Patents

Literature

230results about How to "Reduce solid waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

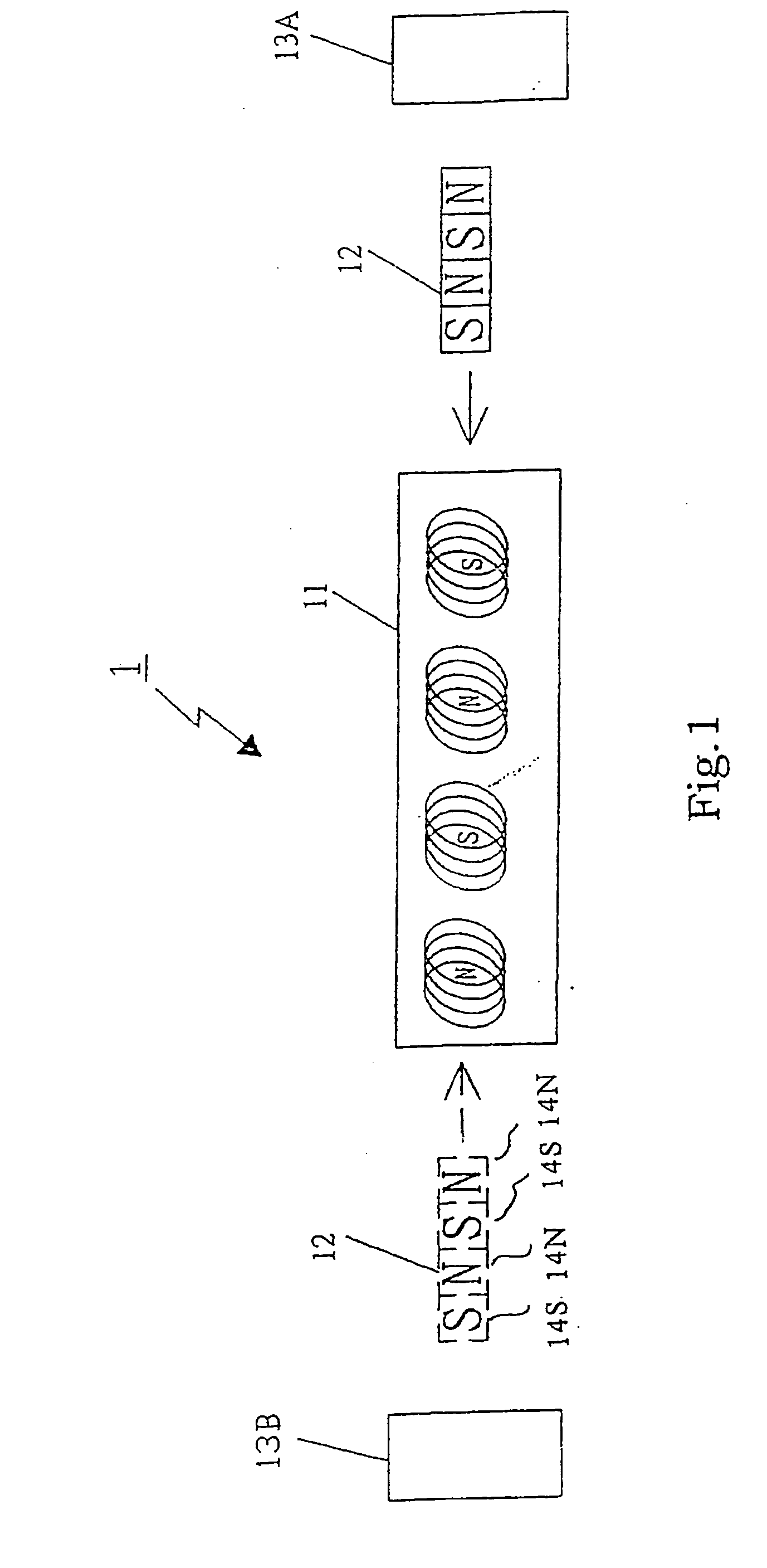

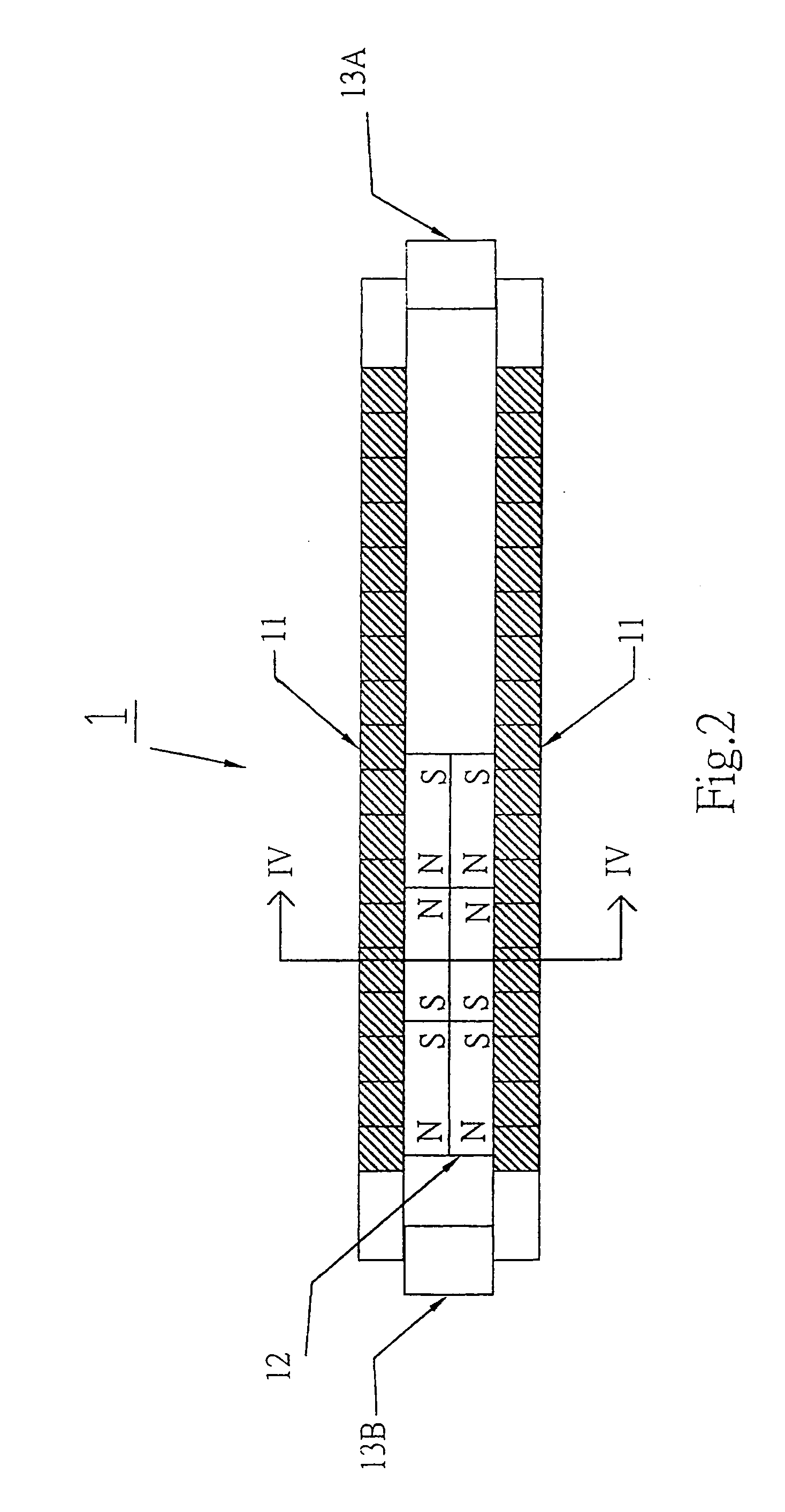

Linear electric generator having an improved magnet and coil structure, and method of manufacture

InactiveUS6936937B2Reduce demandIncrease demandWindingsMagnetic circuitReciprocating motionElectrical polarity

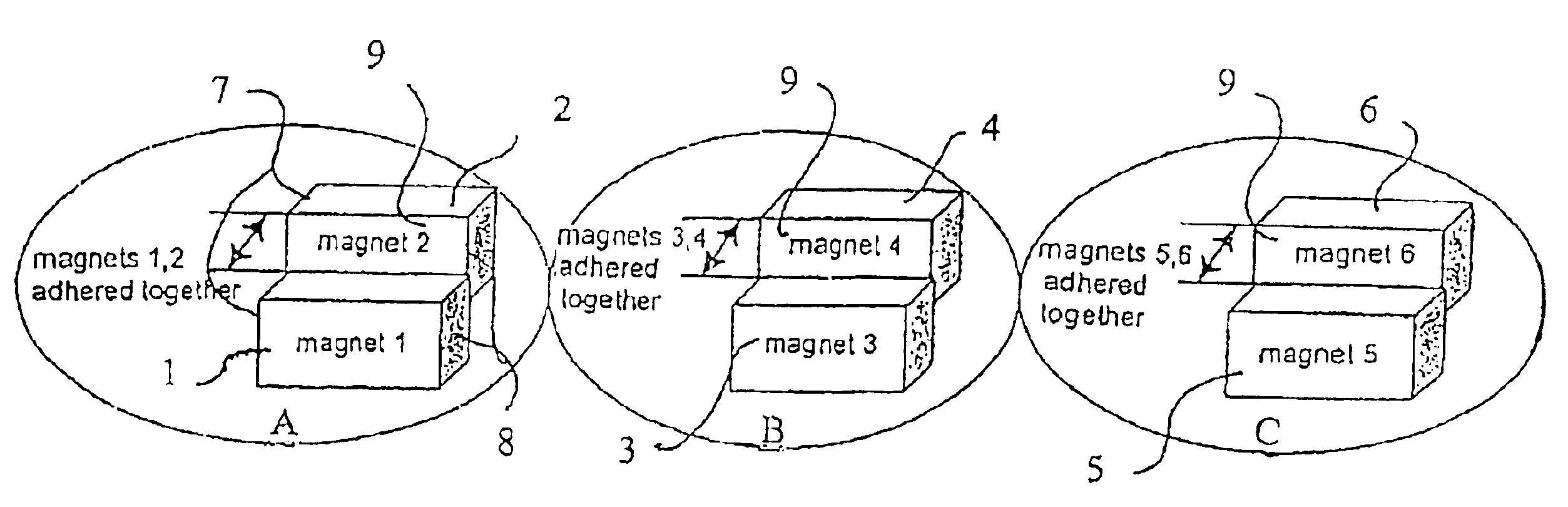

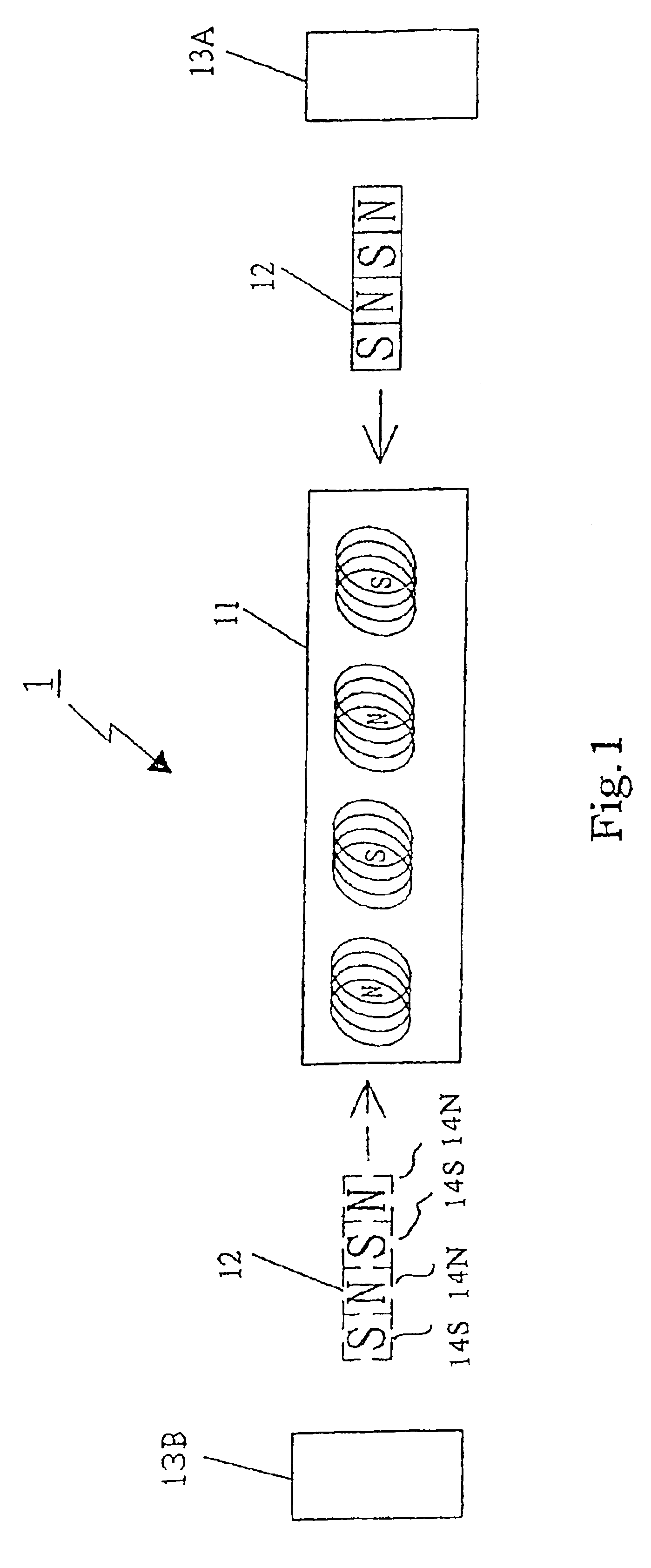

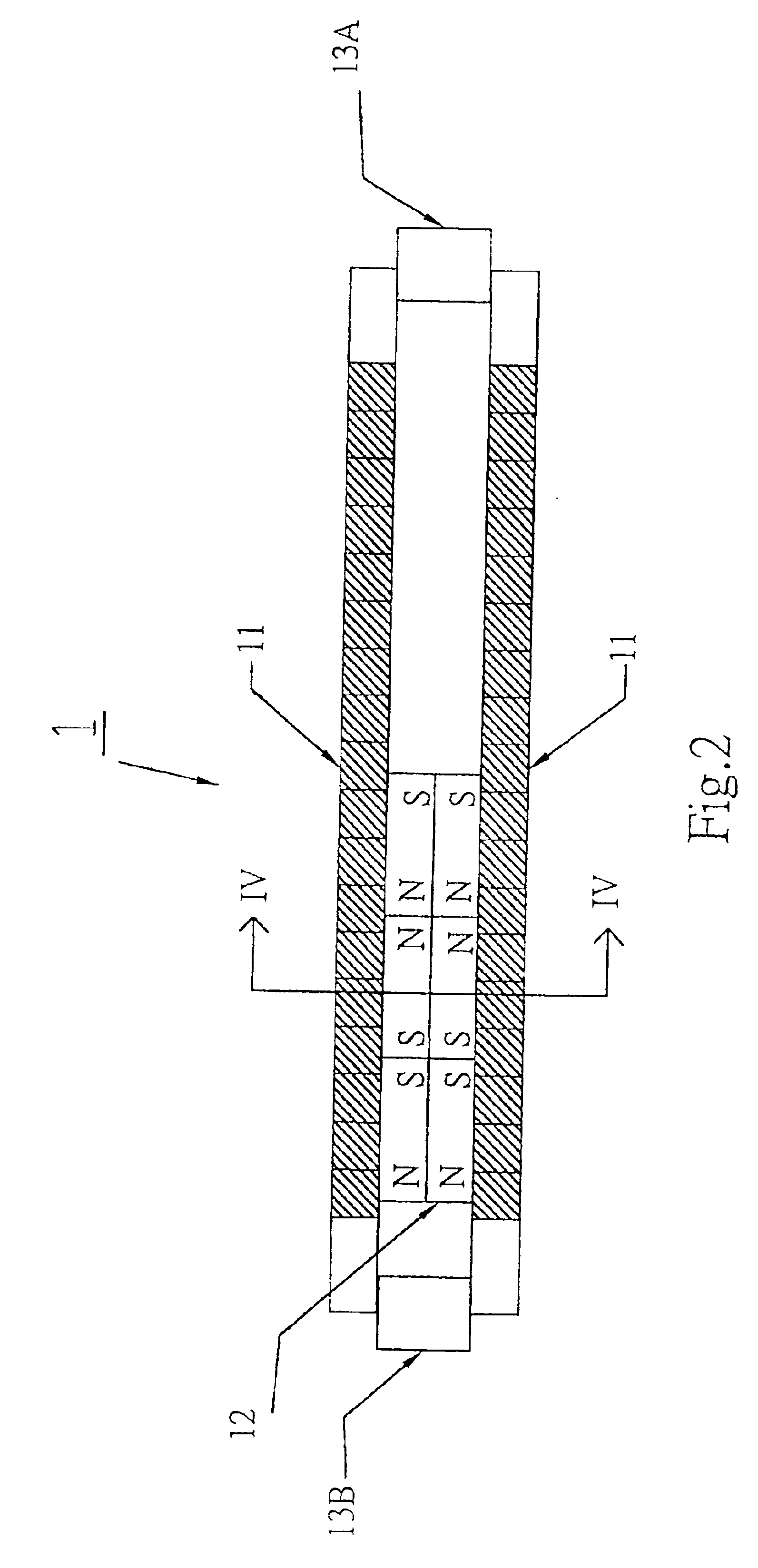

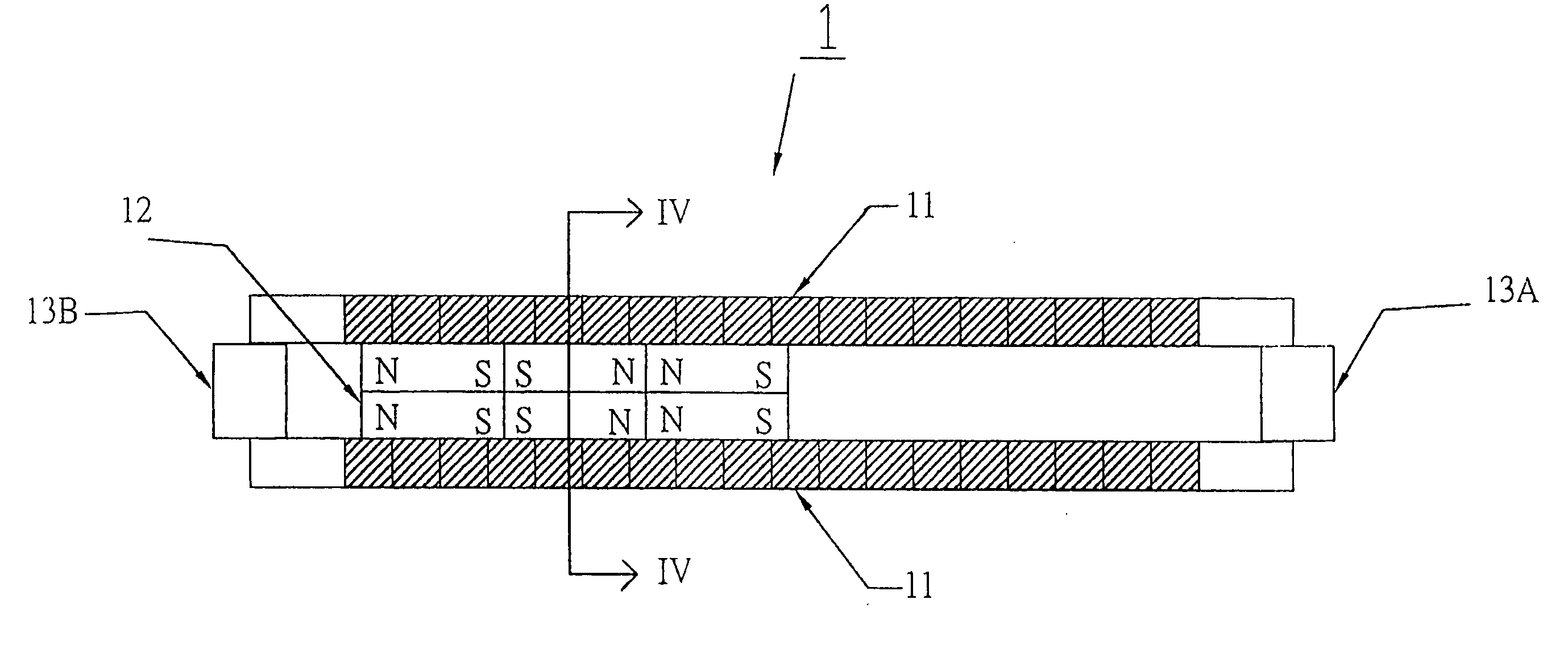

Linear electric generators include stationary windings and armature magnets arranged to reciprocate axially relative to the windings, or stationary magnet structures and movable windings arranged to reciprocate relative to the stationary magnet structures. The armature magnets or stationary magnet structures are in the form of multiple pole magnets made up of a plurality of individual pole structures, each pole structure including a pair of magnets joined to each other with facing poles of like polarity. In addition, the windings may be in the form of a double winding structure including at least one first clockwise winding and at least one second counterclockwise winding arranged in a multi-layered stacked arrangement.

Owner:SUNYEN CO LTD

Linear electric generator having an improved magnet and coil structure, and method of manufacture

InactiveUS20050225181A1Reduce demandIncrease demandReciprocating/oscillating/vibrating magnetic circuit partsMagnetsReciprocating motionElectrical polarity

Linear electric generators include stationary windings and armature magnets arranged to reciprocate axially relative to the windings, or stationary magnet structures and movable windings arranged to reciprocate relative to the stationary magnet structures. The armature magnets or stationary magnet structures are in the form of multiple pole magnets made up of a plurality of individual pole structures, each pole structure including a pair of magnets joined to each other with facing poles of like polarity. In addition, the windings may be in the form of a double winding structure including at least one first clockwise winding and at least one second counterclockwise winding arranged in a multi-layered stacked arrangement.

Owner:SUNYEN CO LTD

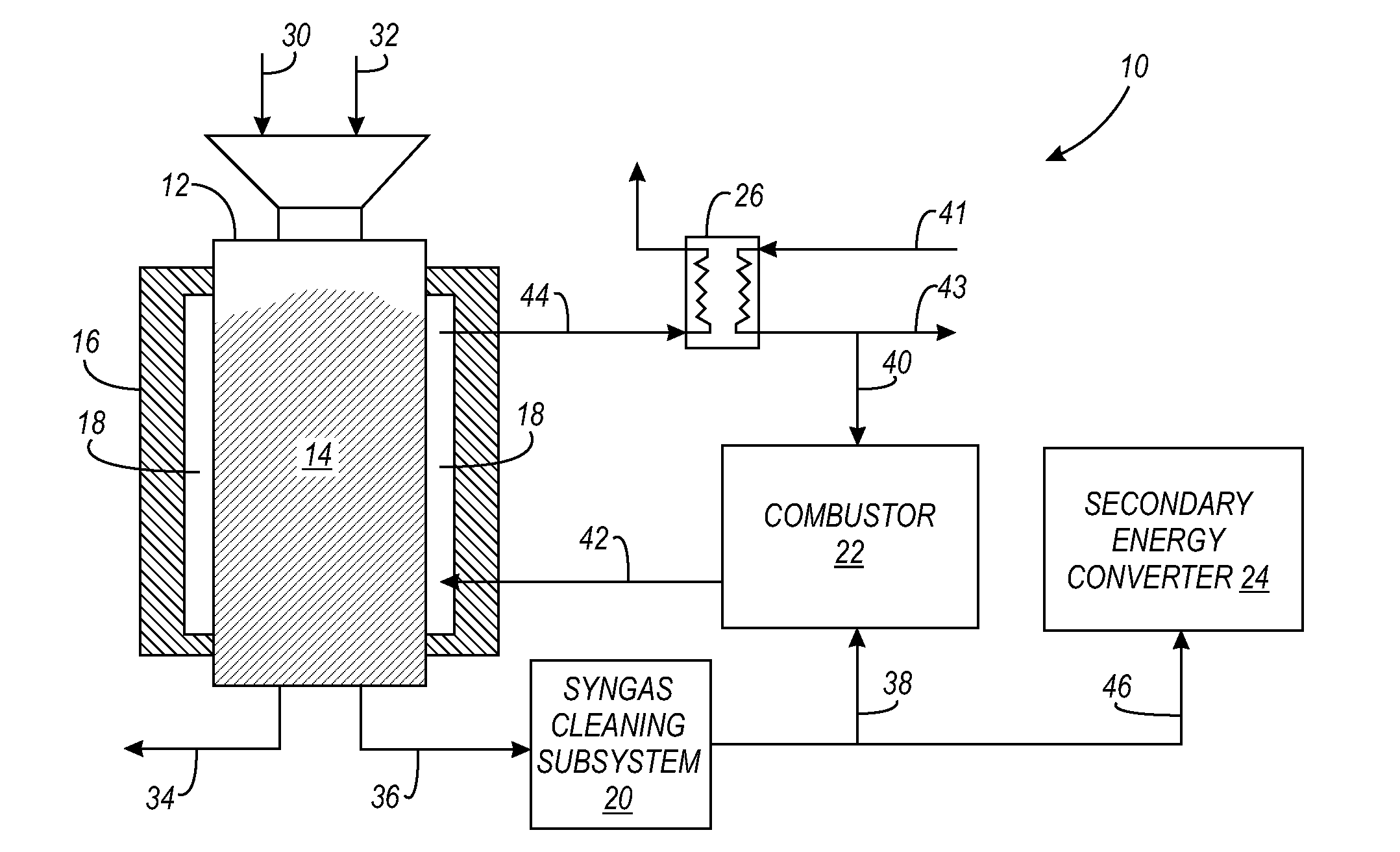

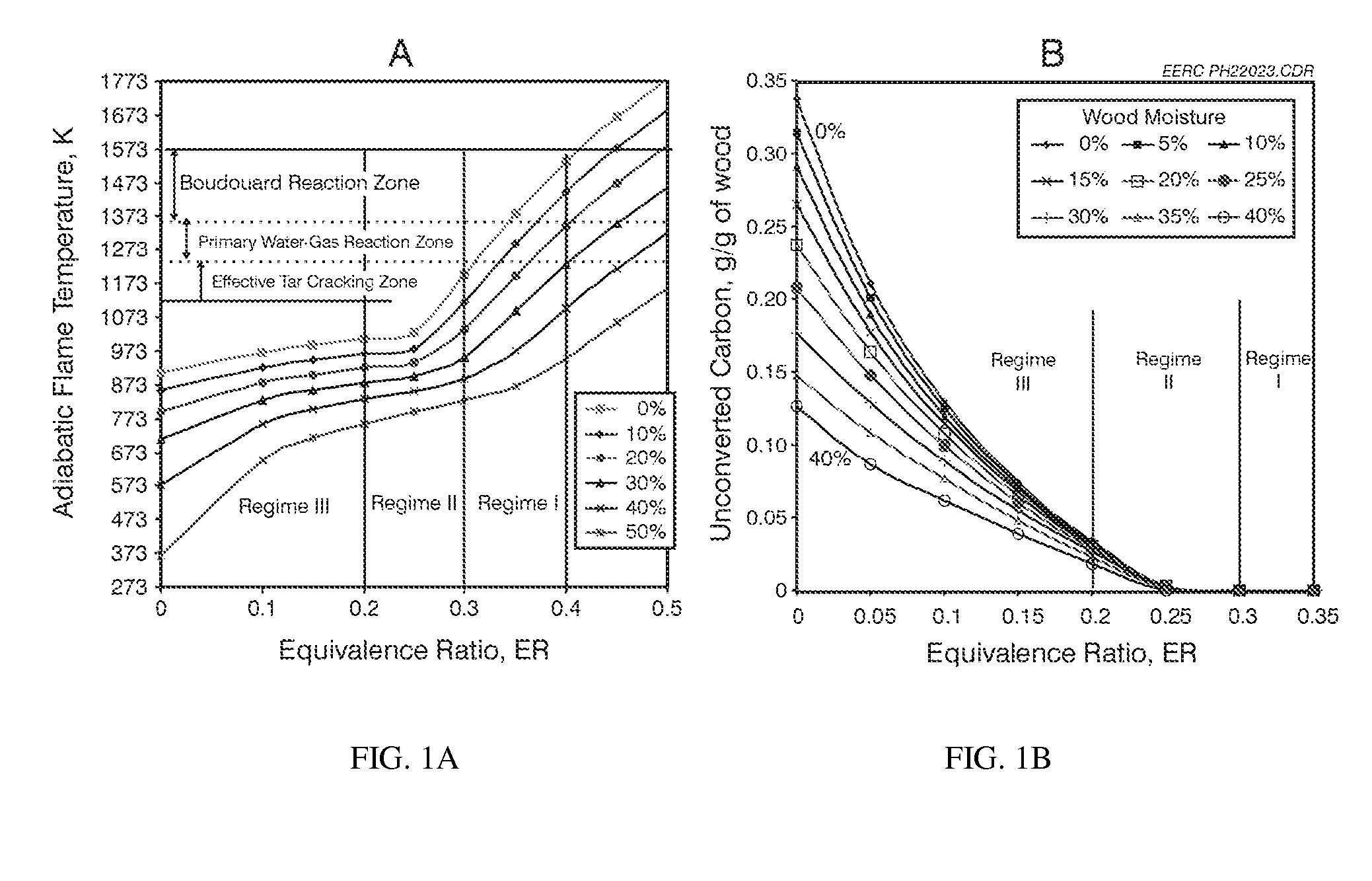

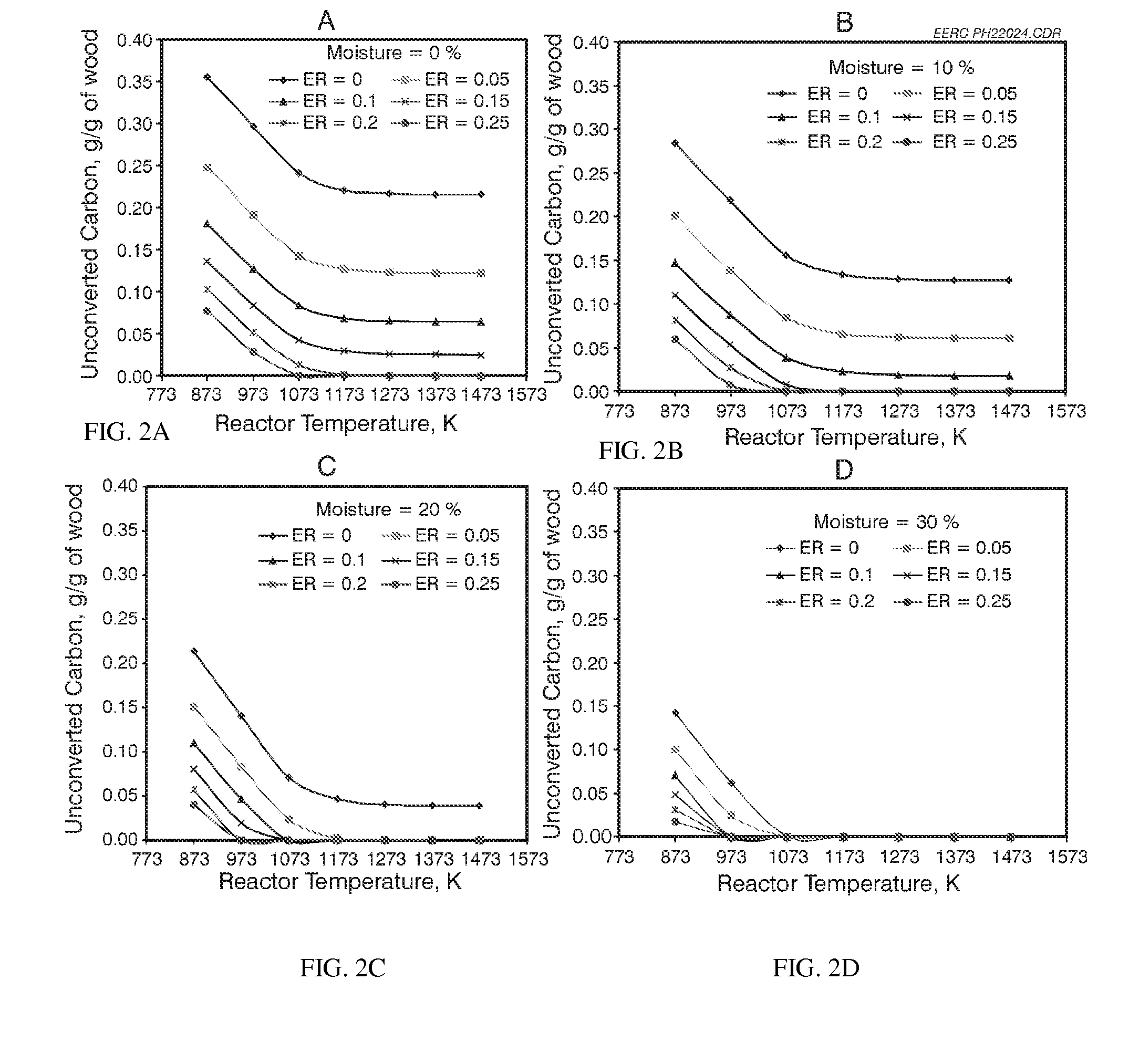

Thermally stable cocurrent gasification system and associated methods

InactiveUS20080196308A1Reduce solid wasteGasification processes detailsCarburetting by solid carbonaceous material pyrolysisOperational costsHigh energy

A method and apparatus, in one example, relates to a system and method for the generation of very low-tar, high-energy synthesis gas from a large variety of carbonaceous feedstock, including those with higher moisture levels than conventional gasifiers. The system comprises a gasification reactor wherein a portion of the energy of the output syngas of the reactor is used to heat the gasification zone of the reactor via an annular space surrounding the gasification zone of the gasifier, to maintain a temperature condition above 800° C. The maintenance of a long, quasi-uniform high-temperature gasification zone reduces the amount of input air or oxygen, reduces bridging within the gasifier, cracks pyrolysis oils, increases the conversion of char, minimizes heat losses from the bed, and converts moisture within the packed bed into a gasification medium. This results in a very low tar synthesis gas with less nitrogen dilution and higher energy content than conventional gasifiers. The reduction in bridging reduces operating costs.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

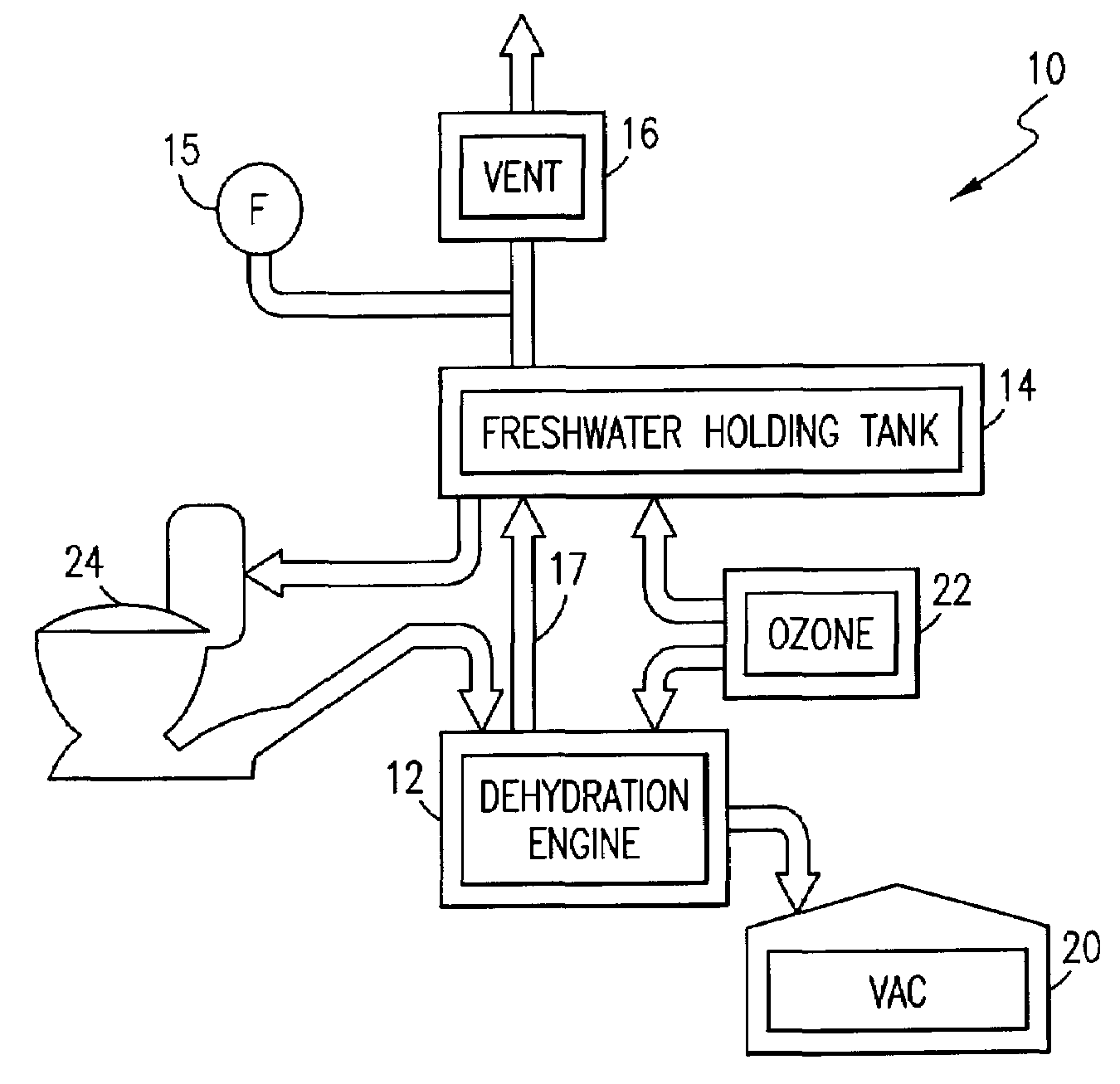

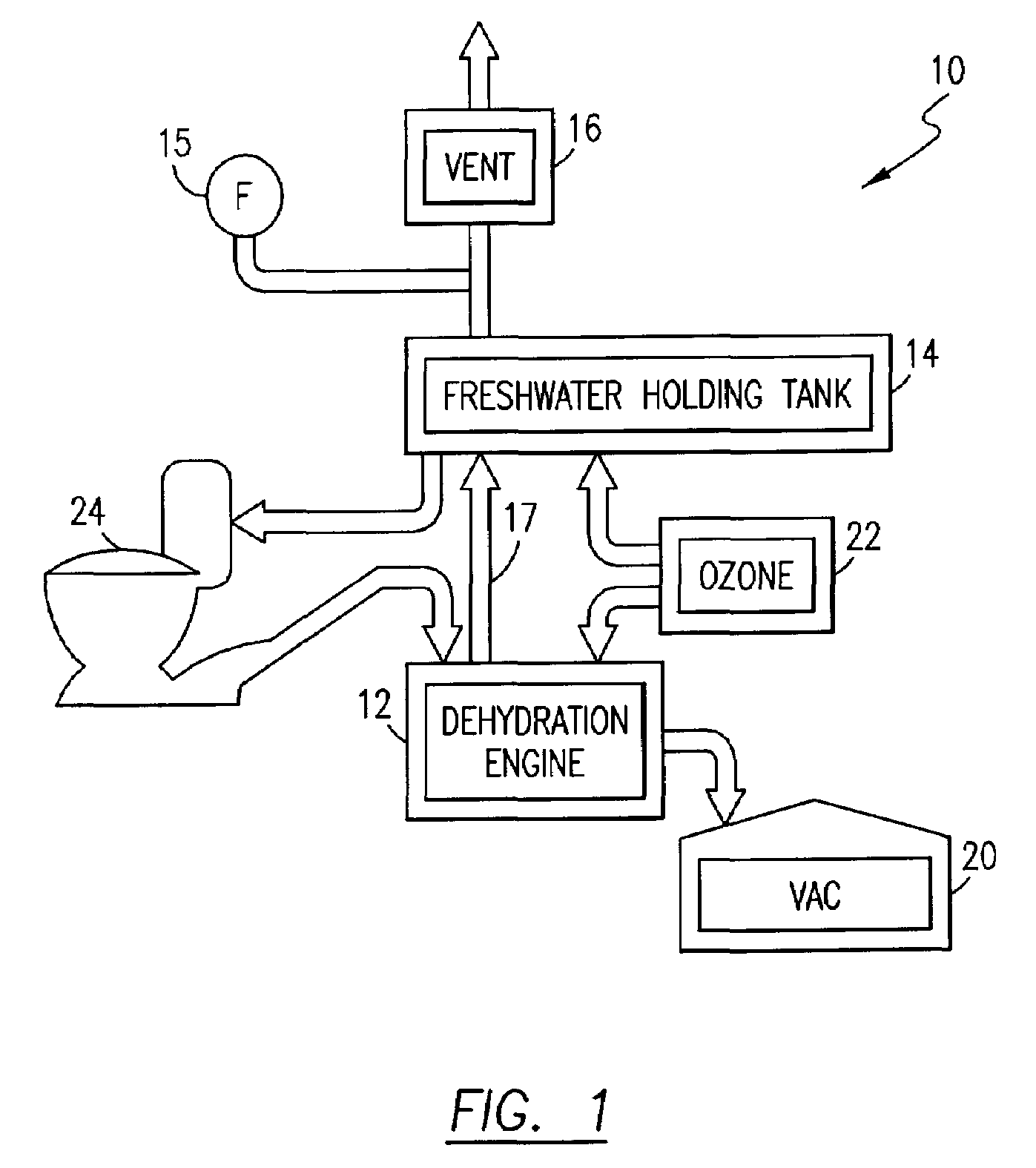

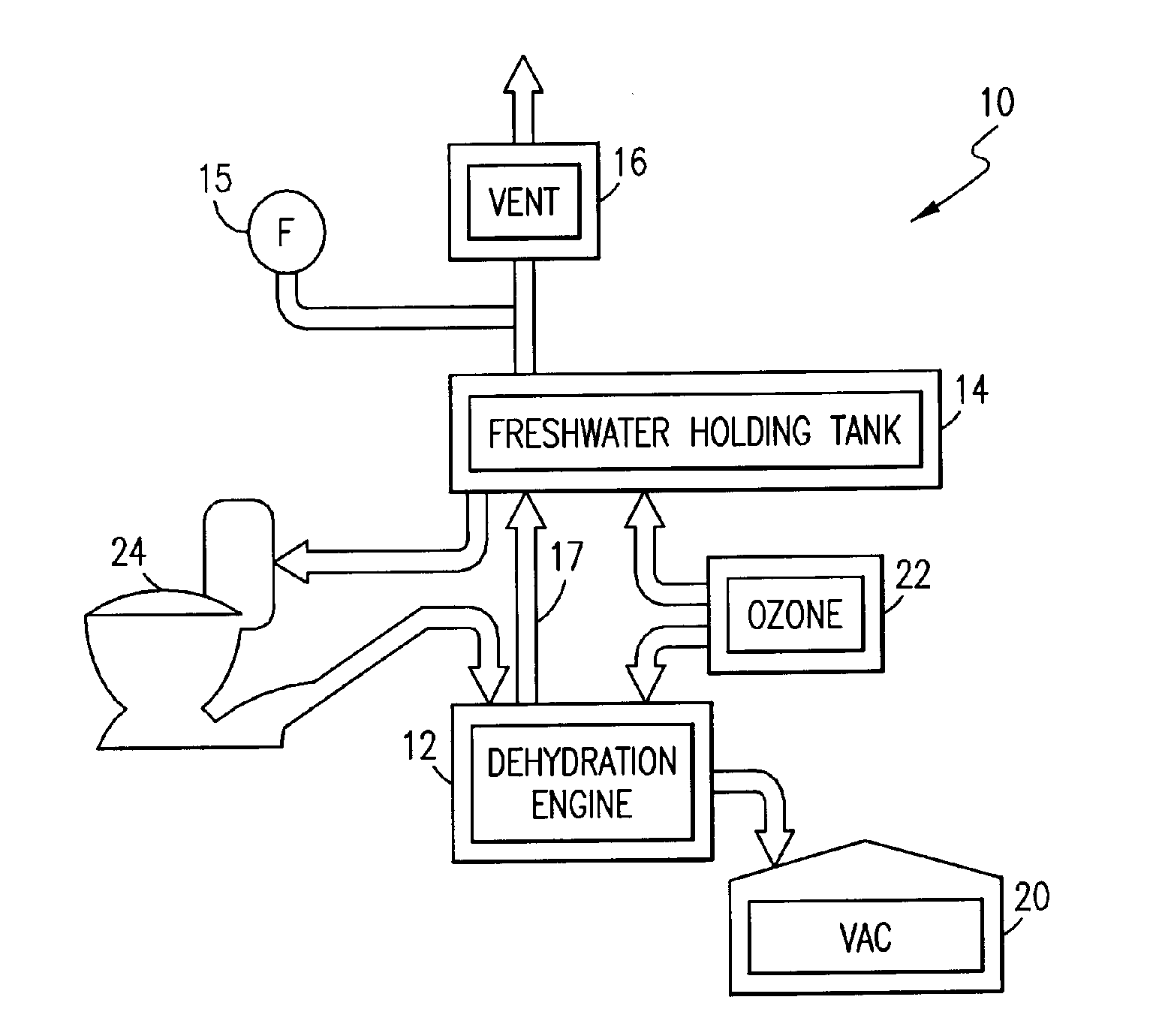

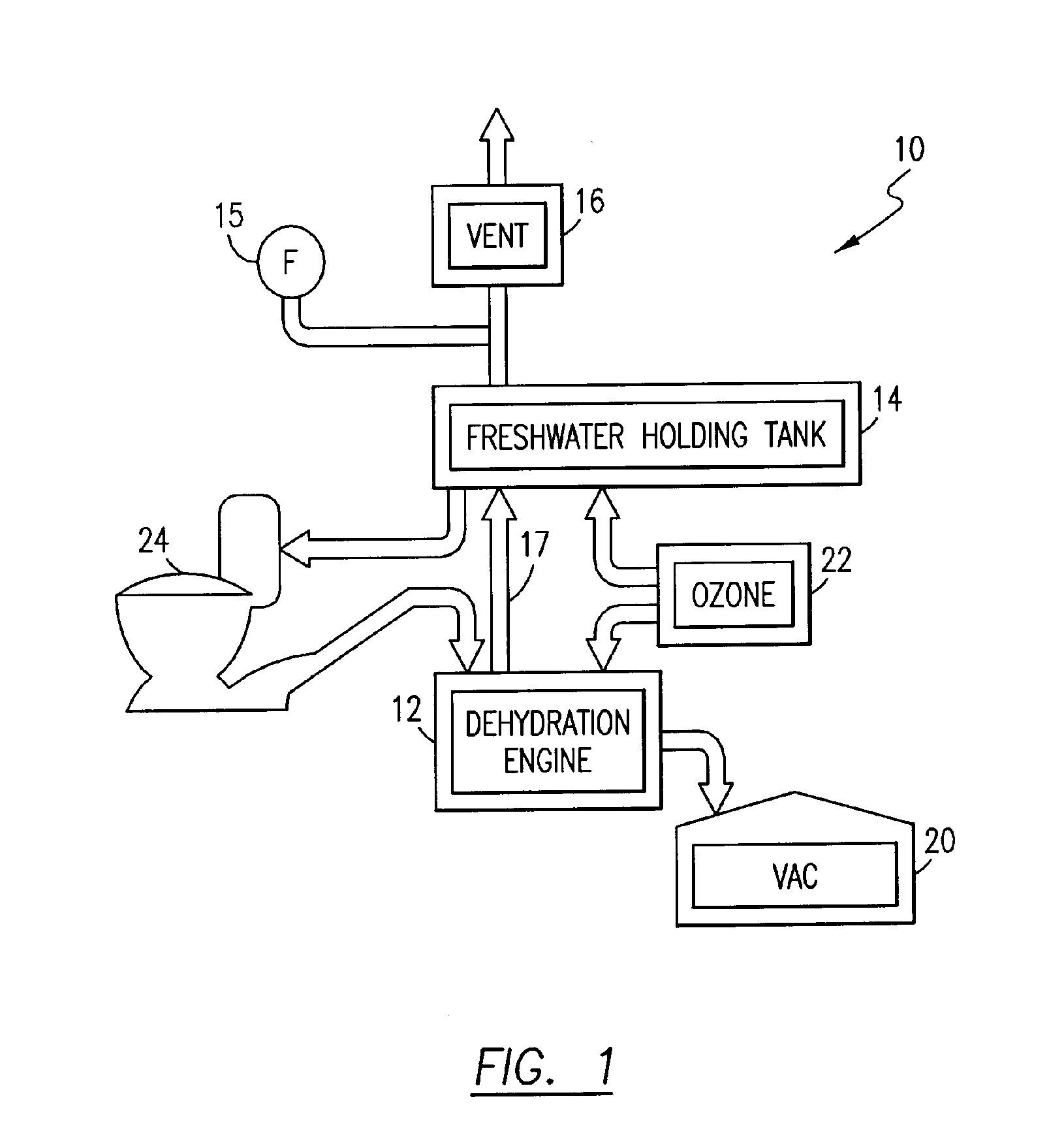

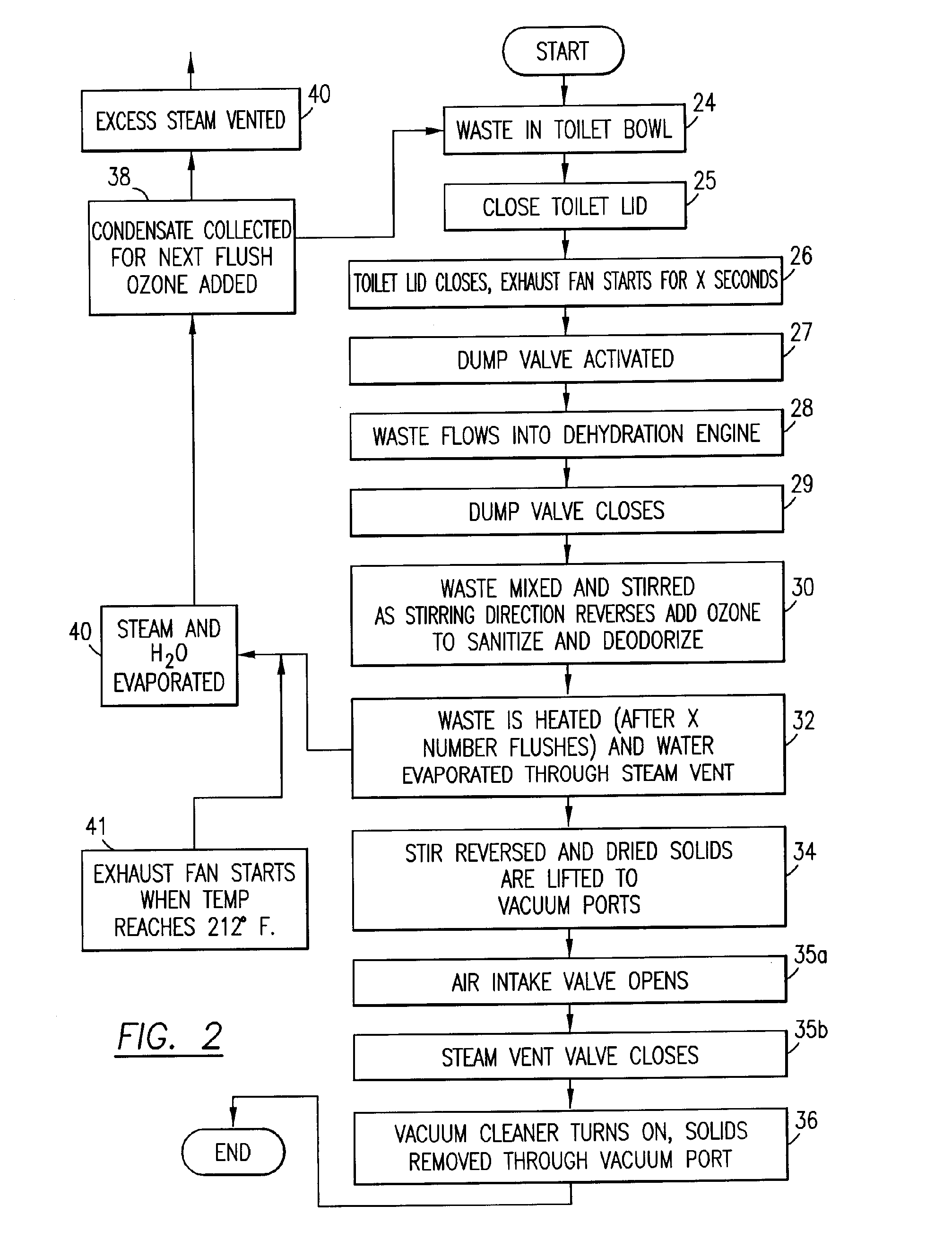

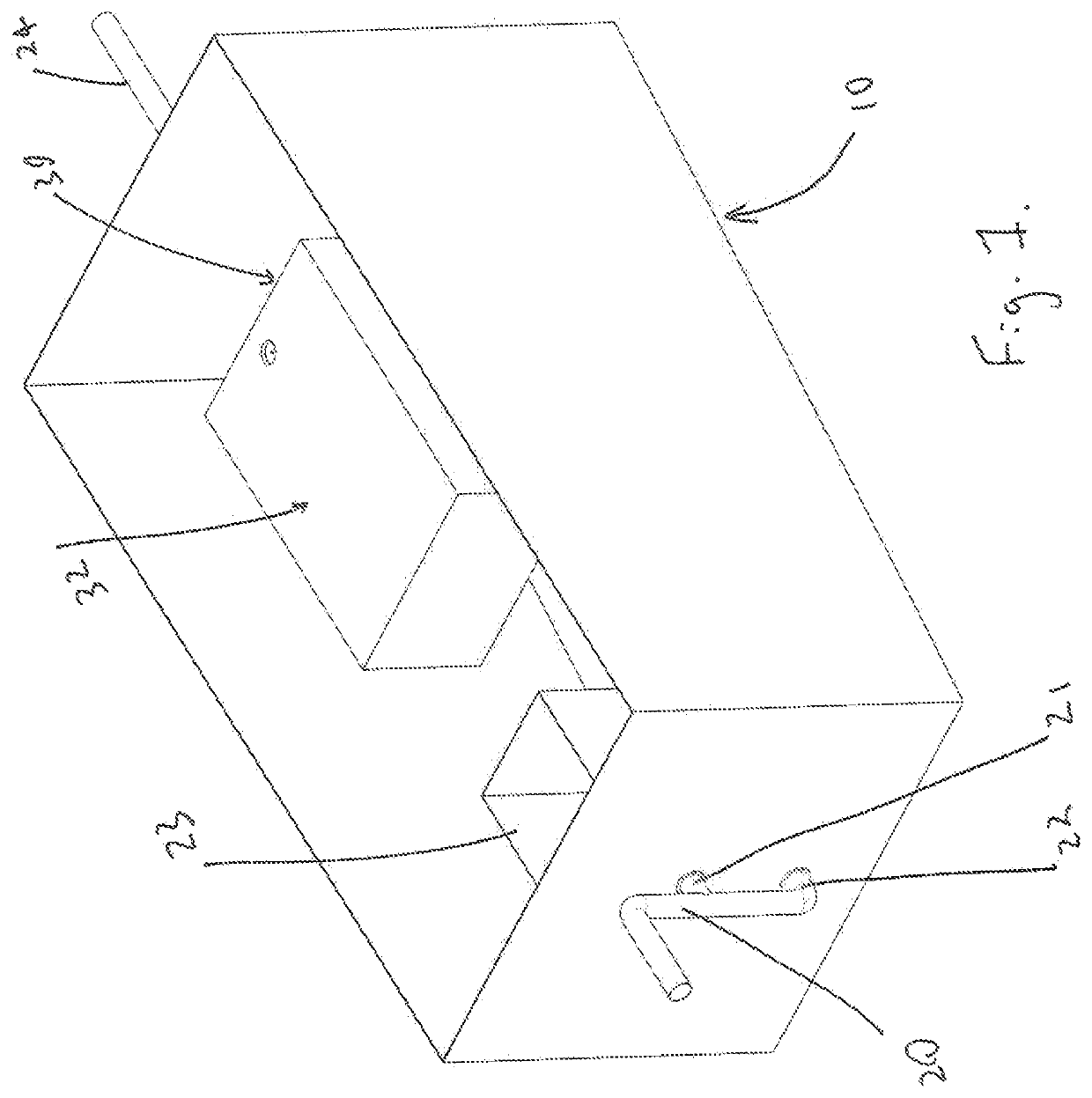

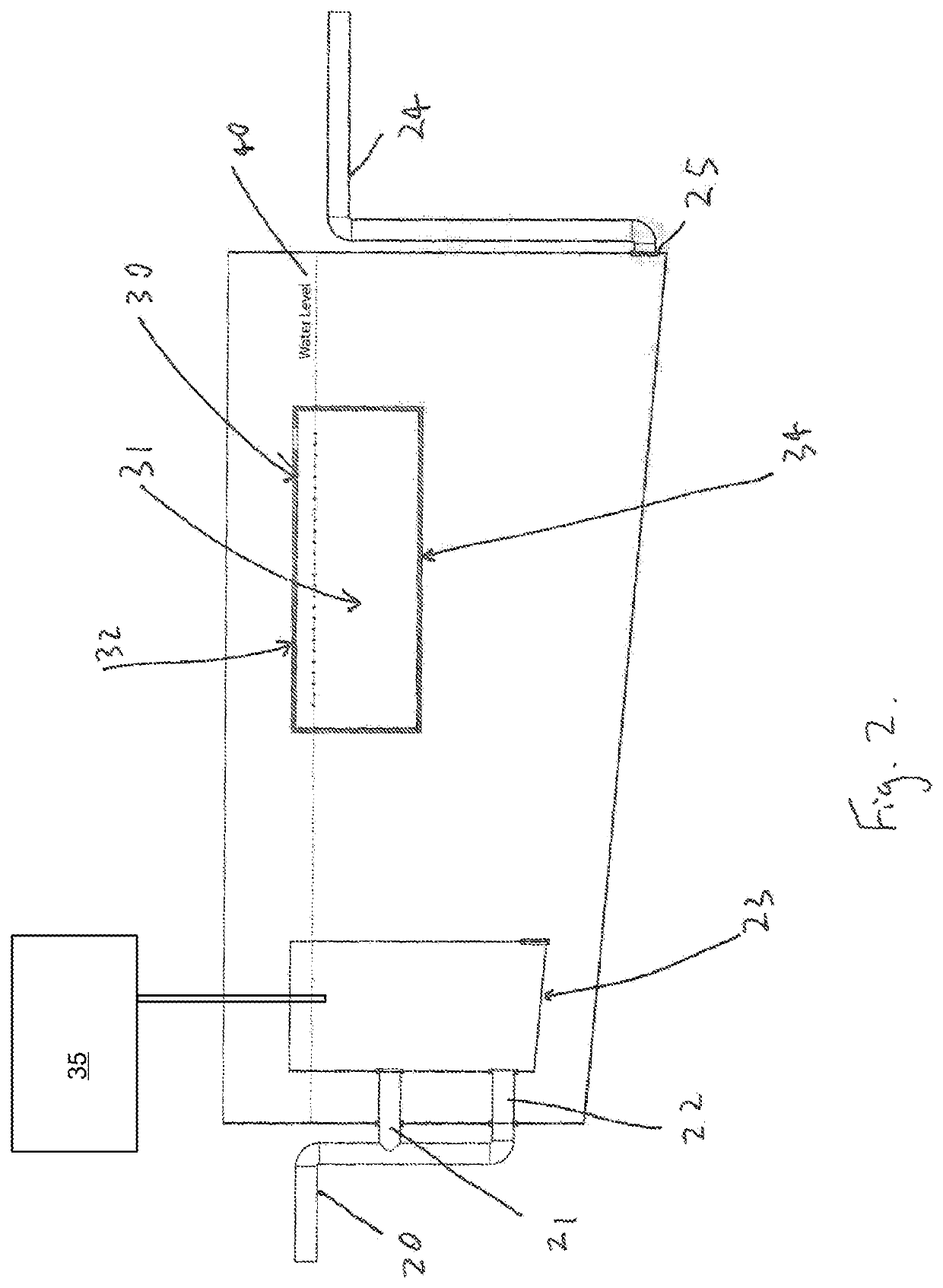

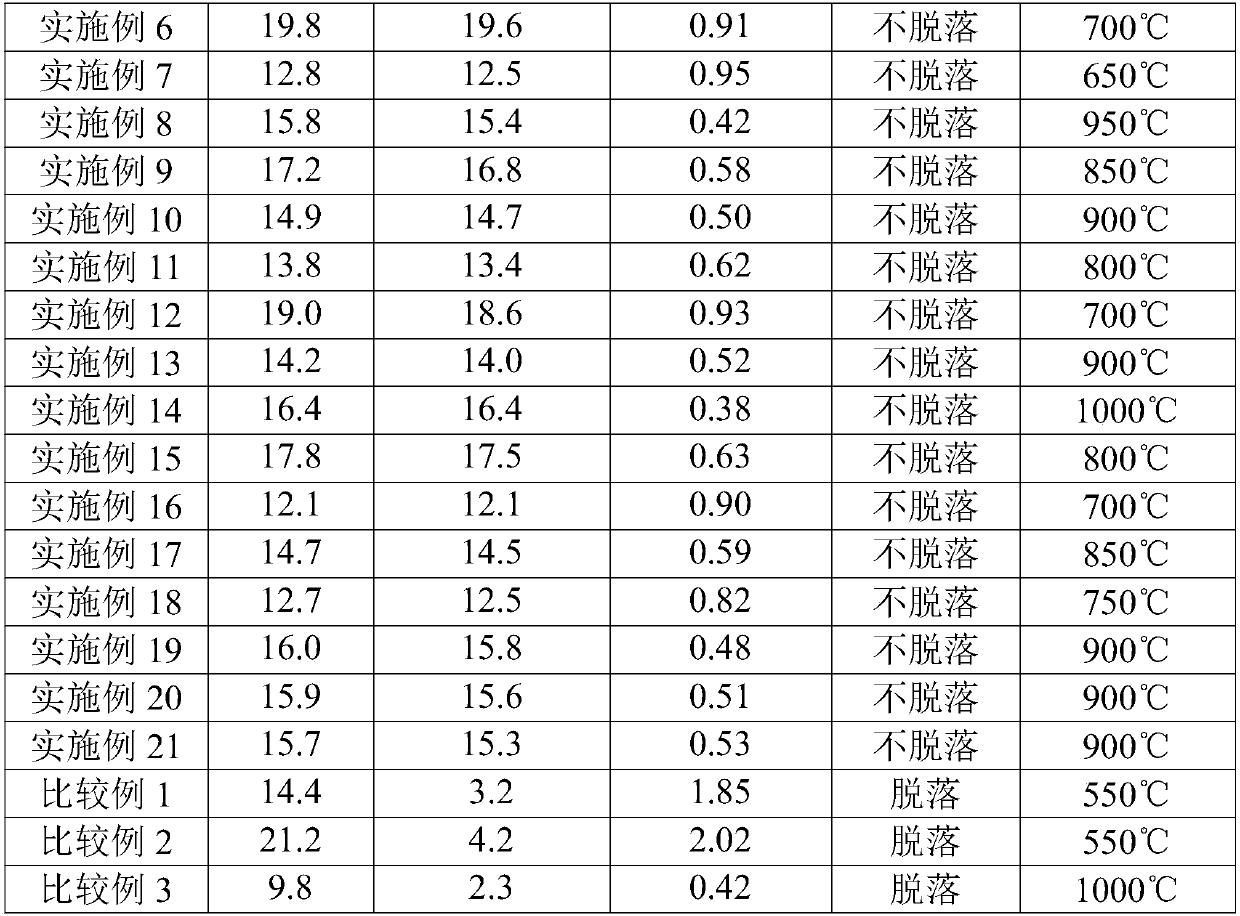

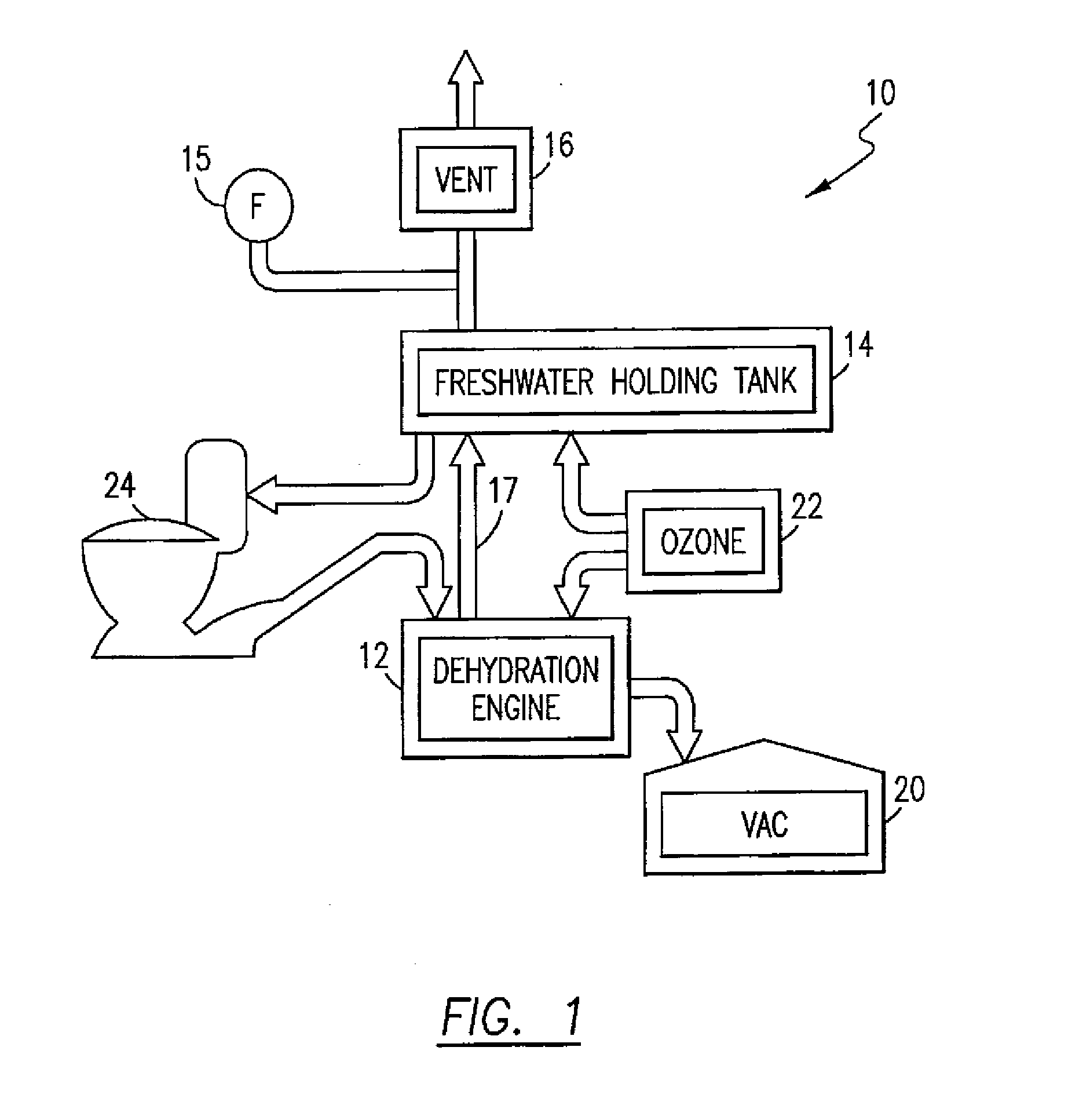

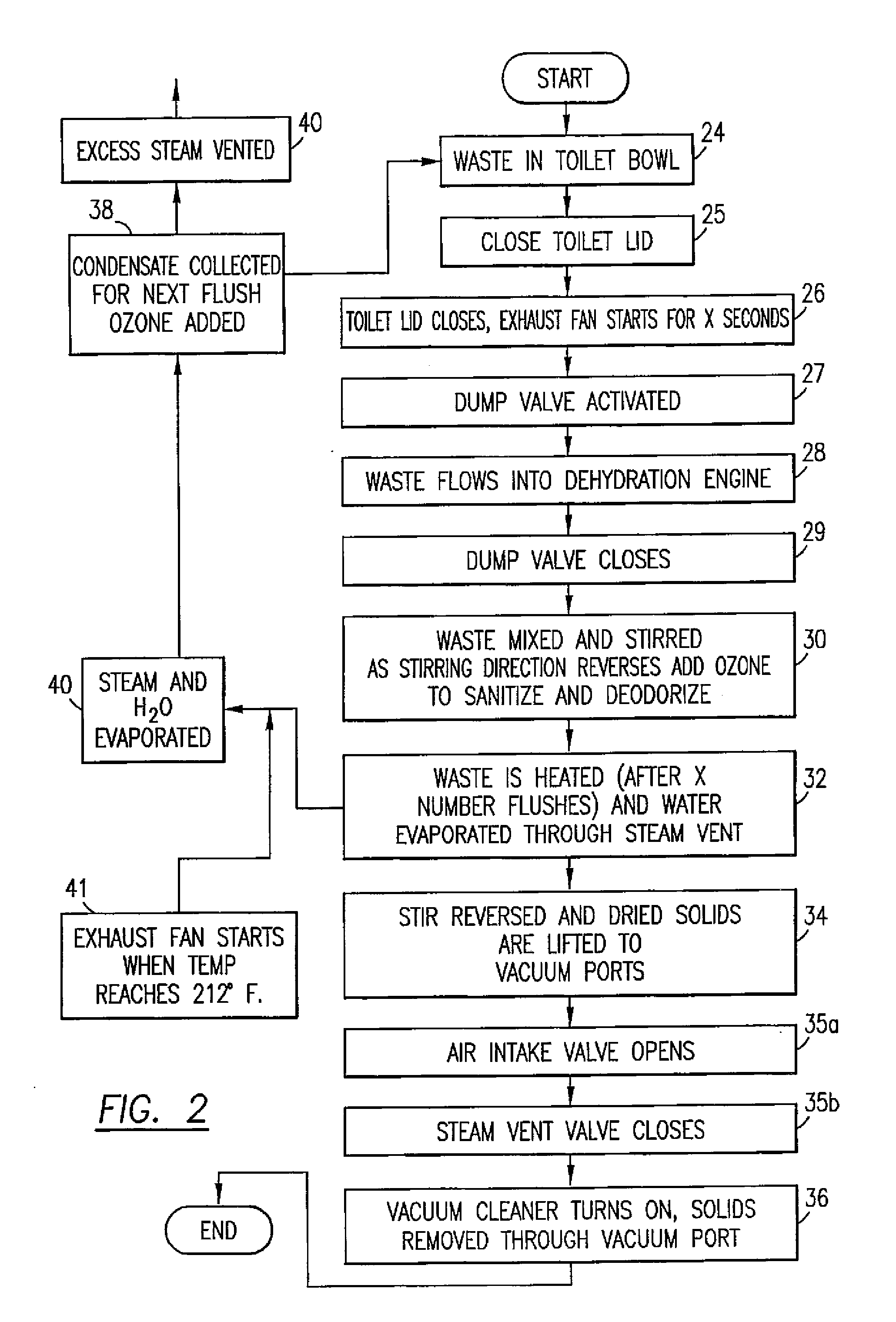

Mobile or stationary modular self-contained dehydration toilet, dehydration engine, and gray water recovery system

InactiveUS7211187B2Reduce solid wasteEliminate dischargeGeneral water supply conservationSustainable biological treatmentHuman wasteWater source

A compact dehydration engine and method for treating human waste and gray water residual electro-coagulants that includes a heated waste dehydration chamber that has low energy consumption and low water consumption in use. The system can be employed in stationary or mobile platforms that include multiple toilets and gray water sources for reclamation.

Owner:ZECO LTD

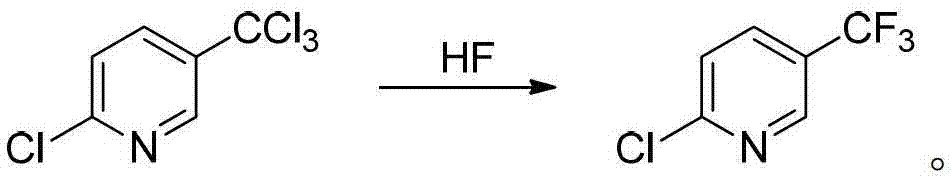

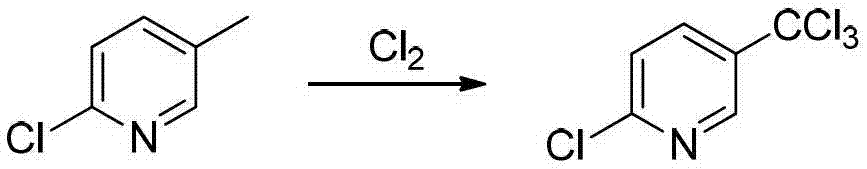

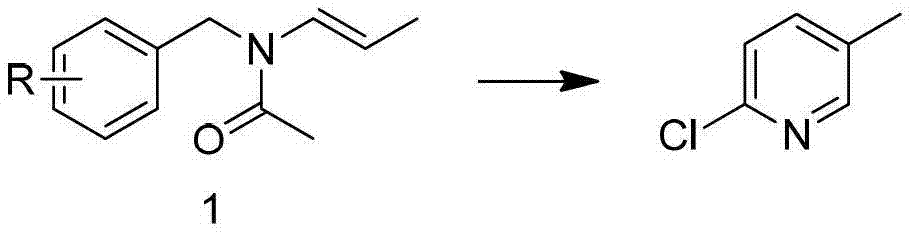

Preparation method of 2-chloro-5-tirfluoromethylpyridine

ActiveCN103288718AReduce manufacturing costReduce solid wasteOrganic compound preparationCarboxylic acid amides preparationHydrogen fluorideAntimony trioxide

The invention discloses a preparation method of 2-chloro-5-tirfluoromethylpyridine. The invention provides a preparation method of 2-chloro-5-tirfluoromethylpyridine, and the preparation method comprises the following steps of: reacting 2-chloro-5-trichloromethylpyridine with hydrogen fluoride in a closed system in the presence of a catalyst to obtain the 2-chloro-5-tirfluoromethylpyridine, wherein the catalyst is antimony trioxide and / or antimony pentoxide. The invention further provides a preparation method of a compound 2, and the preparation method comprises the following steps of: reacting a compound 3 with ammonia in the presence of alkali to obtain the compound 2. The preparation method provided by the invention is cheap and liable to obtain raw materials, low in cost, few in reaction by-products, simple in post treatment, safe to operate, environment-friendly and suitable for large-scale industrial production.

Owner:LIAONING TIANYU CHEM +3

Mobile or stationary modular self-contained dehydration toilet, dehydration engine, and gray water recovery system

InactiveUS20060091083A1Reduce solid wasteEliminate dischargeGeneral water supply conservationSustainable biological treatmentHuman wasteWater source

A compact dehydration engine and method for treating human waste and gray water residual electro-coagulants that includes a heated waste dehydration chamber that has low energy consumption and low water consumption in use. The system can be employed in stationary or mobile platforms that include multiple toilets and gray water sources for reclamation.

Owner:ZECO LTD

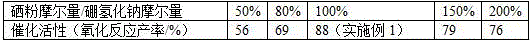

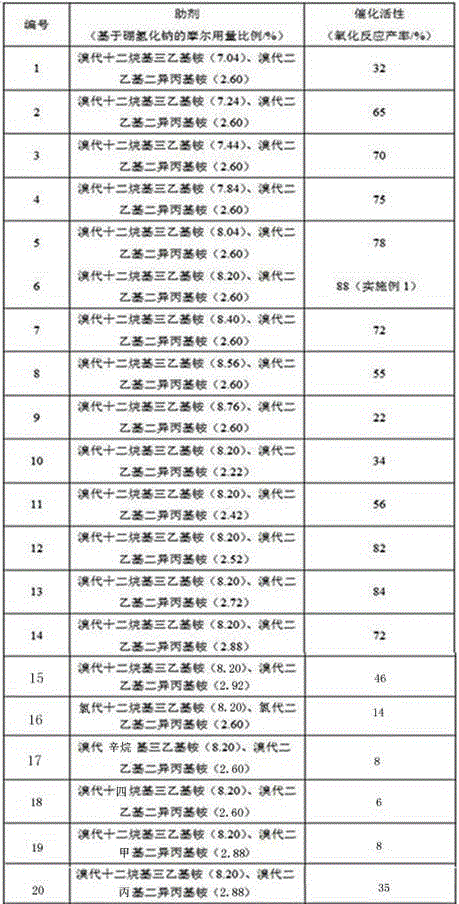

Method for synthesizing nano selenium material

ActiveCN106495105AReduce solid wasteThe reaction steps are simplePhysical/chemical process catalystsNanotechnologyFiltrationSynthesis methods

The invention provides a method for synthesizing a nano selenium material and relates to the application technology of selenium resources. The method includes the following steps: in an environment with a temperature of 0+ / -1 DEG C, mixing an ethanol solution of sodium borohydride with selenium powder while stirring the mixture, adding a mixture composed of sugar, lautyltrethylammonium bromide and diethyldiisopropylammonium bromide in the mixture, and then obtaining a mixture system; increasing the temperature of the mixture system to 20-60 DEG C under a stirring condition for a reaction, obtaining a precipitate after the reaction is completed, conducting suction filtration and then calcinating the precipitate at 450-550 DEG C to obtain the nano selenium material. Compared with a traditional synthesis method, the method has simple and little reaction steps, raw materials are easy to obtain, solid waste is little, the corrosivity is low, and the method is environmentally friendly and is suitable for mass production.

Owner:扬州帮杰新材料有限公司

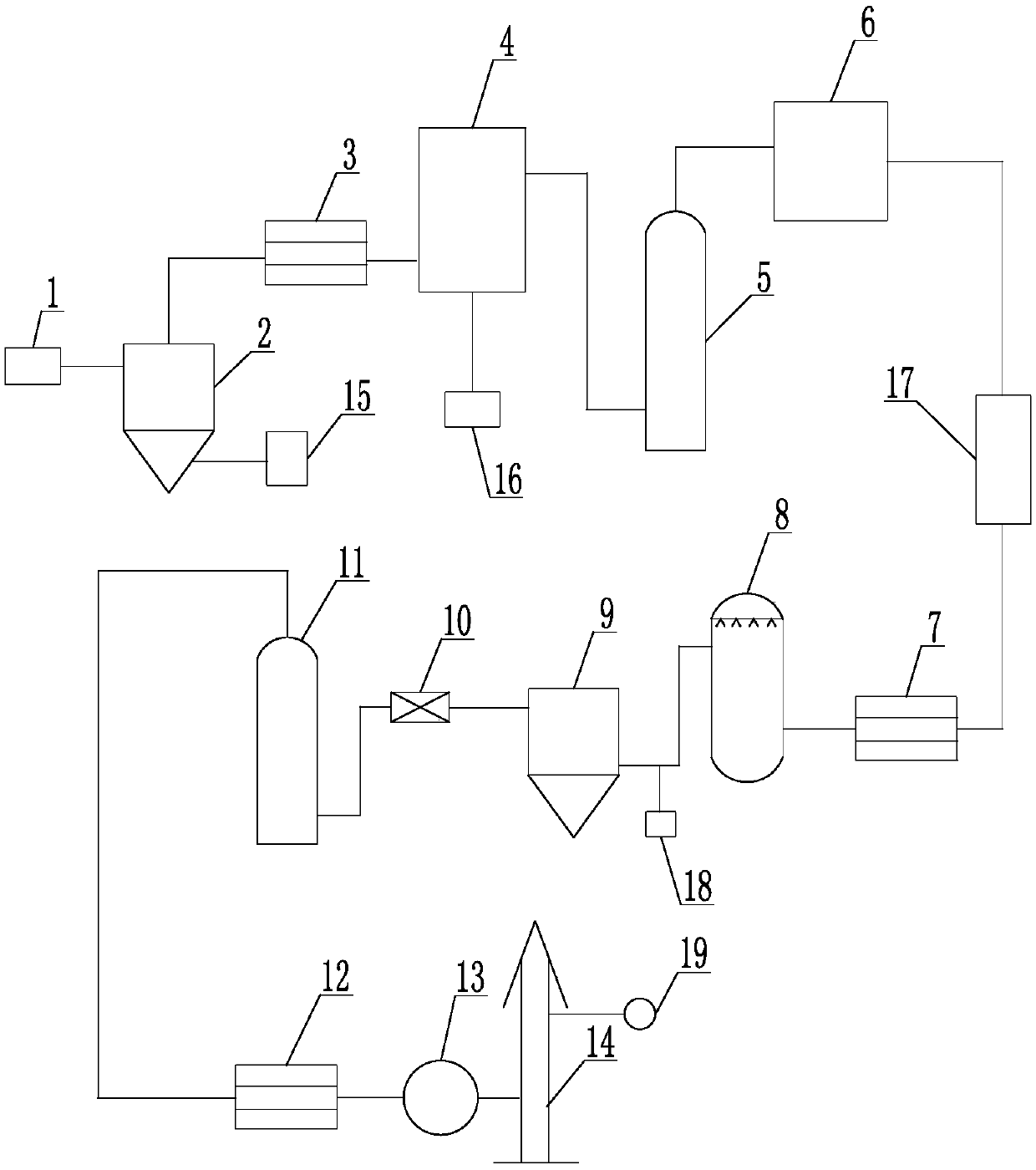

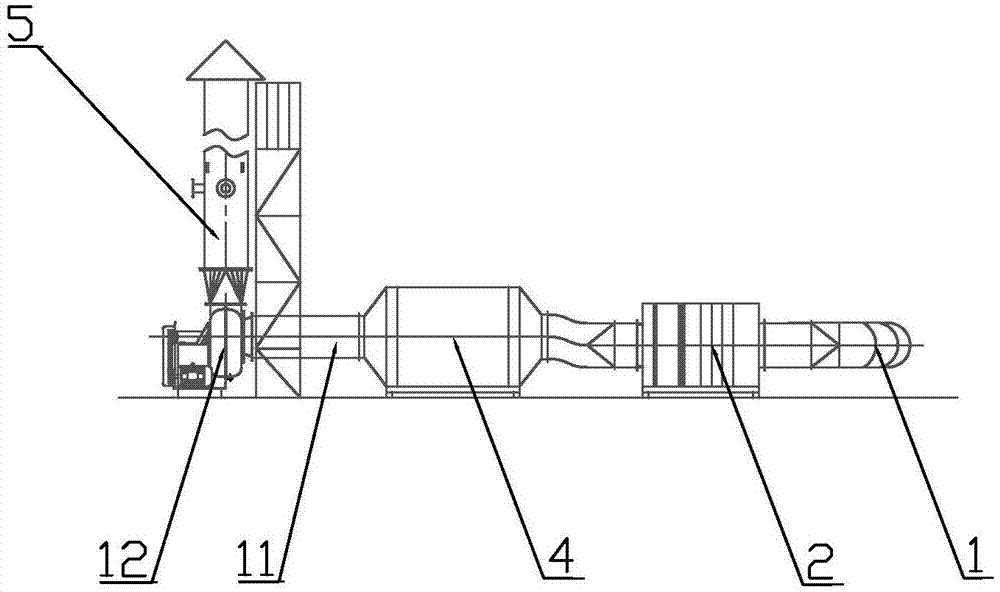

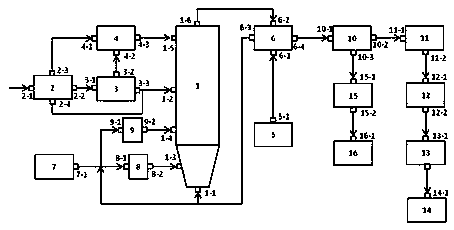

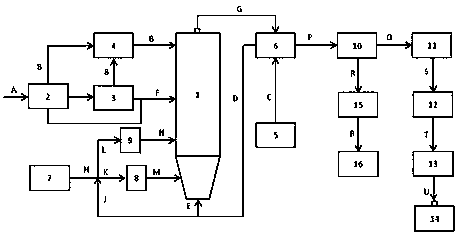

Resource recycling process and system for high-temperature plasma of chlorine-containing waste

InactiveCN109539272AFully harmless treatmentEfficient recyclingDispersed particle filtrationEmission preventionCombustion chamberDecomposition

The invention belongs to the technical field of industrial waste treatment, and particularly relates to a resource recycling process and system for high-temperature plasma of chlorine-containing waste. The method comprises the steps that (1) the chlorine-containing waste is conveyed into a plasma gasifier through a feeding system; (2) synthesis gas produced through splitting decomposition is cooled by a first-stage waste heat exchanger; (3) after entering an acid absorption system to absorb acid, the synthesis gas enters an alkaline tower to be further deacidified; (4) the deacidified synthesis gas enters a secondary combustion chamber to be combusted, and generated high-temperature flue gas is cooled by a second-stage waste heat exchanger; (5) after the cooled flue gas enters a quench cooler to be subjected to quenching, the flue gas enters a bag-type dust remover for dust removal; (6) the flue gas with dust removed enters a flue heater to be warmed; (7) the flue gas enters an SCR catalytic tower to remove nitric oxide in the flue gas; and (8) after the flue gas subjected to SCR treatment enters the heat exchanger for heat exchange, the flue gas is drawn out by an induced draft fan, and the flue gas is discharged into the atmosphere through a chimney. By means of the resource recycling process and system, resource, harmless, reducing and stabilizing treatment of the chlorine-containing waste is achieved, and the system operation cost is low.

Owner:SHANDONG BO RUN IND TECH

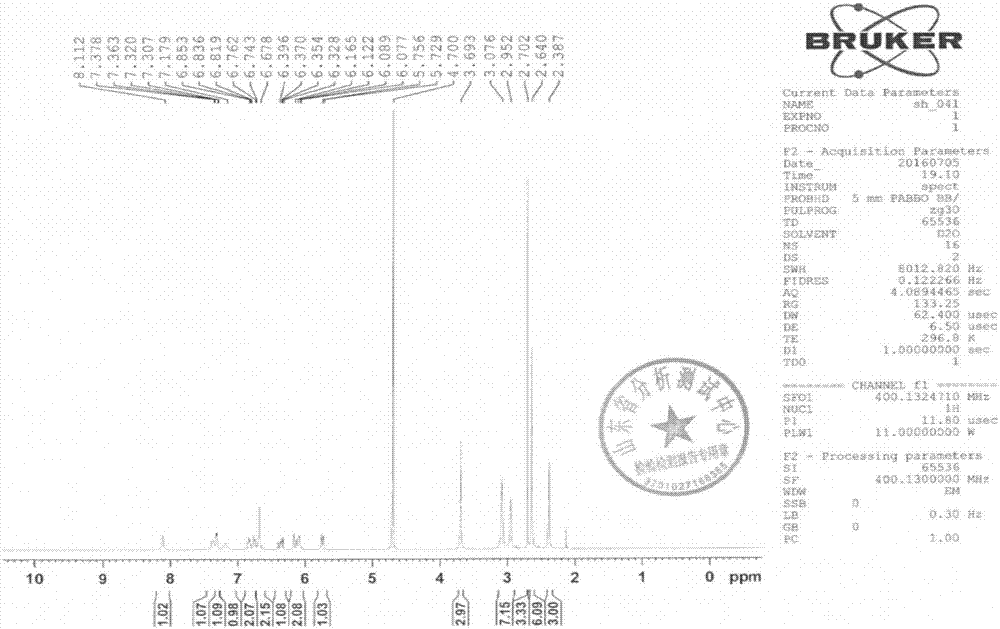

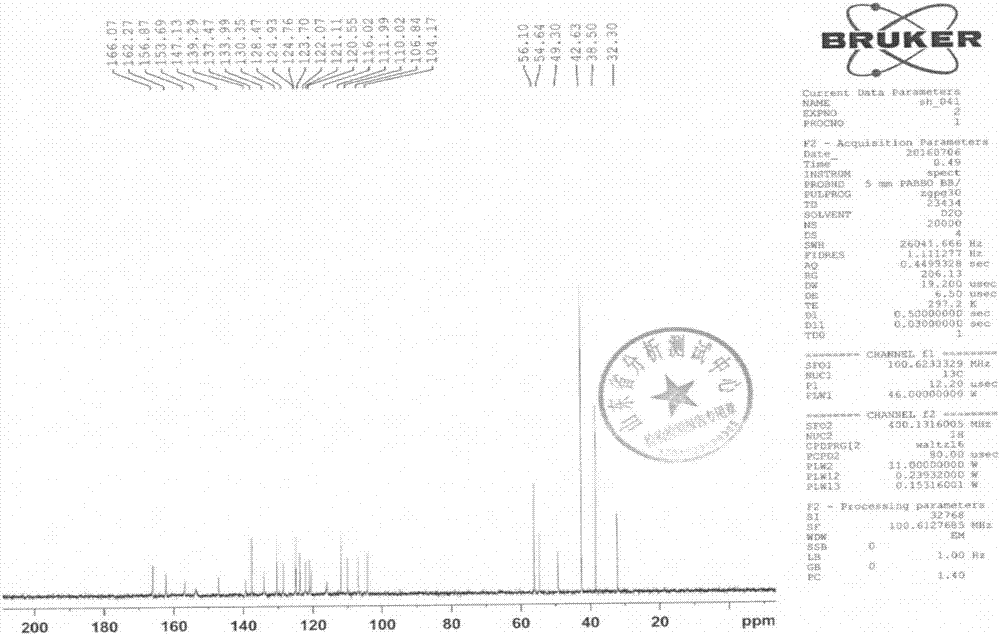

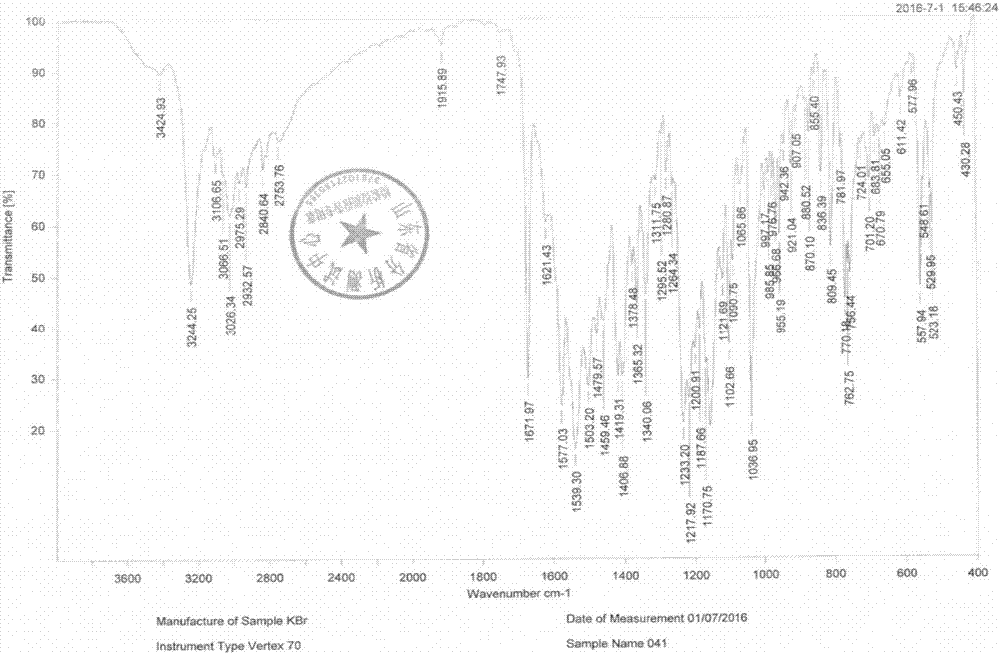

Preparation method of antitumor drug AZD9291

ActiveCN107216313AThe process steps are simpleEasy to operateOrganic chemistryAntineoplastic agents2-methoxy-5-nitroanilinePalladium

The invention discloses a preparation method of antitumor drug AZD9291. The method is as follows: reaction of 4-fluoro-2-methoxy-5-nitroaniline and 3-(2-chloro-pyrimidine-4-yl)-1-methylindole to obtain an intermediate 1; reaction of the intermediate 1 and N, N, N '-trimethylethylenediamine to obtain a compound intermediate 2; hydrogenation reduction of the intermediate 2 to obtain a compound intermediate 3, further introduction of acryloyl group into the intermediate 3 to obtain the AZD9291, and the method is characterized in that activator cuprous bromide is added into the preparing process of the intermediate 2; palladium carbon is used for catalytic hydrogenation reduction, and a mixed anhydride solution of acrylic acid is used for introduction of the acryloyl group of the AZD9291. The method effectively reduces waste solid generation, and improves the purity and the yield of the product.

Owner:山东四环药业股份有限公司

Method for sintering of porous ceramic support and in-situ hydrothermal synthesis of molecular sieve membrane by molecular sieve

ActiveCN108126533AHigh mechanical strengthEliminates coating stepsSemi-permeable membranesMolecular sieveHydrothermal synthesis

The invention discloses a method for sintering of a porous ceramic support and in-situ hydrothermal synthesis of a molecular sieve membrane by a molecular sieve. The method comprises adding an appropriate amount of molecular sieve powder into conventional porous ceramic support ingredients, carrying out molding, carrying out drying, carrying out sintering at a high temperature to obtain a porous ceramic support containing a molecular sieve conversion product, putting the ceramic support into a synthesis solution for preparing a molecular sieve film and carrying out in-situ hydrothermal synthesis to obtain a molecular sieve membrane. Compared with the molecular sieve membrane without the molecular sieve conversion product on the ceramic support, the molecular sieve membrane containing the molecular sieve conversion product is compacter and has better separation performances. The method is easy to operate, reduces a sintering temperature and is free of crystal coating and support post-treatment. The synthetic molecular sieve membrane is continuous and compact, has good separation performances and good repeatability, saves energy, is environmentally friendly and is suitable for large-scale production.

Owner:ZHEJIANG UNIV

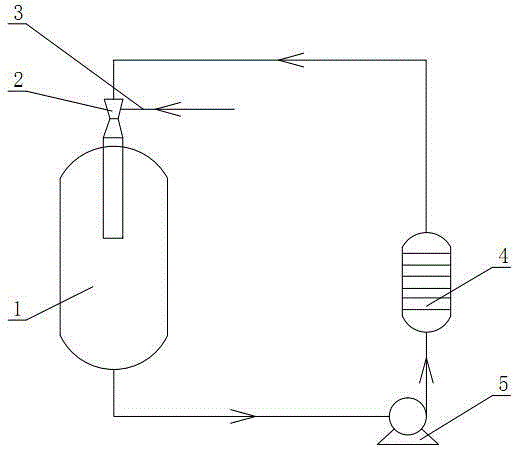

Method for preparing 2-chloro-5-chloromethylthiazole by jet loop reactor

ActiveCN105254583AImprove mixing efficiencyReduce manufacturing costOrganic chemistryOrganic solventBiochemical engineering

The invention discloses a method for preparing 2-chloro-5-chloromethylthiazole by a jet loop reactor, and relates to the technical field of synthesis of the 2-chloro-5-chloromethylthiazole. The jet loop reactor comprises an ejector, wherein the ejector is arranged at the upper part of the reaction kettle; a lower outlet of the reaction kettle is communicated with an inlet of a circulating pump; an outlet of the circulating pump is communicated with the inlet of a heat exchanger; the outlet of the heat exchanger is communicated with the top inlet of the ejector; an air inlet pipe is arranged on the side surface of the ejector; 1-isothiocyano-2-chlorine-2-propylene is dissolved into an inert organic solvent to prepare a liquid-phase material; the liquid-phase material is added to the reaction kettle, and enters from the top inlet of the ejector after passing through the circulating pump and the heat exchanger; chlorine enters the ejector through the air inlet pipe and is mixed with the liquid-phase material; the mixed material passes through the reaction kettle, the circulating pump and the heat exchanger and then returns to the top inlet of the ejector; circular reaction is carried out until the chlorine is introduced; a 2-chloro-5-chloromethylthiazole product is obtained after post-treatment. The method disclosed by the invention is high in yield, few in solid wastes and high in production efficiency; the reaction temperature is easy to control.

Owner:河北德瑞化工有限公司

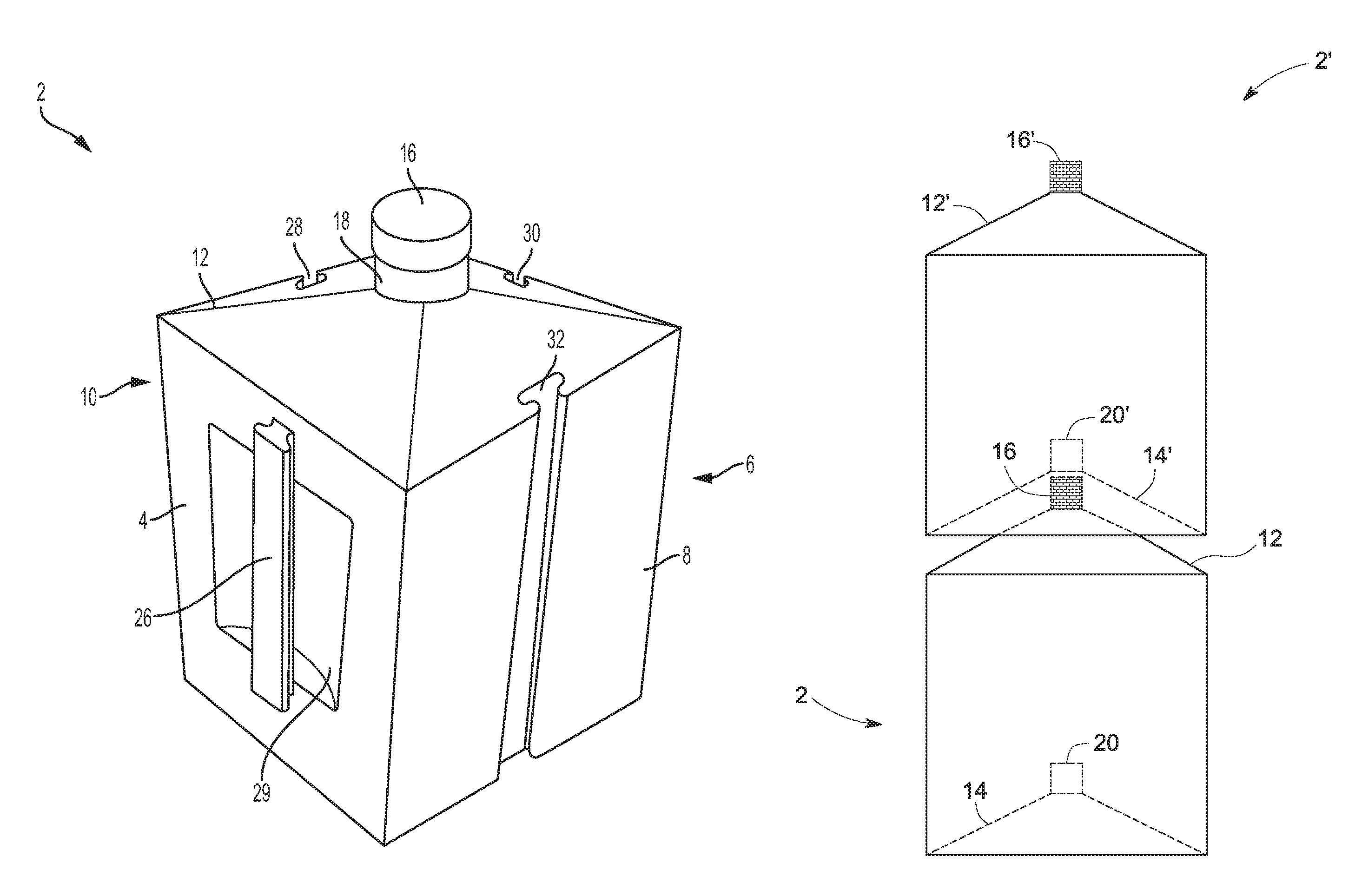

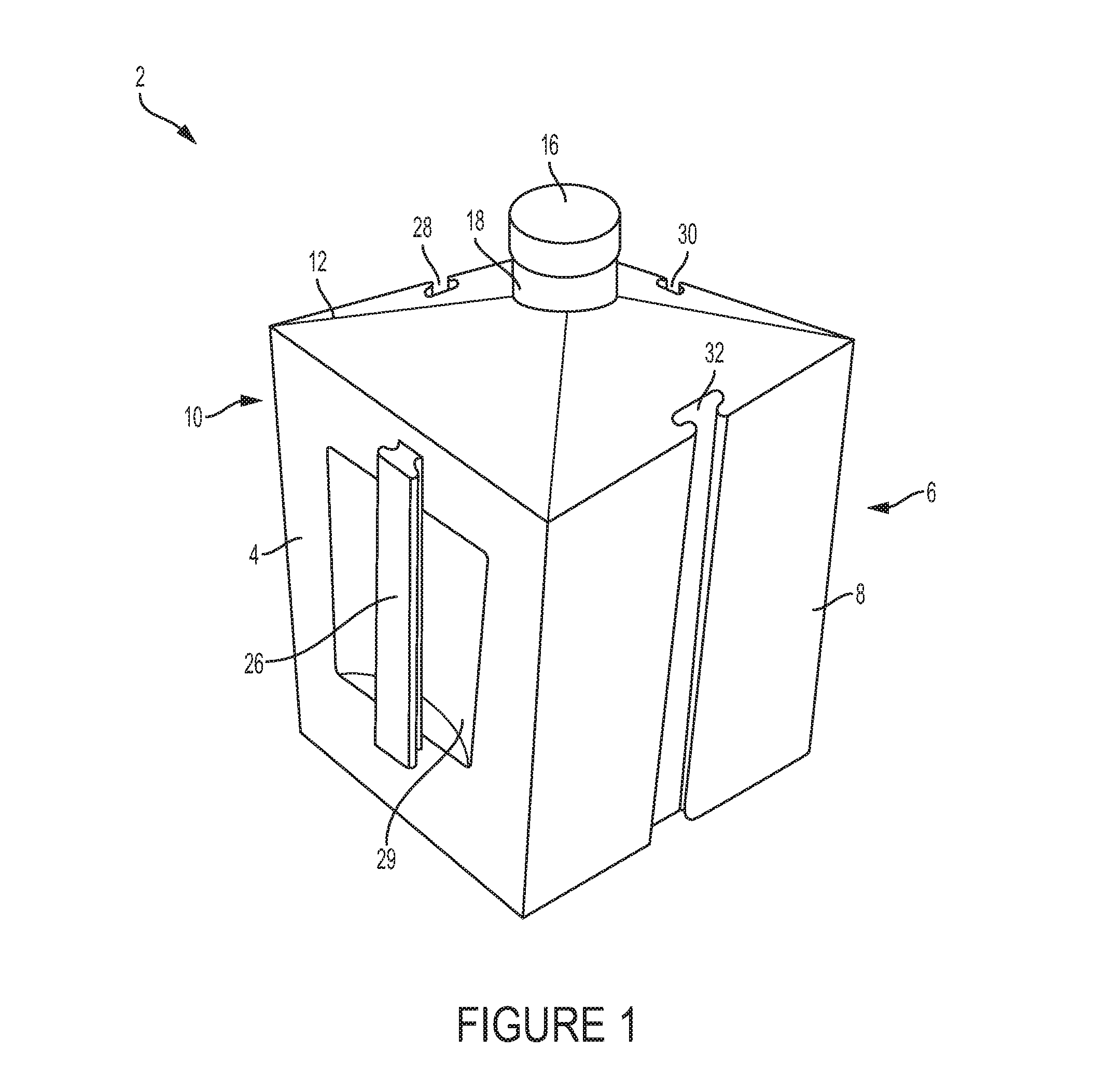

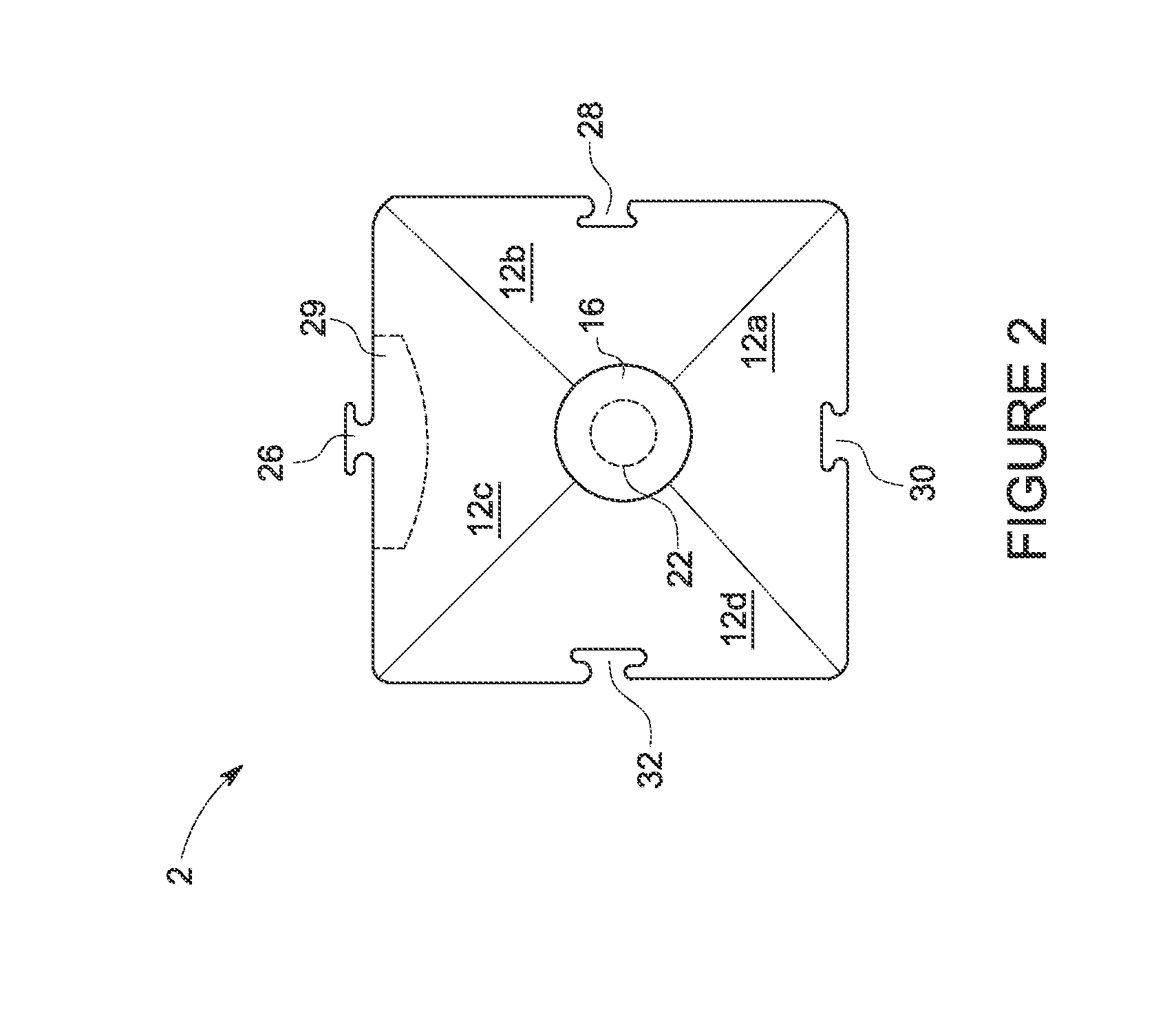

Modular interlocking containers

ActiveUS9290300B2Benefiting environmentCost-effective moldingBottlesLarge containersInterconnectivityTerrain

The invention includes a scalable, modular interlocking container with a multi-purpose use. Vertical and horizontal interconnectivity are achieved through interlocking mechanisms. An exemplary first use is for transporting and / or storing liquids or solids that can be poured. An exemplary second use is for a sturdy, low cost, easily assembled building block material of a standardized nature. Each modular unit slide-locks with other units to form strong wall and building structures that can be filled with natural earth, sand or other such materials, thereby forming a sturdy structure without the use of mortar, and can adapt to uneven base surfaces typically found in natural terrain.

Owner:FRIENDSHIP PRODS

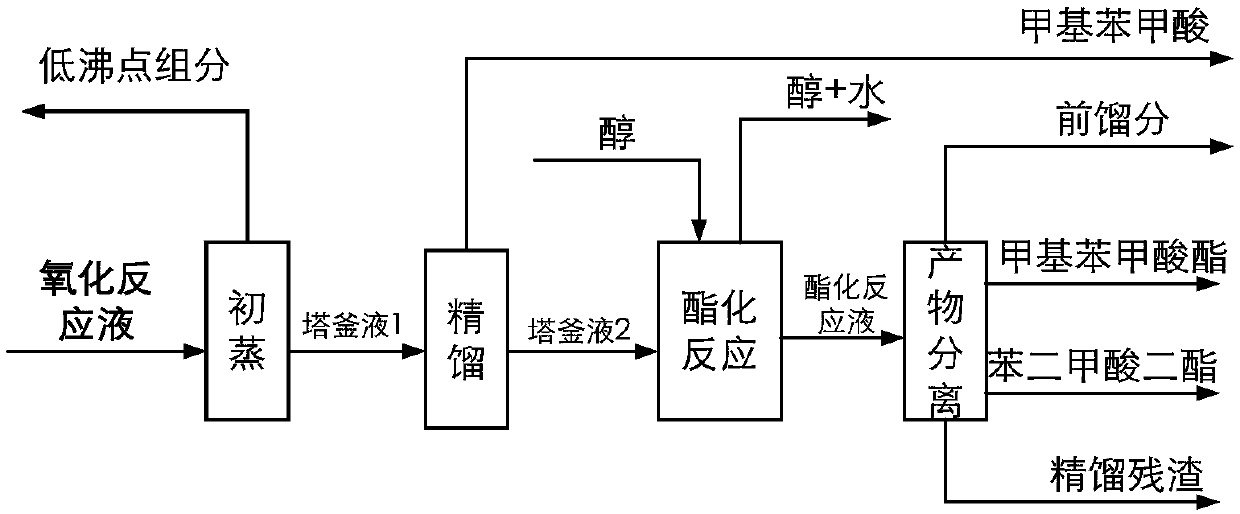

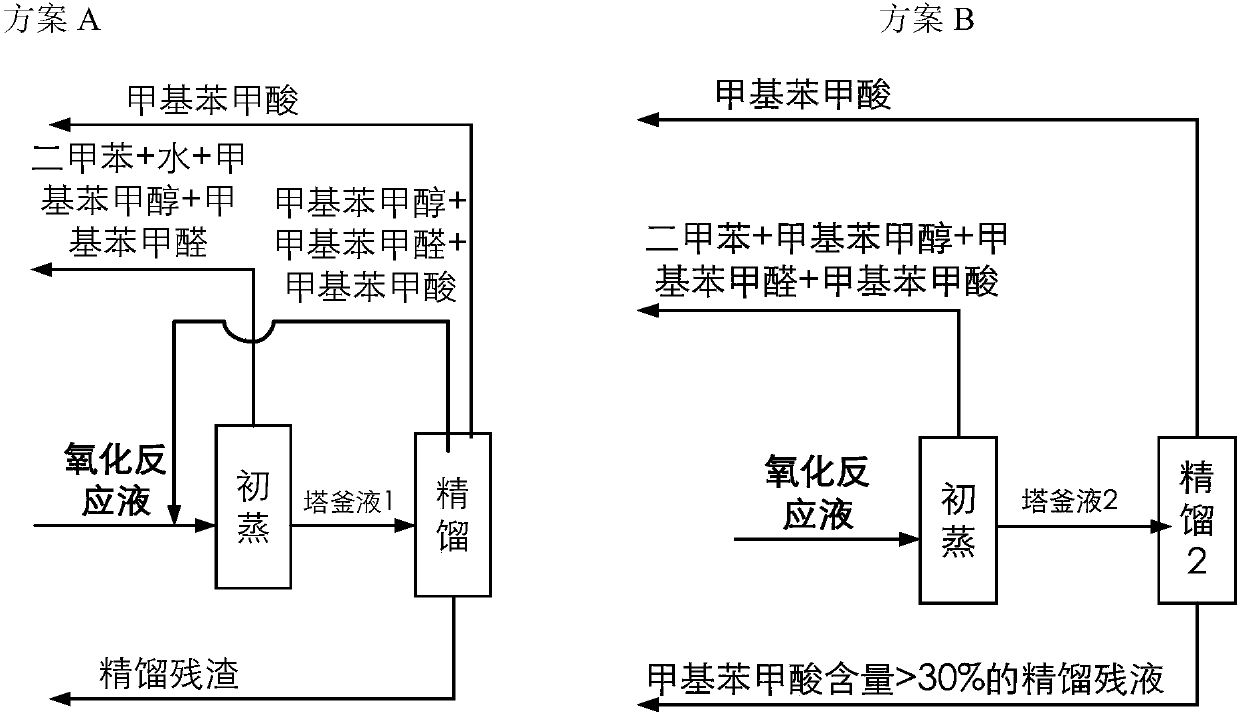

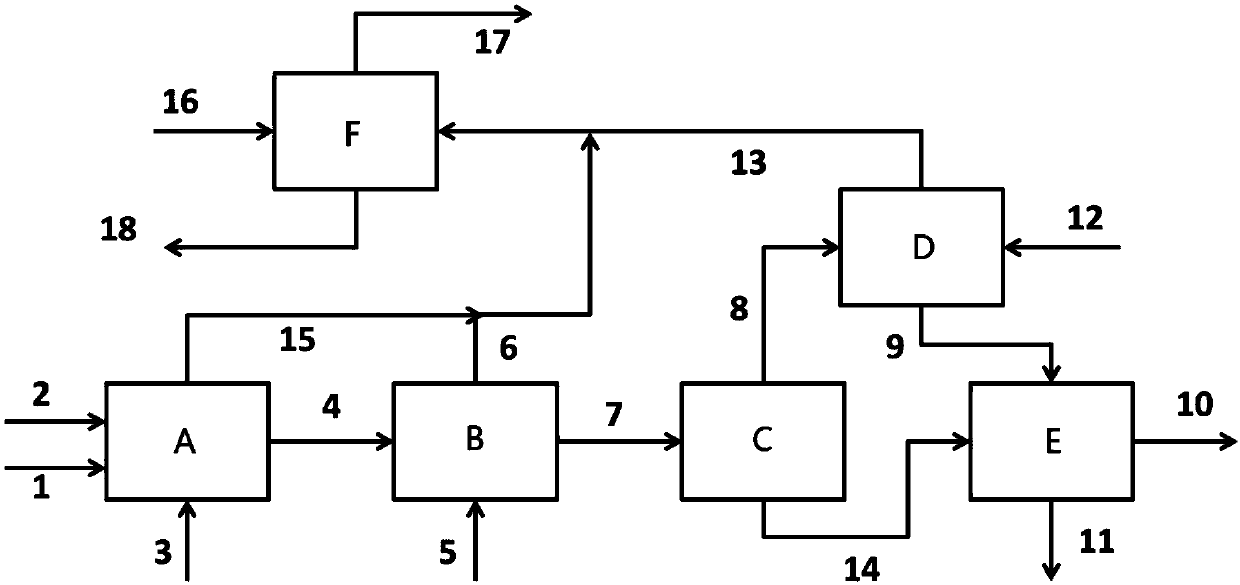

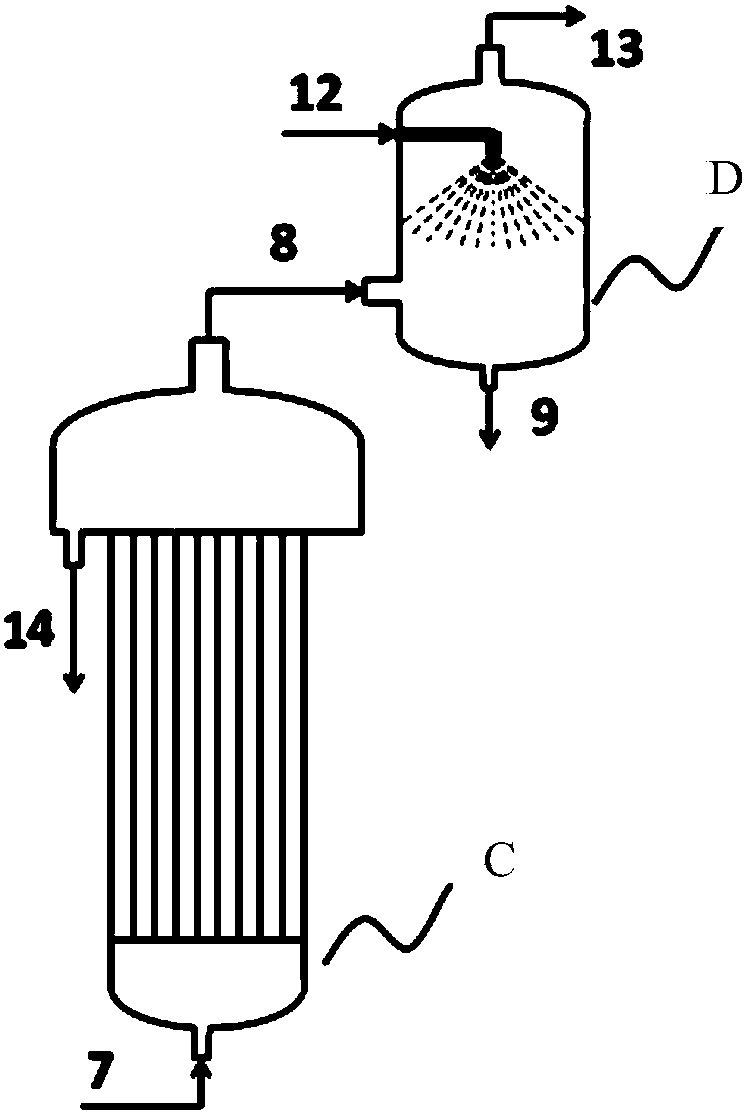

Coproduction method of methylbenzoic acid, methyl benzoate and benzenedicarboxylic acid diester

ActiveCN108047034ARaw materials are easy to getStructural diversificationOrganic compound preparationCarboxylic acid esters preparationAlcoholDistillation

The invention discloses a coproduction method of methylbenzoic acid, methyl benzoate and benzenedicarboxylic acid diester. The method comprises the following steps: (1) continuously introducing xylene, a catalyst and oxygen-containing gas into an oxidation reactor for a reaction, and controlling oxygenic concentration in the tail gas to not exceed 5% by controlling introduction amount of the oxygen-containing gas to obtain an oxidation reaction liquid; (2) feeding the obtained oxidation reaction liquid into a predistillation tower for distillation separation to obtain a low-boiling-point component and a predistillation tower bottom liquid; (3) feeding the predistillation tower bottom liquid into a distillation tower for distillation to obtain a methylbenzoic acid product and a distillationtower bottom liquid; (4) mixing the distillation tower bottom liquid and alcohol for an esterification reaction, and controlling the reaction endpoint to be lower than 0.5wt% of the content of methylbenzoic acid to obtain an esterification reaction liquid; (5) performing distillation separation on the obtained esterification reaction liquid to obtain methyl benzoate and benzenedicarboxylic acid diester products. The method has the advantages that the process is simple, equipment investment is low, and the method is environmentally friendly and has good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

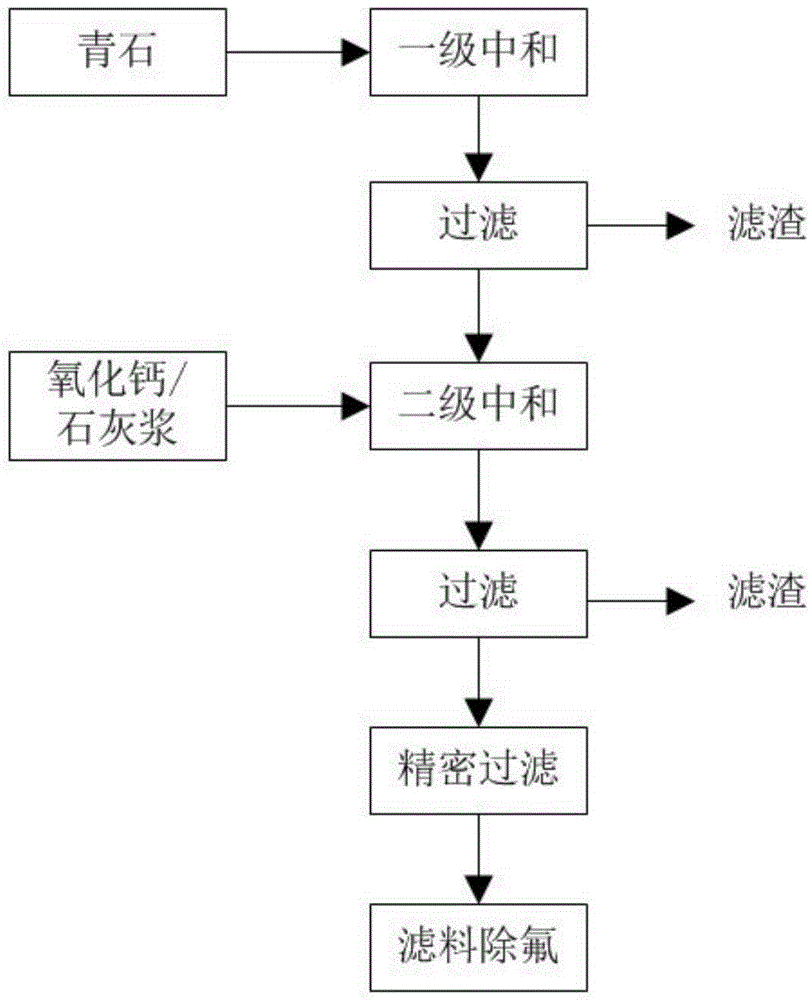

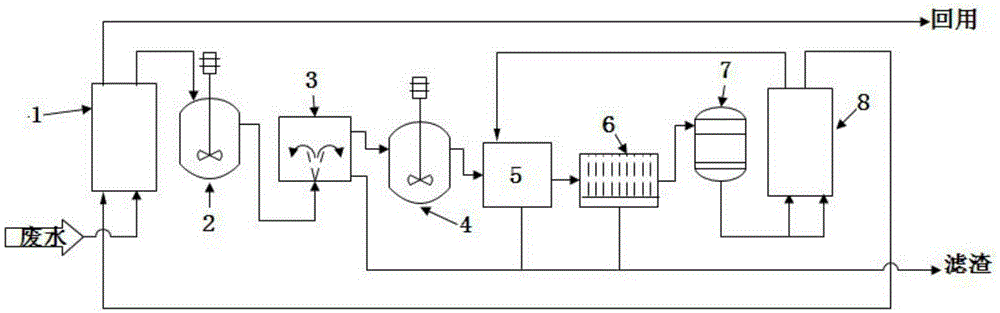

Fluoride removal method of graphite purification waste water and processing system

ActiveCN105347574AReduce solid wasteLess impuritiesWater contaminantsTreatment involving filtrationChemistryFilter material

The invention discloses a fluoride removal method of graphite purification waste water and a processing system. The fluoride removal method comprises the step that the graphite purification waste water is subjected to diffusing dialysis, so as to recover acid therein. Diffusing dialysis processing liquid is neutralized and filtered through two steps, and obtained neutralized filter liquor is in contact with a fluoride removal filter material to remove fluoride, so that fluorine content in obtained effluent reaches the standard, and the effluent reaches the effluent standard. The waste water continuously runs in the processing system, and effluent obtained by processing is recycled in the system. By adopting the processing method provided by the invention, through applying the processing system provided by the invention, not only can the fluoride in the waste water can be effectively removed, but also the waste water processing cost can be obviously reduced, the whole system runs stably, and the operation is simple. Continuous and automatic running can be realized.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

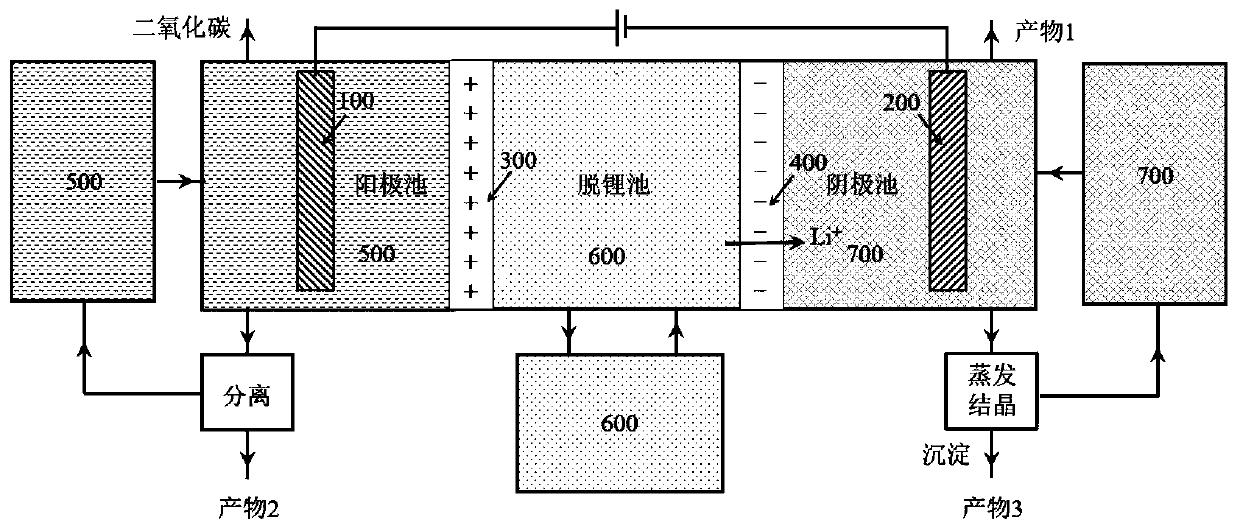

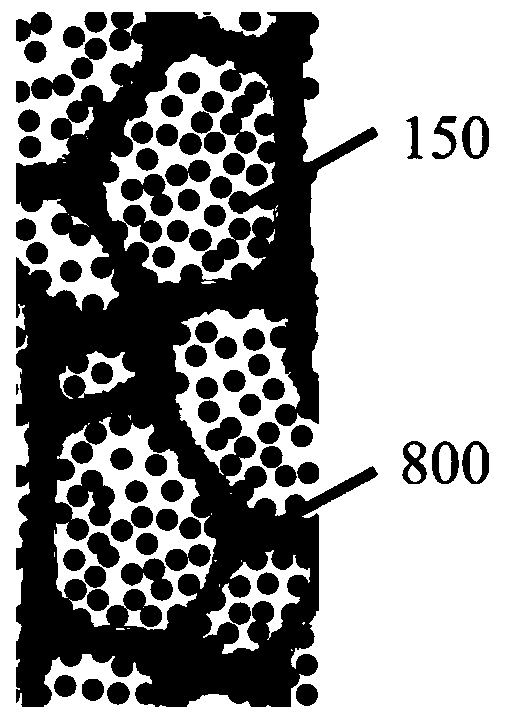

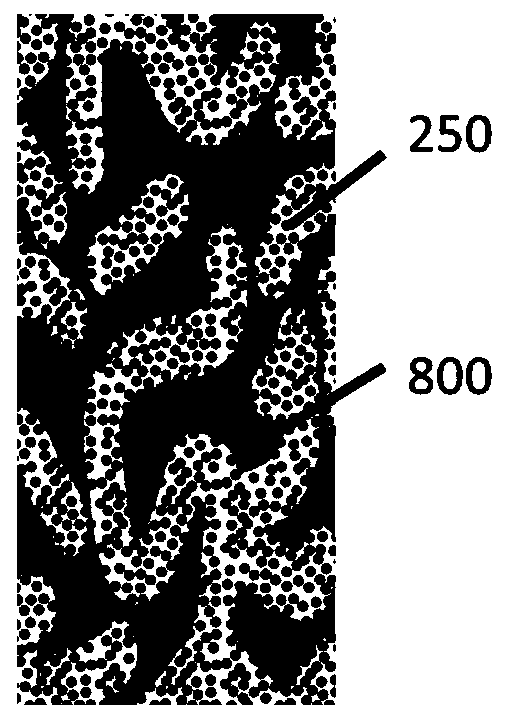

Device and method for electrochemically preparing high-purity battery-grade lithium hydroxide

ActiveCN110616438ASolving Mixing ProblemsLower oxidation potentialCellsElectrodesElectricityLithium hydroxide

The invention provides a device and a method for electrochemically preparing high-purity battery-grade lithium hydroxide. The device comprises two electrocatalytic electrodes and two separators, particularly an oxidation electrode (100), a hydrogen production electrode (200), an anion exchange membrane (300) and a cation exchange membrane (400); wherein the oxidation electrode (100) and the anionexchange membrane (300) form an anode tank; the hydrogen production electrode (200) and the cation exchange membrane (400) form a cathode tank; the device further comprises a lithium removal tank; thelithium removal tank is connected with the anode tank through the anion exchange membrane (300); and the lithium removal tank is also connected with the cathode tank through the cation exchange membrane (400). Compared with the prior art, the method and the device have the following technical effects: (1) electro-catalytic organic matter oxidation, electro-catalytic hydrogen evolution reduction and electro-lithium removal are combined for the first time; the whole system realizes simultaneous preparation of three products which are lithium hydroxide, hydrogen and acid.

Owner:南京宁智高新材料研究院有限公司

UV paint exhaust gas treatment system

PendingCN107261752AEasy to handleImprove treatment effect, waste gas emissionGas treatmentDispersed particle filtrationFlame arresterUltraviolet lights

The invention discloses a UV paint exhaust gas treatment system. The UV paint exhaust gas treatment system comprises a UV spray inlet, a UV tank, an active carbon catalytic combustion tank, an active carbon tank, a high-altitude exhausting chimney, a plurality of ultraviolet lamps, a filter bag, and a catalytic decomposition bed; the active carbon tank and the active carbon catalytic combustion tank are arranged in parallel via a technical pipeline; the active carbon catalytic combustion tank is provided with a desorption fan, the catalytic decomposition bed, and a flame arrester; the ultraviolet lamp and the filter bag are arranged in the UV tank; the ultraviolet lamps are arranged at the front segment of the UV tank; the filter bag is arranged at the back segment of the UV tank. According to the UV paint exhaust gas treatment system, ultraviolet ray irradiation is adopted for curing of viscous UV particles via ultraviolet lamp irradiation, and the filter bag is used for removing UV particles; VOC in exhaust gas is absorbed by active carbon; the UV paint exhaust gas treatment system is provided with the active carbon catalytic combustion tank for low temperature regeneration of active carbon; treatment efficiency is as high as 97%, and is higher than that disclosed in national exhaust gas discharge standards.

Owner:SUZHOU HUYOU IND EQUIP

Waste stream decontamination system

ActiveUS10882758B2Improve efficiencyIncreased/improved complianceFatty/oily/floating substances removal devicesSewerage structuresWaste streamEnvironmental engineering

Owner:SANDYLAKES LTD

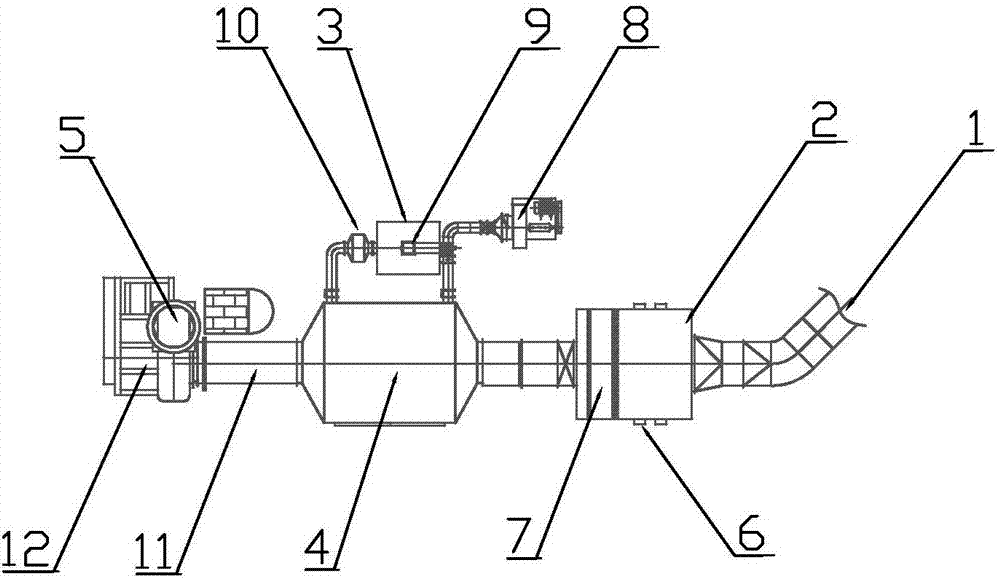

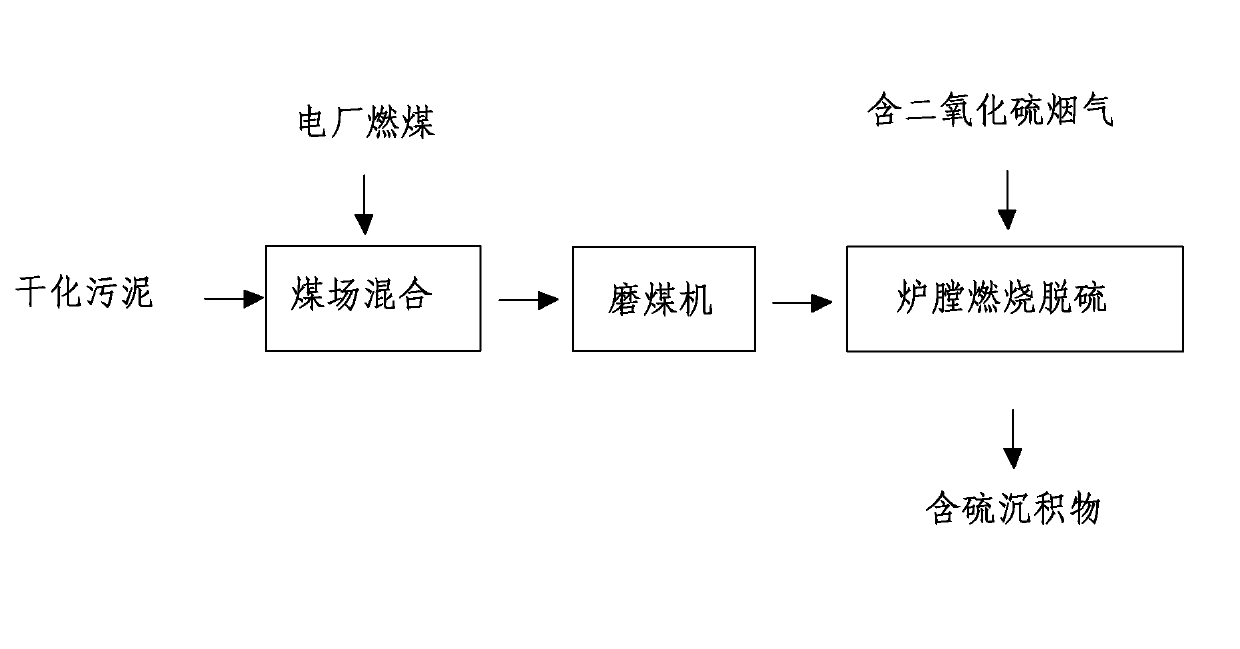

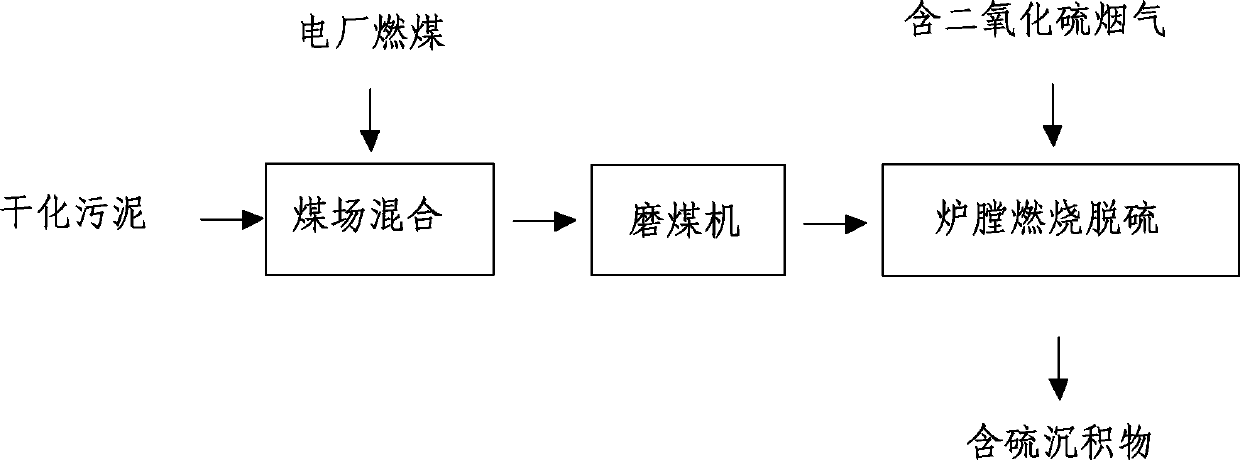

Method for devulcanization by burning power plant fire coal mixed with dried sludge

InactiveCN102676267ASolve the problem of solid waste disposalRelieve pressureSolid fuelsSocial benefitsSludge

The invention relates to the technical field of environment-friendly devulcanization processes, in particular to a method for devulcanization by burning power plant fire coal mixed with dried sludge. The method comprises a first step of making papermaking waster paper sludge into the dried sludge by dewatering, a second step of enabling the dried sludge and the power plant fire coal to be fully mixed, a third step of utilizing a coal mill to grind the power plant fire coal mixed with the dried sludge into powder, a fourth step of enabling the mixed powder of the ground dried sludge and the power plant fire coal to be placed in a hearth to be burnt, enabling calcium ions and magnesium ions in the dried sludge to be combined with sulfur dioxide in flue gas in the high-temperature burning process, generating sulfur-containing sediments, and removing sulfur-containing components in coal. The method is simple in process and low in equipment cost and production cost, can reduce use of a desulfurizer by over 30%, turns the papermaking waster paper sludge into wealth, and is high in economic benefits and social benefits.

Owner:DONGGUAN NINE DRAGONS PAPER IND

Preparation method and system of mono-isocyanate

ActiveCN107935889AHigh yieldReduce solid wasteOrganic compound preparationIsocyanic acid derivatives purification/separationSolventHydrogen chloride

The invention relates to a preparation method and system of mono-isocyanate. According to the method, an excessive amount of phosgene is subjected to phosgenation reaction with corresponding amine, and after obtained reaction liquid is subjected to gas stripping through hydrogen chloride and phosgene is removed, the fact that the phosgene is completely separated with isocyanate is realized, and the purpose that the excessive amount of phosgene can be recycled is achieved. Pyrolysis gas obtained by performing pyrolysis on reaction liquid with phosgene being stripped is captured through an inertsolvent, solution of corresponding isocyanate is obtained, and qualified isocyanate can be obtained through subsequent separation. A process for preparing mono-isocyanate through the method has the characteristics of high yield and low solid waste amount.

Owner:WANHUA CHEM GRP CO LTD

High efficiency extraction method of T-acid mother liquor

ActiveCN105129894ASave energy costsSave production costNature of treatment waterWater/sewage treatment by extractionInorganic saltsKerosene

The invention relates to a high efficiency extraction method of T-acid mother liquor, and belongs to the field of an H-acid production waste water treatment. Tri(octyl-decyl)amine, sulfonated kerosene and n-octyl alcohol are respectively measured and uniformly mixed for obtaining an extractant, the extractant is thrown into the T-acid mother liquor, a heating stirring is carried out, simultaneously sulfuric acid is added, after stirring, standing and layering, the upper layer is an extract, and lower layer is an inorganic salt water phase; after the lower layer inorganic salt water phase is separated, the upper layer extract is heated, sodium hydroxide is added, after stirring and standing, the oil and water separation is carried out. The invention is applied into the H-acid production, thereby avoiding generation of solid waste with simple operation and effectively reducing the production cost.

Owner:JIANGXI MADE FINE CHEM IND

Production method for trioctyl trimellitate

InactiveCN105175256AAvoid darker shadesReduce filtration processOrganic compound preparationCarboxylic acid esters preparationActivated carbonNitrogen

The invention discloses a production method for trioctyl trimellitate. In order to control the quality of trimellitic anhydride serving as a raw material, nitrogen protection is adopted during a production process; a small amount of titanate-like catalyst is added under the conditions that a secondary esterification reaction is completed and water serving as a reaction by-product is removed so that the esterification reaction is performed completely, and the product standards of the synthesized product can meet the requirements of a superior product in the index aspects, such as the chromaticity and the acid value, without being absorbed and de-colored by activated carbon without neutralizing or only by adding a small amount of neutralizing agent; therefore, the problems that the chromaticity is influenced by the existence of tiny activated carbon particles and the addition of a large amount of the neutralizing agent and a large amount of salt residues in the product of the product in downstream application are avoided. When the raw material purity of the trimellitic anhydride is not high, or the acid value of the product exceeds the standard slightly caused by the reasons that acid regurgitation appears in the process of adding water to break the titanate-like catalysts and the like, and remediation can also be performed through a given post-processing method.

Owner:黄裕兵

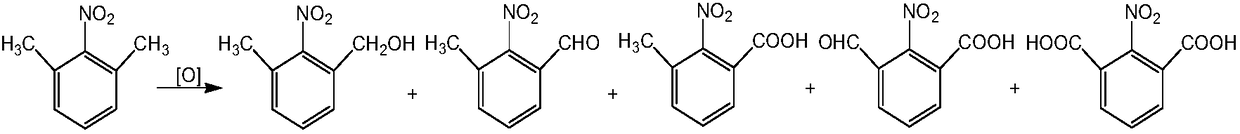

Method for synthesizing 2-nitro-3-methylbenzoic acid

ActiveCN108129322AImprove conversion rateHigh selectivityNitro compound preparationNitrationEconomic benefits

The invention discloses a method for synthesizing 2-nitro-3-methylbenzoic acid. The method comprises that powdery meta-methylbenzoic acid and nitric acid undergo a reaction at -30 to -15 DEG C to produce a nitrification reaction solution, and the nitrification reaction solution is separated and purified to form a 2-nitro-3-methylbenzoic acid product. The method has simple processes, is easy to operate, has a high conversion rate of m-methylbenzoic acid, has high selectivity of 2-nitro-3-methylbenzoic acid, and has obvious environmental protection effects and significant economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

Method for removing halogen series gas and agent for removing halogen series gas

InactiveUS20070253879A1Improve abilitiesSuppress feverGas treatmentOther chemical processesHydrogen halideSorbent

To provide a method for removing a halogen series gas, which has high capability of treating a halogen series gas, can prevent ignition of an adsorbing agent, is free from formation of carbon dioxide and can reduce generation of wastes, and a removing agent to be used for the method. The method for removing a halogen series gas comprises bringing a gas comprising at least one halogen series gas selected from the group consisting of F2, Cl2, Br2, I2 and a compound which undergoes hydrolysis to form a hydrogen halide or hypohalogenous acid into contact with a granulated product comprising from 80 to 99.9 mass % of an alkali metal base and from 0.1 to 20 mass % of a thiosulfate based on the total mass of the granulated product, in the presence of water, to remove the halogen series gas.

Owner:ASAHI GLASS CO LTD

Sodium sulfide production method based on solid waste sodium sulfate generated from vanadium extraction

InactiveCN106495104ALow costReduce consumptionEnergy inputAlkali metal sulfides/polysulfidesEnvironmental resistanceSlag

The invention belongs to the technical field of sodium sulfide production, and particularly relates to a sodium sulfide production method based on waste sodium sulfate generated from metallurgical vanadium extraction. In order to solve the technical problems of high cost, big coal powder consumption, and large amounts of generated slag in the prior art, thus being detrimental to environmental protection, the sodium sulfide production method based on waste sodium sulfate generated from vanadium extraction is provided. The method comprises the steps of A, preparing materials, B, roasting, C, thermalizing and leaching, D, deslagging and clarifying, and E, evaporating and concentrating. The method uses the solid waste sodium sulfate generated from vanadium extraction as the material for a second time use, thus reducing the material cost. The use of fine coke as the reducer to replace the coal powder used in traditional production process, reduces the material consumption. The method applies the production process of material preparation, roasting, thermalizing and leaching, deslagging and clarification, evaporation, concentration and crystallization, and has the advantages of being lower in production cost, friendlier to environment, and able to produce better economic benefits and environmental protection benefits.

Owner:攀枝花市博信化工有限责任公司

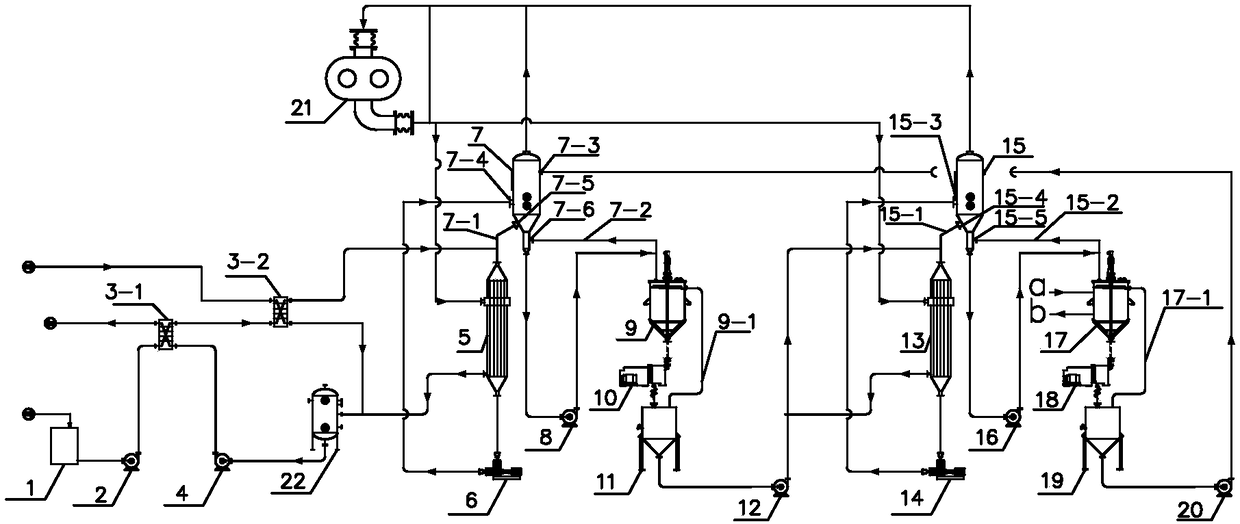

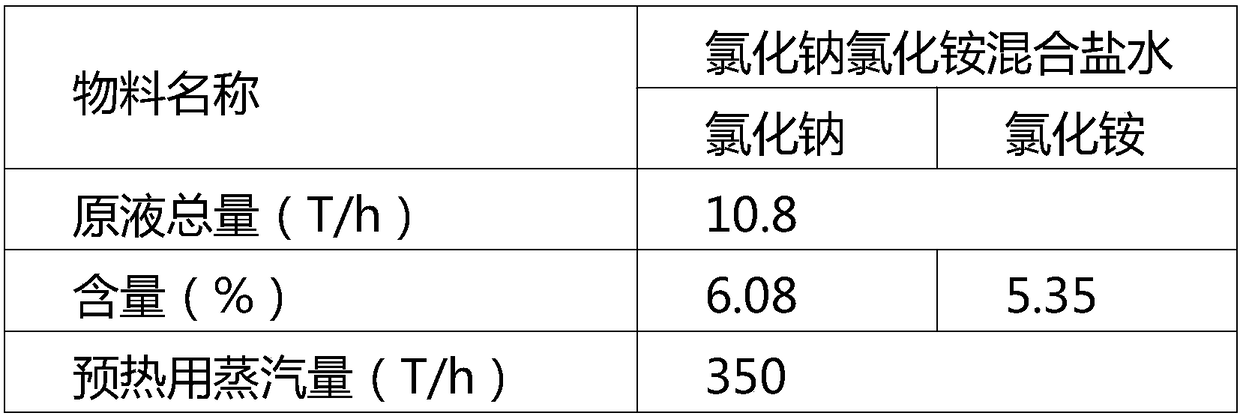

Sodium chloride ammonium chloride separated crystallization process and device

PendingCN108585089AAchieve separationAchieve recyclingWater contaminantsWater/sewage treatment by heatingResource recoveryWastewater

The invention discloses a sodium chloride ammonium chloride separated crystallization process. The process comprises the steps that sodium chloride is crystallized and precipitated at a high-temperature state, and supersaturated ammonium chloride is precipitated at a low-temperature state, thereby achieving the separation and recovery of sodium chloride and ammonium chloride in wastewater to obtain industrial-grade sodium chloride and ammonium chloride products, the generation of solid waste or hazardous waste is reduced, no emissions causing water pollution exist, and the effect of resource recovery with zero discharge of contaminating fluid is achieved. The sodium chloride ammonium chloride separated crystallization device has the advantages that the structure is reasonably set, energy consumption is reduced, the process can be achieved easily, the automation degree is high, the running cost is low, and the device can be widely applied in actual industrial production processes.

Owner:苏州鼎昌节能环保科技有限公司

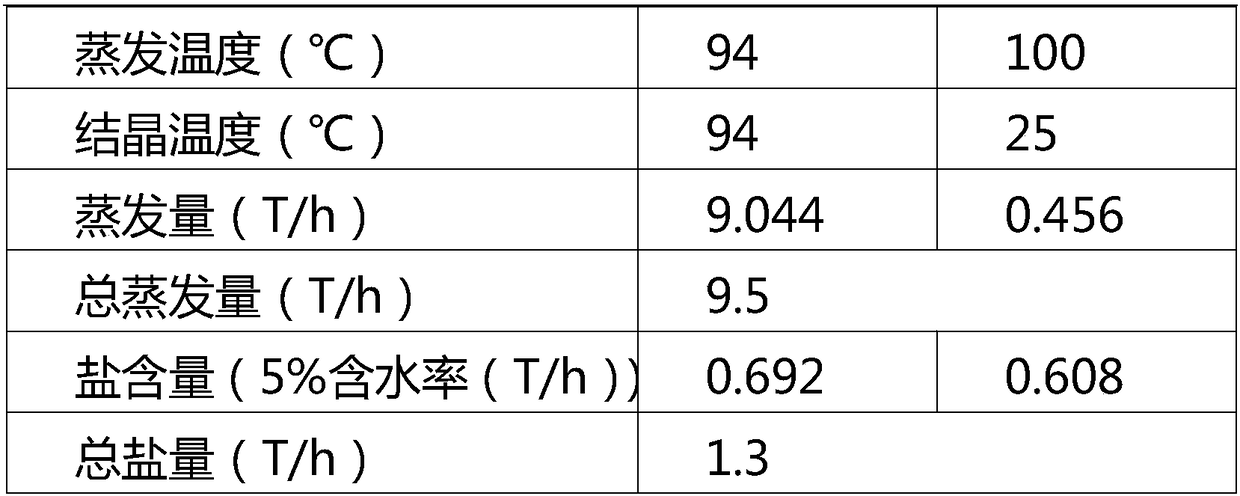

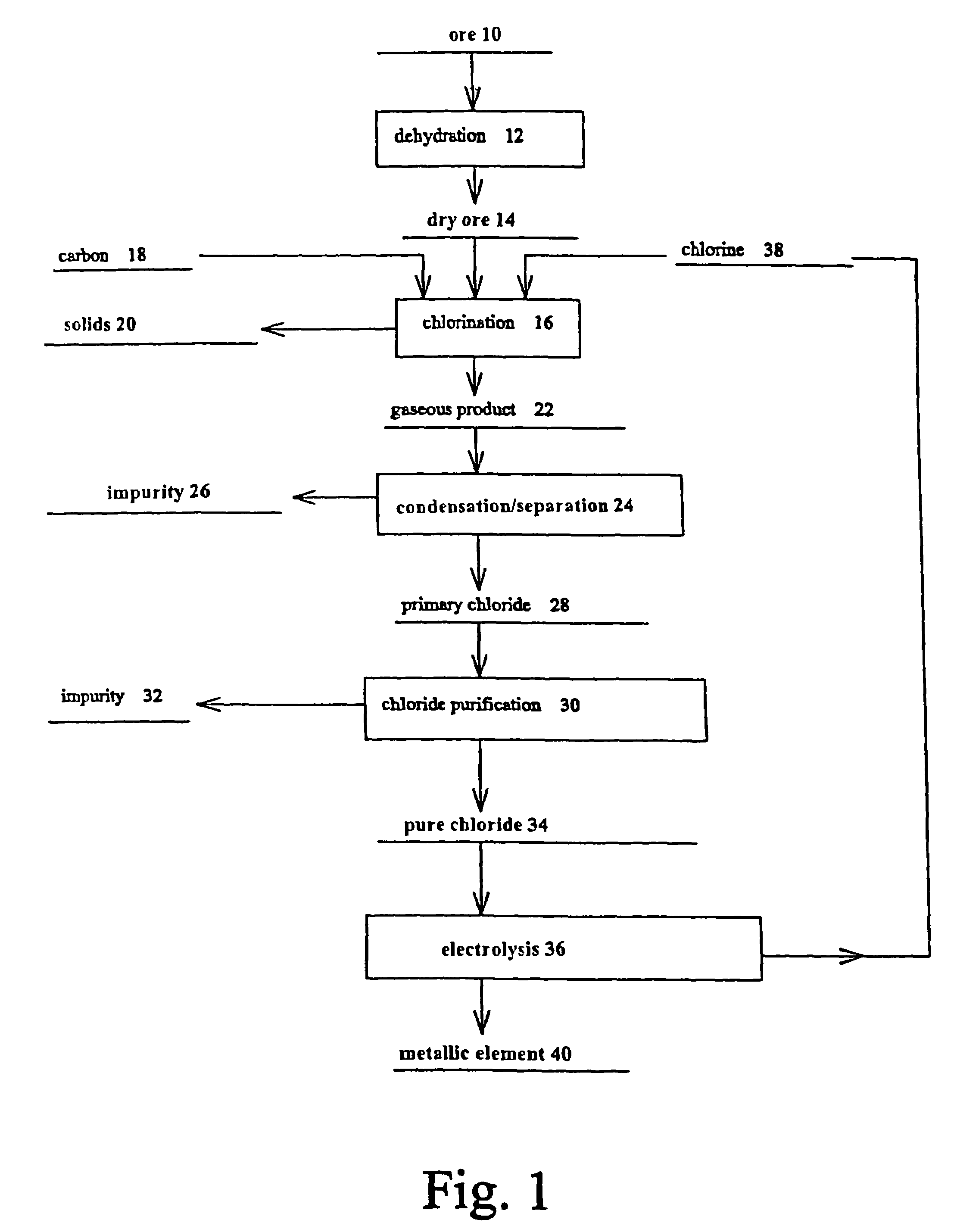

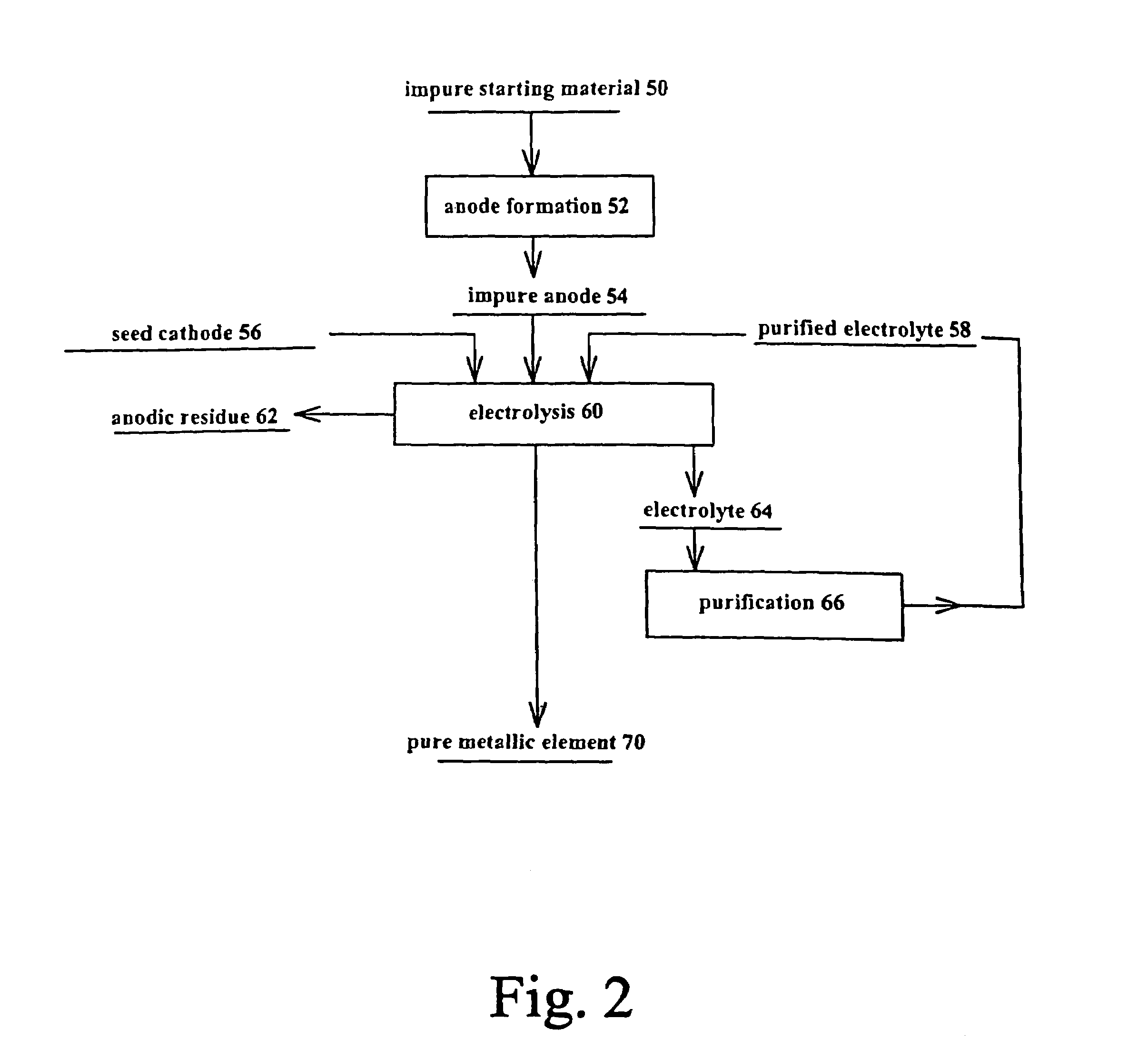

Production, refining and recycling of lightweight and reactive metals in ionic liquids

Lightweight and reactive metals can be produced from ore, refined from alloy, and recycled from metal matrix composites using electrolysis in electrolytes including an ionic liquid containing a metal chloride at or near room temperature. Low electric energy consumption and pollutant emission, easy operation and low production costs are achieved.

Owner:UNIVERSITY OF ALABAMA

Oil-containing sludge incineration system for pressurized fluidized bed and incineration treatment method

PendingCN110375310AHarmlessAchieve reductionFuel feedersIndirect carbon-dioxide mitigationCombustionHazardous substance

The invention discloses an oil-containing sludge incineration system for a pressurized fluidized bed and an incineration treatment method. The process comprises the following steps: introducing preheated pressurized air into a fluidized bed incinerator, adding oil-containing sludge into the incinerator to pressurize and combust under a fluidized state, and supplementing auxiliary fuels to keep a combustion state stable if combustion heat is insufficient; enabling high-temperature pressurized wet flue gas generated in the incinerator to preheat pressurized air for combustion of the fluidized bed incinerator, preliminarily cooling the pressurized air into medium-temperature pressurized wet flue gas; continuously performing dust-removal denitration treatment on the flue gas to obtain medium-temperature pressurized clean wet flue gas, and recycling separated fly ash; recycling sensible heat of the medium-temperature pressurized clean wet flue gas through a waste heat recycling system, andrealizing up-to-standard emission through treatment such as a follow-up decompression system and a dehumidifying system. Reduction, harmless and resource utilization as well as energy conservation andemission reduction are realized on the oil-containing sludge, so that combustion efficiency can be greatly improved, equipment unit area processing ability is improved, and emission of harmful substances in flue gas is reduced.

Owner:陕西正本环境工程有限公司

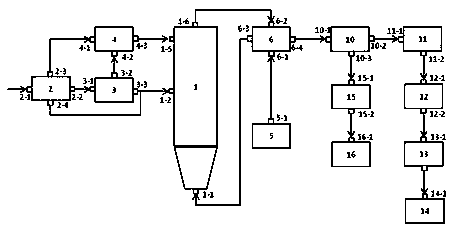

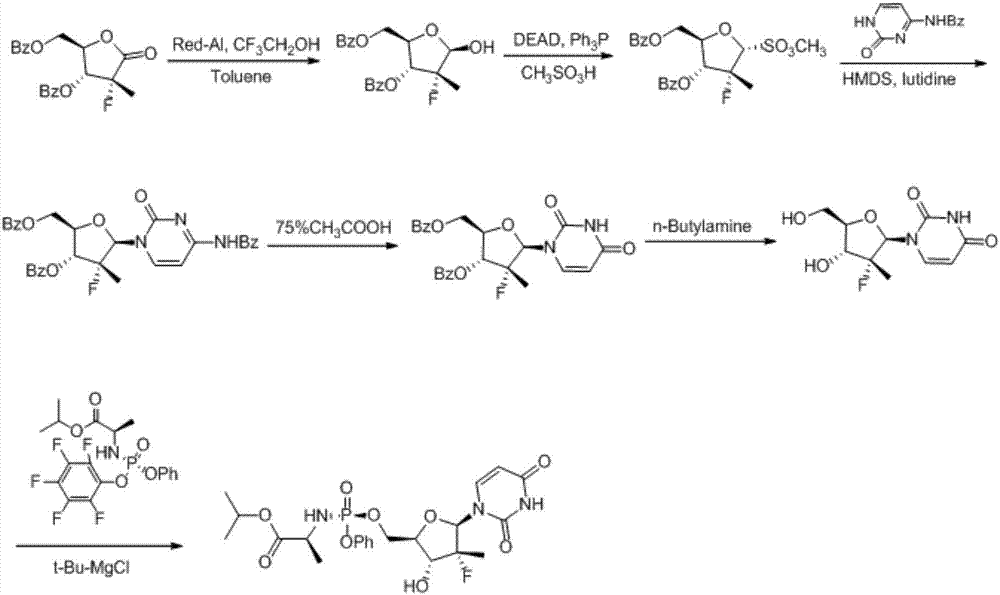

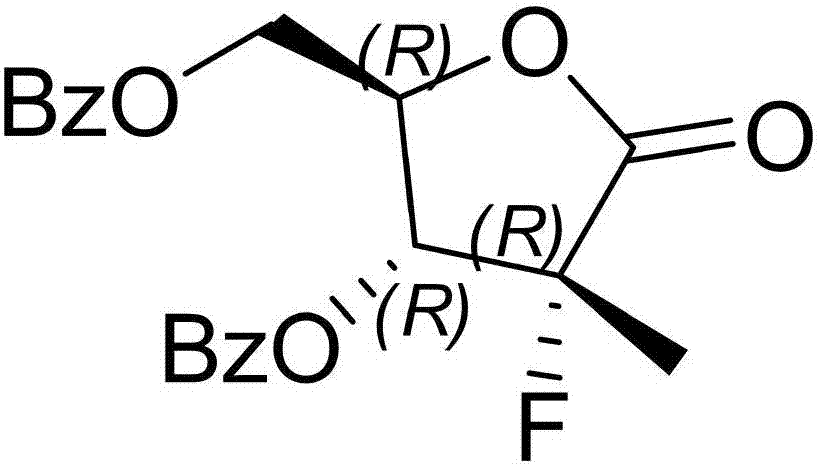

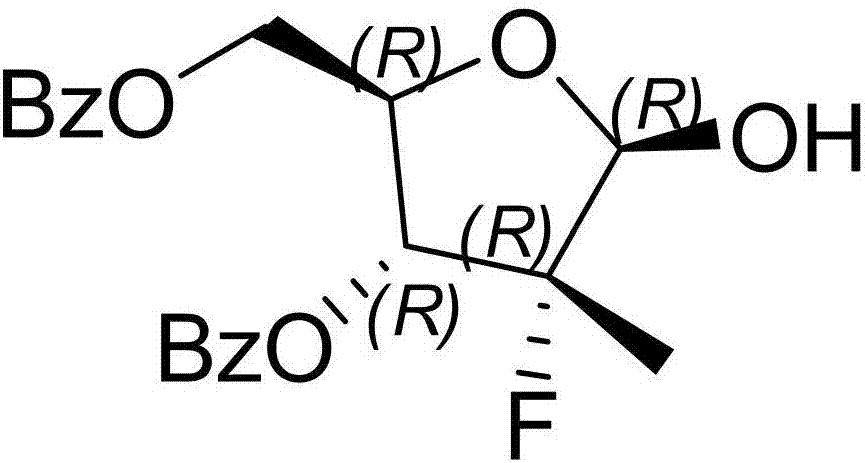

Synthesis method of sofosbuvir

ActiveCN106905398AAvoid generatingReduce usageSugar derivativesSugar derivatives preparationSulfonateSynthesis methods

The invention provides a synthesis method of sofosbuvir. The synthesis method of the sofosbuvir comprises the following steps: performing mitsunobu reaction on ((2R,3R,4R)-3-benzoyloxy)-4-fluorine-5-hydroxyl-4-methyltetrahydrofuran-2-yl)methyl benzoate to produce sulfonate to obtain a compound 1; abutting the compound 1 and N-benzoylcytosine to produce a compound 2. The method adopts mitsunobu reaction to avoid production of an isomer, and the isomer is reduced to 5 percent or below; according to the method, sulfonate and N-benzoylcytosine are abutted, so the use ofa stannic chloride raw material is avoided; furthermore, the yield is high and few solid waste is generated during aftertreatment, so that the method is suitable for large-scale industrialized production.

Owner:ZHEJIANG FORESTRY UNIVERSITY

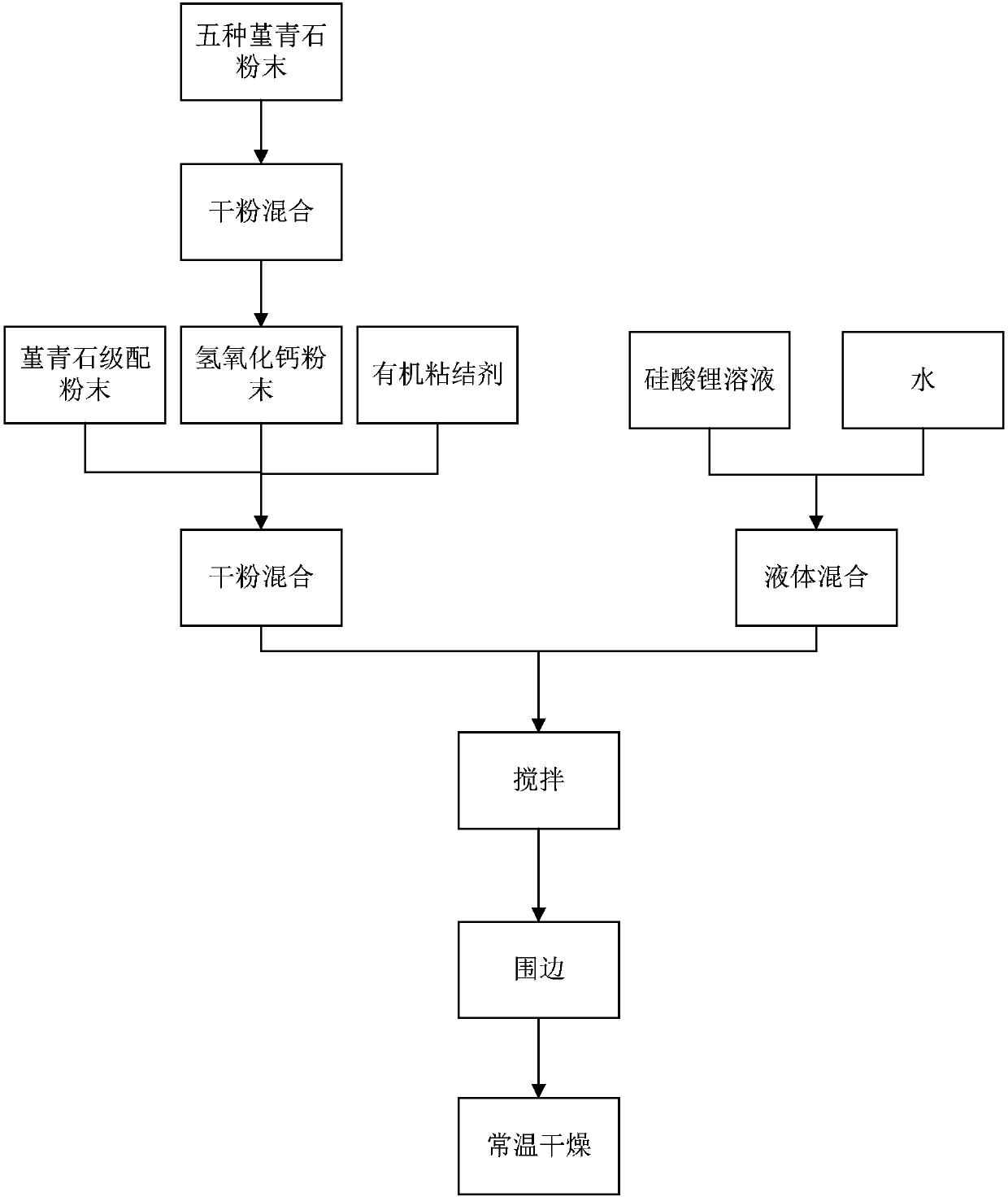

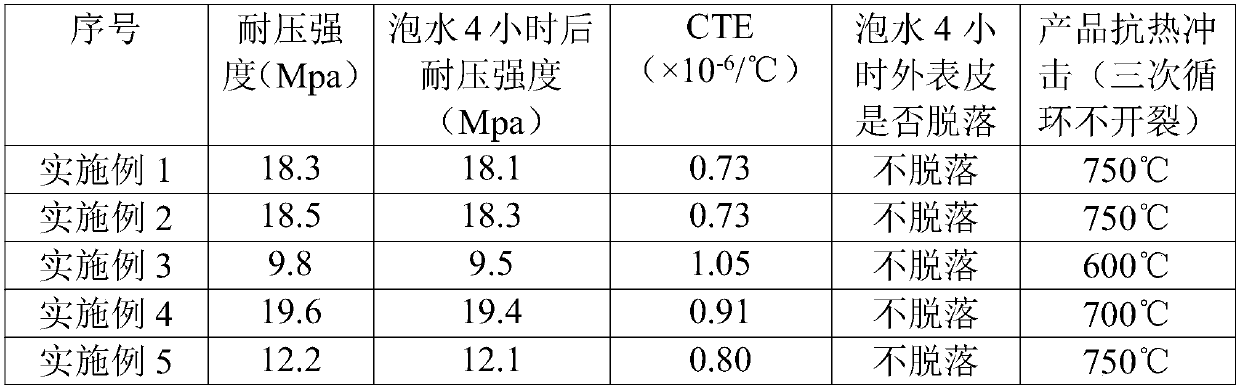

Lower thermal expansion large-diameter ceramic honeycomb carrier and preparation method thereof

ActiveCN107915498ASelf-dryingGood wet and dry resistanceCatalyst carriersDispersed particle separationPhosphateAdhesive

The invention discloses a lower thermal expansion large-diameter ceramic honeycomb carrier and a preparation method thereof. An outer surface of the lower thermal expansion large-diameter ceramic honeycomb carrier contains the following preparative raw materials: multi-graded cordierite powder, lithium silicate solution, calcium hydroxide powder, an organic adhesive and water. After high-temperature drying, the requirements on high strength and high water resistance can be met. The outer surface of the ceramic honeycomb carrier disclosed by the invention solves the problems such as low strength, low water resistance and high thermal expansion coefficient when the outer surface is prepared by using other adhesives such as sodium silicate, phosphate and silica sol, and compared with a process of first edge surrounding and then roasting, the method disclosed by the invention is low in cost and solves the problem of catalyst leakage during catalyst coating.

Owner:CHONGQING AOFU FINE CERAMICS CO LTD

Mobile or stationary modular self-contained dehydration toilet, dehydration engine, and gray water recovery system

InactiveUS20070187338A1Reduce solid wasteEliminate dischargeGeneral water supply conservationSolid sorbent liquid separationHuman wasteGreywater

A compact dehydration engine and method for treating human waste and gray water residual electro-coagulants that includes a heated waste dehydration chamber that has low energy consumption and low water consumption in use. The system can be employed in stationary or mobile platforms that include multiple toilets and gray water sources for reclamation.

Owner:ZECO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com