Patents

Literature

66results about How to "Strong interface adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing Wood-plastic composite material by modified wood powder and waste and old plastics

The invention relates to a preparation technique of a wood plastic composite material, in particular to a method for preparing a wood plastic composite material by using modified wood powder and waste plastics. The method is characterized in that: (1) discarded agriculture and forestry wastes are crushed, milled and dried, and three different surface modification agents are added in sequence and mixed with the waste power one after another in a high-speed mixer to produce the modified water powder; and (2) waste plastics are washed and crushed into granules with the grain size of 2mm to 12mm and then dried; the modified waste powder, the waste plastic granules, a lubricant, a vesicant and a blowing promoter are mixed by weight percentage and put into the high-speed mixer for high-speed mixing and then cooled to the temperature lower than 55 DEG C for discharging so as to prepare a special premix. The composite material has super high strength and anti-bending and anti-impact capacity, wherein, the obvious enhancement of the anti-impact strength causes the great enhancement of the processing capacity of the product, thus causing products to meet different demands and ensuring an extremely wide application range.

Owner:FUJIAN NORMAL UNIV

Polysaccharide/calcium orthophosphate composite bone cement and preparation method thereof

InactiveCN101496909AGood biocompatibilityNo adverse reactionBone implantCalcium biphosphateBiocompatibility Testing

The invention discloses a polysaccharide / autosolidification calcium phosphate composite bone cement composition, which comprises the following components in percentage by weight: 10 to 95 weight percent of autosolidification calcium phosphate bone cement and 5 to 90 weight percent of polysaccharide. The bone cement composition can obtain bone cement with high strength, good toughness, strong plasticity, quick solidification, and good biocompatibility and degradability, thereby overcoming the defects of inadequate toughness and slow degradation in human bodies existing in the prior calcium phosphate bone cement materials and the defects existing in a plurality of enhancement methods in the prior art, and better meeting the requirement of operation use.

Owner:EAST CHINA UNIV OF SCI & TECH

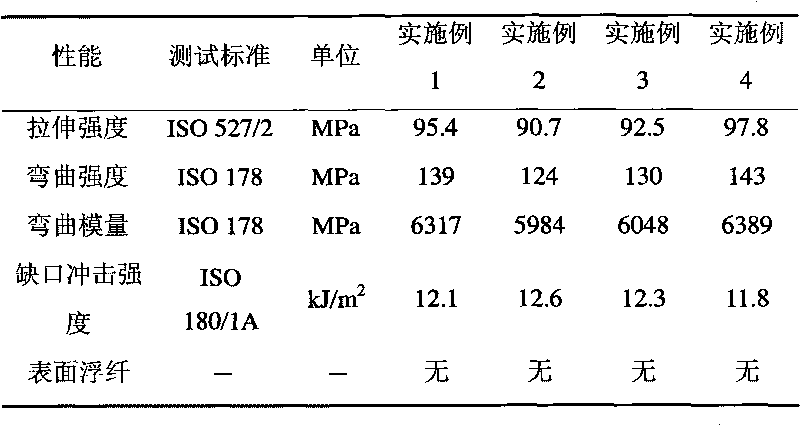

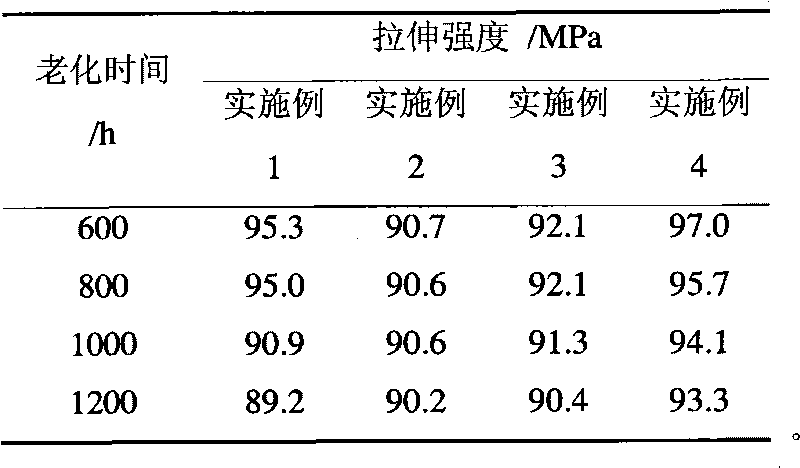

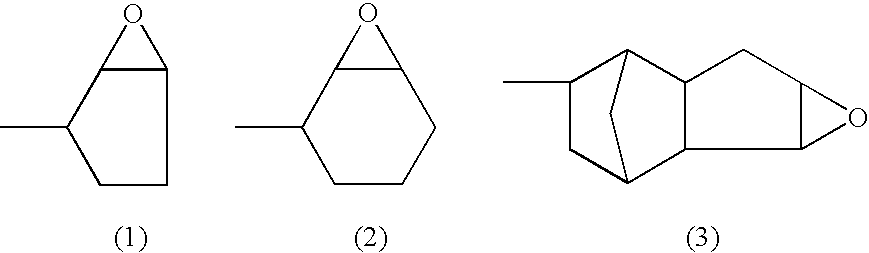

Copper toxicity-resistant glass fiber reinforced polypropylene composite material and preparation method thereof

InactiveCN101698725AStrong interface adhesionImprove adhesionPolypropylene compositesProcedure Agents

The invention relates to a copper toxicity-resistant glass fiber reinforced polypropylene composite material and a preparation method thereof, and the copper toxicity-resistant glass fiber reinforced polypropylene composite material consists of the following raw materials by weight percent: 60-65% of polypropylene, 2-7% of compatilizer, 0.7-2% of composite antioxidant, 0-0.02% of anti-copper toxicity agent, 0.1-0.8% of processing additives and 30-35% of glass fibers. The preparation method comprises the following steps: firstly mixing the polypropylene, the compatilizer, the composite antioxidant, the anti-copper toxicity agent and the processing additives in a high mixing machine, feeding into a twin-screw extruder via a precision meter, further adding the short glass fibers into the extruder via the meter after the materials in the extruder are softened, then melting, extruding and granulating, wherein the extrusion temperature is 200-220 DEG C. The bonding force between the polypropylene and a glass fiber interface is strong, and the product has the advantages of excellent mechanical performances, no obvious surface fiber revealed phenomenon, excellent heat aging resistance and excellent anti-copper toxicity performance; furthermore, the product almost has no loss of the mechanical performances when baking in a baking oven at 150 DEG C for 1000h.

Owner:KINGFA SCI & TECH CO LTD +2

Sizing agent for carbon fiber, aqueous dispersion of the same, carbon fiber treated by sizing, sheet comprising the carbon fiber, and carbon fiber-reinforced composite material

InactiveUS20040191511A1Excellent impregnationStrong interface adhesionCarbon fibresSynthetic resin layered productsIonSurface energy

Owner:MITSUBISHI CHEM CORP

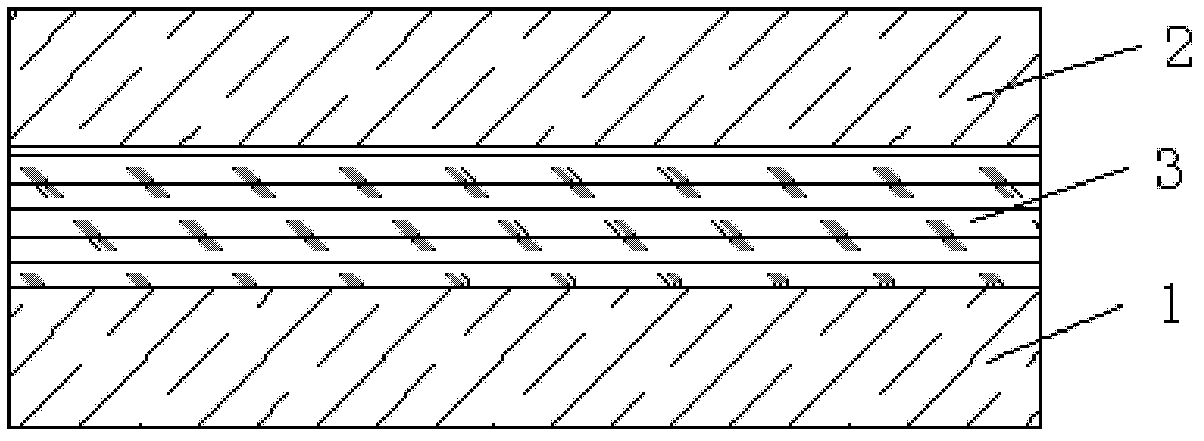

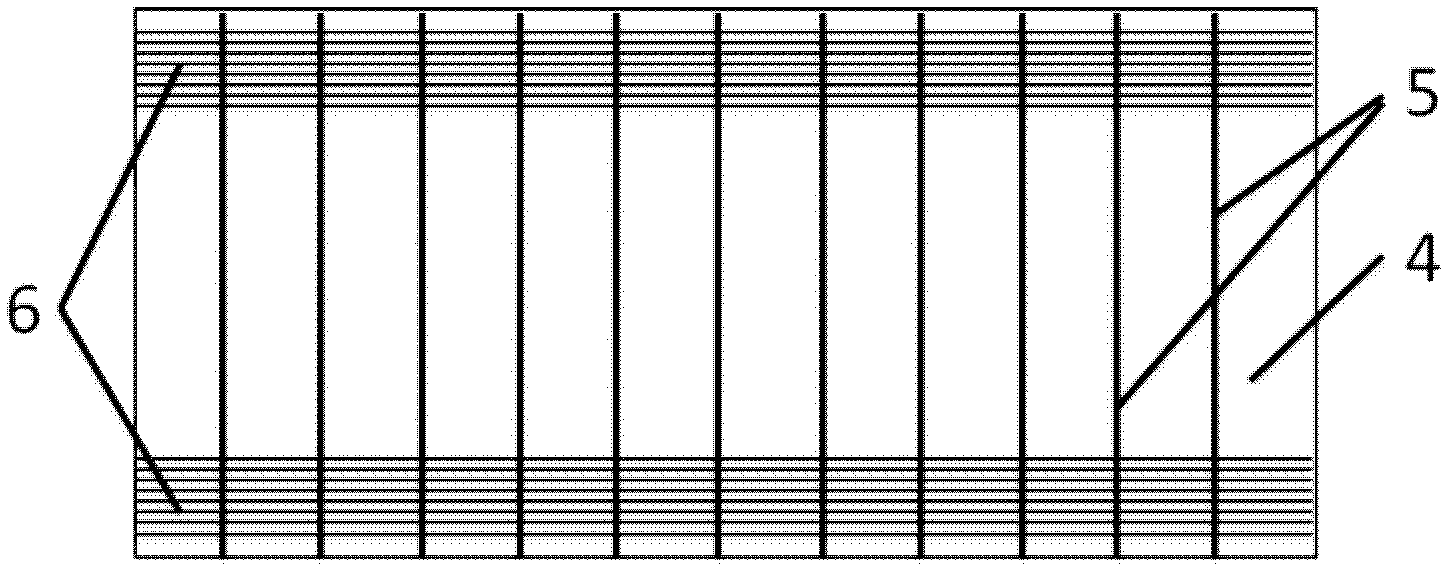

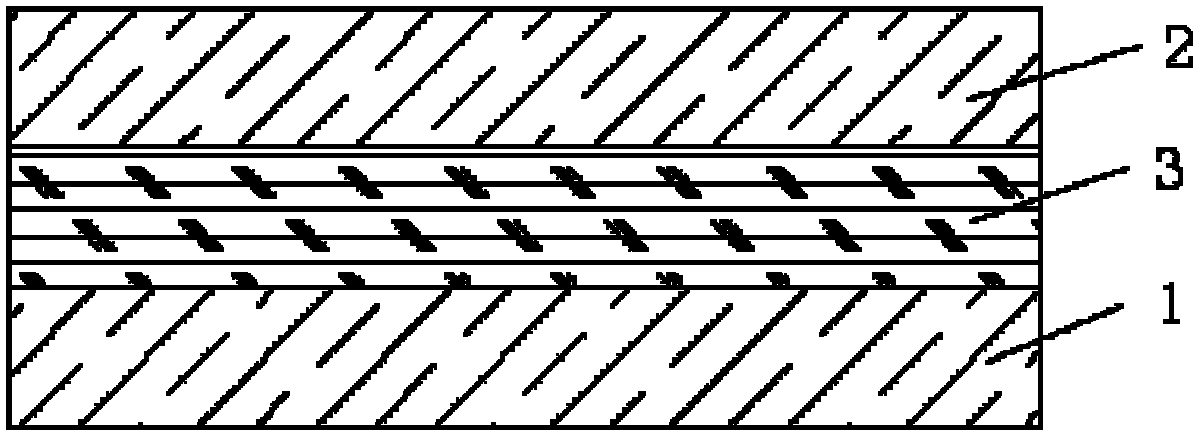

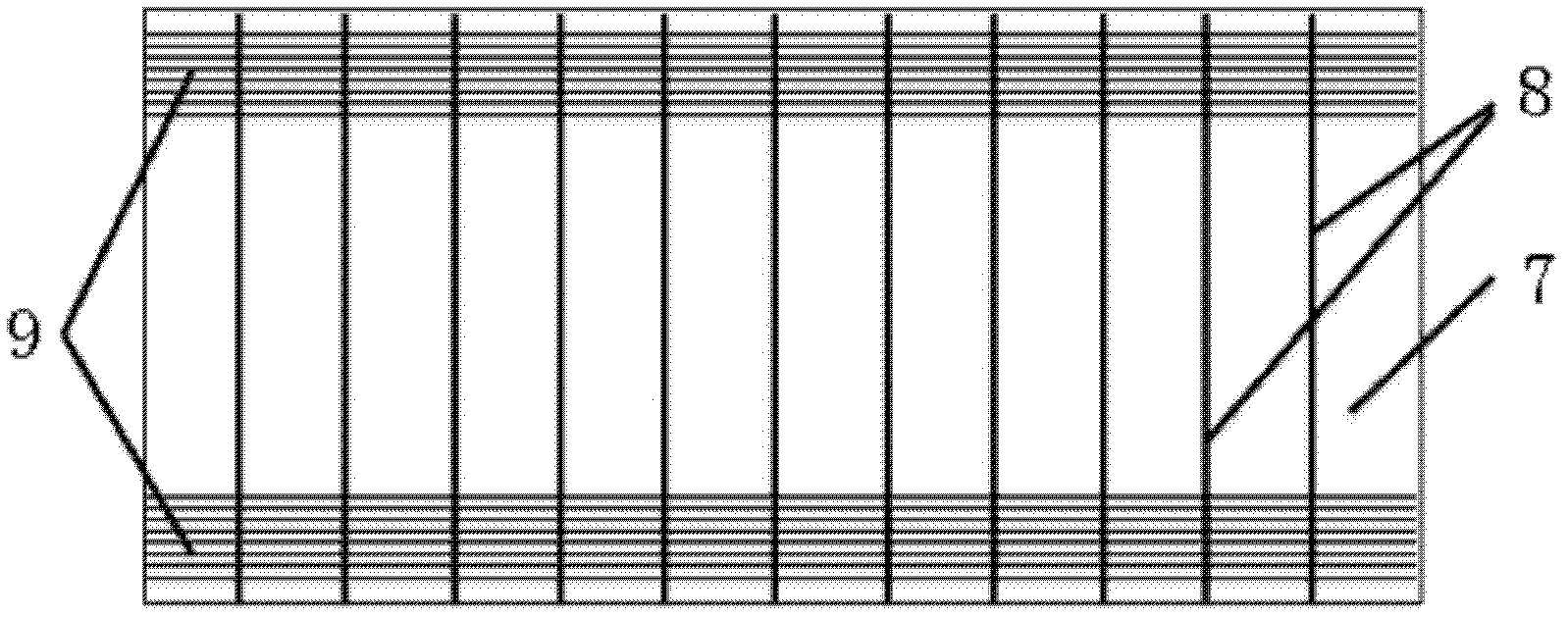

Self-limiting temperature electrothermal membrane of PTC high-molecular conductive fiber and preparation method thereof

ActiveCN102307403ANot easy to formThe coefficient of thermal expansion is roughly equivalent toWoven fabricsHeating element materialsFiberSelf limiting

The invention relates to a self-limiting temperature electrothermal membrane of a high-molecular conductive fiber with a positive temperature coefficient (PTC). The electrothermal membrane comprises a first insulating layer, a second insulating layer and a high-molecular PTC conductive braid layer, wherein the high-molecular PTC conductive braid layer consists of a braid lower layer, a plurality of polyvinyl PTC conductive fibers with carbon black filled type and two current carrying strips. The polyvinyl PTC conductive fiber with carbon black filled type is composed of the following raw materials: a polyethylene resin, an ethylene-vinyl acetate copolymer, carbon black and a carbon fiber and the like. The electrothermal membrane has advantages of stable electrothermal function and good flame retardant property. The preparation method comprises the following steps: preparing polyvinyl PTC conductive fibers with carbon black filled type; preparing a high-molecular PTC conductive braid layer; and carrying out calendaring moulding on a first insulating layer, a second insulating layer and the high-molecular PTC conductive braid layer. The method has advantages of simple process flow, low cost and easy realization.

Owner:XIAN GAIWO THERMAL ENERGY TECH

Method of preparing wood-plastic composite material with modified wood powder and waste plastic

The invention relates to a preparation technology of wood-plastic composite materials and particularly relates to a method of preparing a wood-plastic composite material with modified wood powder and waste plastic. The method includes the steps of (1) crushing, milling and drying agricultural and forestry wastes, successively adding three different surface modifiers and successively mixing the surface modifiers with the waste powder in a high-speed mixing machine to prepare a modified waste powder; (2) cleaning the waste plastic, crushing the waste plastic into granules being 2-12 mm in size, and drying the granules; and (3) according to weight percentage ratio, feeding a mixture composed of the modified waste powder, the waste plastic granules, a lubricant, a foamer and a foamer aid into the high-speed mixing machine to perform high-speed mixing, cooling the mixture until the temperature is lower than 55 DEG C and discharging the material to prepare a special premix. The composite material is very high in strength and anti-bending and anti-impact performance, wherein the anti-impact strength is significantly improved so that the composite material is greatly improved in processability, and further can be used for producing products satisfying different demands. The composite material is greatly wide in application range.

Owner:QUANZHOU NAISI MATERIAL TECH

Lithium ion battery with high energy density and preparation method of lithium ion battery with high energy density

InactiveCN104241696AShorten the transmission distanceImpedance increases proportionallyCell electrodesFinal product manufacturePhysicsElectrical battery

The invention relates to the technical field of lithium ion batteries and in particular relates to a lithium ion battery with the high energy density and a preparation method of the lithium ion battery with the high energy density. The lithium ion battery comprises a positive electrode, a negative electrode, an isolation film and electrolyte, wherein the positive electrode comprises a positive current collector, an active material A layer and an active material B layer; the active material A layer is arranged between the positive current collector and the active material B layer; the particle diameter of an active material B is greater than that of an active material A; the weight ratio of the active material A layer to the active material B layer is 0.1-10; the negative electrode comprises a negative current collector, a conductive polymer C layer and a negative film; the conductive polymer C layer is arranged between the negative current collector and the negative film; the thickness of the conductive polymer C layer is less than or equal to 5 microns. The lithium ion battery prepared by adopting the method is relatively high in dynamics performance; the problem of risk of separating lithium out of a thickly-coated system lithium ion battery at the low temperature can be effectively solved. The prepared battery is safe, reliable, and long in cycle life.

Owner:MCNAIR TECH +1

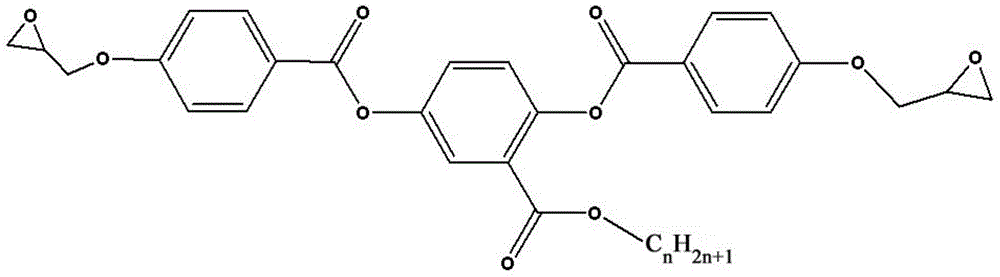

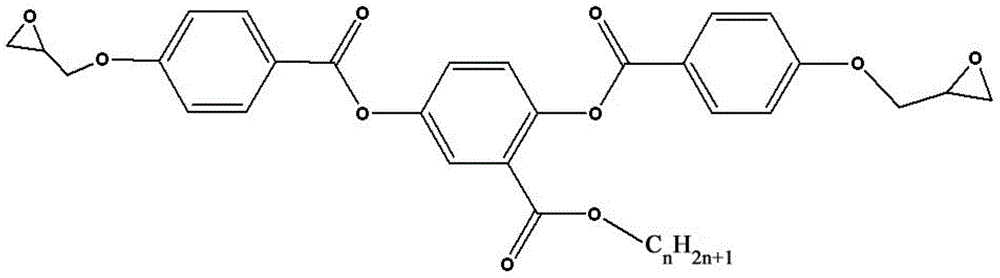

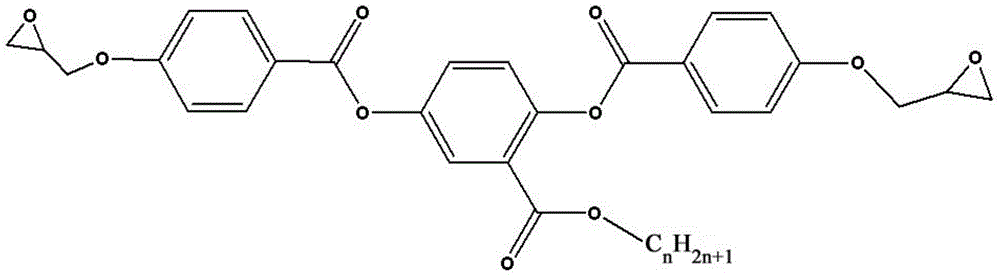

Liquid crystal epoxy resin - carbon fiber composite material and preparation method thereof

The invention belongs to the preparation field of shape memory polymers, specifically discloses a liquid crystal epoxy resin-carbon fiber composite material with shape memory properties and a preparation method thereof. The preparation method of the liquid crystal epoxy resin-carbon fiber composite material comprises three steps: (1) carbon fiber surface treatment; (2) composite material mixture preparation; and (3) curing for forming. According to the preparation method, carbon fiber is used for modifying of liquid crystal epoxy resin with branched chains, the cost can be reduced, and the thermodynamic properties of the material can be improved; and the liquid crystal epoxy resin-carbon fiber composite material prepared by the preparation method has the shape memory property, is high in response rate, is high in recovery stress, and can be applied to the technical field of biomedicine, aerospace and other sciences.

Owner:SICHUAN HUASON ELECTRONICS TECH

Preparation method of jute fiber reinforced polylactic acid composite material

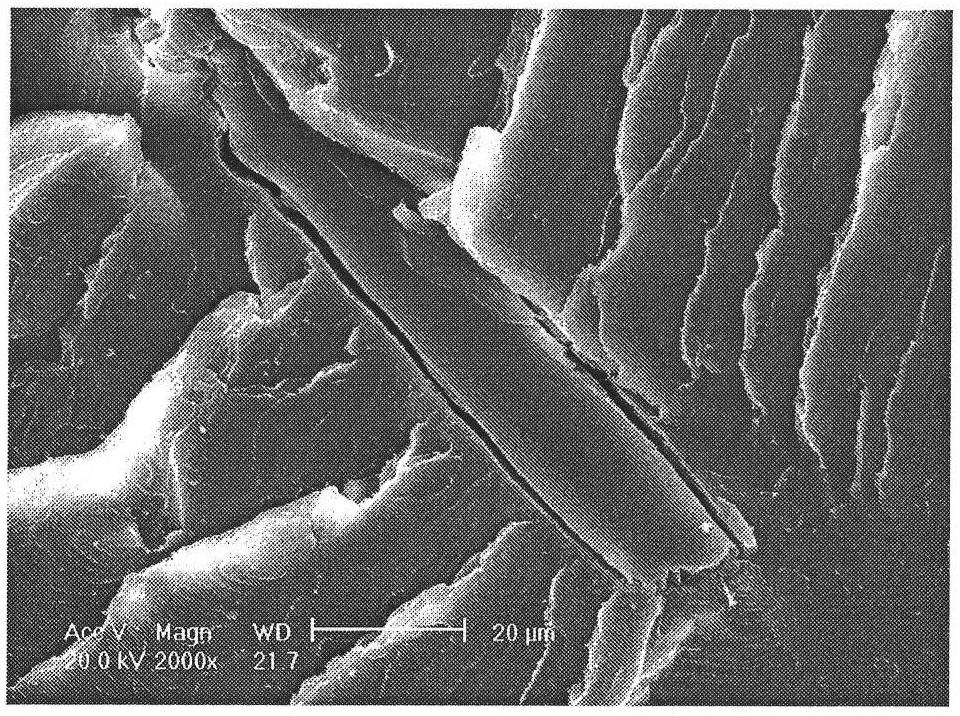

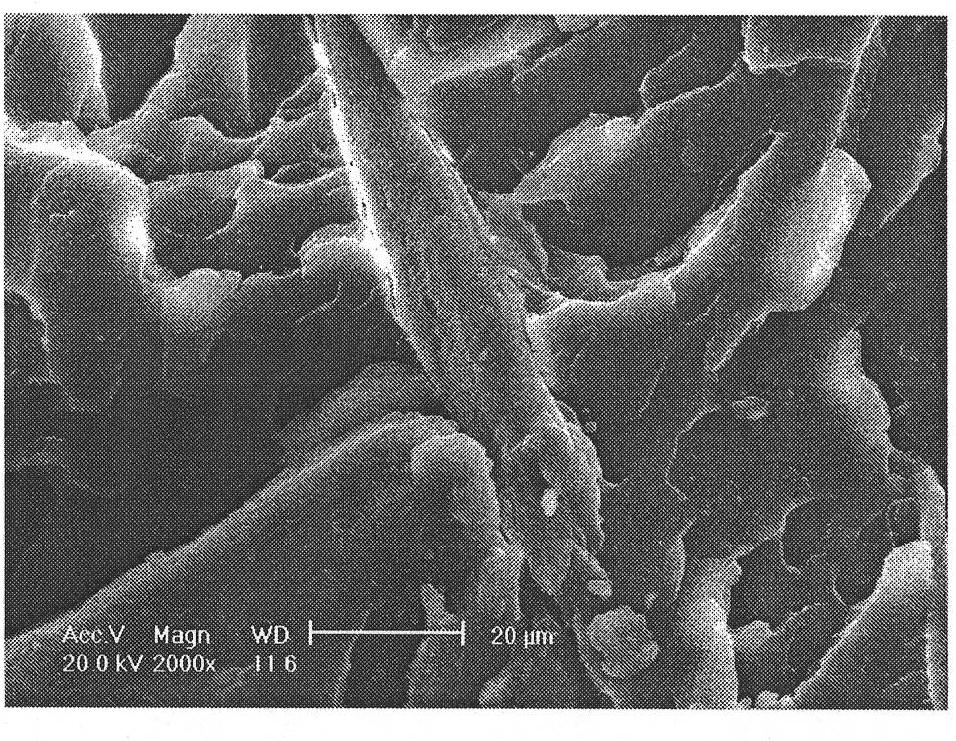

InactiveCN107118528ASimple processProcess parameters are easy to controlVegetal fibresFiberInterface bond

The invention discloses a preparation method of a jute fiber reinforced polylactic acid composite material. The method is characterized by comprising the following steps: pulverizing fibers, scouring, carrying out silicon dioxide sol treatment, and preparing a modified jute fiber reinforced polylactic acid composite material. According to the method disclosed by the invention, the fibers are pulverized and then are modified, so that uniform scouring is facilitated; meanwhile, the production of hydrophilic cross sections caused by interruption during mixed granulation of the fibers and polylactic acid can be effectively reduced, so that the dispersibility and the interface compatibility of the fibers in the polylactic acid are improved; through silicon dioxide sol surface modification treatment, a rough hydrophobic surface is obtained; therefore, the hydrophobic surface and a polylactic acid (PLA) interface have good compatibility, and a good mechanical nail-anchor effect can be produced, thereby improving the interface bond strength.

Owner:SHAOXING UNIVERSITY

Modified chitosan fiber and polylactic acid composite material and preparation method thereof

InactiveCN101792580AEffective combinationStrong interface adhesionAnimal fibresFiberInjection moulding

The invention discloses a preparation method of a modified chitosan fiber and polylactic acid composite material, which comprises the following steps of: (1) mixing a modified chitosan fiber and polylactic acid according to the mixing mass ratio of 5-20:95-80, wherein the viscosity-average molecular weight of the modified chitosan fiber is 2*105-1*106, and the number-average molecular weight of the high-molecular weight polylactic acid is 1*105-3*105; (2) adding the mixture obtained in the step (1) into an injection moulding machine and injecting for moulding for controlling the temperature between 150 DEG C and 210 DEG C and controlling the time between 2 minutes and 20 minutes. The obtained composite material maintains respective favorable performance of the chitosan fiber and the polylactic acid and has good interface compatibility between the chitosan fiber and the polylactic acid and high mechanical strength.

Owner:JINAN UNIVERSITY

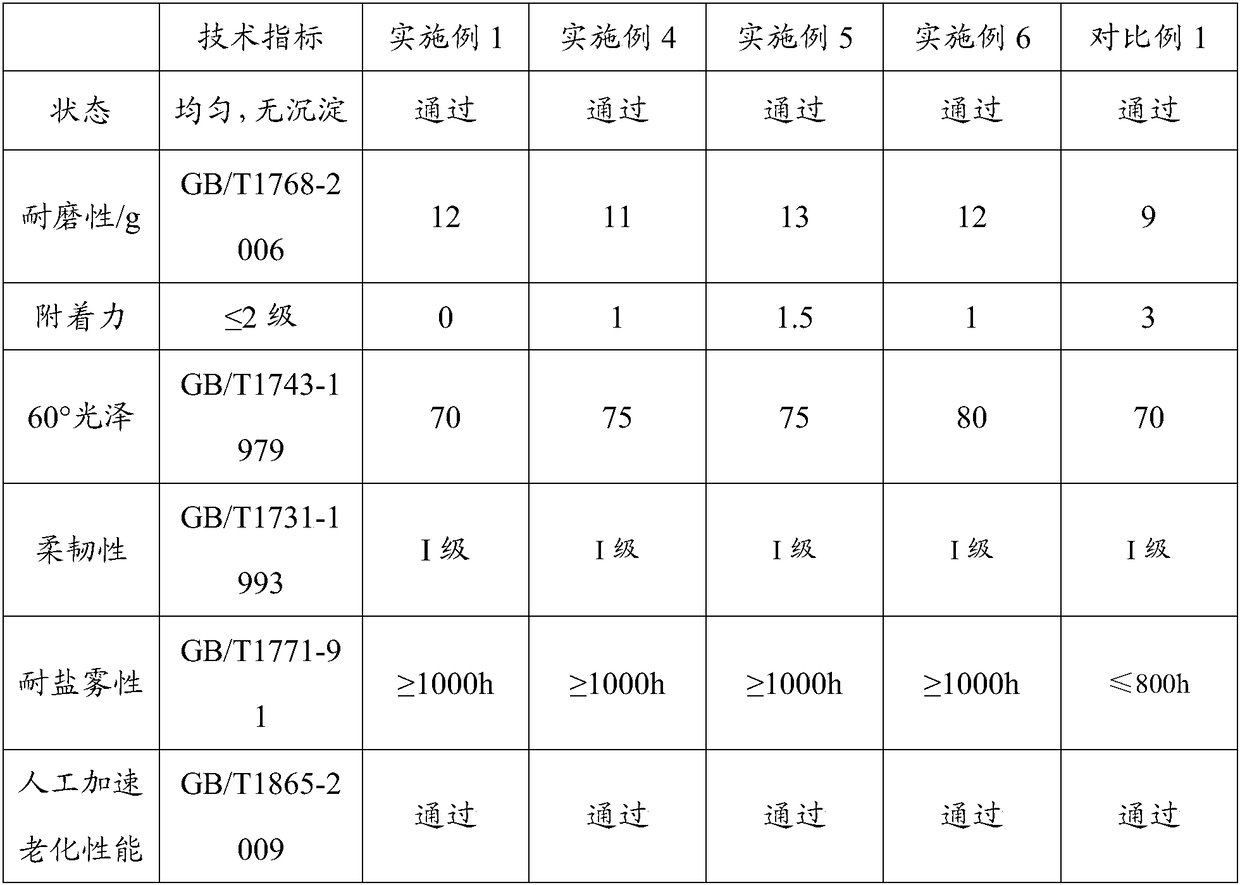

Polyurea coating, preparation method and application thereof, and polyurea coating layer

ActiveCN108559384AImprove anti-corrosion performanceLarge specific surface areaPolyurea/polyurethane coatingsAccelerated agingPolypropylene glycol

The invention provides a polyurea coating, a preparation method and the application thereof, and a polyurea coating layer. The polyurea coating provided by the invention comprises the following components: a component A, a component B and a nano slurry; the component A is prepared from raw materials including diisocyanate and polypropylene glycol; the component B comprises polyoxypropylene diammonium, diethyl maleate, a dispersant, a leveling agent and a defoaming agent; the nano slurry comprises nano silicon dioxide and an accelerator; the mass ratio of the component A to the component B is 1to 1-4; and the mass ratio of the component B to the nano slurry is 1 to 2.5-6%. The polyurea coating and the polyurea coating layer provided by the invention have good wear resistance, adhesive force, 60-degree gloss, flexibility, salt fog resistance and artificial accelerated aging performance, wherein the salt fog resistance is more than or equal to 1000h.

Owner:SHANGHAI UNIV

Sacrificial water corrosion-resistant epoxy paint composition

InactiveCN1451701ANo pollutionLow costAnti-corrosive paintsEpoxy resin coatingsEpoxyWater dispersible

A sacrificial anticorrosion water epoxy paint composition contains water-dispersive basic epoxy resin, multi-metal alloy powder, water-soluble solidifying agent prepared from polyamine and polyol, and rheologic nano assistant. Its advantages are high stability, excellent anticorrosion and mechanical performance of its film, and no release of harmful gas.

Owner:杨瑞影

Amphoteric composite forward osmosis membrane as well as preparation method and application thereof

InactiveCN110841494AQuick evacuationIncrease water fluxSemi-permeable membranesGeneral water supply conservationPolyamidePolyvinylidene difluoride

The invention relates to an amphoteric composite forward osmosis membrane. According to the amphoteric composite forward osmosis membrane, an adopted porous support membrane is a super-hydrophilic polyvinylidene fluoride membrane; a polyamide layer is formed on the porous support membrane, and a zwitterionic layer is formed on the polyamide layer. In the present invention, the zwitterionic layer is formed by amido groups through zwitterionic reaction; through cooperation with the super-hydrophilic characteristic of the polyvinylidene fluoride membrane prepared through water vapor induced phaseseparation, the strong hydration and the charging performance of a catechol derivative modified graphene oxide nano-water channel and the zwitterionic skin layer, the water flux of the composite forward osmosis membrane is greatly improved while a low back-mixing salt flux is kept.

Owner:吾净科技(深圳)有限公司

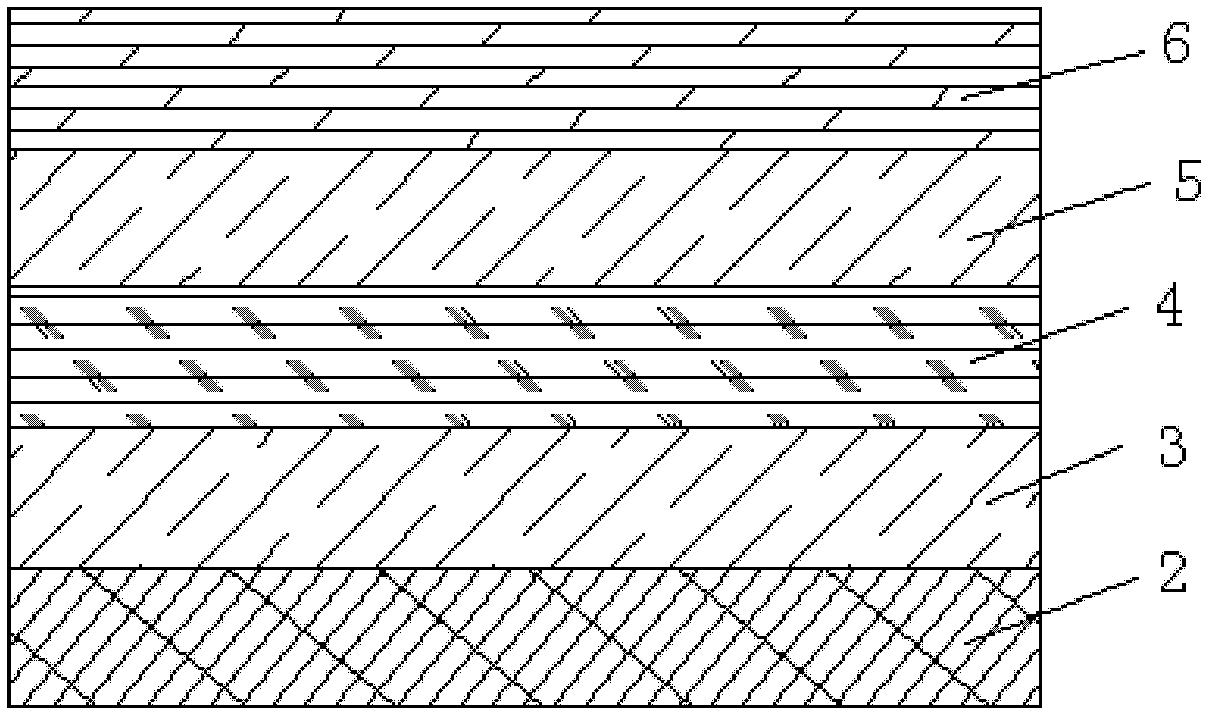

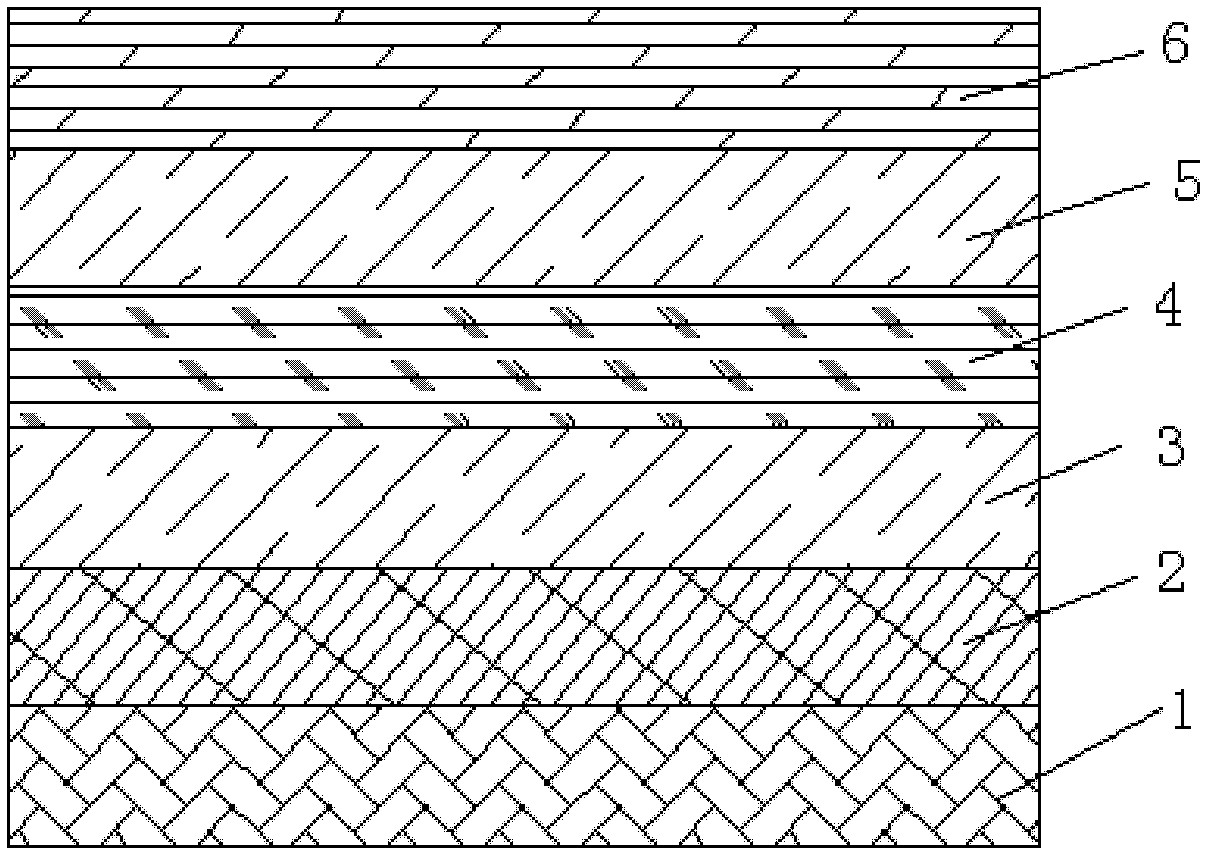

Unidirectional heat transfer flame retardation PTC macromolecule self-limiting temperature electrothermal film and preparation method thereof

ActiveCN102427617AOne way pass goodImprove flame retardant performanceHeating element materialsFiberCarvacryl acetate

The invention discloses a unidirectional heat transfer flame retardation PTC macromolecule self-limiting temperature electrothermal film. The electrothermal film comprises: a reflecting layer, a first insulating layer, a macromolecule PTC conductive woven layer, a second insulating layer and a fire-retardant layer, wherein the reflecting layer, the first insulating layer, the macromolecule PTC conductive woven layer, the second insulating layer and the fire-retardant layer are successively arranged from bottom to top. The macromolecule PTC conductive woven layer comprises: a woven bottom layer, a carbon black filling type polyvinyl PTC conductive fiber and a current-carrying strip. Raw materials of the carbon black filling type polyvinyl PTC conductive fiber comprise: polyethylene, an ethylene-vinyl acetate copolymer, carbon black and the like. A foaming flame retardation insulating layer is arranged under the reflecting layer. The electrothermal film of the invention possesses advantages of unidirectional heat transmission and the flame retardation. Usage performance is stable and a service life is long. In a preparation method of the invention, a three-roller calender is used toperform calendaring and combining, water cooling and rolling the each forming layer so as to obtain the electrothermal film. The method and a technological process are simple. Costs are low and the method is easy to realize.

Owner:XIAN GAIWO THERMAL ENERGY TECH

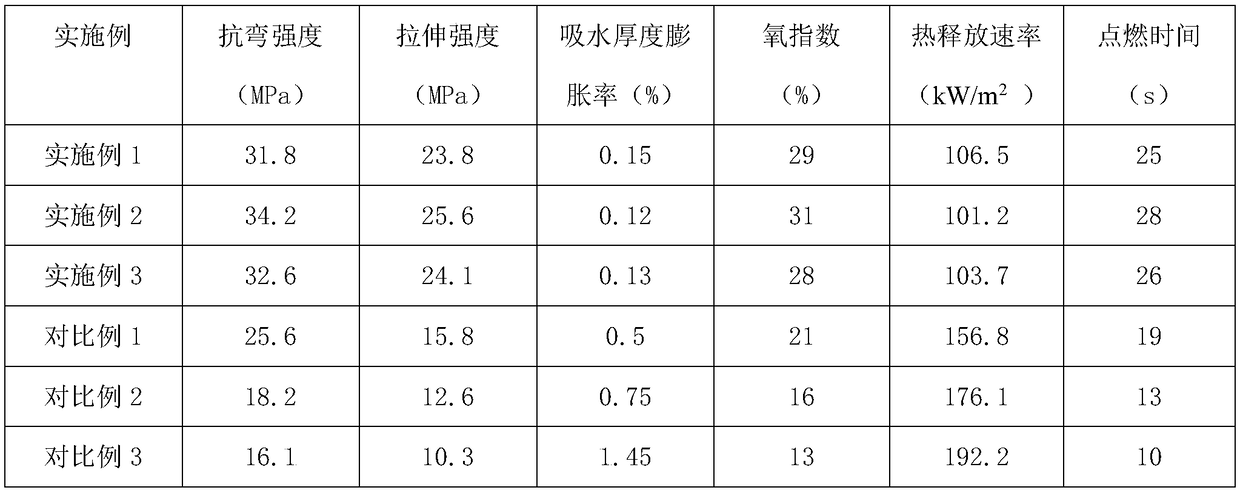

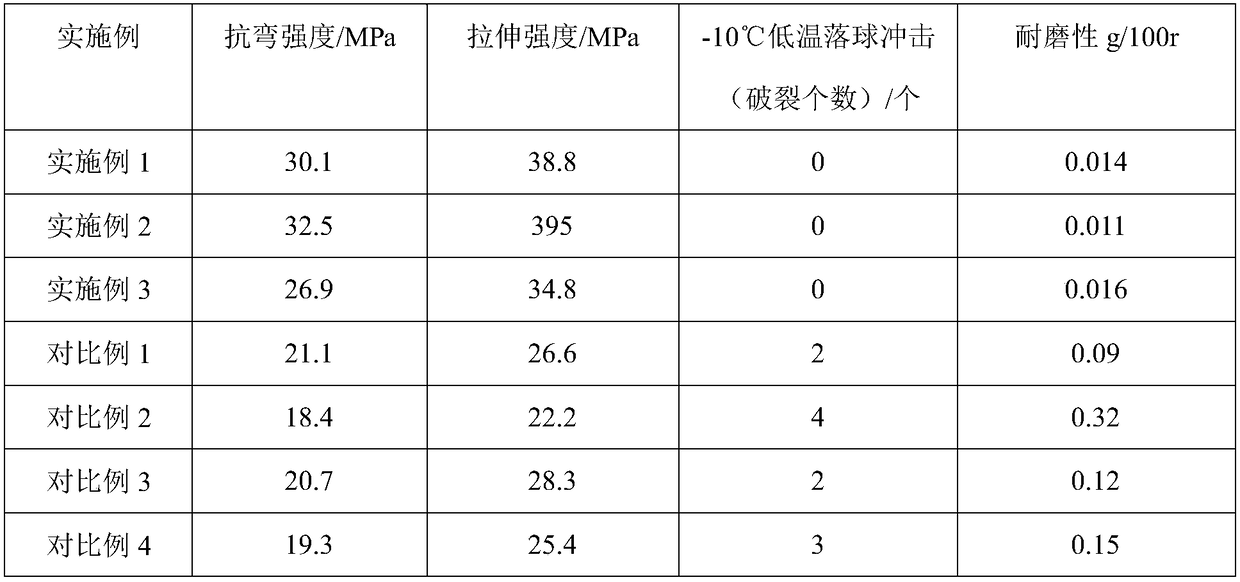

Flame-retardant wood-plastic composite and preparation method thereof

The invention discloses a flame-retardant wood-plastic composite and a preparation method thereof. The flame-retardant wood-plastic composite comprises the following components in percentage by mass:15-18% of waste PE sheets, 14-16% of waste ceramic powder, 60-64% of wood fibers, 1-3% of flame retardant, 0.5-3% of lubricant, 0.05-0.5% of antioxidant, 0.05-0.5% of mildewcide, 0.5-3% of tert-butyldiphenylchlorosilane, 1-2% of ammonium iron sulfate, 0.5-1% of polyhexamethylene biguanidine. Tert-butyldiphenylchlorosilane, ammonium iron sulfate, polyhexamethylene biguanidine and other raw materials are mixed, and a compatilizer is not added, so that the problem of material performance lowering caused by side reactions in a mixing process of the raw materials can be effectively solved, the waste ceramic powder can be uniformly mixed with other raw materials without surface treatment, the preparation method is simple, and the prepared flame-retardant wood-plastic composite has relatively high bending strength and also has good flame retardance and water resistance.

Owner:湖南格林美资源利用有限公司

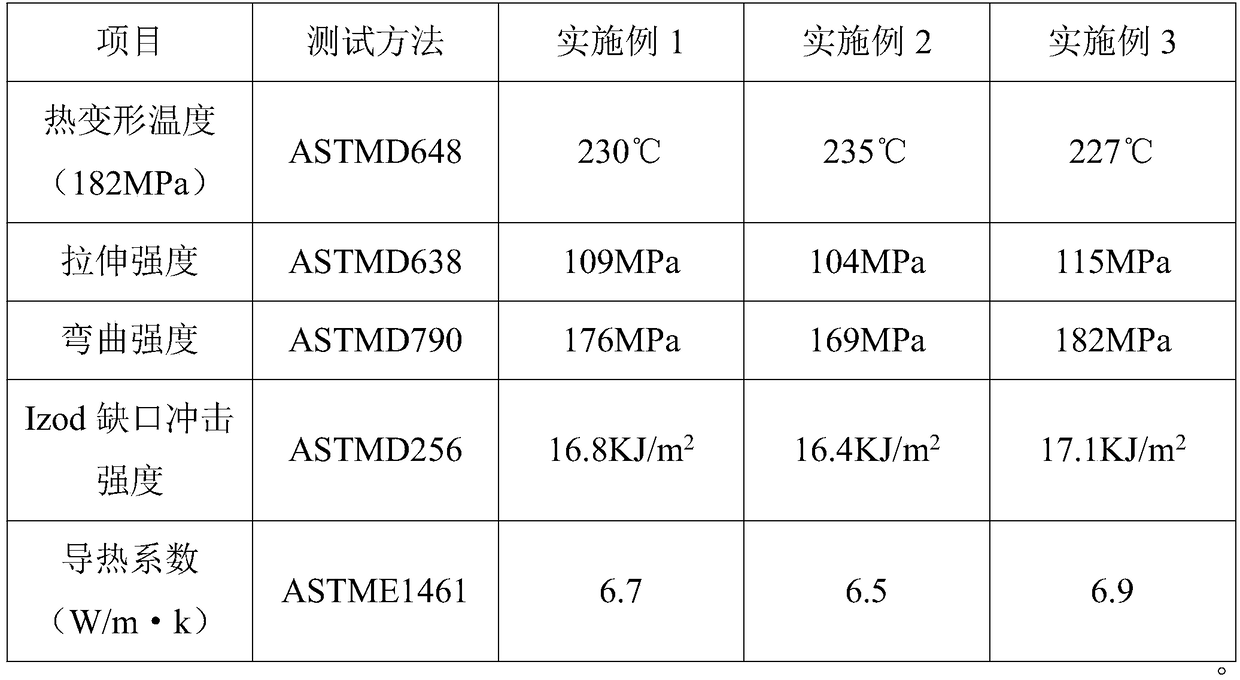

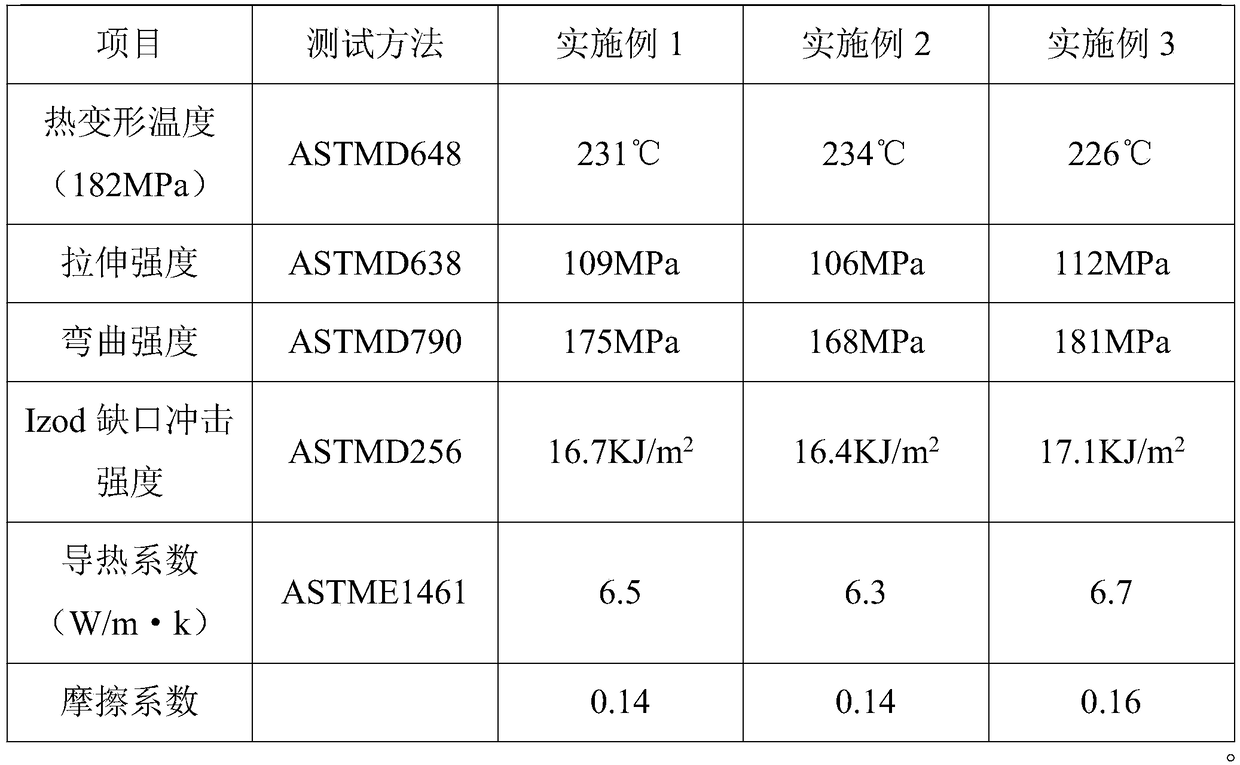

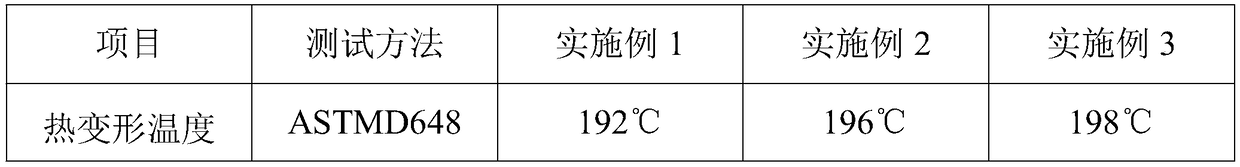

Fiber-reinforced nylon composite material and preparation method thereof

The invention provides a fiber-reinforced nylon composite material and a preparation method thereof. The fiber-reinforced nylon composite material comprises the following raw materials in parts by weight: 60-80 parts of nylon, 10-20 parts of organosilicone modified polyester acrylate, 5-10 parts of aramid fibers, 20-30 parts of modified graphene, 4-8 parts of a flexibilizer, 0.6-1.8 parts of a compatilizer, 0.2-0.6 part of a lubricating agent and 0.2-0.6 part of an antioxidant. The modified graphene is mainly prepared from graphene, oxalic acid and sodium metaaluminate. The preparation methodcomprises the steps of mixing the raw materials in different batches; and then carrying out double-screw extruding and pelletizing. The nylon composite material not only has quite good heat-conductioneffect, but also can resist quite high temperature, and is also quite excellent in other mechanical properties.

Owner:WUHU YUANKUI NEW MATERIAL TECH CO LTD

Alkali-activated cementing material doped with high-silicon iron tailings and red mud and preparation method of alkali-activated cementing material

The invention belongs to the field of alkali-activated inorganic nonmetal cementing materials, and particularly relates to an alkali-activated cementing material doped with high-silicon iron tailings and red mud and a preparation method of the alkali-activated cementing material. The material comprises the following raw materials: 30 to 50 parts of high-silicon iron tailings; 15 to 20 parts of red mud; 20 to 35 parts of coal gangue; 10 to 15 parts of alkaline residues; and 1-5 parts of an alkaline activator. The preparation method comprises the following steps: adding the high-silicon iron tailings, the red mud and the coal gangue into a stirrer, performing uniform stirring, dissolving the alkaline residues into the alkaline exciting agent, adding the mixture into the stirrer after the alkaline residues are completely dissolved, performing stirring and mixing at a low speed, pouring the standard sand into a stirring pot, stopping stirring, and performing stirring again to obtain alkali-activated cementing material slurry; injecting the obtained alkali-activated cementing material slurry into a mold, carrying out coagulation and hardening to remove the mold, and performing curing in a curing device to obtain the target product. The concrete is good in gelling property, ideal in impermeability and high in compressive strength, and has a micro-expansion compensation function.

Owner:NORTHEASTERN UNIV +1

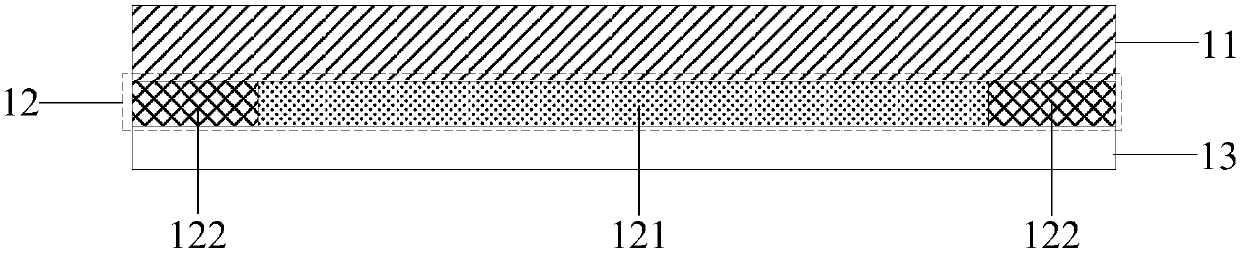

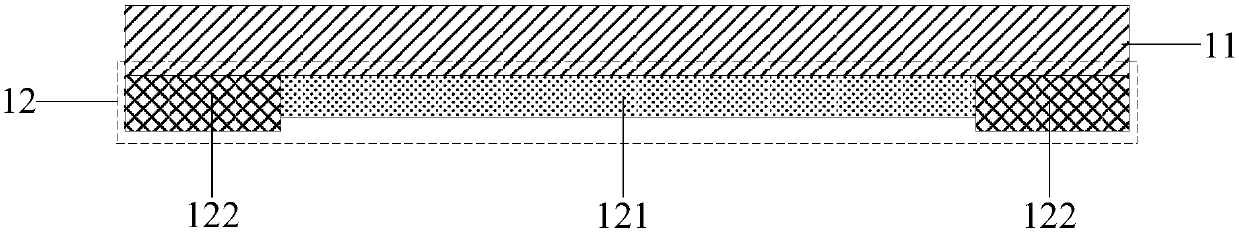

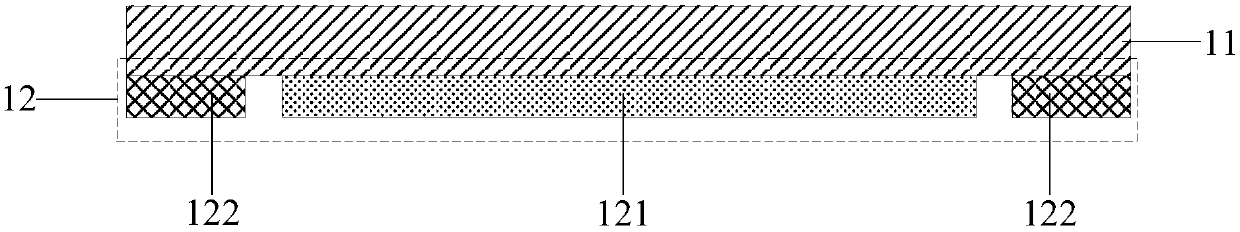

Flexible polarizer and display device

ActiveCN109683226ACompensation for shrinkage stressStrong interface adhesionPolarising elementsIdentification meansInterfacial adhesionPolarizer

The invention discloses a flexible polarizer and a display device. The flexible polarizer comprises a stretched polarizing layer, an adhesive layer located on the surface of one side of the polarizinglayer and a stripping layer located on the surface of the side, deviating from the polarizing layer, of the adhesive layer, wherein the adhesive layer comprises a first bonding portion and two secondbonding portions respectively located at two sides of the first bonding portion, and the interface adhesion of the second bonding portions are greater than the interface adhesion of the first bondingportion. After the stripping layer of the flexible polarizer is striped off, it can be directly attached to the surface of a display panel. The size of the flexible polarizer can be larger than the attached display size of the display panel, so that the second bonding portions can be reversely folded and adhered to the back surface of at least one film layer of the flexible polarizer or the display panel during adhesion, the second bonding portions have strong interfacial adhesion, the shrinkage stress generated by a stretchable polarizer when it is affected by the environment can be compensated, and the problem of unevenness caused by shrinkage stress can be avoided.

Owner:BOE TECH GRP CO LTD

High-heat conduction wear-resistant high-temperature resistant composite material and preparation method thereof

InactiveCN108822531ALow thermal conductivityImprove high temperature resistanceHeat-exchange elementsPolyesterAluminate

The invention provides a high-heat conduction wear-resistant high-temperature resistant composite material and a preparation method thereof. The high-heat conduction wear-resistant high-temperature resistant composite material comprises the following raw materials in parts by weight: 60-80 parts of nylon, 10-20 parts of organosilicon-modified polyester acrylate, 1-3 parts of modified calcium sulfate whisker, 5-10 parts of magnesium oxide, 20-30 parts of modified graphene, 4-8 parts of a flexibilizer, 0.6-1.8 parts of a compatilizer, 0.2-0.6 parts of a lubricant, and 0.2-0.6 parts of an anti-oxidant. The modified graphene is mainly prepared by graphene, pimelic acid and sodium meta aluminate, and the modified calcium sulfate whisker is mainly prepared by the calcium sulfate whisker, zinc sulfate and an aluminate coupling agent. The preparation method is characterized in that the above raw materials are mixed by batches and are subjected to twin-screw extruded granulation. The nylon composite material has good heat conduction effect, high temperature resistance and antifriction performance, and other excellent mechanical properties.

Owner:WUHU YUANKUI NEW MATERIAL TECH CO LTD

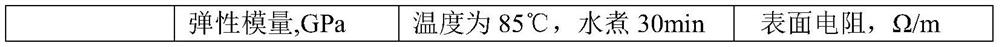

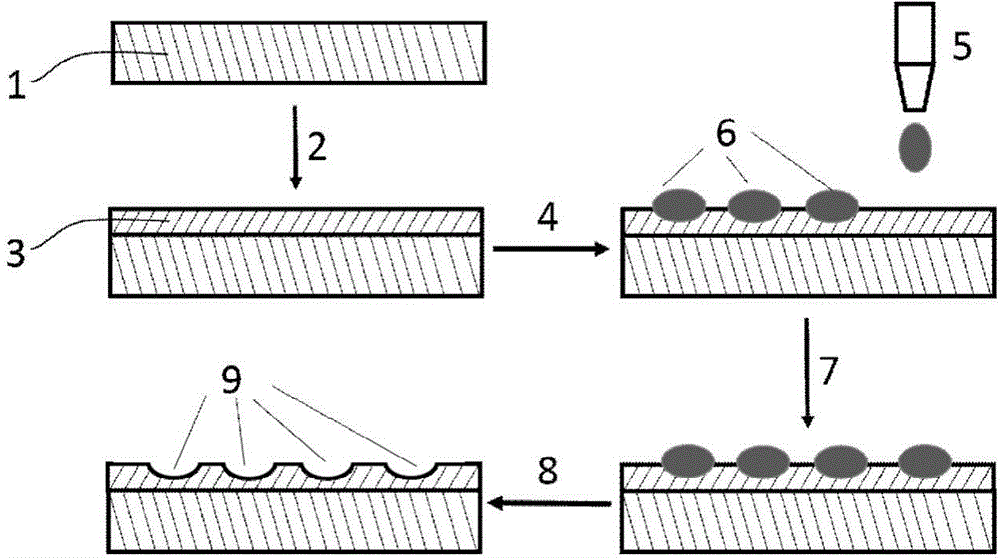

High-strength antistatic 3D sheet and preparation method thereof

The invention discloses a high-strength antistatic 3D sheet and a preparation method thereof. The preparation method of the 3D sheet comprises the following steps; (1) preparing a glue solution, and coating the surface of glass fiber cloth with the glue solution through an electrophoresis method to form a prepreg; (2) attaching a release film to the surface of the prepreg, slitting the prepreg into different shapes, stripping and removing the release film, and stacking the prepreg layer by layer to form a to-be-pressed prepreg; and (3) putting the prepreg to be pressed into a mold, and carrying out compression molding to obtain the high-strength antistatic 3D sheet. The glue solution comprises the following raw materials in parts by weight: 90-120 parts of resin, 24-48 parts of a curing agent, 15-17 parts of pretreated nano diamond powder, 2-5 parts of a cross-linking agent and 0.3-0.7 part of an antioxidant. The 3D sheet prepared by the invention has good mechanical strength, excellent antistatic property, heat dissipation property and heat resistance, and can be widely applied to cover plates and protective jackets of mobile phones, communication equipment and other electronic products.

Owner:HUIZHOU ZONGSHENG ELECTRONICS MATERIAL CO LTD

Toughened and modified PBT resin and preparation method thereof

ActiveCN112778713AImprove mechanical propertiesStrong interface adhesionGroup 5/15 element organic compoundsPolymer scienceInterfacial bonding

The invention relates to the field of modified PBT resin, and discloses toughened and modified PBT resin and a preparation method thereof. The toughened and modified PBT resin is prepared from the following raw materials in parts by weight: 50 to 80 parts of PBT and 5 to 30 parts of an SEBS-g-MAH copolymer. According to the invention, the SEBS-g-MAH copolymer is adopted as the flexibilizer, the interfacial bonding effect between the SEBS-g-MAH copolymer and PBT is strong, and the SEBS-g-MAH copolymer is uniformly dispersed, so that the mechanical properties of PBT can be better improved compared with SEBS.

Owner:NINGBO NENGZHIGUANG NEW MATERIALS TECH

Anti-retaining interface agent and preparation method thereof

The invention relates to an anti-retaining interface agent and a preparation method thereof; the anti-retaining interface agent comprises the following components in the following content by weight percentage: 25 to 30 percent of cement; 2 to 6 percent of lime; 18 to 22 percent of quartz sand; 40 to 44 percent of calcium carbonate; and 4 to 6 percent of dispersed powder. Compared with the prior art, the invention has the advantages that: (1) under the premise of confirming a base layer is firm, old tiles and other finishing material do not need to be removed, new base layers with rough surface can be formed only by treating the surface of the product; (2)the anti-retaining interface agent has super interface adhesion, is not hollow and flaky, has excellent waterproof, temperature and freezing resistant performance, strong flexibility and strong anti-impact capability; (3) the preparation method is applicable to a plurality of construction methods, so that the construction is convenient and simple; (4) the agent does not produce harmful gas, and is safe and environment protective; (5) the method saves working hours and cost.

Owner:上海基成达申防水材料有限公司

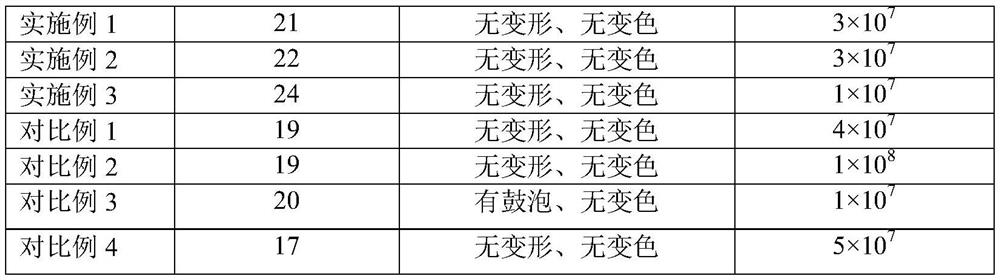

Ink-jet printing plate making method for substrate used for intaglio printing

The invention relates to an ink-jet printing plate making method for a substrate used for intaglio printing. The method comprises the following steps that (1) the surface of the substrate is uniformly coated with an imaging layer composed of polymer precursors, and the polymer precursors are pre-cured through the inducing function triggered by heating or light, so that the imaging layer is in a sticky and elastic state; (2) sacrificed ink is printed on the imaging layer through the ink-jet printing technique, and the polymer precursors are further cured completely through the inducing function triggered by heating or light; (3) after the sacrificed ink is removed through cleaning, concave structures capable of absorbing ink are left on the imaging layer, and thus the substrate used for intaglio printing is obtained; and (4) after the printing task is finished, the surface imaging layer is removed, and therefore the substrate can be utilized repeatedly. Compared with the prior art, the method is simple in technique, low in cost and capable of achieving large-area plate making; all materials are non-poisonous and harmless, and health protection and environment friendliness are achieved; and the substrate can be utilized repeatedly, and the materials are saved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

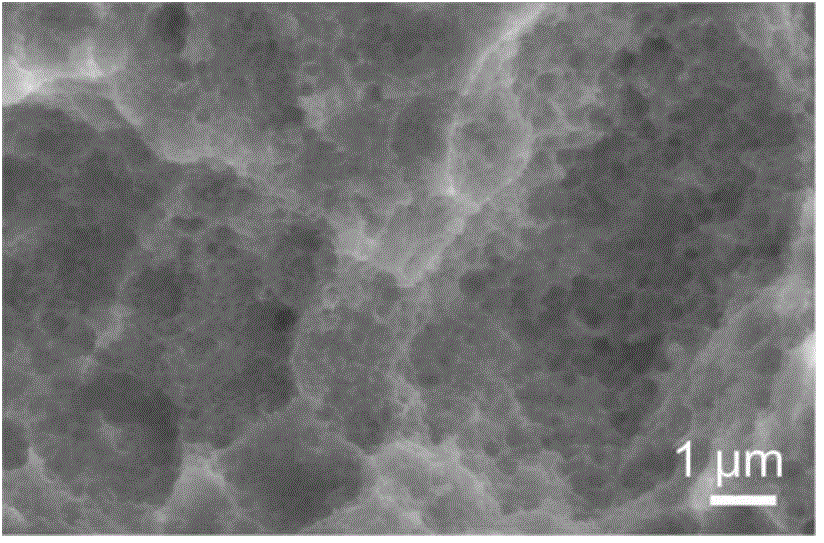

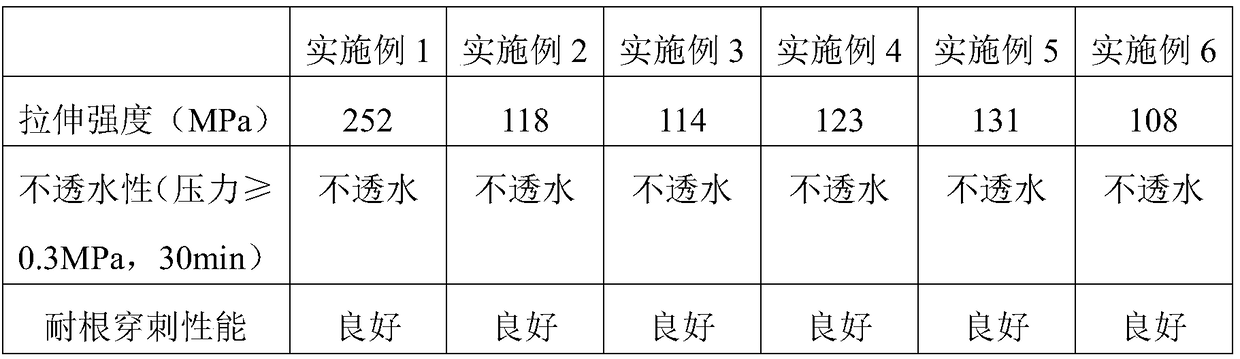

Corrosion-resistant flexible epoxy resin root puncture-resistant waterproof composite material

ActiveCN109504039AHigh mechanical strengthGood resistance to root punctureRoof covering using flexible materialsFibre treatmentFuranEpoxy

The invention discloses a corrosion-resistant flexible epoxy resin root puncture-resistant waterproof composite material. The corrosion-resistant flexible epoxy resin root puncture-resistant waterproof composite material has the advantages that a copper-plating glass fiber is prepared by a chemical plating method, and is used as a reinforcing material and a root blocking agent, furan resin-modified flexible epoxy resin is used as a matrix, and the corrosion-resistant flexible epoxy resin root puncture-resistant waterproof composite material is formed by a vacuum casting or spraying forming technology; the mechanical strength is higher, the root puncture-resistant effect and waterproof effect are good, the acid and alkaline corrosion-resistant property is excellent, and the damage to the waterproof layer by the acid and alkaline corrosion of the soil at the planted roof can be avoided; by adopting the surface copper plating type, the usage amount of noble metal copper is greatly reduced, and the production cost is reduced; by adopting the vacuum casting and spraying forming types, the waterproof layer and the base layer of planted roof are integrated, and the flexible epoxy resin iscured and formed at normal temperature; the energy-saving, environment-friendly and green effects are realized, and the interface adhering to the concrete roof is strong.

Owner:HUBEI UNIV OF TECH

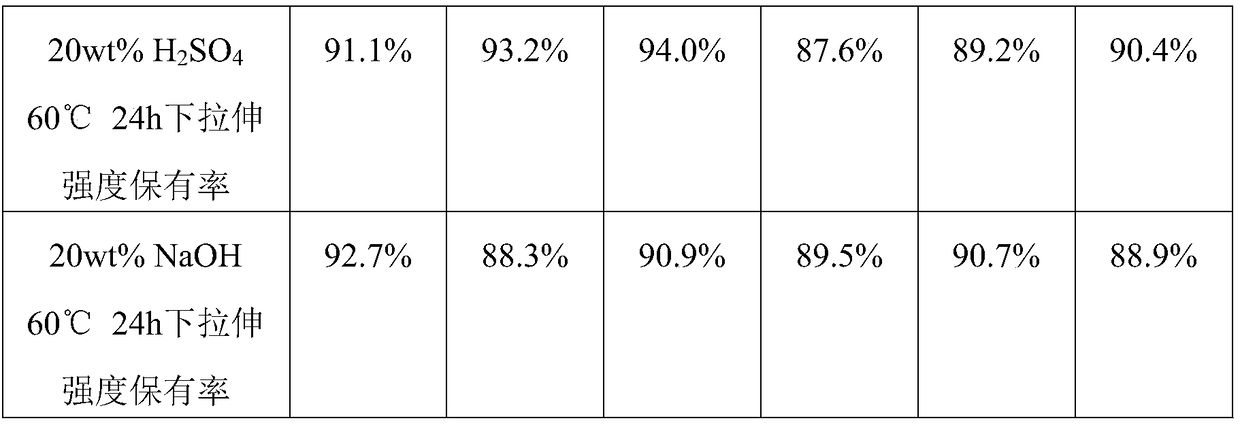

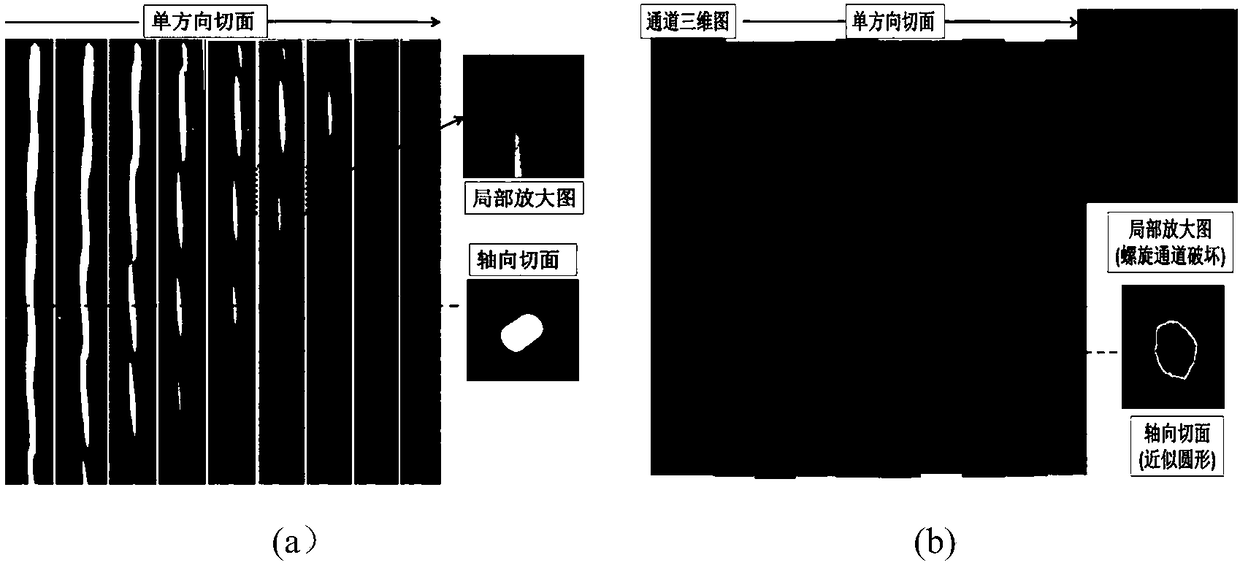

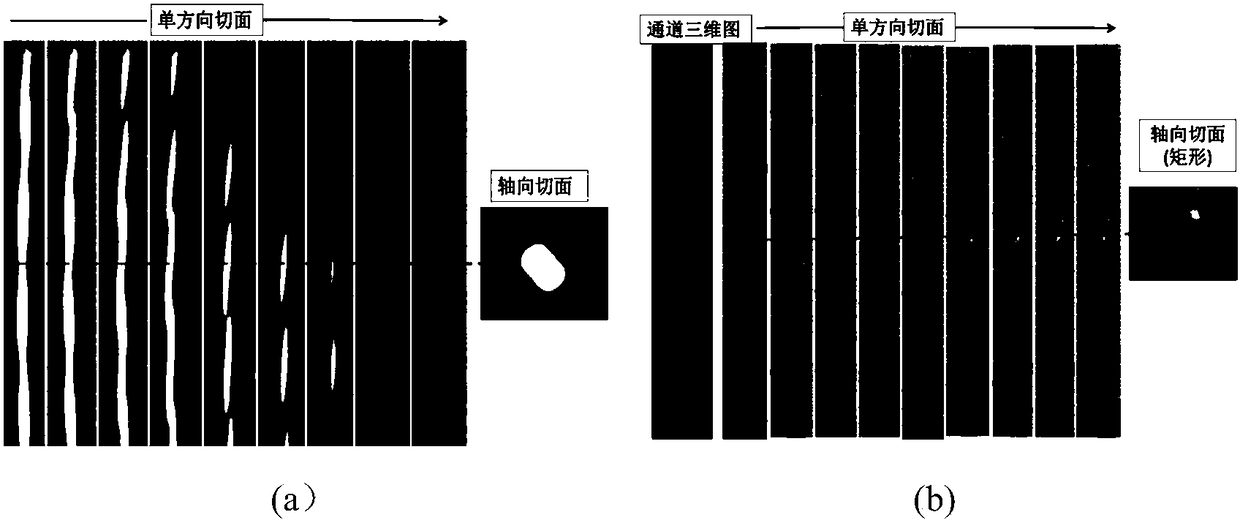

Spiral steel fiber ultra-high-performance concrete and preparation method thereof

The invention provides a spiral steel fiber ultra-high-performance concrete and a preparation method thereof. The concrete material is composed of cement, fine sand, water, quartz powder, high-efficiency water reducing agent and steel fibers, in addition, inorganic mineral admixtures such as fly ash, slag and the like can be selectively added to replace partial cement; and the adopted steel fiberscomprise a linear steel fiber and a spiral steel fiber. The concrete is prepared from, by mass, 1000-1300 parts of the cement, 100-300 parts of silica fume, 900-1200 parts of the fine sand, 100-300 parts of the quartz powder, 30-60 parts of the water reducing agent, 150-400 parts of the water and 50-300 parts of the steel fibers. The obtained spiral steel fiber concrete material has the advantages that compared with the adhesive property between the linear steel fiber and a concrete substrate, the adhesive property between the spiral steel fiber and the concrete substrate can be obviously improved, and the tensile strength of the spiral steel fiber ultra-high-performance concrete is higher than that of conventional steel fiber concrete; since the spiral steel fiber has an 'unspinning' process when being pulled out from the substrate, the deformation ability of the conventional steel fiber concrete can be greatly improved.

Owner:ZHEJIANG UNIV

Wood-plastic material prepared from papermaking waste and preparation method thereof

The invention discloses a wood-plastic material prepared from papermaking waste. The wood-plastic material comprises the following components in percentages by mass: 30% to 35% of papermaking waste, 30% to 40% of wood flour, 15% to 20% of ceramic powder, 1% to 5% of sorbitol, 1% to 3% of a silane coupling agent, 3% to 6% of maleic anhydride grafted polyethylene, 1% to 2% of aluminum chloride, 3% to 5% of poly ethylene glycol monomethyl ether and 1% to 2% of blocking isocyanate. Firstly, the silane coupling agent, maleic anhydride grafted polyethylene and aluminum chloride are added and mixed,the aluminum chloride is beneficial for uniform mixing of the raw materials, and in combination with the adding sequence of the raw materials, the modification effect of each accessory ingredient on plastic, wood flour and ceramic powder can be strengthened; the sorbitol is further added as an activation modifier, and is matched with the blocking isocyanate and poly ethylene glycol monomethyl ether, so that modification on the wood four and ceramic powder can be realized sufficiently, the interfacial compatibility among the wood flour, ceramic powder and plastic is improved, and the performance of the wood-plastic material is strengthened.

Owner:HUNAN YINGHONG SCI & TECH

Bending-resistant air-permeable polyvinyl chloride vamp material and preparation method thereof

InactiveCN105542344AStrong bending resistanceGood air permeabilityMonocomponent cellulose artificial filamentUltrasonic/sonic fibre treatmentAntimicrobialOxide

The invention provides a bending-resistant air-permeable polyvinyl chloride vamp material. The bending-resistant air-permeable polyvinyl chloride vamp material is prepared from the following components in parts by weight: 54-64 parts of polyvinyl chloride, 11-16 parts of a plastifier, 3-4 parts of a stabilizing agent, 7-10 parts of a compatibilizer, 18-22 parts of a filling, 1-2 parts of a lubricant, 3-5 parts of an anti-wear agent, 4-5 parts of a blowing agent, 4-6 parts of an antibacterial agent, 5-6 parts of CPE, 8-10 parts of modified alpinia speciosa fibers, 2 parts of zinc oxide, and 3 parts of stearic acid. The invention further provides a preparation method of the bending-resistant air-permeable polyvinyl chloride vamp material. The polyvinyl chloride vamp material provided by the invention is high in bending resistance and good in air permeability.

Owner:SUZHOU JINGRO TECH

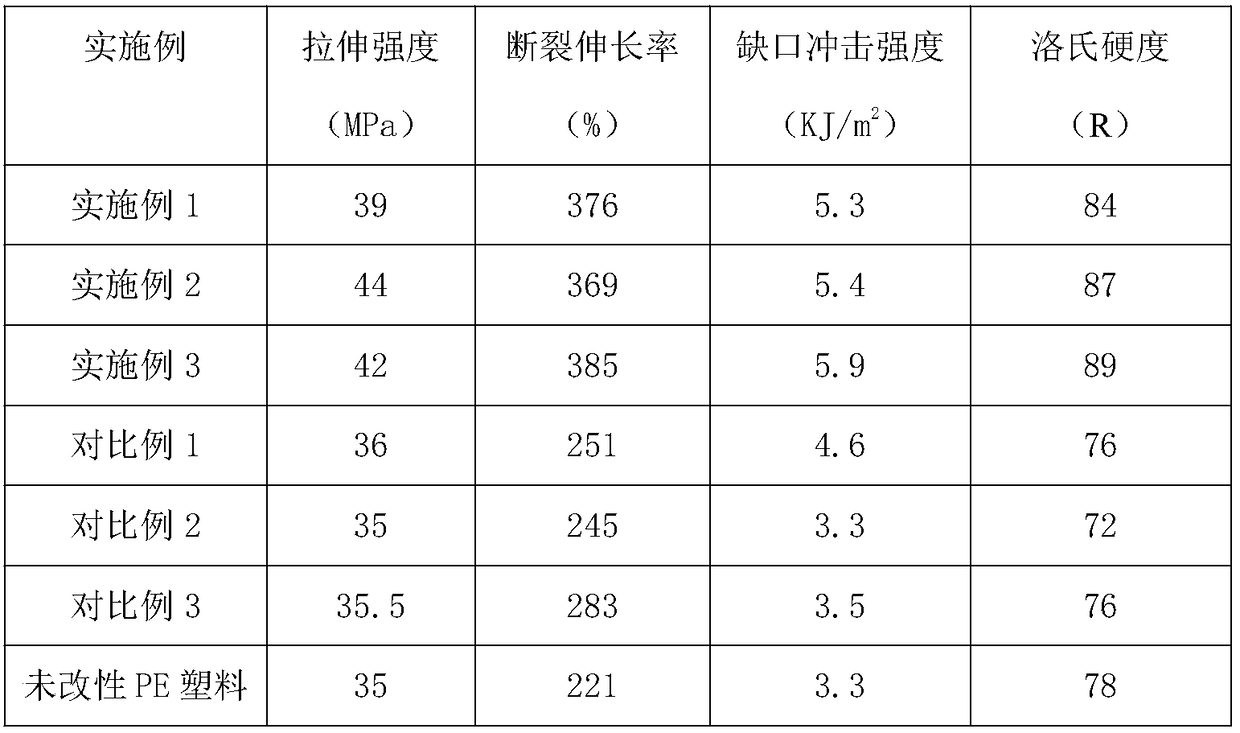

Recycled plastic and preparation method thereof

The invention discloses a recycled plastic. The recycled plastic comprises the following components in percentages by mass: 60-75% of waste plastics, 10-15% of waste ceramic powder, 0.5-2% of a coupling agent, 0.1-0.5% of monostearin, 5-10% of floating beads, 2-4% of SBS, 3-5% of a maleic anhydride grafted ethylene-propylene copolymer, 1-2% of 4-methylcatechol, 2-3% of ammonium ferric sulfate, and1-3% of phthalate. According to the recycled plastic disclosed by the invention, the 4-methylcatechol, the ammonium ferric sulfate, the floating beads are added and mixed with other raw materials, sothat full modification can be performed on the surface of the ceramic powder, and the difference between the polyolefin plastics and the ceramic powder can be reduced; and the ceramic powder and theplastics have good compatibility and strong interfacial adhesion, and the obtained recycled plastic has improved rigidity and toughness compared with a pure plastic substrate, and significantly-improved wear resistance, durability, corrosion resistance and heat resistance.

Owner:HUNAN YINGHONG SCI & TECH

Graphene nylon composite material and preparation method thereof

PendingCN108822532AStrong interface adhesionGood compatibilityHeat-exchange elementsCvd grapheneMechanical properties of carbon nanotubes

The invention provides a graphene nylon composite material and a preparation method thereof. The graphene nylon composite material comprises the following raw materials in parts by weight: 70-90 partsof nylon, 5-10 parts of carbon fiber, 20-30 parts of modified graphene, 4-8 parts of a flexibilizer, 0.6-1.8 parts of a compatilizer, 0.2-0.6 parts of a lubricant, and 0.2-0.6 parts of an anti-oxidant; and the modified graphene is obtained by graphene, citric acid and sodium metaaluminate. The preparation method is characterized in that the above raw materials are mixed by batches and are subjected to twin-screw extruded granulation. The nylon composite material has good heat conduction effect and excellent mechanical properties.

Owner:WUHU YUANKUI NEW MATERIAL TECH CO LTD

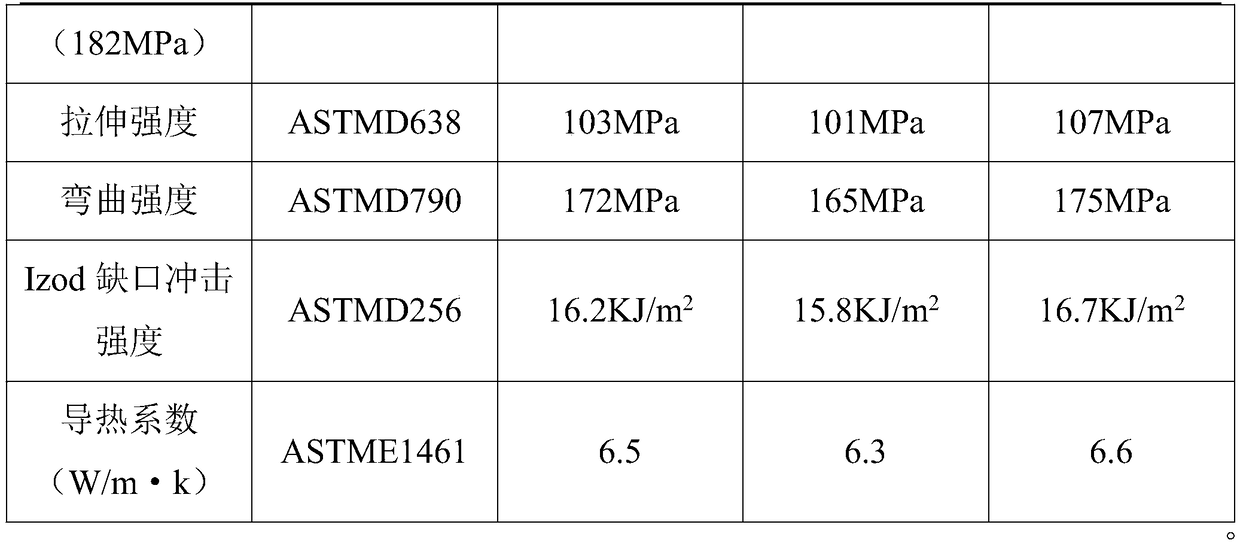

Total heat exchange graphene paper film

ActiveCN111778759ASensible heat exchange rate increasedFast heat conductionWater-repelling agents additionChemical industryCelluloseAntibacterial agent

The invention provides a total heat exchange graphene paper film. The total heat exchange graphene paper film is prepared from plant fiber pulp, a high-molecular polymer, a flame retardant, an antibacterial agent and graphene water-based pulp, wherein the plant fiber pulp is imported softwood pulp or mixed pulp of imported softwood pulp and hardwood pulp, according to the graphene water-based slurry, the content of effective components is 5-15%, and the viscosity is 1000-6000 mpa.s, the raw materials further comprise at least one of polyacrylamide, cationic starch and sodium carboxymethyl cellulose, and the adding amount is 2-5% of the absolute dry fiber amount. The raw materials further comprise at least one of polyacrylamide, cationic starch and sodium carboxymethyl cellulose, and the adding amount is 2-5% of the absolute dry fiber amount. The mass ratio of the high-molecular polymer to the flame retardant is 1: (4-10). The air permeability of the total heat exchange graphene paper film is less than or equal to 0.2 mu m / Pa.s, and the moisture permeability is more than or equal to 1000g / m<2>. 24h.

Owner:潍坊杰高非织材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com