Patents

Literature

171results about How to "Uniform wind speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

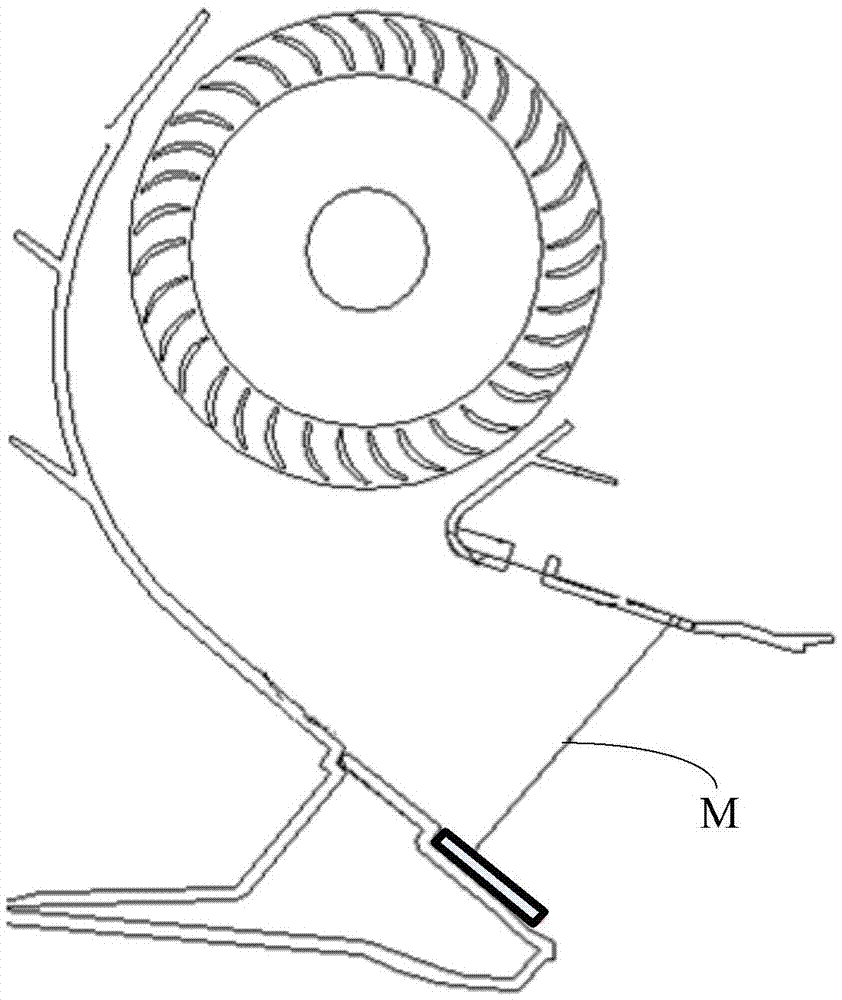

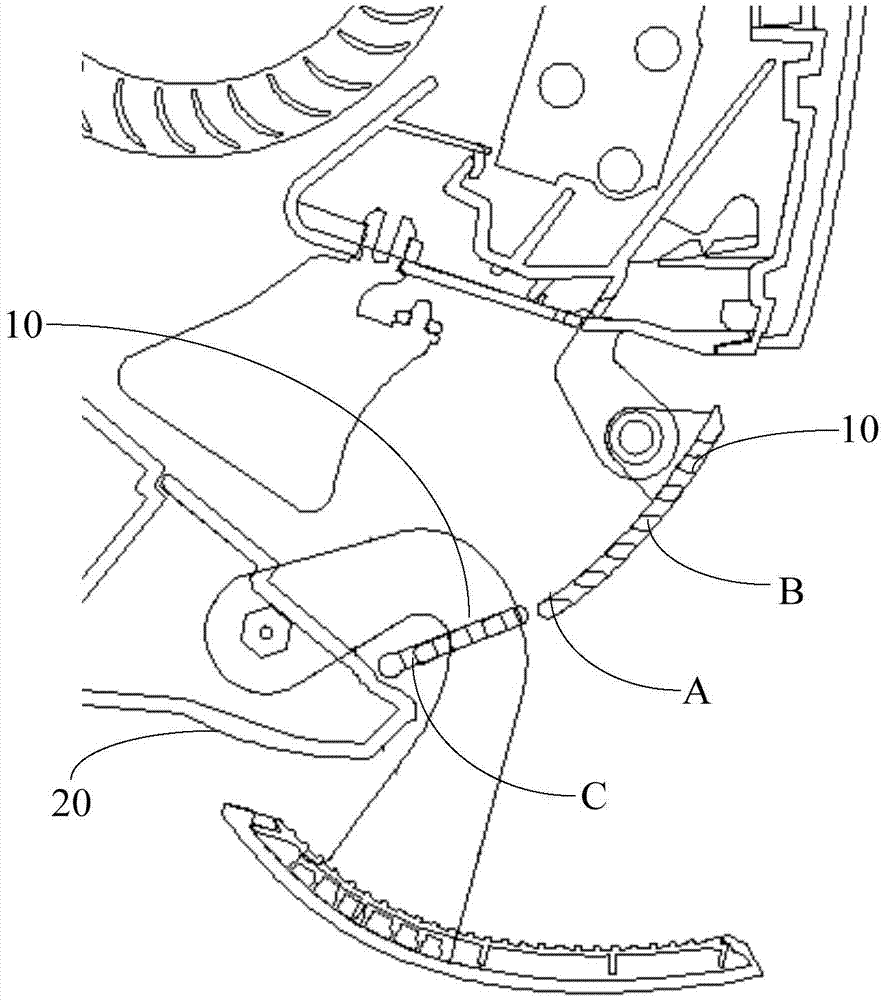

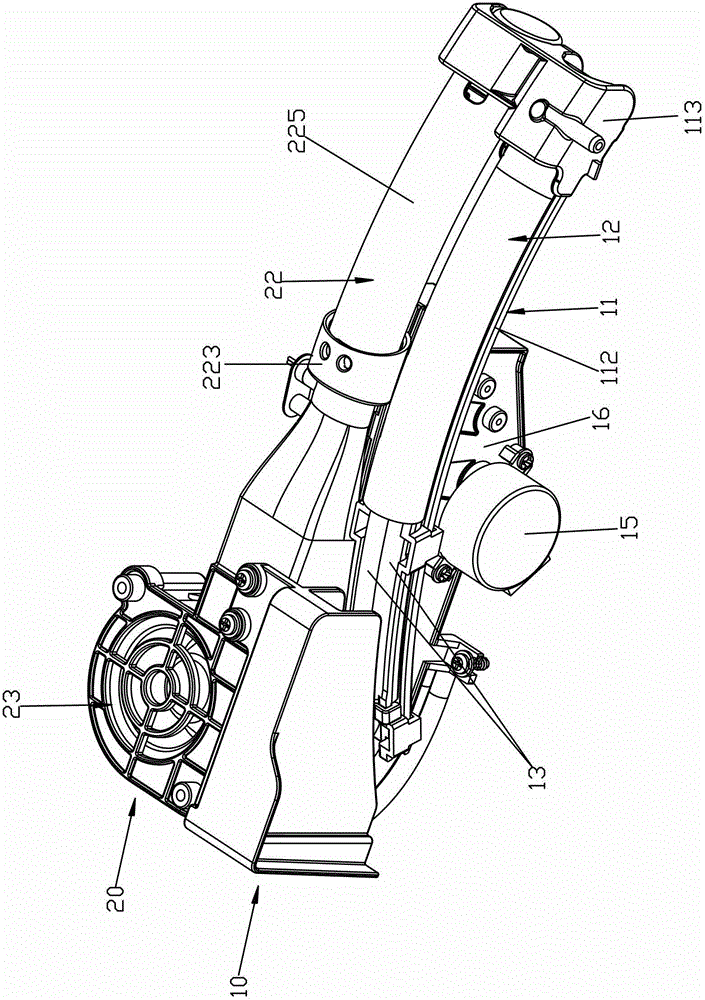

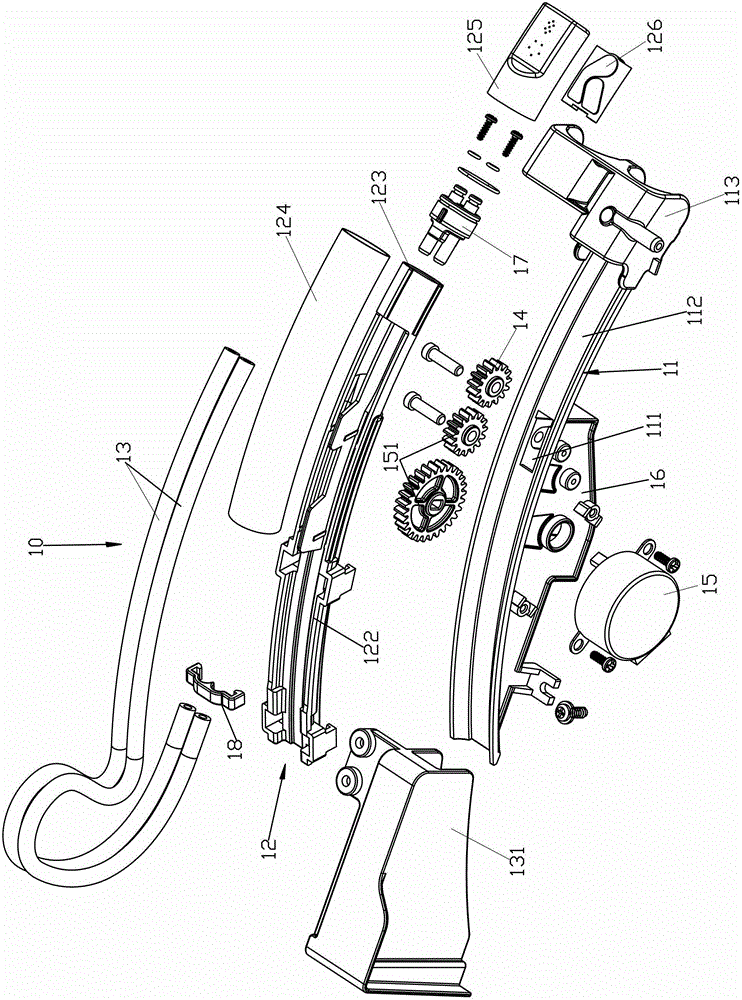

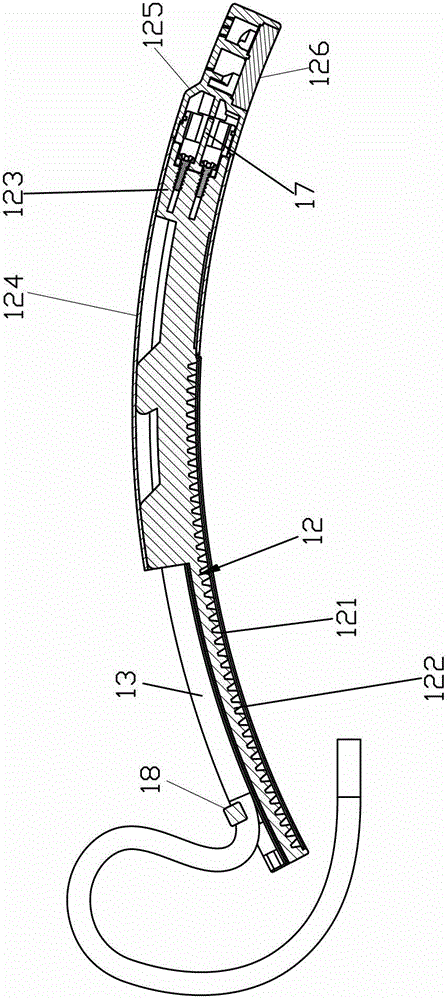

Air outlet adjusting plate and indoor unit of air conditioner

ActiveCN105444387AUniform wind speedImprove comfortLighting and heating apparatusAir conditioning systemsEngineeringWind speed

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP

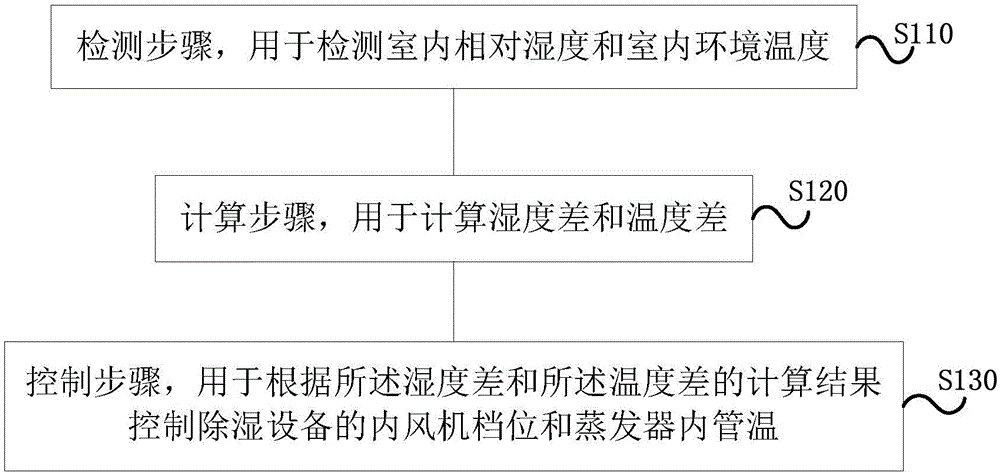

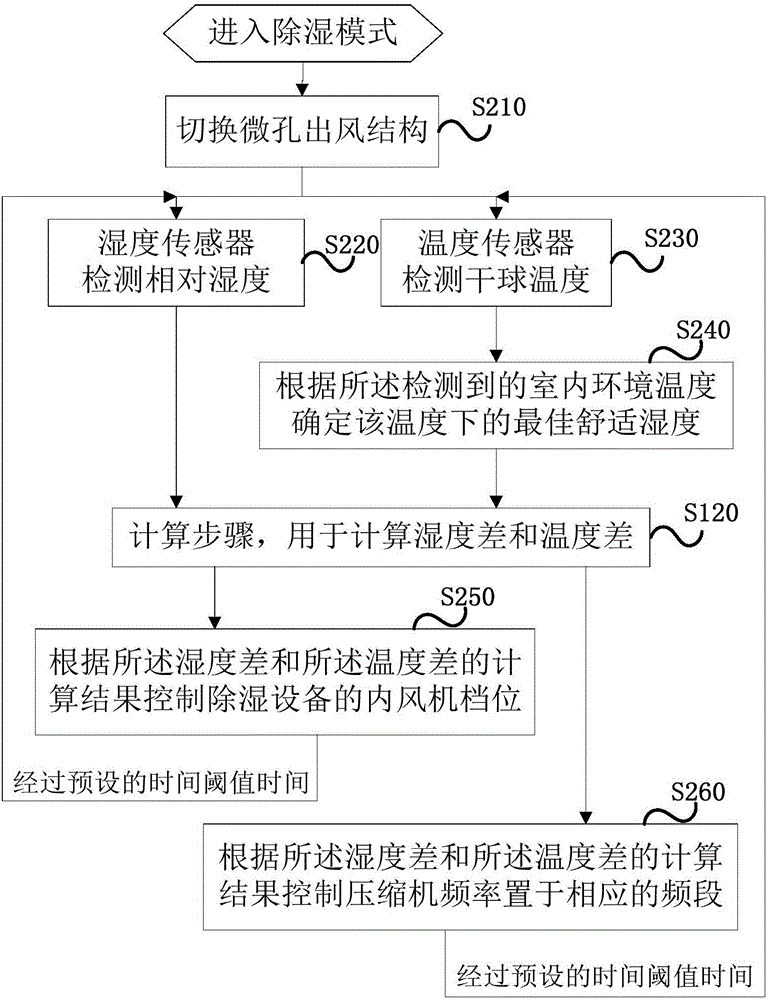

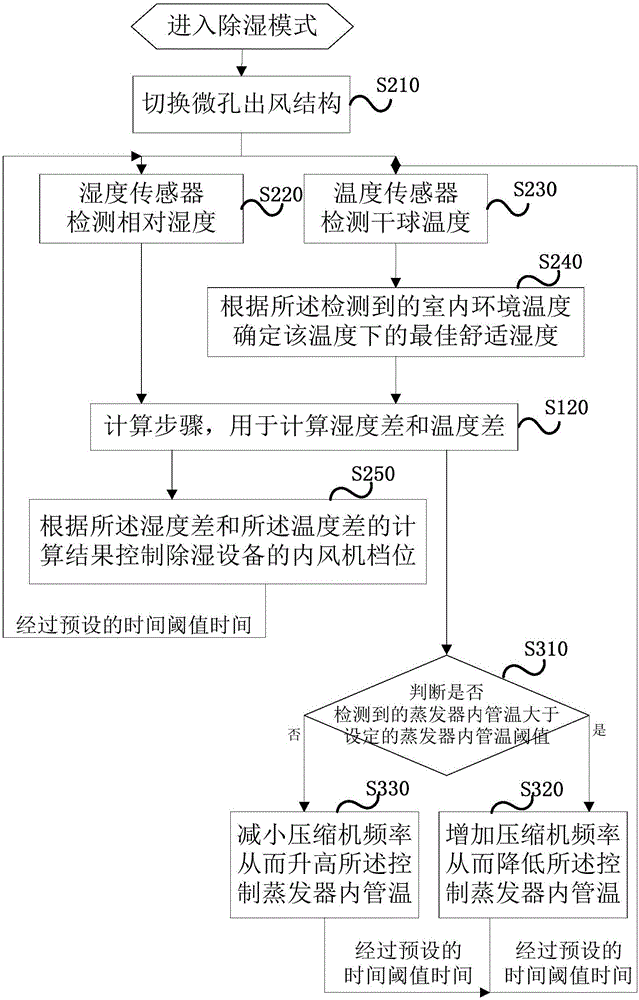

Dehumidifying control method, device and equipment with dehumidifying function

ActiveCN106705383AImprove experienceFast dehumidificationMechanical apparatusSpace heating and ventilation safety systemsTemperature differenceRelative humidity

The invention provides a dehumidifying control method, device and equipment with a dehumidifying function. The dehumidifying control method comprises the steps of the detecting step, the calculating step and the control step. The detecting step is used for detecting the indoor relative humidity and the indoor environment temperature. The calculating step is used for calculating the humidity difference and the temperature difference. The humidity difference is the difference value of the detected indoor relative humidity with the optimal comfort humidity, and the temperature difference is the difference value of the detected indoor environment temperature and the set comfort temperature value. The control step is used for controlling gears of an inner fan and the pipe temperature in an evaporator of the dehumidifying equipment according to the calculating result of the humidity difference and the temperature difference. According to the technical scheme, precision controlling over the comfort environment and the dehumidifying amount is achieved; the dehumidifying speed is high; the situations that indoor humidity decreasing is too large or too small and energy saving is not achieved at the time of dehumidifying are improved; practicability is strong; and good user experience is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

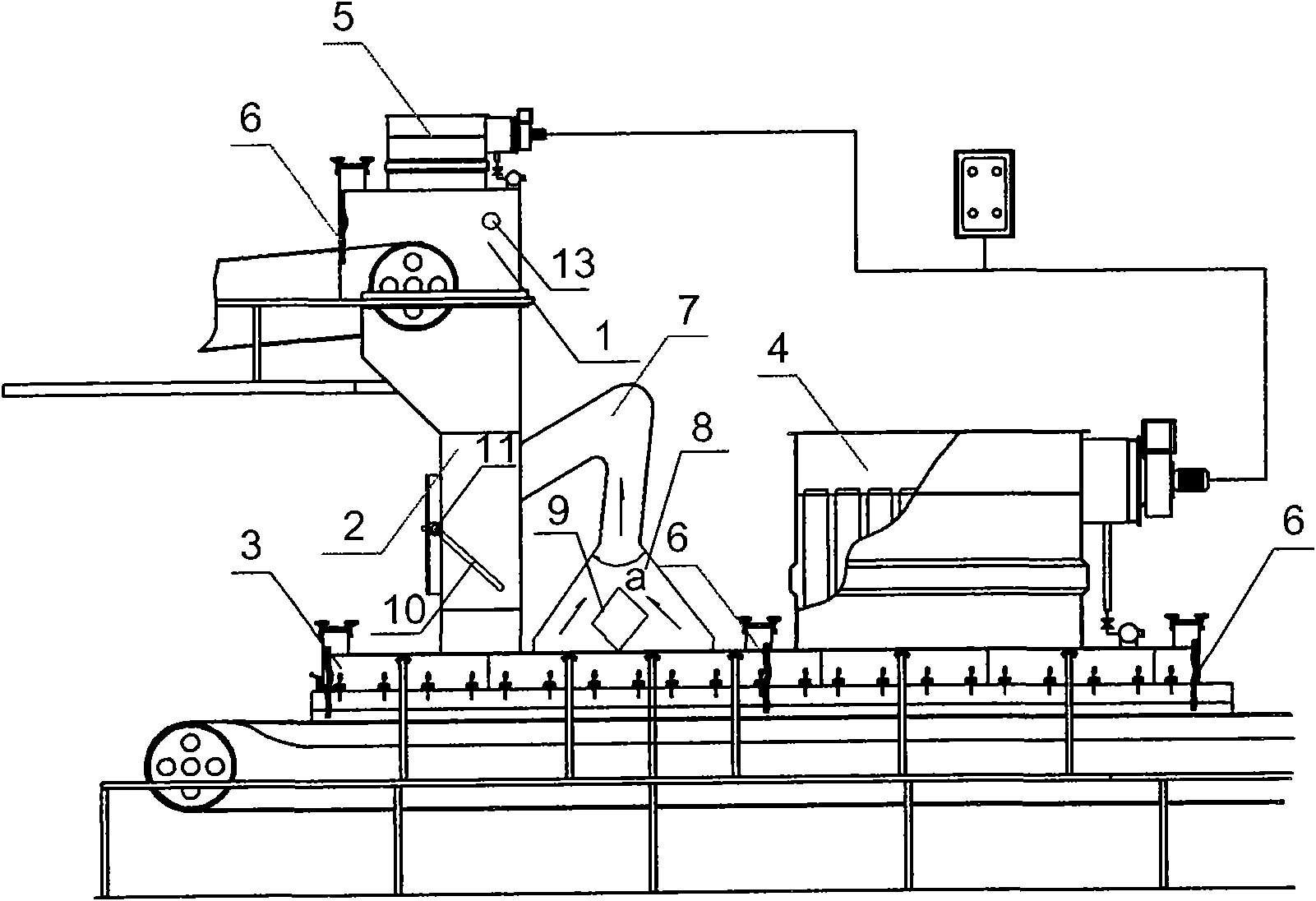

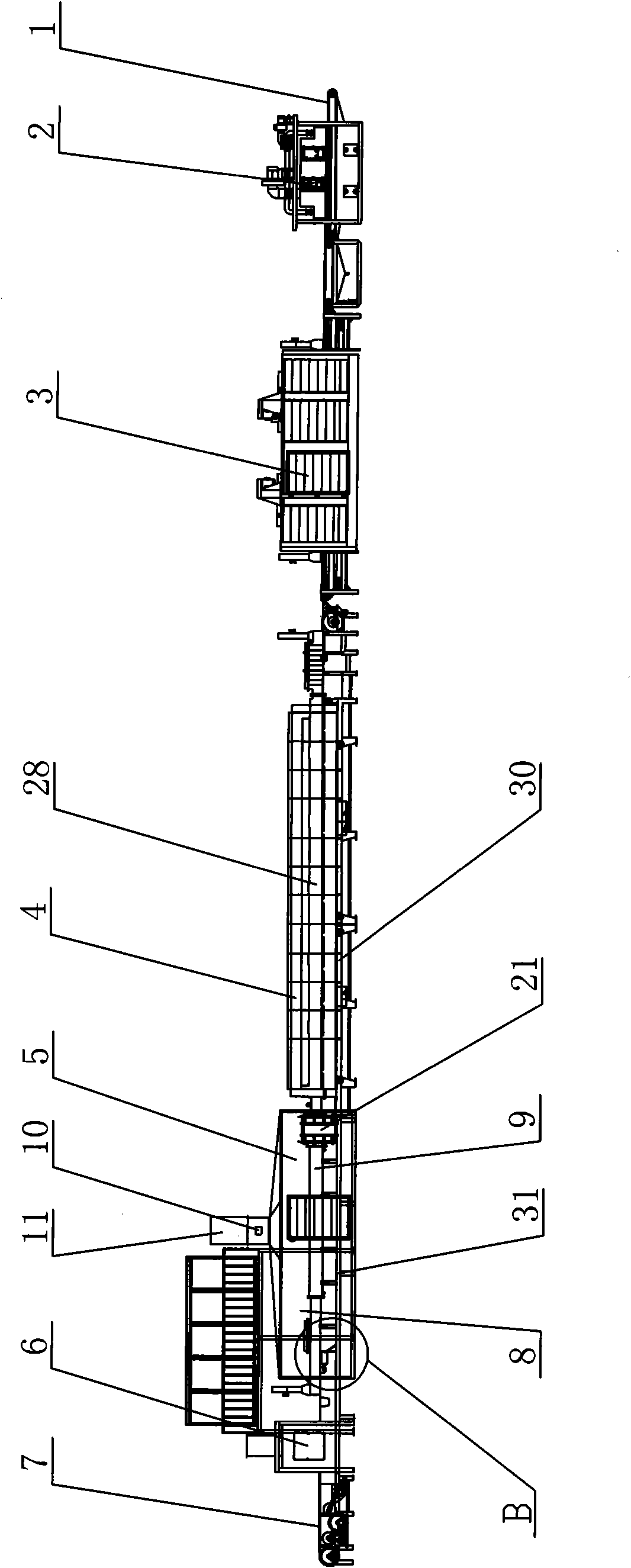

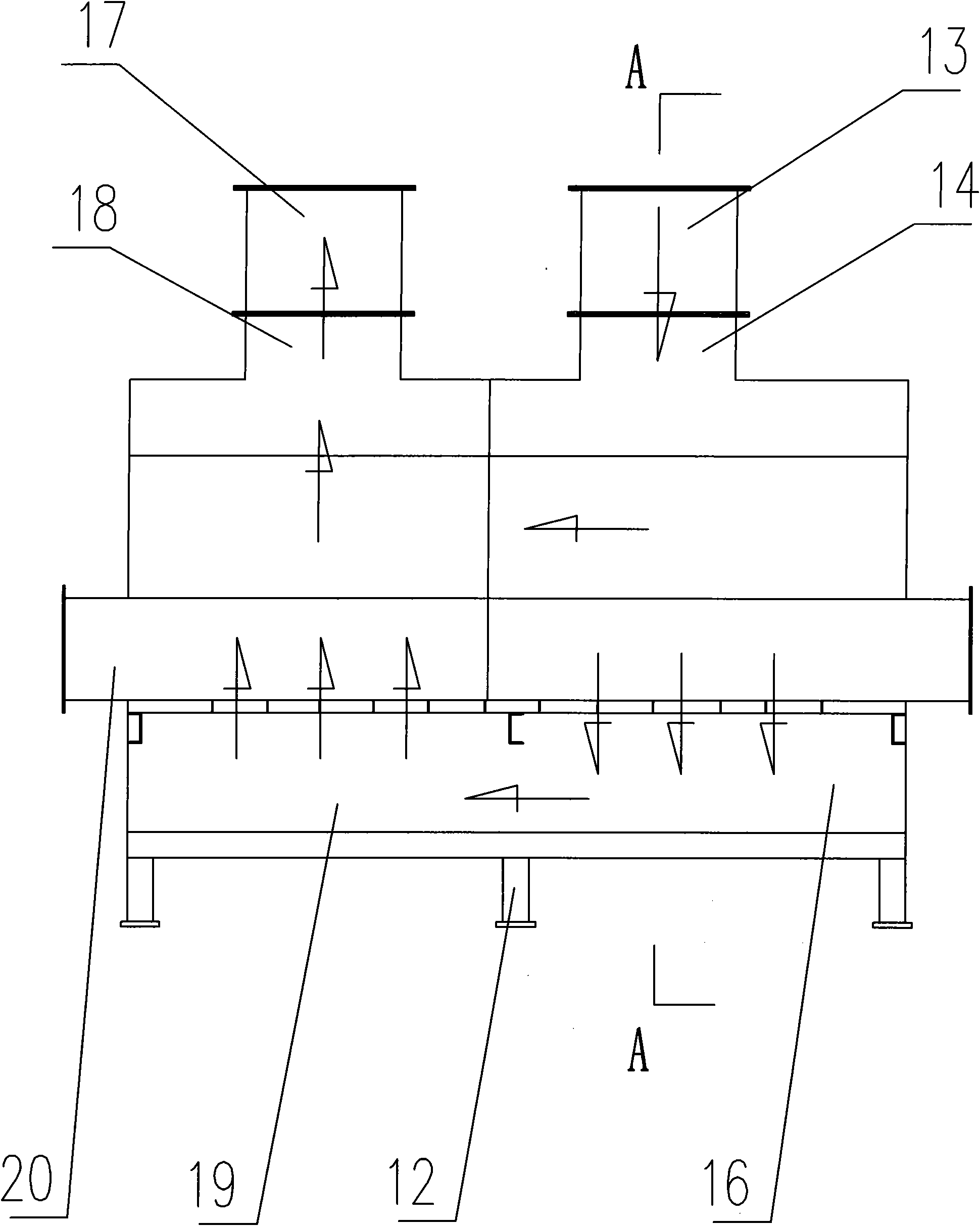

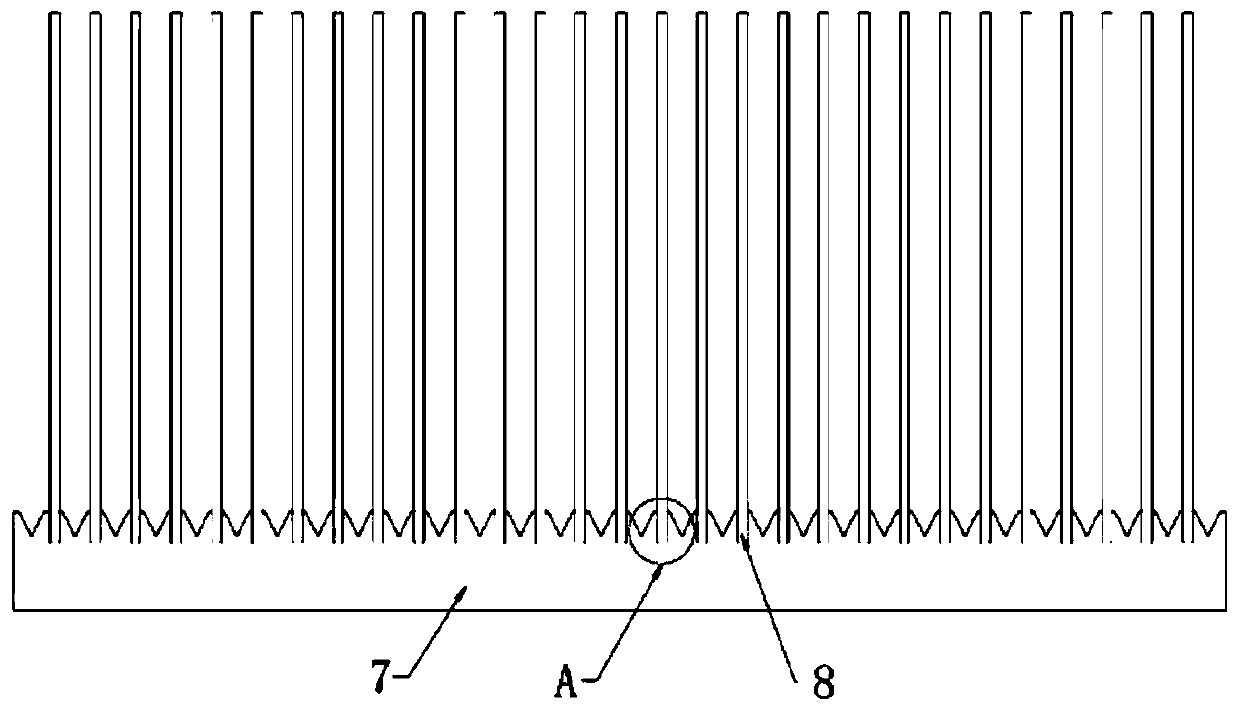

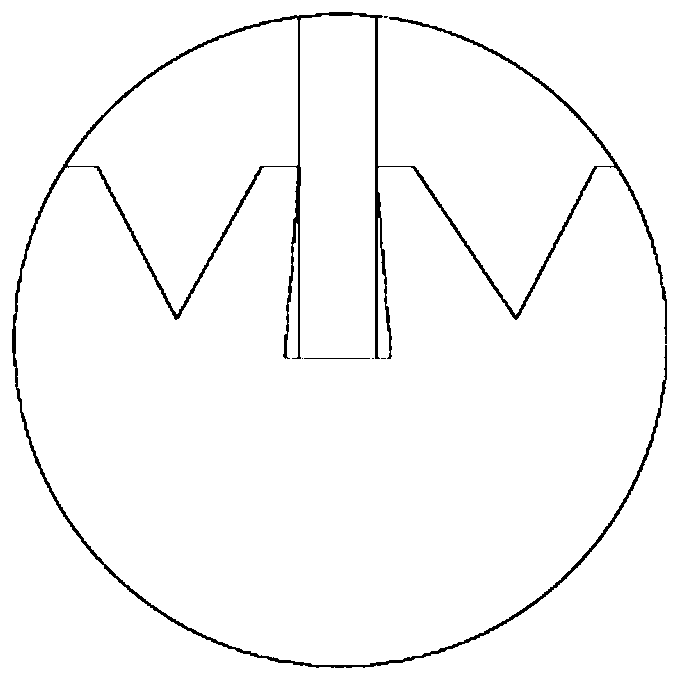

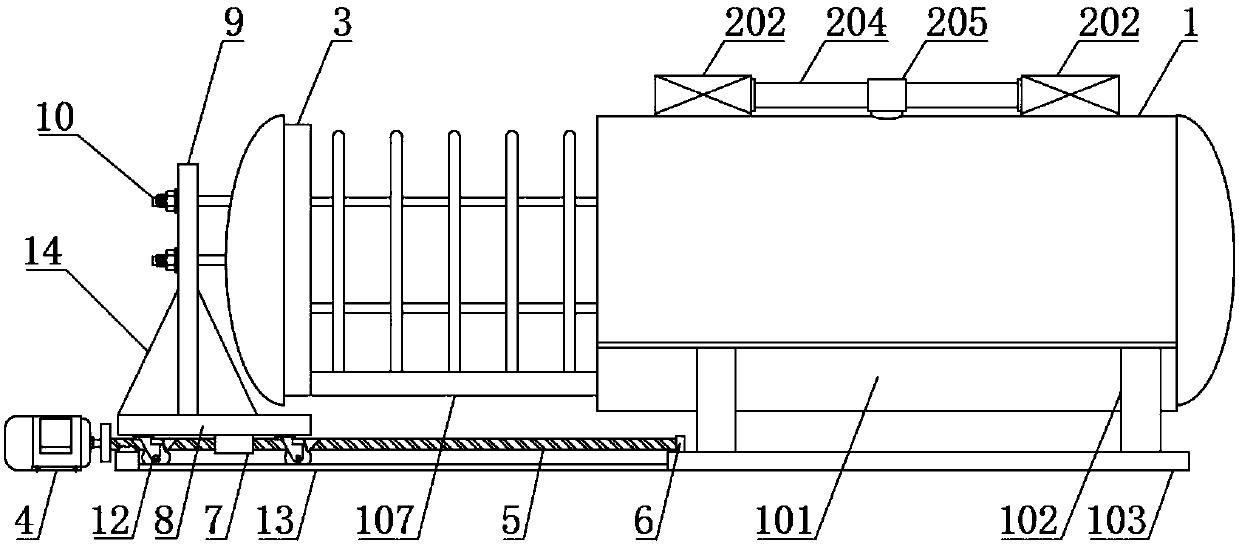

Belt fall point dust removal system

InactiveCN101992944ASmooth movementUniform wind speedDirt cleaningLoading/unloadingWater resourcesEngineering

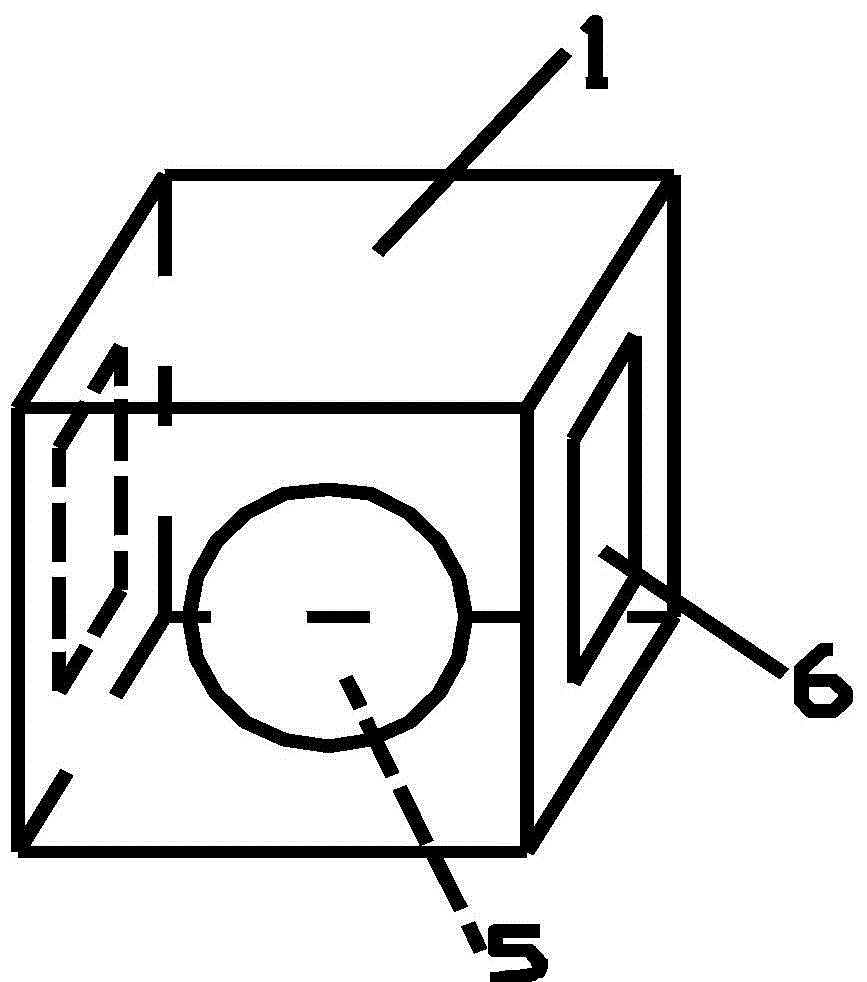

The invention discloses a belt fall point dust removal system which is used by a bulk material in the belt transportation process. The belt fall point dust removal system comprises a handpiece sealing hood (1), a material runner (2) and a sealing hood (3) on the lower part of an engine body, wherein the discharge hole of the handpiece sealing hood (1) is connected with the feed port of the material runner (2); the discharge hole of the material runner (2) is connected with the feed port of the sealing hood (3) on the lower part of an engine body; the top of the sealing hood (3) on the lower part of an engine body is provided with a first dust remover (4); the top of the handpiece sealing hood (1) is provided with a second dust remover (5); a dust gas backflow channel (7) is fixedly arranged between the sealing hood (3) on the lower part of an engine body and the material runner (2); and the port of the dust gas backflow channel (7) is respectively communicated with the material runner (2) and the cavity of the sealing hood (3) on the lower part of an engine body. The invention saves the existing water resource, has ideal dust removal effect, is convenient to install and maintain and does not generate secondary pollution.

Owner:于文祥

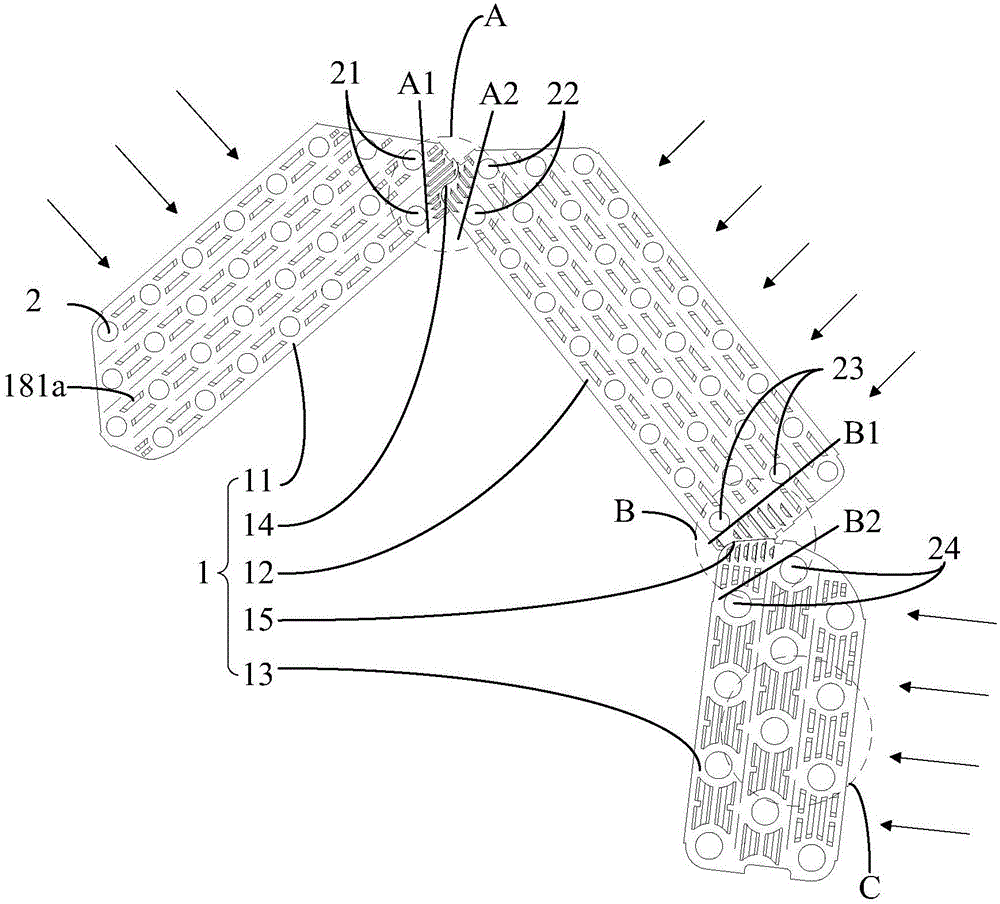

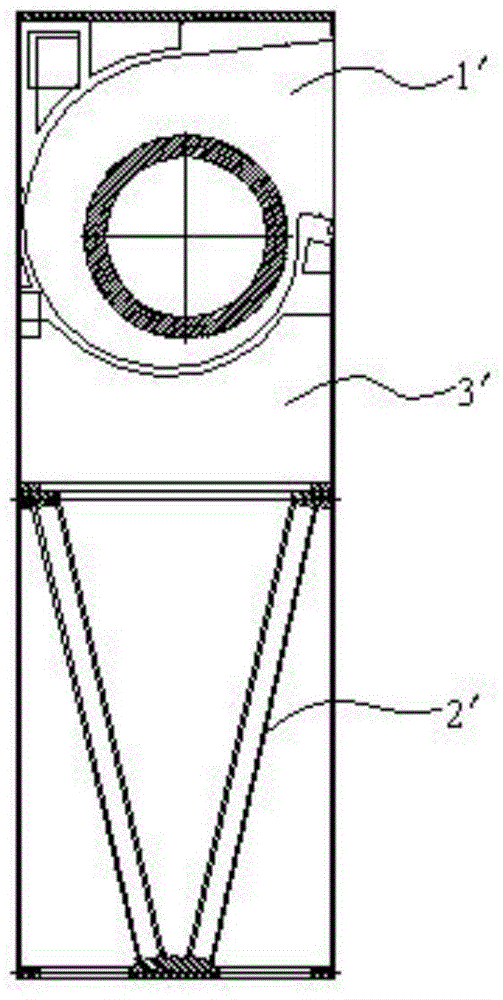

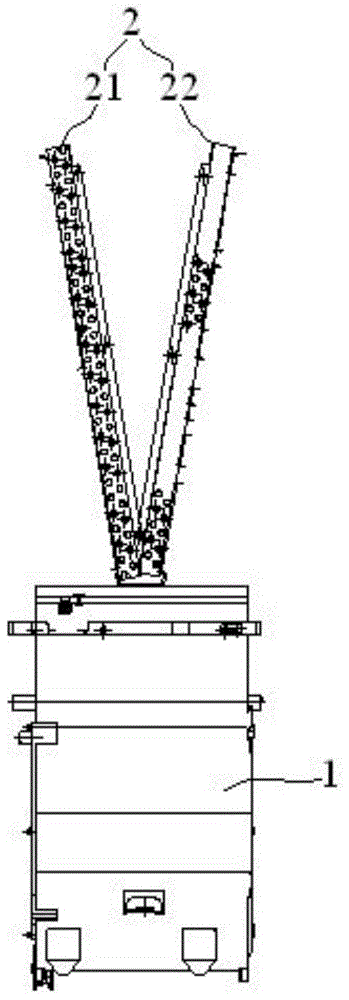

Heat exchange device

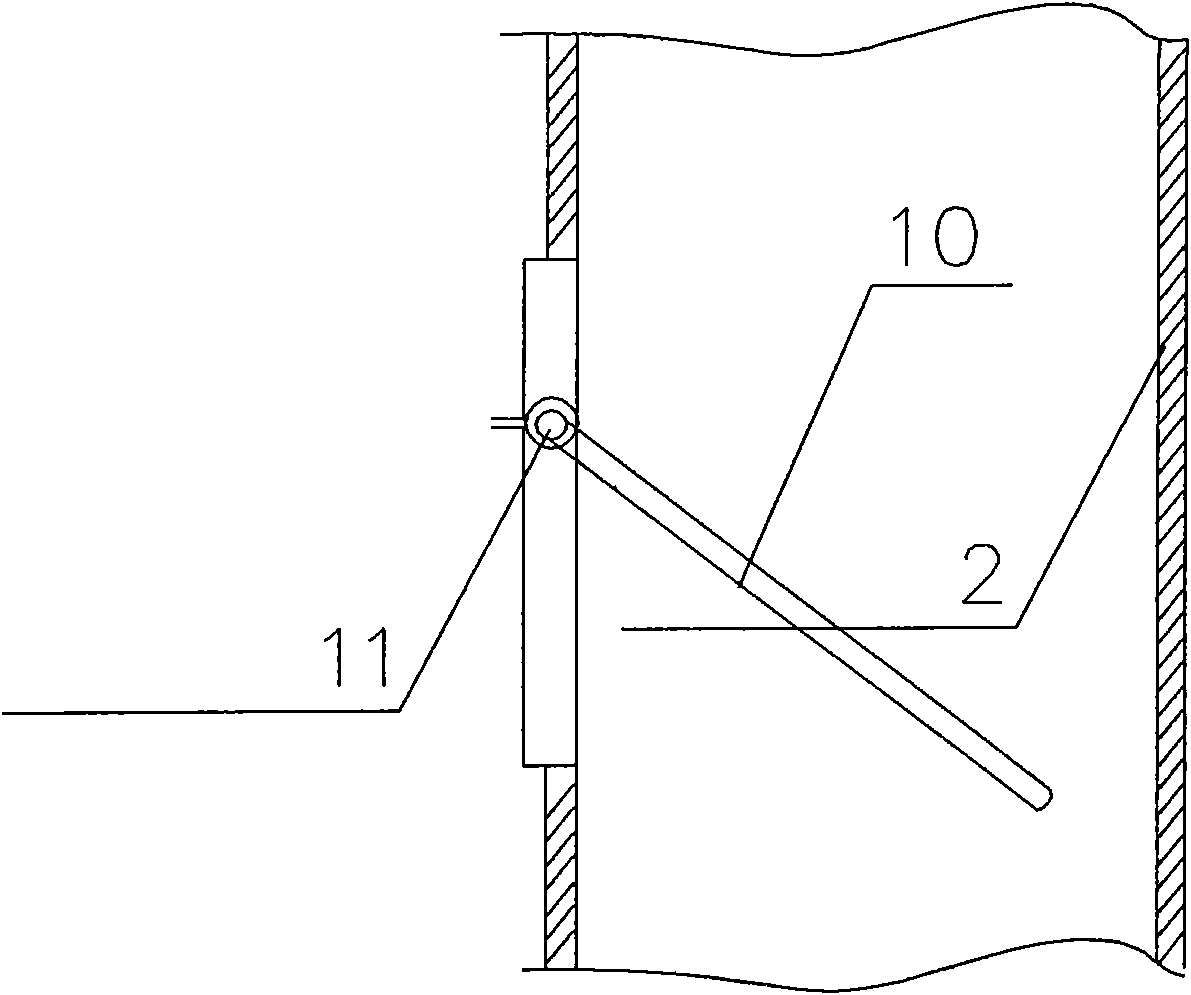

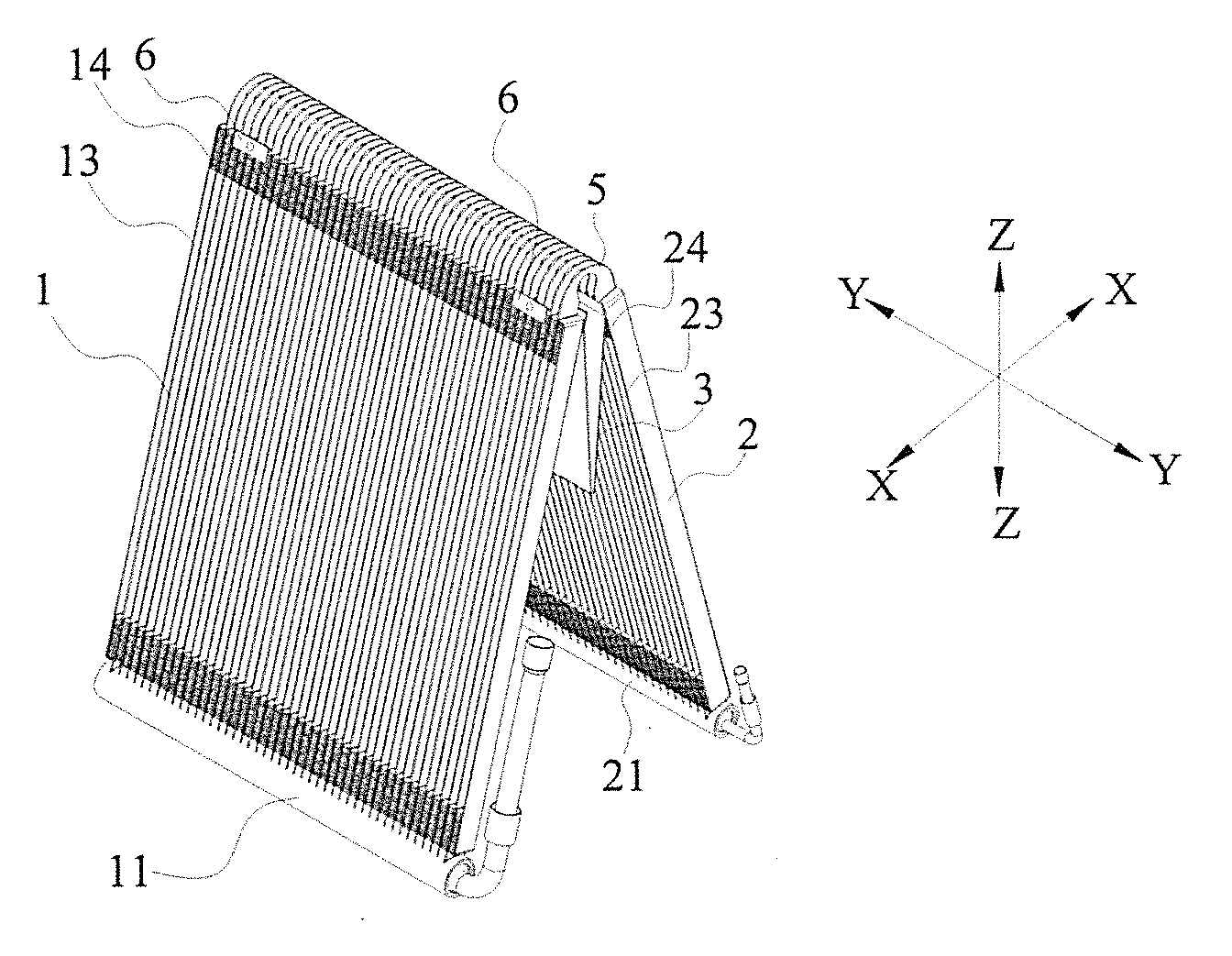

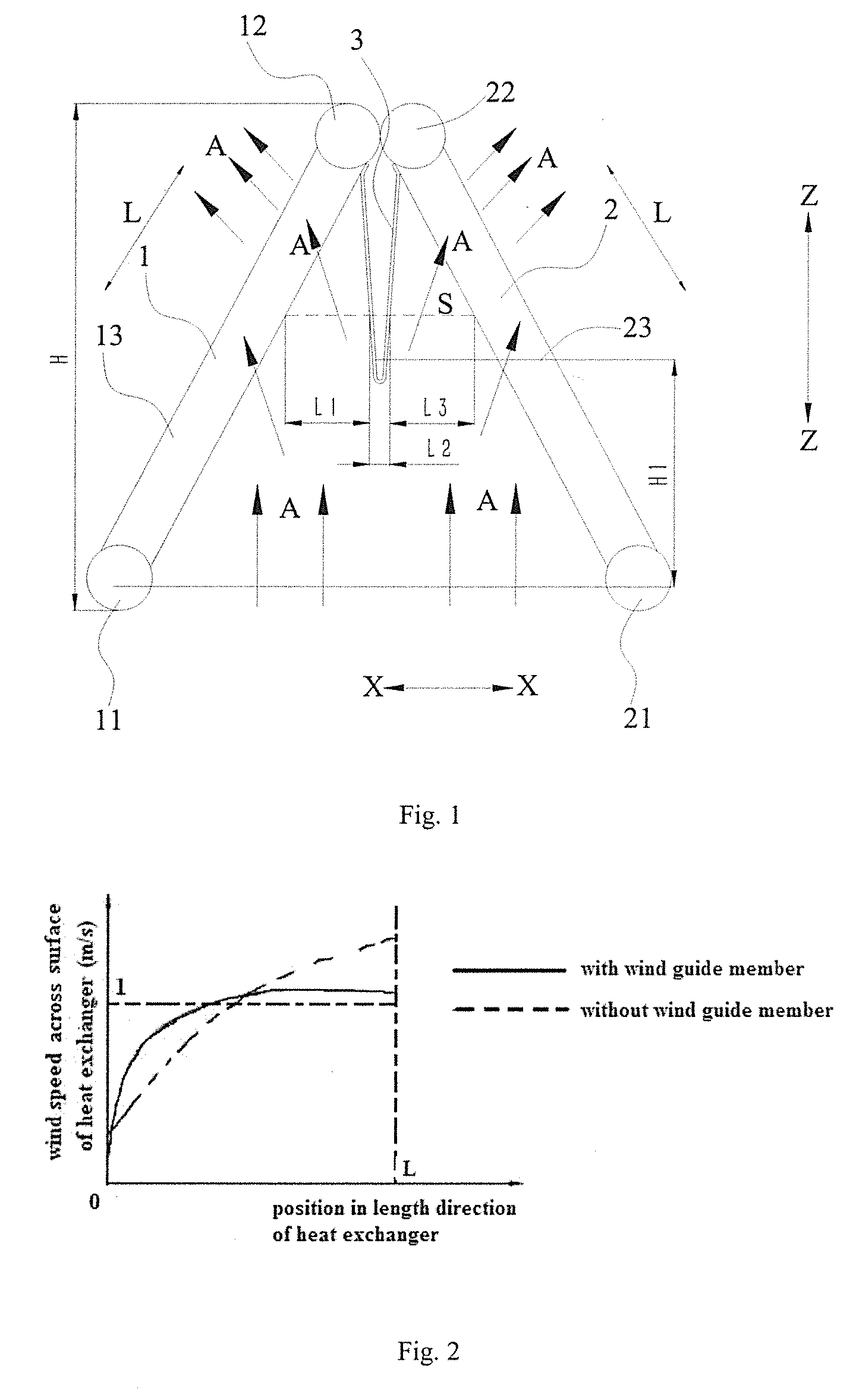

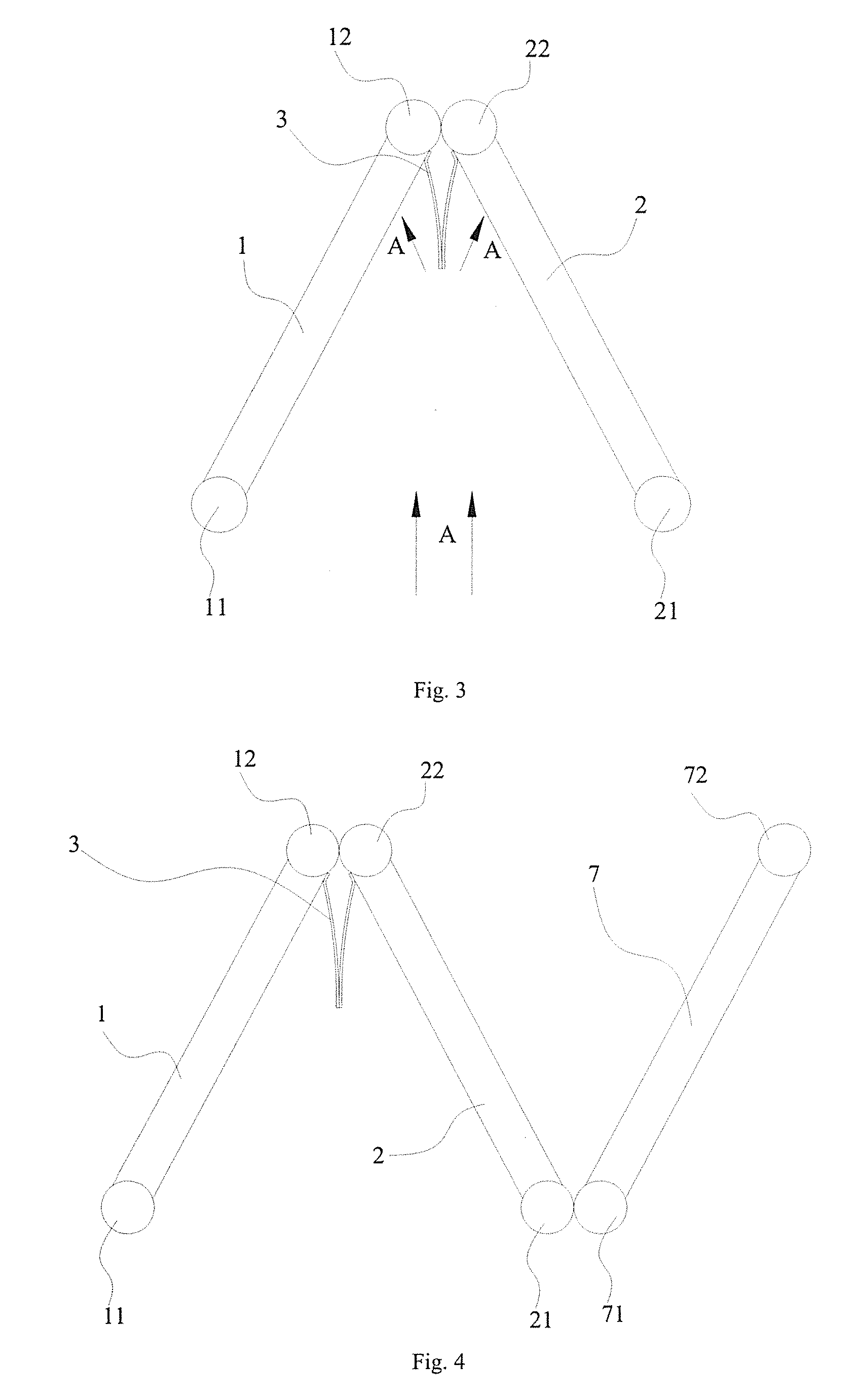

ActiveUS20120279689A1Improves distribution uniformity of wind speedReduce wind speedSteam/vapor condensersStationary conduit assembliesPlate heat exchangerEngineering

A heat-exchange device comprises a first heat exchanger defining an upper end and a lower end. A second heat exchanger defines an upper end connected to the upper end of the first heat exchanger and a lower end spaced apart from the lower end of the first heat exchanger in a substantially longitudinal direction such that a predetermined angle between the first heat exchanger and second heat exchanger is between about 0 and 180°. A wind-guide member is disposed between the first heat exchanger and second heat exchanger for guiding wind toward the first heat exchanger and second heat exchanger.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER +1

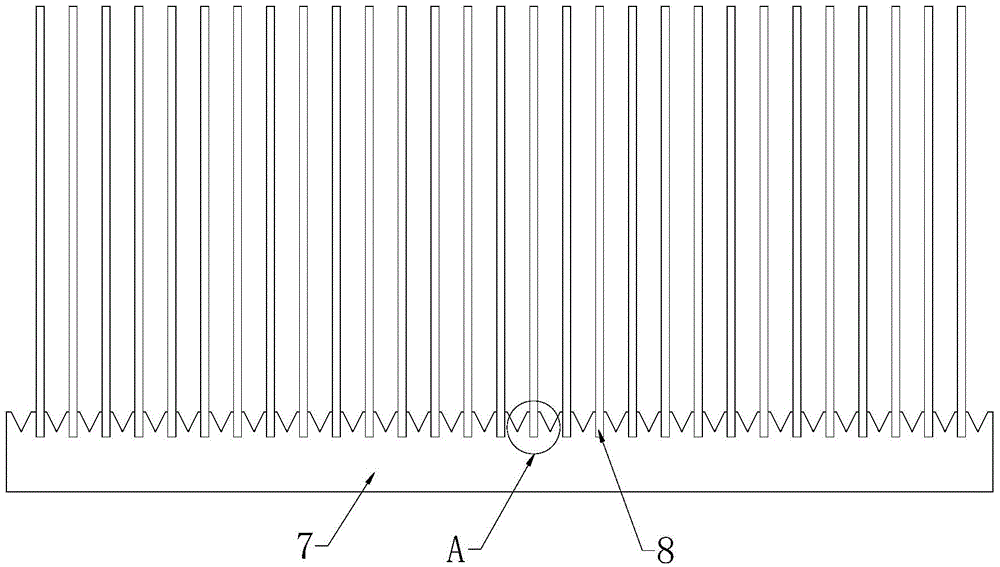

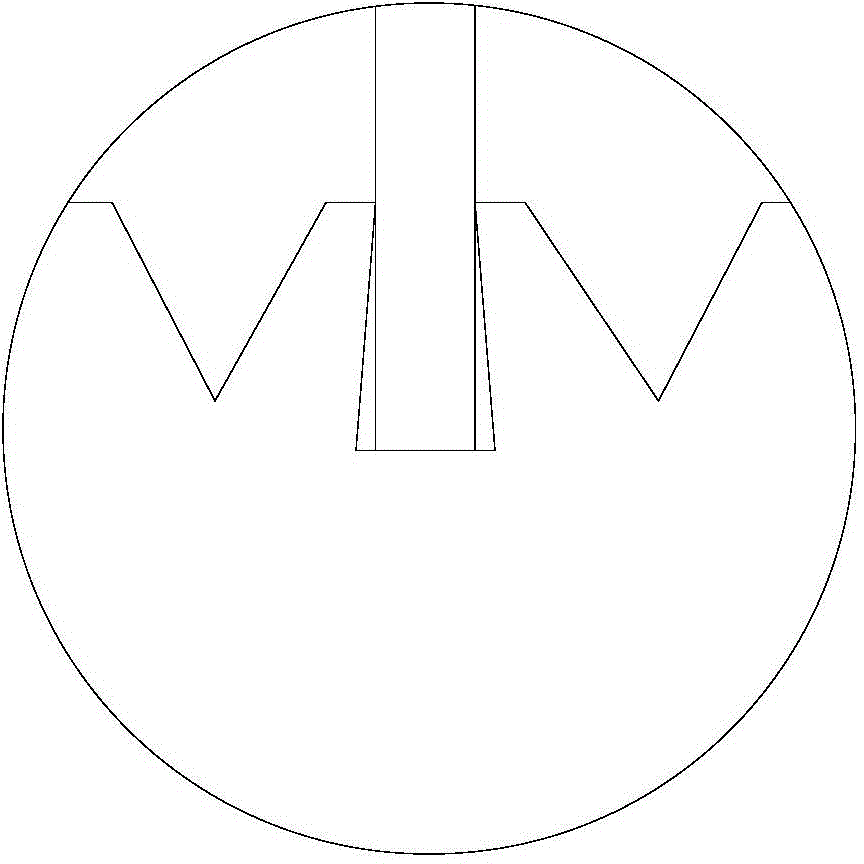

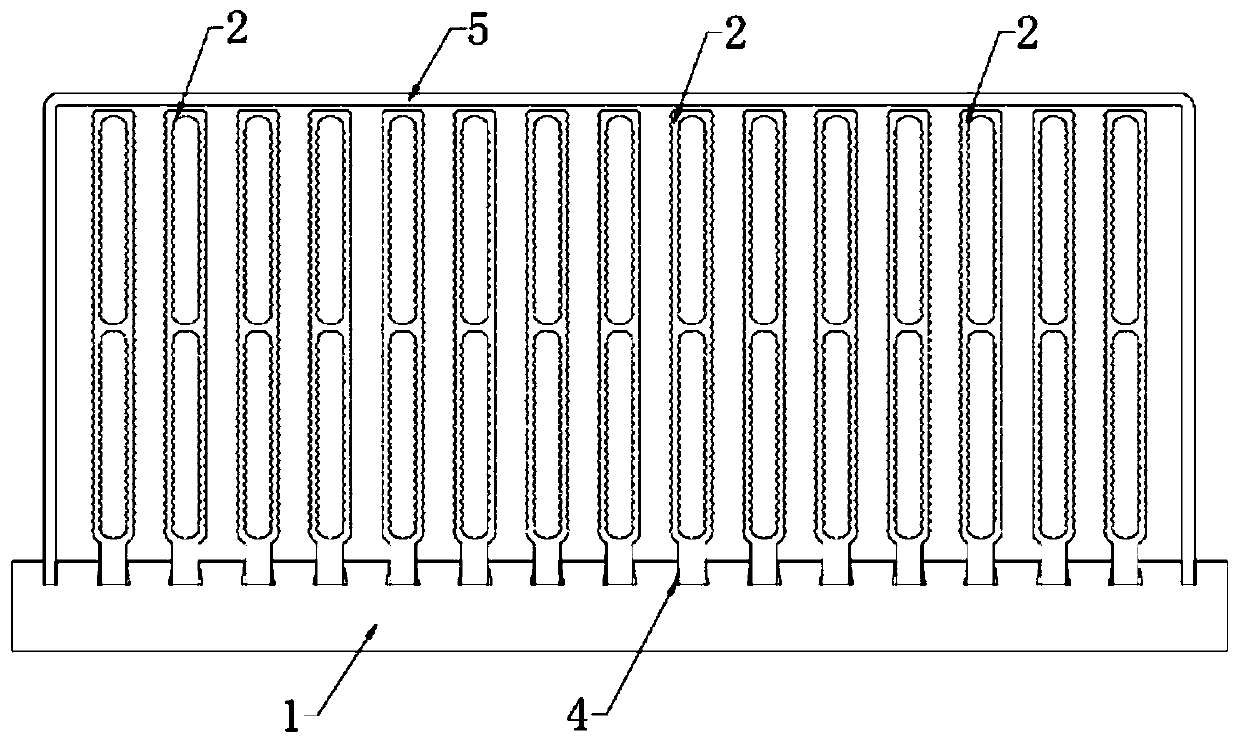

Air-cooling radiator and manufacturing method thereof

InactiveCN103987236ASmall temperature deviationReduce thermal resistanceCooling/ventilation/heating modificationsEngineeringHeat spreader

The invention discloses an air-cooling radiator and a manufacturing method thereof. The air-cooling radiator comprises a thermal conduction substrate and cooling fins. Fin insertion grooves are formed in the thermal conduction substrate. A connecting end of each cooling fin is fixed in the corresponding fin insertion groove in the thermal conduction substrate. The space between the connecting end of each cooling fin and the corresponding fin insertion groove is filled with a thermal conduction medium. An air passing passageway is further formed in each cooling fin. The space between the connecting end of each cooling fin and the corresponding fin insertion groove is further filled with the corresponding thermal conduction medium, thermal resistance between the thermal conduction substrate and the cooling fins can be reduced through the thermal conduction mediums, thermal conduction is facilitated, and the heat dissipation effect of the air-cooling radiator is improved; the cooling fins can be more tightly attached to the side walls of the fin insertion grooves, and therefore thermal resistance can be further reduced; by the adoption of the design of the air passing passageways, air from an external fan can flow through the space outside the cooling fins and the air passing passageways, so that the inner portion and the outer portion of the cooling fins are fully cooled, and heat on the cooling fins can be rapidly taken away.

Owner:深圳市华盛源机电有限公司

Blown air rectifying device of chemical fiber spinning equipment

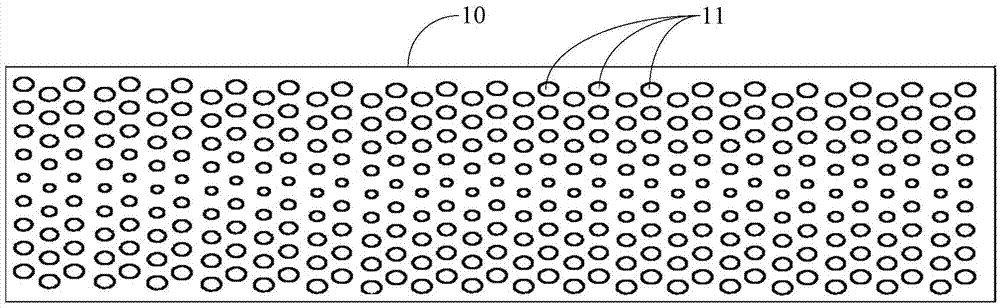

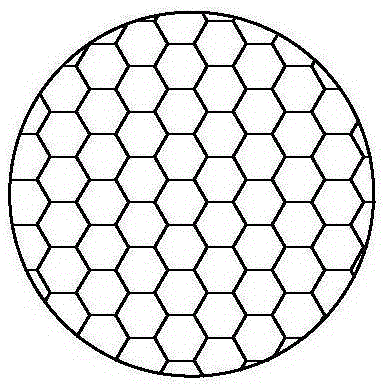

ActiveCN105220249AUniform wind pressureUniform wind speedFilament/thread formingAir velocityHoneycomb

The invention discloses a blown air rectifying device of chemical fiber spinning equipment, which is mounted at the air outlet of an air blowing device of chemical fiber spinning equipment. The blown air rectifying device comprises the components of a perforated plate, a filtering net, a honeycomb plate and an air uniforming net; wherein the perforated plate, the filtering net, the honeycomb plate and the air uniforming net are successively arranged from bottom to top. A plurality of small holes are uniformly distributed on the perforated plate. The filtering net is clamped between an upper flange and a lower flange and is fixed on the perforated plate. A honeycomb plate frame is arranged outside the honeycomb plate and the air uniforming net. The lower flange is fixedly connected with the honeycomb plate frame. The blown air rectifying device of the chemical fiber spinning equipment is advantageous in that the blown air rectifying device is mounted at the outlet of the air blowing device; uniform air pressure and uniform and stable air speed of outgoing air can be realized; balanced air blowing in cooling spun filament can be ensured; and furthermore uneven wind velocity rate is lower than 10%.

Owner:苏州金纬化纤装备有限公司

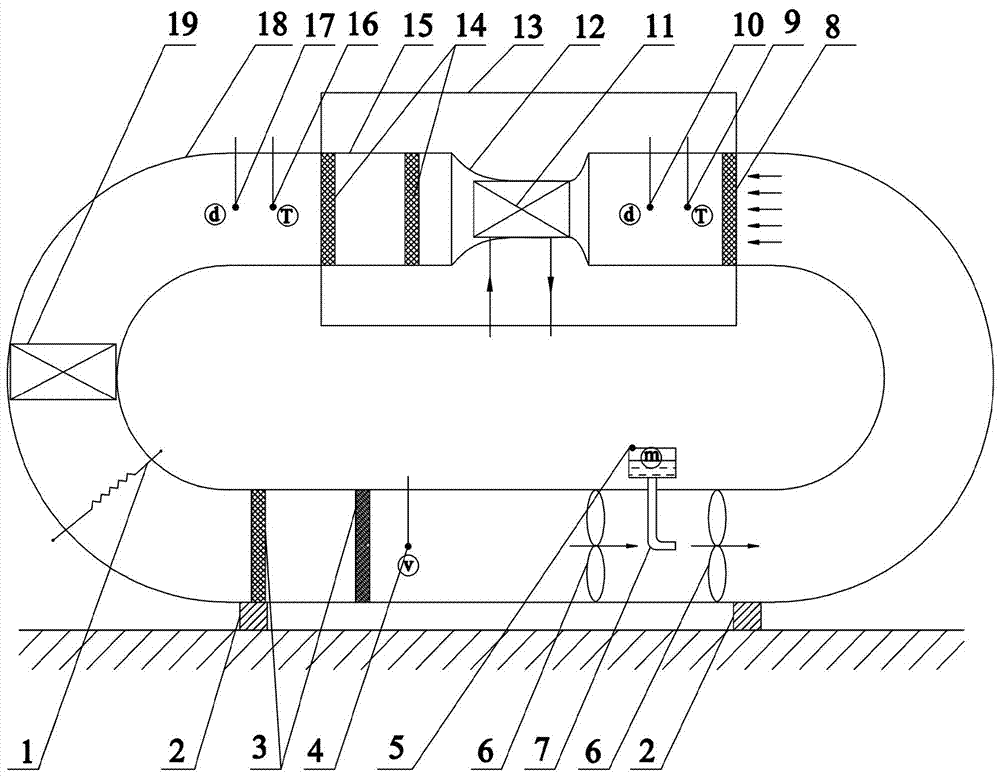

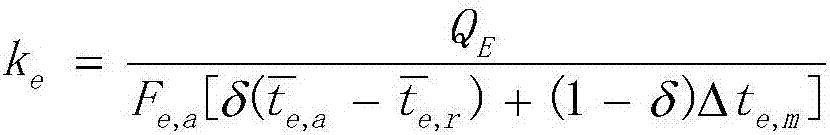

Test air duct system for testing heat exchange performance and dehumidifying/icing amount of air heat exchanger

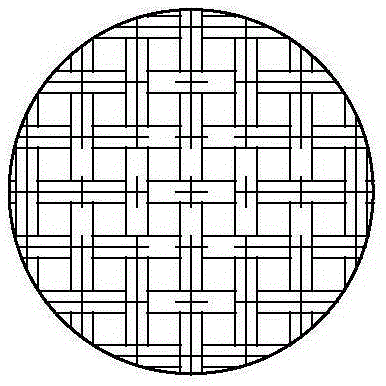

InactiveCN107246974AAccurate measurementUniform wind speedStructural/machines measurementEngineeringPlate fin heat exchanger

The invention relates to a test air duct system for testing the heat exchange performance and dehumidifying / icing amount of an air heat exchanger, in particular to a test air duct system for testing the heat exchange performance and dehumidifying / icing amount of an air evaporator / condenser. The test air duct system includes a temperature-controlled evaporator, an electric heater, a wind speed sensor front damping rectifier, a wind speed sensor, a mass sensor, fans, an ultrasonic humidifier, a test evaporator / condenser front damping rectifier, a test evaporator / condenser front temperature sensor, a test evaporator / condenser front humidity sensor, a test evaporator / condenser, a soft connection of a circular air duct, an insulation can, a test evaporator / condenser rear damping rectifier, a test evaporator / condenser rear temperature sensor, a test evaporator / condenser rear humidity sensor, a circular air duct special heat insulation section, and a circular air duct ordinary heat insulation section. The system has the advantage that the front temperature, humidity and air speed of the test evaporator / condenser can be controlled accurately, and the heat exchange performance of evaporators / condensers of different types and sizes and the dehumidifying / icing amount of evaporators of different types and sizes can be tested. The frosting process and defrosting process of an evaporator can be observed and recorded.

Owner:QINGDAO UNIV +1

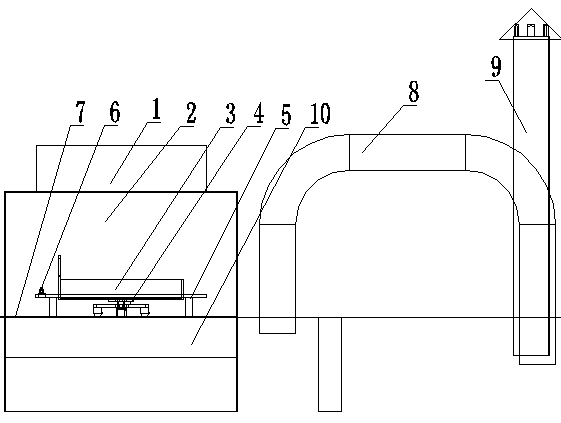

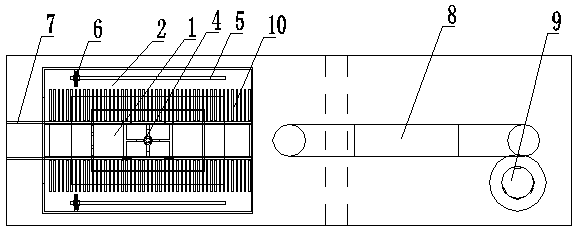

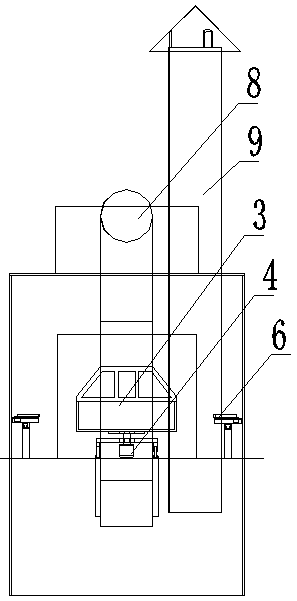

Oil paint spraying system

InactiveCN104001640AReduce disturbanceReduce the possibility of expulsionLiquid surface applicatorsCoatingsInlet channelAir filter

Disclosed is an oil paint spraying system. The oil paint spraying system comprises a spraying chamber (2), an exhaust channel (10), an exhaust pipe (8), a dust fall water curtain (9), an induced draft fan, a purification pool, a pipeline and a circulating water pump, wherein the exhaust channel (10) is placed under the ground plane of the spraying chamber and is communicated with the spraying chamber (2), the exhaust pipe (8) is communicated with the exhaust channel (10), the dust fall water curtain (9) and the induced draft fan are communicated with the exhaust pipe (8), the purification pool is placed below the dust fall water curtain (9), and the pipeline and the circulating water pump are communicated between the purification pool and the dust fall water curtain (9). An air inlet system (1) is arranged on the top of the spraying chamber (2). The air inlet system comprises an air distribution plate communicated with the spraying chamber (2), an air inlet channel communicated with the air distribution plate, an air filter placed in the air inlet channel and an air blower communicated with the air inlet channel.

Owner:CHANGSHA YICHENG AUTO PARTS

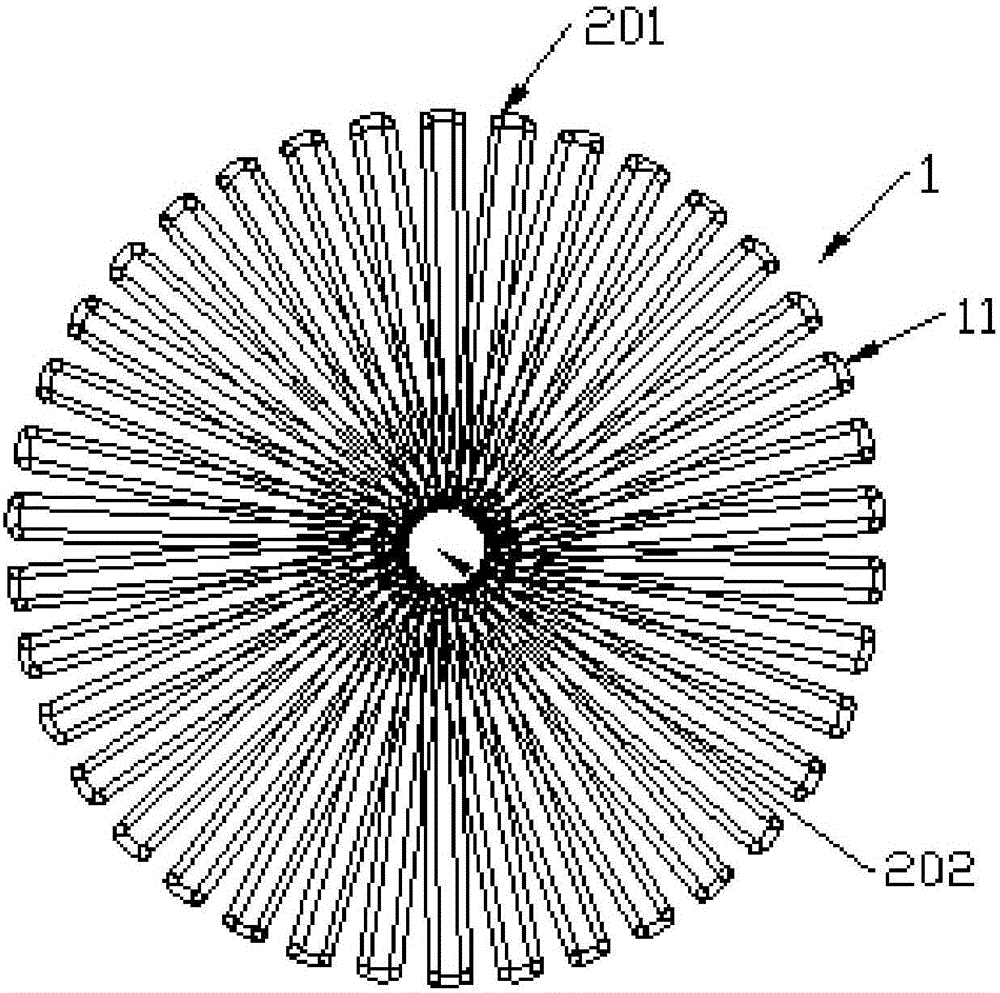

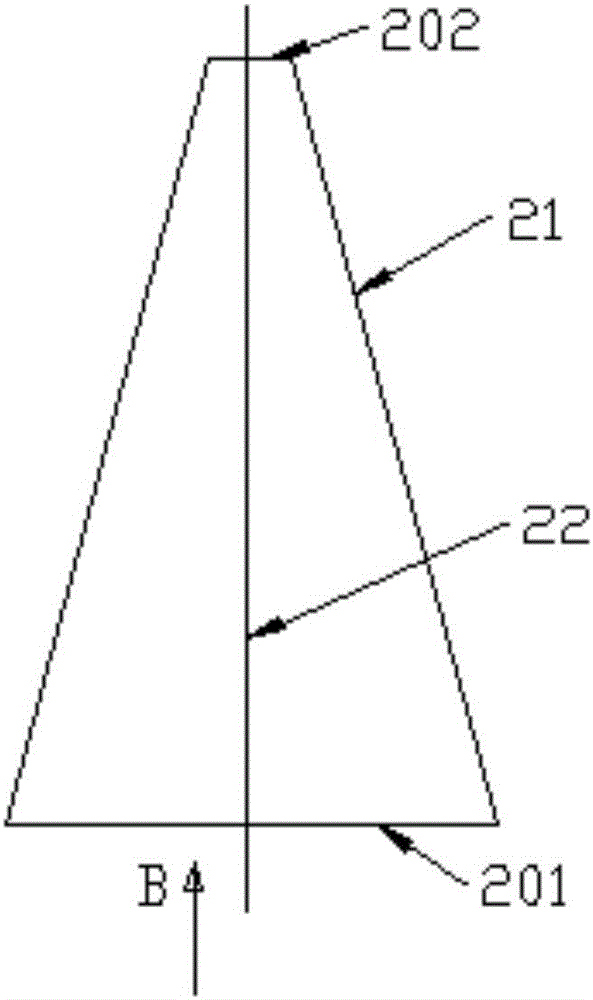

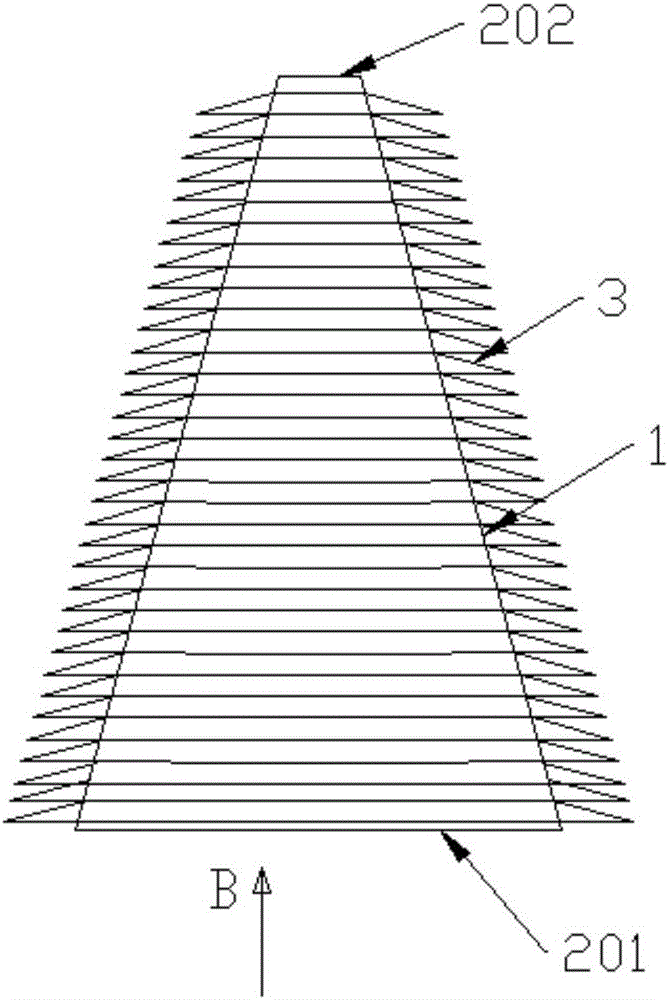

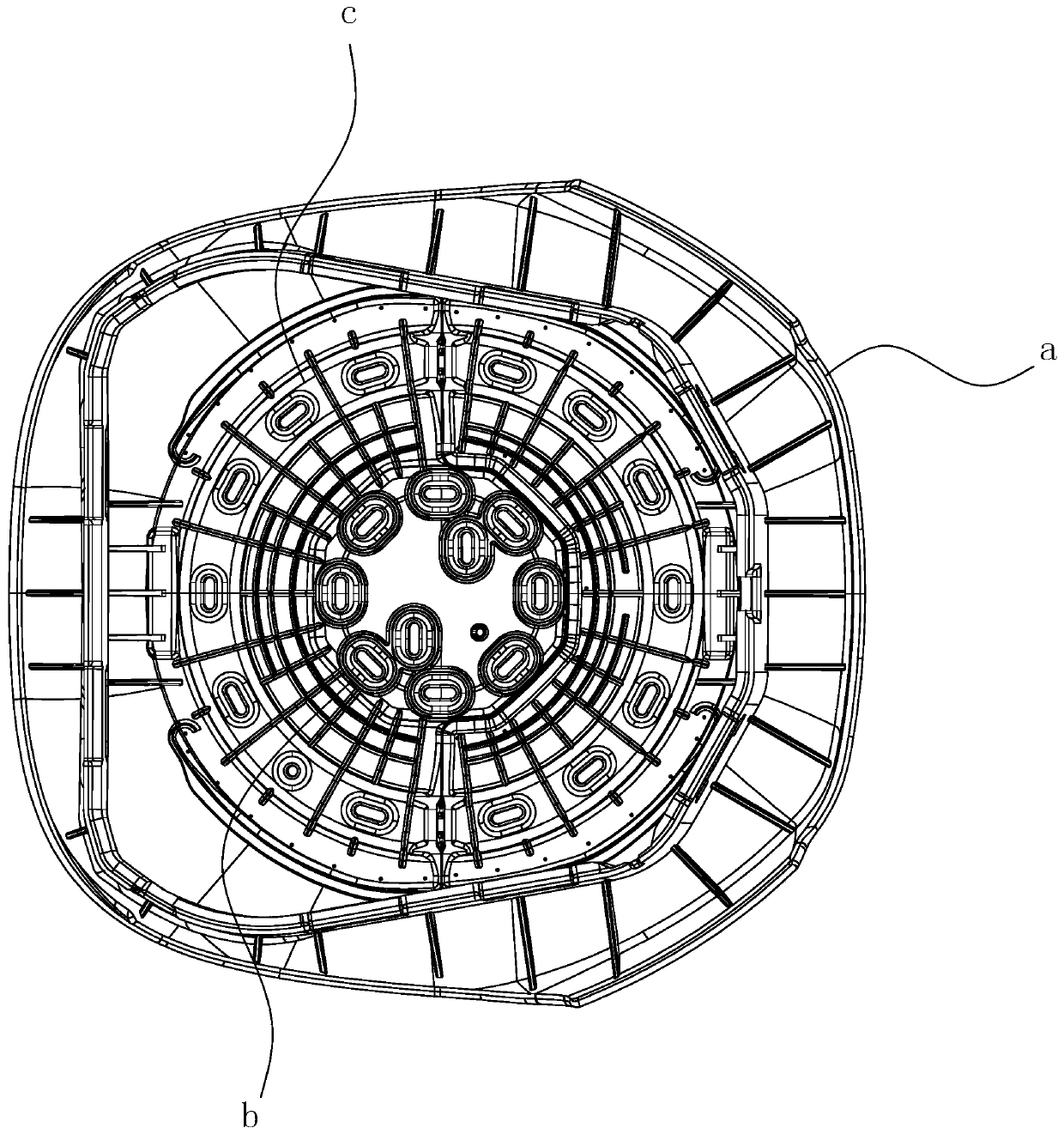

Heat exchanger and vertical type air conditioner provided with same

InactiveCN106247605AImprove heat transfer effectFast heat transferLighting and heating apparatusHeating and ventilation casings/coversEngineeringVertical axis

The invention relates to the heat exchange field, in particular to a heat exchanger and a vertical type air conditioner provided with same. The heat exchanger comprises a heat exchange tube which is positioned in a flow channel for heat exchange gas; and the heat exchange tube is arranged on a plane which is formed by rotating a generatrix around a vertical axis by 360 degrees. The technical problem to be solved in the invention is a space sufficient utilization problem of the heat exchanger in the prior art. Furthermore, in order to solve the problem that static-pressure fluctuating outlet air at a rotary air outlet of a vertical type air conditioner in the prior art fluctuates, the invention further provides a heat exchanger with a greater heat exchange area, and further provides the vertical type air conditioner with the heat exchanger for solving the problem that static-pressure fluctuating outlet air at the rotary air outlet fluctuates.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

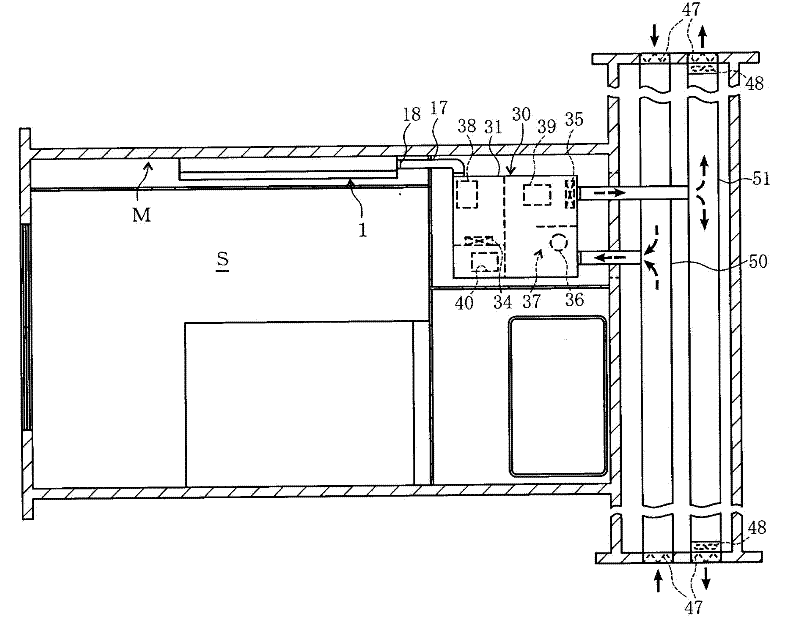

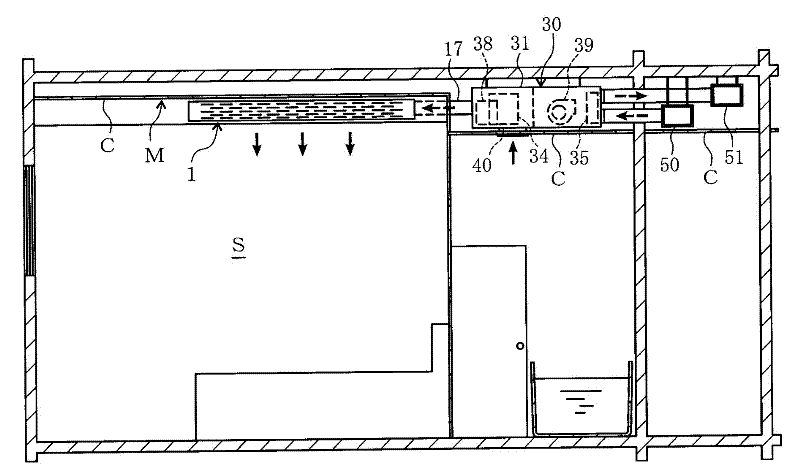

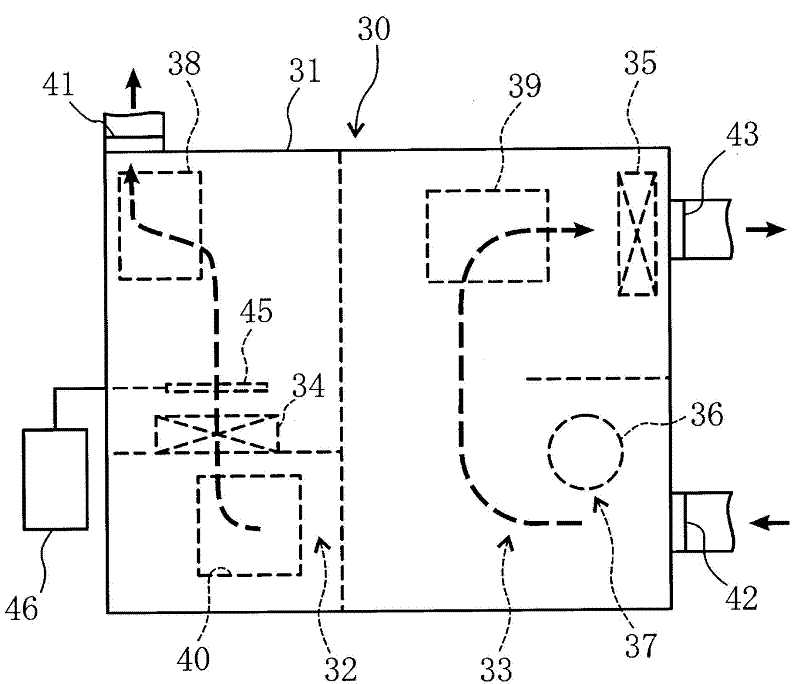

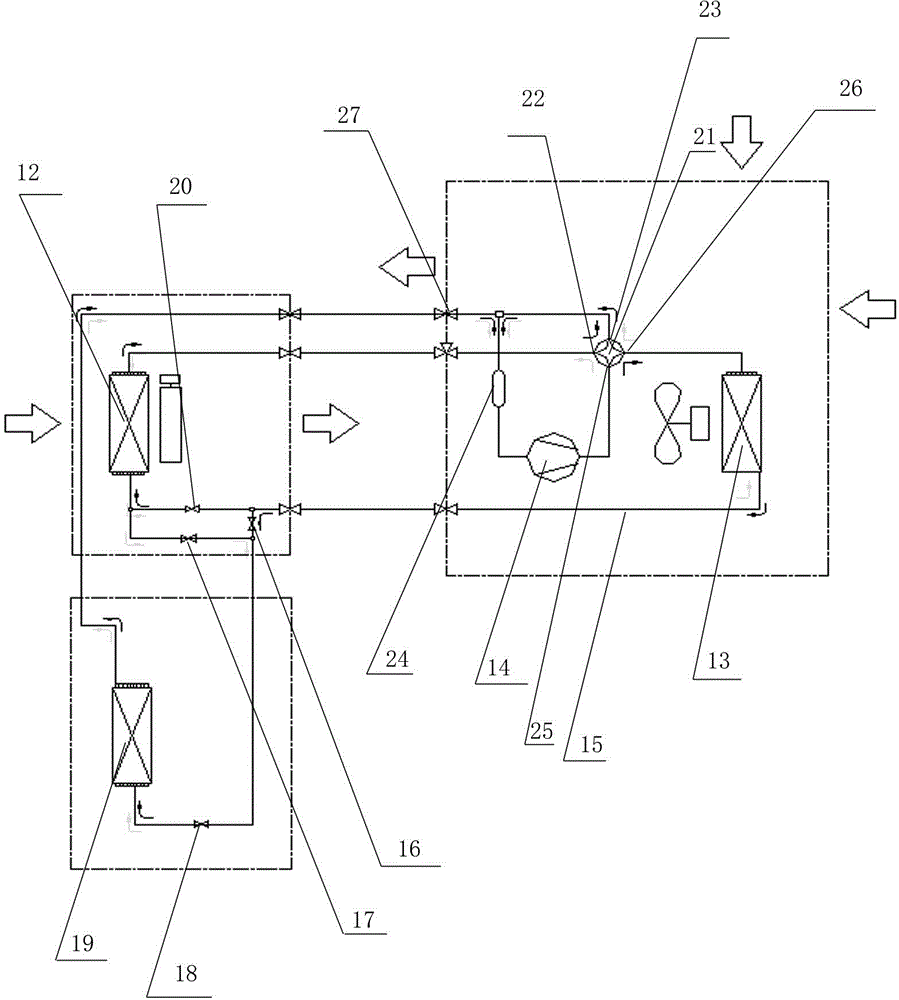

Air heat source heat pump air conditioner

ActiveCN102297485AEvenly distributedSimple structureLighting and heating apparatusSpace heating and ventilation detailsEngineeringAir conditioning

The invention provides an air heat source heat pump-type air conditioner capable of efficiently providing comfortable air conditioning and being easily constructed without requiring a wasted installation space. The air heat source heat pump-type air conditioner includes a housing (31) which is provided inside with a heat pump (37), and the heat pump (37) is composed of a refrigerant-air supply air heat exchanger (34), a refrigerant-heat source air heat exchanger (35), and a compressor (36). An air heat pump air conditioner, i.e. an HP air conditioner (30) mentioned later which gives the air supply via the refrigerant-air supply air heat exchanger (34) is also provided. The air from the HP air conditioner (30) in an air-conditioned space (S) is mixed evenly, and then the air is blown out in a rectified mode, and an induction radiation unit (1) induces the heat of the mixed air to the air-conditioned space (S).

Owner:KIMURA KOHKI CO LTD

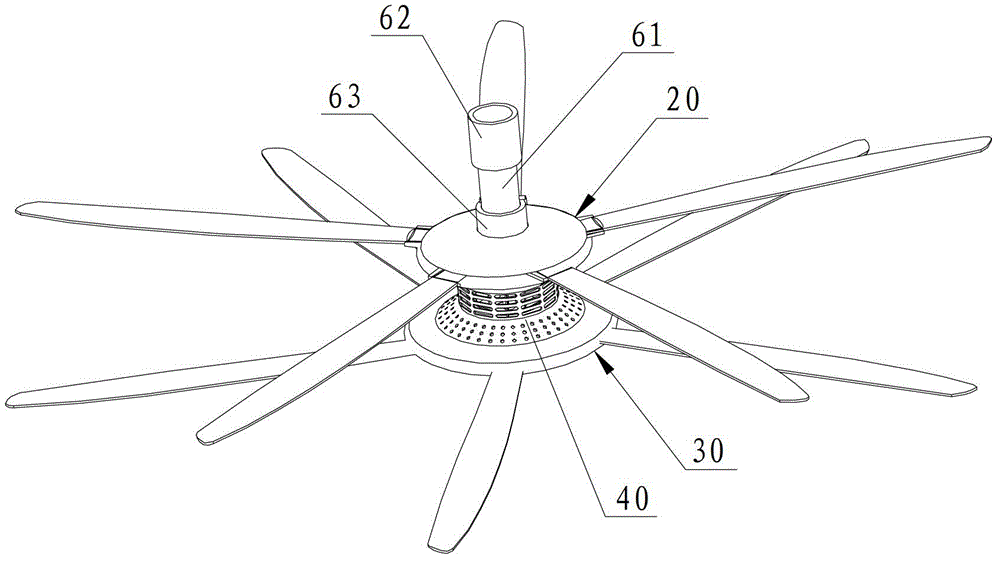

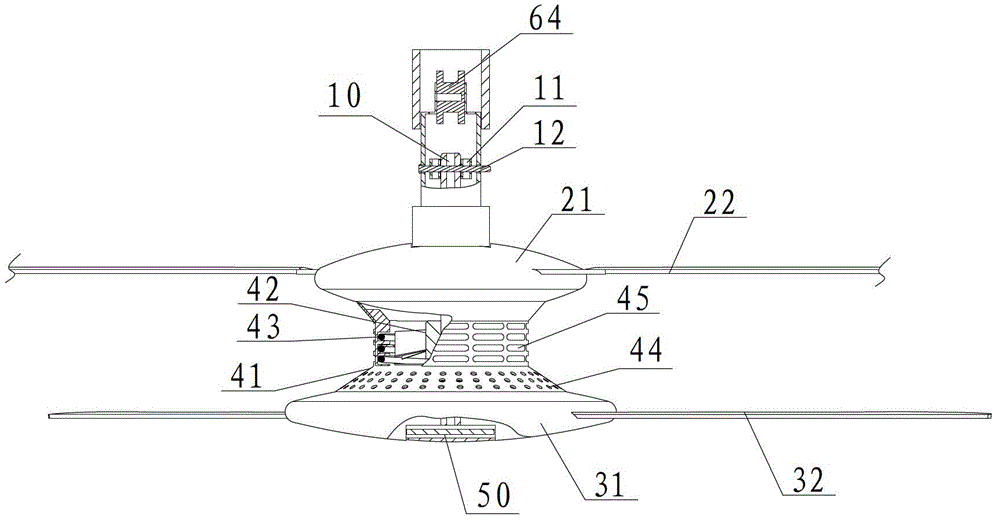

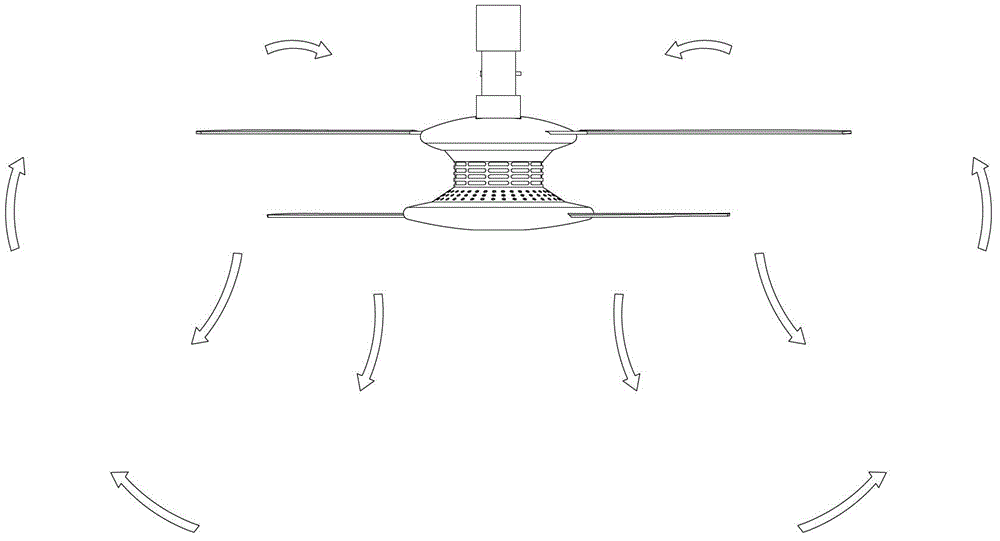

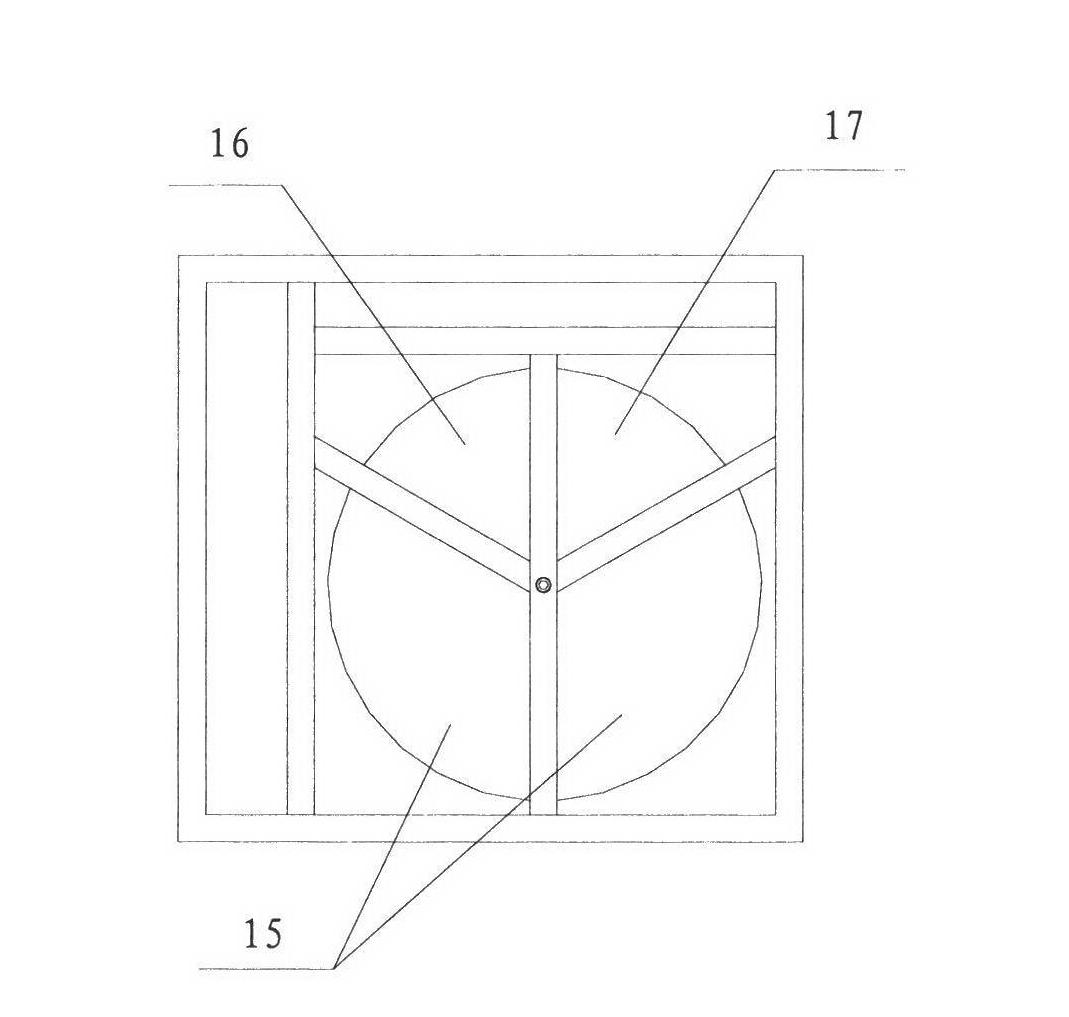

Ceiling fan with warming function

InactiveCN104033397AExtended service lifeSmall diameterPump componentsAir heatersCeiling fanAgricultural engineering

The invention discloses a ceiling fan with a warming function. The ceiling fan comprises a motor fixing shaft, an upper fan blade assembly, a lower fan blade assembly, a warming assembly and an electric control assembly. The upper fan blade assembly comprises a first motor and a first fan blade. The lower fan blade assembly comprises a second motor and a second fan blade. The two motors are fixed on the motor fixing shaft, the installation position of the first motor is higher than that of the second motor, and the diameter of the first fan blade is larger than that of the second fan blade. The warming assembly comprises an air inlet / outlet cover, a heating body and a warming fan. The air inlet / outlet cover is fixed on the motor fixing shaft and located between the upper fan blade assembly and the lower fan blade assembly, the heating body is fixedly arranged in the air inlet / outlet cover, an air inlet and an air outlet are arranged in the air inlet / outlet cover, and the warming fan is installed on the motor fixing shaft and located on a flowing path between the air inlet and the air outlet. The first motor, the second motor, the heating body and the warming fan are electrically connected with the electric control assembly. The ceiling fan has a cooling function and a warming function, two layers of fan blades are adopted and controlled independently, and the ceiling fan is reliable and comfortable to use.

Owner:FUZHOU AQUAPOWER ELECTRIC WATER HEATER

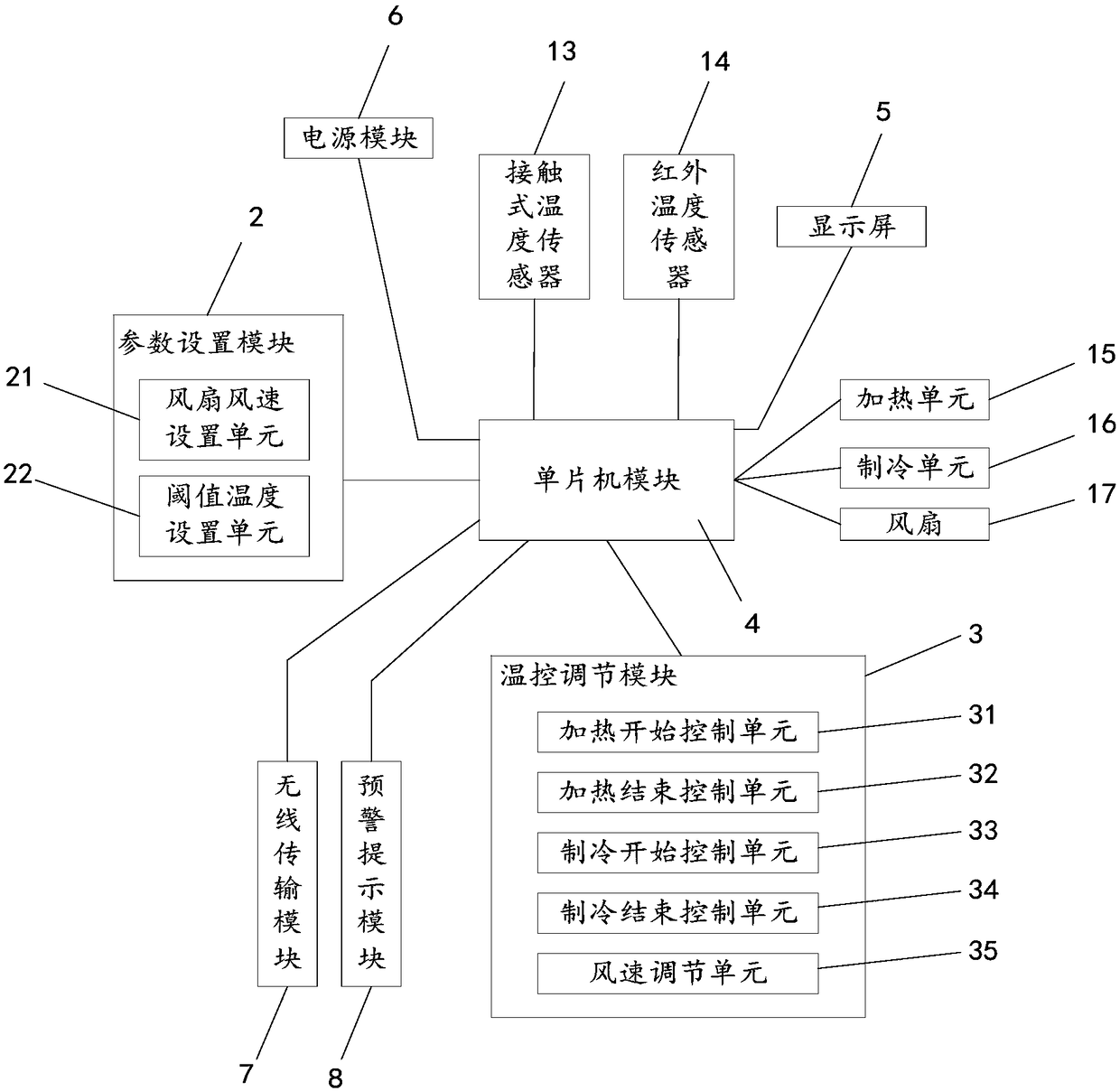

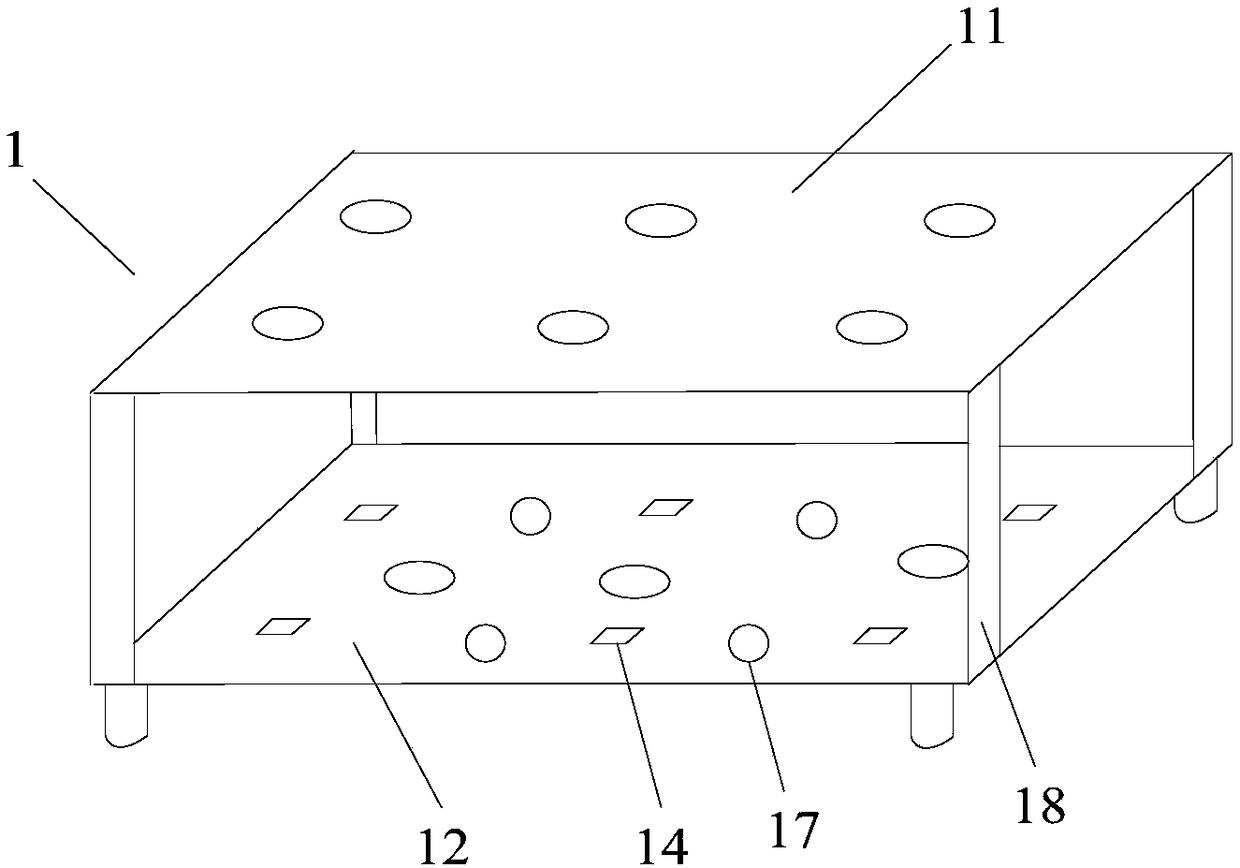

Temperature control electronic system using single chip microcomputer

InactiveCN108508805AHigh precisionAdjust the wind speed in real timeProgramme controlComputer controlMicrocomputerMicrocontroller

The invention discloses a temperature control electronic system using a single chip microcomputer. The system includes a temperature control device, a parameter setting module, a temperature control adjustment module and a single chip microcomputer module. According to the temperature control electronic system, the temperature of a first temperature collecting layer is monitored comprehensively through a contact type temperature sensor and a non-contact type temperature sensor (an infrared temperature sensor) simultaneously. Since the first temperature collecting layer and the second temperature collecting layer are heat transfer plates with holes, effective heat dissipation can be ensured; at the same time, the moment of shutting down a heating unit / refrigerating unit is determined through a temperature average, an average temperature rise / cooling speed value and a threshold temperature, and the heating unit / refrigerating unit is shut down ahead of time, the stable control of the temperature is ensured with high precision, so that the temperature control electronic system is high in precision and good in stability; besides, through the maximum or minimum temperature among the temperatures obtained by the contact type temperature sensor and the non-contact type temperature sensor, the wind speed of a fan is adjusted in real time, uniform heat exchange is effectively ensured, and sudden changes of local temperature are avoided.

Owner:HUANGHUAI UNIV

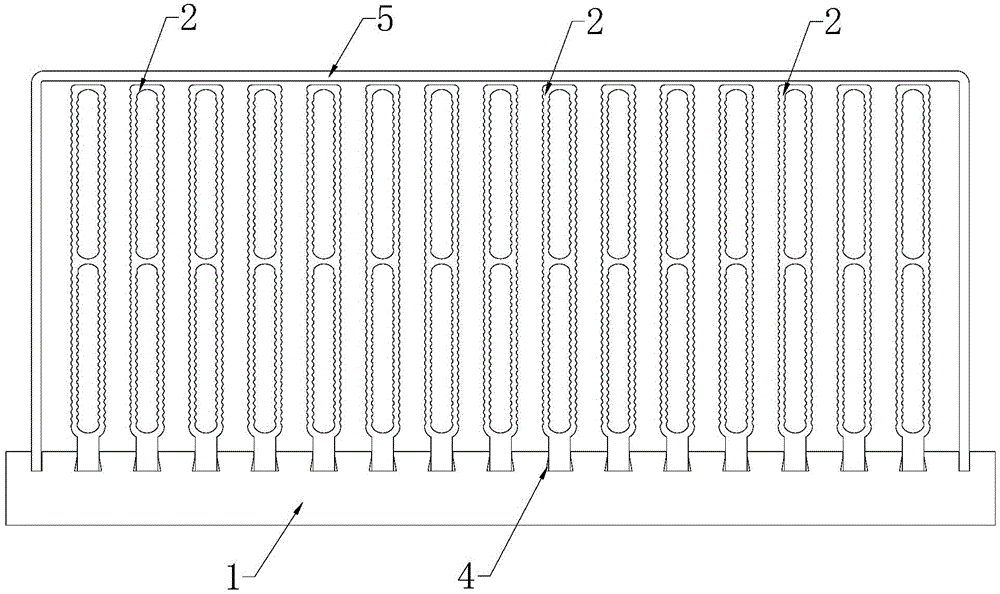

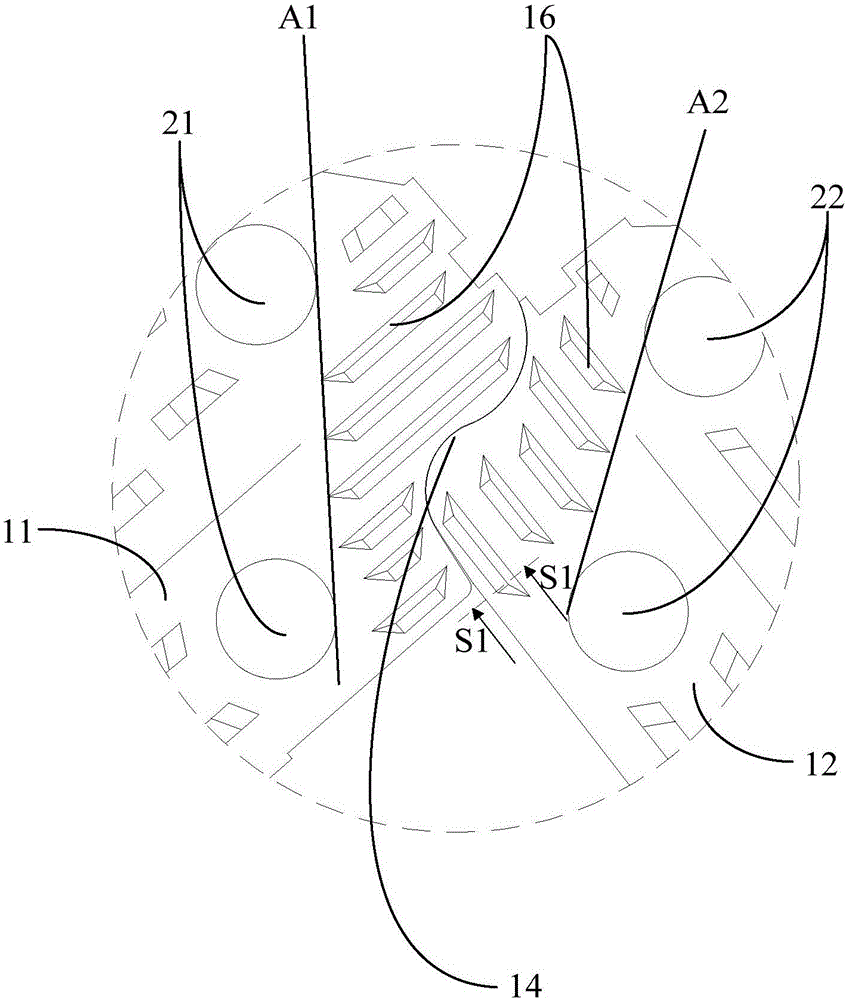

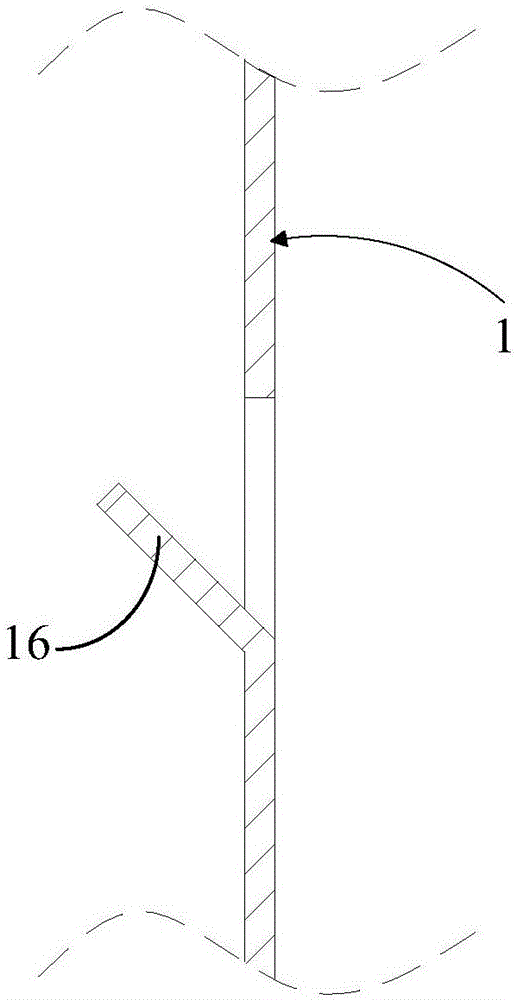

Heat exchanger of indoor unit of air conditioner and indoor unit of air conditioner

PendingCN106500185AGive full play to the heat exchange effectImprove heat transfer efficiencyLighting and heating apparatusSpace heating and ventilation detailsPlate heat exchangerEngineering

The invention discloses a heat exchanger of an indoor unit of an air conditioner and the indoor unit of the air conditioner. The heat exchanger of the indoor unit of the air conditioner comprises fins. Each fin comprises a first folded fin portion, a second folded fin portion and a third folded fin portion, wherein the first folded fin portion, the second folded fin portion and the third folded fin portion are sequentially connected from top to bottom. Each second folded fin portion is located in front of the corresponding first folded fin portion and the corresponding third folded fin portion. Each fin further comprises an upper connecting structure and a lower connecting structure. The upper end of each second folded fin portion is connected with the corresponding first folded fin portion through the corresponding upper connecting structure. The lower end of each second folded fin portion is connected with the corresponding third folded fin portion through the corresponding lower connecting structure. The two sides of each upper connecting structure are provided with first windshield structures. The two sides of each lower connecting structure are provided with second windshield structures. Each third folded fin portion is provided with a third windshield structure. The first windshield structures, the second windshield structures and the third windshield structures all protrude from the heat exchange faces of the fins and are used for stopping the wind entering the fins. By the adoption of the heat exchanger of the indoor unit of the air conditioner and the indoor unit of the air conditioner, the overall distribution uniformity of the wind speed of the heat exchanger can be improved, and therefore the heat exchange effect is improved.

Owner:GUANGZHOU HUALING REFRIGERATION EQUIP +1

Fume hood used for lab

InactiveCN103624051AAvoid sharp up and down movementsUniform wind speedDispersed particle filtrationDirt cleaningEngineeringFume hood

The invention relates to a fume hood used for a lab. The fume hood comprises a hood body, a fan is arranged in the top of the hood body, the hood body comprises an upper hood and a lower hood with a working table top, one side edge of the upper hood and one side edge of the lower hood are connected through a supporting plate, a tapered wide-end-down flow guiding pipe is arranged in the upper hood and is directed at the lower hood, the narrow end of the flow guiding pipe is connected with a net-shaped laminate panel, and a filter net is arranged between the laminate panel and the fan. According to the fume hood used for the lab, the tapered wide-end-down flow guiding pipe is arranged in the upper hood, in this way, harmful gases can ascend spirally in the flow guiding pipe and are prevented from rapidly moving up and down, the turbulence conditions can not happen, the harmful gases can be removed through absorption completely, and even air speed on the working table top is ensured.

Owner:SUZHOU YIDA PURIFICATION LAB EQUIP

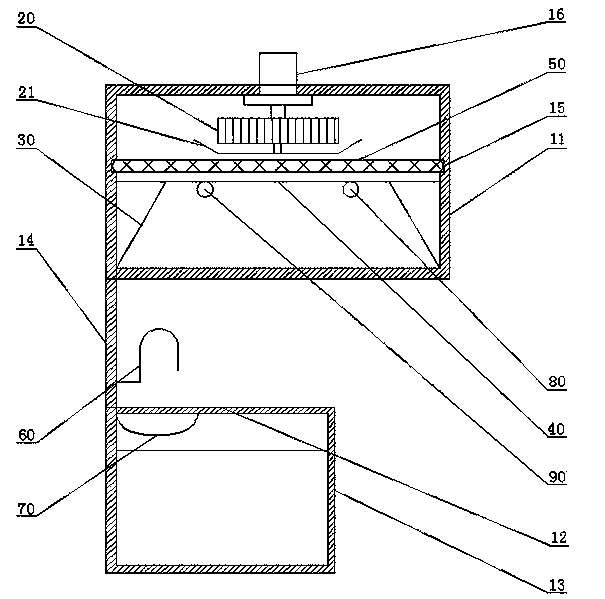

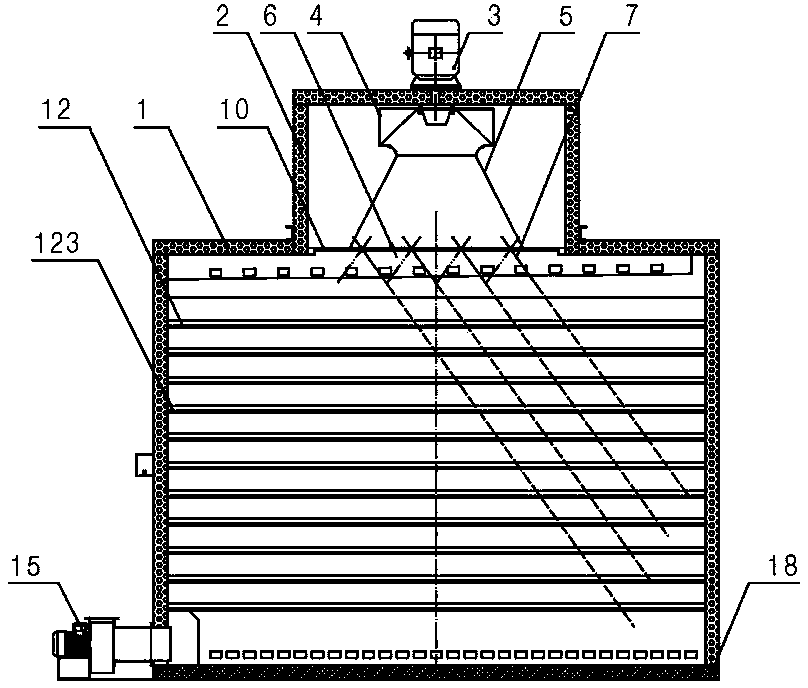

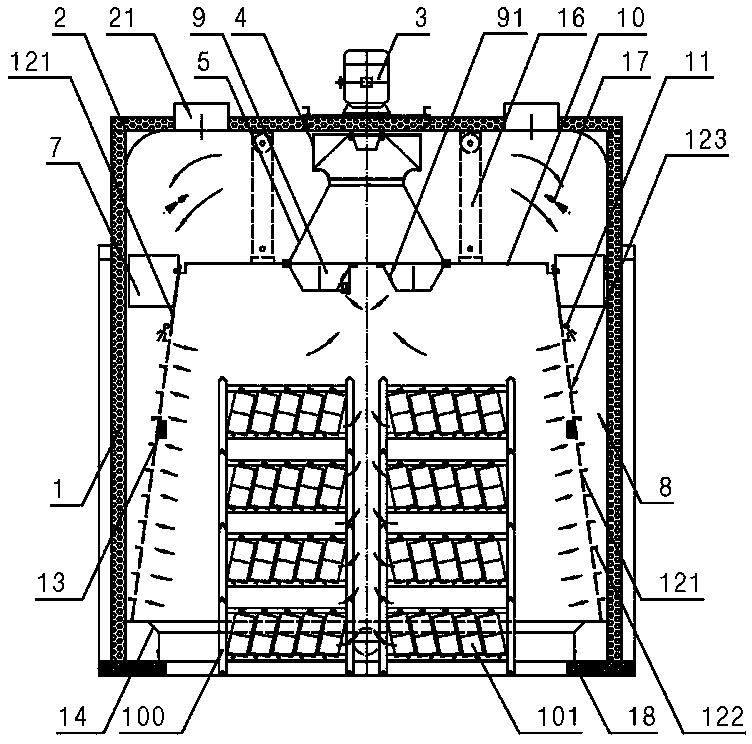

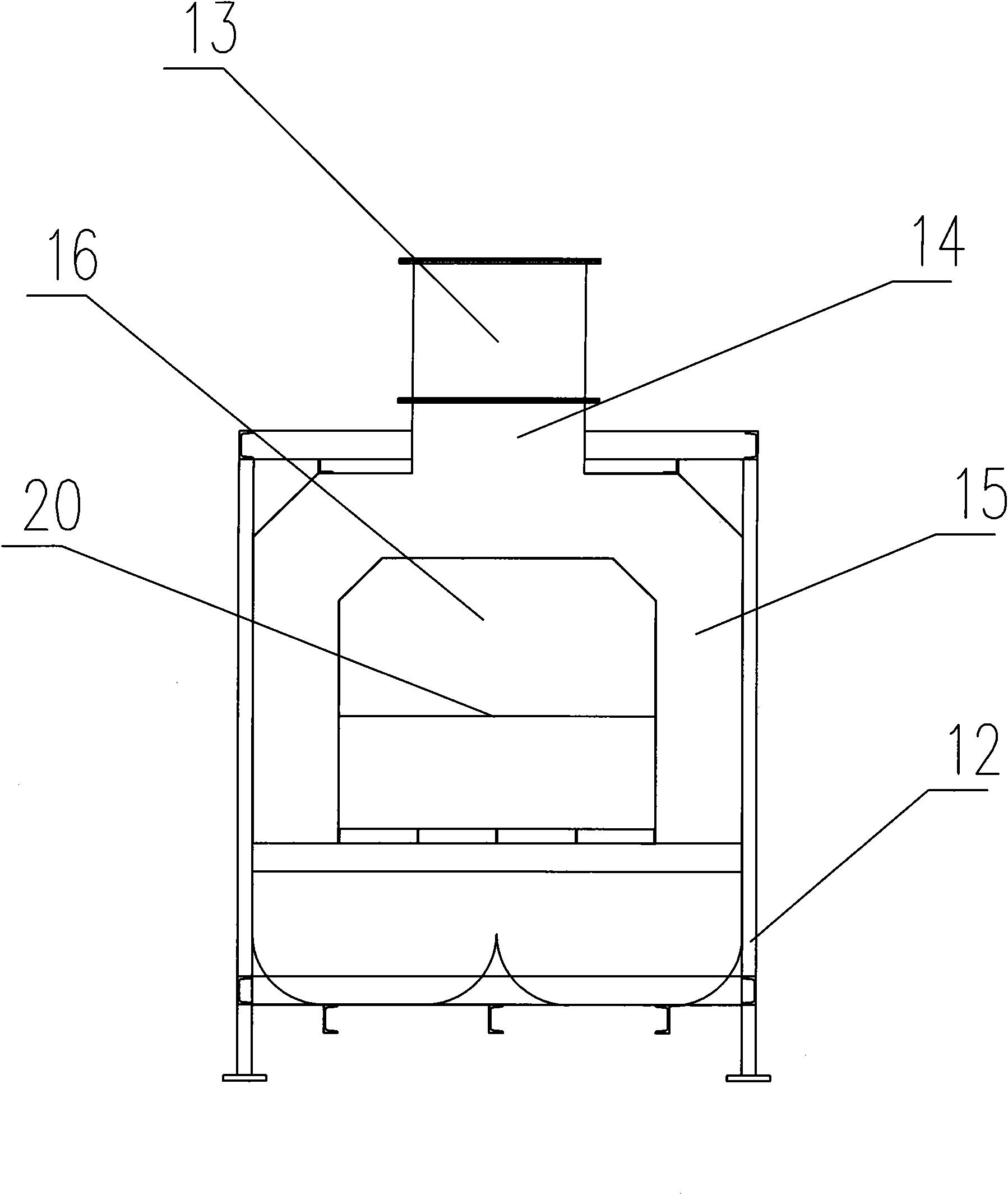

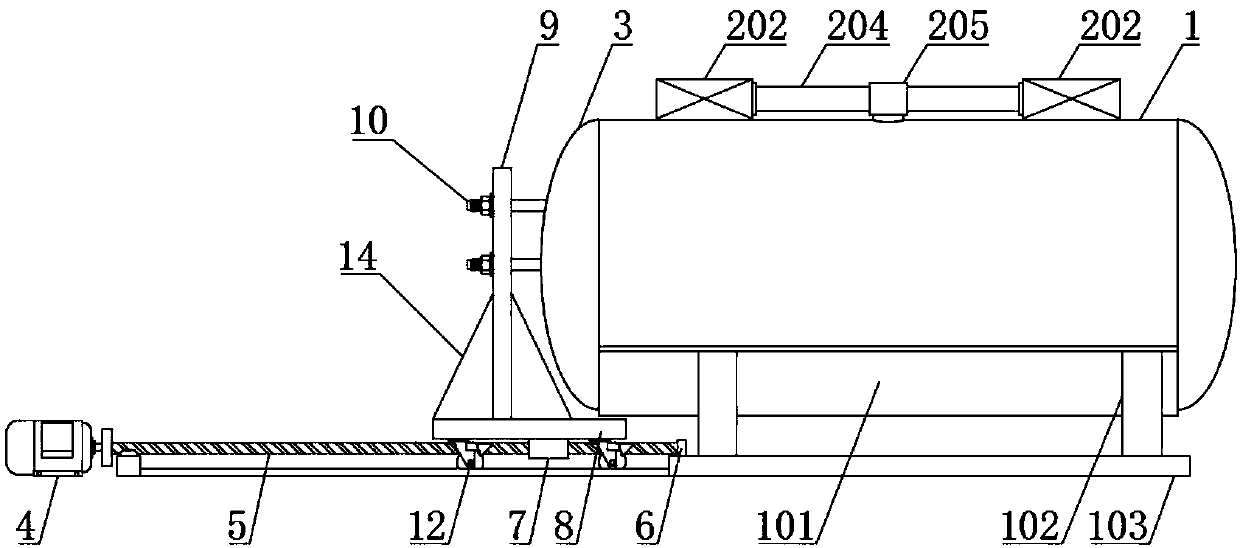

Curing device for accumulator plate and air supply mechanism in curing device

ActiveCN104037387AUniform wind speedUniform air volumeElectrode thermal treatmentElectrical and Electronics engineeringHumidity

The invention discloses an air supply mechanism inside a curing chamber of an accumulator plate, which can enable temperature and humidity at each position inside the curing chamber to be uniformly distributed. The curing device comprises an air supply fan, a secondary box with a bottom board is arranged on the curing chamber, the air supply fan is arranged at the top of the secondary box along the vertical direction, an air guide cover with a downward opening is arranged on the bottom board of the secondary box and below fan blades, an air return hole matched with the air guide cover is formed in the middle of the bottom board, vertical air outlets are respectively formed between two sides of the bottom board of the secondary box and corresponding inner walls of a main box, a pair of air distributing screens is symmetrically arranged below the vertical air outlets at two sides in the main box, transverse air outlets are arranged on the air distributing screens, and external air ducts are formed between the air distributing screens and the corresponding inner walls of the main box. The air supply mechanism is mainly used in the curing device for the accumulator plate.

Owner:江苏金帆新程装备有限公司

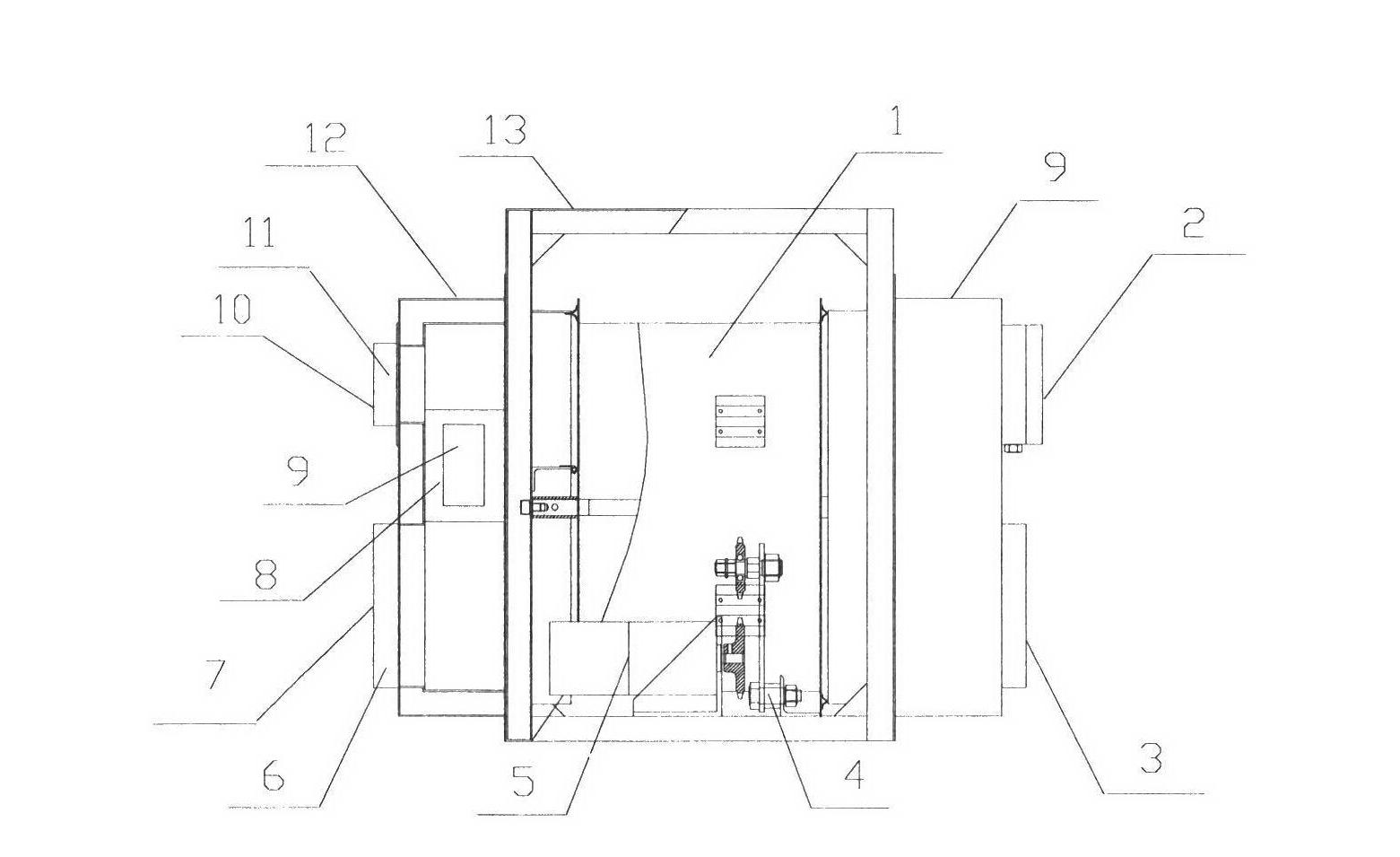

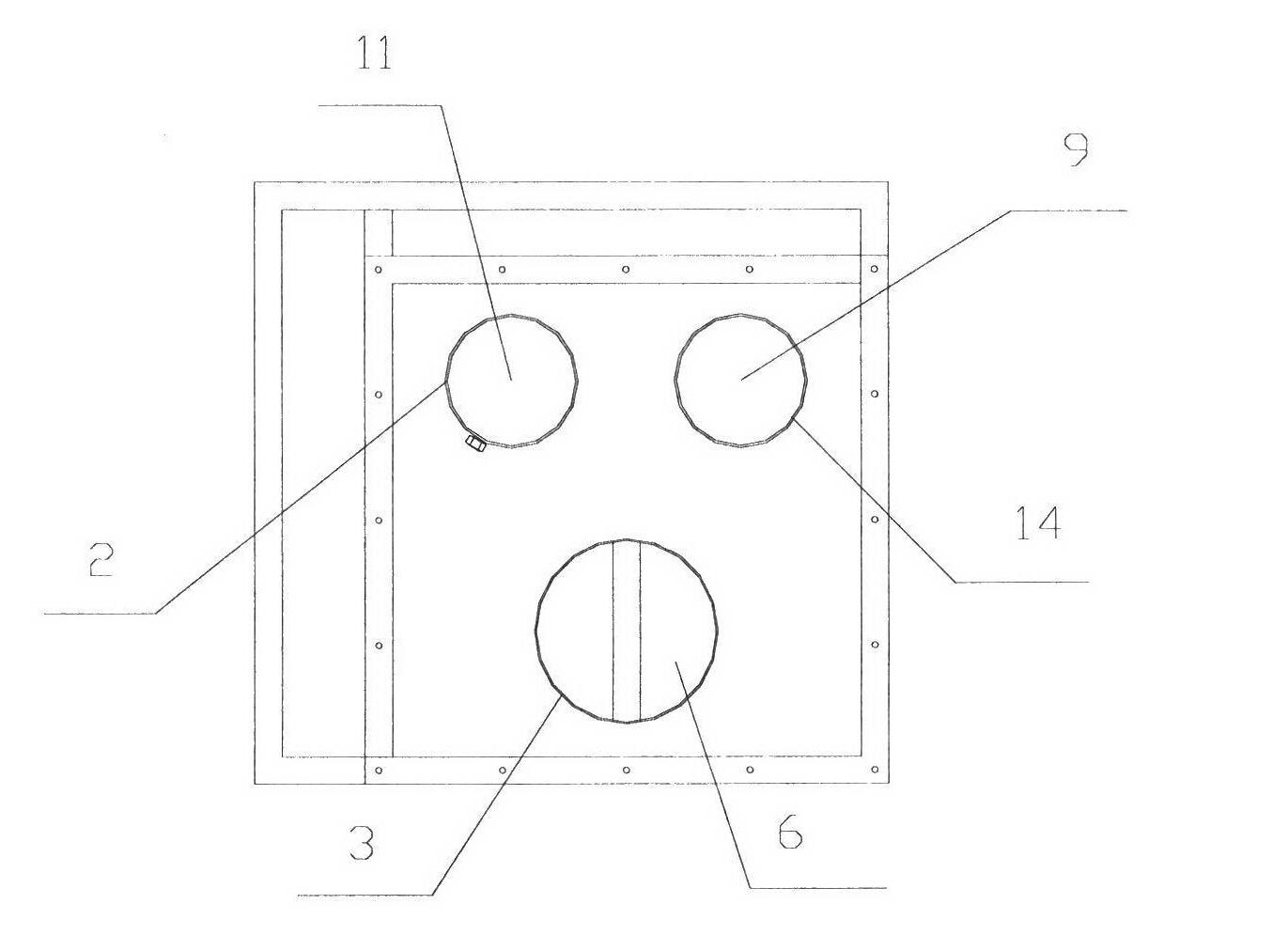

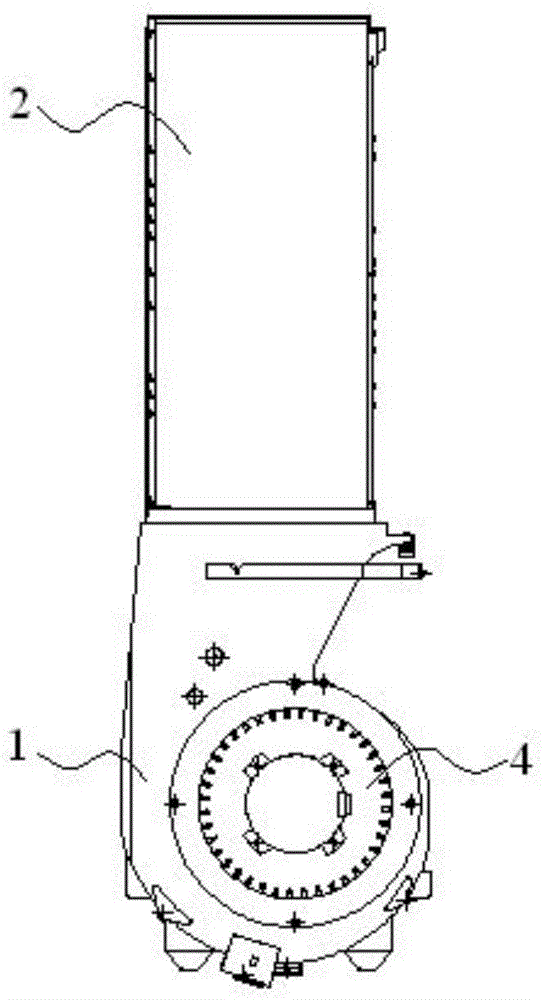

Special rotating wheel dehumidifying equipment for glove box

ActiveCN102614752AAchieve heat preservationGuaranteed validityDispersed particle separationAir volumeEngineering

The invention discloses special rotating wheel dehumidifying equipment for a glove box, which comprises a rotating wheel frame. A dehumidifying rotating wheel is arranged in the rotating wheel frame and is divided into a treatment region, a regeneration region and a cold blowing region which are mutually independent sealed spaces. The special rotating wheel dehumidifying equipment is characterized by further comprising a closed air bellow, and a treatment region airflow channel, a regeneration region airflow channel and a cold blowing region airflow channel are arranged in the closed air bellow. The airflow channels are arranged in the closed air bellow, so that the treatment region, the regeneration region and the cold blowing region are double-layered sealed structures, air interlayer heat insulation is realized, effectiveness of an anti-cold bridge is ensured, airtightness is strengthened, air volume loss is avoided, and air supply parameters are stable. Central angles corresponding to the treatment region, the regeneration region and the cold blowing region are 240 degrees, 60 degrees and 60 degrees respectively, air speeds of the regions of the rotating wheel are balanced due to the area proportional distribution, and accordingly cold and heat exchange balance is realized.

Owner:杭州福达除湿设备有限公司

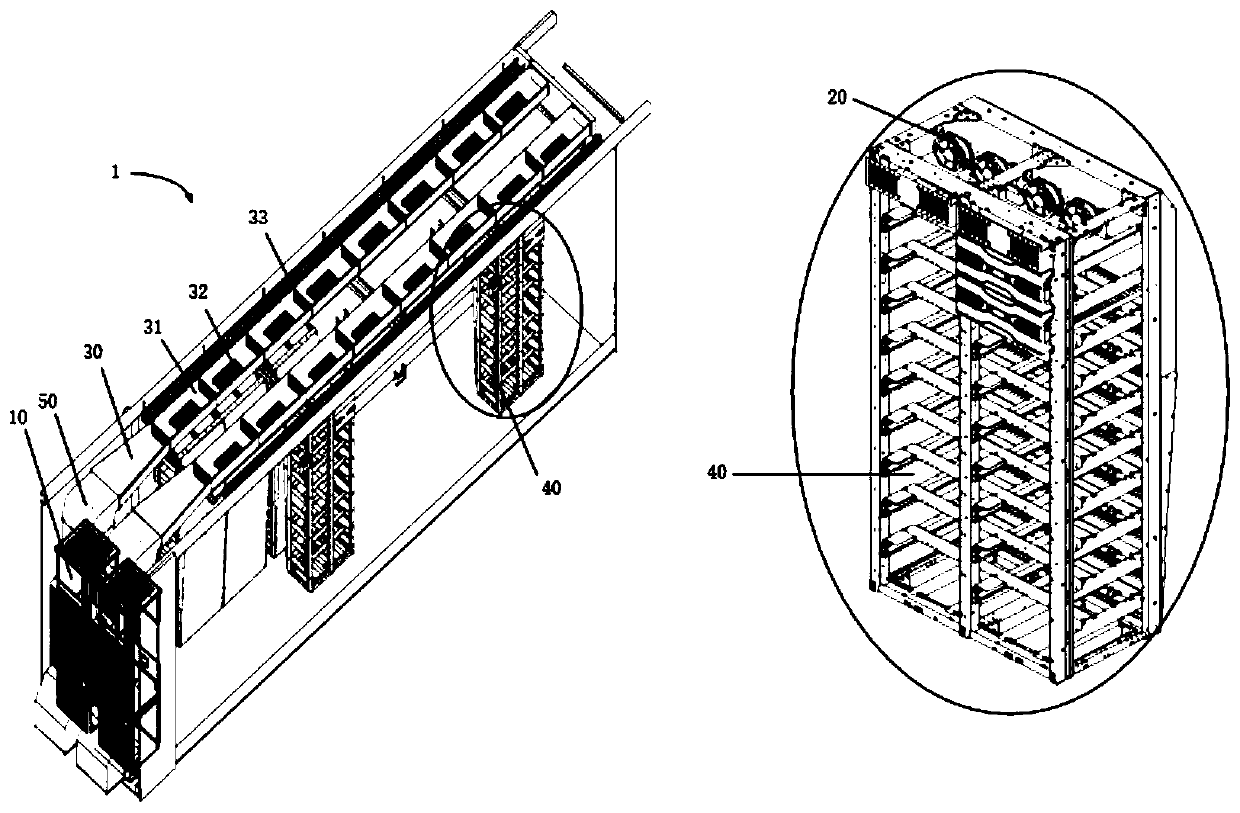

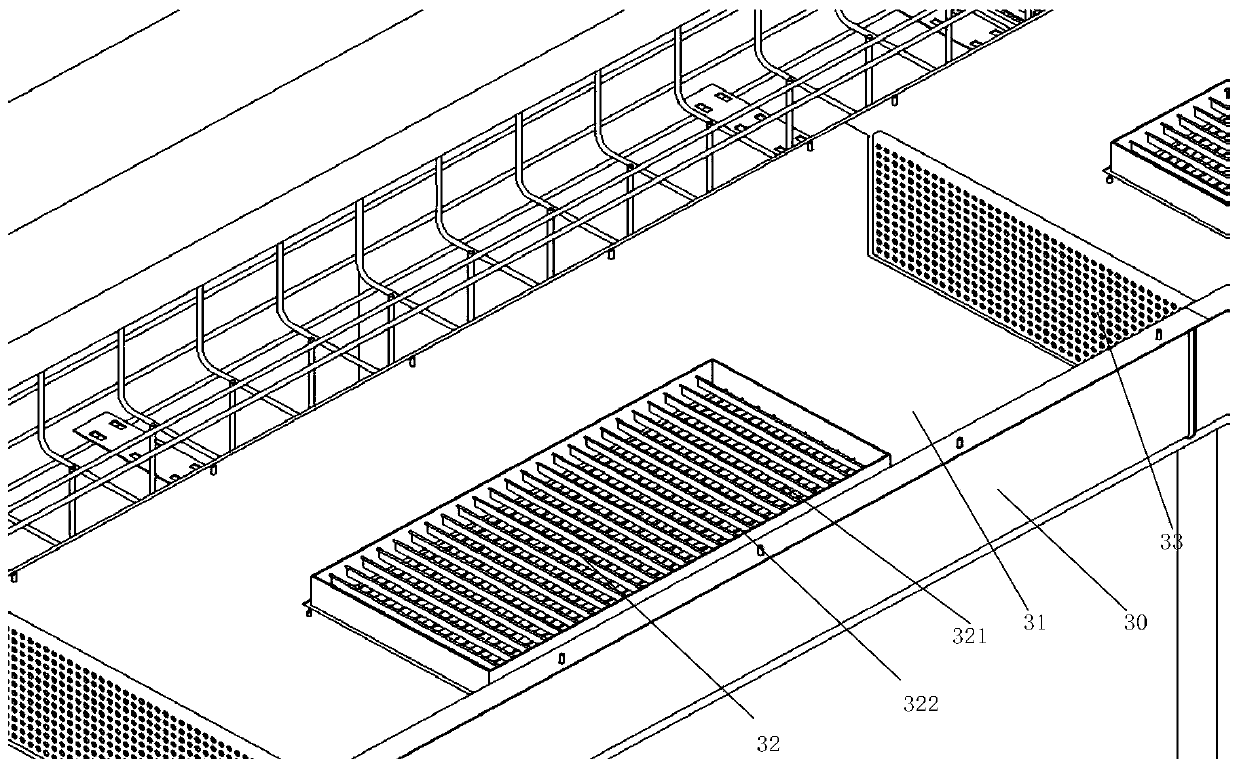

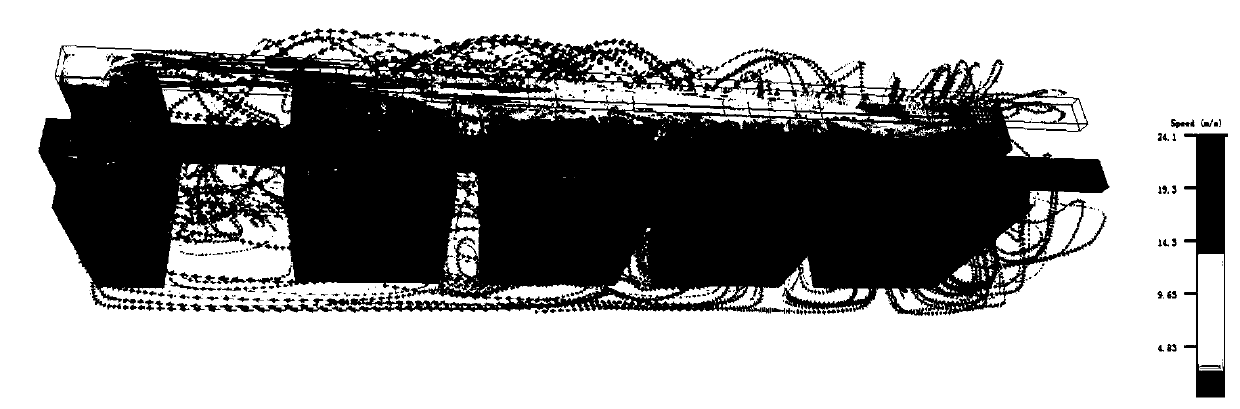

Temperature control system of energy storage box

InactiveCN111082184AImprove temperature fieldReduce air temperature differenceSecondary cellsPhysicsEngineering

The invention relates to a temperature control system of an energy storage box. The system comprises an air conditioner, a fan, an air duct and a battery rack, wherein an air outlet of the air conditioner is communicated with the air duct, the air duct is of a tubular structure defined by sequentially connecting air duct plates, the air duct is arranged above the fan, the fan is arranged above thebattery rack, the air duct plate is provided with an opening facing the fan, an adjustable shutter is arranged on the opening, and outlet air of the air conditioner is guided to the fan by the opening of the air duct and is blown to the battery rack by the fan. According to the mode, the purposes of improving the internal temperature of the energy storage box and reducing the temperature difference of air in the energy storage box can be achieved.

Owner:SHENZHEN CLOU ELECTRONICS

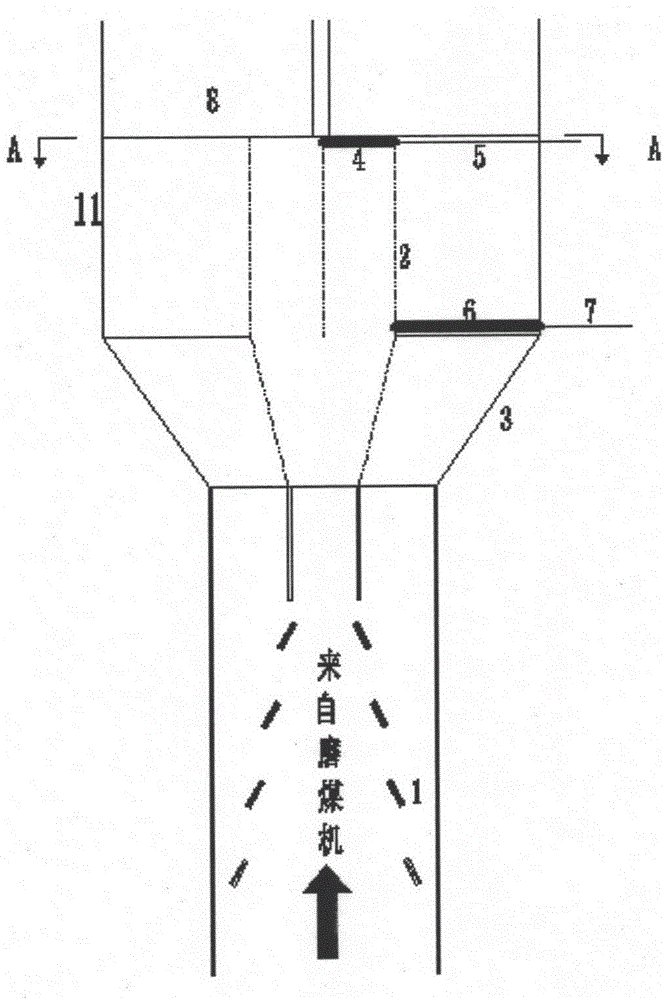

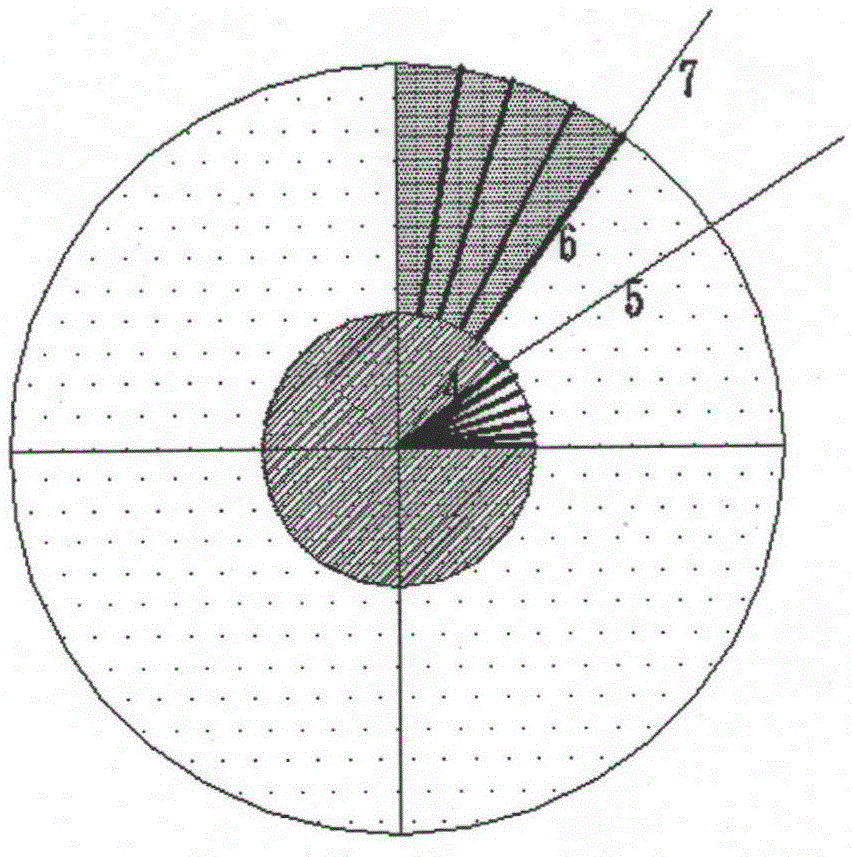

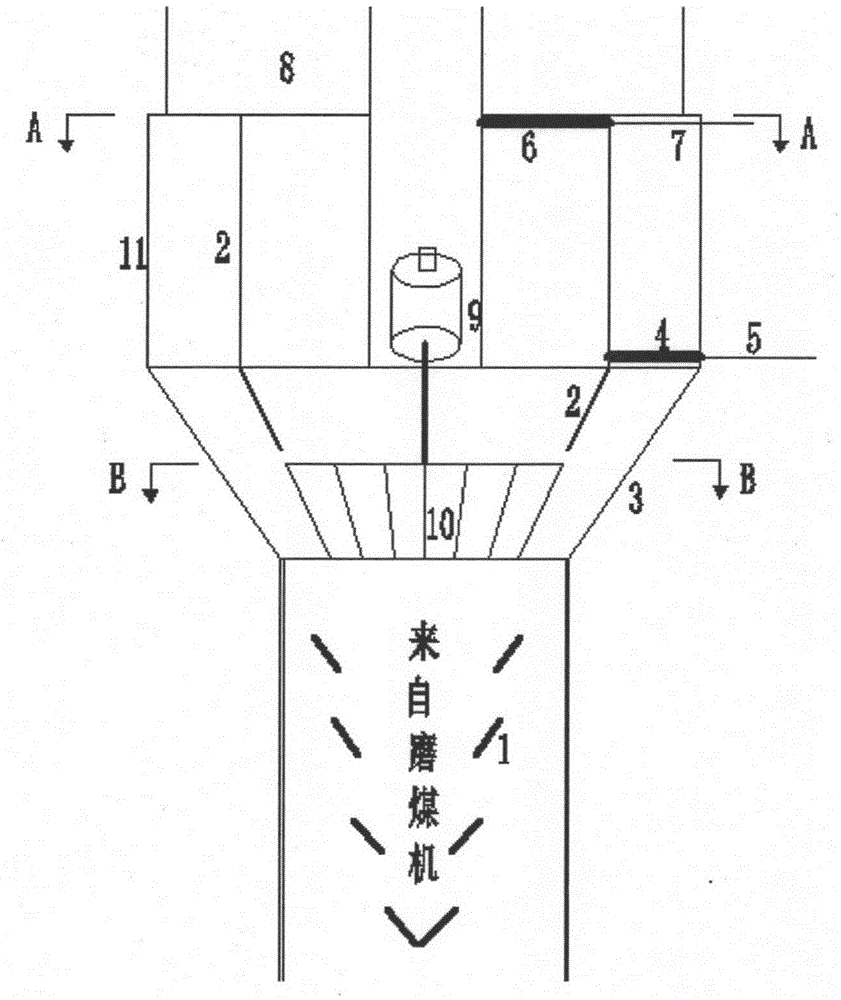

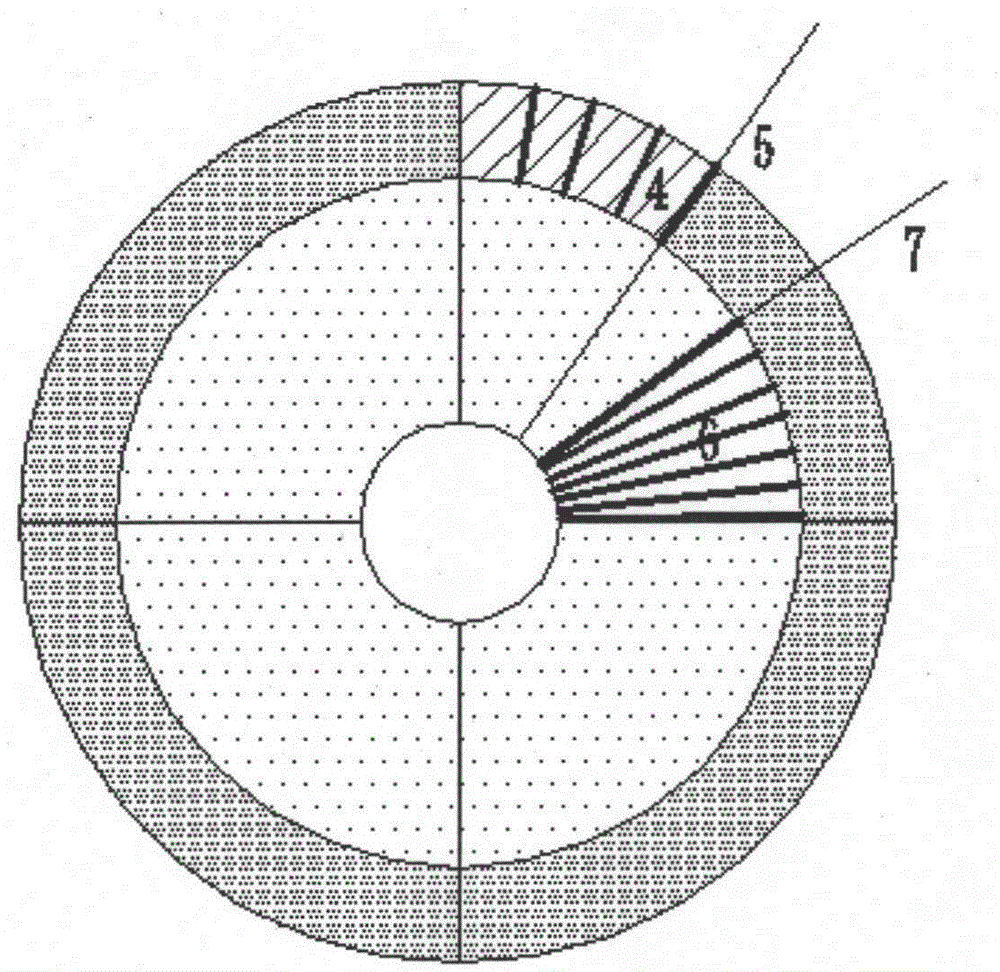

Adjustable coal dust distributor

ActiveCN105485709AUniform concentrationUniform wind speedFuel feeding arrangementsLump/pulverulent fuel feeder/distributionCoal dustDistributor

The invention provides an adjustable coal dust distributor which comprises a thick phase inner pipe coaxially arranged in a coal dust cylinder at an outlet of a coal mill. A thin phase outer ring is formed between the thick phase inner pipe and the wall of the coal dust cylinder at the outlet of the coal mill. The section of the thick phase inner pipe and the section of the thin phase outer ring are coaxial and are equally divided into parts, wherein the number of the parts is the same with that of primary air pipes; and each equally-divided section part is connected with one primary air pipe, and thick phase adjusting valves and thin phase adjusting valves are arranged on the equally-divided section parts respectively. A reducing pipe is arranged at the front end of the coal dust cylinder at the outlet of the coal mill, and a shutter ring is arranged at the front end of the reducing pipe. Coal dust at the outlet of the coal mill is condensed through the shutter ring, under the inertia effect, thick and thin separation with the thick part inside and the thin part outside is conducted, thick coal dust is condensed at the center, thin coal dust is distributed on the periphery, a thick phase and a thin phase are equally divided, all the corresponding parts of thick and thin coal dust enter the primary air pipes and are evenly distributed; and the adjusting valves are arranged for all the parts of the thick phase and the thin phase, and adjustment is convenient.

Owner:SHANGHAI POWER EQUIP RES INST

Pulverized coal distributer capable of adjusting air speed and pulverized coal concentration

ActiveCN105546569AUniform concentrationUniform wind speedFuel feeding arrangementsLump/pulverulent fuel feeder/distributionReducerCoal

The invention provides a pulverized coal distributer capable of adjusting the air speed and the pulverized coal concentration. The pulverized coal distributer comprises a light-phase inner pipe coaxially arranged inside a pulverized coal drum of a coal mill outlet . A dense-phase outer circular ring is formed between the light-phase inner pipe and the drum wall of the pulverized coal drum of the coal mill outlet. The section of the light-phase inner pipe and the section of the dense-phase outer circular ring are coaxially and evenly divided into parts of the same number as primary air pipes. Each equational section is connected with one primary air pipe and provided with a light-phase regulating valve and a dense-phase regulating valve. Rotating blades are arranged in a reducer pipe at the front end of the pulverized coal drum of the coal mill outlet. A shutter ring is arranged at the front end of the reducer pipe. Pulverized coal at the coal mill outlet is compressed twice through the shutter ring and the rotating blades; after two times of light-dense separation under the inertia effect, dense pulverized coal is concentrated at the outer circular ring, light pulverized coal is distributed at the inner circular ring, the dense pulverized coal and the light pulverized coal are evenly divided, each part of the dense pulverized coal and each part of the light pulverized coal are mixed and enter the corresponding primary air pipe, and all pulverized coal is distributed evenly; each part of light-dense pulverized coal is provided with one regulating valve so as to be regulated conveniently.

Owner:SHANGHAI POWER EQUIP RES INST

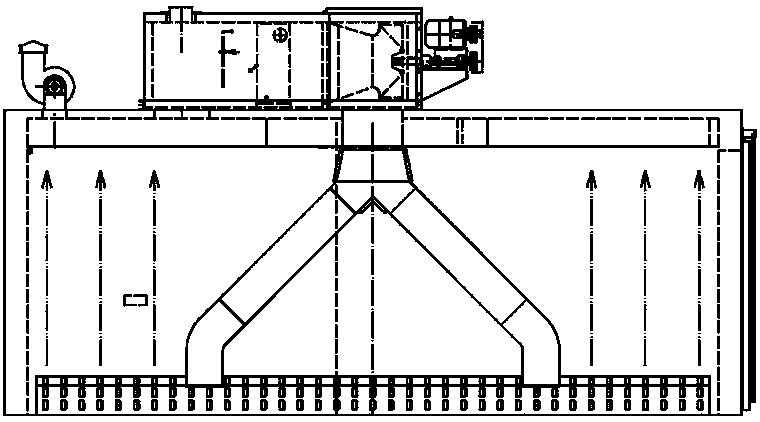

Aluminum brazing furnace

The invention discloses an aluminum brazing furnace which has the advantages of safe use and good cooling effect at a pre-cooling region. When the temperature in an air cooling chamber is higher than a set temperature, a control device can control a circulating fan to be automatically started; the air speed at a forced cooling region is uniform, the cooling effect of a furnace lining at the forced cooling region is good and the cooling area is relatively large; a slag removal chamber is reserved, so that brazing crystals can be immediately cleaned up without manual periodic cleaning, the labor intensity is reduced, the using cost is reduced, the working efficiency is improved, and the influence on the brazing effect is prevented because the shaking of a conveyer belt caused by the accumulation generated by the brazing crystals can be prevented; meanwhile, the slag removal device is also provided with an access door, so that the aluminum brazing furnace can be conveniently examined and repaired; when the furnace lining is subjected to linear expansion, the furnace lining can be helped to quickly move towards one side so as to perform the liner expansion well, reduce the resistance during the expansion and ensure high safety and high reliability for the running of the aluminum brazing furnace; and thus the distance for every linear expansion of the furnace lining is the same, and deformation of the furnace lining caused by the difference in distance of the linear expansion of the furnace lining is prevented.

Owner:JIANGSU KANGJIE MACHINERY

Magnetic attraction type air cooling radiator

InactiveCN111372425AReduce thermal resistanceHelp conductionModifications by conduction heat transferHeat resistanceEngineering

The invention discloses a magnetic attraction type air cooling radiator. The magnetic attraction type air cooling radiator comprises a heat conduction substrate and a cooling fin. The heat conductionsubstrate is provided with a fin inserting groove, the connecting end of the cooling fin is fixed in the fin inserting groove of the heat conduction substrate, and the space between the connecting endof the cooling fin and the fin inserting groove is further filled with heat conduction media. An air passing channel is further formed in the cooling fin. The space between the connecting end of thecooling fin and the fin inserting groove is further filled with the heat conduction medium, the heat resistance between the heat conduction substrate and the cooling fin can be reduced through the heat conduction medium, heat conduction is facilitated, and therefore the heat dissipation effect is improved; in addition, the cooling fins can be more tightly attached to the side walls of the fin inserting grooves, and the thermal resistance can be further reduced; by the adoption of the design of the air passing channel, air of an external fan can flow through the outside of the cooling fins andthe air passing channel to fully cool the inside and the outside of the cooling fins, and heat on the cooling fins can be taken away quickly.

Owner:SUZHOU YONGTENG ELECTRONICS PROD

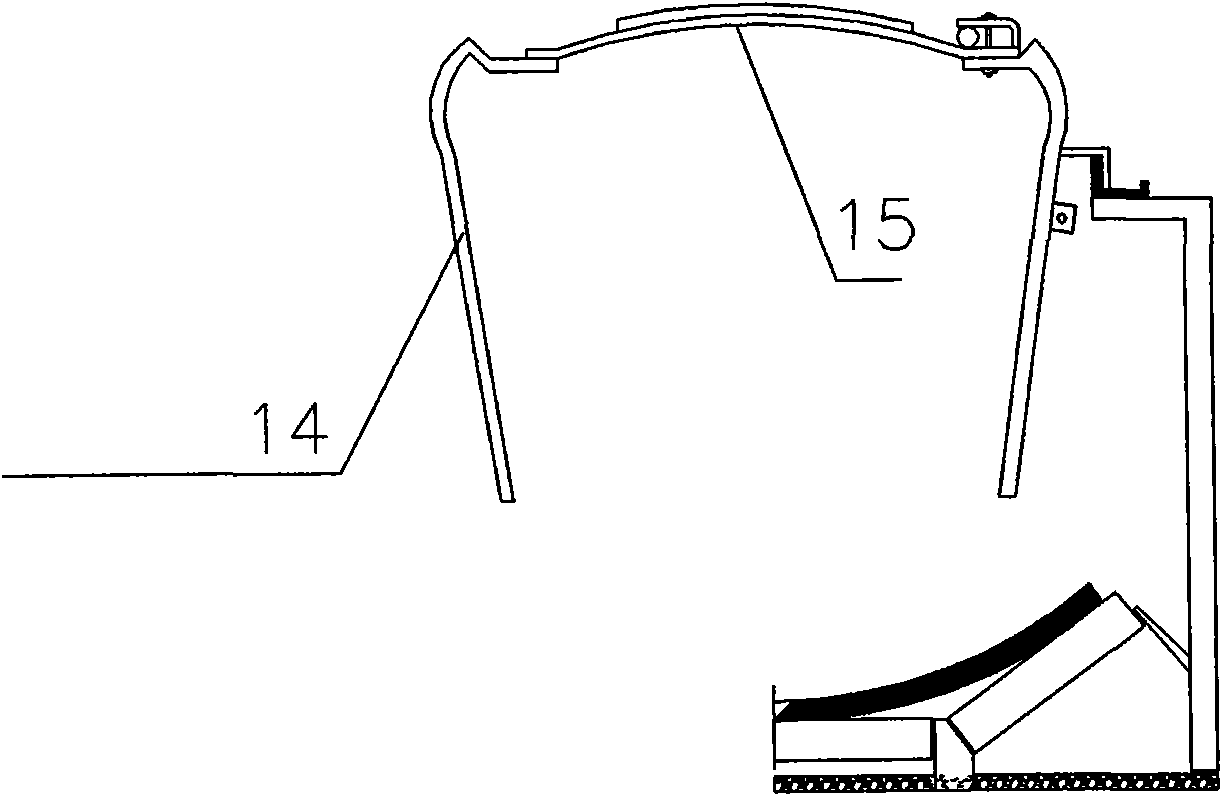

Wall-hanging air purifier

InactiveCN105107299AImprove performanceAvoid backflow phenomenonCombination devicesDispersed particle filtrationImpellerAir filter

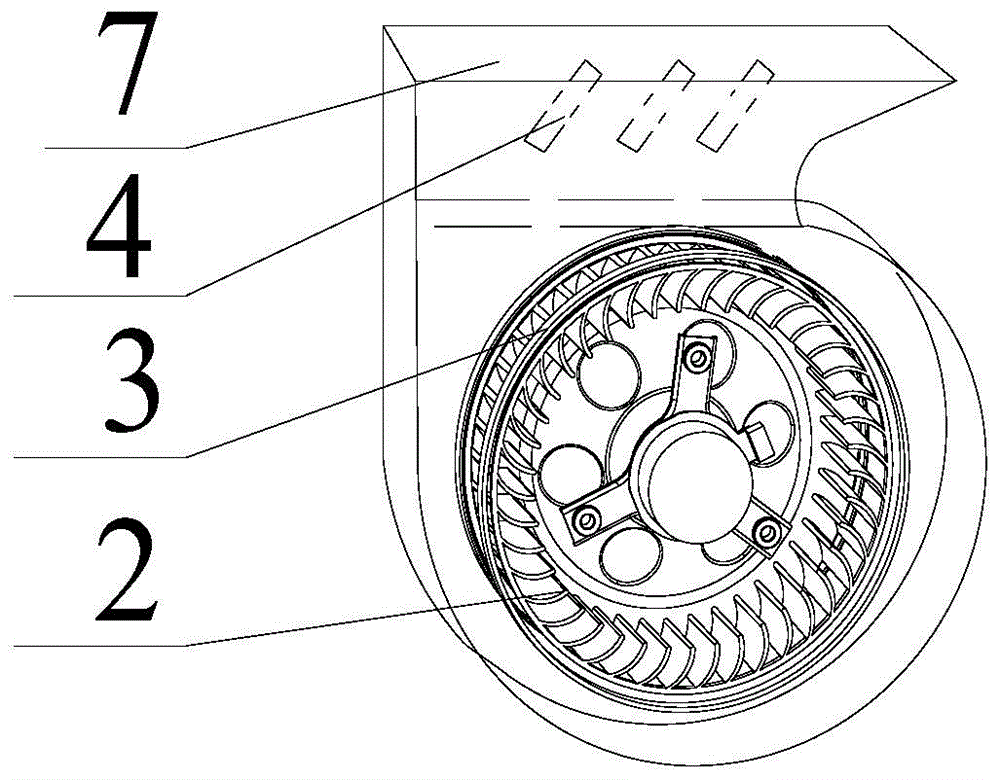

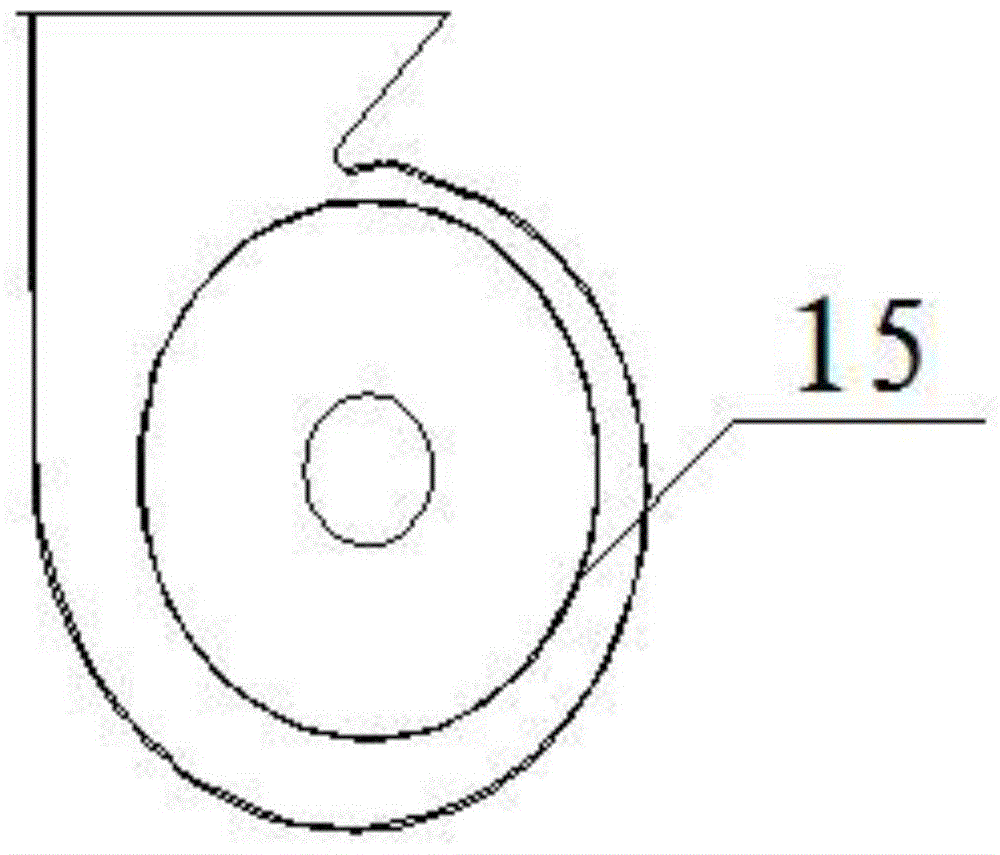

The invention relates to a wall-hanging air purifier. The wall-hanging air purifier comprises a purifier shell with an air purifying apparatus inside, wherein an air inlet is formed in a front panel of the shell, air outlets are formed in two side walls of the shell, the purifying apparatus comprises two fans, air outlets of the two fans are respectively communicated with the air outlets in the two side walls of the shell, air inlets of the two fans are respectively communicated with an outlet of an air filter, an inlet of the air filter is communicated with the air inlet in the front panel of the shell, each fan comprises an impeller shell and an impeller which is arranged in an inner cavity of the impeller shell and fixed on an impeller shaft, the impeller shaft is connected with a driving apparatus. A key point of the invention is that a gap between the impeller shell and the impeller forms a ventilation air duct, an air protection ring 15 which is coaxial with the impeller is arranged on the impeller shell inner wall, adjacent to a peripheral ring of the impeller, of the ventilation air duct, and the diameter of an air stop annular plate is 6 to 10mm greater than that of the impeller. The wall-hanging air purifier is small in air resistance, smooth in air discharging, high in working efficiency, good in performance, capable of greatly lowering the noise, high in air outlet efficiency and capable of greatly improving the performance.

Owner:北京卫家环境技术有限公司

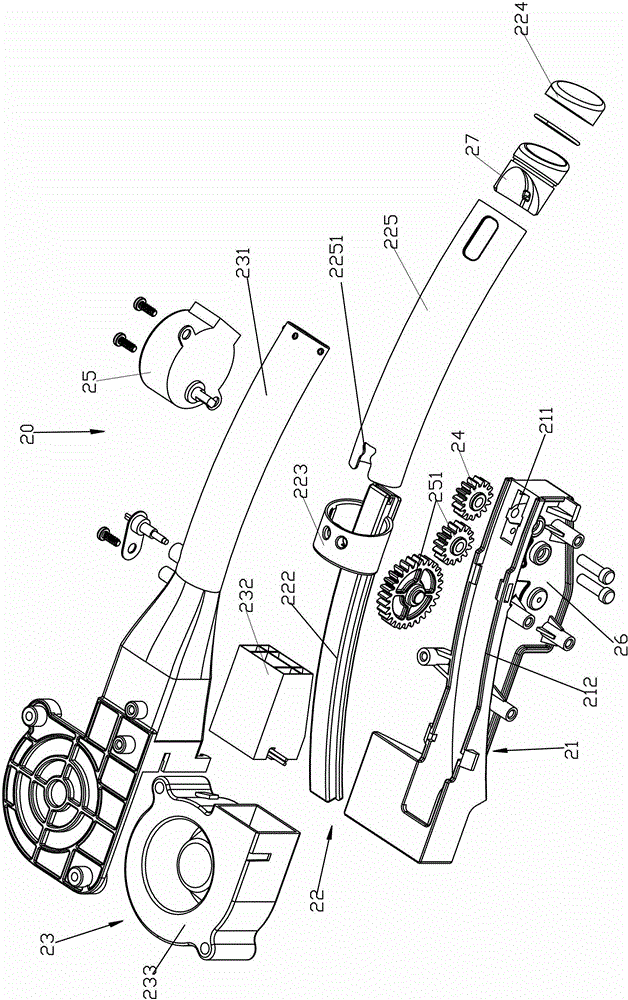

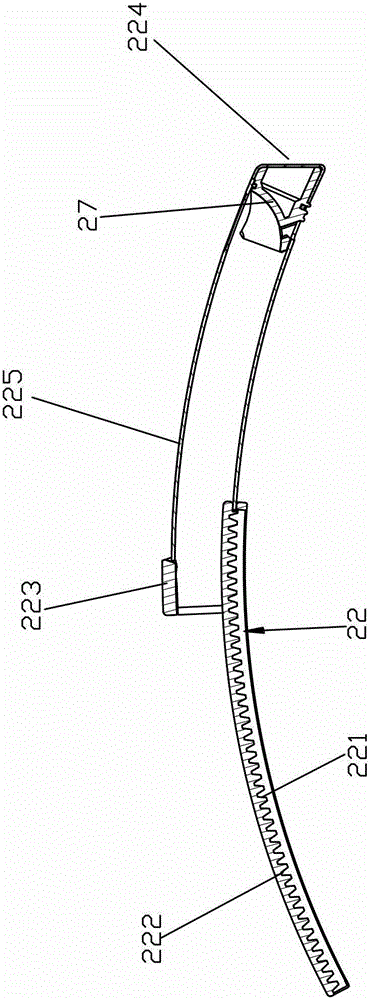

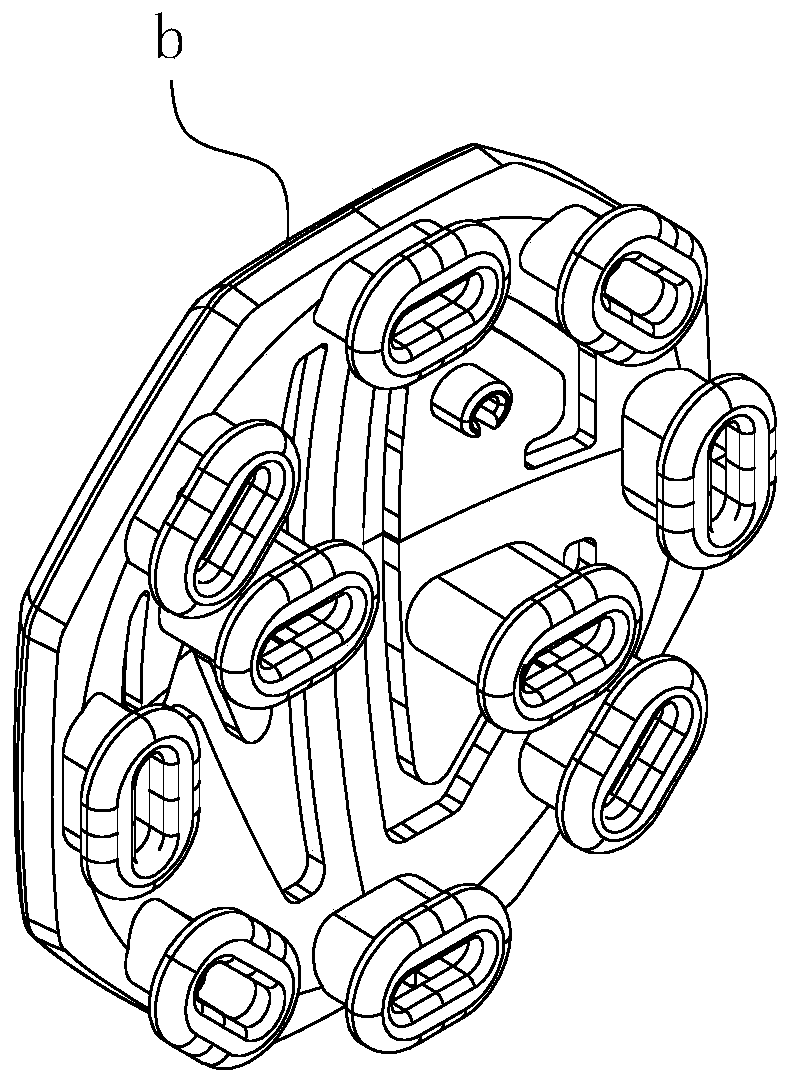

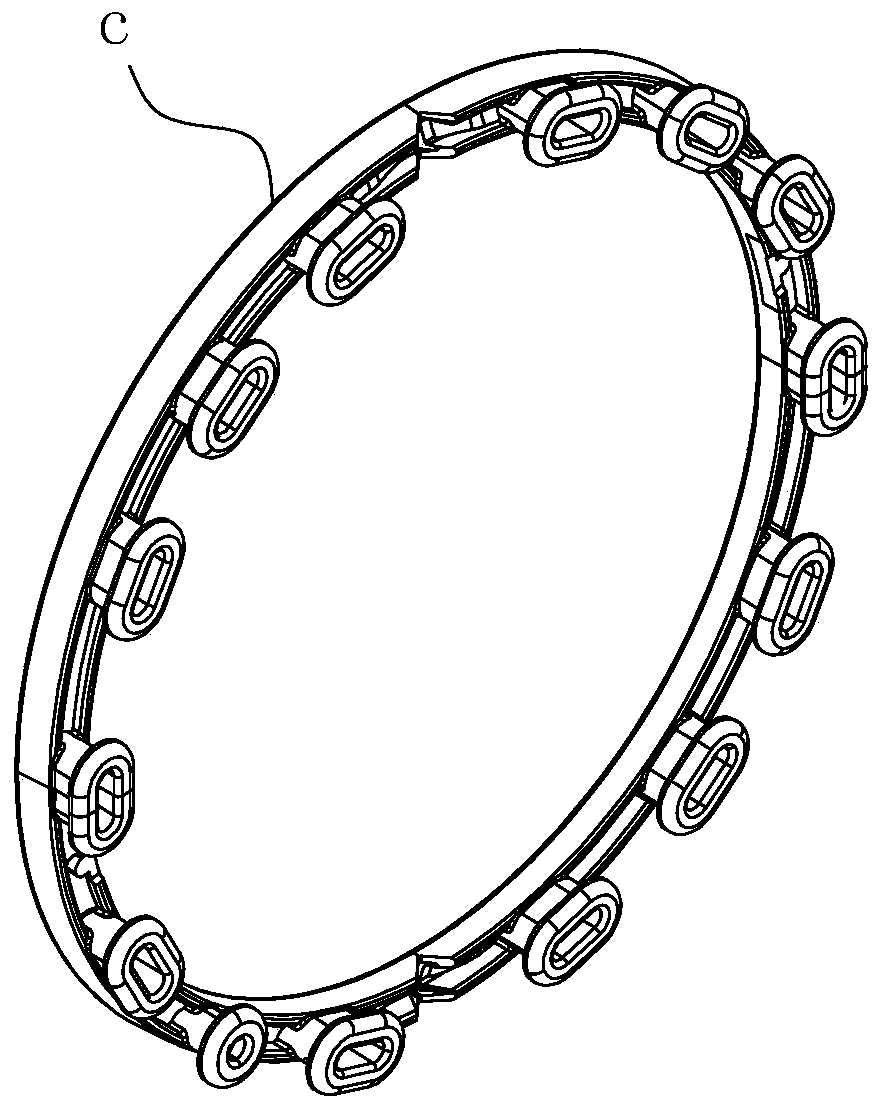

Drying device of water closet (WC) pan

ActiveCN102747769AReduce distanceUniform wind temperature and wind speedLavatory sanitoryPower unitWind speed

The invention discloses a drying device of a WC pan. The device comprises an arc-shaped drying guide rail, an arc-shaped drying body, a hot air generating mechanism, a transmission mechanism and a drying power unit, wherein the arc-shaped drying guide rail is fixed relative to the WC pan, the drying body is in a sliding connection with the arc-shaped drying guide rail, the front port of the hot air generating mechanism stretches into the drying body in a sliding mode, the arc shape of the arc-shaped drying guide rail (21) matches with the arc shape of the drying body (22), and the drying power unit is connected with the drying body through the transmission mechanism so as to drive the drying body to stretch along the arch shape relative to the arc-shaped drying guide rail. The drying device has the advantages that the drying body stretches back and forth in an arc-shaped mode, therefore the distance between an air outlet and an area to be dried on buttocks is reduced, the air temperature and velocity are evener, the soft drying is achieved, the drying is more thorough, and the time is saved.

Owner:XIAMEN AXENT

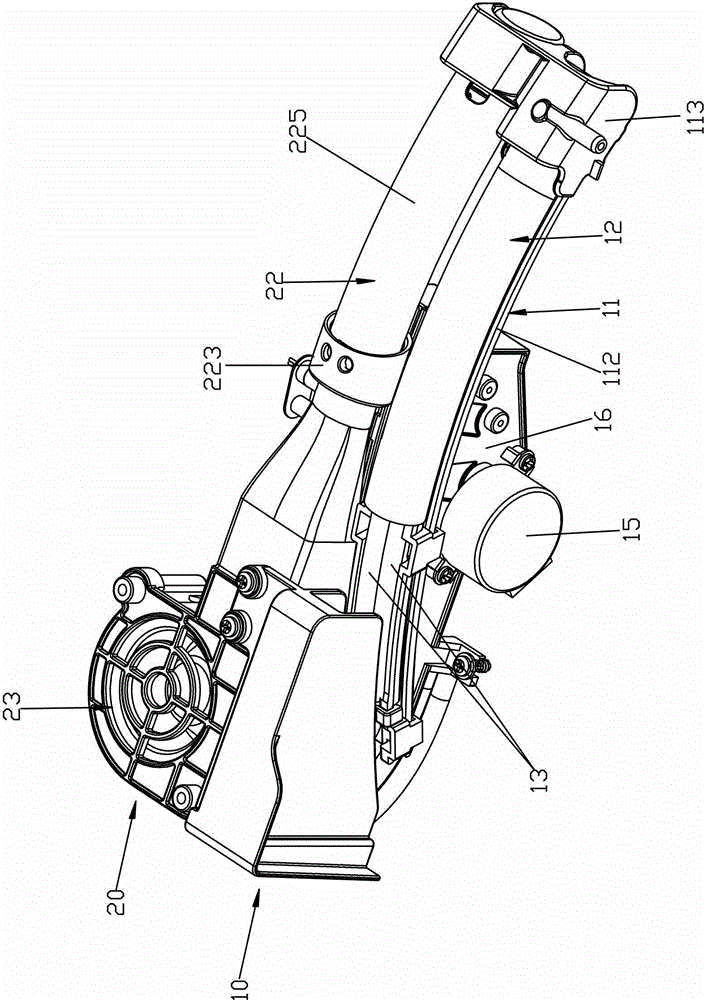

Four-station turntable type hot air welding machine and welding method thereof

The invention belongs to the technical field of automobile part processing, and particularly relates to a four-station turntable type hot air welding machine and a welding method thereof. The four-station turntable type hot air welding machine comprises a machine frame with a working table board, and a turntable assembly, a hot air assembly and a riveting assembly which are arranged at the side ofthe turntable assembly are arranged at the machine frame. The four-station turntable type hot air welding machine has the advantages that automatic welding operation of a company mark and a company mark ring at a safety air bag cover can be realized, and the operation threshold is low, time and labor are saved in the welding process, and no harm is caused to workers in the welding process, and the welding quality of the company mark and the company mark ring can be effectively guaranteed. The welding method applying the four-station turntable type hot air welding machine comprises the following steps of 1) a pre-processing process; 2) a code scanning process; 3) a hot air process; 4) a riveting process; and 5) a shooting and discharging process. The welding method has the advantages thatthat the actual processing efficiency of the welding process is systematically improved.

Owner:明光利拓智能科技有限公司

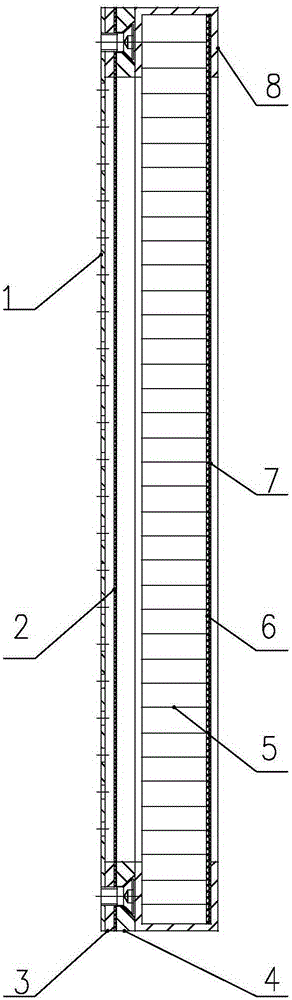

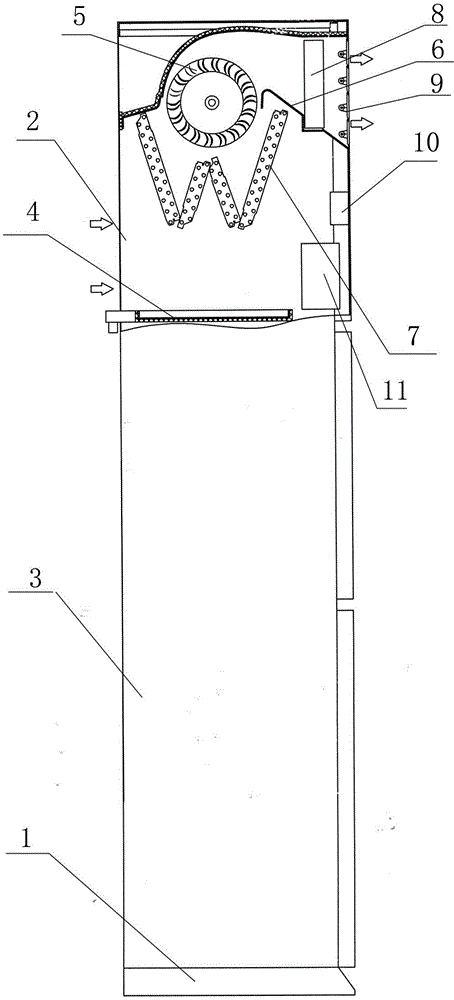

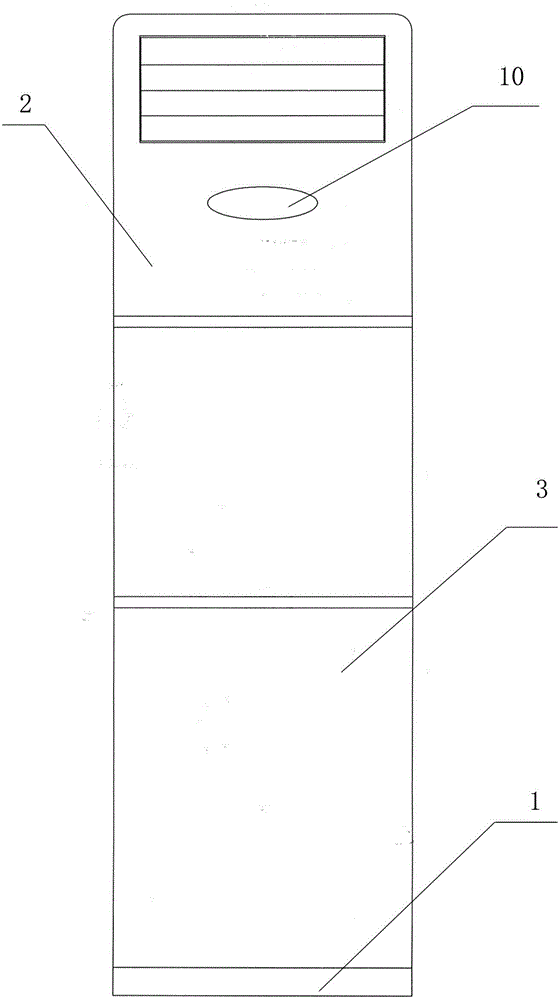

Room frequency conversion refrigerator air conditioner

PendingCN104964359ASave room areaIncrease usageDomestic cooling apparatusLighting and heating apparatusDrive motorEngineering

The invention discloses a room frequency conversion refrigerator air conditioner. A box is arranged in an indoor unit of the air conditioner. A base plate (1) is arranged at the bottom of the box body. An upper air channel (4) of an indoor unit assembly arranged in an upper box body is located at the upper portion of an inner cavity of the upper box body (2), and the upper air channel (4) extends to the back portion of the upper box body (2) from the front portion of the upper box body (2). A cross flow fan (5) is arranged below the upper air channel (4) and is opposite to an air outlet in the front surface of the upper box body (2). A driving motor is arranged on the cross flow fan (5) and drives the cross flow fan (5) to rotate. A lower air channel (6) is arranged between the air outlet and the cross flow fan (5). A W-shaped heat exchanger assembly (7) is arranged below the cross flow fan (5). A displayer (10) is arranged on the front surface of the upper box body (2) and located below the air outlet. An electric appliance box assembly (11) is arranged below the displayer (10), and a lower box body (3) serves as a refrigerator.

Owner:JIANGSU CHUNLAN REFRIGERATING EQUIPMENT CO LTD

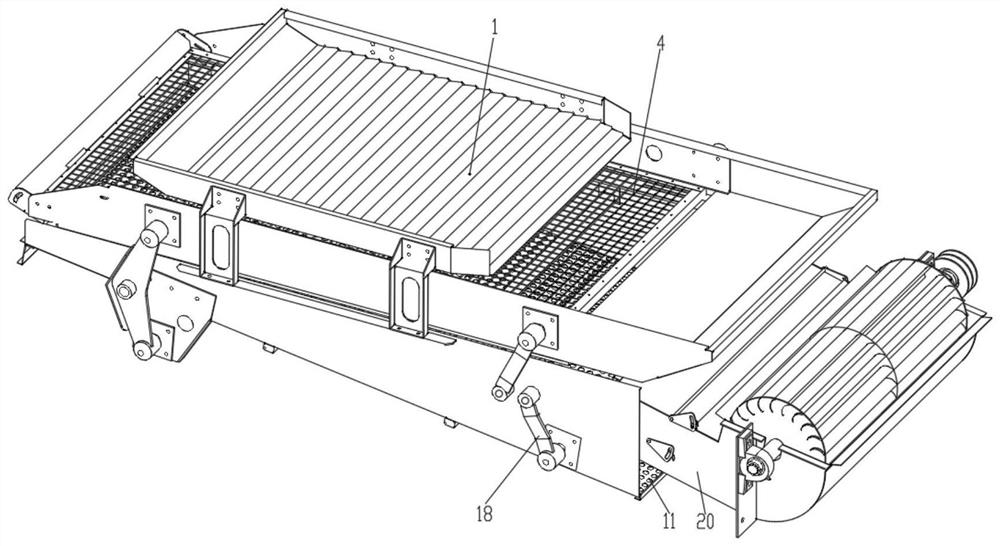

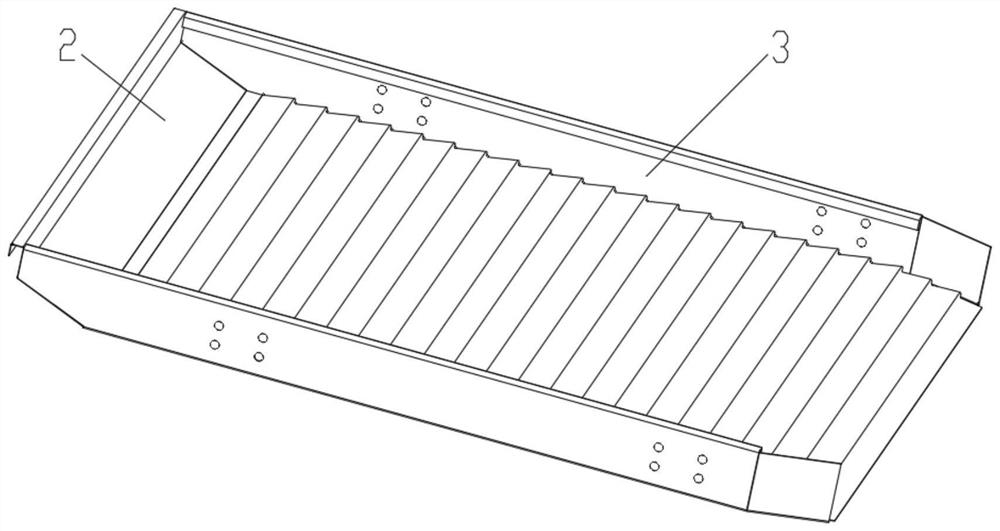

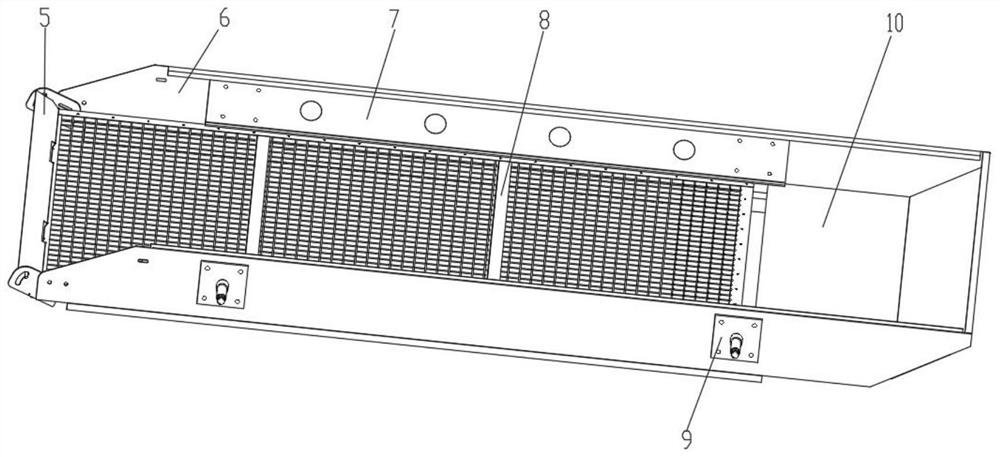

Cross-flow wind screen type edible sunflower cleaning device

PendingCN112371480AQuality improvementEasy to slideSievingGas current separationBiotechnologyAgricultural science

The invention relates to the technical field of agricultural machinery, in particular to a cross-flow wind screen type edible sunflower cleaning device which comprises a shaking plate, an upper screen, a lower screen, a rocker driving device and a cross-flow fan. The shaking plate is fixedly connected with the lower screen, the upper screen and the lower screen are connected with the rocker driving device, and the rocker driving device drives the shaking plate, the upper screen and the lower screen to move. The cross-flow fan is arranged on the right side of the lower screen. Through the combined action of the cross-flow fan, the upper screen and the lower screen, grains of threshed edible sunflowers are separated from impurities, the cleaning rate of the grains of the edible sunflowers isincreased, damage to the grains of the edible sunflowers is small, and a good impurity removing operation effect is achieved.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI +1

Low-temperature circulating air flow device for worsted production

ActiveCN107723963AUniform wind speedTwist balanceTextile treatment containersTextile treatment carriersInternal pressureYarn

The invention provides a low-temperature circulating air flow device for worsted production. The low-temperature circulating air flow device includes a yarn steaming box, a moving assembly and a circulating air flow device. The yarn steaming box is a half-sealed internal pressure thin-wall container. The left end of the yarn steaming box is embedded in a seal cover, the seal cover is provided withthe moving assembly, and the circulating air flow device includes an infrared heating pipe, a suction fan and an air feeder. The left end of the yarn steaming box is fixedly connected with the inletend of the suction fan, the top of the right end of the yarn steaming box is fixedly connected with the outlet end of the air feeder, the outlet end of the suction fan is fixedly connected with an airguide pipe, and a three-way pipe is fixedly mounted at the left end of the air guide pipe and fixedly connected with the yarn steaming box and the inlet end of a fan. Through the circulating air flowdevice, the air speed in the yarn steaming box is uniform, the generation of a heating blind area is avoided, the yarn twist is balanced, yarn quality is improved, the yarn color is durable, the production efficiency is greatly improved while claims for compensation caused by yarn skew are reduced, manpower resources are saved, and the cost is reduced.

Owner:ZHANGJIAGANG YANGTSE SPINNING CO LTD

Air-conditioning duct system and air-conditioning indoor unit

InactiveCN105091273AUniform wind speedImprove heat transfer effectDucting arrangementsLighting and heating apparatusMechanical engineeringMechanics

The invention discloses an air-conditioning duct system and an air-conditioning indoor unit, and relate to the technical filed of air conditioners. The system and the indoor unit are invented for solving problems that pressure of an air inlet end of a heat exchanger is low, and heat exchange effect is poor. The air-conditioning duct system comprises a volute air duct and a heat exchanger. The volute air duct comprises an air duct inlet and an air duct outlet. The heat exchanger comprises an air inlet side and an air outlet side. The heat exchanger is arranged above the volute air duct, and the air inlet side of the heat exchanger is communicated with the air duct outlet of the volute air duct. The air-conditioning duct system can be used for the air-conditioning indoor unit.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

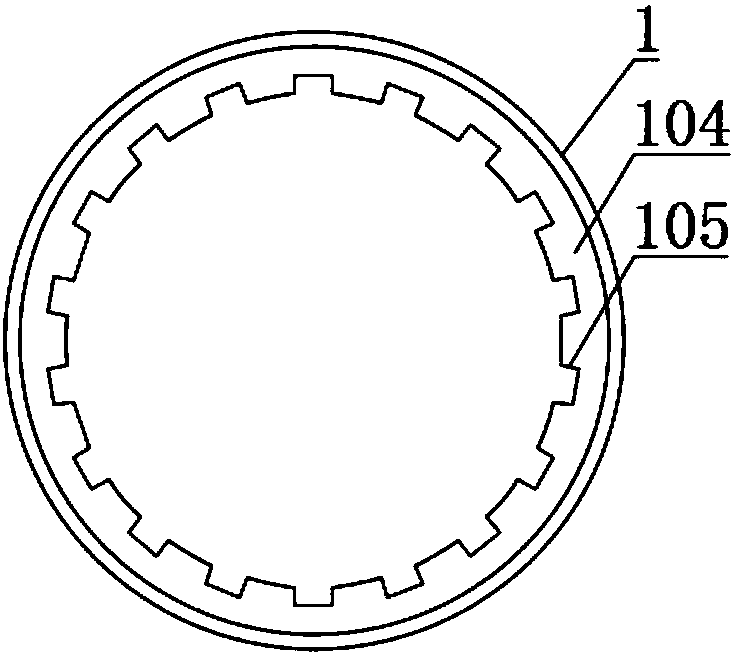

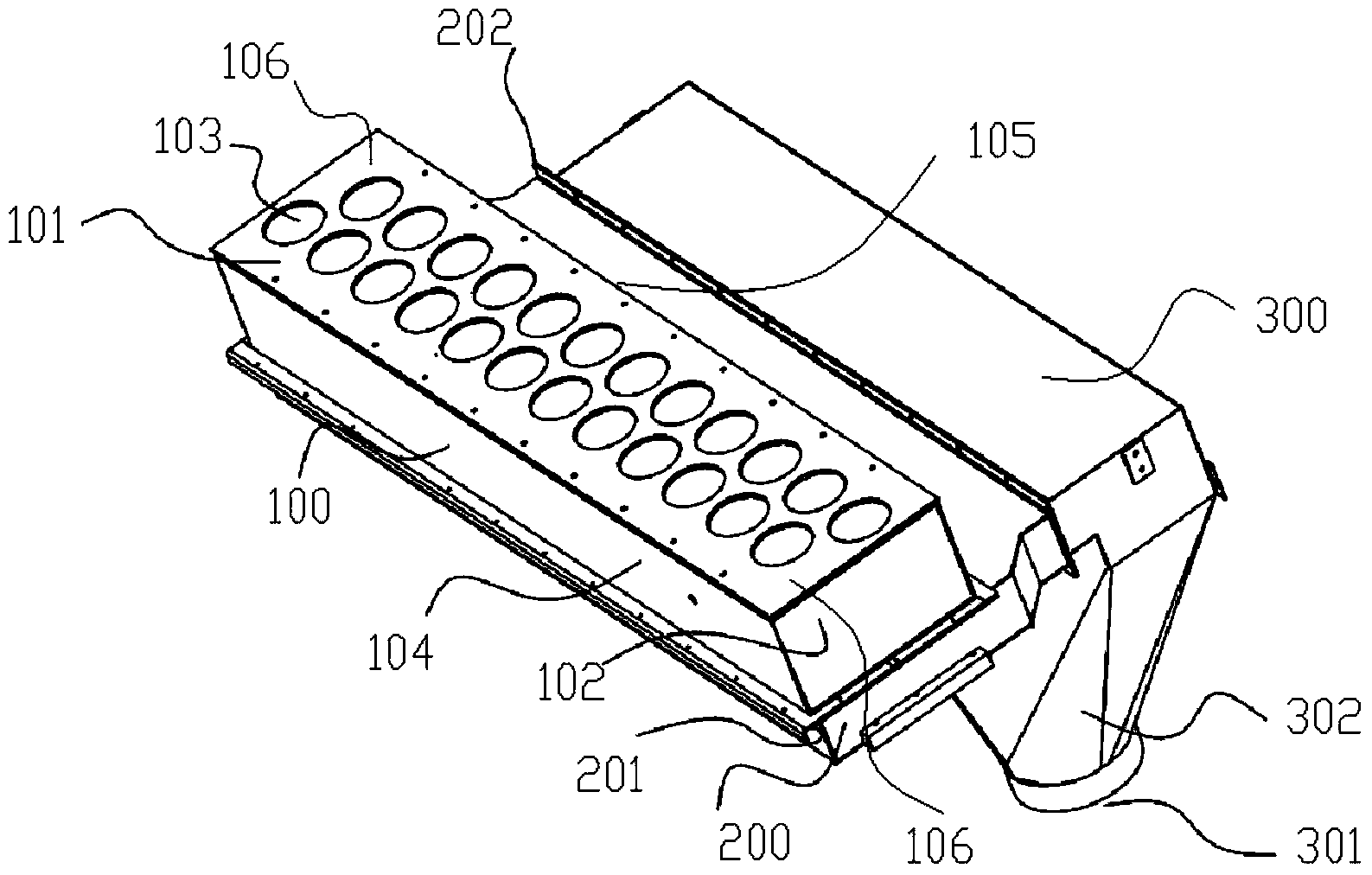

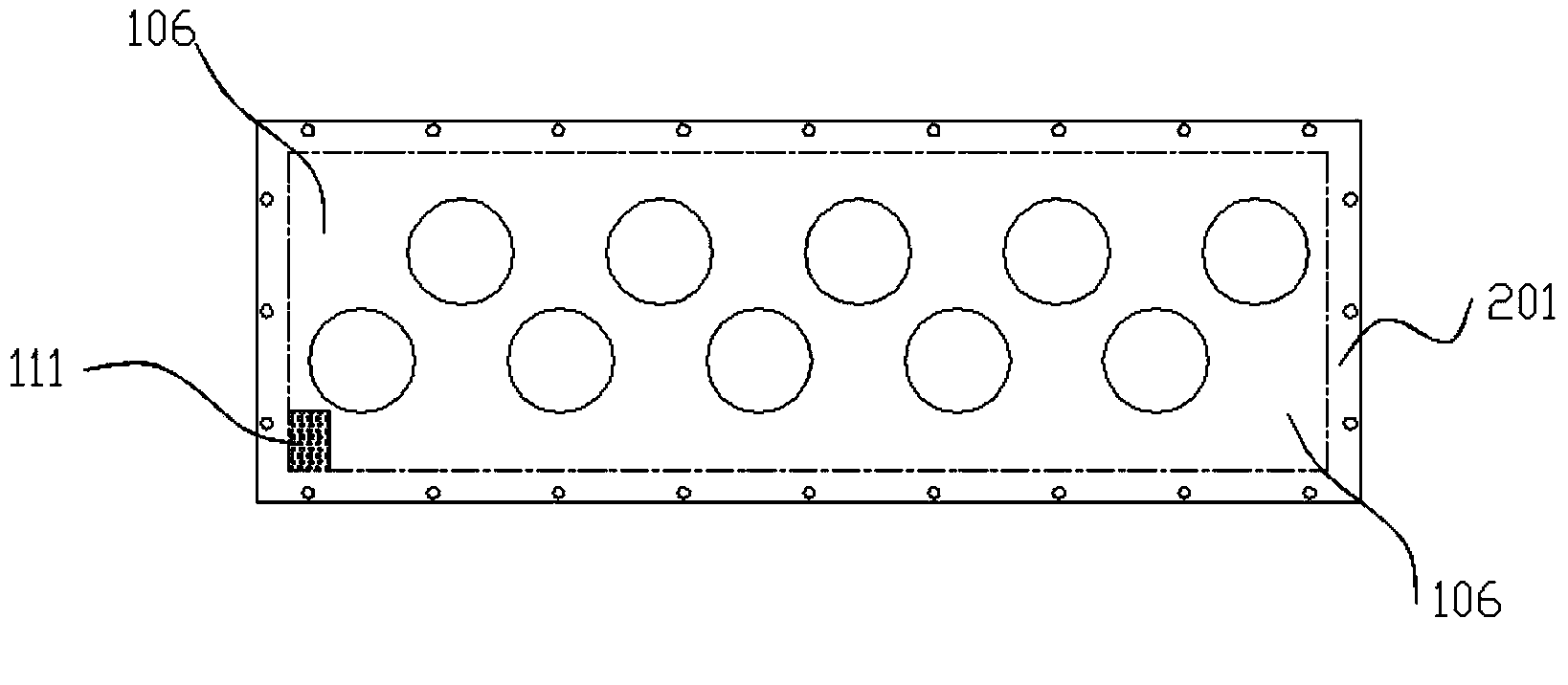

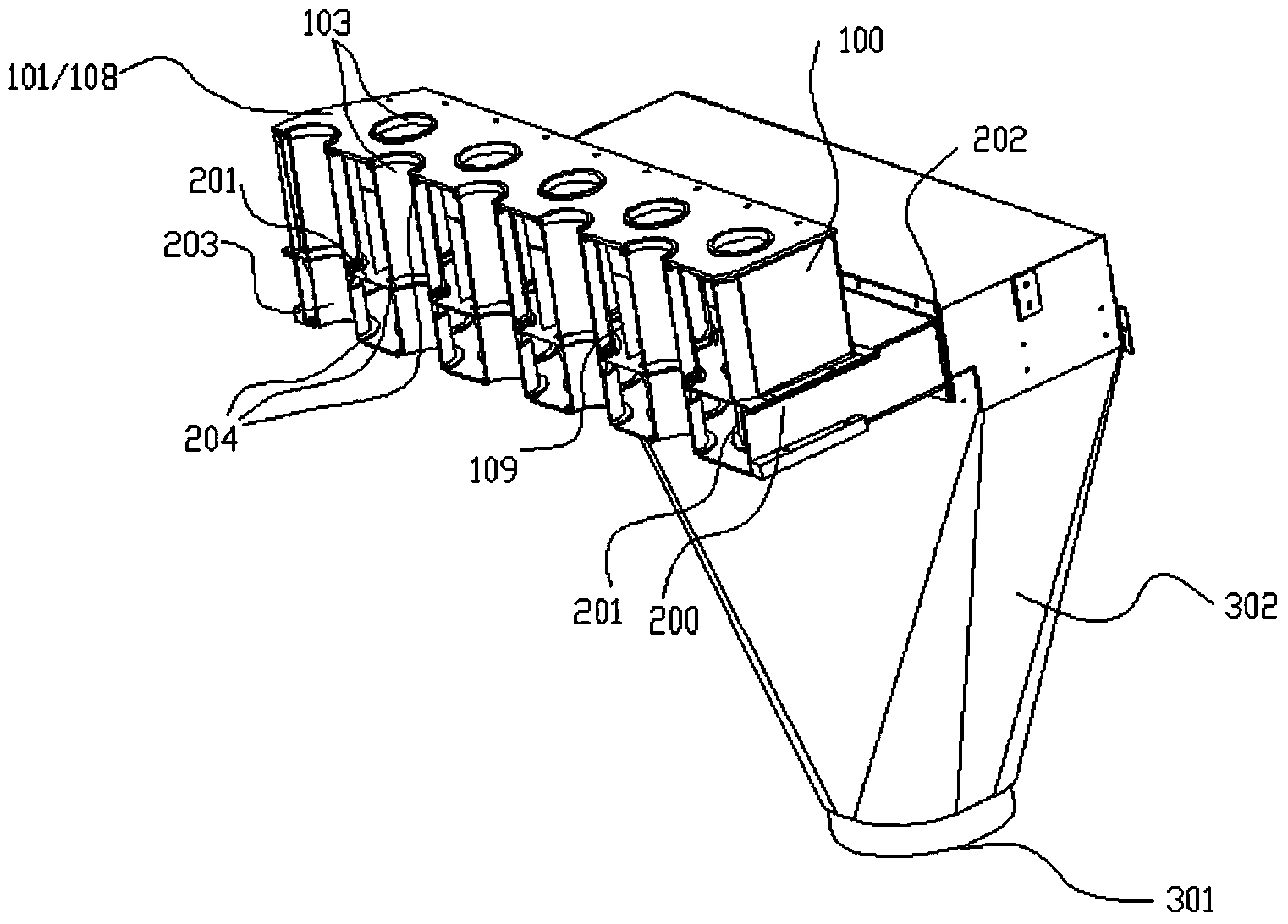

Multi-row synthetic tow cooling device

ActiveCN103526311AGuaranteed homogenization qualityConsistent wind speedArtificial thread manufacturing machinesFilament/thread formingCold airEngineering

The invention provides a multi-row synthetic tow cooling device. The multi-row synthetic tow cooling device comprises a cooling box and an air supply device used for supplying cold air into the cooling box. A plurality of rows of air duct assemblies for tows to pass through are arranged on the cooling box, a perforated plate is arranged between the cooling box and the air supply device, and a plurality of vent holes are formed in the perforated plate. Cold air from the air supply device enters the exteriors of silk screen cylinders in the air duct assemblies through the vent holes and enters the interiors of the silk screen cylinders through the outer circumferences of the silk screen cylinders. Circulation space is formed in the outer circumferences of the silk screen cylinders, and the adjacent silk screen cylinders in the same row, the adjacent silk screen cylinders in different rows and different inner walls of the cooling box are communicated through the circulation space. By controlling the amount of the cold air entering different positions in the circulation space, the differential values between air pressures of the cold air at different positions in the circulation space and air pressures inside the silk screen cylinders are basically consistent.

Owner:王振海

Washing and drying device of closestool

The invention discloses a washing and drying device of a closestool. A washing body of a washing device and a drying body of a drying device can stretch in an arc mode under coordination of a transmission mechanism and a power unit, so that the washing and drying device has the following advantages of a. being capable of reducing whole height from a ceramic face to the top portion of the washing device and applicable to requirements that the existing intelligent closestool trends to flat appearance development on modeling; b. enabling an arc-shaped body to have curve soft sense on the modeling and enabling an arc-shaped mode reciprocating motion to have more novelty and layering sense than straight line mode reciprocating motion; and c. enabling the drying body to stretch front and back in the arc-shaped mode to shorten distance between an air outlet and buttock areas needing drying, enabling wind-temperature and wind speed to be even, achieving soft drying, and enabling drying to be thorough and saving time.

Owner:XIAMEN AXENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com