Patents

Literature

711results about How to "Improve physical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bioabsorable medical devices

InactiveUS20060198869A1Facilitate deploymentImprove physical propertiesStentsPeptide/protein ingredientsYttriumMagnesium

Owner:ICON MEDICAL CORP

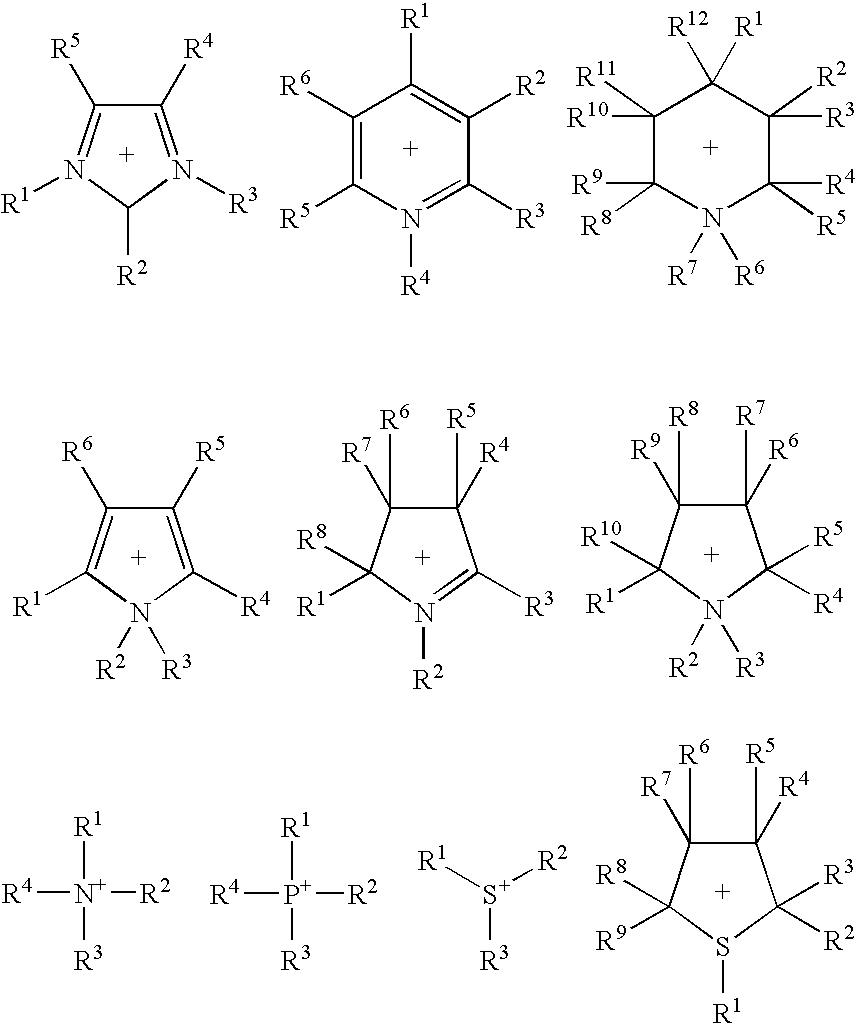

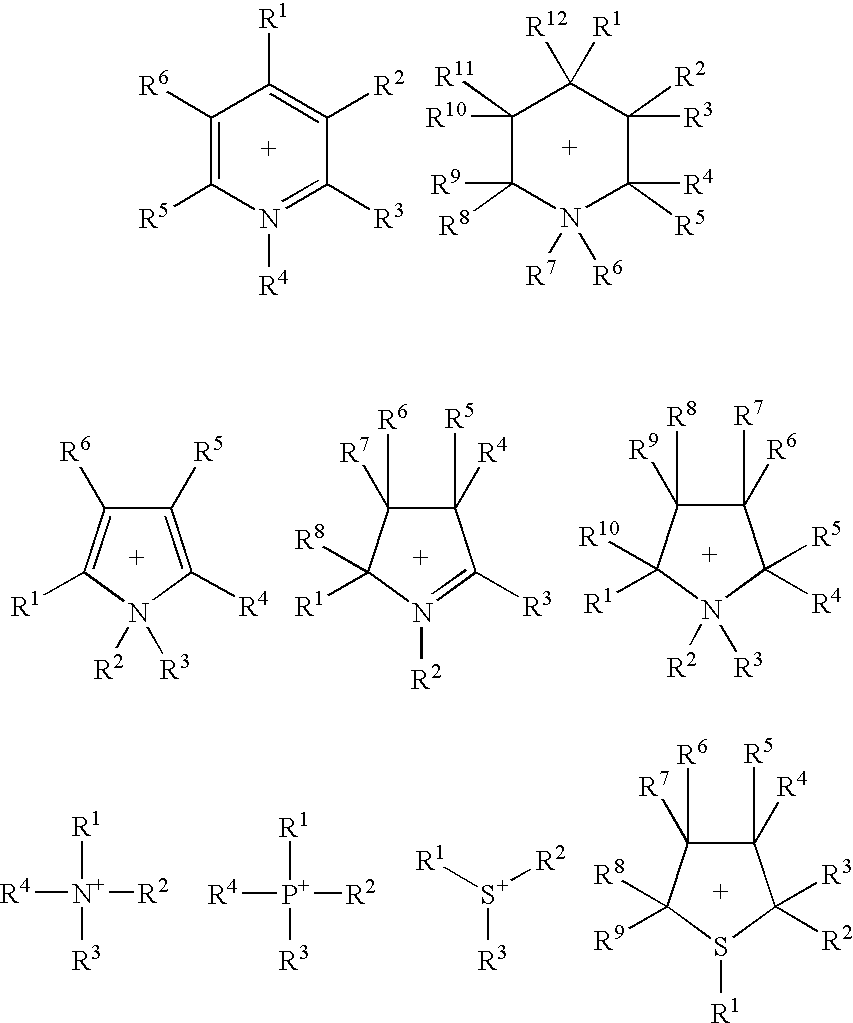

Lubricating oil

InactiveUS20070027038A1Low vapor pressureImprove heat resistanceOrganic chemistryProtective coatings for layersHeat resistanceBase oil

The invention provides a lube oil which exhibits low vapor pressure despite having low viscosity, is non-flammable, exhibits excellent heat resistance, has tribological characteristics equivalent to those of conventional hydrocarbon-based lube oils, and can be used for a long time under very severe conditions such as high temperature and vacuum. The lube oil contains, as a base oil, an ionic liquid formed of a cation and an anion and having an ion concentration of 1 mol / dm3 or more.

Owner:IDEMITSU KOSAN CO LTD +1

Multilayer composite films and articles prepared therefrom

InactiveUS20060165929A1Improve physical propertiesGood physical propertiesBottlesVehicle componentsElectrical and Electronics engineeringComposite film

Owner:PERFORMANCE MATERIALS NA INC

Magnesium cementitious composition

InactiveUS20070017418A1Reduce shrinkReduce crackingSolid waste managementCeramicwareFiberAdditive ingredient

A cementitious product for applications such as stucco, plaster coating, fireproof coatings, casting / molding applications and flooring. The product is a blend of magnesium oxide and magnesium chloride. Suitable fillers such as bottom ash, fly ash, clinker and other pulverized materials may be added. Fibrous materials, foaming agents and surfactants may also be added to achieve product characteristics for specific application. Processes for blending the selected ingredients are also disclosed.

Owner:DENNIS ANDREW C

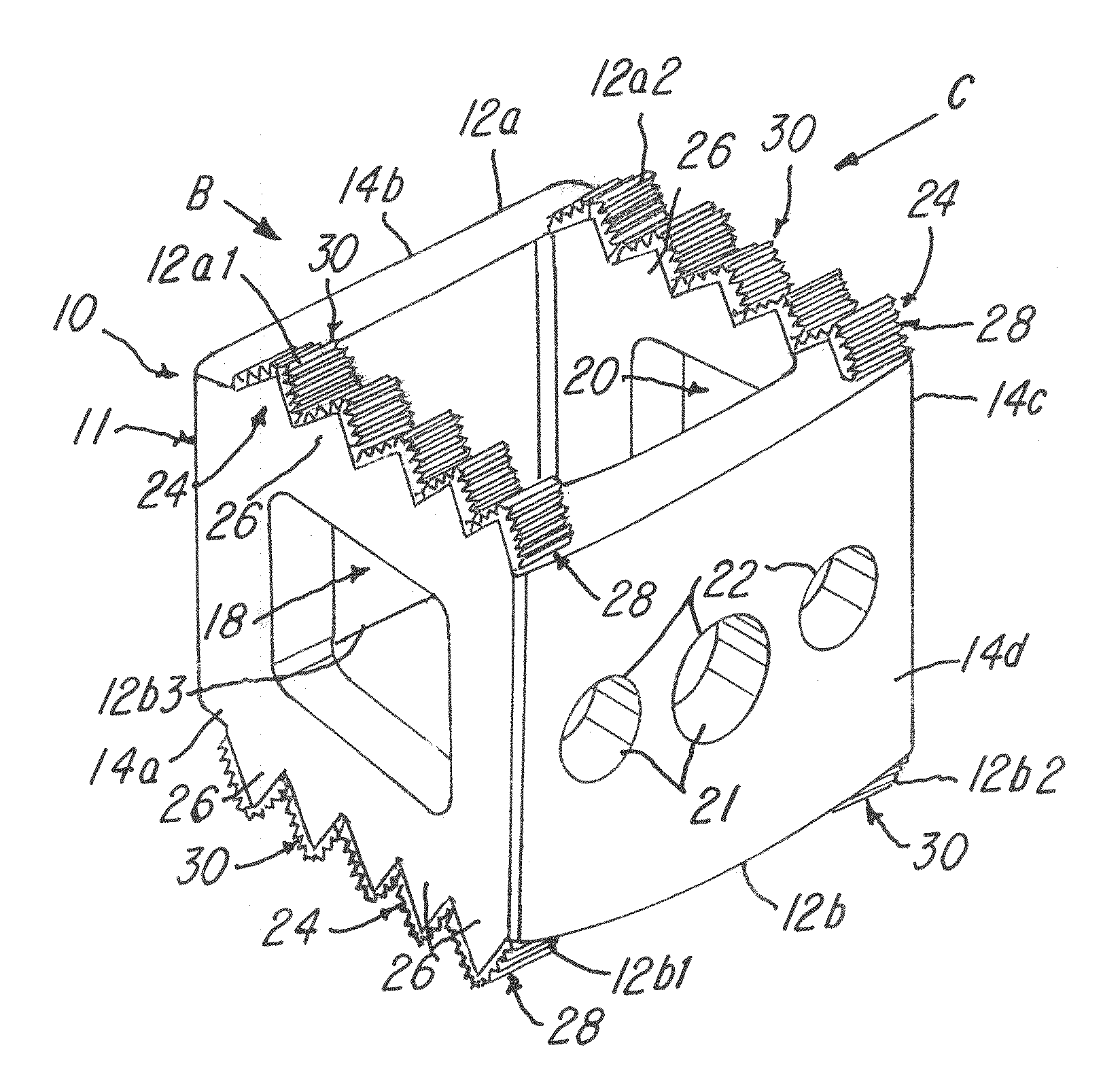

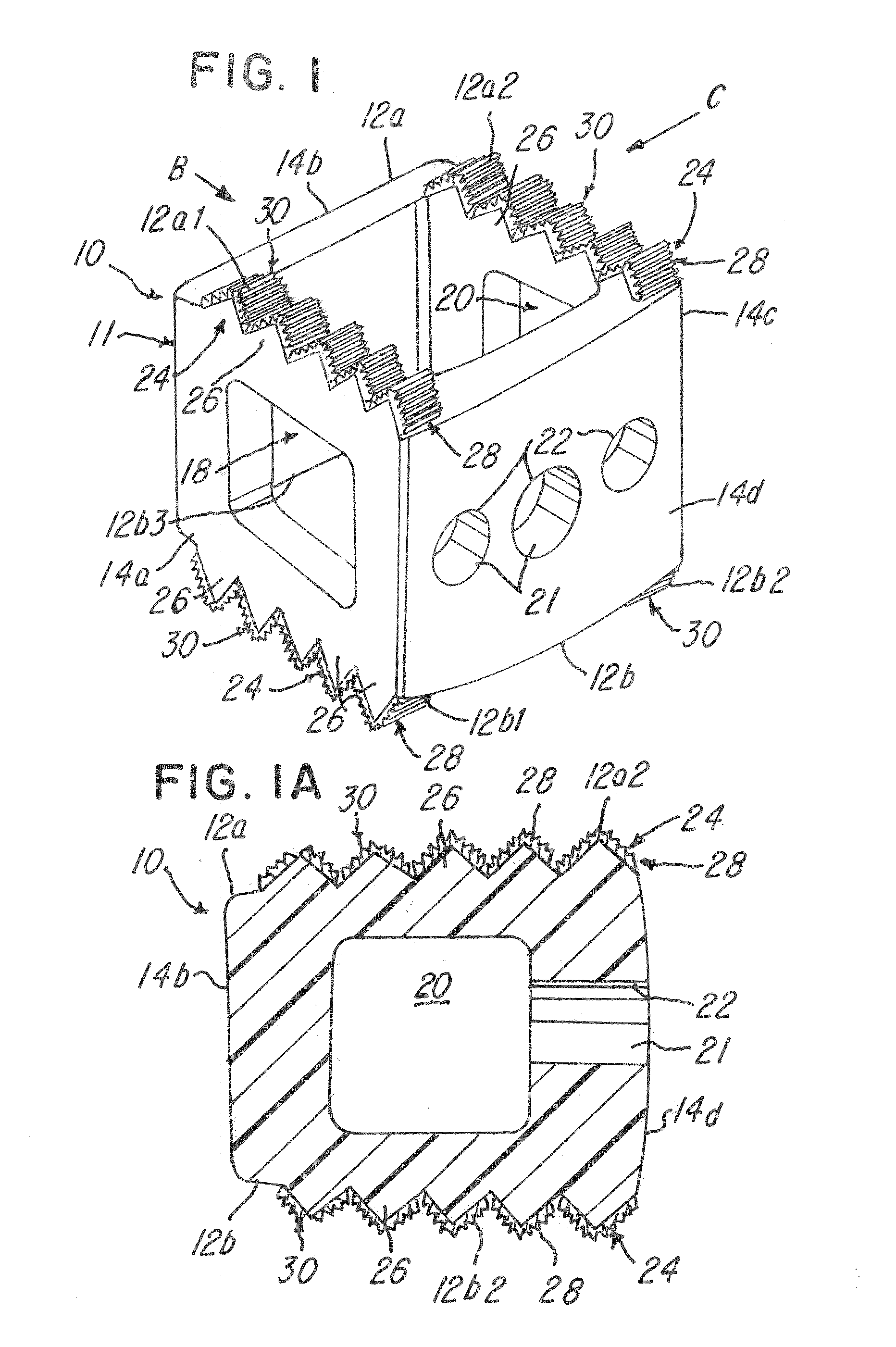

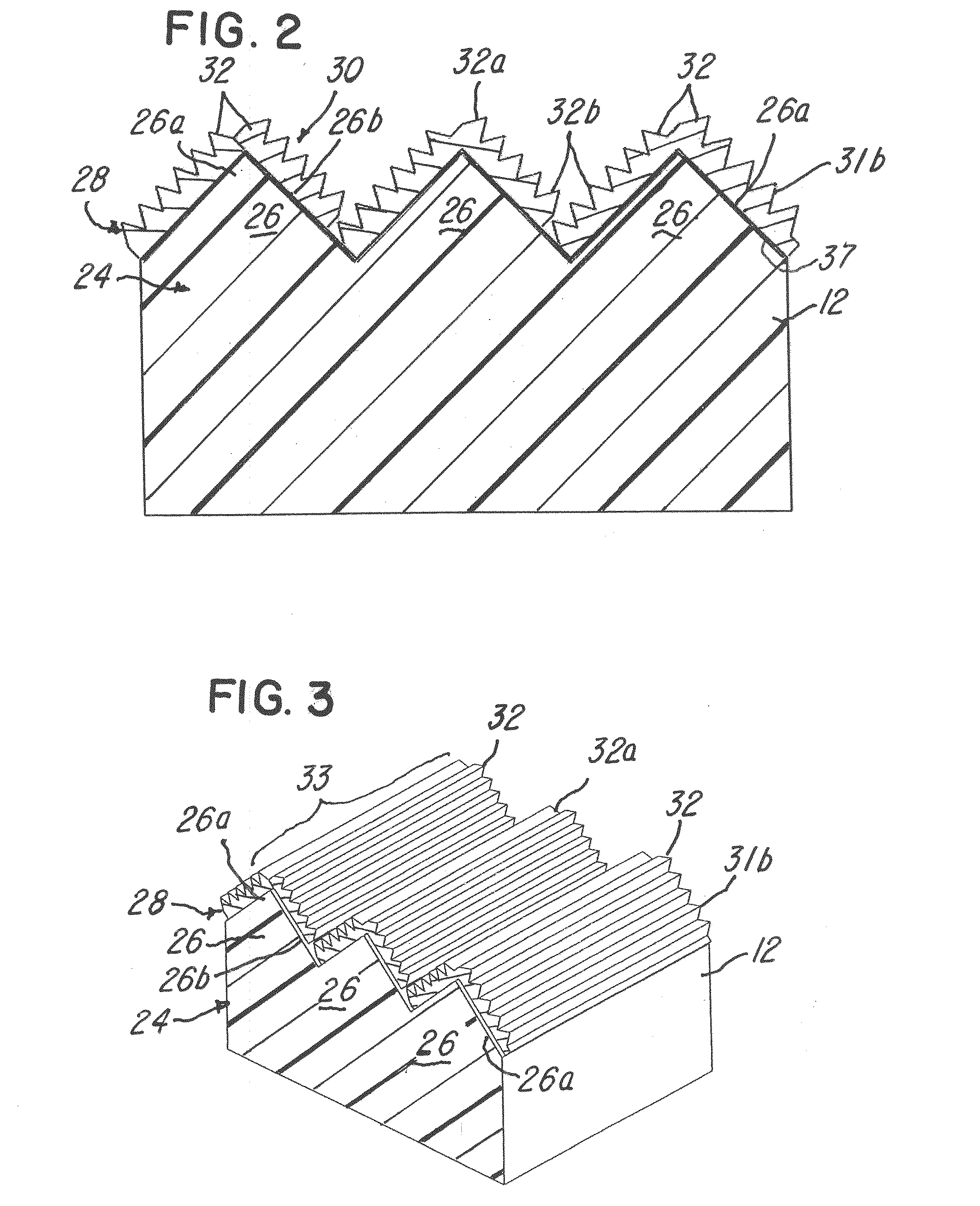

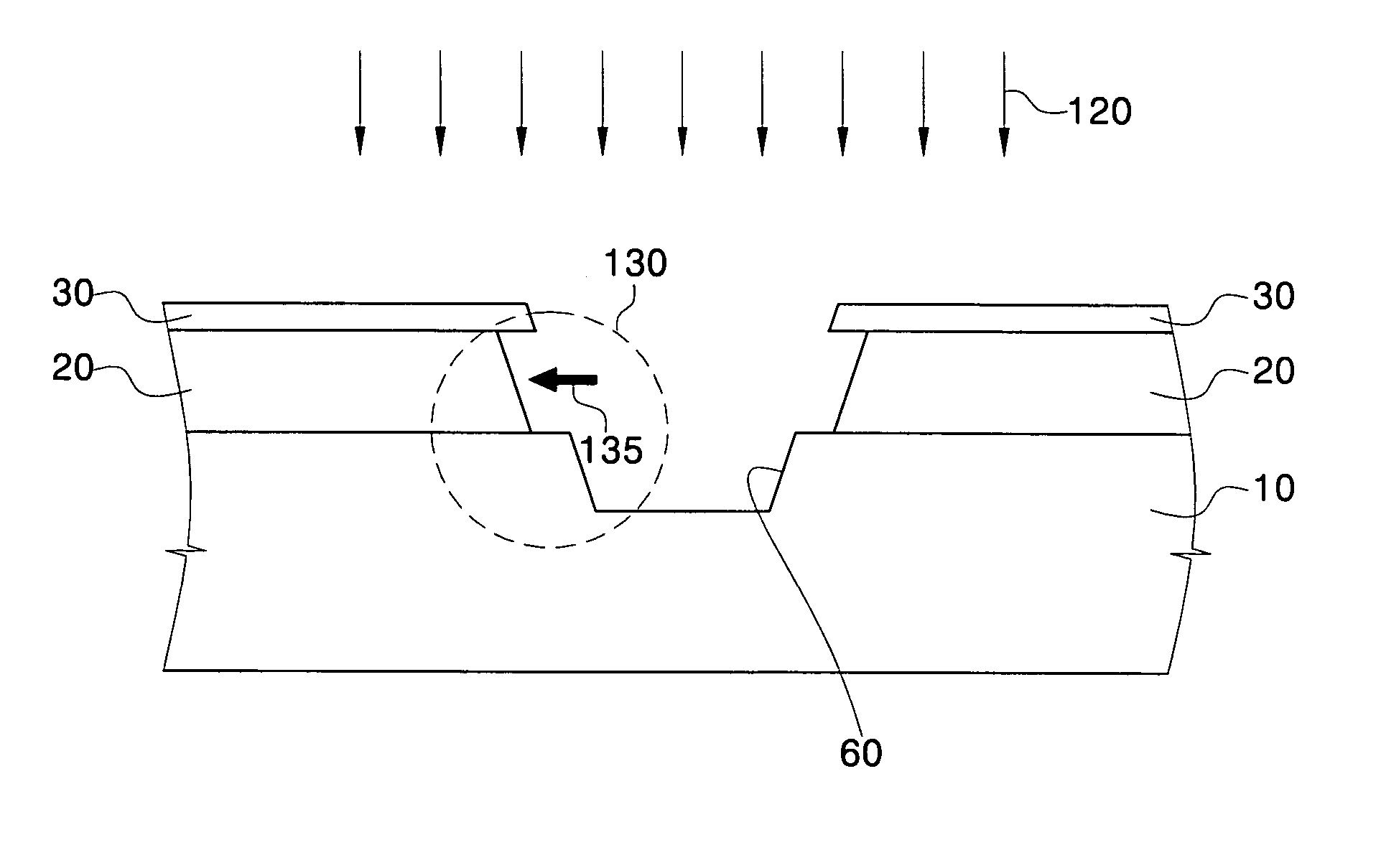

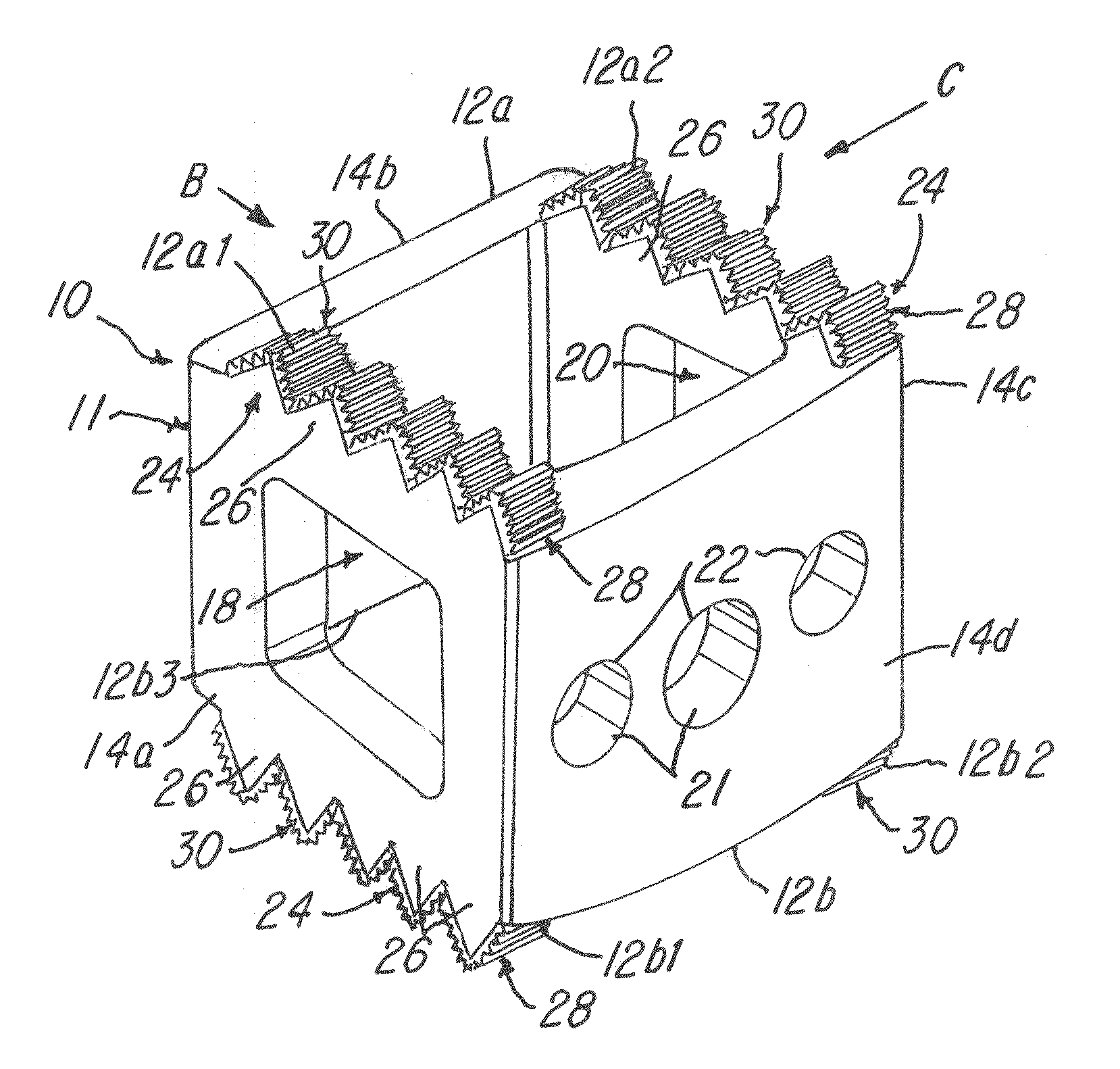

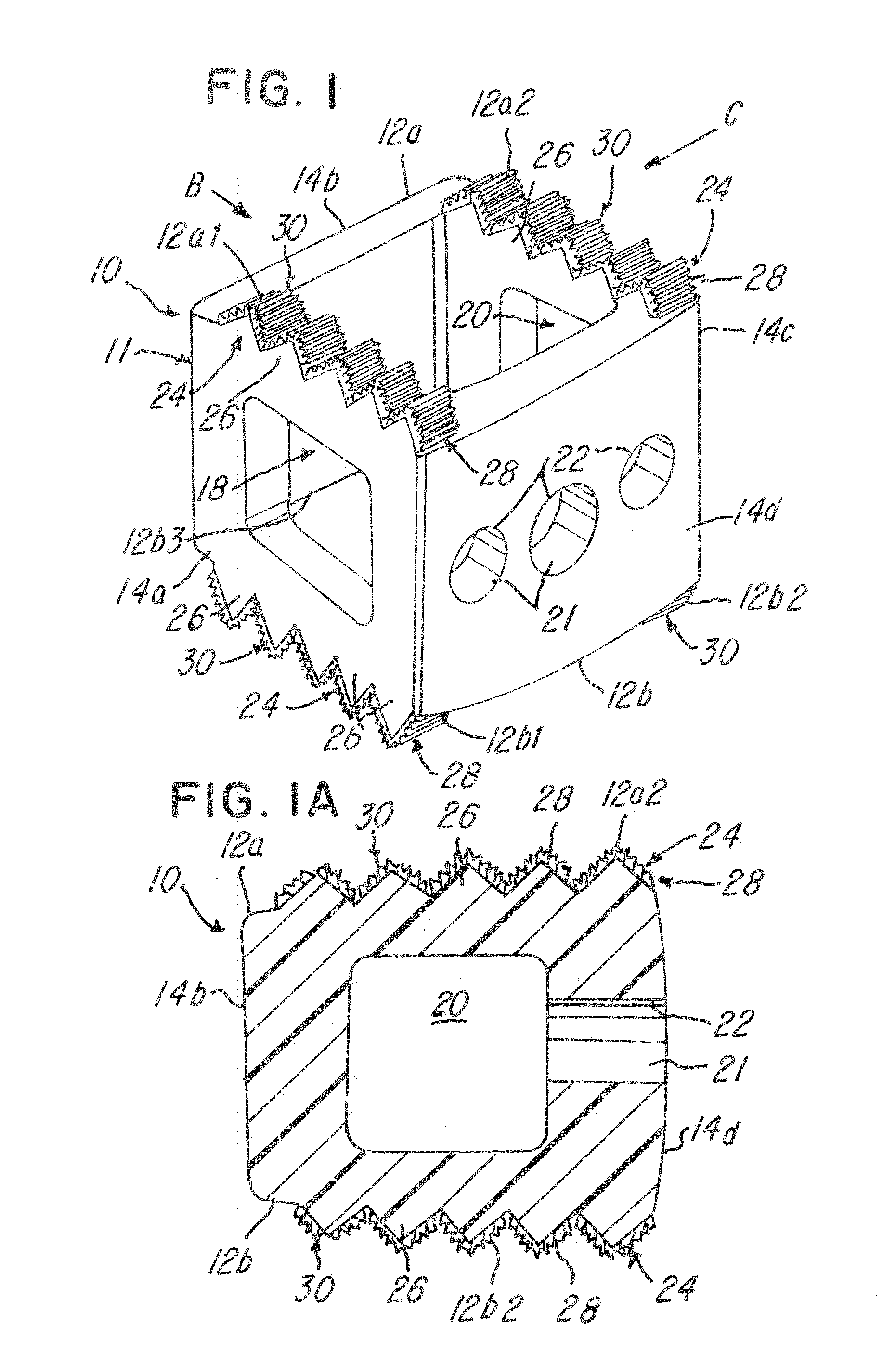

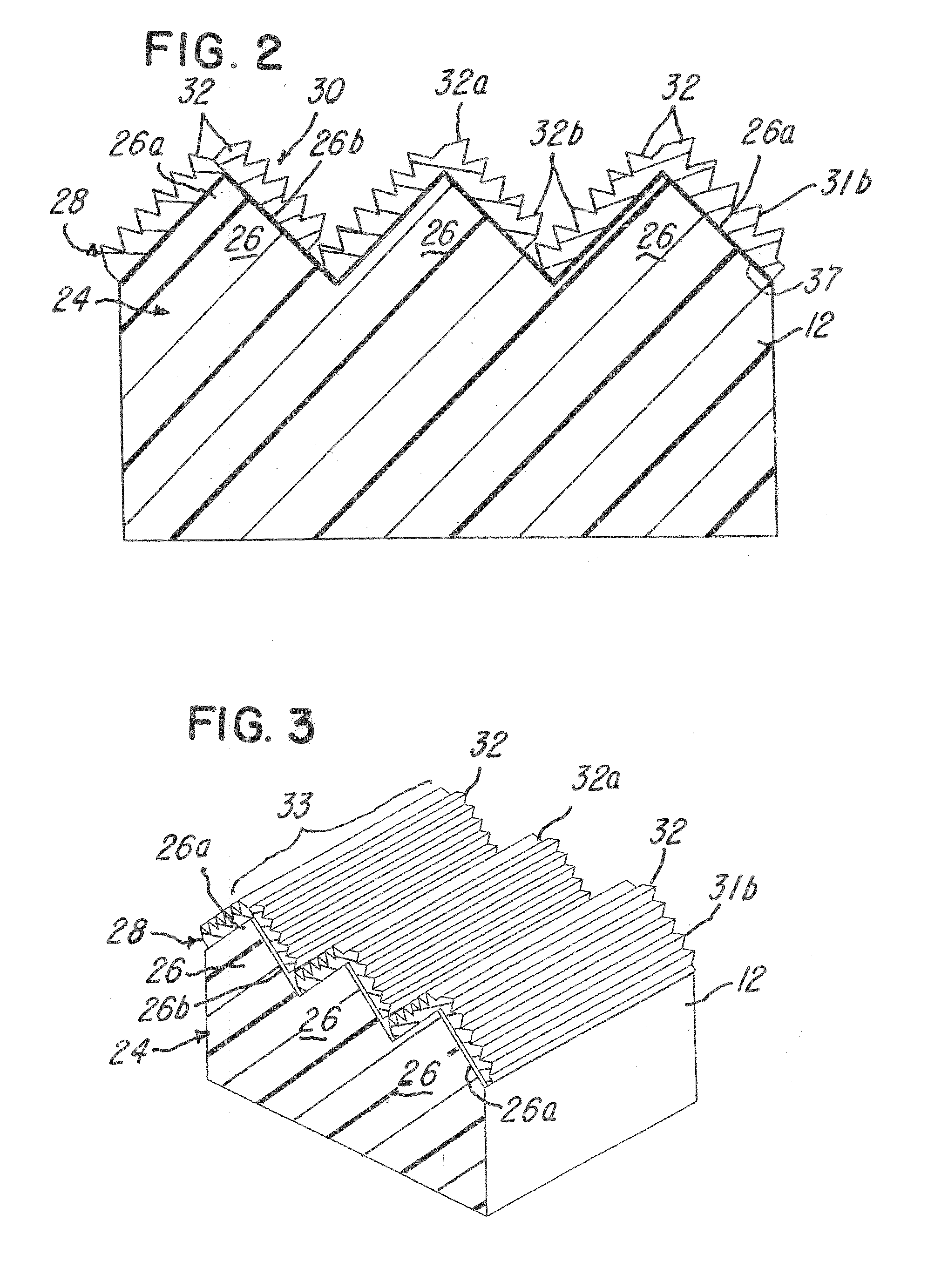

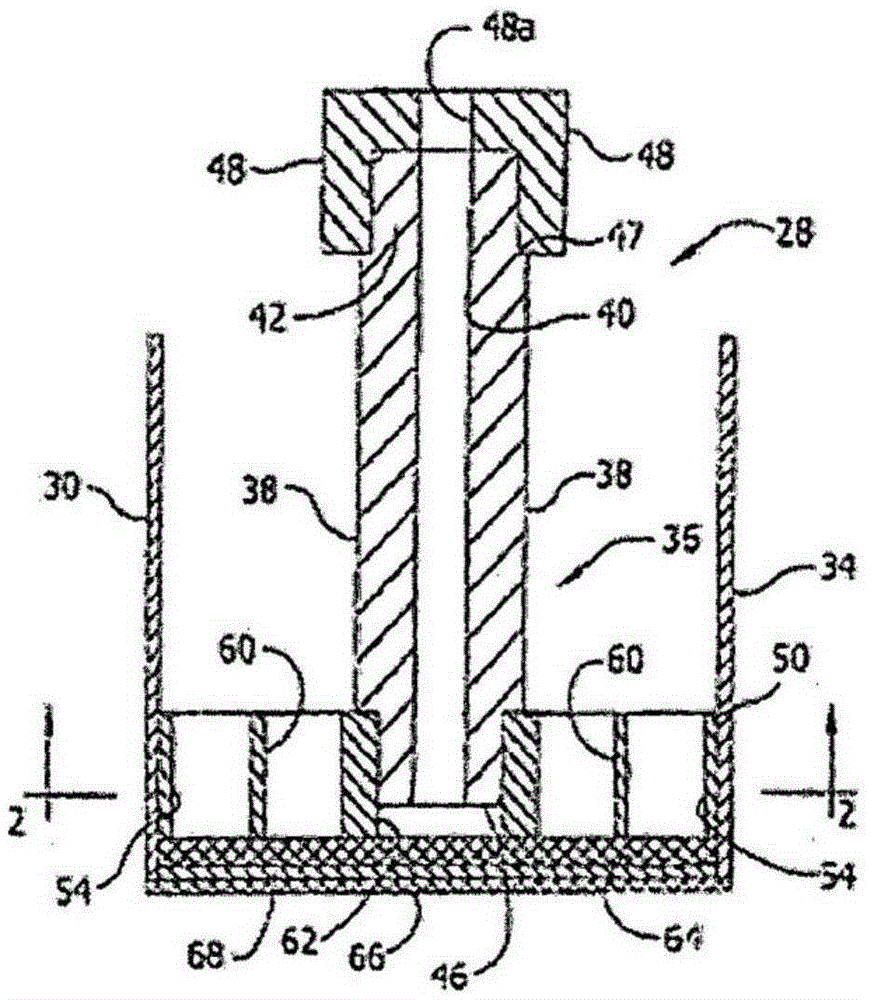

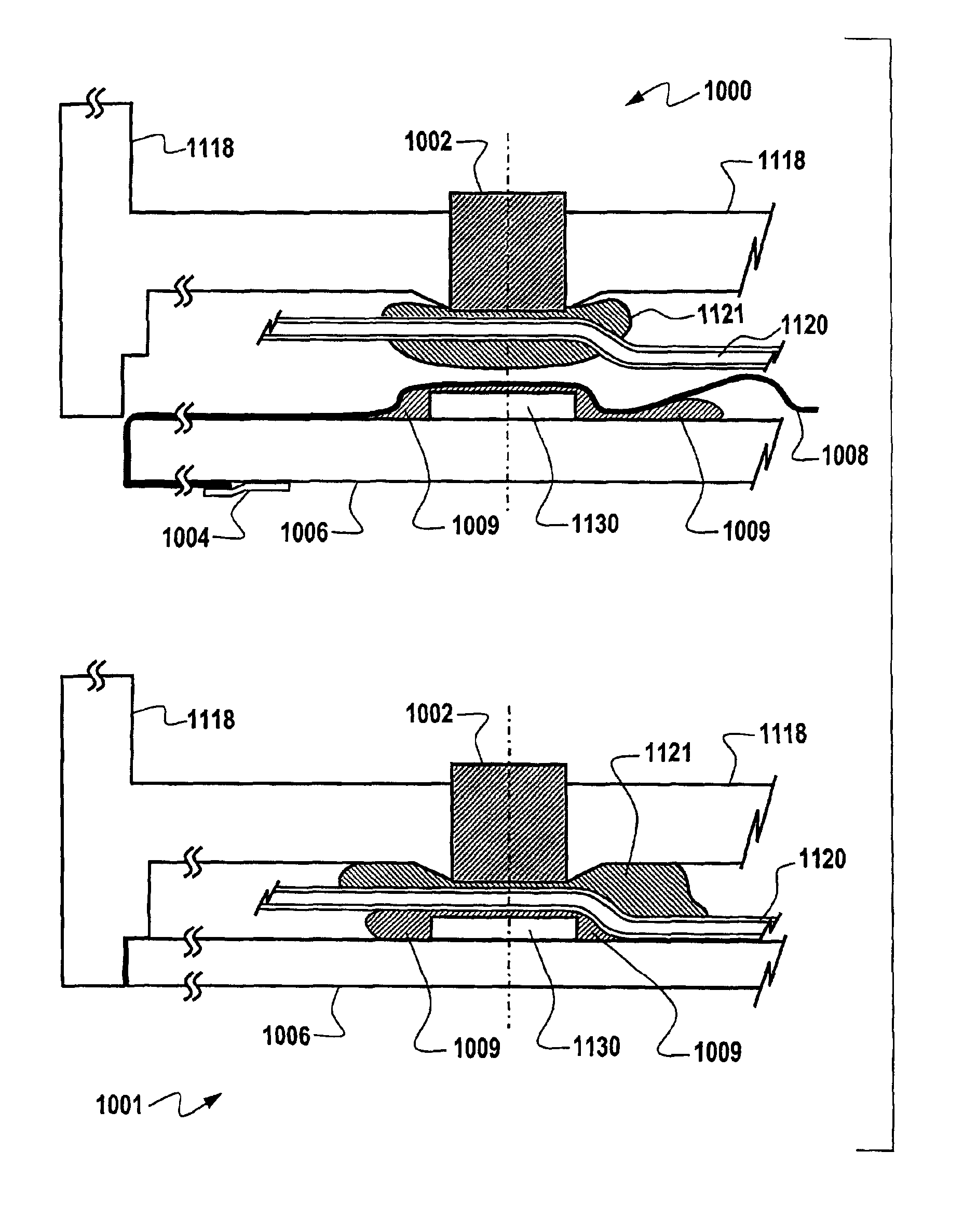

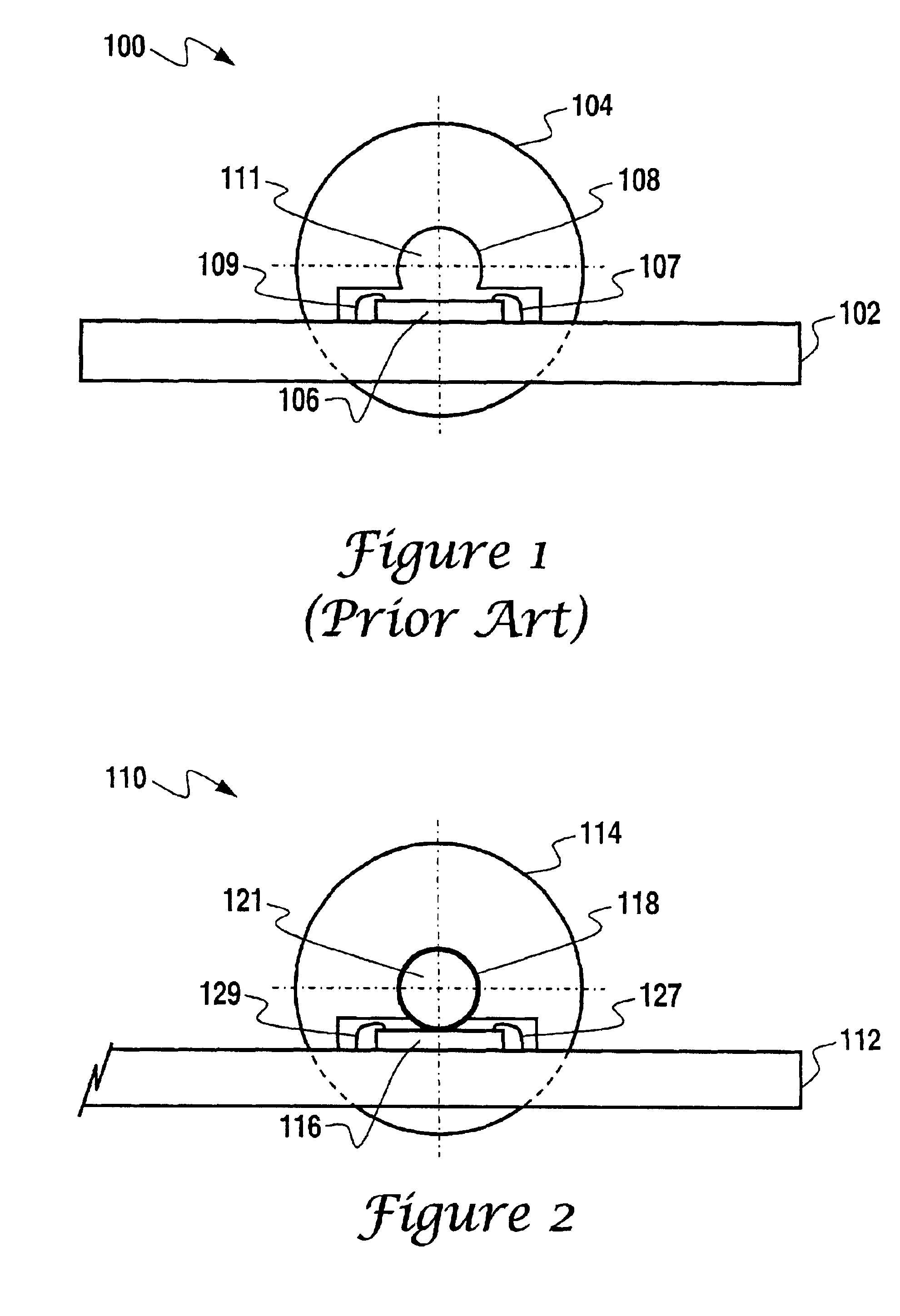

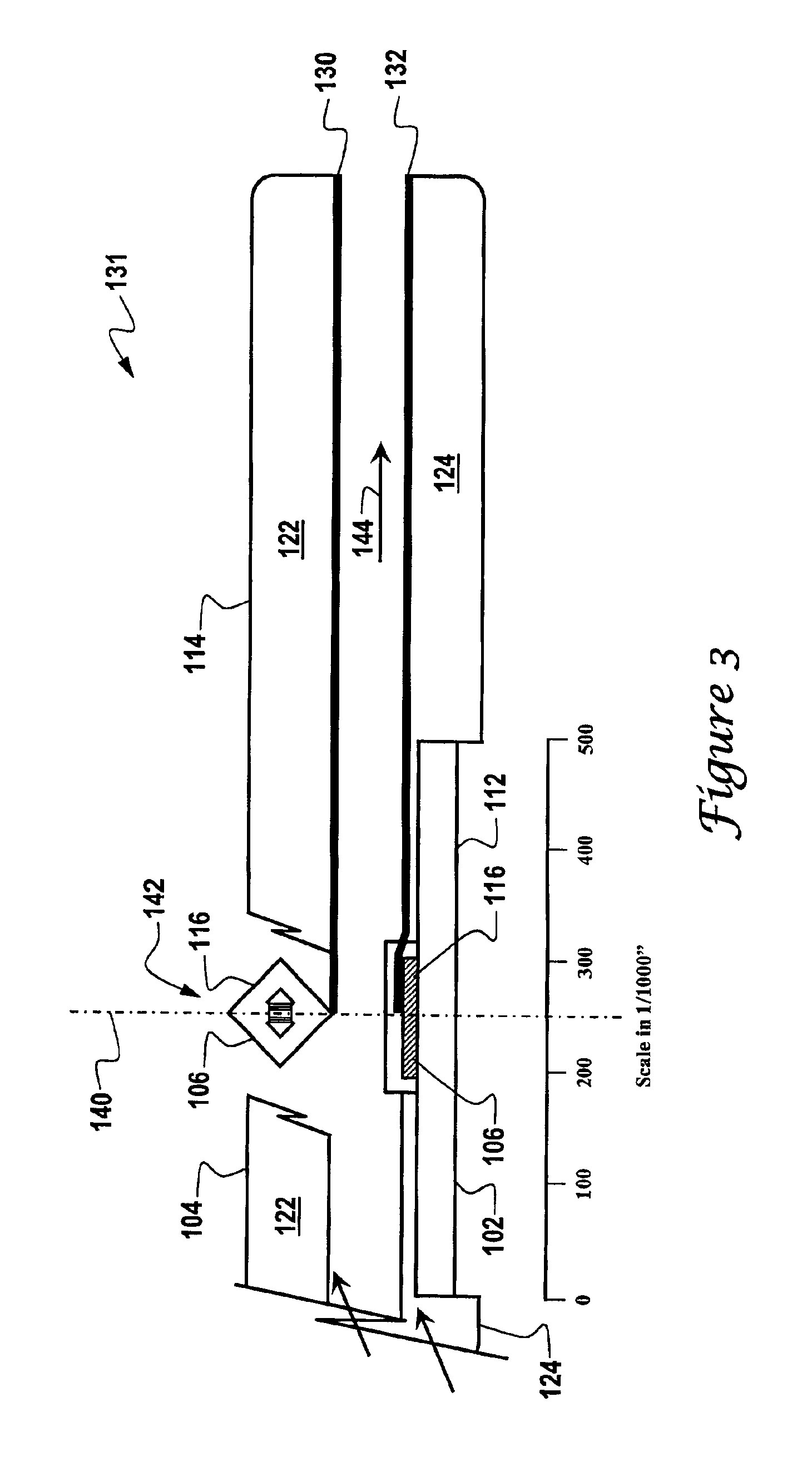

Composite orthopedic implant having a low friction material substrate with primary frictional features and secondary frictional features

ActiveUS20140128980A1Reduce lubricationSimple featuresImpression capsPretreated surfacesSurgical implantPlastic surgery

An orthopedic implant comprising a substrate material adapted to provide the orthopedic implant. The implant has a primary friction area located on or integral with the substrate material. The primary friction area defining an engagement surface having a primary frictional feature. A secondary friction area is located on or integral with the engagement surface and defining a second frictional feature. The primary friction area and the secondary friction area defining a friction interface zone between the orthopedic implant and at least one bone. The secondary friction area increases a friction of the engagement surface and modulus of elasticity to enhance the frictional engagement between the engagement surface and the at least one bone.

Owner:X SPINE SYST

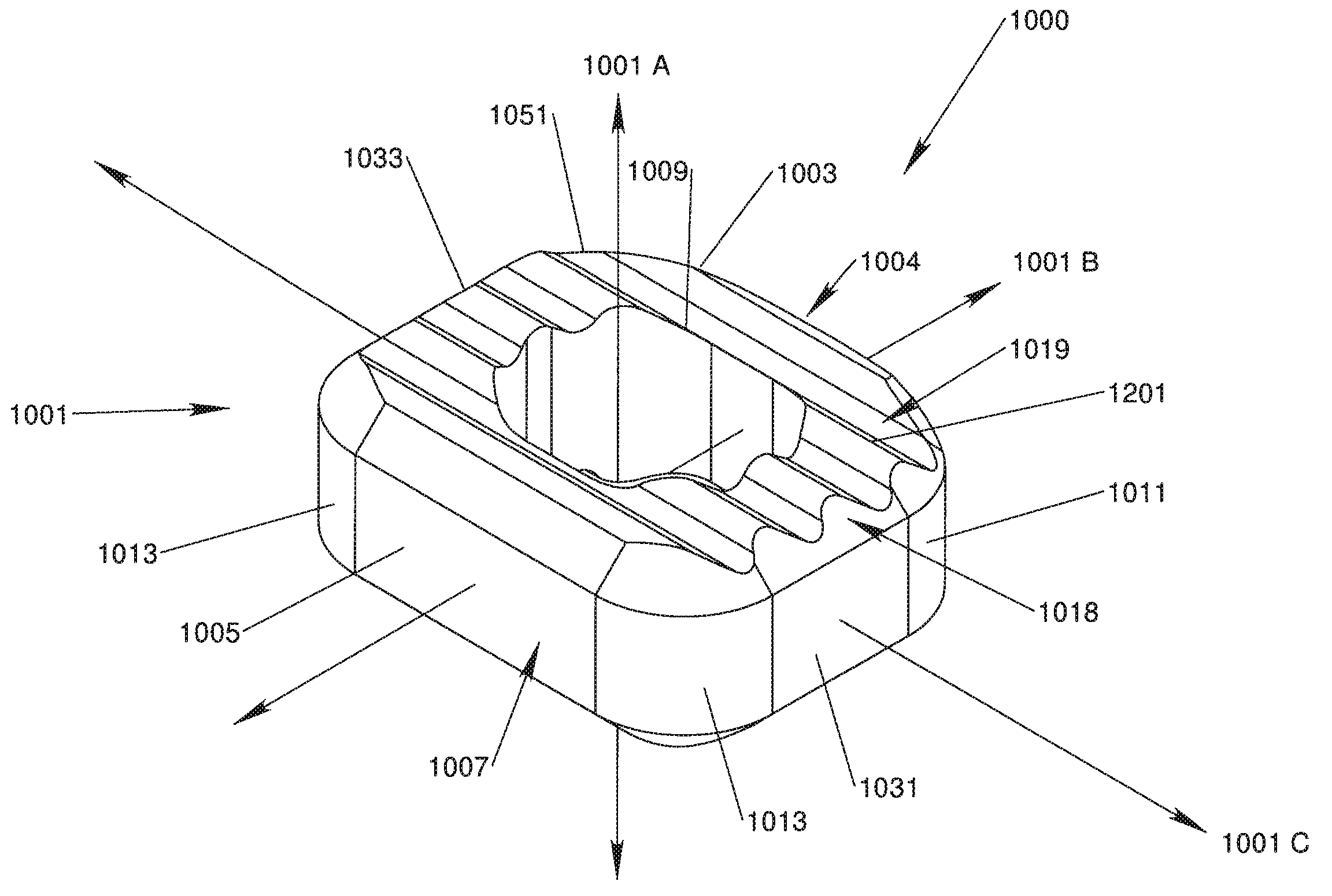

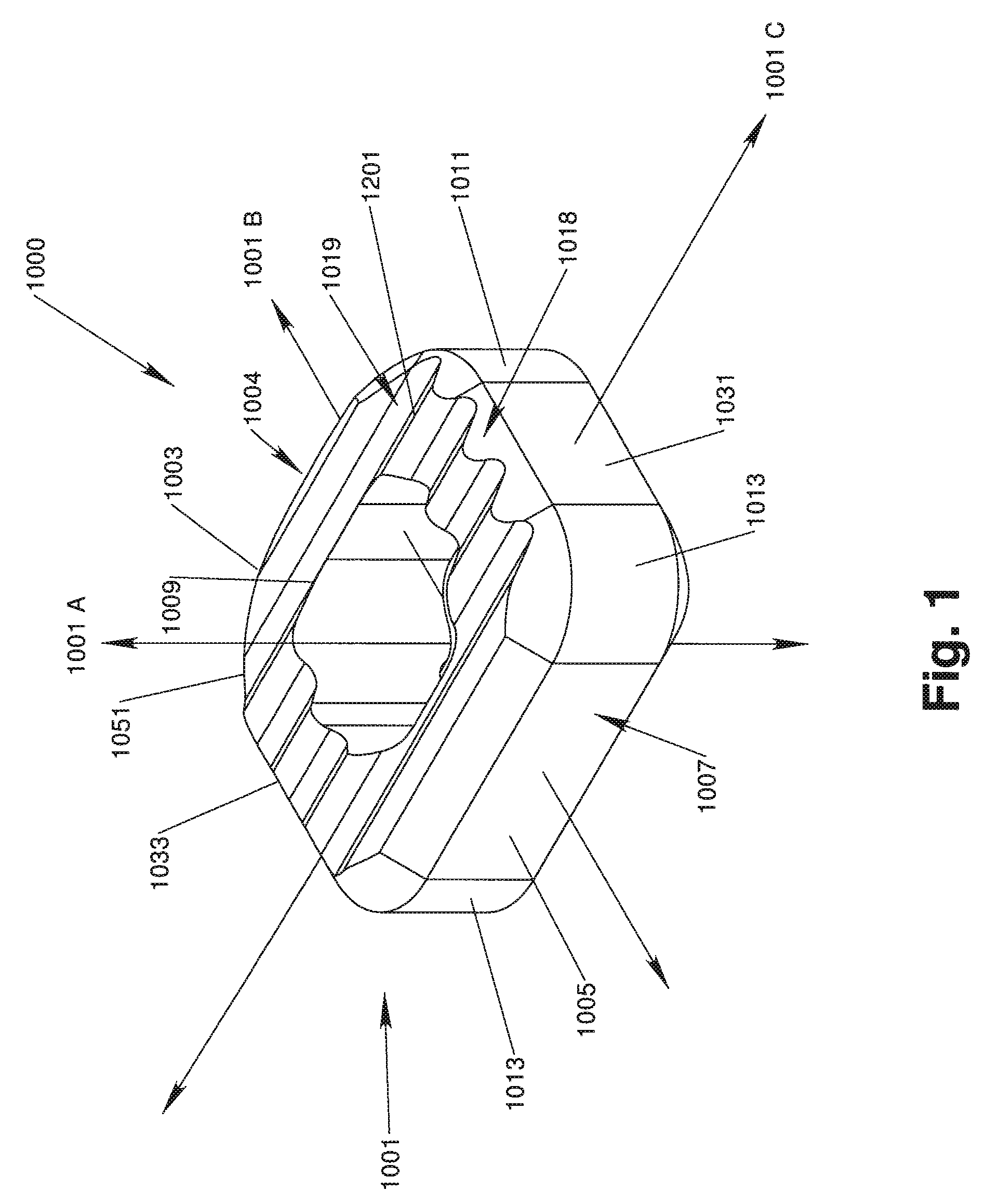

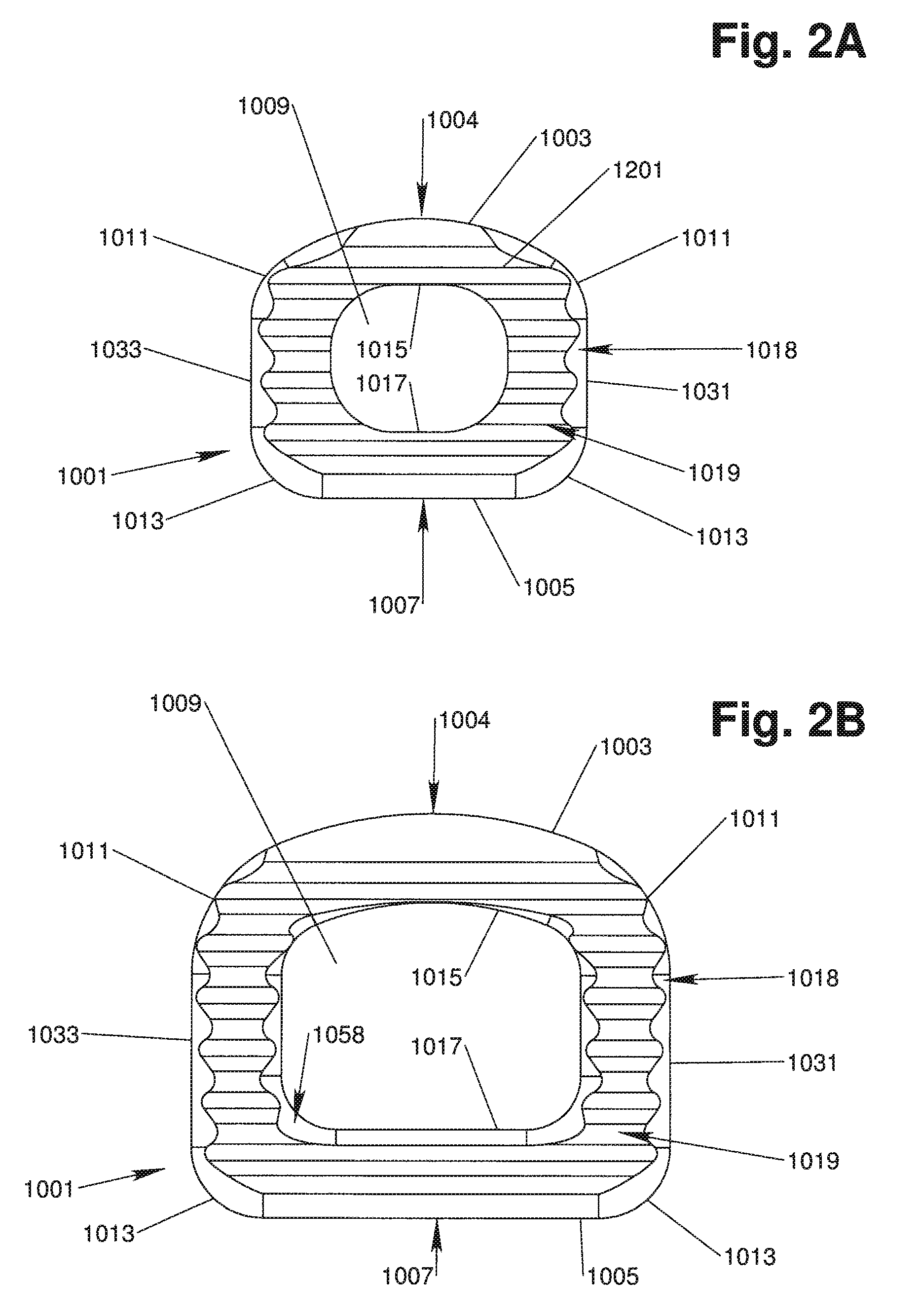

Intervertebral implant devices for supporting vertebrae and devices and methods for insertion thereof

InactiveUS20090254182A1Optimize characteristicMinimize stress concentrationBone implantPharmaceutical delivery mechanismVertebraSynthetic bone

Implant devices for implantation within an intervertebral space are provided, together with methods and tools for use therewith. Implant devices of the present invention include an implant body formed of a synthetic bone substitute material, such as a nanocrystalline calcium phosphate material. The implant body and the methods and tools used therewith are configured to optimize strength and stability of the implant, minimize areas of stress concentration in the implant body and promote bone growth through the implant body and fusion of the vertebra.

Owner:PIONEER SURGICAL TECH INC

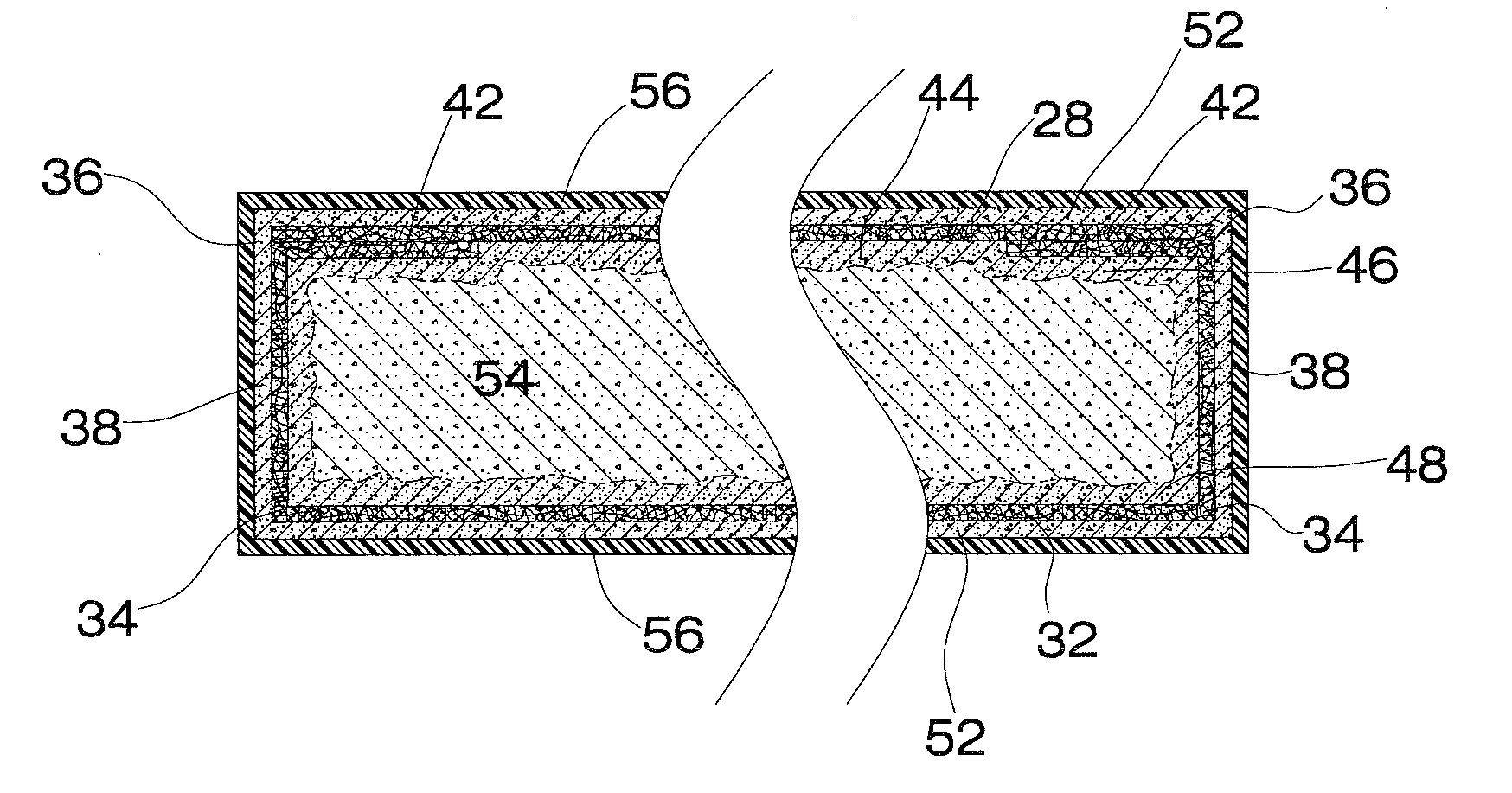

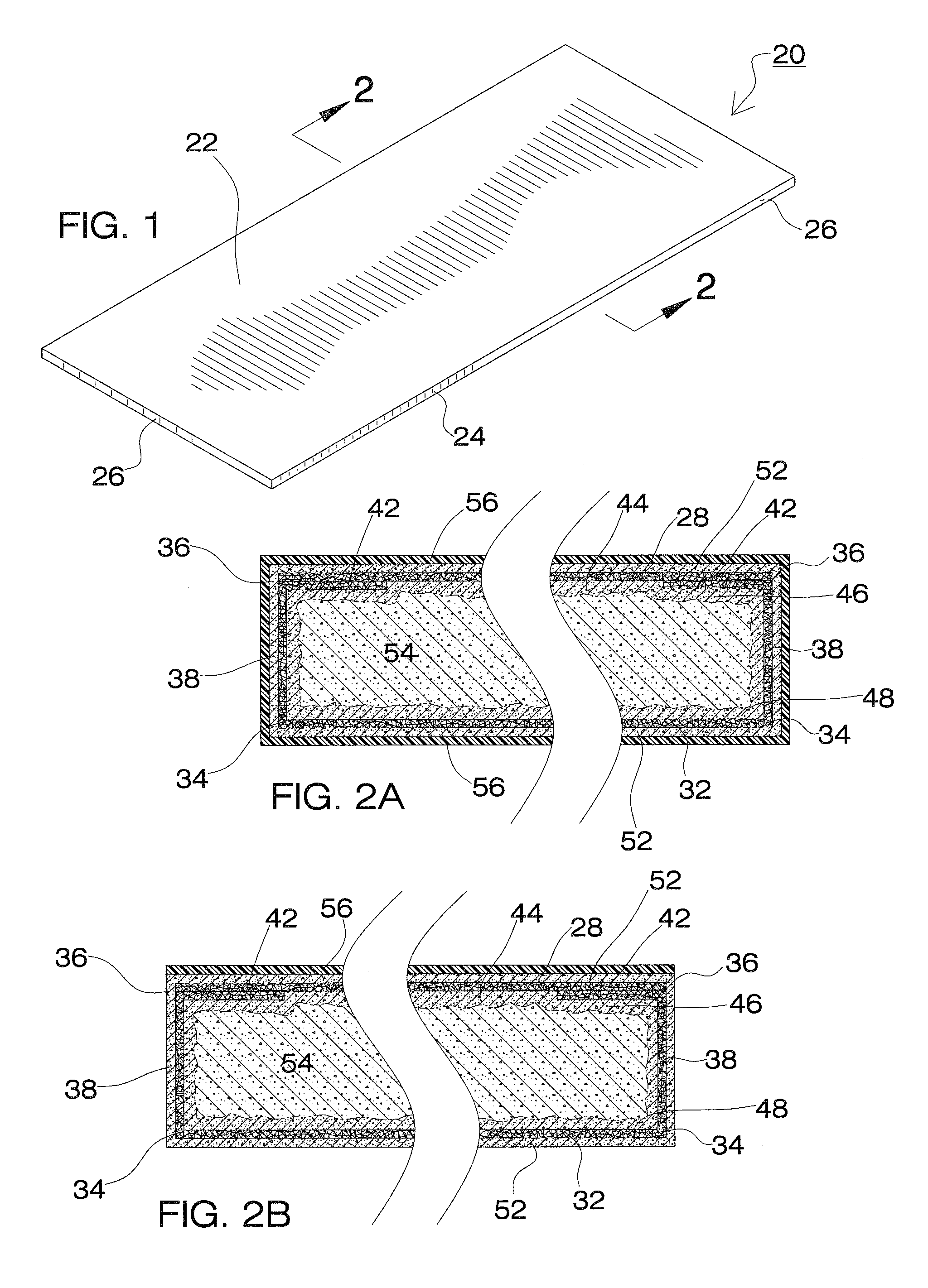

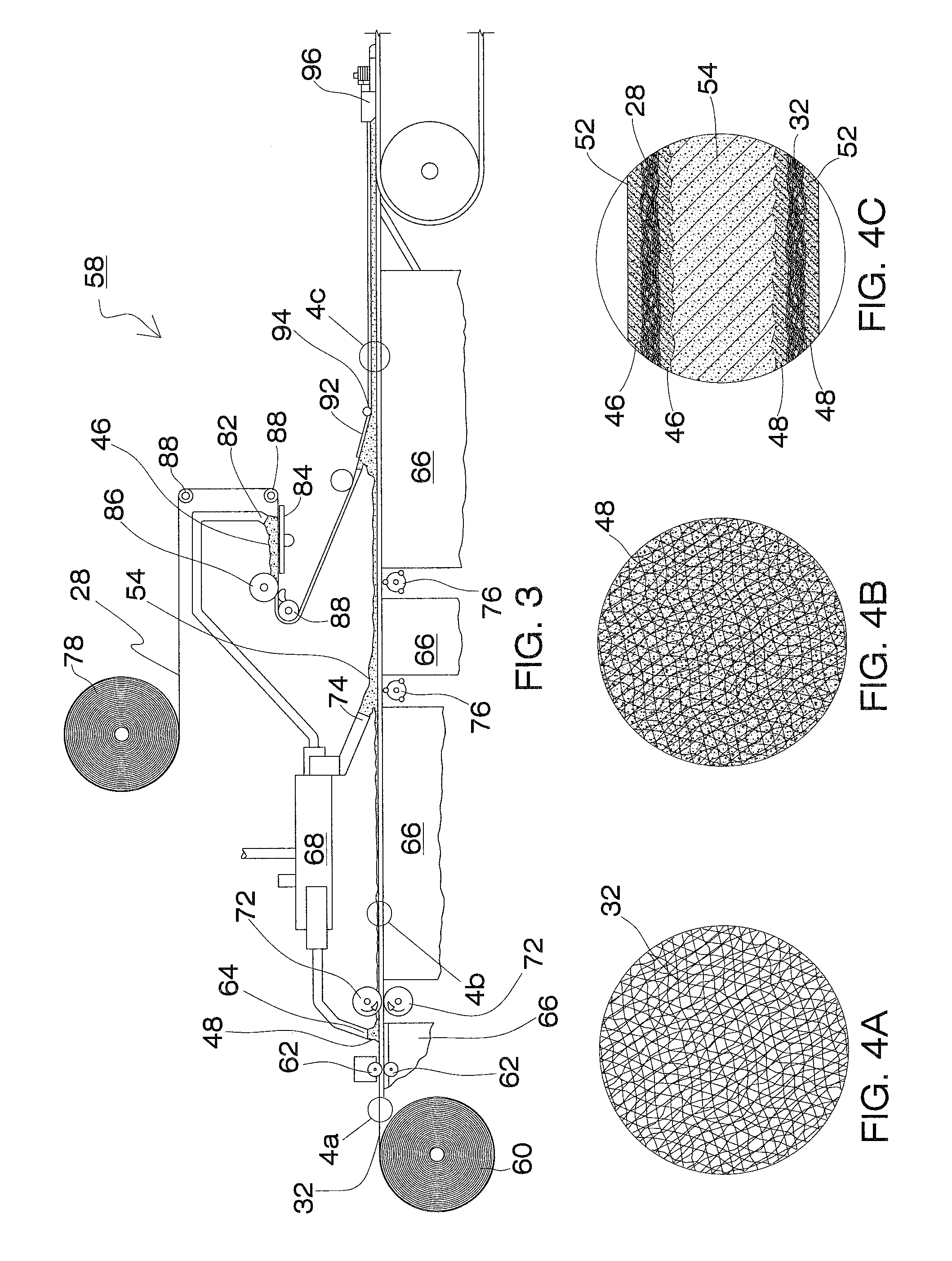

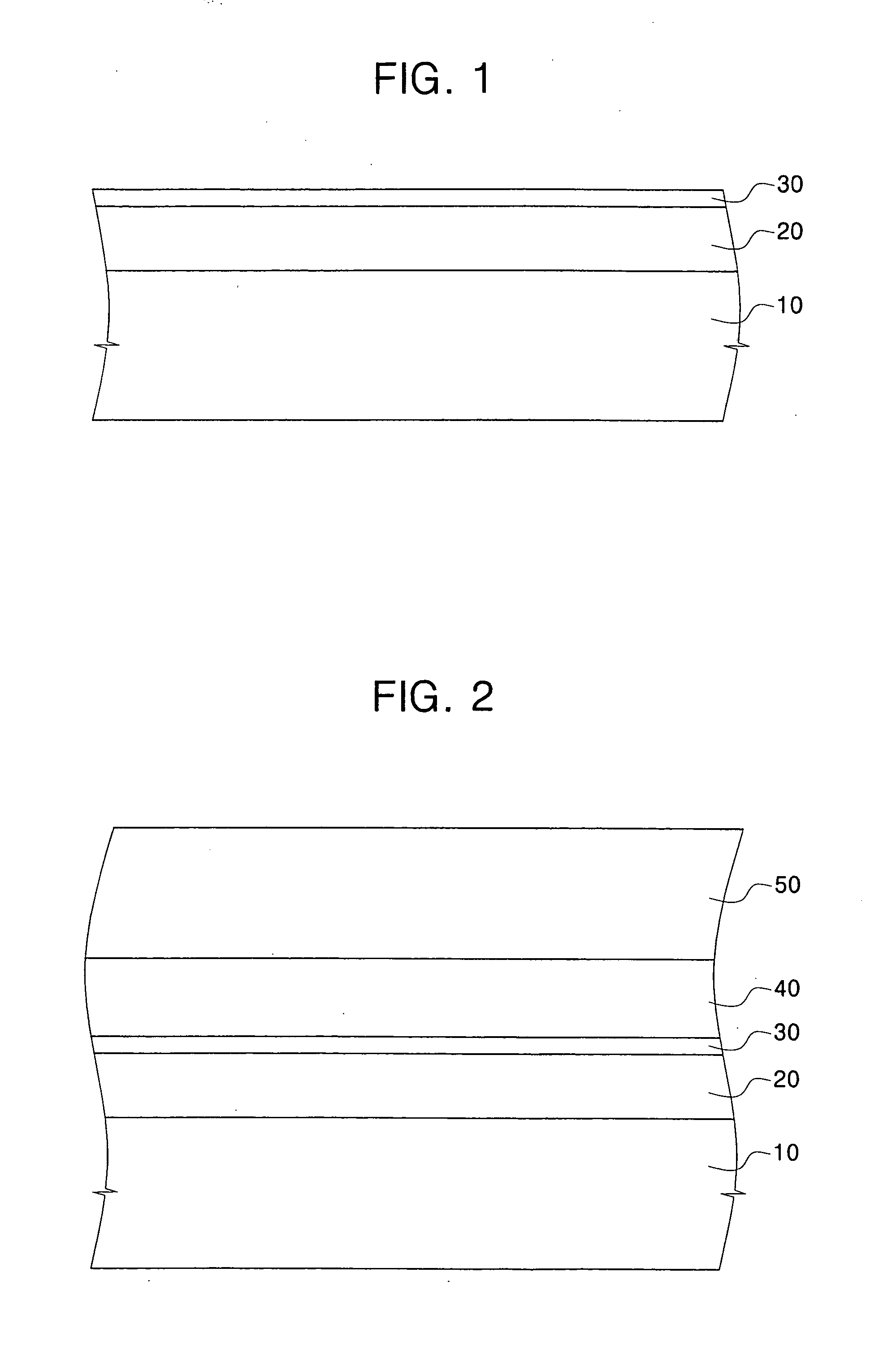

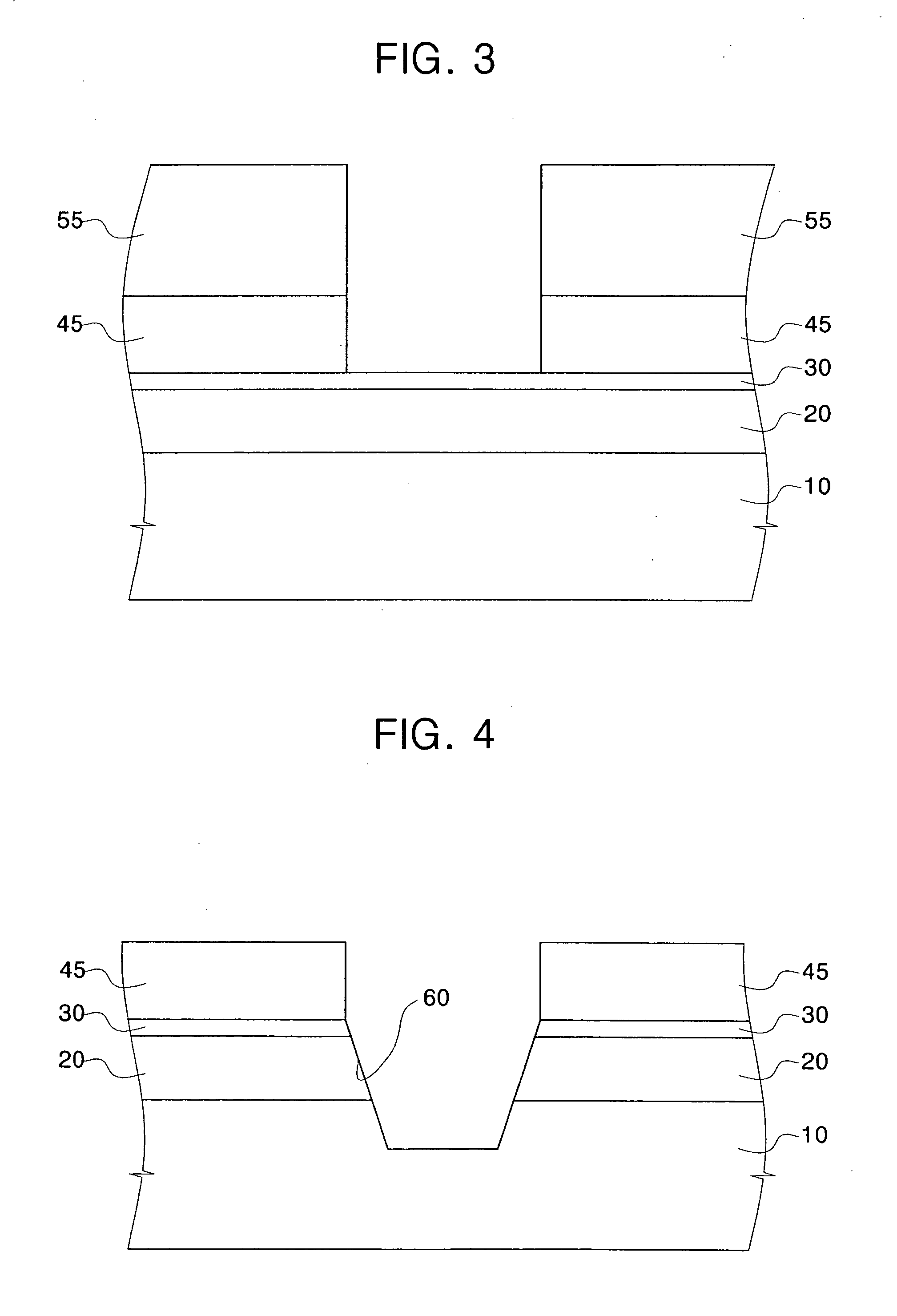

Plastic Coated Composite Building Boards and Method of Making Same

ActiveUS20100055431A1Improve physical propertiesIncrease durability and load carrying capacityGlass/slag layered productsCoatingsCross-linkSlurry

Disclosed are composite building boards and associated manufacturing methods. The composite boards may include, for example, one or more slurry layers with embedded fibrous mats. An exterior plastic coating is mechanically adhered to the underlying slurry layer. The plastic layer chemically bonds and cross-links with polymer additives within the slurry layer. The result is an integrated polymer matrix with greatly improved durability and surface strength.

Owner:CERTAINTEED GYPSUM INC

Methods of fabricating a semiconductor device using a dilute aqueous solution of an ammonia and peroxide mixture

InactiveUS20050260830A1Improve physical propertiesFrom solid stateNon-surface-active detergent compositionsDevice materialAlloy

This invention provides methods of fabricating semiconductor devices, wherein an alloy layer is formed on a semiconductor substrate to form a substrate structure, which methods include using an aqueous solution diluted ammonia and peroxide mixture (APM) to perform cleaning and / or wet etching treatment steps on the substrate structure.

Owner:SAMSUNG ELECTRONICS CO LTD

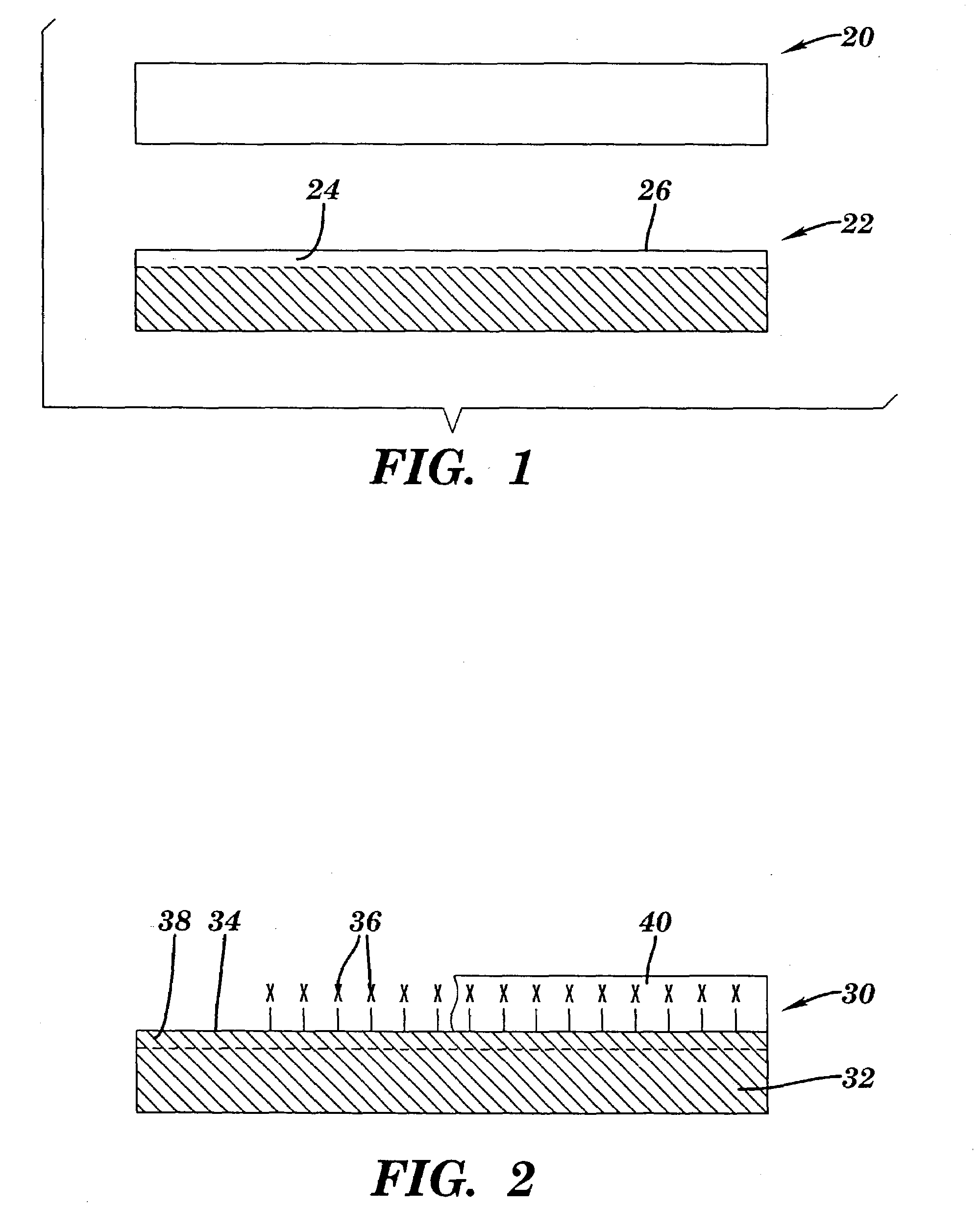

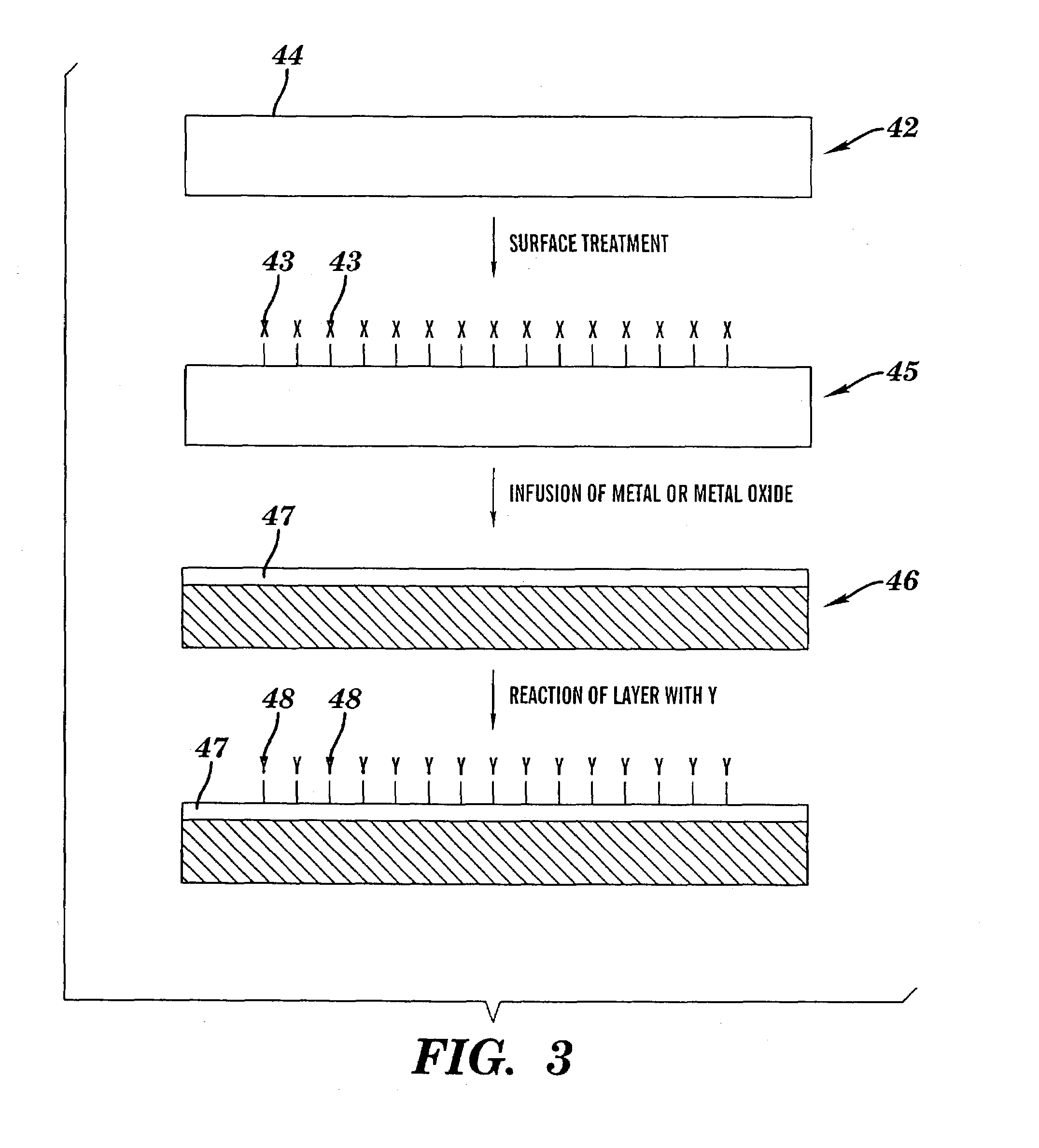

Polymer composites and methods for making and using same

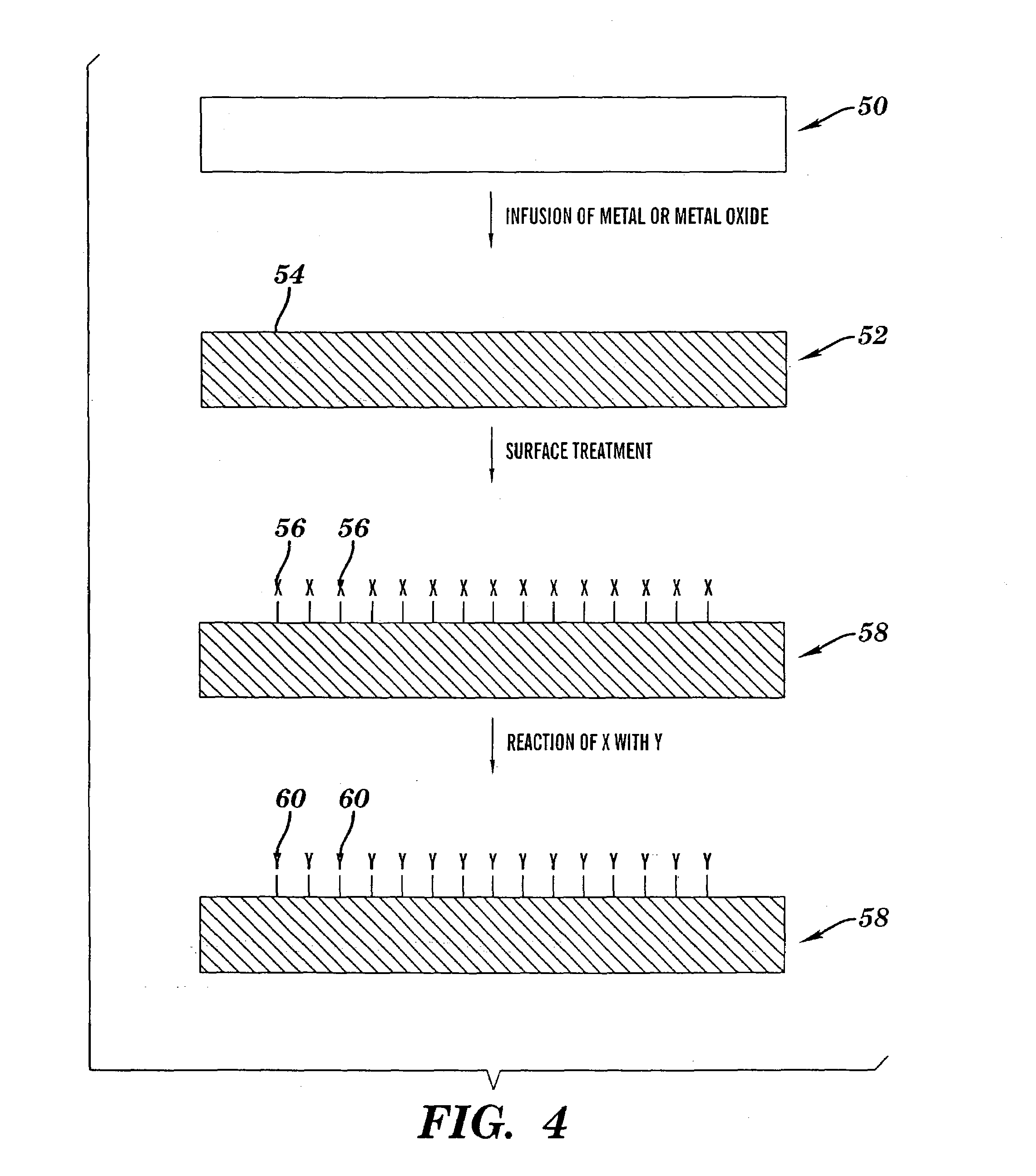

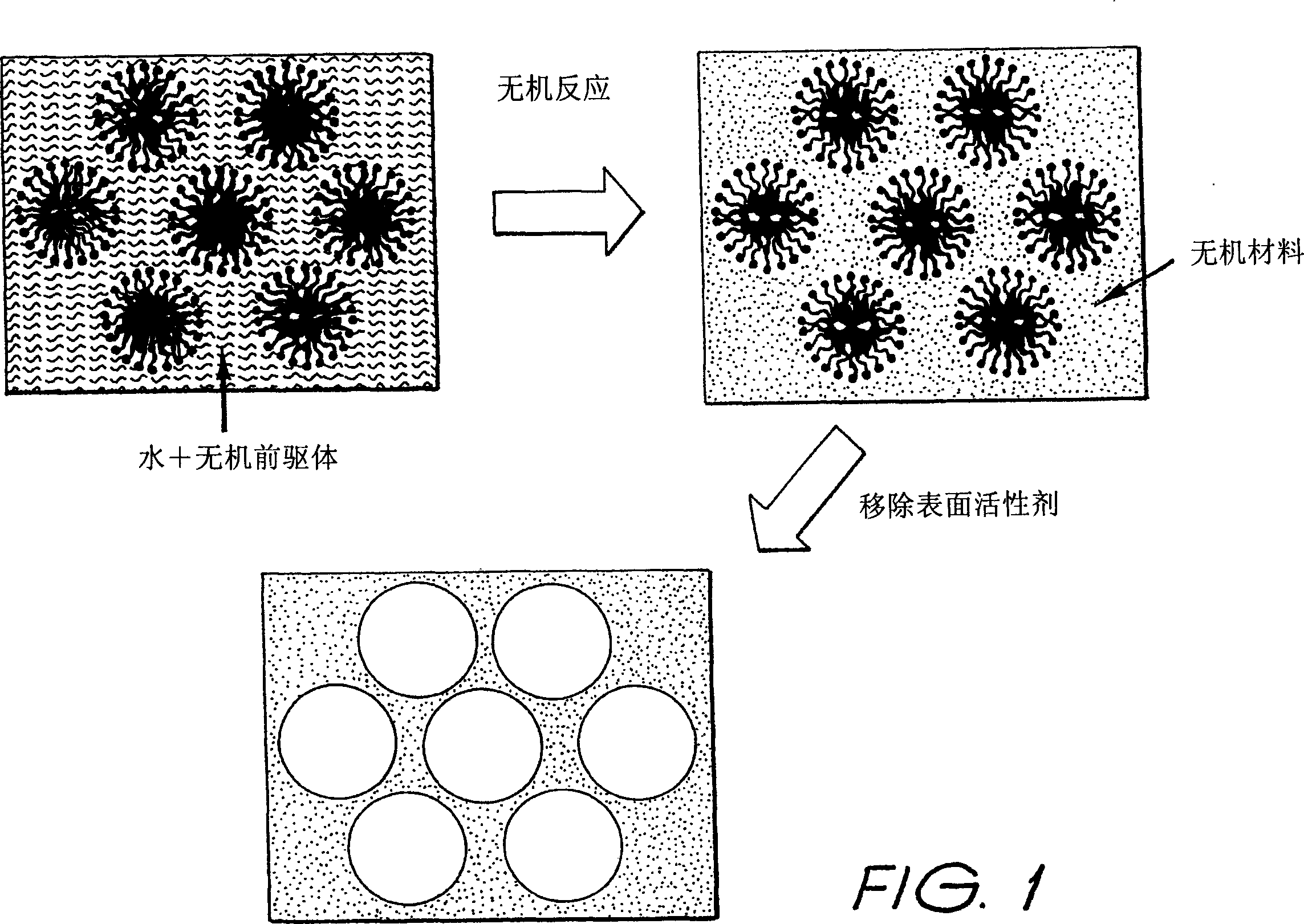

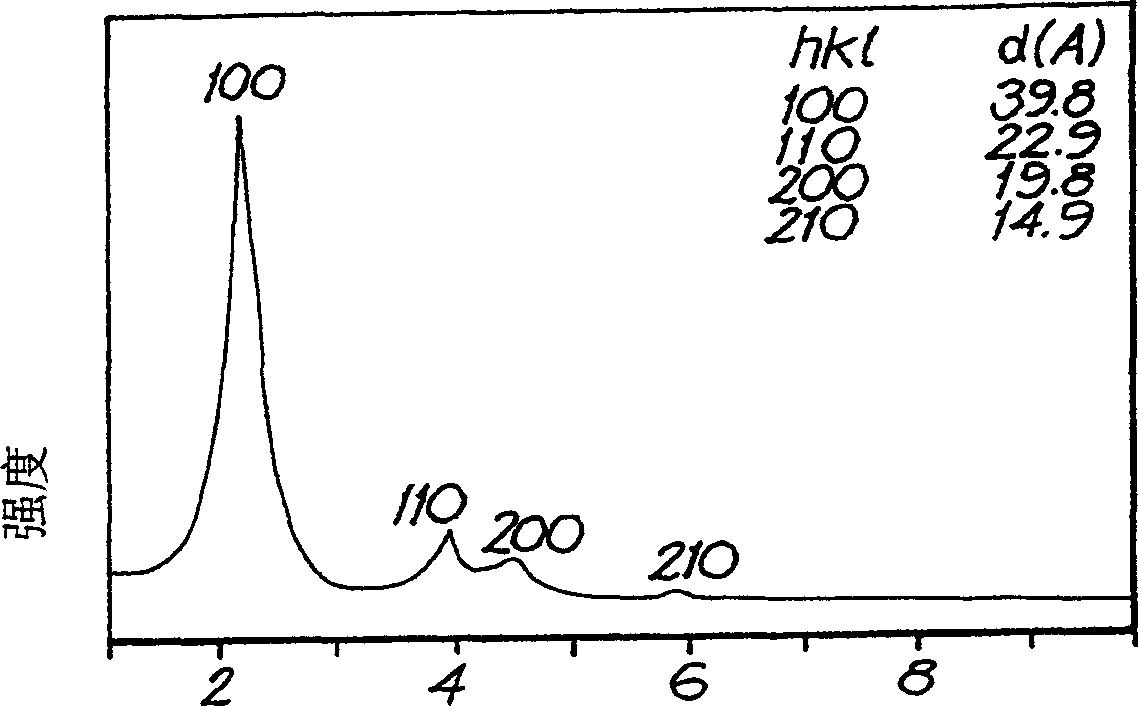

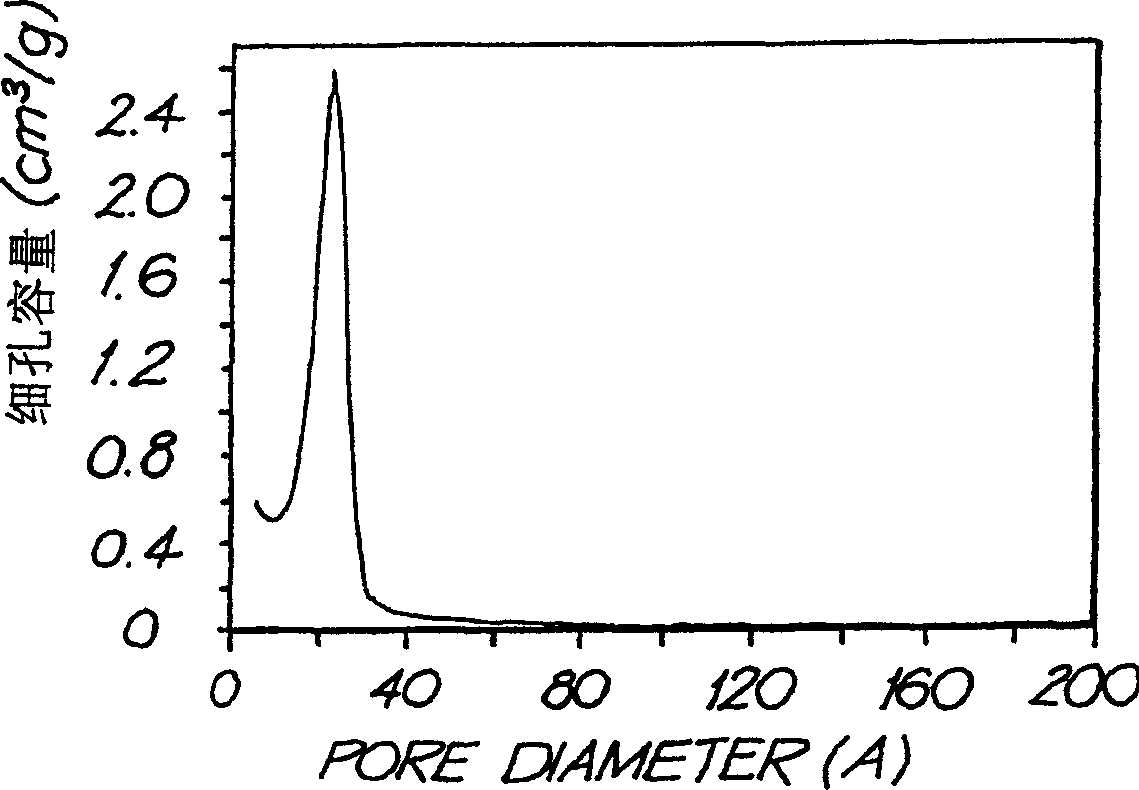

InactiveUS7217754B2More mechanical propertiesImprove physical propertiesAntifouling/underwater paintsCell seperators/membranes/diaphragms/spacersOrganic moleculesNanometre

Composites which include a polymer matrix having natural free volume therein and an inorganic or organic material disposed in the natural free volume of the polymer matrix are disclosed. In addition, methods for making a composite are described. A polymer matrix having free volume therein is provided. The free volume is evacuated, and inorganic or organic molecules are infused into the evacuated free volume of the polymer matrix. The inorganic or organic molecules can then be polymerized under conditions effective to cause the polymerized inorganic or organic molecules to assemble into nanoparticles or other types of macromolecular networks. Alternatively, where the polymer matrix contains a functionality, the inorganic or organic molecules can be treated under conditions effective to cause the inorganic or organic molecules to interact with the polymer matrix's functionality. Use of the disclosed composites as photoradiation shields and filters, electromagnetic radiation shields and filters, antistatic layers, heterogeneous catalysts, conducting electrodes, materials having flame and heat retardant properties, components in the construction of electrolytic cells, fuel cells, and optoelectronic devices, and antifouling coatings is also described.

Owner:INTEGUMENT TECH

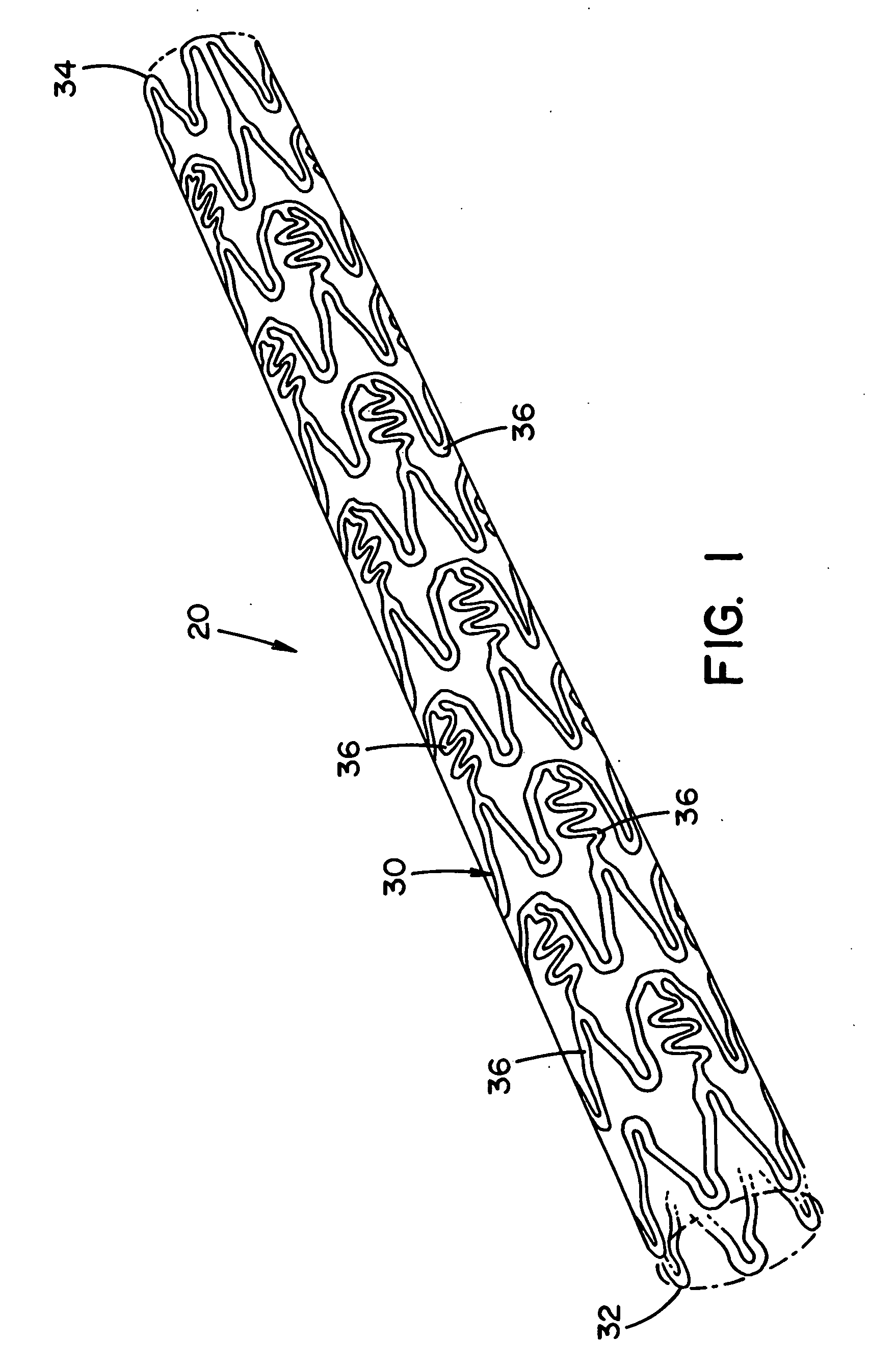

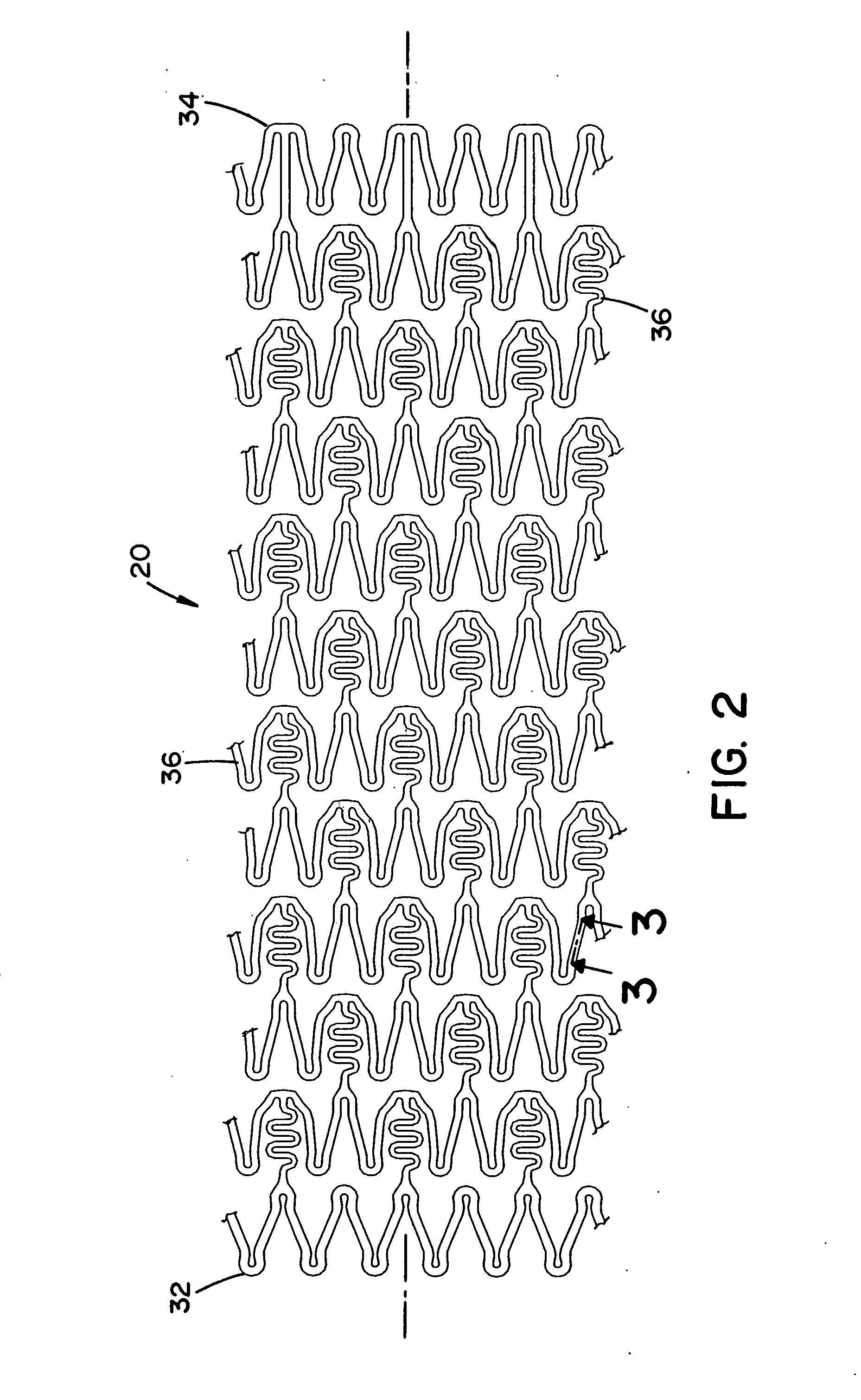

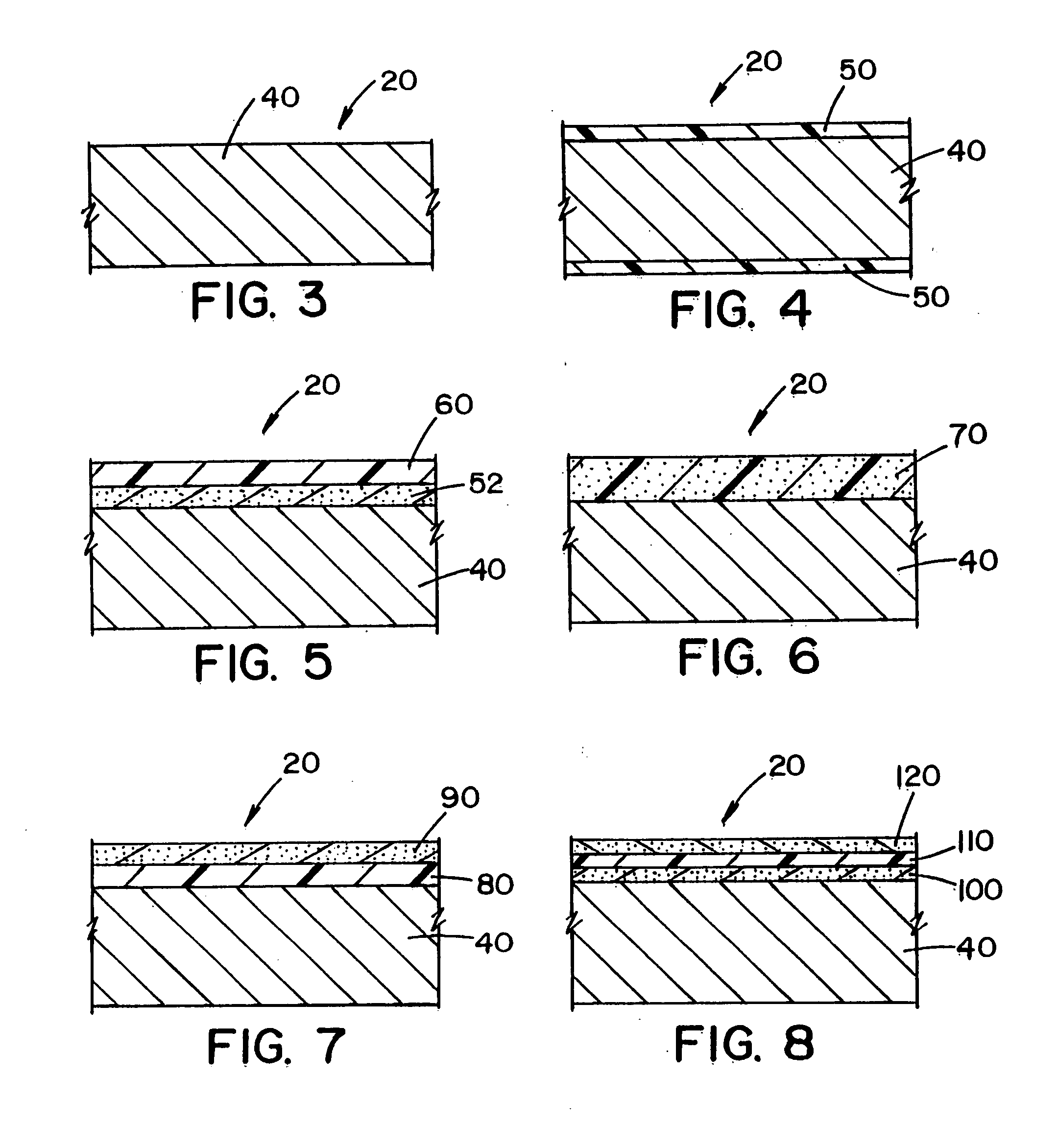

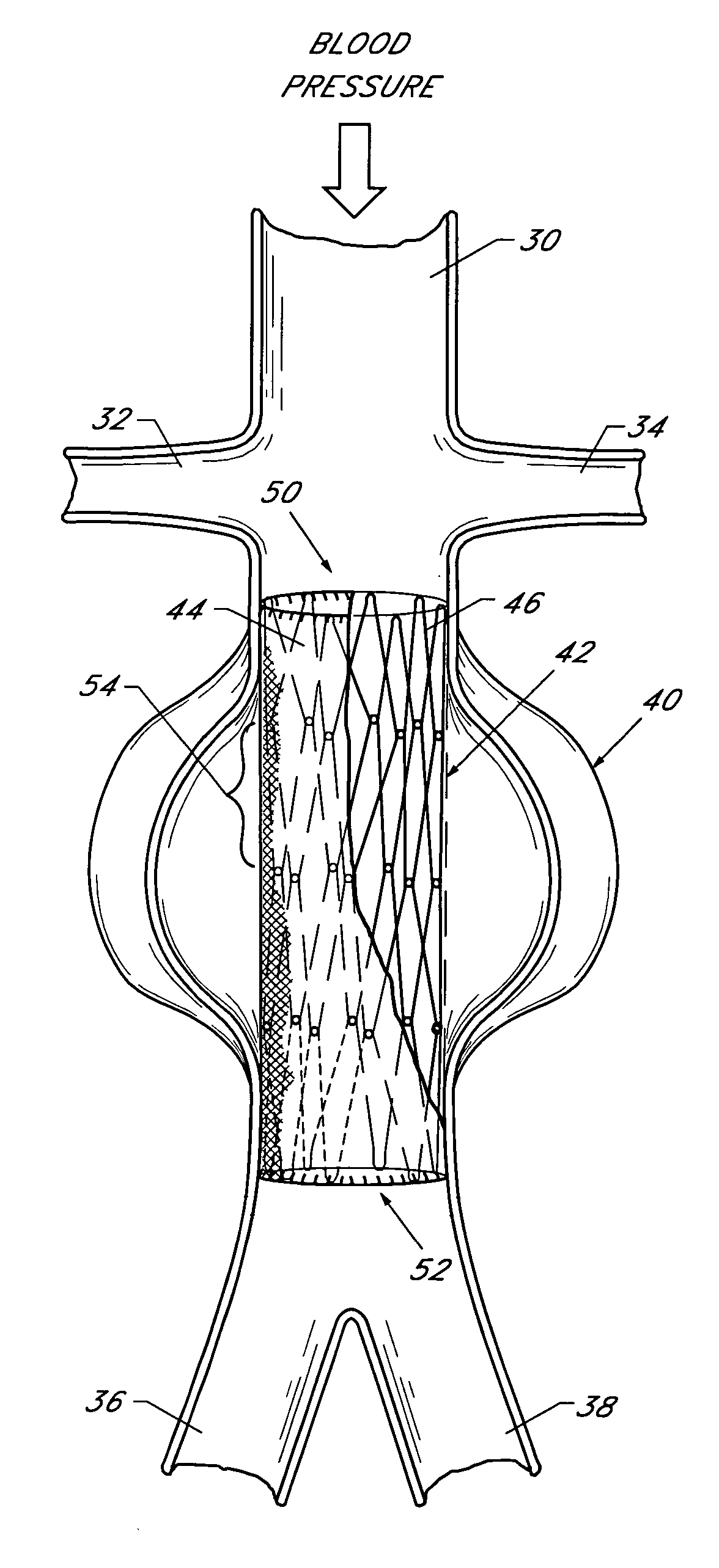

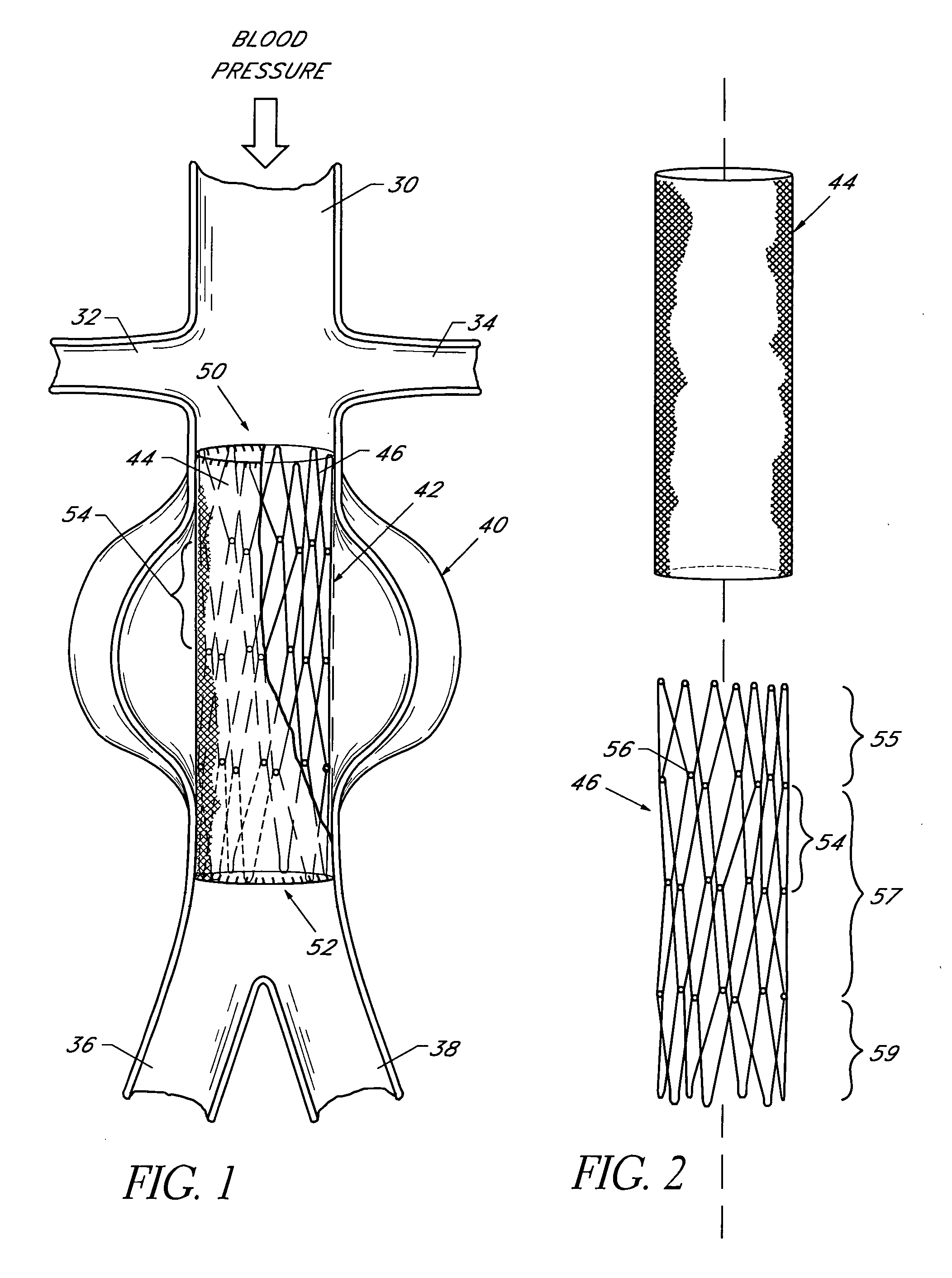

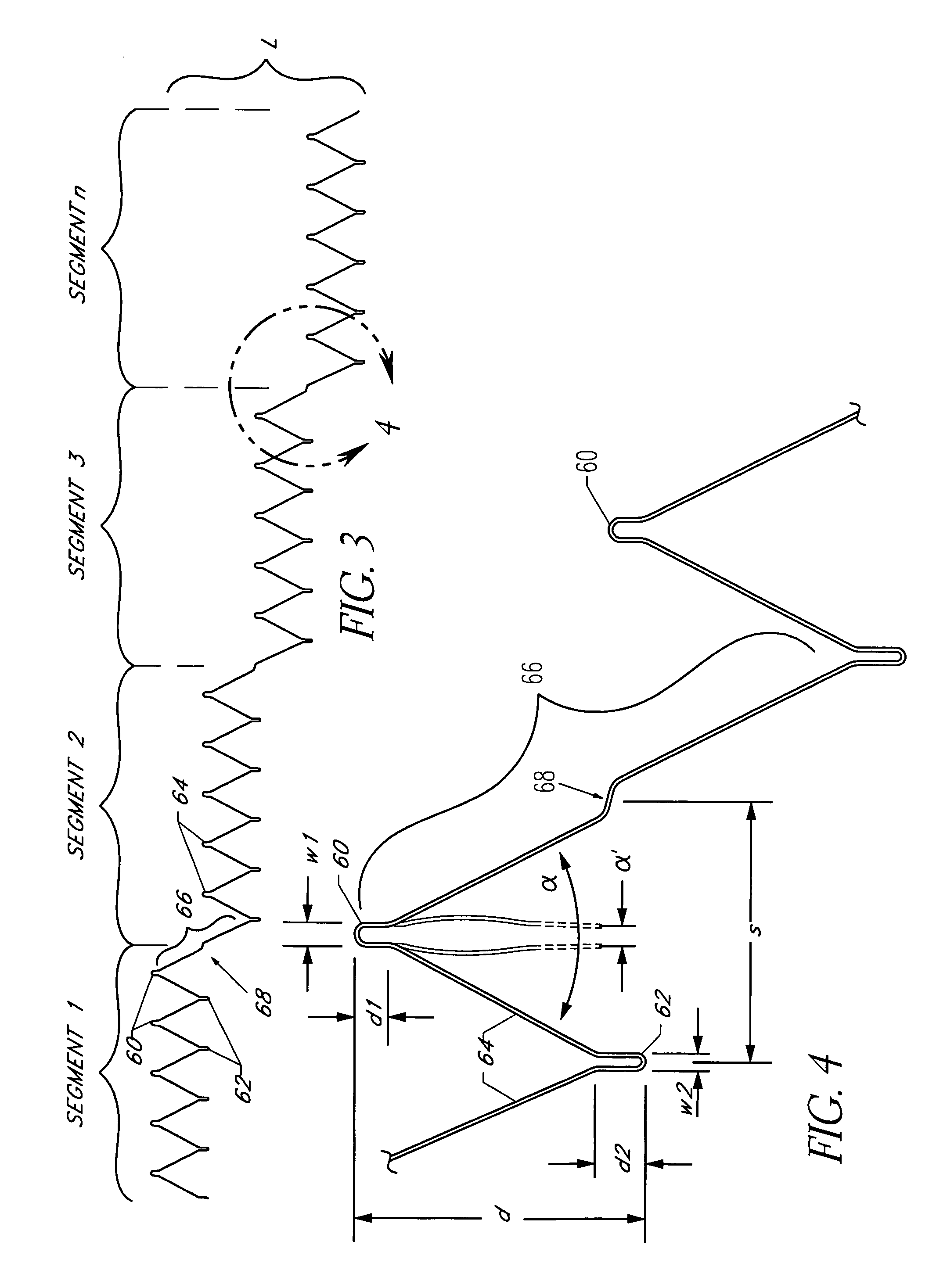

Endolumenal vascular prosthesis with neointima inhibiting polymeric sleeve

ActiveUS20050228480A1Improve physical propertiesInhibition formationStentsBlood vesselsNeointimaTunica intima

The present invention is related to a low profile endolumenal prosthesis. The prosthesis comprises a radially expandable tubular wire support and an expanded PTFE membrane. The density, wall thickness and intranodal distance of the ePTFE are selected to inhibit the formation and nourishment of a viable neointima on the inner surface of the prosthesis, through the ePTFE membrane.

Owner:ENDOLOGIX LLC

Composite orthopedic implant having a low friction material substrate with primary frictional features and secondary frictional features

InactiveUS20120022653A1Reduce lubricationSimple featuresSpinal implantsCoatingsEngineeringSurgical implant

An orthopedic implant comprising a substrate material adapted to provide the orthopedic implant. The implant has a primary friction area located on or integral with the substrate material. The primary friction area defining an engagement surface having a primary frictional feature. A secondary friction area is located on or integral with the engagement surface and defining a second frictional feature. The primary friction area and the secondary friction area defining a friction interface zone between the orthopedic implant and at least one bone. The secondary friction area increases a friction of the engagement surface and modulus of elasticity to enhance the frictional engagement between the engagement surface and the at least one bone.

Owner:X SPINE SYST

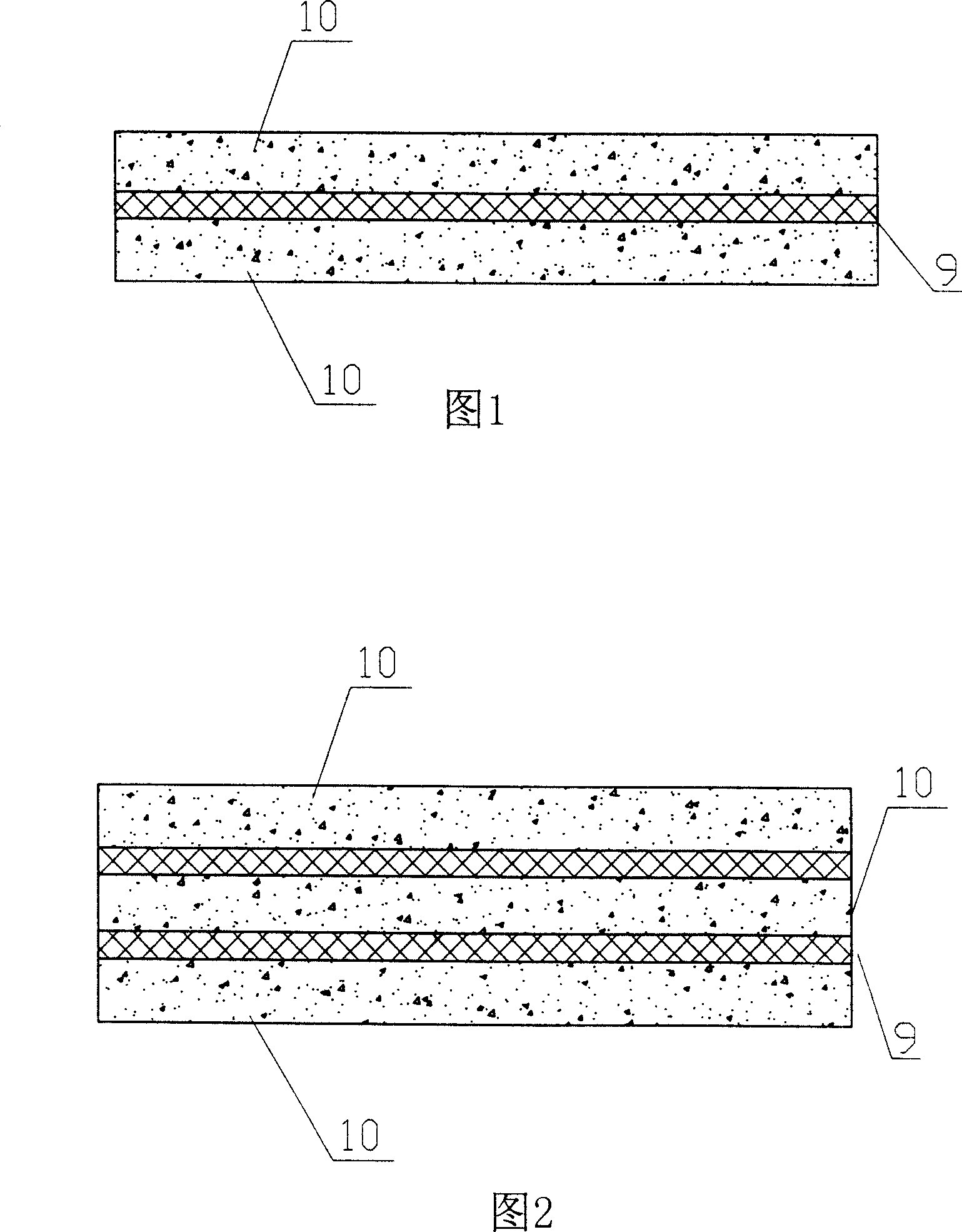

Wood-plastic formwork for construction engineering

InactiveCN1987018AExcellent mechanical propertiesFlat and smooth appearanceSolid waste managementLaminationFiberGlass fiber

A wood-plastics shuttering board for building engineering is composed of at least two basic wood-plastic ply layers made of the filler (vegetative fibers, glass fibers and plastics) and assistant (calcium carbonate, modifier, coupling agent and lubricant), and at least one lattice material layer between two basic wood-plastic ply layers and with two adhesive layers coated on its both surfaces. Its manufacture technology is also disclosed.

Owner:徐肖虎

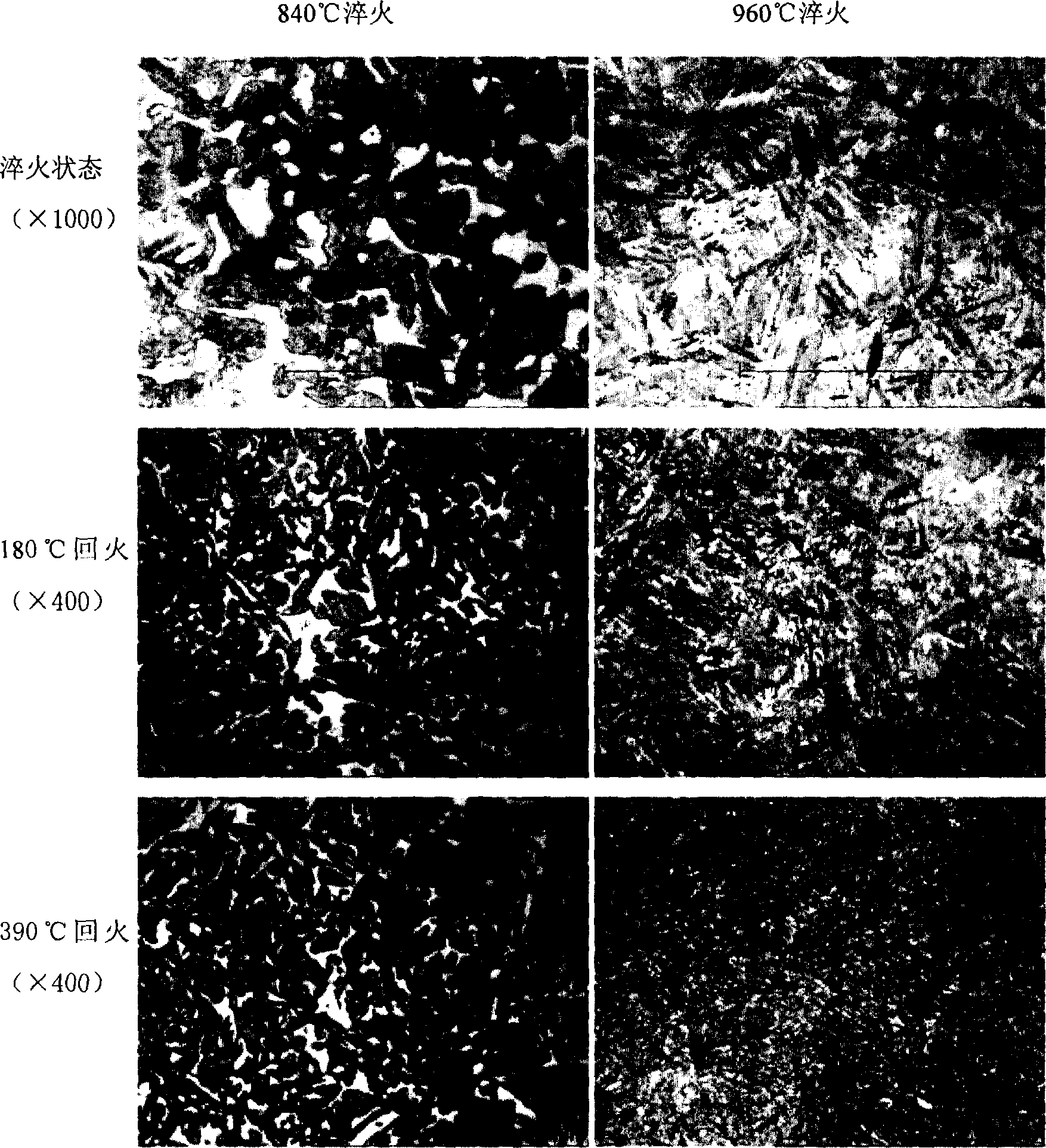

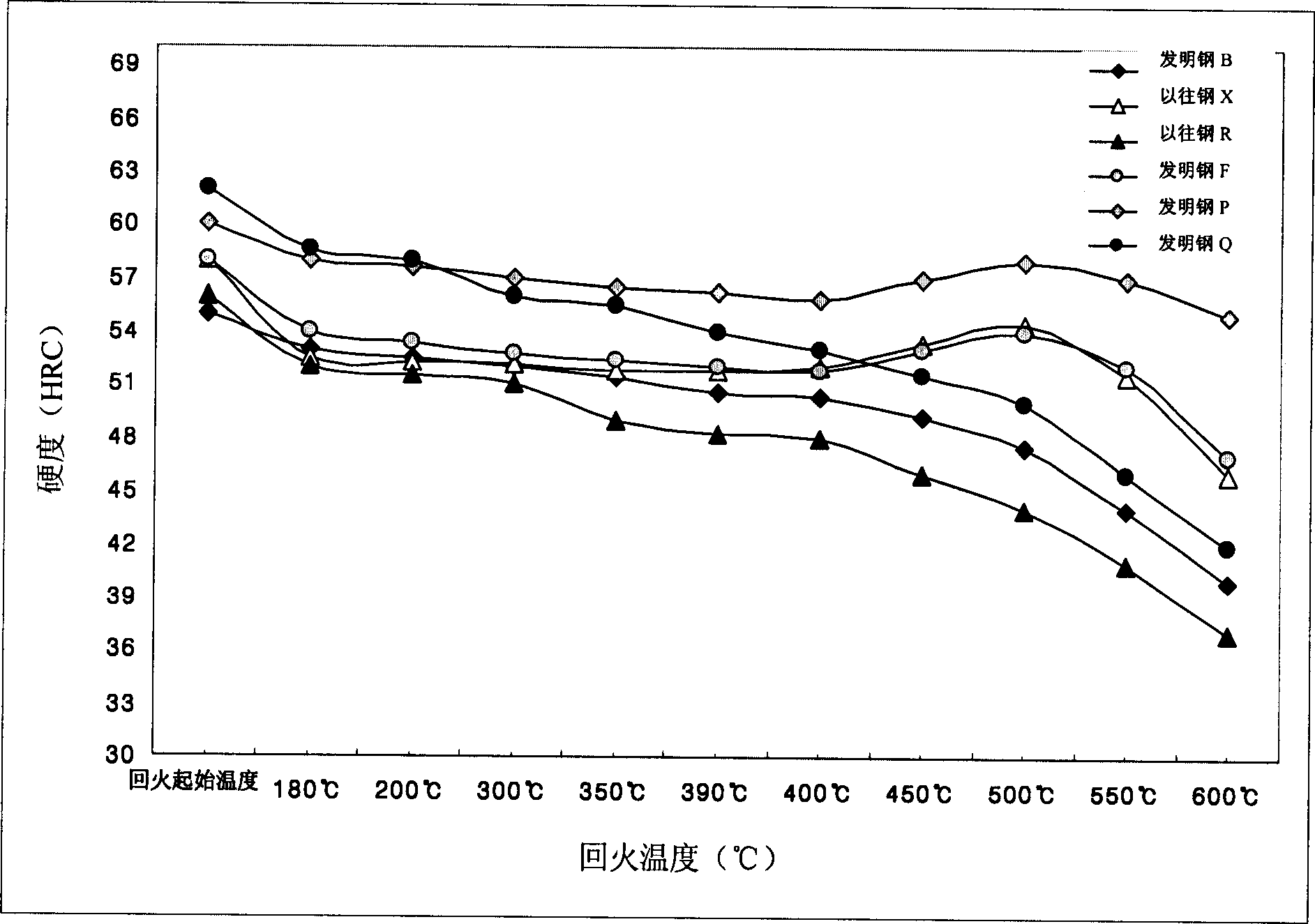

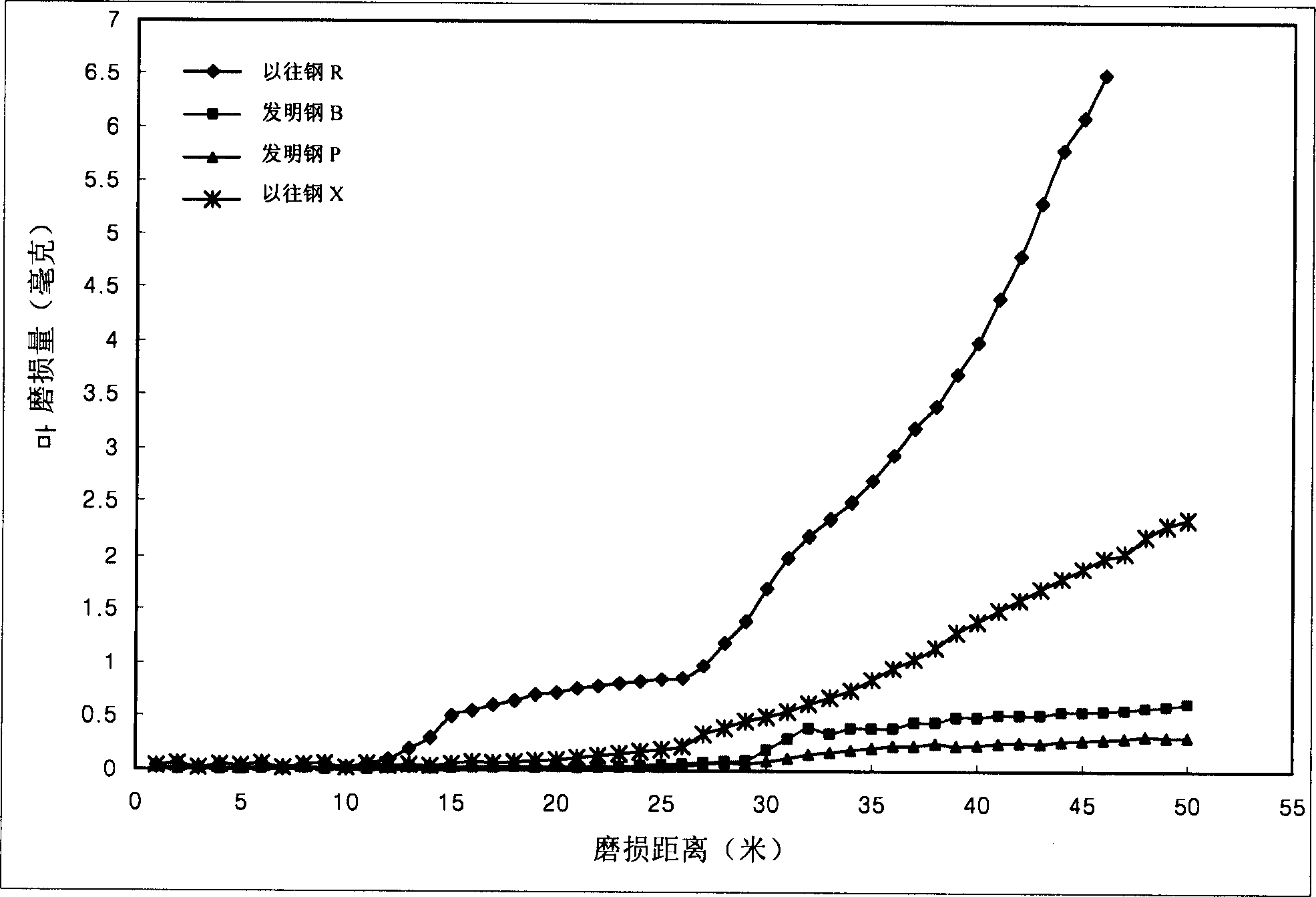

High elasticity and high strengh steel and its producing method

An impact-resistant and wear-resistant high-elasticity and high-strength steel, wherein the steel contains 0.26-0.48 wt% C, 1.4-2.5 wt% Si, 0.5-1.0 wt% Mn, 1.4-2.4 wt% % Cr, 0.01-0.1% by weight of Ni, 0.01-0.5% by weight of Mo, 0.005-0.04% by weight of Al, 0.05-0.1% by weight of V, 0.0025-0.02% by weight of N, the rest is Fe and unavoidable of impurities. The impact-resistant, wear-resistant high-elasticity and high-strength steel of the present invention has high hardness, high strength, high toughness and high elasticity, and the weldability, low-temperature tempering resistance and high-temperature tempering resistance, hardenability, Mechanical properties such as wear resistance, impact toughness, and tensile strength are excellent, so when used under severe conditions, the mold life and component life are much longer than conventional steels.

Owner:CF +2

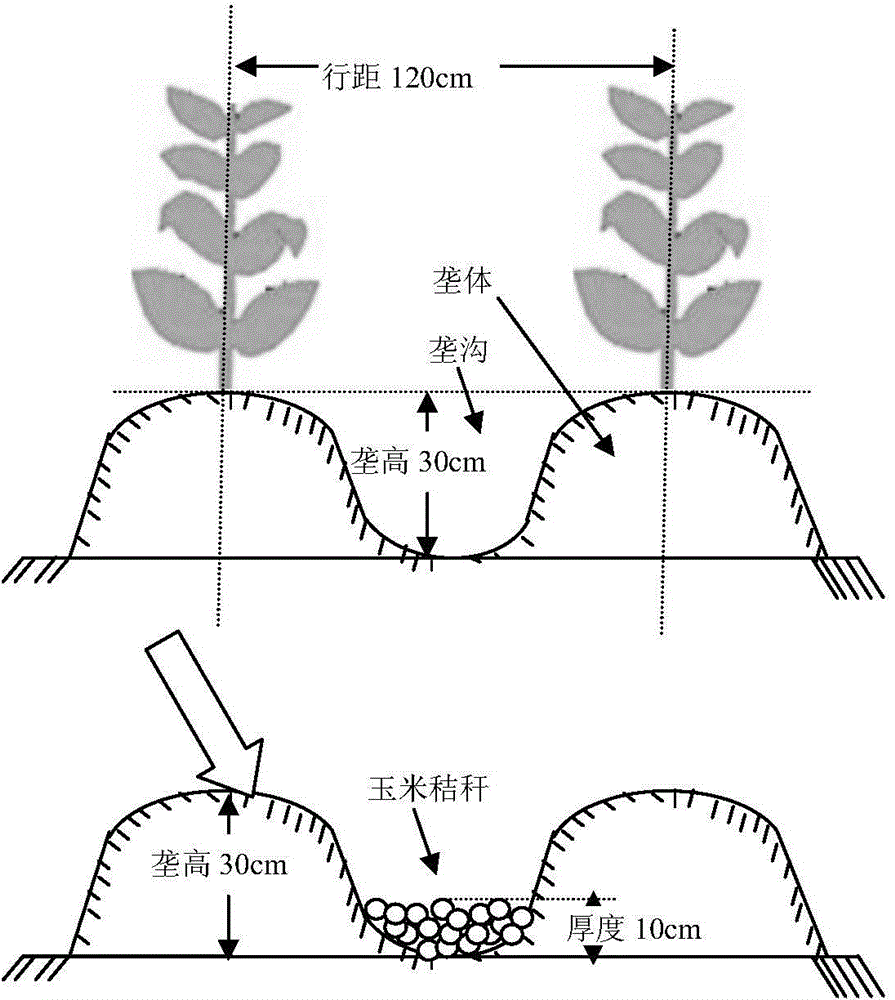

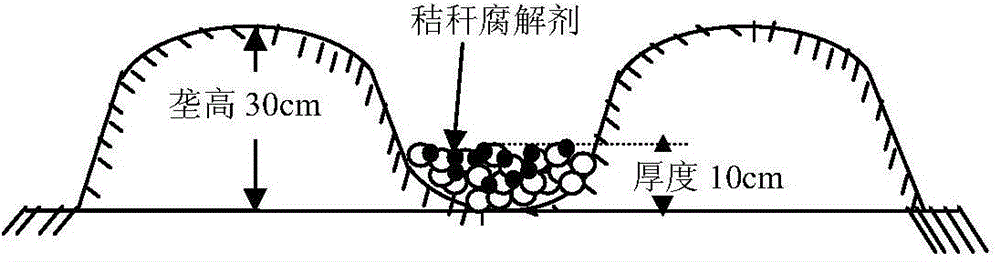

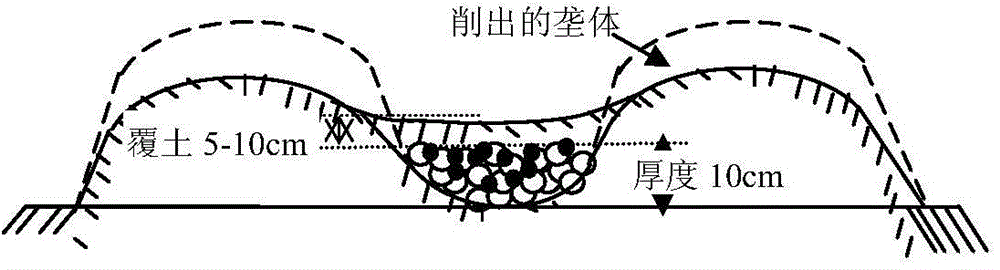

Method for ecologically improving tobacco-planting soil

ActiveCN104813769AReduce the amount of seed usedImprove soil improvement effectHorticultureSoil-working methodsDecompositionGreen manure

A method for ecologically improving tobacco-planting soil is disclosed. In October of the first year, after flue-cured tobaccos or corns are harvested, straws are chopped down and spread on furrows directly without plowing soil, straw decomposition accelerator or other microbe fertilizers are spread on the straws, and then ridge soil is dumped in furrows to cover and bury the straws. Green manure is applied in lines, common vetch green manure is applied on the soil surface burying the straws in lines with a width of 55-65cm, and the green manure is buried by ridging without plowing. In the next year, 10-15days before transplanting flue-cured tobaccos, flue-cured tobacco base fertilizer is applied on the green manure according to the line-spacing requirements of flue-cured tobaccos, soil is gathered to the green manure from two sides of the green manure to bury the green manure and ridge for planting flue-cured tobaccos. The method effectively improves soil, lowers production investment, ensures high yield, improves the physical properties of the soil, and increases organic matters and nutrients of the tobacco-planting soil. Moreover, the microbe amount and enzyme activity of the soil and the tobacco leaves quality are improved, the soil quality is retained and improved, and continuous flue-cured tobacco production and development in tobacco areas are facilitated.

Owner:HUNAN AGRICULTURAL UNIV

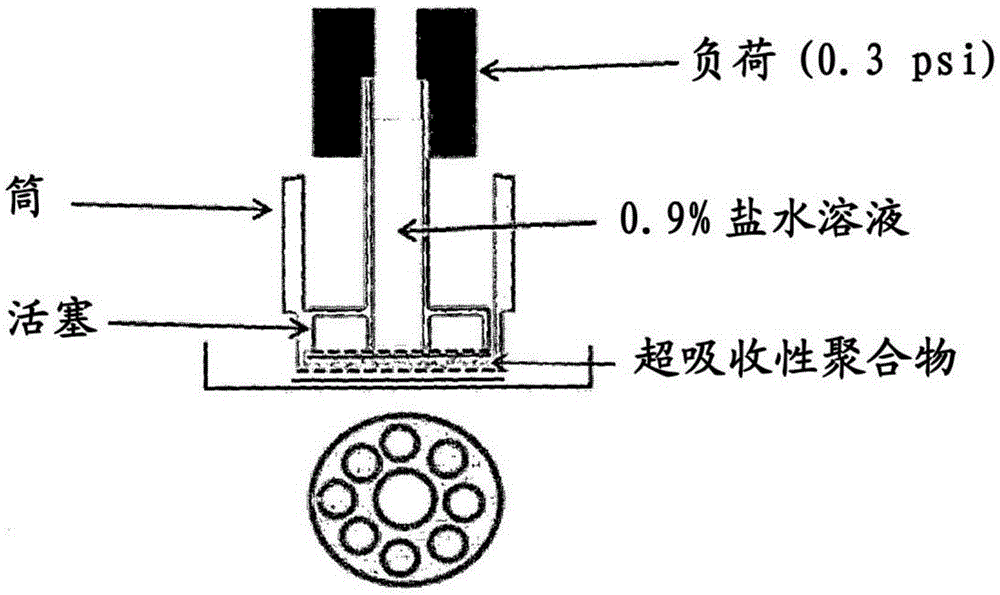

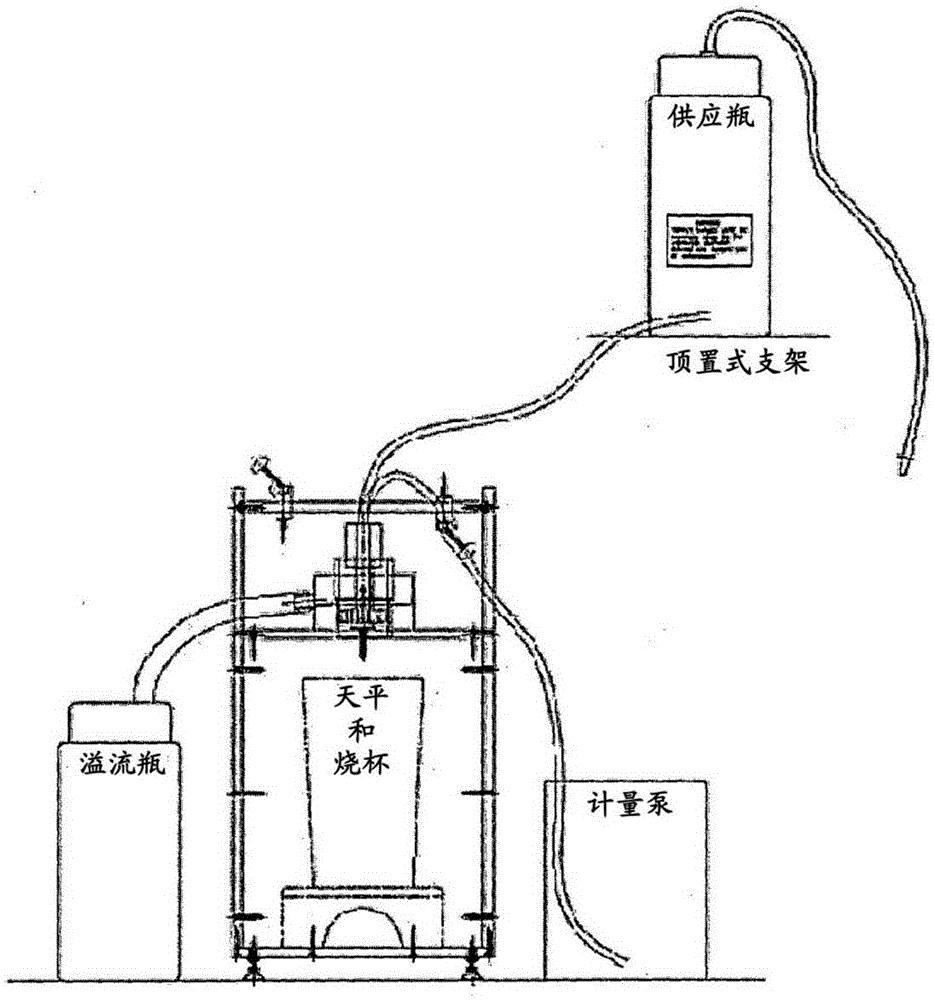

Super absorbent polymer

ActiveCN105392805AImprove physical propertiesEasy and comfortable to wearAbsorbent padsBandagesSuper absorbentEngineering

The present invention relates to a super absorbent polymer which has excellent initial water absorption and which is watertight under pressure, even after time has elapsed, and concurrently optimizes, to predetermined ranges, centrifuge repair capability (CRC), absorbency under load (AUL), gel bed permeability (GBP), and absorption rate under pressure, etc. of the super absorbent polymer, thereby being capable of improving the physical properties of the final diaper, and thereby being capable of manufacturing a diaper to which ultra-thin technology has been applied.

Owner:LG CHEM LTD

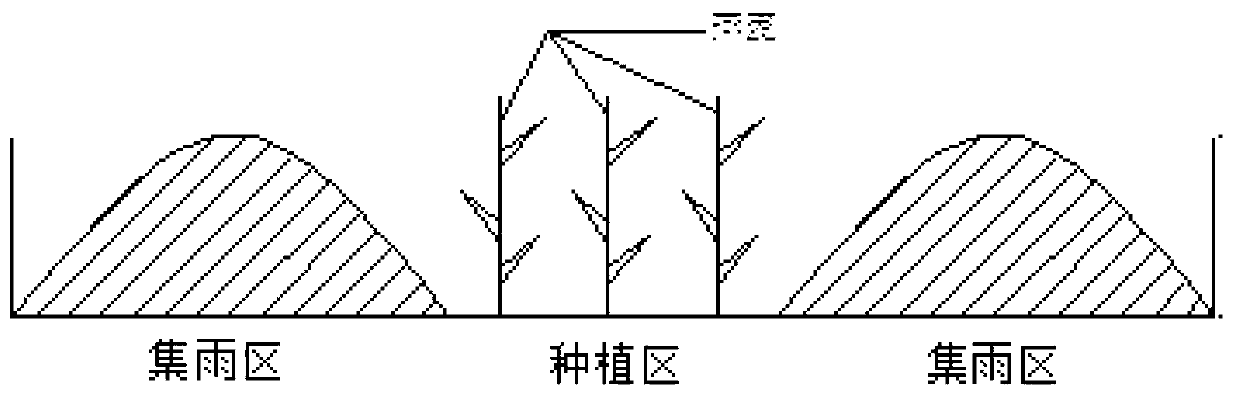

Covering cultivation method for biodegradable mulching films in semi-arid region

InactiveCN103340088AReduce water evaporationIncrease and maintain moisture contentClimate change adaptationPlant protective coveringsAridEvaporation

The invention mainly relates to a covering cultivation method for mulching films, in particular to a covering cultivation method for biodegradable mulching films in a semi-arid region. The covering cultivation method is mainly characterized by comprising the following steps of 1, designing in fields, 2, tidying land, ridging and flattening the ground 3, fertilizing, 4, covering the biodegradable mulching films, 5, sowing, 6, managing in the fields, 7, harvesting, and 8, ploughing and burying mulching film residues into soil at the depth of 20-30cm instead of collecting the mulching film residues after the crops are harvested. The land tidying and ridging are carried out 7 days before crops are sowed, the covering tension of the biodegradable mulching films is 1 / 6 to 1 / 8 of the tension of ordinary mulching films, the biodegradable mulching films are 3-5mm away from the ground, and the biodegradable mulching films are covered 7 days before sowing. The covering cultivation method has the advantages that due to the fact that the biodegradable mulching films have high air tightness, the covered mulching films can reduce soil moisture evaporation and increase land temperature, can increase soil moisture, accelerates crop growth and development, and improves crop yield. Compared with traditional cultivation (covering-free convection planting), a maturation stage of crops covered by the biodegradable mulching films can be brought 7-10 days forwards, and the crop yield and the moisture utilization rate can be respectively improved by 1-58% and 14-45%.

Owner:GANSU AGRI UNIV

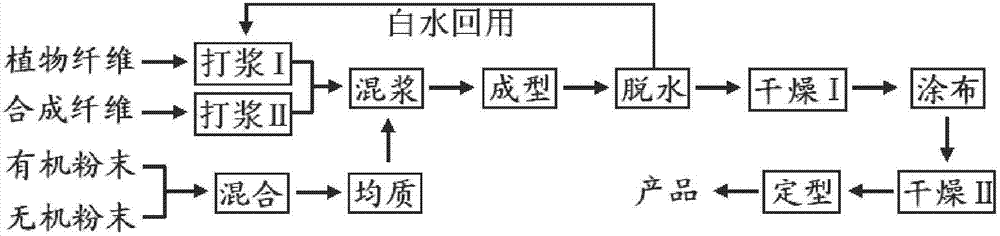

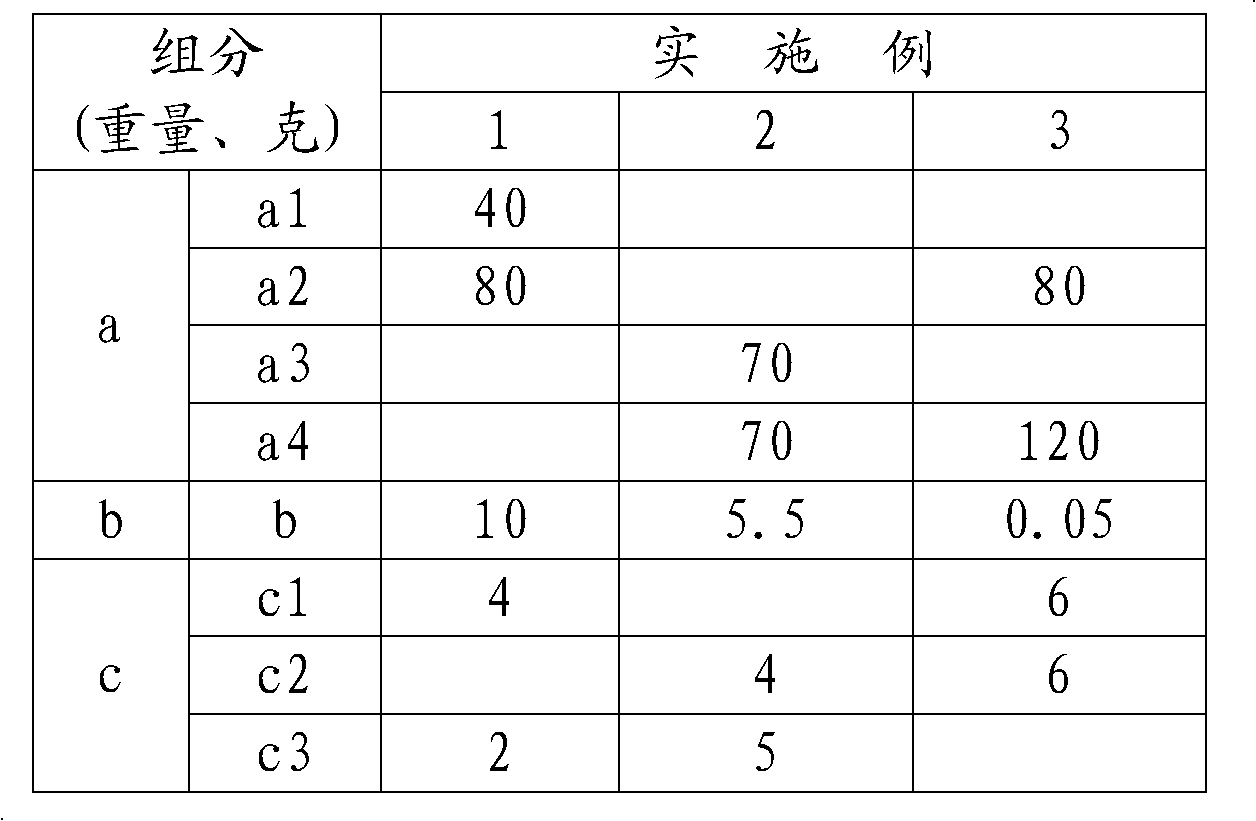

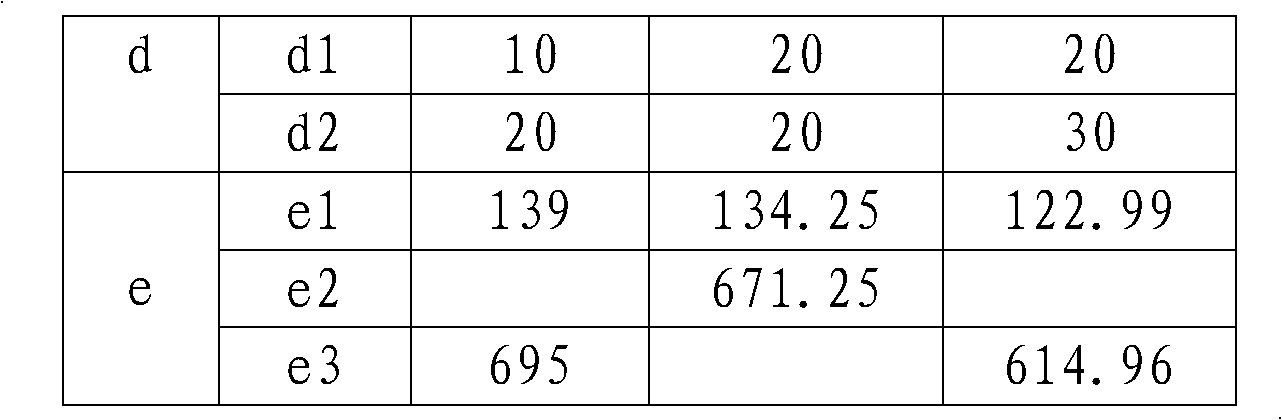

Battery capacitor membrane filtration material prepared by using wet papermaking forming process, and preparation method thereof

InactiveCN102728144AImprove uniformityImprove physical propertiesSpecial paperPaper/cardboardEconomic benefitsPolymer science

The present invention discloses a battery capacitor membrane filtration material prepared by using a wet papermaking forming process, and a preparation method thereof. Raw materials for preparing the material comprise, fibers, inorganic powder, organic powder and a reinforced material, wherein the fibers comprise, by weight, 3-10% of plant fibers and 90-97% of synthetic fibers, the weight of the inorganic powder is 1-40% of the weight of the fibers, the weight of the organic powder is 0.1-20% of the weight of the fibers, and the weight of the reinforced material is 10-30% of the weight of the fibers. The preparation method is characterized by: respectively carrying out pulping on the plant fibers and the synthetic fibers, and respectively carrying out high pressure homogenization mixing on the inorganic powder and the organic powder. The preparation method of the present invention has the following advantages that: the process is simple, the hole size can be effectively controlled, and the hole uniformity can be improved, wherein the holes are the labyrinth type curved holes. The material of the present invention has the following advantages that: filtration accuracy and filtration efficiency are high, internal resistance of the membrane prepared by the material is lowered, the membrane prepared by the material has characteristics of high liquid retention rate, good high temperature resistance, small deformation size, avoidance of dendrite generation and long service life. The raw material and the preparation cost of the material of the present invention are the same as the raw material and the preparation cost of full chemical fiber filtration material, and the performance price ratio of the material of the present invention is more excellent than the performance price ratio of the traditional materials, such that good economic benefits and social benefits are provided.

Owner:吕凯

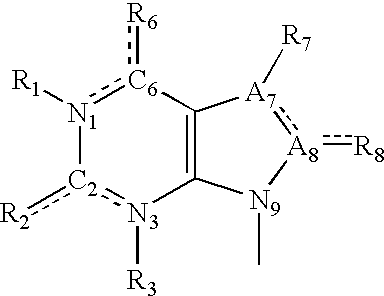

High-performance silicon-based wave absorbing material and preparation method thereof

InactiveCN102585507AExcellent electrical propertiesImprove physical propertiesOther chemical processesAviationAging resistance

The invention relates to a high-performance silicon-based wave absorbing material and a preparation method thereof. The high-performance silicon-based wave absorbing material comprises the following raw materials in percentage by weight: 12-16 percent of silicon rubber, 0.005-1 percent of a silane coupling agent, 0.6-1.2 percent of a vulcanizing agent, 3-5 percent of a flame retardant and 76.8-84.4 percent of an absorbent. The method comprises the following steps of: drying the absorbent, and grading the particle diameter of the absorbent; coating the absorbent; and mixing. The high-performance silicon-based wave absorbing material disclosed by the invention has excellent electric and physical properties, aging resistance, high and low temperature resistance and the like, and can be applied to military electronic equipment such as aviation, space flight, naval vessels and the like, working stations, computers, data communication, communication equipment and the like.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

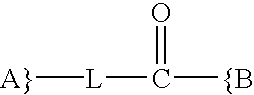

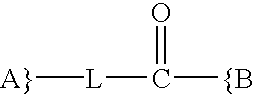

Synthesis and methods of use of purine analogues and derivatives

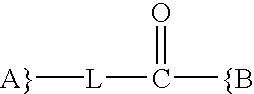

A purine derivative or analogue comprises a 9-atom bicyclic moiety, moiety A, linked through a linker L to a moiety B, where B is a carboxylic acid, a carboxylic acid ester, or a moiety of the structure N(Y1)-D, where Y1 can be one of a variety of substituents, including hydrogen or alkyl, and D is a moiety that enhances the pharmacological effects, promotes absorption or blood-brain barrier penetration of the derivative or analogue. The moiety A has a six-membered ring fused to a five-membered ring. The moiety A can have one, two, or three nitrogen atoms in the five membered ring and has two nitrogen atoms in the six-membered ring. The moiety A can be a purine moiety. The moiety B can be one of a variety of moieties, including moieties having nootropic activity or other biological or physiological activity.

Owner:NEOTHERAPEUTICS

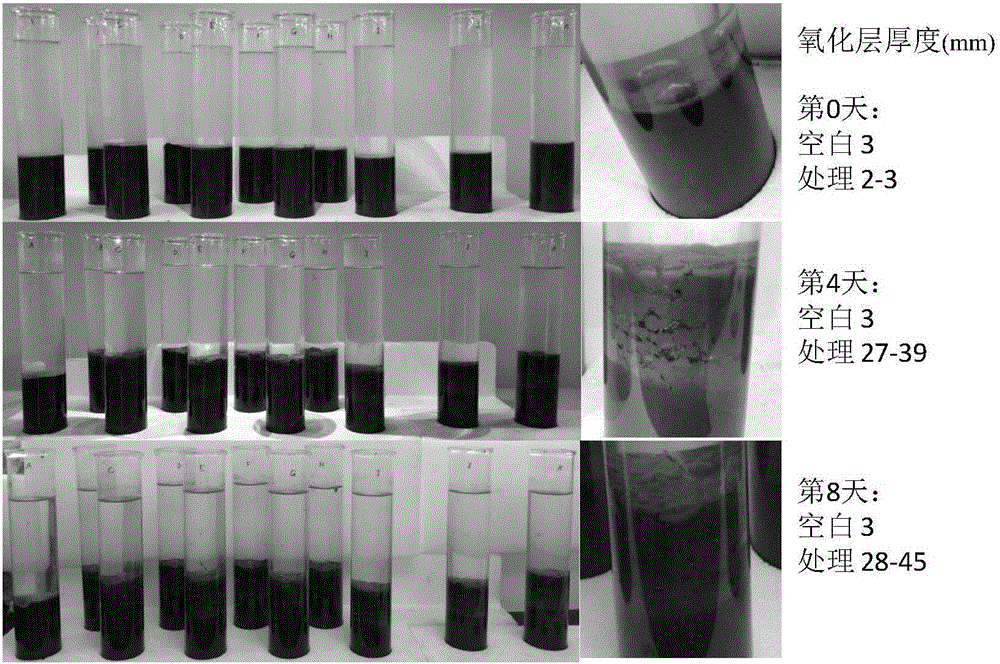

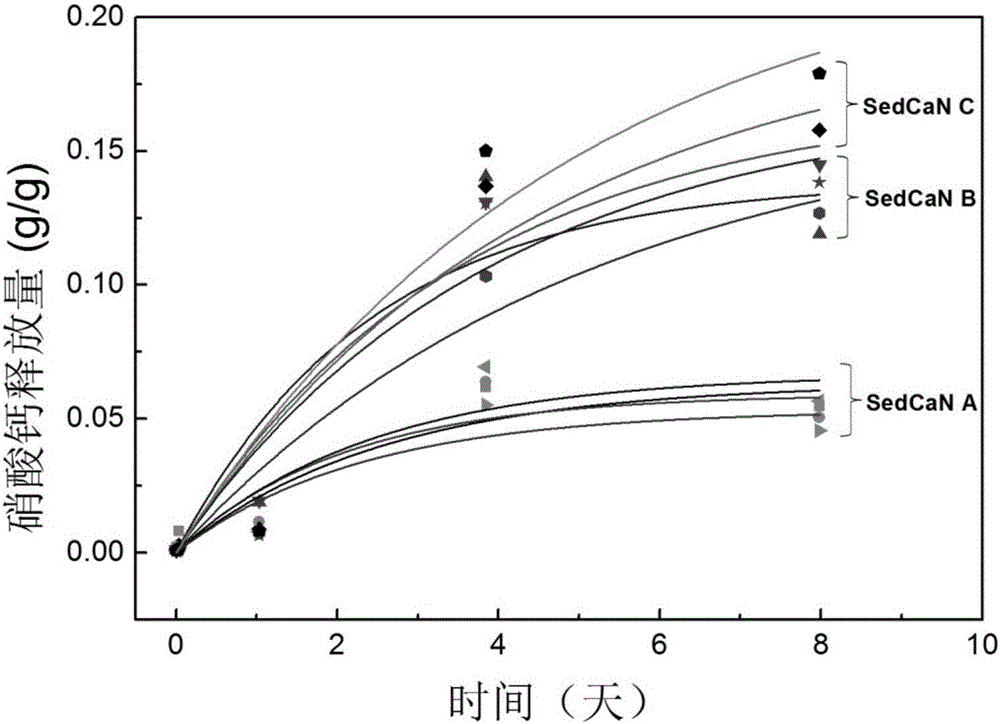

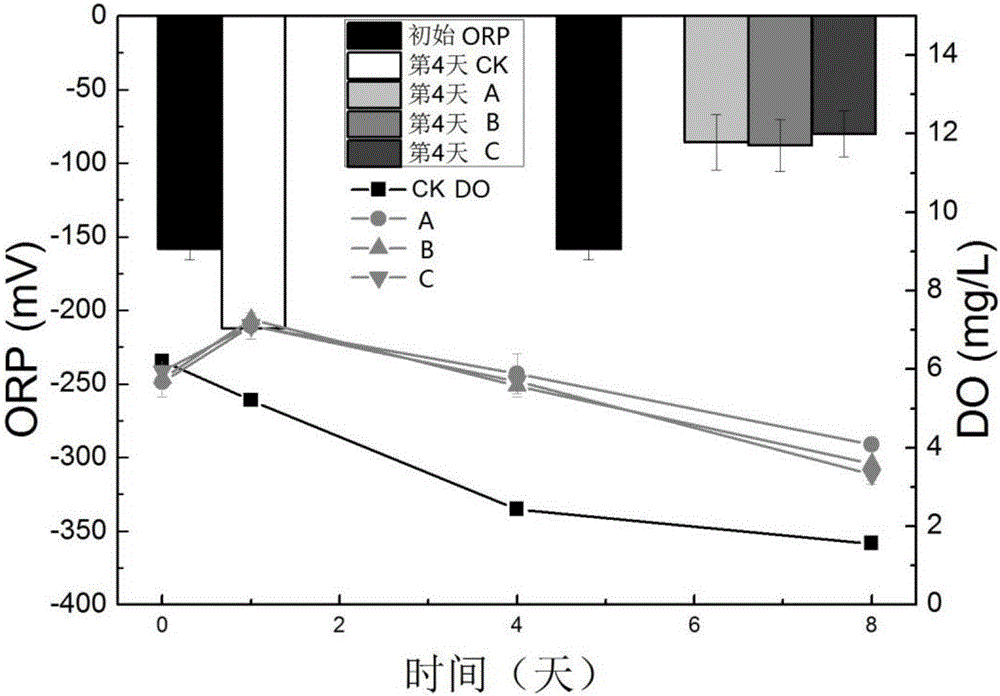

Environment-friendly calcium nitrate slow-release granule for remedying bottom mud of black and odorous river and preparation method of environment-friendly calcium nitrate slow-release granule

ActiveCN105800899AInvalid releaseEffective oxidationSludge treatment by oxidationContaminated waterways/lakes/ponds/rivers treatmentActivated carbonAlcohol

The invention discloses an environment-friendly calcium nitrate slow-release granule for remedying bottom mud of a black and odorous river and a preparation method of the environment-friendly calcium nitrate slow-release granule. The environment-friendly calcium nitrate slow-release granule for remedying bottom mud of the black and odorous river takes the bottom mud as a remediation agent additive; firstly, a great amount of denitrification bacteria are enriched through denitrification modification, secondly, activated carbon is added, and together with polyving alcohol and sodium alginate as slow-release agents and sodium alginate as a coating material, the calcium nitrate slow-release granule can be prepared. The environment-friendly calcium nitrate slow-release granule is capable of effectively eliminating black and odorous pollution of the bottom mud, has characteristics of high efficiency and environment-friendliness, and has a great significance for city environment protection.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

Sizing agent for carbon fiber, aqueous dispersion of the same, carbon fiber treated by sizing, sheet comprising the carbon fiber, and carbon fiber-reinforced composite material

InactiveUS20040191511A1Excellent impregnationStrong interface adhesionCarbon fibresSynthetic resin layered productsIonSurface energy

Owner:MITSUBISHI CHEM CORP

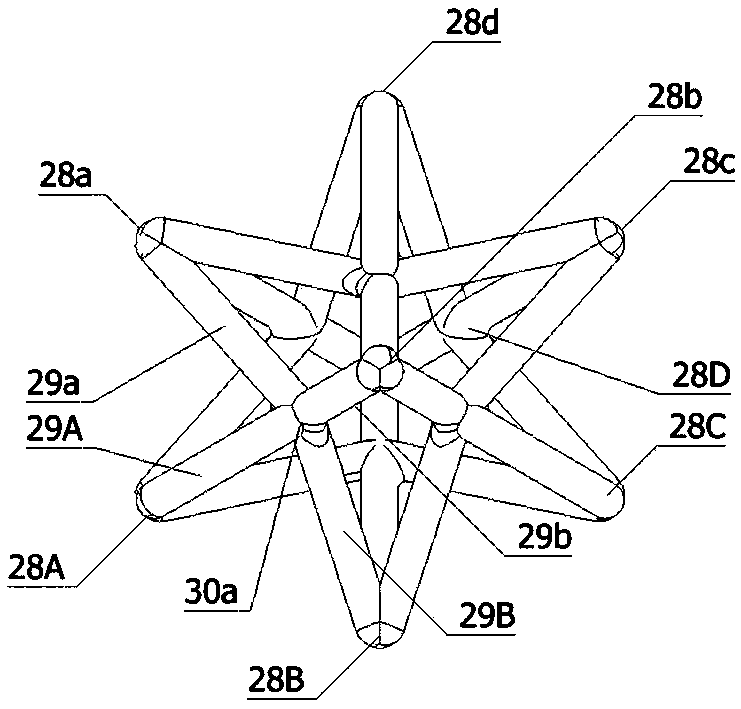

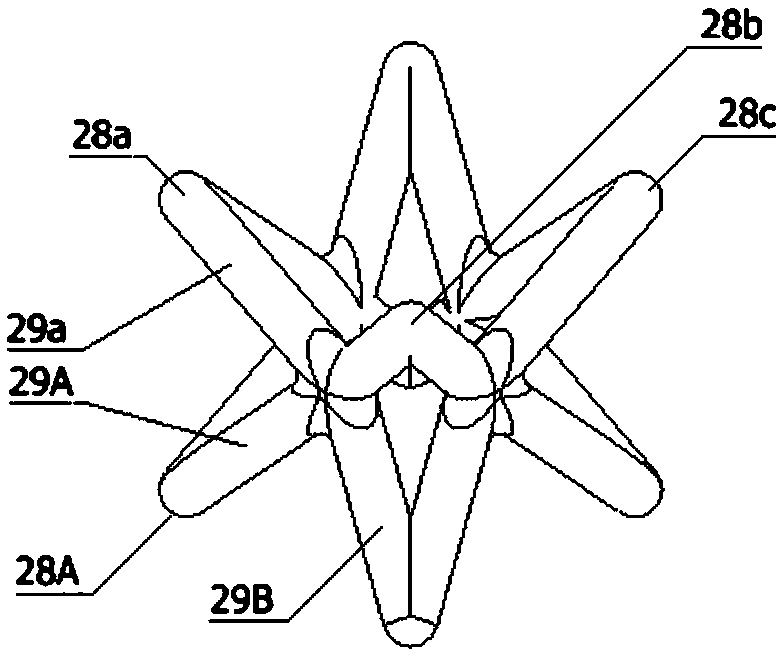

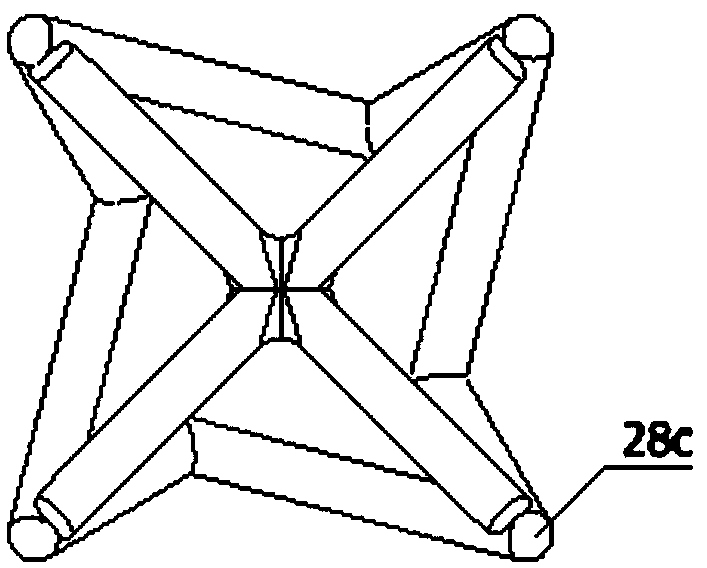

Multi-face inner-sunken pyramid-shaped negative poisson ratio space dot matrix structure and pressure bearing plate thereof

PendingCN108386467AImprove ultimate load capacityImprove deformation abilityRubber-like material springsShock absorbersDot matrixPlastic materials

The invention belongs to the field of pressure resistance or pressure bearing or supporting structures and particularly relates to a multi-face inner-sunken pyramid-shaped negative poisson ratio spacedot matrix structure and a pressure bearing plate thereof. Based on the multi-face inner-sunken pyramid-shaped negative poisson ratio space dot matrix structure, the pressure-resistant or pressure-bearing structure made of an elastic material and used for supporting can be used, the overall pressure-resistant and pressure-bearing capacity is improved, and the structural damage is avoided; and based on the multi-face inner-sunken pyramid-shaped negative poisson ratio space dot matrix structure, the pressure-bearing structure (bridges, flat plates and the like) made of an elastic material or aplastic material and provided with the two ends being constrained can be used, in the middle pressure bearing process, auxiliary supporting lines located on the upper and lower supporting faces can resist thinning of the section of the pressure-bearing structure, breaking of the pressure-bearing structure is prevented, and the pressure-bearing capacity is improved; and based on the multi-face inner-sunken pyramid-shaped negative poisson ratio space dot matrix structure, a protection reinforcing and buffering structure made of a plastic material can be used, the characteristics of small weightand high strength are achieved, and the problems of instantaneous impact damage, reduction of follow-up bearing capacity of a buffering structure and the like are effectively avoided.

Owner:NAVAL UNIV OF ENG PLA

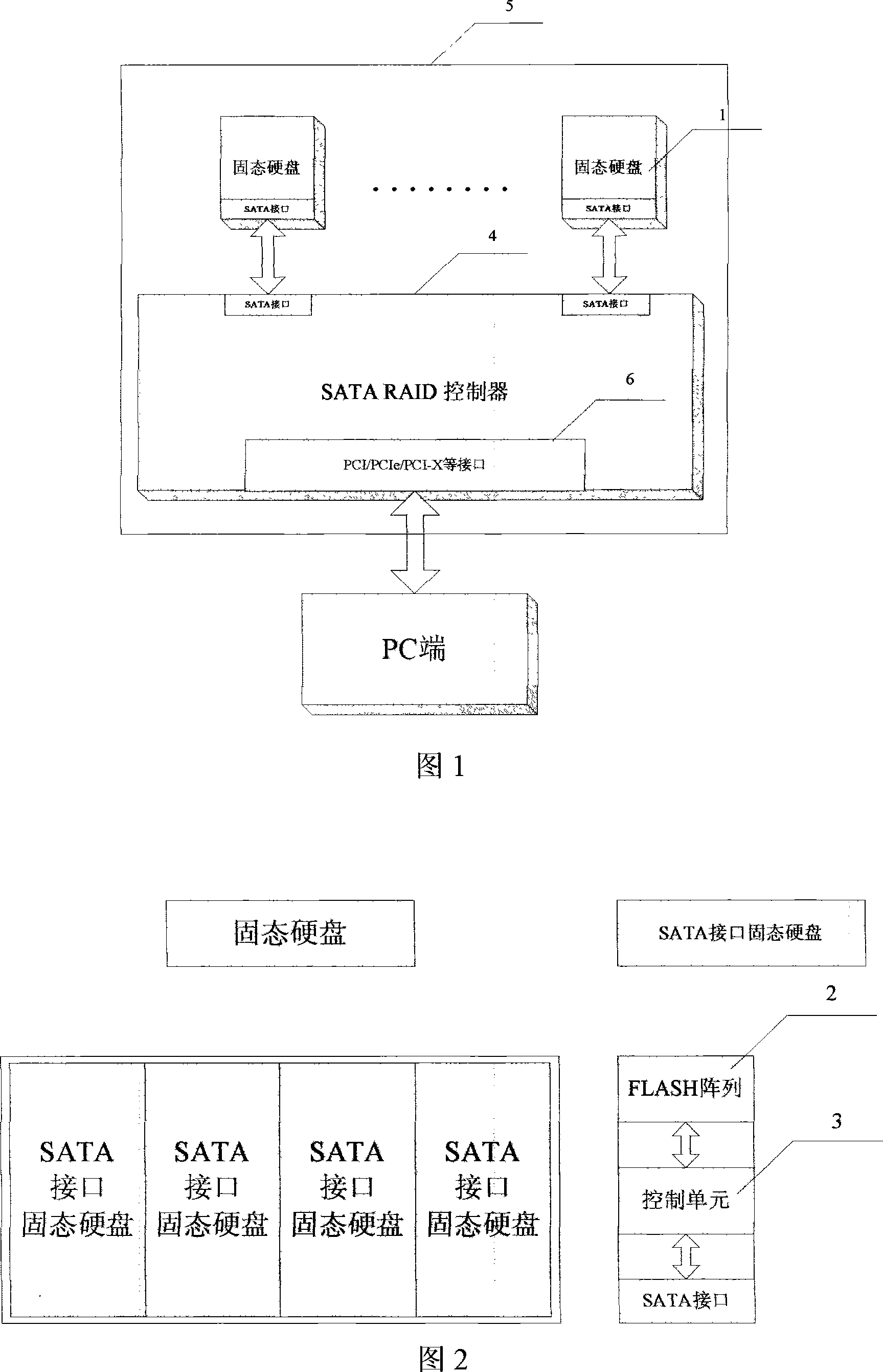

Solid state hard disk memory card based on RAID technology

The invention relates to a solid-state drive memory card based on RAID technology, which comprises a solid-state hard drive (including four SATA interface solid-state drives, each drive includes a FLASH array and a control unit), a SATA RAID controller, and a PCI / PCIe / PCI-X / CPCI interface at PC end. The realization of the RAID among the solid-state drives increases the capacity, read / write speed and I / O processing capacity of the whole hard disk. The invention can be used in specific areas with higher requirements to the capacity and the storage rate.

Owner:RUNCORE HIGH TECH

Sensor package for harsh environments

InactiveUS6911894B2Improve physical propertiesReduce the amount requiredMaterial thermal conductivityVolume/mass flow by thermal effectsEngineeringContamination

A sensor can be configured to generally include a flow channel block having a flow channel formed therein, and a sensor chip for sensing fluid flow, wherein a fluid in the flow channel surrounds the sensor chip. Alternatively, the sensor chip can be fastened at one side to a substrate and on another side of the substrate to a core tube inserted into the flow channel. This core tube provides electrical insulation and corrosion protection to the sensor chip, reduces flow noise, (and by the non-intrusive nature of the measurement) essentially eliminates the risk of fluid leakage, and maintains the fluid super-clean and contamination-free while improving structural integrity for the thermal measurements derived from the sensor chip. The use of such a core tube configuration also can protect the sensor from corrosion, radioactive or bacterial contamination, overheating, or freeze-ups. Such a core tube configuration also enables the core tube to be detachable and disposable, without requiring the replacement of the more costly sensor chip with its electronics and calibration.

Owner:HONEYWELL INT INC

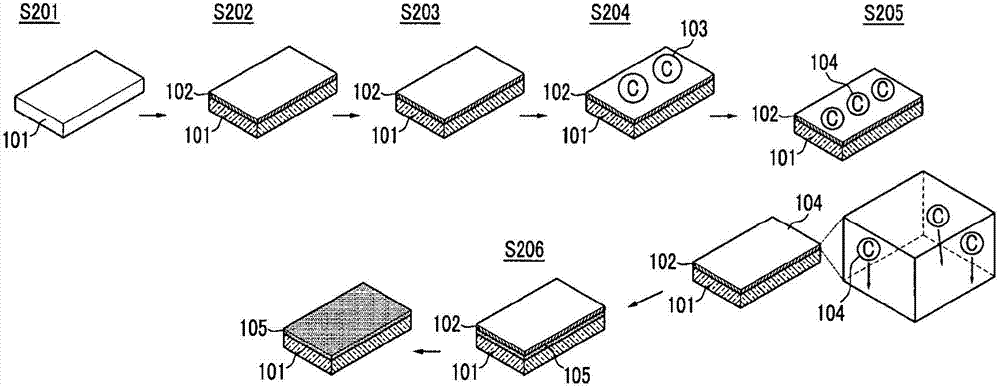

Selective laser sintering forming method

InactiveCN103192080ADegree of small warpageShorten the production cycleIncreasing energy efficiencySelective laser sinteringMetallurgy

The invention relates to a selective laser sintering forming method and a powder material applied to the same. The selective laser sintering forming method comprises the following steps of: (1) preparing the powder material used for the selective laser sintering forming method; (2) drawing the three-dimensional outline of a model to be prepared by using three-dimensional cartographic software, inputting into a laser sintering forming machine, and carrying out layered calculation on the three-dimensional outline according to set layer thickness through the control software of the laser sintering forming machine to obtain multilayer sectional vectograph information and each sectional laser scanning path; (3) initializing the parameters of the laser sintering forming machine according to the model; (4) carrying out laser scanning through the laser sintering forming machine, and paving a new layer of powder materials after one layer of powder materials are completely sintered for sintering; and (5) repeating step (4) till a last layer of powder materials is completely sintered. The selective laser sintering forming method disclosed by the invention has the advantages of sintering at normal temperature, shortened production period and good physical characteristic and low buckling deformation degree of the formed model.

Owner:余振新

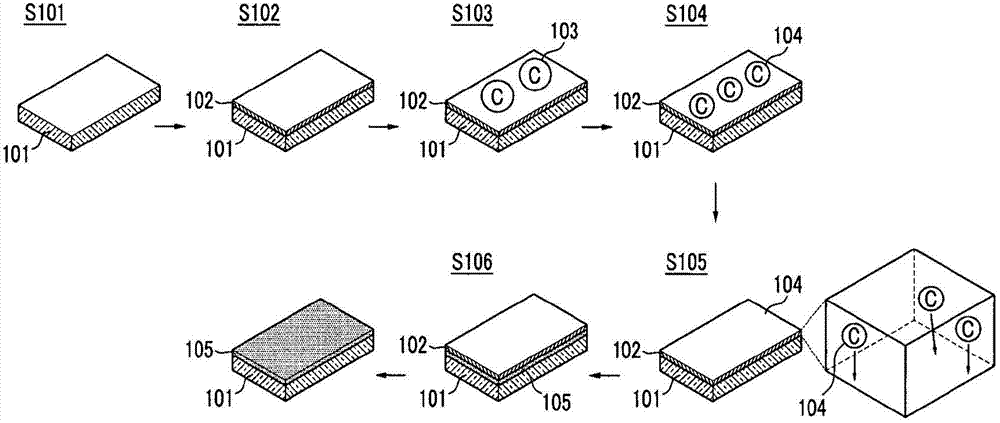

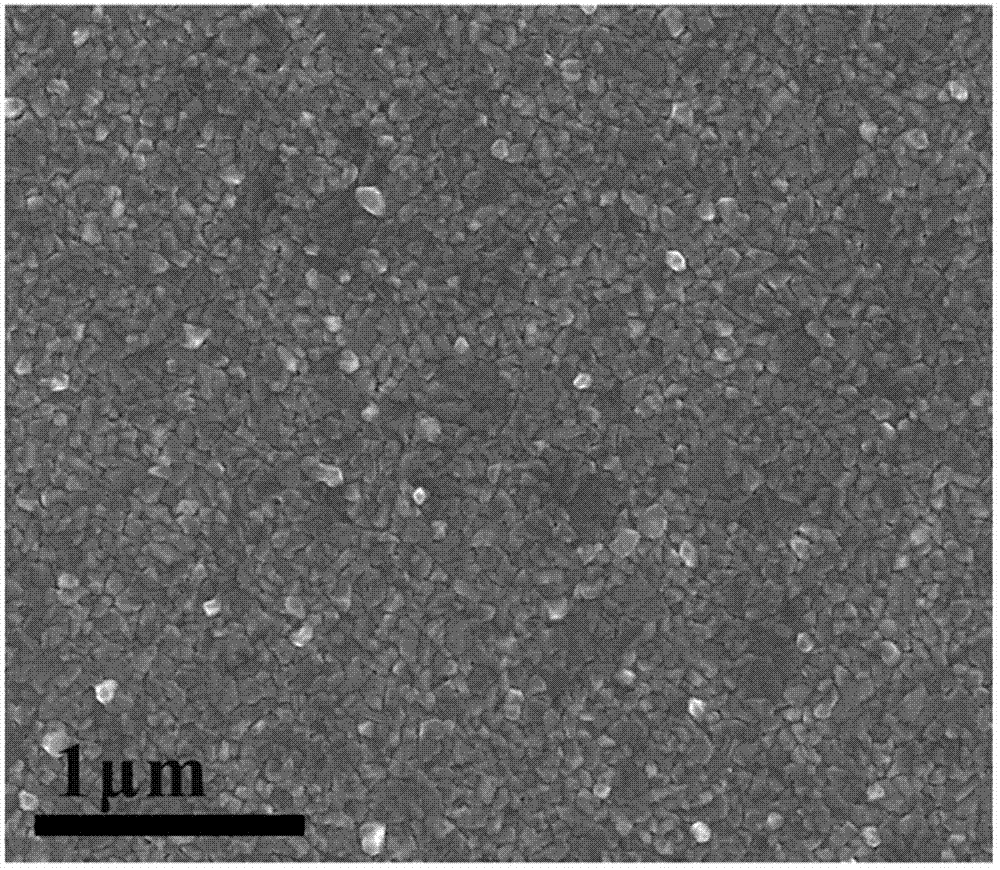

Method for manufacturing graphene, transparent electrode and active layer comprising the same, and display, electronic device, optoelectronic device, battery, solar cell, and dye-sensitized solar cell including the electrode and the active layer

InactiveCN102791626AImprove physical propertiesExcellent electrical propertiesMaterial nanotechnologyFinal product manufactureDisplay deviceSolar cell

Disclosed is a method of manufacturing graphene, a transparent electrode and an active layer including the graphene, and a display, an electronic device, an optoelectronic device, a solar cell, and a dye-sensitized solar cell including the transparent electrode and the active layer. The method of manufacturing graphene includes: (a) preparing a subject substrate; (b) forming a metal thin film on the subject substrate and heat-treating the metal thin film to increase the grain size of the metal thin film; (c) supplying a carbon source material on the metal thin film; (d) heating the supplied carbon source material, the subject substrate, and the metal thin film; (e) diffusing carbon atoms generated from the heated carbon source material due to thermal decomposition into the metal thin film; and (f) forming graphene on the subject substrate by the carbon atoms diffused through the metal thin film.

Owner:UNIST (ULSAN NAT INST OF SCI & TECH)

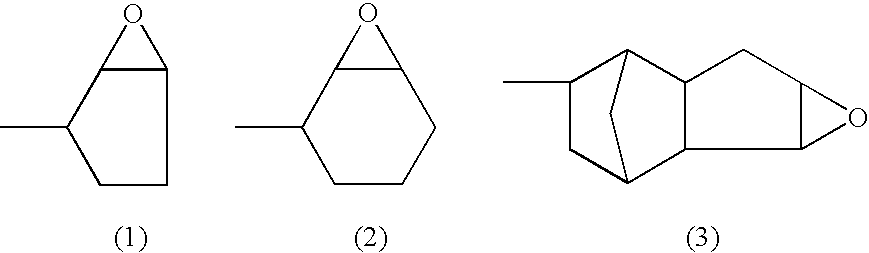

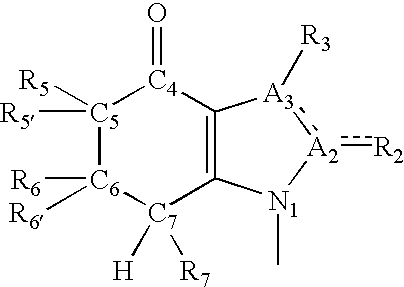

Synthesis and methods of use of tetrahydroindolone analogues and derivatives

InactiveUS6759427B2Improve bioavailabilityImprove physical propertiesBiocideNervous disorderBlood brain barrier penetrationCarboxylic acid

A tetrahydroindolone derivative or analogue comprises a 9-atom bicyclic moiety, moiety A, linked through a linker L to a moiety B, where B is a carboxylic acid, a carboxylic acid ester, or a moiety of the structure N(Y1)-D, where Y1 can be one of a variety of substituents, including hydrogen or alkyl, and D is a moiety that enhances the pharmacological effects, promotes absorption or blood-brain barrier penetration of the derivative or analogue. The moiety A has a six-membered ring fused to a five-membered ring. The moiety A can have one, two, or three nitrogen atoms in the five membered ring. The moiety A can be a tetrahydroindolone moiety. The moiety B can be one of a variety of moieties, including moieties having nootropic activity or other biological or physiological activity.

Owner:SPECTRUM PHARMA INC

Production of fine-grained particles

InactiveCN1476413AImprove physical propertiesMaterial nanotechnologyNanostructure manufactureActive agentPhysical chemistry

Particles of mixed metal oxide include at least two metal species. The particles have a grain size within the range of 1-100 nm. The particles are substantially crystalline. The particles contain only small or negligible amounts of amorphous material. The at least two metal species are uniformly dispersed in the particles.

Owner:VERY SMALL PARTICLE CO LTD

Extrusion process for forming chemically stable drug multiparticulates

ActiveUS7625507B2Reducing drug degradation of drugImprove physical propertiesAntibacterial agentsPowder deliveryExtrusionDrug degradation

Owner:LONZA BEND INC

Dura substitute and a process for producing the same

ActiveUS7374775B2Improve physical propertiesPowder deliveryCeramic shaping apparatusProsthesisUltimate tensile strength

The invention relates to dura substitutes to be used as prostheses for dural defects in the field of neurosurgery and processes for producing the same. The present invention provides artificial dura mater materials comprising sheets of microbial-derived polysaccharide processed to have the necessary strength characteristics, conformability and physical properties.

Owner:SYNTHES GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com