Patents

Literature

475 results about "Graphene foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

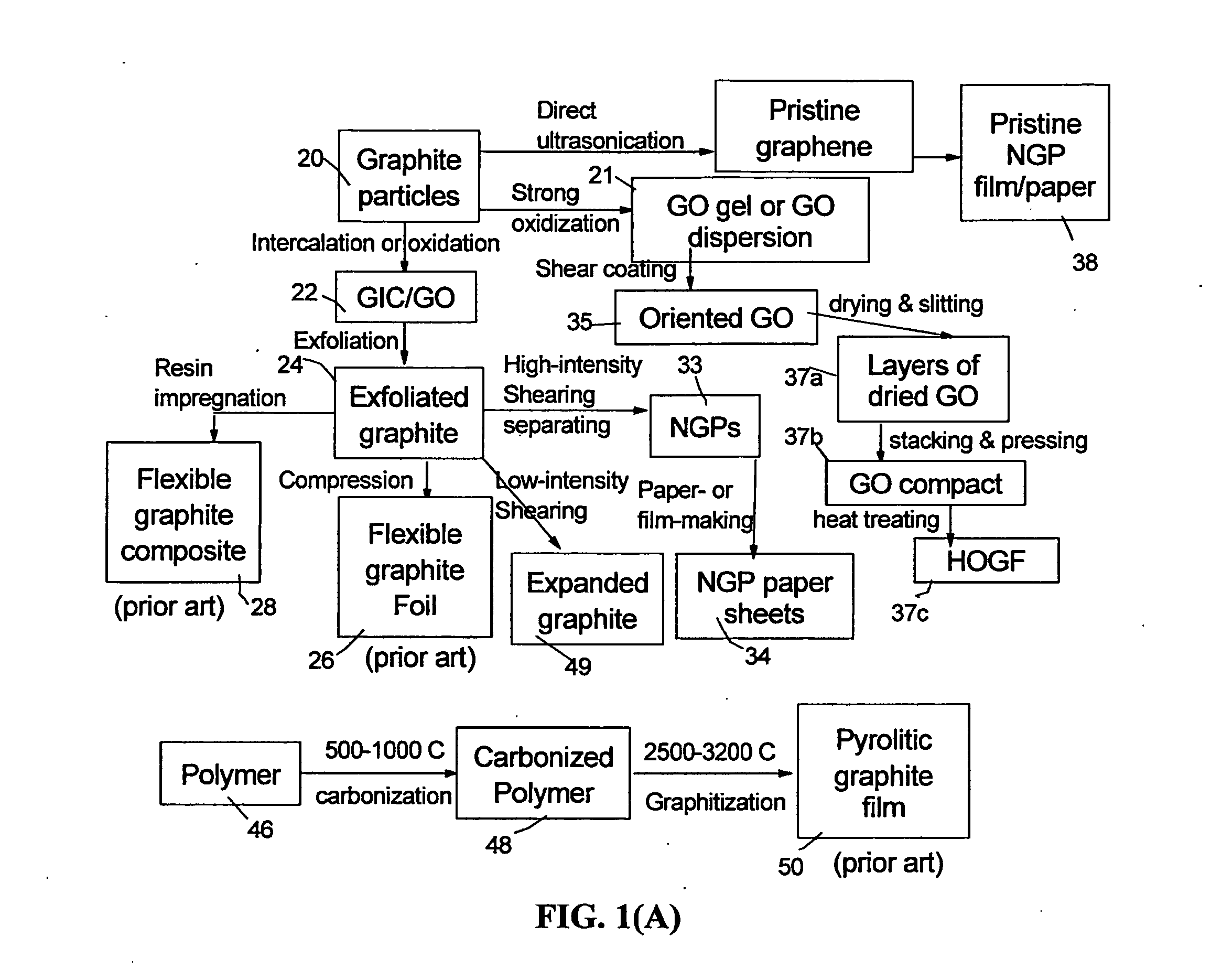

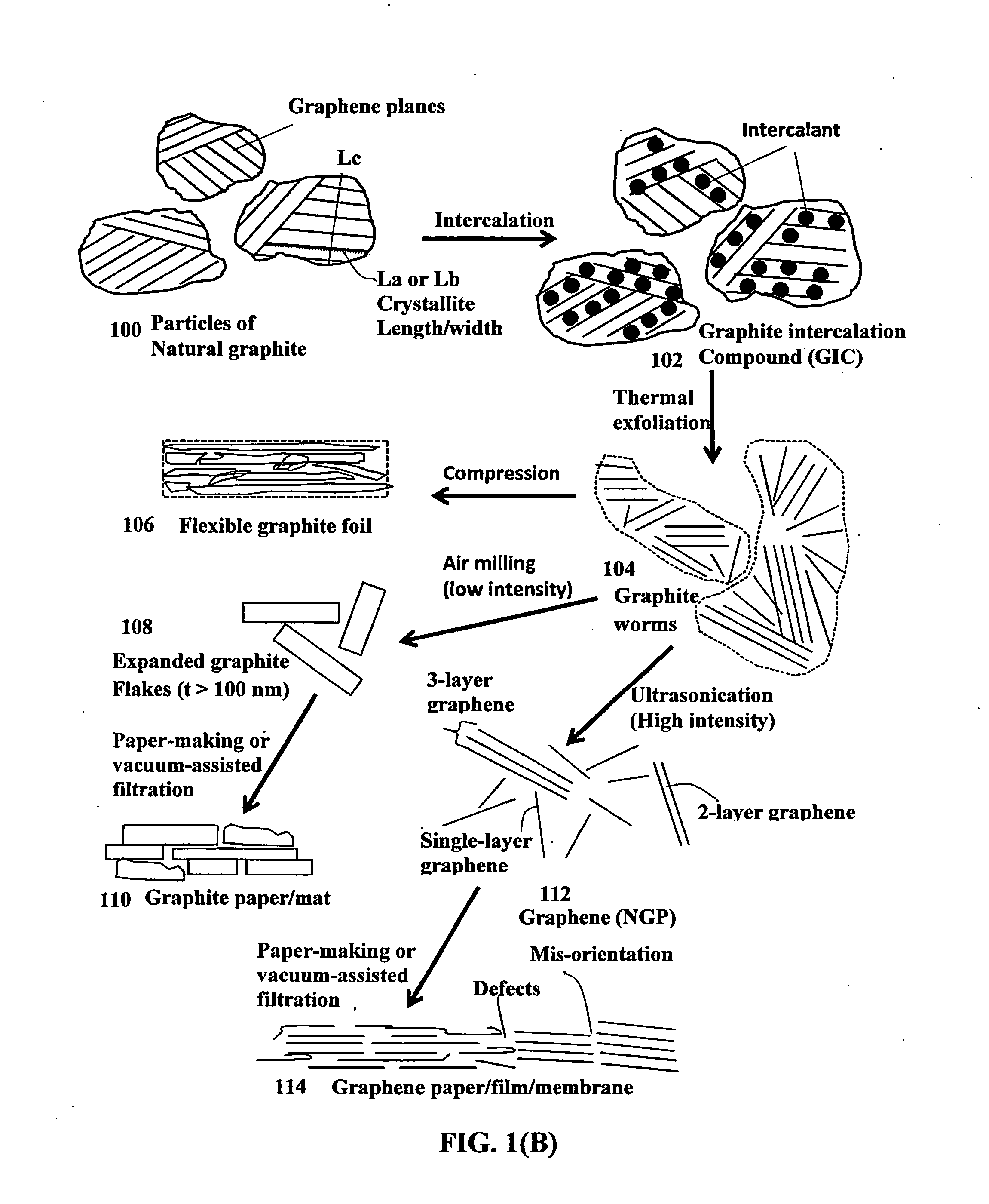

Graphene foam is a solid, open-cell foam made of single-layer sheets of graphene. It is a candidate substrate for the electrode of lithium-ion batteries.

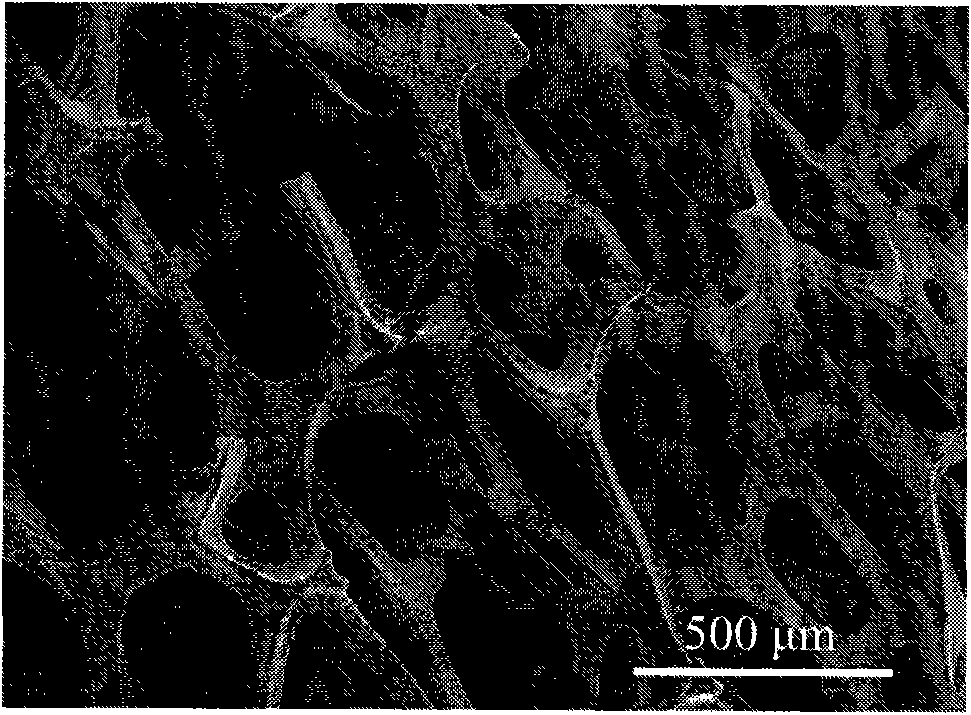

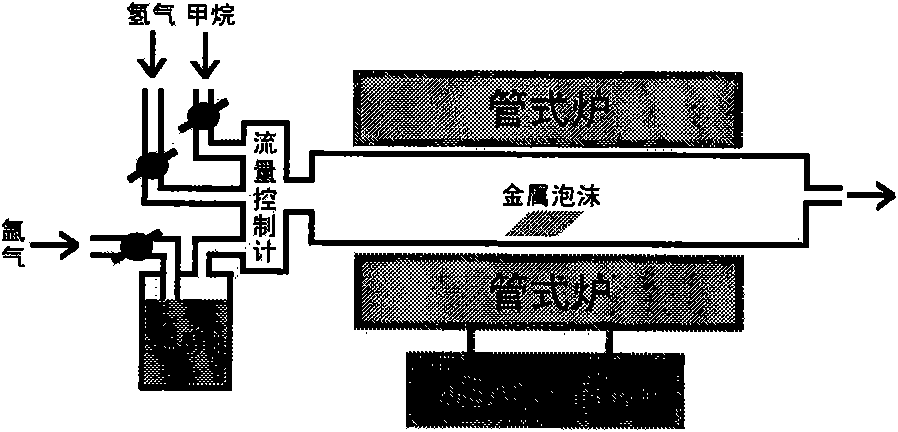

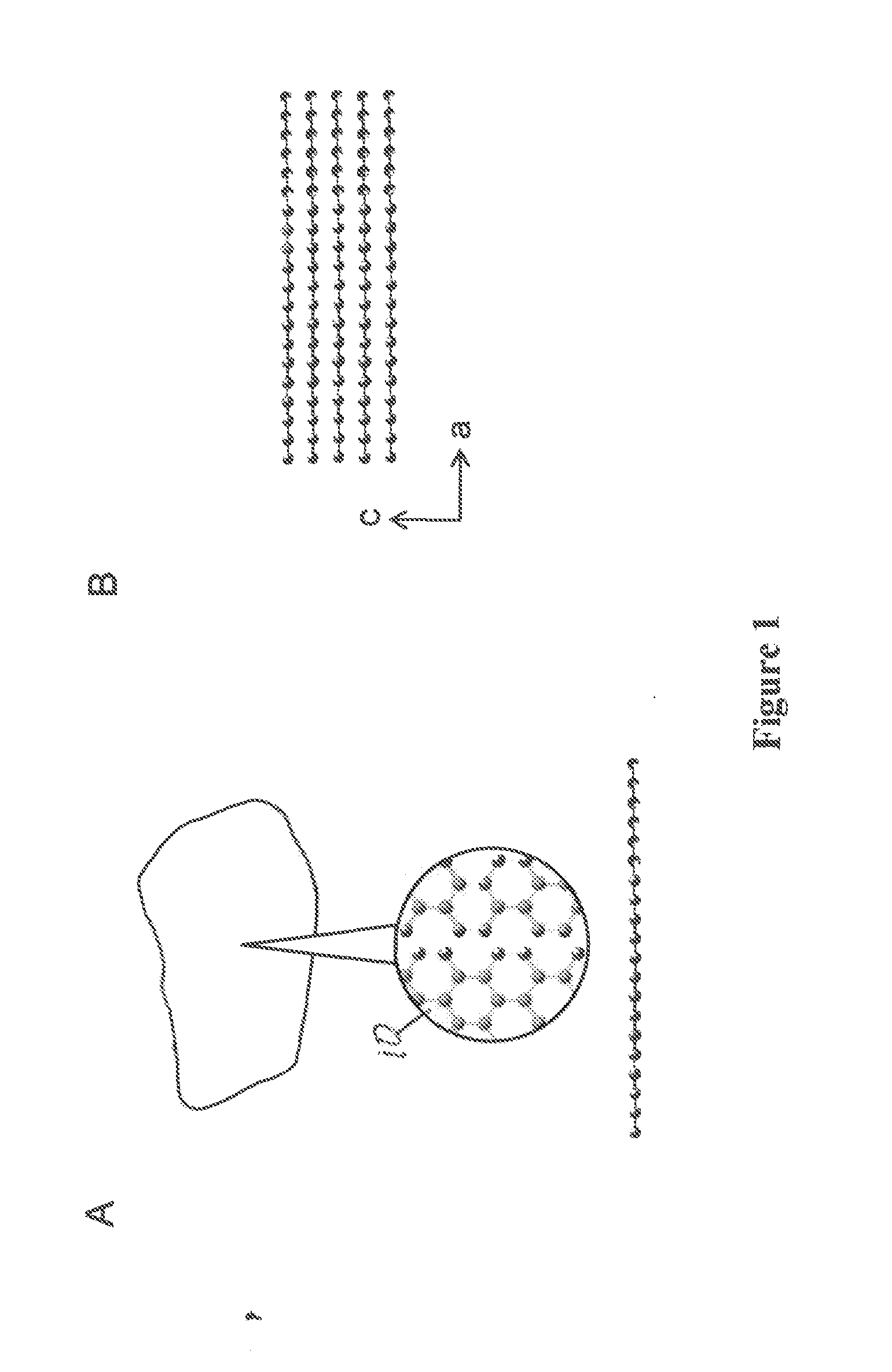

Graphene foam with three dimensional fully connected network and macroscopic quantity preparation method thereof

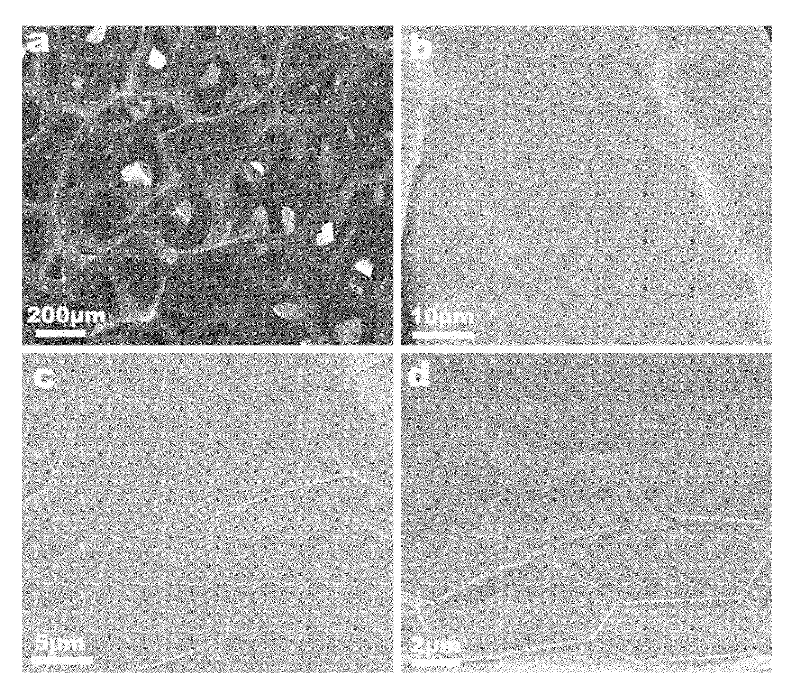

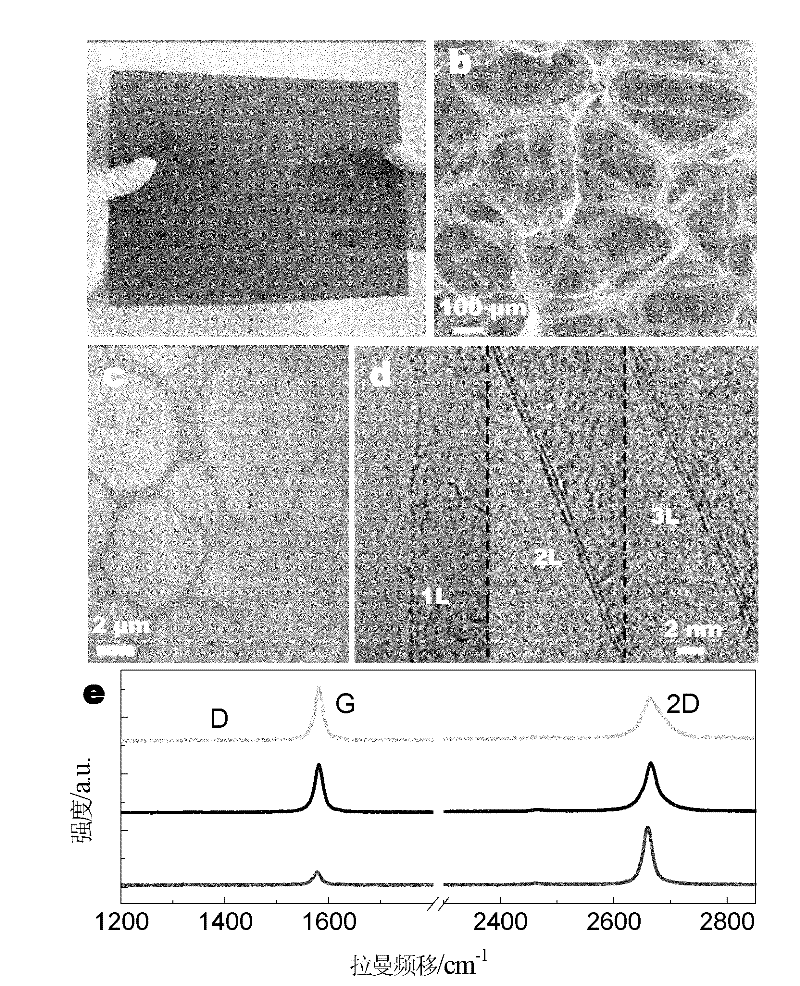

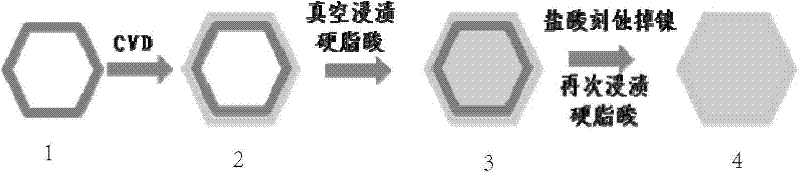

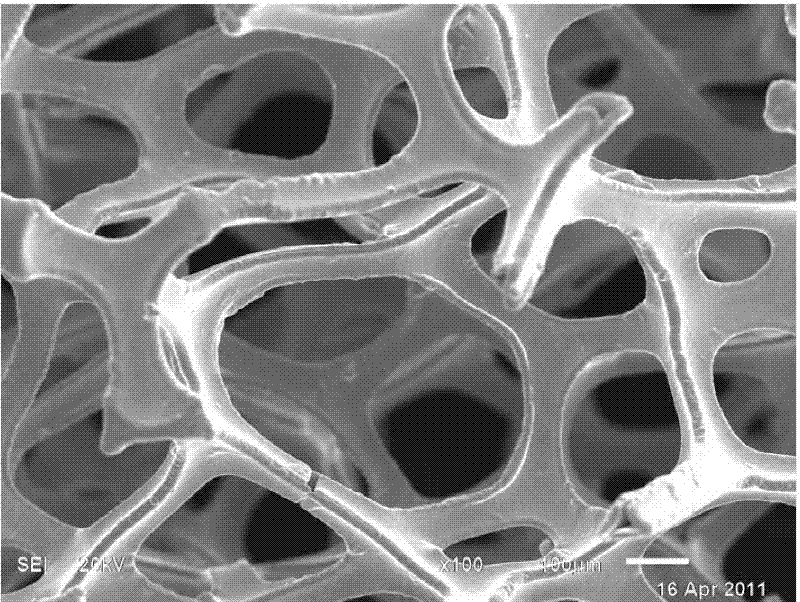

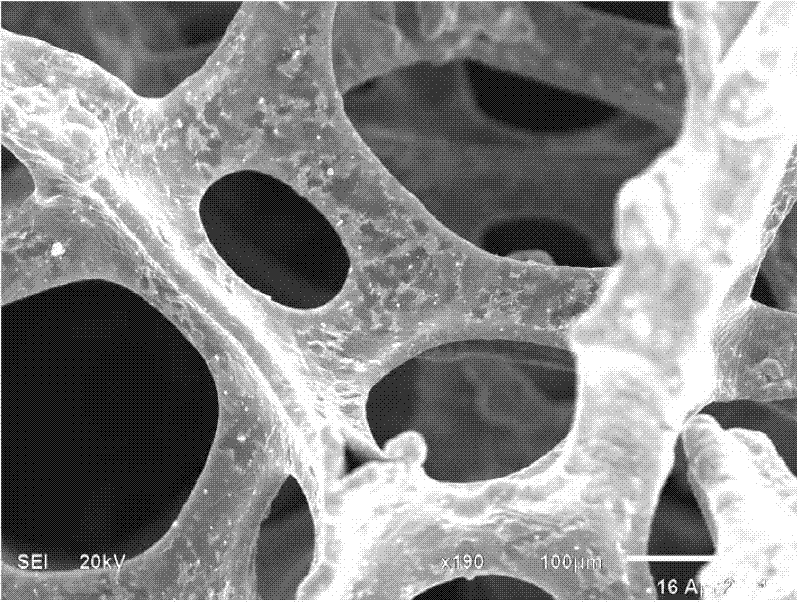

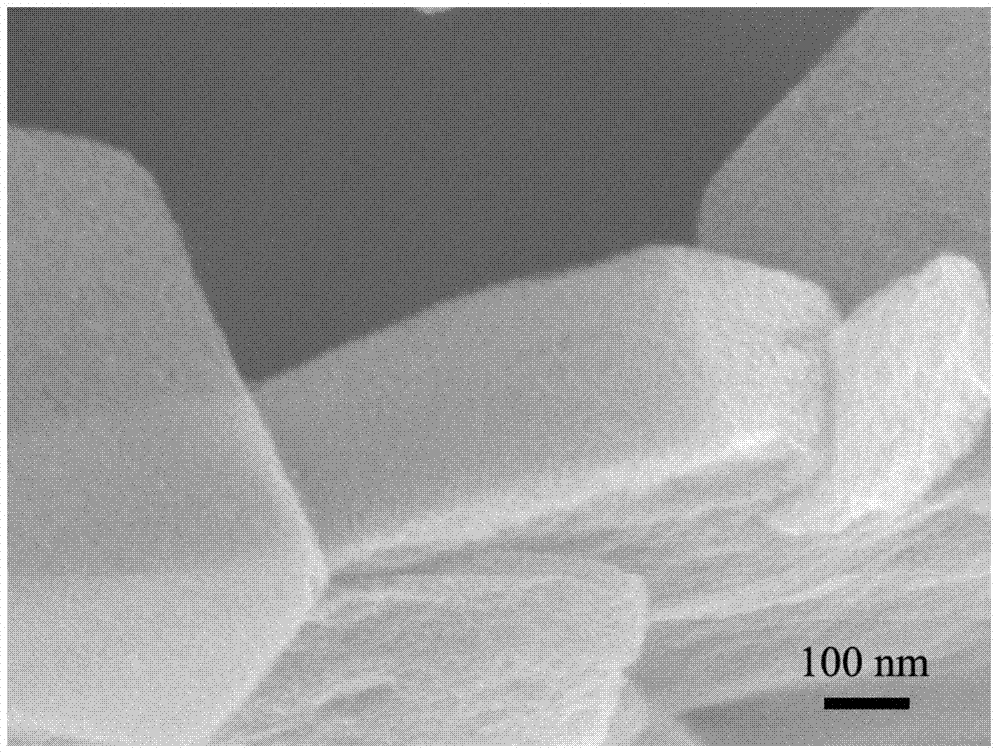

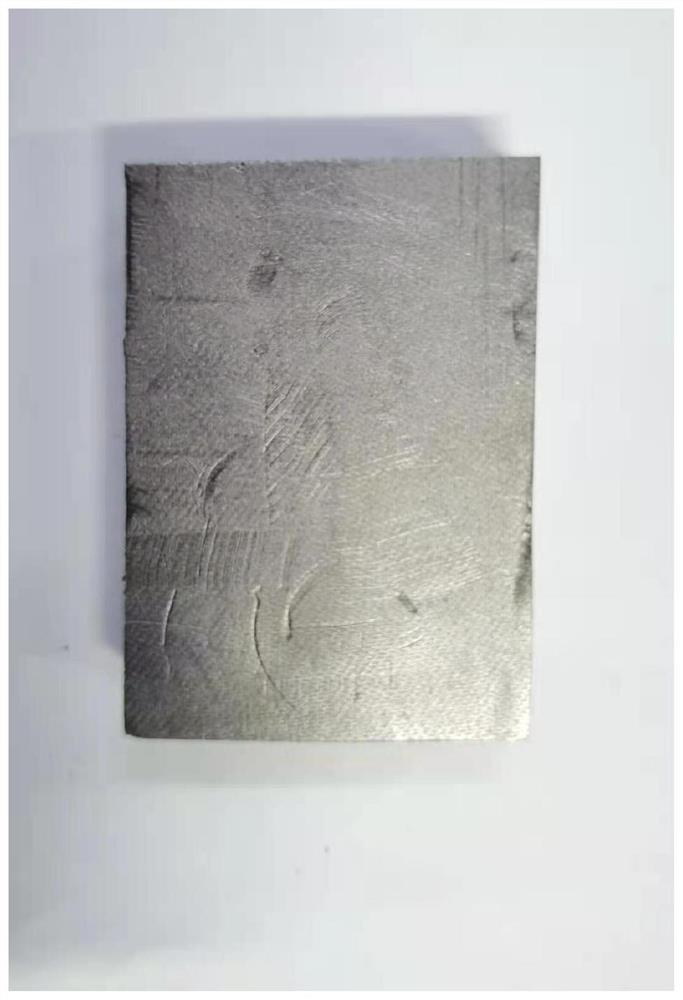

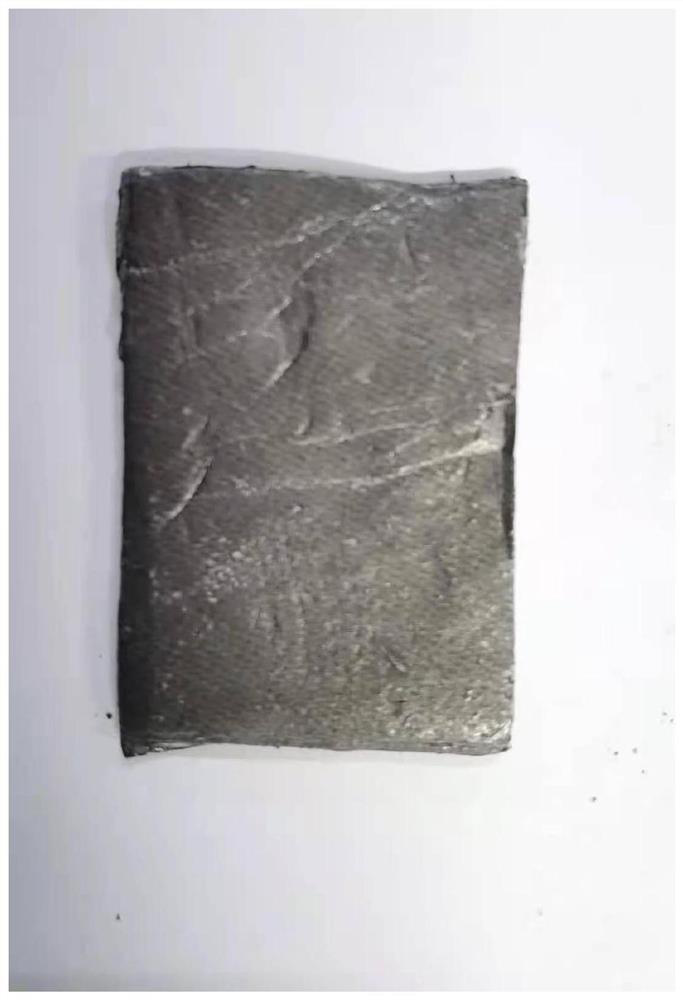

The invention relates to a graphene-based novel material and a chemical vapor deposition preparation technology thereof, in particular to graphene foam with a three dimensional fully connected network and a macroscopic quantity preparation method thereof. The method is suitable for a mass preparation of the graphene foam with high qualities. Three dimensional connected graphene can grow by catalytic cracking of carbon source gases on the surface of a three dimensional porous metal through the chemical vapor deposition technology, and a porous foam-shaped graphene three dimensional macroscopic body can be obtained after a porous metal base is removed by dissolving subsequently. According to the graphene foam with the three dimensional fully connected network and the macroscopic quantity preparation method thereof, a simple template replication method is used for preparing the three dimensional connected graphene macroscopic body, and the method has the advantages that the operation is simple and convenient, the rate of production is high, and the adjustment and control of the structure are easy. The graphene foam forms the fully connected network in a seamless connection mode, has a low density, a high porosity and specific surface area and excellent capabilities of charge conduction and heat conduction and establishes a foundation for applications of graphene in fields of electric conduction, thermally conductive composite materials, electromagnetic shielding, wave absorbing, catalysis, sensing and energy storage materials and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

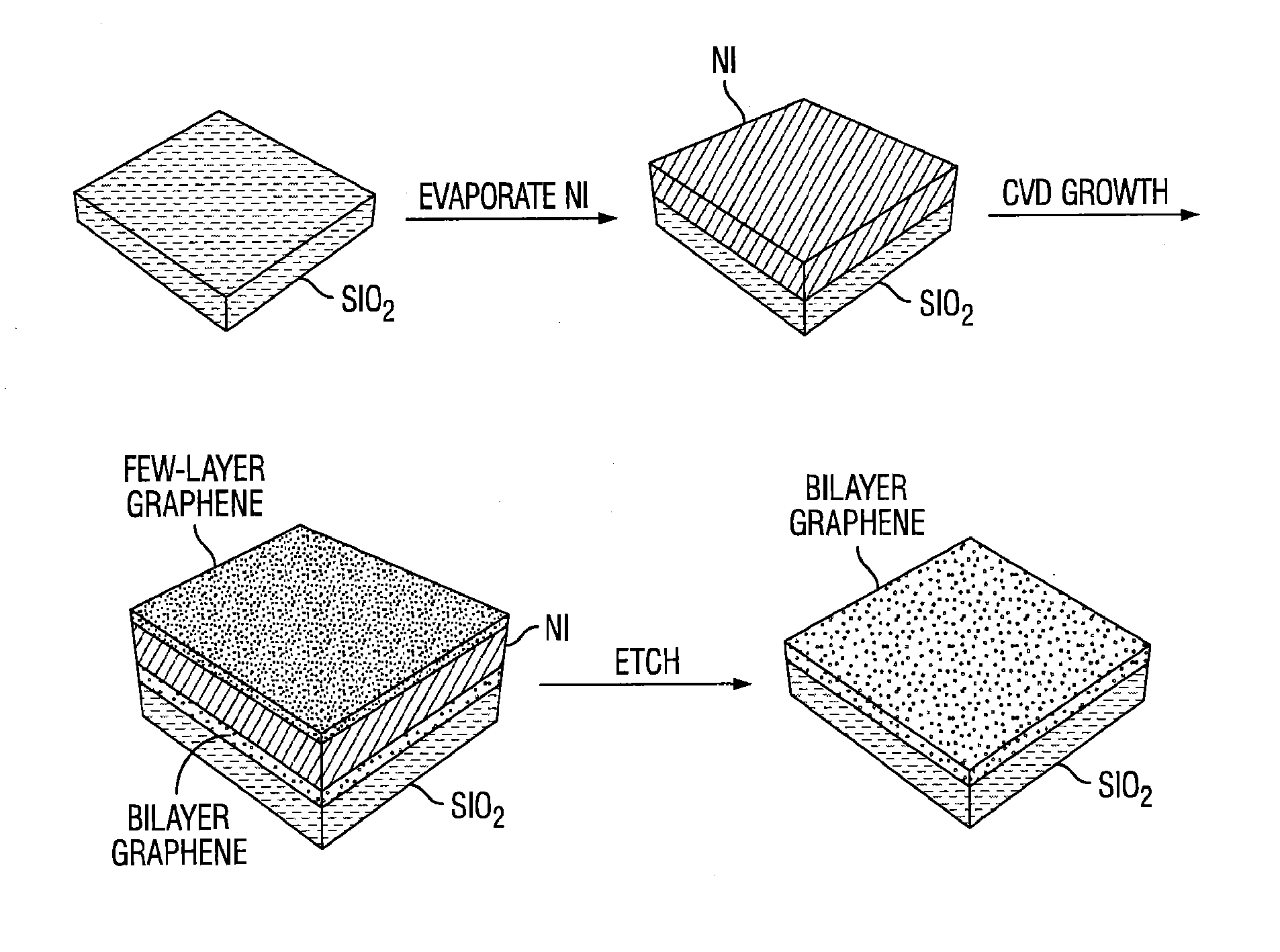

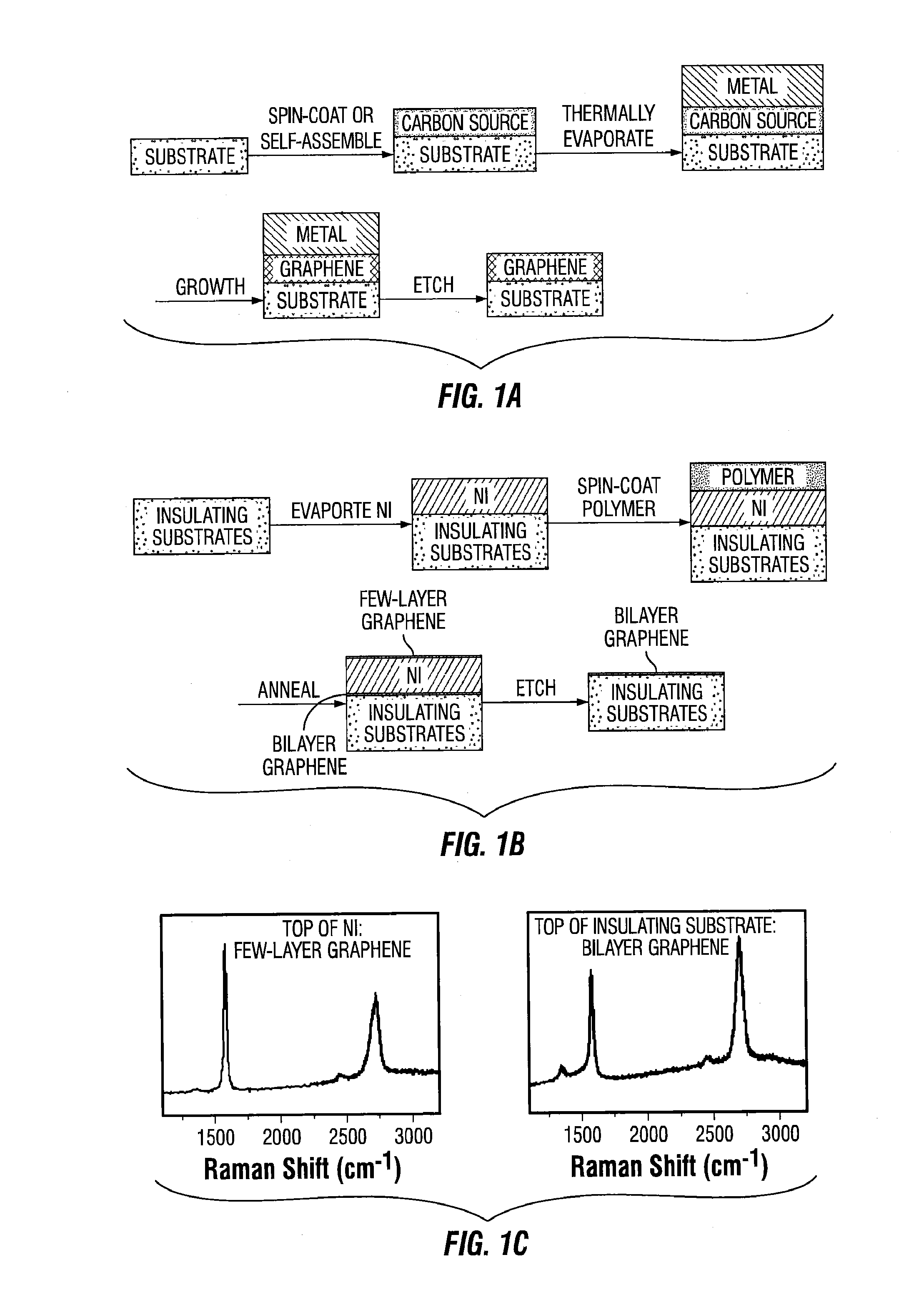

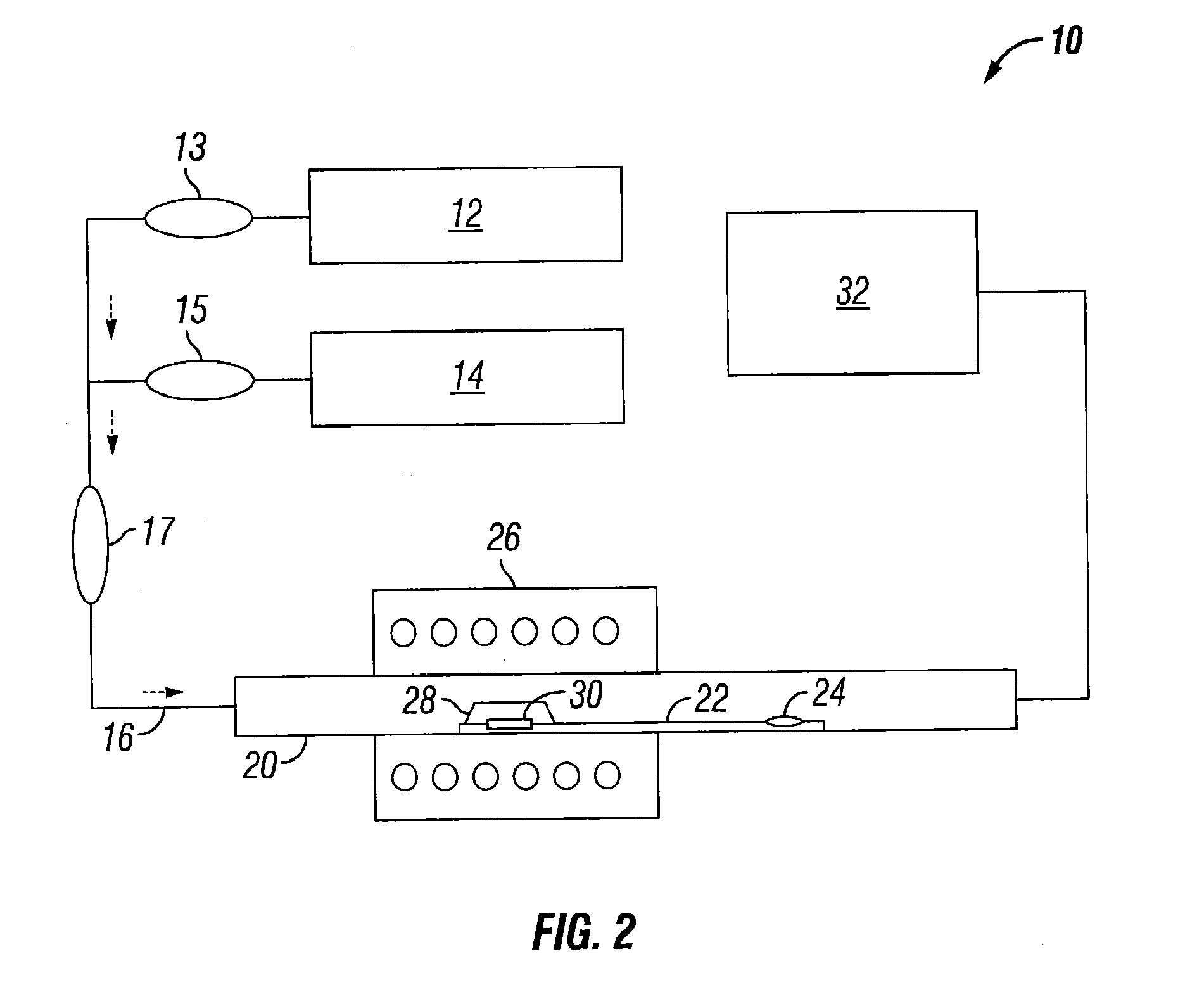

Direct growth of graphene films on non-catalyst surfaces

The present invention provides methods of forming graphene films on various non-catalyst surfaces by applying a carbon source and a catalyst to the surface and initiating graphene film formation. In some embodiments, graphene film formation may be initiated by induction heating. In some embodiments, the carbon source is applied to the non-catalyst surface before the catalyst is applied to the surface. In other embodiments, the catalyst is applied to the non-catalyst surface before the carbon source is applied to the surface. In further embodiments, the catalyst and the carbon source are applied to the non-catalyst surface at the same time. Further embodiments of the present invention may also include a step of separating the catalyst from the formed graphene film, such as by acid etching.

Owner:RICE UNIV

Grapheme foam and preparation method thereof

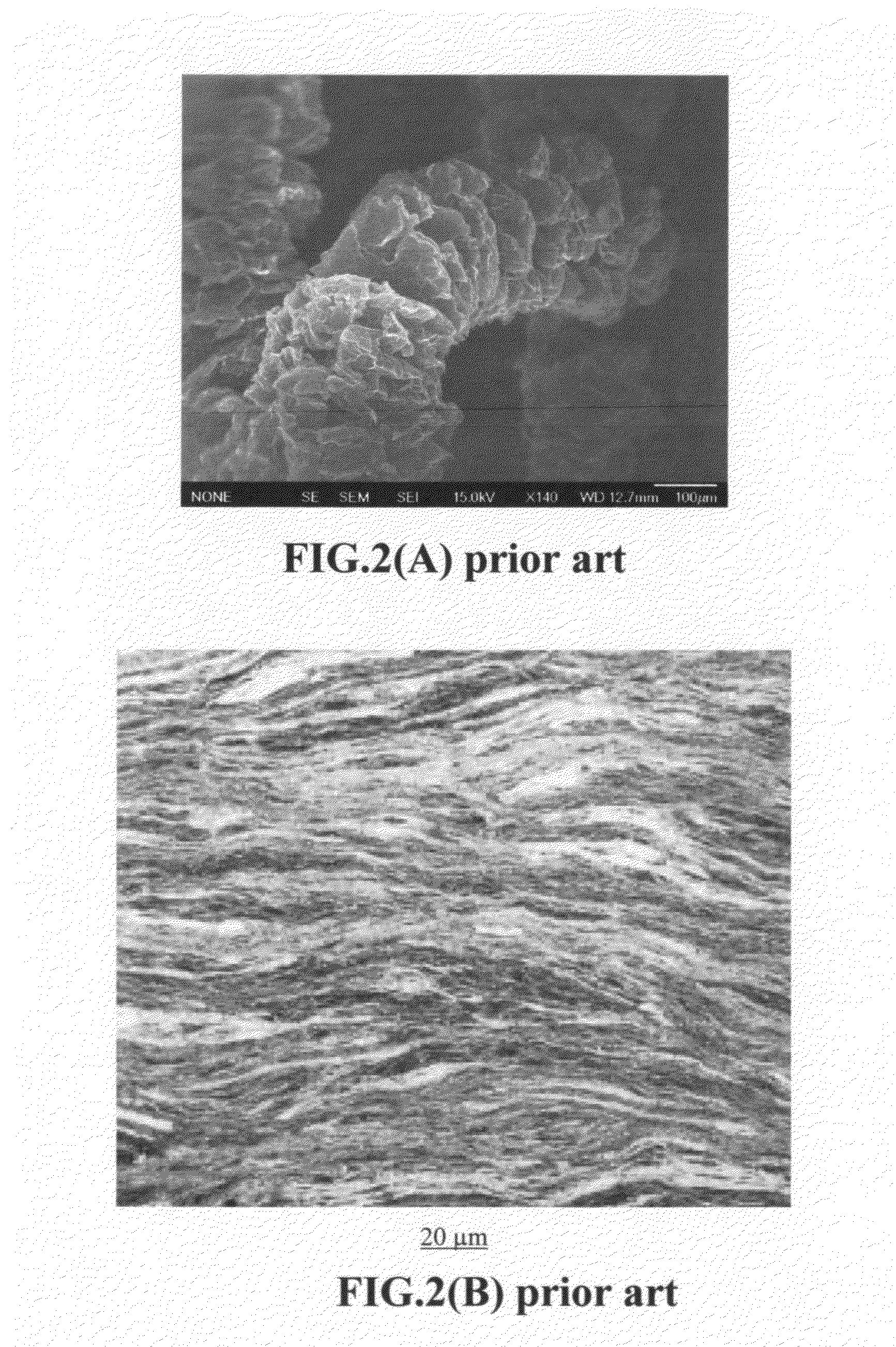

InactiveCN101831622AAvoid reunionHigh temperature resistantChemical vapor deposition coatingEtherConductive materials

The invention discloses grapheme foam and a preparation method thereof. The grapheme foam provided by the invention is prepared by the method comprising the following steps: 1) putting a metal foam material into a vacuum tube type furnace, and calcining the metal foam material under non-oxidizing atmosphere; 2) depositing grapheme on the calcined metal foam material by adopting a chemical vapor deposition method; and 3) removing foam metal from the obtained grapheme modified metal foam material, cleaning the obtained foam material by using deionized water, ethanol and ether in turn, taking the foam material out and drying the foam material to obtain grapheme foam. The grapheme foam material has a three-dimensional hollow porous netlike structure, the grapheme is on the netlike wall, and the structural characteristic effectively prevents the agglomeration of the grapheme; and the grapheme foam material integrates the characteristics of a foam material and a conductive material, and has the advantages of ultra-low density, ultra-high surface area, high heat conduction, high temperature resistance, corrosion resistance and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Graphene foam/polymer high-conductivity composite material preparation method and application thereof

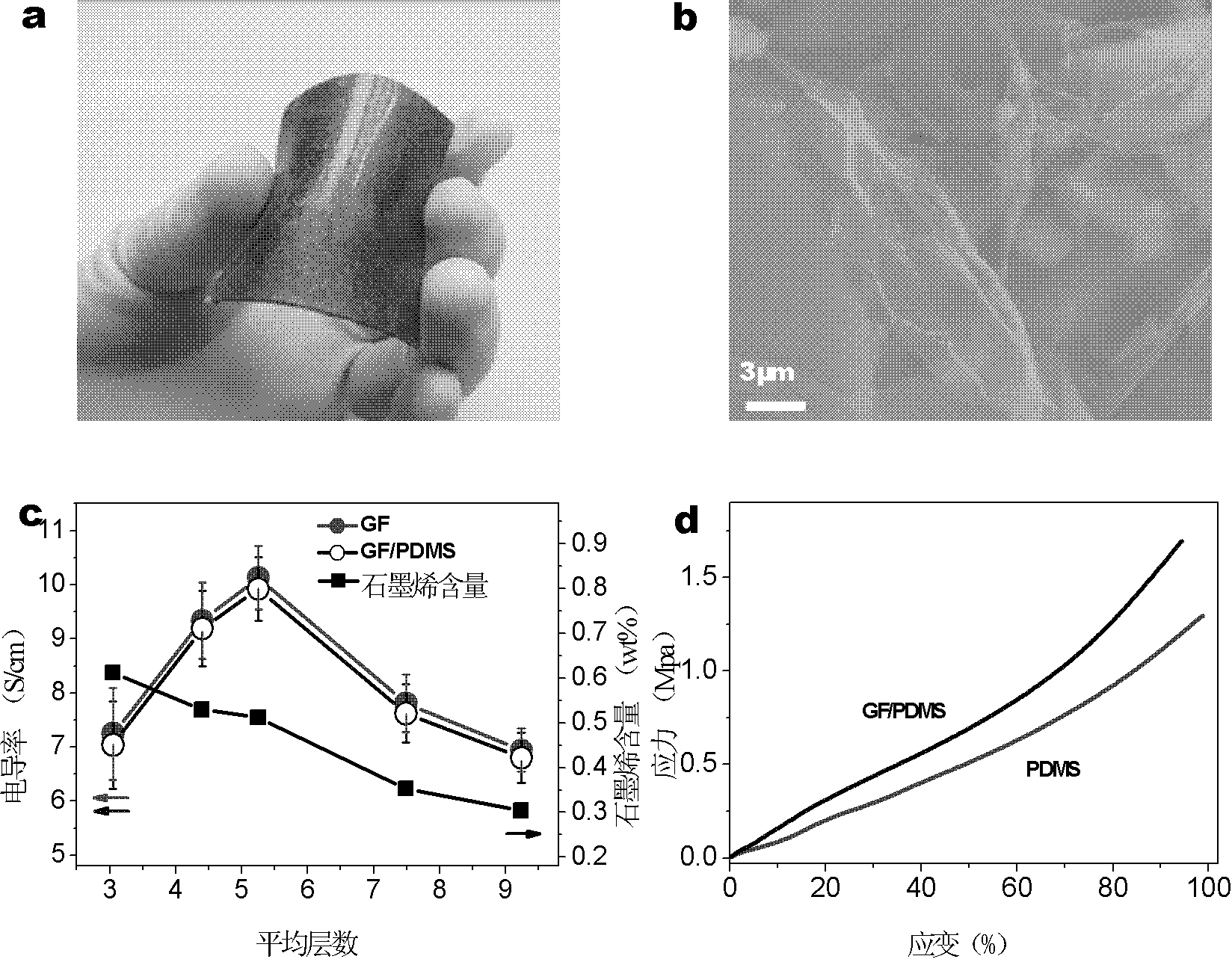

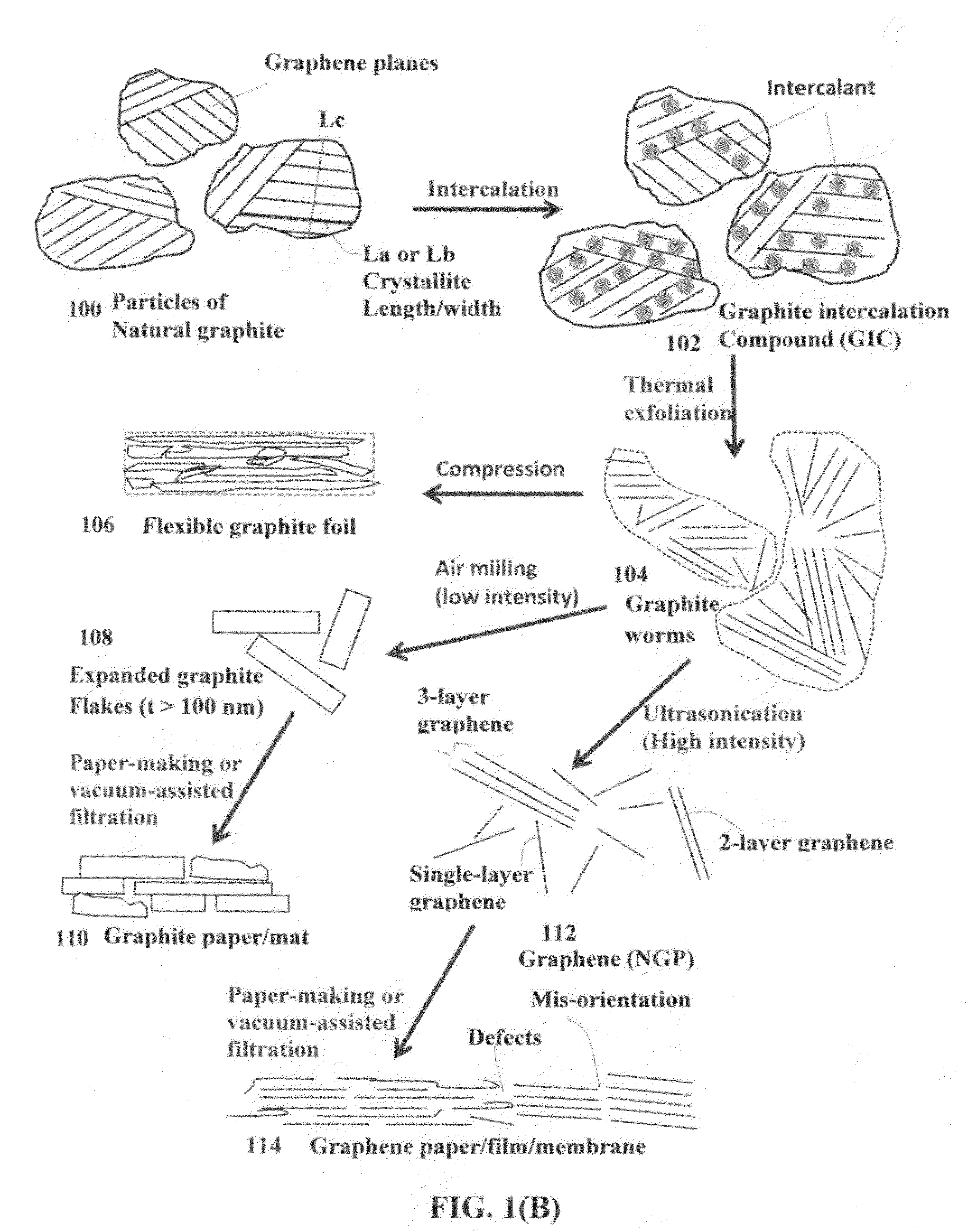

ActiveCN102732037AImprove conductivityEasy to manufactureChemical vapor deposition coatingMaterials preparationGraphite

The invention relates to the graphene composite material field, and particularly to a graphene foam / polymer high-conductivity composite material, a preparation method and applications thereof. Steps of the method comprises as follows: providing a fully communicated three-dimension grapheme foam network and a precursor solution of a high-molecular polymer; mixing the graphene foam with the precursor solution of the high-molecular polymer to form a graphene foam / high-molecule polymer precursor mixture; and solidifying the precursor of the high-molecular polymer in the mixture to form a high-conductivity graphene foam composite material. The invention adopts the three-dimension graphene foam to form a fully- communicated graphite rapid transmission network by a seamless connection, which enables the graphene foam composite material to possess great conductivity and mechanical property and can be widely applied to the conductive composite materials and elasticity conductor field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Process for producing graphene foam supercapacitor electrode

ActiveUS9437372B1Effective orientation-inducing stressEasy to mergeCarbon compoundsHybrid capacitor electrodesLiquid mediumMass loading

A process for producing a supercapacitor electrode, comprising: (a) preparing a graphene dispersion containing an optional blowing agent; (b) depositing the dispersion onto a supporting substrate to form a wet layer; (c) removing the liquid medium from the wet layer to form a dried layer of graphene material; (d) heat treating the dried layer at a temperature from 80° C. to 3,200° C. to induce volatile gas molecules from the non-carbon elements or to activate the blowing agent for producing a layer of solid graphene foam having a physical density from 0.01 to 1.7 g / cm3 and a specific surface area from 50 to 3,300 m2 / g; and (e) impregnating the foam with an electrolyte to form a layer of pre-impregnated graphene foam, which is compressed to form the electrode. This process leads to a supercapacitor having a large electrode thickness, high active mass loading, high tap density, and exceptional energy density.

Owner:NANOTEK INSTR GRP LLC

Thermal management system containing an integrated graphene film for electronic devices

ActiveUS20130264041A1Low densityThermal conductivityMaterial nanotechnologyDigital data processing detailsHeat conductingThermal management system

Disclosed is a graphene-based heat dissipation system for an electronic device, comprising: (a) an electronic device comprising a heat source, wherein the heat source transmits heat to a second component or an external surface of the electronic device; (b) a heat-conducting layer comprising two major surfaces, the heat-conducting layer being positioned such that one of its major surfaces is in operative contact with the heat source such that it is interposed between the heat source and the second component or the external surface of the electronic device; wherein the heat-conducting layer comprises at least one sheet of integrated graphene film which thermally shields the second component or the external surface of the electronic device from heat generated by the heat source.

Owner:GLOBAL GRAPHENE GRP INC

Highly conductive graphene foams and process for producing same

ActiveUS20160019995A1Effective orientation-inducing stressIncrease flexibilityNon-insulated conductorsGraphitePolymer scienceLiquid medium

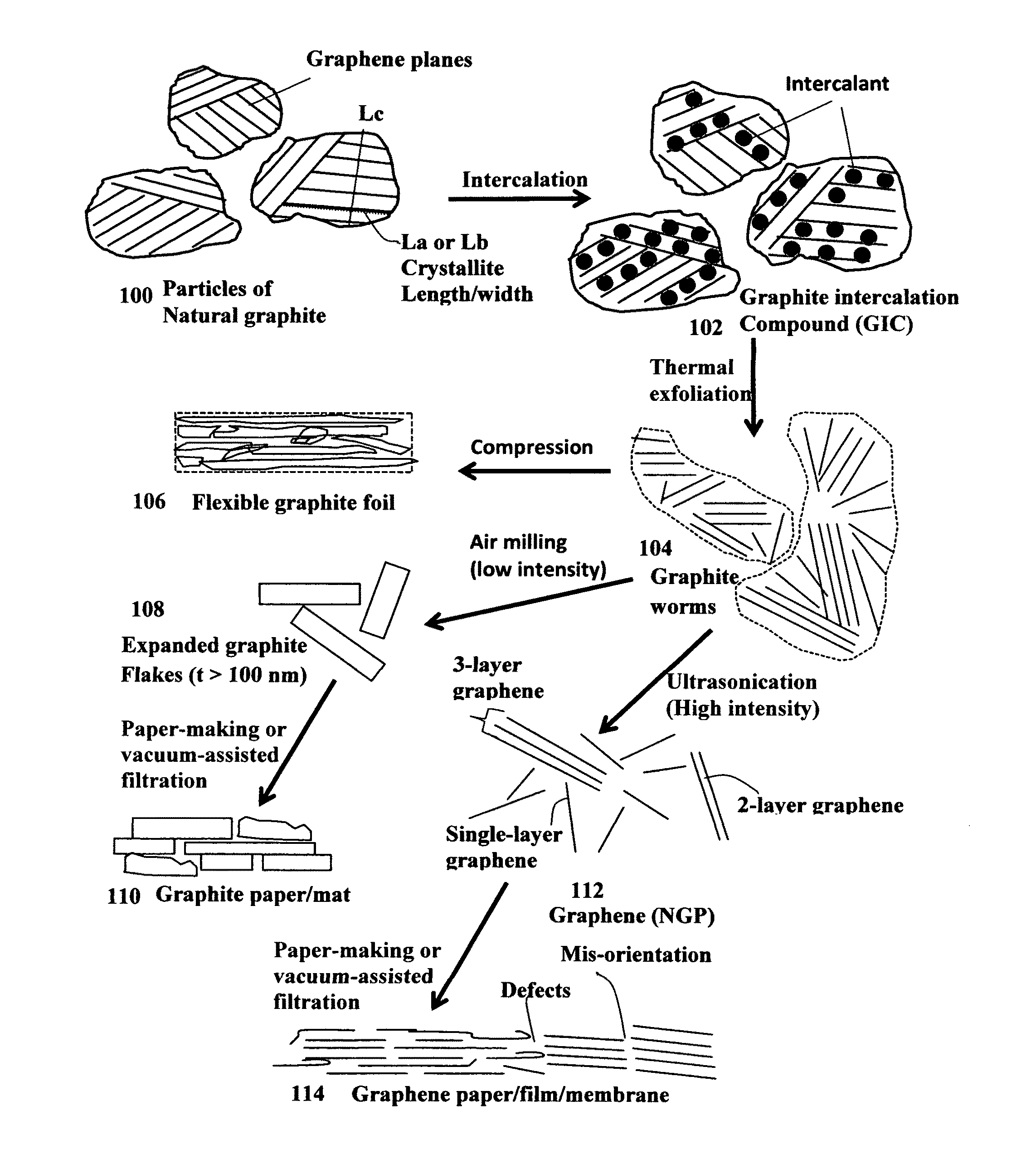

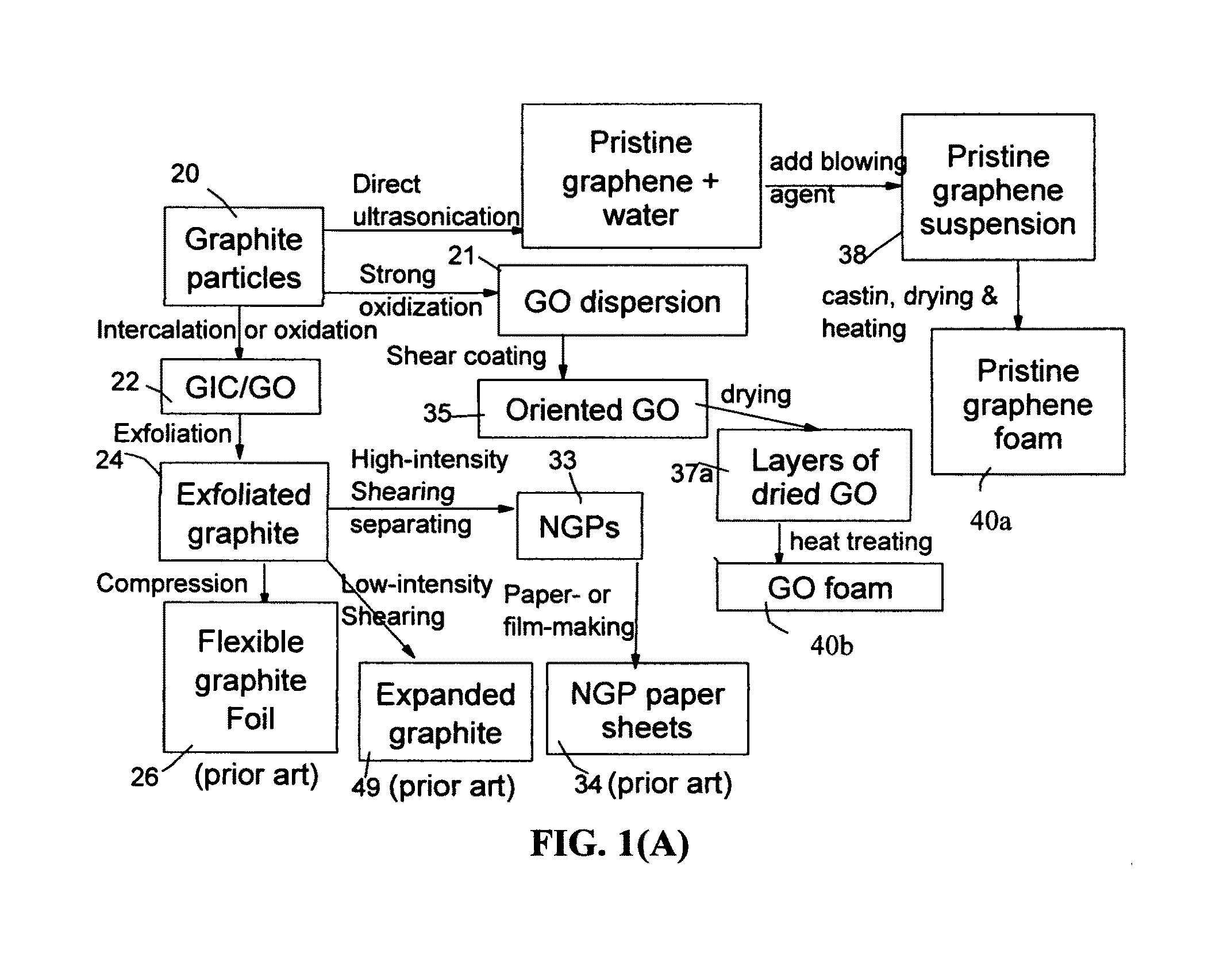

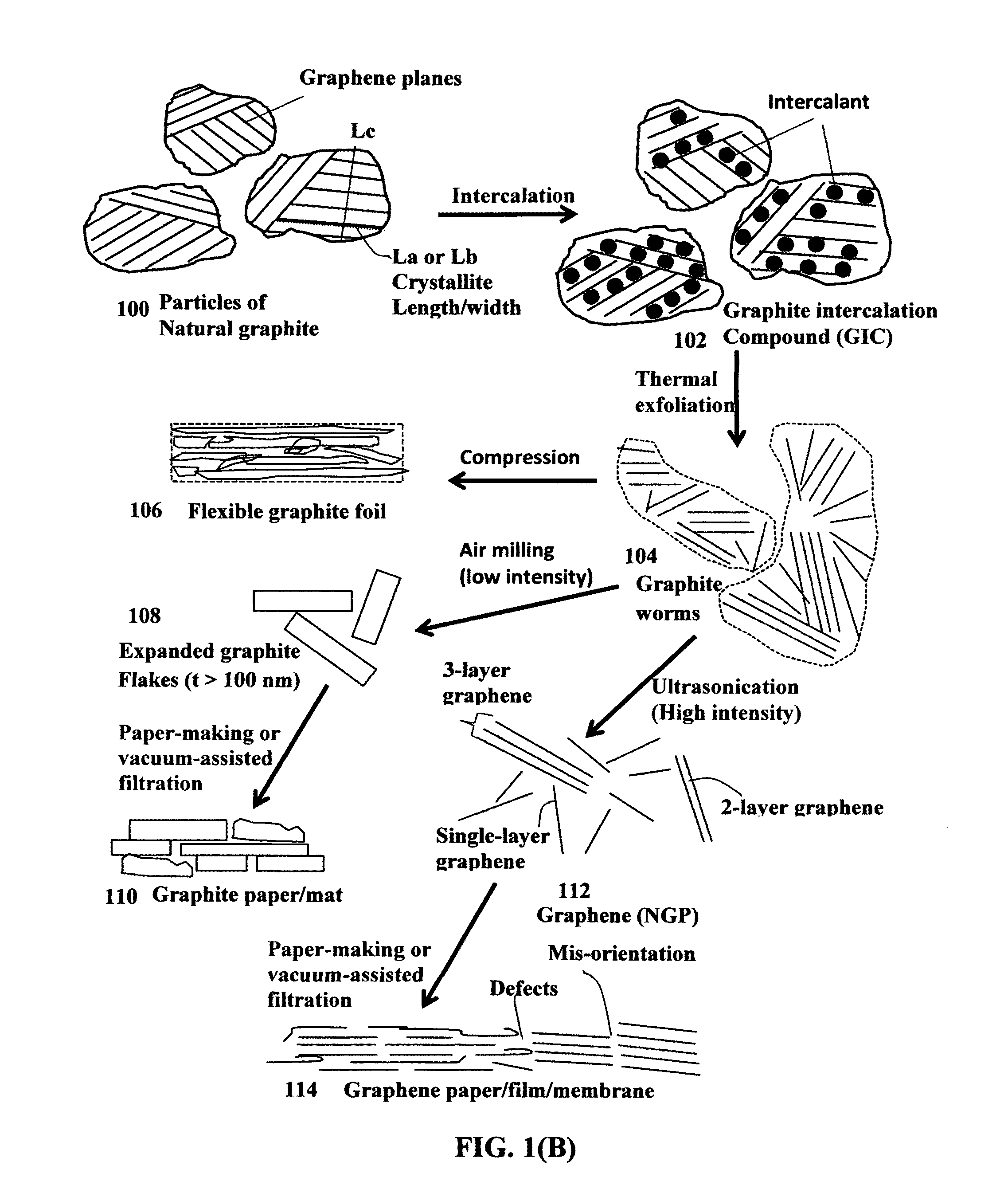

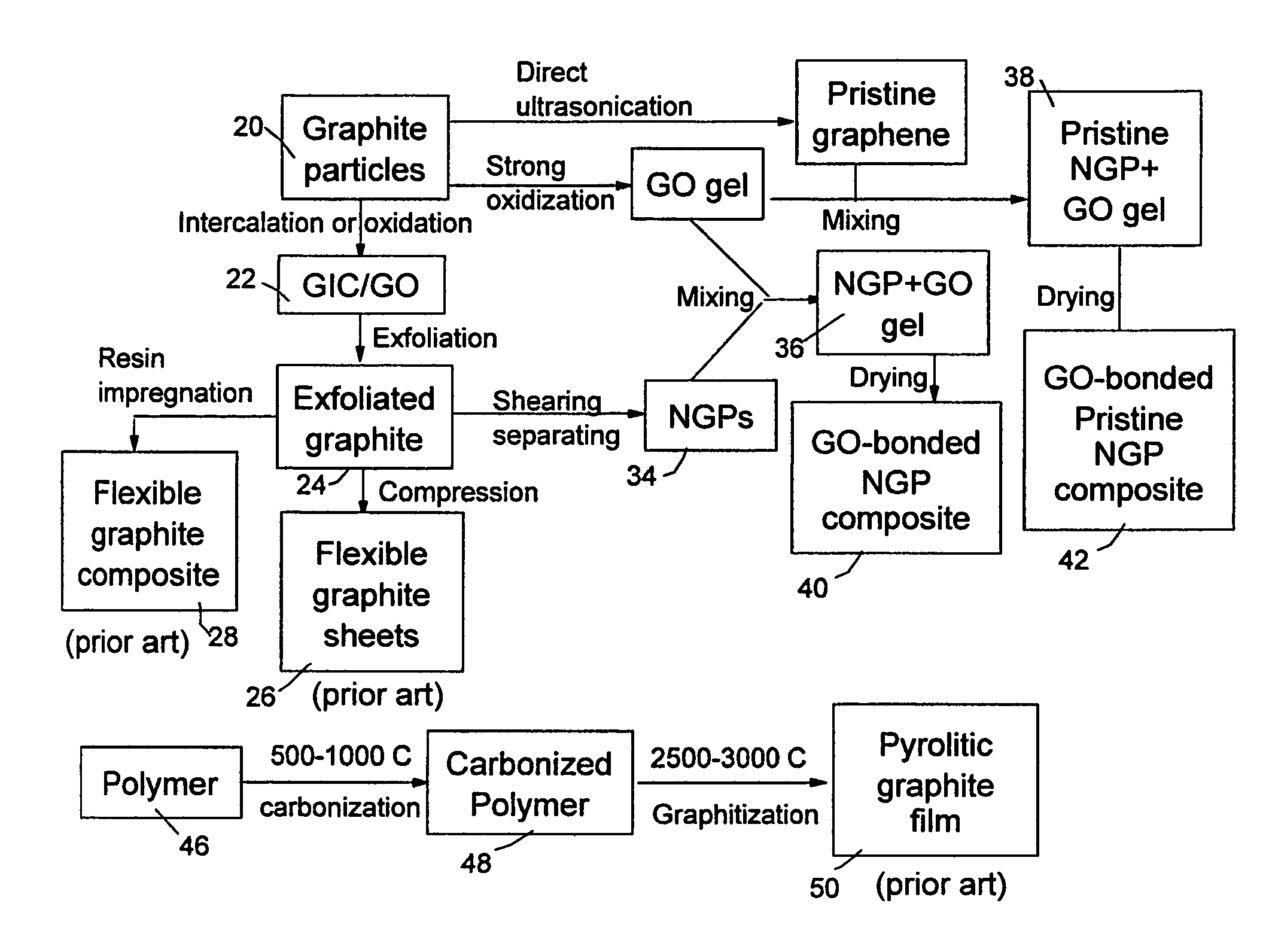

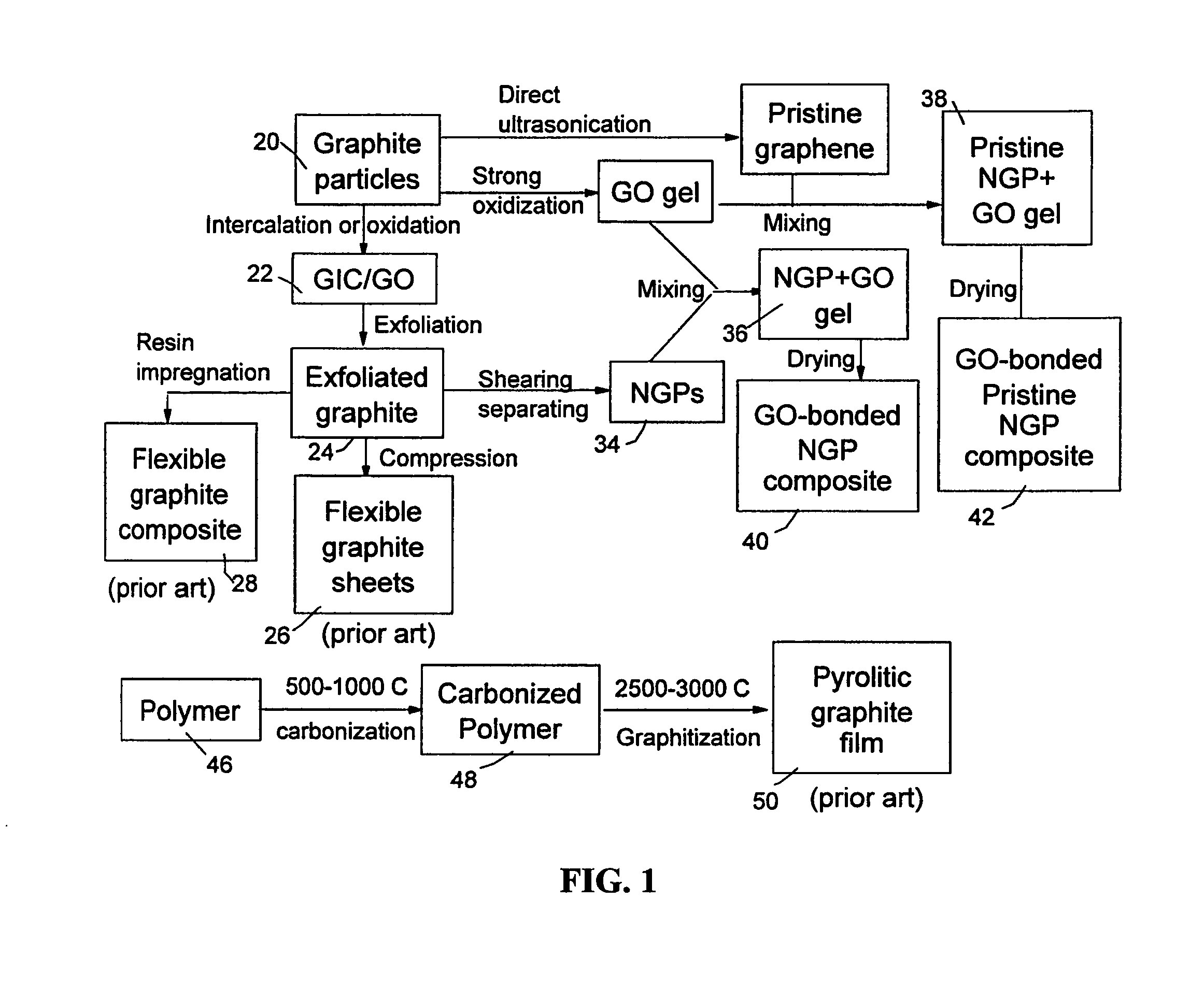

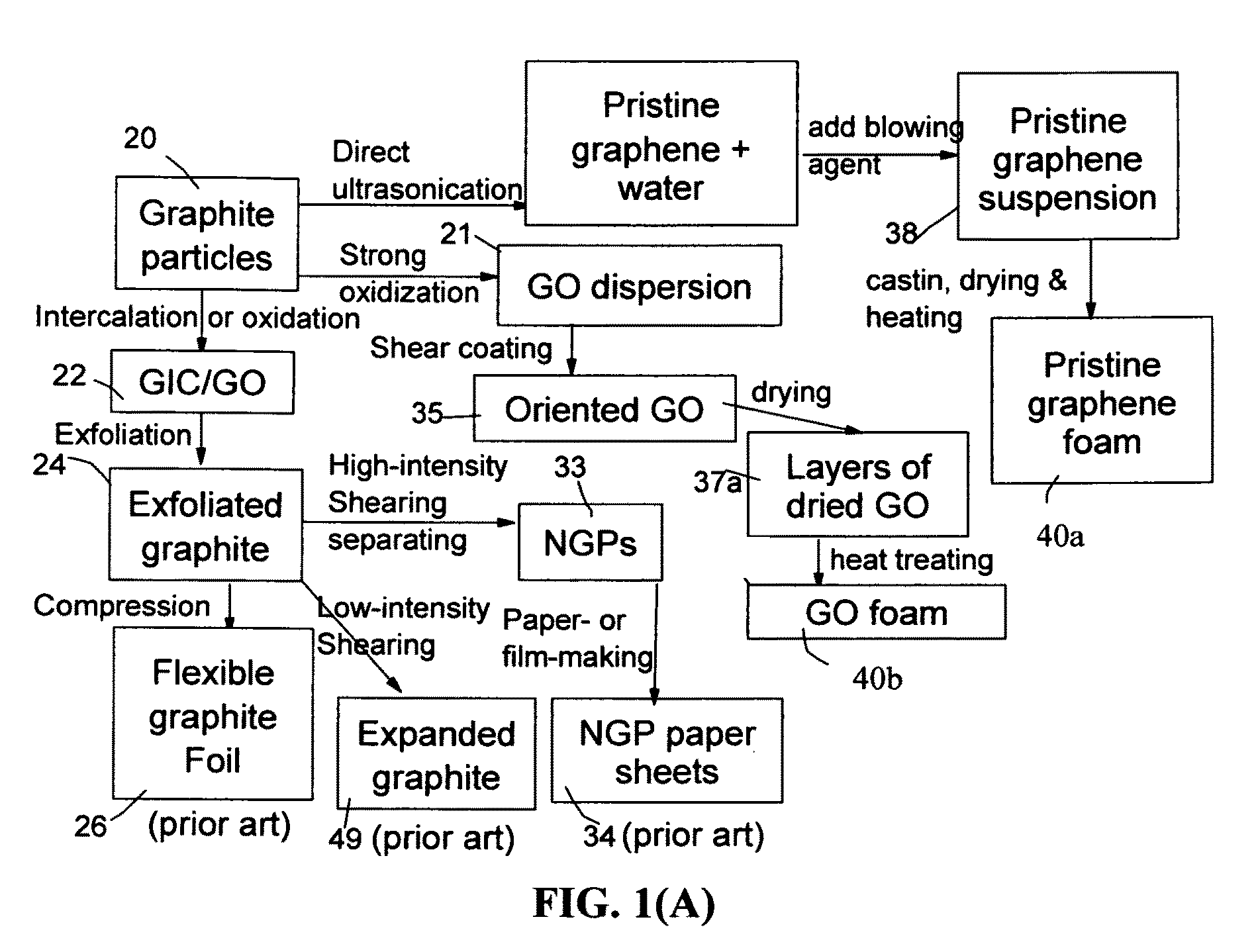

A process for producing a solid graphene foam composed of multiple pores and pore walls The process comprises: (a) preparing a graphene dispersion having a graphene material dispersed in a liquid medium, which contains an optional blowing agent; (b) dispensing and depositing the graphene dispersion onto a supporting substrate to form a wet layer of graphene material having a preferred orientation; (c) partially or completely removing the liquid medium from the wet layer of graphene material to form a dried layer of graphene material having a content of non-carbon elements no less than 5% by weight (including blowing agent weight); and (d) heat treating the layer of graphene material at a first heat treatment temperature from 80° C. to 3,200° C. at a desired heating rate sufficient to induce volatile gas molecules from the non-carbon elements or to activate the blowing agent for producing the graphene foam having a density from 0.01 to 1.7 g / cm3 or a specific surface area from 50 to 3,000 m2 / g.

Owner:GLOBAL GRAPHENE GRP INC

Three-dimensional graphene/phase change energy storage composite material and preparation method thereof

InactiveCN102585776AImprove thermal conductivityLow densityHeat-exchange elementsPorous grapheneLiquid state

The invention provides a three-dimensional graphene / phase change energy storage composite material and a preparation method thereof. The technical scheme is as follows: graphene and a phase change energy storage material are in situ compounded, wherein porous graphene with a three-dimensional structure is used as a heat conductor and a compound die, and a solid-liquid phase change organic material is used as the energy storage material and filler. The three-dimensional porous graphene is compounded with the phase change material, the phase change energy storage material is partitioned in a plurality of pore spaces and is in tight joint with the graphene wall so as to greatly increase the effective heat contact area, and the highly linked graphene three-dimensional heat conduction network channels can realize rapid system heat exchange. In addition, due to the capillary adsorption capacity of porous graphene, the liquid-state phase change energy storage material is localized, so as to effectively prevent seepage. Therefore, the three-dimensional graphene foam has good designability, and becomes a lighter and more effective heat dissipation material for electronic devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

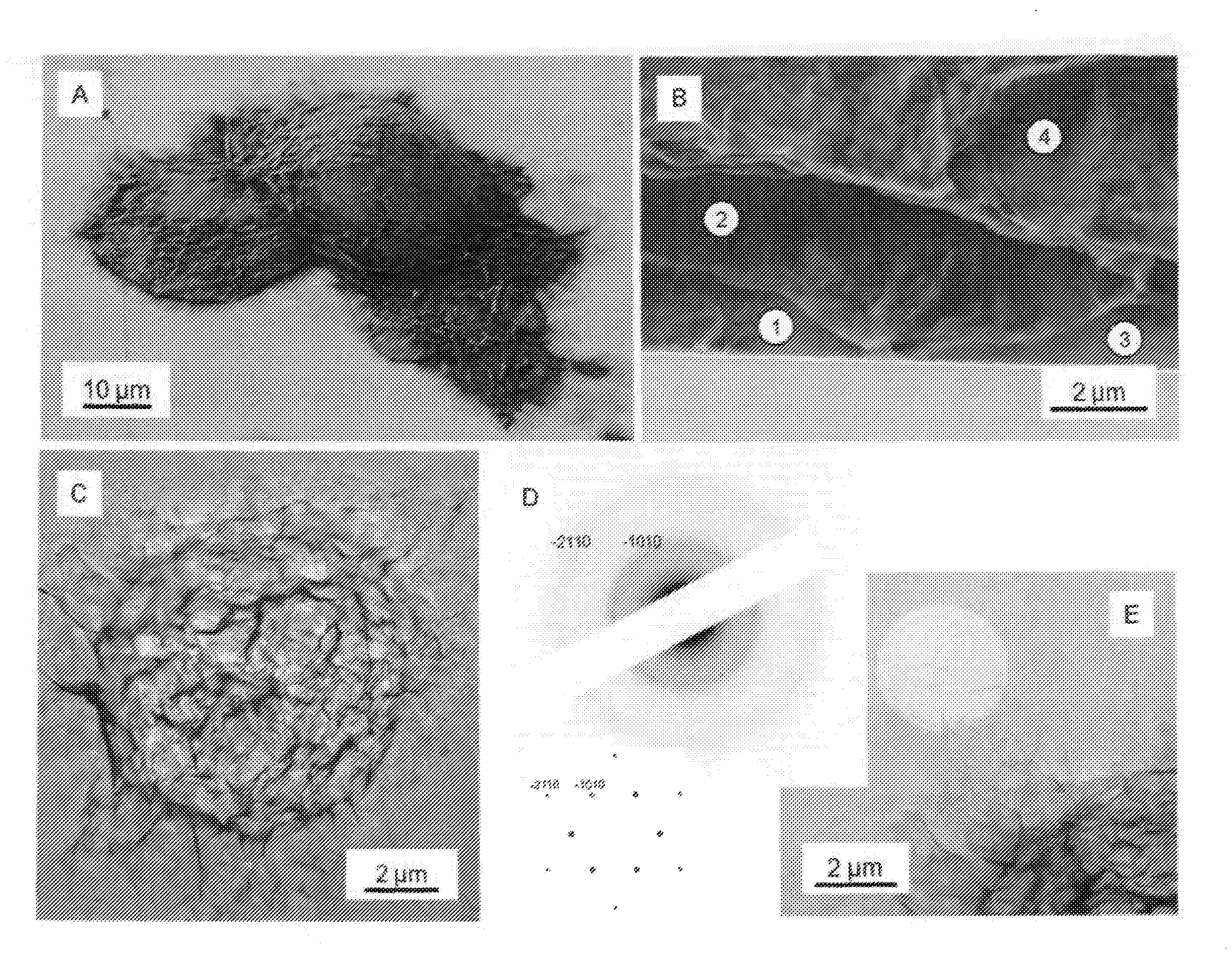

Growth of graphene films from non-gaseous carbon sources

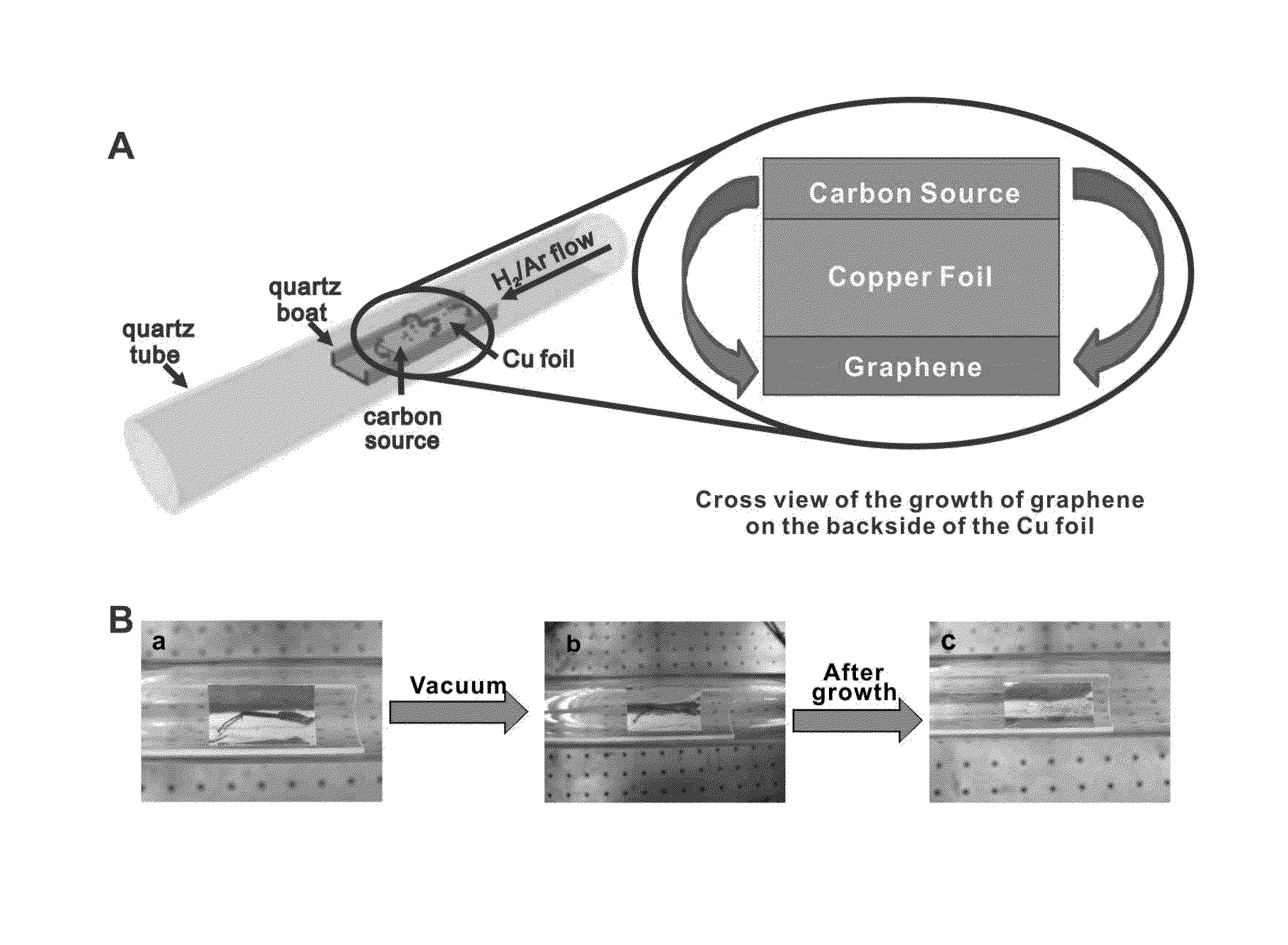

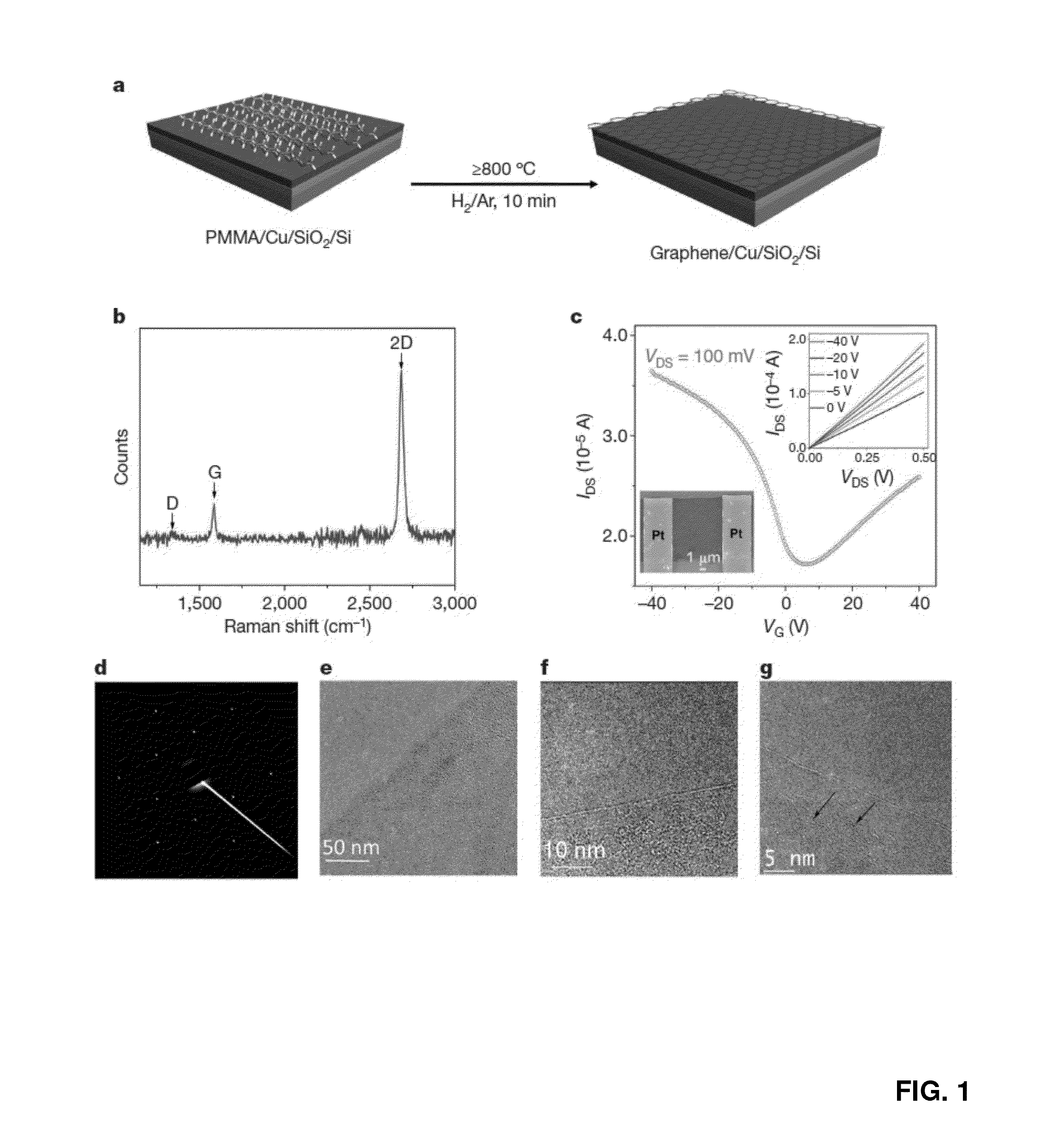

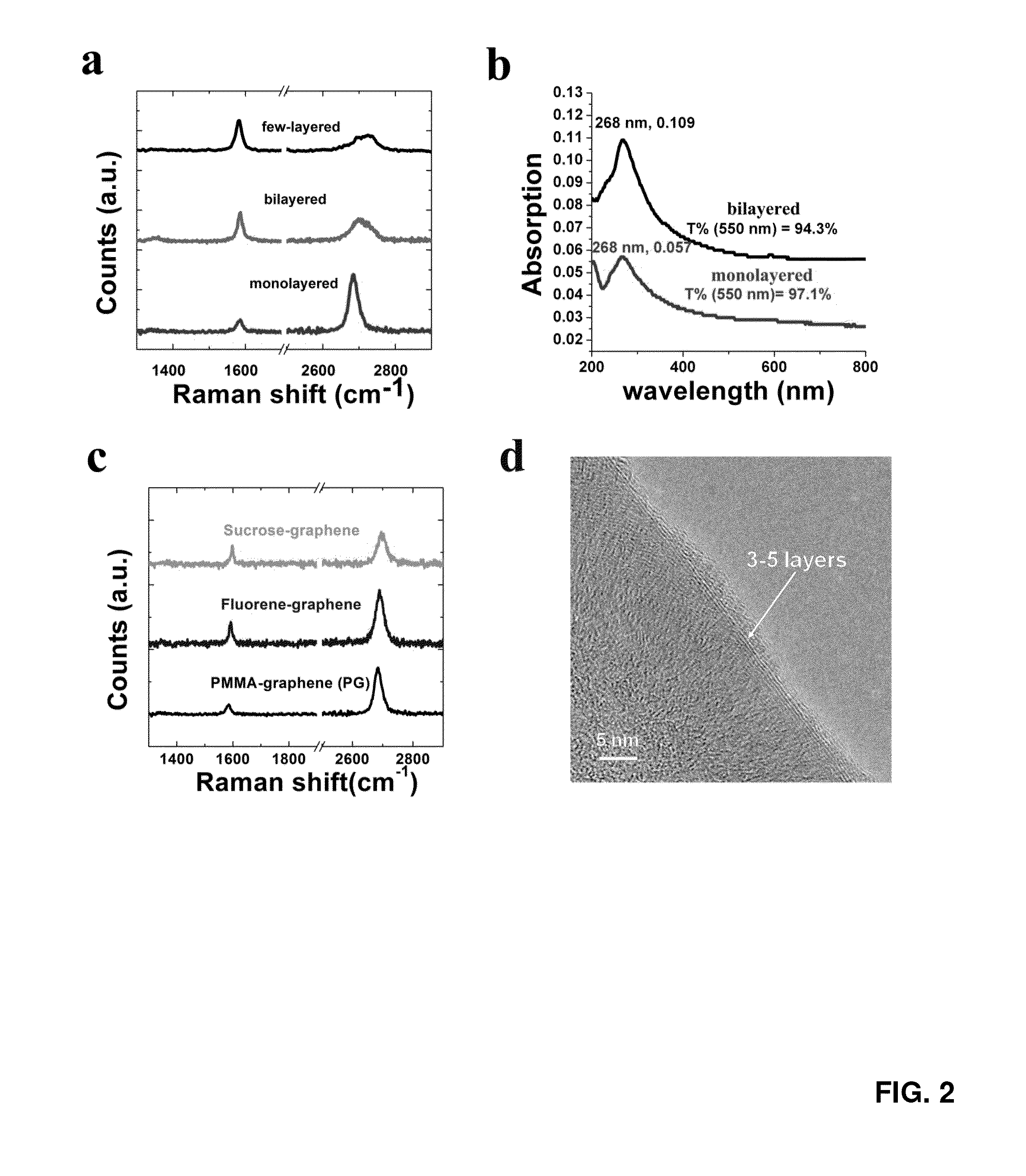

ActiveUS20140234200A1Reduce defectsReduce sheet resistanceSingle layer grapheneGrapheneCarbon source

In various embodiments, the present disclosure provides methods of forming graphene films by: (1) depositing a non-gaseous carbon source onto a catalyst surface; (2) exposing the non-gaseous carbon source to at least one gas with a flow rate; and (3) initiating the conversion of the non-gaseous carbon source to the graphene film, where the thickness of the graphene film is controllable by the gas flow rate. Additional embodiments of the present disclosure pertain to graphene films made in accordance with the methods of the present disclosure.

Owner:RICE UNIV

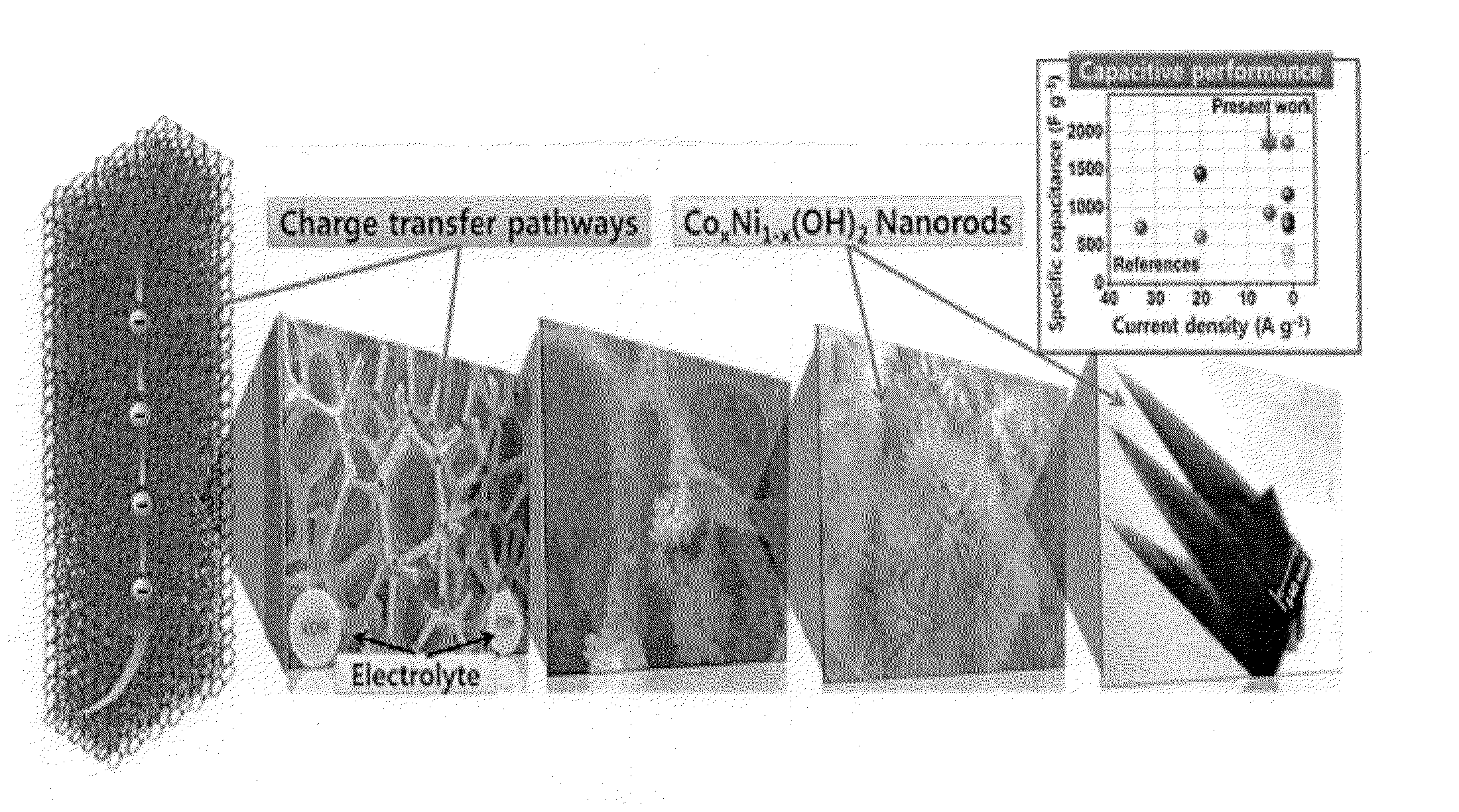

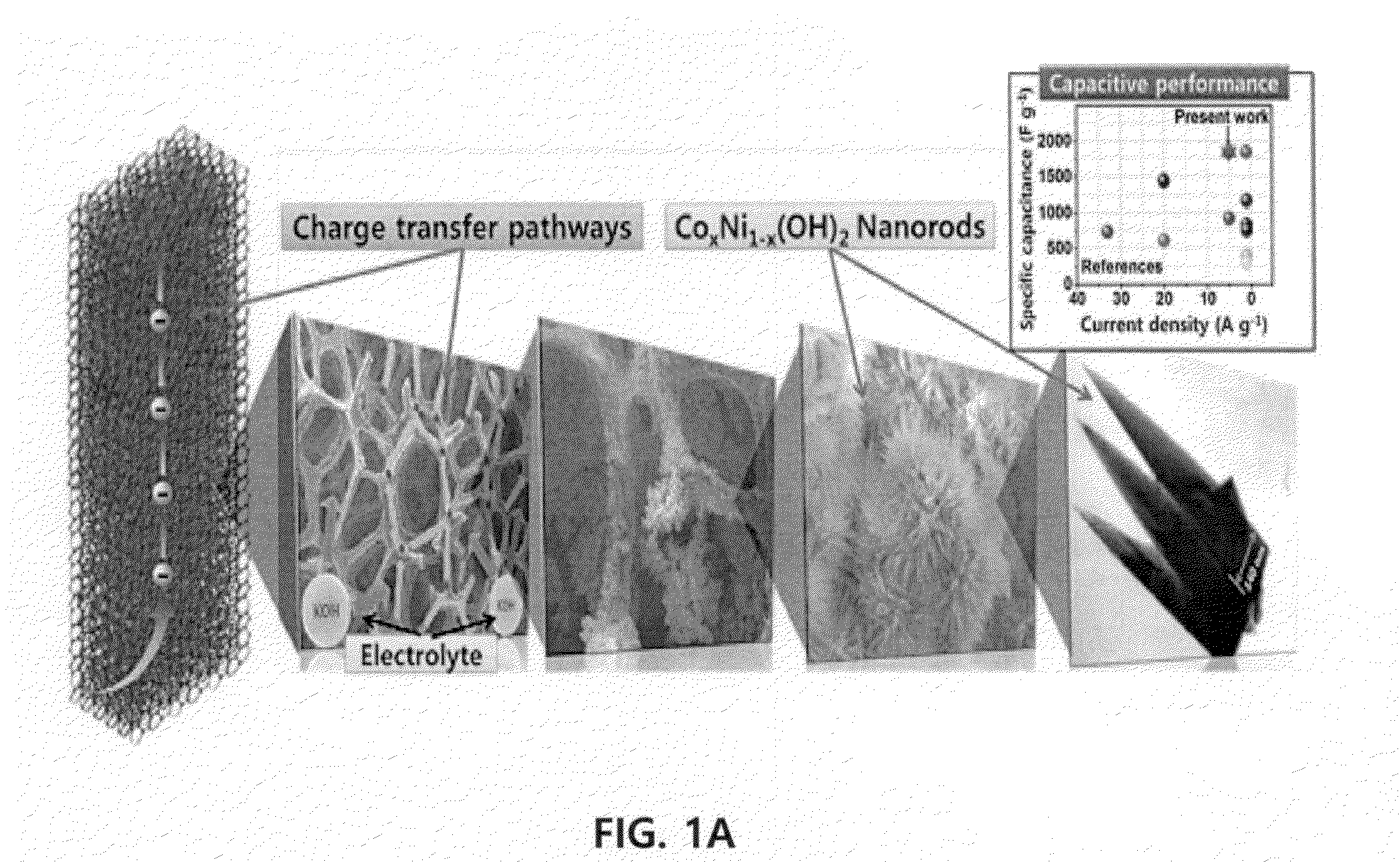

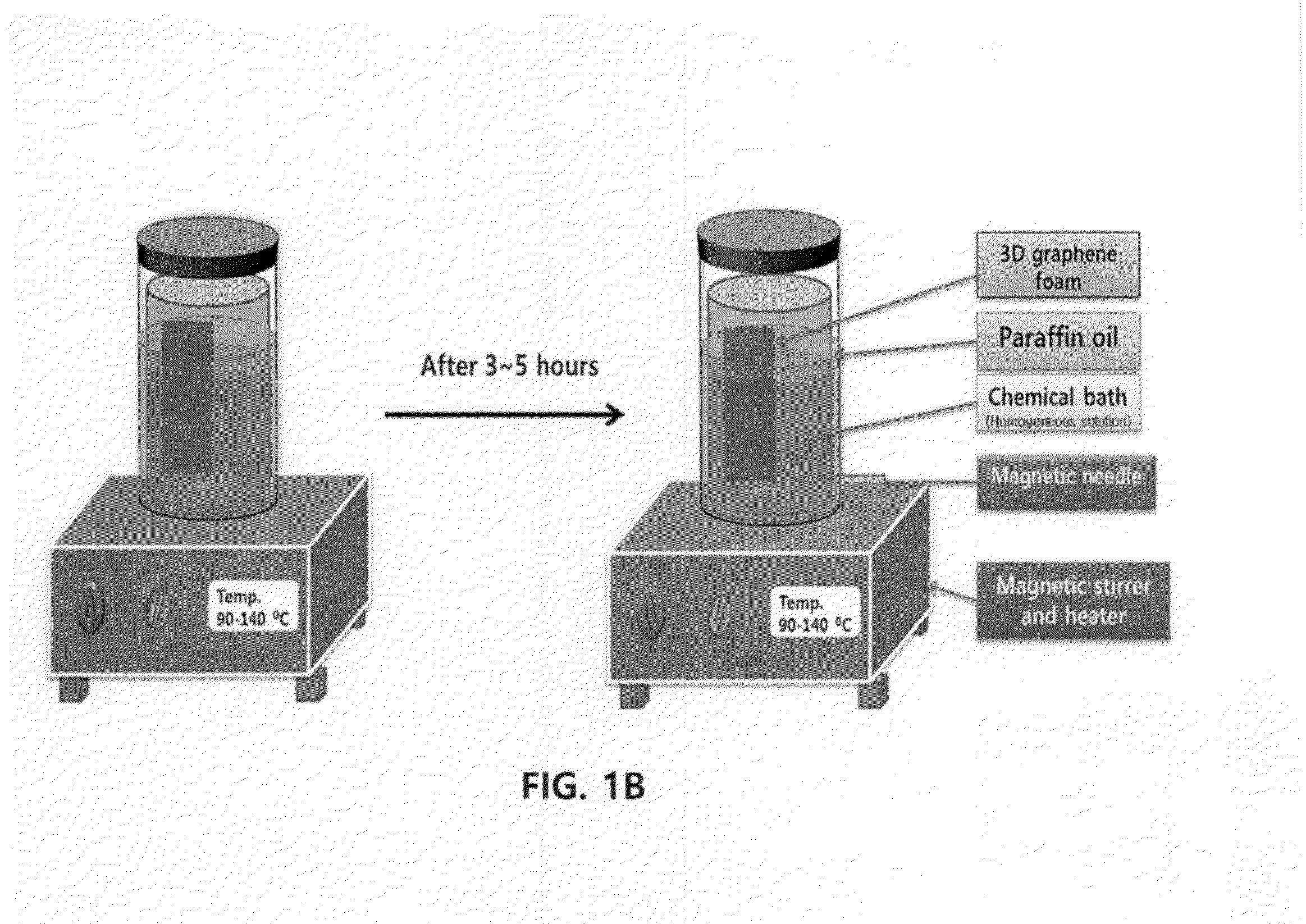

Three-dimensional graphene composite, preparation method for the same, and supercapacitor comprising the same

ActiveUS20150340170A1Improve electrostatic capacityIncrease energy densityHybrid capacitor electrodesElectrolytic capacitorsHigh energyConductive polymer

The present invention relates to a three-dimensional graphene composite, a preparation method for the same, and a supercapacitor including the same, and more particularly to a three-dimensional graphene composite including at least one electrode material nanoparticle selected from a transition metal hydroxide, a transition metal oxide and a conducting polymer as adsorbed onto the surface of a three-dimensional graphene foam, a preparation method for the three-dimensional graphene composite, and a supercapacitor including the three-dimensional graphene composite.The present invention can be used to provide a supercapacitor electrode with greatly enhanced electrostatic capacity and high energy density, by using a foaming resin structure made of a thin graphene frame to achieve lightweightness and also effectively depositing a nanostructure by a relatively simple and economic method such as the chemical bath deposition method or the electrodeposition method, based on an electron collector with high conductivity.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

Method for growing graphene film by using low-temperature chemical vapor deposition

ActiveCN103184425AReduce roughnessReduce nucleation densityPolycrystalline material growthFrom chemically reactive gasesGas phaseMaterials science

The invention relates to a method for preparing a graphene film in a low-temperature condition. The method at least comprises the following steps: (1), performing smooth treatment on a metal substrate; (2), performing doping of a chemical reagent on the surface of the metal substrate obtained in the step (1); (3), under a protective atmosphere, performing annealing treatment on the metal substrate obtained in the step (1); (4), contacting the metal substrate with a carbon source, and performing chemical vapor deposition in the low-temperature condition to obtain the graphene film; and optionally, after the step (4), performing step (5), stopping heating, cooling to the room temperature, and taking out the metal substrate with the graphene film thereon, wherein the chemical reagent is a precursor salt of metal. The method for growing the graphene film is low in growth temperature, low in cost, high in industrialized feasibility and wide in select range of the substrate, and can prepare the complete single-layer or multi-layer graphene film with high quality.

Owner:WUXI GRAPHENE FILM +1

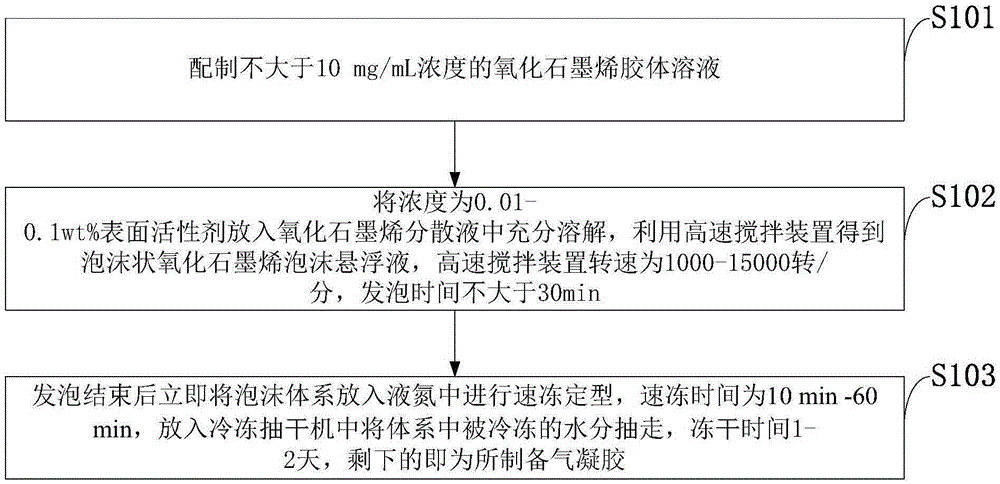

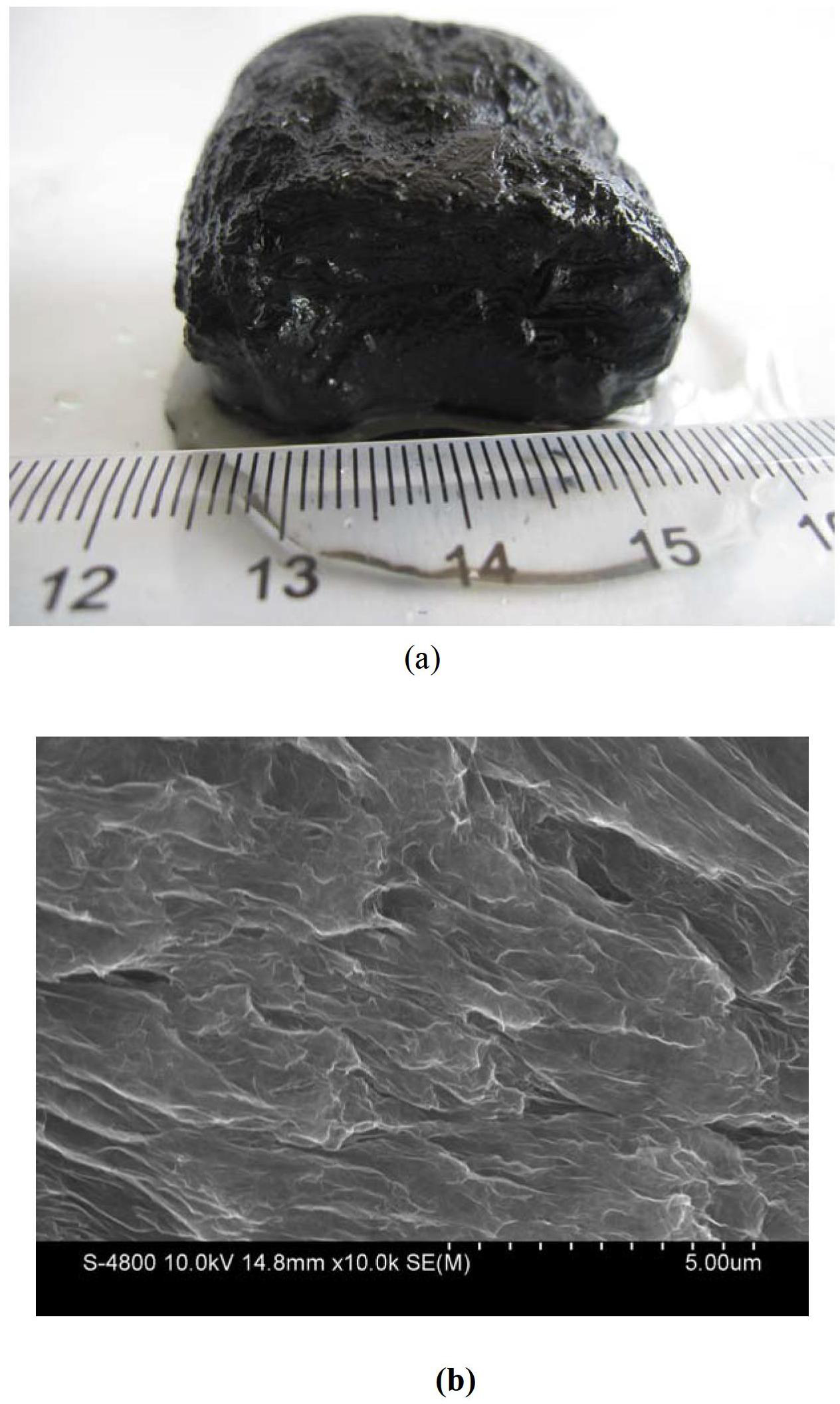

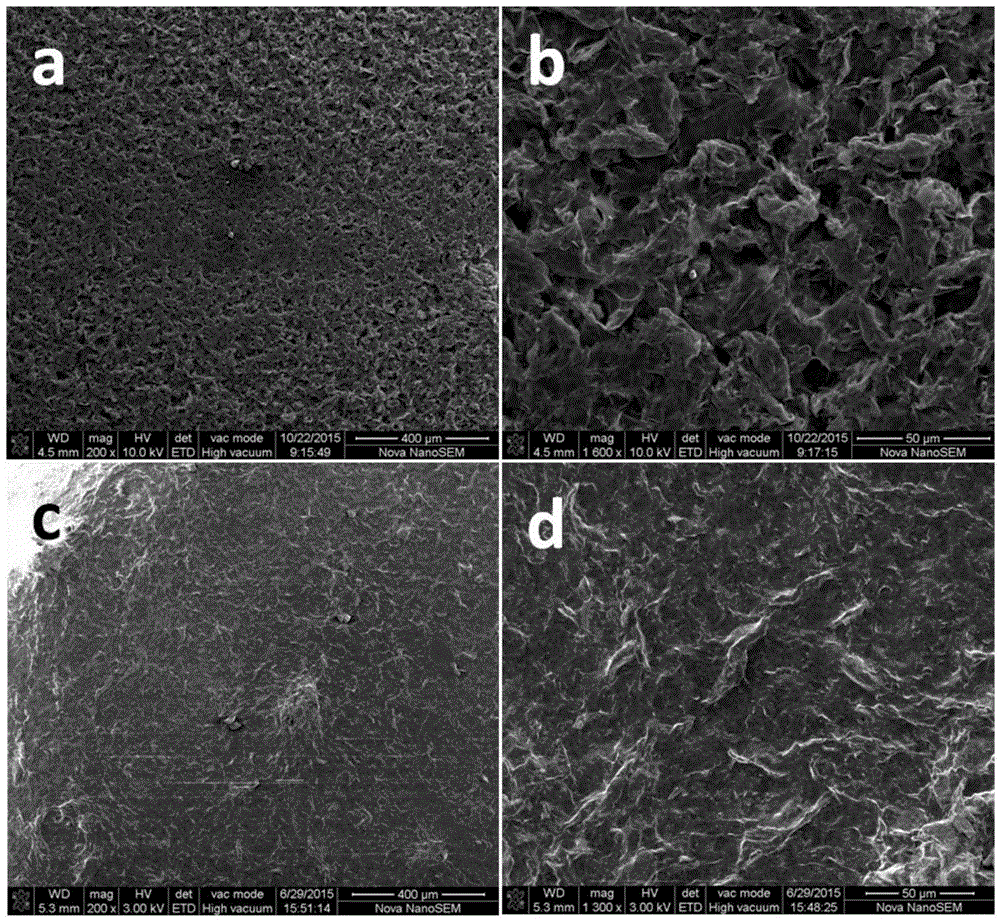

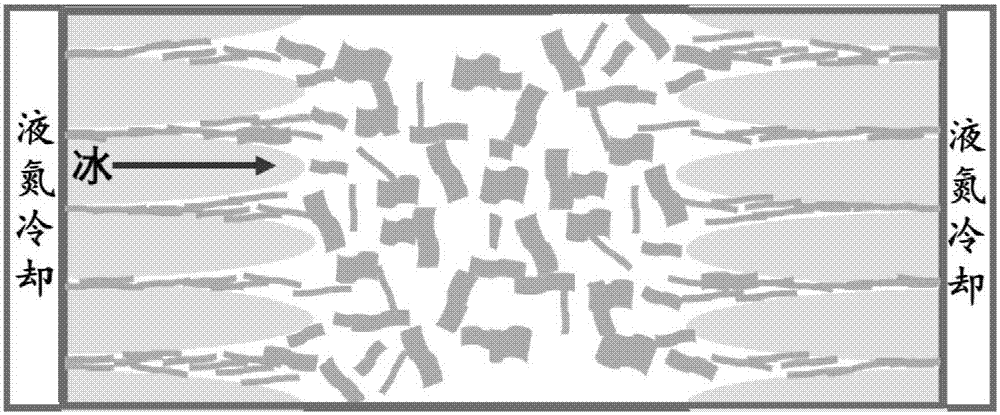

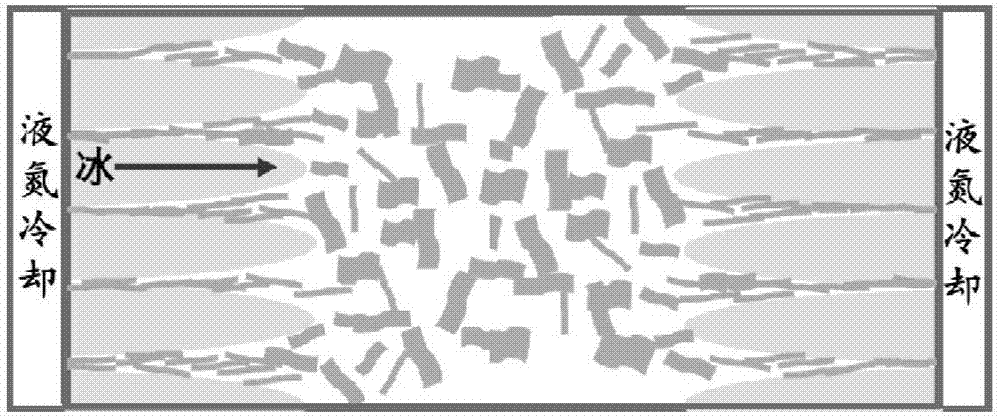

Spongy-like lightweight graphene aerogel preparation method

The present invention discloses a spongy-like lightweight graphene aerogel preparation method, which comprises: preparing a graphene oxide colloid solution with a concentration of not more than 10 mg / mL; adding a surfactant with a concentration of 0.01-0.1 wt% into the graphene oxide dispersion, and completely dissolving to obtain a foam-like graphene oxide foam suspension; and immediately placing the foam system into liquid nitrogen after completing the foaming, carrying out rapid freezing shaping, carrying out freeze drying, and removing the water to obtain the graphene aerogel material. According to the spongy-like lightweight graphene aerogel of the present invention, the solution system surface tension is reduced, and the dispersion property of the graphene oxide in the solvent is improved while the specific surface area of the aerogel material is further increased so as to improve the adsorption property on dyes, organic solvents and other substances; and the prepared spongy-like lightweight graphene aerogel material has characteristics of simple process, low cost, stable structure, excellent performance, and maximal maintaining of the excellent properties of the graphene material.

Owner:CAPITAL NORMAL UNIVERSITY

Preparation methods of flexible substrate-based graphene film and flexible substrate-based graphene composite film

The invention discloses a preparation method of a flexible substrate-based graphene film. The preparation method comprises the following steps of coating a graphene oxide aqueous solution on a paper base material to obtain a uniform graphene oxide film, carrying out drying curing treatment, coating a polydimethylsiloxane (PDMS) layer on the surface of the graphene oxide film, carrying out curing treatment, and dipping the treated paper base material into hydroiodic acid for a reduction reaction, wherein in the reduction reaction, the treated paper base material undergoes a hydrolysis reaction under the acid conditions and simultaneously, reacts with the acid to produce bubbles so that the graphene oxide film is automatically separated from the paper base material and the flexible substrate-based graphene film product is obtained. The invention also discloses a preparation method of a flexible substrate-based graphene composite film. The methods realize graphene reduction without a high temperature condition or a toxic reduction reagent, conveniently and fast realize film stripping and transfer and are especially suitable for large-scale industrial production.

Owner:卫辉市卓力科技有限公司

Highly conducting and oriented graphene film and production process

ActiveUS20170162291A1Reduce resistanceGood orientationProductsConductive layers on insulating-supportsElectrical conductorShear stress

A process for producing a highly conducting film of conductor-bonded graphene sheets that are highly oriented, comprising: (a) preparing a graphene dispersion or graphene oxide (GO) gel; (b) depositing the dispersion or gel onto a supporting solid substrate under a shear stress to form a wet layer; (c) drying the wet layer to form a dried layer having oriented graphene sheets or GO molecules with an inter-planar spacing d002 of 0.4 nm to 1.2 nm; (d) heat treating the dried layer at a temperature from 55° C. to 3,200° C. for a desired length of time to produce a porous graphitic film having pores and constituent graphene sheets or a 3D network of graphene pore walls having an inter-planar spacing d002 less than 0.4 nm; and (e) impregnating the porous graphitic film with a conductor material that bonds the constituent graphene sheets or graphene pore walls to form the conducting film.

Owner:GLOBAL GRAPHENE GRP INC

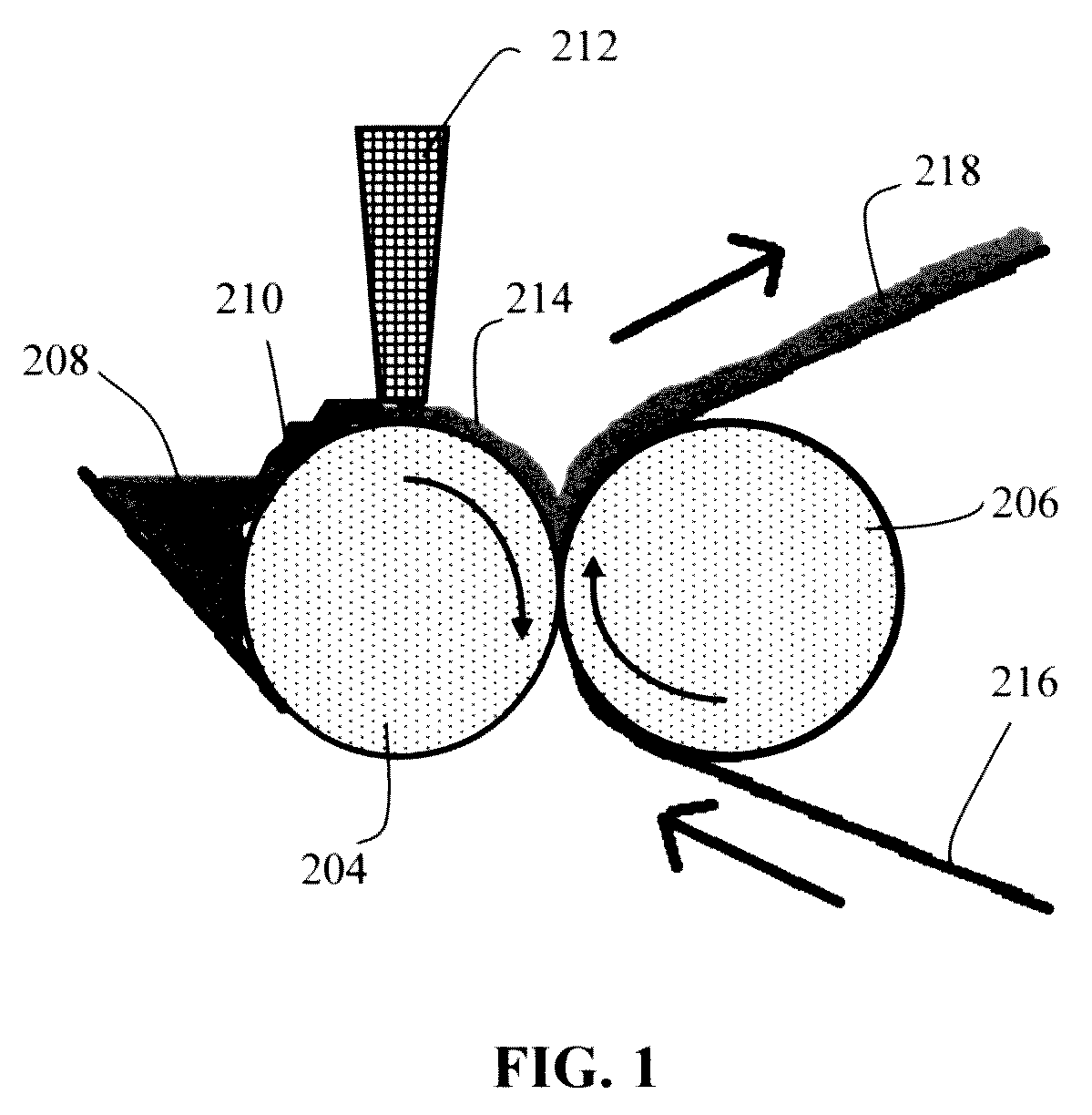

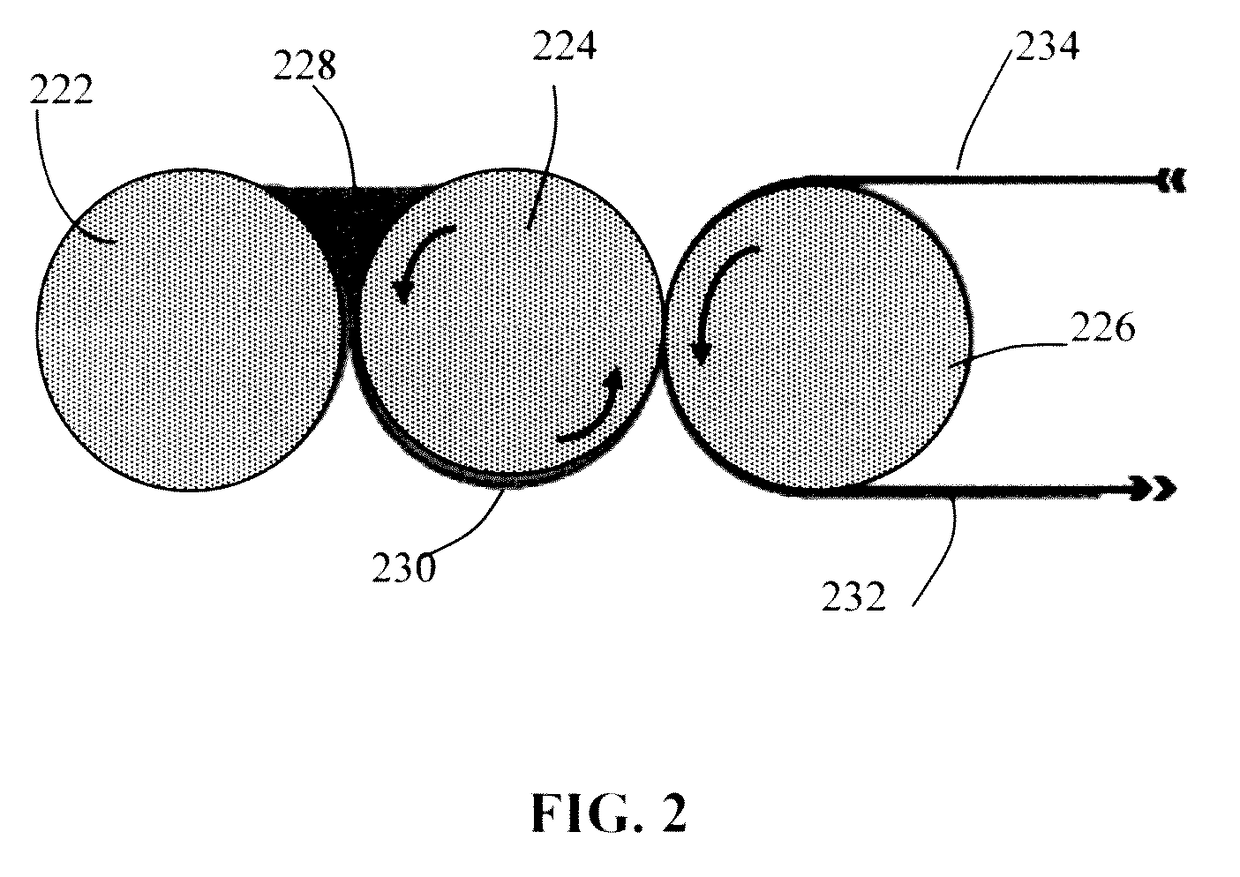

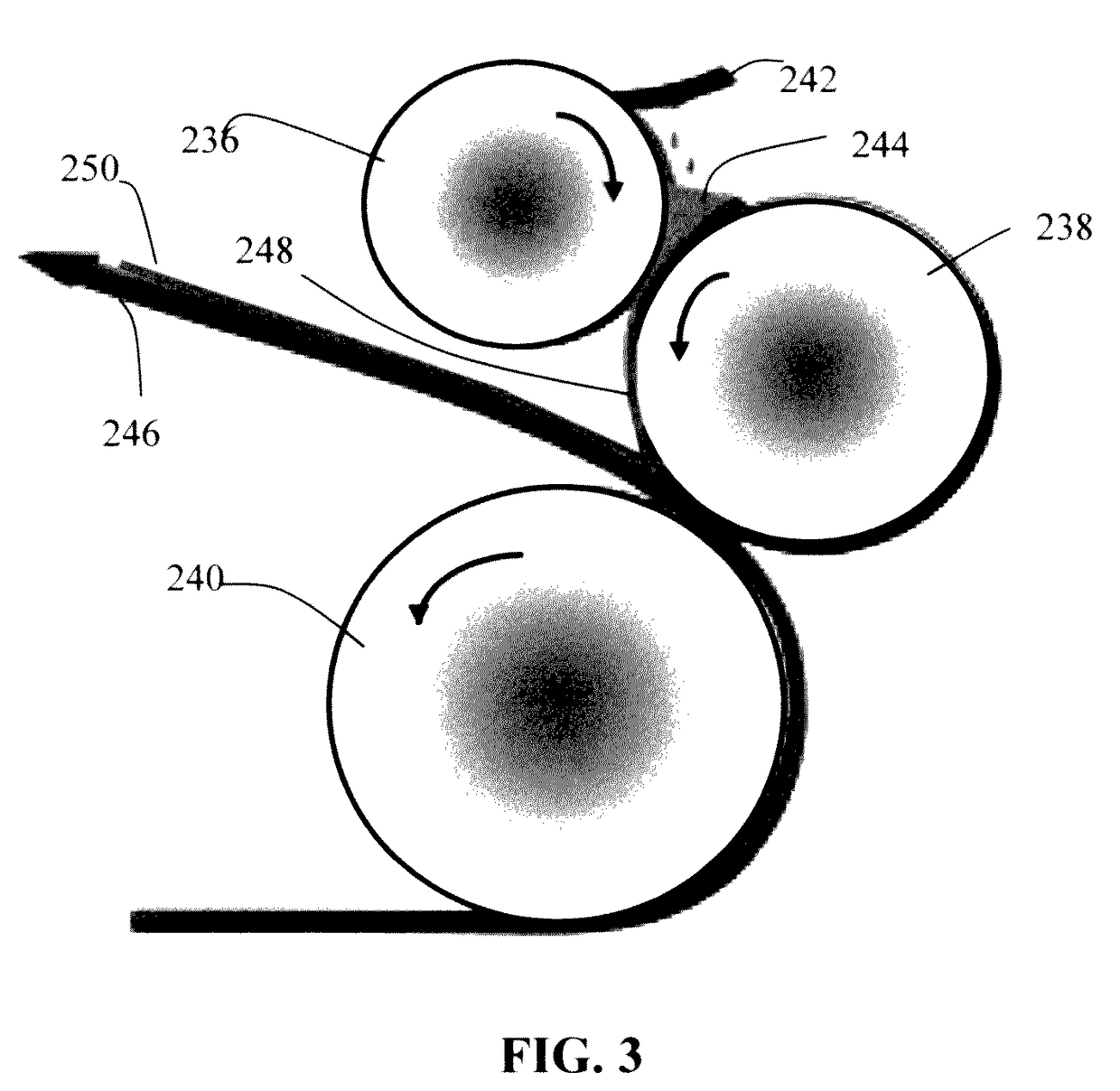

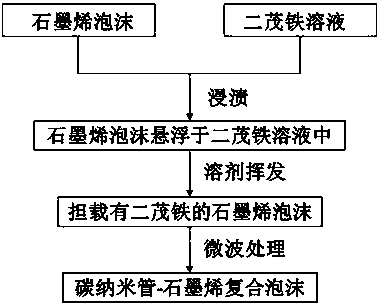

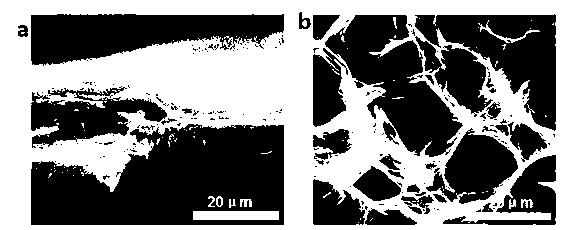

Preparation method for carbon nano tube-graphene composite foam

InactiveCN103738953ASimple processRaw materials are cheap and easy to getMaterial nanotechnologyCarbon compoundsPtru catalystNanotube

The invention belongs to a preparation method of a nano composite material and particularly relates to the field of a microwave preparation method for a grapheme-based composite material. A preparation method for carbon nano tube-graphene composite foam comprises the following steps: firstly, loading ferrocene on graphene foam; and then carrying out microwave treatment on the graphene foam loaded with the ferrocene and decomposing the ferrocene on the graphene foam by a high temperature which is instantly generated, so as to generate a catalyst and a carbon source to realize carbon nano tube in-situ growth and obtain the carbon nano tube-graphene composite foam. A carbon nano tube in the composite material vertically and epitaxially grows on the surface of a hole wall of the graphene foam; the super-hydrophobic and super-lipophilic surface chemical characteristics are represented; the preparation method has a wide application prospect in the aspects of adsorption, oil-water separation and the like; the method has the characteristics that operation is simple and convenient, cost is low, and industrial production is easily realized, and is an important preparation method for nano carbon materials.

Owner:DALIAN UNIV OF TECH

Process for producing highly oriented graphene films

ActiveUS20150218003A1Low heat treatment temperatureLess-energy-intensiveMaterial nanotechnologyLamination ancillary operationsCvd grapheneGraphene foam

A process for producing a highly oriented graphene film (HOGF), comprising: (a) preparing a graphene oxide (GO) dispersion having GO sheets dispersed in a fluid medium; (b) dispensing and depositing the dispersion onto a surface of a supporting substrate to form a layer of GO, wherein the dispensing and depositing procedure includes subjecting the dispersion to an orientation-inducing stress; (c) removing the fluid medium to form a dried layer of GO having an inter-plane spacing d002 of 0.4 nm to 1.2 nm; (d) slicing the dried layer of GO into multiple pieces of dried GO and stacking at least two pieces of dried GO to form a mass of multiple pieces of GO; and (f) heat treating the mass under an optional first compressive stress to produce the HOGF at a first heat treatment temperature higher than 100° C. to an extent that an inter-plane spacing d002 is decreased to a value less than 0.4 nm.

Owner:GLOBAL GRAPHENE GRP INC

Foams of graphene, method of making and materials made thereof

ActiveUS20120322917A1Reduce energy consumptionReduce exposureMaterial nanotechnologyOther chemical processesCvd grapheneCompound s

Method for making a liquid foam from graphene. The method includes preparing an aqueous dispersion of graphene oxide and adding a water miscible compound to the aqueous dispersion to produce a mixture including a modified form of graphene oxide. A second immiscible fluid (a gas or a liquid) with or without a surfactant are added to the mixture and agitated to form a fluid / water composite wherein the modified form of graphene oxide aggregates at the interfaces between the fluid and water to form either a closed or open cell foam. The modified form of graphene oxide is the foaming agent.

Owner:MASSACHUSETTS INST OF TECH

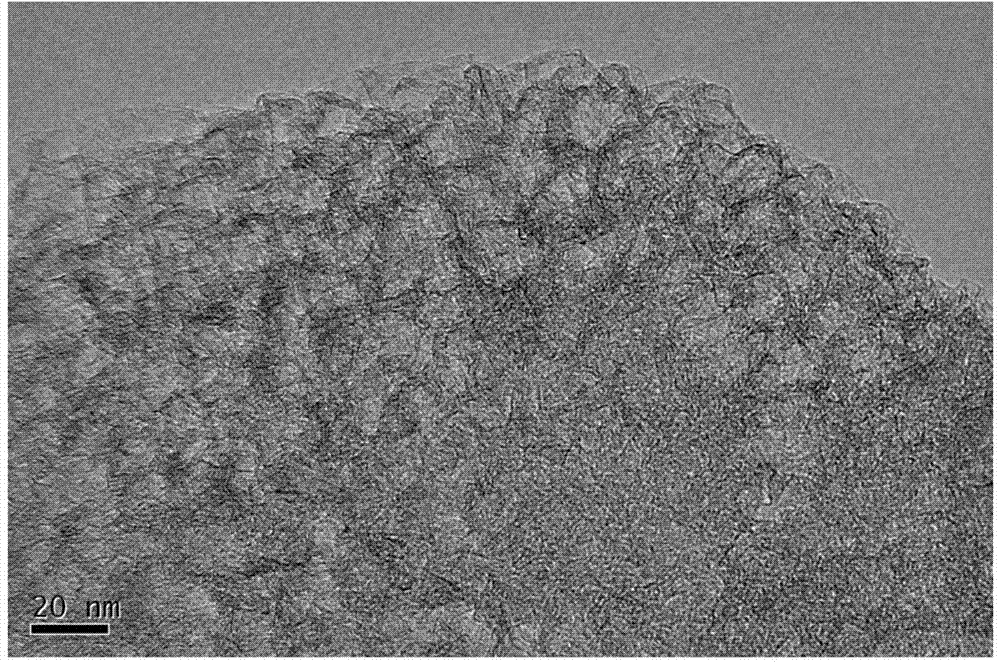

Mesoporous graphene foam as well as preparation method thereof

ActiveCN103482611AStable structureLarge specific surface areaGrapheneNanotechnologyDraw ratioElectric properties

The invention belongs to the technical fields of a novel material as well as preparation, and particularly relates to mesoporous graphene foam as well as a preparation method thereof. The invention realizes hydrothermal preparation of a magnesium oxide texture structure and preparation of the mesoporous graphene foam by using textured magnesium oxide as a template. The mesoporous graphene foam material has abundant mesoporous structures and excellent electric property and can be used as an electrode material of batteries and supercapacitors, so that the energy density and the power density of the batteries or the supercapacitors are expectedly improved to a great extent. The cycling stability of the mesoporous graphene foam material is increased, and the mesoporous graphene foam material combined with materials with high draw ratio or the mesoporous graphene foam material can soften energy storage apparatuses. The advantages have important meaning for realization of commercialization of a new generation of energy storage apparatuses for electromobiles and development of smaller, lighter and flexible portable mobile power supplies. The business prospect is wide. Meanwhile, preparation processes of the high temperature hydrothermal method and a fluidized bed can realize engineering enlargement, so that the method is expected to be industrialized.

Owner:TSINGHUA UNIV

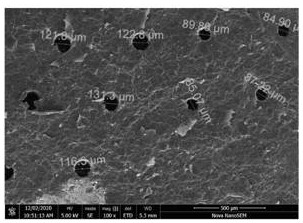

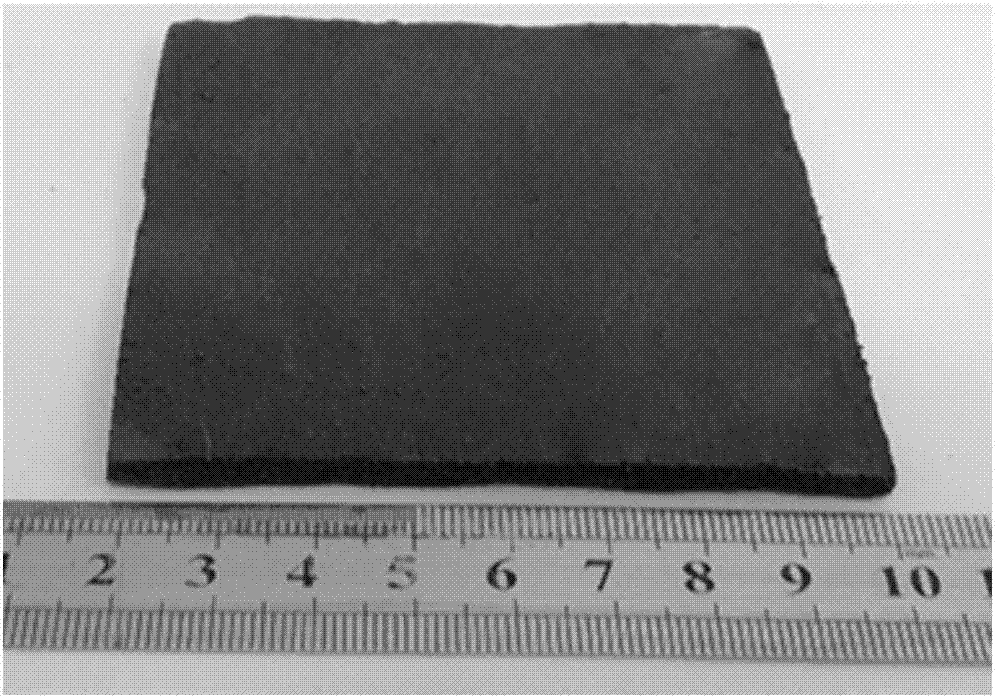

Graphene foam film enhanced heat-conducting gasket and preparation method thereof

PendingCN113290958ALarge poresHigh porosityLamination ancillary operationsLaminationAdhesive cementPolymer science

The invention discloses a graphene foam film enhanced heat-conducting gasket and a preparation method thereof. The graphene foam film enhanced heat-conducting gasket comprises a plurality of layers of graphene foam films and adhesives filled in the graphene foam films and among the layers, and the graphene foam films account for 60-95 wt% of the total weight of the heat-conducting gasket. The graphene is arranged in the heat-conducting gasket in the thickness direction, and the gasket has good heat-conducting performance in the thickness direction; besides, the combination of the graphene foam film and the adhesive has good compressibility and compression resilience, and the application thermal resistance is small.

Owner:CHANGZHOU FUXI TECH CO LTD

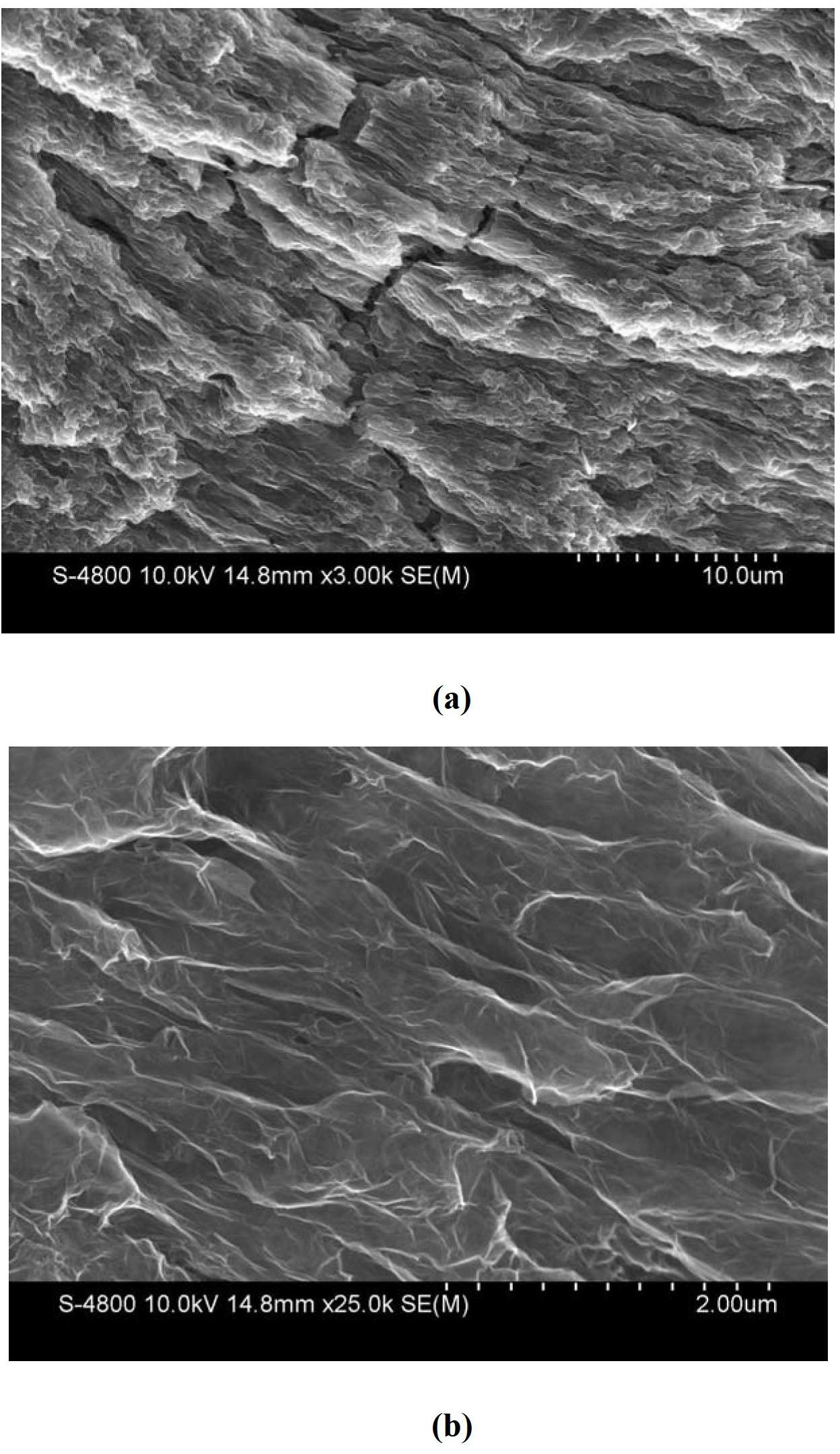

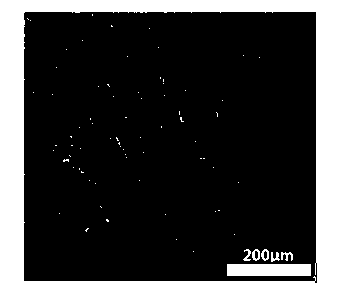

Preparation method of anisotropic graphene foam

The invention relates to a preparation method of anisotropic graphene foam. The method comprises the following steps of: (1) preparing graphite oxide; (2) preparing a graphene oxide dispersion solution, namely dispersing the graphite oxide prepared in the step (1) into a solution to prepare the graphene oxide dispersion solution; (3) preparing a graphene dispersion solution, namely adding a surfactant or a reducing agent with certain surface activity into the dispersion solution of the step (2) to be used as a protection agent; and preparing the graphene dispersion solution through chemical liquid-phase reduction; and (4) preparing the anisotropic graphene foam: damaging a previous graphene stable system to self-assemble the graphene into the anisotropic graphene foam. The graphene foam prepared by the method is composed of at least one layer of graphene structure unit and has anisotropies of a structure and a property in a graphene growth direction and in a direction which is vertical to the growth direction; the specific surface area of the anisotropic graphene foam is 200-2000 m<2> / g; and the heat conductivity difference in the graphene growth direction and in the direction which is vertical to the growth direction reaches to two magnitudes.

Owner:上海二工大资产经营有限公司

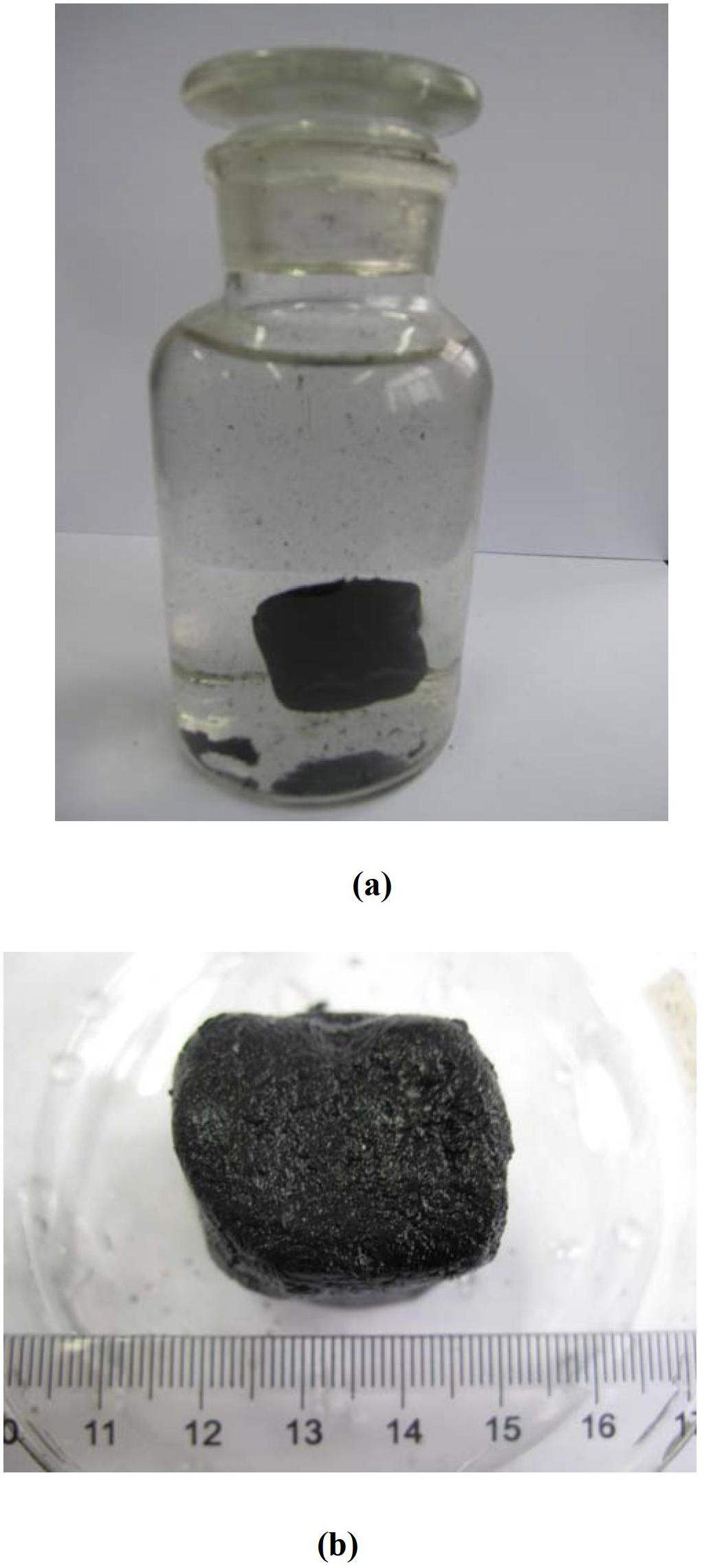

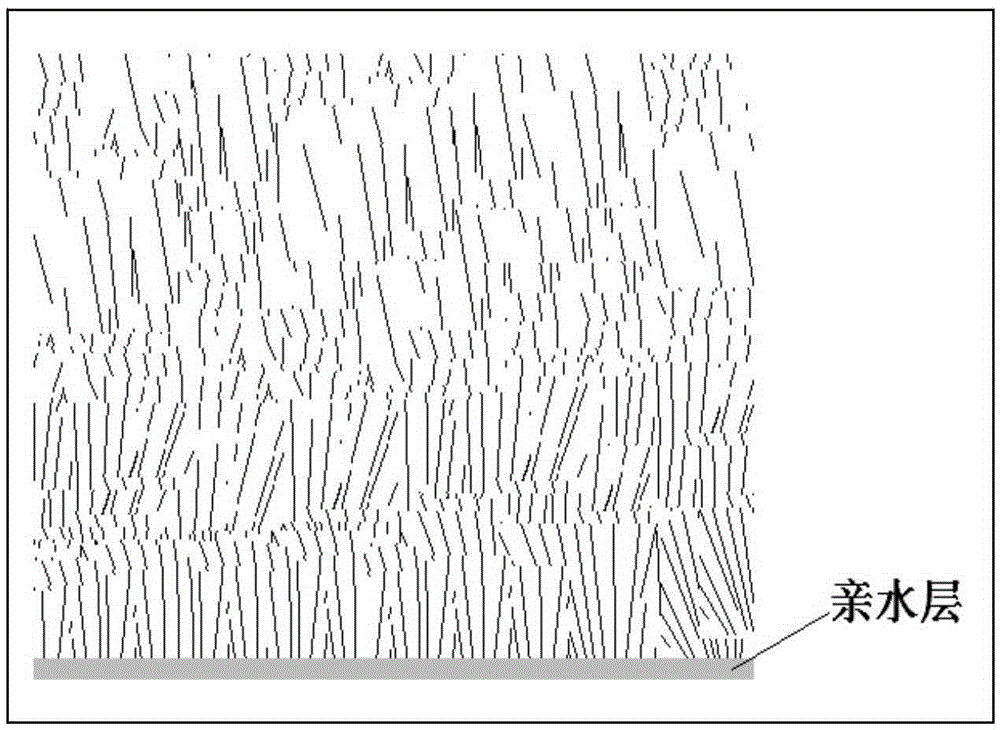

Preparation method of graphene photo-thermal transformation material for sea water desalination and clean water treatment

ActiveCN106809897AIncrease profitEasy to condenseGeneral water supply conservationSeawater treatmentWater desalinationFresh water organism

The invention relates to the field of water treatment materials, in particular to a preparation method of a graphene photo-thermal transformation material for sea water desalination and clean water treatment. The preparation method comprises the steps of preparing graphene powder, a polymer material with a chain molecule structure and a solvent into a sizing agent according to the proportion, adding into a mold for drying and heat treating so as to enable organic substances in the material to be carbonized, and obtaining a graphene foam material with favorable mechanism strength; carrying out hydrophilization treatment on one side of the bottom face of the graphene foam material, and obtaining the graphene photo-thermal transformation material for sewage and sea water distillation purification and desalination. According to the material, a black body structure and a high thermal conductivity property of graphene foams are utilized, so that sunlight can be high-efficiently transformed into heat; a capillary action of the foam structure is utilized for continuously conveying water and reducing an evaporation barrier, so that sea water is quickly distilled and desalted. A graphene foam material is utilized for manufacturing the portable high-efficient sea water desalination and sewage purification device, which meets the demand on quickly preparing clean freshwater on sea and outdoors.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

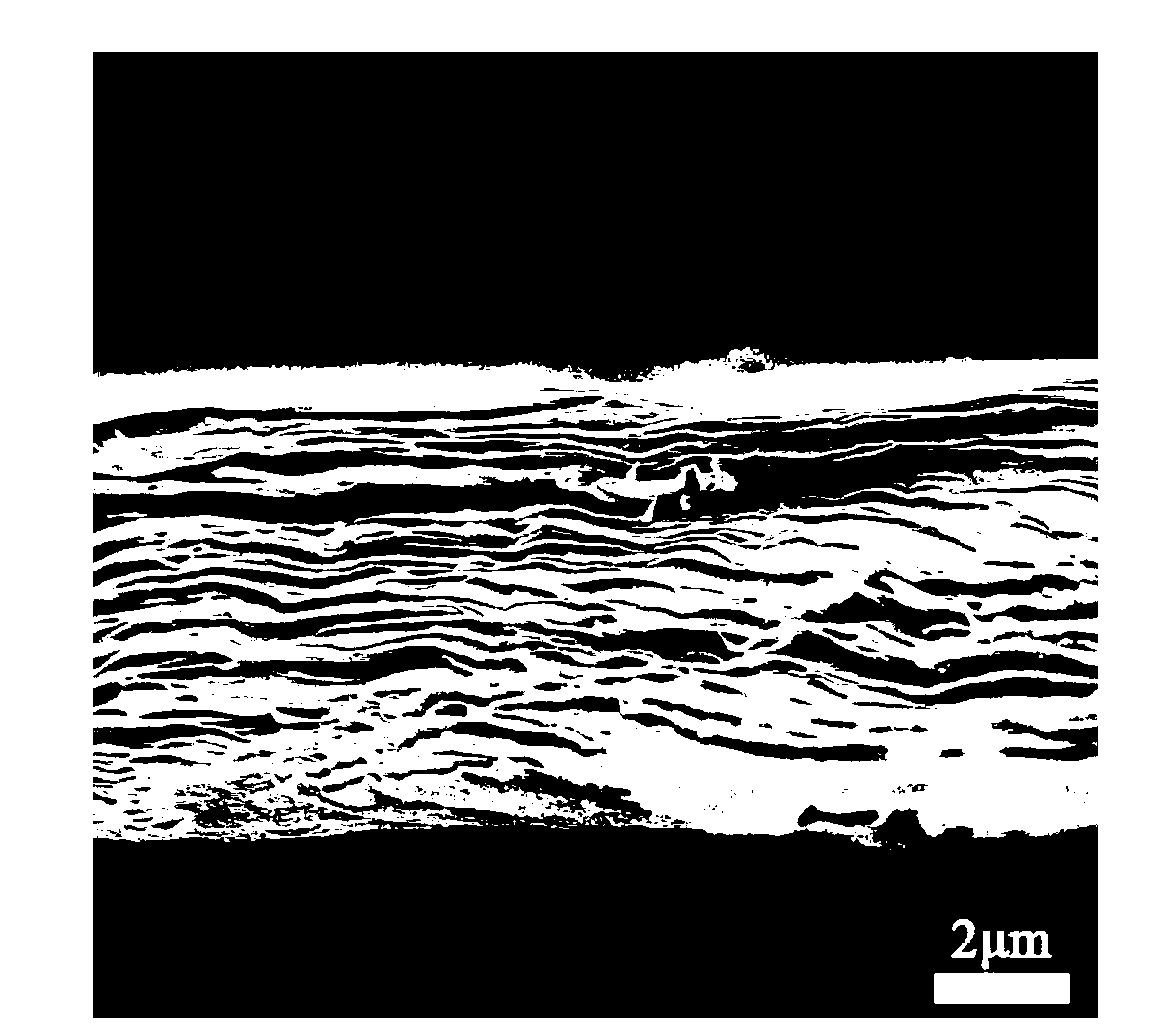

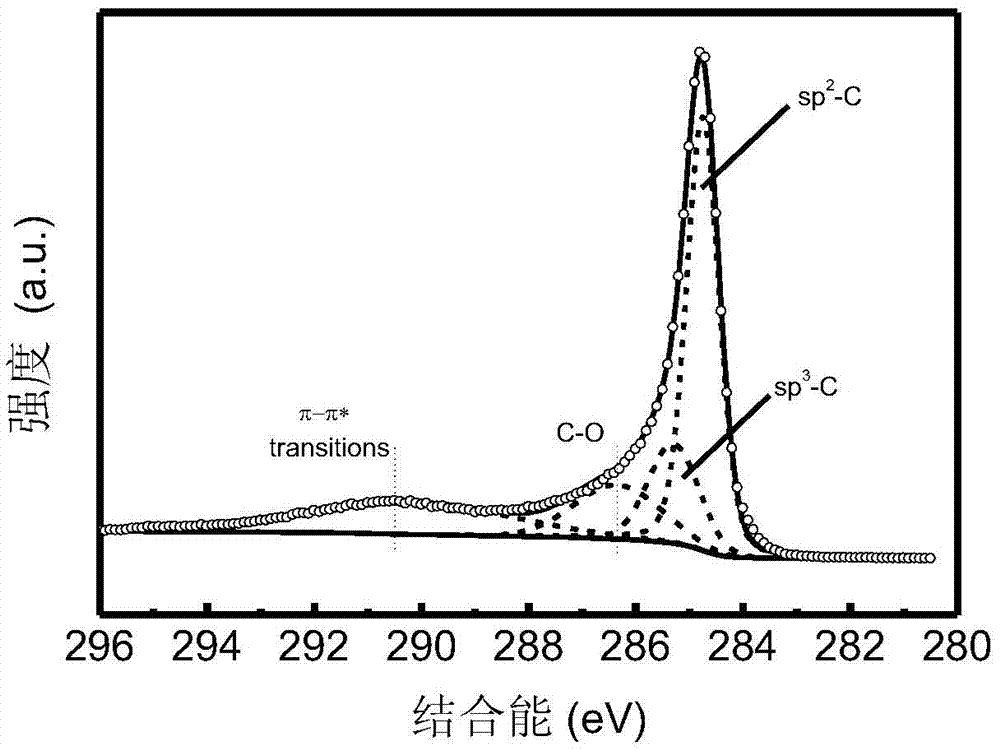

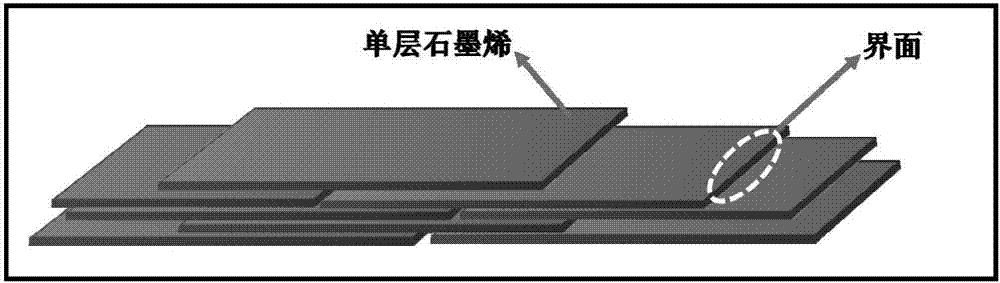

Independent self-support wrinkled graphene film in nano thickness and preparation method thereof

The invention discloses an independent self-support wrinkled graphene film in nano thickness and a preparation method thereof. The independent self-support wrinkled graphene film in nano thickness isobtained through film formation by suction filtration of oxidized graphene prior to chemical reduction and high-temperature treatment. The independent self-support wrinkled graphene film in nano thickness is formed by single-layer graphene through physical crosslinking, wherein the graphene is complete in base structure without obvious defects and rich in wrinkles, and the content of turbostraticstructures among lamellas exceed 30%. Since the independent self-support wrinkled graphene film in nano thickness is extremely thin in thickness (16-130 nm) with a great quantity of superficial wrinkles, thereby being highly flexible.

Owner:杭州德烯科技集团有限公司

PrPrearation method for graphene film

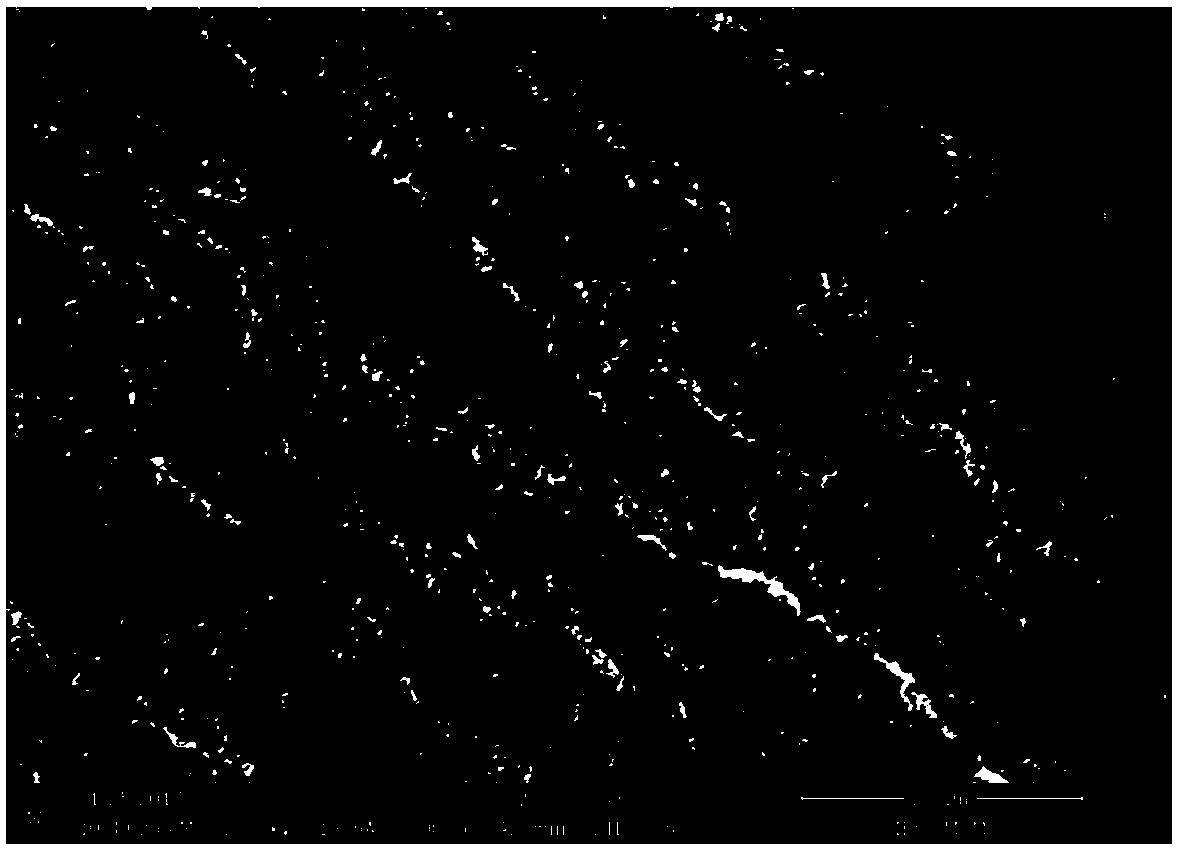

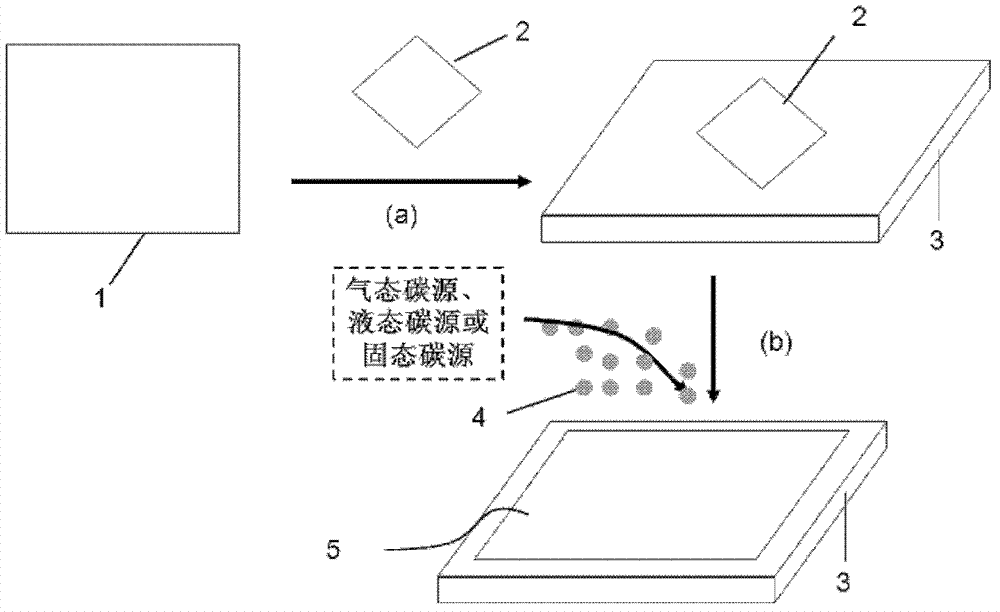

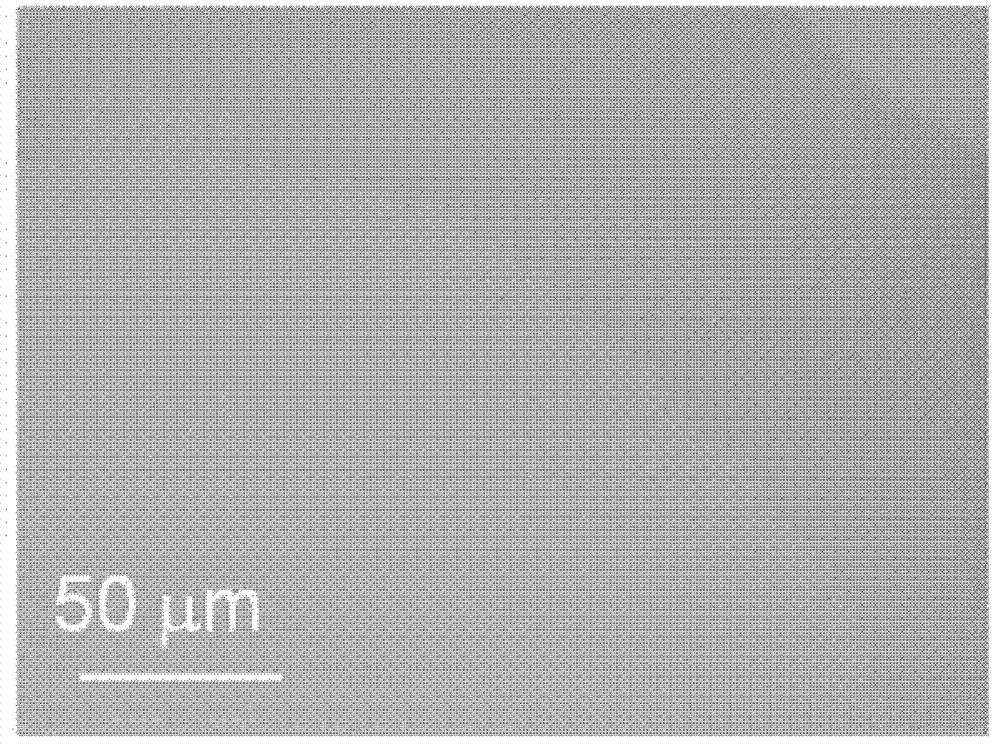

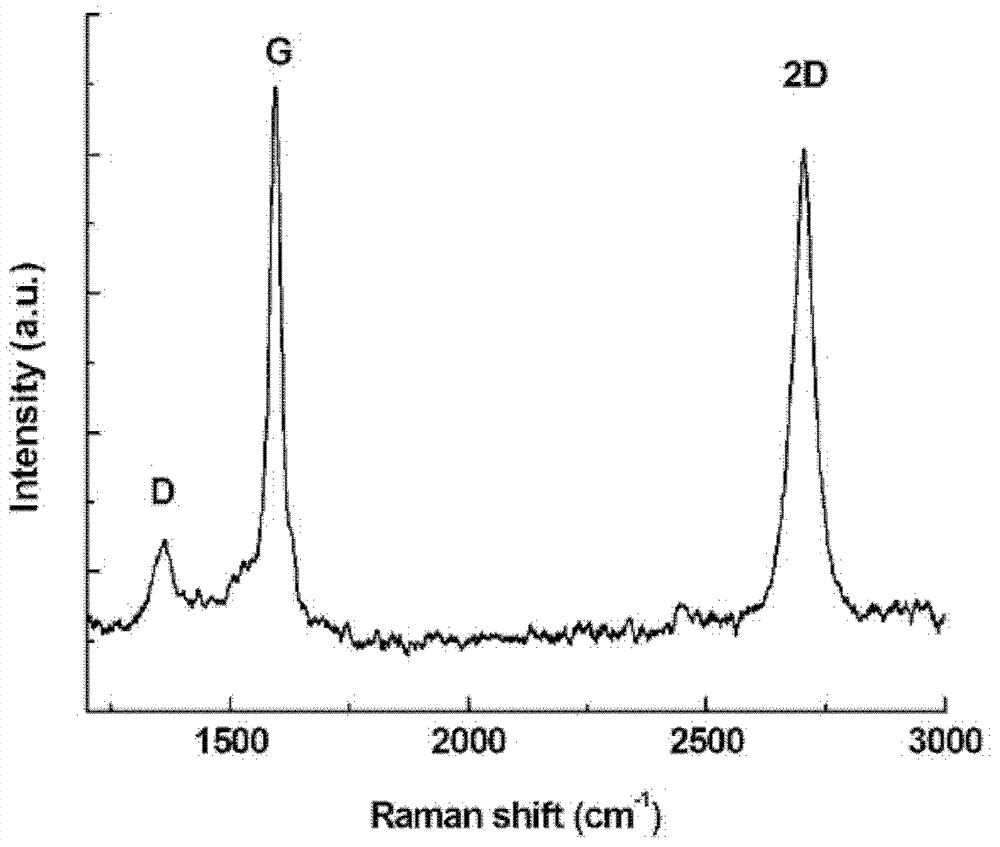

ActiveCN102897750AThickness is easy to controlControllable structureGrapheneCvd grapheneGraphene foam

The invention discloses a preparation method for a graphene film. The method comprises the steps of putting small sheets of the in advance synthetic graphene film on a substrate, and growing the graphene film on the substrate by using the small sheets of the in advance synthetic graphene film as induced points for the growth of s large-area graphene film and adopting carbon atoms released by carbon atom-containing gas carbon source, solid carbon source, liquid carbon source or composite carbon source materials thereof. The graphene film can directly grow on the substrate of practical application graphene film, so that the graphene film needs not to be transferred when being used. The number of layers, the structure and the size of the prepared graphene film are easy to control; the temperature for growing the graphene film can be 0 DEG C-2000 DEG C; the prepared graphene film has excellent photoelectric characteristics and is suitable for large-scale manufacture of optoelectronic devices.

Owner:ZHEJIANG UNIV

Preparation method for doped graphene foams

The invention discloses a preparation method for doped graphene foams. The preparation method comprises the following steps: adopting the hydrothermal method to enable nano particles to dope with and generate on oxidized graphene sheets to obtain oxidized graphene aerogel; reducing the oxidized graphene aerogel doped with the nano particles in a controllable manner at the low-temperature gaseous phase condition to obtain the doped graphene foams. According to the preparation method, a reductant is not used in the growing process of the nano particles, and liquid is not introduced into the reaction system, so that excessive overlap of the graphene layers is avoided, porosity of the graphene foams is maintained, polyporous shrinkage caused by surface stress is prevented, and the uniformly doped graphene foam material with the controllable appearance is obtained. The preparation method is convenient to operate, uniform in doping, controllable in product size, economical and fast, is adopted as the novel technology for the large-scale preparation of the doped graphene foam material, and is expected to provide novel materials for graphene adsorbents, graphene capacitors, graphene catalysts and the like.

Owner:四川烯城环保科技有限公司

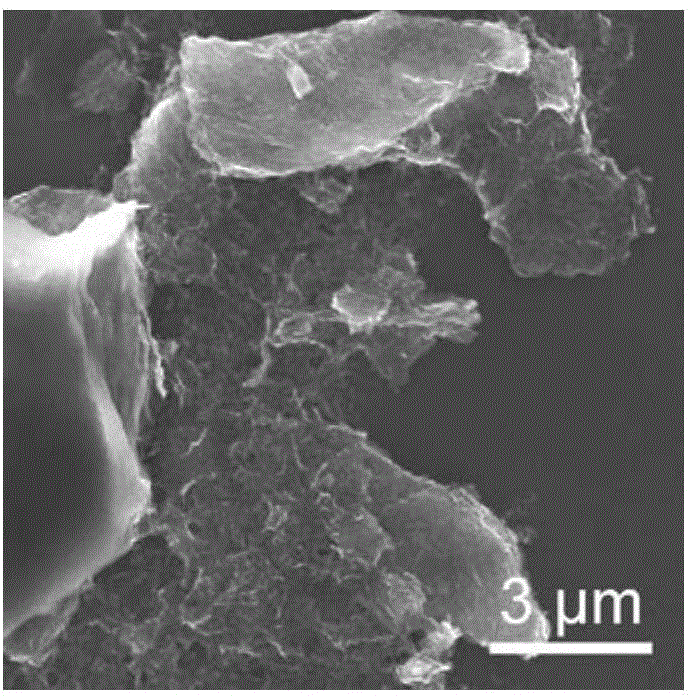

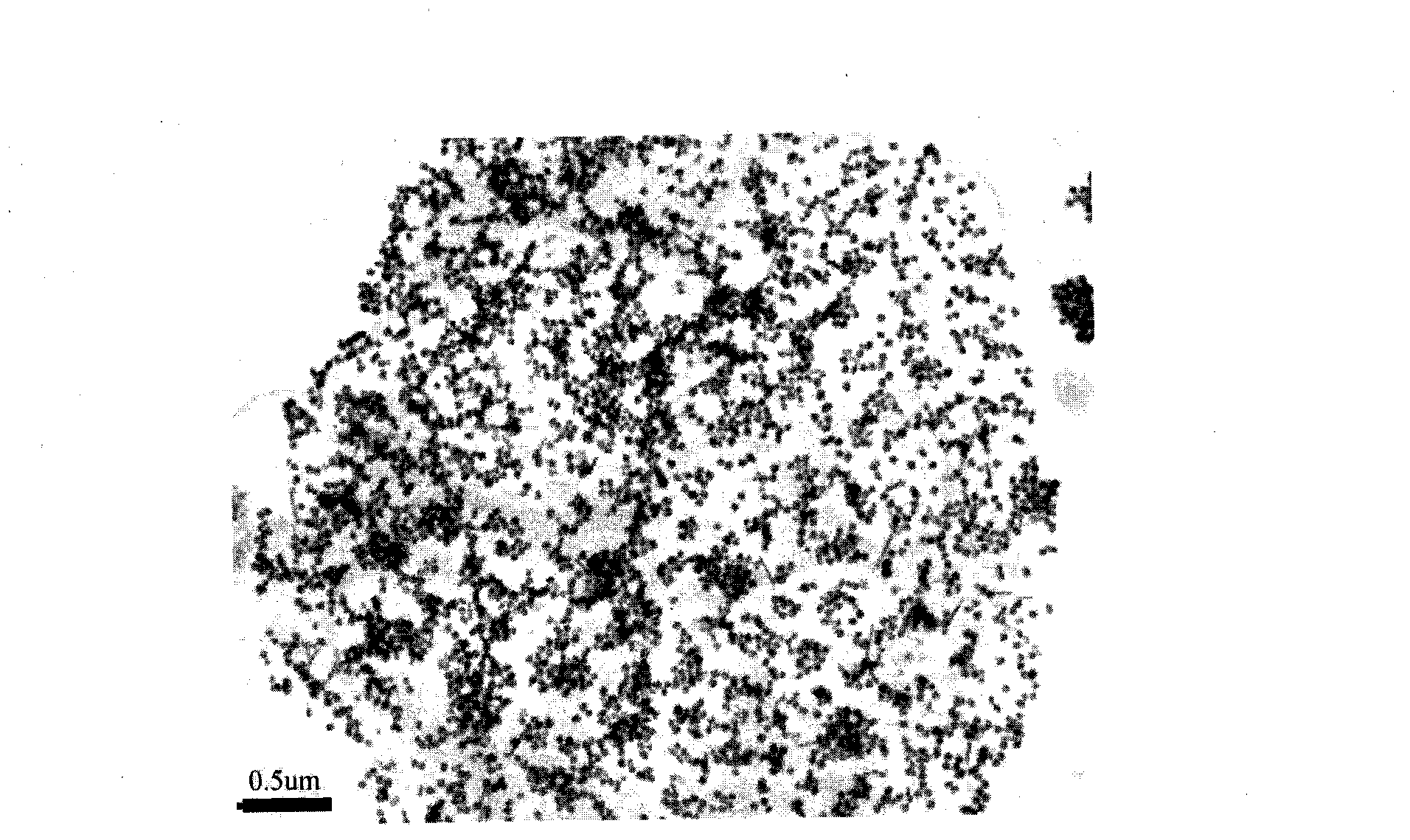

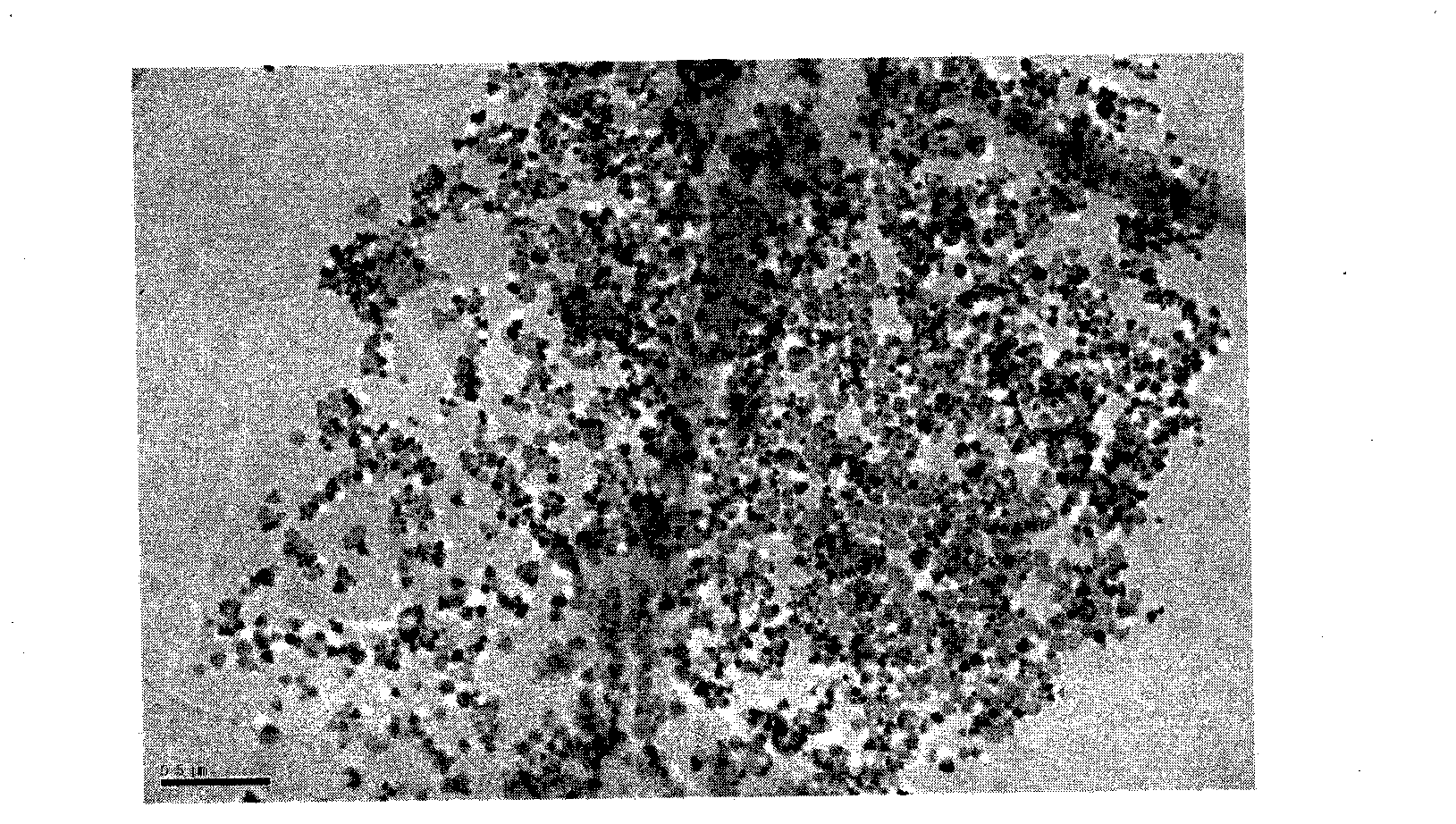

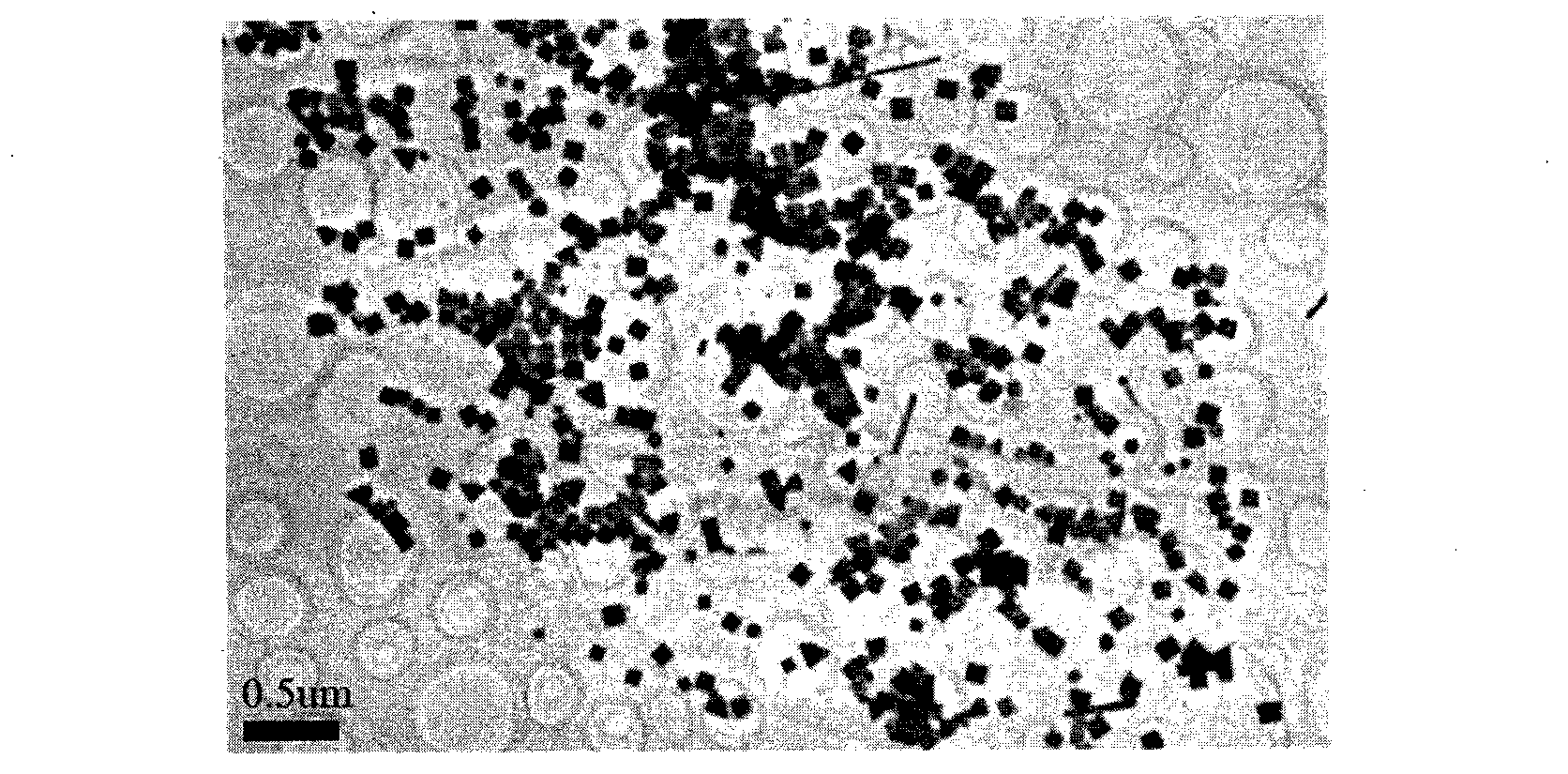

Preparation method of metal nanoparticle modified graphene composite material

InactiveCN103508449AShape is easy to controlEase of industrial scale productionMaterial nanotechnologyGrapheneGraphene flakeCobalt

The invention discloses a preparation method of a metal nanoparticle modified graphene composite material. The preparation method comprises the steps of preparing a graphene flake and a metal nanoparticle: firstly, mixing the graphene flake, the metal nanoparticle and ethanol according to the mass ratio of (1-3): (50-100): (500-1000), and carrying out ultrasonic treatment for at least 10min to obtain a mixed solution; then, centrifuging the mixed solution at the rotating speed of 12000-16500r / min for at least three times to obtain the metal nanoparticle modified graphene composite material, wherein the lasting time for centrifuging every time is at least 10min, the metal nanoparticle is modified on the graphene flake, the graphene flake has the length of 2-4mu m, the width of 1-3mu m and the thickness of less than or equal to 1nm, the metal is one of silver, gold, palladium, platinum, copper, ferrum, cobalt and nickel, and the nanoparticle is one of a nanosphere, a triangular nanoplate, a nanocube and a nanorod. The preparation method is not only convenient and rapid, but also capable of ensuring that the metal nanoparticle in the prepared metal nanoparticle modified graphene composite material is controllable in appearance.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Manufacturing method of graphene foam

ActiveCN103213978ANo generationEasy control of mechanical propertiesGrapheneGraphene flakeEngineering

The invention provides a manufacturing method of graphene foam. The manufacturing method comprises the following steps of: 1) reducing an aqueous dispersion of graphene oxide through a hydrothermal method, and performing self-assembly on graphene sheets to obtain a graphene wet gel block body; 2) freezing the graphene wet gel block body obtained in the step 1) on a metal tray, wherein the metal tray has preset freezing temperature which is controlled within a range of -196 DEG C to -10 DEG C, and the graphene wet gel block body after freezing is completely crystallized to form a gel crystalline solid; and 3) performing vacuum sublimation and drying on the gel crystalline solid obtained in the step 2). The manufacturing method has the advantages of simple process and capability of regulating and controlling a hole structure of the graphene foam, thus the graphene foam has different properties.

Owner:SOUTHEAST UNIV

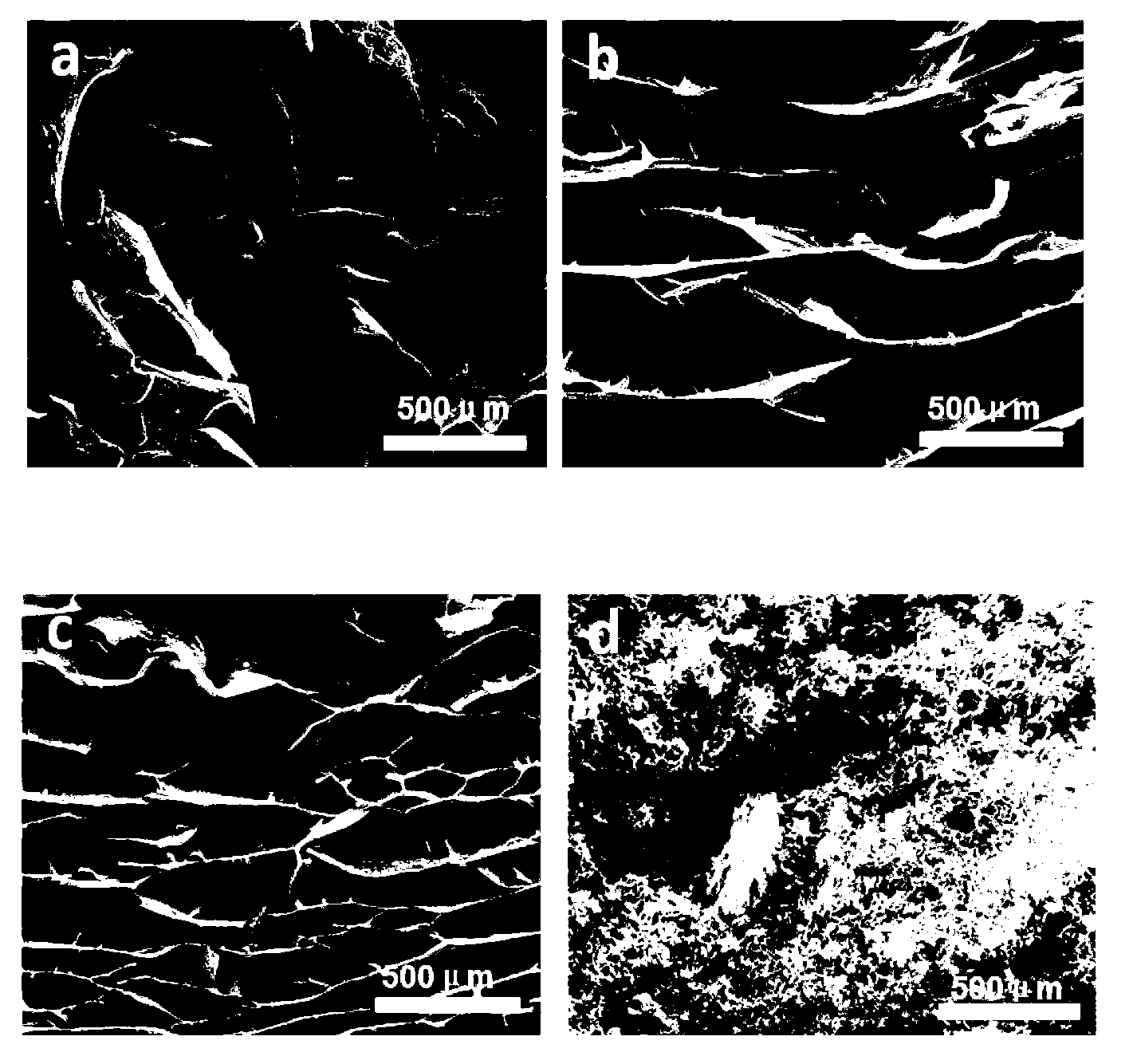

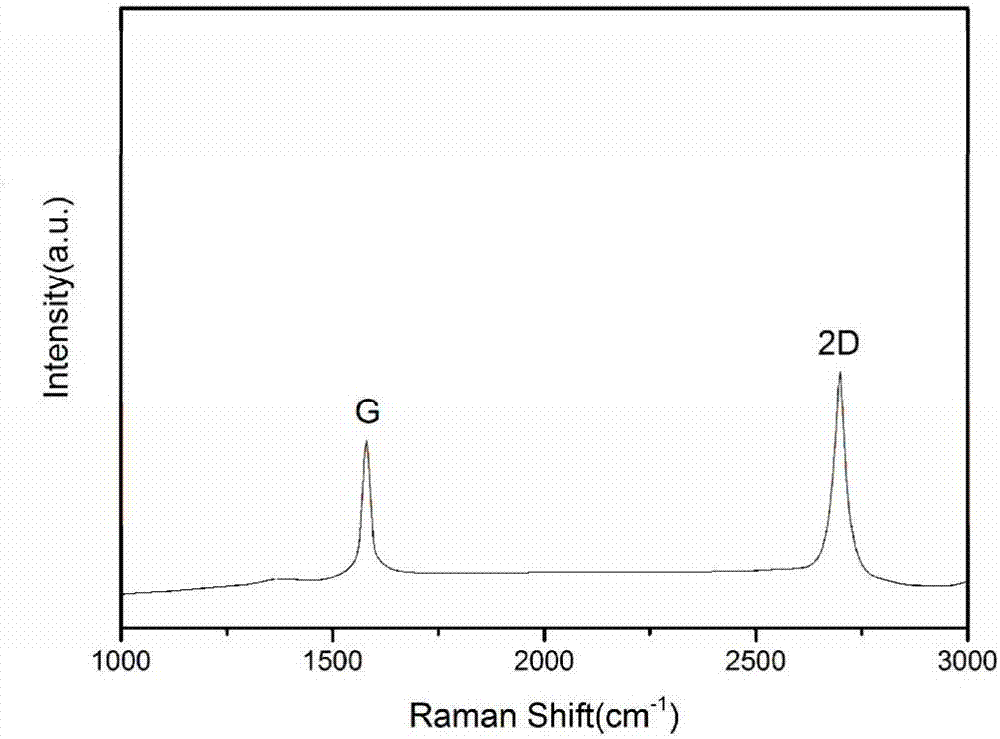

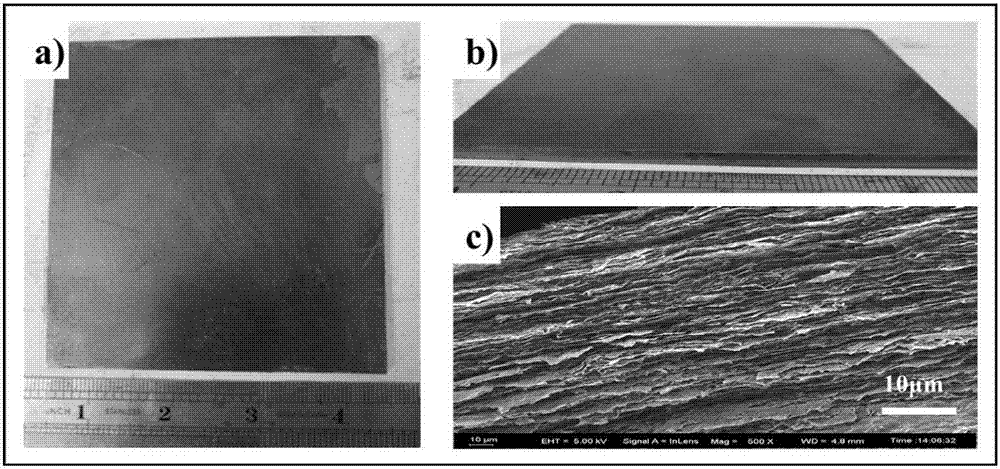

High-oriented graphene radiating film and preparation method thereof

ActiveCN107010618AHigh thermal conductivityLower interface thermal resistanceGrapheneCvd grapheneHeat treated

The invention provides a high-oriented graphene radiating film and a preparation method thereof, solving the problem of high oriented distribution of graphene and realizing the internal ultra-high heat conductivity. The preparation method includes the steps of preparing oxidized graphene dispersion liquid; performing high orientation treatment of graphene; freezing and drying to obtain the oxidized graphene foam; performing hydrazine hydrate reduction and acquiring graphene foam; pressurizing the graphene foam to obtain a graphene film; performing a post thermal treatment. The sample with controllable thickness and highly orienting distributed graphene can be prepared. The internal heat conductivity of the radiating film can reach 2400 W / (m.K), and the radiating filmcan be widely applied to the field of radiation.

Owner:HARBIN INST OF TECH

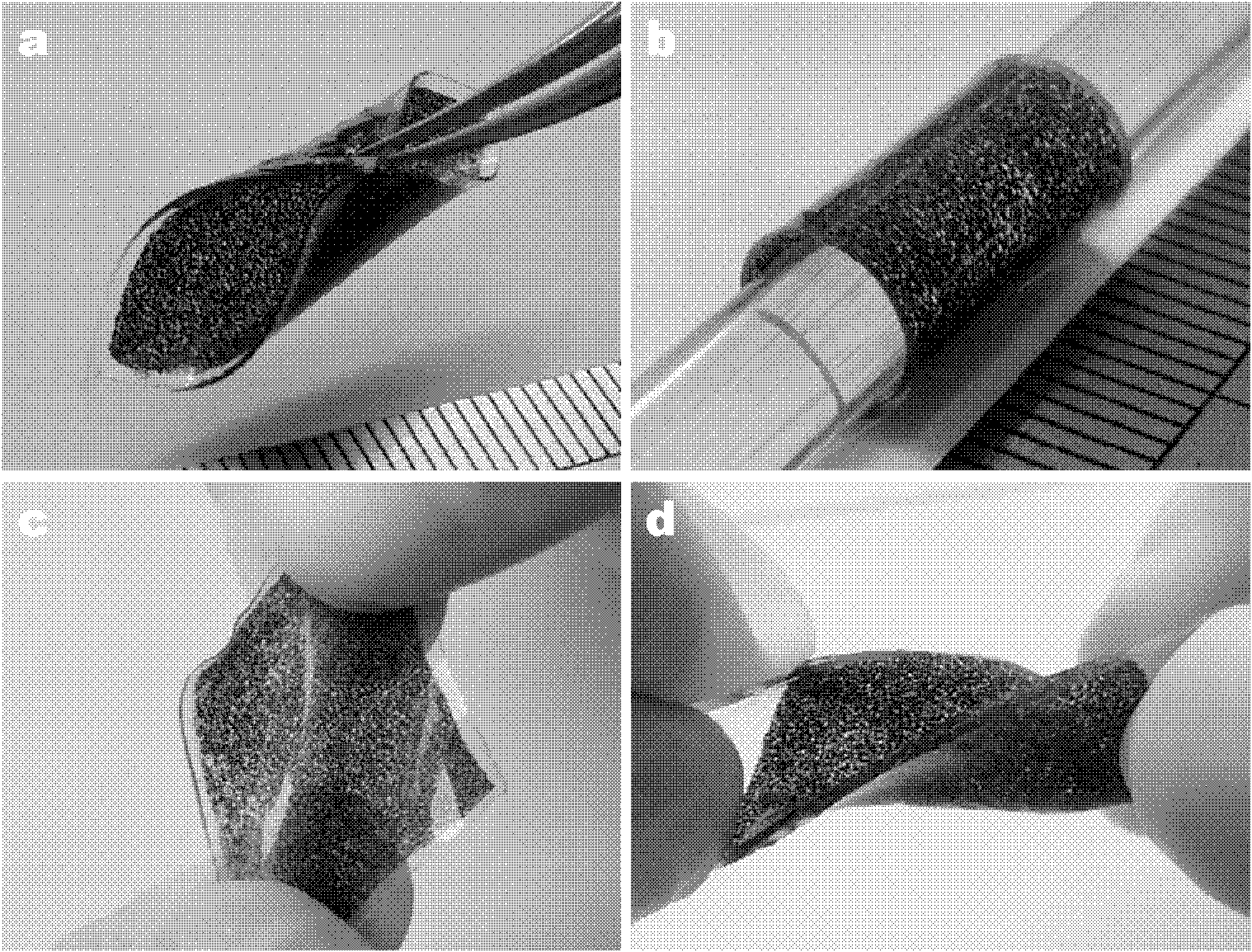

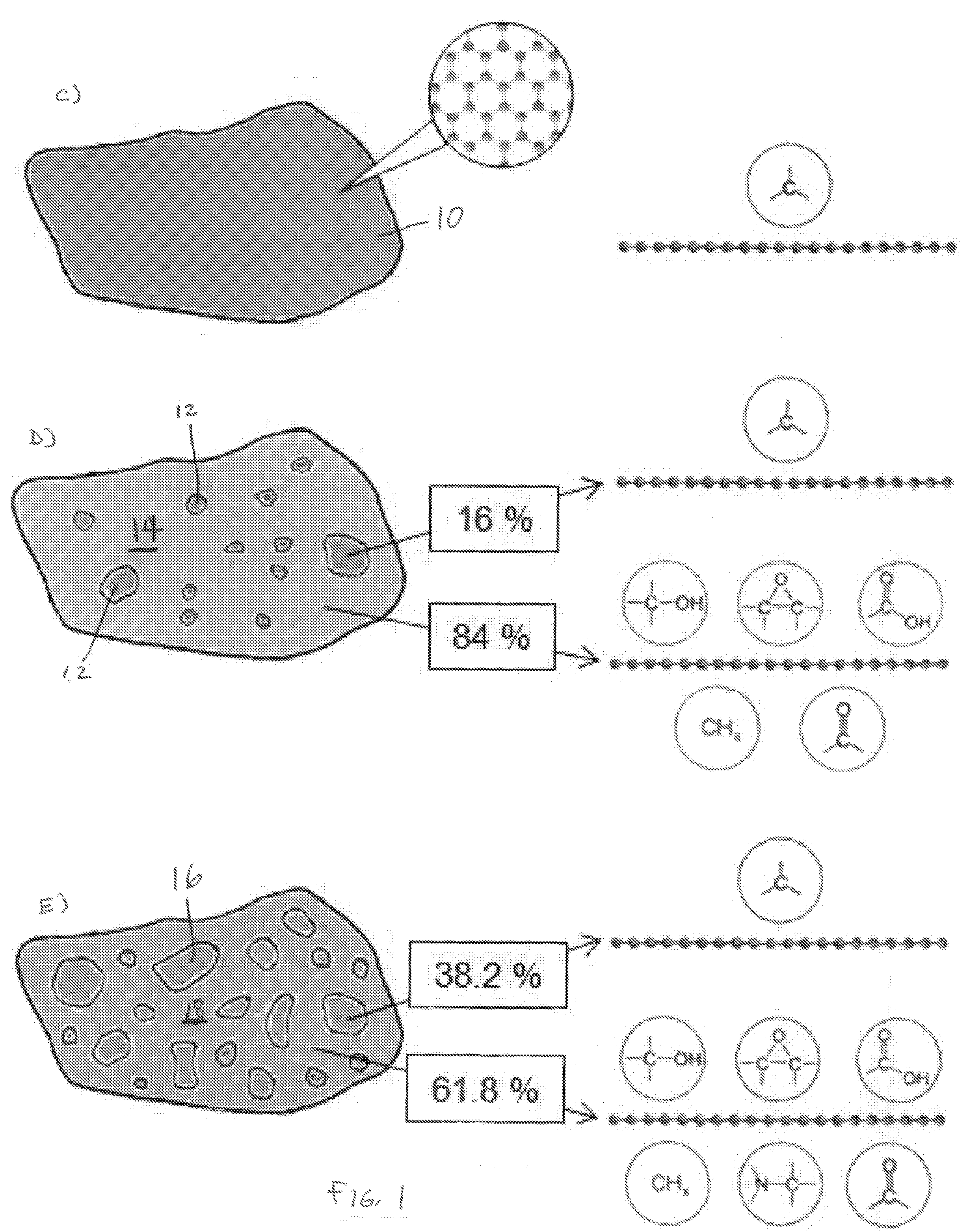

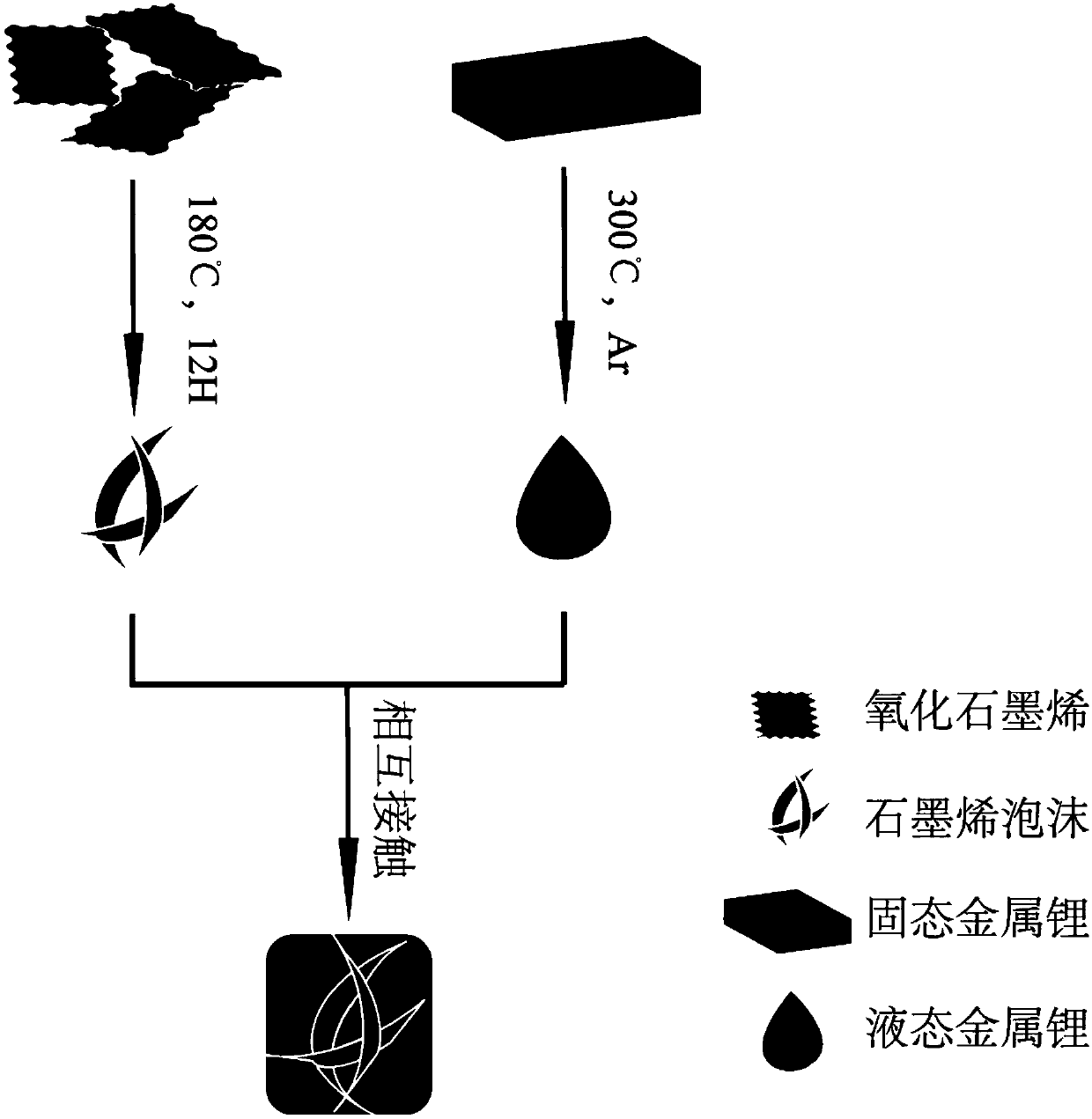

Lithium metal secondary battery negative electrode and preparation method thereof

PendingCN107611391ABuffer volume expansionImprove Coulombic efficiencyCell electrodesLi-accumulatorsLithium metalIon distribution

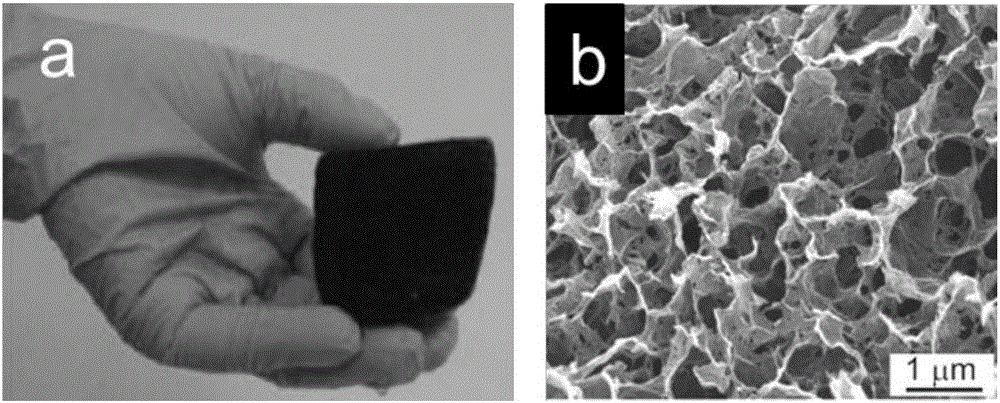

The invention provides a lithium metal secondary battery negative electrode. The lithium metal secondary battery negative electrode comprises graphene foam and metal lithium compounded in the graphenefoam. The graphene foam is combined with the metal lithium, and the graphene foam is filled with the metal lithium; by taking the three-dimensional graphene foam as the framework, the liquid-state metal lithium can be automatically adsorbed in the three-dimensional graphene foam based on the lithium affinity property of the oxygen-containing functional group on the surface of reduced graphene oxide, while the three-dimensional graphene foam is formed by criss-cross flake graphene to form a porous structure, so that a relatively large specific surface area is formed, lithium can be well limited in the internal space, and volume expansion of a lithium negative electrode can be reduced; and meanwhile, the flake graphene also can influence the re-distribution of electric field in the battery,so that the lithium ion distribution on the surface of the electrode can be influenced, formation of dendritic crystal can be suppressed, improvement of the coulombic efficiency of the lithium negative electrode can be facilitated, and the obtained lithium metal negative electrode has relatively high flexibility.

Owner:GREE ELECTRIC APPLIANCES INC

Preparation method of graphene foam-polydopamine composite membrane, product prepared with preparation method and application of product

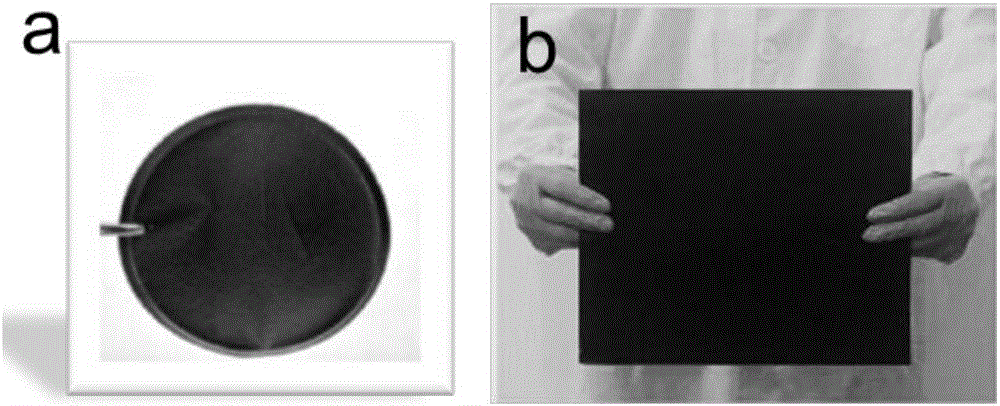

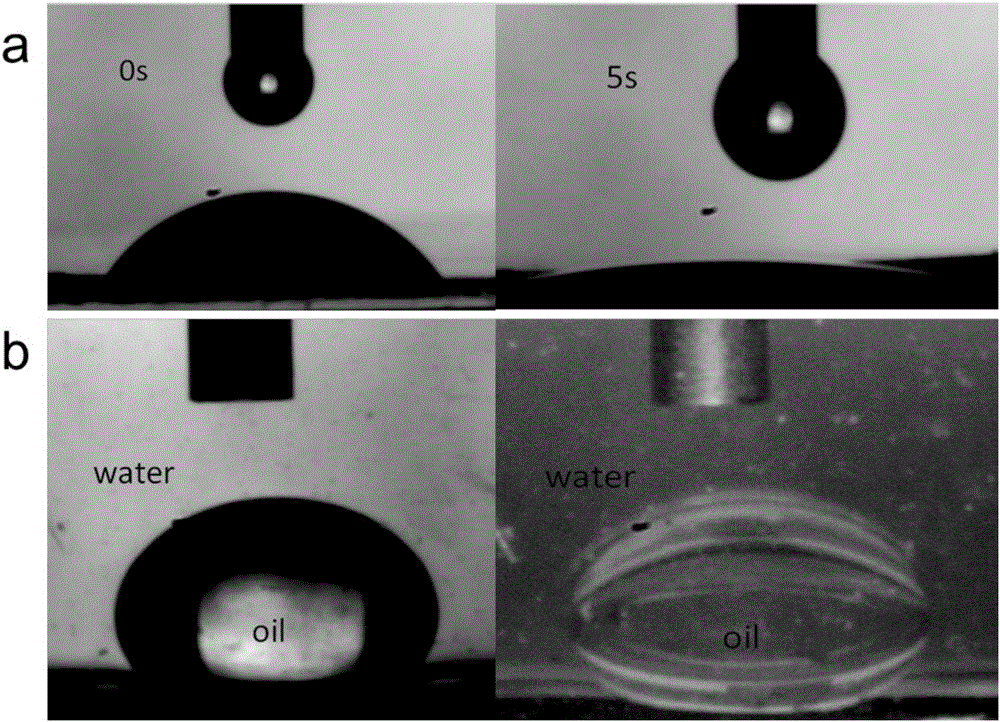

ActiveCN106422816AImprove mechanical propertiesRealize large-scale applicationSemi-permeable membranesFatty/oily/floating substances removal devicesMaterials scienceHydrochloride

The invention discloses a preparation method of a graphene foam-polydopamine composite membrane, a product prepared with the preparation method and an application of the product. The preparation method comprises steps as follows: (1) preparation of graphene foam-polydopamine: the pH value of a graphene oxide solution is adjusted, dopamine hydrochloride is added, a precursor solution is obtained and subjected to a hydrothermal reaction, and graphene foam-polydopamine is obtained; (2) preparation of the graphene foam-polydopamine composite membrane: graphene foam-polydopamine is added to N,N-dihydroxyethylglycine and mixed with a temperature-sensitive polymer, the mixture is stirred and subjected to vacuum filtration, and the temperature-sensitive graphene foam-polydopamine composite membrane is obtained. The graphene foam-polydopamine composite membrane prepared through improvement of overall process design, reaction conditions of steps and the like of a key preparation process has good temperature sensitivity and excellent super-hydrophilic property and underwater super-lipophobicity and is very applicable to oil-water separation.

Owner:HUAZHONG UNIV OF SCI & TECH

High-strength and high-heat-conduction three-dimensional graphene heat dissipating material and preparation method thereof

ActiveCN106967392AHigh thermal conductivityLower interface thermal resistanceHeat-exchange elementsFreeze-dryingVolumetric Mass Density

The invention relates to a high-strength and high-heat-conduction three-dimensional graphene heat dissipating material and a preparation method thereof and aims at solving the problems of orientation arrangement and density of a graphene heat dissipating material so as to prepare the three-dimensional heat dissipating material with ultrahigh heat conductivity. The method comprises the following steps: preparing a graphene oxide dispersion liquid; carrying out high orientation treatment on graphene oxide; carrying out freeze drying to obtain graphene oxide foam; carrying out hydrazine hydrate reduction to obtain grapheme foam; putting the graphene foam into a die for carrying out premolding and hot pressed sintering to obtain the high-strength and high-heat-conduction three-dimensional graphene heat dissipating material. According to the graphene heat dissipating material prepared by the preparation method disclosed by the invention, the thickness is in centimeter size; in addition, the heights of graphene sheets are arranged in an orientated manner, and the difficult problems of orientation and compactness of a graphene heat dissipating film are solved; the heat conductivity of the graphene heat dissipating material can reach 1800W / (m.K); besides, the graphene heat dissipating material has high strength and a good processing property, and is expected to thoroughly solve the difficult problem of heat dissipation.

Owner:哈尔滨烯创新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com