High-temperature hydrogenation and purification process for liquefied gas materials

A purification process and technology for liquefied gas, which is used in the processing of gas mixtures, the petroleum industry, and the treatment of hydrocarbon oil. Good and investment-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

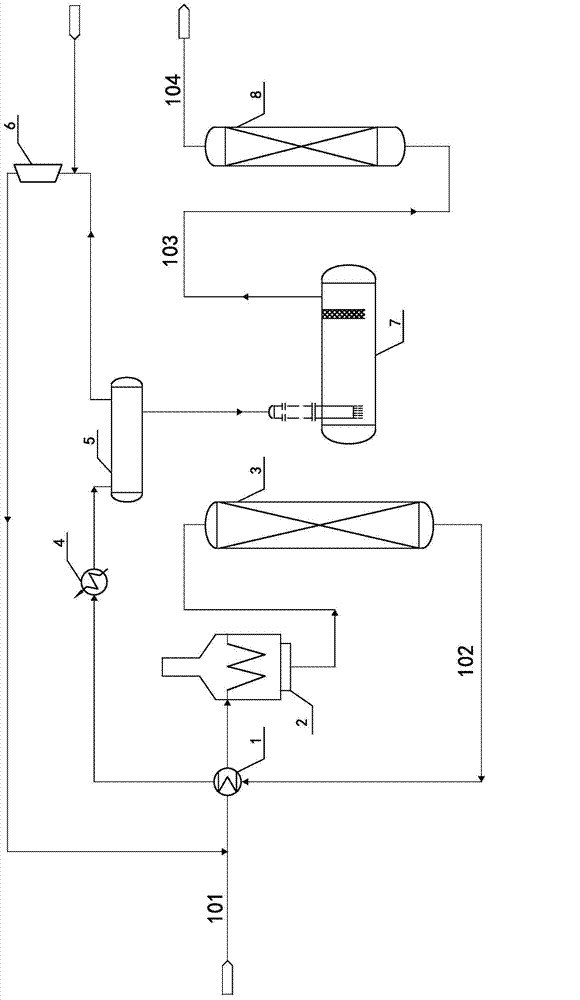

[0022] The present invention will be further described below in conjunction with accompanying drawing.

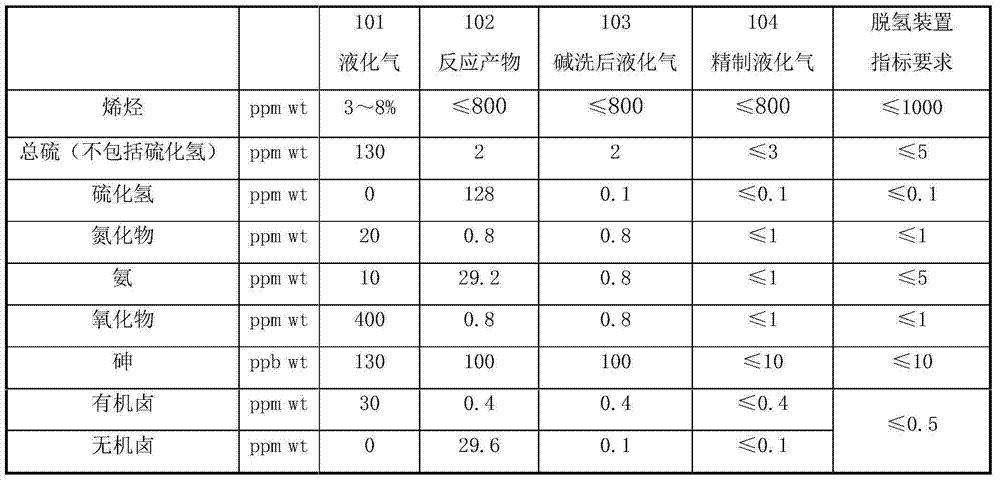

[0023] The purification process of liquefied gas raw materials with a processing scale of 250,000 tons / year is used to illustrate, and the process is as follows figure 1 shown.

[0024] 1) The raw material liquefied gas 101 first passes through the raw material product heat exchanger 1, exchanges heat with the product at the outlet of the hydrogenation reactor 3, then passes through the heating furnace 2, and then enters the hydrogenation reactor 3 from the top to hydrogenate and saturate the olefins in the material For alkanes, simultaneously convert sulfides, oxides, nitrides and halides into hydrogen sulfide, water, ammonia and hydrogen halides respectively. The operating pressure of the reactor is 2.0-3.0MPaG, the operating temperature is 160-400°C, the diameter is 1600mm, the filling height is 7200mm, and the hydrogenation catalyst is 14.47m 3 .

[0025] 2) After ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com