Patents

Literature

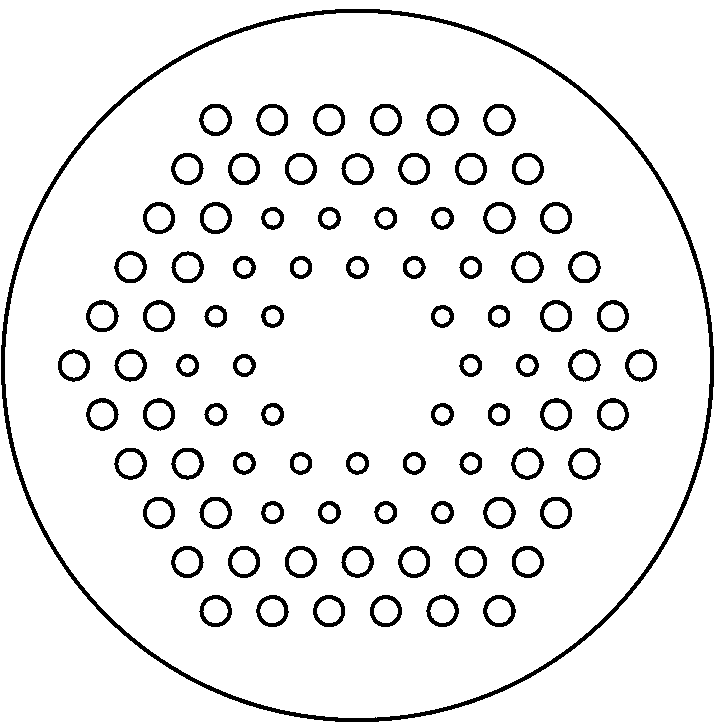

213results about How to "Solve the brittleness problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-flexibility melamino-formaldehyde foam material and preparation method thereof

The invention discloses a high-flexibility melamino-formaldehyde foam material and a preparation method thereof. The preparation method comprises: firstly, preparing melamino-formaldehyde prepolymer modified by polyol into aqueous solution with definite weight concentration; weighting 100 parts by weight of prepolymer aqueous solution; adding 0-15 parts by weight of surfactant, 1-20 parts by weight of foaming agent, 0-10 parts by weight of accelerator and 0-10 parts by weight of curing agent to be fully stirred and mixed to prepare foaming liquid; filling foaming liquid into a microwave chemical reactor or a high-temperature oven; and foaming for 30s-15min at the temperature of 100-300 DEG C to prepare the foam material. The melamino-formaldehyde foam material disclosed by the invention solves the problems of big brittleness, poor flexibility, easy duslting of foam, complex preparation technology, high production cost and the like of the existing melamino-formaldehyde foam material and has wide application prospect.

Owner:SICHUAN UNIV

Method for preparing Wood-plastic composite material by modified wood powder and waste and old plastics

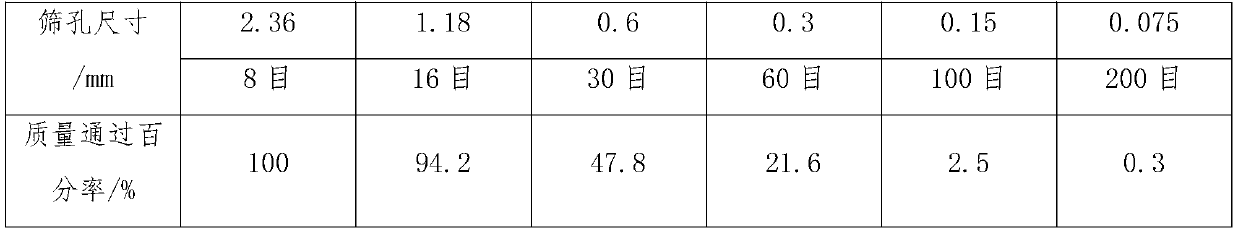

The invention relates to a preparation technique of a wood plastic composite material, in particular to a method for preparing a wood plastic composite material by using modified wood powder and waste plastics. The method is characterized in that: (1) discarded agriculture and forestry wastes are crushed, milled and dried, and three different surface modification agents are added in sequence and mixed with the waste power one after another in a high-speed mixer to produce the modified water powder; and (2) waste plastics are washed and crushed into granules with the grain size of 2mm to 12mm and then dried; the modified waste powder, the waste plastic granules, a lubricant, a vesicant and a blowing promoter are mixed by weight percentage and put into the high-speed mixer for high-speed mixing and then cooled to the temperature lower than 55 DEG C for discharging so as to prepare a special premix. The composite material has super high strength and anti-bending and anti-impact capacity, wherein, the obvious enhancement of the anti-impact strength causes the great enhancement of the processing capacity of the product, thus causing products to meet different demands and ensuring an extremely wide application range.

Owner:FUJIAN NORMAL UNIV

Modified composite material of woods and plastics as well as its usage and manufacturing method

A modified wood-plastics composition is prepared from wood flour, plastic, assistant, and grafting agent through graft modifying of wood flour and plastics, and continuous extruding out. Its advantage is high tension strength, bending strength and impact strength.

Owner:BEI JING NEW BUILDING MATERIALGRP

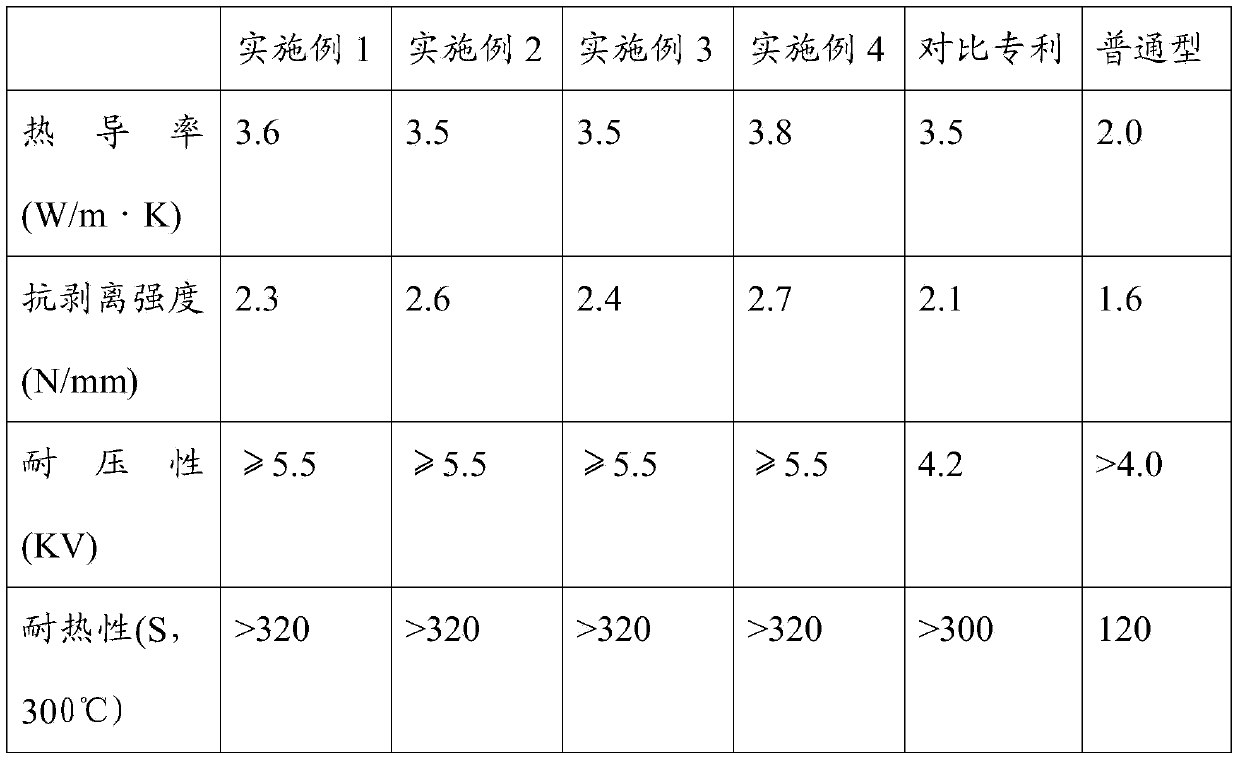

Halogen-free high heat-resistant and heat-conducting resin film and manufacturing method thereof

ActiveCN102660210ASolve the brittleness problemImprove cooling effectNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyHeat conducting

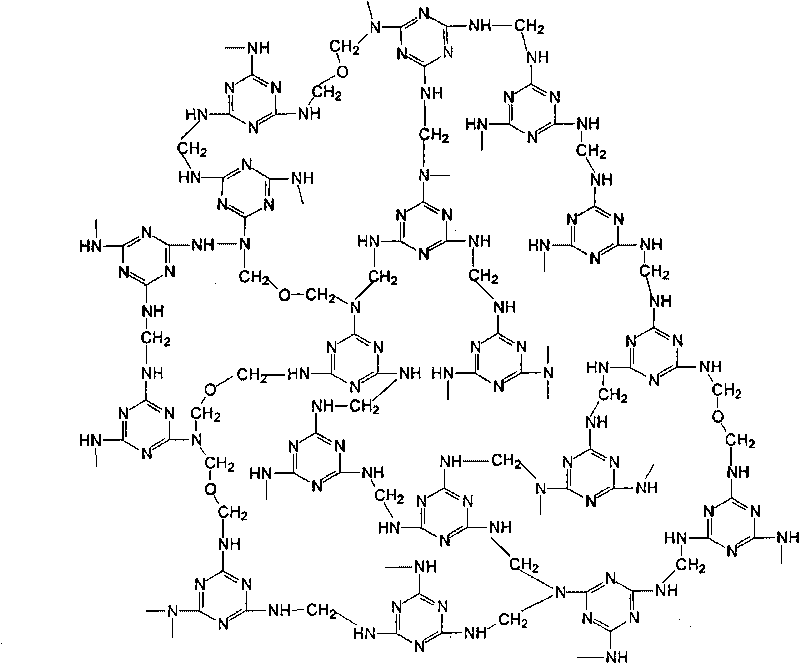

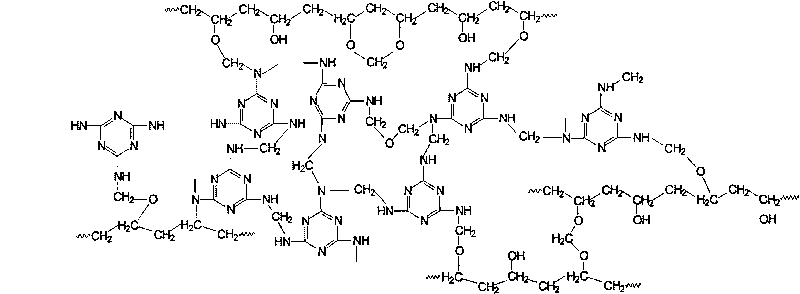

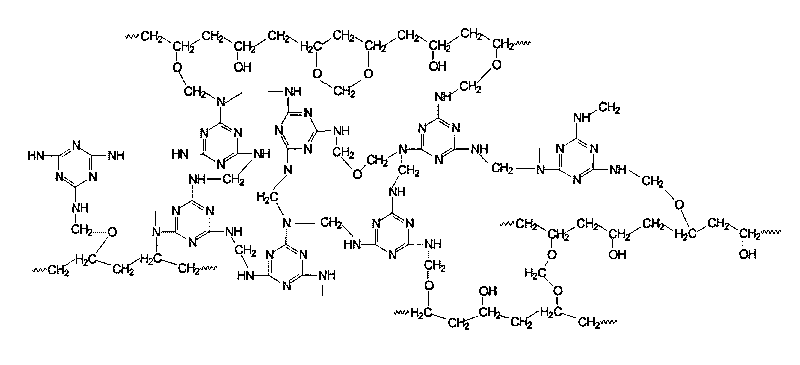

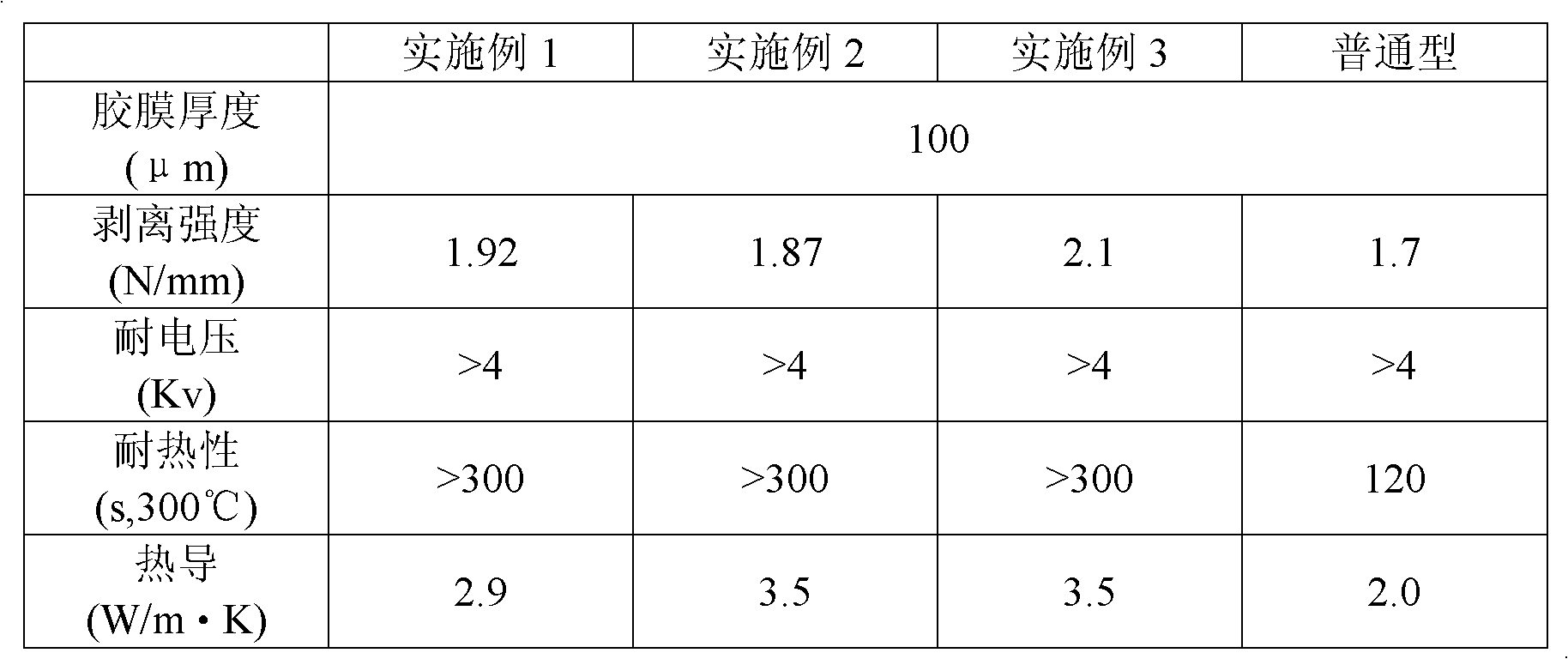

The invention discloses a halogen-free high heat-resistant and heat-conducting resin film and a manufacturing method thereof. The halogen-free high heat-resistant and heat-conducting resin film is prepared by semi-curing of a heat-conducting resin liquid, wherein the heat-conducting resin liquid is prepared from 70 to 100 parts of a halogen-free epoxy resin, 0 to 30 parts of one or more flexibilizers, 80 to 120 parts of one or more solvents, 1 to 20 parts of one or more curing agents, 0.01 to 1 part of one or more promoters, 0.5 to 5.0 parts of a coupling agent and 80 to 600 parts of one or more high heat-conducting filling materials. The halogen-free high heat-resistant and heat-conducting resin film has a thermal conductivity great than or equal to 2.5W / m.K and heat resistance (at a temperature of 300 DEG C) great than or equal to 300s. The halogen-free high heat-resistant and heat-conducting resin film has flexibility so that the problem of brittleness of the traditional heat-conducting materials is solved. An aluminum substrate prepared from the halogen-free high heat-resistant and heat-conducting resin film is suitable for electronic products such as LED, vehicle systems and variable-frequency power sources needing good heat conductivity, can greatly improve the thermal diffusivity of the electronic products, and has high reliability and energy-saving and environmental-protection effects.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

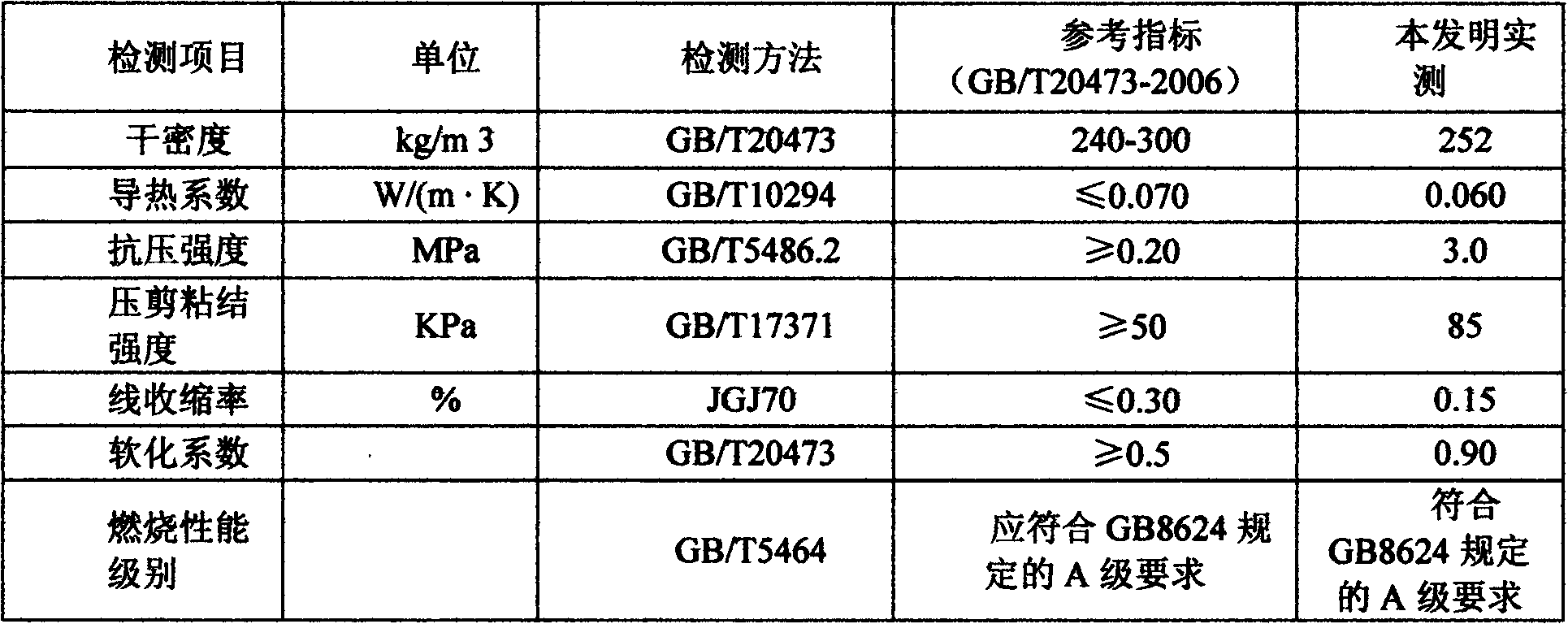

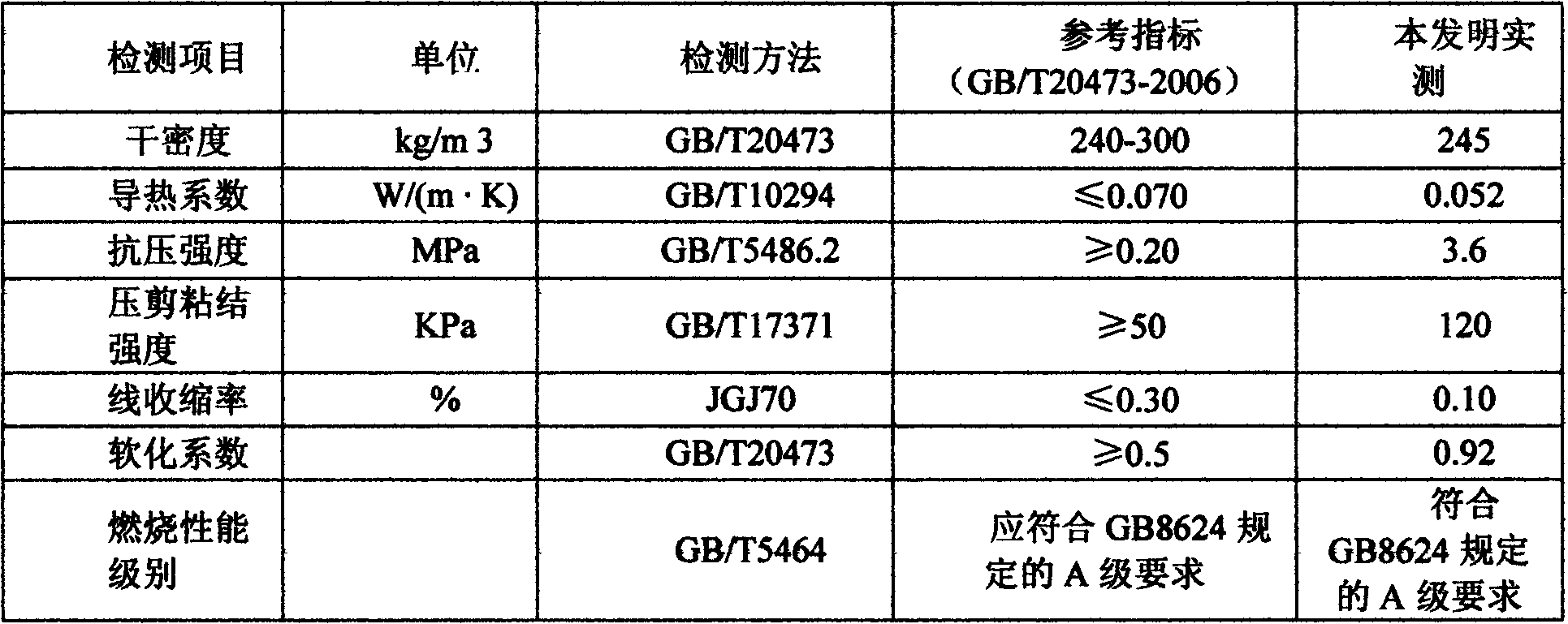

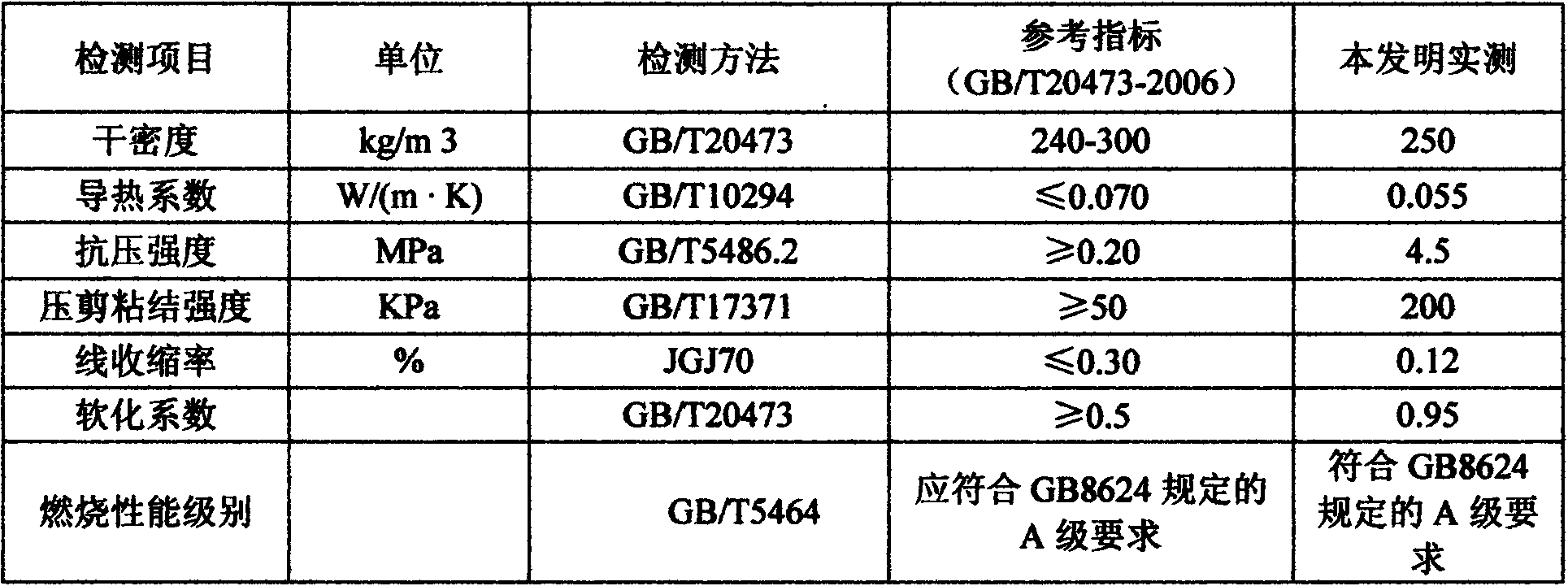

Thermal-insulating anti-flaming building material and preparation method thereof

The invention relates to a thermal-insulating anti-flaming building material and a preparation method thereof. The thermal-insulating anti-flaming building material comprises the following components by weight parts: 45 to50 parts of lightweight aggregates, 45 to 50 parts of inorganic gelled materials, 5 to 10 parts of toughening agents, 3 to10 parts of interface modifying agents and 0.5 to 2 parts of dispersing agents. The quick coagulating function and the closing function of the interface modifying agents are utilized to perform hole-closing treatment on the surfaces of the lightweight aggregates; fibrous inorganic whisker materials with big ratio of length to diameter are selected as the toughening materials; the defects of inferior thermal-insulating effect and fragile property of the inorganic thermal-insulating material are thoroughly overcome; all the raw materials of the thermal-insulating anti-flaming building material are selected from A-level anti-flaming materials and areexcellent in anti-flaming effect; and the production process for the thermal-insulating anti-flaming material is simple and short, is continuously operated, is easily performed and controlled and is beneficial to industrialized application.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

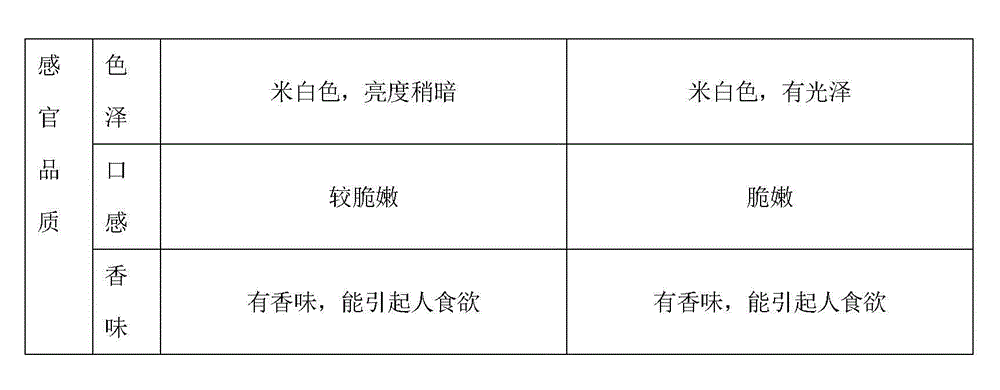

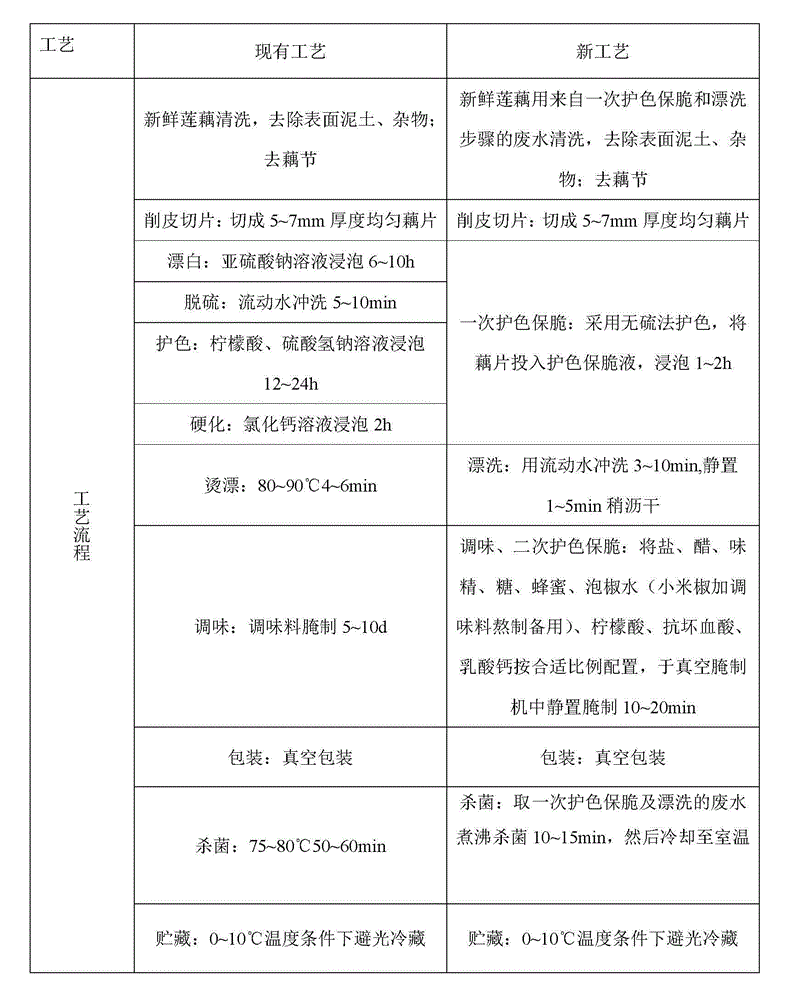

Processing method of instant seasoning lotus root

The invention discloses a processing method of an instant seasoning lotus root, which comprises the steps that a fresh lotus root is cleaned, peeled, sliced, then subjected to primary color protection and crisp keeping, rinsed, seasoned, subjected to secondary color protection and crisp keeping, seasoned, packaged and sterilized at a high temperature, and the instant seasoning lotus root is obtained. The processing method is simple and efficient; the color protection and crisp keeping are conducted simultaneously in the primary color protection and crisp keeping step; the secondary color protection and crisp keeping step is merged into the seasoning step, so that the time is saved and the effect is good. As a vacuum curing method is adopted, the curing time is saved; the appearance of an obtained lotus root sheet is creamy white; and the lotus root sheet has luster and a delicious and crisp taste. Compared with the prior art, the delicious and crisp taste is improved, and the lustrousness is better.

Owner:ZHEJIANG SHANSHUILANG FOOD

Tungsten-titanium co-doped diamond coating material and preparation technique thereof

InactiveCN101787520AOvercoming the problem of increased coefficient of frictionSolve the brittleness problemVacuum evaporation coatingSputtering coatingDlc coatingGas phase

The invention discloses a tungsten-titanium co-doped diamond (DLC) coating material and a preparation technique thereof, which are characterized by: firstly, removing a pollution layer on the surface of a workpiece by ultrasonic cleaning, and performing argon-ion etching cleaning on the surface of the workpiece by glow discharge to obtain an atomic-scale clean surface; secondly, preparing a gradient transition layer by a reactive magnetron sputtering sedimentation method; and finally, preparing a preparing a DLC coating on the transition layer by magnetron sputtering and glow discharge plasma chemical vapor deposition method, wherein the synthesized DLC coating contains carbon element, tungsten element, titanium element and the like; the tungsten content is 2 to 5 percent; and the titanium content is 0.1 to 2.0 percent. The tungsten-titanium co-doped diamond (DLC) coating material is excellent in membrane / base binding force and low in friction coefficient and wear rate.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Preparation method of superfine crystal lead-free delay element for detonator

The invention discloses a preparation method of a superfine crystal lead-free delay element for a detonator. The preparation method comprises the following steps: firstly, preparing a superfine crystal Zn-Al alloy blank pipe by adopting casting, extrusion, rolling and machining; then drawing or rolling the superfine crystal Zn-Al alloy blank pipe with delay powder to form a Zn-Al alloy pipe; and finally, cutting and packaging the prepared Zn-Al alloy pipe so as to obtain the Zn-Al alloy delay element. Through using the technical scheme of the invention, lead pollution is avoided, use occasionis not limited, and production process is safer.

Owner:NANJING UNIV OF SCI & TECH

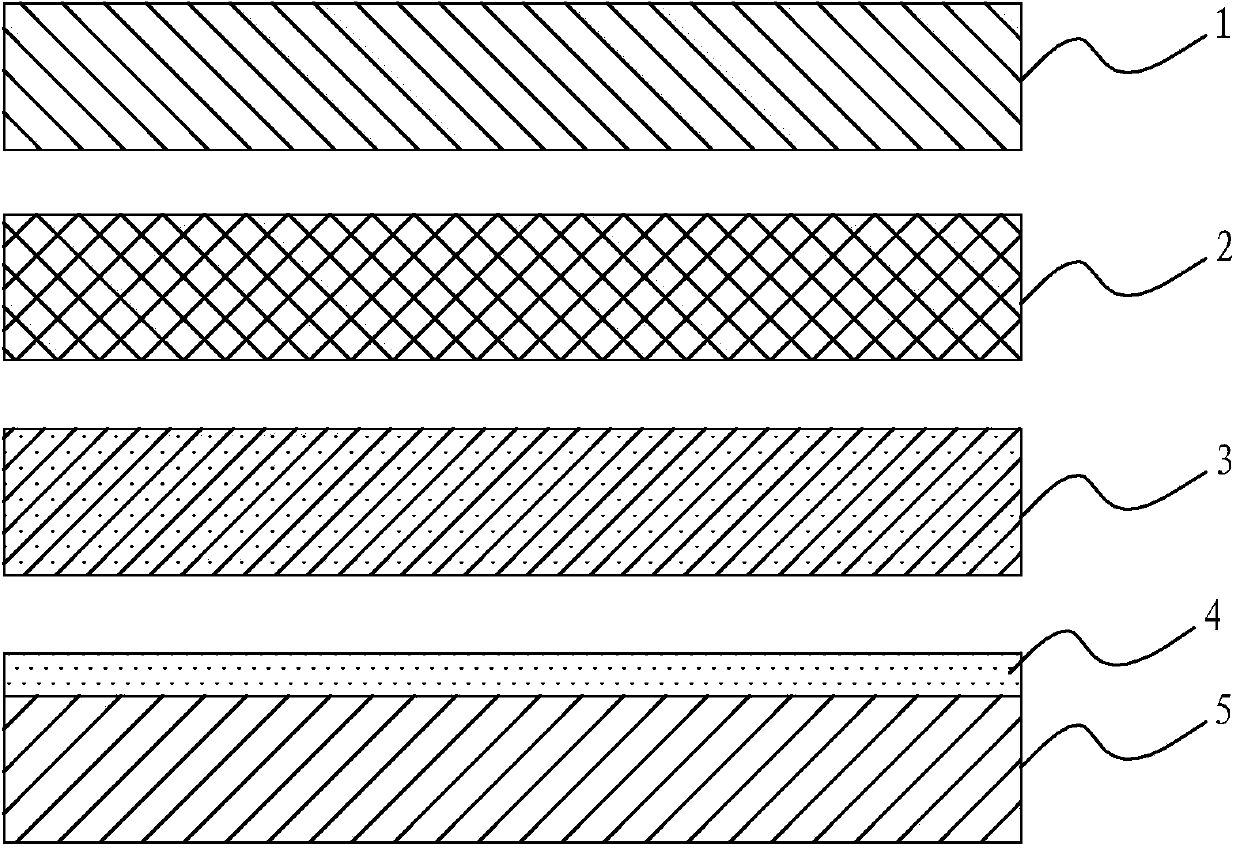

High-thermal-conductivity and high-pressure-resistance aluminum-based copper-clad plate and preparation method thereof

ActiveCN103722807AImprove surface adhesionEliminate internal stressSynthetic resin layered productsLaminationAdhesiveCopper foil

The invention discloses a high-thermal-conductivity and high-pressure-resistance aluminum-based copper-clad plate which comprises copper foil, an insulated thermal conductivity adhesive layer, a binder layer and an aluminum plate, wherein the surface layer of the aluminum plate is subjected to anodic oxidation to form a ceramic protection layer, the insulated conductive adhesive layer is formed by performing high-temperature baking and semi-solidifying on a thermal conductivity adhesive solution, and the copper foil, the insulated thermal conductivity adhesive layer, the binder layer and the aluminum plate are laminated and pressed for formation in sequence. The high-thermal-conductivity and high-pressure-resistance aluminum-based copper-clad plate has the following advantages that 1, the surface adhesion force of the insulated thermal conductivity adhesive layer and the aluminum plate is increased through adding the binder layer and a coupling agent to reduce the difference influence on hot pressing caused by different expansion coefficients; 2, the oxidation resistance of the product is improved through the ceramic protection layer, and meanwhile, the bonding force of the insulated thermal conductivity adhesive layer and the aluminum plate is further enhanced; 3, the flexibility of an adhesive film is increased through adding a flexibilizer to solve the brittleness problem; 4, aluminum oxide, silicon dioxide, silicon carbide and the like are used as thermal conductive filler, so that the technical defect of poor heat dissipation performance is overcome.

Owner:舟山海源生物科技有限公司

Photo-thermal dual-curing anisotropic conductive adhesive film and preparation method thereof

ActiveCN104673113AImprove crosslink strengthHigh bonding strengthNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyCross-link

The invention relates to a photo-thermal dual-curing anisotropic conductive adhesive film and a preparation method thereof. The anisotropic conductive adhesive film is prepared from raw materials in percentage by mass as follows: 35%-45% of epoxy resin, 10%-25% of acrylic resin, 5%-10% of a cross-linking agent, 2%-7% of a diluent, 0.6%-1% of a photoinitiator, 2.5%- 4% of a thermal curing agent, 5%-10% of an accelerant, 0.5%-2% of a silane coupling agent and 20%-35% of conductive balls. The preparation method comprises steps as follows: the raw materials are blended, subjected to rotary coating and then subjected to ultraviolet exposure processing, and the anisotropic conductive adhesive film is prepared. The anisotropic conductive adhesive film has good conductive performance, excellent weather fastness, low curing temperature, long storage time, high curing degree and high bonding strength; the preparation process is simple, the cost is low, and the application prospect is broad.

Owner:DONGHUA UNIV

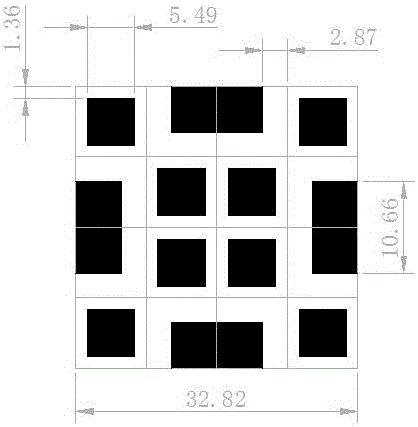

High-temperature-tolerance frequency selection wave-transmitting structure and preparation method thereof

ActiveCN106630979AImprove mechanical propertiesImprove electrical performanceLaser beam welding apparatusFiberElectrical conductor

The invention discloses a high-temperature-tolerance frequency selection wave-transmitting structure. The high-temperature-tolerance frequency selection wave-transmitting structure successively comprises a wave-transmitting layer, a modification bonding layer and a frequency selection layer from inside to outside, wherein the wave-transmitting layer is made of a continuous fiber reinforced ceramic-based wave-transmitting composite material; the modification bonding layer is made of a low-dielectric-constant material; the frequency selection layer is a noble metal physical plating layer or a noble metal glass conductor coating with periodic structure patterns. The high-temperature-tolerance frequency selection wave-transmitting structure can tolerate high temperature of 700 DEG C or more, and has excellent high temperature tolerance. The invention also provides a production method of the high-temperature-tolerance frequency selection wave-transmitting structure; the modification bonding layer is produced by using a plasma spraying process; the thermal damage to the substrate can be avoided, so that the substrate has high strength retention rate; the size accuracy of the frequency selection layer produced by a laser processing process can be higher than 20 microns; the frequency selection layer has high size accuracy.

Owner:NAT UNIV OF DEFENSE TECH +1

Method of preparing wood-plastic composite material with modified wood powder and waste plastic

The invention relates to a preparation technology of wood-plastic composite materials and particularly relates to a method of preparing a wood-plastic composite material with modified wood powder and waste plastic. The method includes the steps of (1) crushing, milling and drying agricultural and forestry wastes, successively adding three different surface modifiers and successively mixing the surface modifiers with the waste powder in a high-speed mixing machine to prepare a modified waste powder; (2) cleaning the waste plastic, crushing the waste plastic into granules being 2-12 mm in size, and drying the granules; and (3) according to weight percentage ratio, feeding a mixture composed of the modified waste powder, the waste plastic granules, a lubricant, a foamer and a foamer aid into the high-speed mixing machine to perform high-speed mixing, cooling the mixture until the temperature is lower than 55 DEG C and discharging the material to prepare a special premix. The composite material is very high in strength and anti-bending and anti-impact performance, wherein the anti-impact strength is significantly improved so that the composite material is greatly improved in processability, and further can be used for producing products satisfying different demands. The composite material is greatly wide in application range.

Owner:QUANZHOU NAISI MATERIAL TECH

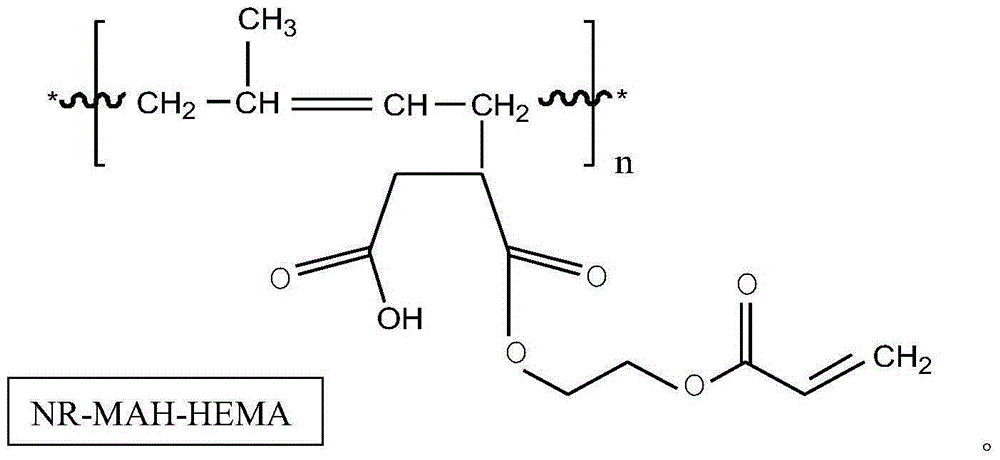

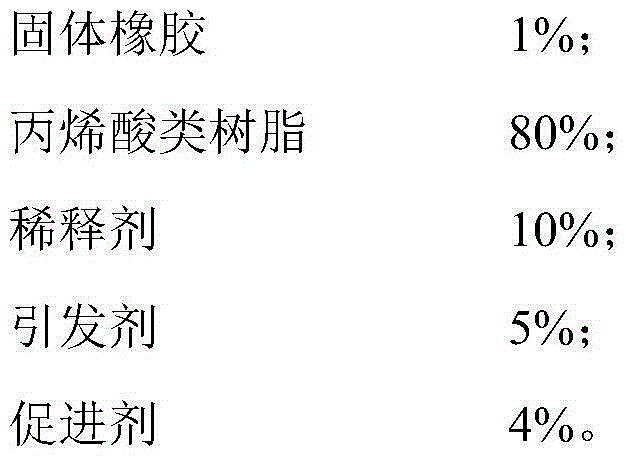

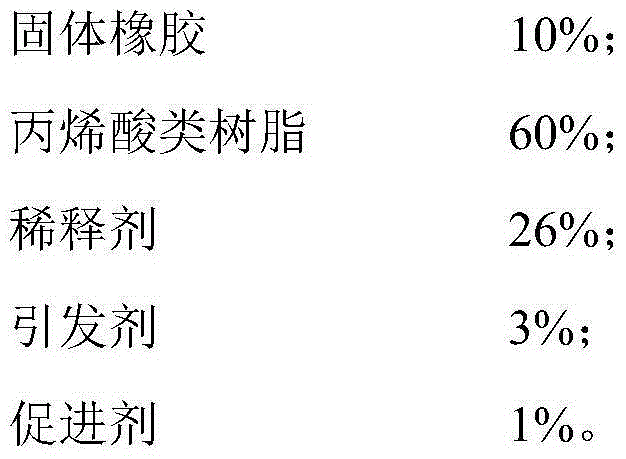

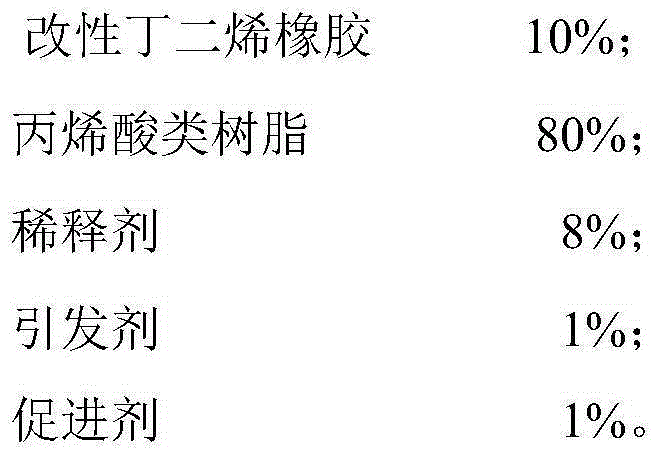

Three-dimensional printing photosensitive resin material containing solid rubber and preparation method

InactiveCN105175651ASolve the brittleness problemImprove performanceRubber derivative coatingsAdditive manufacturing apparatusPolymer scienceAcrylic resin

The invention belongs to the technical field of three-dimensional printing photosensitive resin materials, and discloses a three-dimensional printing photosensitive resin material containing solid rubber. The photosensitive resin material is prepared from, by mass, 1%-20% of the solid rubber, 30%-80% of acrylic resin, 10%-40% of diluents, 1%-5% of initiators and 1%-5% of accelerants. The photosensitive resin material has the advantages that the solid rubber NR-MAH-HEMA is synthesized, the brittleness problem of photosensitive resin for three-dimensional printing on the present market is effectively solved by introducing rubber molecules, and the rubber molecules are added into the photosensitive resin material as the solid parts through a technical mean that the rubber molecules are frozen with liquid nitrogen and then ground; use is easy, the material source is wide, and the toughness of the photosensitive material is greatly improved. The invention further discloses a preparation method of the three-dimensional printing photosensitive resin material containing the solid rubber.

Owner:JIANGSU UNIV OF SCI & TECH

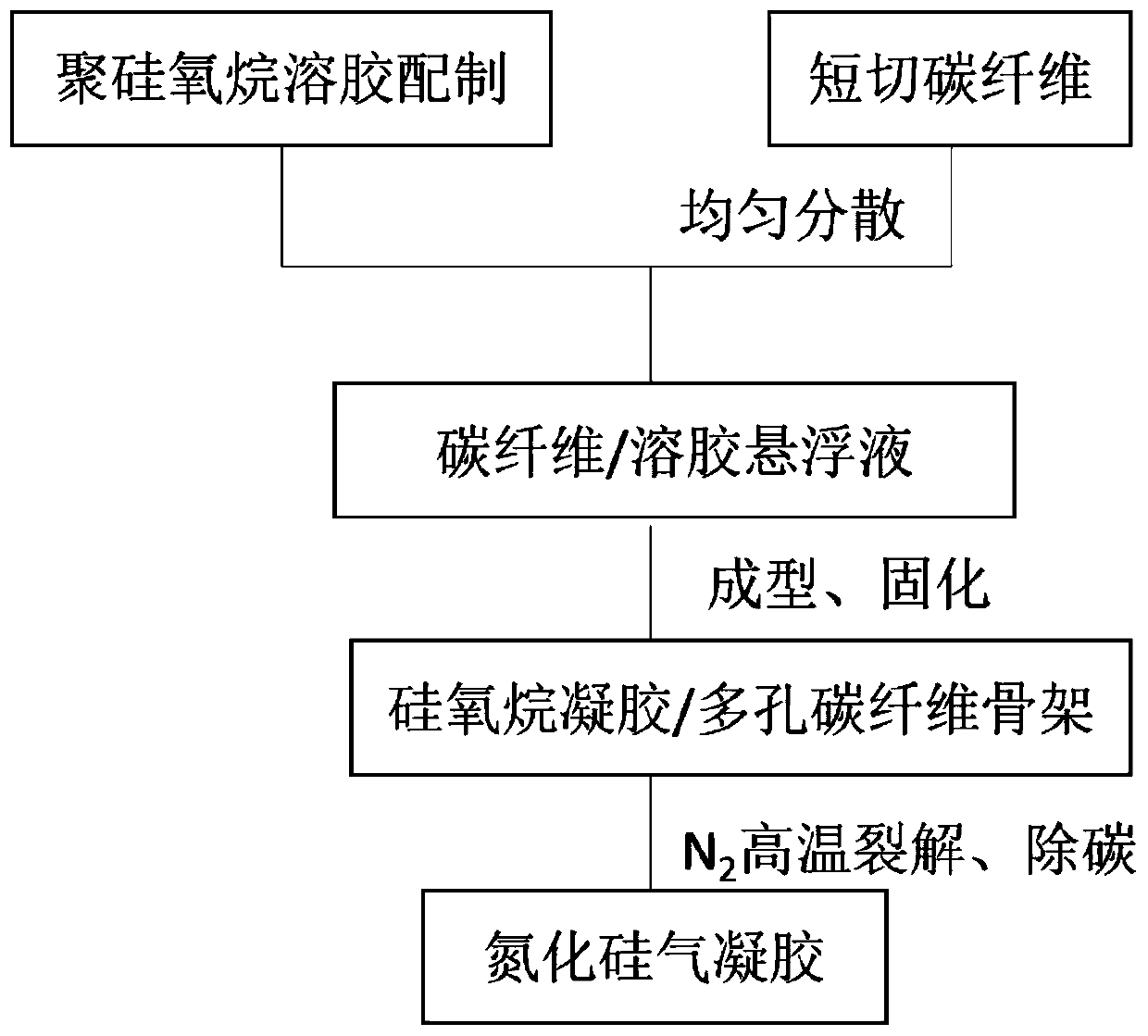

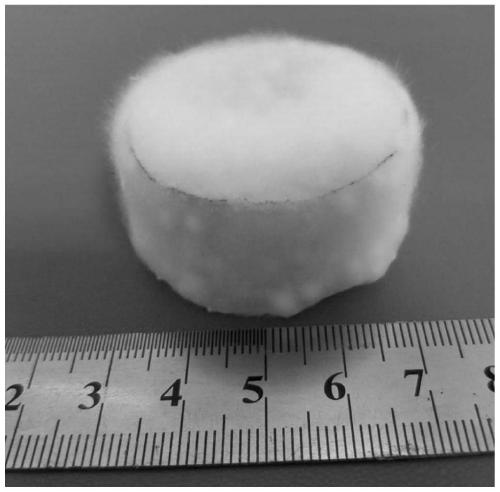

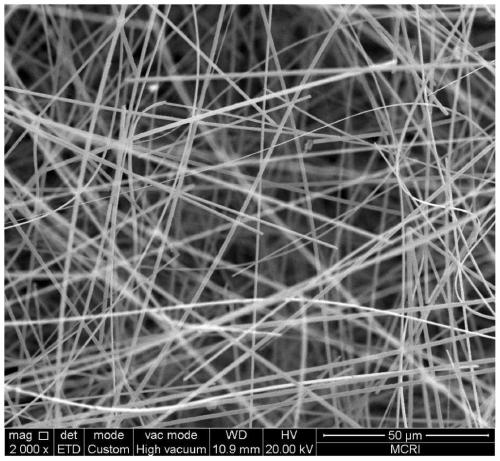

Silicon nitride nanoribbon aerogel and preparation method thereof

The invention discloses a silicon nitride nanoribbon aerogel and a preparation method thereof, and the method comprises the following steps: 1) preparing polysiloxane sol; 2) preparing slurry; 3) constructing a three-dimensional porous carbon fiber framework formed by mutual lap joint of short-cut carbon fibers bonded by the siloxane sol; 4) curing and cracking, to be more specific, heating the three-dimensional porous carbon fiber framework to the curing temperature of the polysiloxane sol, carrying out heat preservation treatment, carrying out heating and heat preservation treatment in a nitrogen atmosphere, and cooling to the room temperature in a furnace so as to obtain a carbon fiber / silicon nitride nano fiber composite block body; and 5) decarbonizing, to be more specific, heating the carbon fiber / silicon nitride nano-fiber composite block to 400-1000 DEG C in air, and carrying out heat preservation treatment for 2-4 hours to obtain the silicon nitride nanoribbon aerogel. The silicon nitride nanoribbon aerogel prepared by the method has quite excellent high-temperature stability and thermal insulation performance, the brittleness problem of the traditional ceramic aerogel isovercome, expensive drying equipment and low-efficiency drying processes are not needed, and the silicon nitride nanoribbon aerogel is low in cost, high in efficiency and suitable for the fields of heat insulation, heat preservation, wave transmission and the like.

Owner:XI AN JIAOTONG UNIV

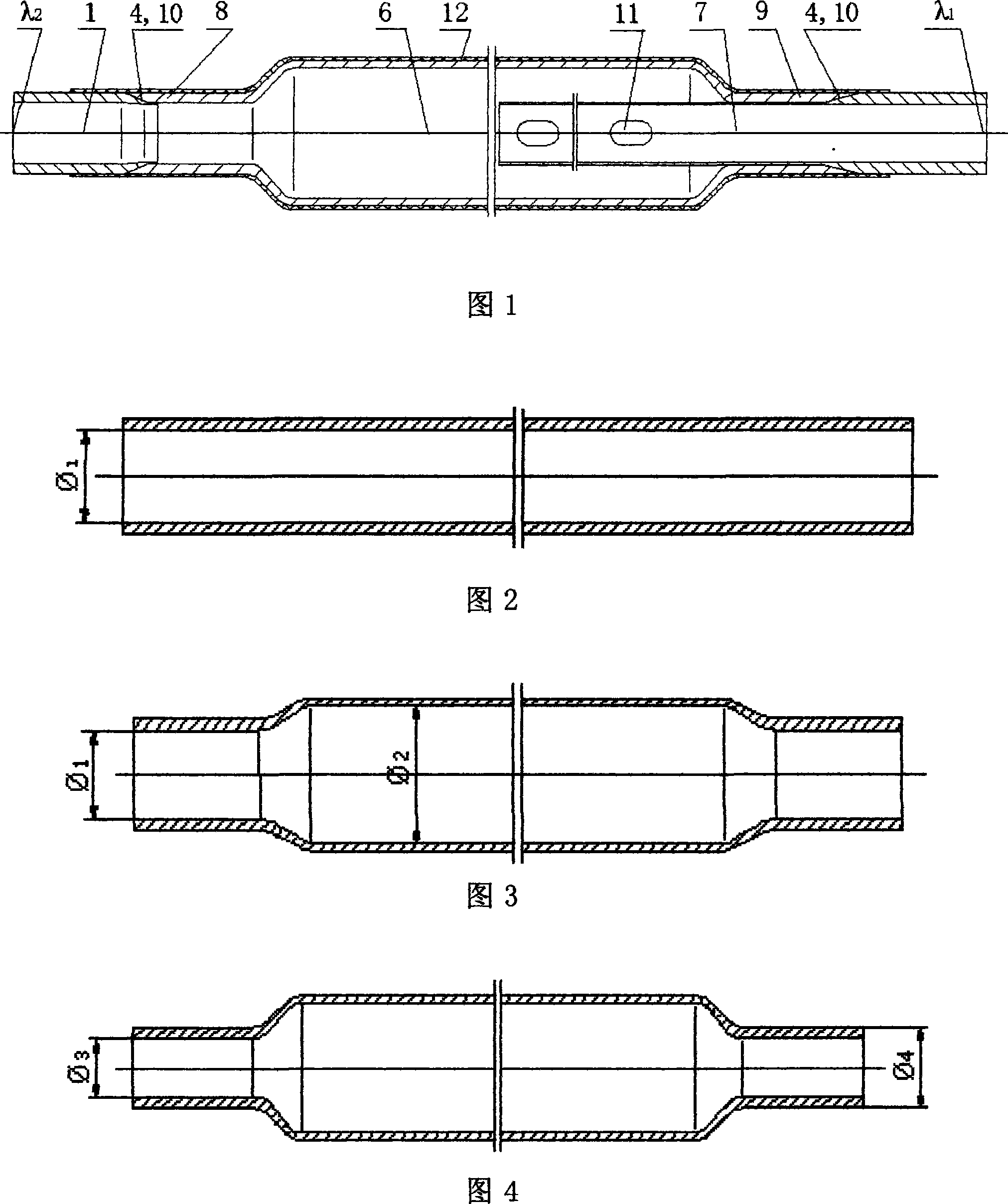

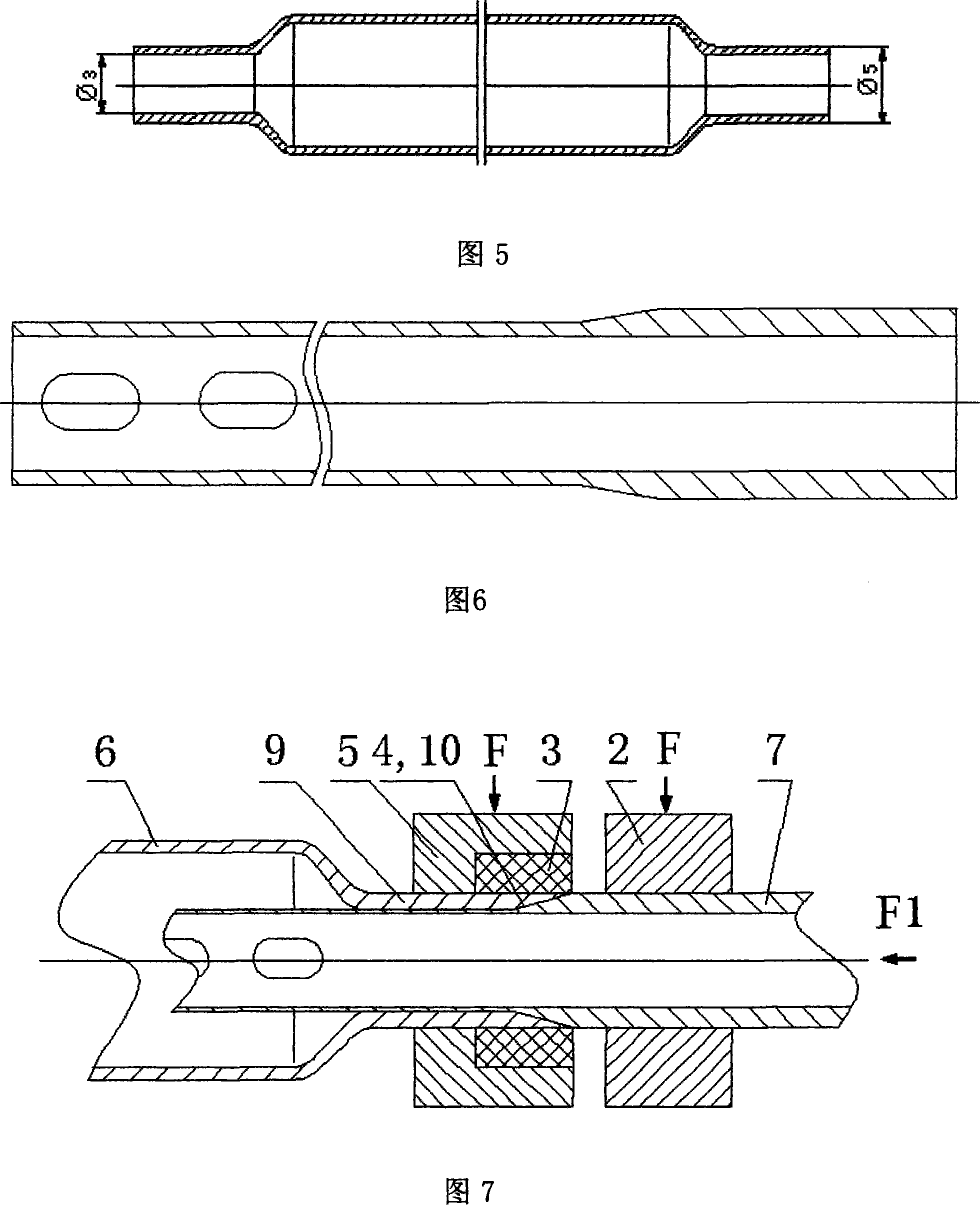

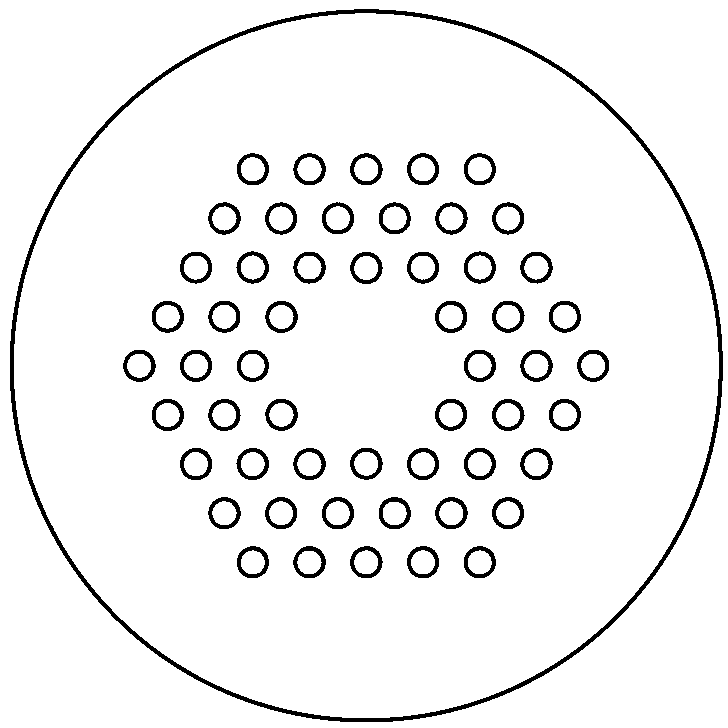

Porous metal hollow fibrous membrane and preparation method

The invention relates to a porous metal hollow fibrous membrane and a preparation method. The porous metal hollow fibrous membrane is characterized in that the outer diameter is 2+ / -0.5 mm, the wall thickness is 0.2-0.6 mm, and the porosity is 15-45 percent; the porous metal hollow fibrous membrane is made of a porous stainless steel hollow fibrous membrane or a porous titanium-aluminum alloy hollow fibrous membrane. The preparation method comprises the steps of uniformly stirring and mixing metal powder, 1-methyl-2-pyrrolidone (NMP), polyether sulfone (PES) and water (H2O) according to a certain mass ratio to prepare a spinning solution; and preparing a hollow fiber green body by a dry / wet spinning method; performing high-temperature roasting under protective atmosphere to obtain the porous metal hollow fibrous membrane. The preparation method disclosed by the invention is simple in operation technology, and the prepared porous metal hollow fibrous membrane is high in bending strength, high in flexibility, high in heat conduction performance and heat stability, high in filling density and high in permeation flux and has wide application prospects and great market potential.

Owner:NANJING UNIV OF TECH

Poly(butylene succinate) and preparation method thereof

The invention discloses a poly(butylene succinate) which is prepared by copolymerizing succinic acid, butylene glycol and cyclic dibasic alcohol. The poly(butylene succinate) comprises succinic acid residue, butylene glycol residue and cyclic diol residue, wherein the butylene glycol residue accounts for 90-98% of the total dibasic alcohol, and the cyclic diol residue accounts for 2-10% of the total dibasic alcohol. The preparation method comprises the following steps: reacting succinic acid, butylene glycol and cyclic dibasic alcohol at 200-230 DEG C under the action of a catalyst to perform direct esterification, thereby obtaining an esterified substance; adding a stabilizer, and carrying out pre-polycondensation reaction at 220-250 DEG C to obtain a prepolymer; carrying out polycondensation reaction on the prepolymer at 235-250 DEG C while gradually reducing the vacuum degree of the reaction system to less than 150Pa; and after the polycondensation finishes, adding carbodiimide compounds into the reaction product, and mixing for 2-15 minutes, thereby obtaining the poly(butylene succinate). The polyester synthesized by the method disclosed by the invention has the advantages of high heat resistance, high melting point, controllable degradation rate, excellent mechanical properties and excellent processability.

Owner:KINGFA SCI & TECH CO LTD +2

Foamable phenolic resin strengthening and filling material for coal mine

ActiveCN102558763AAdjustable curing speedCured body with high strengthUnderground chambersTunnel liningOrganic acidUrea

The invention relates to a foamable phenolic resin strengthening and filling material for coal mine. In the foamable phenolic resin strengthening and filling material for coal mines, a component A is one of inorganic acid and organic acid or a mixture of inorganic acid and organic acid; and a component B is prepared by mixing 90 to 100 weight parts of urea modified phenolic resin with solid content of 65 to 90 weight percent, 6 to 10 weight parts of composite fire retardant, 0 to 15 weight parts of foaming agent, 1 to 5 weight parts of stabilizing agent, 1 to 15 weight parts of cosolvent, 2 to 16 weight parts of antistatic agent and 10 to 30 weight parts of plasticizer, stirring at the temperature of between 30 and 50 DEG C and reacting for 0.5 to 2 hours. When the foamable phenolic resin strengthening and filling material is used, the component A and the component B are mixed and injected into a coal (rock) layer according to the weight ratio of (1-2) : 1 and permeated into small cracks to expand and generate curing reaction for strengthening and sealing the region. According to the foamable phenolic resin strengthening and filling material for coal mines, the compressive strength is more than 40 MPa; the bonding strength is more than or equal to 3.0 MPa; and the foaming coefficient is less than or equal to two times. The foamable phenolic resin strengthening and filling material for coal mines can meet the requirement of coal mine on safety production and can be applied to the industries such as hydroelectric powder, buildings, mining, traffic and the like.

Owner:SHANXI ZHAOXIN BIO TECH

SnBiSb-series low-temperature lead-free solder and preparation method thereof

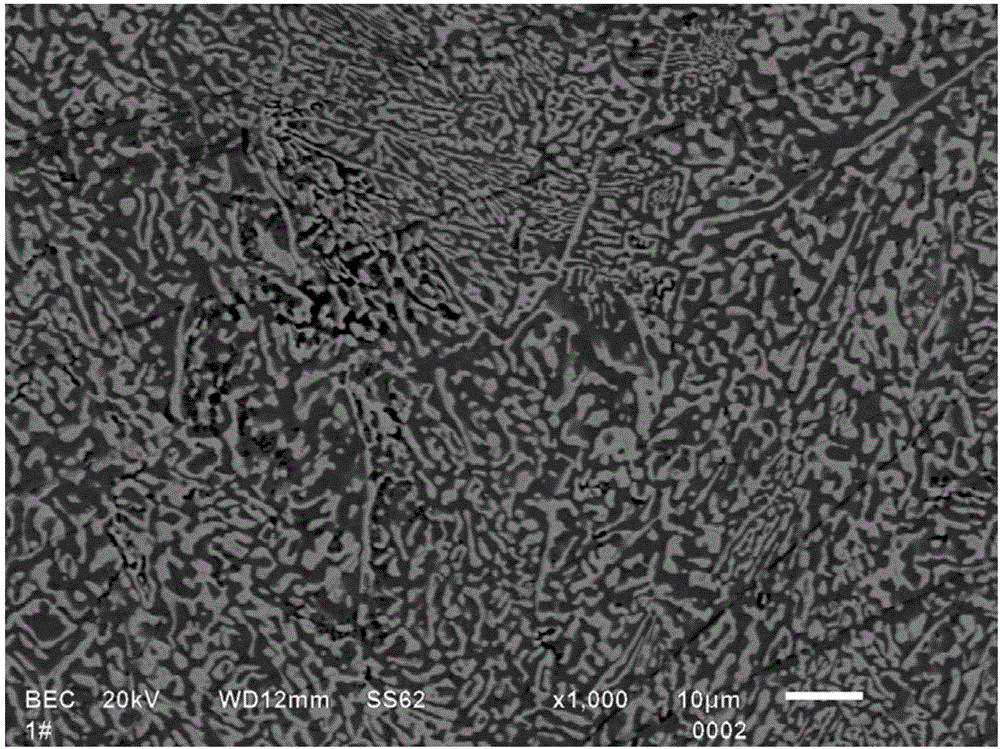

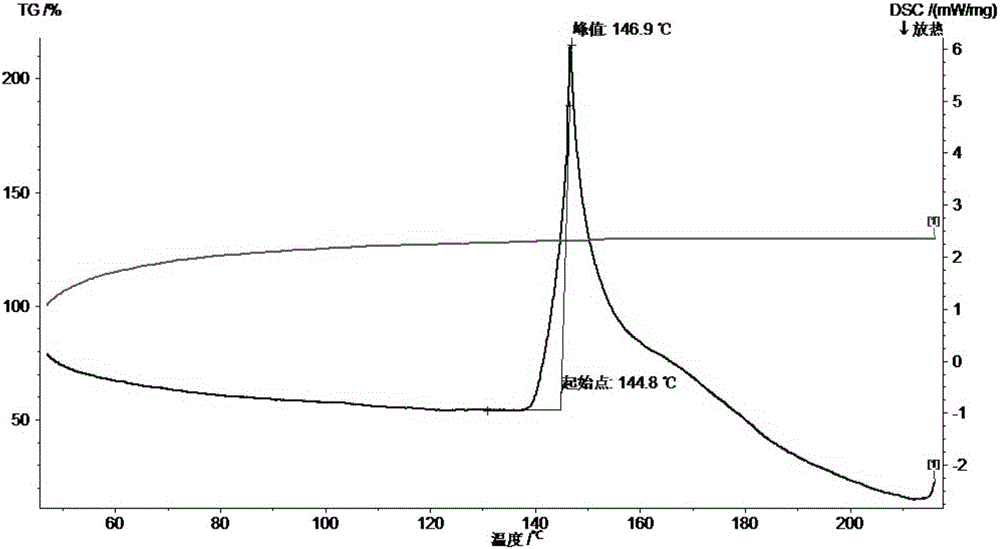

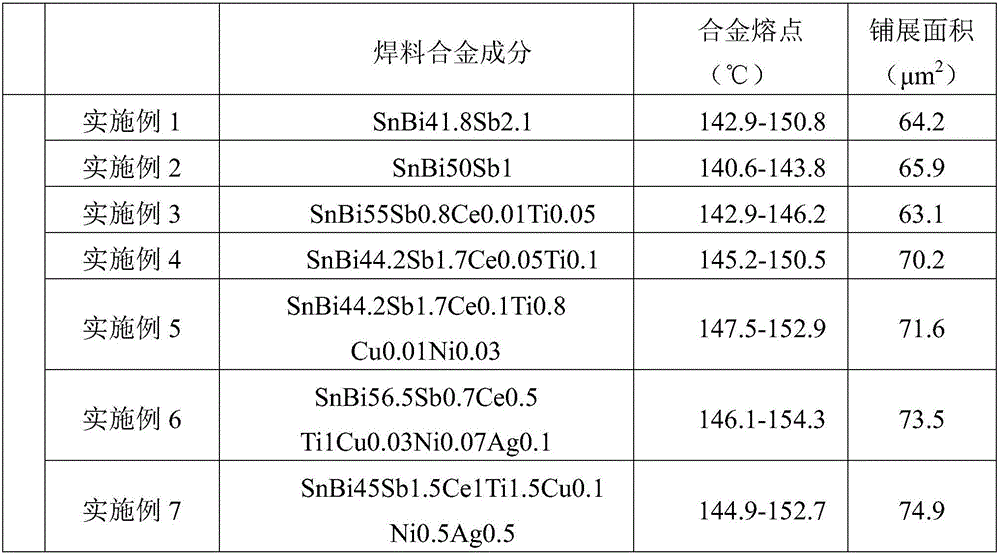

ActiveCN106216872AFine grainSmall grainWelding/cutting media/materialsSoldering mediaMechanical propertyMechanical properties of carbon nanotubes

The invention discloses SnBiSb-series low-temperature lead-free solder and a preparation method thereof, and belongs to the technical field of low-temperature soft solder. The SnBiSb-series low-temperature lead-free solder consists of the following components in percentage by weight: 32.8-56.5% of Bi, 0.7-2.2% of Sb, the balance Sn, wherein weight percentage of Bi and Sb meets a relation b=0.006 a<2>-0.0672a+19.61+c, a is weight percentage of Bi, b is weight percentage of Sb, and c is greater than or equal to c, and smaller than or equal to 1.85. The invention further discloses a preparation method for the lead-free solder. Solder alloy of the SnBiSb-series low-temperature lead-free solder is a ternary eutectic or near-elliptic eutectic structure, is low in melting point, has excellent mechanical property and reliability, and is suitable for the low-temperature solder field.

Owner:BEIJING COMPO ADVANCED TECH

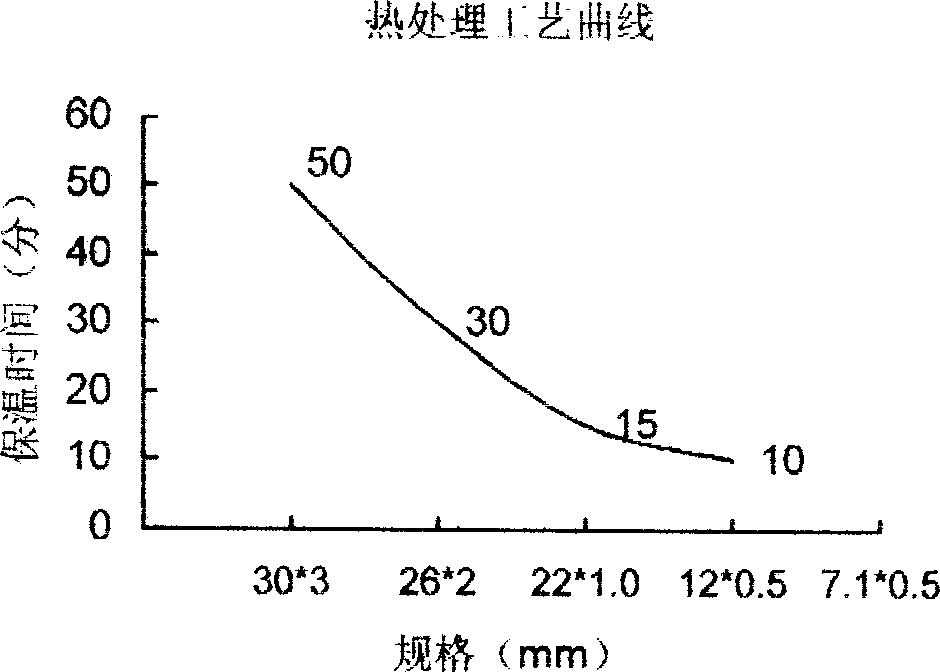

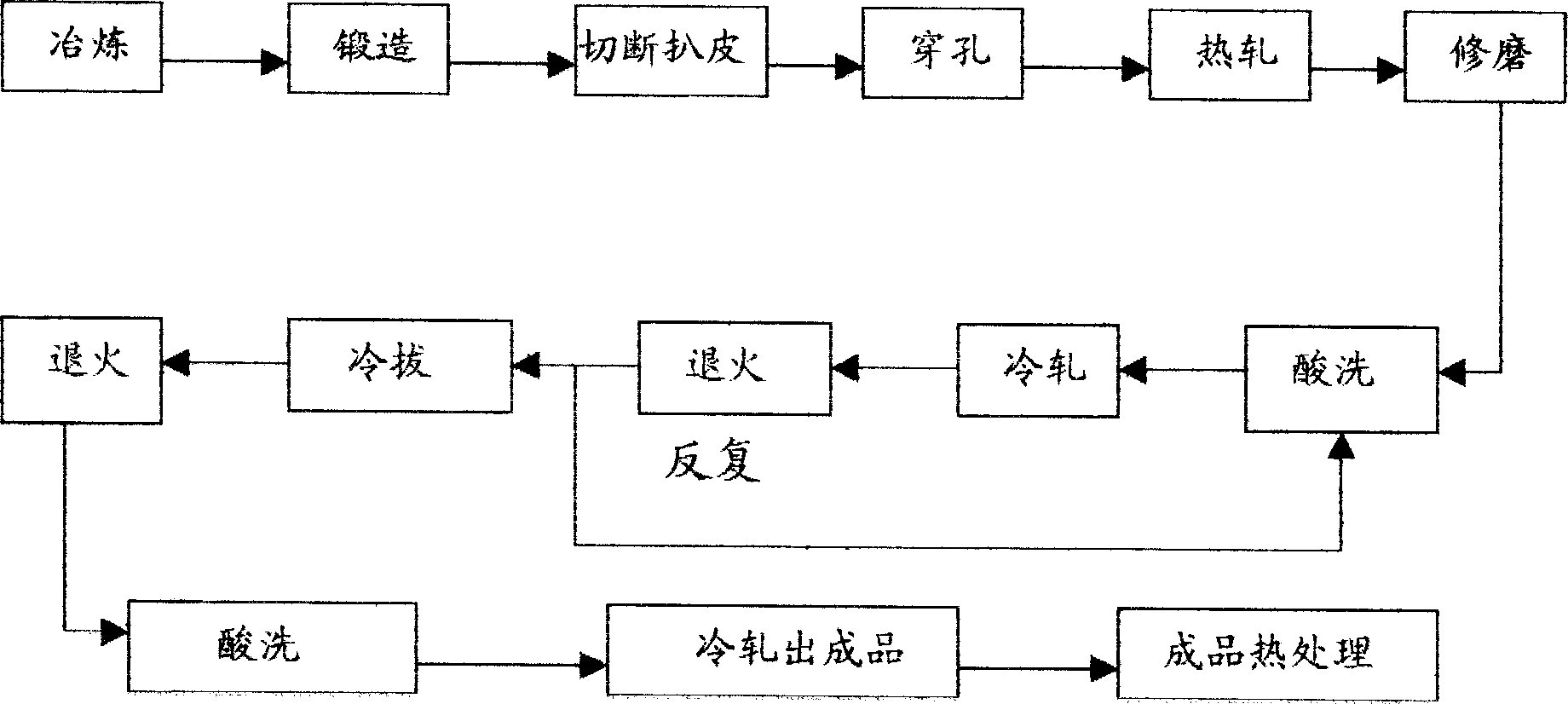

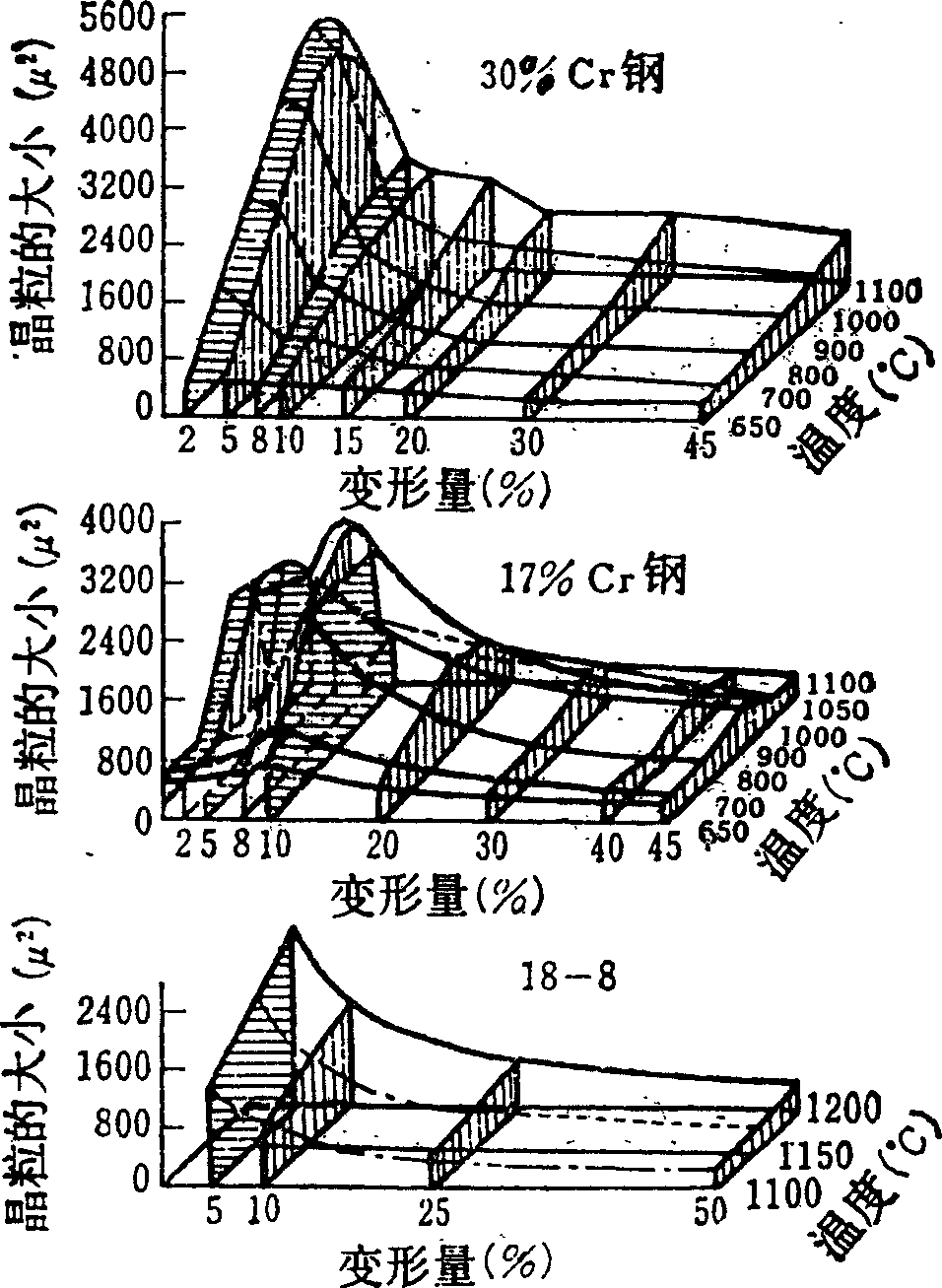

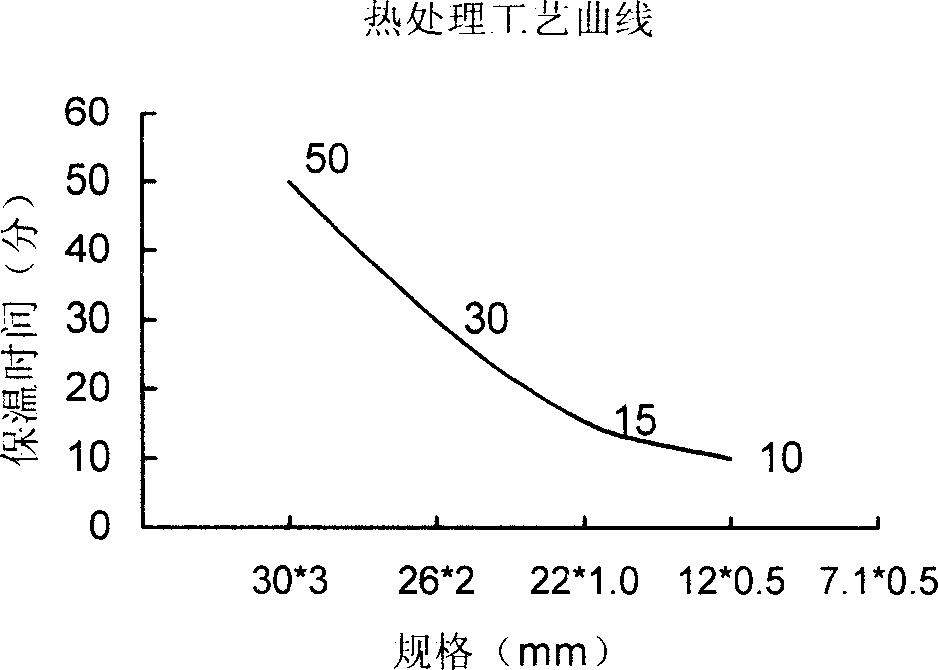

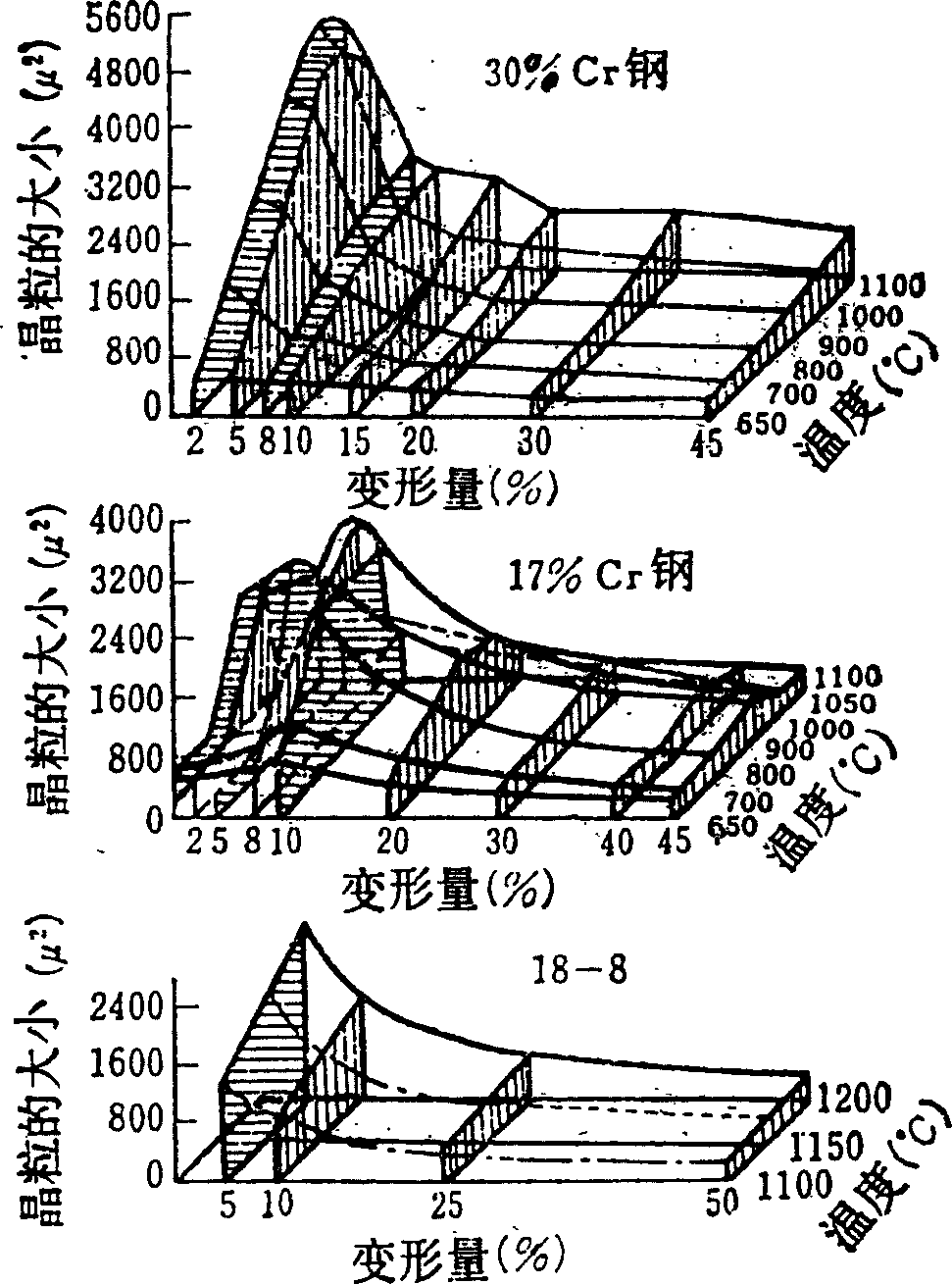

Cold working process for high Cr ferrite stainless steel seamless pipe

InactiveCN1721128AOptimize structural configurationSolve the brittleness problemCrazingAustenitic stainless steel

Cold preparation technique for high chromium ferritic stainless steel seamless tube. Wherein, roll the hot-rolled formed pipe repeatedly and control the deformation value into predetermined value; take anneal for former rolling product, take out and cool with water, straighten, cut off, decrease wall, and control the deformation value into predetermined value; take empty sinking time after time to control deformation; take anneal and air cooling for finished product in vacuum. This invention solves effectively brittleness problem for ferritic stainless steel, decreases even avoids the cement out of carbide and nitride; prevents hypersensitization effectively, avoids intergranular corrosion; and the combination of cold drawing and cold rolling solves the problem that it is easy to appear flaw for ferritic stainless steel seamless tube.

Owner:天津冶金集团天材科技发展有限公司

MAX phase ceramic pipe and preparation method thereof as well as nuclear fuel cladding tube

ActiveCN108147828ASolve the brittleness problemImprove oxidation resistanceOptical rangefindersNuclear energy generationIonNuclear reactor

The invention discloses an MAX phase ceramic pipe and a preparation method thereof as well as a nuclear fuel cladding tube. The preparation method comprises the following steps: S1, weighing the following raw materials in percentage by mass: 5 to 15 percent of binding agent, 5 to 15 percent of plasticizing agent and 2 to 15 percent of fiber toughening phases; adding the raw materials into deionized water to prepare turbid liquid; S2, adding the turbid liquid into MAX phase nano-powder to prepare slurry of which solid content is 60 to 90 percent; S3, making the slurry into an MAX phase ceramicpipe blank by adopting an extrusion molding method; S4, performing pressureless sintering on the MAX phase ceramic blank to prepare the MAX phase ceramic pipe. The MAX phase ceramic pipe disclosed bythe invention is suitable for the accident fault-tolerant nuclear fuel cladding, so that the anti-accident ability that nuclear reactors maintain nuclear fuel assembly structures and function completeness under a serious accident working condition is greatly improved.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +3

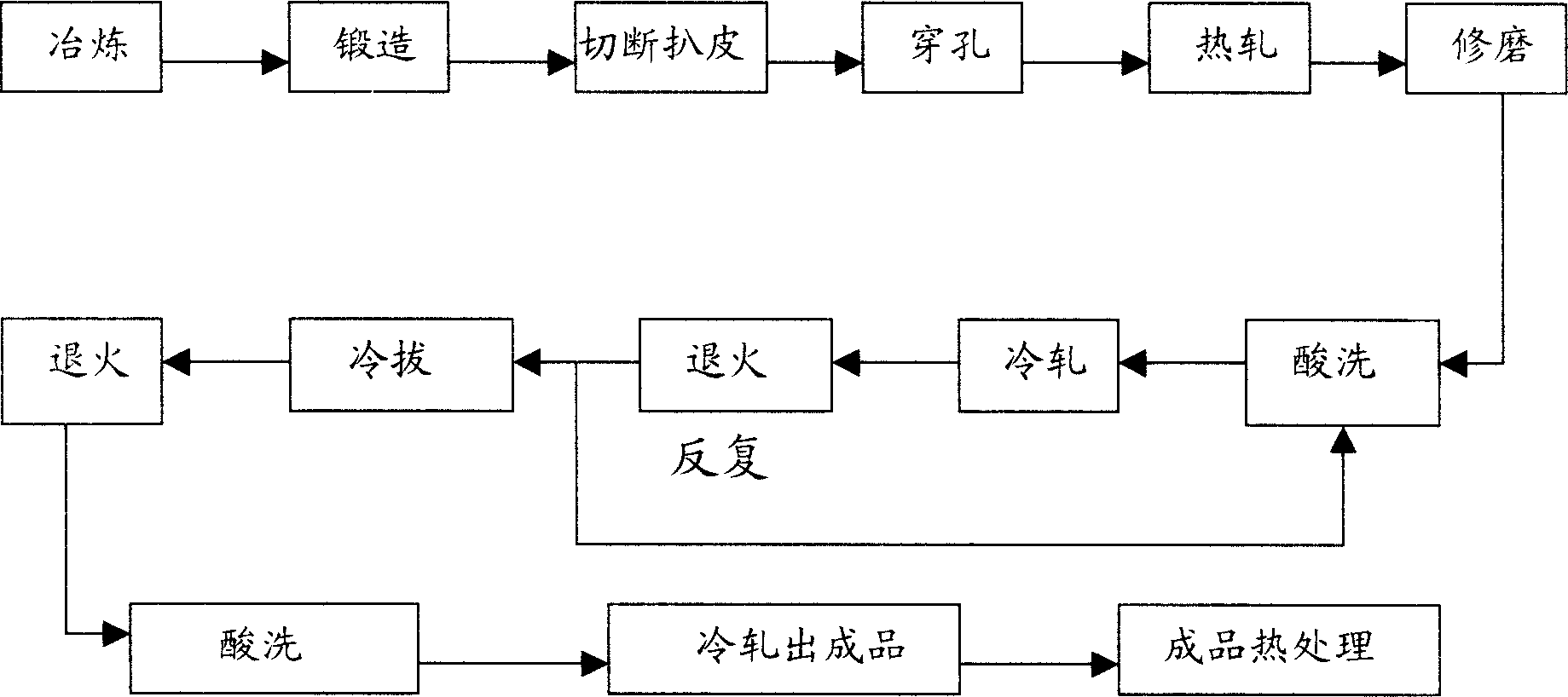

Manufacturing method of ferritic stainless steel seamless pipe with small diameter

InactiveCN1721753ASignificant advantagesSignificant beneficial effectRigid pipesMetal rolling arrangementsIngotProcess conditions

This invention relates to a process method to make stainless steel tube without gap, which comprises the following steps: providing the required steel ingot; forging; heating tube blank; drilling and rolling; processing the rolling, empty sinking, cold-drawing; again empty sinking, final product annealing and final product making.

Owner:天津冶金集团天材科技发展有限公司

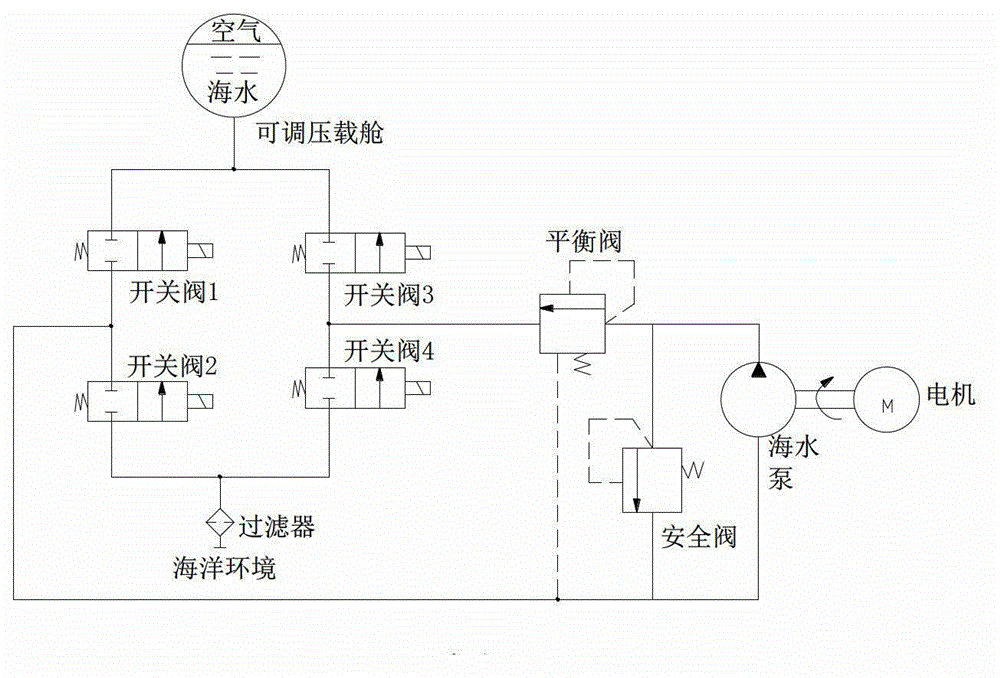

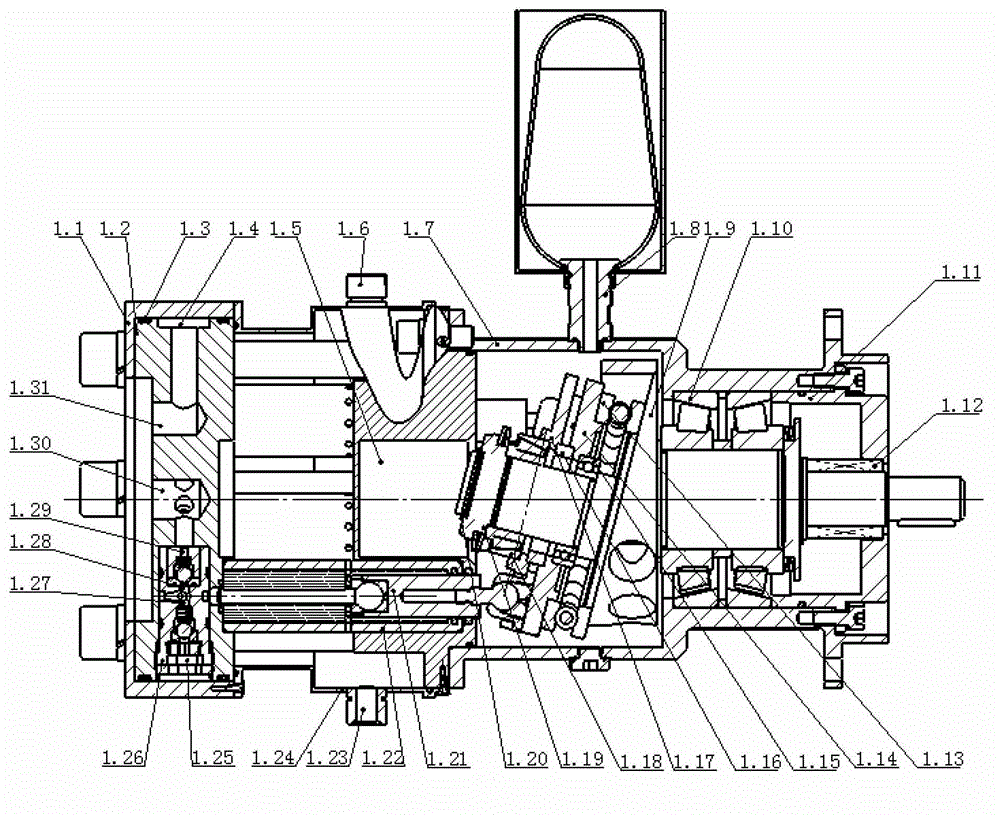

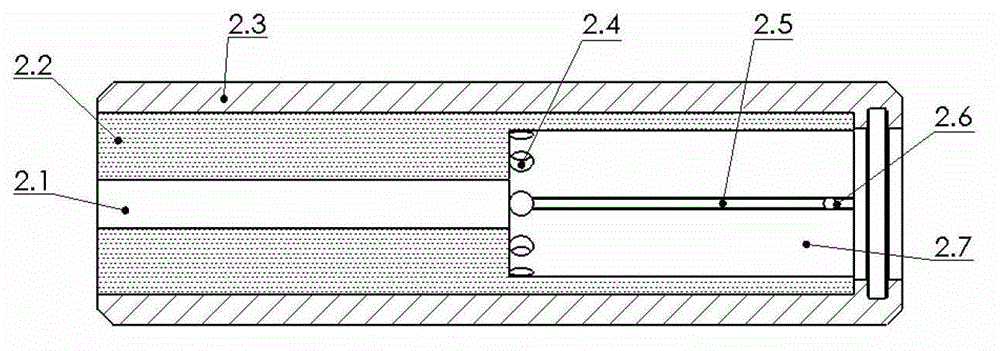

Full depth buoyancy regulating seawater pump

ActiveCN102720648ASolve dynamic sealing problemsSolve pressurePositive-displacement liquid enginesMulti-cylinder pumpsStrength designUltimate tensile strength

The invention discloses a full depth buoyancy regulating seawater pump, which mainly comprises a flat valve module, a plunger piston shoe module, a plunger sleeve, a force transfer and reset mechanism and a pressure compensator, wherein the pressure compensator is used for balancing a lubricating cavity and environmental stress; the force transfer and reset mechanism drives the plunger piston shoe module to alternately cycle for a pressing travel and a sucking travel, so that the flat valve module alternately cyclically sucks water and presses water; the plunger piston shoe module has a fixed interval forced reset structure, so that a plunger is reset reliably; the force transfer and reset mechanism has a bidirectional stress structural design, so that the seawater pump meets the special working condition of regulating the buoyancy by the hydraulic pressure of seawater; and a stepped plunger is adopted, large and small plungers are connected through a spherical hinge, and the problems of strength design, sealing and frictional wear of the crucial friction pair, namely an ultrahigh pressure seawater pump are solved. The full depth buoyancy regulating seawater pump can regulate the buoyancy of a submersible in sea areas with all depth, and has the characteristics of simple structure, high applicability and working reliability.

Owner:HUAZHONG UNIV OF SCI & TECH

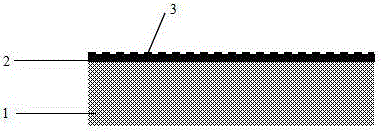

Silicon carbide composite wave absorbing ceramic based on metamaterial and preparation method of silicon carbide composite wave absorbing ceramic

ActiveCN106220211ASolve the technical problem of poor low-frequency absorbing performanceStrong designabilityElectrical resistance and conductanceCordierite

The invention discloses silicon carbide composite wave absorbing ceramic based on a metamaterial. The silicon carbide composite wave absorbing ceramic is composed of a silicon carbide composite layer, an antioxidant bonding layer and a metamaterial layer from inside to outside in sequence. The silicon carbide composite layer is composed of a three-dimensional knitted part reinforced silicon carbide composite sewn through continuous silicon carbide fiber plain cloth in the Z direction, and the fiber electrical resistivity of the composite ranges from 10<5> omega.cm to 10<6> omega.cm; the antioxidant bonding layer is composed of a cordierite coating, and the metamaterial layer is formed by periodically arranging resistance coatings of capacitive or inductive periodic patterns. The advantages of achieving wide frequency and low frequency wave absorption, being resistant to high temperature, high in wave absorbing performance regulation and control performance, achieving bearing and the like are integrated, the technical problem of poor low frequency wave absorbing performance troubling a high-temperature wave absorbing material all the time is solved, the structure is simple, implementation is easy, and high designability is achieved. The invention further discloses a preparation method of the silicon carbide composite wave absorbing ceramic based on the metamaterial. The raw materials are easy to obtain, and engineering application is convenient.

Owner:NAT UNIV OF DEFENSE TECH

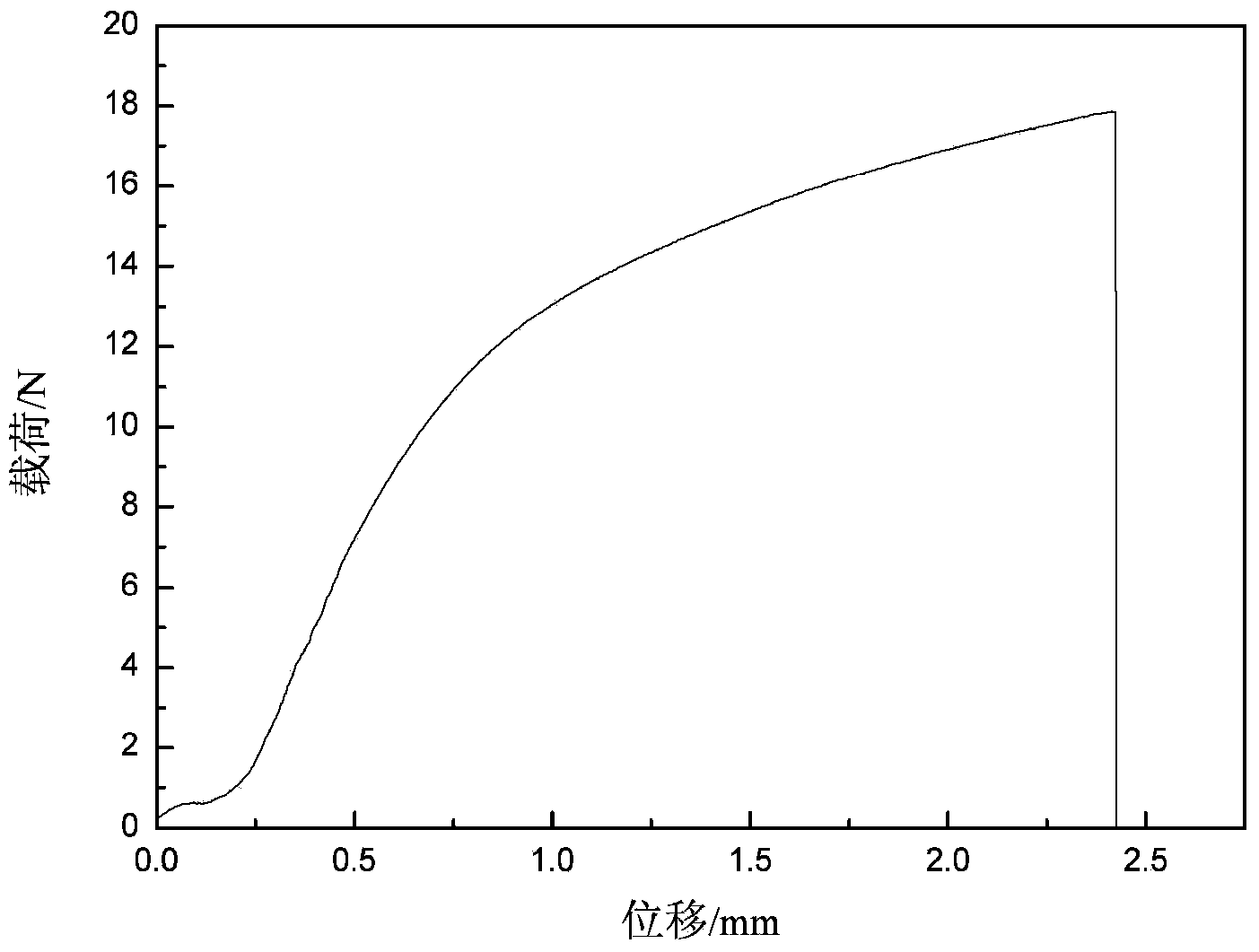

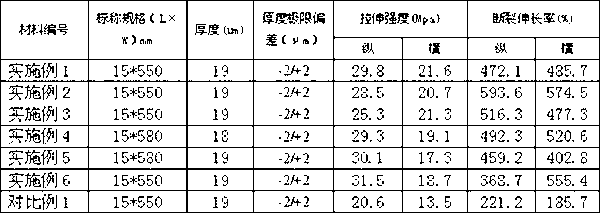

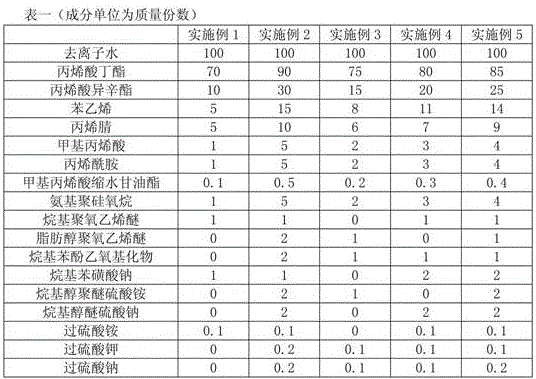

Acrylate elastic emulsion with excellent low-temperature breaking elongation and preparation method thereof

ActiveCN106632823AHigh elongation at breakImprove flexibilityCoatingsIsooctyl acrylateGlycidyl methacrylate

The invention discloses acrylate elastic emulsion with excellent low-temperature breaking elongation, comprising, by weight, 100 parts of deionized water, 70-90 parts of butyl acrylate, 10-30 parts of 2-ethylhexyl acrylate, 5-15 parts of styrene, 5-10 parts of acrylonitrile, 1-5 parts of methacrylic acid, 1-5 parts of acrylamide, 0.1-0.5 part of glycidyl methacrylate, 1-5 parts of aminopolysiloxane, 2-10 parts of an emulsifier, and 0.1-0.5 part of persulfate. The acrylate elastic emulsion has excellent low-temperature breaking elongation.

Owner:上海巴德富实业有限公司

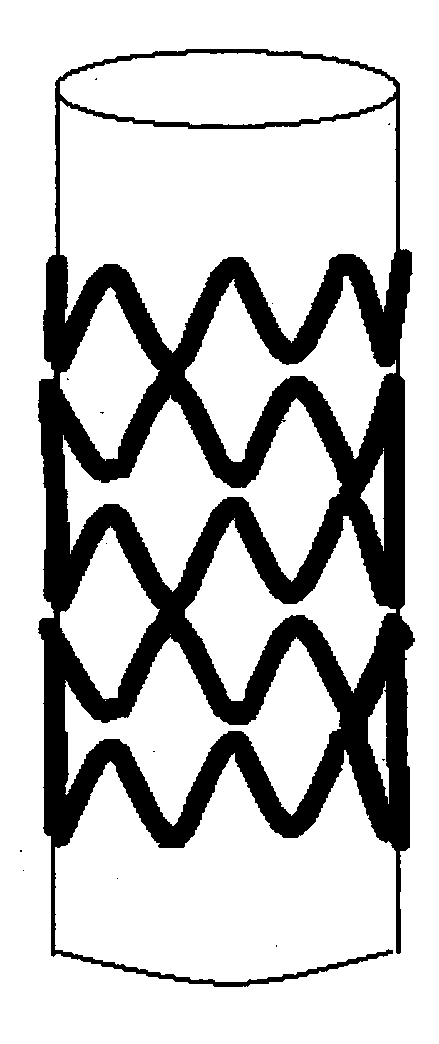

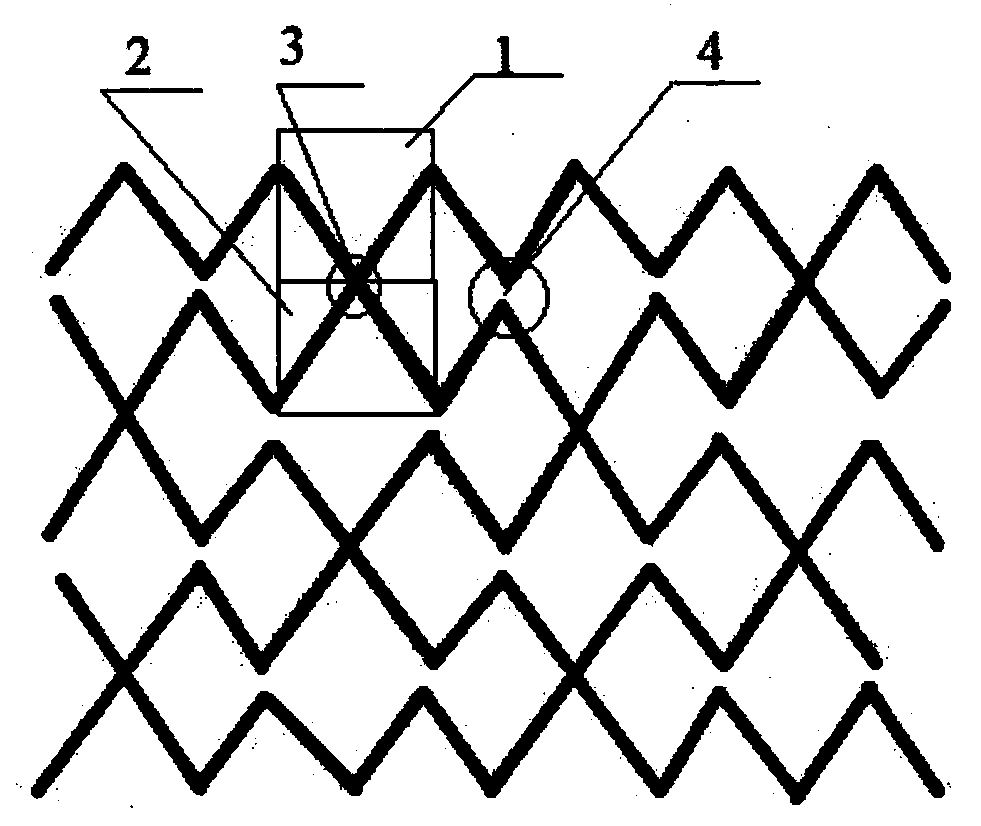

Biodegradable intravascular stent and production method thereof

The invention provides a biodegradable intravascular stent and a production method thereof. The biodegradable intravascular stent is characterized in that the biodegradable intravascular stent comprises an annular net structure made of biodegradable fiber braided threads; the annular net structure is composed of a plurality of rows of wavy structures; each row of wavy structure is composed of a plurality of V-shaped structure units; every two rows of wavy structures are parallel to each other; the endpoint in the middle of each V-shaped structure unit is connected with the endpoint in the middle of the symmetrical V-shaped structure unit in the adjacent row once every other two non-joint points to form a joint point. The biodegradable intravascular stent low in axial shortening rate can radially deform greatly due to the annular net structure, and the V-shaped structure units of two adjacent rows are connected once every other two non-joint points, so that the length of the stent is not changed greatly under the condition of great change of radial diameter of the stent, and the intravascular stent can be implanted conveniently by means of a conveyor.

Owner:DONGHUA UNIV

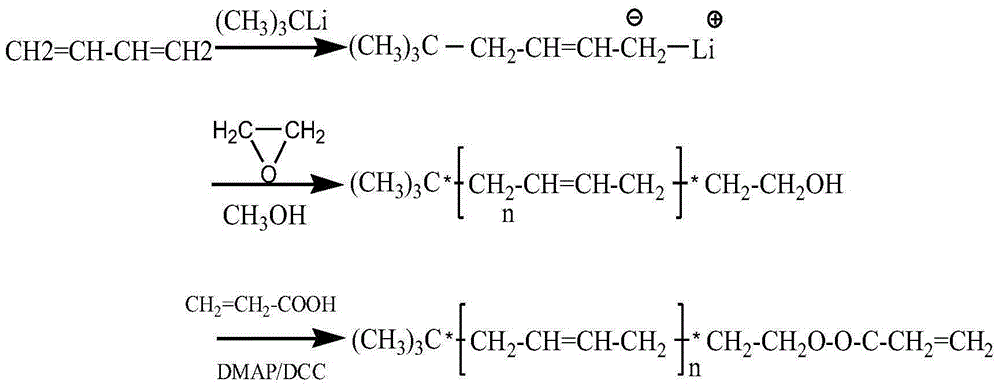

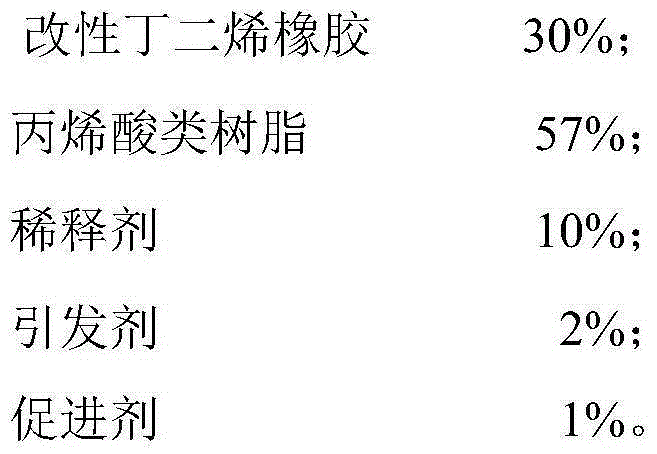

Three-dimensional printing photosensitive resin material containing modified butadiene rubber and preparation method

The invention belongs to the technical field of photosensitive resin materials for 3D printing, and discloses a 3D printing photosensitive resin material containing modified butadiene rubber. The 3D printing photosensitive resin material containing the modified butadiene rubber is prepared from, by mass, 10%-30% of the modified butadiene rubber, 30%-80% of acrylic resin, 10%-40% of diluents, 1%-2% of initiators and 1%-2% of accelerants. A polybutadiene telechelic polymer with a terminal hydroxyl group is obtained through anionic polymerization, esterification is conducted on the polybutadiene telechelic polymer and acrylic acid, and a double-bond group is introduced; the 3D printing photosensitive resin material containing the modified butadiene rubber has the advantages that by means of an anion synthetic method, a polymer with the molecular weight narrower in distribution is obtained, processing is facilitated, a ubiquitous brittleness problem is effectively solved by introducing a rubber chain segment, and after esterification is conducted on the acrylic acid which is one of original systems of the photosensitive resin and double bonds are introduced, the compatibility problem is thoroughly solved. The invention further provides a preparation method of the 3D printing photosensitive resin material containing the modified butadiene rubber.

Owner:JIANGSU UNIV OF SCI & TECH

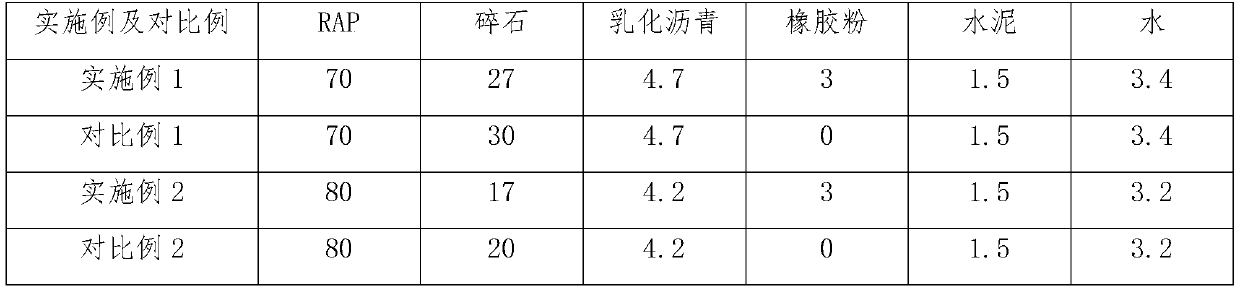

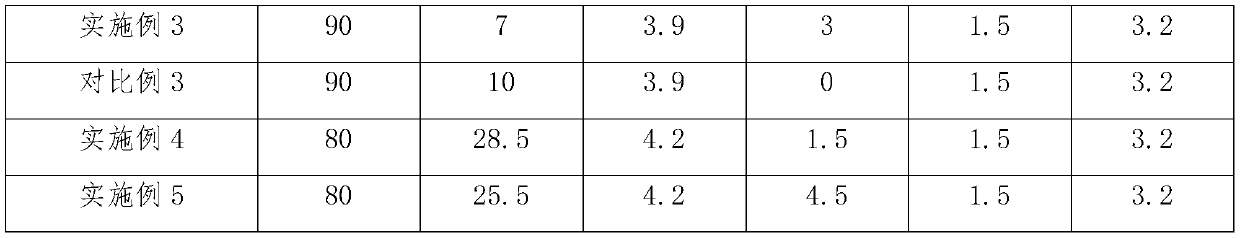

Flexible rubber emulsified asphalt cold in-place recycling mixture and preparation method thereof

InactiveCN109748538AThe composition is simple and easy to obtainIncrease profitSolid waste managementPolymer scienceWaste rubber

The invention provides a flexible rubber emulsified asphalt cold in-place recycling mixture and a preparation method thereof. A flexible rubber emulsified asphalt cold in-place recycling mixture product is prepared by uniformly stirring emulsified asphalt, a recycled asphalt pavement material (RAP), macadam, water, cement and rubber power in a certain blending proportion. The flexible rubber emulsified asphalt cold in-place recycling mixture provided by the invention is simple and easily available in component, is green and environment-friendly by using waste rubber tires and asphalt pavementrecovered materials, and solves the problem of reuse of waste materials. Meanwhile, the mixture provided by the invention has relatively high strength and pavement performance. By adding the rubber powder, high- and low-temperature performance and fatigue performance of the emulsified asphalt cold in-place recycling mixture are improved obviously, the flexibility of a conventional emulsified asphalt cold in-place recycling mixture is improved, and the fragility problem of the conventional mixture is solved.

Owner:SHANDONG JIANZHU UNIV +1

Method for improving brittleness of surface layers of small-package fried fish cakes before eating

ActiveCN103564539AReduce oil contentImprove brittlenessMulti-step food processesFood coatingQuick FreezeFresh fish

The invention relates to a method for improving the brittleness of surface layers of small-package fried fish cakes before eating, and belongs to the field of a convenient food processing technology. The method comprises the steps of selecting fresh fish meat, rinsing, dehydrating and then adding a certain amount of a water-retaining agent into the fish meat for blending; adding seasonings into the fish meat, forming and carrying out gelatinization for 1h; finally, coating a layer of brittleness-increasing starch slurry on the outer side of each fish cake, and frying the fish cakes to prepare the fried fish cakes; quick-freezing the fried fish cakes, and refrigerating to obtain semi-finished products of fish cakes which can be cooked by a microwave oven; reheating the prepared semi-finished products of fish cakes which can be cooked by the microwave oven and contain the brittleness-increasing starch slurry on the surface layers for 90s by adopting 915MHz low-frequency microwaves, so as to enable the brittleness of the small-package fried fish cake to be improved by 20-27% compared with fish cakes which are not subjected to brittleness improving. After the method is adopted, the trouble of repeatedly frying the fish cakes can be omitted, the fish cakes can be eaten after being re-heated by using the low-frequency microwaves, the brittleness of the surface layers of the small-package fried fish cake can be improved, the oil content of the small-package fried fish cake can be reduced, the processing time is shortened, the working efficiency is improved, the fish meat processing market can be relatively well expanded, and the good economic benefit is generated.

Owner:JIANGNAN UNIV +1

Method for preparing cuprum aluminum complex structure metallic can

InactiveCN101176961AReduce manufacturing costHigh compressive strengthResistance welding apparatusAluminum compositesMachining

The invention relates to a manufacture method for copper-aluminum composite structure metal cans, belonging to metal composite structure processing technology field, which comprises an aluminum tube, an inlet copper tube and an outlet copper tube joining together. The invention adopts the steps that: firstly, the middle part of the aluminum tube is squeezed by hydraulic pressure to an enlarged drum aluminum tube, which has invariant diameter on both ends and a raised middle part; secondly, one port of the inlet copper tube and the outlet copper tube is mechanically processed into a conical surface; finally, the conical surface port of the inlet copper tube and the outlet copper tube is inserted into the taper end of the drum aluminum tube. As the conical surface port is pressured into the taper end while being electrically heated, a fixed metallic bond joint of copper-aluminum tube is formed at the contacting segment.

Owner:赵越 +1

Method for preparing multihole infrared chalcogenide glass photonic crystal optical fiber preform

ActiveCN103011575ASolve the problem of brittlenessAccelerated dissipationGlass making apparatusGlass fibre productsExpansion factorPhotonic crystal

The invention discloses a method for preparing a multihole infrared chalcogenide glass photonic crystal optical fiber preform. According to the method, a high-precision optical two-dimensional positioning platform is adopted for fixing a glass bar for mechanical drilling, various series of air holes can be accurately drilled, and the defect of inaccurate arrangement of the air holes by a stacking and drawing method and a casting method is solved. By utilizing the method, a diamond twist drill is adopted in the drilling process, a glass material is cut by a sharp spiral knife-edge in the high-speed revolution process, an efficient cooling system is adopted in the drilling process, heat generated in the drilling process is efficiently taken away by constantly flowing cooling liquid, and heat of the photonic crystal optical fiber preform in the drilling process is conveniently dissipated. Based on the reasons, the method is suitable for preparing the chalcogenide glass photonic crystal optical fiber preform with high expansion factors. By utilizing the method, the problem of embrittlement due to too large expansion coefficient difference between chalcogenide glass and a quartz tube in the casting method is solved.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com