Fluoride removal method of graphite purification waste water and processing system

A graphite purification and treatment system technology, applied in the field of wastewater defluorination, can solve the problems of unrepresentation, simple wastewater composition, large solid waste output, etc., and achieve the effects of simple implementation, simple process, and high treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

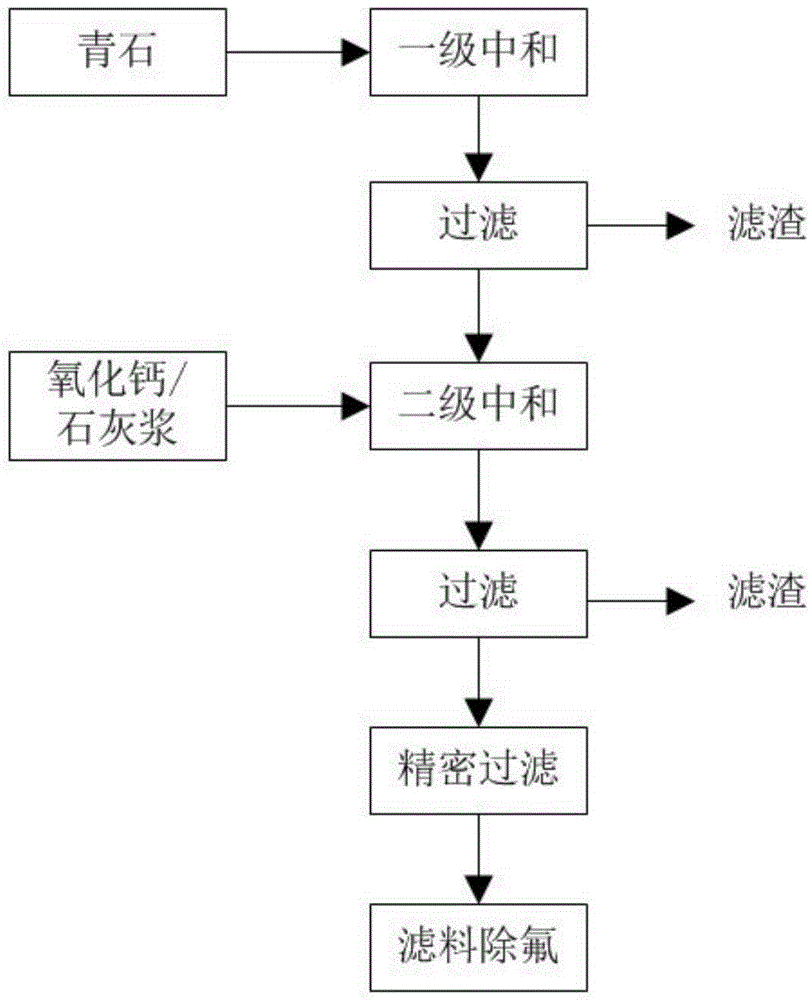

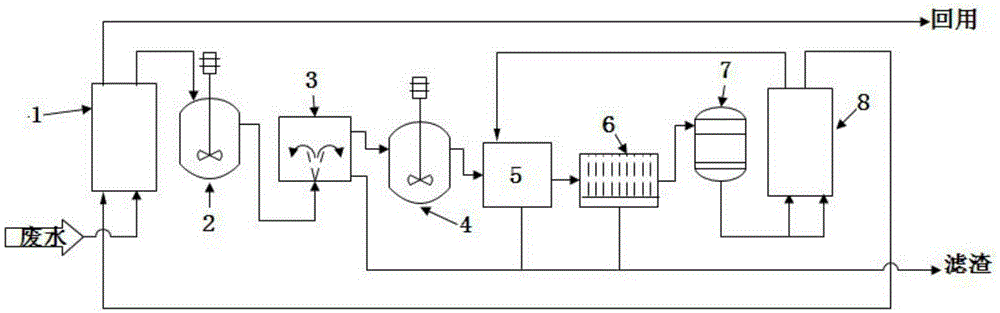

Method used

Image

Examples

Embodiment 1

[0070] Graphite purification wastewater, the fluorine content is 2500mg / L, m(NO 3 - ): m(F - ): m(Cl - )=3:1:2 (molar ratio).

[0071] (1) The clear liquid obtained after the above-mentioned waste water is left to settle is entered by the waste water inlet of the dialysis chamber of the diffusion dialysis membrane system, and the diffusion dialysis treatment solution (pretreatment solution) and mixed acid are obtained through the dialysis negative membrane. Use tap water as the absorbing liquid and enter the diffusion chamber to absorb the mixed acid. The dialysis chamber and the diffusion chamber are reversely fed with water. Diffusion dialysis treatment solution is poured into the first neutralization tank, and the mixed acid is recycled to the graphite purification process. The recovery rate of nitric acid was 95%, the recovery rate of hydrochloric acid was 90%, and the recovery rate of hydrofluoric acid was 45%.

[0072] (2) Add bluestone to the above-mentioned first...

Embodiment 2

[0078] Graphite purification waste water, fluorine content is 4000mg / L, m(F - ): m(SO 4 2- )=1:2.5.

[0079] (1) The clear liquid obtained after the above-mentioned waste water is left to settle is entered by the waste water inlet of the dialysis chamber of the diffusion dialysis membrane system, passes through the dialysis negative membrane, and uses tap water as the absorption liquid. Diffusion dialysis treatment solution (pretreatment solution) and mixed acid are obtained. Diffusion dialysis treatment solution is poured into the primary regulating tank, and the mixed acid is recycled to the graphite purification process. It is measured that the recovery rate of sulfuric acid in the waste water is 94%, and the recovery rate of hydrofluoric acid is 40%.

[0080] (2) Add calcium carbonate to the above-mentioned first neutralization tank, stir to adjust the pH to 4, overflow to the primary sedimentation tank and settle for 30 minutes, and the supernatant I overflows into th...

Embodiment 3

[0086] In the step (5) of embodiment 2, the filter tower is filled with a mixed filter material made of 15wt molecular sieve and 85wt WK-1 type filter material, and the waste water passes through the filter tower under the same conditions, and the fluorine content of the treated effluent obtained is 1.7mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com