Method for separating refinery catalytic dry gas by adopting oil absorption

An oil absorption and dry gas technology, which is applied in the processing of gas mixtures, petroleum industry, and hydrocarbon oil treatment, can solve the problems of high energy consumption, large investment, reduced investment and energy consumption, etc., and achieve low energy consumption and low investment , The effect of improving the recovery rate of ethylene

Active Publication Date: 2010-08-25

CHINA PETROLEUM & CHEM CORP +1

View PDF3 Cites 41 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

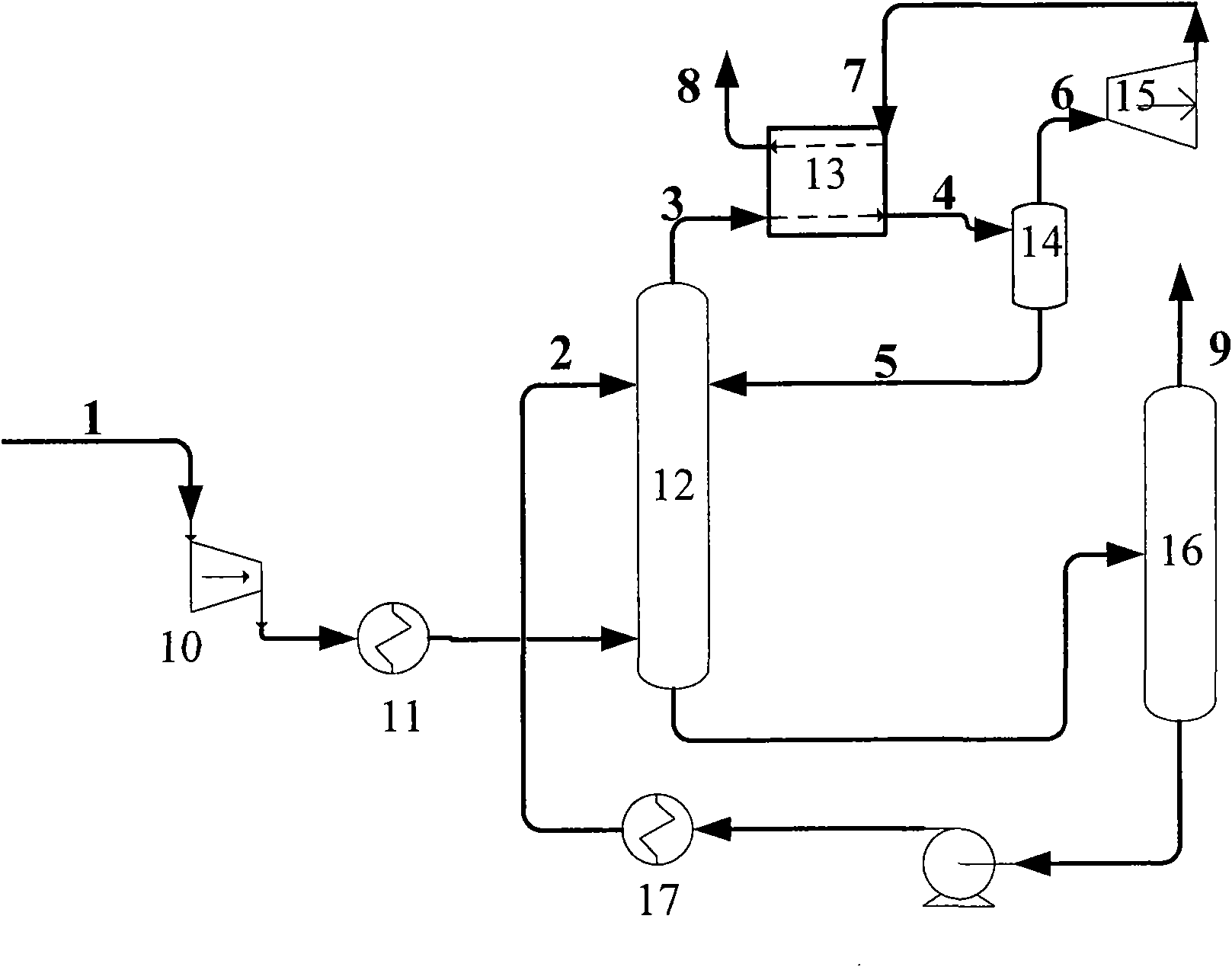

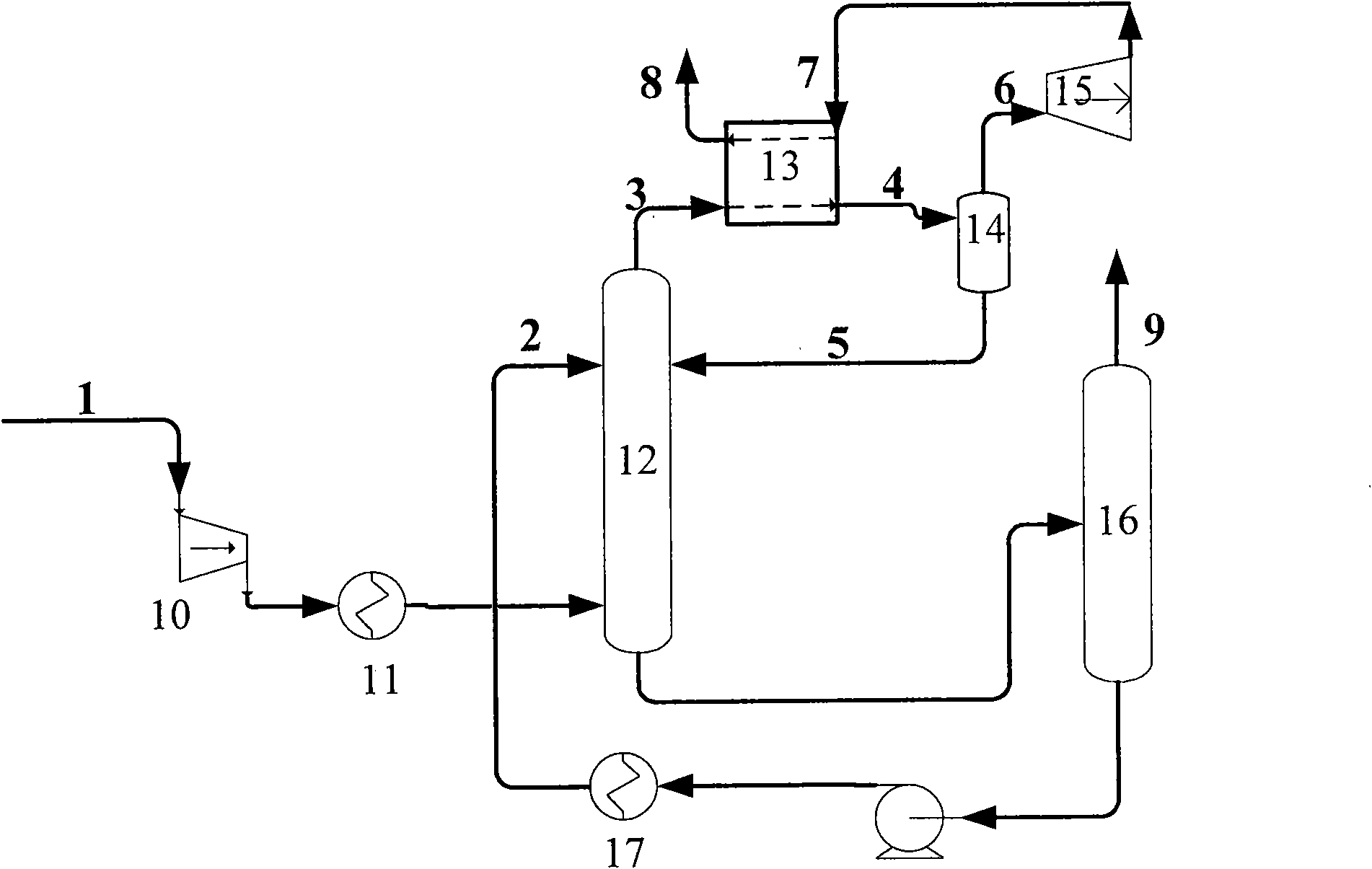

In order to solve the problems of large investment and high energy consumption in the existing technology for recovering ethylene and propylene from refinery dry gas, the present invention proposes a highly efficient method for separating refinery catalytic dry gas by using the oil absorption method. The four fractions are used as absorbent to recover ethylene and propylene, keep the absorption temperature above 5 degrees, use expander and cold box to recover cooling capacity, no ethylene refrigerator is needed, and investment and energy consumption are reduced

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for separating refinery catalytic dry gas by adopting oil absorption. The method comprises the following steps: using a C4 fraction as an absorbent, keeping the absorption temperature at 5 to 15 DEG C, and recycling the refrigeration capacity by adopting an expander and a cold box. Through the method of the invention, the recovery rates of olefin and alkane are greatly improved, and meanwhile, the circulating quantity and the loss quantity of the absorbent are reduced, the energy consumption is reduced, and the problems of large investment and high energy consumption in the existing traditional process for recycling the olefin and the alkane from refinery dry gas are solved.

Description

A method for separating refinery catalytic dry gas by oil absorption technical field The invention relates to a method for separating catalytic dry gas of a refinery, in particular to a method for separating and recovering olefins and alkanes in the catalytic dry gas of a refinery by absorbing carbon four fractions. Background technique Catalytic dry gas in refinery comes from catalytic cracking process. Usually, the content of ethylene in the dry gas is about 12-20 mol%, the content of ethane is about 15-24 mol%, and it also contains alkenes and alkanes such as propylene, propane and butane. At present, catalytic dry gas in refineries is mainly burned as fuel, and its utilization value is low. If the olefins and alkanes in the catalytic dry gas are recovered and sent to the ethylene plant as the raw material for ethylene production, a large amount of cracked raw material oil can be saved, the cost of ethylene production can be greatly reduced, and the enterprise can obtai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G70/06

Inventor 程建民李东风刘智信廖丽华过良王婧

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com