Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

A pressure swing adsorption and gas separation technology, which is applied in the purification of combustible gas, the purification of solid gas with absorbing power, adsorption purification/separation, etc. It can solve the problem of difficult matching between adsorption and regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

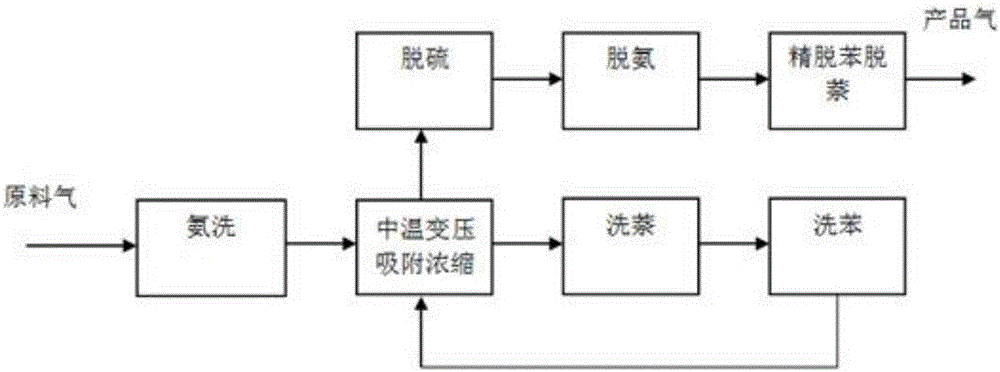

[0076] like figure 1 As shown, a full-temperature PSA gas separation, purification and purification method is applied to the purification of coke oven gas for debenzene and naphthalene removal, and the following operations are performed in sequence:

[0077] (1) Pretreatment process, ammonia washing, the coke oven gas output from the coke oven with a temperature of 650~800°C, the temperature after ammonia washing is 60~120°C, the pressure is 0.3-2.8MPa, the coke oven gas 70~75% of the coal tar and part of benzene are condensed, and the tar is about 80~120g / m 3 Reduced to about 35~40g / m 3 , Benzene from 30~45g / m 3 Reduced to 3~3.5g / m 3 Below, naphthalene ranges from 8 to 12g / m 3 down to 0.8g / m 3 the following.

[0078] (2) Medium-temperature pressure swing adsorption concentration process: coke oven gas washed with ammonia enters the pressure swing adsorption system for adsorption, 8 adsorption towers are connected in series, alternately cycled, the operating temperature ...

Embodiment 2

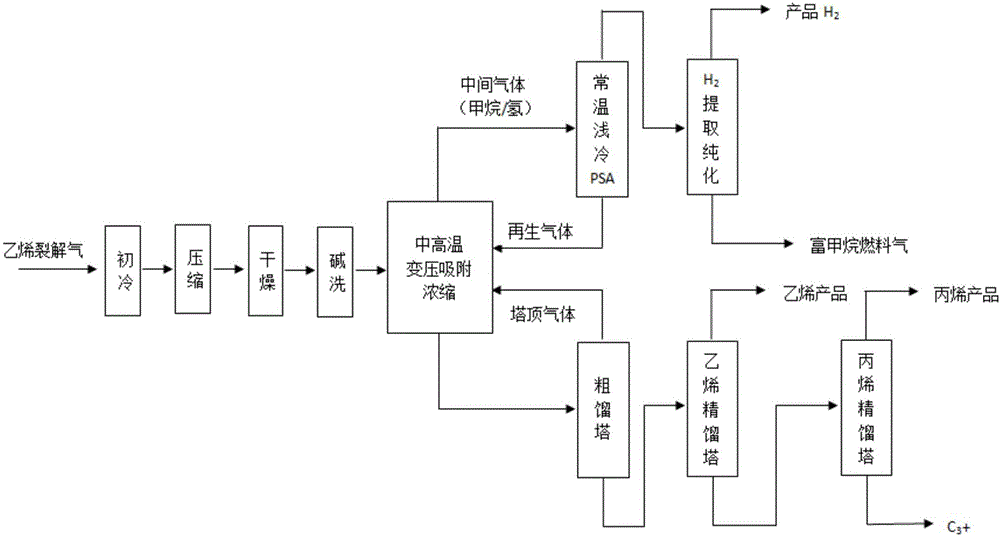

[0089] like figure 2 As shown, a full-temperature PSA gas separation, purification and purification method is applied to the separation and purification of ethylene cracking gas, and the following operations are performed in sequence:

[0090] (1) Pretreatment process: perform initial cooling, compression, drying, and alkali washing in sequence, lower the temperature to 80-200°C, adjust the pressure to 0.3-2.8MPa, and remove heavy oil and heavy hydrocarbons during the initial cooling process.

[0091] (2) Medium and high temperature pressure swing adsorption concentration process: the pretreated raw material gas enters the pressure swing adsorption system for pressure swing adsorption. The pressure swing adsorption system is composed of 10 adsorption towers connected in series. ~200℃, pressure 0.3-2.8MPa, to obtain intermediate gas and concentrated gas, the intermediate gas flows out from the top of the adsorption tower, the intermediate gas is mainly composed of non-polar an...

Embodiment 3

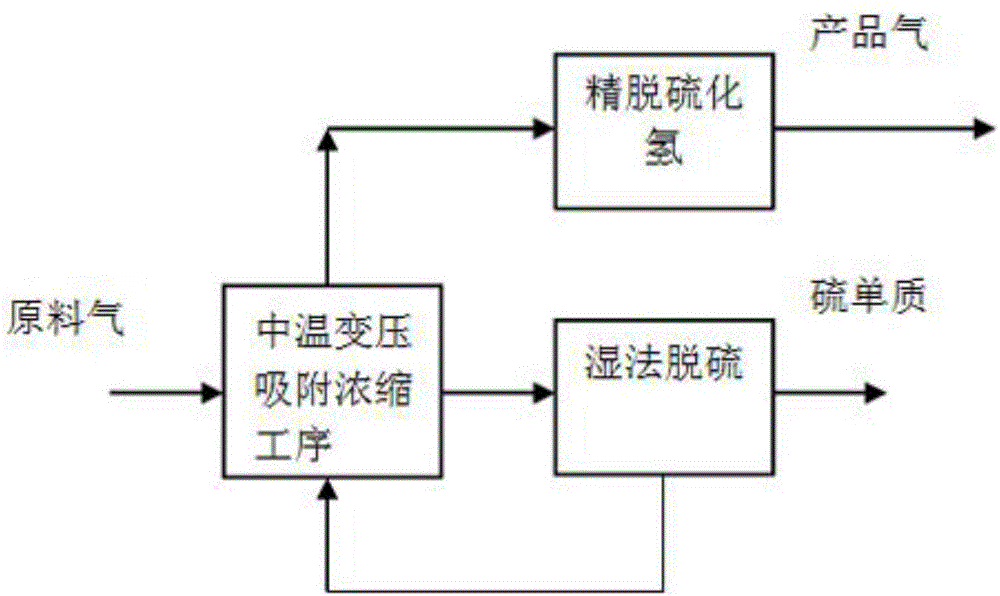

[0097] like image 3 As shown, a full-temperature PSA gas separation, purification and purification method is applied to the field of hydrogen-rich gas source removal of H2S, and the following operations are performed in sequence:

[0098] (1) Medium-temperature pressure swing adsorption concentration process: the hydrogen-rich gas with a flow rate of less than 1000-10,000 standard cubic meters per hour, a temperature of 50-150°C, and a H2S concentration of 4-10% is used as the raw material gas to enter the pressure swing adsorption system through the intake pipe Pressure swing adsorption is carried out in the medium, using 6 towers in series or parallel process, alternate cycle operation, operating temperature is 50~150 ℃, after the adsorption is completed, an intermediate gas containing a small amount of hydrogen sulfide is obtained, and after vacuum desorption, a concentrated gas rich in hydrogen sulfide is obtained.

[0099] (2) Intermediate gas treatment process: The inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com