Patents

Literature

185 results about "Transition metal nitrides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Most transition metal nitrides have much lower nitrogen contents, and they often form with non- or sub-stoichiometric compositions. These materials are typically metallic with often superconducting properties, and they provide highly refractory, high hardness materials with many technological applications.

Metal nitride carbide deposition by ALD

InactiveUS7410666B2Material nanotechnologySemiconductor/solid-state device detailsHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

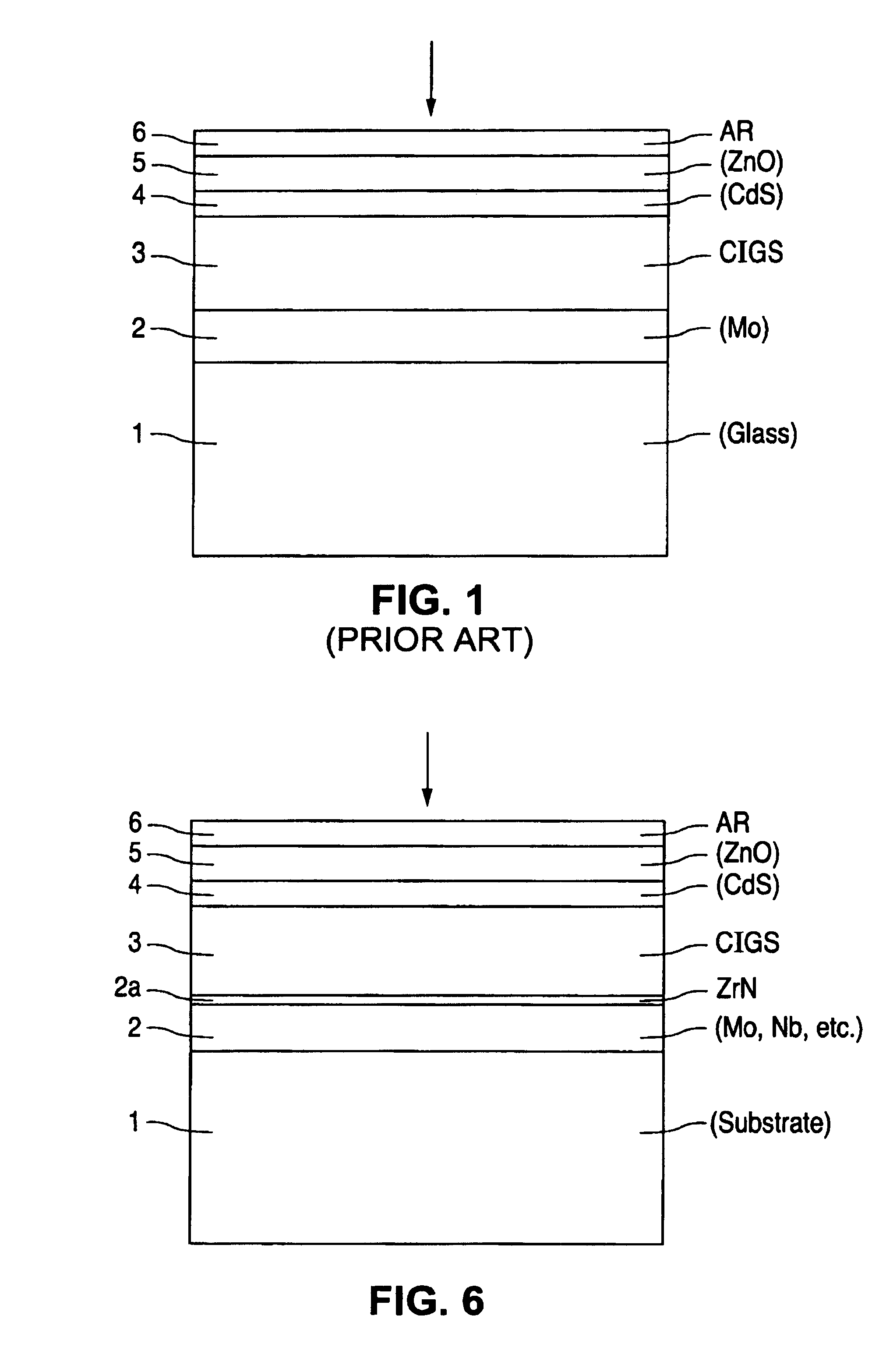

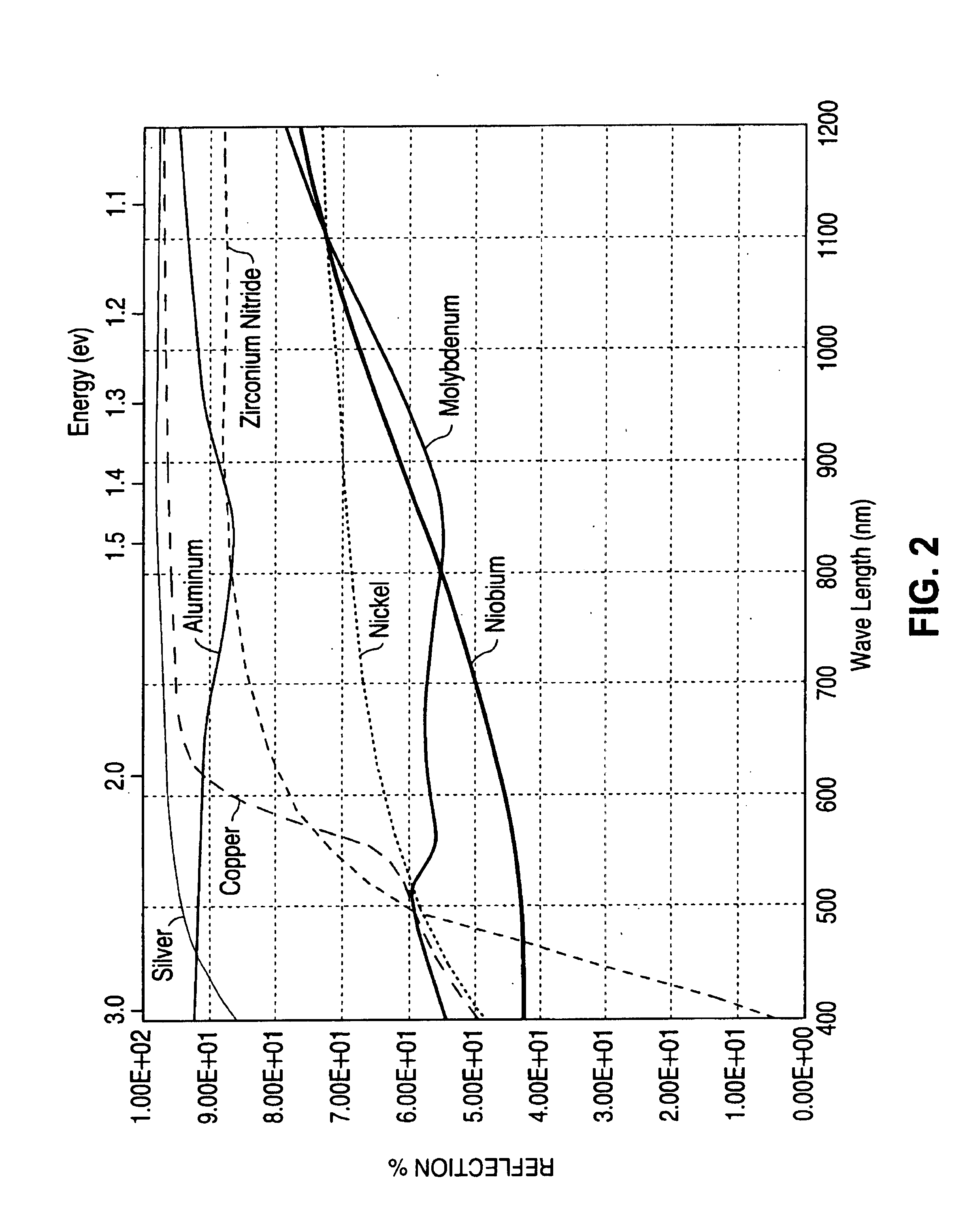

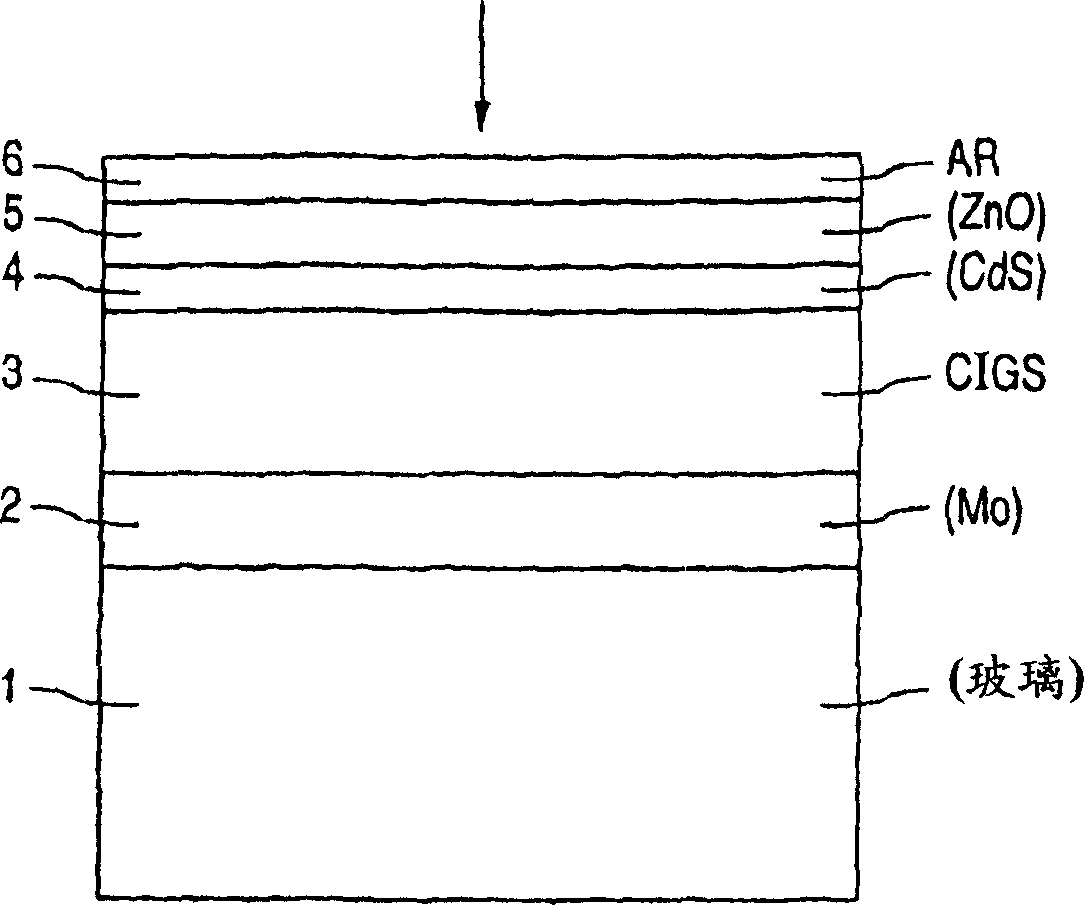

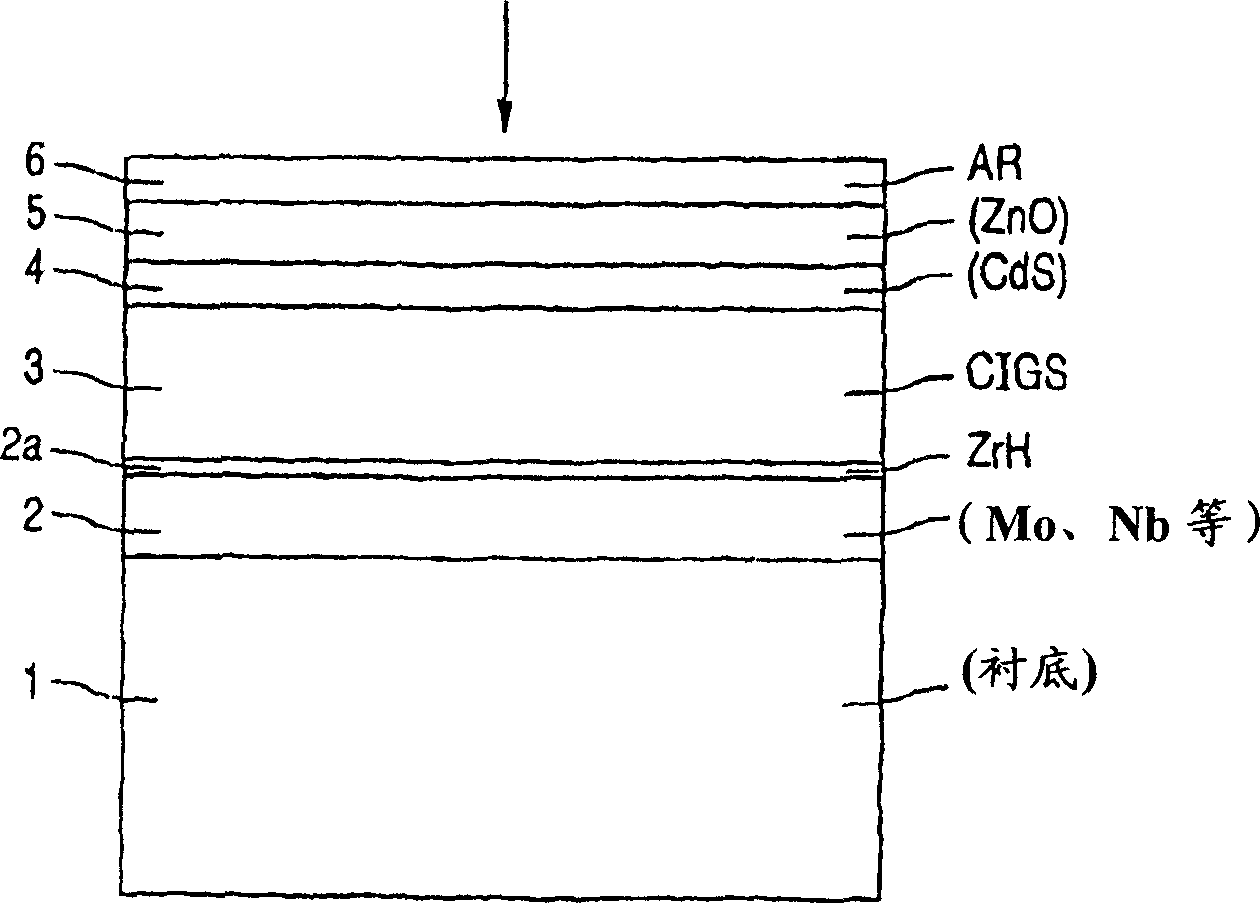

Thin-film solar cells

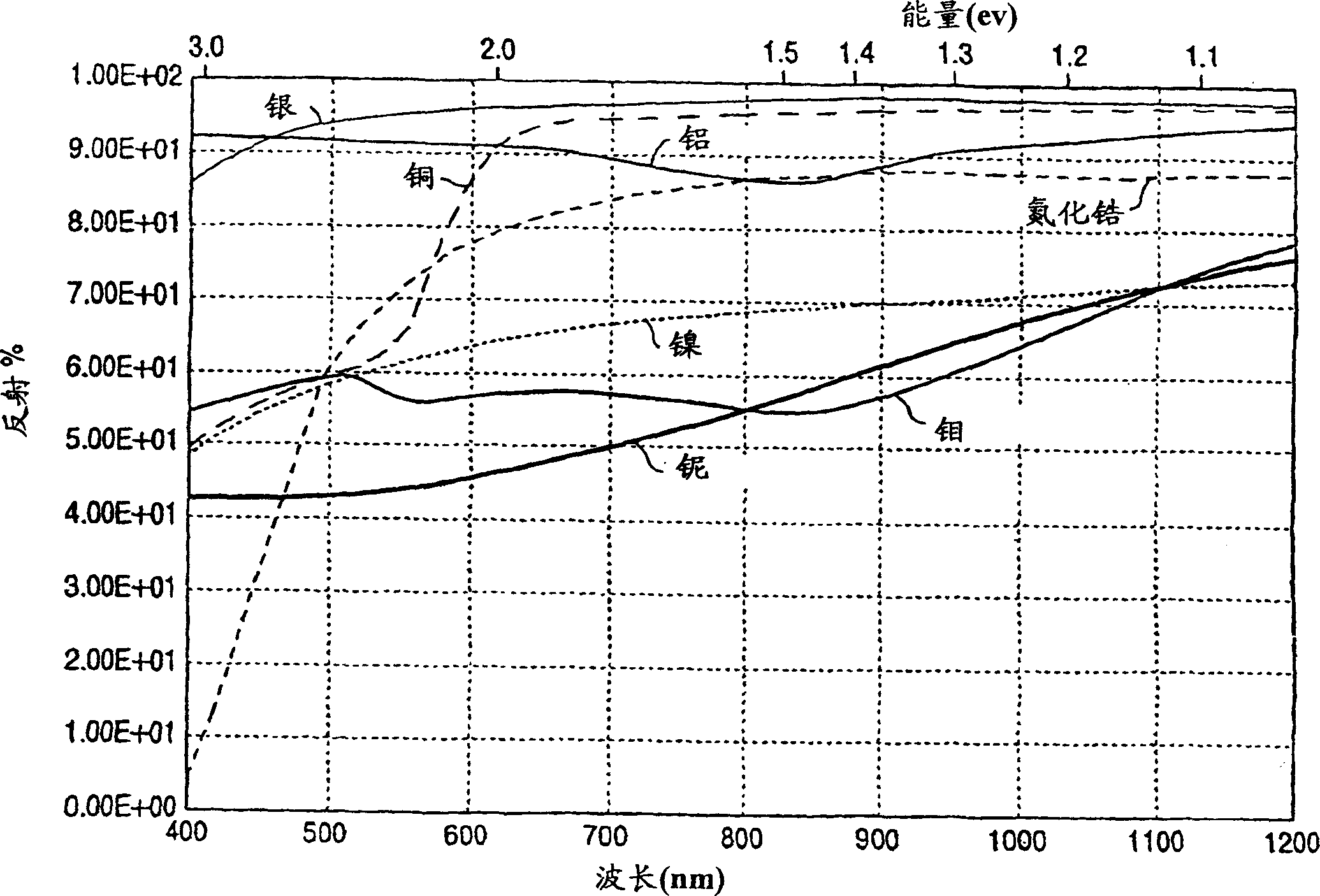

InactiveUS6974976B2Increase reflectionInhibition formationFinal product manufactureVacuum evaporation coatingIndiumElectrical battery

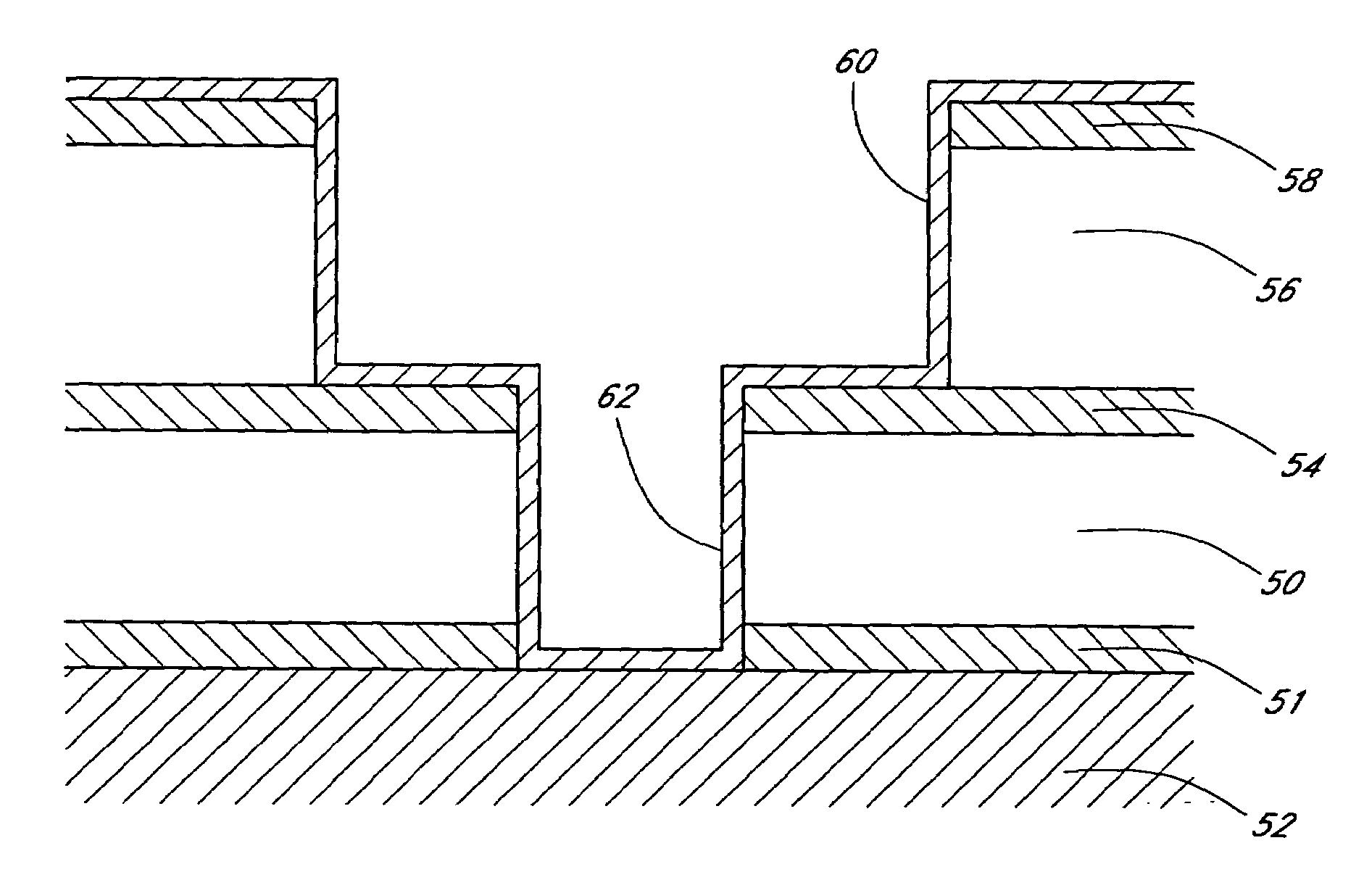

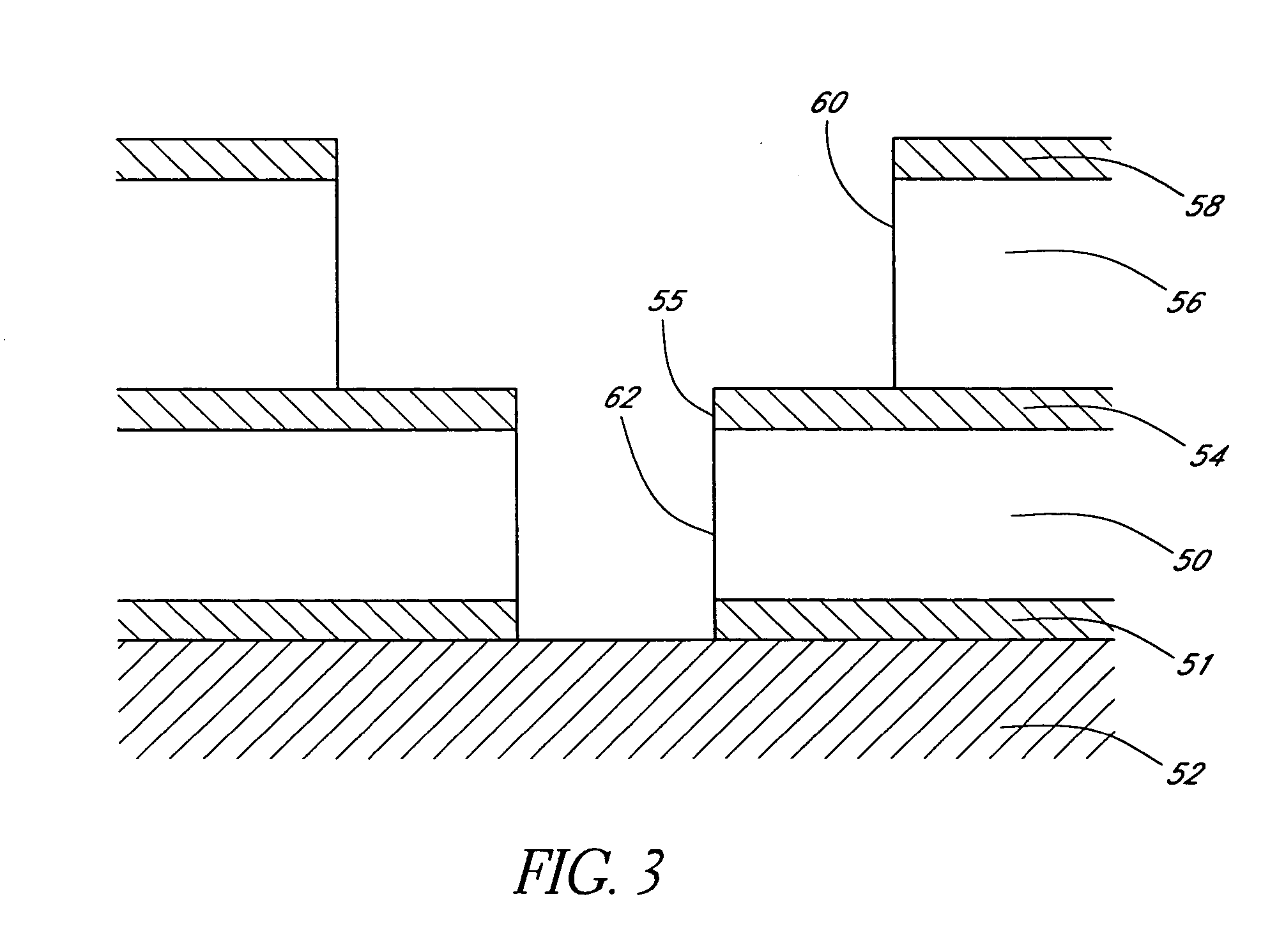

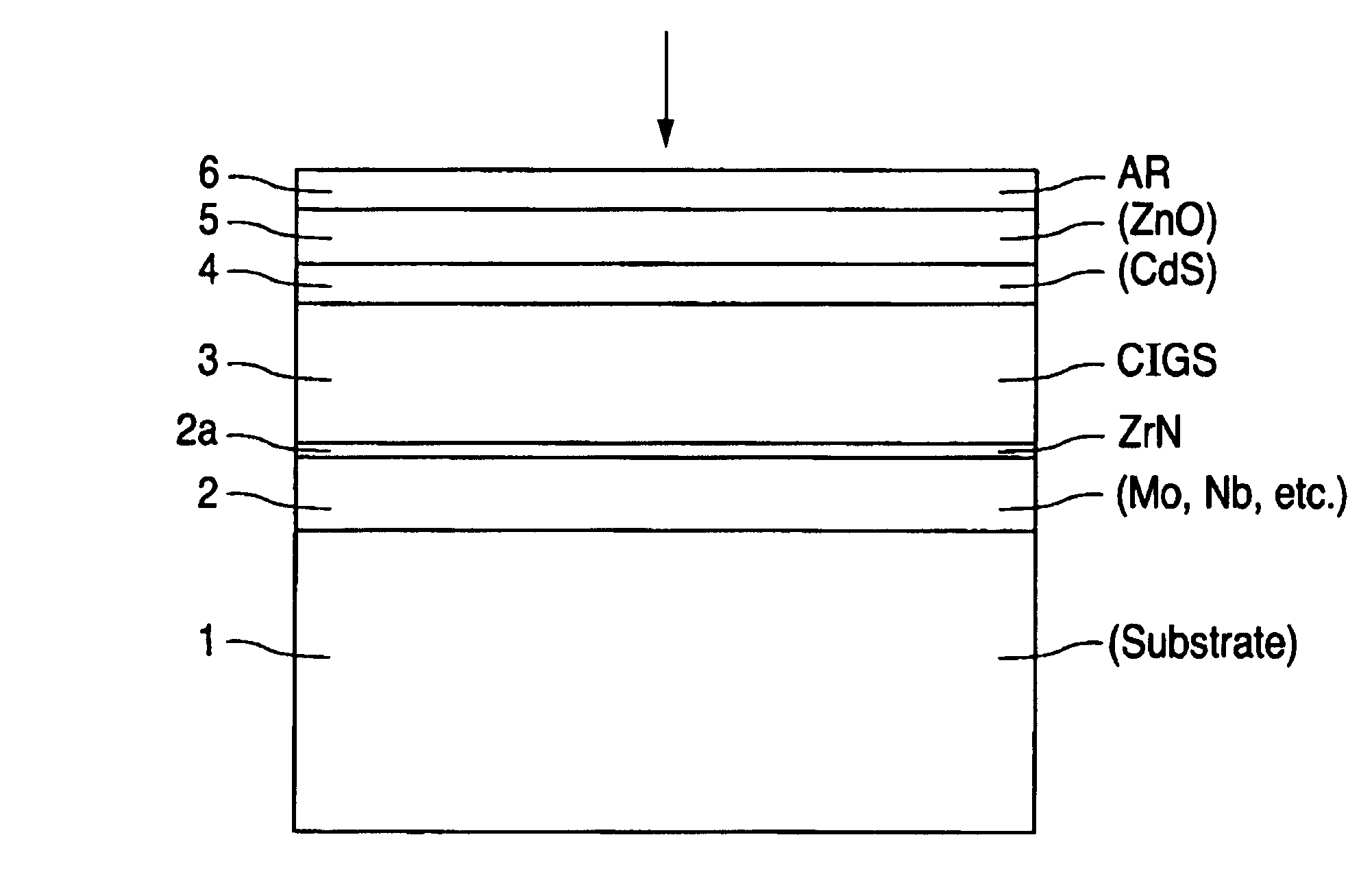

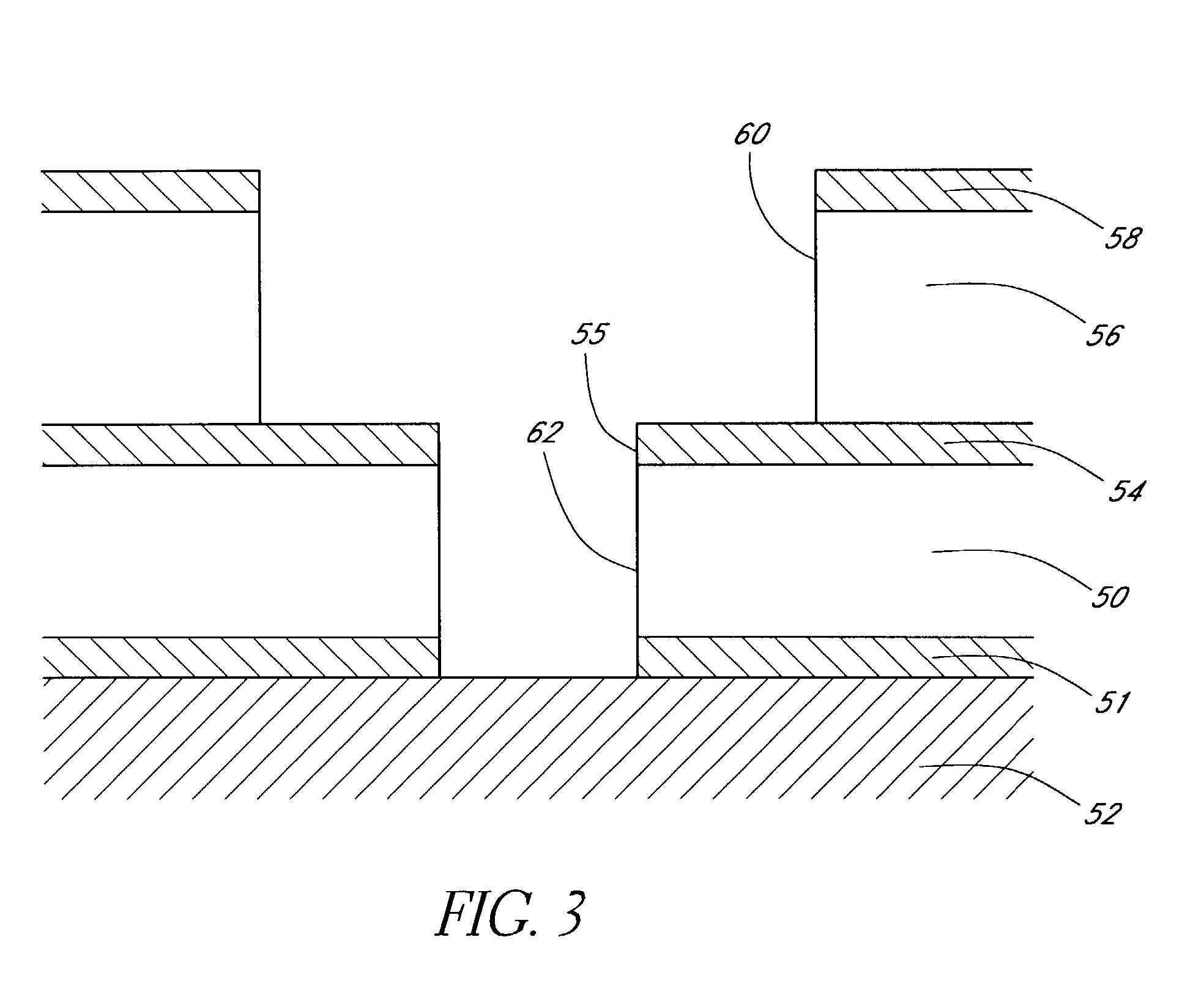

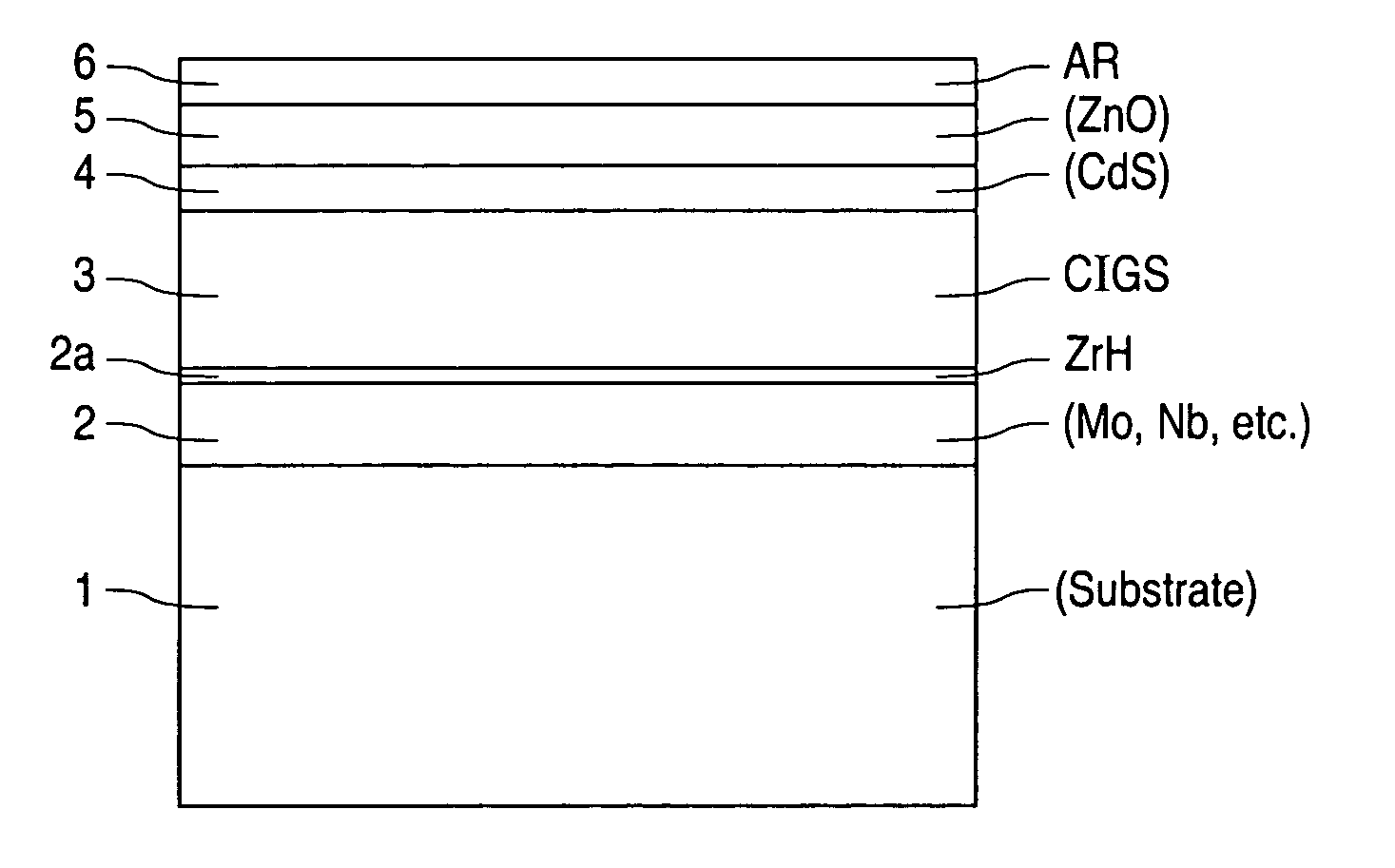

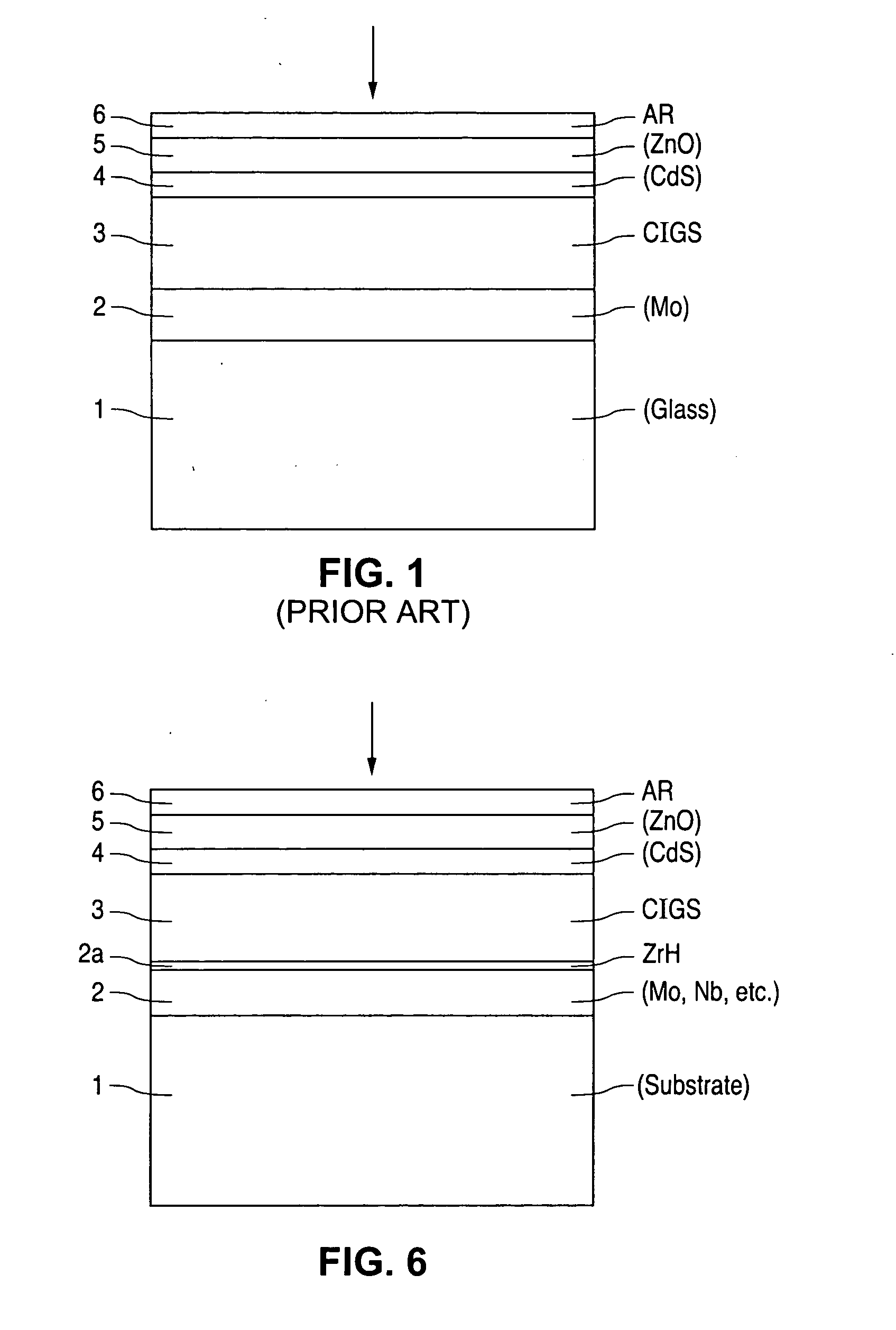

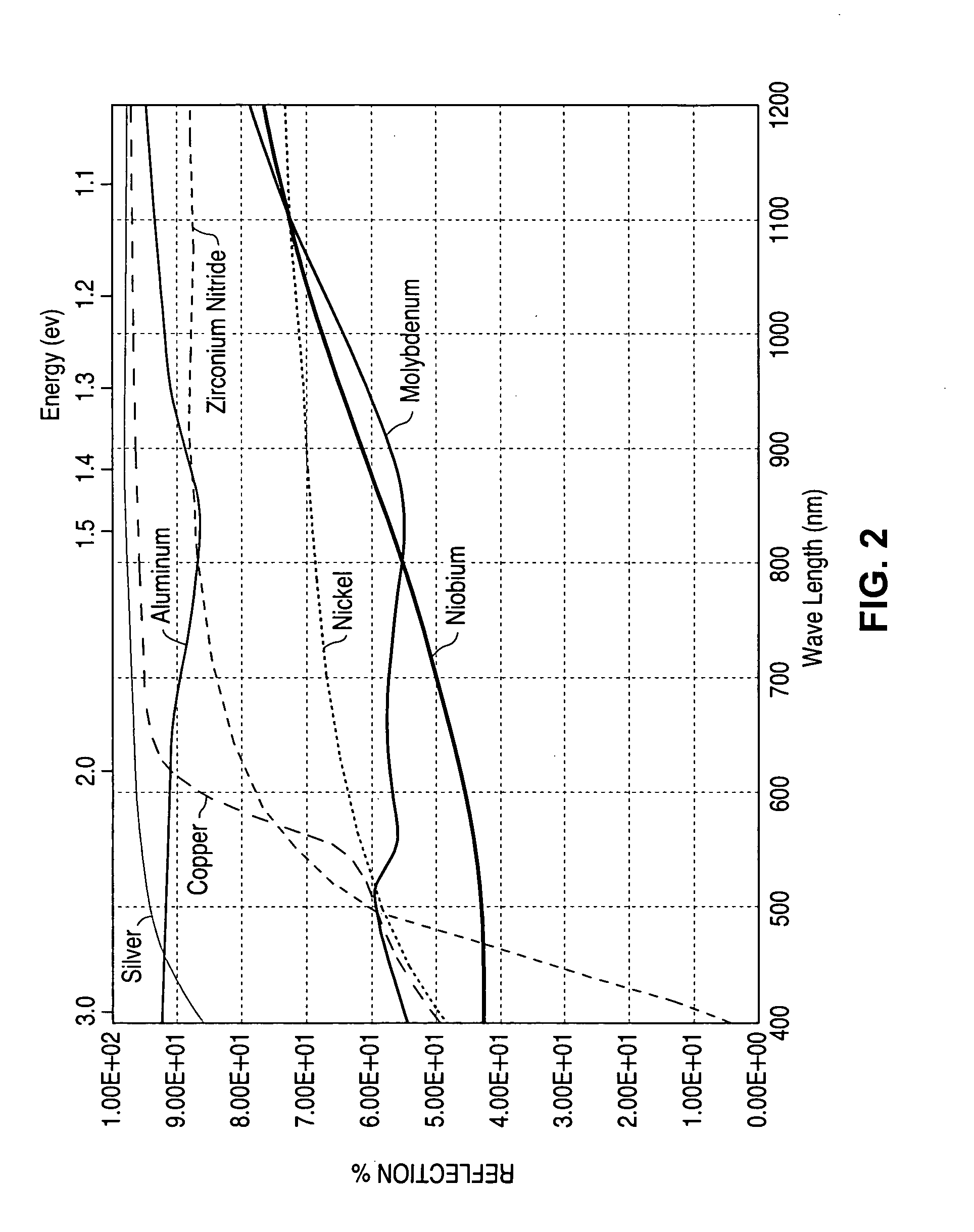

A method of manufacturing improved thin-film solar cells entirely by sputtering includes a high efficiency back contact / reflecting multi-layer containing at least one barrier layer consisting of a transition metal nitride. A copper indium gallium diselenide (Cu(InXGa1−X)Se2) absorber layer (X ranging from 1 to approximately 0.7) is co-sputtered from specially prepared electrically conductive targets using dual cylindrical rotary magnetron technology. The band gap of the absorber layer can be graded by varying the gallium content, and by replacing the gallium partially or totally with aluminum. Alternately the absorber layer is reactively sputtered from metal alloy targets in the presence of hydrogen selenide gas. RF sputtering is used to deposit a non-cadmium containing window layer of ZnS. The top transparent electrode is reactively sputtered aluminum doped ZnO. A unique modular vacuum roll-to-roll sputtering machine is described. The machine is adapted to incorporate dual cylindrical rotary magnetron technology to manufacture the improved solar cell material in a single pass.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

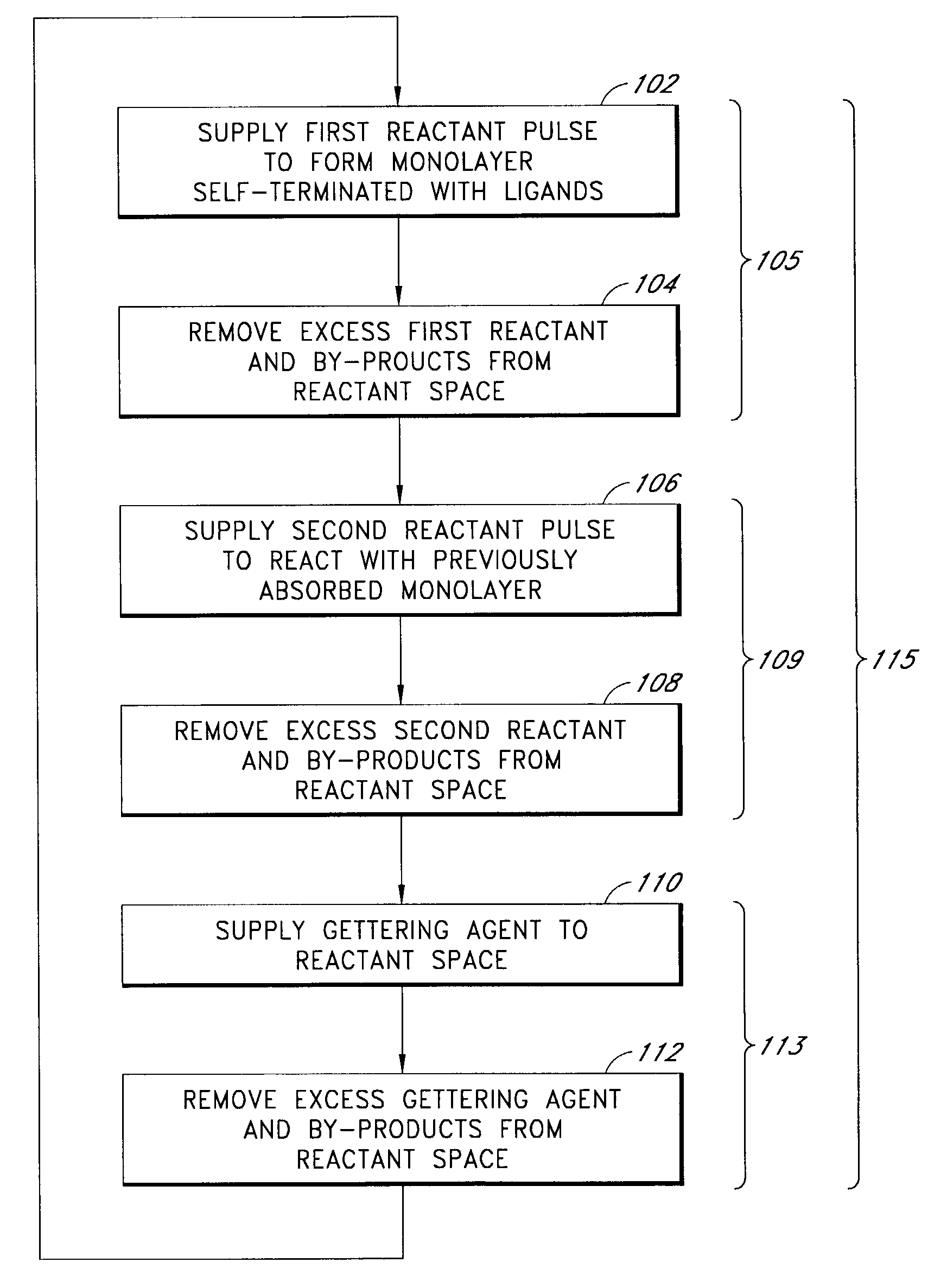

Metal nitride deposition by ALD with reduction pulse

The present methods provide tools for growing conformal metal thin films, including metal nitride, metal carbide and metal nitride carbide thin films. In particular, methods are provided for growing such films from aggressive chemicals. The amount of corrosive chemical compounds, such as hydrogen halides, is reduced during the deposition of transition metal, transition metal carbide, transition metal nitride and transition metal nitride carbide thin films on various surfaces, such as metals and oxides. Getter compounds protect surfaces sensitive to hydrogen halides and ammonium halides, such as aluminum, copper, silicon oxide and the layers being deposited, against corrosion. Nanolaminate structures incorporating metallic thin films, and methods for forming the same, are also disclosed.

Owner:ASM INTERNATIONAL

Manufacturing apparatus and method for large-scale production of thin-film solar cells

ActiveUS20050109392A1Cheap productionLow costPV power plantsFinal product manufactureIndiumElectrical battery

A method of manufacturing improved thin-film solar cells entirely by sputtering includes a high efficiency back contact / reflecting multi-layer containing at least one barrier layer consisting of a transition metal nitride. A copper indium gallium diselenide (Cu(InXGa1-x)Se2) absorber layer (X ranging from 1 to approximately 0.7) is co-sputtered from specially prepared electrically conductive targets using dual cylindrical rotary magnetron technology. The band gap of the absorber layer can be graded by varying the gallium content, and by replacing the gallium partially or totally with aluminum. Alternately the absorber layer is reactively sputtered from metal alloy targets in the presence of hydrogen selenide gas. RF sputtering is used to deposit a non-cadmium containing window layer of ZnS. The top transparent electrode is reactively sputtered aluminum doped ZnO. A unique modular vacuum roll-to-roll sputtering machine is described. The machine is adapted to incorporate dual cylindrical rotary magnetron technology to manufacture the improved solar cell material in a single pass.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

Methods for forming a transition metal nitride film on a substrate by atomic layer deposition and related semiconductor device structures

ActiveUS10229833B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricGas phase

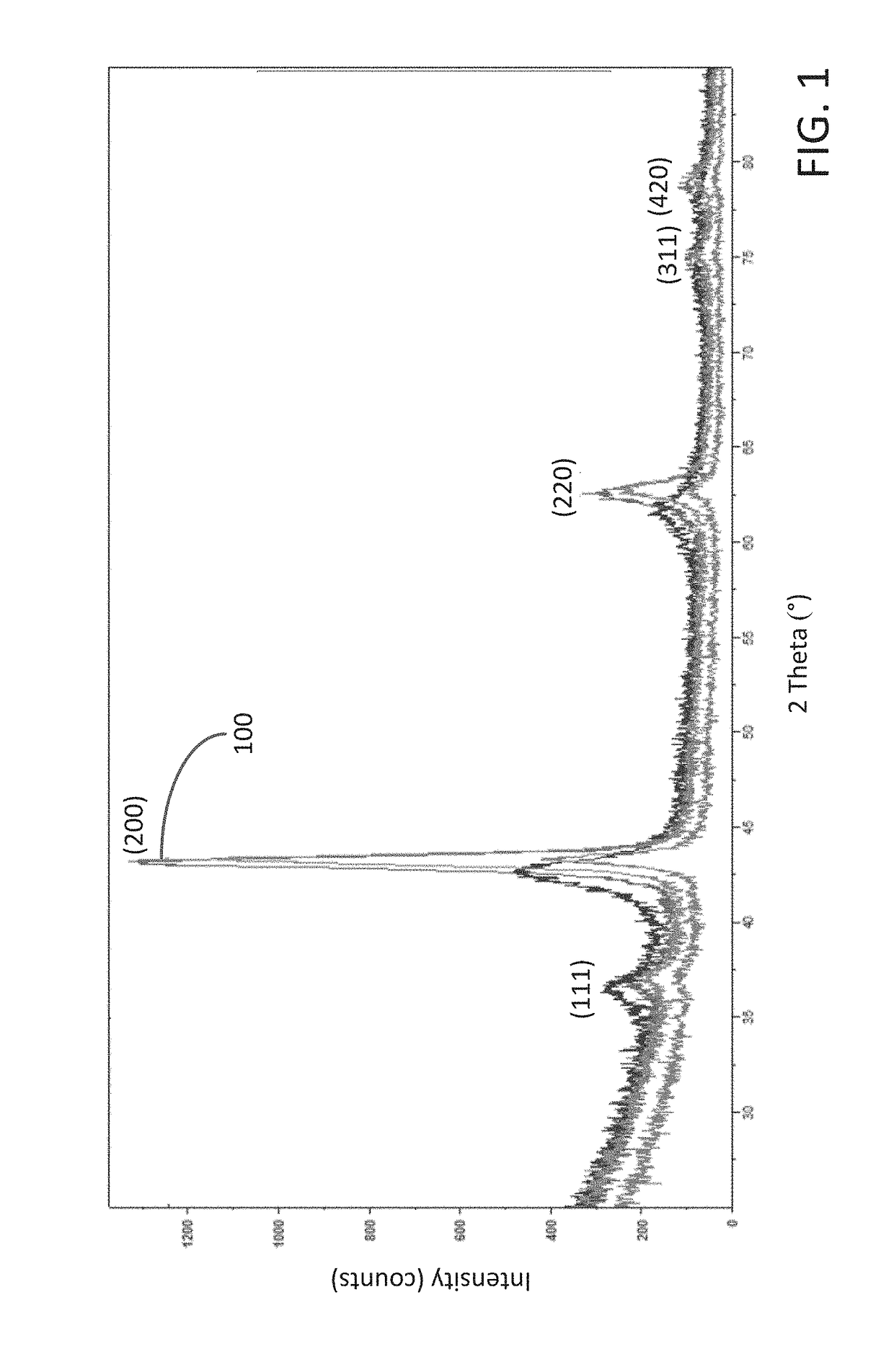

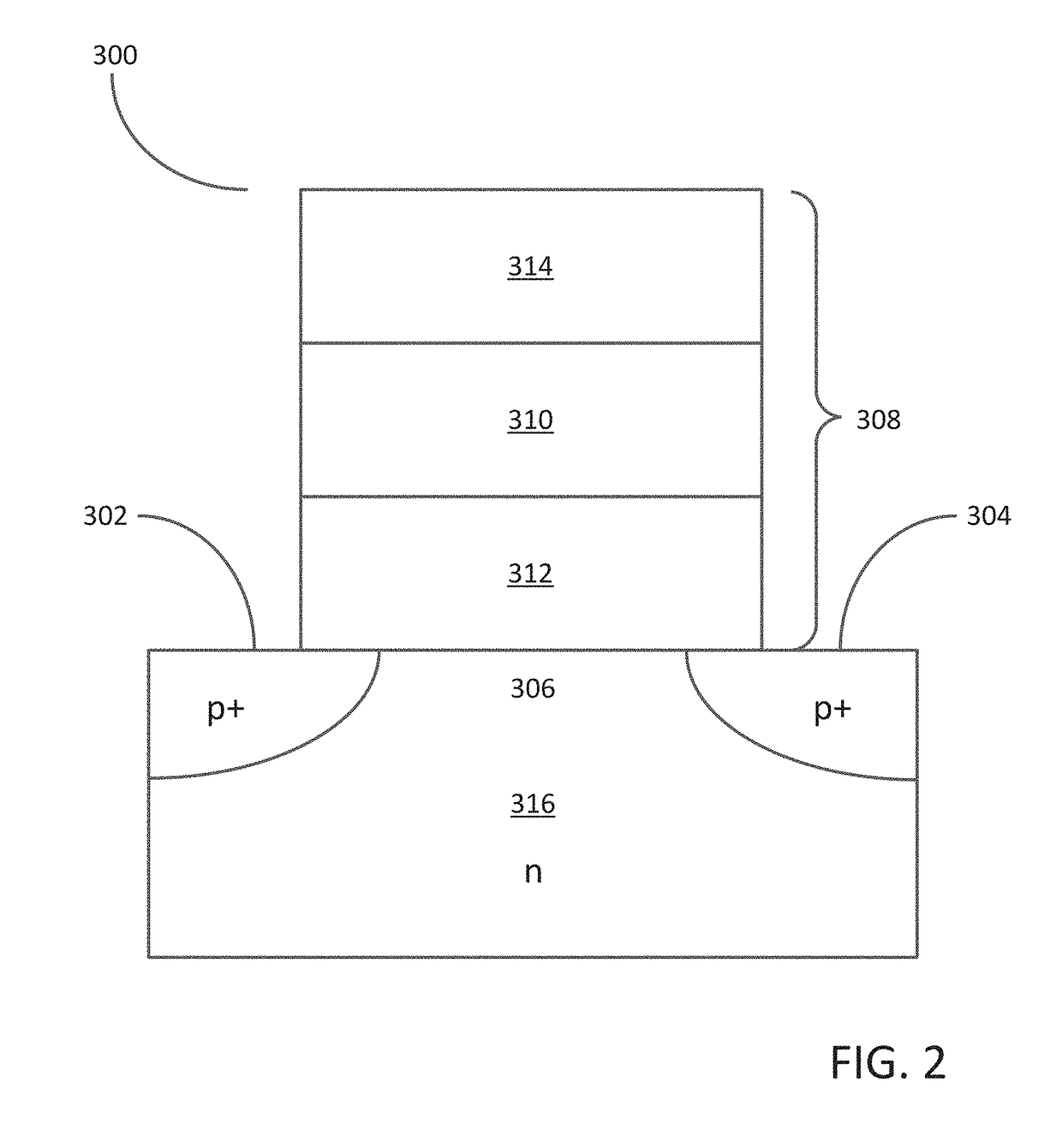

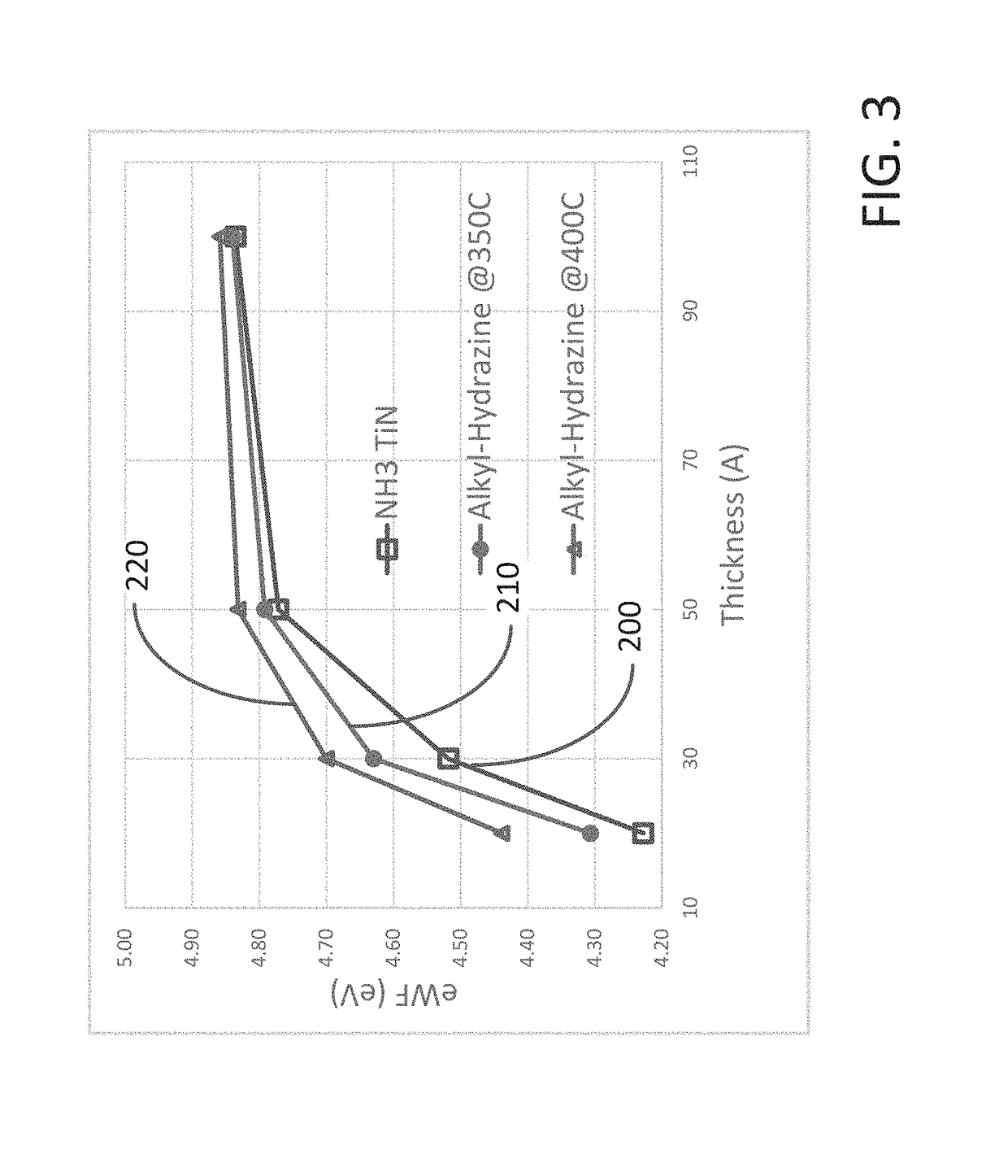

Methods for forming a transition metal nitride film on a substrate by atomic layer deposition and related semiconductor device structures are provided. In some embodiments, methods may include contacting a substrate with a first vapor phase reactant comprising a transition metal precursor and contacting the substrate with a second vapor phase reactant comprising an alkyl-hydrazine precursor. In some embodiments, related semiconductor device structures may include a PMOS transistor gate structure, the PMOS transistor gate structure including a transition metal nitride film and a gate dielectric between the transition nitride film and a semiconductor body. The transition metal nitride film includes a predominant (200) crystallographic orientation.

Owner:ASM IP HLDG BV

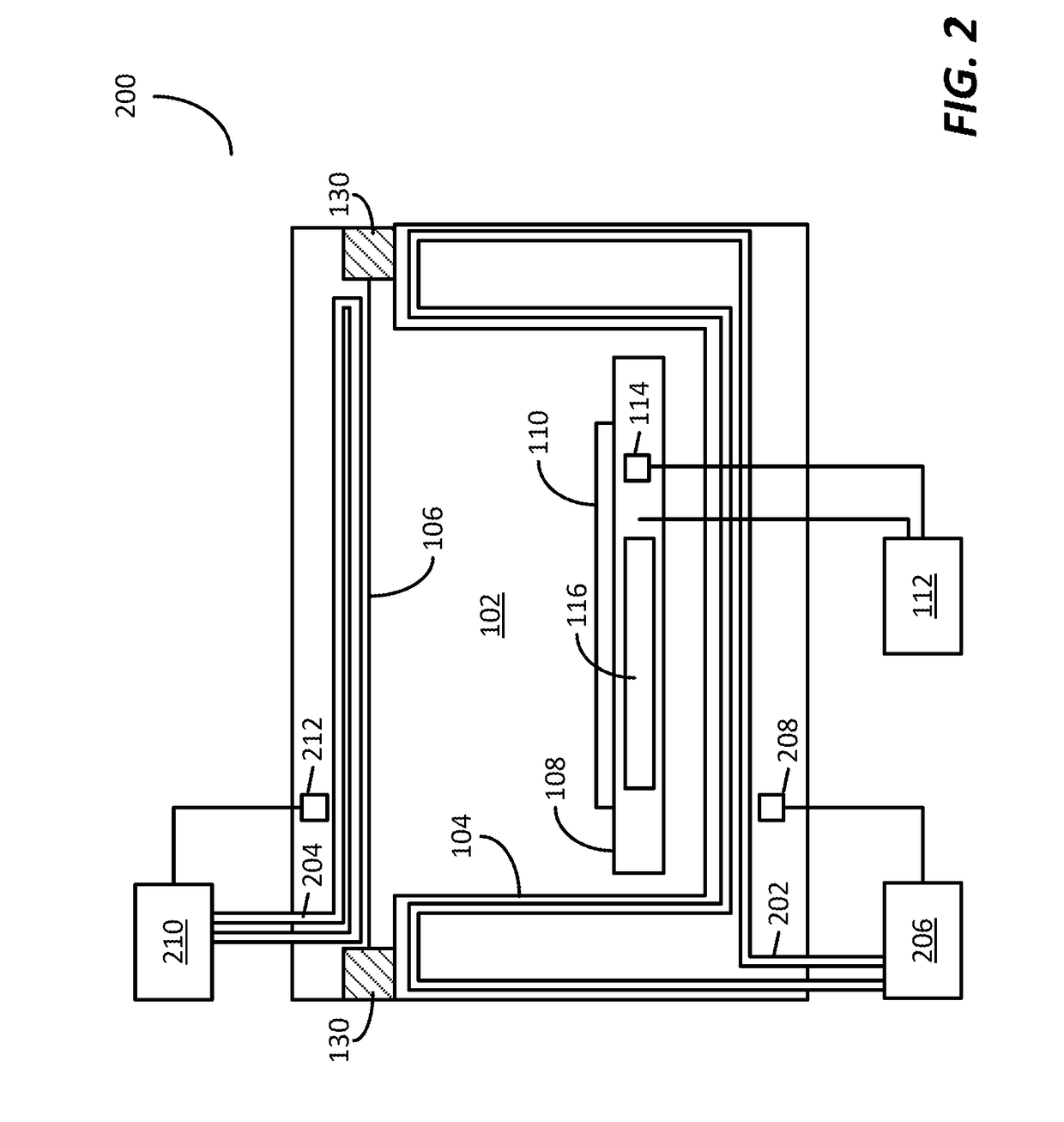

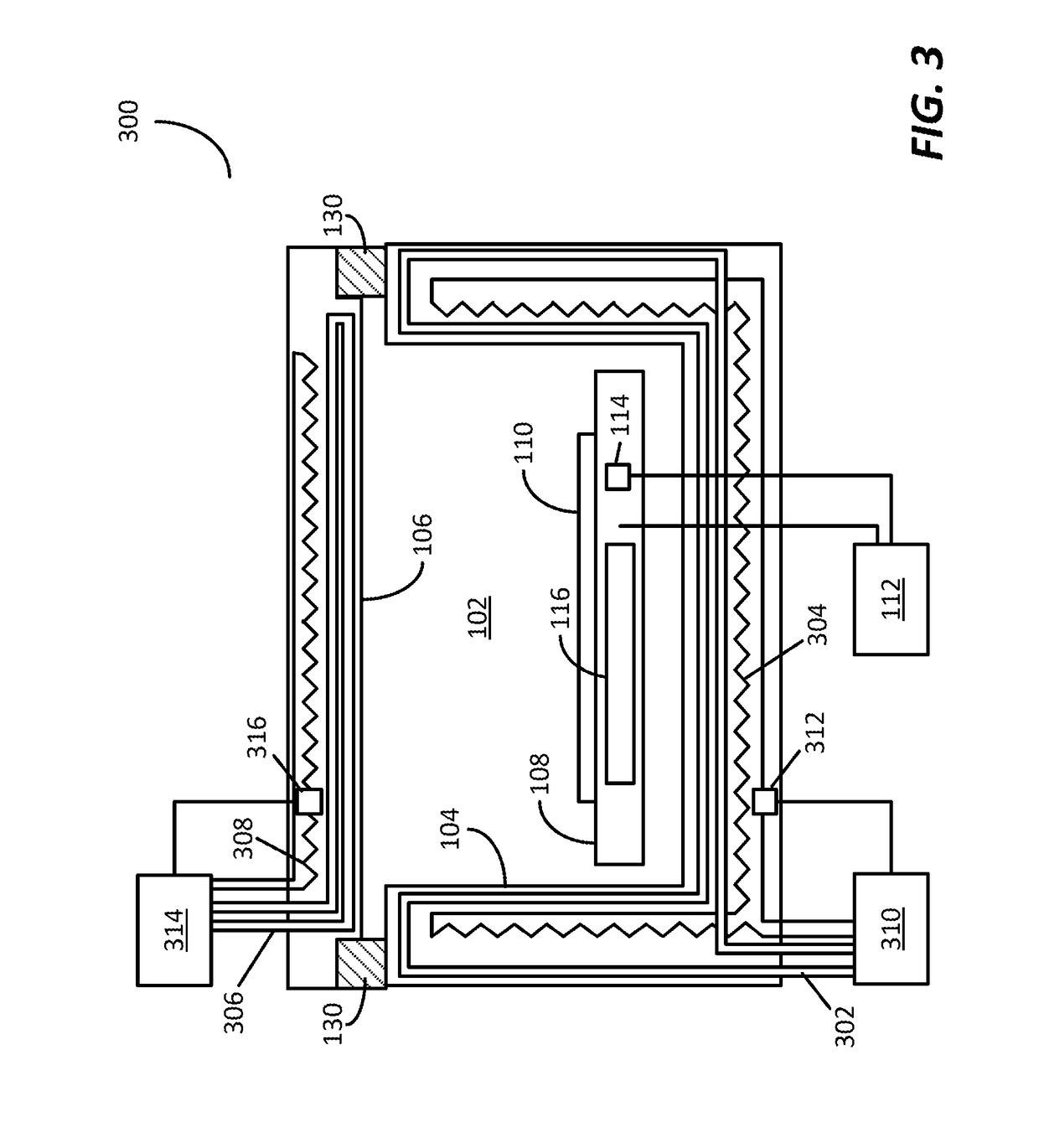

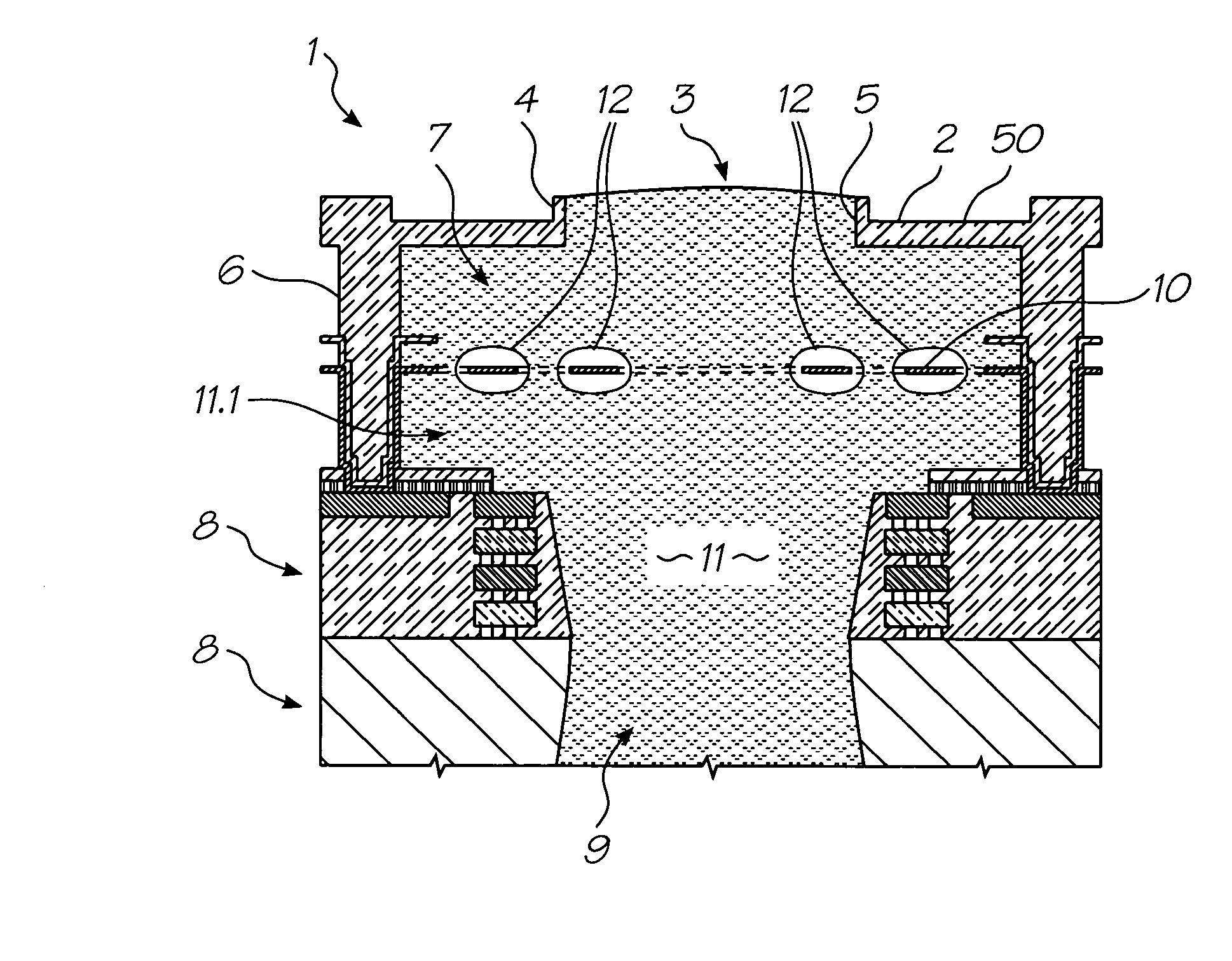

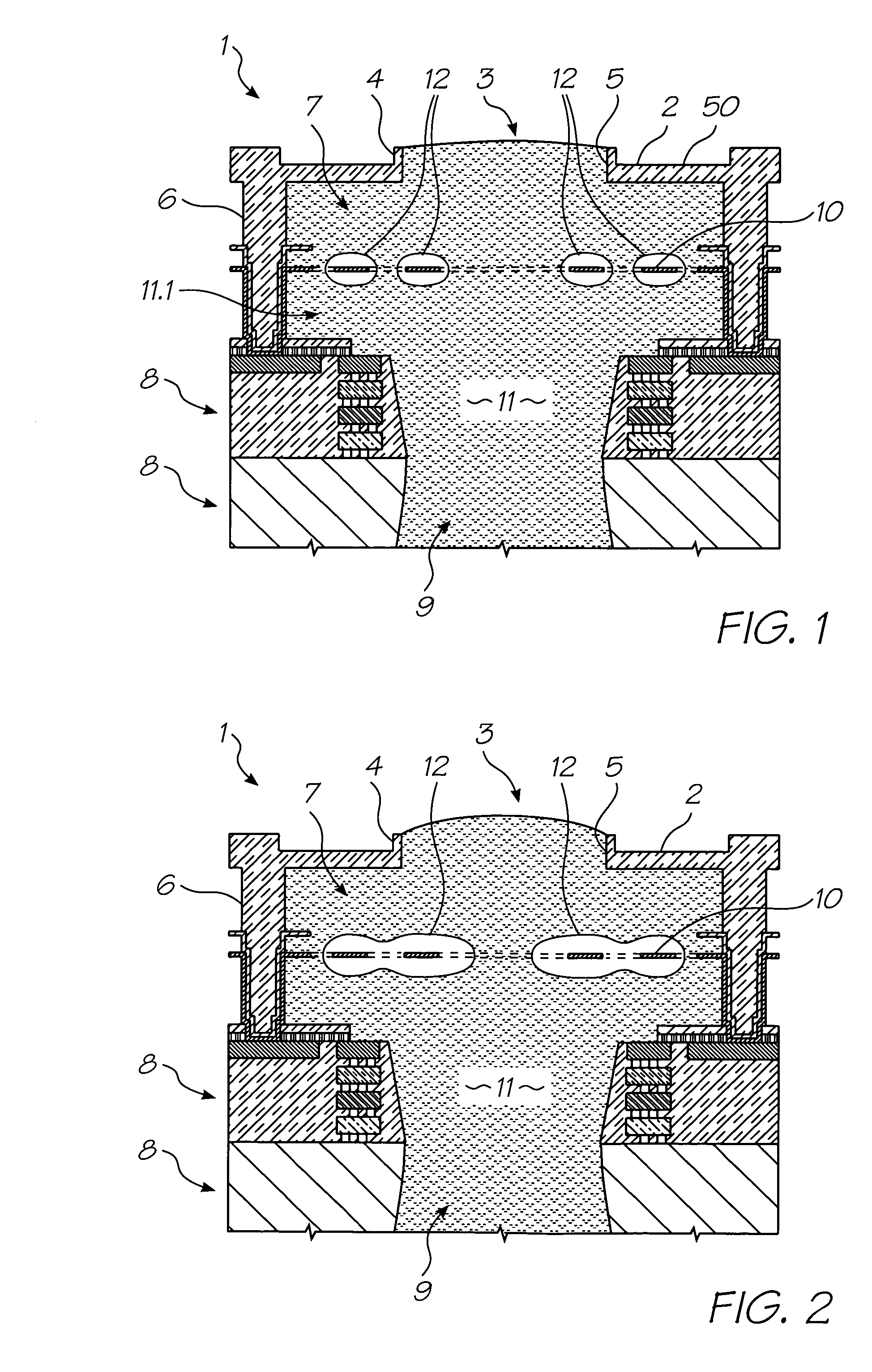

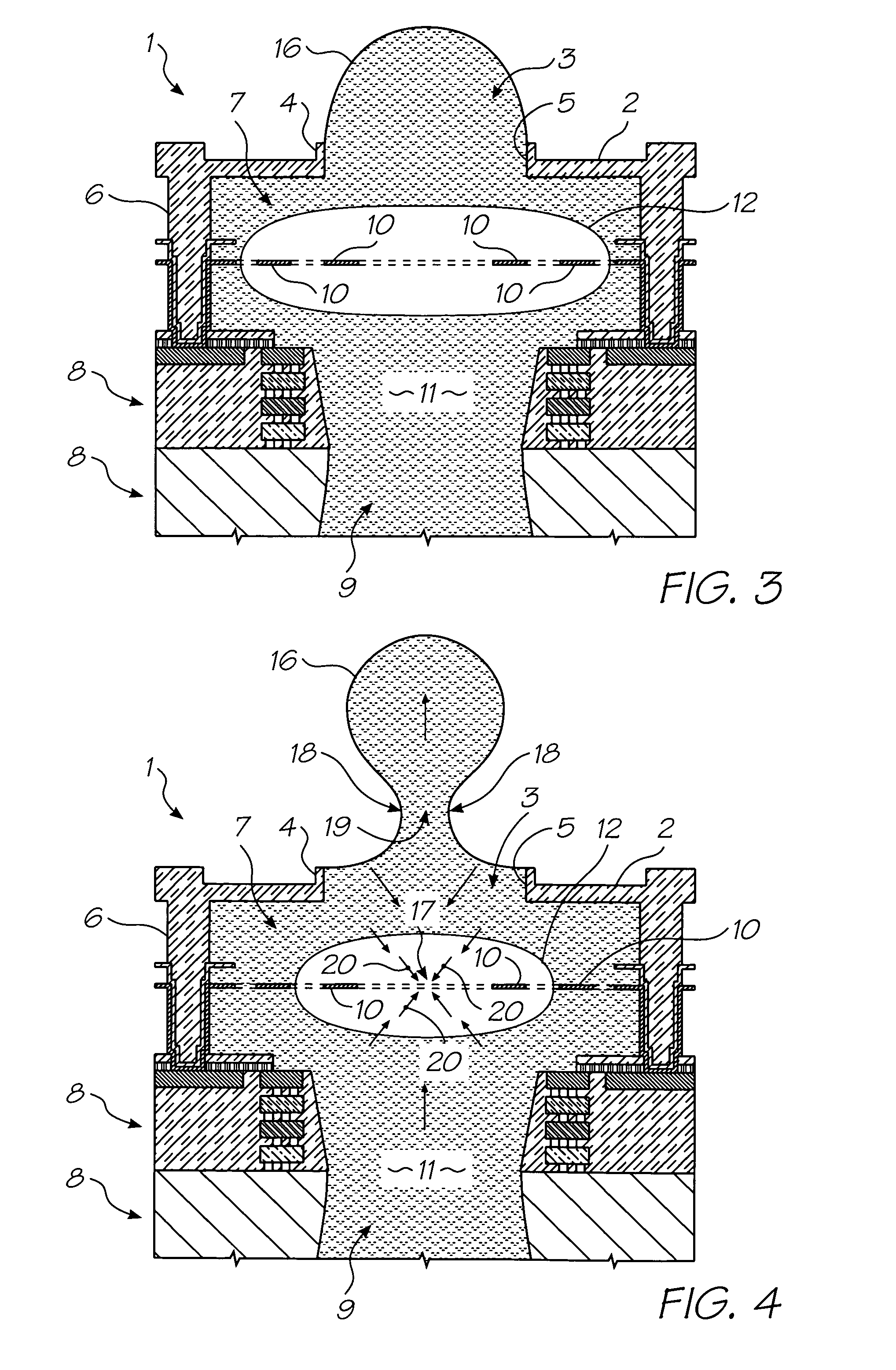

Methods for depositing a transition metal nitride film on a substrate by atomic layer deposition and related deposition apparatus

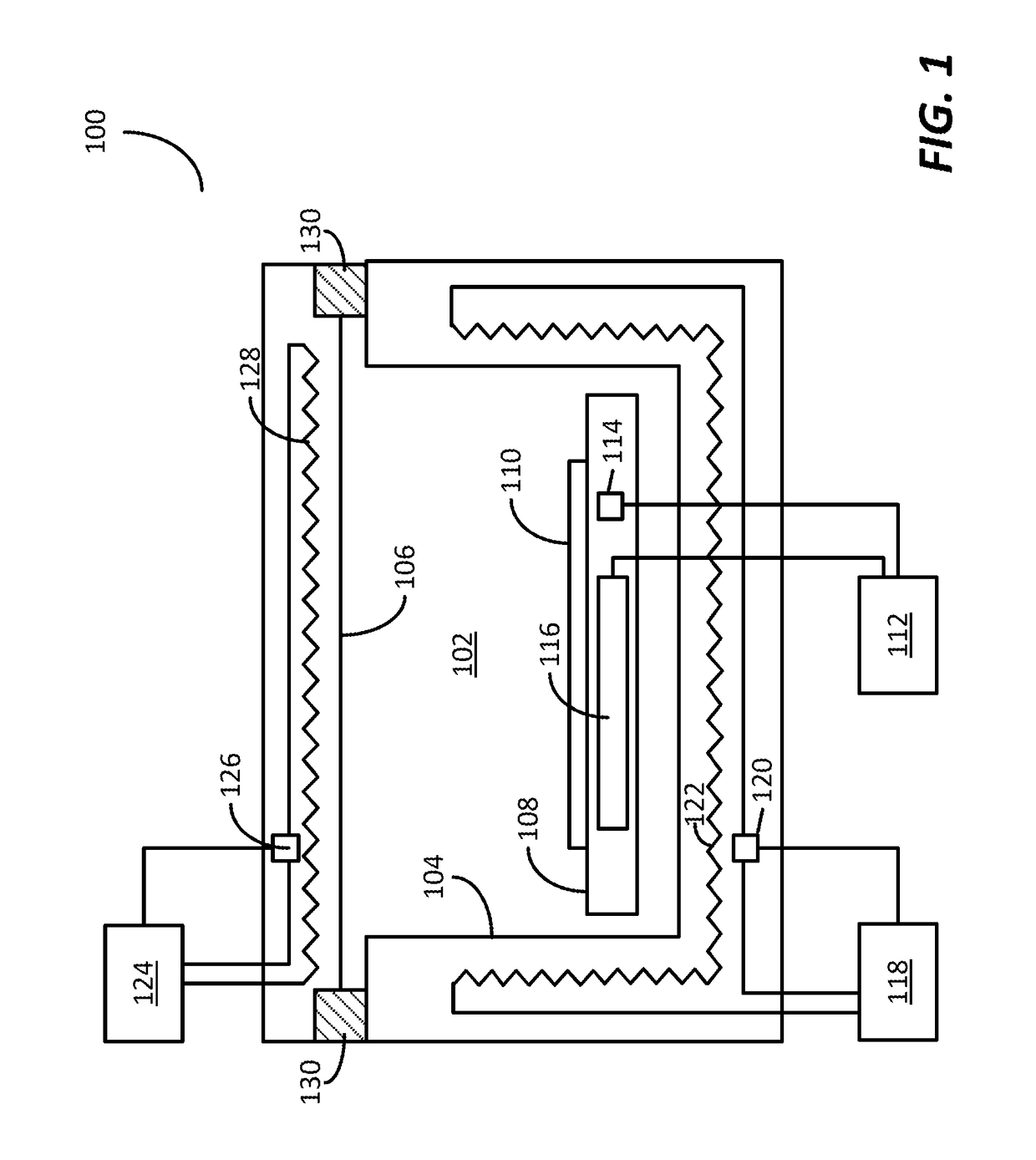

An apparatus and method for depositing a transition metal nitride film on a substrate by atomic layer deposition in a reaction space defined by an at least one chamber wall and showerhead is disclosed. The apparatus may include, a substrate support disposed within the reaction space, the substrate support configured for supporting at least one substrate and a temperature control system for controlling a temperature of the at least one chamber wall at those portions of the at least one chamber wall that is exposed to a vapor phase reactant. The apparatus may also include a temperature control system for controlling a temperature of the showerhead, wherein the temperature control system for controlling a temperature of the showerhead is configured to control the temperature of the showerhead to a temperature of between approximately 80° C. and approximately 160° C. The method may include, providing at least one substrate on a substrate support within the reaction space and controlling a temperature of the at least one chamber wall at least at those portions of the at least one chamber wall that is exposed to a vapor phase reactant and controlling a temperature of a showerhead. The method may also include, alternatively and sequentially feeding at least two vapor phase reactants into the reaction space, wherein the temperature of the showerhead is controlled to a temperature between approximately 80° C. and approximately 160° C.

Owner:ASM IP HLDG BV

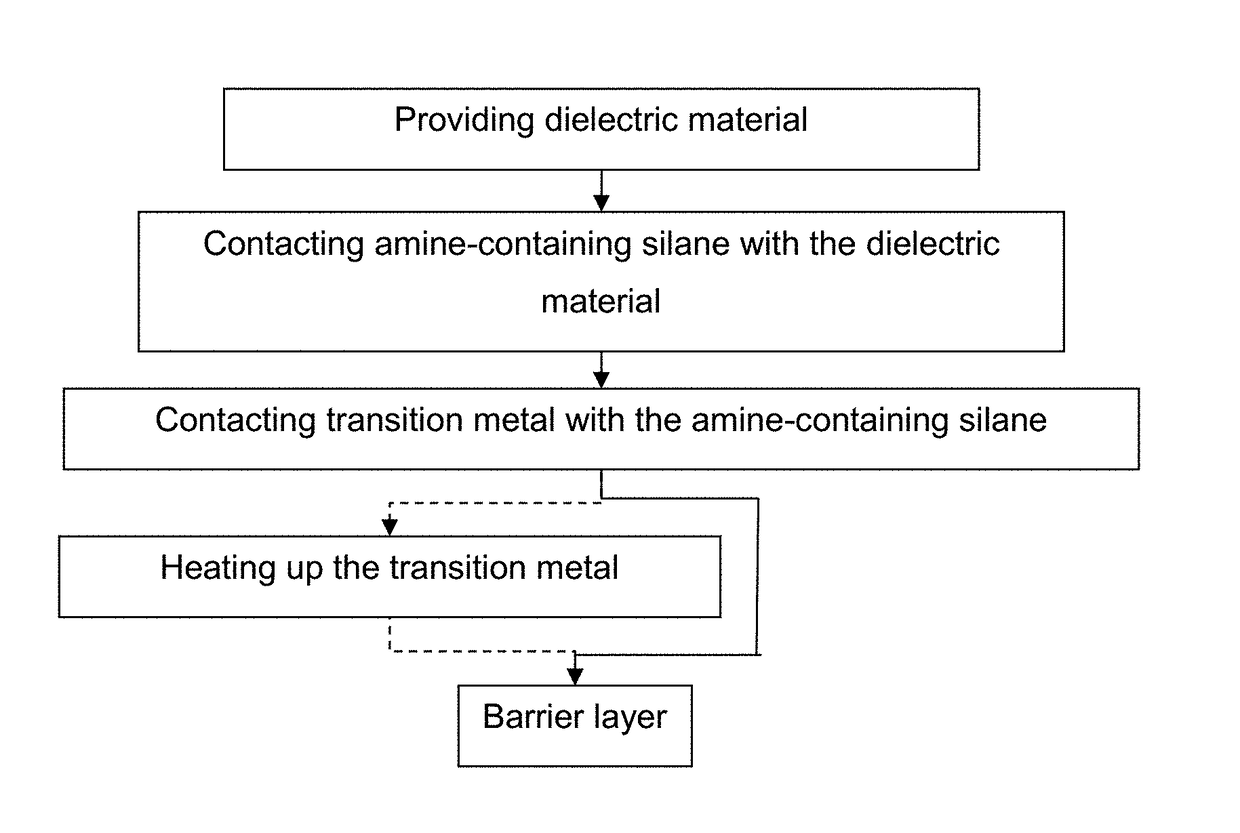

Formation of a transition metal nitride

ActiveUS20180047621A1Inhibited DiffusionSemiconductor/solid-state device detailsSolid-state devicesSilanesNitrogen

A use of an amine-containing silane for forming a transition metal nitride is provided. In this use, the amine of the amine-containing silane is the source of at least some, preferably most and most preferably all of the nitrogen present in the transition metal nitride.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

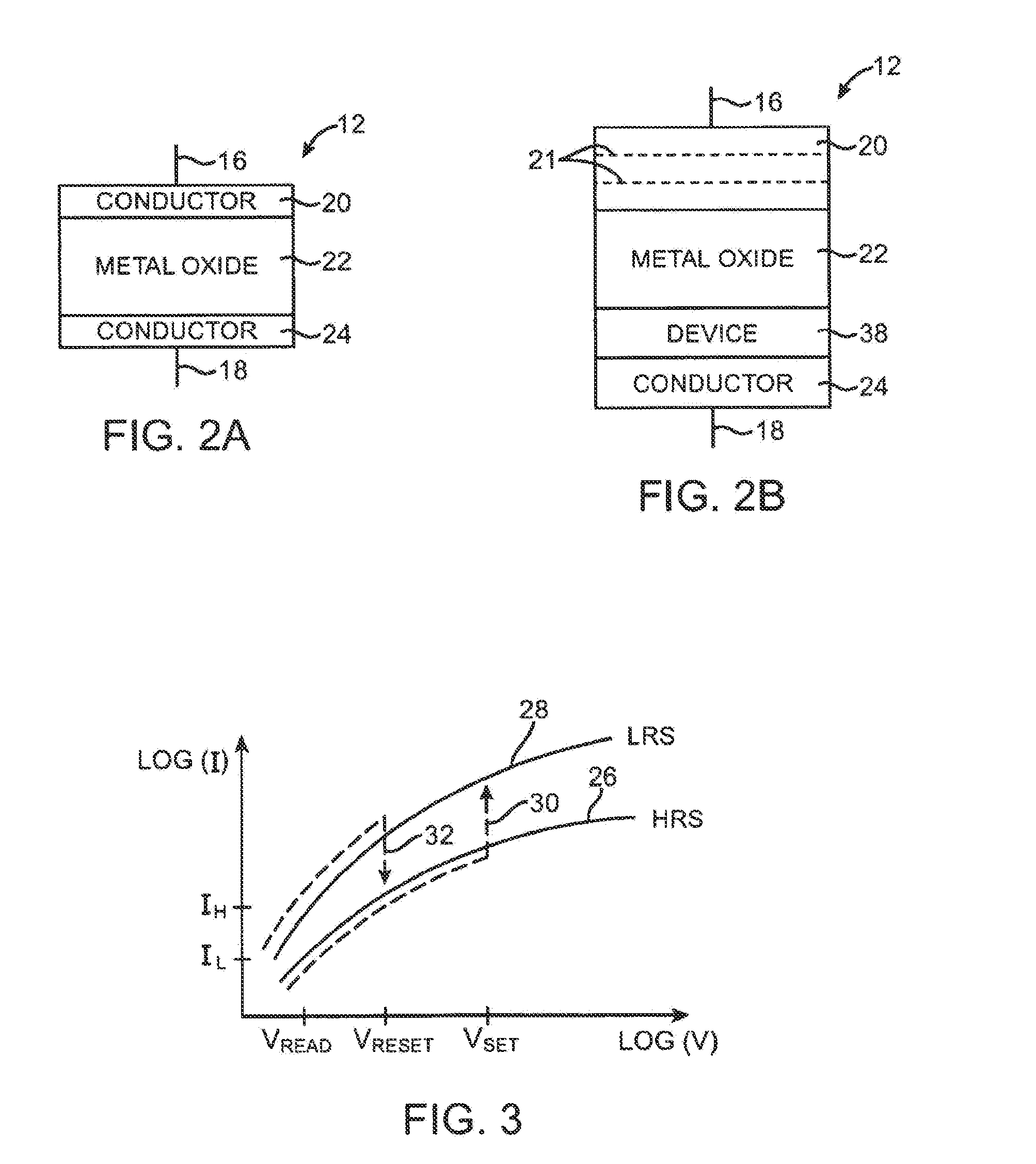

Multifunctional electrode

A nonvolatile memory element is disclosed comprising a first electrode, a near-stoichiometric metal oxide memory layer having bistable resistance, and a second electrode in contact with the near-stoichiometric metal oxide memory layer. At least one electrode is a resistive electrode comprising a sub-stoichiometric transition metal nitride or oxynitride, and has a resistivity between 0.1 and 10 Ω cm. The resistive electrode provides the functionality of an embedded current-limiting resistor and also serves as a source and sink of oxygen vacancies for setting and resetting the resistance state of the metal oxide layer. Novel fabrication methods for the second electrode are also disclosed.

Owner:SANDISK TECH LLC +2

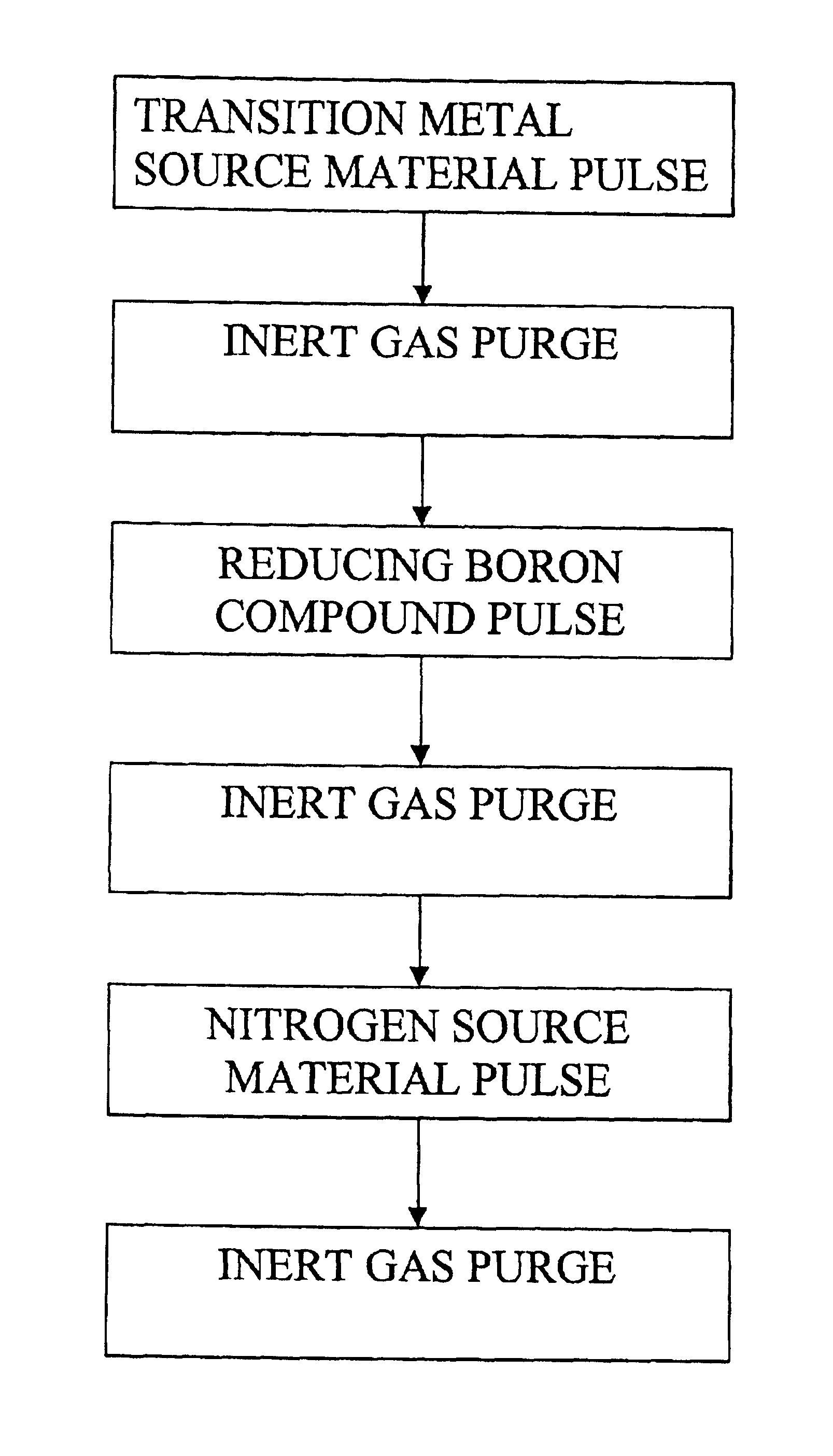

Method of depositing transition metal nitride thin films

InactiveUS6863727B1Low resistivityEasy to disassemblePolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseSource material

This invention concerns a method for depositing transition metal nitride thin films by an Atomic Layer Deposition (ALD) type process. According to the method vapor-phase pulse of a source material, a reducing agent capable of reducing metal source material, and a nitrogen source material capable of reacting with the reduced metal source material are alternately and sequentially fed into a reaction space and contacted with the substrate. According to the invention as the reducing agent is used a boron compound which is capable of forming gaseous reaction byproducts when reacting with the metal source material.

Owner:ASM INTERNATIONAL

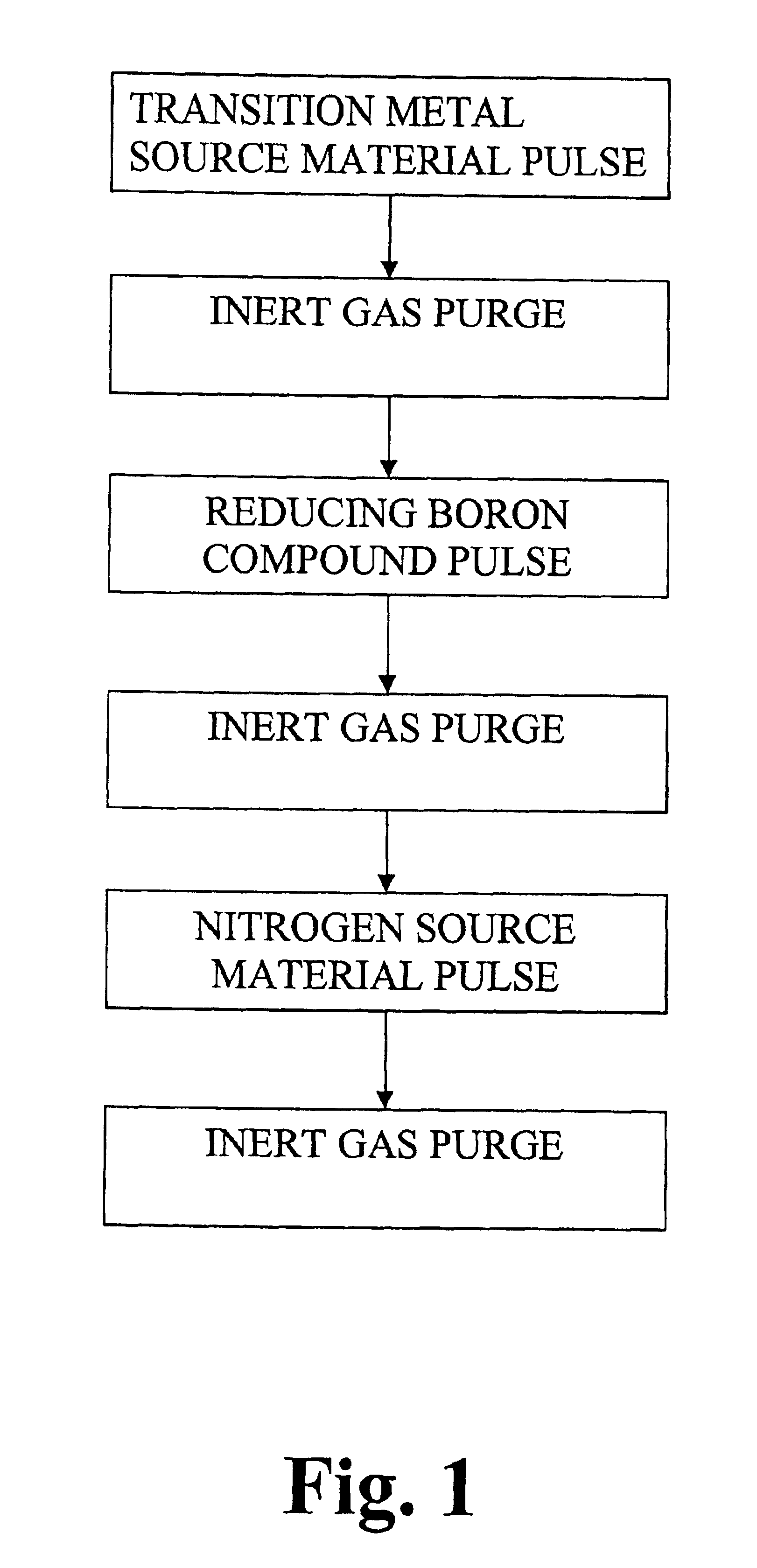

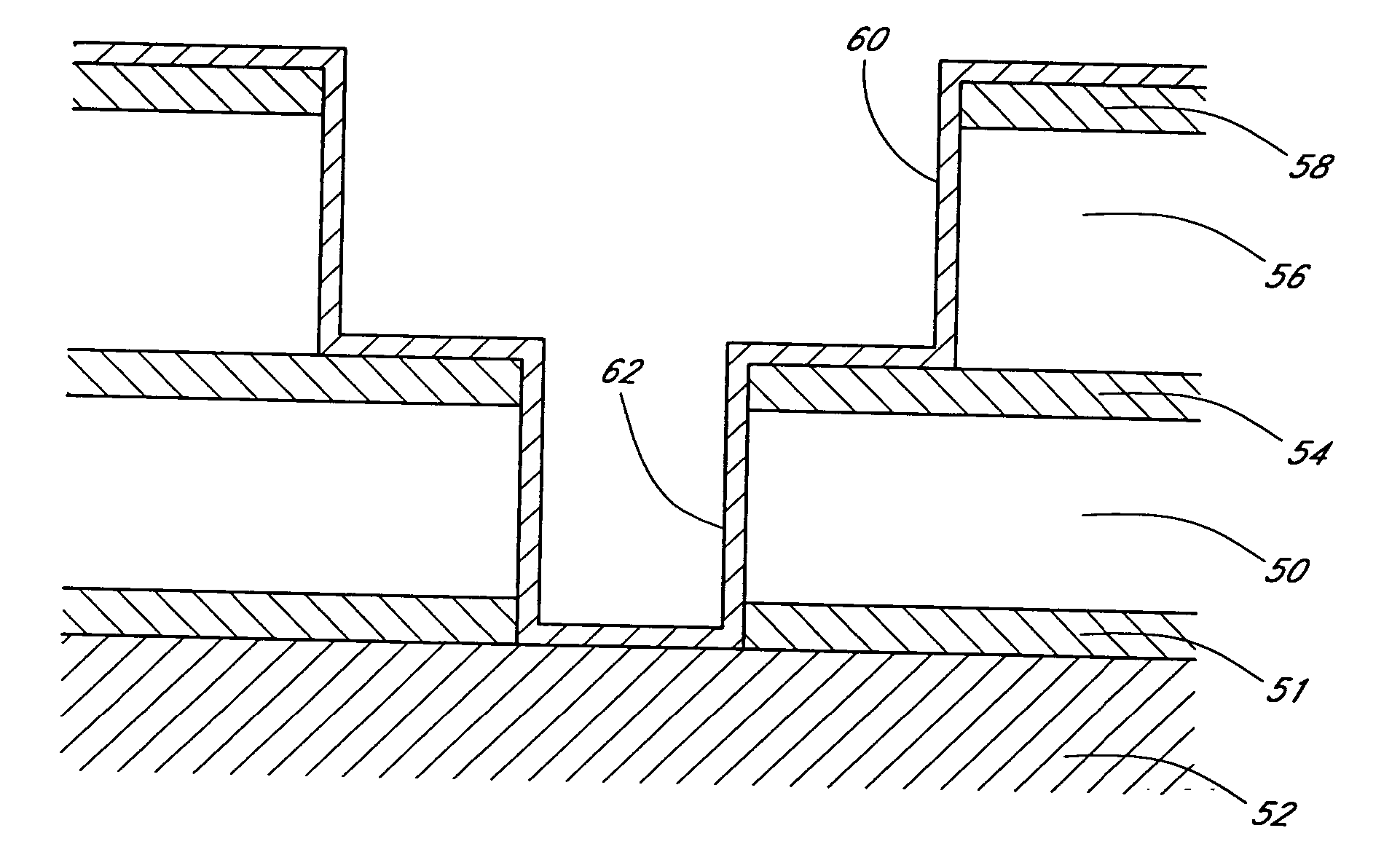

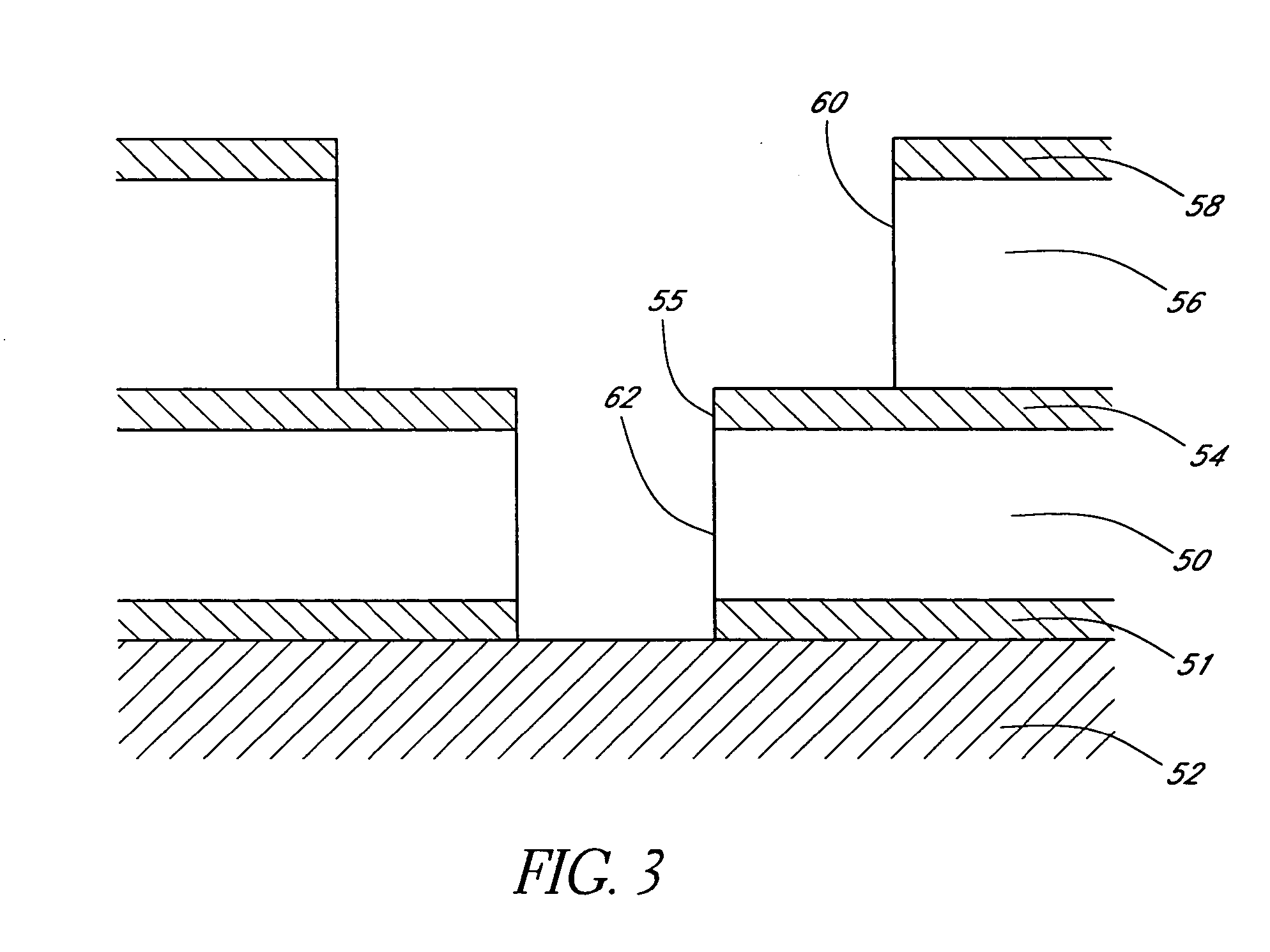

Method for depositing nanolaminate thin films on sensitive surfaces

InactiveUS20050106877A1Polycrystalline material growthSemiconductor/solid-state device manufacturingHydrogen halideCorrosive chemical

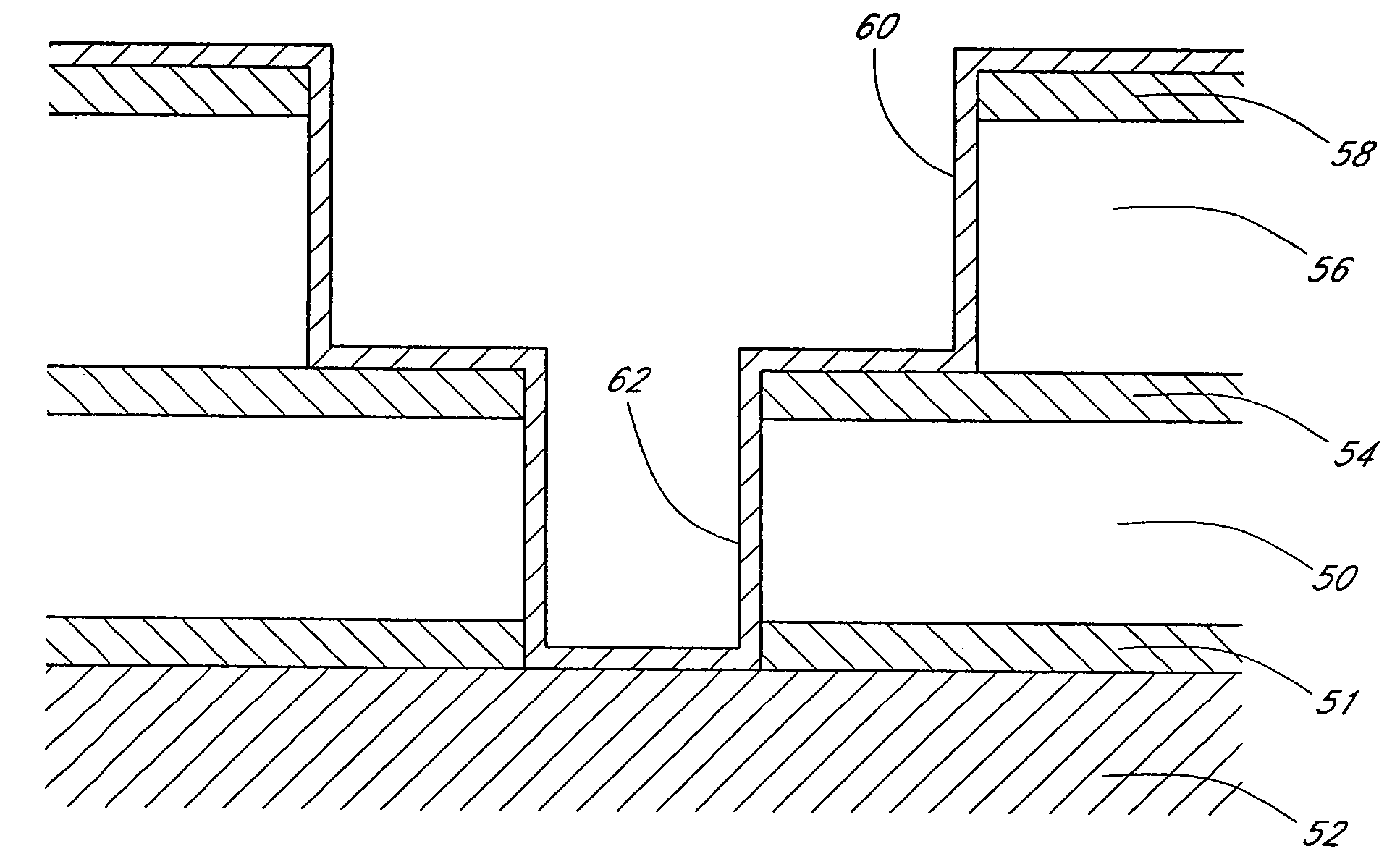

The present method provides tools for growing conformal metal nitride, metal carbide and metal thin films, and nanolaminate structures incorporating these films, from aggressive chemicals. The amount of corrosive chemical compounds, such as hydrogen halides, is reduced during the deposition of transition metal, transition metal carbide and transition metal nitride thin films on various surfaces, such as metals and oxides. Getter compounds protect surfaces sensitive to hydrogen halides and ammonium halides, such as aluminum, copper, silicon oxide and the layers being deposited, against corrosion. Nanolaminate structures (20) incorporating metal nitrides, such as titanium nitride (30) and tungsten nitride (40), and metal carbides, and methods for forming the same, are also disclosed.

Owner:ASM INTERNATIONAL

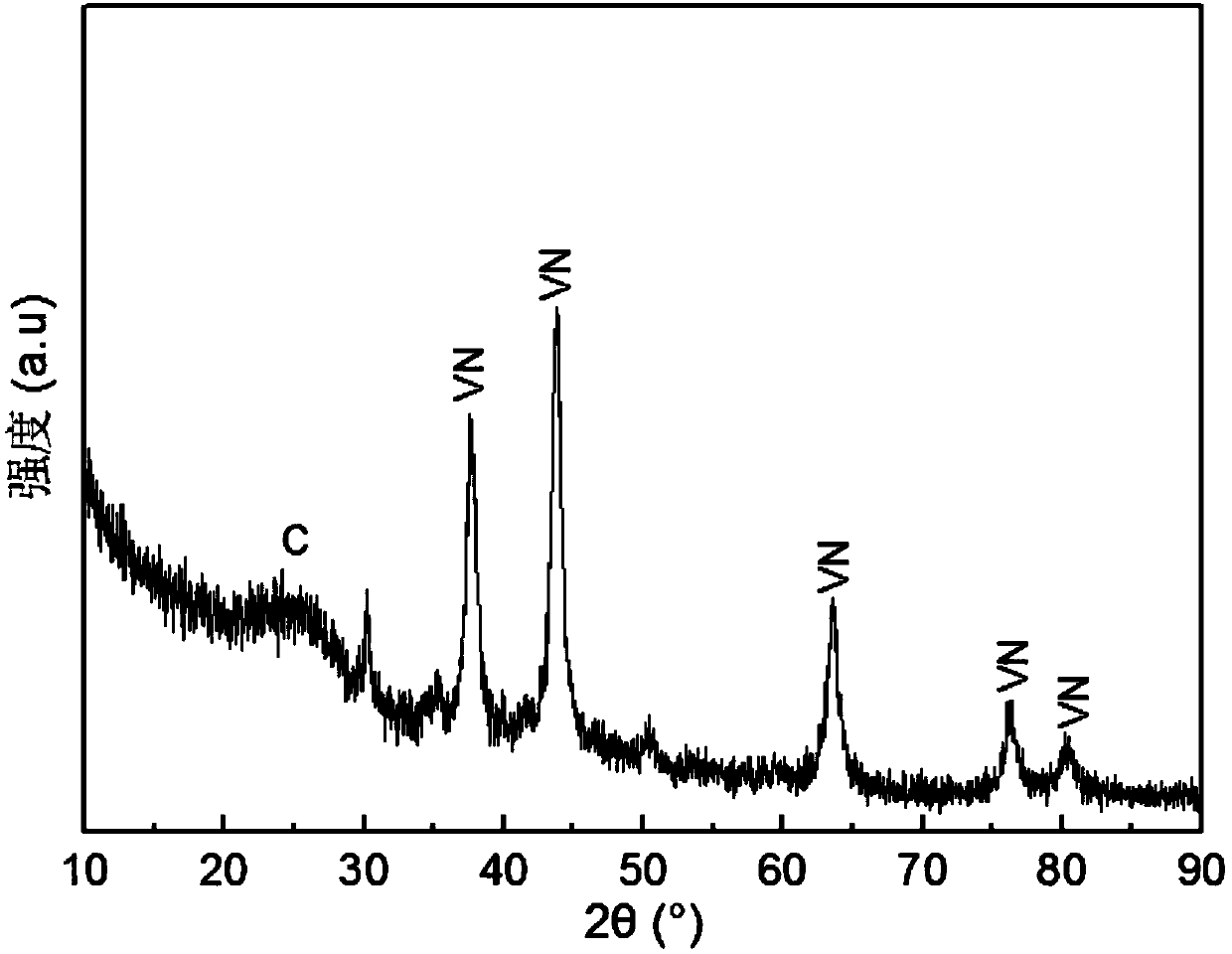

Nitride and Carbide Anode Materials

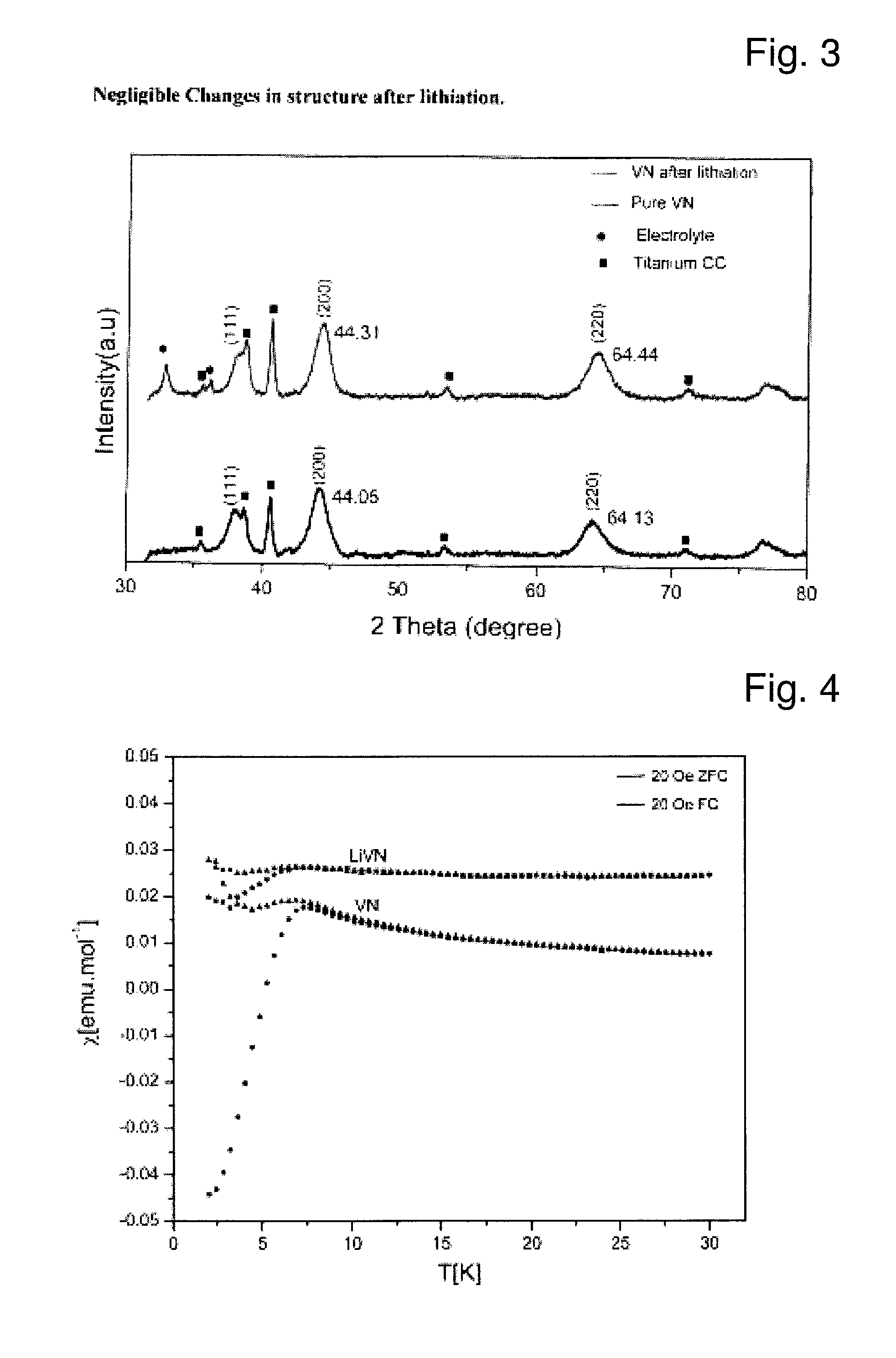

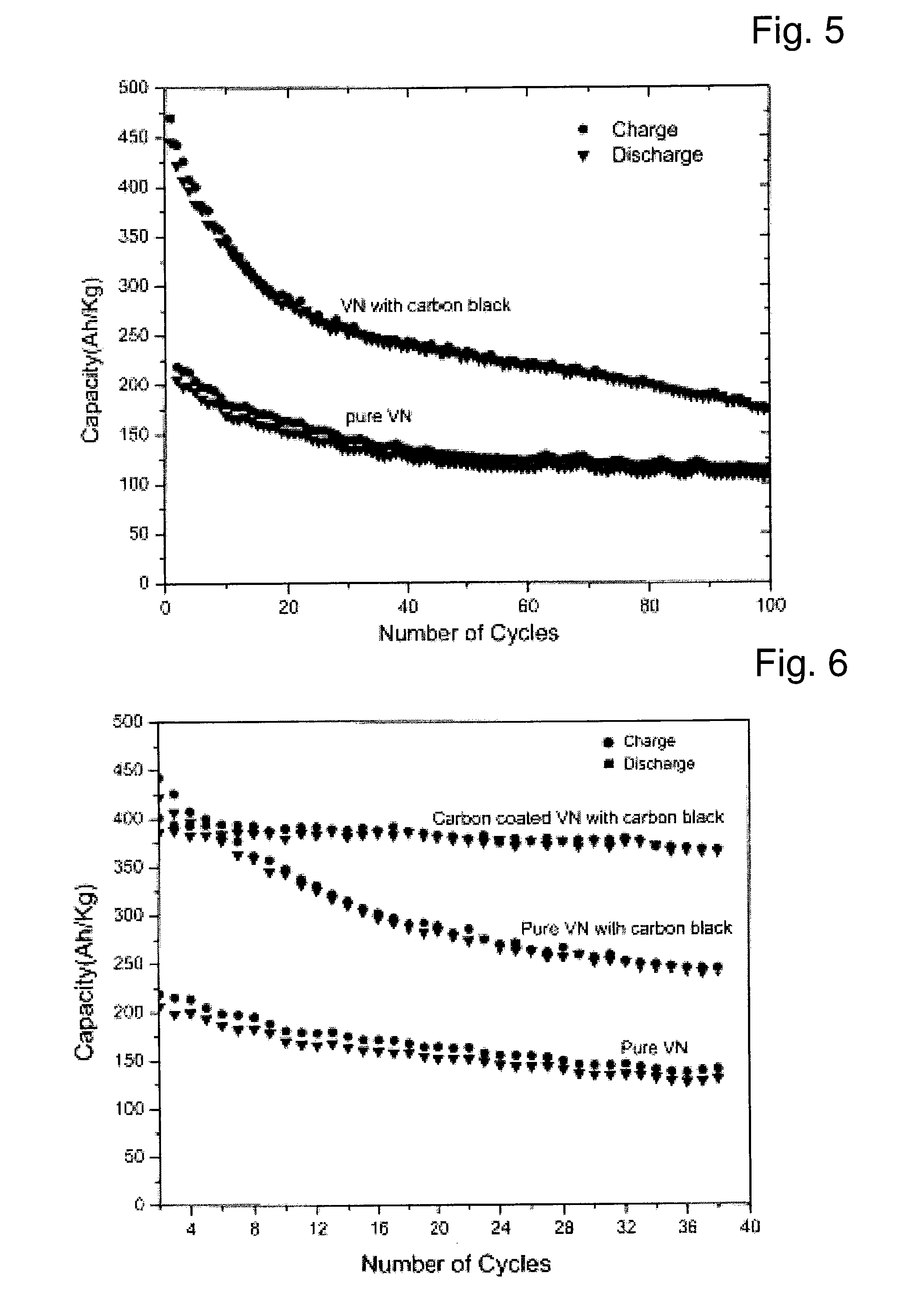

ActiveUS20100233546A1High chemicalHigh environmental stabilityFinal product manufactureConductive materialNanoparticleVanadium nitride

Described is an anode material which is a transition metal nitride or carbide in form of nanoparticles, preferably a nitride or carbide with one nitrogen or carbon per metal, and especially a nitride or carbide having rock salt structure. A preferred anode material is vanadium nitride, in particular carbon coated vanadium nitride having a mean particle size of <500 nm. Embedded in an electrically conducting environment, such nanoparticulate material, in particular the vanadium nitride shows exceptional good charging-discharging cycle stability.

Owner:BELENOS CLEAN POWER HLDG

Metal nitride carbide deposition by ALD

InactiveUS20060078679A1Material nanotechnologySemiconductor/solid-state device detailsHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

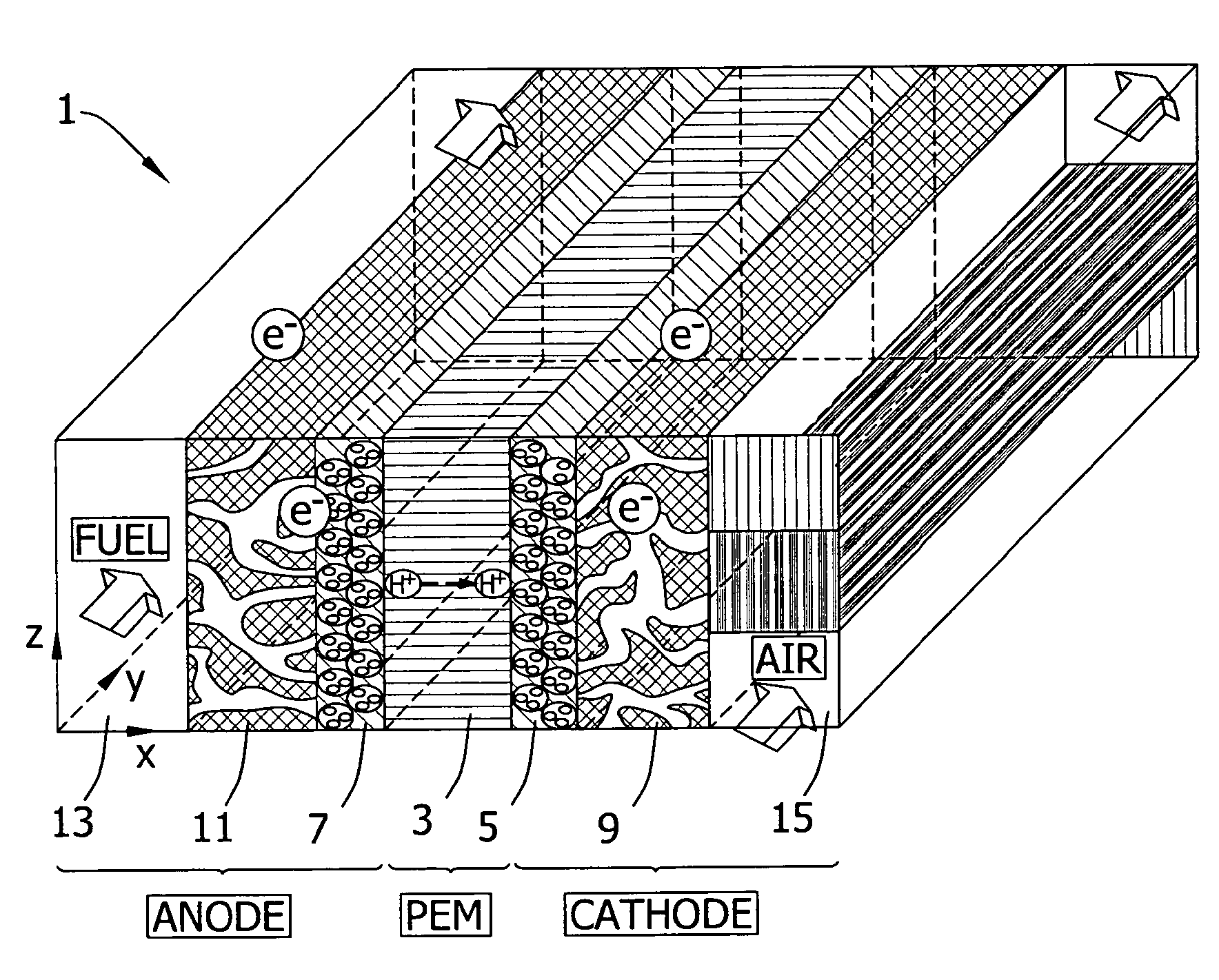

Transition metal-containing catalysts and processes for their preparation and use as fuel cell catalysts

InactiveUS20090130502A1Suitable for useRaise transfer toCell electrodesFuel cell auxillariesFuel cellsNitrogen

This invention relates to the field of fuel cell catalysts, and more particularly to fuel cell catalysts including carbon supports having compositions which comprise one or more transition metals in combination with nitrogen (e.g., a transition metal nitride) formed on or over the surface of a carbon support. The present invention also relates to methods for preparation of fuel cell catalysts. The present invention further relates to the use of fuel cell catalysts described herein in processes for the generation of electric power.

Owner:MONSANTO TECH LLC

Method for depositing nanolaminate thin films on sensitive surfaces

InactiveUS20060079090A1Polycrystalline material growthSemiconductor/solid-state device manufacturingHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

Photomask blank, photomask and fabrication method thereof

ActiveUS20060088774A1Reduce the burden onImprove accuracyDecorative surface effectsSemiconductor/solid-state device manufacturingSilicon oxideChromium nitride

Owner:TOPPAN PHOTOMASK CO LTD +1

Self passivating transition metal nitride printhead heaters

InactiveUS7431431B2Improve antioxidant capacityLower energy requirementsInking apparatusOther printing apparatusOxygenNitride

A thermal inkjet printhead with heater elements formed from a self passivating transition metal nitride, but it oxidizes readily. By introducing an additive that allows the metal nitride to self passivate, the heater element forms a surface oxide layer, where the oxide has a low diffusion coefficient for oxygen so as to provide a barrier to further oxidation. With enhanced oxidation resistance, coatings to protect the heater from oxidative failure become unnecessary and the energy needed to form a bubble is reduced.

Owner:MEMJET TECH LTD +1

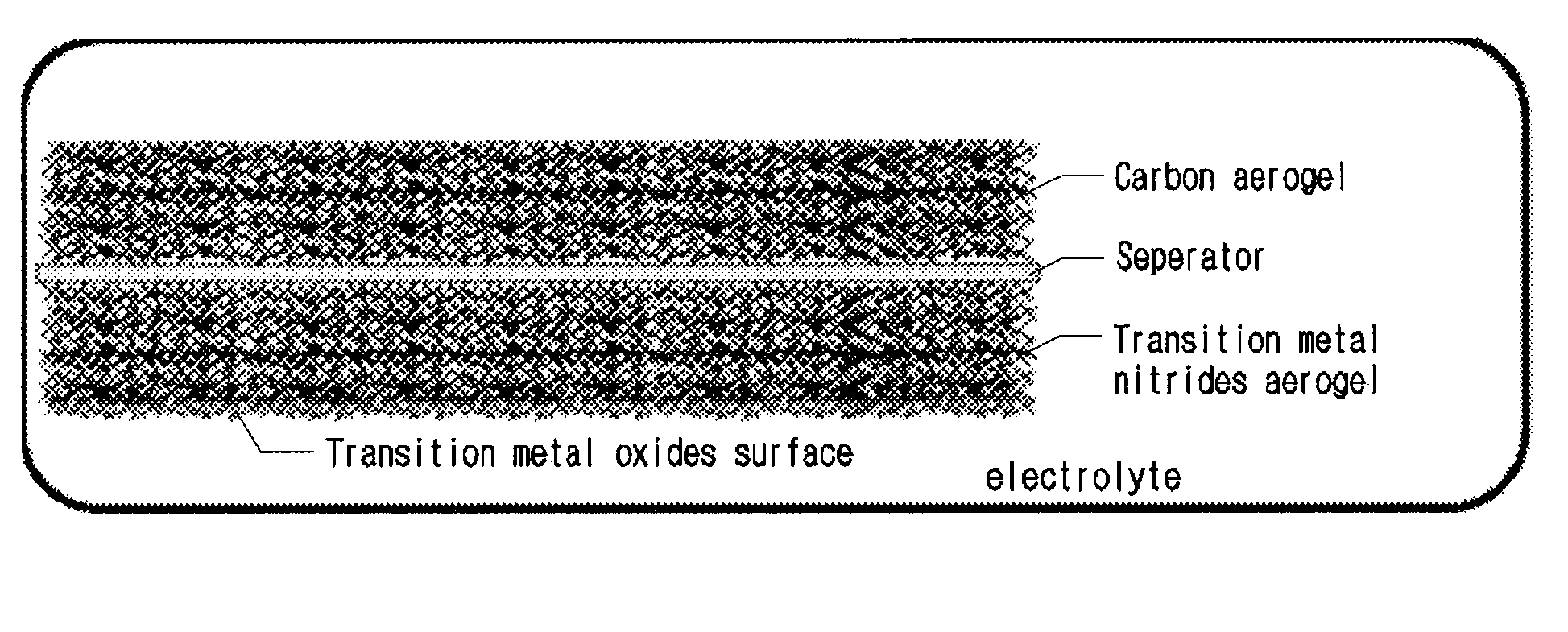

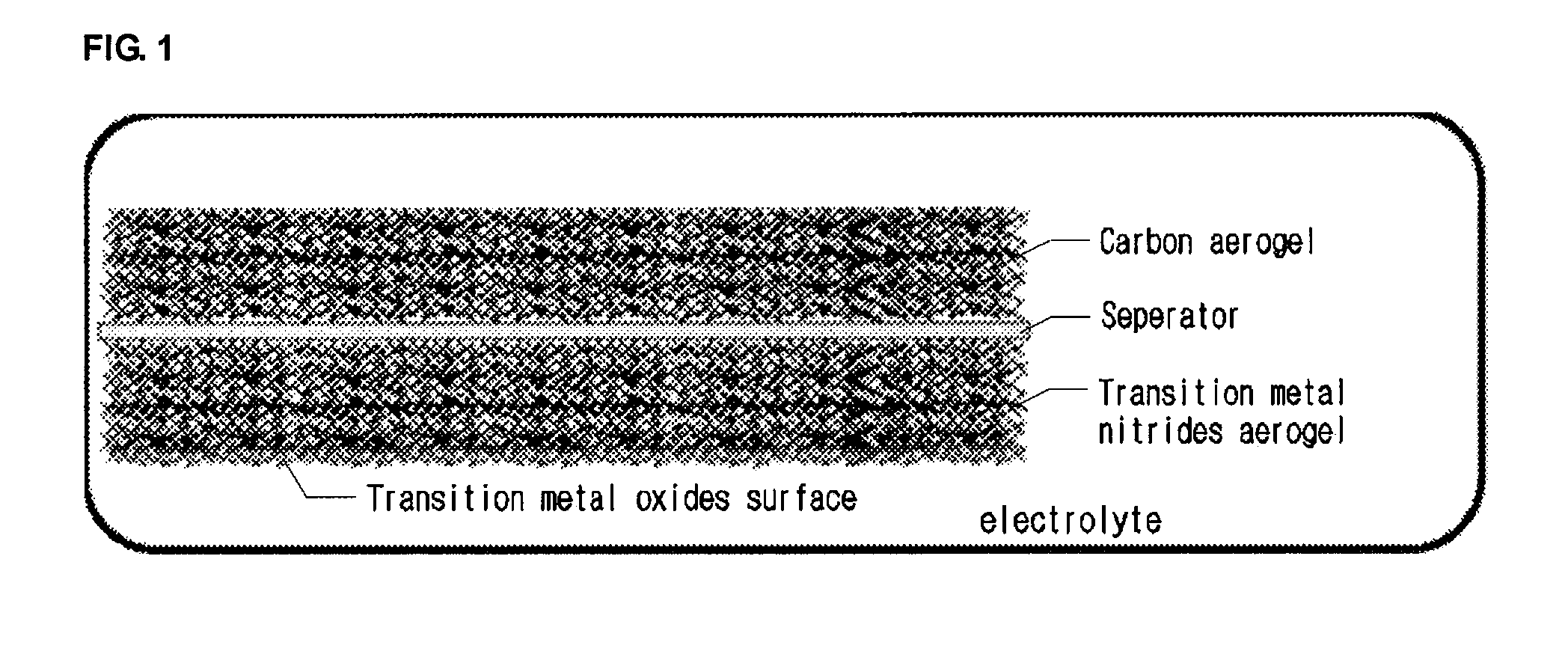

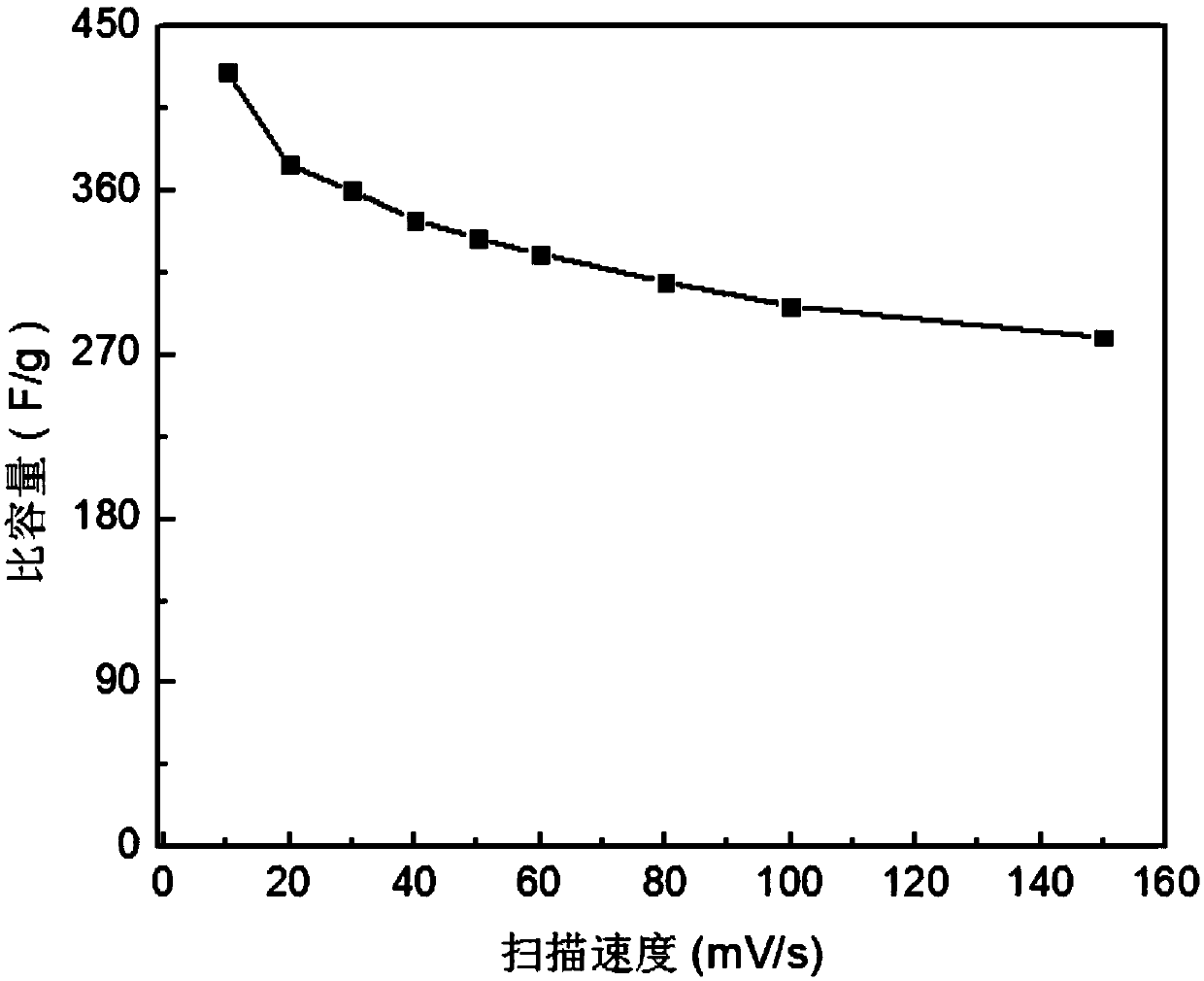

Hybrid supercapacitor using surface-oxidized transition metal nitride aerogel

InactiveUS20100195269A1Increase capacitanceIncrease energy densityHybrid capacitor electrodesDouble layer capacitorsInternal resistanceMaterials science

It discloses a hybrid supercapacitor including a carbon aerogel cathode and a surface-oxidized transition metal nitride aerogel anode which is able to increase energy density and power density with increase of overall cell potential and at the same time lower internal resistance of the electrode and equivalent series resistance by using a monolithic electrode with no use of current collector and binder.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

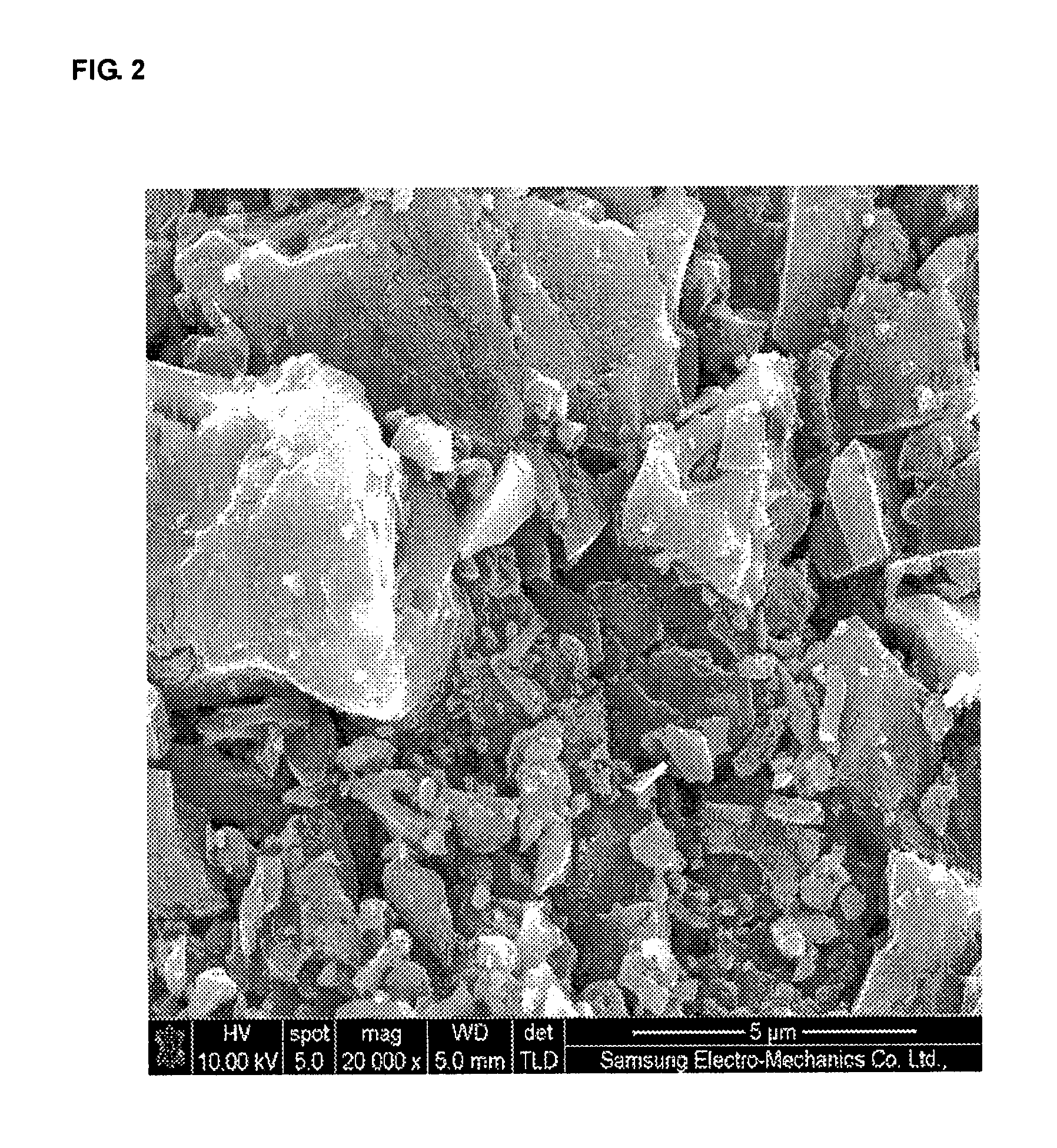

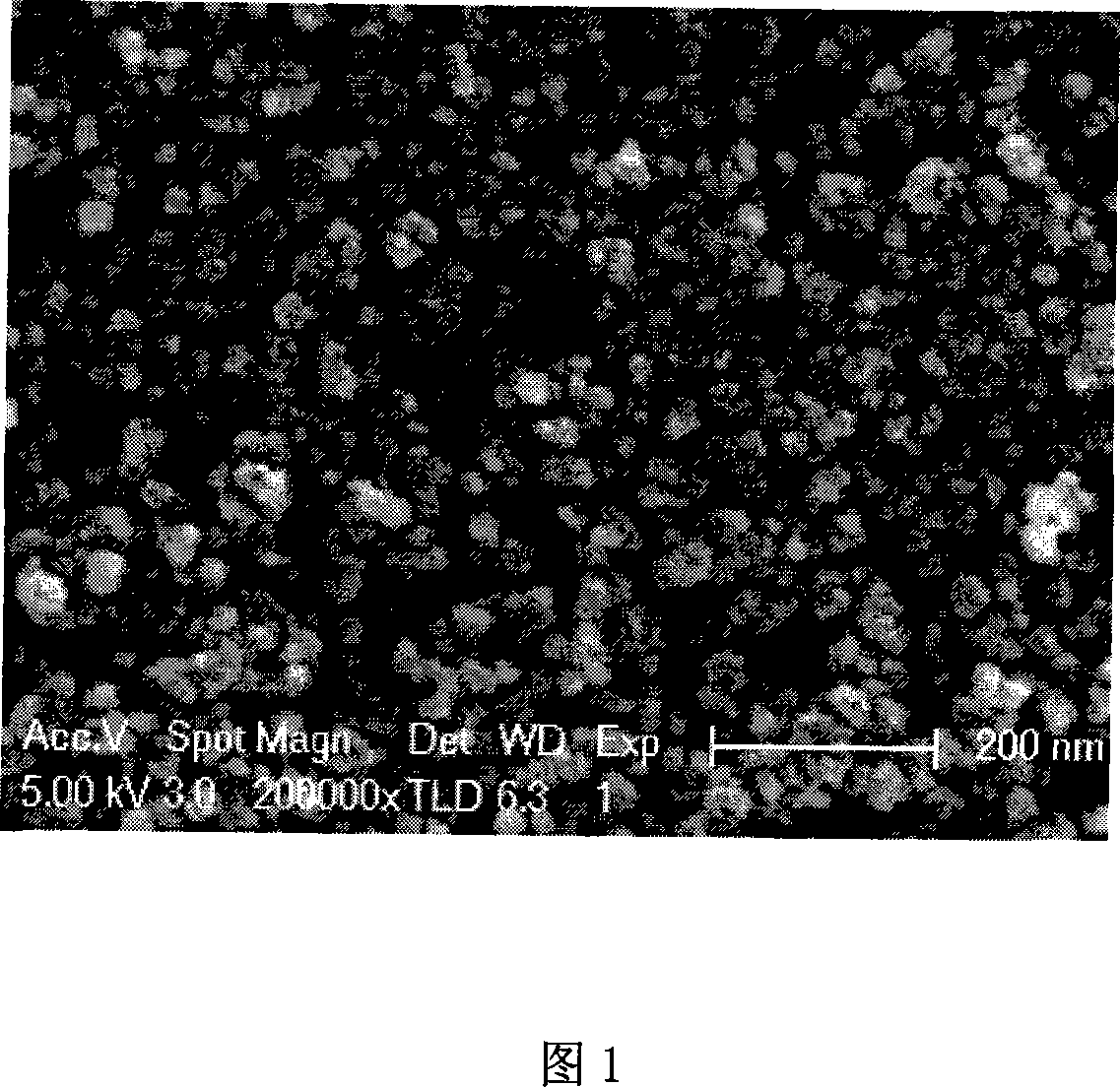

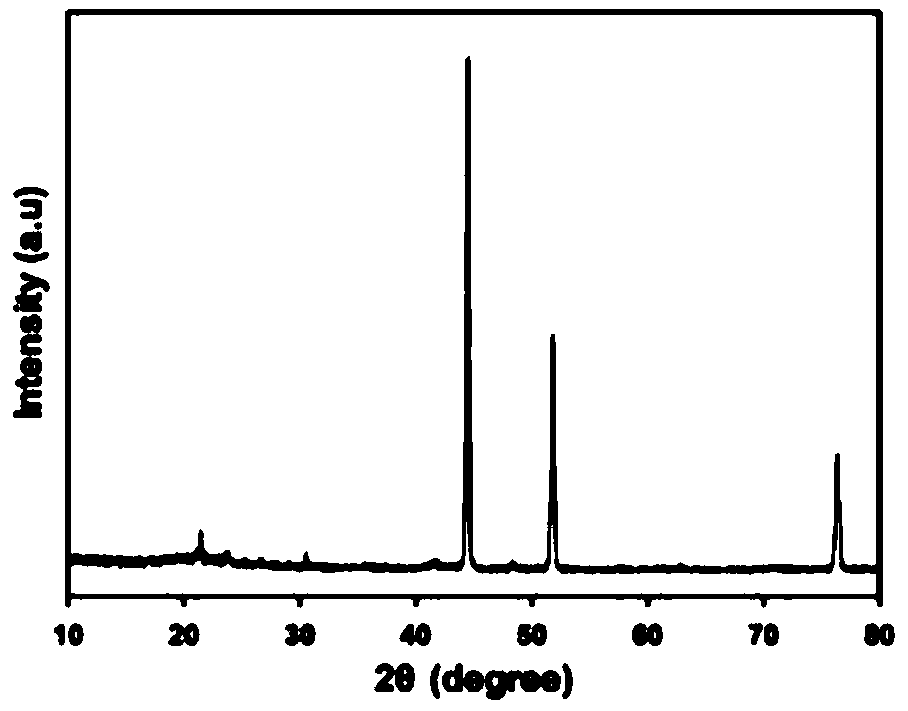

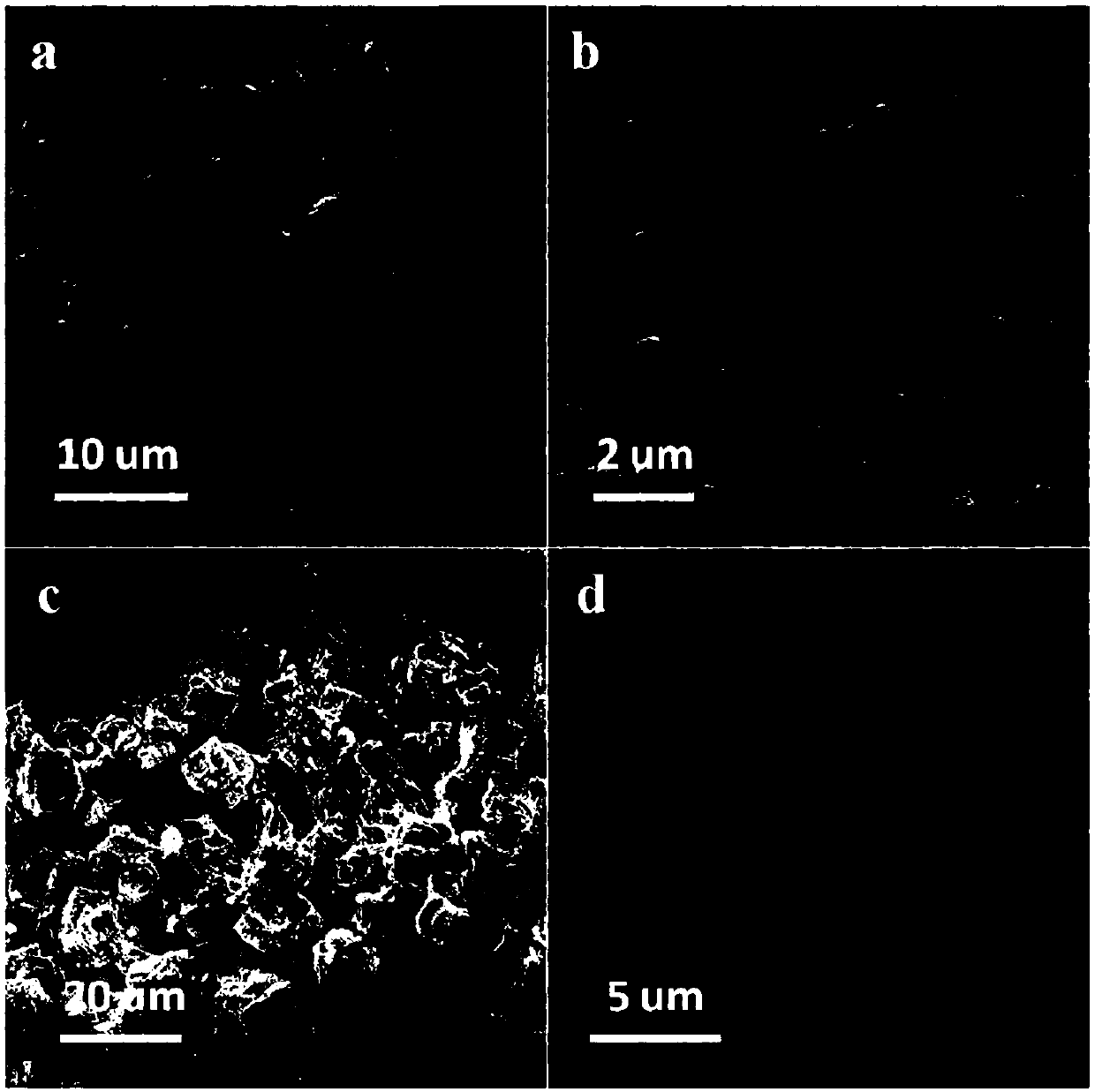

Transition metal nitride/nitrogen-doped graphene nanometer composite material and preparation method and application thereof

ActiveCN107610938ALarge specific surface areaImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesMixed materialsNitrogen doped graphene

The invention provides a transition metal nitride / nitrogen-doped graphene nanometer composite material and a preparation method and application thereof. In the composite material, transition metal nitride nanoparticles with sizes being 5-20 nanometers are embedded into a nitrogen-doped graphene framework, and the composite material is relatively large in specific area, contains mesopores uniformlydistributed and has favorable electrical conductivity. The preparation method of the composite material comprises the steps of (1) mixing a template precursor, a carbon source and a metal source to obtain a mixed material; and (2) placing the mixed material of the step (1) in an atmosphere furnace, and performing calcination in a non-oxidization atmosphere to obtain the transition metal nitride / nitrogen-doped graphene nanometer composite material. The composite material is used for the supercapacitor, a fuel cell or a lithium ion battery and has excellent application prospect. Compared with the prior art, the preparation method of the composite material is simple in process, low in equipment requirement and low in energy consumption, the raw material is low in cost, and mass production iseasy.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

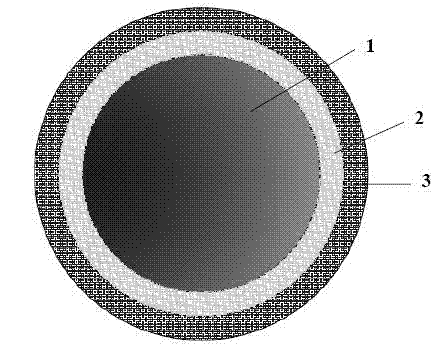

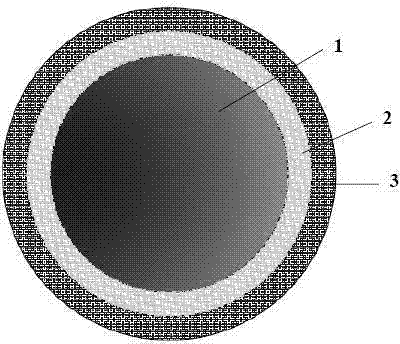

Cathode active material of lithium ion battery, preparation method thereof and lithium ion battery

ActiveCN102479948AAvoid reunionIncrease capacityMaterial nanotechnologyCell electrodesPhysical chemistryInterface layer

The invention relates to a cathode active material of a lithium ion battery. The cathode active material comprises a core body, an interface layer cladding on an external surface of the core body and an outmost layer cladding on an external surface of the interface layer. The core body comprises carbon materials; the interface layer consists of a first material, which is one or more selected from elements capable of forming an alloy with lithium; the outmost layer consists of a second material, which is one or more selected from transition metal oxide, transition metal nitride and transition metal sulfide. The invention also relates to a preparation method of the cathode active material and a lithium ion battery prepared from the cathode active material. The cathode active material of the present invention contains the first material, which can increase capacity of the battery, and also contains the second material, which clads the first material and can effectively inhibit volume expansion of the first material caused by multiple charge and discharge. Therefore, cycle performance of the battery is improved.

Owner:BYD CO LTD

Method for depositing nanolaminate thin films on sensitive surfaces

InactiveUS7329590B2Polycrystalline material growthSemiconductor/solid-state device manufacturingCorrosive chemicalHydrogen halide

The present method provides tools for growing conformal metal nitride, metal carbide and metal thin films, and nanolaminate structures incorporating these films, from aggressive chemicals. The amount of corrosive chemical compounds, such as hydrogen halides, is reduced during the deposition of transition metal, transition metal carbide and transition metal nitride thin films on various surfaces, such as metals and oxides. Getter compounds protect surfaces sensitive to hydrogen halides and ammonium halides, such as aluminum, copper, silicon oxide and the layers being deposited, against corrosion. Nanolaminate structures (20) incorporating metal nitrides, such as titanium nitride (30) and tungsten nitride (40), and metal carbides, and methods for forming the same, are also disclosed.

Owner:ASM INTERNATIONAL NV

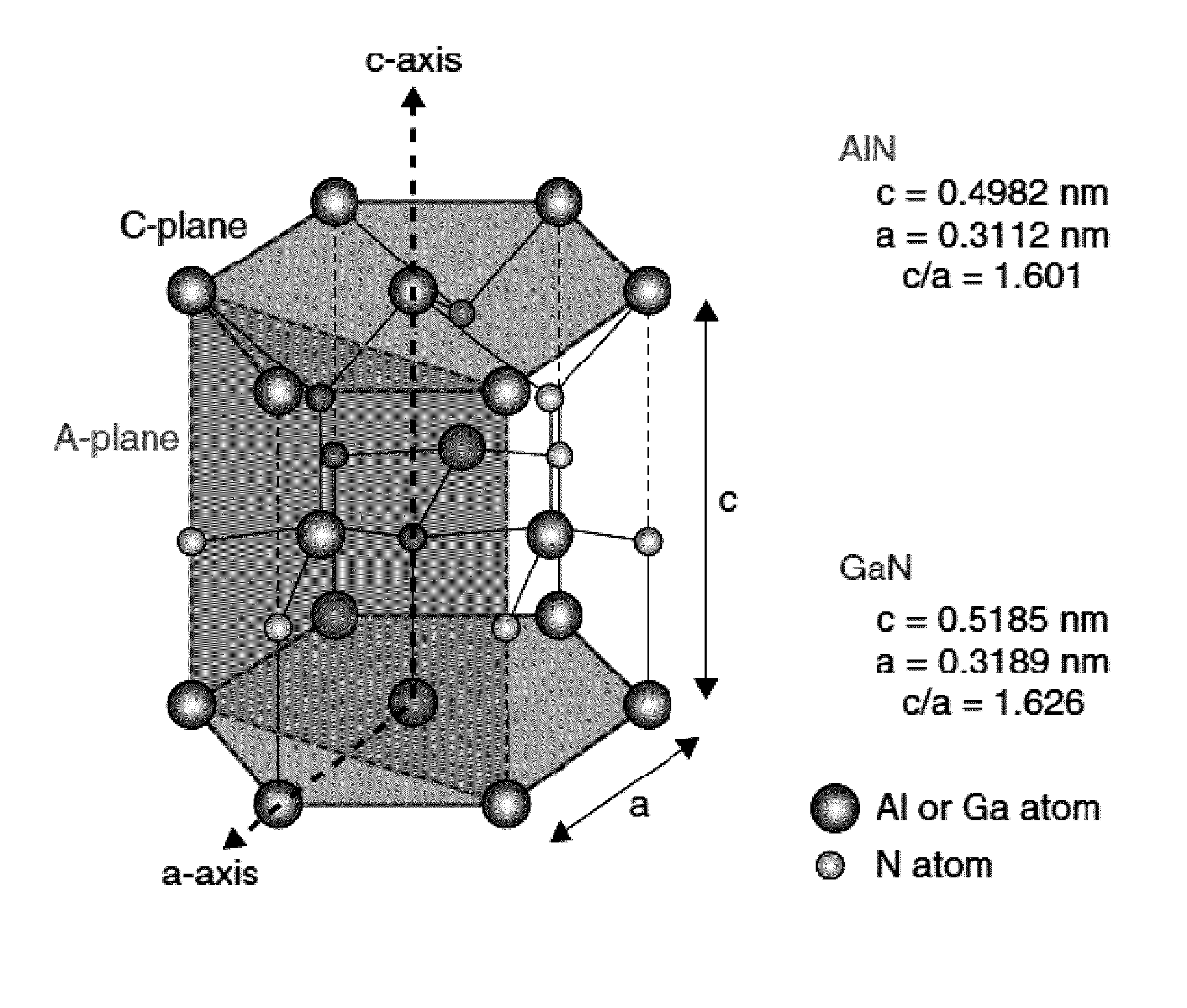

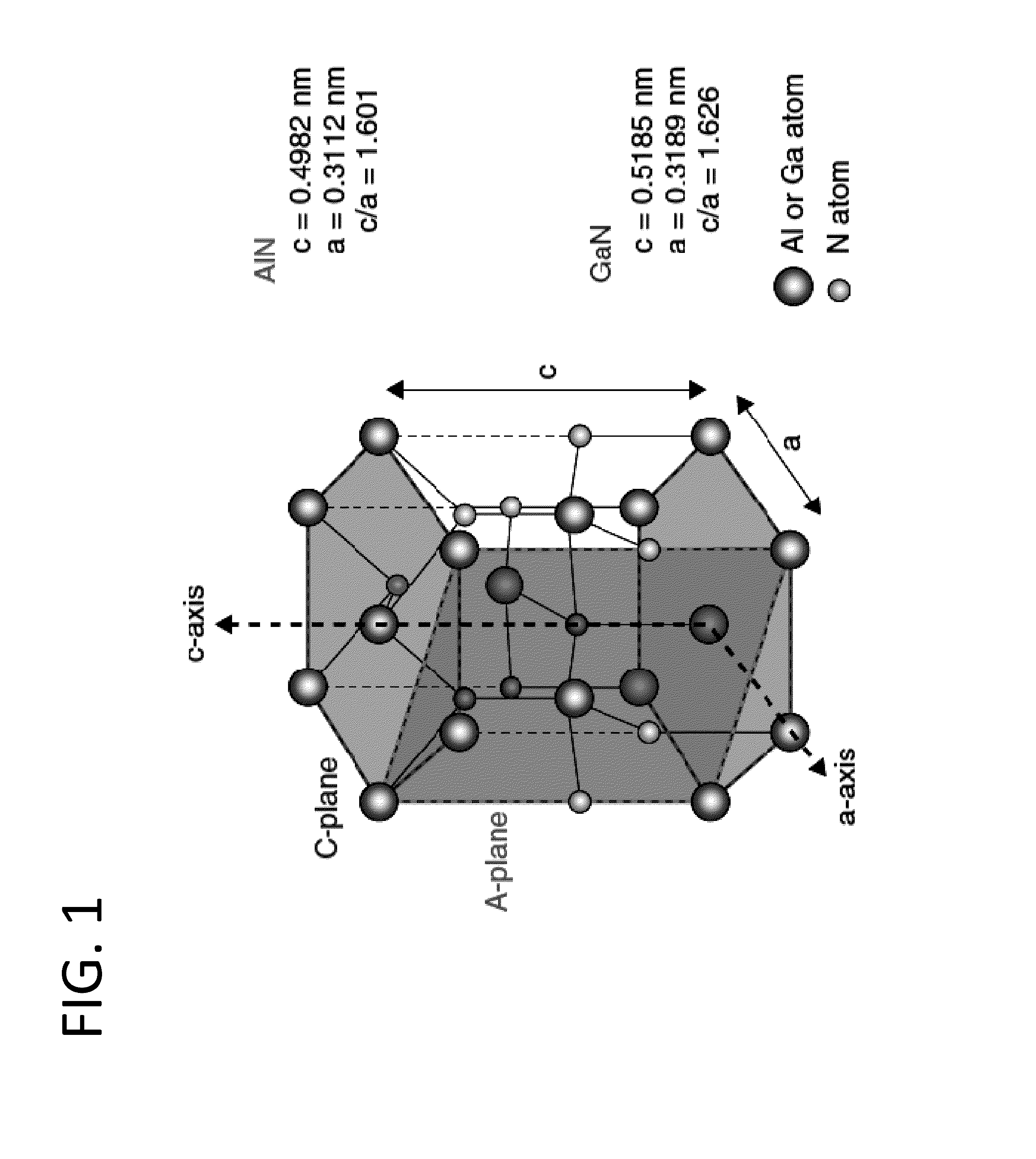

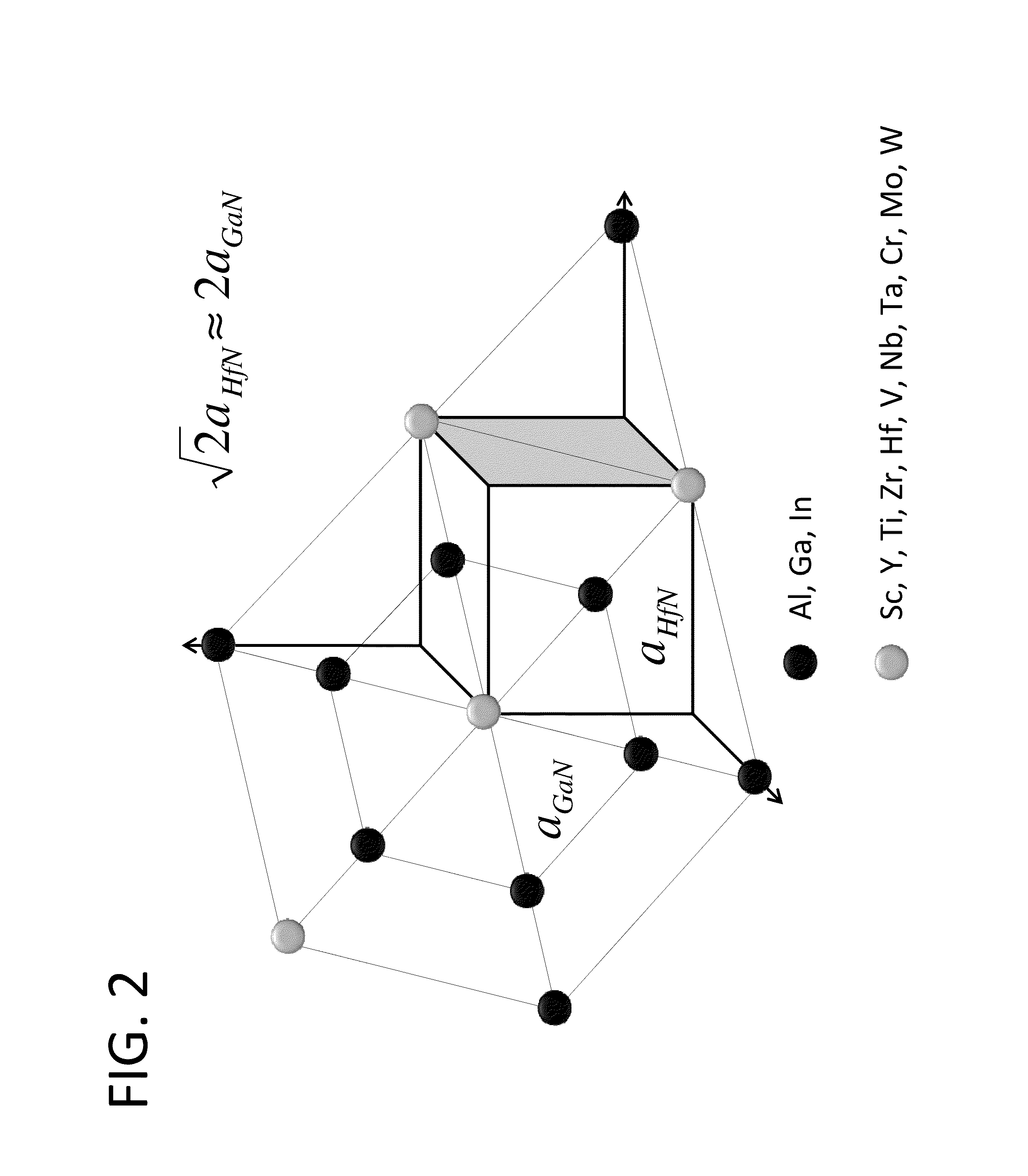

Light emitting device having group iii-nitride current spreading layer doped with transition metal or comprising transition metal nitride

InactiveUS20130048939A1Increase the doping concentrationReduce strainConductive materialSemiconductor/solid-state device manufacturingQuantum wellConductive materials

A light-emitting device, such as a light-emitting diode (LED), has a group III-nitride current spreading layer which is either doped with transition metal, or comprises alternating transition metal nitride layer and group III-nitride layer. Also provided is a light-emitting device, such as a light-emitting diode (LED), having a quantum well doped with transition metal. Also provided is a method of forming transition-metal containing AlInGaN electrical conductive material.

Owner:ZHEJIANG INVENLUX TECH

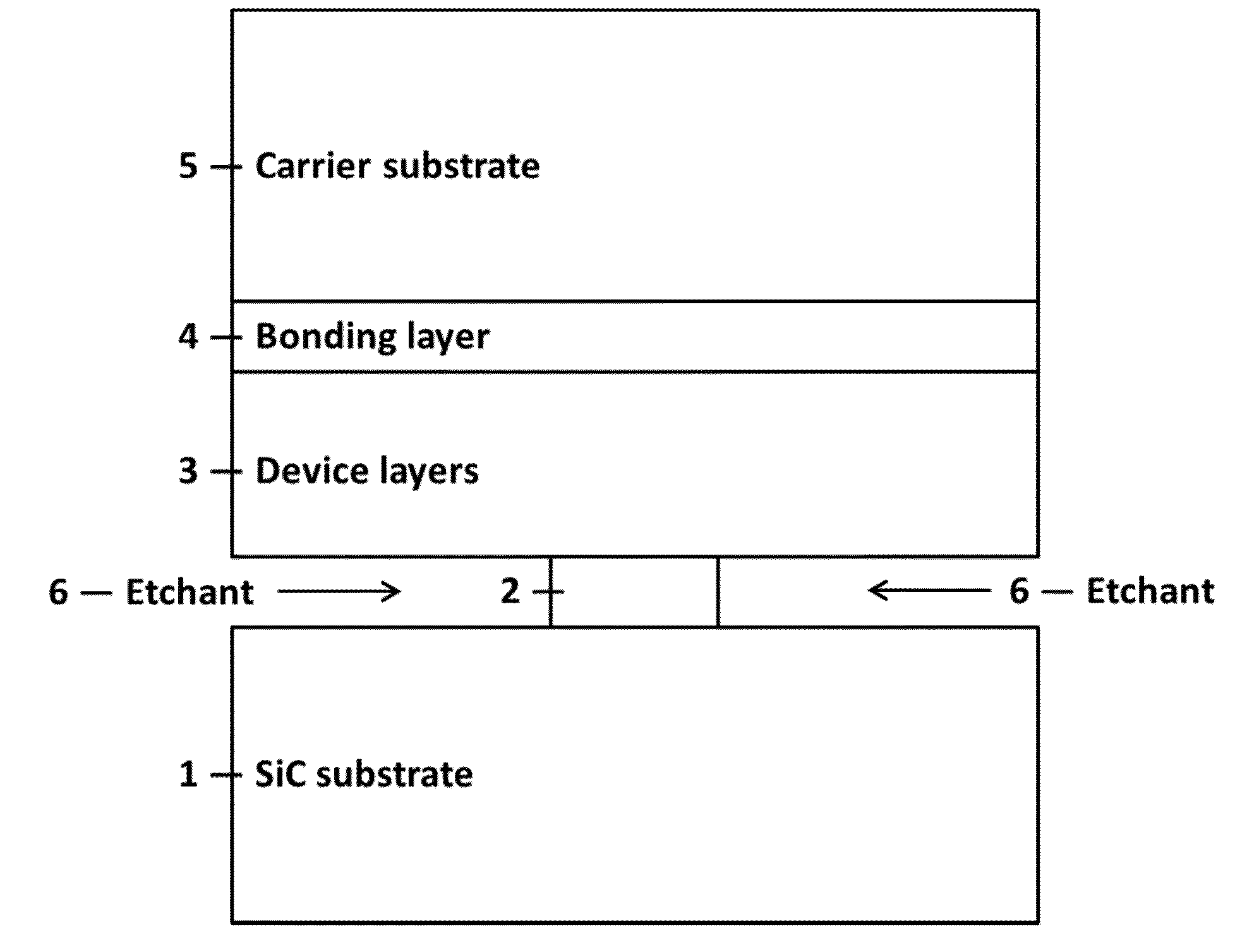

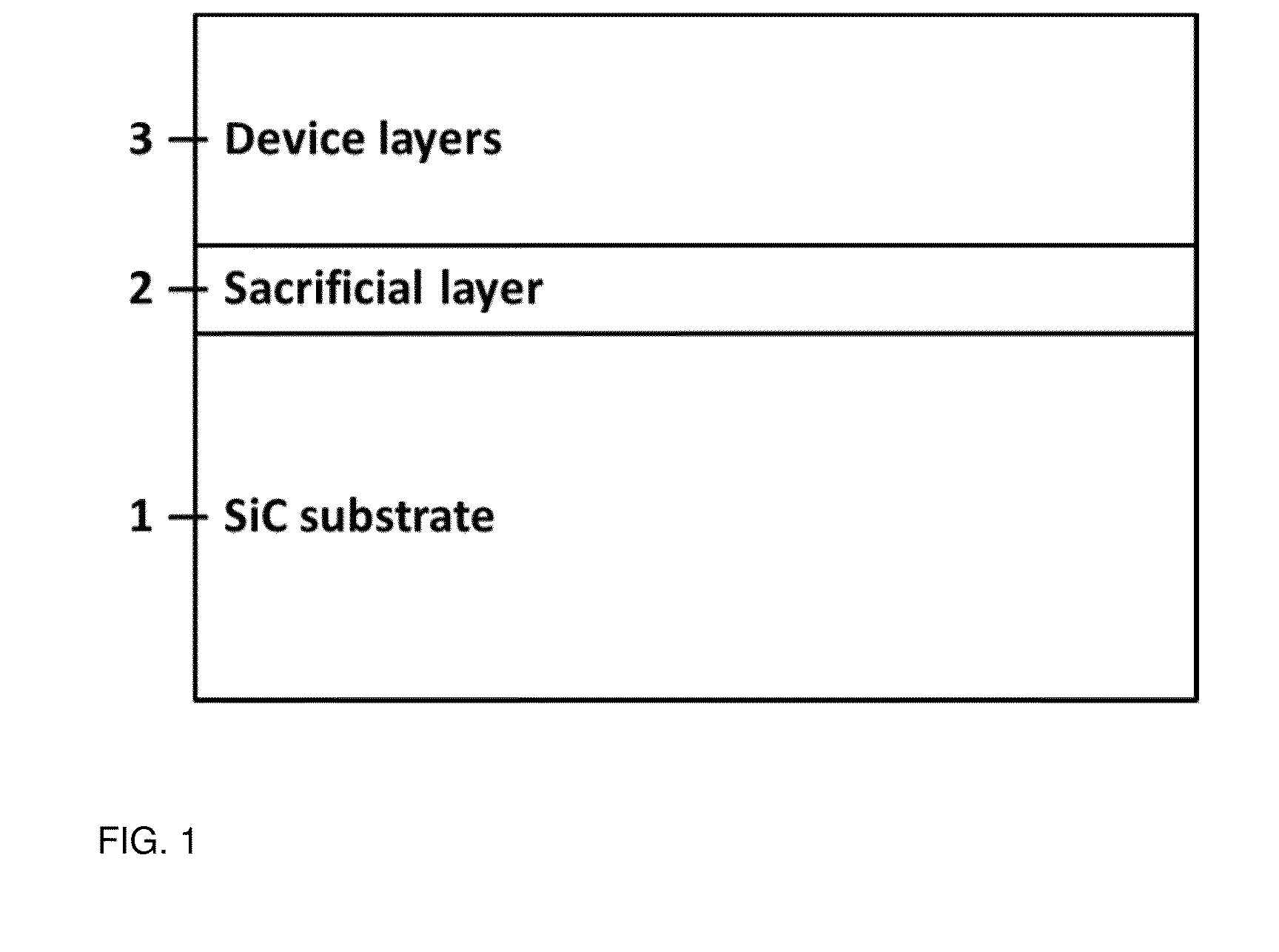

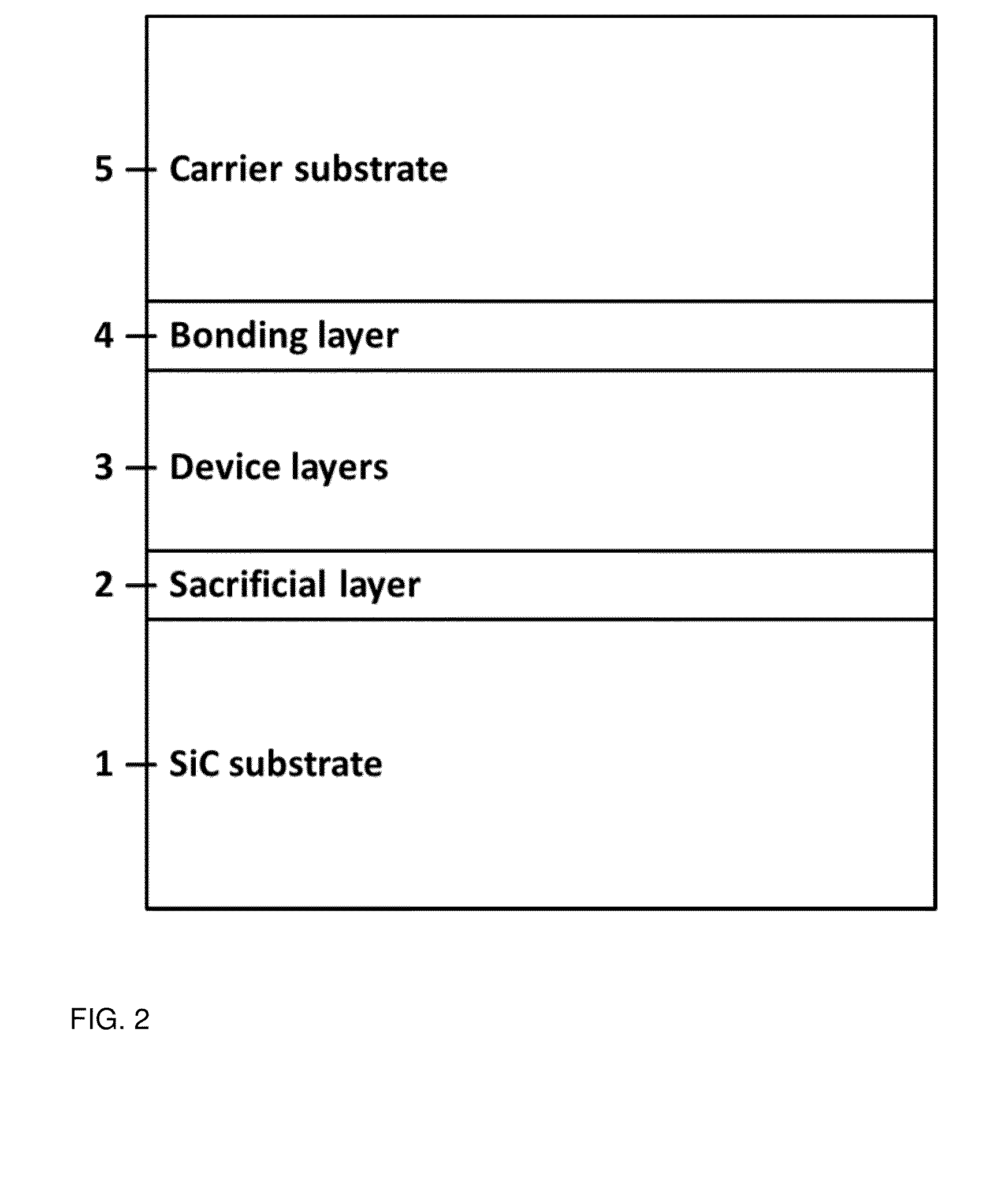

Lift-off of epitaxial layers from silicon carbide or compound semiconductor substrates

ActiveUS20150021624A1Minimal cleaningTimely controlSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsTernary compound

A method to remove epitaxial semiconductor layers from a substrate by growing an epitaxial sacrificial layer on the substrate where the sacrificial layer is a transition metal nitride (TMN) or a TMN ternary compound, growing one or more epitaxial device layers on the sacrificial layer, and separating the device layers from the substrate by etching the sacrificial layer to completely remove the sacrificial layer without damaging or consuming the substrate or any device layer. Also disclosed are the related semiconductor materials made by this method.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

A manufacture method of carbon-based metal nitrides, and carbonide supercapacitance material

InactiveCN101060037AHigh specific capacitanceEvenly dispersedElectrode manufacturing processesElectrolytic capacitorsSodium acetateCapacitance

The preparation method for super-capacitance material comprises: with meta-dihydroxybenzene and formaldehyde as the reacting material, with sodium acetate or sodium propionate or the mixture as additive, adding transition metal oxide during the gelling to obtain the uniform distributed RF aqueous gel with rich transition metal salt; then, with N2 or H2, drying on common pressure, and charring to obtain the final product with 400F / g-870F / g capacity.

Owner:HEFEI UNIV OF TECH

Cathode material used for lithium-sulfur secondary battery

InactiveCN105932242AEasy accessEasy to manufactureCell electrodesLi-accumulatorsLithium sulfurIntermediate product

The invention relates to a cathode material used for a lithium-sulfur secondary battery. The cathode material is characterized in that transition metal nitrides are contained in the cathode material. The transition metal nitrides are anchored on the surface of a carbon substrate well to form a conductive network together by using higher conductivity of the transition metal nitrides and affinity with the carbon substrate; moreover, the redox liquid phase conversion reaction speed of a polysulfide intermediate product is strengthened in the cathode reaction process of the lithium-sulfur battery by using the polarity characteristics of the metal nitrides, the utilization rate of the sulfur active material in the lithium-sulfur battery is improved, and the cathode material is beneficial for promoting the practicability of sulfur in the lithium-sulfur secondary battery.

Owner:TSINGHUA UNIV

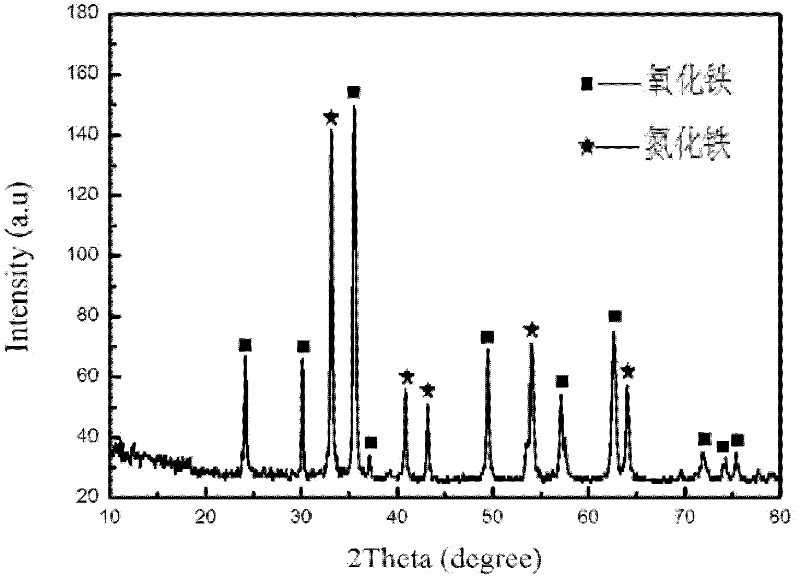

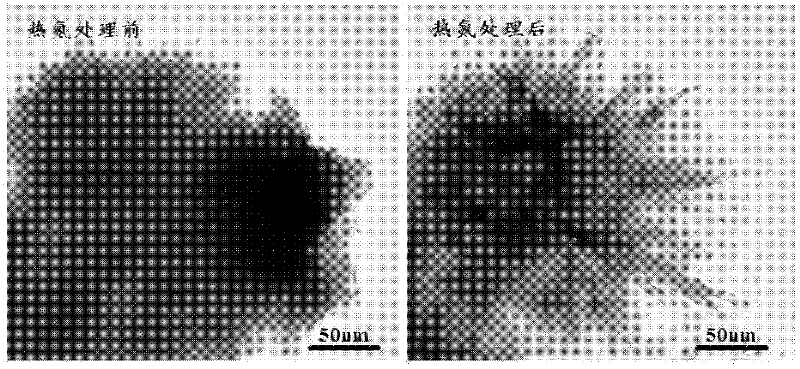

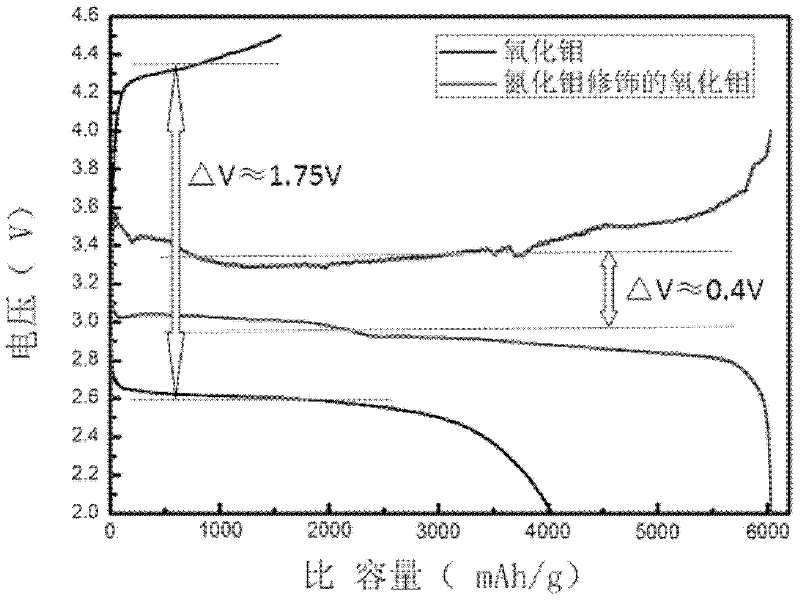

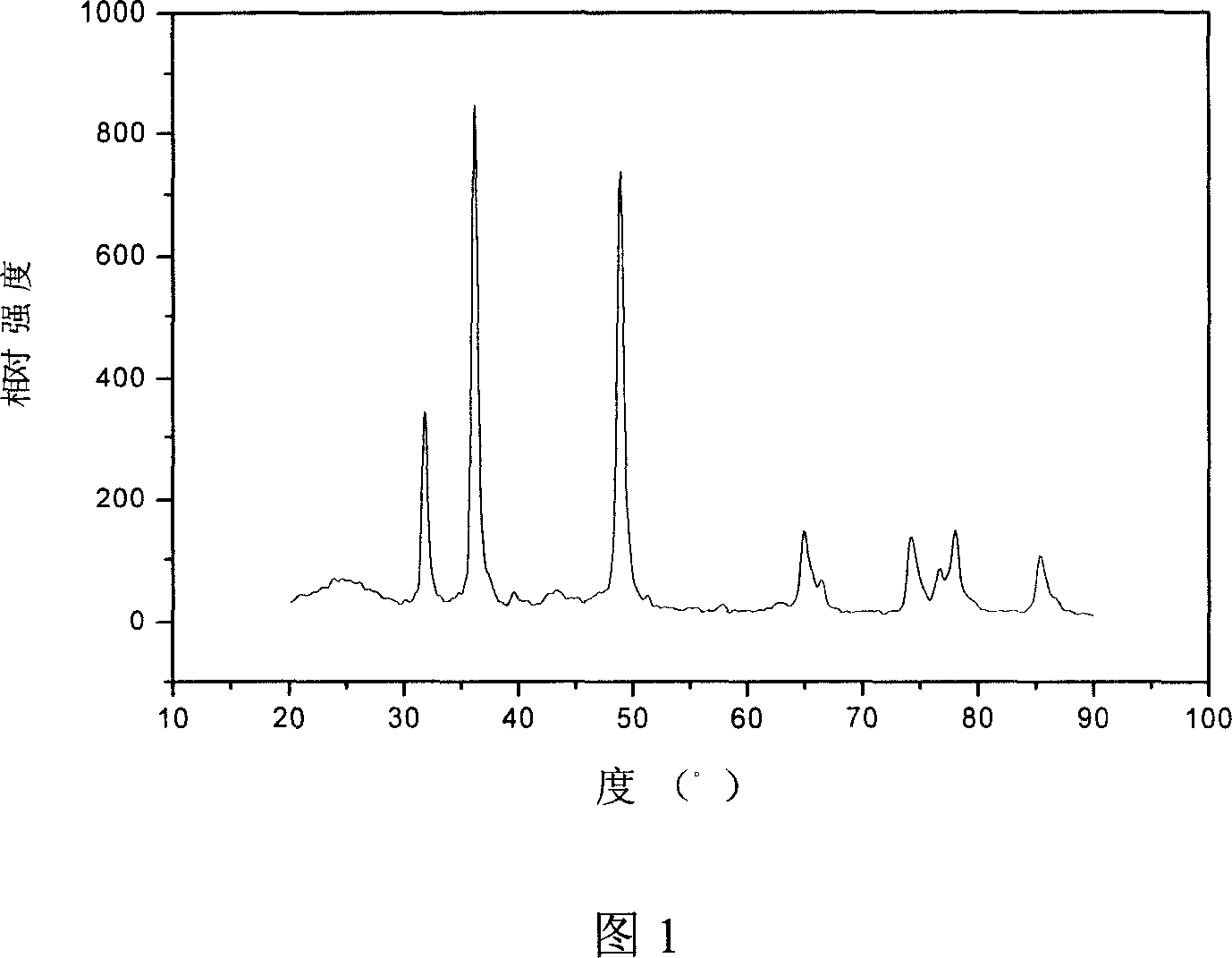

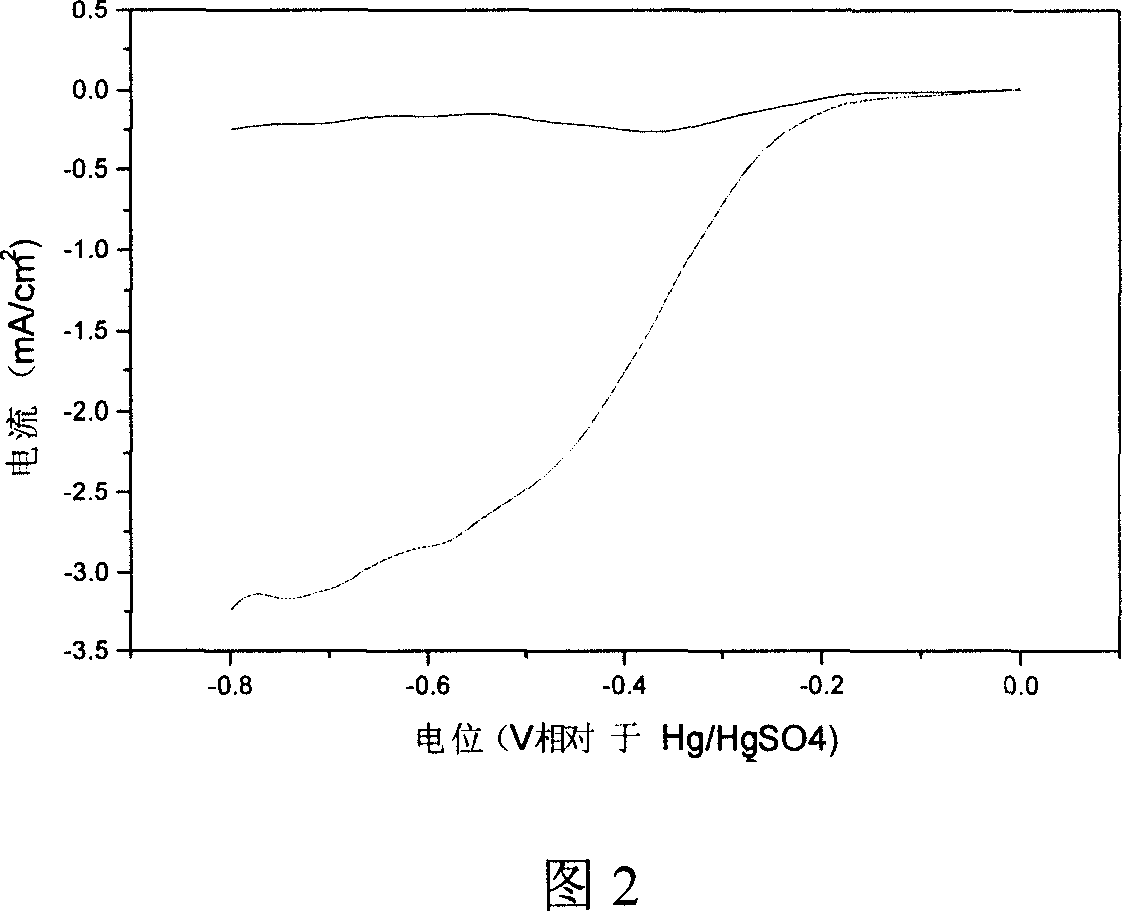

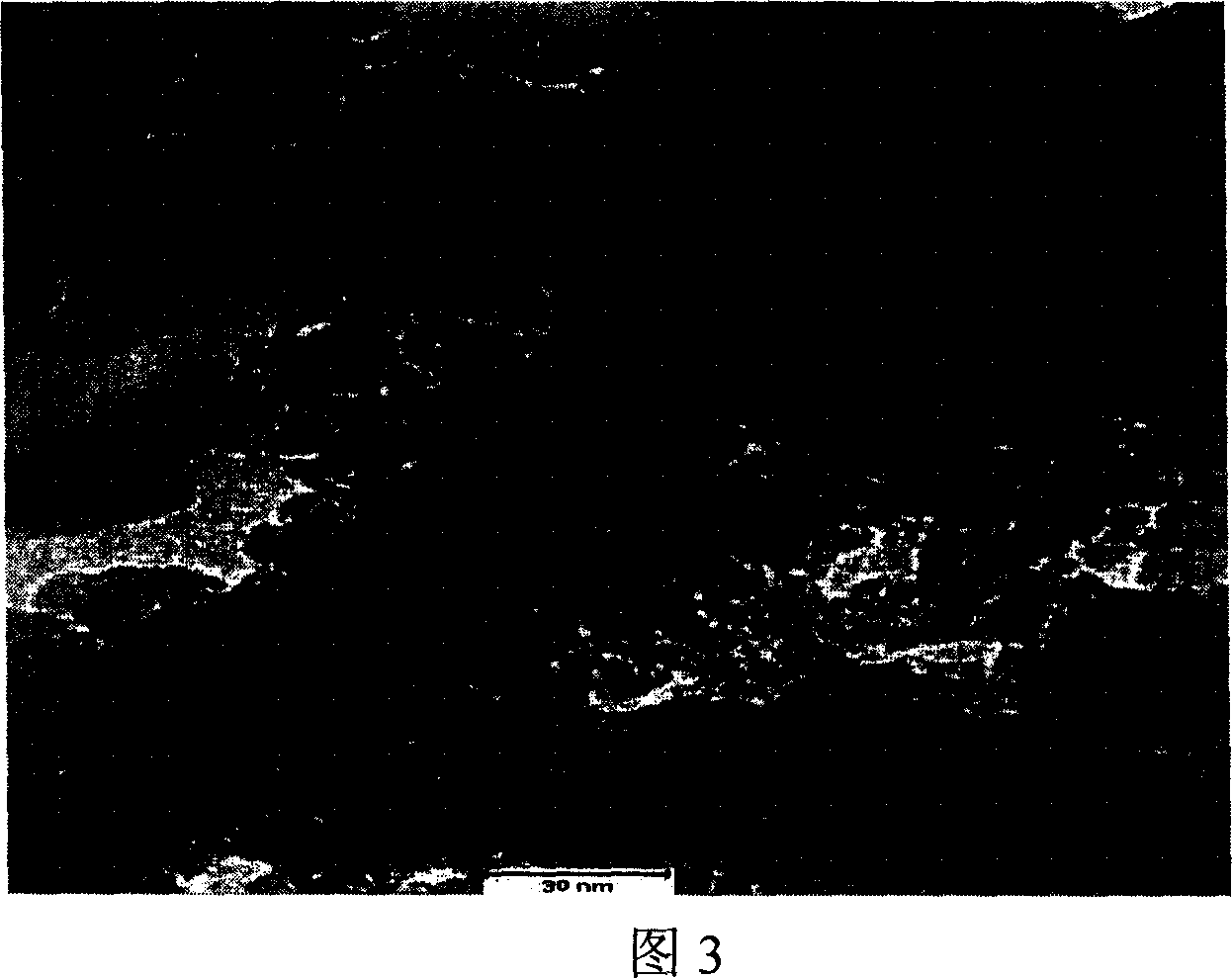

Composite electrocatalyst material used for Li-air batteries and preparation method thereof

InactiveCN102694185AImprove stabilityImprove conductivityPhysical/chemical process catalystsCell electrodesArgon atmosphereLithium–air battery

A composite electrocatalyst material used for Li-air batteries and a preparation method thereof. The transition metal oxide composite electrocatalyst modified by surface conductive transition metal nitride is obtained by conducting thermal nitrogen treatment, in an ammonia atmosphere or an ammonia and argon atmosphere, for transition metal oxide powder or transition metal oxide powder pretreated by nitrogen overlying, wherein the technology of the thermal nitrogen treatment is heating up the powder at a rate of 2-10 DEG C / min to reach the thermal nitrogen treatment temperature of 300-800 DEG C, preserving heat for 10min to 2h and then cooling in furnace. By controlling the content and flow rate of ammonia and the temperature and time of sintering, the thickness of the surface transition metal nitride can be controlled selectively. The method of the invention is simple in technology, convenient for operation, low in cost and strong in controllability. In addition, the obtained composite electrical catalyst has good conductivity and stability and can reduce the charging and discharging polarization of Li-air batteries effectively. The catalyst decreases the inner resistance of batteries and has good discharge capacity. The industrialization prospect of the catalyst is good.

Owner:CENT SOUTH UNIV

Non noble metal catalyst for cathode of direct methanol fuel cell, and preparation method

Existing catalysts are noble metals generally, which are costly and easy poisoning. Active component of the disclosed catalyst is transition metal nitride. Carrier is activated carbon powder Vulcan XC-72. Percentage content of mass of transition metal nitride in active component is 1-6%. The preparation method includes steps: dissolving macrocyclic compound of transition metal, Vulcan XC-72 into organic solvent, and carrying out ultrasonic action for 30-60 minutes; stirring up and drying out the said solution under normal temperature, and obtaining powder after drying; loading the powder to closed container and letting ammonia into the container; controlling temperature of heat treatment at 600-1000 deg.C, and time as 0.5-10h so as to obtain the catalyst after natural cooling. Area ratio activity of carbon carried platinum catalyst is 1.5mA / cm2, and the disclosed carbon carried nitride catalyst reaches to 3.1 mA / cm2. Features are: simple flow and easy controlled procedure.

Owner:BEIJING UNIV OF TECH

Preparation method for nanoscale transition metal nitride/carbon composite material

ActiveCN102139920AUniform particlesNo reunionNitrogen compoundsTitanium compoundsCarbon compositesFiltration

The invention relates to a preparation method for nanoscale transition metal nitride / carbon composite material, the chemical formula of nanoscale transition metal nitride / carbon composite material is MeN / C (Me is one or a mixture of more of organic compounds such as titanium, vanadium, chromium, nickel, manganese, molybdenum and the like; N and C are respectively nitrogen and carbon); the anoscale transition metal nitride / carbon composite material is obtained by the following methods: a tri-block copolymer P123 of PEO-PPO-PEO is taken as a template, the tri-block copolymer P123 and the urea resin, melamine resin or carbon nitride polymer are mixed and heated so as to obtain mesoporous carbon nitride, then the mesoporous carbon nitride is added into a metal organic compound or an ethanol solution of various mixtures of the metal organic compound, the removal of air in holes by decompression after ultrasonic vibration is carried out on the mixture, and finally the nanoscale transition metal nitride / carbon composite is obtained after the mixture undergoes ethanol pumping filtration, is scrubbed, dried and processed at high temperature under the protection of inert gas; and the product is uniform and is environmental friendly.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Manufacturing apparatus and method for large-scale production of thin-film solar cells

InactiveCN1703782ALow costFinal product manufactureSemiconductor/solid-state device manufacturingIndiumManufactured apparatus

A method of manufacturing improved thin-film solar cells entirely by sputtering includes a high efficiency back contact / reflecting multi-layer containing at least one barrier layer consisting of a transition metal nitride. A copper indium gallium diselenide (Cu(InxGa1-x)Se2) absorber layer (X ranging from 1 to approximately 0.1) is co-sputtered from specially prepared electrically conductive targets using dual cylindrical rotary magnetron technology. The band gap of the absorber layer can be graded by varying the gallium content, and by replacing the gallium partially or totally with aluminum. Alternately the absorber layer is reactively sputtered from metal alloy targets in the presence of hydrogen selenide gas. RF sputtering is used to deposit a non-cadmium containing window layer of ZnS. The top transparent electrode is reactively sputtered aluminum doped ZnO. A unique modular vacuum roll-to-roll sputtering machine is described. The machine is adapted to incorporate dual cylindrical rotary magnetron technology to manufacture the improved solar cell material in a single pass.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

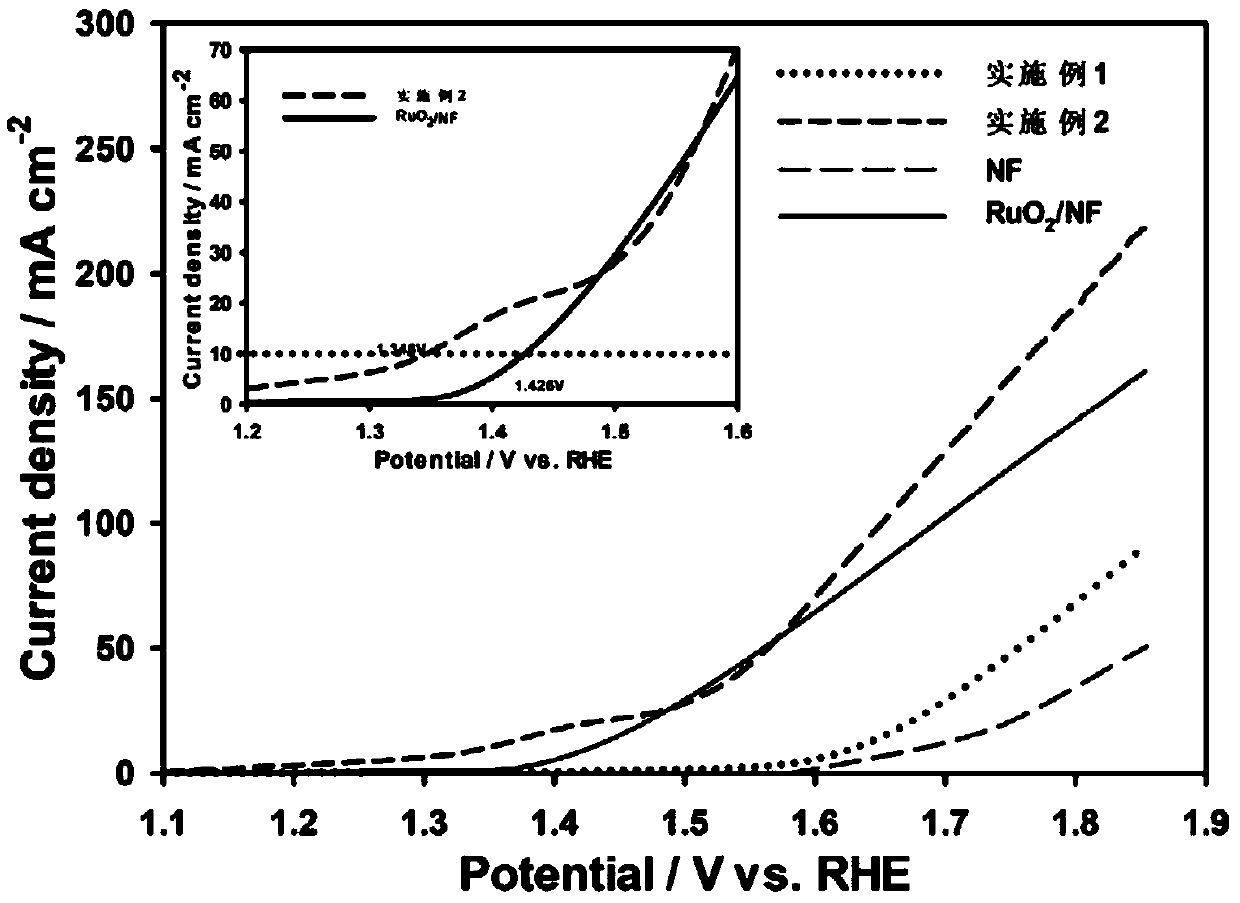

Transition metal nitride/carbon electrocatalyst and preparation method and application of transition metal nitride/carbon electrocatalyst

ActiveCN108671953AImprove electrocatalytic performanceImprove HER performancePhysical/chemical process catalystsElectrodesElectrolysisHydrogen

The invention relates to electrochemical power sources and the field of electrochemical catalysis, and particularly relates to a transition metal nitride / carbon electrocatalyst. The transition metal nitride / carbon electrocatalyst comprises a substrate and a shell, the substrate is coated by the shell, and the shell comprises copper nitride and further comprises a carbon material or a nitrogen doped carbon material. The invention further provides a preparation method of the electrocatalyst, and the electrocatalyst is prepared by forming MOF of copper in advance, then further aminating and calcining through one step, and preparing the electrocatalyst. The processes of oxygen precipitation and hydrogen precipitation show the low overpotential in the alkaline environment, and the electrocatalyst can be used as a catalyst material of alkaline efficient electrolysed water.

Owner:CENT SOUTH UNIV

Transition metal-nitrogen doped carbon composite material and preparation method thereof

ActiveCN109078649AHigh degree of carbonationLarge specific surface areaPhysical/chemical process catalystsCarbon compositesNitrogen doped

The invention discloses a transition metal-nitrogen doped carbon composite material and a preparation method thereof. Transition metal chlorine salt and nitrogenous small organic molecules serve as atransition metal source and carbon and nitrogen sources, and transition metal coordinated macro-cyclic mixture is directly obtained by a one-step method and then carbonized to obtain the transition metal-nitrogen doped carbon composite material. The preparation method is simple, convenient, rapid and suitable for large-scale production and preparation, the synthesized transition metal-nitrogen doped carbon composite material structures a nano-sheet, transition metal on the nano-sheet exists in two forms, one form is transition metal nanoparticles, and the other form is transition metal nitridenanoparticle. The synthesized transition metal-nitrogen doped carbon composite material has nitrogen doped carbon, transition metal and nitrogen atom coordinated active sites with more defects, has large specific surface area and can be applied to the field of catalysis and energy storage.

Owner:SHAANXI NORMAL UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com