New spinning quenching unit

A side blowing and spinning technology, which is applied in the field of chemical fiber processing, can solve the problems of slow speed, affecting fiber quality, end breakage and paralleling, etc., and achieves the effects of uniform wind speed, easy disassembly and cleaning, and improved fiber quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

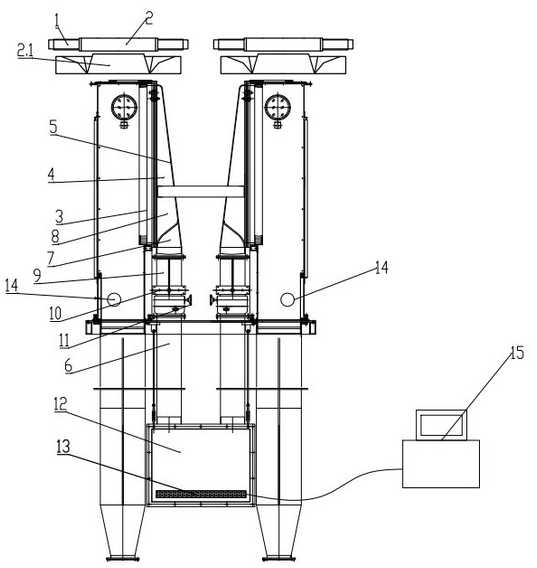

[0010] In order to gain an in-depth understanding of the structure of the new spinning side blowing device, combined with figure 1 , 2 , 3 instructions are as follows:

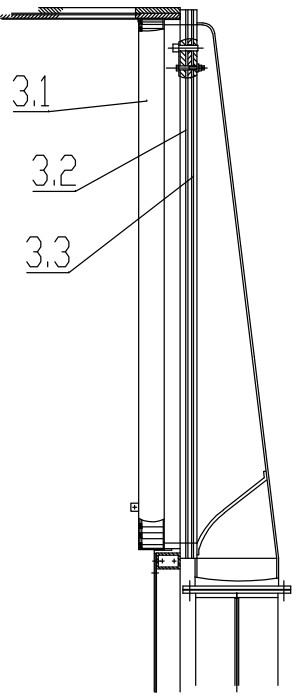

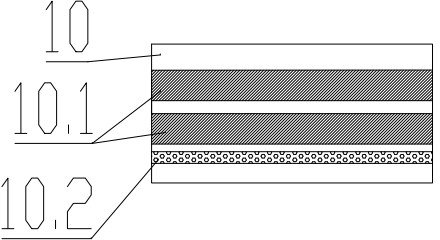

[0011] The new spinning side blowing device includes a spinning box 1, a spinning assembly 2 is arranged on the spinning box 1, and a side blowing device is provided on the side below the spinneret 2.1, and the side blowing device includes two sets of air flow chambers. The rectifying device 5, the silk room wind flow rectifying device 5 includes a fine filter 3 and a hollow body 4, the fine filter 3 is sequentially composed of a porous plate 3.1, a rectifying honeycomb plate 3.2, and a protective net 3.3 from the inside to the outside, and the porous plate 3.1 It is a P-shaped blowing curve, and the lower ends of the two sets of silk chamber air flow rectification devices 5 are connected through the air inlet pipe 6; a pressure and temperature detection device 14 is installed in the spinning channel, and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com