Patents

Literature

93 results about "Thermal transformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal transformations. Thermal energy is derived from the motion of moving or vibrating molecules. The kinetic energy of these molecules produces thermal energy. When a substance is heated, its molecules “gain energy and vibrate more vigorously.

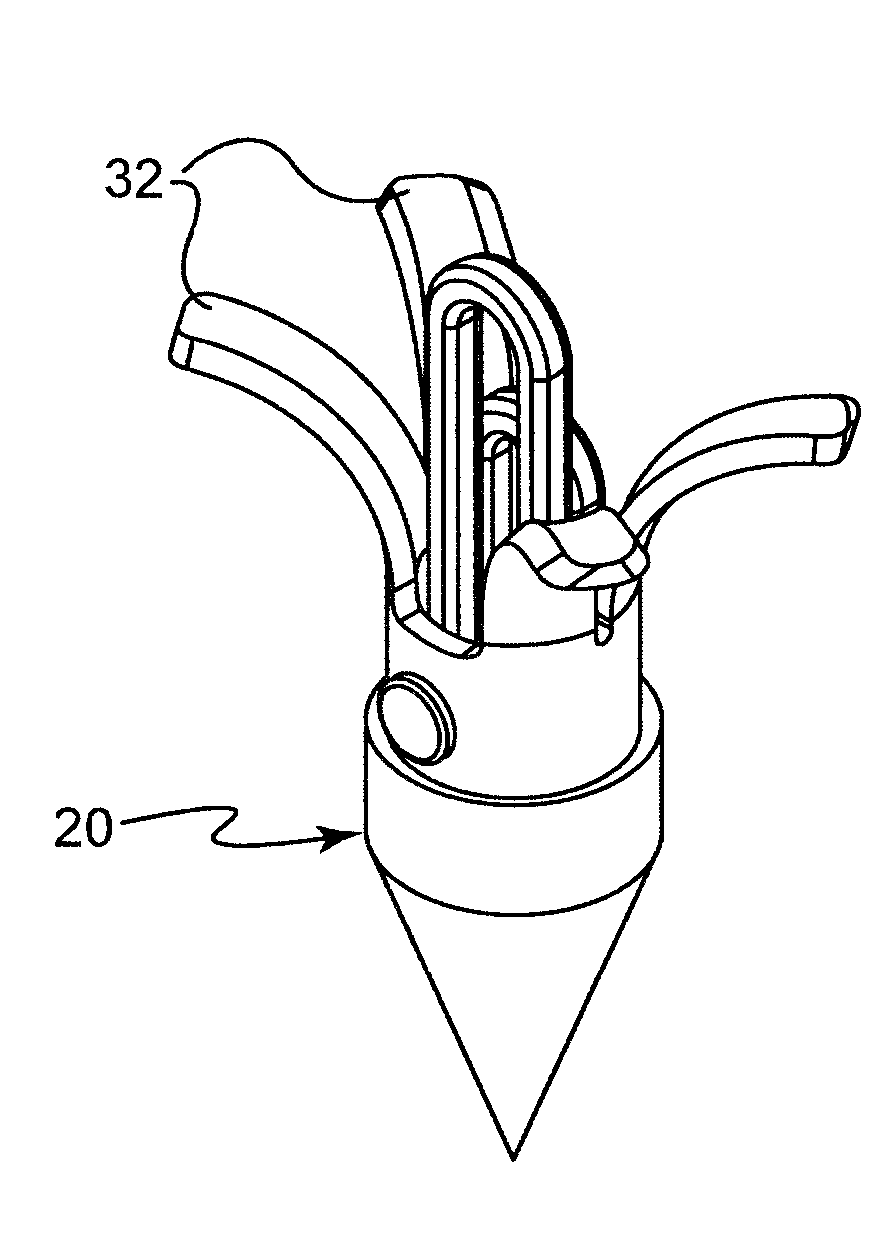

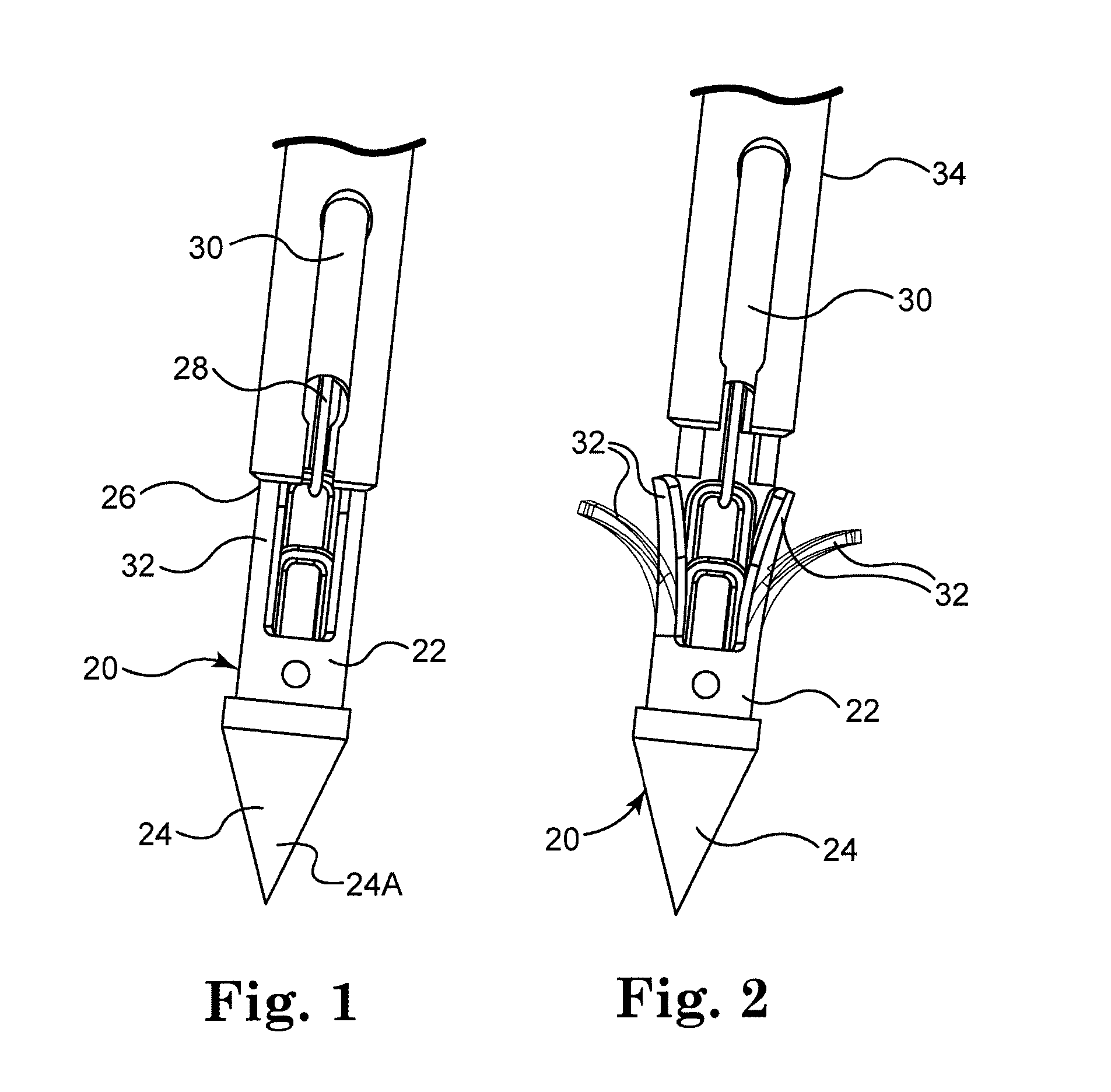

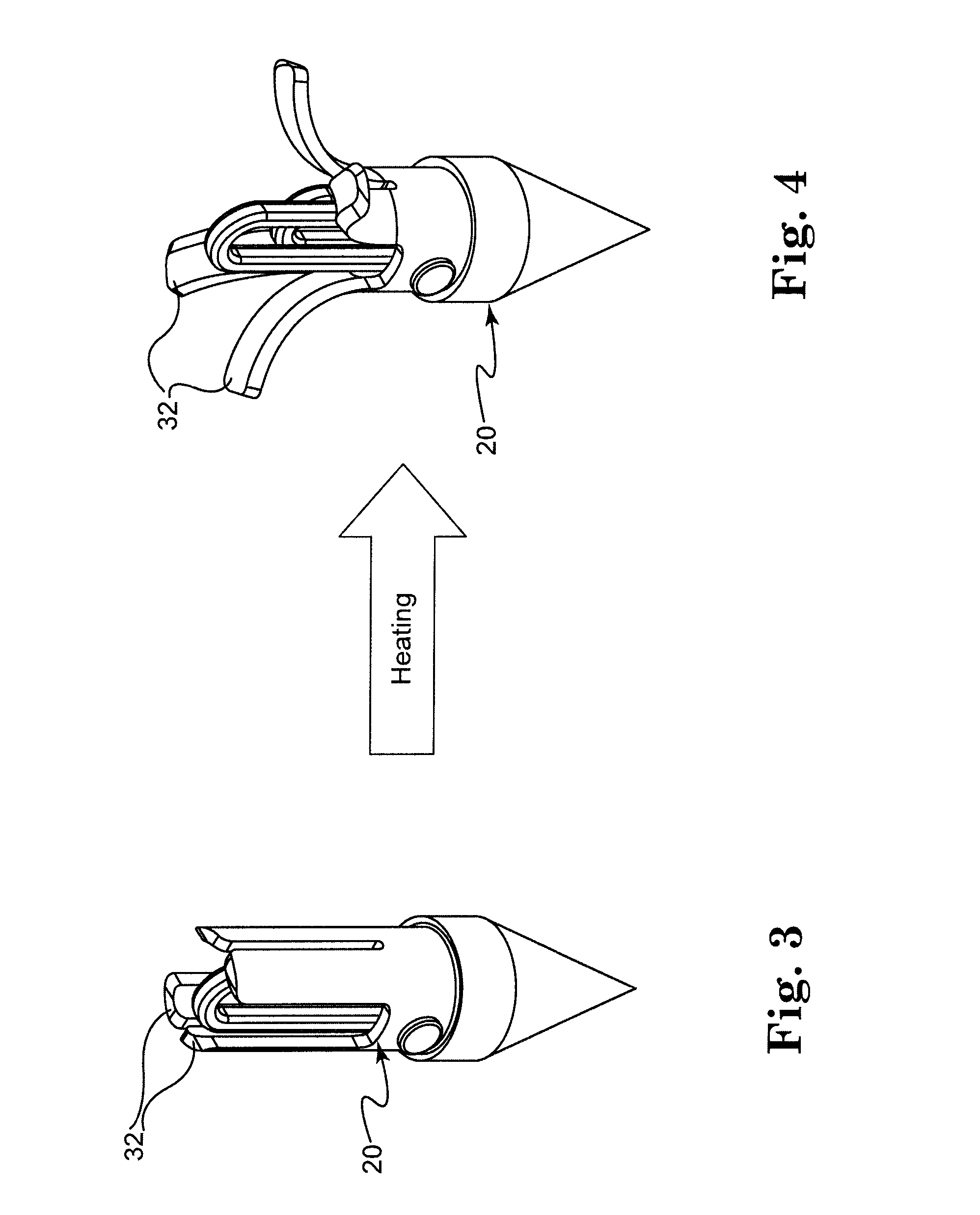

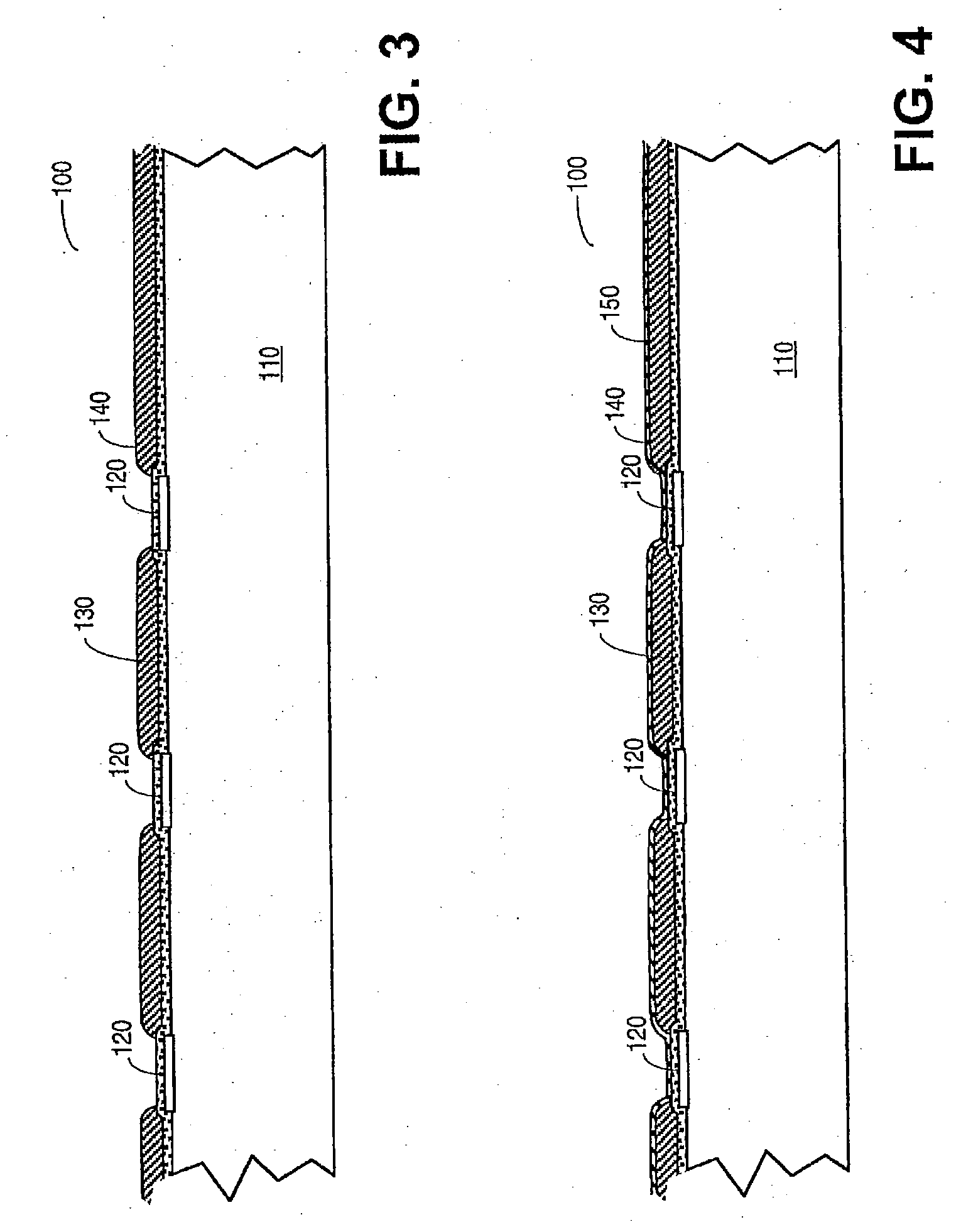

Bone anchor comprising a shape memory element and utilizing temperature transition to secure the bone anchor in bone

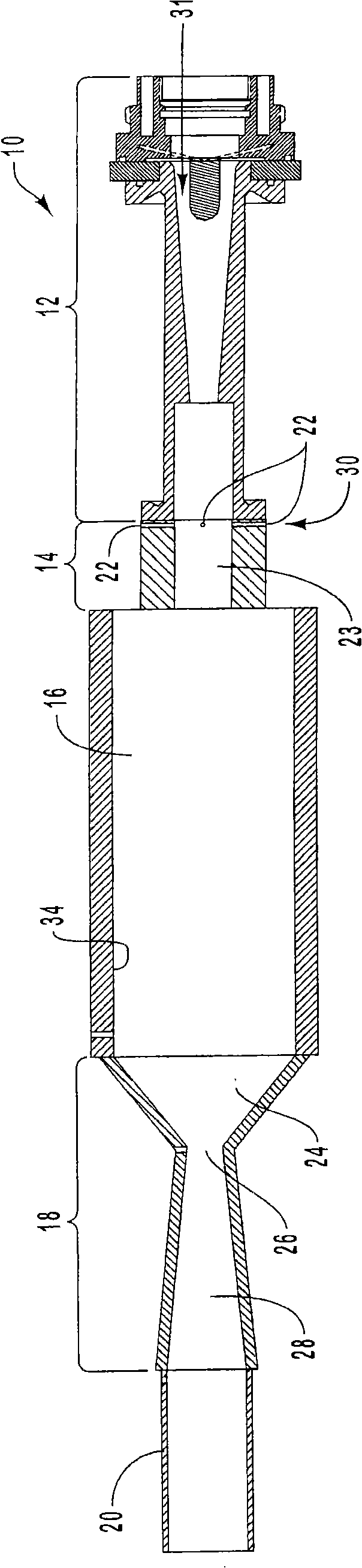

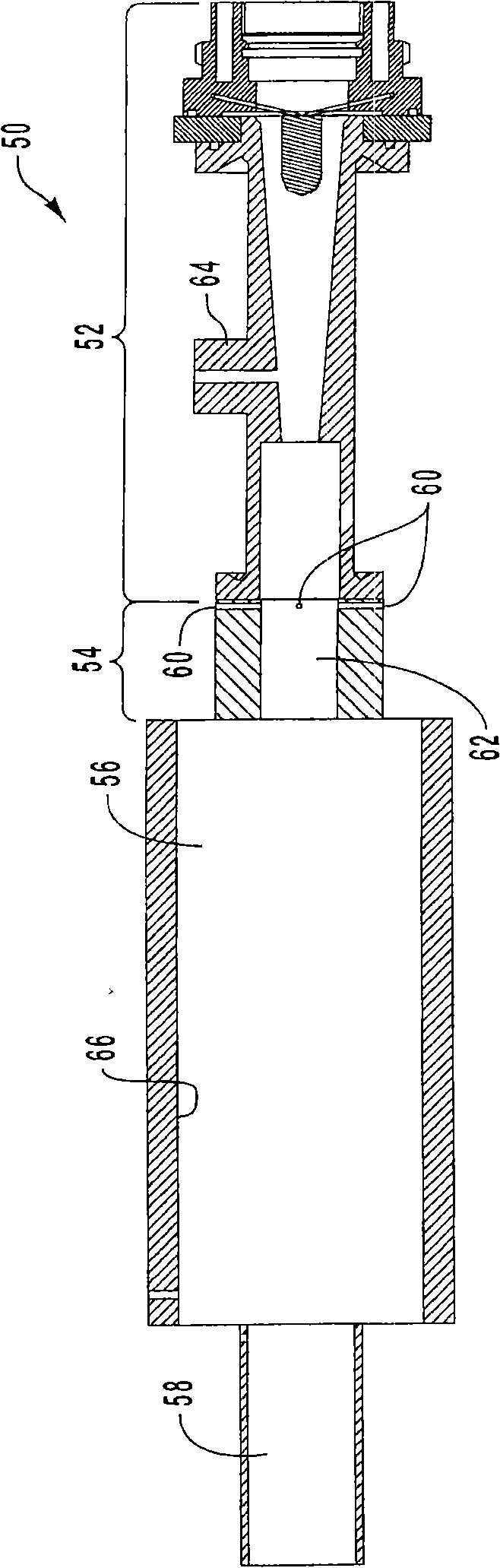

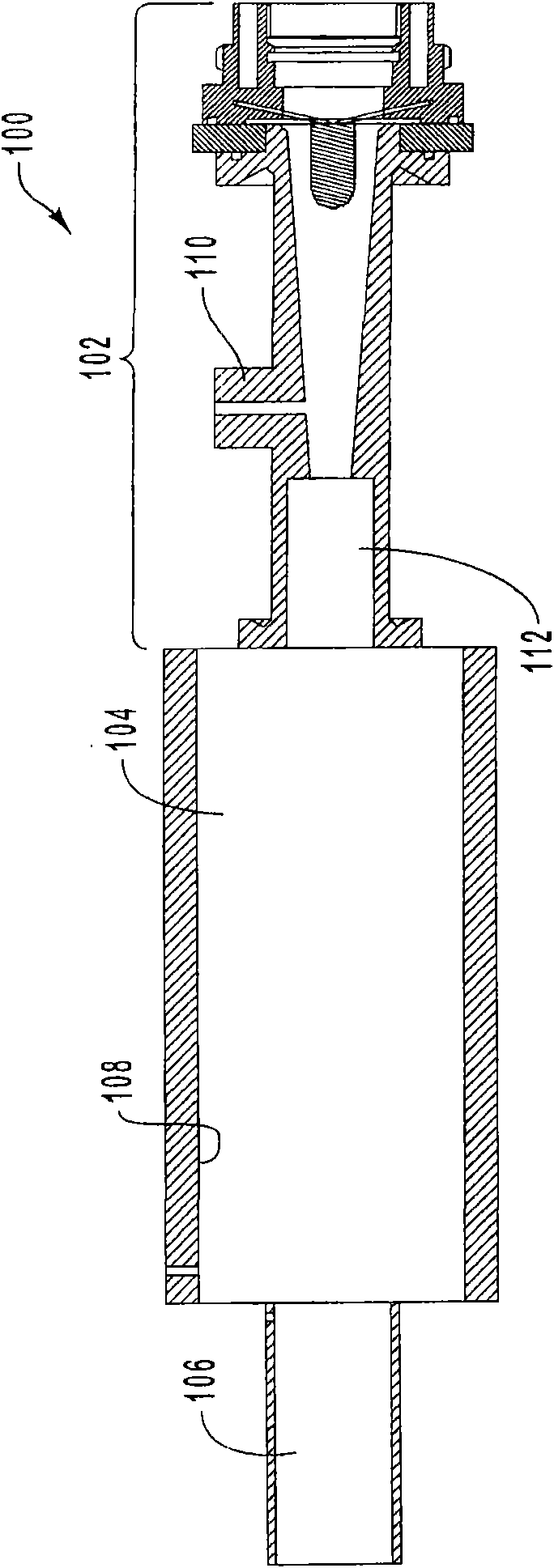

A bone anchor that uses temperature transition of a shape memory material to expand the anchor within a bone. Thermal transformation of the metallic crystal state (and hence the stress / strain properties) of shape memory alloy (e.g., Nitinol, NiTi) expands engagement elements within the bone to fix the bone anchor in place. Various self-locking assemblies for attached suture material to the bone anchor are also disclosed.

Owner:TORNIER INC

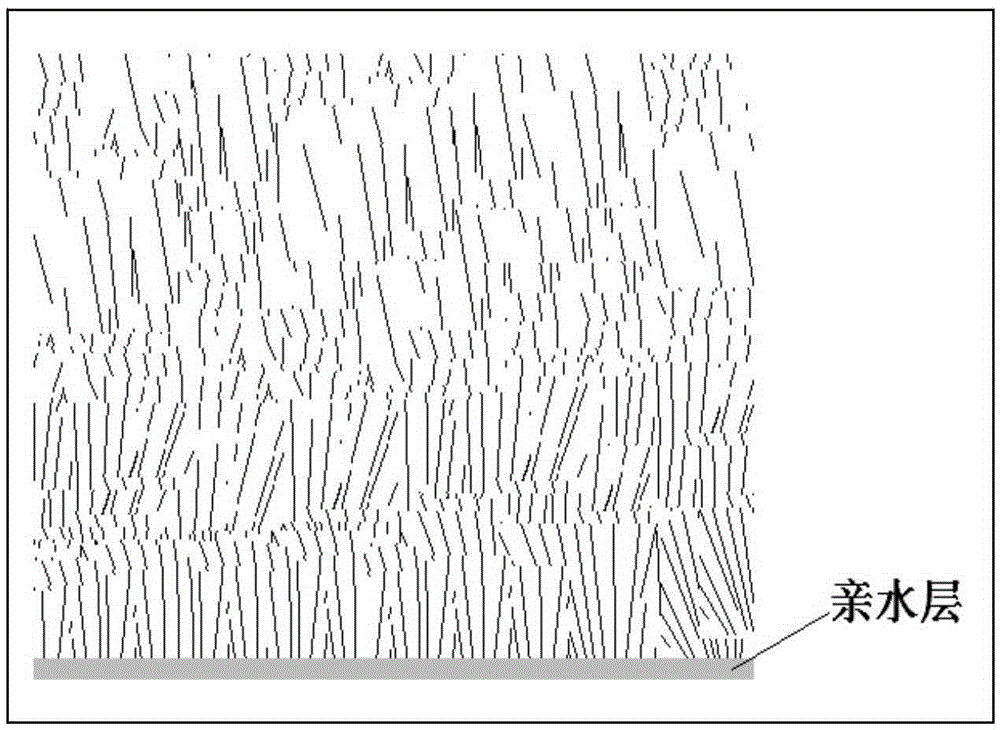

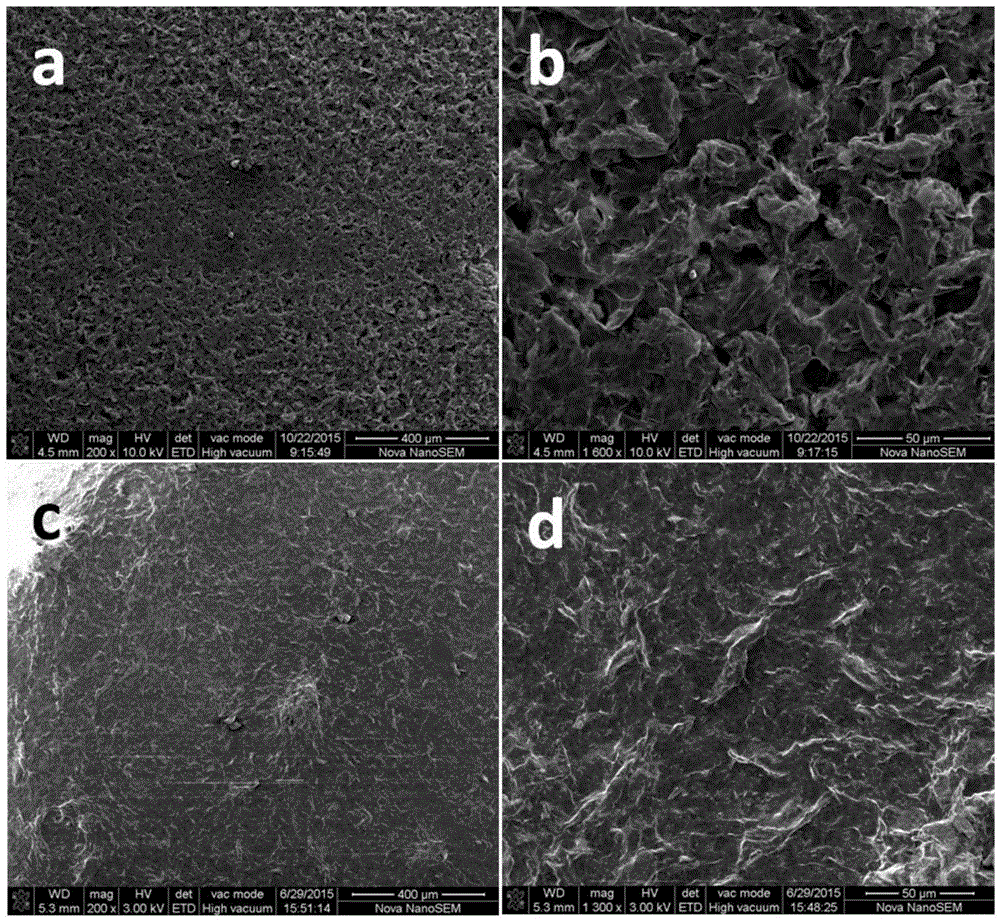

Preparation method of graphene photo-thermal transformation material for sea water desalination and clean water treatment

ActiveCN106809897AIncrease profitEasy to condenseGeneral water supply conservationSeawater treatmentWater desalinationFresh water organism

The invention relates to the field of water treatment materials, in particular to a preparation method of a graphene photo-thermal transformation material for sea water desalination and clean water treatment. The preparation method comprises the steps of preparing graphene powder, a polymer material with a chain molecule structure and a solvent into a sizing agent according to the proportion, adding into a mold for drying and heat treating so as to enable organic substances in the material to be carbonized, and obtaining a graphene foam material with favorable mechanism strength; carrying out hydrophilization treatment on one side of the bottom face of the graphene foam material, and obtaining the graphene photo-thermal transformation material for sewage and sea water distillation purification and desalination. According to the material, a black body structure and a high thermal conductivity property of graphene foams are utilized, so that sunlight can be high-efficiently transformed into heat; a capillary action of the foam structure is utilized for continuously conveying water and reducing an evaporation barrier, so that sea water is quickly distilled and desalted. A graphene foam material is utilized for manufacturing the portable high-efficient sea water desalination and sewage purification device, which meets the demand on quickly preparing clean freshwater on sea and outdoors.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

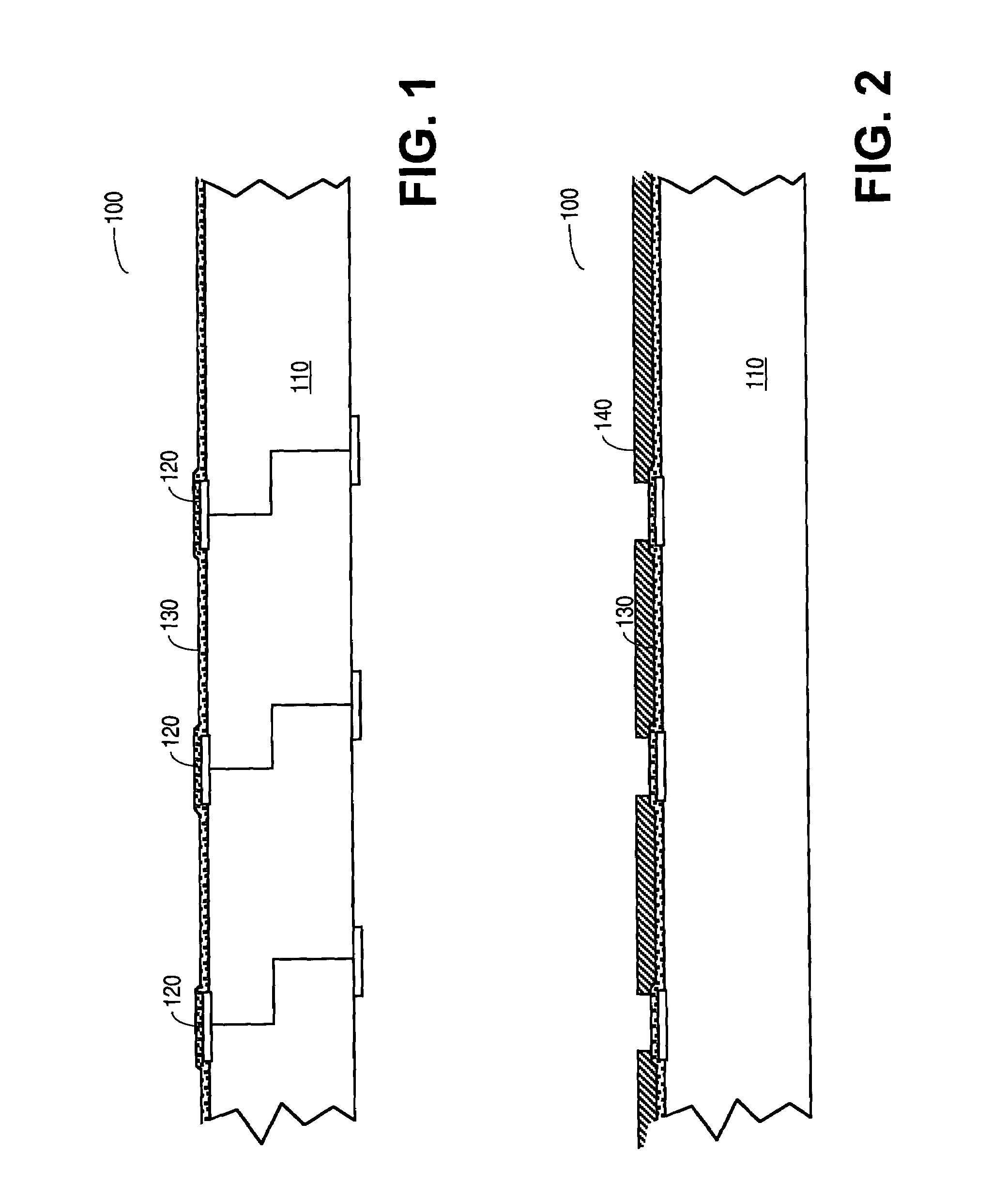

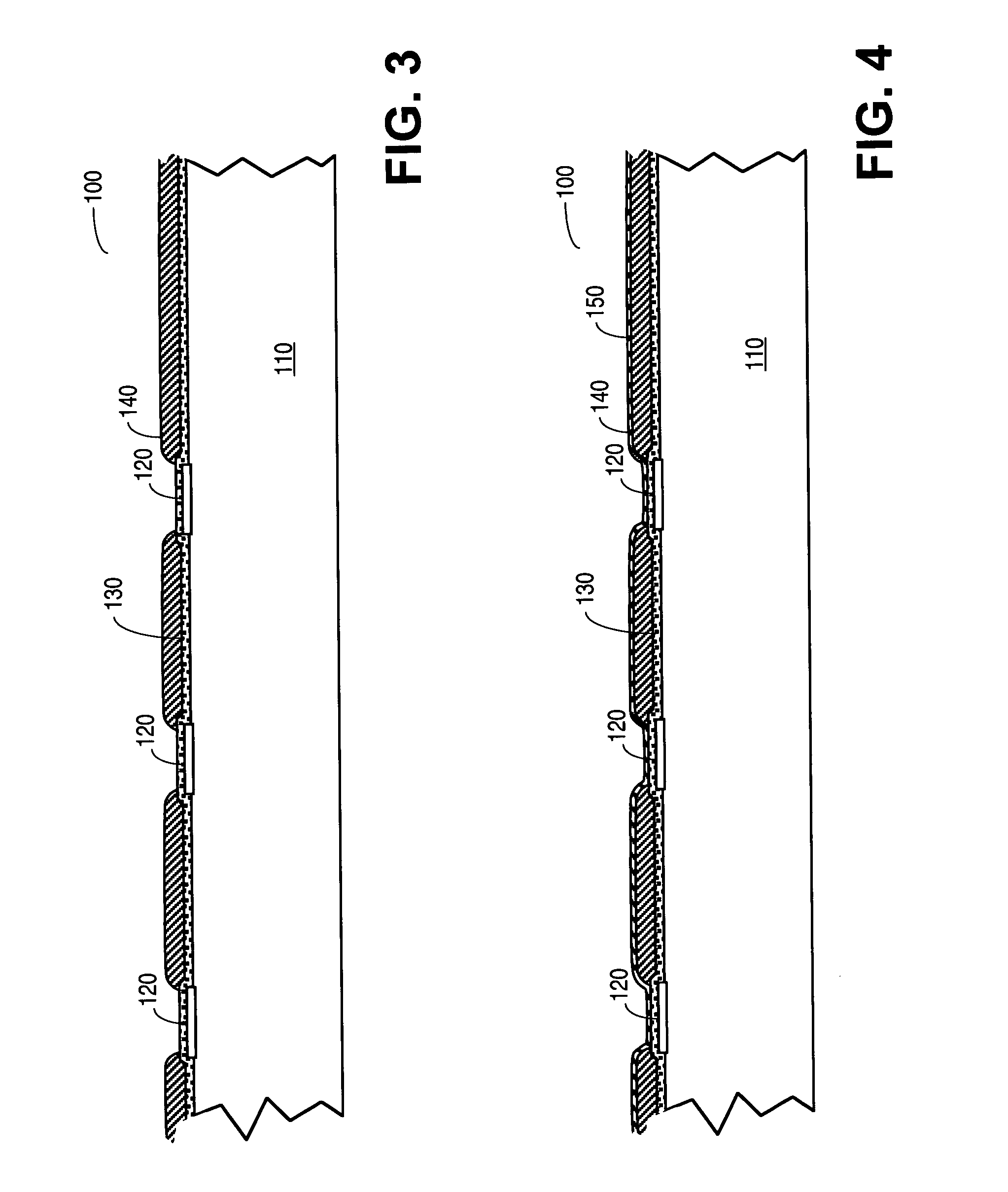

Shaped spring

InactiveUS7458816B1Increase the spring constantElectrical measurement instrument detailsPrinted circuit manufactureInterconnectionAbnormal shaped

An interconnection element that includes a first element material adapted to be coupled to a substrate and a second element material comprising a material having a transformable property such that upon transformation, a shape of the interconnection is modified. An example is a material that has a transformable property such that a volume of the first and / or second element material may undergo a thermal transformation from one volume to a different volume (such as a smaller volume).

Owner:FORMFACTOR INC

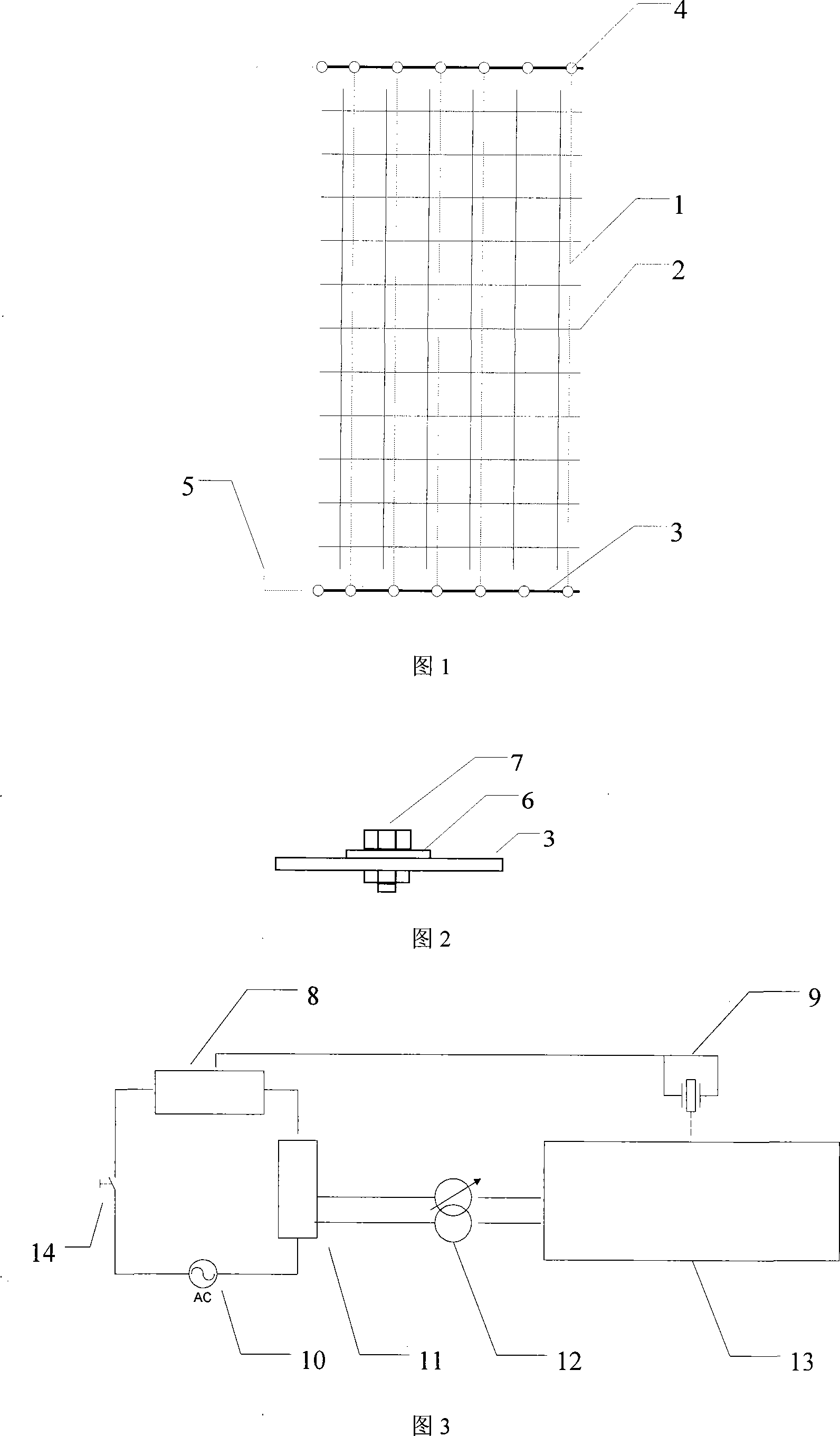

Electric heating method for melting snow and ice on cement concrete bridge floor

InactiveCN101235621ATimely and effective meltingEnsure safetyPaving detailsBridge structural detailsFiberCarbon fibers

The invention discloses an electrothermal method for melting snow and deicing on cement concrete pavement, which is characterized in that the method comprises: arranging an electrical heating layer 2-3cm from the pavement, wherein main electrical heating material which is used is 12k or 24k silica gel skin carbon fiber heater wire, adopting parallel connection to pave the carbon fiber heater wire, wherein the distance is 3-10cm, using a reinforcing mesh (or a steel wire mesh) to erect, using zonal steel plates on two ends as electrodes, and fixing the end portion of the carbon fiber heater wire with the electrode through a screw. The working current of the carbon fiber heater wire is no more than 1.8A and the pavement paving power is 250-1000W / m2. A control circuit for deicing and melting snow realizes power on-off control for a circuit according to signals which are returned by a temperature and humidity sensor on the cement concrete pavement, and the temperature and humidity alarming value is regulated according to environment and concrete condition demands to realize power off-on time control. The effects and benefits of the method of the invention are that ice and snow on the pavement can be effectively melted in time, traffic is kept to be smooth, the safety of pedestrians is guaranteed, the cost for constructing, operating and maintaining is low, the thermal transformation efficiency is high, the method is environmental-protective and economic, and the operation is simple, safe and reliable.

Owner:DALIAN UNIV OF TECH +2

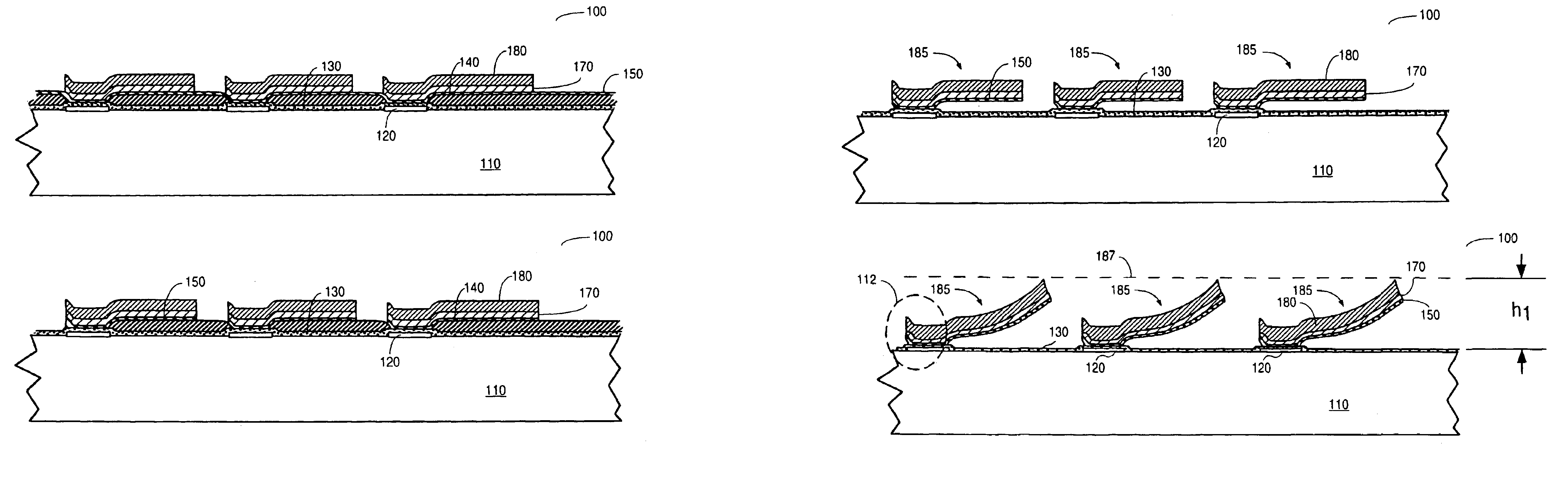

Methods of fabricating and using shaped springs

InactiveUS7127811B2Increase the spring constantContact member manufacturingElectrical measurement instrument detailsInterconnectionThermal transformation

A method of fabricating and using an interconnection element that includes a first element material adapted to be coupled to a substrate and a second element material comprising a material having a transformable property such that upon transformation, a shape of the interconnection is deformed. An example is a material that has a transformable property such that a volume of the first and / or second element material may undergo a thermal transformation from one volume to a different volume (such as a smaller volume) resulting in the deformation of the interconnection element.

Owner:FORMFACTOR INC

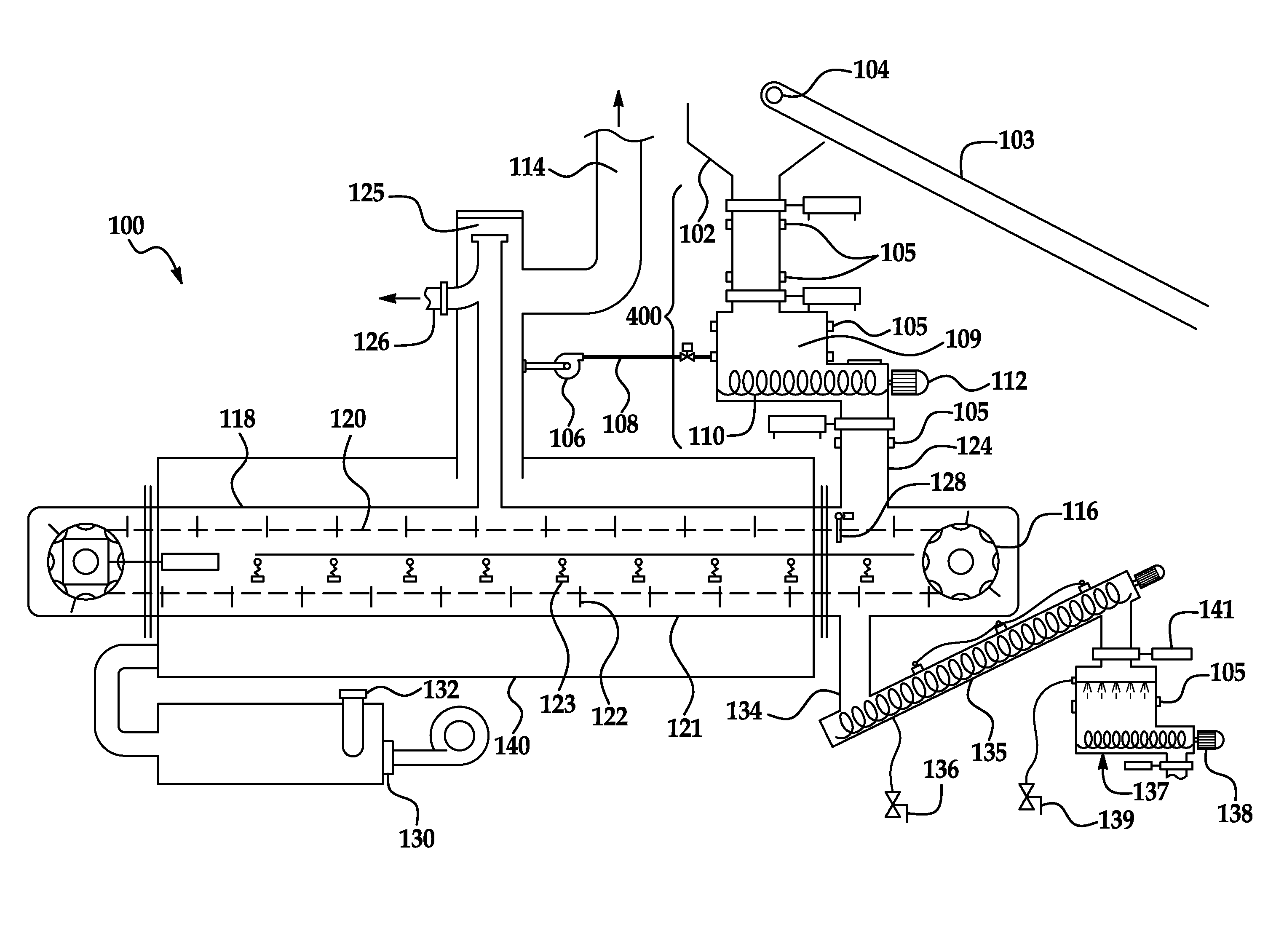

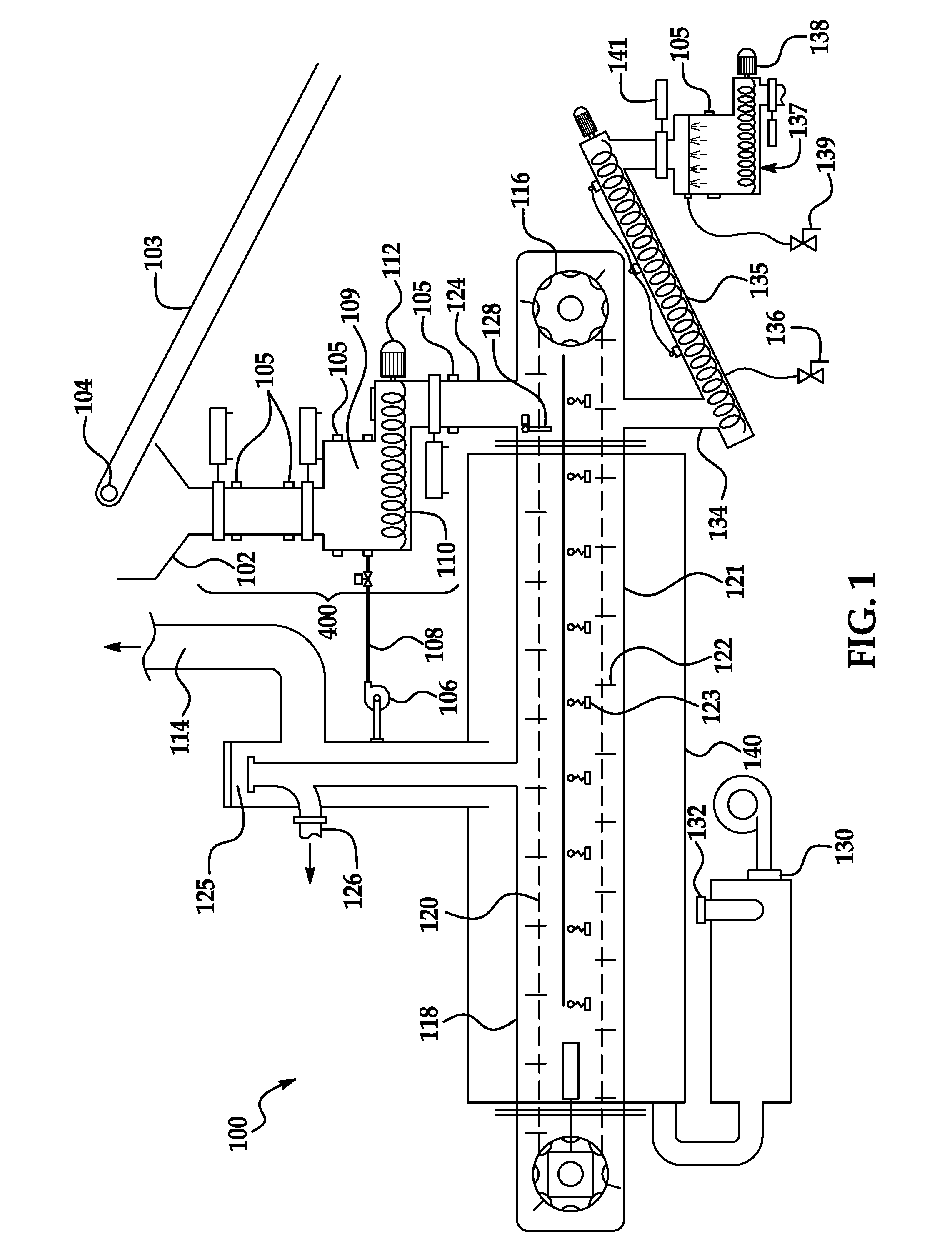

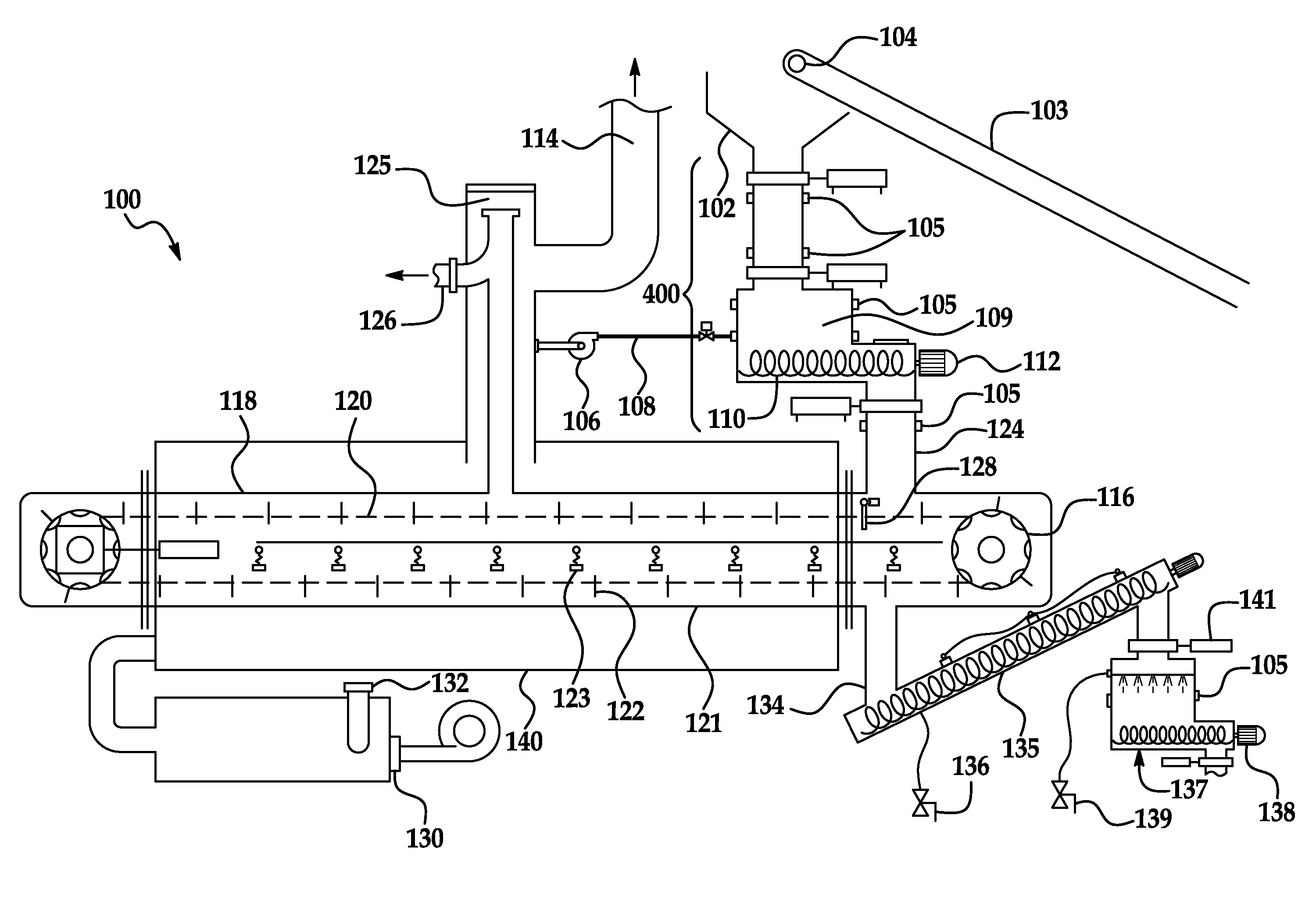

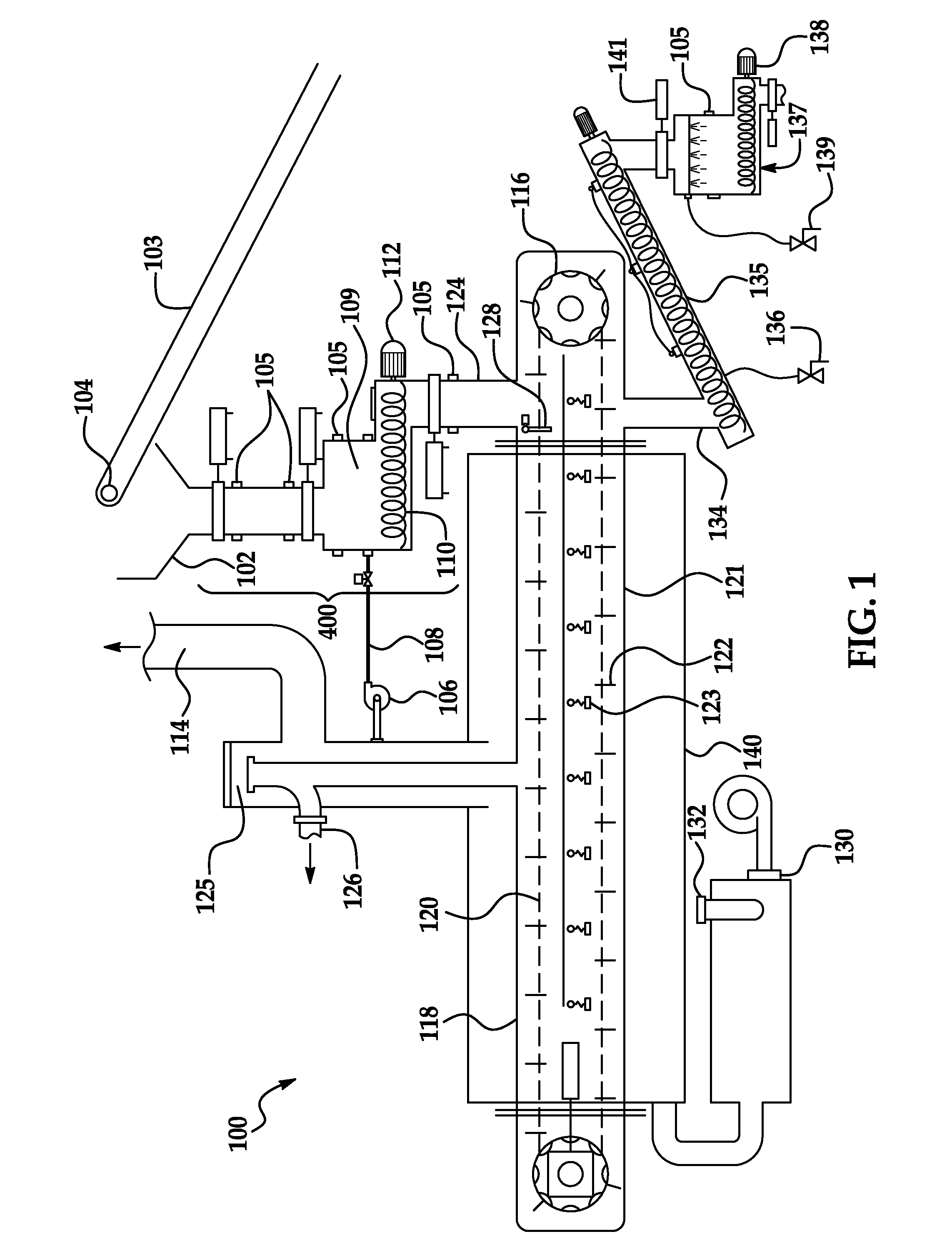

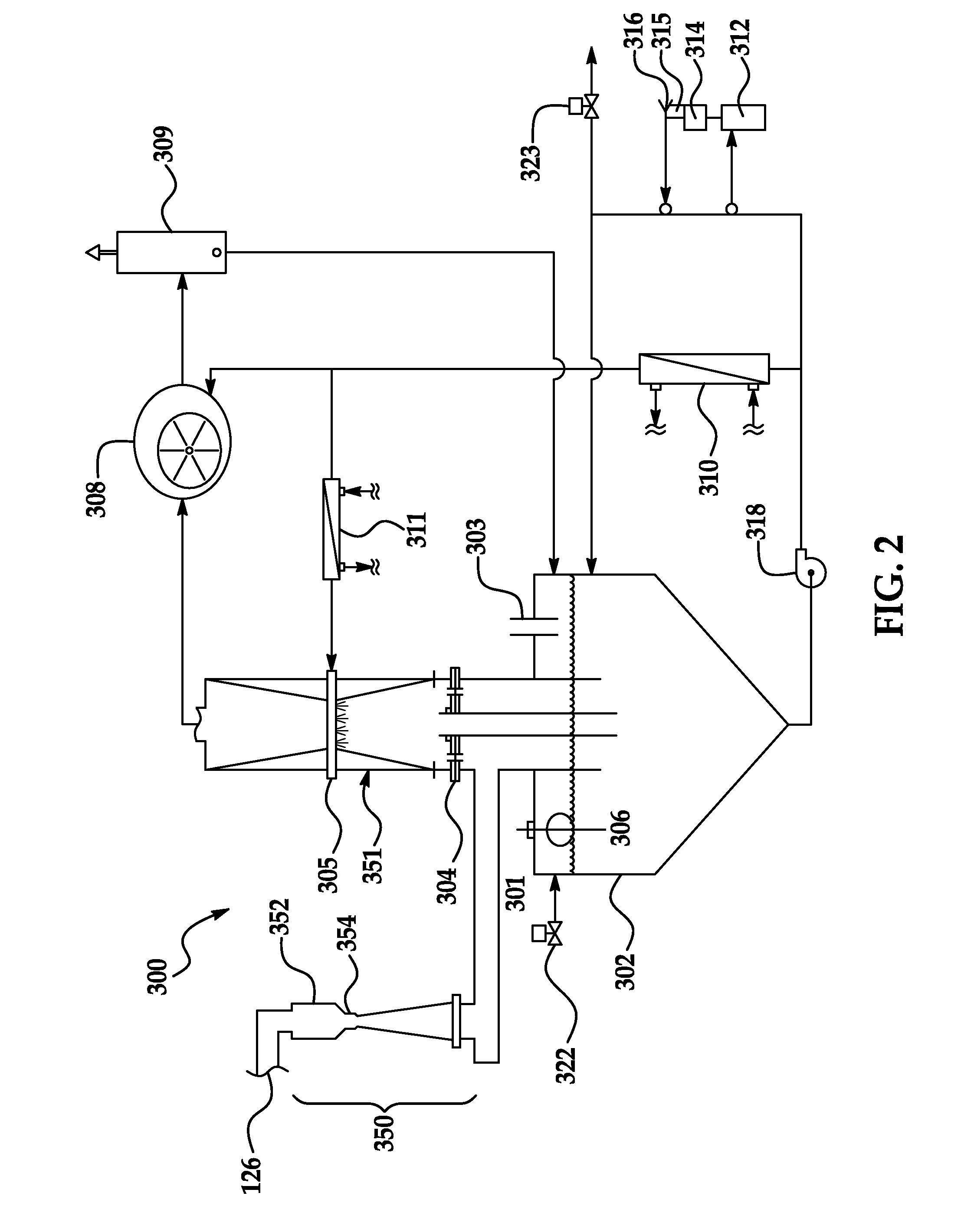

Chain drag system for treatment of carbaneous waste feedstock and method for the use thereof

ActiveUS8801904B2Prevent escapeCombustible gas coke oven heatingIndirect heating destructive distillationProgrammable logic controllerEngineering

A drag chain carbonizer is provided with a system and methods for anaerobic thermal transformation processing to convert waste into various solid carbonized products and varied further co-products. The drag-chain carbonizer includes an adjustable bed depth mechanism, a heating mechanism, a pressure management mechanism, and a chain tensioning mechanism containing at least one position sensor for communication of an actuator position to at least one programmable logic controller (PLC). Carbonaceous waste is transformed into useful co-products that can be re-introduced into the stream of commerce at various economically advantageous points. Depending upon the input materials and the parameters selected to process the waste, including real time economic and other market parameters, the system adjusts co-products output to reflect changing market conditions.

Owner:AEMERGE

Chain drag carbonizer, system and method for the use thereof

ActiveUS20140008206A1Prevent escapeIndirect heating destructive distillationPyrolysis reactionsProgrammable logic controllerProcess engineering

A drag chain carbonizer is provided with a system and methods for anaerobic thermal transformation processing to convert waste into various solid carbonized products and varied further co-products. The drag-chain carbonizer includes an adjustable bed depth mechanism, a heating mechanism, a pressure management mechanism, and a chain tensioning mechanism containing at least one position sensor for communication of an actuator position to at least one programmable logic controller (PLC). Carbonaceous waste is transformed into useful co-products that can be re-introduced into the stream of commerce at various economically advantageous points. Depending upon the input materials and the parameters selected to process the waste, including real time economic and other market parameters, the system adjusts co-products output to reflect changing market conditions.

Owner:AEMERGE

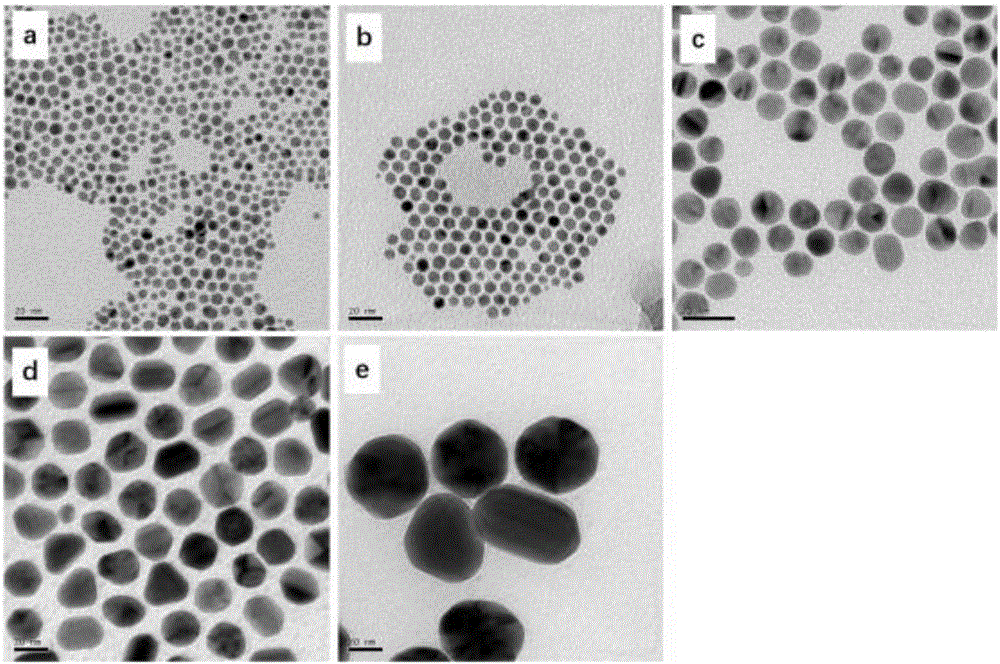

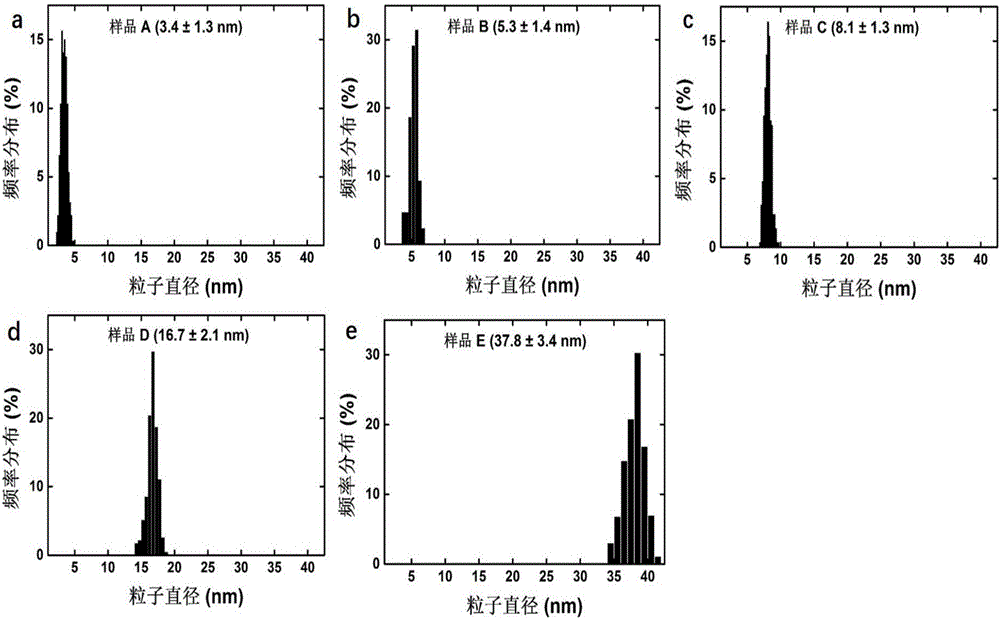

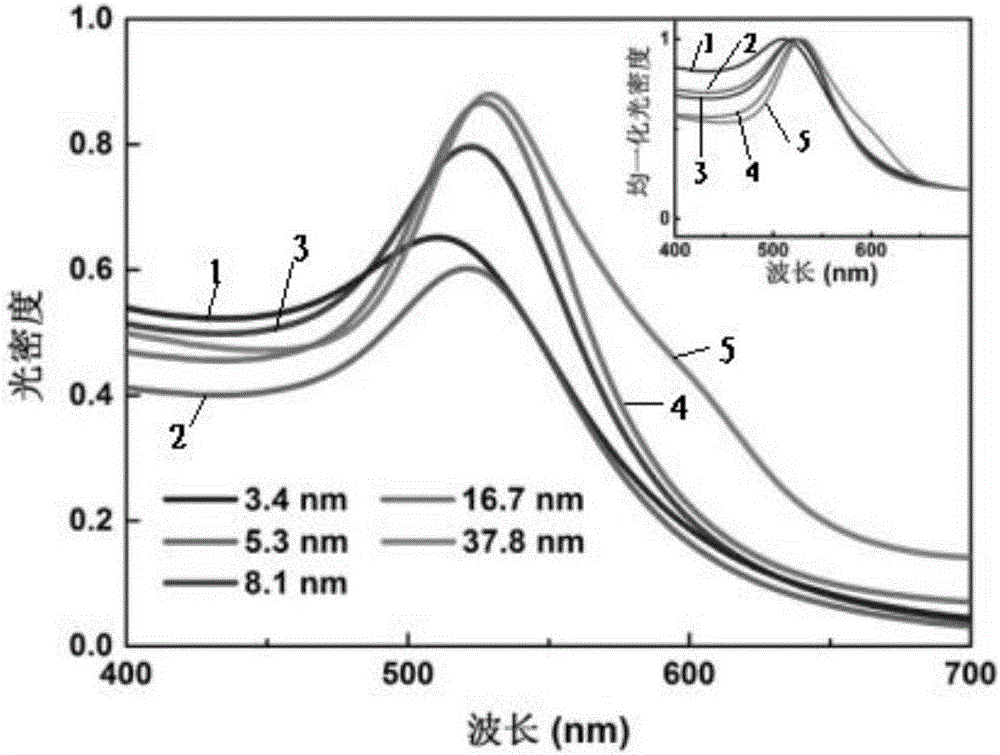

Preparation method and application of multi-sized monodisperse gold nanoparticles

The invention provides a preparation method of multi-sized monodisperse gold nanoparticles. The preparation method of the multi-sized monodisperse gold nanoparticles includes the steps of (1) subjecting gold salt to a reduction reaction in water under the joint action of citrate and a first reducing agent to obtain seed crystals of the gold nanoparticles; (2) mixing chloroauric acid, citrate and a surfactant with water to obtain seed crystal growth liquid; (3) subjecting the seed crystals of the gold nanoparticles to iterative growth in the seed crystal growth liquid under the action of a second reducing agent so as to obtain the multi-sized gold nanoparticles. The preparation method and application of the multi-sized monodisperse gold nanoparticles have the advantages that with the surfactant coating the different particle diameters of monodisperse gold nanoparticles evenly during gradual growth, particle agglomeration is improved, and the problems that the gold nanoparticles with large particle diameters are widely dispersed and poor in monodispersity are solved, so that the gold nanoparticles can give full play to a photo-thermal transformation performance under a light condition.

Owner:江苏台益纳米科技有限公司

Preparation of high-performance composite grease sulphonate lubricating grease

InactiveCN101235331AGood mechanical stabilityImprove thermal stabilityAdditivesBase-materialsPolymer scienceWater resistant

The invention discloses a process for preparing complex calcium sulfonate grease with excellent performance, which comprises the following components and mass fractions which are that base oil 40-75, complex calcium sulfonate 10-20, 12 hydroxy stearine, acid 5-15, acetic acid 1-4, boric acid 1.5-6, calcium hydroxide 4-8, anti-oxidant 0.3-1.5, extreme pressure agent 1-5 and oiliness additive 1-4. The complex calcium sulfonate grease of the invention has the advantages of excellent mechanical stability and excellent thermal stability, and the maximum use temperature is 260 DEG C, excellent thermal transformation performance, structure can not be changed under instant high temperature, excellent extreme pressure and antiwear behavior, PD value can reach to 4900N, strongest oxidation resistance, very excellent water-resistant performance and excellent low temperature performance, the process for preparing complex calcium sulfonate grease can be normally used below 15 DEG C. The process for preparing complex calcium sulfonate grease is widely used in the places whose work environment are rougher such as iron, steel, mine and the like.

Owner:益田润石(北京)化工有限公司

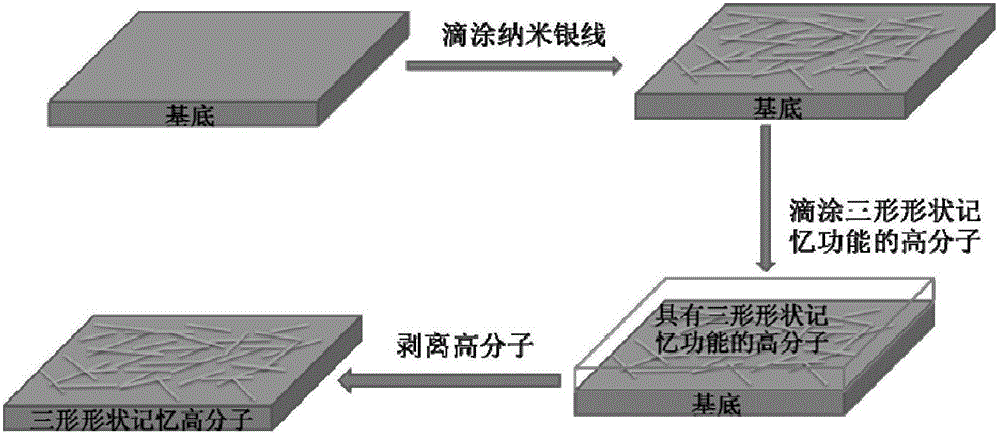

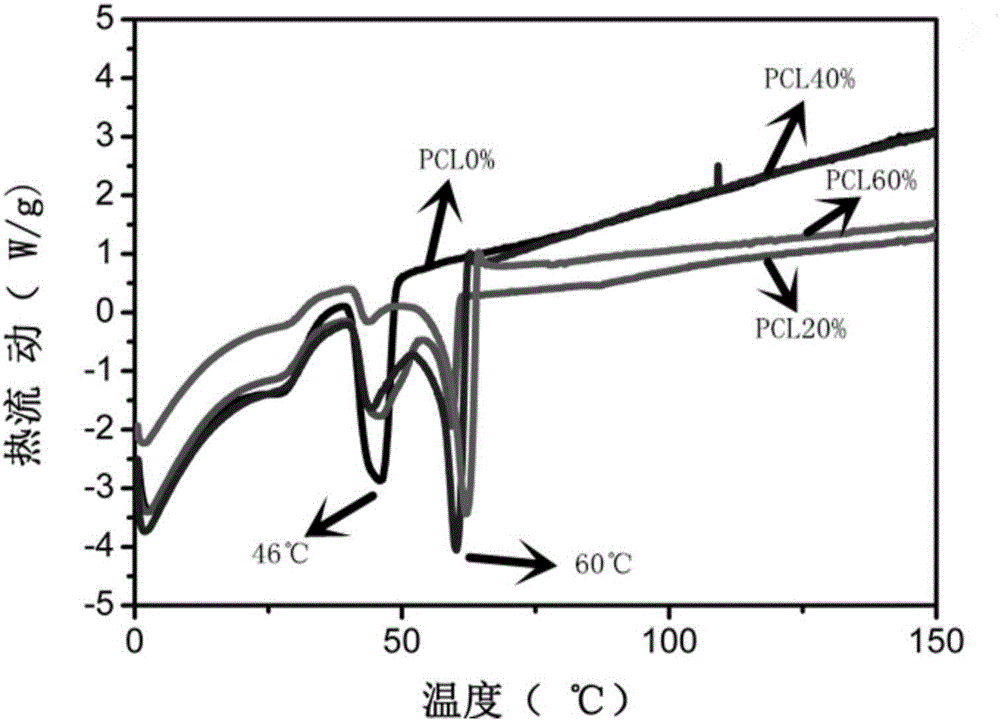

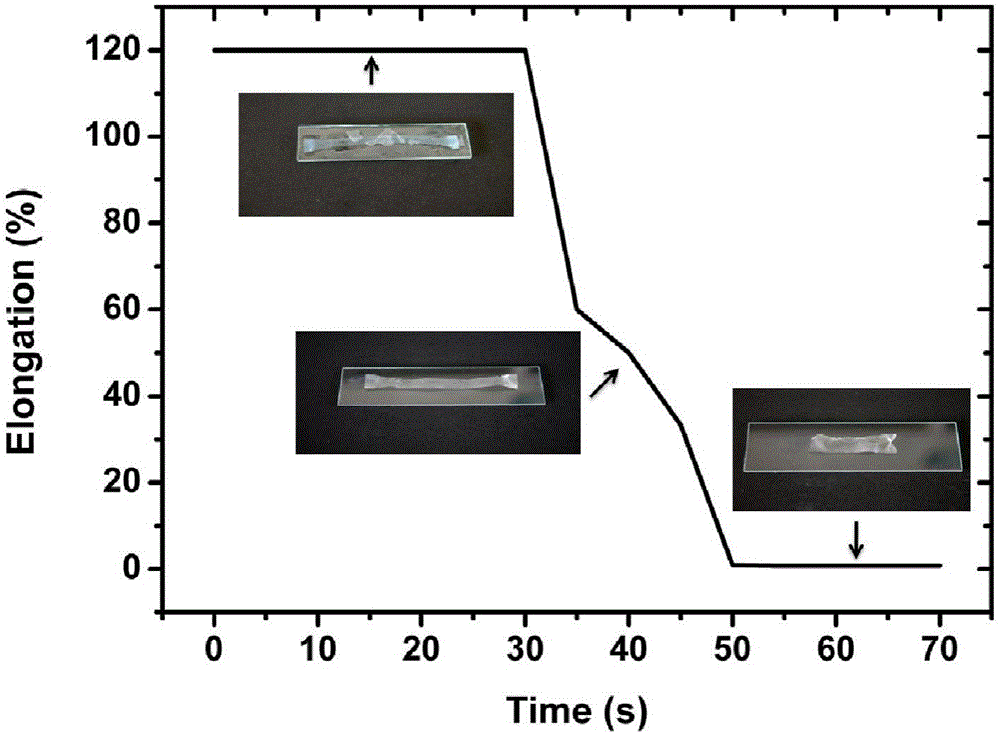

Tri-shape shape memory conductive polymeric nanocomposite and preparation method thereof

InactiveCN106566398AImprove ductilityImprove rigidityMaterial nanotechnologyPolyurea/polyurethane coatingsChemical synthesisSurface layer

The invention discloses a tri-shape shape memory conductive polymeric nanocomposite and a preparation method thereof. The composite contains a biswitch tri-shape shape memory polymeric and nanoconductive material and can sense remarkable change of electrical properties at two different temperature changes. The preparation method comprises the following steps: a conductive nanometer network is embedded into the upper surface layer through a transfer technology, wherein the composite surface layer provides an electronic channel and a polymer substrate provides flexibility, mechanical properties and shape memory performance; through physical blending or chemical synthesis of polymer for design of the polymeric structure, two transformation temperatures T1 and T2 are obtained; and after forming treatment, two thermal transformations at different temperatures are conducted so as to lead to tri-shape deformation recovery.

Owner:GUANGDONG UNIV OF TECH

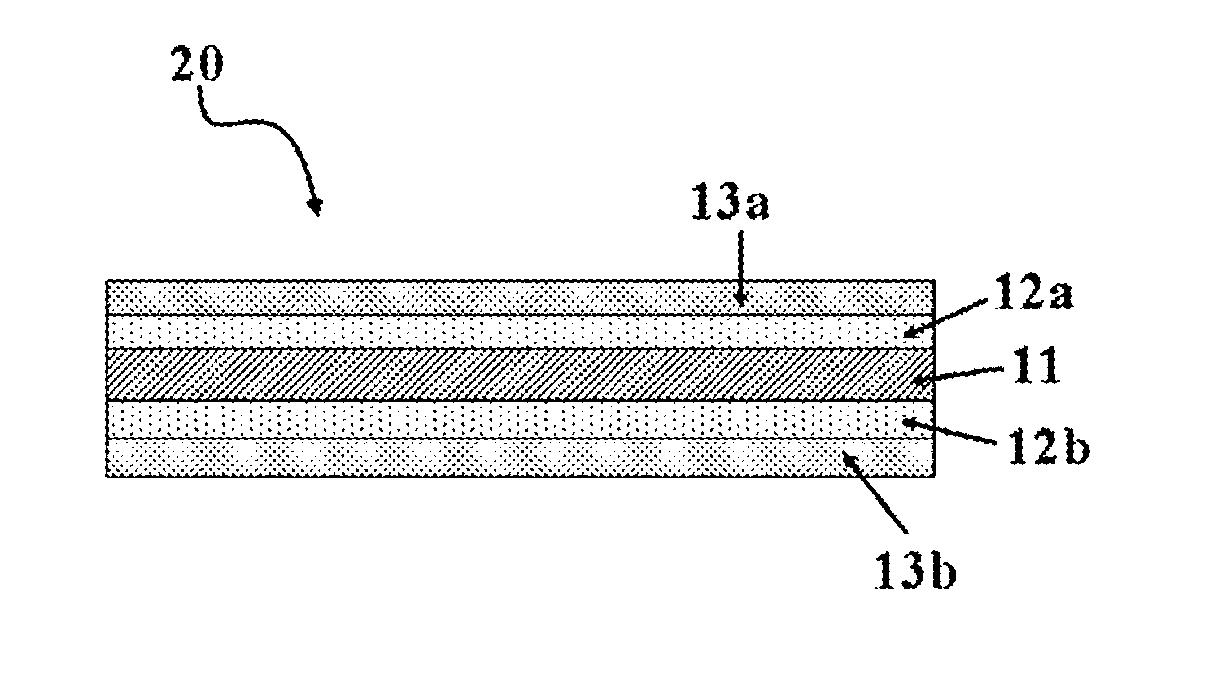

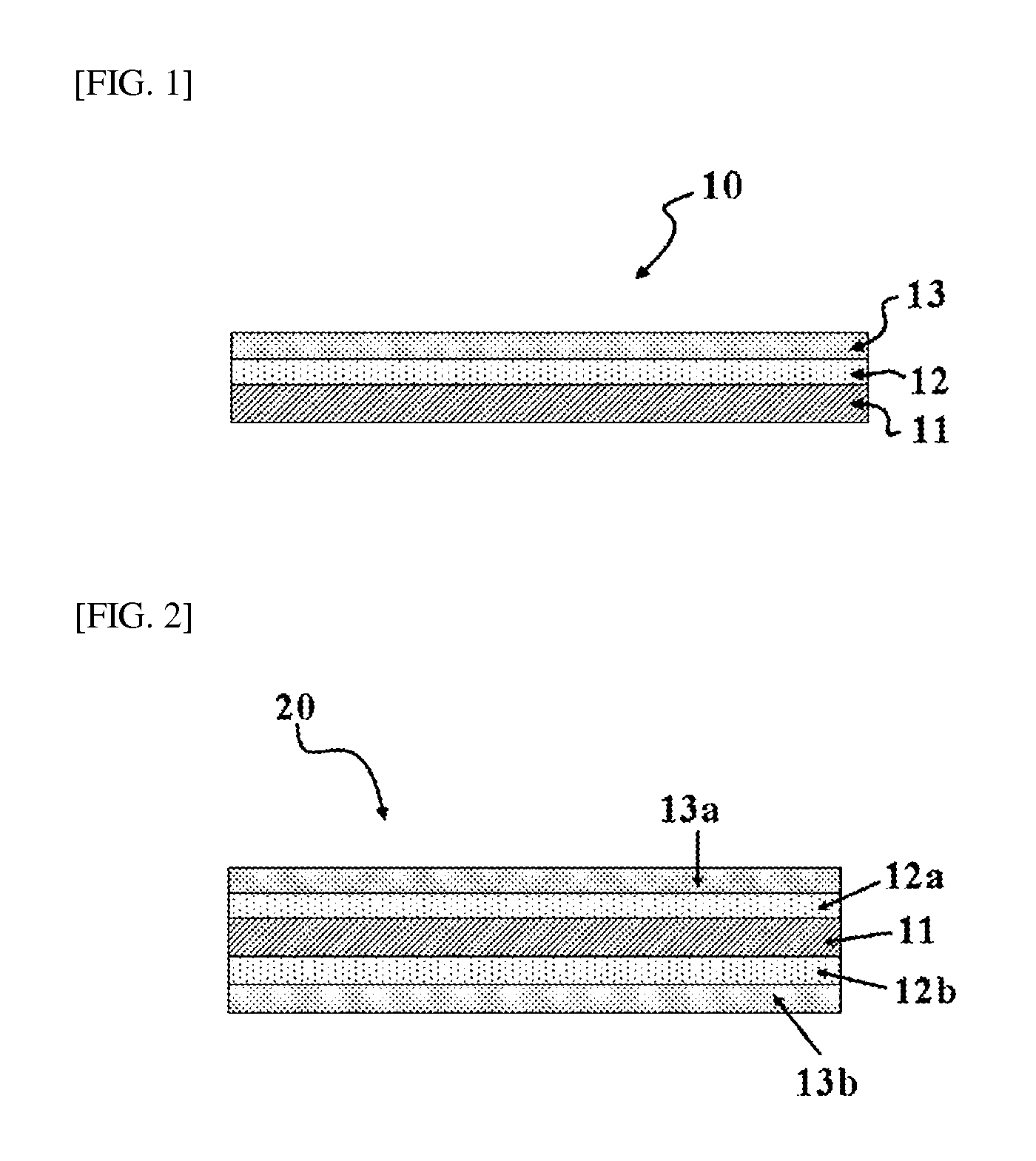

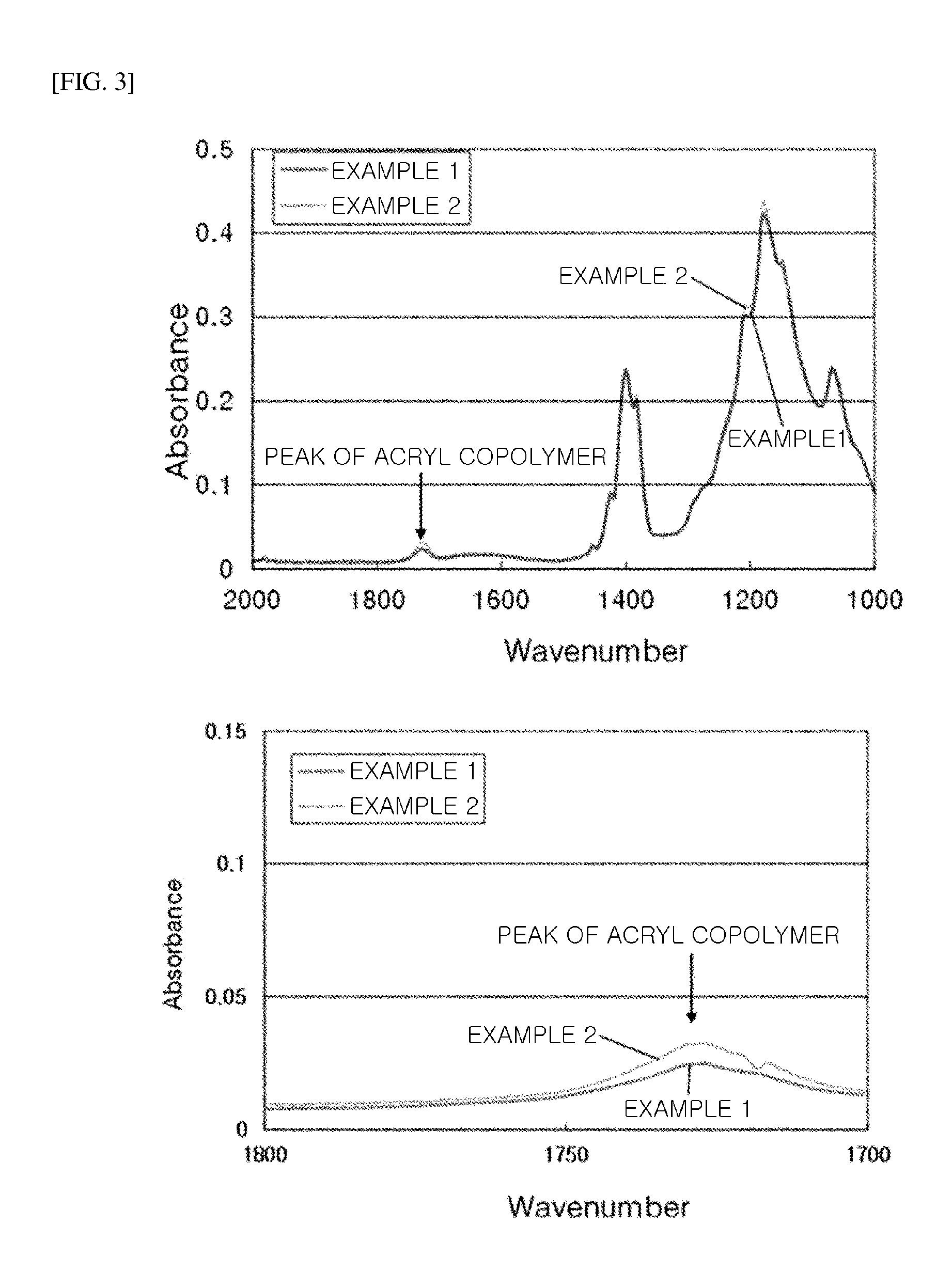

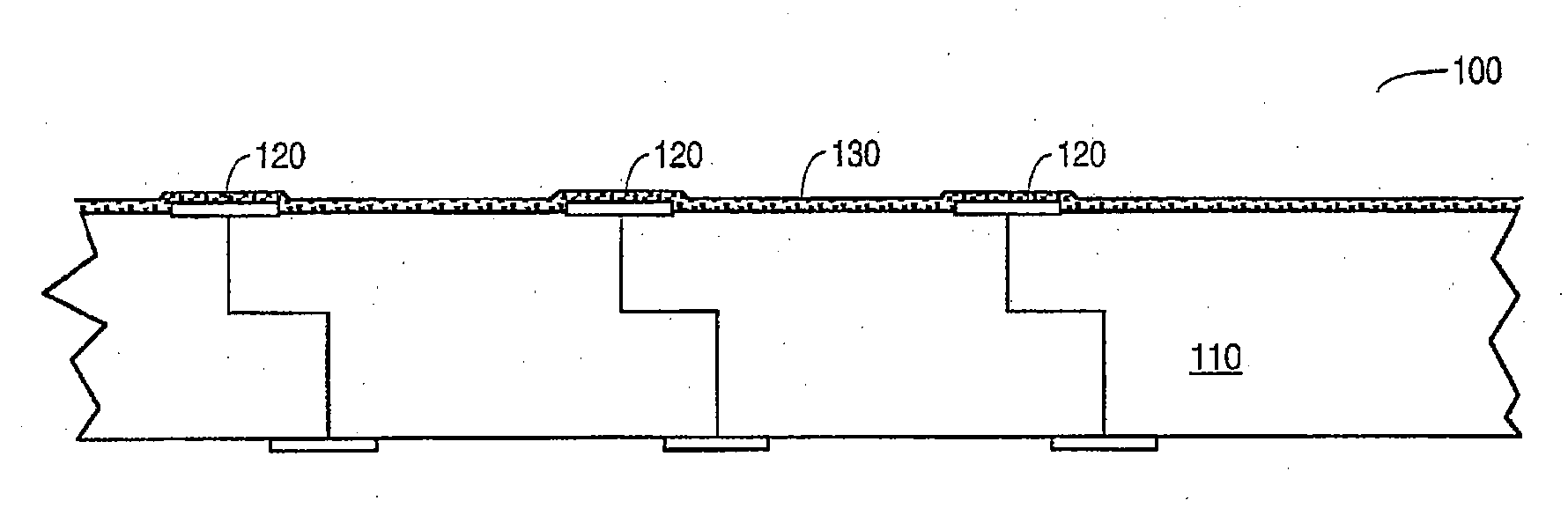

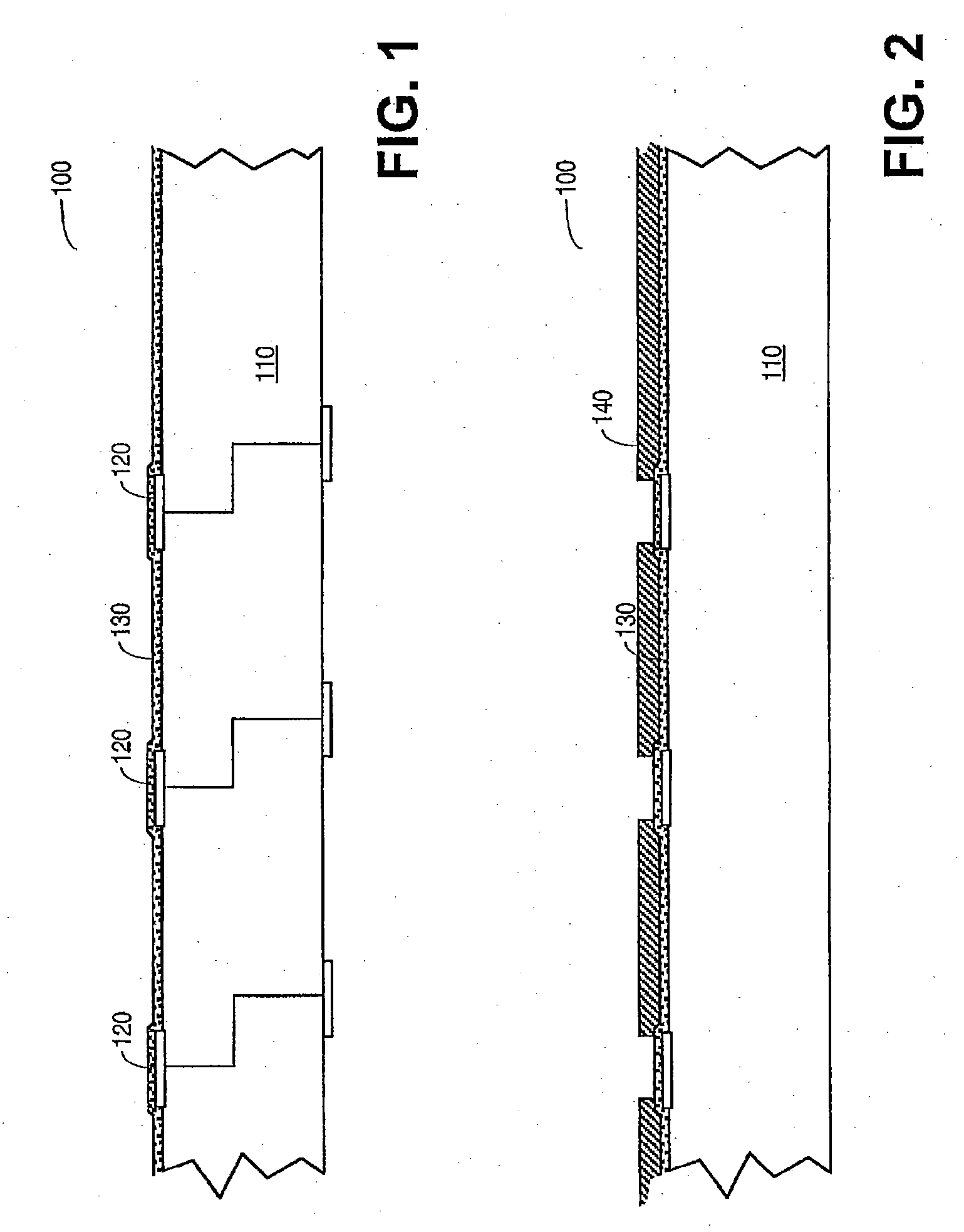

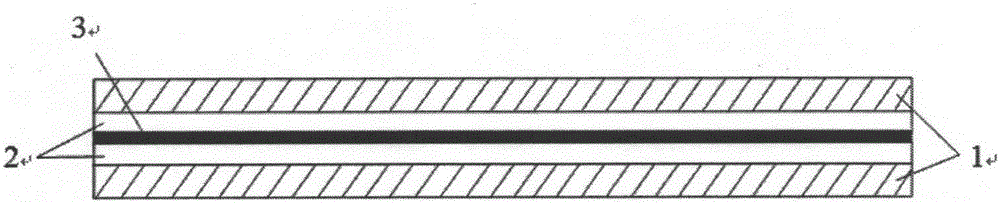

Multilayer film and manufacturing method thereof

ActiveUS20140209153A1High bonding strengthPV power plantsSynthetic resin layered productsWeather resistanceSurface layer

Provided are a multi-layered film, a backsheet for a photovoltaic cell, a method of forming the same and a photovoltaic module. The multi-layered film may include a primer layer and a fluoropolymer coating layer formed by coating, and thus the fluoropolymer coating layer, which is a surface layer, may have excellent durability and weather resistance due to an inter-diffusion effect between materials in the respective layers, and a high interface adhesive strength with a substrate and the primer layer. In addition, in the preparation of the multi-layered film, a production cost may be reduced, productivity may be increased, and degradation in quality of a product caused by thermal transformation or heat shock may be prevented. The multi-layered film may be effectively used as a backsheet for various photovoltaic modules.

Owner:LG CHEM LTD

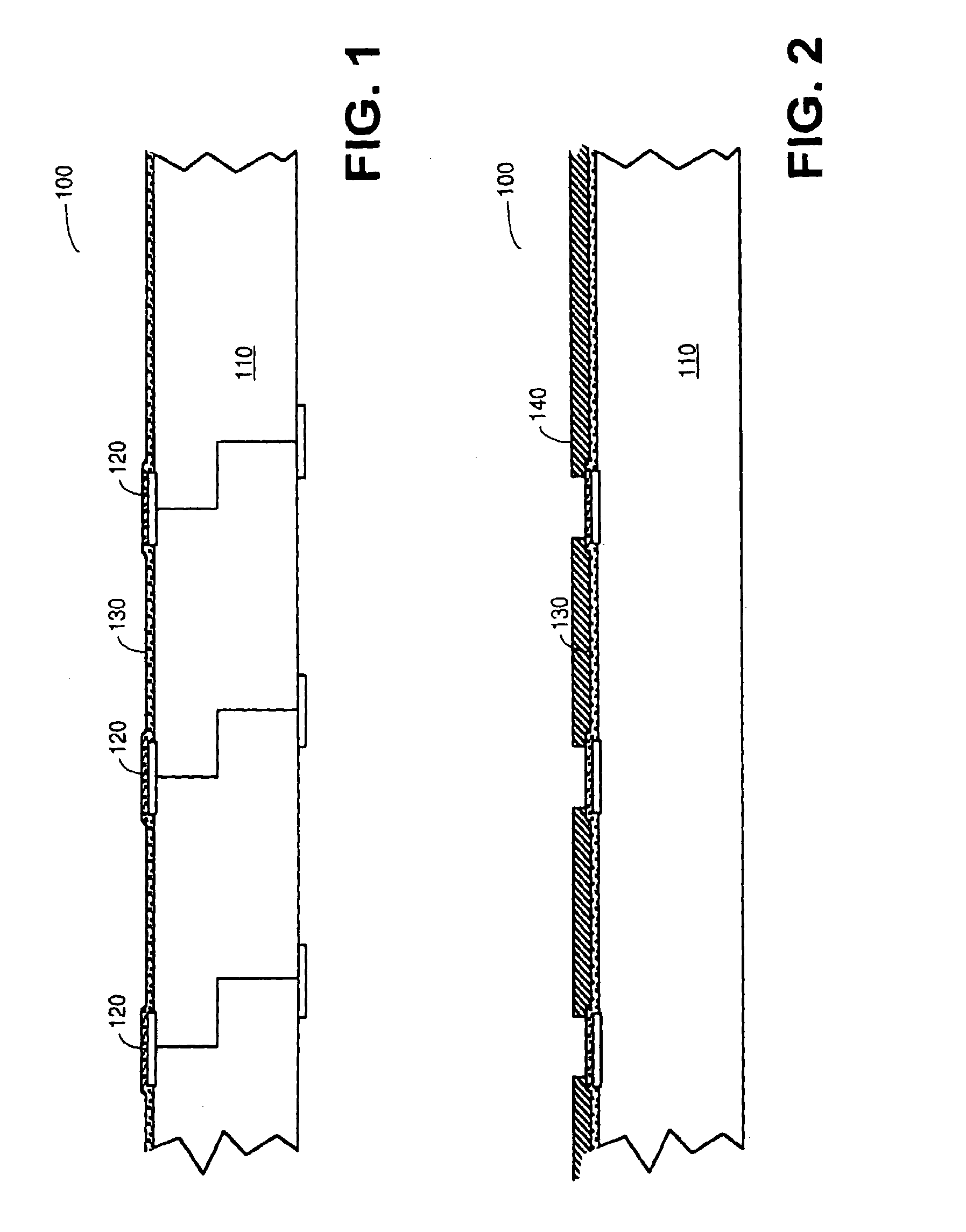

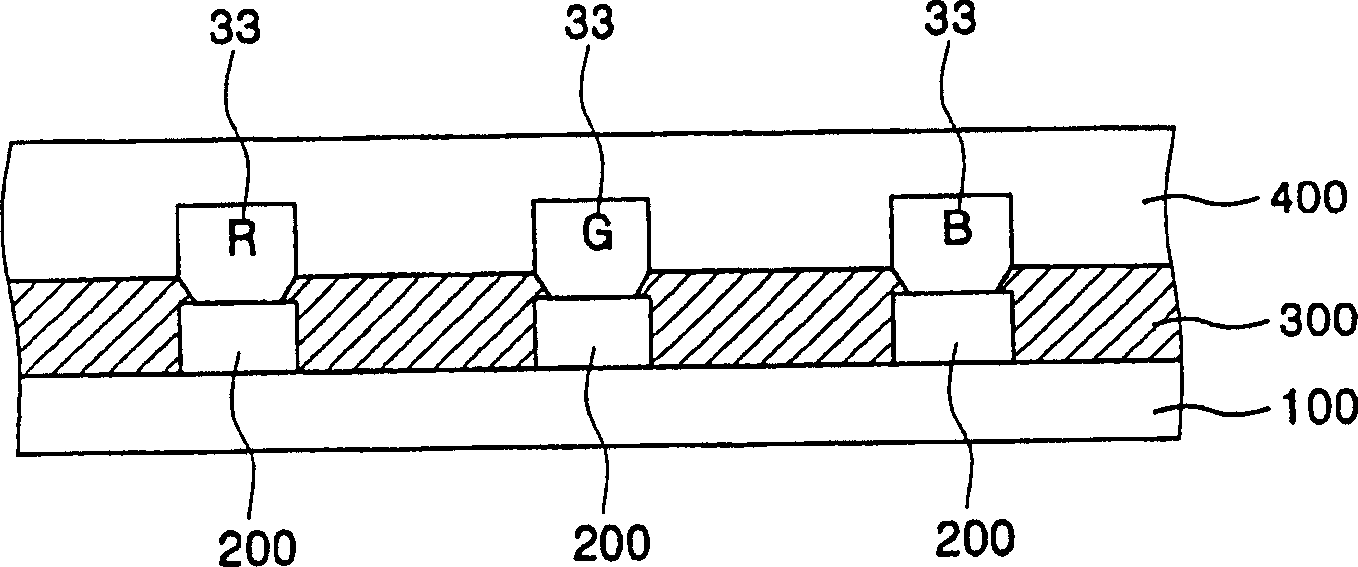

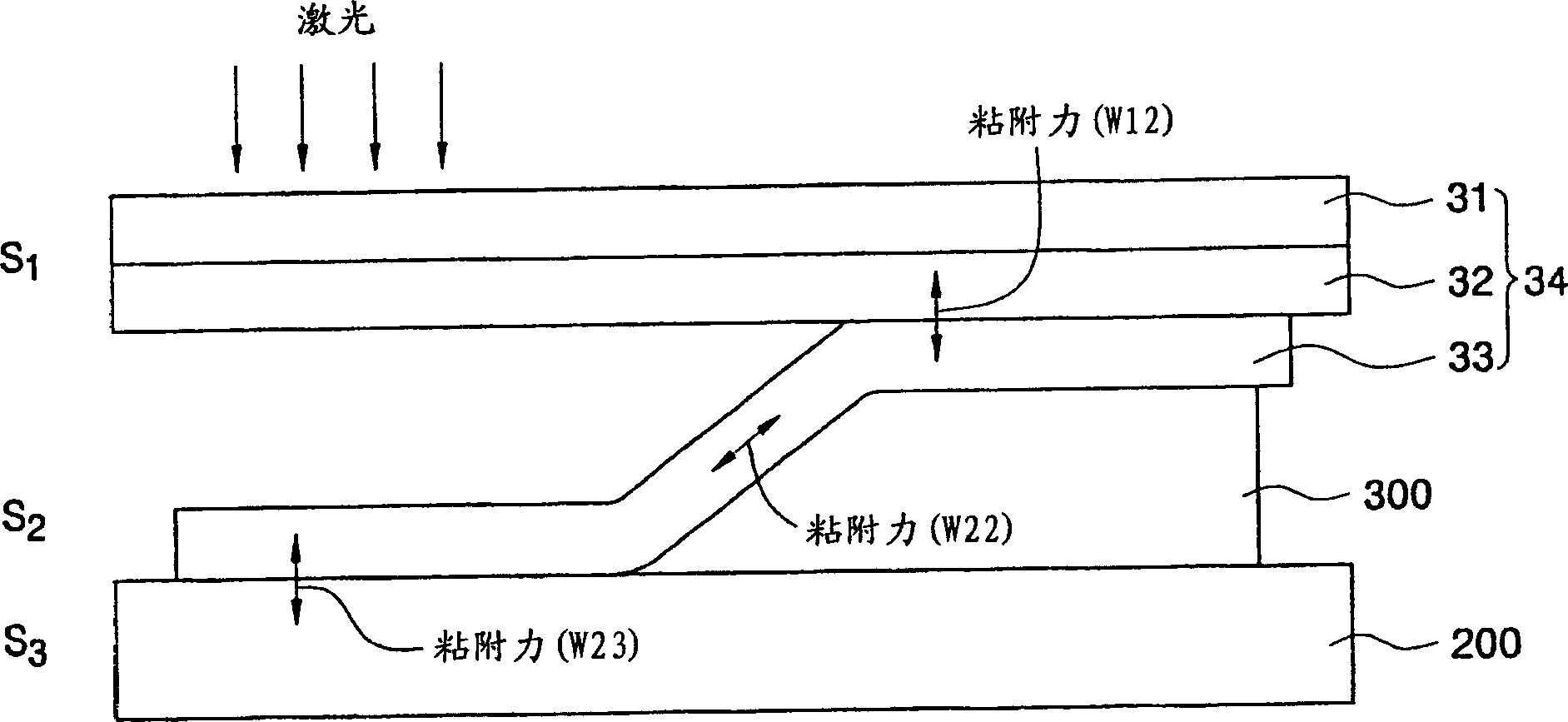

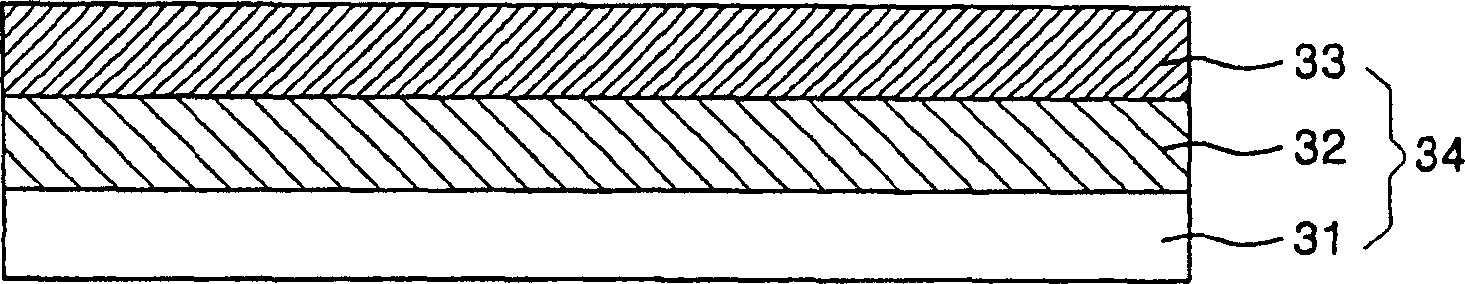

Donor substrate for laser transfer and organic electroluminescence display

ActiveCN1622725AWon't breakInflow will not occurElectroluminescent light sourcesSynthetic resin layered productsOrganic electroluminescenceFull color

A donor substrate for laser transfer is provided, comprising: a base film; a light-to-heat conversion layer formed on the base film; and a transfer layer formed on the light-to-heat conversion layer. The transfer layer includes a thermosetting electroluminescence material, and an organic electroluminescence display device is fabricated using the transfer substrate. Thus, R, G, B emission layers with fine patterns are simply formed by a thermal curing process after laser transfer. As a result, the emission layer is not damaged, and the manufacturing cost of the full-color organic electroluminescent display device is reduced due to the application of a simplified mask process. The donor substrate has advantages when used in the manufacture of large-scale organic electroluminescent display devices.

Owner:SAMSUNG DISPLAY CO LTD

Methods of fabricating and using shaped springs

InactiveUS20070054513A1Increase the spring constantElectrical measurement instrument detailsSemiconductor/solid-state device detailsInterconnectionThermal transformation

A method of fabricating and using an interconnection element that includes a first element material adapted to be coupled to a substrate and a second element material comprising a material having a transformable property such that upon transformation, a shape of the interconnection is deformed. An example is a material that has a transformable property such that a volume of the first and / or second element material may undergo a thermal transformation from one volume to a different volume (such as a smaller volume) resulting in the deformation of the interconnection element.

Owner:FORMFACTOR INC

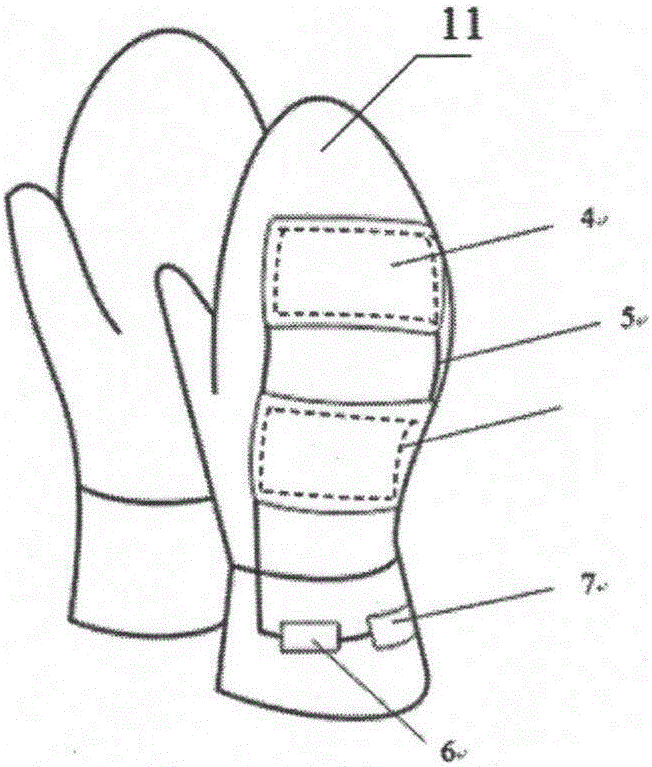

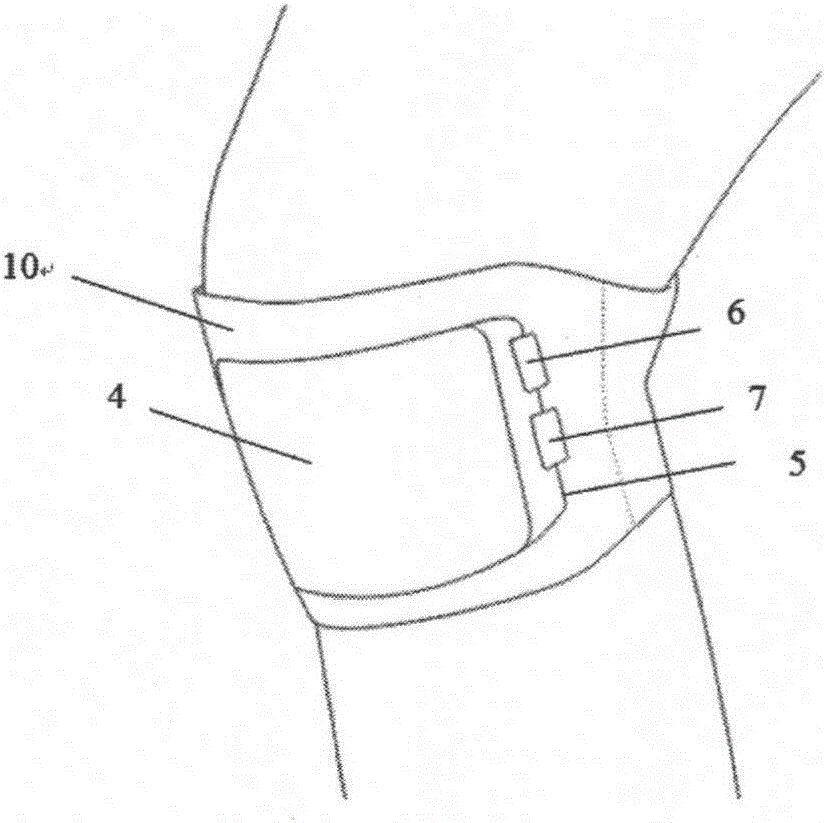

Electric heating compound fabric and preparation method thereof

ActiveCN106003930AIncrease elasticityLight in massSynthetic resin layered productsClothingsEngineeringThermal transformation

The invention provides an electric heating compound fabric and a preparation method thereof. The electric heating compound fabric is characterized by comprising an elastic fabric layer, wherein a flexible nano conducting film is adhered on the upper surface of the elastic fabric, and another elastic fabric layer is adhered on the upper surface of the flexible nano conducting film. The prepared high-elastic electric heating compound fabric is light, thin and soft, has good elasticity and can be repeatedly stretched for more than or equal to 10000 times at elongation of 40%; and secondly, the electric heating compound fabric is stable and uniform in heating, thermal transformation efficiency is high, energy is saved, and safety and reliability are realized. Therefore, the electric heating compound fabric can be widely applied to intelligent textile structures and intelligent materials, especially to the field of intelligent wearable materials.

Owner:DONGHUA UNIV

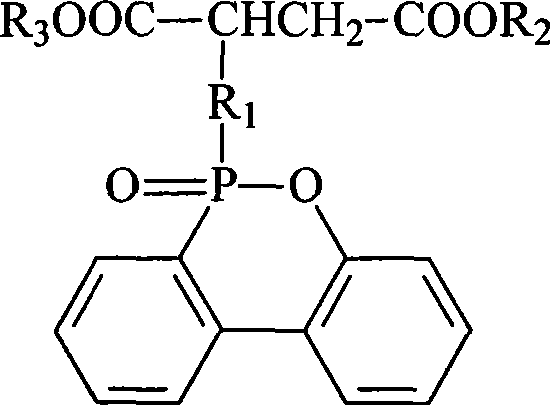

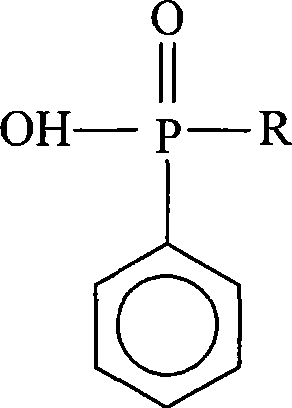

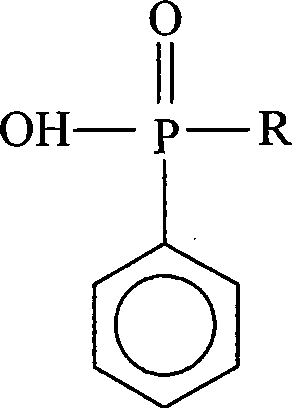

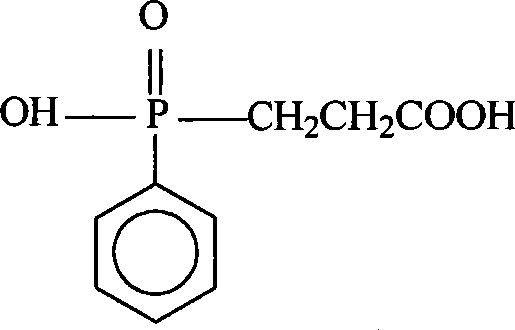

Preparation of flame-retardant polyester for preparing industrial yarn

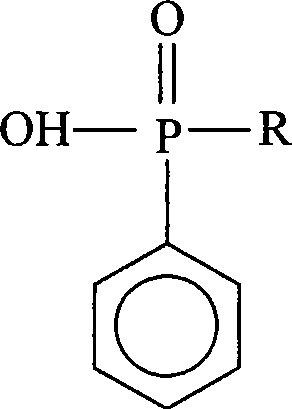

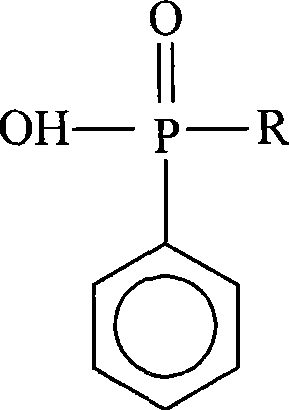

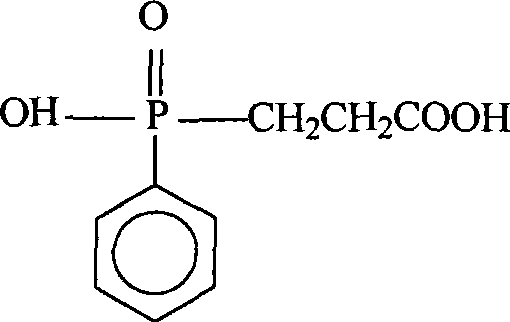

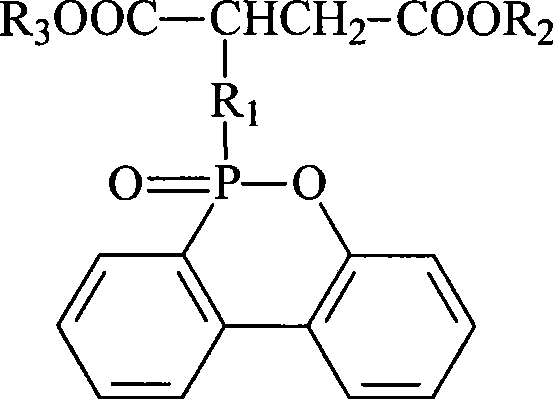

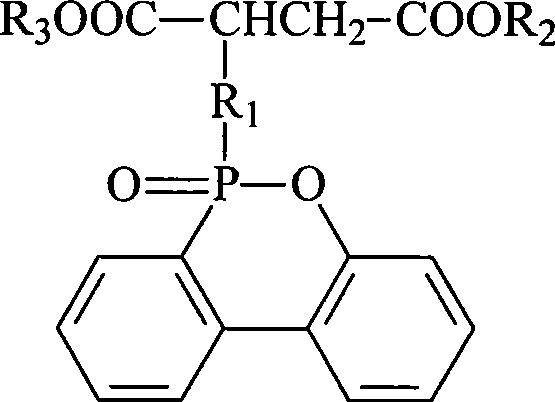

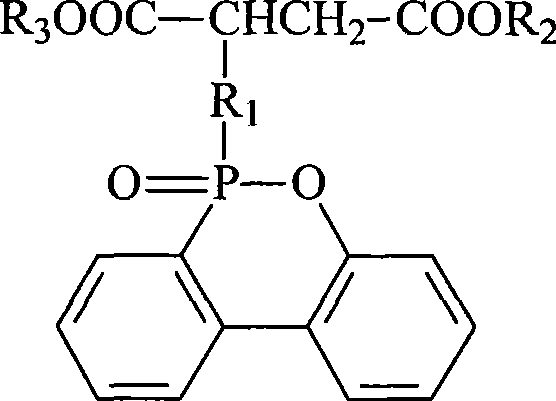

ActiveCN101376700AReduce negative impactSmall mechanical propertiesFlame-proof filament manufactureMonocomponent polyesters artificial filamentYarnFiber

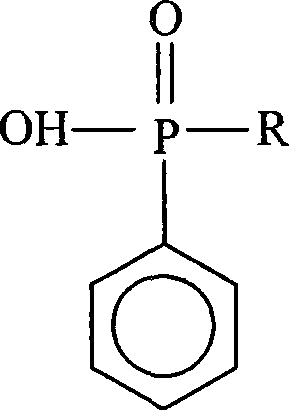

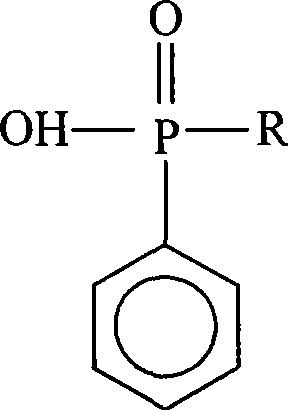

A method for preparing flame-retardant polyester for manufacturing industrial fiber comprises the following steps: 1) carrying out the esterification of monomer terephthalic acid (TPA), ethylene glycol, pentaerythritol ester and a reactive flame-retardant having a structural formula I, wherein R in the structural formula I is hydroxyalkyl or carboxyalkyl of C1 to C4; and 2) sequentially carrying out the pre-polymerization reaction and the polycondensation reaction of the esterification products in the presence of a polycondensation catalyst to obtain the esterification product, that is, the flame-retardant polyester. Nano kaolin particles which serve as a flame-retardant polyester crystallization nucleating agent are added to the reaction system, wherein the nano kaolin particles are added before the esterification or before the pre-polymerization reaction, and the adding amount by the content of the nano kaolin particles existing in the polycondensation products at the end is 0.06 wt% to 1.0 wt%. The deviation of the thermal transformation performance existing between the conventional polyester and the prepared flame-retardant polyester is obviously reduced, so that the conventional polyester fiber manufacturing equipment and the manufacturing process thereof can be adopted to reliably manufacture the flame-retardant industrial fiber.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

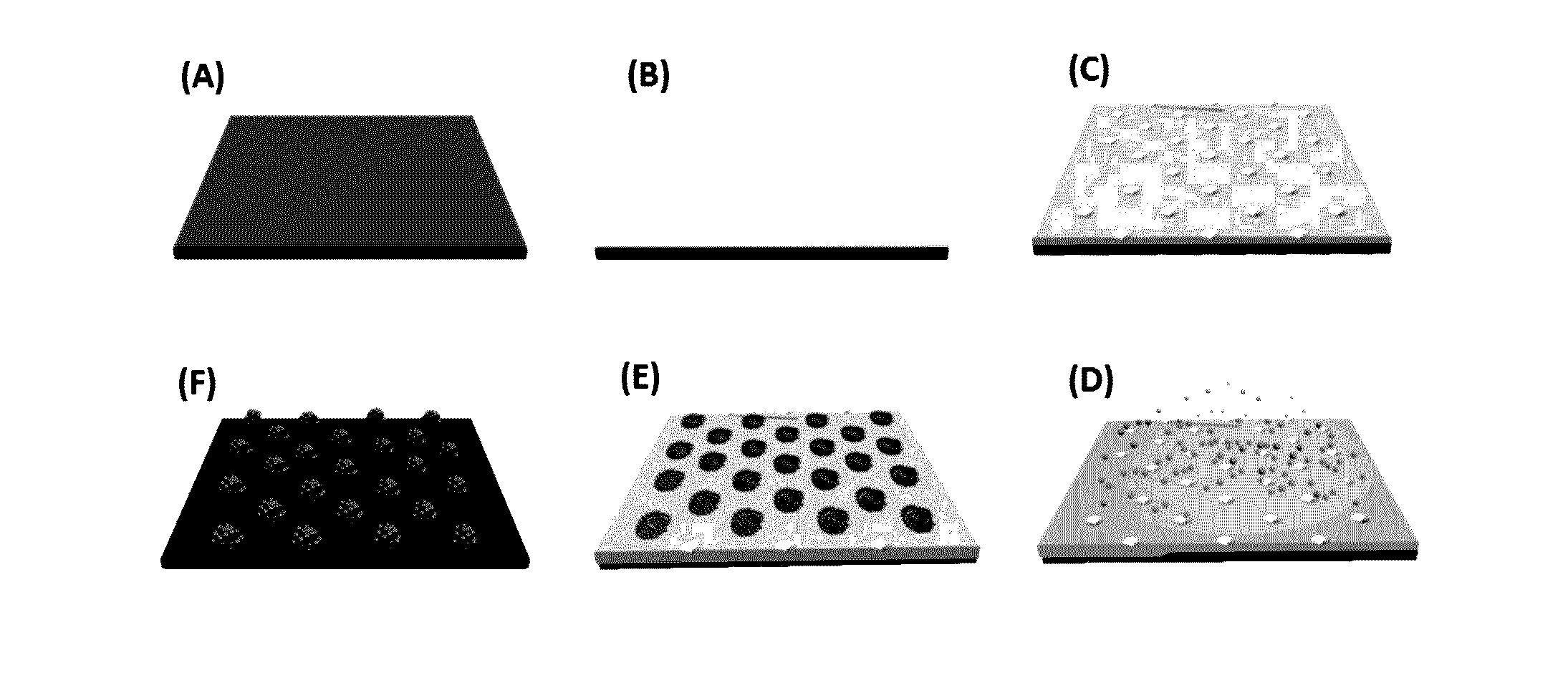

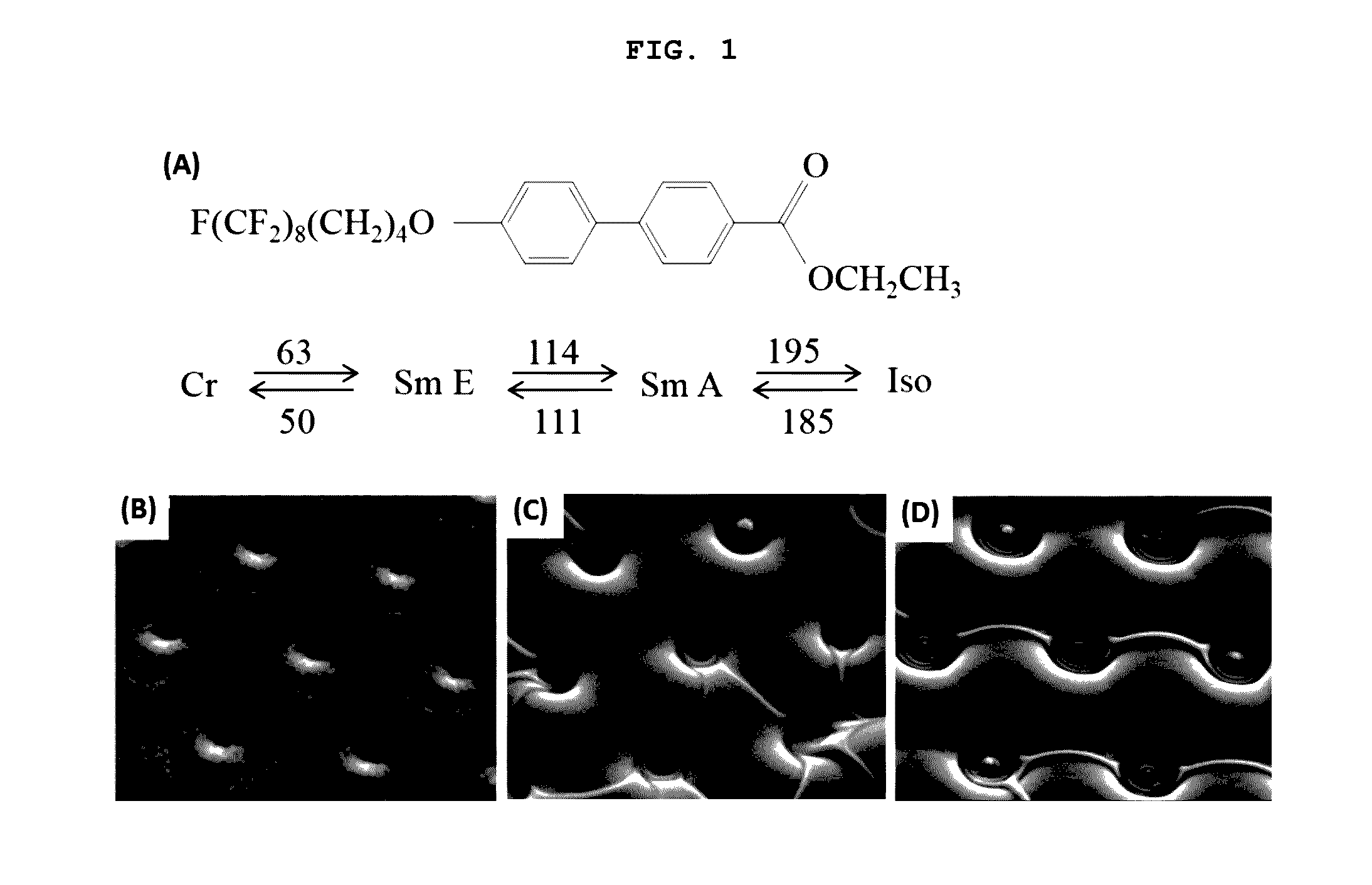

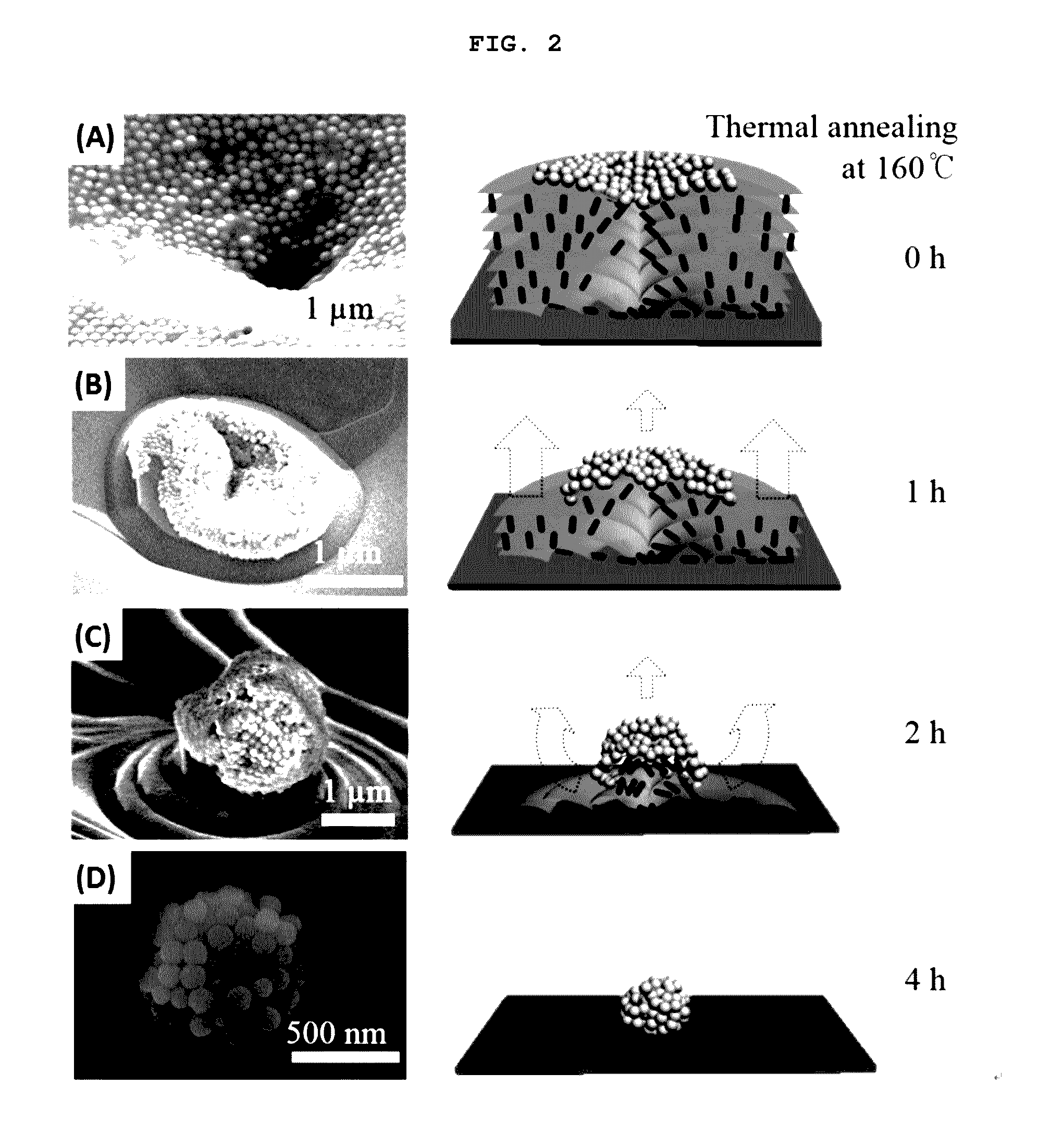

Method of fabricating array of nanoparticle clusters using thermal transformation of sublimable liquid crystal film

InactiveUS20160355405A1Improve mobilityIncrease the areaLiquid crystal compositionsSilicaNanoparticleThermal transformation

The present invention relates to a method for fabricating an array of nanoparticle clusters, in which a thermally transformable organic liquid crystal film having a periodic array of micro-sized dimple-like defect structures spontaneously transformed by thermal sublimation of liquid crystal molecules is used as a template, and nanoparticles form self-assembled clusters having a uniform size with respect to the defect structures, thereby achieving a periodic array of nanoparticle clusters.

Owner:KOREA ADVANCED INST OF SCI & TECH

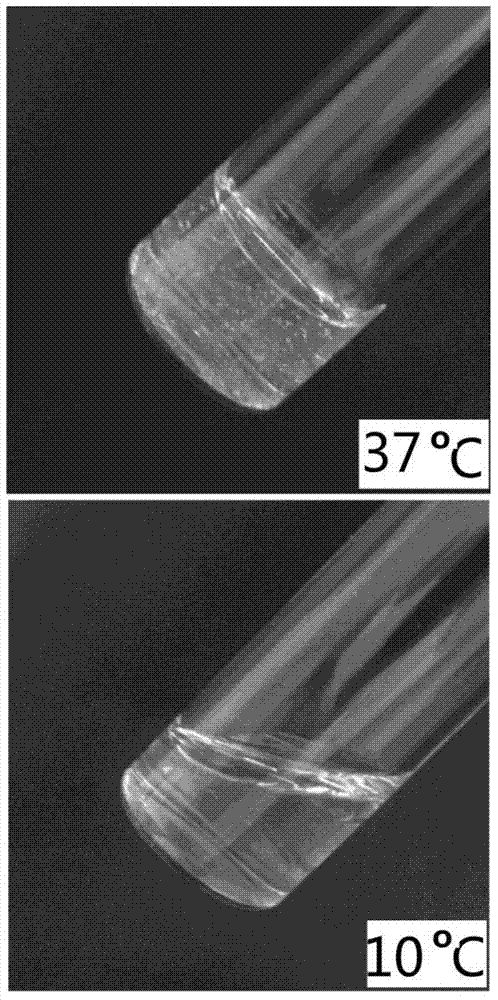

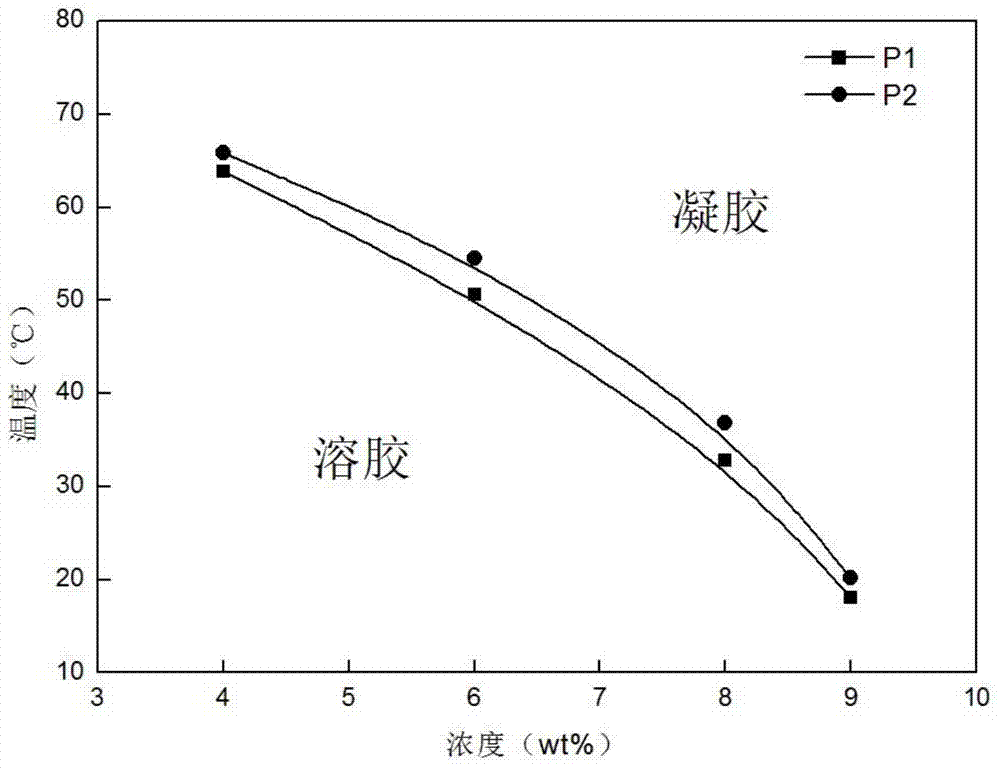

Thermosensitive copolymer as well as synthesis method and hydrogel system of thermosensitive copolymer

ActiveCN104292455AGood reversible thermal transition behaviorReduce hydrogen bondingSynthesis methodsPolyethylene glycol

The invention discloses a thermosensitive copolymer as well as a synthesis method and a hydrogel system of the thermosensitive copolymer. The thermosensitive copolymer refers to a polyethylene glycol-poly(alanine-valine) block copolymer, wherein the poly(alanine-valine) is taken as a hydrophobic chain segment, while polyethylene glycol monomethyl ether is taken as a hydrophilic chain segment; in the hydrophobic chain segment poly(alanine-valine), the content of the alanine is 15.2-23.5wt% and the content of the valine is 76.5-84.8wt%; in the copolymer, the content of the hydrophilic chain segment polyethylene glycol monomethyl ether is 45.0-55.0wt%, and the content of the hydrophobic chain segment poly(alanine-valine) is 45.0-55.0wt%. The polypeptide-polyether hydrogel disclosed by the invention is composed of two amino acid components so that the hydrogen-bond interaction in the hydrogel can be weakened; the strength of the hydrogen-bond of the beta-folded chain can be regulated and controlled by regulating the composition of the alanine and the valine in the polypeptide, and therefore, the polypeptide hydrogel having good reversible thermal transformation behavior can be obtained.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

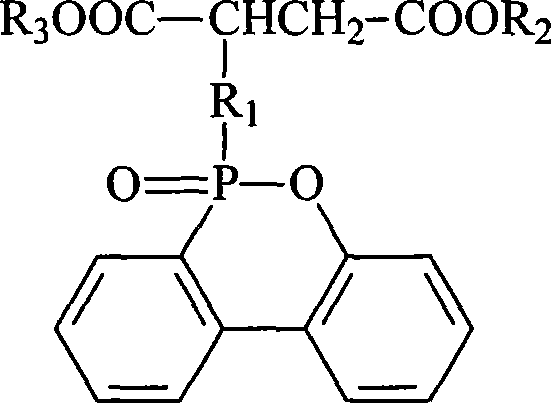

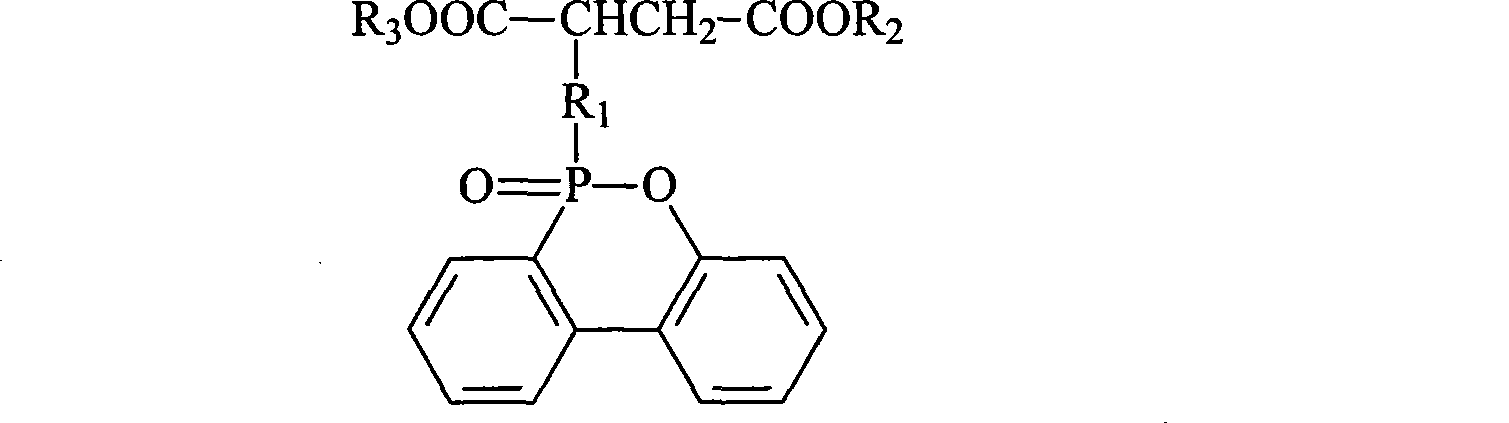

Flame-retardant polyester composition for preparing industrial polyester fibre

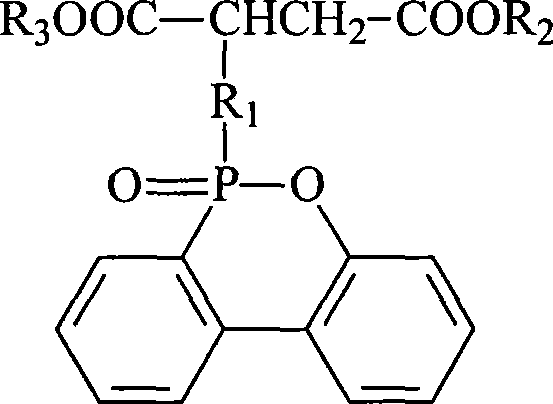

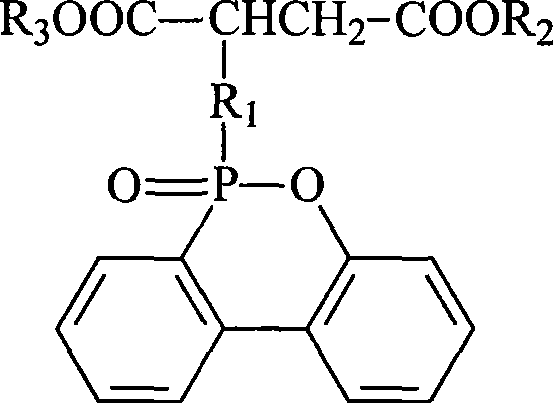

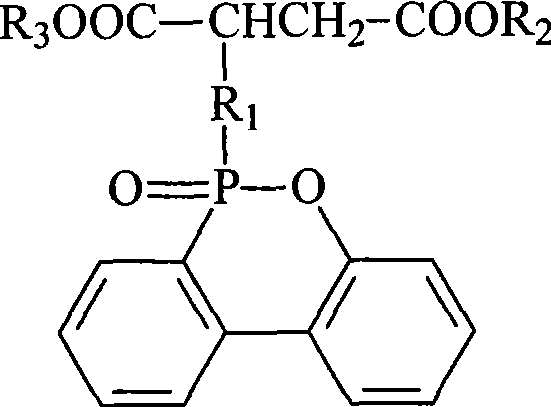

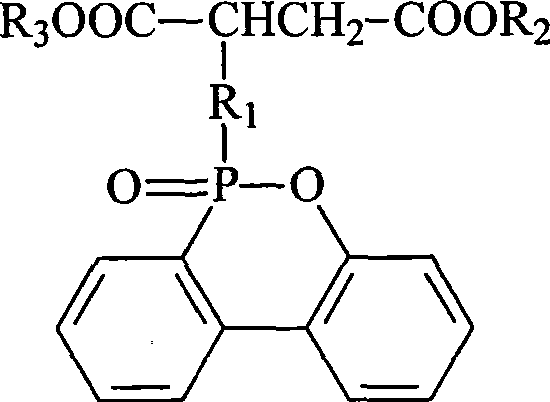

InactiveCN101376739AReduce negative impactSmall mechanical propertiesFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberPentaerythritol

The invention relates to a flame-retardant polyester compound used for manufacturing industrial polyester fiber which includes the components as follows: a) the polyester of a reaction type flame-retardant which comprises a structural formula as I and is formed by the copolycondensation of terephthalic acid, glycol, pentaerythritol and the flame-retardant. In the formula I, R refers to the hydroxyalkyl or the car boxyalkyl of C1 to C4. The content of the pentaerythritol in the polyester is 0.01 to 0.10wt percent; the content of the flame-retardant in the polyester is 2 to 10wt percent; the characteristic viscidity of the polyester is 0.60 to 0.75 dl / g; b) a nucleating agent which relates to the grain of Nano-Kaolin with an average grain diameter of 200 to 600nm. The nucleating agent is uniformly stored in the polyester compound and the content of the nucleating agent is 0.06 to 1.0wt percent. The departure on the thermal transformation performance existed between the flame-retardant polyester compound and the normal polyester is remarkably reduced; the manufacturing industrial polyester fiber can be produced by adopting the normal polyester fiber manufacture device and technique.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Preparation of flame-retardant polyester for preparing fiber

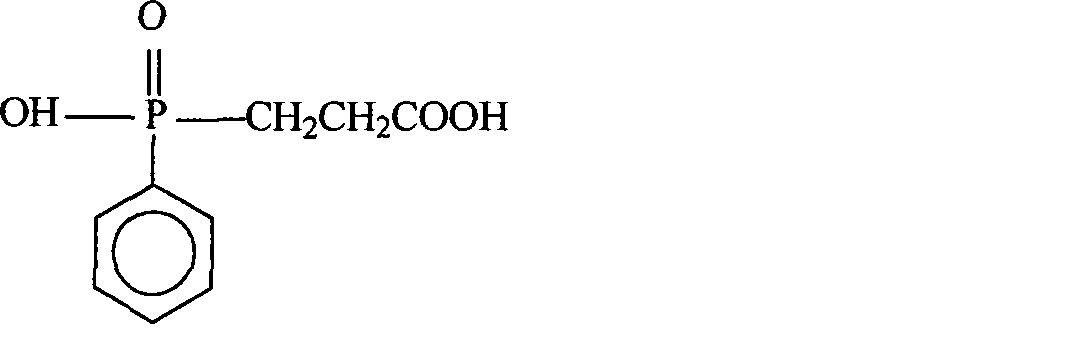

ActiveCN101376690AReduce negative impactSmall mechanical propertiesMonocomponent polyesters artificial filamentFiberStructural formula

A method for preparing flame-retardant polyester for manufacturing fiber comprises the following steps: 1) carrying out the esterification of monomer terephthalic acid and ethylene glycol; and 2) adding a reactive flame retardant having a structural formula I to the esterification products, and sequentially carrying out the pre-polymerization reaction and the polycondensation reaction in the presence of a polycondensation catalyst to obtain the polycondensation product, that is, the flame-retardant polyester, wherein R1 in the structural formula I is alkylidene of C1 to C4, and R2 and R3 are respectively H and hydroxyalkyl or carboxyalkyl of C2 to C4. Nano kaolin particles which serve as a flame-retardant polyester crystallization nucleating agent are added to the reaction system, wherein the nano kaolin particles are added before the esterification or before the pre-polymerization reaction, and the adding amount by the content of the nano kaolin particles existing in the polycondensation products at the end is 0.05 wt% to 0.9 wt%. The deviation of the thermal transformation performance existing between the conventional polyester and the prepared flame-retardant polyester is obviously reduced, so that the conventional polyester fiber manufacturing equipment and the manufacturing process thereof can be adopted to reliably manufacture the flame-retardant fiber.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

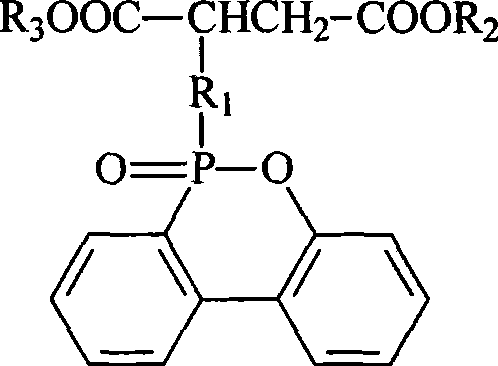

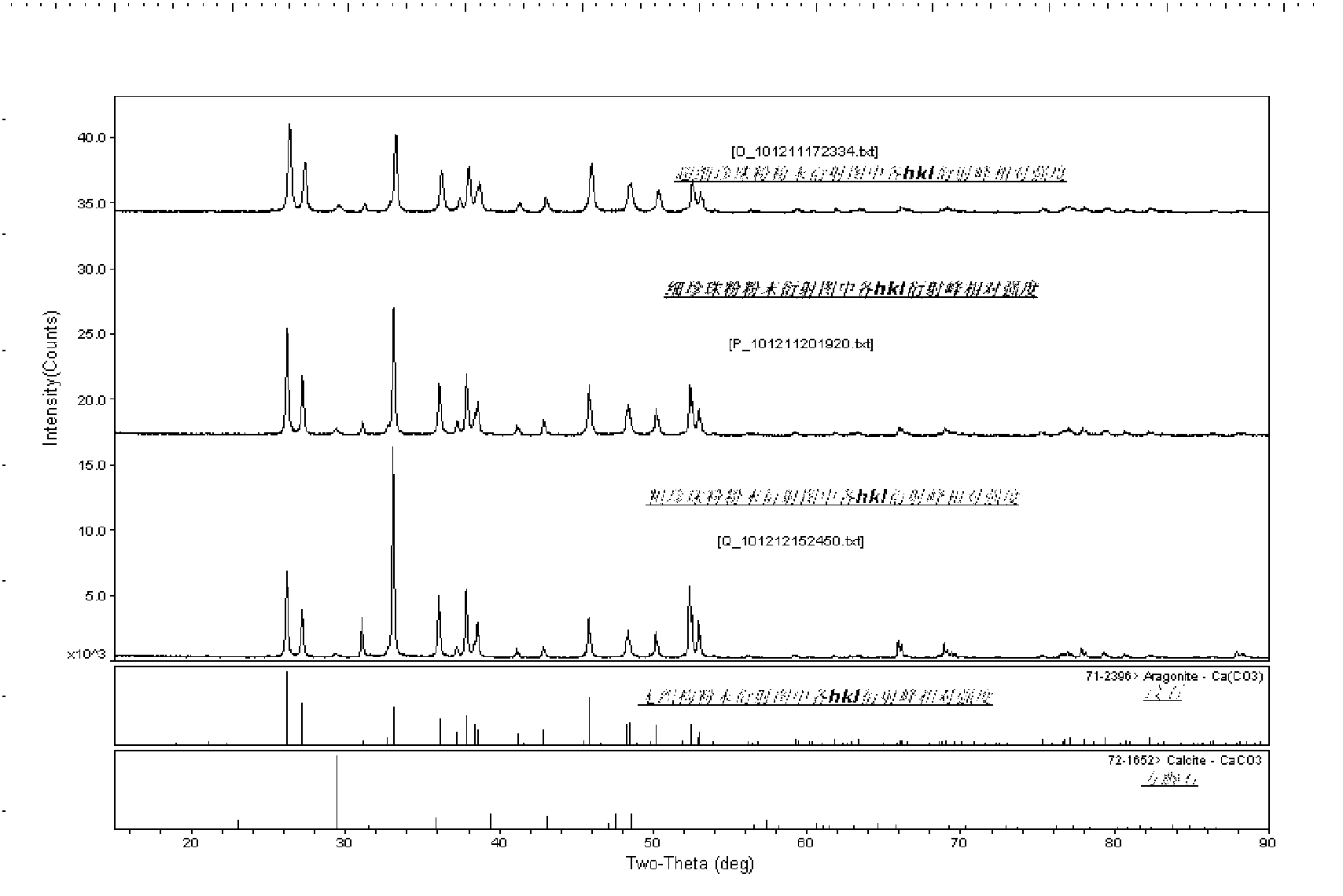

Method for detecting quality of pearl powder by using thermal transformation hemodynamic difference combined with X-ray diffraction (XRD) and application thereof

InactiveCN102706911APhase change rate is slowPhase change rate is fastMaterial weighingMaterial analysis using radiation diffractionRoom temperatureX-ray

Owner:浙江华才检测技术有限公司

Thermosynthesis device

InactiveCN101524633AHigh yieldReduce yieldGas-gas reaction processesHydrocarbon by hydrocarbon condensationProcess engineeringReaction zone

A device for thermal transformation of one or a plurality of reagents into at least one needed product comprises an axial reactor, a torch part and an injector part, wherein the axial reactor comprises an inlet end, an outlet end, a reaction zone arranged between the inlet end and the outlet end, and a reactor inlet arranged on the inlet end; the torch part is constructed to generate thermal gas; and the injector part is inserted between the torch part and the axial reactor and comprises a thermal gas inlet and at least one reagent inlet.

Owner:BECHTEL BWXT IDAHO

Preparation of flame-retardant polyester for preparing industrial yarn

ActiveCN101376691AReduce negative impactSmall mechanical propertiesFlame-proof filament manufactureMonocomponent polyesters artificial filamentYarnFiber

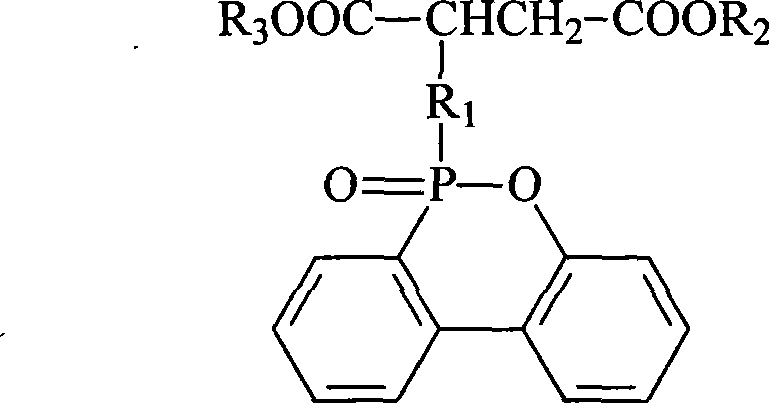

A method for preparing flame-retardant polyester for manufacturing industrial yarn comprises the following steps: 1) carrying out the esterification of monomer terephthalic acid (TPA), ethylene glycol, pentaerythritol ester and a reactive flame-retardant having a structural formula I, wherein R1 in the structural formula I is alkylidene of C1 to C4, and R2 and R3 are respectively H and hydroxyalkyl or carboxyalkyl of C2 to C4; and 2) sequentially carrying out the pre-polymerization reaction and the polycondensation reaction of the esterification products in the presence of a polycondensation catalyst to obtain the esterification product, that is, the flame-retardant polyester. Nano kaolin particles which serve as a flame-retardant polyester crystallization nucleating agent are added to the reaction system, wherein the nano kaolin particles are added before the esterification or before the pre-polymerization reaction, and the adding amount by the content of the nano kaolin particles existing in the polycondensation products at the end is 0.06 wt% to 1.0 wt%. The deviation of the thermal transformation performance existing between the conventional polyester and the prepared flame-retardant polyester is obviously reduced, so that the conventional polyester fiber manufacturing equipment and the manufacturing process thereof can be adopted to reliably manufacture the flame-retardant industrial yarn.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

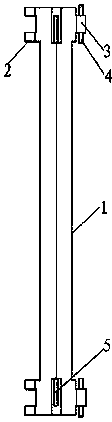

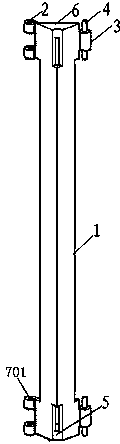

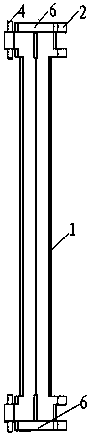

Silk yarn transforming device

The invention provides a silk yarn transforming device. The silk yarn transforming device comprises a machine frame, an upper caterpillar track, a lower caterpillar track, a power system, an air supplying system, a yarn supplying system and a yarn winding system. The upper caterpillar track and the lower caterpillar track are oval and are respectively formed by a plurality of caterpillar track parts and two caterpillar track wheels. Transforming silk yarns are manufactured in an upper caterpillar track and lower caterpillar track clamping mode, due to the fact that the width of the caterpillar tracks is large, a plurality of strands of silk yarns can be produced side by side at the same time, and due to the fact the length of the caterpillar tracks is large, the silk yarns can be transformed and shaped for a long time. An upper air pipe and a lower air pipe are connected with an external hot air source and an external cold air source. A valve is used for adjusting temperature so that the temperature of the upper caterpillar track and the temperature of the lower caterpillar track can be set and controlled to be different, and thermal transformation can be not consistent. In addition, the revolving speed and pressure of the caterpillar tracks can be adjusted, various silk yarn transformation technique parameters can be designed for various fiber silk yarns, and the different fiber silk yarn transformation technique parameters can be stored for use later.

Owner:桐乡市来得宝家纺股份有限公司

Preparation of flame-retardant polyester for preparing industrial yarn

ActiveCN101376699AReduce negative impactSmall mechanical propertiesFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberYarn

A method for preparing flame-retardant polyester for manufacturing industrial yarn comprises the following steps: 1) carrying out the esterification of terephthalic acid and ethylene glycol; and 2) adding pentaerythritol ester and a reactive flame-retardant having a structural formula I to the esterification products, and sequentially carrying out the pre-polymerization reaction and the polycondensation reaction in the presence of a polycondensation catalyst to obtain the flame-retardant polyester, wherein R1 in the structural formula I is alkylidene of C1 to C4, and R2 and R3 are respectively H and hydroxyalkyl or carboxyalkyl of C2 to C4. Nano kaolin particles which serve as a flame-retardant polyester crystallization nucleating agent are added to the reaction system, wherein the average particle diameter thereof is 200 to 600 nm, the nano kaolin particles are added before the esterification or before the pre-polymerization reaction, and the adding amount by the content of the nano kaolin particles existing in the polycondensation products at the end is 0.06 wt% to 1.0 wt%. The deviation of the thermal transformation performance existing between the conventional polyester and the prepared flame-retardant polyester is obviously reduced, so that the conventional polyester fiber manufacturing equipment and the manufacturing process thereof can be adopted to reliably manufacture the flame-retardant polyester industrial yarn.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

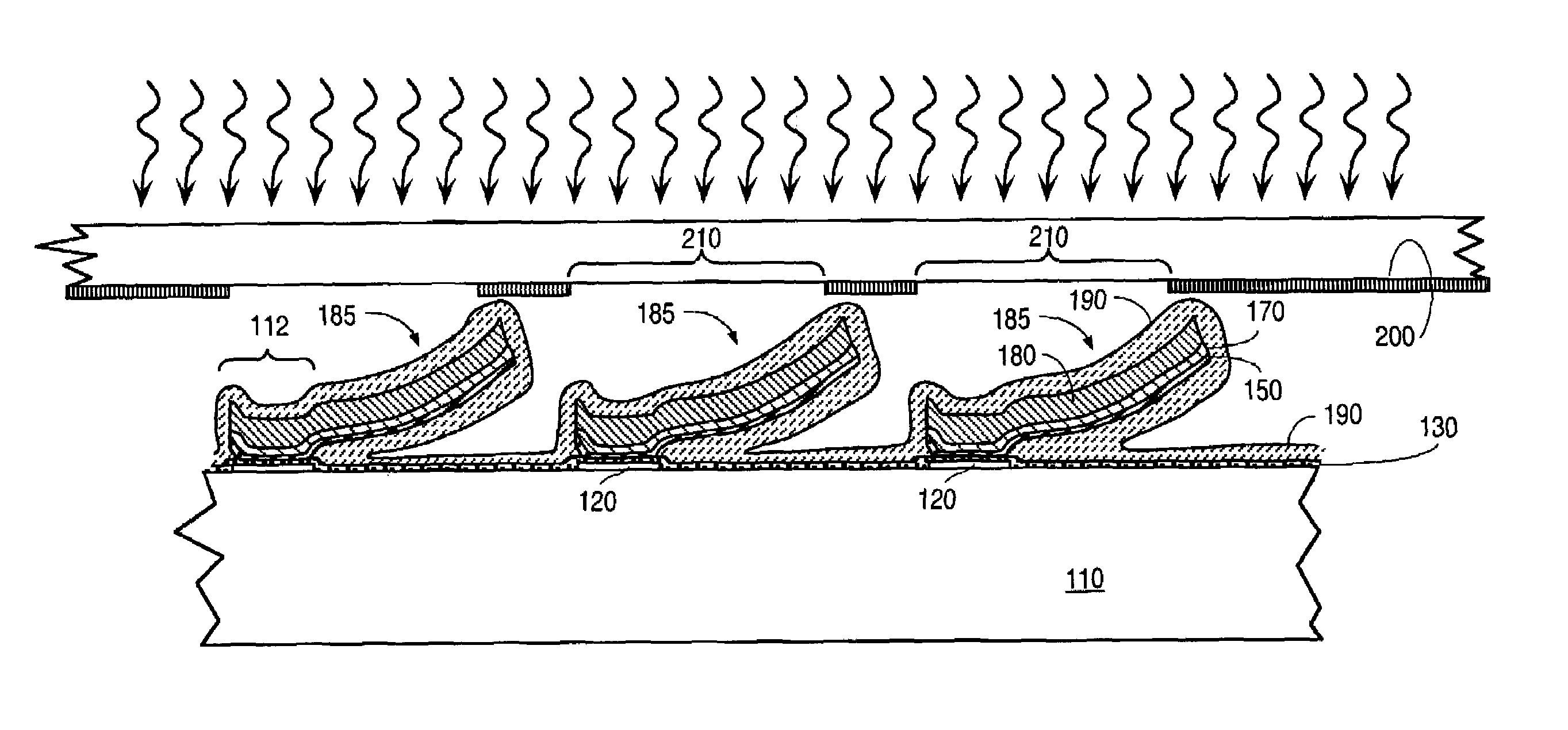

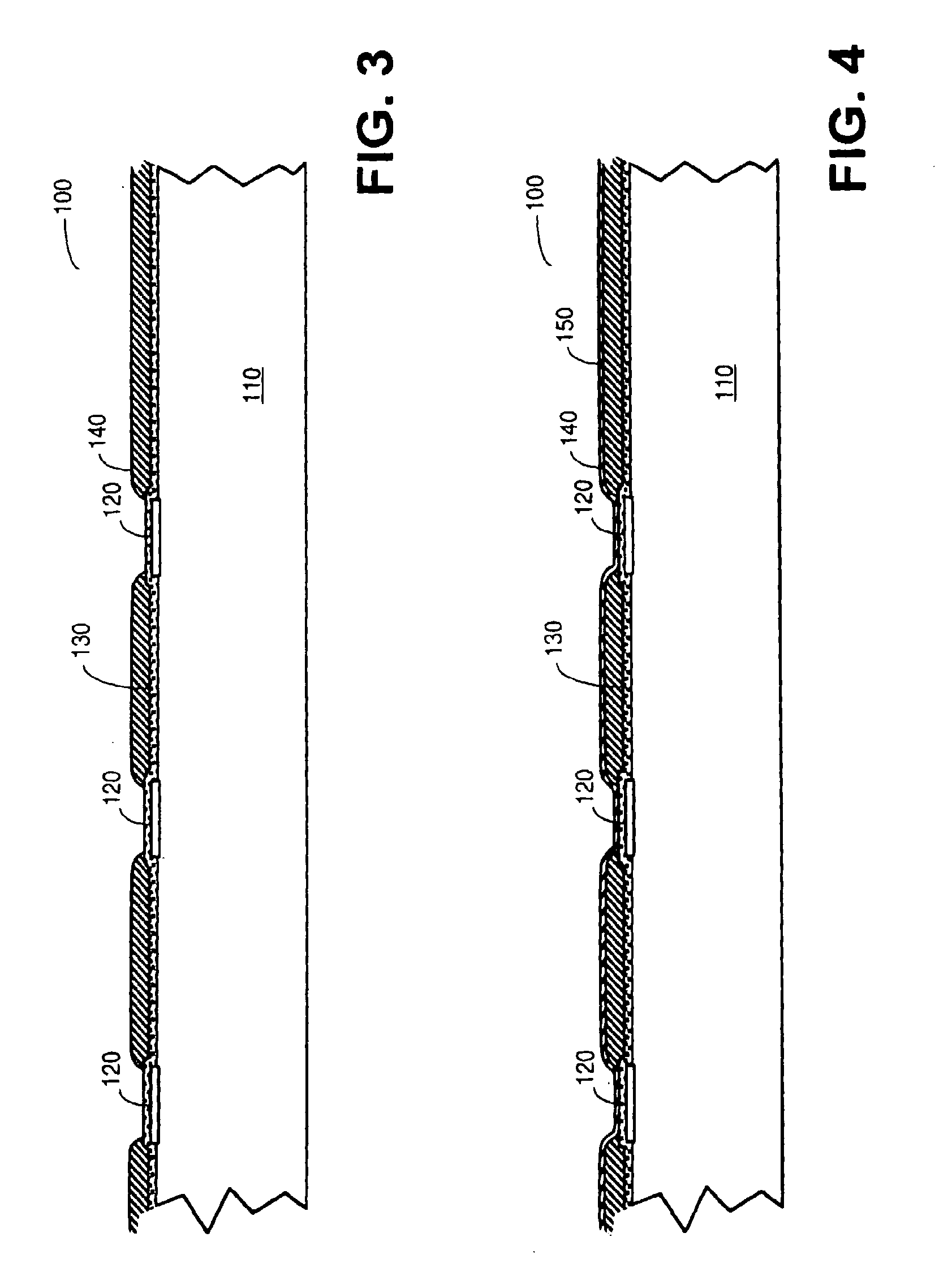

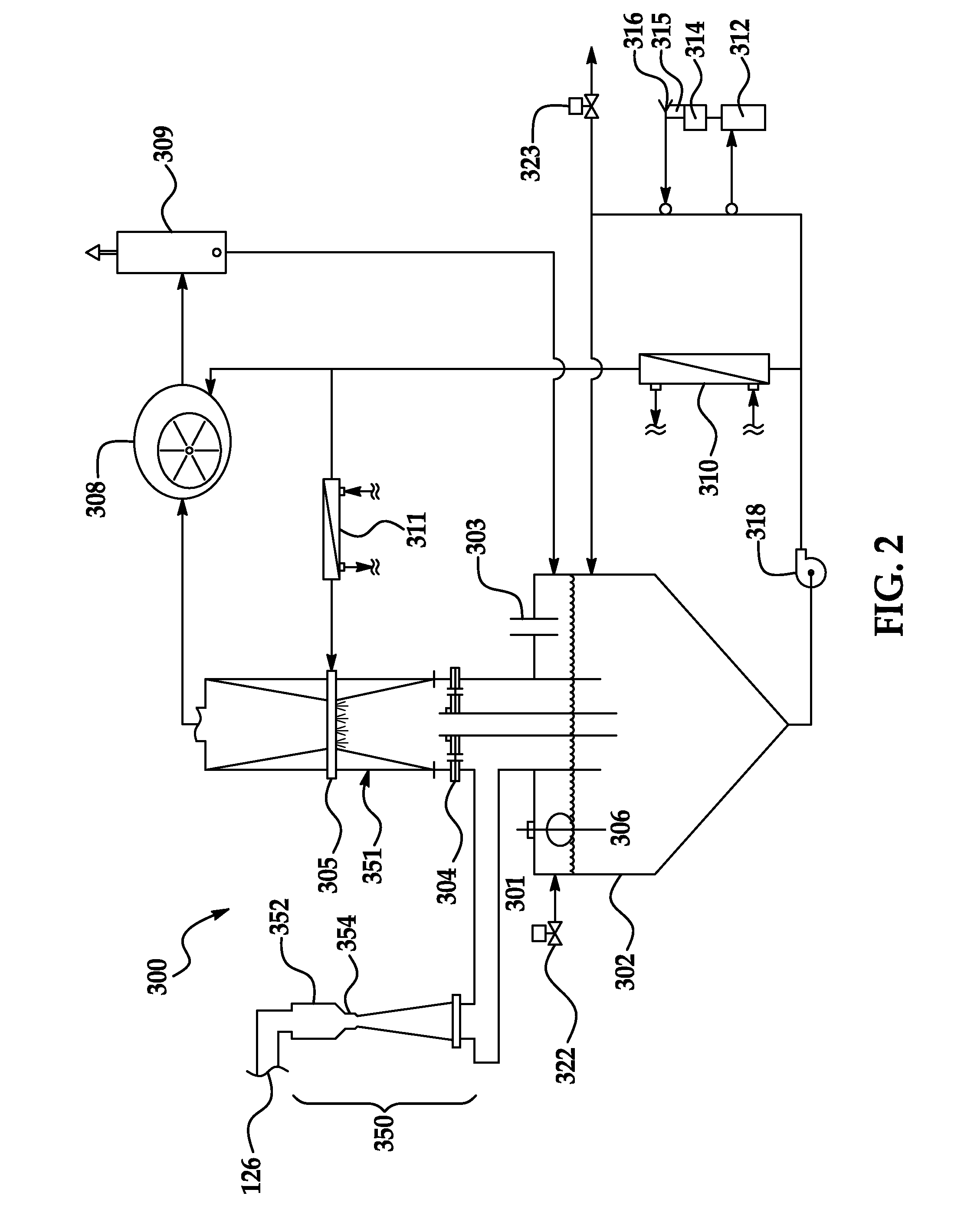

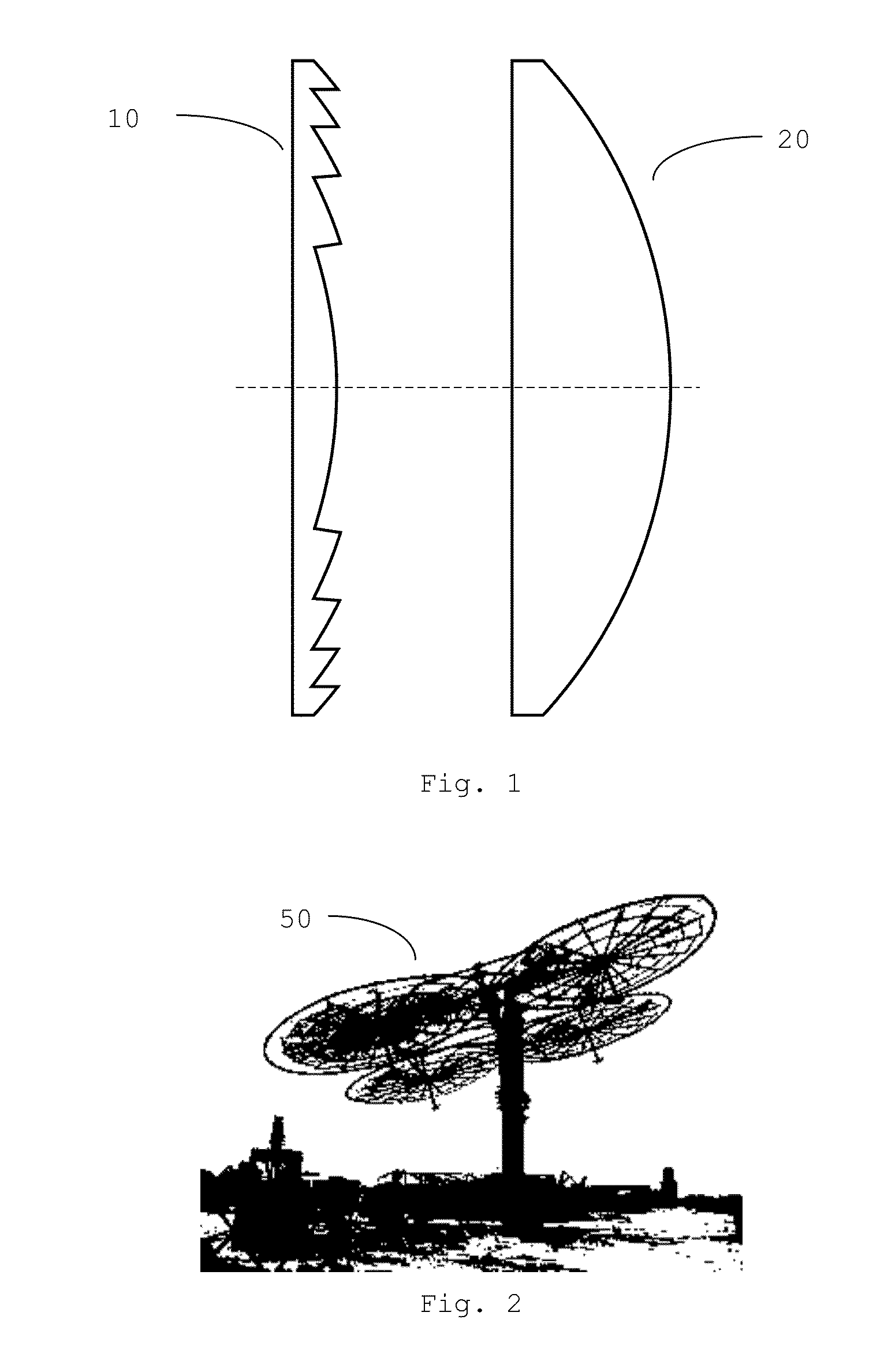

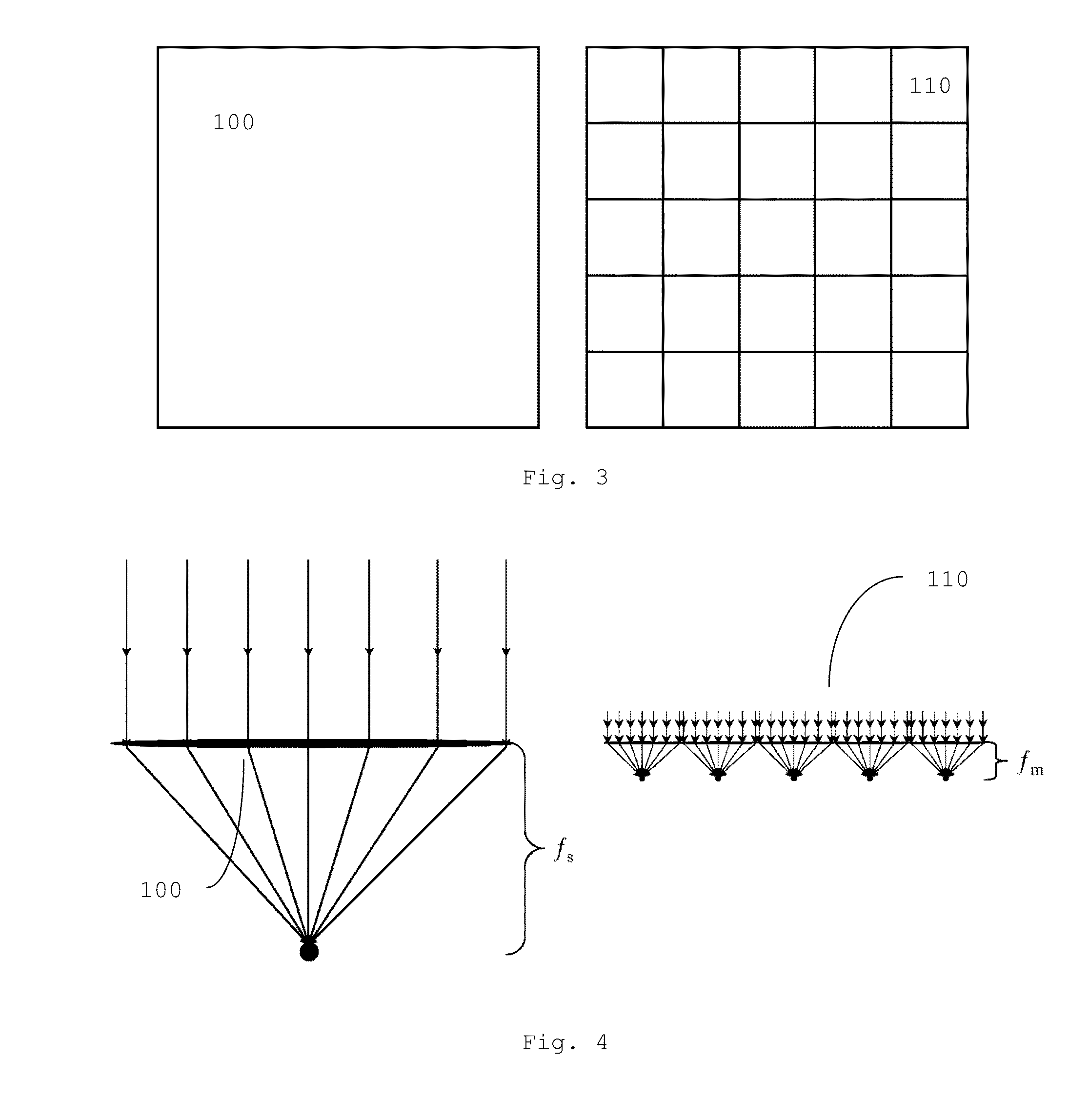

Method and apparatus for electricity production by means of solar thermal transformation

ActiveUS20130255256A1Short focal lengthMounting is very lowSolar heating energyFrom solar energyAbove groundEnergy absorption

We present an improved system for solar energy collection and electricity generation, comprising a solar collector apparatus, said apparatus comprising an array of square Fresnel lenses arranged in rows with modular energy absorption devices located below, wherein the array is mounted on arms at a low height above ground, the rows of said array are rotatable horizontally about their lengthwise axis, and the array is mounted on a rotatable baseThe system further comprises transportable insulated storage tanks containing a storage medium, Stirling engines and generators. The solar collection apparatus heats the storage medium, the storage medium supplies the Stirling engines with heat, and each engine is coupled to a generator.In a preferred embodiment, the system additionally comprises embedded controllers using real-time algorithms providing smart on-the-fly management of the system.

Owner:LOGOTHETIS GEORGIOS

Methods for preparing biodegradable body temperature induction material and degradable body temperature induction memory bioscaffold for 4D printing

PendingCN110527075ARegularityQuick shape replyAdditive manufacturing apparatusSurgeryVitrificationZero temperature

Owner:LINYI UNIVERSITY

Preparation of flame-retardant polyester for preparing fiber

ActiveCN101376689AReduce negative impactSmall mechanical propertiesFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberPolymer science

A method for preparing flame-retardant polyester for manufacturing fiber comprises the following steps: 1) carrying out the esterification of monomer terephthalic acid, ethylene glycol and a reactive flame retardant having a structural formula I, wherein R in the structural formula I is hydroxyalkyl or carboxyalkyl of C1 to C4; and 2) sequentially carrying out the pre-polymerization reaction and the polycondensation reaction in the presence of a polycondensation catalyst to obtain the polycondensation product, that is, the flame-retardant polyester. Nano kaolin particles which serve as a flame-retardant polyester crystallization nucleating agent are added to the reaction system, wherein the nano kaolin particles are added before the esterification or before the pre-polymerization reaction, and the adding amount by the content of the nano kaolin particles existing in the polycondensation products at the end is 0.06 wt% to 1.0 wt%. The deviation of the thermal transformation performance existing between the conventional polyester and the prepared flame-retardant polyester is obviously reduced, so that the conventional polyester fiber manufacturing equipment and the manufacturing process thereof can be adopted to reliably manufacture the flame-retardant fiber.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

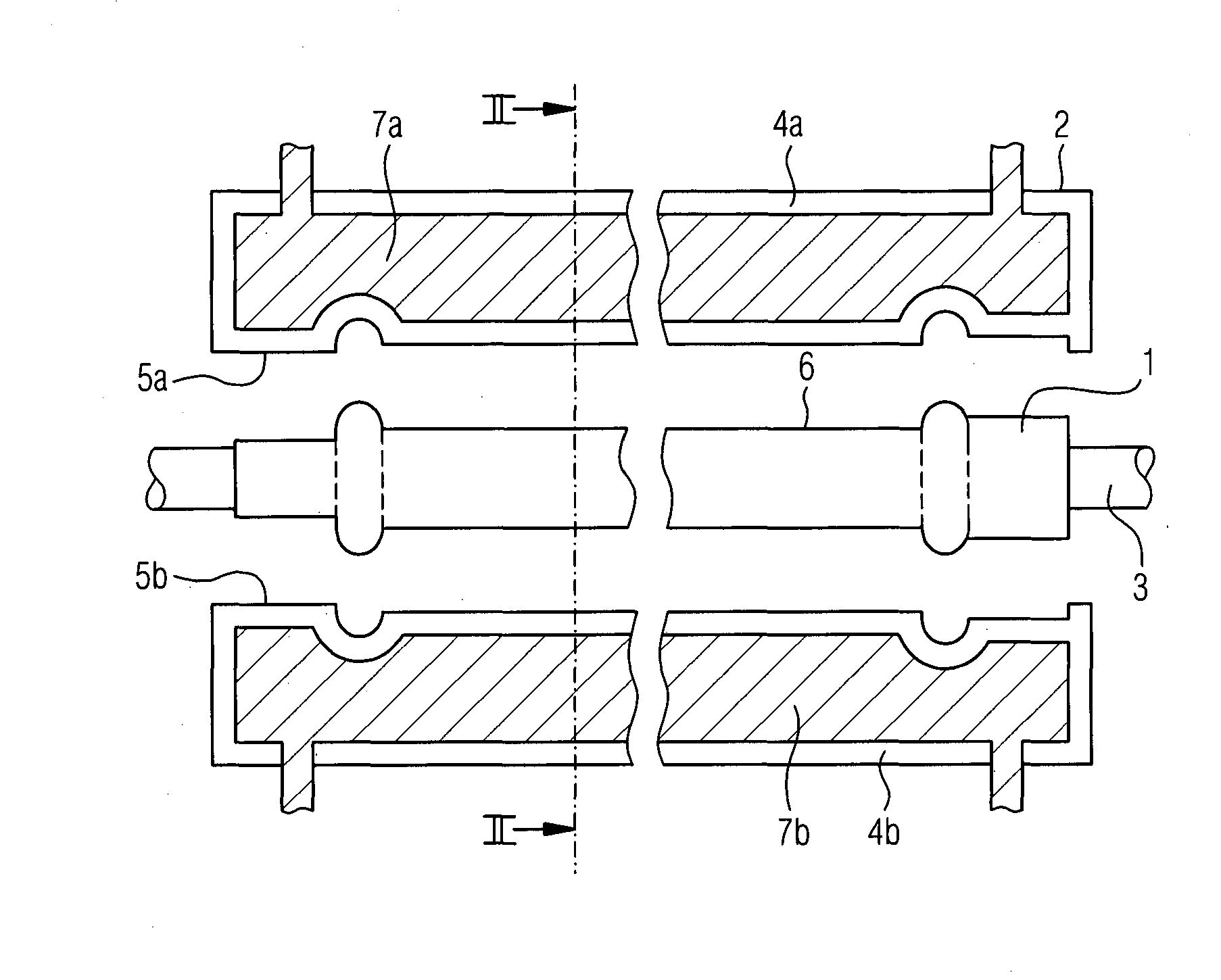

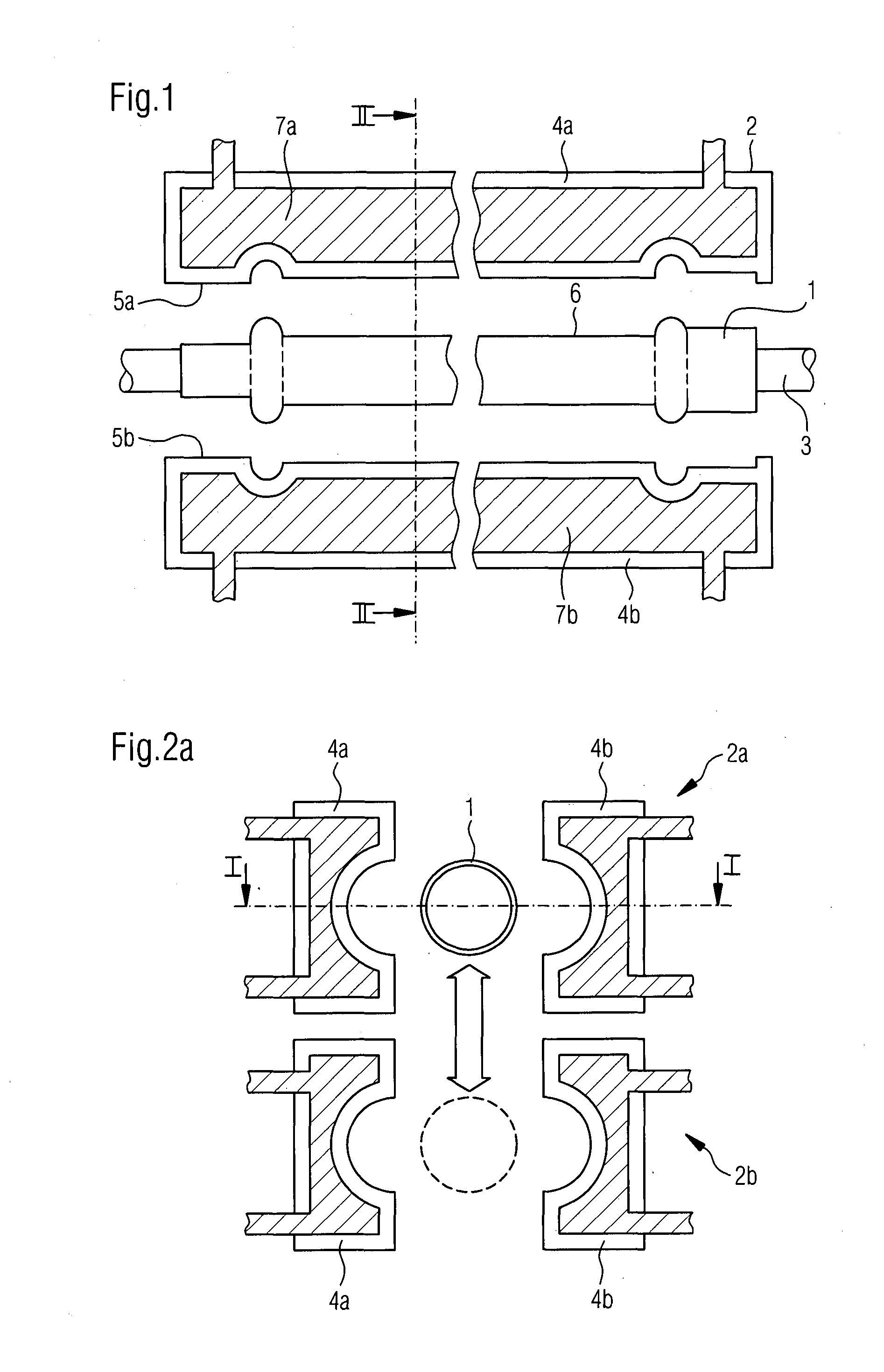

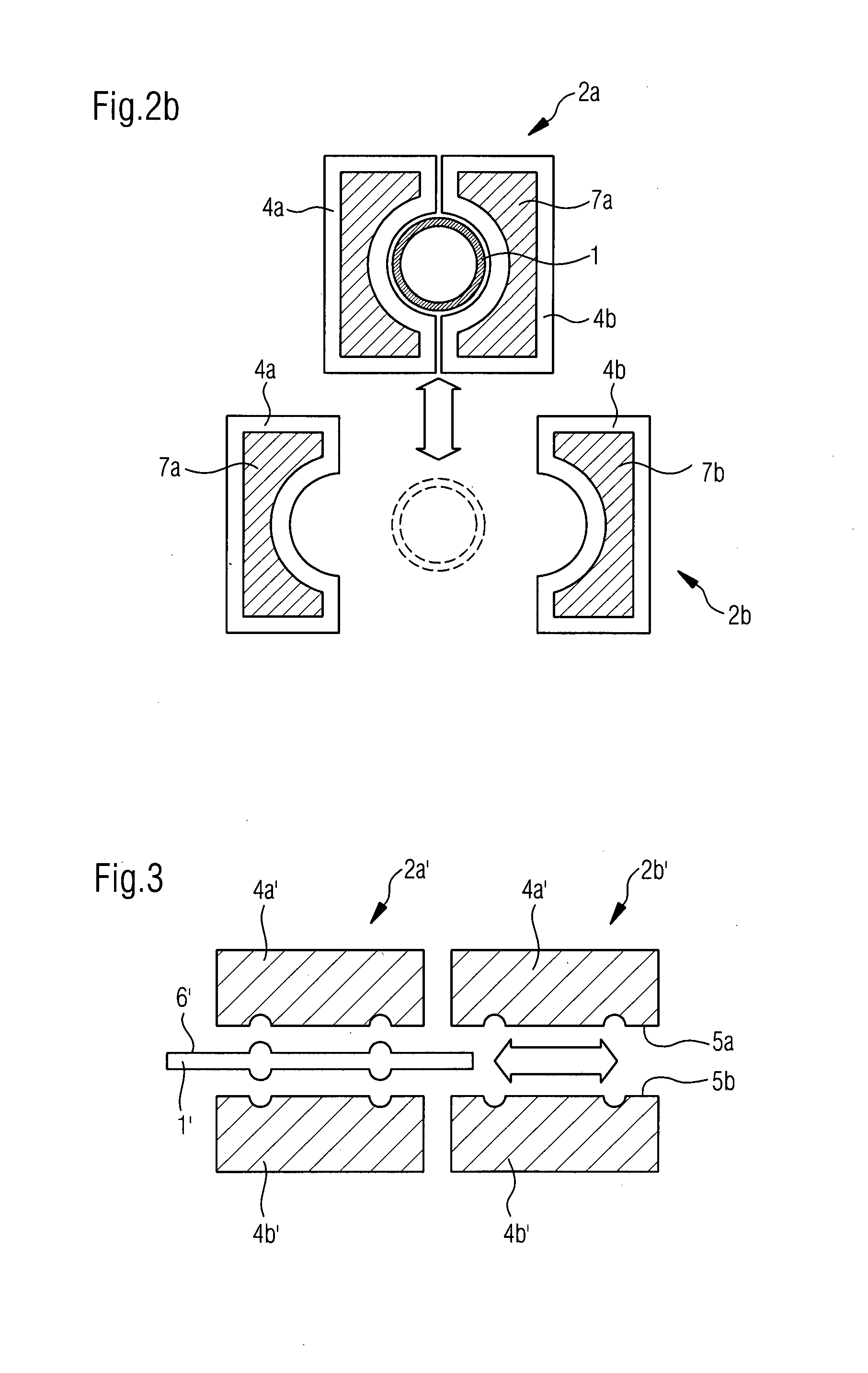

Device and method for cycle- and cost-optimized thermal transformation of hose blanks

ActiveUS20170043507A1Improve thermal conductivitySimple and cost-effectiveHollow wall articlesDomestic articlesEngineeringPerfusion

The invention relates to a device and a method for the thermal reshaping of hose blanks from preferably pre-extruded elastic raw hose material, wherein during the reshaping the hose blank is arranged in a shell-like, single- or multi-piece molding tool with a hollow body, wherein the inner side of the hollow body corresponds as a negative to the shape to be impressed onto the hose blank, wherein the tempering of the molding tool that is necessary for reshaping occurs by means of clamp-like tempering elements which are shaped congruently to the outer surface of the mold and which close form-fittingly over the mold, while the molding tool itself does not comprise any tempering system at all, in particular no ducts or other hollow spaces for circulating a tempering medium, and wherein the temperature of each tempering element is kept constant during the process, while, to modify the temperature of the molding tool, a different tempering element with a correspondingly constant temperature is positioned against the molding tool; in the claimed device, the molding tool is free of internal ducts and other hollow spaces for the circulation of a tempering medium, while half or partial shells, which are separate from the mold and which close form-fittingly over the mold, are provided to temper the molding tool, wherein the inner sides of said shells which face the molding tool are congruent with the outer side of said molding tool and wherein the shells comprise an arrangement for keeping the temperature of each tempering element constant during the process, in particular internal hollow spaces for the perfusion of a tempering medium, and wherein at least one mechanism is provided for selectively closing different tempering elements at different temperatures around the molding tool.

Owner:CREATIVE BALLOONS GMBH

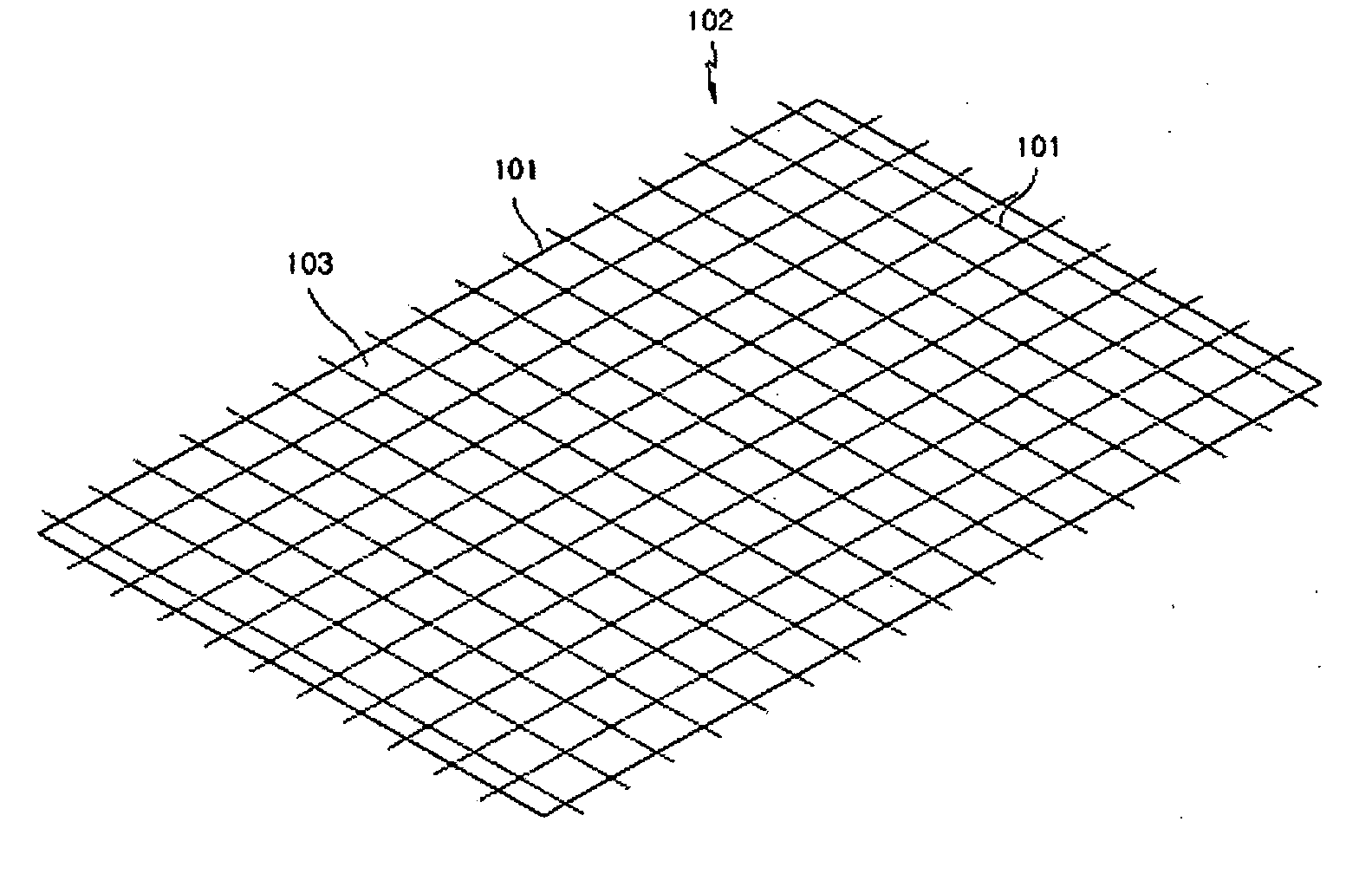

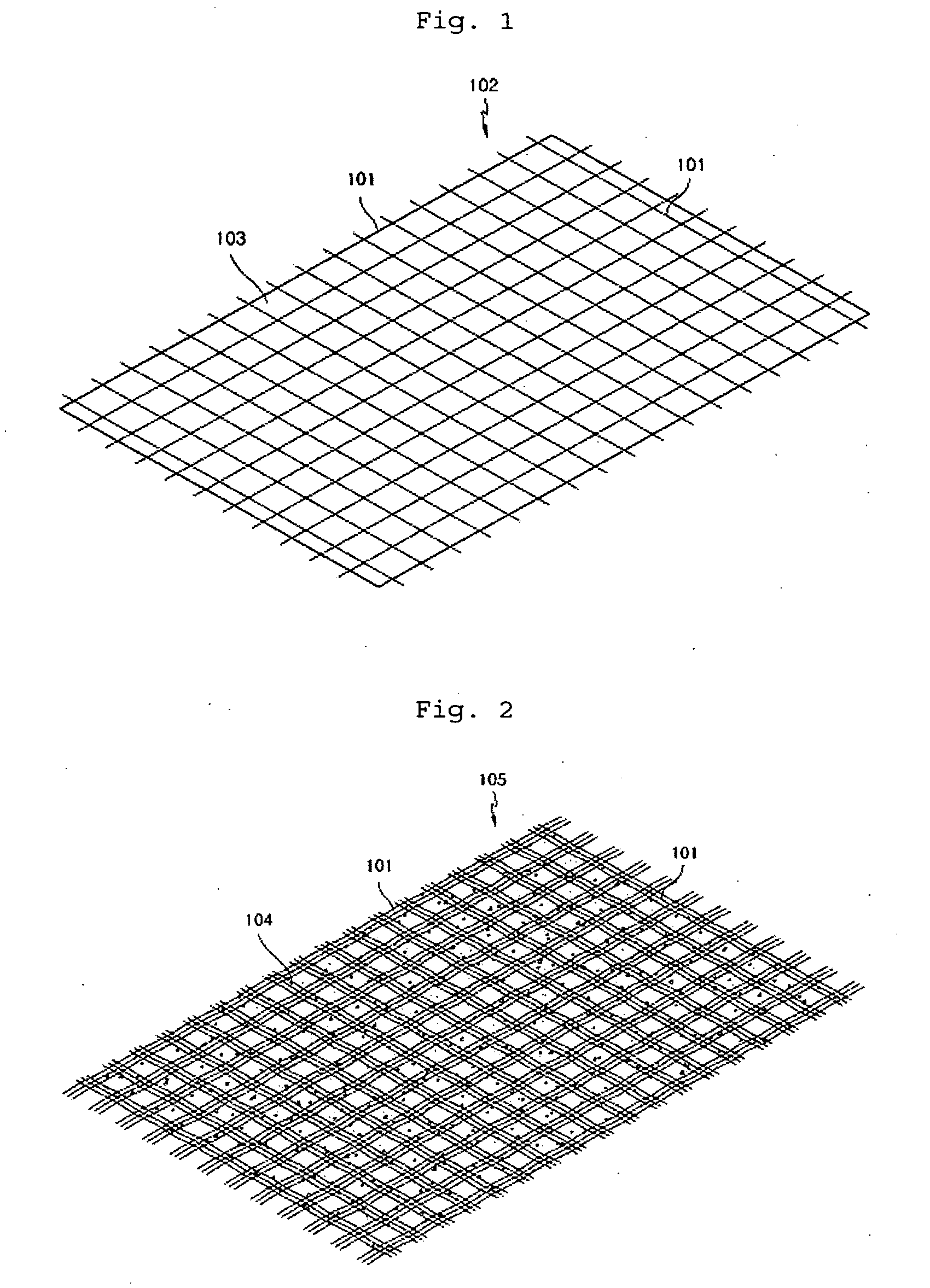

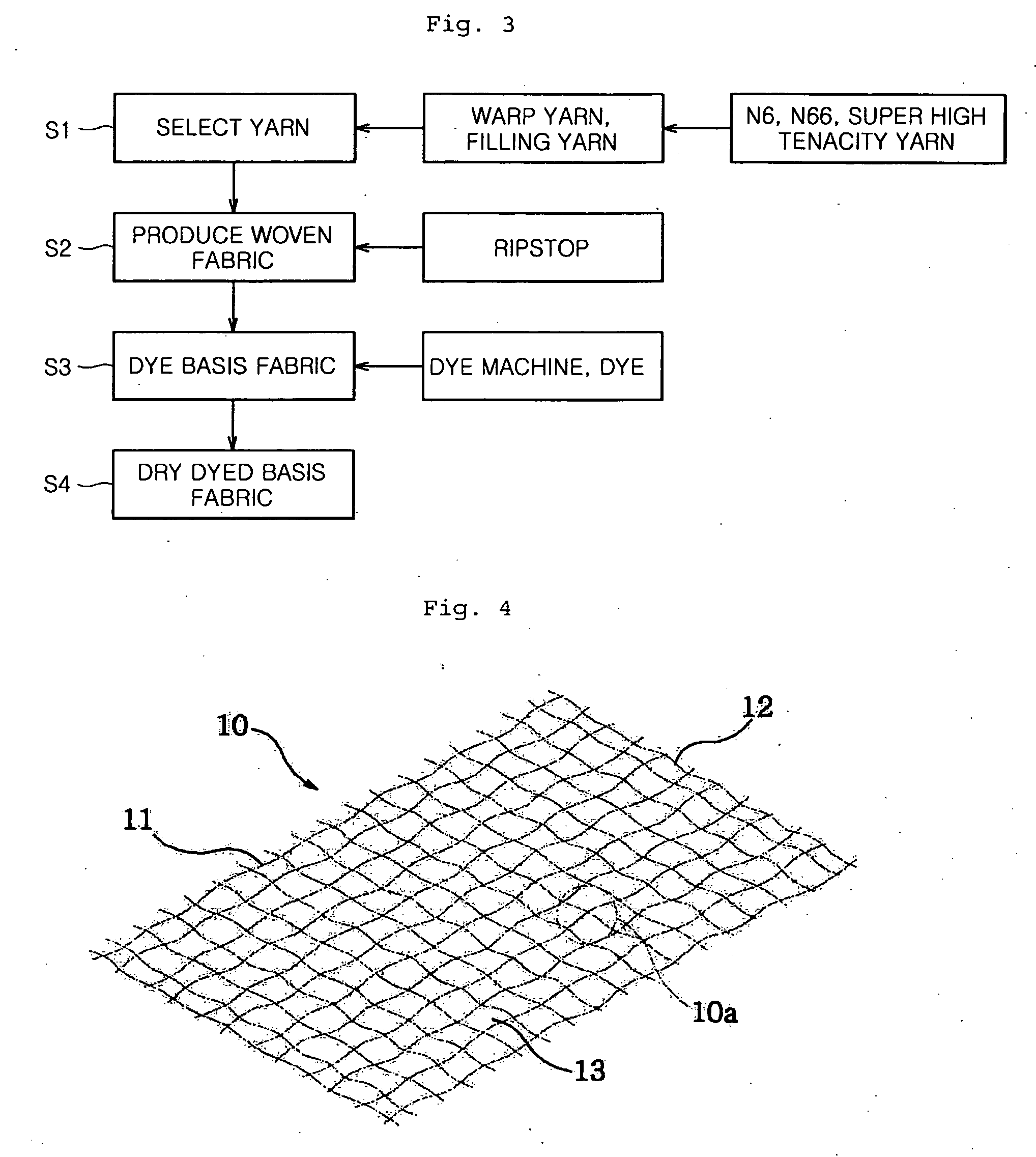

Method for manufacturing three-dimensional fabric and three dimensional fabric using the same

InactiveUS20060032003A1Easy workabilityImprove productivityLiquid/gas/vapor open-width material treatmentPattern makingYarnRoom temperature

A method for manufacturing a three-dimensional fabric and a three-dimensional fabric using the same is provided. The method includes the steps of: selecting at least more than one yarn among nylon6, nylon66 and a super high tenacity yarn to be used as a warp yarn and a filling yarn; weaving the selected warp and filling yarns to produce a basis fabric with ripstops; inserting the basis fabric into a dyer and dyeing the basis fabric by providing a predetermined concentration of a dye at a predetermined temperature for a predetermined period, so that a special pattern and a color are expressed on the basis fabric because of a difference in density, material characteristics and thermal transformation temperatures between the warp yarn and the filling yarn; and drying the dyed basis fabric for a predetermined period at room temperature to make the ripstops, the pattern and the color clear without deformation.

Owner:KIM MUN SU

Flame-retardant polyester composition for preparing industrial polyester fibre

ActiveCN101376738AReduce negative impactSmall mechanical propertiesFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberPentaerythritol

The invention relates to a flame-retardant polyester compound used for manufacturing industrial polyester fiber which includes the components as follows: a) the polyester of a reaction type flame-retardant which comprises a structural formula as I is formed by the copolycondensation of terephthalic acid, glycol, pentaerythritol and the flame-retardant. In the formula I, R1 refers to the alkylidene groups of C1 to C4; R2 and R3 respectively refer to the hydroxyalkyl of C2 to C4 or the car boxyalkyl of C2 to C4. The content of the pentaerythritol in the polyester is 0.01 to 0.10wt percent; the content of the flame-retardant in the polyester is 2 to 10wt percent; the characteristic viscidity of the polyester is 0.60 to 0.75 dl / g; b) a nucleating agent which relates to the grain of Nano-Kaolin with an average grain diameter of 200 to 600nm. The nucleating agent is uniformly stored in the polyester compound and the content of the nucleating agent is 0.06 to 1.0wt percent. The departure on the thermal transformation performance existed between the flame-retardant polyester compound and the normal polyester is remarkably reduced; the manufacturing industrial polyester fiber can be produced by adopting the normal polyester fiber manufacture device and technique.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com