Patents

Literature

185results about How to "Uniform air volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

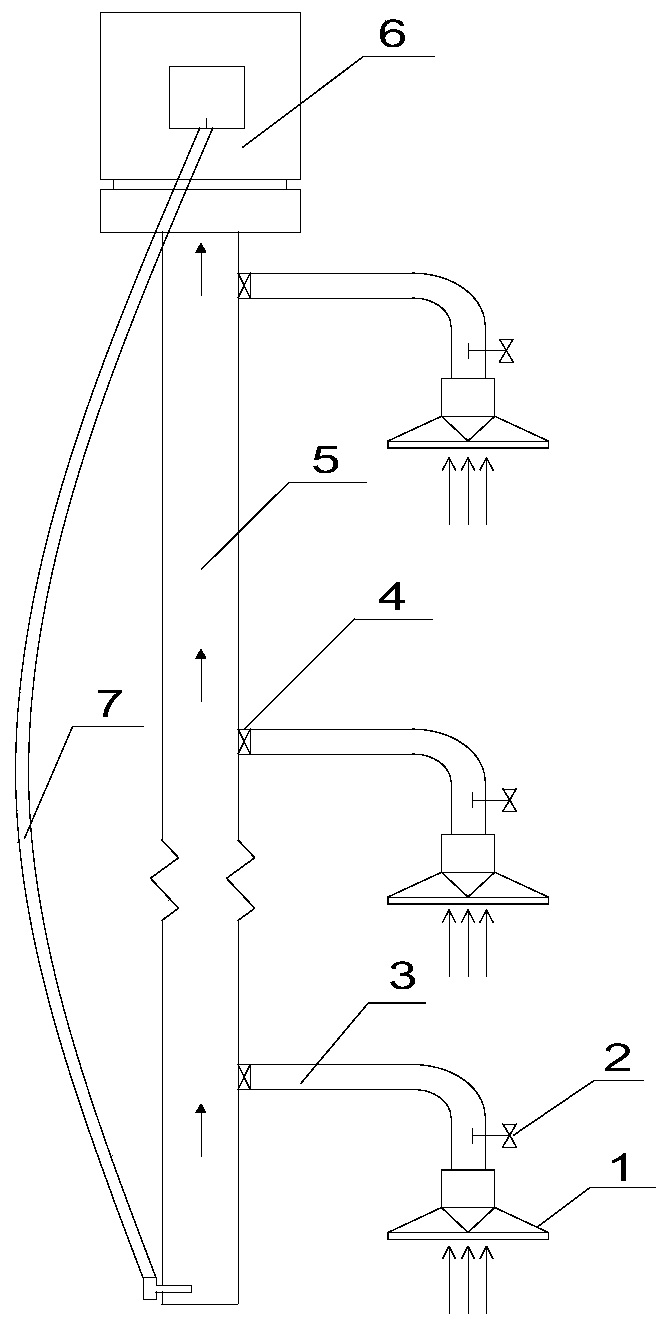

Intelligent building smoke exhaust system and control method thereof

ActiveCN110375365AUniform air volumeReduce the impactDomestic stoves or rangesLighting and heating apparatusAir volumeEngineering

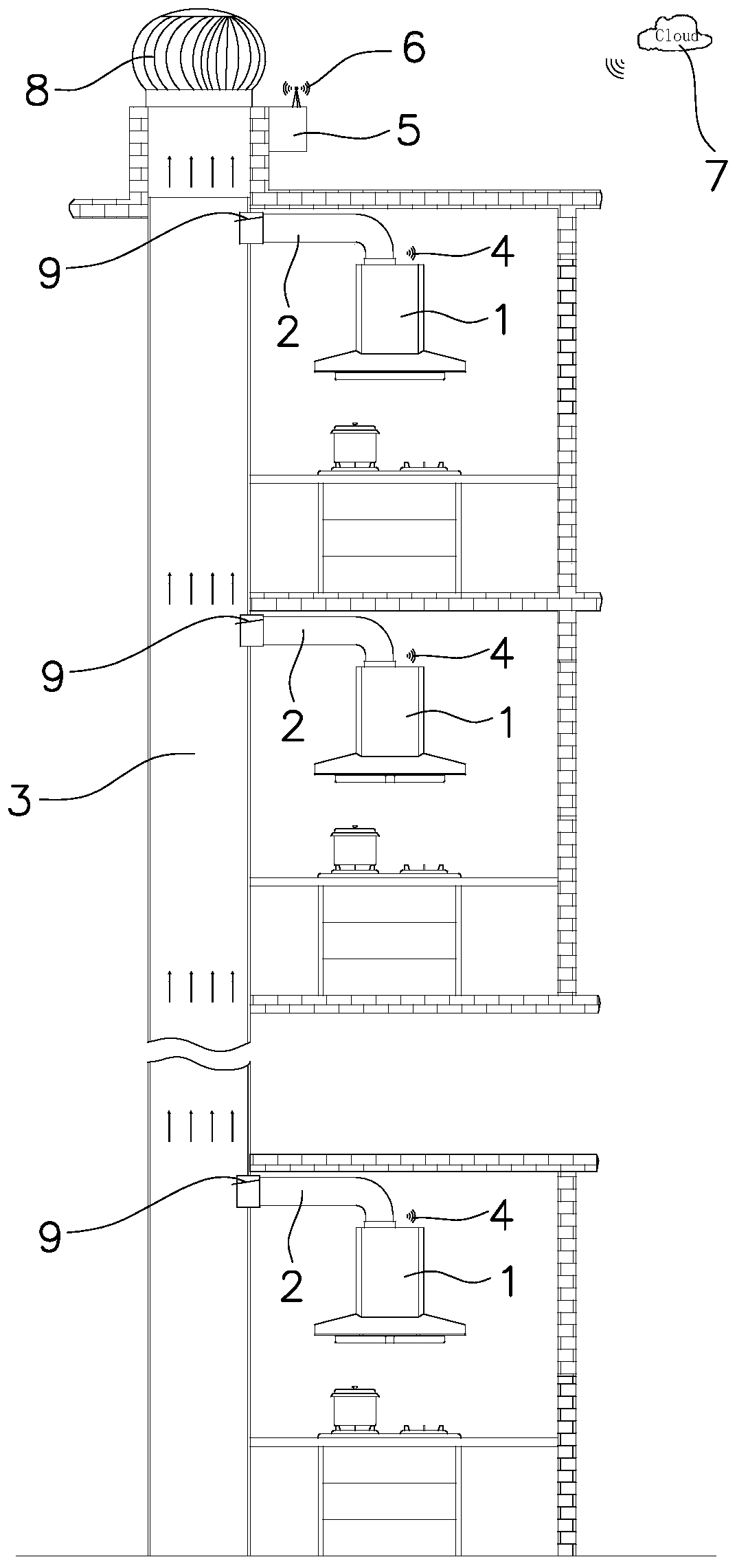

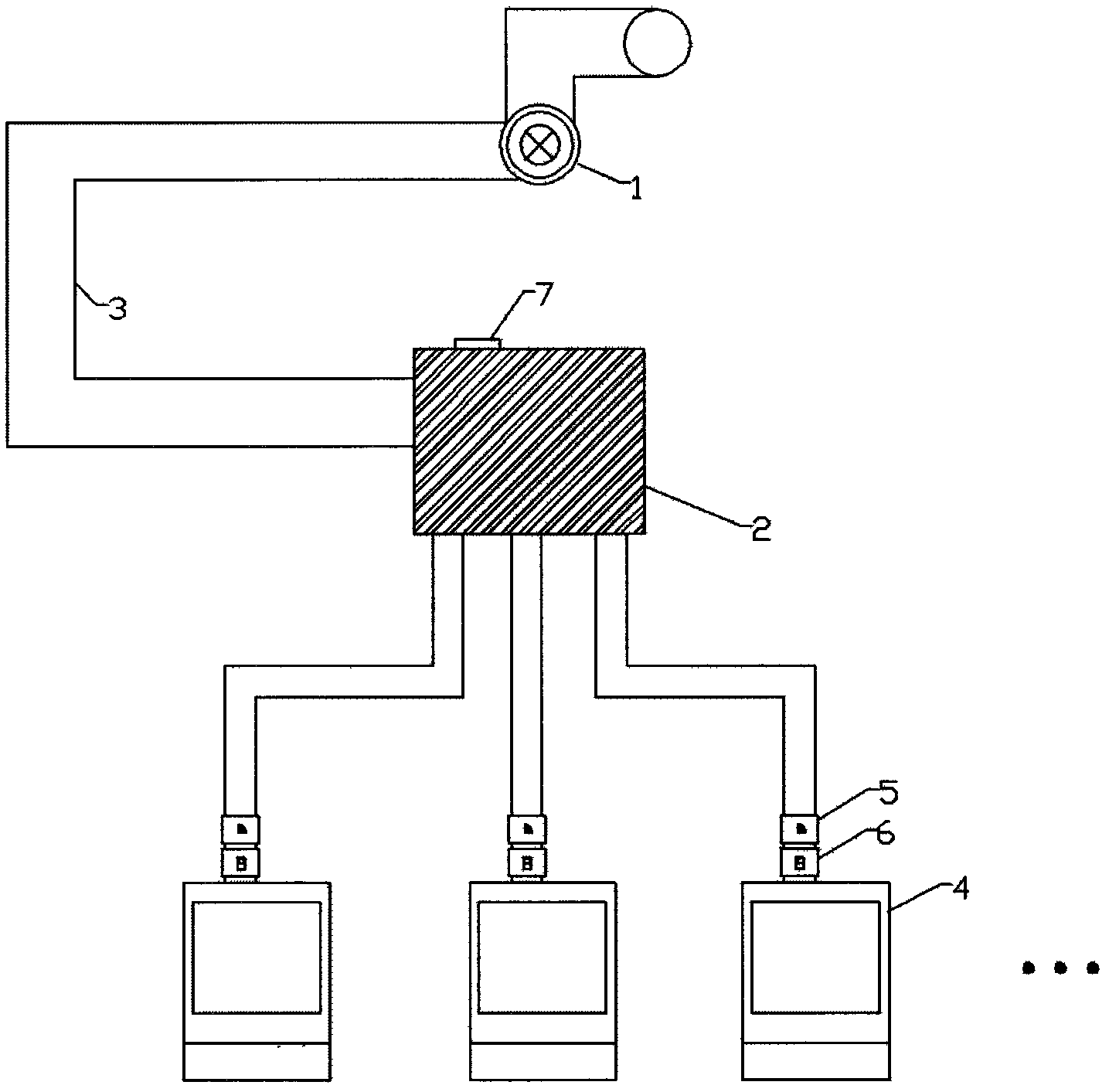

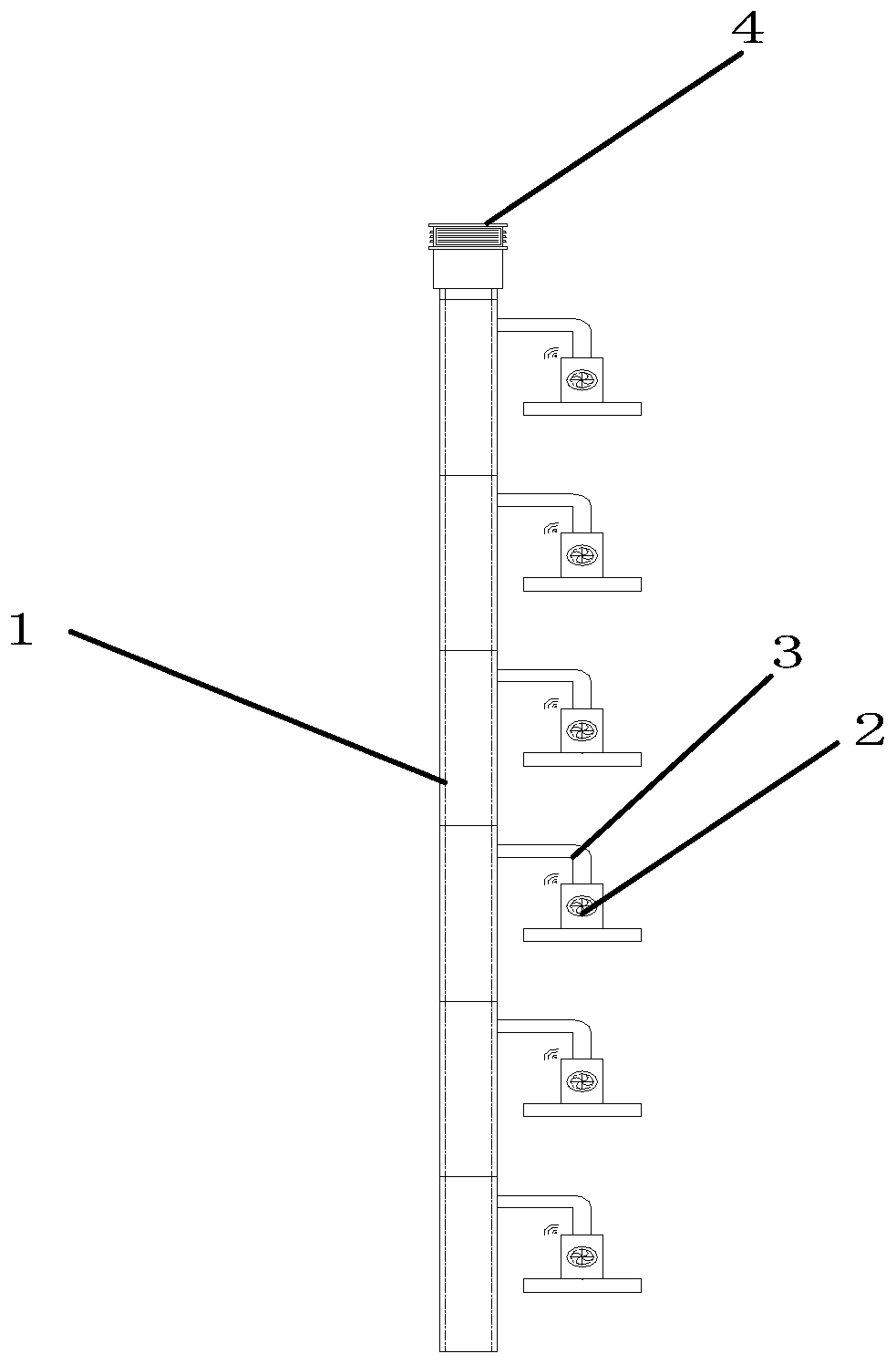

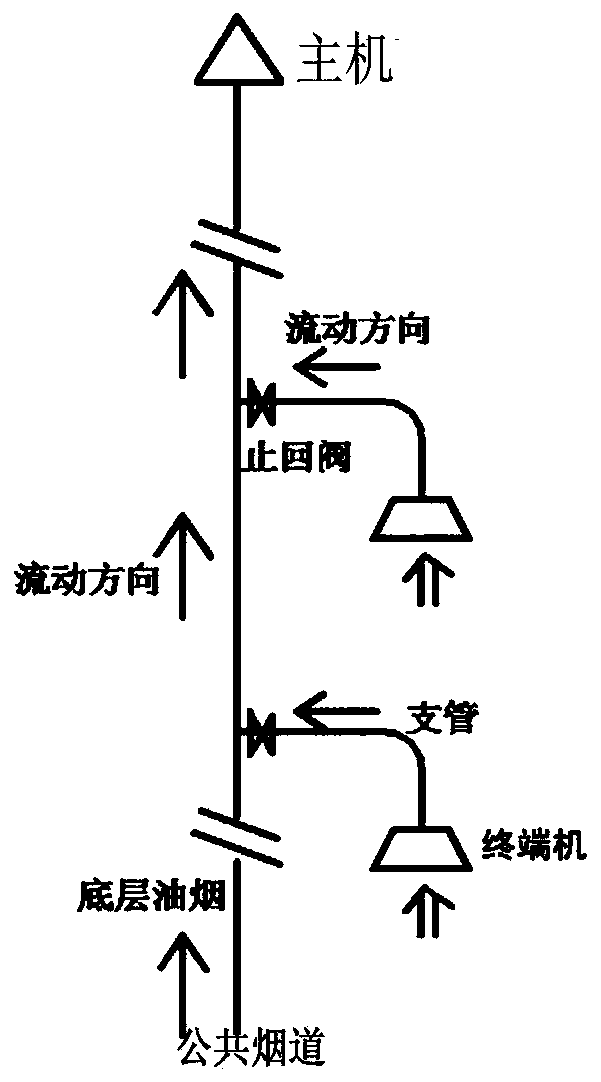

The invention discloses an intelligent building smoke exhaust system. The intelligent building smoke exhaust system comprises range hoods arranged on different floors, and further comprises a cloud platform capable of communicating with an outdoor main control device; each range hood comprises a fan and is provided with a Lora module; and the outdoor main control device capable of adjusting the target air volume of the range hoods is arranged at the top of a public flue and communicates with the Lora modules through signal receiving transmitters. The intelligent building smoke exhaust system has the advantages that the outdoor main control device of the smoke exhaust system can realize target air volume adjustment of the range hoods through mutual communication between the signal receivingtransmitters and the Lora modules, and in addition, the operation parameters and states of the system are checked online through the cloud platform. The invention further discloses a control method for the smoke exhaust system. According to the control method for the smoke exhaust system, the multi-gear adjustment change of the range hood of each floor can be realized, in addition, each floor hasa good oil smoke suction effect at a low start-up rate, meanwhile, the noise of a kitchen is low, when the start-up rate is high, the oil smoke suction effect is relatively good, and the noise of thekitchen is not high.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

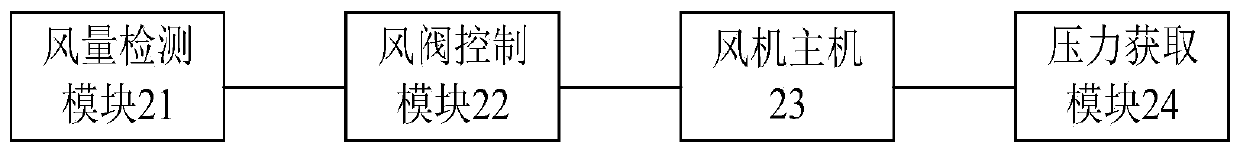

Air quantity control device and air quantity control method of centralized smoke extraction system and centralized smoke extraction system

ActiveCN110186092AUniform air volumePowerfulDomestic stoves or rangesLighting and heating apparatusMachine controlAir volume

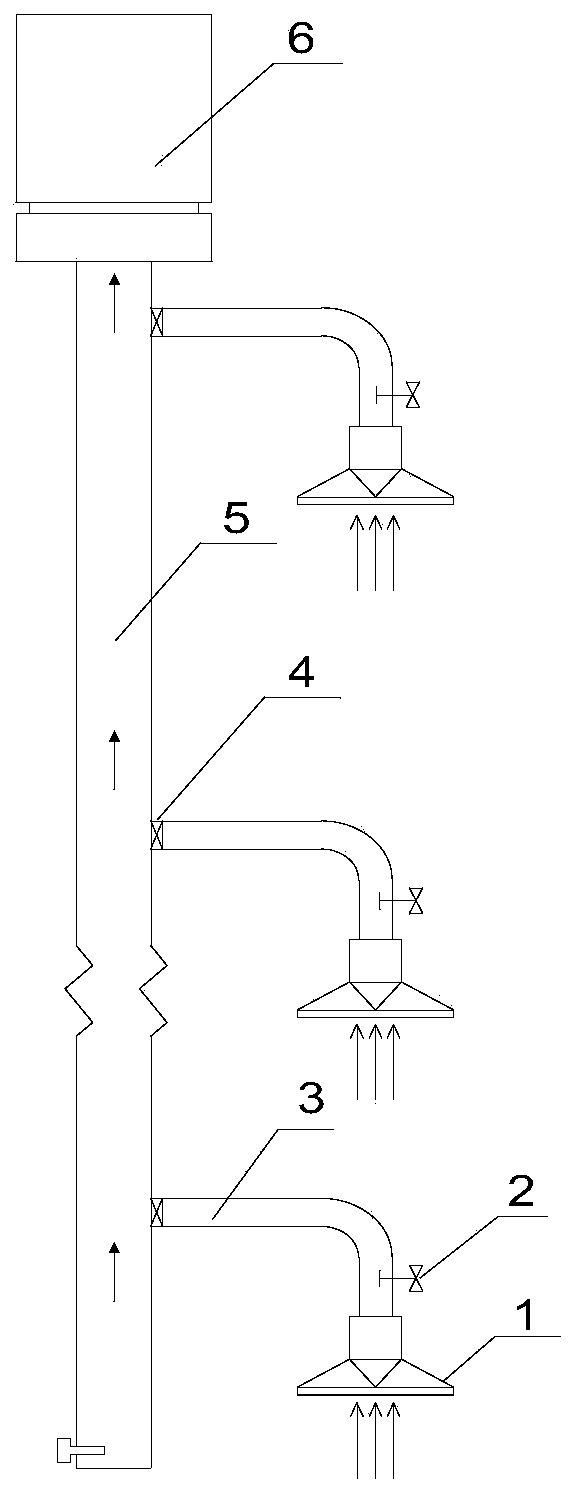

The invention provides an air quantity control device and air quantity control method of a centralized smoke extraction system and the centralized smoke extraction system and relates to the technicalfield of air purification. The air quantity control device comprises a fan main machine, an air valve control module, an air quantity detection module and a pressure acquisition module. The air quantity detection module detects the air quantity of a branch pipe in real time and sends the air quantity of the branch pipe to the air valve control module; the air valve control module controls switch-on of an air quantity regulating valve of a started range hood, sends a range hood starting signal to the fan main machine and regulates the air quantity regulating valve according to the air quantityof the branch pipe, so that the air quantity of the branch pipe is within a set air quantity valve range; the pressure acquisition module acquires the bottom pressure of a smoke extraction pipeline and sends the bottom pressure to the fan main machine; and the fan main machine controls a roof fan to operate according to the range hood starting signal and regulates the rotating speed of the roof fan according to the bottom pressure. The air quantities of floors are kept balanced, power of the roof fan is sufficient, and the air quantity is self-adapted and is not affected by the structure of the centralized smoke extraction system.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

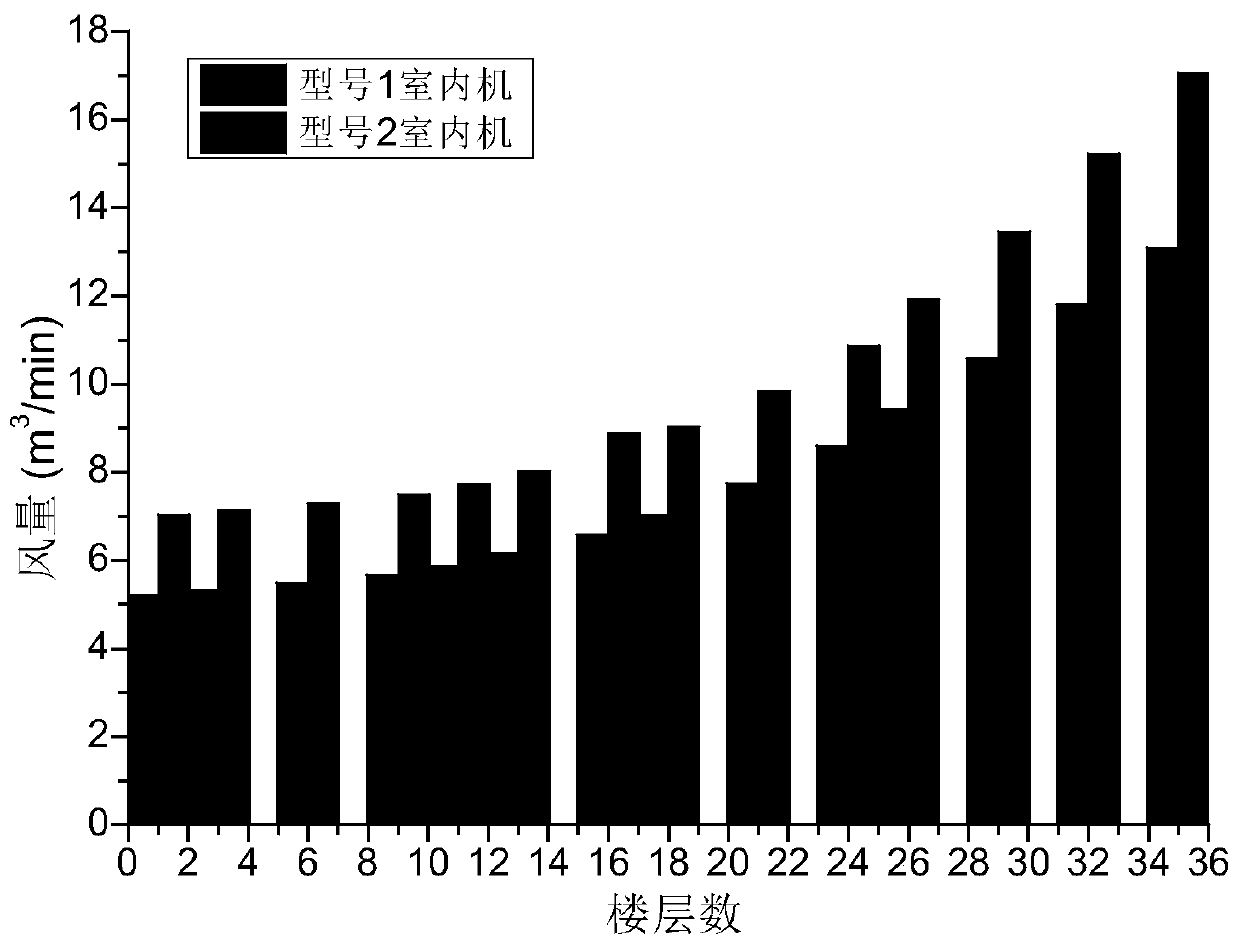

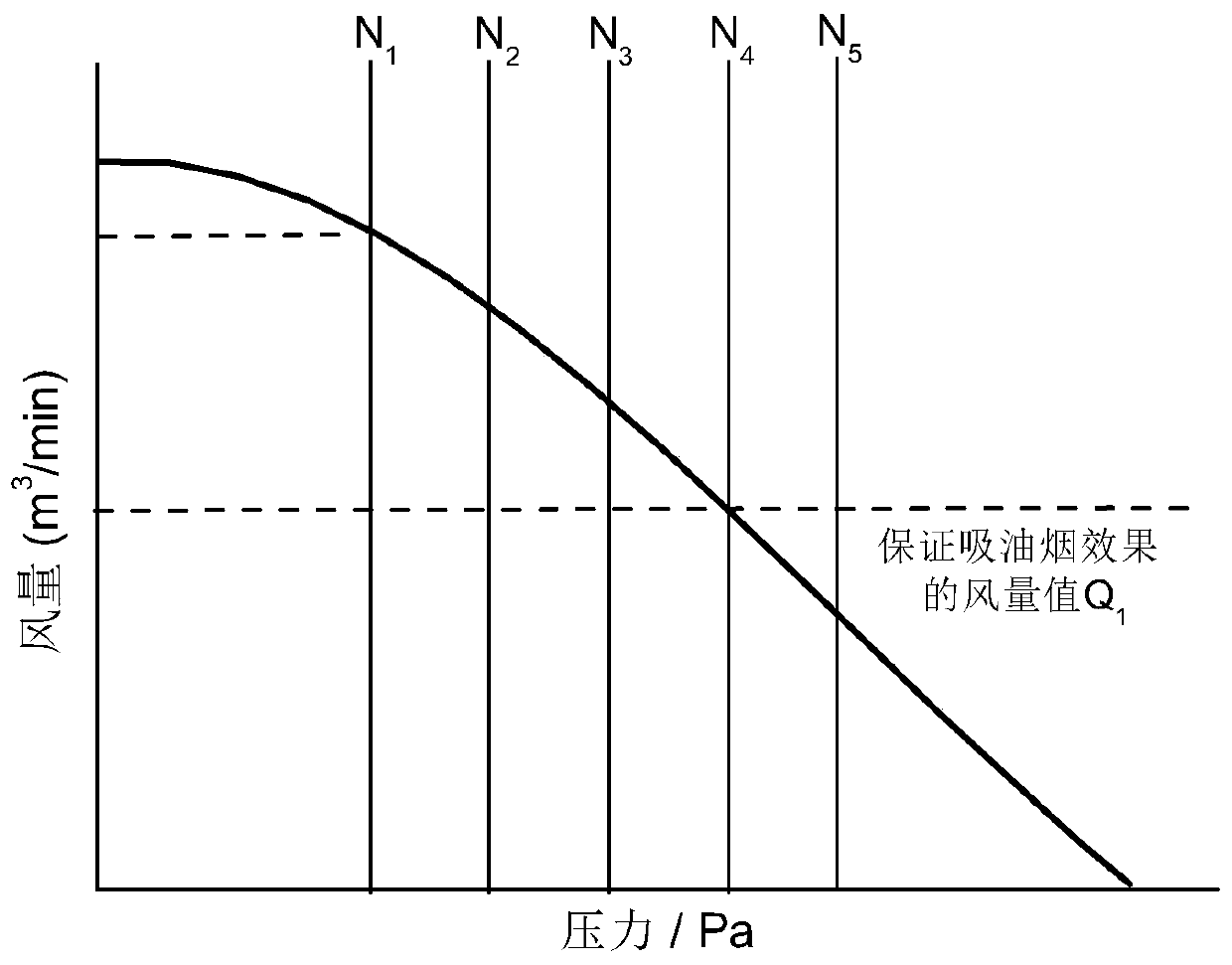

Constant-air-volume control method for range hood

ActiveCN110375362AIncrease air volumeUniform air volumeDomestic stoves or rangesLighting and heating apparatusAir volumeEngineering

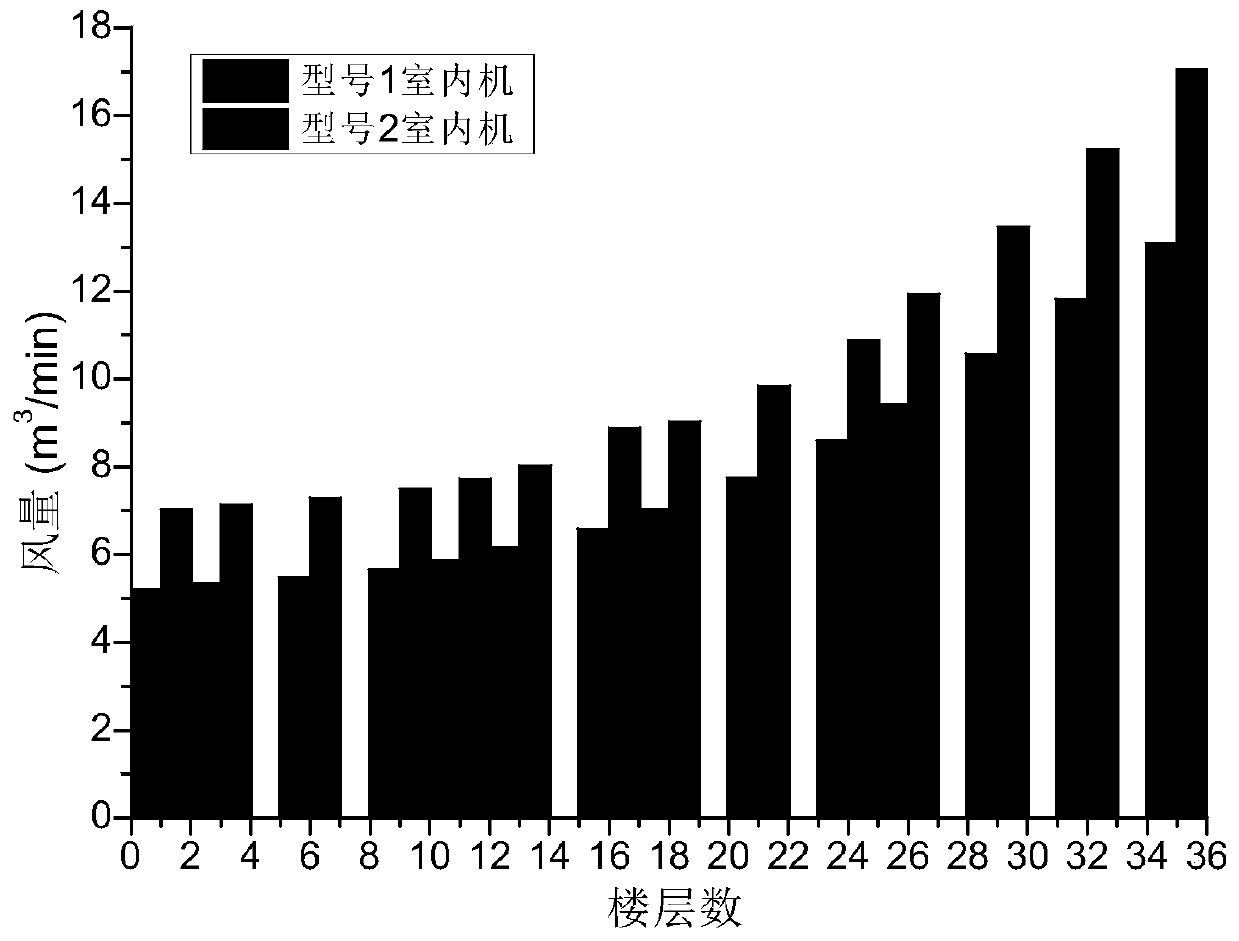

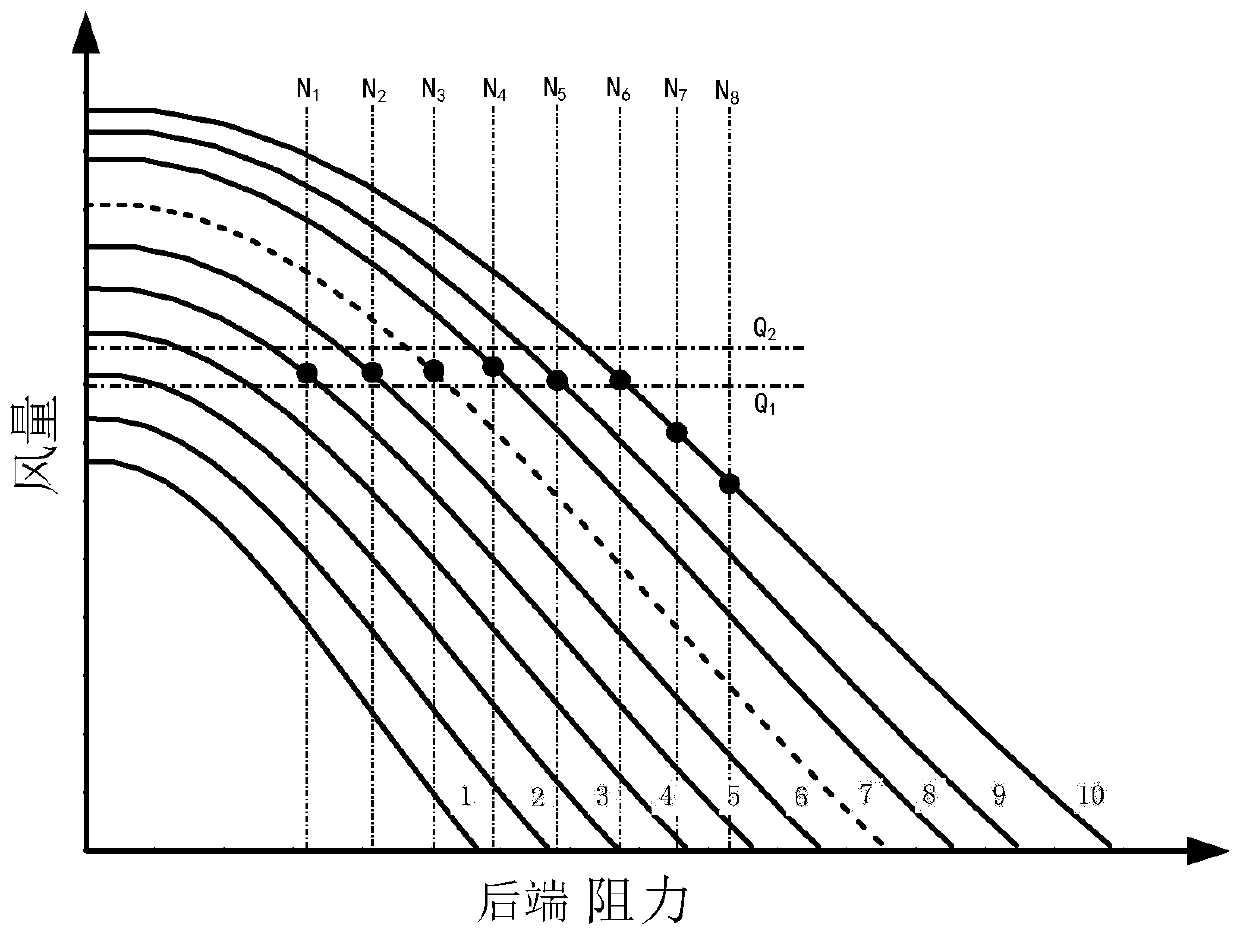

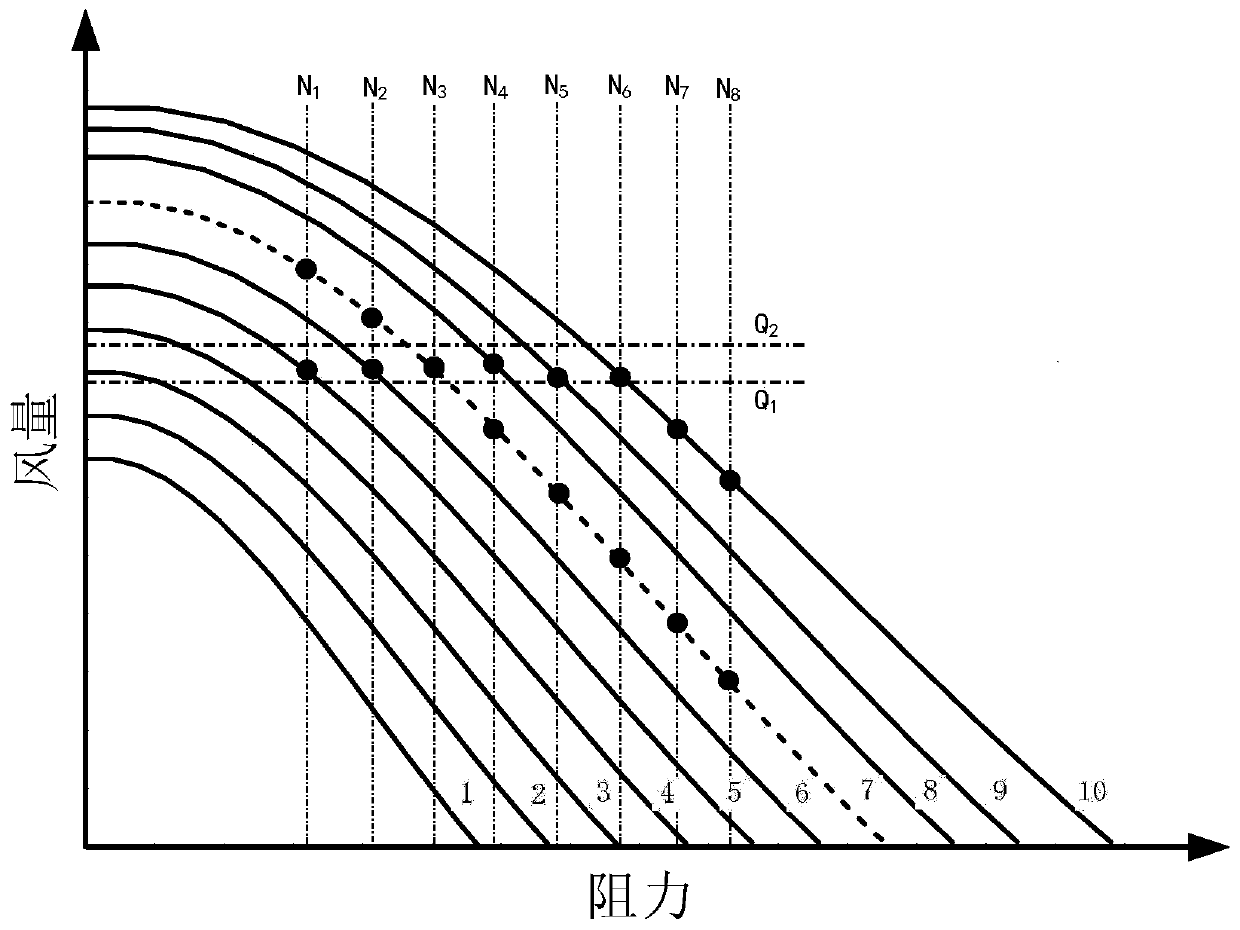

The invention discloses a constant-air-volume control method for a range hood. According to the method, the number of all internally-arranged gears of an indoor unit is x, and the default initial gearof a high gear air volume interval [ Q1, Q2 ] is x / 2; when the operating gear of an indoor range hood is equal to x and the air volume is smaller than Q1, target air volume is reduced from [ Q1, Q2 ]to [ q1, q2 ], so that the gear is reduced, and noise is reduced; and when the target air volume is in the interval [ q1, q2 ], the number of the operating gear is smaller than x-2, the target air volume is changed from [ q1, q2 ] to [ Q1 and Q2 ], so that the air volume is increased, and the oil fume suction effect is improved. The method has the advantages that a constant-air-volume control method of the range hood is applied to a central flue system; from the point of reducing noise, when the start-up rate is extremely high, the air volume interval is properly reduced, a bit of the oil fume suction effect is sacrificed, so that the noise is reduced; the air exhaust amount of high floors is reduced, so that the flue exhaust power of low floors is increased, and the air exhaust volume ofthe low floors is increased; and meanwhile, the air volume of all the floors is ensured to be balanced and capable of meeting the flue exhaust requirement, so that the use experience of users is good.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

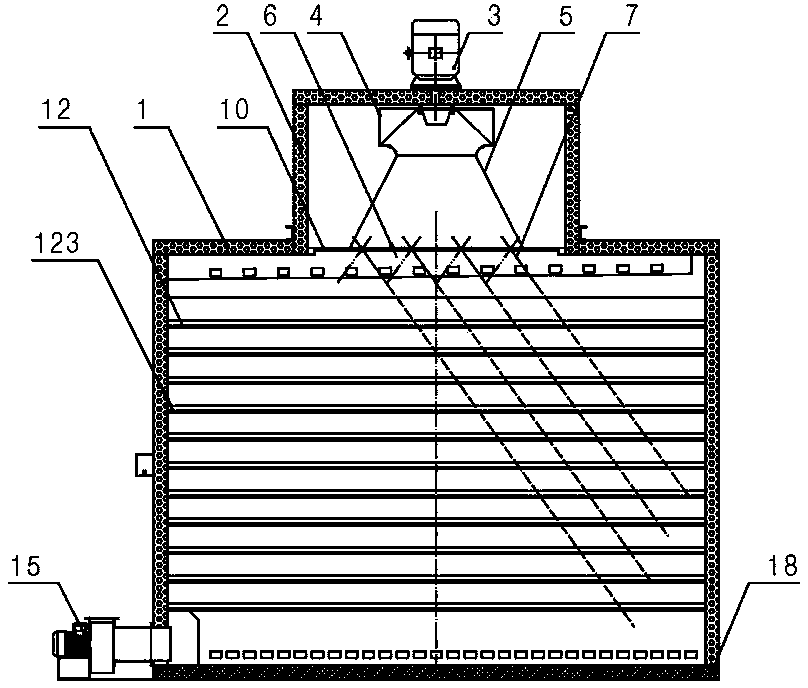

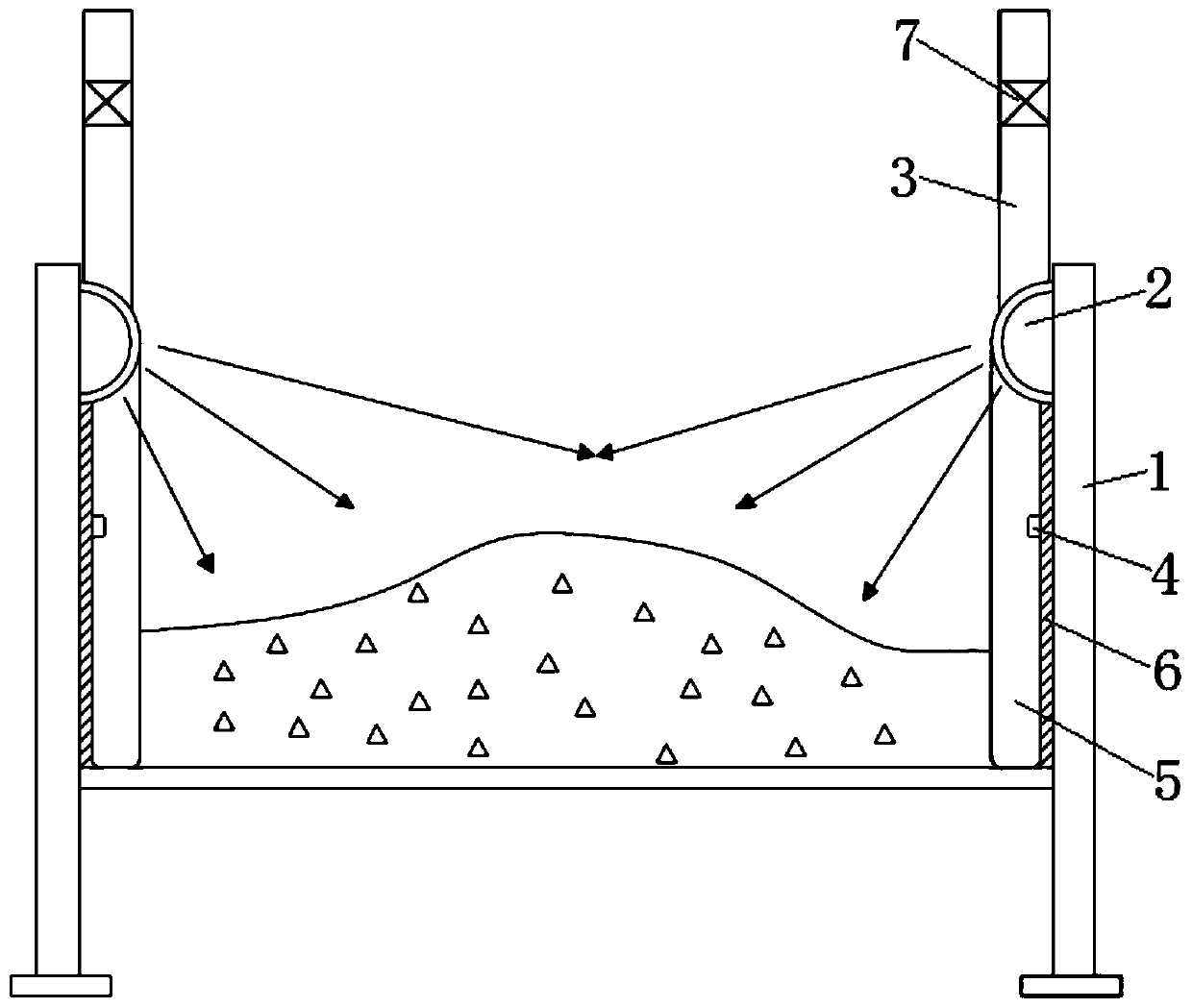

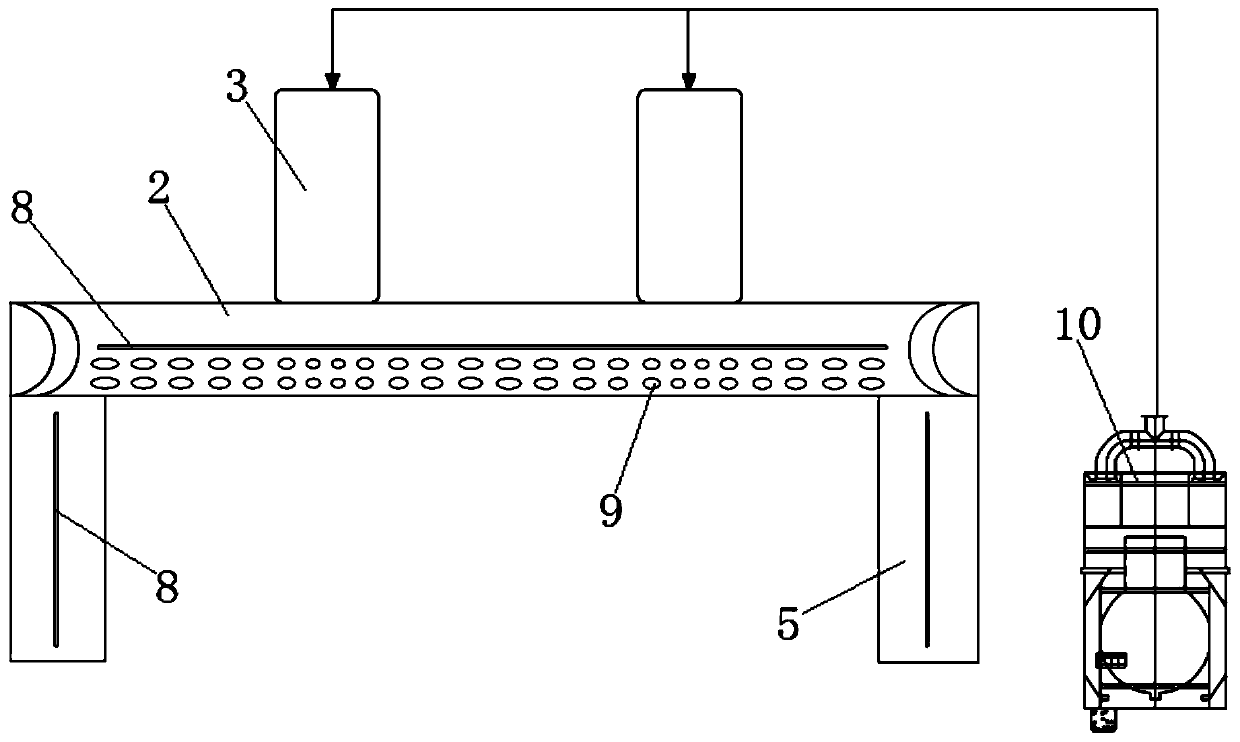

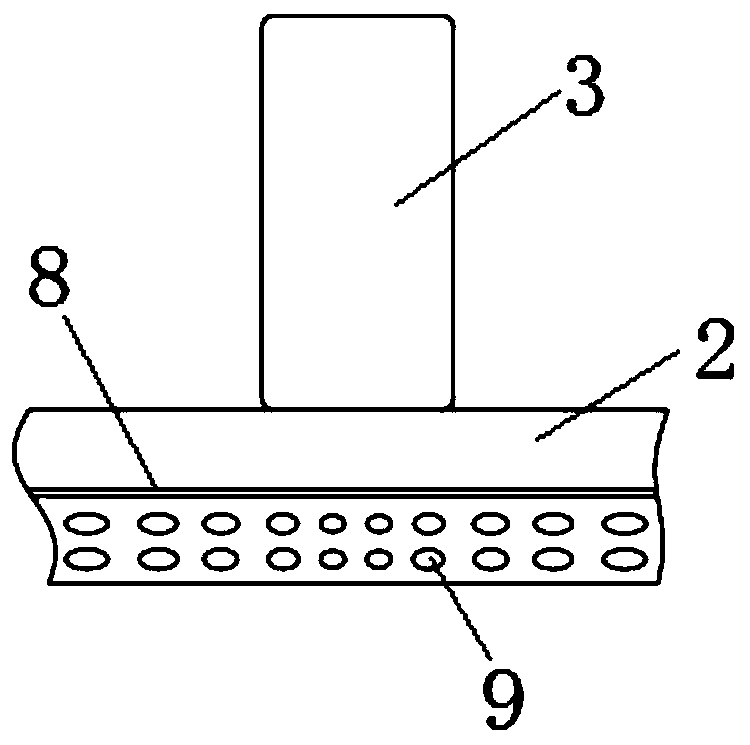

Drying room with movable air supply system

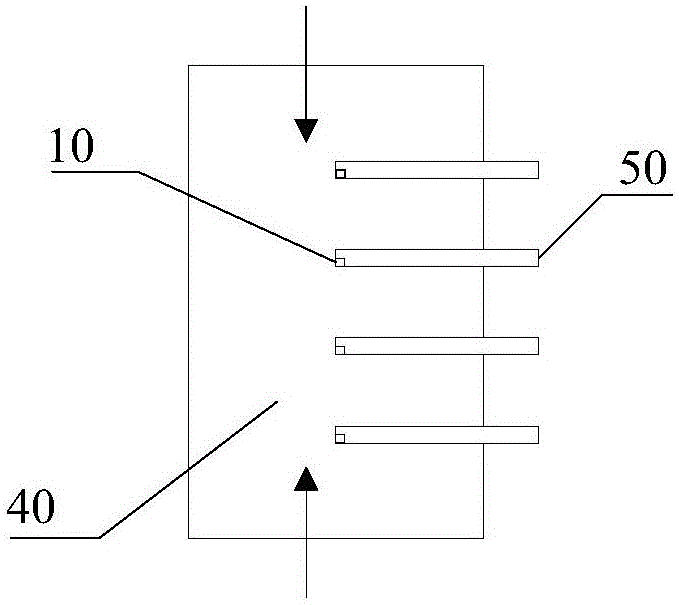

InactiveCN104061764AAvoid ventilation dead endsImprove drying efficiencyDrying gas arrangementsDrying solid materialsEngineeringPhysics

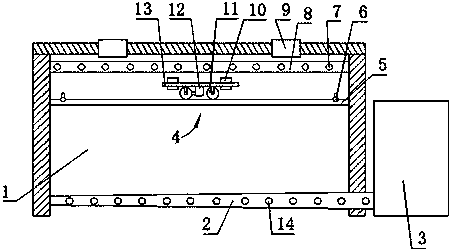

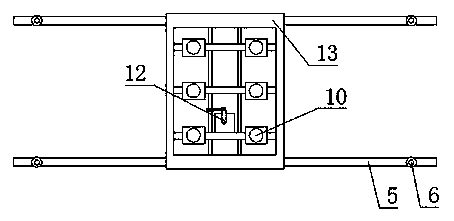

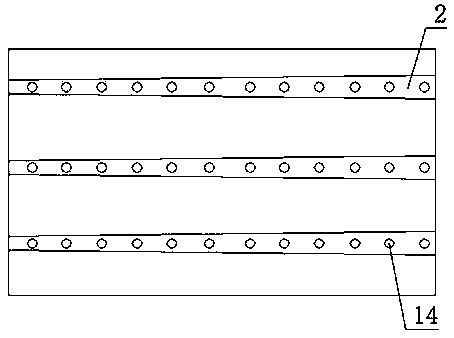

A drying room with a movable air supply system comprises a room body. The movable air supply system is arranged on the upper portion of the inner side of the room body. The movable air supply system is mainly composed of a fan, a rack and a guide rail. The guide rail is fixed to two corresponding side walls of the room body. The rack stretches above the guide rail. Under the action of guide wheels fixed to the two ends of the rack, the rack drives the fan above the rack to move back and forth above the guide rail, and the moving distance of the rack is controlled by limit switches arranged at the two ends of the guide rail. According to the drying room with the movable air supply system, the fan moves transversely or longitudinally in the drying room, so that a ventilation dead angle of materials is avoided, and drying efficiency is improved.

Owner:盐城江跃机械制造有限公司

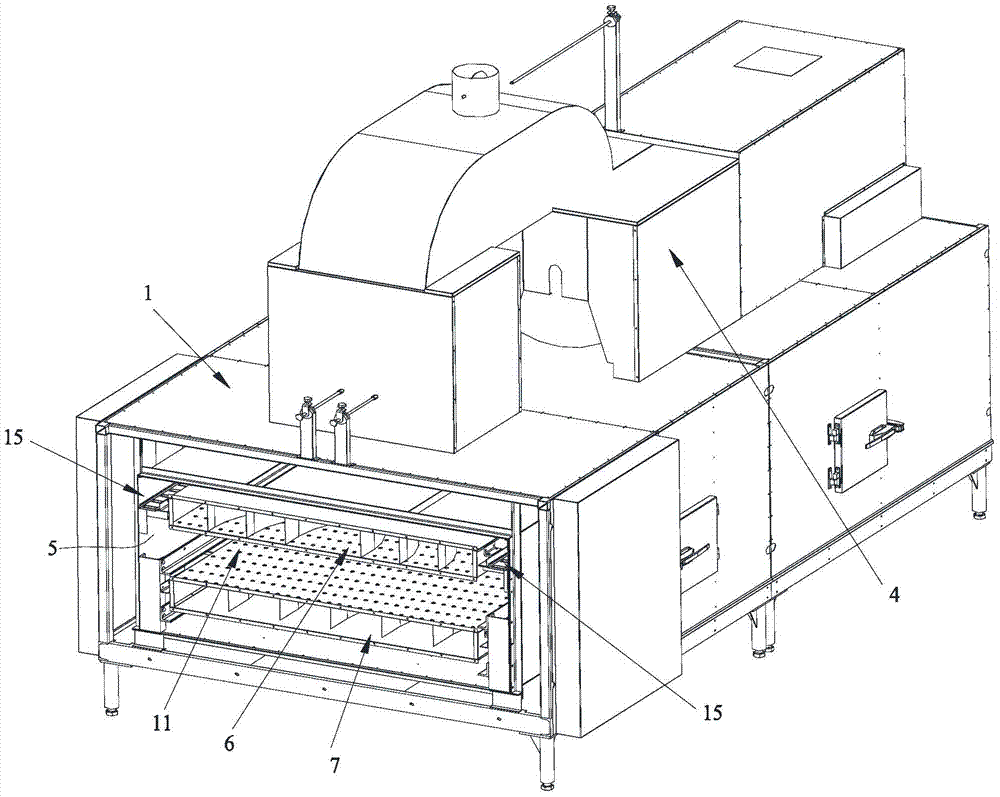

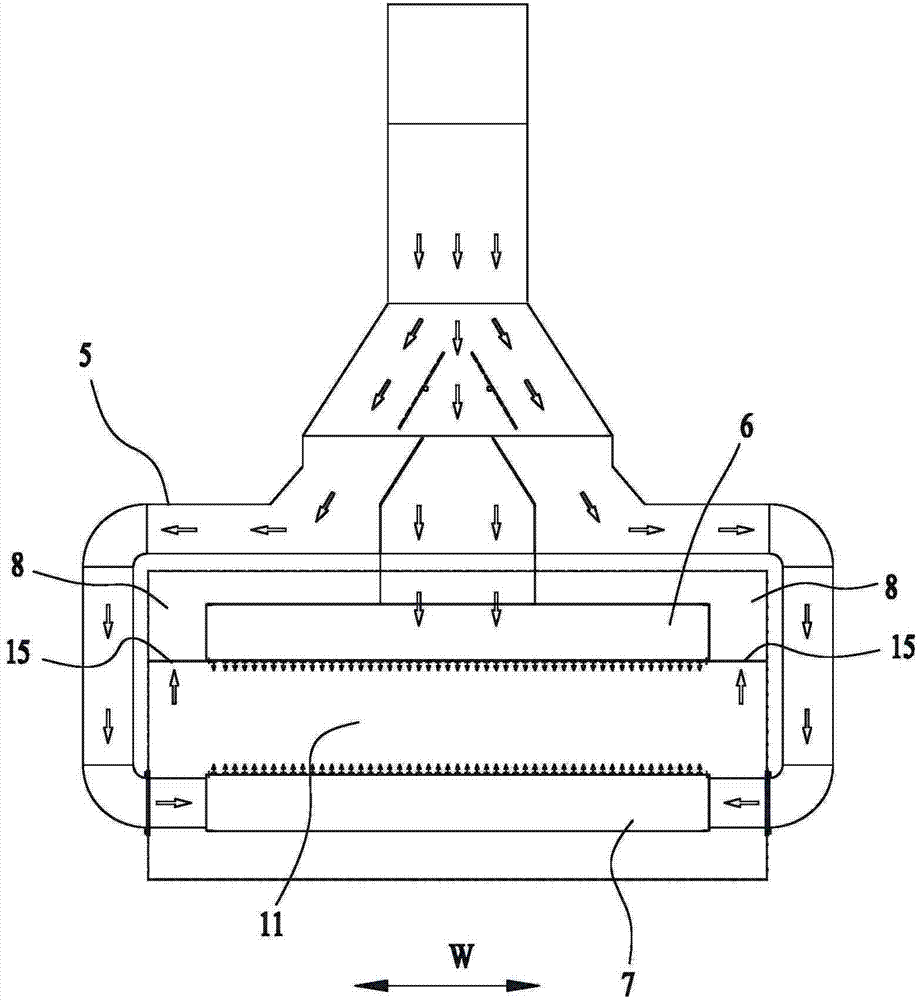

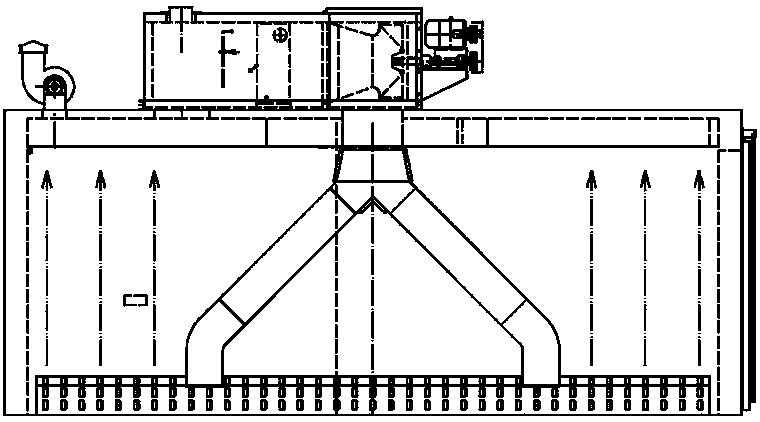

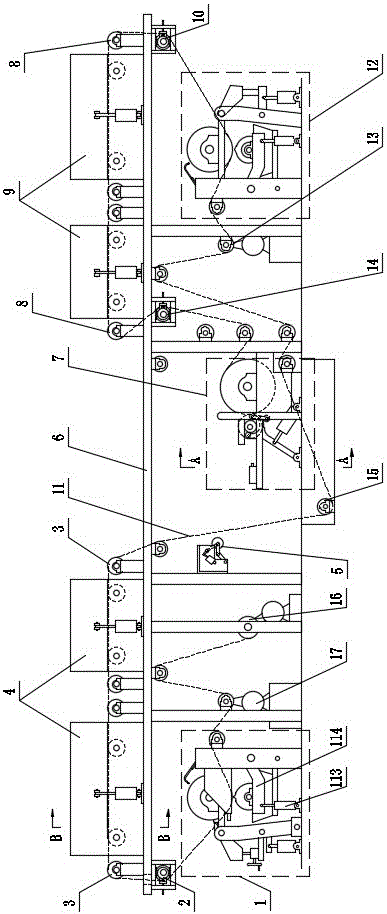

Tunnel type hot air circulation tunnel furnace

The invention discloses a tunnel type hot air circulation tunnel furnace. The tunnel type hot air circulation tunnel furnace comprises a furnace body, a hot air circulation device, a conveying belt and a heating device. The hot air circulation device comprises a hot air generator, a draught fan, a four-way connector, an upper air box and a lower air box. The four-way connector comprises a horizontal air inlet shell and two air distribution shells, wherein the two ends of the air inlet shell vertically extend to form the two air distribution shells. The top face of the air inlet shell is provided with an inlet. The bottom face of the air inlet shell is provided with a first outlet. The upper ends of the two air distribution shells are communicated with the inlet. The lower end of each air distribution shell is provided with a second outlet. The outlet of the draught fan is communicated with the inlet. The first outlet is communicated with the upper air box. The second outlets are communicated with the lower air box. The bottom of the upper air box is provided with a plurality of first air outlet holes. The top of the lower air box is provided with a plurality of second air outlet holes. A return air passage is arranged in the furnace body. The first air outlet holes and the second air outlet holes are connected with the hot air generator through the return air passage. According to the tunnel type hot air circulation tunnel furnace, hot air output by the hot air circulation device can be evenly and circularly led to products to be baked, and the air temperature, the air volume and the air speed can be controlled.

Owner:GUANGZHOU BAKE OVEN MACHINERY

System for controlling variable air rate ventilating laboratory in segments

ActiveCN102486331ARealize on-demand ventilationReduce exhaust noiseSpace heating and ventilation safety systemsLighting and heating apparatusAir volumeEngineering

The invention discloses a system for controlling variable air rate ventilating laboratory in segments and is used for leading waste gas generated in a scientific experiment process to discharge outside. The system comprises a frequency conversion fan, a static pressure box, an air valve and fume chambers, wherein a first ventilated section is from the frequency conversion fan to the static pressure box, the frequency conversion fan is arranged on a housetop or outside and is connected with the static pressure box through a ventilating duct; the static pressure box is arranged close to a ventilated terminal, and the specific position of the static pressure box is a geometric center of multiple fume chamber positions; the static pressure box is provided with a pressure sensor, and the pressure sensor can detect air pressure value in the static pressure box so as to adjust the rotation rate of a fan; and a second ventilated section is from the static pressure box to the terminal, the static pressure box is connected with the fume chambers through the ventilating duct, a manual drive air valve is arranged between the static pressure box and the fume chambers and is used for adjusting air quantity, and a motor-driven air valve is arranged and used for variable air rate control in work. The ventilating system provided by the invention adopts a segmentation control mode on ventilation, thereby realizing exact adjustment of each part air quantity and being capable of reducing ventilated noises and ventilated energy consumption.

Owner:WUHAN KEBEI TECH

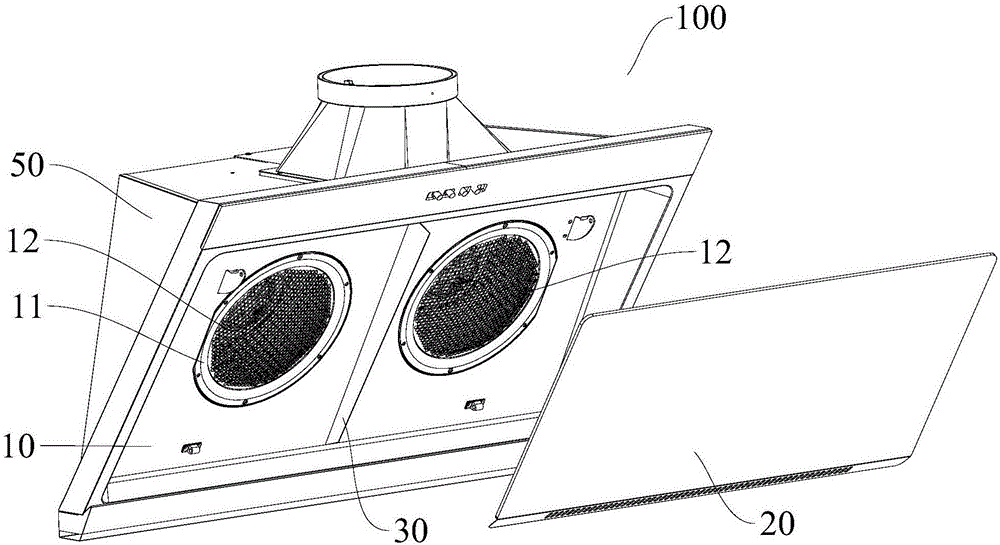

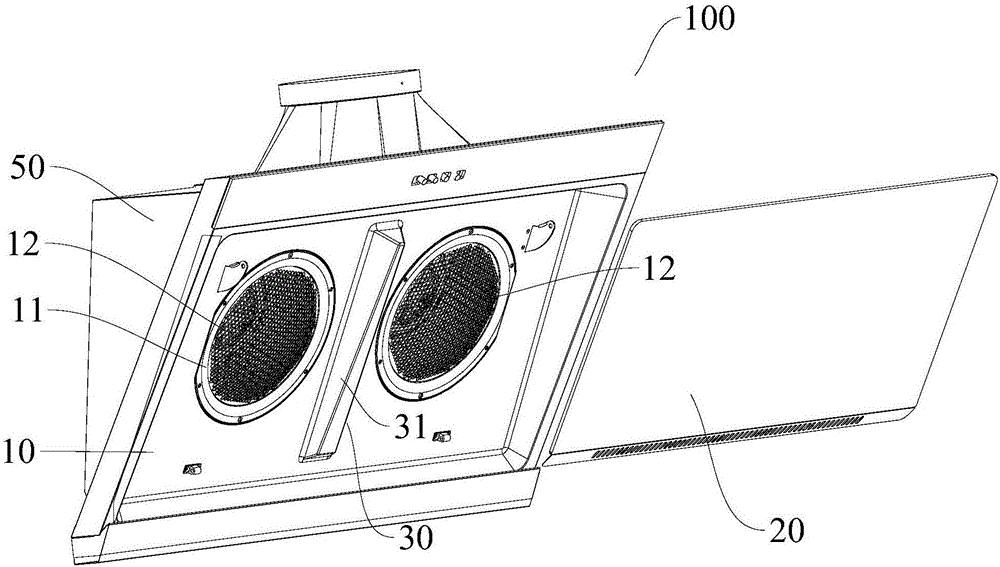

Extractor hood

ActiveCN106091062ASolve the problem of rushing windReduce noiseDomestic stoves or rangesLighting and heating apparatusIndustrial engineering

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

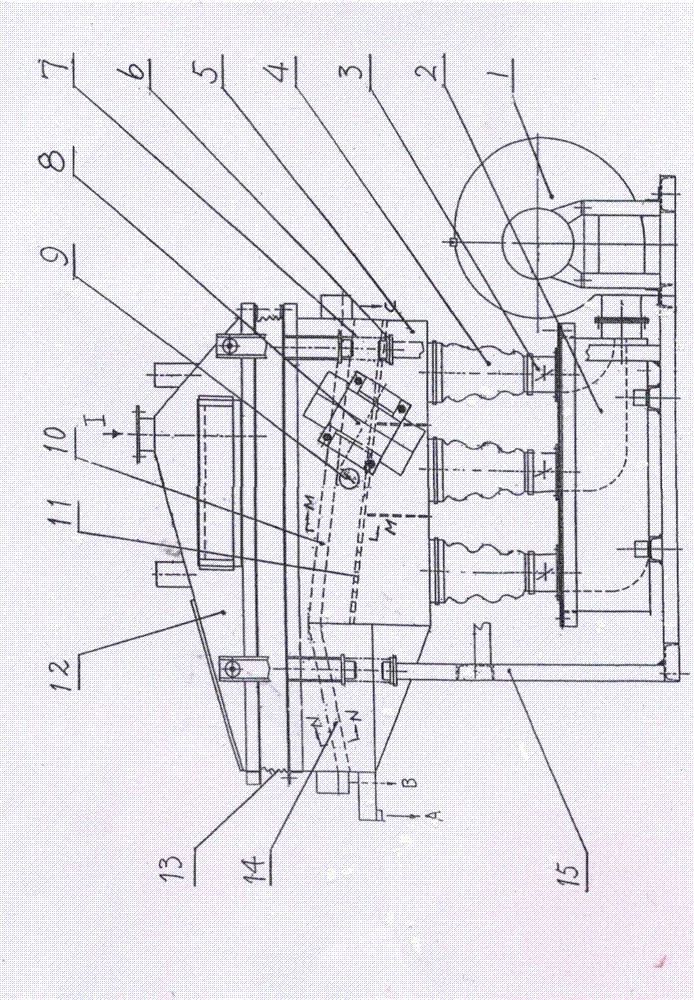

Novel gravity separator

InactiveCN102728552AEasy to sortAvoid cloggingSievingGas current separationAir filterElectric machinery

The invention relates to a novel gravity separator. The novel gravity separator is characterized by comprising a machine frame, wherein an air filter, an air blower and an air box are arranged on an underbed of the machine frame; a vibrating box is arranged on the machine frame; an outlet of the air filter is connected with an inlet of the air blower, and an outlet of the air blower is connected with an inlet of the air box; vibrating motors are respectively arranged in the middle rear positions of the two outer sides of the vibrating box, and an air pressure gauge is arranged in the middle of one outer side of the vibrating box; a box cover is arranged on the vibrating box, and a material inlet is formed on the box cover; a plurality of material outlets are formed at the side face of the vibrating box, and the underside of the vibrating box is connected with an outlet of the air box through a flexible pipe; a gravity separating sieve is arranged in the upper position in the vibrating box; a vibrating sieve is arranged at the front end of the gravity separating sieve; and an air uniformizing plate is arranged below the gravity separating sieve. The novel gravity separator provided by the invention is especially suitable for being used for separating two types of particles with relatively large difference on specific weight from the mixed particles of the two particles under a dry condition and has a good effect.

Owner:杭州太阳铸造工程技术有限公司

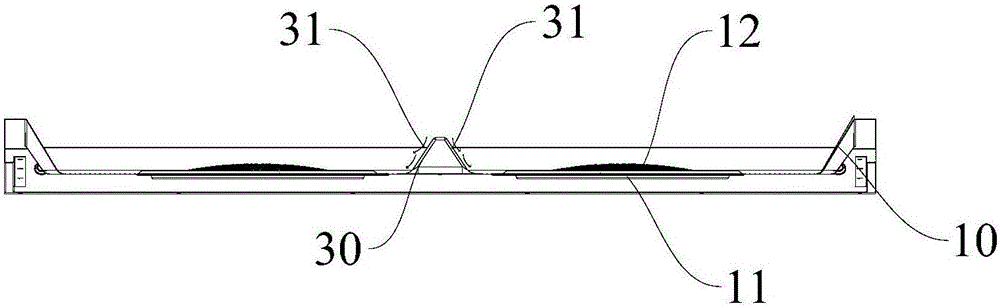

Air cooled refrigerator and air flue thereof

ActiveCN104061734AReduce energy consumptionUniform air volumeLighting and heating apparatusDomestic refrigeratorsIceboxCool storage

The invention discloses an air cooled refrigerator and an air flue thereof. The air cooled refrigerator comprises a box body, a door body, the air flue, a fan and an evaporator, wherein the box body is internally provided with a cooling chamber and a freezing chamber; the door body is arranged on the box body; the air flue comprises an air flue plate and an air supply pipe; the air flue plate is arranged in the freezing chamber; an air passage is defined by the air flue plate and the wall of the freezing chamber, and provided with first air outlets and return air inlets, which are communicated with the freezing chamber; a second air outlet is formed in the air flue plate and in the middle part of the air flue plate in the horizontal direction; one end of the air supply pipe is connected with the second air outlet, and the other end of the air supply pipe is communicated with the cooling chamber; the fan and the evaporator are arranged in the air passage. According to the embodiment of the invention, since the air cooled refrigerator is provided with the air flue, the air cooled refrigerator has the advantages of being uniform in temperature in the refrigeration chamber, low in energy consumption and the like.

Owner:HEFEI HUALING CO LTD

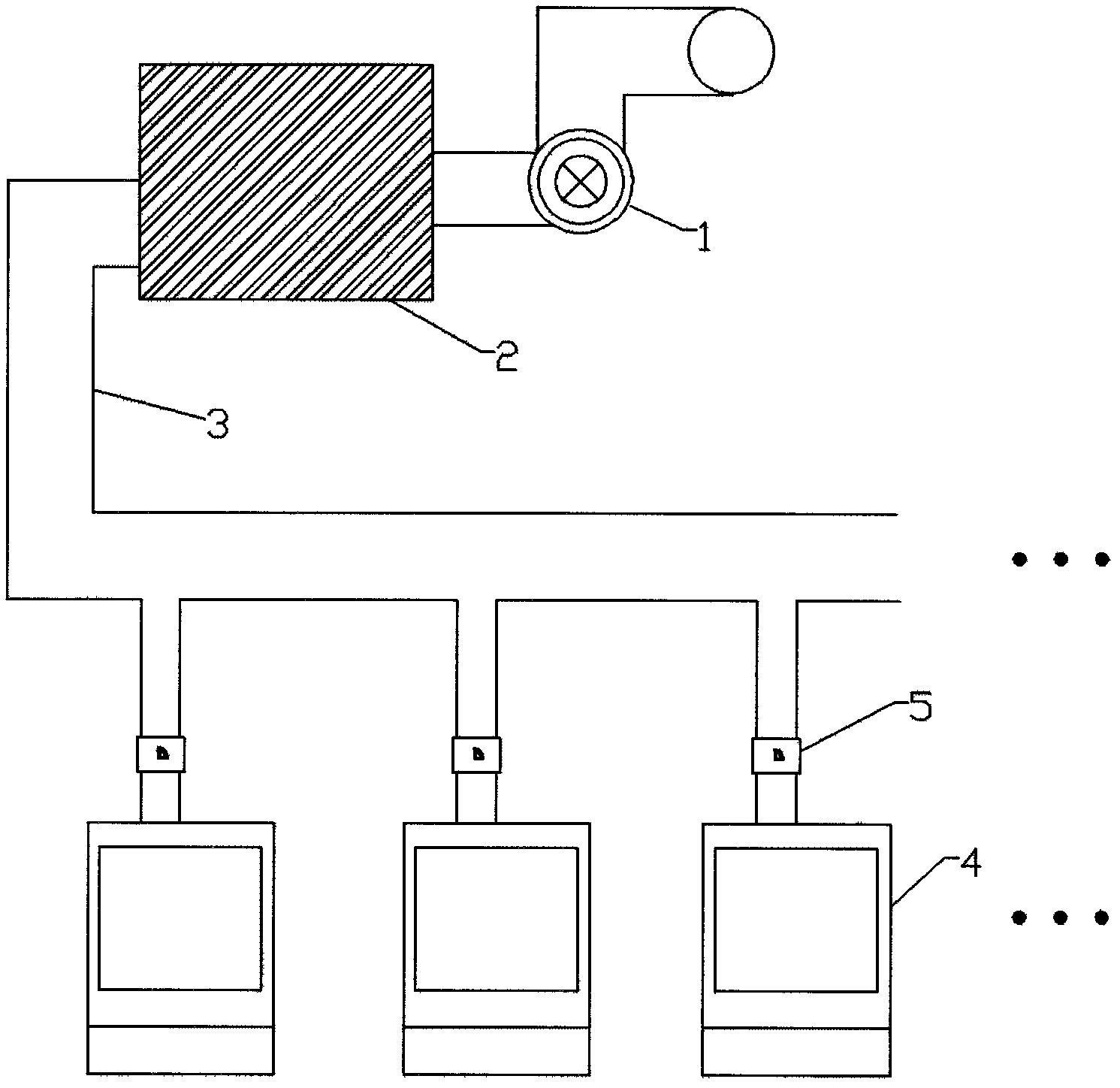

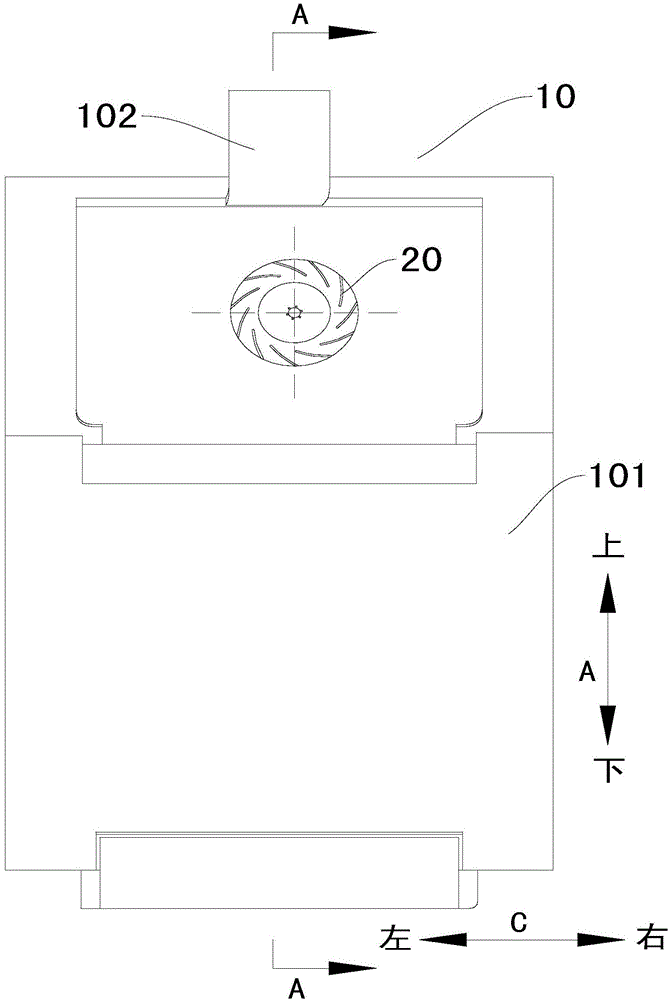

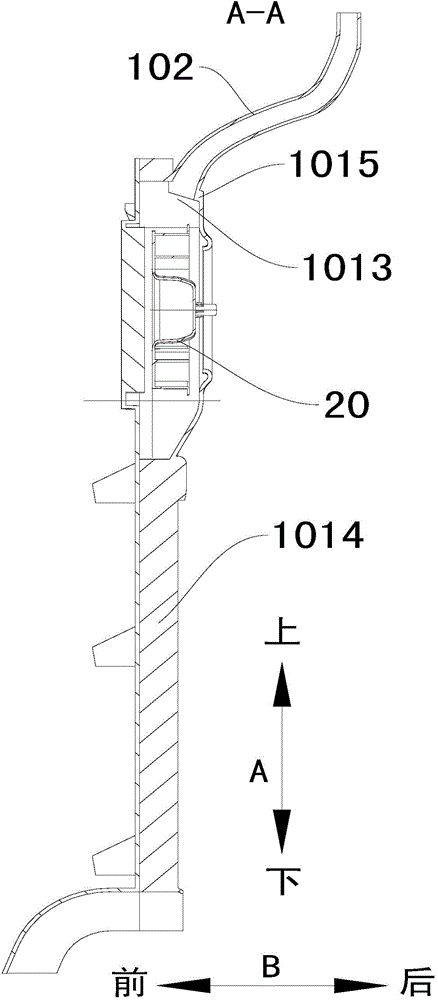

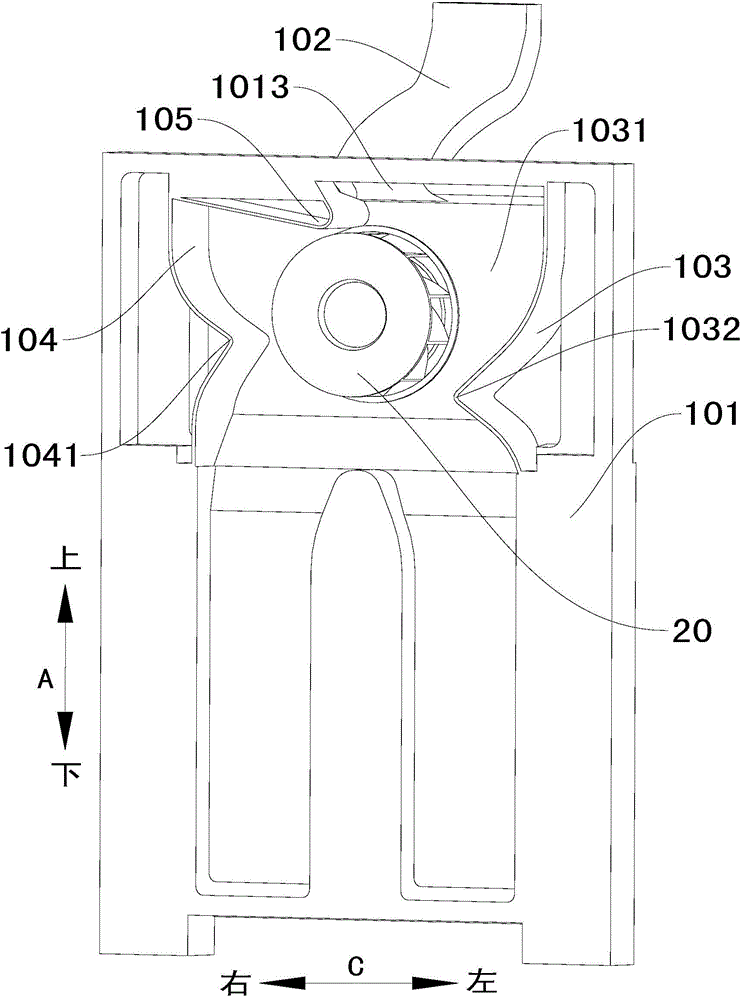

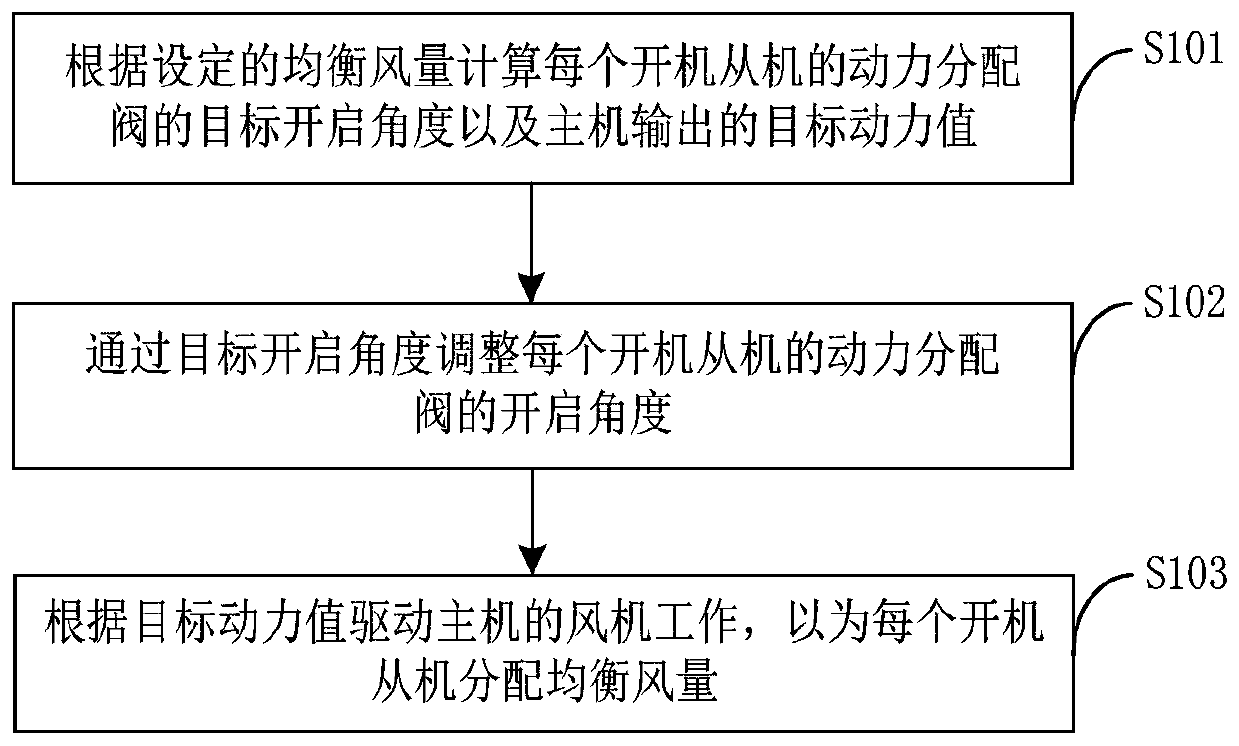

Power distribution method and device of central air purification system and computer readable medium

InactiveCN109764471AUniform air volumeMechanical apparatusDomestic stoves or rangesAir volumeDistribution method

The invention provides a power distribution method and device of a central air purification system and a computer readable medium. The central air purification system comprises a main machine arrangedon a roof and a plurality of slave machines correspondingly arranged on floors, wherein the slave machines are connected with branch pipelines through power distribution valves, the branch pipelinesare connected with common pipelines, and the main machine distributes air volume to the slave machines. The power distribution method comprises the steps that a target opening angle of the power distribution valve of each slave machine and a target power value output by the main machine are calculated according to a set balanced air volume; the opening angle of the power distribution valve of eachslave machine is adjusted through a target opening angle; and according to the target power value, a fan of the main engine is driven to work to distribute balanced air volume to each slave machine which is turned on. According to the power distribution method and device and the computer readable medium, the air volume of each slave machine in the central air purification system can be balanced,the air volume of each slave machine is still balanced under a changed working condition by dynamically adjusting the air volume of the slave machine, and the main machine can generate appropriate airvolume to supply each slave machine by dynamically adjusting the power of the main machine.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

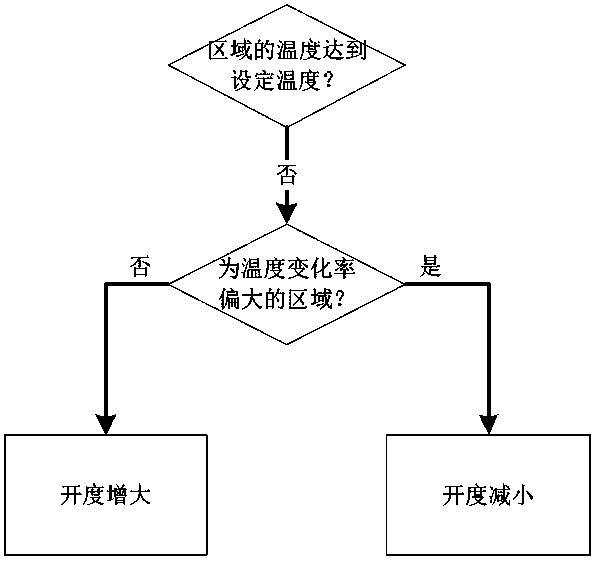

Air conditioner and area control method thereof

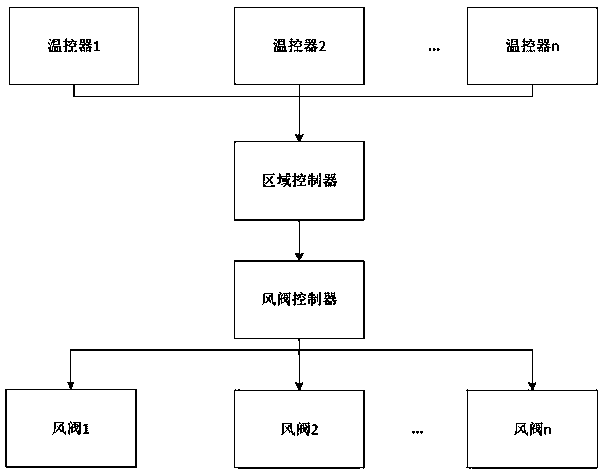

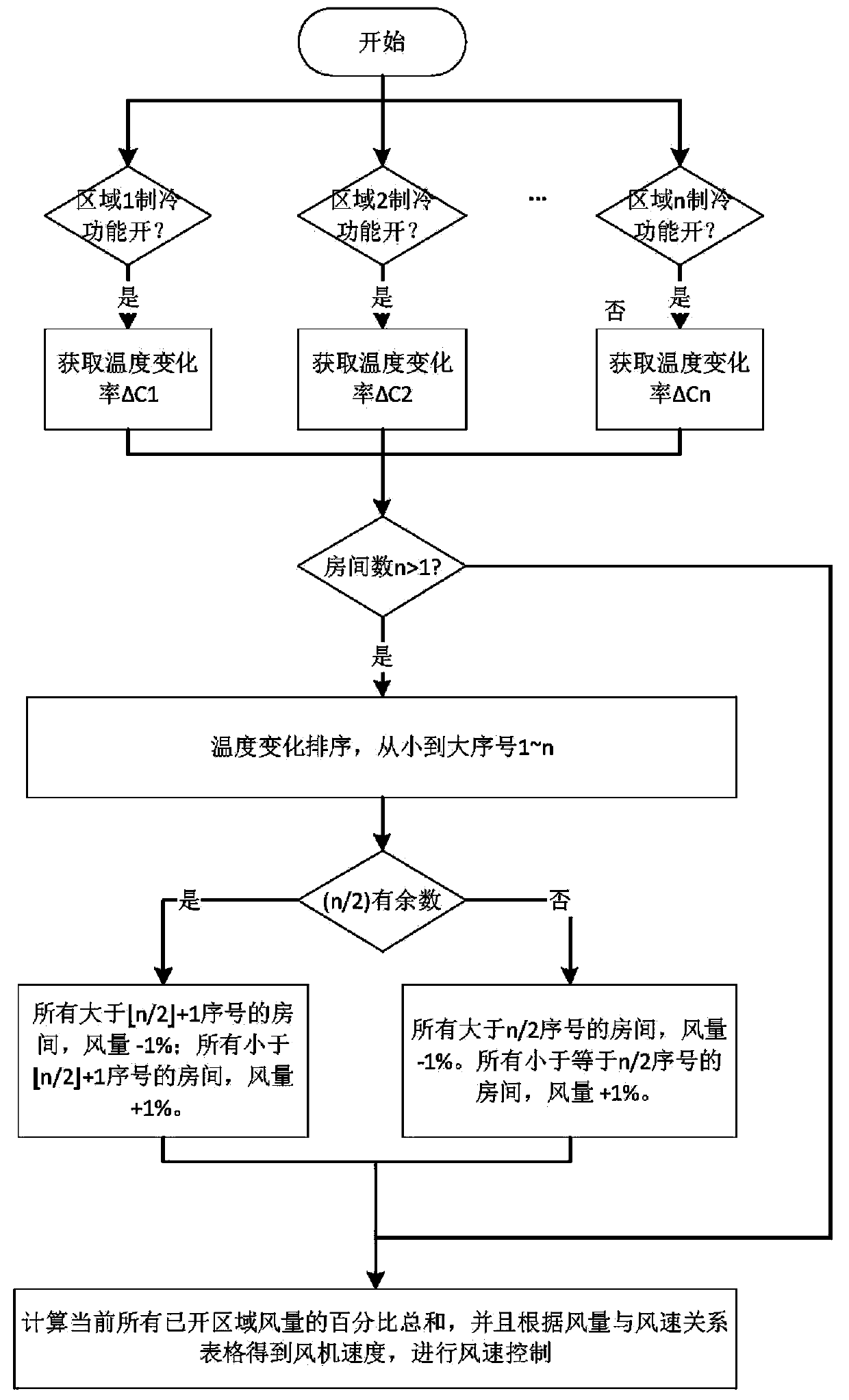

ActiveCN110285549AUniform air volumeReduce the impactMechanical apparatusEfficient regulation technologiesAir volumeEngineering

The invention discloses an air conditioner and an area control method thereof. The area control method of the air conditioner comprises the following steps of 1, calculating a temperature change rate of an area opening an air conditioner function in each unit time; and 2, judging a latest temperature change rate of the area is larger or smaller, adjusting down air volume of the area with a larger temperature change rate by a certain percentage, and adjusting up air volume of the area with a smaller temperature change rate by the same percentage. According to the method, the self-adjusting can be carried out according to specific temperature change conditions of the area, so that the air outlet quantity of each area and the fan rotating speed of the air conditioner meet the requirements of users.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

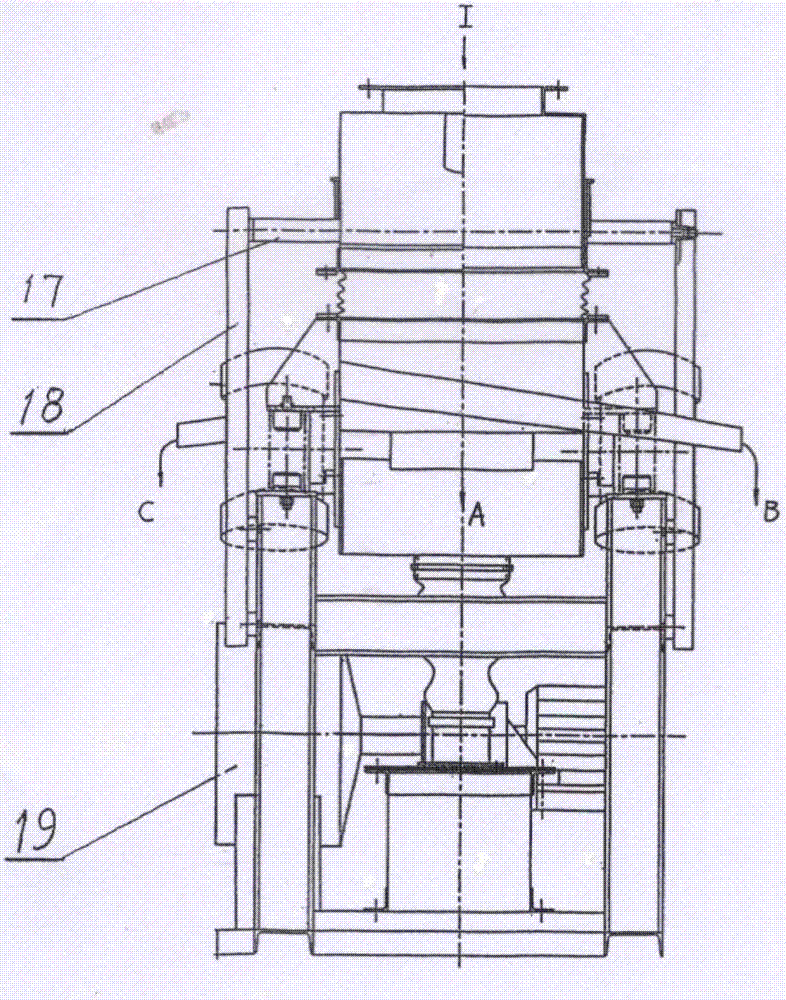

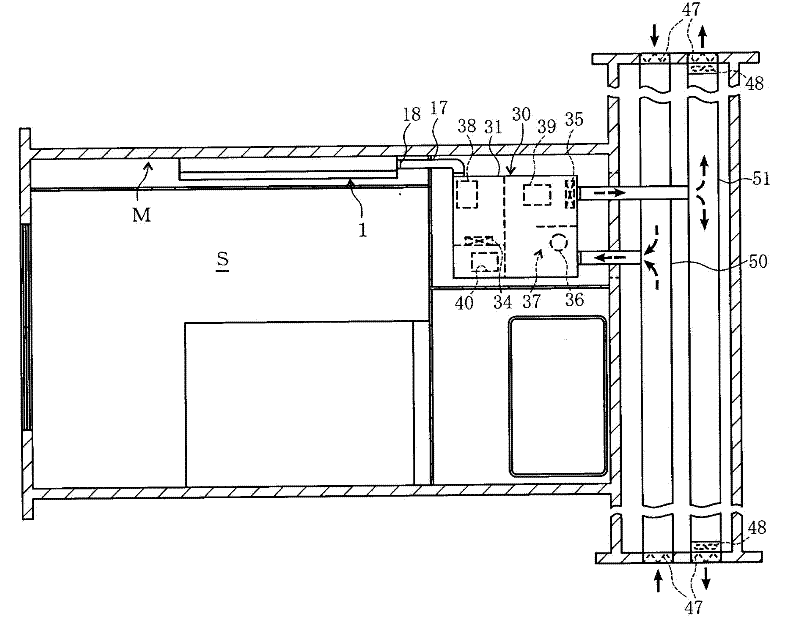

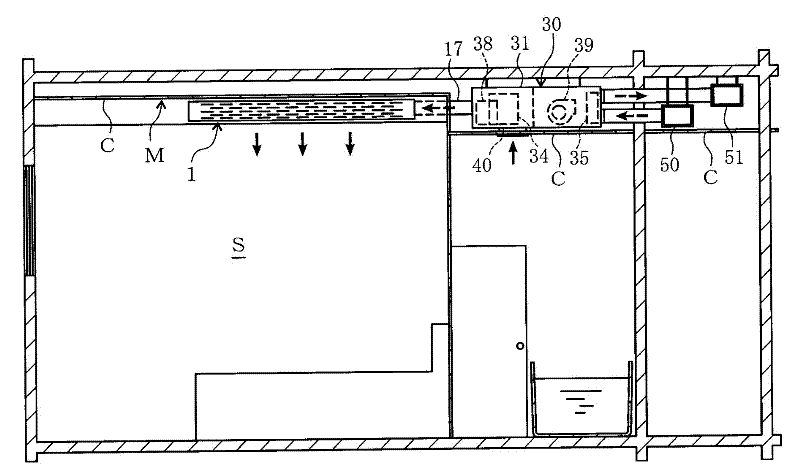

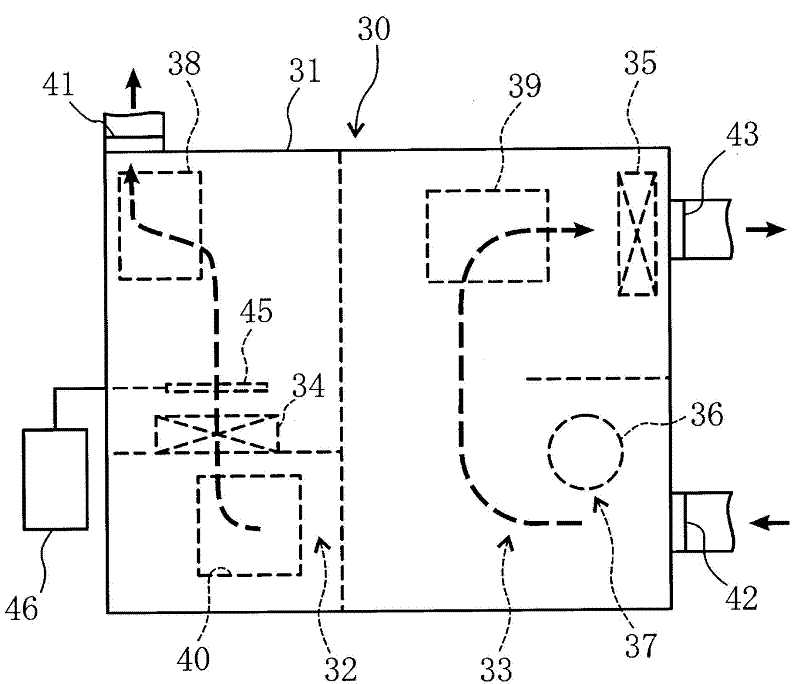

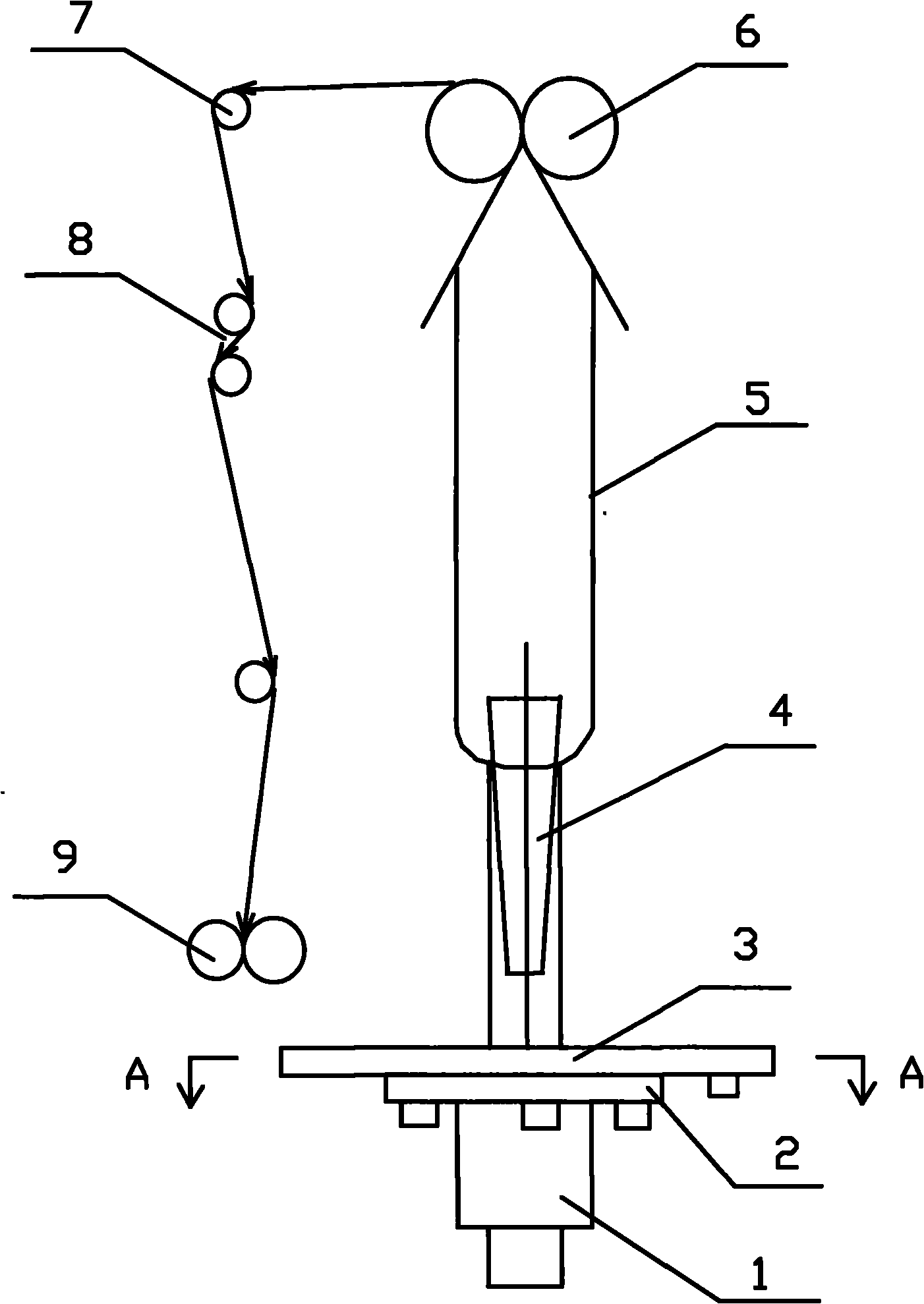

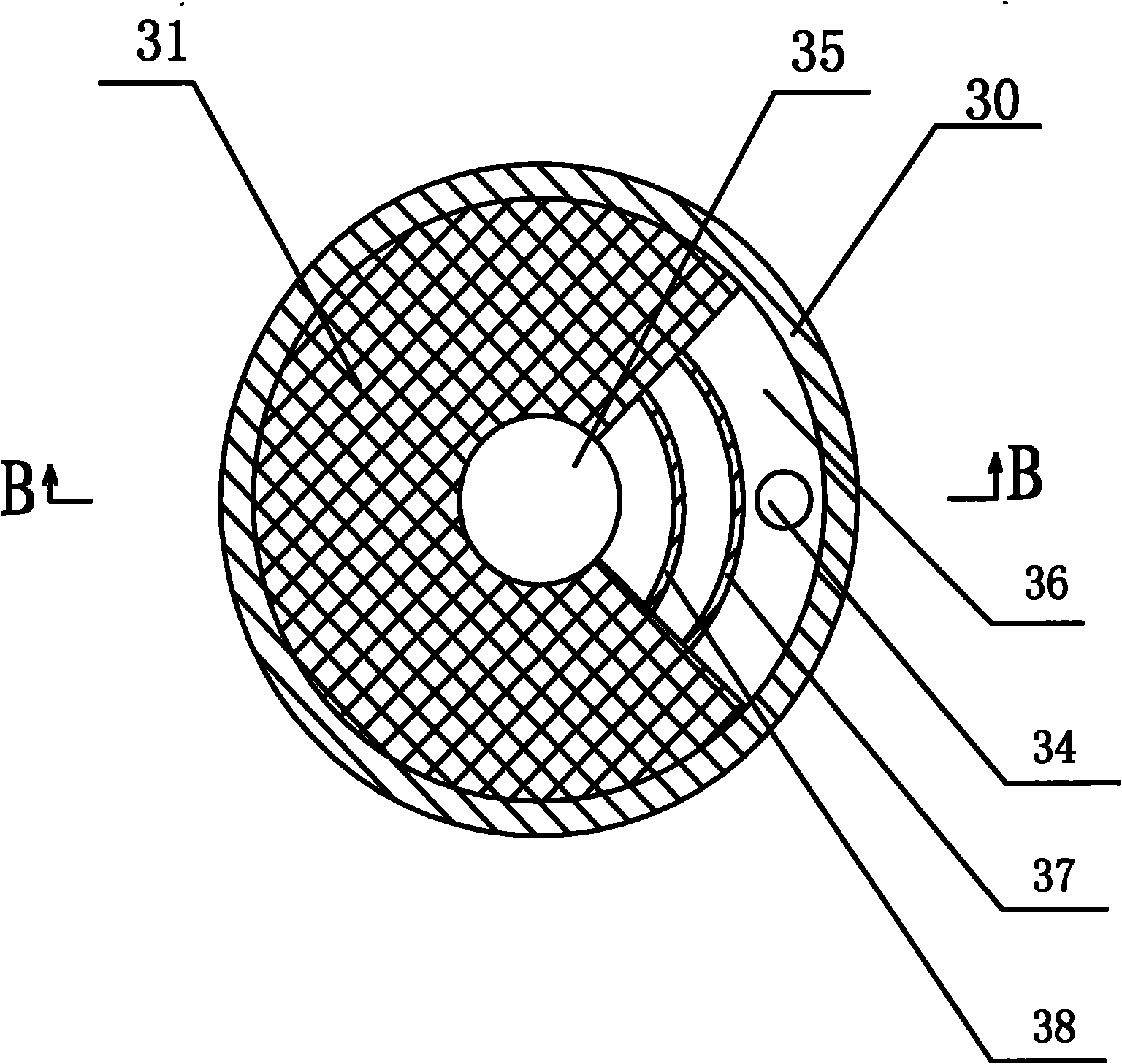

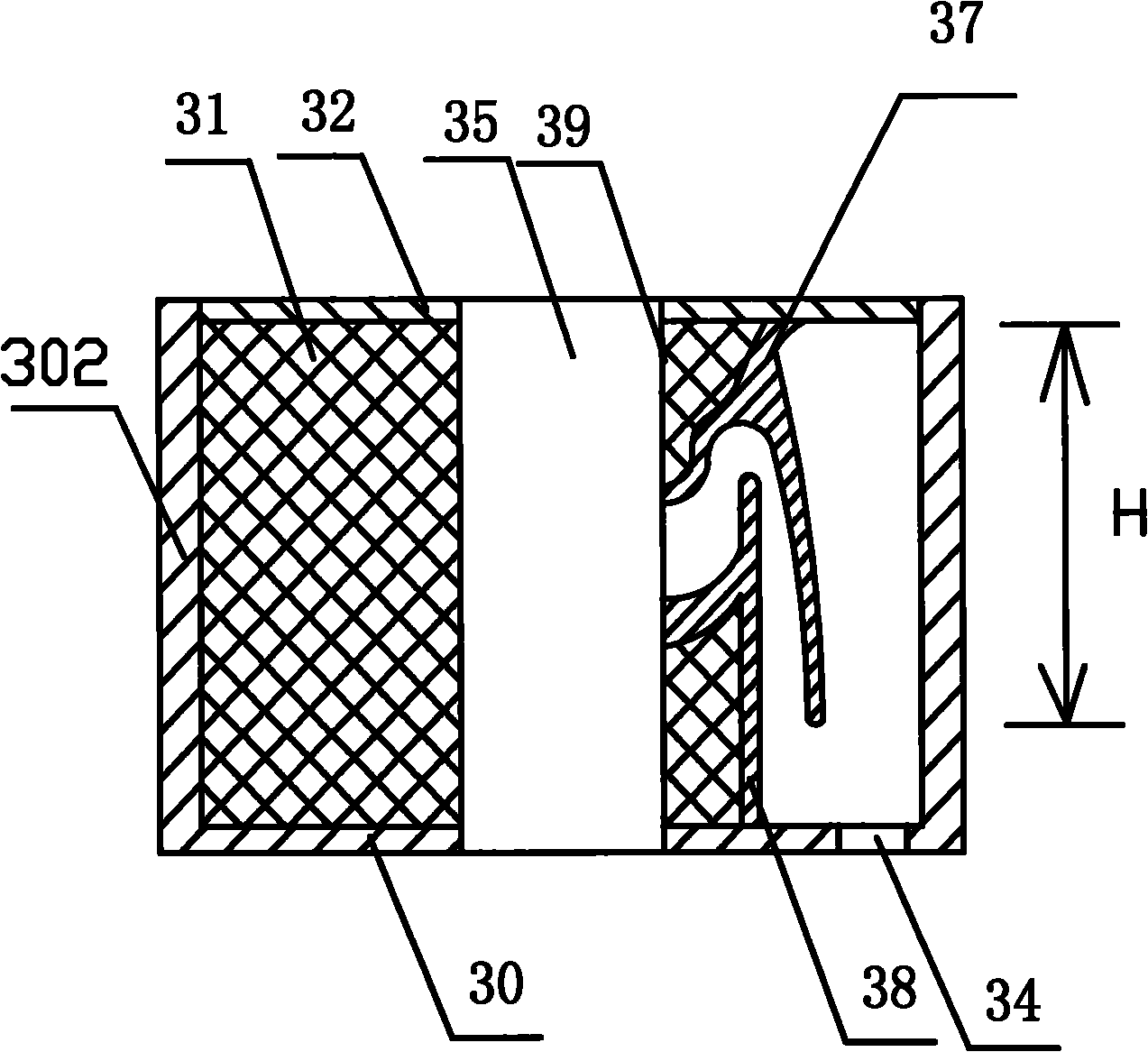

Air heat source heat pump air conditioner

ActiveCN102297485AEvenly distributedSimple structureLighting and heating apparatusSpace heating and ventilation detailsEngineeringAir conditioning

The invention provides an air heat source heat pump-type air conditioner capable of efficiently providing comfortable air conditioning and being easily constructed without requiring a wasted installation space. The air heat source heat pump-type air conditioner includes a housing (31) which is provided inside with a heat pump (37), and the heat pump (37) is composed of a refrigerant-air supply air heat exchanger (34), a refrigerant-heat source air heat exchanger (35), and a compressor (36). An air heat pump air conditioner, i.e. an HP air conditioner (30) mentioned later which gives the air supply via the refrigerant-air supply air heat exchanger (34) is also provided. The air from the HP air conditioner (30) in an air-conditioned space (S) is mixed evenly, and then the air is blown out in a rectified mode, and an induction radiation unit (1) induces the heat of the mixed air to the air-conditioned space (S).

Owner:KIMURA KOHKI CO LTD

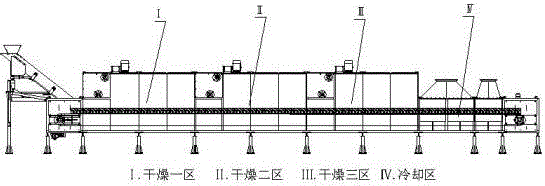

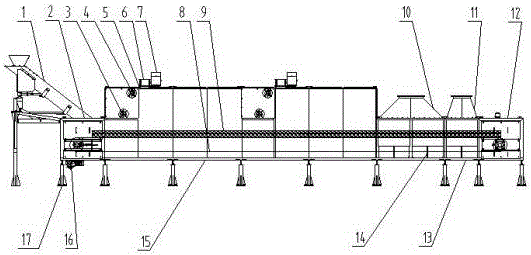

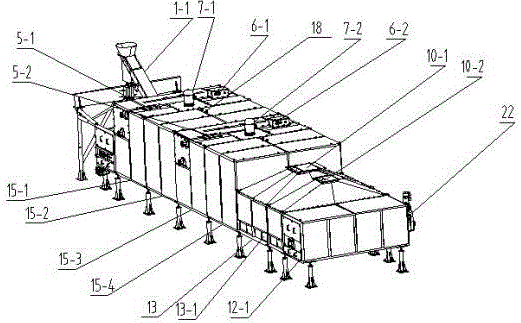

Belt-type dry cooler

ActiveCN106839730AConsider moisture uniformityUniform moistureDrying gas arrangementsDrying solid materialsEngineeringVariable frequency control

The invention relates to a belt-type dry cooler which comprises a distributing device, a feeding section, a drying section, a cooling section and a discharging section. The distributing device is communicated with the feeding section through a distributing-device hosepipe connected on the distributing device, and a conveying belt in the dry cooler sequentially penetrates the feeding section, the drying section, the cooling section and the discharging section; the drying section comprises at least one drying area, and an air supplement port, an air outlet, a circulating fan, a hot-air inlet, a temperature sensor and a heat exchanger are independently arranged on the upper portion of each drying area; the cooling section comprises at least one cooling area, each cooling area is provided with an independent air duct, an exhaust fan and an air inlet, a second wind screen is arranged between every two neighboring drying areas, and a third wind screen is arranged between the drying section and the cooling section. The distributing device is under variable frequency control, hot air is capable of operating in a more balanced and stable manner through reasonable air-inlet and-outlet arrangement and a tight sealing structure, and dried materials are ensured to be uniform in moisture.

Owner:JIANGSU MUYANG HLDG

Laboratory ventilation system

InactiveCN104456820ASimple structureUniform air volumeMechanical apparatusSpace heating and ventilation safety systemsElectrical controlPollution

The invention relates to the technical field of laboratory ventilation and discloses a laboratory ventilation system. The laboratory ventilation system comprises an air compensation system, an air exhaust system and a laboratory, wherein an air outlet of the air compensation system and an air inlet of the air exhaust system are communicated with the laboratory, air is connected with the air exhaust system through the air inlet of the air exhaust system after passing the laboratory so as to form a circulating ventilation system, and the air compensation system and the air exhaust system are connected with an electrical control cabinet respectively. The laboratory ventilation system is simple in structure, uniform in displacement, good in ventilation effect and capable of purifying waste gas and discharging clean air without causing pollution and is easy to implement, applicable to various types of labs and low in using cost.

Owner:安徽金鑫实验设备科技有限公司

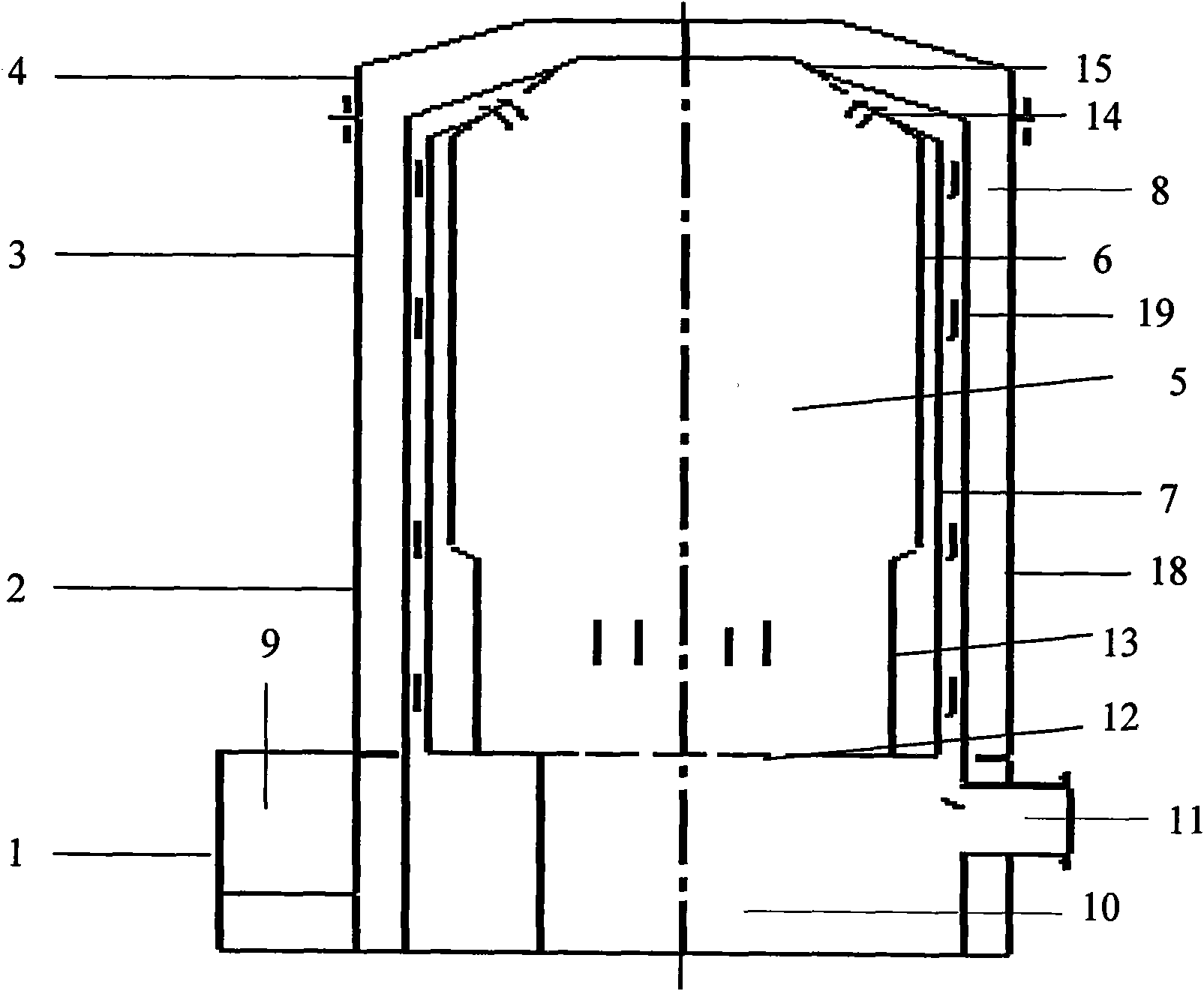

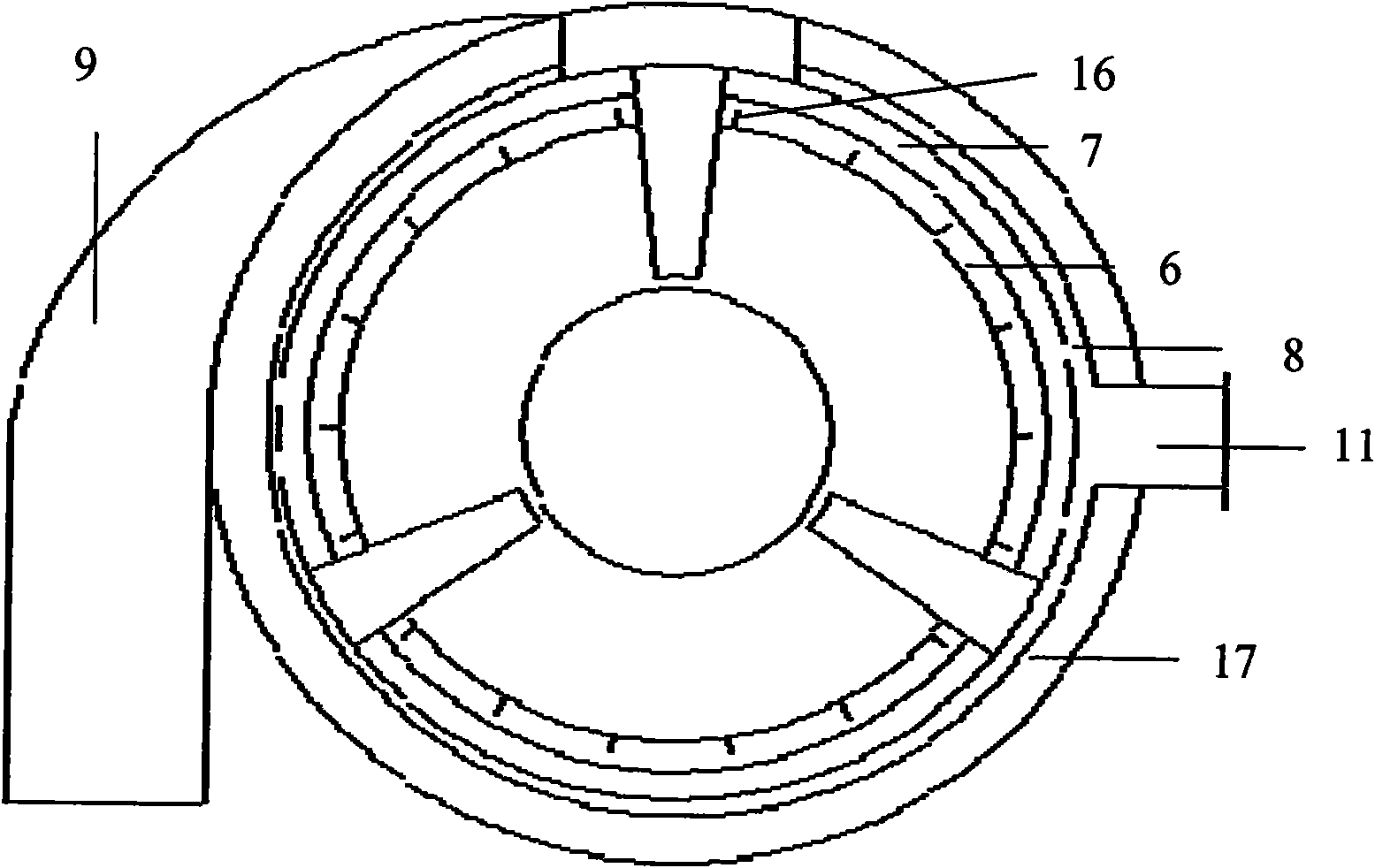

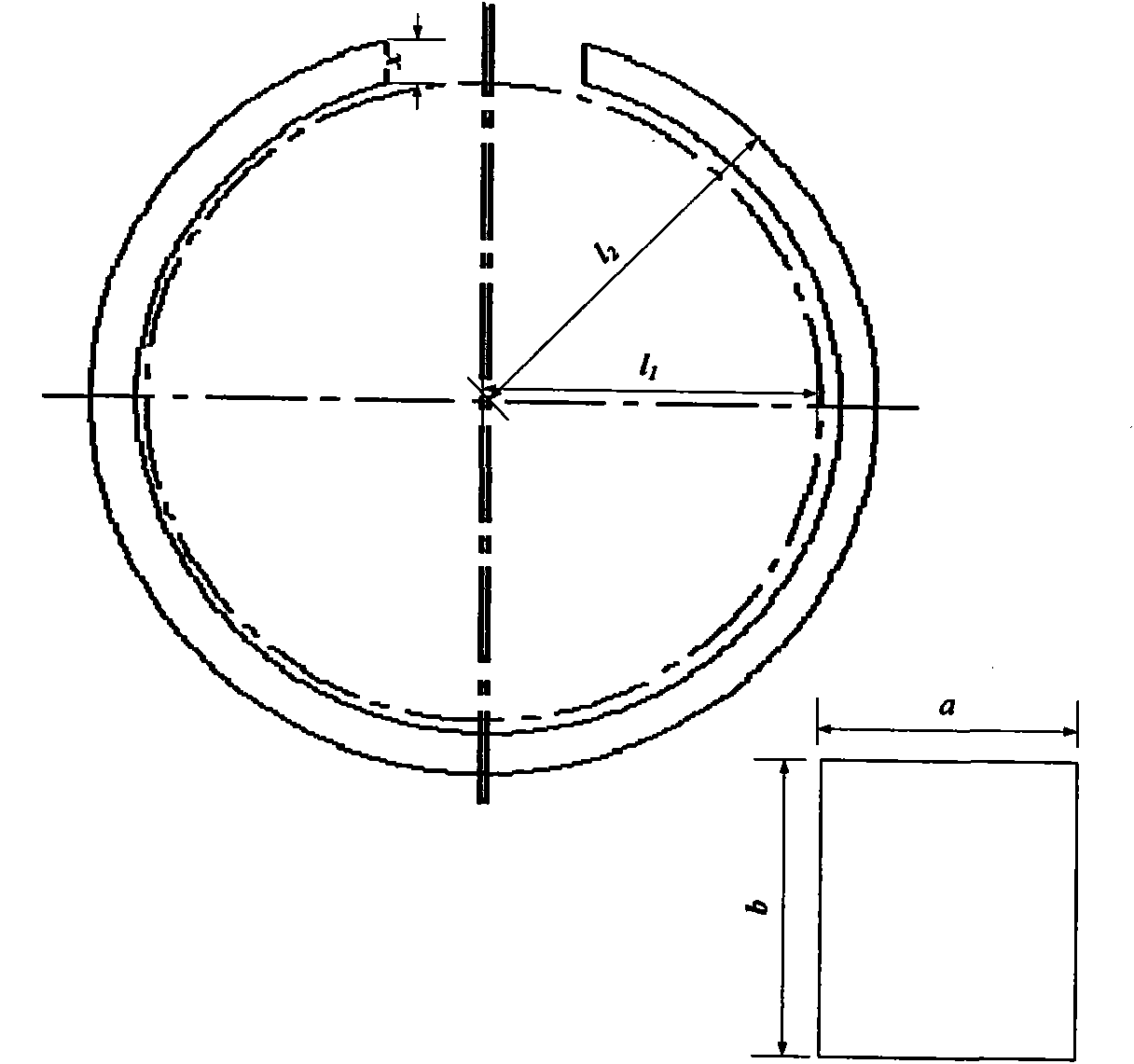

Eccentric air heating furnace

The invention discloses an eccentric air heating furnace for heating foods, tea, medicines, and the like. The air heating furnace structurally comprises a furnace body lower part (1), a furnace body middle part (2), a furnace body upper part (3) and a furnace body top part (4) and comprises four layers from inside to outside, i.e. a combustion chamber (5), a warm air space layer (6), an exhaust space layer (7) and a cold air space layer (8), wherein the furnace body lower part (1) comprises an air inlet (9), a coal cinder chamber (10) and an exhaust port (11), a fire grate (12) is arranged between the furnace body middle part (2) and the furnace body lower part (1), the innermost face of the furnace body middle part (2) is provided with a fireproof wall (13), the furnace body middle part (2) and the furnace body upper part (3) are totally called as the combustion chamber (5), the combustion chamber (5) and the exhaust space layer (7) at the top of the furnace body are mutually communicated through a flue (14), and the warm air space layer and the cold air space layer are sealed and communicated through an upper cover (15). The air heating furnace is mainly characterized in that the cold air space layer of the furnace body lower part (1) is provided with an eccentric air uniform plate, and air entering the furnace is uniformly preheated in an improved mode to absorb heat emitted by the exhaust space layer (7) to the maximum limit so that the heat efficiency is effectively improved.

Owner:CHANGSHA XIANGFENG TEA MACHINERY MFG

Automobile air conditioning system

InactiveCN102358143AGood energy saving and environmental protectionReduce fuel consumptionAir-treating devicesLighting and heating apparatusAutomotive engineeringWater supply

The technical scheme of the invention relates to an automobile air conditioning system. The automobile air conditioning system is characterized by comprising an air inlet channel which is arranged on the top of an automobile body and extends along a front-and-after direction of the automobile body, air outlet channels which are arranged on the left side and the right side of the air inlet channel respectively, wet curtains blocked between the air inlet channel and the air outlet channels, fans which are arranged at the entrances of the air outlet channels and used for extracting air from the air inlet channel to the air outlet channels, water distribution pipelines which are arranged on the top or lateral parts of the wet curtains and used for distributing water on the wet curtains, and a water supply device connected with the water distribution pipelines to supply water, wherein an air inlet for communicating the air inlet channel with air outside the automobile body is formed on the top of the automobile body; and air outlets for communicating the air outlet channels with air in a carriage are formed on the top or the lateral parts of the carriage. The automobile air conditioning system realizes temperature reduction by adopting a water evaporation effect theory and using a physical method; and the automobile air conditioning system is a complete coolant-free, heat pollution-free, energy-saving and environment-friendly automobile air conditioner.

Owner:齐峰

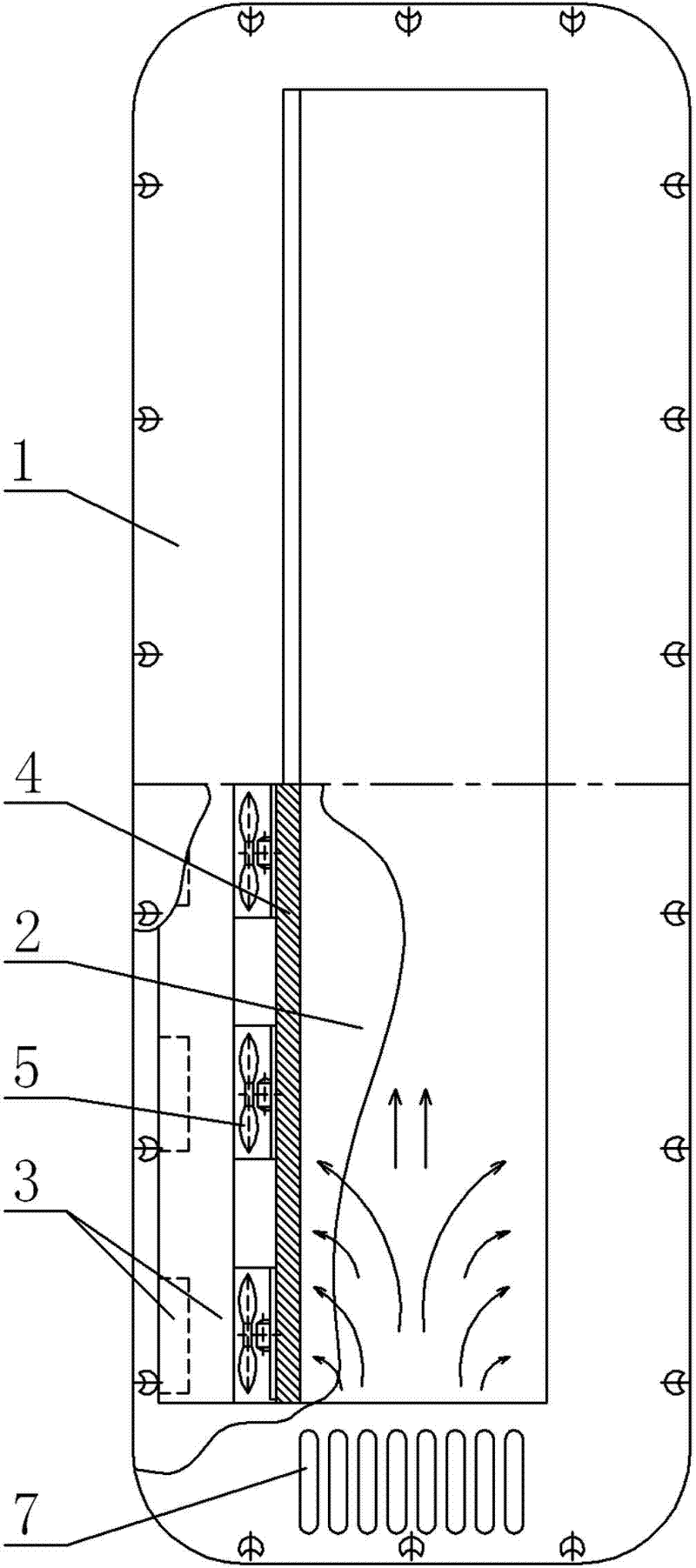

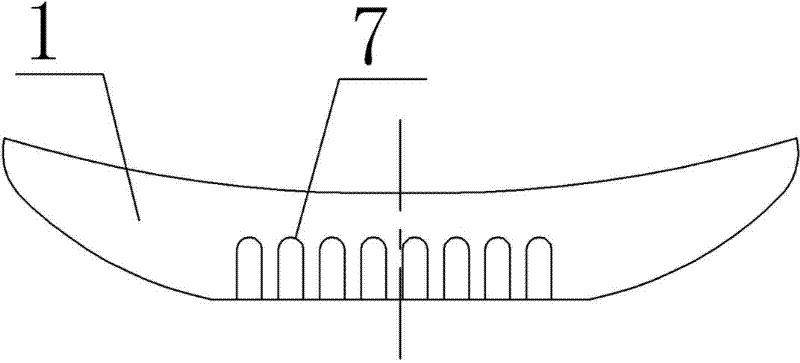

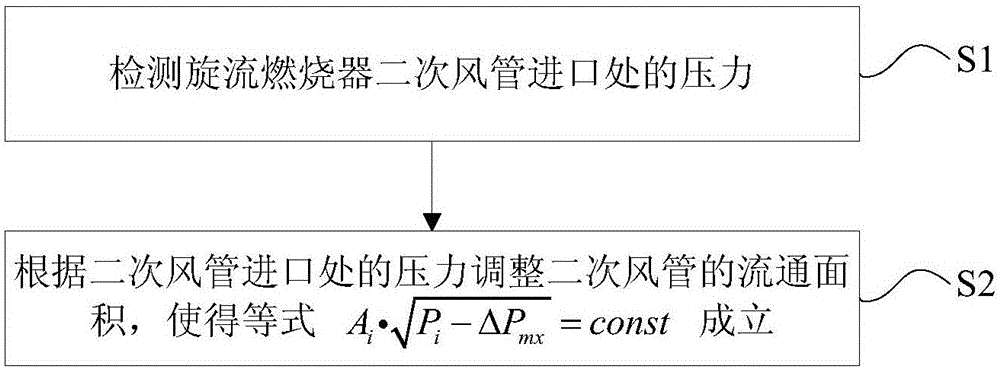

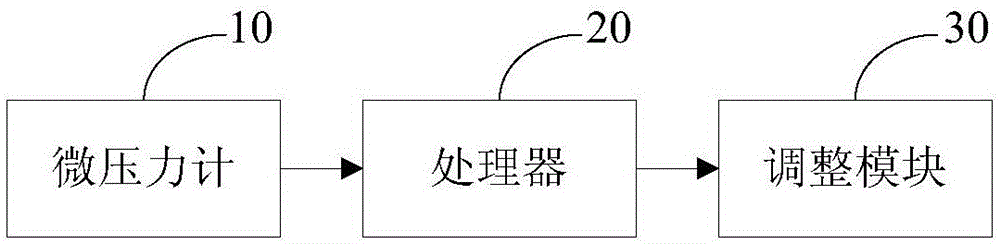

Method for making air inflows of secondary air pipes of turbulent burner even and measuring device

ActiveCN105090949AUniform air volumeStable combustionPulverulent fuel combustion burnersEngineeringBellows

The invention provides a method for making the air inflows of secondary air pipes of a turbulent burner even and a measuring device. The method includes the steps that the pressure of an inlet of each secondary air pipe of the turbulent burner is detected; and according to the pressure of the inlet of each secondary air pipe of the turbulent burner, the flow area of each secondary air pipe is adjusted, so that the equation shown in the specification is satisfied, wherein Ai is the flow area of the ith secondary air pipe of the turbulent burner, Pi is the pressure of the inlet of the ith secondary air pipe of the turbulent burner, deltaPmx is the largest difference value of the pressure of the corresponding secondary air pipe of the turbulent burner and the negative pressure of a hearth, and const is a constant. By the adoption of the method and the cutter, the problems that the air inflows of the secondary air pipes of the turbulent burner are not even due to the fact that the pressures inside an air box are not uniform can be solved.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

Thick and thin bag production device

The invention relates to a thick and thin bag production device which comprises an extruder, a die connected with a discharge port of the extruder, and a standard air ring and an upper traction roller arranged on the upper end of the die; the upper end of the standard air ring is provided with a mold air ring; a through hole for a film bubble crude embryo to pass through is arranged in the middle of the mold air ring; one side in the mold air ring is provided with a cavity communicated with the through hole; the upper end of the cavity is provided with an upper windshield which extends downwards, and the lower end thereof is provided with a lower windshield which extends upwards; a buffer air duct is formed between the upper and the lower windshields; the mold air ring is provided with an air inlet hole of a connecting air pipe; the air inlet hole and the cavity are communicated; and the gas enters the cavity through the air inlet hole, and is blown to the film bubble crude embryo in the through hole from the buffer air duct. The mold air ring is used to control the thickness of a side wall of a film bubble, the air outlet of the air pipe is not arranged directly to one side of the film bubble crude embryo but is blown to the film bubble crude embryo through the buffer air duct, so that the thickness of the thin side and the thick side of a produced thick and thin bag is uniform, and the strength is good.

Owner:NANTONG HUASHENG PLASTIC PRODS

Pipeline structure for equally distributing purifying smoke pipe air quantity

The invention relates to a pipeline structure, in particular to the pipeline structure for equally distributing purifying smoke pipe air quantity, which ensures that the air quantity distributed into each branch pipe is uniform and the flow is stable. The pipeline structure comprises a total purifying smoke pipe, wherein at least two separating tubes are arranged on the total purifying smoke pipe; and the outlets of the separating tubes are communicated with reactors. The pipeline structure has the advantages that: the air quantity distributed into each reactor is ensured to be uniform by adjusting all the control valves to make the dynamic pressure value displayed on each pressure meter equal; and a deflector is used for adjusting the flow direction of smoke to ensure that the smoke flow rate is vertical upwards, is uniformly distributed on the cross sections of the reactors and does not deflect and cause turbulence. The pipeline structure can effectively improve the uniformity of the air quantity distribution in the total purifying smoke pipe, reduce the local damage due to pressing of a reactor tube section, avoid airflow turbulence caused by violent change of the flow rate and the flow direction of the smoke and reduce the abrasion of a tube wall and the breaking rate of aluminum oxide particles.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

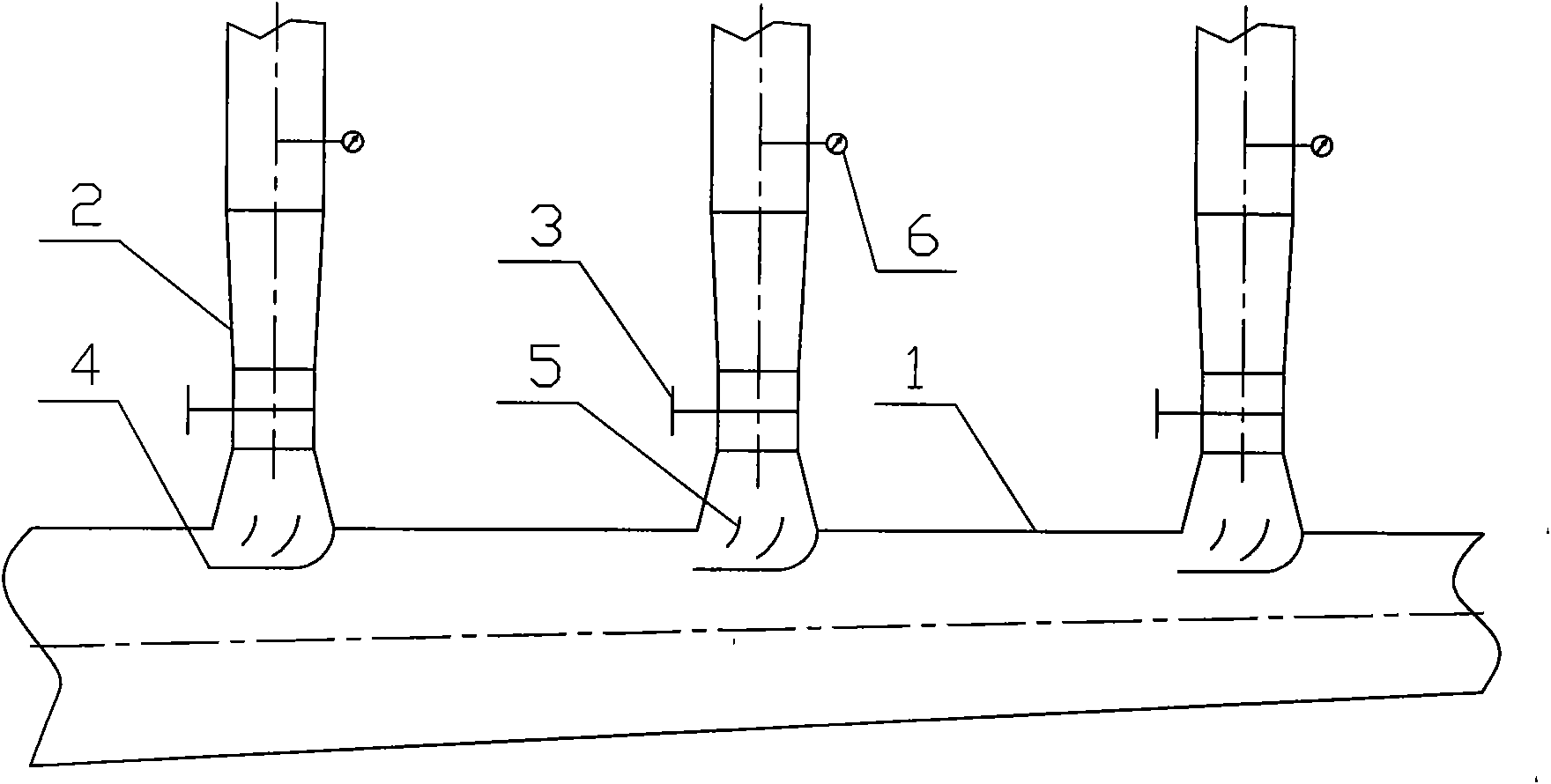

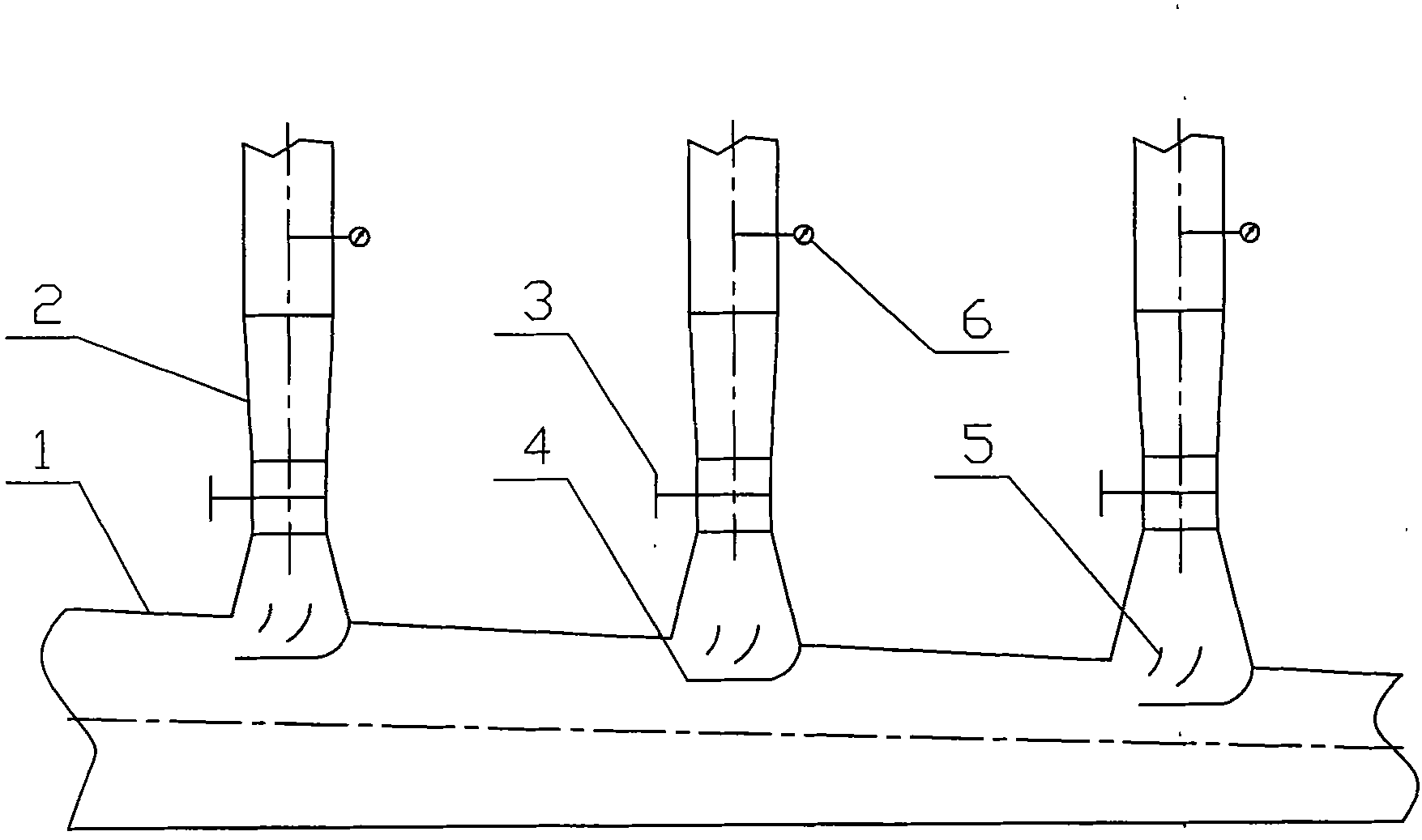

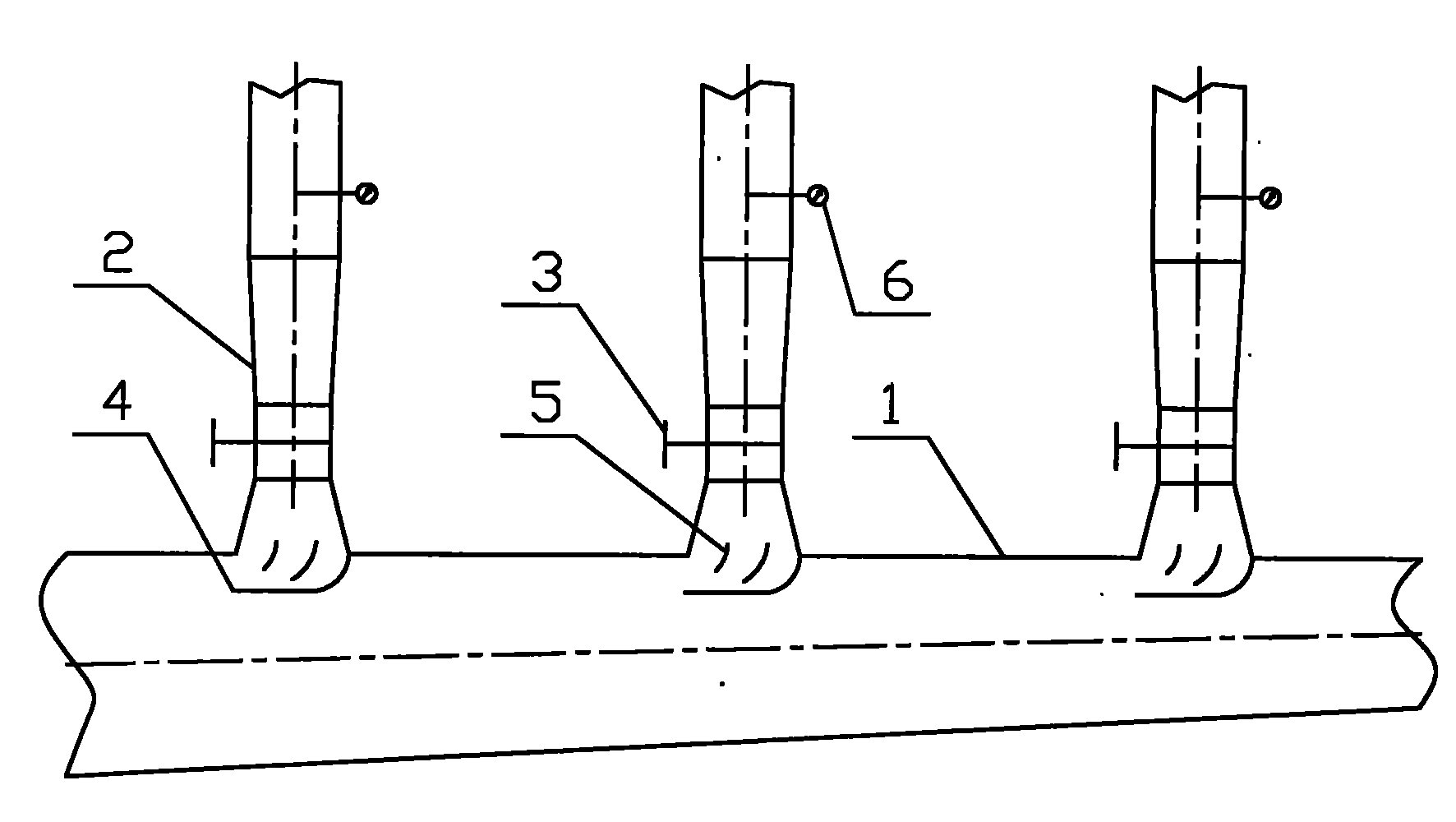

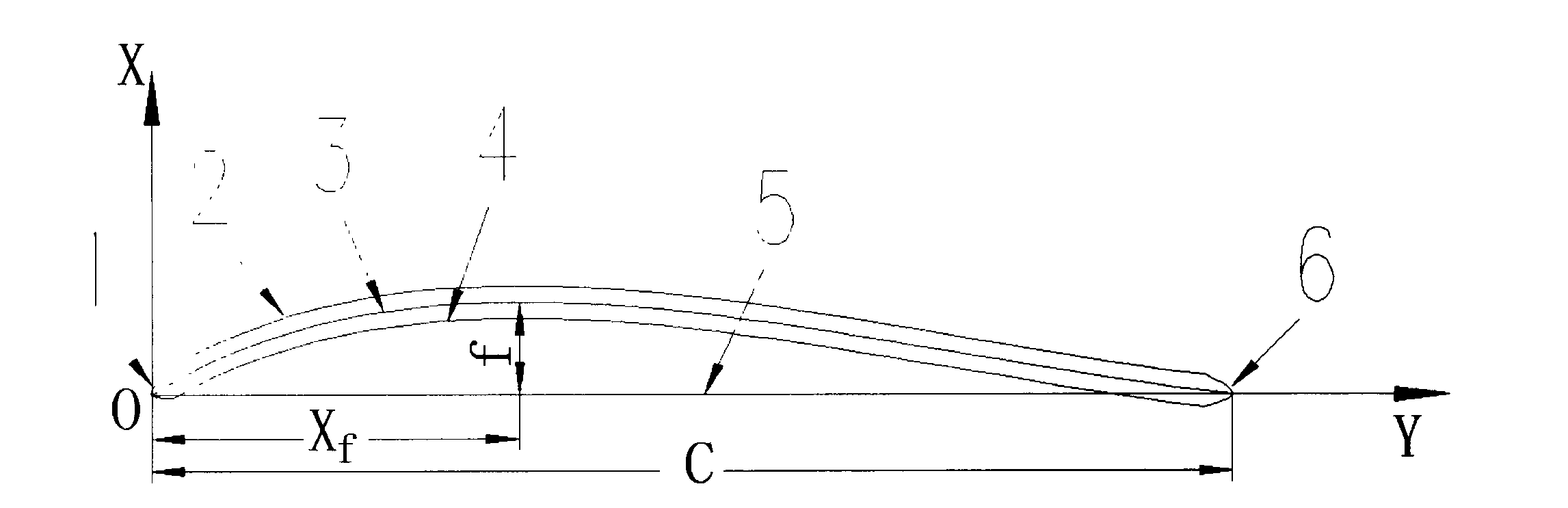

Variable-curvature arc equal-thickness plate wing section for fan group

The invention relates to a variable-curvature arc equal-thickness plate wing section for a fan group, and particularly to eight high-performance equal-thickness plate wing sections which are designed by applying an advanced pneumatic analysis technology in the aviation technology and aiming at the practical work condition of a fan with a small size, a low rotating speed and a low Reynolds number (generally less than 106). The invention discloses the maximum camber and position of the group of the wing sections; f is the maximum camber; xf is a transverse coordinate value at the maximum camber place of the wing section; C is a chord length; the original point of the coordinate system where the wing section locates is defined as the front edge point of a mean camber line of the wing section; the X-axis is overlapped with a chord line and points from the front edge of the wing section to the back edge of the wing section; and the Y-axis is vertical to the X-axis which points to the bending direction of the middle arc line of the wing section. Under the same work condition, the fan adopting the variable-curvature arc equal-thickness wing section when being compared with the traditional simple equal-thickness wing section fan is better matched with the practical work condition, has greater blowing rate of the fan, lower noise, higher energy efficiency value (the energy efficiency value=blowing rate / power), higher maximum air speed value and uniform air speed.

Owner:张胜利 +2

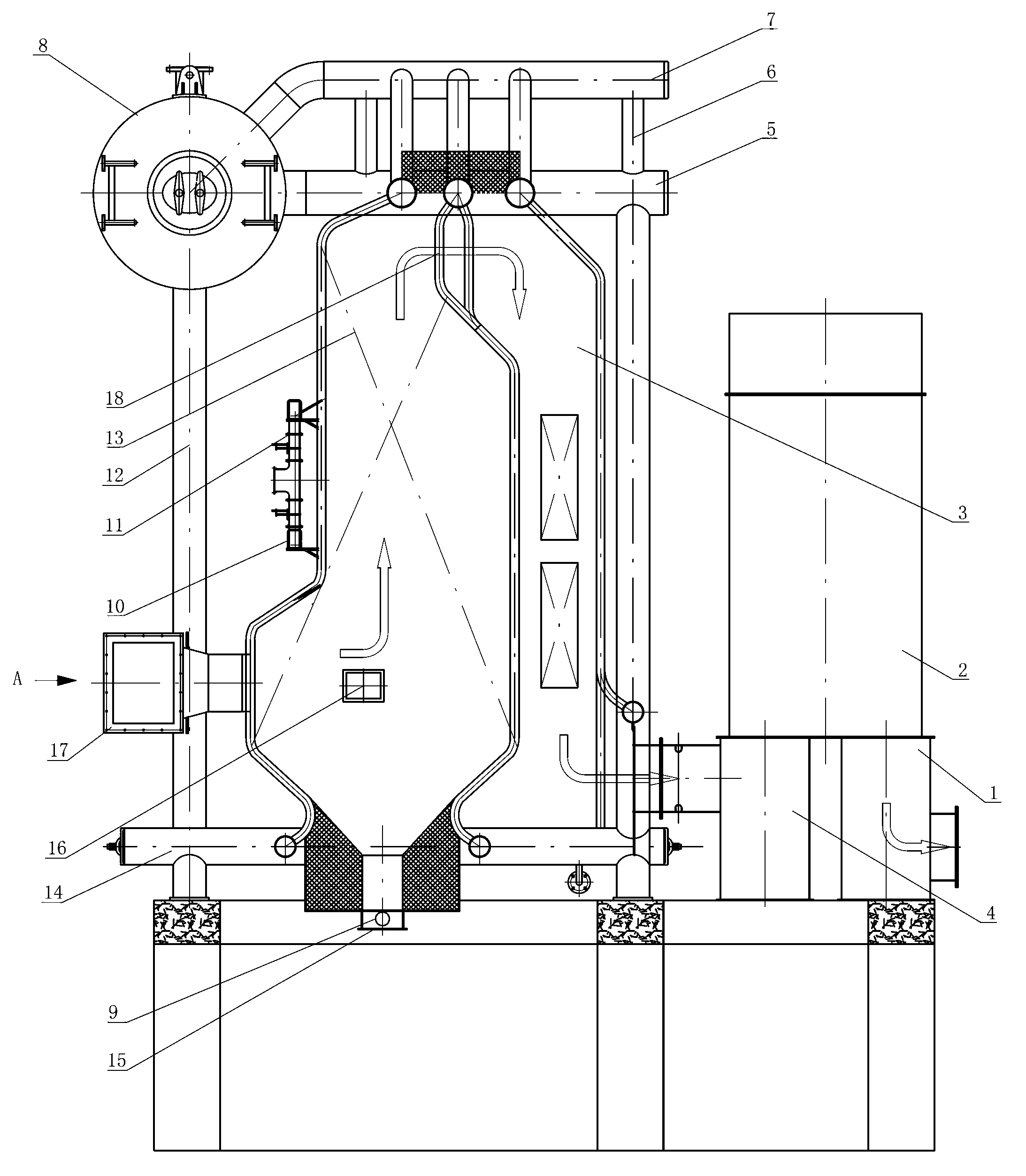

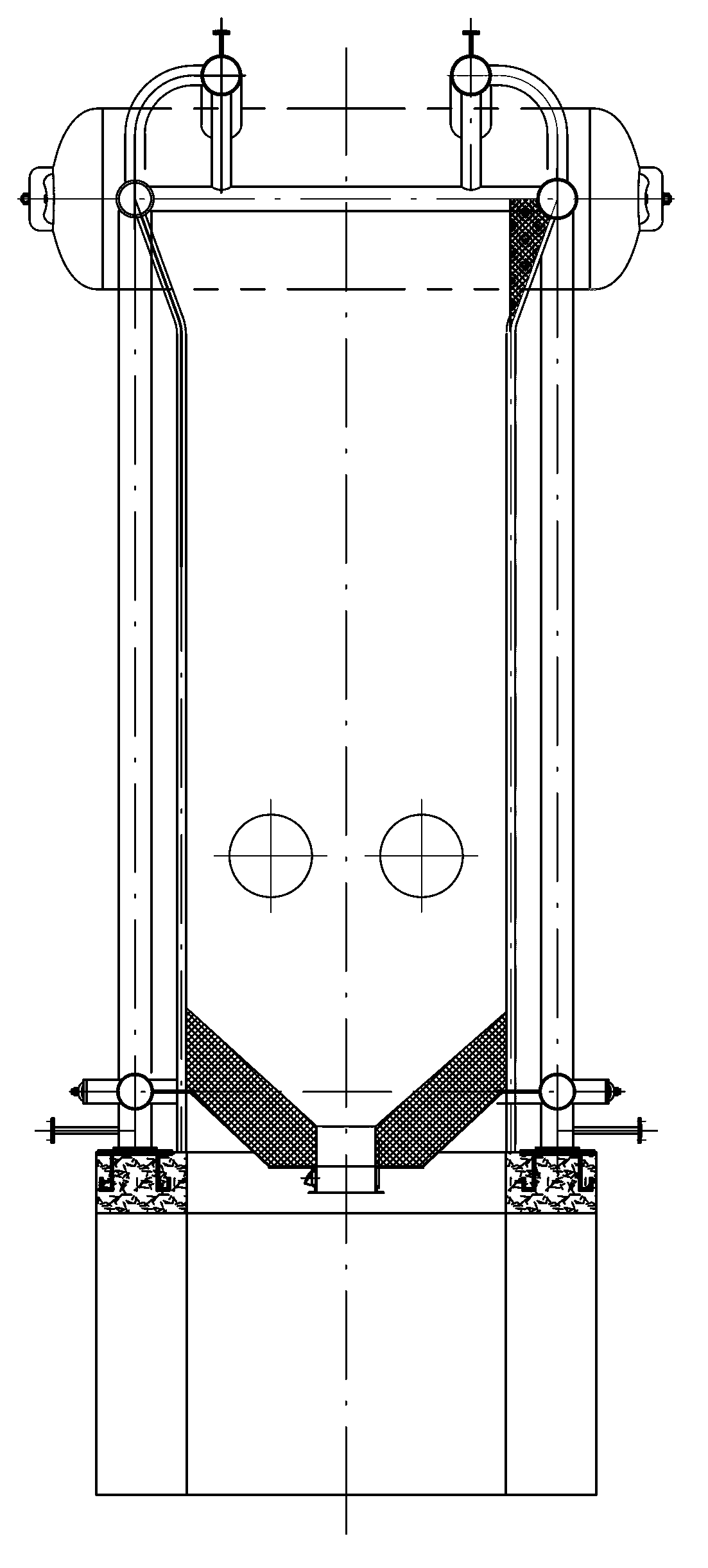

Vertical type coal dust corner tube boiler

InactiveCN103062747AFull reaction combustionImprove sealingSteam boilersAir preheaterDifferential pressure

The invention discloses a vertical type coal dust corner tube boiler which comprises a burner, a boiler furnace, a high temperature air preheater, a coal economizer, a low temperature air preheater convection tube bundle, an upper collecting box, a top collecting box, a boiler barrel and a lower collecting box. The lower collecting box is arranged at the bottom of a boiler body, and the upper collecting box and the top collecting box are arranged at the top of the boiler body and are communicated through a vapor communicating pipe. The vertical type coal dust corner tube boiler is characterized in that the burner is arranged in the front of the boiler body, the boiler body is of a vertical type tubular membrane type water-cooled wall structure, four down pipes are arranged at four corners, and the down pipes and two ends of the membrane type water-cooled wall are communicated with the upper collecting box and the lower collecting box respectively. The convection tube bundle is arranged on the outer side of the membrane type water-cooled wall, the top of the convection tube bundle is communicated with a hearth smoke outlet, and the bottom of the convection tube bundle is communicated with the high temperature air preheater. The vertical type coal dust corner tube boiler has the advantages that an integral structure is compact, the appearance is arranged simply, an occupied area is small, steel consumption is small, water circulating differential pressure of the boiler is large, and water circulation is safe and reliable, and the like.

Owner:HANGZHOU JUNENG BOILER

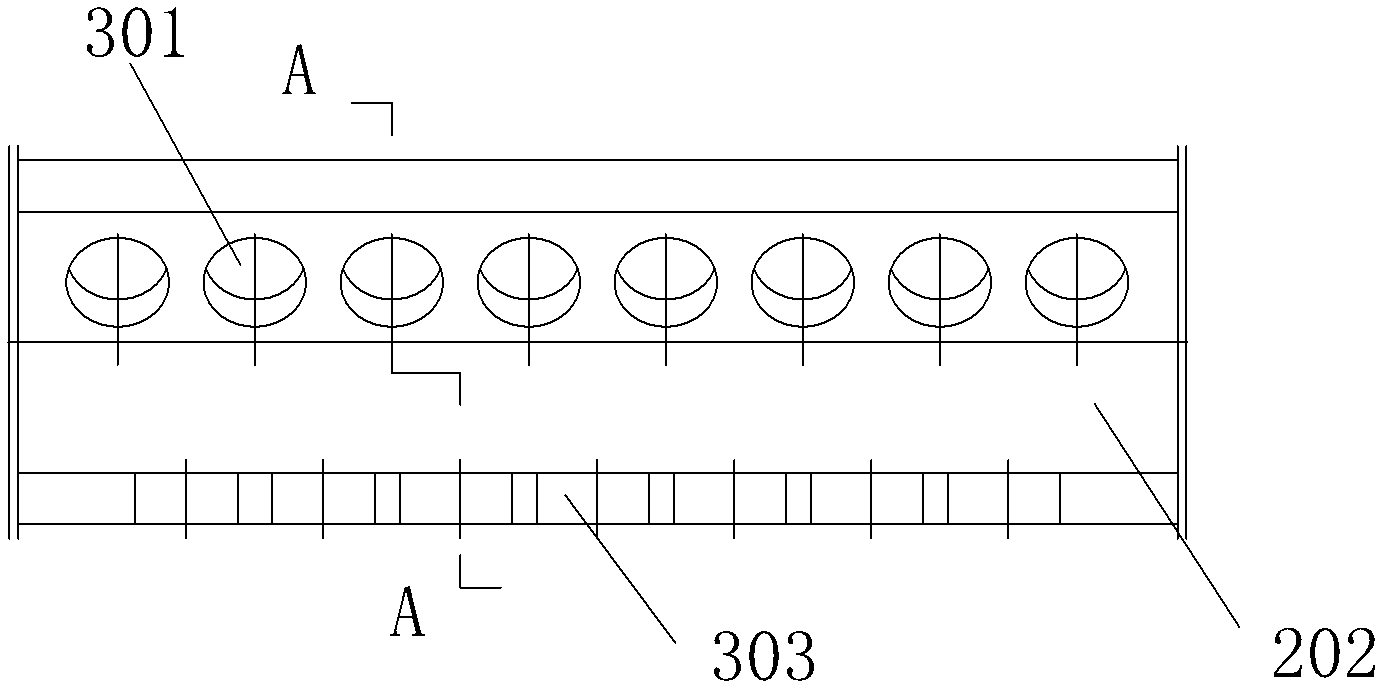

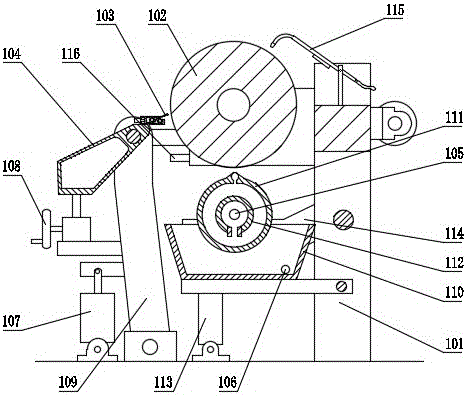

Air inlet rice mill with double air sources

ActiveCN102430441AUniform air volumeReduce loss along the wayGrain huskingGrain polishingEngineeringAtmosphere

The invention discloses an air inlet rice mill with double air sources, which comprises a framework. A rice milling chamber mechanism is arranged in the framework, the lower side of the rice milling chamber mechanism in the framework is connected with a bran suction hopper, the framework at the tail end of the rice milling chamber mechanism is connected with a rice milling discharging mechanism, the rice milling chamber mechanism comprises a spindle, a rice milling roller, a rice sieve component, a feeding hopper and a conveying mechanism, the spindle is connected with the rice milling roller, the rice sieve component and the feeding hopper are arranged in the framework, the spindle in the framework is connected with the conveying mechanism and a transmission and is a hollow structure, a partition board is disposed in a hollow cavity of the spindle, an air spraying hole is arranged on a spindle wall at one end of the partition board, a spindle section with the air spraying hole is connected and communicated with an air spraying fan, an air suction hole is arranged on a spindle wall at the other end of the partition board, a spindle section with the air suction hole is communicatedwith the atmosphere, and an air spraying section and an air suction section are formed on the spindle. The air inlet rice mill is compact in structure and fine in stability.

Owner:WUHAN ZHONGJIXING GRAIN MACHINERY CO LTD

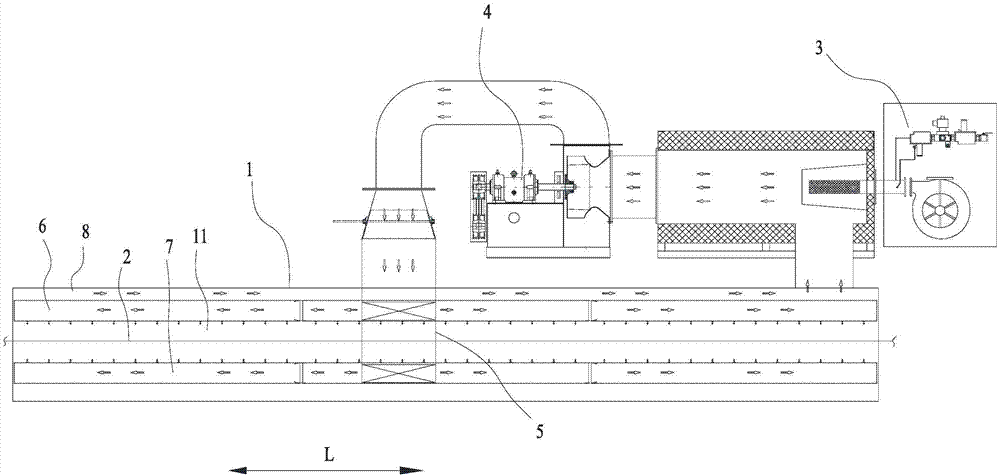

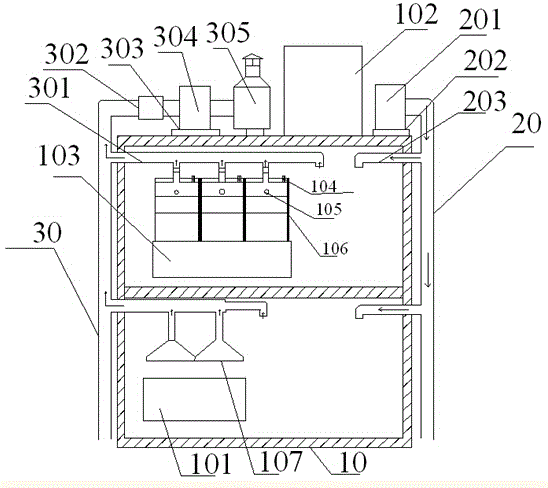

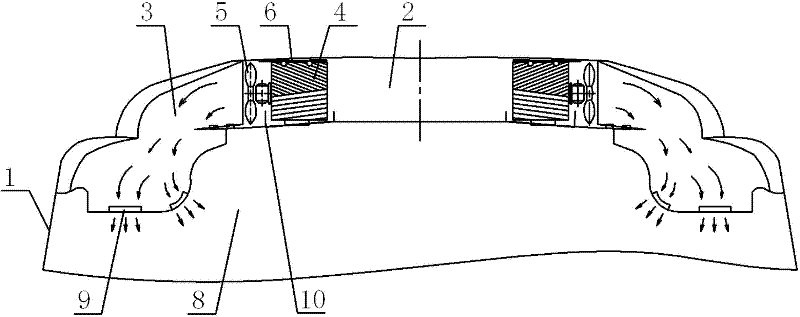

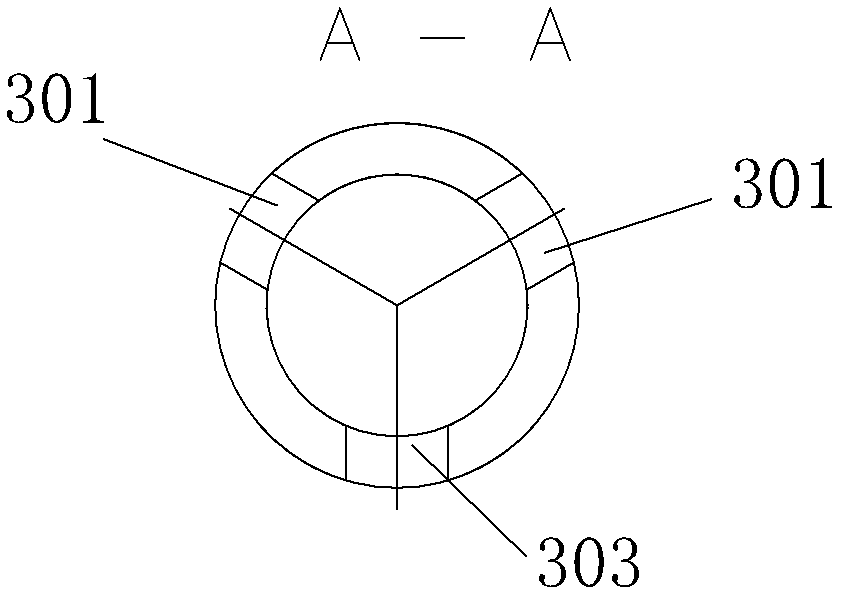

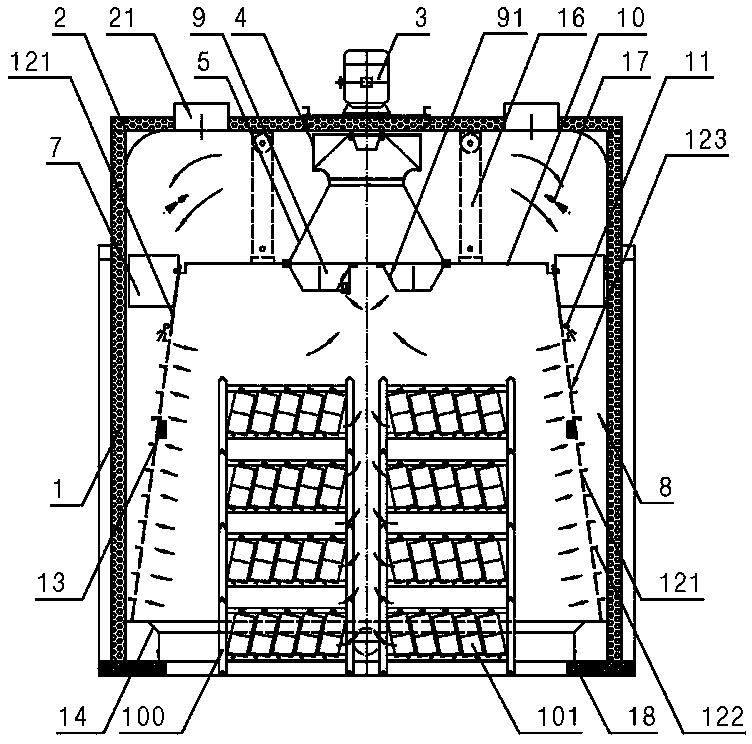

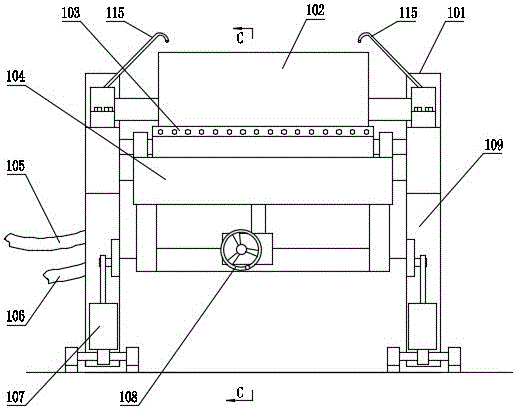

Curing device for accumulator plate and air supply mechanism in curing device

ActiveCN104037387AUniform wind speedUniform air volumeElectrode thermal treatmentElectrical and Electronics engineeringHumidity

The invention discloses an air supply mechanism inside a curing chamber of an accumulator plate, which can enable temperature and humidity at each position inside the curing chamber to be uniformly distributed. The curing device comprises an air supply fan, a secondary box with a bottom board is arranged on the curing chamber, the air supply fan is arranged at the top of the secondary box along the vertical direction, an air guide cover with a downward opening is arranged on the bottom board of the secondary box and below fan blades, an air return hole matched with the air guide cover is formed in the middle of the bottom board, vertical air outlets are respectively formed between two sides of the bottom board of the secondary box and corresponding inner walls of a main box, a pair of air distributing screens is symmetrically arranged below the vertical air outlets at two sides in the main box, transverse air outlets are arranged on the air distributing screens, and external air ducts are formed between the air distributing screens and the corresponding inner walls of the main box. The air supply mechanism is mainly used in the curing device for the accumulator plate.

Owner:江苏金帆新程装备有限公司

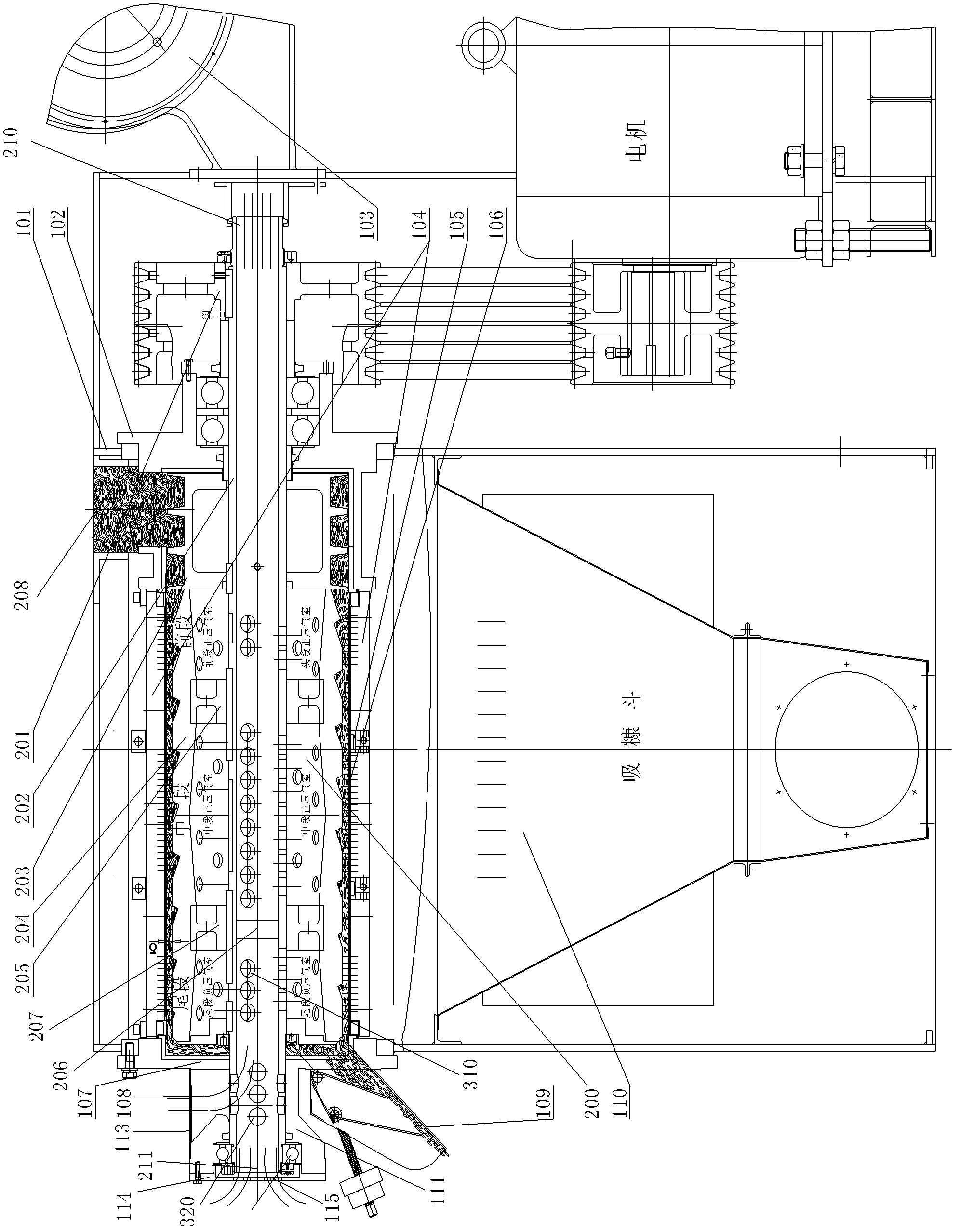

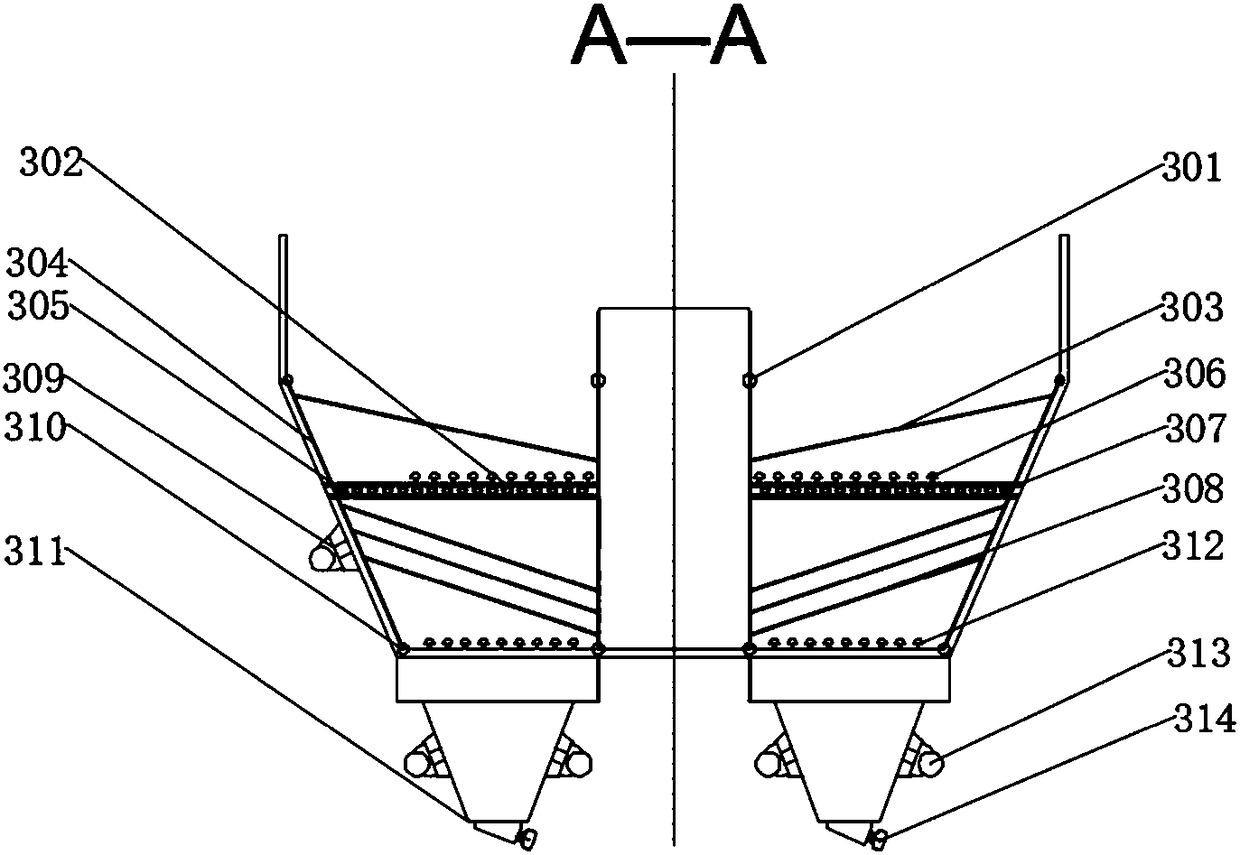

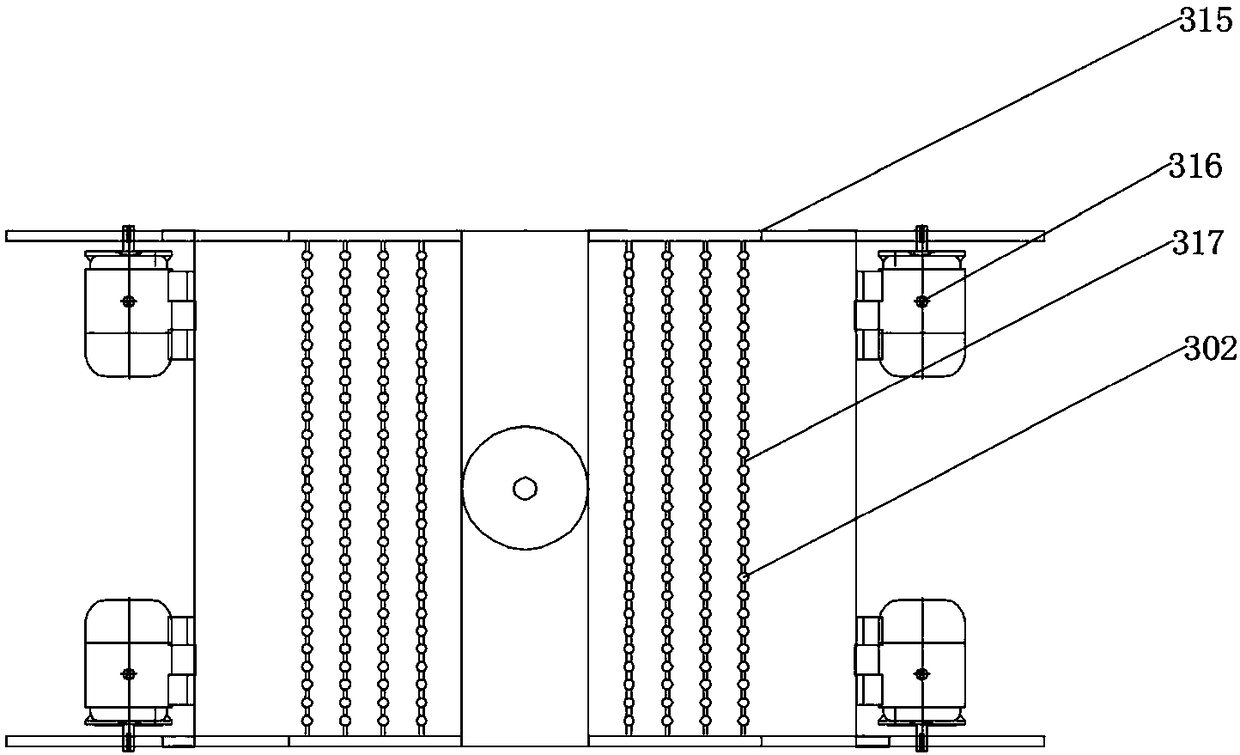

Movable bed device for recovering sensible heat of high-temperature bulk materials

ActiveCN108411054AImprove cooling conditionsSolidify as soon as possibleRecycling and recovery technologiesWaste heat treatmentSlagProcess engineering

The invention discloses a movable bed device for recovering sensible heat of high-temperature bulk materials. The device comprises a movable bed; the movable bed comprises furnace walls and collectingbins; the furnace walls are encircled to form two symmetrical accommodating cavities with large tops and small bottoms; the two accommodating cavities are separated by a middle furnace wall; the collecting bins are formed in the bottoms of the accommodating cavities; lean-phase zone buried pipes are arranged at the upper parts of the conical accommodating cavities; scrapers are arranged at the lower parts of the lean-phase zone buried pipes; wind distribution devices are arranged at the lower parts of the scrapers; and dense-phase zone buried pipes are arranged in space between the wind distribution devices and flat pushing scrapers. The device overcomes the technical bottlenecks of slag particle heat returning, bonding, low conversion rate of glass bodies, low afterheat recovery efficiency and the like, is uniform in specific material layer, facilitates slag discharge, is high in heat recovery efficiency, and can effectively and efficiently recover high-temperature sensible heat of granulated blast furnace slag particles.

Owner:XI AN JIAOTONG UNIV

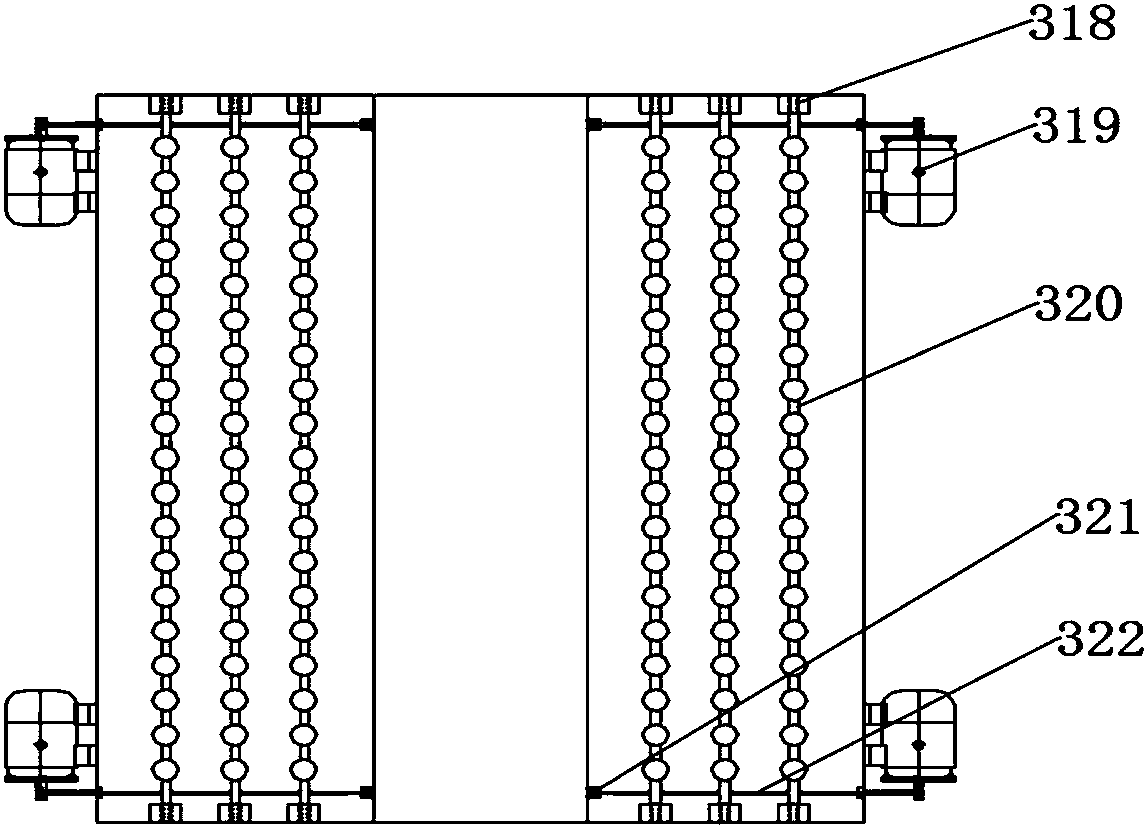

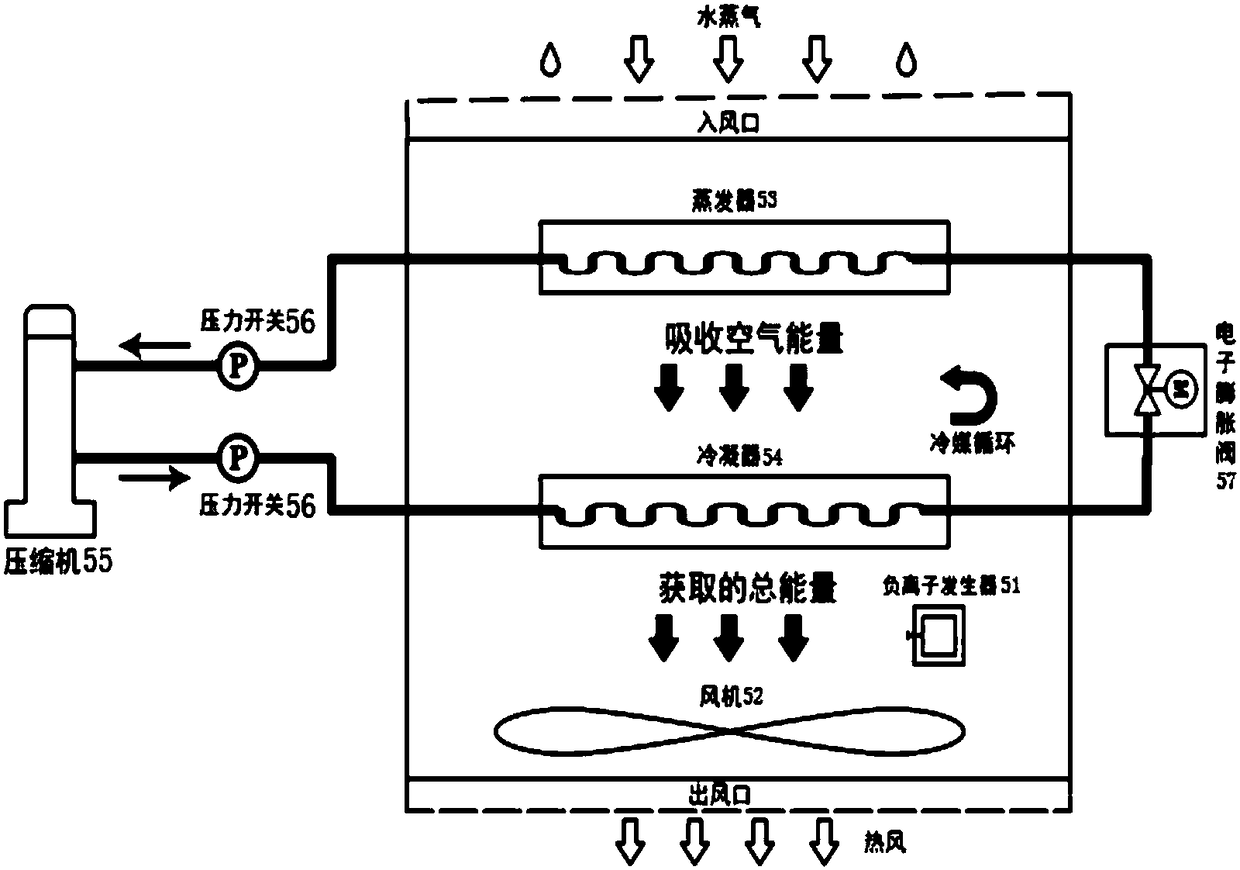

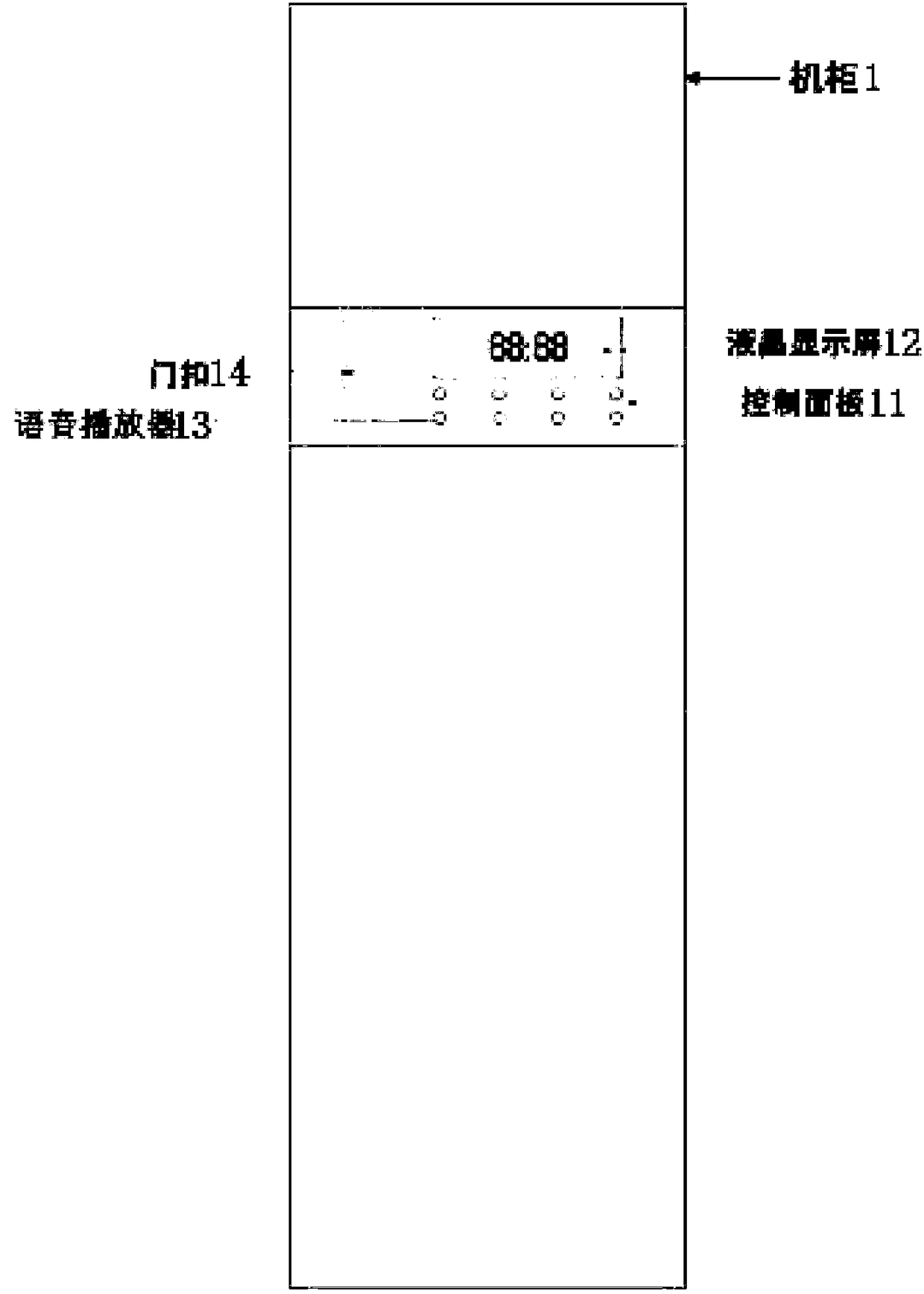

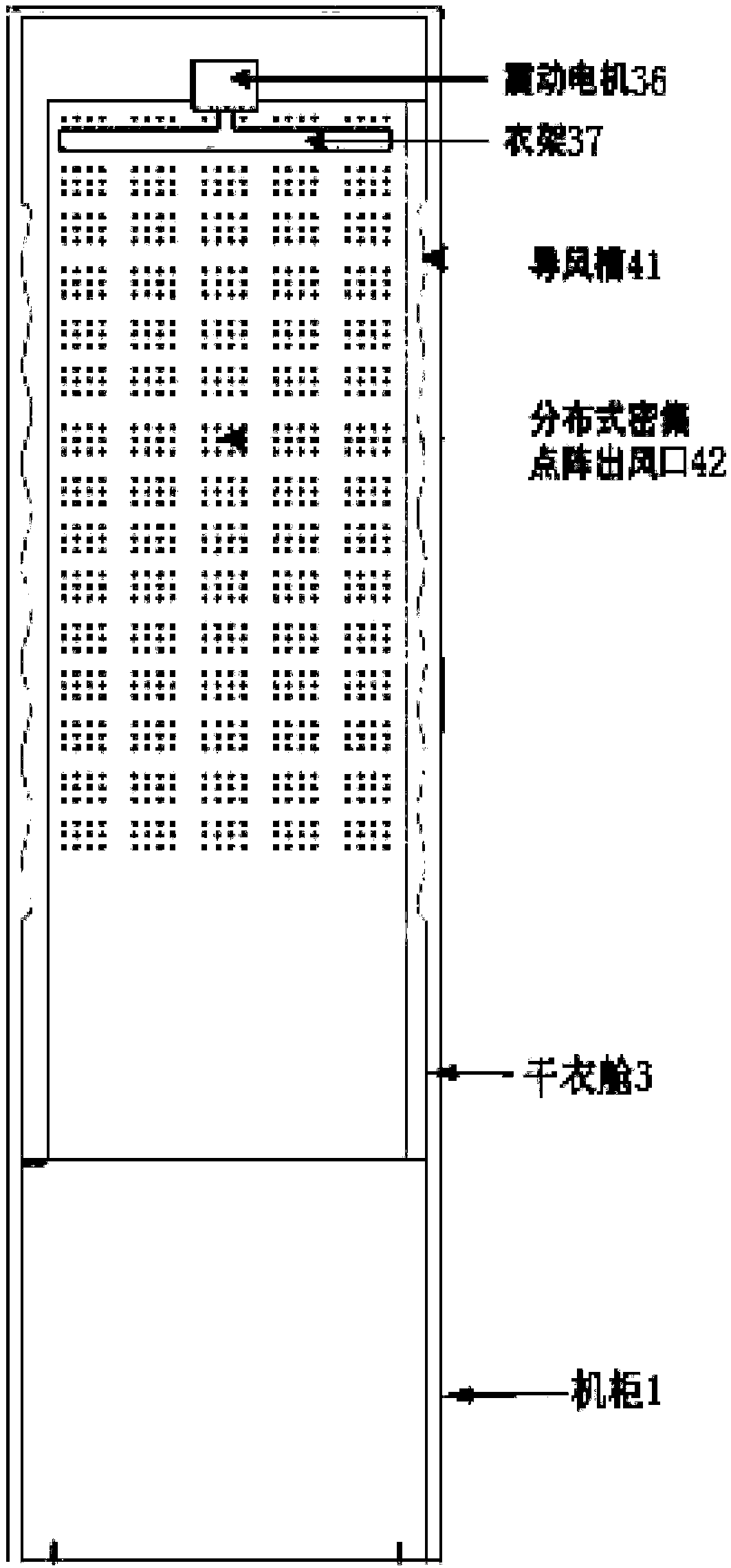

Anion high-temperature thermal-energy clothes dryer

InactiveCN108252056AImprove heat exchange efficiencyImprove heating energy efficiency ratioIroning apparatusTextiles and paperThermal energyWater tanks

The invention discloses an anion high-temperature thermal-energy clothes dryer. The clothes dryer includes an equipment cabinet, a controller, a clothes drying chamber formed in the upper portion of the equipment cabinet and a thermal energy chamber formed in the lower portion of the equipment cabinet; the clothes drying chamber is connected with the thermal energy chamber through an air flue, a water tank is arranged on the lower portion of the clothes drying chamber and internally provided with a PTC heater and an ultrasonic atomizer, and the clothes drying chamber is internally provided with a variable-frequency ultrasonic device and an atomizing sprayer which is connected with the ultrasonic atomizer through an atomizing conduit; the thermal energy chamber is internally provided with athermal energy circulating pump, the thermal energy circulating pump adopts a working principle of latent heat of vaporization for circularly utilizing the thermal energy of water vapor in the clothes drying chamber and circularly acting on the clothes drying chamber. The air outlet volume of the clothes dryer is large and uniform, clothes can be ironed flat, cleaning of the clothes is thorough and environmentally friendly, diversified functions are integrated on the clothes dryer, and the energy efficiency ratio of heating is greatly increased.

Owner:山东白鹿知善文化产业发展有限公司

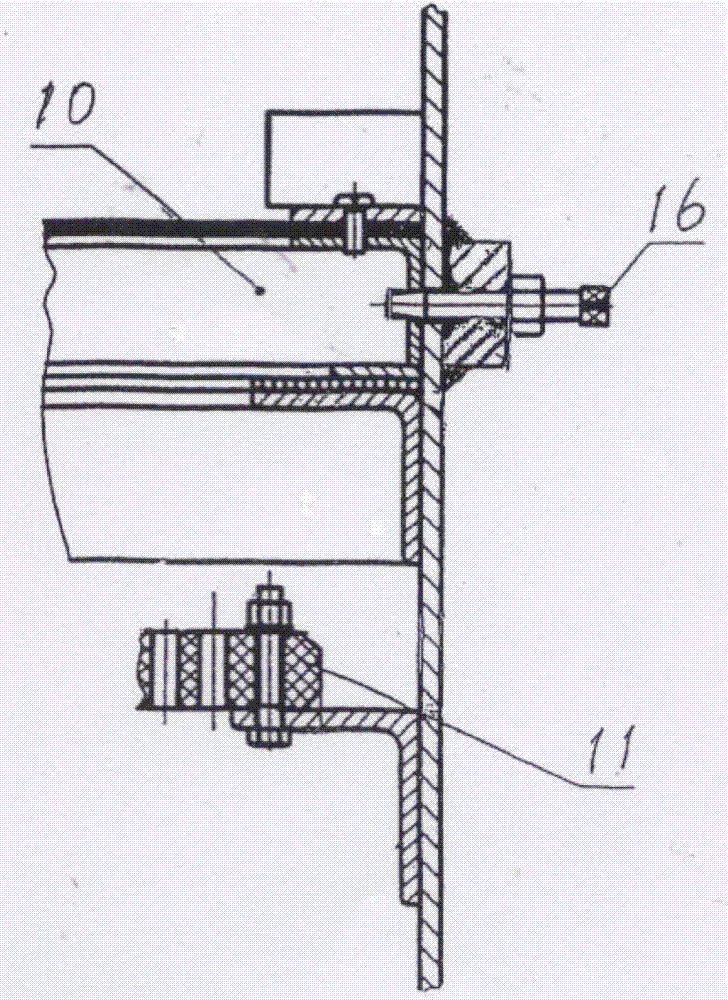

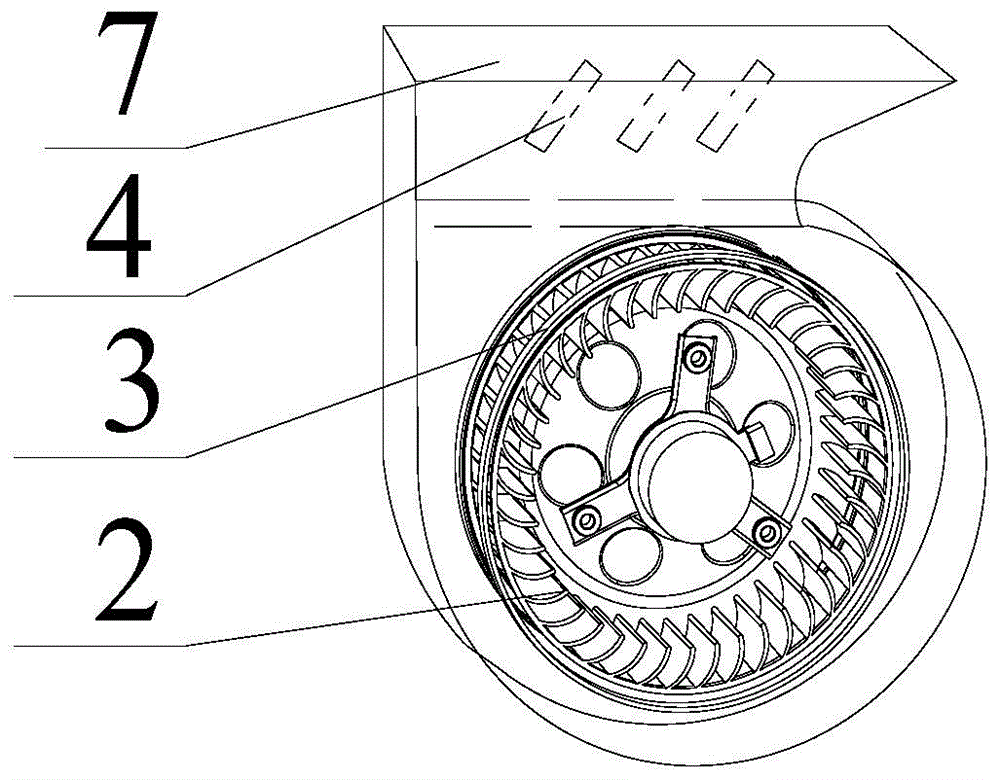

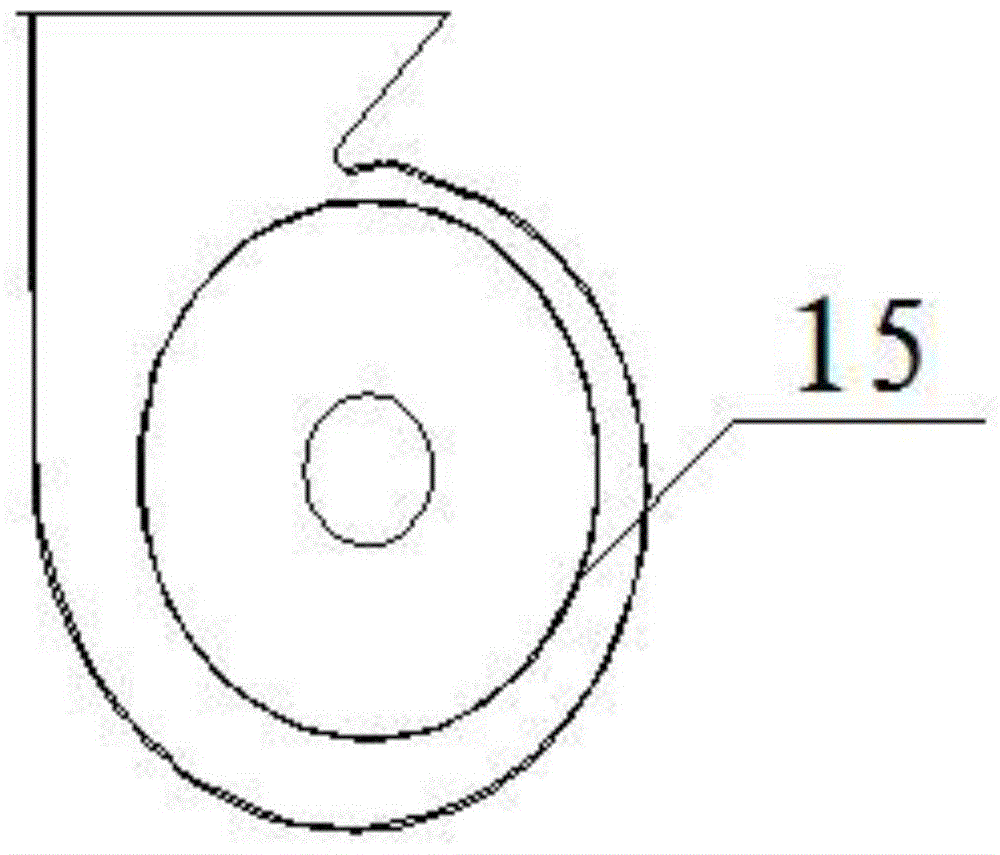

Wall-hanging air purifier

InactiveCN105107299AImprove performanceAvoid backflow phenomenonCombination devicesDispersed particle filtrationImpellerAir filter

The invention relates to a wall-hanging air purifier. The wall-hanging air purifier comprises a purifier shell with an air purifying apparatus inside, wherein an air inlet is formed in a front panel of the shell, air outlets are formed in two side walls of the shell, the purifying apparatus comprises two fans, air outlets of the two fans are respectively communicated with the air outlets in the two side walls of the shell, air inlets of the two fans are respectively communicated with an outlet of an air filter, an inlet of the air filter is communicated with the air inlet in the front panel of the shell, each fan comprises an impeller shell and an impeller which is arranged in an inner cavity of the impeller shell and fixed on an impeller shaft, the impeller shaft is connected with a driving apparatus. A key point of the invention is that a gap between the impeller shell and the impeller forms a ventilation air duct, an air protection ring 15 which is coaxial with the impeller is arranged on the impeller shell inner wall, adjacent to a peripheral ring of the impeller, of the ventilation air duct, and the diameter of an air stop annular plate is 6 to 10mm greater than that of the impeller. The wall-hanging air purifier is small in air resistance, smooth in air discharging, high in working efficiency, good in performance, capable of greatly lowering the noise, high in air outlet efficiency and capable of greatly improving the performance.

Owner:北京卫家环境技术有限公司

Leaf storage cabinet

PendingCN111109644ADirect temperature and humidity controlStable temperature and humidity controlDucting arrangementsTobacco treatmentHEAT/MOISTURE EXCHANGEAir volume

The invention provides a leaf storage cabinet. The cabinet comprises a cabinet body, at least one first air supply pipe, connecting pipes and a temperature and humidity detector. A first air outlet isformed in each first air supply pipe, an included angle is formed between the air outlet direction of each first air outlet and the inner wall where the corresponding first air supply pipe is installed, and outgoing air is suitable for forming an air curtain above materials in the cabinet body so as to isolate the external environment and avoid heat and humidity exchange with the external environment. A row of microporous air ports are formed in each first air supply pipe, the microporous air ports blow modulated air-conditioning air towards materials below the air curtain, and the hole diameters of the microporous air ports are increased along with increase of the distance between the microporous air ports and the connecting ends, connected with the first air supply pipes, of the connecting pipes. Through variable-diameter arrangement of the air ports, the air outlet amount of the air ports far away from the connecting ends is guaranteed, and the air amount in the cabinet body is more uniform. The first air supply pipes are directly arranged in the cabinet body, so that the temperature and humidity of materials in the cabinet body are more directly and stably controlled.

Owner:CHINA TOBACCO GUANGXI IND

Art paper coating machine

ActiveCN106676968AIncrease profitReduce labor intensityPhysical paper treatmentPulp and paper industrySurface coating

The invention discloses an art paper coating machine. The art paper coating machine comprises a drying machine and a coating machine body, wherein the drying machine is arranged above a rack; the coating machine body is arranged under the rack; the coating machine body is divided into two groups of a first coating machine body and a second coating machine body; the two groups of coating machine bodies are oppositely arranged on two ends under the rack; an unreeling machine and a reeling machine are arranged between the two groups of the coating machine bodies; the drying machine is also divided into two groups of a first-stage drying machine and a second-stage drying machine and is in corresponding arrangement with the coating machine body under the rack; art paper guiding roller groups are arranged between the unreeling machine and the first coating machine body, the first coating machine body and an inlet of the first-stage drying machine, an outlet of the first-stage drying machine and the lower parts of approximate middle positions of the unreeling machine and the reeling machine, the rear part of the reeling machine and the second coating machine body, the second coating machine body and an inlet of the second-stage drying machine as well as an outlet of the second-stage drying machine and the reeling machine. According to the art paper coating machine disclosed by the invention, double-surface coating of art paper is completed in one step, the production efficiency is high, the land occupation area is small, and the production cost is reduced.

Owner:臧健

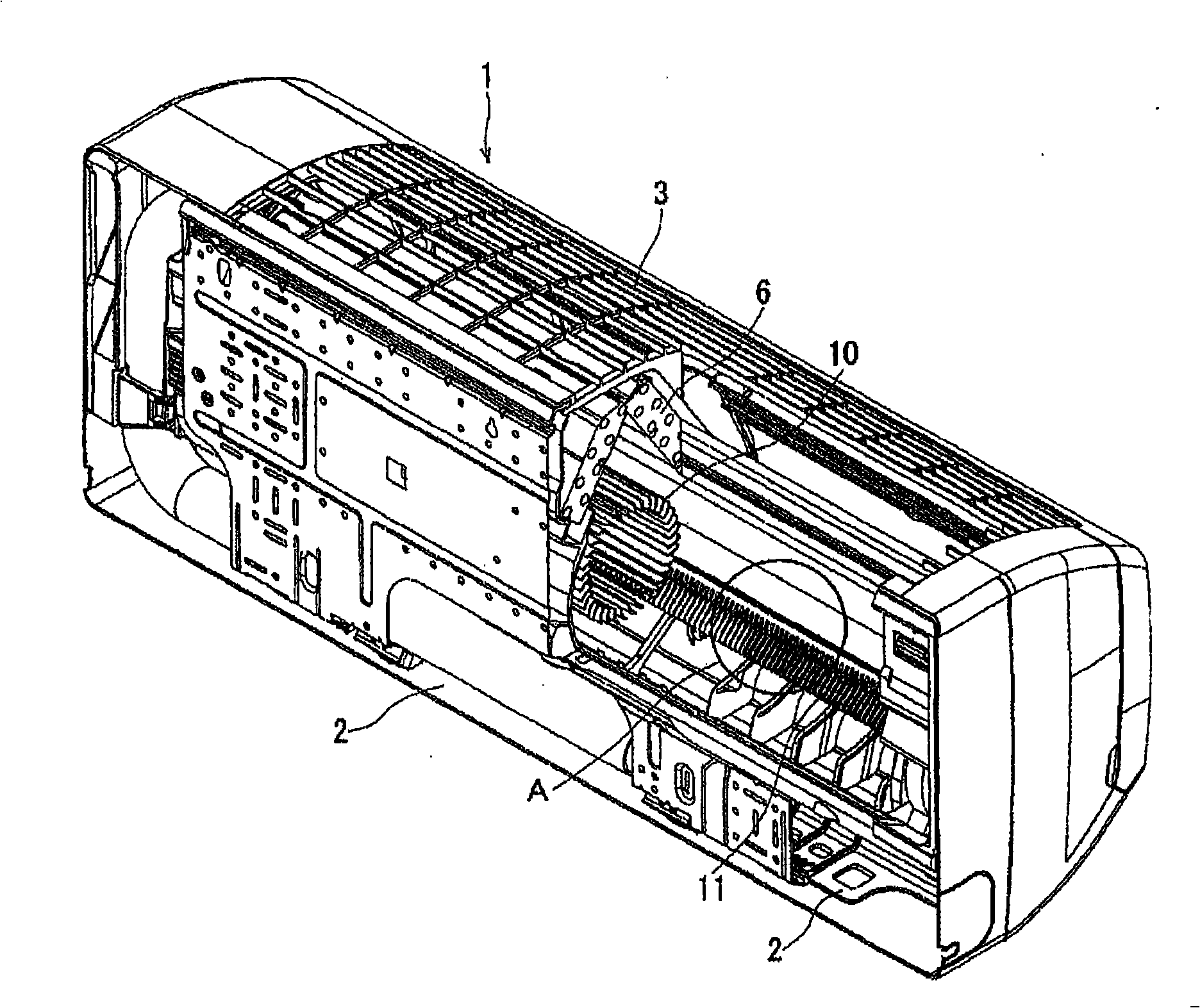

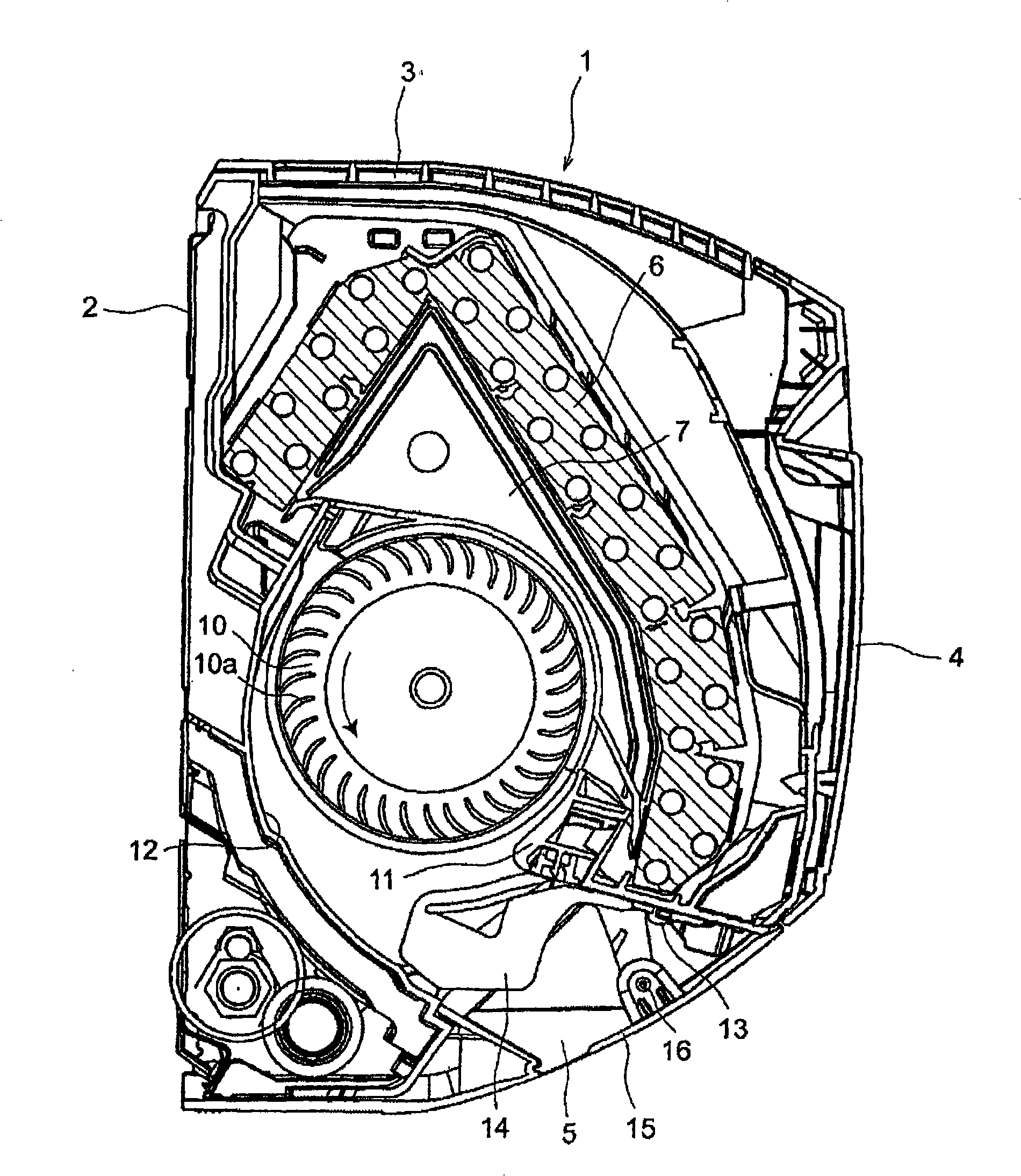

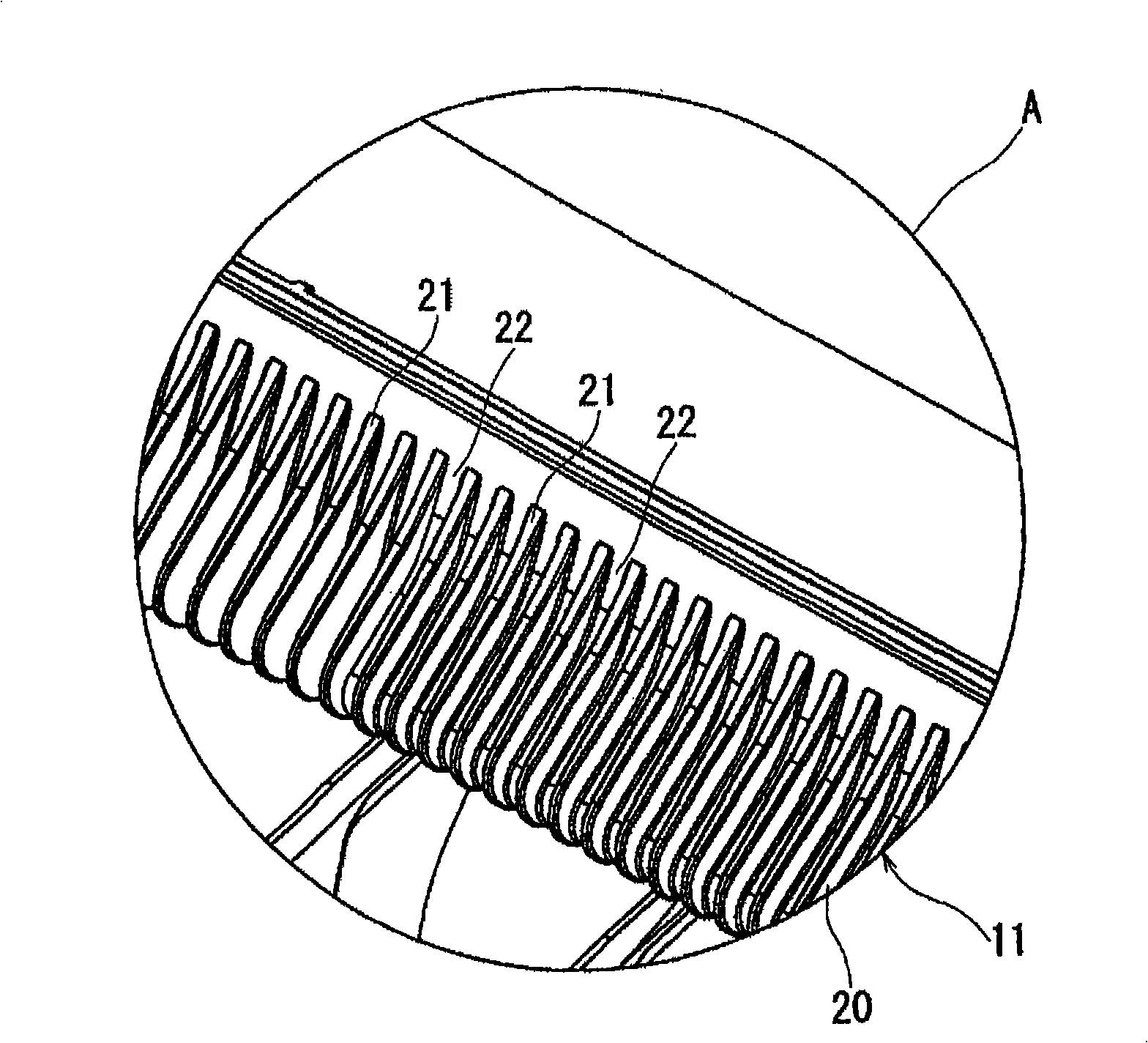

Air conditioner

InactiveCN101517321AReduce noiseComfortable environmentLighting and heating apparatusNoise suppressionAir volumeEngineering

The present invention provides an air conditioner having, in order to reduce noise with sufficient amount of airflow achieved, a heat exchanger, a cross flow fan, a tongue section (11), and an outlet opening. A comb-like section (20) formed by alternately arranging comb teeth (21) and grooves (22) is placed at the tongue section (11) facing the cross flow fan, along the longitudinal direction of the tongue section (11). The grooves (22) include deep grooves (22a) and shallow grooves (22b). The comb-like section (20) has a deep groove comb-like section (20a) constructed from comb teeth (21) and the deep grooves (22a) and a shallow groove comb-like section (20b) constructed from comb teeth (21) and the shallow grooves (22b).

Owner:DAIKIN IND LTD

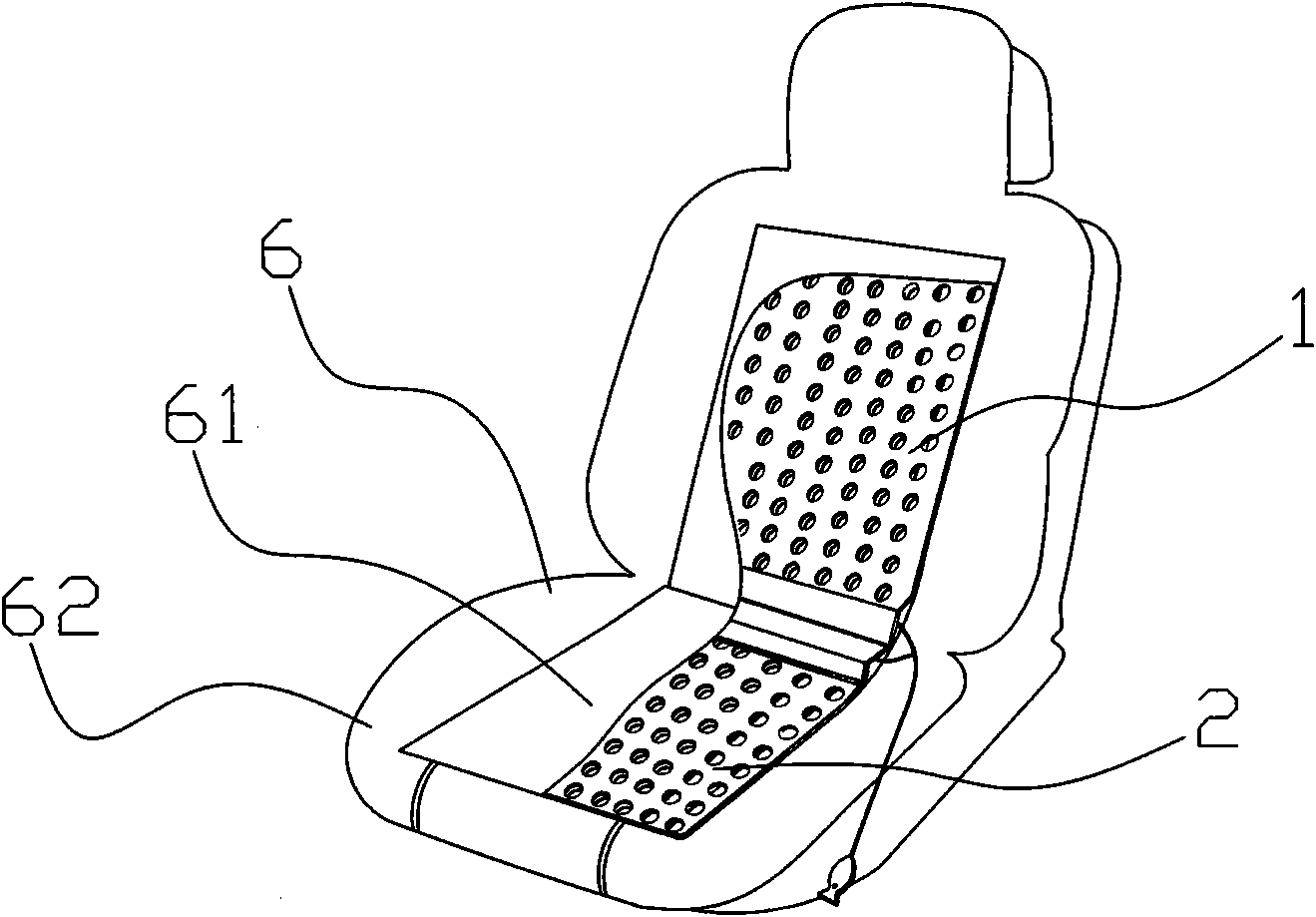

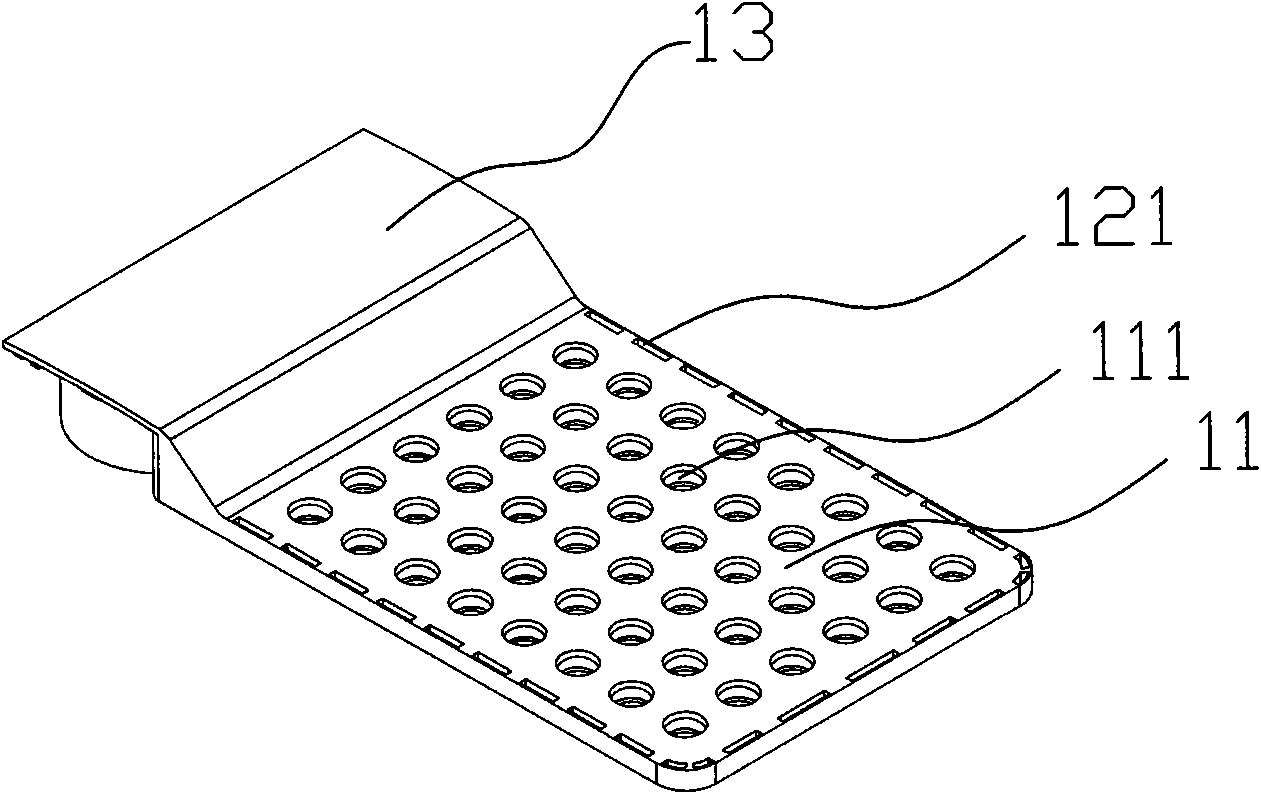

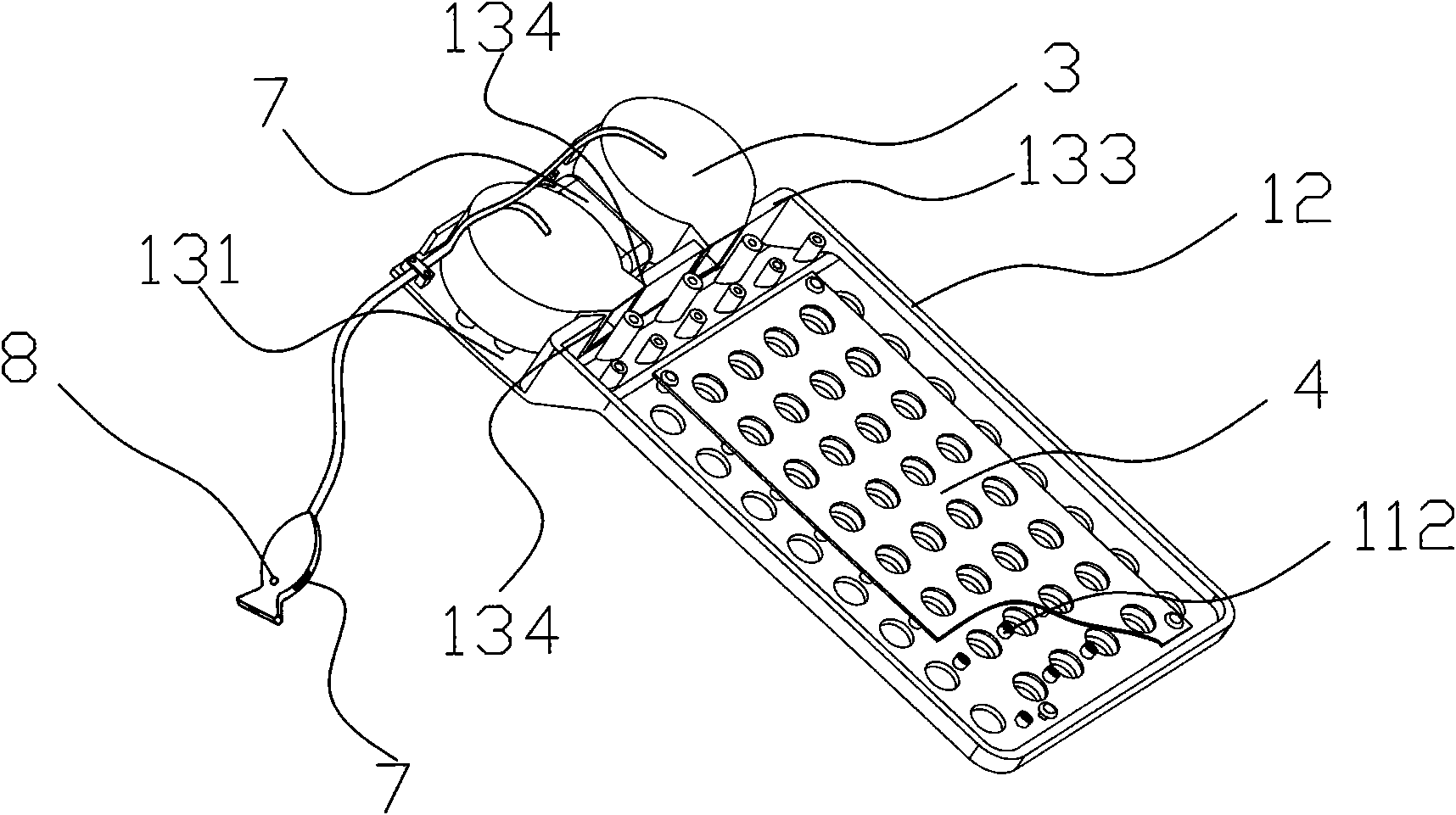

Ventilation cushion

InactiveCN101658369ASmooth dischargeUniform air volumeVehicle seatsStuffed mattressesSurface layerMarine engineering

The invention relates to a cushion, in particular to a cushion paved on various chairs, which comprises a cushion and a back cushion. The cushion comprises a cushion surface layer and cushion edges arranged at the edge of the cushion surface layer; the cushion surface layer is provided with air holes; a fan is arranged below the cushion surface layer at the end closing to the neighboring back cushion; the air outlet direction of the fan is parallel to the cushion surface layer; and an air outlet of the fan is communicated with the air holes. The air outlet direction of the fan of the ventilation cushion is parallel to the cushion surface layer; the fan is arranged below the cushion surface layer; the direction of wind force is vertical to the air holes arranged on the cushion surface layer; therefore, the air exhausted from the air holes is vertical to the direction of the wind force of the fan; and the air exhausted by a plurality of air holes are very uniform. The cushion is especially applicable to automobiles.

Owner:蒋孝秋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com