Patents

Literature

236 results about "Nitrogen treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Applying small amounts of liquid nitrogen to various skin problems is now a standard treatment. The medical term for this treatment is cryotherapy. Warts and verrucas, skin tags, small fleshy growths and similar small 'lumps and bumps' on the skin are ideal for liquid nitrogen treatment.

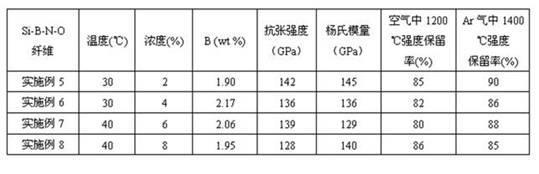

Method for continuously preparing Si-B-N-O fiber by using PCS (Polycarbosilane) fiber

The invention discloses a method for continuously preparing an Si-B-N-O fiber by using a PCS fiber, which comprises the following steps of: after air curing treatment is carried out on the PCS fiber, firstly carrying out nitrogen treatment on a PCS curing fiber and then carrying out boronization treatment or firstly carrying out the boronization treatment and then carrying out the nitrogen treatment; then sintering the PCS curing fiber after the nitrogen treatment and the boronization treatment under the high temperature condition of 1200-1400 DEG C under the protection of high-purity N2 gas or argon atmosphere to prepare the Si-B-N-O fiber. Compared with an Si-N-O fiber, the prepared Si-B-N-O fiber has better temperature resistance, lower dielectric performance and simpler preparation process and is easy to realize industrialized batch preparation.

Owner:NAT UNIV OF DEFENSE TECH

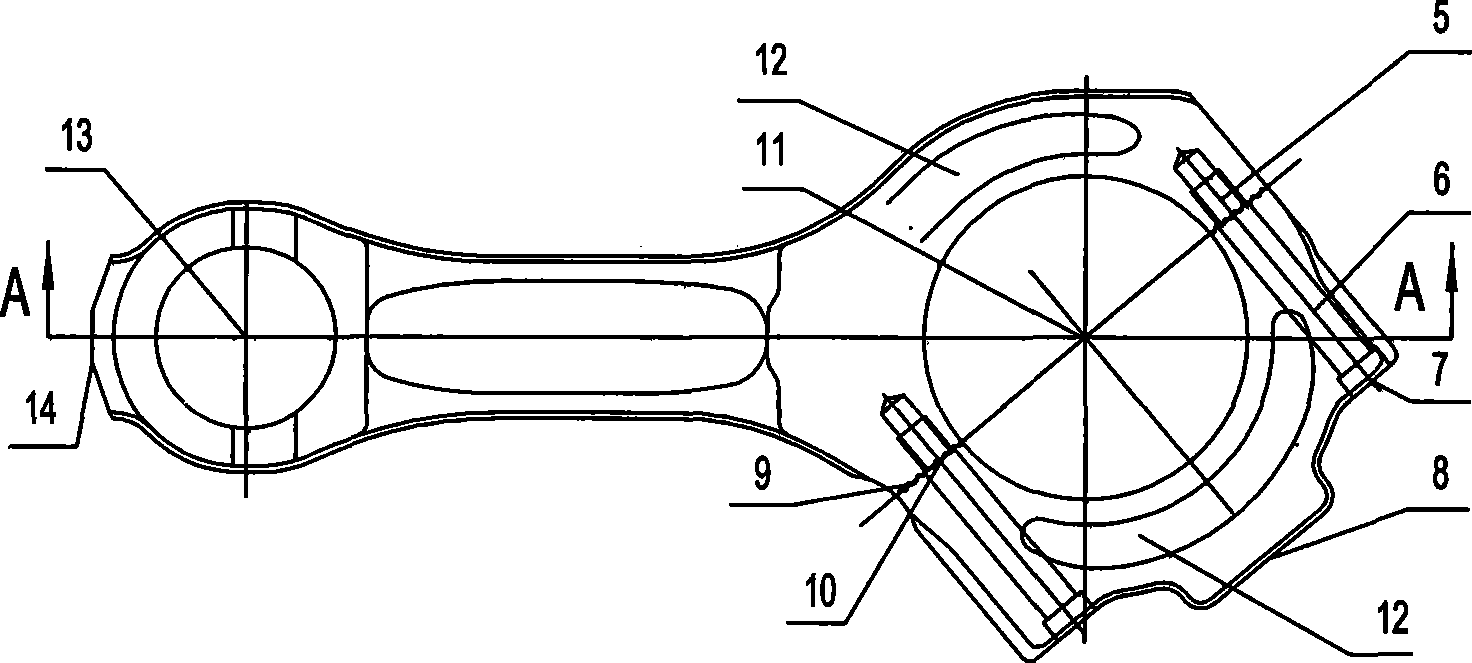

Method for manufacturing diesel engine connecting bar

The invention relates to a manufacturing method of a connecting bar of a diesel engine, which comprises the following processing steps: (1) roughly milling an upper end surface (3); (2) taking the upper end surface (3) as a positioning benchmark, correcting circular processing lines of a large hole (11) and a small hole (13); roughly milling a lower end surface (4); expanding the large hole (11) and the small hole (13), and the like. The manufacturing method is characterized in that in the step (10), the rough and precise counterboring of the flush socket (7) and the drilling, the expanding and the reaming of the bolt hole (6) are finished in one step; in the step (2) and the step (12), the large hole (11) and the small hole (13) are simultaneously half precisely bored, the sequential processing is positioned by the large hole (11), the small hole (13) and the upper end surface (3); in the step 22), plating protective layers positioned on the inner surfaces of the large hole (11) and the small hole (13) are chromium plating layers; in the step (23), the surface chemistry treatment adopts nitrogen treatment; and in the step (28), the surface layer strengthening treatment adopts shot blasting. The manufacturing method of a connecting bar of a diesel engine provided by the invention has reasonable step arrangement and can effectively enhance the quality and the efficiency of the processing of the connecting bar.

Owner:KUNSHAN JIANGJIN MACHINERY

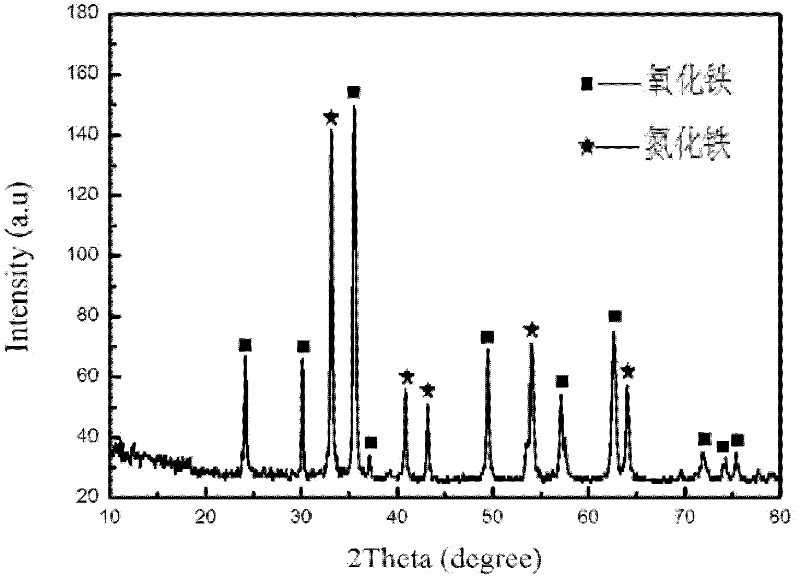

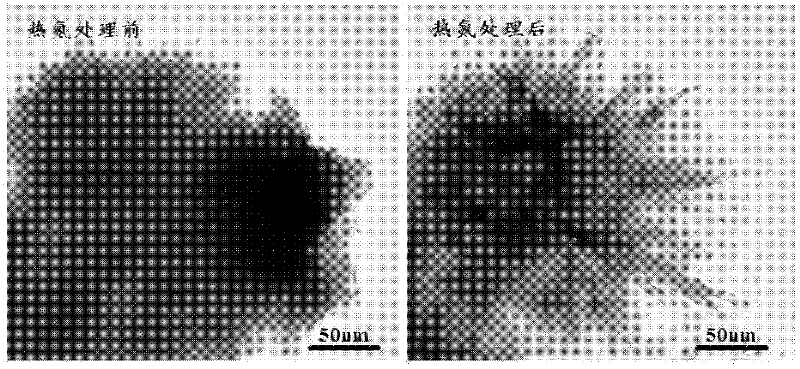

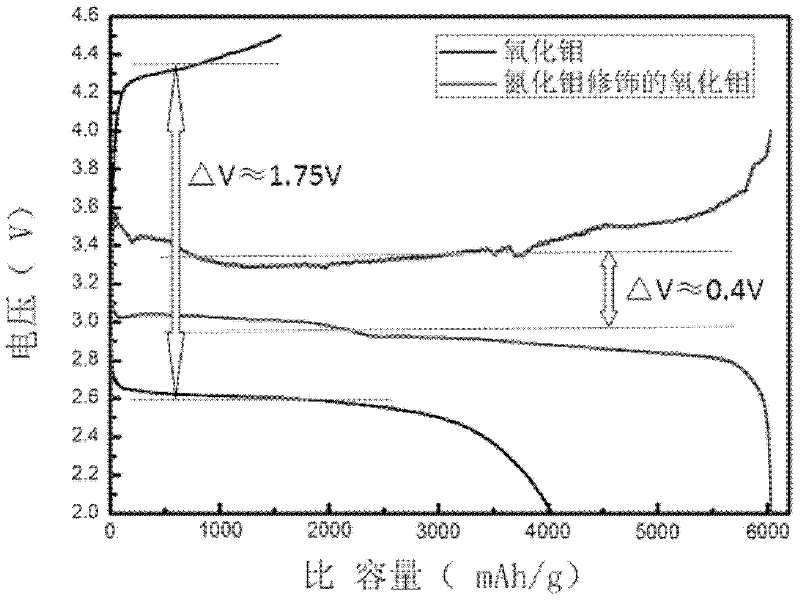

Composite electrocatalyst material used for Li-air batteries and preparation method thereof

InactiveCN102694185AImprove stabilityImprove conductivityPhysical/chemical process catalystsCell electrodesArgon atmosphereLithium–air battery

A composite electrocatalyst material used for Li-air batteries and a preparation method thereof. The transition metal oxide composite electrocatalyst modified by surface conductive transition metal nitride is obtained by conducting thermal nitrogen treatment, in an ammonia atmosphere or an ammonia and argon atmosphere, for transition metal oxide powder or transition metal oxide powder pretreated by nitrogen overlying, wherein the technology of the thermal nitrogen treatment is heating up the powder at a rate of 2-10 DEG C / min to reach the thermal nitrogen treatment temperature of 300-800 DEG C, preserving heat for 10min to 2h and then cooling in furnace. By controlling the content and flow rate of ammonia and the temperature and time of sintering, the thickness of the surface transition metal nitride can be controlled selectively. The method of the invention is simple in technology, convenient for operation, low in cost and strong in controllability. In addition, the obtained composite electrical catalyst has good conductivity and stability and can reduce the charging and discharging polarization of Li-air batteries effectively. The catalyst decreases the inner resistance of batteries and has good discharge capacity. The industrialization prospect of the catalyst is good.

Owner:CENT SOUTH UNIV

Method for extension of plumbago alkene with ultra-thin hexagonal phase silicon carbide membrane on insulated substrate

InactiveCN101492835AElectrical performance independent of substratePolycrystalline material growthFrom chemically reactive gasesHydrogenAlkene

The invention provides a method for preparing graphene by epitaxy of an ultrathin hexagonal phase silicon carbide film on an insulating substrate. The method is characterized by comprising the following steps: step one, taking the insulating substrate; step two, carrying out high-temperature etching pretreatement on the insulating substrate by hydrogen to remove surface scratch and other deficiencies so as to obtain flat surface; step three, carrying out high-temperature nitrogen treatment on the insulating substrate to activate the epitaxial surface so as to ensure that subsequent silicon carbide can be easily adhered on the surface of the substrate and maintain the same crystallographic orientation relationship with the substrate; step four, extending the hexagonal phase monocrystal silicon carbide on the insulating substrate; and step five, vaporizing silicon ions in the silicon carbide to complete preparation of the graphene on the insulating substrate.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Salt-bath heat treatment technology of piston rod

InactiveCN101580926AReduce brittlenessExtended service lifeSolid state diffusion coatingNitrogen treatmentHardness

The invention relates to a salt-bath heat treatment technology of a piston rod, which comprises the following steps of primary processing of the piston rod and surface heat treatment of the piston rod, wherein the surface heat treatment technology of the piston rod puts emphasis on first nitrogen treatment and second oxidation treatment, thus realizing the combination of wearing resistance and corrosion resistance and the combination of heat treatment technique and aseptic technique. The heat treatment technology is simple in operation, easy for realization and low in cost; the piston rod produced by the method has smooth surface, strong corrosion resistance and wearing resistance, low rejection rate, long service life, and no air leakage. The technology accomplishes the heat treatment and anti-corrosion treatment at one time, has low treatment temperature, short time, and ability for improving the hardness, wearing resistance, corrosion resistance and fatigue strength of the surfaces of the parts simultaneously, reduces friction coefficient and lowers the brittleness of the piston rod, leads to small deformation, is nuisanceless and obviously expands the range of materials suitable to nitrocarburizing, namely the treatments of all materials have good effects, thus having the advantages of optimizing processing procedures, shortening production period and lowering production cost.

Owner:QINGDAO ZHANGSHI MACHINERY

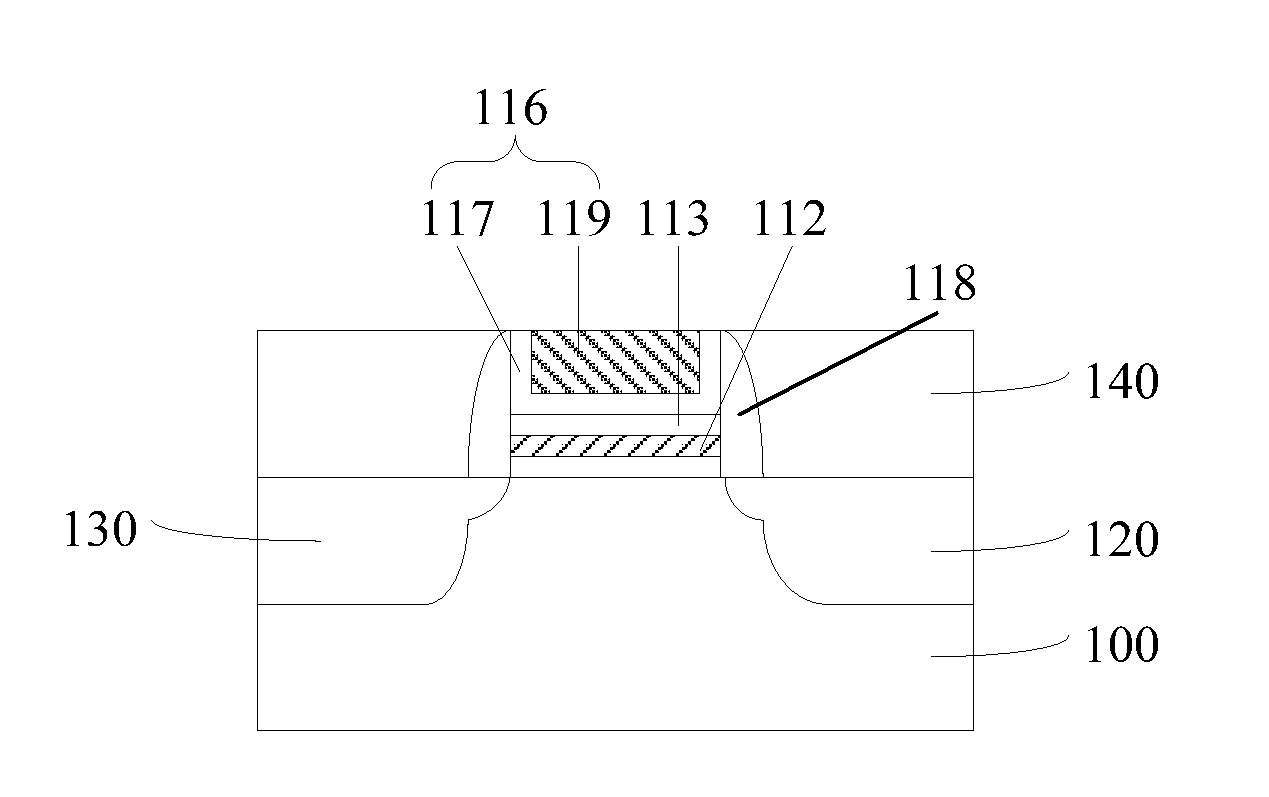

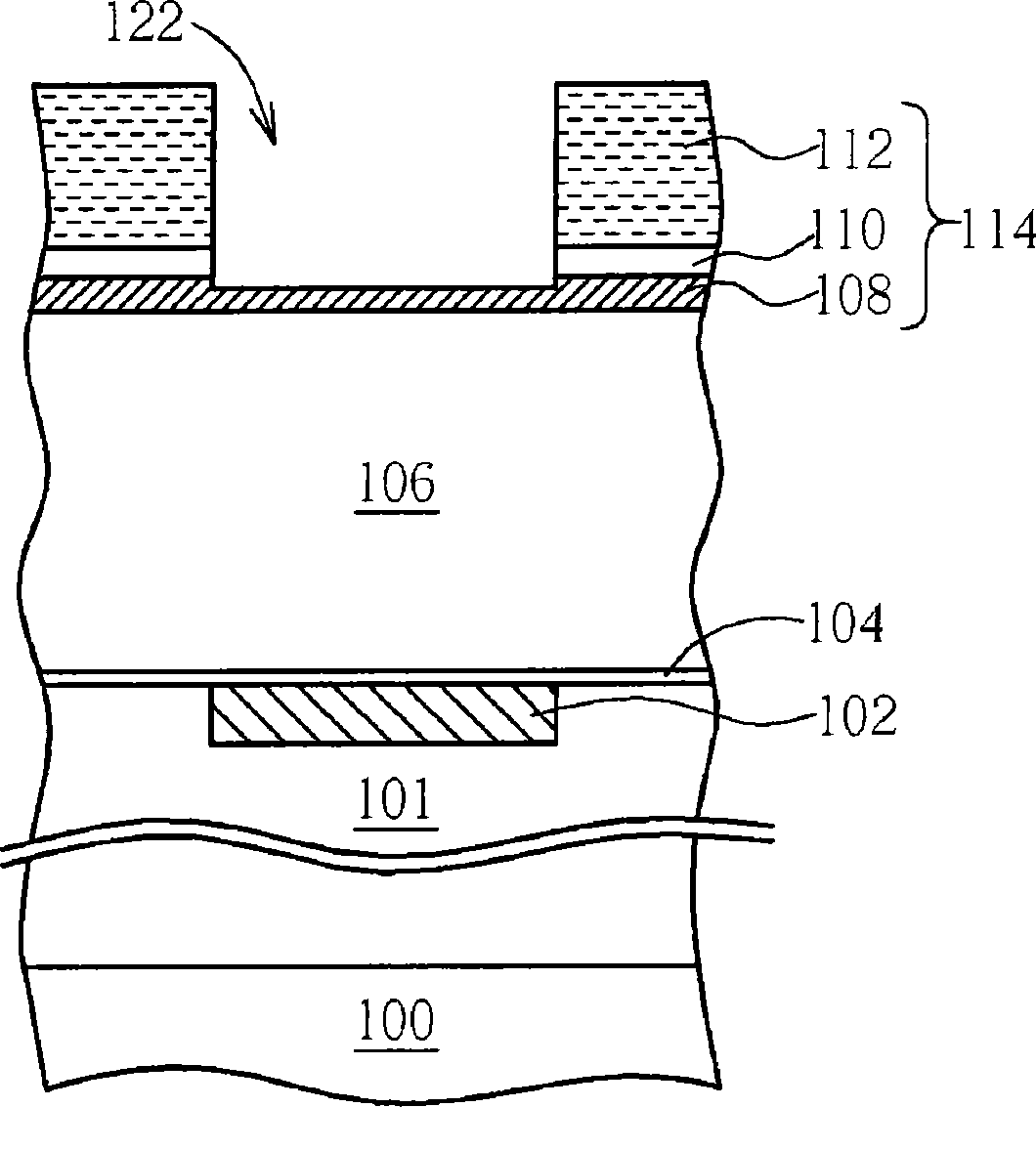

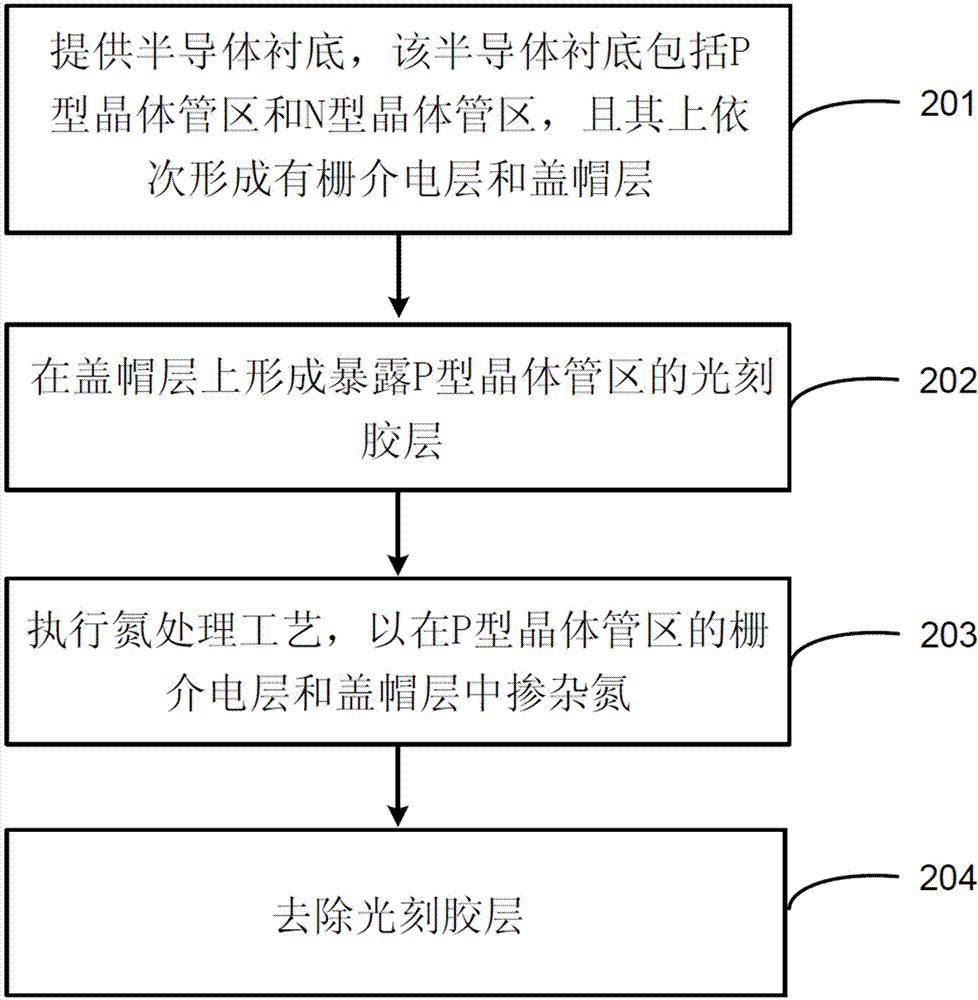

Mos transistors and fabrication method thereof

ActiveUS20150035084A1Semiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricEngineering

Owner:SEMICON MFG INT (SHANGHAI) CORP

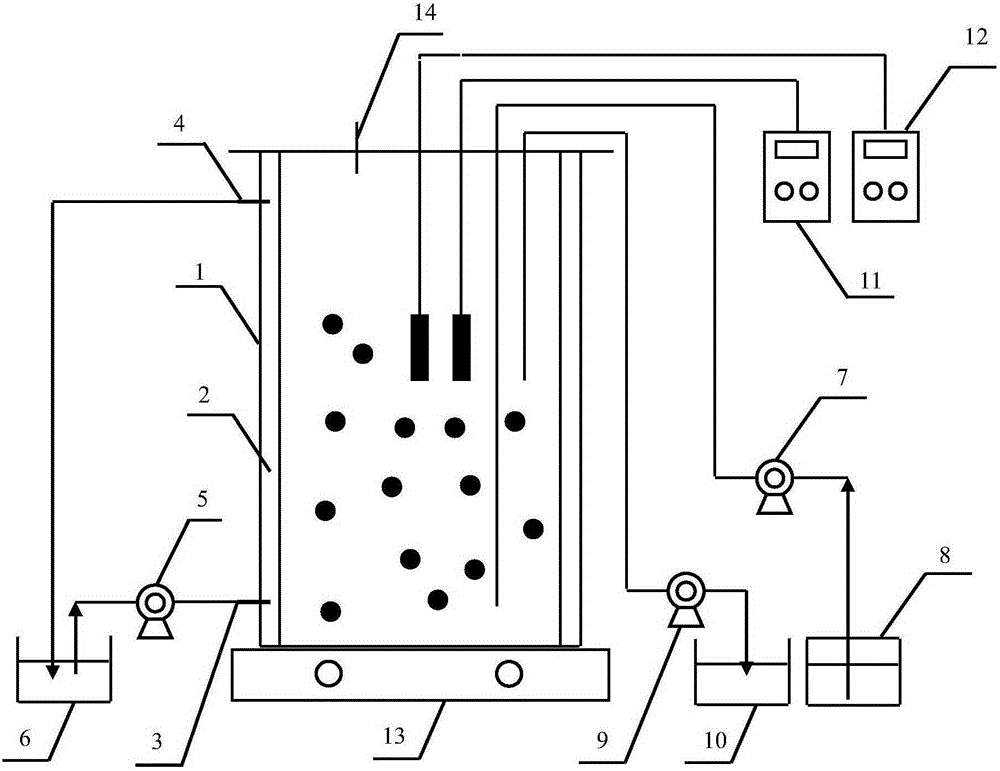

Biological nitrogen removal method based on anaerobic Feammox and application thereof

ActiveCN105271514AHigh energy consumptionReduce energy consumptionWater contaminantsTreatment with anaerobic digestion processesAnaerobic reactorOperating cost

The invention discloses a biological nitrogen removal method based on anaerobic Feammox and application thereof. The biological nitrogen removal method comprises the following steps that sludge containing Feammox microorganisms is added into an anaerobic reactor, ammonia containing wastewater is led into the reactor, NH4 + in the Fe (III) NTA oxidized wastewater is utilized to generate NO2-, and then nitrogen treatment is performed. The biological nitrogen removal method comprises the specific steps that 1, the Feammox enriched microorganisms are cultivated: the sludge is pretreated and the Feammox microorganisms are cultivated; 2, the Feammox microorganisms are utilized to perform wastewater treatment; 3, nitrogen removal treatment is performed by using the liquid collected after anaerobic Feammox treatment. The method has the advantages of lower power consumption, few carbon source demands, less greenhouse gas emissions, less produced NO3- and the like, is lower in investment and operating costs and wide in application prospect.

Owner:CHONGQING UNIV

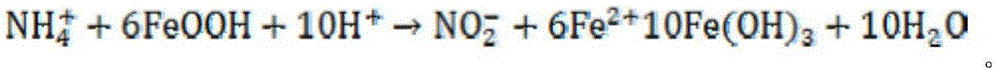

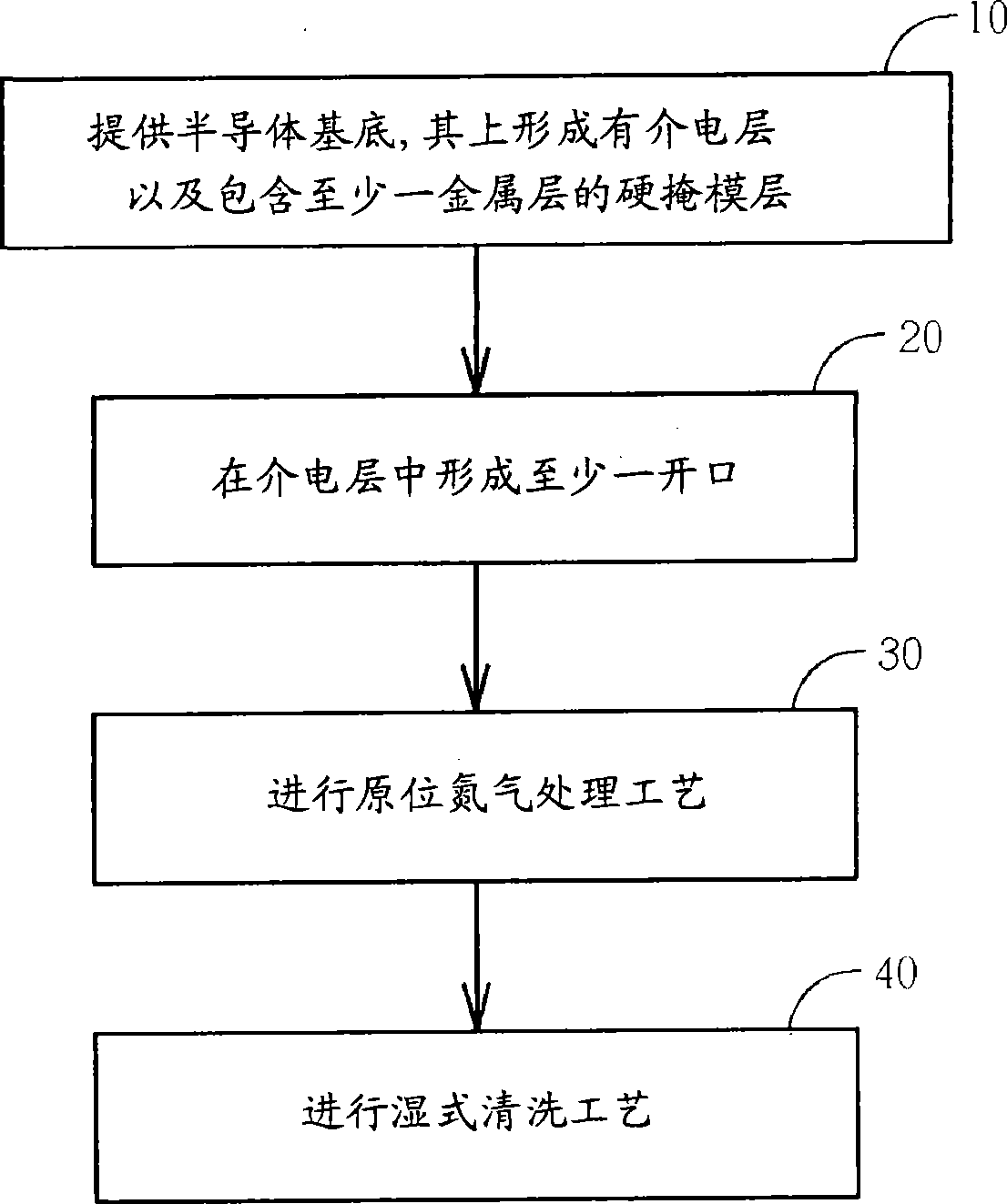

Cleaning method after opening etching

InactiveCN101452879AEfficient removalAvoid damageSemiconductor/solid-state device manufacturingEtchingCleaning methods

The invention provides a washing method after etching openings. The method comprises the steps of providing a semiconductor substrate with a dielectric layer, etching openings to form at least one opening in the dielectric layer, carrying out a nitrogen treatment process to wash C-F polymer residue in the opening and finally carrying out a wet washing process.

Owner:UNITED MICROELECTRONICS CORP

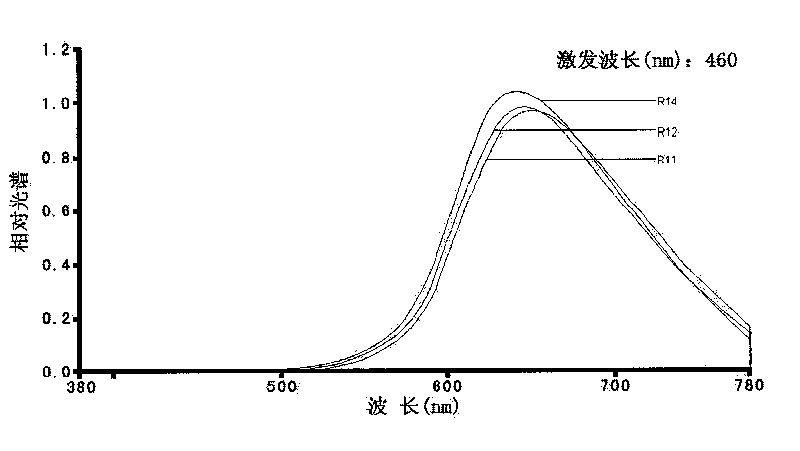

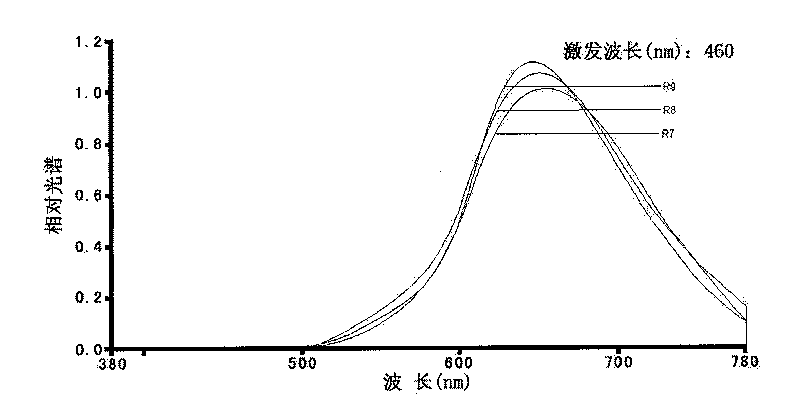

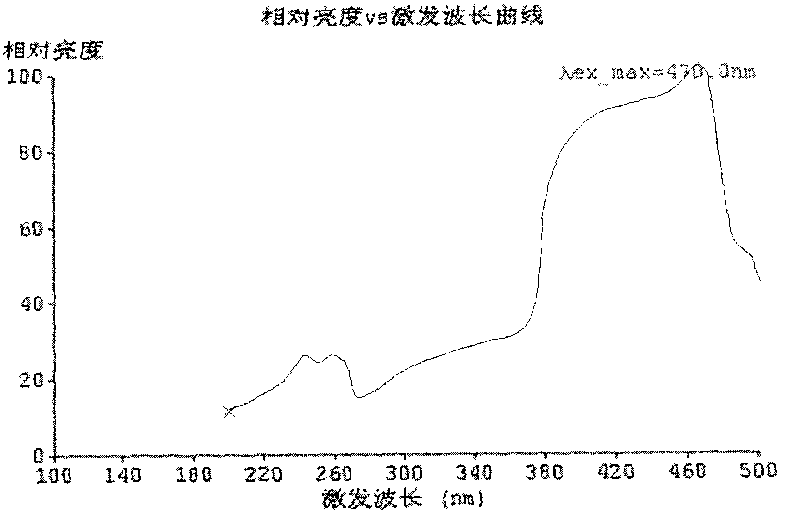

Red fluorescent powder used by white light LED and preparation method thereof

ActiveCN101760194ALow color temperatureGood colorGas discharge lamp usageLuminescent compositionsPeak valueChemical measurement

The invention relates to a red fluorescent powder used by a white light LED and a preparation method thereof. The chemical composition formula of the fluorescent powder is A2-x-2mYmLimSi5-nAlnN8-pFp: XEu, wherein A is one or more of Ca, Ma, Sr and Ba; x is more than or equal to 0.01 but less than or equal to 0.1; m is more than or equal to 0.001 but less than or equal to 1; and p is more than or equal to 0 but less than or equal to n / 2+3m. When metals are used as the raw materials, the nitrogen treatment is required. The preparation method thereof comprises the steps of: accurately weighting various nitride raw materials according to the chemometry, adding a given mass of fluxing agent, ball-milling the mixture for 2 hours, combining at high temperature by using a tubular resistor furnace, burning for 2 to 5 hours at 500 to 1650 DEG C, taking out after naturally cooling to lower than 100 DEG C, and then processing by using a grinding screen so as to acquire the finished product of the fluorescent powder. In the whole process, the ammonia is blown into and is used as the protecting, reducing and nitriding gas. The fluorescent powder can be efficiently aroused by the blue light and can emit the red light which has a peak value close to 620 nm.

Owner:昆山艺全夜光材料科技有限公司

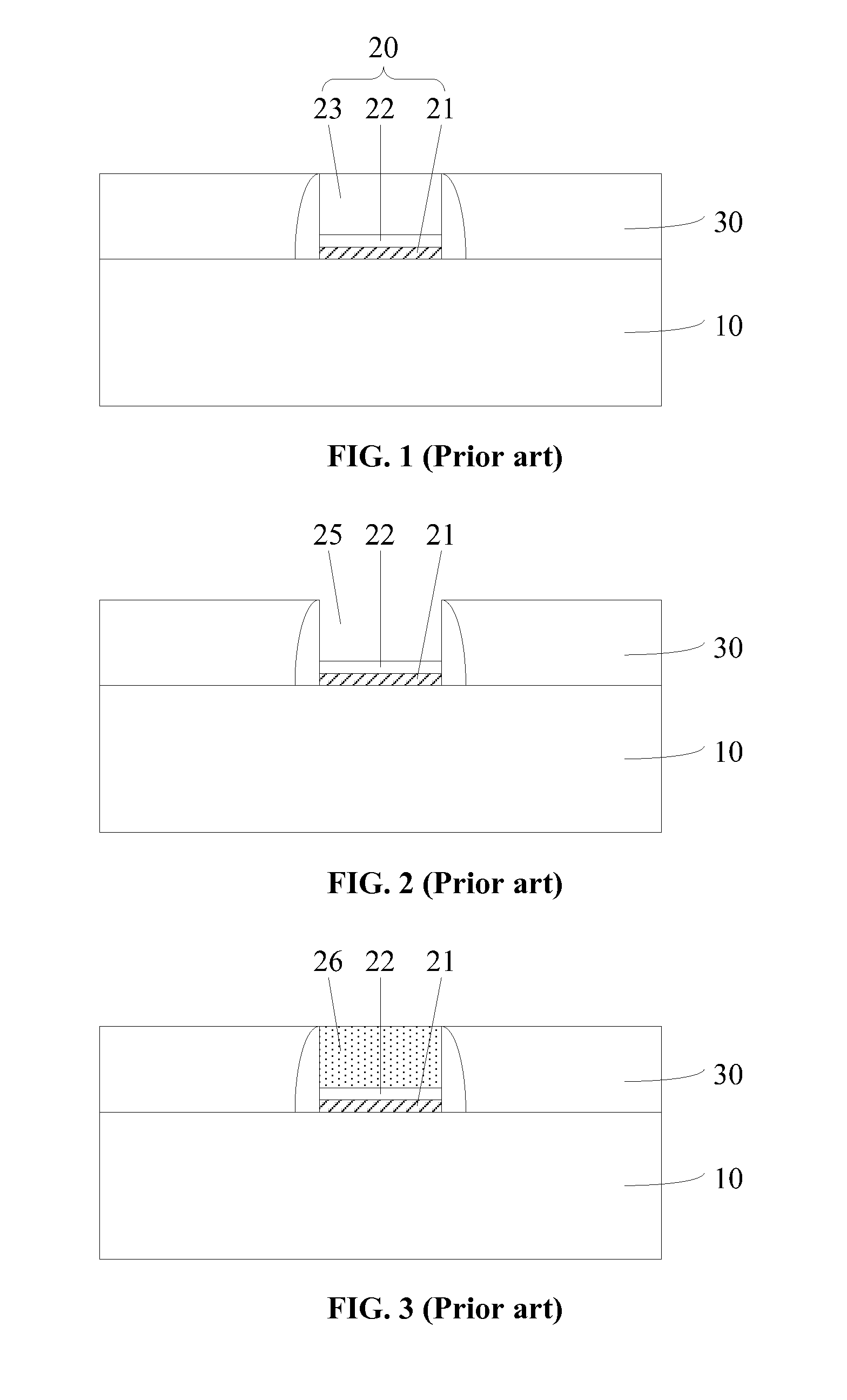

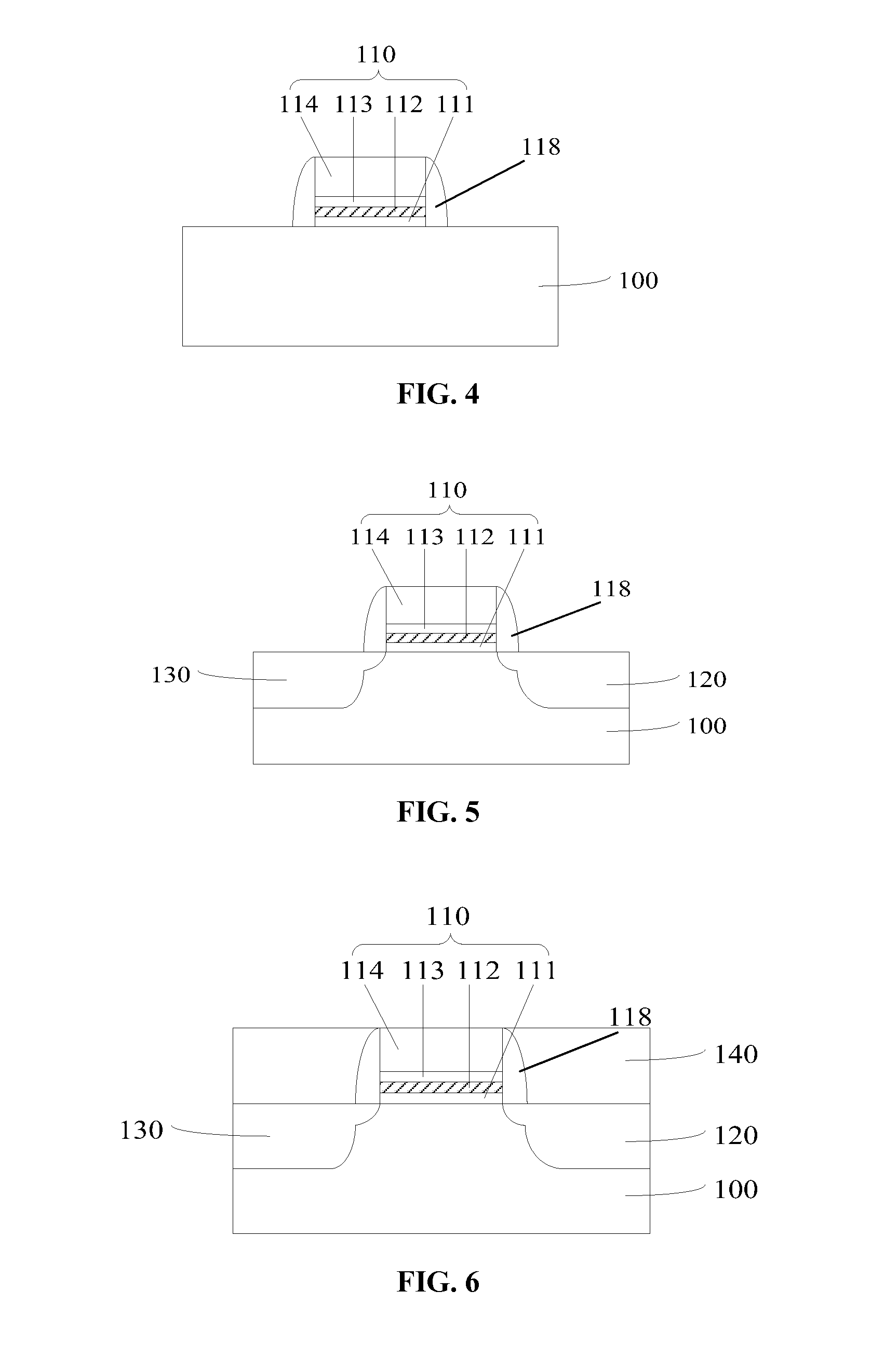

Grid structure from material with high dielectric constant and preparing technique

InactiveCN1540769AEffective isolation of diffusionPrevent penetrationTransistorSemiconductor/solid-state device manufacturingDielectricThin layer

Oxidizing surface of silicon chip grows a very thin silicon oxynitride layer as a buffer of interface between material with high dielectric constant and silicon substrate in order to insulate diffusion between impurity element in material with high dielectric constant and silicon substrate. Carrying out nitrogen treatment for surface of material with high dielectric constant or depositing a thin layer of silicon nitride covers material with high dielectric constant. The nitrogen treated surface or deposited thin layer as interface layer between material with high dielectric constant and polysilicon blocks off penetration from boron P+ polycrystal. In the invention , grid structure is in sandwich type. The invention is applicable to not more than 65 Nano CMOS technique.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

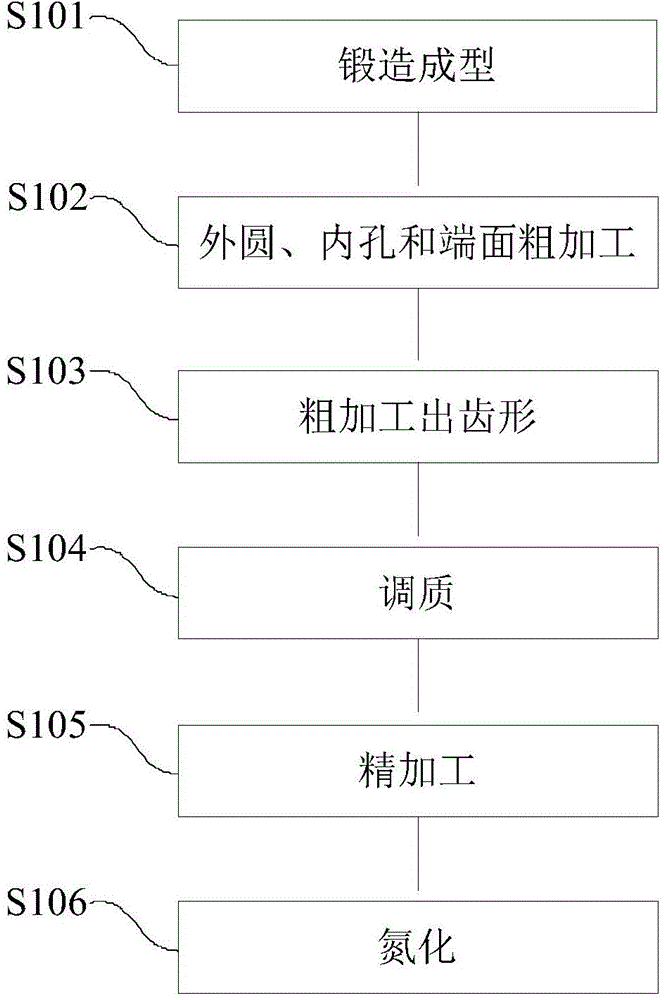

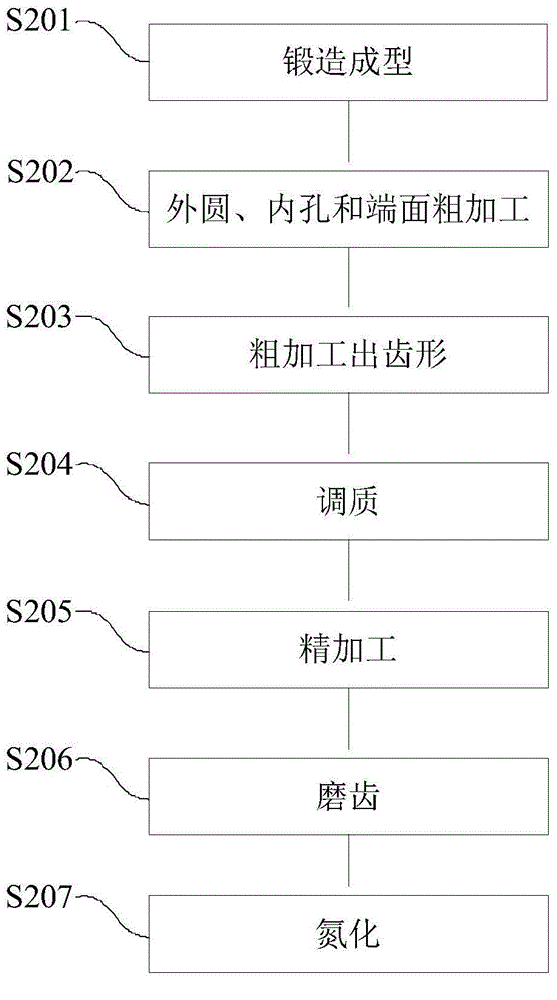

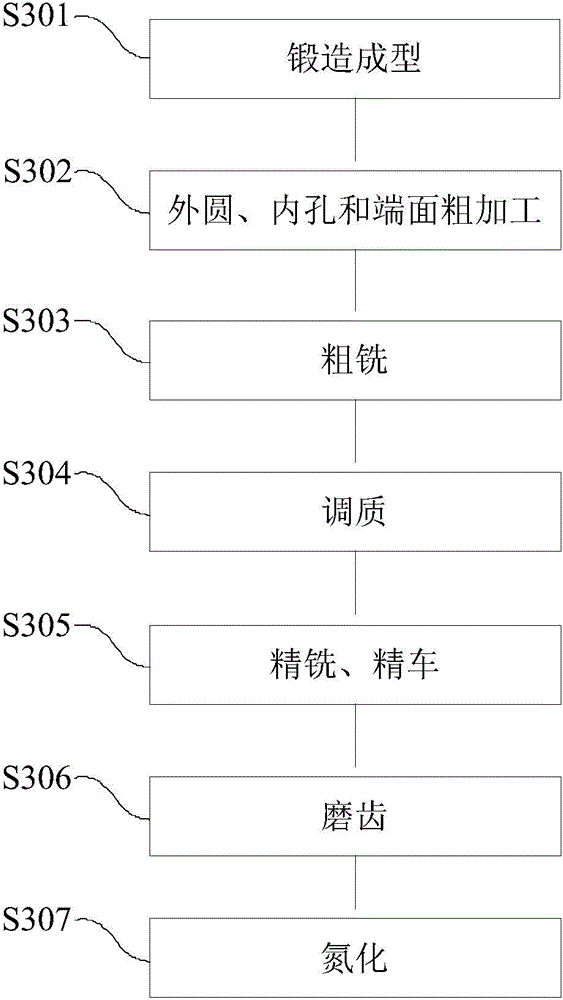

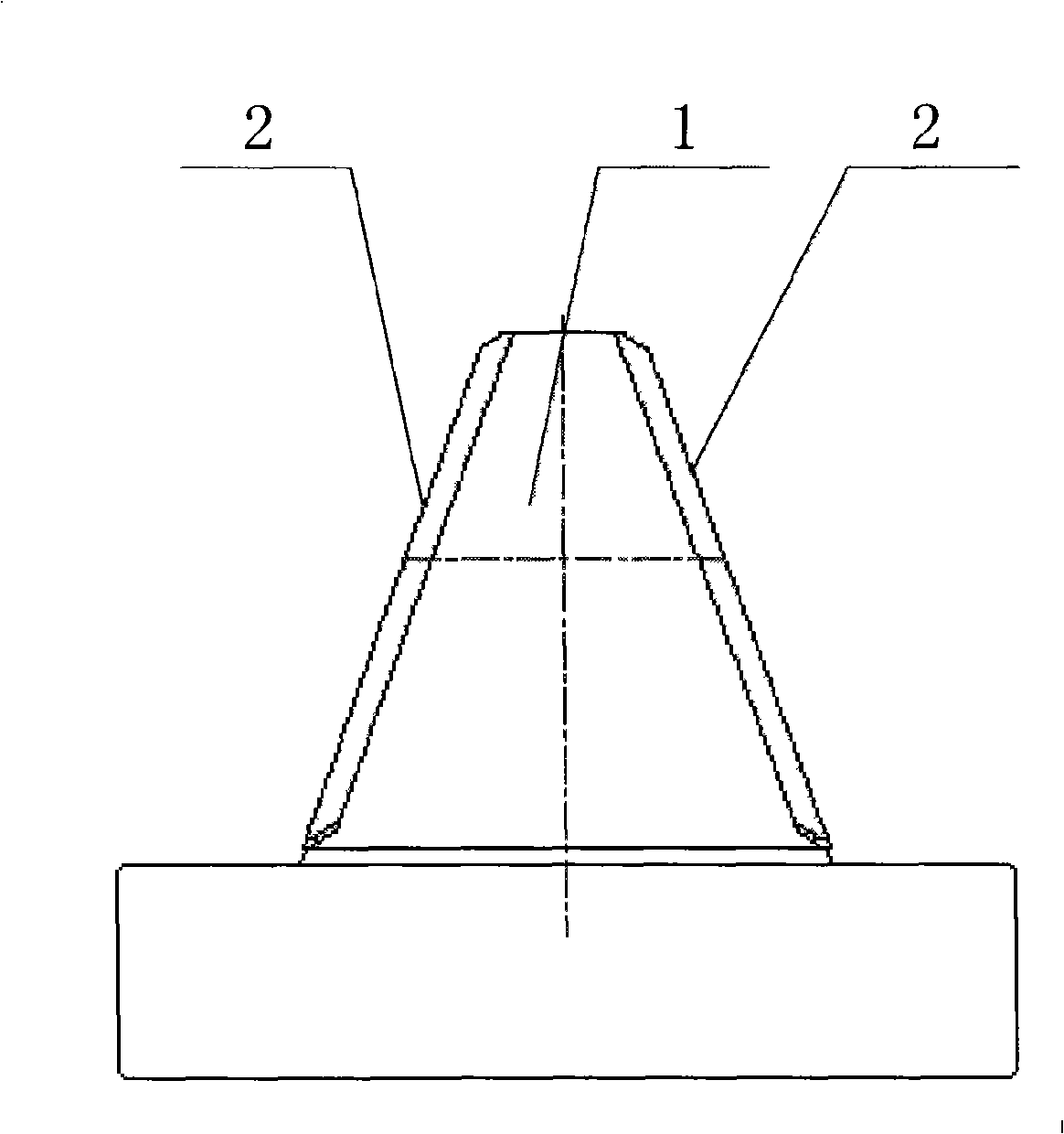

Method for machining large inner gear ring of wind turbine gear box

The invention discloses a method for machining a large inner gear ring of a wind turbine gear box. The method includes the steps that 1, an inner gear ring blank is formed in a forging forming mode according to the specification and forging standard of the inner gear ring; 2, outer circle rough machining, inner hole rough machining and end face rough machining are conducted on the inner gear ring blank, the outer circle, an inner hole and an end face are primarily formed, and allowance is reserved; 3, rough machining is conducted on the inner gear ring obtained after outer circle rough machining, inner hole rough machining and end face rough machining are conducted to enable the inner gear ring to be in a tooth shape; 4, quenching and tempering are conducted on the tooth-shaped inner gear ring obtained after rough machining is conducted; 5, the profile and the inner hole of the inner gear ring obtained after quenching and tempering are machined through finish machining; 6, nitrogen treatment is conducted on the inner gear ring obtained after finishing machining is conducted. By means of the method for machining the large inner gear ring of the wind turbine gear box, quenching and tempering are conducted on the inner gear ring which is machined to be in the tooth shape through rough machining, the quenching and tempering effects on the tooth top, the tooth root and the tooth surface are the same, the uneven quenching and tempering effect caused by the limited quenching and tempering hardenability is avoided, and the comprehensive mechanical performance of the interior of the inner gear ring is improved; meanwhile, working allowance of follow-up finishing machining is lowered, and machining deformation is reduced.

Owner:CHONGQING GEARBOX

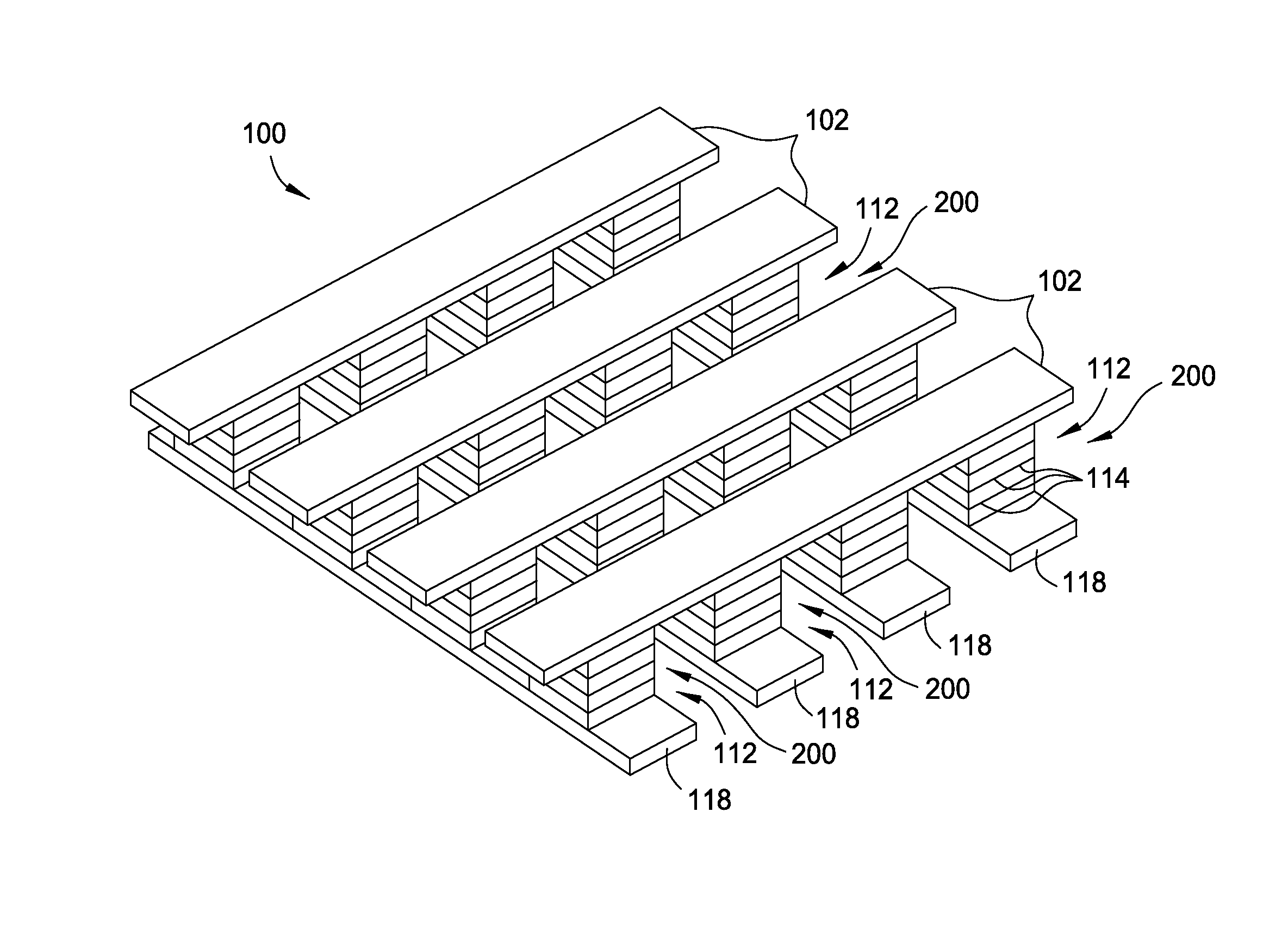

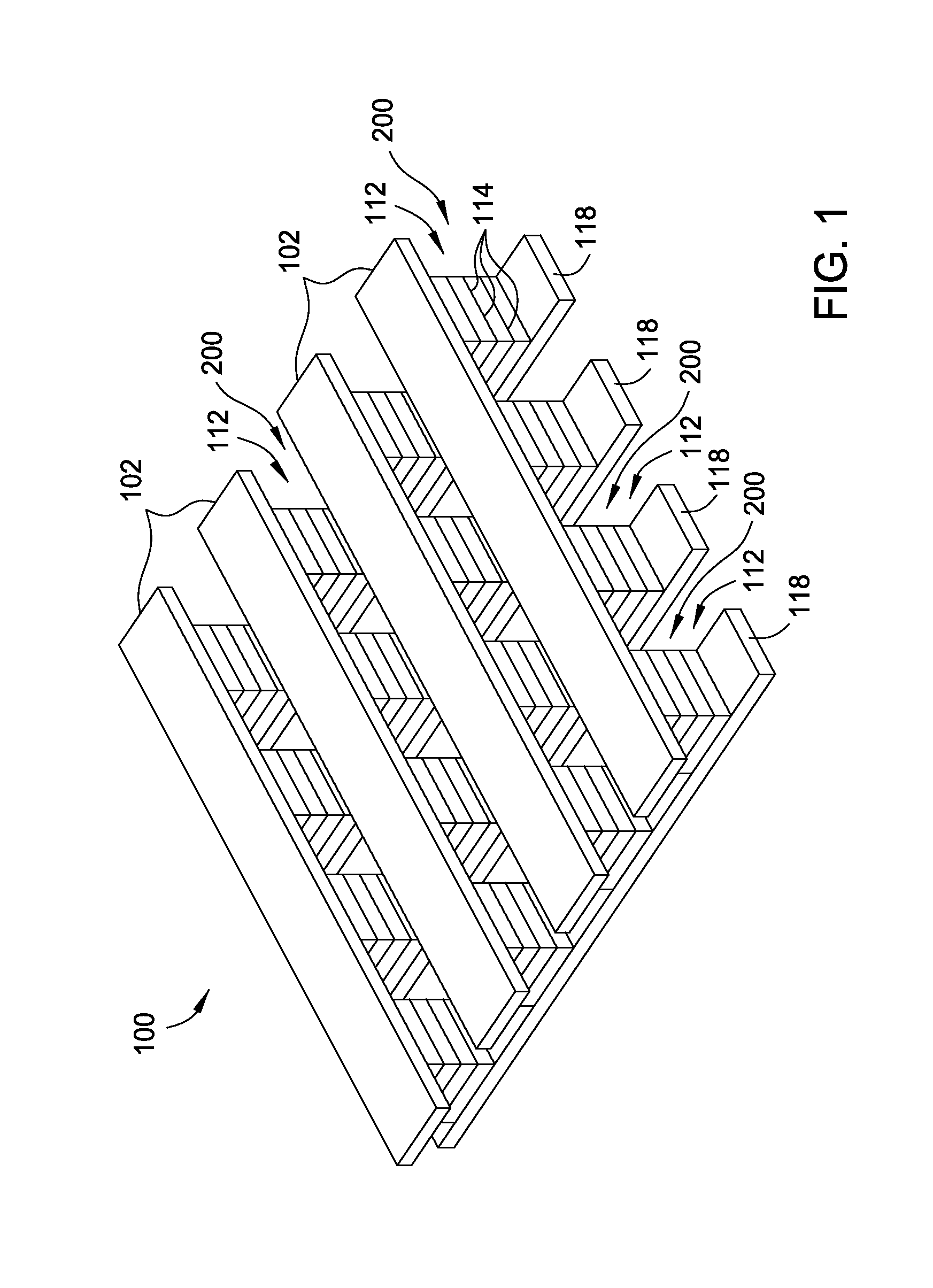

Interface layer improvements for nonvolatile memory applications

InactiveUS20130065377A1Reduce operating currentSolid-state devicesSemiconductor/solid-state device manufacturingSilicon electrodeInterface layer

A resistive switching nonvolatile memory device having an interface layer disposed between a doped silicon electrode and a variable resistance layer fabricated in the nonvolatile memory device and methods of fabricating the same. In one embodiment, the interface layer is a high-k layer having a lower electrical EOT than native silicon oxide to act as a diffusion barrier between the variable resistance layer and the silicon electrode. Alternatively, the high-k interface layer may be formed by performing a nitrogen treatment on a fabricated silicon oxide layer. In another embodiment, the interface layer may be fabricated by performing a nitrogen or ozone treatment on the native oxide layer. In another embodiment, the interface layer is a fabricated silicon oxide layer resulting in an improved diffusion barrier between the variable resistance layer and the silicon electrode. In all embodiments, the interface layer also passivates the surface of the silicon electrode.

Owner:KK TOSHIBA +1

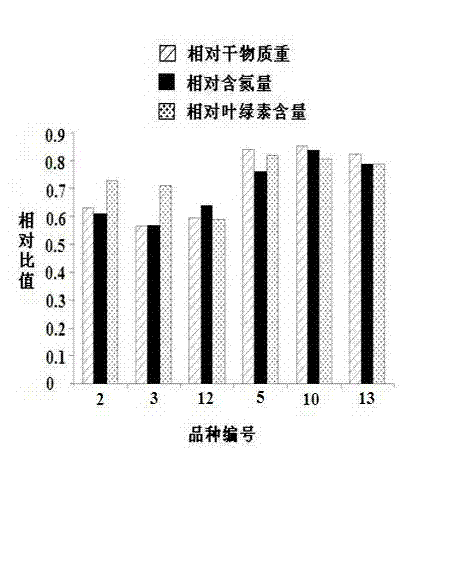

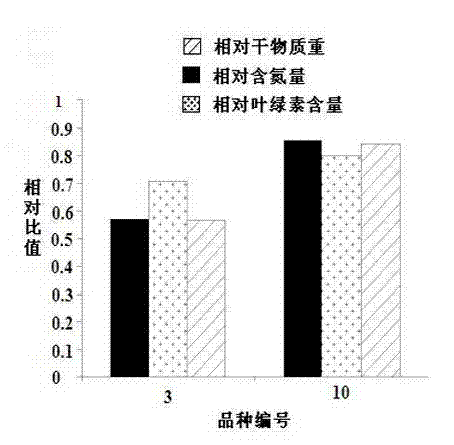

Method for screening variety with highest nitrogen use ratio from various cut-flower chrysanthemum varieties

InactiveCN102175554AImprove nitrogen use efficiencyEasy to operateWeighing by removing componentColor/spectral properties measurementsCut flowersBiochemical mechanism

The invention belongs to the technical field of plant cultivation and breeding and discloses a method for screening a variety with the highest nitrogen use ratio from various cut-flower chrysanthemum varieties, wherein the method comprises the following steps: a) acquiring a water planting seedling; b) performing the sandy culturing primary screening: dividing the water planting seedling into two groups, performing the low-nitrogen treatment on one group while performing the normal nitrogen treatment on the other group, respectively measuring the screening indexes of each variety containing the relative dry weight, relative nitrogen content and relative chlorophyll content, and then screening 2 to 6 varieties with higher nitrogen use ratio and 2 to 6 varieties with lower nitrogen use ratio for the purpose of performing comparison; and c) performing the nutrient solution cultivating repeated screening: cultivating the varieties screened from the step b) in the nutrient solution, and repeatedly screening one variety with the highest nitrogen use ratio and one variety with the lowest nitrogen use ratio. The cut-flower chrysanthemum variety which is finally screened by using the method is used for further improving the existing cut-flower chrysanthemum variety and providing the material for researching the biological characteristics and the physiologic biochemical system of the cut-flower chrysanthemum variety.

Owner:NANJING AGRICULTURAL UNIVERSITY

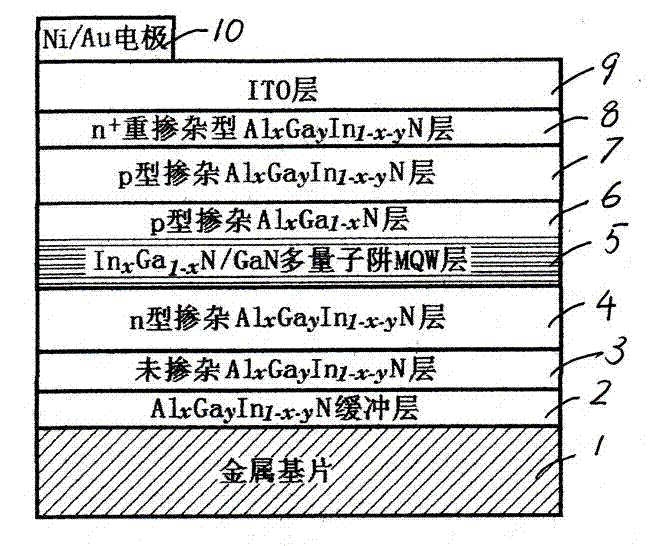

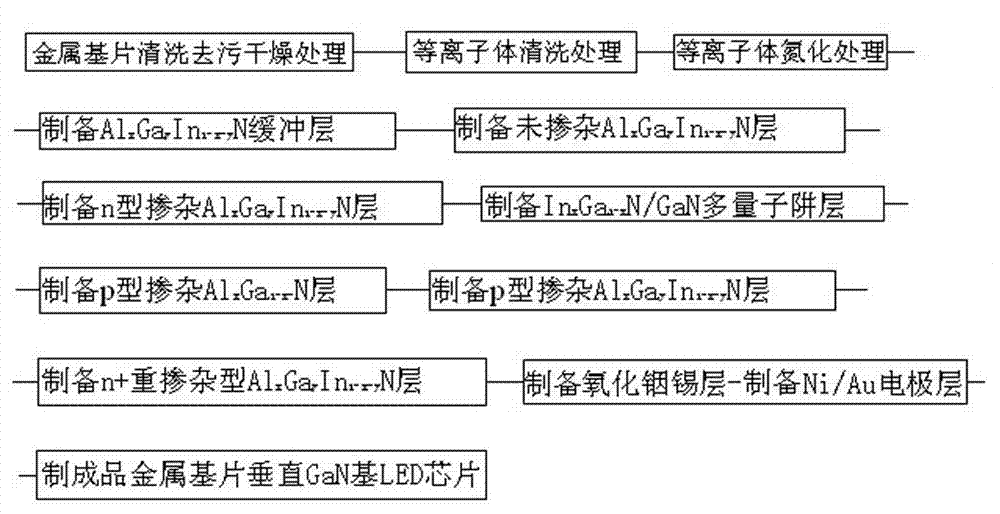

Metal substrate vertical GaN-based LED (Light-Emitting Diode) chip and manufacturing method thereof

ActiveCN102738325AReasonable structureWide spectral rangeChemical vapor deposition coatingSemiconductor devicesQuantum wellIndium tin oxide

The invention discloses a metal substrate vertical GaN-based LED (Light-Emitting Diode) chip and a manufacturing method of the metal substrate vertical GaN-based LED chip. The LED chip is formed by compounding and depositing a metal substrate, an AlxGayIn1-x-yN buffer layer, an undoped AlxGayIn1-x-yN layer, an n-type doped AlxGayIn1-x-yN layer, an InxGa1-xN / GaN multi-quantum well (MQW) layer, a p-type AlxGa1-x-N layer, a p-type doped AlxGayIn1-x-yN layer, an n+ heavy doping type AlxGayIn1-x-yN layer and an indium tin oxide (ITO) layer, wherein an Ni / Au electrode layer is formed on the surface of the ITO layer. The method for manufacturing the metal substrate vertical GaN-based LED chip sequentially comprises the following steps of: arranging materials, performing plasma cleaning, performing nitrogen treatment, manufacturing a buffer layer, manufacturing an undoped layer, manufacturing an n-type doping layer, manufacturing a MQW layer, manufacturing a p-type doping layer, manufacturing a second p-type doping layer, and manufacturing an n+ heavy doping layer, the ITO layer and the electrode layer. The chip has the advantages of reasonable structure, wide spectrum range and the like, and the manufacturing method has the advantages of reasonable process, low temperature, environment friendliness, high quality of finished product, low manufacturing cost and the like.

Owner:GAOYOU INST CO LTD DALIAN UNIV OF TECH

Manufacturing method of grid dielectric layer and grid

InactiveCN101290886AReduce oxidation rateHigh sensitivitySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringMedia layer

A method for making a gate medium layer comprises the following steps that: a semiconductor substrate is provided; nitrogen treatment of the surface of the semiconductor substrate is carried out; and oxidation process of the surface of the semiconductor substrate is carried out after the nitrogen treatment so as to form an oxygenous medium layer. The invention also provides a method for making a grid electrode. The gate medium layer formed through the method has thinner thickness and better thickness evenness.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Cement-free in-situ silicon nitride combined silicon carbide prefabricated member and preparation method thereof

The invention discloses a cement-free in-situ silicon nitride combined silicon carbide prefabricated member and a preparation method thereof. The cement-free in-situ silicon nitride combined silicon carbide prefabricated member is formed by taking silicon carbide, metallic silicon powder, alumina micro powder, silicon dioxide micro powder and hydraulic alumina as materials and additionally adding dispersing agent, water or silica sol. The prefabricated member is formed by adopting a vibration pouring method, is cured and dried and subjected to high-temperature nitrogen treatment in a high-purity flowing nitrogen gas. The prefabricated member has the advantages of easy construction, low cost, flexible product shape, high hot strength, strong corrosion resistance, high wear resistance and the like and is widely applied to parts strictly requiring the hot-state performance, such as a wind-force pipeline of a cement kiln, a blast-furnace throat, an air port, a delivery pipeline of melt metal, a garbage incinerator and the like.

Owner:HENAN UNIV OF SCI & TECH

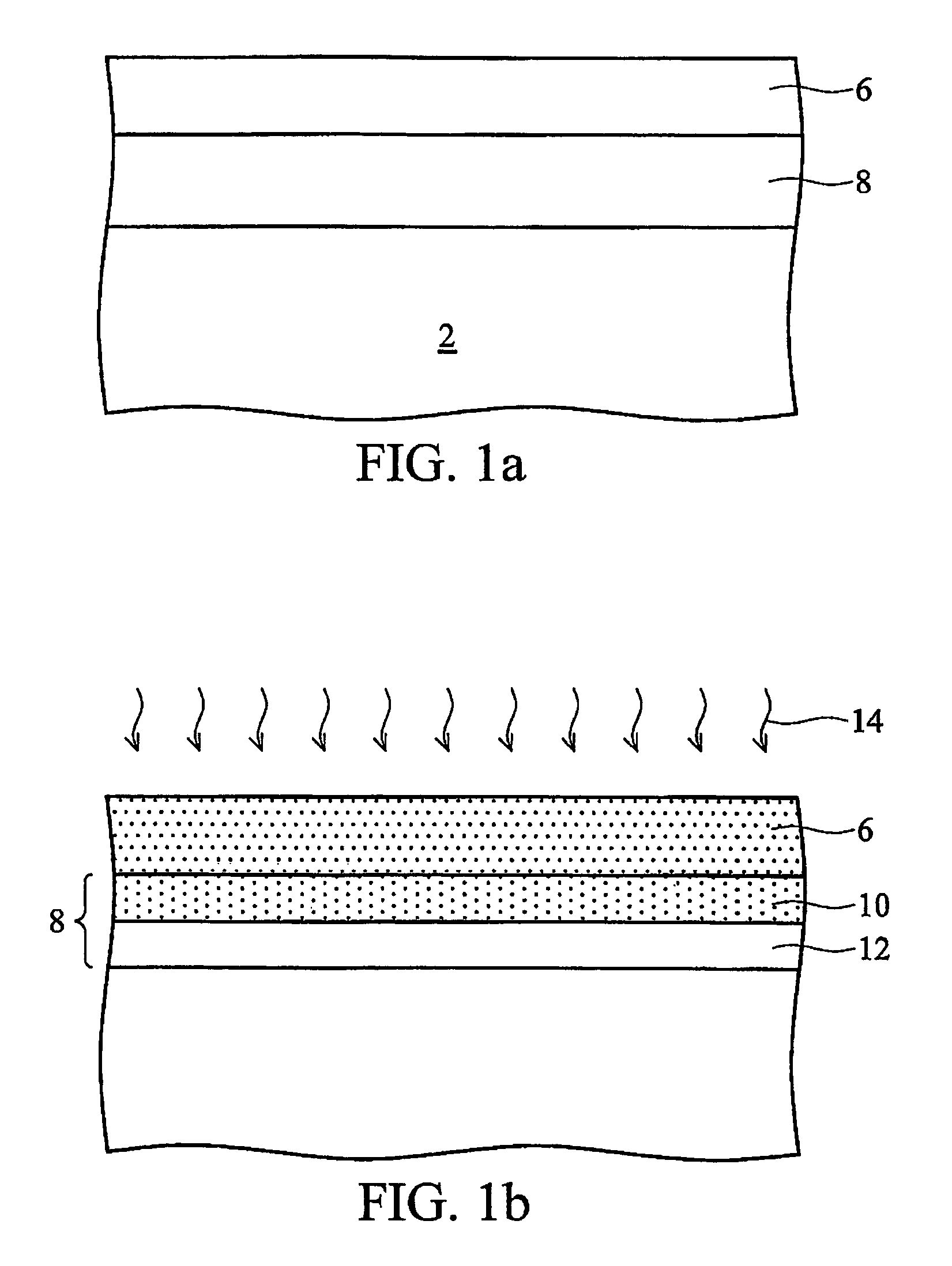

Nitrogen treatment to improve high-k gate dielectrics

ActiveUS7564108B2Overcome problemsTransistorSemiconductor/solid-state device manufacturingDielectricMOSFET

A MOSFET having a nitrided gate dielectric and its manufacture are disclosed. The method comprises providing a substrate and depositing a non-high-k dielectric material on the substrate. The non-high-k dielectric comprises two layers. The first layer adjacent the substrate is essentially nitrogen-free, and the second layer includes between about 1015 atoms / cm3 to about 1022 atoms / cm3 nitrogen. The MOSFET further includes a high-k dielectric material on the nitrided, non-high-k dielectric. The high-k dielectric preferably includes HfSiON, ZrSiON, or nitrided Al2O3. Embodiments further include asymmetric manufacturing techniques wherein core and peripheral integrated circuit areas are separately optimized.

Owner:TAIWAN SEMICON MFG CO LTD

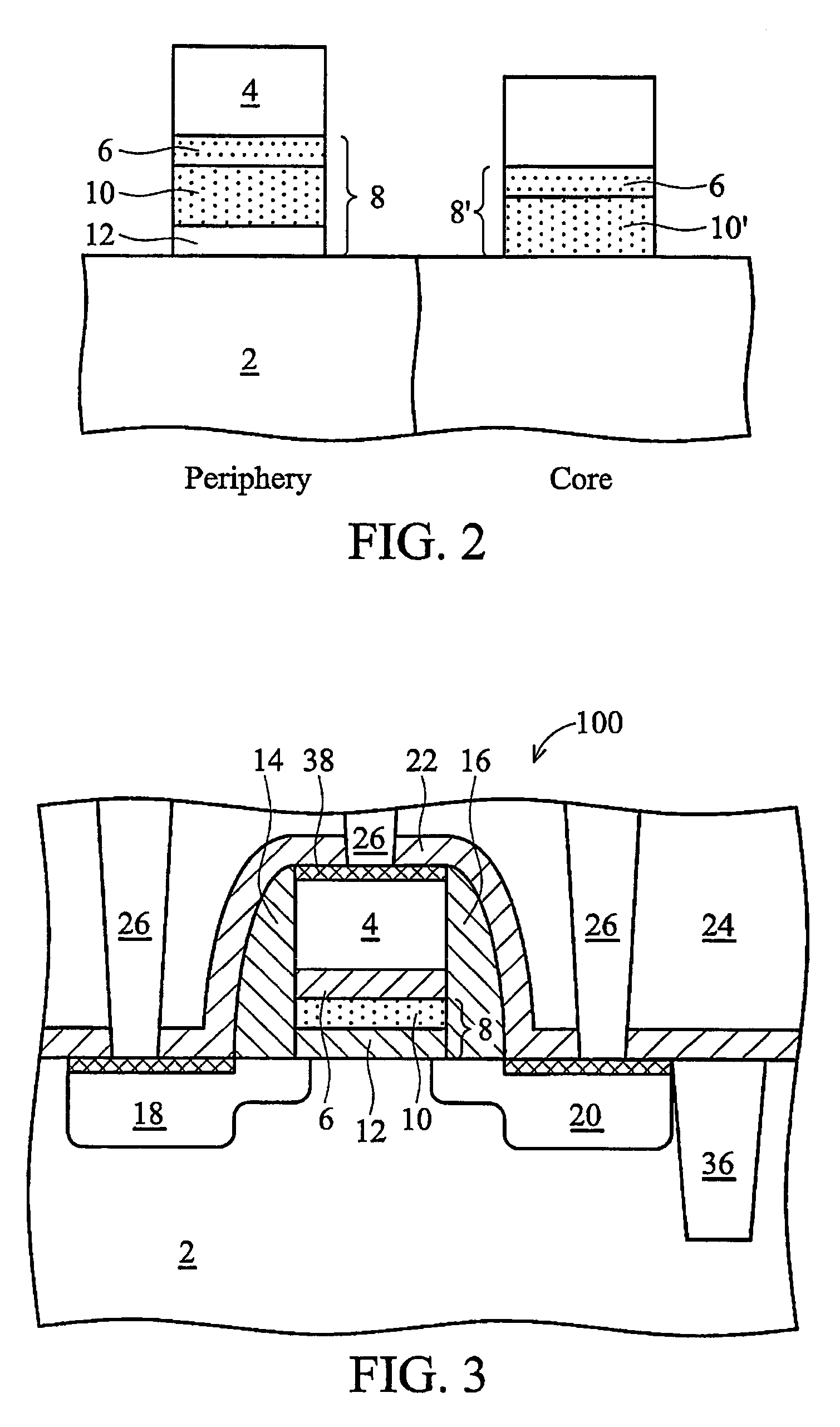

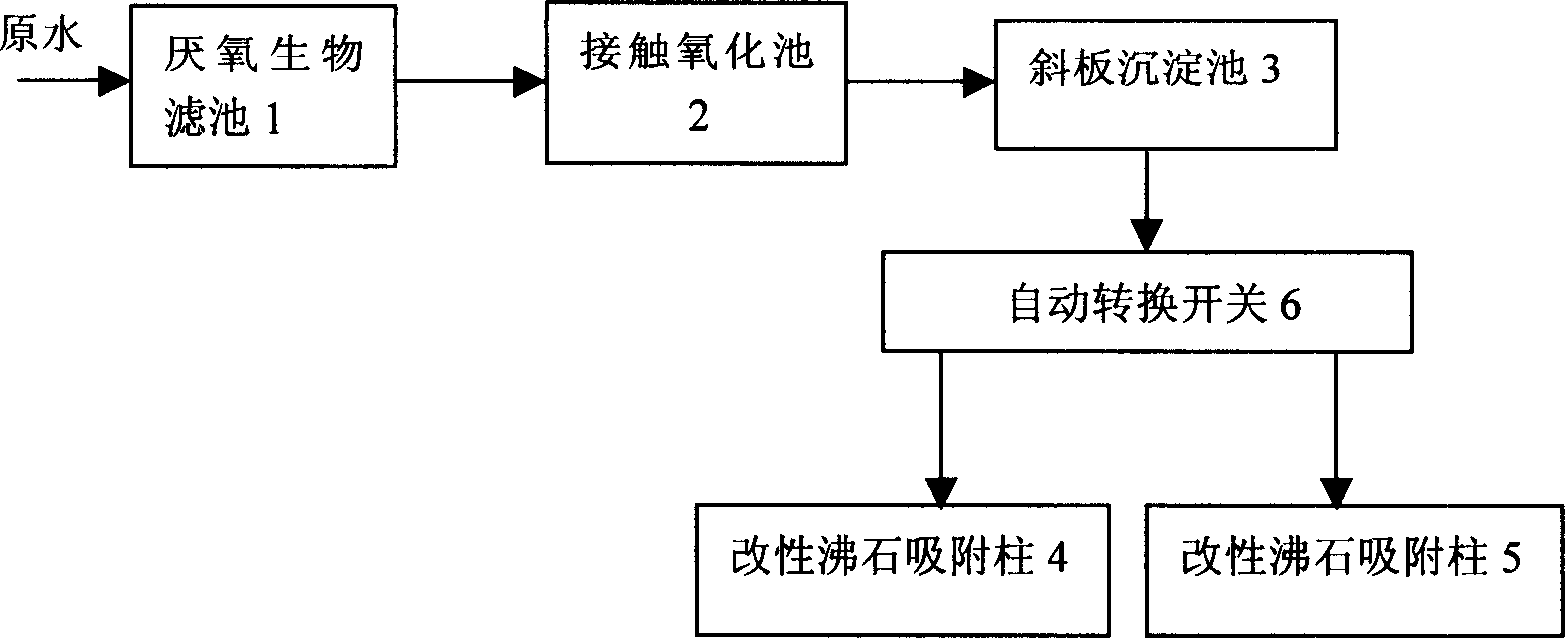

Method for removing ammonia nitrogen from sewage in subzone

InactiveCN1686872AAchieve regenerationContinuous regenerationTreatment with anaerobic digestion processesMultistage water/sewage treatmentAnaerobic filterSewage

The present invention relates to a method for deamination and denitrification of residential quarter sewage, belonging to the field of sewage treatment technology. It is characterized by that after the sewage is passed through anaerobic filter tank, contact oxidation tank and precipitation tank to obtain treatment, then sewage can upwards flow and be fed into two parallel modified zeolite adsorption regeneration columns to implement ammonia and nitrogen adsorption at twice successively, so that said invention can obtain high ammonia and nitrogen treatment efficiency. Said invention also provides the regeneration method of the above-mentioned zeolite adsorption regeneration column by using backflush process.

Owner:HARBIN INST OF TECH

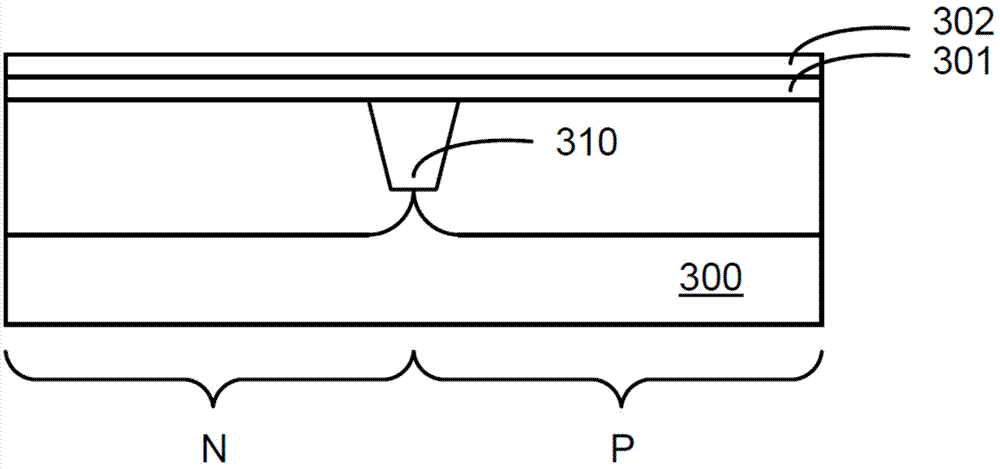

GaN/beta Ga2O3 composite substrate material and preparation method thereof

InactiveCN1694225ASmall mismatchSimple preparation processLaser detailsSemiconductor/solid-state device manufacturingMaterials preparationComposite substrate

A GaN / beta-Ga2O3 compound substrate material and its preparation method, it is equipped with one GaN overburden layer constituted on beta-Ga2O3 single crystal. This compound substrate material preparation method is: Forming the GaN overburden layer with the use of perfect vacuum nitrogen treatment stove on beta-Ga2O3 single crystal substrate, then through anneal processing, obtaining the crystallized GaN thin film on beta-Ga2O3 single crystal substrate. The advantages are simple technology easy operation, suitable for the extension growth of high grade GaN.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

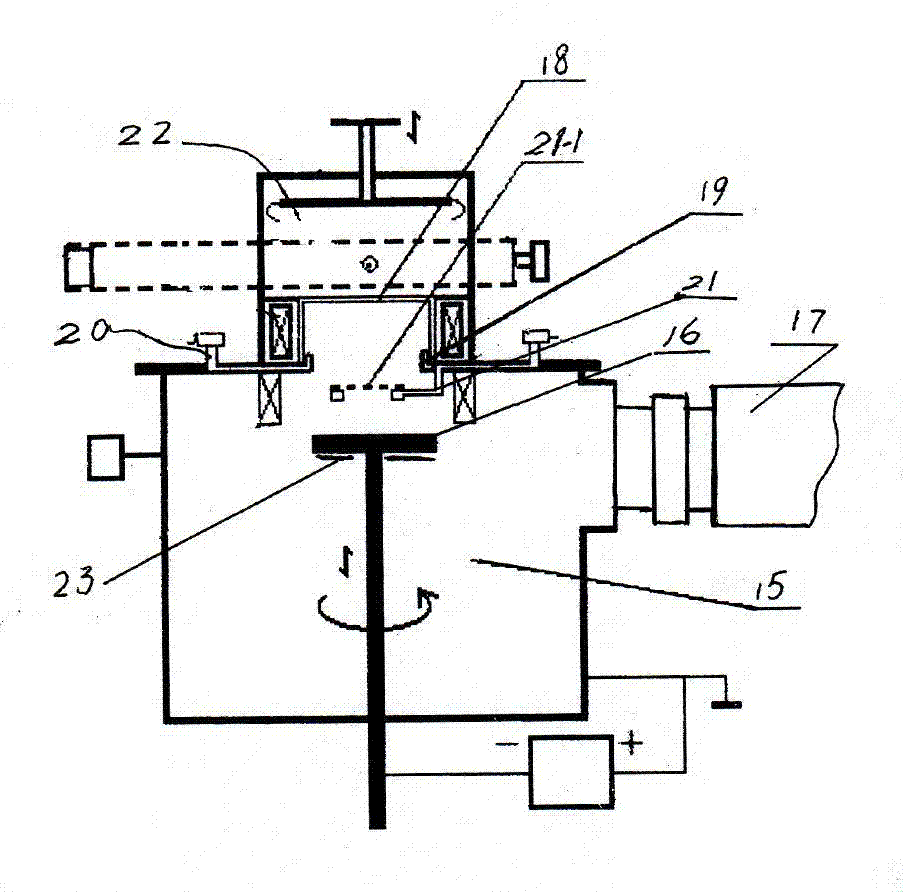

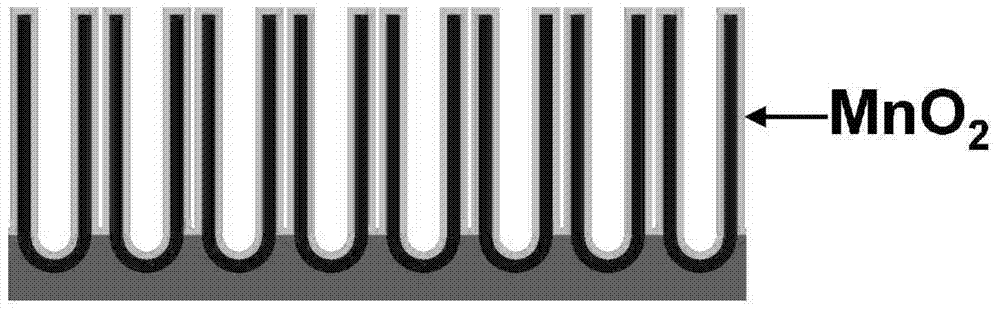

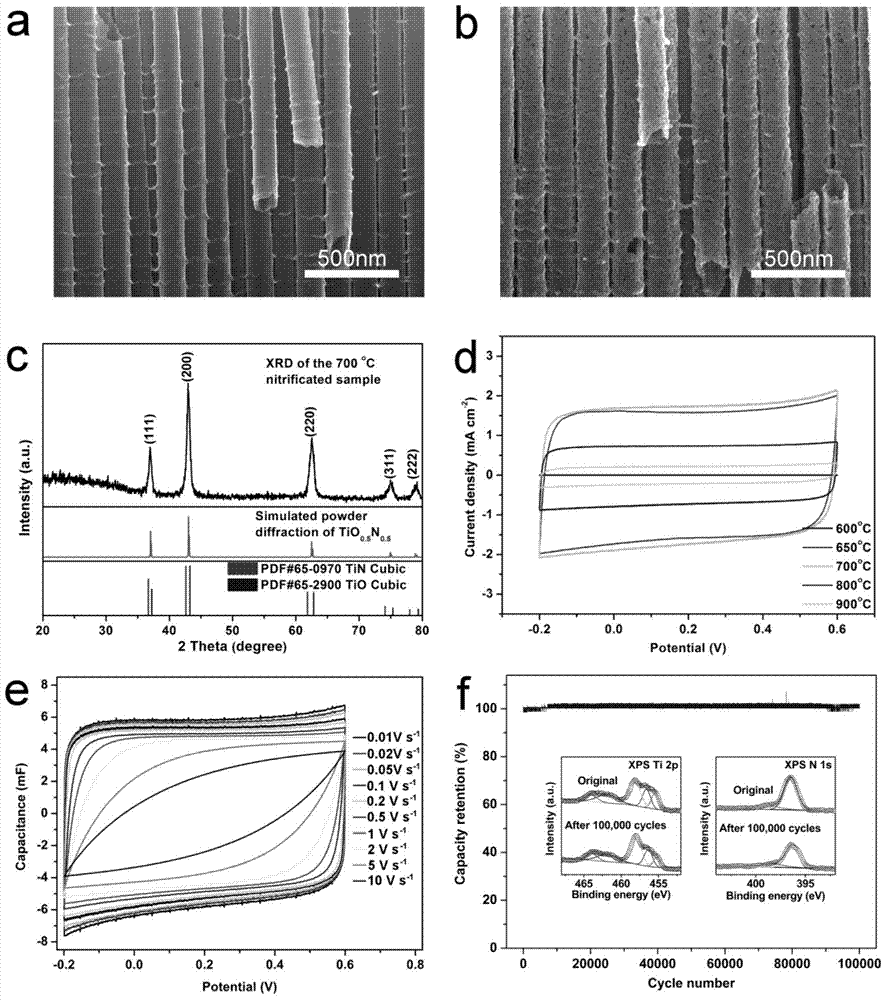

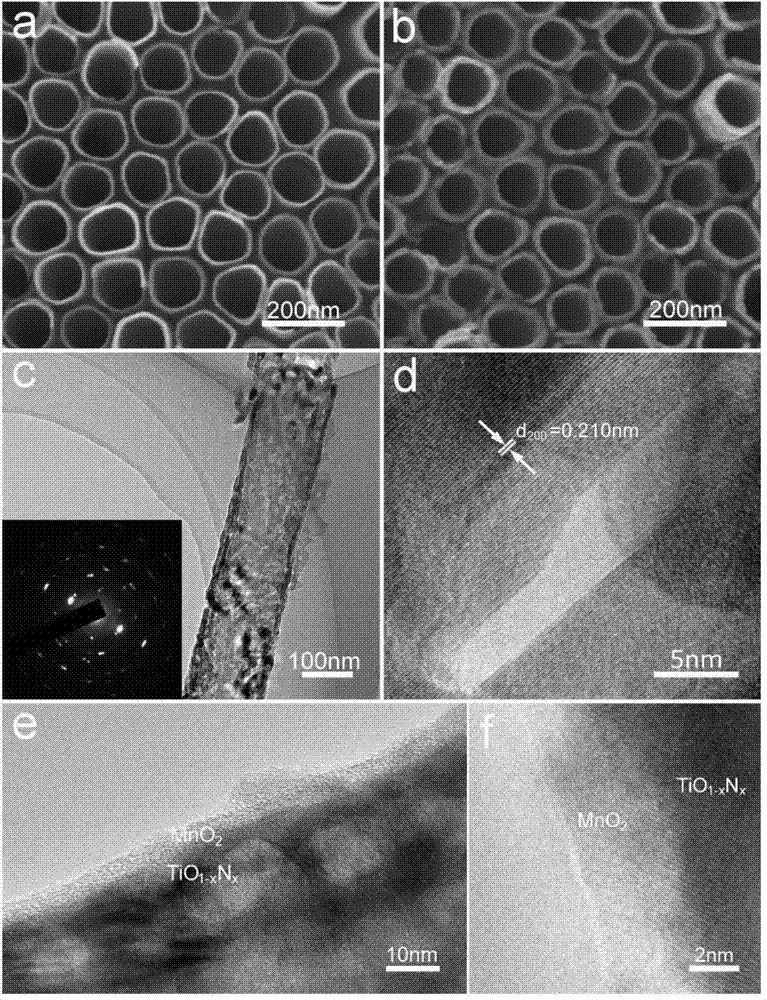

High-energy density and long-lived MnO2/TiO(1-x)Nx supercapacitor material and preparation thereof

ActiveCN103594250AImprove stabilityImprove power densityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceTio2 nanotube

The invention relates to preparation of a high-energy density and long-lived MnO2 / TiO(1-x)Nx supercapacitor material, which comprises the steps of: (1) preparing a titanium dioxide nanotube by using an anodic oxidation method, that is, a titanium foil with the thickness being 50+ / -10 micrometers and the purity being 99.8% is taken as an anode, wherein one side of the titanium foil is contacted with an ethylene glycol electrolyte solution, and cathode is also made of the titanium foil; the stability of the electrolyte solution is kept at constant 20+ / -5 DEG C, voltage between the anode and the cathode is kept at 50+ / -8V, and a TiO2 nanotube array is acquired; (2) carrying out thermal insulation nitrogen treatment on the TiO2 nanotube at a temperature of 600 DEG C-900 DEG C for 35+ / -15 minutes in a tubular furnace to acquire a TiO(1-x)Nx nanotube array, wherein 0.6>=x>0; and (3) depositing a manganese dioxide nanolayer on the surface of the TiO(1-x)Nx nanotube array, thereby acquiring the flexible supercapacitor material.

Owner:NANJING UNIV

Nitrogen treatment and destressing process

InactiveCN102453919AHeat treatment stress reliefControl Nitriding DistortionSolid state diffusion coatingAmmoniaMachining

The invention provides a nitrogen treatment and destressing process and adopts a technical scheme which is characterized by comprising the following steps of: placing a blank of a cylinder sleeve into a tempering furnace after rough machining of an inner bore and rough turning of an excircle; heating to 240 DEG C at a speed of not more than 50 DEG C per hour and keeping warm for 1 hour; uniformly heating to 460 DEG C and keeping warm for 1 hour; uniformly heating to 560 DEG C and keeping warm for 2 hours; taking the blank of the cylinder sleeve out from the tempering furnace after cooling to about 260 DEG C at a speed of less than 30 DEG C / H per hour; putting the machined cylinder sleeve, which passes an inspection, into a nitriding furnace after being cleaned and introducing ammonia into the nitriding furnace; slowly heating the nitriding furnace at the speed of less than 50 DEG C / H and emptying air in the nitriding furnace at 200 DEG C; heating to 510-510 DEG C at the speed of not more than 50 DEG C / H; keeping warm for 4 hours in the condition that the ammonia resolution ratio is 60-70%; keeping warm for 3 hours at a temperature of 510-520 DEG C in the condition that the ammonia resolution ratio is 70-80%; and cooling to 180 DEG C at the speed of not more than 50 DEG C / H and taking the cylinder sleeve out of the nitriding furnace.

Owner:徐金兰

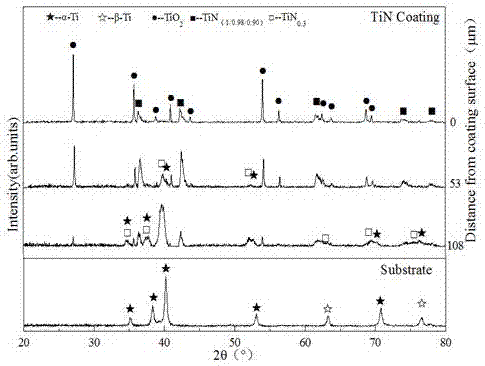

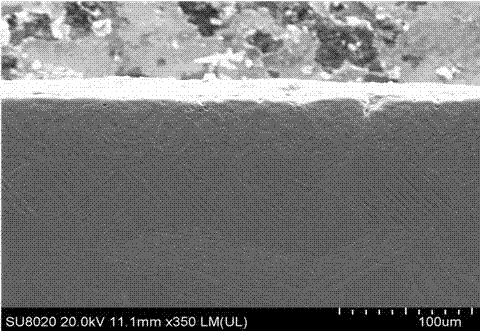

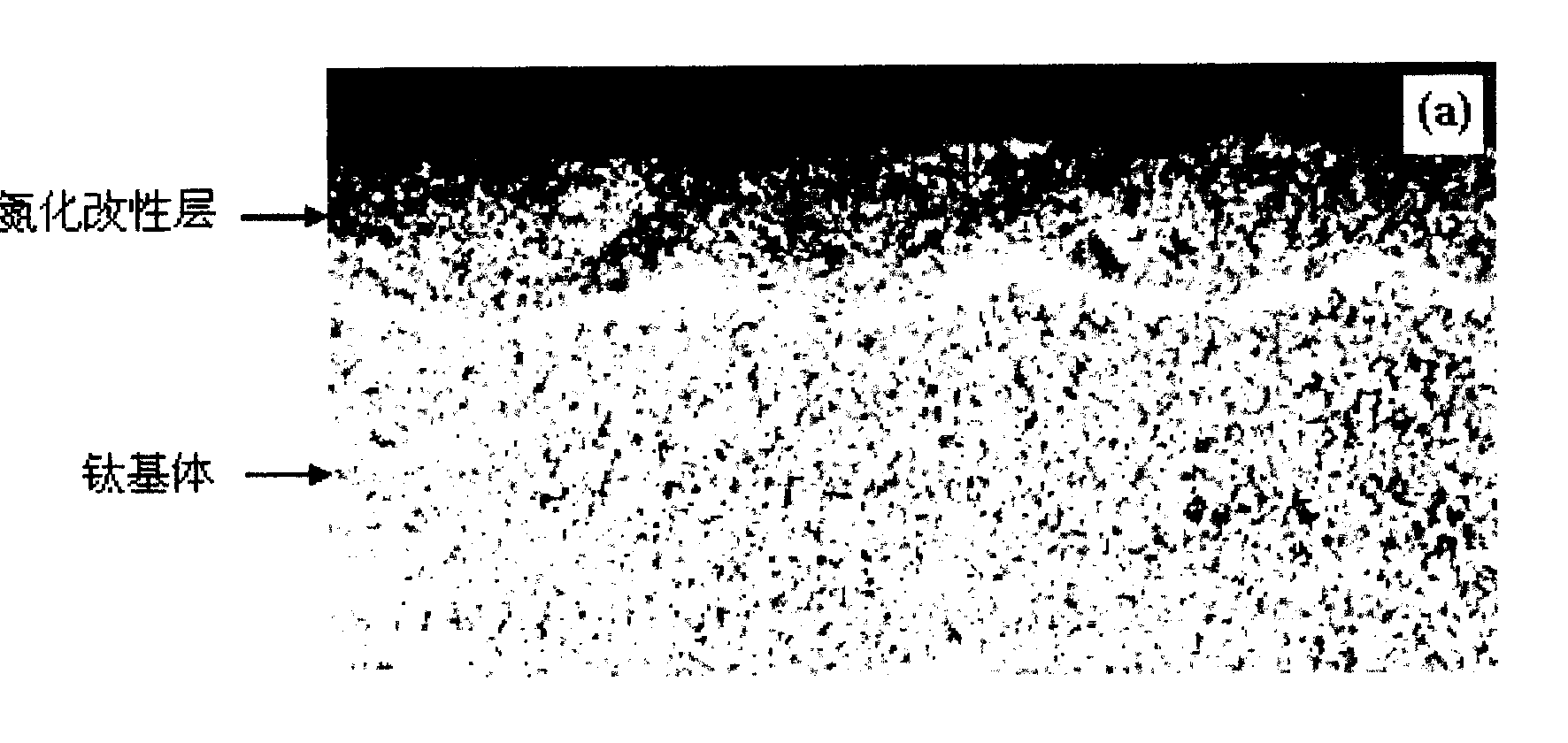

Method for low-laser-power preparation of TiN gradient coating on titanium alloy surface

The invention discloses a method for low-laser-power preparation of a TiN gradient coating on a titanium alloy surface. The high-hardness and good-abrasion-performance TiN coating is obtained through the technological steps of titanium alloy base pretreatment, air supply treatment and laser nitrogen treatment. The TiN coating prepared through the method and a titanium alloy base layer are subject to metallurgical bonding, the coating is compact, and gaps and cracks are avoided; the hardness of the TiN coating is greatly improved compared with a titanium alloy base, and the hardness is gradually increased from an interface to the coating and is increased by 4 times to 5 times to the greatest extent; and compared with a traditional nitriding technological process, the preparing environment is under the normal temperature atmosphere scope, an air sealing device is not needed, powder or a pre-coating material is not needed, requirements for the base material, specification and size are avoided, local nitriding on the base material can be carried out, other materials are not needed except for nitrogen, cost is low, the technology is simple, efficiency is high, and industrialization is easy to achieve.

Owner:柳州市恒丰利刀具有限公司

Pressure cooker and manufacturing method thereof

InactiveCN101653337ASimple structureImprove heat transfer efficiencyPressure-cookersSheet steelPhysical well being

The invention discloses a pressure cooker. The body of the pressure cooker is a cold-rolled steel sheet. The manufacturing method of the pressure cooker is as follows: 1) preparing a cold-rolled steelsheet the thickness of which is 1.3-1.7mm; 2) punching the cold-rolled steel sheet into the body prototype of the pressure cooker by a punch; 3) using a spinning machine to spin the side wall of thepunched body prototype of the pressure cooker into the thickness of 0.6-0.9mm; 4) welding a steel sheet the thickness of which is 1.5-3.0mm on the outer bottom surface of the spun body of the pressurecooker; 5) performing QPQ nitrogen treatment on the whole body of the pressure cooker to form the finished product. The pressure cooker has simple structure, high heat transfer efficiency, high manufacturing efficiency and low cost, and is more safe and beneficial to body health. The pressure cooker combines the advantages of the present aluminum pressure cookers and the stainless steel pressurecookers but has no disadvantages of the two kinds of pressure cookers, so that the pressure cooker of the invention becomes a new pressure cooker and can replace the present aluminum pressure cookersand stainless steel pressure cookers.

Owner:惠州宏利五金塑胶制品厂有限公司

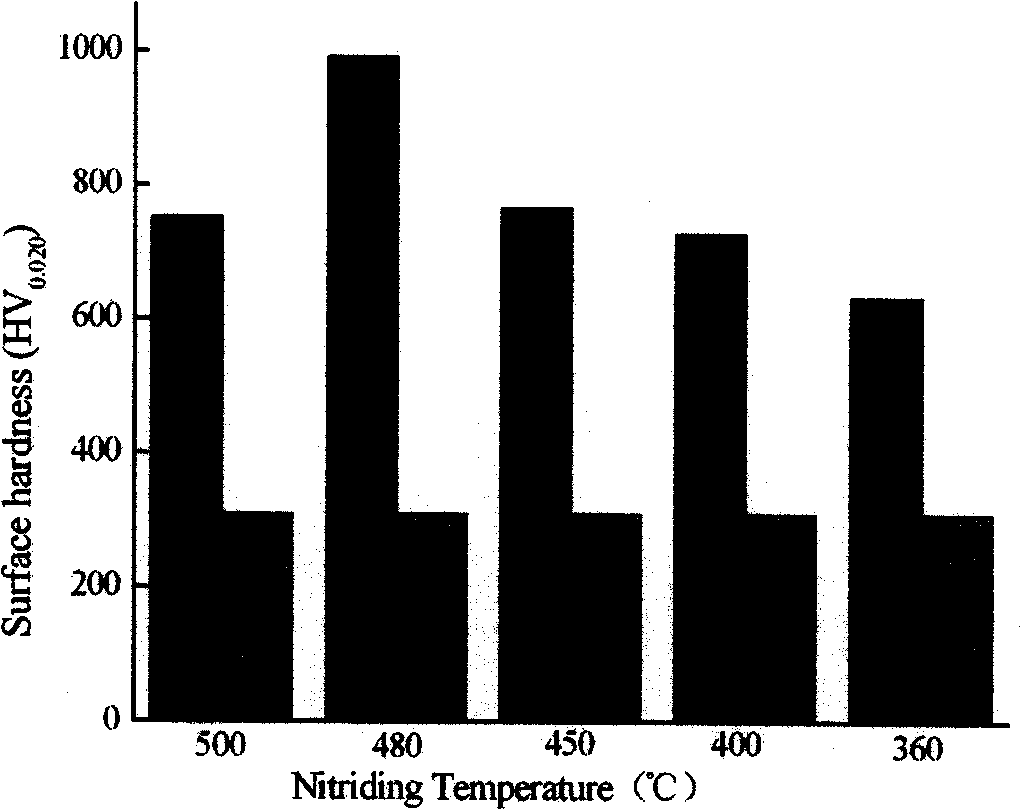

Novel method for carrying out low-temperature surface catalysis and nitriding on alloy cast iron

ActiveCN101880851AHigh catalytic activityPromote spreading rateSolid state diffusion coatingCatalytic decompositionAlloy

The invention relates to a novel method for carrying out low-temperature surface catalysis and nitriding on alloy cast iron, belongs to the technical field of the surface chemical heat treatment application of metal materials and is suitable for low-temperature and rapid surface nitrogen treatment (in the strengthening nitriding process, the temperature is less than 480 DEG C and the time is less than 10 hours; and in the corrosion-resisting nitriding process, the temperature is between 500 and 520 DEG C and the time is less than 4 hours) of an alloy cast iron cylinder sleeve and an alloy cast iron piston ring. Based on the surface catalysis theory, the invention designs an active catalyst component, utilizes an adjustable bidirectional pulse power supply to form a catalytic film, i.e. a surface catalyst, on the surface of the alloy cast iron, improves the activity that the metal surface carries out catalytic decomposition on ammonia at the low temperature and also effectively adsorbs the decomposed free nitrogen to form a nitrogen adsorption layer. Moreover, the catalyst can permeate into a substrate to form solid solution so as to promote the diffusion rate of nitrogen. Compared with the conventional gas nitriding method, the process increases a working procedure of adjustable bidirectional pulse surface deposition treatment. The working procedure has the advantages of stable conditioning fluid and short processing time. The novel process is suitable for the existing gas nitriding equipment.

Owner:SHANDONG UNIV OF SCI & TECH

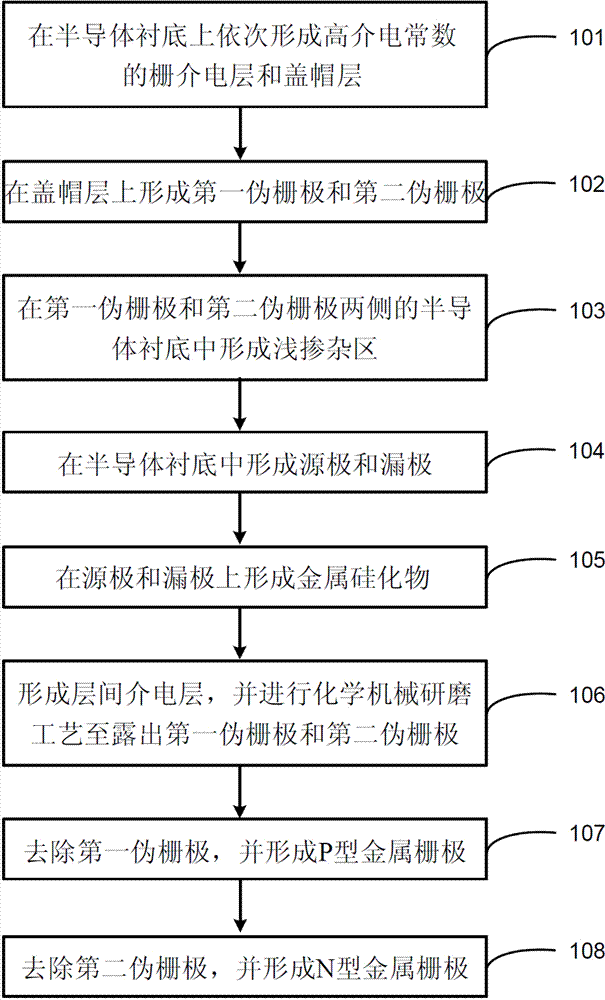

Manufacturing method for semiconductor device

ActiveCN103094214AImprove the effective work function valueLower threshold voltageSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricWork function

The invention discloses a manufacturing method for a semiconductor device. The manufacturing method for the semiconductor device comprises: a) a semiconductor substrate is provided, wherein the semiconductor substrate comprises a P-type transistor area and an N-type transistor area, and a gate dielectric layer and a covering layer are sequentially formed on the semiconductor substrate; b) a photoresist layer which exposes the P-type transistor area is formed on the covering layer; c) nitrogen treatment process is carried out, and nitrogen is mixed in the gate dielectric layer and the covering layer of the P-type transistor area; d) the photoresist layer is removed. By the fact that the nitrogen-atoms are mixed in the gate dielectric layer and the covering layer of the P-type transistor area to replace oxygen atoms at the interface, effective work function value of the covering layer in the P-type transistor area is increased, threshold voltage of a P-type transistor is reduced, so that the covering layer can be matched with work function layers of the P-type transistor area and the N-type transistor area at the same time.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Technique for preparing machine holding carbide alloy rack type gear shaper cutter

The invention relates to a manufacturing process of a machine-clamped hard alloy rack type cutter; the blade of the cutter chooses YT798 and is pre-punched out a positioning wire hole by an electro discharge drilling machine; a grinder is used for grinding the thickness and the width of two sides of the blade to satisfy the thickness size and the roughness required by the design, and then a wire electro-discharge machining is used for cutting the shape of the blade and a positioning hole used for assembling; AlTiN is coated on the blade evenly; a special fixture is used for finish milling the shape of a blade groove, at last an assembly positioning hole is bored in a coordinated borer. The knife body chooses 42CrMo, and the special fixture is used for milling the knife body shape of the rack type cutter, including clamping sizes and front angles; the hardening and tempering process and the nitrogen treatment are carried out to reach HB265-305, and the special fixture is used for crude grinding and fine grinding the clamping position surfaces and the planes of the front angles of the knife body; a special clamping fixture is used for cutting the tooth shape of the knife body on the wire electro-discharge machining; the tooth shape and back angles are clamped and cut once time. The machine-clamped hard alloy rack type cutter can be formed by finishing and grinding the blade groove through once assembly by template fitters; the manufacturing process of the machine-clamped hard alloy rack type cutter can be applied to the processing of gears with large module and high hardness.

Owner:CITIC HEAVY INDUSTRIES CO LTD

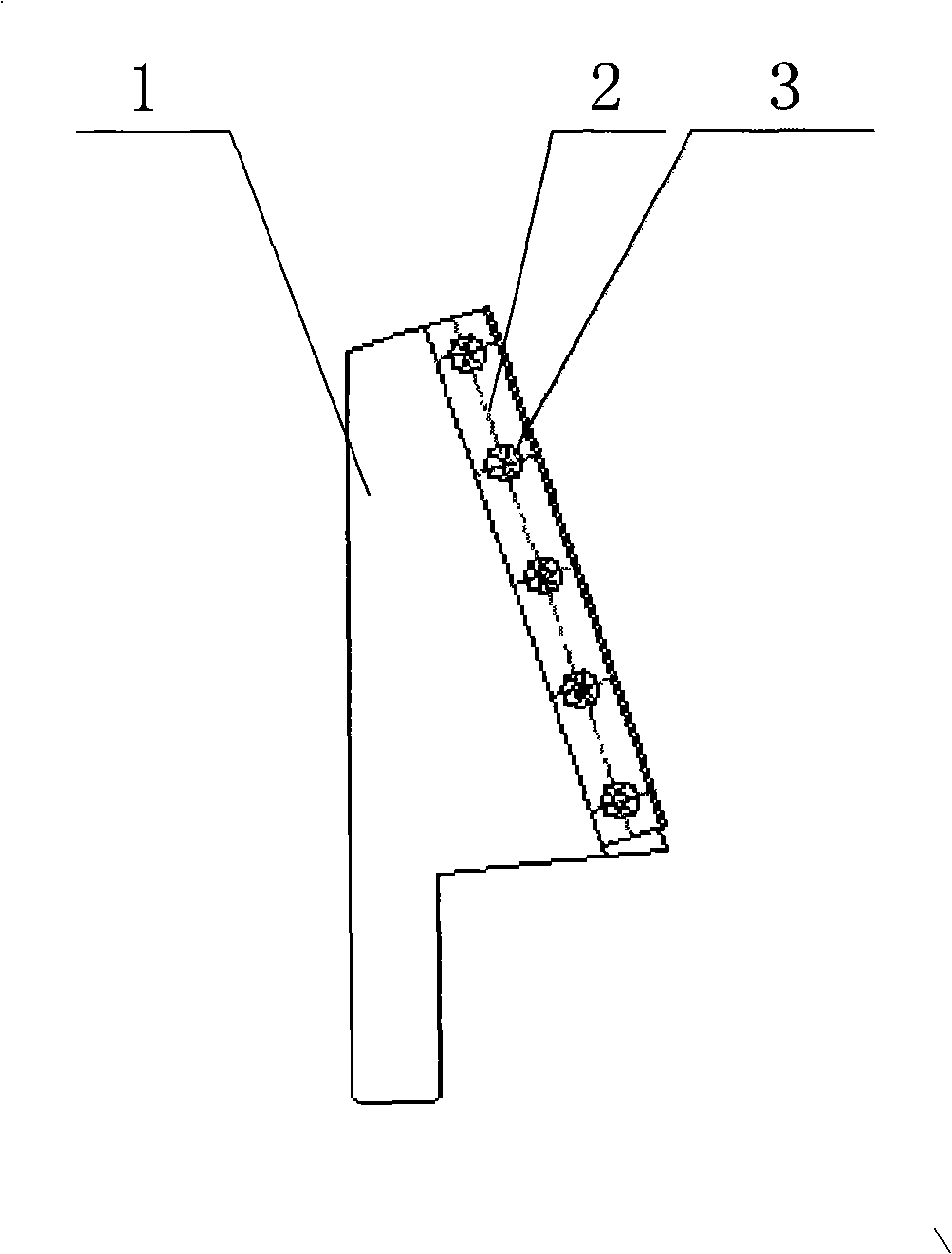

Method for manufacturing cutter shafts of longitudinally-shearing disc scissors

The invention provides a method for manufacturing cutter shafts of longitudinally-shearing disc scissors. The method includes the steps of material selection, rough machining, thermal treatment, center hole lapping, external circle accurate grinding, polishing and combination of a reasonable thermal treatment procedure (quenching and tempering, high-temperature tempering, low-temperature tempering and oil boiling), surface nitrogen treatment, a three-time center hole lapping and grinding technology (rough grinding, semi-accurate grinding, rounding, accurate grinding and fine grinding) and a grinding and polishing technology, so that the longitudinally-shearing disc scissors is in a high accuracy state in the process of production, a machining and manufacturing technical method without deformation and abrasion is conducted, through technological innovation of a measurement method and bold development of a measurement instrument in the manufacturing process, the high-accuracy cutter shafts of the longitudinally-shearing disc scissors are measured through a pneumatic measurement instrument according to the comparative measurement method, and the error of the two cutter shafts with the diameter absolute error within 0.002 mm is measured. By the adoption of the high-accuracy cutter shafts manufactured through the method and the technological process, key indexes such as the diameter tolerance and the roundness of the cutter shafts can reach and even exceed technical indexes of cutter shafts of import disc scissors.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

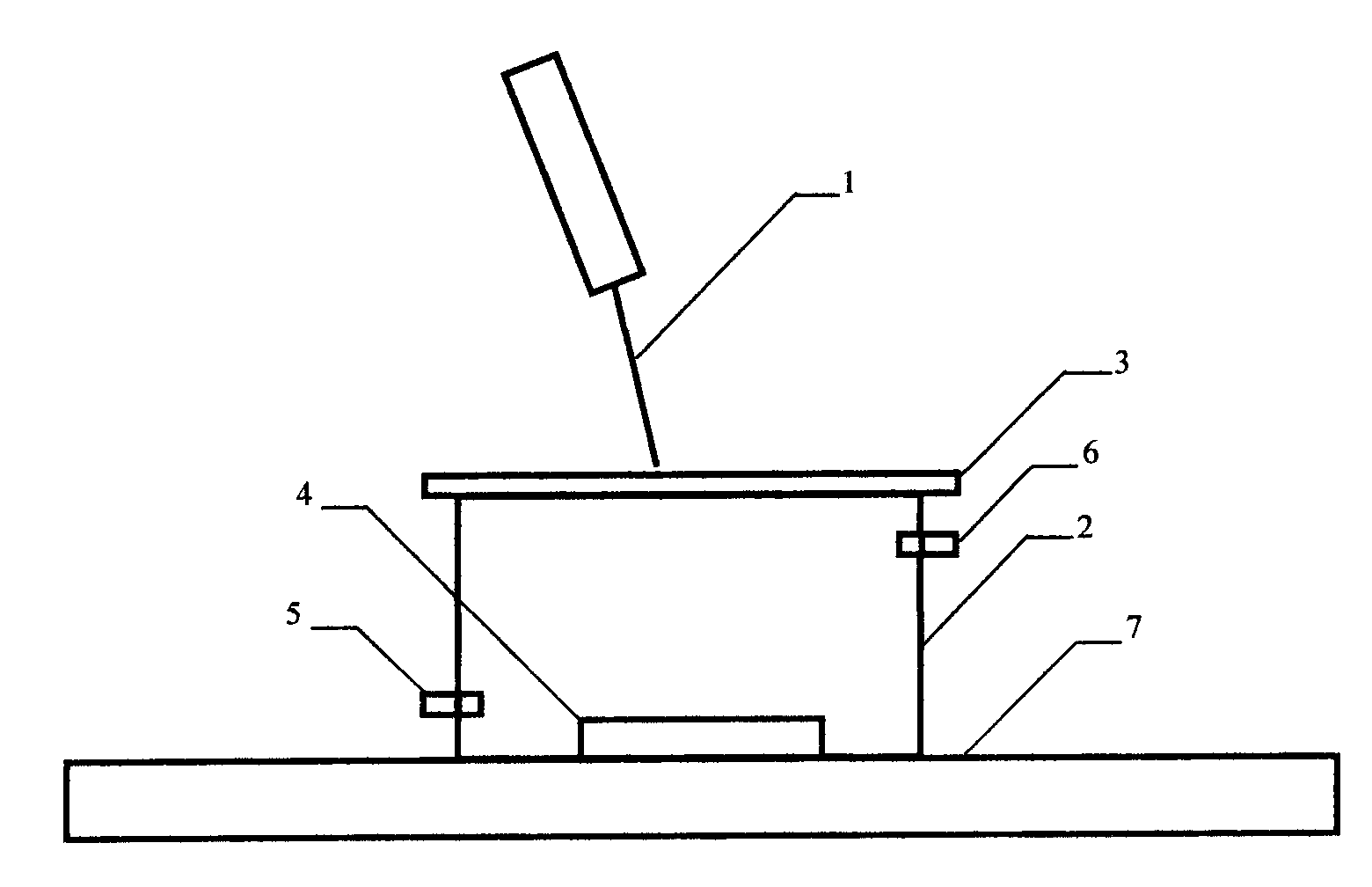

Laser microscopy processing method of porous surface structure

InactiveCN101633077AMeet the use requirementsLaser beam welding apparatusProsthesisOptoelectronicsVolumetric Mass Density

The invention discloses a laser microscopy processing method of a porous surface structure. Firstly, adopting a laser gas nitrogen treatment mode to perform surface treatment to a processed surface; then, performing laser microscopy processing. The invention has the advantages that the method can obtain an omega-shaped porous surface structure with wide application range, the porous surface structure can form certain array form or other arrangement forms satisfying using requirements, and the depth, ratio between depth and diameter, distribution density and the like of holes can be designed and adjusted according to using requirements. The invention has favourable characteristics of satisfying using requirements in medical fields and the like and has foreseeable huge economic value and social value.

Owner:SHENYANG POLYTECHNIC UNIV +1

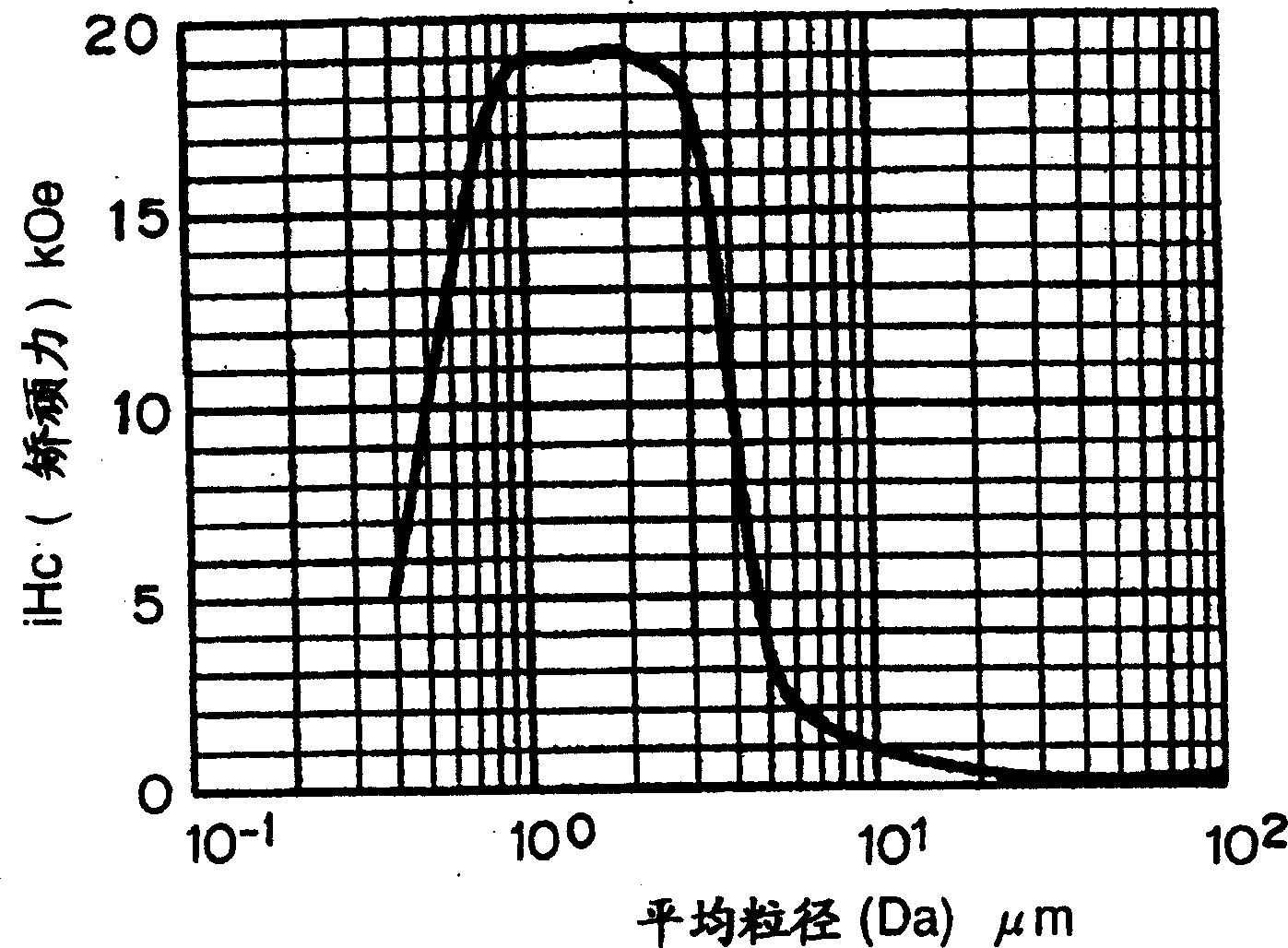

Process for producing Sm-Fe-N alloy powder

InactiveCN1286602CEnhanced magnetic forceImprove coercive forceNitrogen-metal/silicon/boron binary compoundsMagnetic materialsCoprecipitationAlloy

Owner:NICHIA CORP

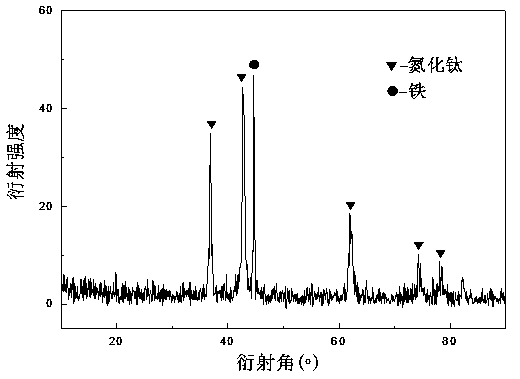

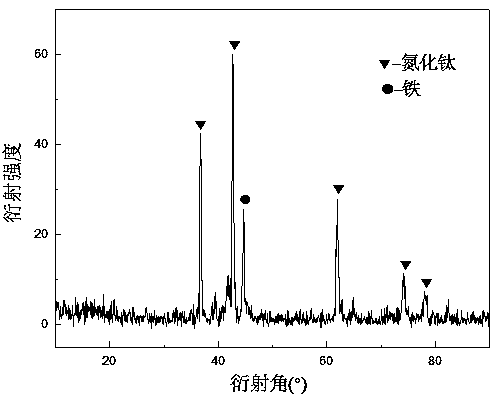

Preparation method of titanium nitride-ferrous metal ceramics

The invention relates to a preparation method of titanium nitride-ferrous metal ceramics. The preparation method comprises the steps of preparing a titanium-ferrous (Ti-Fe) alloy cast ingot with a vacuum melting method to enable Fe to exist in Ti in a form of solid solution and TiFe intermediate phase; carrying out hydrogenation embrittlement, ball-milling crushing and dehydrogenation and nitrogen treatment on the Ti-Fe alloy cast ingot to obtain titanium nitride-ferrous (TiN-Fe) metal-ceramic composite powder; sintering the composite powder subjected to green compacting to obtain a TiN-Fe metal-ceramic material. The TiN-Fe metal-ceramic composite powder prepared by the method provided by the invention consists of two phases, i.e. TiN and Fe, and is uniform in powder size and good in fluidity, the TiN-Fe block metal-ceramic material obtained by sintering the TiN-Fe metal-ceramic composite powder subjected to green compacting is uniform in phase distribution and relatively high in density, and the average microscopy Vickers hardness of the materials reaches 1023 HV.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com