Method for extension of plumbago alkene with ultra-thin hexagonal phase silicon carbide membrane on insulated substrate

A technology of silicon carbide film on insulating substrate, applied in the field of semiconductor low-dimensional thin film material preparation, can solve the problems of restricting the performance of graphene devices and high cost of epitaxial graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

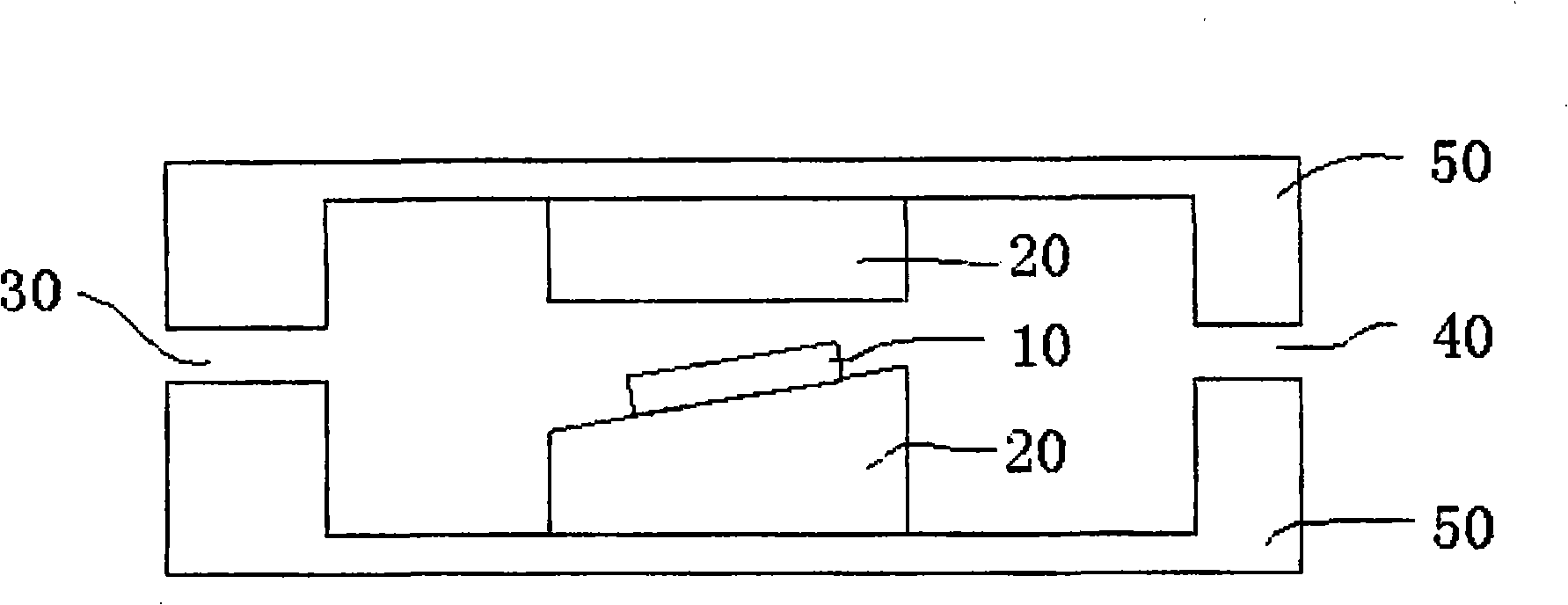

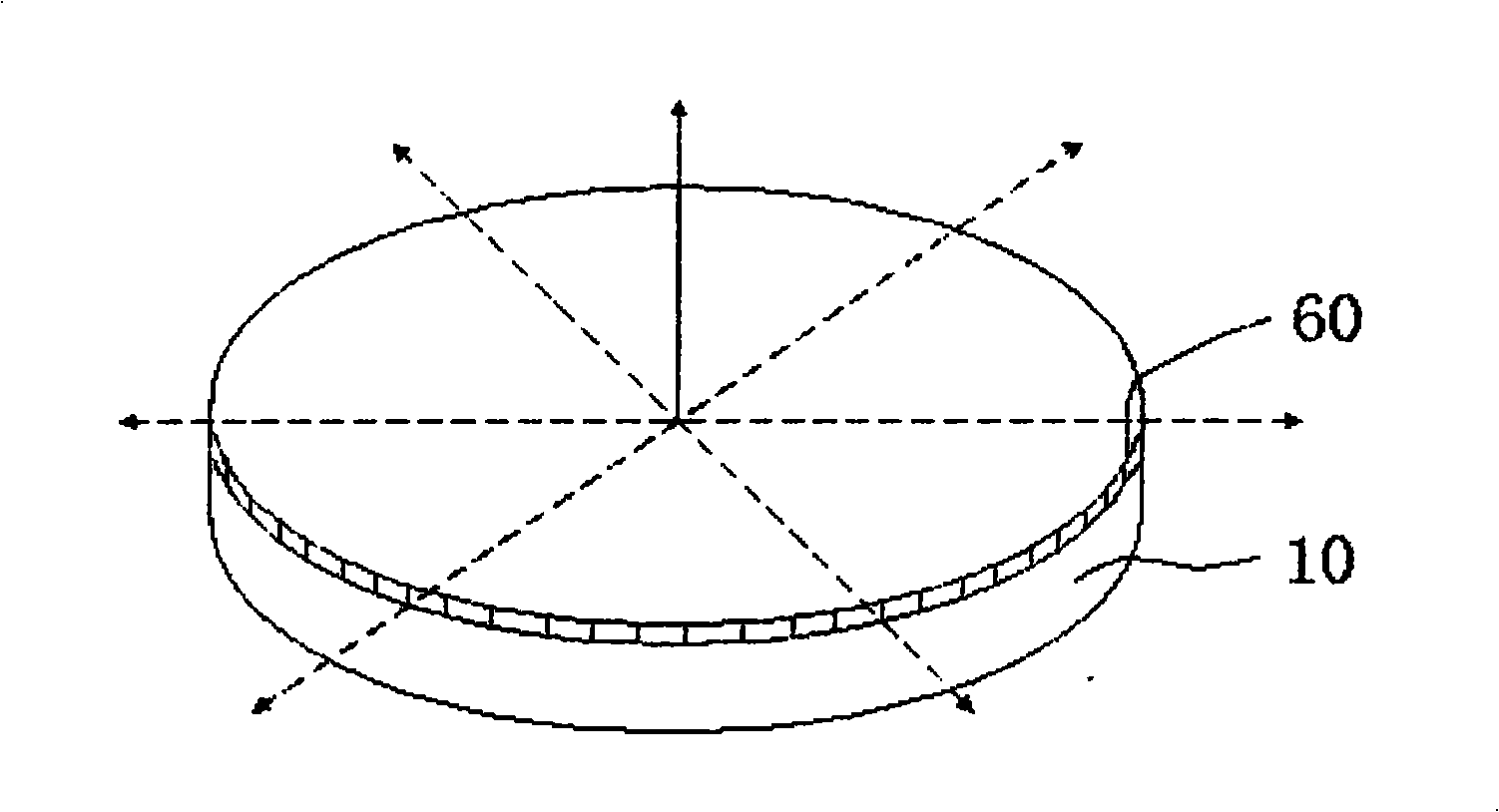

[0050] Single crystal sapphire substrate (α-Al 2 o 3 ) (insulating substrate 10), the surface of C (0001) is chemically polished, cleaned and placed in a growth furnace, and hydrogen gas is introduced to etch and polish the surface of the single crystal sapphire substrate. The hydrogen flow rate during etching is 3000 sccm, The surface temperature of the single crystal sapphire substrate is 1350° C., the pressure in the growth chamber is normal pressure, and the etching is performed for 30 minutes. After etching, the surface of the substrate can be seen under the microscope to be flat at the atomic level, without defects such as scratches. Then feed ammonia gas to carry out nitriding treatment on the surface of the single crystal sapphire substrate. During nitriding, the flow rate of ammonia gas is 1 sccm, the surface temperature of the single crystal sapphire substrate is 1500° C., the growth chamber pressure is 40 Torr, and the nitriding treatment is carried out for 10 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com