Recycled plastic and preparation method thereof

A technology of recycled plastics and waste plastics, applied in the field of polymer materials, can solve the problems of not being able to improve the wettability of plastics and fibers, low strength and toughness of plastic alloys, weak interface adhesion, etc., to achieve rigidity and toughness Improvement, strong interfacial cohesion, and strong interfacial cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

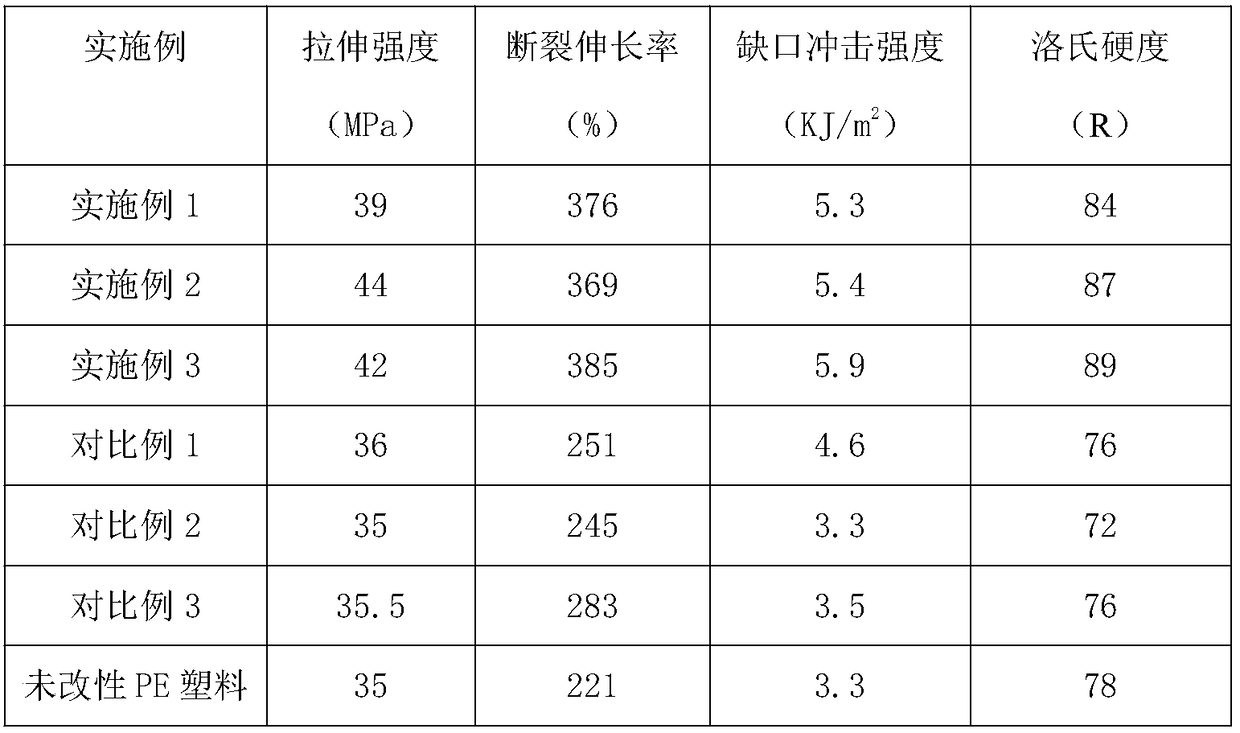

Examples

Embodiment 1

[0033] A recycled plastic, including the following components in mass percentage: waste plastic 75%, waste ceramic powder 10%, titanate coupling agent 201 0.5%, monoglyceride 0.5%, floating beads 5%, SBS 2 %, maleic anhydride grafted ethylene-propylene copolymer 3%, 4-methylcatechol 1%, ferric ammonium sulfate 2%, phthalate 1%; the fineness of the floating beads is 100- 200 mesh.

[0034] Preparation method: 1) Add waste ceramic powder, coupling agent, monoglyceride, and floating beads into the mixer according to the stated ratio and mix for 1.5 hours. The mixing temperature is 80°C, and the mixture is obtained after thorough mixing;

[0035] 2) Add the dried waste plastics and SBS into the mixer according to the stated ratio and mix for 40 minutes. The mixing temperature is 110°C. After fully mixing, the temperature is raised to 140°C, and the mixture obtained in step 1) and grafted with maleic anhydride are added. Ethylene-propylene copolymer, 4-methylcatechol, ferric ammon...

Embodiment 2

[0038]A recycled plastic, including the following components in mass percentage: waste plastic 65%, waste ceramic powder 10%, titanate coupling agent 201 1%, monoglyceride 0.3%, floating beads 7.7%, SBS 4 %, maleic anhydride grafted ethylene-propylene copolymer 5%, 4-methylcatechol 1%, ferric ammonium sulfate 3%, phthalate 3%; the fineness of the floating beads is 200- 300 mesh.

[0039] Preparation method: 1) Add waste ceramic powder, coupling agent, monoglyceride, and floating beads into the mixer according to the stated ratio and mix for 1.5 hours. The mixing temperature is 90°C, and the mixture is obtained after fully mixing;

[0040] 2) Add the dried waste plastics and SBS into the mixer according to the stated ratio and mix for 50 minutes. The mixing temperature is 120°C. After fully mixing, the temperature is raised to 140°C. Add the mixture obtained in step 1), maleic anhydride grafted Ethylene-propylene copolymer, 4-methylcatechol, ferric ammonium sulfate and phthala...

Embodiment 3

[0043] A recycled plastic, including the following components in mass percentage: waste plastic 60%, waste ceramic powder 15%, titanate coupling agent 201 2%, monoglyceride 0.1%, floating beads 10%, SBS 3 %, maleic anhydride grafted ethylene-propylene copolymer 3.5%, 4-methylcatechol 2%, ferric ammonium sulfate 2.4%, phthalate 2%; the fineness of the floating beads is 300- 400 mesh.

[0044] Preparation method: 1) Add waste ceramic powder, coupling agent, monoglyceride, and floating beads into a mixer according to the stated ratio and mix for 1 hour at a mixing temperature of 100°C, and mix thoroughly to obtain a mixture;

[0045] 2) Add the dried waste plastics and SBS into the mixer according to the stated ratio and mix for 30 minutes. The mixing temperature is 120°C. After fully mixing, the temperature is raised to 130°C. Add the mixture obtained in step 1), maleic anhydride grafting Ethylene-propylene copolymer, 4-methylcatechol, ferric ammonium sulfate and phthalate were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com