Tobacco process secondary charging technique

A technology of secondary feeding and processing, which is applied in the direction of tobacco, tobacco preparation, tobacco processing, etc., can solve the blocking of the wire feeding port or the protruding string from the wire feeding port, affecting the uniformity of the moisture content of tobacco leaves and the uniformity of the shredder. Unstable feeding and other problems, to improve the quality of drying silk, reduce the phenomenon of sticking knife agglomeration, and improve the quality of shredding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

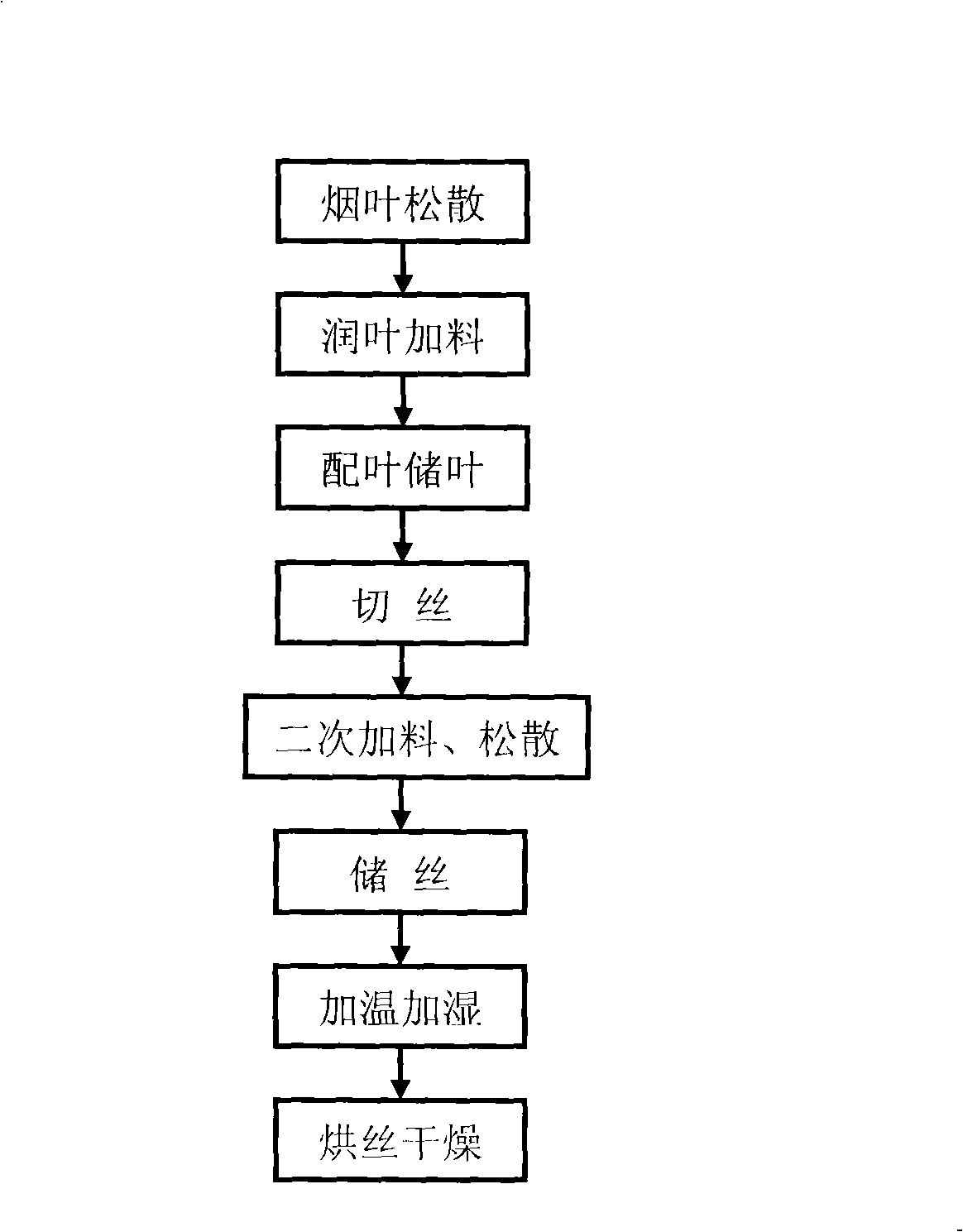

[0015] As shown in the figure, the process steps of the present invention are as follows:

[0016] (1) Tobacco leaf loosening: Send the whole piece of tobacco into the tobacco leaf loosening equipment to loosen into loose sheet tobacco materials.

[0017] (2) Leaf moistening and feeding: moisten the loosened tobacco leaves and feed for the first time, increase the moisture content and temperature of the tobacco laminae to improve its damage resistance, improve the uniformity of shredded and leaf laying, and improve the tobacco material physical properties.

[0018] (3) Leaf blending and storage: blend different types and grades of tobacco in the same batch, and store them in storage equipment to balance the moisture content and temperature of the tobacco.

[0019] (4) Shredded: Cut the sliced tobacco into shredded tobacco with a set fineness with shredded equipment.

[0020] (5) Secondary feeding: Carry out secondary feeding to the shredded tobacco, increase the uniformity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com