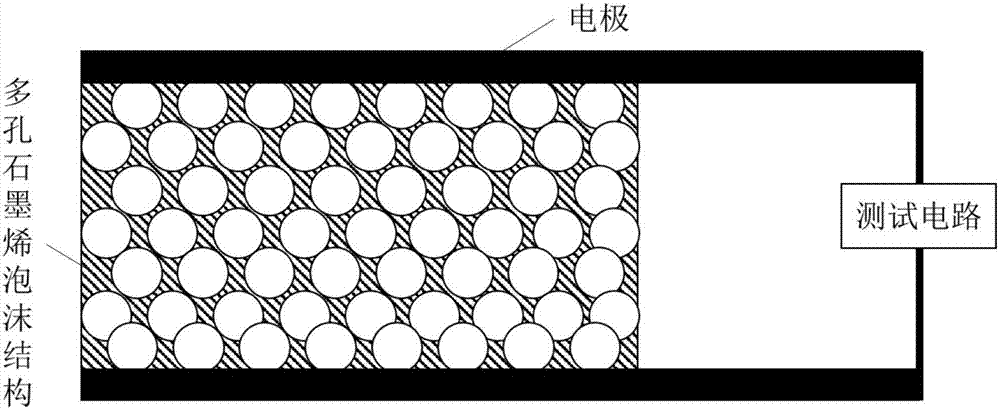

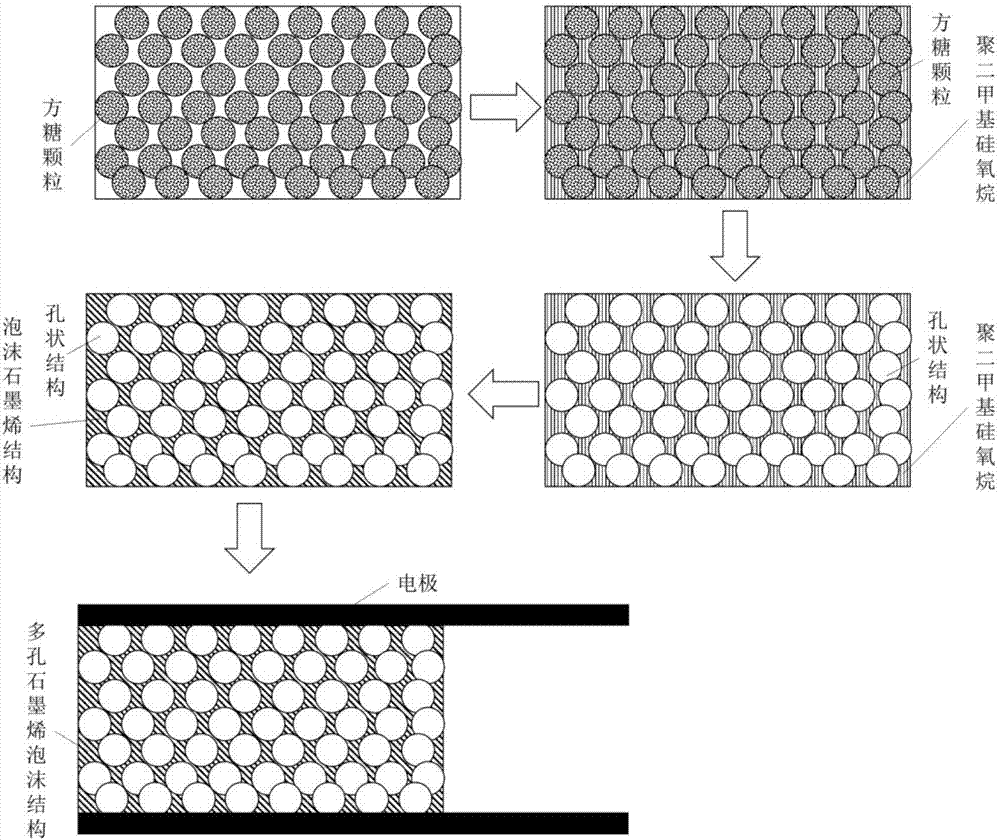

[0029] figure 1 The schematic diagram of the basic structure of the novel pressure sensor provided by the present invention, wherein the sensor includes an electrode, a porous graphene foam structure, and silver paste is used as the connection between the porous graphene foam structure and the electrode to increase conductivity, and the electrode is aluminum The electrodes are bonded on the upper and lower sides of the porous graphene foam structure through silver paste. The electrodes are connected to the test circuit. The porous graphene foam structure is composed of porous polydimethylsiloxane and reduced graphene oxide.

[0030] Since the porous graphene foam structure has more porous structures, when pressure acts on the pressure sensor, the structure will be squeezed, and the connection state of the reduced graphene oxide will change, and its resistance will also change. Thereby converting the pressure signal into an electrical signal. The electrodes are made of alumi...

Embodiment 2

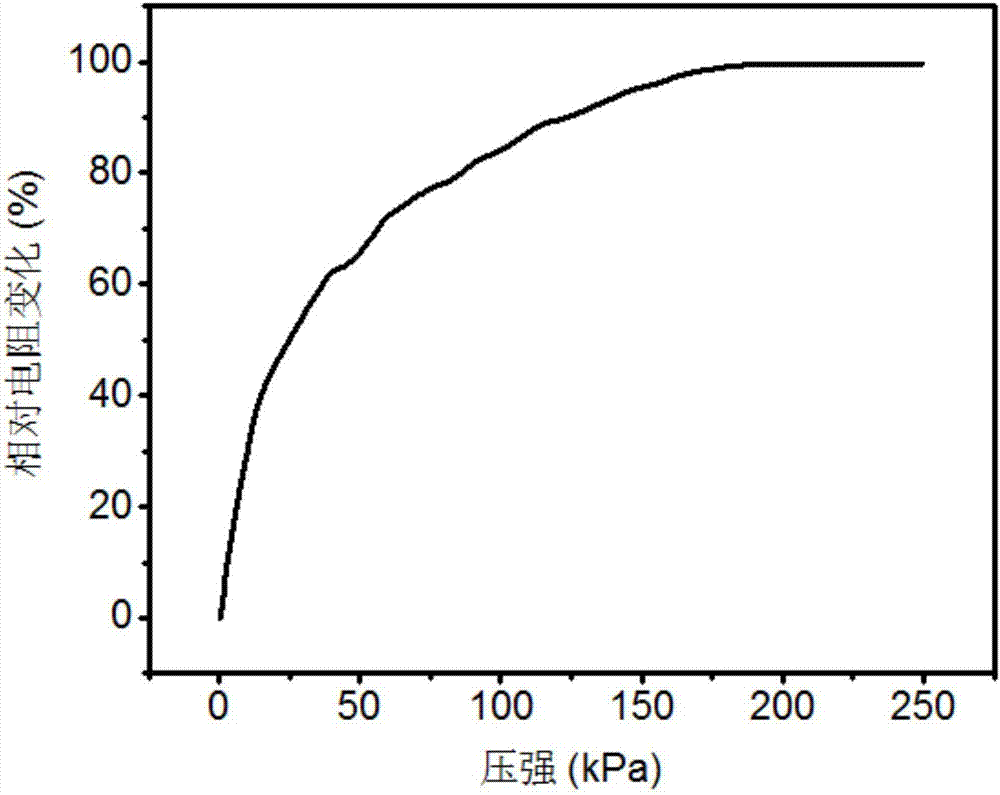

[0037] The pressure sensor made in Example 1 was connected to the test circuit, and the pressure was applied with a pull-pressure tester (model SHIMADZUAGS-X), and the resistance value was recorded with a digital multimeter (model ROGOL DM3068). When no pressure is applied, the initial resistance is 300 kΩ.

[0038] image 3 It shows the pressure characteristic curve of the sensor in Example 1 of the present invention, wherein the measurement range can reach above 150kPa, and the sensitivity can reach above 3.5, and the sensor that reflects the pressure has a larger sensitivity and a larger measurement range at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com