Patents

Literature

366 results about "Diffusion chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diffusion Chambers, Culture. Devices used in a technique by which cells or tissues are grown in vitro or, by implantation, in vivo within chambers permeable to diffusion of solutes across the chamber walls.

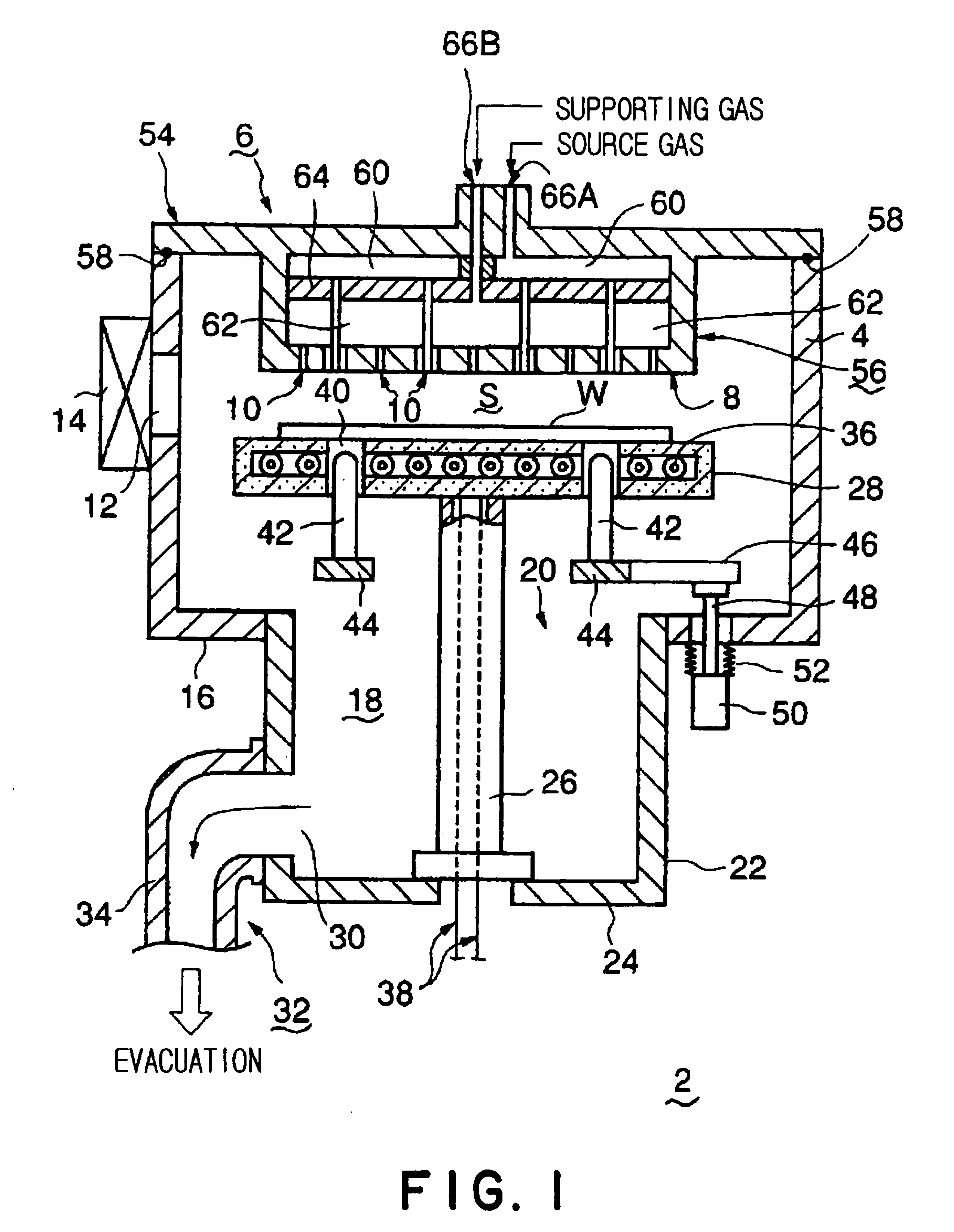

Processing apparatus

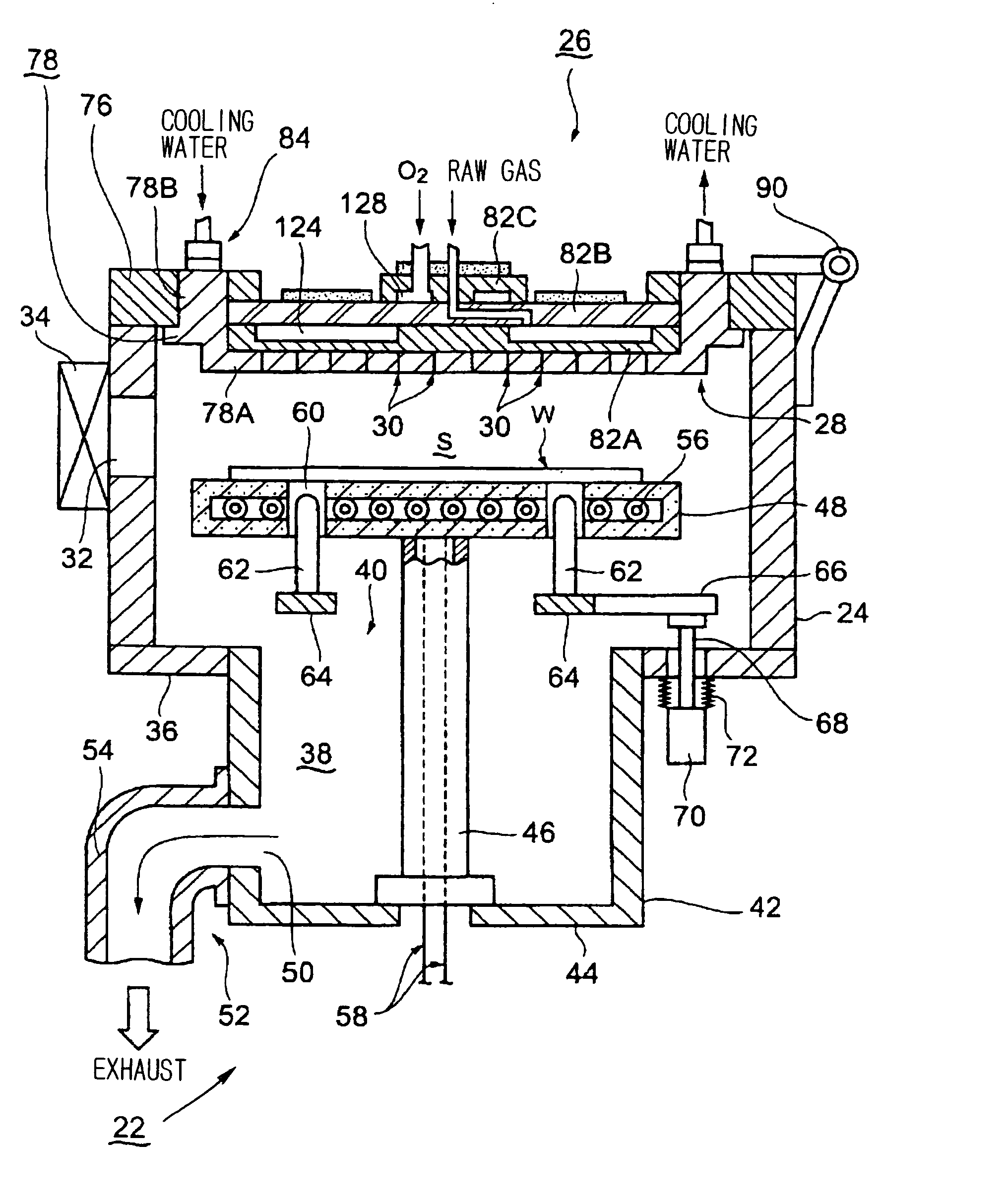

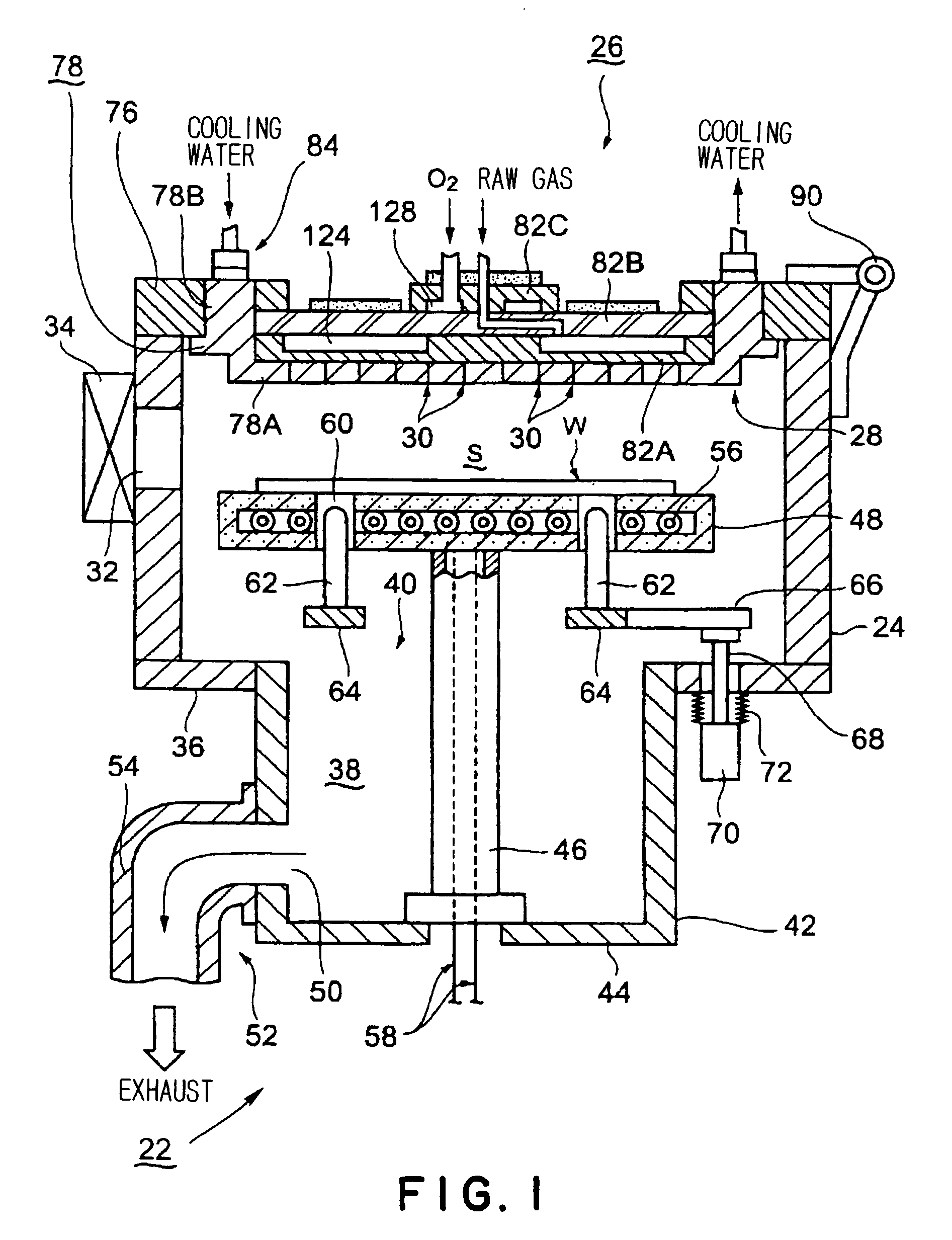

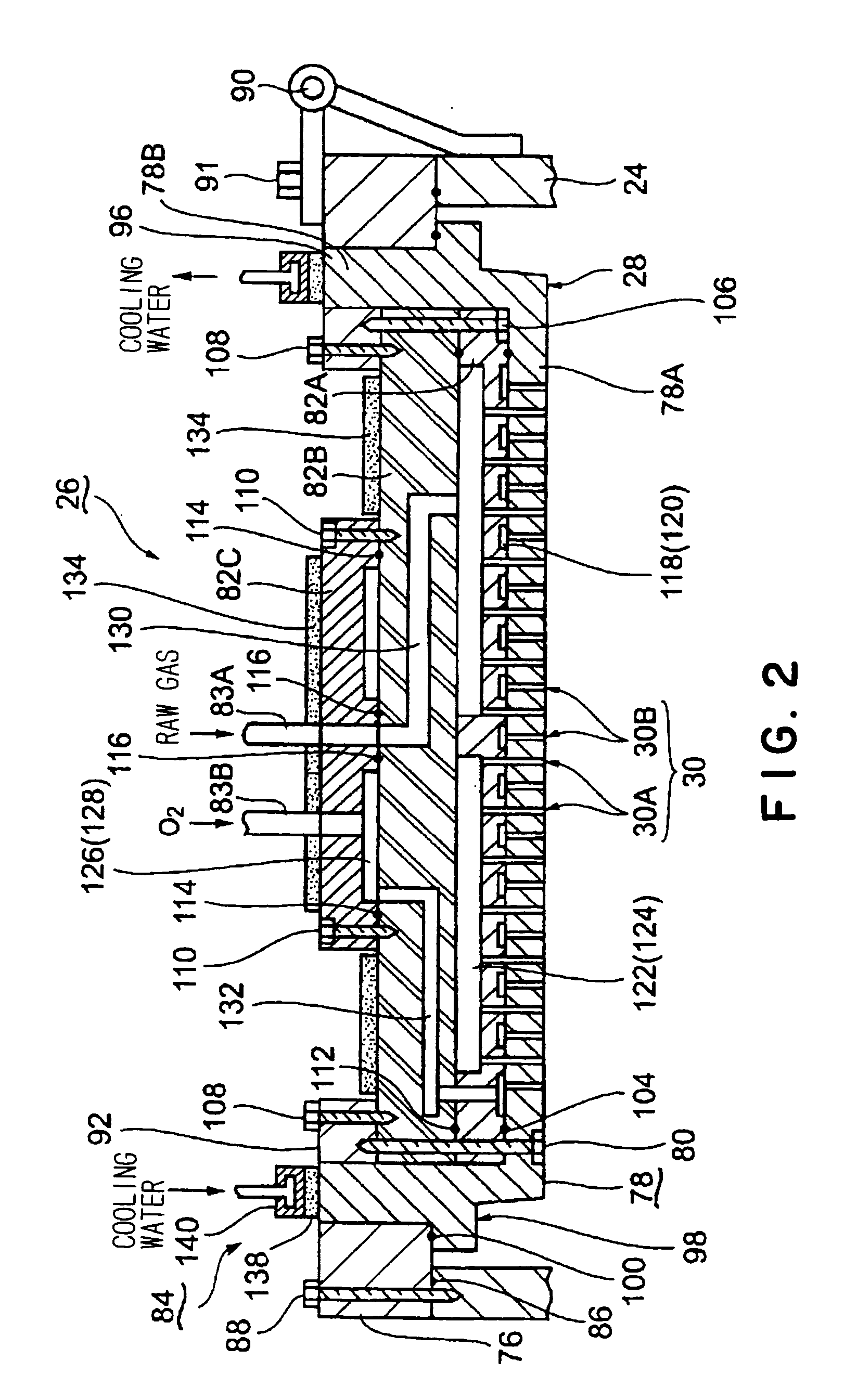

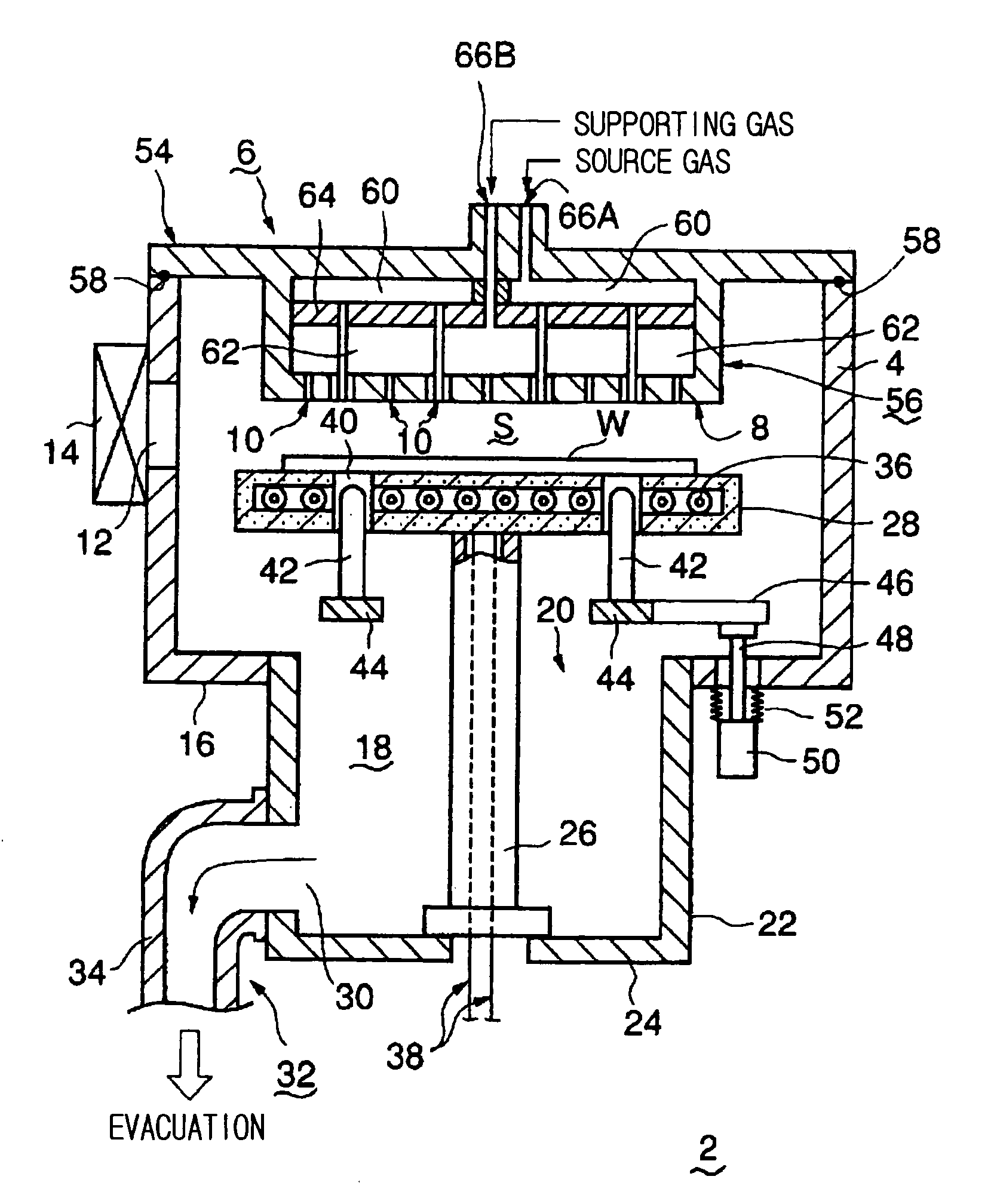

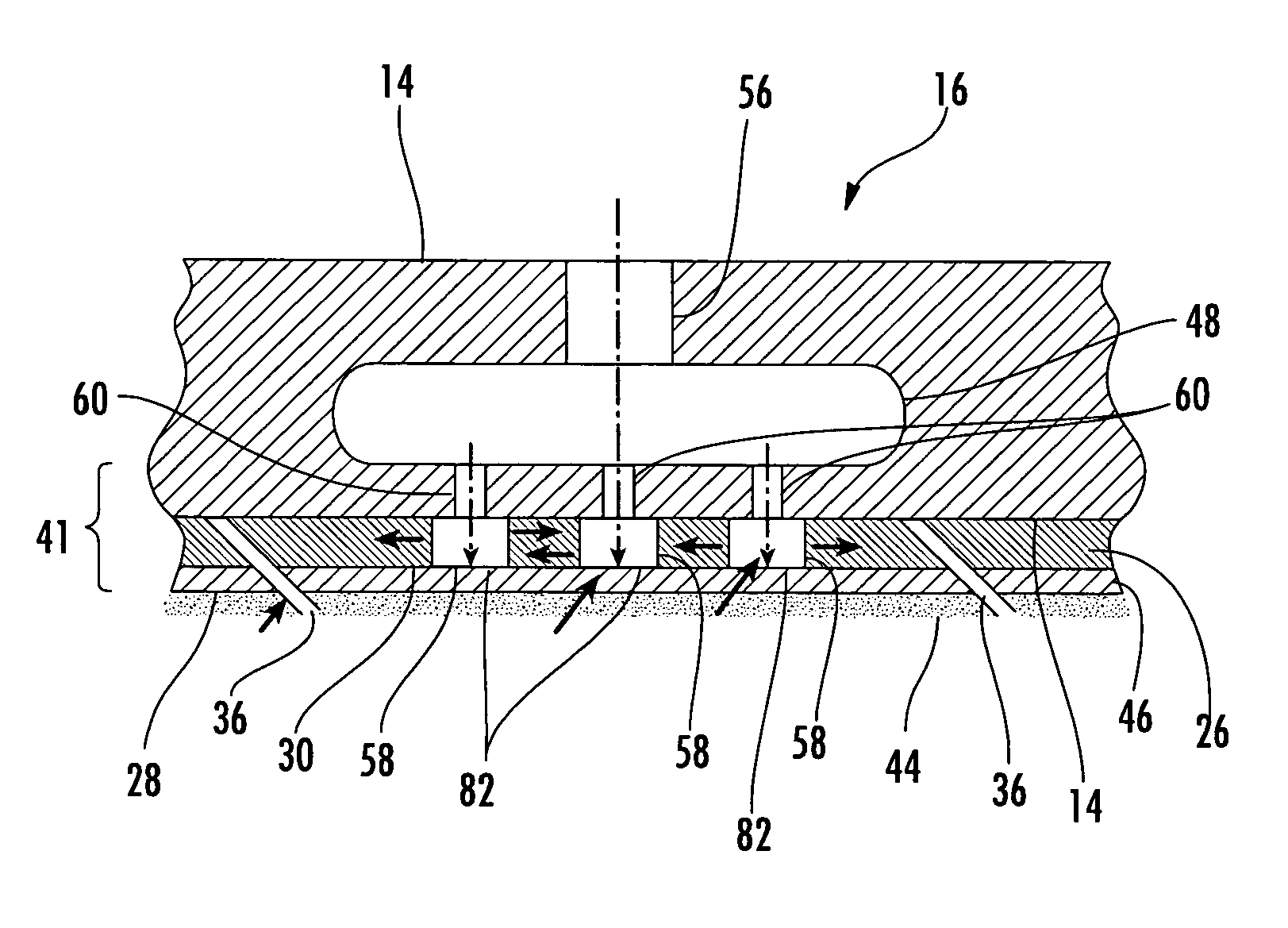

InactiveUS20070158026A1High temperature controllabilityEasy maintenanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

A shower head structure (26) includes a shower head main body (78) of a one-piece structure formed in a generally cup shape and having a bottom wall (78A) provided with a plurality of gas injection holes (30A, 30B) formed therein and a side wall (78B) rising from a peripheral portion of the bottom wall. A plurality of gas diffusion chamber forming plates (82A-82C) are housed in the shower head main body (78). A through-hole is formed in a head mounting frame (76) disposed on a ceiling of a processing vessel (24). An upper portion of the side wall (78B) of the shower head main body (78) is inserted into the through-hole, so that a part of the side wall (78B) is exposed to the exterior of the processing vessel. A cooling mechanism (84) is disposed at the upper end portion of the side wall (78B). Heat transfer between the cooling mechanism (84) and the bottom wall (78A) is enhanced, so that the temperature of the bottom wall (78A) can be controlled at a proper value, thereby preventing any adhesion of an unnecessary film onto the bottom wall (78A).

Owner:TOKYO ELECTRON LTD

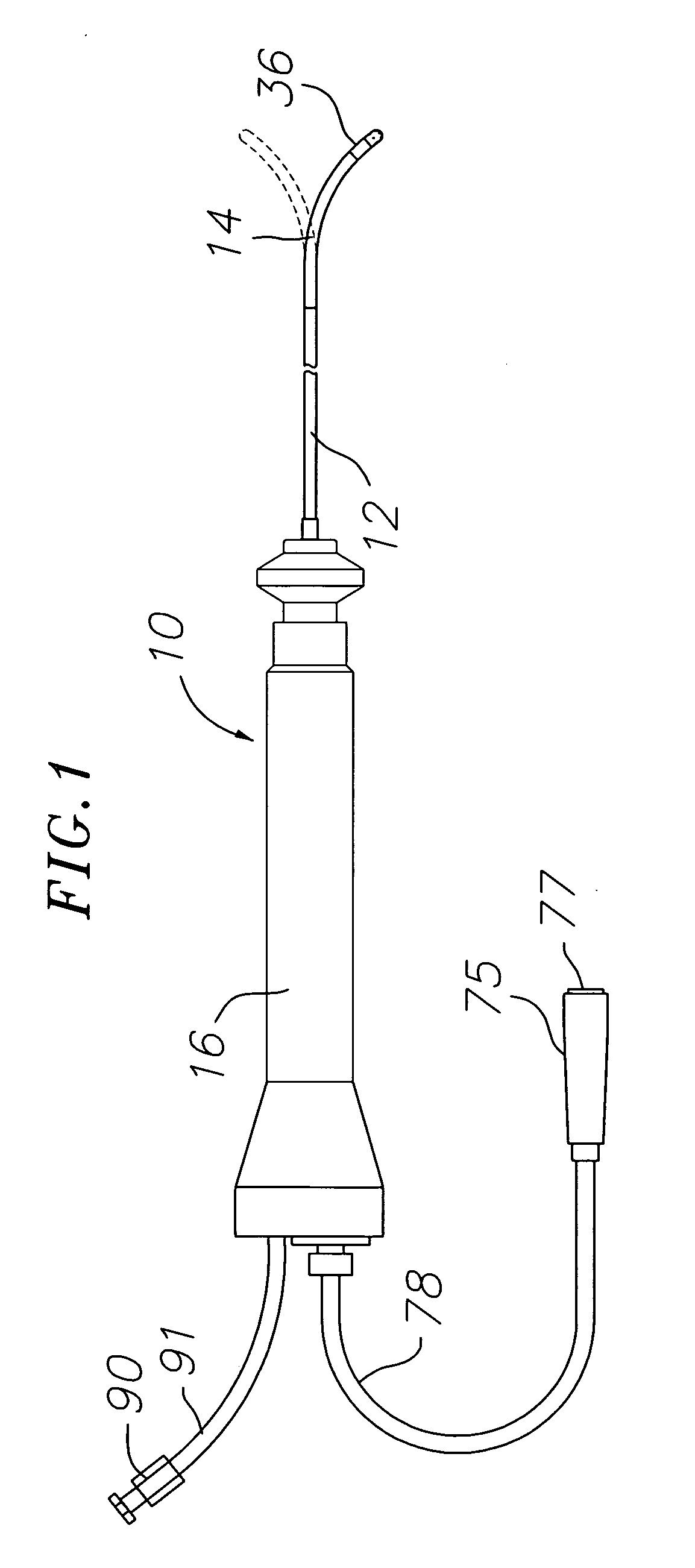

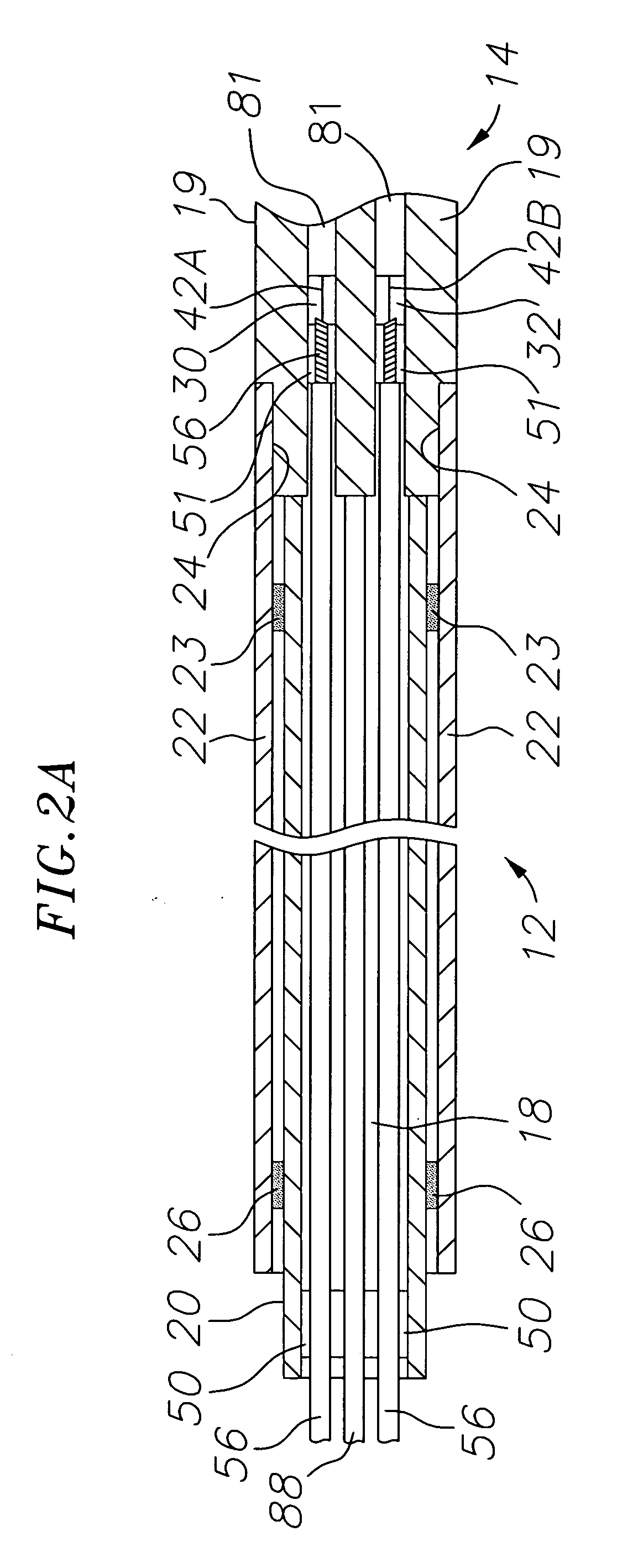

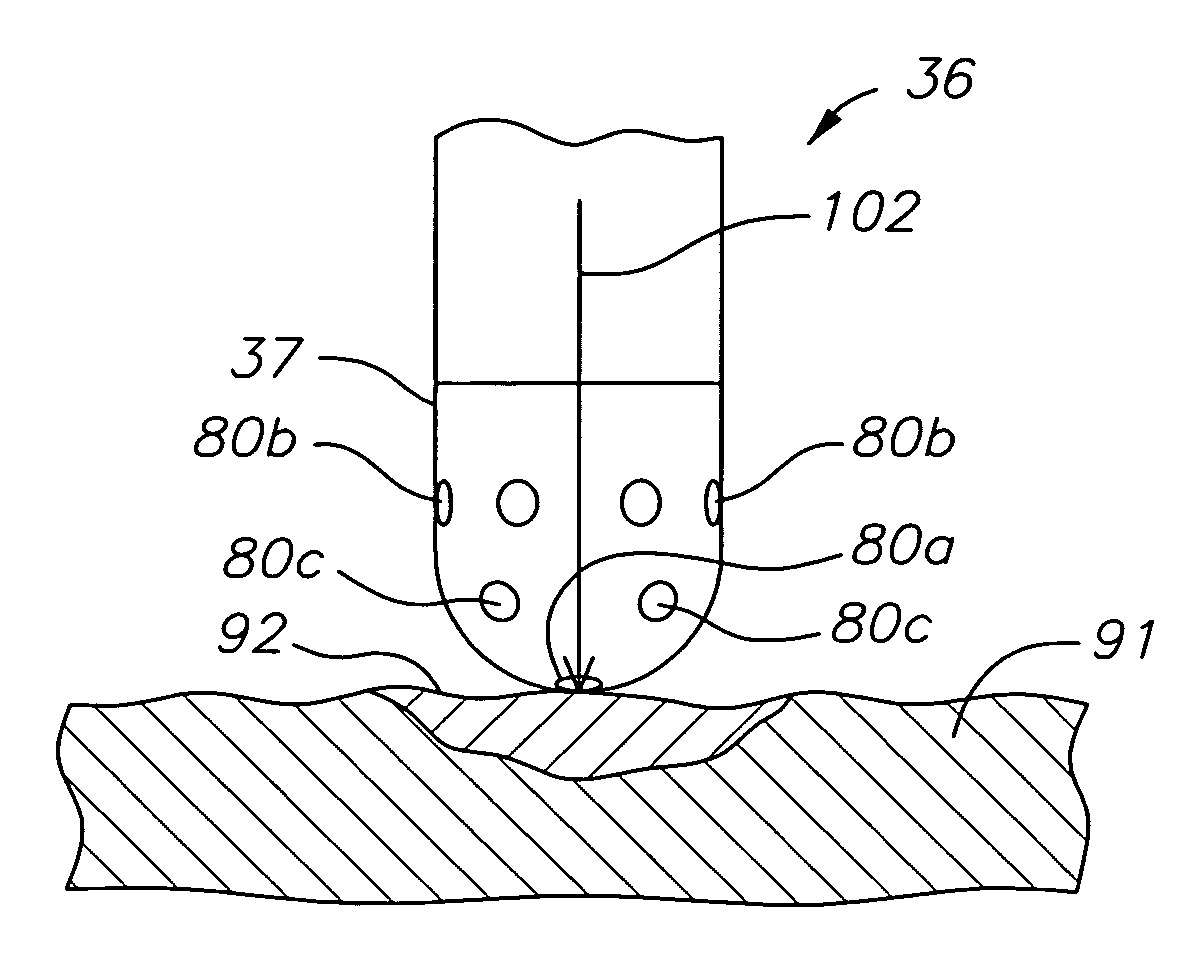

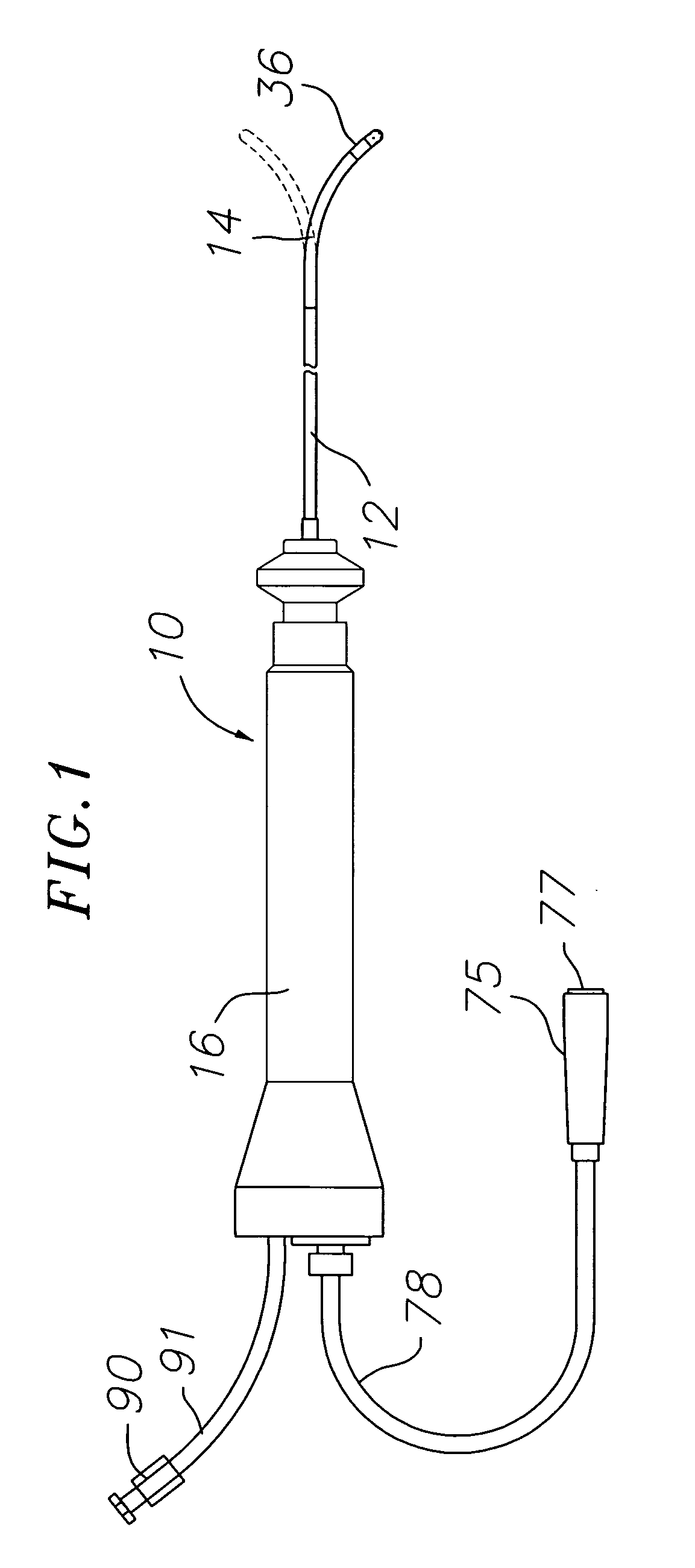

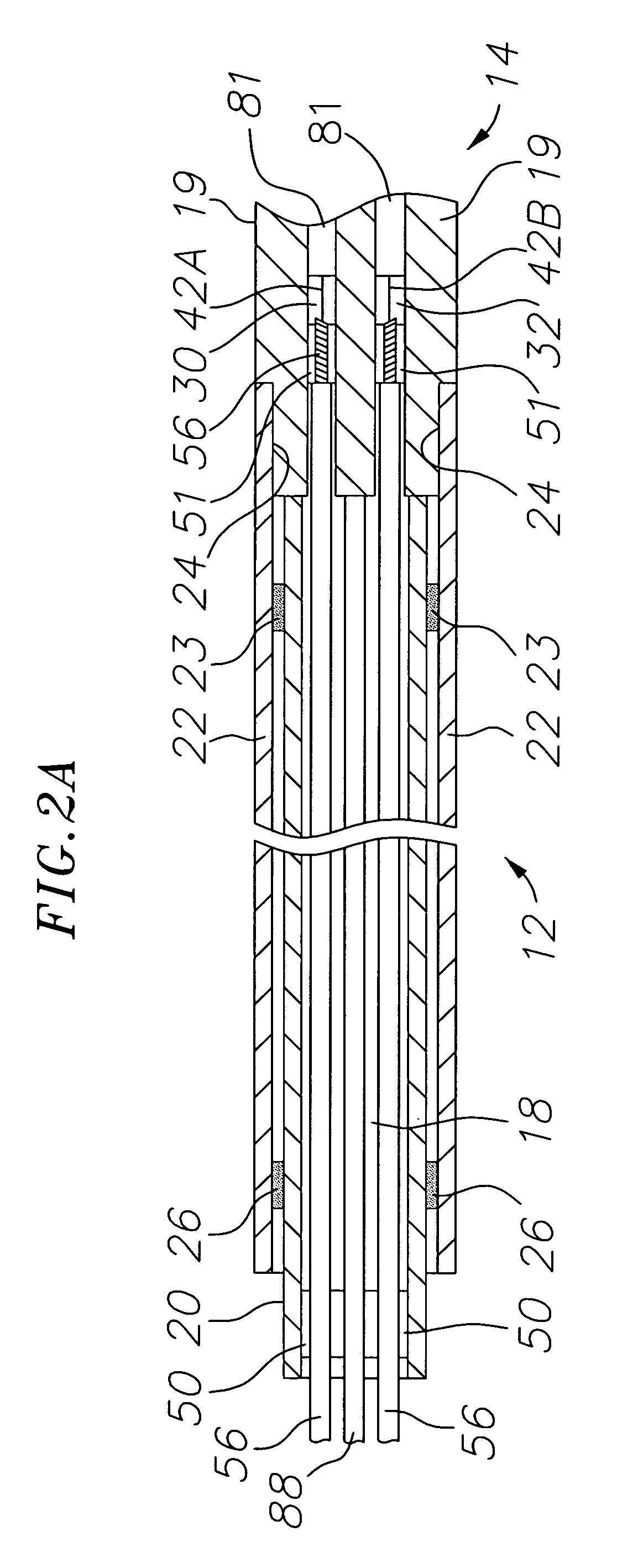

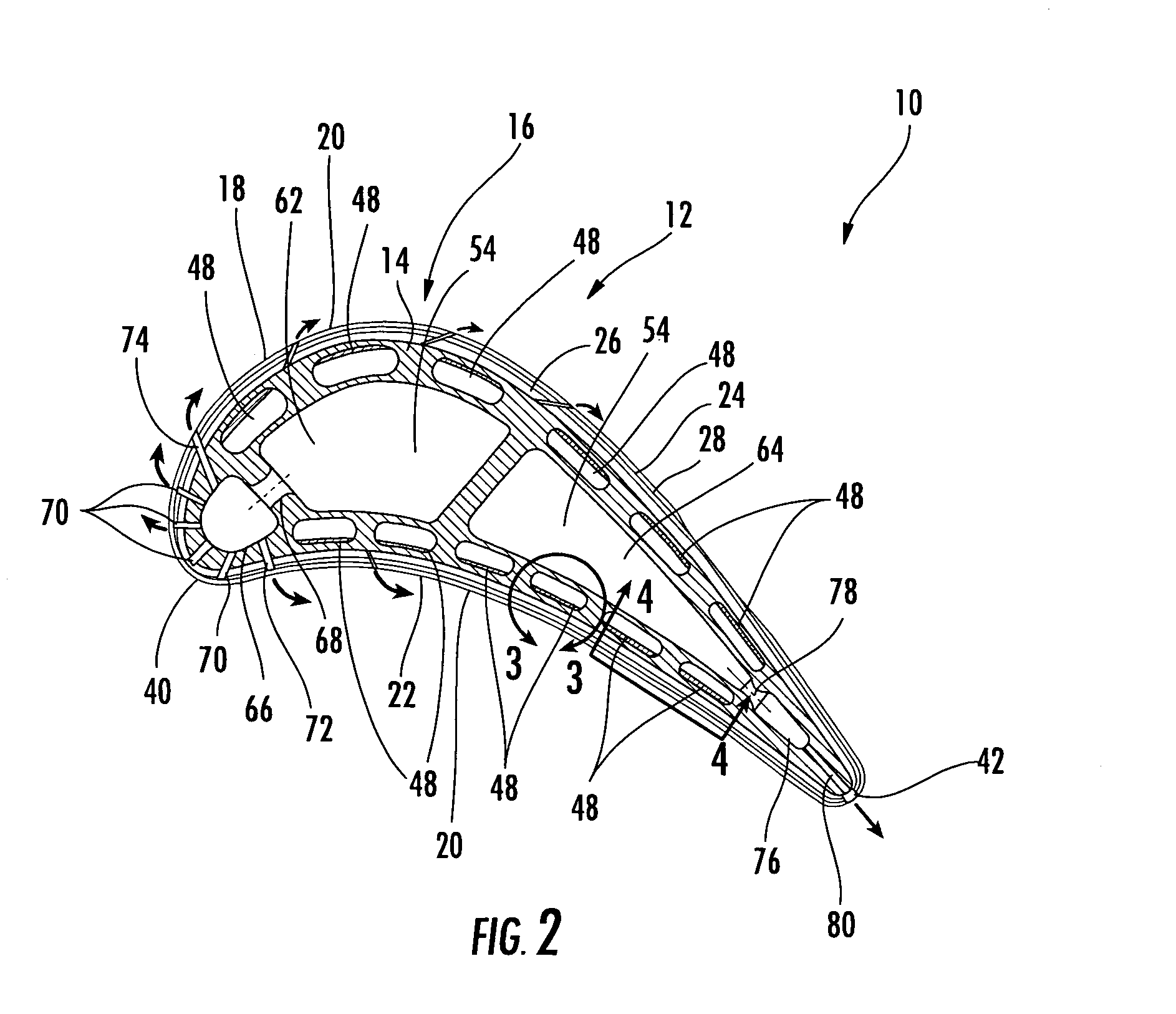

Catheter with omni-directional optical lesion evaluation

ActiveUS20090005768A1Extended service lifeMinimize damageDiagnosticsSurgical navigation systemsLight energyPositive pressure

A catheter is adapted to ablate tissue and provide lesion qualitative information on a real time basis, having an ablation tip section with a generally omni-directional light diffusion chamber with one openings to allow light energy in the chamber to radiate the tissue and return to the chamber. The chamber is irrigated at a positive pressure differential to continuously flush the opening with fluid. The light energy returning to the chamber from the tissue conveys a tissue parameter, including without limitation, lesion formation, depth of penetration of lesion, cross-sectional area of lesion, formation of char during ablation, recognition of char during ablation, recognition of char from non-charred tissue, formation of coagulum around the ablation site, differentiation of coagulated from non-coagulated blood, differentiation of ablated from healthy tissue, tissue proximity, and recognition of steam formation in the tissue for prevention of steam pop.

Owner:BIOSENSE WEBSTER INC

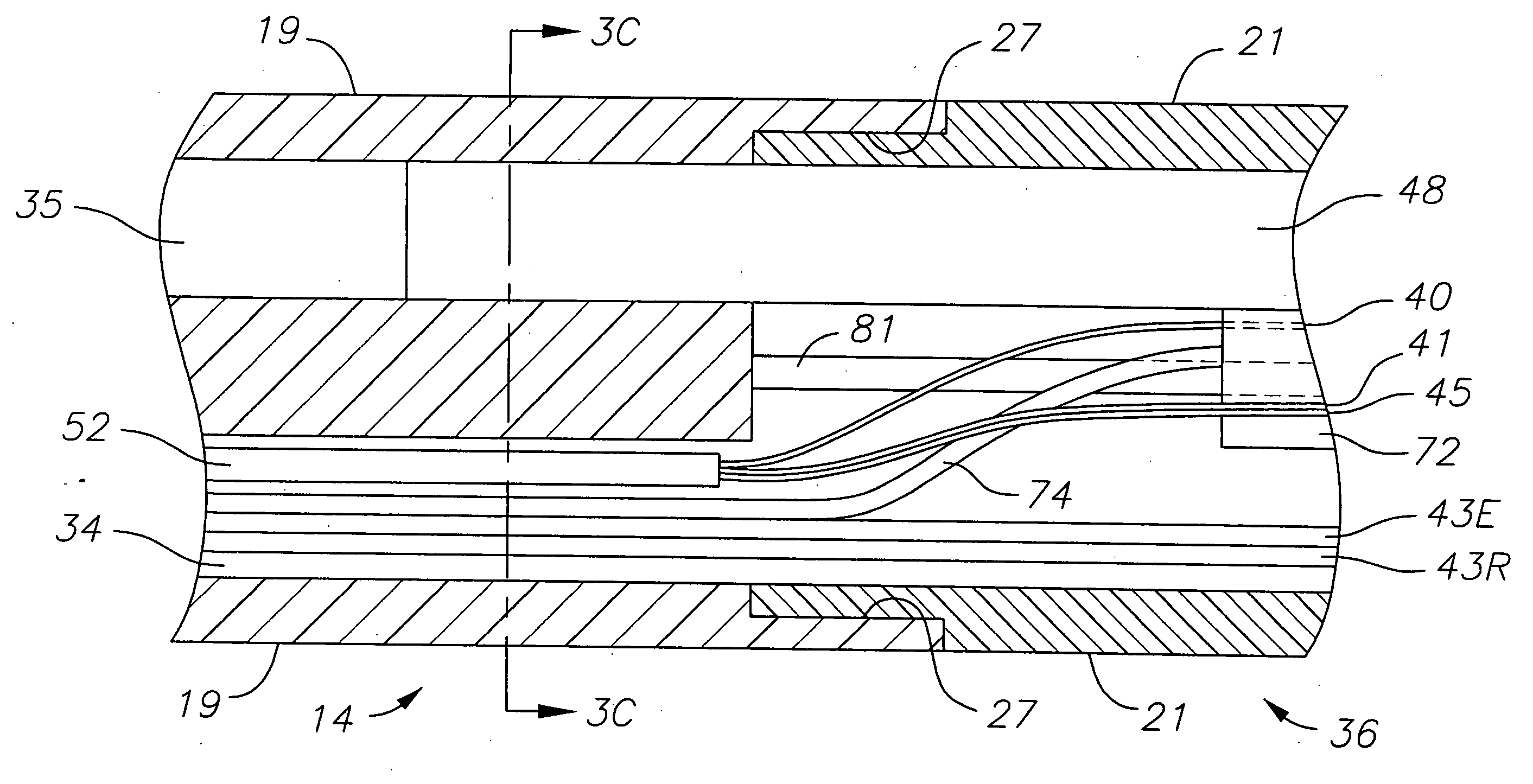

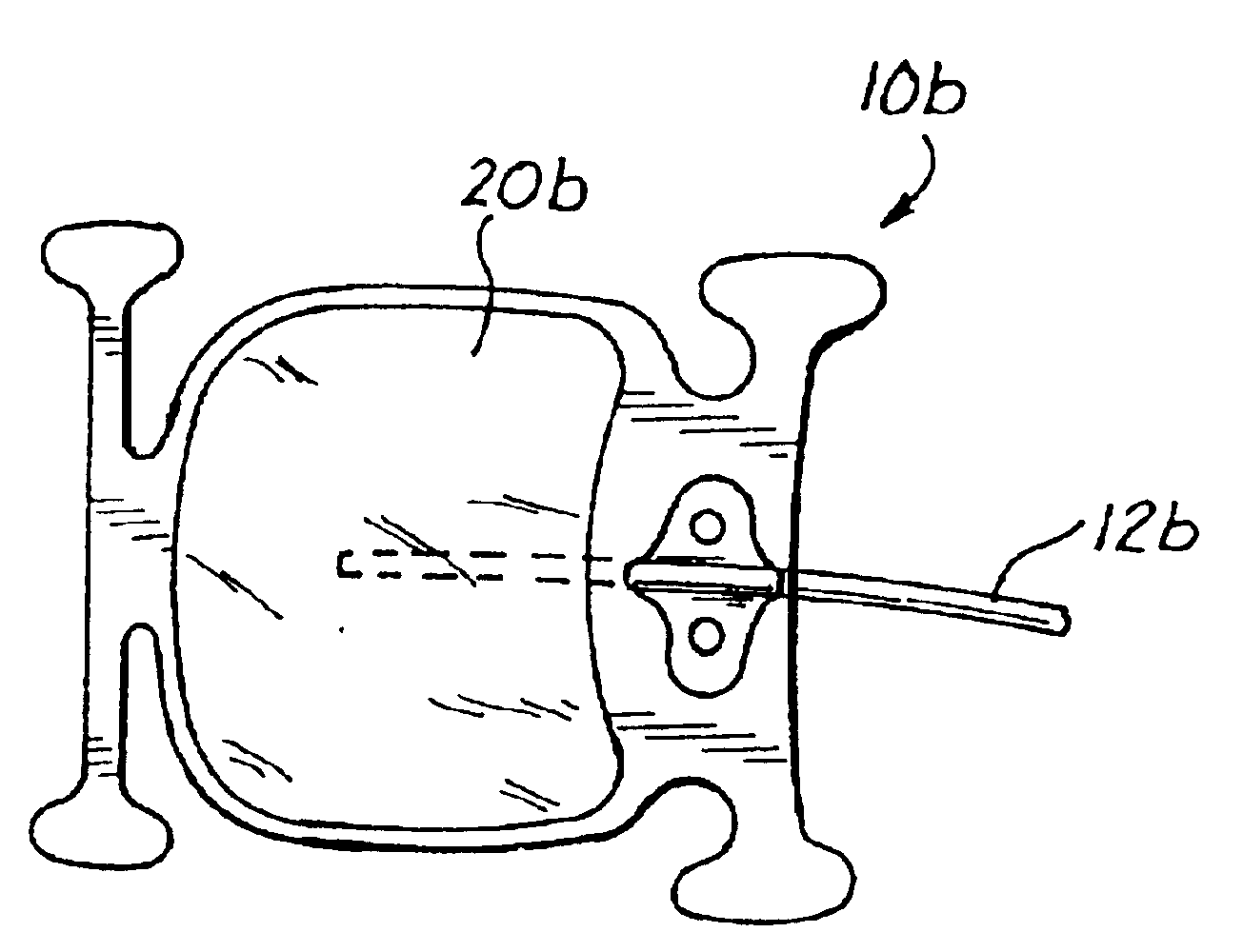

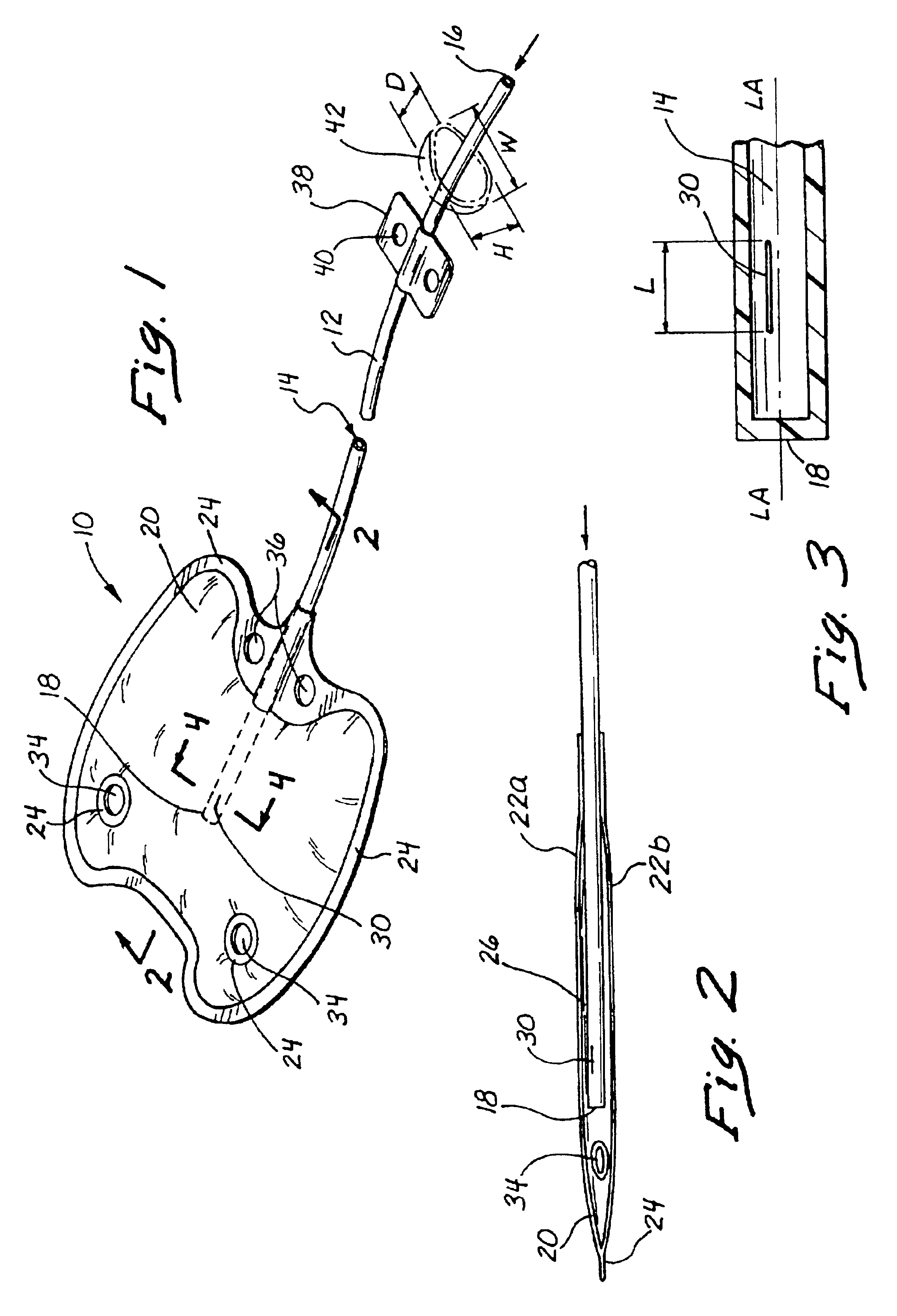

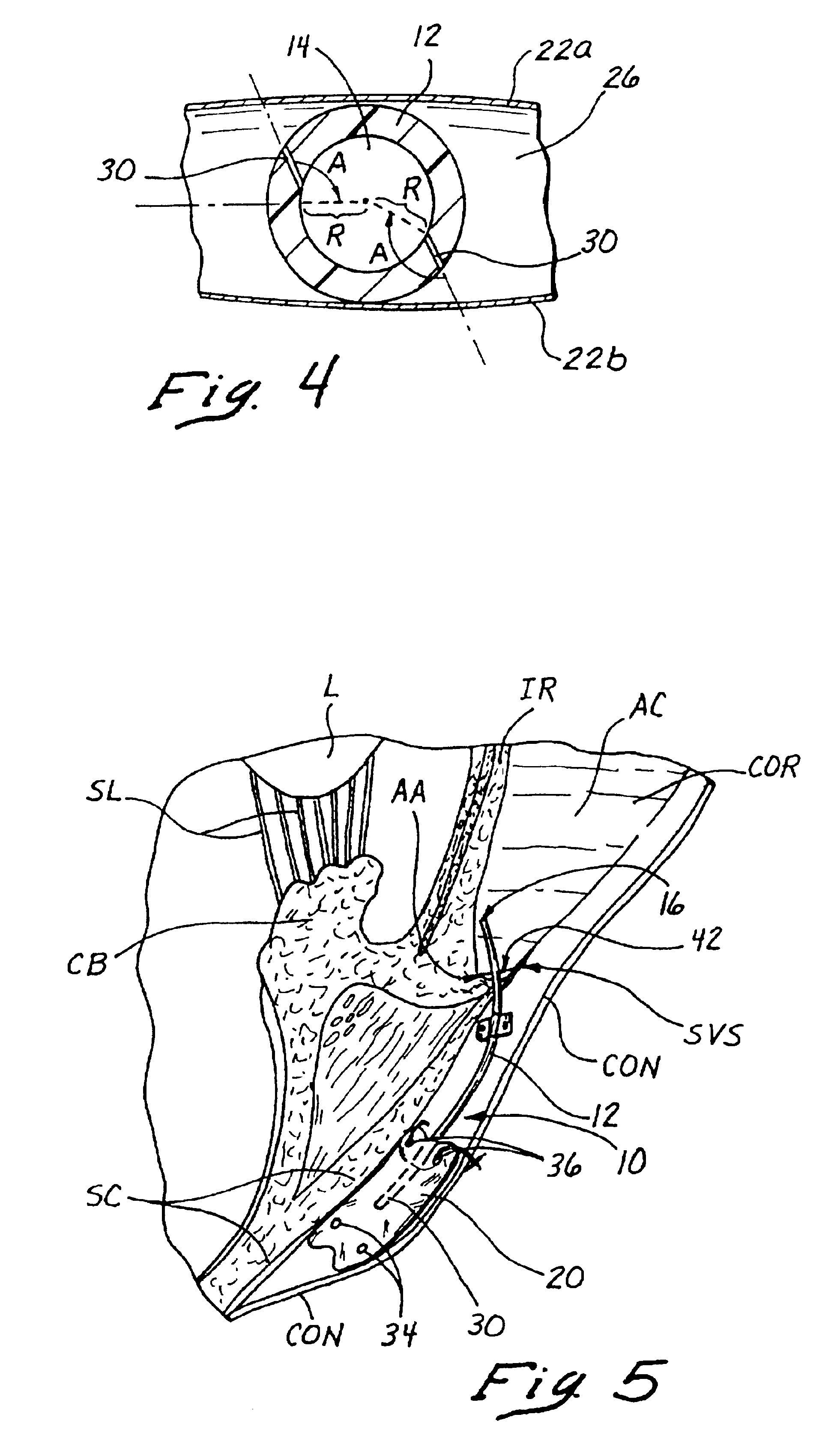

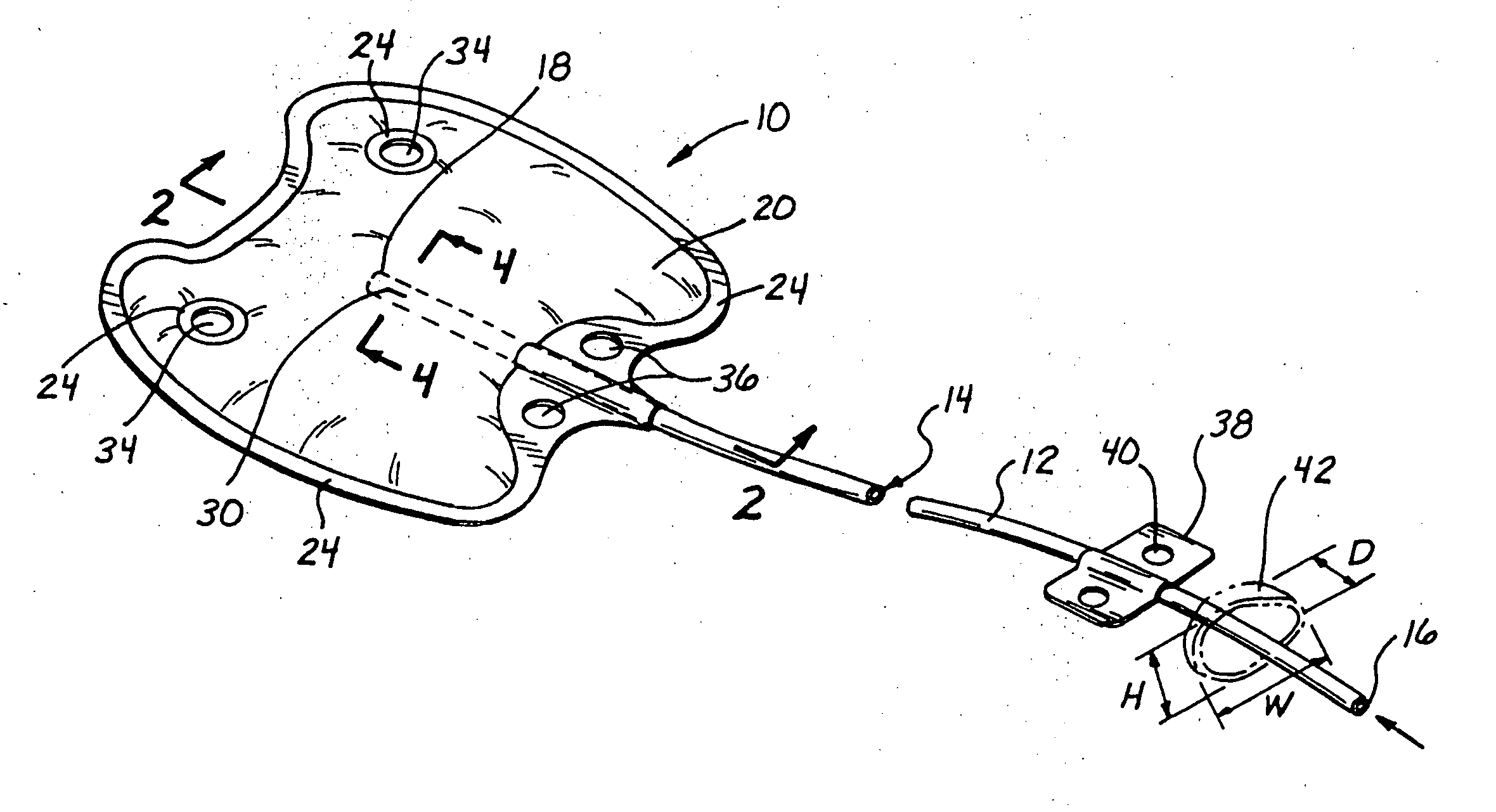

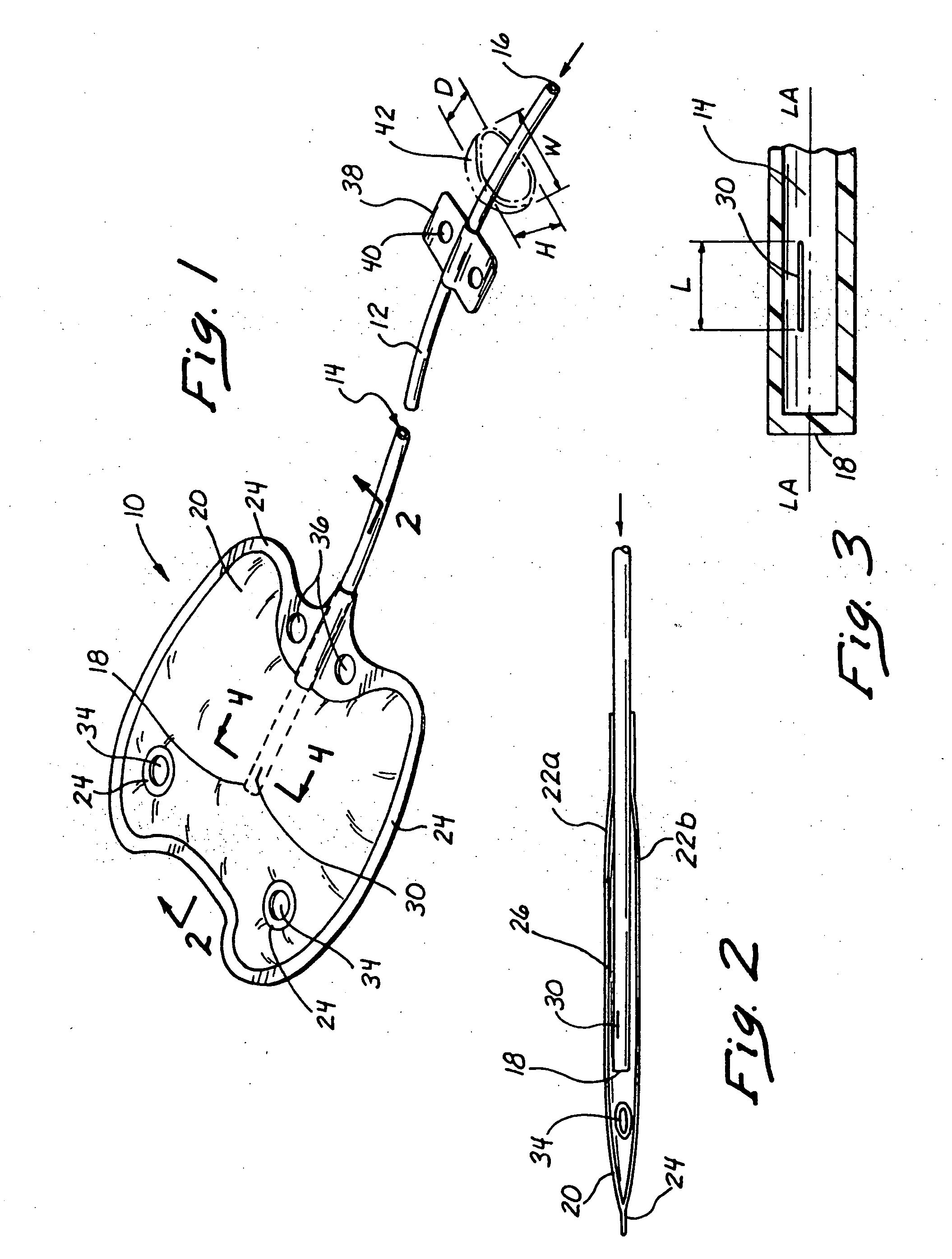

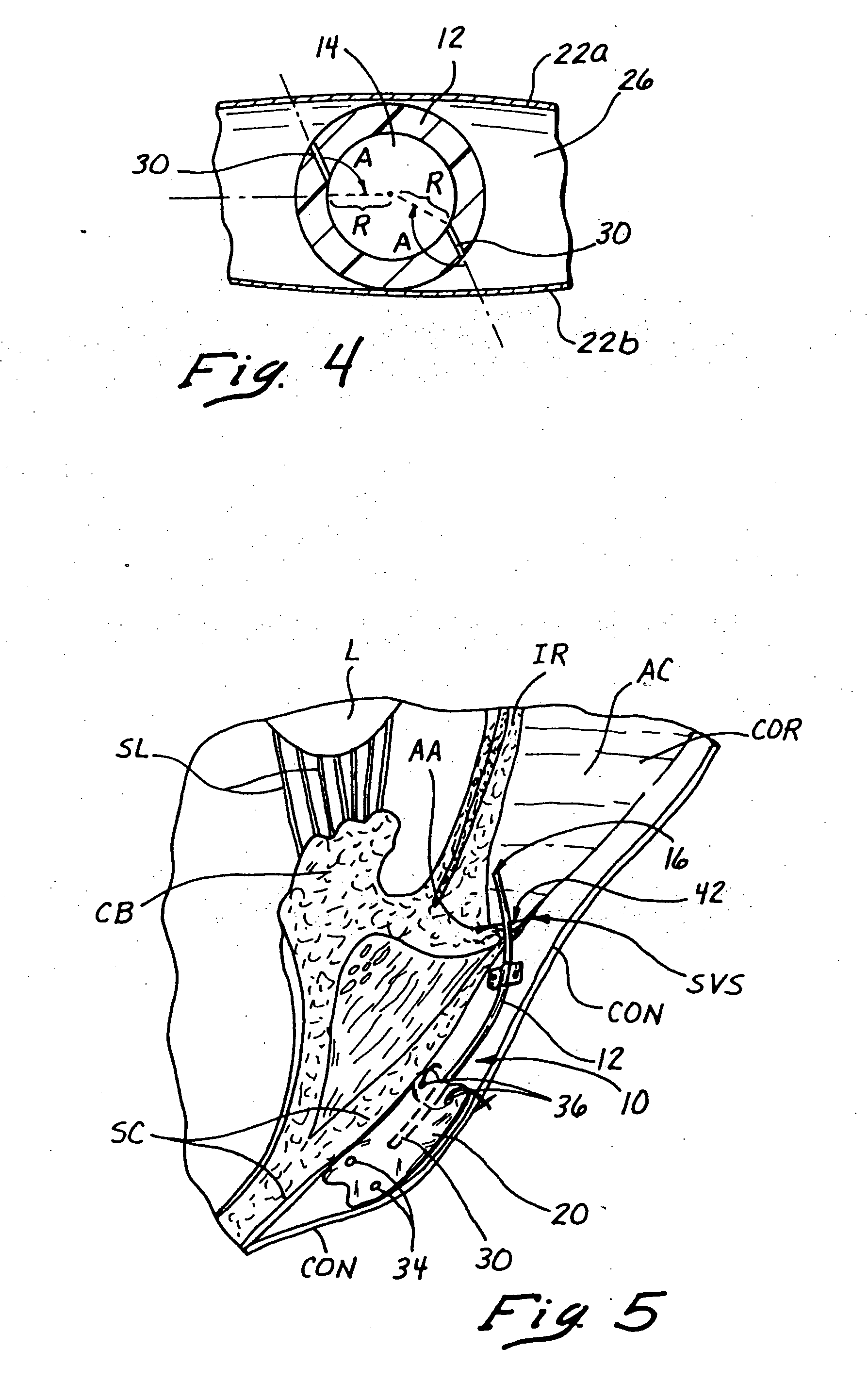

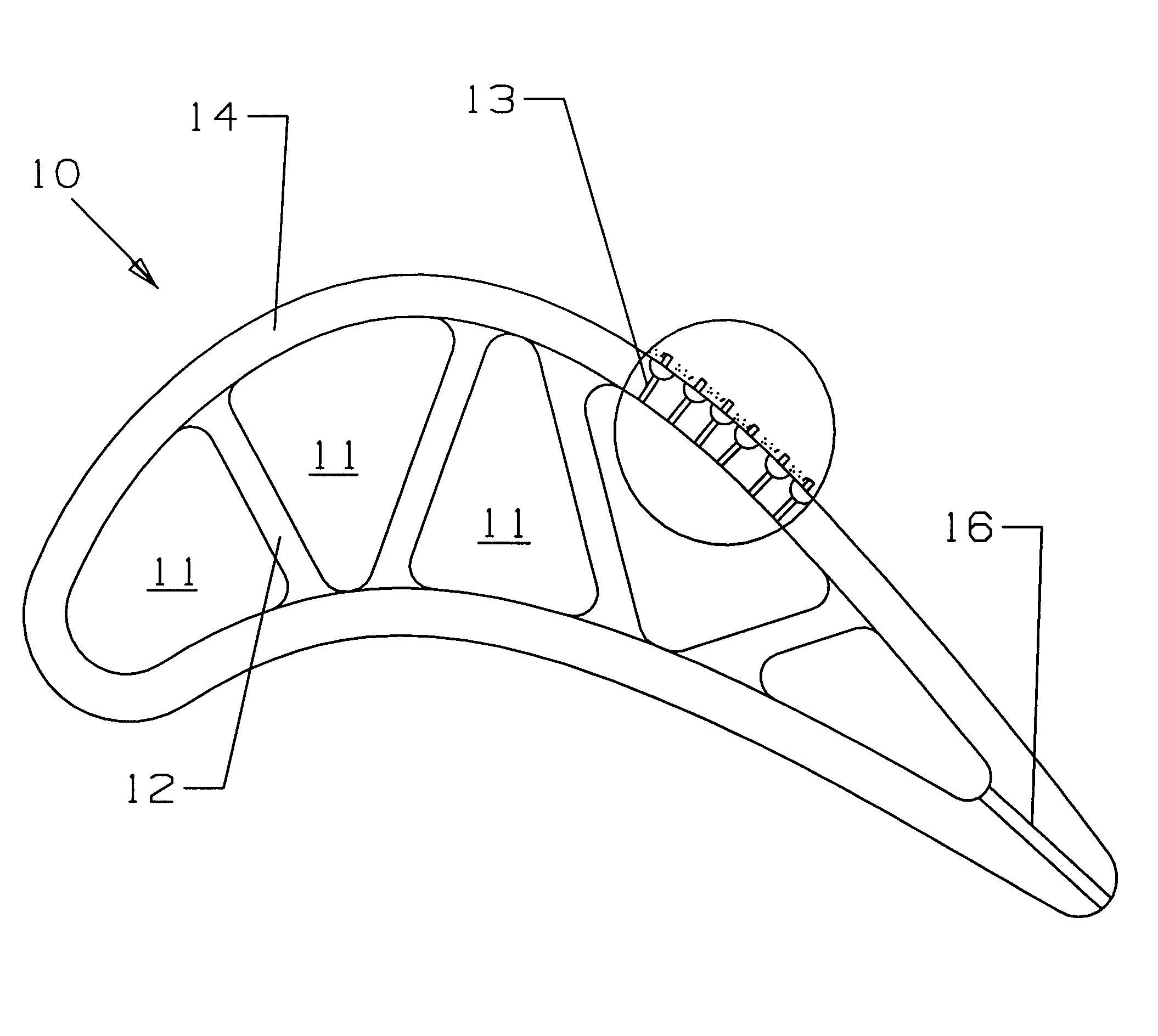

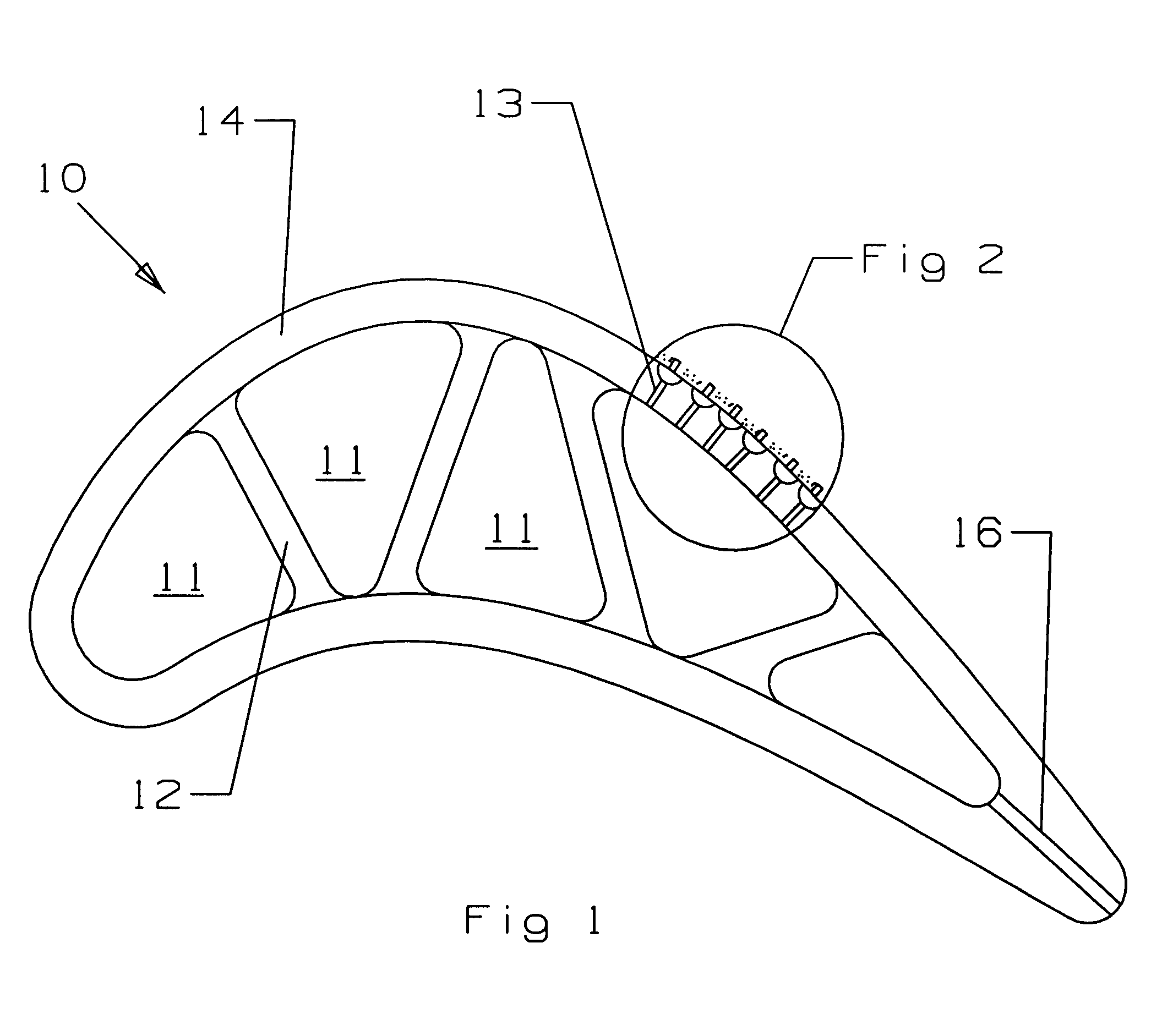

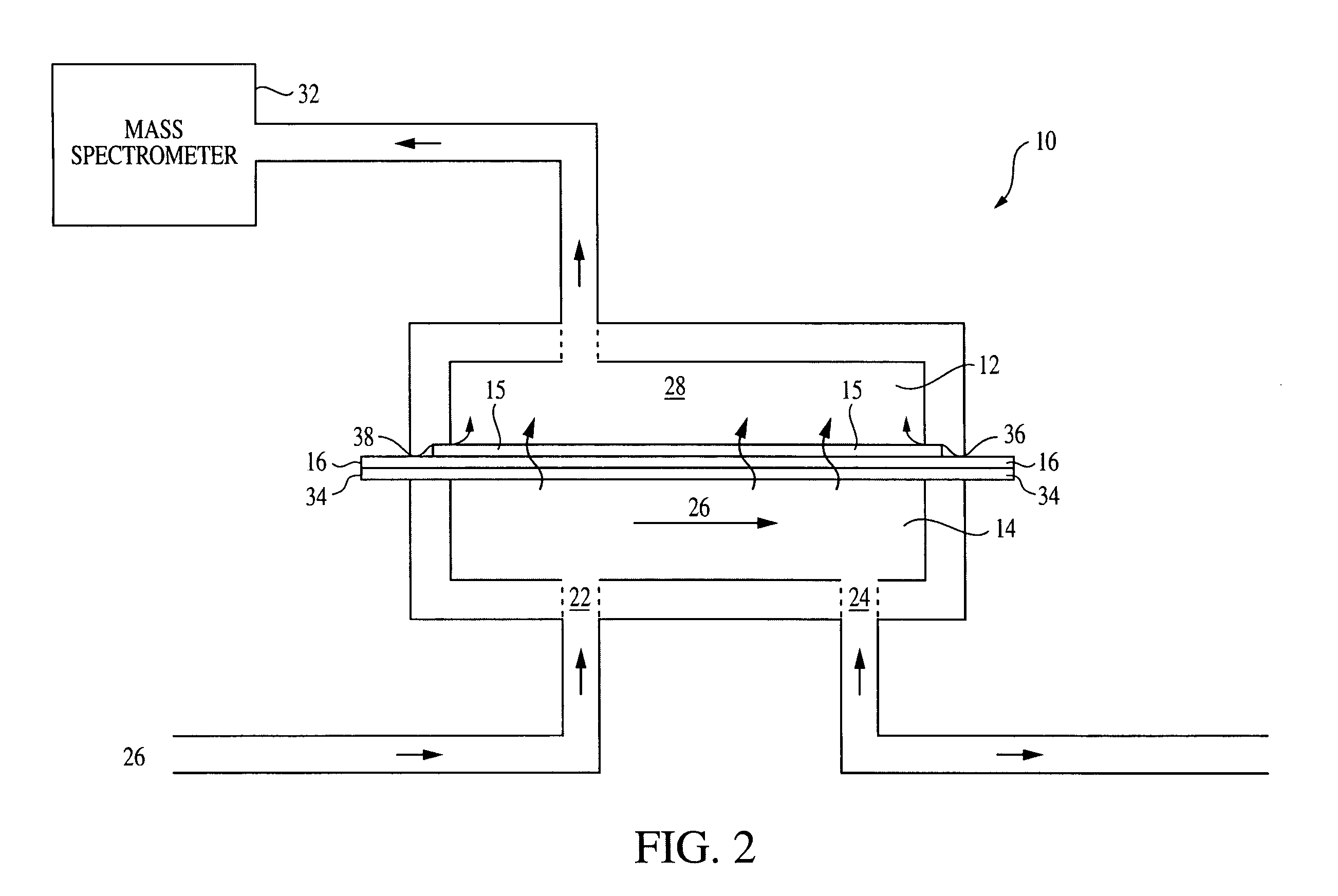

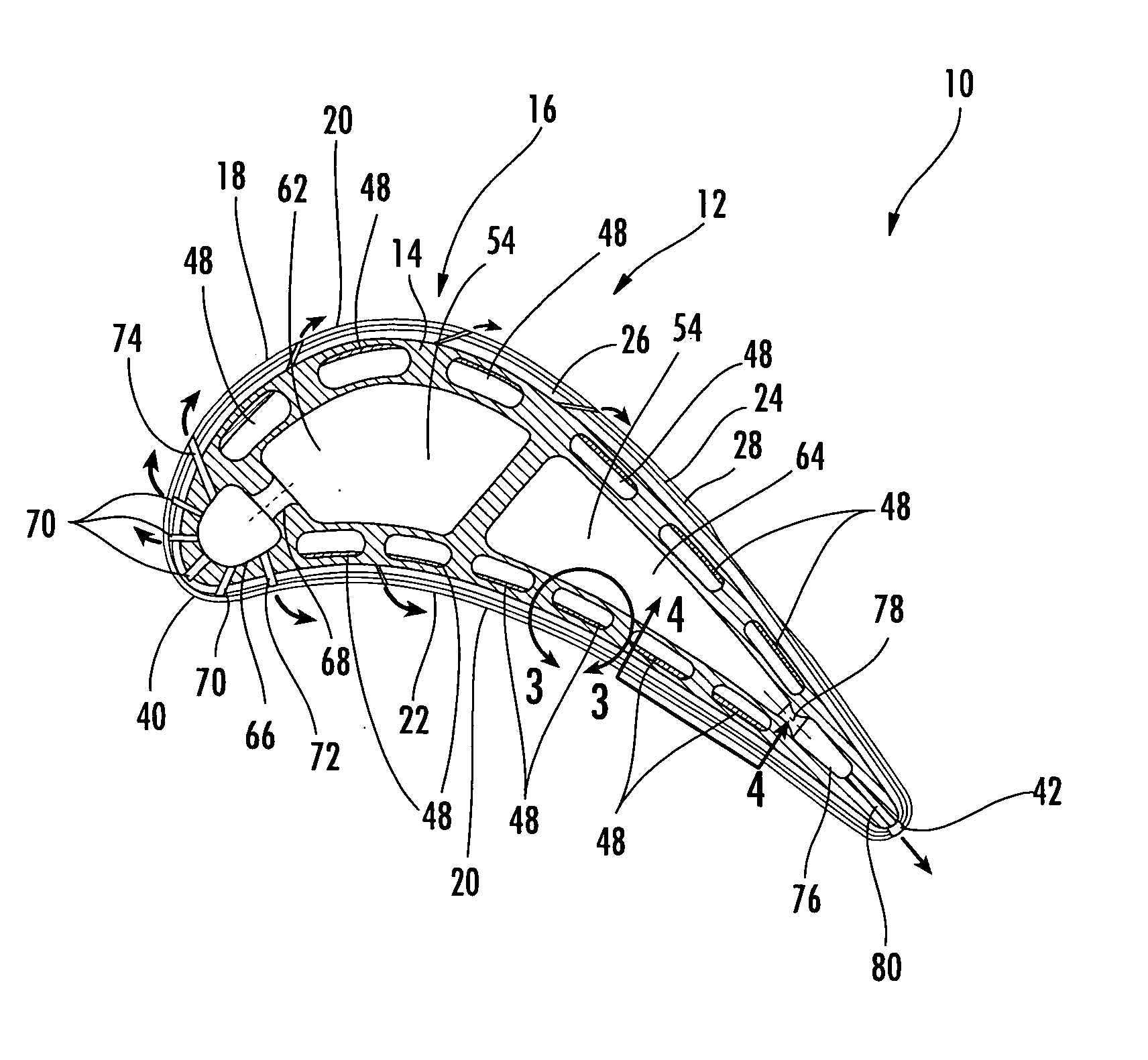

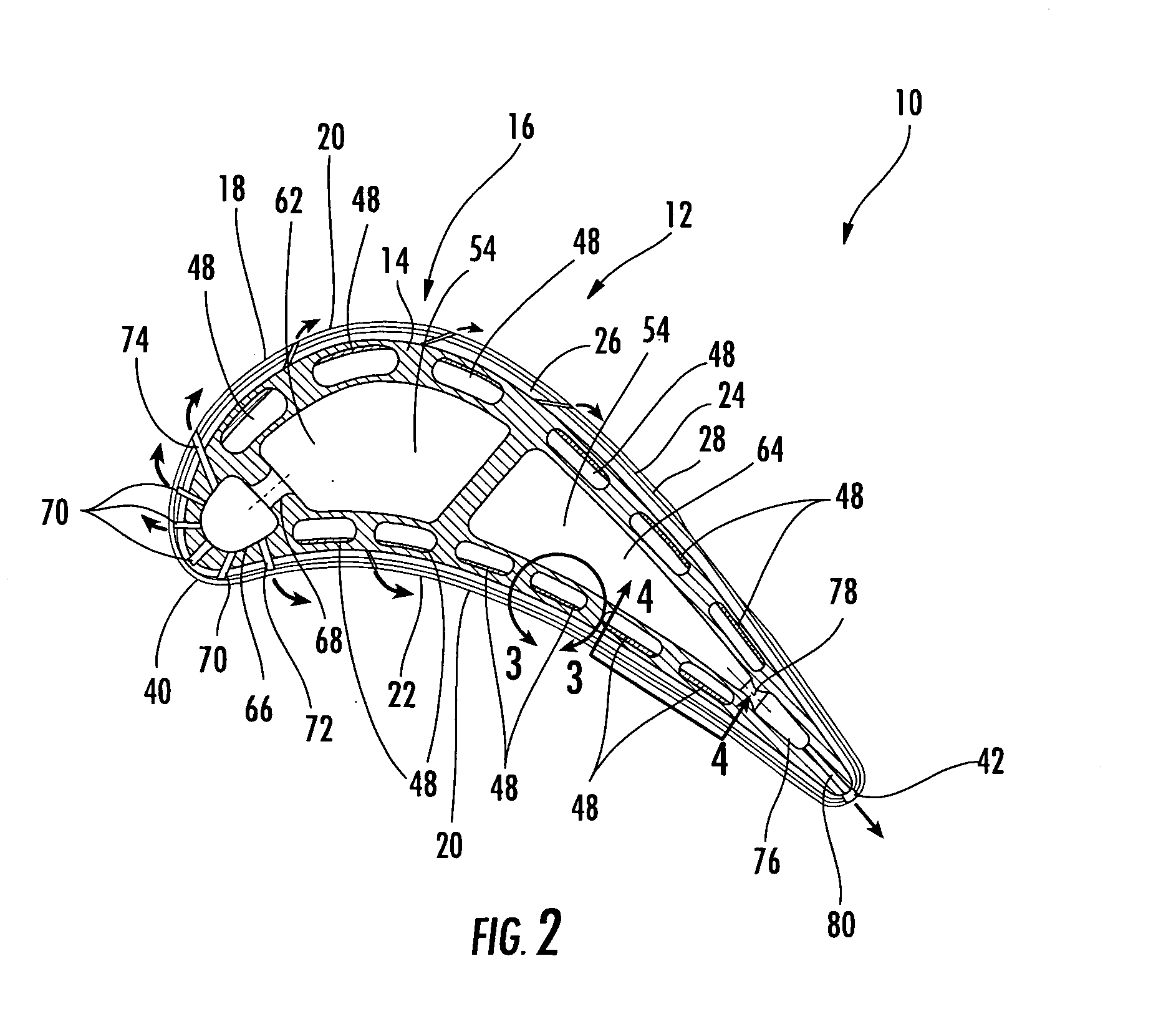

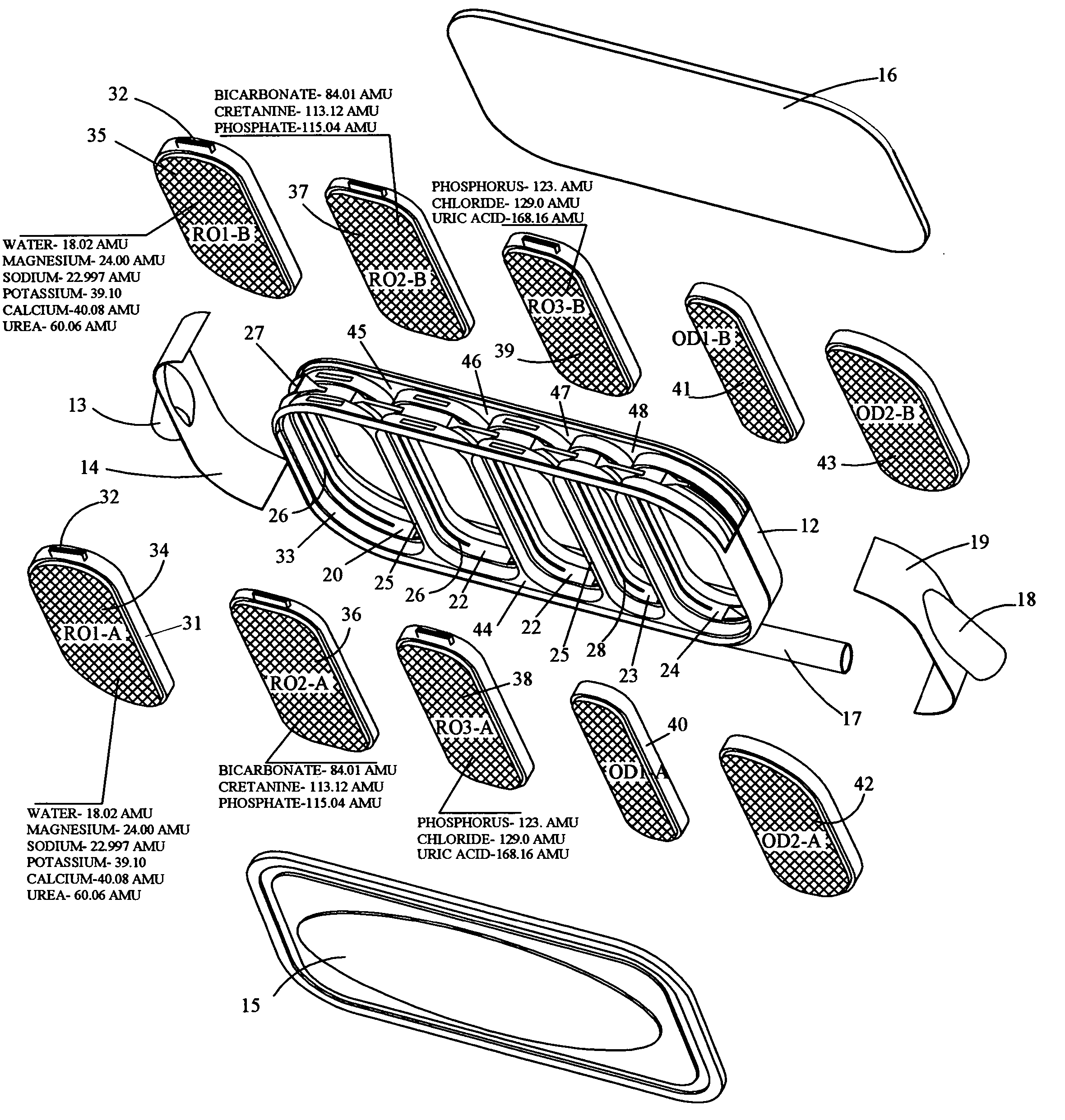

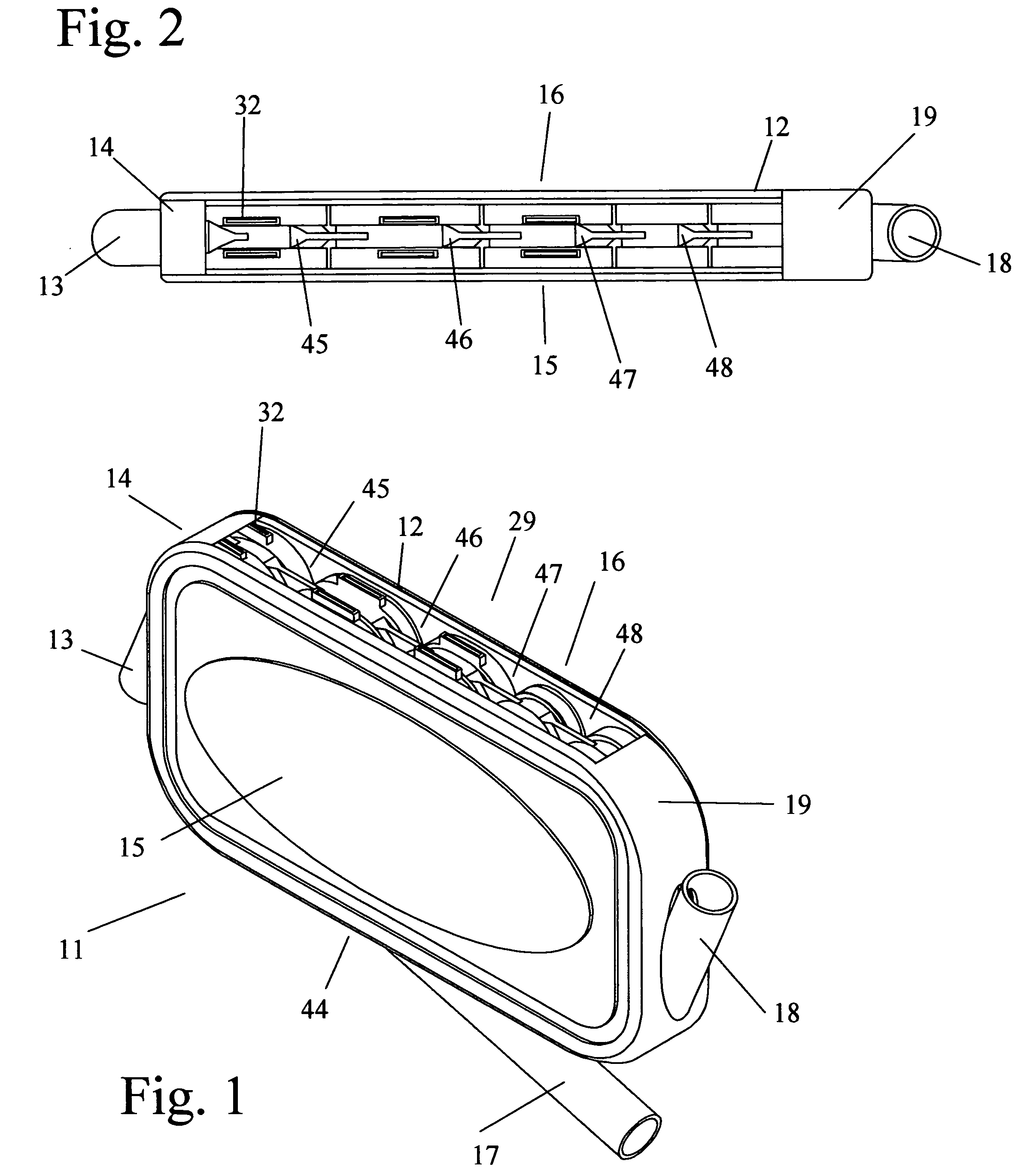

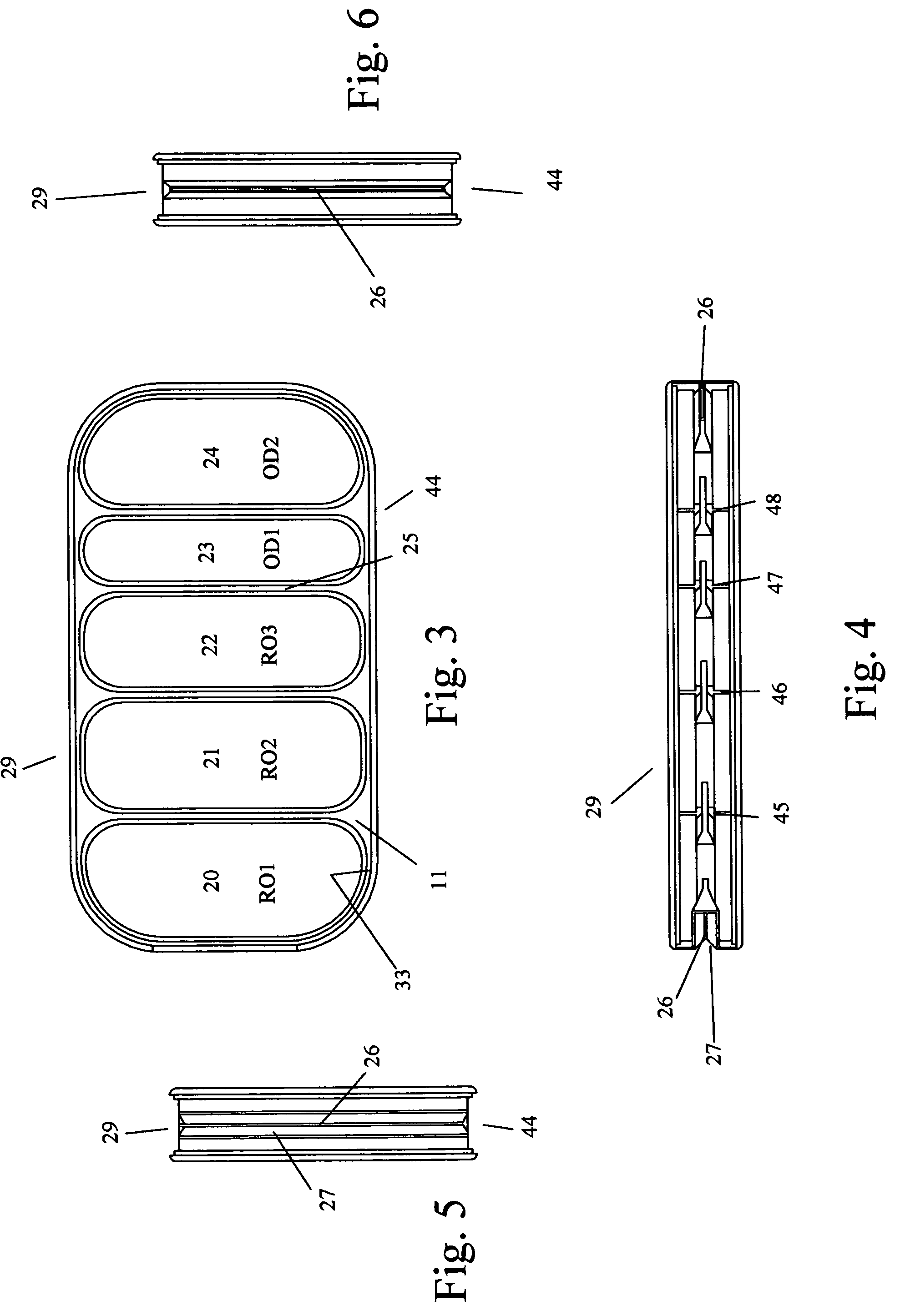

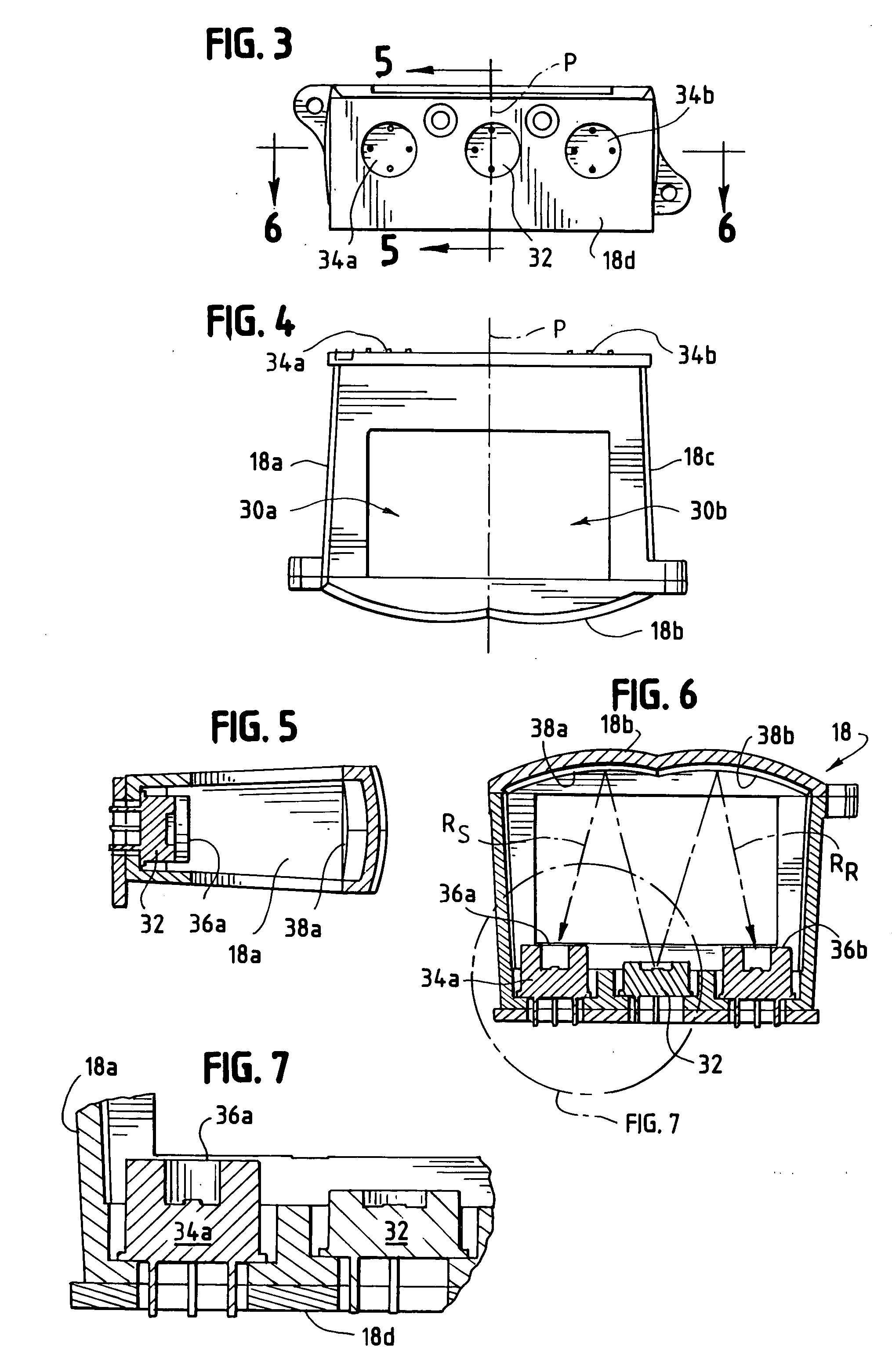

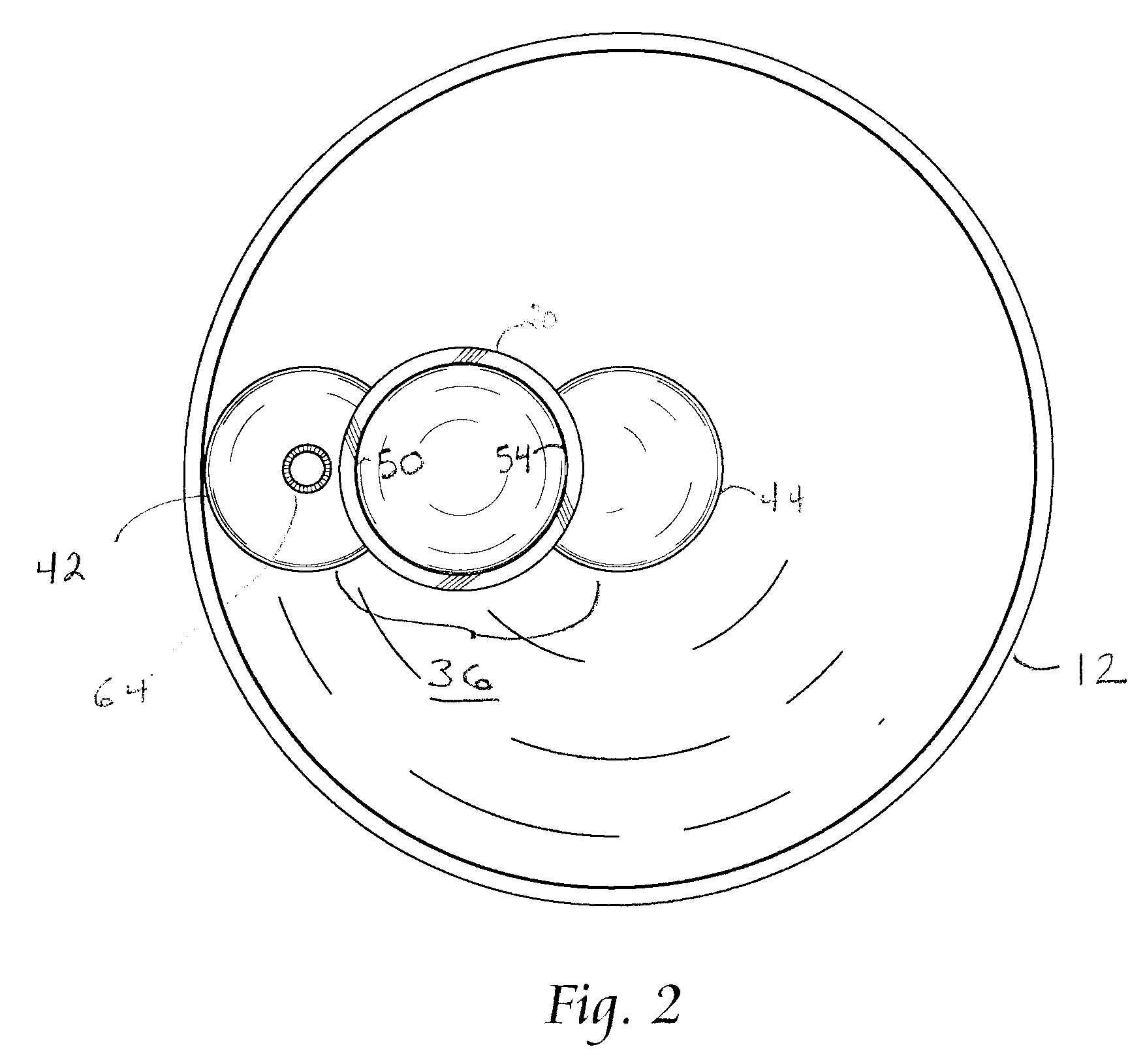

Sutureless implantable device and method for treatment of glaucoma

InactiveUS6881197B1Easy to installControl pressureEye surgeryWound drainsDiffusion barrierMaximum pressure

Sutureless, implantable fluid shunting devices and associated methods for controlling the pressure of fluids within anatomical spaces or cavities of the body. The device generally comprises a tube having a diffusion barrier (e.g., diffusion chamber) formed on a proximal end thereof. Fluid which flows through the tube will collect within the diffusion chamber and will diffuse outwardly therethrough. However, the presence of the diffusion chamber will prevent microbes, cells or other matter from interfering with or backflowing through the tube. Additionally, the tube may be provided with a pressure-openable aperture through which fluid from the tube may flow into the diffusion chamber. Such pressure-openable aperture will remain closed, until the pressure of fluid within the tube exceeds a predetermined maximum pressure PMAX. In this manner, the pressure-openable aperture will limit the amount of fluid drained from the anatomical space or cavity of the body, thereby avoiding hypotony within such anatomical space or cavity. The diffusion barrier of the device is preferably configured to fit between, and to be engaged by, adjacent recti muscles of the eye. Such engagement of the diffusion barrier with the adjacent recti muscles serves to prevent unwanted migration or post-implantation movement of the device, without the need for suturing of the device to the tissue of the eye.

Owner:REVISION OPTICS

Sutureless implantable device and method for treatment of glaucoma

InactiveUS20050182350A1Easy to installMinimal discomfort to the patientEye surgeryWound drainsDiffusion barrierMaximum pressure

Sutureless, implantable fluid shunting devices and associated methods for controlling the pressure of fluids within anatomical spaces or cavities of the body. The device generally comprises a tube having a diffusion barrier (e.g., diffusion chamber) formed on a proximal end thereof. Fluid which flows through the tube will collect within the diffusion chamber and will diffuse outwardly therethrough. However, the presence of the diffusion chamber will prevent microbes, cells or other matter from interfering with or backflowing through the tube. Additionally, the tube may be provided with a pressure-openable aperture through which fluid from the tube may flow into the diffusion chamber. Such pressure-openable aperture will remain closed, until the pressure of fluid within the tube exceeds a predetermined maximum pressure PMAX. In this manner, the pressure-openable aperture will limit the amount of fluid drained from the anatomical space or cavity of the body, thereby avoiding hypotony within such anatomical space or cavity. The diffusion barrier of the device is preferably configured to fit between, and to be engaged by, adjacent recti muscles of the eye. Such engagement of the diffusion barrier with the adjacent recti muscles serves to prevent unwanted migration or post-implantation movement of the device, without the need for suturing of the device to the tissue of the eye.

Owner:REVISION OPTICS

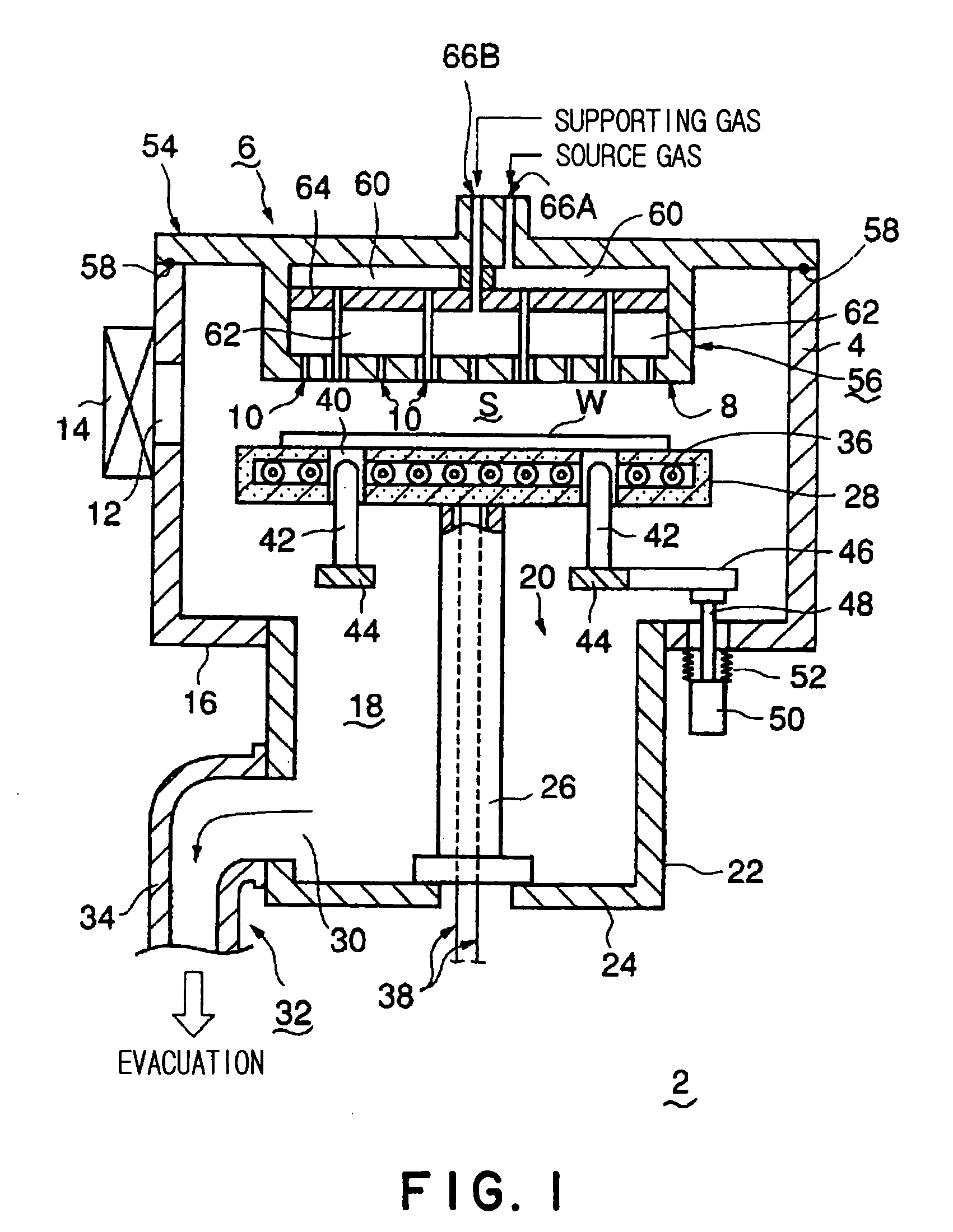

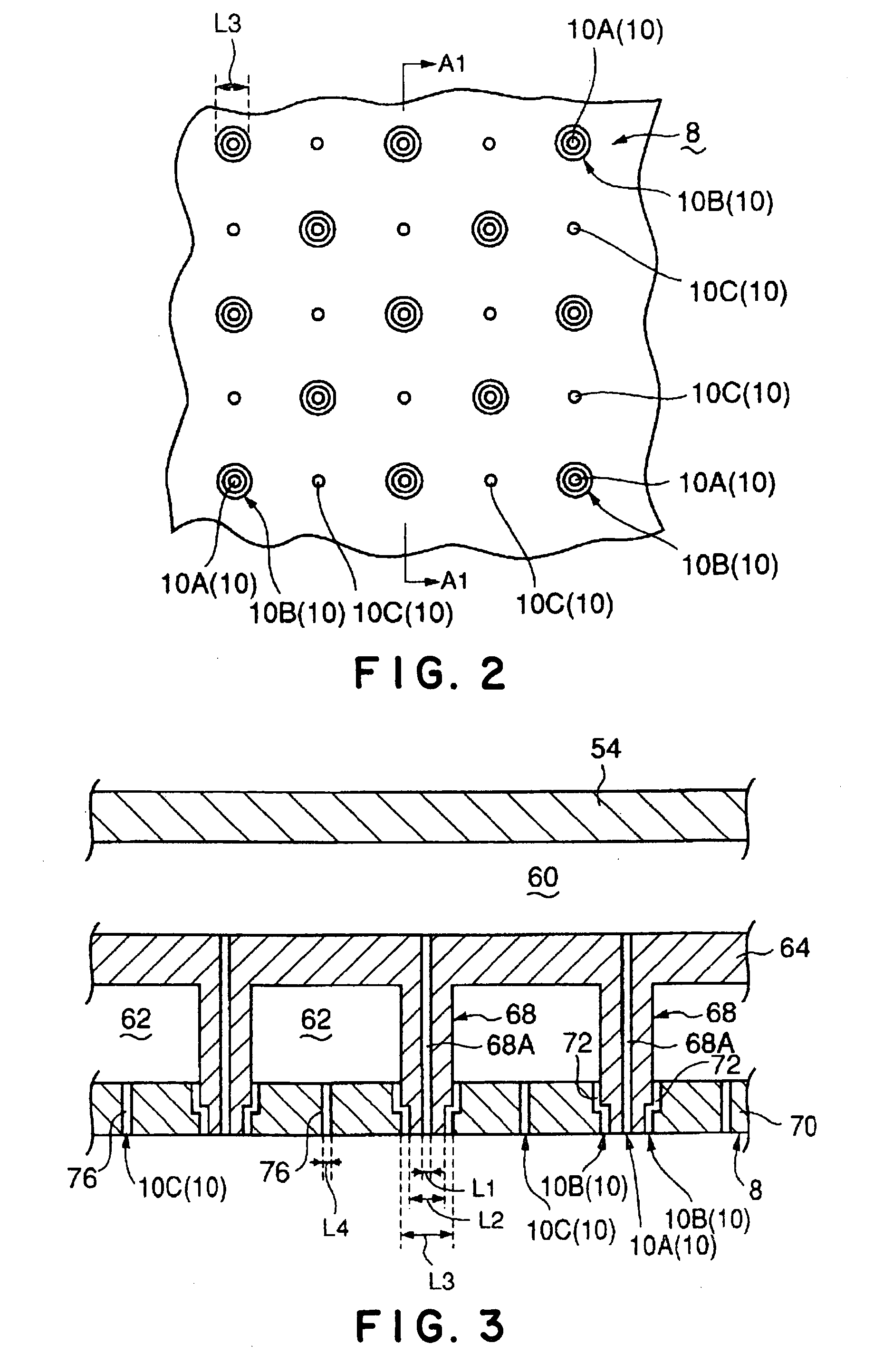

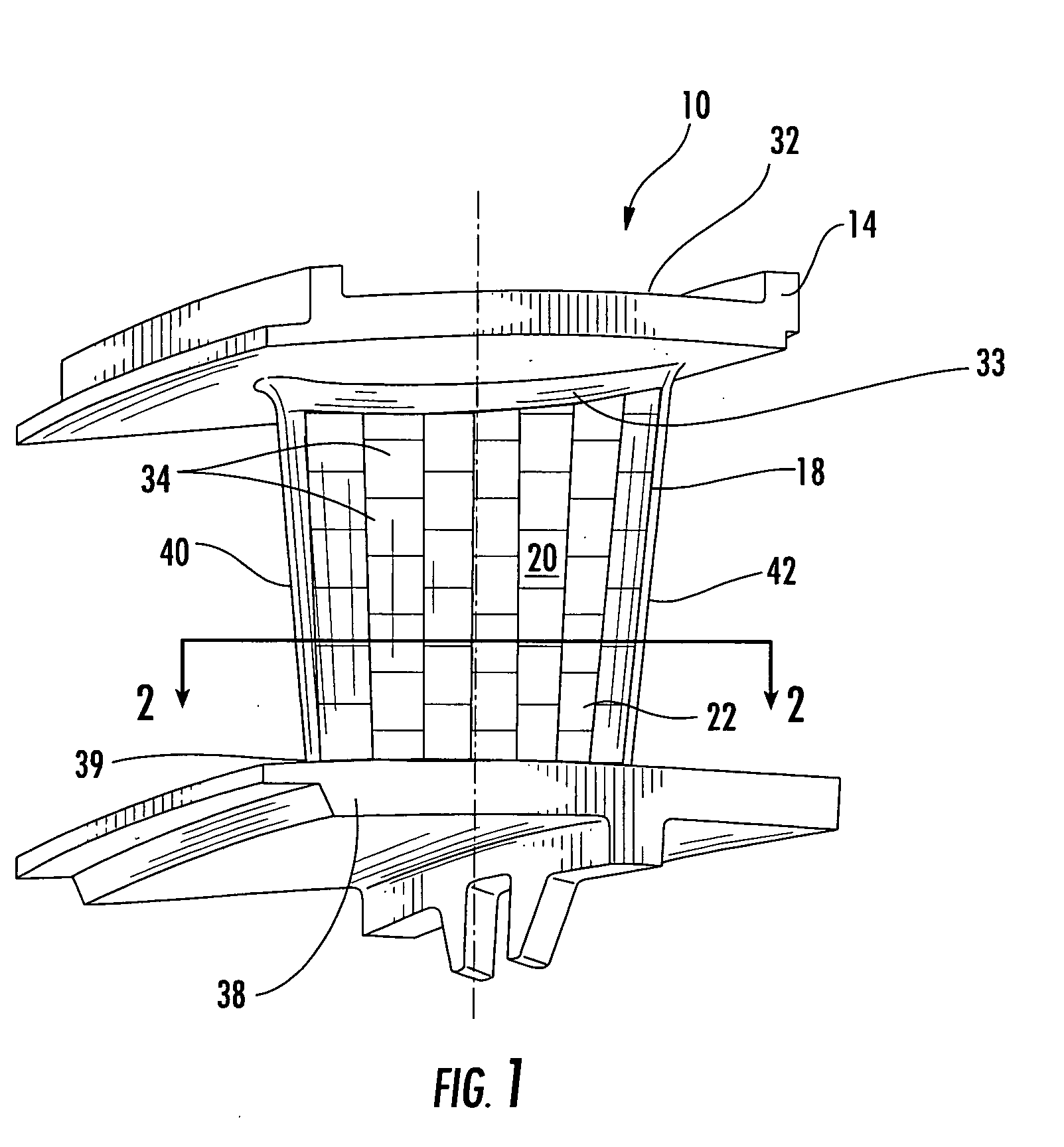

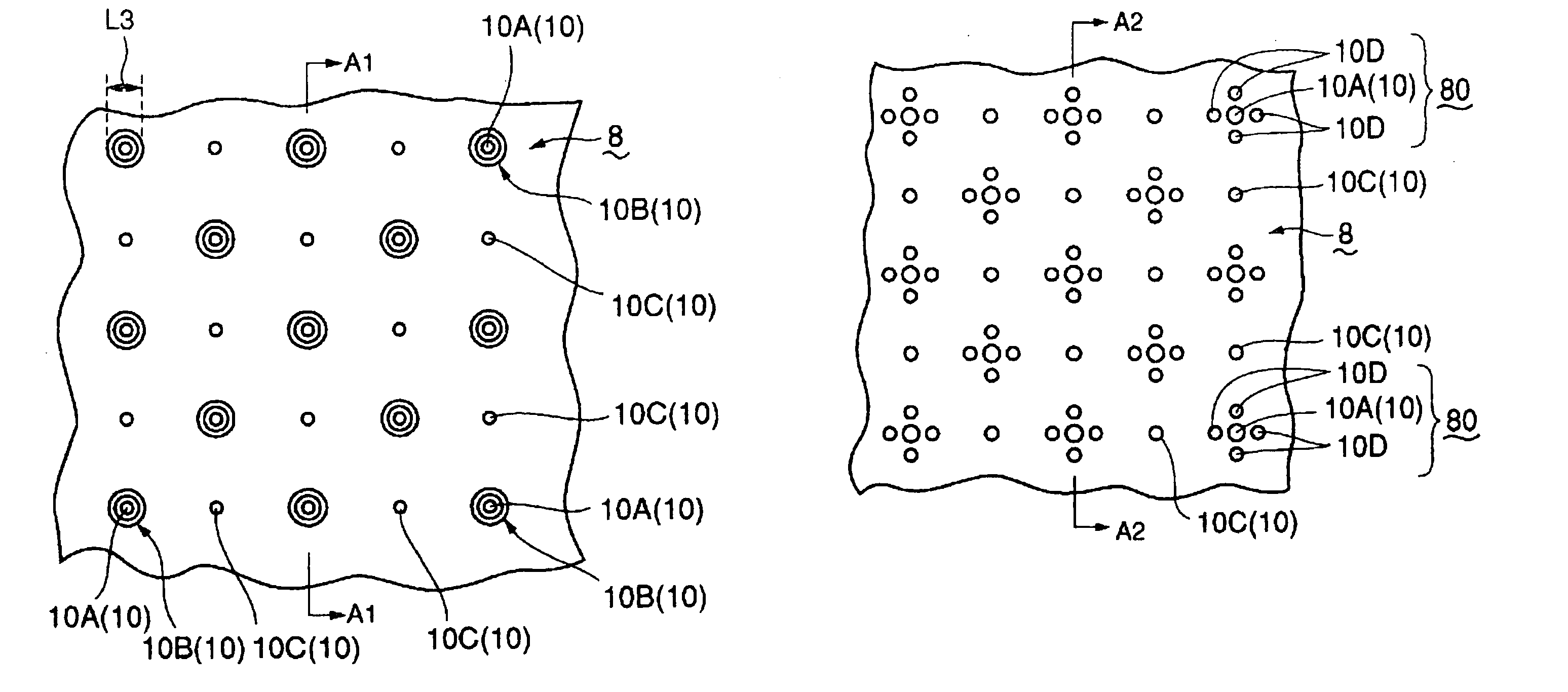

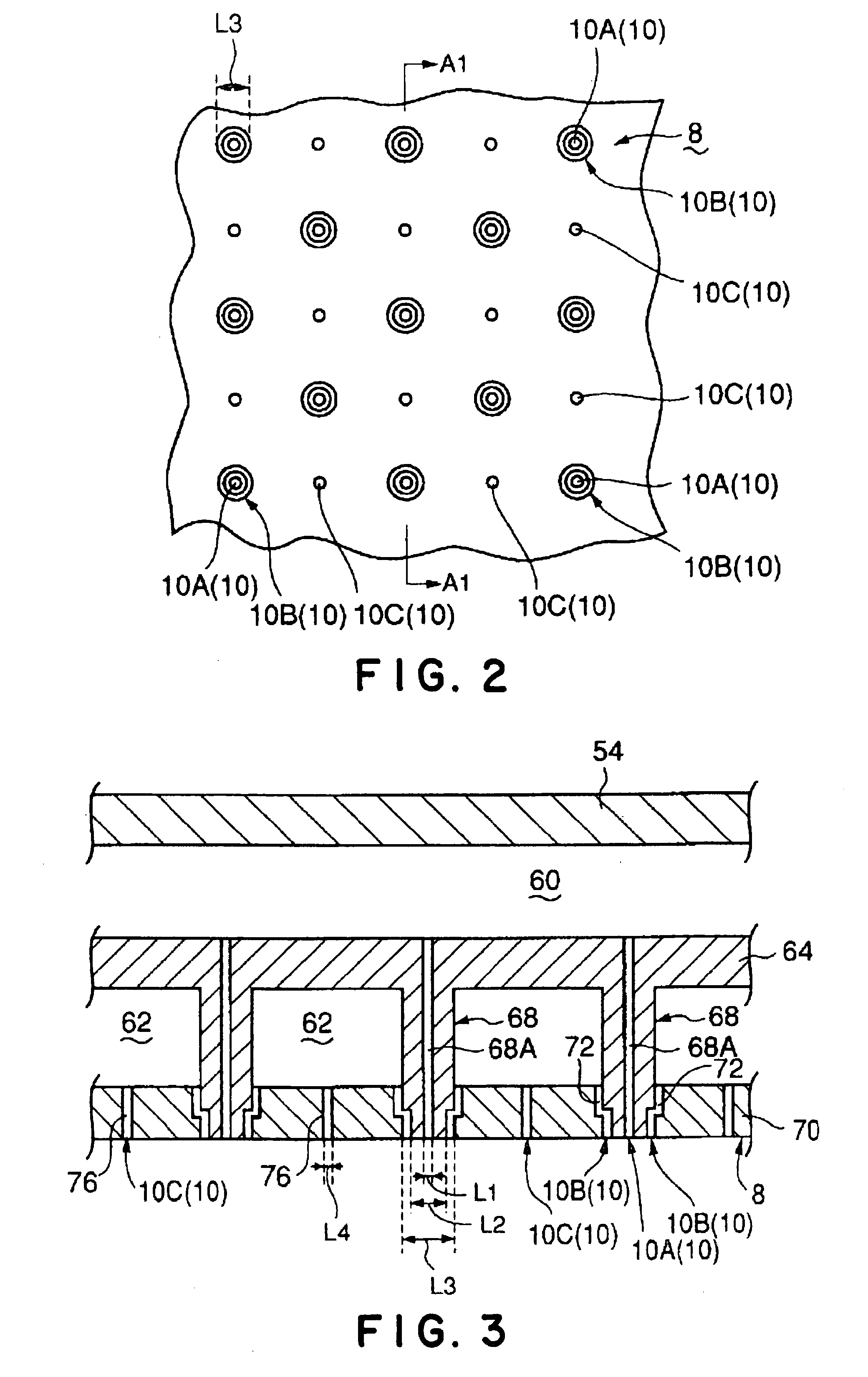

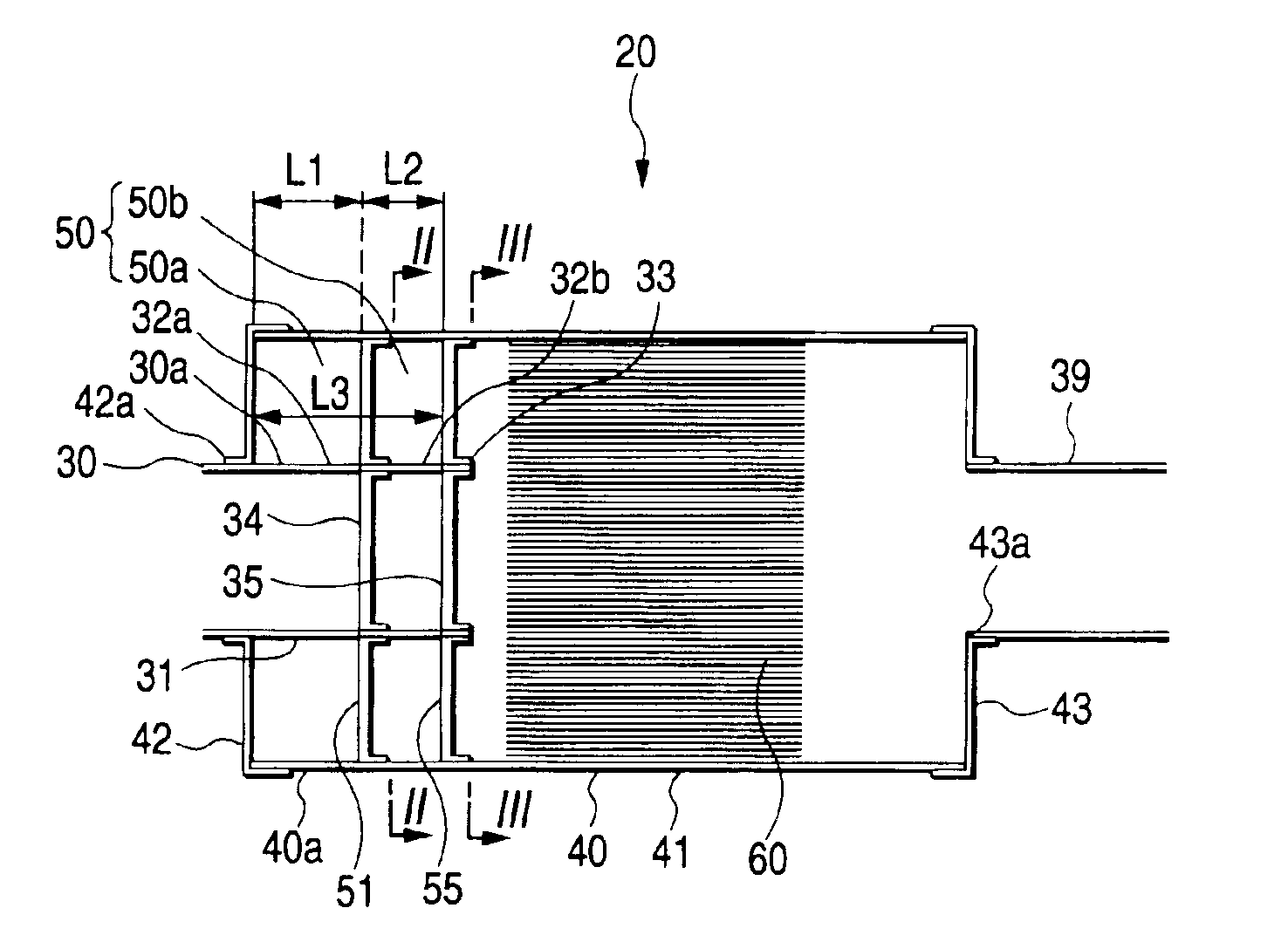

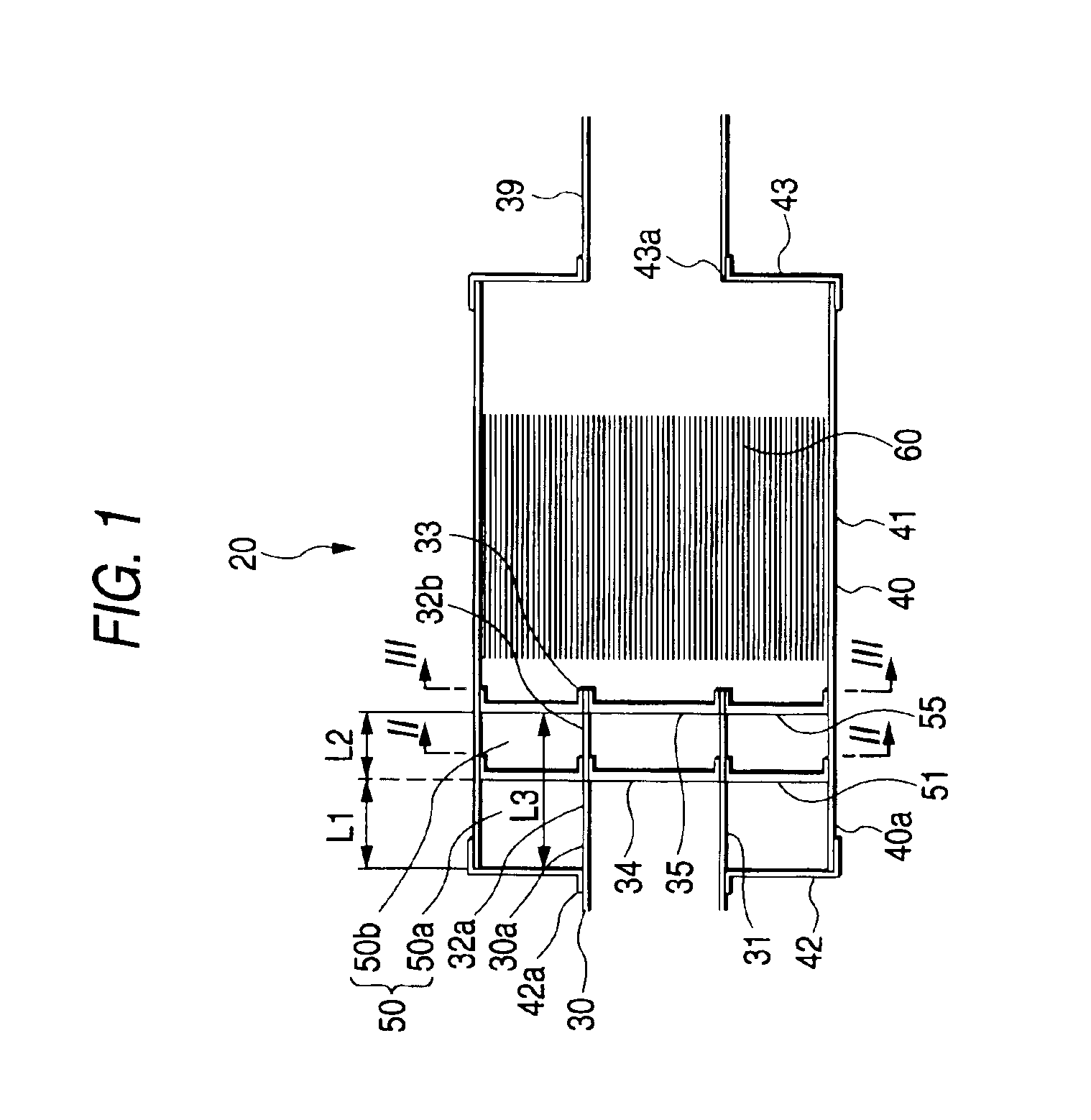

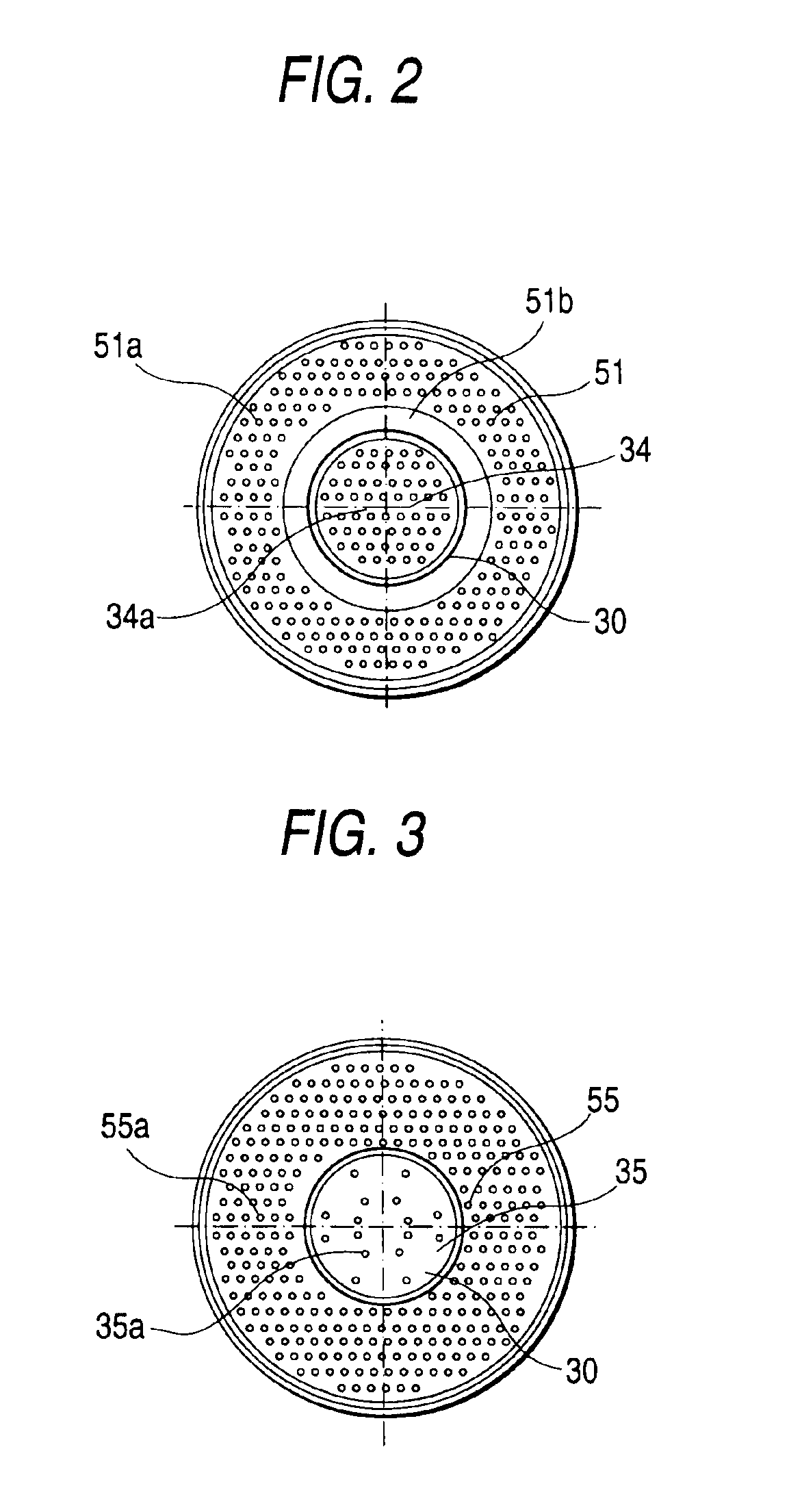

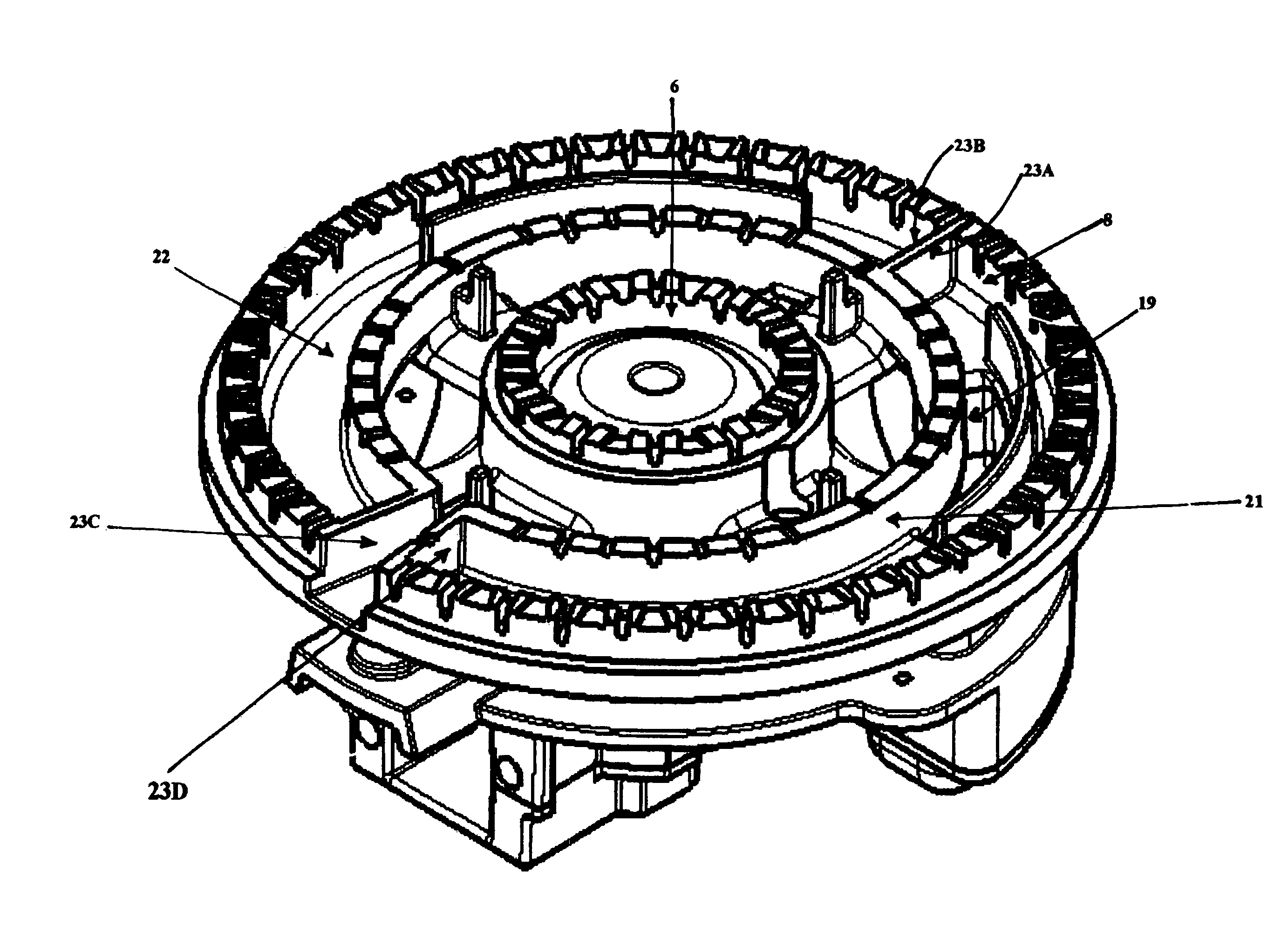

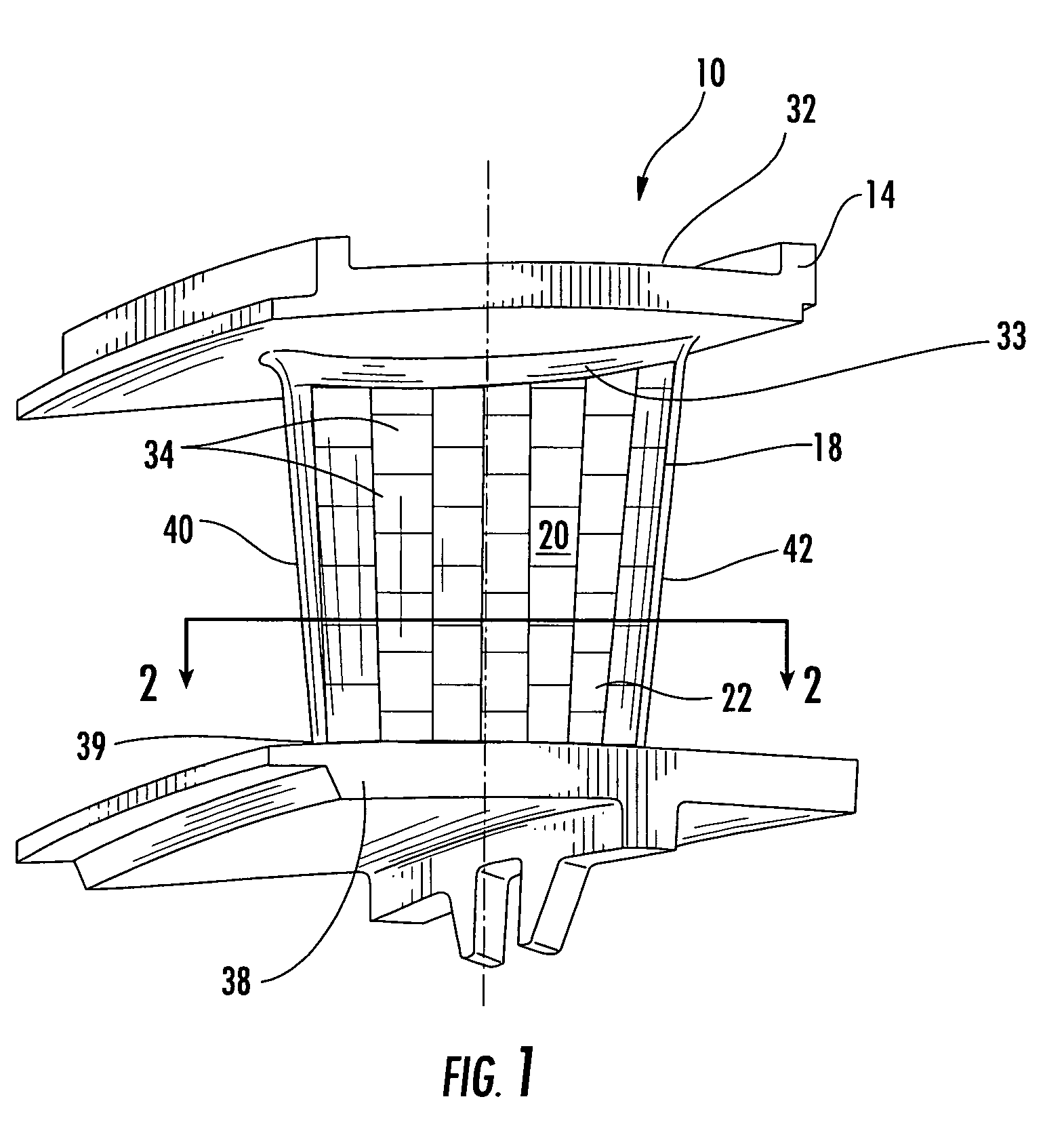

Shower Head and Film-Forming Device Using the Same

ActiveUS20070272154A1Efficient solutionAvoid depositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringShower

The present invention relates to a showerhead that supplies a source gas and a supporting gas for depositing a film into a processing vessel of a film deposition apparatus. The showerhead includes a body which is provided with a gas jetting surface (8). In the showerhead body, there are defined a first diffusion chamber (60) that receives the source gas and diffuses the same, and a second diffusion chamber (62) that receives the supporting gas and diffuses the same. The gas jetting surface has source-gas jetting orifices (10A) that are in communication with the first diffusion chamber, and first supporting-gas jetting orifices (10B) that are in communication with the second diffusion chamber. Each of the first supporting-gas jetting orifices (10B) are formed into a ring shape that adjacently surrounds a corresponding one of the source-gas jetting orifices (10A).

Owner:TOKYO ELECTRON LTD

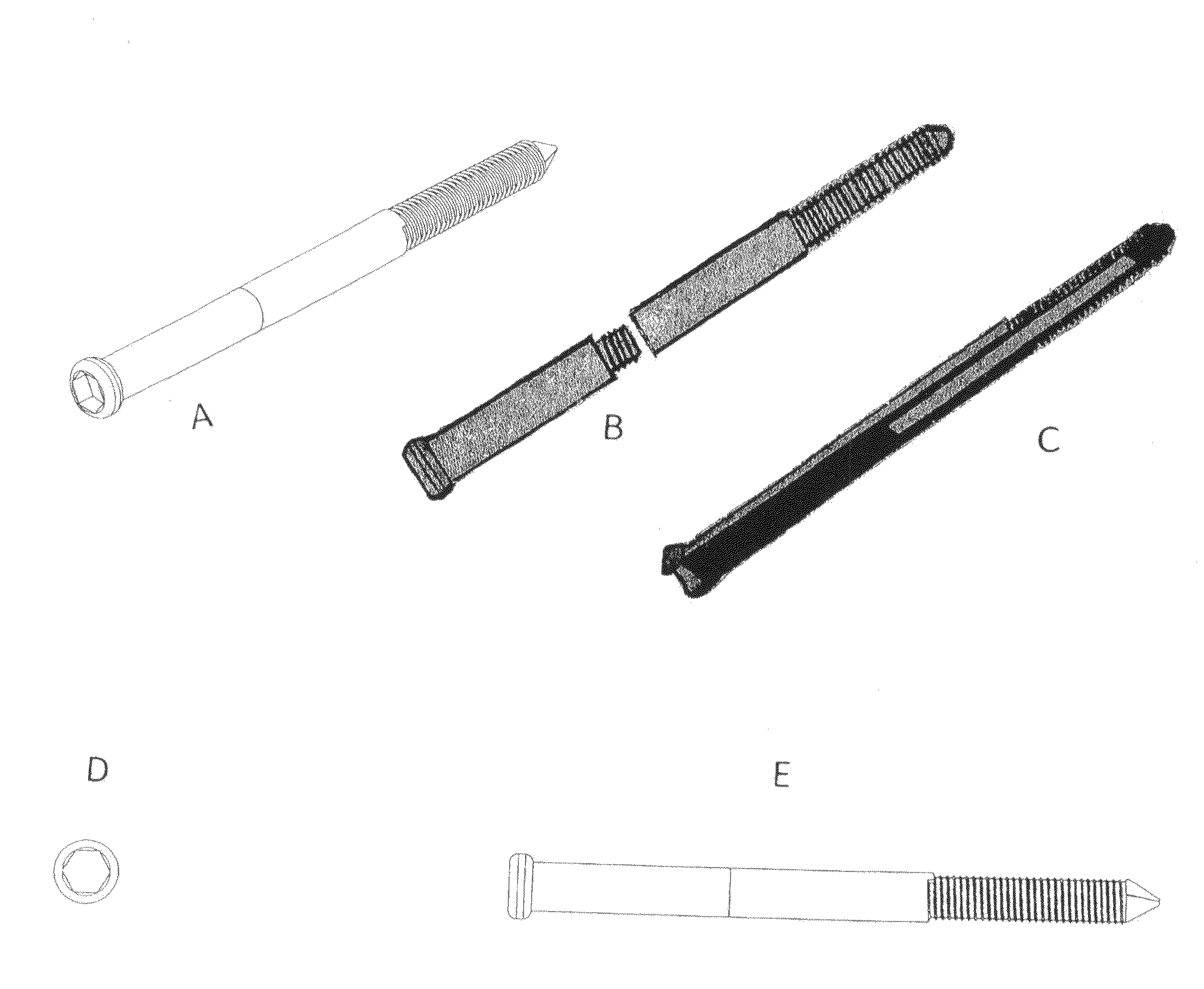

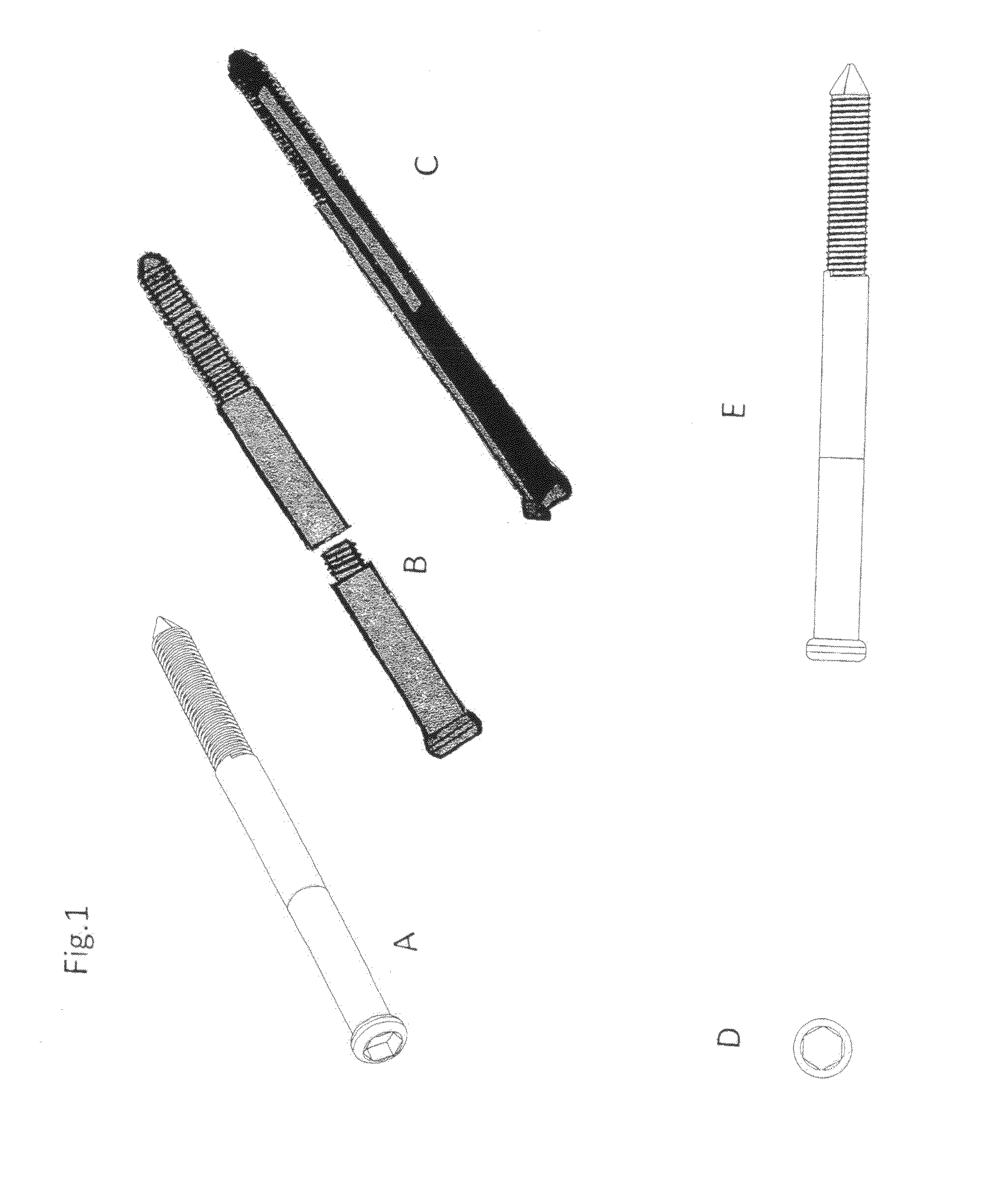

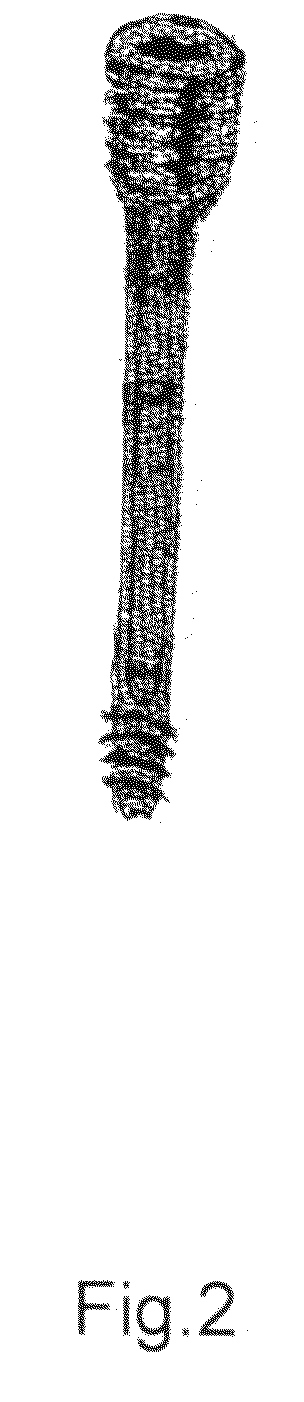

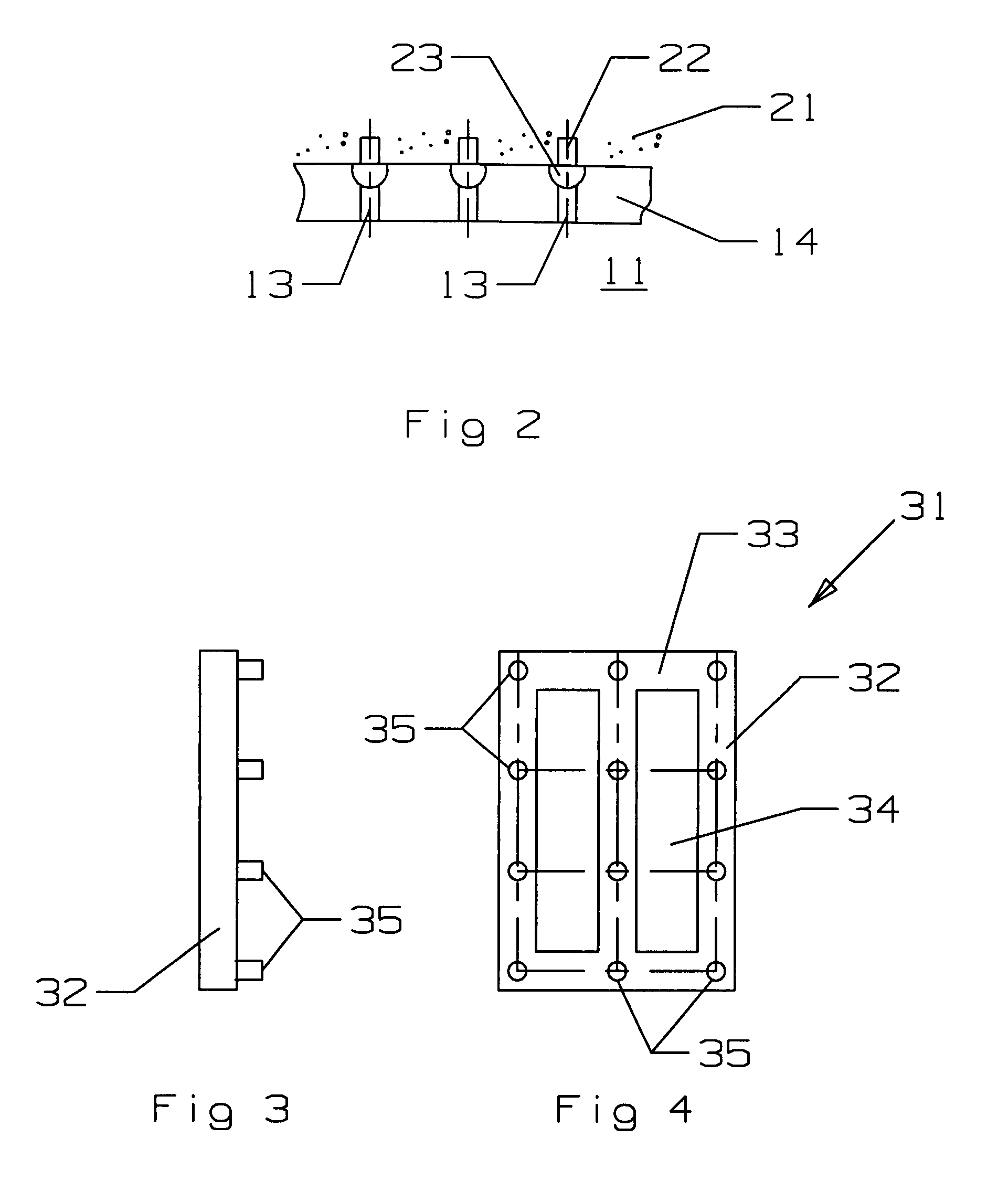

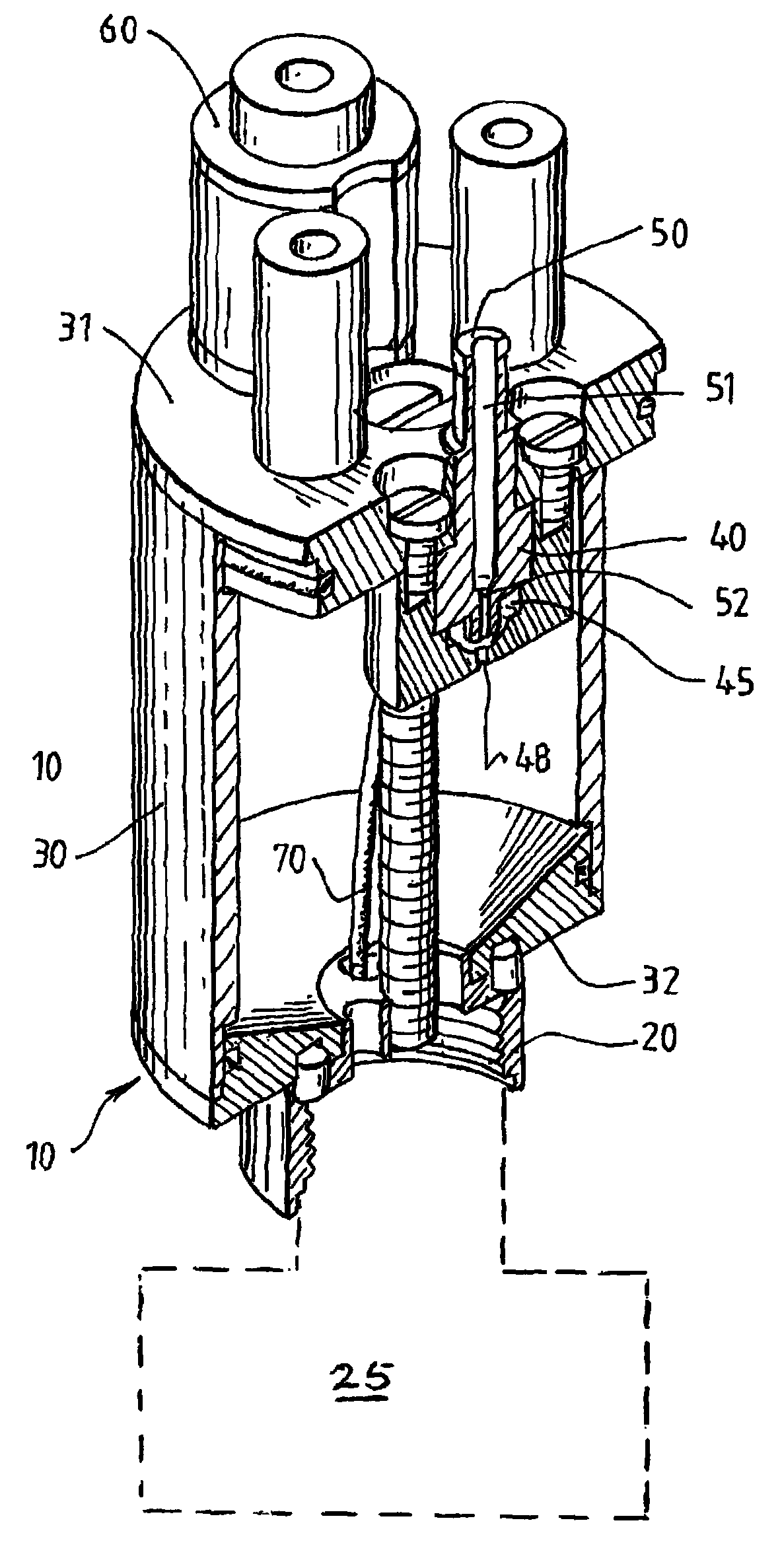

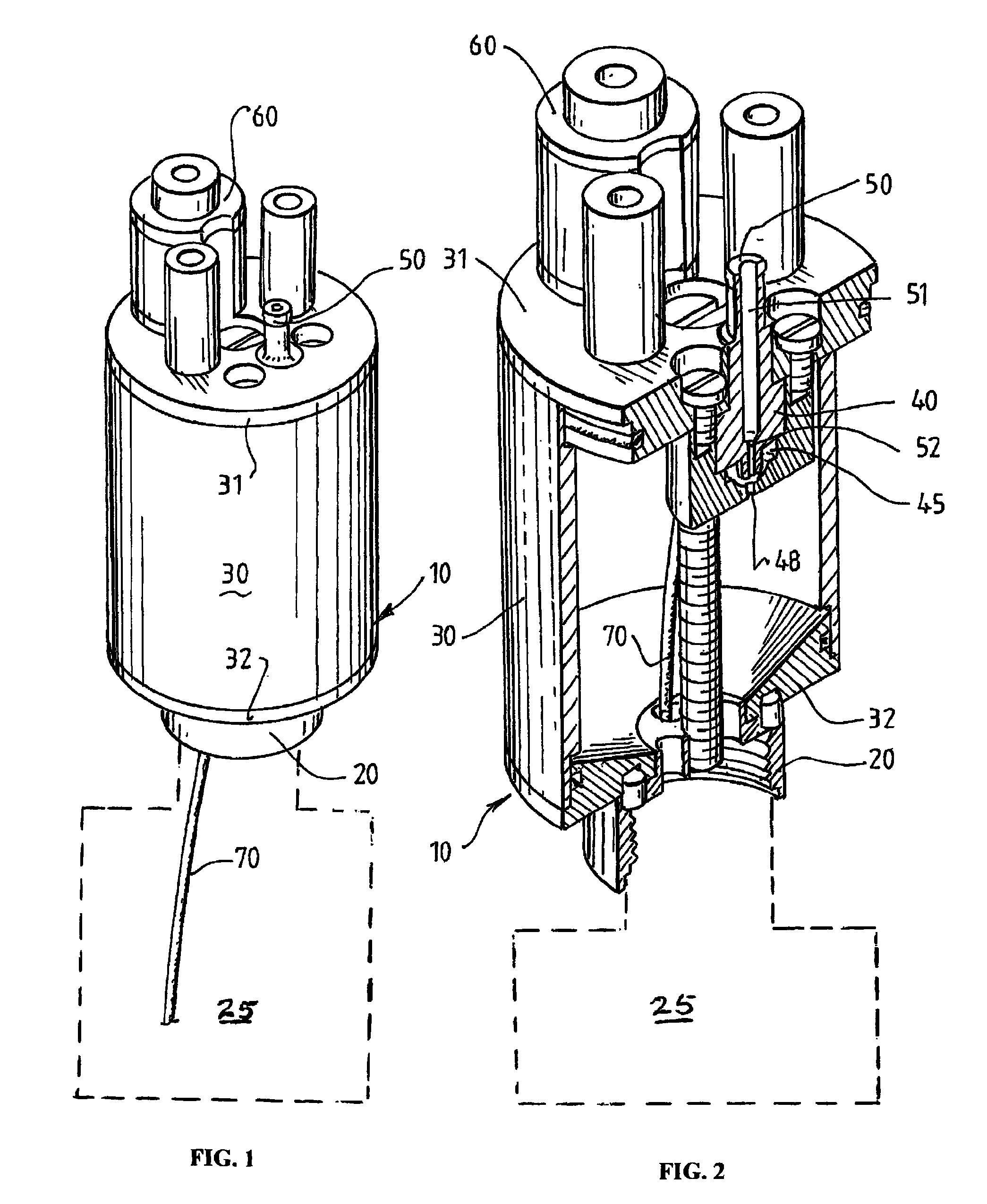

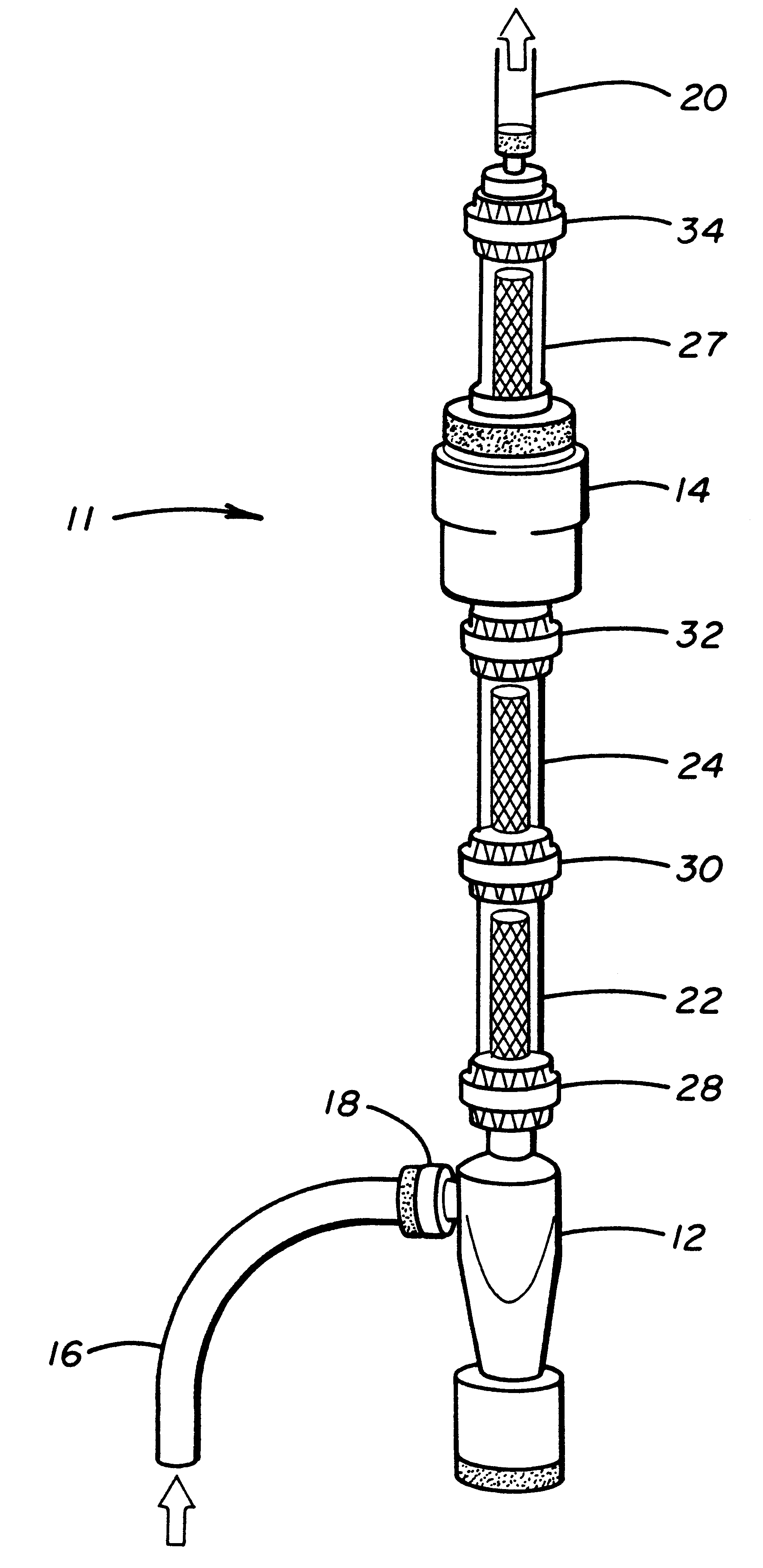

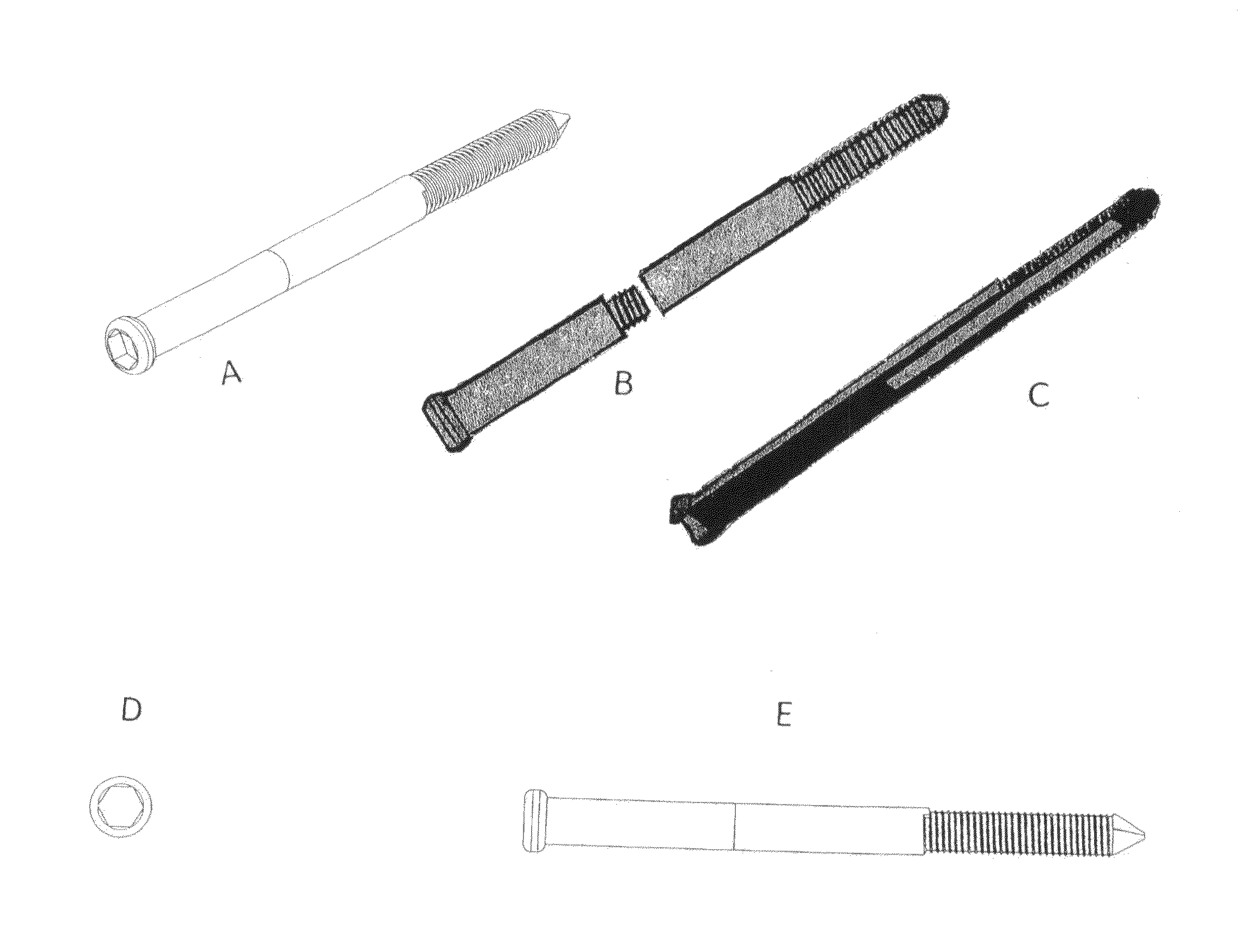

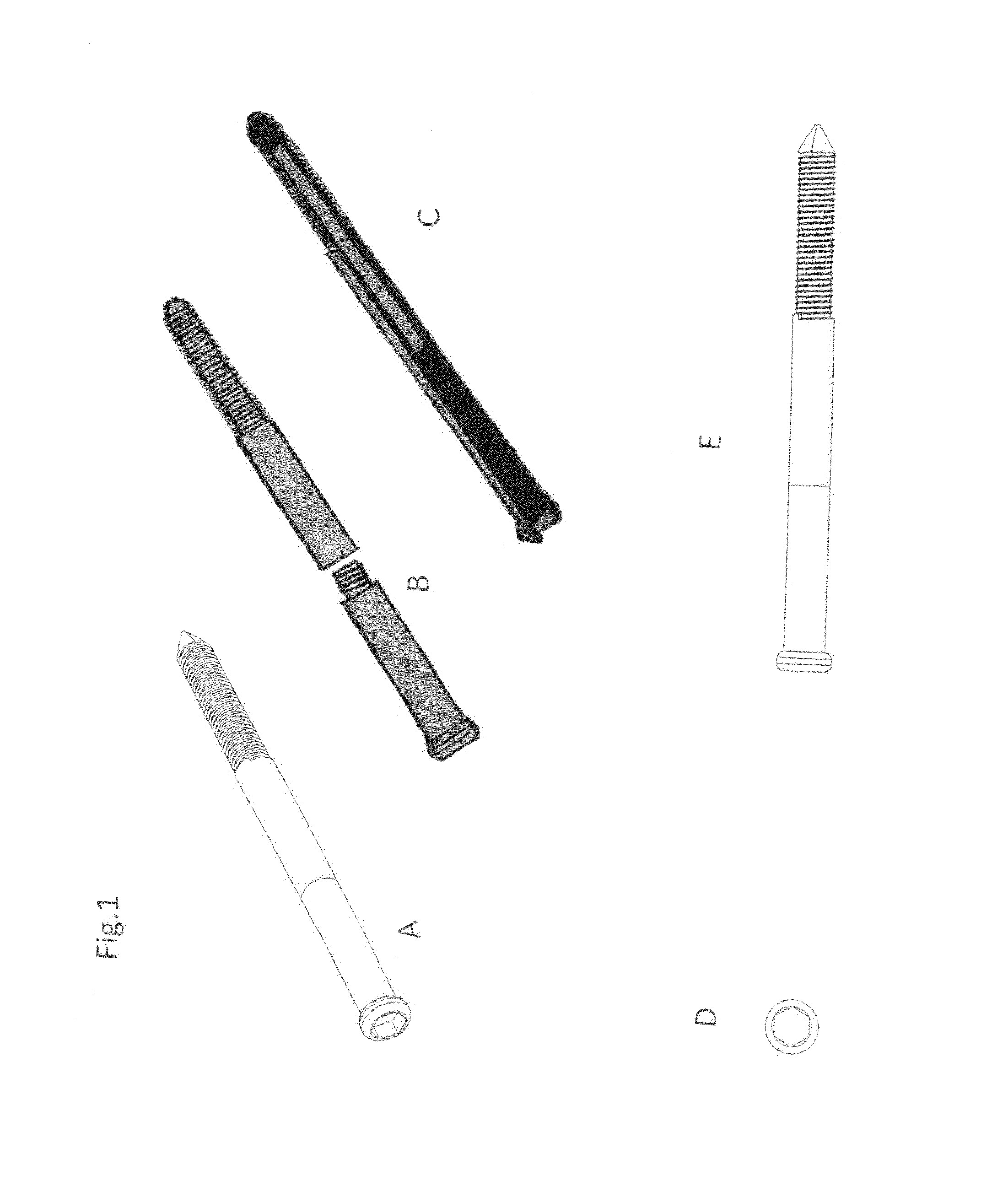

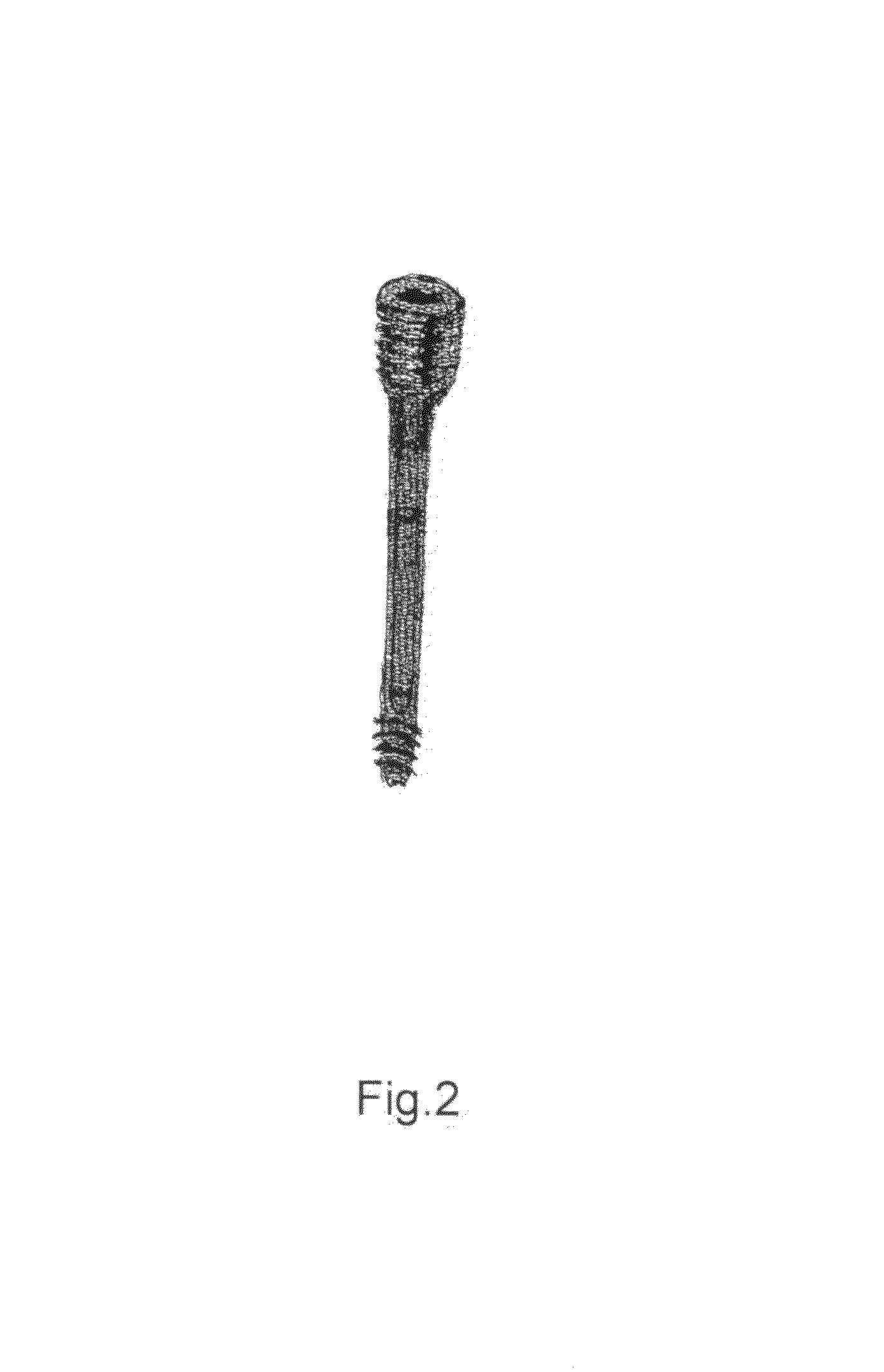

Poly-porous hollow screw for target delivery of growth factors and stem cells:the design and potential clinical application

Present invention depicts a poly-porous (micropore) hollow screws as diffusion chamber filled with core matrix for targeted delivery of growth factors and bone marrow stem cells. The screws comprise at least two parts: the distal part of the screw consists of the tip of the screw made of poly porous material and hollow inside proximally. It has threaded navel attached to the threaded nipple of the distal part of the proximal screw which has the screw head and is made of the solid material of the same kind. The screw head had hexagonal recess targeted for screw driver insertion. Assembly of screw created a chamber in the middle of the screw. The chamber is filled with core matrix consisting of gelatin nano-particles pre-impregnated with BMPs (BMP2 / BMP7 for bone or BMP12 for tendon, ligament) and fibrin sealants or Chitosan dispersed with bone marrow stem cells and / or other growth factors. Bioactive protein core material is prepared during the surgery and filled the chamber of the screw by the surgeon. Fibrin sealants or Chitosan will polymerize to form a gel to hold the growth factors and stem cell in place. The screw can be used as the lag screw or other function to provide mechanical fixation in variety of condition. Once the screw implanted in the human body, the fibrin sealant or Chitosin / gelatin nano-particles are gradually degraded and slowly release growth factors and stem cells via micropores of screw to facilitate the bone healing and regeneration. The gelatin nanoparticles and fibril sealant / or Chitosan matrix also serve as the scaffold and platform for bone in-growth to the screw or alternatively, the stem cell inside of screw can regenerate new bone, providing the biological fixation. At the mean time as the bone regenerate and / or in growth, mechanical strength of the screw increased.

Owner:WU YANGGUAN

Transpiration cooled turbine airfoil

A turbine airfoil or a substrate exposed to a high temperature environment having a plurality of modular formed cooling circuits with diffusion chambers and cooling holes for each module. Each module includes diffusion chambers and transpiration cooling holes and is placed on the airfoil substrate and a refractory material is formed over the modules. The modules are then leached away leaving the diffusion chambers and cooling holes formed between the substrate and the refractory coating.

Owner:FLORIDA TURBINE TECH

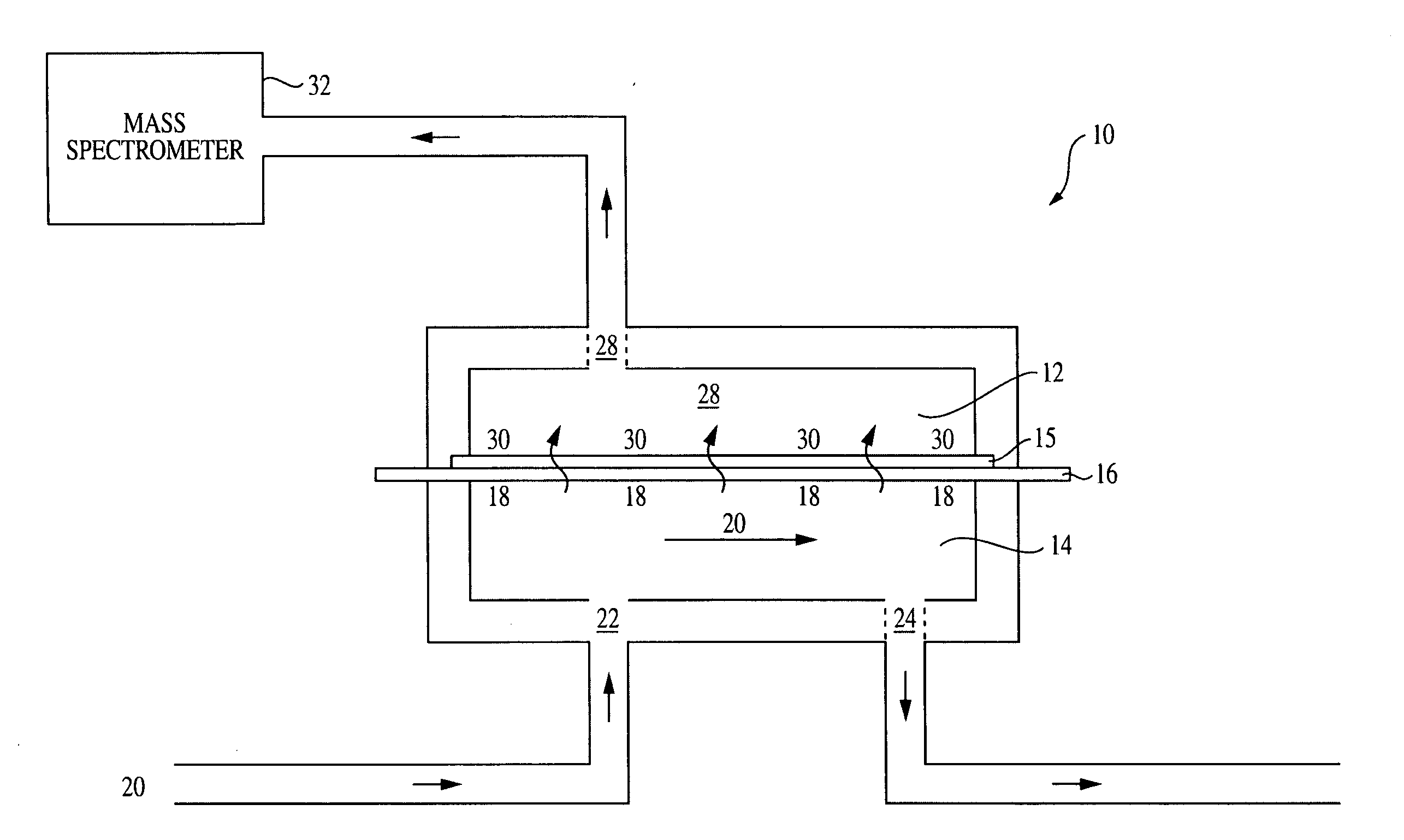

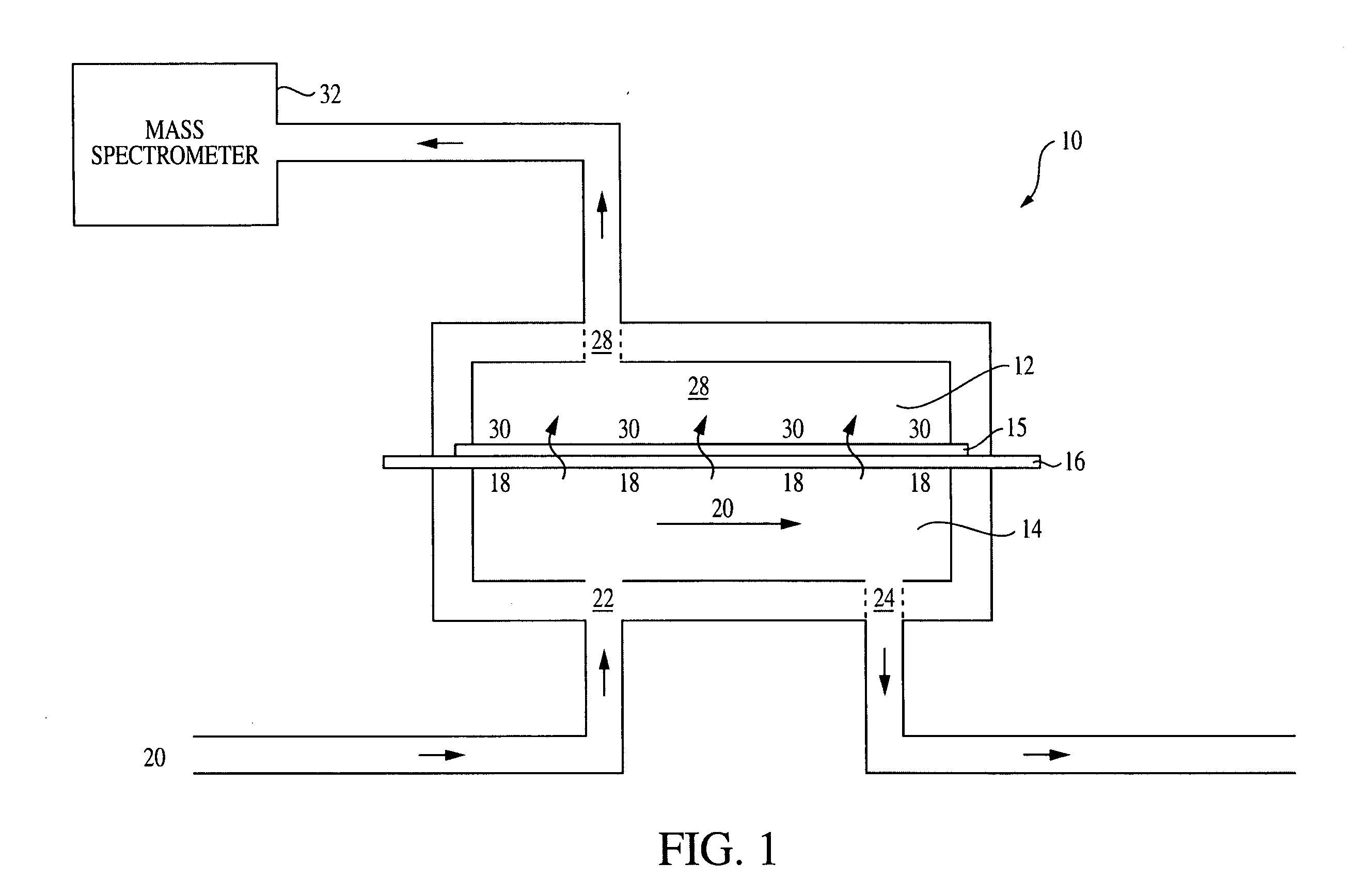

Method and apparatus for measuring gas transmission rates of deformable or brittle materials

ActiveUS20050092068A1Apparent advantageHigh precisionParticle spectrometer methodsPermeability/surface area analysisTest roomEngineering

Provided are an apparatus and a method for measuring gas transmission rates and nanoleaks of deformable and brittle materials. The apparatus includes a test chamber having an upper and lower diffusion cells that when closed form a chamber wall seal, a gas inlet and a gas outlet in fluid communication with the lower diffusion cell, the upper diffusion cell being fluidly connected to a high-vacuum mass spectrometer. The method of measuring gas transmission rates and nanoleaks includes placing a sealed package containing the test gas in the lower diffusion cell, closing the upper and lower diffusion cells, flushing the lower diffusion cell with a source of a second gas other than the test gas, closing off the source of the second gas; and measuring the leak rate of the sealed package.

Owner:MODERN CONTROLS

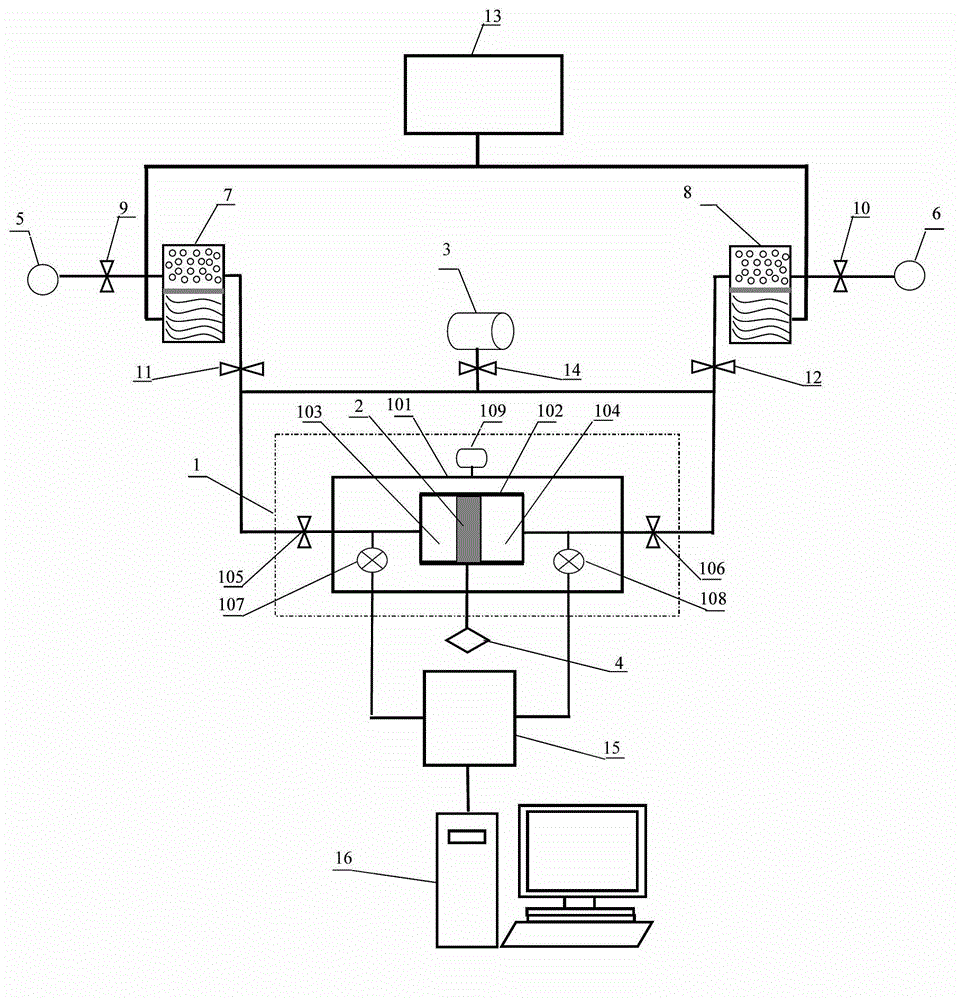

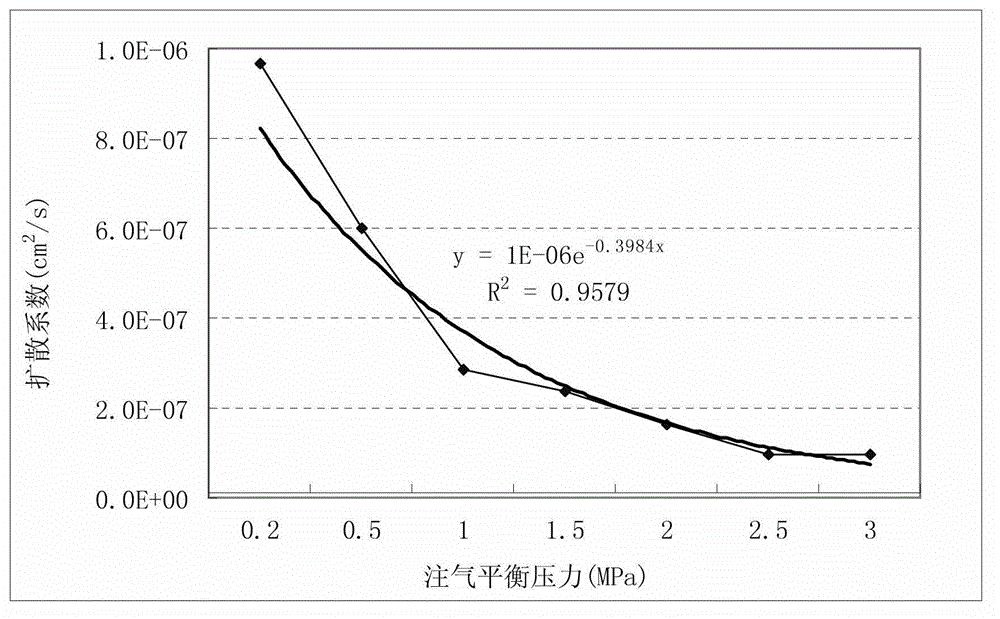

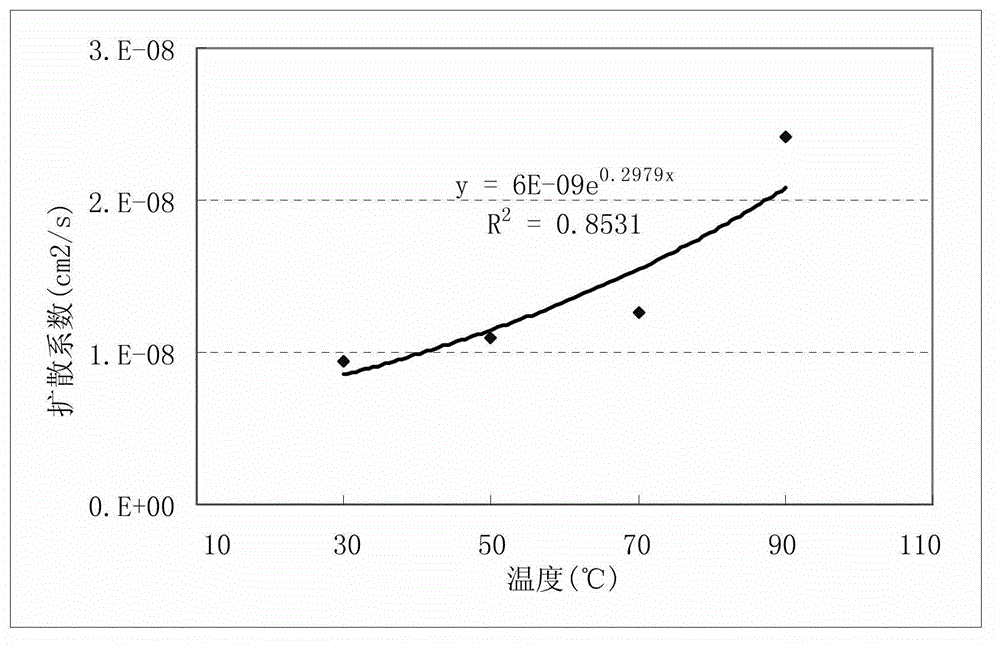

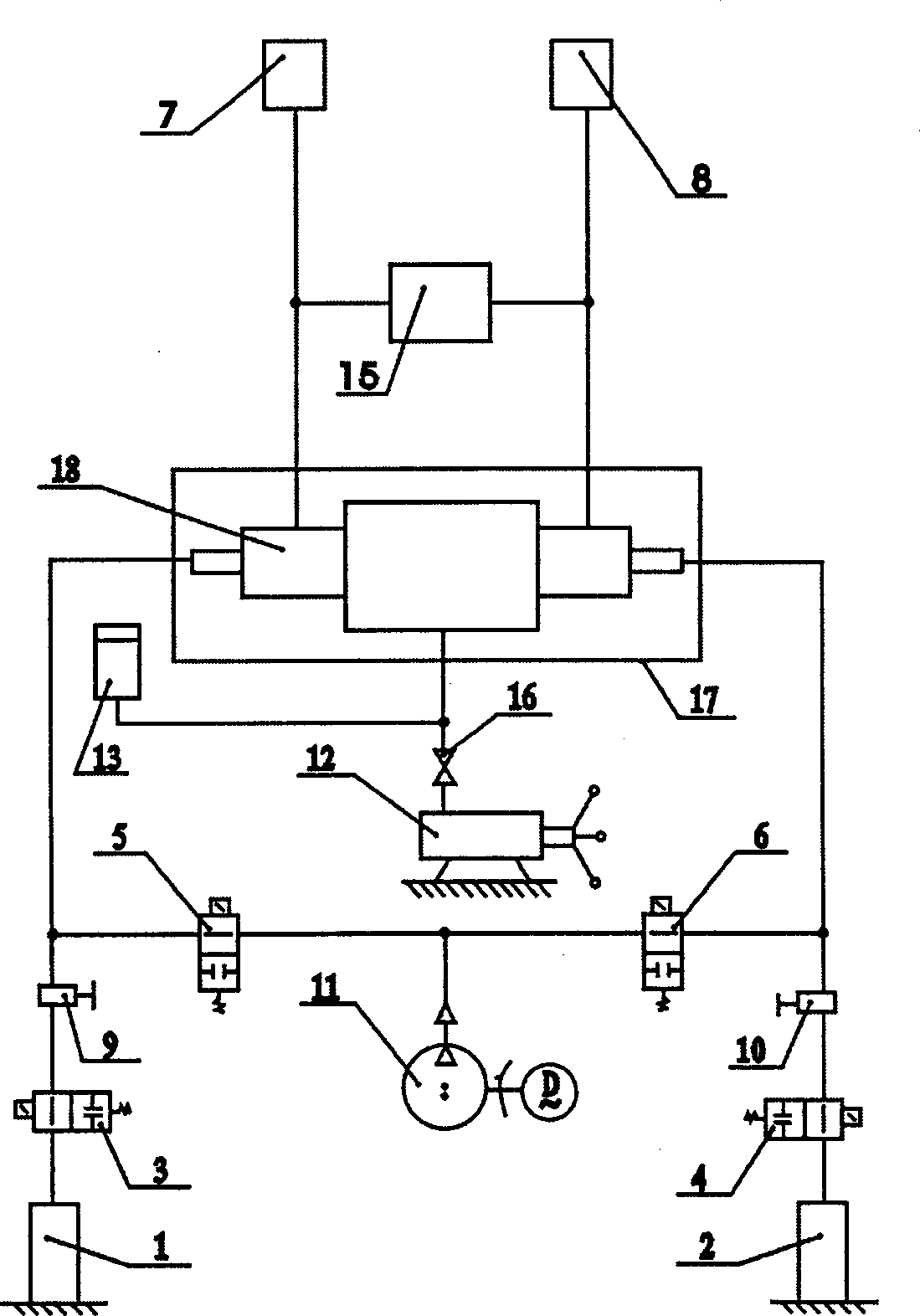

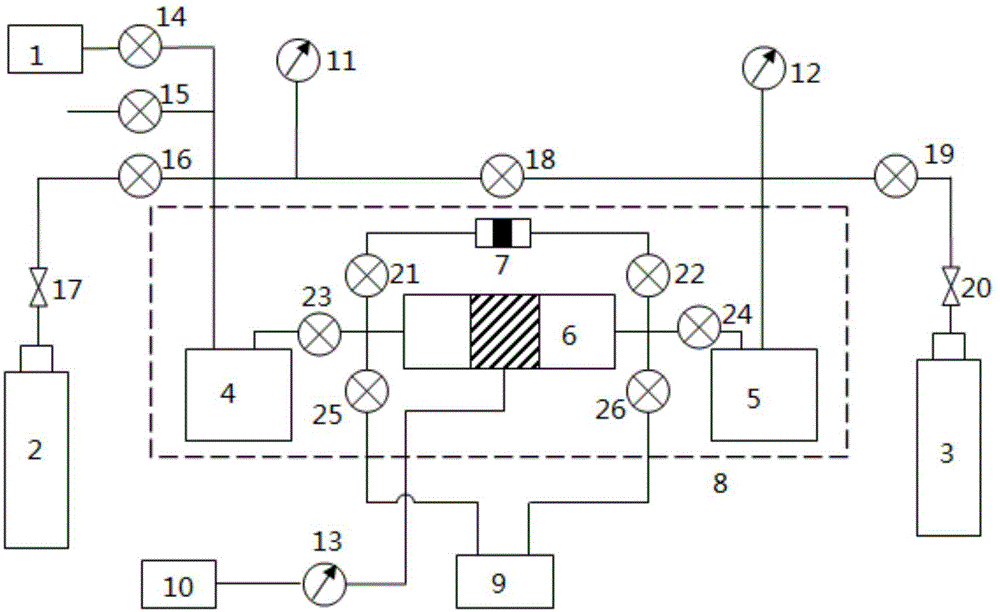

Device and measuring method for hydrocarbon diffusion coefficient in rocks under high temperature and high pressure

ActiveCN102980837AGas injection balance pressure is accurate and consistentSolve stressSurface/boundary effectConcentration gradientNormal diffusion

The invention provides a device and measuring method for the hydrocarbon diffusion coefficient in rocks under high temperature and high pressure. The device mainly comprises a rock diffusion coefficient tester, a vacuum pump, a confining pressure pump, hydrocarbon gas source, nitrogen (N2) gas source, a left piston container, a right piston container, an automatic pressure pump, a chromatographic detector, a computer, a drying device and a rock saturated water device and the like. According to the device and method, the consistent accurate accordance of the gas injection balance pressure in the diffusion chambers respectively arranged at two ends of a core holder can be achieved and the existence of the hydrocarbon diffusion driven by the concentration gradient not by the pressure gradient in the whole process of experiment is ensured. Meanwhile, according to the device and method, the problem of low gas injection balance pressure, relatively low experimental temperature and having difference with the actual formation condition of the gas source balance pressure control device in the measuring of normal diffusion coefficient is resolved.

Owner:PETROCHINA CO LTD

Catheter with omni-directional optical lesion evaluation

ActiveUS8628520B2Improve lesionExtended service lifeDiagnosticsSurgical navigation systemsLight energyPositive pressure

A catheter is adapted to ablate tissue and provide lesion qualitative information on a real time basis, having an ablation tip section with a generally omni-directional light diffusion chamber with one openings to allow light energy in the chamber to radiate the tissue and return to the chamber. The chamber is irrigated at a positive pressure differential to continuously flush the opening with fluid. The light energy returning to the chamber from the tissue conveys a tissue parameter, including without limitation, lesion formation, depth of penetration of lesion, cross-sectional area of lesion, formation of char during ablation, recognition of char during ablation, recognition of char from non-charred tissue, formation of coagulum around the ablation site, differentiation of coagulated from non-coagulated blood, differentiation of ablated from healthy tissue, tissue proximity, and recognition of steam formation in the tissue for prevention of steam pop.

Owner:BIOSENSE WEBSTER INC

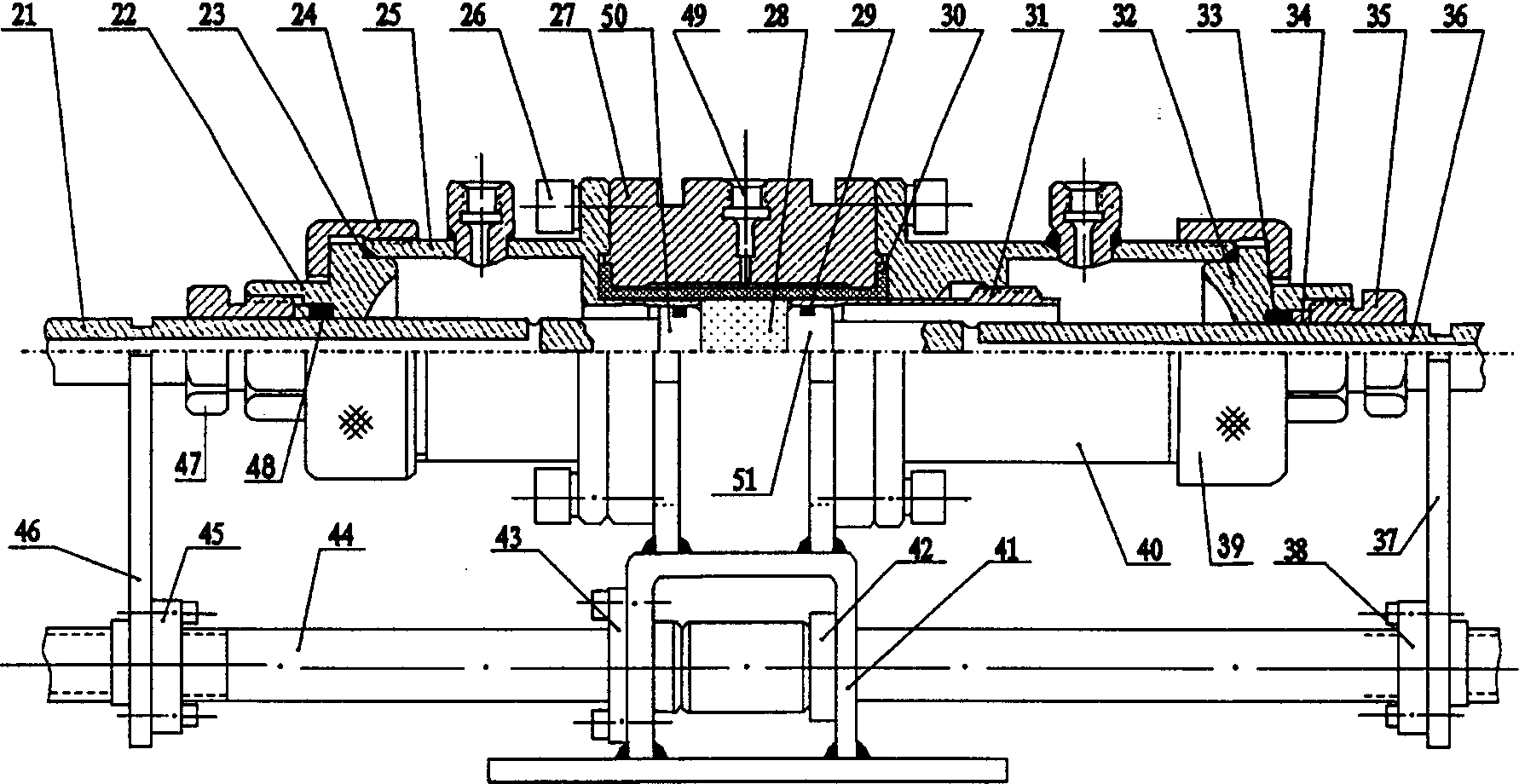

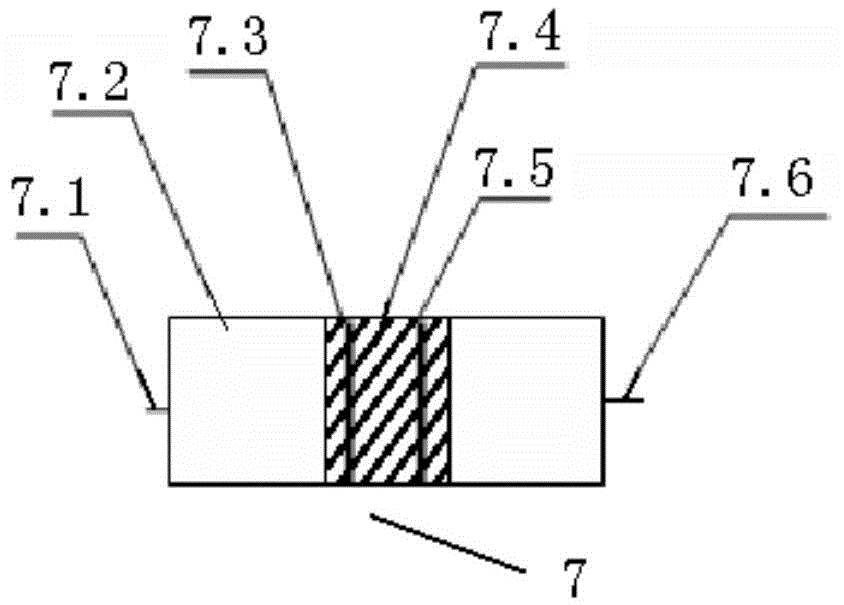

Diffusion coefficient analyzer

ActiveCN1773246AIncrease authenticityImprove accuracyComponent separationSurface/boundary effectDiffusionMeasuring instrument

The present invention provides a diffusion coefficient measuring instrument, in the concrete, it relates to a device for measuring rock diffusion coefficient. Said measuring instrument includes rock sample diffusion device, pressure balance device, pressure pump and vacuum pump. Said rock sample diffusion device, includes core chamber, rock sample sealing cover, diffusion chamber, plunger, plunger-pulling bar, end cover, regulating screw rod and fixing frame. Besides, said invention also provides the working principle of said diffusion coefficient measuring instrument.

Owner:CHINA PETROLEUM & CHEM CORP +1

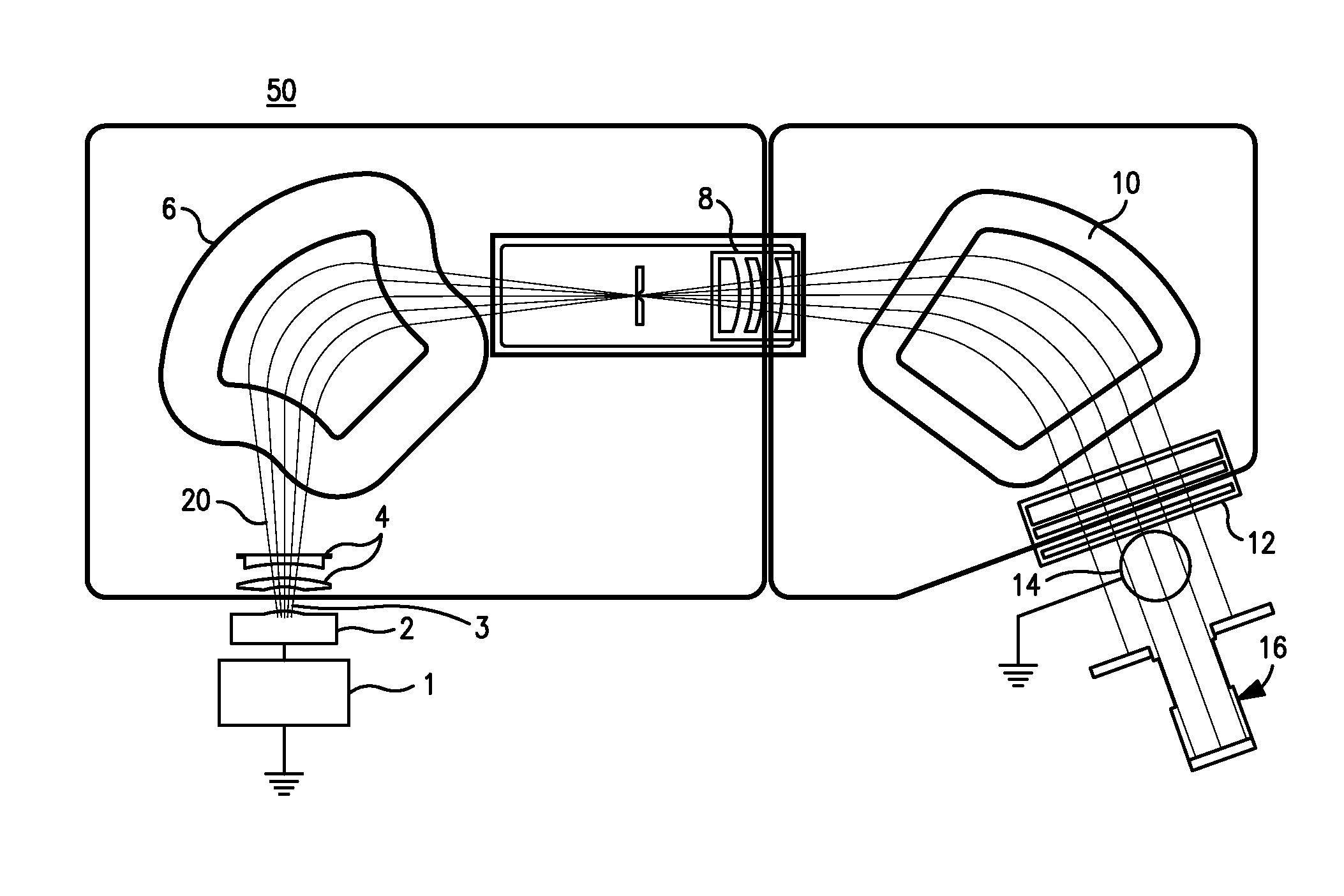

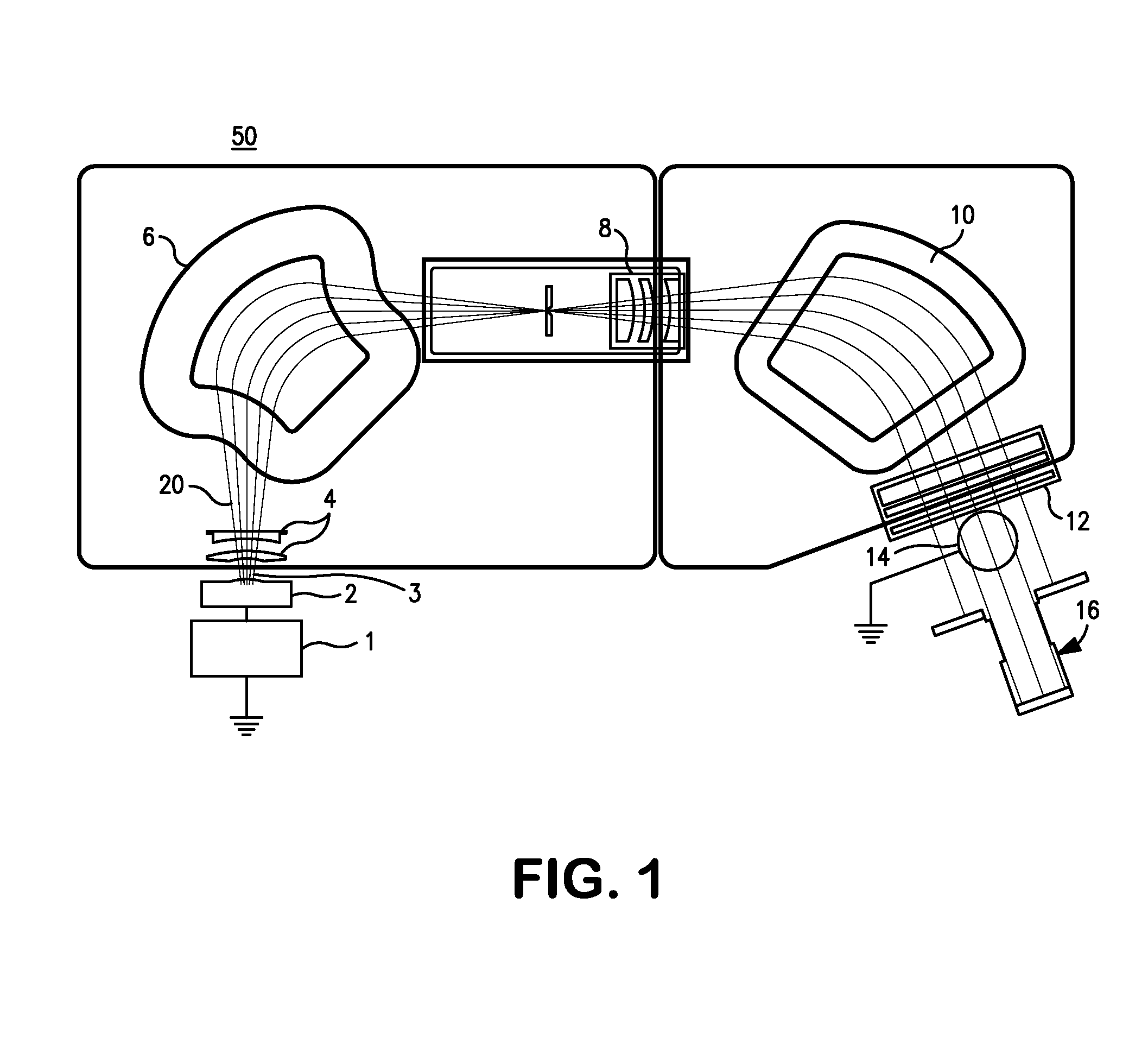

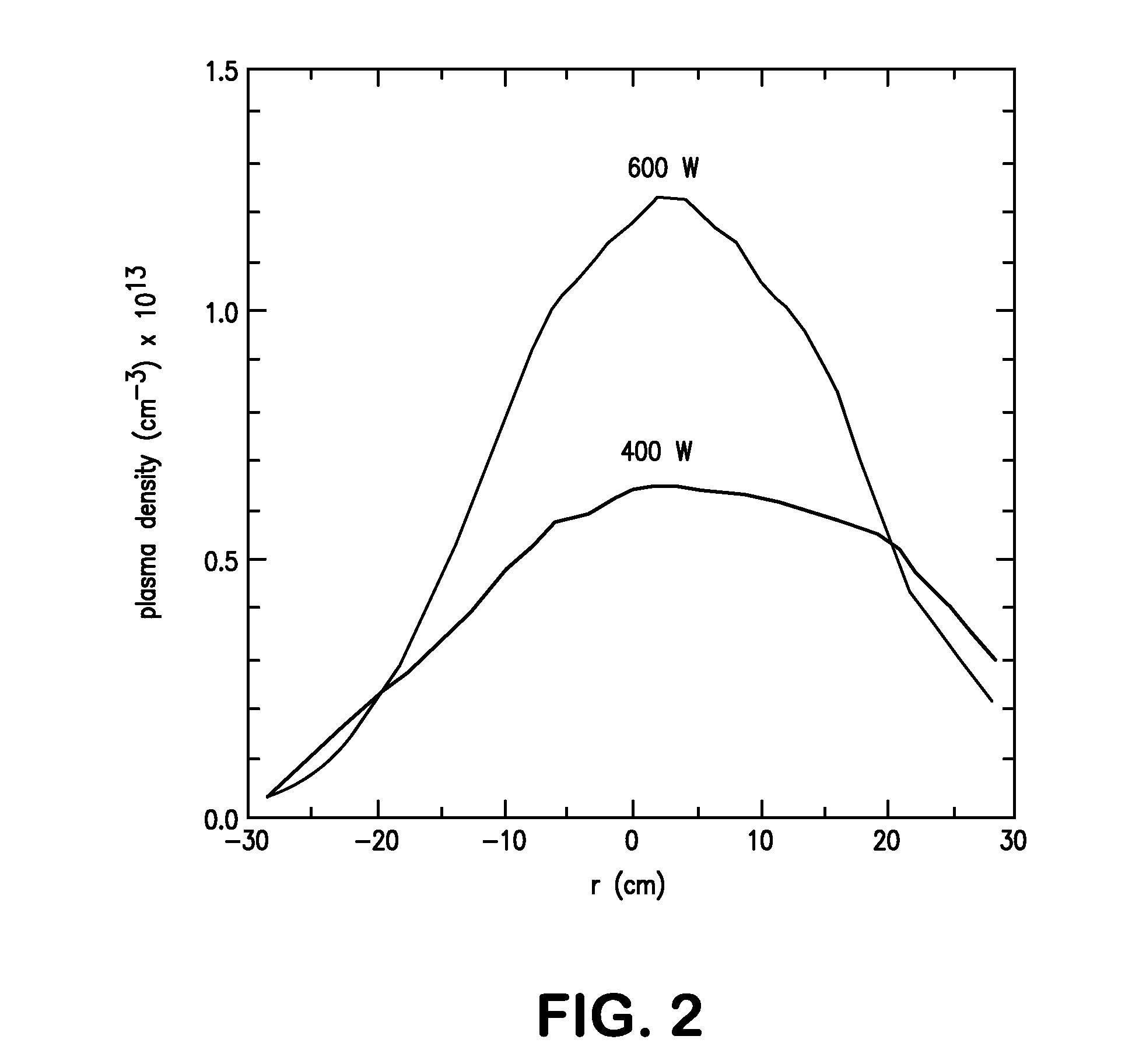

High density helicon plasma source for wide ribbon ion beam generation

ActiveUS20100055345A1Improve uniformityElectric arc lampsSemiconductor/solid-state device manufacturingHigh densityDielectric cylinder

An ion source, capable of generating high density wide ribbon ion beam, utilizing one or more helicon plasma sources is disclosed. In addition to the helicon plasma source(s), the ion source also includes a diffusion chamber. The diffusion chamber has an extraction aperture oriented along the same axis as the dielectric cylinder of the helicon plasma source. In one embodiment, dual helicon plasma sources, located on opposing ends of the diffusion chamber are used to create a more uniform extracted ion beam. In a further embodiment, a multicusp magnetic field is used to further improve the uniformity of the extracted ion beam.

Owner:VARIAN SEMICON EQUIP ASSOC INC

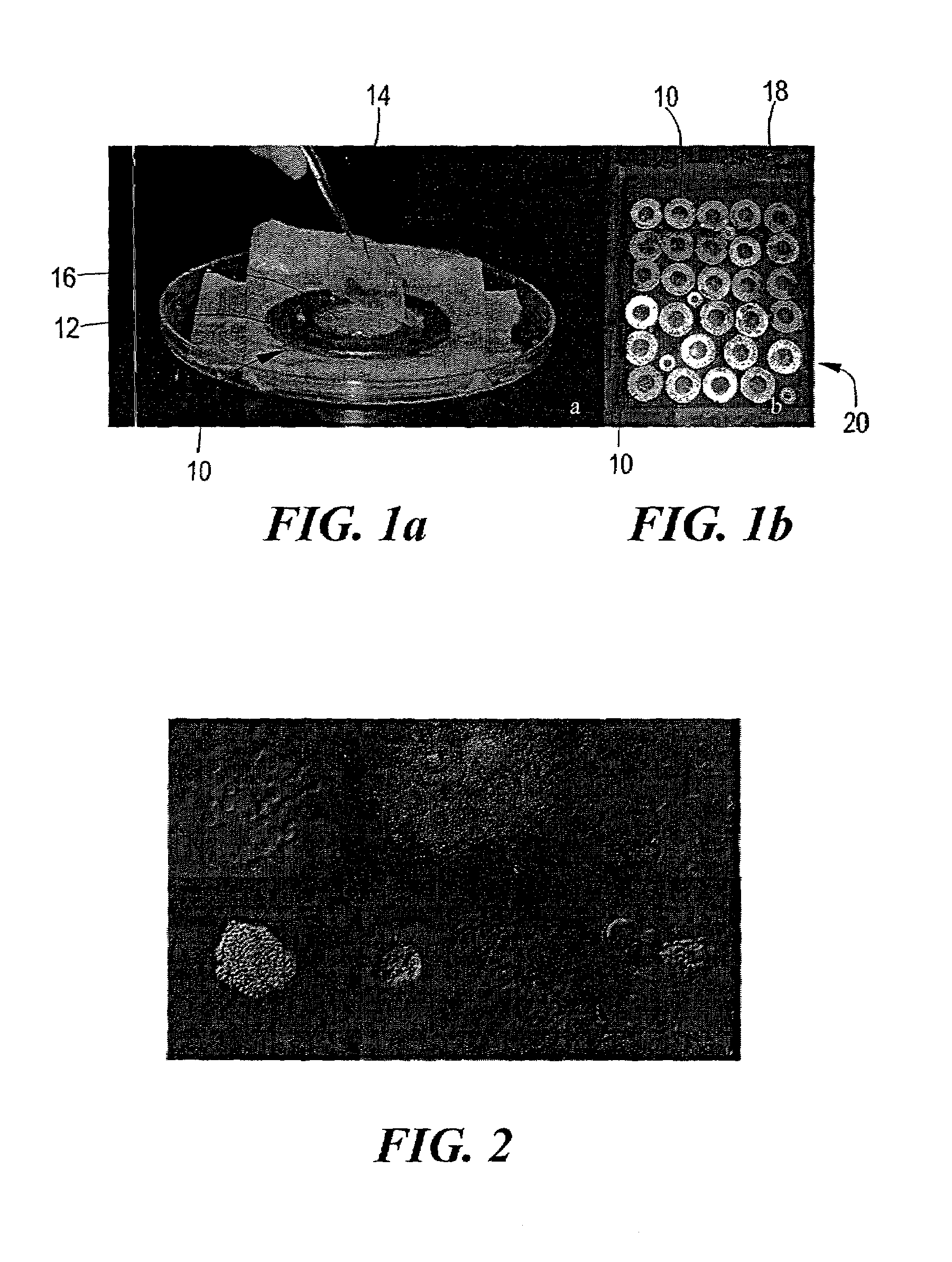

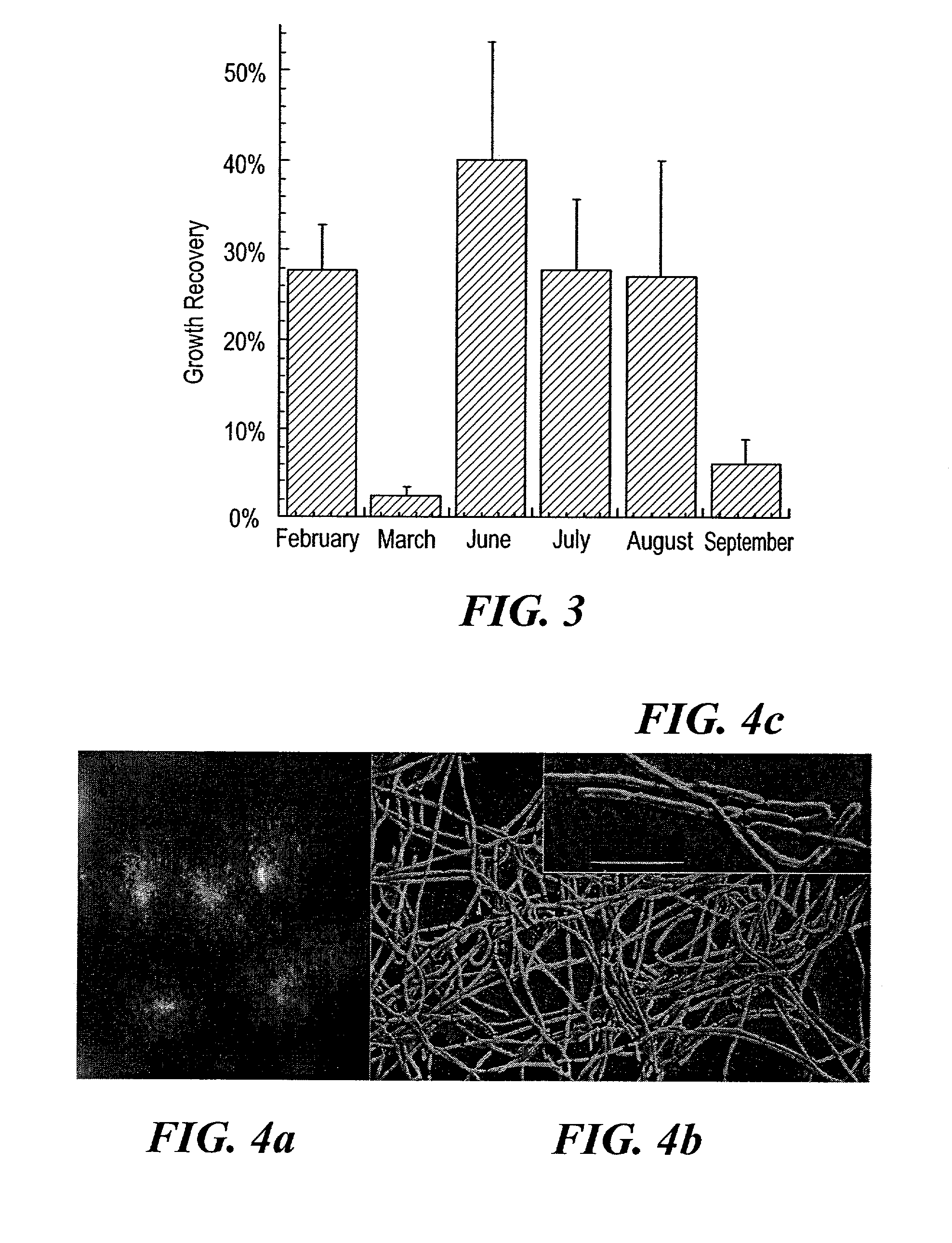

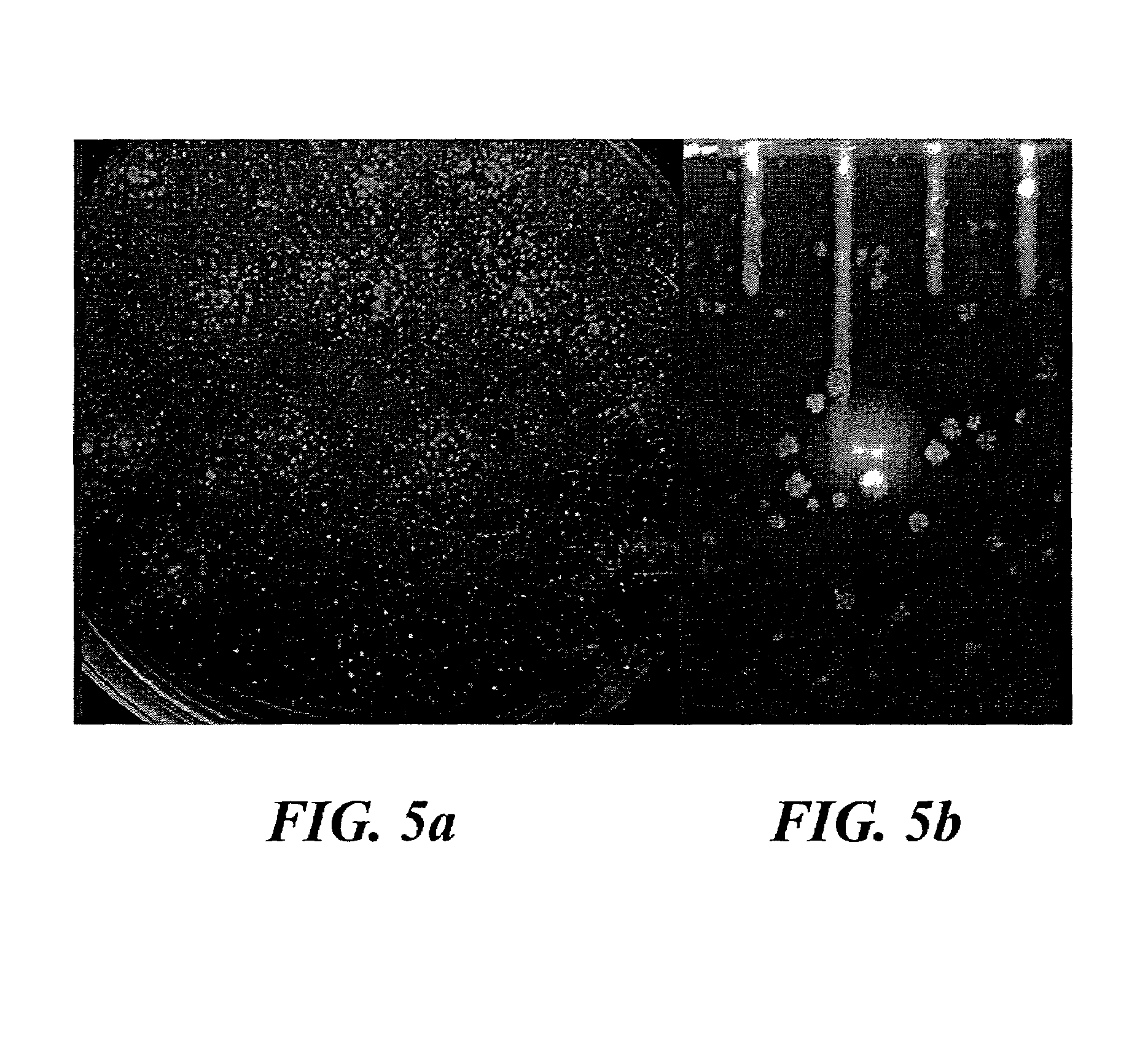

Isolation and cultivation of microorganisms from natural environments and drug discovery based thereon

InactiveUS7011957B2Simple wayCompound screeningBioreactor/fermenter combinationsMicroorganismMicrobiology

The method of the invention is directed to the novel use of a diffusion chamber within which previously “uncultivatible” microorganisms can be isolated. Rather than attempting to replicate the natural environment of an unknown microorganism, the method of the invention provides for exposing dividing microorganisms to all the components of the original environment while simultaneously containing the resulting colonies so that they can be isolated. The method of the invention can take advantage of the recognition that the preponderance of difficult-to-grow microorganisms do not form colonies visible to the naked eye. Therefore, these organisms must be isolated under a compound microscope as “microcolonies.” In addition, methods according to the invention permit the isolation of novel microorganisms capable of growing in artificial media only in co-culture in the presence of a companion microorganism.

Owner:NORTHEASTERN UNIV

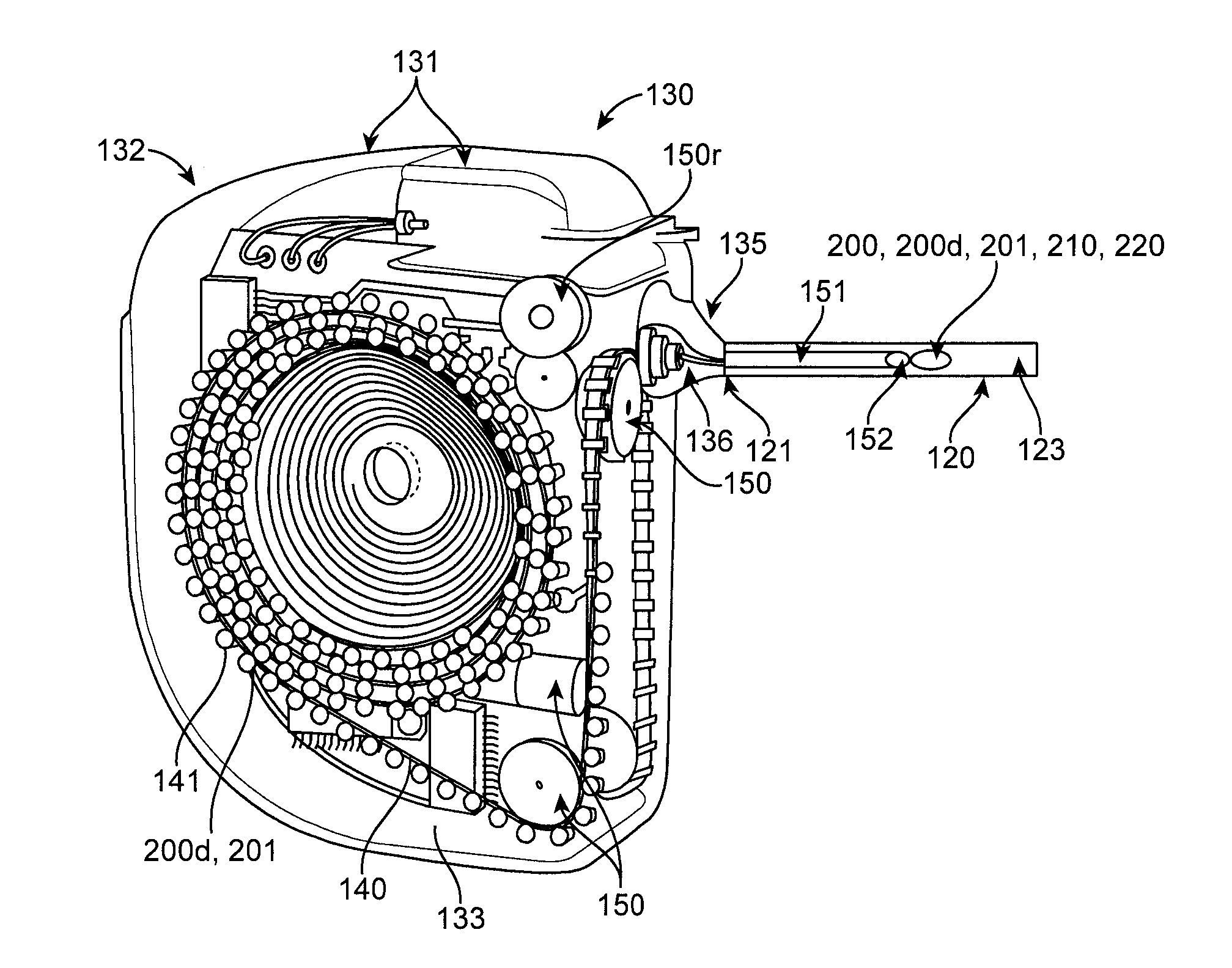

Essential oil atomiser

Owner:AIR AROMA RES

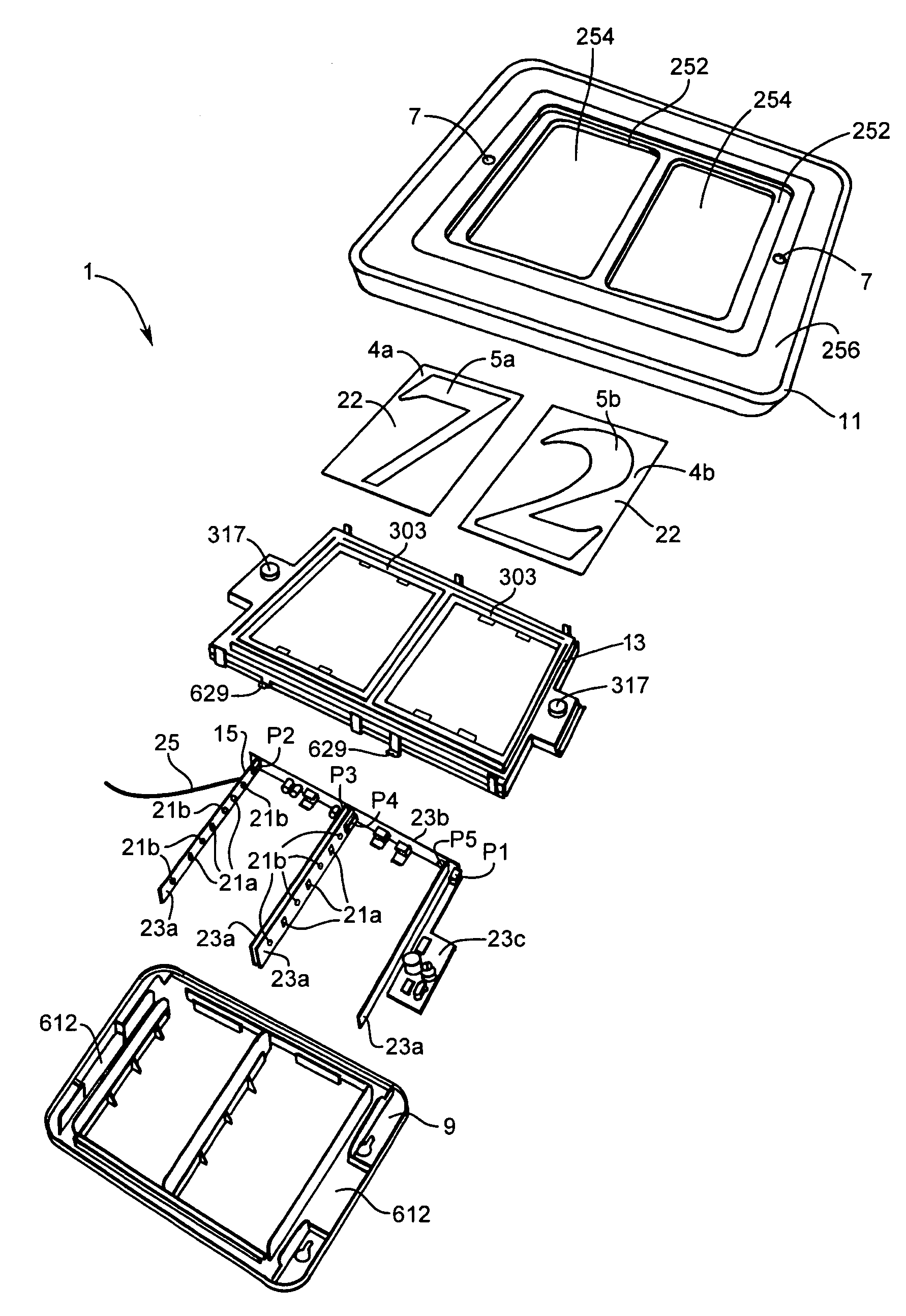

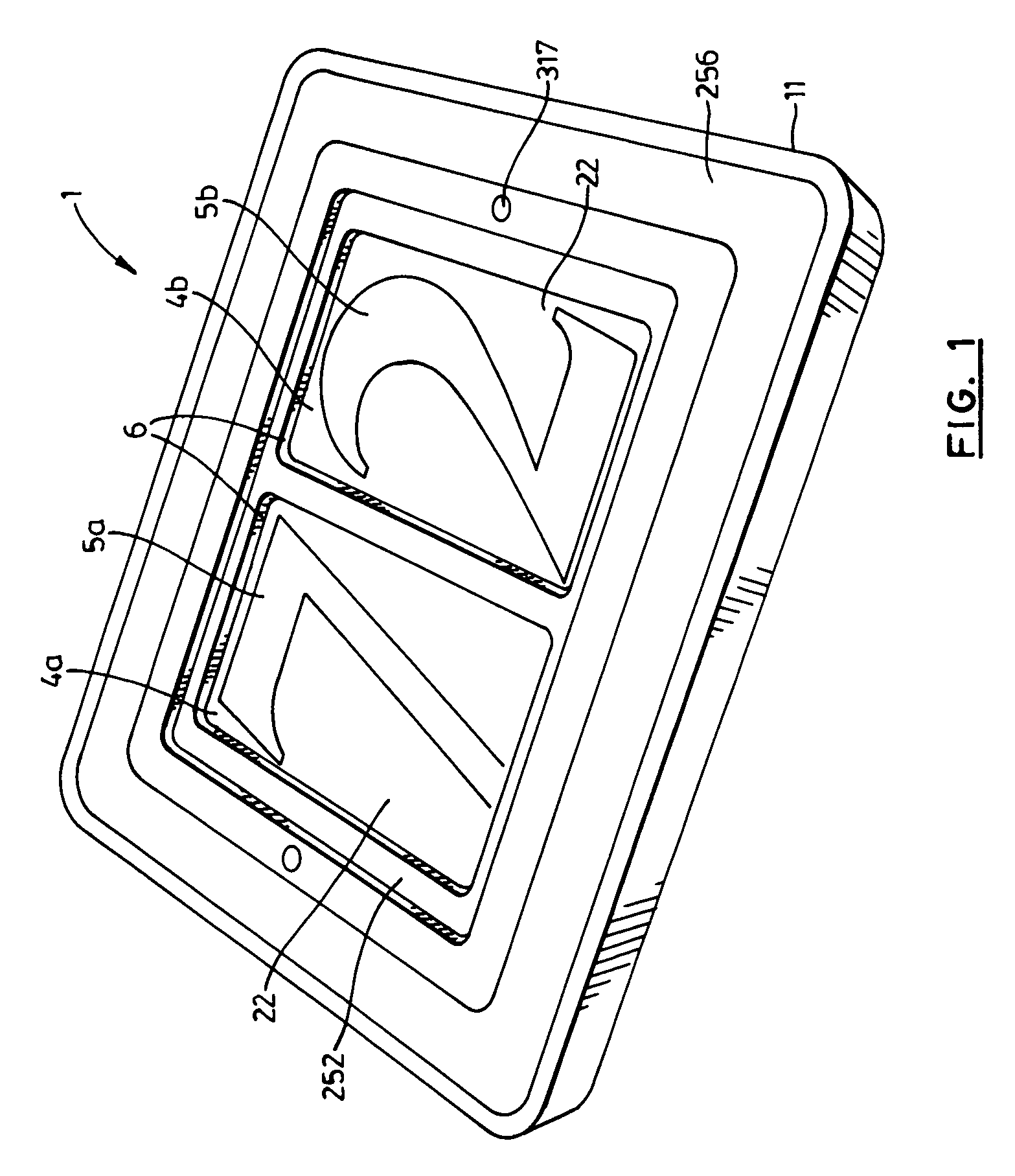

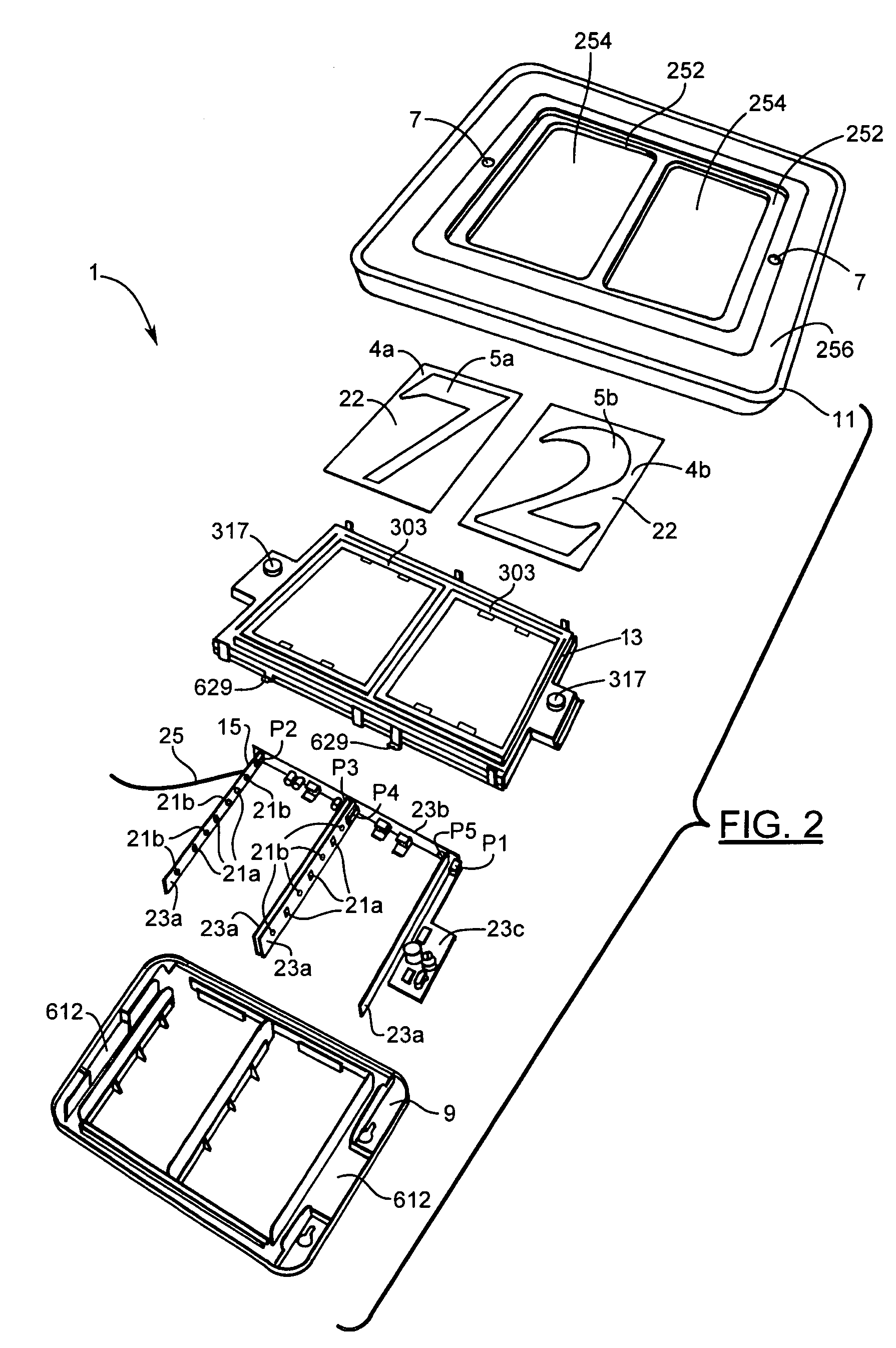

Address and/or alarm indicator sign

InactiveUS7012544B2Static indicating devicesElectric/electromagnetic visible signallingAlarm messageEngineering

Sign 1 has frame 13 attaching to base 9 and supporting character plates 4. Casing 11 attaches to frame 13 and holds character plates 4 against frame 13. Light assembly 15 and base 9 backlight character plates 4. Backlight is diffusion chamber 17 sidelit by light assembly 15. Casing 11 hides access to the mount and is not easily removable. Light assembly 15 is externally powered and is activated by external messages and by low ambient light. An Emergency Alarm message causes flashing in one colour and intermittent activation of sound. For non-emergency, alternate light mode is used with constant sound. Transmitter 1501 transmits messages for the sign 1. The transmitter 1501 learns emergency telephone numbers for dial detection on a telephone line, in addition to standard emergency telephone number. Emergency button 1507 can begin transmission of emergency alarm message. Transmitter 1501 may have other alarm inputs.

Owner:CUBE INVESTMENTS

Turbine airfoil with floating wall mechanism and multi-metering diffusion technique

InactiveUS20070280832A1Shorten speedIncrease the cross-sectional areaEngine fuctionsBlade accessoriesTurbineCooling fluid

A turbine airfoil usable in a turbine engine and having at least one cooling system. The turbine airfoil may include an interlayer coupled to an outer surface of the outer wall of the airfoil, wherein the interlayer may be formed from a porous material that allows cooling fluids to pass through the interlayer. The floating wall may be coupled to an outer surface of the interlayer, wherein the floating wall may be formed from a plurality of floating wall segments positioned in close proximity to each other but with a film cooling slot positioned between the adjacent wall segments to enable cooling fluids to be exhausted from the elongated hollow airfoil. The cooling system may include an outer wall diffusion chamber positioned in the outer wall and an interlayer diffusion chamber. One or more metering holes may be in communication with the outer wall and interlayer diffusion chambers.

Owner:SIEMENS ENERGY INC

Method for fabricating a quantitative integrated diffusion vapor-particle sampler for sampling, detection and quantitation of semi-volatile organic gases, vapors and particulate components

InactiveUS6226852B1Displacement minimizationEliminate artifactsOther chemical processesWithdrawing sample devicesTest sampleOrganic vapor

A method for fabricating a quantitative organic vapor-particle sampler for efficient sampling, detection and quantitation of semi-volatile organic gases, vapors and particulate components. The sampler comprises a diffusion chamber and at least one annular denuder of which surface is coated with a macroreticular resin agglomerates which selectively absorbs organic gases, vapors or particulate matter present in tested samples.

Owner:RGT UNIV OF CALIFORNIA

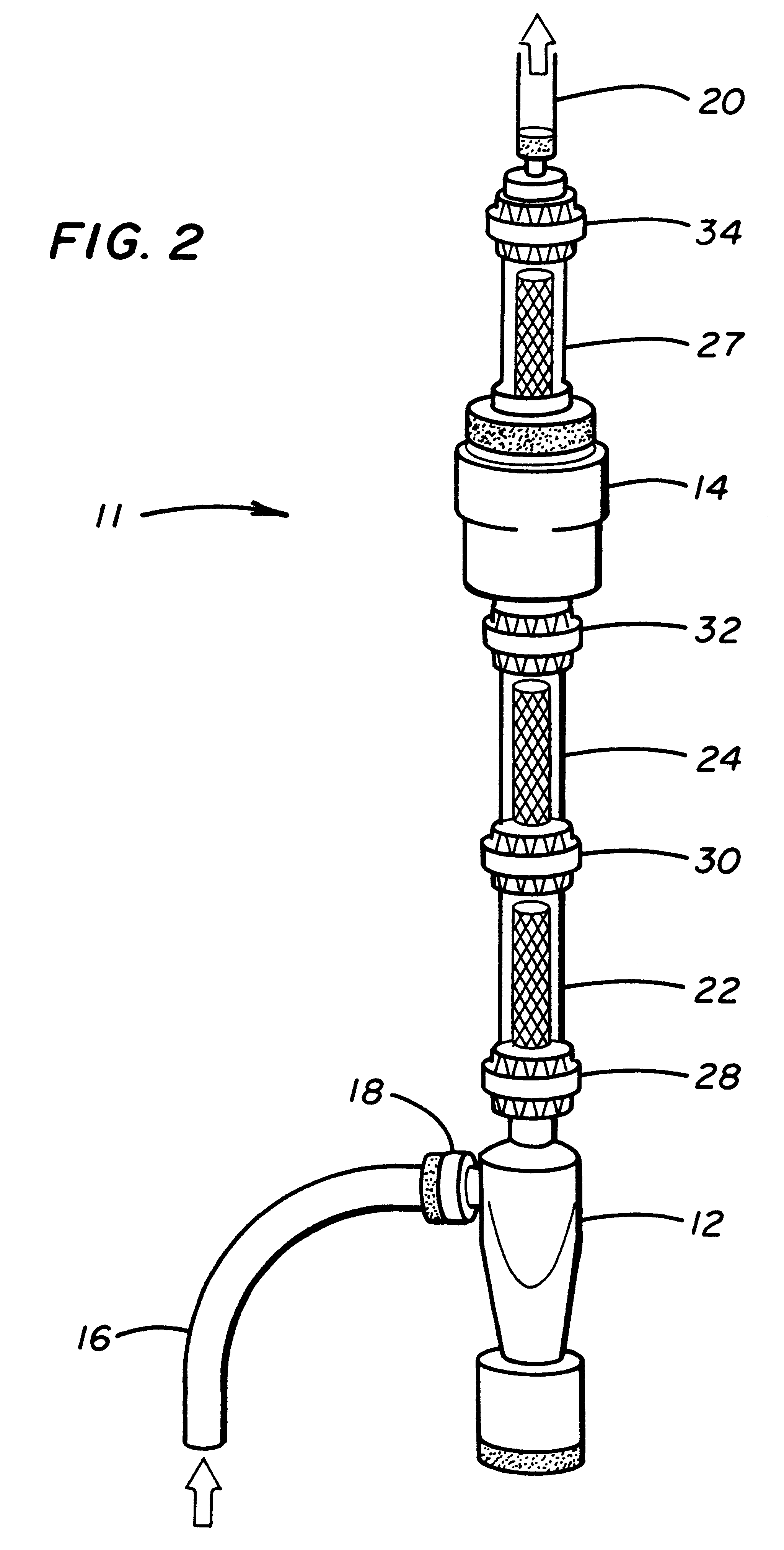

Implantable human kidney replacement unit

An implantable human kidney replacement unit. Fully functional self contained, providing patients with end stage renal disease the freedom of traveling and moving about normally. Replacing donor kidneys. Implanted in the flank with at least one inlet and outlet tube each, sutured to the iliac artery and vain, at least one urine tube to the ureter. The housing constructed of anti-coagulant bacteriostatic materials has a plurality of reverse-osmosis process chambers with semipemeable membranes through the unit, followed by osmosis-diffusion chambers and membranes. Blood from the artery enters the first of the chambers. Small molecules such as water, magnesium, sodium, potassium, calcium, urea etc. are extracted from the blood according to their weight in atomic mass units as blood wipes past the self-cleaning membrane cartridges in the chambers. Molecules are further separated and urea sent to the bladder with excess water and electrolytes. The remainder is channeled to at least one diffusion chamber and reabsorbed into the blood. The same process is repeated in the other chambers where selected larger molecules such as creatinine and phosphorus are excreted, and some diffused back into the blood.

Owner:LUDLOW ROLAND G

Diffusion coefficient and isothermal adsorption/desorption curve test system and method

ActiveCN104897525AImprove responseReduce the impact of diffusionSurface/boundary effectShale gasDiffusion chamber

The invention discloses a test system and method for the diffusion coefficient and isothermal adsorption / desorption curve of shale gas. The test system includes: a core holder, the to-be-tested core contained at the center of which separates two ends into two gas diffusion chambers; a confining pressure component, which is connected to the core holder to load confining pressure to the core to replace the formation pressure; two gas containers loaded with different gases to inflate the gas diffusion chambers at two ends of the core holder respectively; a pressure balancer, which is connected to the core holder to balance the pressure of the two gas diffusion chambers; a constant temperature box, which is used for keeping the temperature of the core holder, the gas containers and the pressure balancer constant; and an acquisition and test component, which is used for collecting the gas at both ends of the core at different time so as to test the diffusion coefficient and collecting the pressure at different time to obtain the isothermal adsorption / desorption data curve. The test system saves the equipment cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

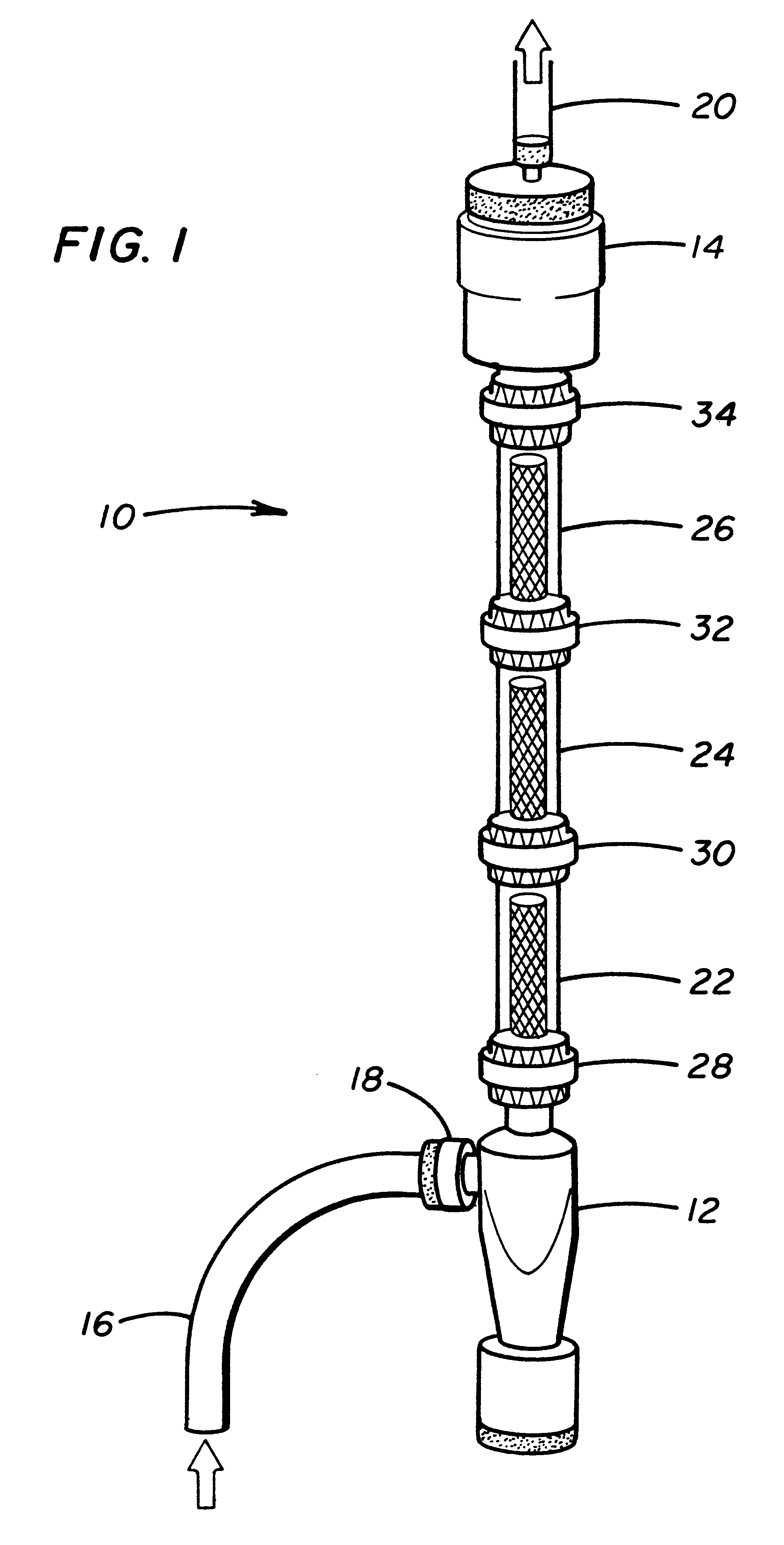

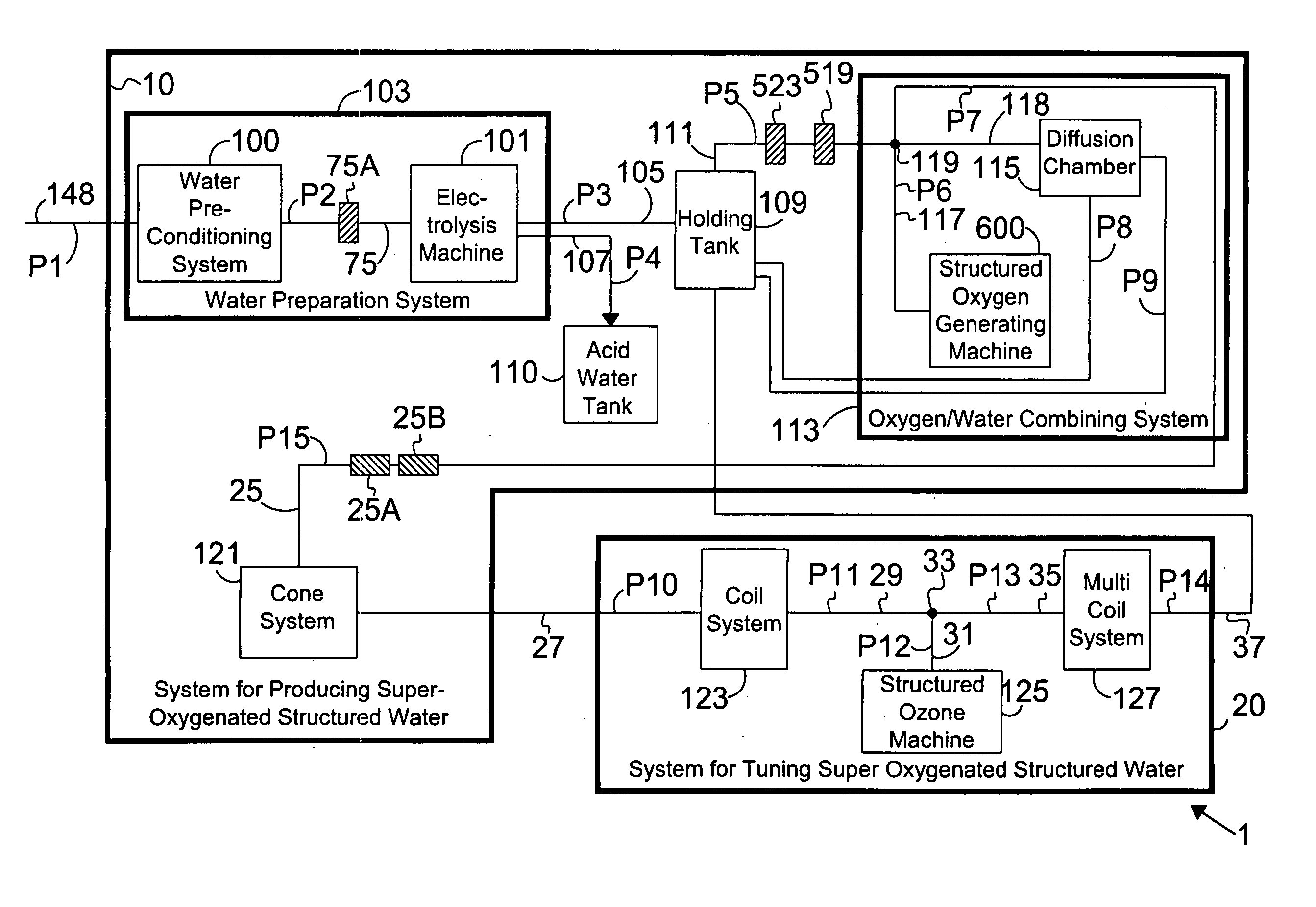

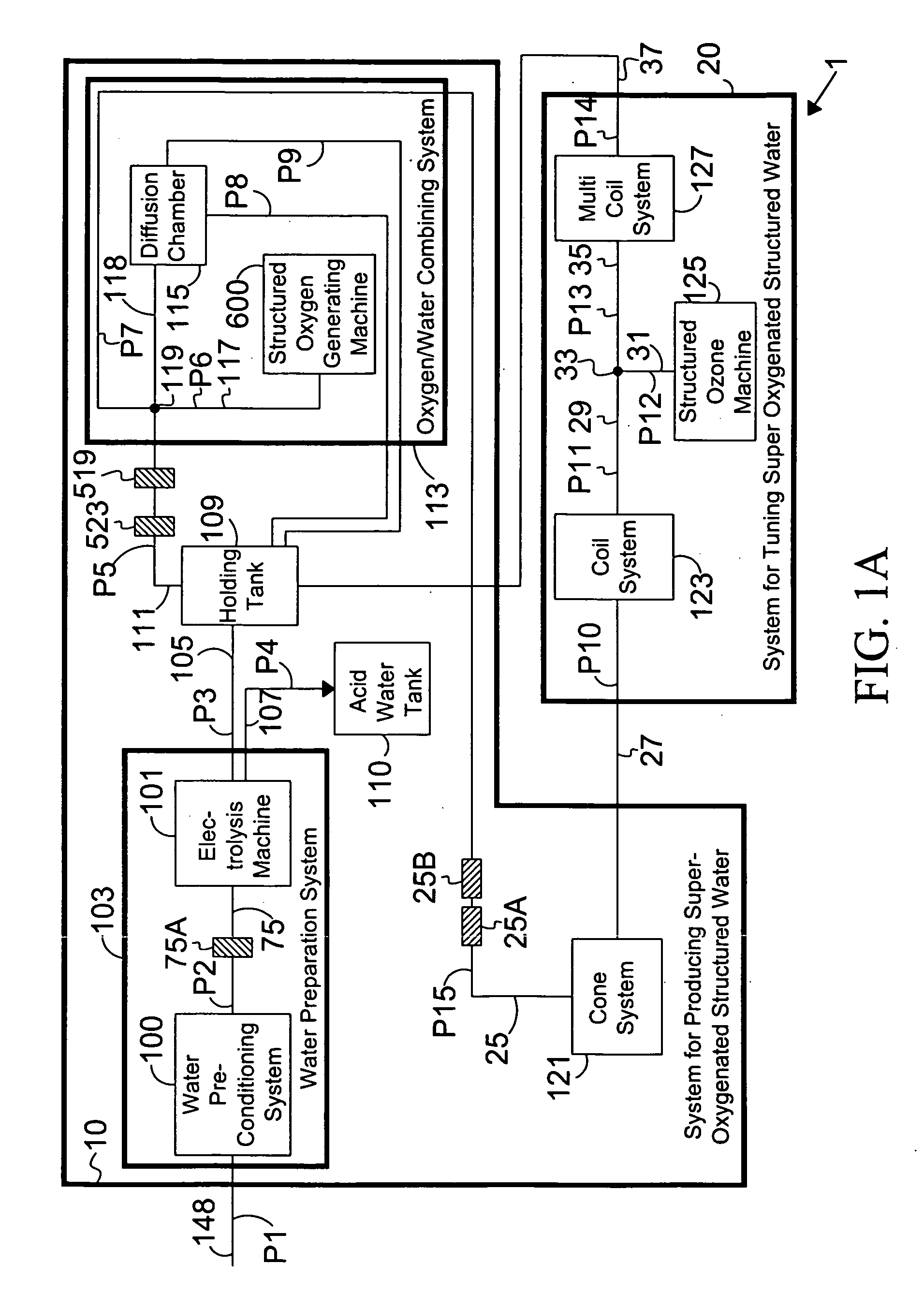

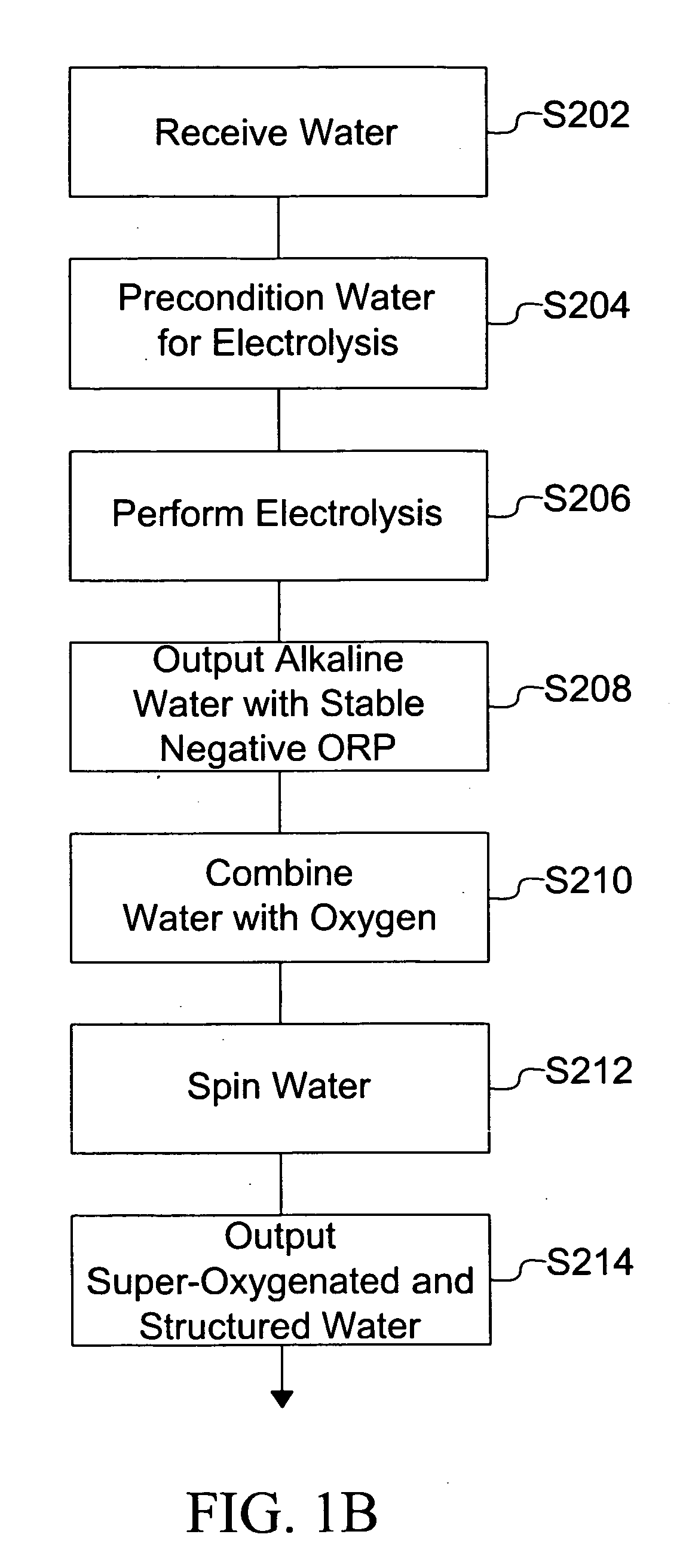

Method for super-oxygenating water

A method for super-oxygenating water is provided. The method includes combining water and first oxygen, manipulating the combined water and first oxygen into a vortex so as to cause the first oxygen to diffuse into the water and yield first oxygenated water, combining the first oxygenated water with second oxygen, and passing the first oxygenated water / second oxygen combination through a cone system that spins the combination to yield super-oxygenated structured water. Water and oxygen are directed through a spray nozzle and manipulated into a vortex as the water and oxygen enter a diffusion chamber. The spray nozzle is sized and oriented such that the vortex generated in the diffusion chamber is adequate to diffuse the oxygen into the water as they travel through the vortex and exit the diffusion chamber.

Owner:BAGLEY DAVID

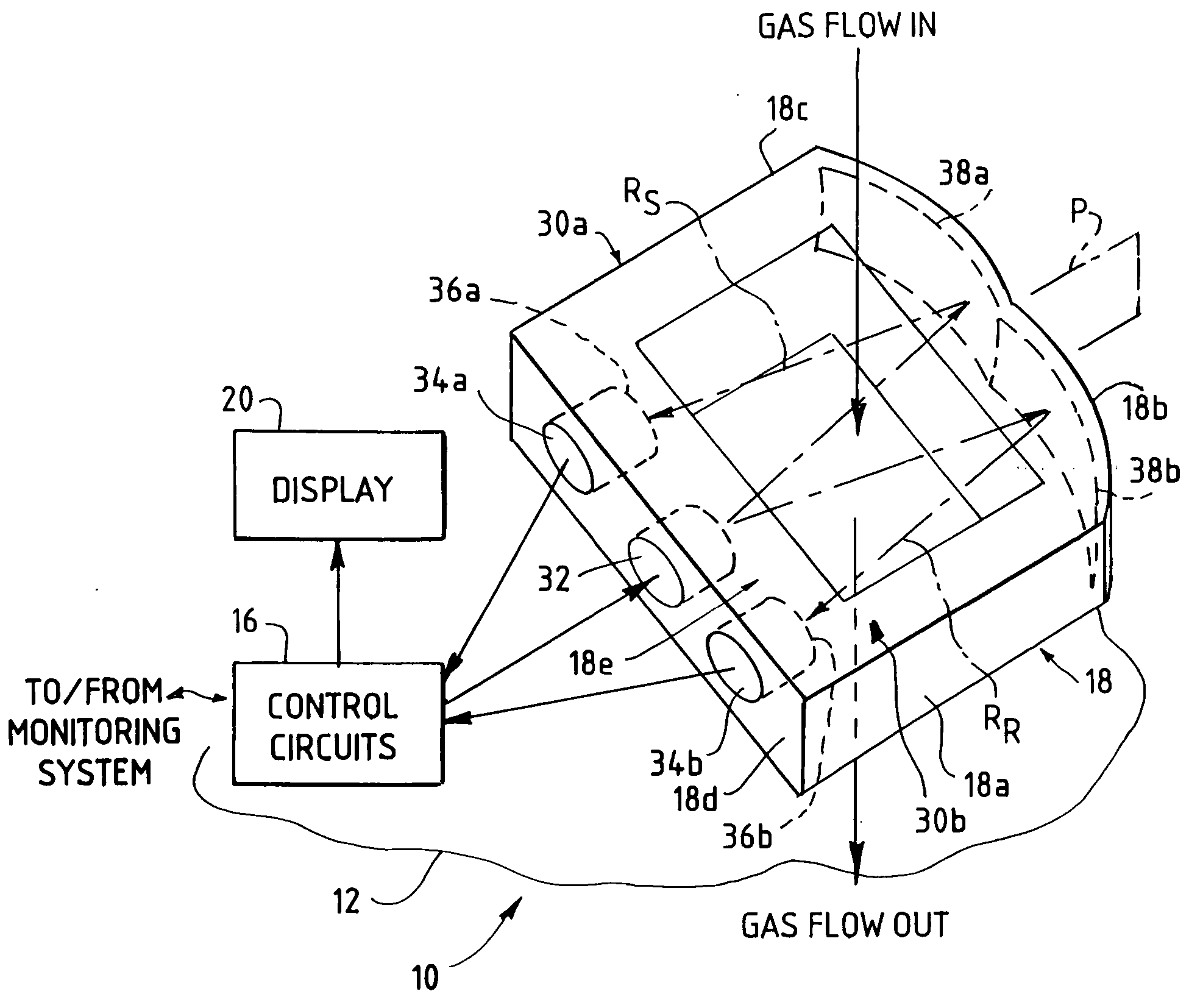

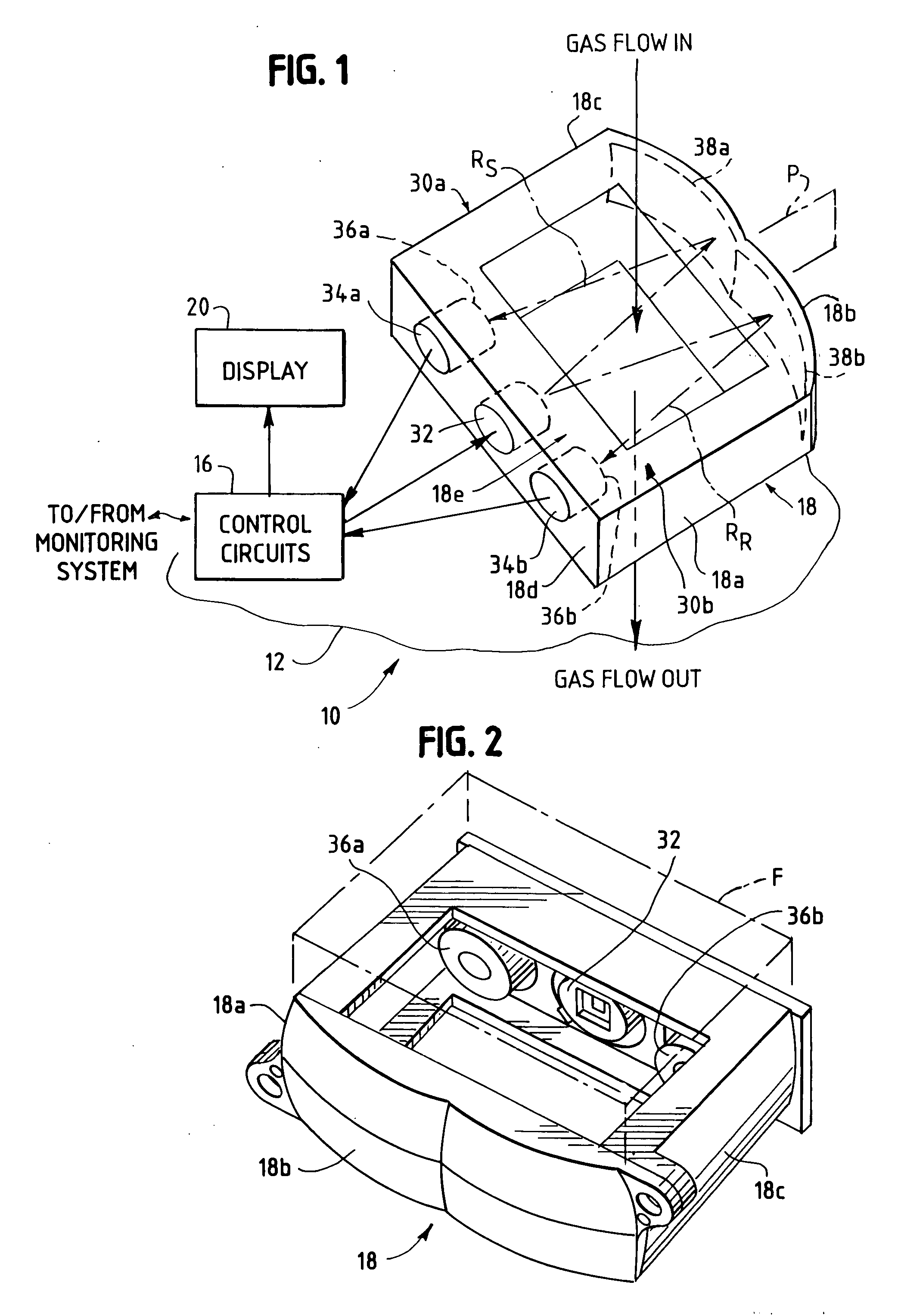

Chamber for gas detector

InactiveUS20050017206A1Affect performanceEqual performanceRadiation pyrometryInvestigating moving fluids/granular solidsPhase detectorGas detector

A gas sensor, which could be a sensor of combustible gases, incorporates a diffusion chamber having symmetrical sensing and reference portions. A common source emits infrared-type radiant energy symmetrically into the two portions. Each portion incorporates a curved reflective surface which reflects incident infrared onto a respective sensor. Each sensor has a filter which passes a different selected band of energy. A fluid, such as gas being sensed, passes laterally through the chamber.

Owner:HONEYWELL INT INC

Shower head and film-forming device using the same

ActiveUS7931749B2Efficient solutionAvoid depositionSemiconductor/solid-state device manufacturingSolid state diffusion coatingEngineeringShower

The present invention relates to a showerhead that supplies a source gas and a supporting gas for depositing a film into a processing vessel of a film deposition apparatus. The showerhead includes a body which is provided with a gas jetting surface (8). In the showerhead body, there are defined a first diffusion chamber (60) that receives the source gas and diffuses the same, and a second diffusion chamber (62) that receives the supporting gas and diffuses the same. The gas jetting surface has source-gas jetting orifices (10A) that are in communication with the first diffusion chamber, and first supporting-gas jetting orifices (10B) that are in communication with the second diffusion chamber. Each of the first supporting-gas jetting orifices (10B) are formed into a ring shape that adjacently surrounds a corresponding one of the source-gas jetting orifices (10A).

Owner:TOKYO ELECTRON LTD

Diesel particulate filter apparatus

InactiveUS6887294B2Increase the diffusion lengthIncrease airflow resistanceCombination devicesAuxillary pretreatmentDiesel particulate filterDiffusion chamber

A DPF apparatus includes: a container; an exhaust inlet pipe; a diesel particulate filter; a pair of perforated plugs; a pair of partition plates; and a diffusion chamber. The exhaust inlet pipe is inserted into the container and having openings formed in a pipe wall thereof. The diesel particulate filter is disposed inside the container. The perforated plugs are separately disposed inside an end portion of the exhaust inlet pipe. The partition plates have one or more openings and disposed on the pipe wall of the exhaust inlet pipe. The diffusion chamber is defined by an inner wall face of the container, the perforated plugs, the partition plates, and the pipe wall of the exhaust inlet pipe.

Owner:CALSONIC KANSEI CORP

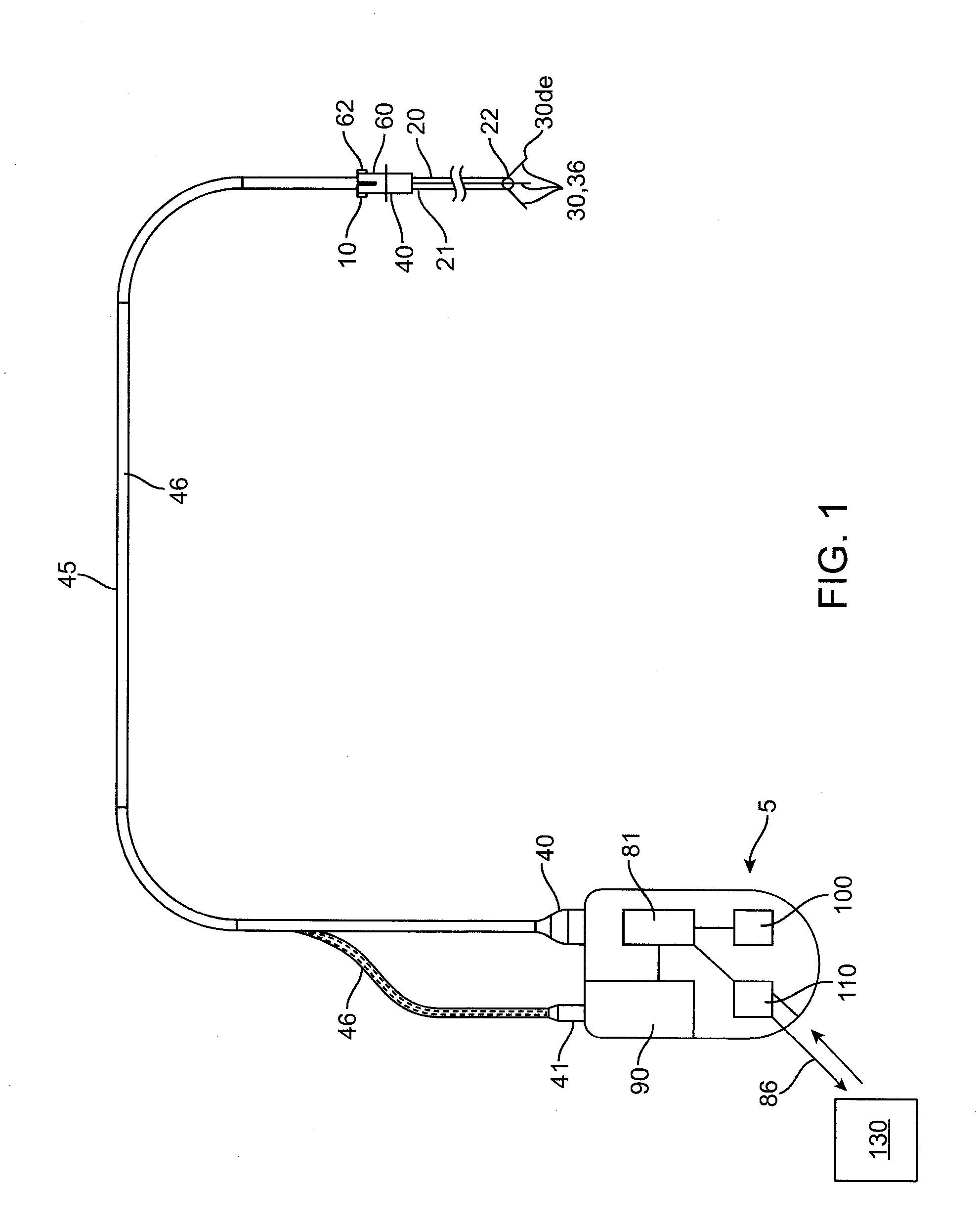

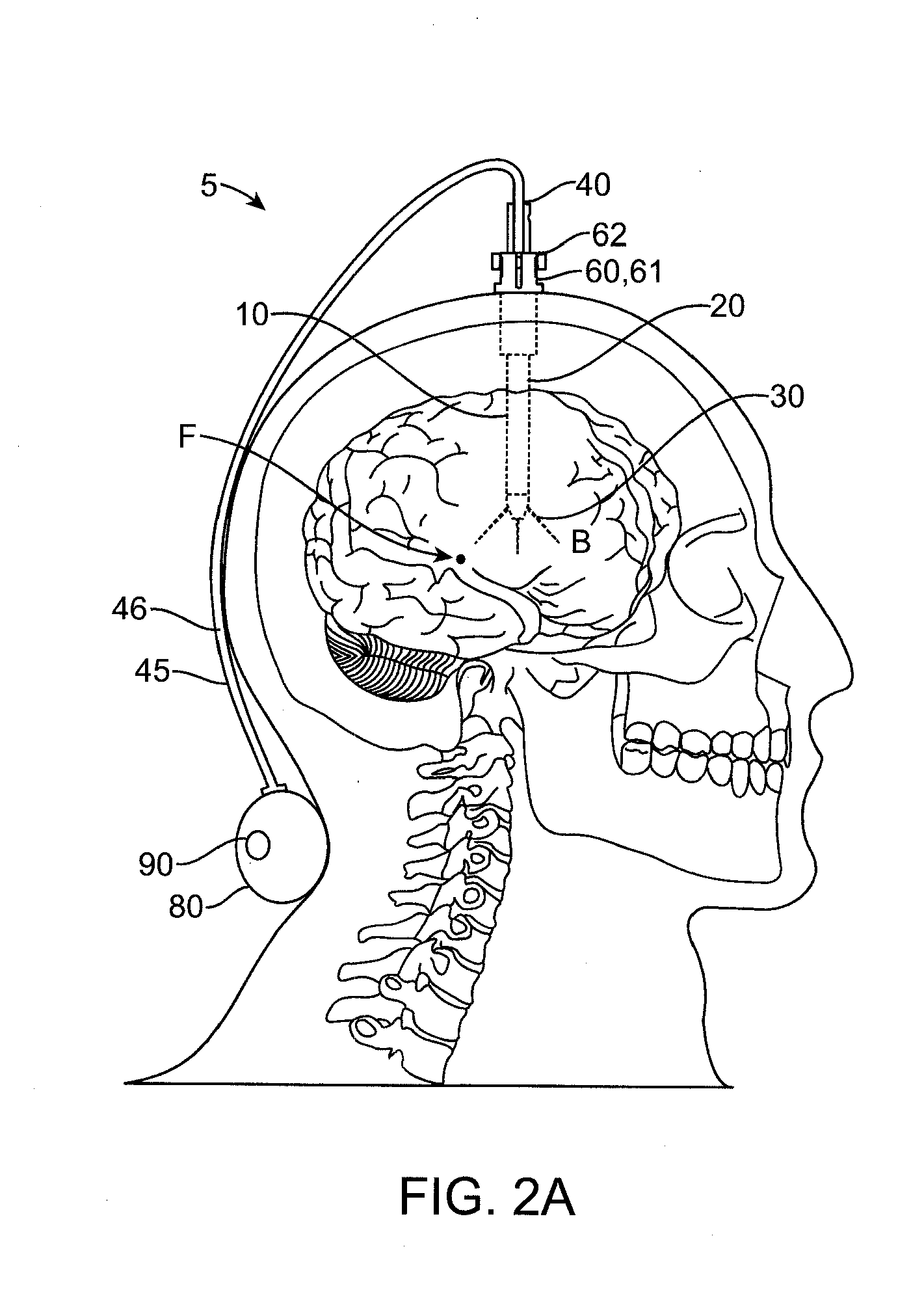

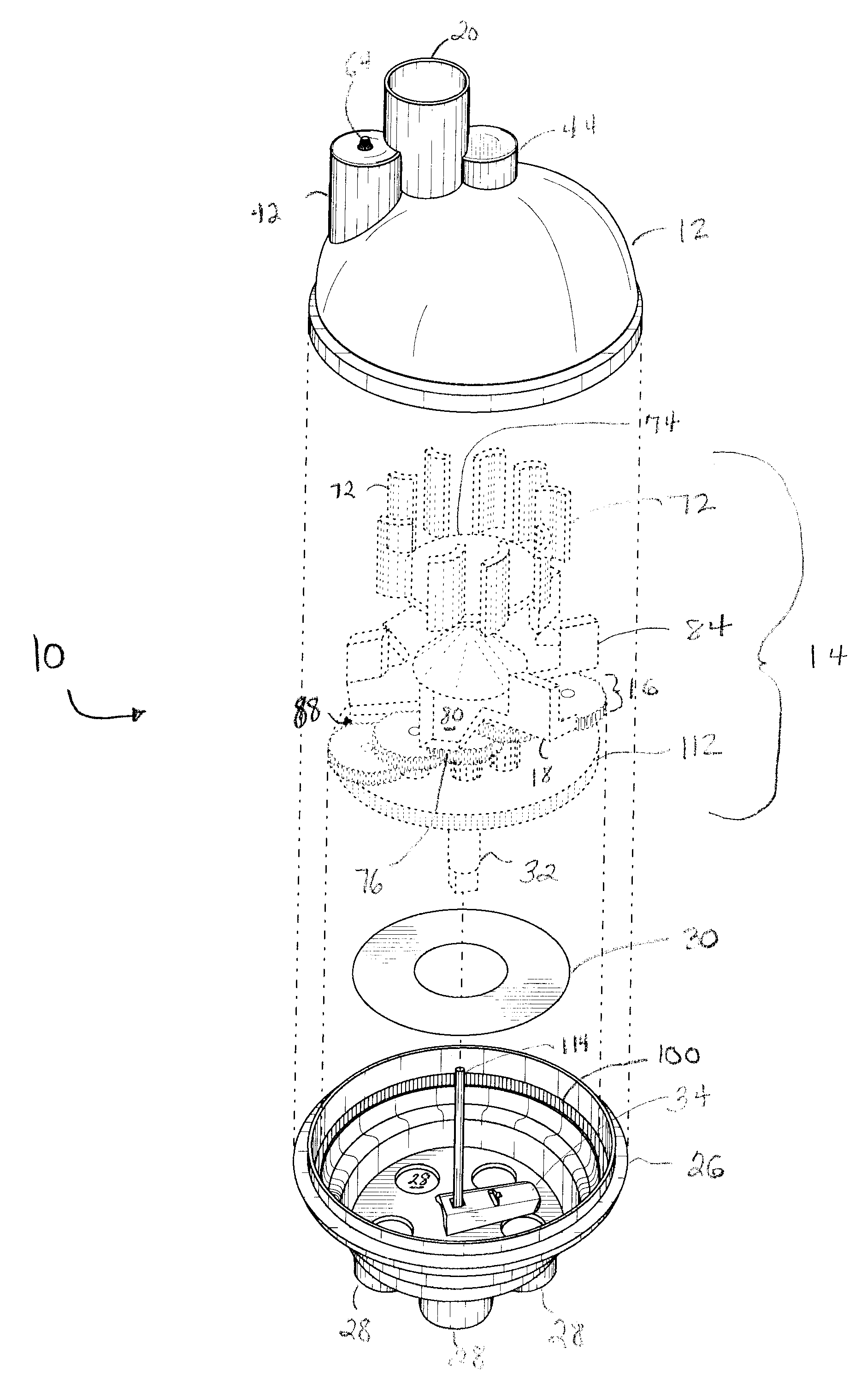

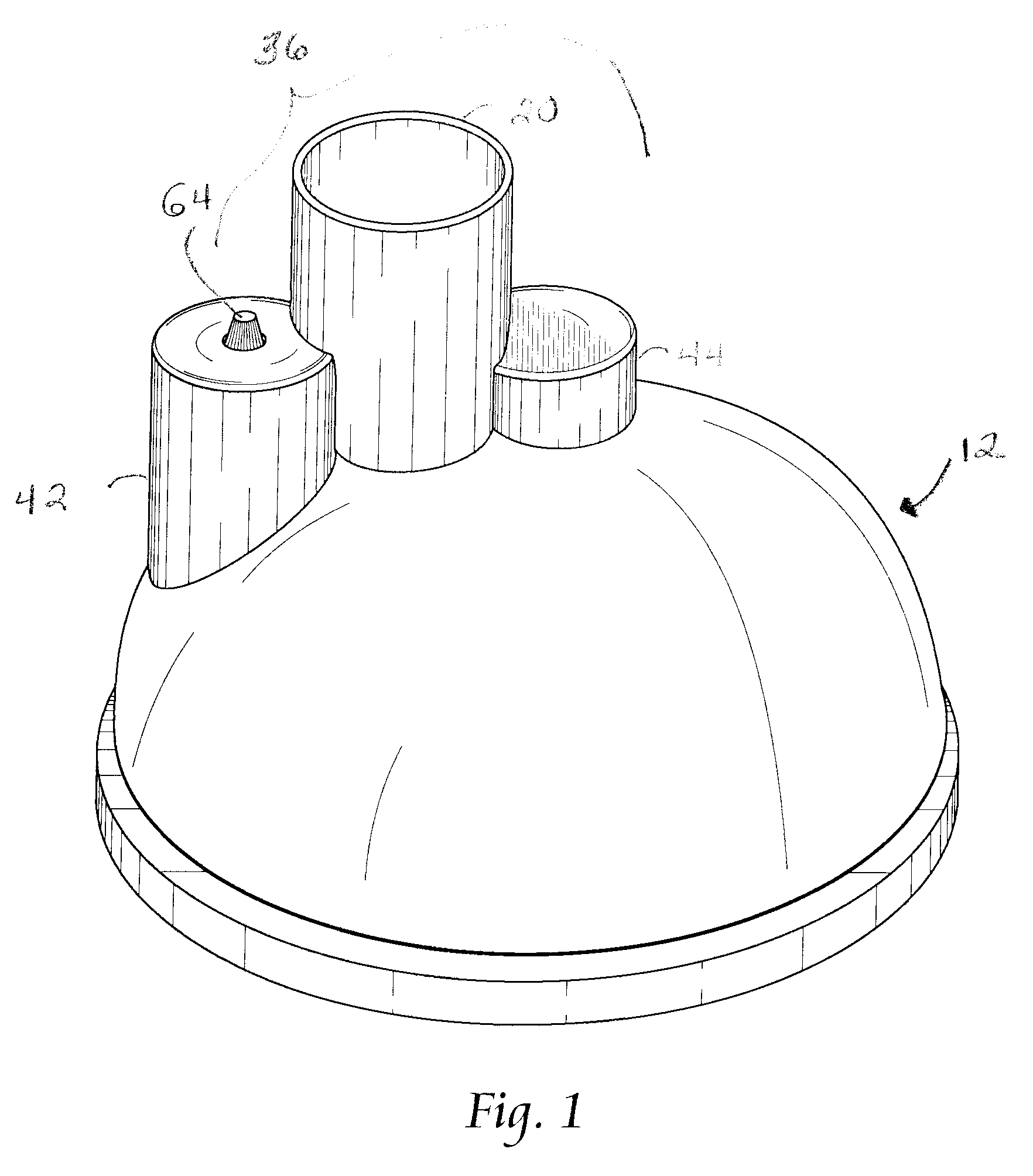

Apparatus, systems and methods for delivery of medication to the brain to treat neurological conditions

ActiveUS20130267928A1Sufficient flexibilityReduce productionElectroencephalographyHead electrodesSystems approachesCerebral ventricle

Various embodiments provide an apparatus, system method for treating neurological conditions by delivering solid form medication to the ventricles or other areas of the brain. Particular embodiments provide an apparatus and method for treating epilepsy and other neurological conditions by delivering solid form medication to ventricles in the brain wherein the medication is contained in a diffusion chamber so as to allow the medication to dissolve in the cerebrospinal fluid of the brain and then diffuse out of the diffusion chamber to be delivered to the ventricles and brain tissue. In one or more embodiments, portions of apparatus have sufficient flexibility to conform to the shape of the ventricles of the brain when advanced into them and / or to not cause deformation of the ventricle sufficient to cause a significant physiologic effect.

Owner:INCUBE LABS

Distribution valve and method

InactiveUS20090211641A1Reduce maintenanceReduce repair costsOperating means/releasing devices for valvesMultiple way valvesImpellerWater flow

An improved distribution valve is provided that distributes water from a swimming pool pump to cleaning heads located along the inner surface of a swimming pool. The distribution valve includes a housing having a fluid inlet and a plurality of fluid outlet ports. The housing includes a lower section and a removable upper section. A gear reduction assembly located in the housing includes a gear reduction mechanism and impeller located near the inlet port and connected to a rotary input shaft of the gear reduction mechanism. A cam device engages a rotary output shaft of the gear reduction mechanism so as to rotate the cam device in response to rotation of the impeller. The cam device rotates under a pliable annular disc on the rotary output shaft and lifts and lowers portions of the annular disc to sequentially open and close fluid paths through the fluid outlet ports.The improved distribution valve may include a bypass chamber with a rotatable drum therein and a diffusion chamber in fluid communication with the fluid inlet. The drum wall includes a cutout. The drum is rotatable to fully or partially align the cutout with a bypass chamber inlet to permit water flow through the bypass chamber to help rotate the impeller. The impeller speed may be controlled by adjusting the water flow through the bypass chamber. The more water flow, the faster the impeller rotates. The drum is also rotatable to block the bypass chamber inlet to prevent water flow through the bypass chamber, in which case water from the diffusion chamber rotates the impeller. Impeller rotation will be at a slower speed due to the decreased water flow.

Owner:TIPOTSCH DONALD

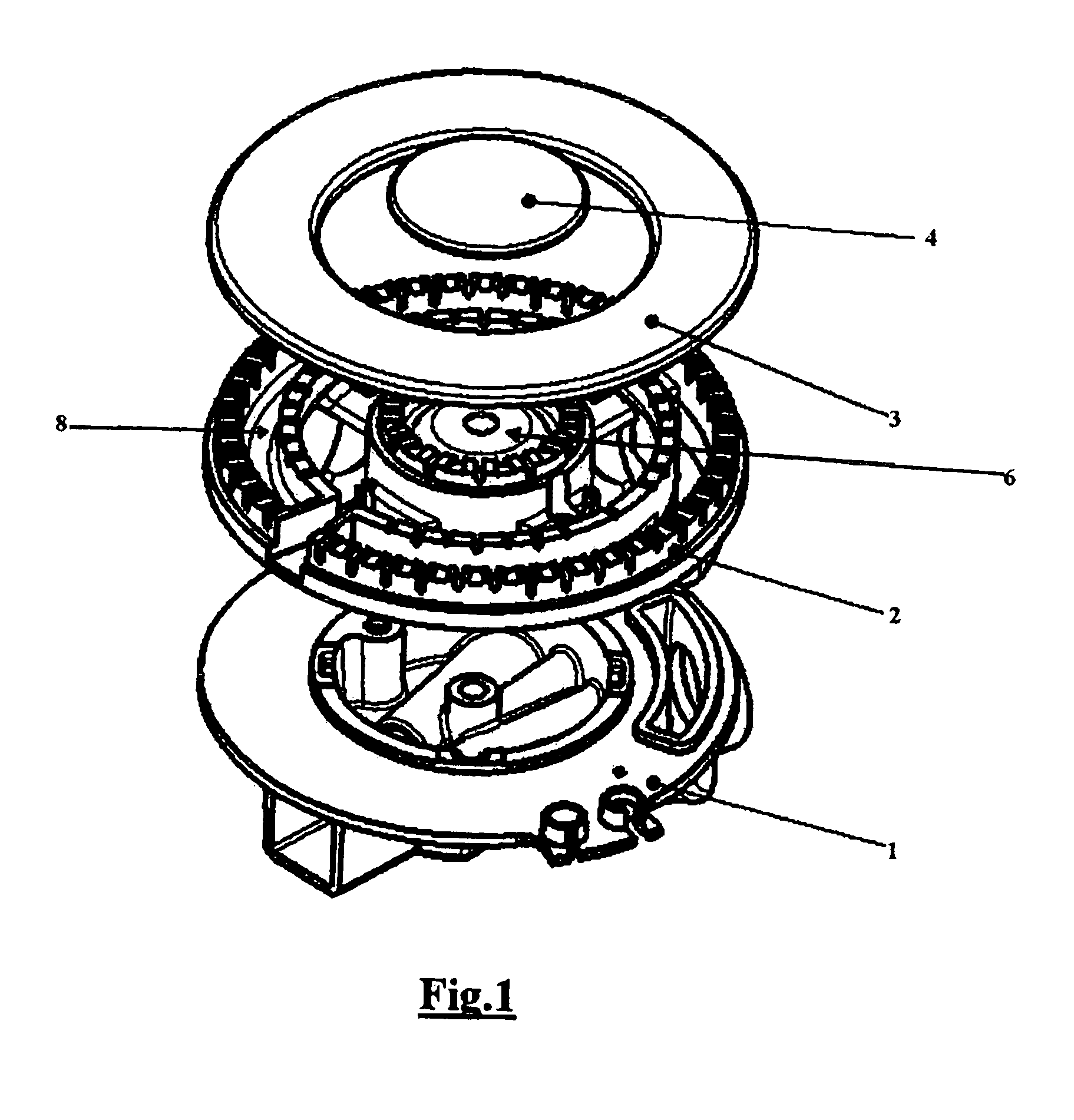

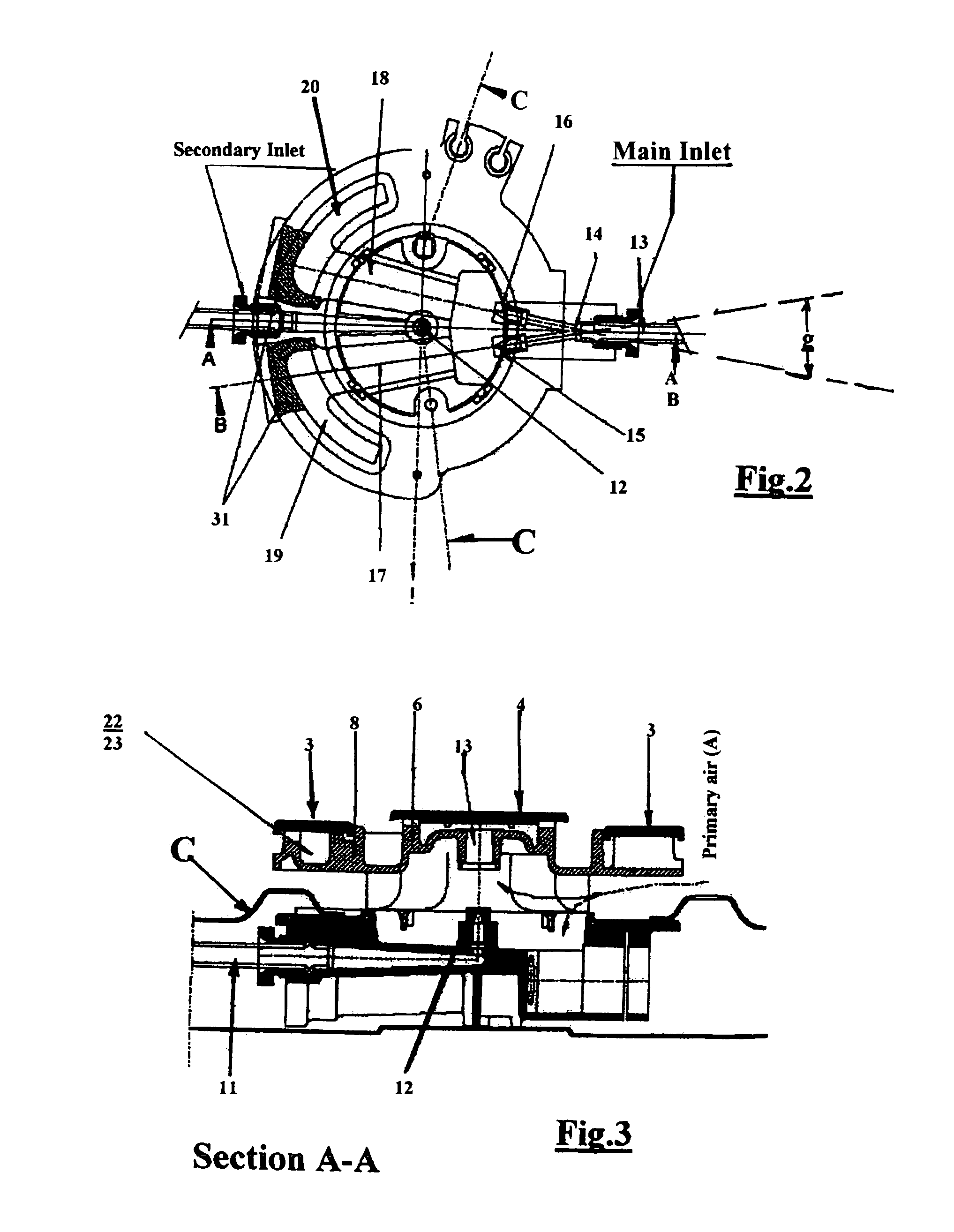

Gas burner

ActiveUS8221116B2Increase thermal powerDomestic stoves or rangesElectric spark ignitersGas syringeEngineering

Gas burner provided with a plurality of concentric flame crowns, and comprising a first central burner to supply a peripheral flame ring, a second annular burner surrounding the central burner at a defined distance and able of supplying at least a respective peripheral ring, a burner body apt to be mounted on the surface of a cooking hob, a first gas inlet in communication with the body, a first vertical gas injector, the central burner being provided with a first chamber for the diffusion of the air / gas mixture, a second gas inlet in communication with the body, wherein the second annular burner is provided with two separate chambers for the diffusion of the mixture, wherein the second gas inlet is in communication with the two separate chambers through suitable injection and conveying means, which comprise two distinct injectors in communication with the second gas inlet, and two respective horizontal Venturi pipes each of which being able of supplying with the air / gas mixture a respective of the two diffusion chambers; these are physically separate and not in communication to each other. The two horizontal and separate injectors are placed on the same end position of the second gas inlet.

Owner:ELECTROLUX HOME PROD CORP NV

Turbine airfoil with floating wall mechanism and multi-metering diffusion technique

InactiveUS7488156B2Shorten speedIncrease the cross-sectional areaPropellersRotary propellersMesosphereTurbine

Owner:SIEMENS ENERGY INC

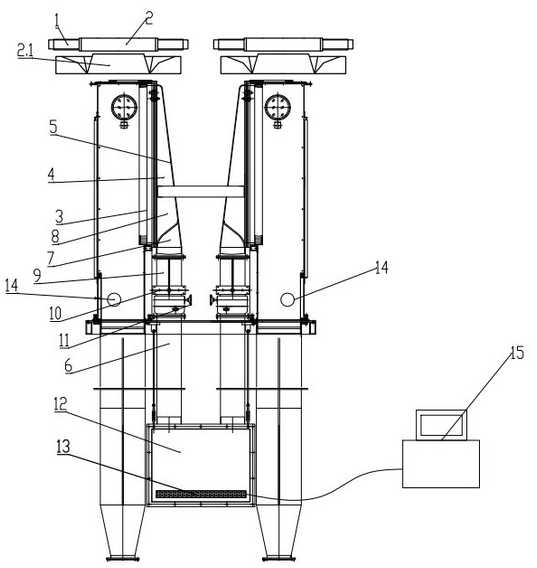

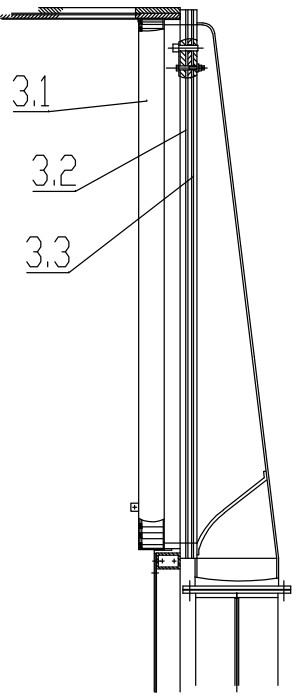

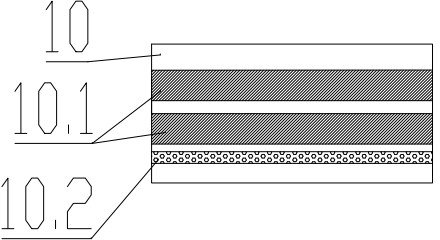

New spinning quenching unit

InactiveCN102199797AUniform wind speedOn-line process adjustmentFilament/thread formingFiberTemperature control

The invention provides a new spinning quenching unit, belonging to the technical field of chemical fiber processing. The quenching unit comprises two cabinet air flow rectifying devices, wherein each cabinet air flow rectifying device comprises a fine filter and an empty cavity; each fine filter comprises a perforated plate, a rectifying honeycomb plate and a protecting net in sequence from inside to outside; the lower ends of the two cabinet air flow rectifying devices are communicated with the empty cavities by blast pipes; deflector diffusion chambers are communicated below the empty cavities; horizontal drawer type coarse filters are arranged at the inlets of the deflector diffusion chambers and multilayer stainless steel screens and nonwovens are used for filtering; a computer is connected with an electric heating plate and air quantity regulating valves in a wired or wireless manner and controls the electric heating plate and the air quantity regulating valves; and the computer adjusted the temperature of the electric heating plate and the sizes of the air quantity regulating valves after processing the data measured by pressure and temperature detection devices. The quenching unit has the following beneficial effects: the speed of the quench air for cooling is uniform; the quenching unit can improve the quality of the formed fibers, is easy to dismantle and clean and has the functions of wind zone temperature control and adjustment of online processing technic of the computer.

Owner:DALIAN SYNTHETIC FIBER RES & DESIGN INST

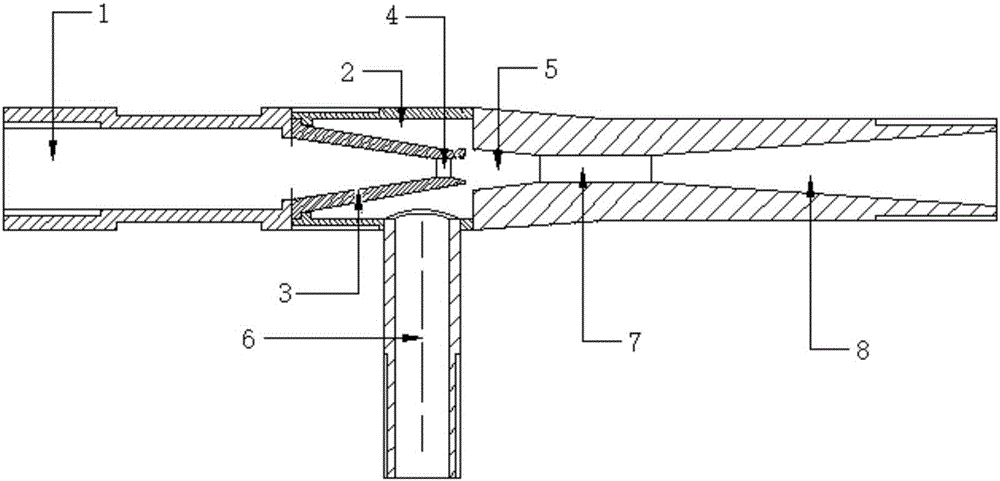

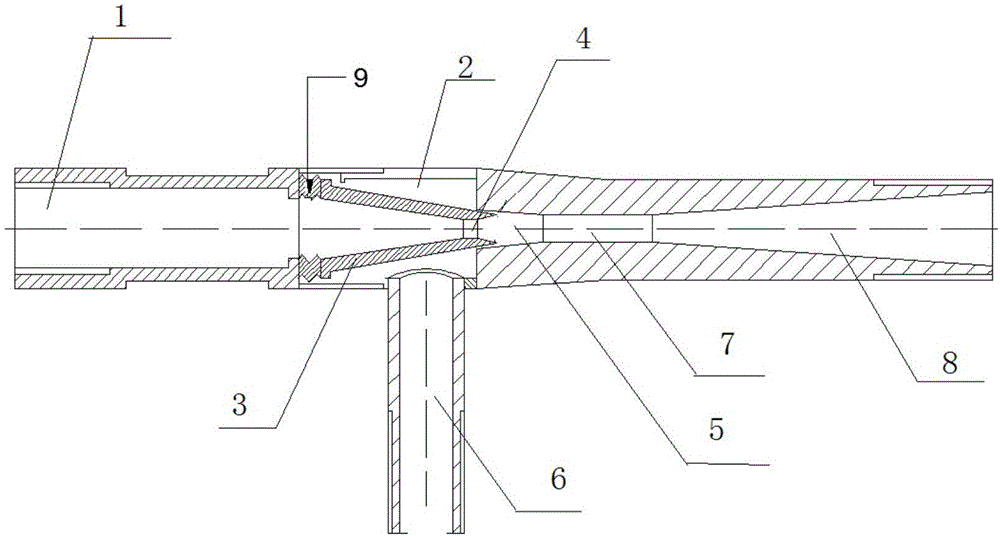

Ejector with spray nozzle position adjustable and device

InactiveCN106423608ATo achieve the purpose of adaptive controlImprove performanceLiquid spraying apparatusSpray nozzleMixing chamber

The invention discloses an ejector with a spray nozzle position adjustable and a device. The ejector with the spray nozzle position adjustable comprises a primary flow tube, a spray nozzle, a receiving chamber, a secondary flow tube, a blending chamber and a diffusion chamber. An expansion device with the length varying along variation of pressure is arranged at the joint of the primary flow tube and the spray nozzle. The primary flow tube, the expansion device, the spray nozzle, the blending chamber and the diffusion chamber are sequentially connected along the axis. The spray nozzle position of the ejector is automatically adjusted simply through variation of the flow rate of primary flow, the performance of the ejector is changed accordingly, and the ejector can have good performance under different working conditions.

Owner:SHANDONG UNIV

Polyporous hollow bone screw

Present invention depicts a poly-porous (micropore) hollow screws as diffusion chamber filled with core matrix for targeted delivery of growth factors and bone marrow stem cells. The screws comprise at least two parts: the distal part of the screw consists of the tip of the screw made of poly porous material and hollow inside proximally. It has threaded navel attached to the threaded nipple of the distal part of the proximal screw which has the screw head and is made of the solid material of the same kind. The screw head had hexagonal recess targeted for screw driver insertion. Assembly of screw created a chamber in the middle of the screw. The chamber is filled with core matrix consisting of gelatin nano-particles pre-impregnated with BMPs (BMP2 / BMP7 for bone or BMP12 for tendon, ligament) and fibrin sealants or Chitosan dispersed with bone marrow stem cells and / or other growth factors. Bioactive protein core material is prepared during the surgery and filled the chamber of the screw by the surgeon. Fibrin sealants or Chitosan will polymerize to form a gel to hold the growth factors and stem cell in place. The screw can be used as the lag screw or other function to provide mechanical fixation in variety of condition. Once the screw implanted in the human body, the fibrin sealant or Chitosin / gelatin nano-particles are gradually degraded and slowly release growth factors and stem cells via micropores of screw to facilitate the bone healing and regeneration. The gelatin nanoparticles and fibril sealant / or Chitosan matrix also serve as the scaffold and platform for bone in-growth to the screw or alternatively, the stem cell inside of screw can regenerate new bone, providing the biological fixation. At the mean time as the bone regenerate and / or in growth, mechanical strength of the screw increased.

Owner:WU YANGGUAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com