Patents

Literature

249results about How to "Uniform moisture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

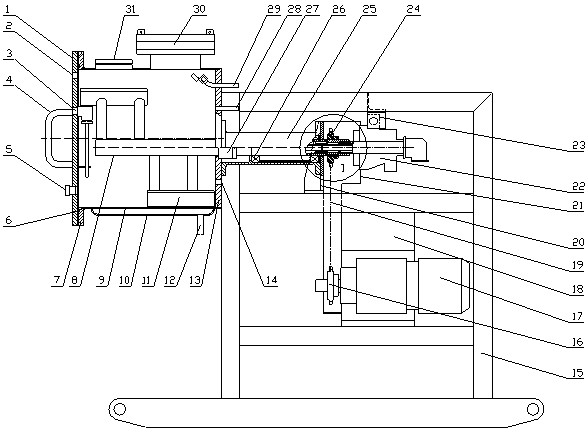

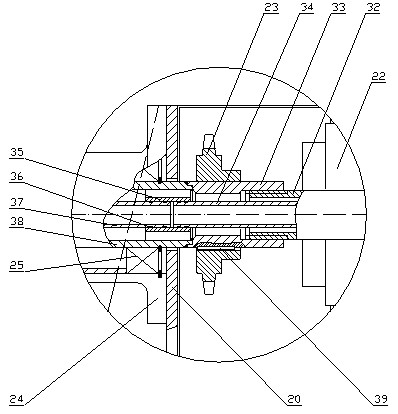

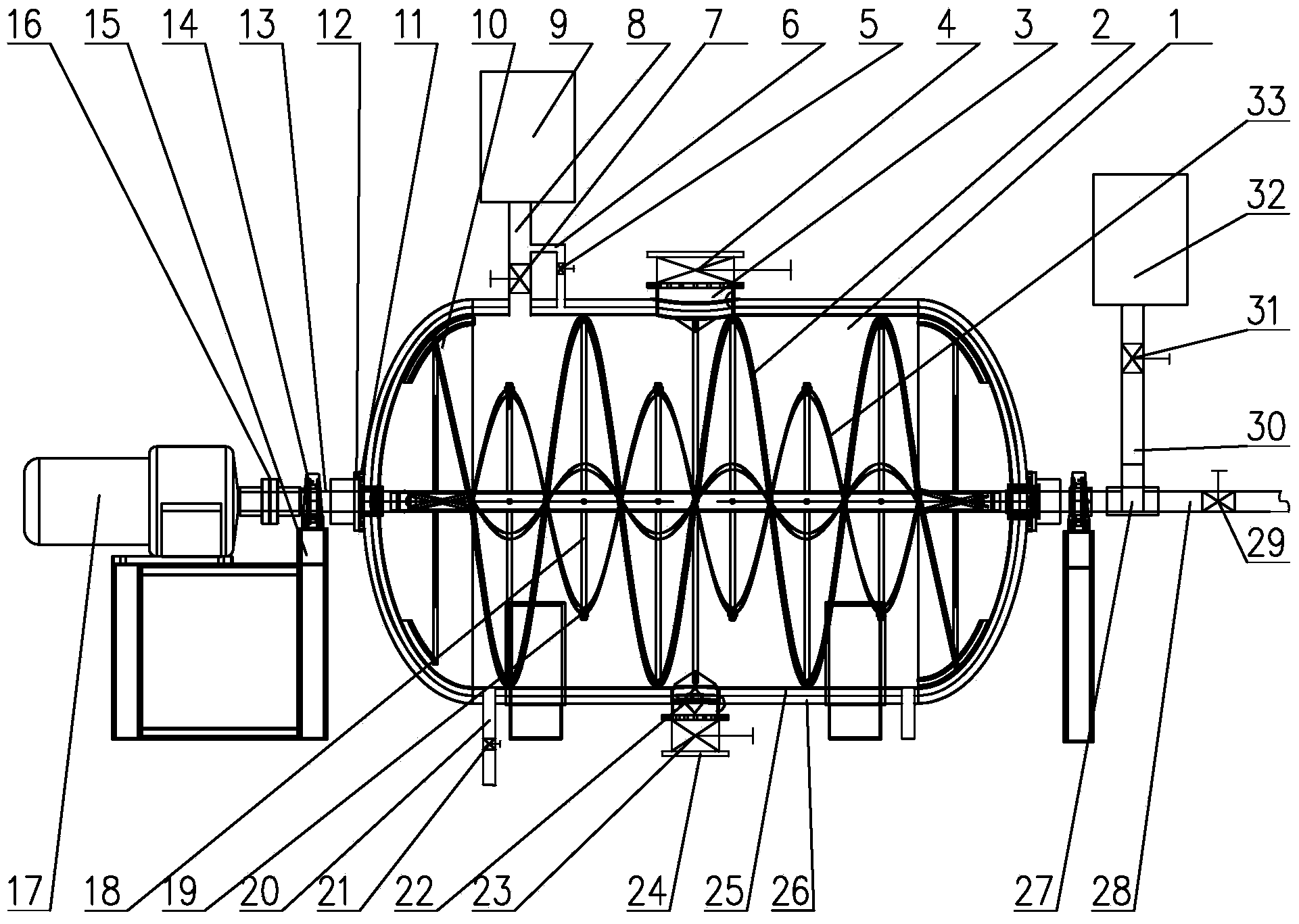

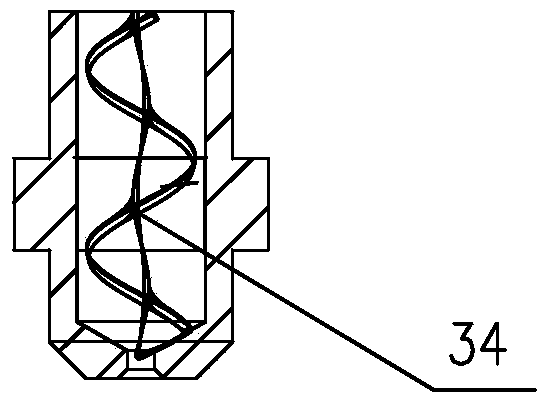

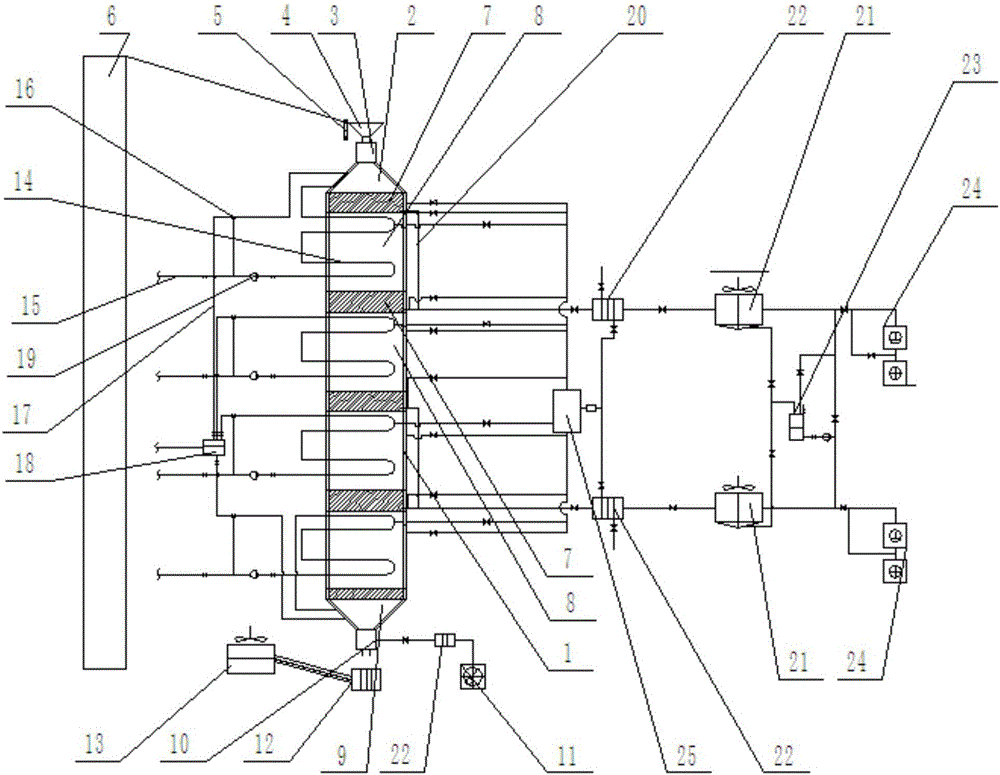

Rotary shaft type solid state fermentation tank

InactiveCN102358883AUniform moistureHigh precision of humidity controlBioreactor/fermenter combinationsBiological substance pretreatmentsSolid mediumSolid-state fermentation

The utility model discloses a rotary shaft type solid state fermentation tank, which comprises a fermentation tank body, a support, a rotary stirring mass transfer heat transfer device and a driving device. The fermentation tank body and the rotary stirring mass transfer heat transfer device are both fixed on the support, and the rotary stirring mass transfer heat transfer device is driven by the driving device. In a fermentation process of the rotary shaft type solid state fermentation tank, water can be replenished in the solid state fermentation tank in atomization mode, moisture is even, and humidity control accuracy is high. A clamp sleeve is arranged outside the fermentation tank, and a stirring shaft and a stirring paddle are positioned inside the fermentation. Steam or cooling water can circularly flow in the clamp sleeve, the stirring shaft and the stirring paddle. With appropriate stirring, solid media can be fully in contact with spawn, heat in the solid media is quickened to be radiated, heat exchange efficiency is improved under the venting condition, and temperature control accuracy is high. Simultaneously, in-site sterilization of the solid media is achieved, the media after off-site sterilization are prevented from contacting external environment when moved into the solid state fermentation tank, and requirements for environment are reduced. The fermentation tank can be installed laboratories or workshops in non-purification areas, thereby avoiding configuring media sterilization equipment and achieving an effect of saving investment.

Owner:JIANGSU HAIHUA BIOTECH +1

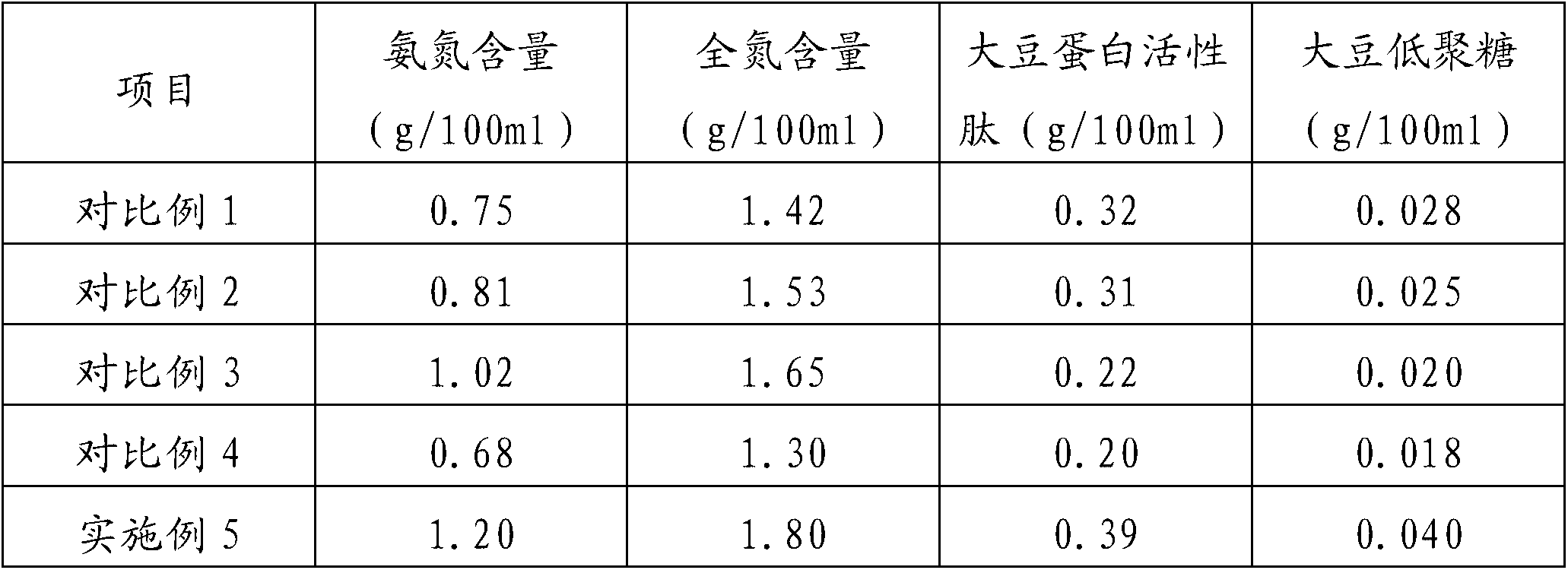

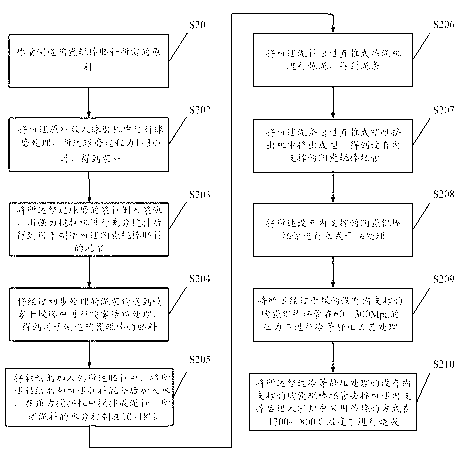

Production method of high-salt diluted and low-temperature fragrant soy sauce

The invention discloses a production method of a high-salt diluted and low-temperature fragrant soy sauce, which comprises the following steps of: (1) curing raw materials including wheat and defatted soybeans, and then uniformly mixing the wheat and the defatted soybeans; (2) inoculating aspergillus oryzae strains to the obtained raw material mixture so as to obtain a yeast; (3) cultivating the yeast for 44-48 hours at a temperature of 25-30 DEG C so as to obtain a mature yeast; (4) adding 2.0-2.5 weight times of saline water into the mature yeast so as to obtain a raw soy sauce mash; (5) moving the raw soy sauce mash to the inside of an airtight fermentation tank for fermenting: firstly fermenting for 23-27 days at a temperature of 13-17 DEG C, then continuing to ferment at a temperature of 28-32 DEG C, and on the 28-32nd days, adding mixed fermentation strains into the fermentation tank and continuing to ferment; in the process of fermentation, stirring by using a compressed air flow; and fermenting for more than six months so as to obtain a mature soy sauce mash; and (6) squeezing and filtering the mature soy sauce mash so as to obtain the low-temperature fragrant soy sauce. According to the invention, the conversion rate of proteins in raw materials is high, and the contents of ammonia nitrogen, total nitrogen, soybean peptides and soybean oligosaccharides in the prepared soy sauce are high.

Owner:好太太食品有限公司

Preparation process of ceramic roller rod

The invention discloses a preparation process of a ceramic roller rod. The preparation process comprises the following steps of: atomizing and prilling on primarily-treated slurry; adding a binder, mixing, then adding water, and mixing in a into pug into a powerful mixer, wherein the water content of the pug is 10-18%; refining the pug through a direct pushing-type pug refining machine, and obtaining pug stripes; enabling the pug stripes to conduct extrusion molding through a direct pushing-type plastic extruder, and obtaining ceramic roller rod blank tubes provided with inner supports; conducting vertical type drying treatment on the ceramic roller rod blank tubes; conducting isostatic cool pressing process treatment on the ceramic roller rod blank tubes at the pressure of 60-300Mpa; and removing the inner supports of the ceramic roller rod blank tubes, putting the ceramic roller rod blank tubes into a kiln, and burning by a hanging and burning mode at the temperature of 1200-1800 DEG C. By means of preparation process, the prepared ceramic roller rod is high in density, high in flexure strength, big in load capacity and good in appearance regulation degree.

Owner:广东金刚新材料有限公司 +1

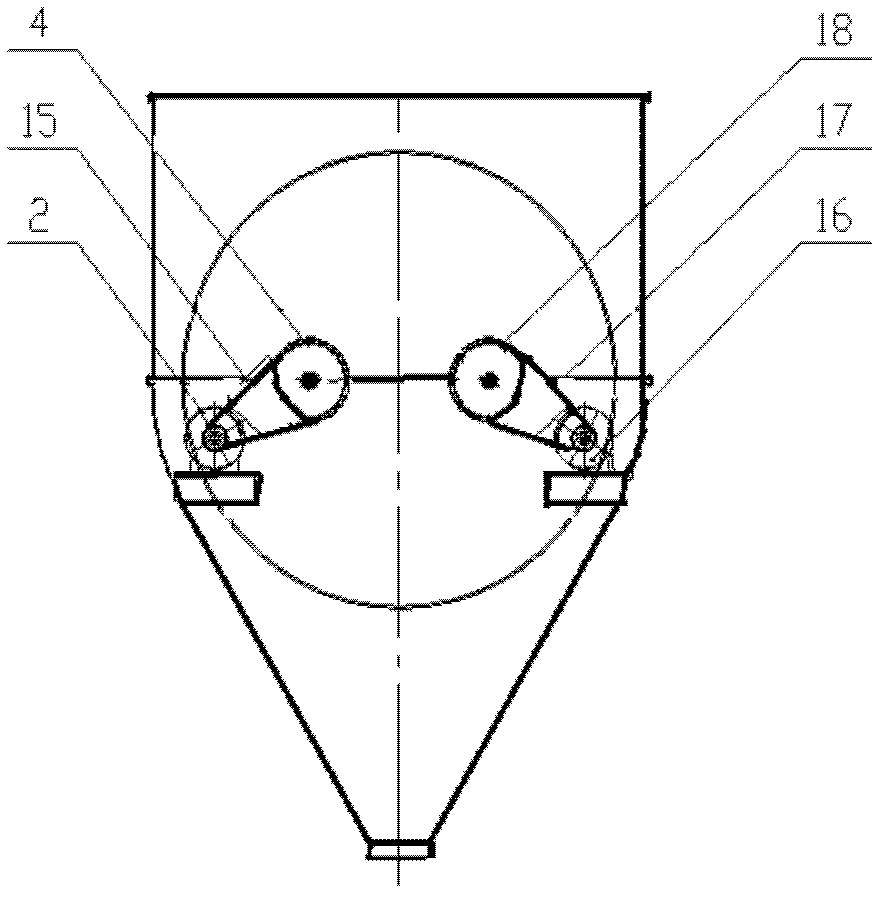

Automatic mixing type sterilization pot for edible fungi

ActiveCN103623439AGuaranteed sterilization qualityShort sterilization timeHeatHorticultureCold airSolenoid valve

The invention relates to an automatic mixing type sterilization pot for edible fungi. The sterilization pot comprises a sterilization pot barrel body, wherein a feeding assembly is arranged at the top of the sterilization pot barrel body; a discharging assembly is arranged at the bottom of the sterilization pot barrel body; a power mechanism is arranged at one end of the sterilization pot barrel body and is connected with a rotary shaft. The sterilization pot is characterized in that the rotary shaft is a hollow shaft pipe and is connected with a steam pipeline through a rotary connector after penetrating the sterilization pot barrel body; a solenoid valve is arranged between the rotary connector and the steam pipeline; the rotary connector is connected with aseptic cold air preparation equipment; multiple layers of spiral mixing blades are fixedly arranged on one section of the hollow shaft pipe in the sterilization pot barrel body through a plurality of fixing support pipes; one end of each fixing support pipe is communicated with the hollow shaft pipe, and the other end of the fixing support pipe is used for supporting each spiral mixing blade; a plurality of spray nozzles are formed in the periphery of the hollow shaft pipe and the fixing support pipes. Therefore, the sterilization quality is guaranteed; compared with conventional sterilization equipment, the sterilization time is greatly shortened and the production efficiency is improved.

Owner:淄博隆泰机械科技有限公司

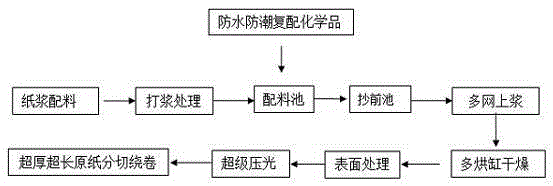

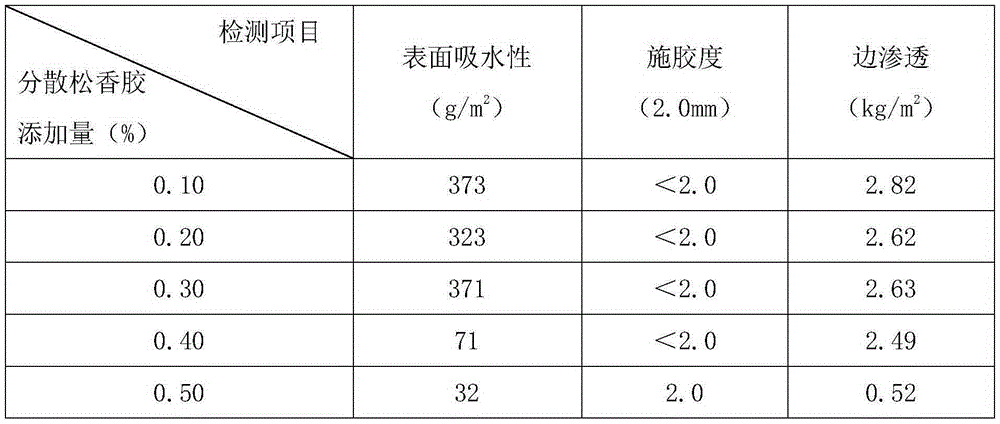

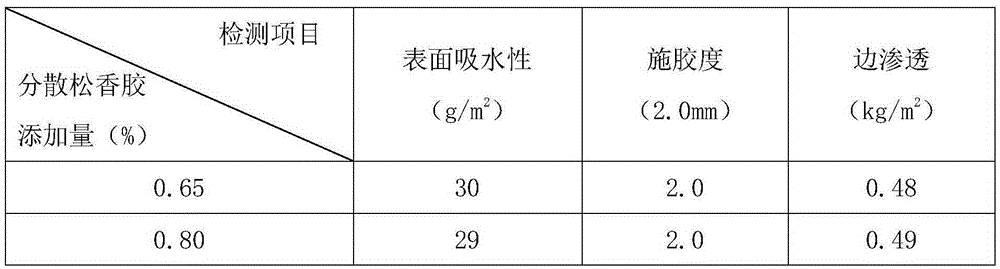

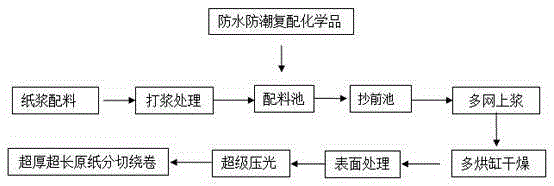

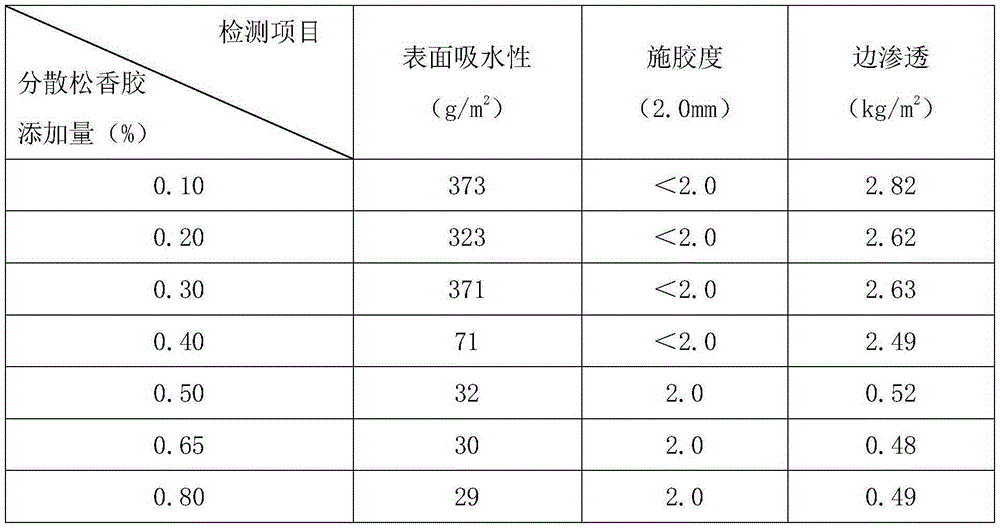

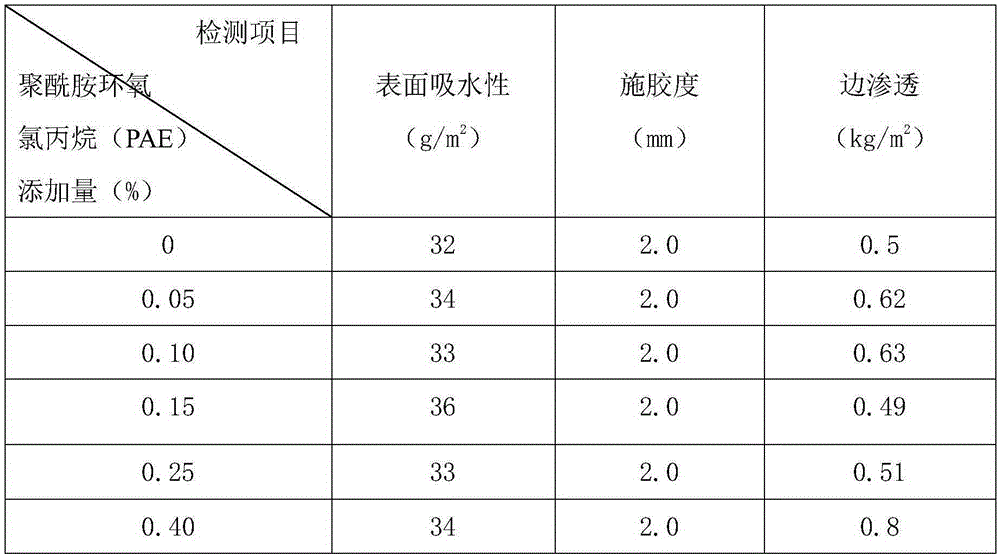

Waterproof and damp-proof raw paper dedicated for electronic paper tape, and preparation method thereof

InactiveCN105350375AGuaranteed StrengthImprove bondingWater-repelling agents additionPulp beating methodsFiberFibrillation

The present invention discloses a waterproof and damp-proof raw paper dedicated for electronic paper tapes, and a preparation method thereof. The method is characterized in that untwining and fibrillation are carried out on pulp fibers, fibrillation and cutting are further carried out so as to enable a pulp beating degree to reach 45 degree SR to 48 degree SR and a fiber wet weight to be reduced to 5.5 g to 8.0 g; and a water-resistant damp-proof composition is added in each layer, 1.0%-2.5% of the water-resistant damp-proof composition is added in relative to 100 parts of the pulp fibers, the water-resistant damp-proof composition including 0.15+-0.015 % of a wet strength agent PAE, 0.50+-0.05 % of gum rosin or an alkyl ketene dimer (AKD), 0.10+-0.01 % of silicon and fluorine type polymers, and 0.15+-0.015 % of ammonium zirconium carbonate. According to the above method, defibrination treatment is utilized, and a water-resistant damp-proof functional chemical is added in the pulp and coated on the surface of paper, surface water absorption and an edge permeation index of the raw paper are lowered than like products on the market, and water-resistance and damp-proofness of the raw paper are the best.

Owner:JIANGXI JIEMEI ELECTRONICS INFORMATION MATERIAL CO LTD

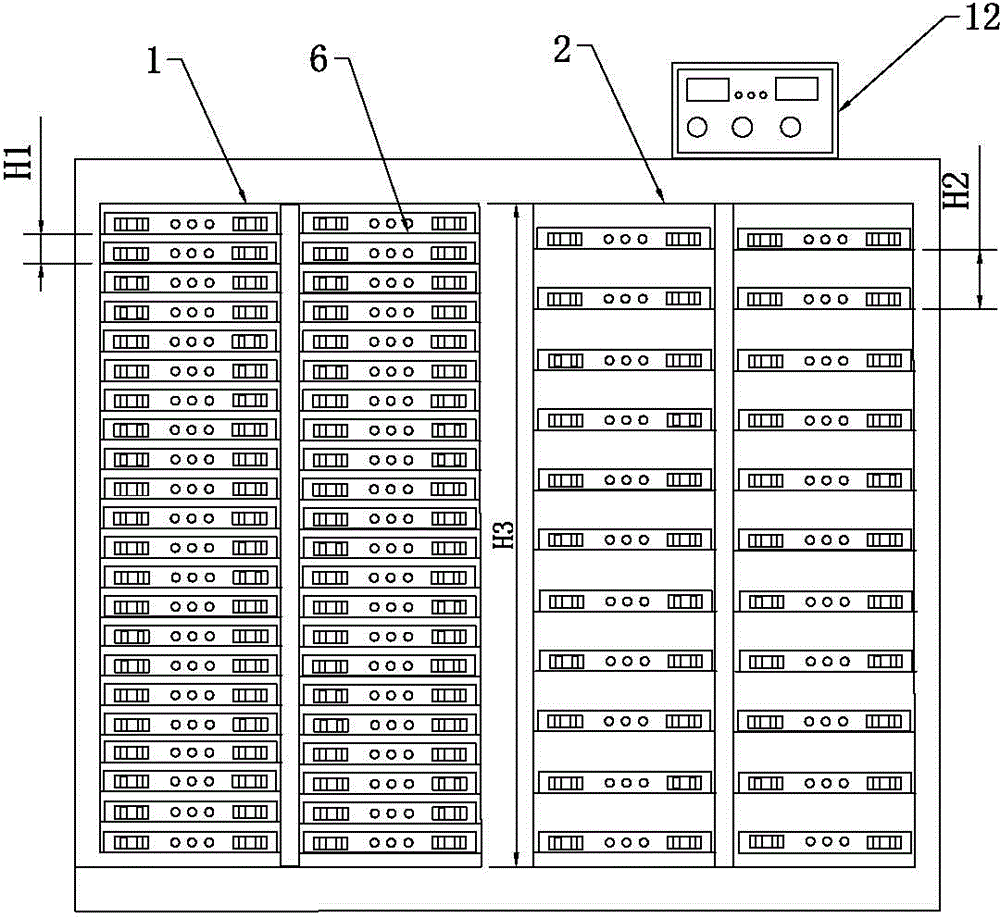

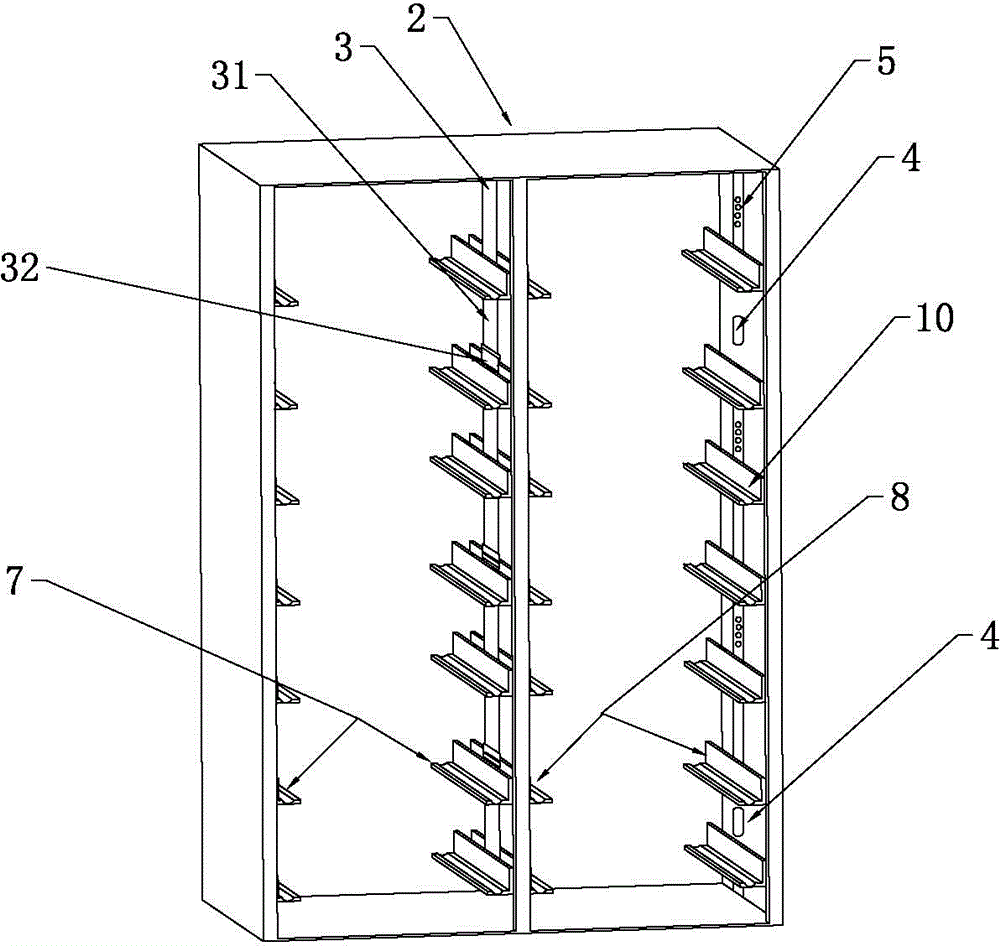

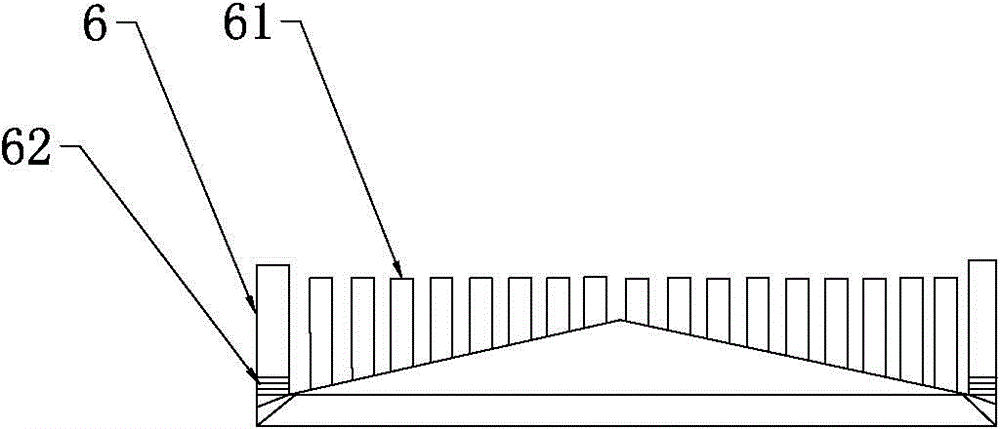

Seed sprouting hydroponic device

ActiveCN104521372AReduce pollutionAccelerate the growth of seedlingsAgriculture gas emission reductionCultivating equipmentsTemperature controlAgricultural engineering

The invention relates to the technical field of crop seed hydroponic equipment and specifically relates to a seed sprouting hydroponic device which comprises a main box and a central control system electrically connected with the main box, wherein a heat insulation material layer is arranged in the wall body of the main box, and germinating chambers and seedling cultivating chambers are arranged in the main box; a central spray device is longitudinally arranged in the middle of each germinating chamber, and ultraviolet sterilization lamps are arranged in the germinating chamber; a central spray device is longitudinally arranged in the middle of the seedling cultivating chamber, and ultraviolet sterilization lamps and plant lamps are arranged in the seedling cultivating chamber; high-density layered supporting frameworks for holding seedling cultivating discs are arranged in the germinating chambers and the seedling cultivating chambers, and each layered supporting framework comprises a left framework and a right framework which are transversely arranged in parallel; the central spray device is arranged between the left framework and the right framework, and a temperature control device is arranged at the bottom of the main box. The seed sprouting hydroponic device has the characteristics of simple structure, high product yield, high production, safe and sanitary cultivating mode, small occupied area, low labor cost, and high marketing value, and is pure natural and pollution-free.

Owner:彭柱强

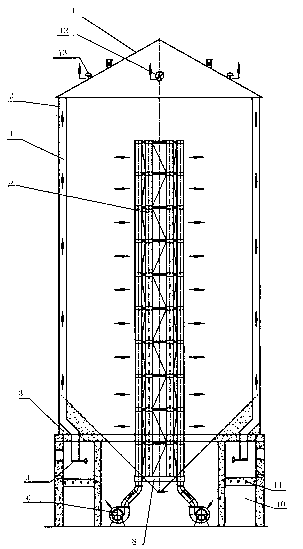

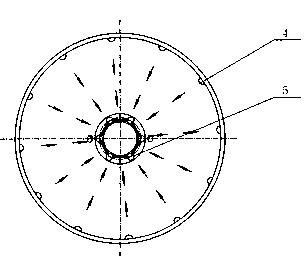

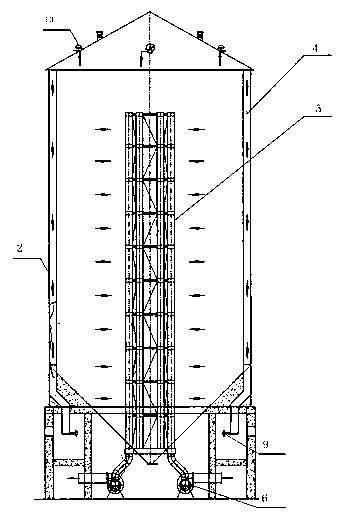

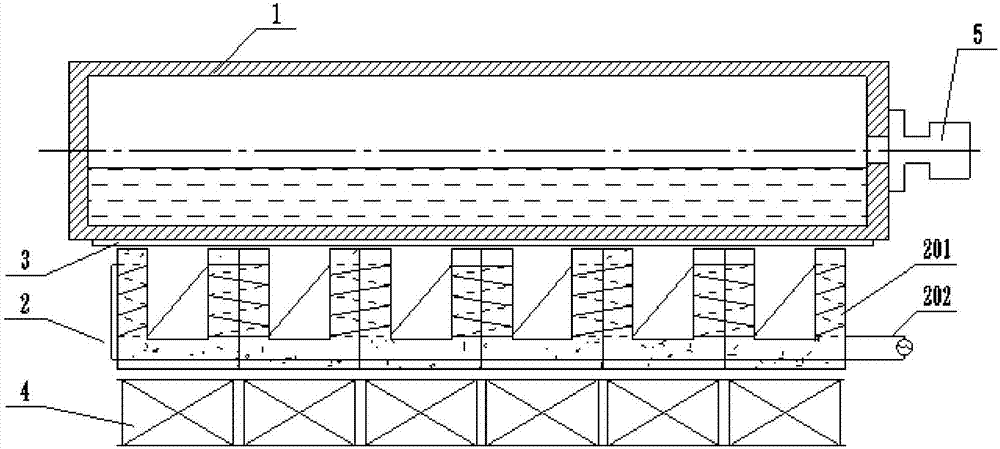

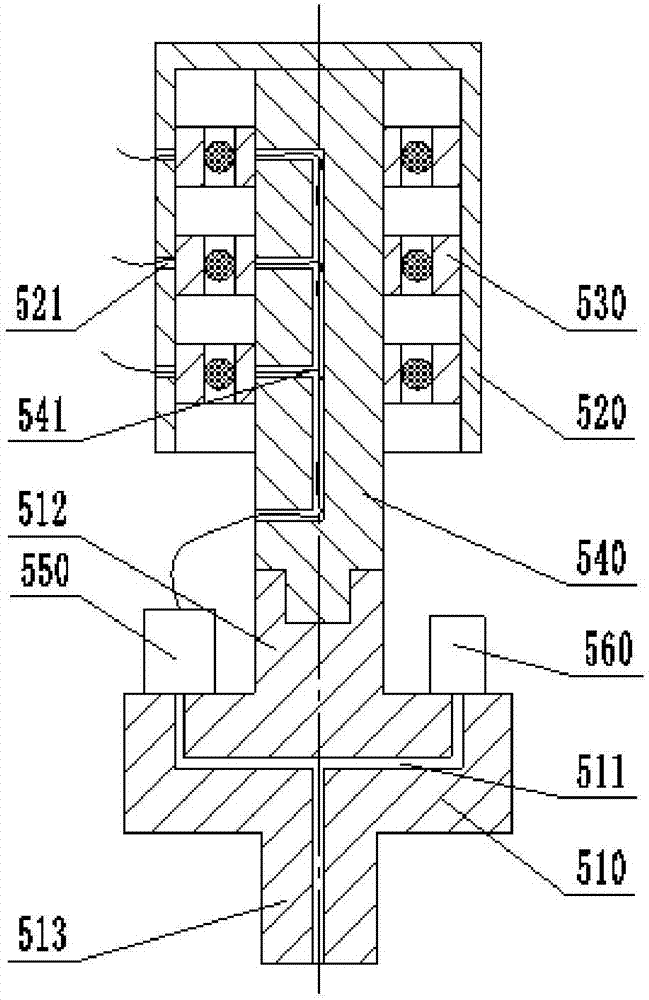

Positive-negative pressure ventilation drying cylindrical silo and drying method

InactiveCN103340066AKeep dryEasy to take awayAgriculture tools and machinesDrying gas arrangementsEngineeringRice grain

The invention relates to a positive-negative pressure ventilation drying cylindrical silo. Currently, a dryer is widely used for drying. However, according to the drying method of the dryer, the energy consumption is large, cost is high, the mechanical damage to rice after drying is large, the breaking rate is increased, the quality is poor, the head rice rate is reduced, the taste is poor, and the processing quality and the edible quality of rice are effectively influenced. A main body silo and a matched applicable device which are capable of drying a grain layer through the natural wind and the low temperature in a ventilating mode are designed to solve the problems. The positive-negative pressure ventilation drying cylindrical silo comprises a silo ceiling (1), a silo body (2) connected with the silo ceiling (1), a base (3) connected with the silo body, externally looped ventilation cages (4) fixed on the inner wall of the cylindrical silo, a central ventilation cage (5) installed in the cylindrical silo, wherein the external annular ventilation cages are evenly distributed in an annular shape. The ventilation cages comprise the externally looped ventilation cages and the central ventilation cage, wherein the externally looped ventilation cages and the central ventilation cage are respectively connected with a fan (6). A positive-pressure drying mode or a negative-pressure drying mode is used for achieving mechanical ventilation drying of grain.

Owner:HARBIN BEICANG GRAIN STORAGE PROJECT & EQUIP

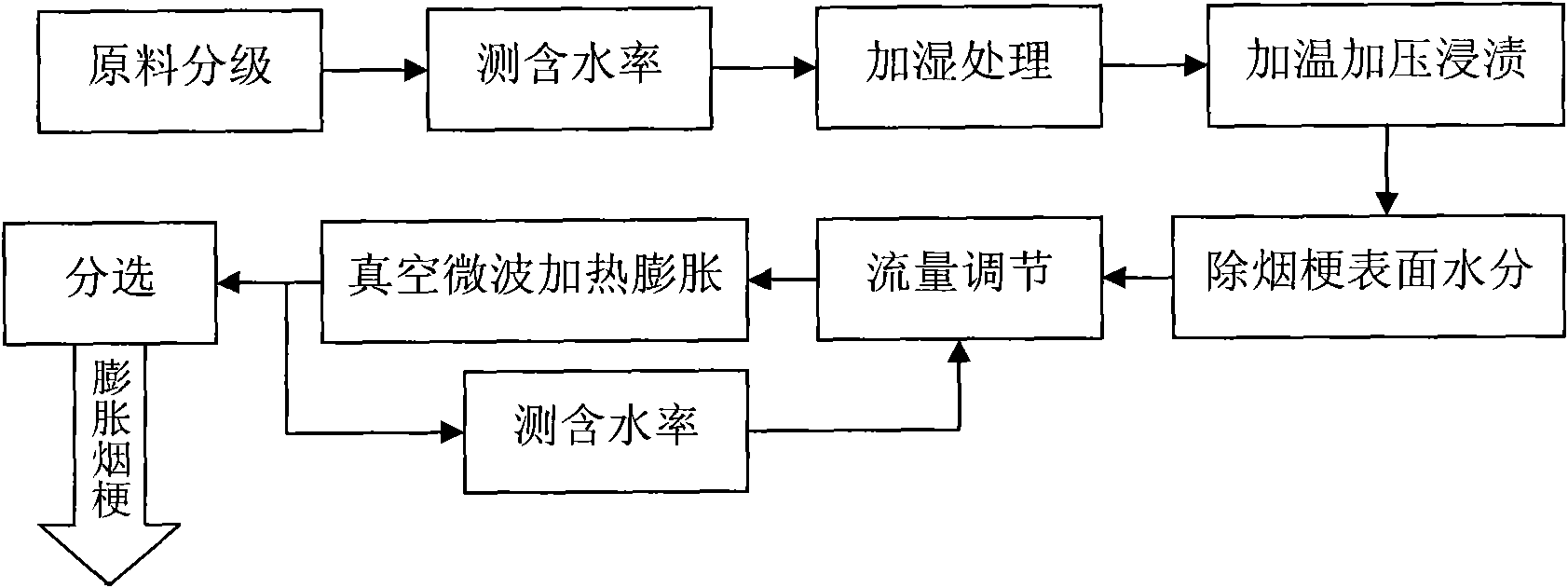

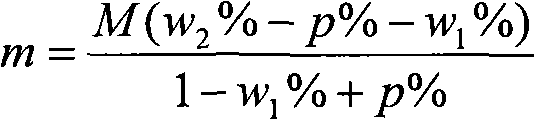

Tobacco stalk expansion method

InactiveCN101862023AUniform moistureUniform expansionTobacco preparationTobacco treatmentMicrowaveEngineering

The invention provides a tobacco stalk expansion method, which comprises the following steps of: grading tobacco stalks, performing impregnation remoistening on the graded tobacco stalks and expanding the tobacco stalks, wherein a microwave heating expansion method is adopted in the expansion of the tobacco stalks; preferably, the microwave heating expansion is performed on the tobacco stalks under a vacuum condition; more preferably, the microwave heating expansion is performed on the tobacco stalks by adopting more than two different kinds of continuous microwave output power under the vacuum condition, wherein the former two kinds of continuous microwave output power are 4.0 to 8.0 kw and 1.5 to 2.5 kw respectively for every kilogram of remoistened tobacco stalks; and the impregnation remoistening comprises the steps of: spraying water onto the tobacco stalks, and performing the impregnation remoistening under the pressure of 0.112 to 0.203 MPa and at the temperature of 50 to 100 DEG C. The expanded tobacco stalk has the characteristics of greater volume that is 1 to 3 times that of the conventional tobacco stalk, uniform expansion, remarkable fragrance, less wood smell, high resilience, the water content of 0.5 to 3 percent, high combustibility, improved intrinsic quality and relatively better smoke characteristic maintenance.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

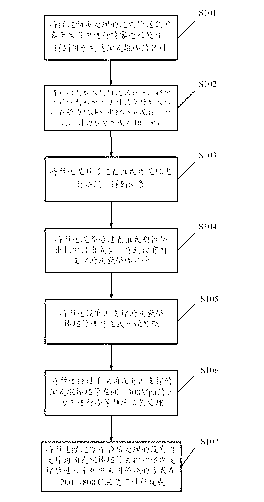

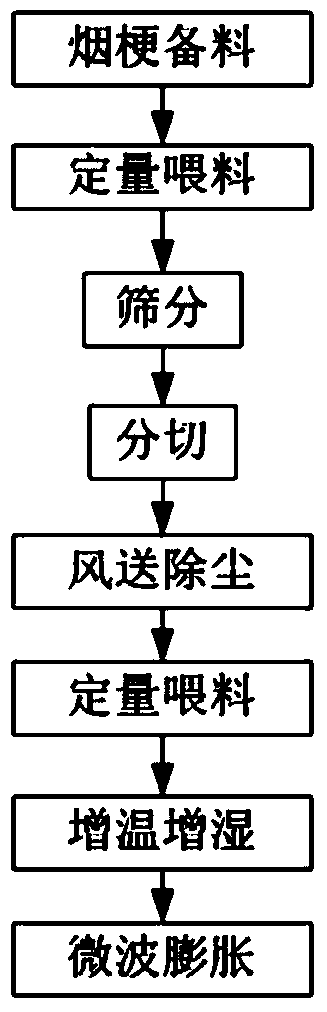

Pretreatment technology for reducing carbonization of tobacco stems after being expanded by microwave

The invention relates to a pretreatment technology for reducing carbonization of tobacco stems after being expanded by microwave, and belongs to the technical field of tobacco processing. The pretreatment technology for reducing carbonization of tobacco stems after being expanded by microwave is the improvement on basis of prior art. The pretreatment technology for reducing carbonization of tobacco stems after being expanded by microwave provided by the invention comprises the following steps: preparing tobacco stems, primary feeding, screening, slitting, air-conveying, secondary feeding, warming and wetting, and expanding by microwave. The pretreatment technology for reducing carbonization of tobacco stems after being expanded by microwave has the advantages that, the production flow is controlled by quantitatively feeding, and obvious effect is provided for keeping stable quality of each process; when the tobacco stems are in the warming and wetting process, the tobacco stem slitting technology is used for enabling moisture and temperature of the core parts, cambiums and cortexes of the tobacco stems to be more uniform, and the carbonization of the core part in the microwave expansion process due to that the core part has more moisture and lower heat radiating effect than the surface is reduced. The method provided by the invention is significant in improving cut stem quality and use ratio, and reducing the cost of cigarette enterprises.

Owner:YUNNAN RES INST OF TOBACCO SCI

Electronic carrier tape special base paper with treated surface and manufacturing method thereof

ActiveCN105401481AGuaranteed StrengthImprove bondingWater-repelling agents additionPulp beating methodsPaper sheetSurface finishing

The invention discloses an electronic carrier tape special base paper with a treated surface and a manufacturing method thereof. The electronic carrier tape special base paper has two layers or more than two layers of papermaking structures. The paper is characterized in that the surface and back surface of the paper are coated with a layer of treating fluid containing a hot melting glue binding modifier, so tension for tearing the processed paper tape surface and a hot melting upper adhesive tape reaches 10 g to 70 g after hot melt adhesion, and peeling and fluffing would not occur when the hot melting upper adhesive tape is peeled. The treating fluid contains 1.5%-2.0% of polyvinyl alcohol, 1.5%-2.0% of polyacrylamide modifier, 0.7%-0.9% of acrylate copolymer, 0.02% of cyanoethyl chitosan, and 0.50%-0.80% of hot melting glue binding modifier. The tension for tearing the processed paper tape surface and the hot melting upper adhesive tape reaches 10 g to 70 g after hot melt adhesion, and peeling and fluffing would not occur when the hot melting upper adhesive tape is peeled. The electronic carrier tape special base paper satisfies requirements in industries.

Owner:JIANGXI JIEMEI ELECTRONICS INFORMATION MATERIAL CO LTD

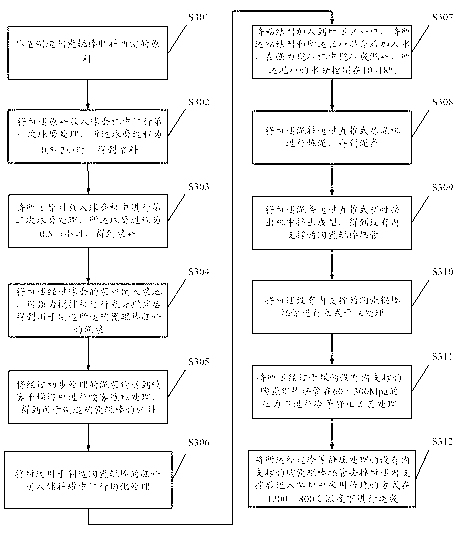

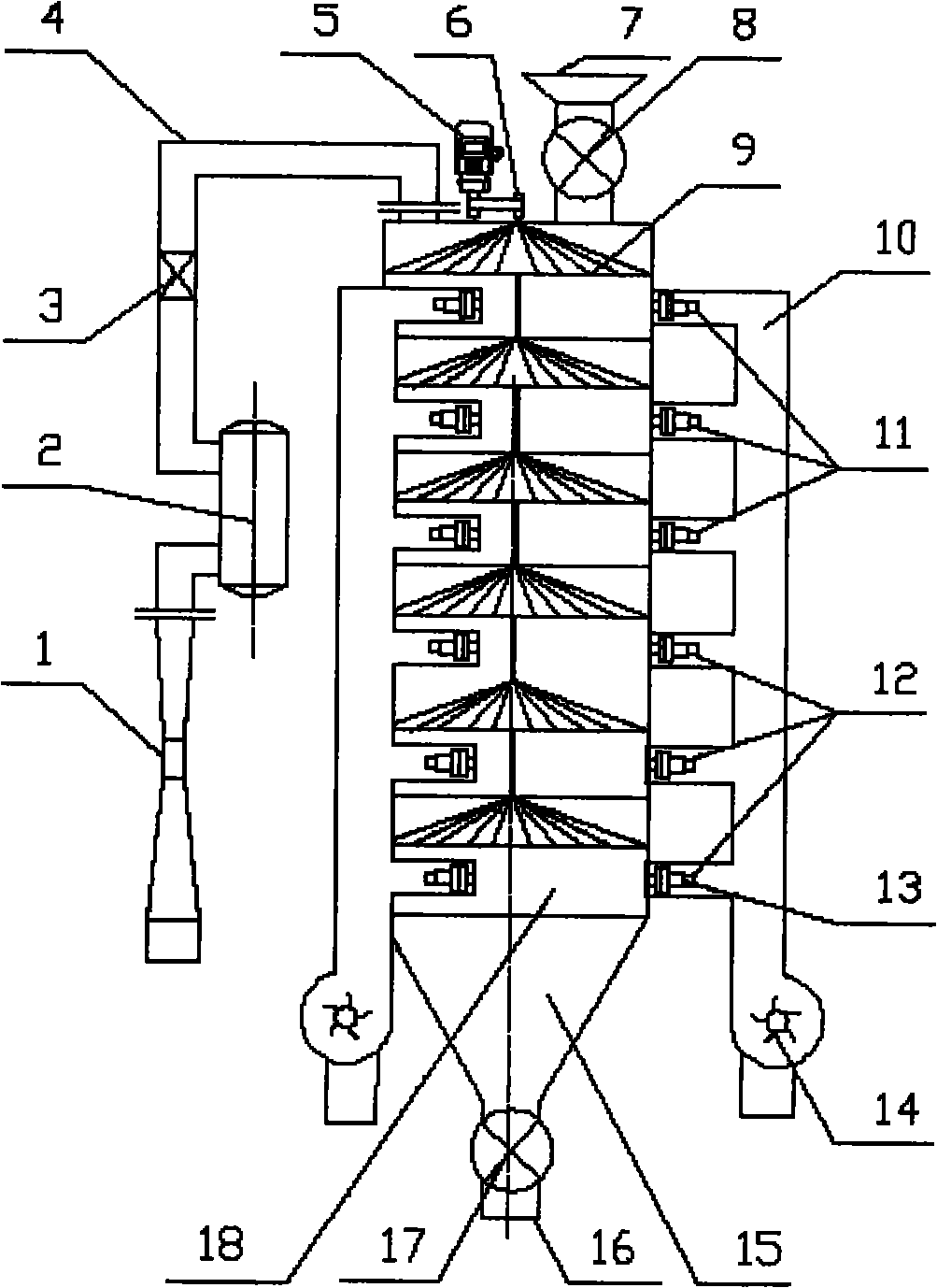

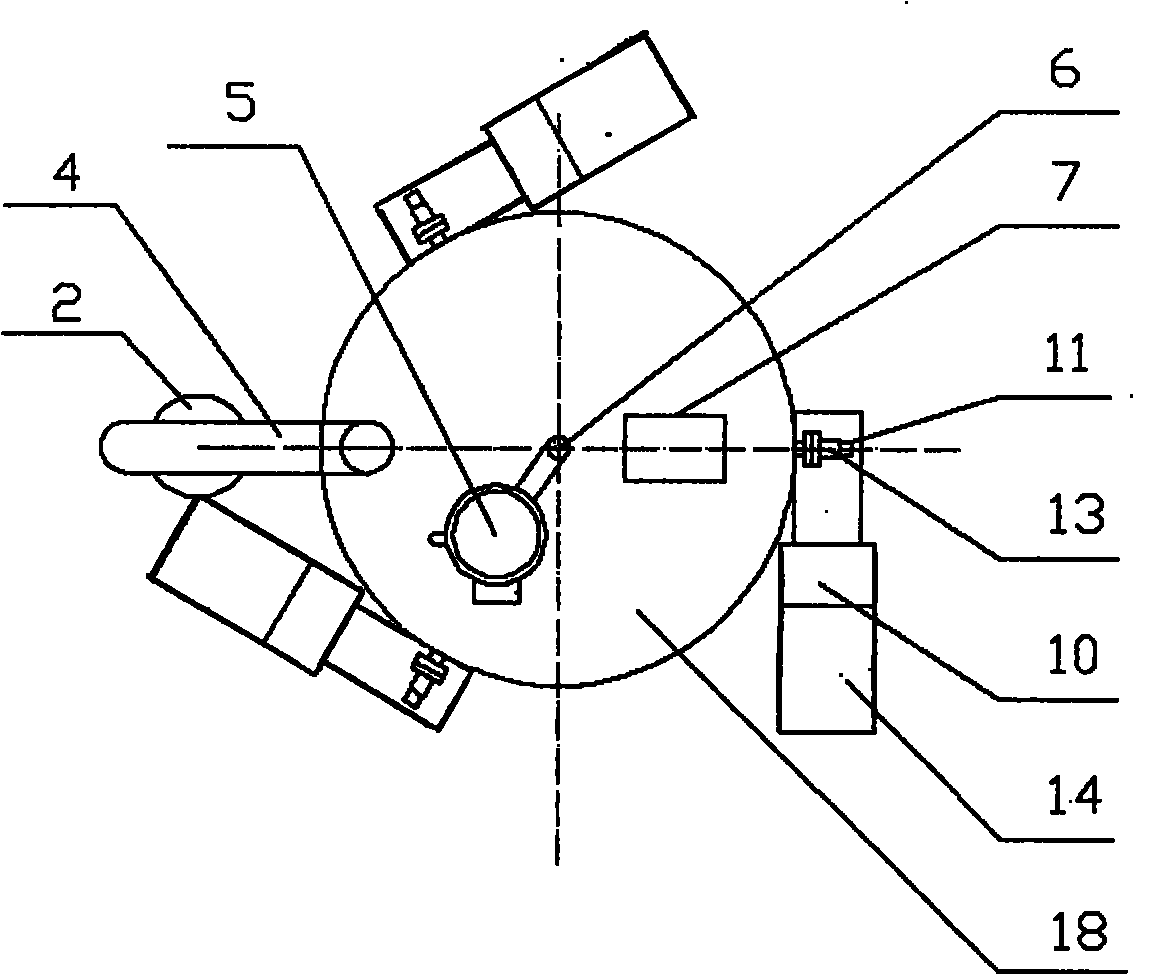

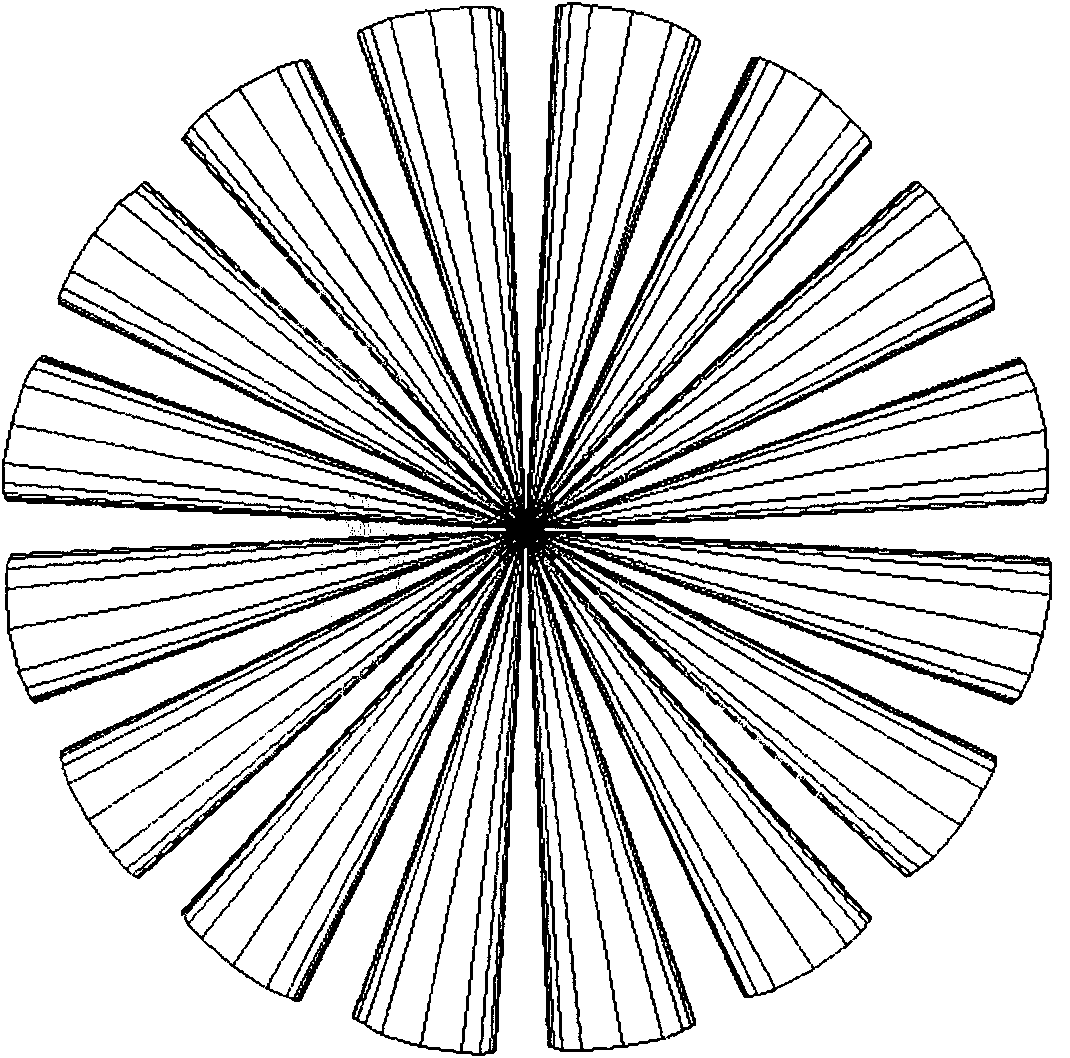

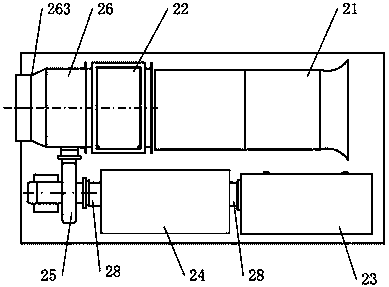

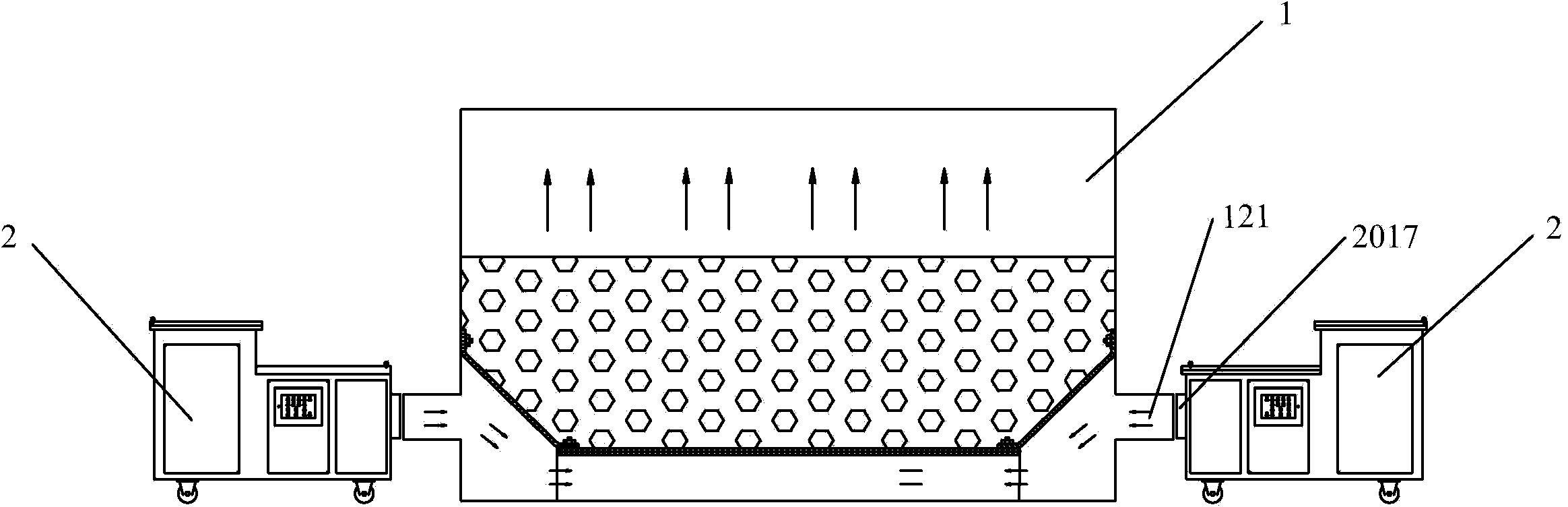

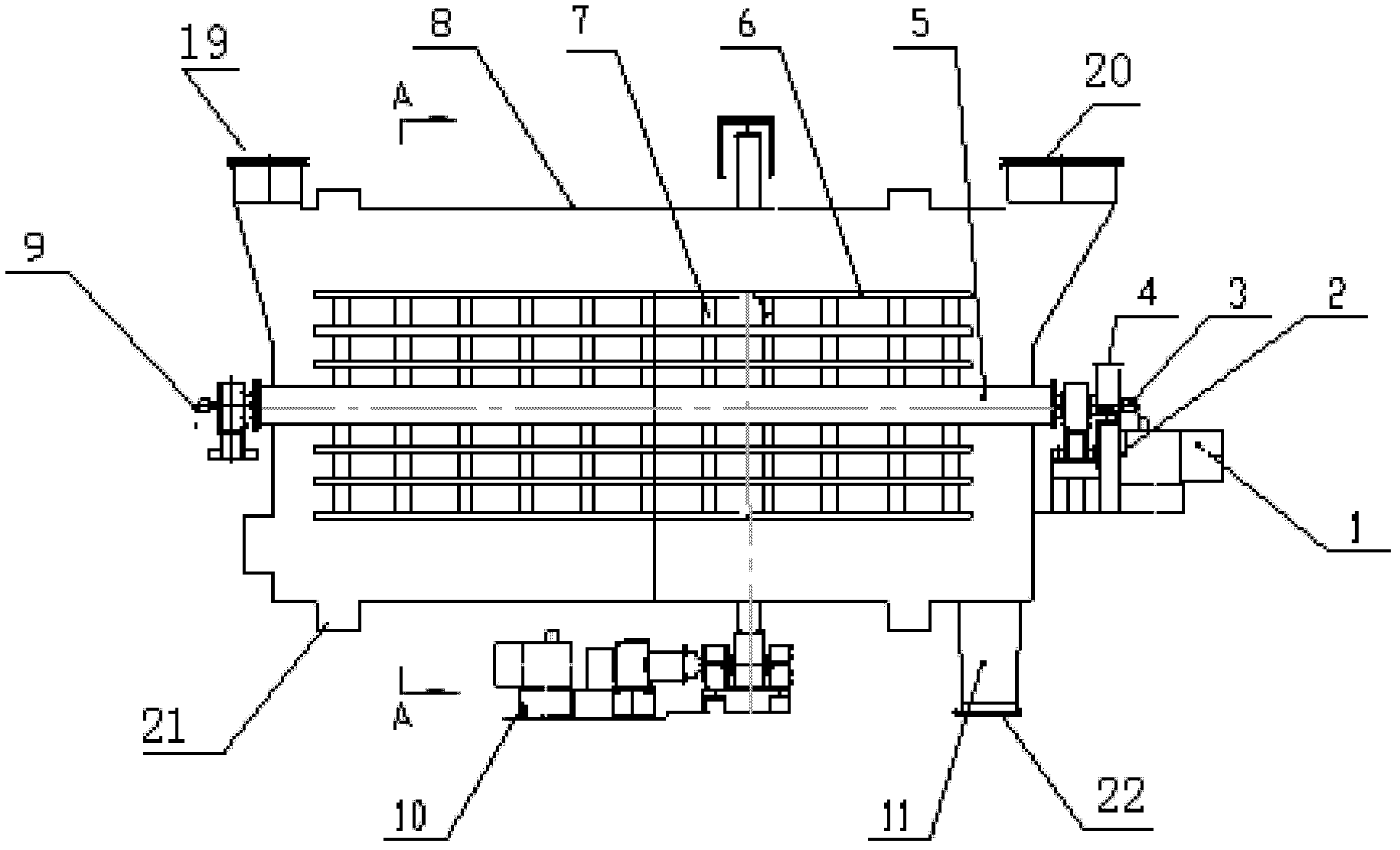

Cut leaf tobacco microwave vacuum drying equipment

ActiveCN101822415AImprove sensory qualityKeep the aromaTobacco preparationVacuum pumpingElectric machinery

Cut leaf tobacco microwave vacuum drying equipment is characterized by comprising a vertical cylinder-shaped drying cavity, a vacuum-pumping system communicated with the drying cavity, and a microwave heating system, wherein the top part and the bottom part of the drying cavity are respectively provided with a feed port and a discharge port, the drying cavity is internally provided with a material dispersion mechanism, the material dispersion mechanism comprises a spindle arranged on the axle center of the drying cavity, and multi-layer material dispersion plates arranged on the spindle, the spindle is driven to rotate by a motor, the microwave heating system is divided into a continuous microwave heating unit arranged on the upper part of the drying cavity and a pulsed microwave heating unit arranged on the lower part of the drying cavity, and the two heating units can respectively hierarchically arranged in multi groups along the shell of the drying cavity. Compared with the prior art, the invention has the advantages that the cut leaf tobacco microwave vacuum drying equipment can carry out the microwave drying in stages to the cut leaf tobacco under the a vacuum status, reduces the drying temperature of the cut leaf tobacco, keeps the fragrant of the cut leaf tobacco, improves the aesthetic quality of the cut leaf tobacco, at the same time, can realize the rapid dehydration and drying of the cut leaf tobacco, and improves the filling value of the cut leaf tobacco.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Production method for lining paper for cigarette

ActiveCN102899957AGood paper evennessUniform moistureWater-repelling agents additionPaper/cardboardPaper sheetHardwood

The invention discloses a production method for a lining paper for a cigarette. The production method comprises the following steps: A) preparing grinding pulp, and then allocating the pulp which contains 15-30 wt.% of bleached needle bush pulp, 55-75 wt.% of bleached hardwood pulp and 10-15 wt.% of straw pulp, separately pulping, and then mixing the grinding pulp, and controlling pulp intensity at 30-40 OSR and wet weight being 2.5-5.5g; B) adding padding and a degassing agent before primarily slushing the pulp, and then entering into multi-stage deslagging; C) adding pulp glue and starting the secondary slushing; D) after ending the secondary slushing, adding a sizing agent, placing into a pressure screen for treating, and adding a retention agent at an outlet of the pressure screen; E) pouring the pulp into a pulp flowing box, loading a net and preparing paper with the pulp; F) extracting and dewatering; G) drying; H) performing soft calendaring dual-pressing treatment; and I) coiling, rewinding and cutting, packaging and putting into a storage. The lining paper for the cigarette produced according to the production method has the beneficial effects: the paper sheet uniformity is excellent; the horizontal width rated difference is small; the tensile force is high; the lining paper is easy to cut; the front surface of the paper sheet has higher smoothness; and the back surface of the paper sheet has certain smoothness.

Owner:XIANHE CO LTD

Whole bin whole-base ventilation low-speed drying grain storage system

InactiveCN104034130AMaintain commodity valueNo mildew lossDrying gas arrangementsSeed preservation by dryingLow speedPesticide residue

The invention relates to a whole bin whole-base ventilation low-speed drying grain storage system which comprises a grain bin and a grain bin treatment device. The system is characterized in that the grain bin is a whole-base ventilation grain bin, a ventilation structure is arranged on a base plate of the grain bin, the ventilation structure is connected with a ventilation inlet formed in the grain bin, and the ventilation structure is communicated with an inner cavity of the grain bin. The grain bin treatment device comprises a shell, and an air inlet and an air outlet are formed in the shell. The air outlet of the grain bin treatment device is connected with the ventilation inlet of the grain bin. According to the whole bin whole-base ventilation low-speed drying grain storage system, no drying pipelines exist in the grain bin, drying efficiency and the drying effect are greatly improved, the system can adapt to unprocessed grain conditions and climatic features in different areas, and the commodity value of the grain is ensured through low-temperature low-speed drying. In addition, by the adoption of technology application of ozone mould prevention and sterilization and pesticide residue degradation, it is ensured that no mould loss is produced in the treatment process, and meanwhile the drying season can be prolonged.

Owner:中机天安(北京)粮储安全技术研究院

Method for graded drying of camellia seeds

InactiveCN102433219AUniform moistureImprove drying efficiencyFatty-oils/fats productionVibration amplitudeCamellia oleifera

The invention discloses a method for graded drying of camellia seeds, belonging to the technical field of agricultural product processing. The invention discloses a method for graded drying of camellia seeds, which is characterized in that: in the case of controlling vibration amplitude of a grading vibrating screen, rotating speed of an eccentric shaft, steam heating pressure of a flat dryer and operating speed of a chain, fresh camellia seeds, which are used as raw materials, are dried to the condition that the temperature is below normal temperature and the content of safe storage moisture is below 9%. According to the method, the addition of graded treatment results in uniform moisture in the dried camellia seeds and improved drying efficiency, and the crushing process subsequent to dehulling can be omitted when small camellia seeds are dried.

Owner:JIANGNAN UNIV

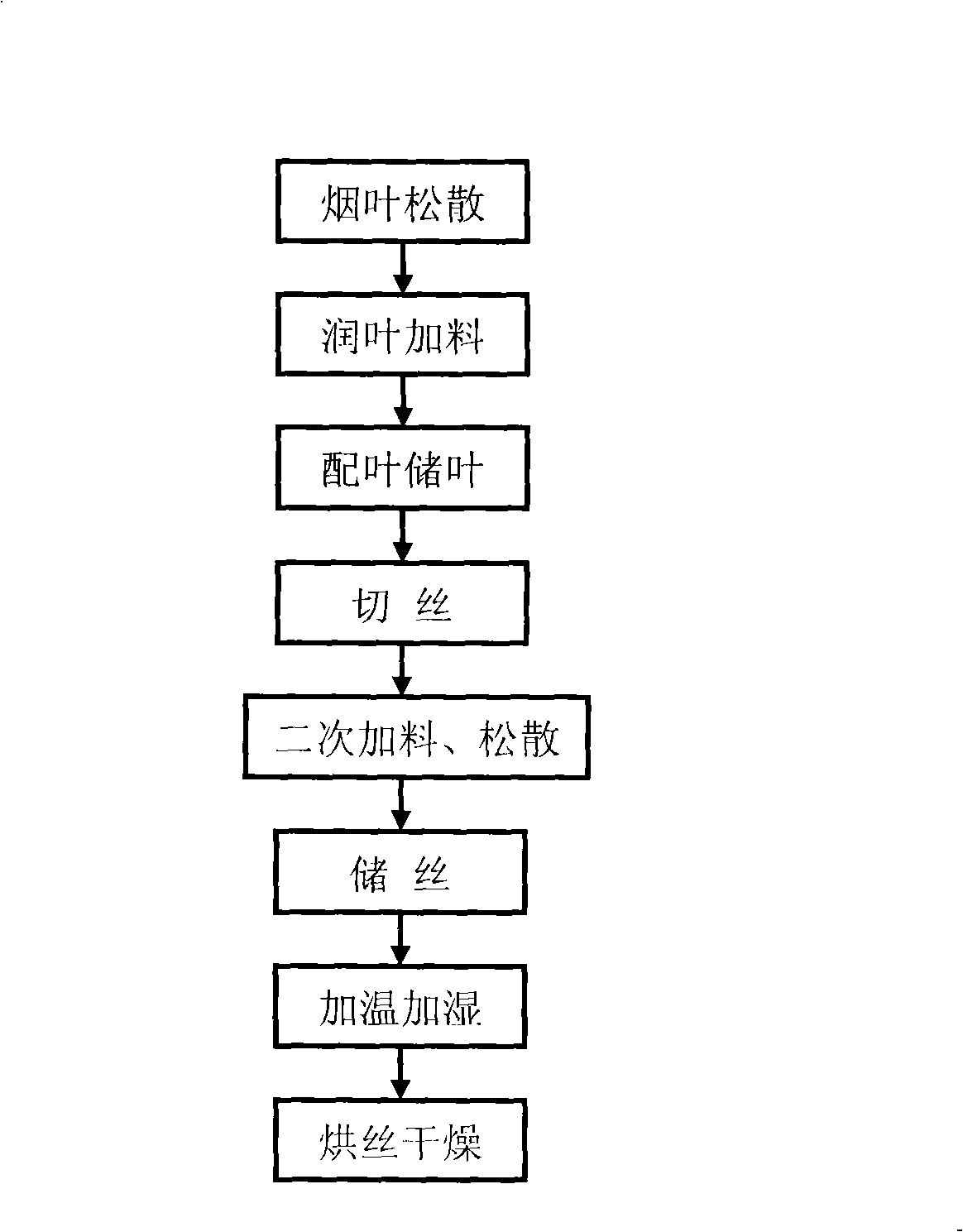

Tobacco process secondary charging technique

InactiveCN101263927AReduce the disadvantages of sticking and cakingEnsure smooth and uniformTobacco preparationTobacco treatmentEngineeringHigh water content

The invention relates to a two-times feeding process in tobacco processing, which is characterized in that: the feeding process is completed in two steps; the first feeding is wetting and casing after the tobacco leaf is loosened, feeding part of the feed liquid to the tobacco leaf; the second feeding is conducted to the shredded tobacco after tobacco cutting and before drying. The two-times feeding process can prevent the tobacco leaf containing too high water content and viscosity before tobacco cutting, make the cutting stable and improve the uniformity and permeability of feeding the feed liquid to the tobacco material, thus obtaining shredded tobacco with better quality.

Owner:KUNMING SHIPBUILDING EQUIP +1

Preparation method of nutritious noodle

InactiveCN102366049AUniform moisturePrevent water absorptionDough treatmentFood preparationEconomic benefitsEngineering

The invention provides a preparation method of a nutritious noodle. The preparation method comprises the following steps: 1, putting flour and purified water in a dough kneading machine, carrying out dough kneading for 5-20min, adding vegetable powder to the dough kneading machine, continuously carrying out dough kneading for 5-20min, carrying out dough rest for 5-20min in a dough rest machine, and successively carrying out calendering, strip cutting, drying, and cutting processing to obtain finished products. According to the invention, the method that the vegetable powder is added after the flour is subjected to the dough kneading for a period of time is adopted to replace a traditional method that the dough kneading is carried out after the vegetable powder is mixed with the flour, and the change which produces unexpected positive effects allows the excess water absorption of the vegetable powder to be avoided, water in the dried noodle to be uniform, and the shelf life of the dried noodle to be prolonged. The shelf life of the vegetable noodle produced by the method of the invention is prolonged to one year, and the prepared noodle which is soft and tasty can be treated as an auxiliary food for the vegetable feeding of children. The method of the invention has the advantages of simple preparation, good economic benefit and high quality of the finished product.

Owner:宜垦(天津)农业制品有限公司

Process for preparing cordyceps black tea

InactiveCN102210364ARemove green smellUniform moisturePre-extraction tea treatmentWater contentChemistry

The invention relates to a process for preparing cordyceps black tea. The process for preparing the cordyceps black tea comprises the following steps of: performing in-coming inspection and acceptance on fresh tea leaves; selecting fresh tea leaves without deterioration, peculiar smell, pesticide residues and other impurities as raw materials; withering until the water content of the tea leaves is 45 to 50 percent at the temperature of 25 to 38 DEG C and relative humidity of 65 to 70 percent; shaking green for 2 hours by using a green-shaking machine; kneading for 1 hour by using a kneading machine; fermenting for 1 to 5 hours at the temperature of 17 to 33 DEG C and the relative humidity of over 80 percent; drying by using a drying machine at the gross fire temperature of between 100 and 110 DEG C until the water content of the tea leaves is 25 percent and drying continuously at the complete fire temperature of between 80 and 90 DEG C until the water content of the tea leaves is 5 to 6 percent; mixing the dried black tea leaves and Northern cordyceps bodies according to the ratio of the dried black tea leaves to the Northern cordyceps bodies of 4:1; and packaging the mixture to prepare the finished product. The cordyceps black tea prepared by the new process is convenient to package and transport, can effectively remove foreign flavor and obviously increases the tea polyphenol content and the amino acid content.

Owner:FUDING FANGMING TEA

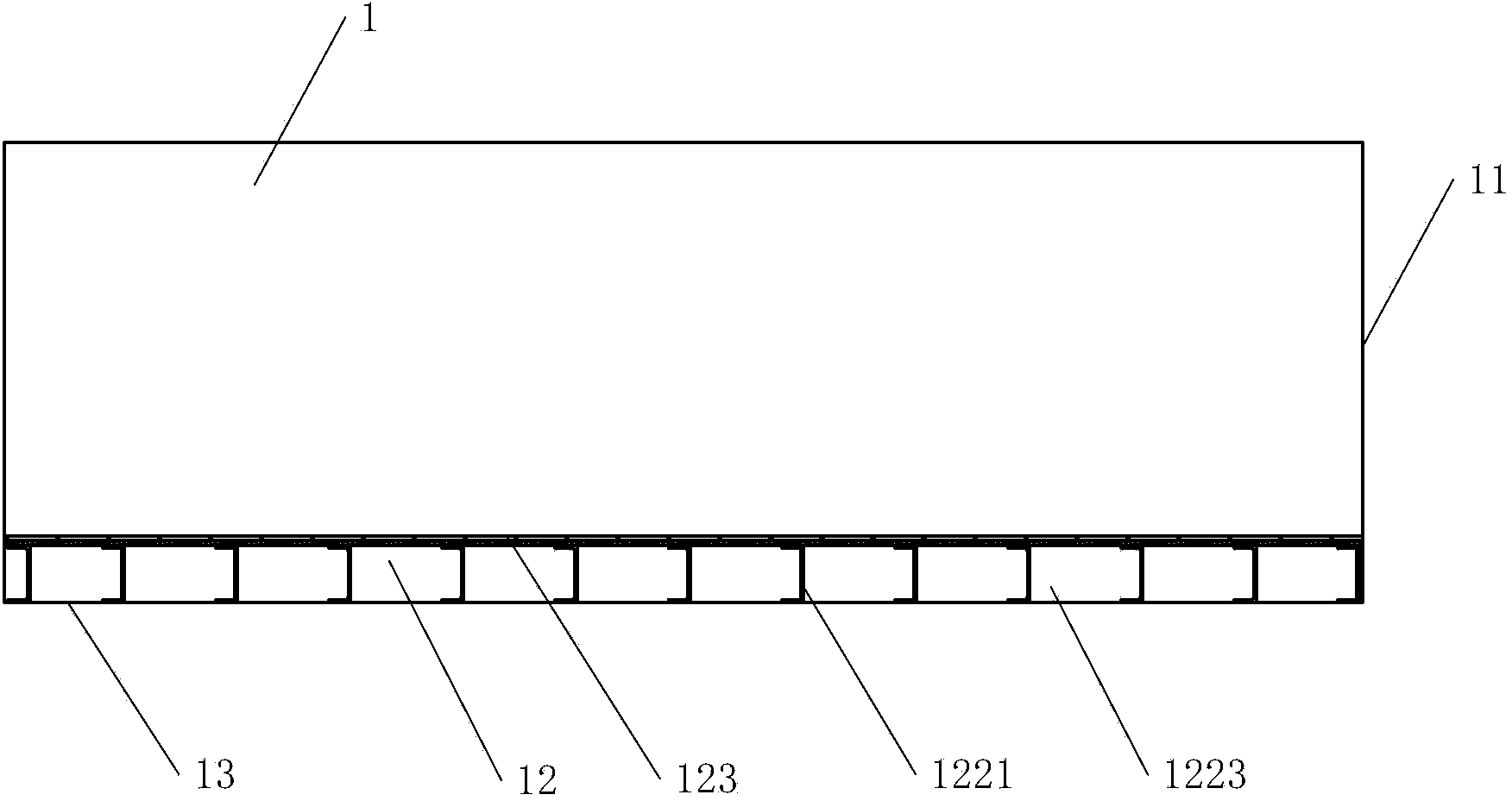

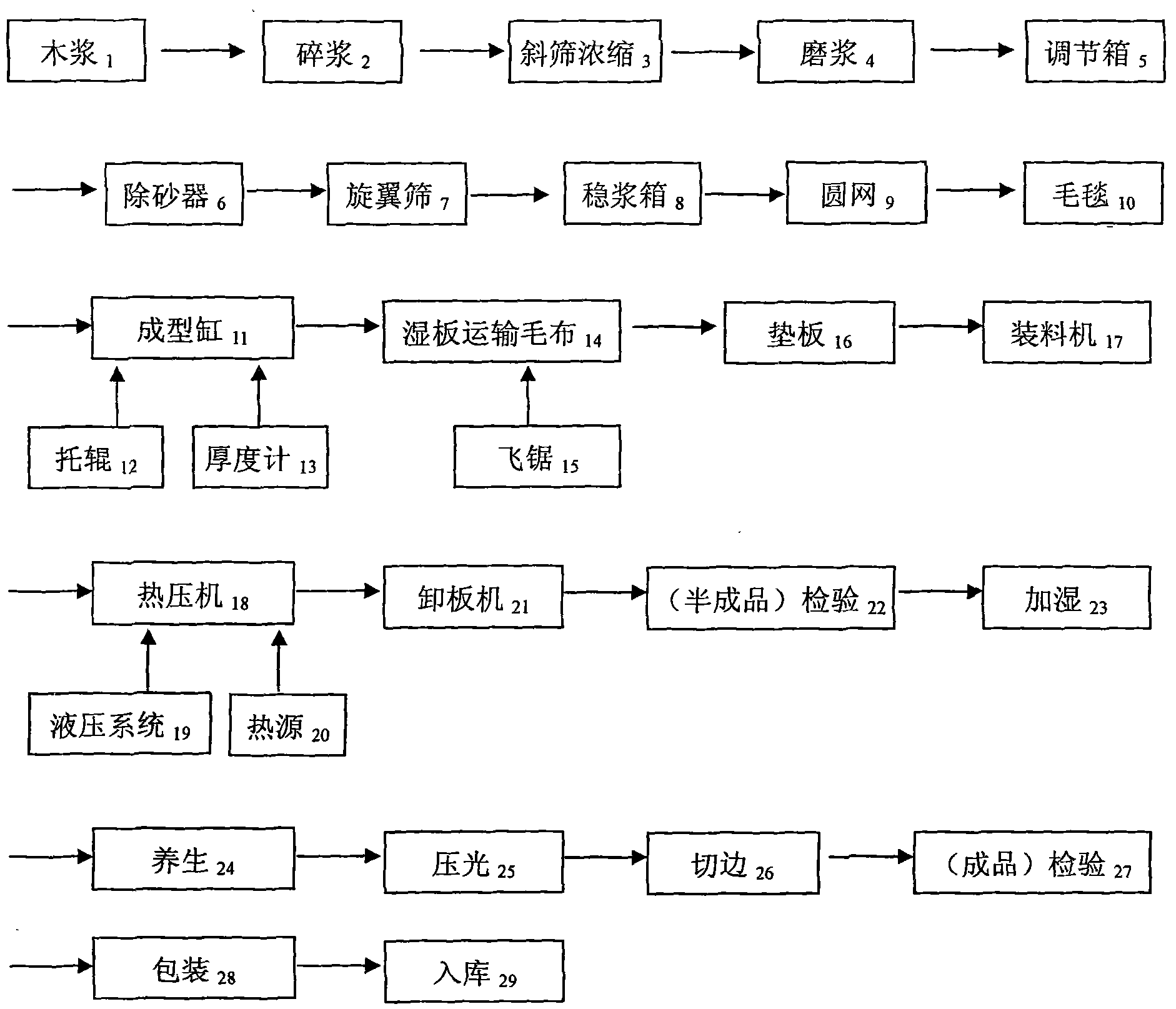

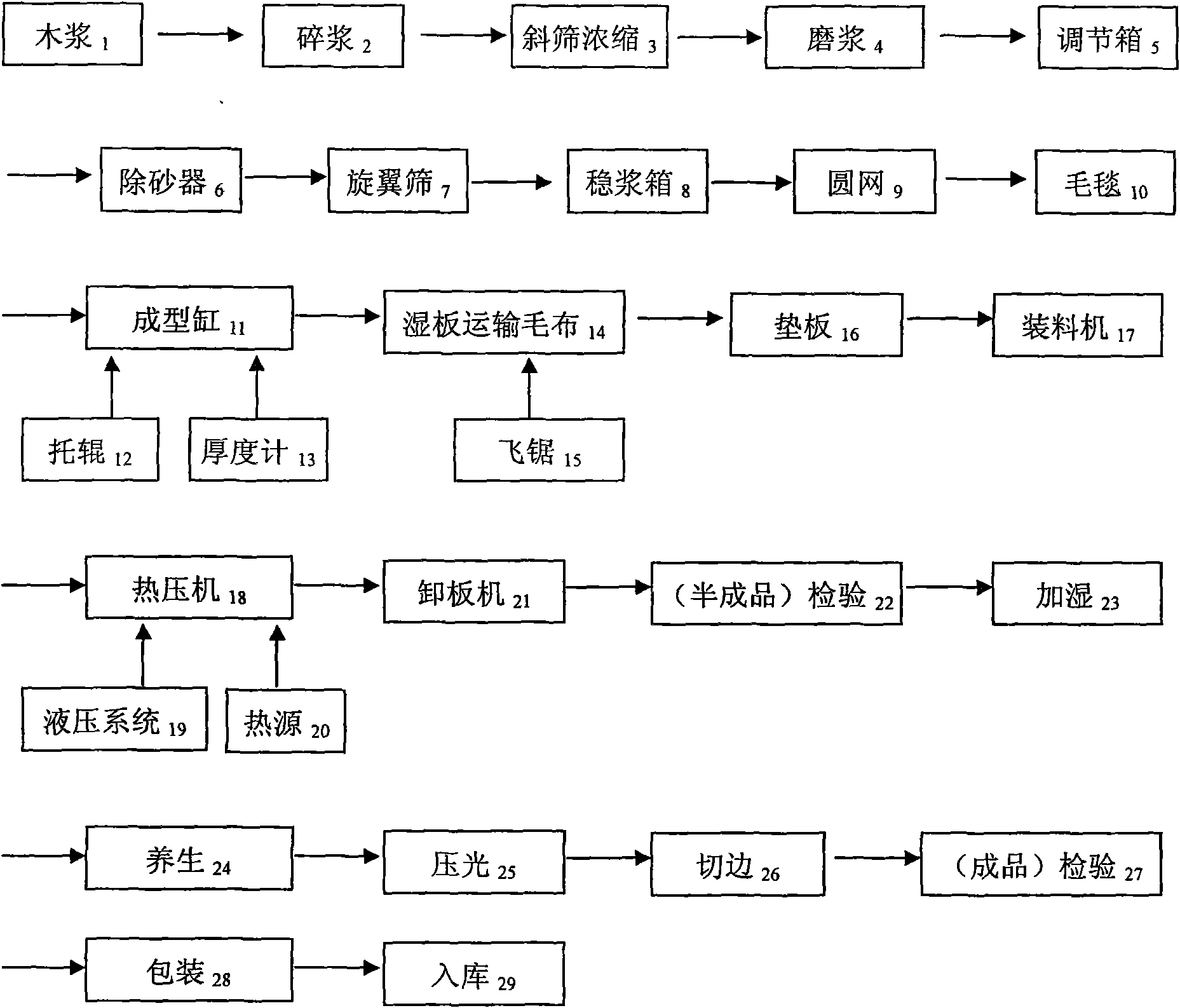

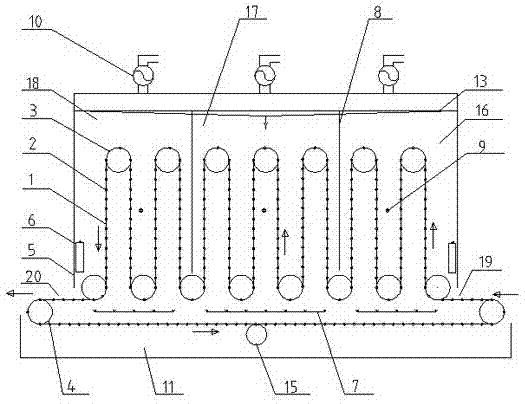

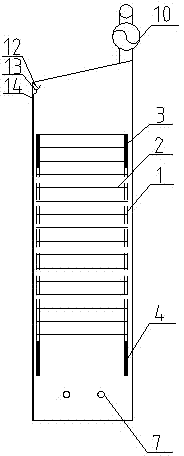

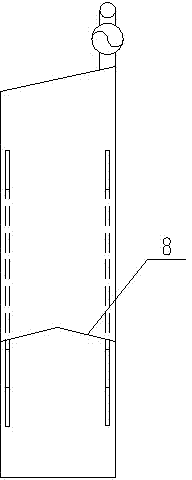

Hot-pressing production process of standard paperboard

ActiveCN101781868AUniform thicknessThe difference between the same version is smallFibreboardPulp beating/refining methodsPaperboardWaste product

The invention relates to a hot-pressing production process of a standard paperboard, belonging to the technical field of papermaking process and aiming to produce the standard paperboard through adopting the new hot-pressing production process. The hot-pressing production process comprises the following steps of: molding wood pulp into a wet paper blank in a molding cylinder after smashing, concentrating, grinding and stabilizing; then pressurizing and drying the wet paper blank in a hot press to form a semi-finished product; and finally, curing, calendaring and cutting, and packaging and warehousing a finished product qualified through inspection. The paperboard produced by adopting the hot-pressing process has uniform thickness, small homogeneous difference, uniform moisture and enhancement of processing precision. Meanwhile, the hot-pressing production process has high mechanical degree, can reduce production links and relieve labor intensity and has high finished product rate to reduce the recycling and consumption of waste products and save energy.

Owner:XINSHAO GUANGXIN ELECTRICAL INSULATING MATERIALS

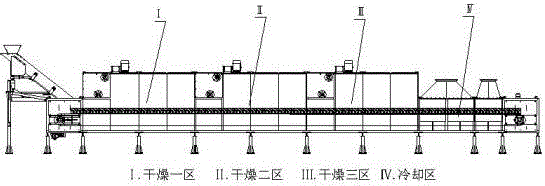

Dough sheet fermentation process and continuous fermentation device

InactiveCN104757041AProof evenlyIncrease proofing effectProversDough processingWater contentChemistry

The invention relates to a dough sheet fermentation process and a continuous fermentation device. The process comprises three stages; the temperatures of the various stages are respectively 30-35 DEG C, 35-40 DEG C and 32-37 DEG C; the humidity of each stage is controlled at 75%-90%; the lasting time of each stage is 2-15 minutes; the average moisture content of dough sheets is 30%-40%; the thickness of the dough sheets is 10-20mm; the dough sheets are in a hanging state. The continuous fermentation device is correspondingly divided into three areas; the setting of the temperature and the humidity of each area can correspond to that of the process; the fermentation time is controlled by adjusting the operation speed of a dough sheet conveyer; and the dough sheets pass through the various areas under the conveying of the conveyer, so as to finish the fermentation process. By virtue of the dough sheet fermentation process and the continuous fermentation device, segmented accurate measurement and control on the fermentation condition can be realized, so that the dough sheet fermentation effect is increased, and the quality of noodles is improved; and the device is high in automatic degree and suitable for different production by adjusting the operating speed.

Owner:NINGXIA ZHONGHANG ZHENGFEI SAIWAIXIANG HALAL FOOD CO LTD

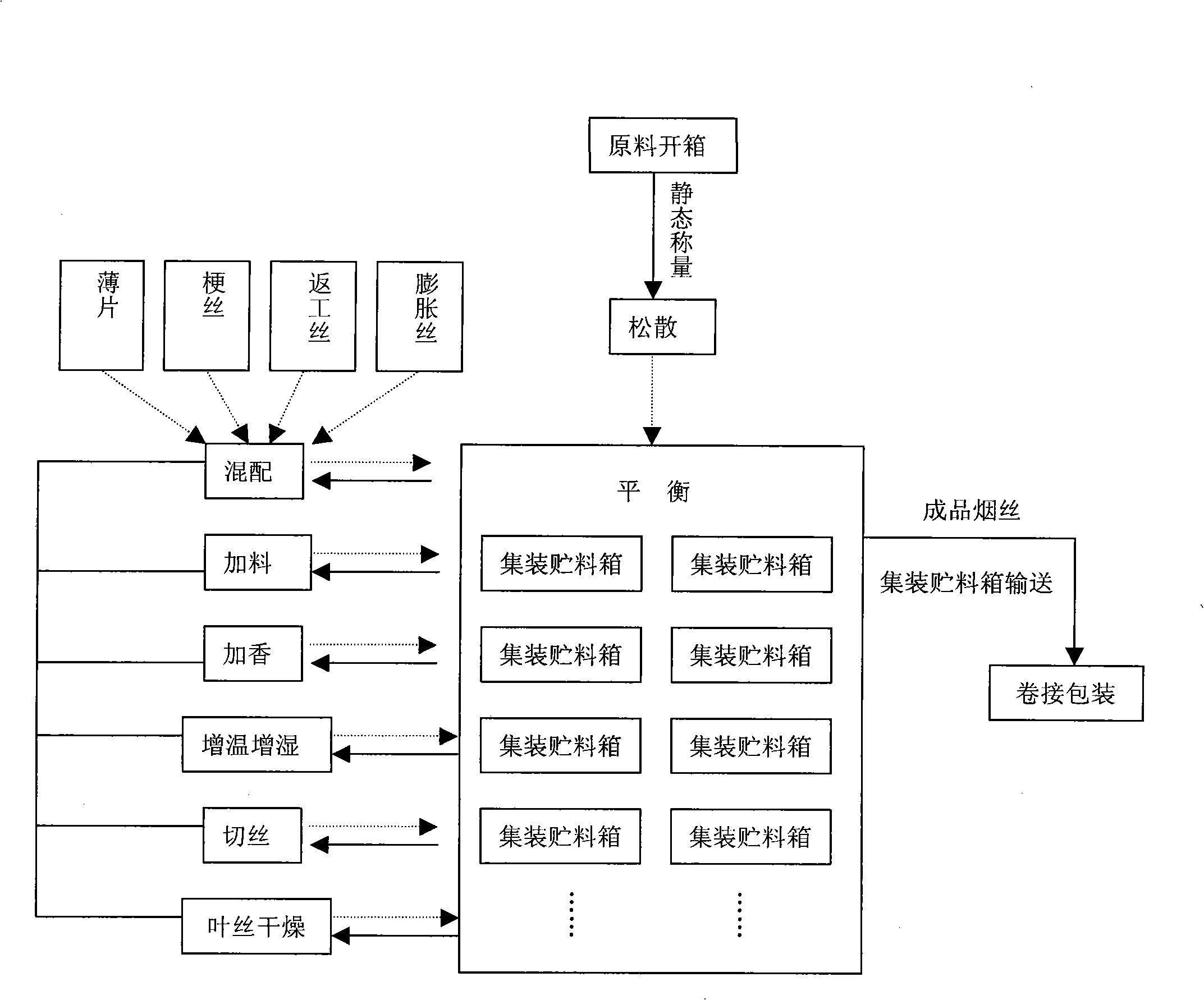

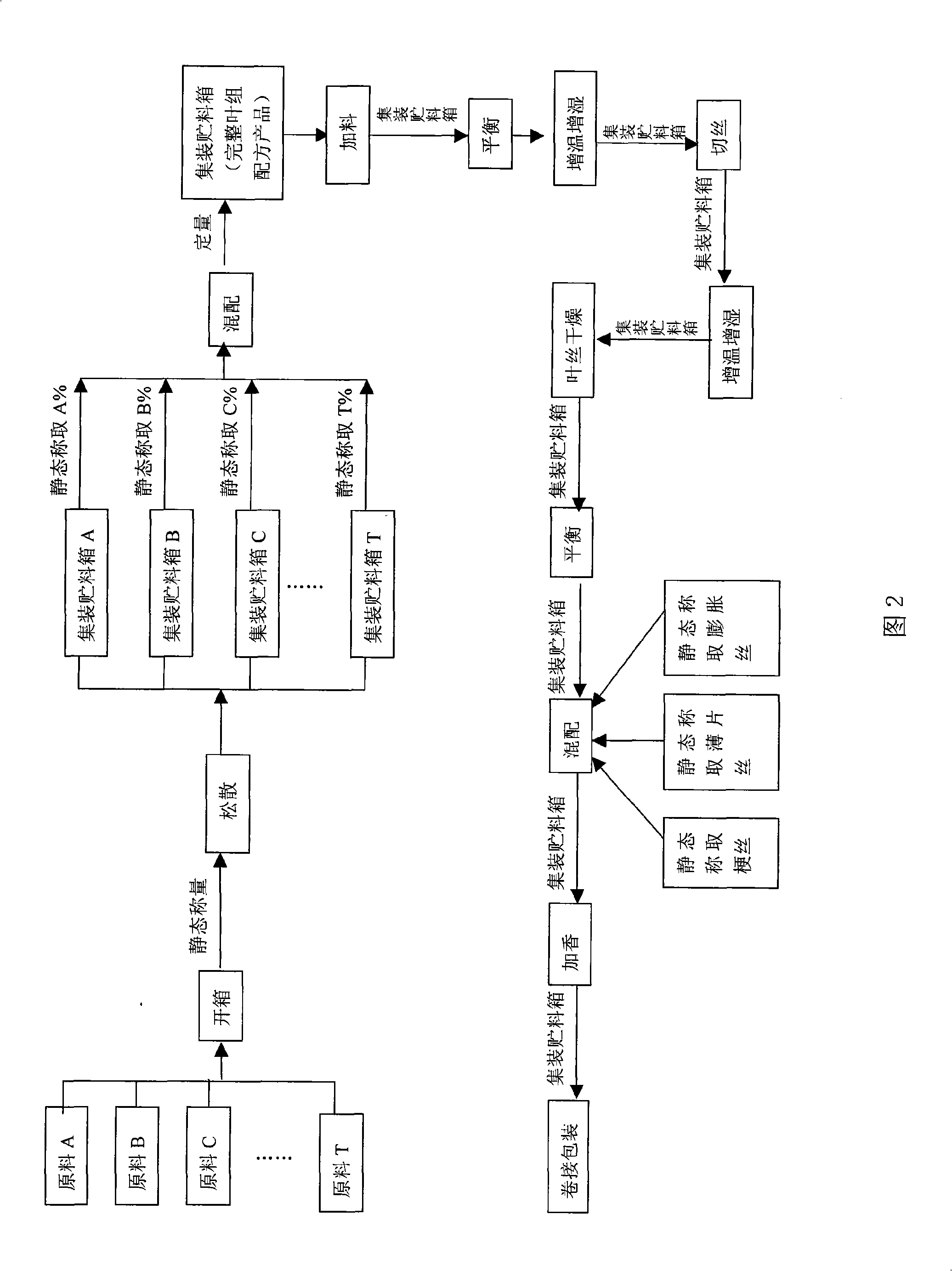

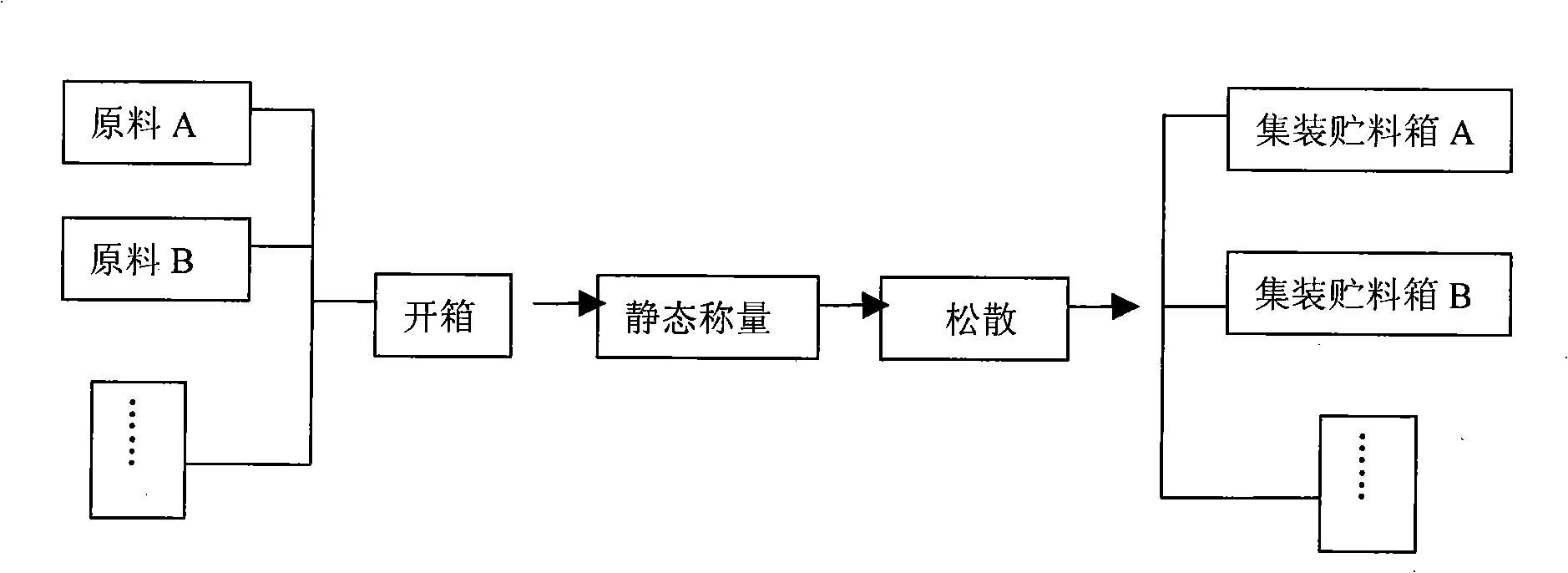

Cigarette static state throwing technique

InactiveCN101283834AFlexible adjustment processFacilitate process optimizationTobacco preparationProcess engineeringTobacco product

The invention discloses a static tobacco shredding process for cigarettes, which comprises following steps: opening a box, loosening, balancing, feeding, increasing temperature and humidity, cutting tobacco, drying tobacco shreds, mixing and flavoring. The process is characterized in that the processing process and the processing equipment are determined according to the product design; the apparatuses executing the process are discrete and independent; the materials are transferred among different steps through storage containers and are fed and discharged once in each step; a static scale is adopted for statically weighting the materials in the steps of loosening, feeding, drying, mixing and flavoring; and the tobacco product is stored in a storage container for later use. The process can flexibly set and adjust the processing process, which is beneficial to process optimization, and can accurately blend, flavor and feed the materials and increase temperature and humidity. The materials are balanced among different steps according to requirements, and each of the processing apparatuses is independent so that the apparatuses are prevented from being influenced mutually even if a single apparatus is defective, thus simplifying the control flow.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

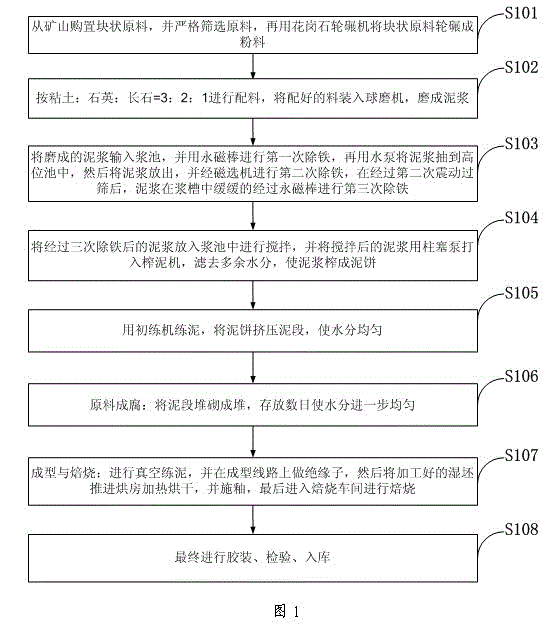

Preparation method of anti-photoaging ceramic insulator

The invention discloses a preparation method of an anti-photoaging ceramic insulator. The preparation method is characterized by comprising the following steps: purchasing block raw materials from a mine, strictly screening the raw materials, and milling the block raw materials into powder by use of a granite edge runner mill; dosing clay, quart and feldspar at a ratio of 3:2:1; putting the dosed materials into a ball mill, and milling the dosed materials into mud; feeding the milled mud into a slurry pool, and performing iron removal for three times by use of a permanent magnet rod; putting the mud into the slurry pool and stirring; pumping the stirred mud into a mud squeezing machine by use of a plunger pump, and filtering out excessive moisture so that the mud is squeezed into a mud cake; stirring the mud by use of a primary stirring machine, and extruding the mud cake into mud segments; aging the raw materials; forming and roasting; finally performing mucilage binding, inspection and storage. The method disclosed by the invention is simple and easy to operate, and can be used for greatly reducing the production cost; the ceramic insulator produced by the process provided by the invention is resistant to aging and corrosion and has good insulating property and high mechanical strength.

Owner:JINLING INST OF TECH

Grain variable-temperature vacuum drying equipment and method

ActiveCN105841472AWell mixedUniform moistureFood processingSeed preservation by dryingWater vaporEngineering

The invention provides grain variable-temperature vacuum drying equipment and method. The equipment comprises a drying chamber, wherein a feeding opening and a discharging opening are separately formed in the top and the bottom of the drying chamber, and multiple layers of grain dischargers are arranged on the drying chamber; drying sections are arranged in the drying chamber between every two layers of grain dischargers, and heating pipes are inserted into the drying sections; one ends of the heating pipes are water inlet ends, and the other ends of the heating pipes are water return ends; the water inlet ends communicate with a hot water boiler through water inlet pipes, and three-way valves are arranged at the water return ends; water inlets of the three-way valves communicate with the water return ends, and water outlets of the three-way valves separately communicate with water return pipes and the water inlet pipes; and the water return pipes are connected with water return tanks, and hot water pumps are arranged on the water inlet pipes. By arranging multiple layers of grain dischargers, grains are uniformly mixed in the drying chamber. Each drying section can be separately controlled, and different heat supply temperatures are adopted in different drying sections, so that sectional variable-temperature drying is realized on the grains, and more energy is saved. Steam left after the grains are dried is condensed and can be reutilized as a high-class beverage, so that economical benefits are increased.

Owner:李洪毅 +2

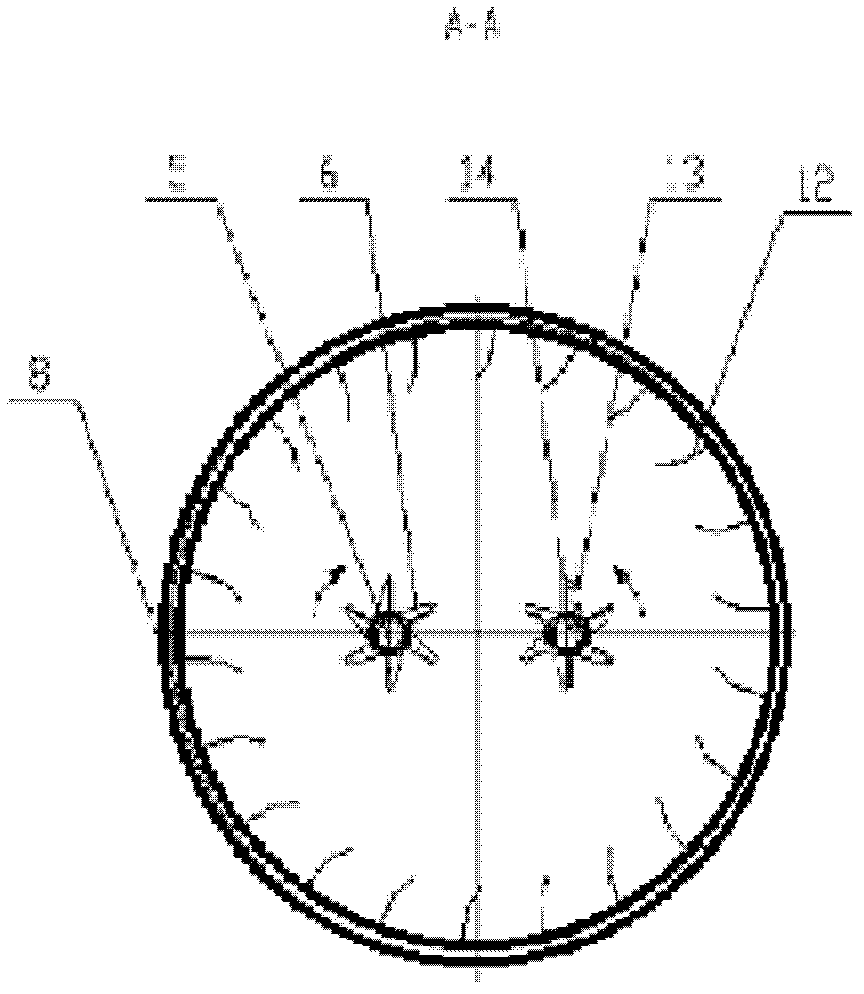

Double-scattering structure-type rotary cylinder dryer with shaft cooling

InactiveCN102506567AHigh thermal efficiencyFully contactedDrying machines with non-progressive movementsDrying solid materialsEngineeringDrive motor

The invention discloses a double-scattering structure-type rotary cylinder dryer with shaft cooling, comprising a frame, wherein the frame is provided with a rotary cylinder and a motor I for driving the rotary cylinder to rotate; a shovelling plate is arranged on the inner wall of the rotary cylinder; scattering devices are arranged inside the rotary cylinder; two groups of scattering devices are provided and each scattering device comprises a rotating shaft and a drive device; the drive device is connected with the rotating shaft; an axis of the rotating shaft of each scattering device deviates from the axis of the rotary cylinder; the axis of each rotating shaft is parallel to the axis of the cylinder body of the rotary cylinder; a bracket is arranged on each rotating shaft; scattering teeth are arranged on the bracket; each rotating shaft is a hollow revolving shaft; one end of the hollow revolving shaft is provided with a cooling medium outlet and the other end of the hollow revolving shaft is provided with a cooling medium inlet; a cooling medium is arranged in the hollow part; the drive device comprises a drive motor II, a small belt pulley, a belt and a large belt pulley; the small belt pulley is connected with the drive motor II; and the large belt pulley is connected with the rotating shafts. The double-scattering structure-type rotary cylinder dryer has the advantages of simple structure, convenience in manufacturing and maintenance and high heat exchange efficiency, and reliability in quality.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Electromagnetic heating roller used for corrugating machine, application of electromagnetic heating roller and corrugating machine electromagnetic heating method

PendingCN106903932AIncreased complexitySimplify complexityMechanical working/deformationStorage heatersMagnetic heatingEngineering

The invention discloses an electromagnetic heating roller used for a corrugating machine, an application of the electromagnetic heating roller and a corrugating machine electromagnetic heating method, and belongs to the technical field of electromagnetic heating. The electromagnetic heating roller comprises a roller body and an electromagnetic heater. The electromagnetic heater is used for heating the roller body. The roller body is provided with a cavity for encapsulating heat-conducting liquid. The electromagnetic heater can heat the heat-conducting liquid through the roller body, so that steam is produced in the cavity of the roller body. The electromagnetic heater comprises a plurality of U-shaped magnets and an electromagnetic wire. The multiple U-shaped magnets are arranged on a straight line side by side in the axis direction of the roller body. The electromagnetic wire is wound at the two ends of the U-shaped magnets in a single-loop wire winding mode to form a coil. Corrugated paper can be uniformly heated through the electromagnetic heating roller, moisture balance of the corrugated paper in the whole width direction is ensured, and the product quality is improved.

Owner:ANHUI RESUDA ELECTRONICS TECH

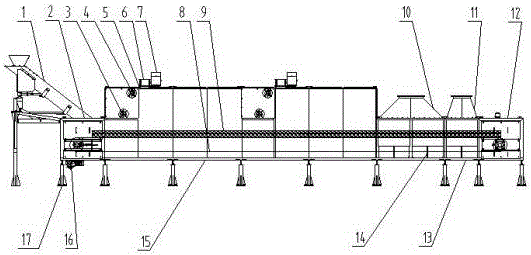

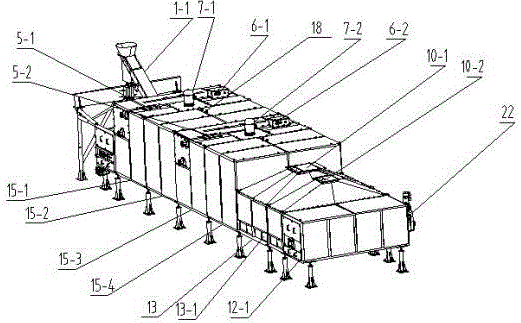

Belt-type dry cooler

ActiveCN106839730AConsider moisture uniformityUniform moistureDrying gas arrangementsDrying solid materialsEngineeringVariable frequency control

The invention relates to a belt-type dry cooler which comprises a distributing device, a feeding section, a drying section, a cooling section and a discharging section. The distributing device is communicated with the feeding section through a distributing-device hosepipe connected on the distributing device, and a conveying belt in the dry cooler sequentially penetrates the feeding section, the drying section, the cooling section and the discharging section; the drying section comprises at least one drying area, and an air supplement port, an air outlet, a circulating fan, a hot-air inlet, a temperature sensor and a heat exchanger are independently arranged on the upper portion of each drying area; the cooling section comprises at least one cooling area, each cooling area is provided with an independent air duct, an exhaust fan and an air inlet, a second wind screen is arranged between every two neighboring drying areas, and a third wind screen is arranged between the drying section and the cooling section. The distributing device is under variable frequency control, hot air is capable of operating in a more balanced and stable manner through reasonable air-inlet and-outlet arrangement and a tight sealing structure, and dried materials are ensured to be uniform in moisture.

Owner:JIANGSU MUYANG HLDG

Method for preparing golden mushroom nutritional noodles

InactiveCN102342432AUniform moistureAvoid excessive water absorptionDough treatmentFood preparationFerrous GluconateLYSINE HYDROCHLORIDE

The invention provides a method for preparing golden mushroom nutritional noodles. The method comprises the following steps of: putting common flour and water into a dough kneader, after kneading the dough for 5-10 minutes, adding golden mushroom powder, whole-egg powder, cabbage powder, corn starch, ferrous gluconate, calcium gluconate and L-lysine hydrochloride to the dough kneader, continuing kneading the dough for 5-20 minutes, then putting the dough into a ripening machine to be ripened for 5-20 minutes, and then carrying out calendering, strip cutting, drying and cutting-off processes in sequence to obtain the golden mushroom nutritional noodles. The invention has the following advantages: the preparation process is simple; the quality of a finished product is high; the shelf life is long; the noodles prepared by the method have balanced nutrition and fragrant and sweet taste; the taste of the noodles is easy to like by the children; and the noodles are especially suitable for serving as the complementary food of vegetables eaten by the children.

Owner:宜垦(天津)农业制品有限公司

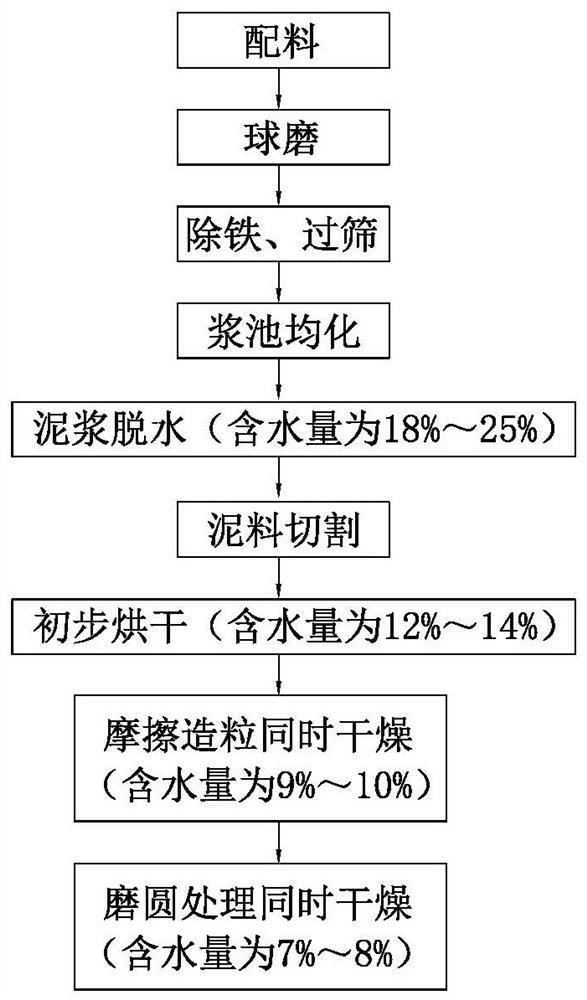

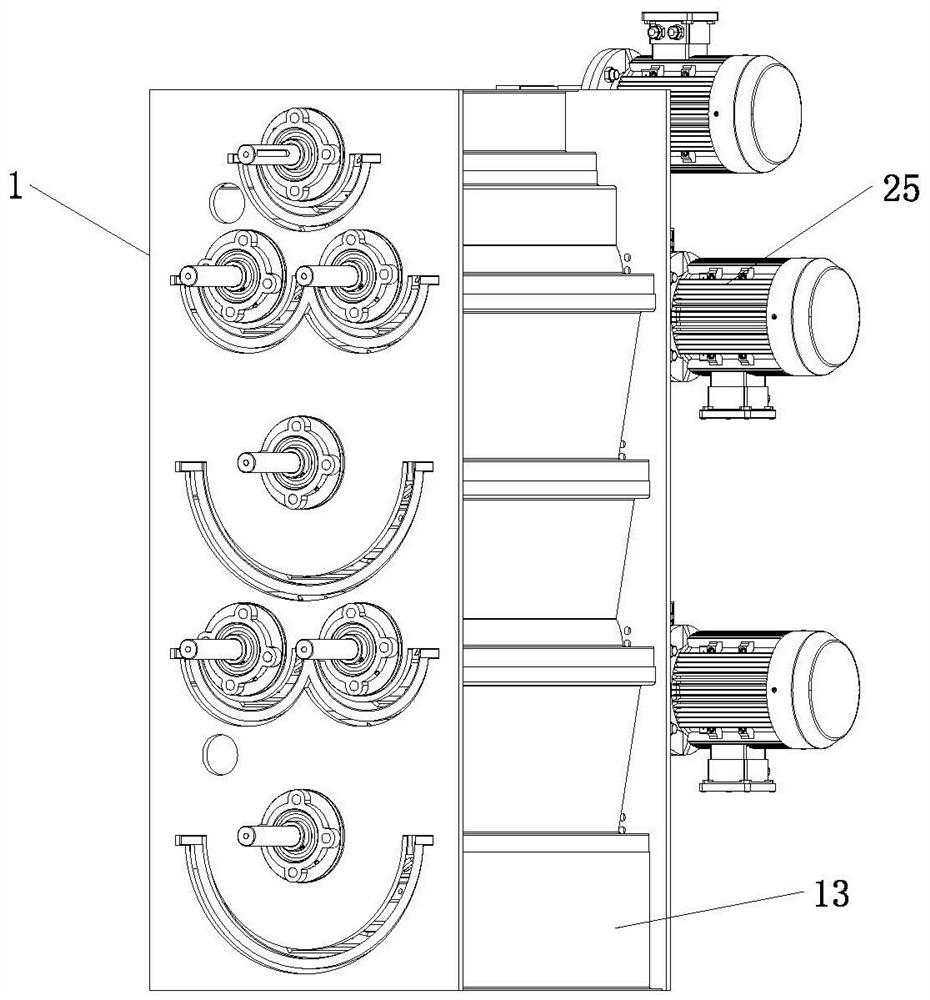

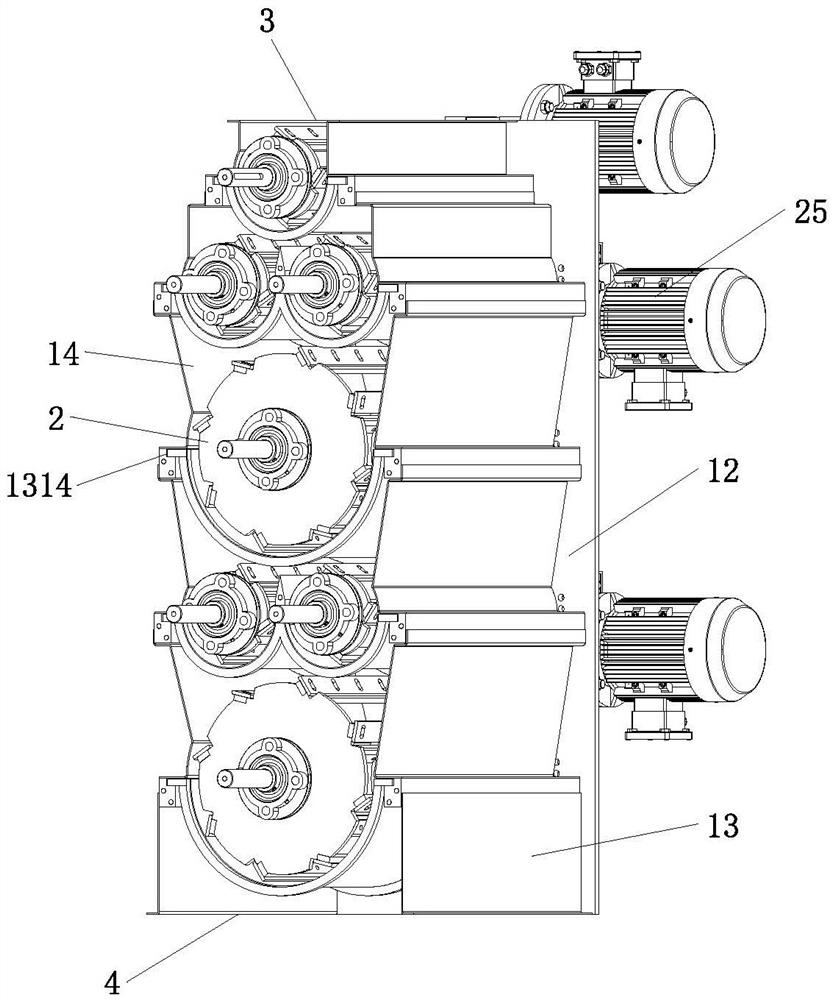

Ceramic powder preparation process and system

PendingCN112321303AReduced time to dry mud clodsSpeed up dryingDrying solid materials with heatDrying gas arrangementsWater contentPowder

The invention relates to the technical field of ceramic wet powder preparation, in particular to a ceramic powder preparation process and system. The ceramic powder preparation process comprises the following steps: S1, drying mud to obtain mud blocks with the water content of 12%-14%; s2, rubbing the mud blocks with more than two screens which are sequentially arranged layer by layer, reducing the apertures of screen holes of the screens layer by layer, and reducing the particle sizes of the mud blocks when the mud blocks pass through the screen holes of the screens layer by layer; meanwhile,hot air is introduced below the screen so that the mud blocks are repeatedly heated and dried by the flowing hot air in the friction movement and falling process, and finally powder particles with the particle size being smaller than 1.5 mm and the water content being 9%-10% are obtained; according to the invention, the drying of the mud is decomposed into three processes of preliminary drying, granulation and rounding which are carried out step by step, and the specific surface area of powder particles is rapidly increased in the later two processes so that the rapid volatilization of wateris facilitated, the drying speed is increased, and the energy consumption is reduced.

Owner:FOSHAN LANZHIJING SCI & TECH CO LTD

Plant cultivation medium and preparation method thereof

InactiveCN106106081AContinuous growthGuaranteed healthy growthBio-organic fraction processingExcrement fertilisersGrowth plantPreservative

The invention discloses a plant cultivation medium and a preparation method thereof. The plant cultivation medium includes paper pulp, an organic fertilizer and a preservative agent; and the weight ratio of the paper pulp, the organic fertilizer and the preservative agent is the paper pulp: the organic fertilizer: the preservative agent= 100: 1-50: 0.05-0.5. Compared with the prior art, the preparation method has the following beneficial effects: 1), the plant cultivation medium can keep water in long term, can avoid waterlogging, and can facilitate the growth of plants; 2), the paper pulp covers the organic fertilizer, which can ensure continuous growth of the plants; 3), the preservative agent can prevent the plant cultivation medium from decomposition, and ensure the healthy growth of roots of the plants; 4) the paper pulp has high plasticity, various colors and shapes can be set, and the ornamental value is high; 5) drying treatment is performed on the paper pulp, the dried paper pulp is light, is clean, and is easy to use and transport; and 6), the plant cultivation medium is easy to prepare and is low in cost, can be recycled, and has a wide market prospect in the field of potted plants.

Owner:石远大

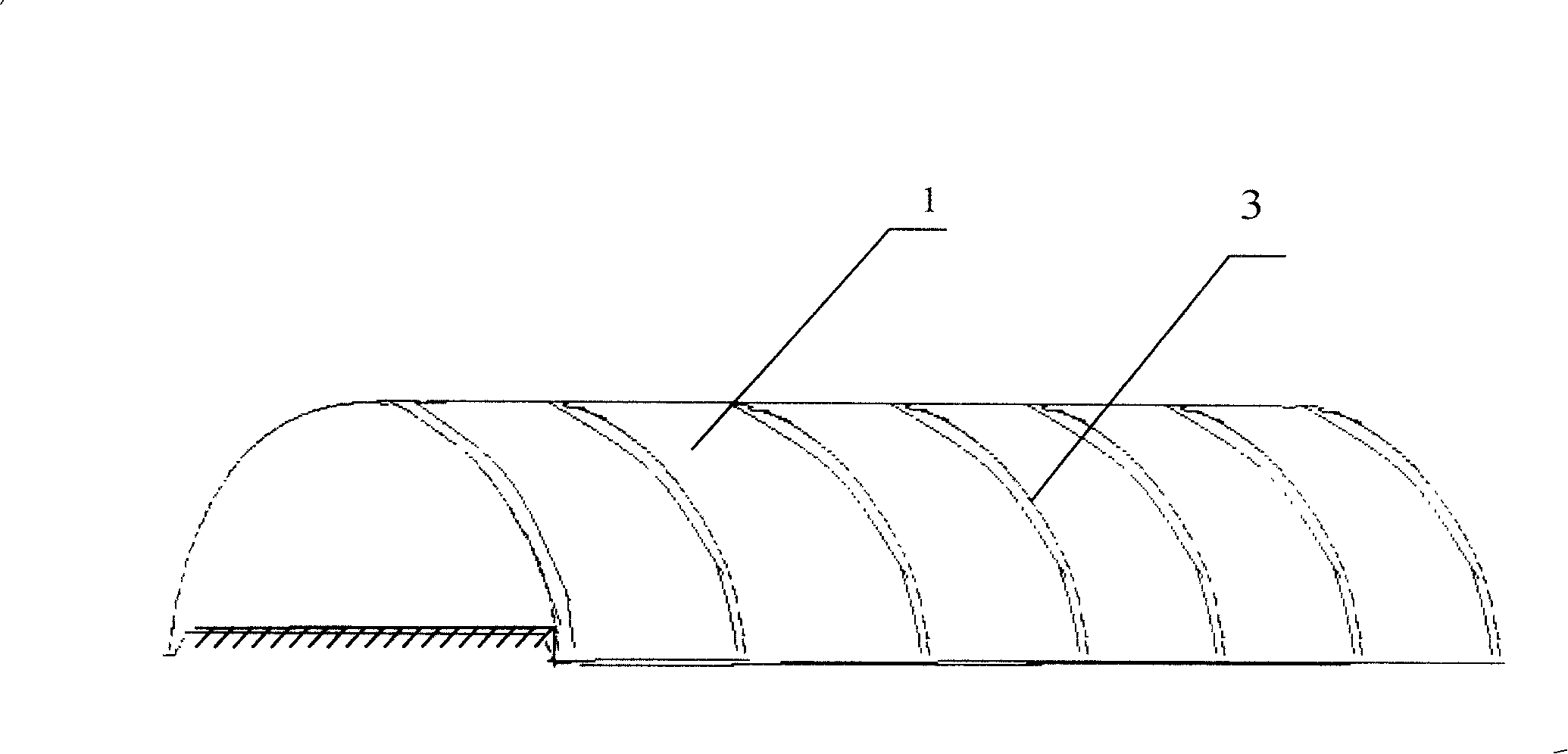

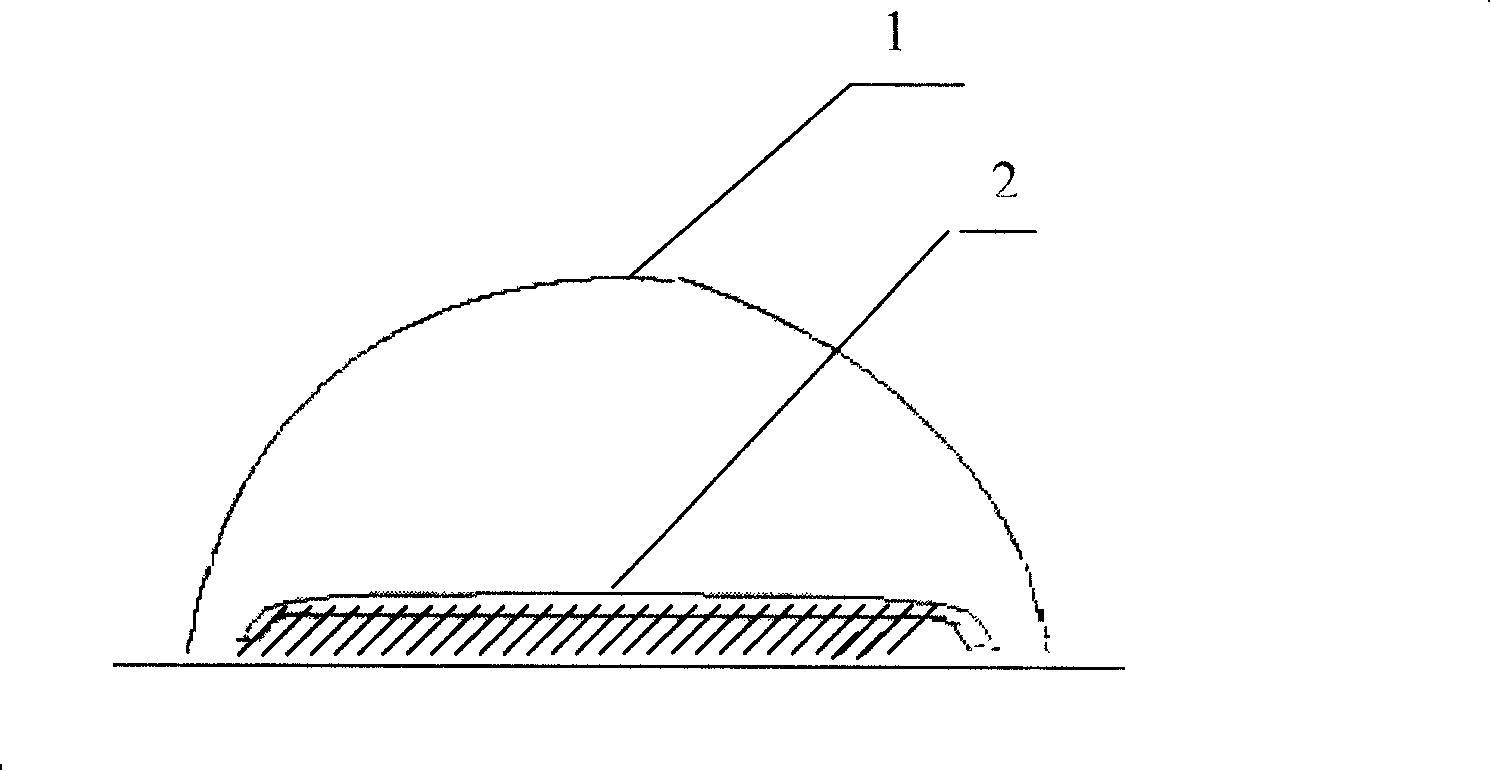

Laminating method for seedling raising in dry land

InactiveCN101218880ASolve the problem of insufficient moistureUniform moisturePlant protective coveringsComing outEngineering

The invention relates to a method for covering film for cultivating seedlings on a dry land, belonging to the technical field of agricultural planting, which is characterized in that a tiling film (2) is covered on a box surface after fertilizing, watering, seeding and covering earth on a dry land seedbed; the thickness of the tiling film can be smaller or equal to 0.008mm and the periphery of the tiling film is compacted by clod; arc strips (3) with a length of 200cm to 220cm are inserted into the soil beside the box at both sides of the box and the depth for soil insertion is 10cm to 15cm to lead the arc strip to be in a natural arc shape. The distance between the arc strips is 60cm to 80cm to form an arc frame. An arc frame film (1) is covered on the arc frame and the thickness of the arc frame film is larger than or equal to 0.014mm, both ends of the seedling box are respectively covered by one more bamboo strip to lead the plastic films at both ends to be positioned between two layers of the bamboo strips. After covering the film, the periphery is compacted by clod; after more than 80 percent of seeds come out of the land or the rice is in the stage of needle leaf, the tiling film is removed. The invention is applied during early spring in lower temperature period so as to better solve the problem of water insufficiency on the surface soil horizon of the seedling box and lead the seeds to acquire sufficient water supply; the invention has the advantages of very uniform moisture on the box surface, good insulating effect and slow change of temperature, which is very beneficial to the growth of early spring crops.

Owner:YANGTZE UNIVERSITY

Parboiled rice production and graded soaking method

InactiveCN105725057AImprove permeabilityIncrease contentYeast food ingredientsFood dryingYeastFiltration

The invention discloses a parboiled rice production and graded soaking method.The method is technically characterized in that cleaned unhulled rice is subjected to graded soaking two times.The cleaned unhulled rice is soaked in a solution of citric acid with the concentration being 1% and cellulose enzyme (enzyme activity is 5000 u / g and concentration is 0.010-0.015%) for the first time, soaking temperature is 45-55 DEG C, soaking pressure is 300-400 kpa, and soaking time is 1-2 h.The unhulled rice soaked for the first time is subjected to filtration so that soaking liquid can be filtered out, second time of normal pressure soaking is performed, and soaking is performed for 2-3 h in a selenium solution with the concentration being 60 micron mol / L at the temperature of 30-45 DEG C.After the unhulled rice is processed, water content is controlled to be 40-42%, the unhulled rice is conveyed into a cooking vessel through a conveying device, the cooking vessel is closed, 120 DEG C saturated steam is introduced, and starch of unhulled rice endosperms is fast gelatinized.The cooked unhulled rice is gradually dried till the water content is 14%, the temperature of the unhulled rice is gradually lowered through a tempering technology after each drying procedure, and it is guaranteed that temperature and water of various portions of the unhulled rice are uniform; the dried unhulled rice is hulled, ground and packaged, and parboiled rice finished products are made.

Owner:国粮武汉科学研究设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com