Automatic mixing type sterilization pot for edible fungi

An automatic stirring and sterilizing pot technology, applied in application, gardening, heating, etc., can solve problems such as long cooling time and blockage, and achieve the effects of improving production efficiency, ensuring sterilization quality, and shortening sterilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

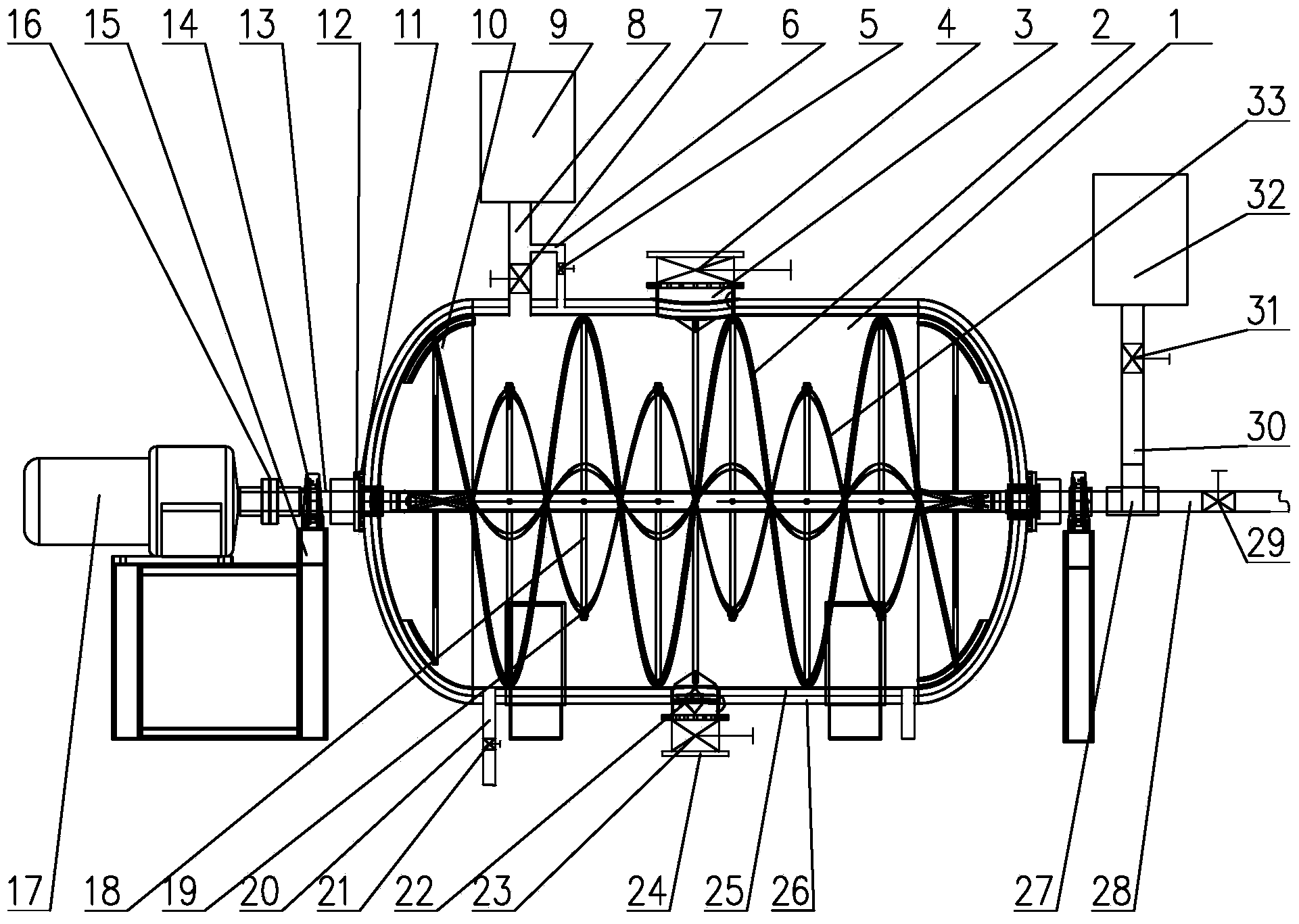

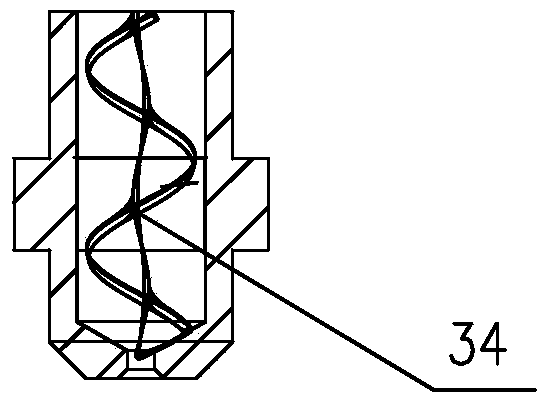

[0023] Such as figure 1 The edible mushroom automatic stirring sterilizer shown mainly includes a sterilizing pot cylinder body 1, a spiral stirring device 2, a feeding assembly 3, a discharging assembly 24, a motor reducer 17, and a sterile cold air preparation device 32 , Water ring vacuum unit 9, steam pipeline 28, sterile cold air pipeline 30, vacuum main pipeline 8, water pipeline 20, automatic control system, etc. The center of the double-helix stirring device 2 inside the sterilization pot is a hollow shaft tube 13. One end of the steam branch pipe 18 supporting the spiral stirring blade 33 communicates with the hollow shaft tube 13, and the other end is equipped with a spiral nozzle 19. Around the hollow shaft tube 13 And the surrounding of steam branch pipe 18 also all is equipped with spiral nozzle 19. A flange 11 with a mechanical seal 12 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com