Flame-retardant polyester composition for preparing industrial polyester fibre

A technology of flame-retardant polyester and polyester fiber, which is applied in the manufacture of fire-retardant and flame-retardant filaments, single-component polyester rayon, etc., can solve the problems of reducing the difficulty of fiber manufacturing and processing, reducing production costs, and breaking ends. The effect of reducing the mechanical properties of fibers to improve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0024] A flame-retardant polyester composition for producing industrial polyester fibers, the components of which include:

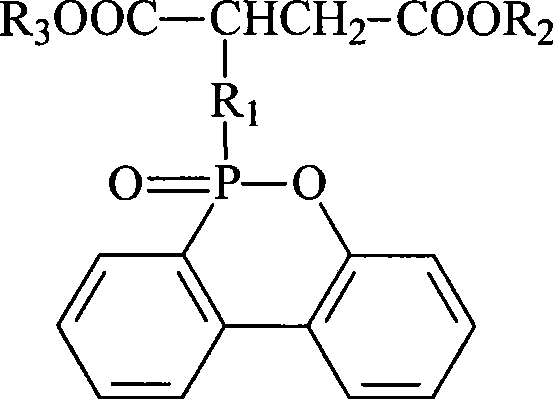

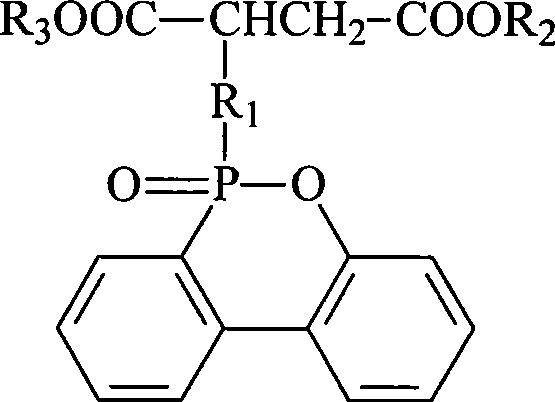

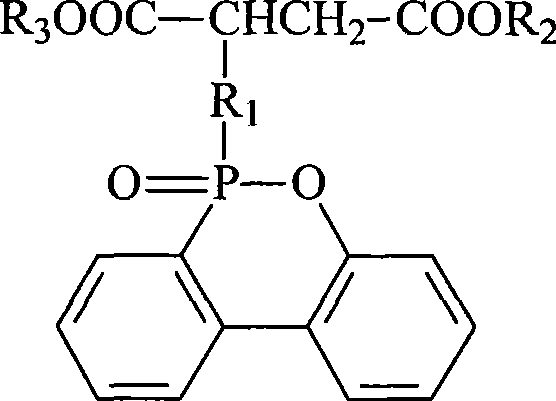

[0025] a) Polyester containing reactive flame retardant, which is formed by polycondensation of terephthalic acid, ethylene glycol, pentaerythritol and flame retardant. Flame retardants are compounds with the following structural formula:

[0026]

[0027] Among them, R 1 is methylene, R 2 , R 3 is hydroxyethyl;

[0028] The content of pentaerythritol in the polyester is controlled to be 0.05-0.10wt%, the intrinsic viscosity of the polyester is controlled to be 0.60-0.70dl / g, and the content of the flame retardant in the polyester is shown in Table 1;

[0029] b) The nucleating agent is nano kaolin particles with an average particle size of 200-500nm. The nucleating agent is uniformly present in the polyester composition. The content of the nucleating agent in the polyester composition is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com