Patents

Literature

138 results about "Reactive magnetron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tungsten-titanium co-doped diamond coating material and preparation technique thereof

InactiveCN101787520AOvercoming the problem of increased coefficient of frictionSolve the brittleness problemVacuum evaporation coatingSputtering coatingDlc coatingGas phase

The invention discloses a tungsten-titanium co-doped diamond (DLC) coating material and a preparation technique thereof, which are characterized by: firstly, removing a pollution layer on the surface of a workpiece by ultrasonic cleaning, and performing argon-ion etching cleaning on the surface of the workpiece by glow discharge to obtain an atomic-scale clean surface; secondly, preparing a gradient transition layer by a reactive magnetron sputtering sedimentation method; and finally, preparing a preparing a DLC coating on the transition layer by magnetron sputtering and glow discharge plasma chemical vapor deposition method, wherein the synthesized DLC coating contains carbon element, tungsten element, titanium element and the like; the tungsten content is 2 to 5 percent; and the titanium content is 0.1 to 2.0 percent. The tungsten-titanium co-doped diamond (DLC) coating material is excellent in membrane / base binding force and low in friction coefficient and wear rate.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

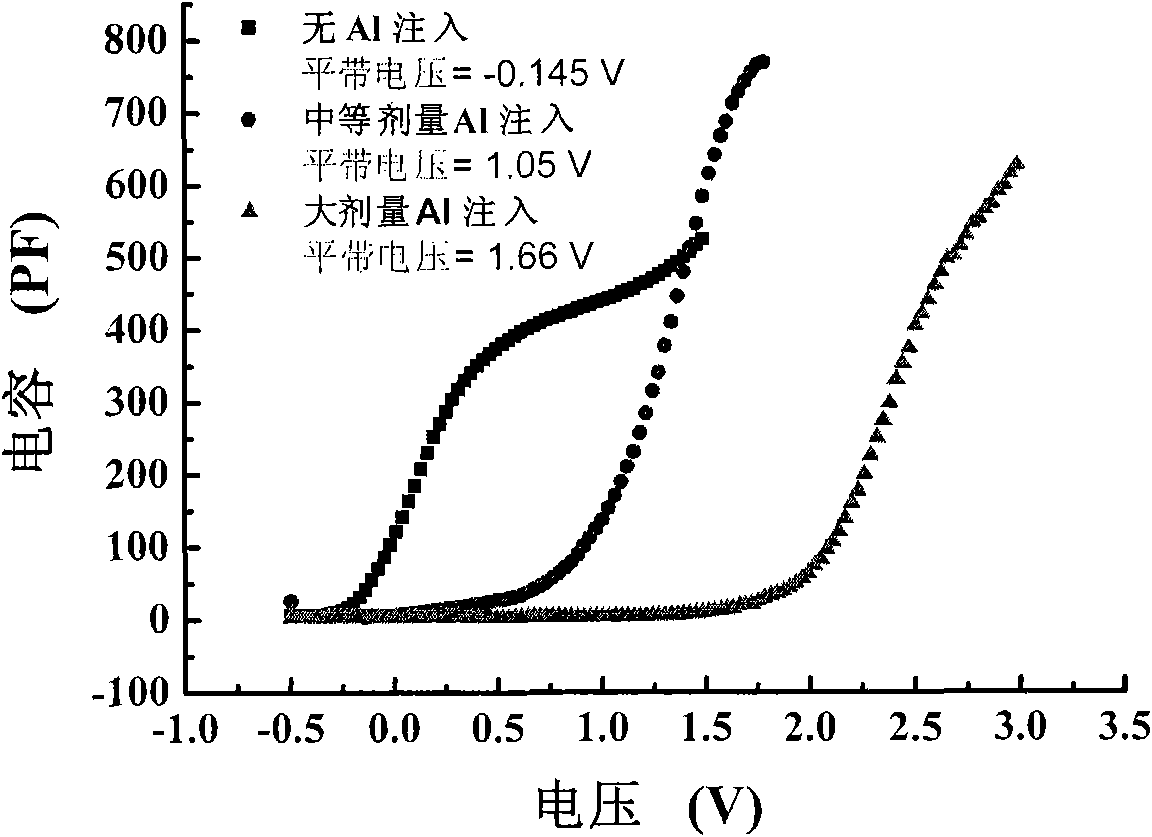

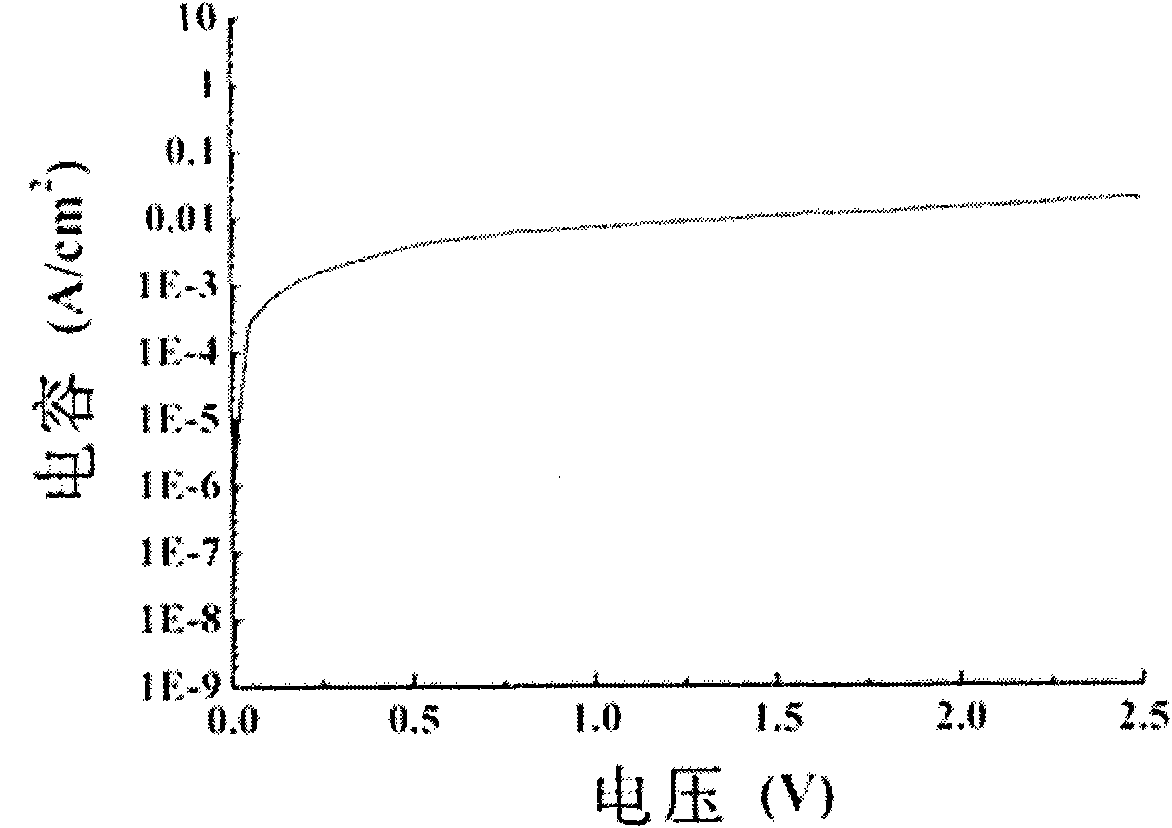

Adjustment method of bimetal gate work function

ActiveCN101800196AEasy to industrializeSimple methodSemiconductor/solid-state device manufacturingReactive magnetronRapid thermal annealing

The invention relates to an adjustment method of a bimetal gate work function, which mainly comprises the following steps: (1) growing a ultrathin interface oxide layer or a nitrogen oxide layer through rapid thermal oxidation; (2) alternately sputtering and depositing gate dielectrics with a high dielectric constant (K) on the ultrathin interface oxide layer through reactive magnetron sputtering; (3) after the gate dielectrics with the high K are deposited, carrying out rapid thermal annealing; (4) depositing metal nitride gates through reactive magnetron sputtering; (5) injecting metal ions for doping the metal nitride gates; and (6) after metal gate electrodes are formed by etching, carrying out rapid thermal annealing to drive the metal ions onto the interfaces of the metal gates and the gate dielectrics with the high K. The method can be simply and easily realized, has good thermal stability and capacity of adjusting a metal gate work function, is completely compatible with the CMOS process, and is convenient for industrialization of integrated circuits.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

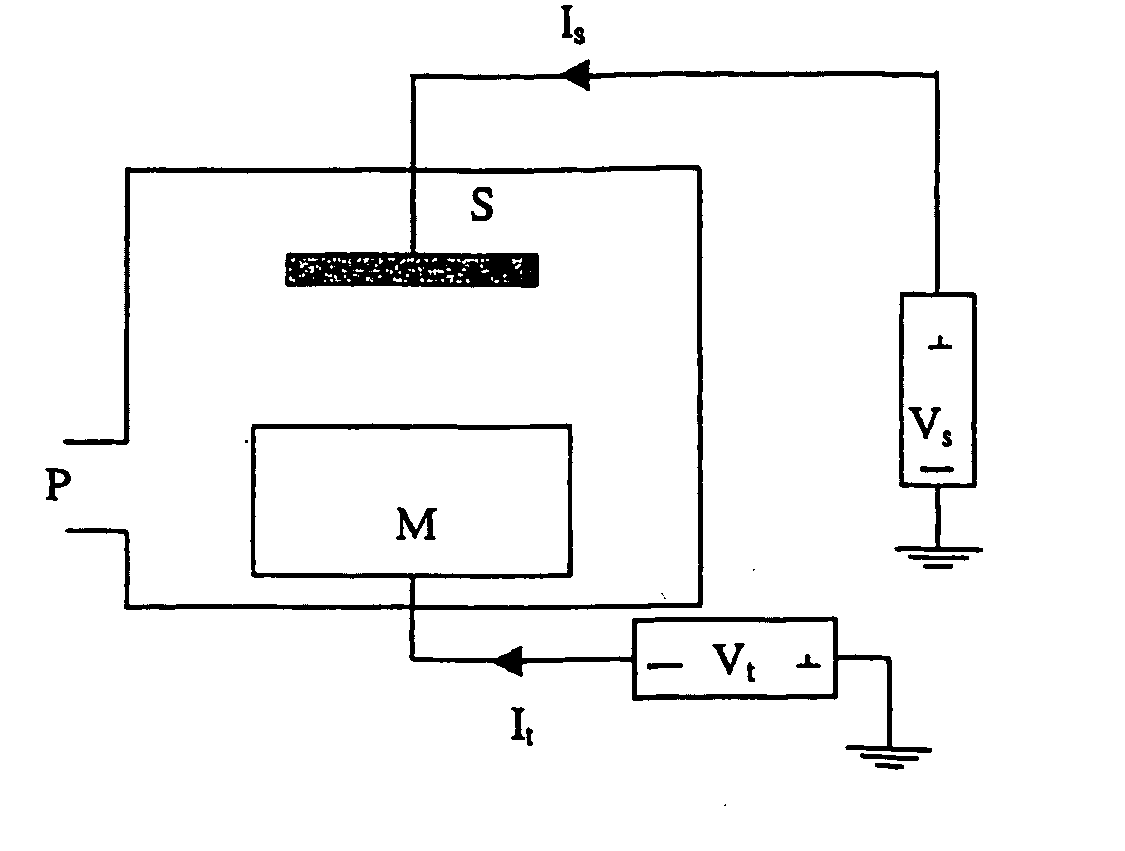

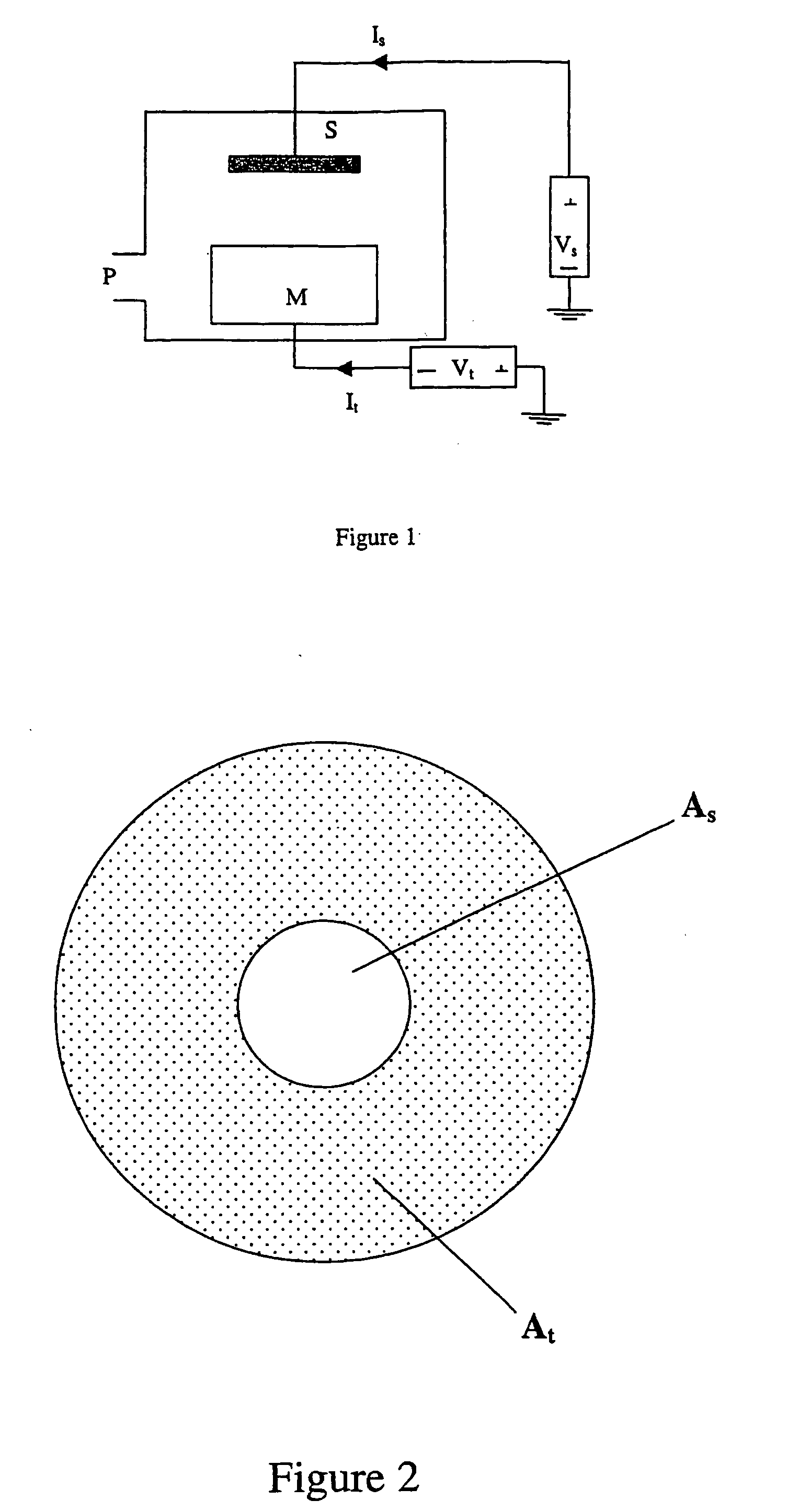

Method of coating a cutting tool

InactiveUS20050145479A1Reduce residual stressImproved thickness distributionVacuum evaporation coatingSputtering coatingTarget surfaceSputtering

A method of depositing a nitride-based wear resistant layer on a cutting tool for machining by chip removal using reactive magnetron sputtering has a deposition rate, td, higher than 2 nm / s, a positive bias voltage, Vs, (with respect to ground potential) between +1 V and +60 V applied to the substrate, a substrate current density, Is / As, larger than 10 mA / cm2, a target surface area, At, larger than 0.7 times the substrate surface area, As, and a distance between the target surface and the substrate surface, dt, less than (At)0.5.

Owner:SECO TOOLS AB

Solar selective coating having higher thermal stability useful for harnessing solar energy and a process for the preparation thereof

InactiveUS7585568B2Improve thermal stabilitySolar heat devicesVacuum evaporation coatingAbsorptanceReactive magnetron

The disclosure provides an improved solar selective multilayer coating having higher thermal stability and a process therefor. According to the disclosure, a tandem stack of three layers of TiAlN, TiAlON and Si3N4 is deposited on metal and non-metal substrates using a planar reactive magnetron sputtering process. The first two layers function as the absorber and the third antireflection layer further enhances the coating's absorptance. The solar selective coatings were annealed in air and vacuum to test the thermal stability at different temperatures and durations. The coatings deposited on copper substrates are stable in air up to a temperature of 625° C. and exhibit higher solar selectivity and these coatings also show no change in the absorptance and the emittance values even after vacuum annealing at 600° C. for 3 hours. The solar selective coatings exhibit high hardness, high oxidation resistance, chemical inertness and stable microstructure.

Owner:COUNCIL OF SCI & IND RES

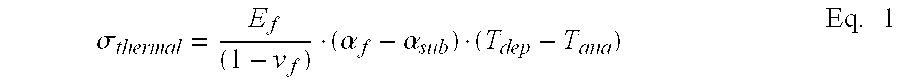

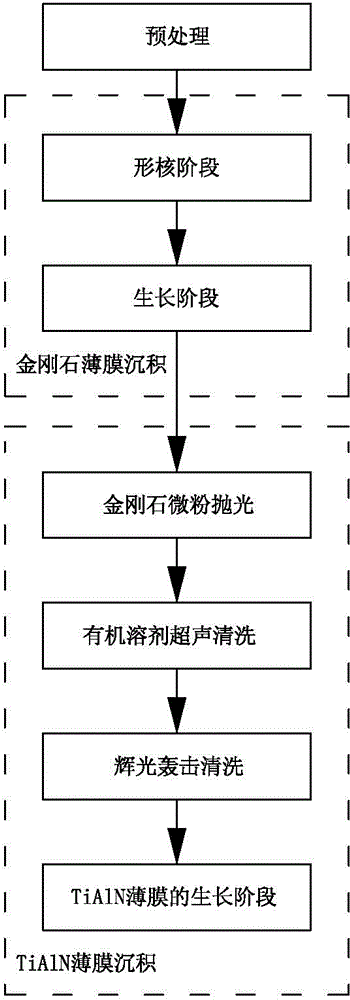

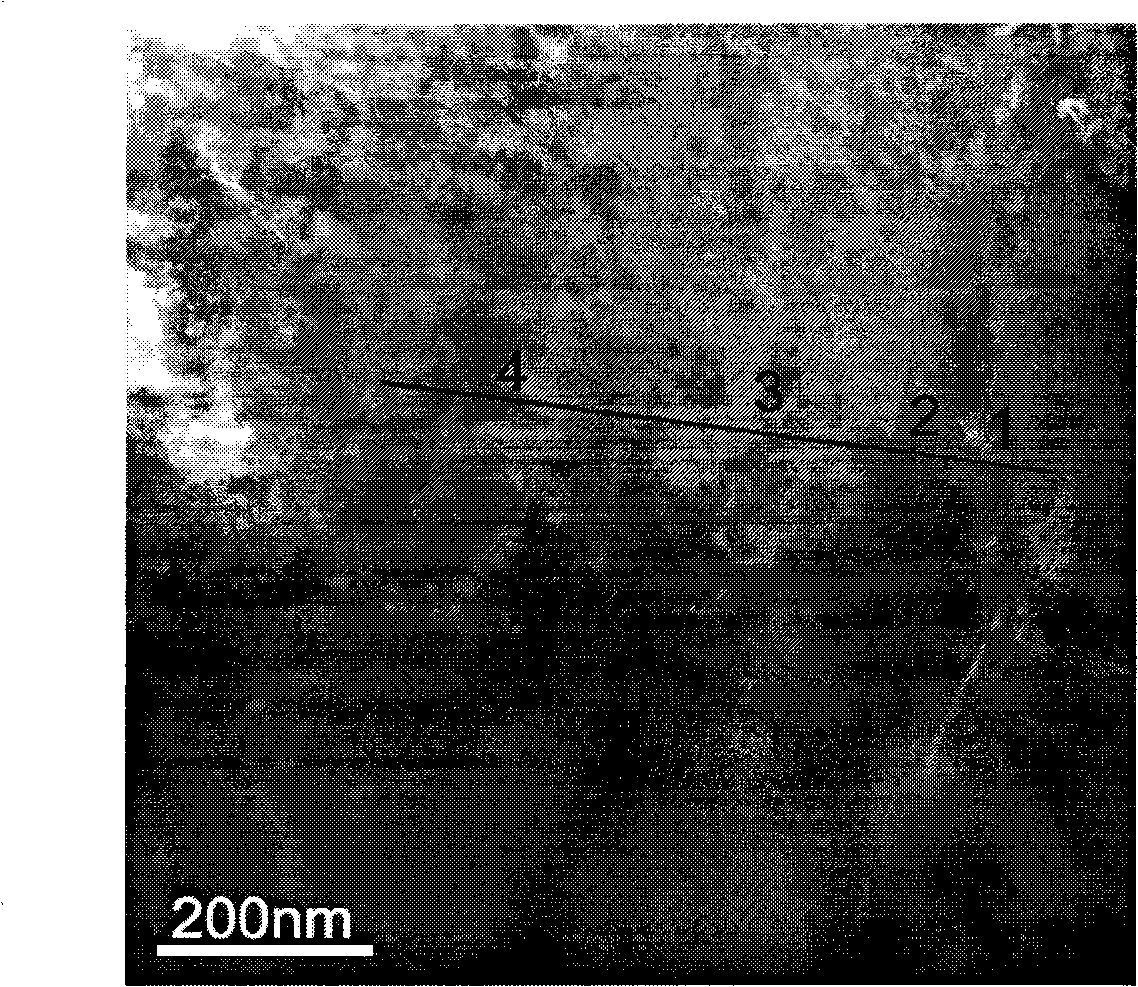

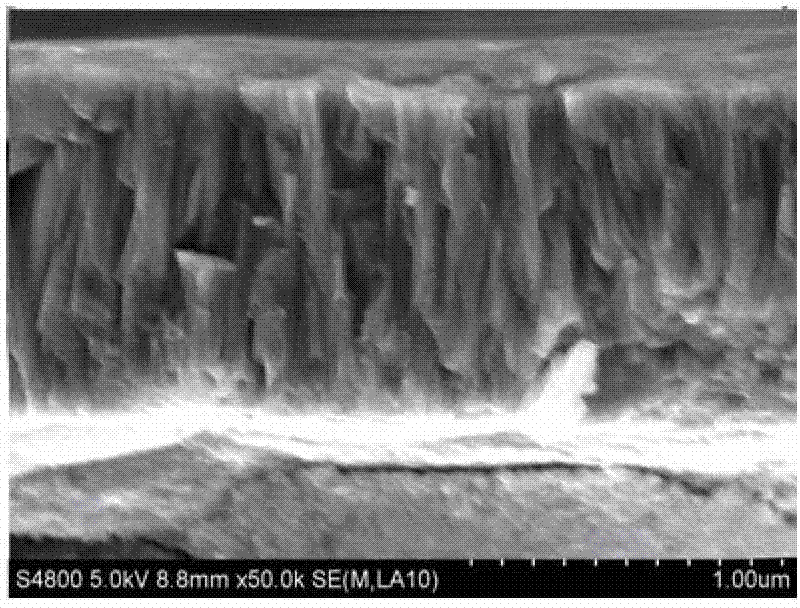

Preparation method of diamond/TiAlN composite coating on surface of hard alloy cutter

ActiveCN105624677AExcellent film-substrate adhesion strengthEnhanced membrane-substrate adhesion strengthVacuum evaporation coatingSputtering coatingOrganic solventAlloy

The invention discloses a preparation method of a diamond / TiAlN composite coating on the surface of a hard alloy cutter. The technical problems that as composite coatings are not flat in surface and prone to peeling off in the prior art, a cutter is easily abraded and the service life is short are solved. The method comprises the steps that the surface of the hard alloy cutter is preprocessed through an acid-alkali two-step method; a diamond film deposits on the preprocessed surface of the hard alloy cutter through a hot filament chemical vapor deposition device, specifically, deposition of the diamond film comprises the nucleation stage and the growth stage; and a TiAlN film deposits through a direct current reactive magnetron sputtering method, specifically, deposition of the TiAlN film sequentially comprises diamond micro-powder polishing, organic solvent ultrasonic washing, glow bombardment washing and the growth stage of the TiAlN film. A composite coating prepared by the invention has the excellent film-matrix adhesion strength, the technical problem that the films are prone to peeling off is avoided, the abrasion resistance and high temperature resistance of the cutter are remarkably improved, and the service life of the cutter is greatly prolonged.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Preparation method for Ti-Si-N nano-coating

InactiveCN101403116AImproved resistance to shock loadsImprove antioxidant capacityVacuum evaporation coatingSputtering coatingSputter cleaningCritical load

The invention relates to a method for preparing a Ti-Si-N nano-coating and belongs to a method for preparing coatings for tool and mould. The method solves the problem of easy shedding of the coating in working conditions prepared by the existing method of reactive magnetron sputtering, and realizes metallurgical binding between a transition layer and the coating, thus improving the mechanical property of the coating. The method comprises the following steps of: (1) preheating; (2) sputter cleaning; (3) ion nitriding; (4) preparing the transition layer; and (5) preparing a surface layer. The method has the advantages of high production efficiency and low cost, the critical load Lc of the prepared coating and the substrate of a metal ceramic cutting tool is more than or equal to 65N, and the surface micro hardness HV is more than or equal to 3400. The method is suitable for manufacturing coating tools for low machinability materials, high speed dry-type milling stainless steel, iron-base super-alloy, high strength construction steel, wear-resistance cast steel, glass sealing alloy, and the like, and has good popularization and application prospect in manufacturing industries, such as automobile, aviation, space flight, resource equipment, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Zirconia and alumina gradient composite coat and production method thereof

InactiveCN104711541AChange the coefficient of thermal expansionImproved thermal cycling performanceVacuum evaporation coatingSputtering coatingHydrogenThermal expansion

The invention relates to a zirconia and alumina gradient composite coat and a production method thereof. The coat comprises composite layers composed of zirconia and alumina according to different mass percentage ratios, and the composite layers composed of zirconia and alumina are laid on a steel substrate. The composite coat can be produced through a metal organic matter chemical vapor deposition technology or a reactive magnetron co-sputtering technology. The zirconia and alumina gradient composite coat combines the hydrogen resistance and penetration characteristics of zirconia and alumina, and the thermal expansion coefficient of the composite coat can be changed by adjusting the proportions of zirconia and alumina in the composite coat to improve the thermal physical matching performance between the composite coat and the substrate, so the thermal cycle use performance of the composite coat is improved.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Ti/TiN/MaN composite coating on surface of cutter and preparation method of Ti/TiN/MaN composite coating

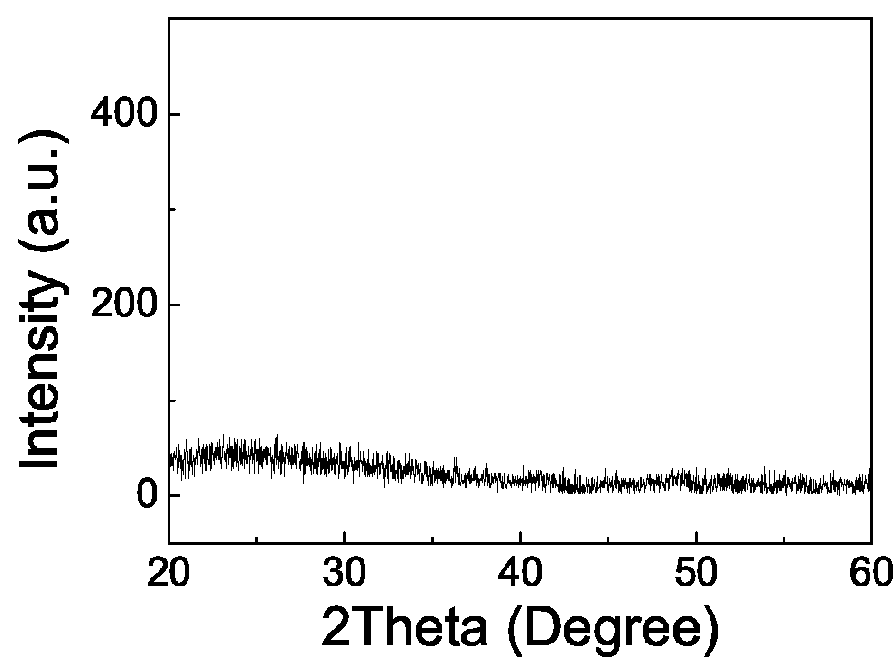

InactiveCN103071819ATissueHigh purityVacuum evaporation coatingSputtering coatingIntermediate frequencyEvaporation

The invention discloses a Ti / TiN / MaN composite coating on the surface of a cutter. The Ti / TiN / MaN composite coating is divided into three layers, namely a Ti transition layer, a TiN layer and an (Al, Ti, Cr) N layer in sequence outwards from the surface of the cutter, wherein the thicknesses of the Ti transition layer, the TiN layer and the (Al, Ti, Cr) N layer are respectively 50-200nm, or 100-500nm or 2-5Mu m; the tissue structure of the Ti / TiN / MaN composite coating is a nanocrystalline structure; the (111) surface diffraction intensity I of the Ti / TiN / MaN composite coating in X-ray diffraction is lower than 400 and the surface of the Ti / TiN / MaN composite coating is 22-33GPa in hardness and 1-2-level in indentation grade. The invention also discloses a preparation method of the Ti / TiN / MaN composite coating. According to the invention, because a plasma reinforced intermediate-frequency reactive magnetron sputtering technology is used as the preparation method of the composite coating, not only is sputtering evaporation of various reactants facilitated, but also the obtained Ti / TiN / MaN composite coating is dense in tissue, high in purity, flat in surface, high in binding force with a cutter and good in wear resistance, the segregation of film components can be furthest restricted, the ionization rate and the deflection property are greatly improved, and therefore the life of the Ti / TiN / MaN composite coating in cutting machining of stainless steel is prolonged by 50-100 percent; and in addition, the Ti / TiN / MaN composite coating is simple in process, easy to master and control and is convenient for industrial production of a cutter coating.

Owner:SICHUAN UNIV

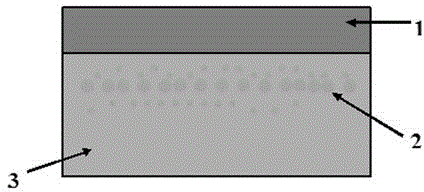

Antifogging self-cleaning glass, and preparation method

InactiveCN1872758AImprove hydrophilicityOvercome the disadvantage of strong dependenceRadio frequency magnetron sputteringTriple layer

This invention provides a method for mass production of fog-proof and self-cleaning glass. The method comprises: coating TiO2 and SiO2 onto a cleaned glass substrate by DC reactive magnetron sputtering technology and radiofrequency magnetron sputtering technology using pure titanium target and pure silicon dioxide (quartz) target respectively, thus obtaining TiO2 / SiO2 double-layer fog-proof and self-cleaning glass or SiO2 / TiO2 / SiO2 triple-layer fog-proof and self-cleaning glass. The obtained product has better hydrophilicity, lower initial wetting angle, and longer maintaining time after stopping UV radiation than those of TiO2 single-layer glass, and overcomes the shortcoming of strong dependence on environment of present fog-proof and self-cleaning glasses.

Owner:HUBEI UNIV

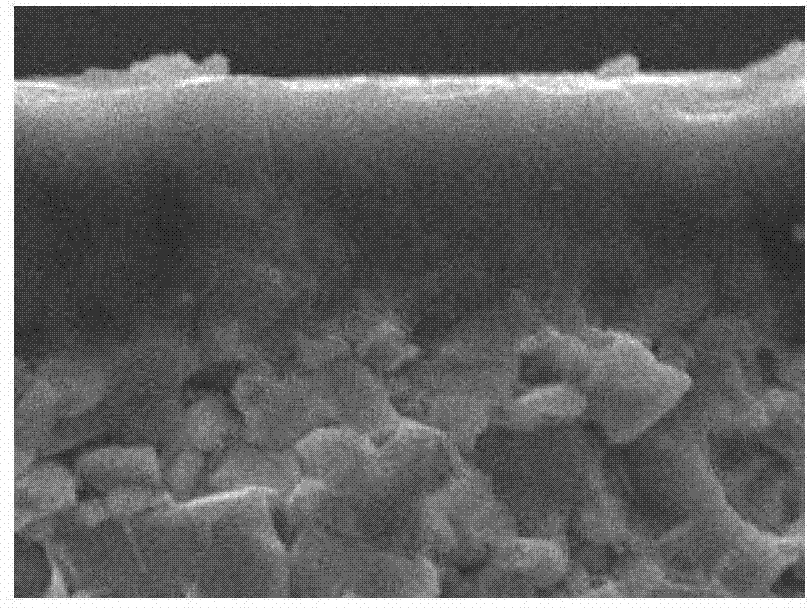

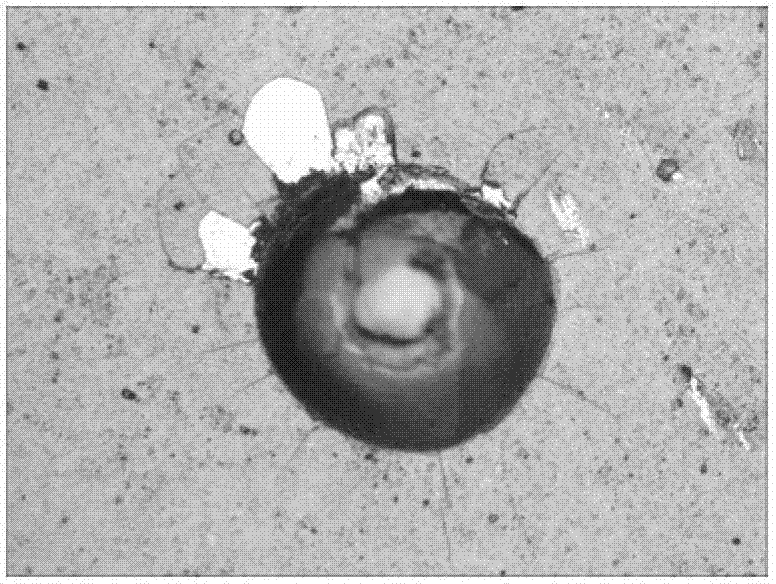

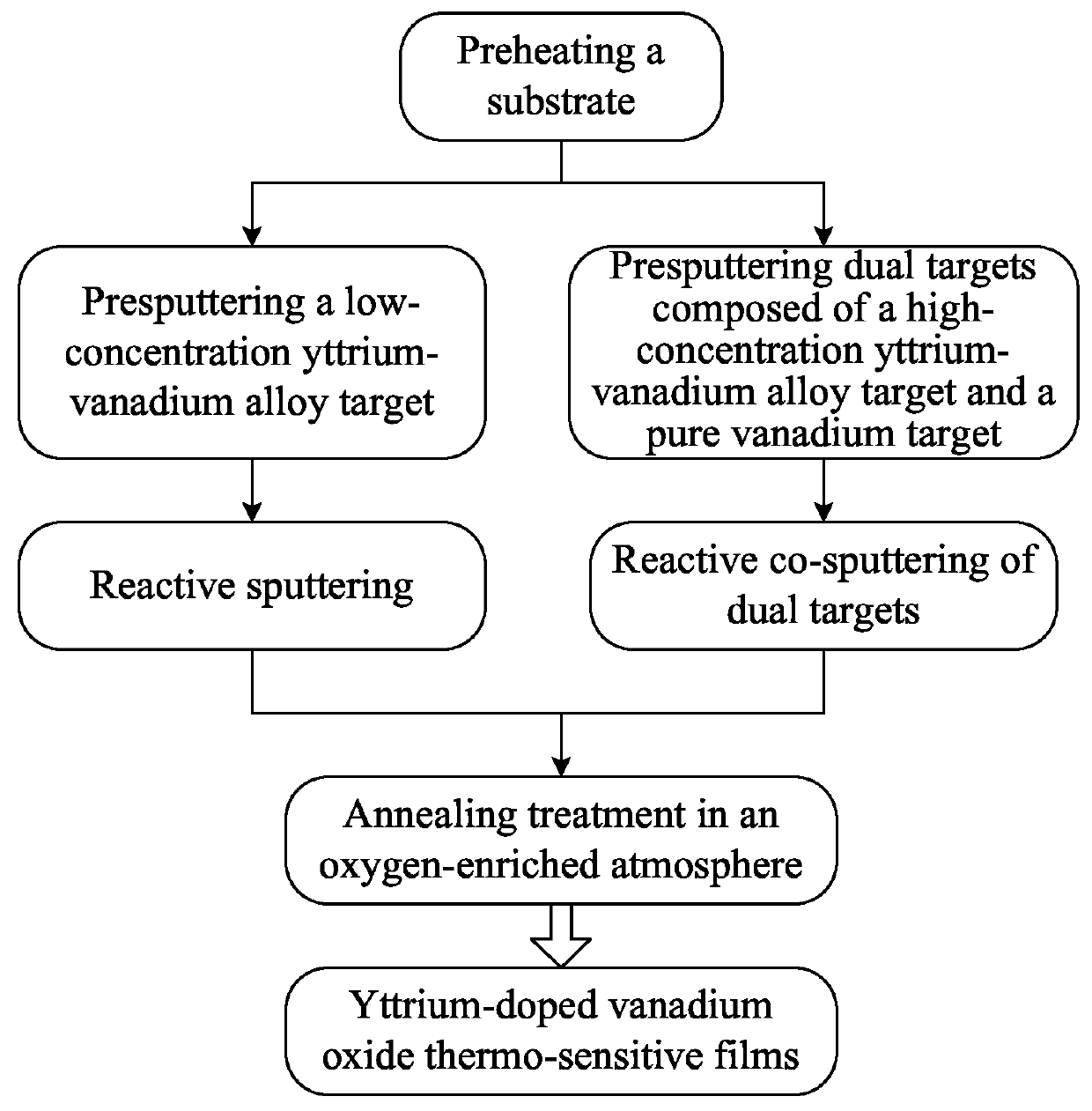

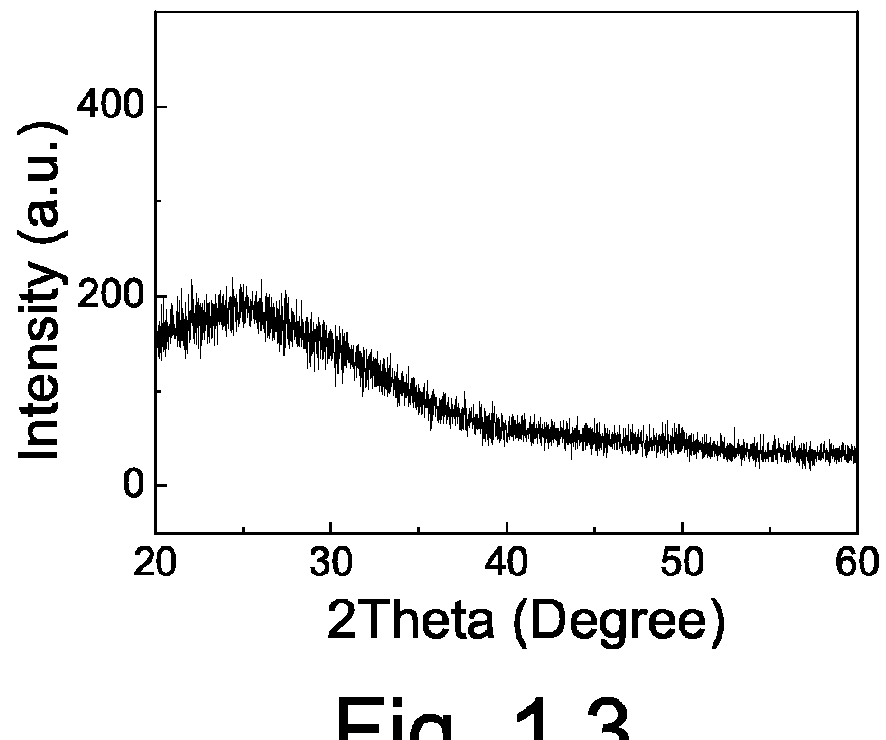

Vanadium oxide thermo-sensitive film material with high temperature coefficient of resistance and a preparing method thereof

ActiveUS20160032443A1Accurate modificationHigh TCRConductive materialVacuum evaporation coatingHigh concentrationRare-earth element

A vanadium oxide thermo-sensitive film material with a high temperature coefficient of resistance (TCR) contains a rare earth element of Yttrium serving as a dopant in a preparation process. The vanadium oxide thermo-sensitive film material includes a substrate and a yttrium-doped vanadium oxide film layer. The yttrium-doped vanadium oxide film layer includes three elements of vanadium, oxygen and yttrium, wherein the atomic concentration of yttrium is at a range of 1%-8%, the atomic concentration of vanadium is at a range of 20-40% and the residue is oxygen. The method for preparing the vanadium oxide thermo-sensitive film material with high TCR includes a reactive magnetron sputtering method using a low-concentration yttrium-vanadium alloy target as a sputtering source or a reactive magnetron co-sputtering method using dual targets including a high-concentration yttrium-vanadium alloy target and a pure vanadium target as a co-sputtering source.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Light-induction anti-soil anti-fogging self-cleaning resin glasses lens and preparing method thereof

InactiveCN101441330AIncreased durabilityReduce surface tensionVacuum evaporation coatingSputtering coatingOptoelectronicsLens plate

The invention relates to a photoinduction anti-soil anti-fog self-cleaning resin lens and a producing method therefor. The resin lens comprises a resin lens substrate, a hard film layer arranged on the resin lens substrate, a antireflection coating covered on the hard film layer. The antireflection coating includes at least five layers of the film, wherein the outmost layer film is a TiO2-x-yCxNy film and the other layers film alternatively arrange by the TiO2-xCx flim and the SiO2 film and the first layer adjacent to the hard film layer is a TiO2-xCx film. The antireflection coating of the resin lens is prepared by the reactive magnetron sputtering technology on the resin lens plated with the hard film. The carbon doping of the titanium dioxide film is realized in the magnetron sputtering process by the reactive gas. The nitrogen doping is further realized by the plasma treatment to the carbon doped titanium dioxide film at the outmost layer of the antireflection coating. The resin lens has the advantages of many functions, stable performance, simple preparation process, low manufacturing cost and long-acting anti-soil anti-fog self-cleaning and anti-wear performance.

Owner:SCHOOL OF OPHTHALMOLOGY & OPTOMETRY WENZHOU MEDICAL COLLEGE

Self-lubricating antifriction composite thin film based on MoS2-TiC-C and preparation method thereof

InactiveCN101921984AGrain refinementPrevent oxidationVacuum evaporation coatingSputtering coatingSputteringComposite film

The invention relates to a self-lubricating antifriction composite thin film based on MoS2-TiC-C and a preparation method thereof, belonging to the technical field of nano-surface treatment, and the MoS2-TiC-C composite thin film is prepared by sputtering pure titanium or pure nickel on a stainless steel substrate and further carrying out reactive magnetron sputtering. The preparation process is simple, the deposition process is easy to control, and the composite thin film after deposition does not need to carry out heat treatment and can be directly used as the antifriction protective thin film on the surface of a mechanical part. The composite thin film prepared by the process has high hardness, the nano-hardness can achieve 7.6GPa, the anti-wear and antifriction performance is excellent, the friction coefficient can achieve 0.04, and the surface of the thin film can avoid the phenomena of wearing through and shedding after the friction and wear test.

Owner:SHANGHAI JIAO TONG UNIV +1

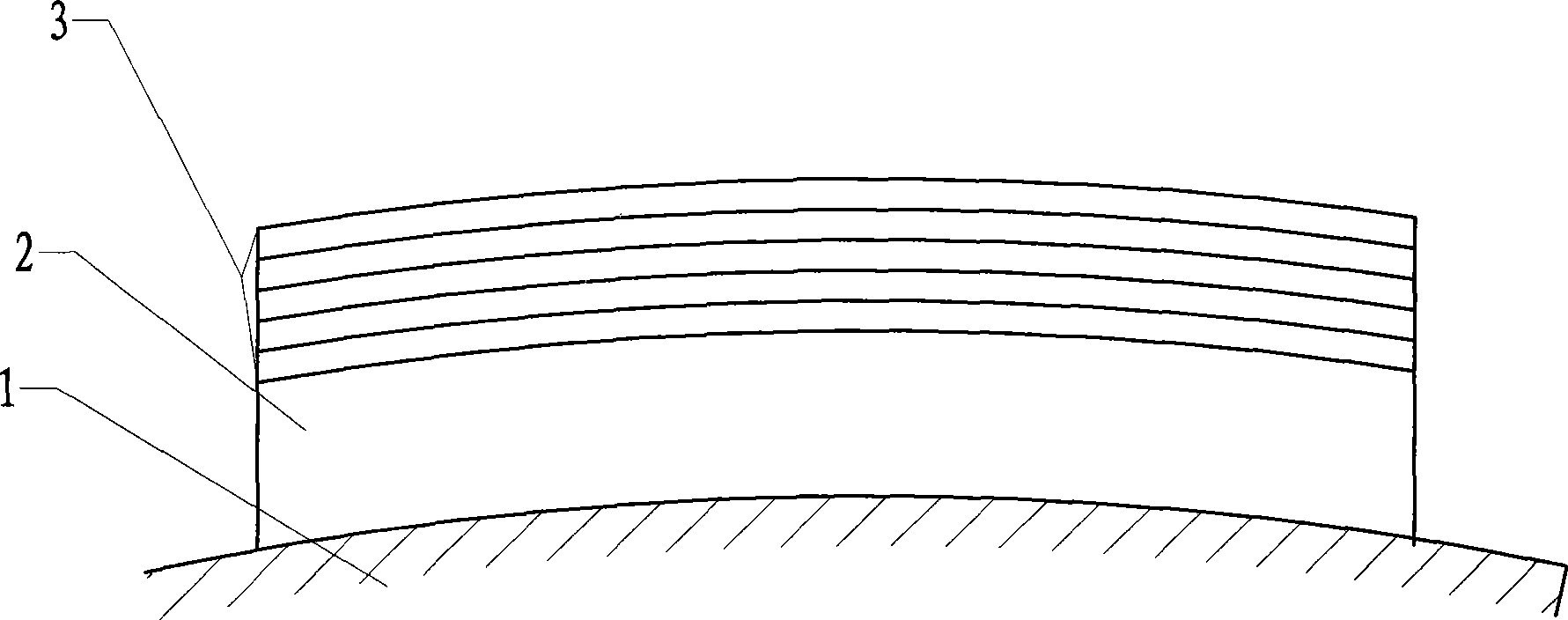

Preparation method of composite coating used for gas bearing

InactiveCN101798679AResolve frictionHigh hardnessVacuum evaporation coatingSputtering coatingIntermediate frequencyHardness

The invention discloses a preparation method of a composite coating used for a gas bearing, which adopts a mid-frequency reactive magnetron sputtering system to deposit a Ti / AlTiN / Ti: DLC high- hardness and high-abrasion-resistance composite membrane. The smaller the friction coefficient between a rotor and a stator of the dynamic gas bearing is, the better to the starting of a motor, and in the high-speed rotation process, the stator and the rotor can possibly collide with each other or even have instant melting lock faults. The dynamic gas bearing made of single material can not satisfy the current requirements, and the surface modification technique of the bearing material is the key technology that limits the application of the dynamic gas bearing. The coating prepared through the method reduces the friction coefficient, improves the abrasion resistance and at the same time solves the problems of corrosion resistance and abrasive resistance of the coating. The preparation method is easy to realize and all the materials are common, so the preparation method can realize industrial production.

Owner:UNIV OF SCI & TECH BEIJING

Vacuum deposition of coating materials on powders

A powder material moved and mixed by the application of a mechanical force. The moving of the bed of powder in a container while the container is in a vacuum under a vapor source produced by magnetron sputtering, thermal evaporation, or other means of producing a coating vapor such as plasma enhanced chemical vapor deposition (PECVD), provides a means of coating the particles of powder with a material which will impart certain other desirable characteristics to the base material of which the powder is composed. The range of and combinations of coatings include a pure metal, co-deposited metals, and non-metals formed by reactive magnetron sputtering, evaporation or PECVD, or a sequentially deposited coating of both metals and non-metals. The mechanical means may be by striking, stirring or a piezoelectric transducer may be used. The mechanical force may be imposed on an open moving container of the bulk material in a vacuum or an open stationary container of the bulk material in a vacuum.

Owner:CARLOTTO JOHN A

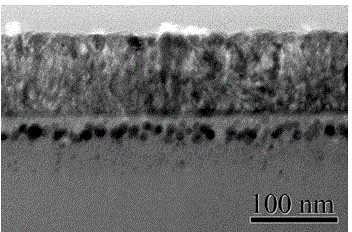

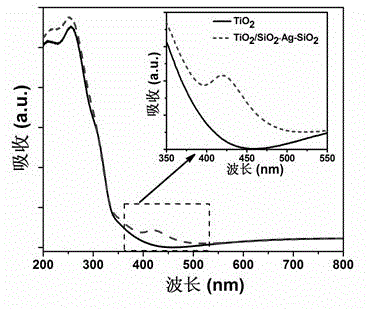

Preparation method for TiO2/SiO2-Ag-SiO2 nanocomposite film

InactiveCN102909008AOvercome oxidationPromote absorptionMetal/metal-oxides/metal-hydroxide catalystsSputteringComposite film

The invention provides a preparation method for a TiO2 / SiO2-Ag-SiO2 nanocomposite film. The method comprises the steps of: injecting Ag ions and then forming Ag nanoparticles in a quartz glass substrate; and then depositing a TiO2 film on the surface of a silica substrate by virtue of direct-current reactive magnetron sputtering so as to obtain the TiO2 / SiO2-Ag-SiO2 composite film. The Ag nanoparticles prepared by the method provided by the invention are inlaid in quartz glass, thus greatly overcoming the problem that the Ag nanoparticles are oxidized. Via the nanocomposite structure prepared by the method provided by the invention, the absorption of titanium dioxide to an ultraviolet ray part is greatly improved, so that the photocatalytic efficiency is improved. The preparation method can be widely applied to the field of optoelectronics.

Owner:HUBEI UNIV OF TECH

Technology for preparing multilayer film thermoelectric materials through physical vapor deposition method

InactiveCN104538542AGood adhesionEase of industrial productionThermoelectric device manufacture/treatmentSputteringLayer thickness

The invention discloses a technology for preparing multilayer film thermoelectric materials through a physical vapor deposition method. The technology is applied to the field of preparing of multilayer film thermoelectric materials. A proper base is selected, and the multilayer film thermoelectric materials are prepared through reactive magnetron sputtering. In the preparing process, different bases can be selected for deposition, and meanwhile material kinds, film layer thicknesses, film layer numbers and the like can be selected. Compared with other methods for preparing multilayer film thermoelectric materials, the physical vapor deposition method is obvious in layered structure, high in precision, capable of reaching the nanometer level and improving the thermoelectric performance, easy to operate, capable achieving batched production, good in controllability and capable of preparing diverse multilayer film thermoelectric materials.

Owner:SHANGHAI UNIV

Soft and hard composite coated cutting tool and preparation method thereof

ActiveCN107058948AWell formedReduce coefficient of frictionVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringAlloy

The invention discloses a soft and hard composite coated cutting tool and a preparation method thereof. The cutting tool comprises a substrate and a soft and hard composite coating coated on the outer surface of the substrate, wherein the substrate is made from hard alloy; the soft and hard composite coating sequentially comprises a ZrN transition layer, a CNx hard coating and a WS2 soft coating from inside to outside; the ZrN transition layer is prepared through a direct current reactive magnetron sputtering method; and both the CNx hard coating and the WS2 soft coating are prepared through a radio frequency magnetron sputtering method. The soft and hard composite coating in the invention combines the advantages of the WS2 soft coating and the CNx hard coating; the high hardness and the high wear resistance of the hard coating and the antifriction property of the soft coating are combined; and the therefore, the cutting tool can simultaneously have high wear resistance and very low friction coefficient.

Owner:XIAMEN UNIV

Method for depositing nano-grade TiO2 film on textile material

InactiveCN102899623ASmall particle sizeReduce surface roughnessVacuum evaporation coatingSputtering coatingFiberOptoelectronics

The invention provides a method for depositing a nano-grade TiO2 film on a textile material. The method comprises the steps that: high-purity metal Ti target is adopted as a target material; a pretreated textile material is adopted as a substrate; and the textile-material-based nano-grade TiO2 film is prepared under room temperature by using a DC reactive magnetron sputtering device. All samples adopt a structure that the substrate is on the upper side and the target is on the lower side, such that the nano-grade TiO2 film is prepared by sputtering from bottom to top, and impurity particles are prevented from falling onto the surface of the substrate. Also, the substrate is cooled with a water cooling device, such that substrate temperature during film deposition is controlled, and substrate deformation caused by high temperature is avoided. For ensuring the purity of the nano-grade TiO2 film, a reaction chamber is first pumped to base vacuum; high-purity argon is delivered as a sputtering gas; and high-purity oxygen is adopted as a reaction gas. With the method provided by the invention, a relatively uniform and compact TiO2 film can be deposited on the non-woven fabric fiber surface. The average particle size of the film is relatively small, and the surface roughness of the film is relatively low.

Owner:KUNSHAN TIENIU SHIRT FACTORY

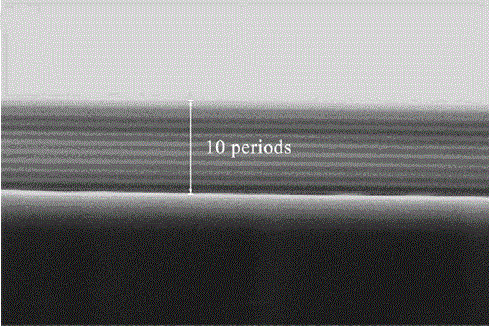

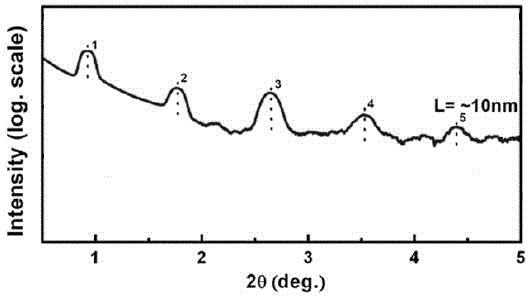

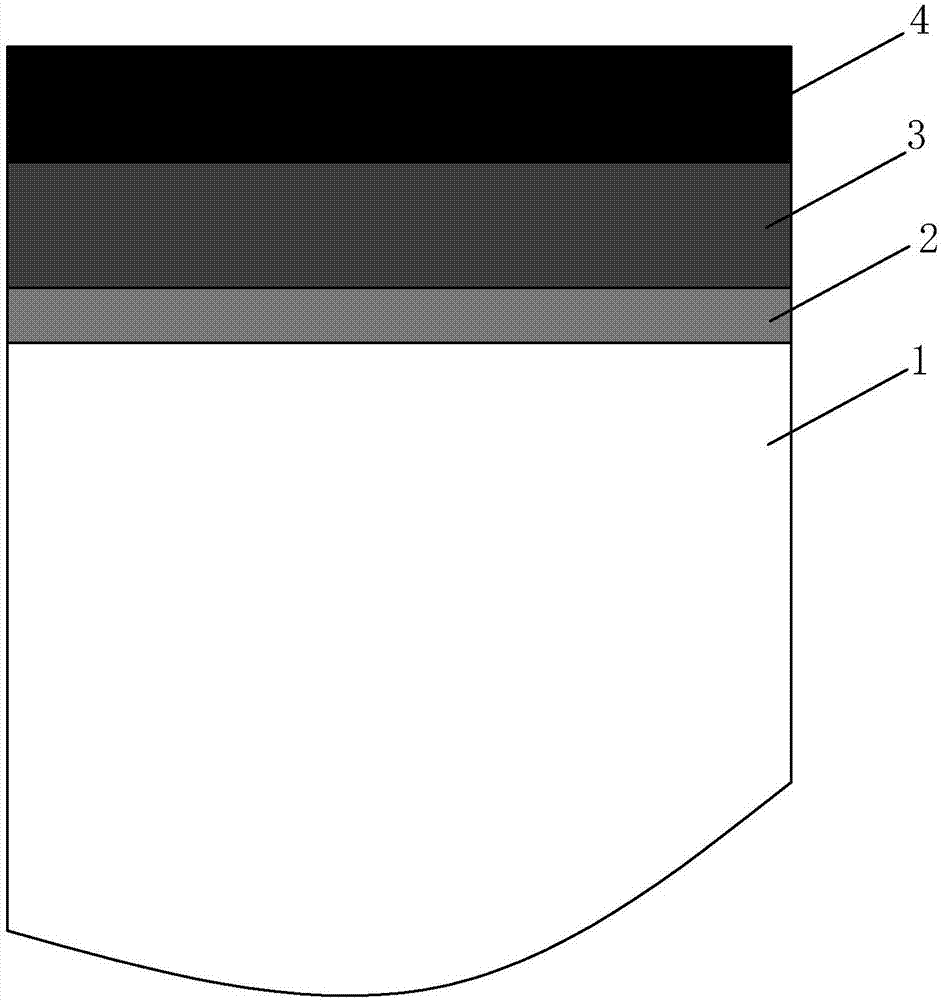

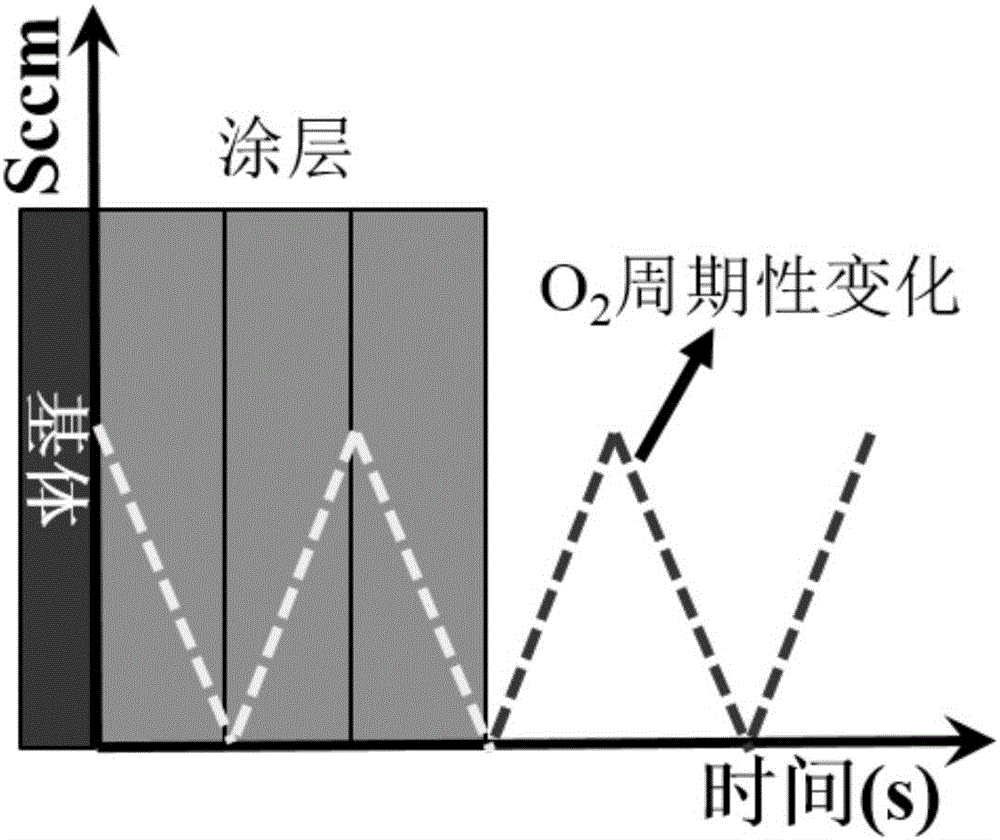

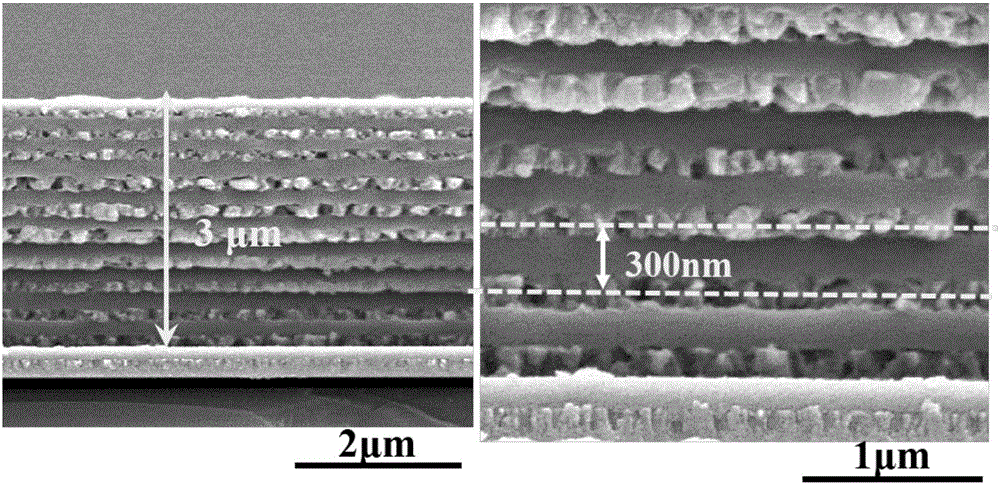

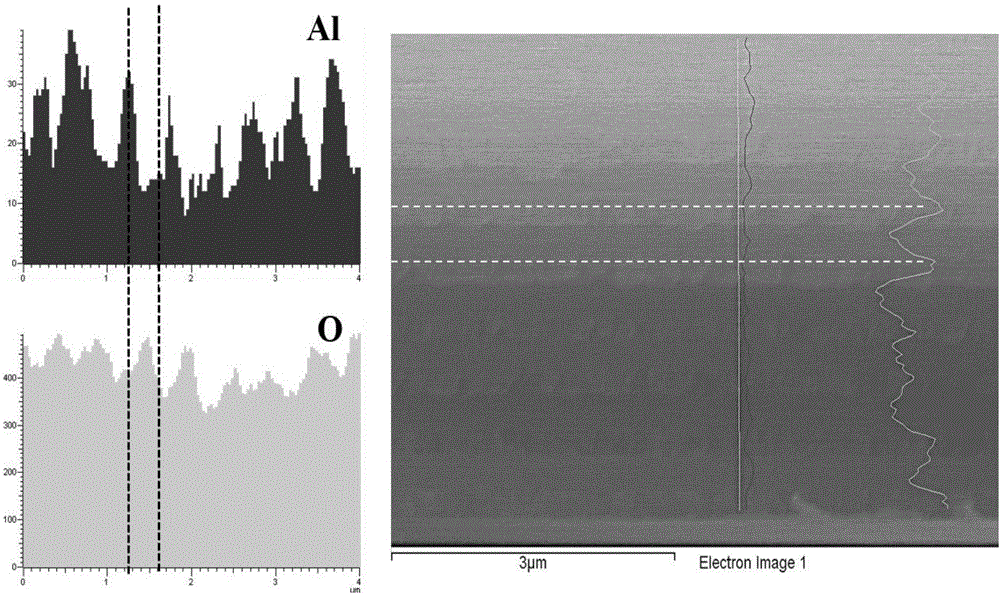

Method for preparing A12O3 tritium permeation barrier by adopting gas pulse response sputtering method

InactiveCN106609353AEasy to operateGood repeatabilityVacuum evaporation coatingSputtering coatingSputteringPhysical chemistry

The invention discloses a process for preparing an A12O3 tritium permeation barrier by adopting a gas pulse response sputtering method. The process comprises the following steps: carrying out substrate pretreatment; carrying out bias backwash cleaning; depositing the A12O3 tritium permeation barrier on the surface of a CLF-1 substrate material by adopting high vacuum reactive magnetron sputtering equipment; and carrying out annealing. In the sputtering process, the O2 flow rate changes periodically. The process provided by the invention is simple to operate; the prepared A12O3 tritium permeation barrier has a multi-layer and compositional gradient hybridization two-phase structure; after the annealing, the phase formation of alpha-Al2O3 is easier; and the oxidation degree of the CLF-1 substrate material is obviously reduced.

Owner:SICHUAN UNIV

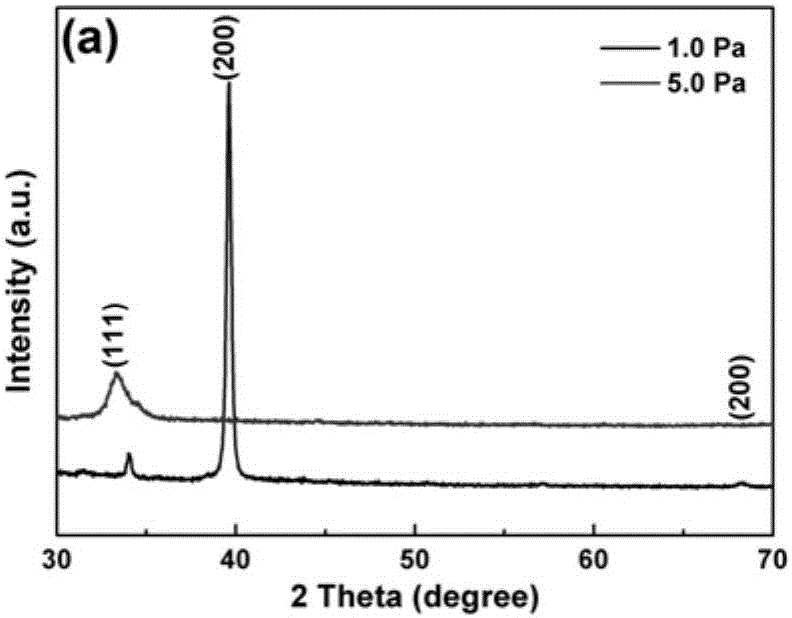

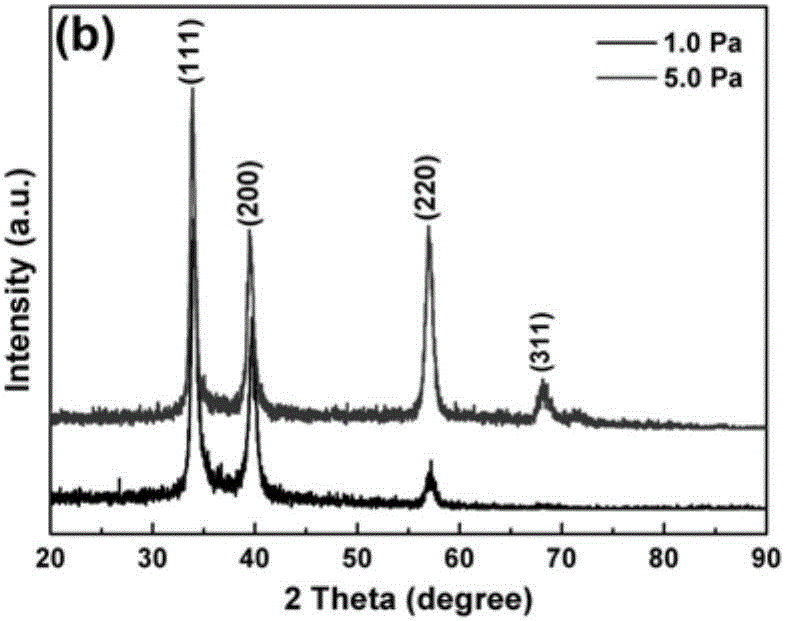

Preparation method for transition metal nitride super-capacitor coating material

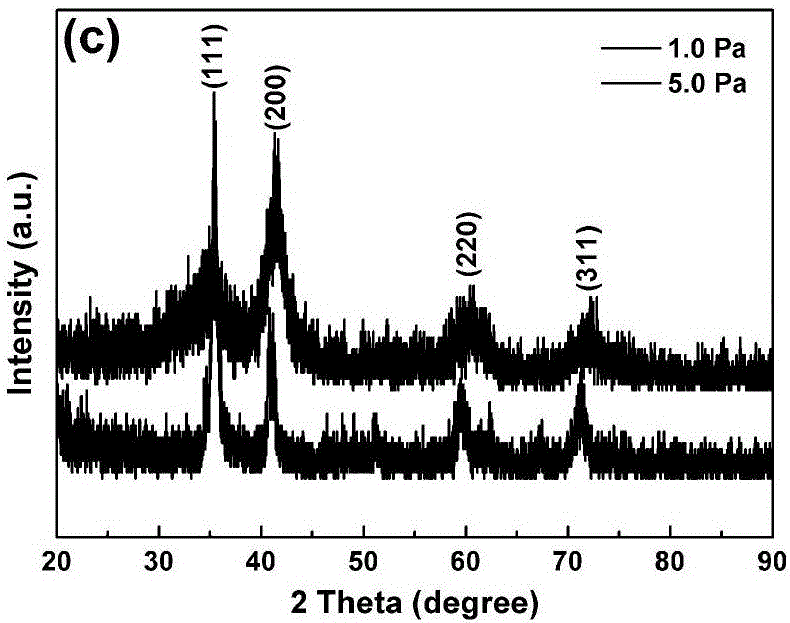

The invention discloses a preparation method for a transition metal nitride super-capacitor coating material, and relates to a super-capacitor. The transition metal nitride super-capacitor coating material is obtained by performing reactive magnetron sputtering at different deposition pressures. The different deposition pressures are between 1.0 and 5.0 Pa; the transition metal nitride is ZrN, HfN and NbN. By regulating and controlling the deposition pressure during a thin film depositing process, the maximum specific capacitance values of the transition metal nitrides can be respectively 12.0, 13.5, and 10.2 mF / cm<2>; after 20,000 times of recycling, the capacity retention rates are all up to 90 percent.

Owner:XIAMEN UNIV

Cuprous oxide-zinc oxide heterojunction solar cell and preparation method thereof

InactiveCN110112225AImprove efficiencyReduce defect densityMaterial nanotechnologyFinal product manufactureHeterojunctionSilicon nanocrystals

The invention discloses a cuprous oxide-zinc oxide heterojunction solar cell and a preparation method thereof. Corning glass is used as a substrate, metal titanium is grown by a magnetron sputtering method, and then a silver electrode is sputtered on a titanium thin film; a nitrogen-doped Cu2O thin film is grown by using a reactive magnetron sputtering method; a microcrystalline silicon oxide thinfilm is grown on the surface of the nitrogen-doped Cu2O thin films by using an isotopic chemical vapor deposition method; a Al-doped ZnO thin film is grown by using the magnetron sputtering method; and a layer of Ag electrode is deposited on the ZnO thin film by using the magnetron sputtering method through a mask plate. The amorphous silicon oxide in microcrystalline silicon oxide is applied topassivate CuO deep level defect on the Cu2O surface, the doped silicon nanocrystals transport photogenerated carriers, and the hydrogen introduced in the growth process is diffused into Cu2O at subsequent annealing temperatures so as to reduce the defect density and improve the efficiency of the Cu2O solar cell.

Owner:ZHEJIANG NORMAL UNIVERSITY

Intermediate-frequency reactive magnetron sputtering preparing method for AlN piezoelectric film

InactiveCN106222611AConducive to selective growthReduce surface roughnessVacuum evaporation coatingSputtering coatingIntermediate frequencySurface roughness

The invention relates to the field of preparing of wide bandgap semiconductors, in particular to an intermediate-frequency reactive magnetron sputtering preparing method for an AlN piezoelectric film. The method includes the following steps that firstly, a substrate is pretreated; secondly, a target is pretreated; thirdly, N2 and Ar mixed gas is led in to sputter and deposit a bottom-layer AlN film; and fourthly, the N2 and Ar mixed gas is led in to sputter and deposit the AIN film, the content of N2 is not changed, and the gas pressure of gas in a cavity is increased. The AlN film prepared through the method has the beneficial effects that (002) face preferred orientation growth is achieved, the surface grain size is uniform, and the surface roughness is small; and the method is suitable for preparing high-quality AlN piezoelectric films of acoustic surface wave devices.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

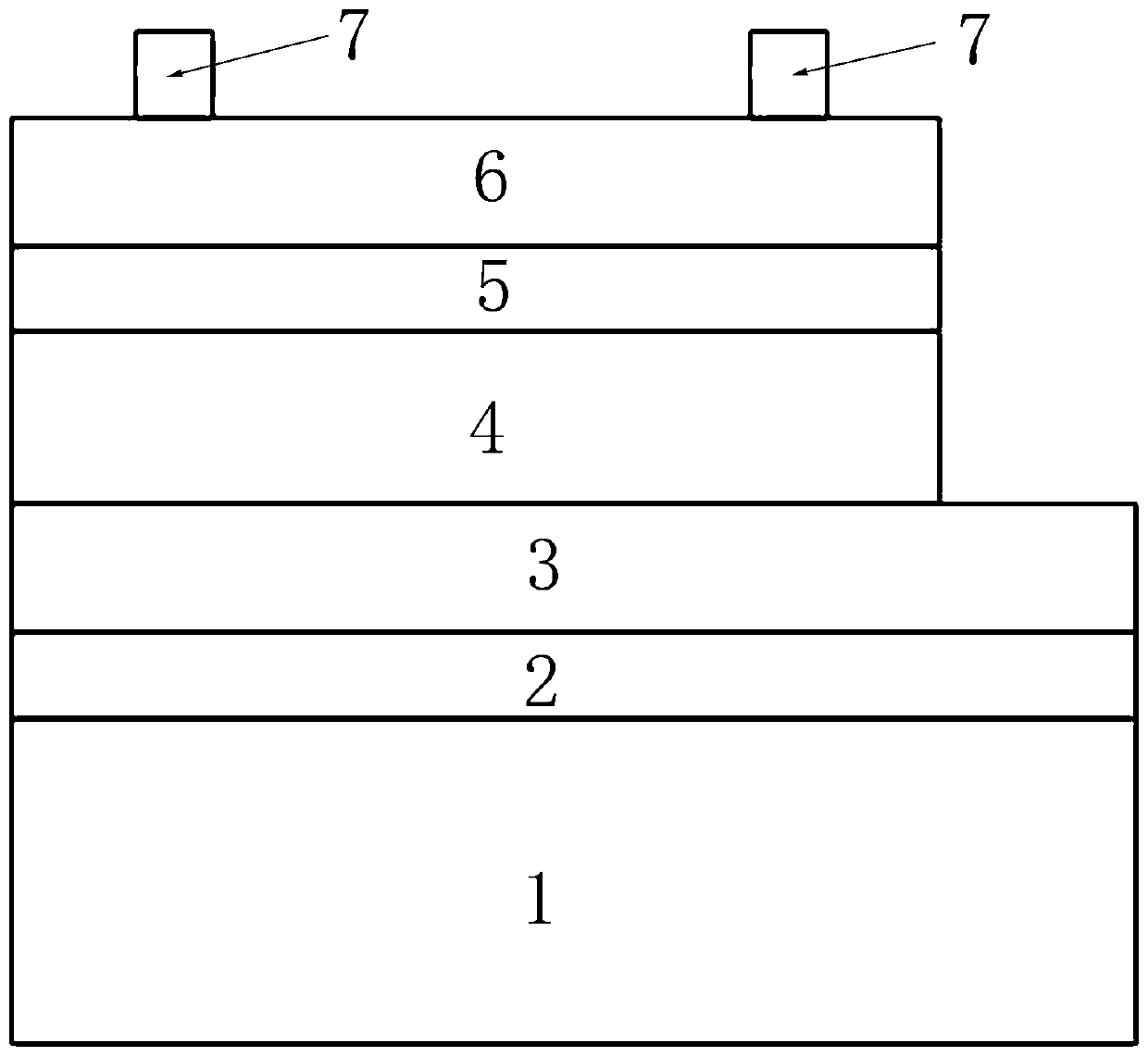

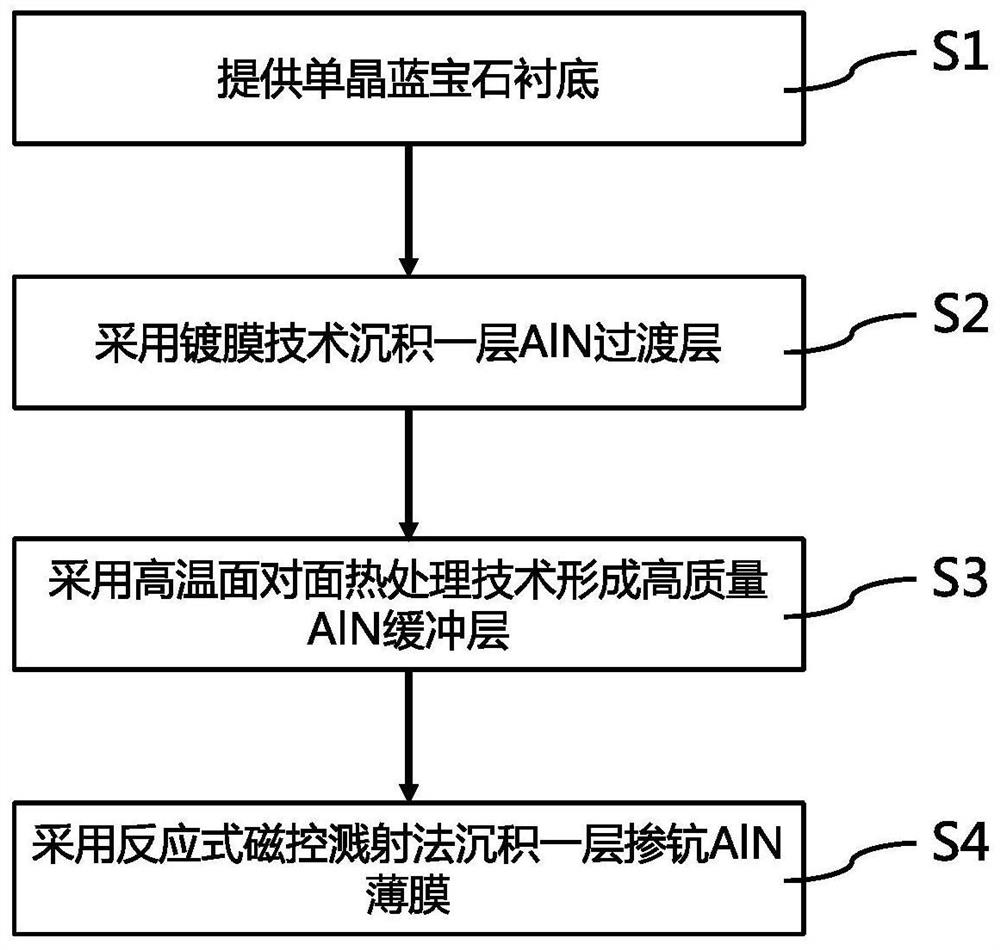

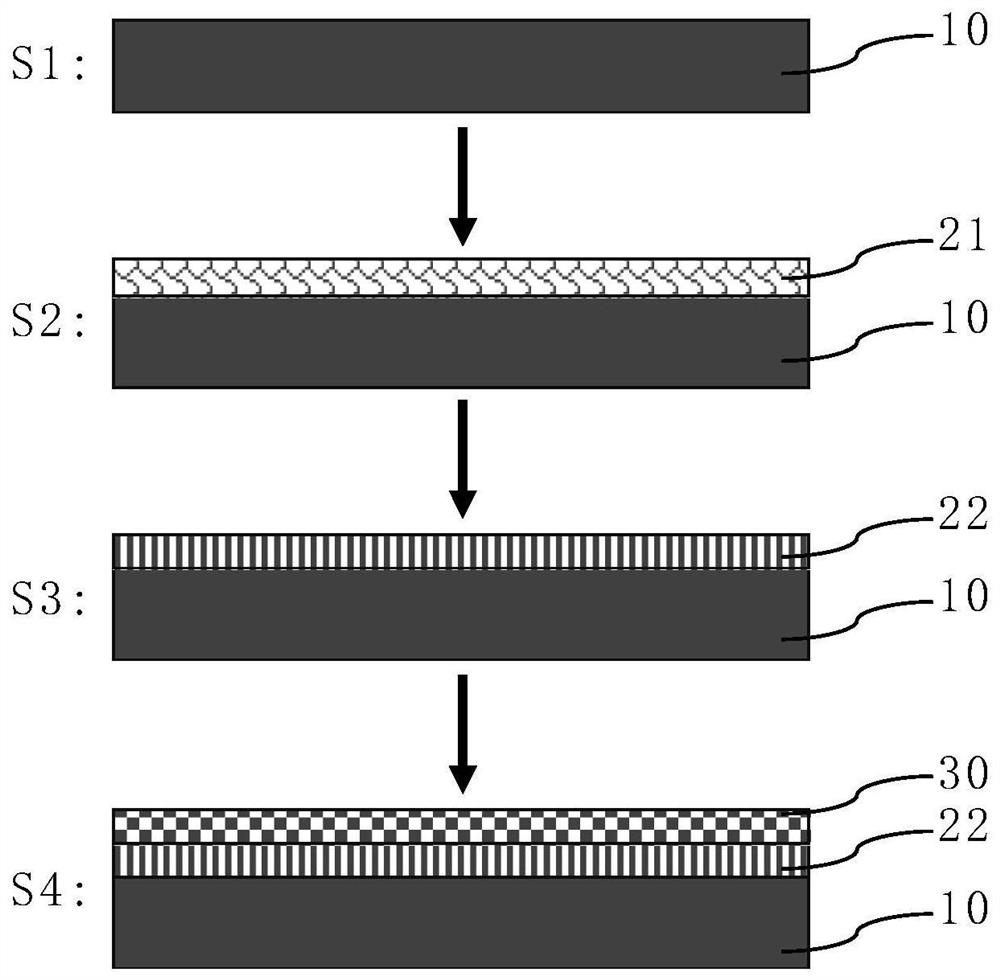

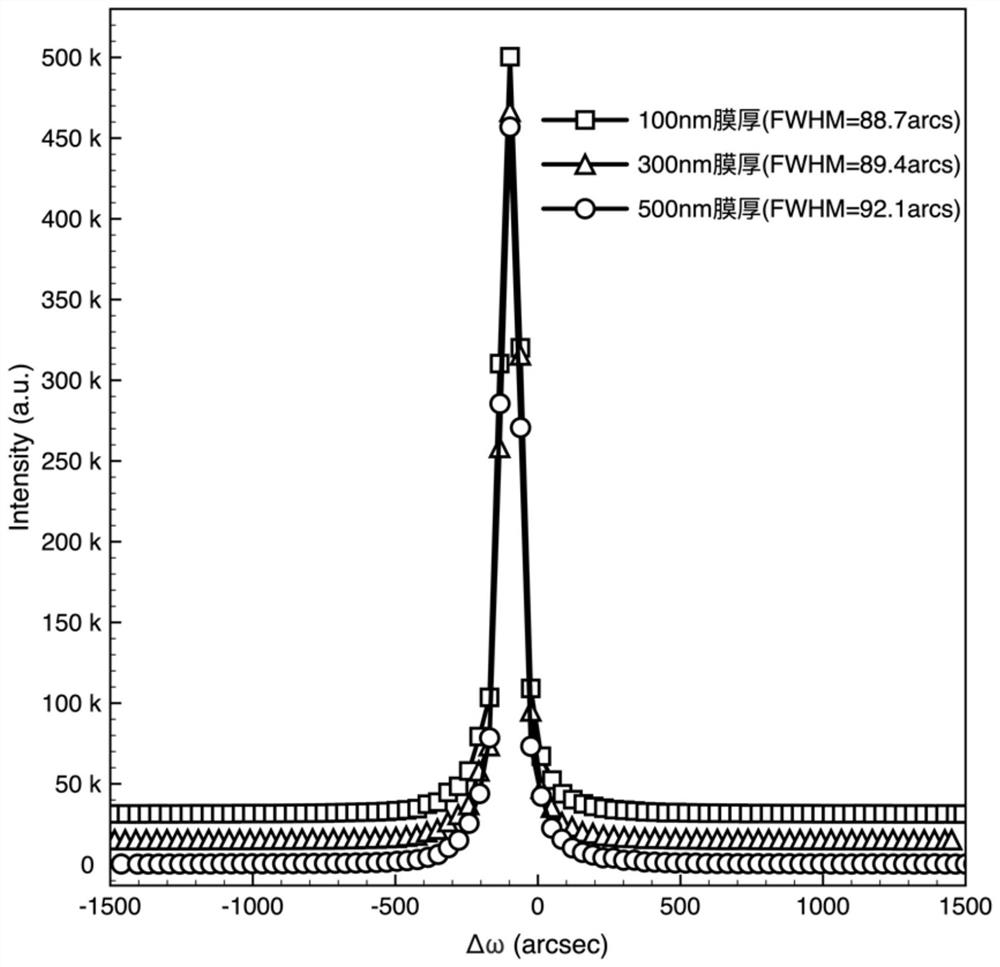

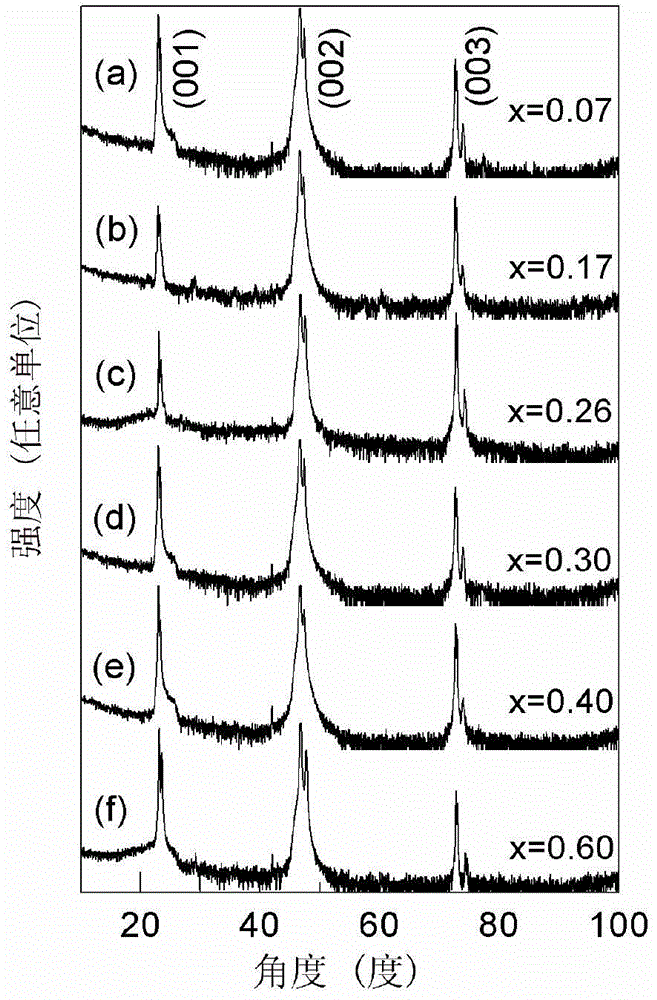

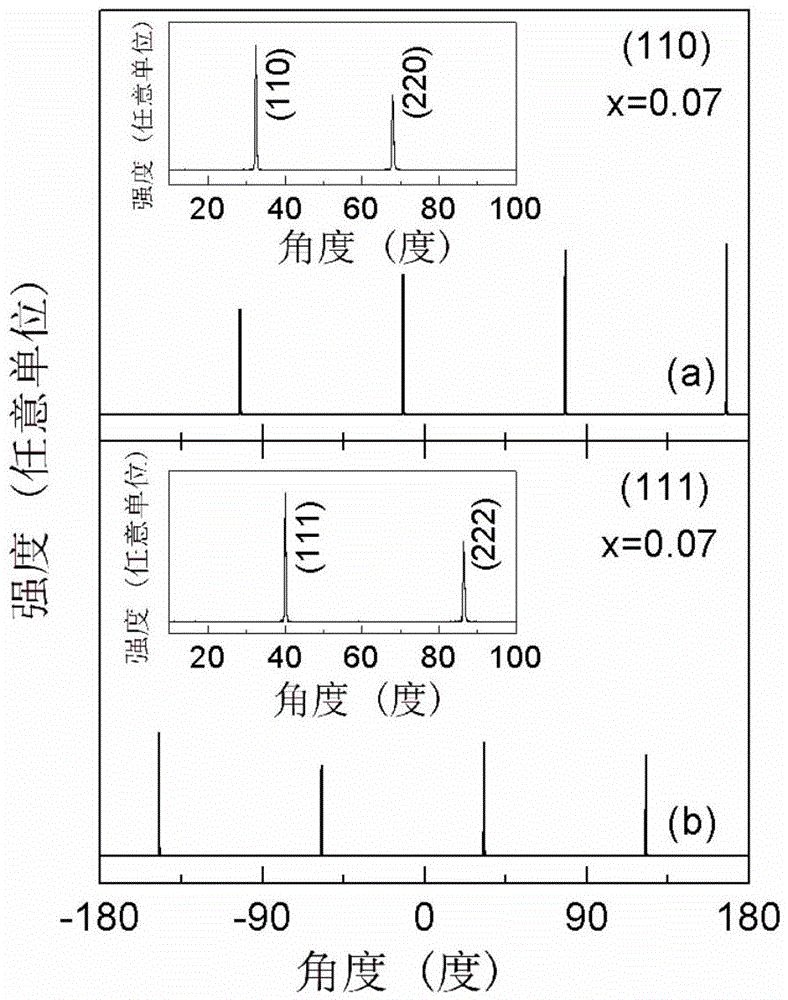

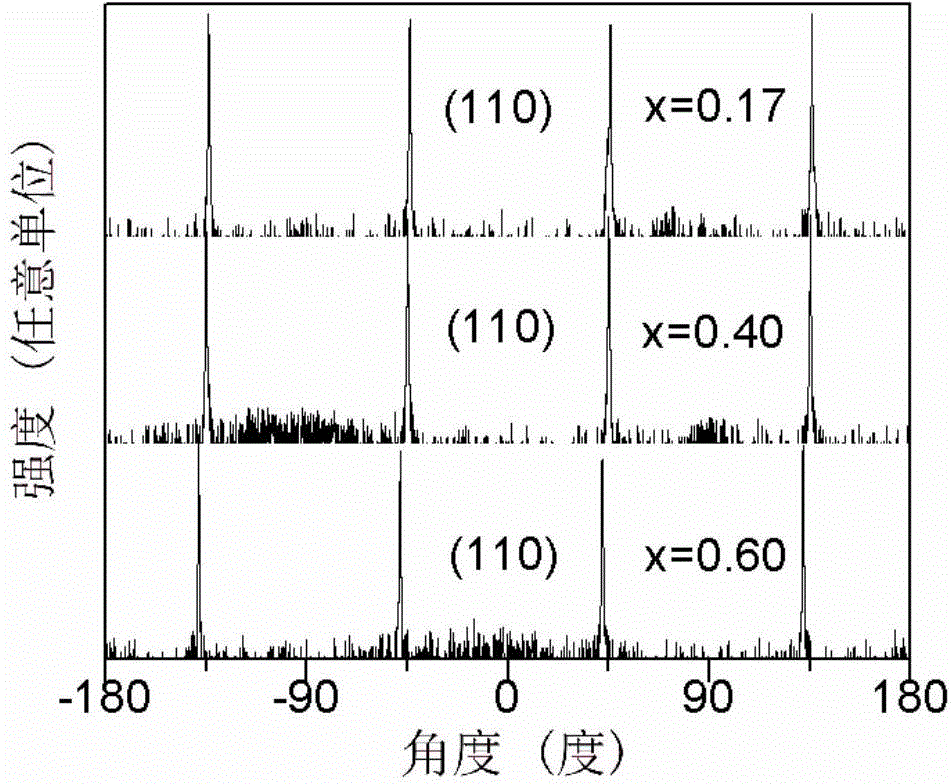

Preparation method of high-quality scandium-doped aluminum nitride film template

PendingCN113174574AImprove crystal qualitySolve the important problem of poor crystal qualityVacuum evaporation coatingSputtering coatingHigh concentrationElectromechanical coupling coefficient

The invention provides a preparation method of a high-quality scandium-doped aluminum nitride film template. The preparation method includes the following steps of: S1, preparing a substrate; S2, depositing a film transition layer on the substrate by adopting a coating technology; S3, thermally treating the film transition layer at a high temperature in a pure nitrogen atmosphere by adopting a high-temperature face-to-face heat treatment technology to form a high-quality buffer layer; and S4, depositing a scandium-doped aluminum nitride film on the buffer layer by adopting a reactive magnetron sputtering deposition method. The preparation method provided by the invention can be used for preparing a scandium-doped aluminum nitride thin film with a high crystallization property, solves the problem that the orientation of the aluminum nitride thin film is seriously deteriorated due to doping of a high Sc concentration, and achieve results of far exceeding the level of the prior art under different film thicknesses, and lays a solid foundation for application of SAW / BAW devices with a higher frequency, enhanced piezoelectric response, a higher electromechanical coupling coefficient and a higher Q value.

Owner:ULTRATREND TECH INC

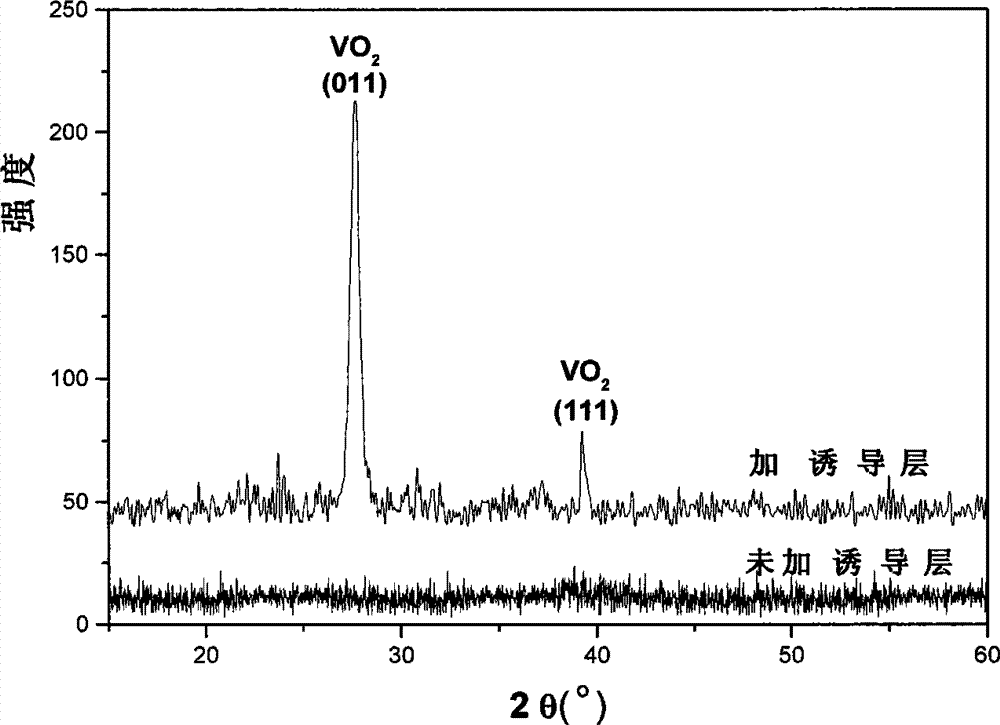

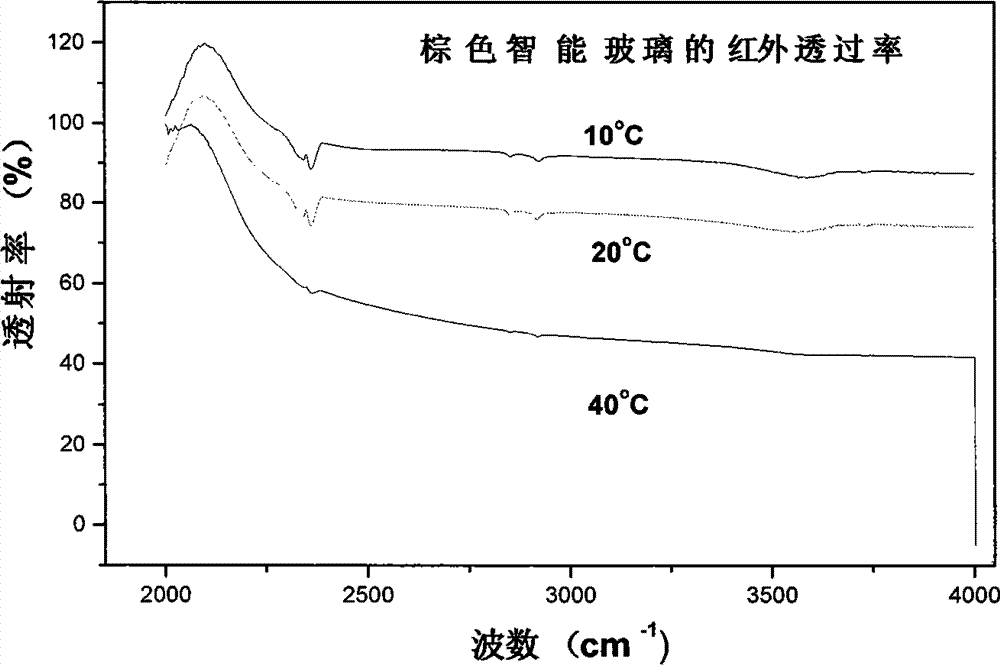

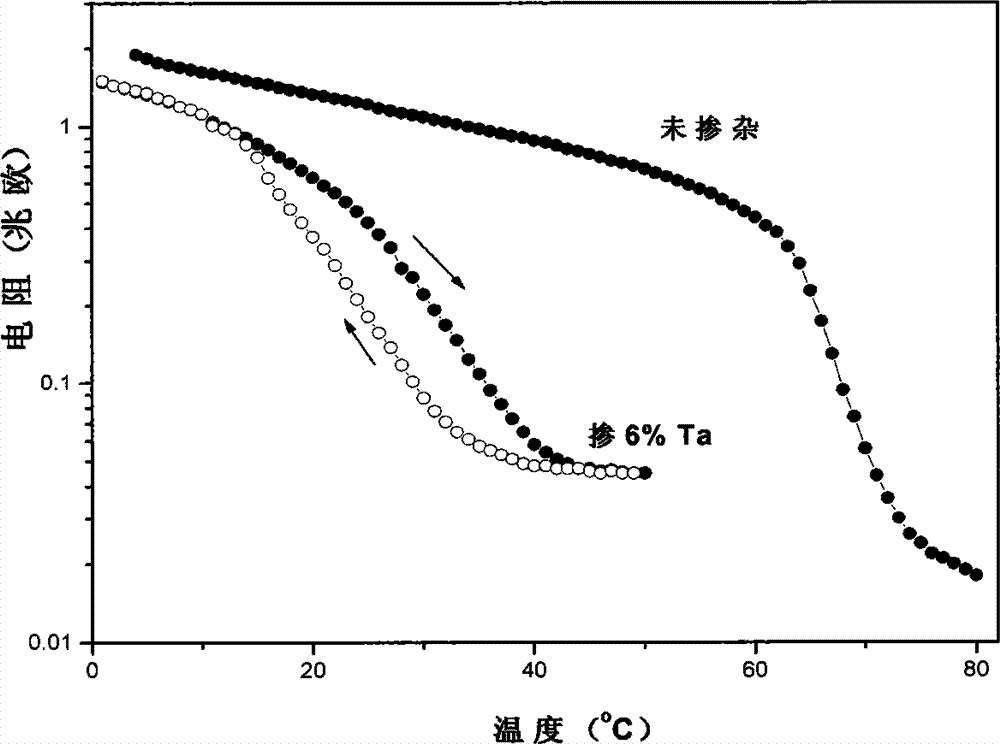

Industrial preparation method of smart glass capable of automatically regulating infrared transmittance

InactiveCN104261694ARapid large-area film formationImprove circulation speedSmart glassVanadium oxide

The invention relates to an industrial preparation method of smart glass capable of automatically regulating infrared transmittance. The industrial preparation method comprises the following steps: (1) conventionally cleaning glass, and then performing sputtering deposition of a Ti or Si elemental element film with the thickness of 5-20nm on the surface of the glass by an ion beam sputtering method as a crystallization inducing layer; (2) performing reactive sputtering deposition of a vanadium oxide film on the crystallization inducing layer by a direct current reactive magnetron sputtering method, wherein a reactive sputtering target is prepared by fusion of high-purity vanadium with the purity of 99.96% and doping elements with different atomic ratios; reactive sputtering source gas is Ar / O2 mixed gas, and the flow proportion of Ar / O2 is 5%-10%; and (3) performing heat treatment by adopting a fast heat treatment technology for heating by light of a halogen lamp after deposition of the vanadium oxide film, wherein the temperature in the whole heat treatment process is 450-550 DEG C, and the time is 10-20min; an annealing atmosphere adopts N2 / O2 mixed gas, N2 and O2 are formed by gasification of liquid nitrogen and liquid oxygen, and the flow proportion of N2 to O2 is (98%-99%): (2%-1%).

Owner:李金华

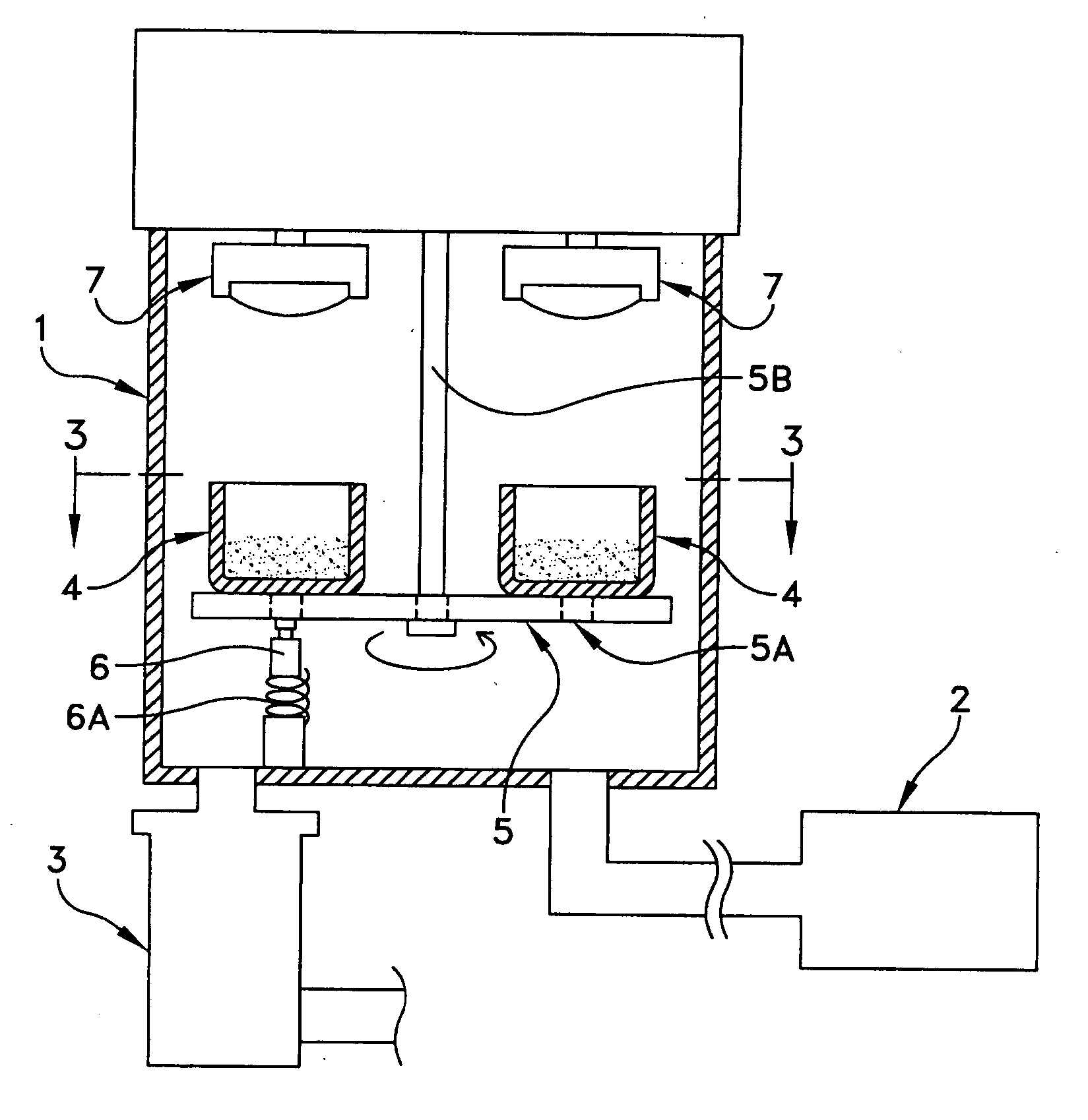

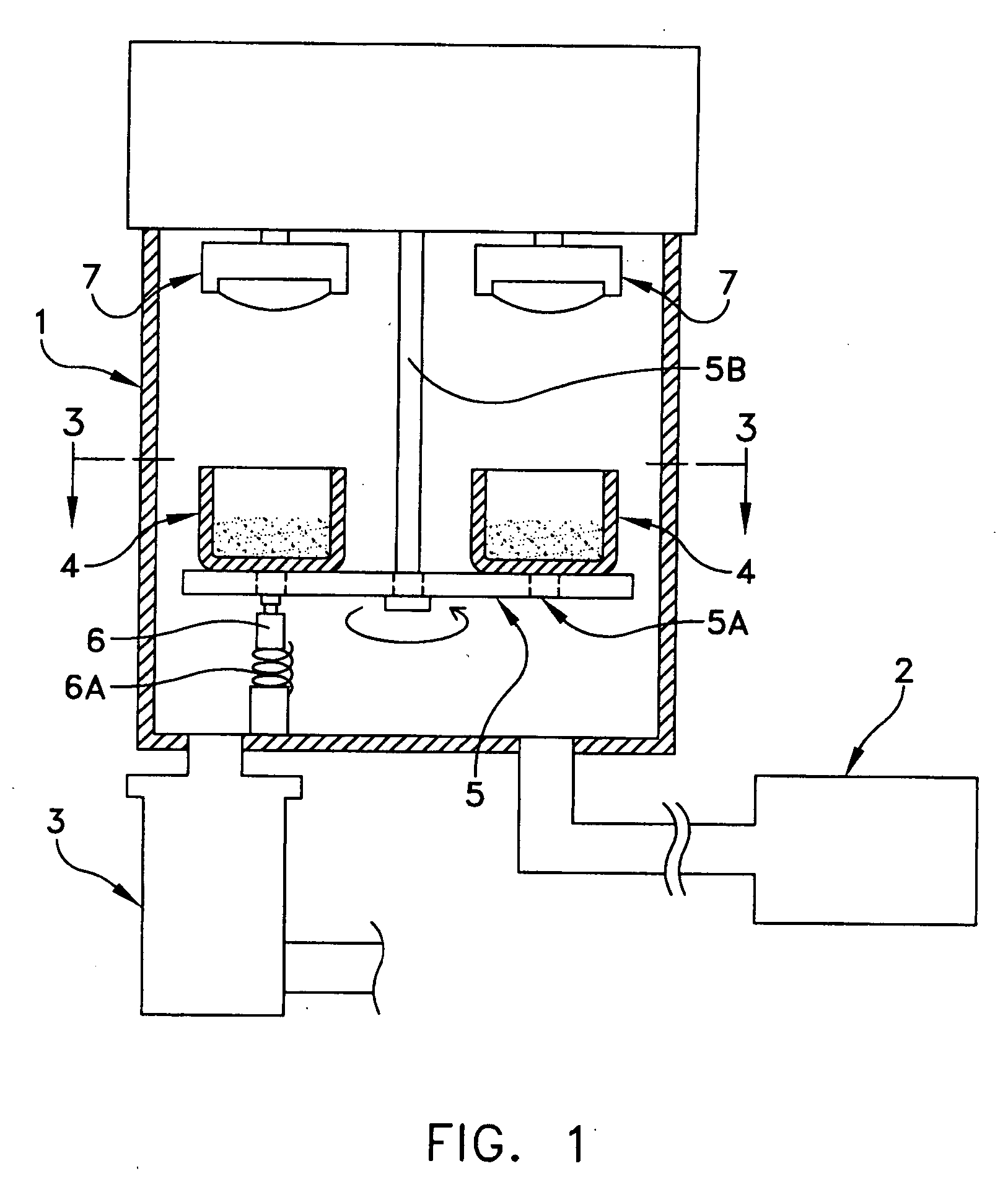

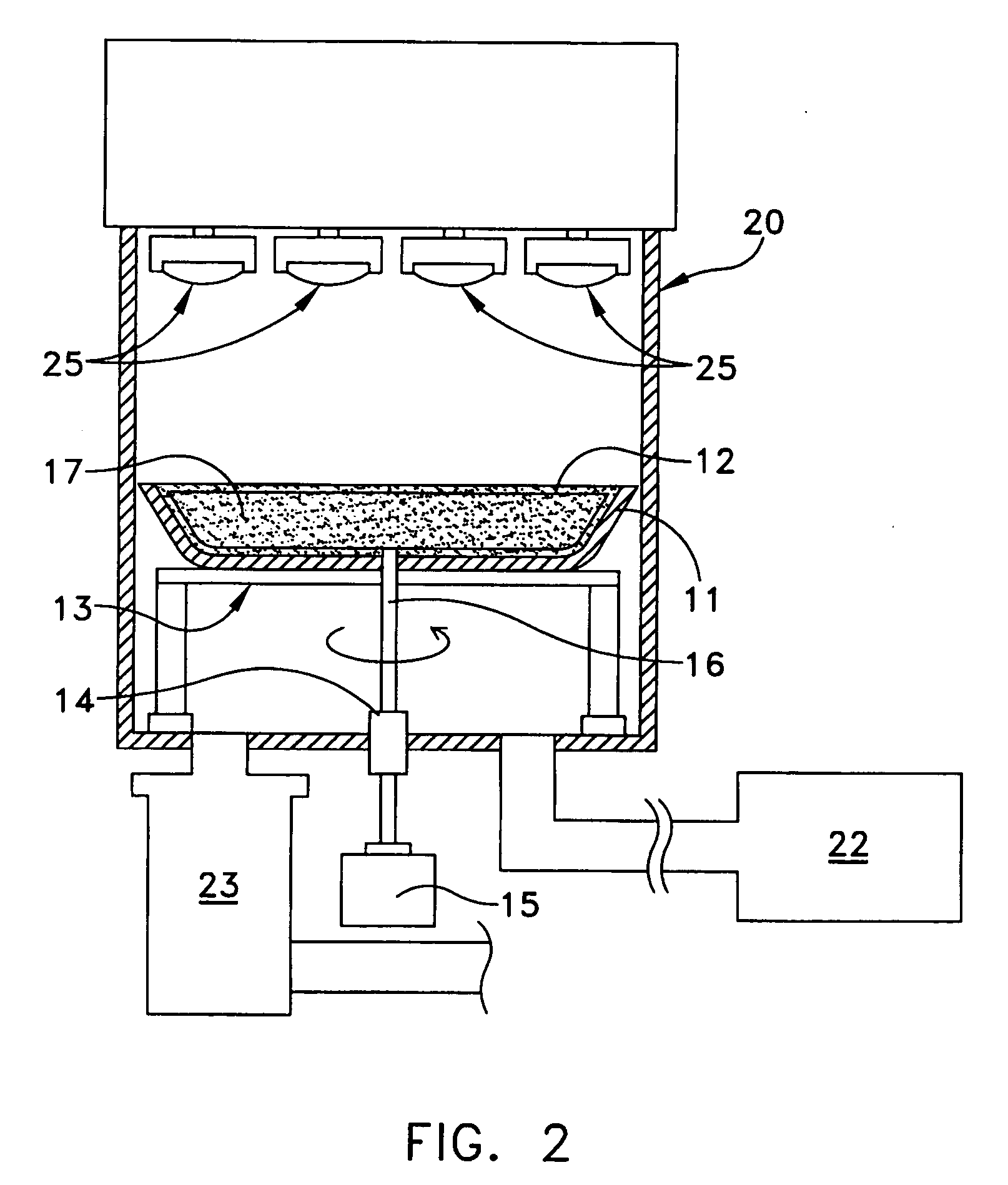

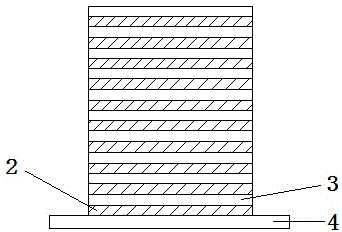

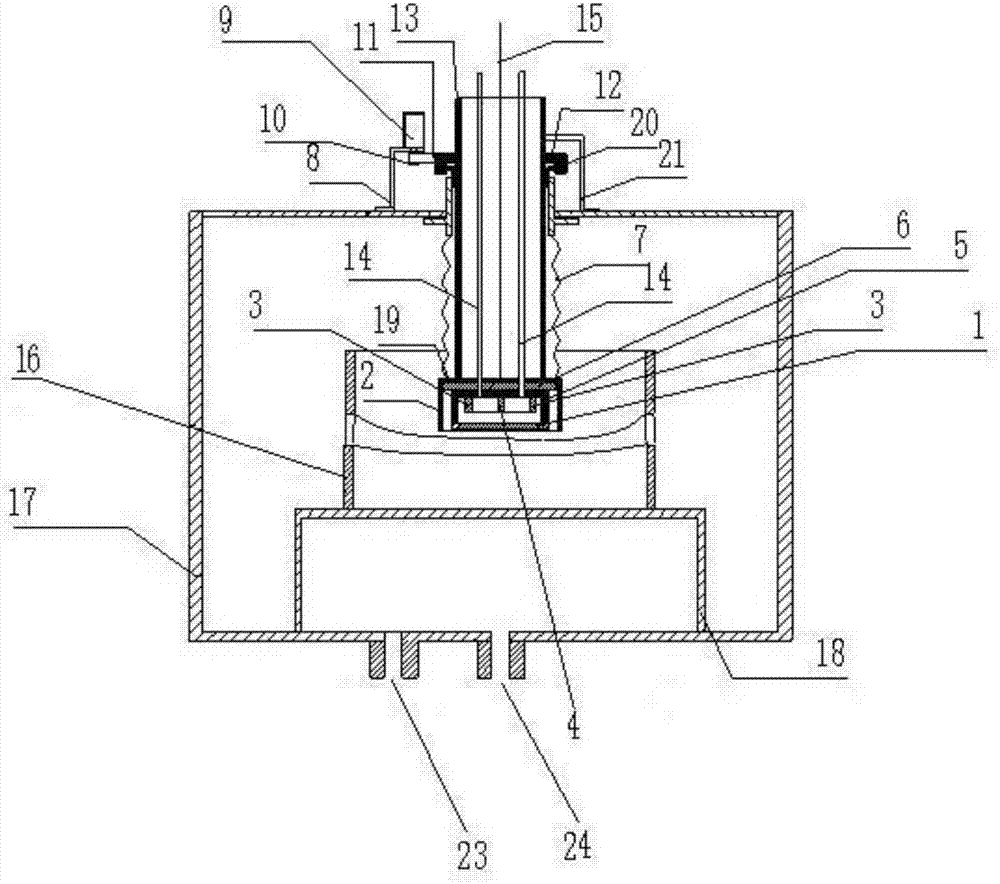

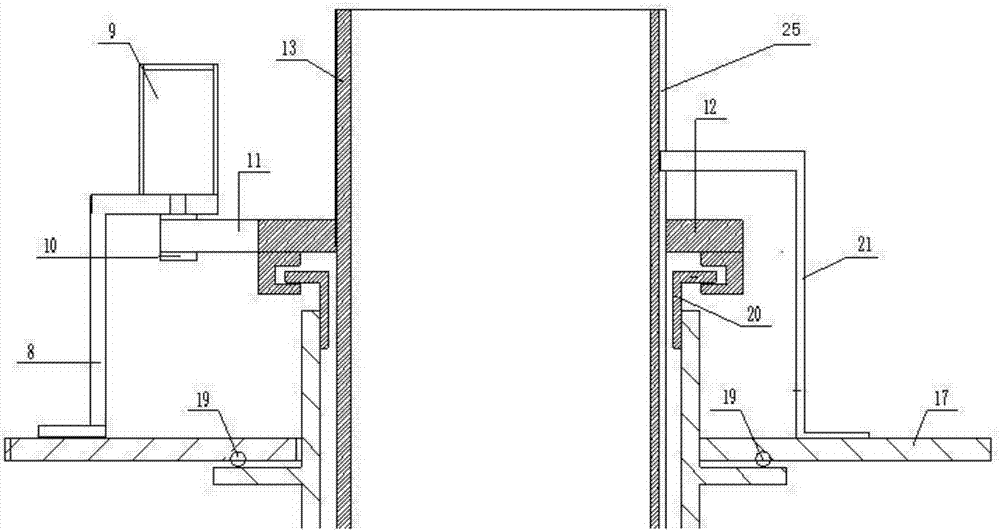

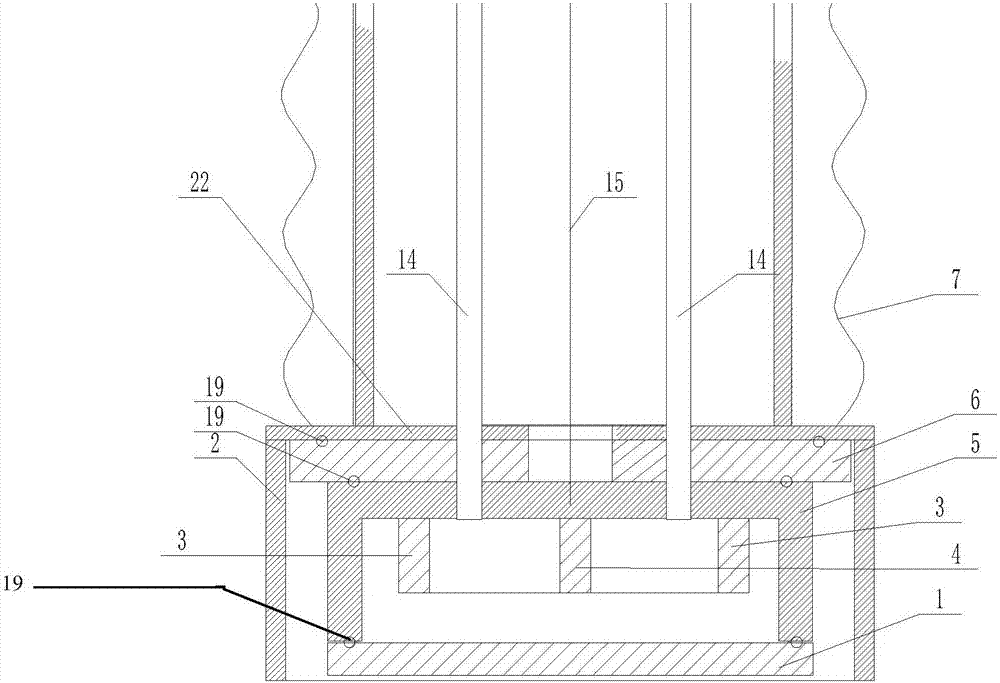

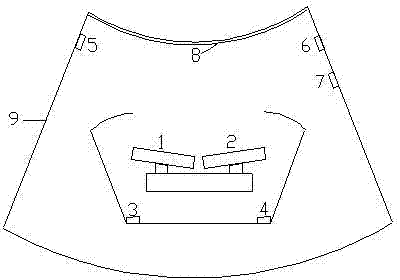

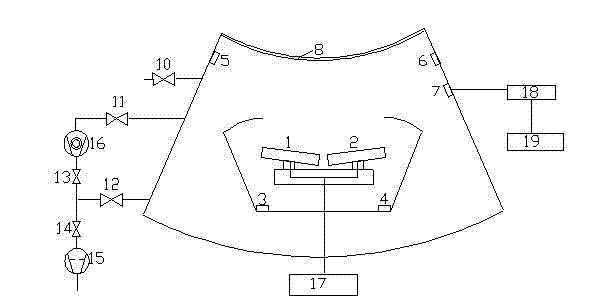

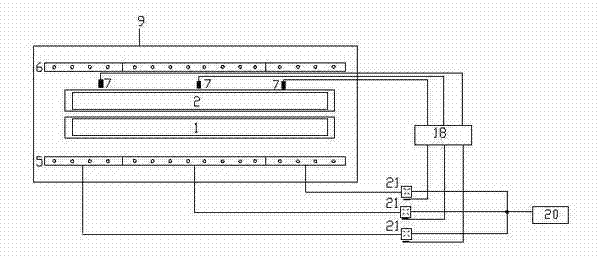

Vacuum reaction magnetron sputtering coating device and method in engine cylinder liner inner chamber

PendingCN107955938AImprove high temperature resistanceImprove wear resistanceVacuum evaporation coatingSputtering coatingSputteringEngineering

The invention discloses a vacuum reaction magnetron sputtering coating device in engine cylinder liner inner chamber. The device comprises a vacuum sputtering chamber, a cylinder liner support seat, amagnetic control cathode structure, and a motion control mechanism; the cylinder liner support seat is fixed at the bottom of the vacuum sputtering chamber; the motion control mechanism is arranged at the top portion of the vacuum sputtering chamber, and connected to the magnetic control cathode structure and drives the magnetic control cathode structure. The device adopts vacuum reaction magnetron sputtering coating method to film the inner surface of the cylinder liner, therefore, the inner surface of the cylinder liner has better resistance to high temperature and wear resistance; the inner surface of the cylinder liner can be fully covered with coating is realized, and the uniform coating is achieved.

Owner:JILIN UNIV

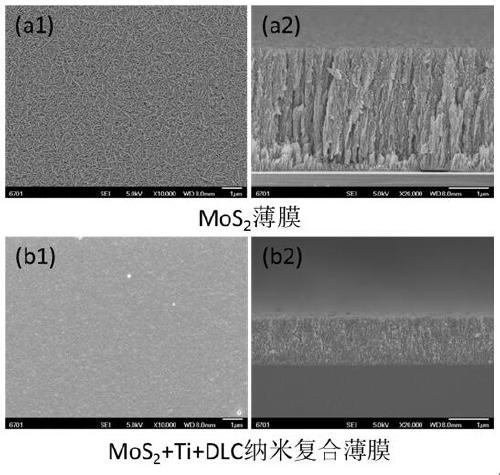

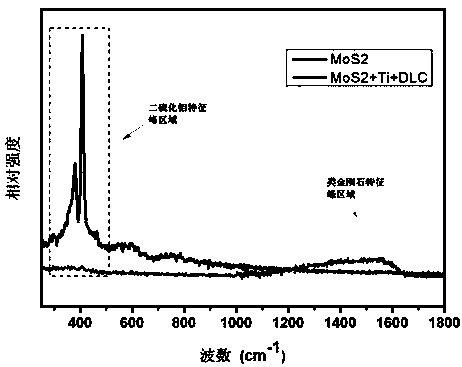

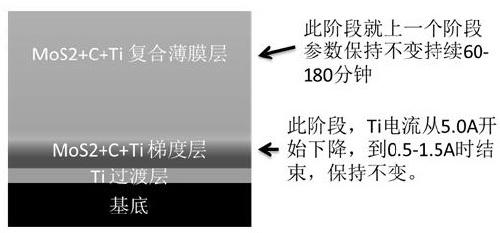

Preparation method of molybdenum disulfide (MoS2) based nanocomposite film doped with Ti and C

InactiveCN111304616AImprove lubricating propertiesImprove adaptabilityVacuum evaporation coatingSputtering coatingComposite filmNanoscopic scale

The invention discloses a preparation method of a molybdenum disulfide (MoS2) based nanocomposite film doped with Ti and C. The preparation method comprises the steps that a multi-target reactive magnetron sputtering system is utilized, MoS2 is used as a matrix material, nanoscale porous channels of the MoS2 film are filled with active Ti and DLC hard cluster particles through a reactive sputtering means, and thus a nanocomposite solid lubricating film with high environmental adaptability is constructed; and meanwhile through the deposition of Ti element gradient layers, the strength and film-base adhesion of the film are improved by using the principle of element mutual diffusion, so as to prolong the wear resistance life of the composite film. The mechanical properties test results showthat the hardness, elastic modulus and elastic recovery of the nanocomposite film are all significantly higher than those of pure MoS2 film; and the friction performance test results show that the nanocomposite film has a low friction coefficient and long wear resistance life under vacuum and atmospheric environment, and thus the service requirements of a remote control system of a nuclear fusiondevice are met.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

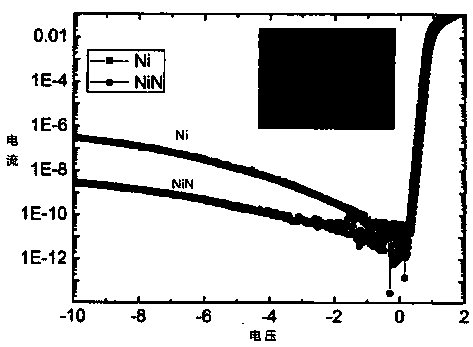

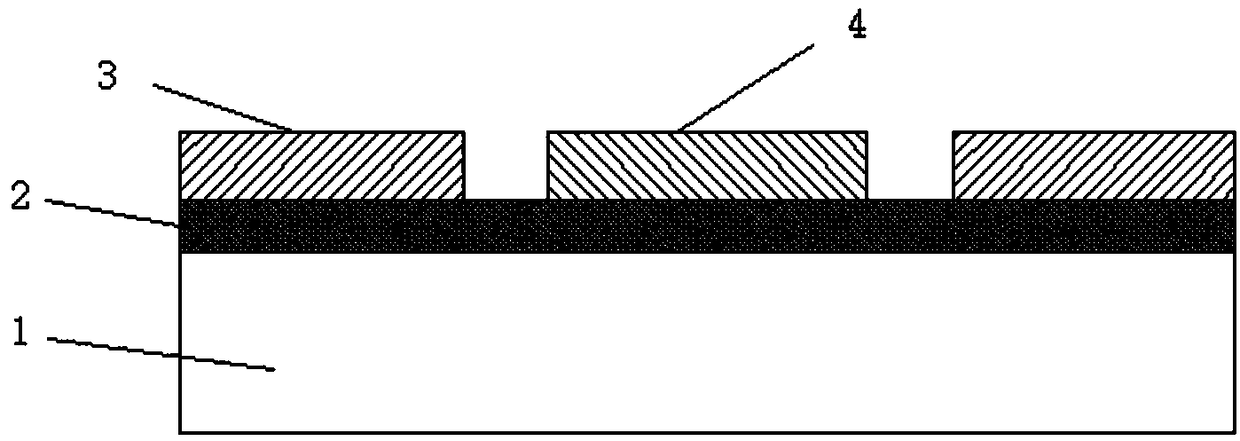

Gallium nitride Schottky barrier diode and manufacturing method thereof

InactiveCN108550622AImprove efficiencyImprove stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSputteringArgon atmosphere

The invention discloses a gallium nitride Schottky barrier diode and a manufacturing method thereof. The gallium nitride Schottky barrier diode comprises a substrate and an epitaxial layer grown on the substrate, wherein the epitaxial layer is provided with an ohmic electrode and a Schottky electrode. The invention further discloses the manufacturing method of the gallium nitride Schottky barrierdiode. The manufacturing method comprises the steps of forming a nickel nitride thin film layer on a Schottky electrode region on the epitaxial layer by adopting a reactive magnetron sputtering methodin a nitrogen and argon atmosphere, then adopting a delamination method to form a Schottky contact and further form the Schottky electrode, and replacing nickel metal with the nickel nitride thin film layer to serve as a Schottky contact. The gallium nitride Schottky barrier diode and the manufacturing method thereof solve the technical problem that the diode stability is not good enough and thereverse leakage current is high in the prior art.

Owner:江西誉鸿锦芯片科技有限公司

Preparation method of epitaxial lanthanum strontium cobalt oxide film based on radio-frequency reactive sputtering

InactiveCN104404464AChoose simpleIncrease usageVacuum evaporation coatingSputtering coatingSr elementOxygen vacancy

The invention relates to a preparation method of an epitaxial lanthanum strontium cobalt oxide film based on radio-frequency reactive sputtering. A radio-frequency reactive magnetron sputtering technology is adopted, and factors such as sputtering power, sputtering air pressure, the flow ratio of argon to oxygen and the temperature of a substrate are taken into comprehensive consideration in the sputtering process. According to the method, the importance of post-annealing is specially emphasized, sufficient oxygen is needed in the preparation process of La(1-x)SrxCoO3 film to avoid influence on the related physical characteristics of the film caused by forming of an oxygen vacancy, the defects such as the oxygen vacancy can be overcome by the post-annealing, and the surface of the film can be smoother. The preparation method of the epitaxial La(1-x)SrxCoO3 film has the advantages of compatibility with conventional industrial production, convenience in doping, simplicity in regulation of the concentration of a doped Sr element, simplicity in selection of a target material, higher utilization rate of the target material and the like, and is widely applicable to the preparation of related spintronics devices.

Owner:TIANJIN UNIV

A method for improving the magnetron sputtering deposition rate of SiO2 thin film

InactiveCN103290381ADoes not affect the growth processIncrease productivityVacuum evaporation coatingSputtering coatingOperating pointIntermediate frequency

The invention belongs to the technical field of magnetron sputtering coating, and particularly relates to a method for improving the magnetron sputtering deposition rate of SiO2 thin film. A plasma emission and detection system is employed for real-time monitoring an intermediate frequency reactive magnetron sputtering plasma emission spectrum, and stabilizing the reactive magnetron sputtering at any operating point in a transition state according to the set value of the detection system; wherein gas atmosphere comprises argon as a process gas and oxygen as a reactive gas; and the process gas is fed below twin targets, and the reactive gas is fed above the twin targets. The in situ monitoring of the plasma emission spectrum in the present invention does not affect the thin film growth process, and is conducive to the development of the process of thin film preparation in an intelligentization direction and the combination of spectral analysis with a computer, effectively improving production efficiency and reducing production costs.

Owner:NANCHANG O FILM TECH CO LTD

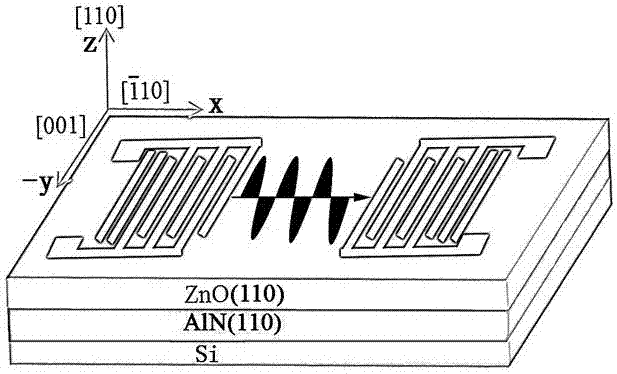

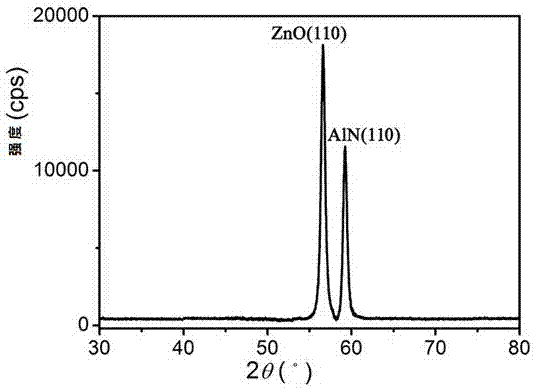

ZnO/AlN/Si multi-layer structure film and preparation method and application thereof

ActiveCN107385394ASimple processLow costVacuum evaporation coatingSputtering coatingSingle crystalFilm material

The invention discloses a ZnO / AlN / Si multi-layer structure film and a preparation method and application thereof. The ZnO / AlN / Si multi-layer structure film comprises an Si substrate, an AlN film and a ZnO film, wherein the AlN film and the ZnO film are laminated on the Si substrate in sequence and have the c-axis preferred orientation. The preparation method of the ZnO / AlN / Si multi-layer structure film comprises the steps that good-compatibility single-crystal Si (100) in a traditional semiconductor process serves as a substrate material, a reactive magnetron sputtering technique is adopted, an Al target is subjected to reactive sputtering onto the Si substrate to produce an AlN (110) film, a Zn target is subjected to reactive sputtering onto the AlN (110) film to produce a ZnO (110) film through the low lattice fitness degree between the crystal face of the AlN (110) film and the crystal face of the ZnO (110) film, and finally the ZnO (110) / AlN (110) / Si multi-layer structure film is formed. According to the preparation method, equipment is simple, the process is easy and convenient to implement, cost is low, and a novel piezoelectric film material is provided for a Love-SAW sensor.

Owner:HUI YU & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com