Patents

Literature

713results about "Gaseous mixture working up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

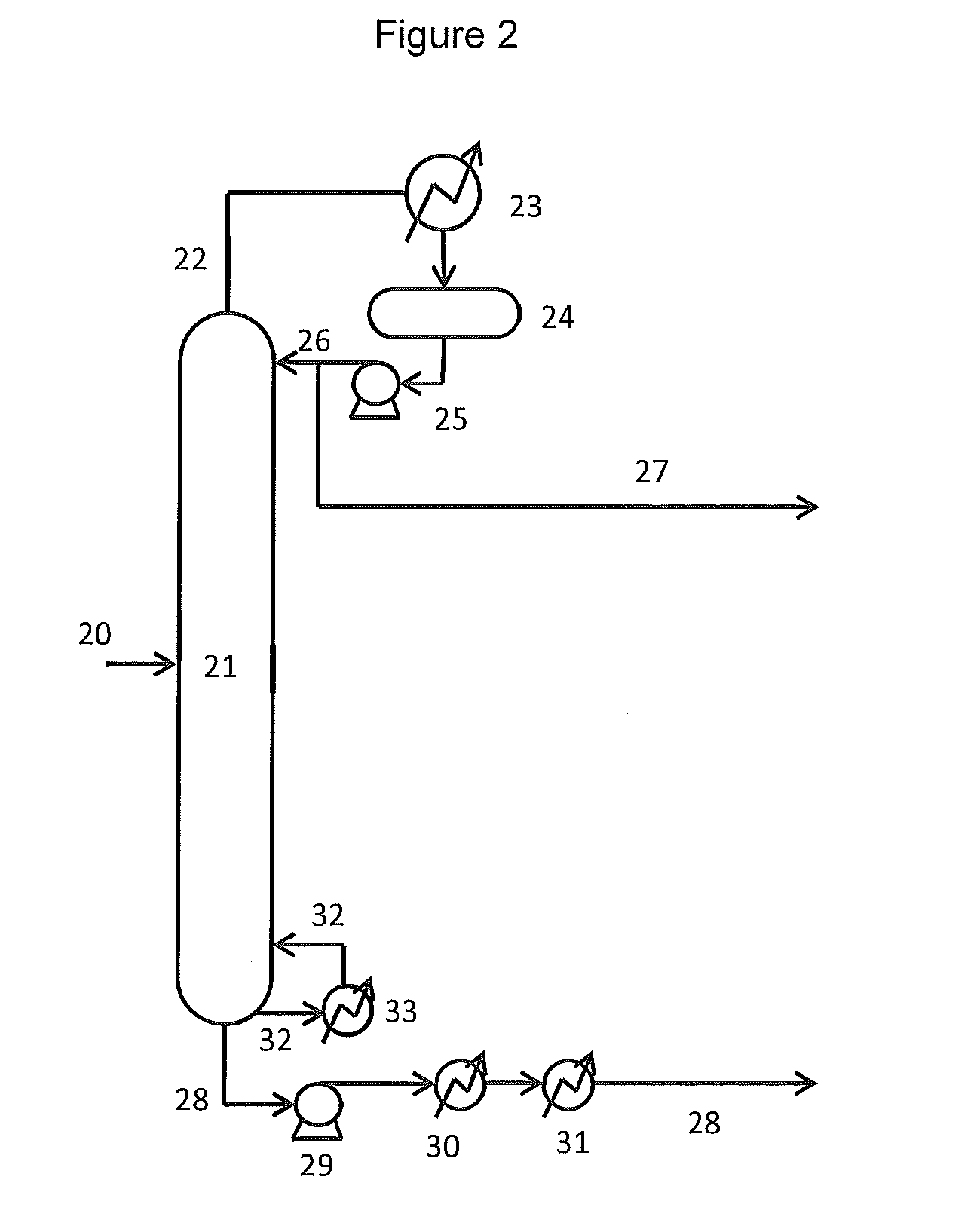

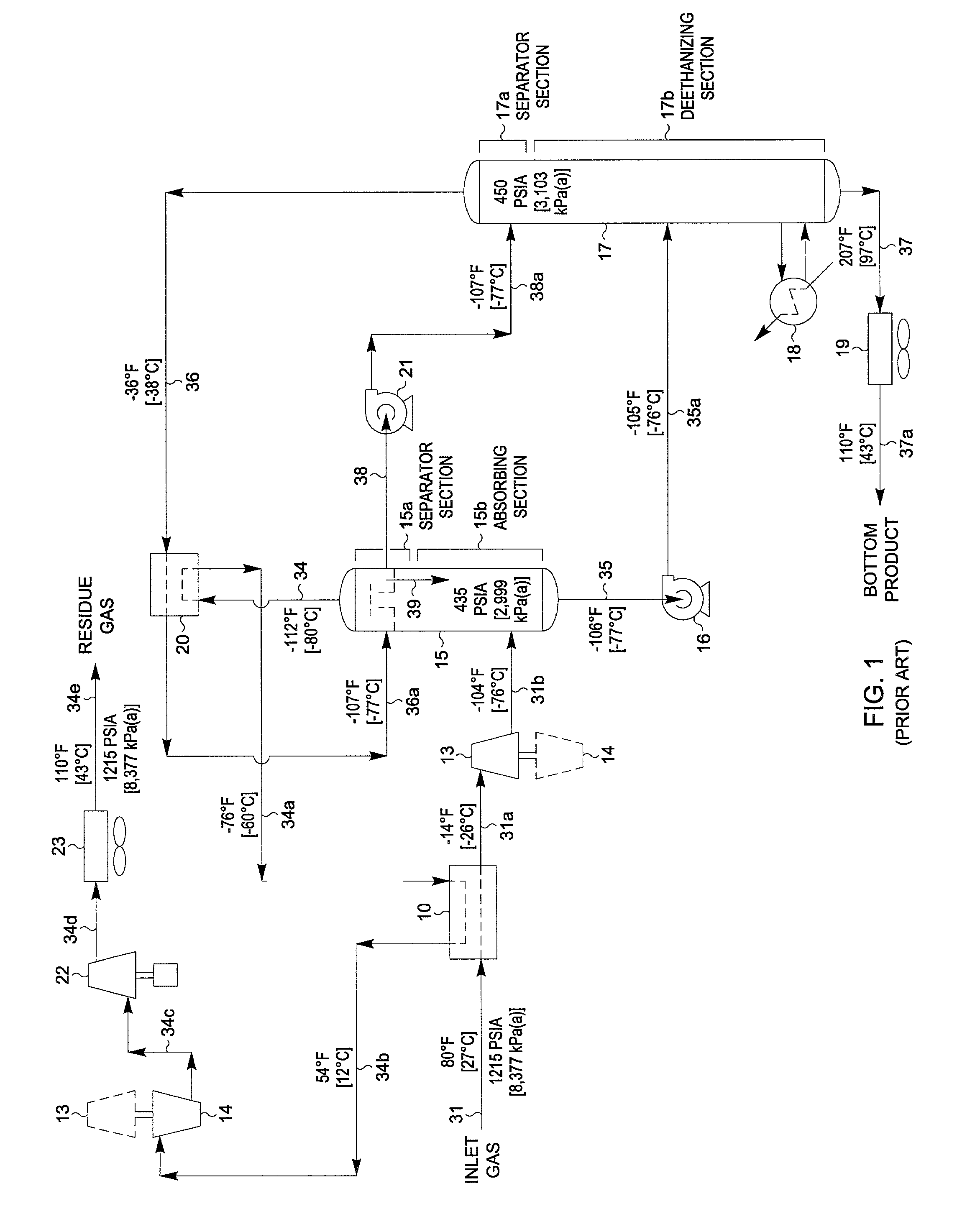

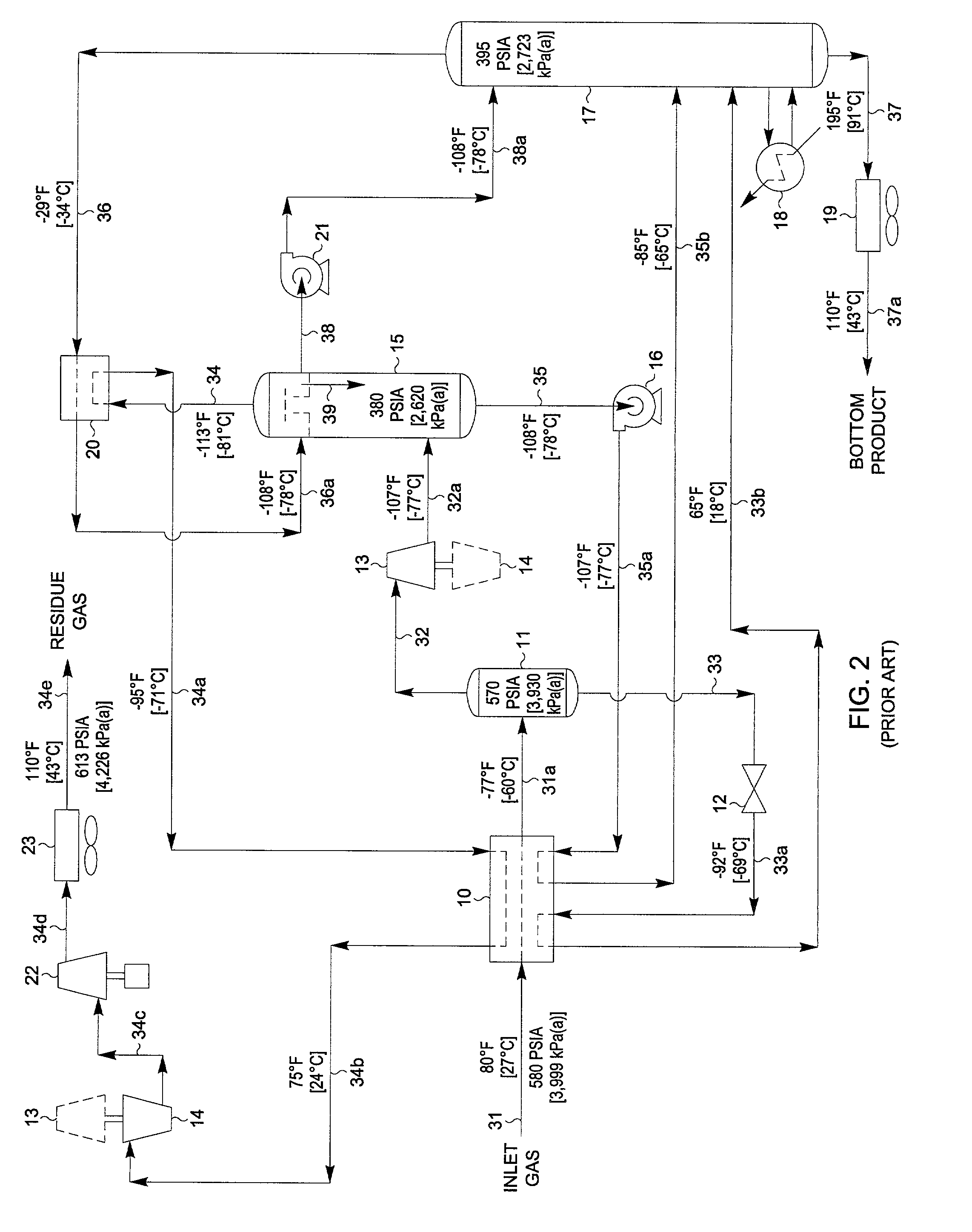

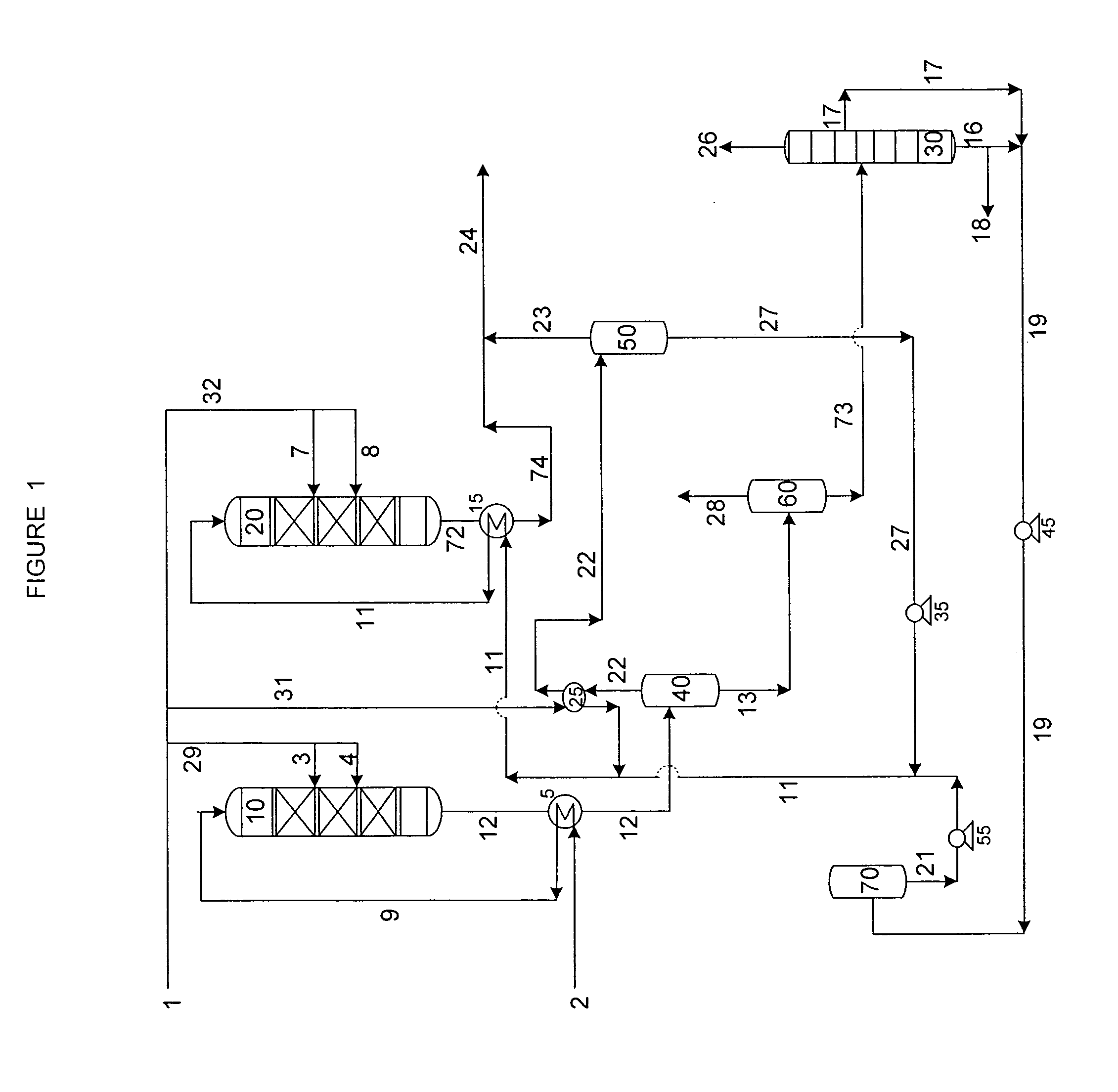

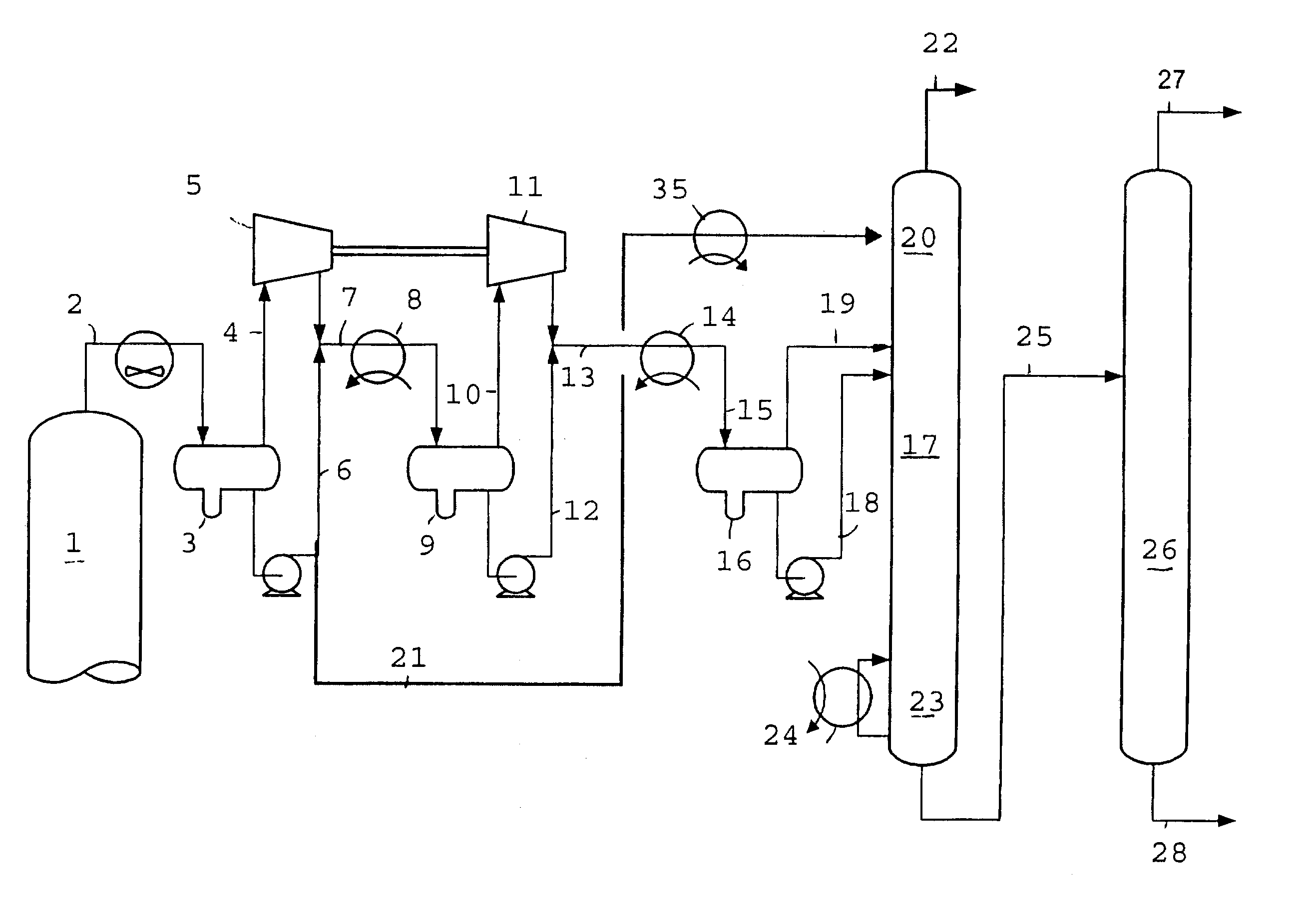

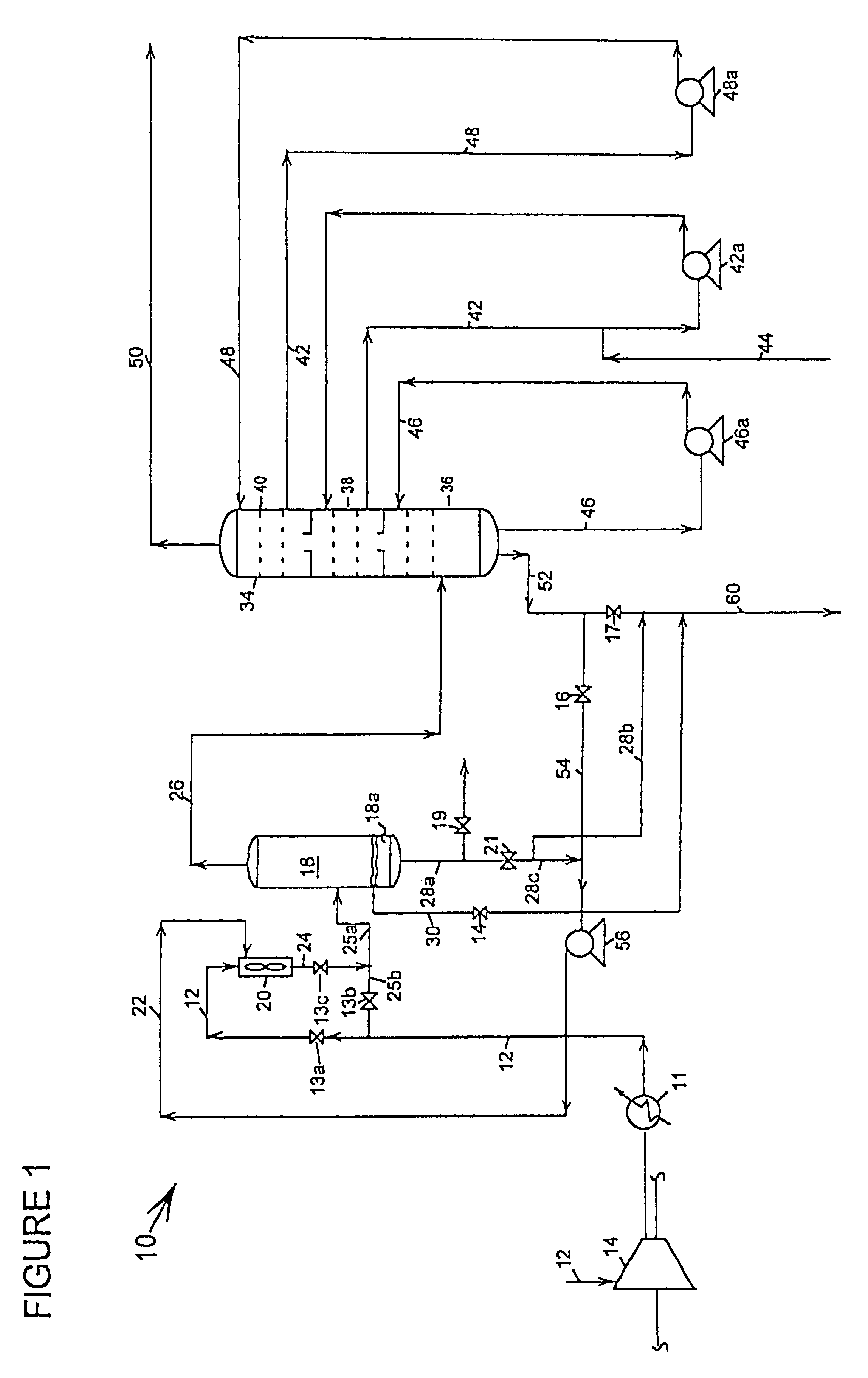

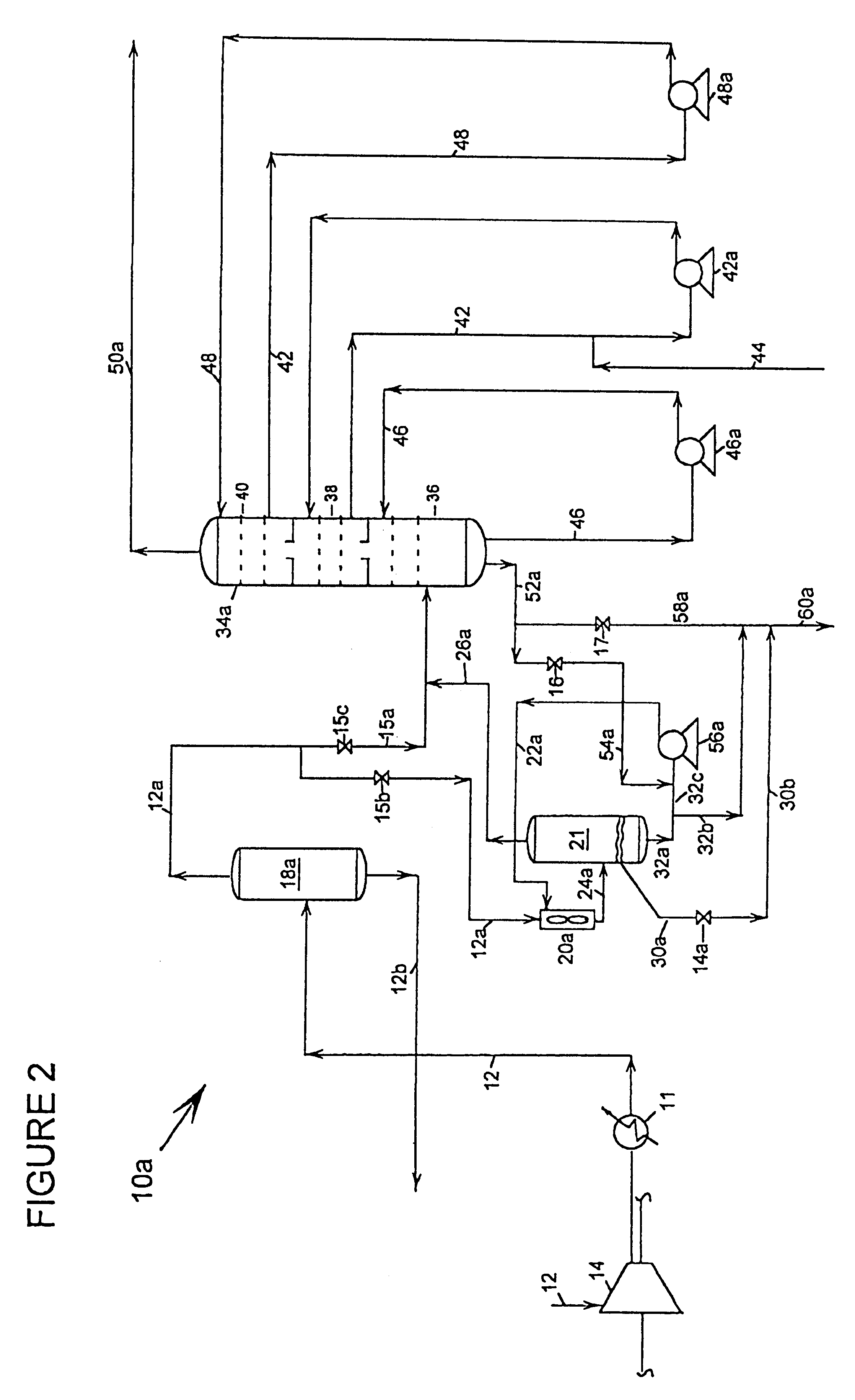

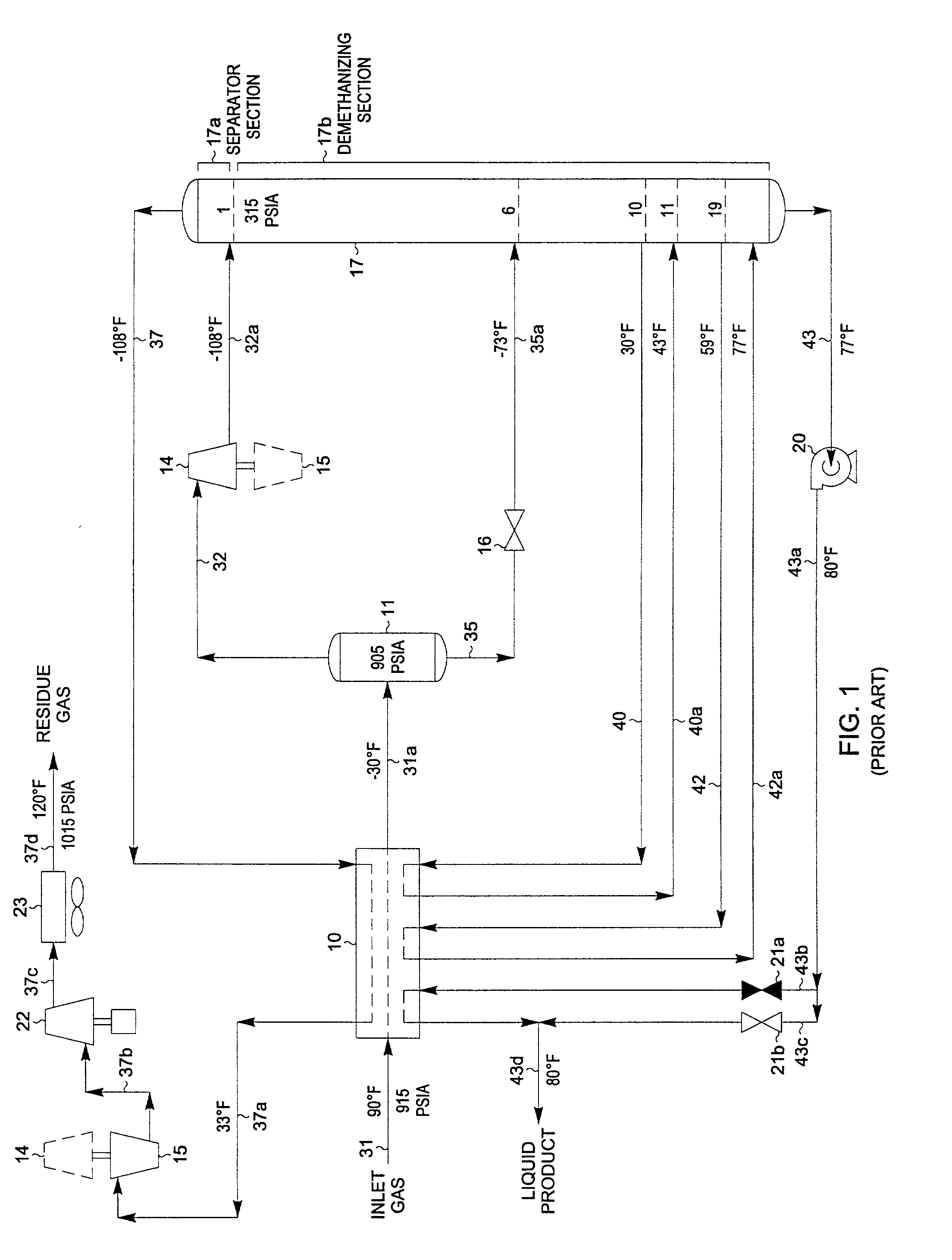

Hydrocarbon gas processing

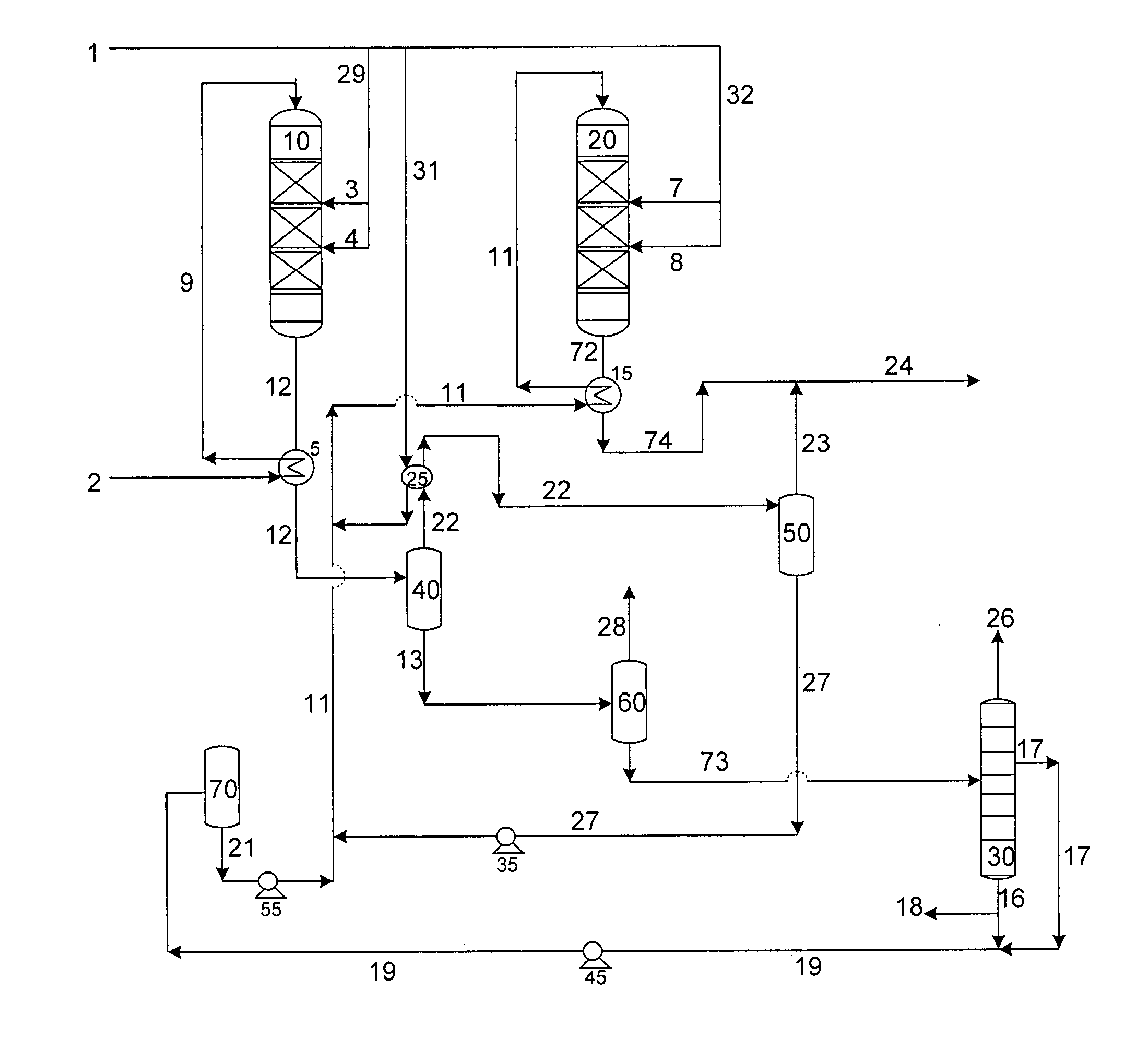

A process for the recovery of ethane, ethylene, propane, propylene and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. In recent years, the preferred method of separating a hydrocarbon gas stream generally includes supplying at least portions of the gas stream to a fractionation tower having at least one reboiler, and often one or more side reboilers, to supply heat to the column by withdrawing and heating some of the tower liquids to produce stripping vapors that separate the more volatile components from the desired components. The reboiler and side reboilers (if any) are typically integrated into the feed stream cooling scheme to provide at least a portion of the refrigeration needed to condense the desired components for subsequent fractionation in the distillation column. In the process disclosed, the tower reboiling scheme is modified to use one or more tower liquid distillation streams from a point higher in the column than is used in the conventional reboiling scheme, providing colder stream(s) for the reboiler(s) that allow more effective cooling of the feed streams and thereby improve the efficiency with which the desired components are recovered. In addition, the tower liquid streams withdrawn from a higher point in the column contain larger quantities of the more volatile components, which when vaporized provide better stripping of undesirable components like carbon dioxide without reducing the recovery of the desired components. The heated distillation stream is returned to a lower point on the fractionation tower that is separated from the withdrawal point by at least one theoretical stage.

Owner:UOP LLC

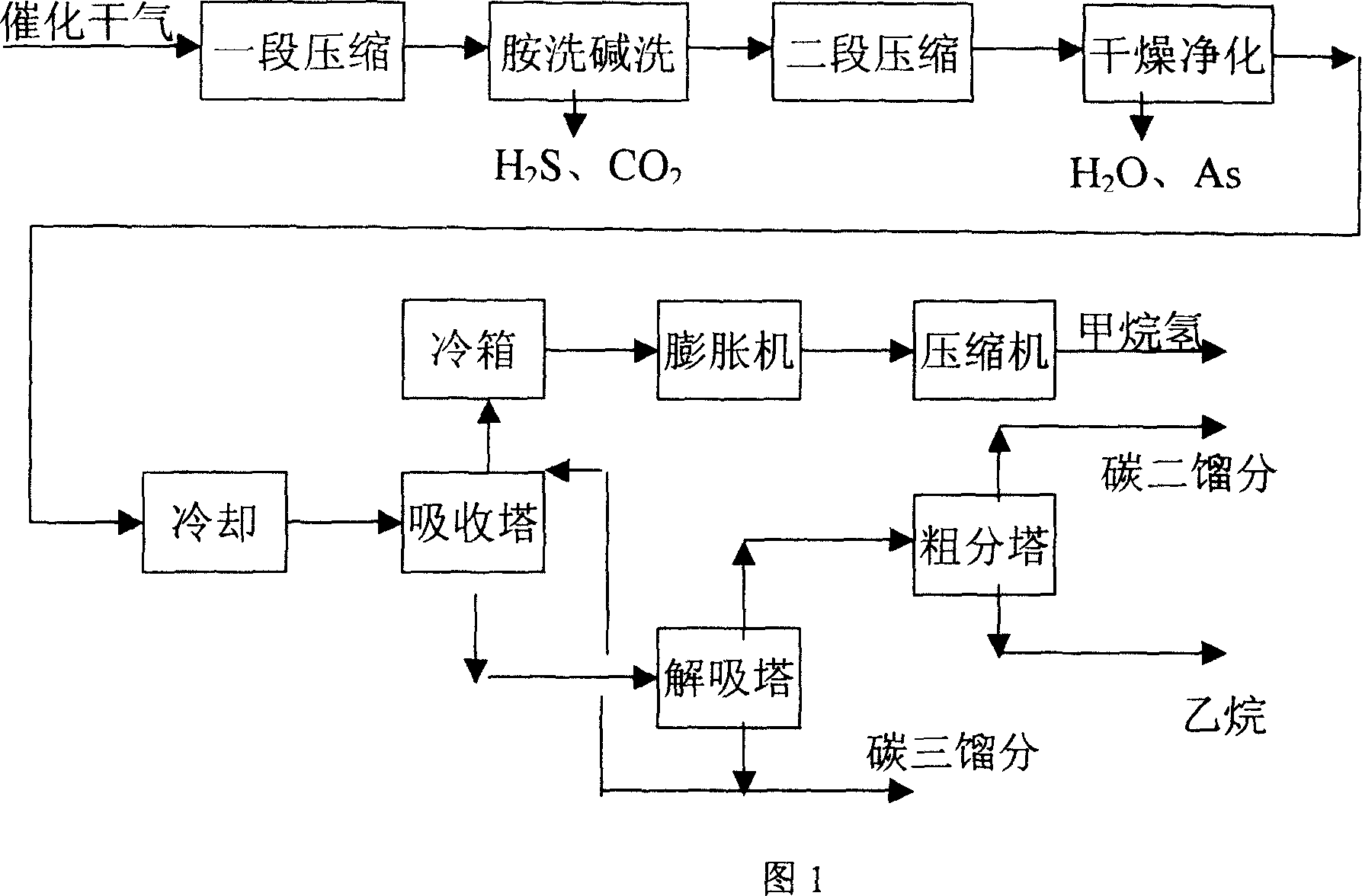

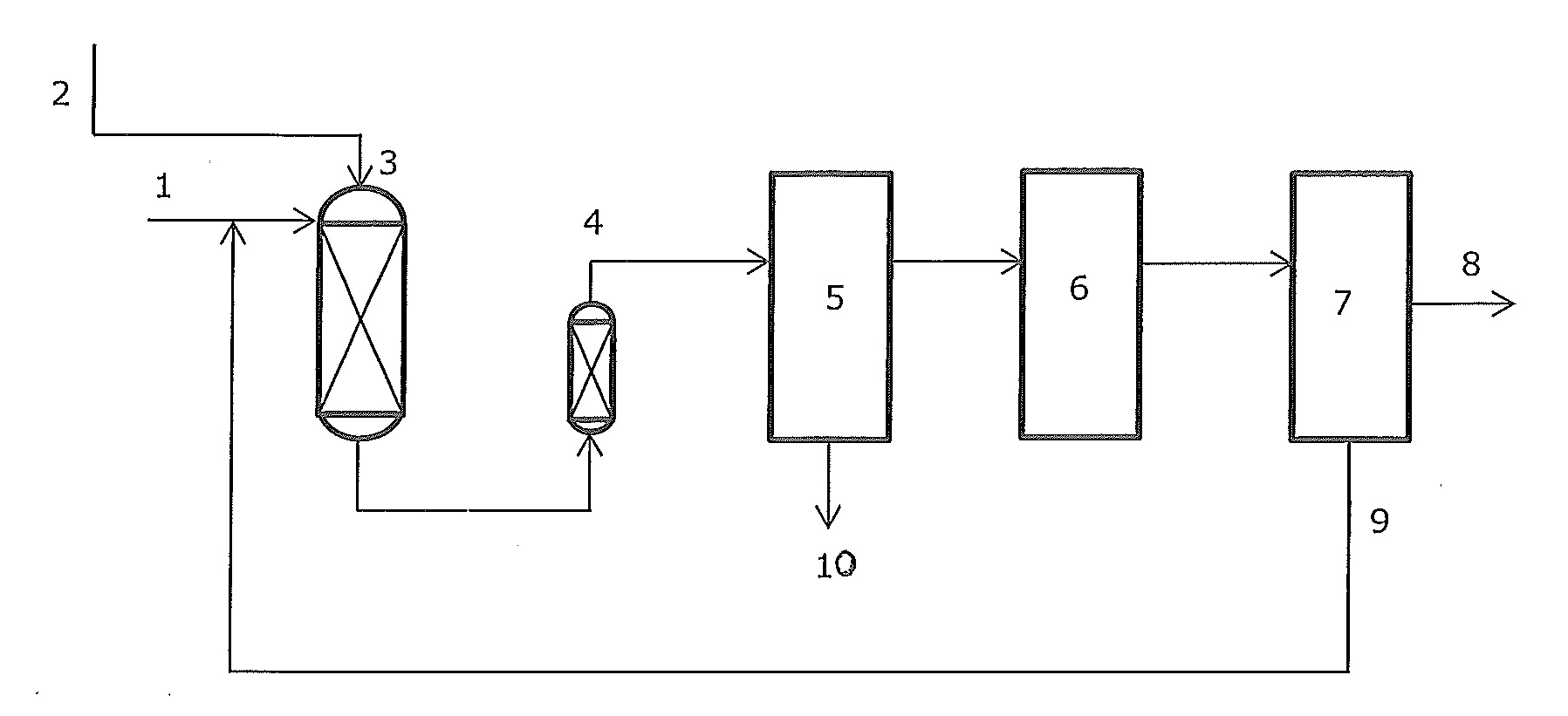

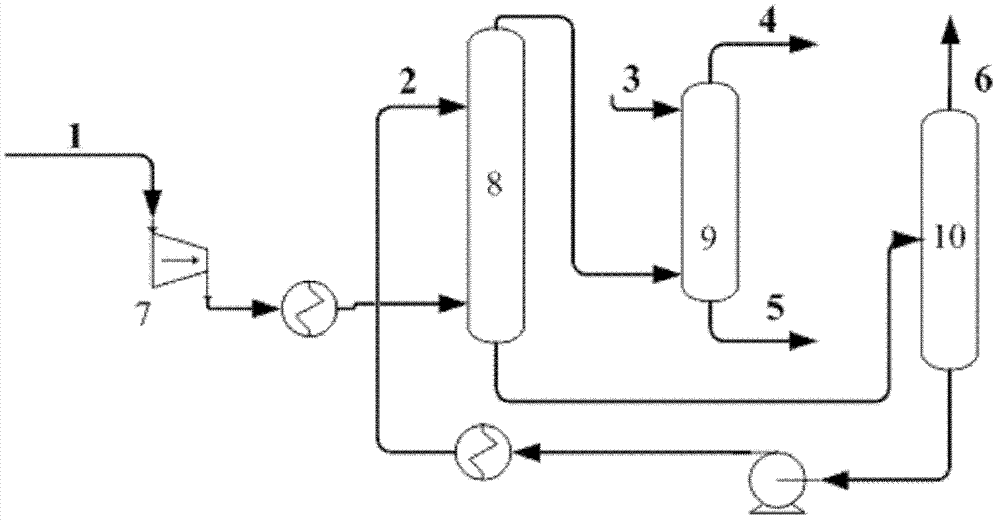

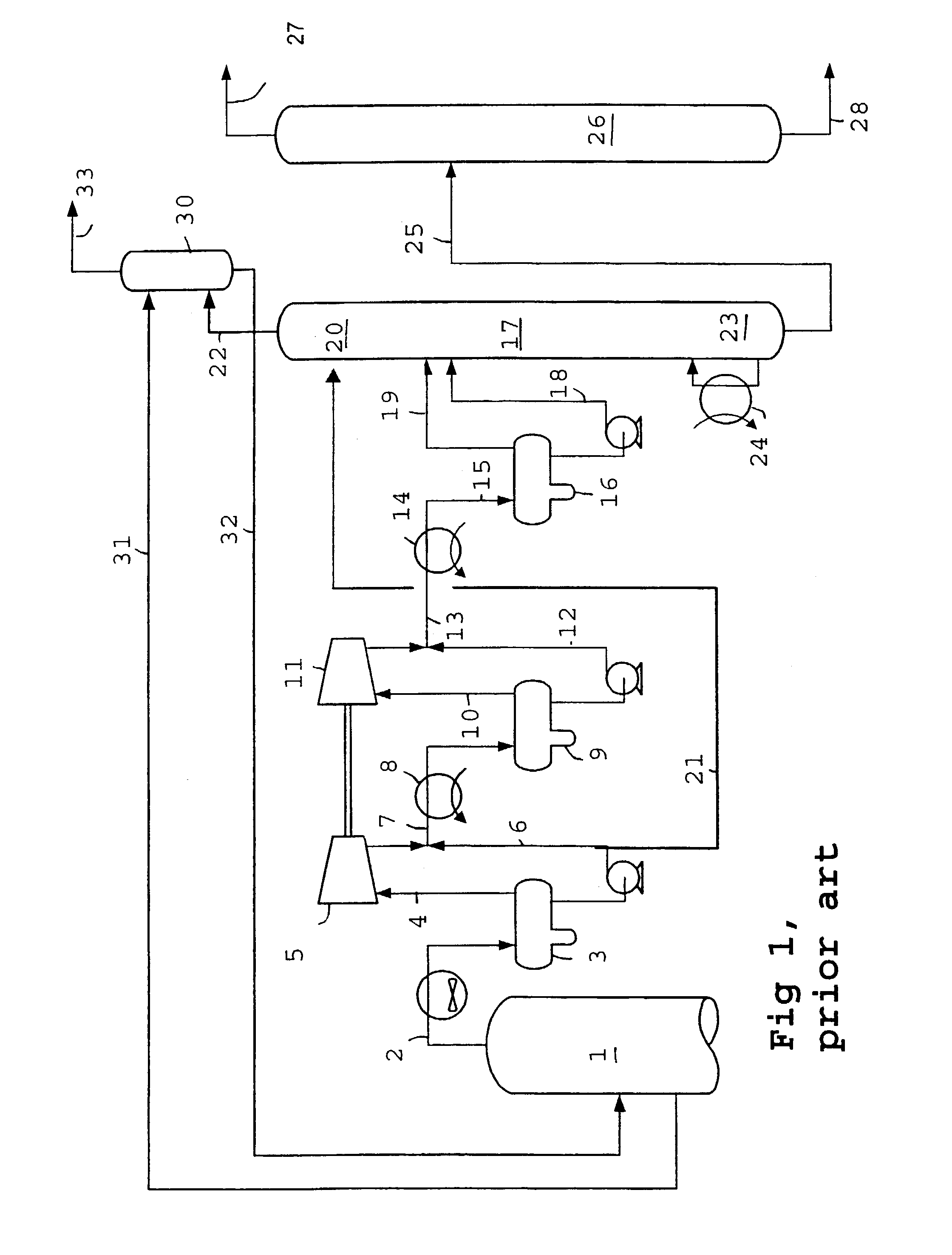

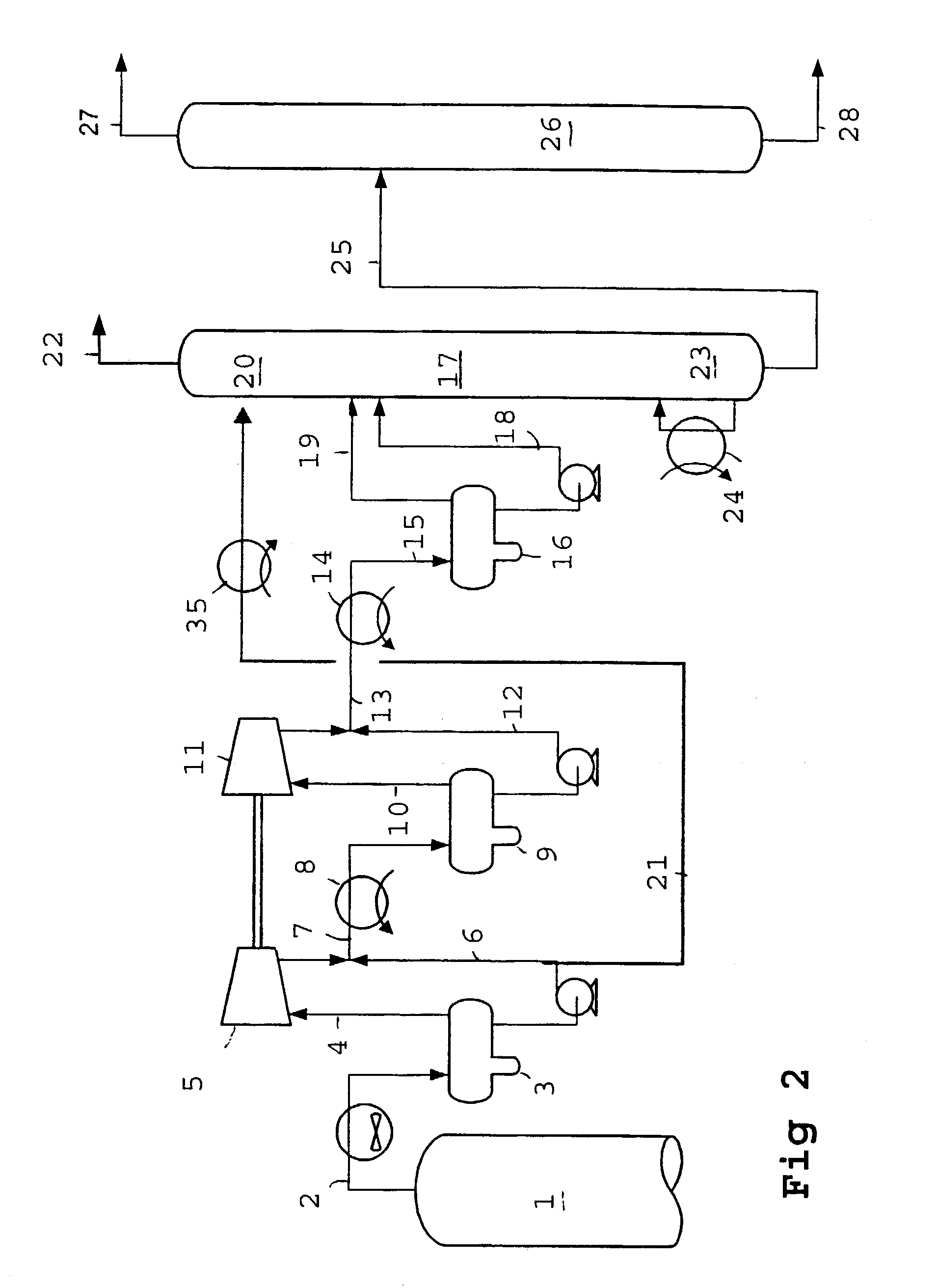

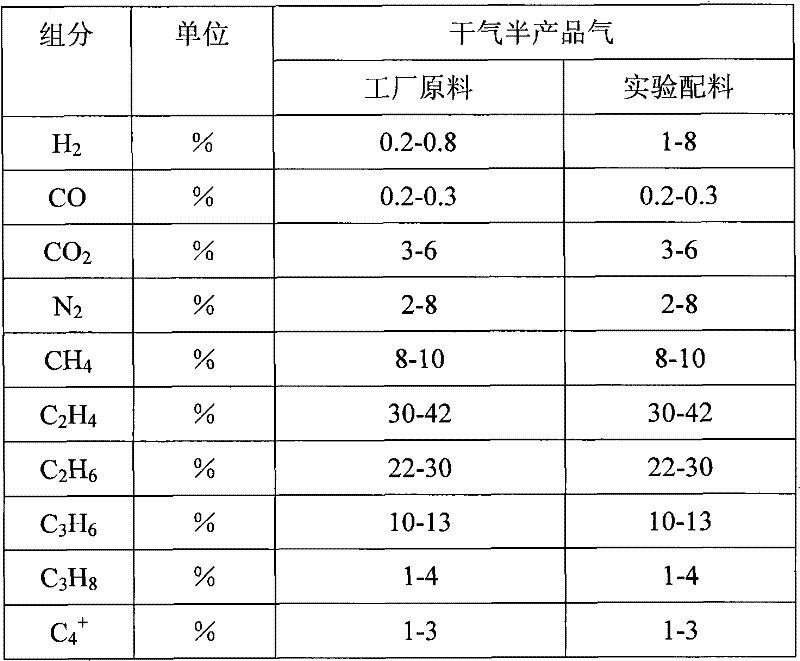

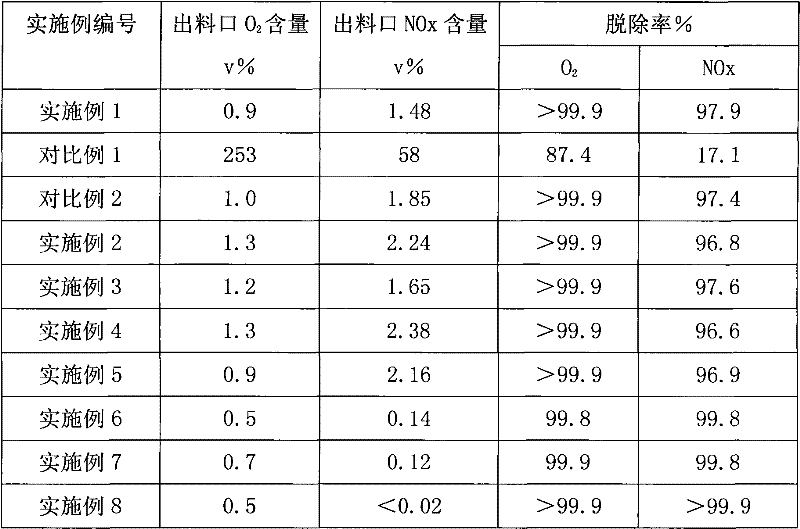

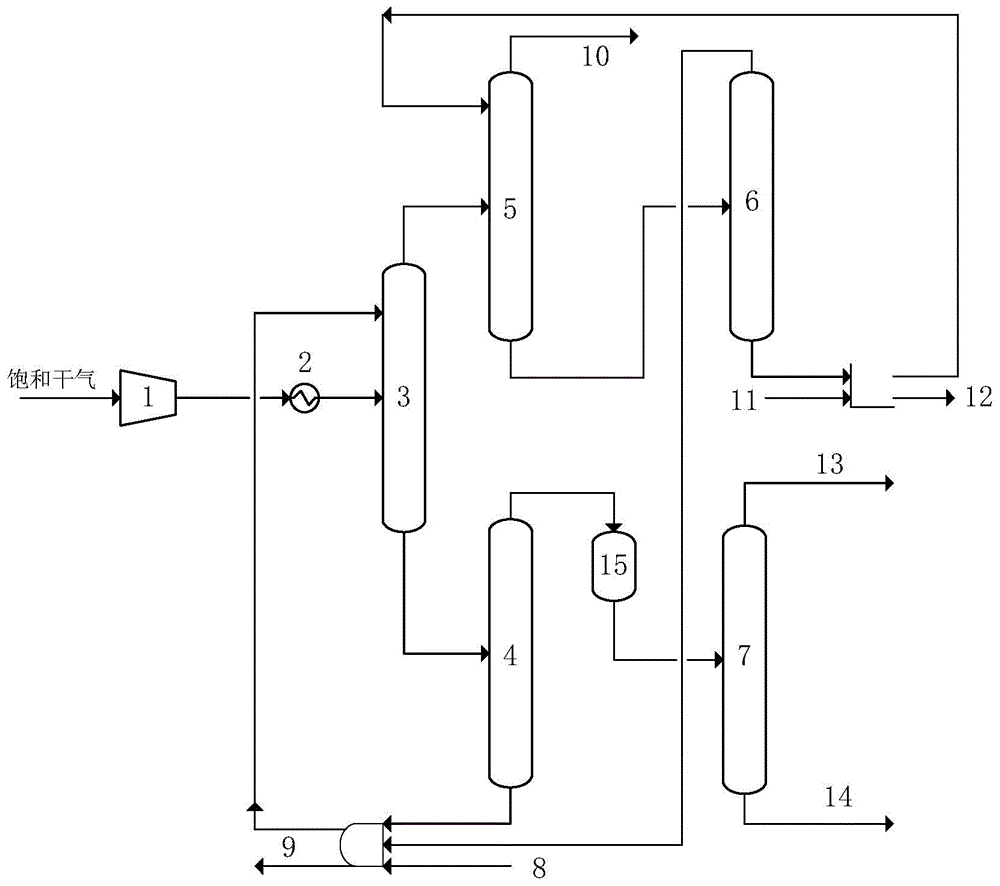

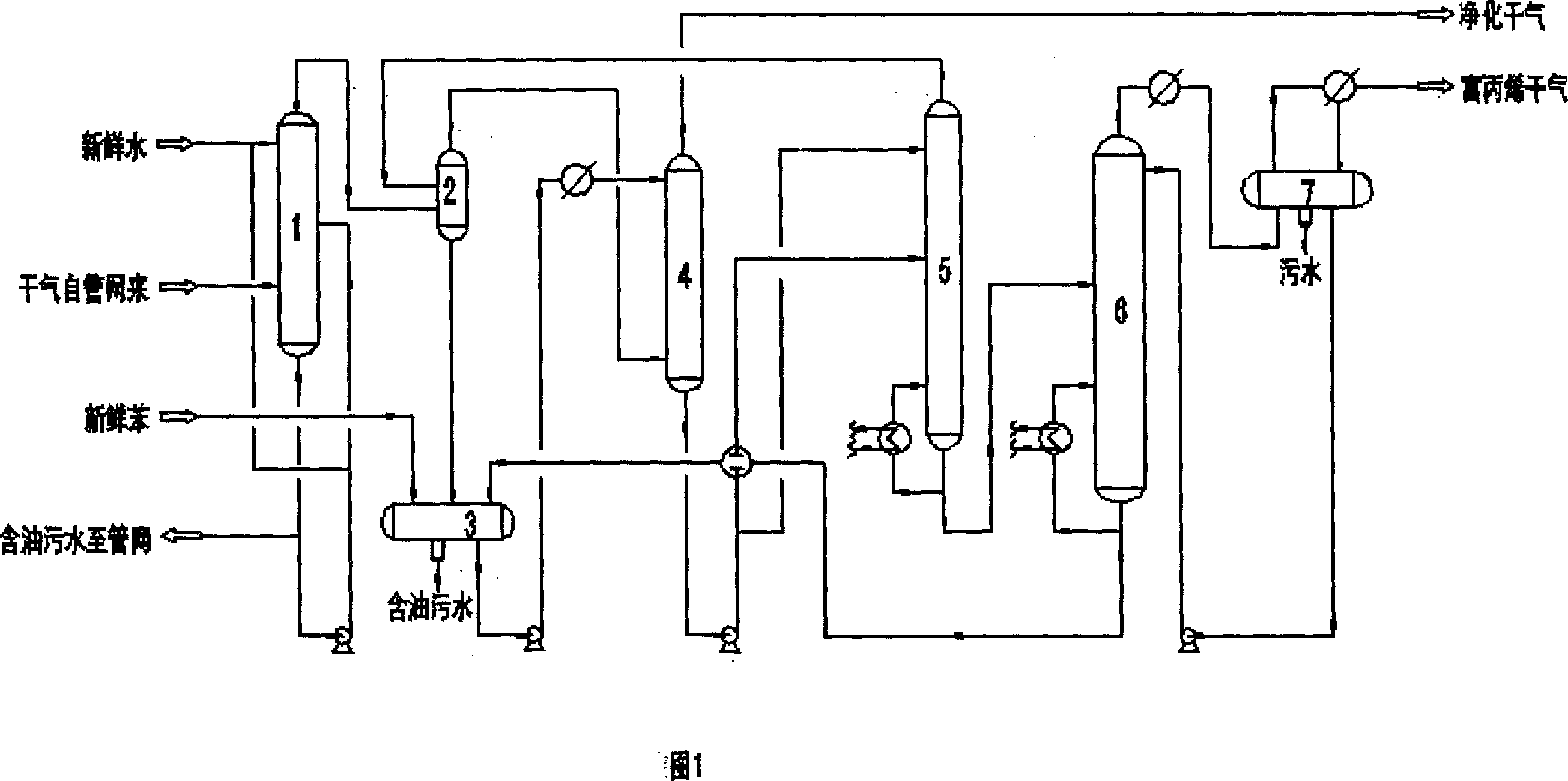

Method for separating plant catalytic dry gas by employing middle-cool-oil absorption process

InactiveCN101063048AEasy to getLow costOrganic chemistryEthylene productionProduct gasEnergy consumption

The invention discloses a separating refinery catalytic dry gas method with middle cold oil absorptive method in separating refinery catalytic dry gas technical domain, which comprises the following steps: compressing; stripping acid gas; drying; purifying; absorbing; desorbing; reclaiming cold energy; crude-separating. This invention possesses cheap cost, low lost, simple operation, little investment and low energy consumption, which can get C2 fraction and ethane.

Owner:CHINA PETROLEUM & CHEM CORP +1

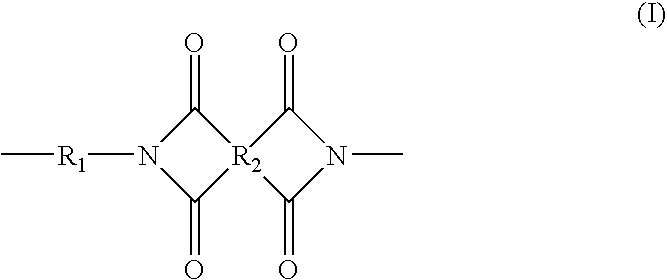

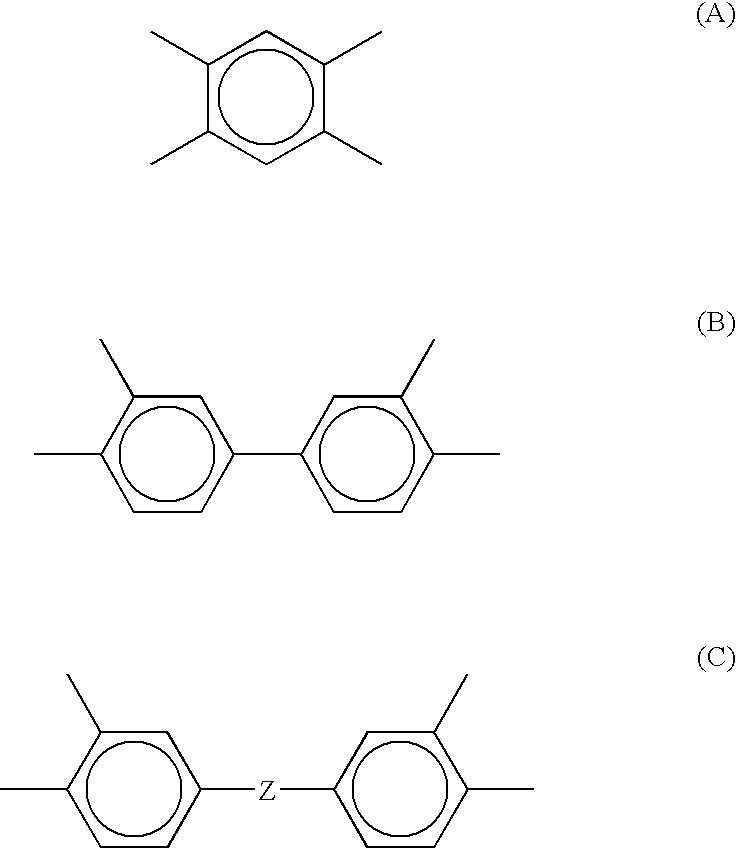

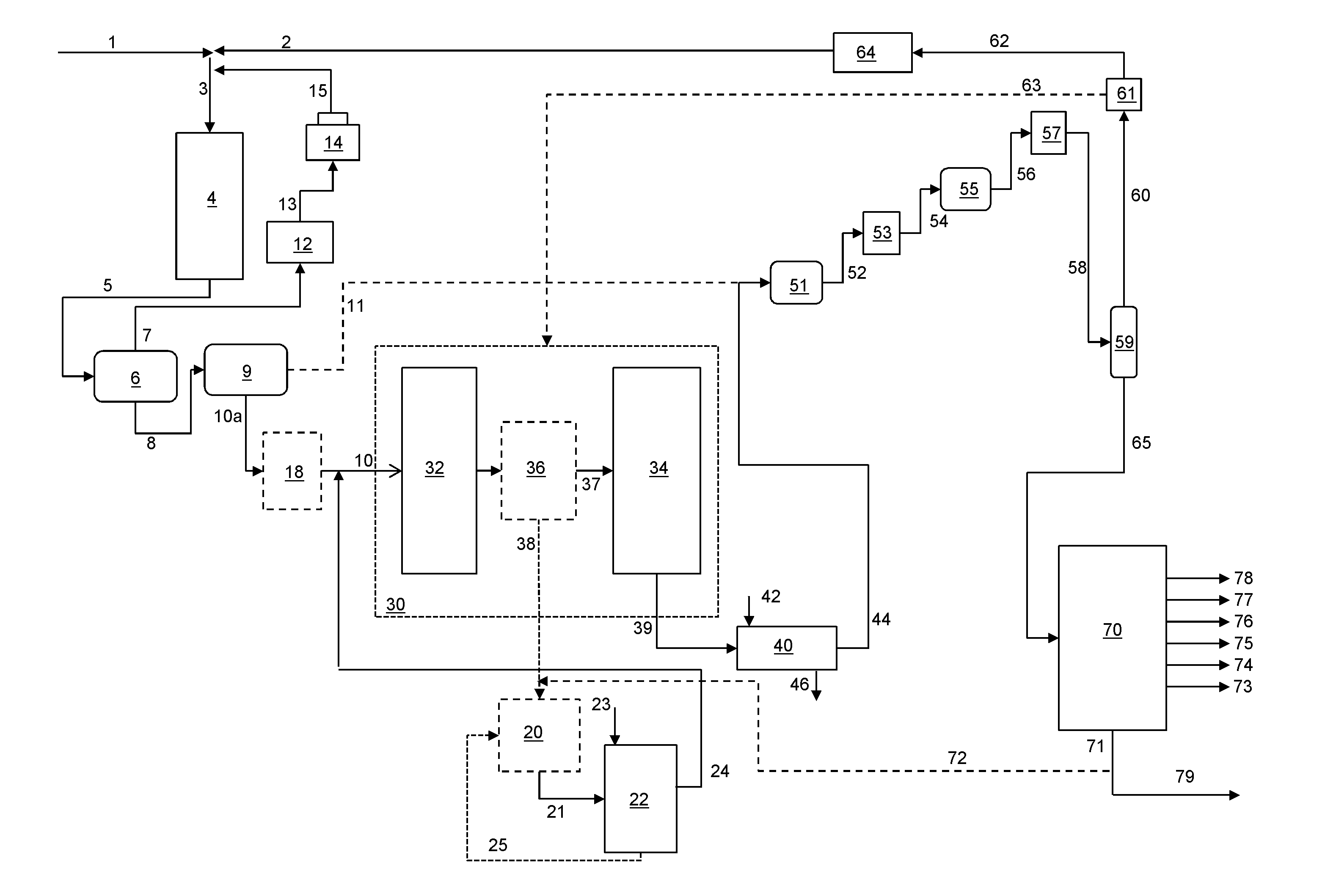

Complex comprising oxidative dehydrogenation unit

ActiveUS20140249339A1Consumes lotThermal non-catalytic crackingSequential/parallel process reactionsAlkaneDehydrogenation

Oxidative dehydrogenation of paraffins to olefins provides a lower energy route to produce olefins. Oxidative dehydrogenation processes may be integrated with a number of processes in a chemical plant such as polymerization processes, manufacture of glycols, and carboxylic acids and esters. Additionally, oxidative dehydrogenation processes can be integrated with the back end separation process of a conventional steam cracker to increase capacity at reduced cost.

Owner:NOVA CHEM (INT) SA

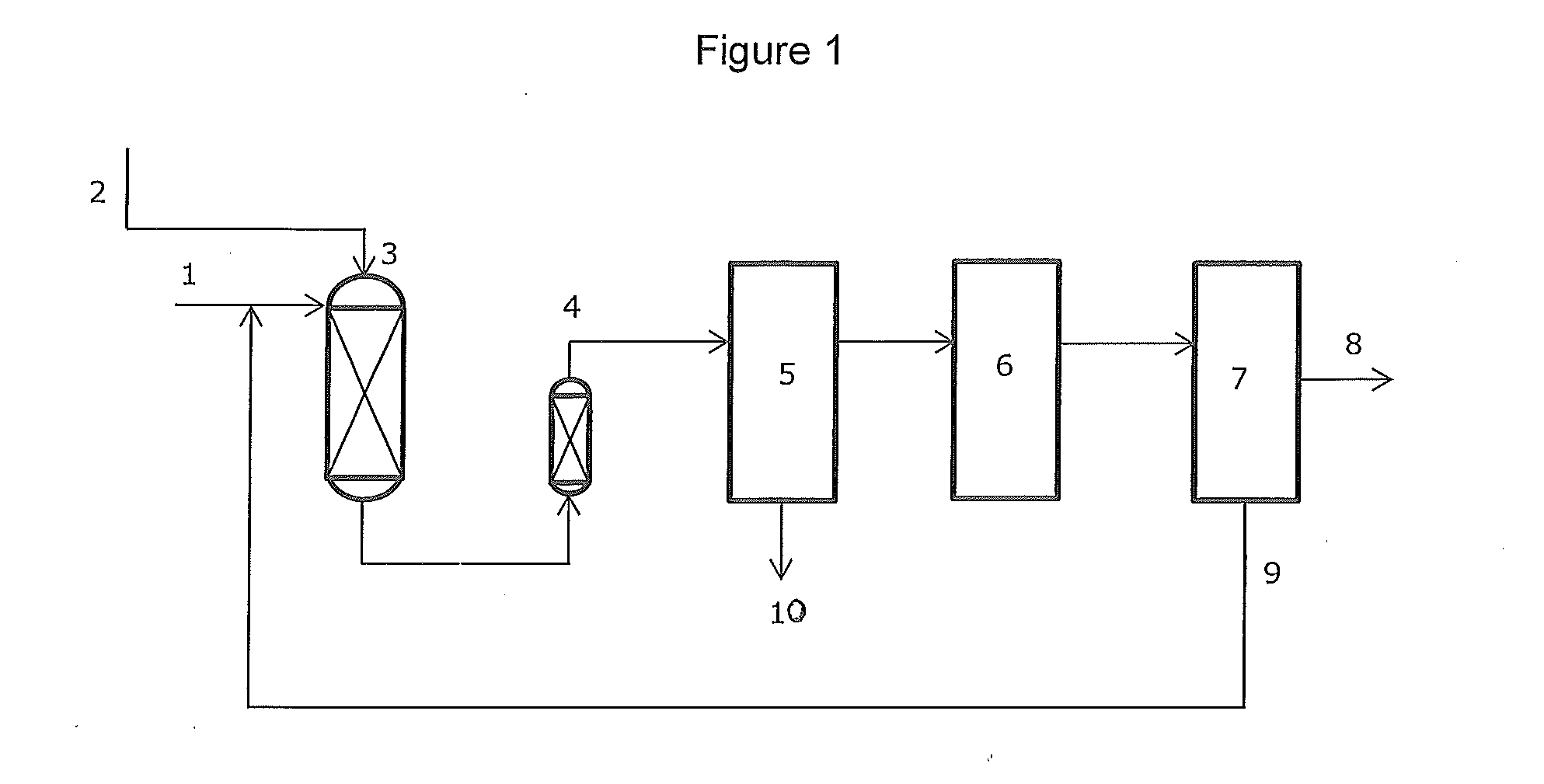

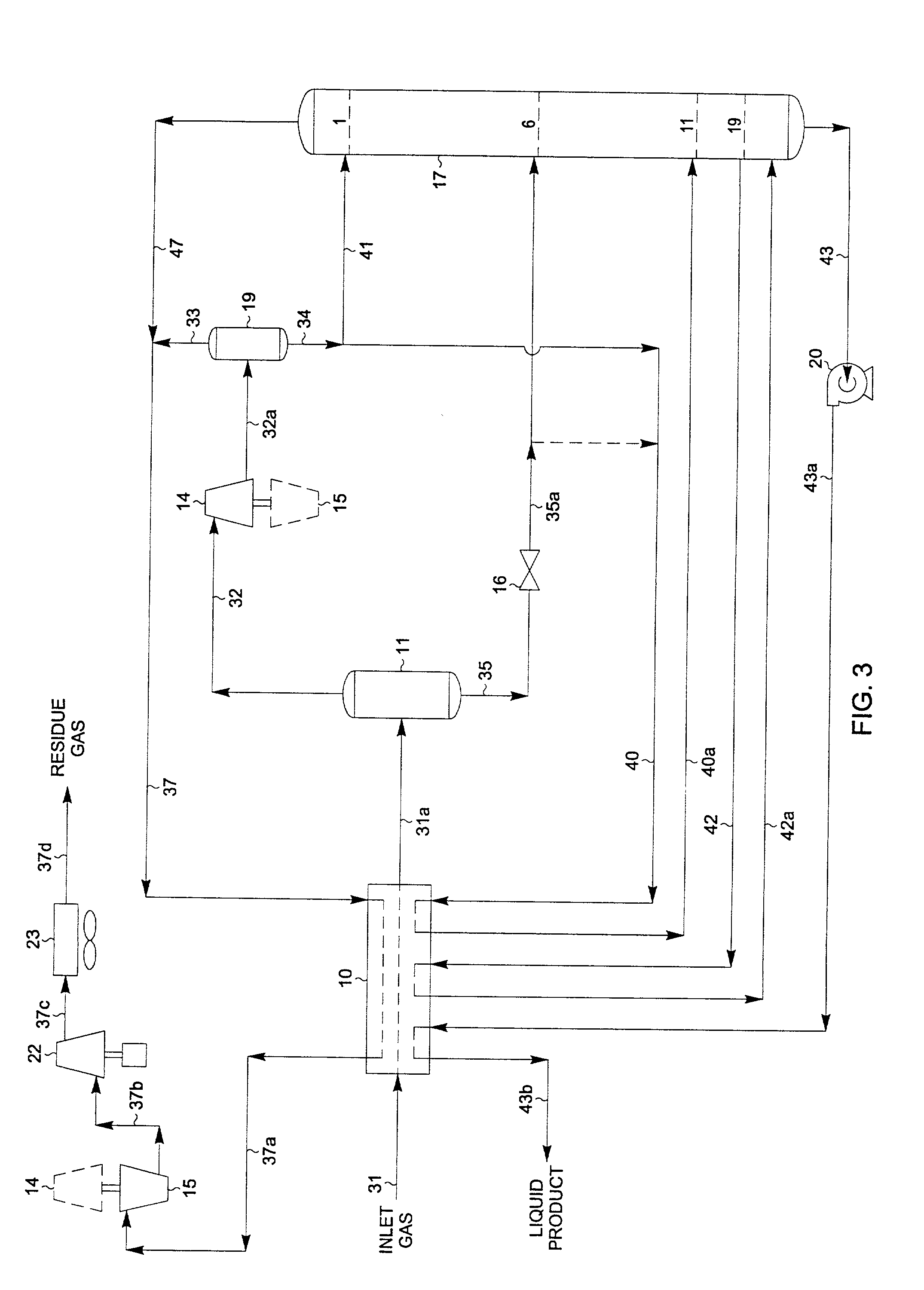

Hydrocarbon gas processing

A process for the recovery of propane, propylene and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. The stream is cooled and / or expanded to partially condense it, then separated to provide a first vapor stream. The first vapor stream is directed into a contacting device whereby vapors and liquids are formed. The liquids are directed to a distillation column operating at lower pressure wherein a second vapor stream is separated to recover a product containing the major portion of the C3 components and heavier hydrocarbon components. The second vapor stream is directed into heat exchange relation with the vapors to cool the second vapor stream and condense at least a part of it, forming a condensed stream. At least a portion of the condensed stream is directed to the contacting device to intimately contact the first vapor stream; the remaining portion (if any) of the condensed stream can be supplied to the distillation column as its top feed. The quantities and temperatures of the feeds to the contacting device and the distillation column are effective to maintain the overhead temperatures of the contacting device and the distillation column at temperatures whereby the major portion of the desired components is recovered.

Owner:ELCOR CORP

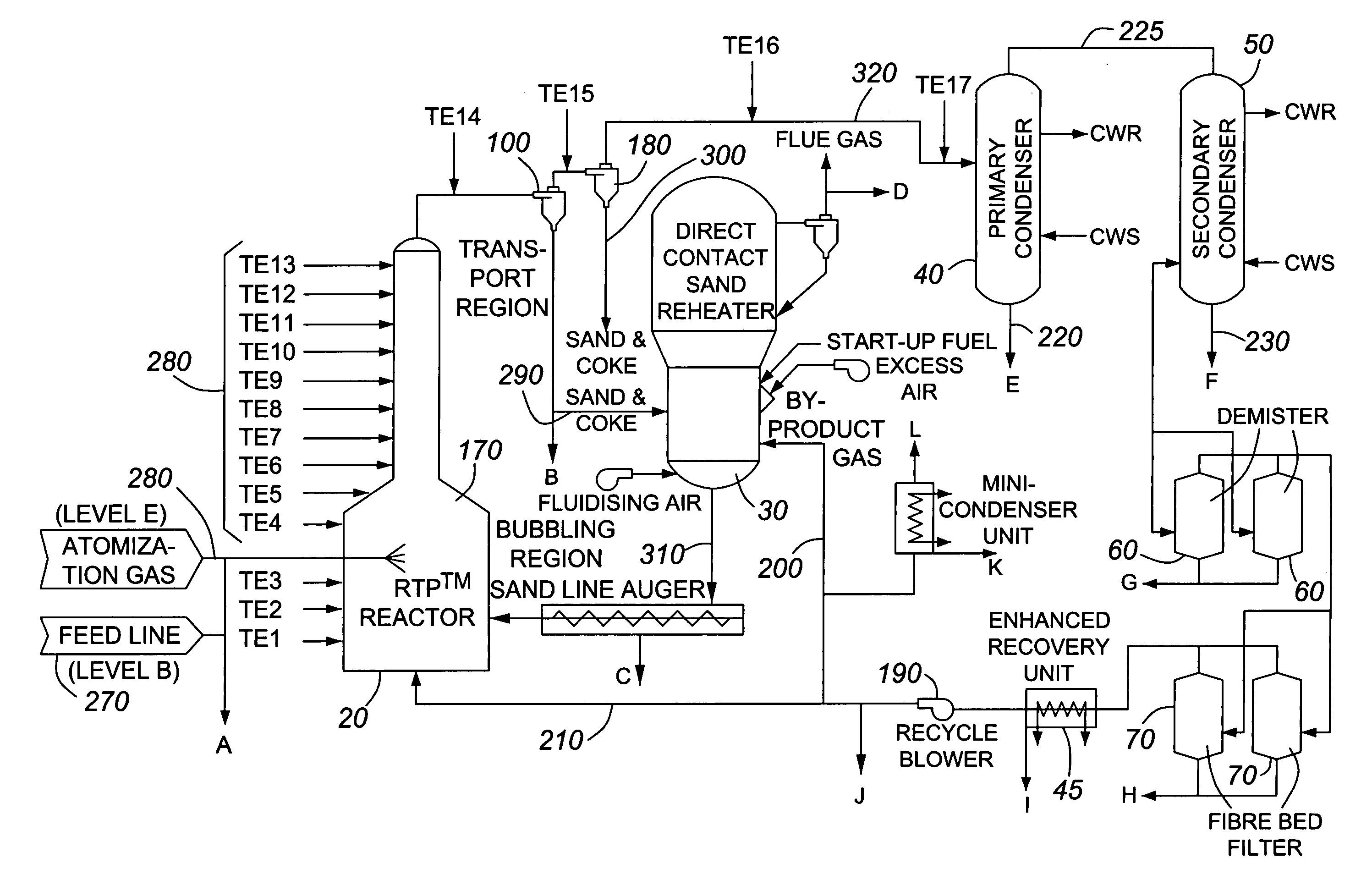

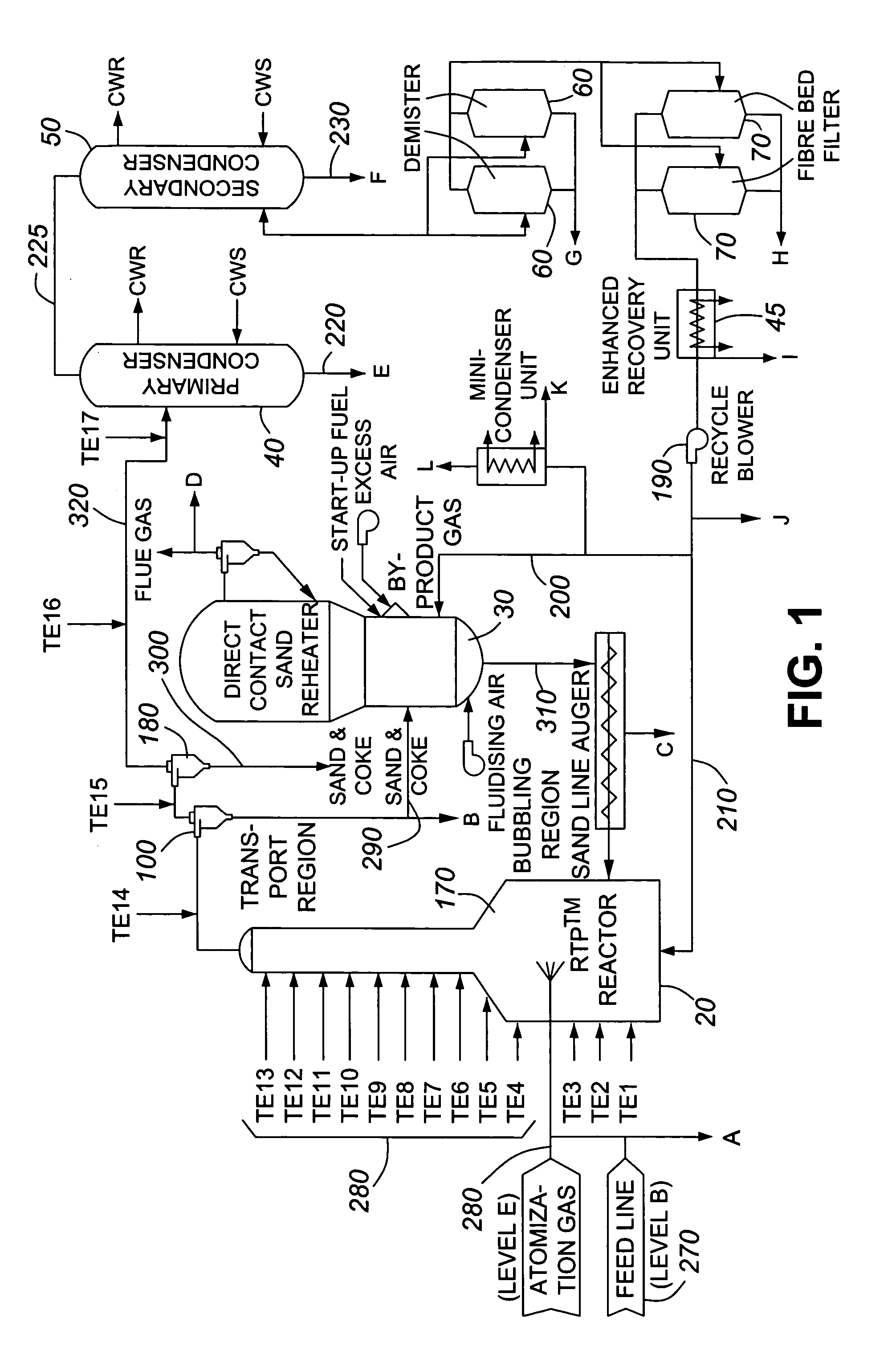

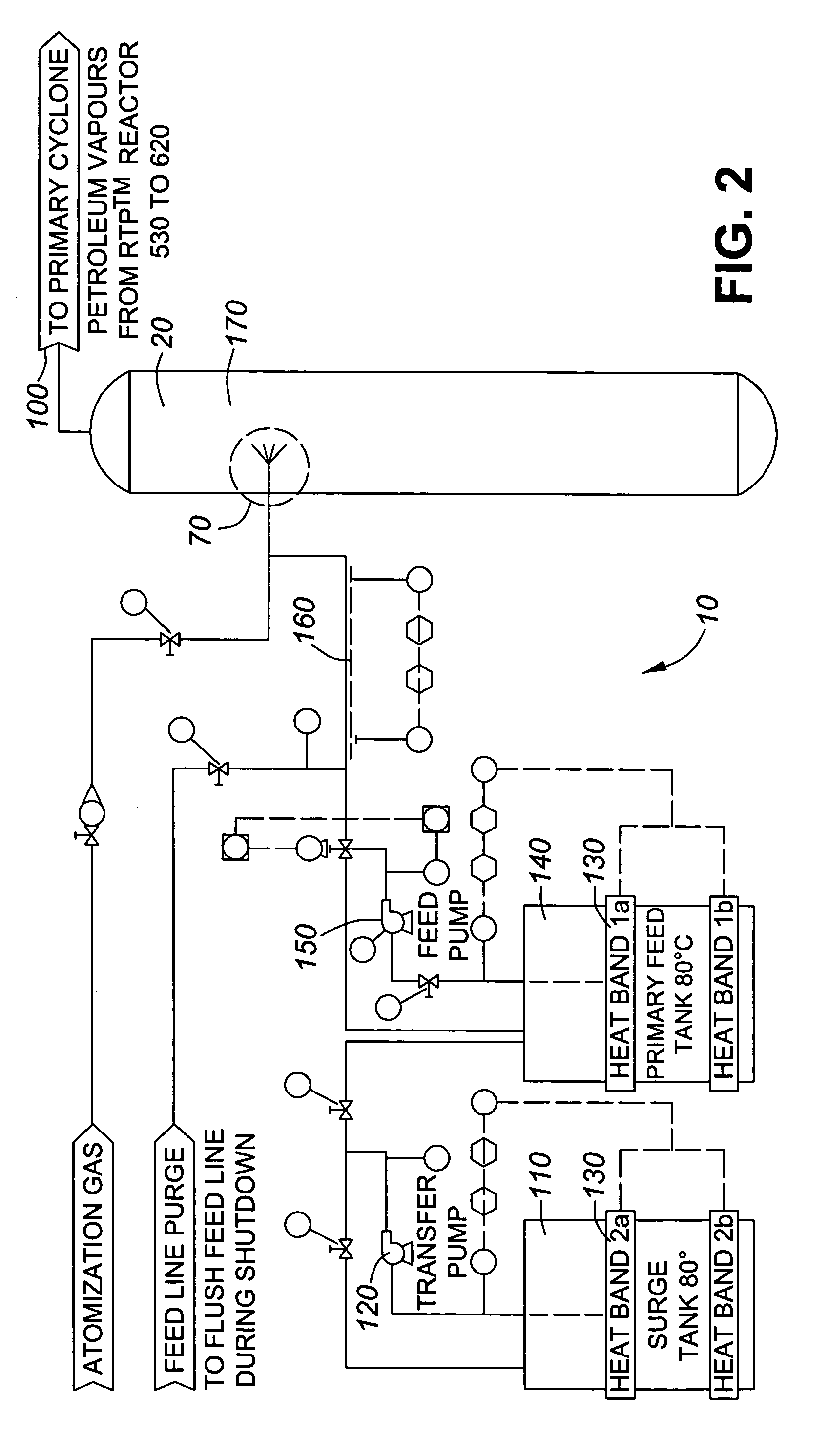

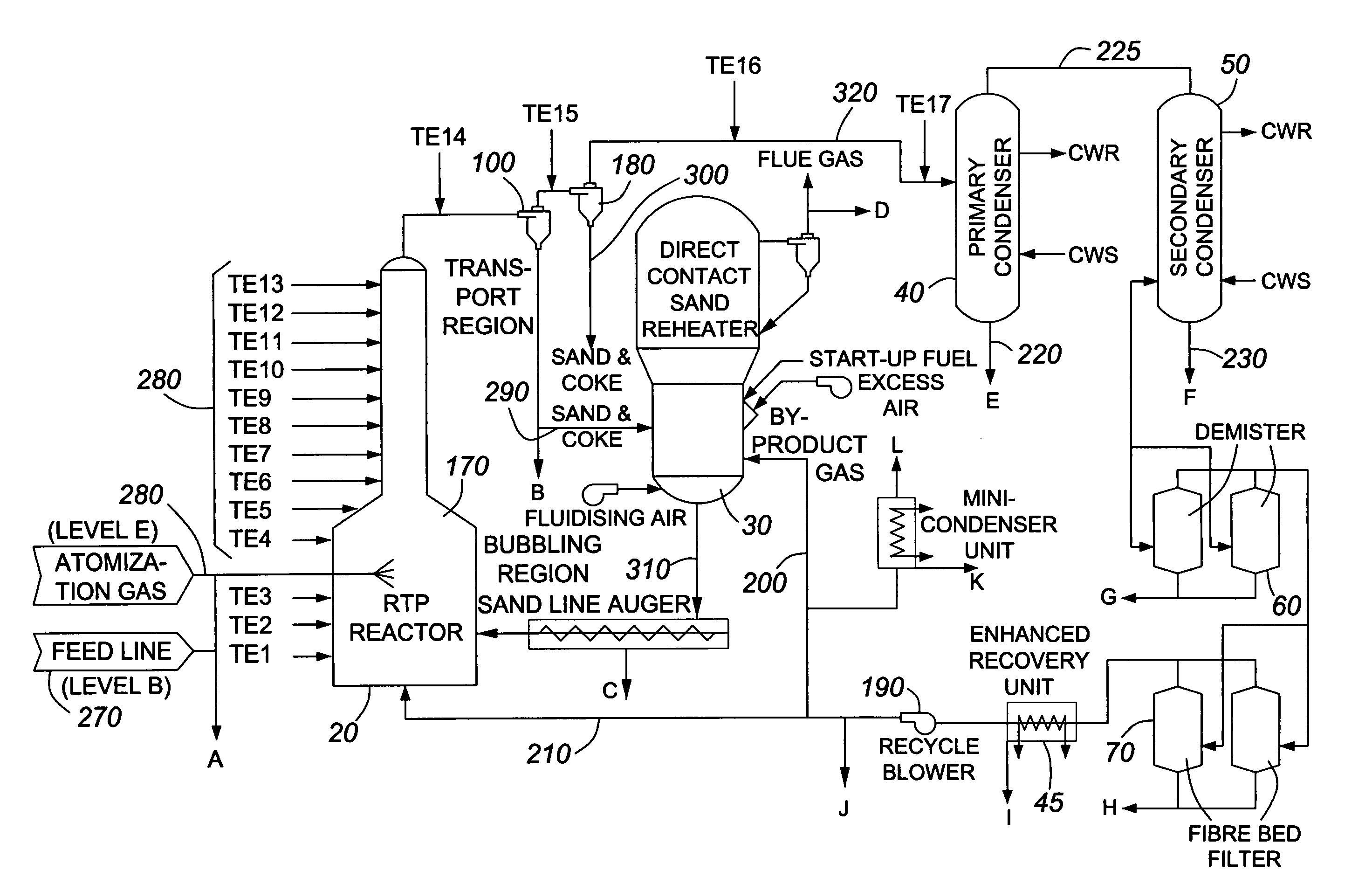

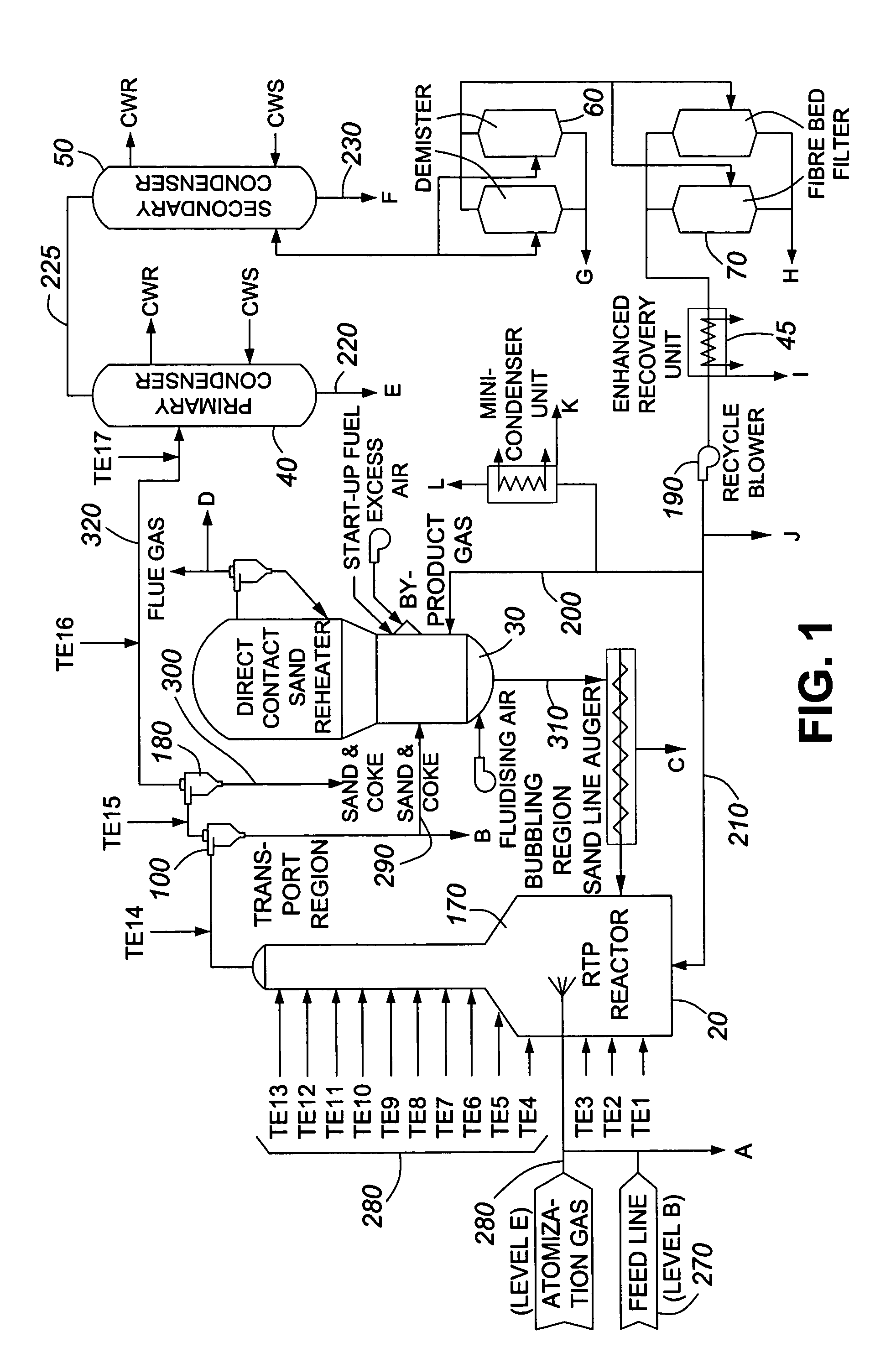

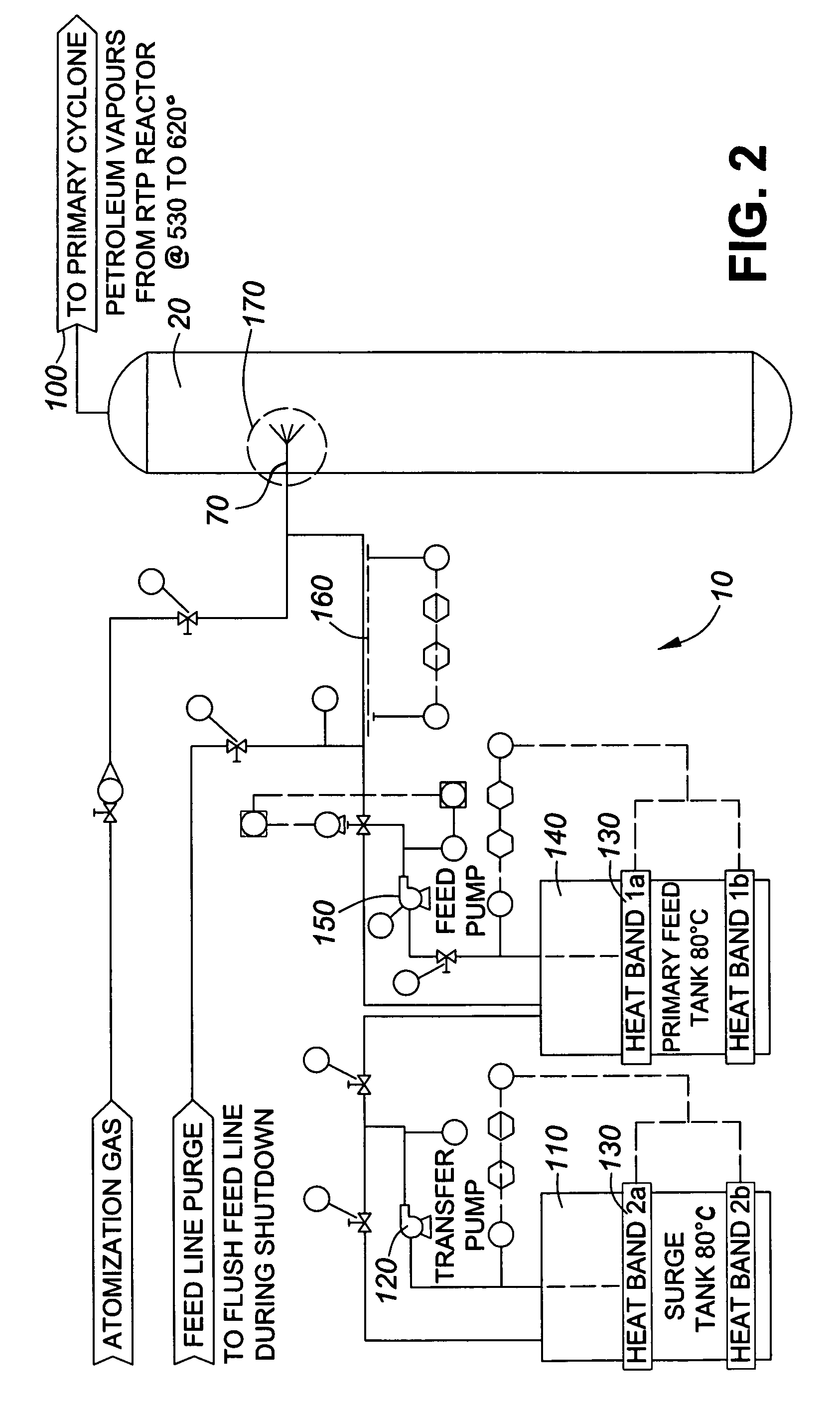

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572362B2Quick upgradeReducing H2S contentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas), to reducing the total acid number (TAN) of the liquid product, and to reducing the hydrogen sulfide content of one, or more than one component of the product stream. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

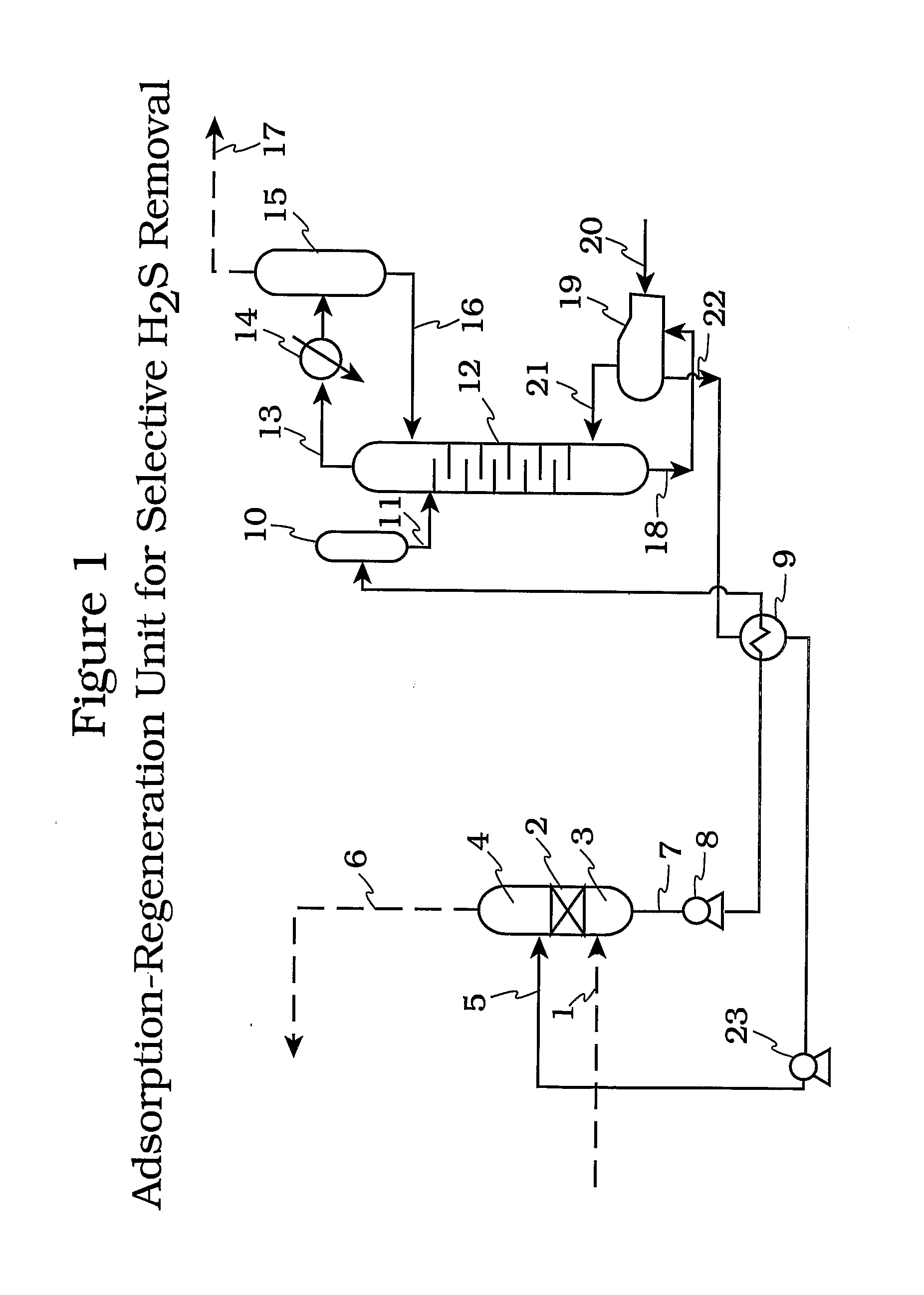

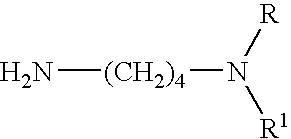

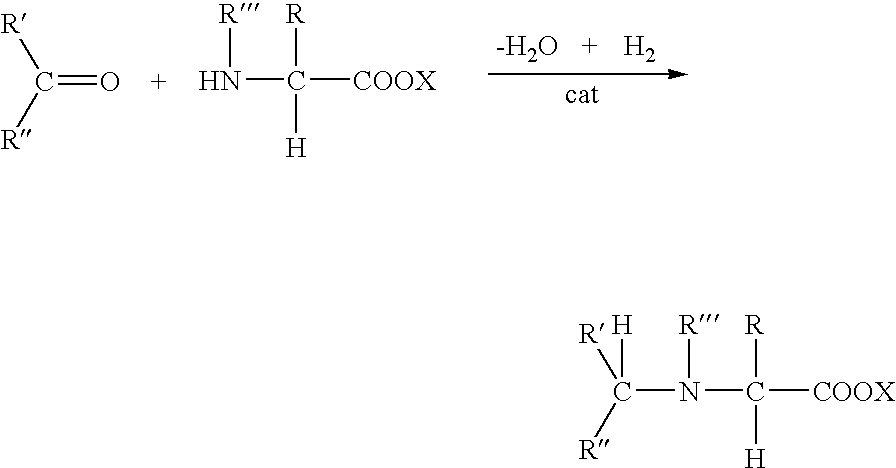

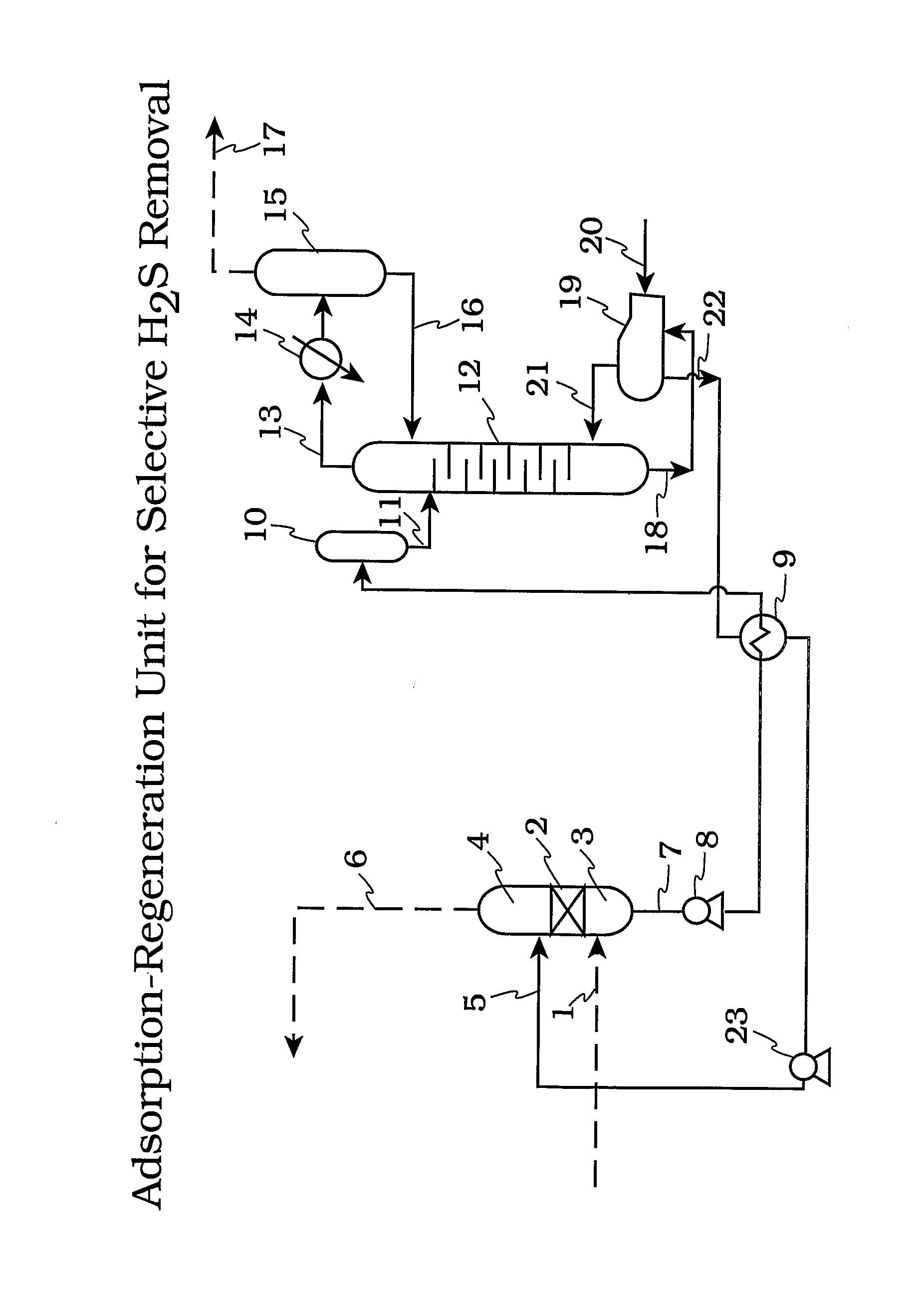

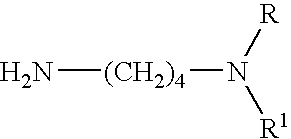

Absorbent composition containing molecules with a hindered amine and a metal sulfonate, phosphonate or carboxylate structure for acid gas scrubbing process

An acid gas absorbent comprising a metal sulfonate, phosphonate or carboxylate of a hindered amine and a process for the selective removal Of H2S as well as other acidic components such as carbon disulfide, carbonyl sulfide and oxygen and sulfur derivatives of C1 to C4 hydrocarbons from mixtures containing such acidic components and CO2 using said absorbent.

Owner:EXXON RES & ENG CO

Method for separating hydrocarbon-containing gas mixtures using hydrocarbon-resistant membranes

A method of separating or concentrating hydrocarbon-containing gas mixtures such as hydrogen from hydrocarbons, carbon dioxide from hydrocarbons, nitrogen from hydrocarbons, and hydrocarbons from one another using a selectively permeable membrane. The method is well suited to separate hydrocarbon-containing mixtures such as those generated by petroleum refining industries, petrochemical industries, natural gas processing, and the like. The membranes exhibit extremely good resistance to plasticization by hydrocarbon components in the gas mixture under practical industrial process conditions.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Targeted hydrogenation hydrocracking

InactiveUS20090159493A1Hydrocarbon oil crackingTreatment with hydrotreatment processesProcess engineeringEngineering

This invention is directed to a process scheme in which a partial conversion hydrocracking (HCR) unit, preferably preceded by a hydrotreating unit, feeds unconverted oil to a FCC (fluid catalytic cracking ) unit. Most refineries run the FCC unit at the full capacity for optimal asset utilization. During shutdowns of Residue Desulfurization unit(s) which feed an FCC unit, it is desirable to reduce the conversion in the FCC feed hydrocracker. In this way, the feed to FCC unit is maximized. Jet and Diesel products that conform to specifications may be produced during low conversion HCR operation. Furthermore, undesirable over-saturation of the unconverted oil (UCO) from the HCR unit feeding the FCC unit can be avoided. Excess hydrogen consumption can also be avoided. Normally, further aromatic saturation of the middle distillate products from a low conversion HCR is achieved in a separate, post treatment, unit.

Owner:CHEVROU USA INC

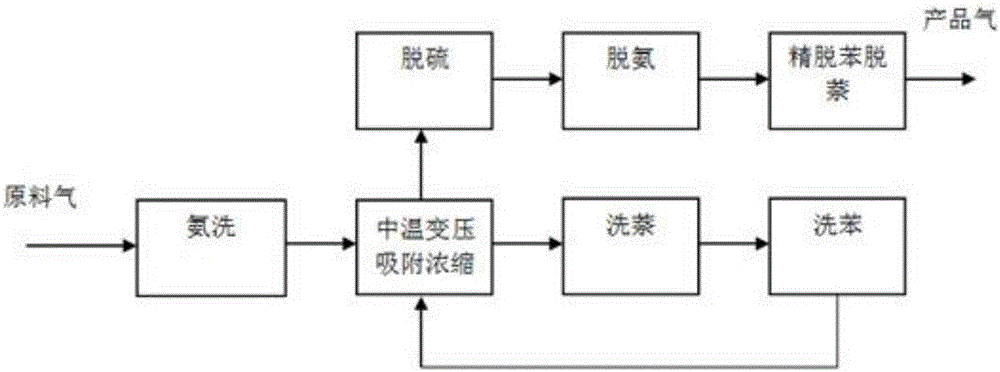

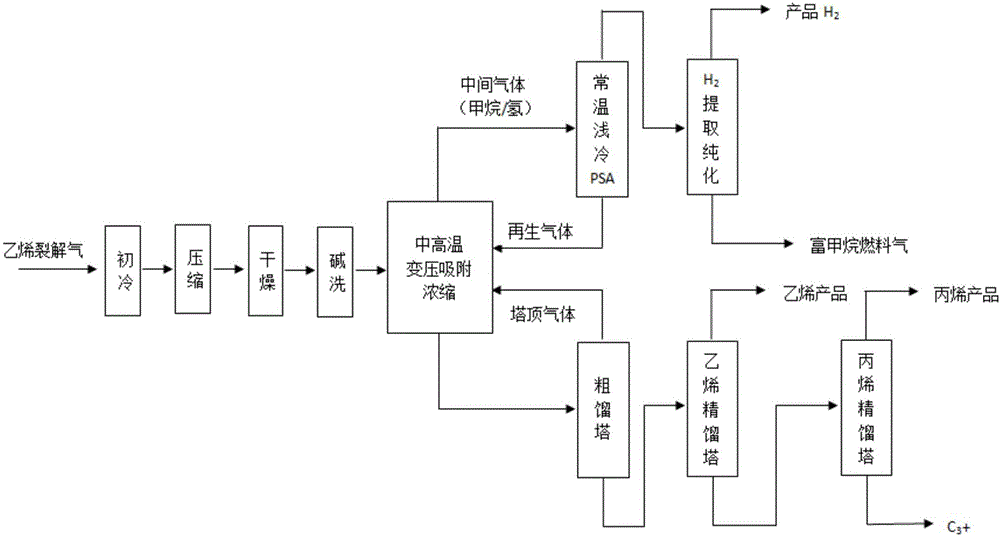

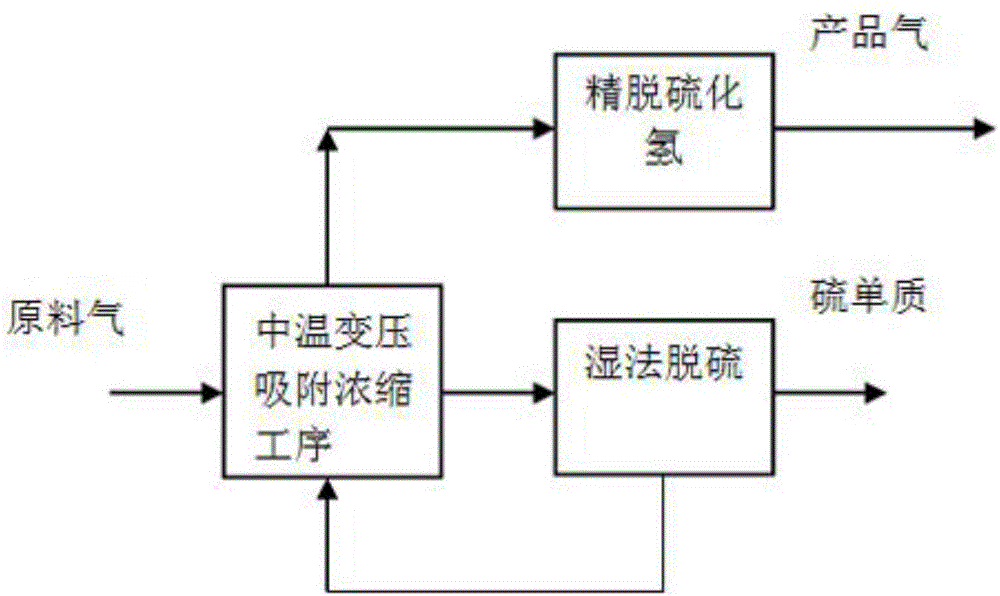

Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

ActiveCN105749699AReduce energy consumptionBroaden the scope of adsorption separation applicationsSolidificationLiquefactionEnergy gradientPurification methods

The invention discloses a full-temperature-range pressure swing adsorption gas separation, refinement and purification method.By means of the difference of the temperatures and pressures of different raw material gases and the difference of the adsorption separation coefficients and physical chemistry properties of all components in the raw material gases in the temperature range of 80-200 DEG C and the pressure range of 0.03-4.0 MPa, the adsorption or desorption regeneration operation of the pressure swing adsorption circulation process is adjusted by coupling all separation methods, the adsorption theory that the pressure or temperature swing adsorption separation process is only limited to the adsorption and desorption regeneration circulation operation through pressure or temperature changes is expanded, and therefore all raw material gases are separated, refined and purified by achieving the energy gradient utilization in the gas separation, refinement and purification process and achieving the circulation operation, where adsorption, desorption and regeneration are easily matched and balanced, in the moderate to low cold and moderate to high temperature pressure swing adsorption separation process, and it is changed that a traditional adsorption method is only limited to the auxiliary effect of refinement and purification, and adsorption becomes the basic separation unit operation just as important as refinement, absorption and extraction separation.

Owner:SICHUAN TECHAIRS

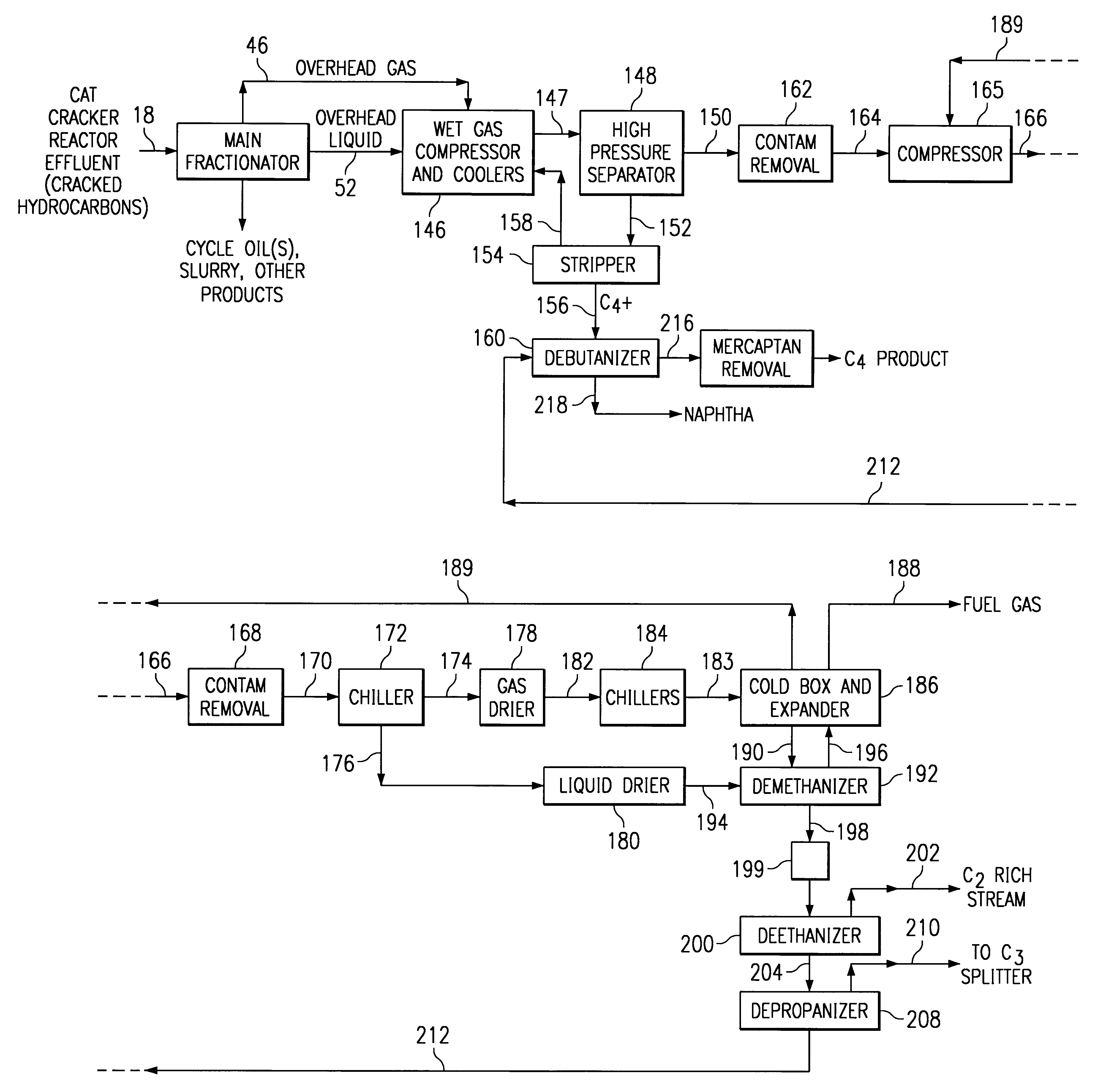

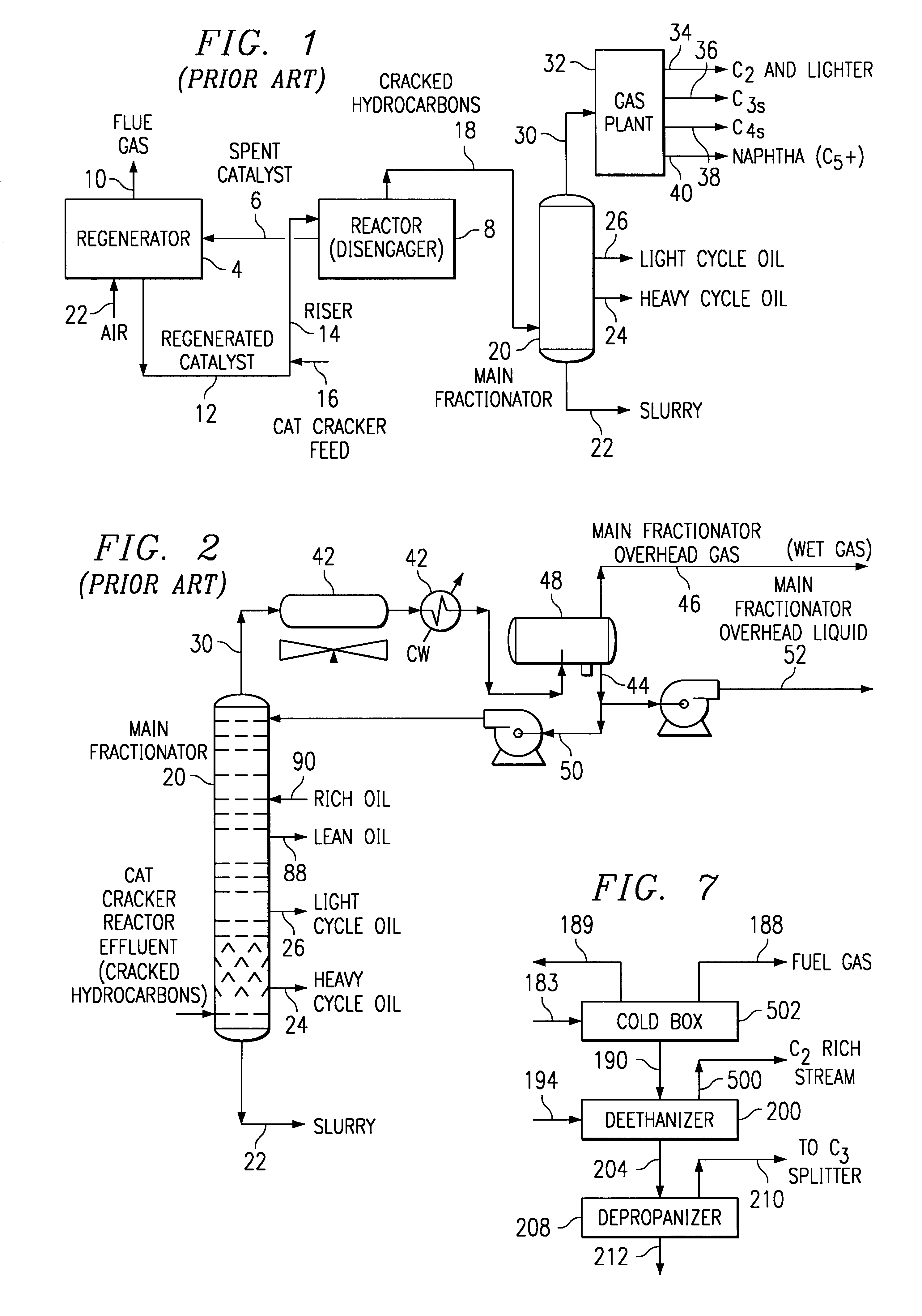

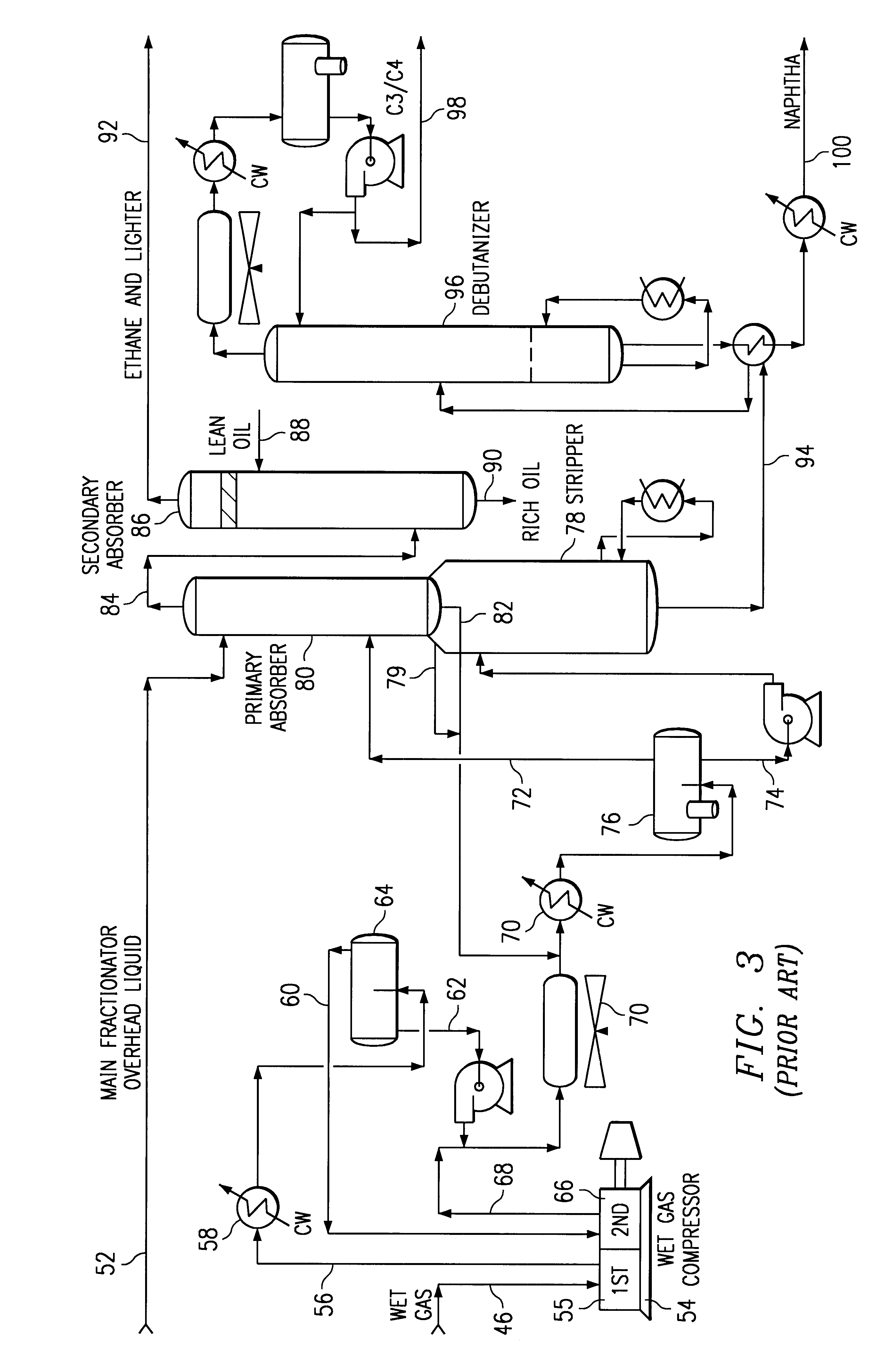

Cat cracker gas plant process for increased olefins recovery

The invention relates to a new process for more efficient separation and recovery of light olefins such as ethylene and propylene from a fluid catalytic cracking unit. The new process invention for recovering olefins from a mixture of cracked hydrocarbons from a fluid catalytic cracker comprises the steps of: (a) providing a mixture of cracked hydrocarbons including methane, ethylene, ethane, propylene, propane, butylene, butane and heavier hydrocarbons such as naphtha produced in a fluid catalytic cracker; (b) separating said mixture into (i) a first stream comprising substantially all of said ethane, ethylene, and methane and a major portion of said propane and propylene and (ii) a second stream comprising a portion of said butylene and butane, and a major portion of said heavier hydrocarbons; and (c) processing said first stream to recover the ethylene and propylene therefrom, and the details of such process described herein.

Owner:STONE & WEBSTER PROCESS TECH

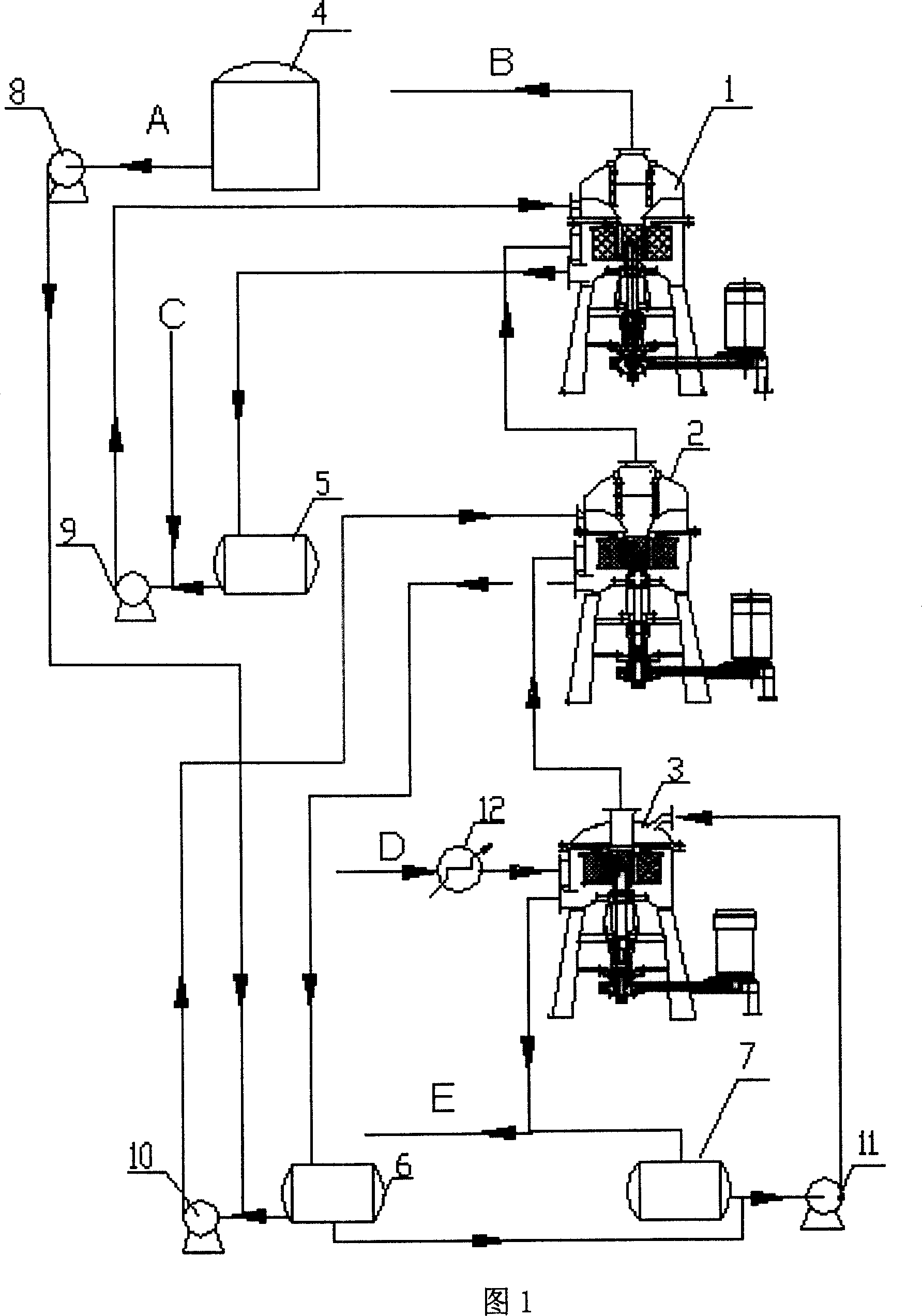

Device and method for separating refinery dry gas through oil absorption

InactiveCN103087772AEasy to getLow costGaseous mixture working upAbsorption purification/separationDesorptionGasoline

The invention discloses a device and a method for separating refinery dry gas through oil absorption. The device comprises a C4 absorption tower and a C4 desorption tower. A gasoline absorption tower is arranged after the C4 absorption tower. A top outlet of the C4 absorption tower is connected to the lower part of the gasoline absorption tower. The bottom and the top of the gasoline absorption tower respectively communicate with the outside world. The method comprises the steps that: catalytic dry gas is subjected to compression and cooling, and is delivered into the C4 absorption tower and is absorbed by using a C4 absorption agent; the tower kettle material of the C4 absorption tower is delivered into the C4 desorption tower; the tower kettle material of the C4 desorption tower is delivered back to the C4 absorption tower; tower top gas of the C4 absorption tower is delivered into the gasoline absorption tower and is absorbed by a gasoline absorption agent. According to the invention, no equipment such as ethylene cooling machine, expansion machine, or cold box is needed, such that investment and energy consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

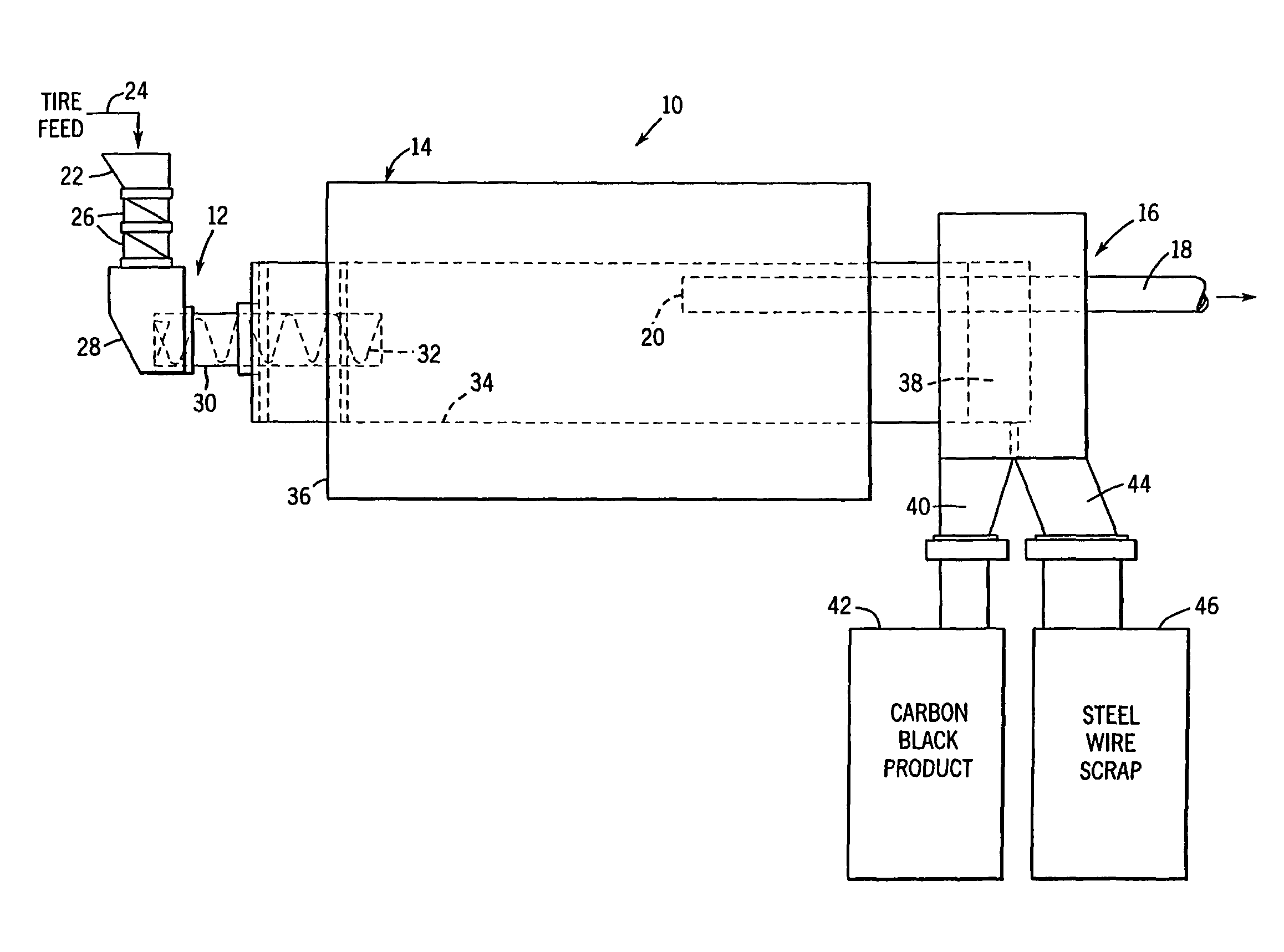

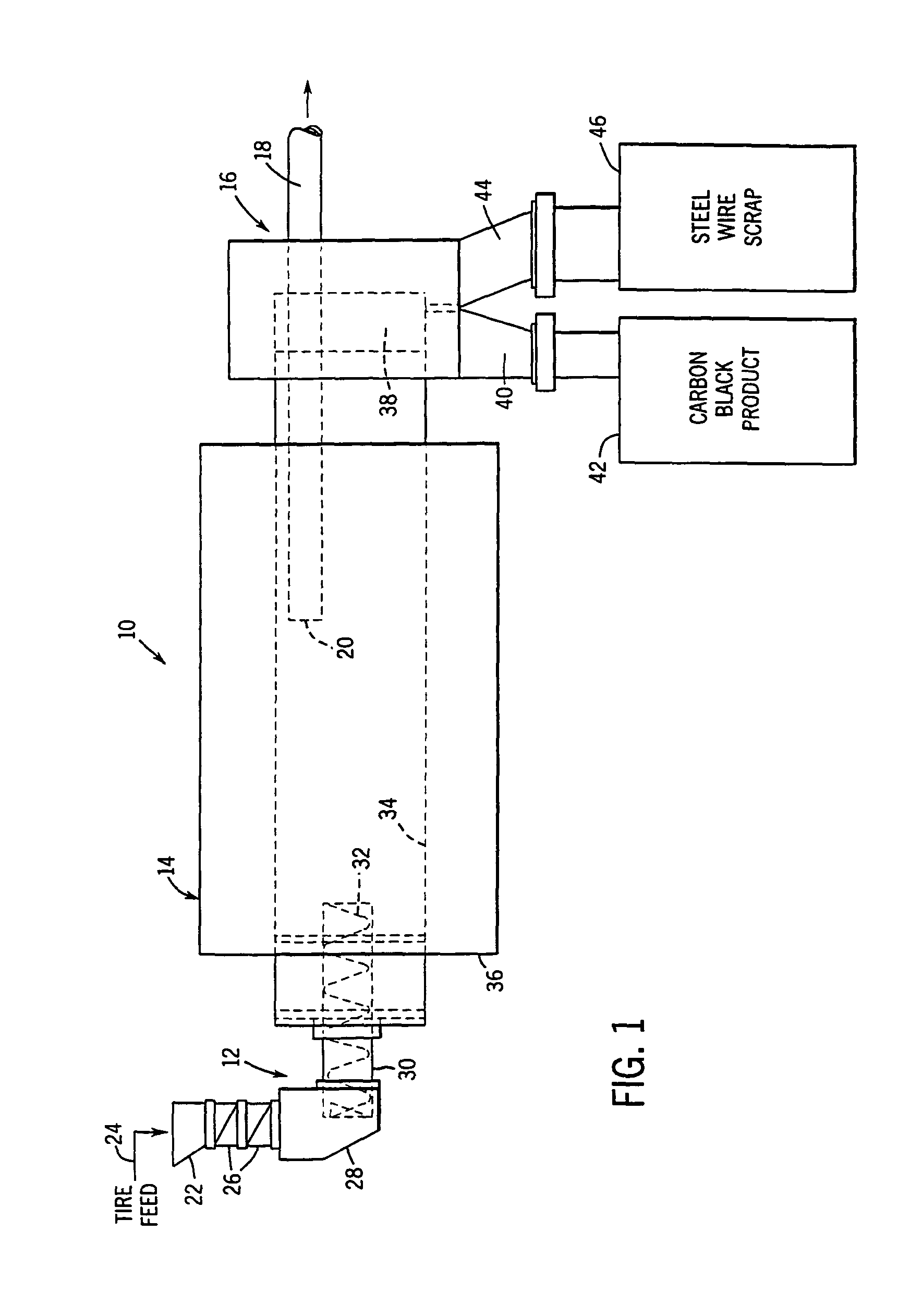

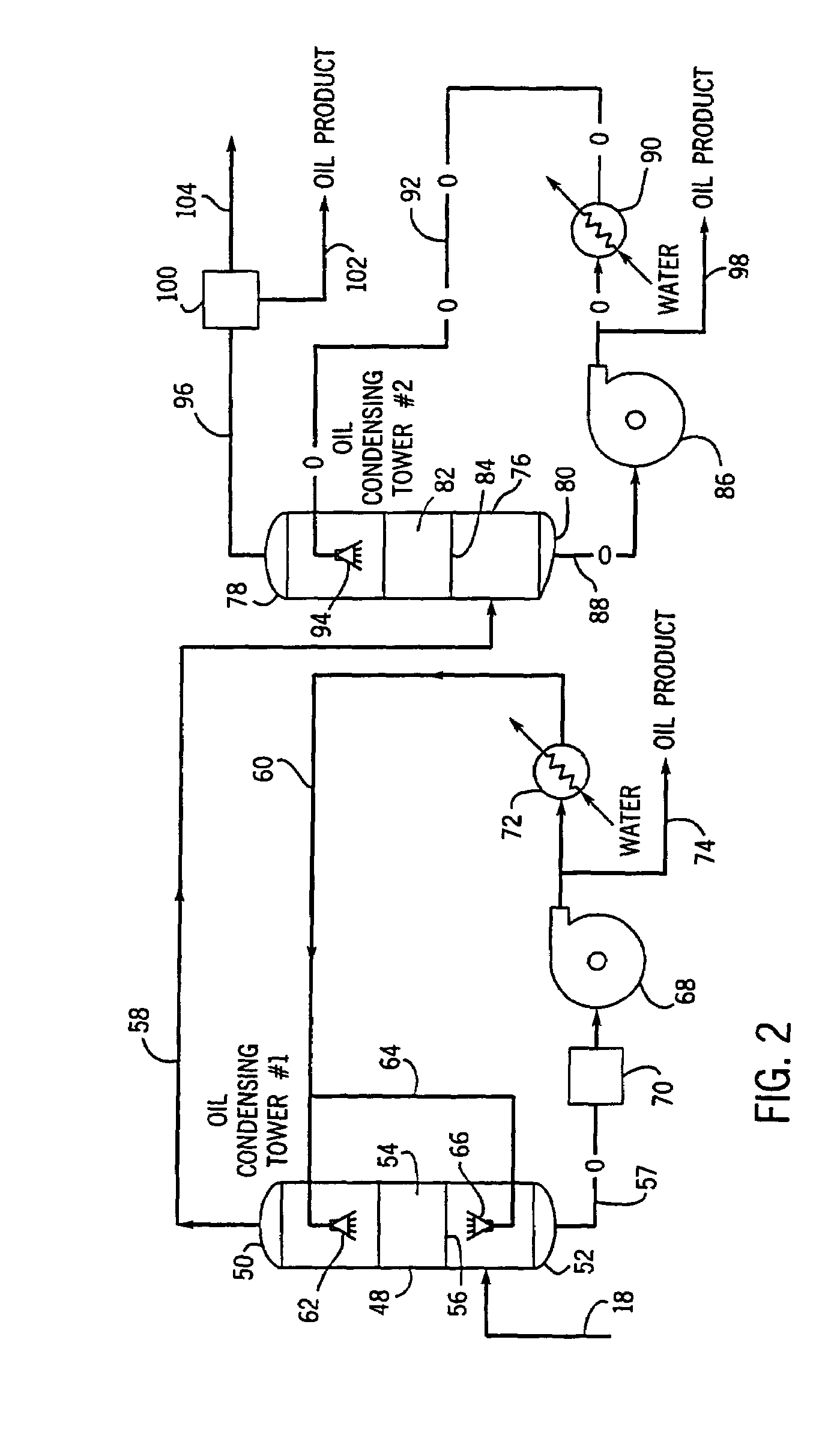

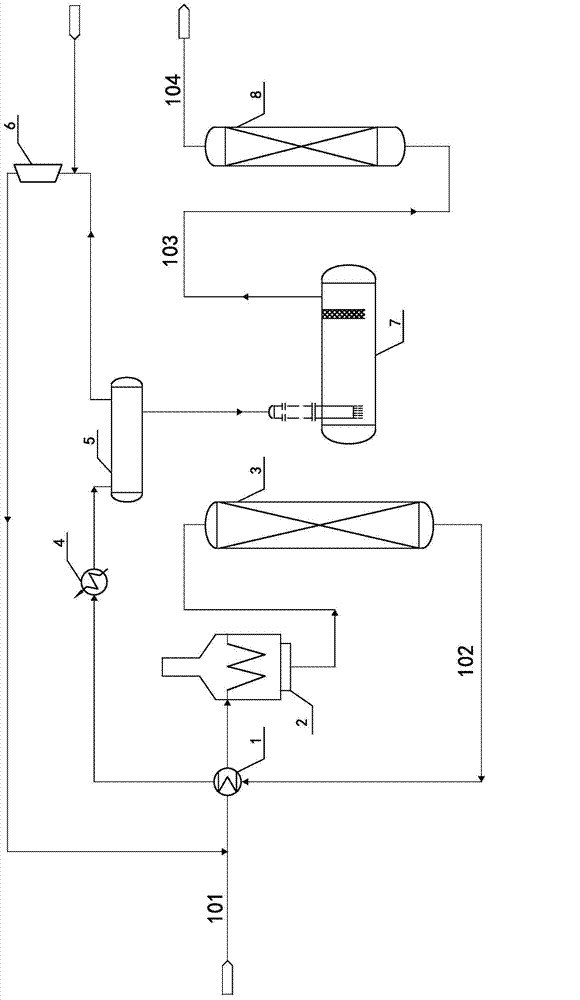

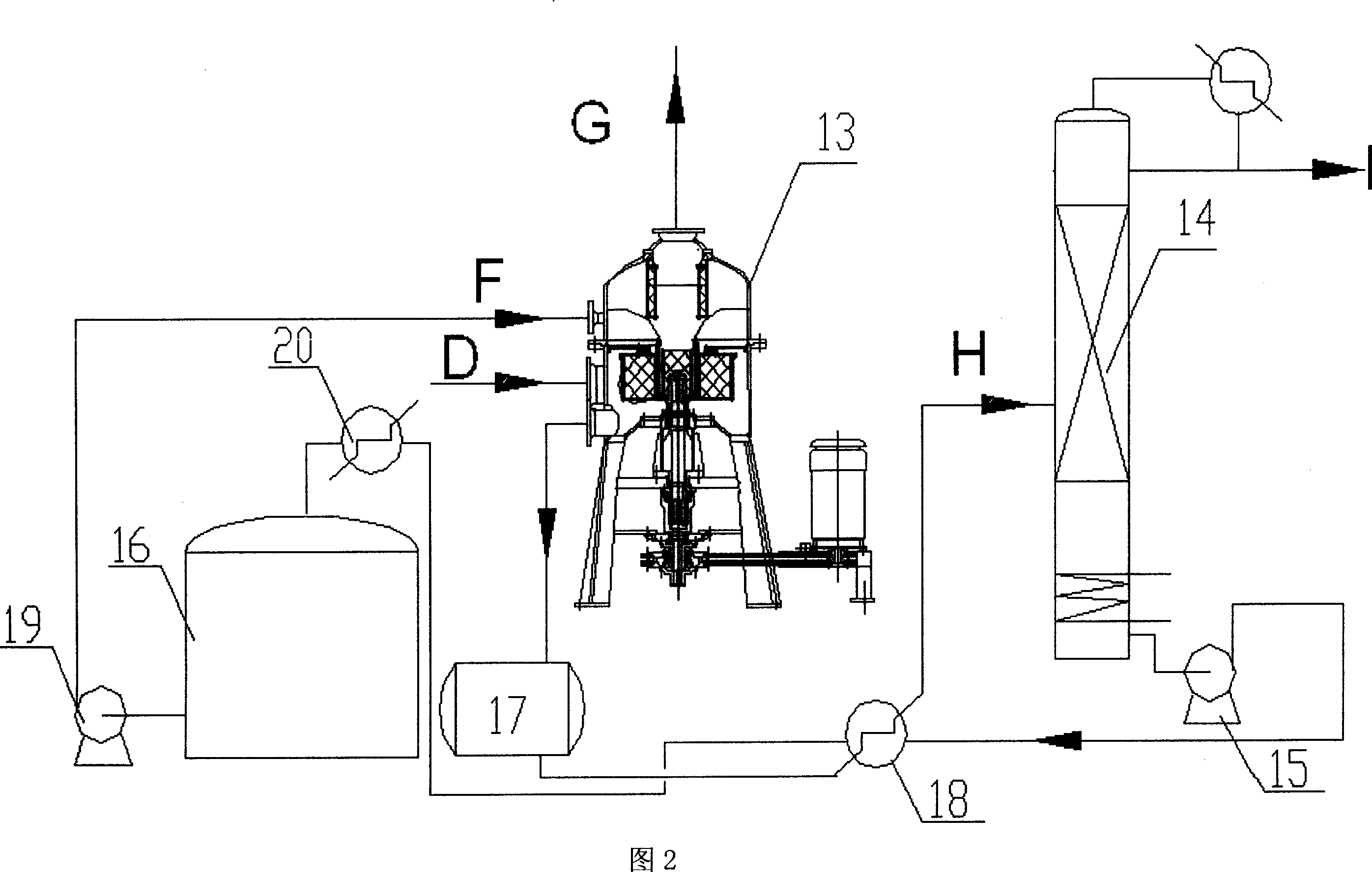

Condensation and recovery of oil from pyrolysis gas

InactiveUS7101463B1Large specific surface areaTemperature controlMultiple-effect/fractional condensationDirect heating destructive distillationWater vaporProduct gas

A system and process for the recovery of oil from the pyrolysis of material containing hydrocarbons such as shredded vehicle tires. The system utilizes a pair of sequentially positioned packed towers to recover at least 95% of the oil contained in the pyrolysis gases. The first packed tower operates above the dew point of the water vapor in the pyrolysis gases to insure that no water is condensed and obtain a primary oil fraction having oil with a high flash point of about 60° C. or greater and a primary vapor fraction containing additional oils, fuel gases and water vapor. The primary vapor fraction is fed to the second packed tower which operates below the dew point of the water vapor to condense the water and oil having a low flash point of 34° C. or below, and provide a secondary vapor fraction containing valuable fuel gases.

Owner:METSO MINERALS IND INC

Use of low pressure distillate as absorber oil in a FCC recovery section

InactiveUS7074323B2Less equipmentImprove throughputThermal non-catalytic crackingCatalytic crackingNaphthaDistillation

A process for the recovery of gaseous products from the product mixture obtained by contacting a hydrocarbon feed with a catalyst in a fluid catalytic cracking process, wherein the liquid, obtained by separating the top product of main fractionators into gaseous and liquid fraction, when supplied to the absorber has a temperature of between about 8–25 DEG C. This liquid may be pre-saturated with gaseous top product from absorber; or also a high boiling fraction (cat cracker naphtha / light cycle oil) may be first separated from this liquid by distillation.

Owner:SHELL OIL CO

A kind of sulfuration method of hydrogenation catalyst and its application

ActiveCN102284299AGood vulcanization rateNo abnormal smellCatalyst regeneration/reactivationCatalyst activation/preparationPtru catalystHydrogenation reaction

The invention relates to a method for pre-vulcanizing a hydrogenation catalyst outside a hydrogenation reactor and activating the hydrogenation catalyst in the hydrogenation reactor. The method comprises the following steps of: (1) pre-vulcanizing the catalyst outside the hydrogenation reactor; (2) passivating the catalyst; and (3) reactivating the catalyst. A vulcanization method for the hydrogenation catalyst provided by the invention can guarantee high vulcanization rate of the catalyst; the passivated catalyst does not have abnormal odor and does not release hydrogen sulfide gas when being in contact with air or vapor; and the catalyst does not spontaneously combust and is not required to be protected by inert gas. Storage, transportation and filling methods and the like of the catalyst are simple and convenient. The catalyst can reach an activated state in a few hours during reactivation of an atmosphere containing a vulcanizing agent and hydrogen, is short in processing time, convenient to operate and has high catalytic performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572365B2Quick upgradeReduce sulfur emissionsThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas) and to reducing the total acid number (TAN) of the liquid product. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

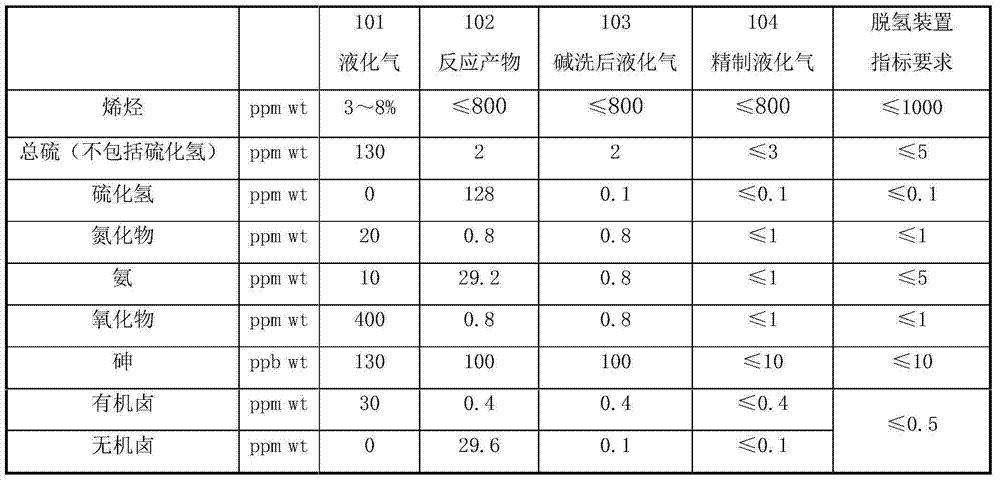

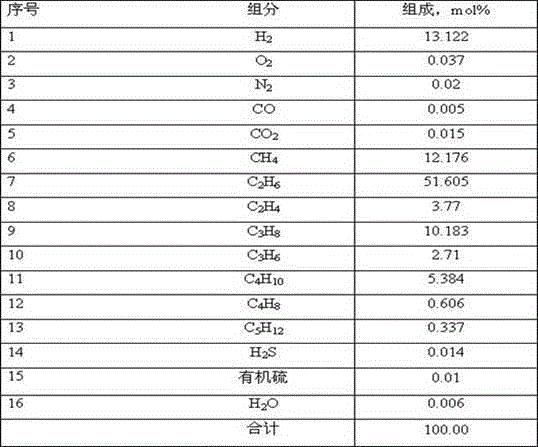

High-temperature hydrogenation and purification process for liquefied gas materials

The invention relates to a purification process of liquefied gas and particularly provides a high-temperature hydrogenation and purification process for liquefied gas materials. The high-temperature hydrogenation and purification process is characterized by comprising the following steps: (1) carrying out heat exchange on raw material liquefied gas and a reactor outlet product in a heat exchanger, heating by a heating furnace to a reaction temperature, then feeding the material into a reactor from the top, carrying out saturation hydrogenation on olefin in the material to obtain alkane, and respectively hydrogenating and converting sulfide, oxide, nitride and halide into hydrogen sulfide, water, ammonia and hydrogen halide; (2) carrying out sufficient heat exchange on the reactor outlet product and the raw material by an efficient heat exchanger, carrying out water cooling by a water cooler and enabling the material to enter a gas-liquid separation tank, compressing a flashing gas phase and fresh hydrogen by a compressor and circulating to the raw material liquefied gas; (3) enabling the flashing liquid phase to enter an alkali washing deposition tank and carrying out fiber membrane alkali washing to remove hydrogen sulfide, ammonia and hydrogen halide; (4) enabling the material which is subjected to the alkali washing to enter a dearsenicator, and removing arsenic and metal to obtain refined liquefied gas. The high-temperature hydrogenation and purification process mainly aims at a project which is very strict in requirement on the impurity content of a catalyst, and is short in flow, small in investment, low in cost and less in solid wastes.

Owner:山东海成石化工程设计有限公司

Catalysts grading method for coker dry gas hydrogenation for preparation of ethylene cracking feed

ActiveCN105273756AHigh activityLow costGaseous mixture working upHydrogenation reactionReaction temperature

The invention discloses a catalysts grading method for coker dry gas hydrogenation for preparation of ethylene cracking feed. According to the method, coker dry gas is contacted with a hydrogenation catalyst to carry out a hydrogenation reaction, and olefin in coker dry gas is saturated to further obtain an ethylene cracking feedstock, wherein three hydrogenation reaction zones are successively arranged in a hydrogenation reactor. By reasonable grading of catalysts in different systems, advantages of the respective catalysts during different hydrogenation processes are fully performed. By synergism among the catalysts and by cooperation of reaction temperature gradients of the three hydrogenation reaction zones, activity of the monolithic catalyst is raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

Absorbent composition containing molecules with a hindered amine and a metal sulfonate, phosphonate or carboxylate structure for acid gas scrubbing process

Owner:EXXON RES & ENG CO

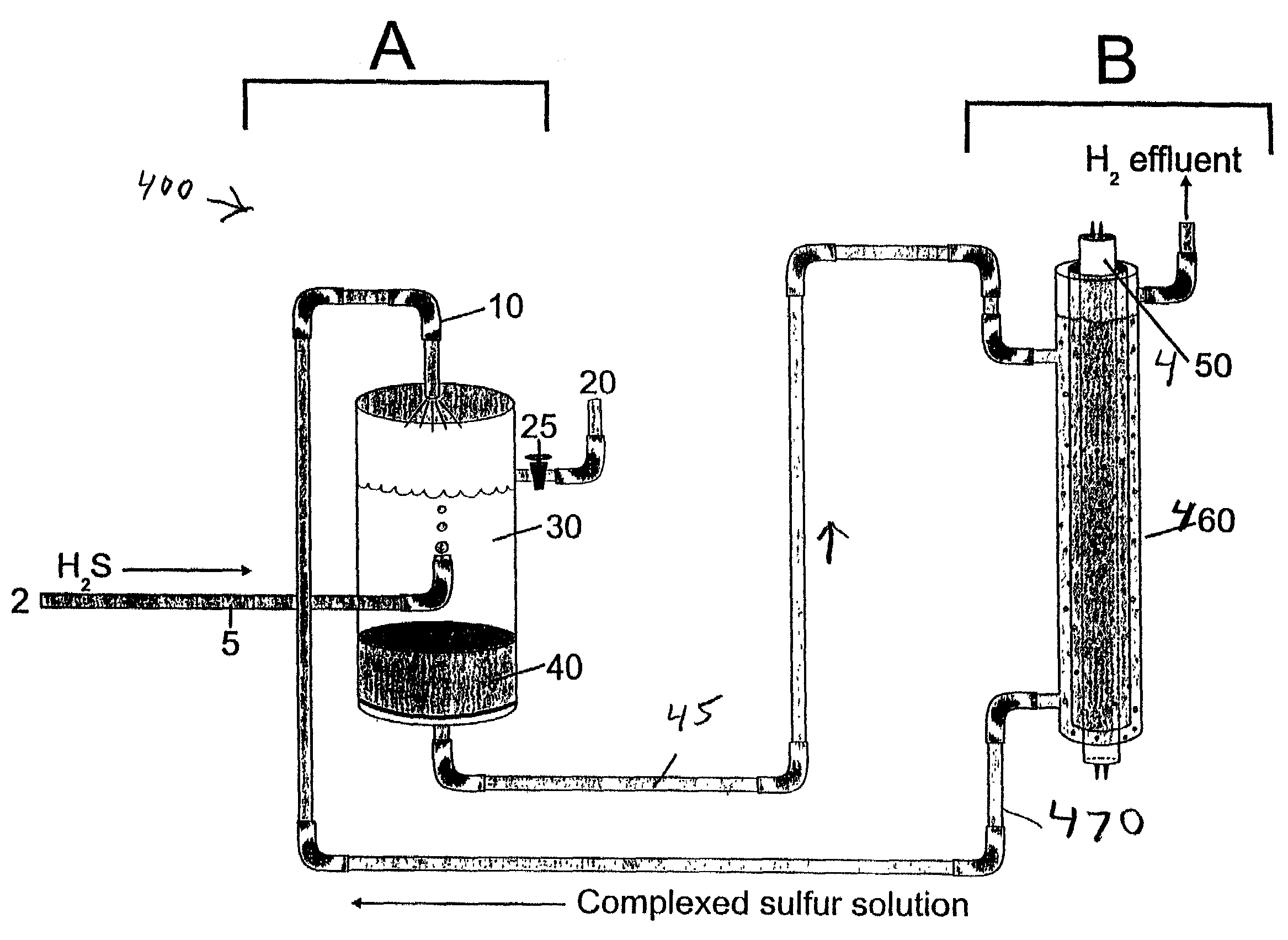

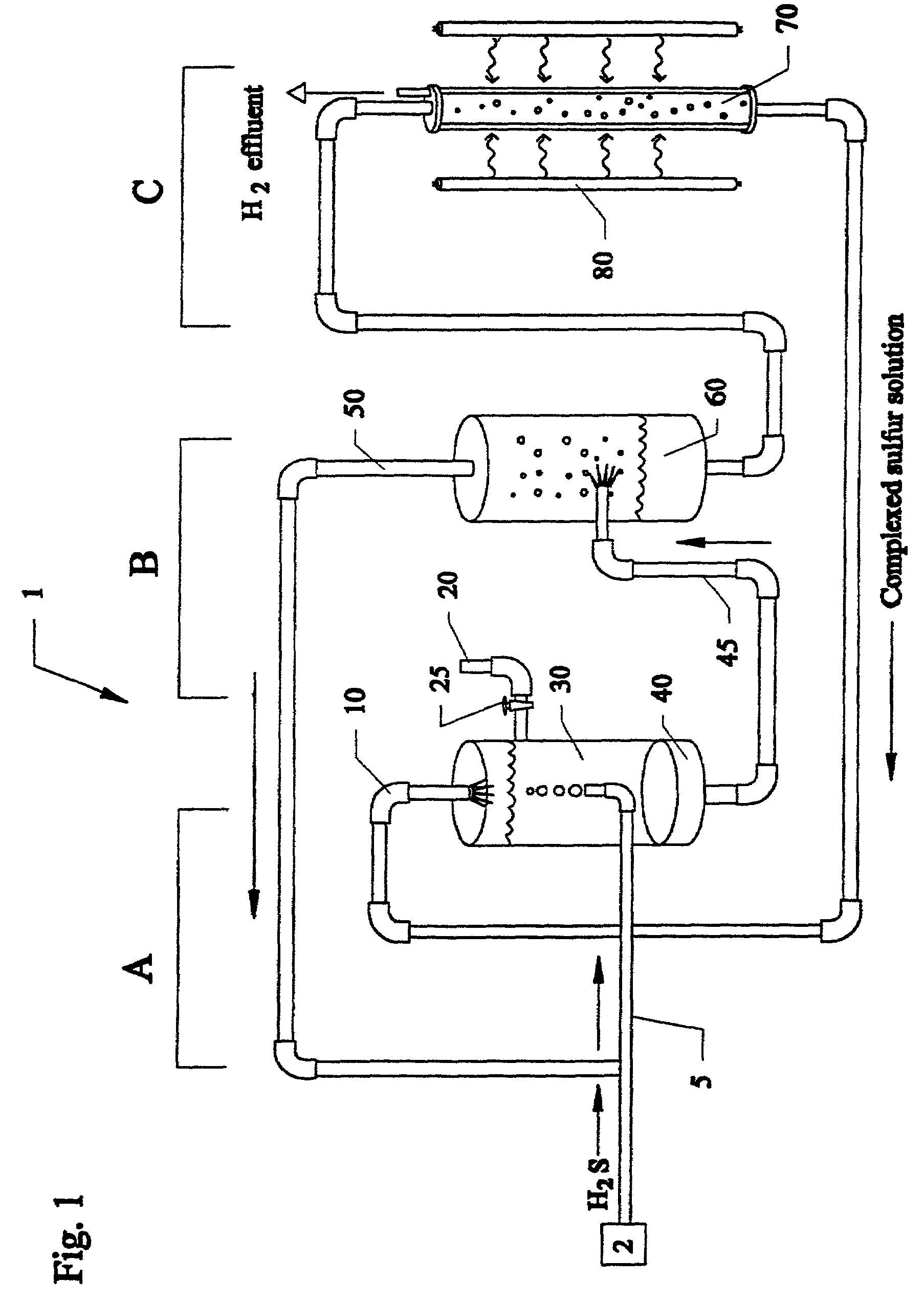

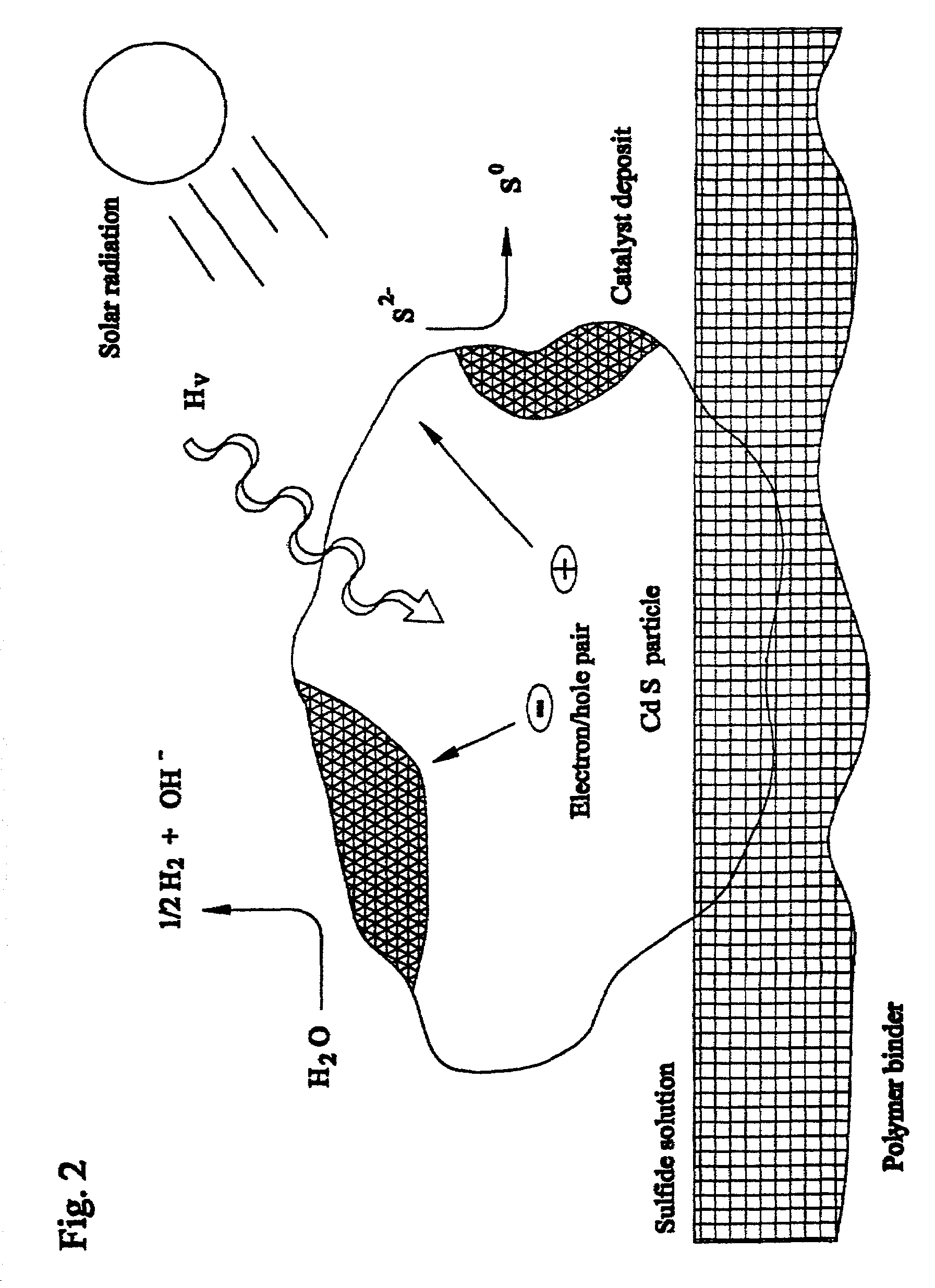

UV photochemical option for closed cycle decomposition of hydrogen sulfide

Methods and systems for separating hydrogen and sulfur from hydrogen sulfide(H2S) gas. Hydrogen sulfide(H2S) gas is passed into a scrubber and filtration unit with polysulfide solution. Interaction frees elemental sulfur which is filtered, excess continues to a stripper unit where the excess H2S is removed. The excess H2S returns to the scrubber and filtration unit, while the sulfide solution passes into a photoreactor containing a photocatalyst and a light source. The sulfide solution is oxidatively converted to elemental sulfur and complexed with excess sulfide ion to make polysulfide ion, while water is reduced to hydrogen. Hydrogen is released, while the polysulfide solution is fed back to the scrubber unit where the system operation repeats. In a second embodiment, the photocatalyst is eliminated, and the hydrogen sulfide solution is directly illuminated with ultraviolet radiation with a light source such as a low pressure mercury lamp operating at approximately 254 nm.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

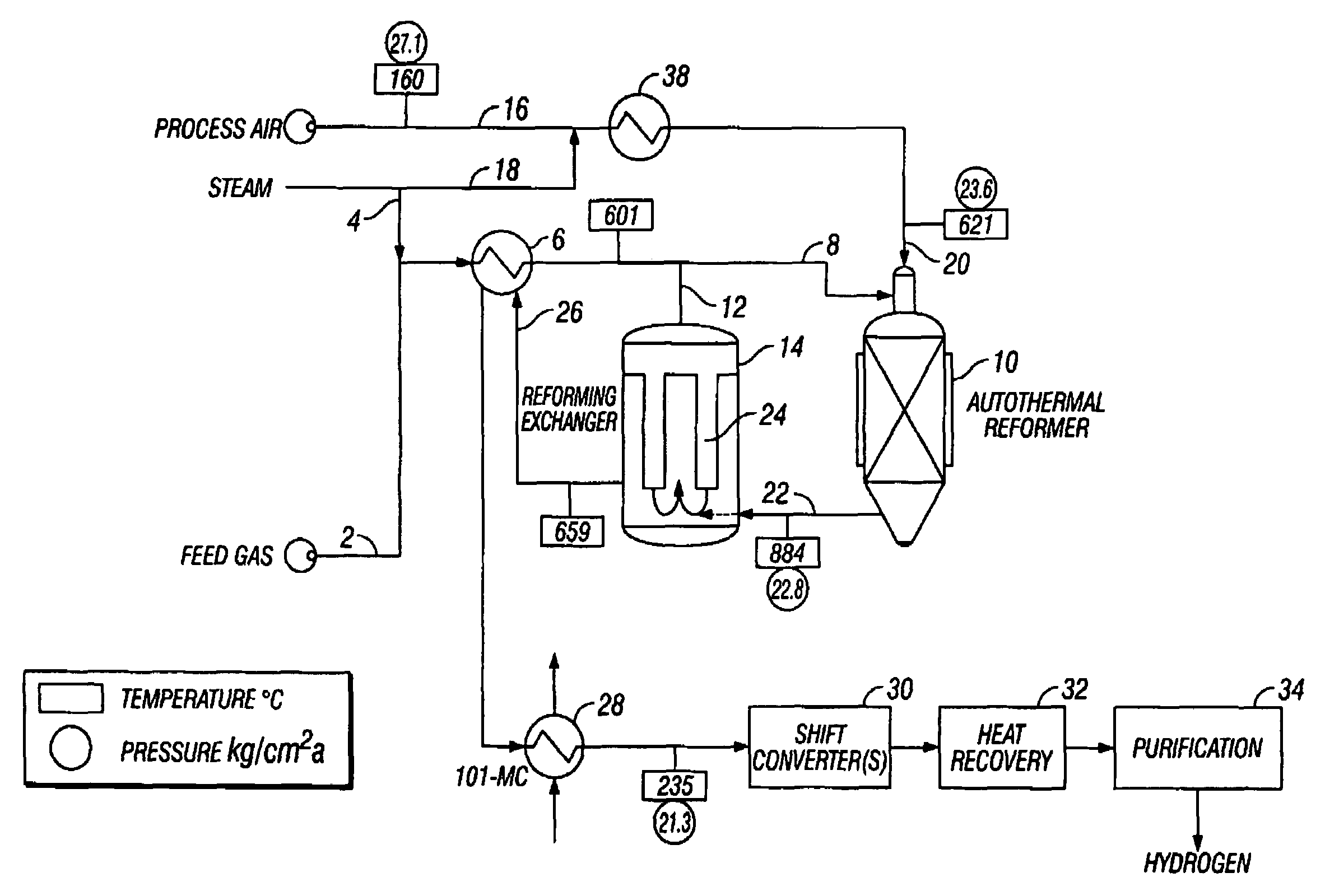

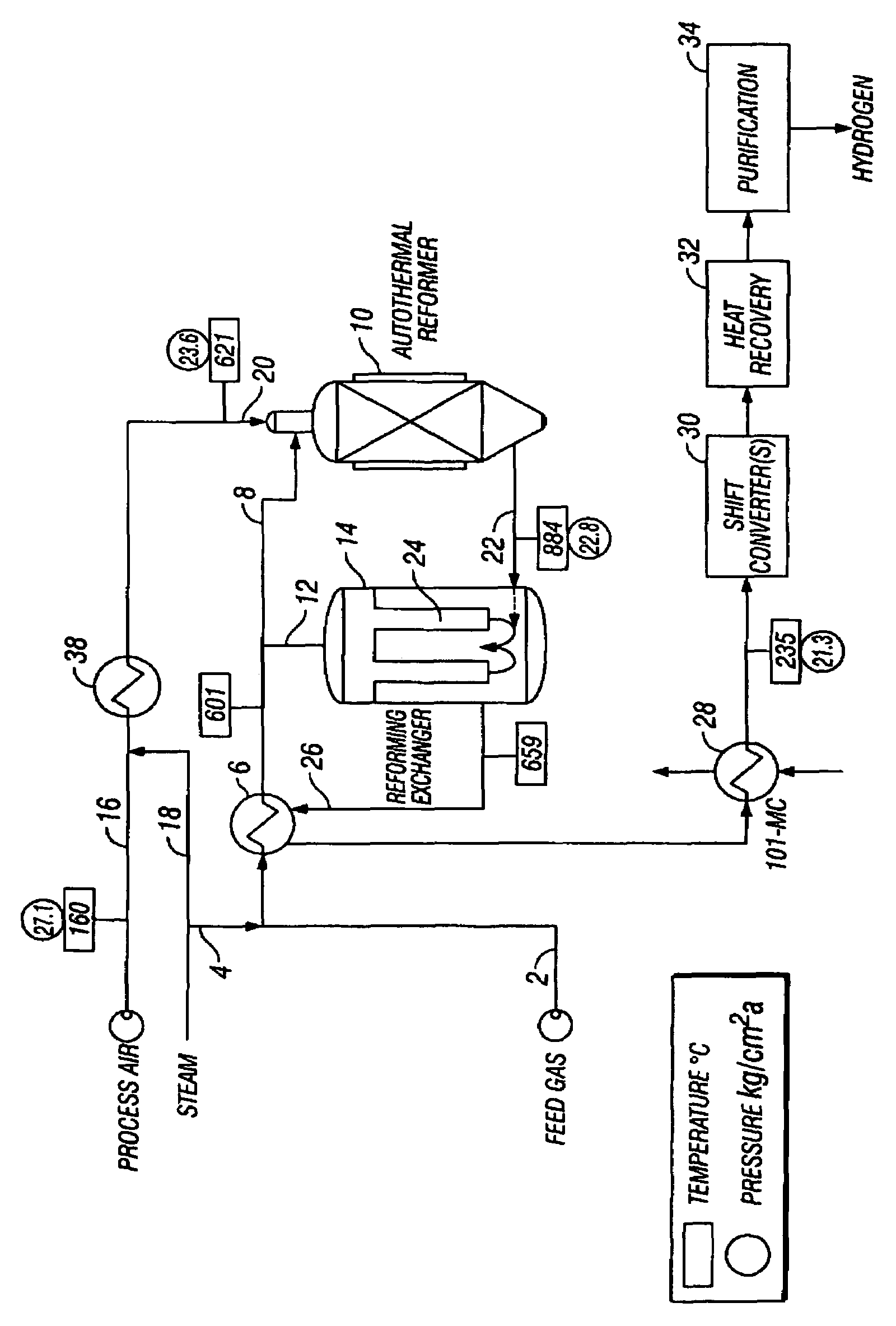

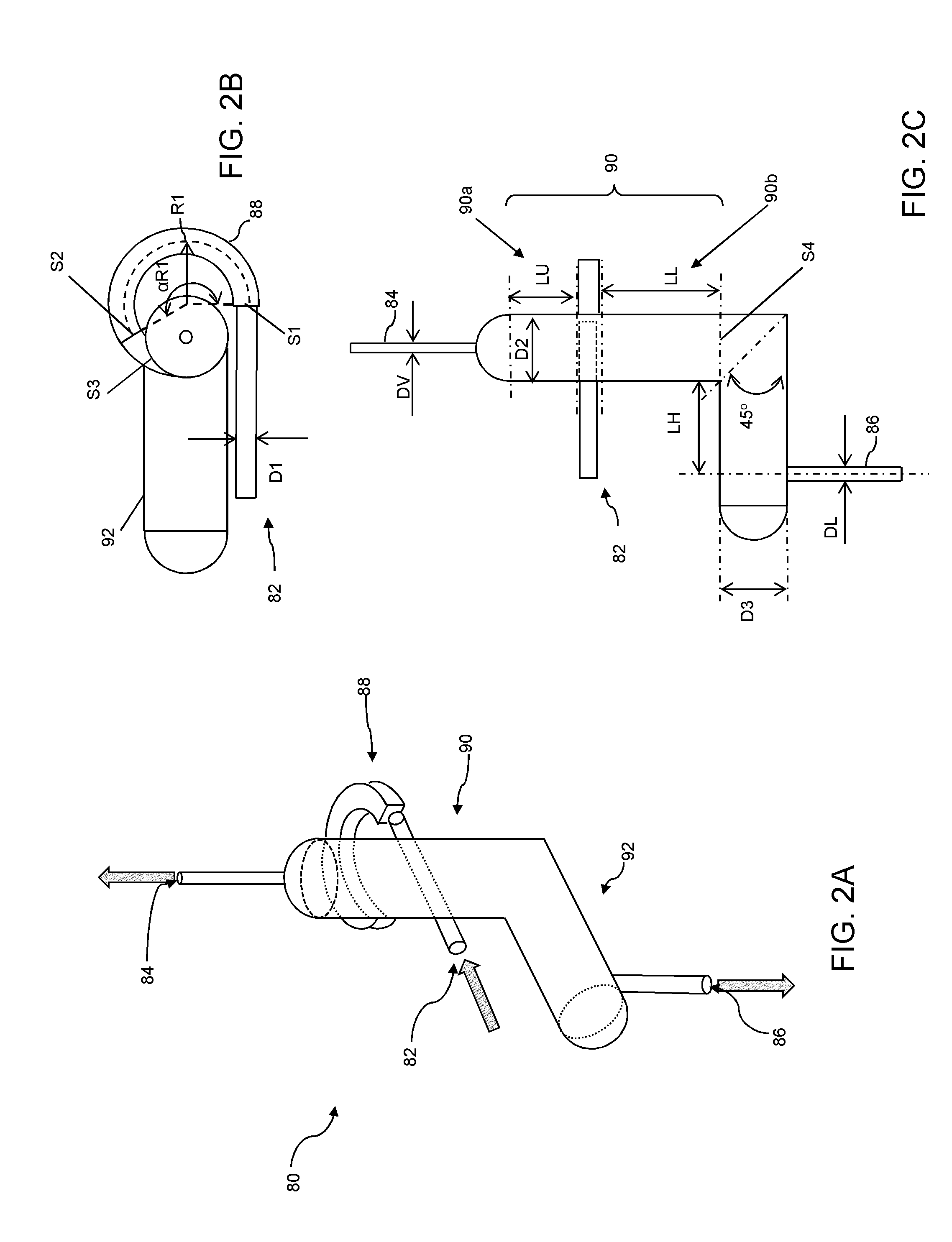

Autothermal reformer-reforming exchanger arrangement for hydrogen production

ActiveUS7220505B2Lower cost of capitalGreat ease of operationHydrogenHydrocarbon from carbon oxidesMethane reformerSyngas

Low-energy, low-capital hydrogen production is disclosed. A reforming exchanger 14 is placed in parallel with an autothermal reformer (ATR) 10 to which are supplied a preheated steam-hydrocarbon mixture. An air-steam mixture is supplied to the burner / mixer of the ATR 10 to obtain a syngas effluent at 650°-1050° C. The effluent from the ATR is used to heat the reforming exchanger, and combined reformer effluent is shift converted and separated into a mixed gas stream and a hydrogen-rich product stream. High capital cost equipment such as steam-methane reformer and air separation plant are not required.

Owner:KELLOGG BROWN & ROOT LLC

Butter inhibitor for ethylene unit alkaline washing tower

InactiveCN101838553ASuppress generationAntioxidantGaseous mixture working upTreatment apparatus corrosion/fouling inhibitionAnoxomerMaterials science

The invention relates to a butter inhibitor used for an ethylene unit alkaline washing tower. Problems of the background technology are solved, so the butter inhibitor has the performance of oxidation resistance, polymerization inhibition, cleanness, dispersion, metallic ion passivation and a better inhibition effect. The butter inhibitor is prepared from the following raw materials of: 1 to 30 percent of antioxidant, 5 to 40 percent of polymerization retarder, 2 to 30 percent of dispersant, 5 to 25 percent of metallic ion passivating agent and the balance of solvent; and the butter inhibitor is prepared by heating, uniformly mixing and cooling the materials.

Owner:浙江杭化科技股份有限公司

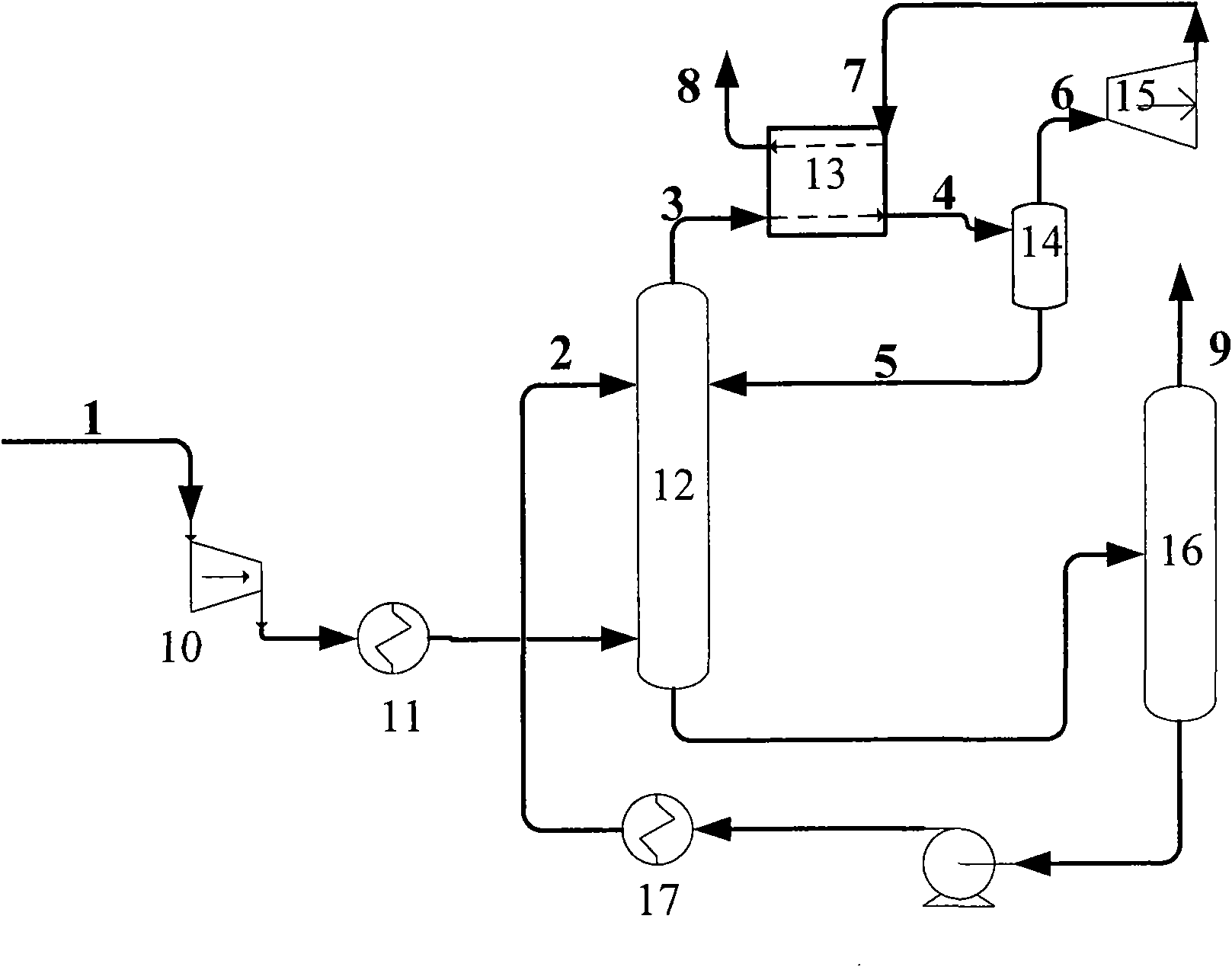

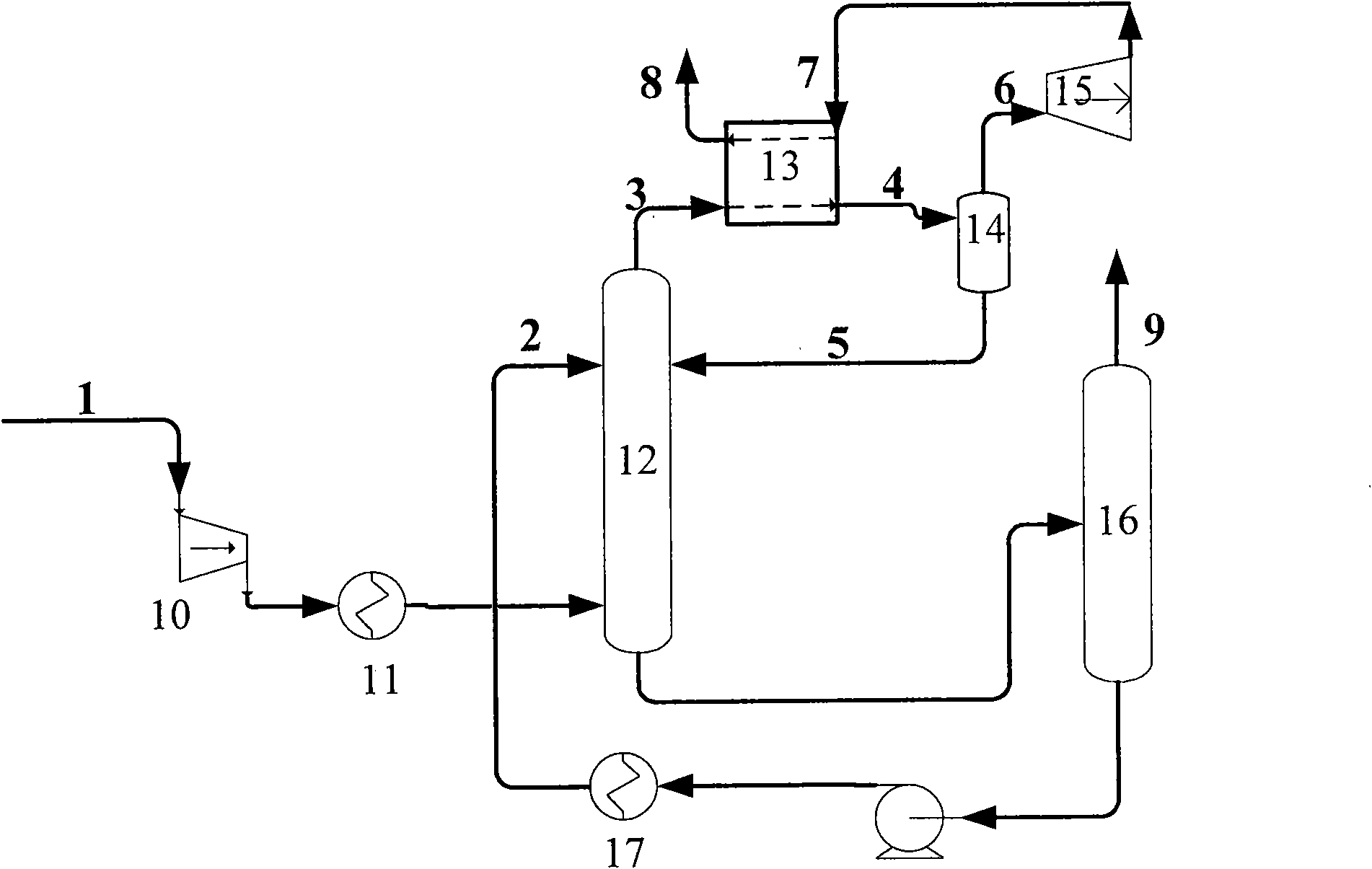

Method for separating refinery catalytic dry gas by adopting oil absorption

The invention discloses a method for separating refinery catalytic dry gas by adopting oil absorption. The method comprises the following steps: using a C4 fraction as an absorbent, keeping the absorption temperature at 5 to 15 DEG C, and recycling the refrigeration capacity by adopting an expander and a cold box. Through the method of the invention, the recovery rates of olefin and alkane are greatly improved, and meanwhile, the circulating quantity and the loss quantity of the absorbent are reduced, the energy consumption is reduced, and the problems of large investment and high energy consumption in the existing traditional process for recycling the olefin and the alkane from refinery dry gas are solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

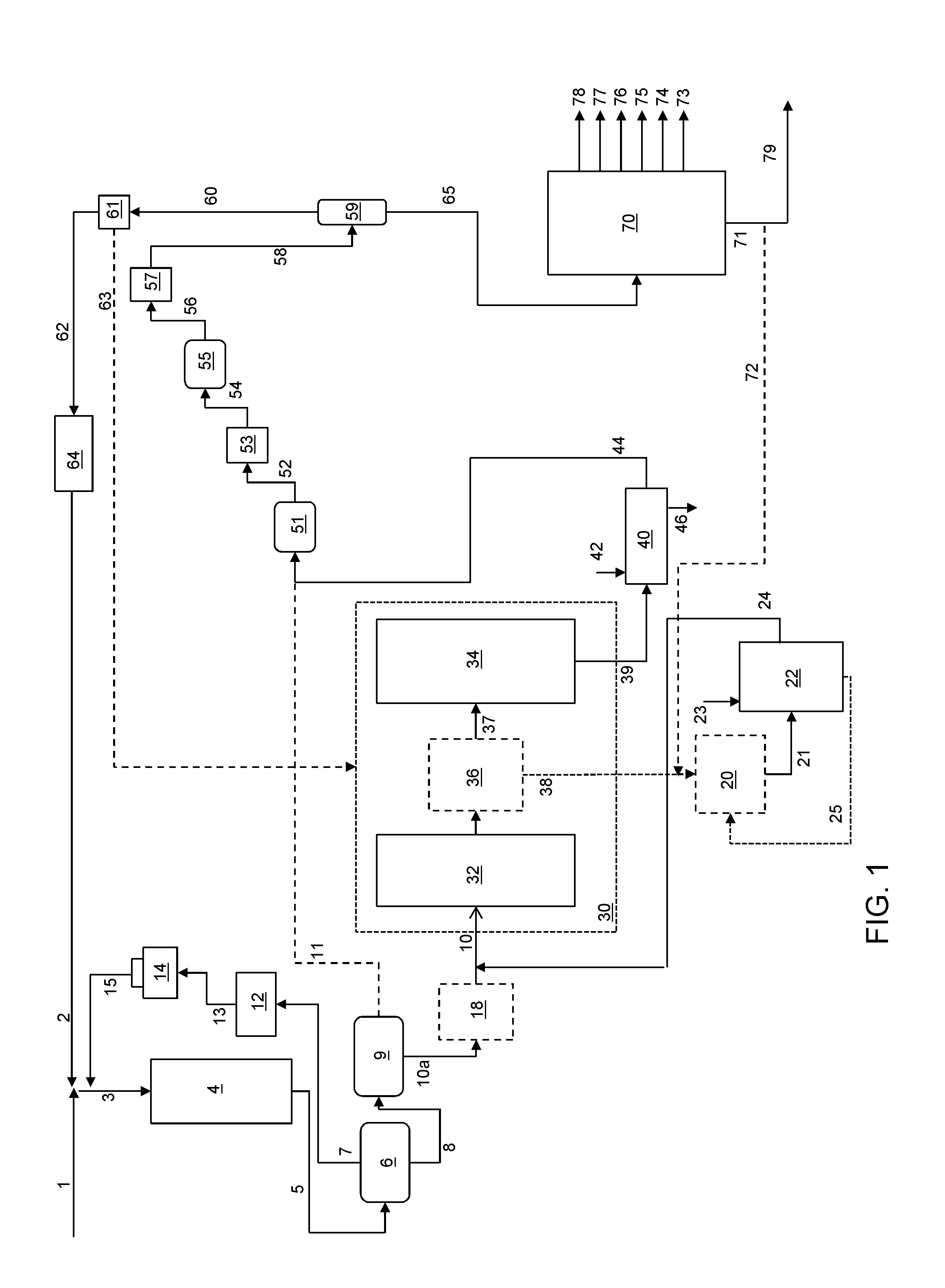

Refinery mixed dry gas recovery system and recovery method

ActiveCN104557387AReduce total usageReduce lossesHydrocarbonsGaseous mixture working upUnsaturated hydrocarbonGasoline

The invention discloses a refinery mixed dry gas recovery system and a recovery method. The system comprises an absorption tower, a desorption tower, a rough separation tower, a purification device, a gasoline absorption tower and a gasoline desorption tower, wherein a compressor is connected with a heat exchanger and then is connected with the absorption tower, the top of the absorption tower is connected with the gasoline absorption tower, and the bottom of the absorption tower is connected with the desorption tower; the top of the desorption tower is connected with the purification device and then is connected with the rough separation tower, the bottom of the gasoline absorption tower is connected with the gasoline desorption tower, the top of the gasoline desorption tower is connected with the upper part of the absorption tower, and the bottom of the gasoline desorption tower is connected with the upper part of the gasoline absorption tower. According to the recovery system, a C2 component is recovered from dry gas through one set of absorption-desorption, a tower top gas phase of the desorption tower enters the rough separation tower, and an entrained absorbent is recovered through another set of absorption-desorption; ethylene-rich gas is recovered from the tower top of the rough separation tower and is delivered to an ethylene unit demethanizer, and ethane-rich gas is recovered from a reactor of the rough separation tower and is delivered to an ethylene unit cracking furnace. According to the recovery method disclosed by the invention, the flow is simple, the recovery rate is high, saturated hydrocarbons and unsaturated hydrocarbons are treated separately, and the operation of an ethylene unit is hardly affected.

Owner:CHINA PETROLEUM & CHEM CORP +1

Integrated hydroprocessing, steam pyrolysis and slurry hydroprocessing of crude oil to produce petrochemicals

ActiveUS20130248417A1Increased paraffinicityReduce pollutant contentThermal non-catalytic crackingPhysical/chemical process catalystsSteam pyrolysisSlurry

Crude oil is charged to a hydroprocessing zone in the presence of hydrogen operating under conditions effective to produce a hydroprocessed effluent, which is thermally cracked in the presence of steam in a steam pyrolysis zone to produce a mixed product stream. Heavy components, which are derived from one or more of the hydroprocessed effluent, a heated stream within the steam pyrolysis zone, or the mixed product stream catalytically cracking are charged to a slurry hydroprocessing zone to produce a slurry intermediate product which is then thermally cracked. Olefins and aromatics are recovered from the separated mixed product stream as product.

Owner:SAUDI ARABIAN OIL CO

Process flow for raw material pretreatment portion of catalytic dry gas produced phenylethane

The invention discloses a predisposing technological flow path of ethylbenzene through catalyzing dried gas, which comprises the following steps: adsorbing propylene; desorbing ethylene; desorbing propylene; adding raw material to strip propylene; washing most of MEDA; entering standard dried gas in the delivery tank; entering into propylene adsorbing tower; draining purified dried gas from top of propylene adsorbing tower; making one path as cool material in the ethylene stripping tower and one path to exchange heat with base material of propylene stripping tower under 10-300 deg.c in the ethylene stripping tower; desorbing ethylene component; draining ethylene gas; returning in the dried gas delivery tank; circulating between ethylene stripping tower and propylene stripping tower; desorbing propylene component from adsorbant with 150ppm-0.7% dried propylene in the stripped propylene.

Owner:中国寰球工程有限公司辽宁分公司

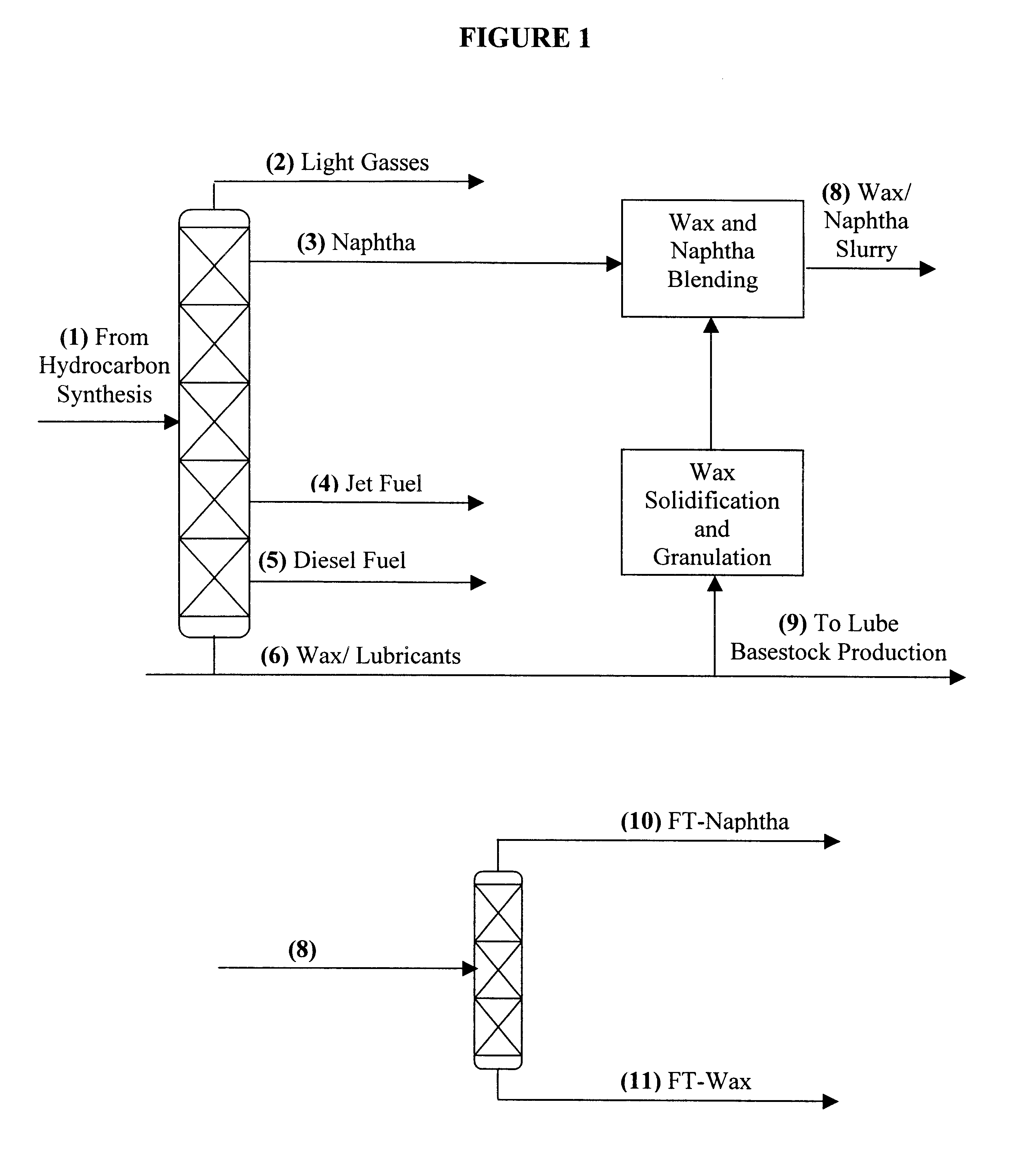

Fischer-Tropsch wax and hydrocarbon mixtures for transport (law938)

The invention is a process for producing a mixture of Fischer-Tropsch product that is solid at ambient conditions (between 32° F. and 95° F.), such as wax, and hydrocarbon liquid, such as naphtha, that can be pumped at ambient temperature (between 32° F. and 95° F.). The temperature of the mixture is controlled below the melting point of the Fischer-Tropsch product. The present invention provides for the transport of Fischer-Tropsch product from a remote location in a readily available medium, such as naphtha, via pipeline, tanker or railcar. At the completion of the transport, the hydrocarbon liquid and Fischer-Tropsch product are separated by conventional methods such as flashing, distillation, or filtration with minimal contamination from the hydrocarbon liquid.

Owner:EXXON RES & ENG CO

Method for removing acid gases in cracked gas

ActiveCN101092576AGood dispersionHigh volumetric mass transfer coefficientGaseous mixture working upGas phaseProduct gas

This invention provides a method for removing acidic gas from cracked gas. The method comprises: introducing cracked gas containing acidic gas through a gas inlet into a super-gravitational revolving bed device, adequately contacting with alkaline absorbent or water in the rotor filler layer, removing acidic gas, and exhausting through a gas outlet to obtain cracked gas with acidic gas content below 1 ppm. The method has such advantages as low apparatus investment, low energy consumption, low operation cost, and low apparatus space occupation.

Owner:CHINA PETROLEUM & CHEM CORP +2

Process for pretreating cracked gas before caustic tower treatment in ehtylene plants

InactiveUS6235961B1Improve efficiencyIncrease capacityThermal non-catalytic crackingCatalytic crackingProduct gasTower

An inline, high-shear mixer is provided in a cracked gas stream upstream of a caustic tower in an ethylene production unit. Spent caustic is withdrawn from the bottom of the caustic tower and pumped to the mixer, where the spent caustic mixes with and absorbs acid gas components from the cracked gas stream. The spent caustic is separated from the cracked gas, forming a partially treated cracked gas stream. The partially treated cracked gas stream is then fed to the caustic tower. Polymer deposition in the caustic tower is reduced because polymeric material is formed when the cracked gas stream is mixed with the spent caustic and is removed before the cracked gas stream is fed to the caustic tower.

Owner:STONE & WEBSTER PROCESS TECH

Selective hydrogenation catalyst for alkadiene

ActiveCN1631526AImprove hydrogenation activityHydrocarbon by hydrogenationGaseous mixture working upAlkadieneHydrogen

This is about a kind of catalyst of adding hydrogen of choosing. The catalyst includes a kind of Oxidize the aluminum placer and Gu and / or Ni in ó°, Mu and / or Wu in ó÷ and alkali metal. Its feature is: the catalyst includes 0.5--8% by weight that is chosen Gu and / or Ni in ó°, 2--15% is chosen Mu and / or Wu in ó÷, >2--8% alkali metal. Compared to the current catalyst, the catalyst offend in the invention has much higher choosing ability and activity in adding hydrogen of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

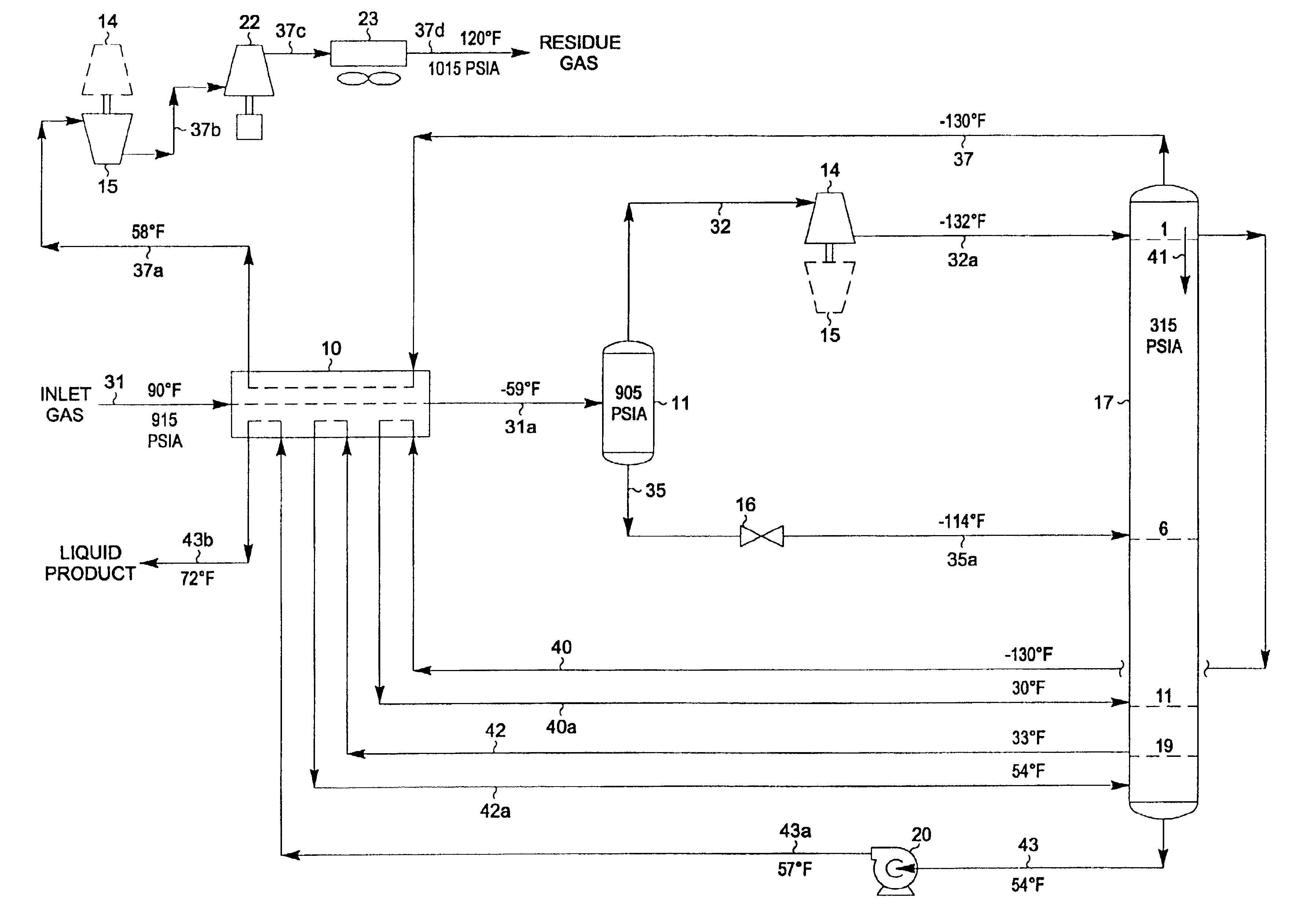

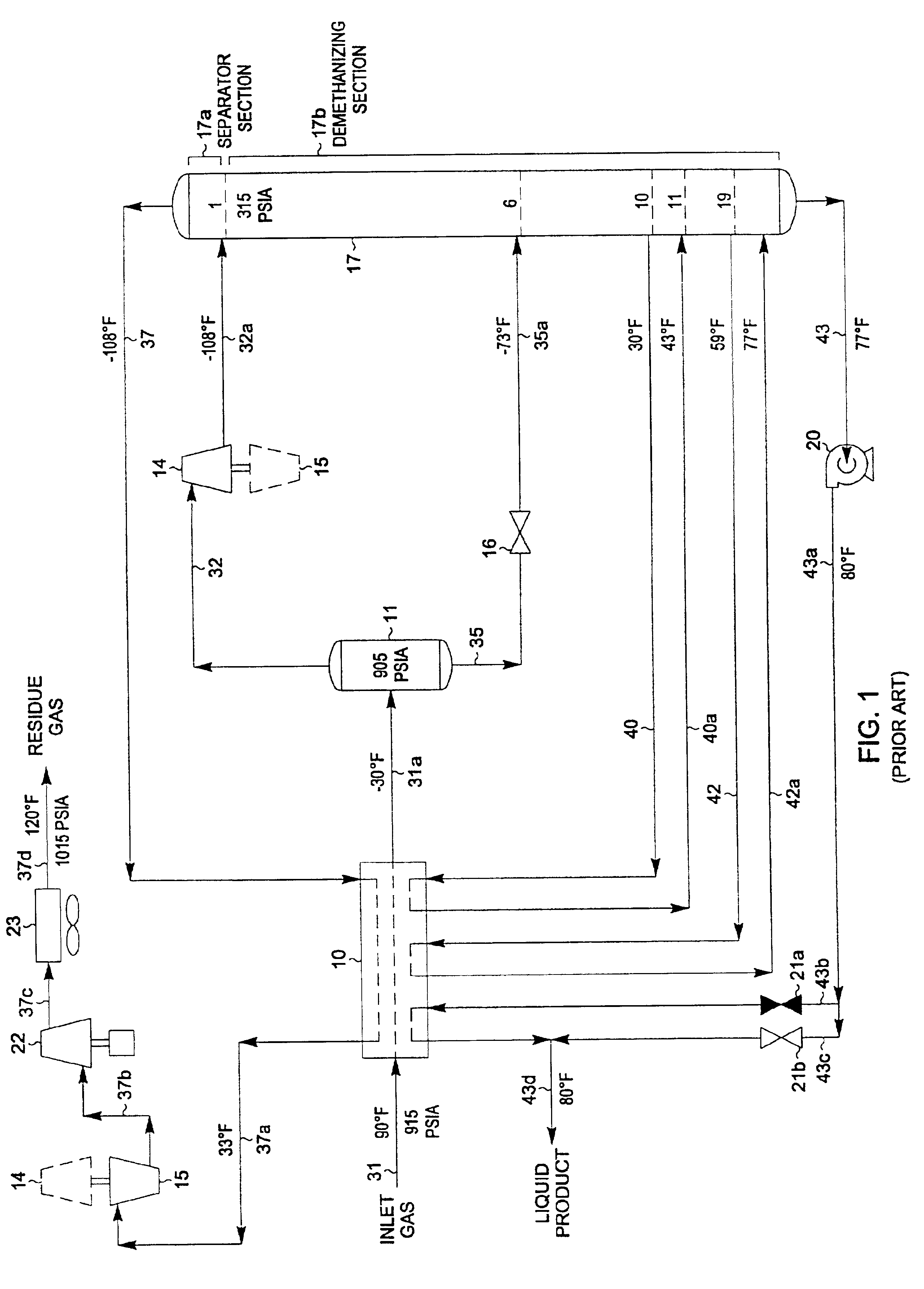

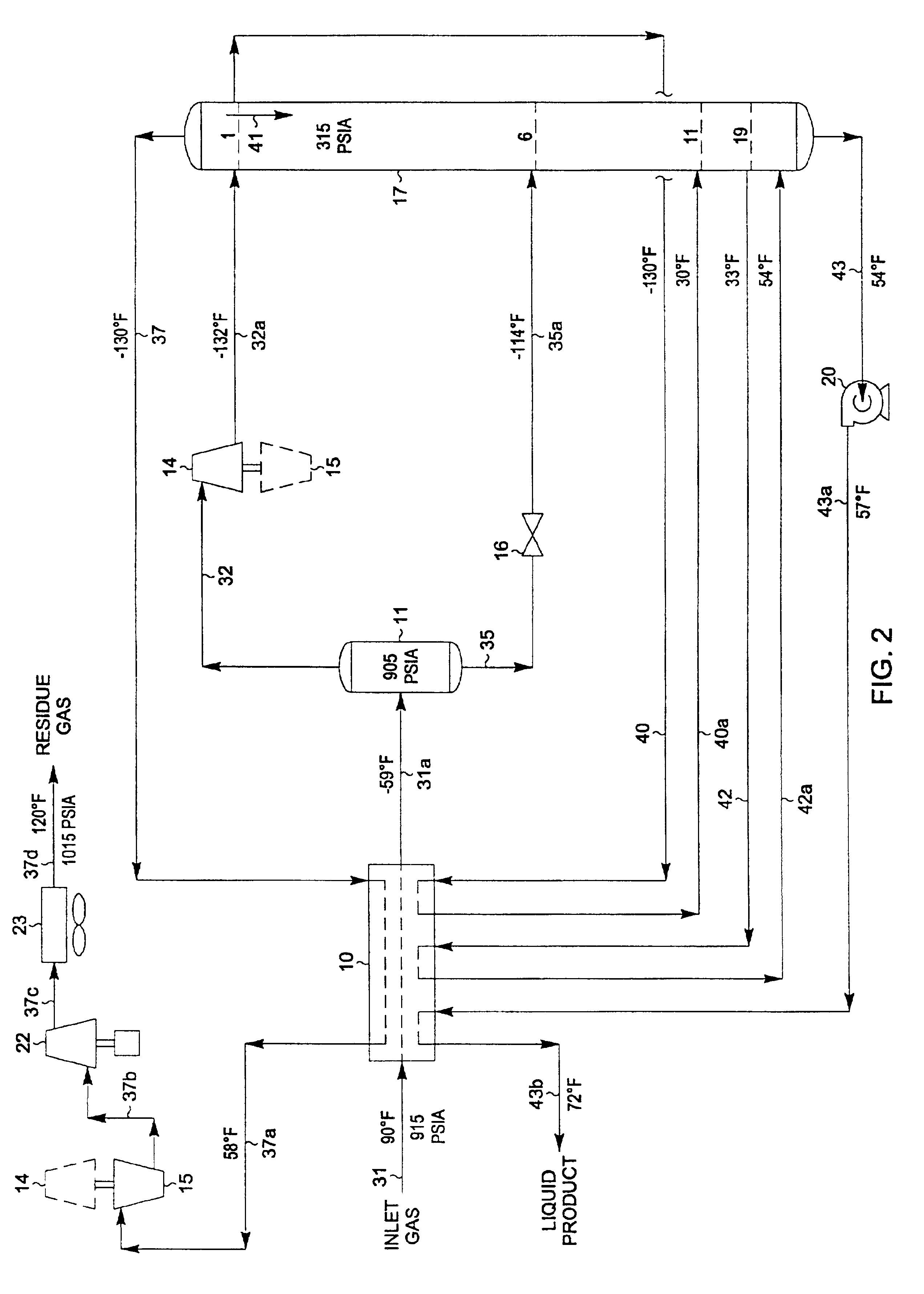

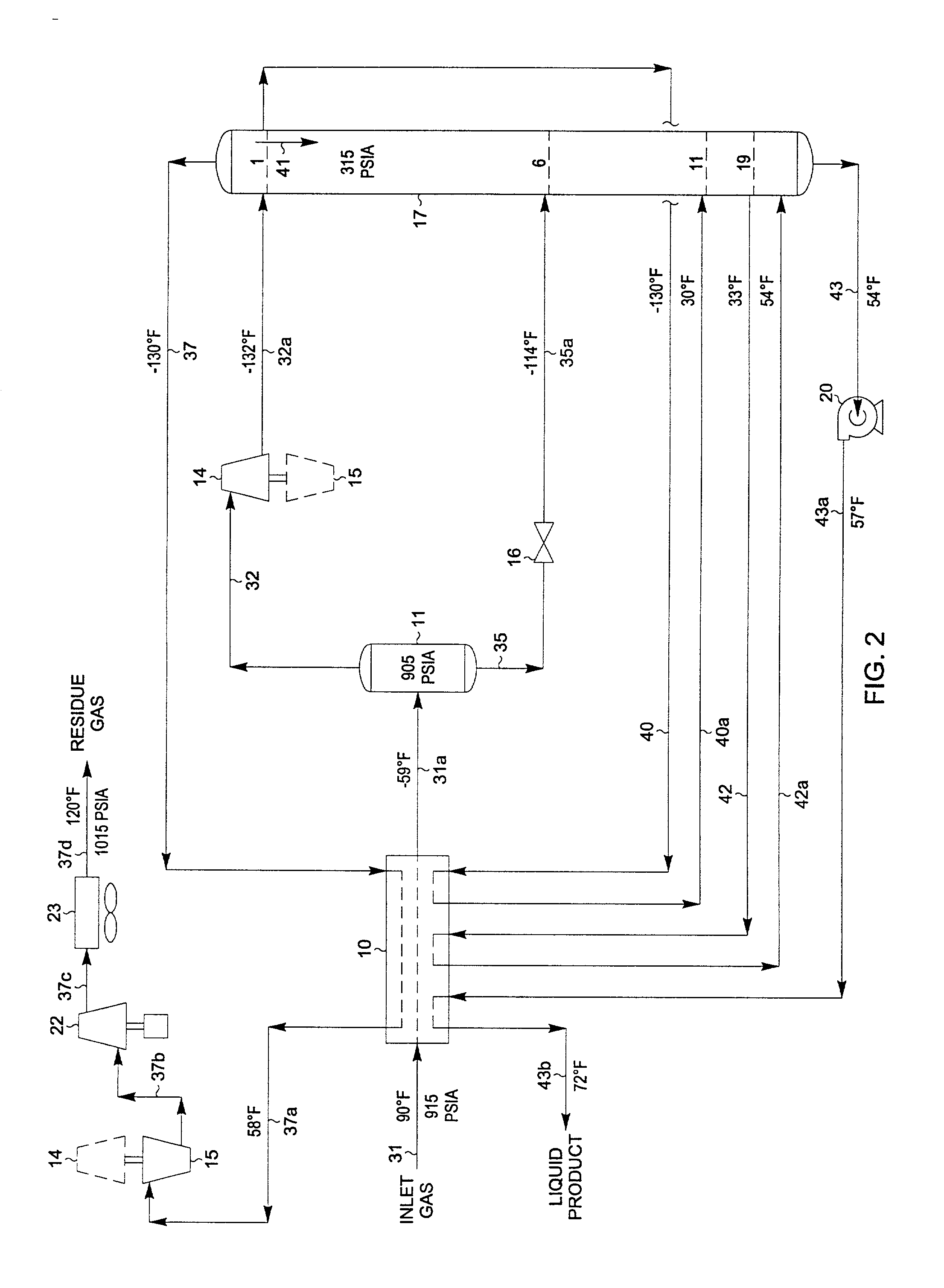

Hydrocarbon gas processing

InactiveUS20020065446A1More dutyReduce the introductionSolidificationLiquefactionReboilerFractionation

A process for the recovery of ethane, ethylene, propane, propylene and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. In recent years, the preferred method of separating a hydrocarbon gas stream generally includes supplying at least portions of the gas stream to a fractionation tower having at least one reboiler, and often one or more side reboilers, to supply heat to the column by withdrawing and heating some of the tower liquids to produce stripping vapors that separate the more volatile components from the desired components. The reboiler and side reboilers (if any) are typically integrated into the feed stream cooling scheme to provide at least a portion of the refrigeration needed to condense the desired components for subsequent fractionation in the distillation column. In the process disclosed, the tower reboiling scheme is modified to use one or more tower liquid distillation streams from a point higher in the column than is used in the conventional reboiling scheme, providing colder stream(s) for the reboiler(s) that allow more effective cooling of the feed streams and thereby improve the efficiency with which the desired components are recovered. In addition, the tower liquid streams withdrawn from a higher point in the column contain larger quantities of the more volatile components, which when vaporized provide better stripping of undesirable components like carbon dioxide without reducing the recovery of the desired components. The heated distillation stream is returned to a lower point on the fractionation tower that is separated from the withdrawal point by at least one theoretical stage.

Owner:UOP LLC

Popular searches

Hydrocarbon purification/separation Liquid hydrocarbon mixture recovery By rectification and condensation Cold treatment separation Carboxylic acid esters preparation Refining by selective hydrogenation Bulk chemical production Hydrocarbon oils treatment products Organic compound preparation Refining with oxygen compounds

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com